Patents

Literature

834 results about "Oxygen enhanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

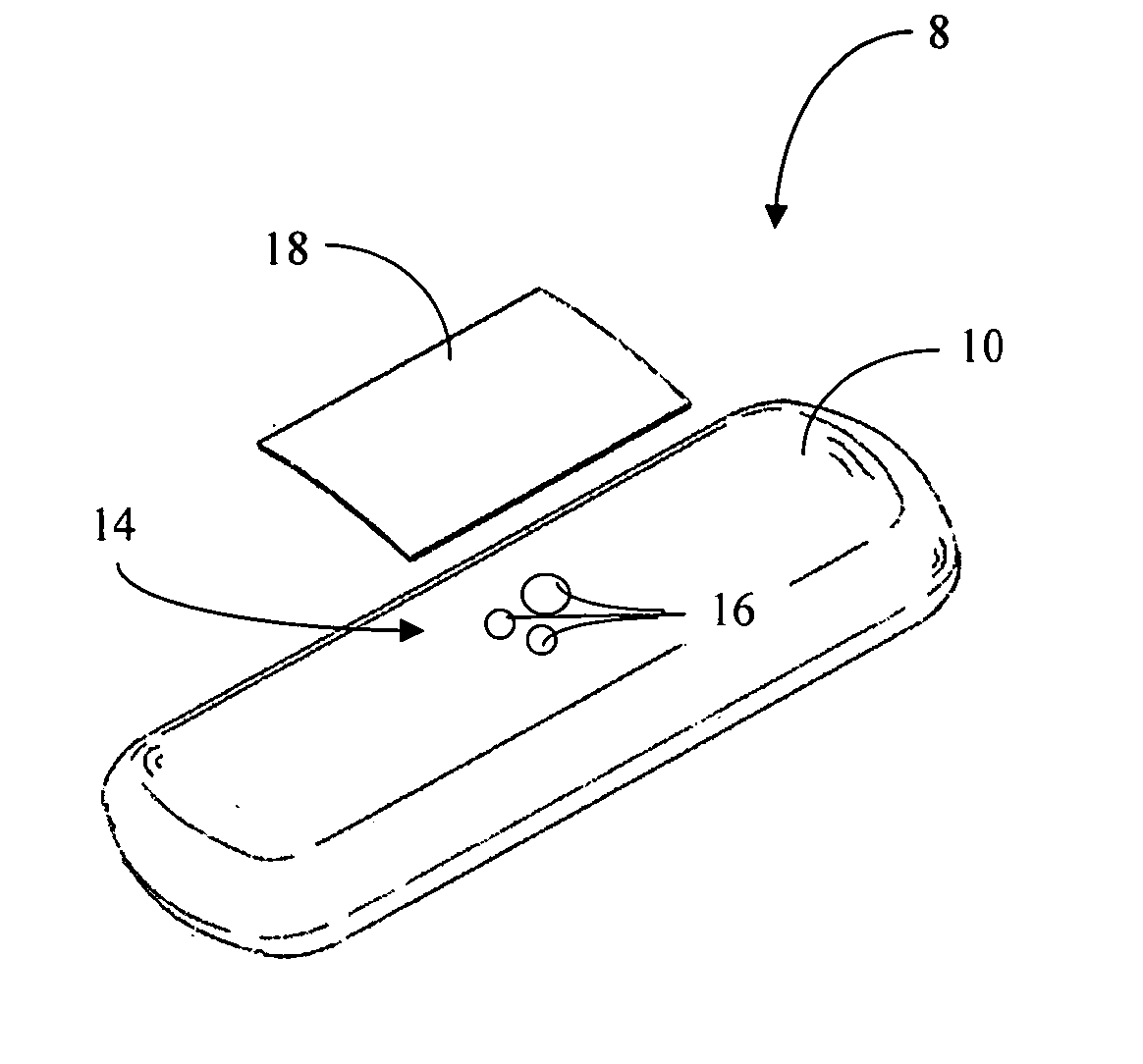

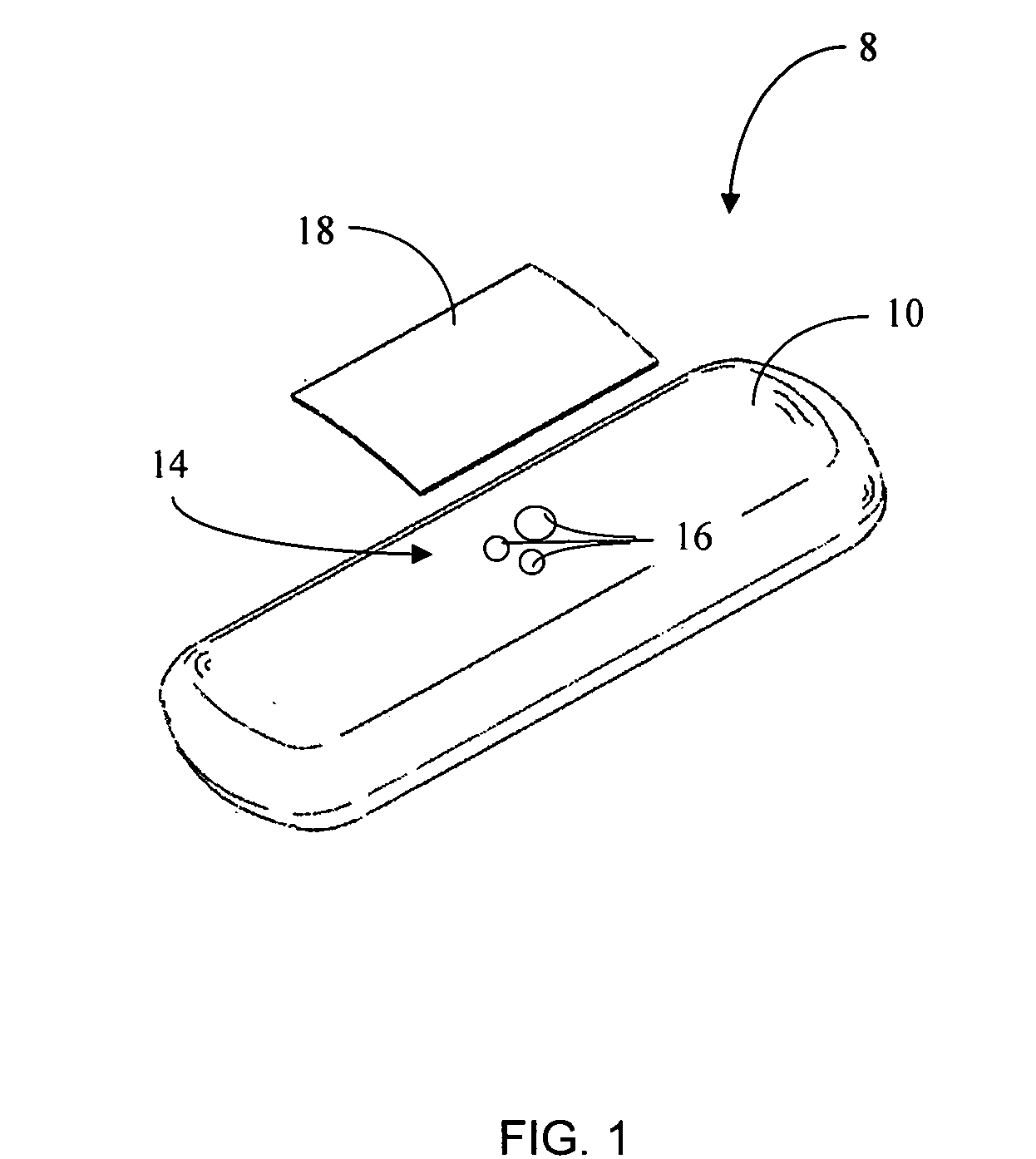

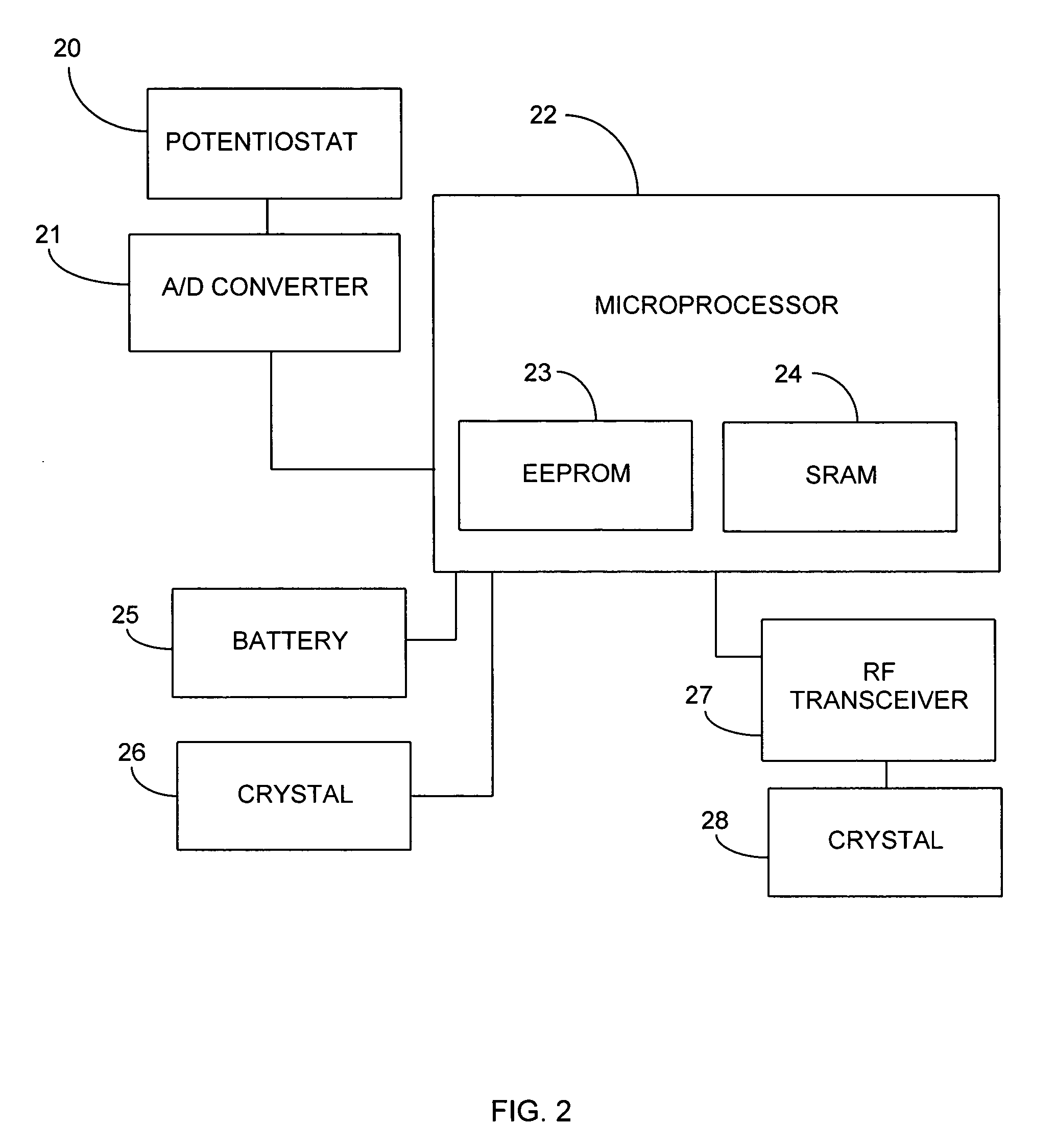

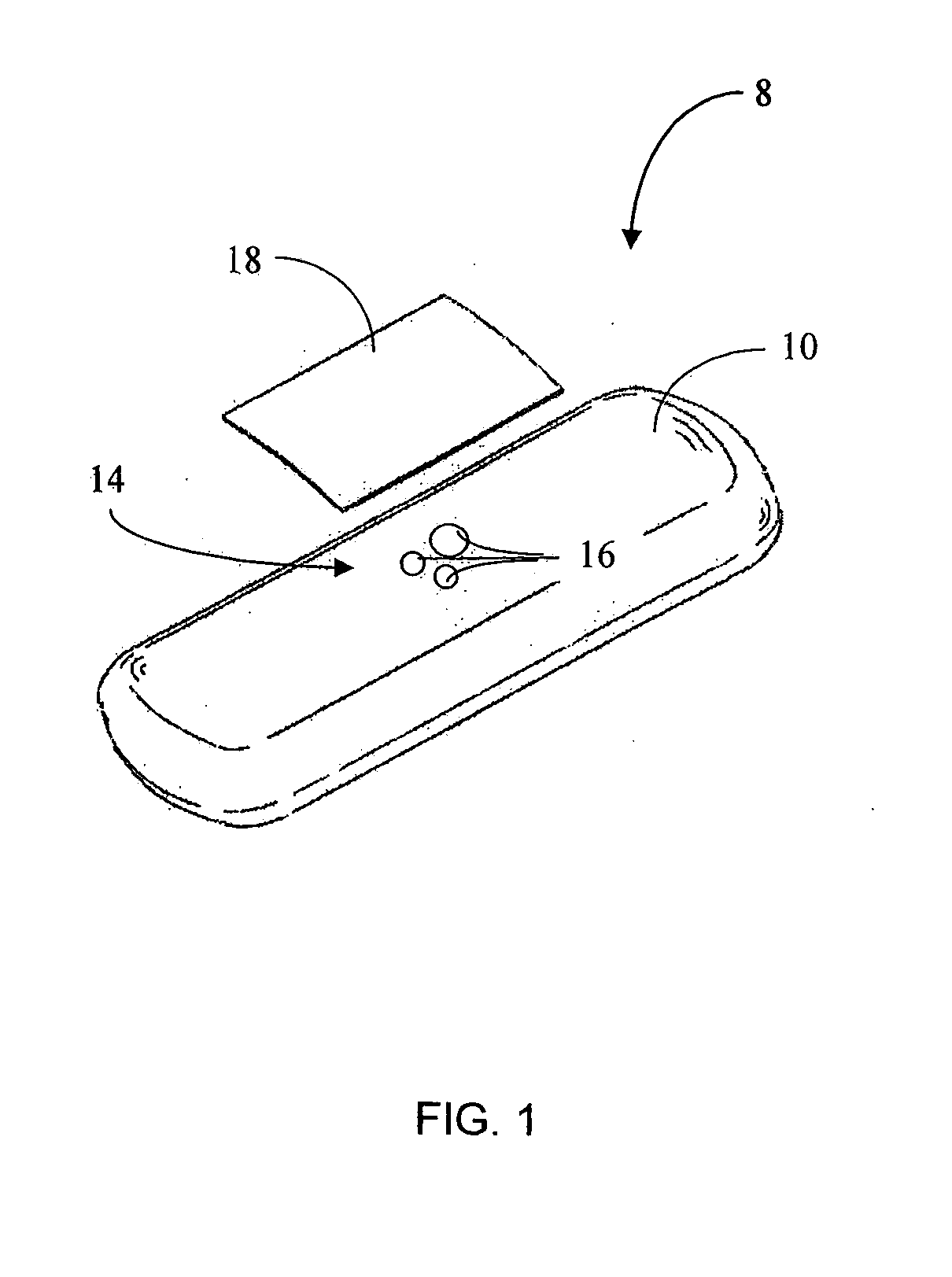

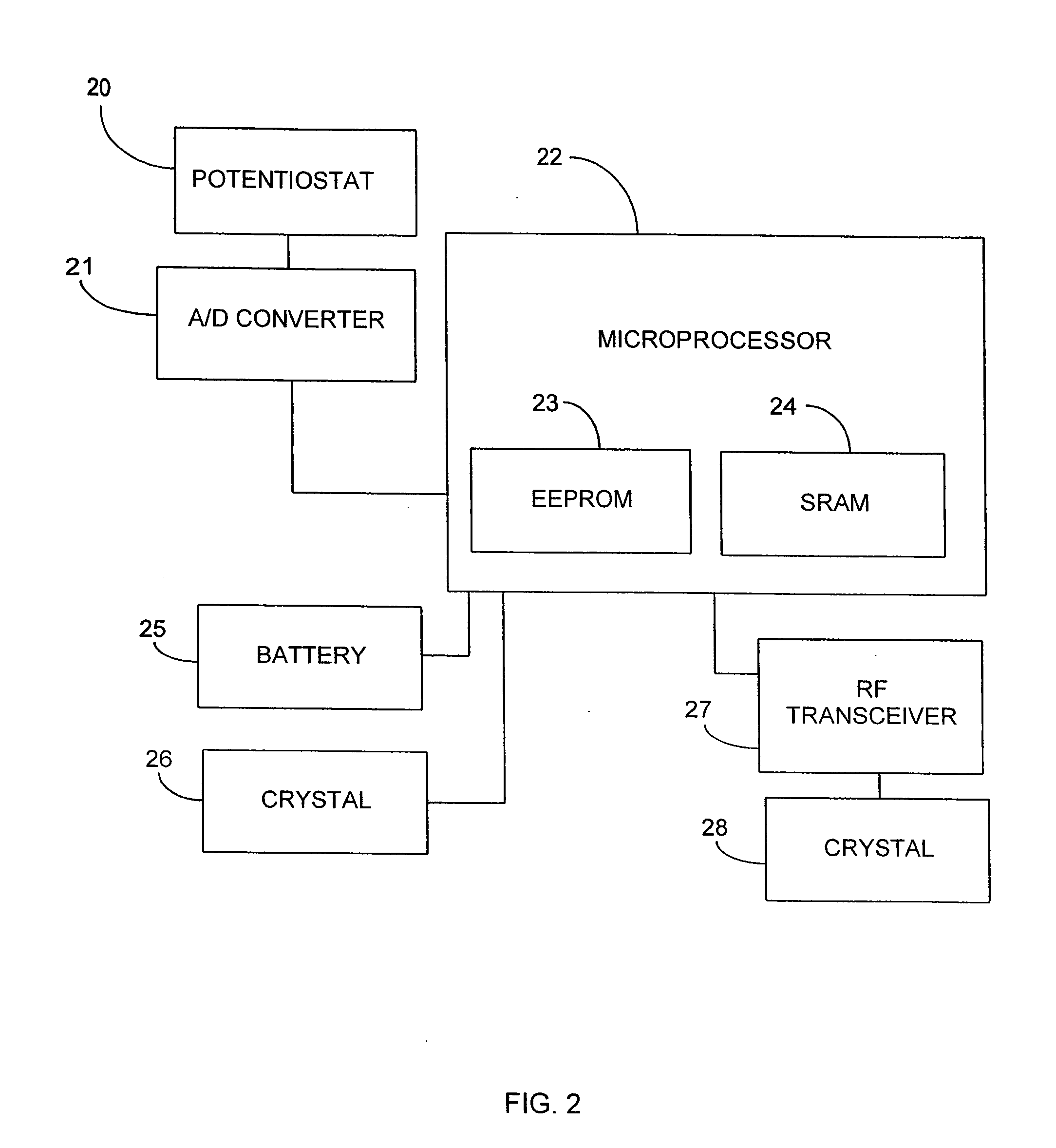

Oxygen enhancing membrane systems for implantable devices

ActiveUS20050054909A1Immobilised enzymesBioreactor/fermenter combinationsImplanted deviceOxygen enhanced

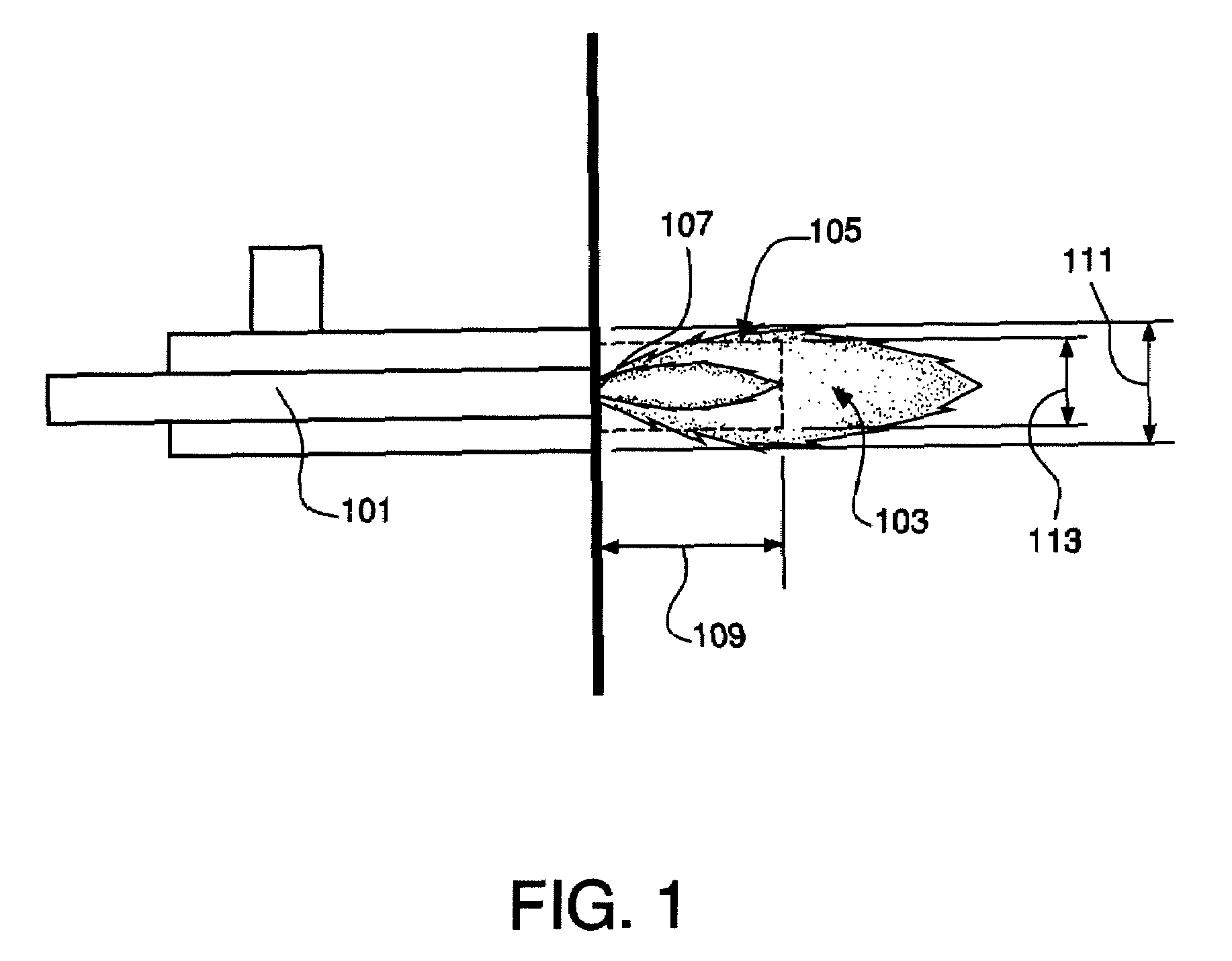

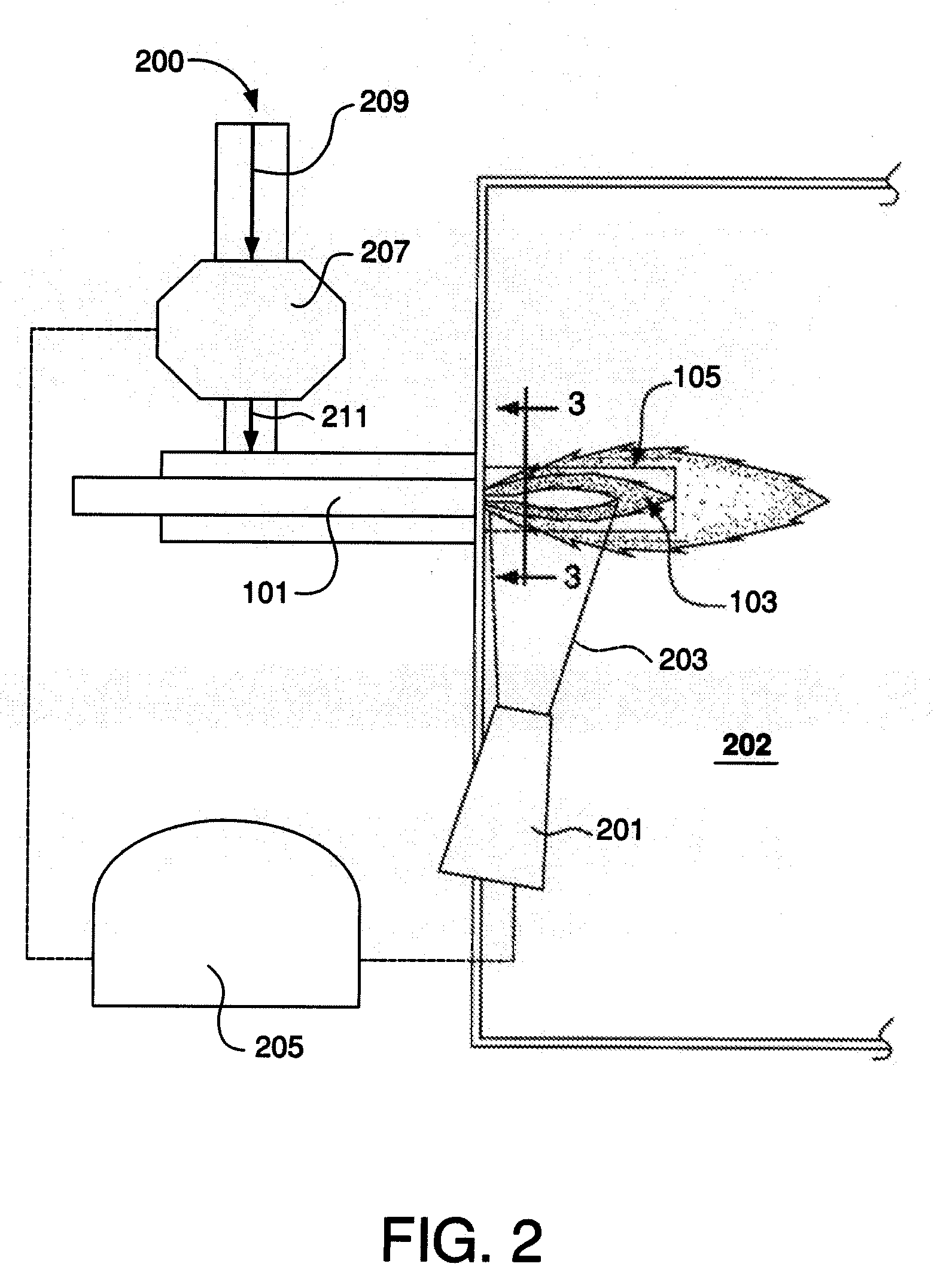

The present invention relates generally to systems and methods for increasing oxygen availability to implantable devices. The preferred embodiments provide a membrane system configured to provide protection of the device from the biological environment and / or a catalyst for enabling an enzymatic reaction, wherein the membrane system includes a polymer formed from a high oxygen soluble material. The high oxygen soluble polymer material is disposed adjacent to an oxygen-utilizing source on the implantable device so as to dynamically retain high oxygen availability to the oxygen-utilizing source during oxygen deficits. Membrane systems of the preferred embodiments are useful for implantable devices with oxygen-utilizing sources and / or that function in low oxygen environments, such as enzyme-based electrochemical sensors and cell transplantation devices.

Owner:DEXCOM

Oxygen enhancing membrane systems for implantable devices

ActiveUS20060189856A1Microbiological testing/measurementMaterial analysis by electric/magnetic meansImplanted deviceOxygen enhanced

The present invention relates generally to systems and methods for increasing oxygen availability to implantable devices. The preferred embodiments provide a membrane system configured to provide protection of the device from the biological environment and / or a catalyst for enabling an enzymatic reaction, wherein the membrane system includes a polymer formed from a high oxygen soluble material. The high oxygen soluble polymer material is disposed adjacent to an oxygen-utilizing source on the implantable device so as to dynamically retain high oxygen availability to the oxygen-utilizing source during oxygen deficits. Membrane systems of the preferred embodiments are useful for implantable devices with oxygen-utilizing sources and / or that function in low oxygen environments, such as enzyme-based electrochemical sensors and cell transplantation devices.

Owner:DEXCOM INC

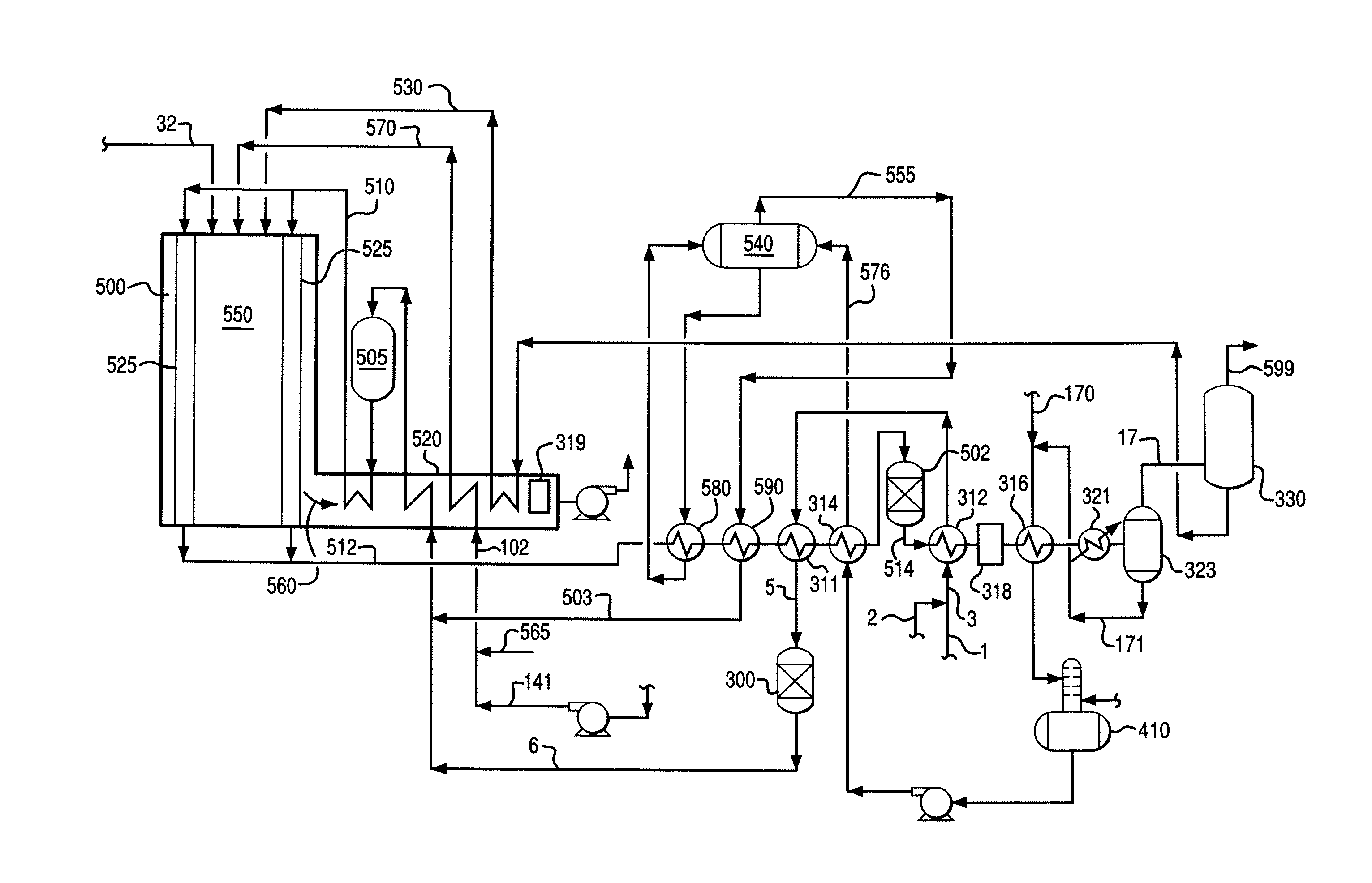

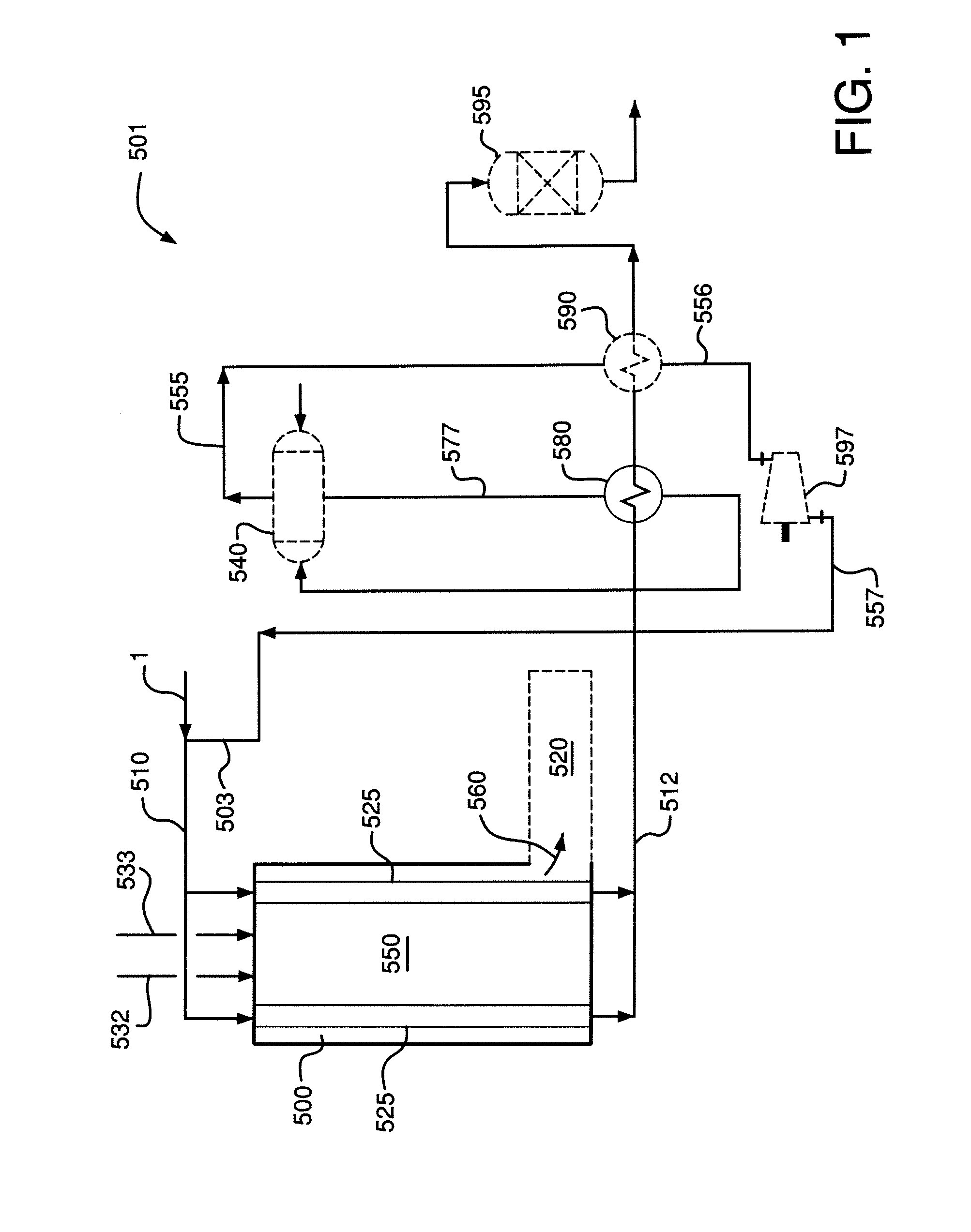

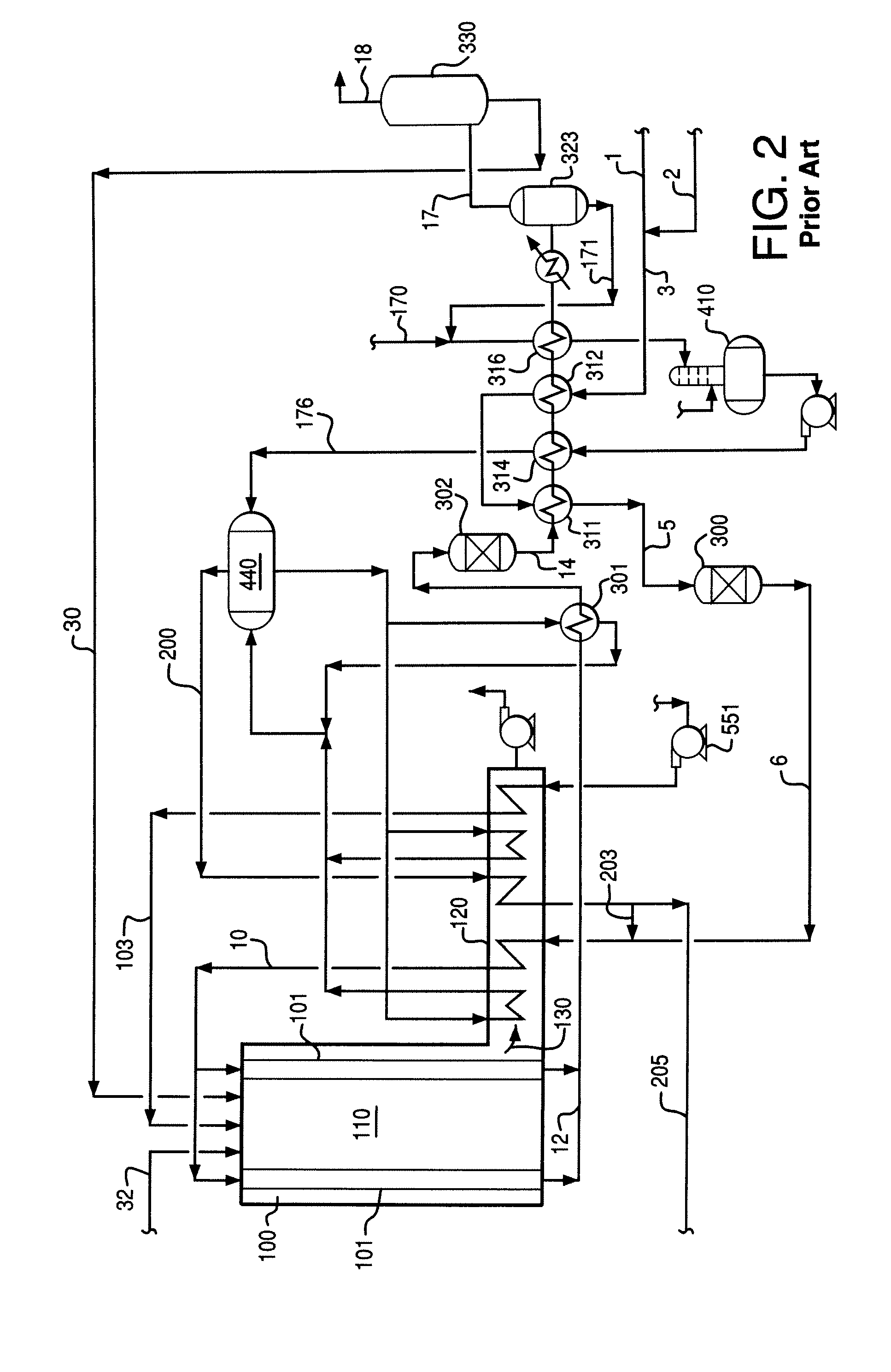

Steam-Hydrocarbon Reforming Method with Limited Steam Export

A method for generating hydrogen and / or synthesis gas in a production facility where little or no export steam is produced. Most or all of the high pressure steam produced from the waste heat from the process is used in the steam-hydrocarbon reformer with little or no steam export. The method uses oxygen enhanced combustion which may involve oxygen lancing and / or oxygen-enrichment. Plant efficiencies using the method and prior art-type methods are compared.

Owner:AIR PROD & CHEM INC

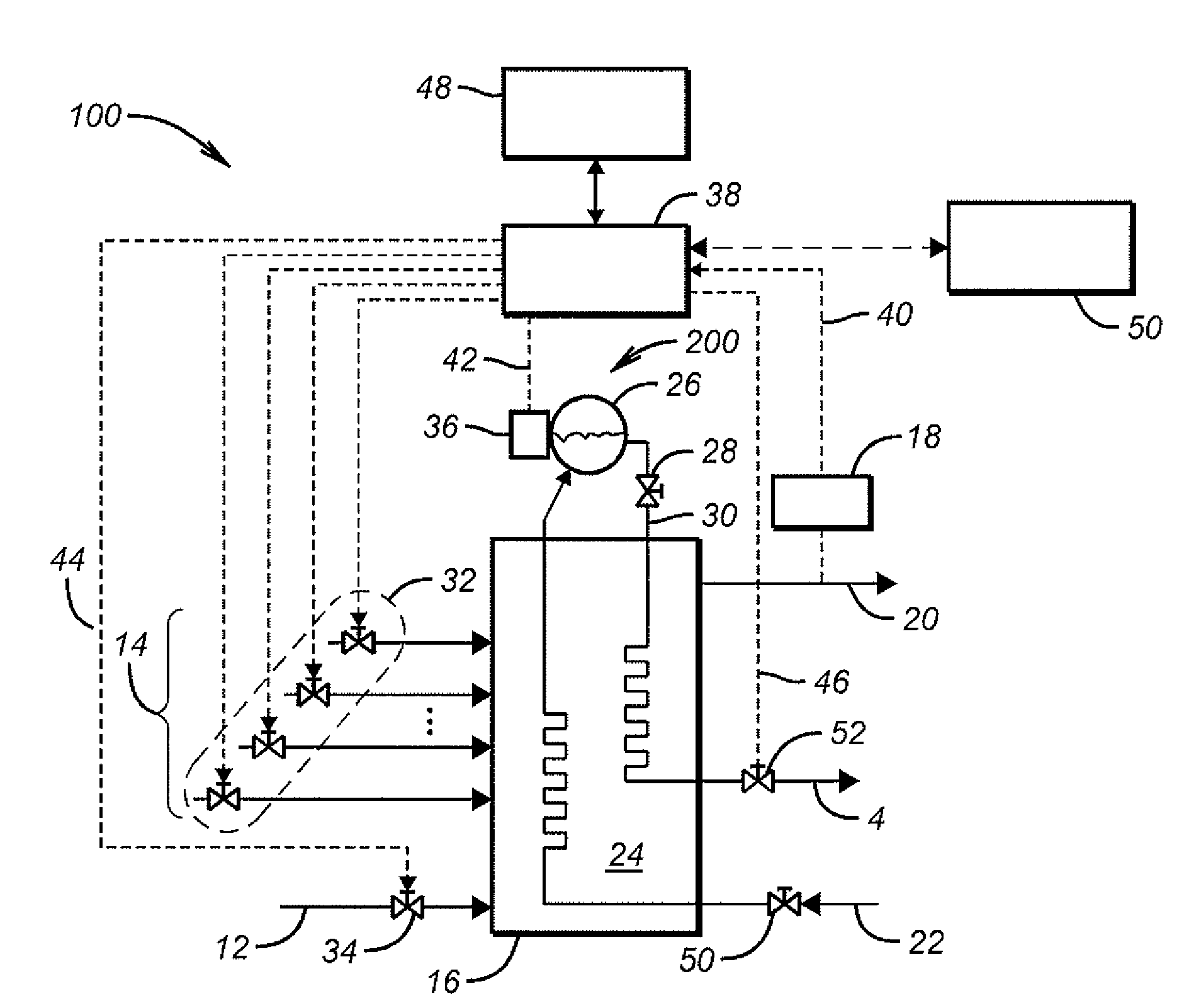

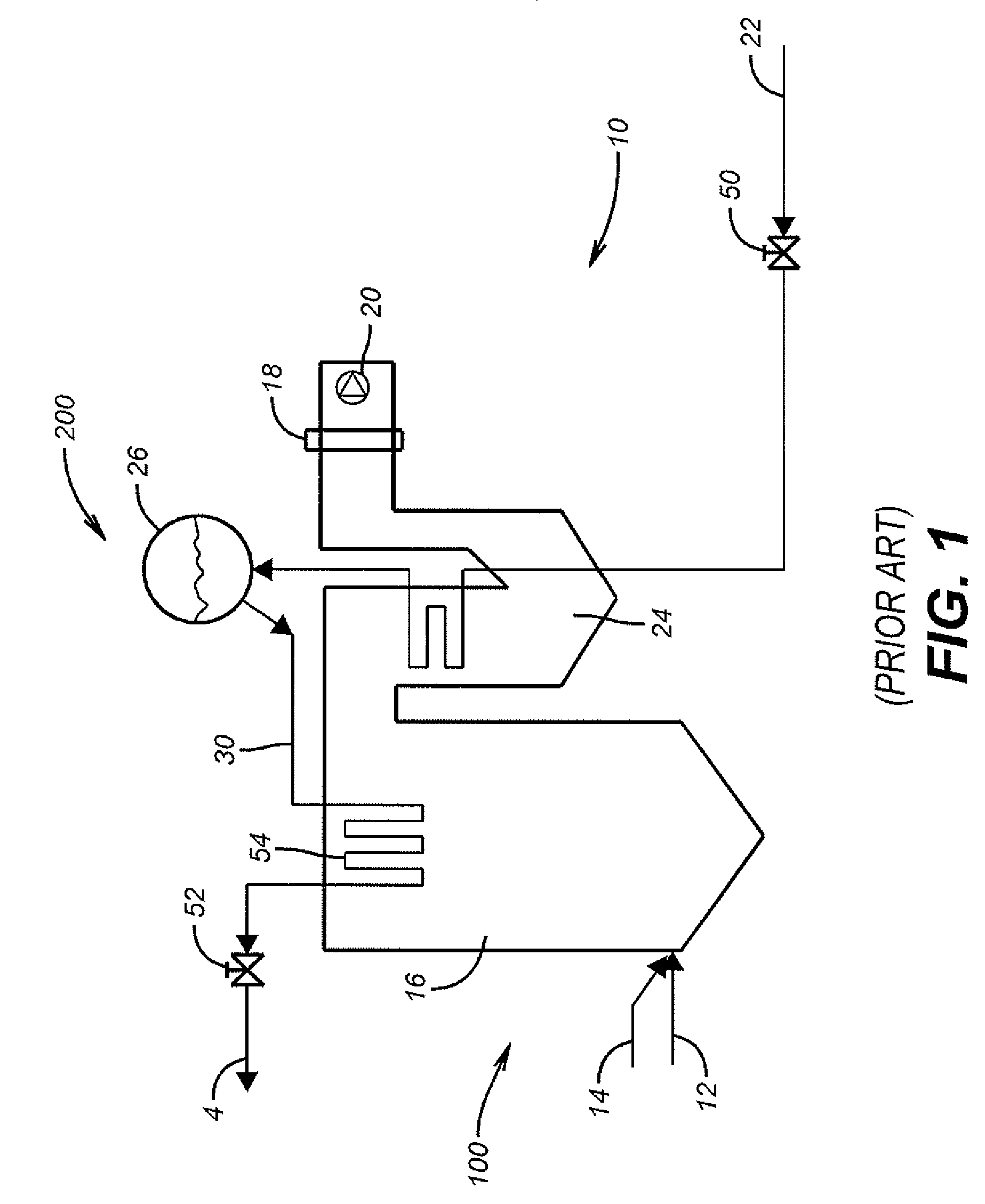

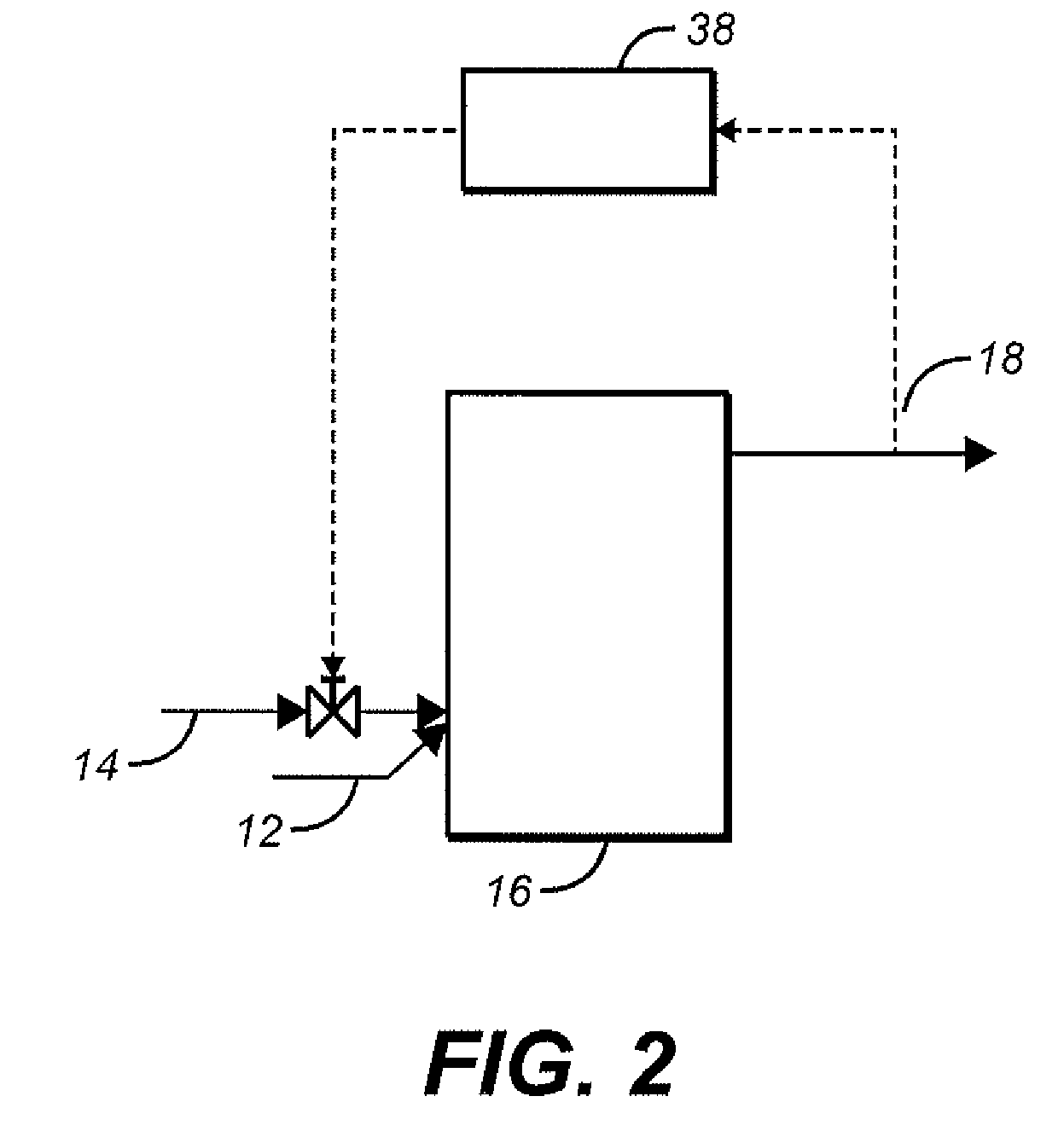

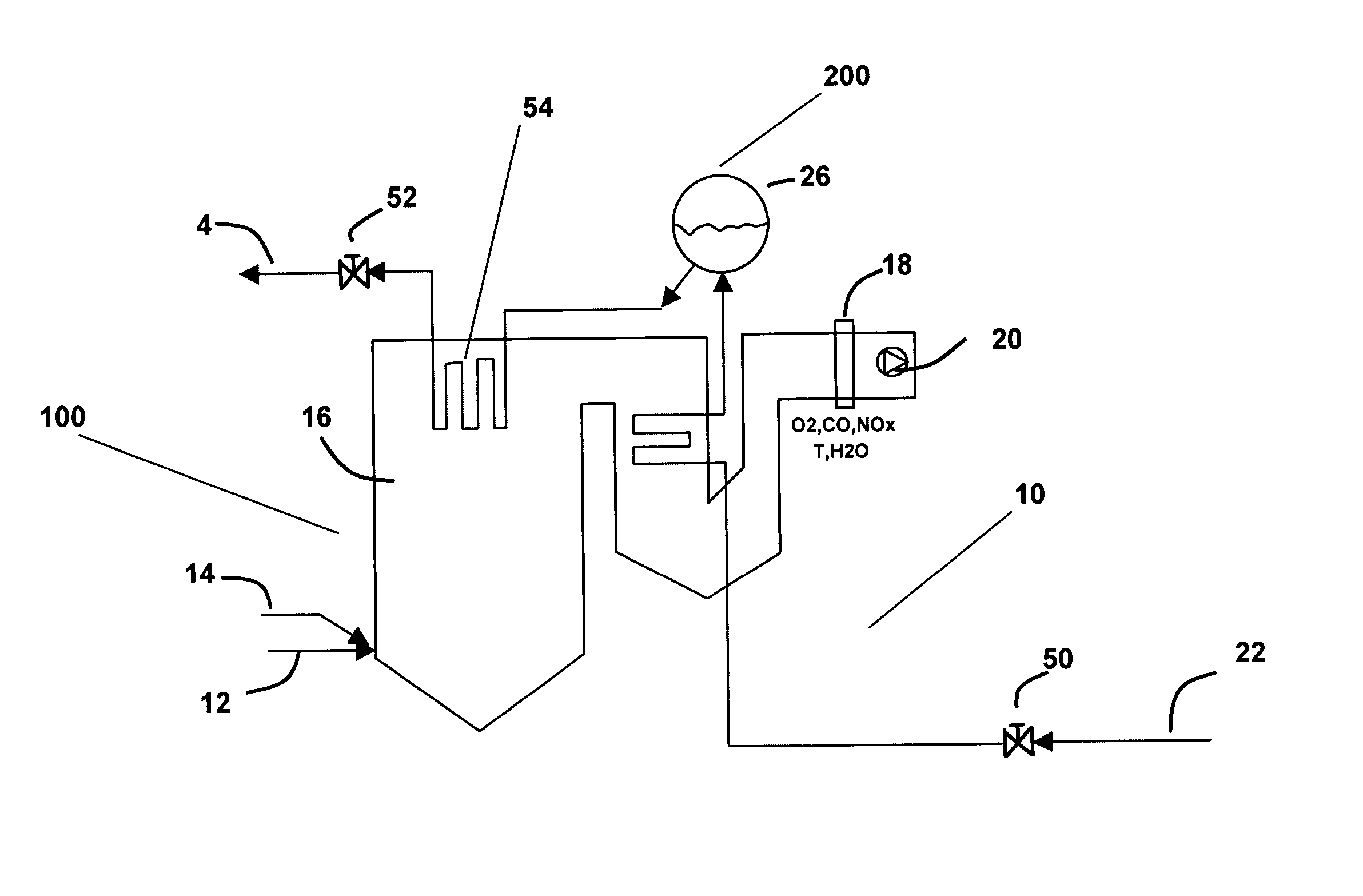

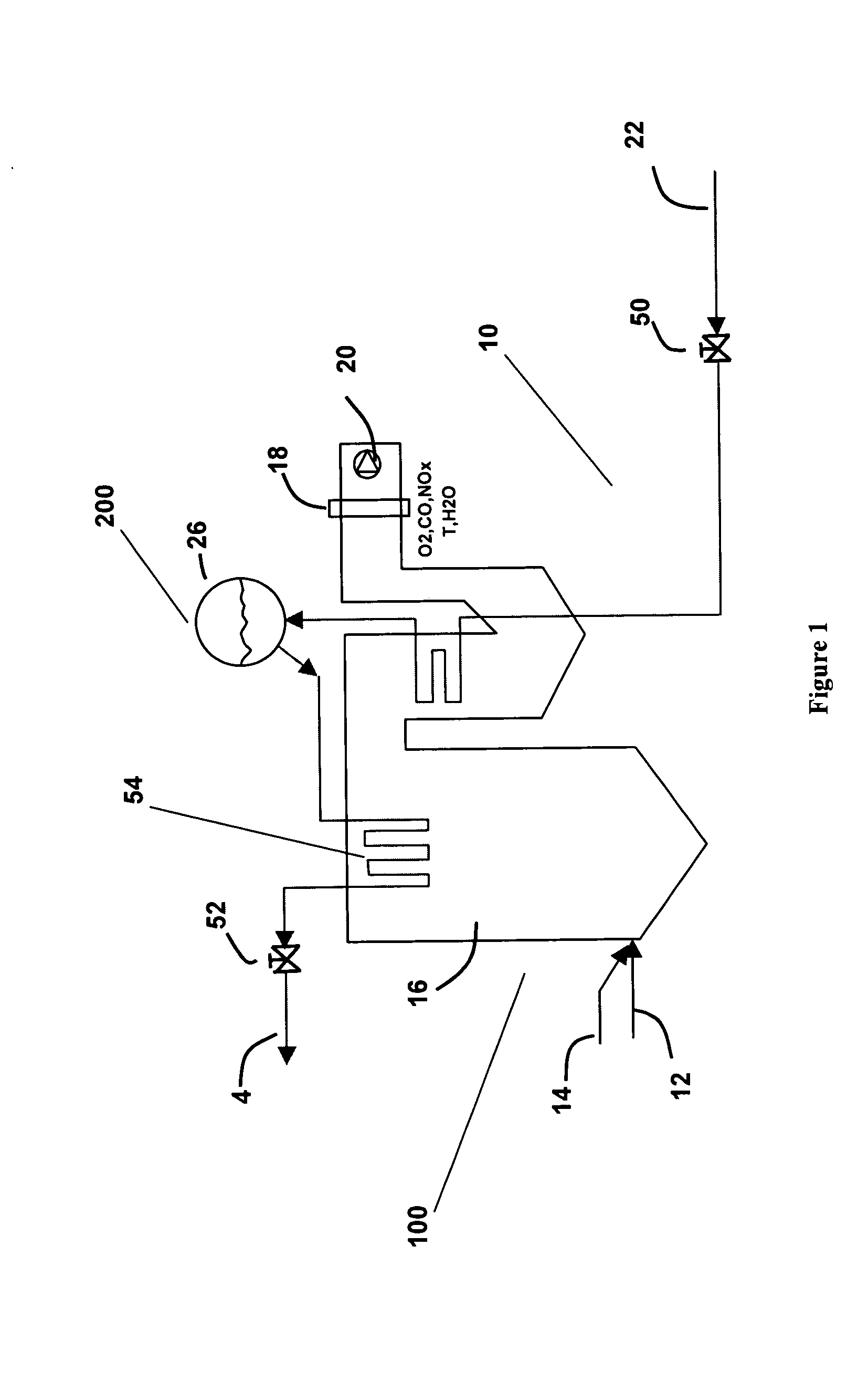

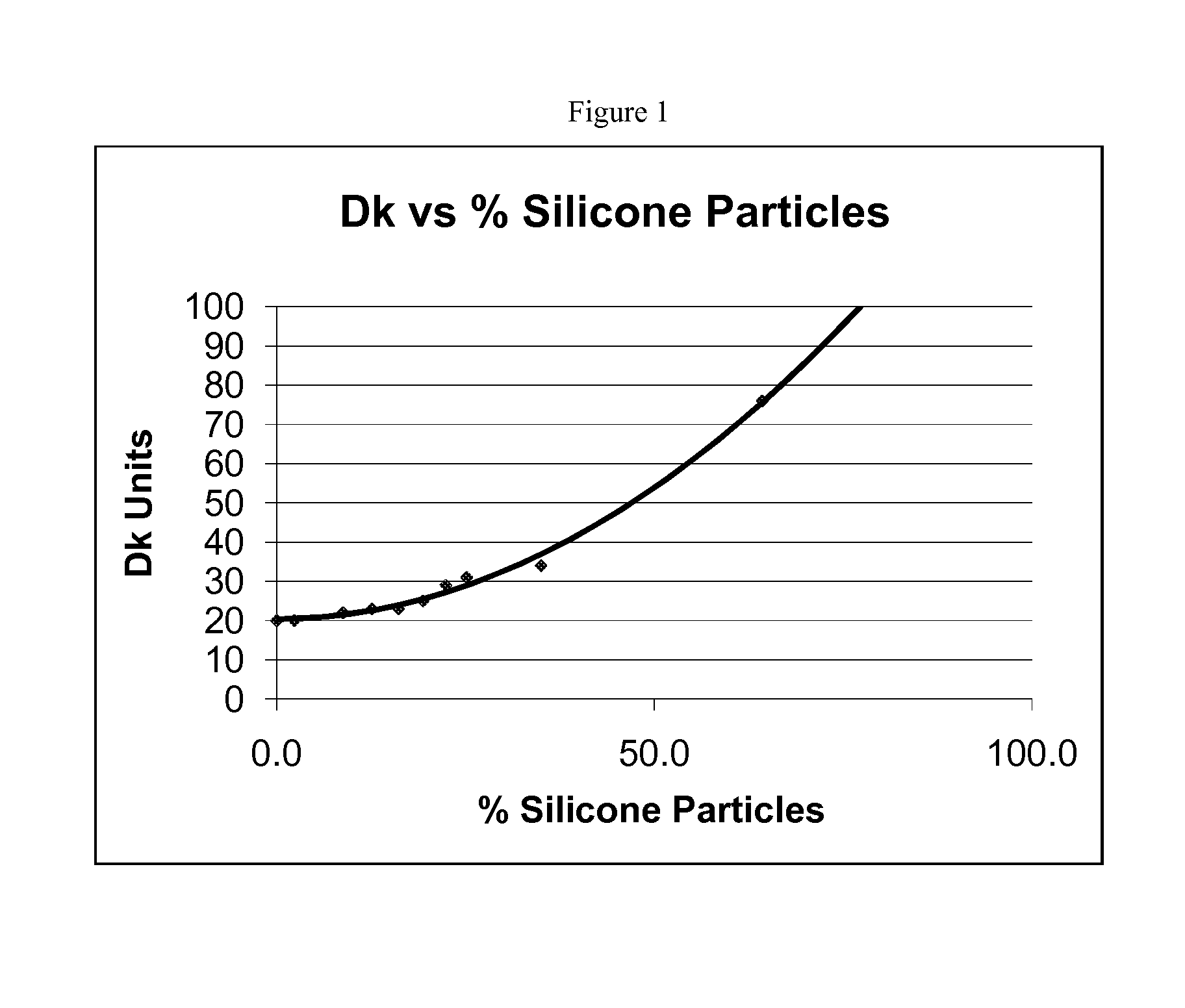

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

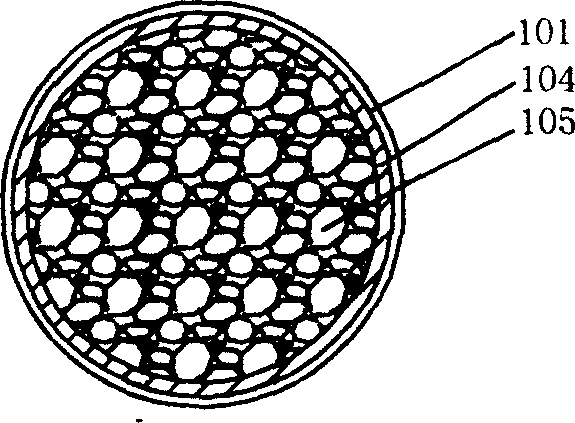

Polymeric articles comprising oxygen permeability enhancing particles

InactiveUS20100249273A1Increasing the thicknessPaper coatingCoatingsOxygen enhancedOxygen permeability

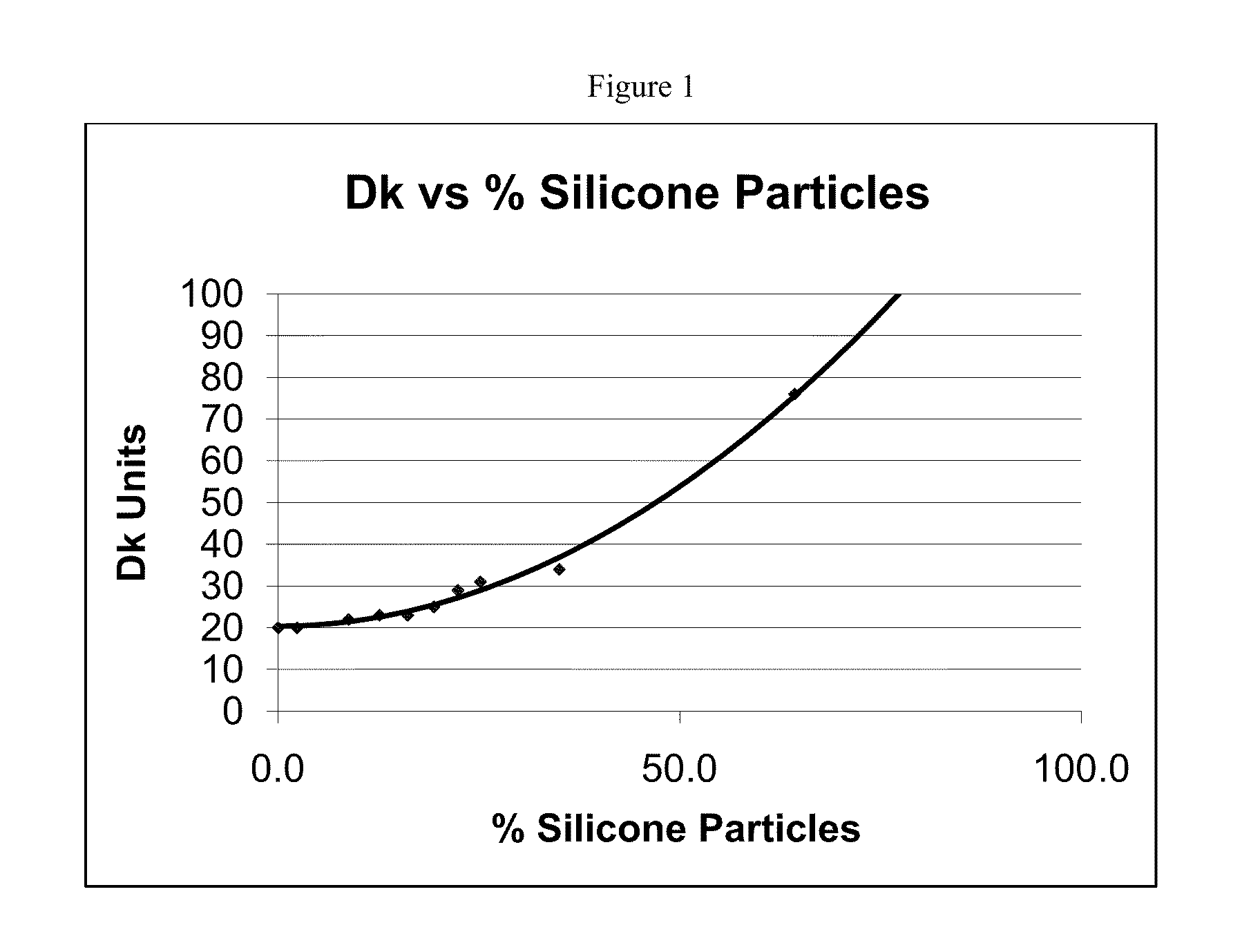

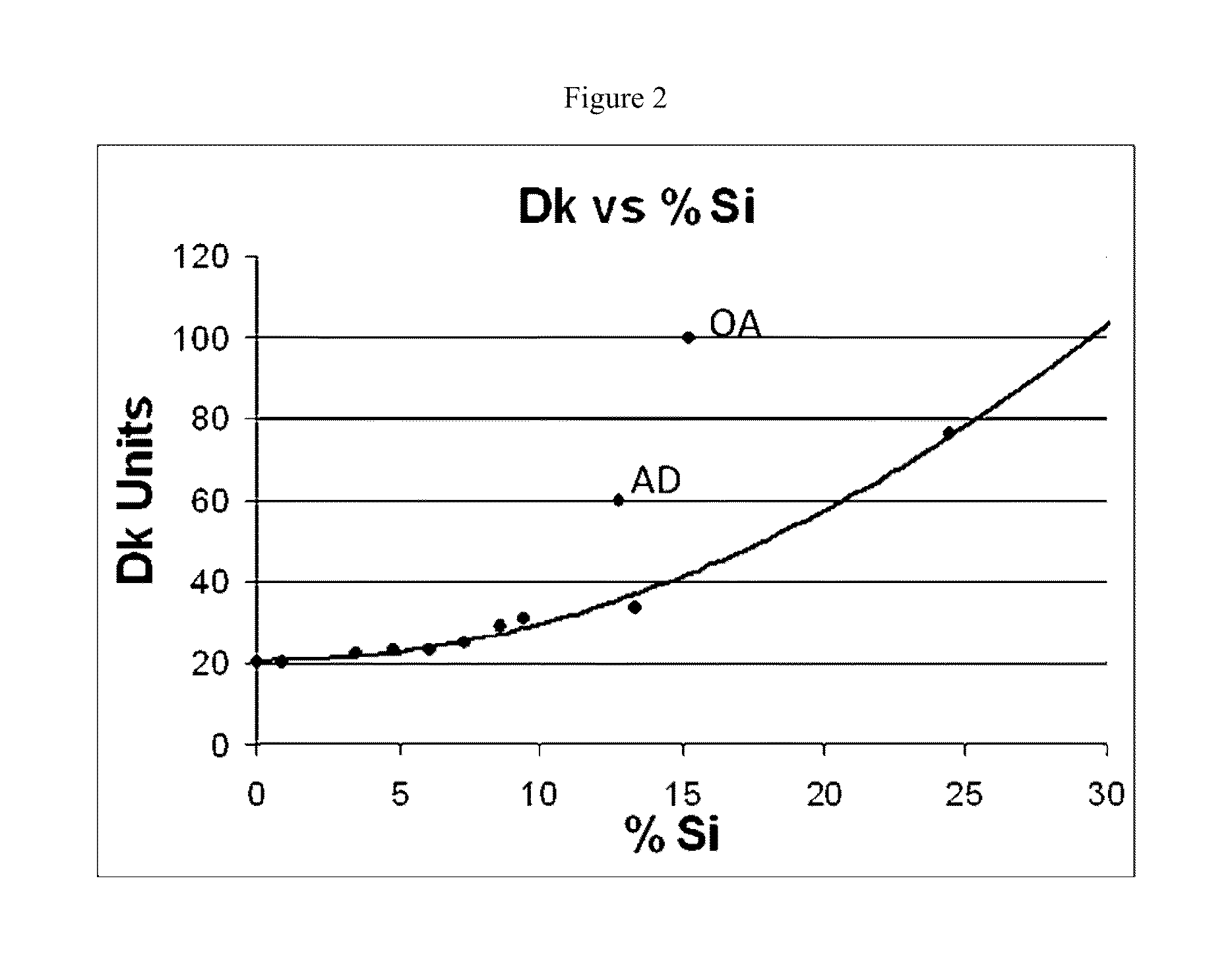

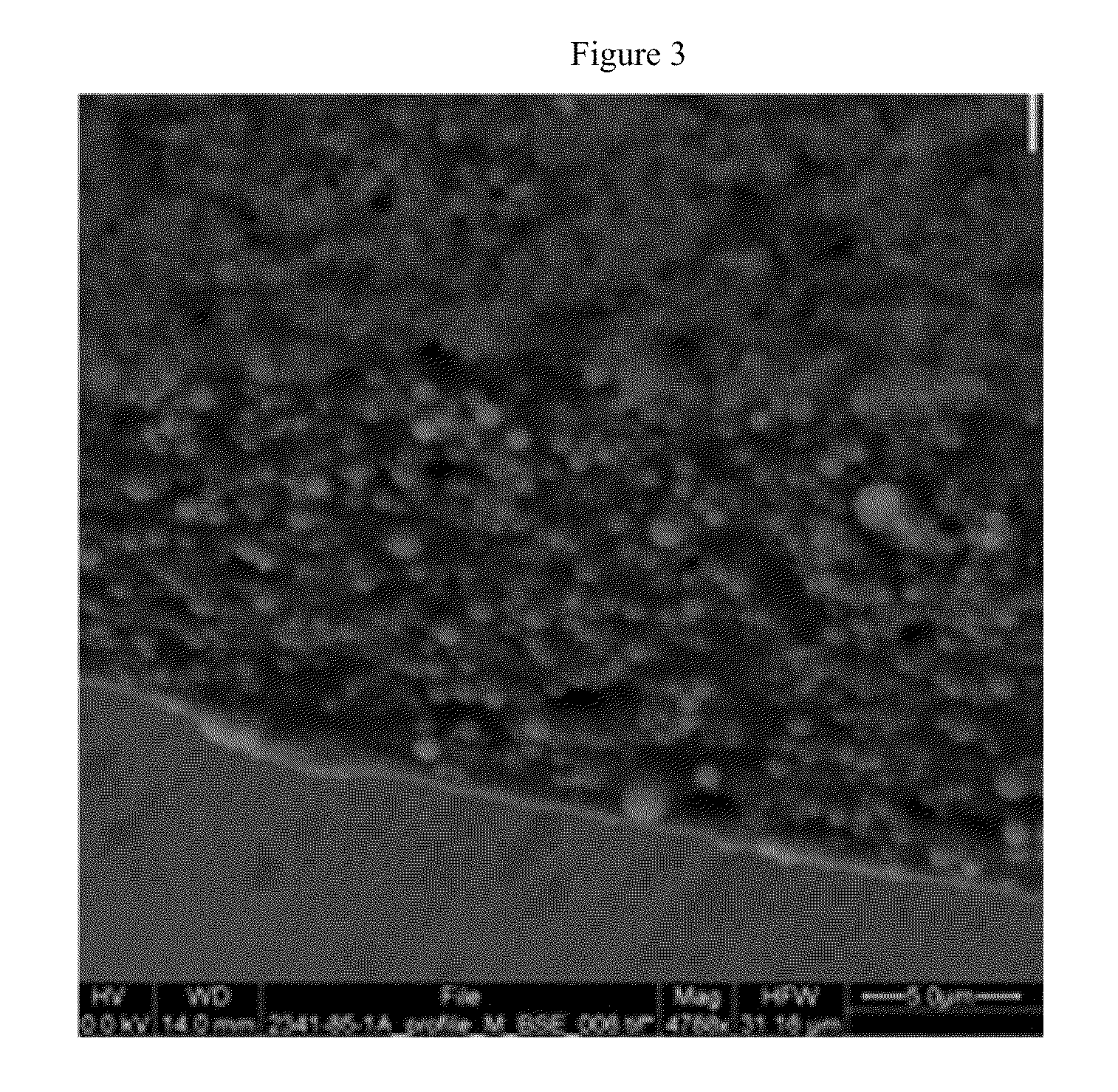

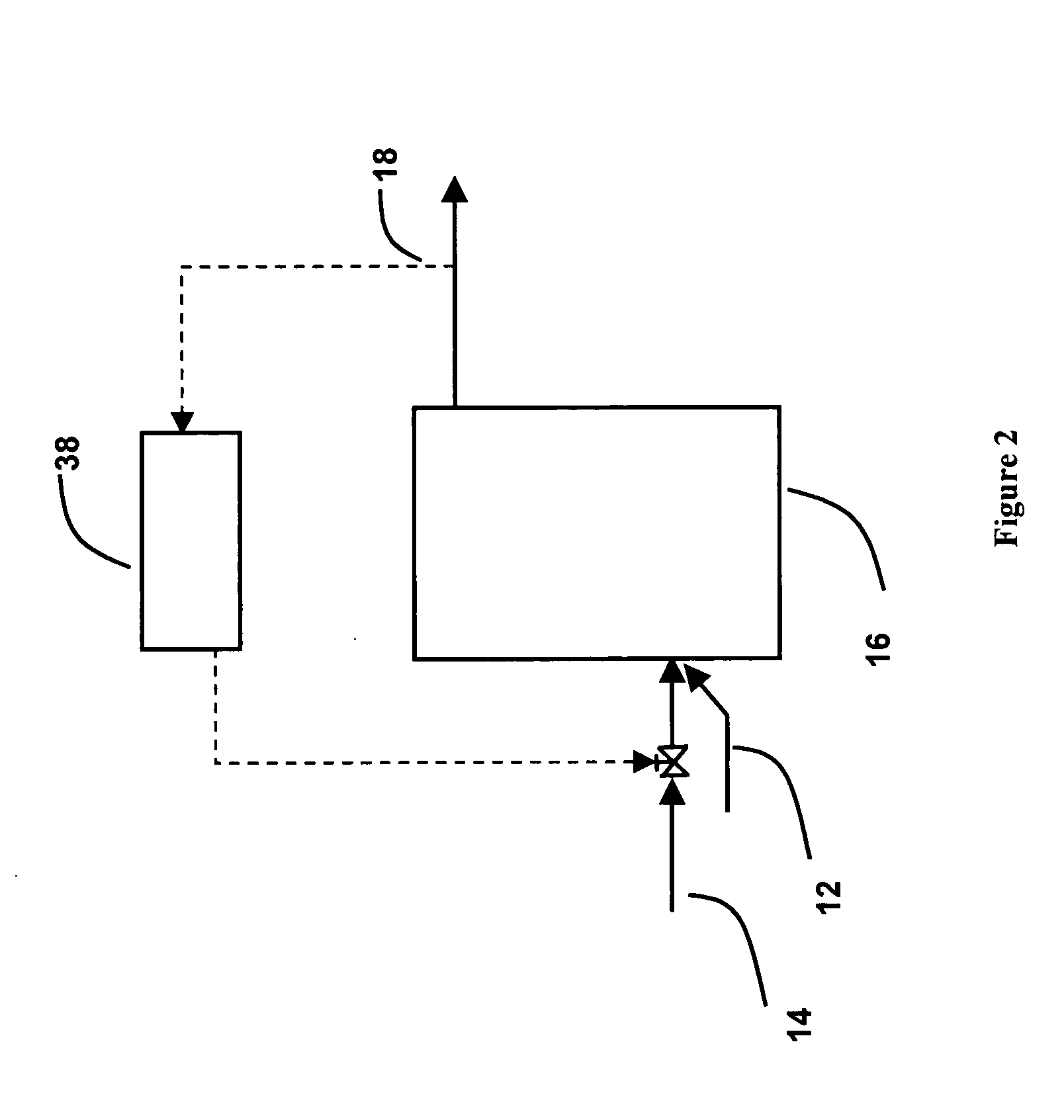

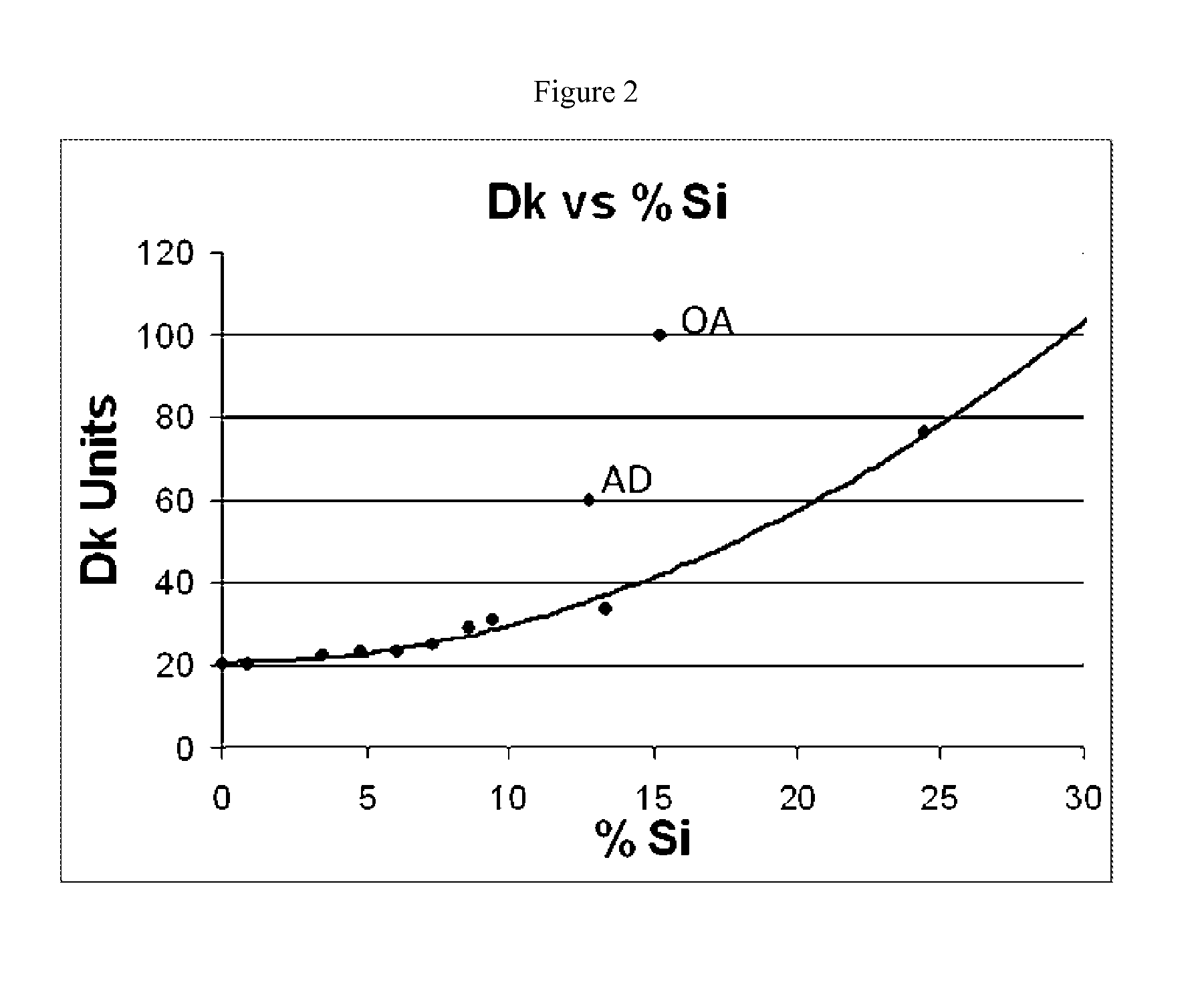

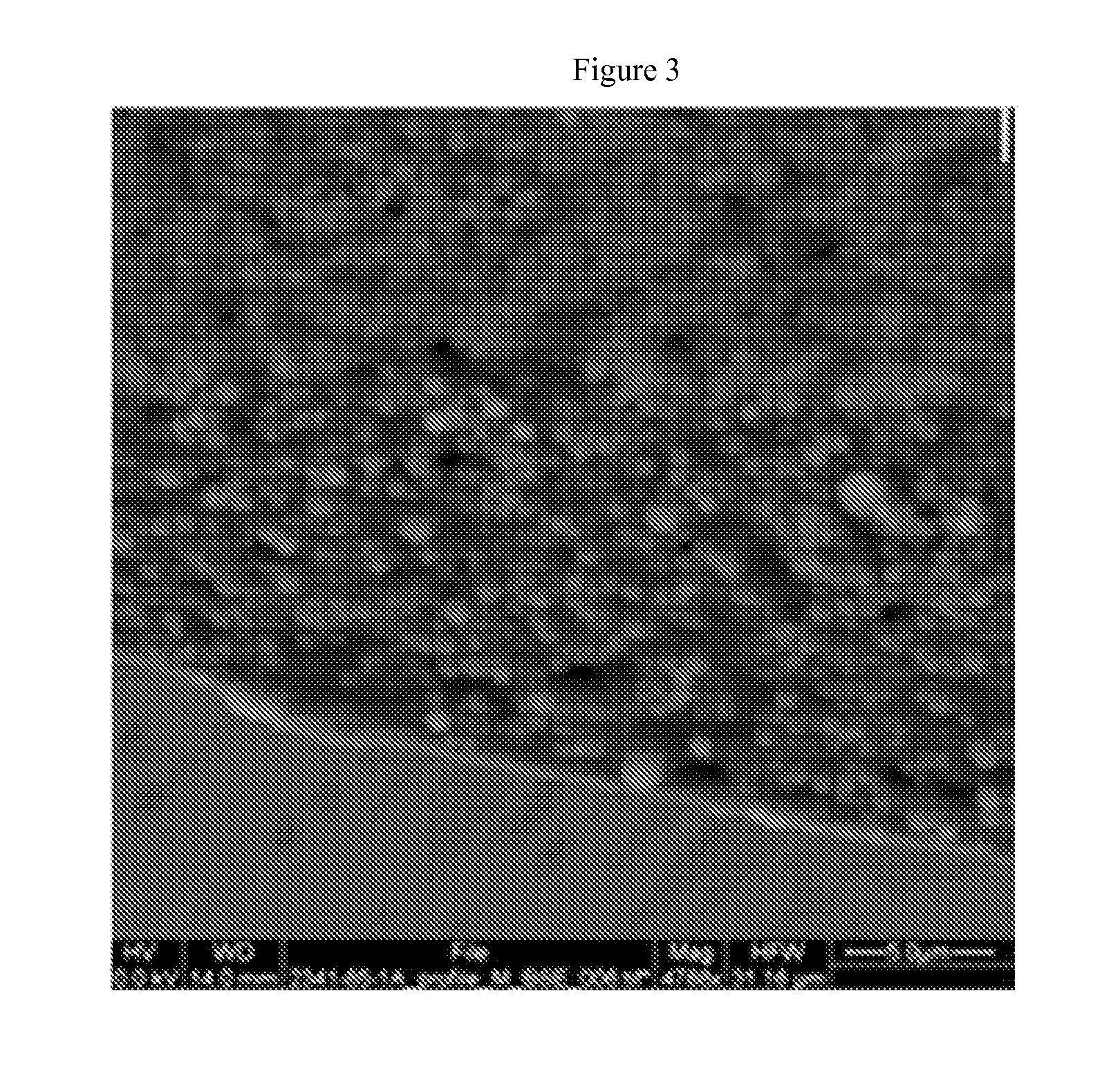

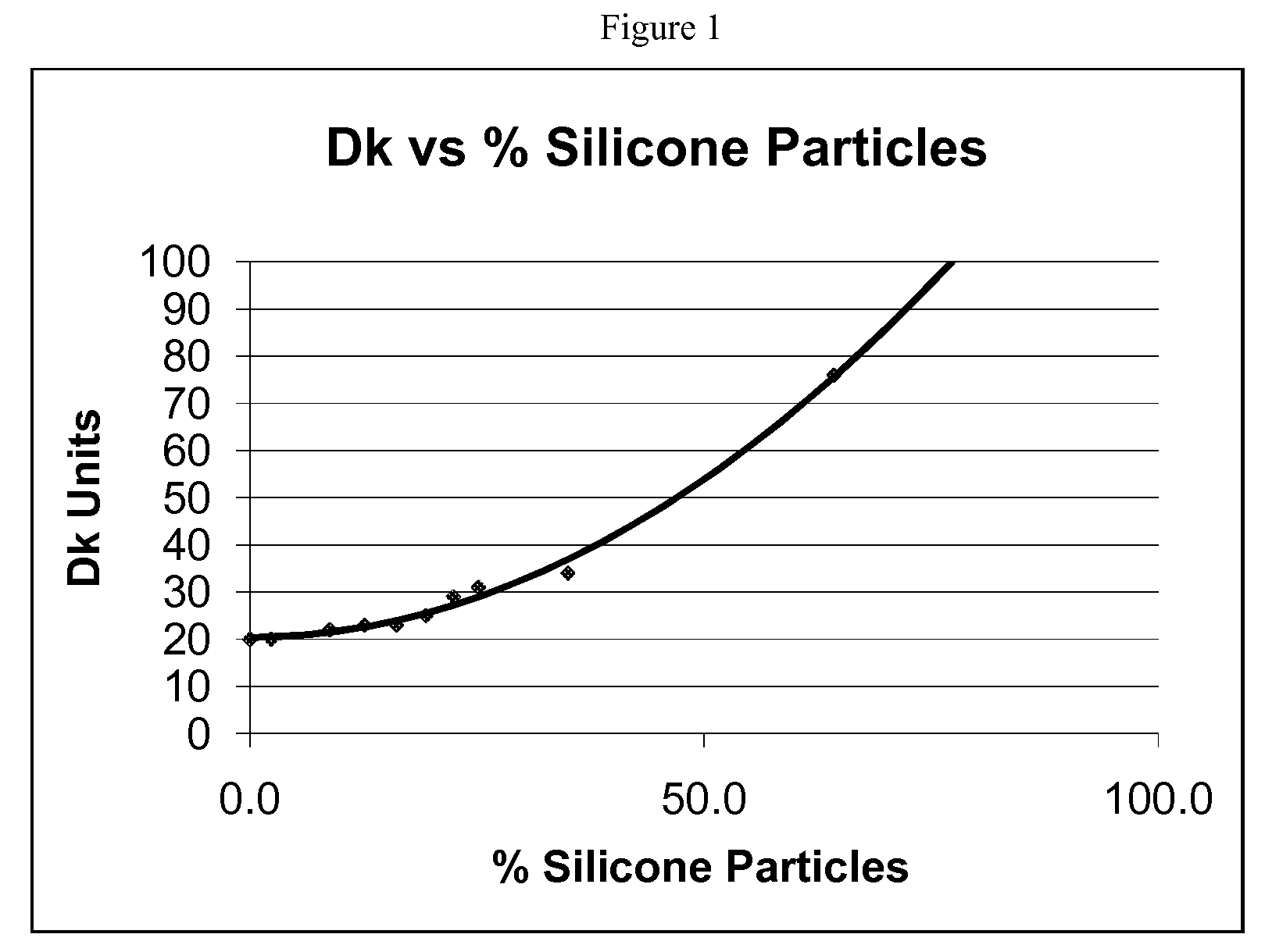

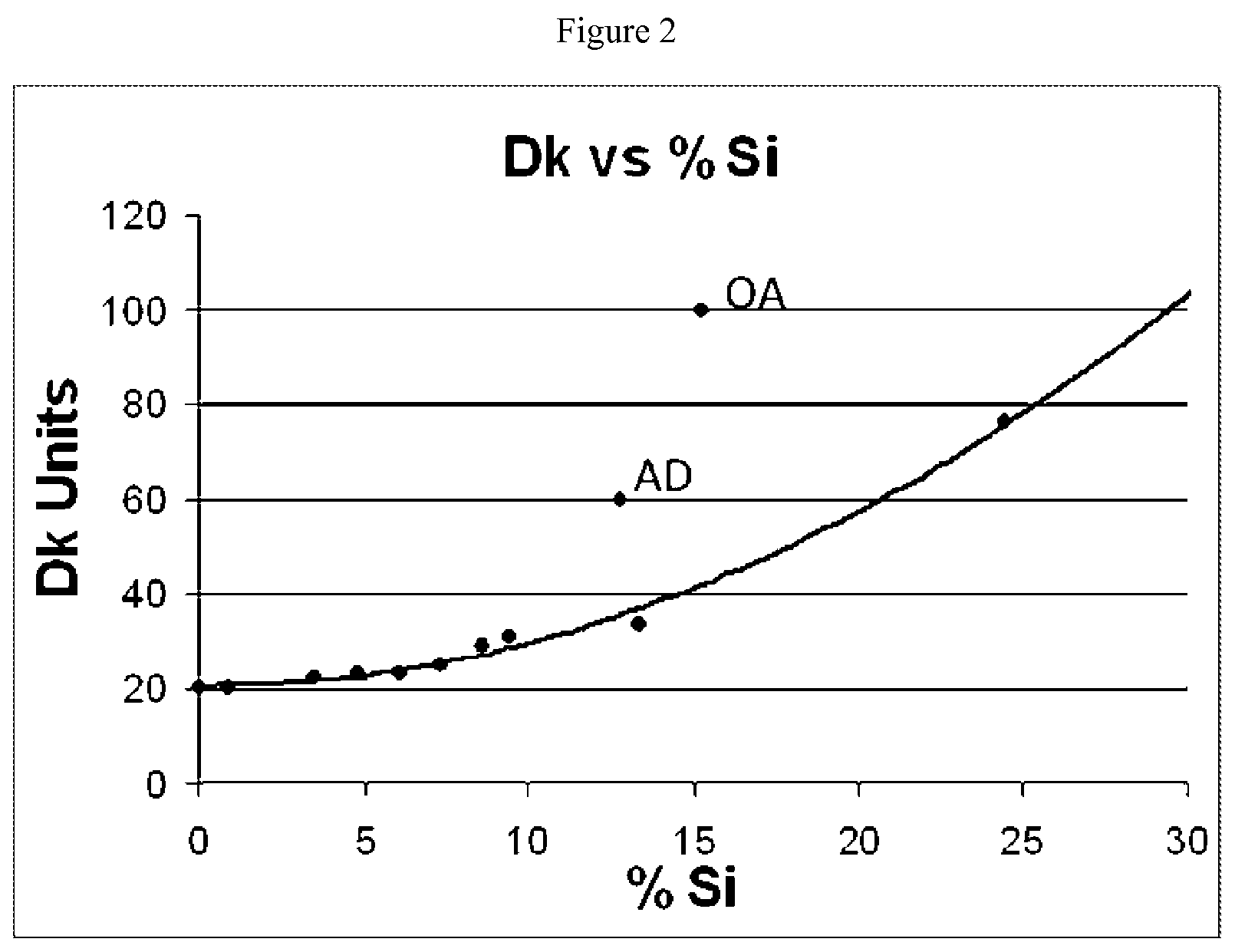

The present invention relates to a composition comprising a hydrogel polymer having less than 100% haze, and distributed therein an oxygen enhancing effective amount of oxygen permeable particles having an oxygen permeability of at least about 100 barrer, average particle size less than about 5000 nm.

Owner:JOHNSON & JOHNSON VISION CARE INC

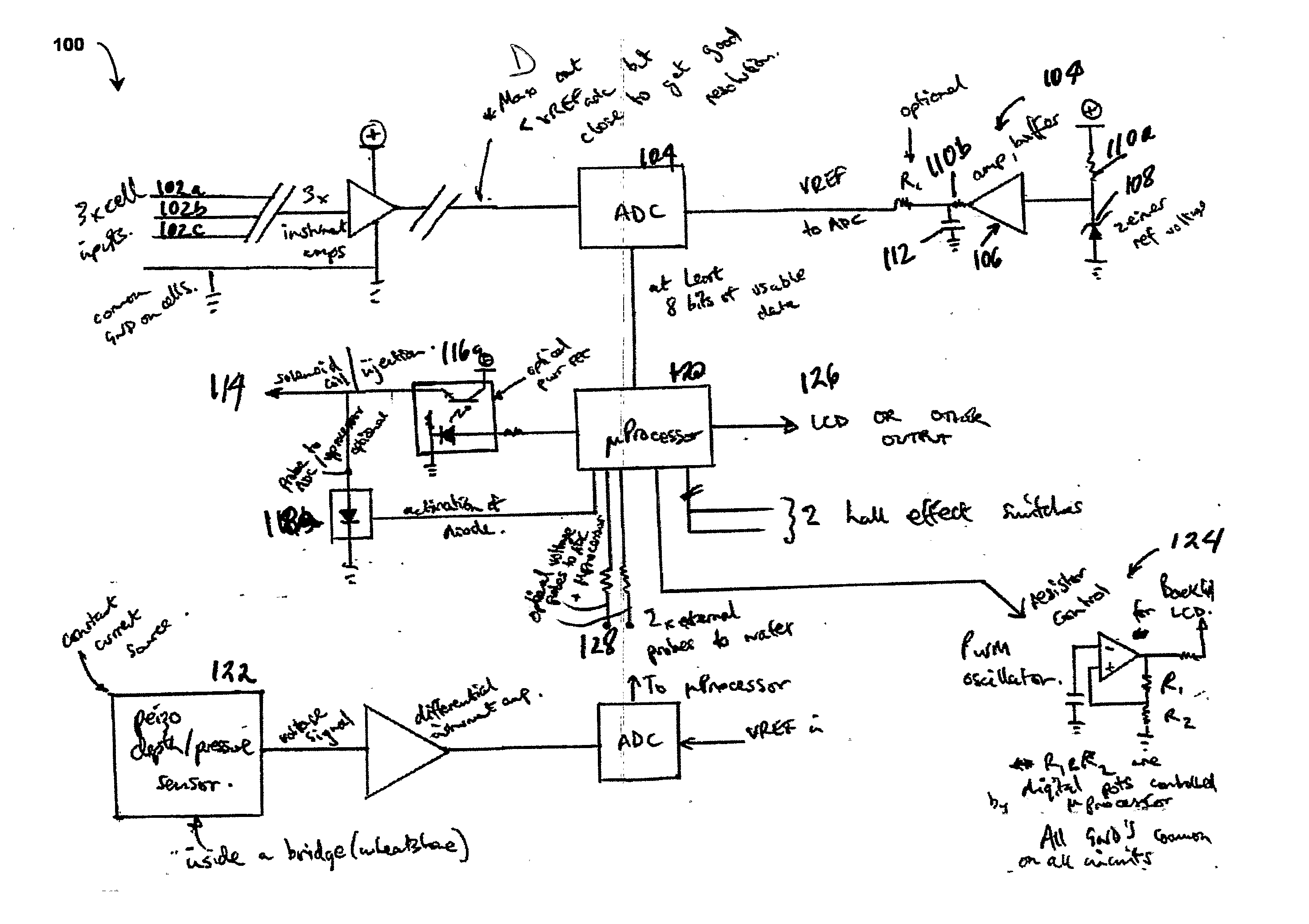

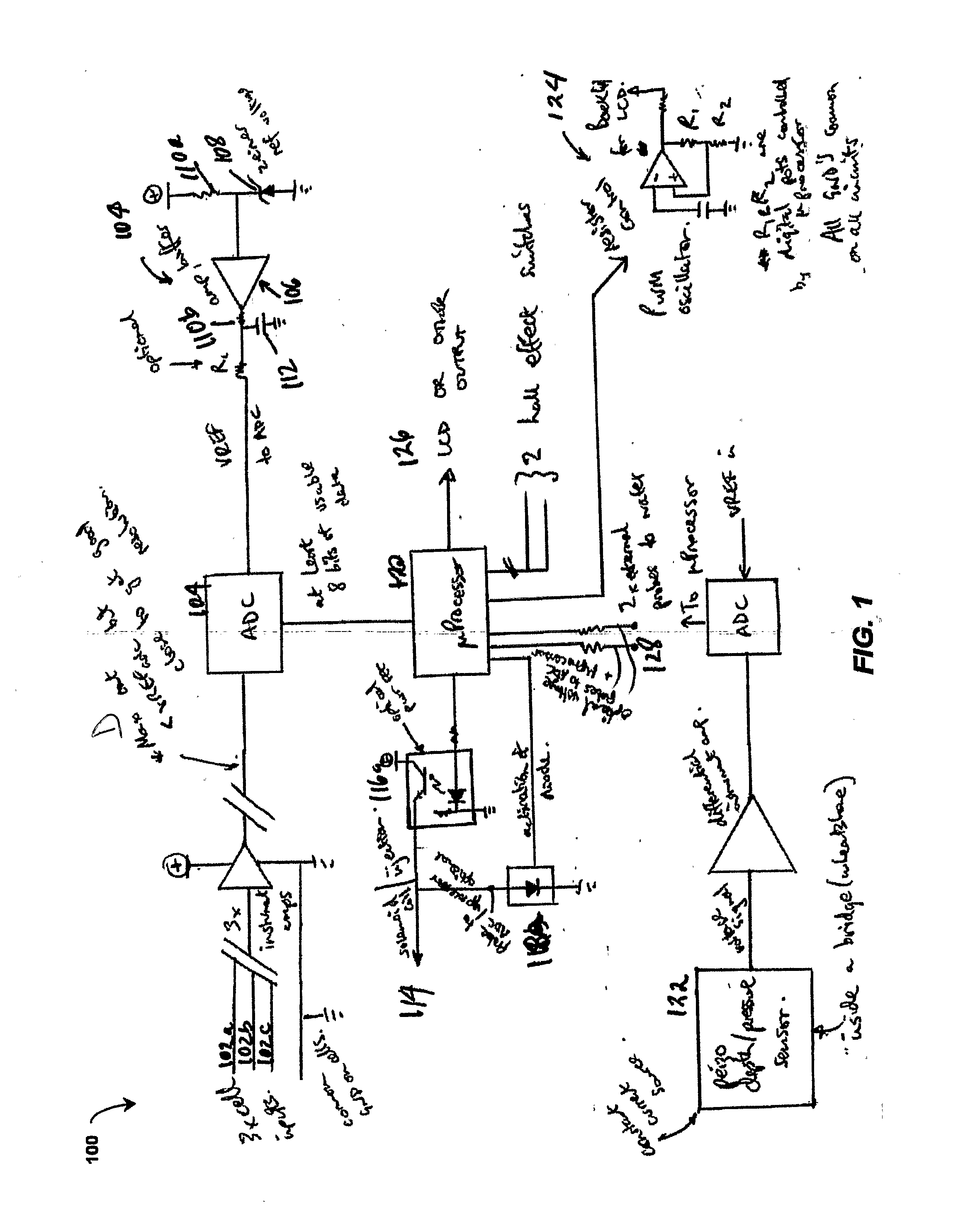

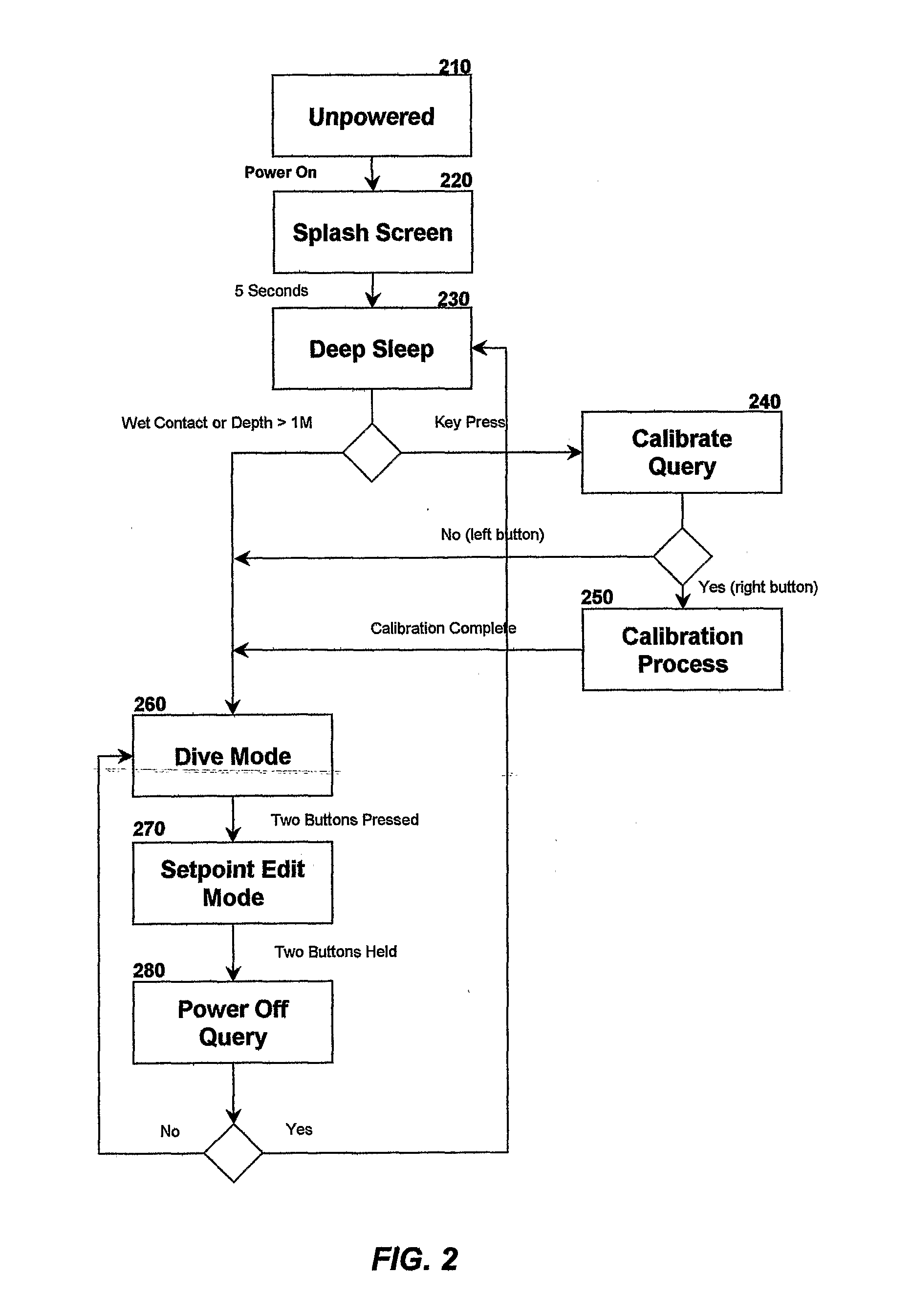

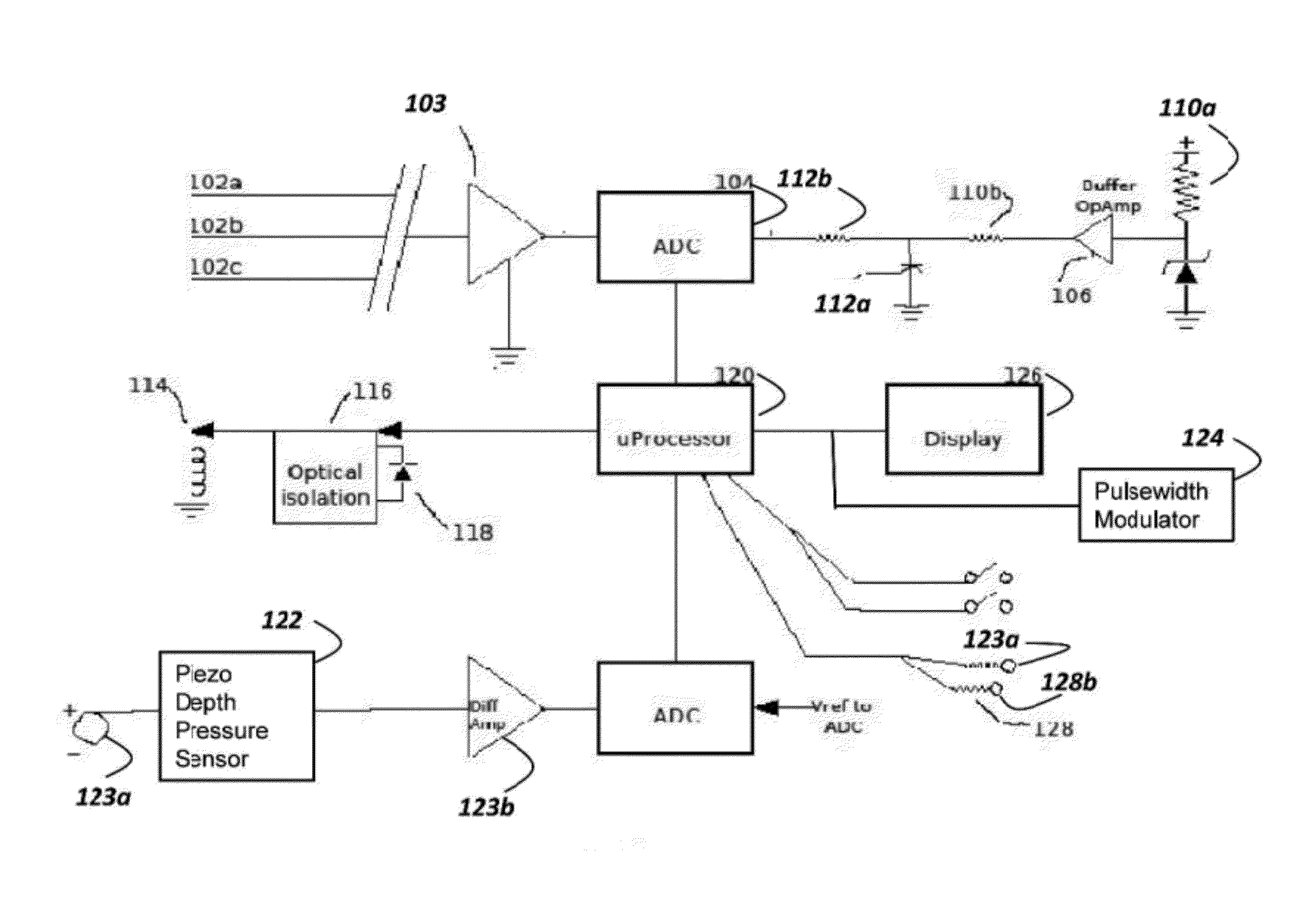

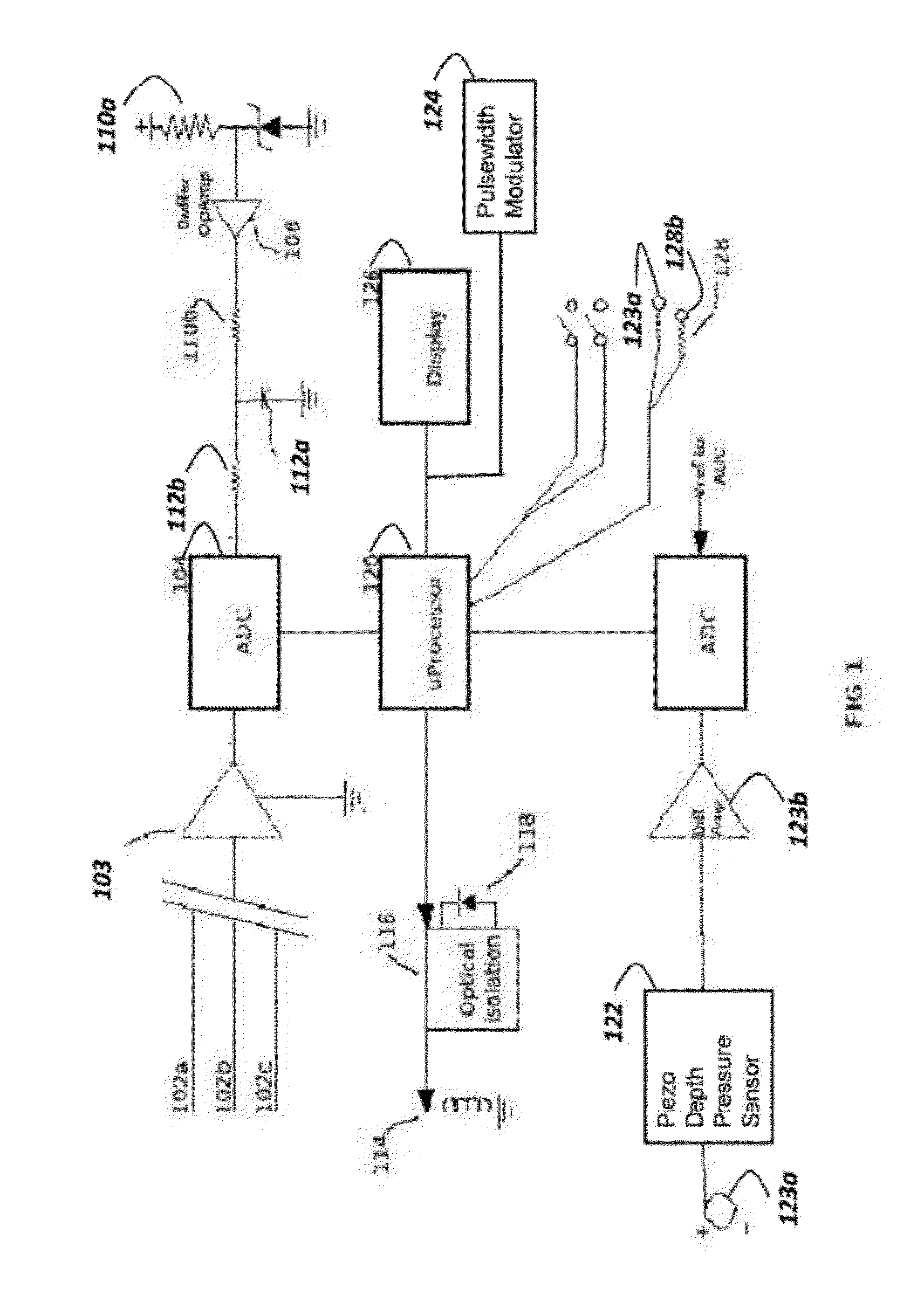

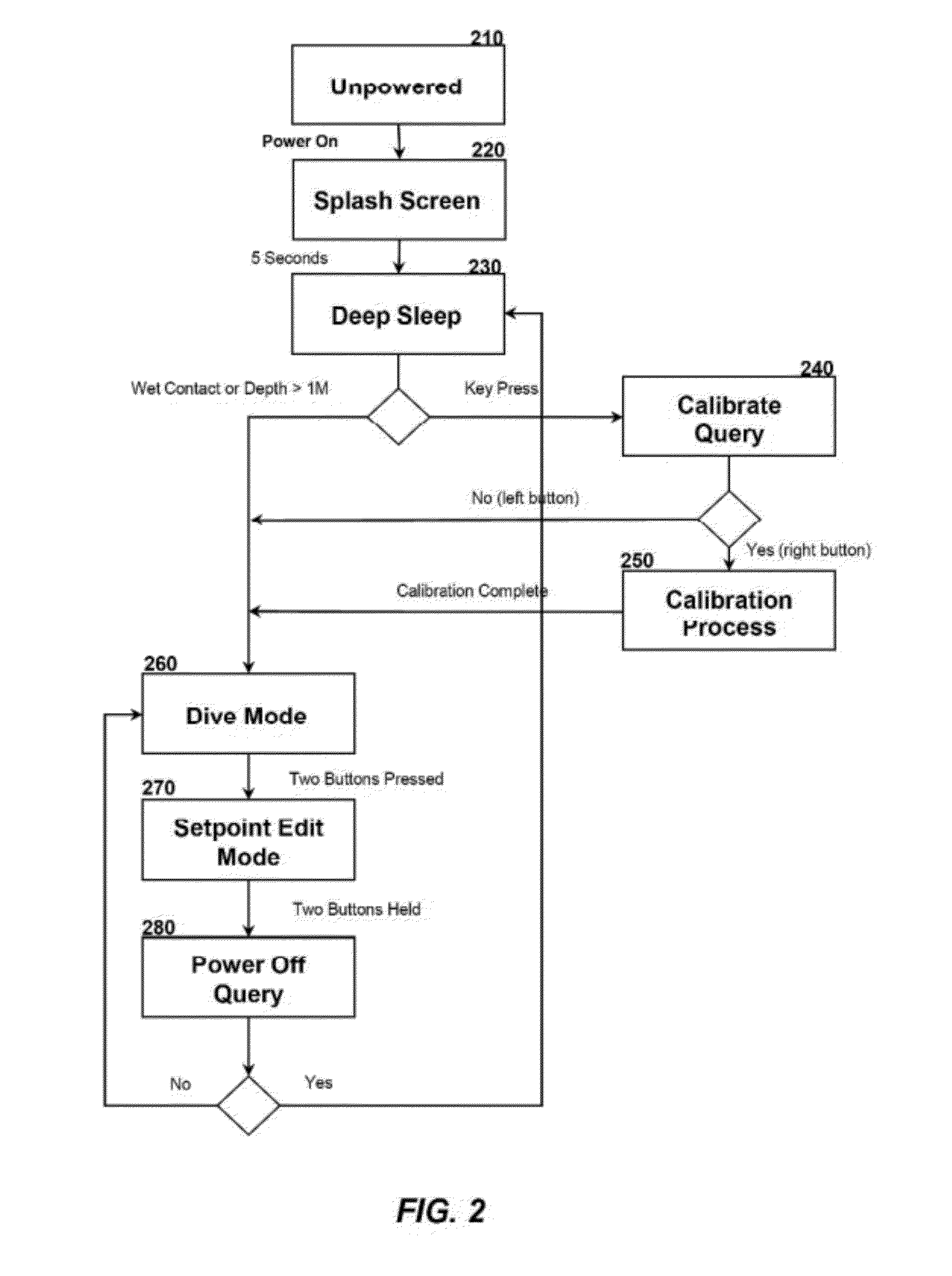

Rebreather Setpoint Controller and Display

InactiveUS20070215157A1Reduces susceptibility to noiseImproving rebreather performanceRespiratorsBreathing filtersHead-up displayLED display

An oxygen setpoint controller (SPC) and a user's display for a rebreathing apparatus wherein the user exhales oxygen depleted breath into a closed rebreathing loop, the CO2 is scrubbed from the exhaled gases, oxygen is added to the rebreathing loop to maintain the oxygen at a specified partial pressure, and the oxygen enhanced gases in the rebreathing are provided to the user. The SPC is able to detect the failure of any of the oxygen sensors and provide an alarm condition to the user. The SPC further operates to provide dive data such as rate of ascent, time of dive, depth, and PPO2 to the uses, and to store and retain dive data for further review. The SPC further provides numerical dive data to a heads up display (HUD). The HUD further includes a tricolor LED displaying selected analog parameters.

Owner:HELIOX TECH

Real time optimization and control of oxygen enhanced boilers

InactiveUS20040231332A1Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

Polymeric articles comprising oxygen permeability enhancing particles

The present invention relates to a composition comprising a hydrogel polymer having less than 100% haze, and distributed therein an oxygen enhancing effective amount of oxygen permeable particles having an oxygen permeability of at least about 100 barrer, average particle size less than about 5000 nm.

Owner:JOHNSON & JOHNSON VISION CARE INC

Polymeric articles comprising oxygen permeability enhancing particles

The present invention relates to a composition comprising a hydrogel polymer having less than 100% haze, and distributed therein an oxygen enhancing effective amount of oxygen permeable particles having an oxygen permeability of at least about 100 barrer, average particle size less than about 5000 nm.

Owner:JOHNSON & JOHNSON VISION CARE INC

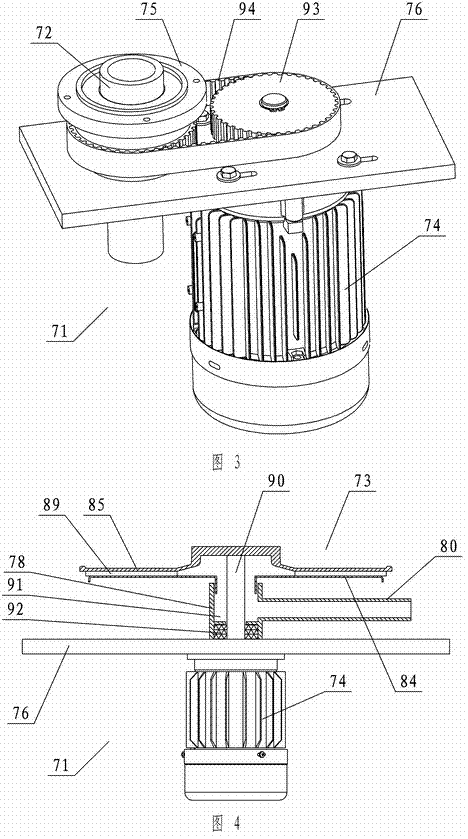

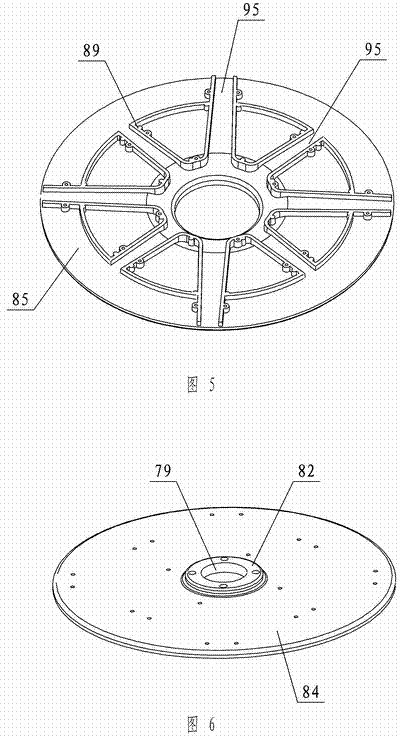

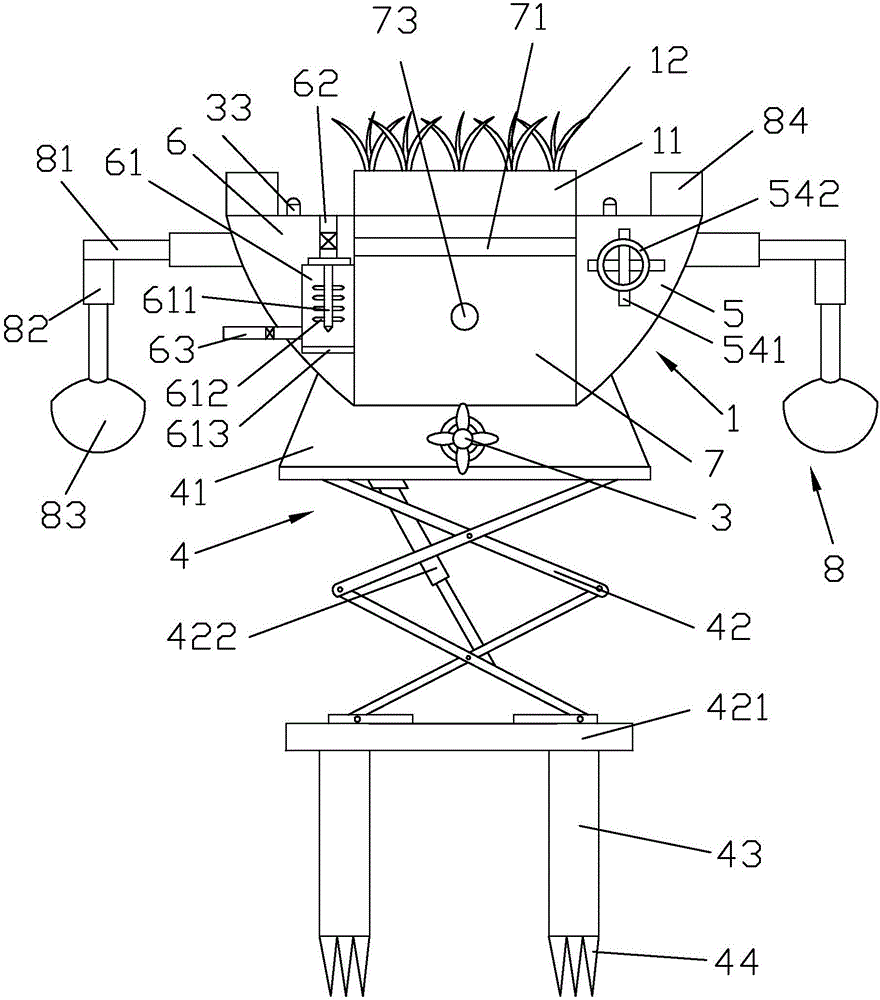

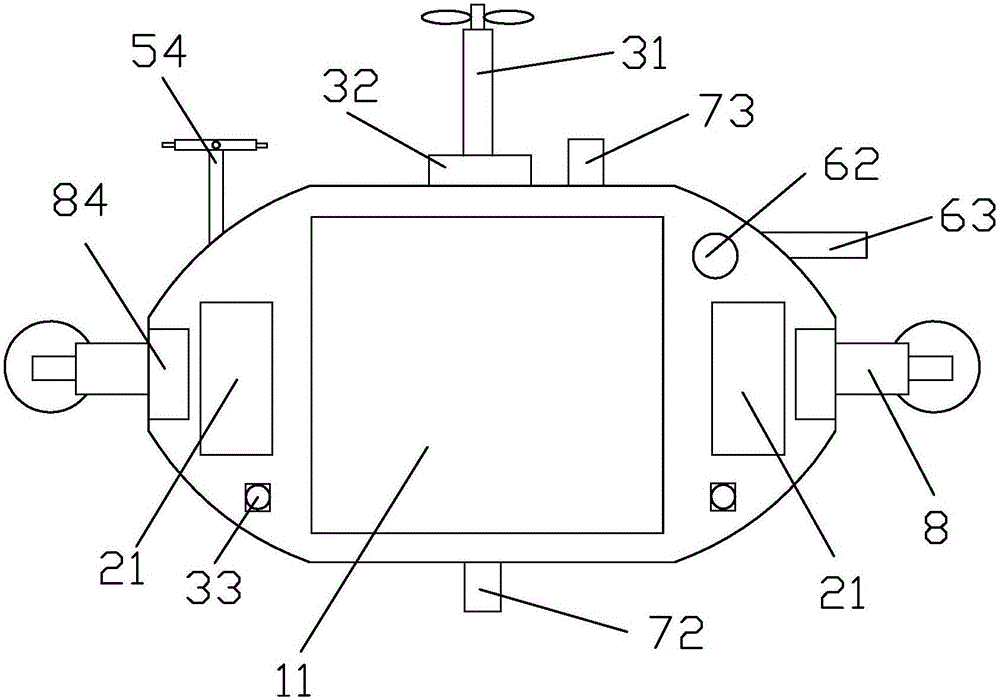

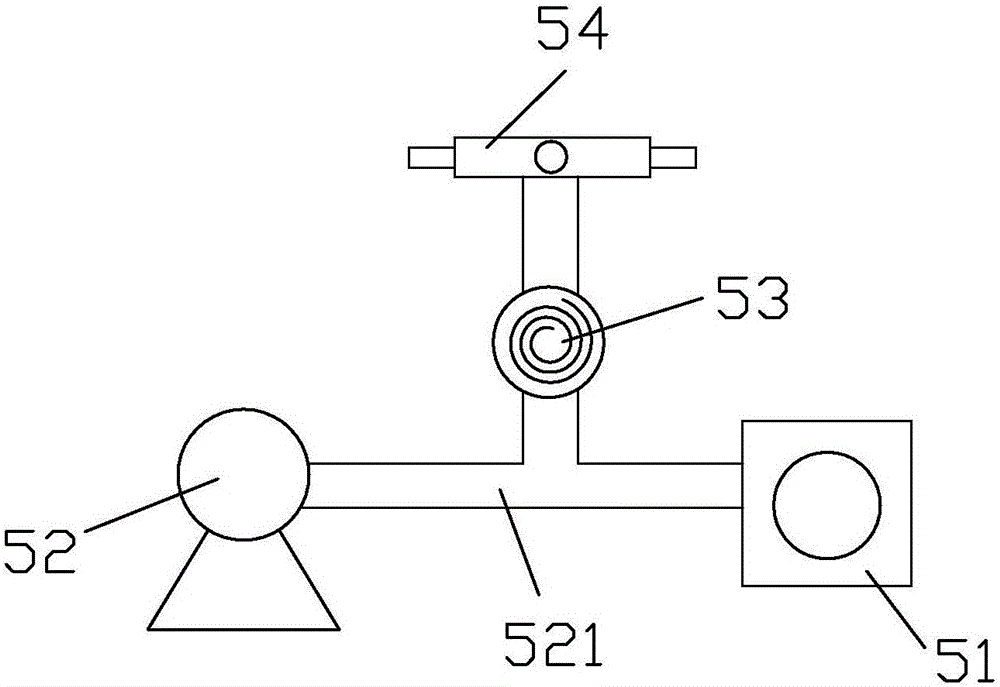

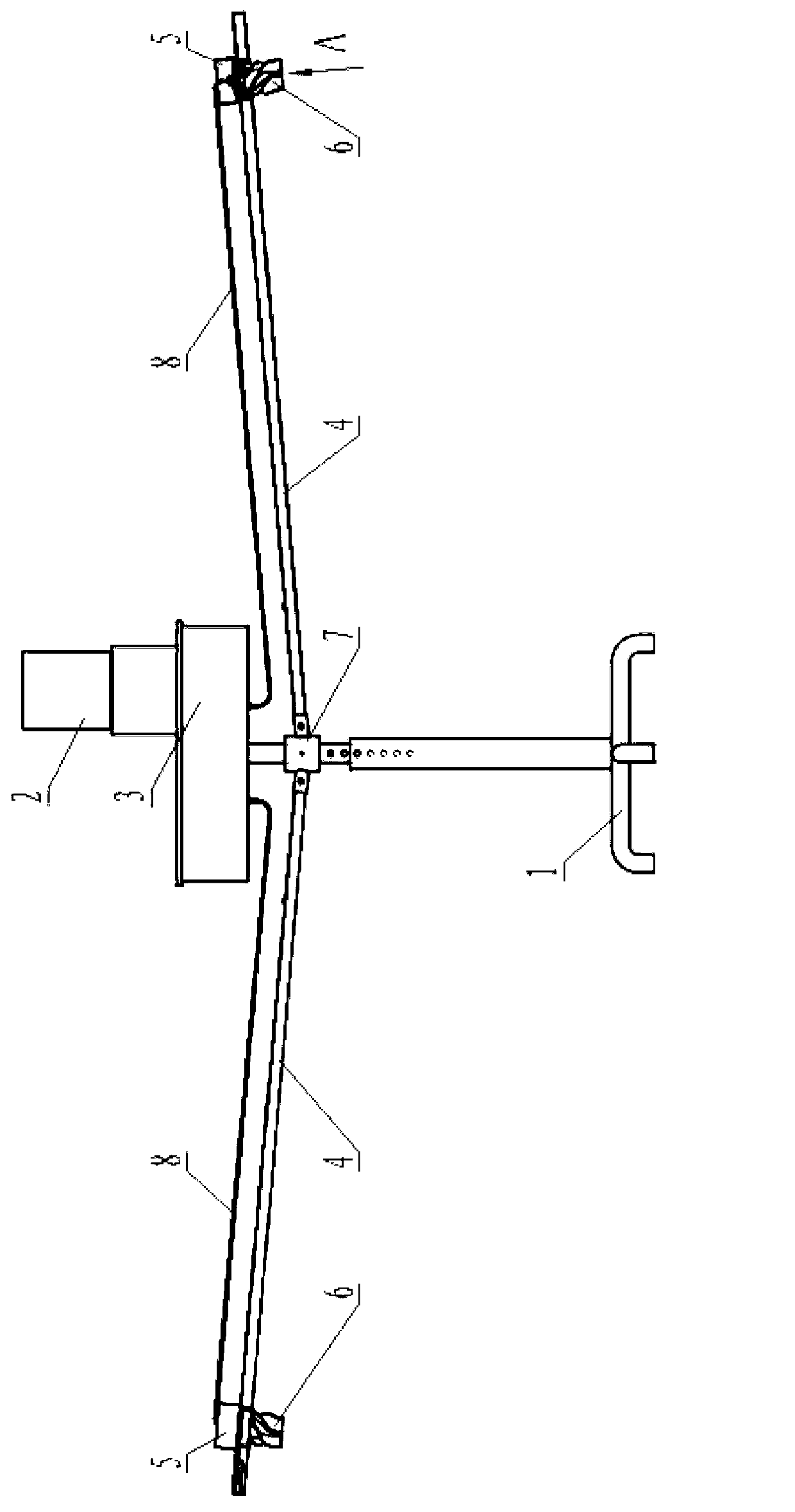

Pneumatic conveying remote feeding and oxygenation equipment

ActiveCN104285870ARealize timing and quantitative feedingPisciculture and aquariaAgricultural scienceAgricultural engineering

The invention relates to pneumatic conveying remote feeding and oxygenation equipment. The pneumatic conveying remote feeding and oxygenation equipment mainly comprises a fan, throwers, a storage container, a splitter and a conveying air pipe, wherein the throwers are fixed in the feeding area on the water surface of a fishpond, compressed air generated by the fan blows fodder split by the splitter in the storage container to the throwers through the conveying air pipe, and then the fodder is thrown to the water surface. The pneumatic conveying remote feeding and oxygenation equipment adopts the Roots fan, and the granular fodder is blown to the distant throwers and then thrown into the fishpond by throwing discs. The pneumatic conveying remote feeding and oxygenation equipment can further inflate and oxygenate the fishpond, the same Roots fan, the storage container and the splitter supply fodder to the multiple throwers, and the fodder is put at regular times and fixed quantity.

Owner:ZHEJIANG FORDY MACHINERY

Solar water purifier for lakes and water purification method thereof

ActiveCN106467330AFast dissolutionDrug works wellWater cleaningWater contaminantsSolar waterSolar cell

The invention mainly discloses a solar water purifier for lakes and a water purification method thereof. According to the technical scheme, the solar water purifier comprises a main body, a purification system, an energy system, a drive unit, a lighting device and a fixation device. The energy system comprises a solar cell panel, a storage battery and a charging panel. An oxygenation chamber, a disinfection chamber and a purifying chamber are arranged inside the main body. An ozone generator, an air compressor, a bubble generator and an aerator pipe are disposed inside the oxygenation chamber. A drug blending tank is arranged inside the disinfection chamber. A purifier is disposed inside the purifying chamber. When the device operates, installation and pilot run of the device are firstly carried out. After successful pilot run, the device is put into a lake. By mobile positioning of the drive unit, a water body undergoes disinfection, oxygenation and purification. The energy system provides energy. Thus, energy is self-sufficient. The solar water purifier has a simple structure, is low-cost and clean. By various purification methods, purification efficiency is high. By the floating and stationary combined design, position of the device can be controlled freely. Thus, repair rate of water body is high. The solar water purifier is easy to operate.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

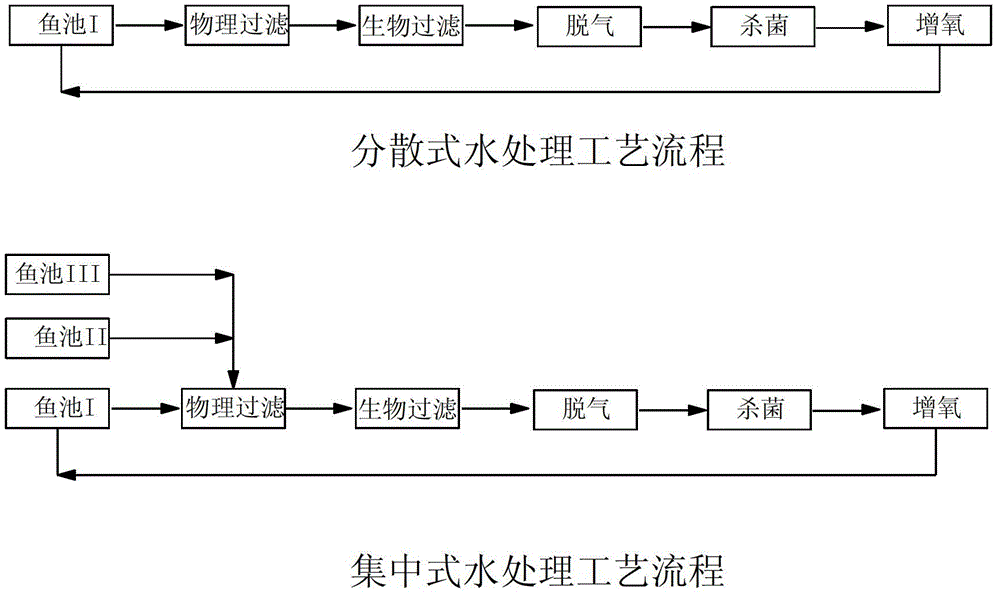

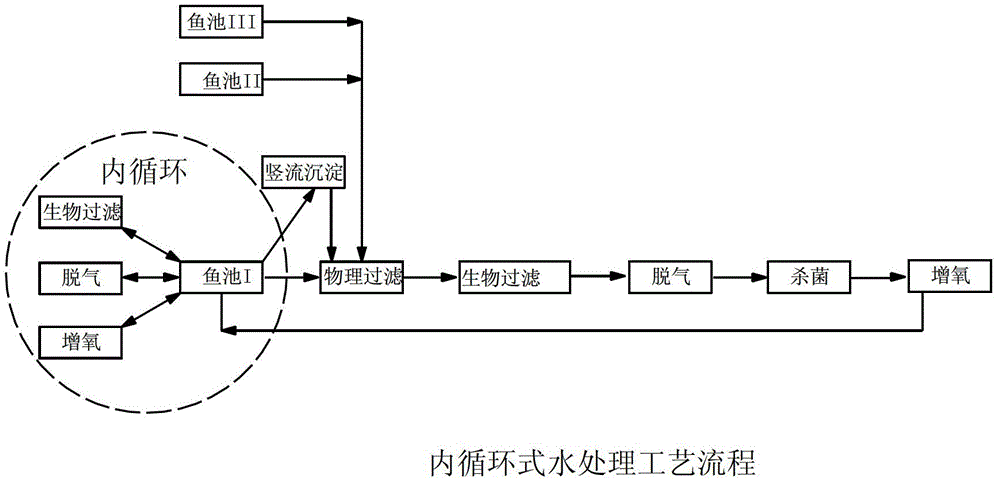

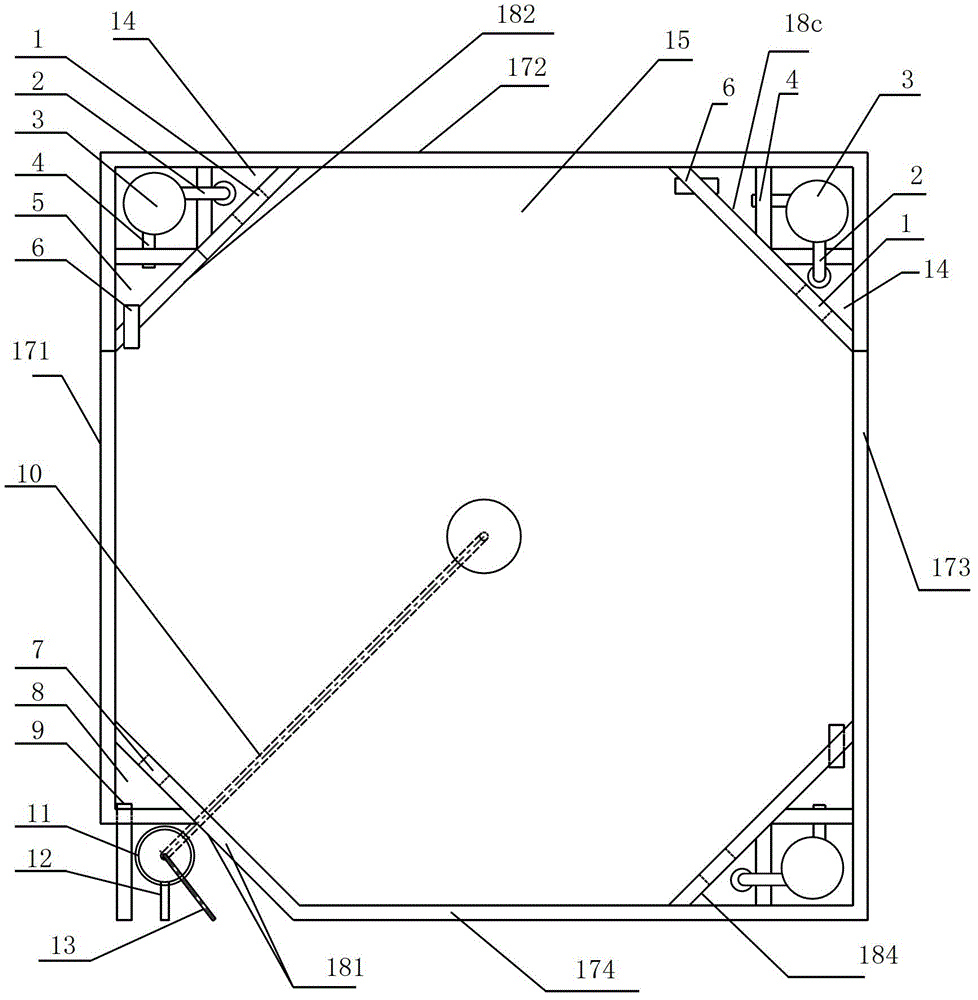

Internal circulation fishpond and circulating water treatment process

The invention relates to the technical field of aquaculture, and discloses an internal circulation fishpond and a circulating water treatment process. According to the internal circulation fishpond and the circulating water treatment process, an air striping device, a physical filtration device and a biological filtration device are arranged in vacant regions, such as corners of the fishponds; multiple functions, such as plug flow, oxygenation, degassing, solid filtration and biological filtration, are integrated in the design of the fishpond; through arranging an air stripping pump, a moving bed biofilter and a vertical flow precipitator and the like, the water treatment function of the fishpond is perfected and enhanced, and the fishpond has the functions of oxygenation, degassing, physical filtration and biological filtration; the circulating speed of a water body is reduced while the solid utilization rate is improved; through reducing the treatment load amount of a water treatment system, the circulating speed of the water body and the operating energy consumption of a circulating water pump are reduced.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

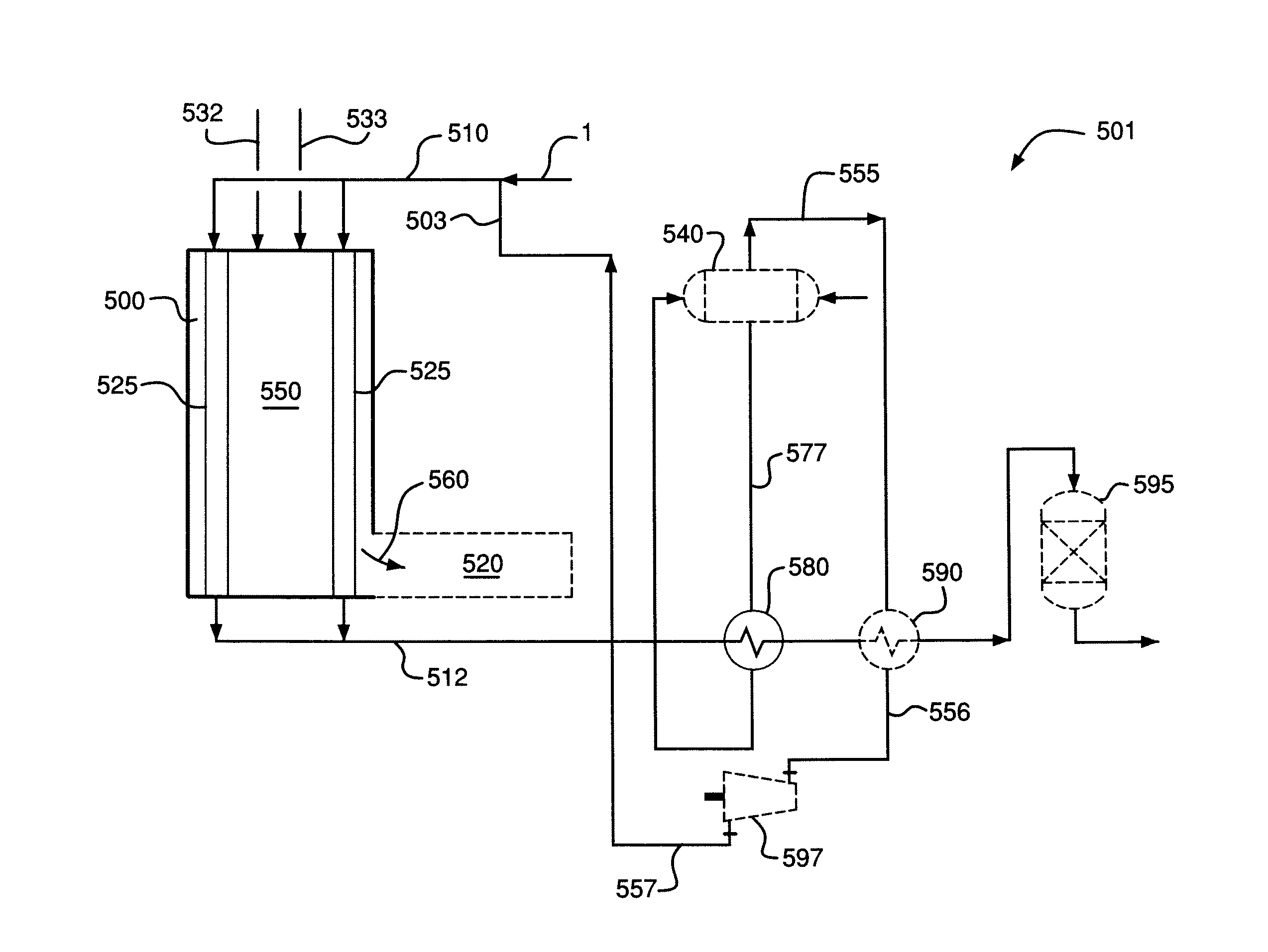

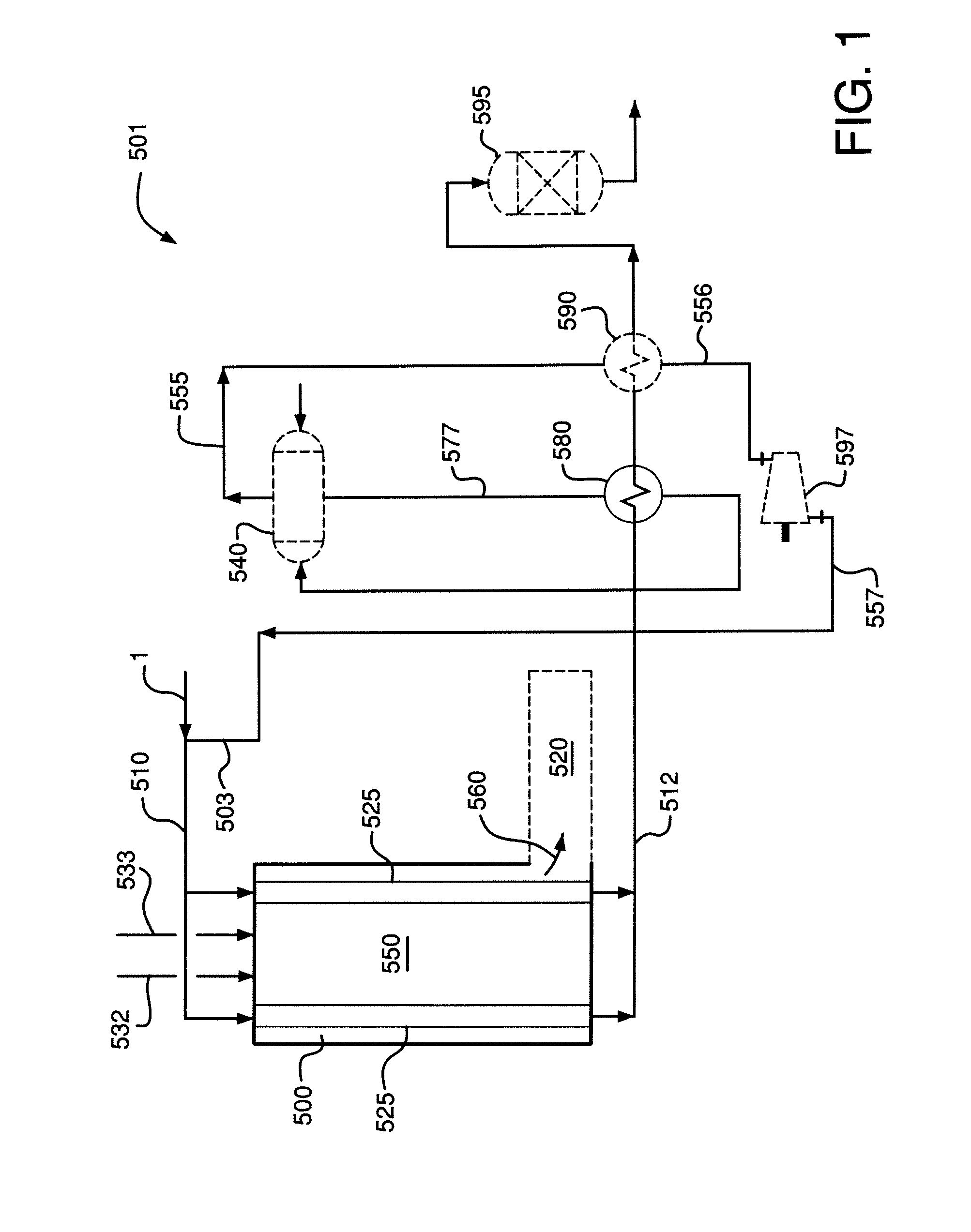

Steam-hydrocarbon reforming method with limited steam export

A method for generating hydrogen and / or synthesis gas in a production facility where little or no export steam is produced. Most or all of the high pressure steam produced from the waste heat from the process is used in the steam-hydrocarbon reformer with little or no steam export. The method uses oxygen enhanced combustion which may involve oxygen lancing and / or oxygen-enrichment. Plant efficiencies using the method and prior art-type methods are compared.

Owner:AIR PROD & CHEM INC

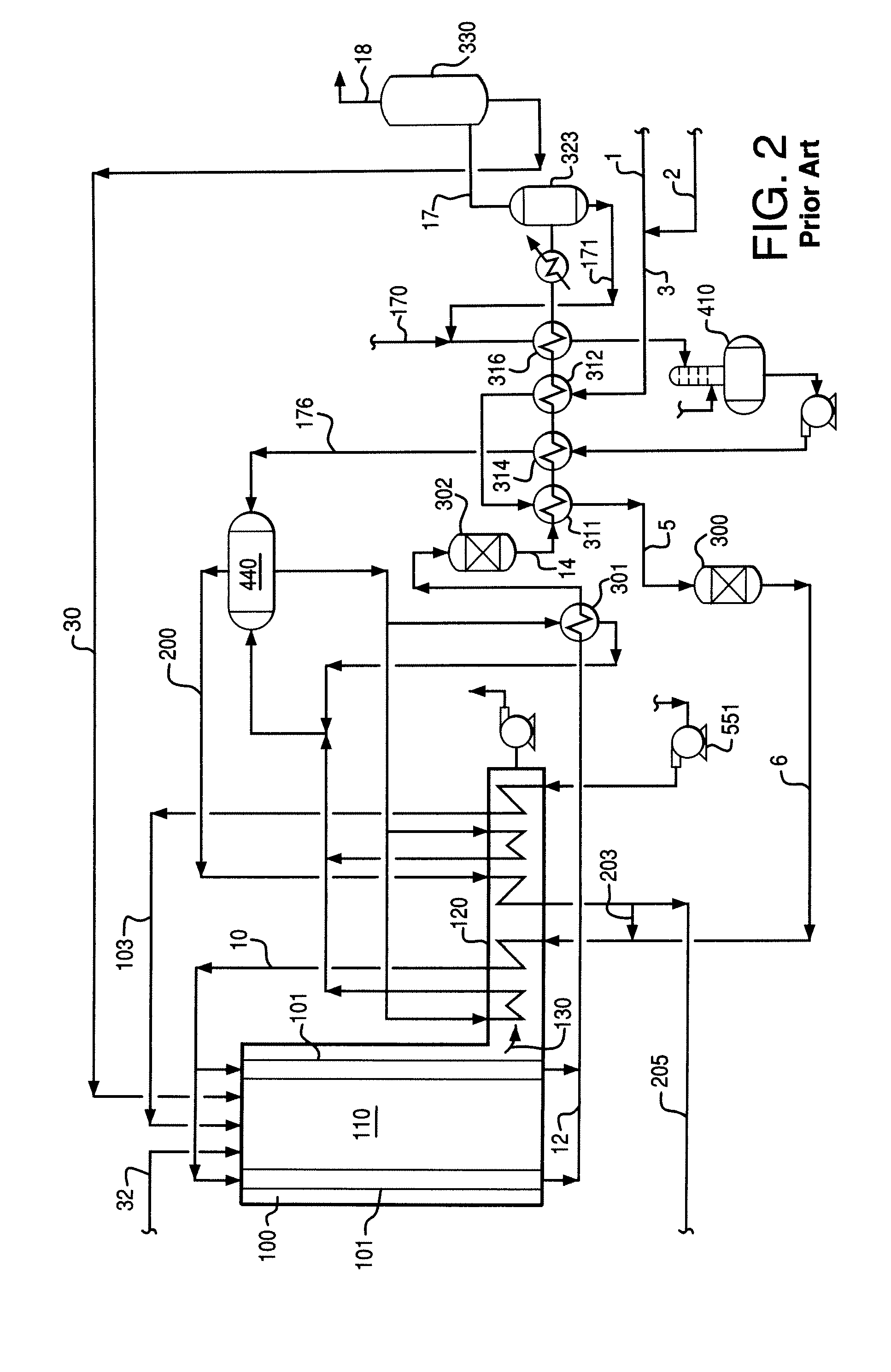

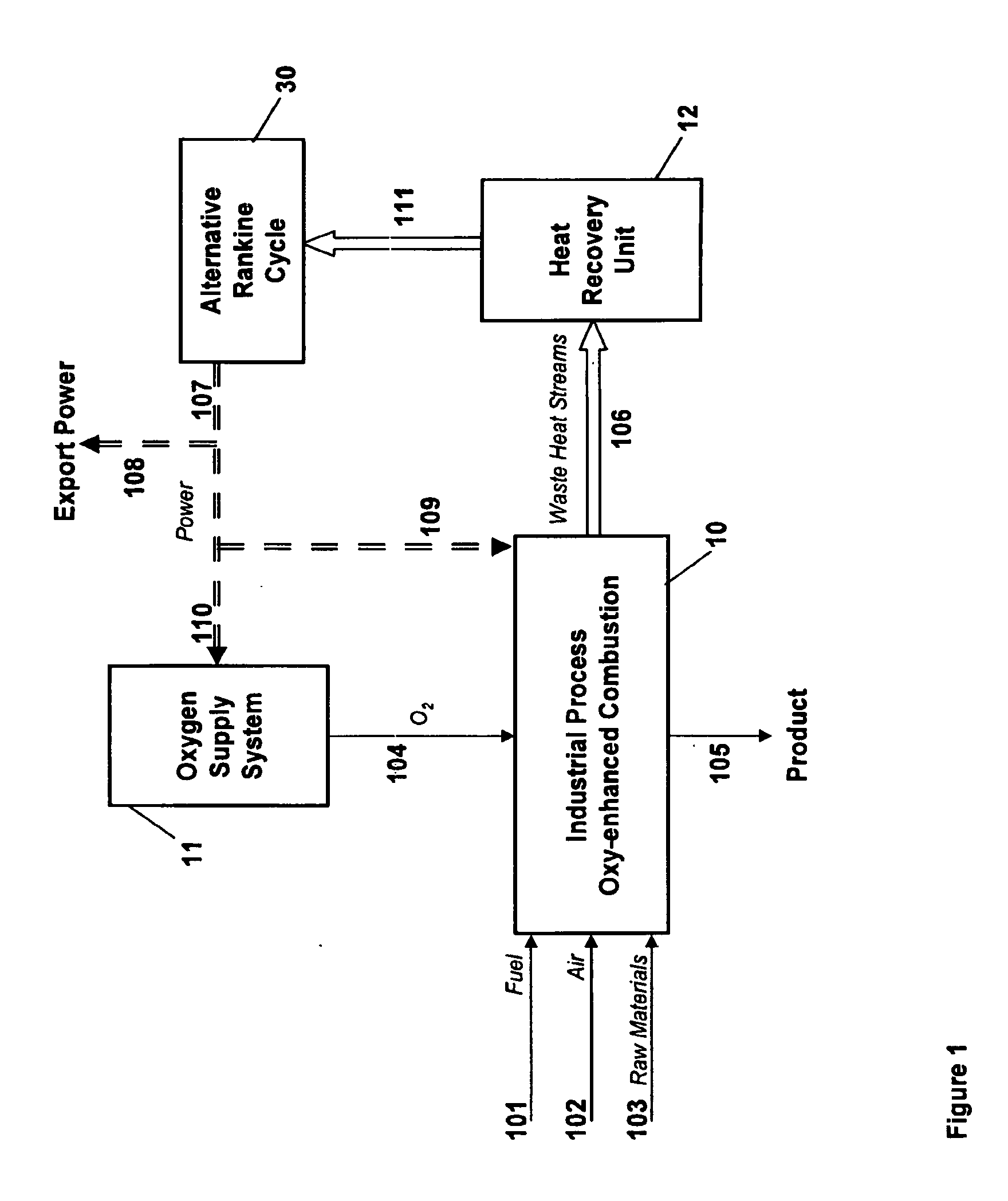

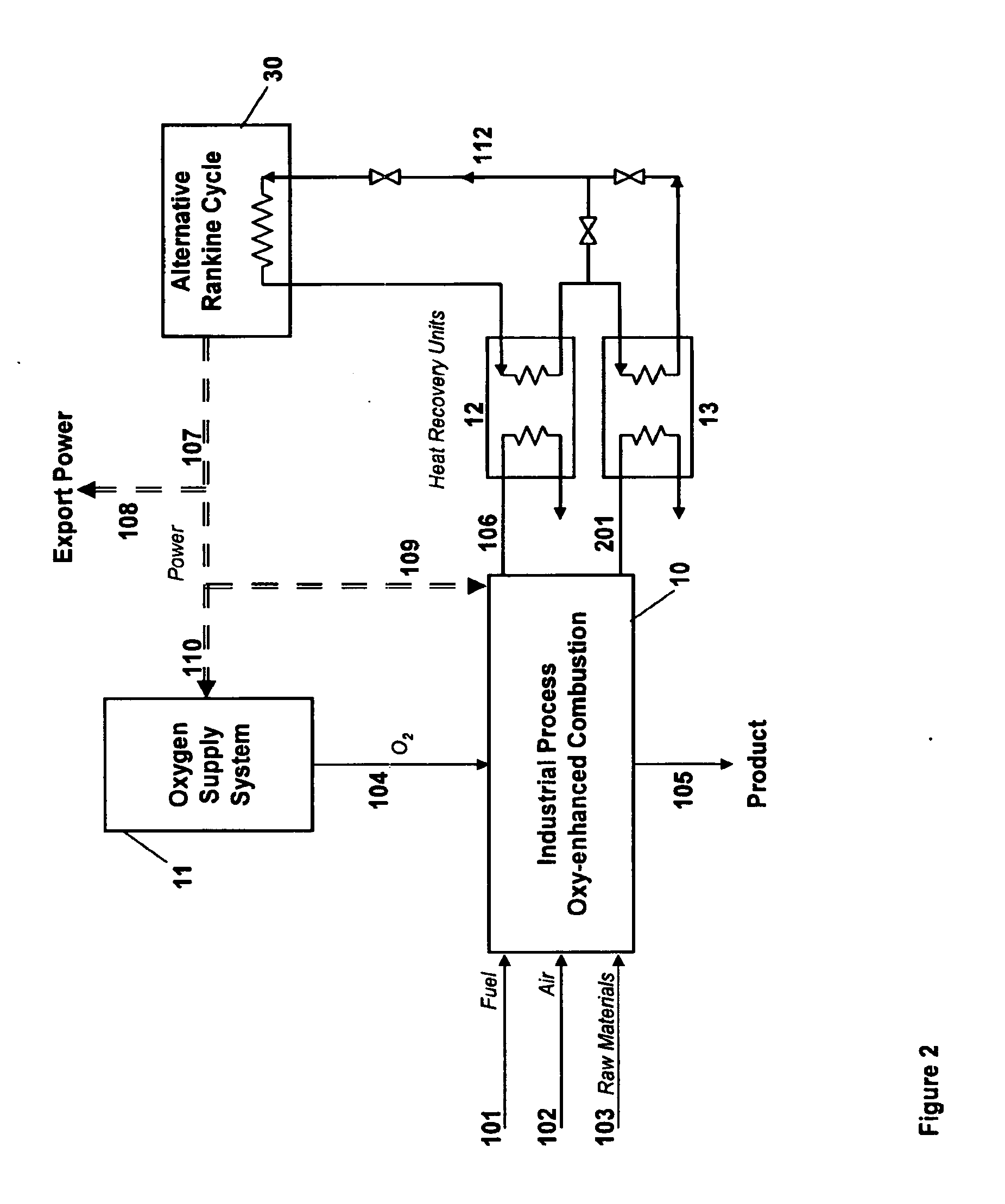

Oxygen enhanced combustion in industrial processes

InactiveUS20090308073A1Reduce equipment costsProvide such operationSolidificationLiquefactionWorking fluidCombustion

The present invention relates to a system for carrying out oxygen-enhanced combustion in an industrial process wherein the industrial process, an oxygen supply system or a source of oxygen, a heat recovery network, and an alternative Rankine cycle system based on a working fluid other than steam are integrated to achieve improved throughput and efficiency, and a method for oxygen-enhanced combustion in an industrial process using said system. Examples of industrial processes include cement production, steel reheat applications, glass production, aluminum and copper melting, as well as any industrial process that uses process heater, furnaces where combustion is carried out using an oxidant stream with oxygen content higher’ than that in ambient air and up to 100%.

Owner:PRAXAIR TECH INC

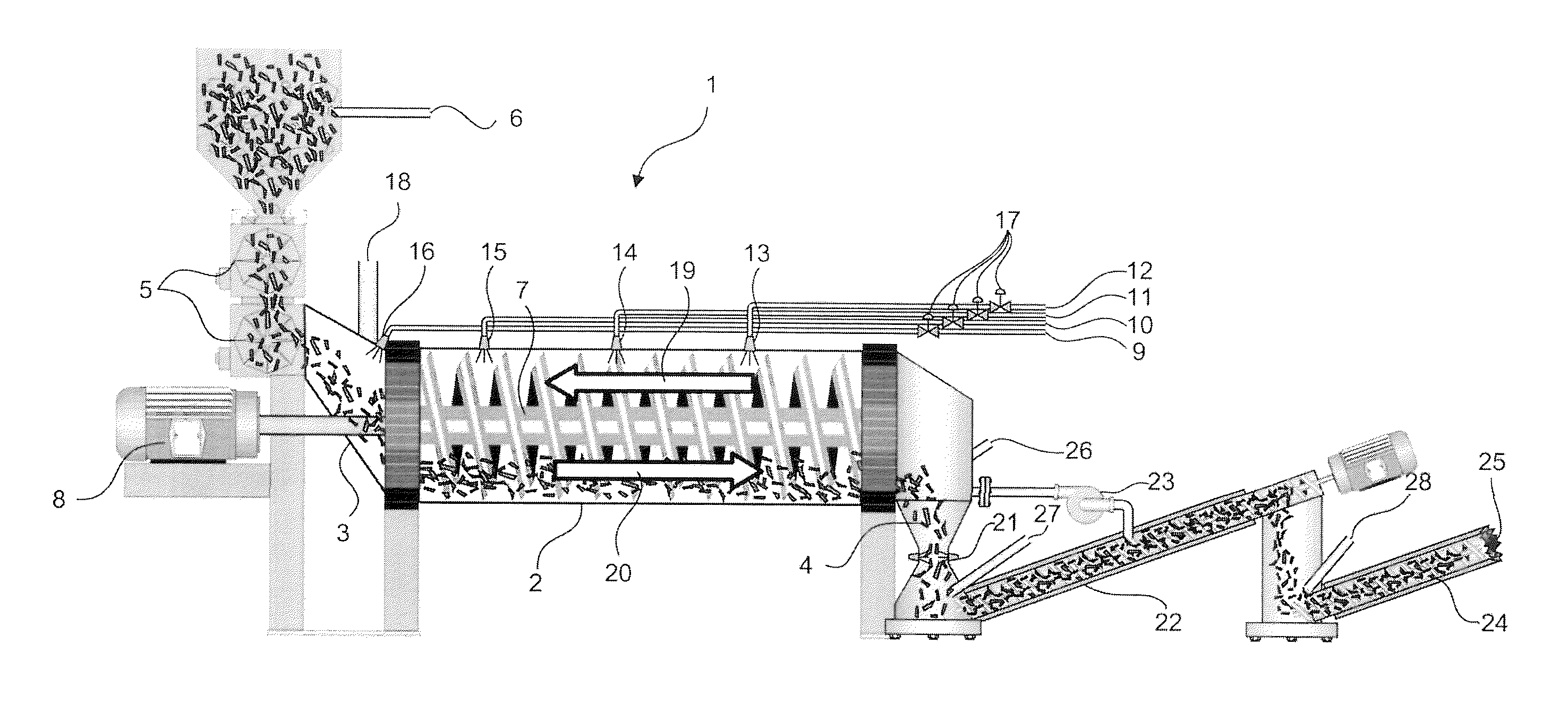

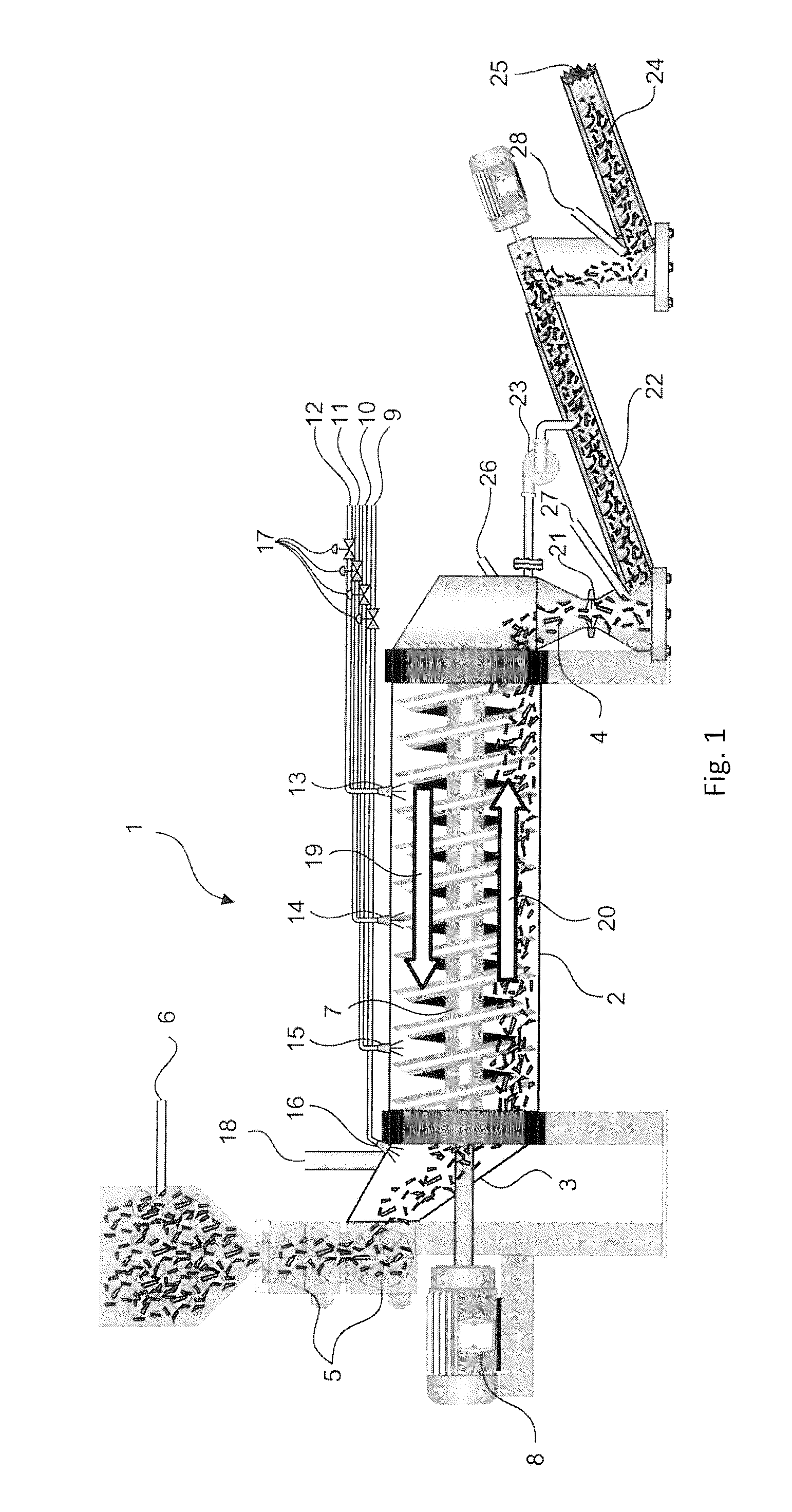

Countercurrent oxygen enhanced torrefaction

ActiveUS20140208995A1Reduce shipping costsLow calorific valueHydrogenHydrocarbon from carbon oxidesOxygen enhancedTorrefaction

The invention relates to a method of torrefaction of an optionally predried biomass in a torrefaction reactor such that torrefied biomass and torrefaction gases are obtained, and wherein an oxygen-containing gas is supplied to the torrefaction reactor at a first position in the reactor such that oxygen reacts with components of the torrefaction gases under the formation of heat and wherein torrefaction gases are withdrawn from the torrefaction reactor at a second position of the torrefaction reactor and wherein the first position is located downstream of the second position in relation to a biomass transport direction in the torrefaction reactor such that the torrefaction gases moves through the torrefaction reactor countercurrent with the biomass transport and wherein the optionally predried biomass has a temperature of between 30° C. and 230° C., preferably between 50° C. and 200° C., most preferably between 60° C. and 180° C. when entering the torrefaction rector.

Owner:BIOENDEV

Oxygen enhanced plasma waste treatment system and method

ActiveUS20060075945A1Improve efficiencyReduce amountSolid fuel combustionIncinerator apparatusParticulatesSolid carbon

A method and apparatus that improves the efficiency of waste processing in waste treatment systems utilizing a high temperature plasma as the a energy source by delivering pressurized oxygen to the waste products while the waste products are exposed to the high temperature plasma. Providing oxygen at a speed of at least fifty feet per second obtains more energy content in the syngas, less solid carbon particulate, and faster gasification rates, improving process economics.

Owner:INENTEC

Oxygen control system for oxygen enhanced combustion of solid fuels

InactiveUS20090308331A1Reduce processing costsReduce riskFurnace typesIndirect carbon-dioxide mitigationCombustion systemControl system

A combustion system and method for operating a combustion system, such as a furnace or boiler. The method includes providing a burner system having one or more burner elements configured to combust solid fuel and one or more oxygen providing devices configured to introduce oxygen into the near burner zone of one or more burner flames. A sensor is provided and arranged and disposed to measure a flame parameter in the near burner zone of the burner flame associated with one or more the burner elements. The flame parameter is measured with the sensor and an oxygen flow is determined in response to the measured flame parameter. Oxygen flow is introduced to one or more locations in the combustion system with the one or more oxygen providing devices.

Owner:AIR PROD & CHEM INC

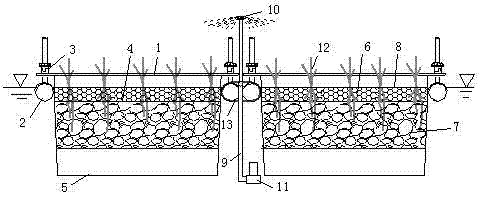

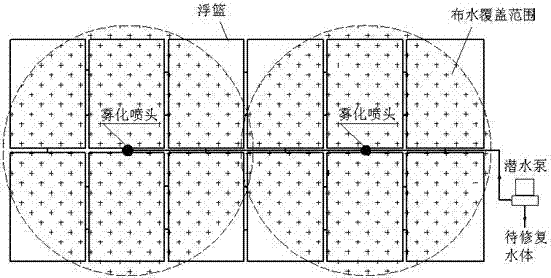

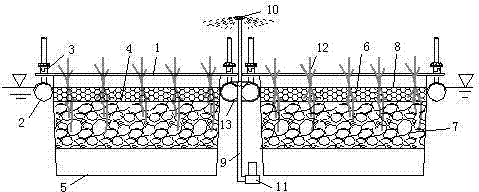

Suspended combined ecological filter bed and method for remediation of eutrophicated water

InactiveCN102351314ALow implementation costSimple structureTreatment with aerobic and anaerobic processesSustainable biological treatmentGrowth plantEutrophication

The invention discloses a suspended combined ecological filter bed and a method for remediation of eutrophicated water. The method for remediation of eutrophicated water is characterized in that a lift suspended basket is utilized as a container unit; a suspended double-filter layer composed of fly ash floating beads and ultralight attapulgite-based filter materials is loaded in the lift suspended basket; the suspended double-filter layer is a base layer for plant growth; and sewage filtration and system oxygen increasing are realized by water atomization distribution processes. Through a structural design of the suspended double-filter layer, the method provided by the invention solves effectively the problems that filter material blocking happens easily, realizes transformation from an ecological filter bed technology to a water surface remediation technology similar to an ecological suspended bed technology, avoids land occupation and construction, realizes efficient eutrophicated water remediation, reduces greatly construction and operation costs, enlarges a selection range of water cleaning plants, and is especially suitable for remediation of high-eutrophication degree water which is difficult to be treated by a single technical means.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

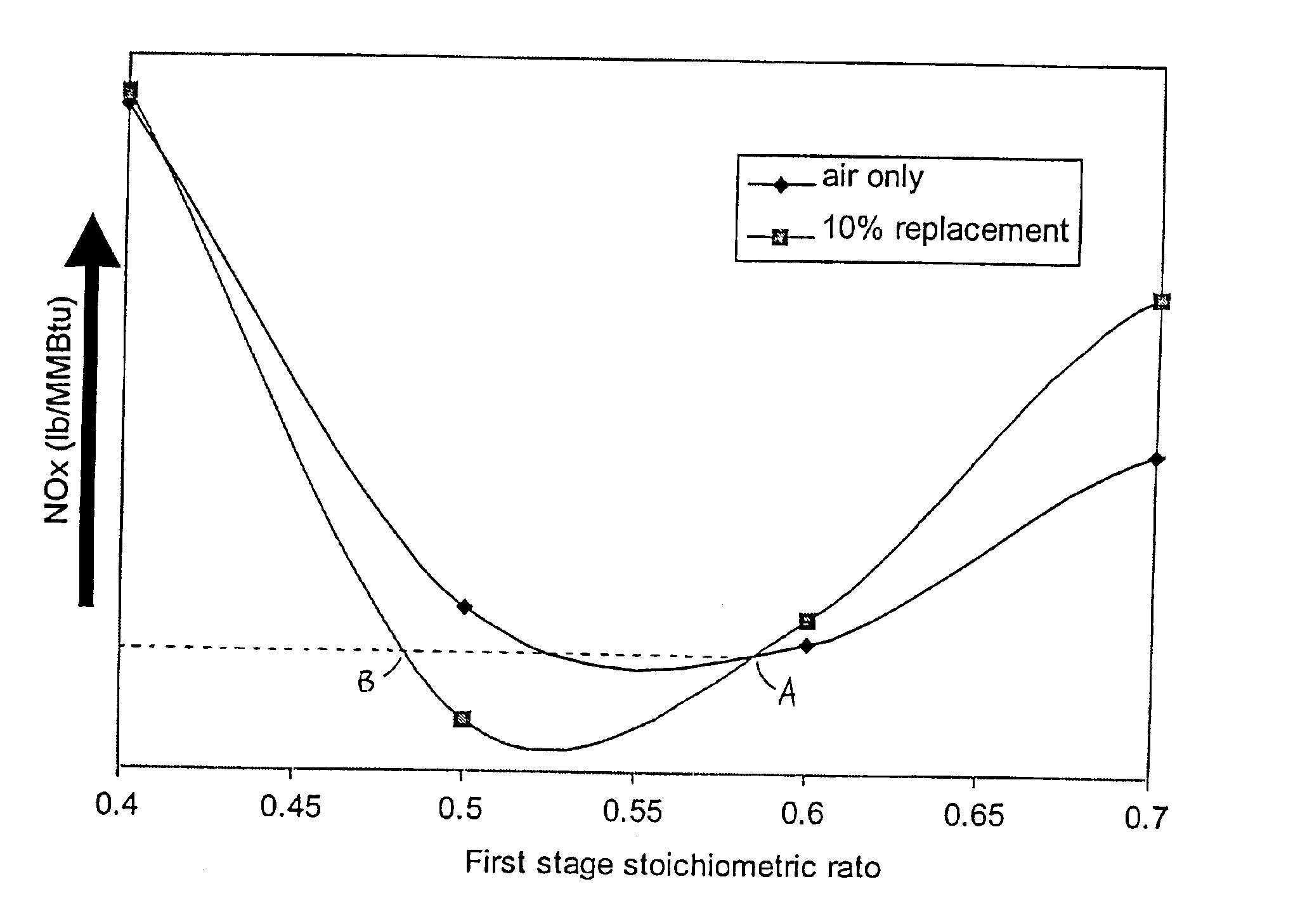

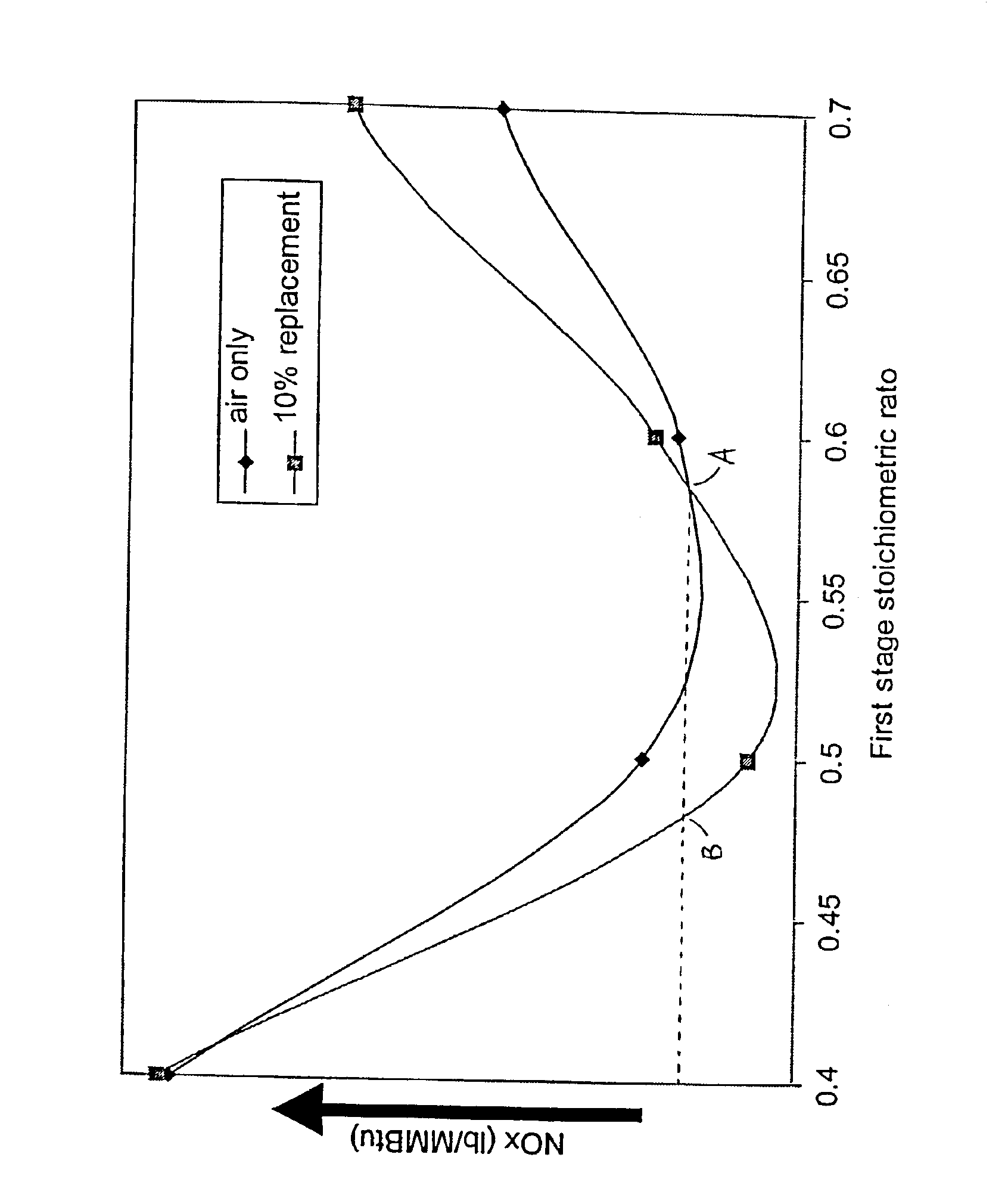

Oxygen enhanced low NOx combustion

InactiveUS6957955B2Minimize additional formation of NOxCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelOxygen enhancedEngineering

Fuel such as coal is combusted by feeding fuel and gaseous oxidant containing more than 21 vol. % oxygen, and preferably 21.8 to 29 vol. % oxygen, to a combustion stage at a stoichiometric ratio below that at which, if the stage were operated with air as the only oxidant, the same amount of NOx would be produced, and combusting the fuel and oxidant in said stage to produce combustion products and unburned fuel.

Owner:PRAXAIR TECH INC

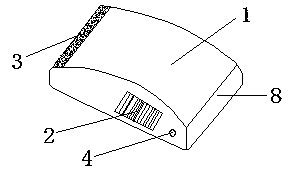

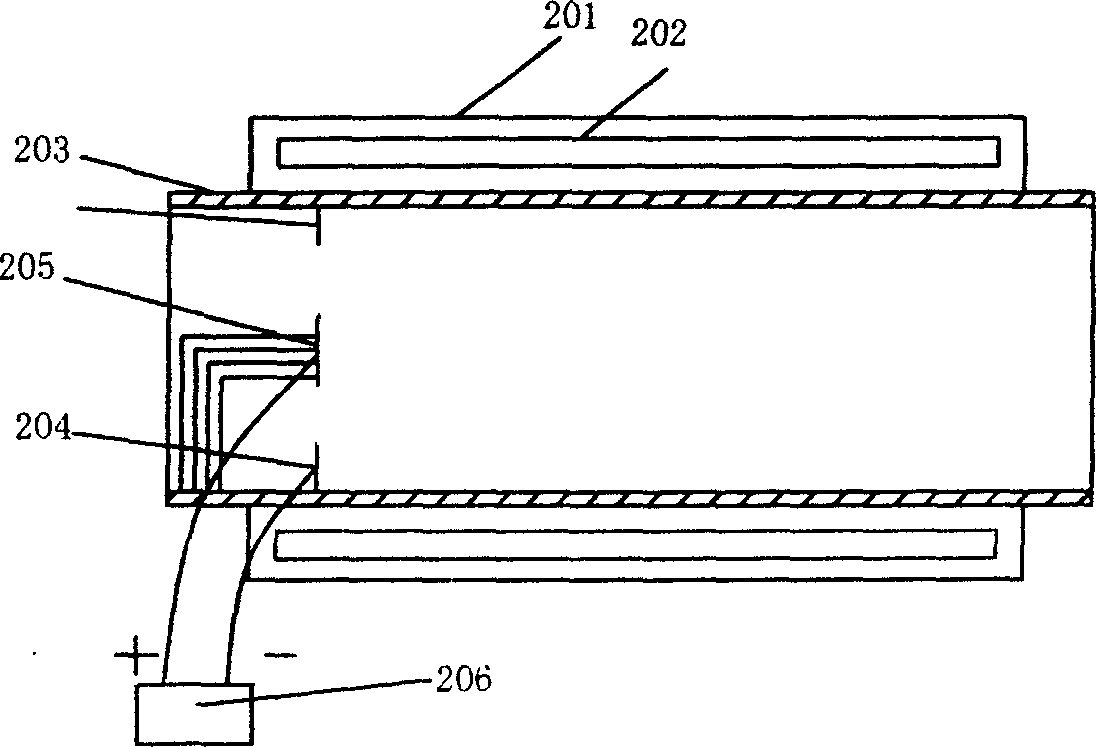

Vehicle type plasma air purifier

InactiveCN104315613APromote circulationIncrease oxygen contentMechanical apparatusLighting and heating apparatusAir purifiersIn vehicle

The invention discloses a vehicle type plasma air purifier. The vehicle type plasma air purifier comprises an outer casing. The vehicle type plasma air purifier is characterized in that a lateral plate which is arranged on each side of the outer casing is provided with an air inlet; each air inlet is shaped like a strip-shaped gap; an upper cover plate of the outer casing is provided with an air outlet; a fan, a plasma purifier and a plasma power supply are arranged in the outer casing; an air outlet of the fan faces the plasma purifier; an air outlet of the plasma purifier faces the air outlet which is formed in the outer casing; the plasma purifier is electrically connected with the plasma power supply. According to the vehicle type plasma air purifier, the air purification disinfection function is achieved, the vehicle type plasma air purifier is suitable for the purification disinfection of the environment inside a vehicle, meanwhile negative ions which are beneficial to a human body can be provided, the oxygen increase and freshness effect is achieved, the peculiar smell is removed, the economical and practical effect is achieved, and the vehicle type plasma air purifier is suitable for various small environments such as families, offices and the environment inside the vehicle.

Owner:SUZHOU BOHAN ENVIRONMENTAL PROTECTION TECH

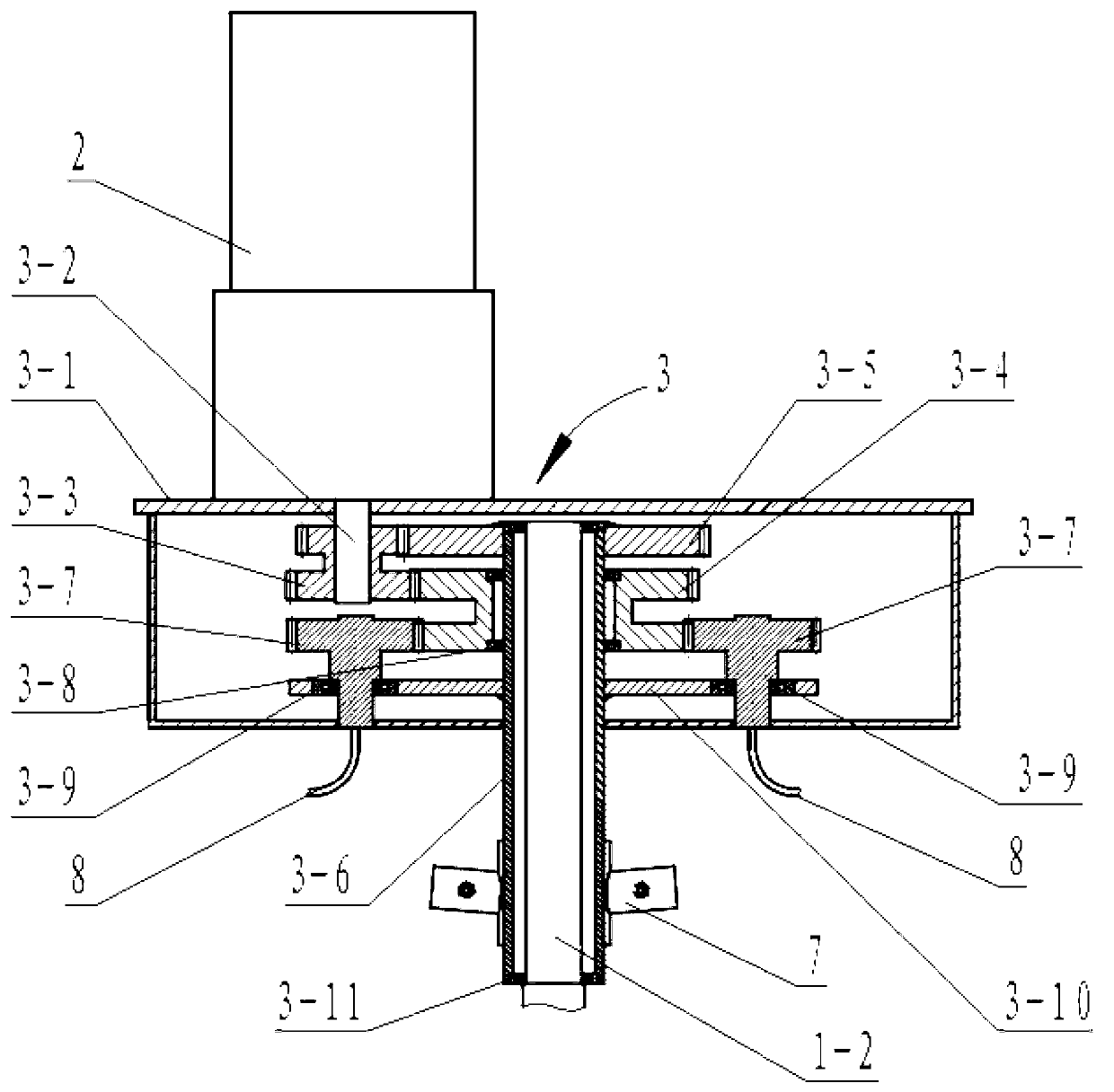

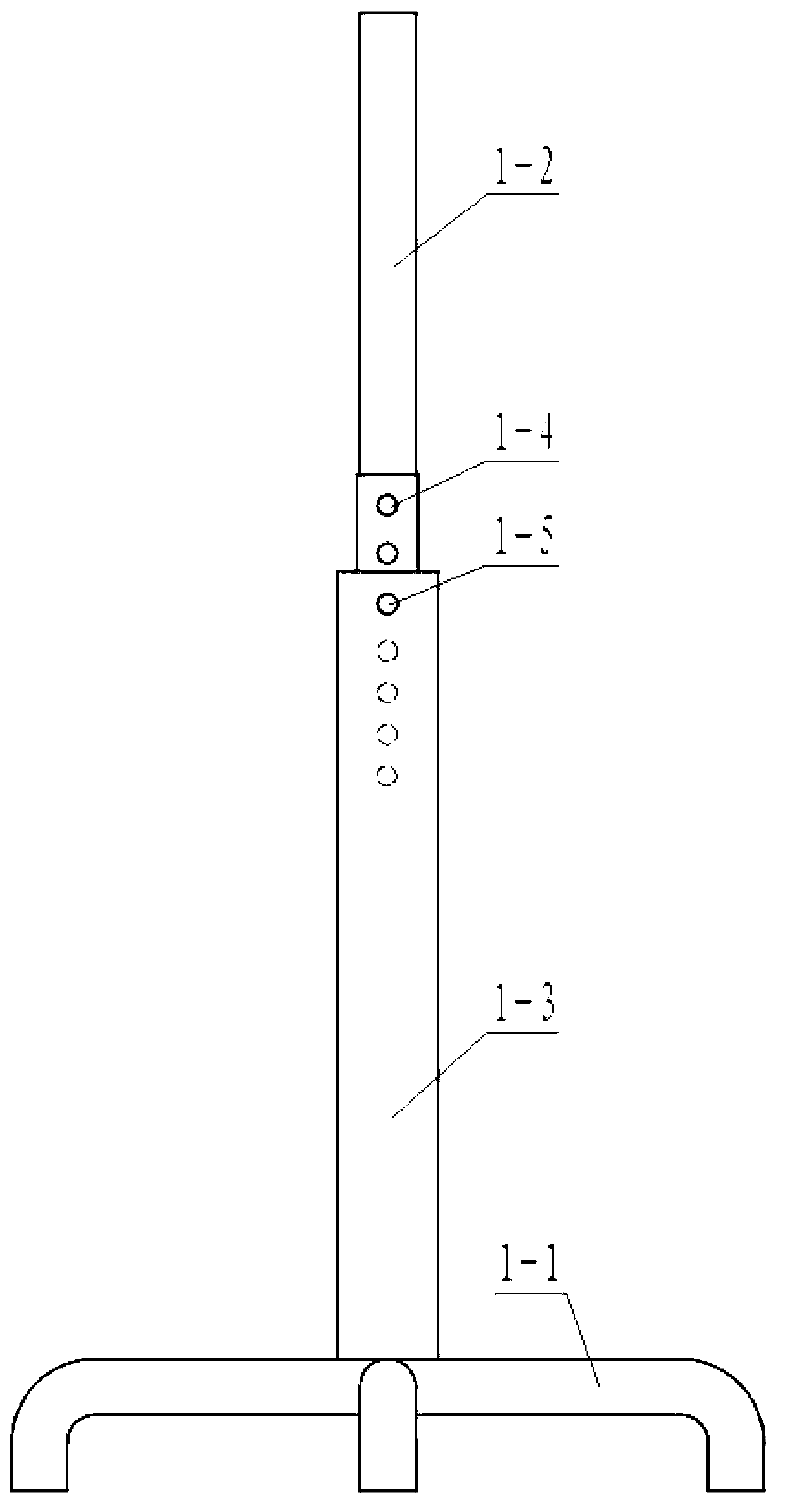

Automatic feeding and aerating device for pound

InactiveCN103004683AIncrease dissolved oxygenSmooth rotationToothed gearingsPisciculture and aquariaImpellerElectric machinery

The invention relates to cultivation of fish, in particular to an automatic feeding and aerating device for a pound. The device comprises a supporting seat, an electric motor, an epicyclic gearbox, revolving arms fixed with the epicyclic gearbox together and extended towards both sides and impeller wheels respectively arranged at the remote ends of the revolving arms, and is characterized in that the epicyclic gearbox divides the rotation of the electric motor into two paths of output, wherein one path of output drives the revolving arms so as to realize that the impeller wheels revolve around a center rod, and the other path of output drives the impeller wheels to rotate axially through a flexible shaft so as to realize aerating. In the aerating device, the revolution of the impeller wheels does not depend on the axial rotation of the impeller wheels; and therefore, the impeller wheels can be screw impeller wheels, so that the rotation direction of the impeller wheels is changed, water on the surface of the pound can be conveyed underwater, and water at the lower part of the pound can be conveyed towards the surface so as to increase the dissolved oxygen in the pound.

Owner:朱铁峰

Vertical sewage treatment device and method

ActiveUS20160376178A1Improve oxygenation efficiencyReduce occupancyBiological treatment apparatusTreatment with aerobic and anaerobic processesAnaerobic chamberHeat losses

The present invention provides a vertical sewage treatment device including an anaerobic chamber, an anoxic chamber, an aerobiotic chamber, and a secondary precipitation chamber, wherein the anaerobic chamber, the anoxic chamber, the aerobiotic chamber, and the secondary precipitation chamber are vertically arranged in sequence from the bottom to the top. According to another aspect, the present invention also provides a sewage treatment method using the foregoing vertical sewage treatment device. The sewage treatment device and method of the present invention have the advantages such as a reduced occupied area, improved oxygenation efficiency, a decreased head loss, a reduced invalid structure volume, and a low heat loss.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

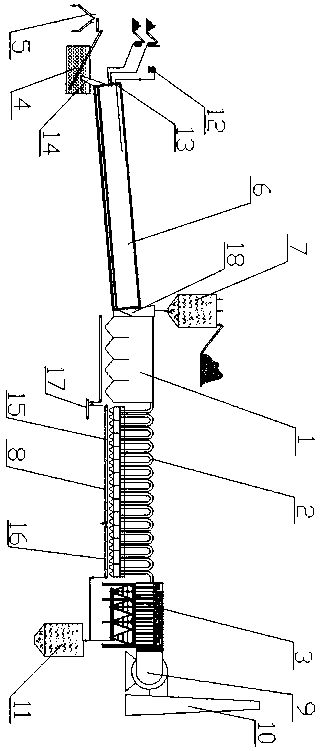

Production line and technology for producing metallized furnace burden by blast furnace gas ash

ActiveCN107760875AMeet the needs of converter productionRotary drum furnacesProcess efficiency improvementSlagMaterials science

The invention discloses a production line and a technology for producing metallized furnace burden by blast furnace gas ash and belongs to the technical field of metallurgy and mineral engineering, aiming at solving the problems of an existing technology that the grade and the metal conversion ratio of zinc oxide and the iron grade in kiln slag are relatively low, the content of the zinc oxide inthe kiln slag is too high and resources are wasted. The production line comprises a rotary kiln, a range hood, a chimney, a heat-preservation and settling chamber, a cooler, a bag-type dust collector,a cooling cylinder and a magnetic separator; the technology comprises the following steps: mixing raw materials, reducing the kiln slag, cooling the materials, carrying out magnetic selection and separation, carrying out heat preservation and settling, bonding and depositing, returning the materials and preparing the materials, carrying out dust removal and dust collection and discharging tail gas. According to the production line and the technology, disclosed by the invention, beneficial elements including iron, zinc and the like in the zinc-extracted kiln slag of the blast furnace gas ash are sufficiently utilized and the zinc-extracted kiln slag of the blast furnace gas ash are treated by adopting a rotary kiln carbon-hydrogen combined reduction and carbon circulating oxygenation reduction method; the iron grade in the treated kiln slag can reach 54 percent or more, the content of the zinc oxide reaches 0.4 percent or lower and the metal conversion rate reaches 90 percent or more;the requirements on converter production are completely met.

Owner:JIUQUAN IRON & STEEL GRP

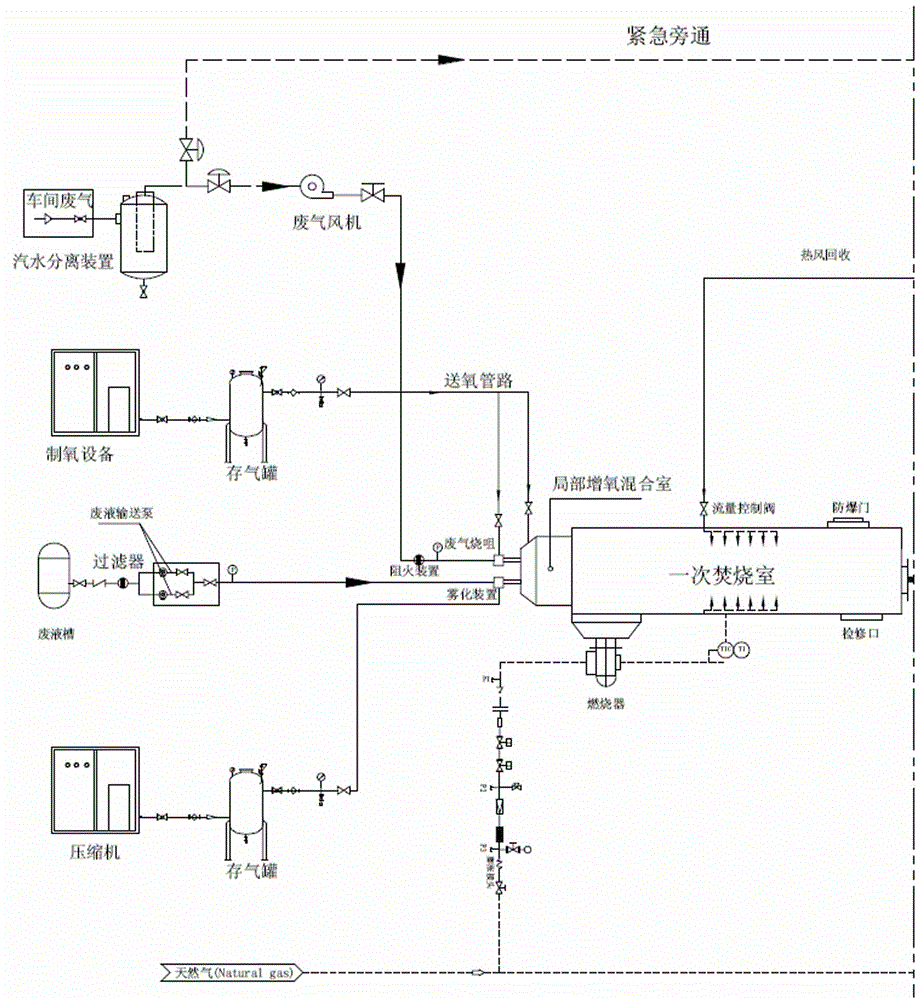

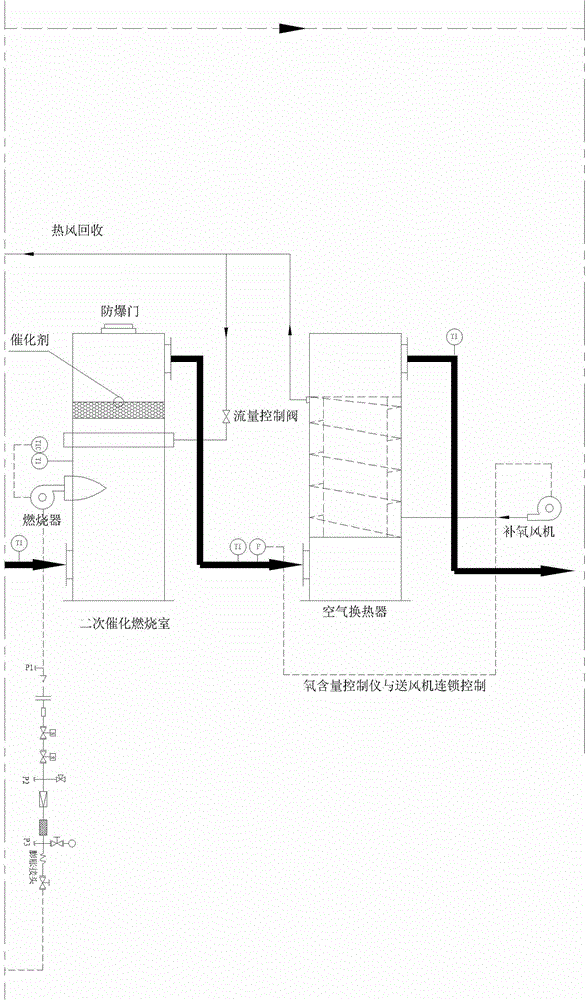

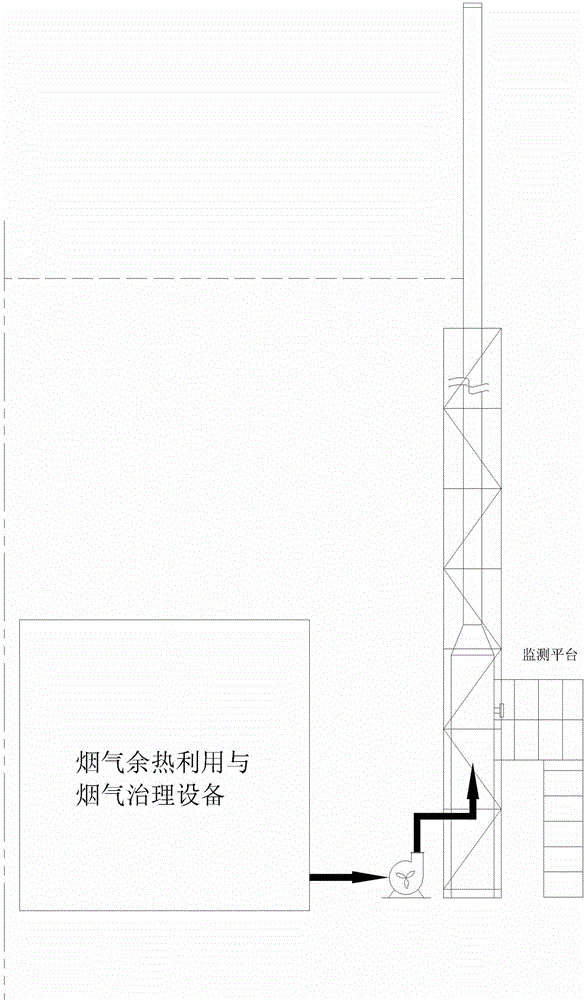

Waste gas and waste liquid incineration system and method

ActiveCN104359113AIncrease contentReduce exhaustIncinerator apparatusAir quality improvementPtru catalystPollution

The invention discloses a waste gas and waste liquid incineration system. The system comprises oxygen production equipment, a local oxygen increasing, combustion and mixing chamber, a primary incineration chamber, a secondary catalytic incineration chamber, an air heat exchanger and a waste heat utilization and smoke purification device which are sequentially connected; harmful waste gas or atomized waste liquid, compressed air and pure oxygen are proportionally mixed in the mixing chamber and then are fed into the primary incineration chamber for incineration. The waste gas and waste liquid incineration system has the advantages that the content of oxygen is locally improved in the primary incineration chamber for waste gas and waste liquid, the combustion speed is accelerated, the complete combustion is facilitated, the smoke exhaust amount after combustion is reduced, and the heat utilization ratio is improved; smoke after primary incineration enters the secondary catalytic incineration chamber and reacts with catalyst, toxic gases such as ammonia and hydrogen cyanide produced after primary incineration is decomposed into N2, H2 and CO2, the problem of environmental pollution caused by smoke exhaust is solved, and the energy saving and emission reduction are facilitated.

Owner:宜兴市智博环境设备有限公司

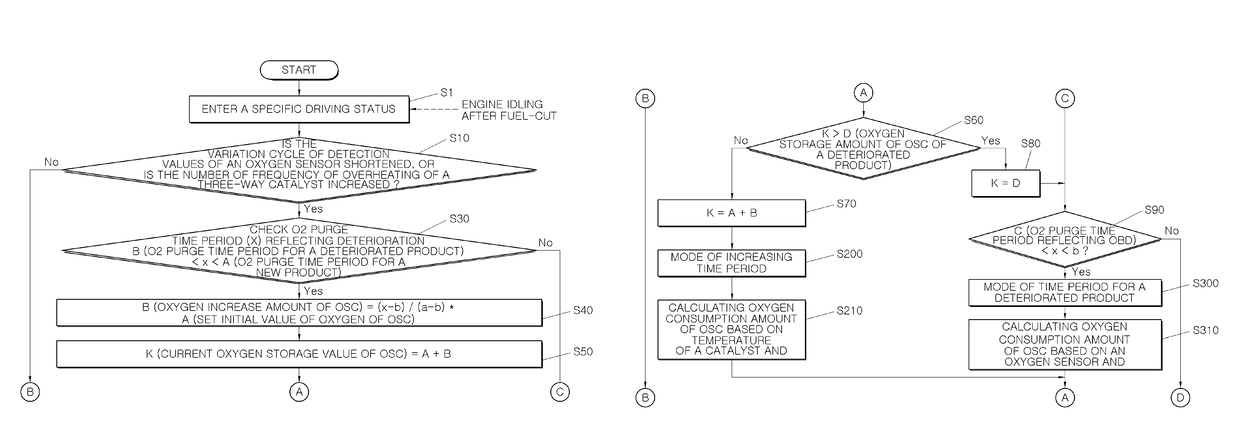

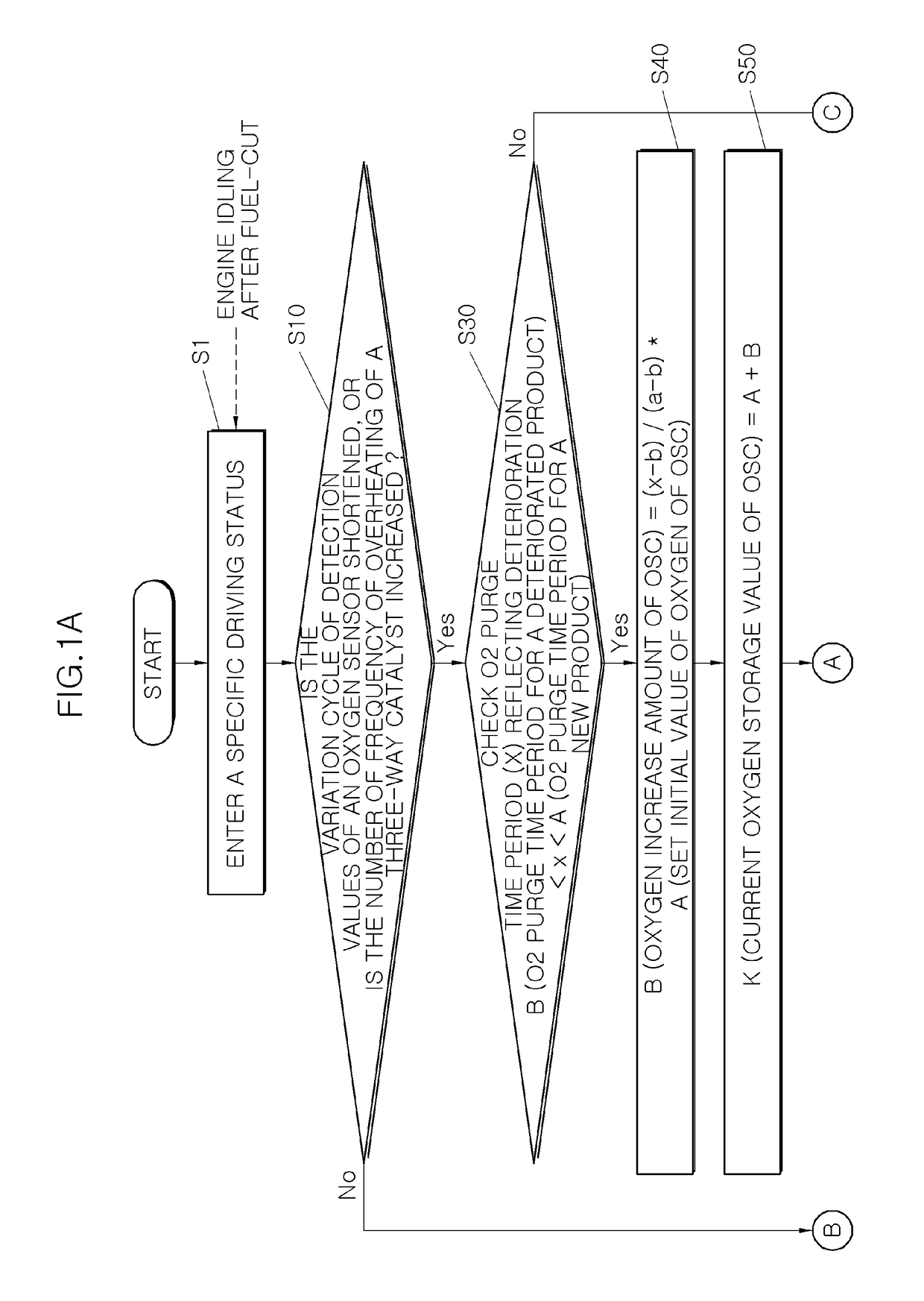

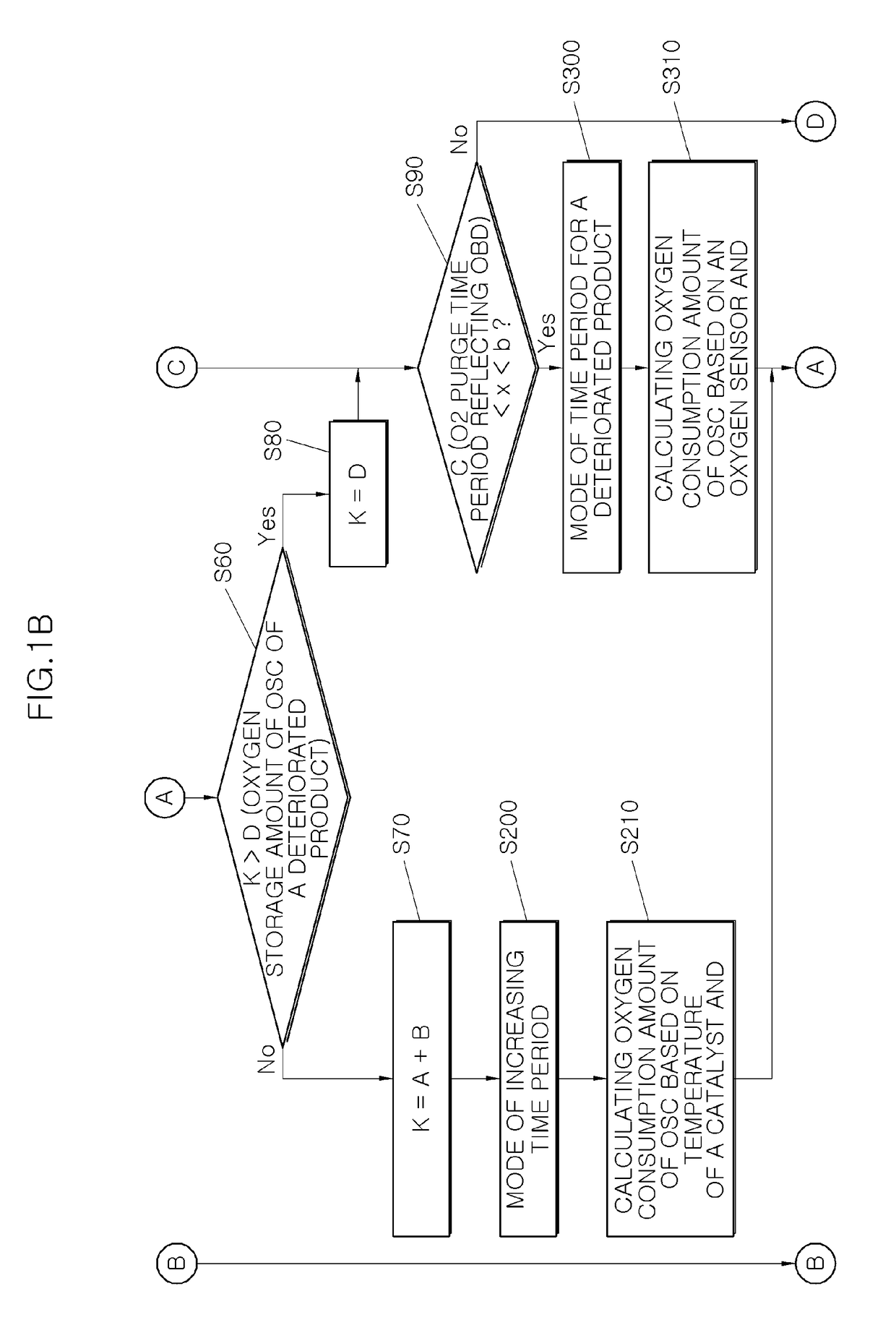

Three way catalytic control method and system for decreasing fuel consumption and vehicle having the same

A three-way catalytic control method for reducing fuel consumption is provided. The method includes determining whether oxygen storage capacity of the three-way catalyst is under condition of increasing oxygen, when condition of performing O2 purge control for the three-way catalyst is detected and performing O2 purge control by applying a predetermined O2 purge time period to which a set initial value of oxygen of OSC is applied, when the OSC is not under the condition of increasing oxygen. The O2 purge control is performed by applying O2 purge time period for a deteriorated product based on an oxygen sensor or O2 purge time period for on board diagnosis, when an increase amount of the calculated O2 purge time period is equal to or greater than the O2 purge time period for the deteriorated product during the O2 purge control.

Owner:HYUNDAI MOTOR CO LTD

Rebreather setpoint controller and display

InactiveUS20120132207A1Reduce noiseImprove performanceRespiratorsBreathing filtersHead-up displayLED display

Owner:HELIOX TECH

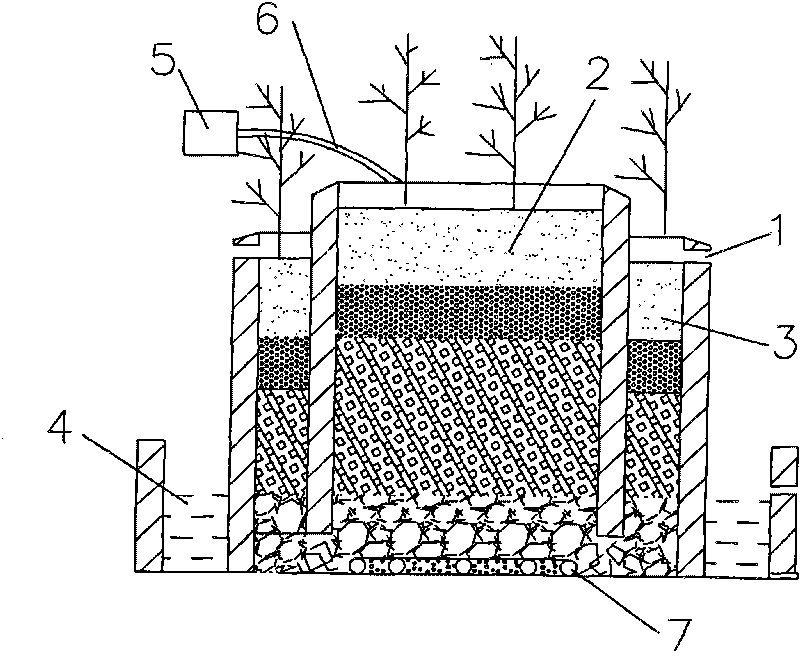

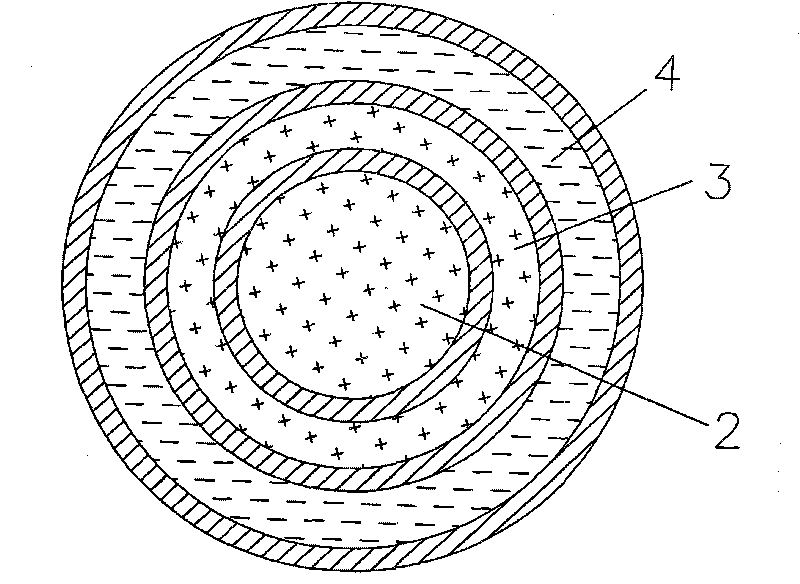

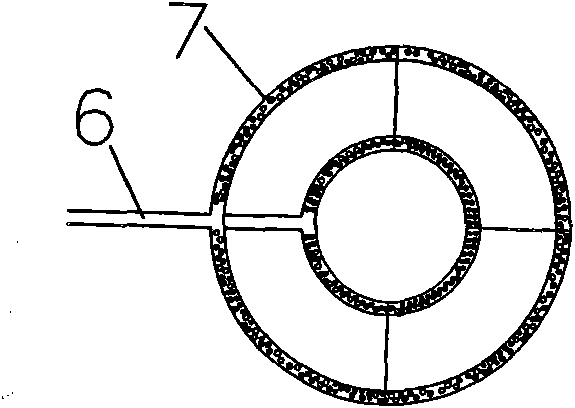

Nested oxygen-enhanced landscape vertical current artificial wetland

ActiveCN101708925AIncrease profitEnhance landscape valueTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandLand resources

The invention provides a nested oxygen-enhanced landscape vertical current artificial wetland. The artificial wetland comprises a downflow tank, an upflow tank and a landscape tank, wherein the downflow tank, the upflow tank and the landscape tank are arranged in a nesting manner, the heights of the three tanks are gradually reduced, the bottoms of the downflow tank and the upflow tank are communicated, at least three layers of substrate packings are paved in the downflow tank and the upflow tank, coarse sands are paved on the top layer, a water outlet groove is arranged on the upper part of the upflow tank, perforated aerator pipes are paved at the bottom of the downflow tank; and landscape plants are planted in the three tanks. The artificial wetland of the invention adopts the concentric nesting structure so as to increase the utilization rate of the land resource; and the effluent of the upflow tank falls into the landscape tank from all around in a high dropping manner and the dissolved oxygen content of the effluent is further increased during the dropping process, thus increasing the water quality of the effluent, promoting the removal of oxygen element in the sewage, improving the landscape value of the wetland system and facilitating that the wetland can be popularized widely.

Owner:SHANDONG UNIV

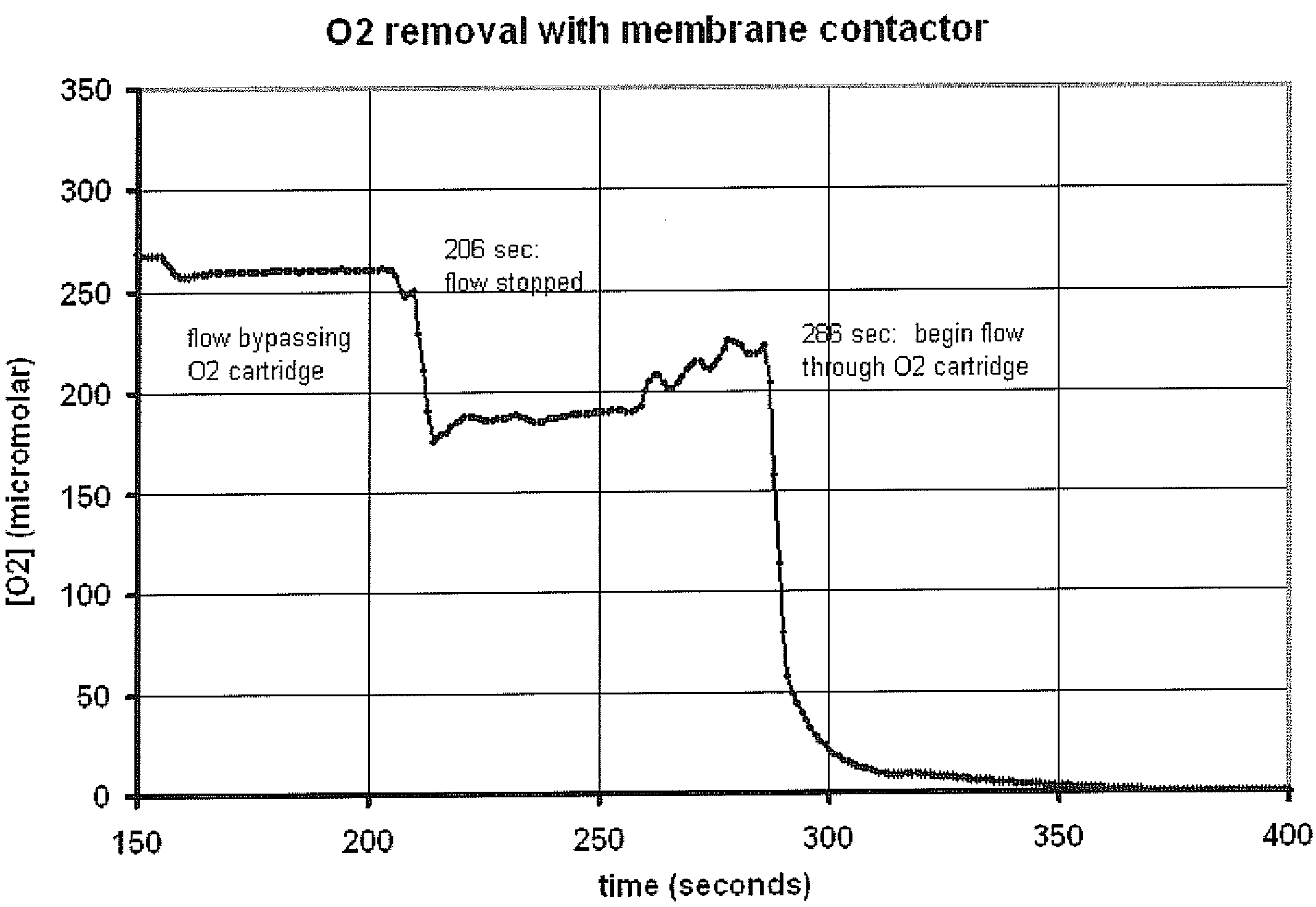

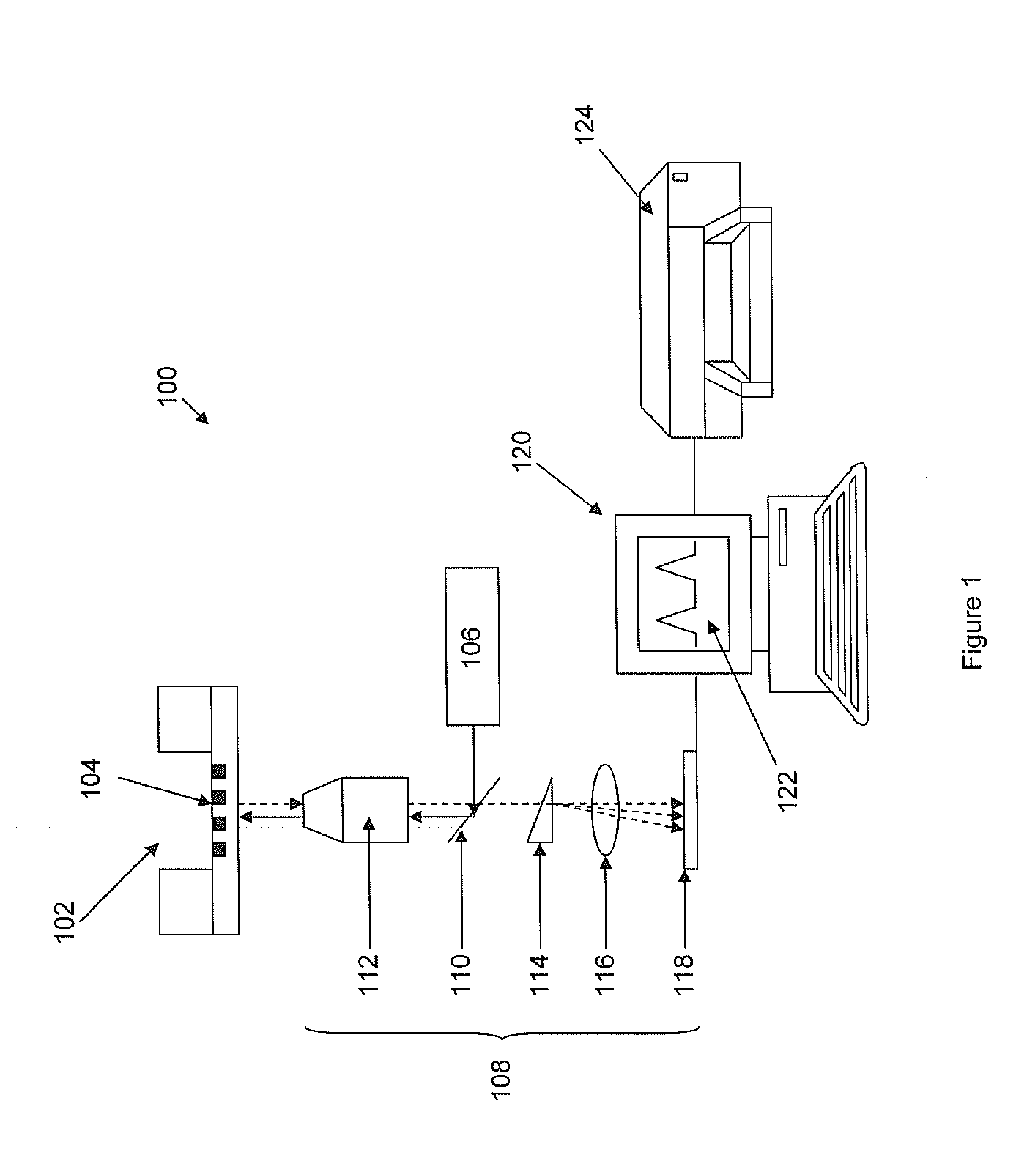

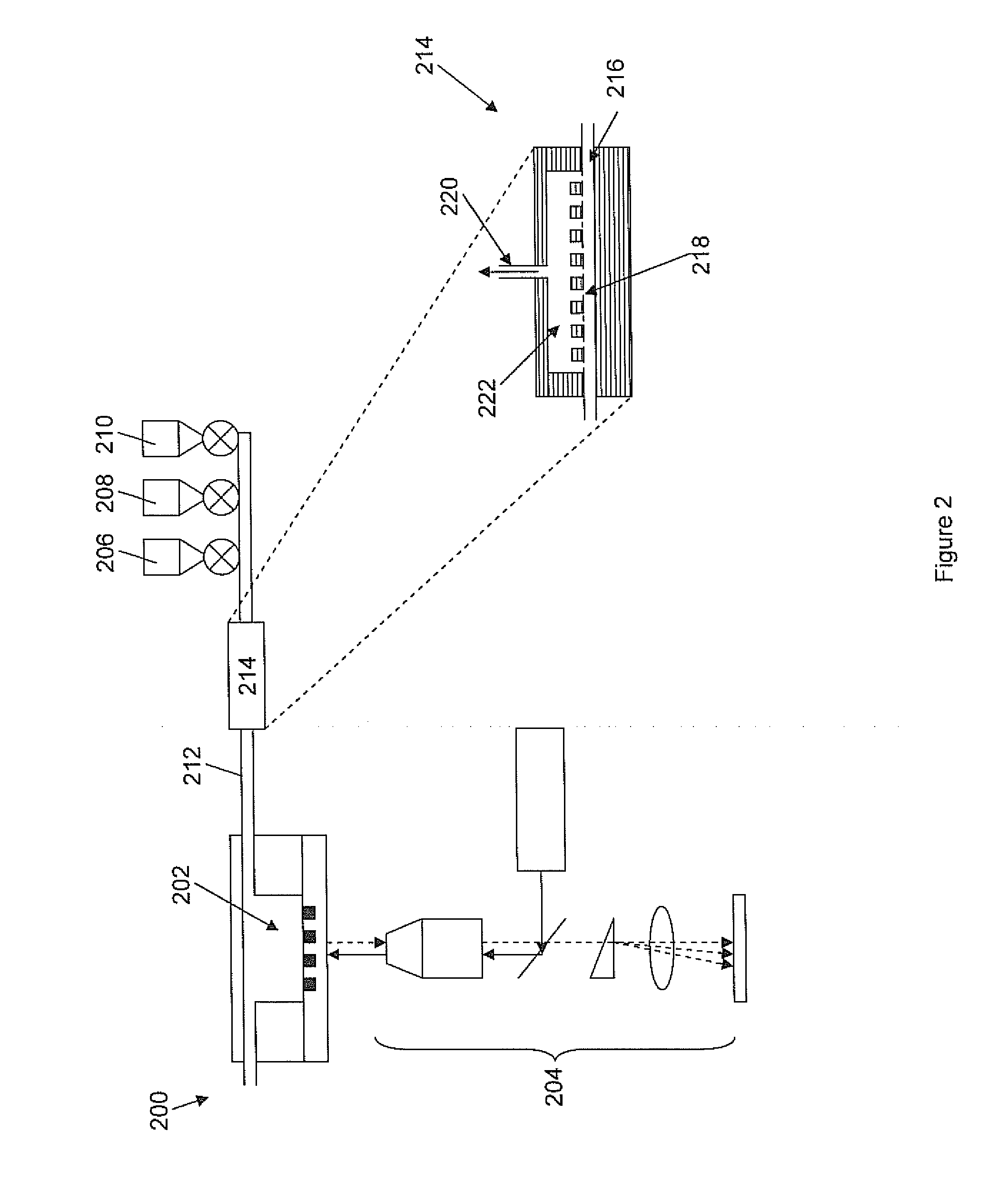

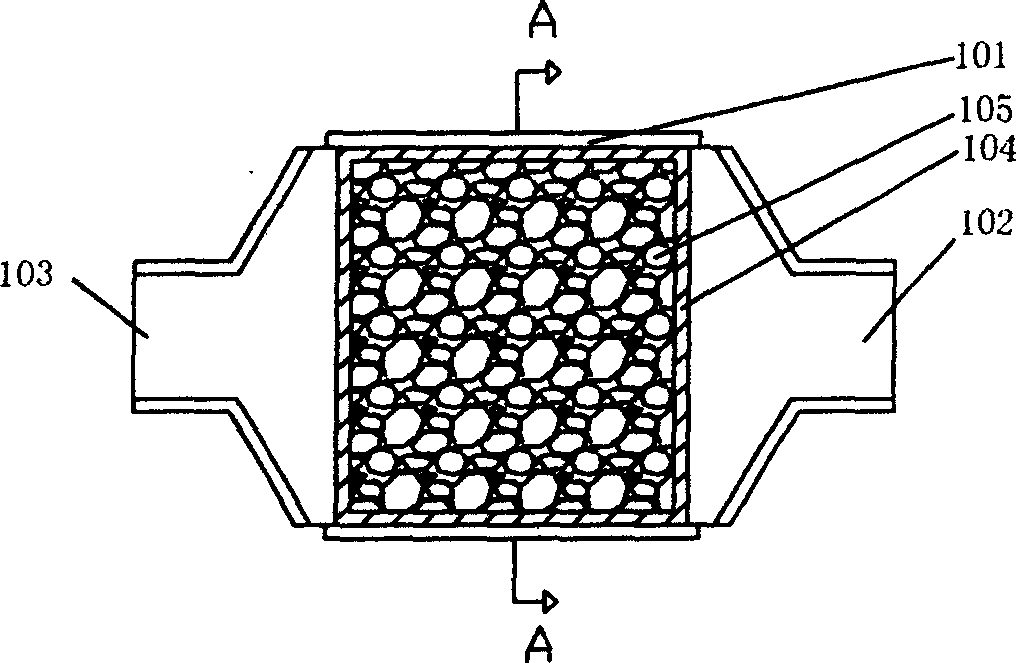

Methods and systems for mitigating oxygen enhanced damage in real-time analytical operations

Methods and systems for performing analytical reactions under reduced or non-oxygen conditions, where such reactions are potentially subject to damaging effects of oxygen, including particularly fluorescent based detection methods where fluorescent species may be prone to generation of reactive oxygen species.

Owner:PACIFIC BIOSCIENCES

Method and its device for treating air in closed space

InactiveCN1749659AImprove cleanlinessImprove freshnessLighting and heating apparatusDeodrantsActivated carbon filtrationUltraviolet

The present invention relates to method and device for treating air in closed space, especially method and device for treating air in long distance transportation means and room. The method includes the following steps: adsorbing with active carbon to eliminate suspended matter in the air; sterilizing with ultraviolet ray; deodorizing with ozone; regulating oxygen concentration; regulating air humidity; replenishing negative ion; adding plant essence gas and regulating temperature. The present invention has the beneficial effects of killing most of the germ, raising air cleanness, raising air freshness, raising the negative ion concentration and oxygen concentration, regulating air temperature and humidity and creating local environment like that in forest.

Owner:张昌荣

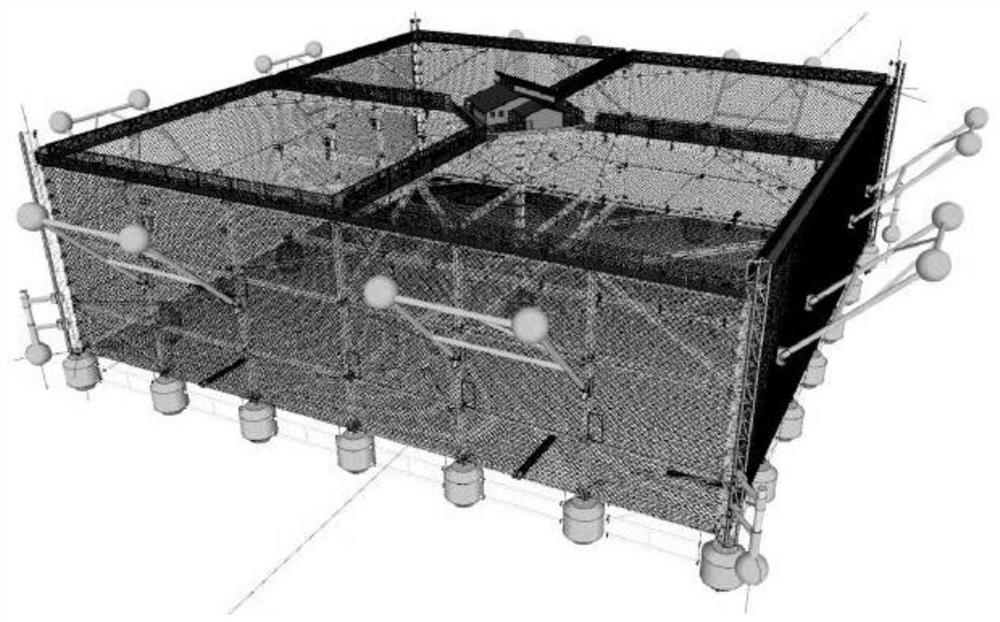

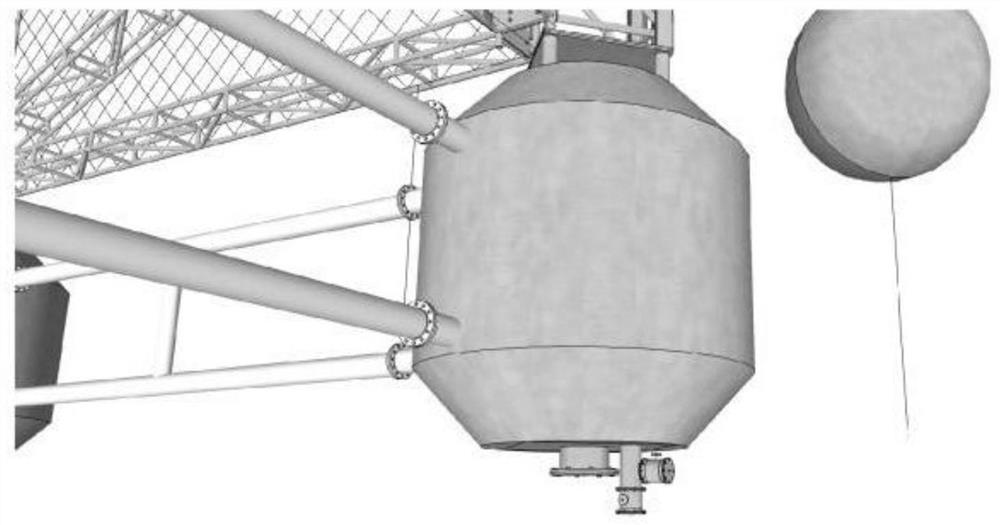

Assembled stable sinking and floating deep sea culture net cage and using method thereof

PendingCN112243917AMaintain safety and stability factorResolve artificial dependenciesClimate change adaptationPisciculture and aquariaBuoyancy regulationFood chain

The invention relates to the technical field of deep-sea culture, in particular to an assembled stable sinking and floating deep sea culture net cage and a using method thereof. The assembled stable sinking and floating deep sea culture net cage comprises a frame system, a buoyancy adjusting system, an auxiliary buoyancy stabilizing system, an anchoring system, an inner and outer net system, a netcleaning system, an underwater measurement and control and oxygenation system and a fish collecting system. The culture net cage has the advantages that the assembled structure is beneficial to standardized manufacturing and installation and facilitates corrosion prevention and maintenance; the stability during sinking and floating is enhanced by using a method of adjusting and controlling auxiliary buoyancy; layered culture is conducted, and a three-dimensional food chain and a culture ecological chain are constructed; remote management and control can be realized through a mobile terminal according to real-time data of an Internet of Things management system and a water area information acquisition center; buoyancy is adjusted by adjusting the water amount, sinking and floating are controlled, and regular net cleaning and maintenance are facilitated; dissolved oxygen is supplemented layer by layer, so that the culture density can be multiplied; and fish automatically swims into a cabin along a fish collecting water slideway, so that the manual operation cost is greatly reduced.

Owner:梅长茂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com