Patents

Literature

2741 results about "Oxygen enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen enrichment is an established technology for increasing the efficiency of combustion, and has been adopted in various forms by a number of industries using high-temperature combustion processes.

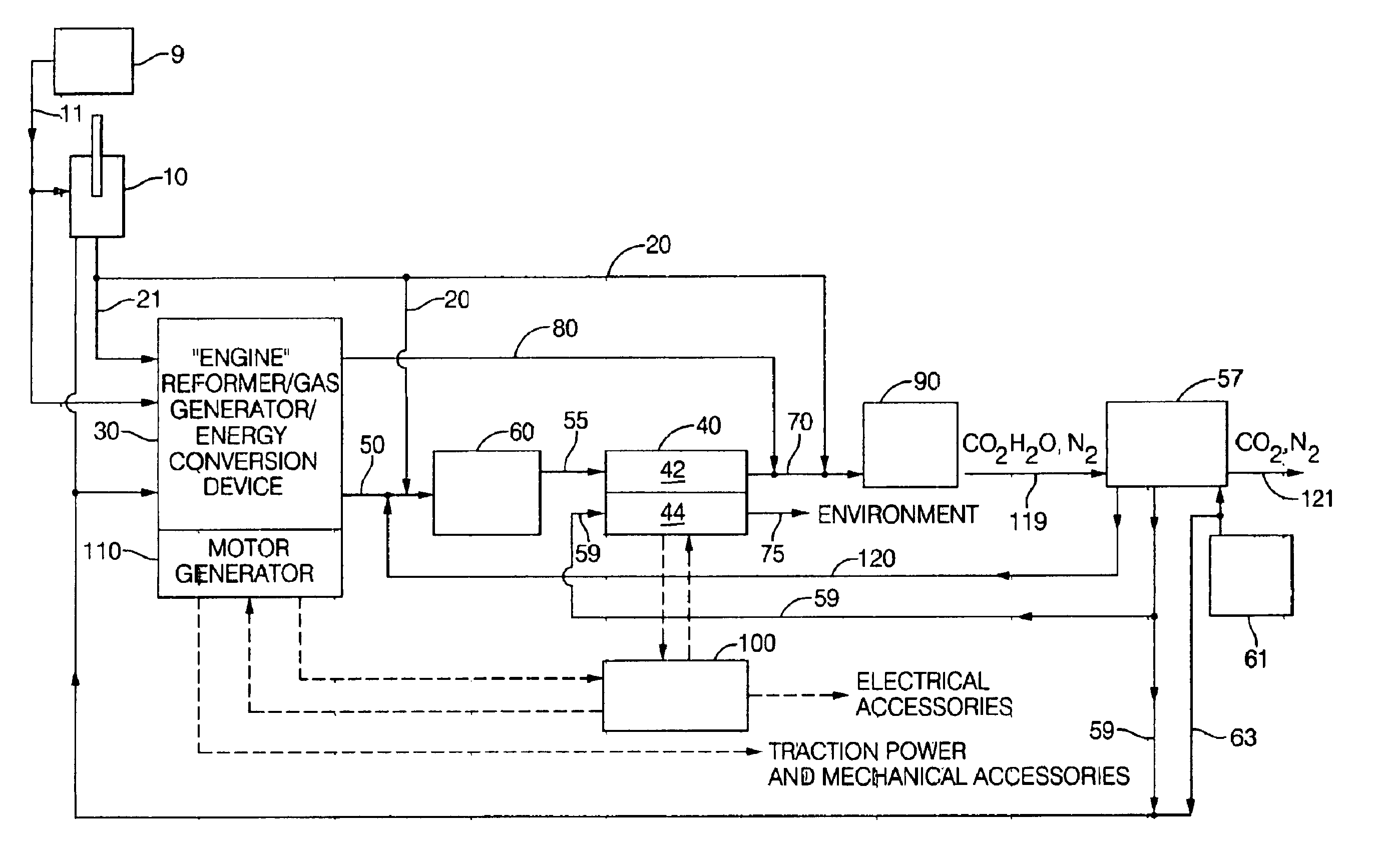

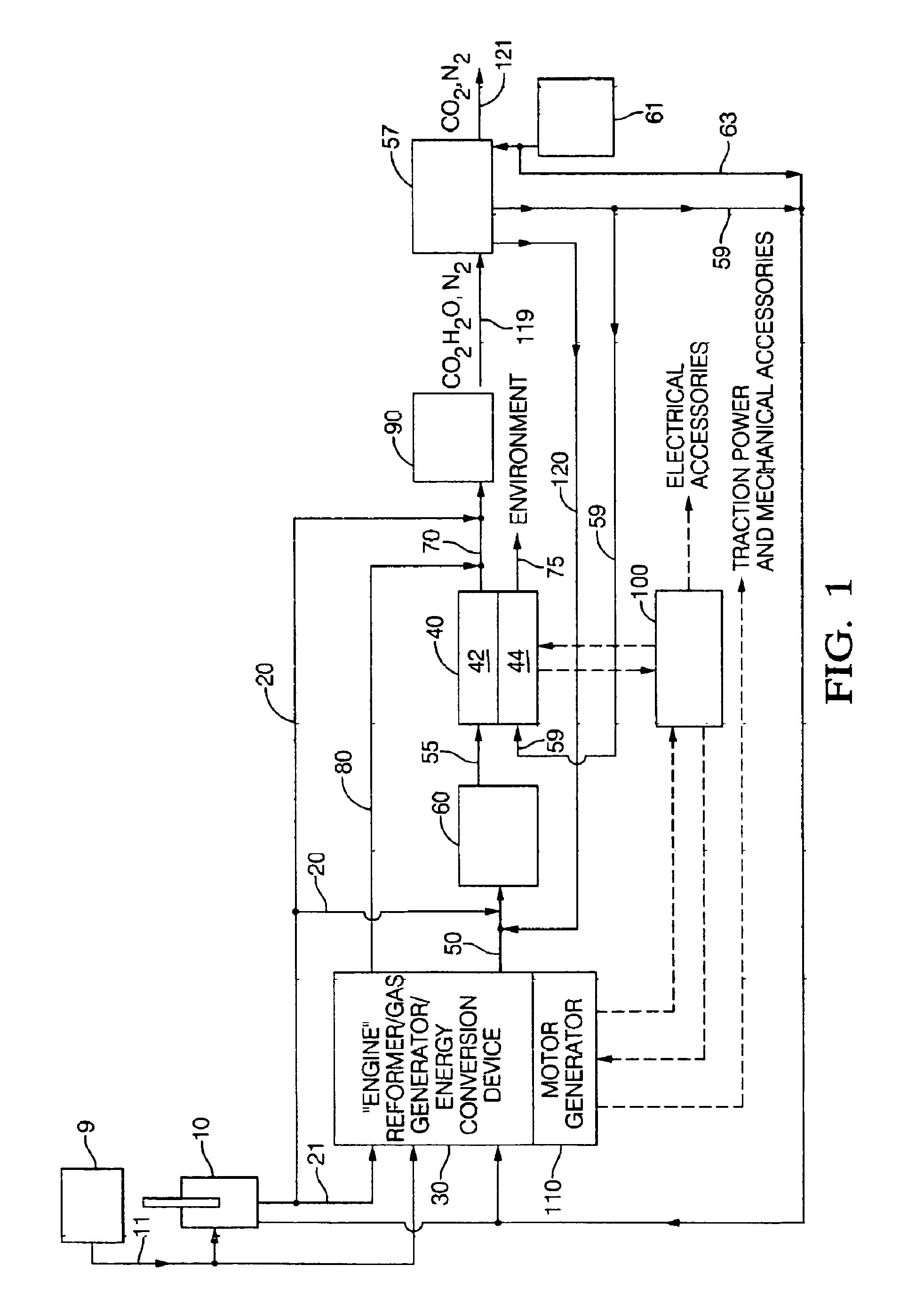

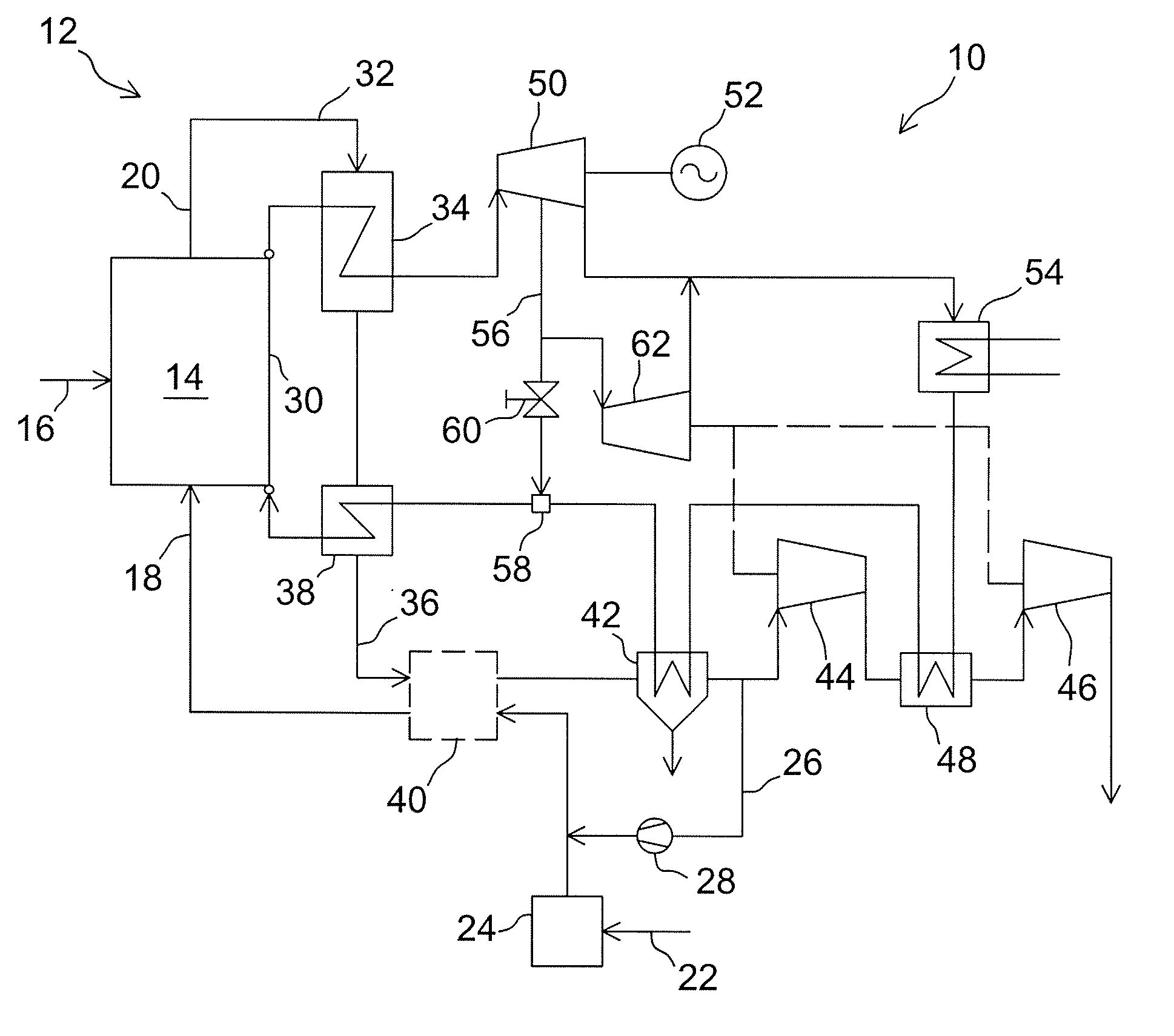

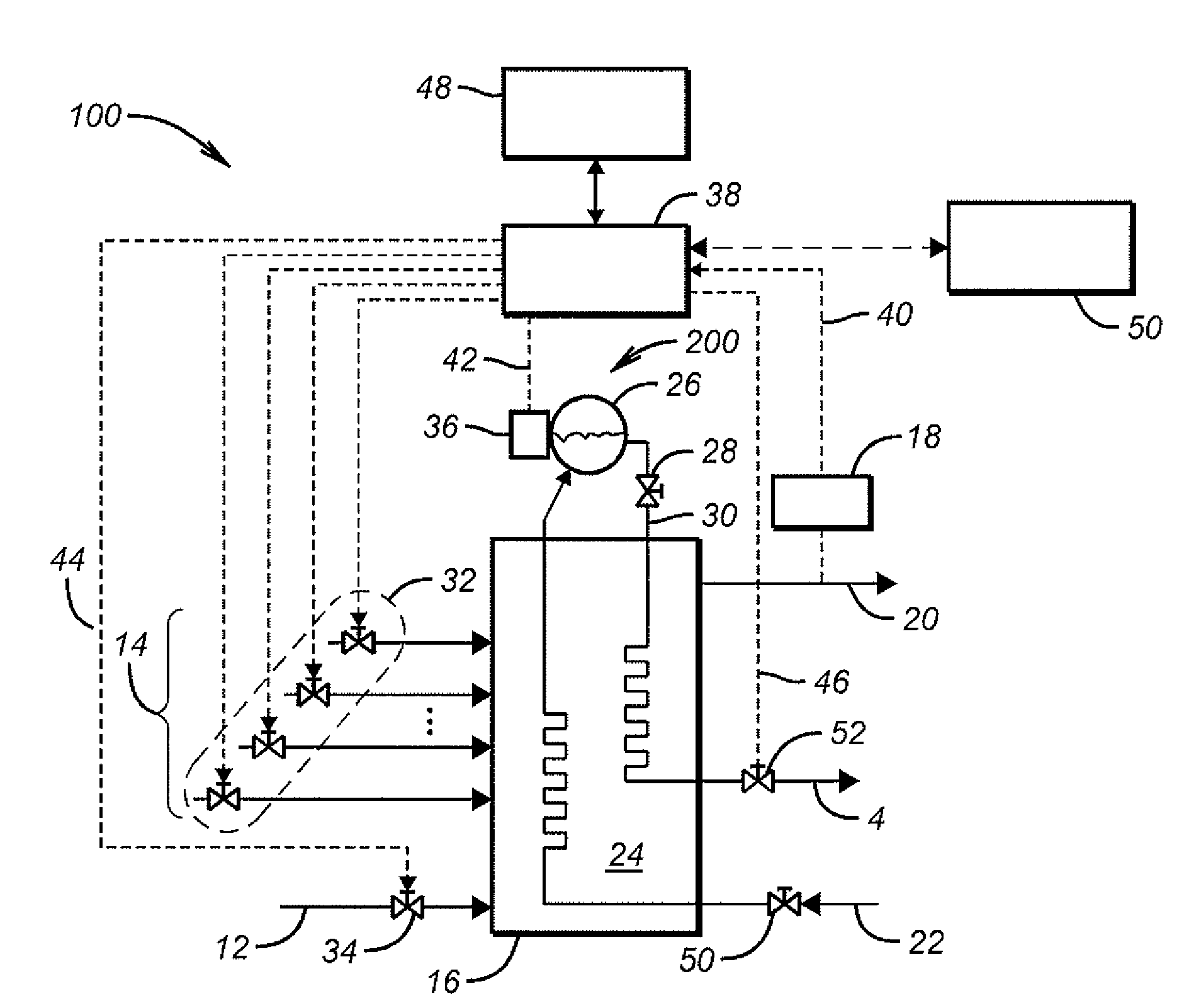

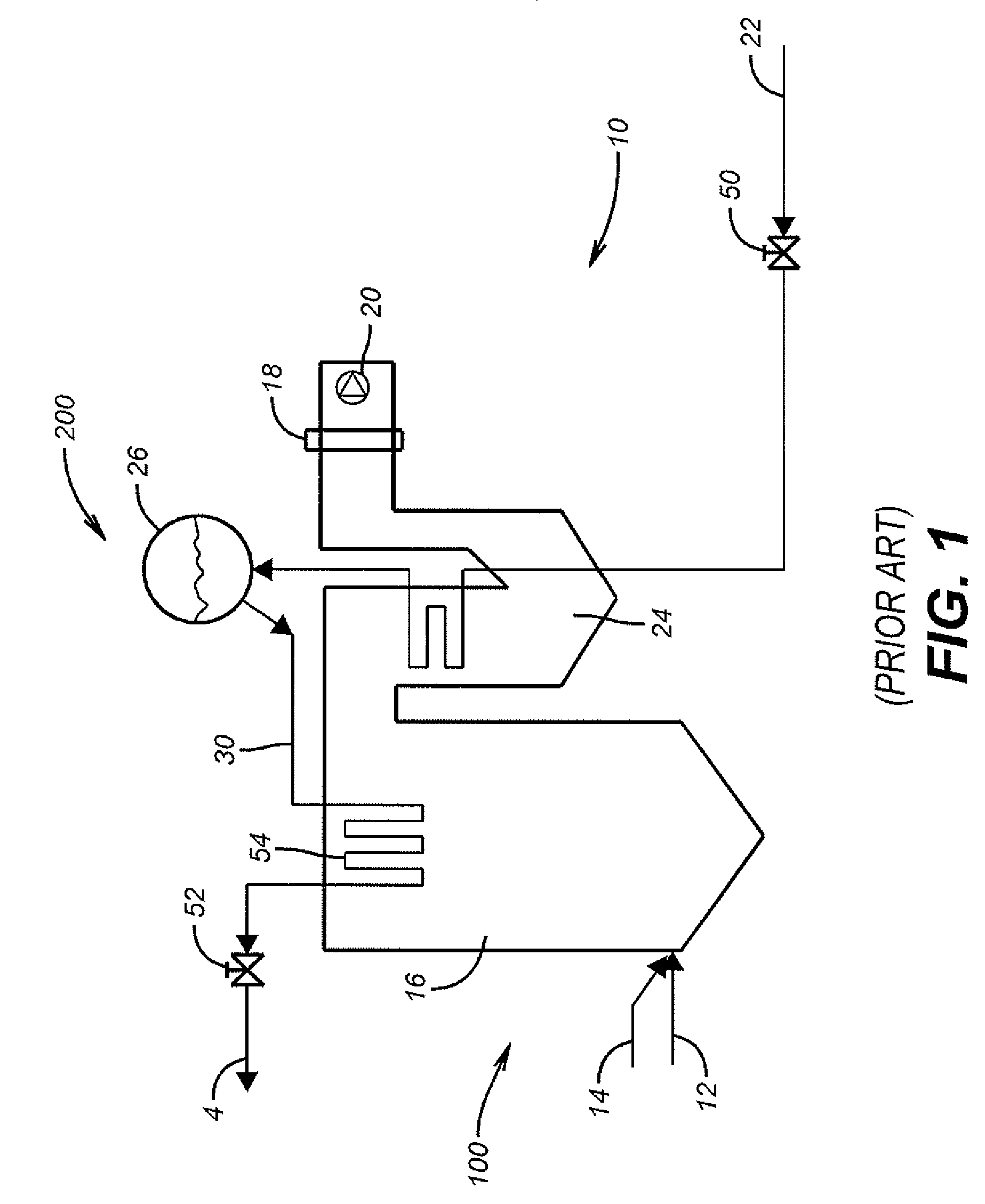

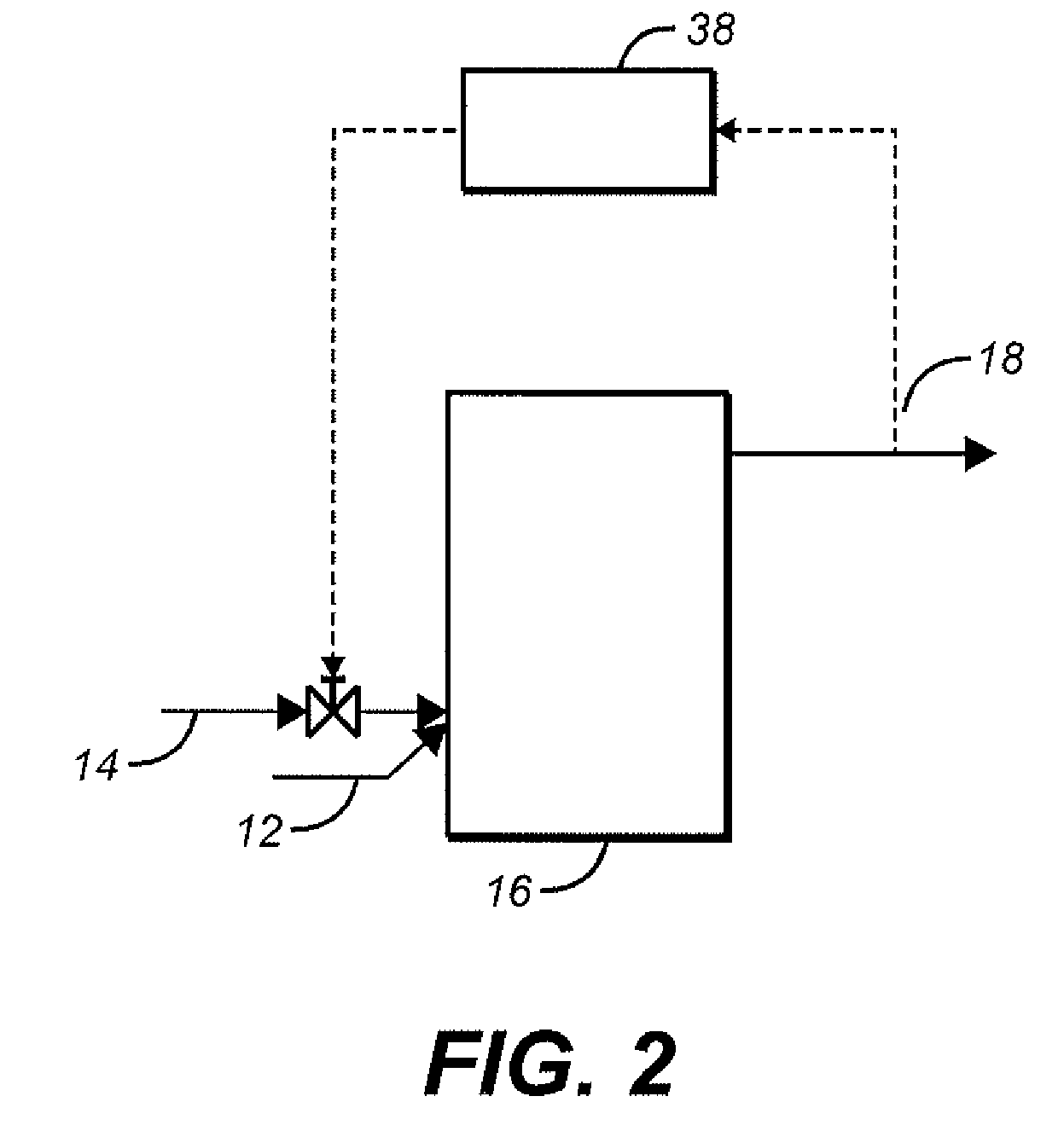

Power generation system and method

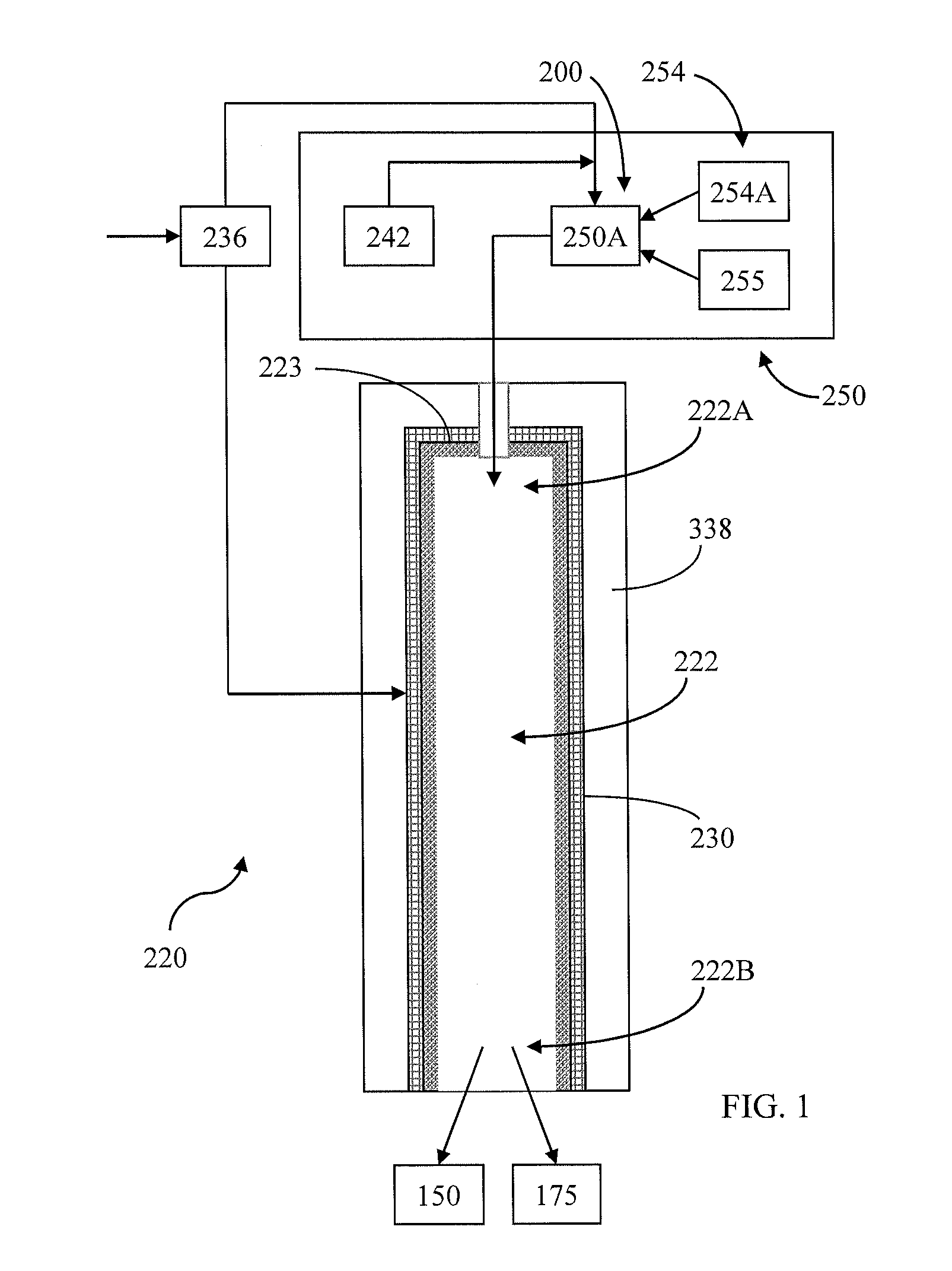

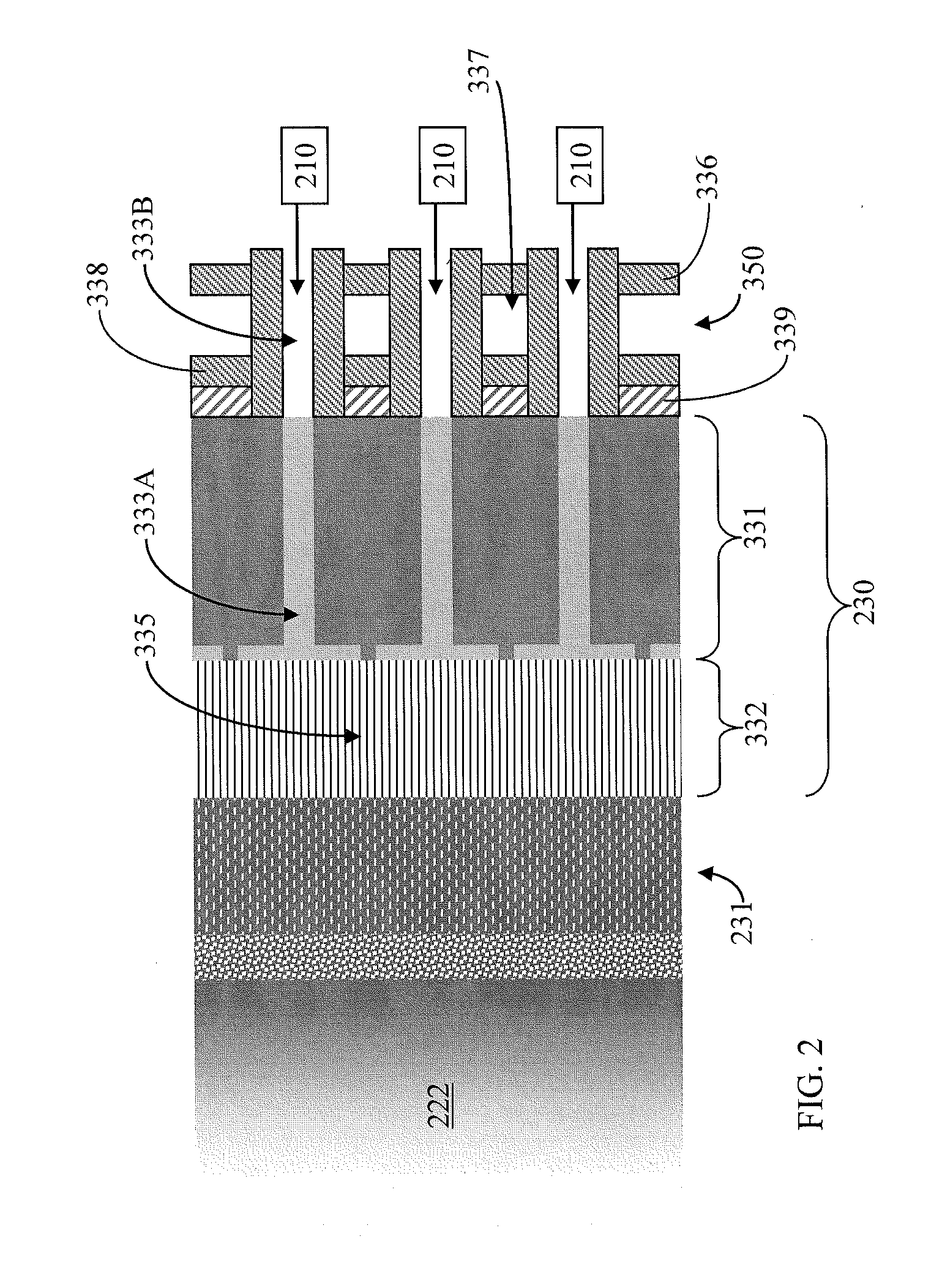

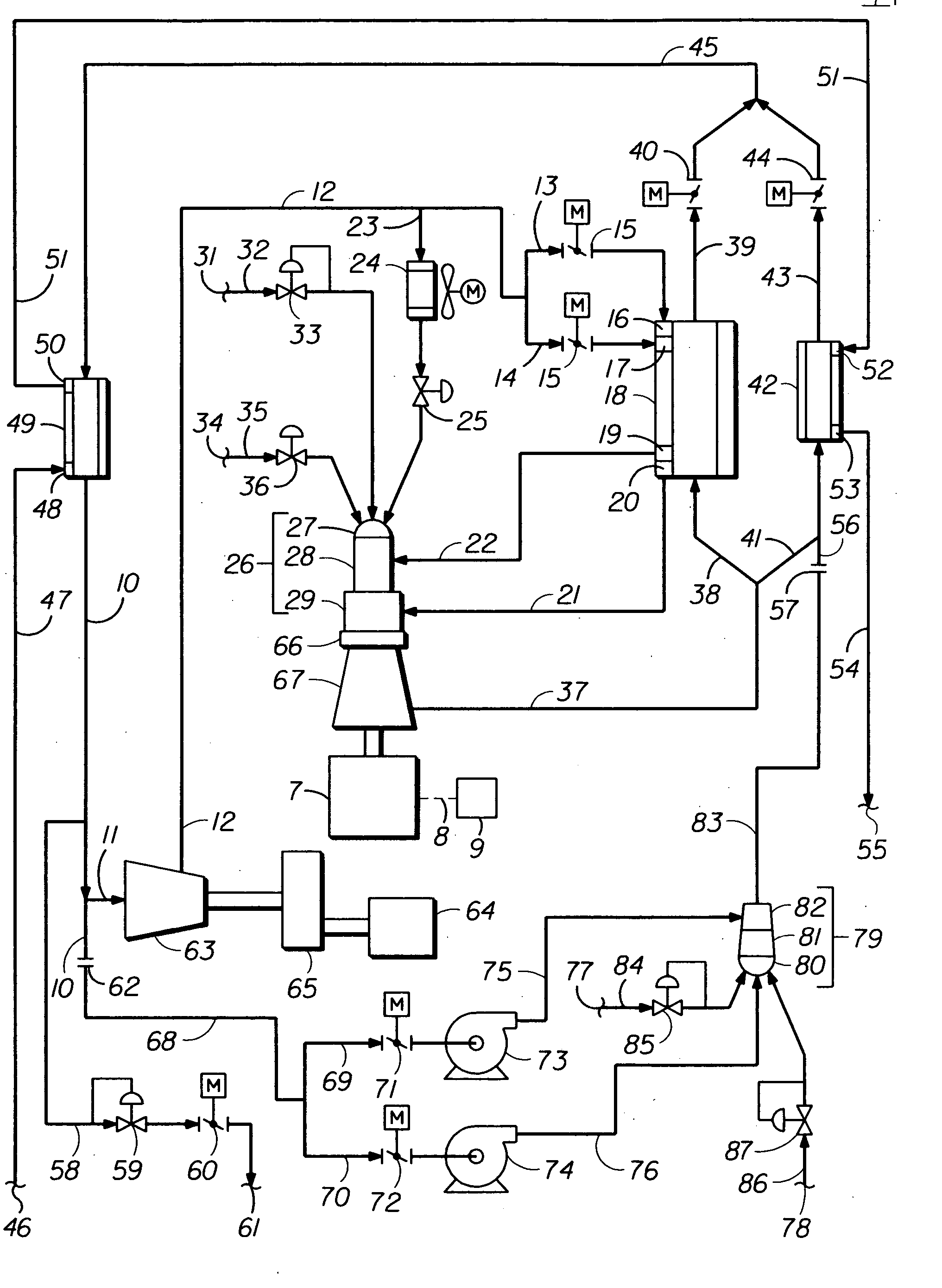

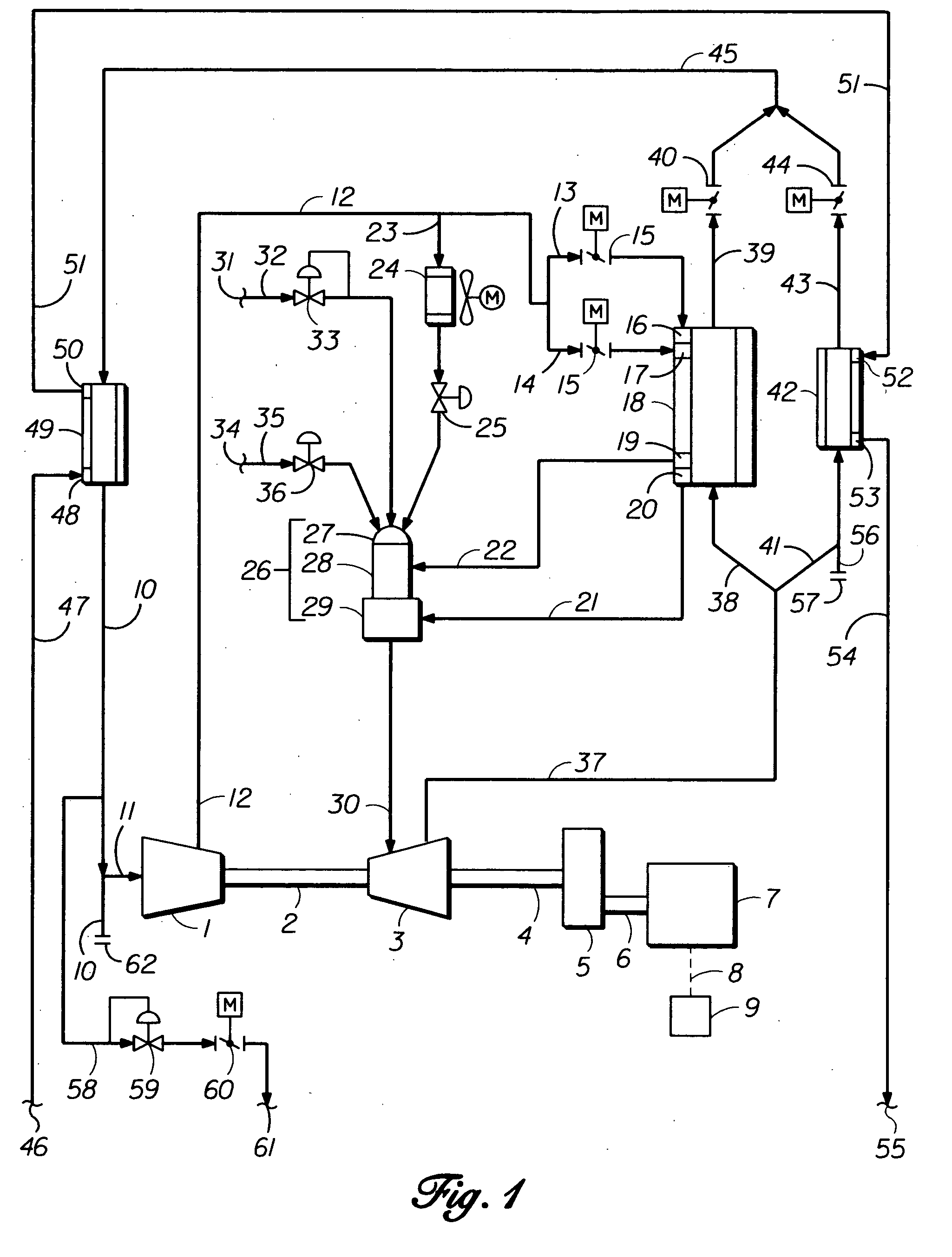

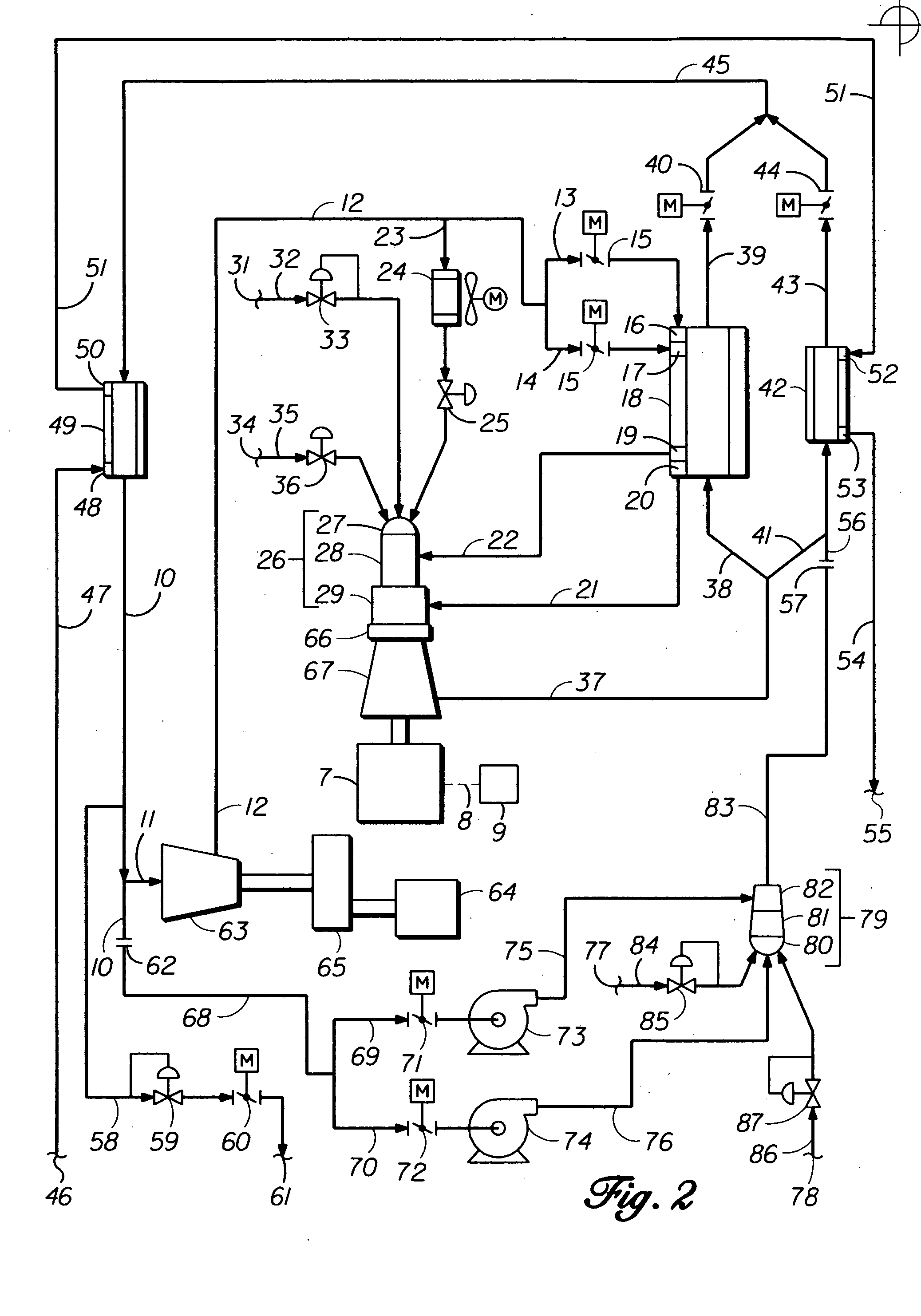

InactiveUS6915869B2Internal combustion piston enginesElectric propulsion mountingInternal combustion engineFuel supply

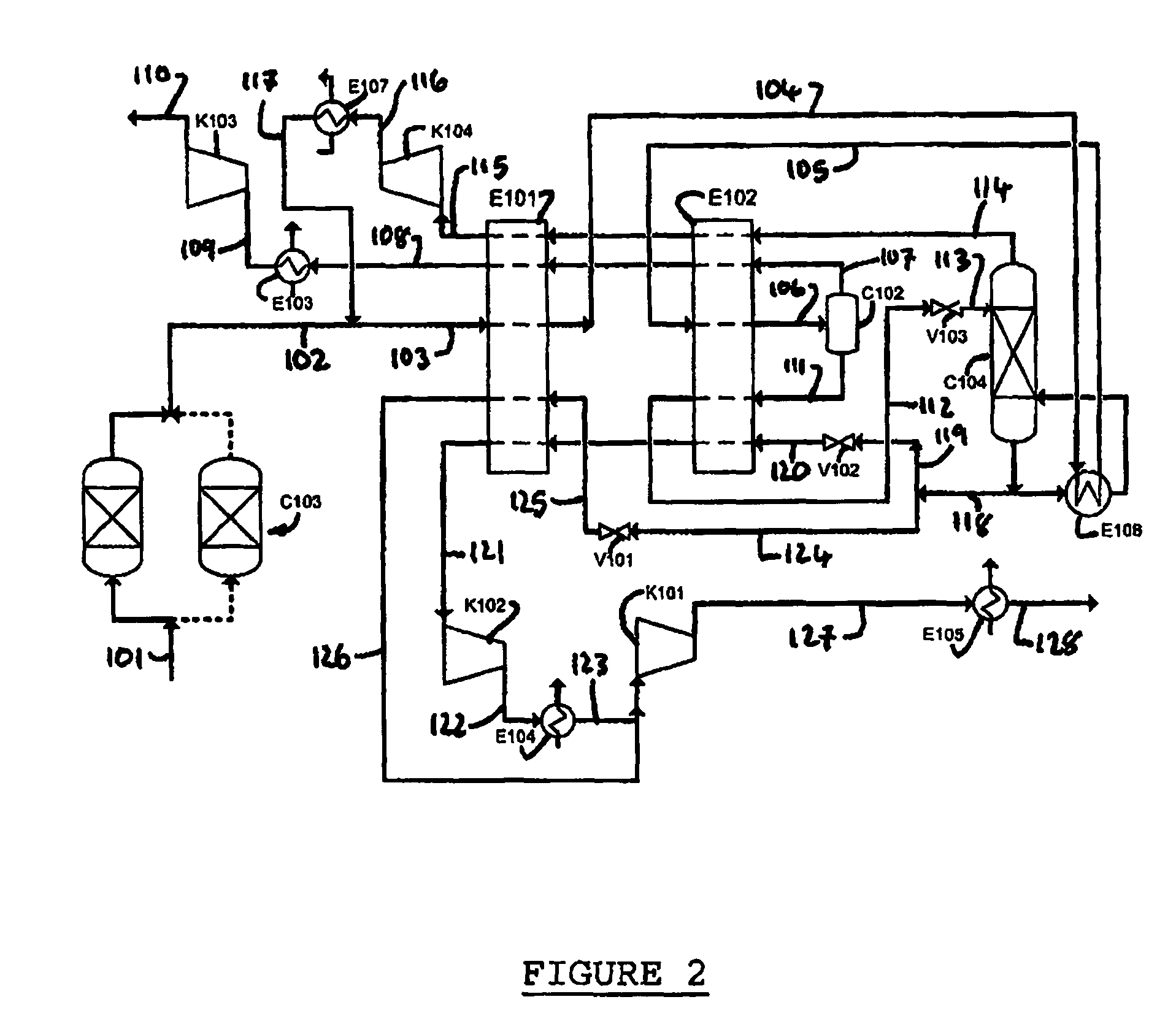

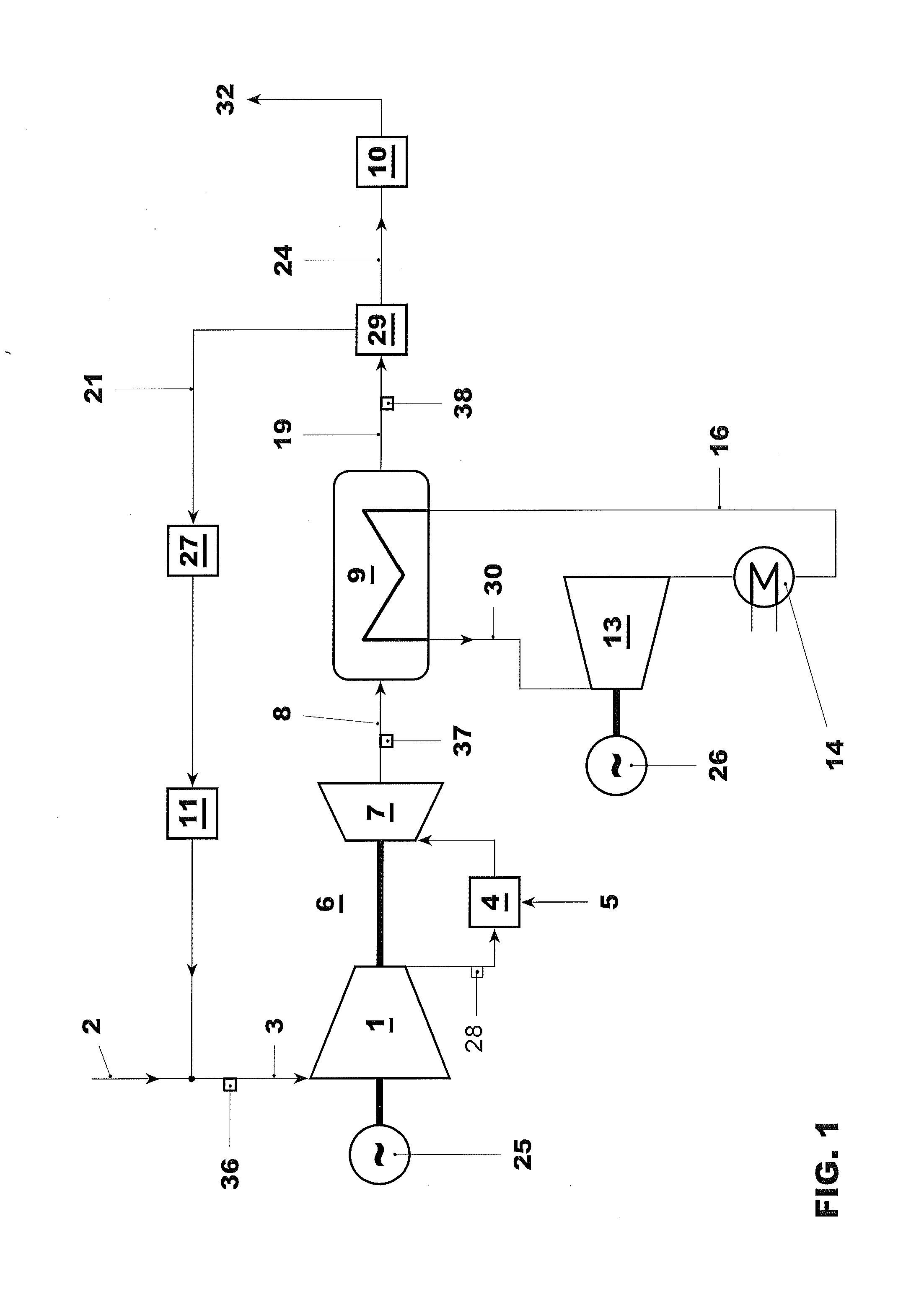

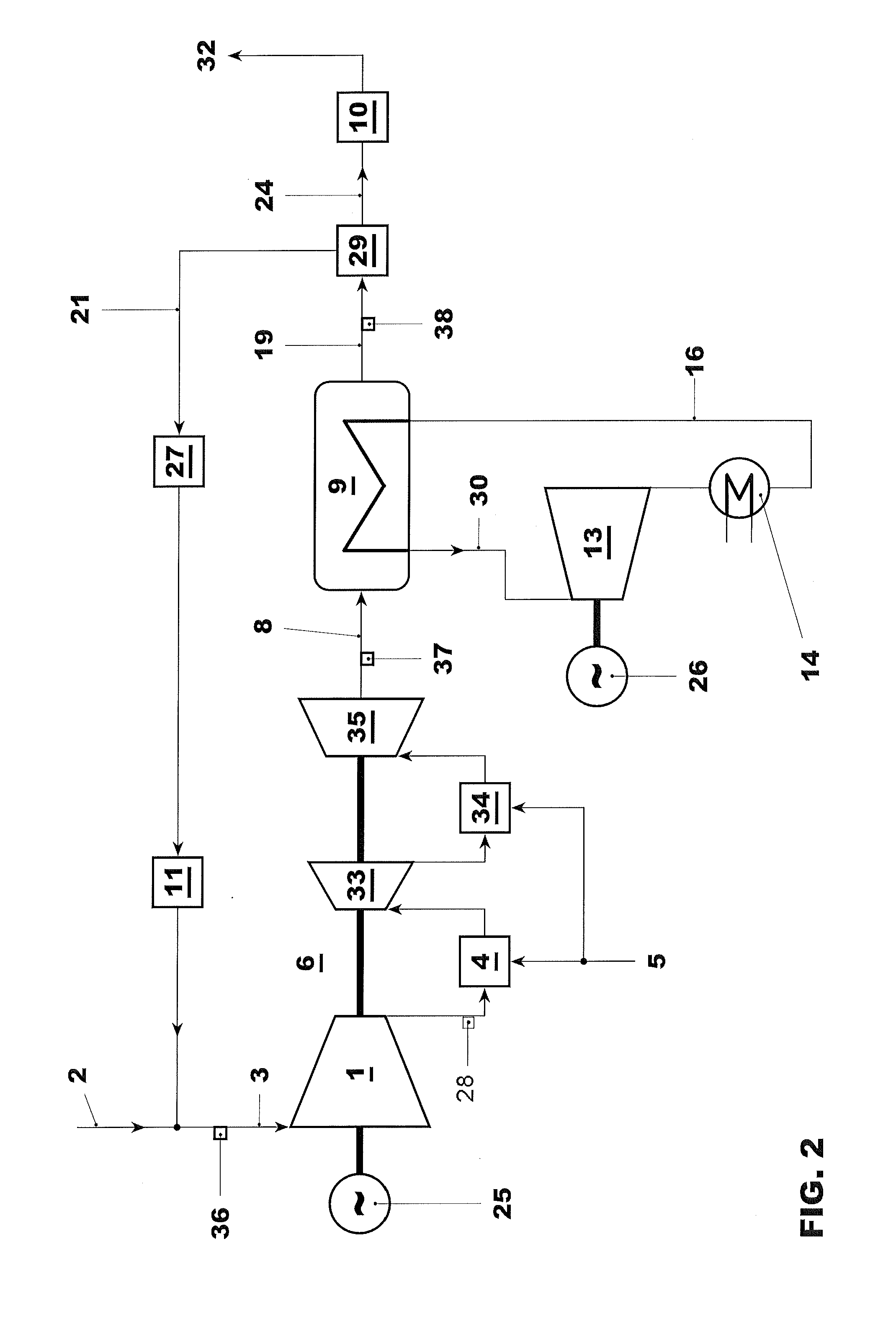

A power generation system and method providing an engine configured to produce hydrogen rich reformate to feed a solid oxide fuel cell includes an engine having an intake and an exhaust; an air supply in fluid communication with the engine intake; a fuel supply in fluid communication with the engine intake; at least one solid oxide fuel cell having an air intake in fluid communication with an air supply, a fuel intake in fluid communication with the engine exhaust, a solid oxide fuel cell effluent and an air effluent. Engines include a free piston gas generator with rich homogenous charge compression, a rich internal combustion engine cylinder system with an oxygen generator, and a rich inlet turbo-generator system with exhaust heat recovery. Oxygen enrichment devices to enhance production of hydrogen rich engine exhaust include pressure swing absorption with oxygen selective materials, and oxygen separators such as an solid oxide fuel cell oxygen separator and a ceramic membrane oxygen separator.

Owner:DELPHI TECH INC

Purification of carbon dioxide

Carbon dioxide is separated from a feed gas, preferably derived from flue gas from an oxyfuel combustion process, in a membrane separation system to produce separated carbon dioxide gas which is fed to the oxyfuel combustion process to improve the performance of the process.

Owner:AIR PROD & CHEM INC

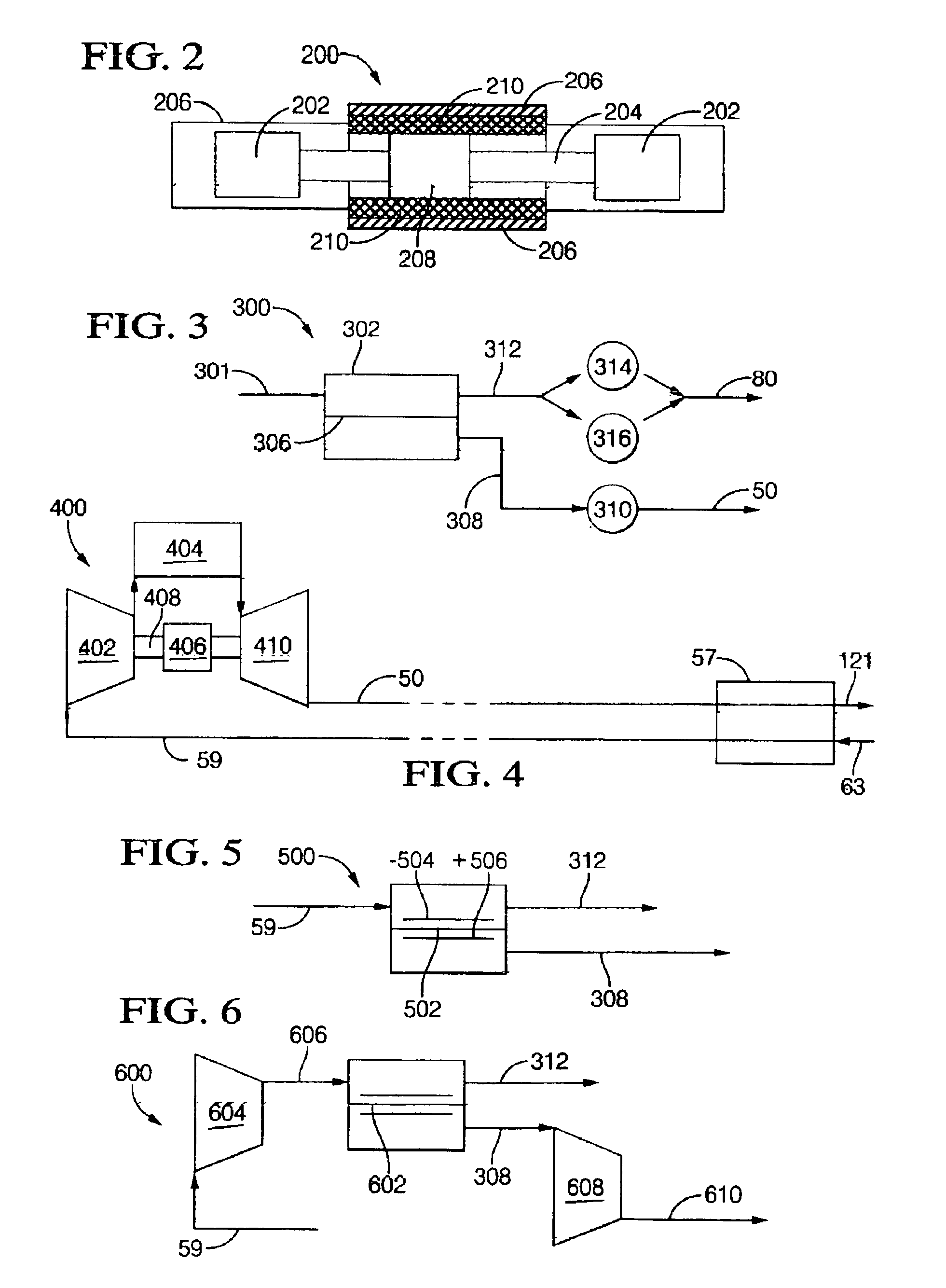

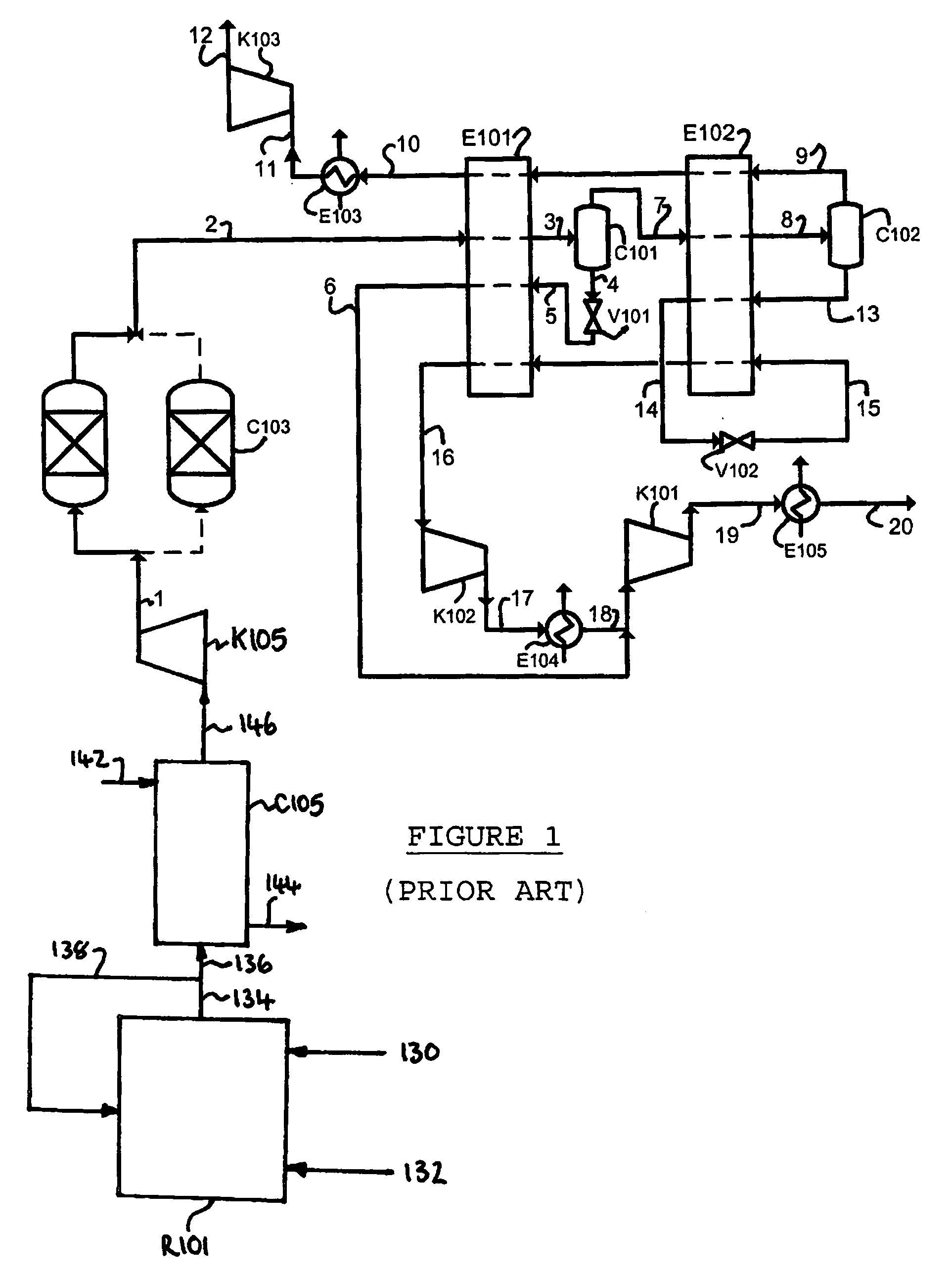

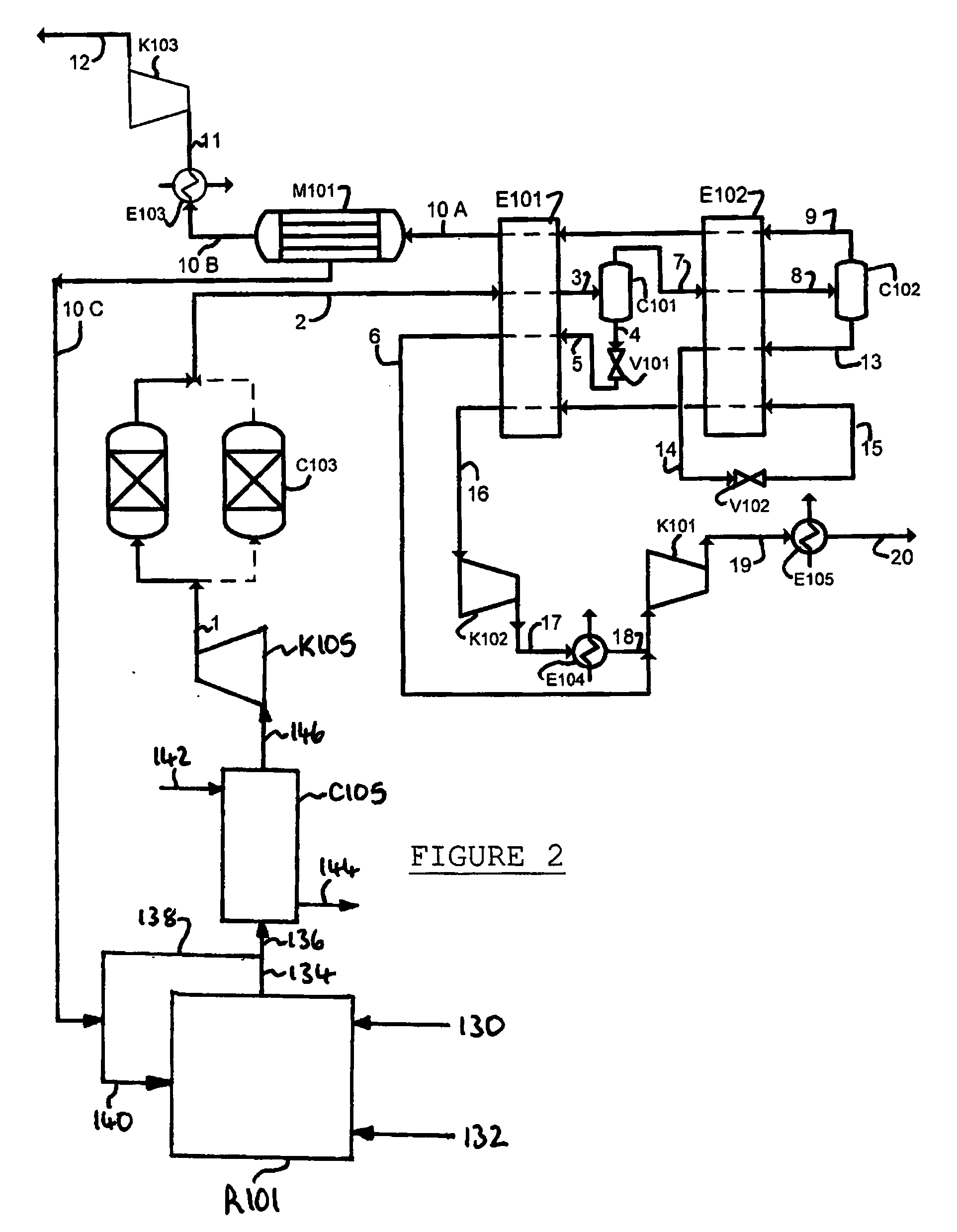

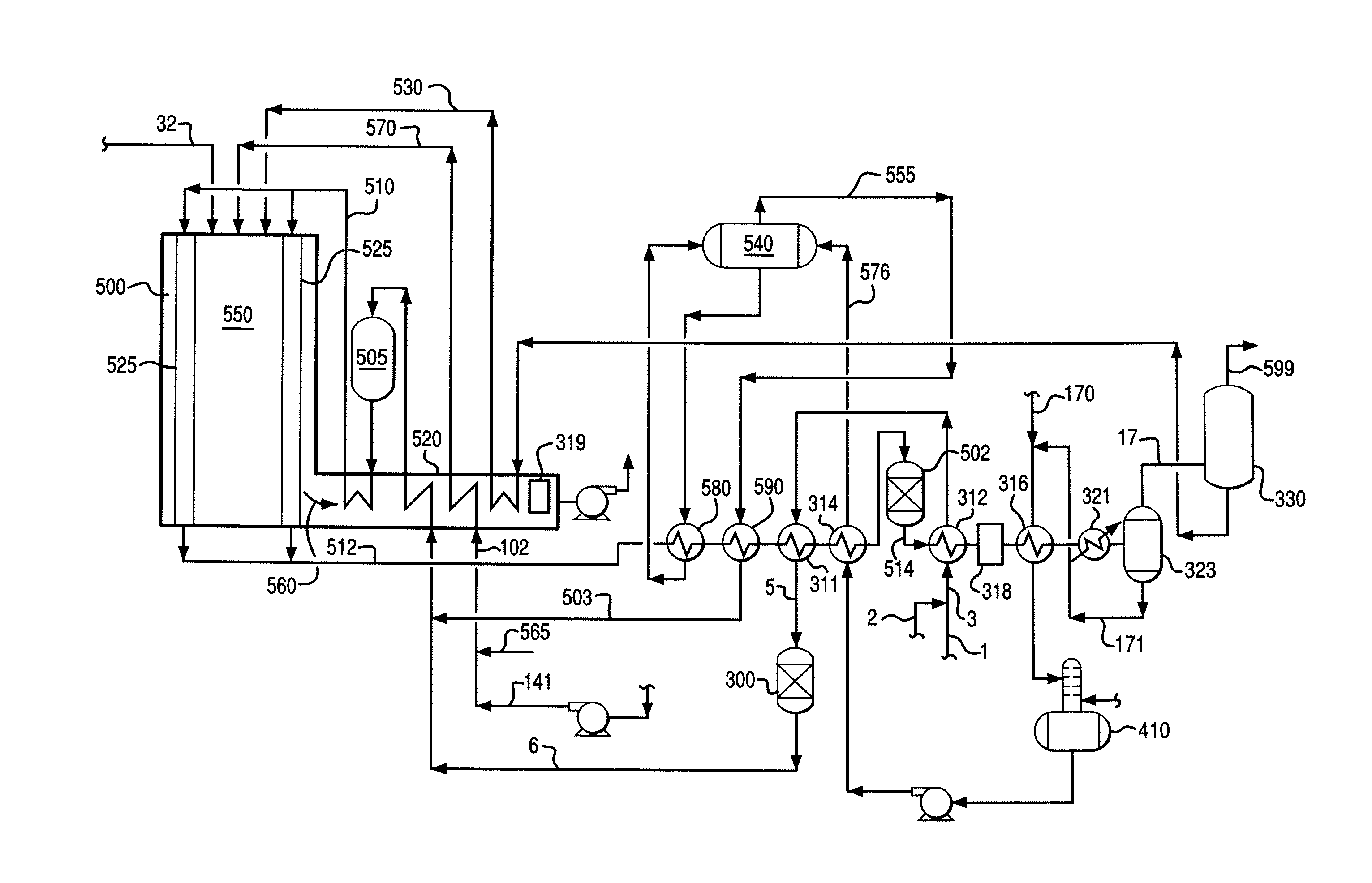

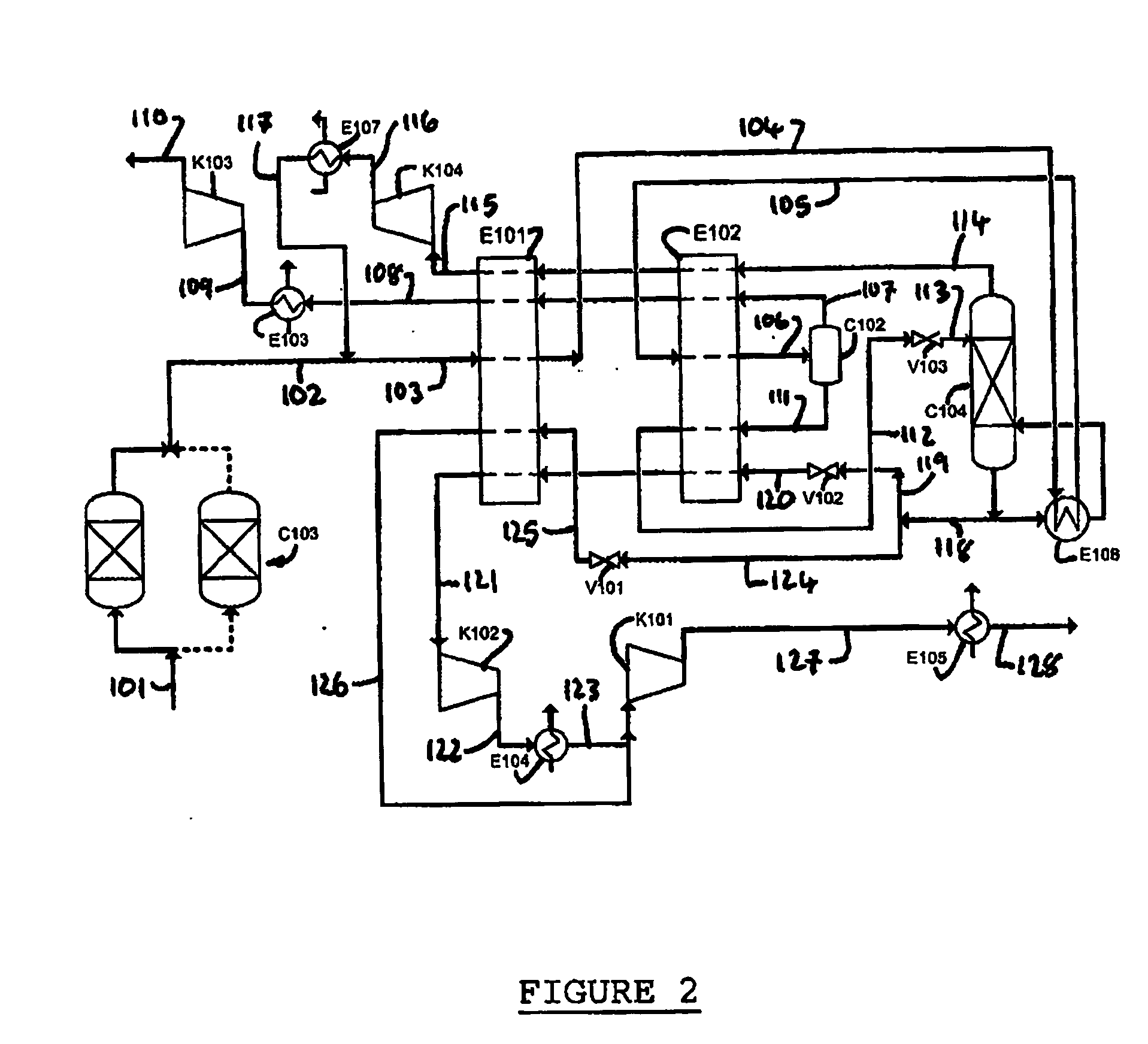

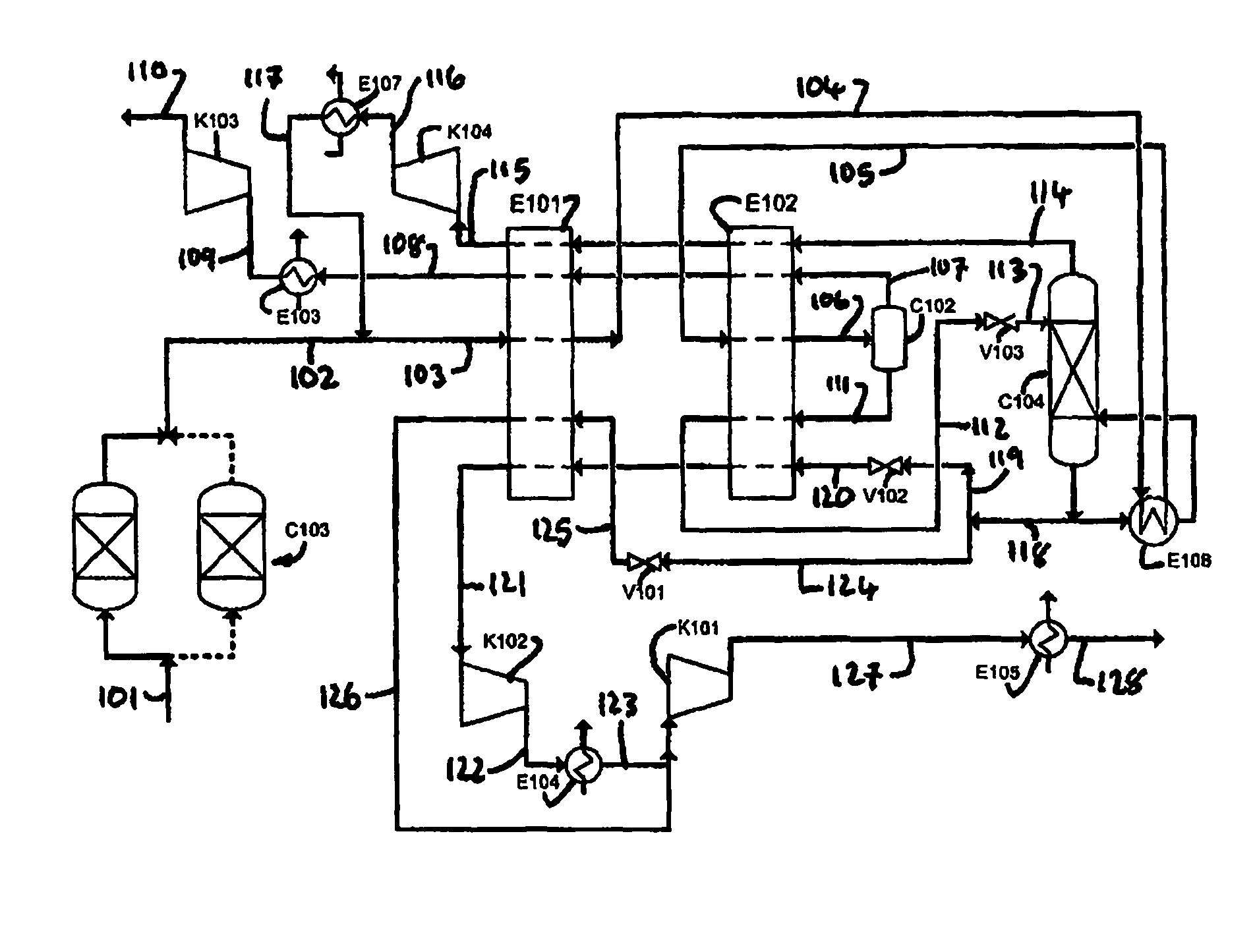

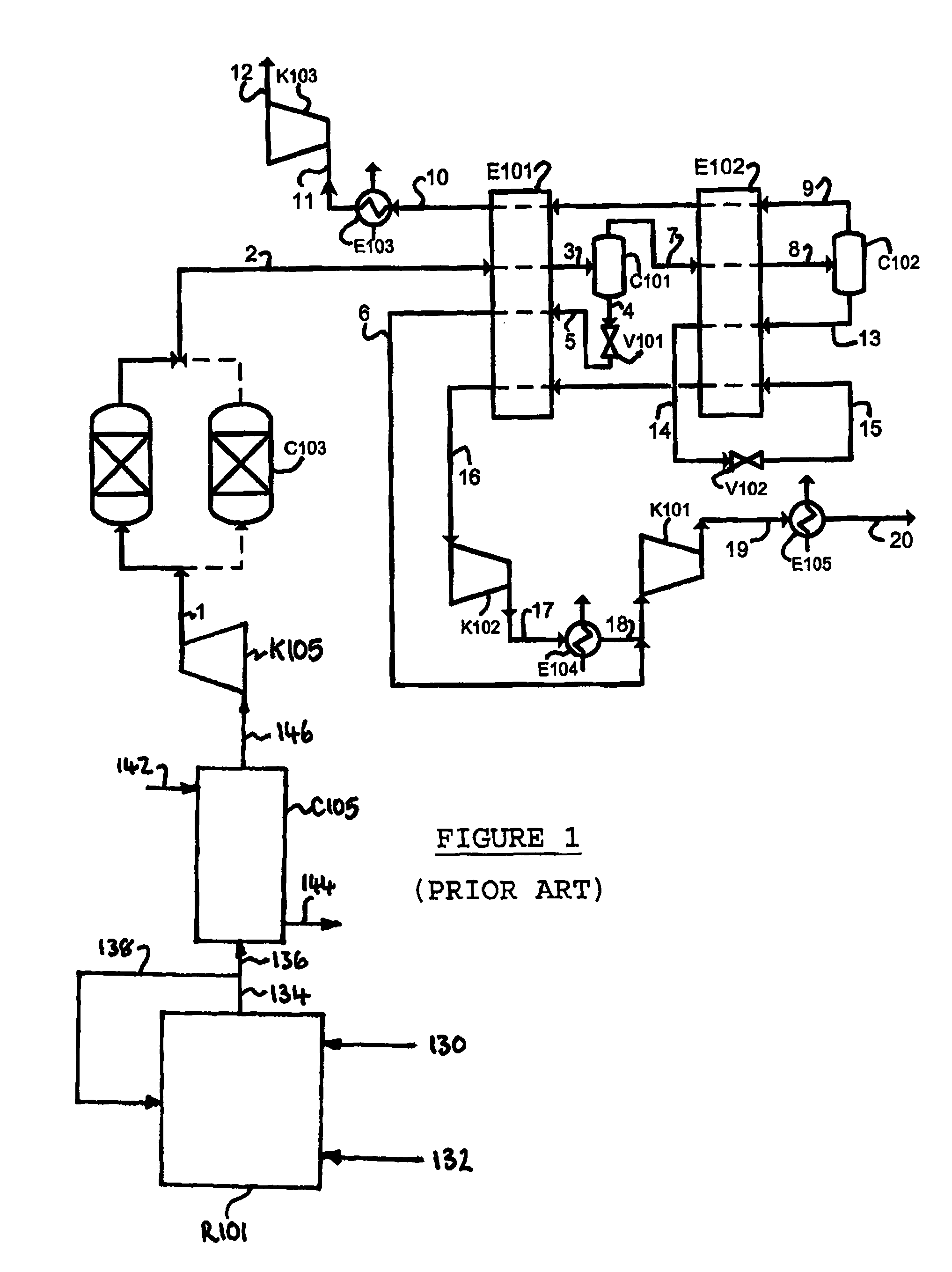

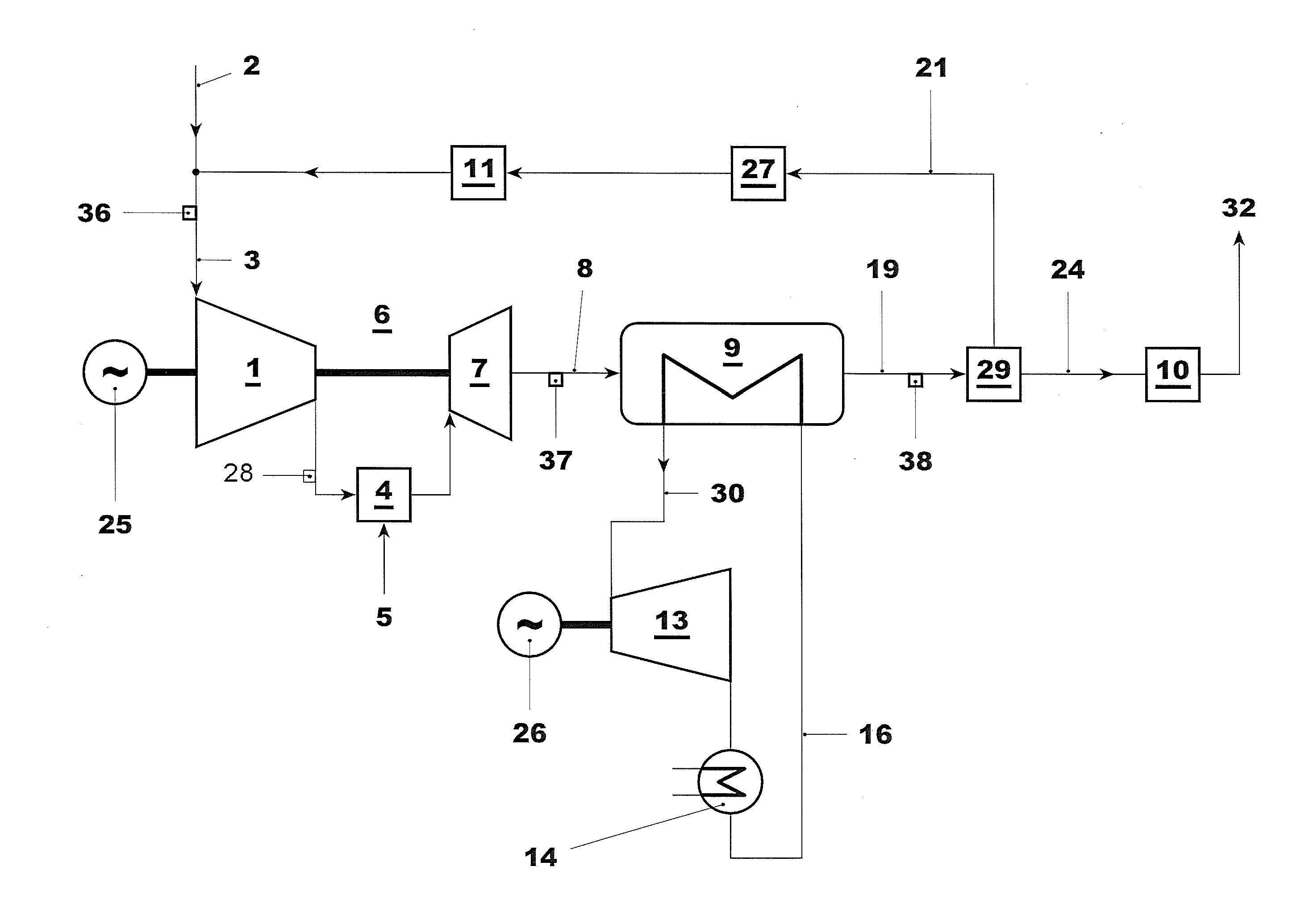

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

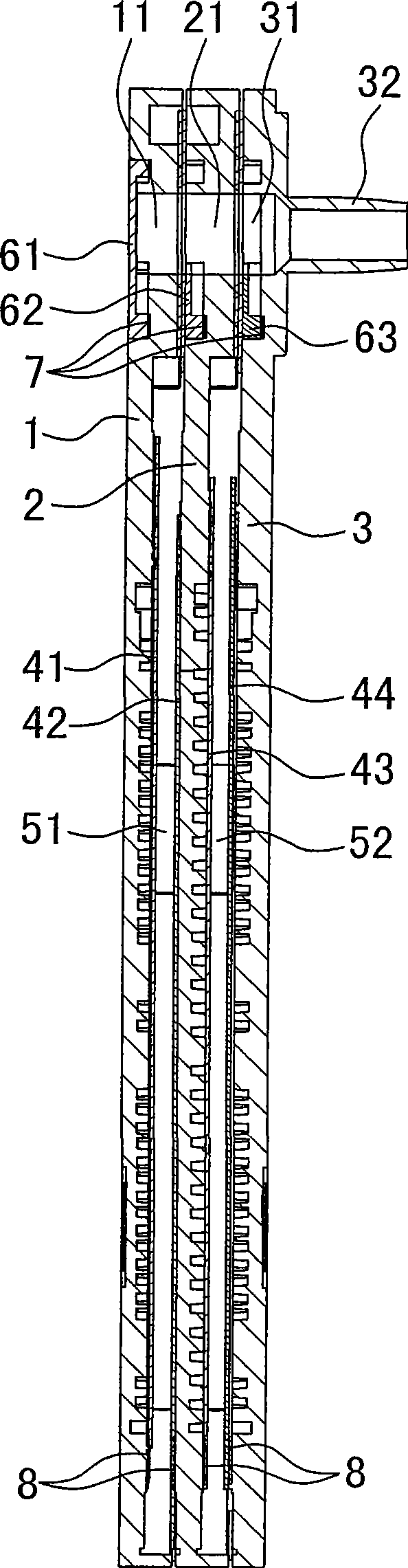

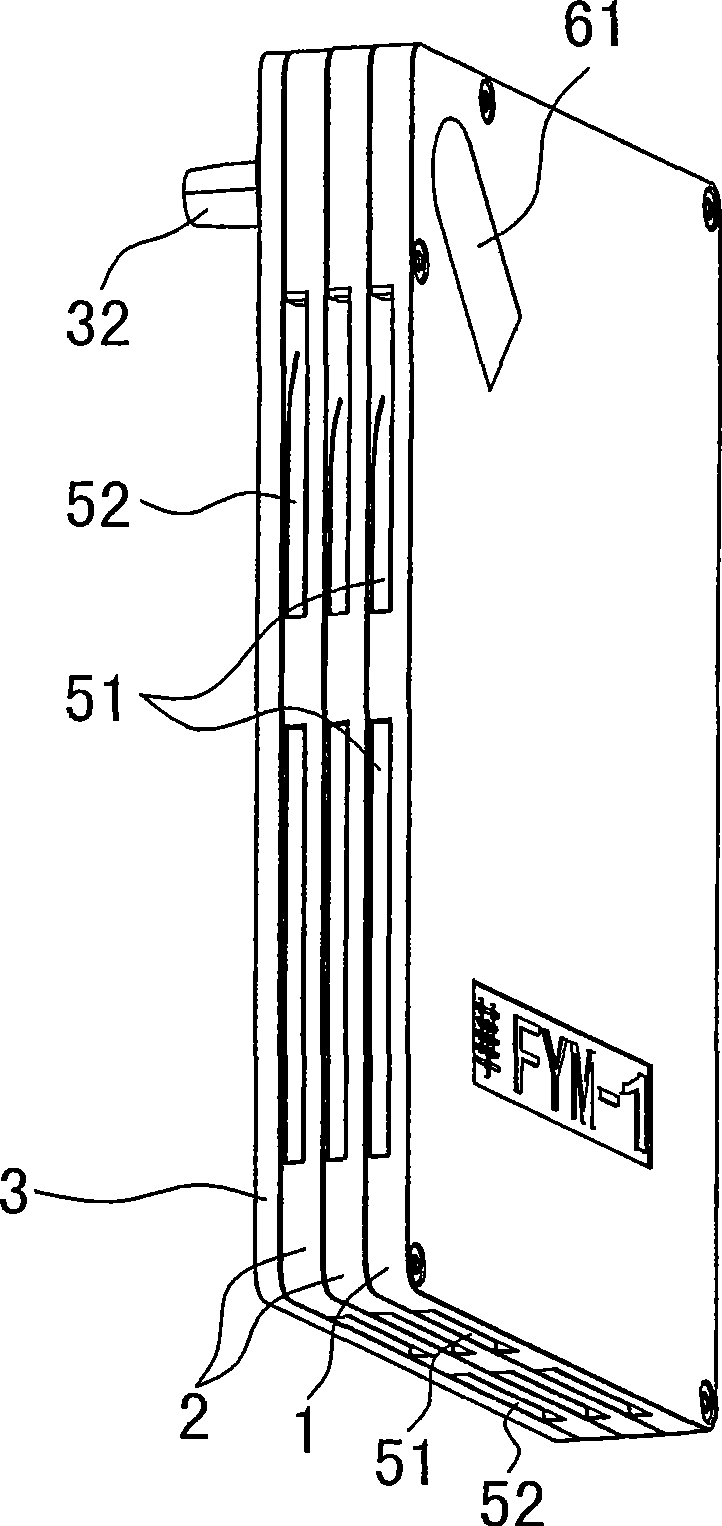

Oxygen enrichment device for ventilator

An enrichment device for mixing ambient air with a gas such as oxygen has a rigid outer housing defining a reservoir. The housing has an outlet port for attachment to a cyclic low pressure source, an ambient air inlet, and a second inlet for connection to a supply of pressurized gas. The reservoir has a plurality of internal walls defining a passageway having a plurality of turns defining a tortuous path for gas flow between the ambient air inlet and the outlet port, and the second inlet communicates with the passageway at a location at or close to the outlet port.

Owner:TYCO HEALTHCARE GRP LP

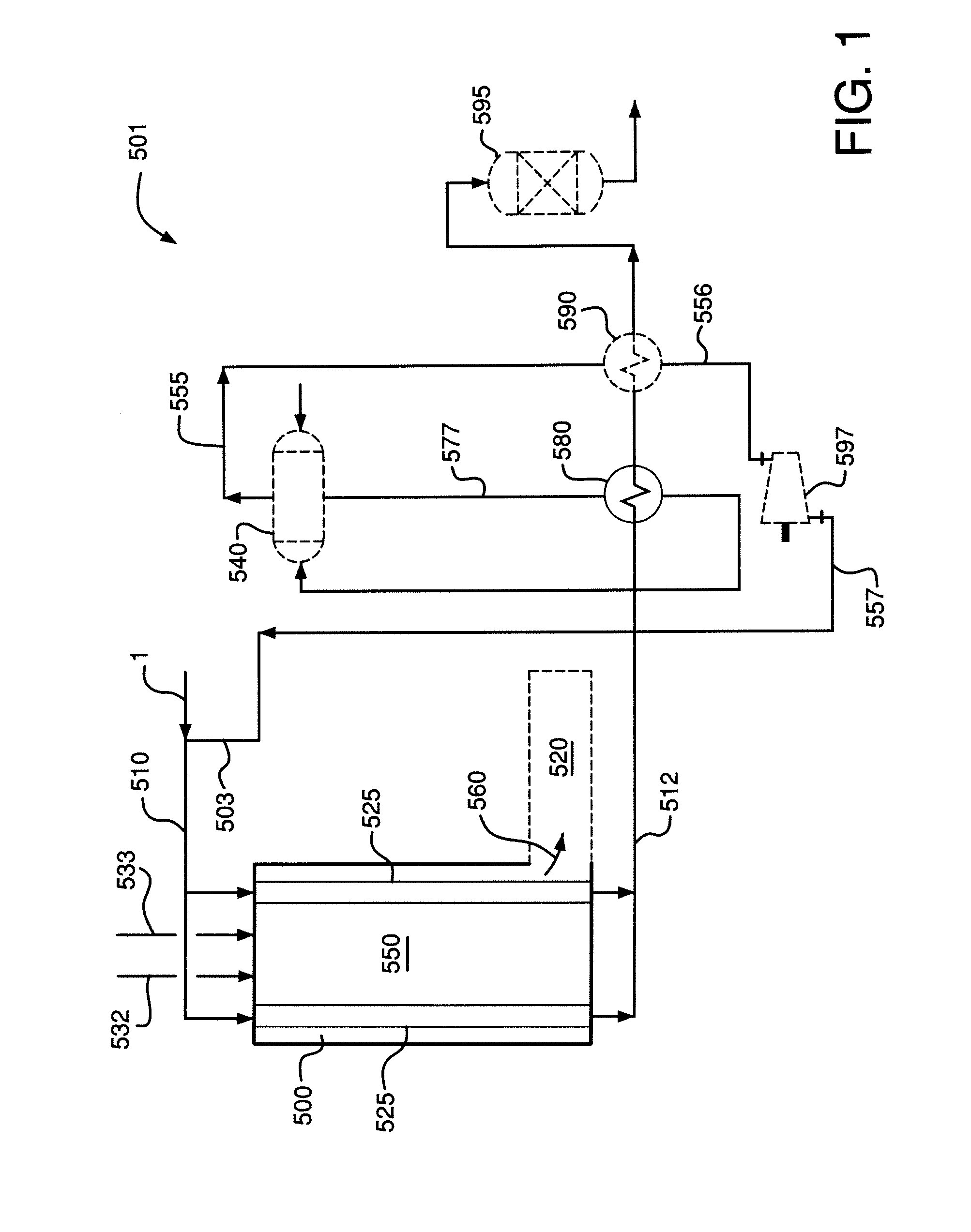

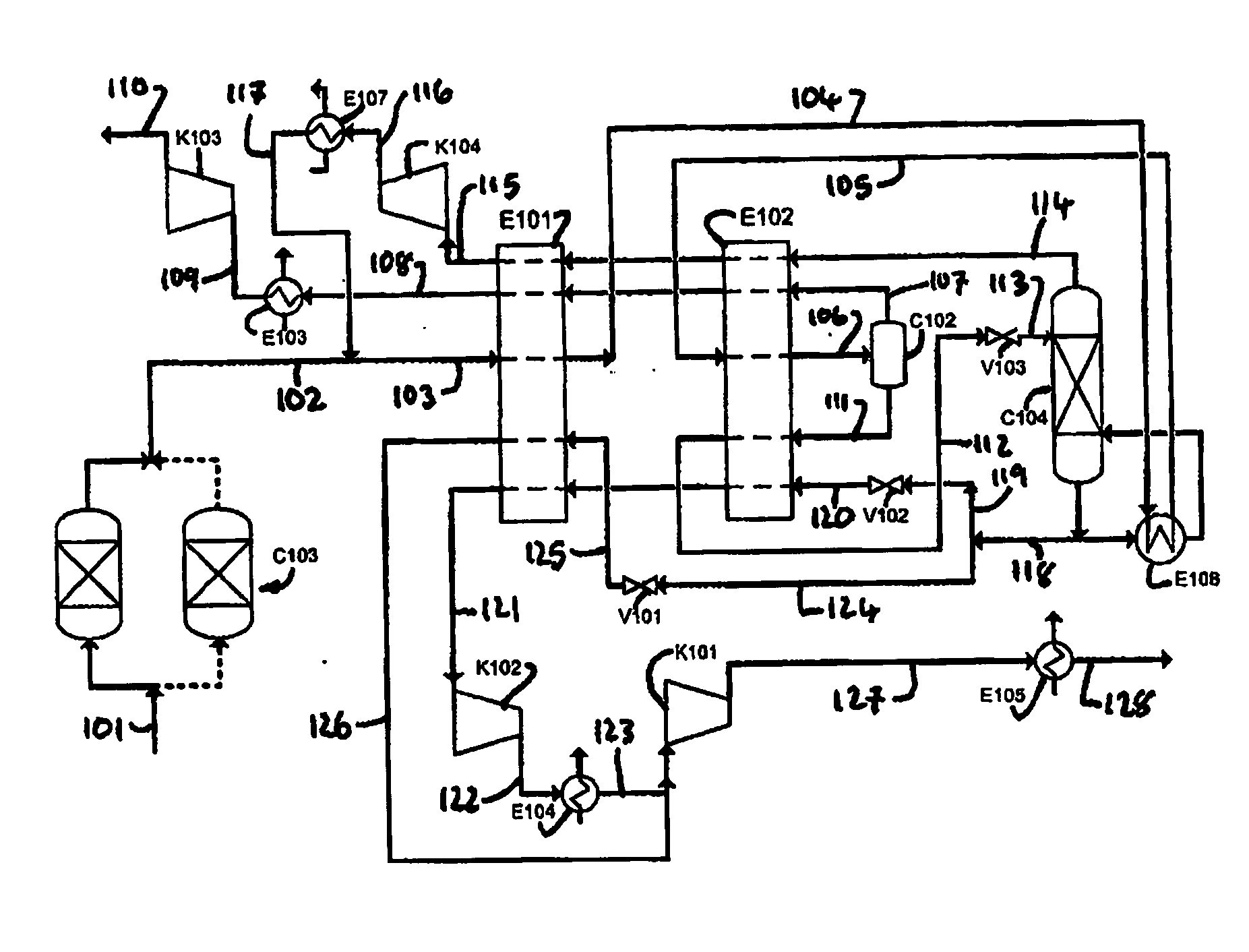

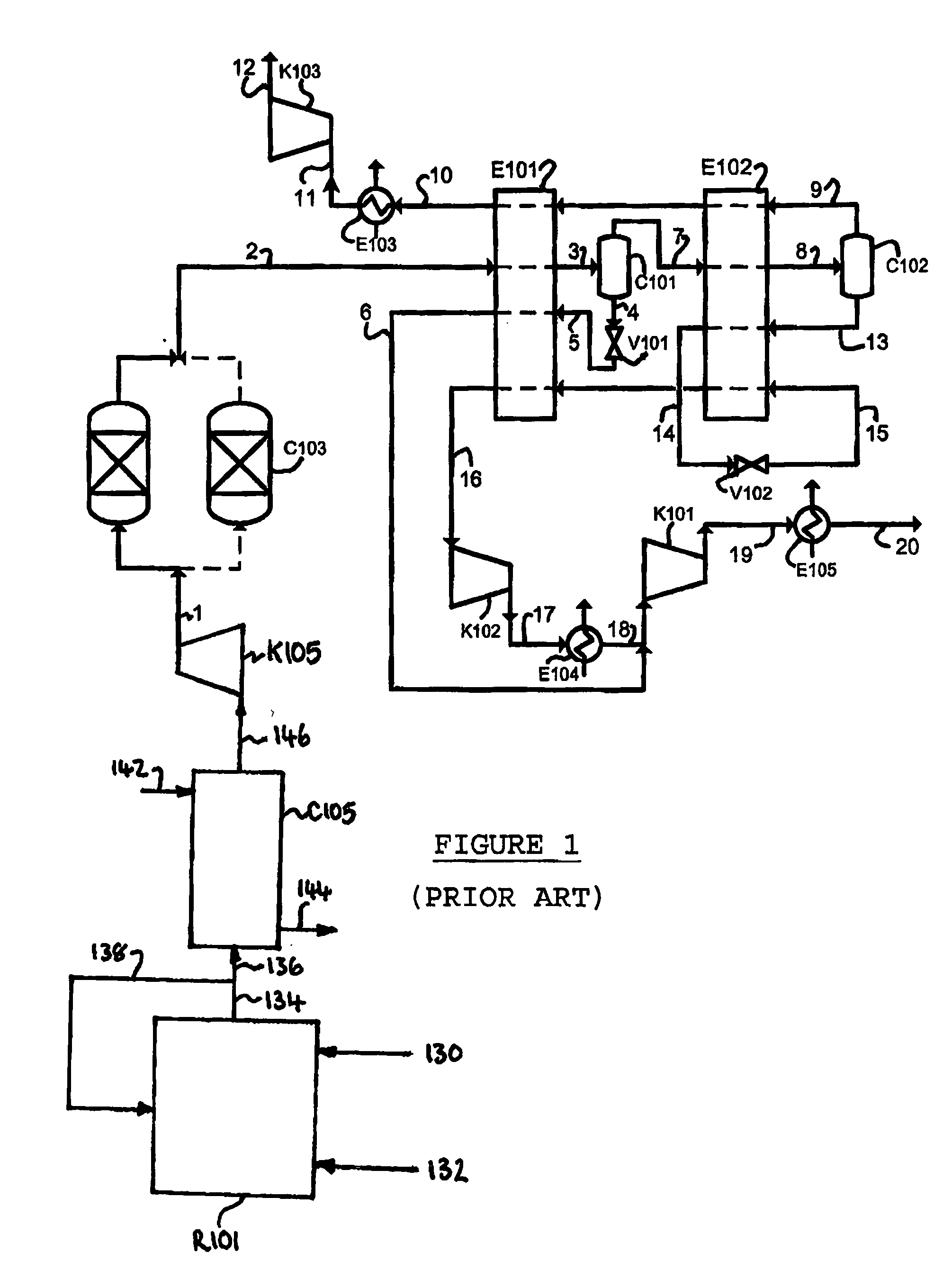

Steam-Hydrocarbon Reforming Method with Limited Steam Export

A method for generating hydrogen and / or synthesis gas in a production facility where little or no export steam is produced. Most or all of the high pressure steam produced from the waste heat from the process is used in the steam-hydrocarbon reformer with little or no steam export. The method uses oxygen enhanced combustion which may involve oxygen lancing and / or oxygen-enrichment. Plant efficiencies using the method and prior art-type methods are compared.

Owner:AIR PROD & CHEM INC

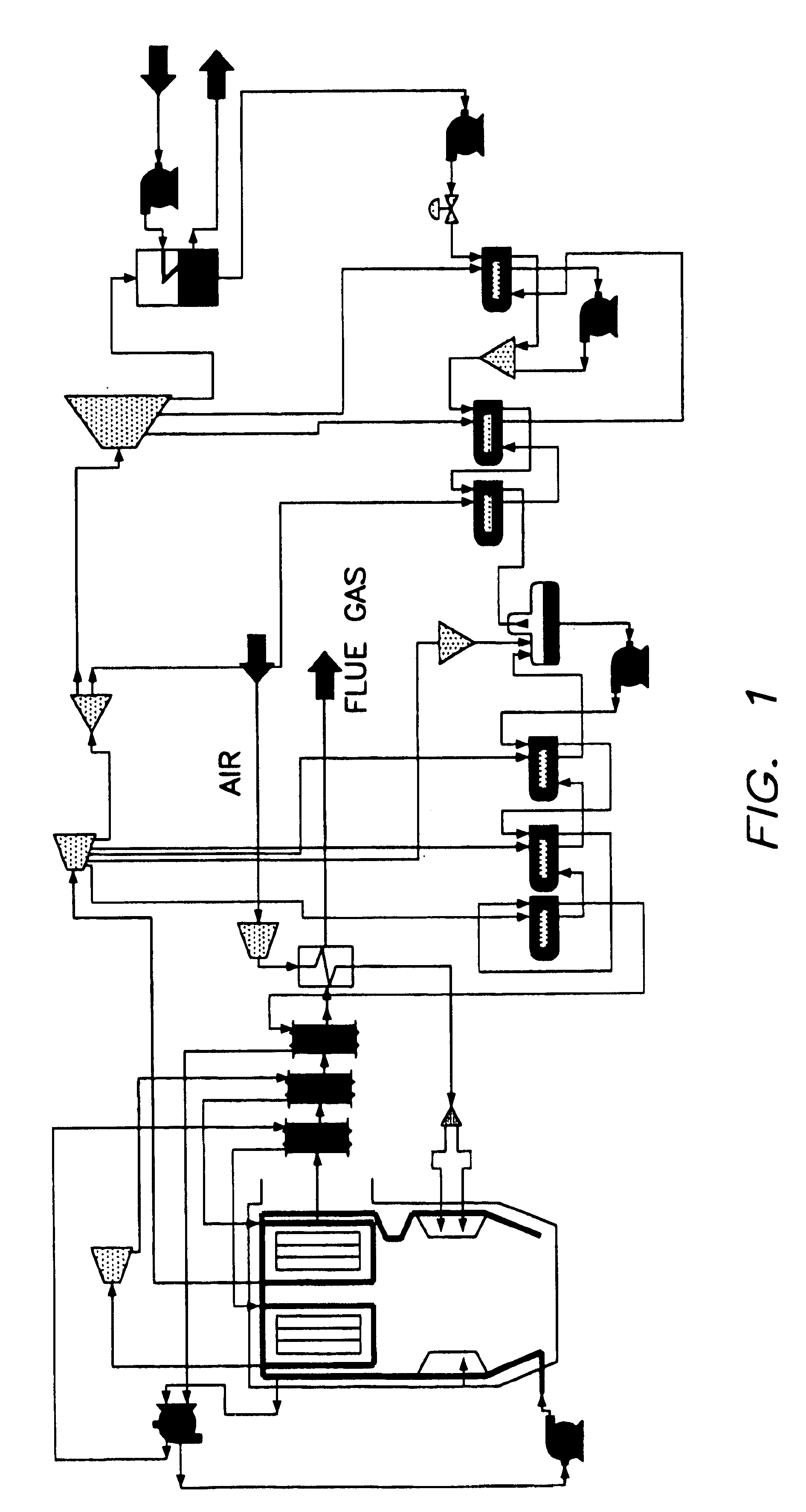

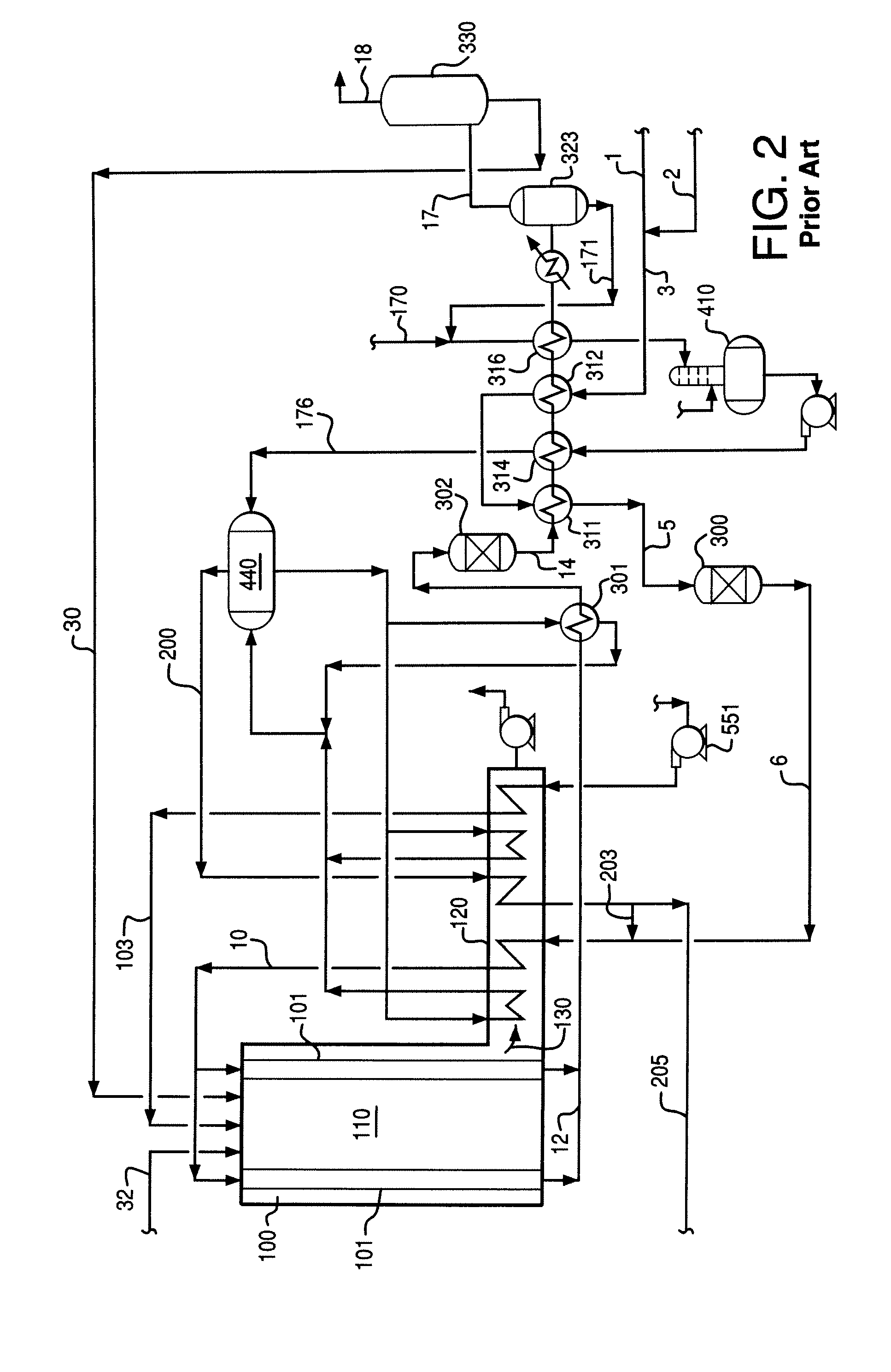

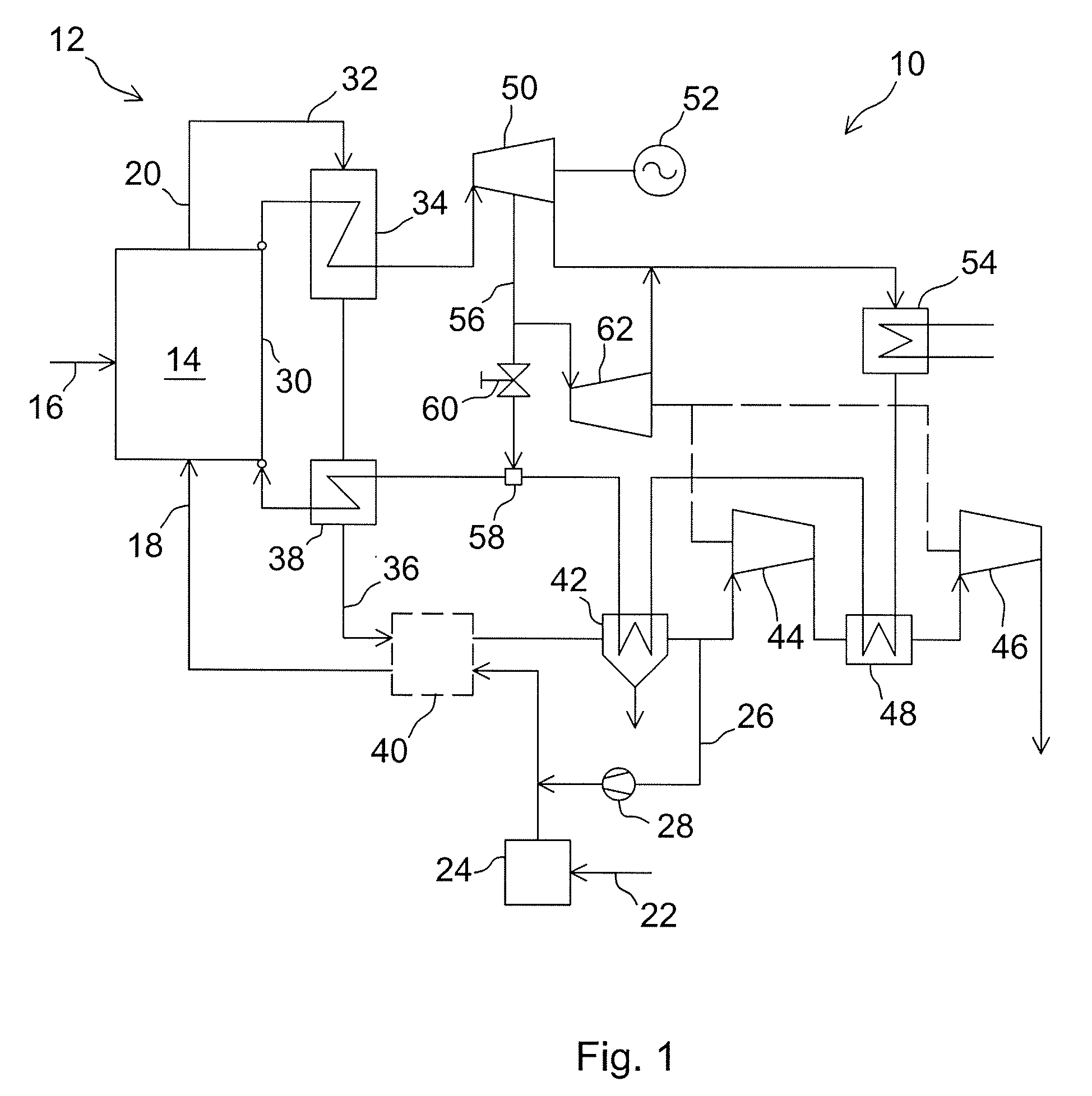

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

Low emission energy source

Owner:BRIGHTSOURCE ENERGY

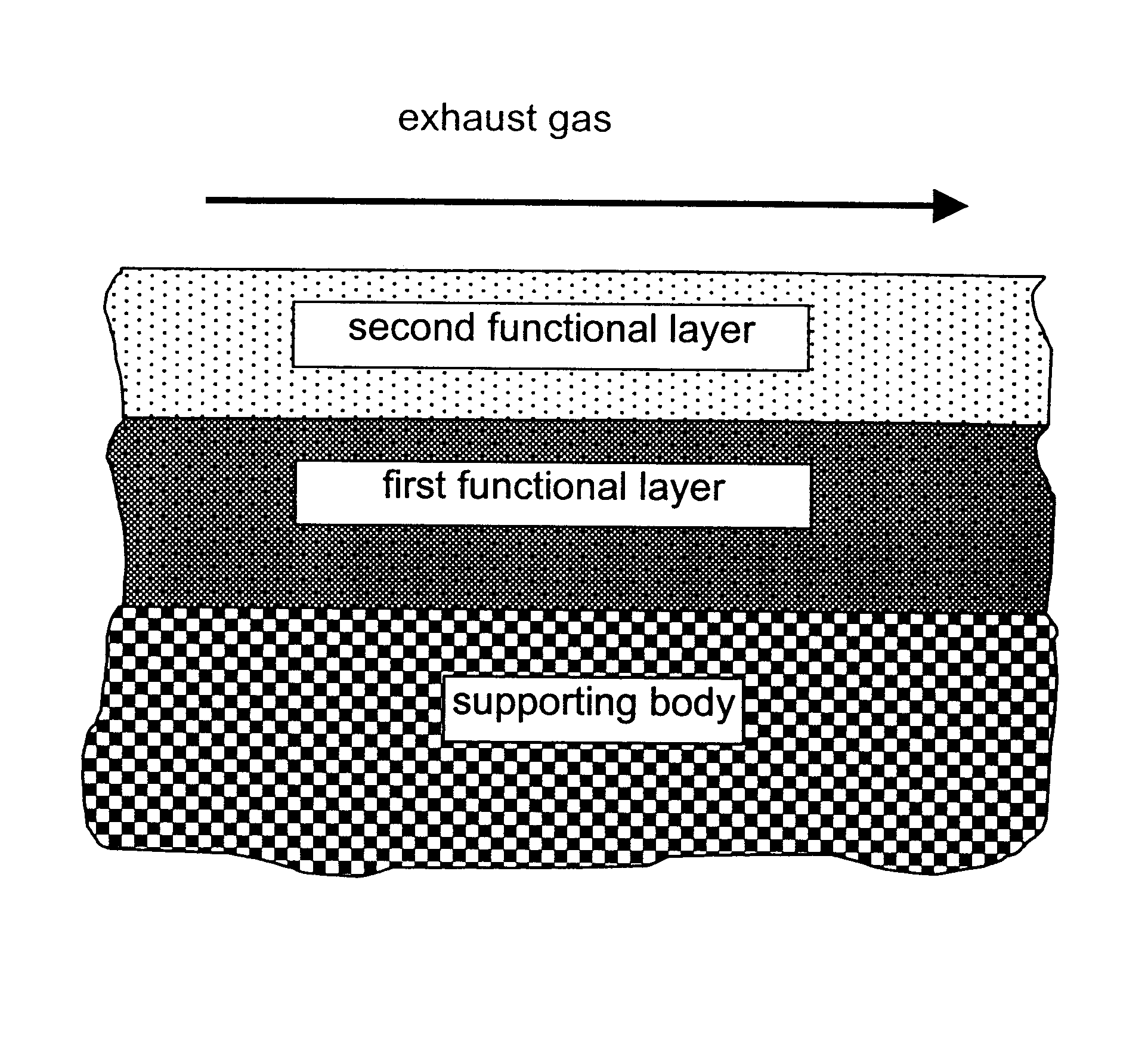

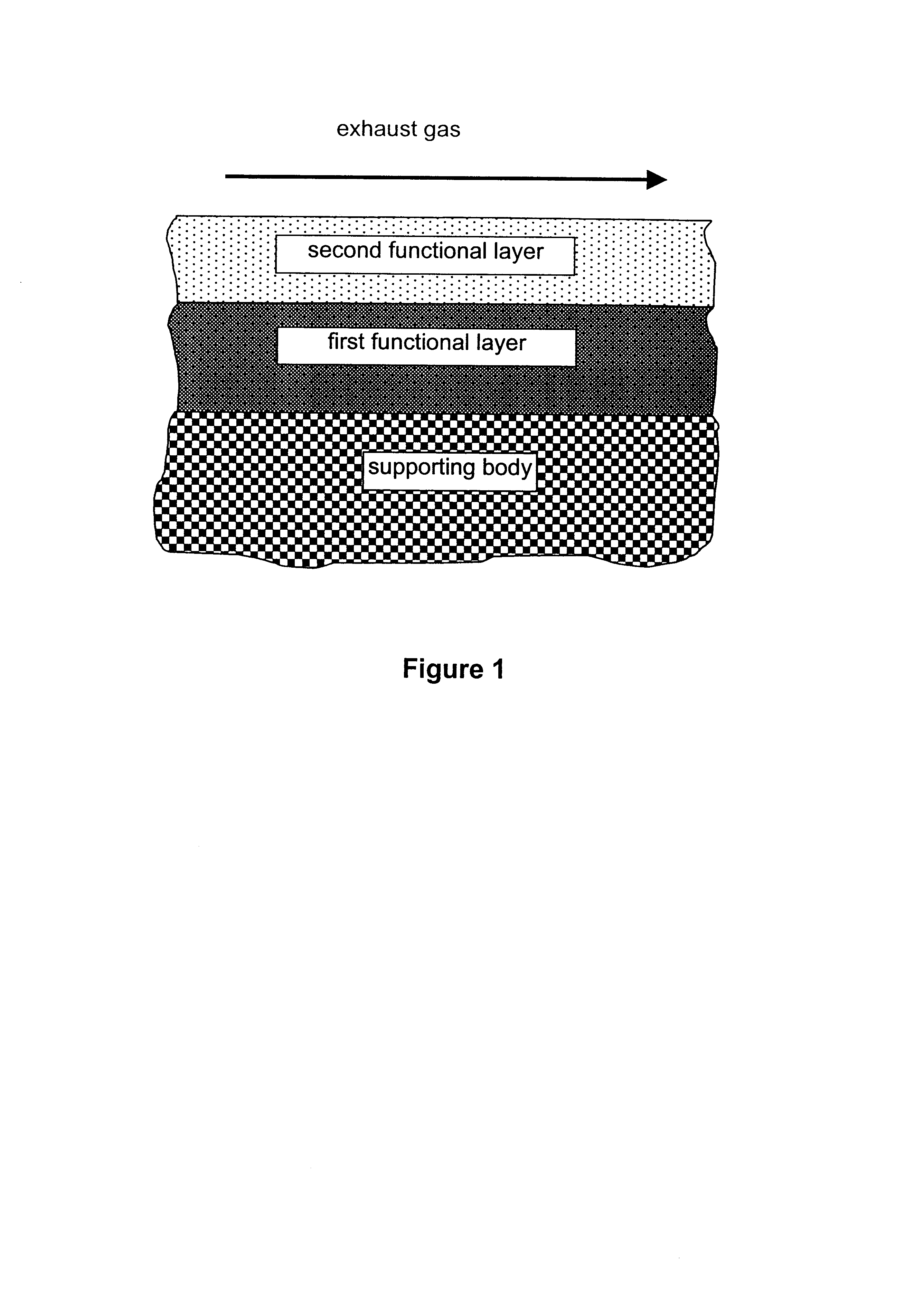

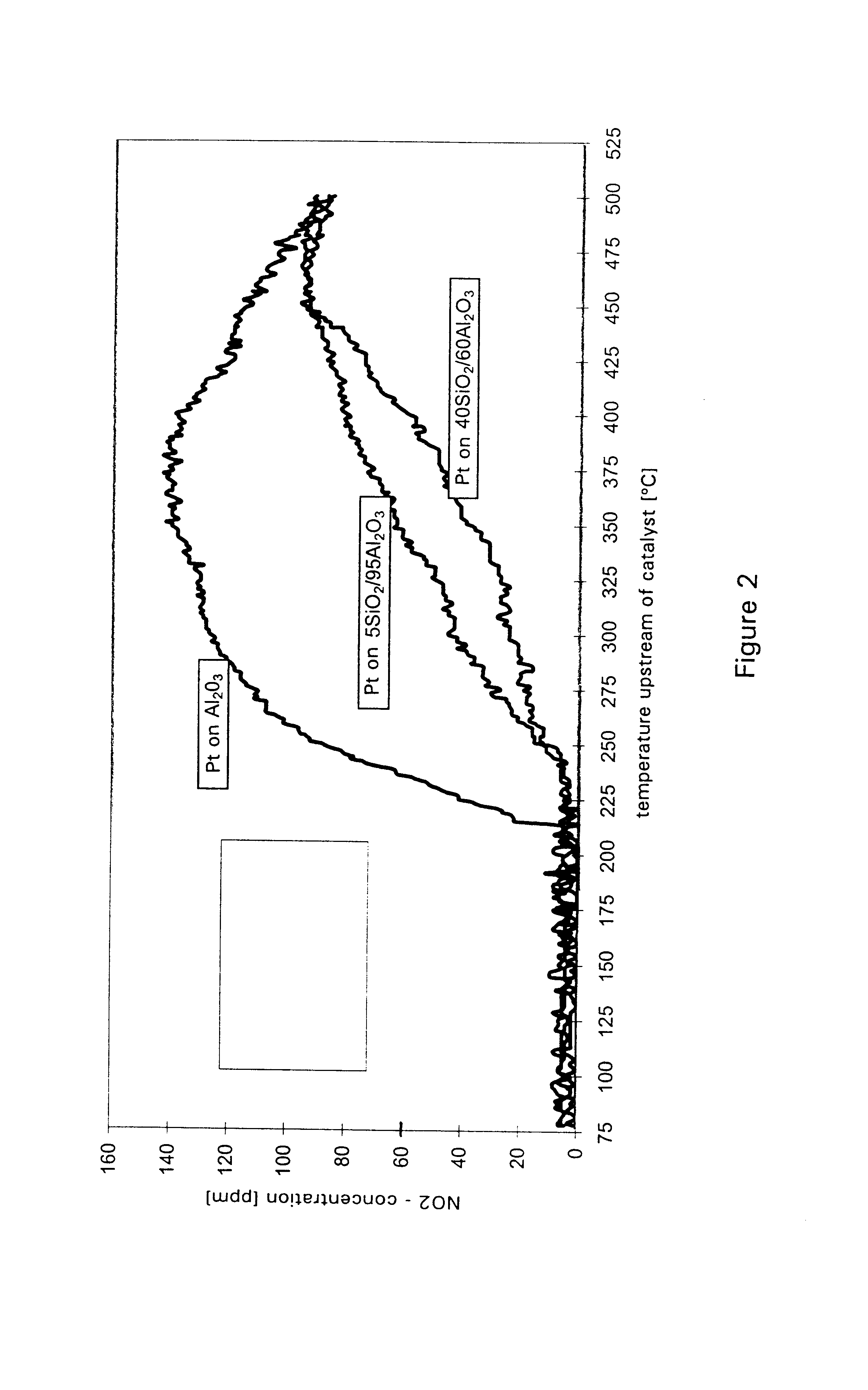

Catalyst for cleaning up the exhaust gases of a diesel engine

InactiveUS6677264B1Reduced activityReduce componentsMolecular sieve catalystsInternal combustion piston enginesCatalytic functionComponents of crude oil

A catalyst for purifying exhaust gases of a diesel engine. The catalyst contains two functional layers superimposed on an inert supporting body, whereby the first layer, which is situated directly on the supporting body, has a nitrogen oxide storage function and the second layer, which is in direct contact with the exhaust gas, has a catalytic function. The second functional layer additionally has a hydrocarbon-storage function and its catalytic function is provided by catalytically active noble metals of the platinum group which are deposited in highly dispersed form on finely divided, acidic carrier materials. Nitrogen oxides in the oxygen-rich exhaust gas of a diesel engine can be converted with optimal utilization of the reductive constituents contained in the exhaust gas. For this purpose, no reducing agents going beyond the reductive components (carbon monoxide and hydrocarbons) which are contained as a consequence of incomplete combustion need to be added to the exhaust gas. Nevertheless, rates of conversion in respect of the nitrogen oxides are obtained, averaged over practical driving cycles, which lie distinctly above the rates of conversion of conventional reduction catalysts.

Owner:UMICORE AG & CO KG +1

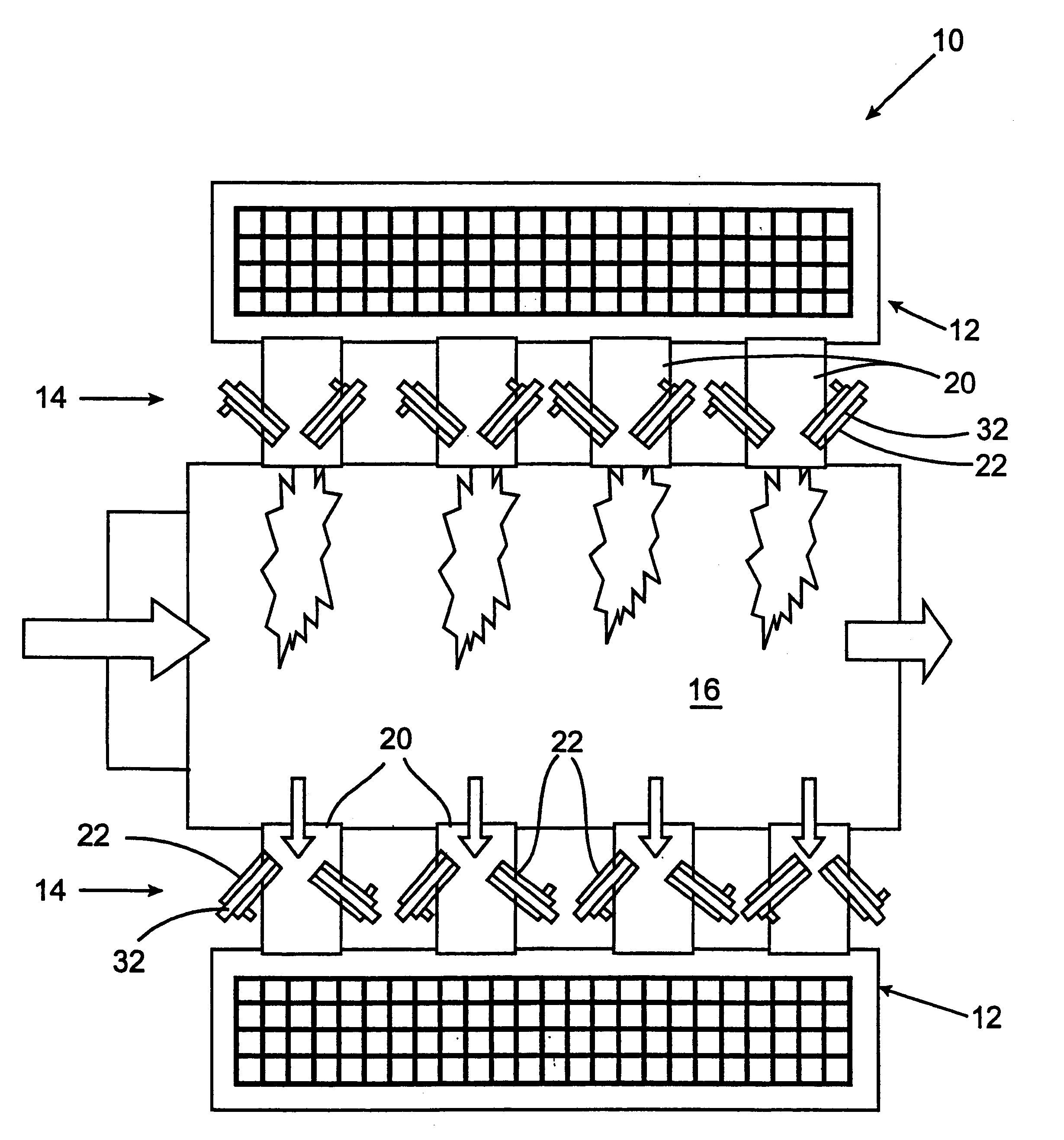

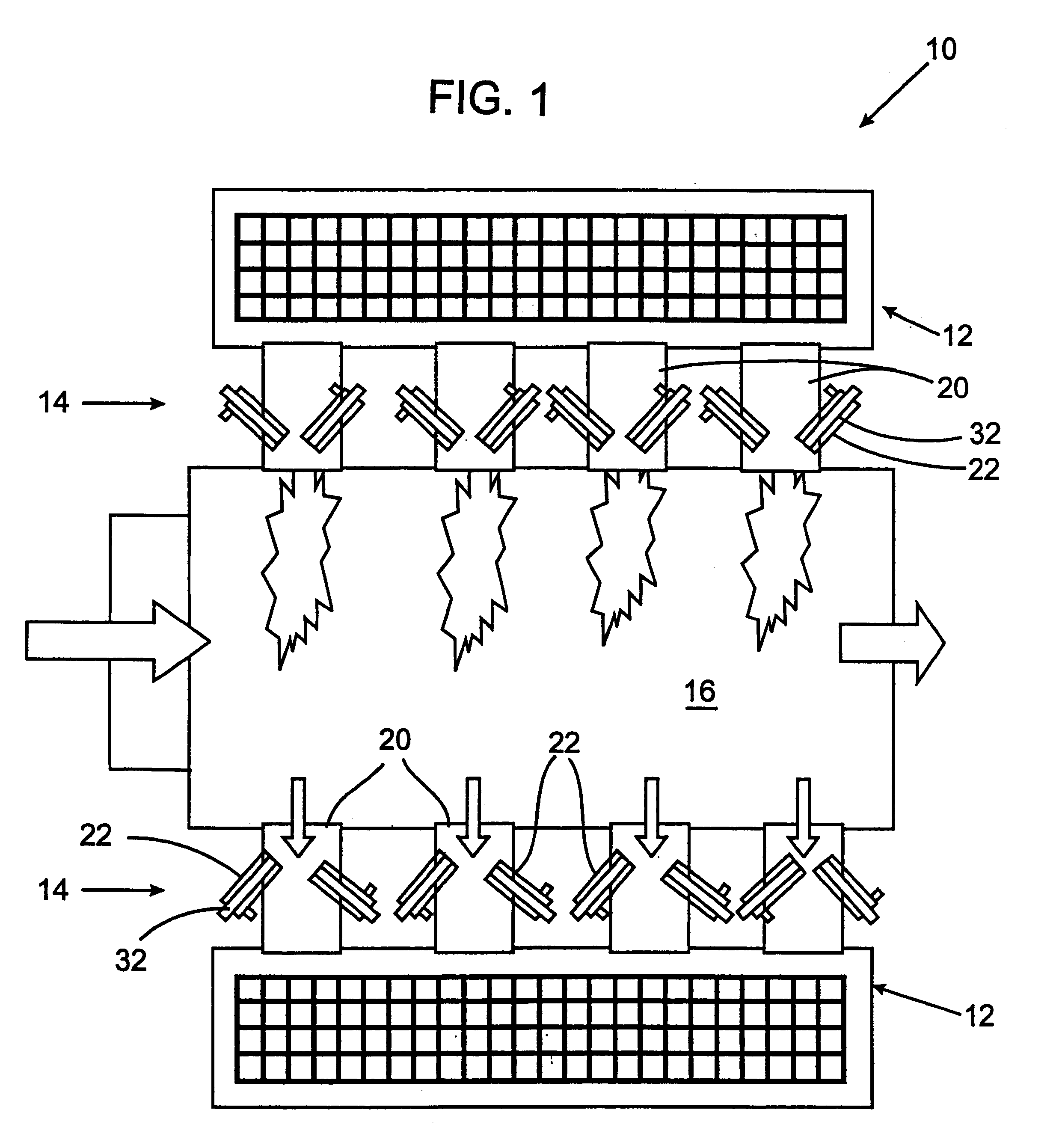

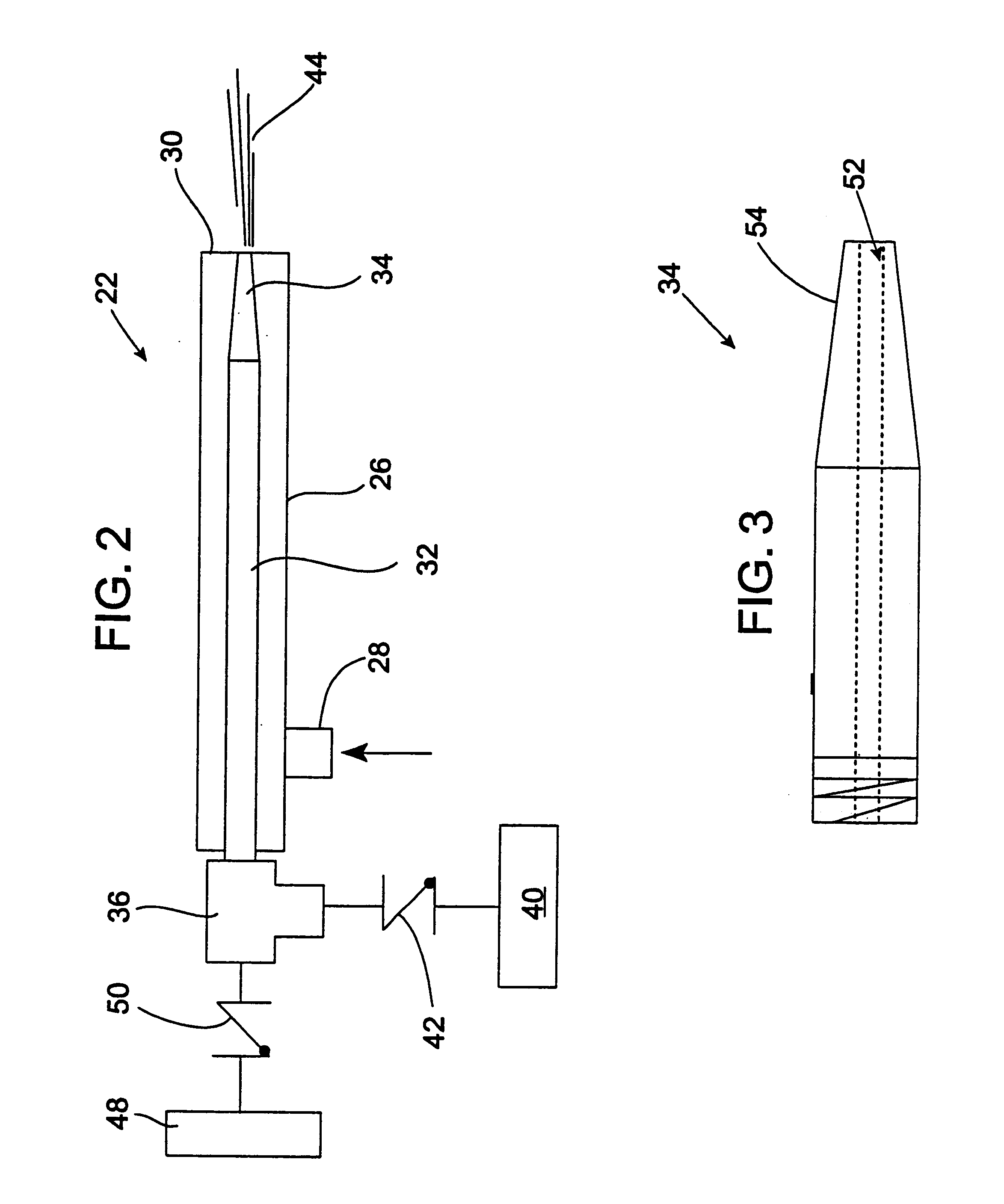

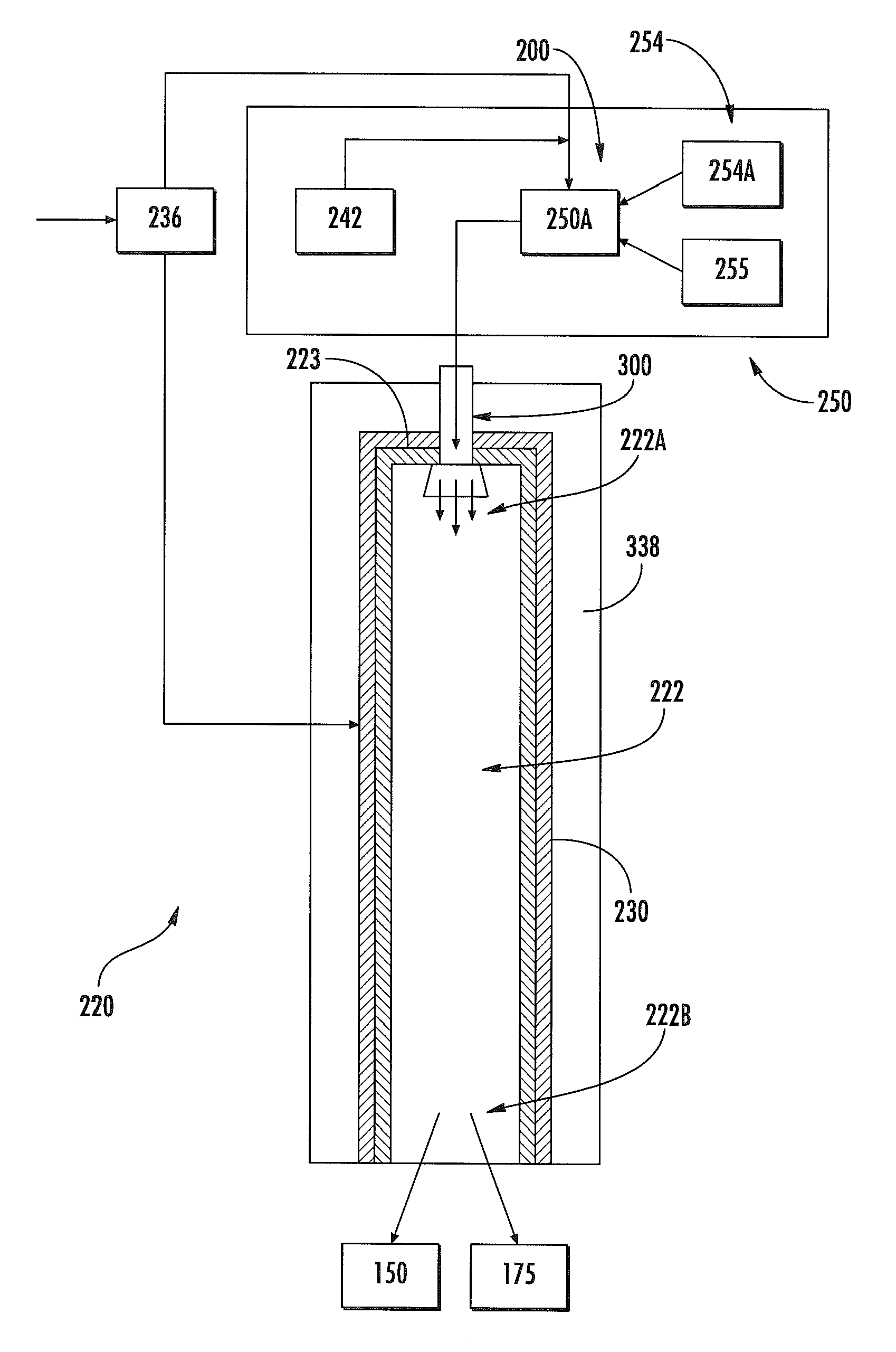

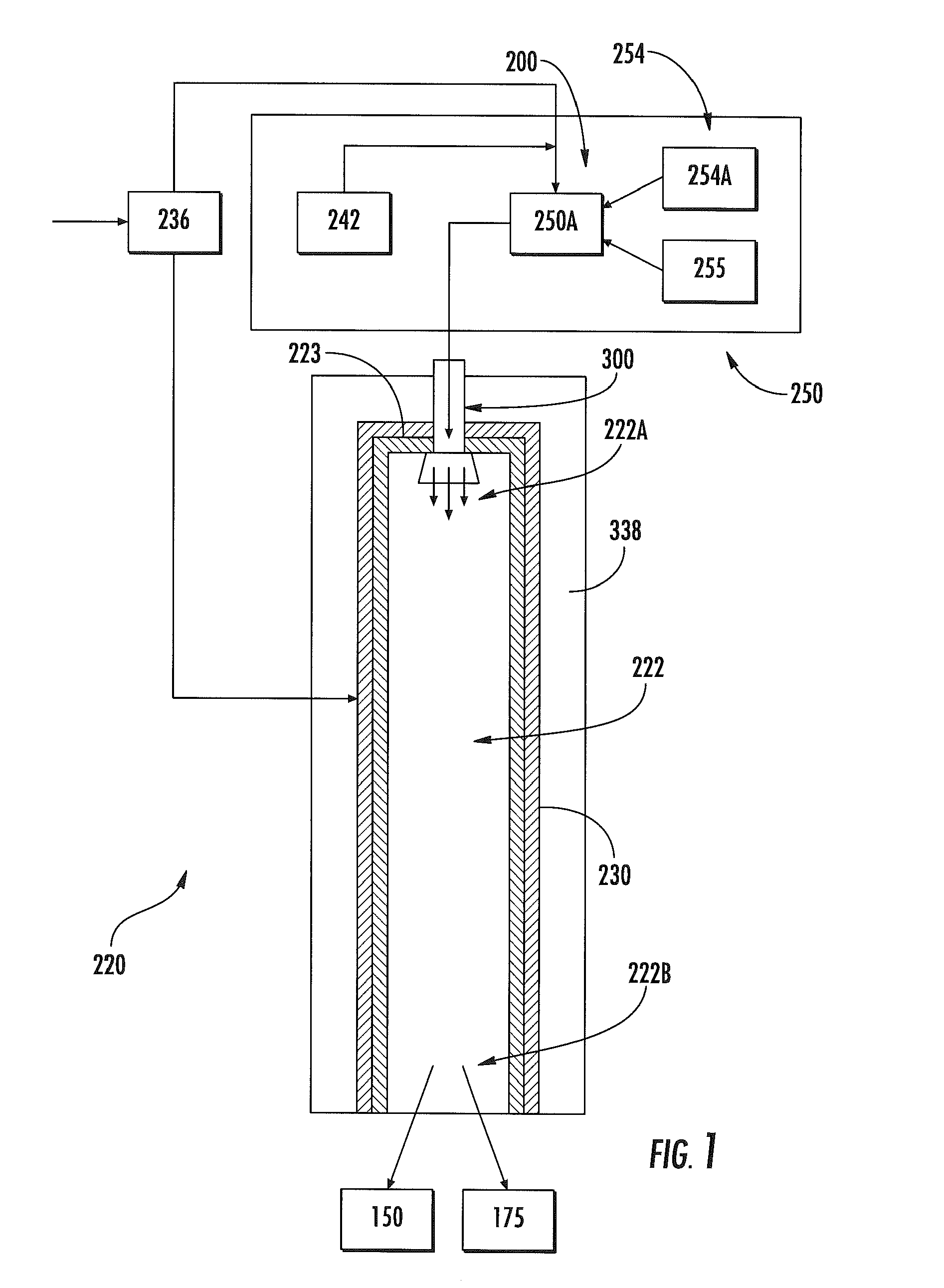

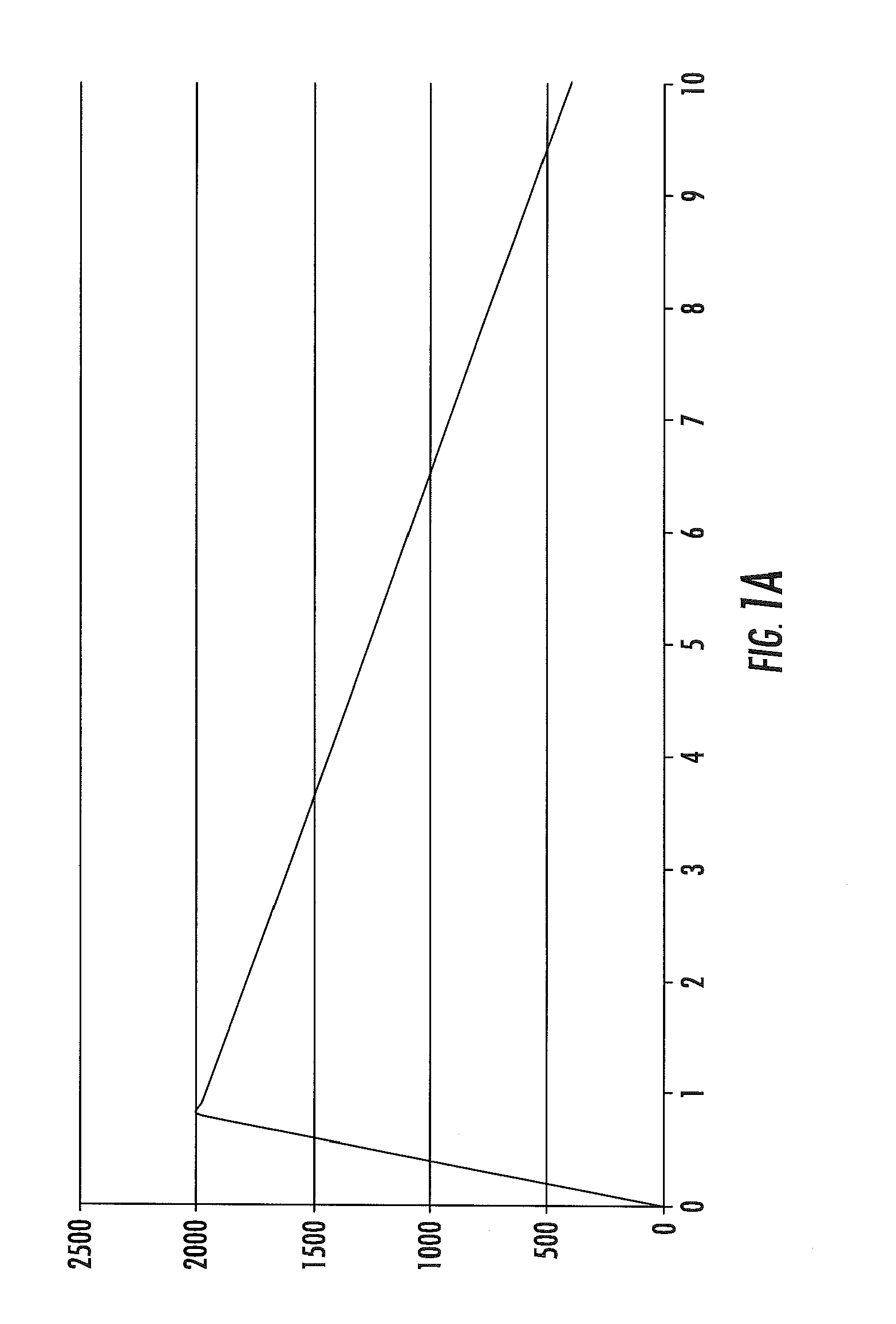

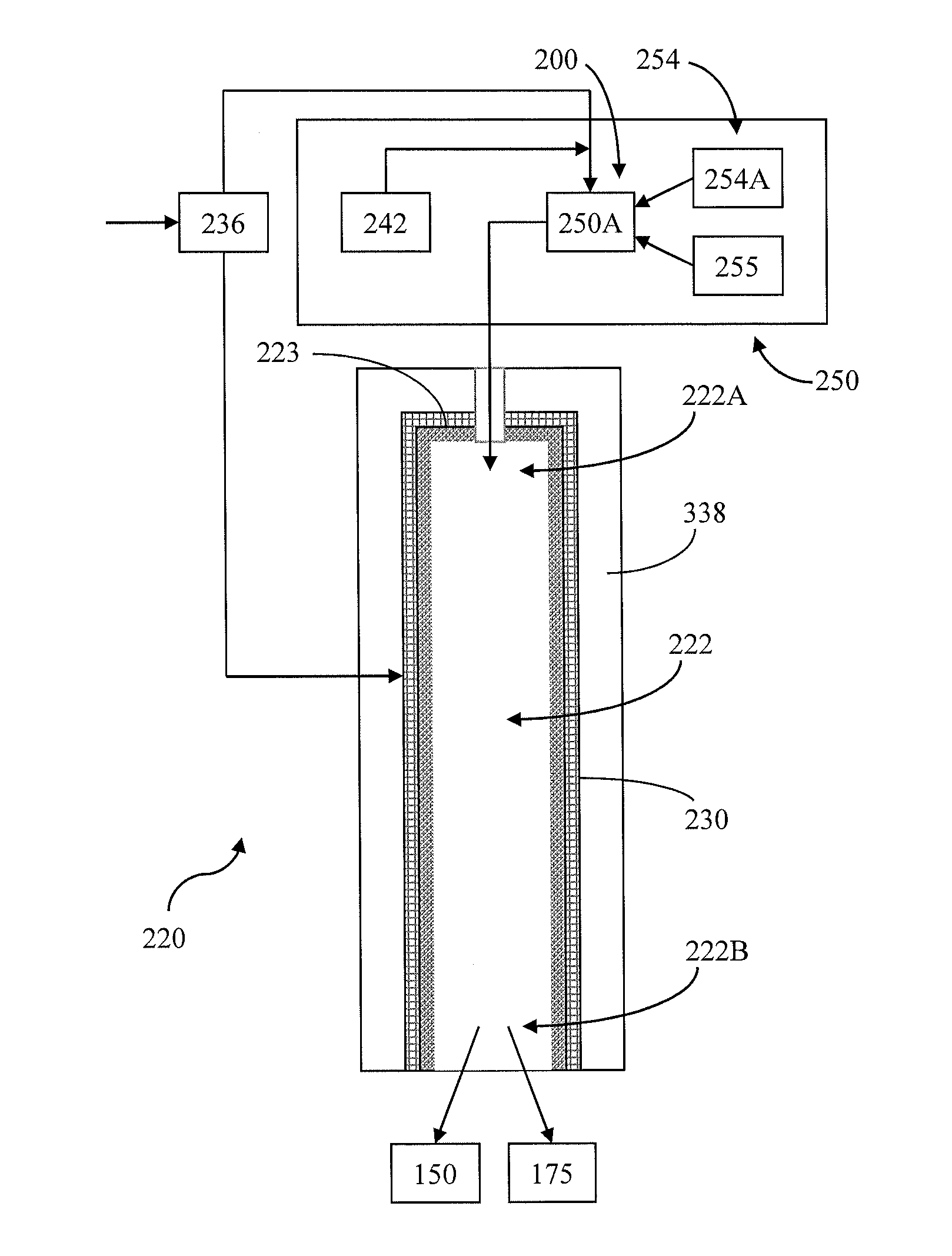

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

Purification of carbon dioxide

A first contaminant selected from oxygen and carbon monoxide is removed from impure liquid carbon dioxide using a mass transfer separation column system which is reboiled by indirect heat exchange against crude carbon dioxide fluid, the impure liquid carbon dioxide having a greater concentration of carbon dioxide than the crude carbon dioxide fluid. The invention has particular application in the recovery of carbon dioxide from flue gas generated in an oxyfuel combustion process or waste gas from a hydrogen PSA process. Advantages include reducing the level of the first contaminant to not more than 1000 ppm.

Owner:AIR PROD & CHEM INC

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS8986002B2Reducing and eliminating needEliminate damage to and build-upContinuous combustion chamberGas turbine plantsWorking fluidCombustor

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus and Method for Combusting a Fuel at High Pressure and High Temperature, and Associated System and Device

ActiveUS20100300063A1Enhanced overall recoveryReducing and eliminating needSolidificationLiquefactionWorking fluidCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a transpiration member. The transpiration member is at least partially surrounded by a pressure containment member. The combustion chamber has opposed inlet and outlet portions. The inlet portion of the combustion chamber is configured to receive the fuel mixture for the fuel mixture to be combusted at a combustion temperature. The combustion chamber is further configured to direct the resulting combustion product toward the outlet portion. The transpiration member directs a transpiration substance therethrough toward the combustion chamber for buffering interaction between the combustion product and the transpiration member. Associated systems, apparatuses, and methods are also provided.

Owner:8 RIVERS CAPTTAL LLC

Purification of carbon dioxide

Owner:AIR PROD & CHEM INC

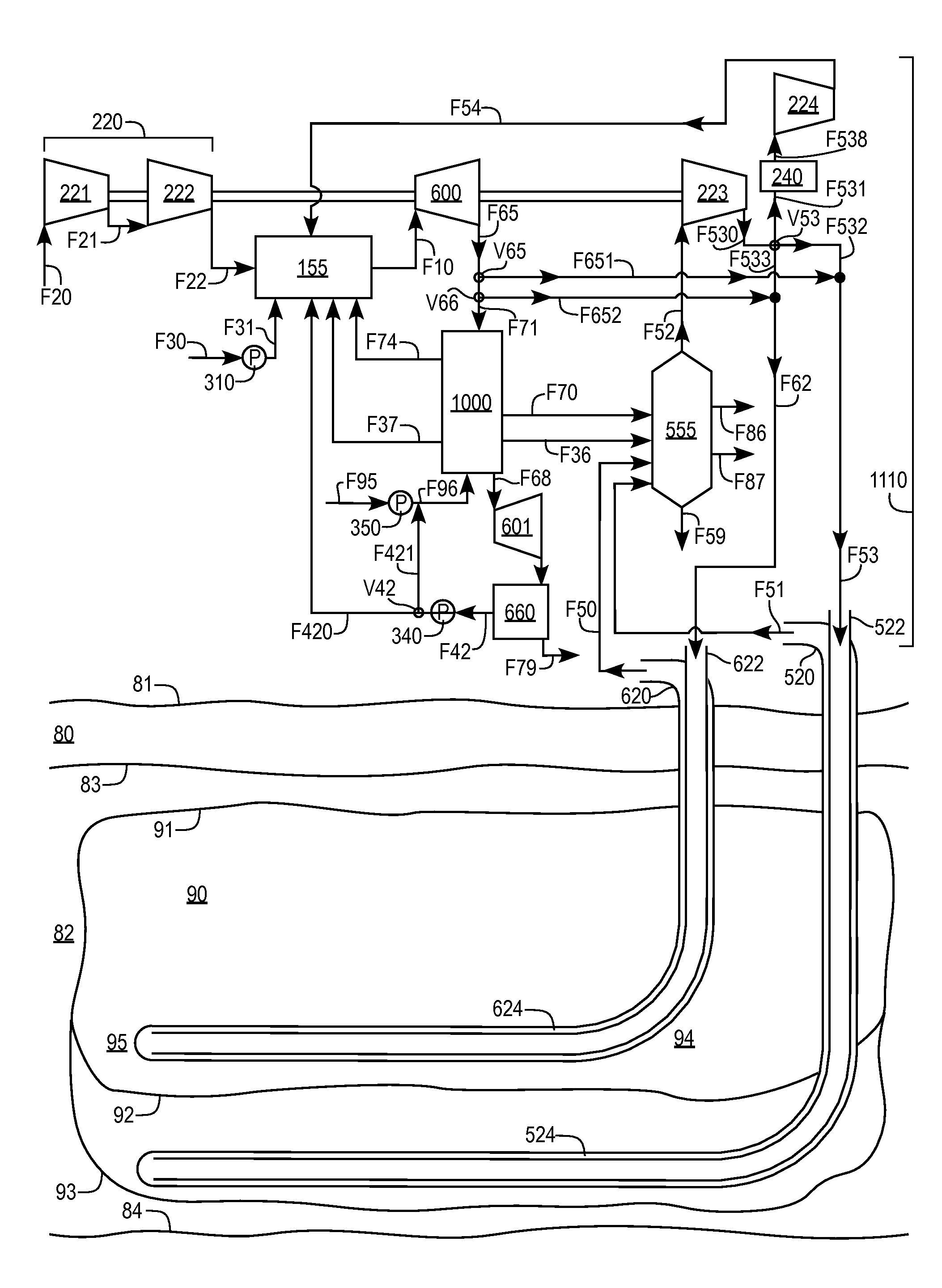

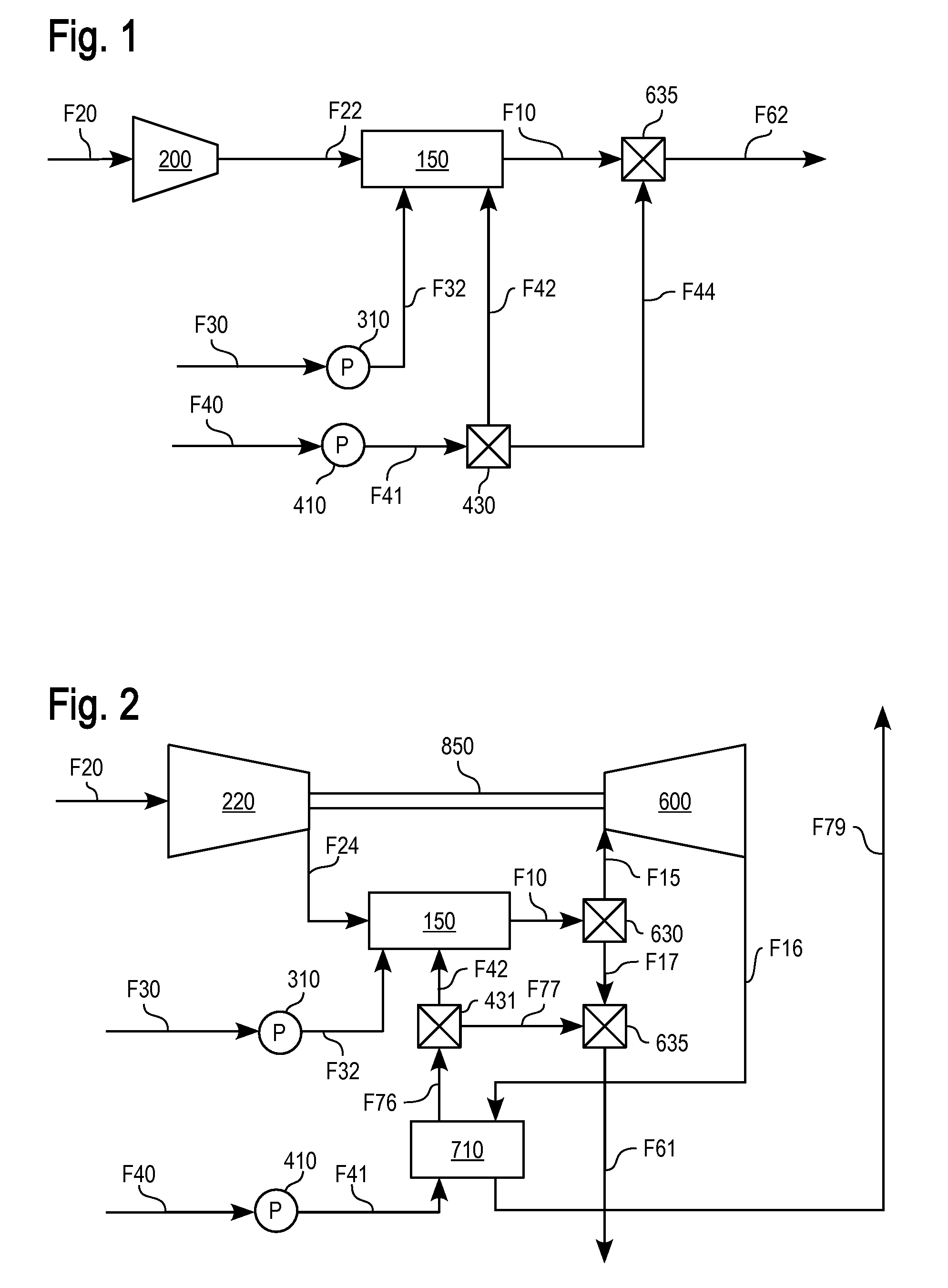

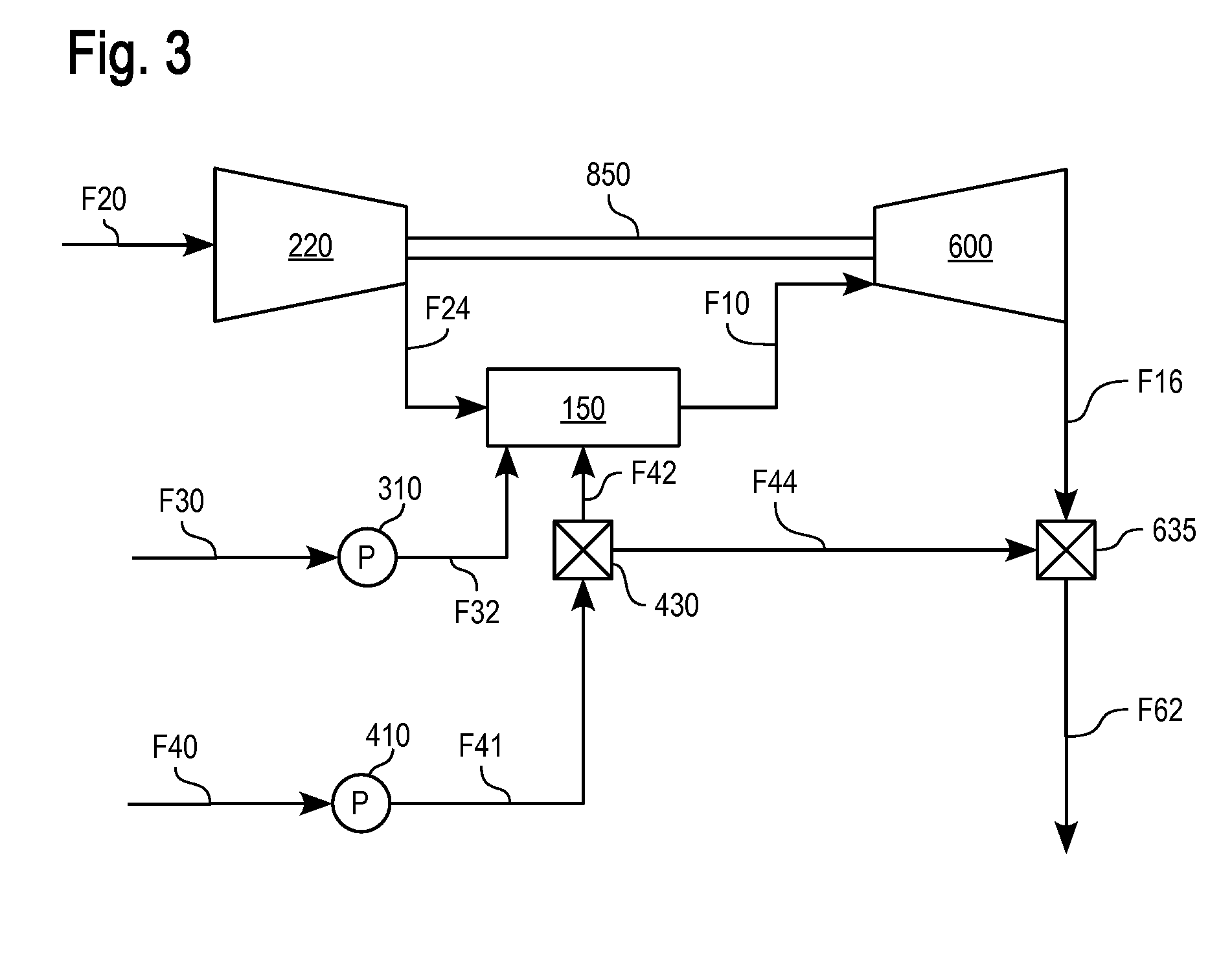

Heavy oil recovery with fluid water and carbon dioxide

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

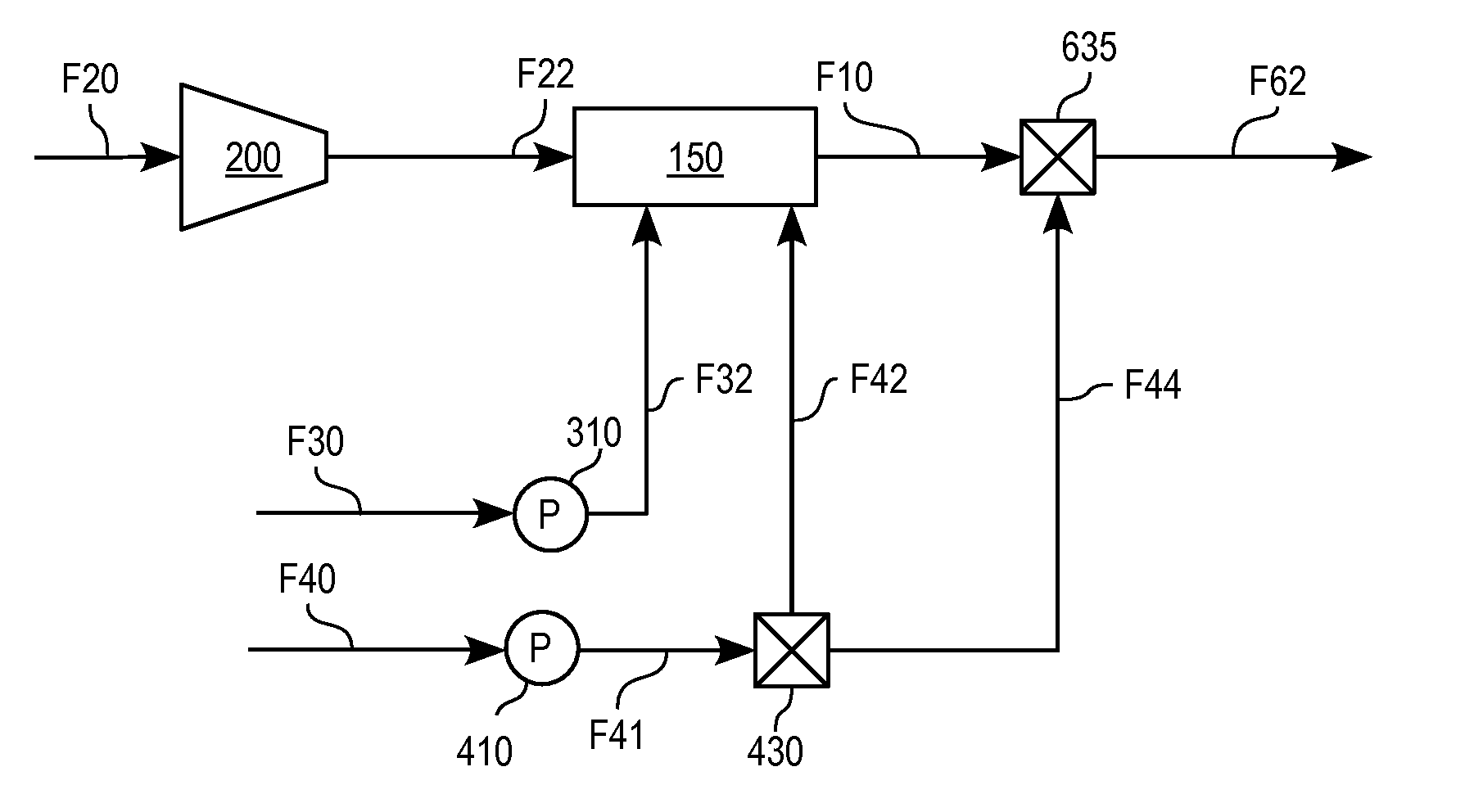

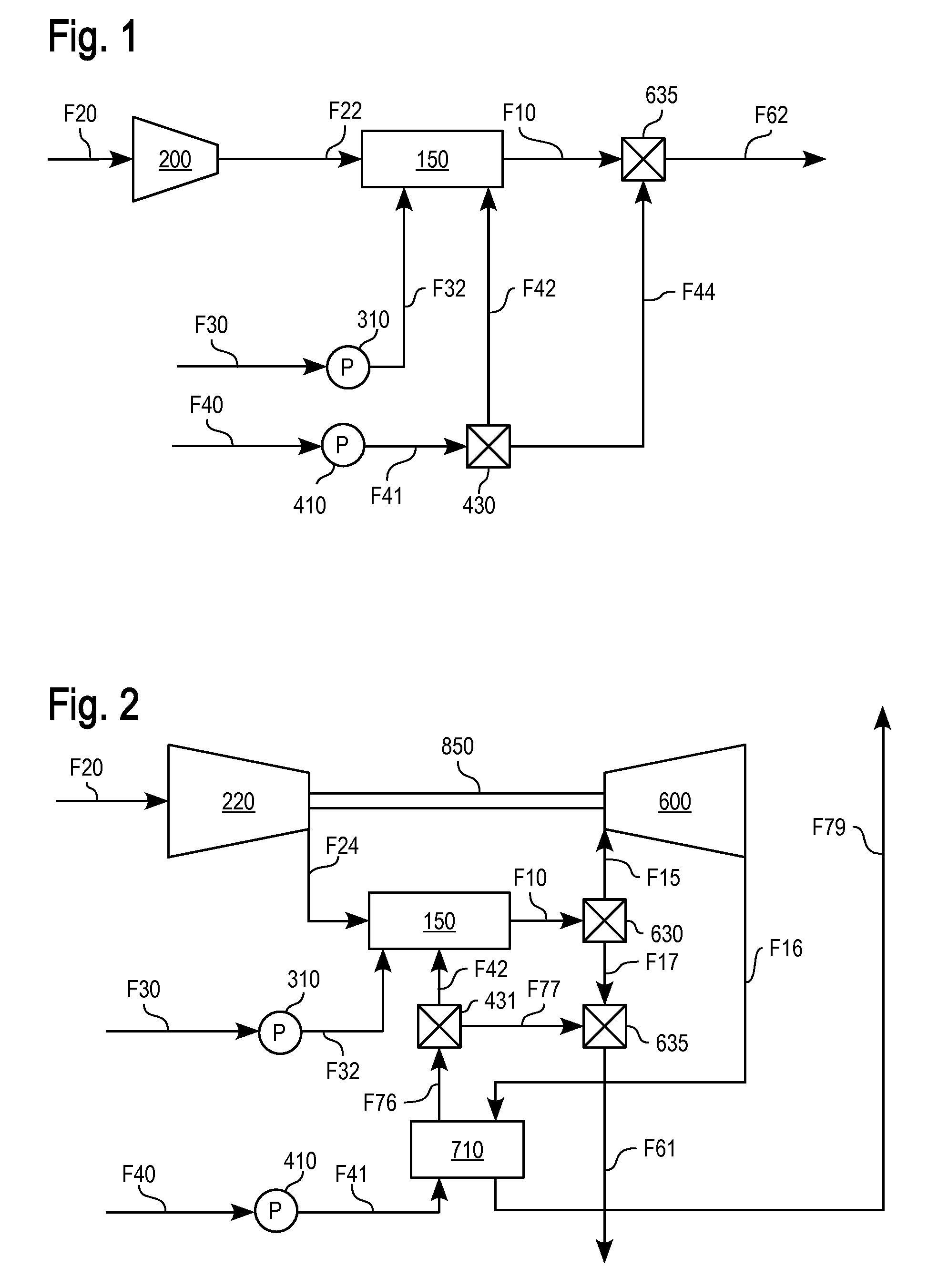

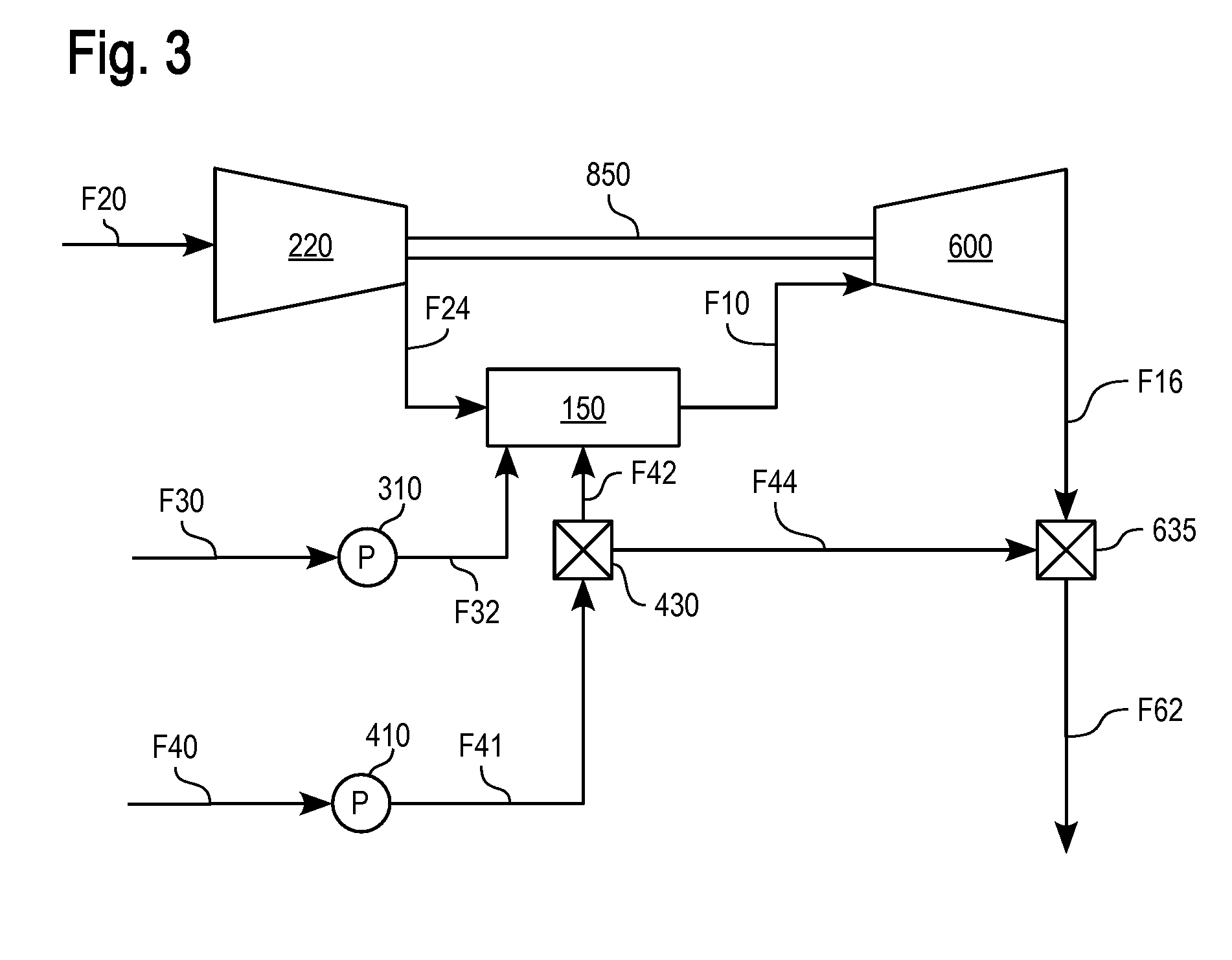

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

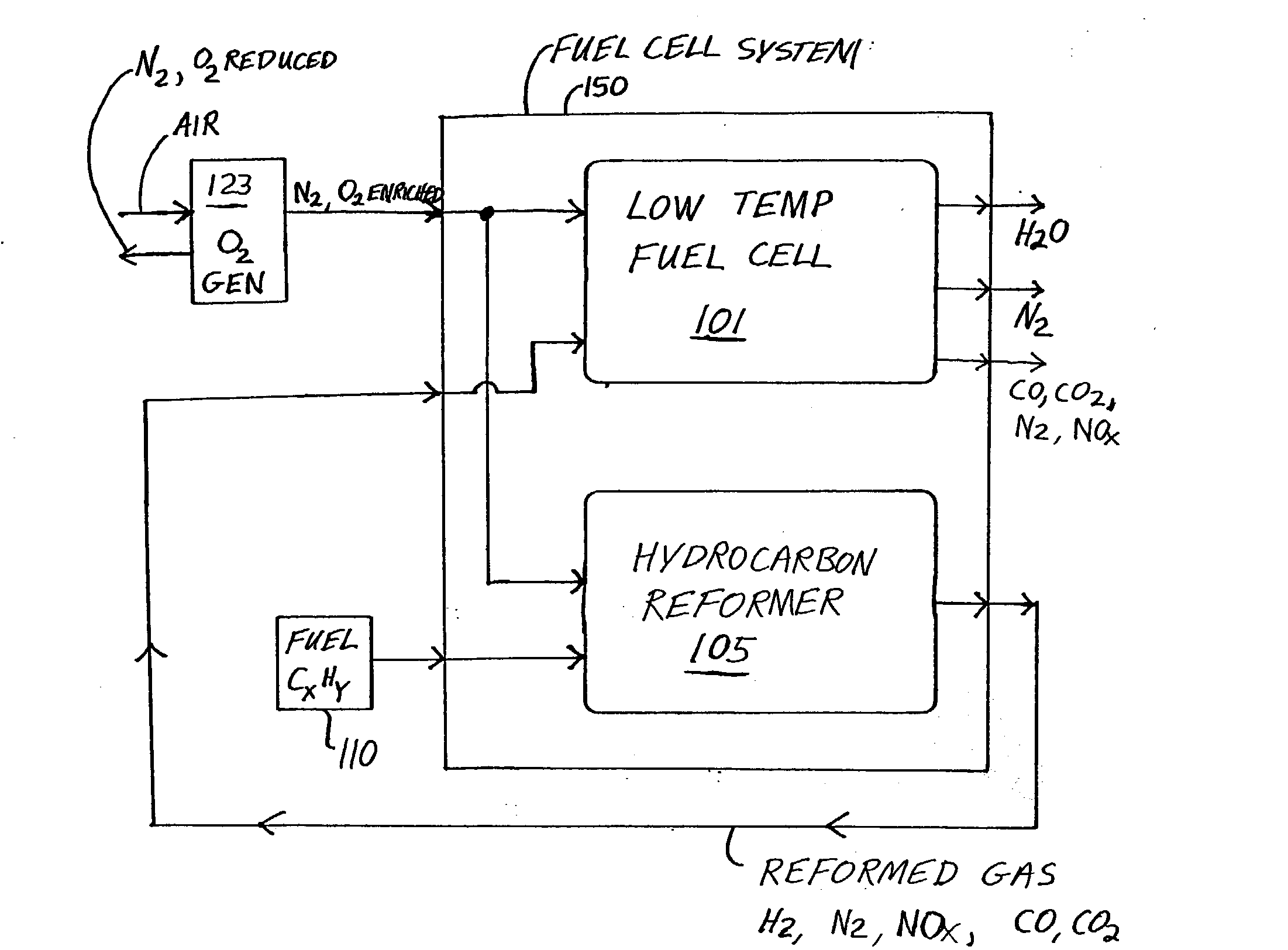

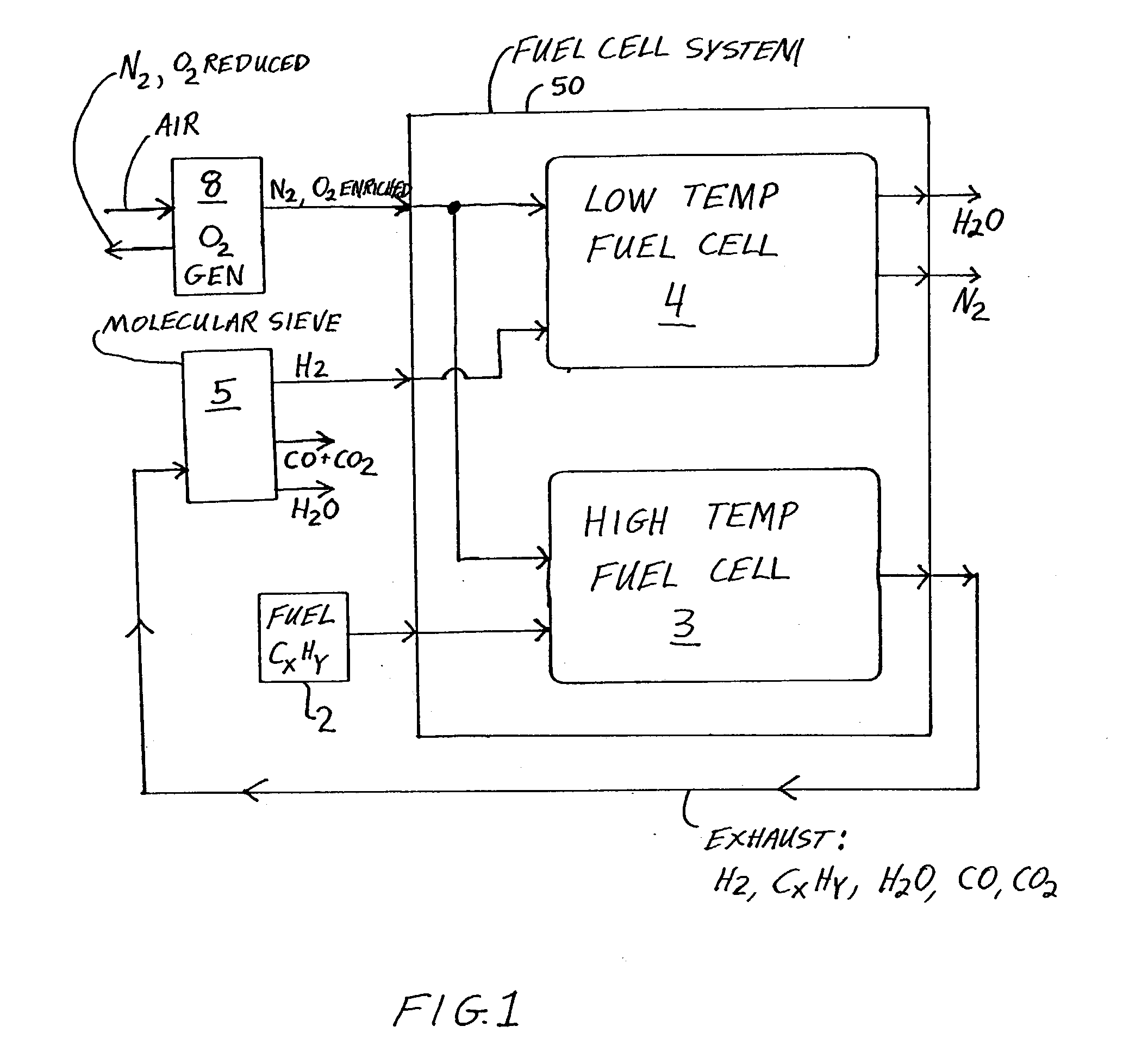

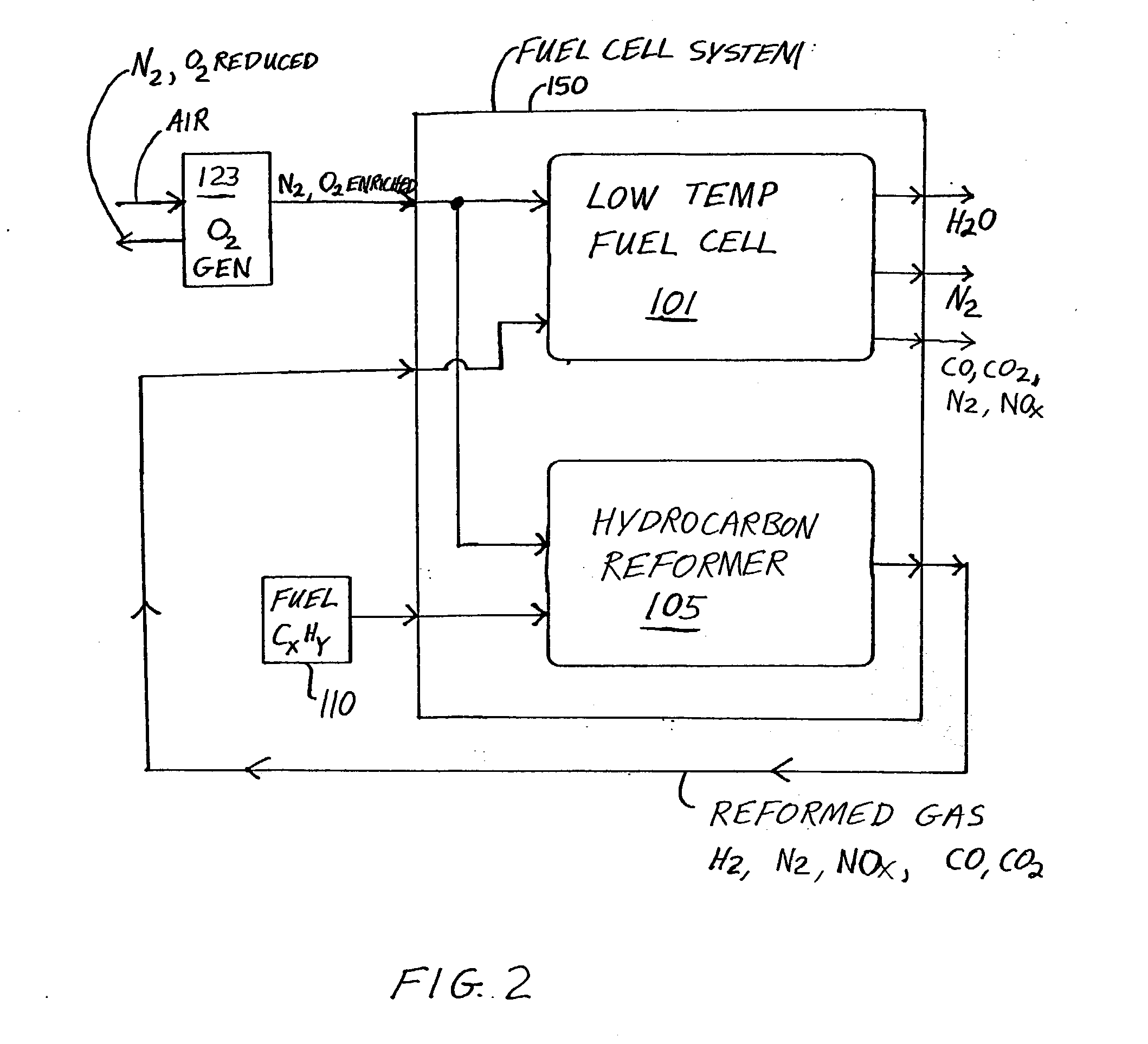

Fuel cell system and method with increased efficiency and reduced exhaust emissions

InactiveUS20040043276A1Improve efficiencyEfficient and effective usePower installationsFuel cells groupingAtmospheric airNitrogen gas

An apparatus includes a low temperature fuel cell, a high temperature fuel cell or a hydrocarbon reformer, a hydrocarbon fuel supply, an oxygen generator, and a molecular sieve. The oxygen generator separates air to provide oxygen enriched air to the fuel cells and the reformer. Hydrocarbon fuel is provided to the high temperature fuel cell or the reformer, and the exhaust gas thereof may be separated through the molecular sieve, to provide hydrogen enriched gas to the low temperature fuel cell, water, carbon monoxide, and carbon dioxide. The low temperature fuel cell outputs nitrogen gas and high purity water. The emitted carbon oxides and nitrogen oxides are catalytically converted to nitrogen and carbon dioxide being returned to the atmosphere. The process and apparatus are very efficient, produce high purity water and electrical energy, and are environmentally friendly.

Owner:AIRBUS OPERATIONS GMBH

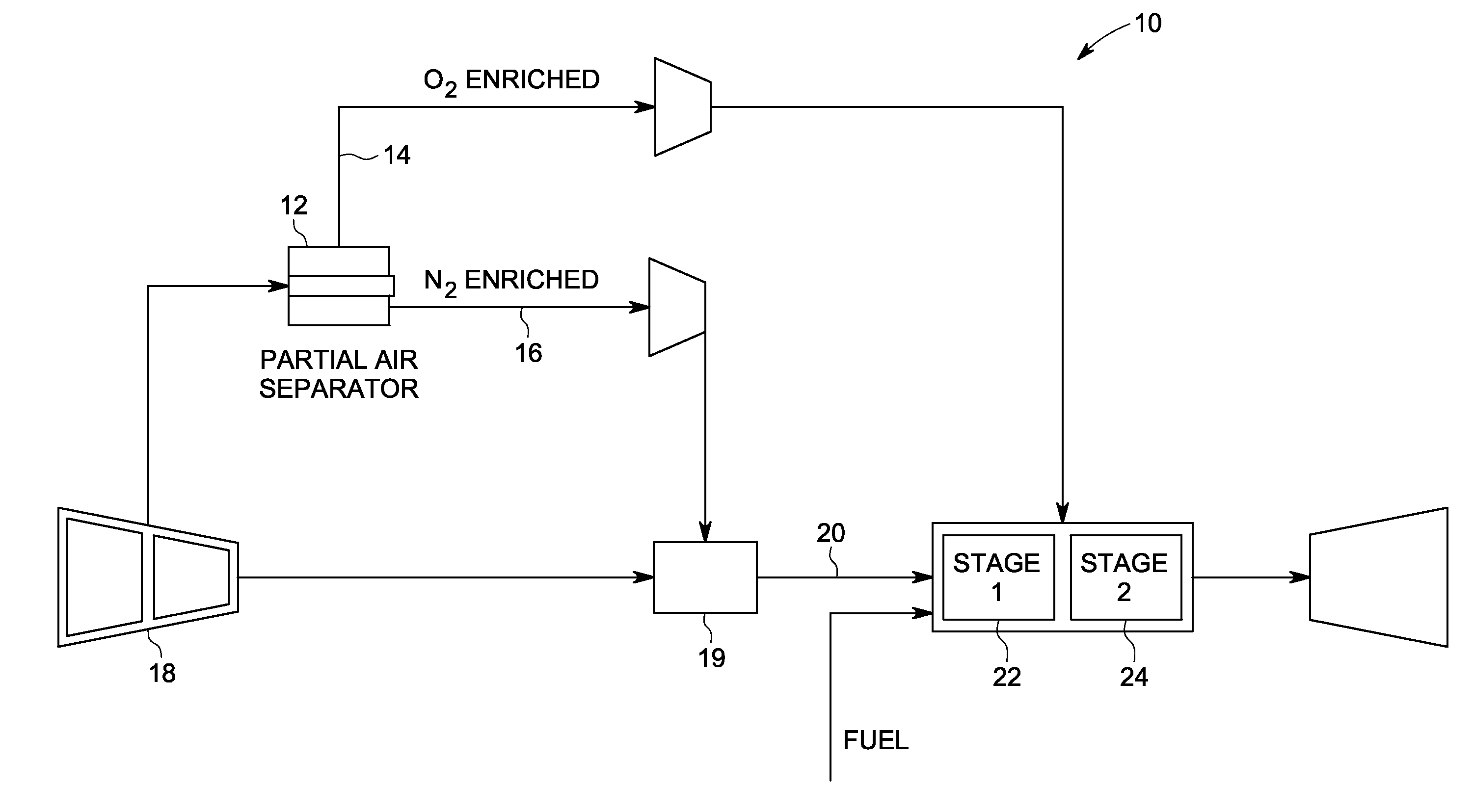

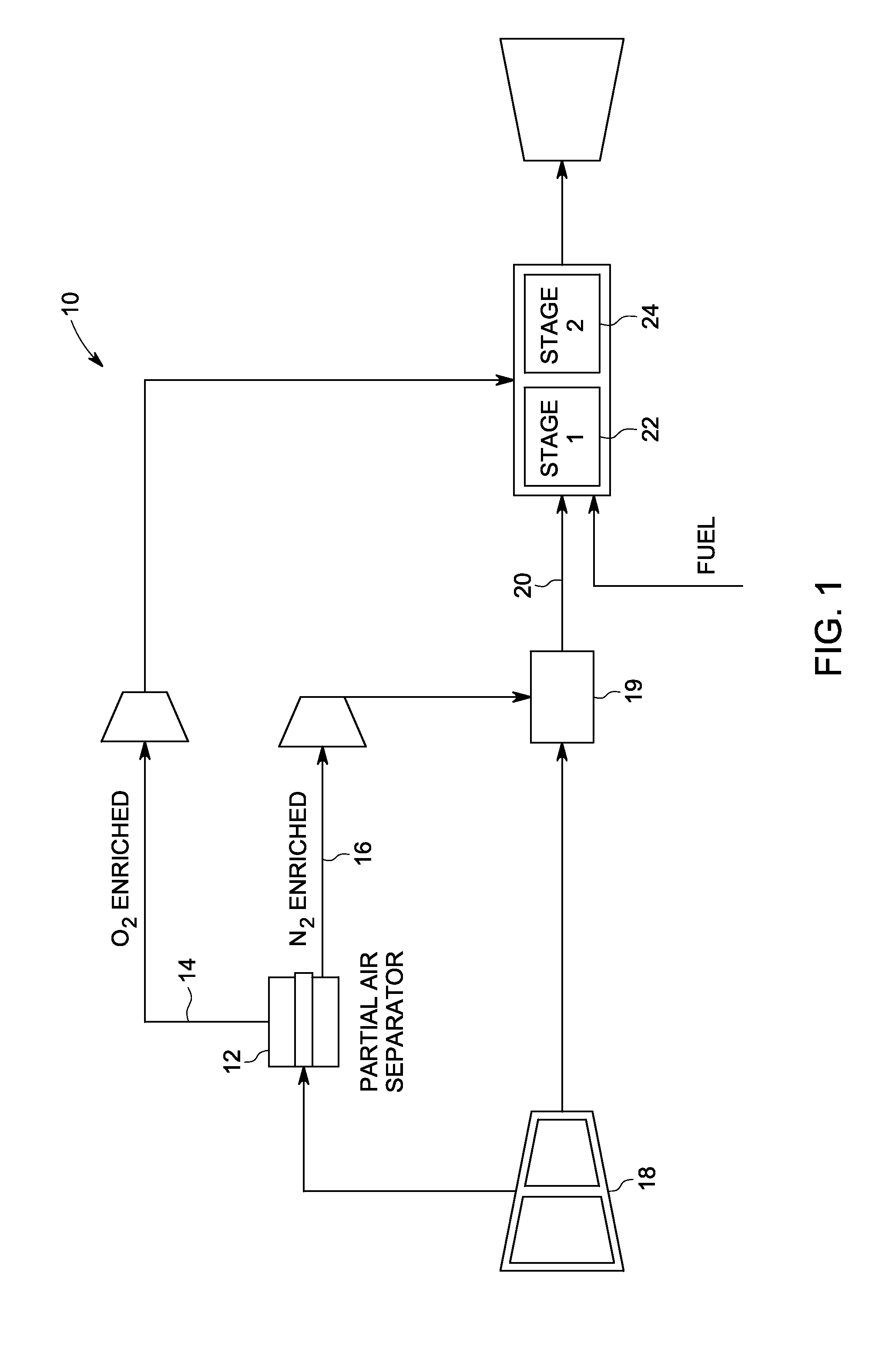

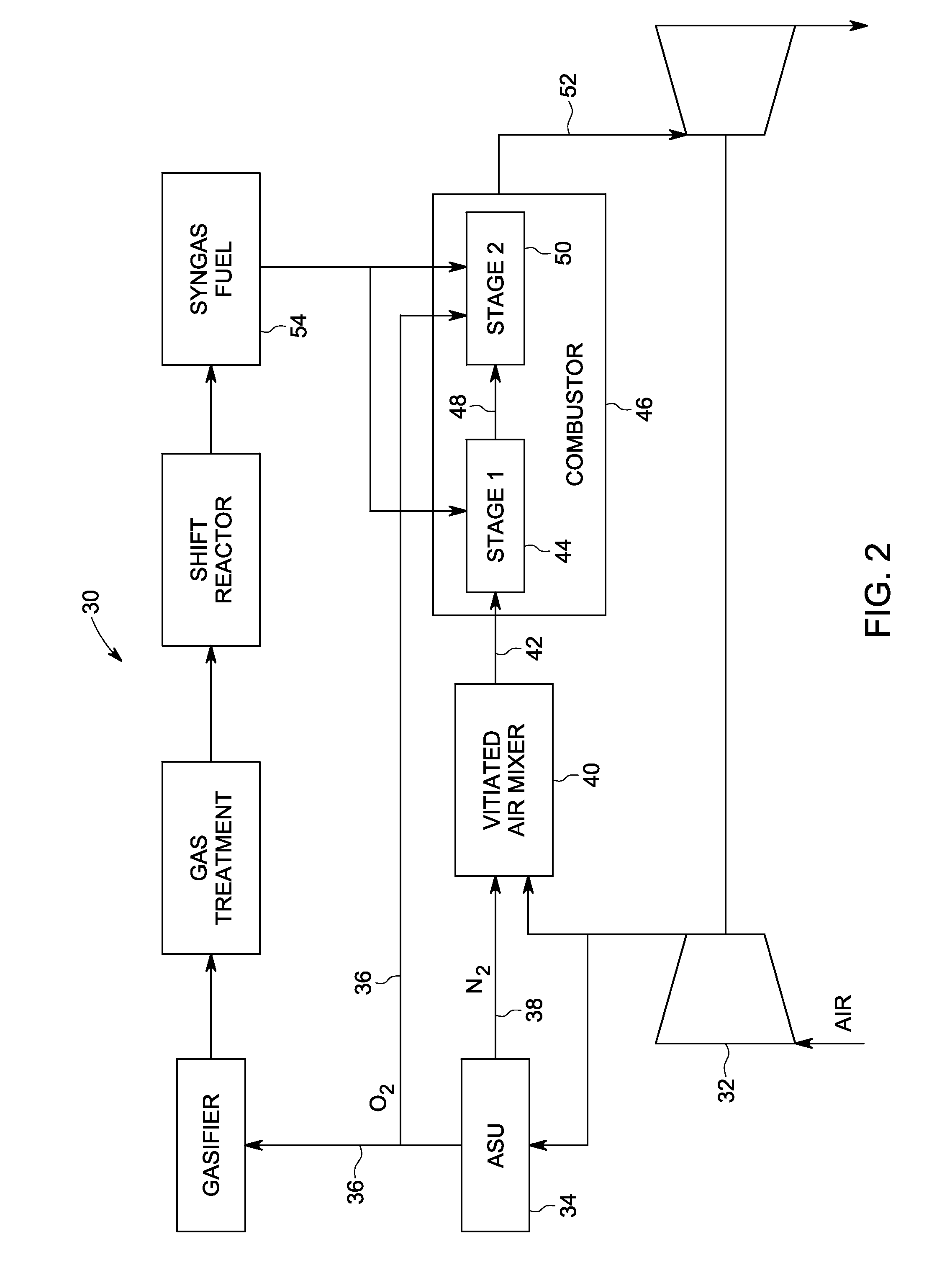

System and method using low emissions gas turbine cycle with partial air separation

A system and method of reducing gas turbine nitric oxide emissions includes a first combustion stage configured to burn air vitiated with diluents to generate first combustion stage products. A second combustion stage is configured to burn the first combustion stage products in combination with enriched oxygen to generate second combustion stage products having a lower level of nitric oxide emissions than that achievable through combustion with vitiated air alone or through combustion staging alone.

Owner:GENERAL ELECTRIC CO

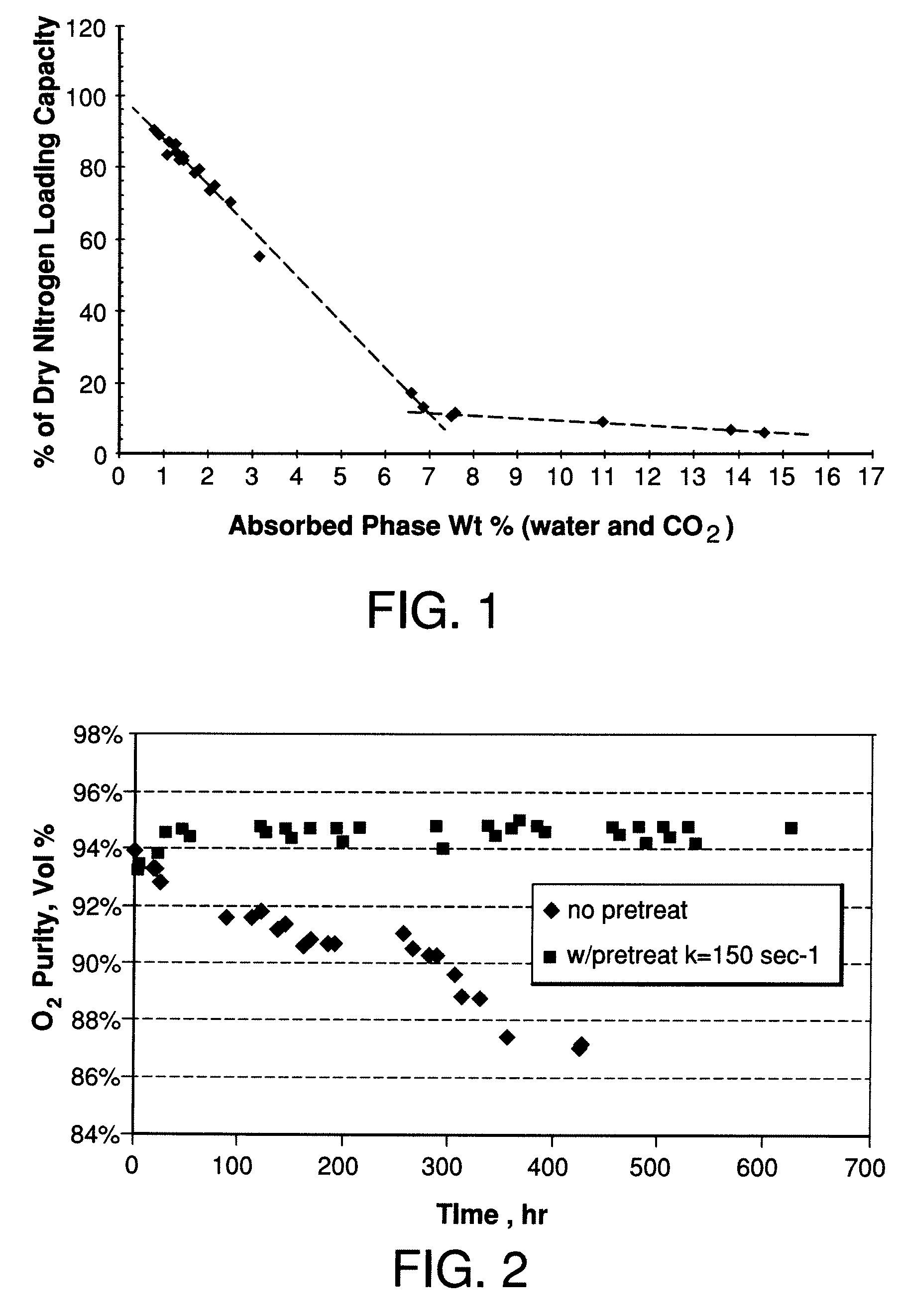

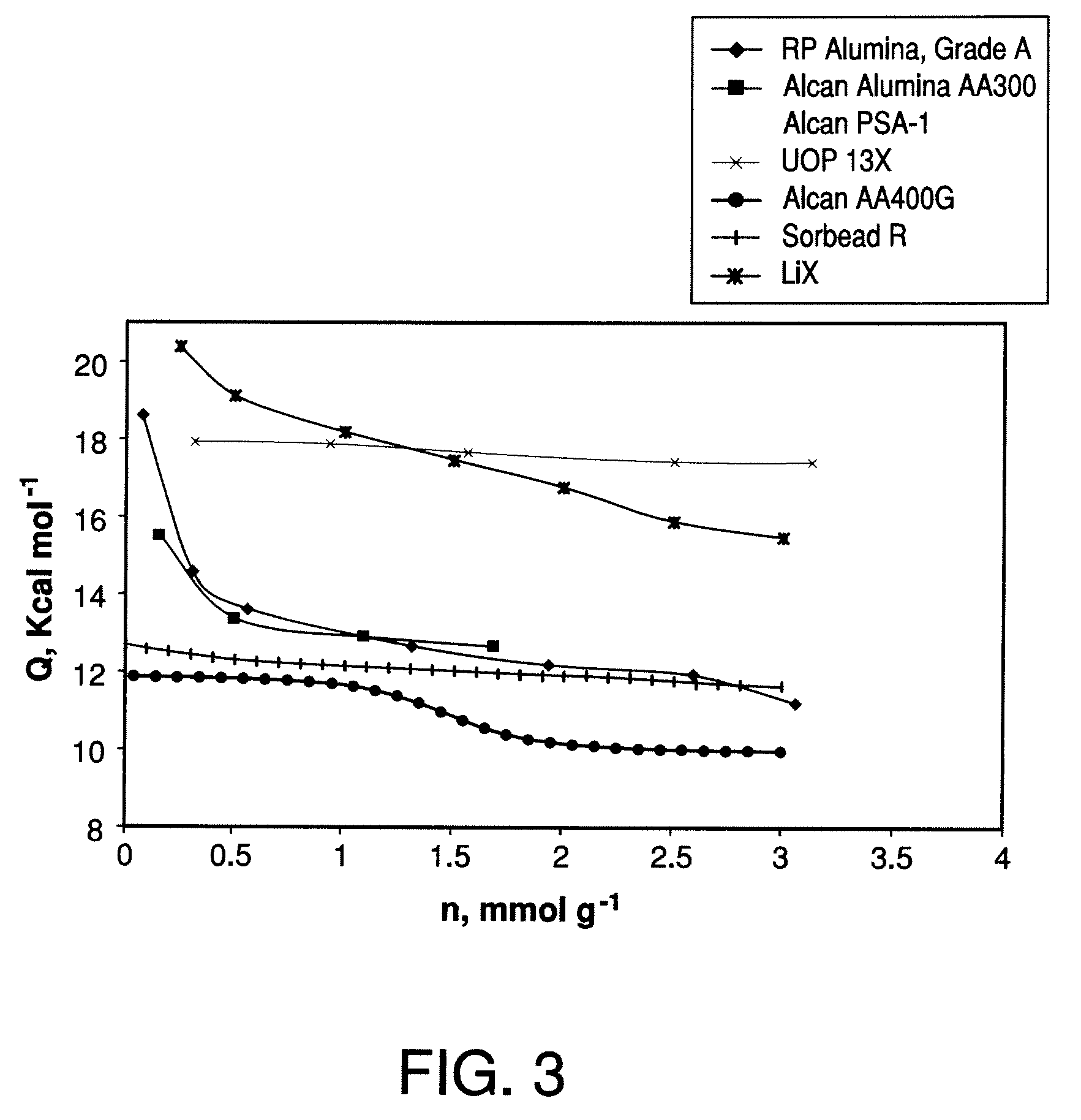

Performance Stability in Shallow Beds in Pressure Swing Adsorption Systems

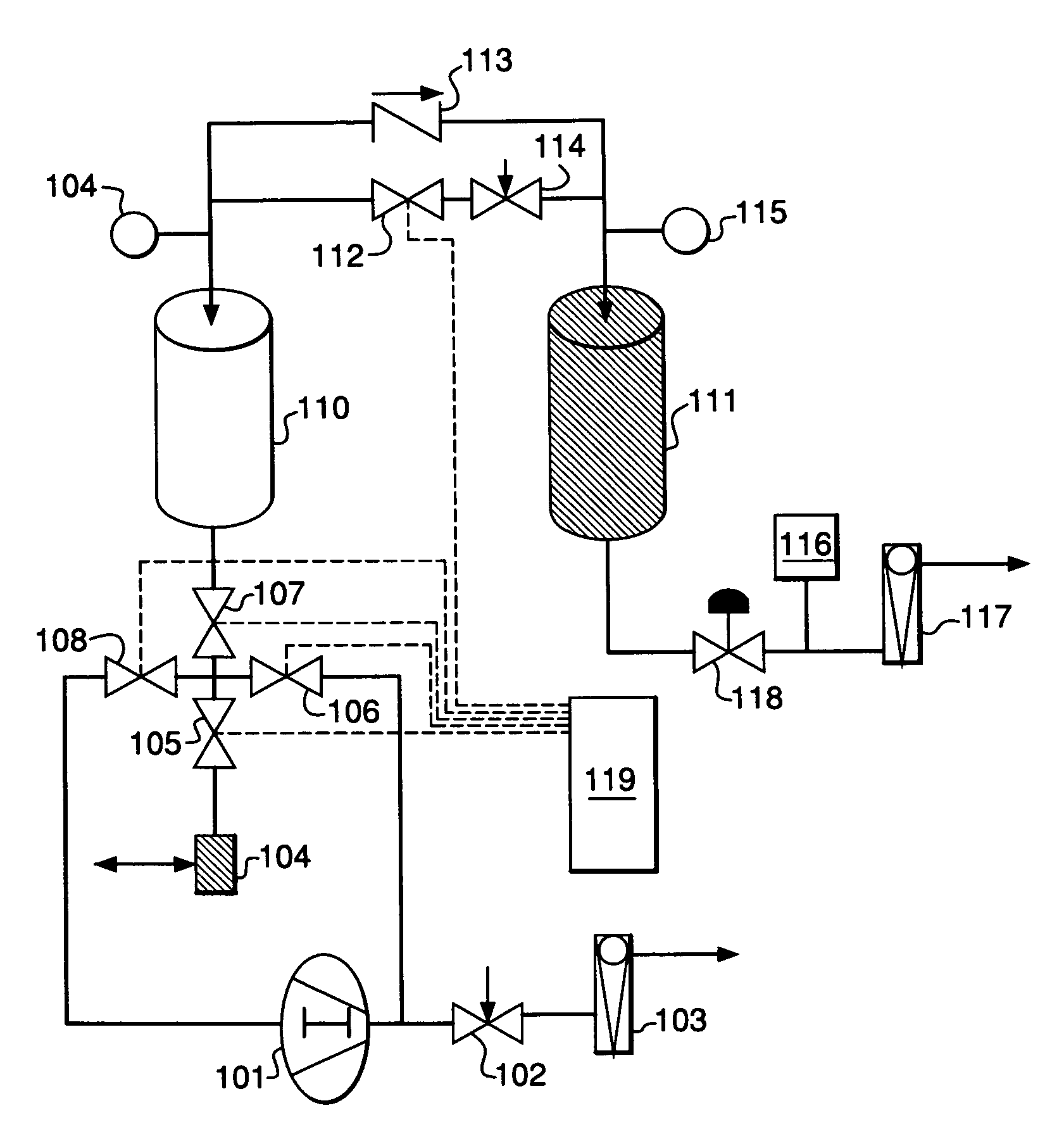

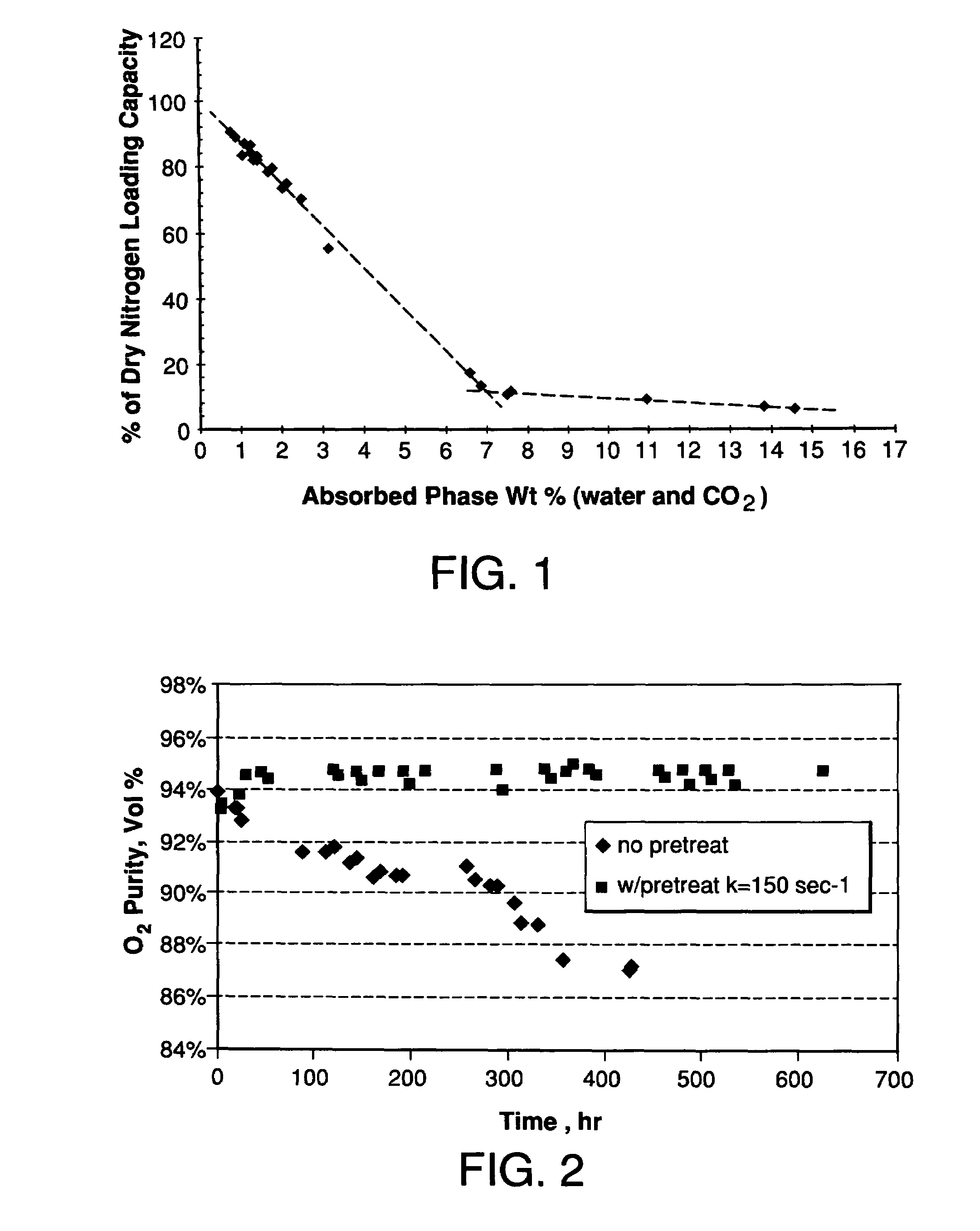

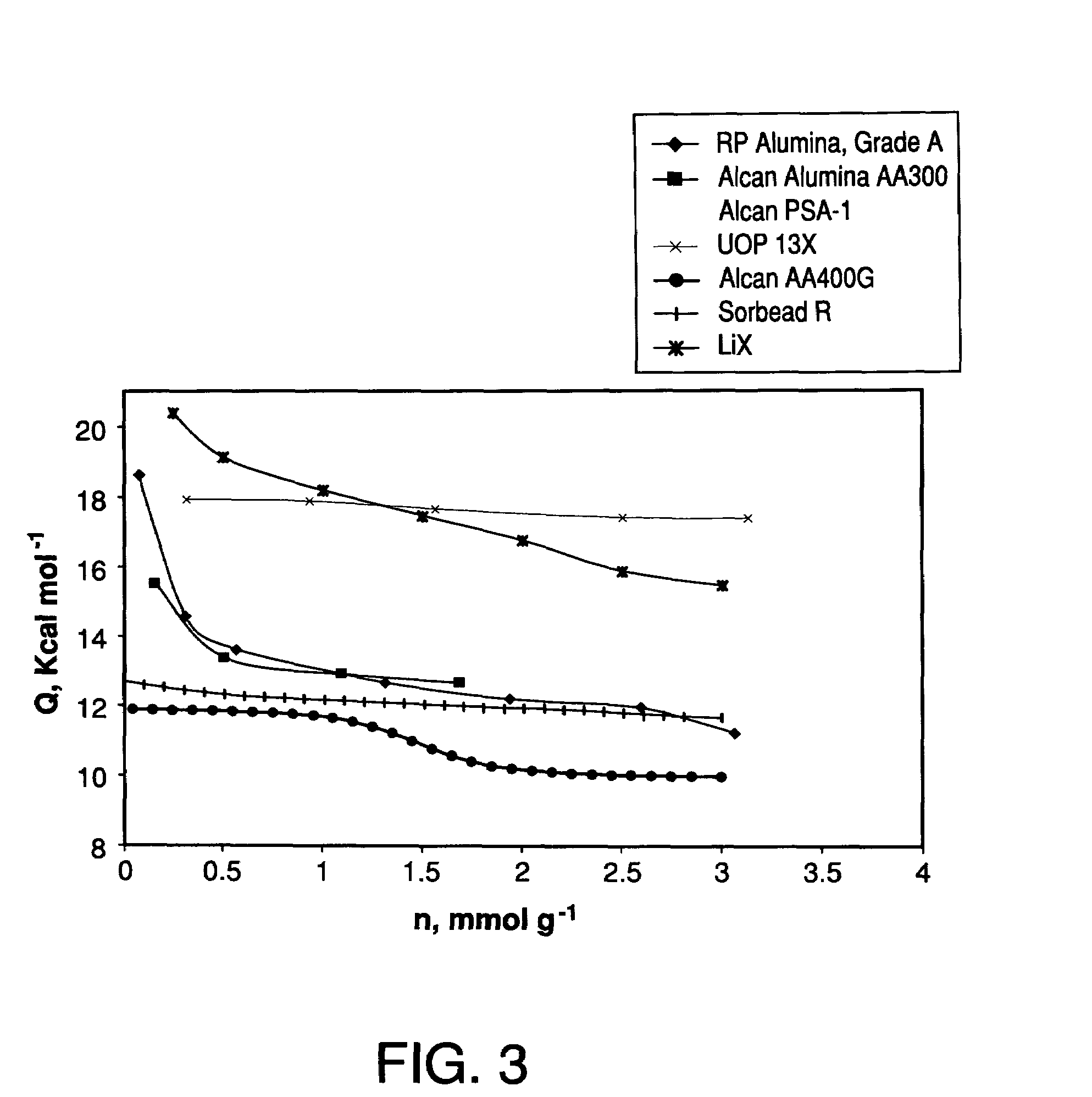

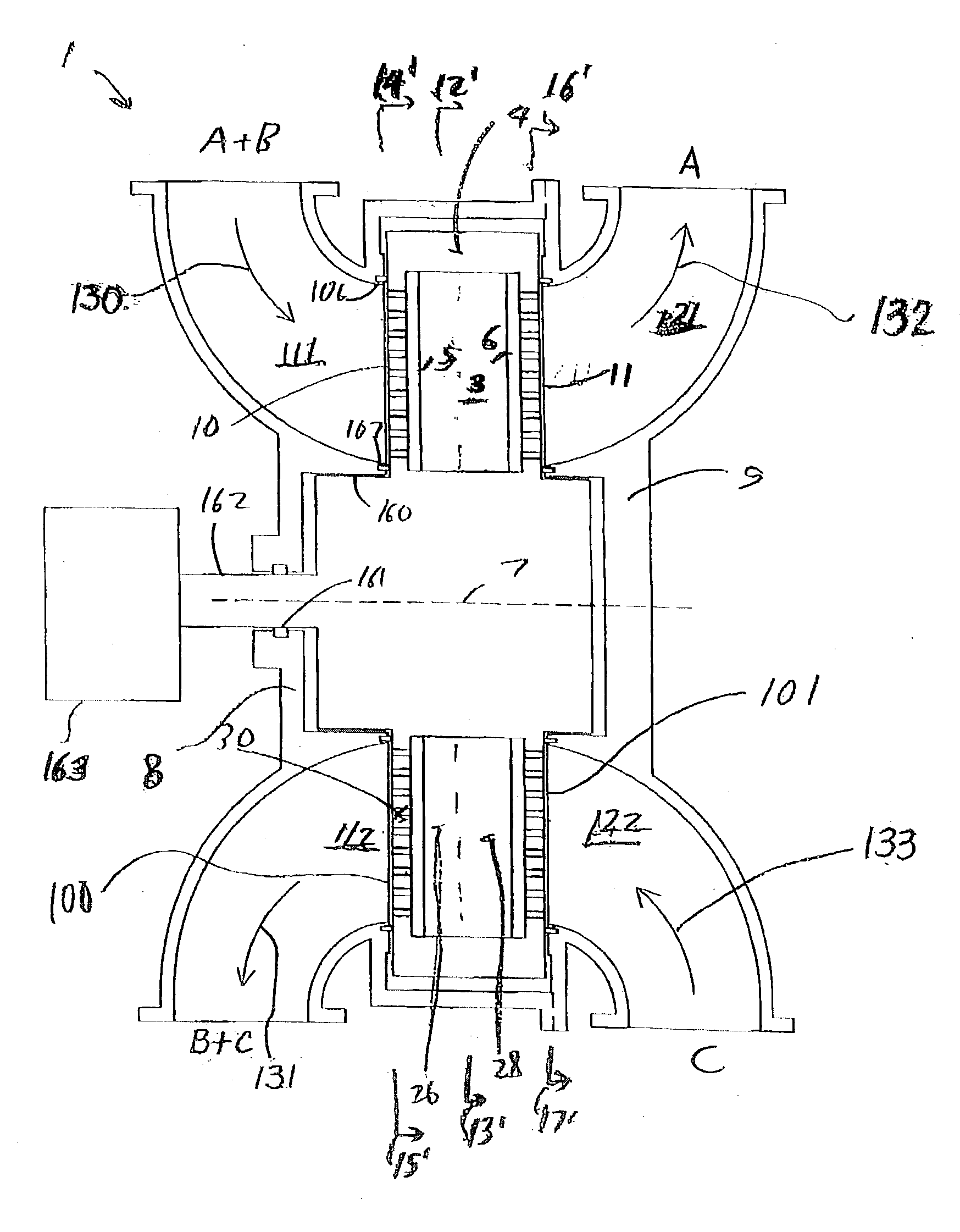

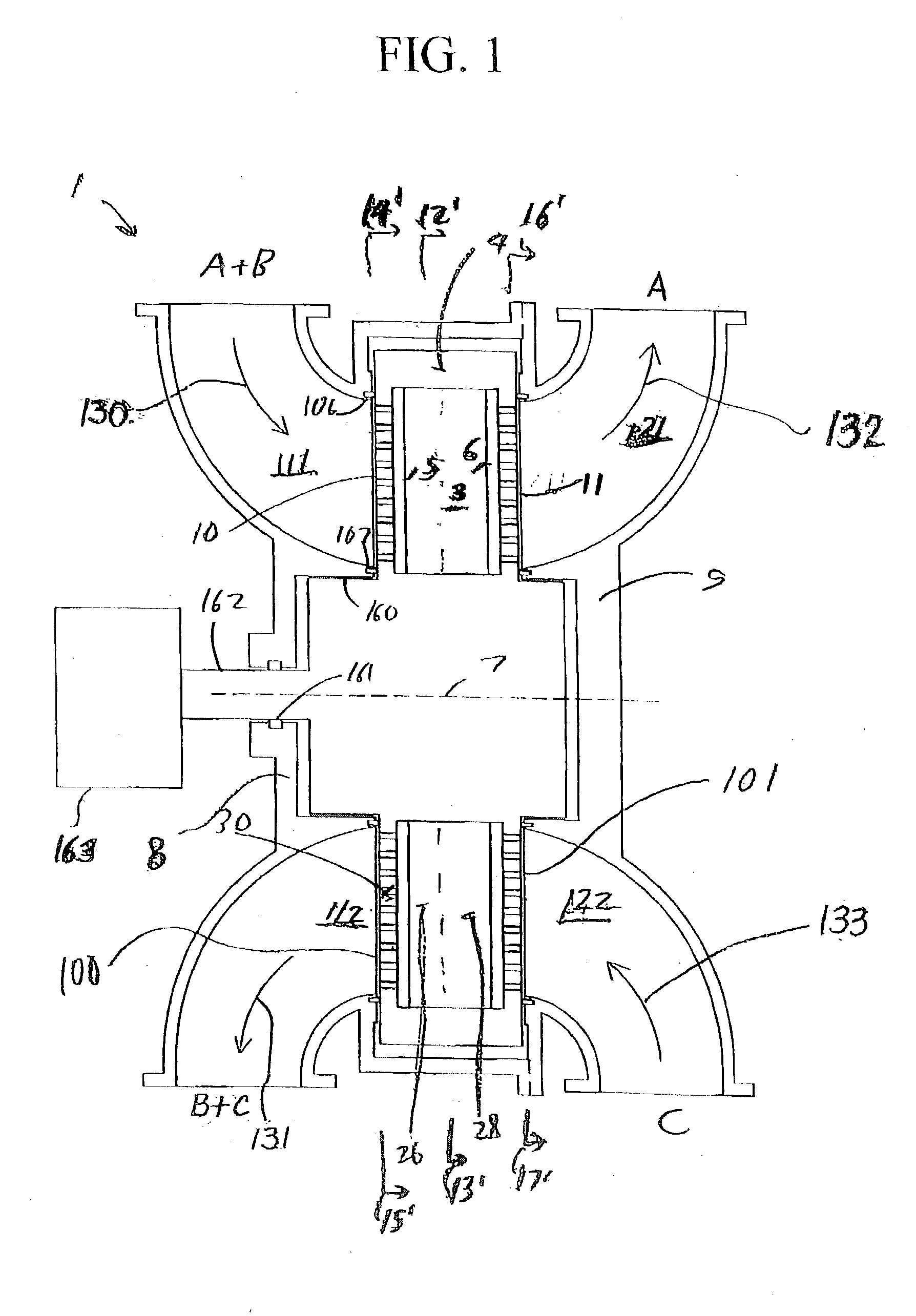

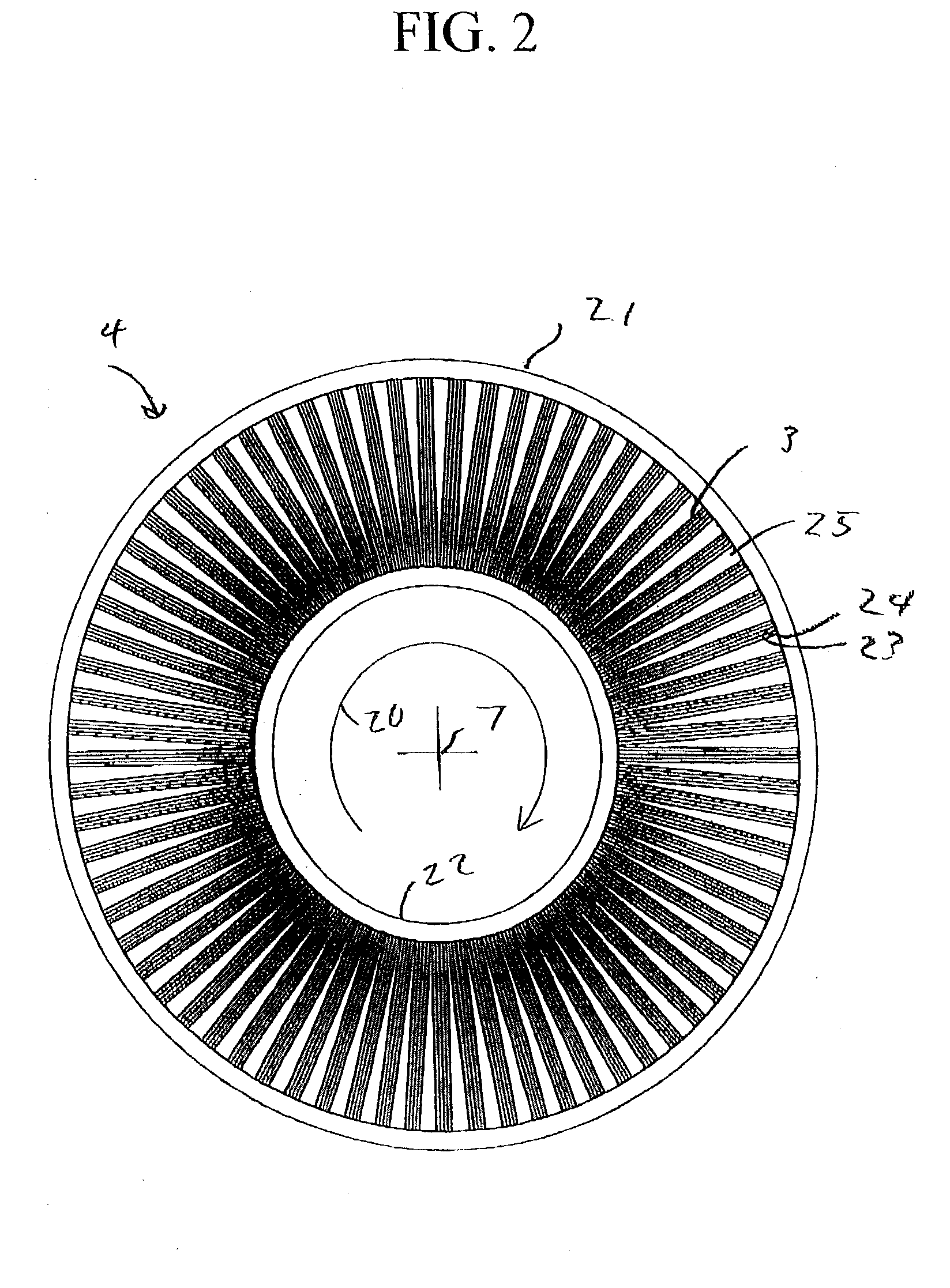

PSA process for oxygen production comprising (a) providing an adsorber having a first layer of adsorbent selective for water and a second layer of adsorbent selective for nitrogen, wherein the heat of adsorption of water on the adsorbent in the first layer is equal to or less than about 14 kcal / mole at water loadings less than about 0.05 mmol per gram; (b) passing a feed gas comprising at least oxygen, nitrogen, and water successively through the first and second layers, adsorbing water in the first layer of adsorbent, and adsorbing nitrogen in the second layer of adsorbent, wherein the mass transfer coefficient of water in the first layer is in the range of about 125 to about 400 sec−1 and the superficial contact time of the feed gas in the first layer is between about 0.08 and about 0.50 sec; and (c) withdrawing a product enriched in oxygen from the adsorber.

Owner:AIR PROD & CHEM INC

Heavy oil recovery with fluid water and carbon dioxide

Diluted wet combustion forms a hot process fluid or VASTgas including carbon dioxide (CO2) and fluid water which is delivered to geologic formations and / or to surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be used to pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into a well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

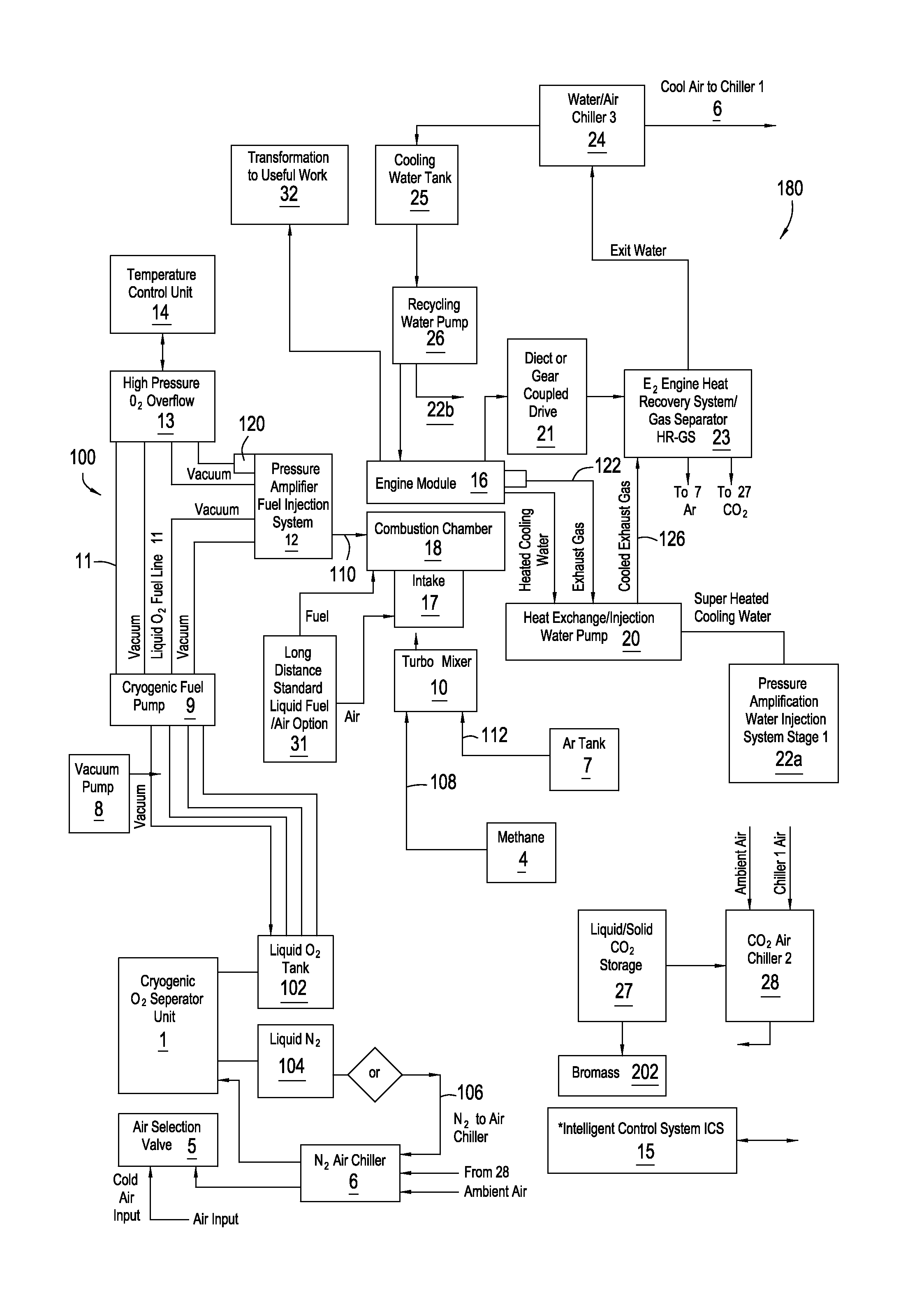

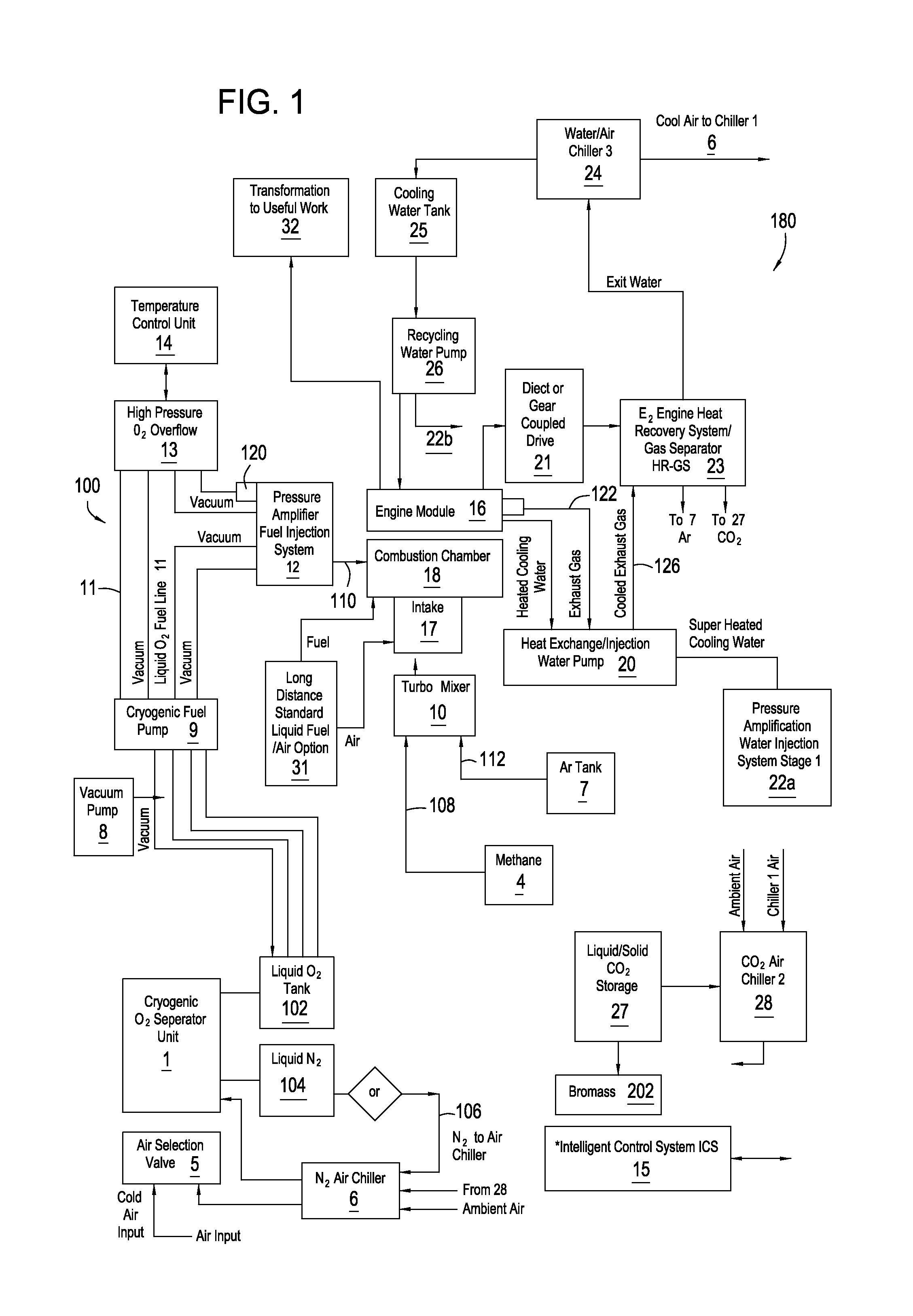

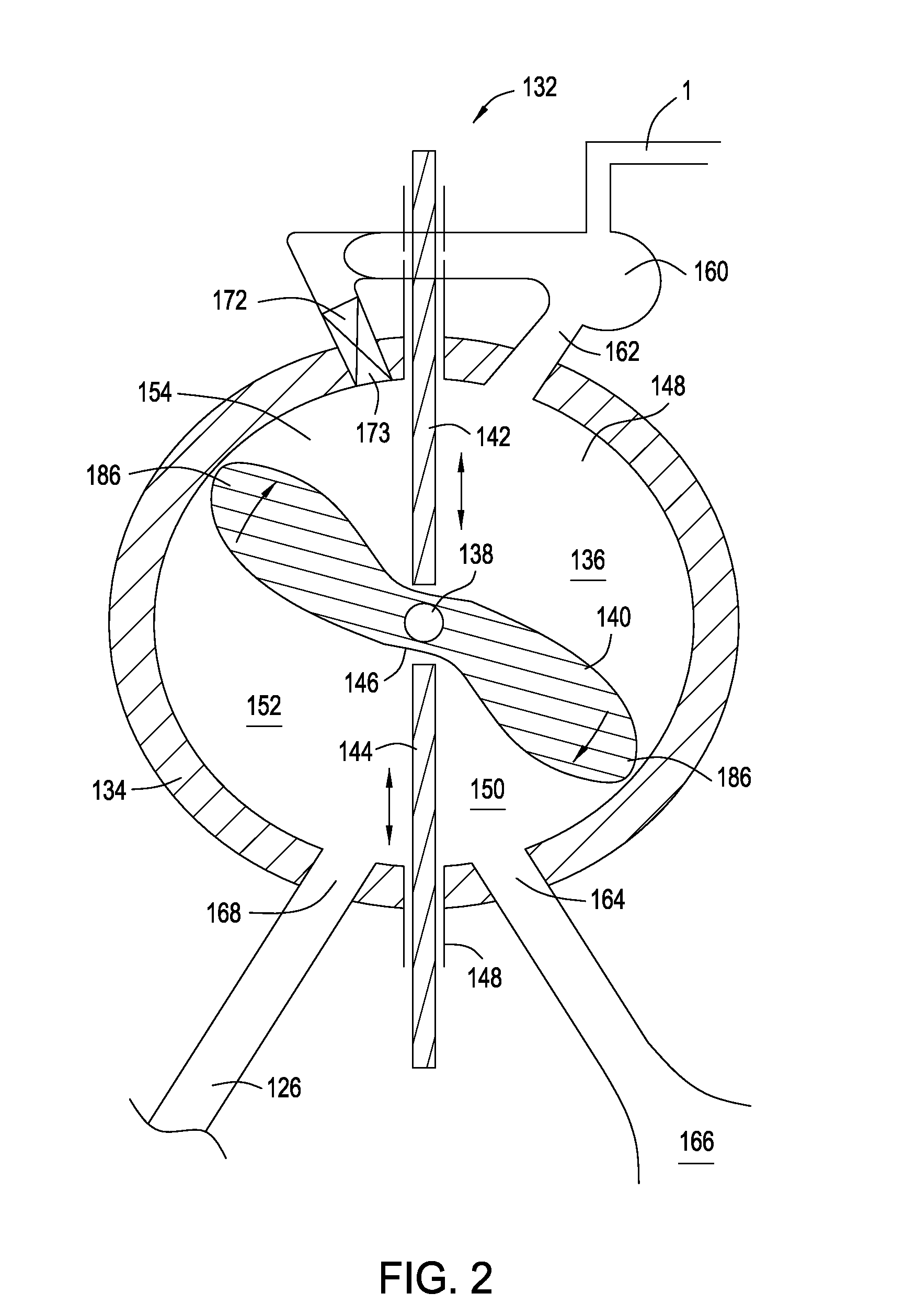

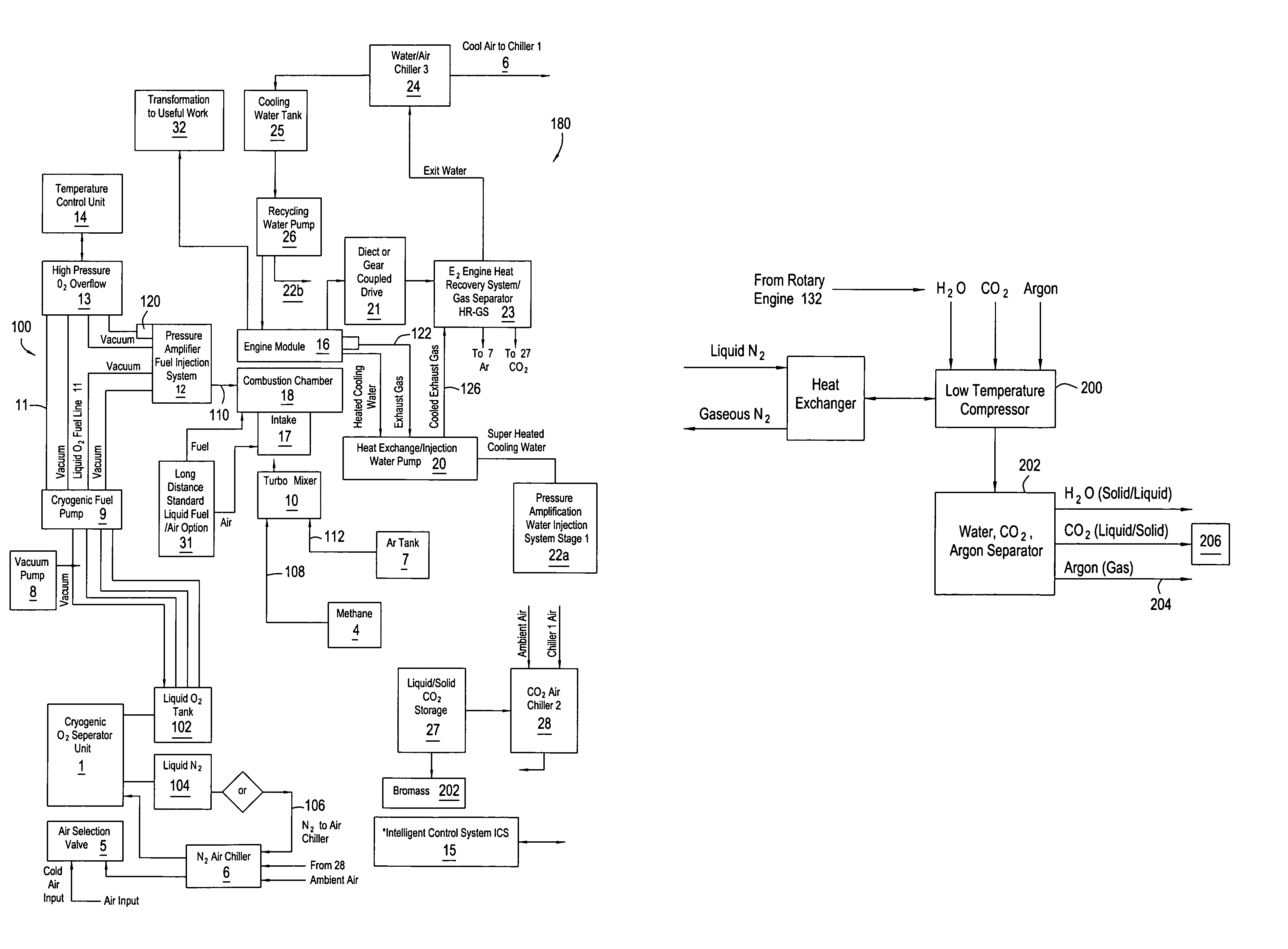

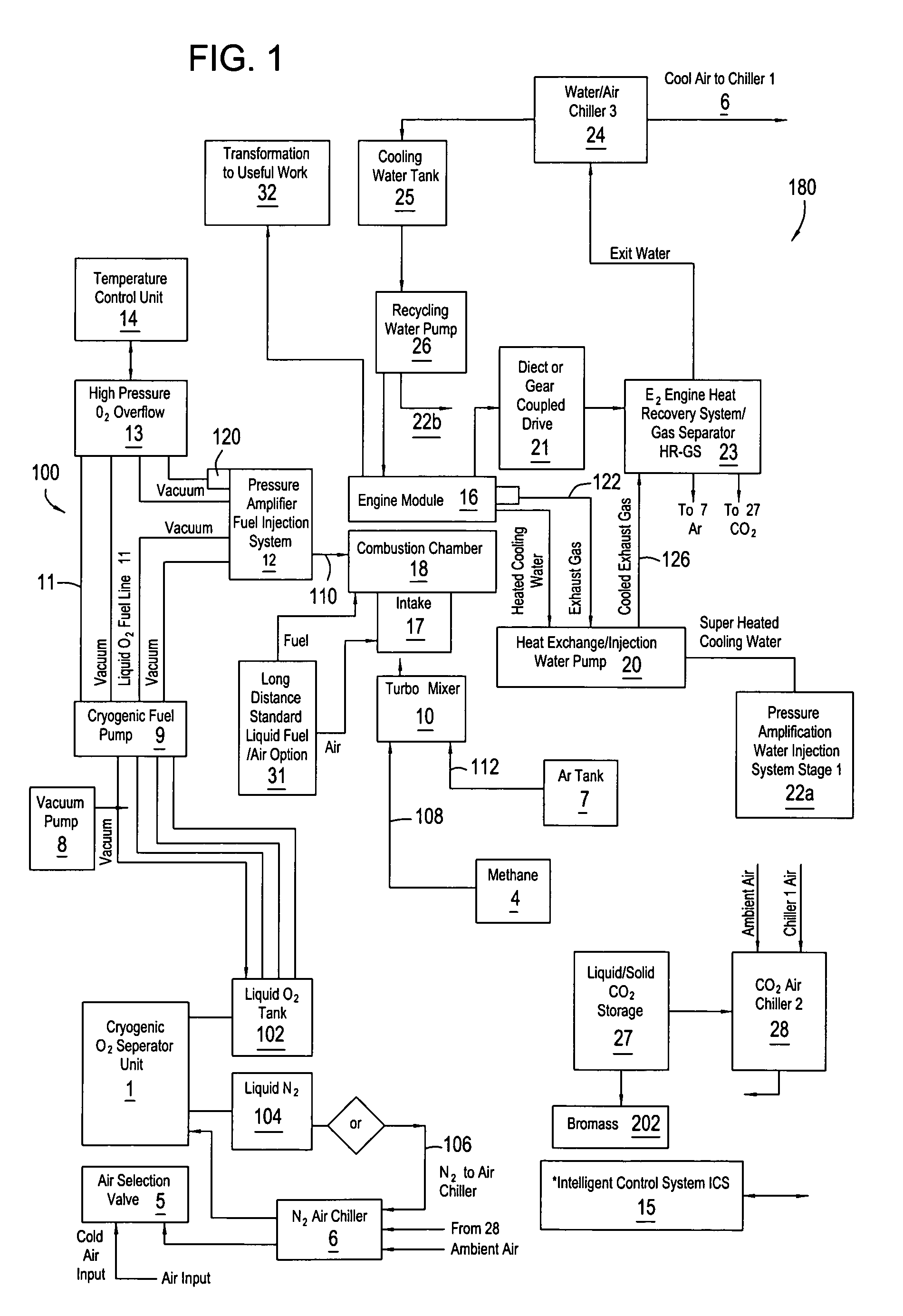

Low emission energy source

A power generator provides power with minimal CO2, NOx, CO, CH4, and particulate emissions and substantially greater efficiency as compared to traditional power generation techniques. Specifically nitrogen is removed from the combustion cycle, either being replaced by a noble gas as a working gas in a combustion engine. The noble gas is supplemented with oxygen and fuel, to provide a combustion environment substantially free of nitrogen or alternatively working in 100% oxygen-fuel combustion environments. Upon combustion, Very little to no nitrogen is present, and thus there is little production of NOx compounds. Additionally, the exhaust constituents are used in the production of power through work exerted upon expansion of the exhaust products, and the exhaust products are separated into their constituents of noble gas, water and carbon dioxide. The carbon dioxide may be used in conjunction with a biomass to accelerate the biomass growth and to recover the oxygen enriched air resulting from algae photosynthesis for enhancing the operation of the power generator using the as Biomass for processing into methanol / ethanol and biological oils as fuel for the power generator. The biomass fuel is seen as a solar fuel and may be used in conjunctions with other solar fuels like heated thermal oil and others, as well as clean fossil fuels to optimize to clean, and efficient operation of the power generator in various regulatory contexts.

Owner:BRIGHTSOURCE ENERGY

Combined cycle power plant with flue gas recirculation

ActiveUS20110289898A1Continuous combustion chamberNon-fuel substance addition to fuelPower stationFlue gas

An exemplary system method for the operation of a CCP P with flue gas recirculation to reduce NOx emissions and / or to increase the CO2 concentration in the flue gases to facilitate CO2 capture from the flue gases is disclosed. The flue gas recirculation rate (rFRG) is controlled as function of the combustion pressure and / or the hot gas temperature. Operability is enhanced by admixing of oxygen or oxygen enriched air to the gas turbine inlet gases or to the combustion.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Performance stability in shallow beds in pressure swing adsorption systems

Owner:AIR PROD & CHEM INC

Hydrogen recycle for solid oxide fuel cell

InactiveUS20040005492A1High outputImprove voltage efficiencyDispersed particle separationFuel cell auxillariesContaminationRadiochemistry

The present disclosure relates to solid oxide fuel cells (SOFCs) exploiting gas separation devices in which a first gas mixture including components A (for example hydrogen) and B (for example carbon dioxide) is to be separated so that a first product of the separation is enriched in component A, while component B is mixed with a third gas component C (for example air, oxygen-enriched air or oxygen-depleted air) contained in a displacement purge stream to form a second gas mixture including components B and C, and with provision to prevent cross contamination of component C into the first product containing component A, or of component A into the second gas mixture containing component C. The invention may be applied to hydrogen (component A) enrichment from fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:AIR PROD & CHEM INC

Blast-furnace smelting method for vanadium titano-magnetite

InactiveCN101775451ARaise the gradeReduce tons of iron slagBlast furnace detailsMagnetiteBlast furnace smelting

The invention discloses a blast-furnace smelting method for vanadium titano-magnetite. The method is realized in a way that: vanadium titano-magnetite accounts for 30-60% of ferrous burden which is fed into a blast furnace, and the burden comprises 40-65% of agglomerate, 30-50% of pellet and 5-10% of lump ore; the diacidic basicities CaO / SiO2 of agglomerate, pellet and blast-furnace slag are respectively controlled at 1.6-2.5, 0.6-1.0 and 1.05-1.20; the content of MgO in blast-furnace slag is controlled at 7.5-9.0%; by adding two batches of ore and three batches of coke and using the charging operation of the development center, manganese oxide ore or sintered manganese ore powder, and fluorite are incorporated into injection coal and injected into the blast furnace along with the coal powder; and thus, the content of MnO in the slag and the content of CaF2 in the slag are respectively controlled at 1.0-4.5% and 0.50-2.0%, and the oxygen-enrichment percentage of the blast furnace is controlled at 2.0-4.0%. Compared with the smelting blast furnace using the same quality and structure of the burden, the comprehensive coke ratio of the invention is reduced by 20-50kg per ton of iron, the content of TFe in the slag is reduced by 50%, and the comprehensive cost per ton of iron is reduced by 30-50 yuan. The invention has wide prospects for popularization and application.

Owner:CENT SOUTH UNIV

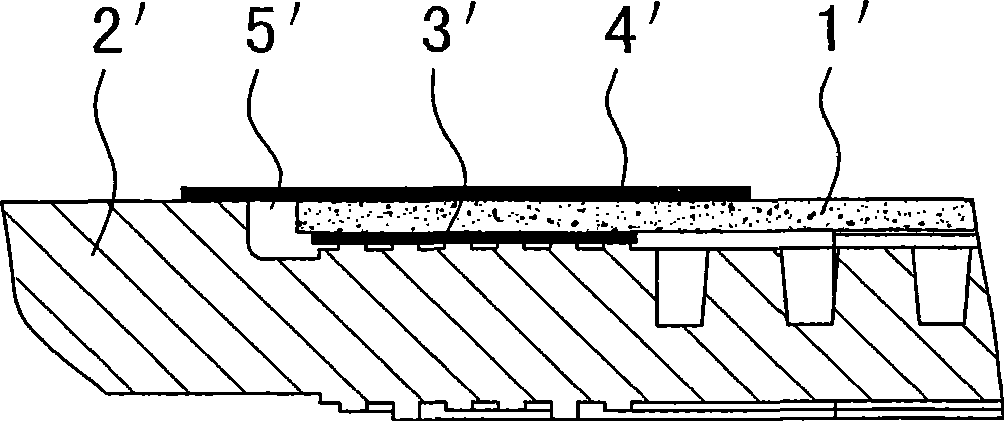

Flat oxygen-enriched membrane component

InactiveCN101544356AGuaranteed service lifeIncrease profitSemi-permeable membranesDispersed particle separationAdhesiveHeat fusion

The invention relates to a flat oxygen-enriched membrane component, which consists of an upper template, a middle template and a lower template which are fastened. One end of the upper template, one end of the middle template and one end of the lower template are provided with oxygen outlets A, B and C which are communicated; the insides of the upper template and the lower template are provided with oxygen-enriched membranes A and D respectively; two sides of the middle template are provided with oxygen-enriched membranes B and C respectively; air passages A and B are arranged between the adjacent oxygen-enriched membranes; one end of the air passage A and one end of the air passage B are communicated with the atmosphere, and the other end of the air passage A and the other end of the air passage B are communicated with the oxygen outlets A, B and C; the oxygen outlets B and C are provided with oxygen passage covers B and C of through holes; and the flat oxygen-enriched membrane component is characterized in that heat fused welding layers are arranged between the oxygen-enriched membranes A, B, C and D and the corresponding upper template, the middle template and the lower template respectively. The oxygen-enriched membranes are physically welded and fixed by adopting heat fusion, the defects of adhesion and fixation of adhesive are thoroughly changed, the service life is ensured, and the utilization ratio is improved.

Owner:周纪昌

Tertiary oil recovery combined with gas conversion process

A process for the recovery of oil from a subsurface reservoir in combination with the production of liquid hydrocarbons from a hydrocarbonaceous stream involving:(i) separating an oxygen / nitrogen mixture into a stream enriched in oxygen and an oxygen depleted stream;(ii) partial oxidation of the hydrocarbonaceous feed at elevated temperature and pressure using enriched oxygen produced in step (i) to produce synthesis gas;(iii) converting synthesis gas obtained in step (ii) into liquid hydrocarbons; and(iv) recovering oil from a subsurface reservoir using at least part of the oxygen depleted gas stream produced in step (i).

Owner:SHELL OIL CO

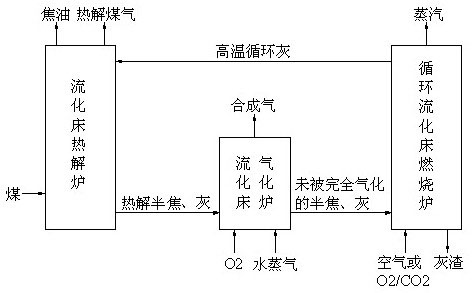

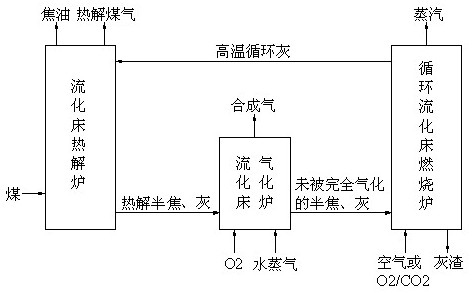

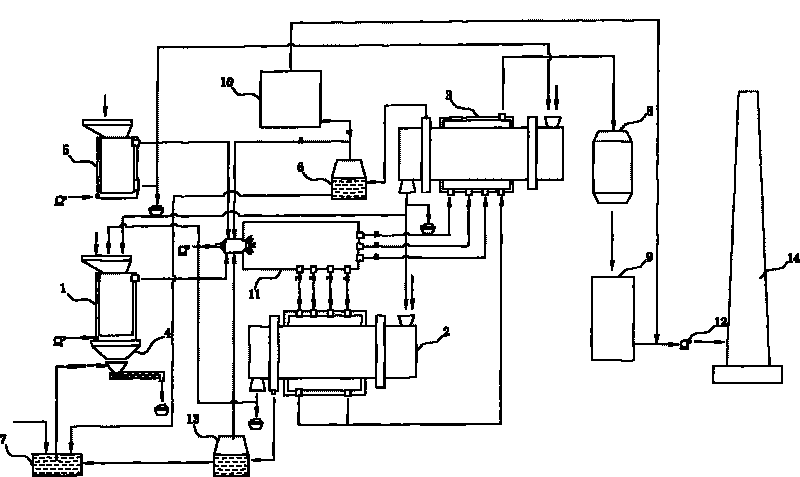

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

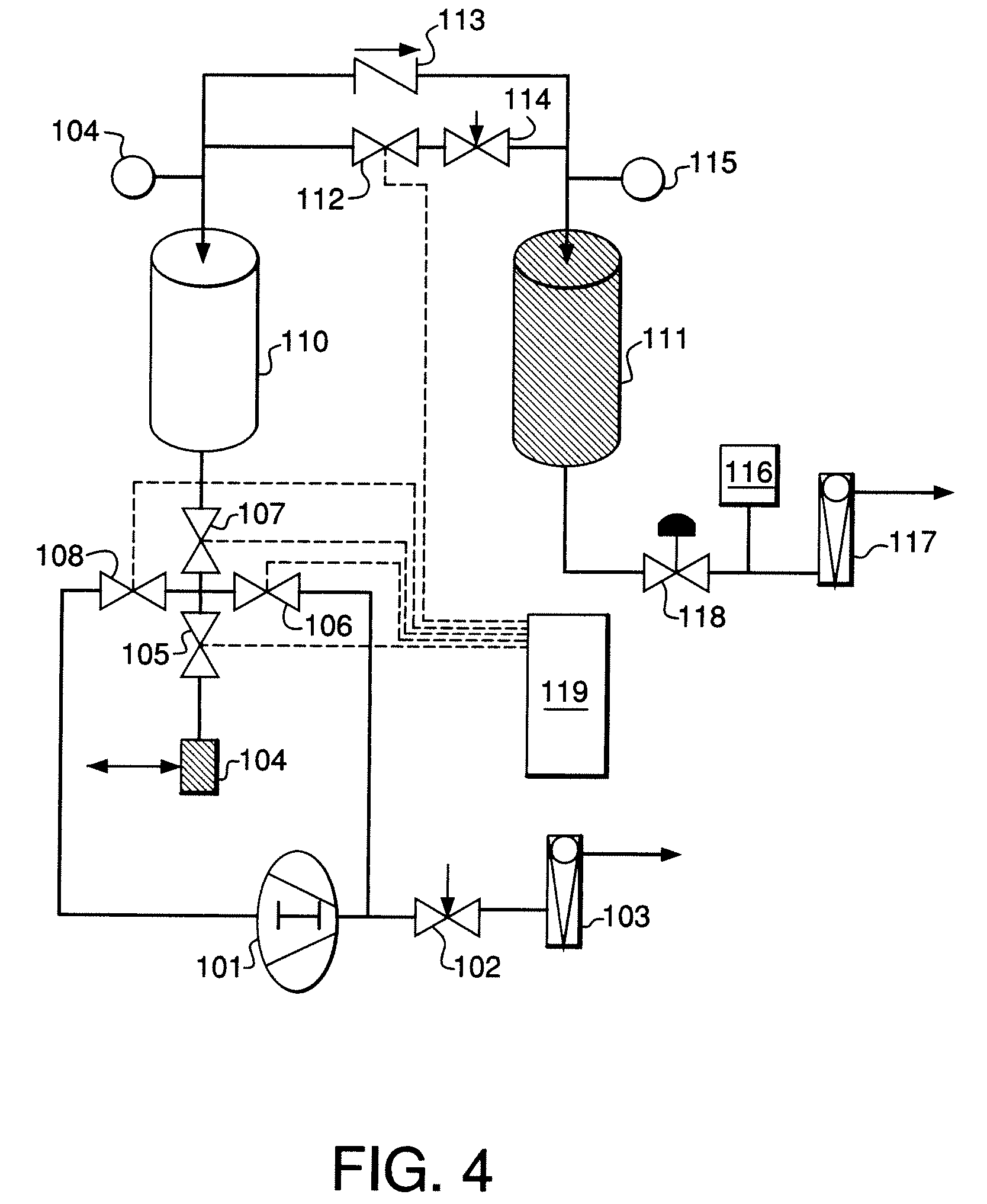

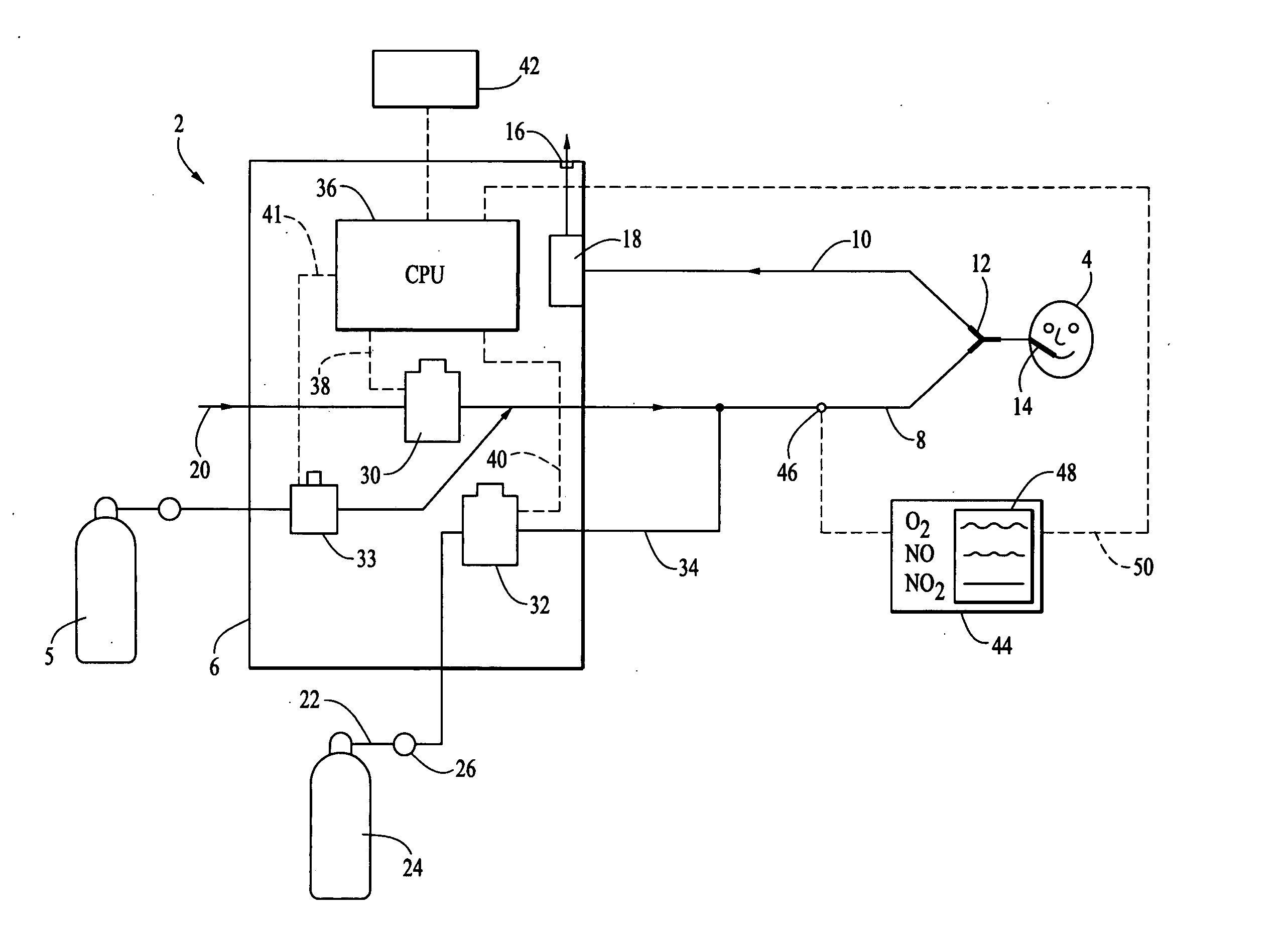

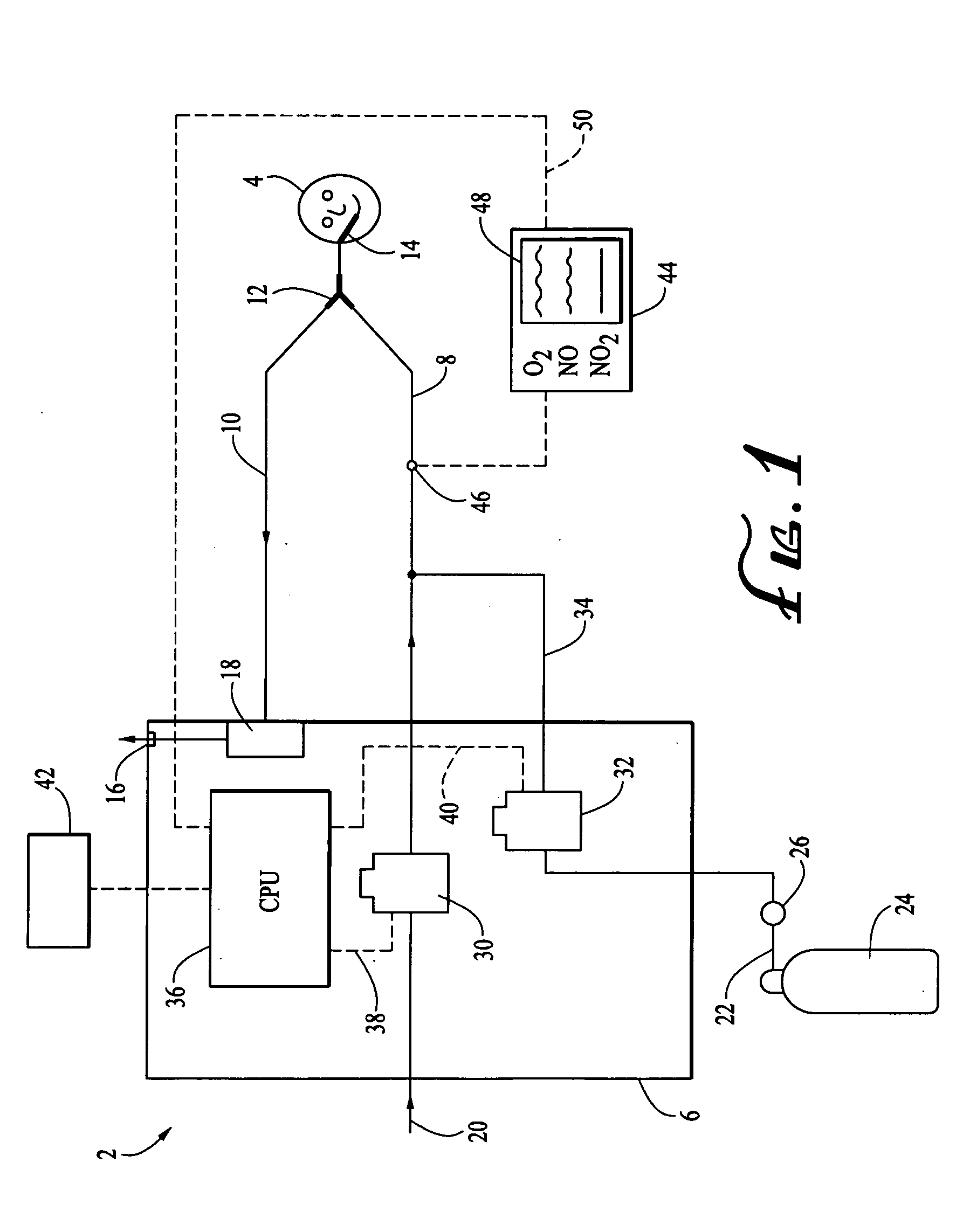

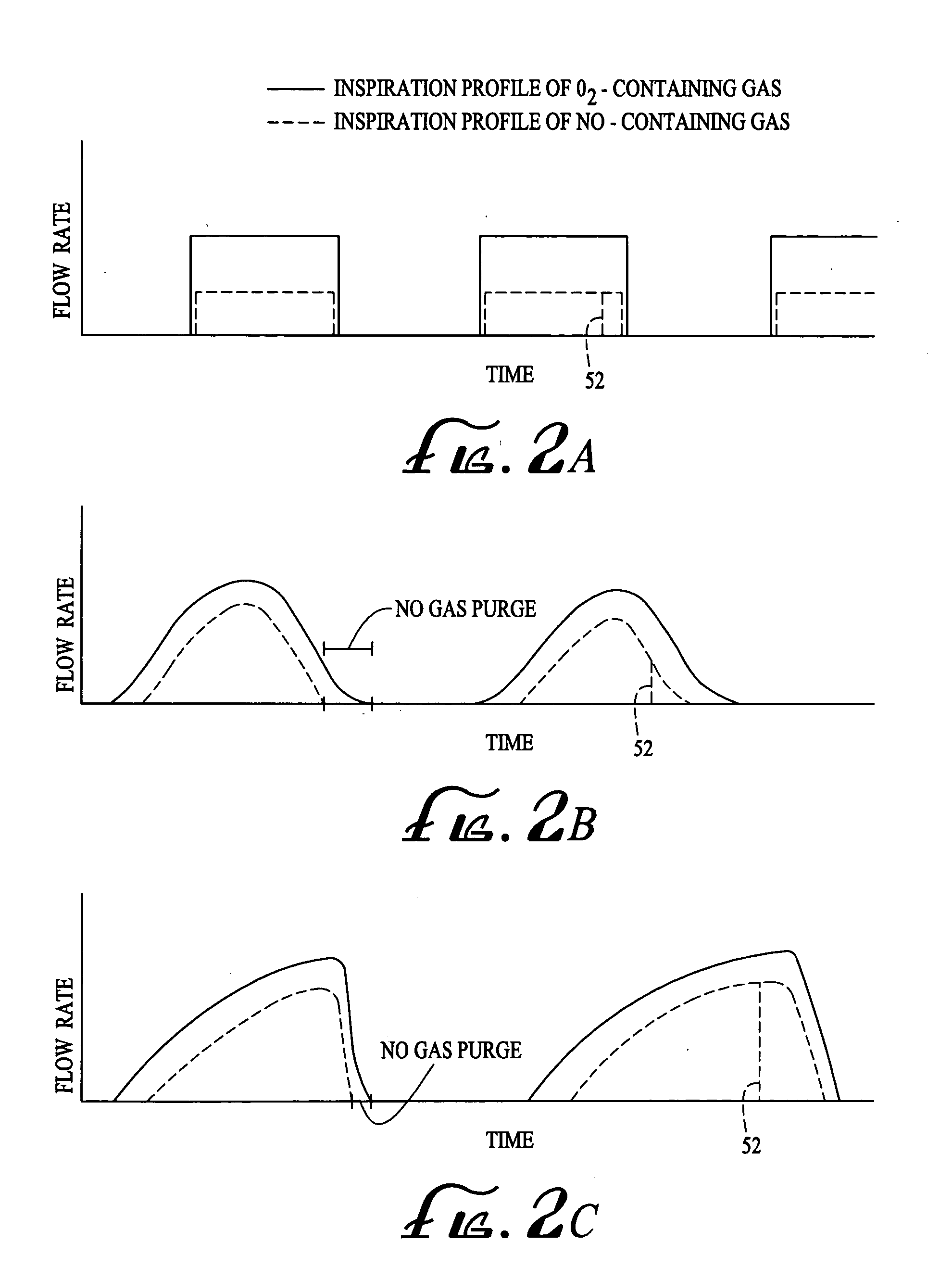

Method and apparatus for delivery of inhaled nitric oxide to spontaneous-breathing and mechanically-ventilated patients

InactiveUS20050076907A1RespiratorsOperating means/releasing devices for valvesAutonomous breathingNitric oxide

A device and method is disclosed for delivering NO to a patient. The device utilizes a single controller that controls two separate flow controllers to deliver an oxygen-containing gas and a NO-containing gas to the patient. The flow profiles of the oxygen-containing gas and the NO-containing gas are controlled by the controller. In one aspect of the invention, the flow profile of the NO-containing gas is proportional to the flow profile of the oxygen-containing gas throughout patient inspiration. In this regard, the patient receives a steady concentration of NO. In another aspect of the invention, the flow profile of the NO-containing gas is quasi-proportional to the flow profile of the oxygen-containing gas. In this regard, the NO-containing gas flow profile is altered to provide an increased concentration of NO either at the beginning or end of inspiration. In one aspect, the delivery device is used with mechanically-ventilated patients. In the other aspect of the delivery device, the device is used with spontaneously-breathing patients. The device and method, in a preferred embodiment, further contemplates using a gas purge or air flush feature to remove enriched-oxygen and / or NO from the device.

Owner:STENZLER ALEX

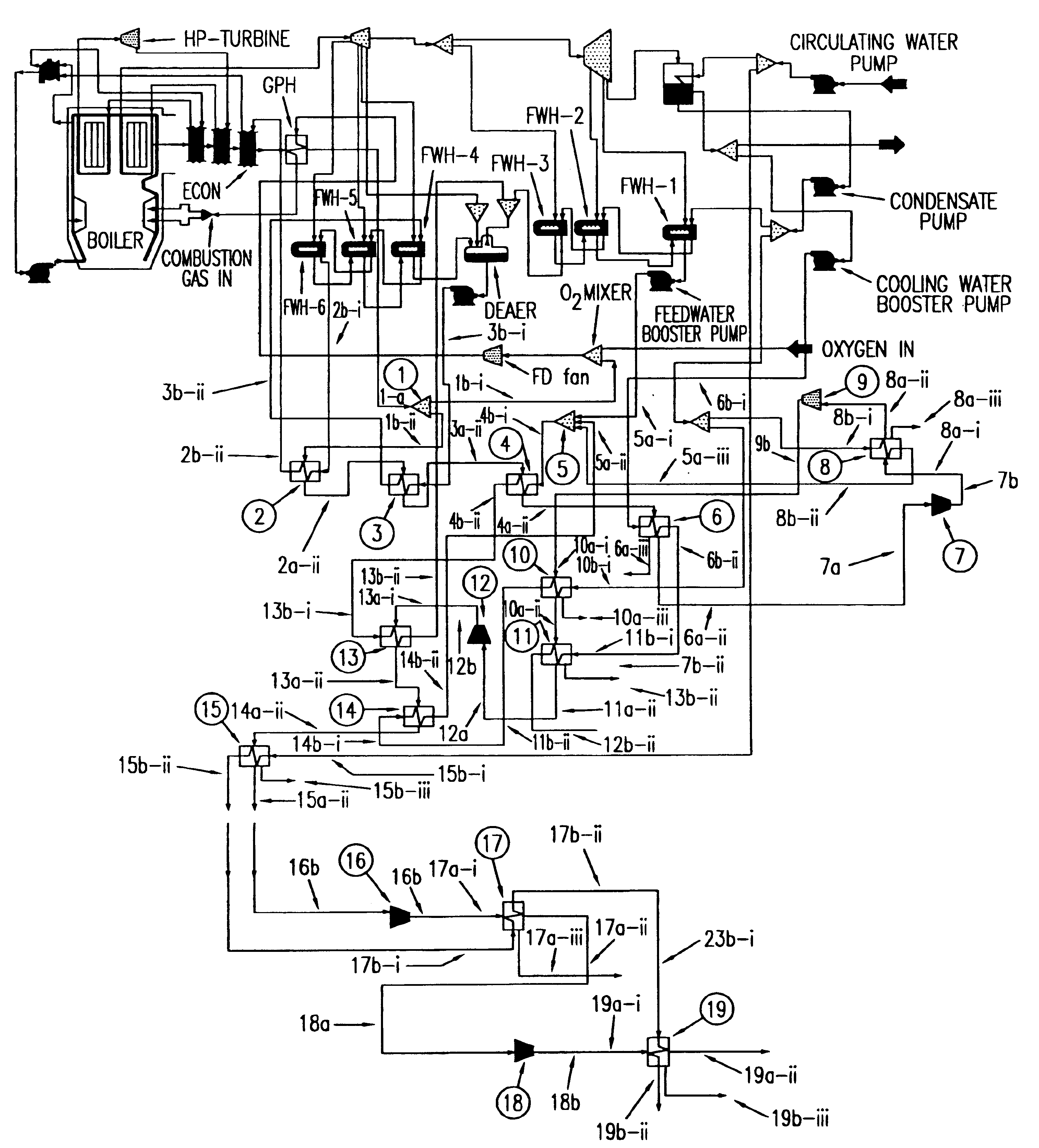

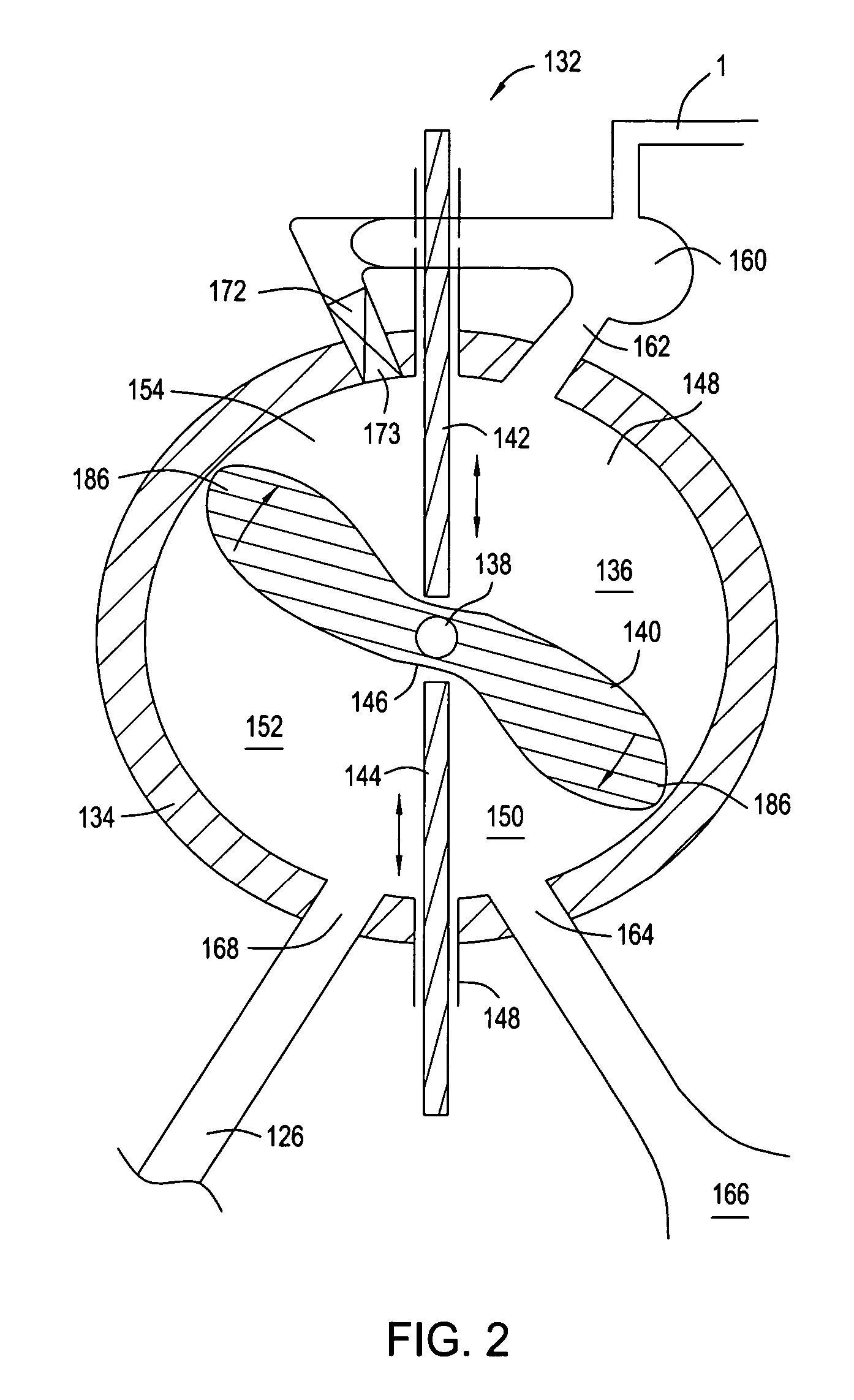

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS20050132713A1Improve thermal efficiencyMaximum efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

Sludge or organic garbage high-low temperature coupling themolysis method

InactiveCN101708938AFlexible to adapt to changes in natureSimple processSludge treatment by pyrolysisBiofuelsSludgeCarbonization

The invention provides a sludge or organic garbage high-low temperature coupling themolysis method which is characterized in that: the method comprises the following steps: step I: the sludge or organic garbage is fed in a low temperature drying depolymerizing furnace; material with partial carbonization is used as raw material of soil organic fertilizer; step II: the material with partial carbonization, generated in pyrolysis, is fed into a middle temperature carbonizing furnace for carrying out carbonization; the obtained bio-organic carbon is used as raw material of soil organic fertilizer or soil conditioner; step III: the material with partial carbonization, bio-organic carbon and one or more than two mixtures of the sludge, straws or organic garbage are fed in a high-temperature pyrolysis furnace for gasification; step IV: fixed carbon remained in a high-temperature depolymerizing furnace after aerogenesis is fed in a high-temperature sub-fusion activated device, and then oxygen-enriched air enters in, and then liquid in a regulating solution storage tank is prayed in for regulation, and then, compound charcoal is obtained after being cooled. The method has high efficiency, simple steps and diversified products.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com