Patents

Literature

4180 results about "Activated carbon filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shortened purification process for the production of capsular streptococcus pneumoniae polysaccharides

ActiveUS20080286838A1Increase polysaccharide concentrationReduce the presence of impuritiesAntibacterial agentsSugar derivativesPurification methodsActivated carbon filtration

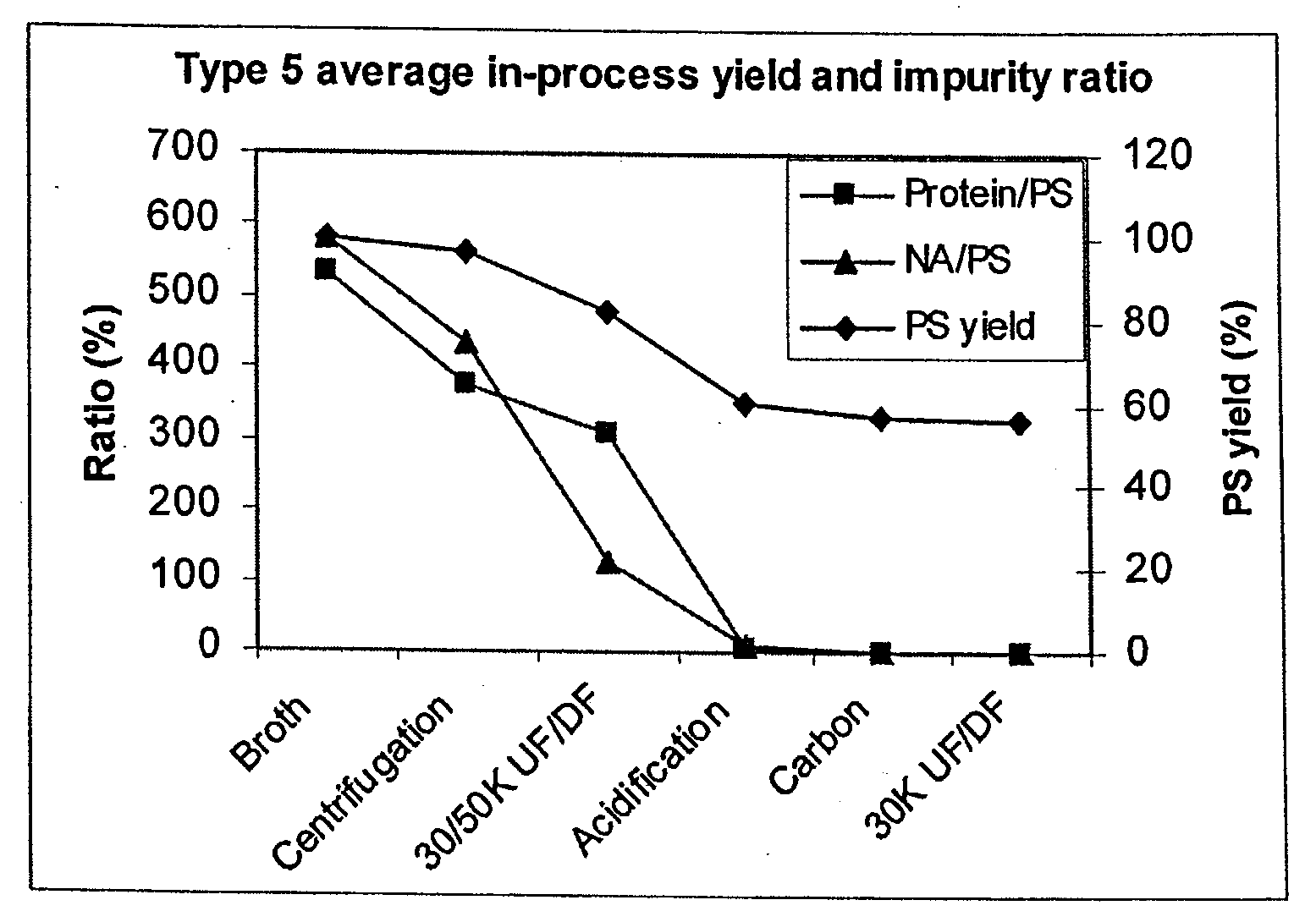

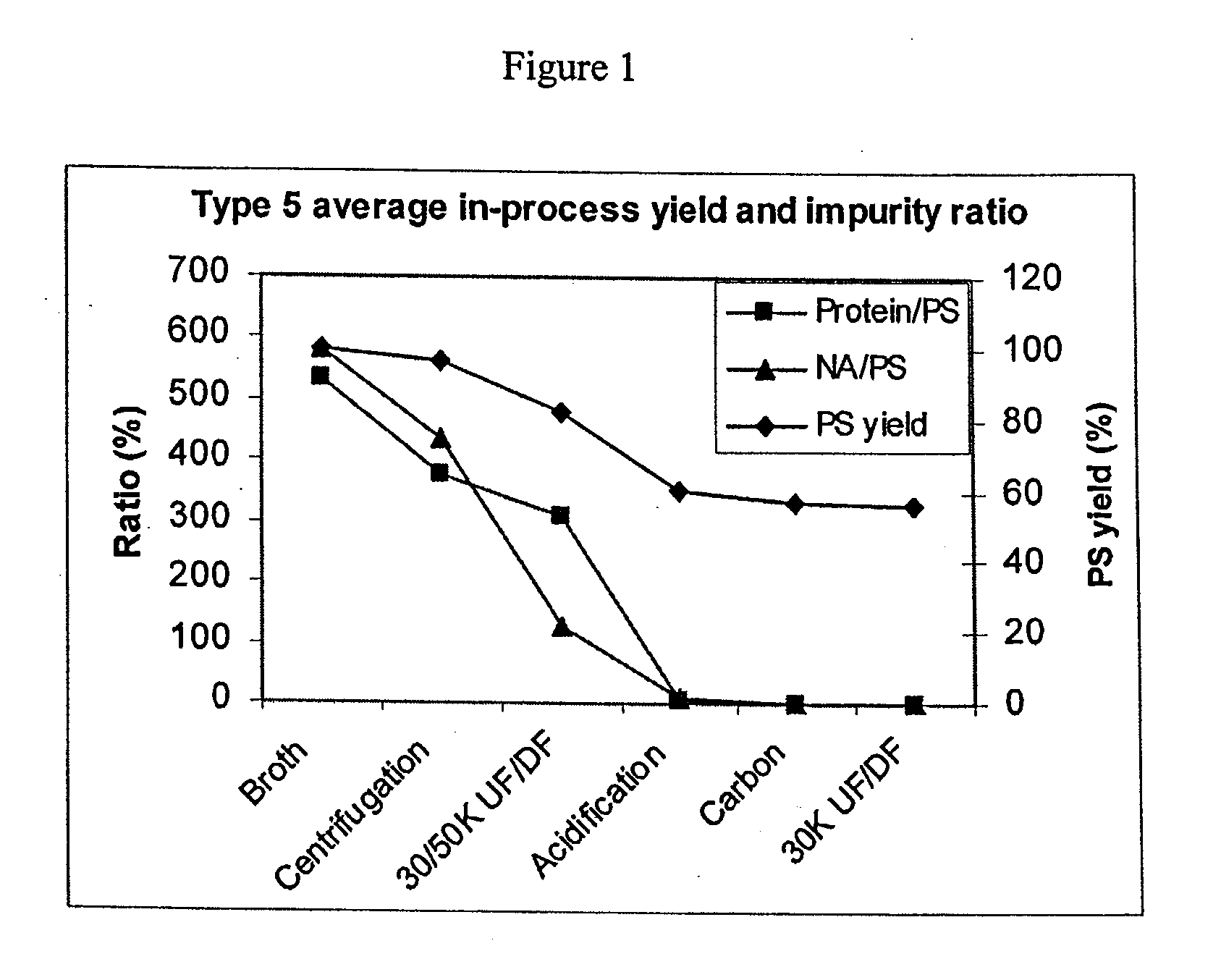

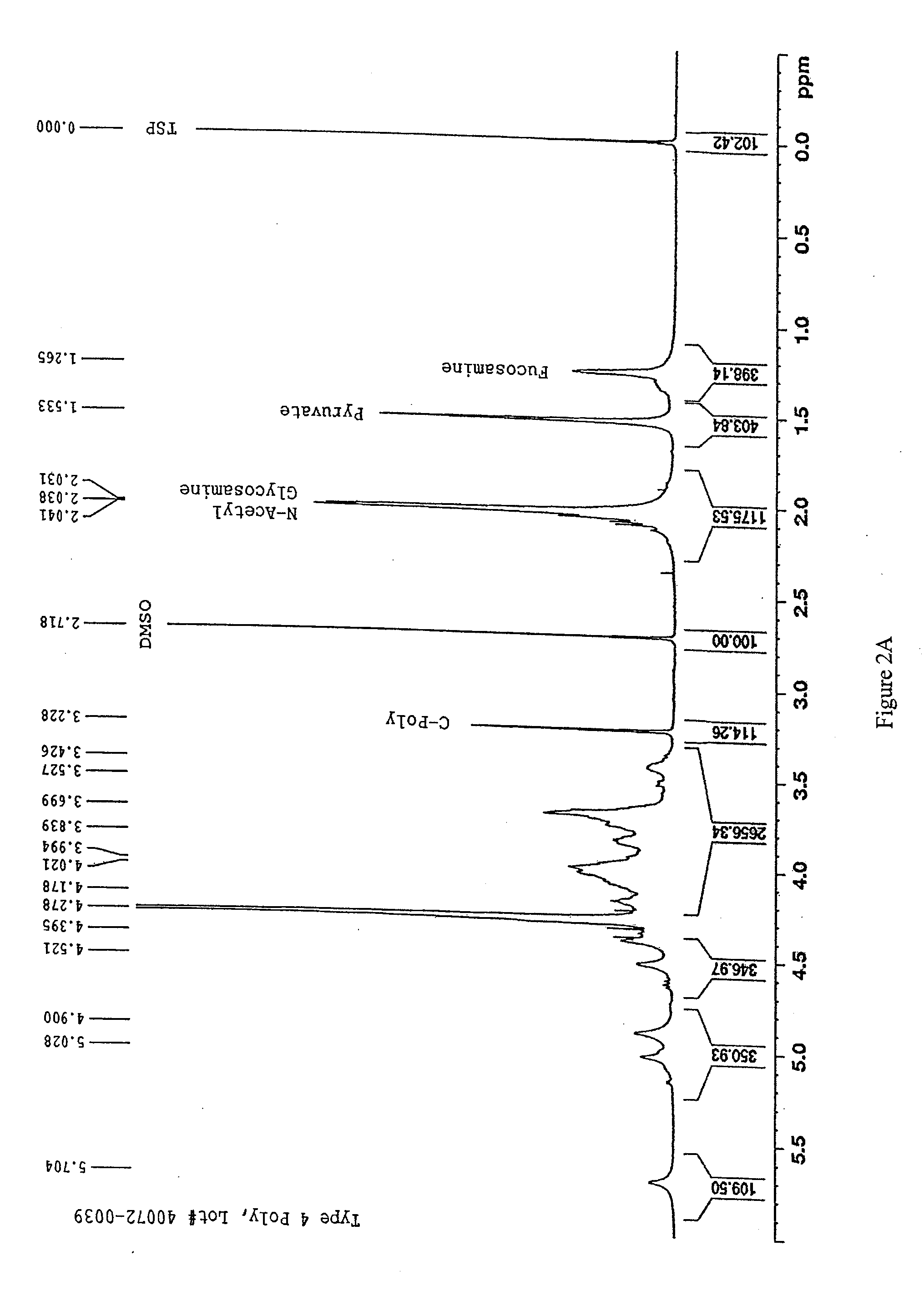

A shortened process for producing a solution containing substantially purified capsular polysaccharides from a cellular Streptococcus pneumoniae lysate broth is described. Ultrafiltering and diafiltering a clarified S. pneumoniae lysate followed by pH adjustment to less than 4.5, preferably about 3.5, precipitated at least 98% of the protein in the solution without seriously affecting polysaccharide yield. Furthermore, following ultrafiltration and diafiltration and acidification to a pH of less than 4.5, filtration using activated carbon precipitated at least 90% of remaining protein without seriously affecting polysaccharide yield. Exemplary, non-limiting S. pneumoniae serotypes that can be purified using the shortened process of the invention are 1, 4, 5, 6A, 6B, 7F, 9V, 14, 18C, 19A, 19F, and 23F. In one embodiment, the Streptococcus pneumoniae cells are lysed using deoxycholate sodium (DOC), while in another embodiment the lytic agent is a non-animal derived lytic agent such as N-lauryl sarcosine sodium (NLS).

Owner:WYETH LLC

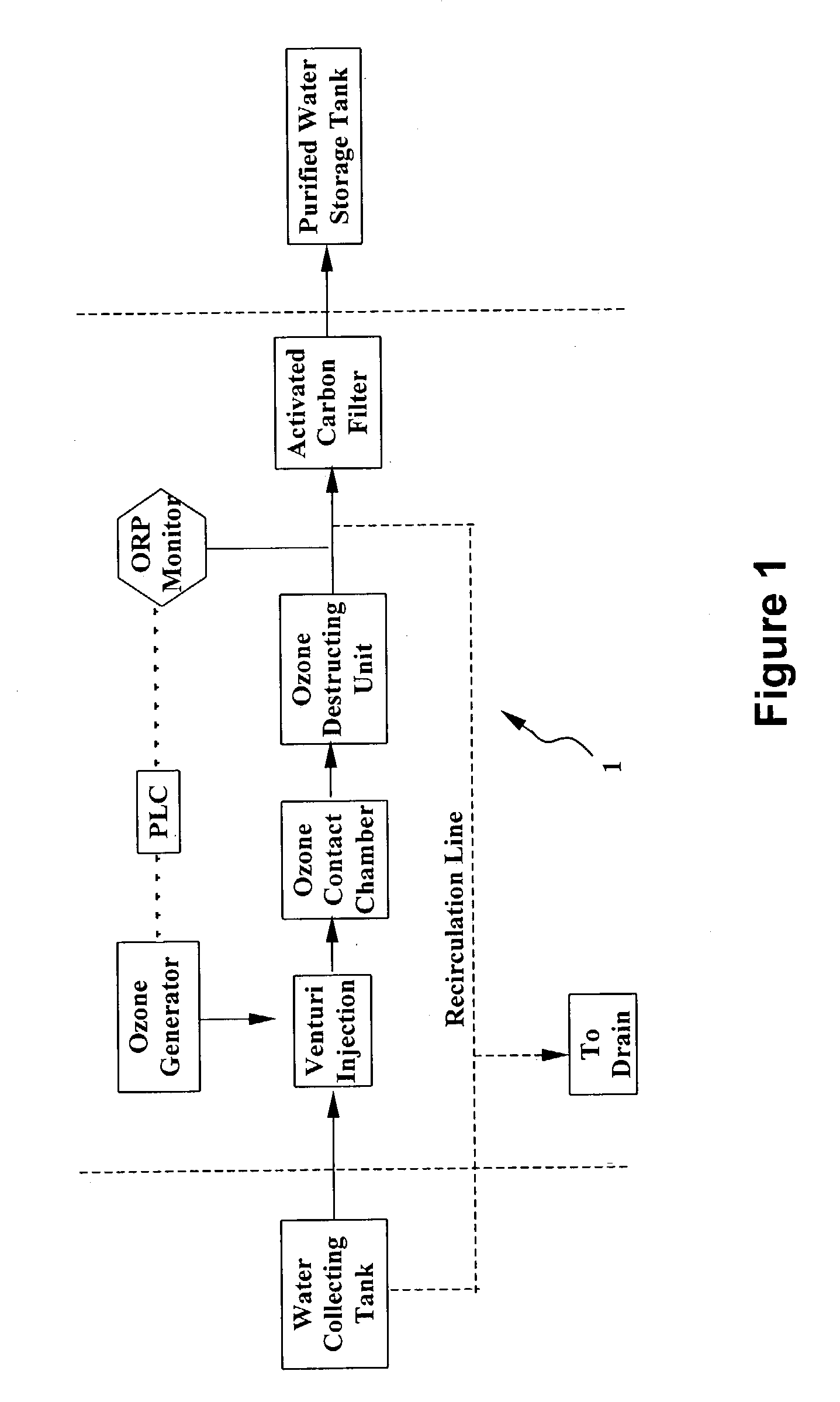

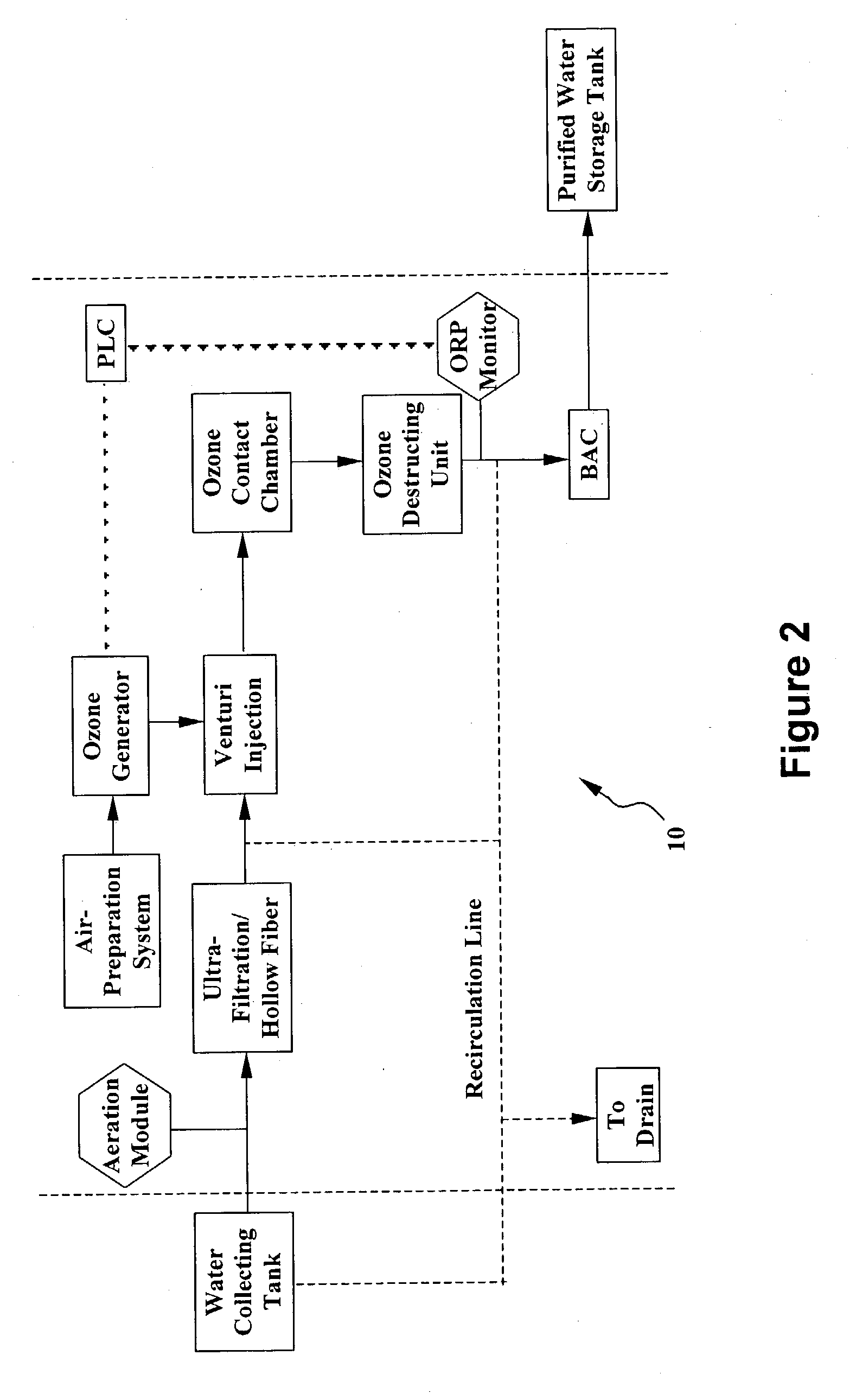

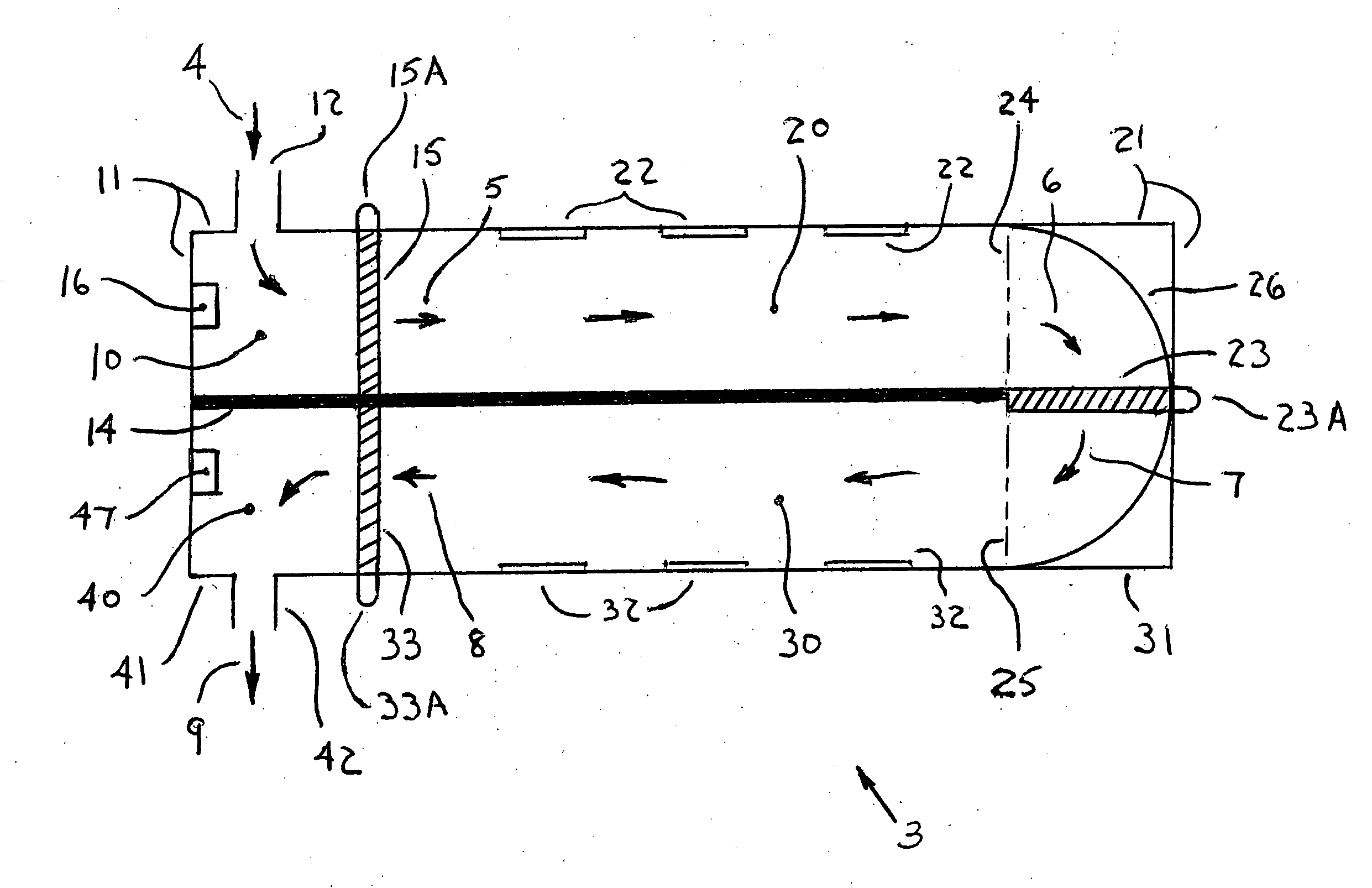

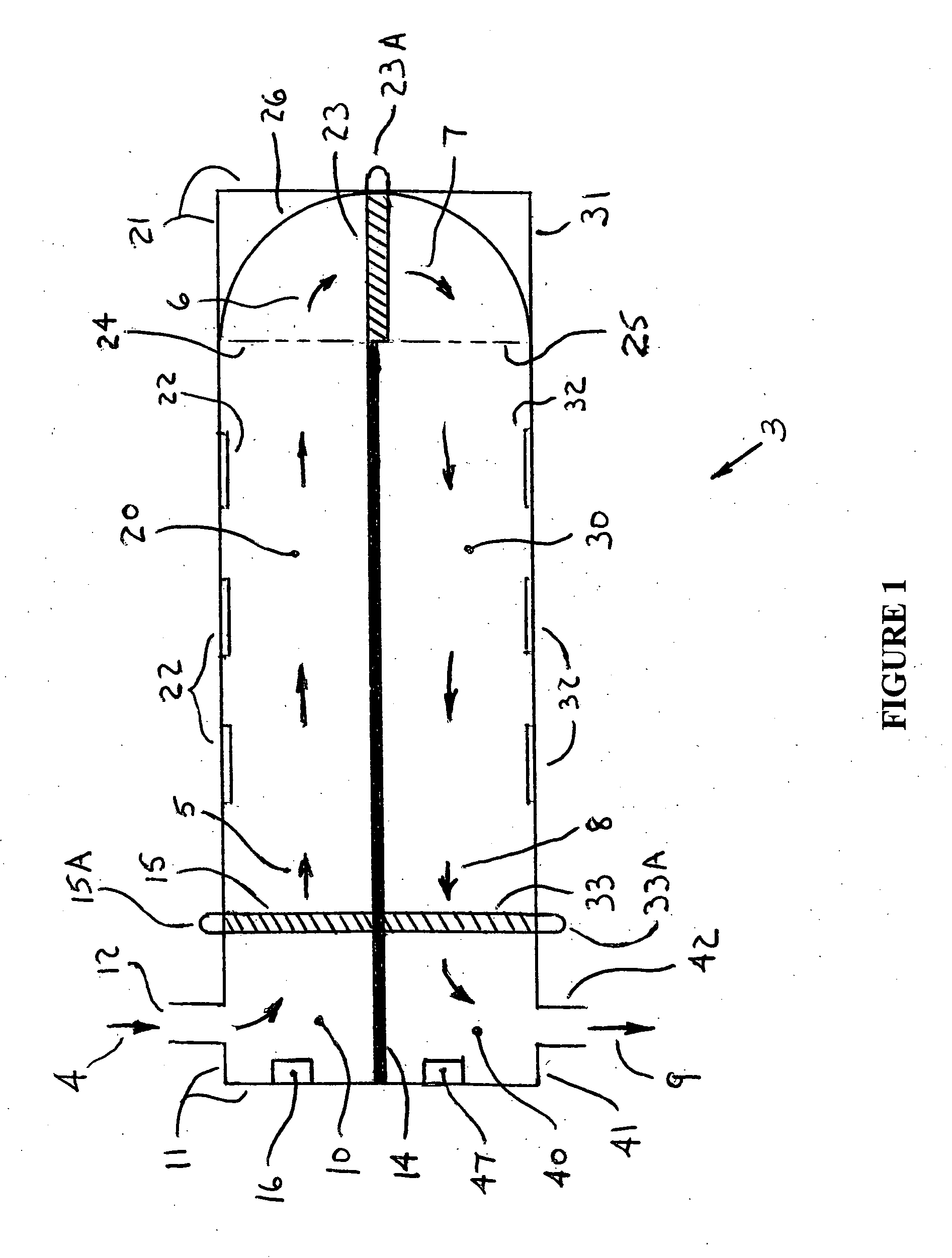

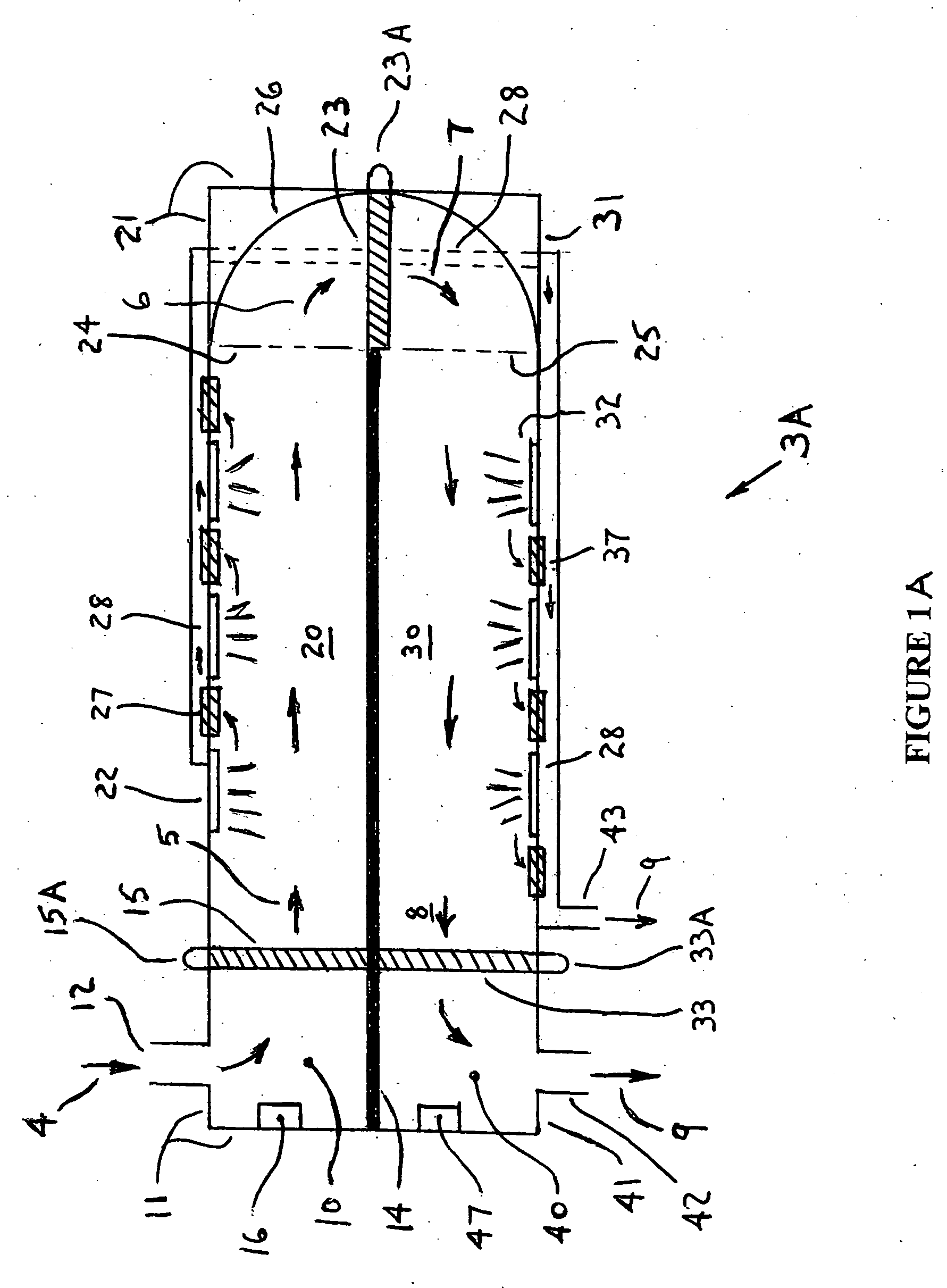

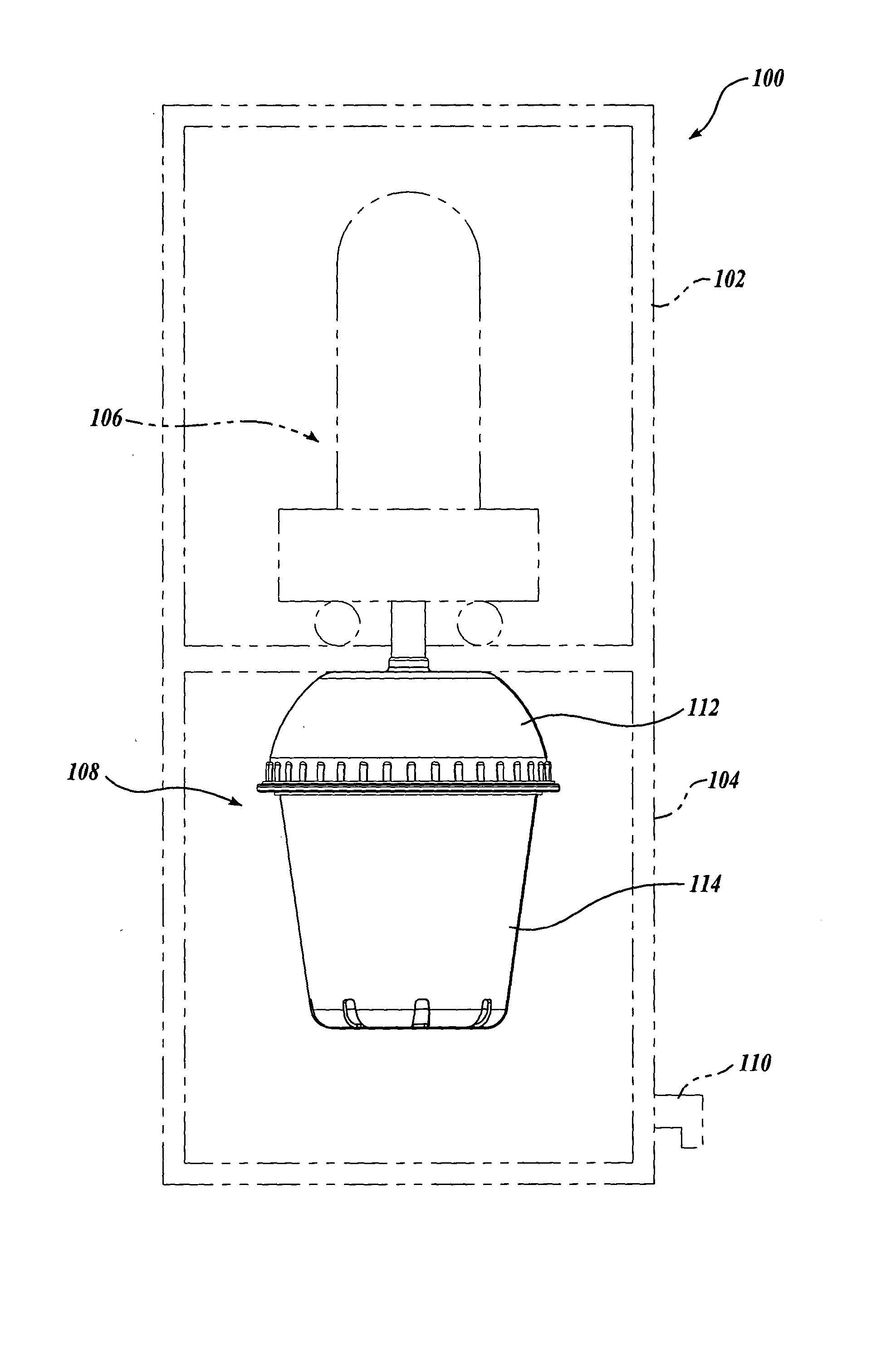

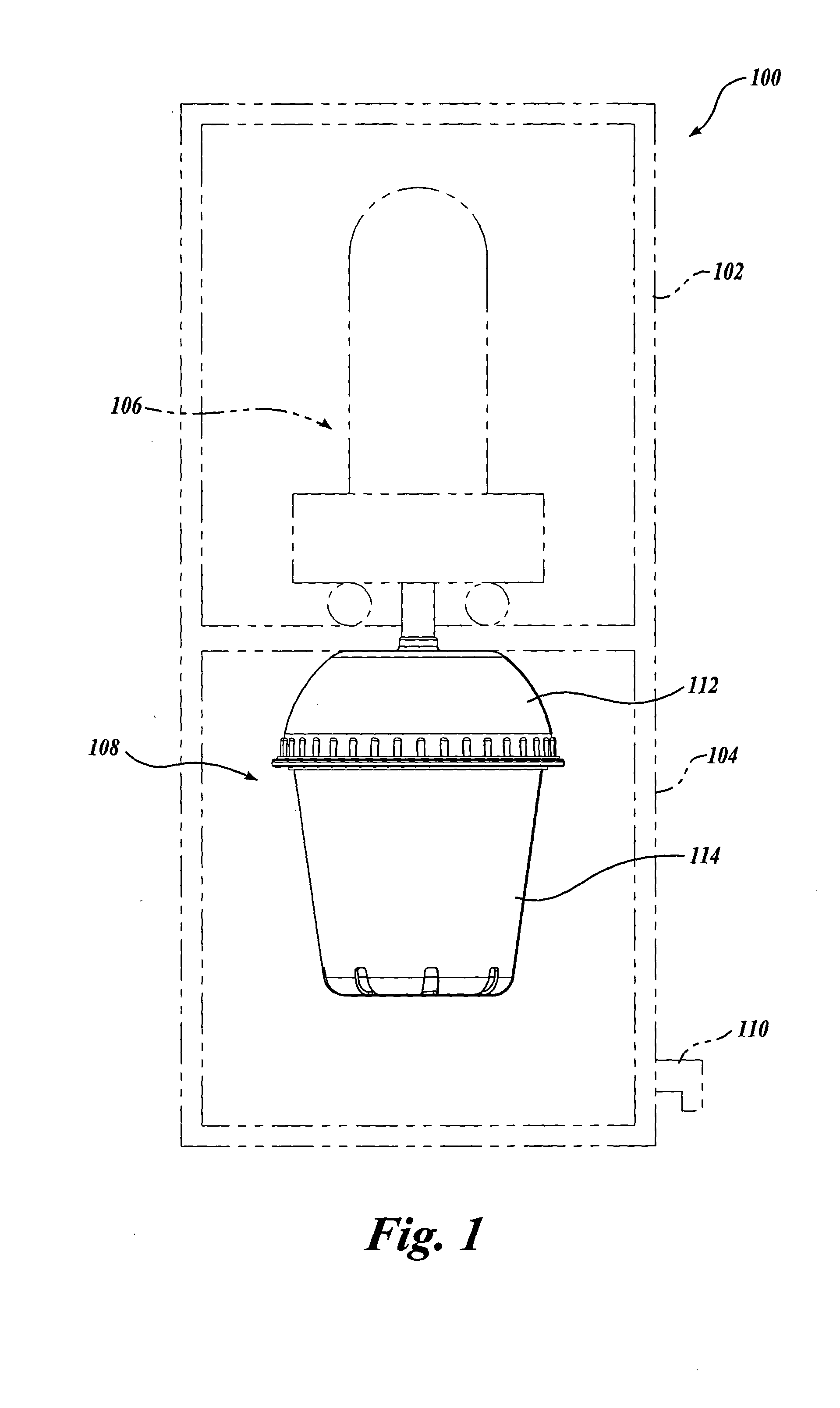

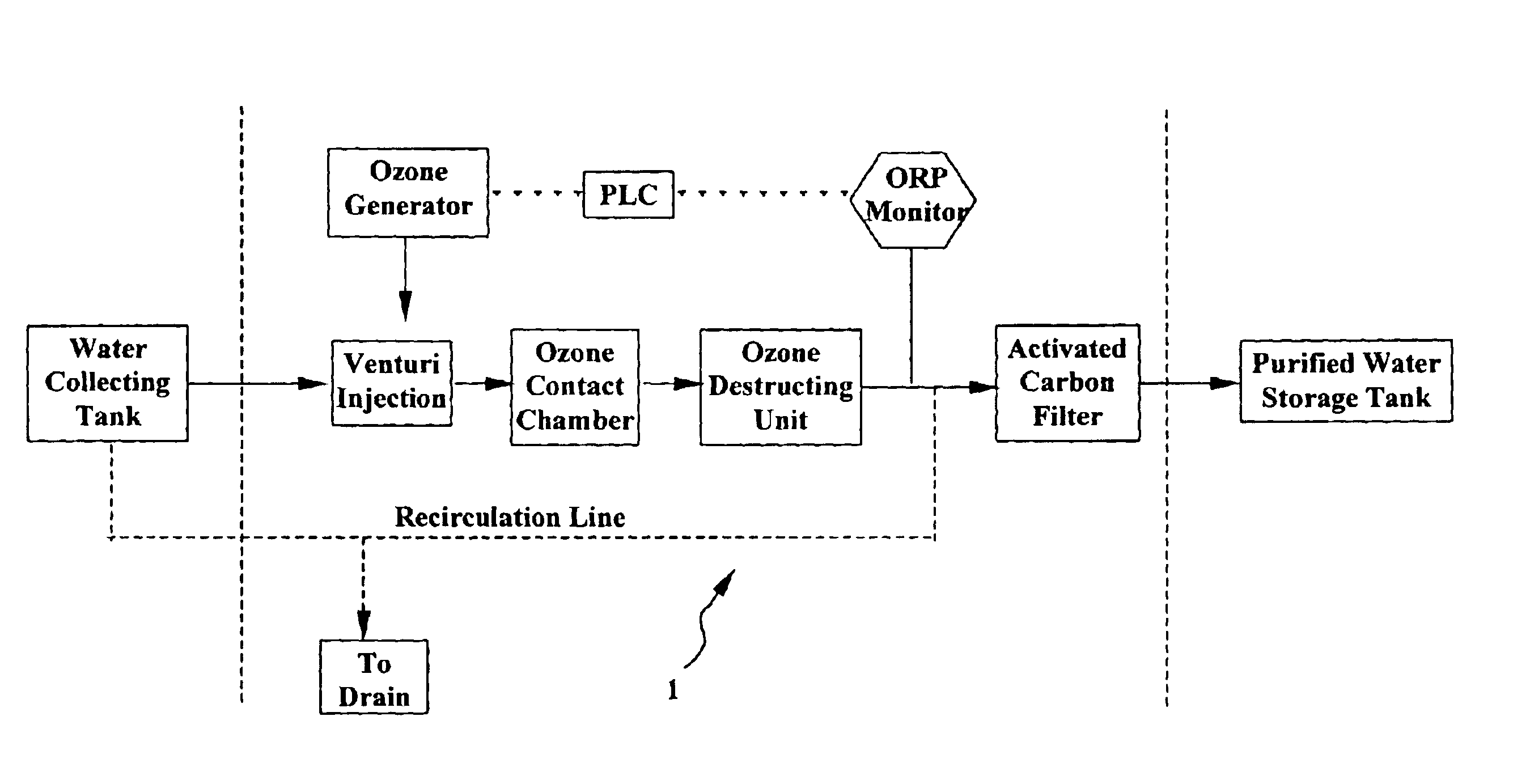

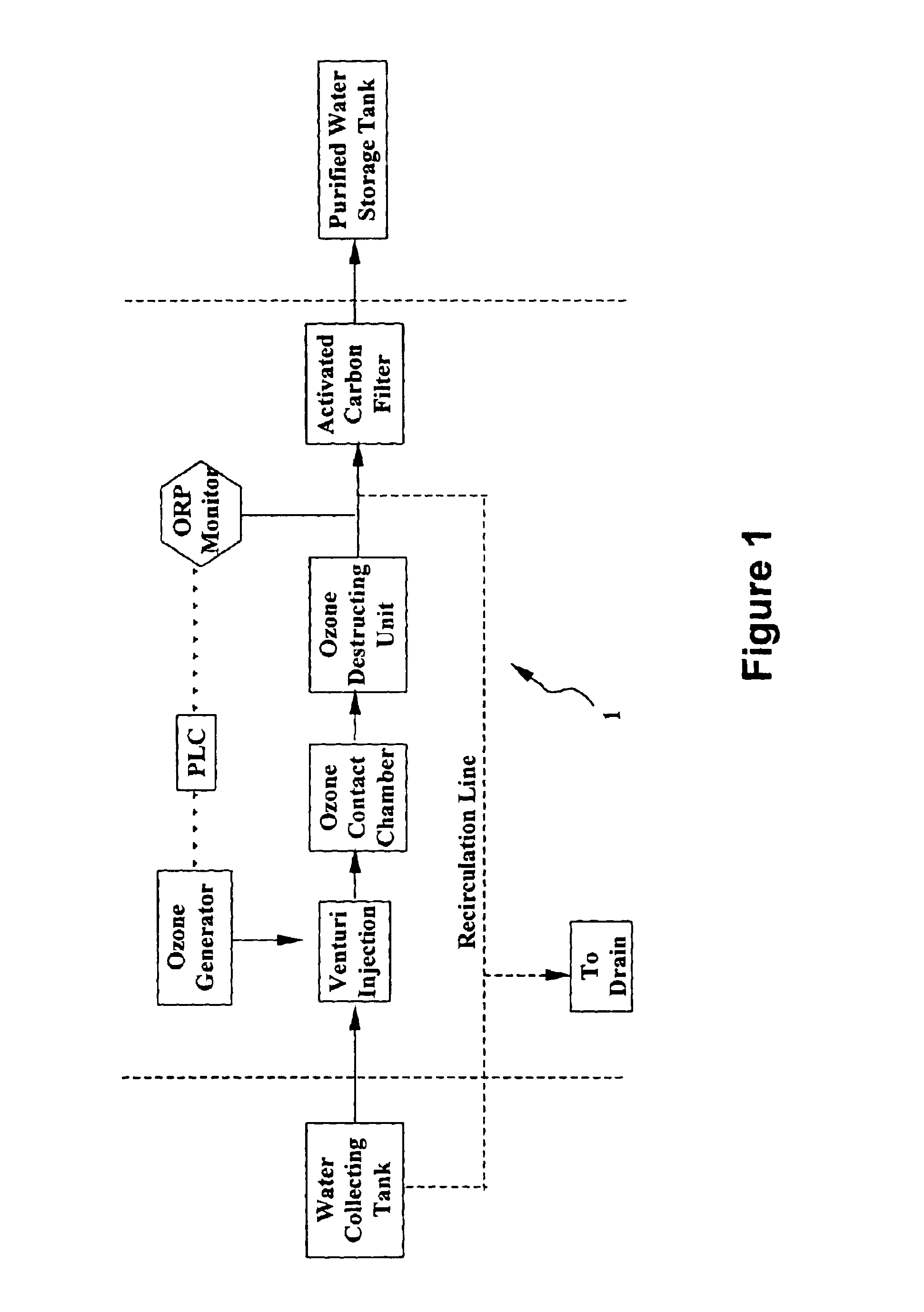

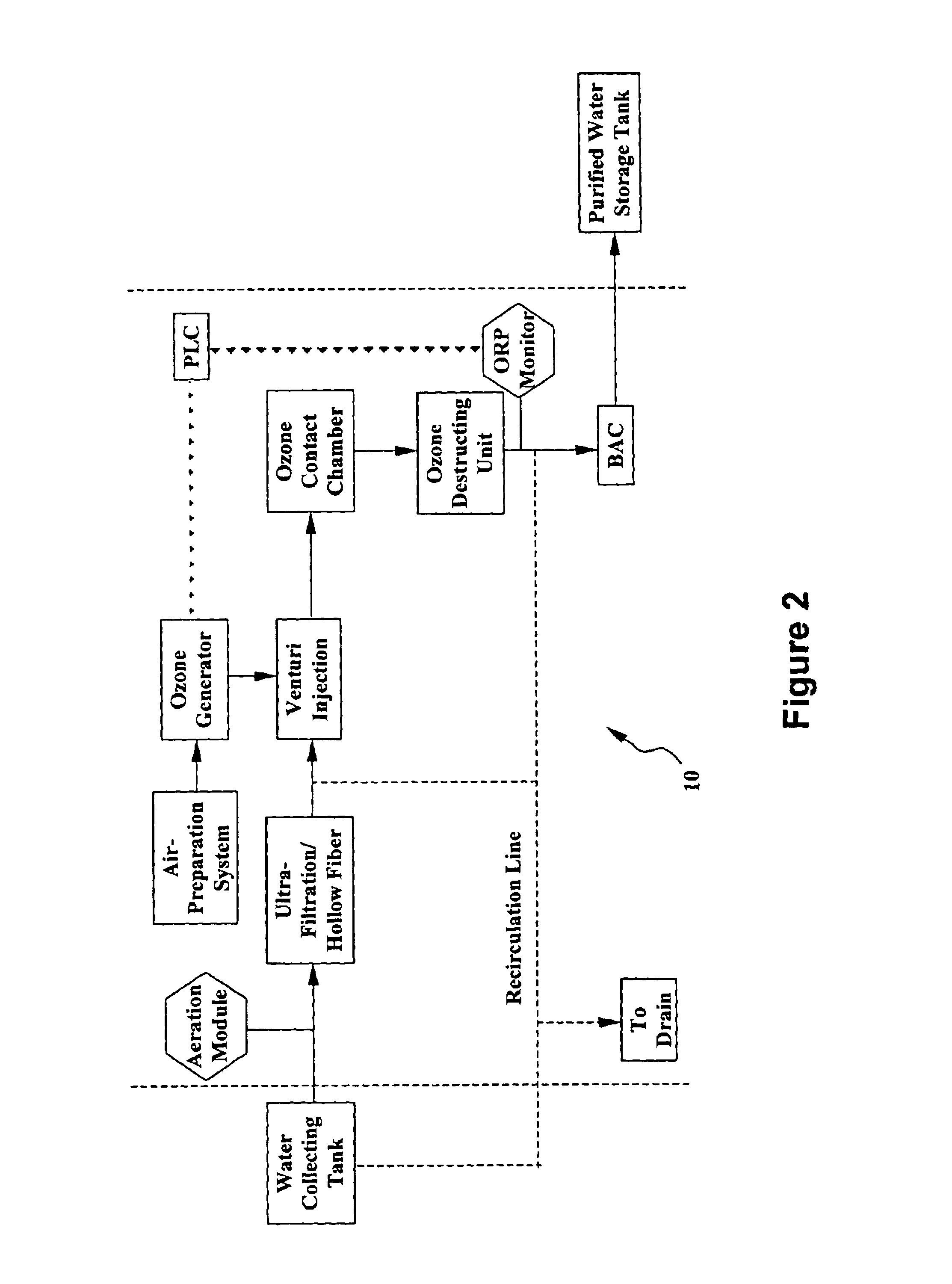

System and method for water purification

InactiveUS20040168989A1Treatment using aerobic processesSedimentation separationBiological activated carbonActivated carbon filtration

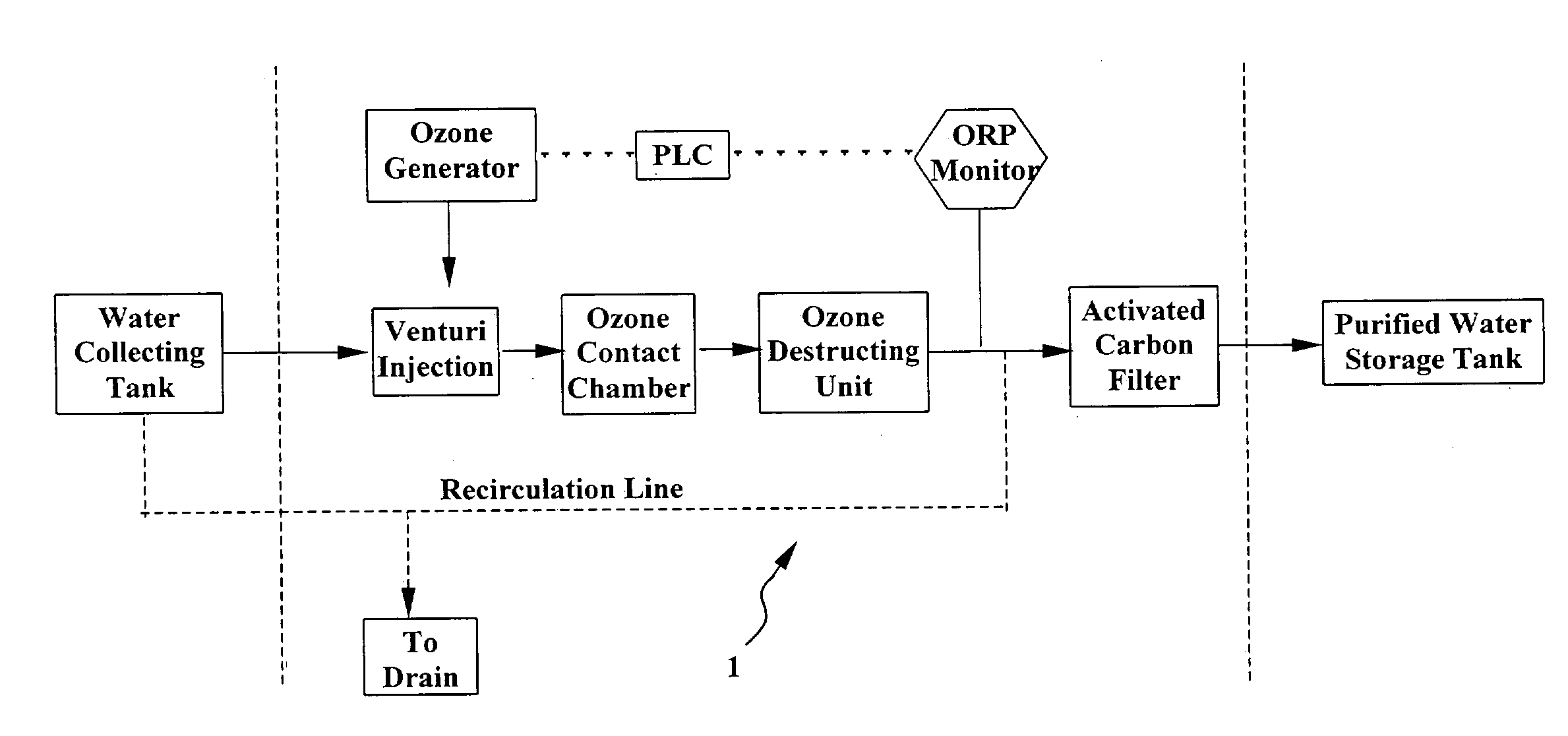

A self-contained, portable water purification system, including (a) an ozone supply, (b) an ozone contact chamber for mixing a contaminated or potentially contaminated water stream with ozone generated by such ozone supply, (c) an ozone destruction unit for destructing ozone contained in the water stream and converting said water stream into an oxygen-rich and ozone-depleted water stream, and (d) a downstream biologically active carbon filter, for receiving such oxygen-rich and ozone-depleted water stream and biologically destructing at least a portion of contaminants contained therein.

Owner:TEMPEST ENVIRONMENTAL SYST

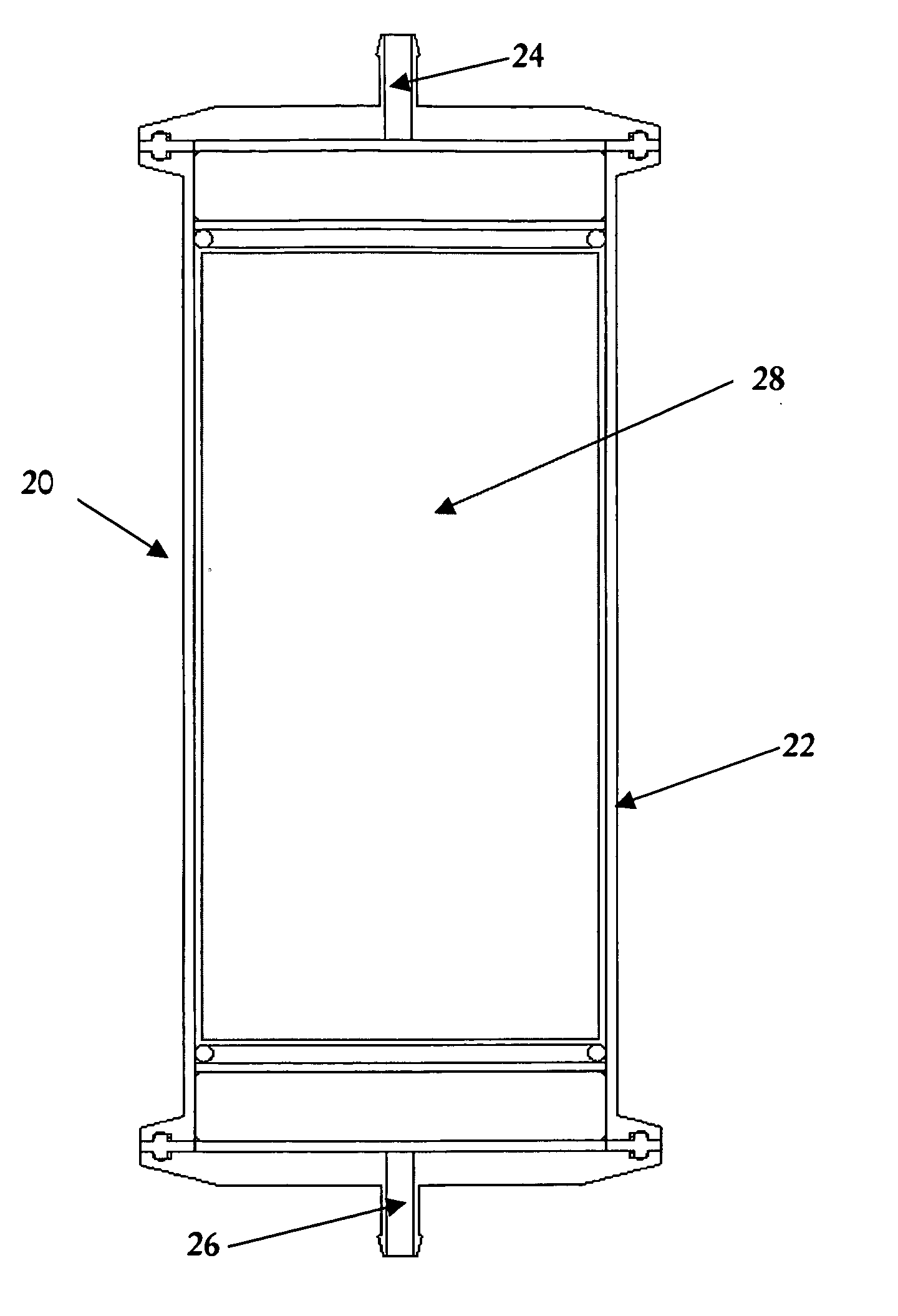

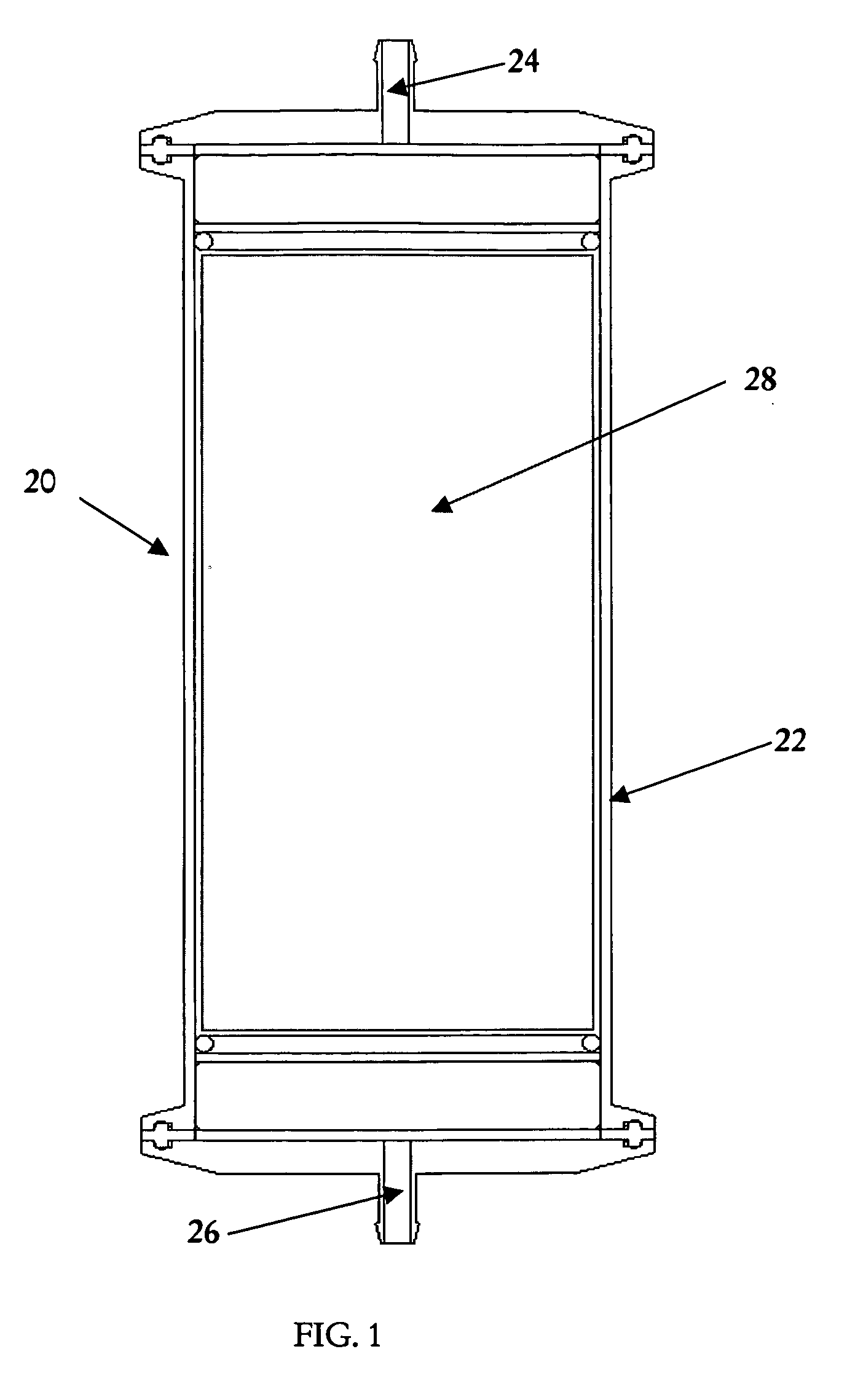

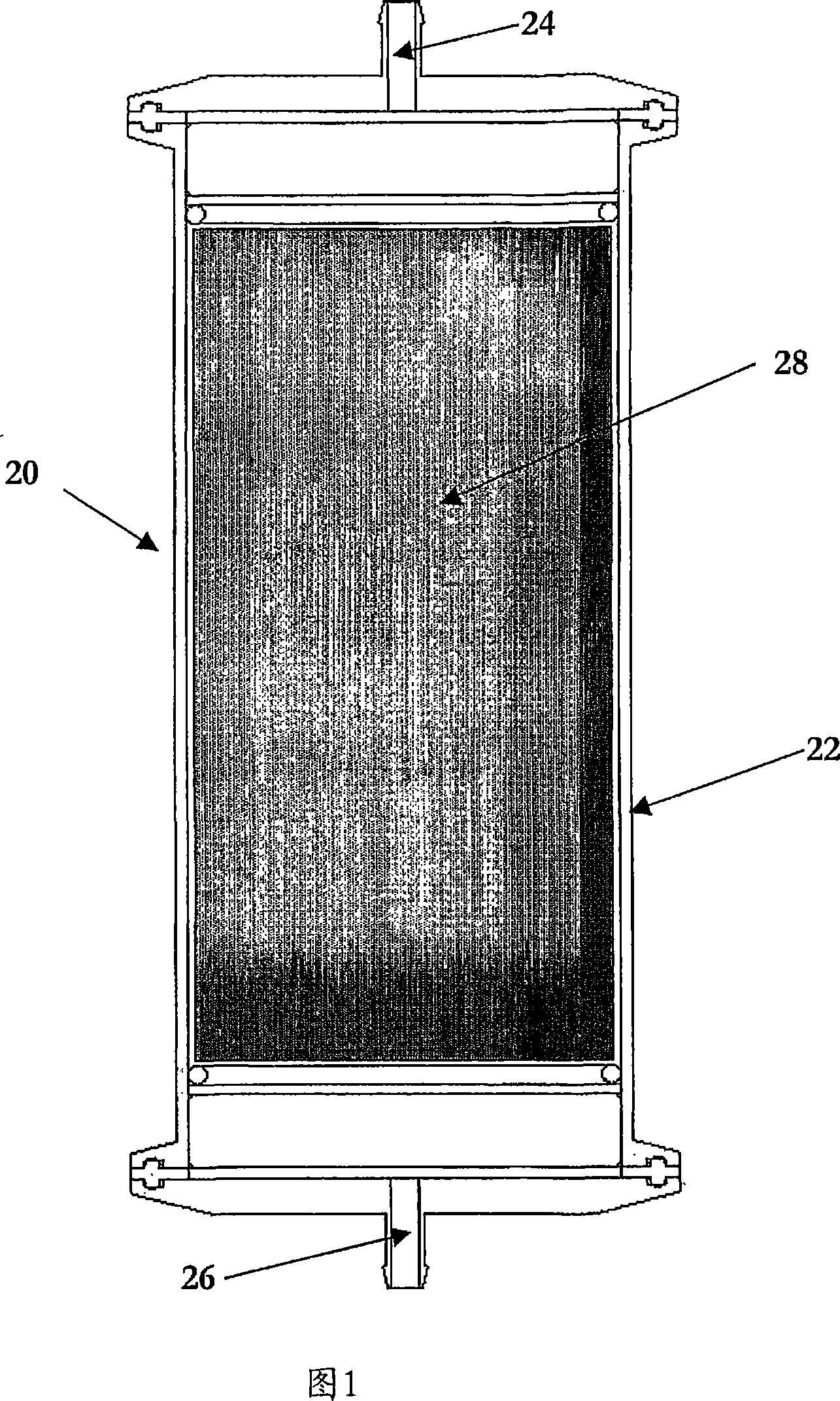

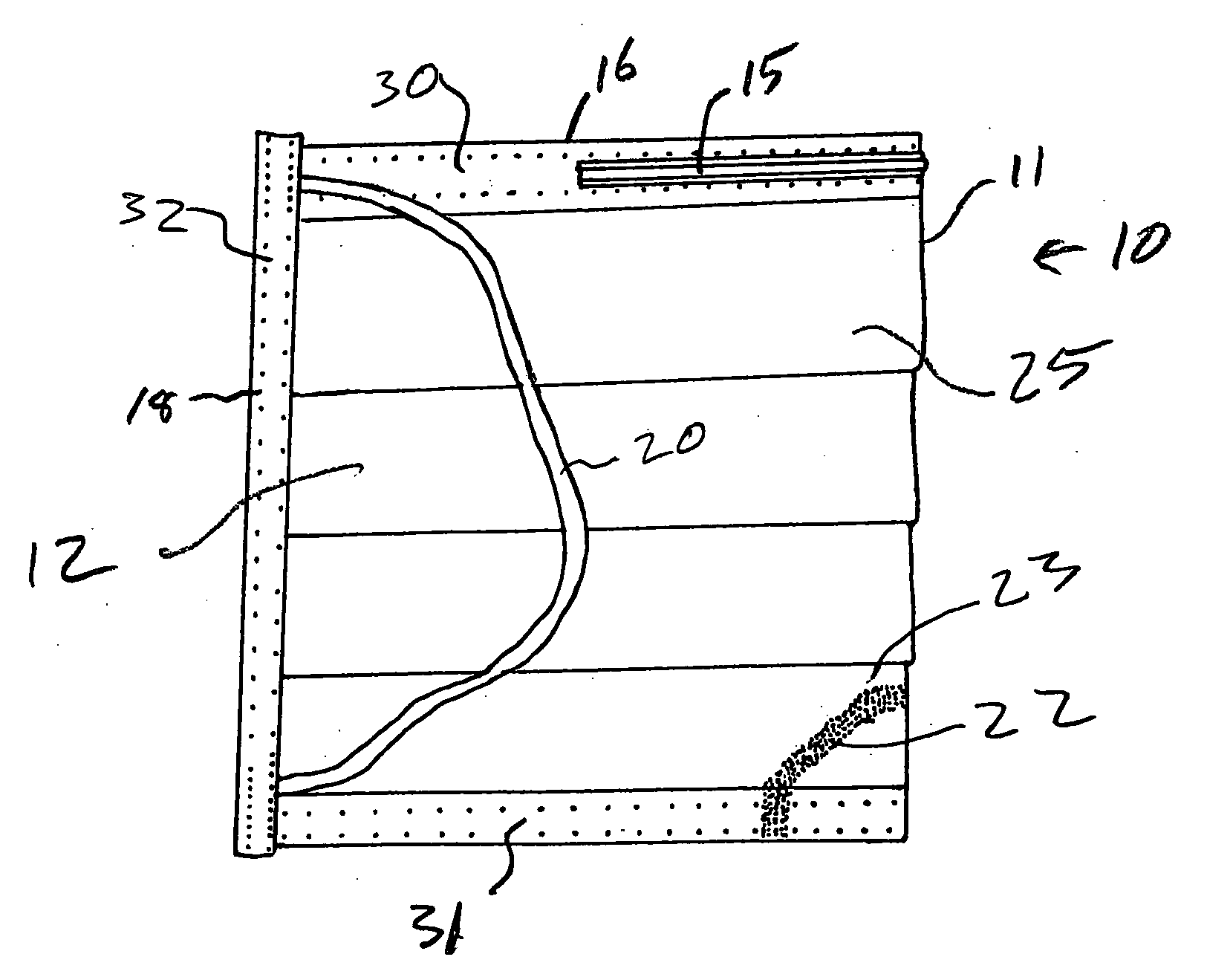

Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles

InactiveUS20050279696A1Reduce bacteriaReduce virusMembrane filtersLoose filtering material filtersWater filterActivated carbon filtration

A filter and filter material for providing or treating potable water is provided. The filter includes a housing having an inlet and an outlet, a filter material disposed within the housing, the filter material formed at least in part from a mixture of a plurality of mesoporous and microporous activated carbon particles. Preferably, at least some of the mesoporous activated carbon filter particles are coated with a cationic polymer, and even more preferably, at least some of the particles are coated with a cationic polymer and silver or a silver containing material. Kits comprising filters and information relating to the reduction, killing or removal of bacteria, viruses, microbials, and TTHM are also provided.

Owner:PUR WATER PURIFICATION PRODUCTS INC +2

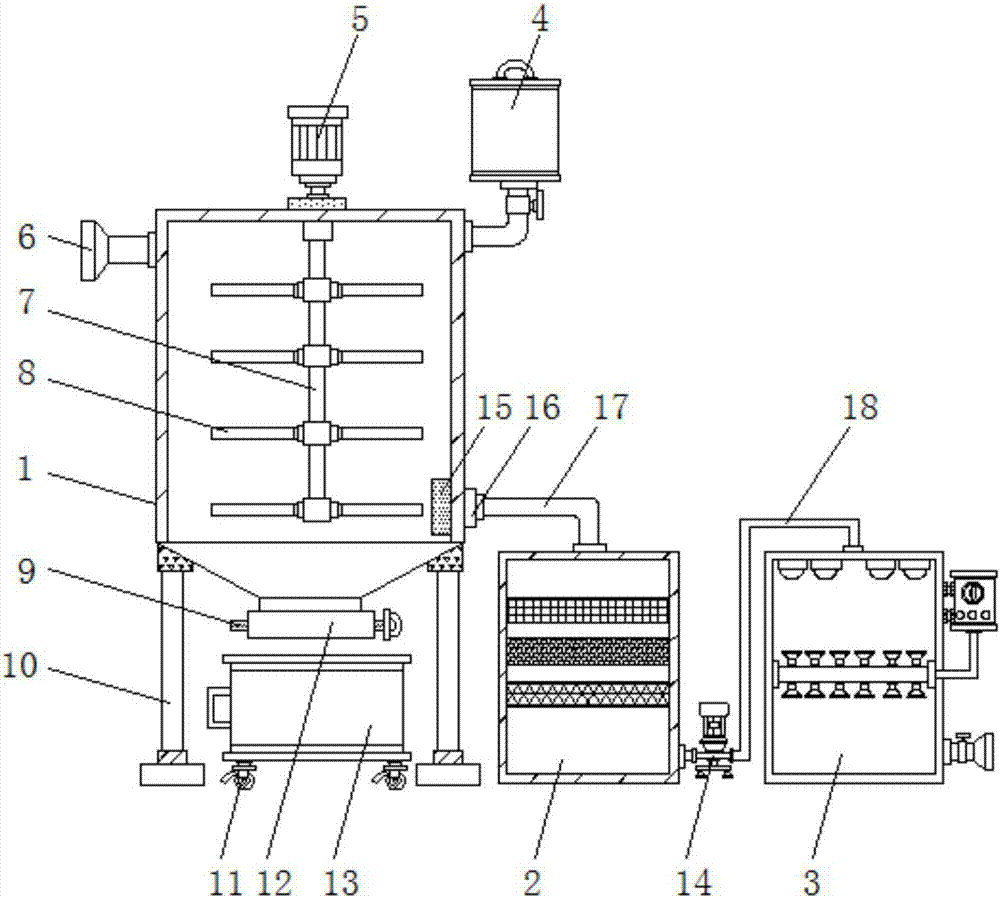

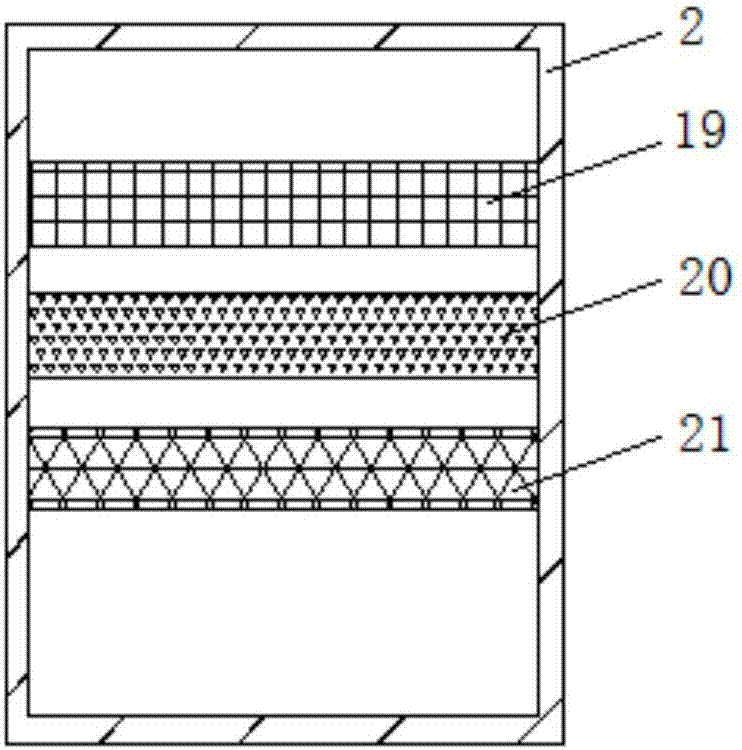

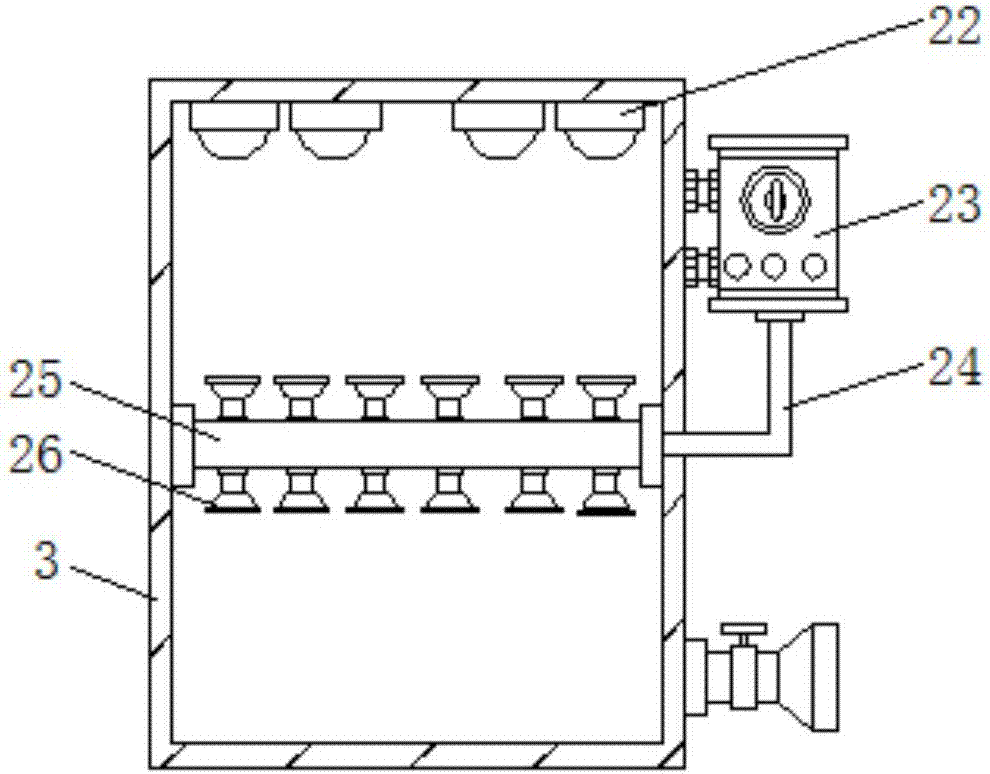

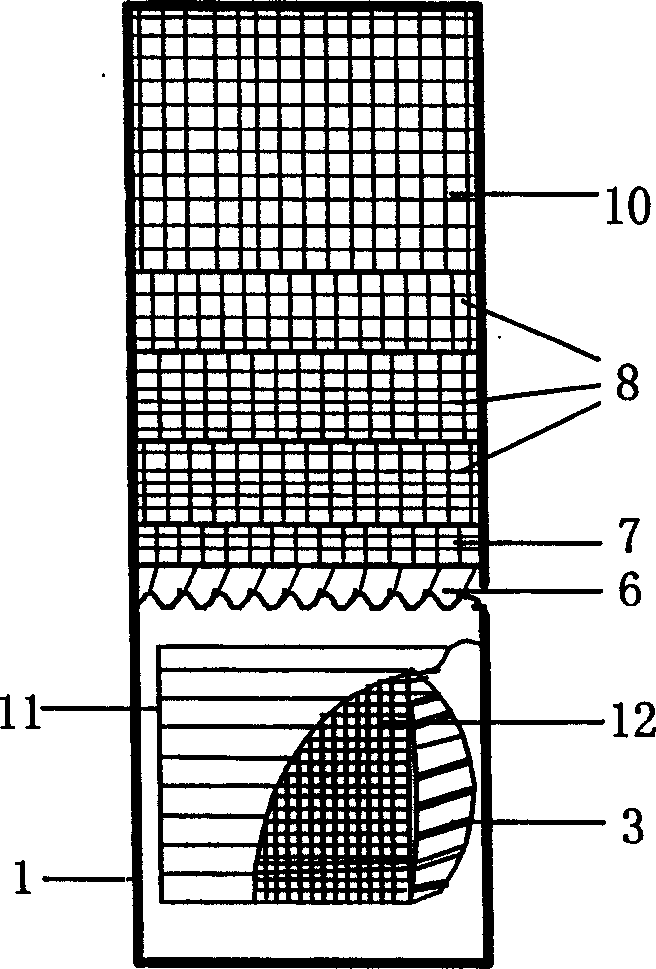

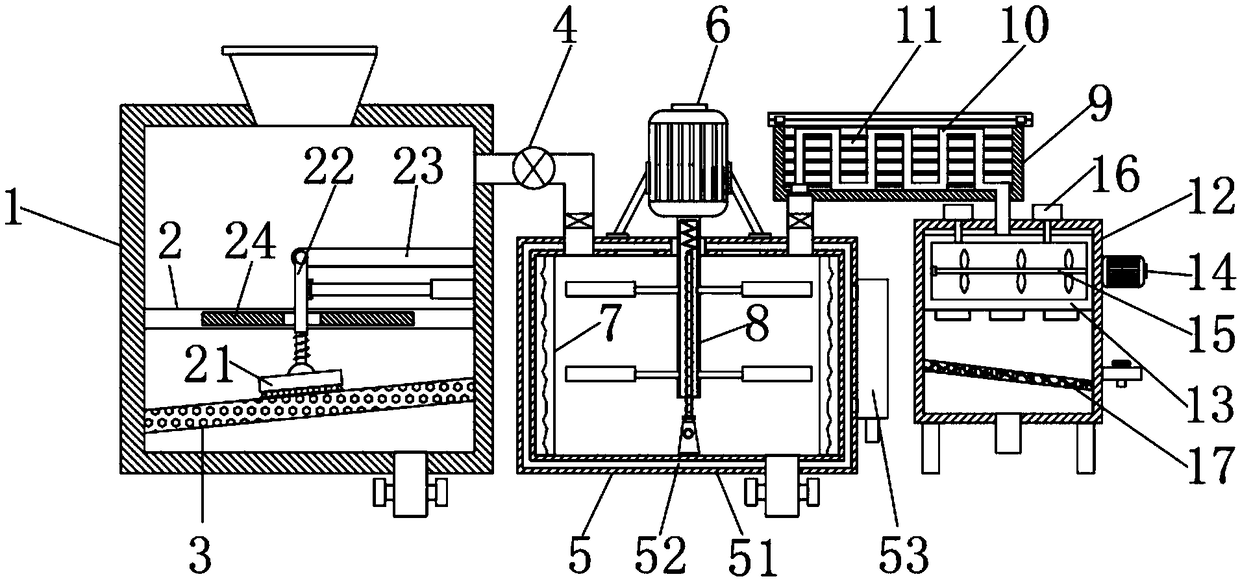

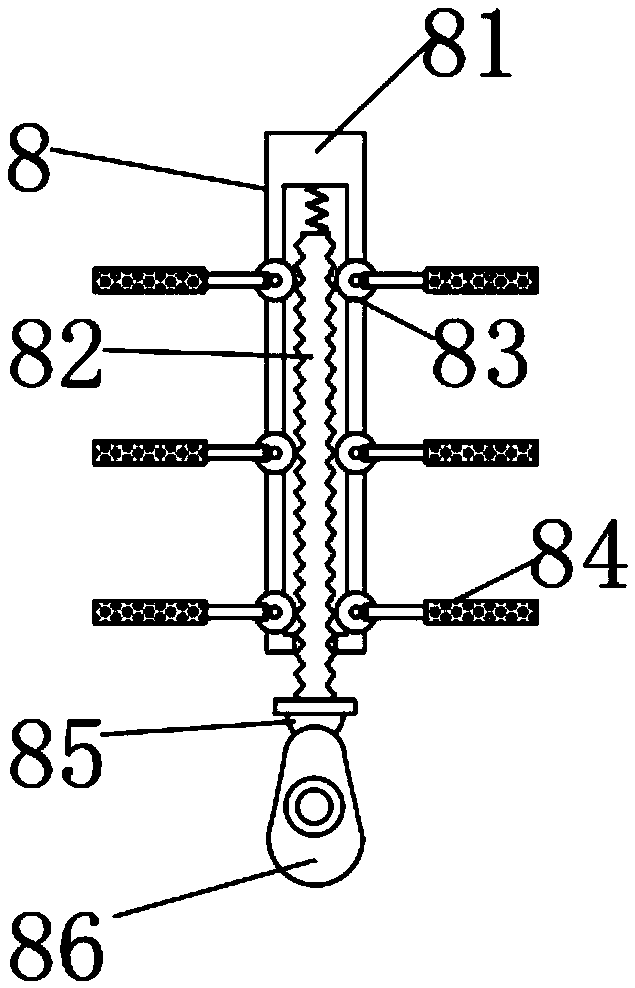

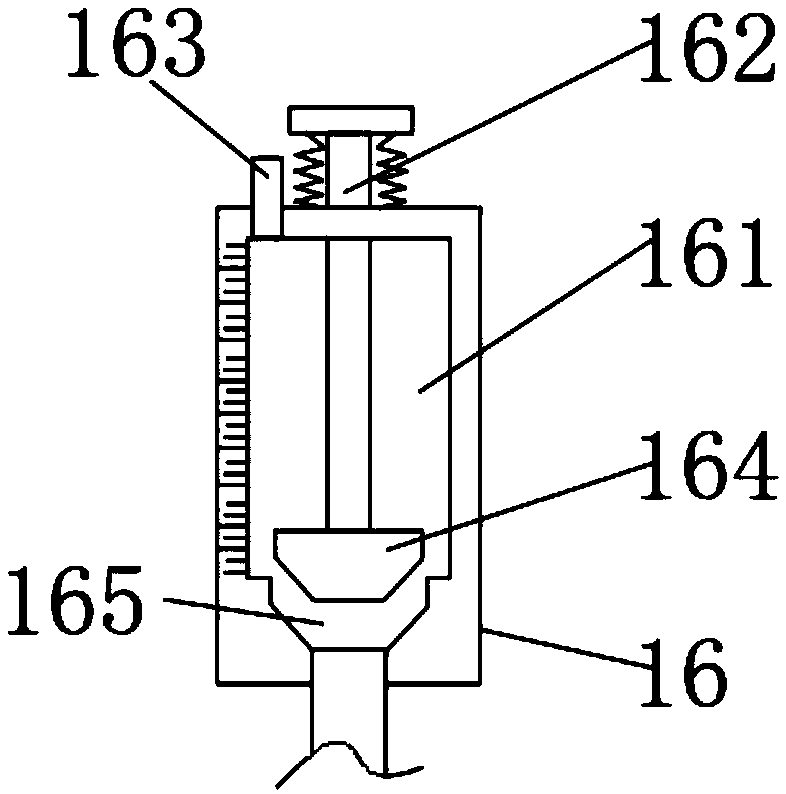

Sewage treatment unit with good practicality

InactiveCN107010792AEasy to handleRemove fullyWater/sewage treatment by irradiationSpecific water treatment objectivesSludgeActivated carbon filtration

The invention discloses a sewage treatment unit with good practicality. The sewage treatment unit comprises a settling box, a purifying box and a disinfection box, wherein the top end of one side of the settling box is provided with a chemical reagent tank; the top of the settling box is provided with a stirring motor; a sludge discharge outlet is formed in the bottom end of the settling box; the interior of the purifying box is provided with, from top to bottom, a magnet adsorption screen, a biomembrane filter screen and an active carbon filter screen; the sidewall of the disinfection box is provided with an ozone generator; and gas-distributing pipes are arranged in the disinfection box. The sewage treatment unit provided by the invention can effectively eliminate heavy metals, microbes, organic harmful substances, particulate matters and other impurities in water, is capable of removing pigments and peculiar smell in water, and has improved sewage treatment effect; and since the ozone generator is mounted on the sidewall of the disinfection box, ozone generated by the ozone generator can be used for sterilization and disinfection of purified clear water after purification of sewage, so sewage is allowed to reach discharge standard.

Owner:盐城百利豪环保机械制造有限公司

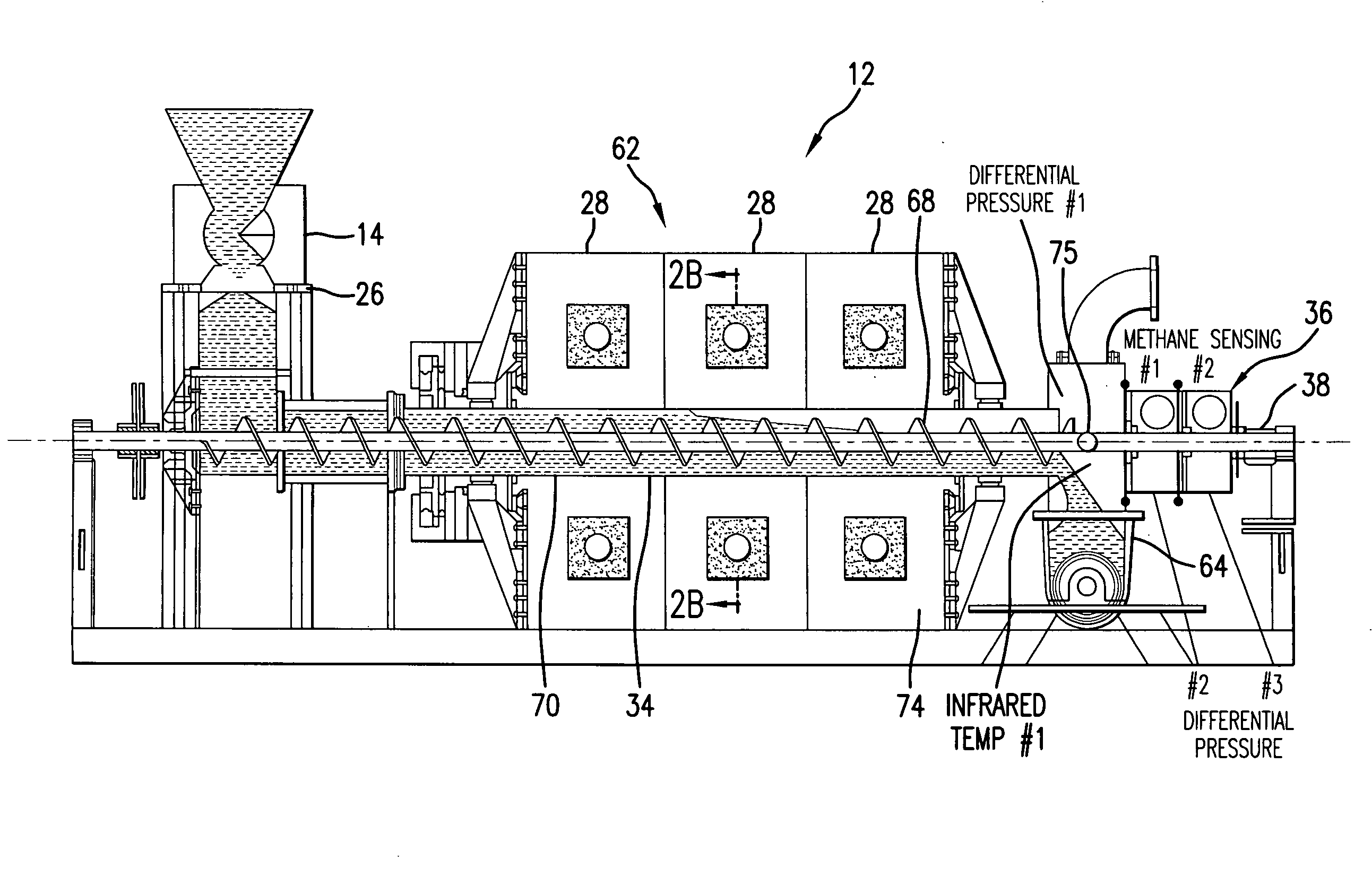

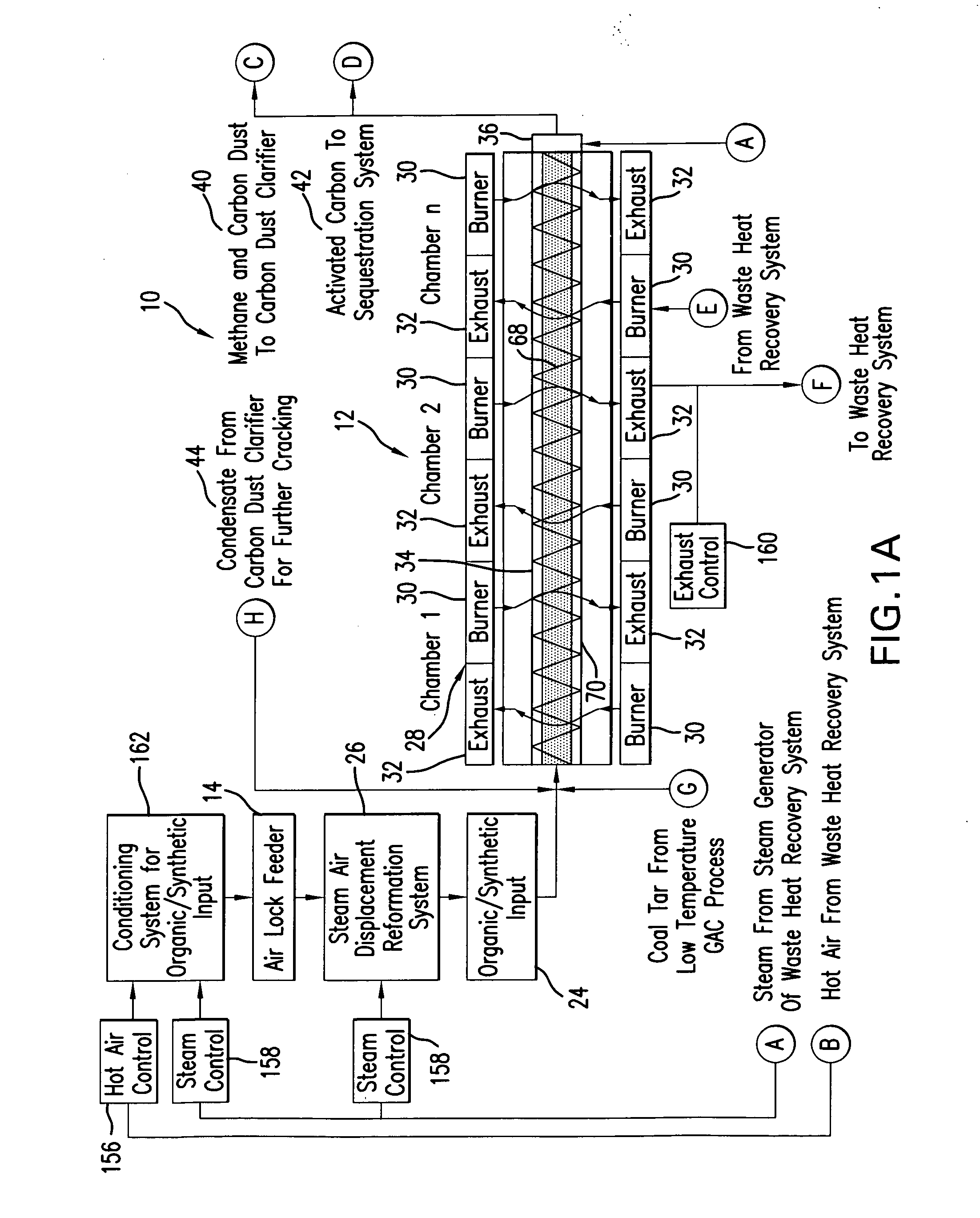

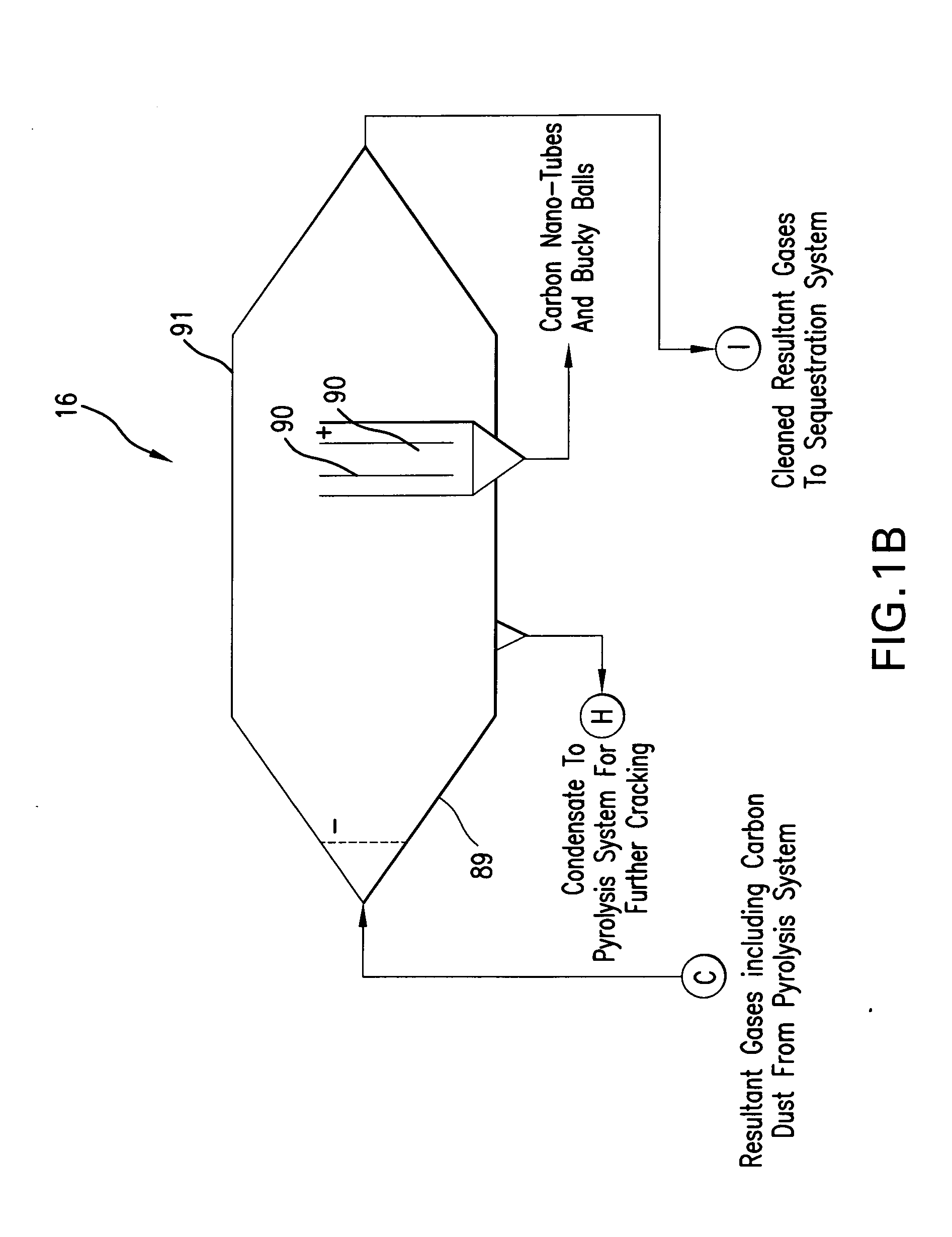

Pyrolysis Systems, Methods, and Resultants Derived Therefrom

ActiveUS20080286557A1Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentActivated carbon filtrationSilicon dioxide

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

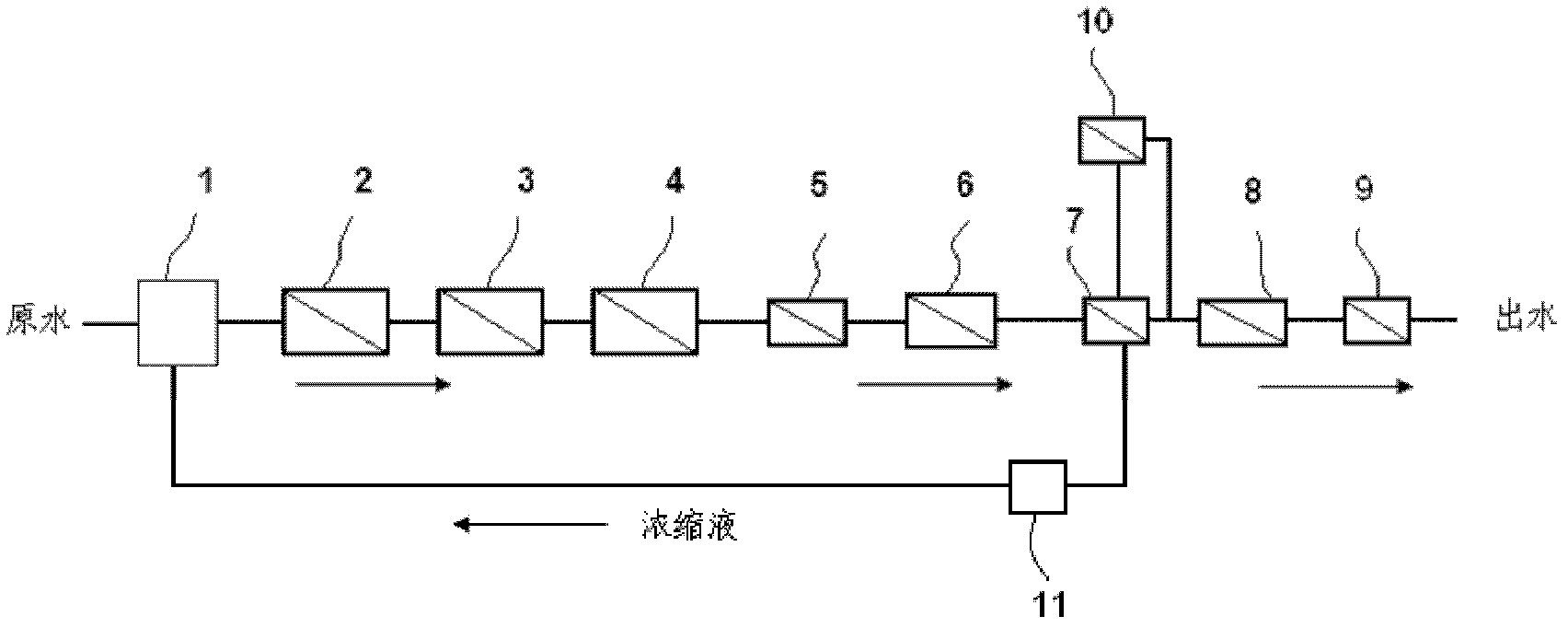

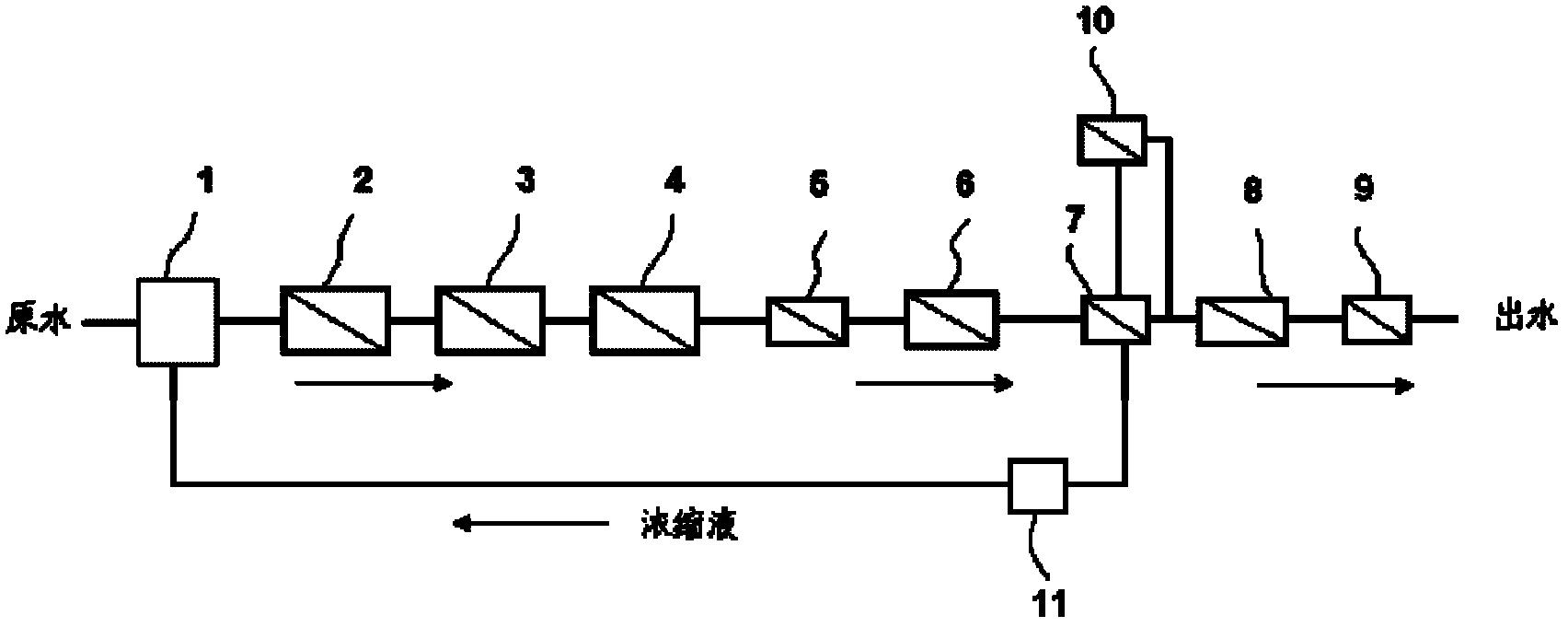

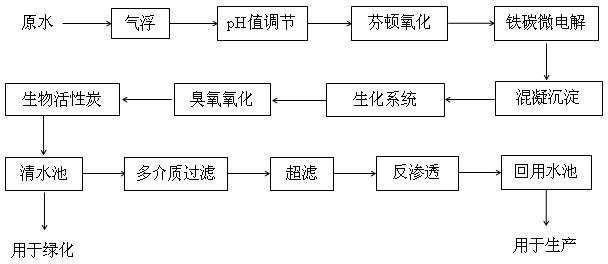

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

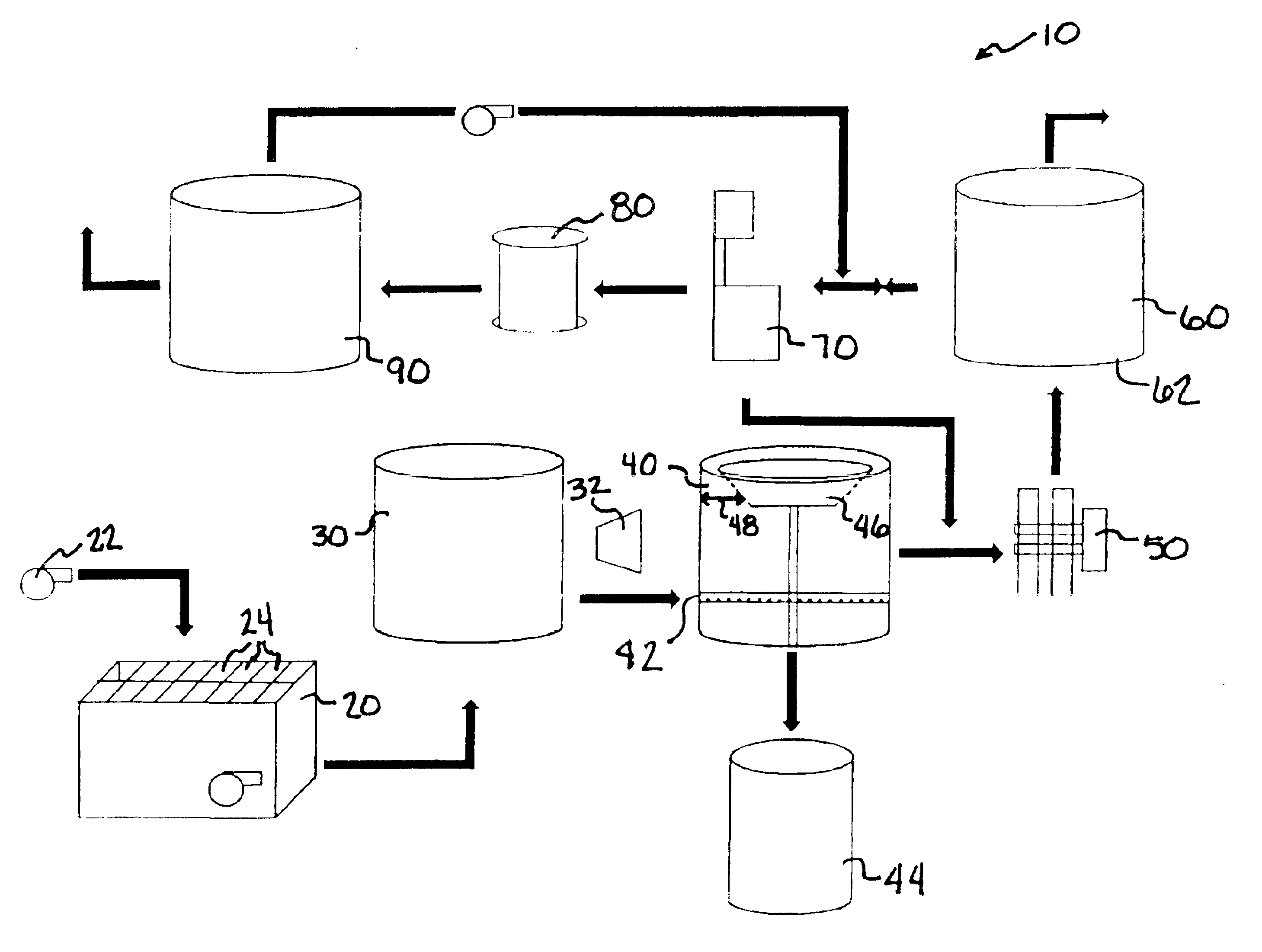

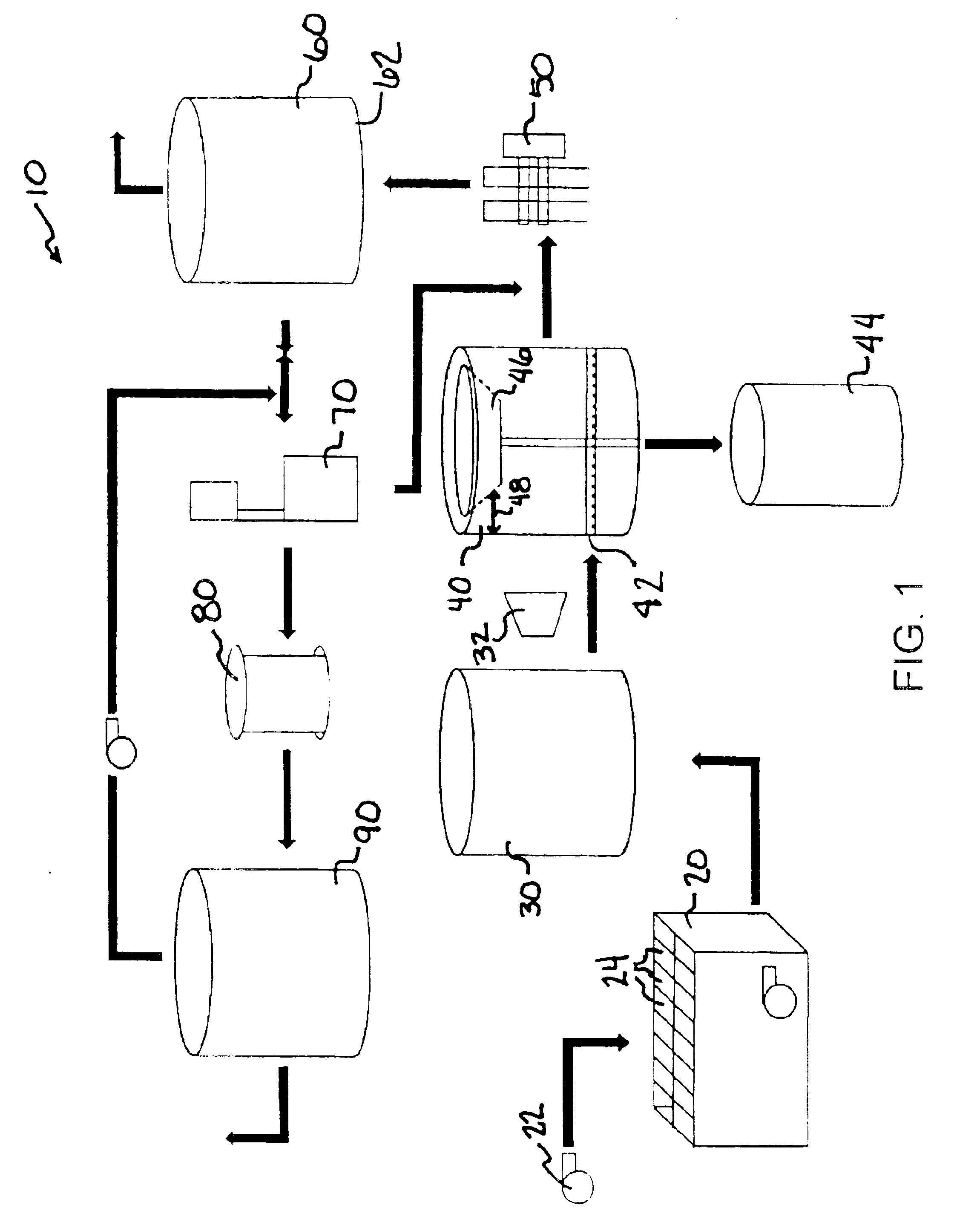

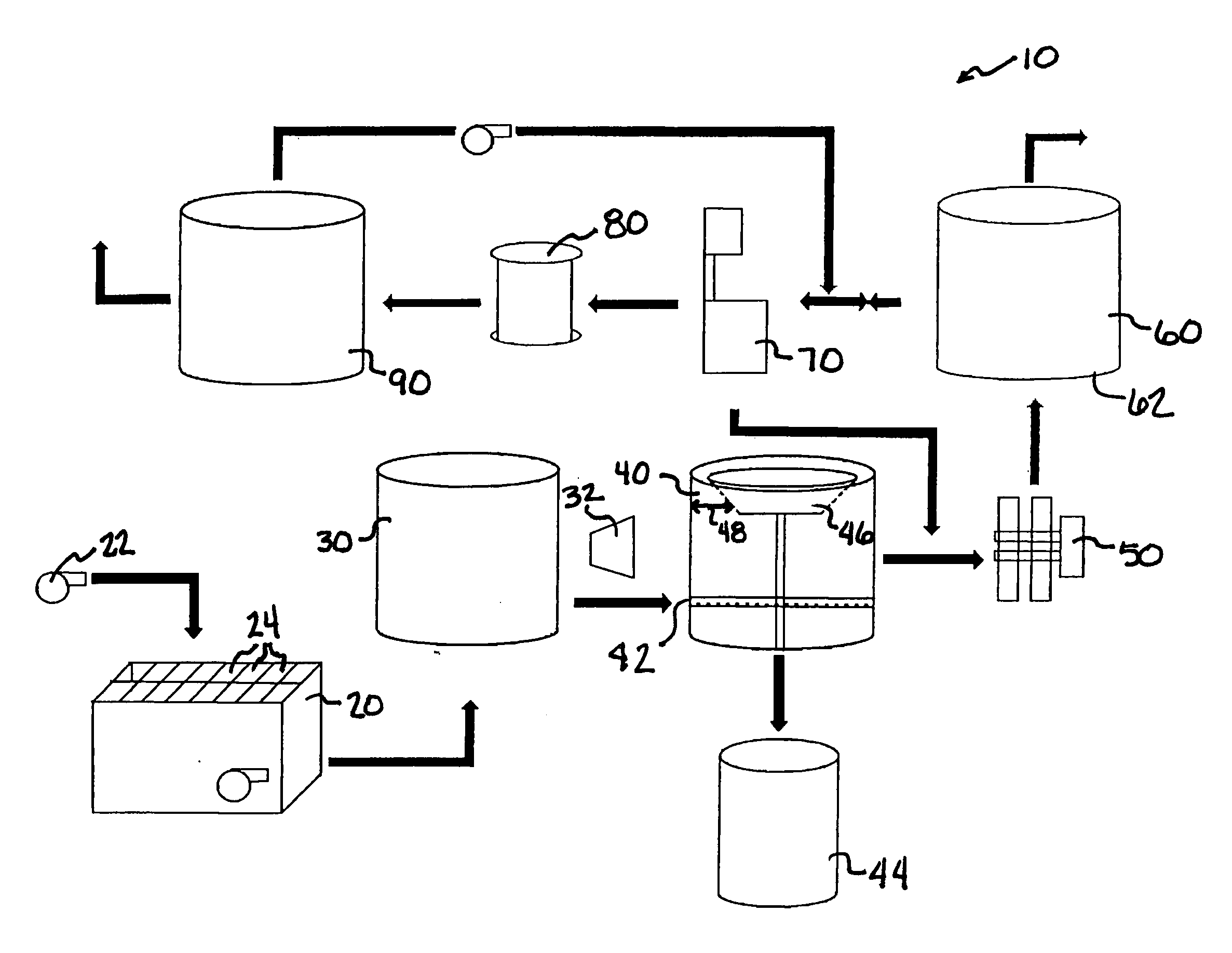

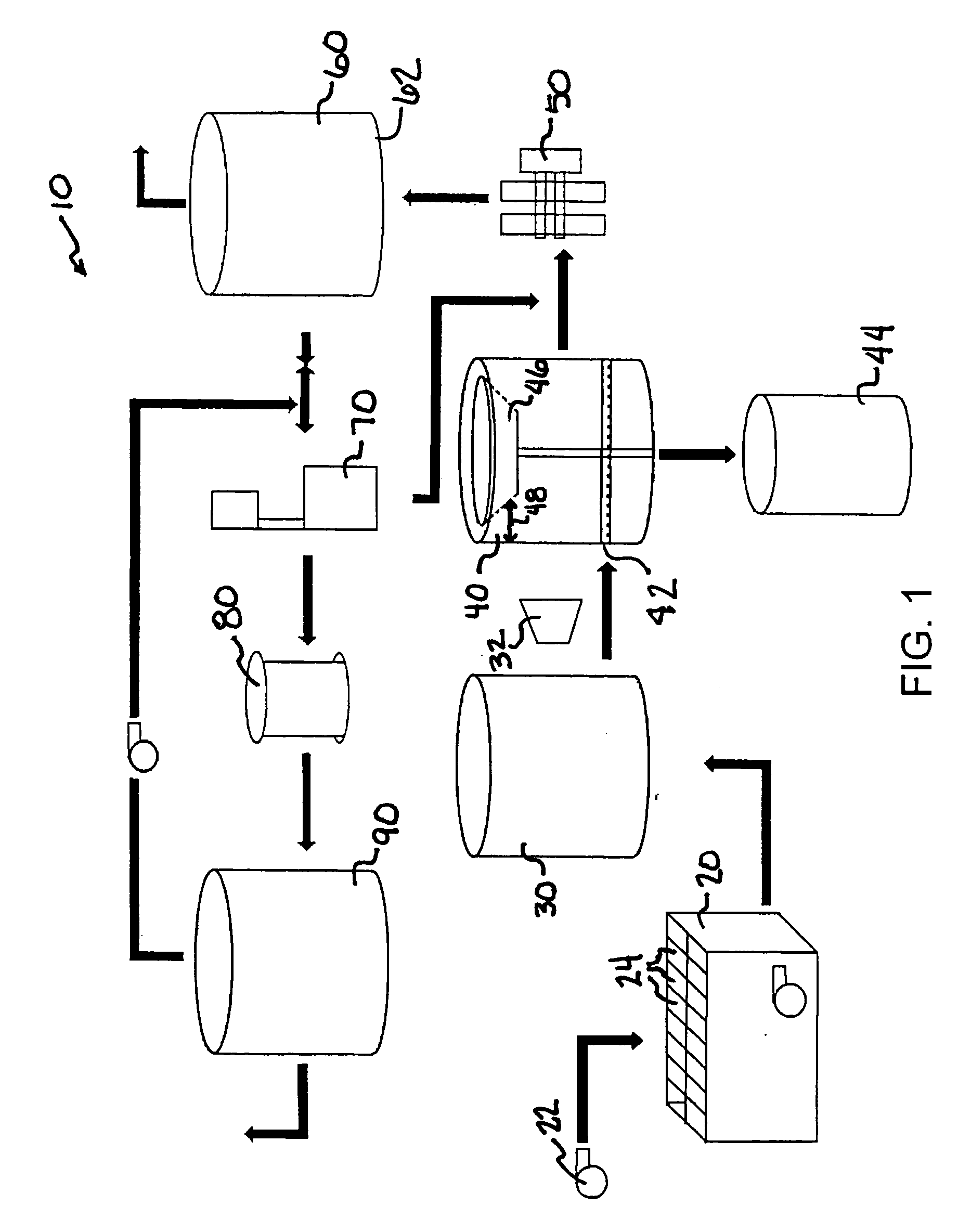

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

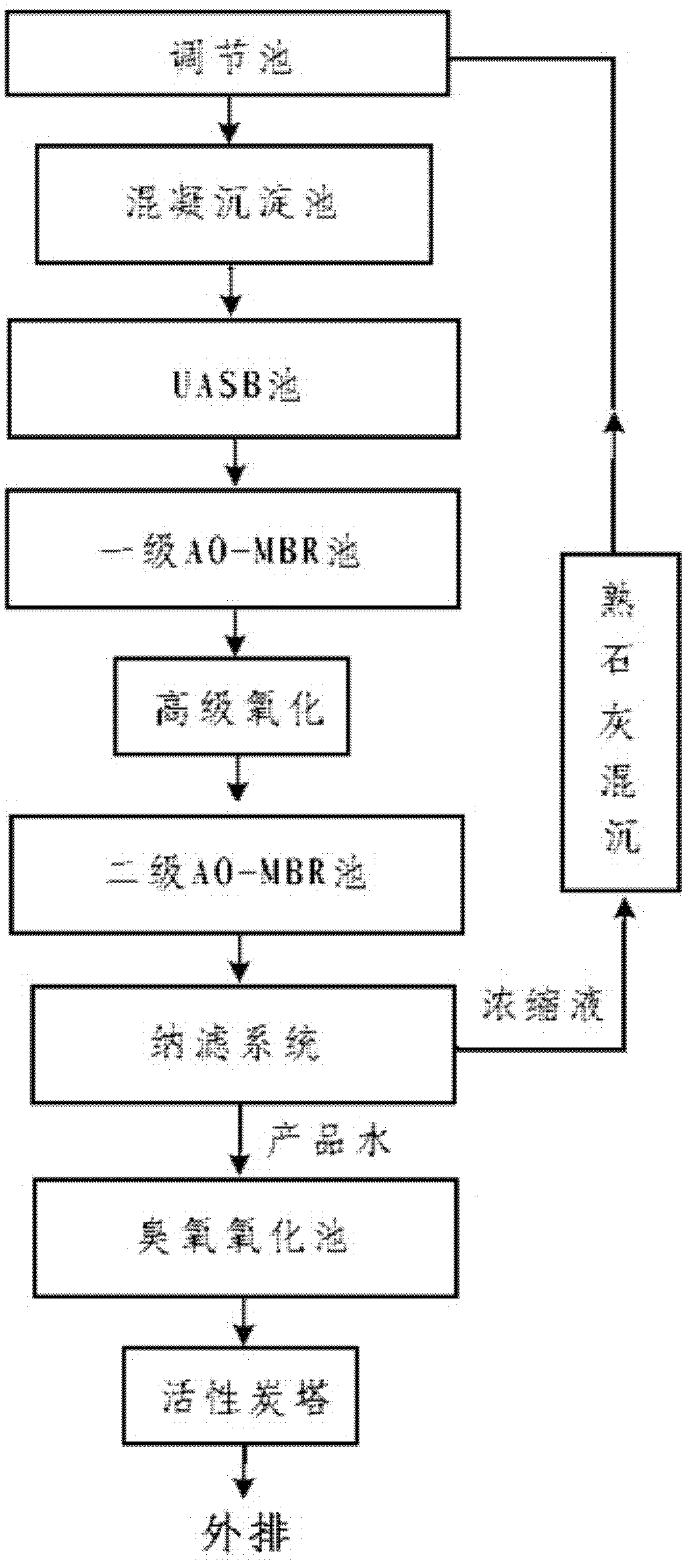

Advanced treatment system and method for high-concentration percolate in comprehensive garbage disposal plant

InactiveCN102503046AEasy to handleRequirements to meet emission concentration limitsMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention discloses an advanced treatment system and method for high-concentration percolate in a comprehensive garbage disposal plant, belonging to the field of industrial waste water treatment. The system is formed by connecting a regulating tank, a coagulative precipitation tank, an upflow anaerobic sludge bed reaction tank, a primary anoxic and aerobic membrane bioreactor, advanced oxidation treatment equipment, a secondary anoxic and aerobic membrane bioreactor, nanofiltration membrane treatment equipment, an ozone contact tank and an active carbon filtering tower in sequence. According to the system, garbage percolate can be treated comprehensively, different pollutants in garbage percolate are treated in a classified way by combining physical, chemical and biological treatment,advanced treatment of garbage percolate is realized, and classified treatment for removing pollutants such as organic matters, heavy metals, ammonia, nitrogen and the like is performed, so that treated effluent strictly reaches the requirement of water pollution discharge degree limit in the Household Garbage Landfill Pollution Control Standard, the system runs stably for a long time, and treatment cost is lower than that of a secondary disc pipe reverse osmosis membrane process.

Owner:BEIJING YIPU INT WATER AFFAIRS

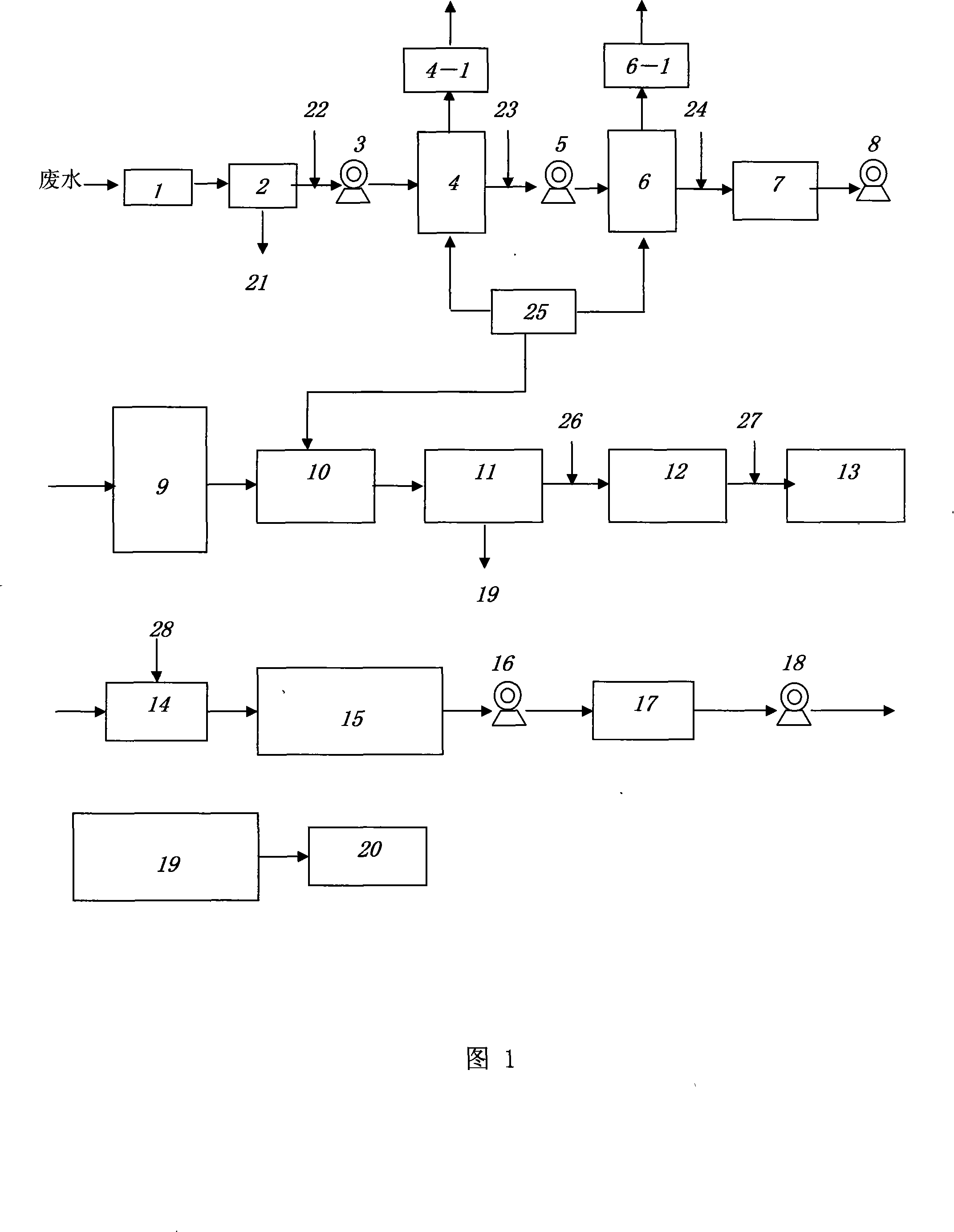

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

Atmospheric molecular respirator

InactiveUS20100111792A1Purifying substantial volumes of room airRobust methodProductsGas treatmentActivated carbon filtrationAtmospherics

An apparatus for removing contaminants from air, including nitrogen oxides, carbon monoxide, carbon dioxide, and sulphur dioxide. In one of the chambers of a multi-chambered enclosure, polluted inlet air is exposed to one or more first light sources emitting light at wavelengths less than or equal to 242.3 nm to cause dissociation of contaminant molecules, creating ozone plus remaining atoms. The remaining atoms are largely filtered by activated charcoal filters having an appropriate thickness which is sized to achieve suitable dwell times, and which also serves as an oxygen rich medium permitting the ozone generated to undergo atomic rearrangement, whereby ozone molecules (O3) and atomic oxygen atoms (O) form oxygen molecules (O2). In another downstream chamber, the air flow is exposed to one or more second light sources emitting light at wavelengths greater than 242.3 nm but less than 280 nm, causing conversion of remaining ozone into oxygen molecules.

Owner:NELSON EDWARD D

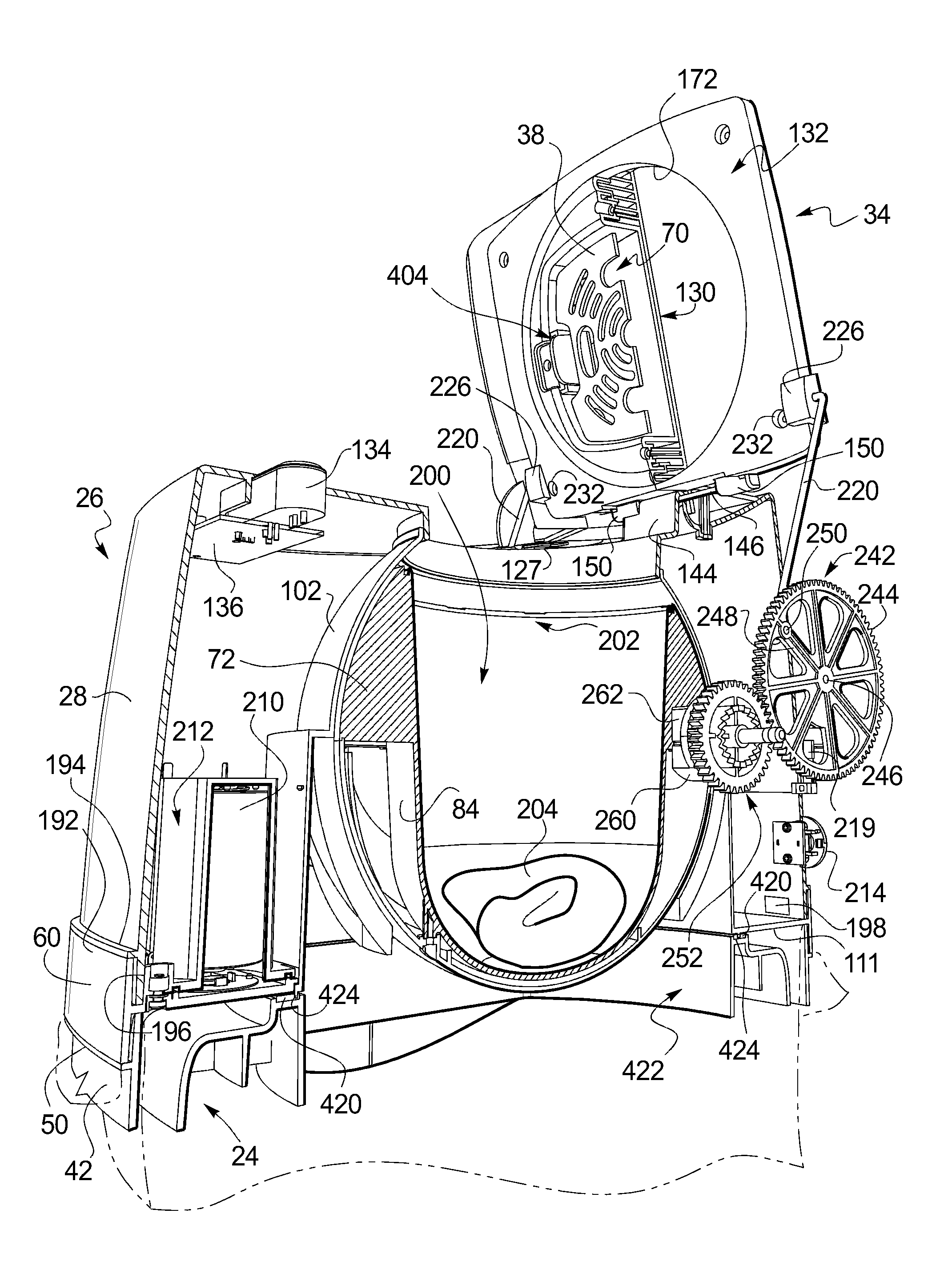

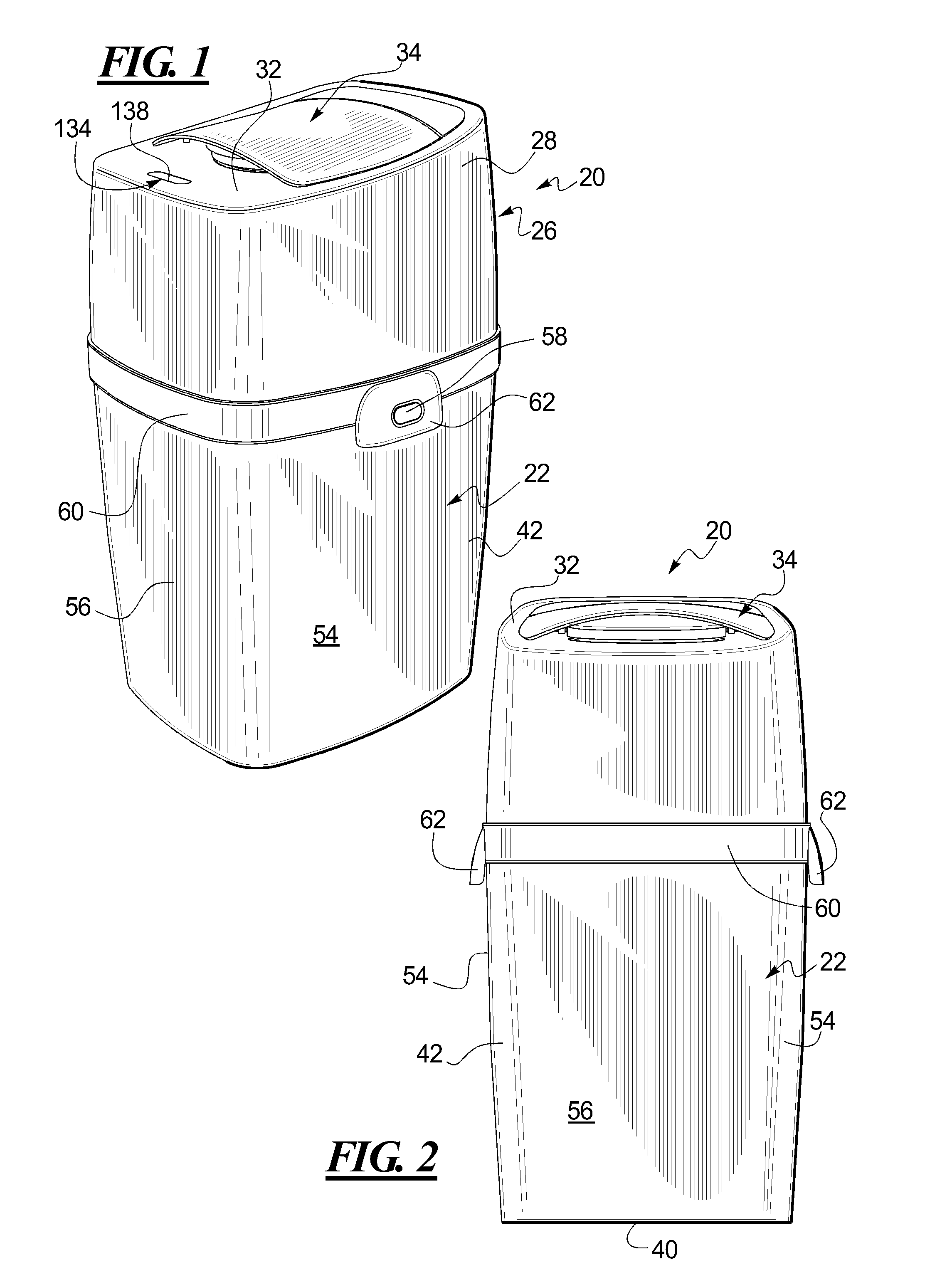

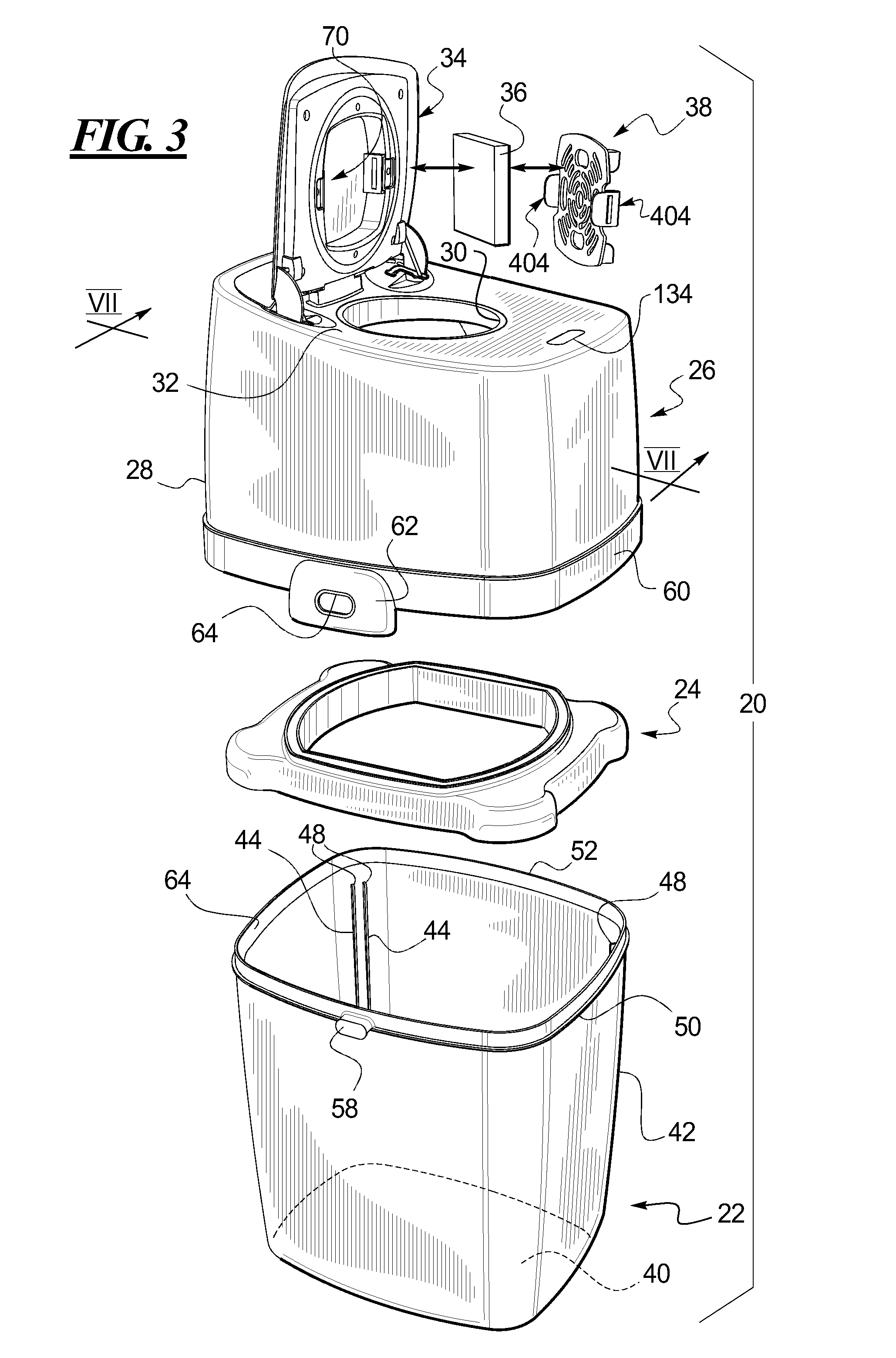

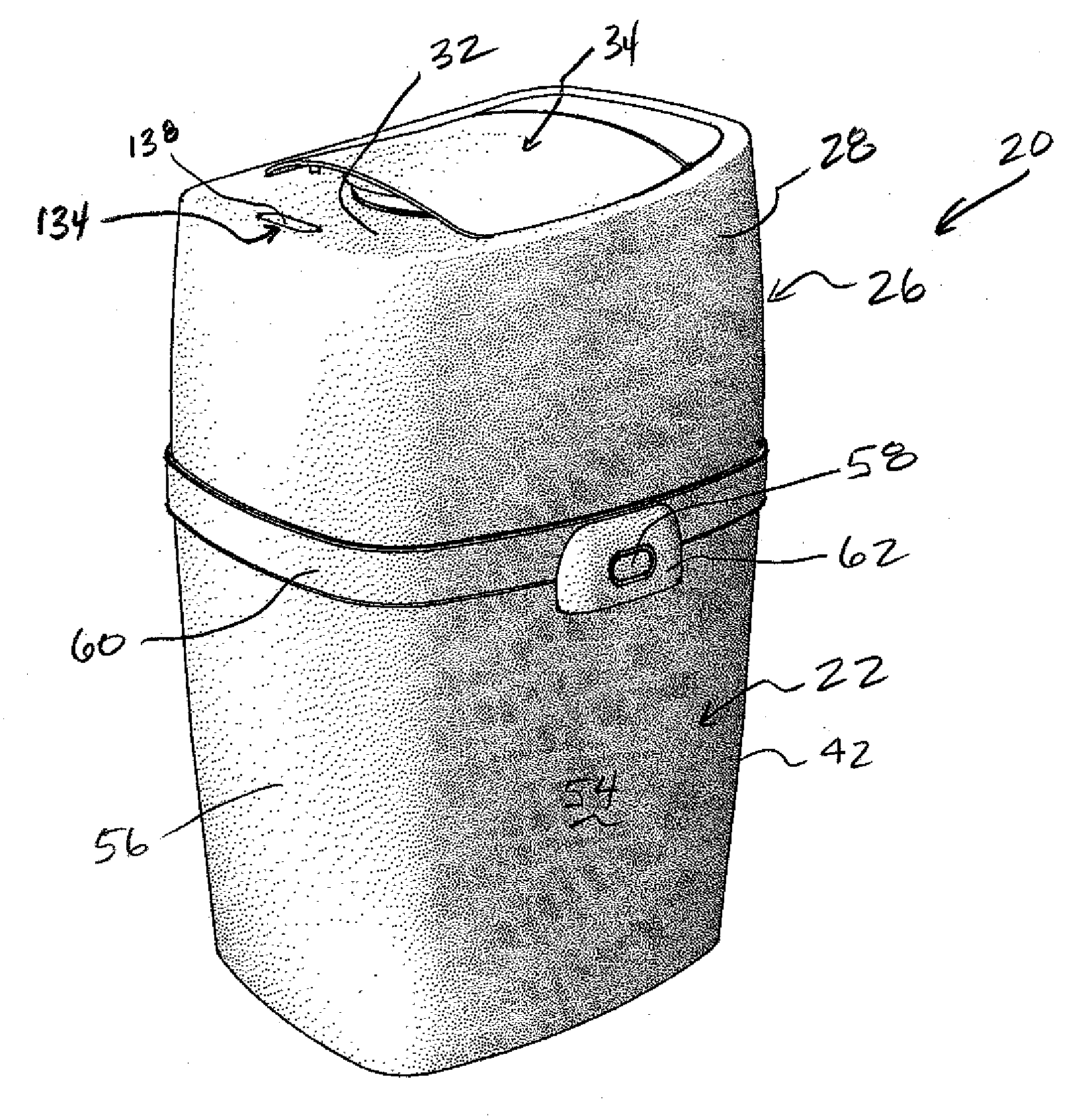

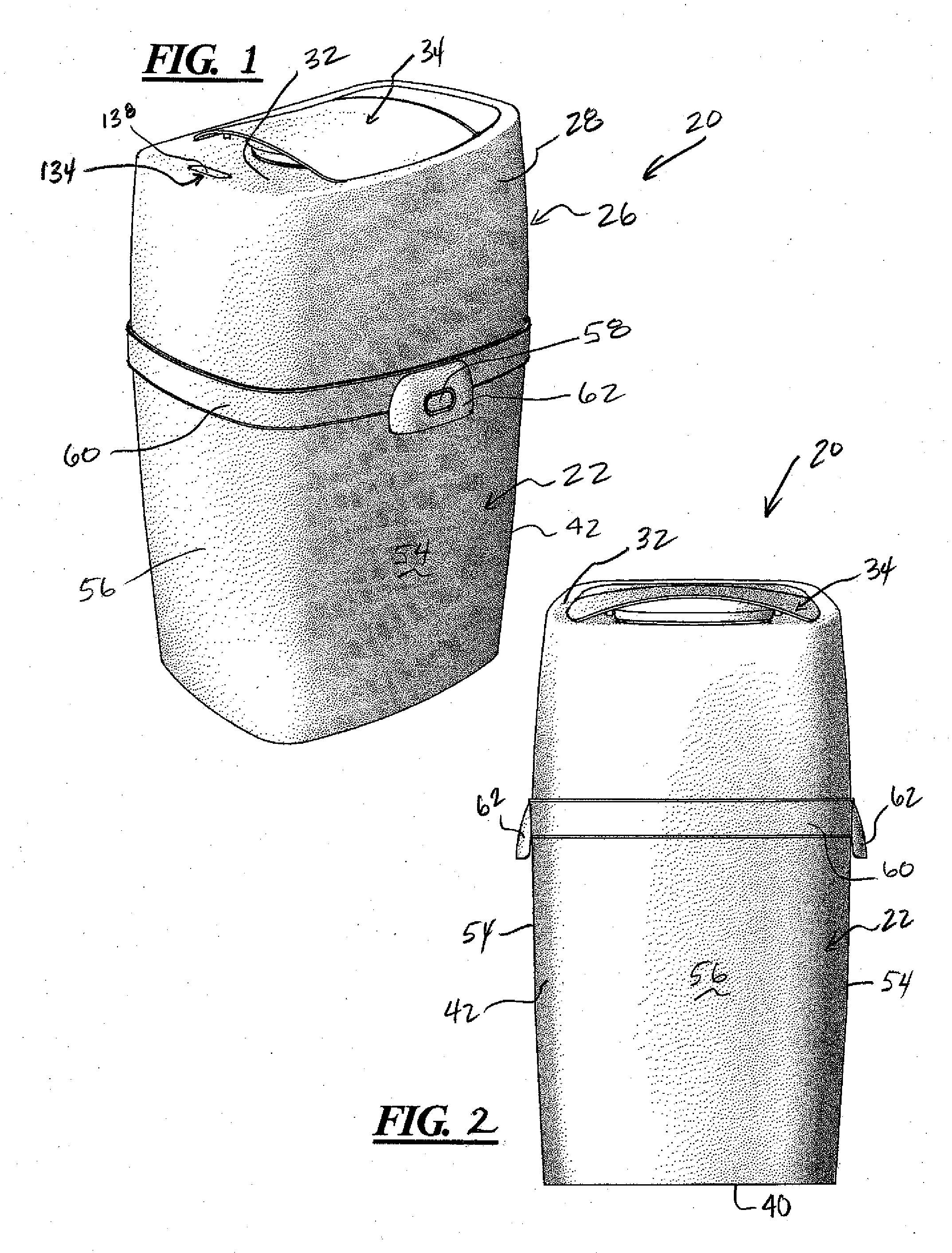

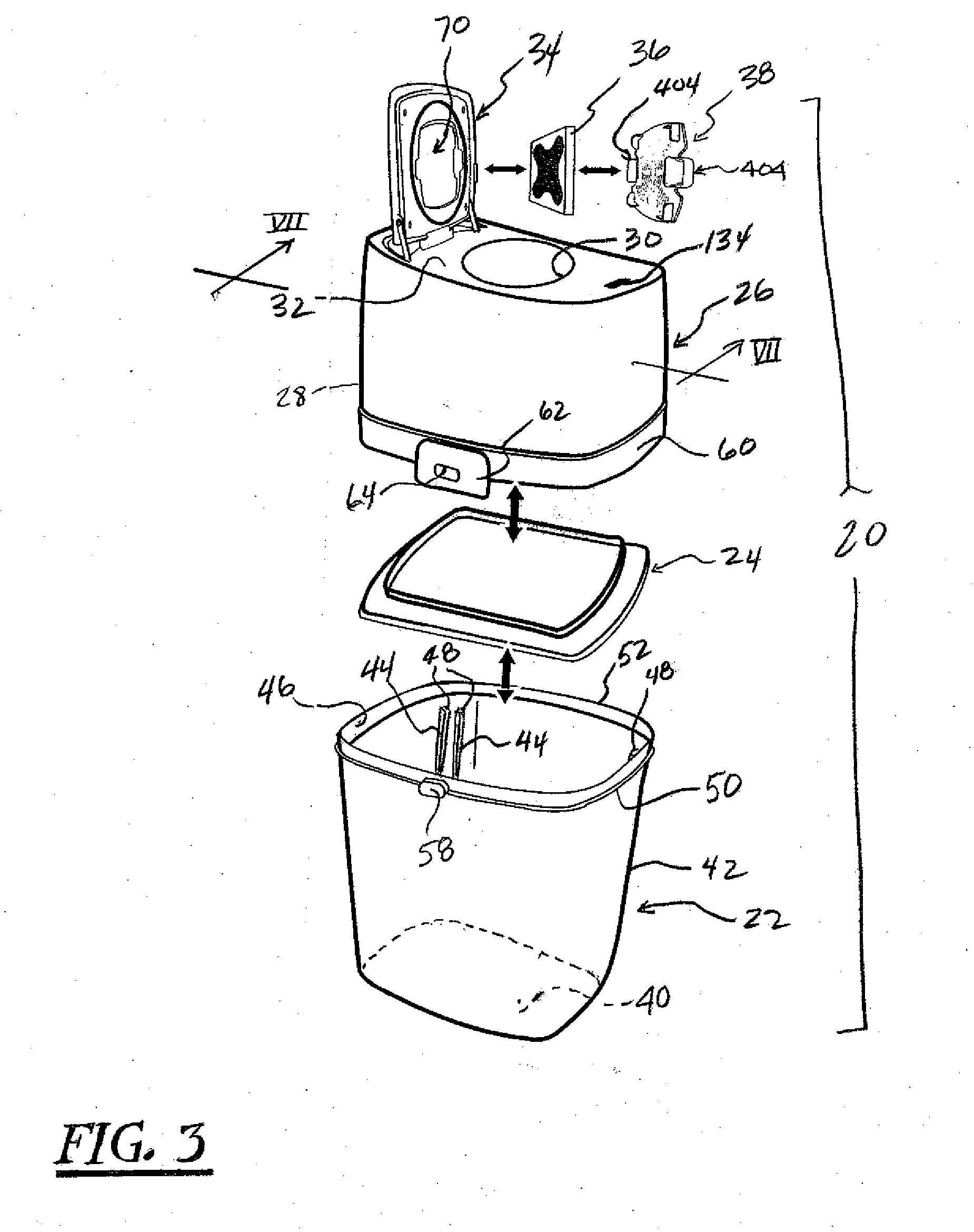

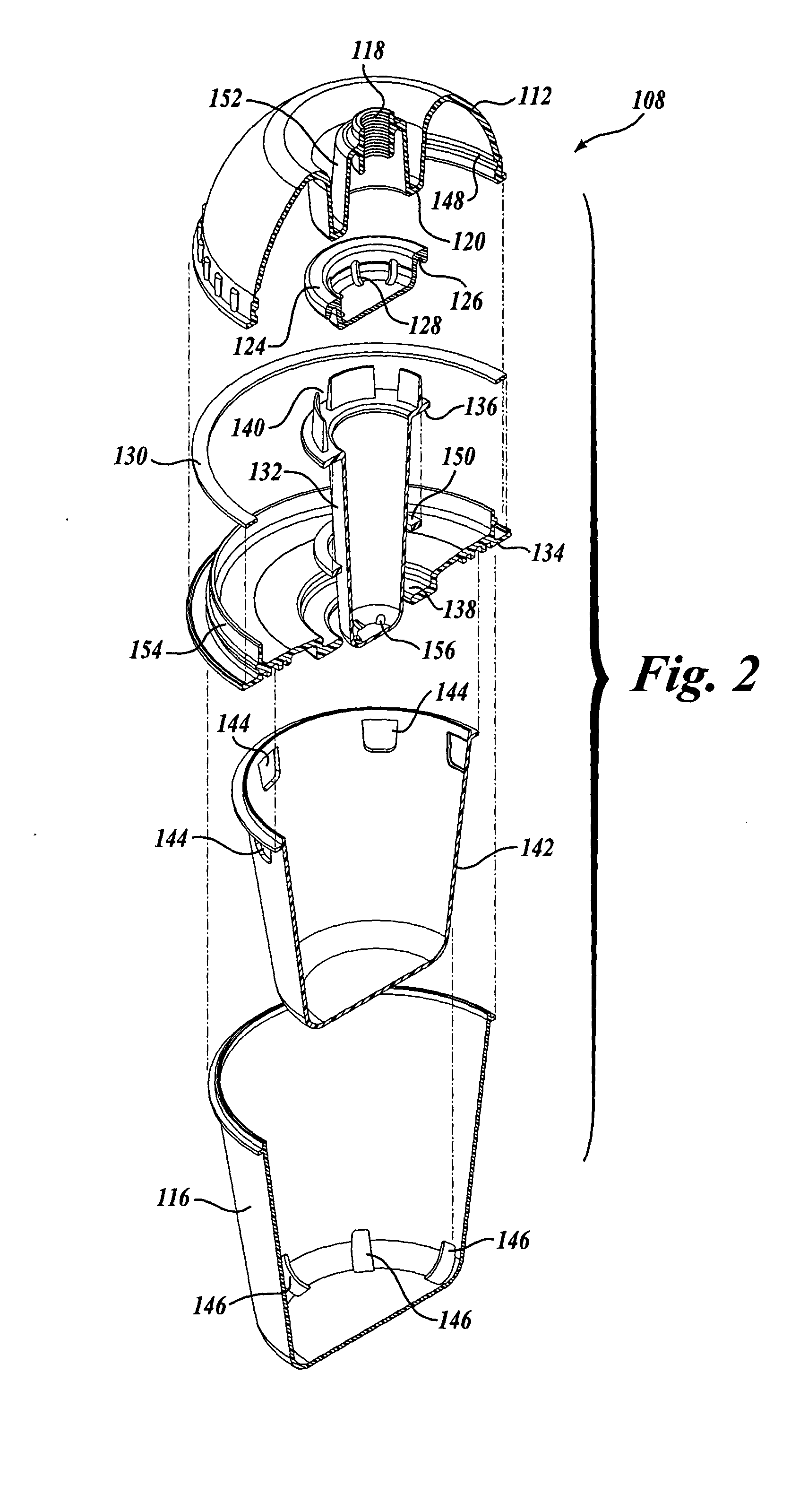

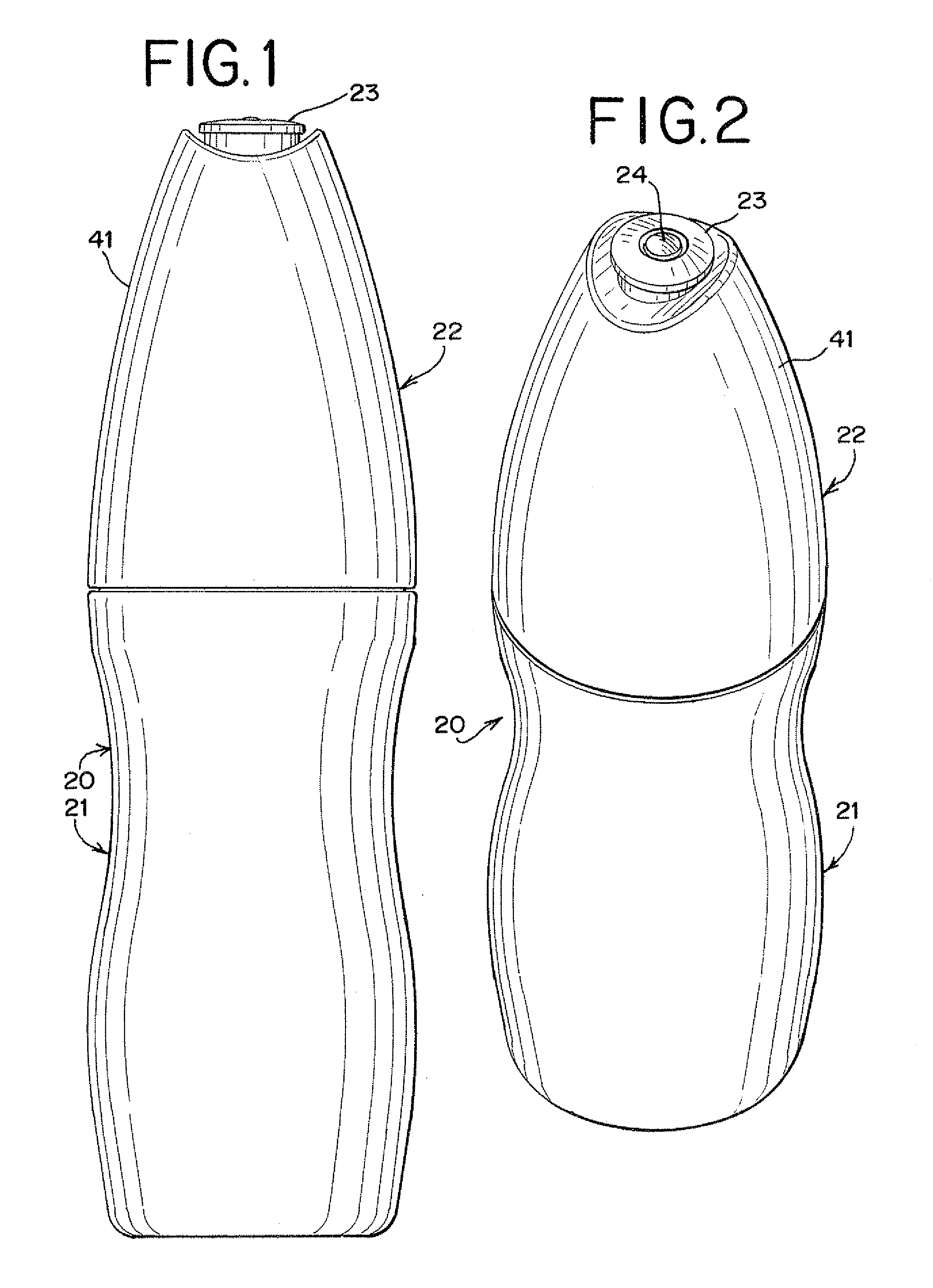

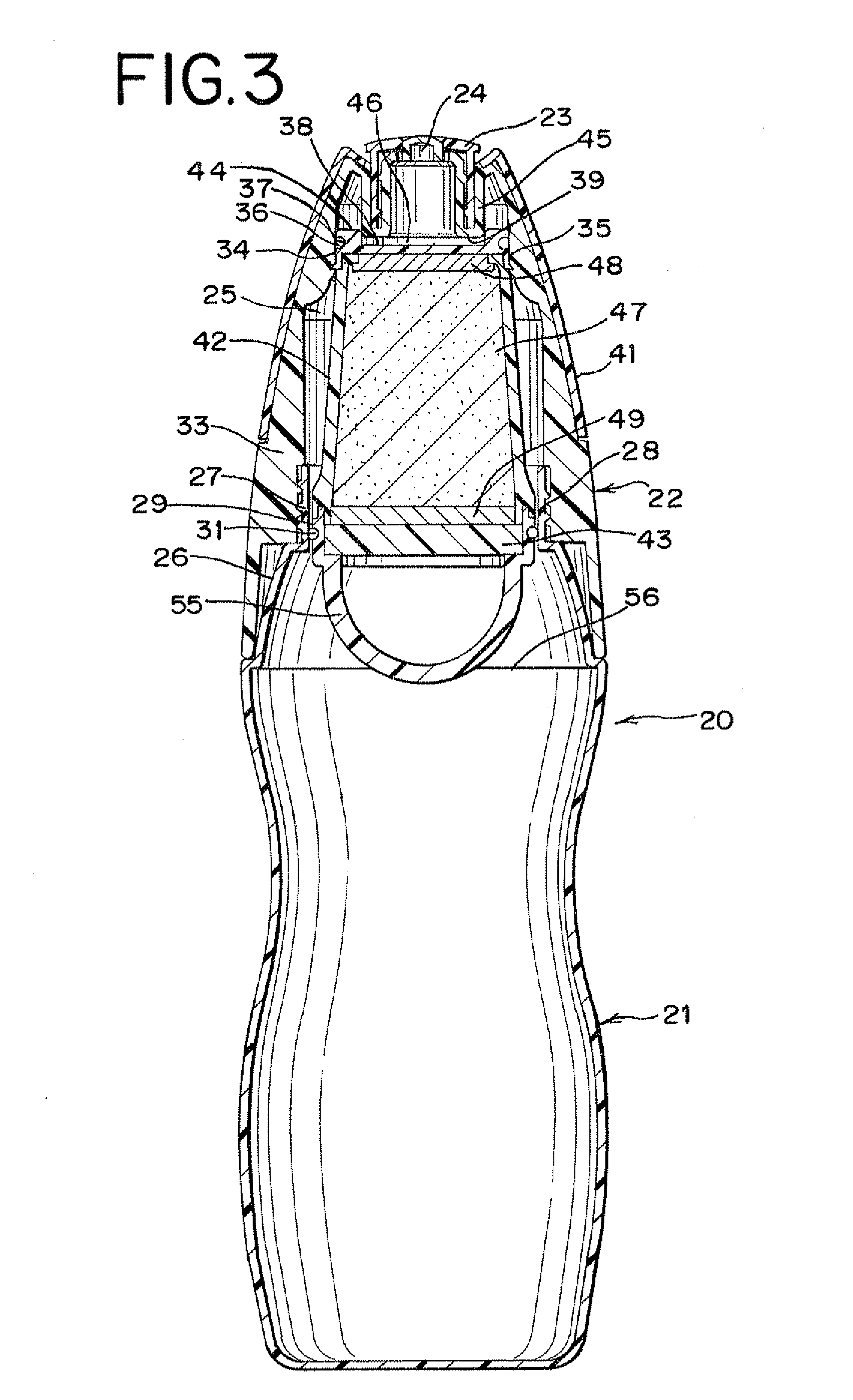

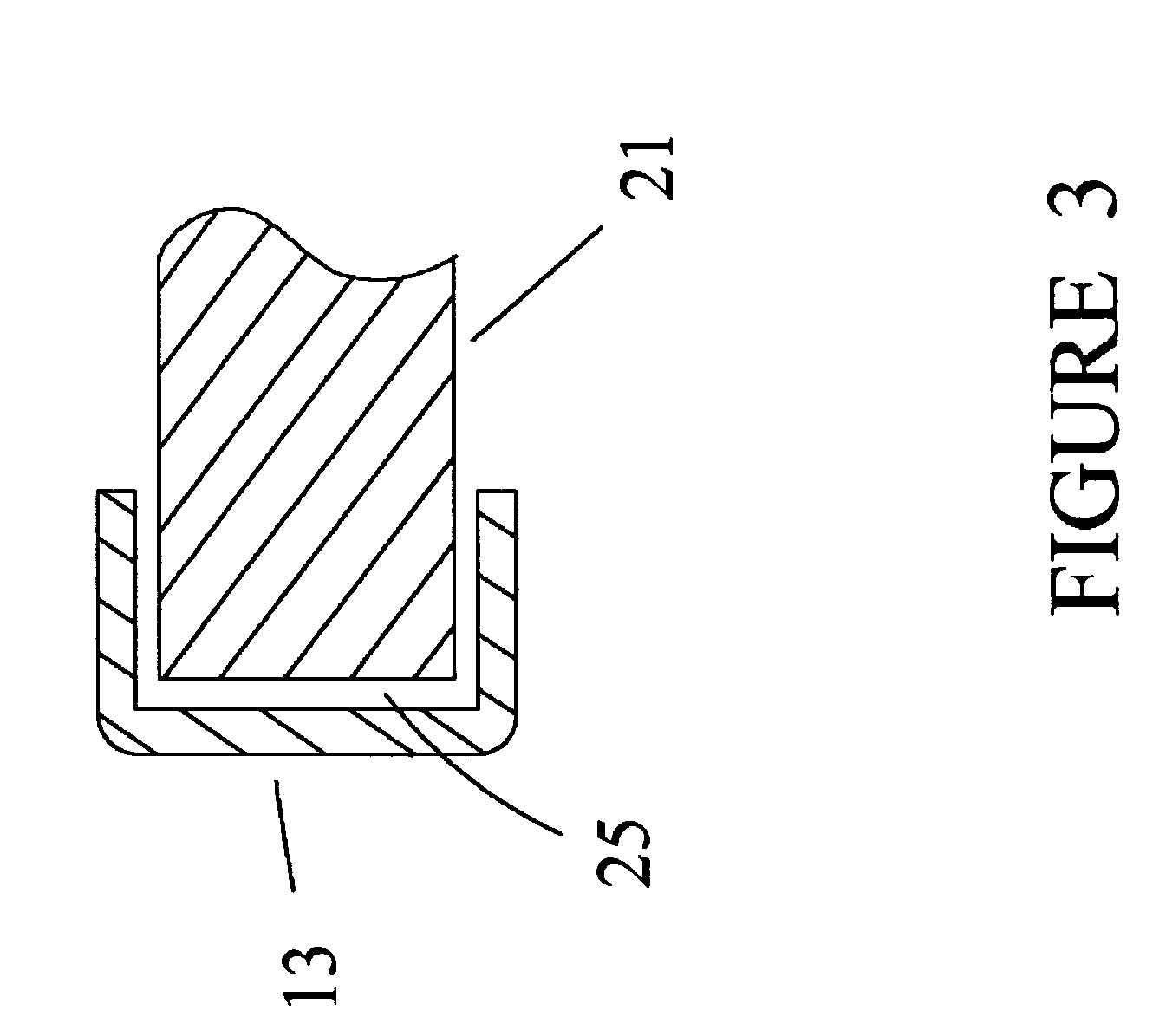

Diaper pail

InactiveUS7696711B2DC motor speed/torque controlPackaging cigaretteActivated carbon filtrationEngineering

A diaper pail has a body with an interior container space and an access opening into the interior container space. A diaper receptacle is also in the body and has a diaper receiving opening into the receptacle. An obstruction is provided that can be moved between a receiving orientation and a dumping orientation. In one aspect, an input device I configured to signal a part of the diaper pail to automatically operate the obstruction between the dumping orientation and the receiving orientation to receive a soiled diaper into the diaper receptacle and to dump the soiled diaper from the diaper receptacle into the interior container space. In another aspect, an activated charcoal filter is in communication with at least the interior storage space and is designed to chemically eliminate odors that emanate from the soiled diapers in the interior storage space.

Owner:GRACO CHILDRENS PROD INC

Bilge water reclamation system and process

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

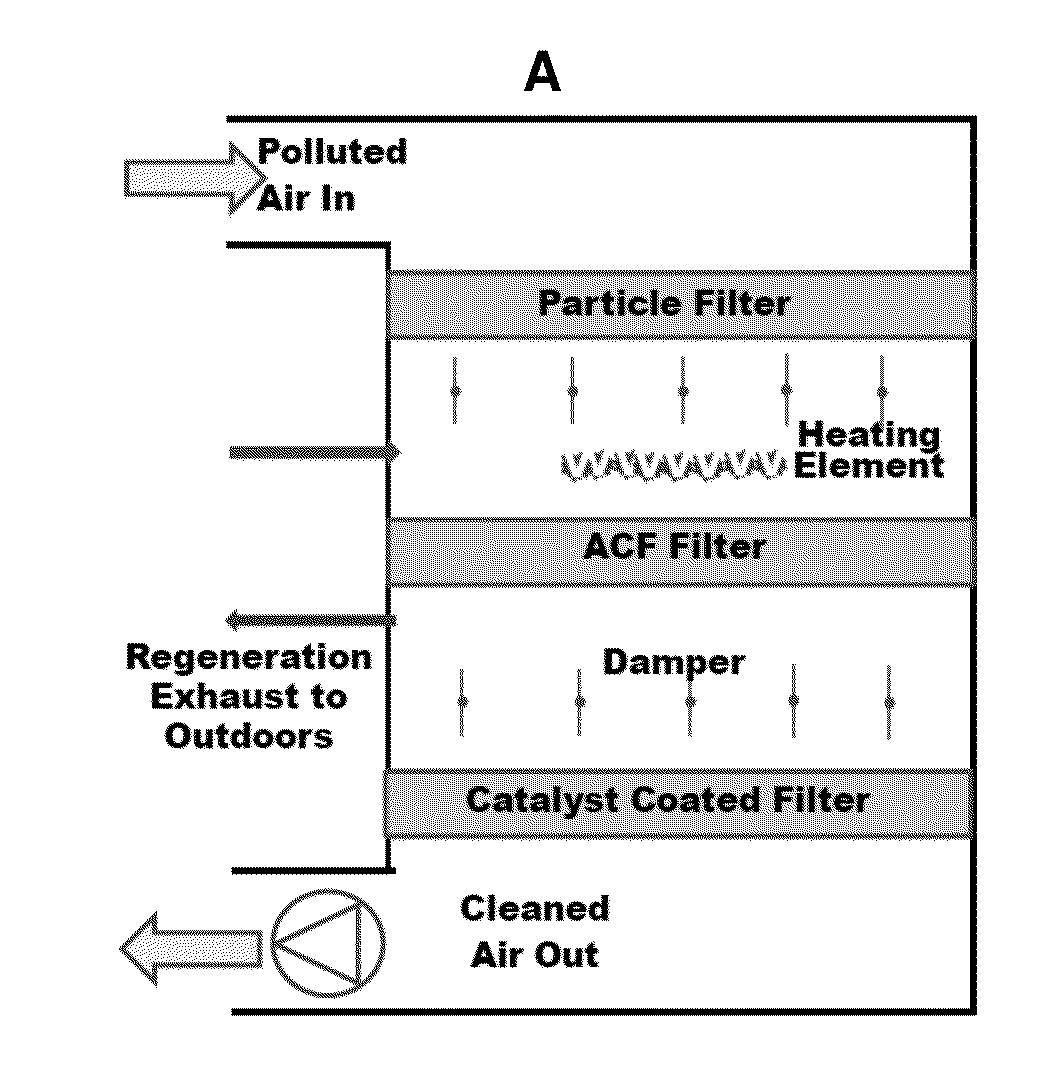

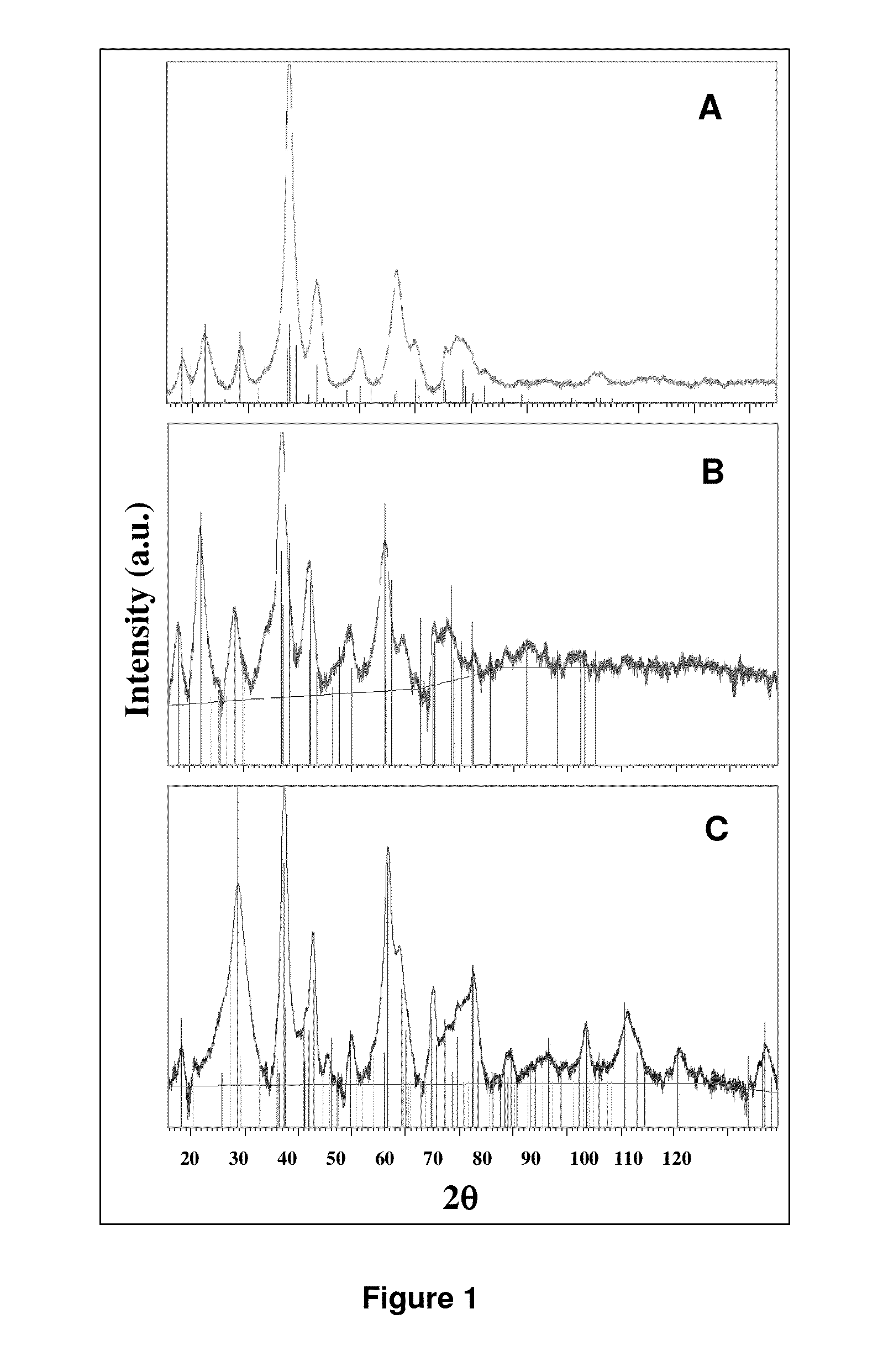

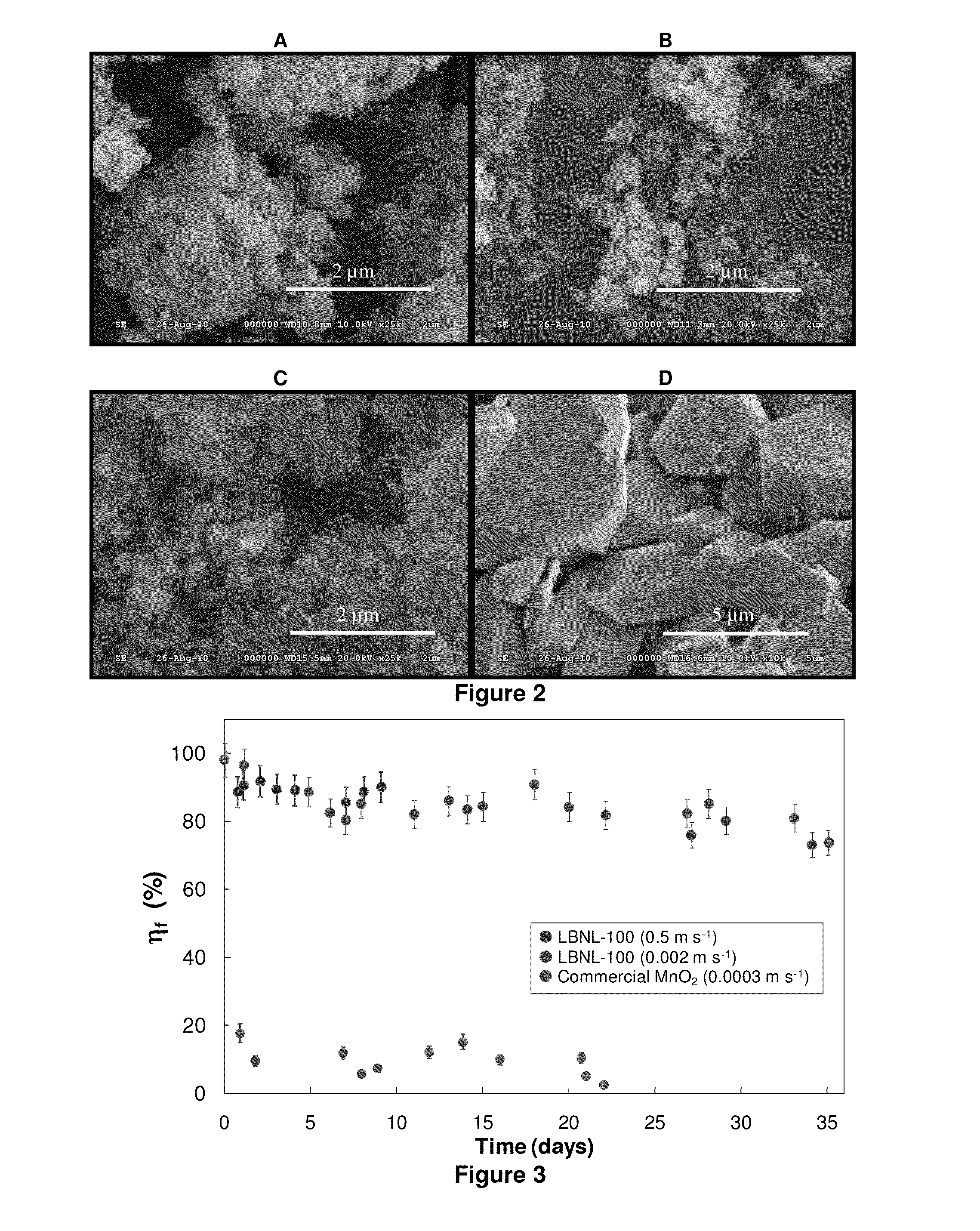

Use of Manganese Oxide and Activated Carbon Fibers for Removing a Particle, Volatile Organic Compound or Ozone from a Gas

InactiveUS20140255283A1Reduce contentLow VOC contentOrganic chemistryManganese oxides/hydroxidesFiberCarbon fibers

The present invention provides for a device for reducing a volatile organic compound (VOC) content of a gas comprising a manganese oxide (MnOx) catalyst. The manganese oxide (MnOx) catalyst is capable of catalyzing formaldehyde at room temperature, with complete conversion, to CO2 and water vapor. The manganese oxide (MnOx) catalyst itself is not consumed by the reaction of formaldehyde into CO2 and water vapor. The present invention also provides for a device for reducing or removing a particle, a VOC and / or ozone from a gas comprising an activated carbon filter (ACF) on a media that is capable of being periodically regenerated.

Owner:RGT UNIV OF CALIFORNIA

Diaper pail

InactiveUS20070125792A1DC motor speed/torque controlEmergency protective circuit arrangementsActivated carbon filtrationEngineering

A diaper pail has a body with an interior container space and an access opening into the interior container space. A diaper receptacle is also in the body and has a diaper receiving opening into the receptacle. An obstruction is provided that can be moved between a receiving orientation and a dumping orientation. In one aspect, an input device I configured to signal a part of the diaper pail to automatically operate the obstruction between the dumping orientation and the receiving orientation to receive a soiled diaper into the diaper receptacle and to dump the soiled diaper from the diaper receptacle into the interior container space. In another aspect, an activated charcoal filter is in communication with at least the interior storage space and is designed to chemically eliminate odors that emanate from the soiled diapers in the interior storage space.

Owner:GRACO CHILDRENS PROD INC

Water purification cartridge

InactiveUS20050072729A1More energyEqually distributedTreatment involving filtrationSettling tanks feed/dischargeCeramic water filterHalogen

The water purification cartridge treats water with a halogen liberated from halogenated hydantoinyl resins and polymers, resulting in the safe, complete, and economical purification of non-potable water at low flow rates typically found in gravity feed filtration systems and at water pressures of less than 1 psig. The cartridge of the invention purifies non-potable water of bacteria, viruses, and some protozons without the need for additional power sources or risk to the consumer for exposure to chemicals that have been identified to have harmful, long-term effects. The cartridge described herein enables a gravity fed water purification system by combining the cartridge with conventional filters, such as porous diatomaceous earthen ceramic water filters or activated carbon filters packed either with granular activated carbon or block.

Owner:HALOSOURCE INC

Multi-functional protective fiber and methods for use

InactiveUS20050026778A1Efficient and effective adsorptionChemical protectionMaterial nanotechnologyFiberChemical reaction

A reactive and adsorptive (i.e., protective) fiber, a multi-element protective filter and methods for constructing and using same which possess at least chemically reactive and biocidal properties. Nanoparticles from different classes such as metal oxides, metal hydroxides, metal hydrates and POMs are incorporated into elements which can be utilized in a wide variety of protective materials. The nanoparticles may be treated to reduce water solubility or combined with halogens, alkali metals or secondary metal oxides to specifically engineer the nanoparticle to address a particular chemical or biocidal threat. When arranged upstream of an activated carbon filter, the nanoparticles provide enhanced adsorption or additional reactive properties to the protective filter. When used with carbon specially treated with metal ions, the protective filter retains the ability to adsorb blood agents as well. Significant advances in nanoparticle technology are described wherein clusters made from about 1 nm to about 200 nm sized nanoparticles are reduced to tangible filter element precursors.

Owner:GENTEX CORP

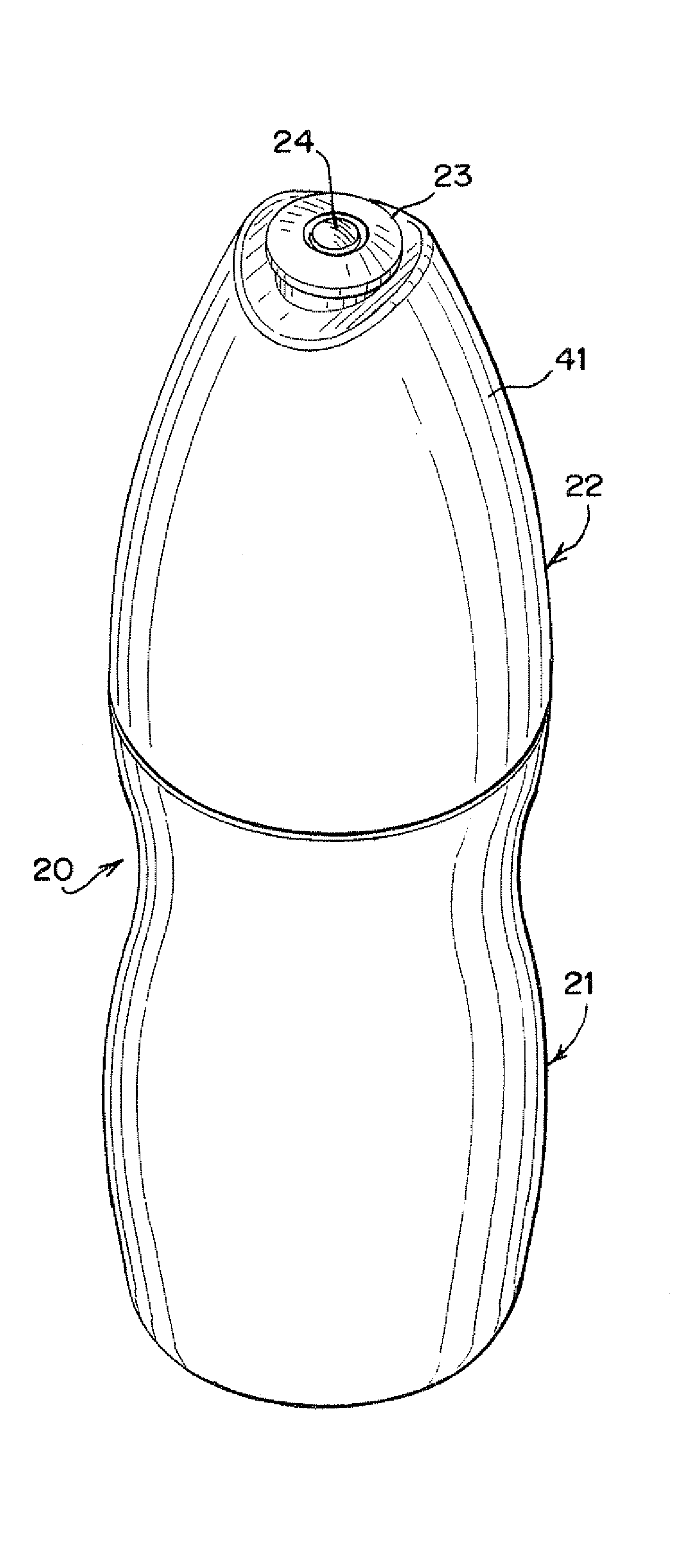

Water Bottle with Filtration Feature

InactiveUS20090145839A1Easily removableEasily replaceableTreatment involving filtrationWater treatment locationFiltrationActivated carbon filtration

A flexible water bottle is provided that includes an approach for filtering unfiltered water within the bottle. The bottle includes a filter assembly located within the cap of the bottle such that the filter assembly need not descend into the bottle cavity when the cap is screwed on, thereby not displacing water while screwing on the cap. The filter assembly has an axial flow orientation. An illustrated filter assembly includes paper filters covering the upper and lower ends and can include an activated charcoal filter in between the paper filters. Water is filtered when pressure generated by squeezing the bottle forces water from the bottle cavity through the filter along an axial flow path and out through a spout.

Owner:MEDPORT

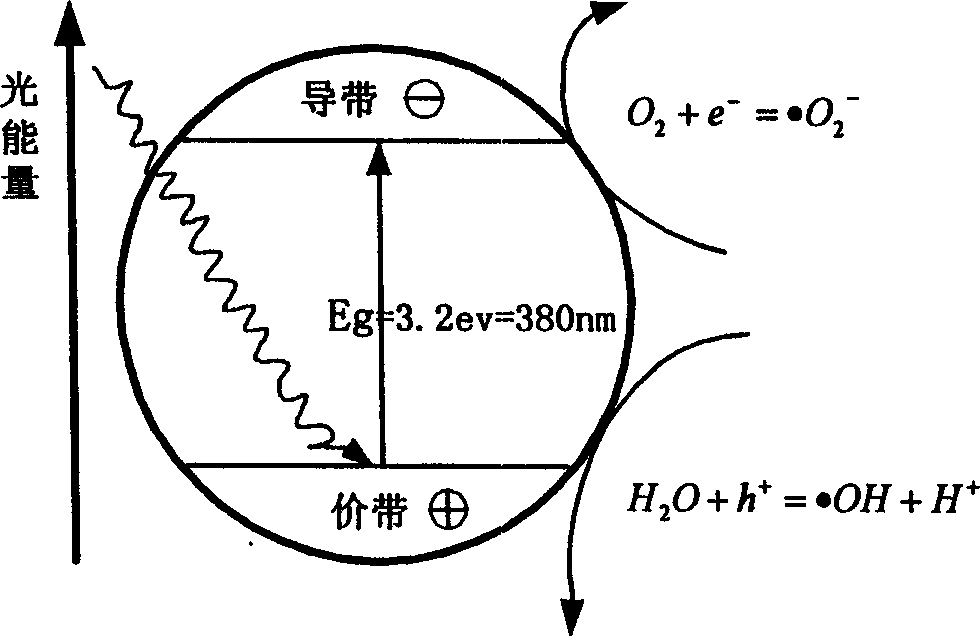

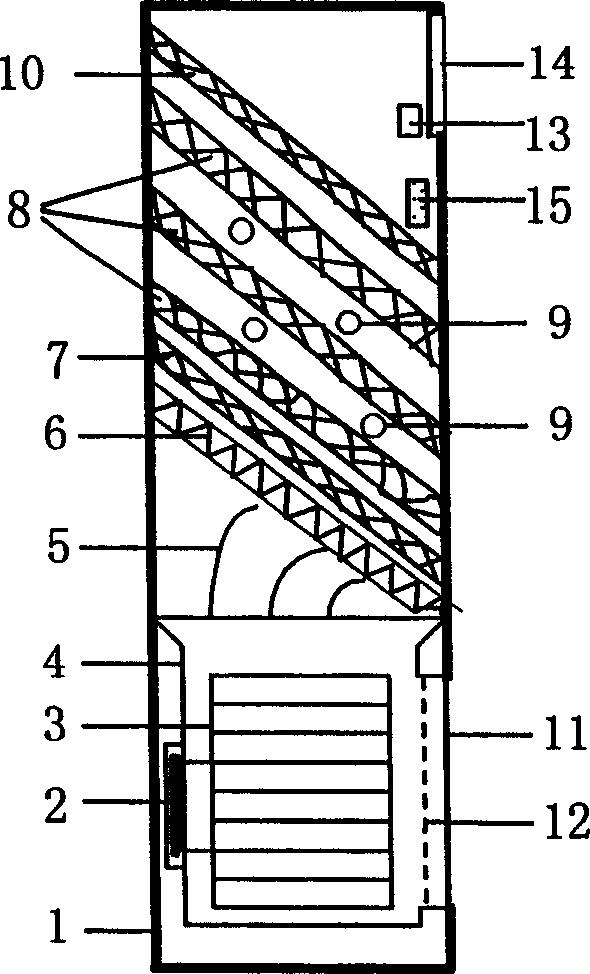

Vertical light catalytic air purifier

InactiveCN1614322AIncreased contact surface areaLarge amount of processingLighting and heating apparatusDispersed particle separationAir purifiersActivated carbon filtration

A vertical photocatalytic air purifier is composed of casing with air inlet, primary net filter, through-flow fan, motor for fan, airflow guiding volute, air outlet, circuit board, secondary net filter, an guide plate, plasma duster, photocatalyzing unit consisting of photocatalytic cellular net filter and UV lamp, activated carbon net filter, and negative ion generator.

Owner:中投亿星新能源投资有限公司

System and method for water purification

InactiveUS6824695B2Treatment using aerobic processesSedimentation separationBiological activated carbonActivated carbon filtration

A self-contained, portable water purification system, including (a) an ozone supply, (b) an ozone contact chamber mixing a contaminated or potentially contaminated water stream with ozone generated by such ozone supply, (c) an ozone destruction unit for destructing ozone contained in the water stream and converting said water stream into an oxygen-rich and ozone-depleted water stream, and (d) a downstream biologically active carbon filter, for receiving such oxygen-rich and ozone-depleted water stream and biologically destructing at least a portion of contaminants contained therein.

Owner:TEMPEST ENVIRONMENTAL SYST

Water filter materials comprising a mixture of microporous and mesoporous carbon particles and water filters with said filter materials

ActiveCN101160169AReduce virusReduce TTHMOther chemical processesFiltration separationActivated carbon filtrationWater filter

A filter and filter material for providing or treating potable water is provided. The filter includes a housing having an inlet and an outlet, a filter material disposed within the housing, the filter material formed at least in part from a mixture of a plurality of mesoporous and microporous activated carbon particles. Preferably, at least some of the mesoporous activated carbon filter particles are coated with a cationic polymer, and even more preferably, at least some of the particles are coated with a cationic polymer and silver or a silver containing material. Kits comprising filters and information relating to the reduction, killing or removal of bacteria, viruses, microbials, and TTHM are also provided.

Owner:PUR WATER PURIFICATION PRODUCTS INC +1

Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles

InactiveUS20050263453A1Reduce bacteriaReduce virusSolvent extractionLoose filtering material filtersWater filterActivated carbon filtration

A filter and filter material for providing or treating potable water is provided. The filter includes a housing having an inlet and an outlet, a filter material disposed within the housing, the filter material formed at least in part from a mixture of a plurality of mesoporous and microporous activated carbon particles. Preferably, at least some of the mesoporous activated carbon filter particles are coated with a cationic polymer, and even more preferably, at least some of the particles are coated with a cationic polymer and silver or a silver containing material. Kits comprising filters and information relating to the reduction, killing or removal of bacteria, viruses, microbials, and TTHM are also provided.

Owner:PUR WATER PURIFICATION PRODUCTS INC +1

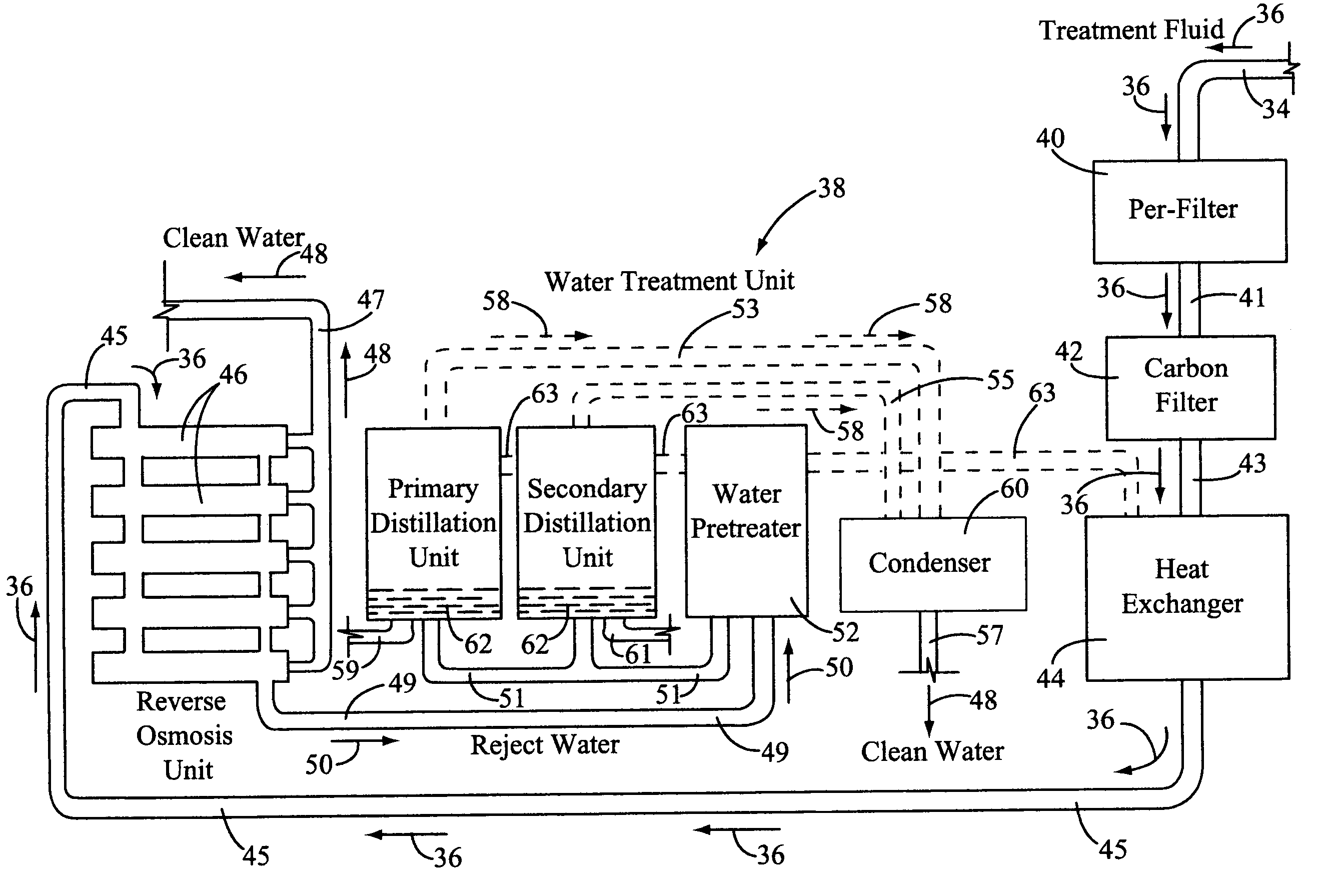

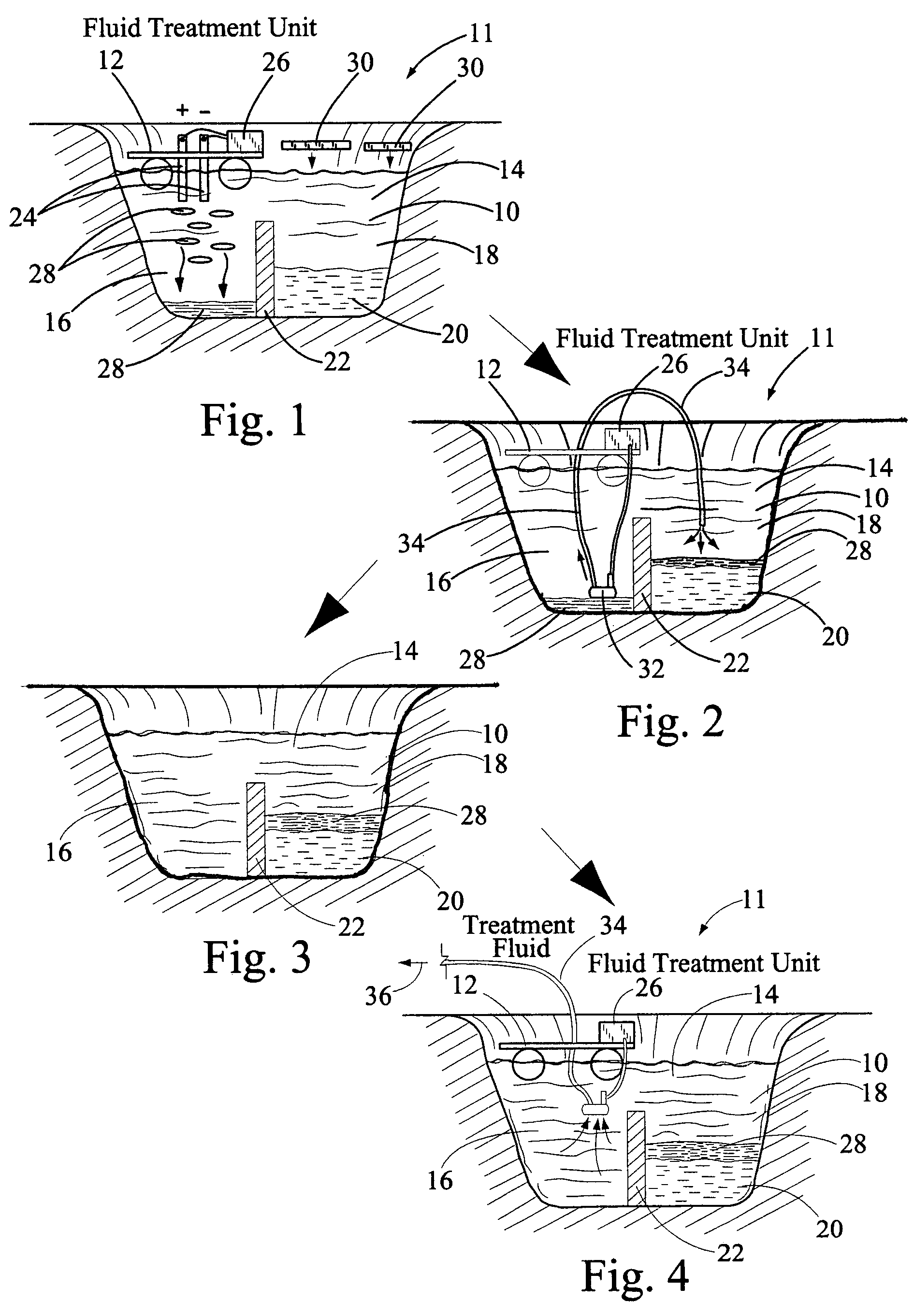

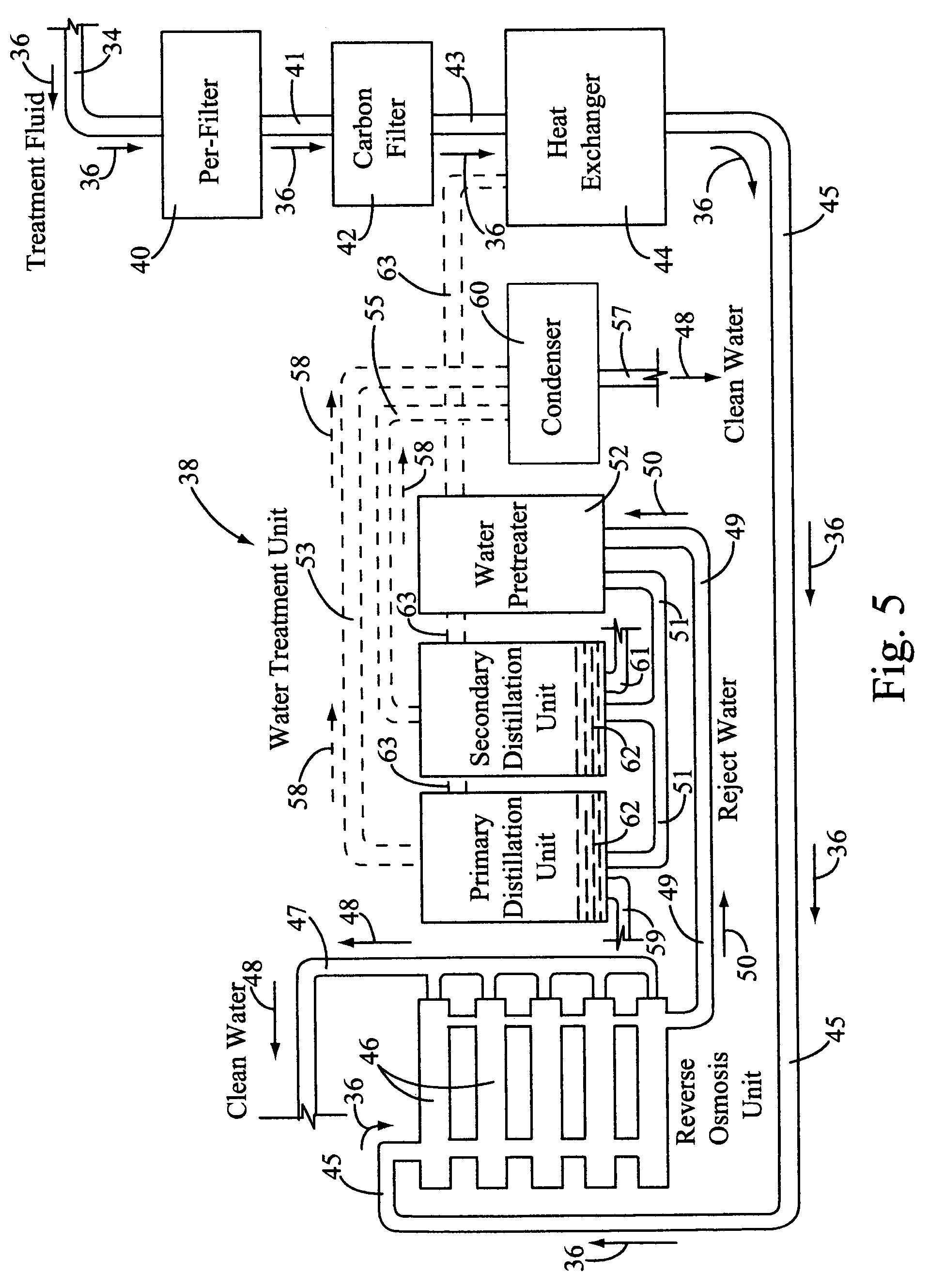

Situ system and method for treating an oil and gas well drilling fluid

InactiveUS7731854B1Low costEasy to disassembleWaste water treatment from quariesElectrostatic separatorsActivated carbon filtrationDistillation

An in situ system used for treating an oil and gas well drilling fluid and treating water after a well is completed. The system includes a fluid treatment unit used in a reserve pit and a water treatment unit disposed next to the pit. The fluid treatment unit includes a floating electrocoagulation unit in the reserve pit for destabilizing contaminates in the fluid and dropping out stable precipitates. The clear treated fluid is then pumped, using a submersible pump, to the water treatment unit. The water treatment includes a number of components including a pre-filter, an activated carbon filter and a heat exchanger for first treating the fluid. The filtered and heated fluid is then piped into a reverse osmosis unit for removing salt and any remaining minerals found therein. From the reverse osmosis unit, approximately 70 to 80% of the filtered water is cleaned and piped to a clean water storage tank for reuse. Reject water from the reverse osmosis unit is transferred to a water pre-heater and a primary and secondary distillation unit for converting the heated water to steam. The steam is now piped to a condenser where the steam is cooled to distilled, clean water. The remaining clean water from the condenser is now transferred to the clean water storage tank.

Owner:H2O TECH

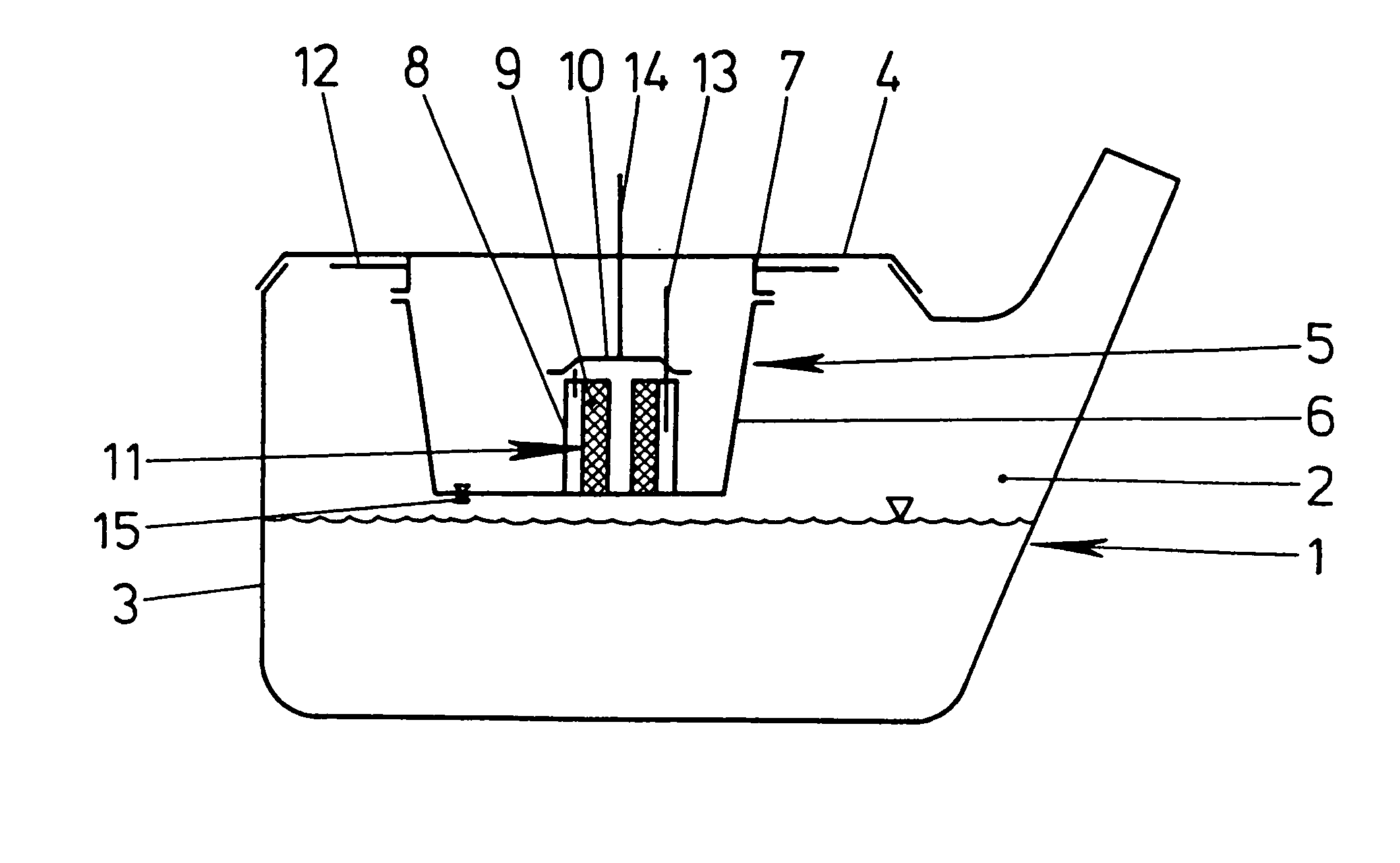

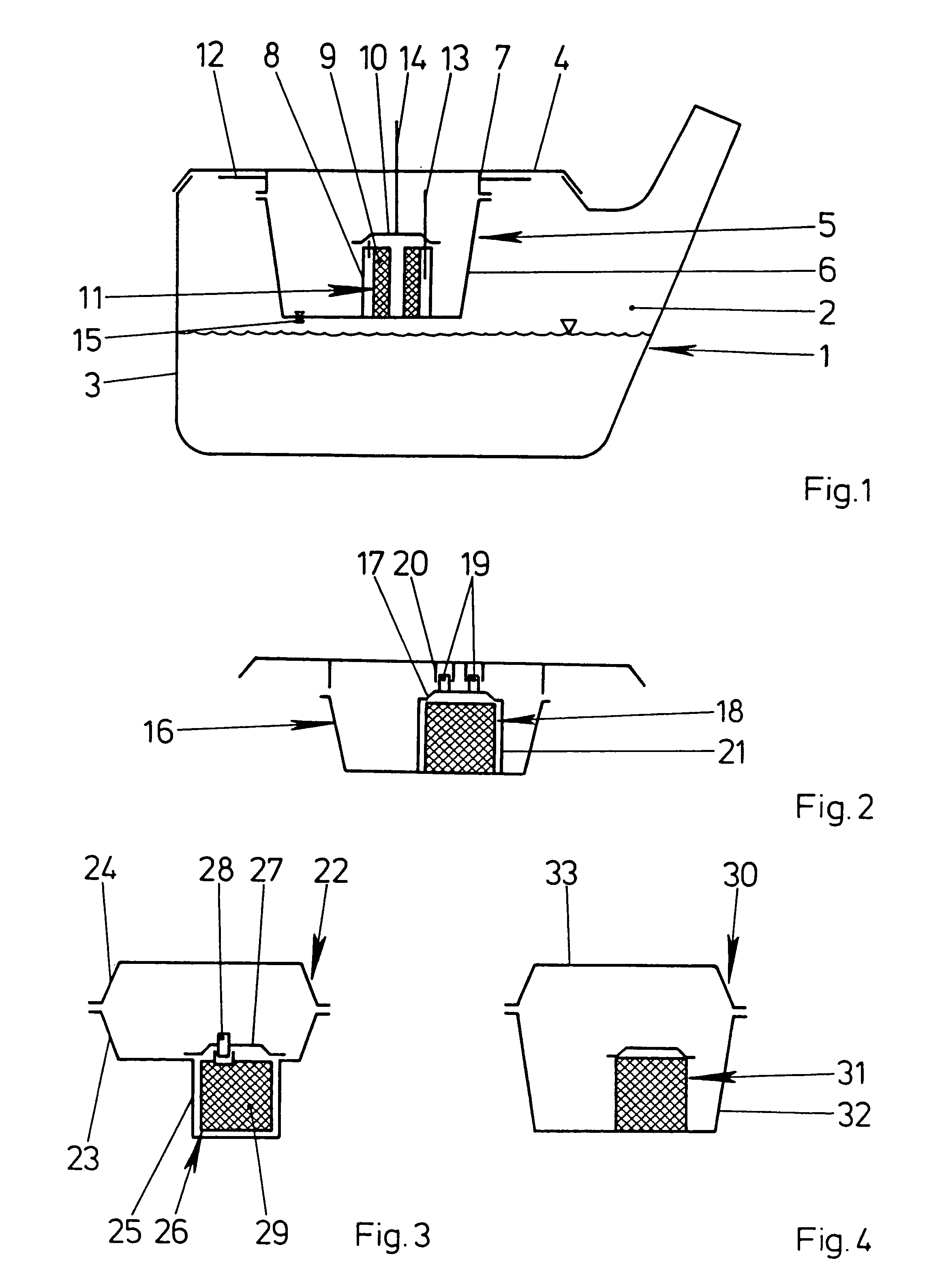

Fuel tank

InactiveUS7047948B2Easy to assembleNumberLarge containersMachines/enginesMobile vehicleActivated carbon

A fuel tank for a motor vehicle having a chamber delimited by a wall and having an activated carbon filter located to ventilate the volume of the fuel chamber located above the level of fuel in the tank.

Owner:CONTINENTAL AUTOMOTIVE GMBH

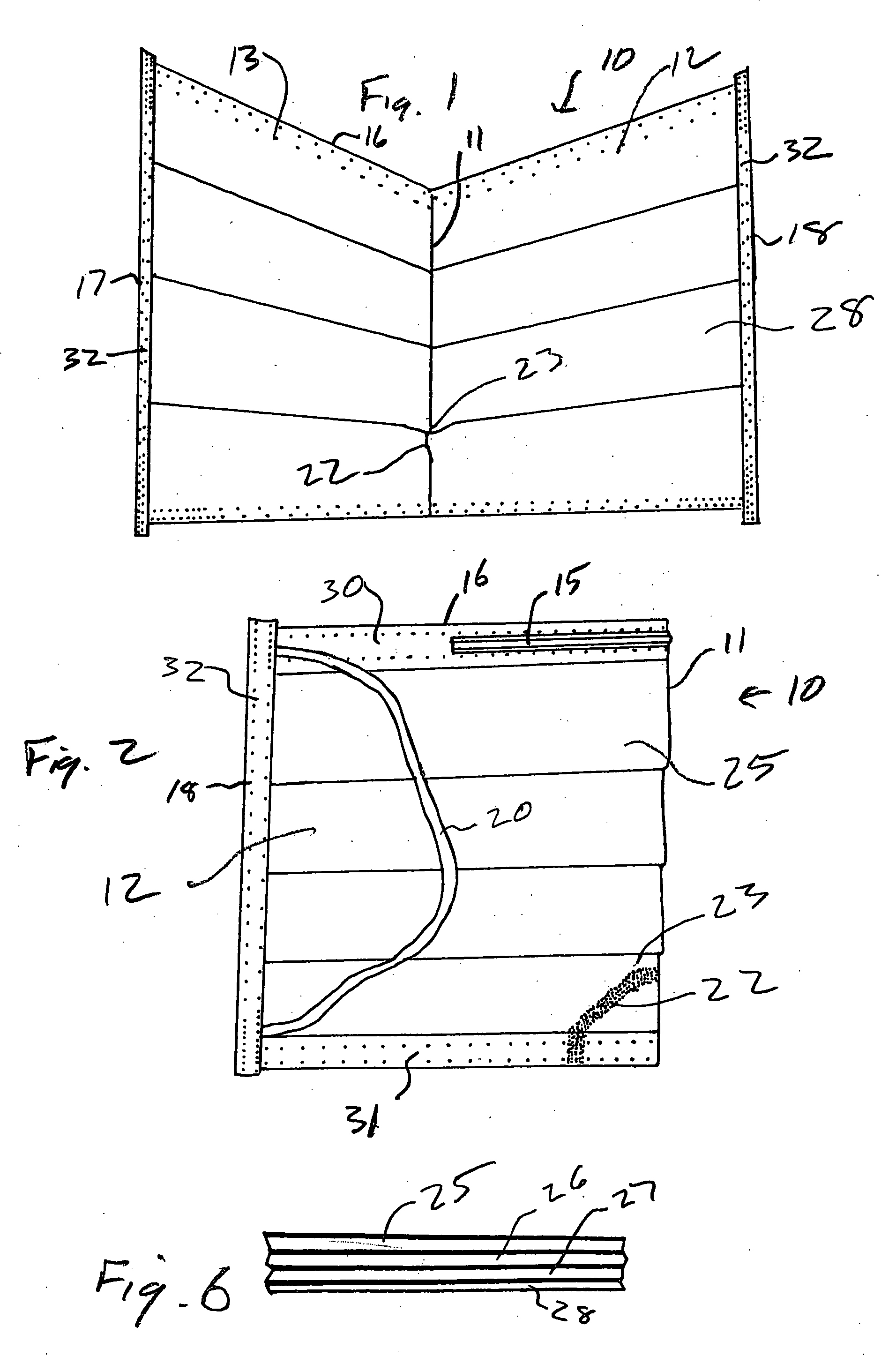

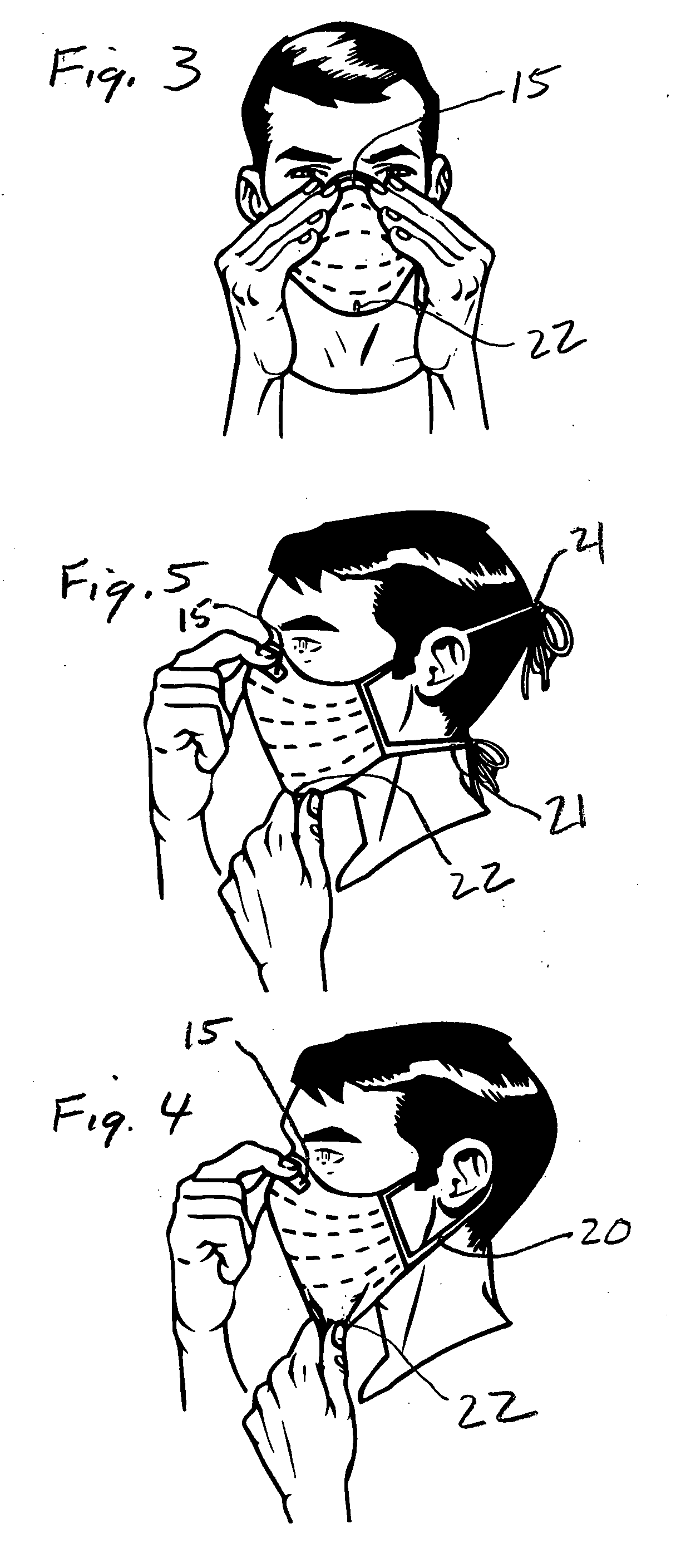

Nostril filtering system

InactiveUS7156099B1Effective resistanceEasy to useRespiratorsBreathing filtersNostrilActivated carbon filtration

A nostril filtering system is described for providing clean, filtered air for breathing in through the nose. The filtering system includes a soft, pliable filter material held in a flexible frame that can be inserted into each nostril of a user. In the case of foul odors or noxious fumes, for example, the filter can include an activated charcoal filter portion. The device can be offered in several sizes to accommodate adults and children.

Owner:JENKINS CLOYTILLIA M

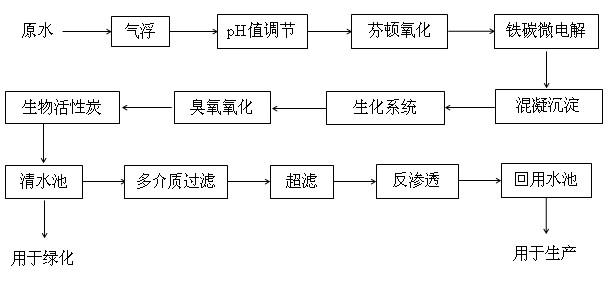

Treatment method for recycling complex waste water in coal chemical industry

InactiveCN102515442AImprove biodegradabilityRealize resourcesMultistage water/sewage treatmentWater useBiological activated carbon

The invention provides a treatment method for recycling complex waste water in the coal chemical industry and relates to recycling technologies for enhanced pretreatment, biochemical treatment, deep purification and regeneration process of waste water. The invention provides the process scheme as follows: first enhanced pretreatment for the complex waste water in the coal chemical industry is carried out by using the combined process of air floatation, Fenton oxidation and ferric-carbon micro-electrolysis, so as to improve the biodegradability of the waste water; then the waste water is poured into a biochemical system comprising a hydrolyze acidification zone pool, an anoxic pool and an aerobic pool; the biodegraded water is discharged into a deep purification system with the function ofozone-biological activated carbon filtration, so that materials which are difficult to degrade are further removed, and the discharged water can be used for green spaces and other landscapes; after that, most of salt ions are removed by using a regeneration recycling system with the functions of multi-media filtration, ultrafiltration and reverse osmosis, so as to obtain water can be reused for production.

Owner:蓝星环境工程有限公司

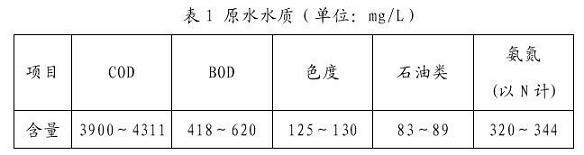

Dyeing and printing waste clearing, synthetic wastewater advanced treatment circulation production and recycle technique

InactiveCN101172741AGood denitrification functionIncrease profitMultistage water/sewage treatmentWater/sewage treatment by oxidationComing outAir bearing

The invention discloses a deep treatment technique used for the printing and dyeing sewage recovery. The technique consists of a BAF pond, an air-bearing system, an ozone contact oxidation tower, a filter, an active carbon filter, an ozone generator and a medicine adding system. The technique is the improvement of the traditional BAF technique, removes the resolvable organism in the sewage through the biological degradation, outtakes the water into the air-bearing system and combines the flocculation medicine adding technique, so as to eliminate the non-solvent organism and colloidal substance in the sewage. The outtaken water enters into the ozone contact oxidation tower and gets mixed with ozone, so that the organism which is difficult to undergo the biological degradation in the printing and dyeing sewage is removed with the help of the strong oxidizing property of the ozone. The water flowing out of the ozone contact oxidation tower enters into the pond at the middle, and 30 percent of the water returns to a gas dissolving can under the action of a pressurizing pump, gets mixed with the pressurized air and then enters into the air-bearing system through utilizing the remaining pressure. The gas-water solution is dispersed into the small and equable drips through a dissolved gas releaser, and the drips drive the suspending substances and the colloidal substance to float up to the water surface so as to achieve the removal. The water coming out of the middle pond enters into the filter to remove the small suspending substances and enters into the ozone / active carbon filtering system so that the reaction of the ozone basic chain is caused under the action of the active carbon, thereby speeding up the decomposition of the ozone into OH and other free radicals, degrades a small amount of organism, eliminates the color and finally ensures that the outtaken water reaches the recovery standard of the printing and dyeing sewage.

Owner:王爱月 +1

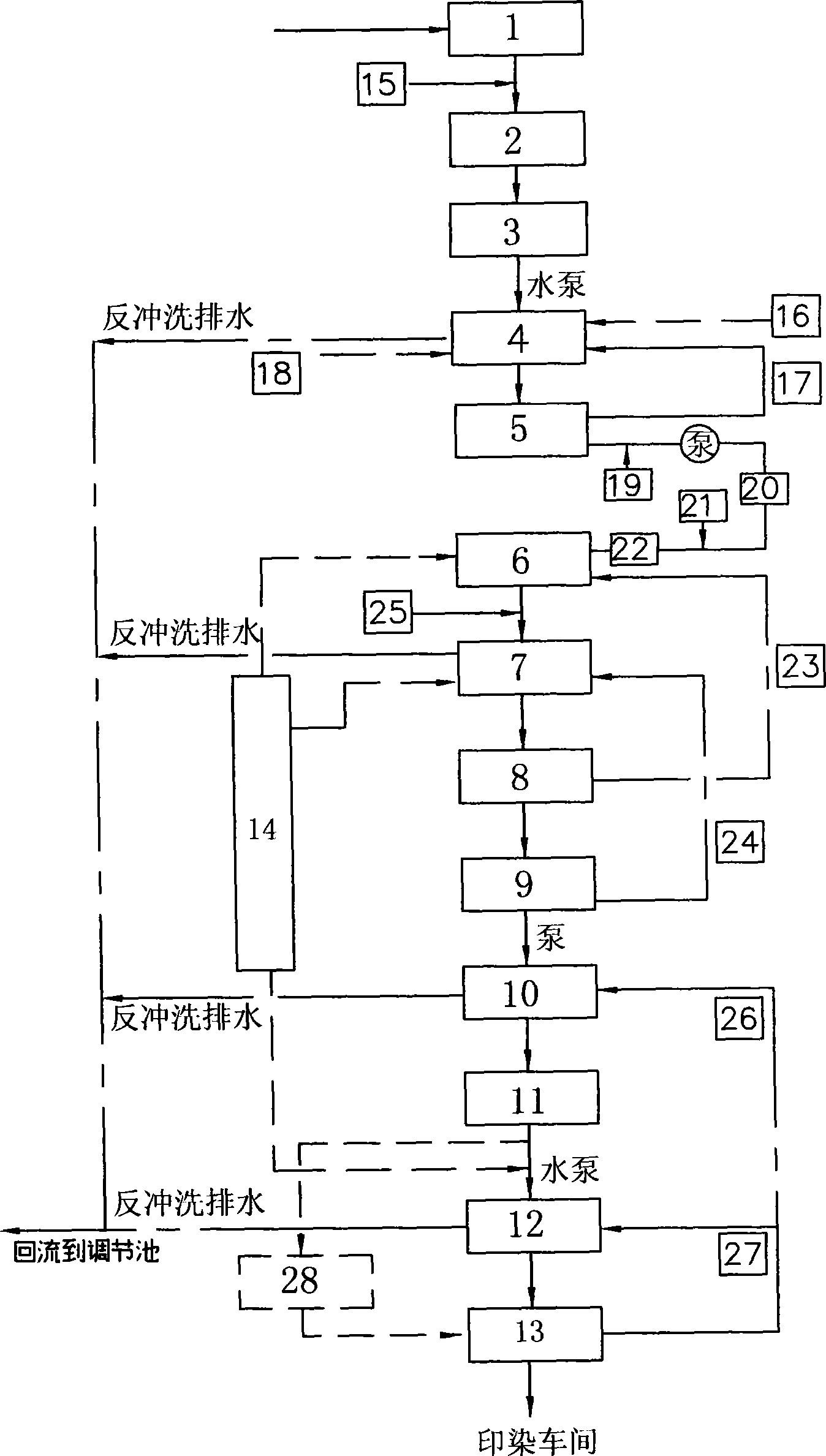

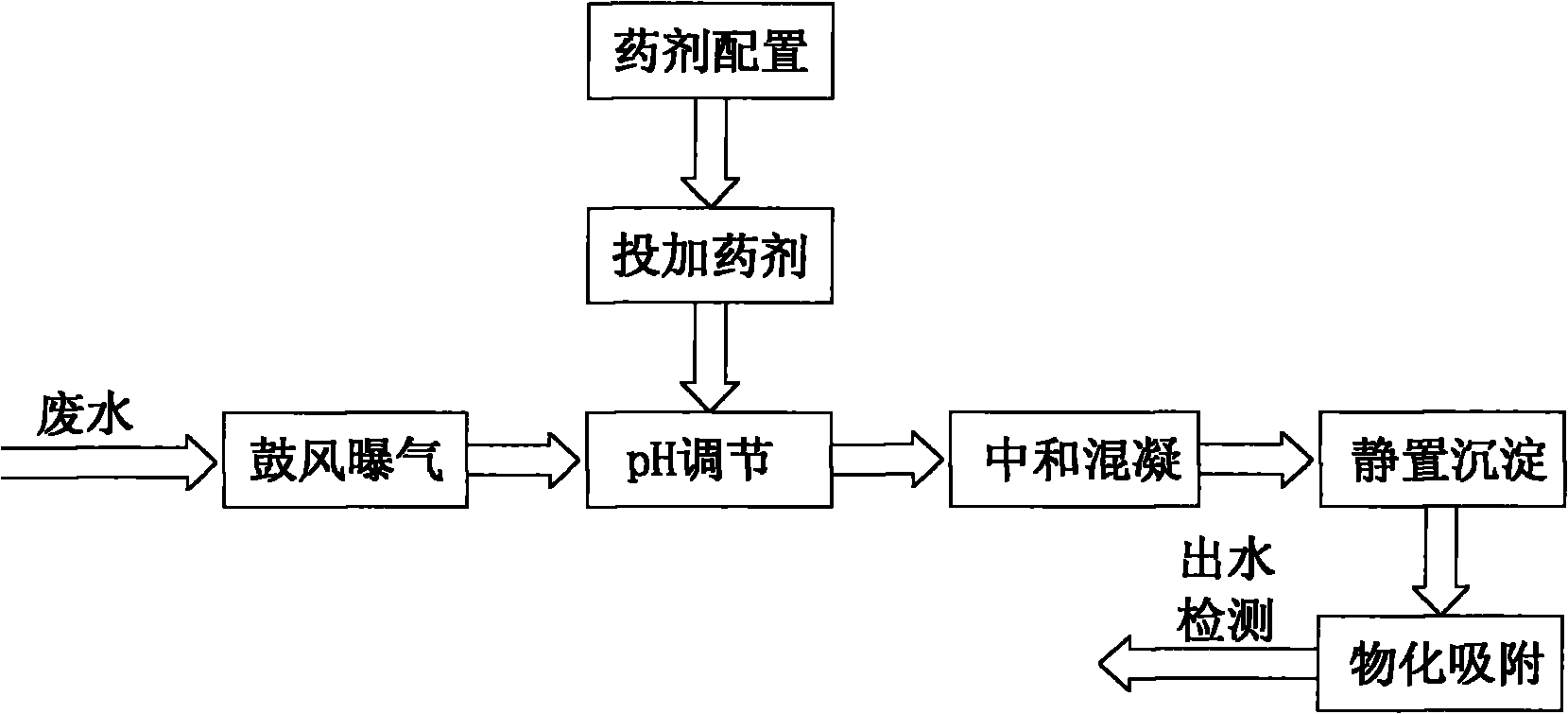

Process for treating mine wastewater containing sulfur minerals, As, Pb and Cd

InactiveCN101805084APrevent precipitationSolve the smellWaste water treatment from quariesEnergy based wastewater treatmentActivated carbon filtrationChemical adsorption

The invention discloses a process for treating mine wastewater containing sulfur minerals, As, Pb and Cd, which comprises the following steps: (1) performing blast aeration and oxidation treatment on the mine wastewater containing the sulfur minerals, As, Pb and Cd in an aeration tank; (2) neutralizing and coagulating the wastewater after the aeration and oxidation in a neutralization tank and controlling the pH to be between 8.6 and 9.5; (3) standing and depositing the wastewater after the neutralization and the coagulation treatment in a sedimentation tank; and (4) after the wastewater is clear after standing for a certain period of time, performing advanced treatment on heavy metal in a supernatant in a physical and chemical adsorption device and an activated carbon filtering system to obtain clean water meeting the environmental-protection or agricultural requirement. Through the process, peculiar smell in the mine wastewater can be eliminated, the wastewater color is changed to be normal, and the requirement of the quality of mine wastewater containing the discharged sulfur minerals, As, Pb and Cd in 'Standards for irrigation water quality' (GB5084-2005) can be met.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

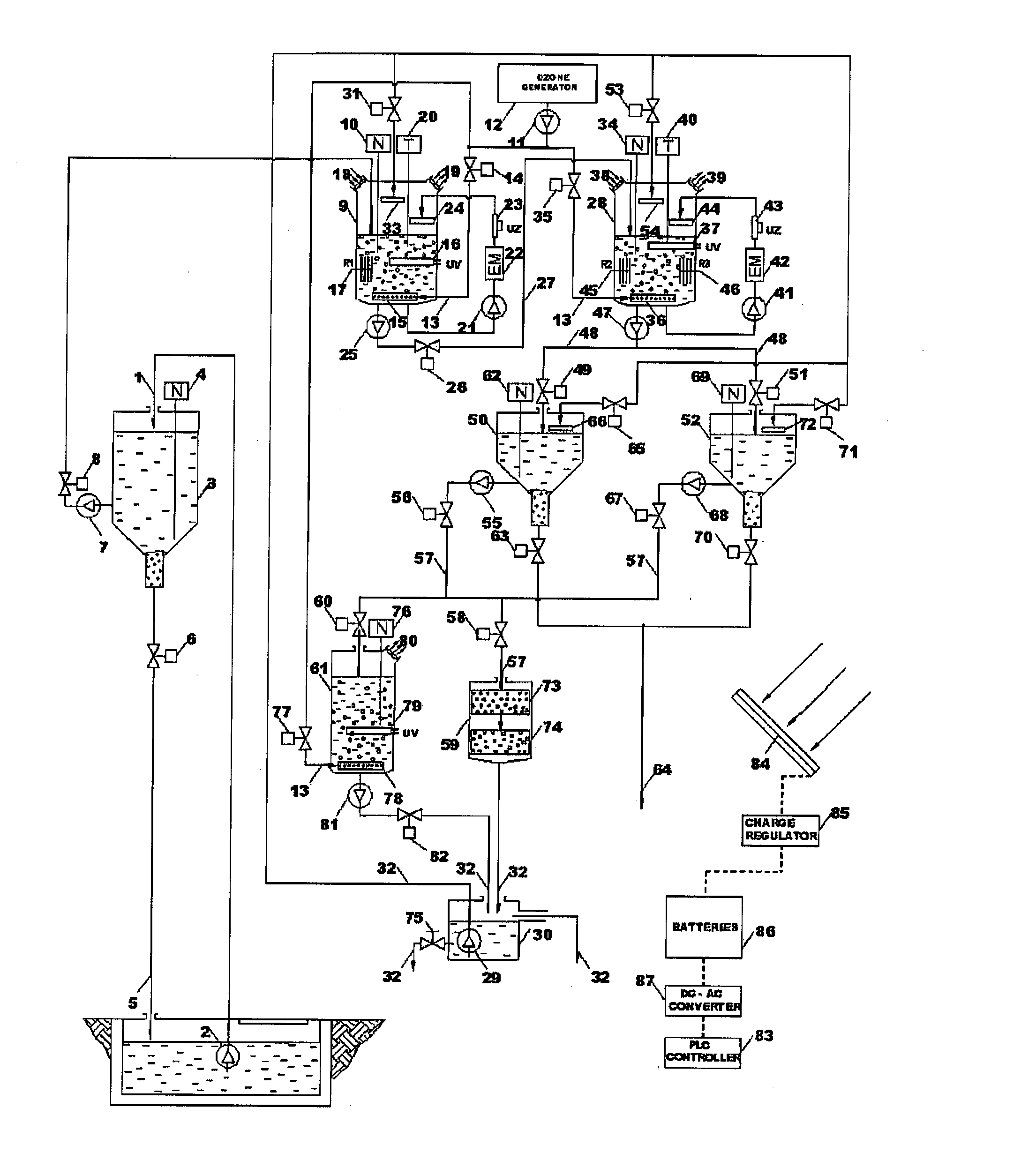

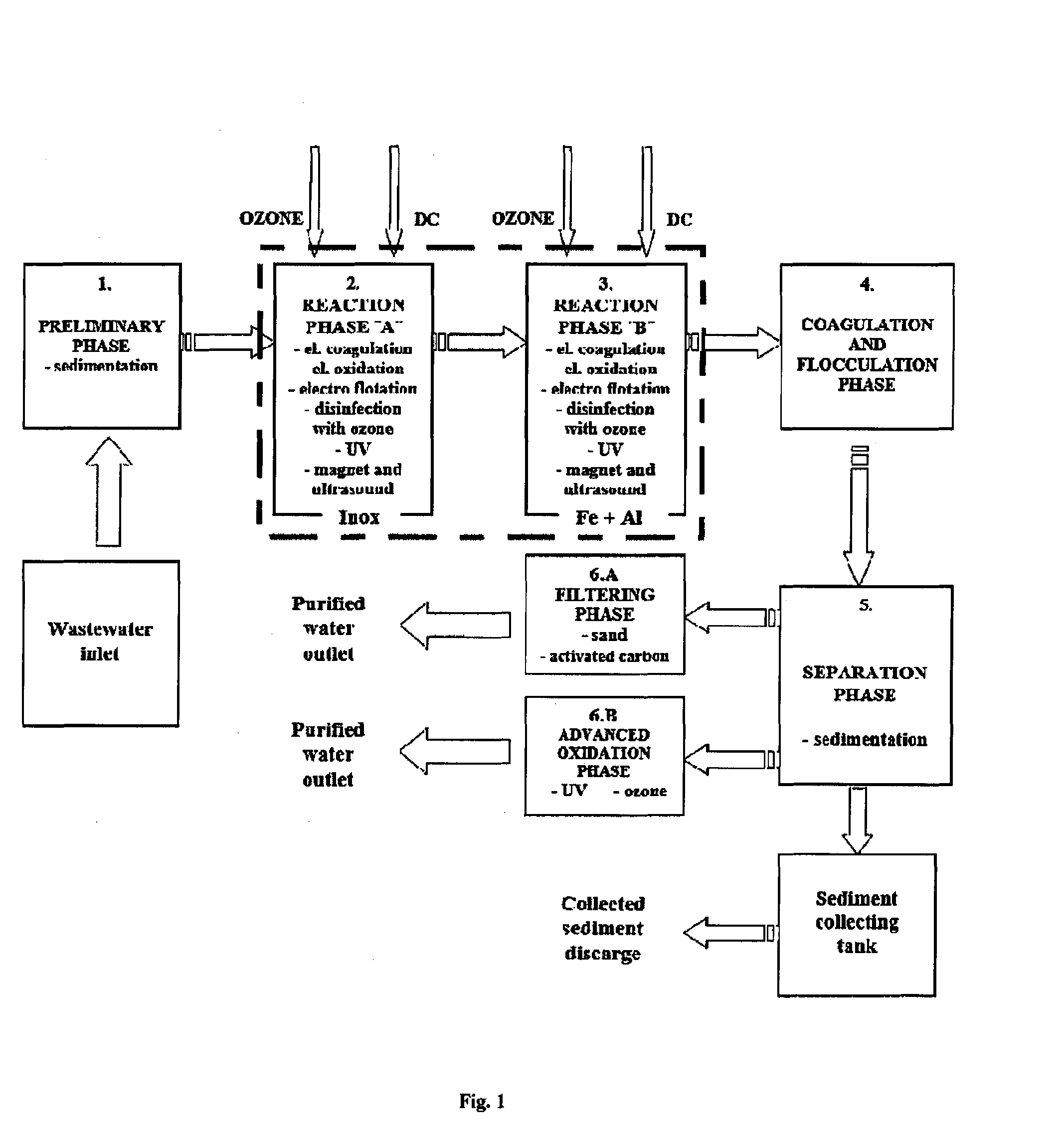

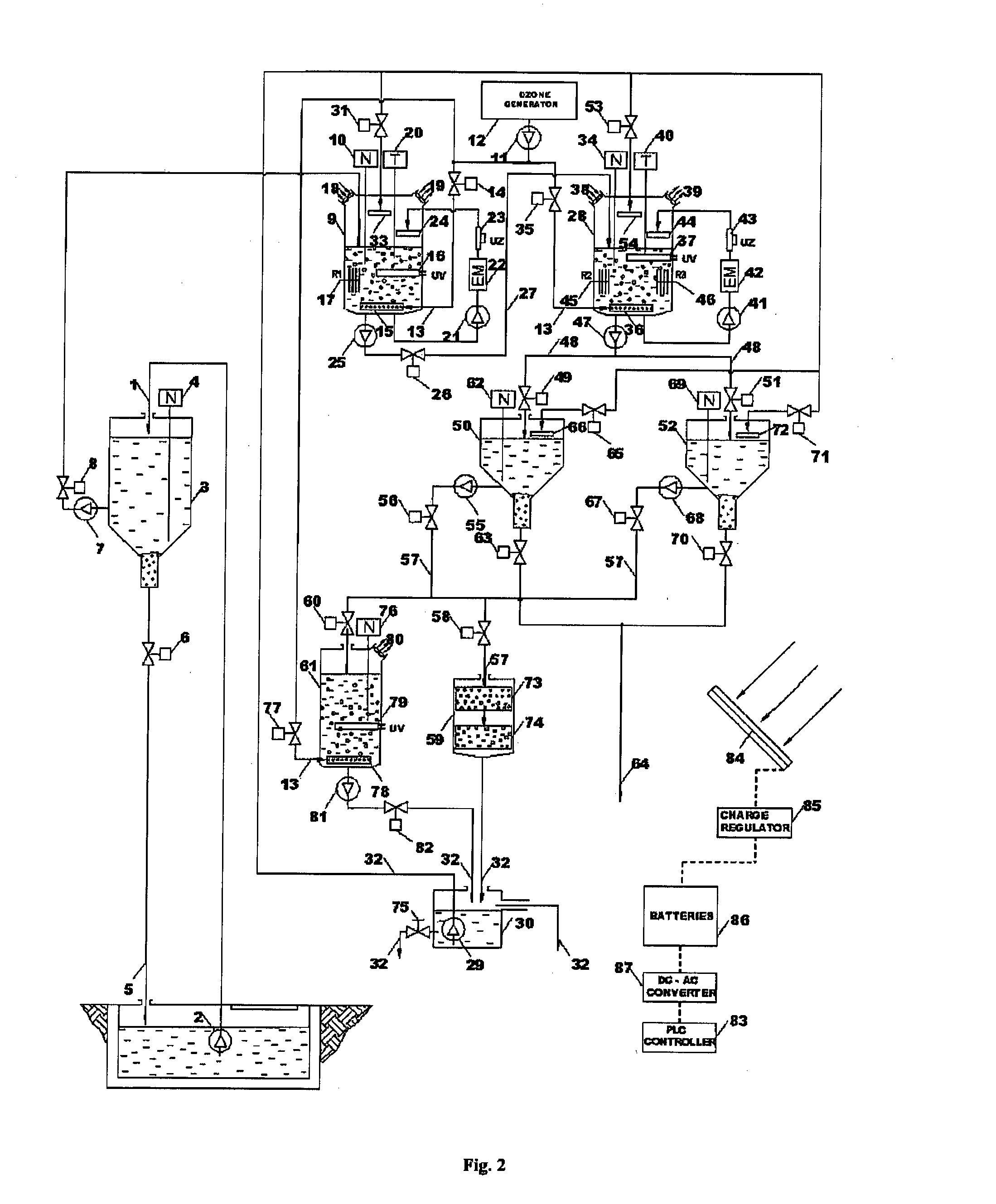

Process and device for electrochemical treatment of industrial wastewater and drinking water

InactiveUS20150166383A1Lower Level RequirementsTreatment involving filtrationSedimentation separationChemical treatmentIndustrial waste water

Subject matter of the invention is the procedure and plant for industrial wastewater and / or drinking water treatment by means of electrochemical methods and advanced oxidation processes. The preparatory phase of gravitational sedimentation is followed by main treatment consisting of electrocoagulation, electrooxidation and electroflotation through action of metal electrode sets made of inox, steel and aluminium respectively, with parallel disinfection / oxidation with ozone, UV irradiation and ultrasonic treatment, as well as recirculation in the electromagnetic field. At the end of the main treatment, the mixture of floccule and water is subject to coagulation / flocculation by electrochemically generated steel and aluminium floccule with slow infusion of ozone. The next phase is separation of sediment from clean water which is discharged through sand and activated charcoal filters for the purpose of removal of light floating floccule in the collection tank. If required, the water is subject to oxidation with simultaneous action of UV irradiation and ozone for the purpose of final destruction of organic matter and ammonia, and potential residues of microbiological contamination.

Owner:VISNJA ORESCANIN +2

Salt-containing high concentrated organic wastewater treatment device and method

PendingCN108773960AEasy to handleImprove purification qualityWater contaminantsTreatment involving filtrationFiltrationActivated carbon filtration

The invention discloses a salt-containing high concentrated organic wastewater treatment device and method in technical field of wastewater treatment. The high concentrated organic wastewater treatment device comprises a separation precipitation tank, an inner cavity of the separation sedimentation tank is provided with a precipitation auxiliary component, the left and right inner walls of an evaporation tank component are symmetrically provided with heating radiant tubes, the other end of a condenser pipe penetrates through the right side at the bottom of the condensing tank and is connectedwith a central part of the top of a neutralization filtration tank, the top of the inner chamber of the neutralization filtration tank is provided with a mixing box, and the inner chamber of the neutralization filtration tank is provided with an activated carbon filter net obliquely; the treatment device has a good treatment effect and high purification quality; the wastewater is placed in the separation precipitation tank for precipitation, the precipitated wastewater enters the evaporation tank component and is heated at a high temperature by the heating radiant tubes to complete the sewageand salt separation, the water vapor passes through the condensing tank, the condenser pipe and the ice bag cooperate with each other, so that the steam is cooled to form water and then enters the mixing box, then the rotating rod is driven by the stirring motor to perform neutralization stirring, and finally the wastewater is filtered.

Owner:南京御楠枫技术转移有限公司

Personal protection, procedural and surgical mask

InactiveUS20070175477A1Reduce air leakageAvoid passingBreathing filtersBreathing masksChinRespirator

A preformed seam, crease, or fold in the bottom portion of a surgical, procedural, or personal protection mask forms a chin pocket in the bottom of the mask to receive the user's chin therein. This pocket has been found to provide a better mask fit to reduce the air leakage around the mask not only around the user's chin, but around the entire face. The mask may also have a unique construction of the filter material which includes a filter layer and a moisture resistant layer. The mask also may include a soft comfortable layer for placement against the face of a user. The filter layer can provide an activated charcoal filter and / or a particulate filter which allows gas to pass therethrough but resists passage of bacteria, viruses, and particulate materials.

Owner:MEDSPRING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com