Patents

Literature

1285results about How to "Low VOC content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

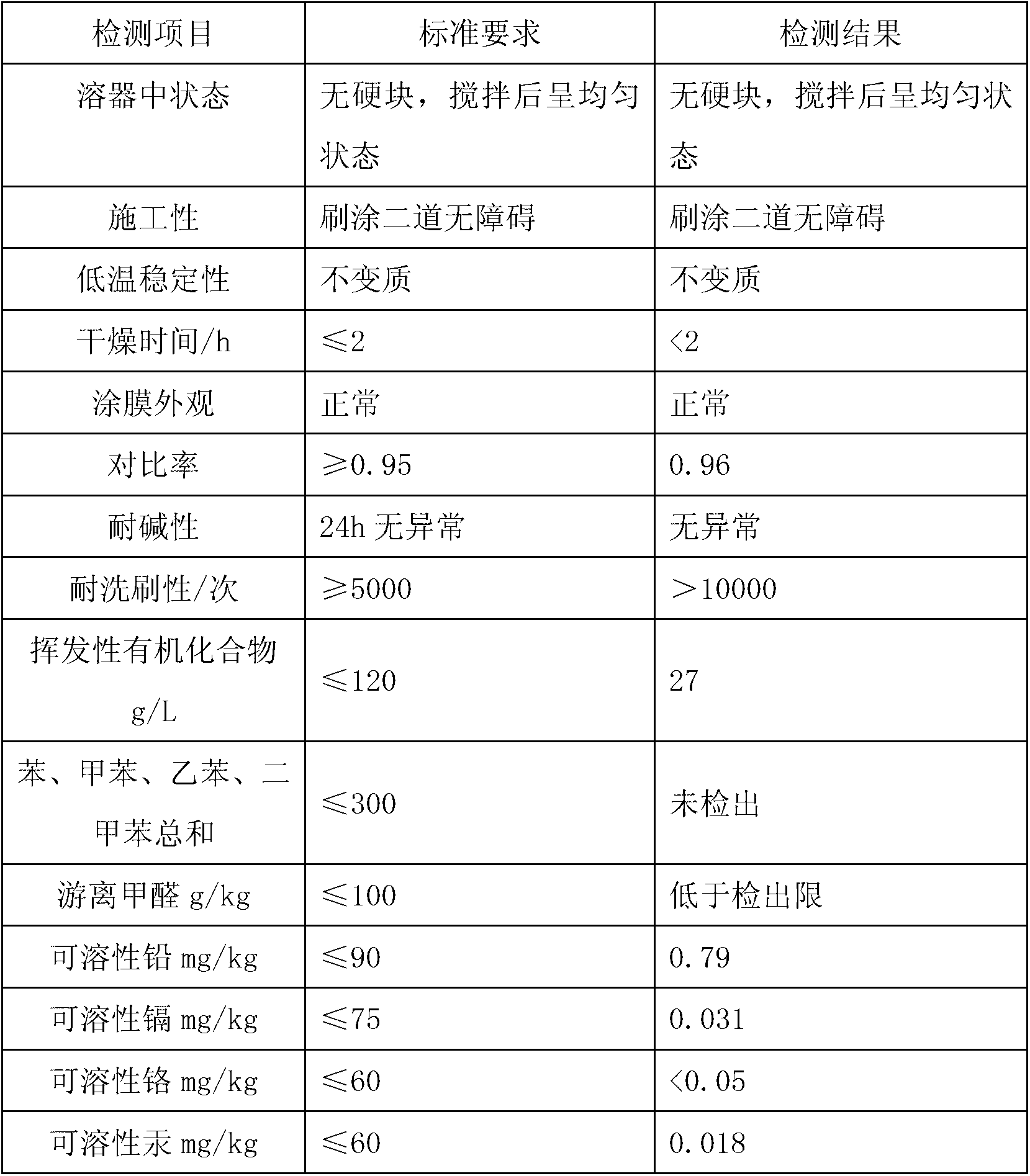

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

Low-VOC aqueous coating compositions with excellent freeze-thaw stability

InactiveUS6933415B2Improve freeze-thaw stabilityLow in VOCsOrganic compound preparationSpecial tyresFreezing thawingSURFACTANT BLEND

The present invention is an aqueous coating composition having excellent freeze-thaw stability and a low-VOC content. The aqueous coating composition of the invention includes at least one latex polymer derived from at least one monomer and at least one polymerizable alkoxylated surfactant, at least one pigment, and water. In accordance with the invention, less than 3.0% by weight of anti-freeze agents based on the total weight of the aqueous coating composition are used in the composition. The present invention also includes a method of preparing an aqueous coating composition such as a latex paint including the above components.

Owner:BASF AG

Water epoxy paint for ground floor and its mfg. process and construction technology

The invention relates to a water epoxy ground floor coating and its making method and constructing process, where one component is low-molecular weight liquid-state epoxy resin assorted with active diluter in a proper proportion, and the other component is a dispersoid with hydrophilic curing agent as the principal thing, containing water-borne curing agent, water, acid-resistant wearable color filler, various auxiliaries, etc. and its producing method is simple and mainly includes mechanical dispersing and mixing; it does need to clean paint-covered surface as used on humid basal surface; the paint film has excellent properties of oily products and unilateral permeability. It uses water as dispersing medium, has no VOC, safe and environmental-protection.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

High-solid hydroxyl fluorine-containing acrylic resin and preparation method thereof

The invention relates to high-solid hydroxyl fluorine-containing acrylic resin and a preparation method thereof. The high-solid hydroxyl fluorine-containing acrylic resin comprises the following components in parts by weight: 10-25 parts of fluorine-containing acrylic ester monomer, 10-30 parts of hydroxyl group-containing acrylic ester monomer, 5-20 parts of methyl acrylic alkyl ester monomer, 5-15 parts of acrylic alkyl ester monomer, 0.3-6 parts of initiator, 0.2-4 parts of chain transfer and 30-50 parts of solvent. According to the hydroxyl fluorine-containing acrylic resin, the solid content reaches up to 75-90 percent, the viscosity is only 900-3,000 mPa.s, the number-average molecular weight is 1,200-6,000, and the molecular weight distribution index is 1.4-2.5; and the resin has the advantages of superior performance, high transparency, no odor of mercaptan, low VOC (Volatile Organic Compound) content, a fluorine carbon group included on a polymer chain and superior corrosion resistance of the resin and can be applied to the fields such as heavy anticorrosive coatings, marine antifouling coatings, aircraft surface coatings, anti-doodling coatings, exterior wall coatings of high weathering resistance and the like.

Owner:SOUTHEAST UNIV

All-in-one water-borne inorganic-organic hybrid architectural coating and preparation method thereof

ActiveCN102408220AWaterproof and breathableIncrease viscosityEmulsion paintsThermal insulationOragene

The invention relates to an all-in-one water-borne inorganic-organic hybrid architectural coating and a preparation method thereof, wherein the all-in-one water-borne inorganic-organic hybrid architectural coating is prepared by taking a compounded product of a water-borne inorganic film-forming matter and an organic polymer emulsion as a base material through the steps of adding various pigments / fillers and auxiliaries into the base material, then carrying out beating, grinding and paint mixing on the obtained mixture. In the invention, through a Si-O-Si polymer net structure which can be formed by compounding alkali metal silicates and small-particle-size silica sols in the process of film forming, the early water resistance of a paint film is greatly increased, and the eventual hardness, scraping resistance and stain resistance of the paint film are greatly increased; and through adding the organic polymer emulsion, the film-forming performance of the coating can be improved, and the defects that the traditional two-component inorganic coating is easy to crack, bad in decorative properties, poor in storage stability, and the like are overcome. The coating prepared by using the method disclosed by the invention has various functions of environmental friendliness, non-toxicity, thermal insulation, ultra scrubbing resistance, abrasion resistance, yellowing resistance, ageing resistance, fouling resistance, good air permeability, sound insulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH

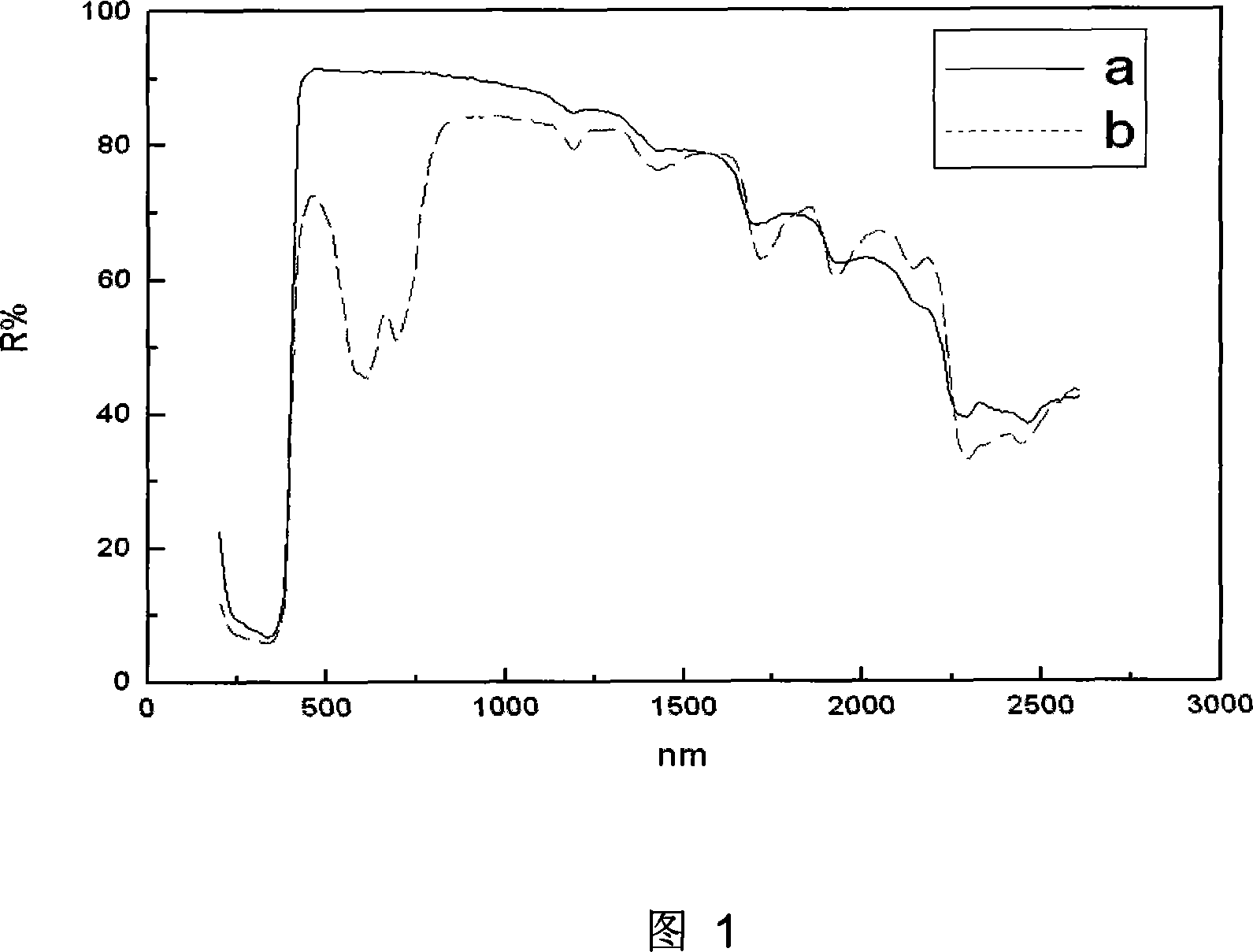

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

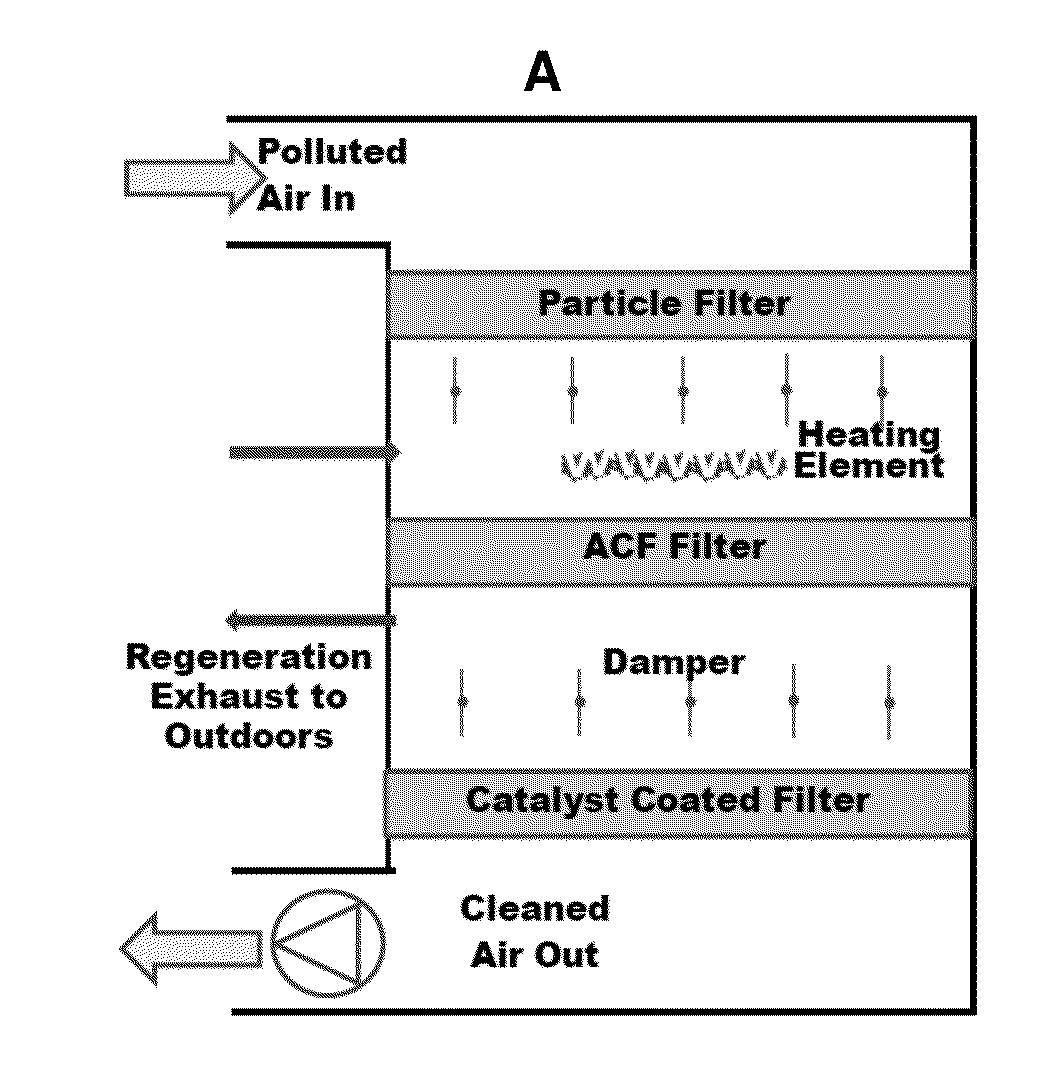

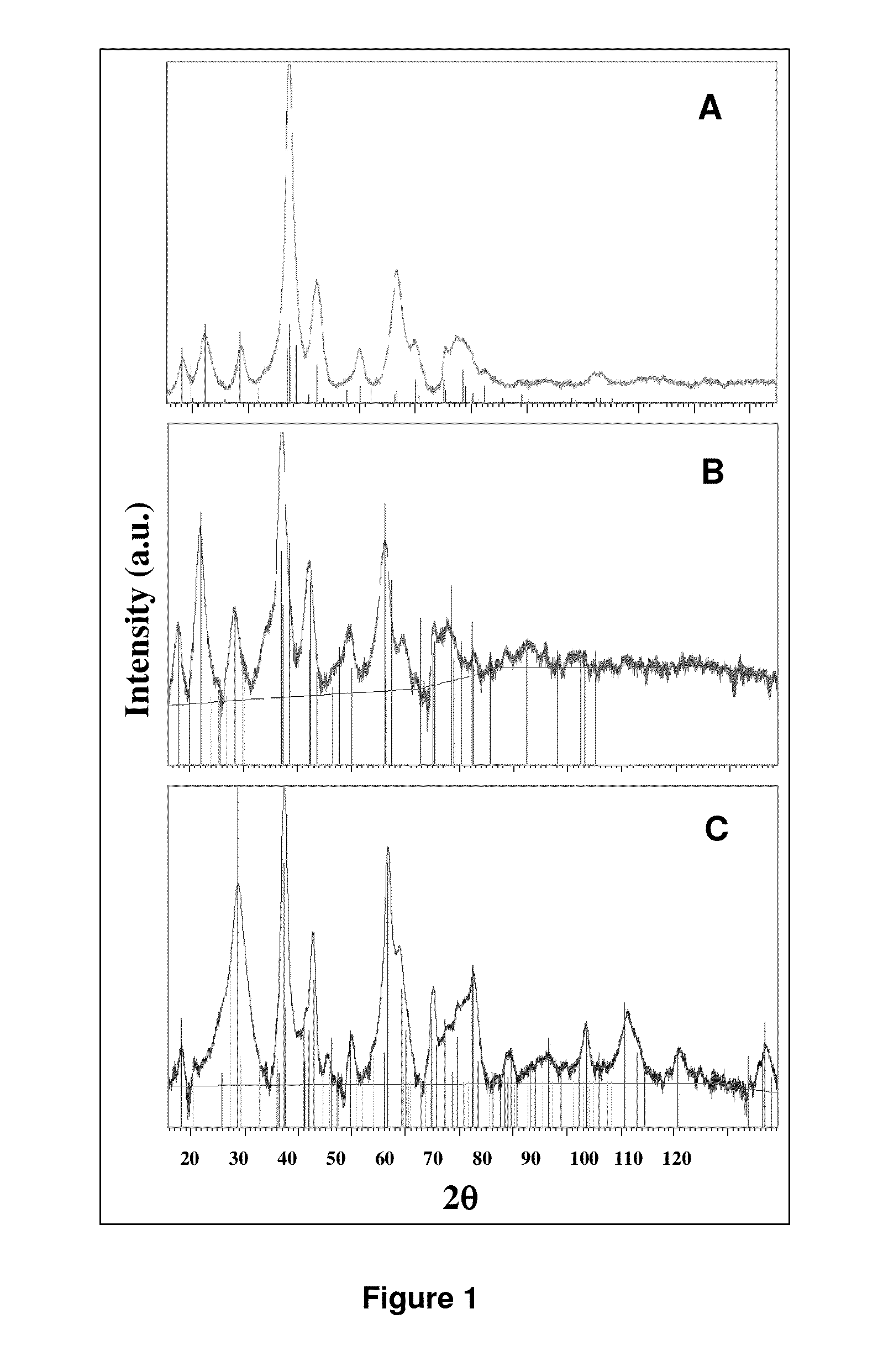

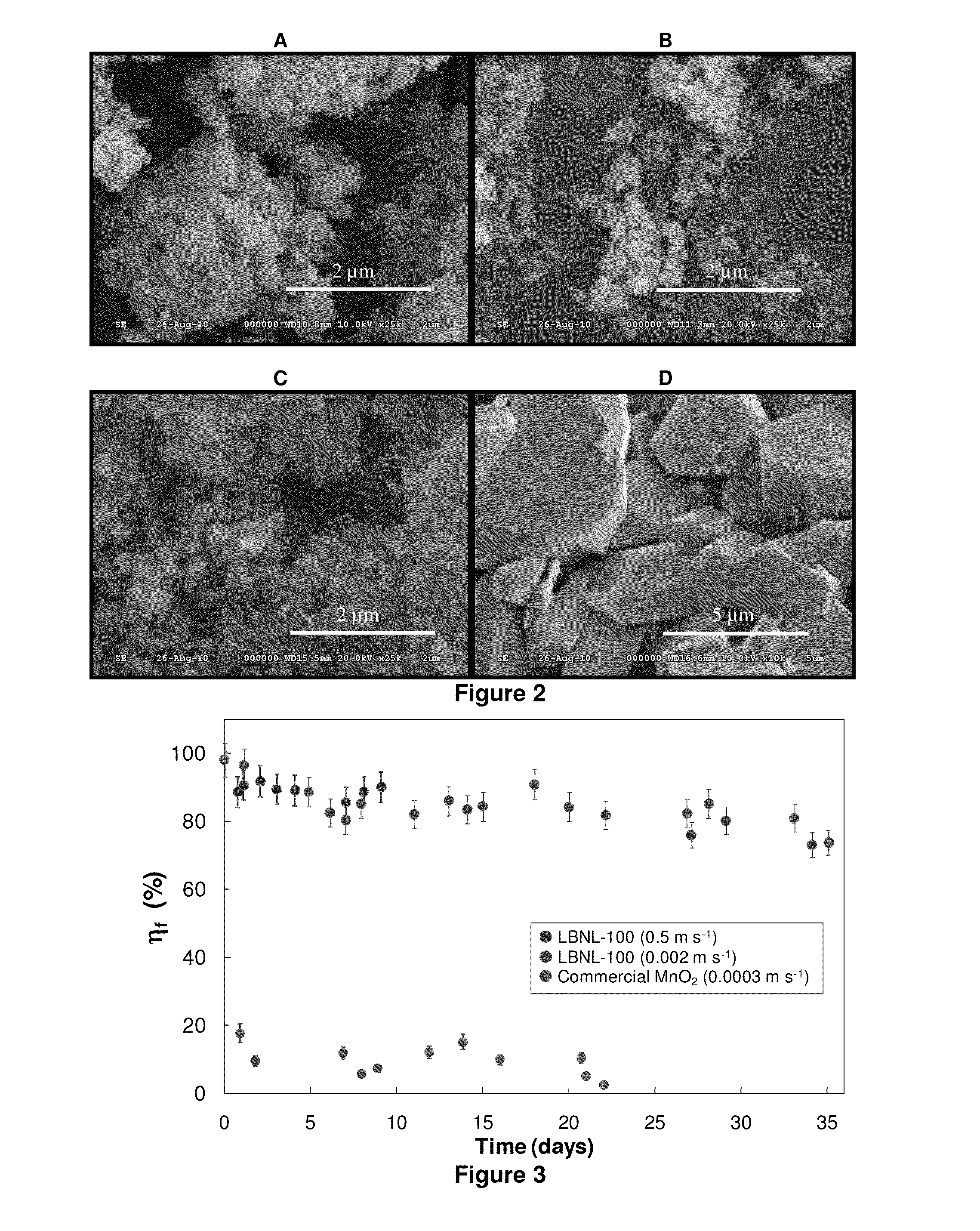

Use of Manganese Oxide and Activated Carbon Fibers for Removing a Particle, Volatile Organic Compound or Ozone from a Gas

InactiveUS20140255283A1Reduce contentLow VOC contentOrganic chemistryManganese oxides/hydroxidesFiberCarbon fibers

The present invention provides for a device for reducing a volatile organic compound (VOC) content of a gas comprising a manganese oxide (MnOx) catalyst. The manganese oxide (MnOx) catalyst is capable of catalyzing formaldehyde at room temperature, with complete conversion, to CO2 and water vapor. The manganese oxide (MnOx) catalyst itself is not consumed by the reaction of formaldehyde into CO2 and water vapor. The present invention also provides for a device for reducing or removing a particle, a VOC and / or ozone from a gas comprising an activated carbon filter (ACF) on a media that is capable of being periodically regenerated.

Owner:RGT UNIV OF CALIFORNIA

Environment-friendly type aqueous aluminum foil protecting agent and preparation thereof

InactiveCN101407655ALow VOC contentReduce manufacturing costPolyurea/polyurethane coatingsPolyamide coatingsGeneral purposeOrganosolv

The invention relates to an environmental-friendly waterborne aluminum foil protective agent and a prepration method thereof, wherein, the protective agent comprises the following components according to the formula by weight: 45 percent to 70 percent main resin; 0 percent to 20 percent assisted resin; 10 percent to 50 percent water; 0 percent to 35 percent cosolvent; 0 percent to 0.5 percent film-forming auxiliary agent; 0 percent to 0.5 percent leveling agent; 0 percent to 0.5 percent defoamer; 0 percent to 2 percent anti-abrasion agent; and 0 percent to 0.5 percent pH regulator. Compared with the prior art, the environmental-friendly waterborne aluminum foil protective agent and the prepration method have the advantages: (1) the aluminum foil protective agent contains no organic solvent which is harmful to human body and has very low content of VOC, and water and ethanol are used for dilution during the using process, thereby being non-toxic and low in production cost; (2) the aluminum foil protective agent has good adhesion, good transparency, high smoothness and high thermal resistance performance; (3) the aluminum foil protective agent belongs to the general purpose products, and the range of application is broad; and (4) the production process is reasonable, the operation is simple and the production efficiency is high.

Owner:SHANGHAI WEIKAI CHEM

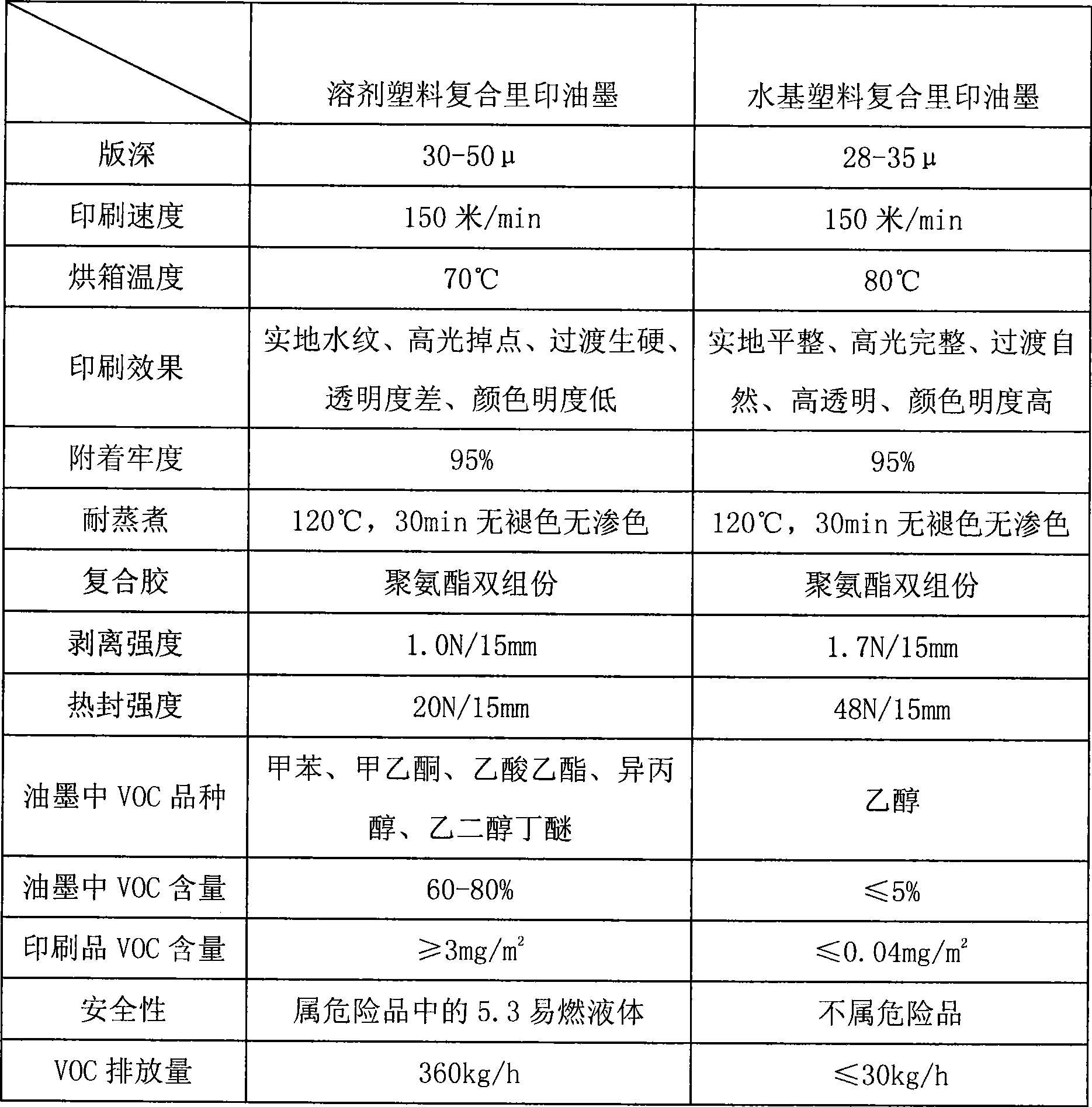

Water-based plastic composite inner-printing ink

The invention discloses a water-based plastic composite printing ink, in particular to a water-based ink needed in the plastic film intaglio printing composite process. To solve problems, the invention provides the water-based ink which remarkably improves composite strength, sealing strength and printing mass relative to the prior solvent ink on the premise of not reconstructing the prior printing equipment or adjusting the printing process; the water-based ink adopts the following technical proposal: the water-based plastic composite printing ink is prepared from the following raw materials in weight portion: 10 to 35 portions of aqueous polyurethane emulsion, 0 to 8 portions of aqueous acrylic resin, 0 to 7 portions of aqueous wetting dispersant, 0.2 to 2 portions of aqueous dampness levelling agent, 0.1 to 2 portions of aqueous defoaming agent, 0.1 to 5 portions of PH regulator, 6 to 30 portions of pigment, 0 to 5 portions of ethanol and 6 to 73.6 portions of water. The water-based ink can be widely applied in the field of ink manufacturing.

Owner:山西鹰鲲科技有限公司 +1

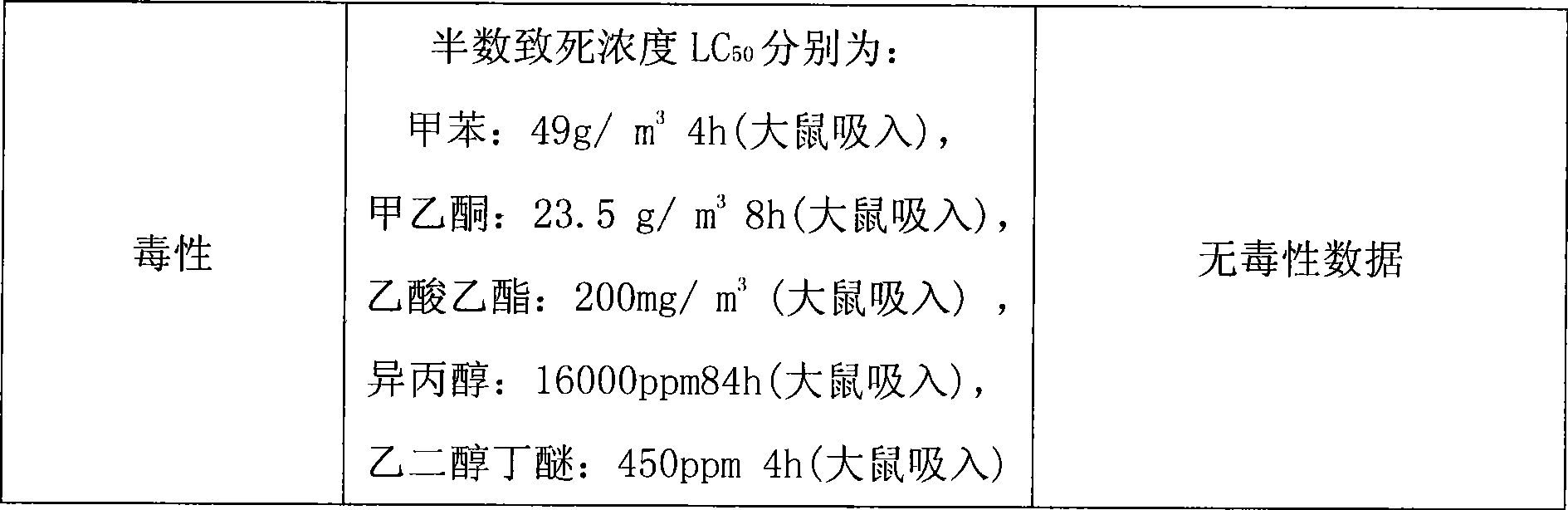

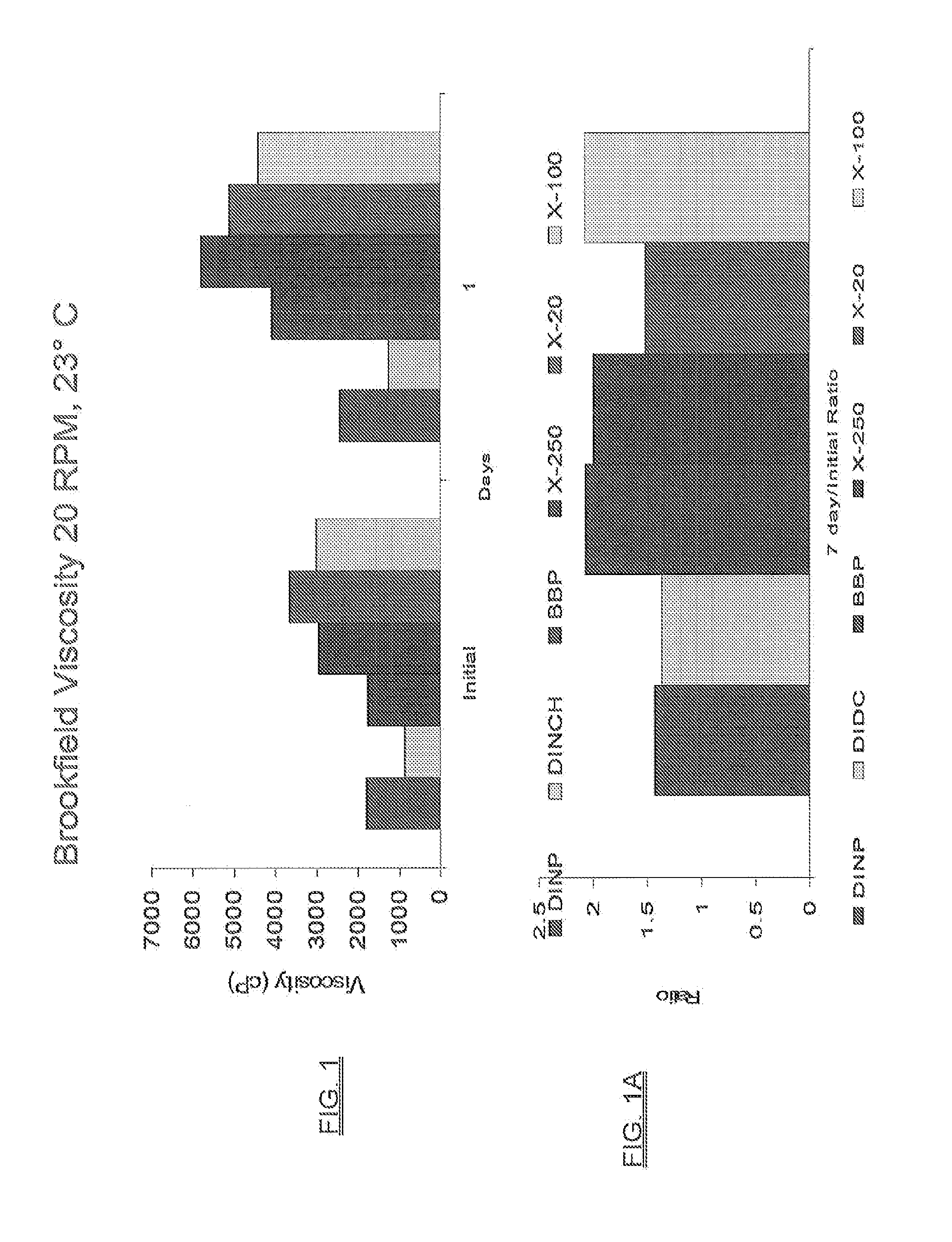

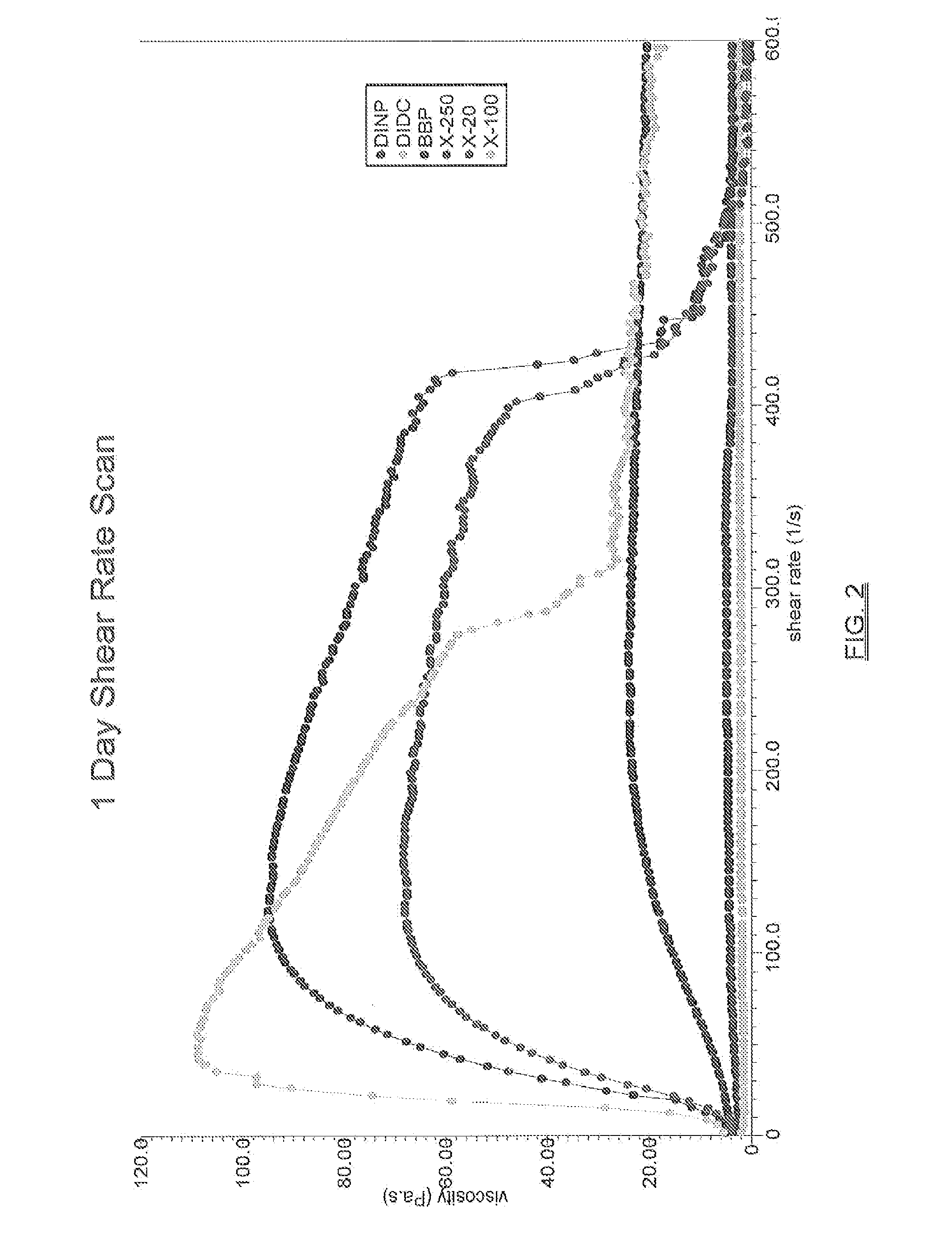

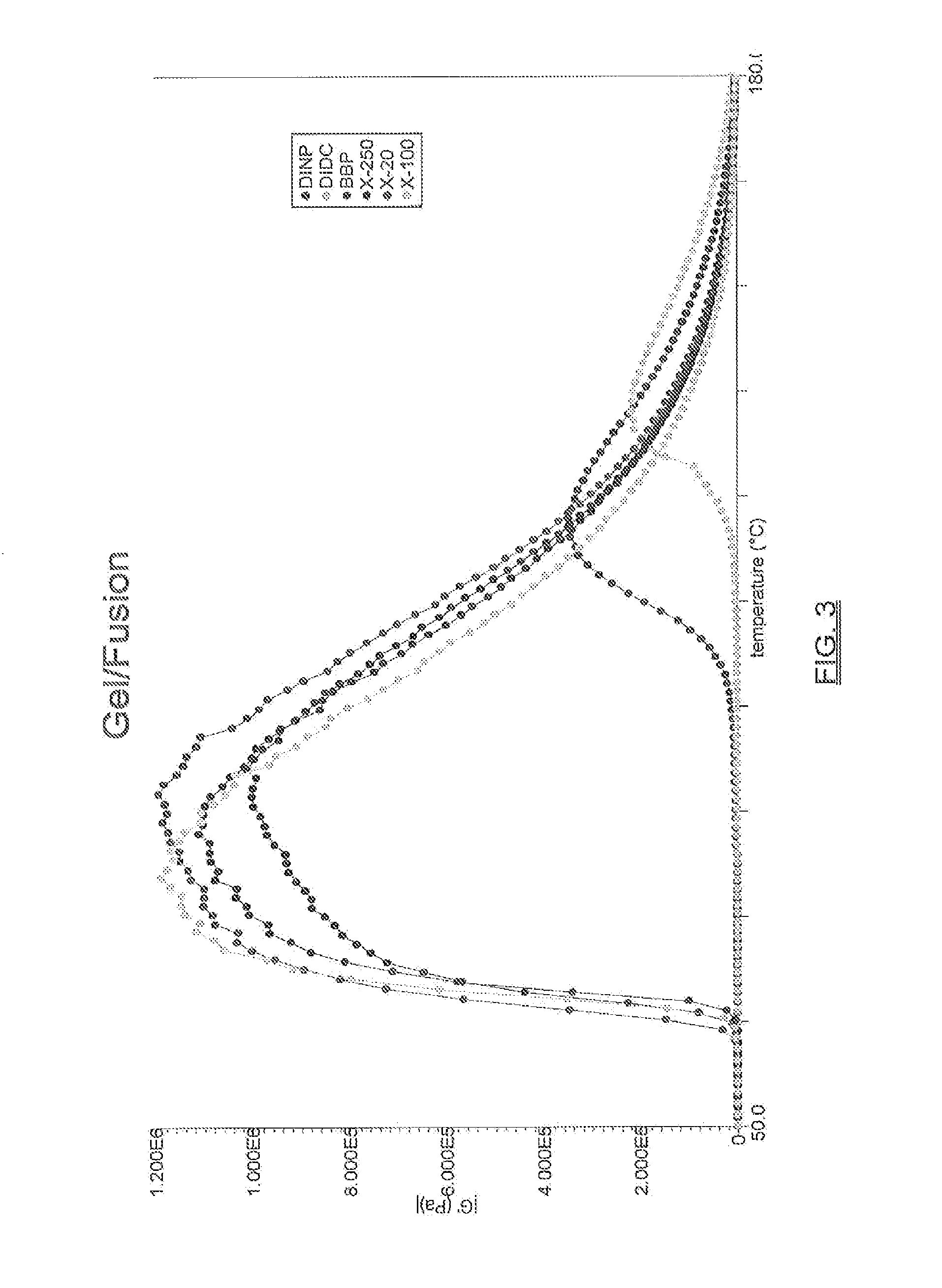

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

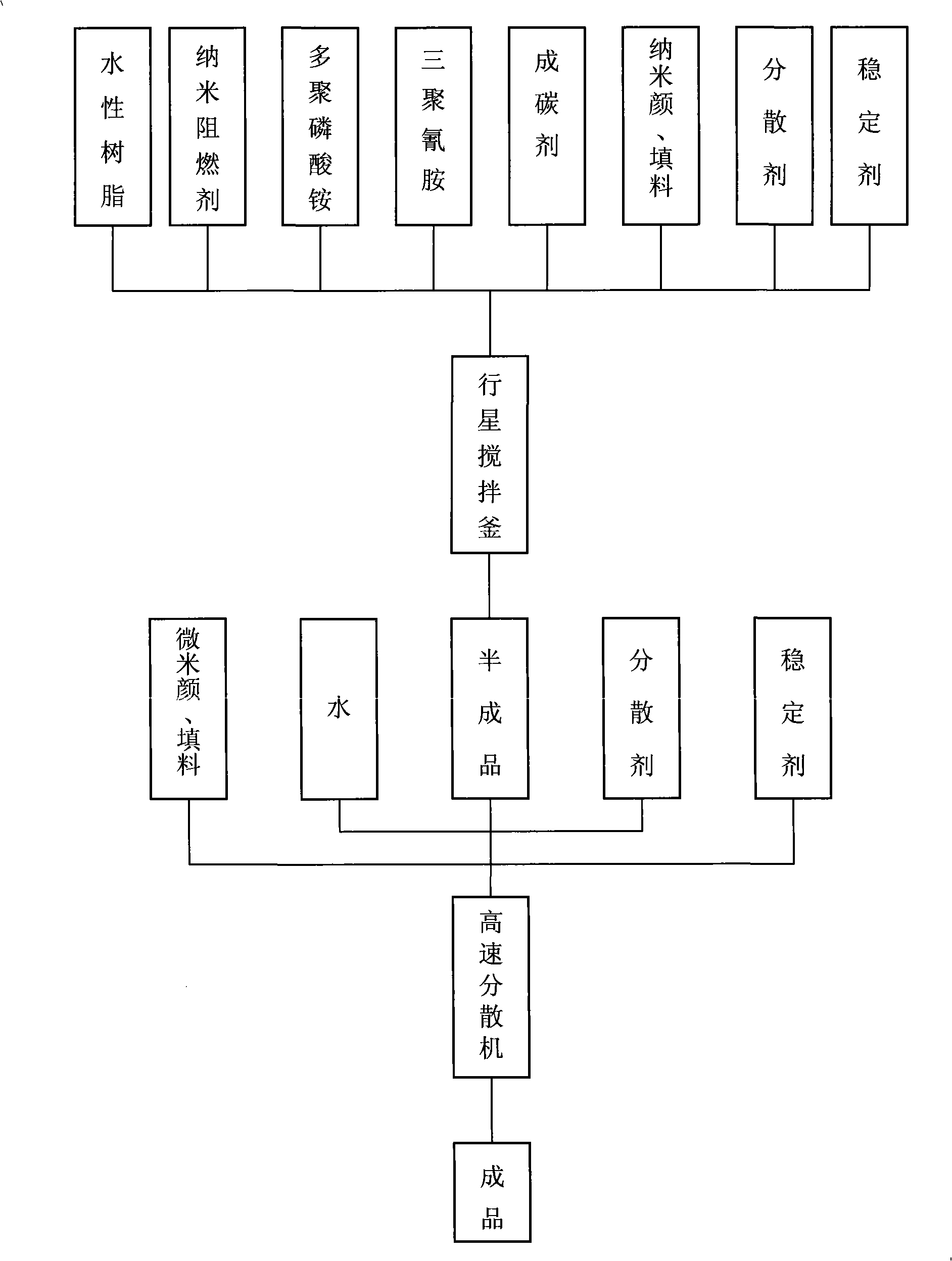

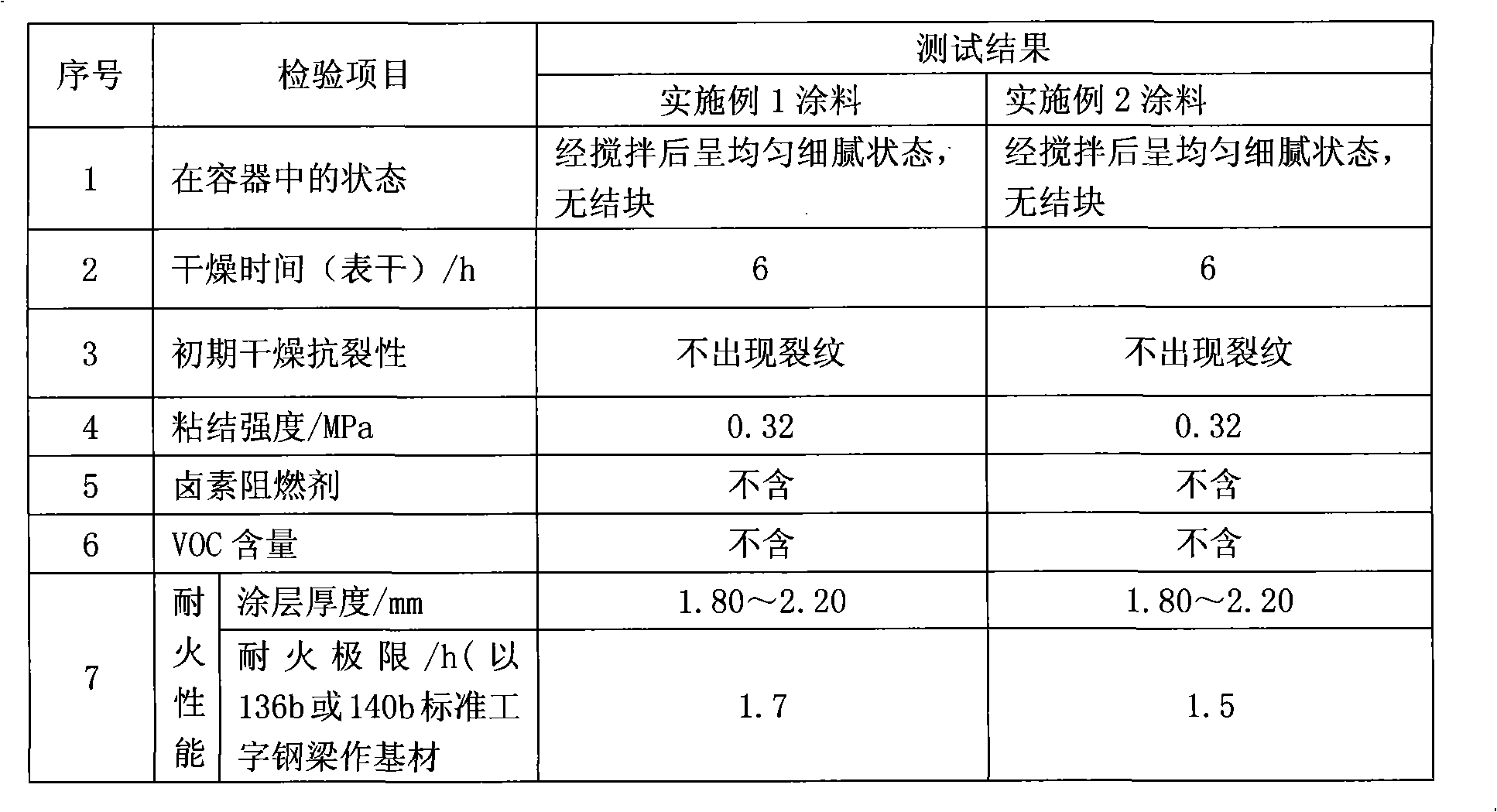

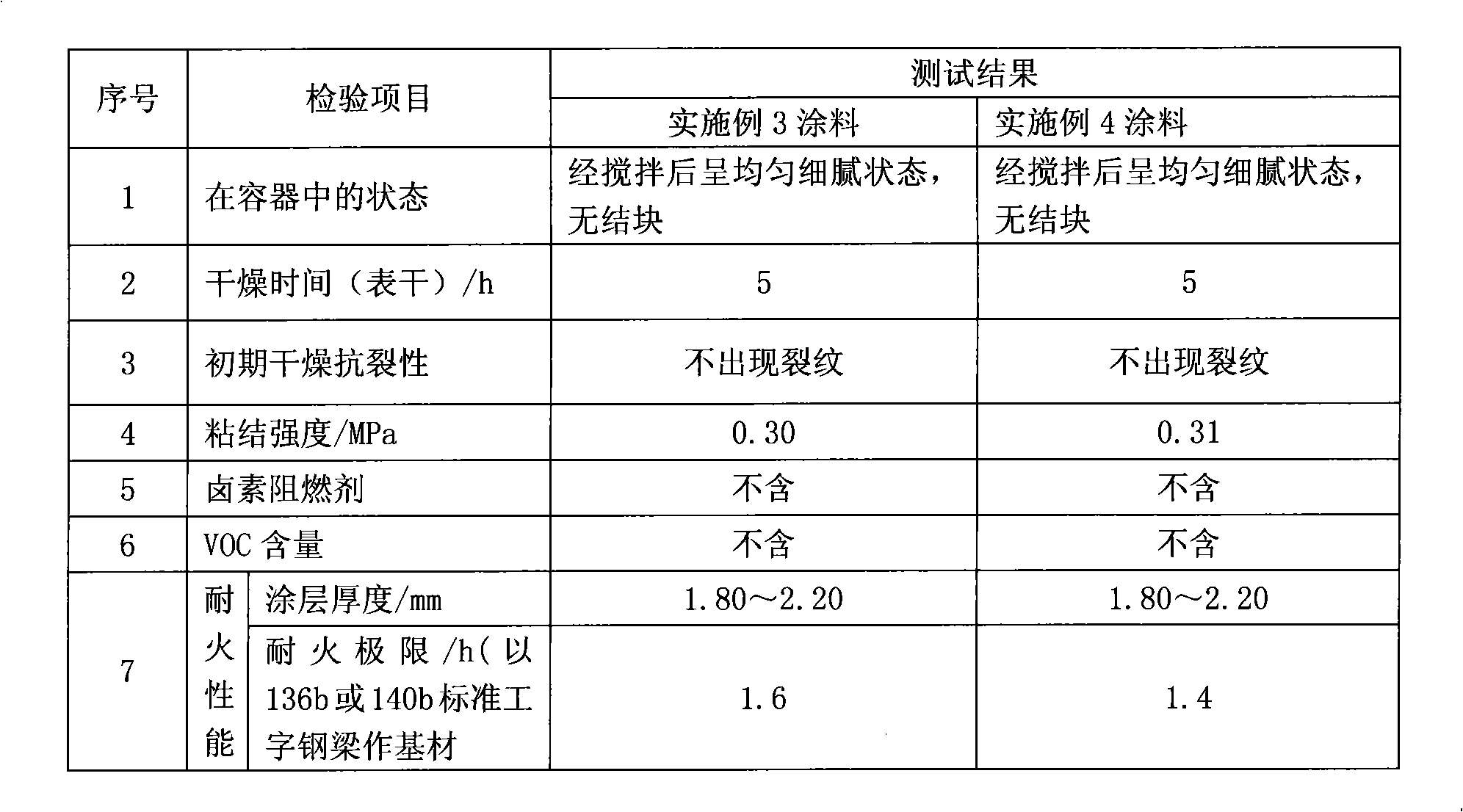

Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

InactiveCN101280142AImprove fire performanceLow VOC contentFireproof paintsEmulsion paintsPolymerStabilizing Agents

The invention is environmental-friendly waterborne nanometer fireproof flame-retardant coating and the preparation method, which belong to the fireproof flame-retardant coating manufacturing industry. The flame-retardant coating is obtained through the compounding of two types of flame-retardant agents, waterborne resin, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and filler, micrometer pigment and filler and other auxiliary agent; the flame-retardant coating contains no organic agent and halogen flame retardant, low VOC content, good fireproof property, good physical and chemical properties; the composition of the flame-retardant coating is as follows: the content of waterborne resin is 10-90%; the content of phyllo-silicate nanometer flame retardant which contains phosphor, nitrogen organic intercalation is 1-50%; the content of nanometer magnesium hydroxide flame retardant wrapped by polymer is 1-50%; the content of ammonium polyphosphate is 1-30%; the content of melamine is 1-20%; the content of carbon-forming agent is 1-30%; the content of nanometer pigment and filler is 0.1 to 30%; the content of micrometer filler is 0.1 to 60%; the content of dispersant is 0.1 to 10%; the content of stabilizer is 0.1 to 10%; the content of water is 0.1 to 50%; the content of micrometer pigment is proper; firstly, waterborne resin, nanometer flame retardant, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and fillers, dispersant and stabilizer are put into a planet stirring reactor for stirring and even dispersion; micrometer pigment and filler, water, dispersant and stabilizer are added to the discharged mixture and then put into a high-speed dispersion machine for even dispersion so that the product is obtained.

Owner:中山市孙大化工科技有限公司

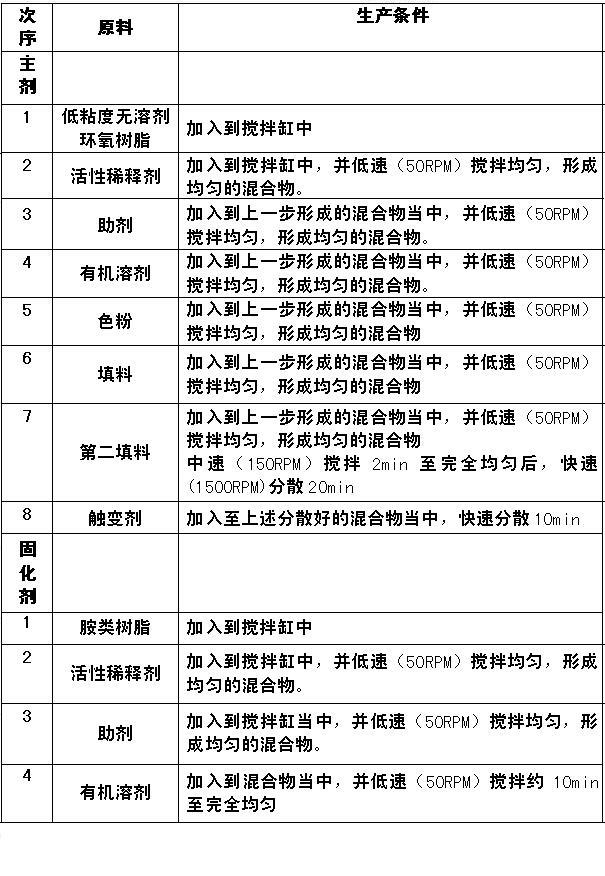

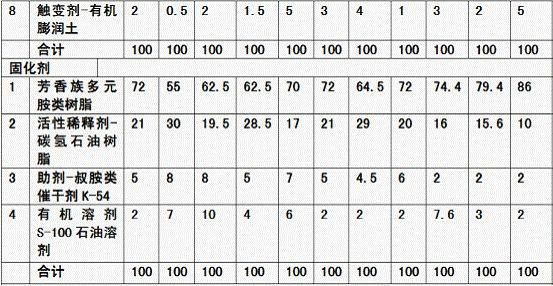

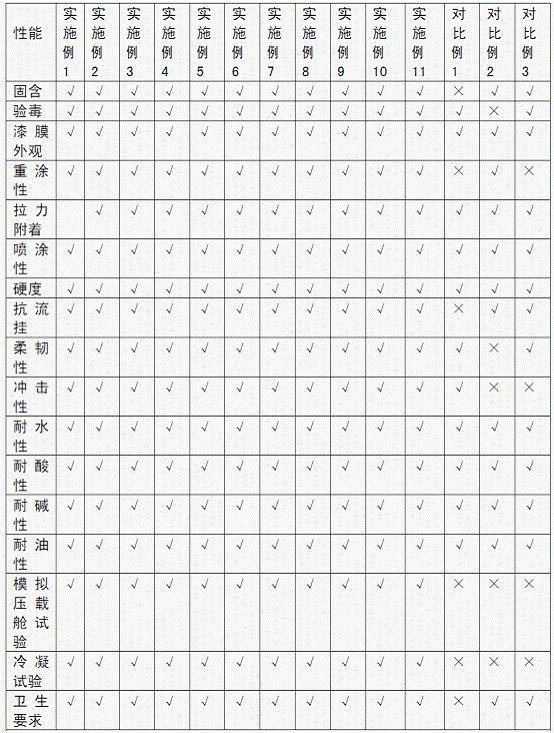

Novel environment-friendly coating with superhigh marine environment corrosion resistance and preparation method and application thereof

ActiveCN102352171AImprove anti-corrosion performanceGood resistance to salt sprayAnti-corrosive paintsEpoxy resin coatingsEpoxyEnvironmental resistance

The invention discloses a novel environment-friendly coating with superhigh marine environment corrosion resistance and a preparation method and application thereof. The environment-friendly coating with superhigh marine corrosion resistance consists of the following components in part by weight: a main agent comprising 22 to 35 parts of low-viscosity solvent-free epoxy resin, 9 to 15 parts of activated thinner, 0.2 to 5 parts of aid, 5 to 8 parts of organic solvent, 0.5 to 15 parts of toner, 10 to 25 parts of first filler, 20 to 45 parts of second filler and 0.5 to 5 parts of thixotropic agent, and a curing agent comprising 60 to 90 parts of amine resin, 10 to 30 parts of activated thinner, 2 to 8 parts of aid and 2 to 10 parts of organic solvent. During use, the main agent and the curing agent are uniformly mixed, and the mixture is applied to the surface of a substrate. A film formed by the coating is high in corrosion resistance and low in content of volatile organic compounds (VOC), does not contain any toxic or harmful substance, can be universally used in a drinking water tank, and also can be used for a ship ballast tank, a ship bottom, a deck and each position of a marine platform.

Owner:CHINA PAINT MFG CO SHENZHEN

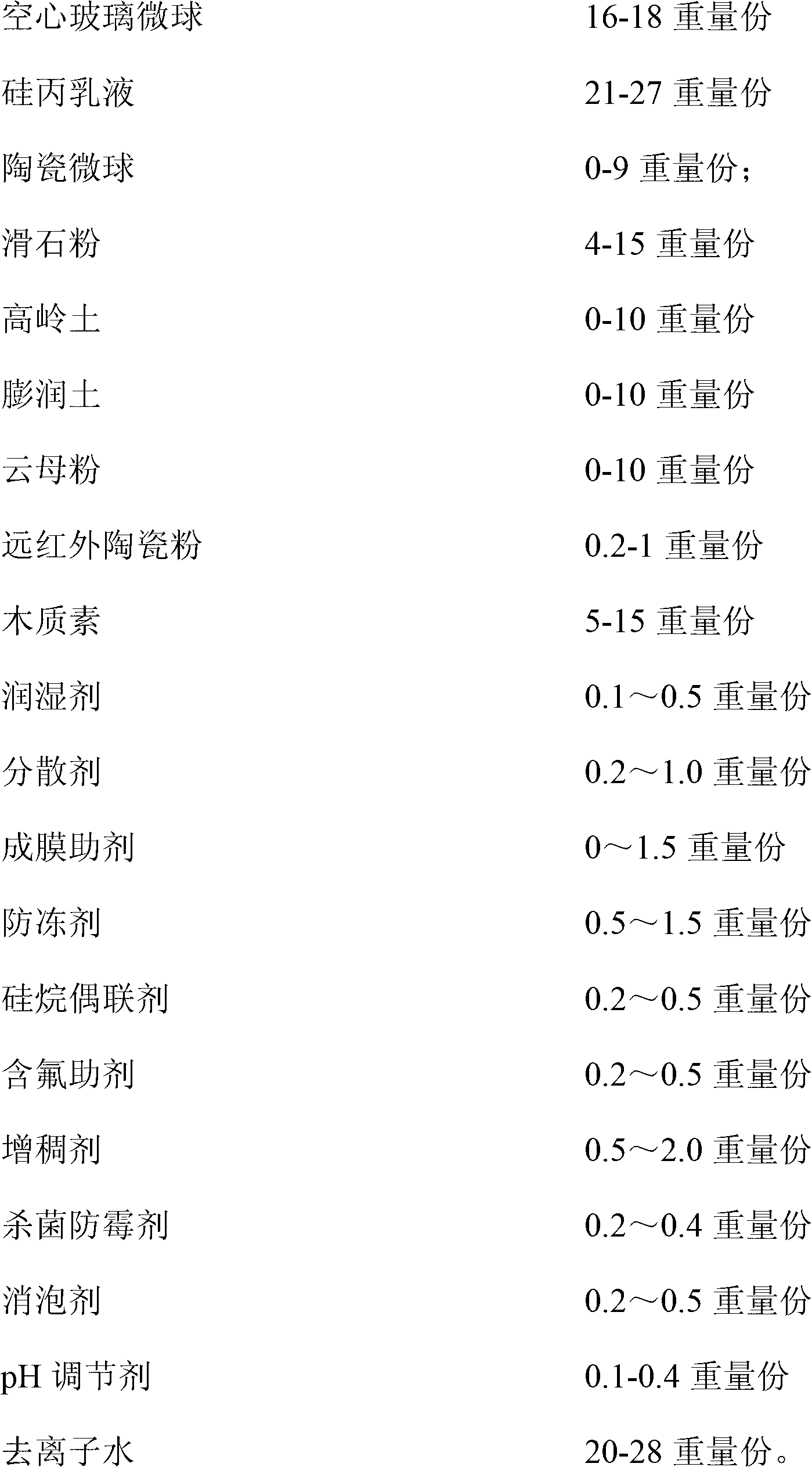

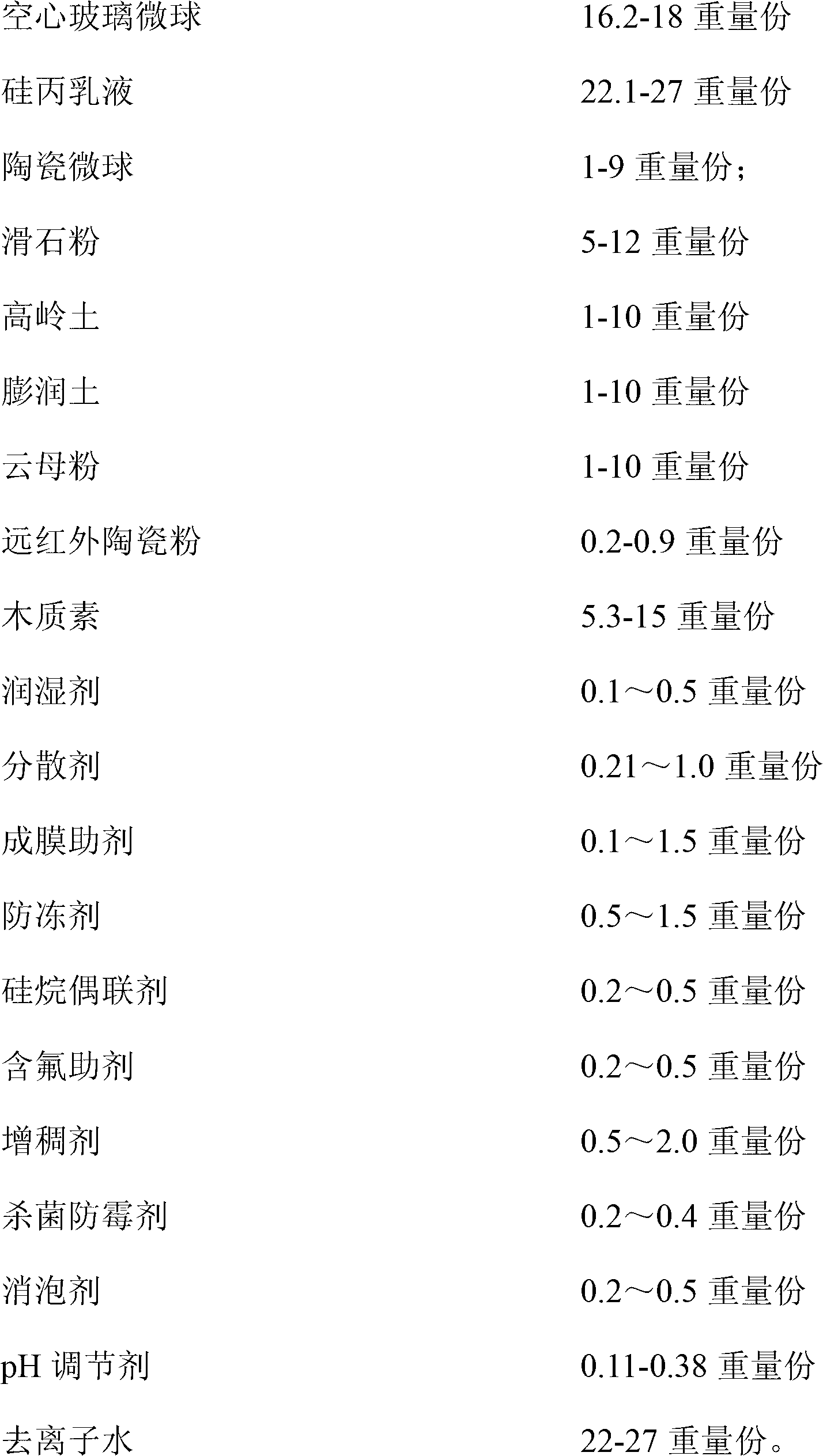

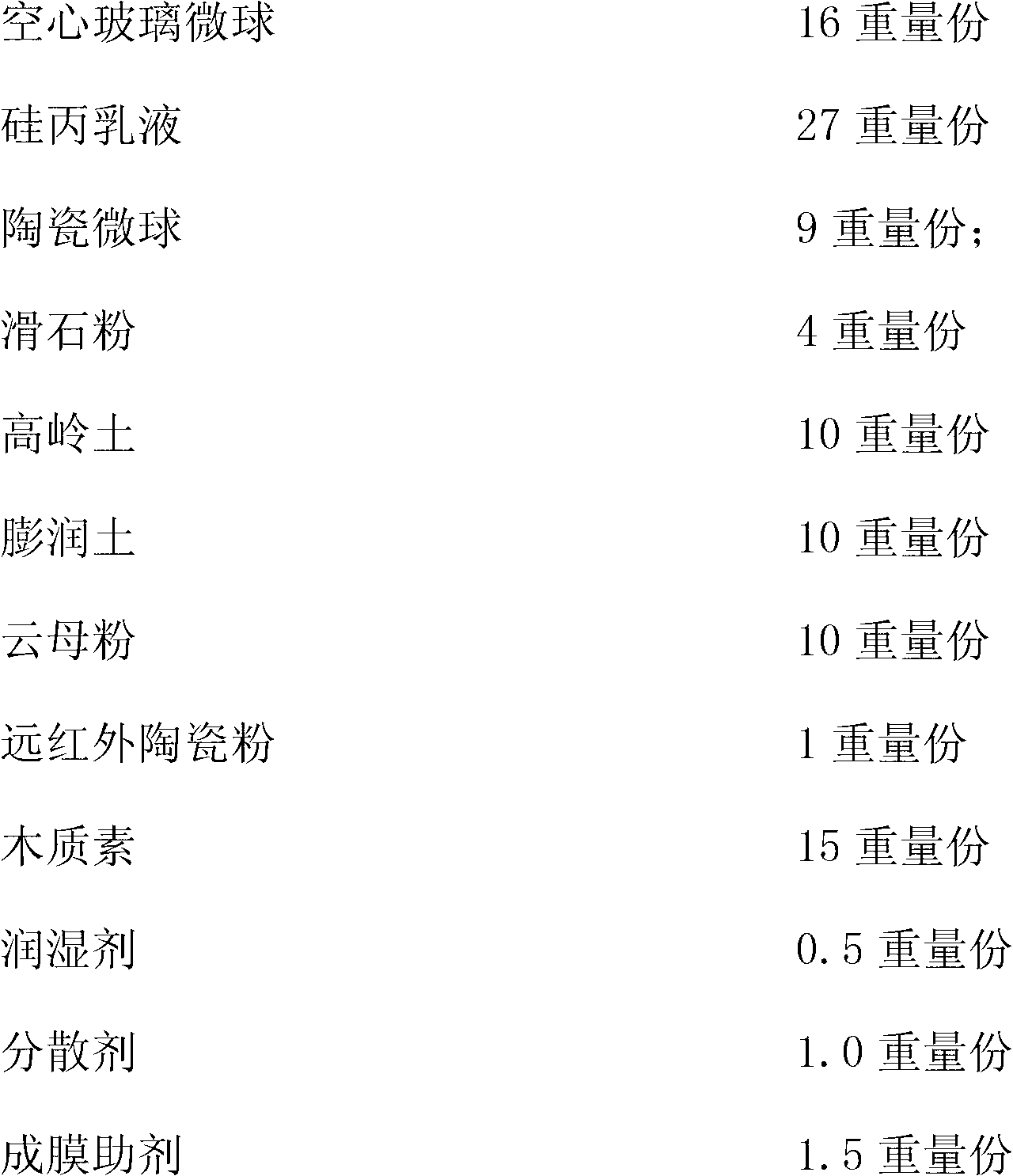

Waterproof thermal insulation coating composition and preparation method thereof

InactiveCN102702904AStir wellHigh solar reflectanceAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

The invention relates to a waterproof thermal insulation coating composition, which comprises an aggregates, a substrate, an auxiliary filling and an assistant, and is characterized in that the aggregates are hollow glass microspheres, and the substrate is silicone acrylic emulsion; in the thermal insulation coating composition, 6-18 parts by mass of hollow glass microspheres and 21-27 parts by mass of silicone acrylic emulsion are provided. According to the invention, the silicon acrylic emulsion is selected, so that the thermal insulation coating has excellent thermal insulation property, and good waterproof and antifouling performance, and the waterproof and antifouling performance is more excellent for fluorine-containing silicone acrylic emulsion.

Owner:TIANCHANG JULONG TRAVEL PAINT

Epoxy acrylate modified waterborne alkyd resin and preparation method and application thereof

The invention discloses an epoxy acrylate modified waterborne alkyd resin and a preparation method and an application thereof. The method comprises the steps: firstly, synthesizing a waterborne alkyd resin from a polyol, a polybasic acid and an oil monomer by adopting a dehydration condensation reaction; then carrying out an epoxy resin ring opening reaction to graft onto the waterborne alkyd resin so as to modify the waterborne alkyd resin; followed by carrying out free radical solution polymerization of acrylic soft and hard monomers with the modified alkyd resin, and modifying the alkyd resin by using acrylic ester; and finally pumping out a part of a polymerization solvent to neutralize the obtained waterborne alkyd resin, adding a cosolvent, and dispersing the alkyd resin to prepare an aqueous dispersion by adopting a high-speed disk dispersion machine and with water as a dispersion medium. In the addition to retaining own excellent characteristics, the modified alkyd resin also has good dryness, adhesive power and corrosion resistance of epoxy resin and the acrylic resin advantages of excellent drying, water resistance, chemical medicine resistance, high hardness, good weathering resistance and the like, and effectively improves the alkyd resin performance of water resistance, weather resistance and the like.

Owner:SOUTH CHINA UNIV OF TECH

Hydroxyl-containing crylic acid polyurethane aqueous dispersion body and application

The invention provides a preparation method of hydroxyl-containing crylic acid polyurethane aqueous dispersion body, comprising the following steps: (1) hydroxyl-containing terminal isocyanate group polyurethane prepolymer is obtained by reaction; (2) hydroxyl acrylic ester monomer is added in the obtained polyurethane prepolymer in the step (1) for further reaction, so as to obtain a molecular chain hydroxyl-containing terminal ethenyl containing polyurethane prepolymer; (3) neutralizer is added in the polyurethane prepolymer obtained in the step (2), the pH of the system reaches 7-8, and then distilled water is added to disperse the prepolymer, so as to obtain the dispersion-type polyurethane prepolymer; and (4) vinyl monomers and chain transfer agent are added in the step (3), and then the solution formed by radical initiators and distilled water is dropwise added, so as to obtain the hydroxyl-containing crylic acid polyurethane aqueous dispersion body by reaction; the invention further provides aqueous finish varnish for vehicle, which is formed by aqueous dispersion body and polyisocyanate curing agent.

Owner:清远明宇材料科技有限公司

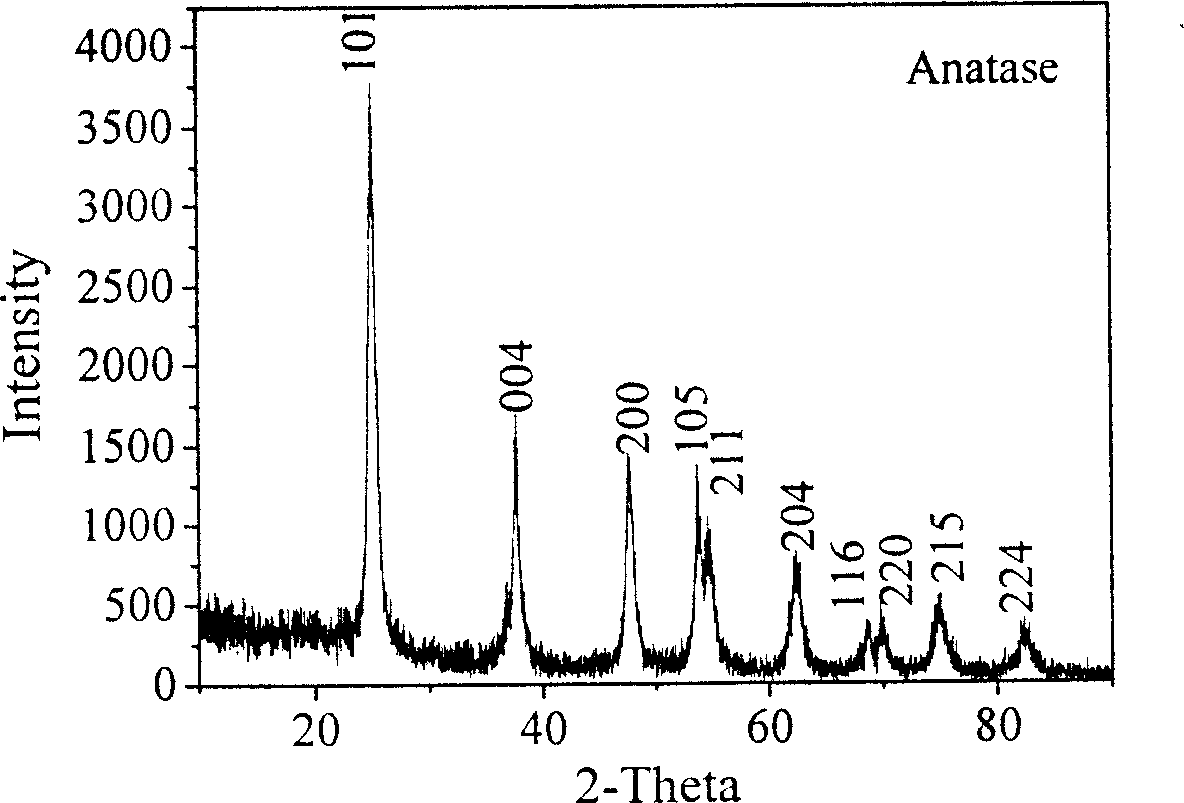

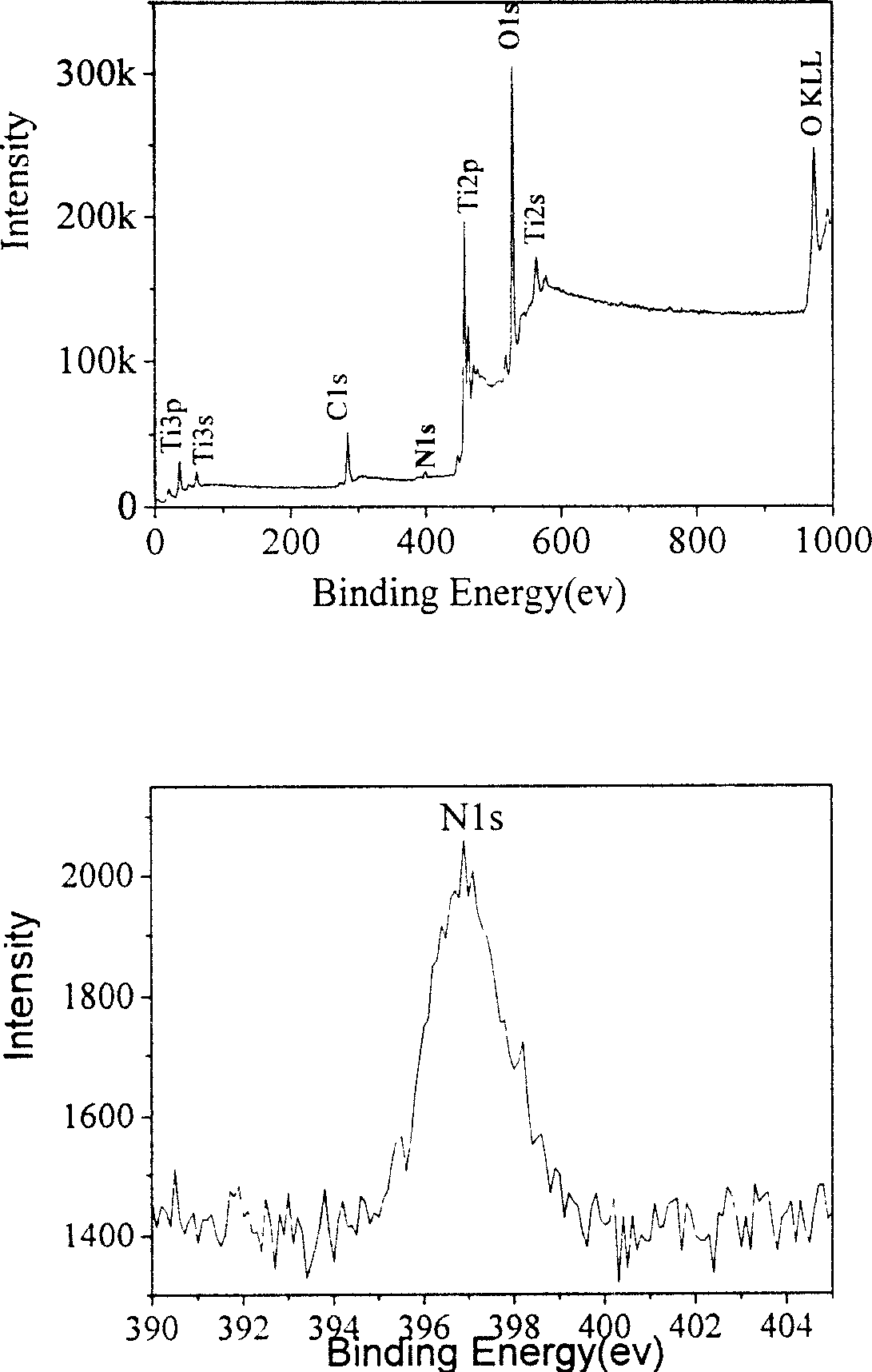

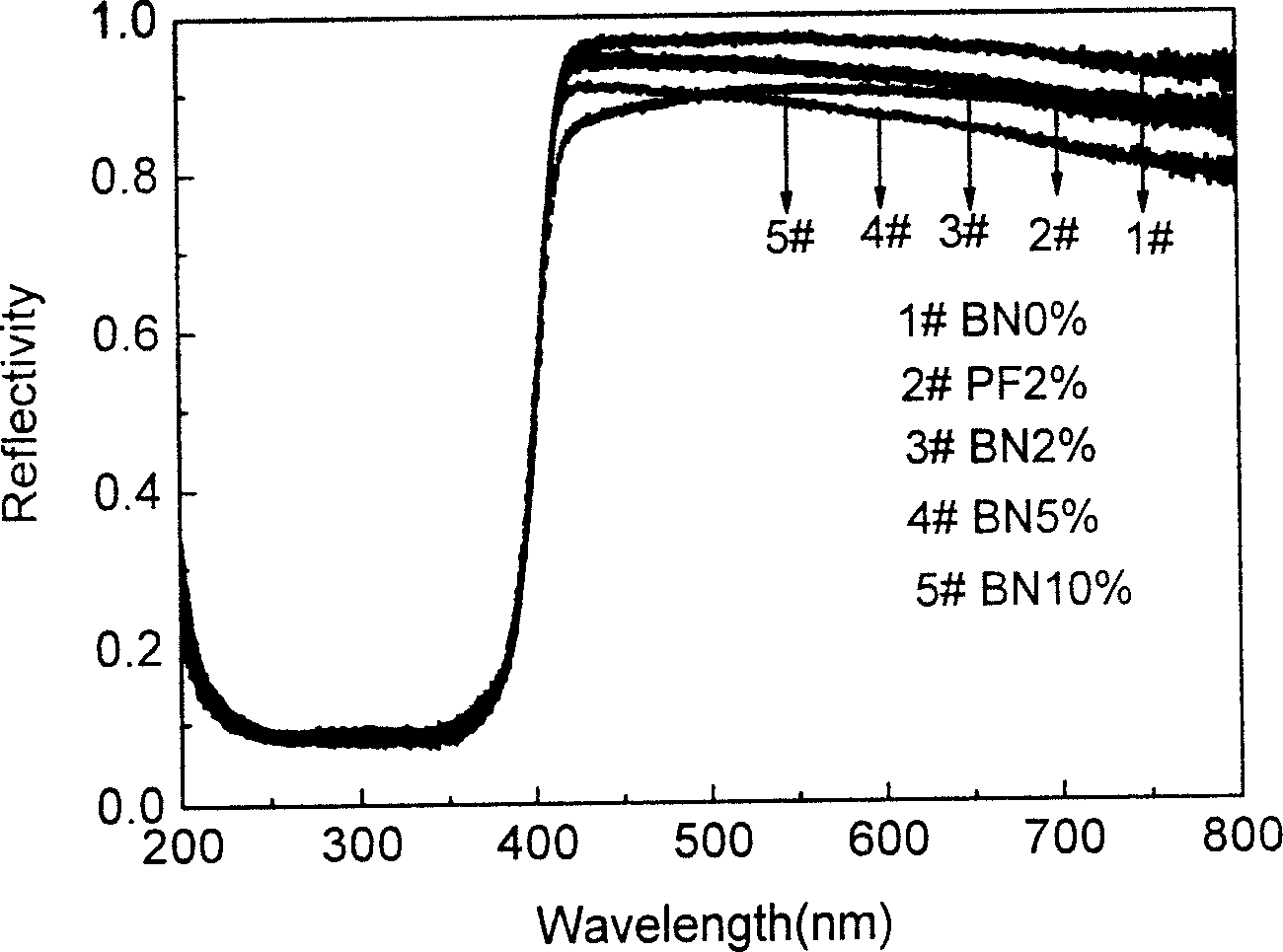

Light catalyzed coating modified by nitrogen dopen Nano titanium dioxide and preparation method

InactiveCN1696228AImprove efficiencyGood bactericidal and antibacterial effectCoatingsUltravioletTitanium oxide

A nitrogen doped nano-TiO2 modified photocatalytic paint with low content of volatile VOC, and high ultraviolet shielding-absorbing and antibacterial effect is prepared from silicic acrylate emulsion, nitrogen doped nano-TiO2, ordinary nano-TiO2, titanium oxide powder, kaolin, heavy and light calcium carbonate, wallastonite powder, assistant, water, ammonia water, defoaming agent and antimildew agent through proportional mixing, stirring and filtering.

Owner:UNIV OF SCI & TECH BEIJING

Multifunctional waterproof antiseptic aldehyde-eliminating glue and preparation method

InactiveCN103131270AEasy to useLow toxicityAntifouling/underwater paintsPaints with biocidesResistEmulsion

The invention discloses multifunctional waterproof antiseptic aldehyde-eliminating glue, and belongs to the technical field of construction materials, wherein the glue is mainly for sealing, waterproofness, moisture-proofness, anticorrosion, mold prevention, insect prevention, termite prevention and aldehyde elimination of materials such as bamboo wood, timber, rattan wood, wall faces, ground, emulsion varnish, wallpaper, floor boards and wooden doors. The multifunctional waterproof antiseptic aldehyde-eliminating glue is characterized by comprising 10-90 parts of water-dilutable resin, 0.01-30 parts of antiseptic and mold inhibitor, 0.01-20 parts of insect-resist agents, 0.01-15 parts of termite-resisting agents, 0.1-20 parts of aldehyde-eliminating agents, 0.1-30 parts of coalescing agents, 0.5-15 parts of anti-freezing agents and 5-95 parts of water. After being treated by the multifunctional waterproof antiseptic aldehyde-eliminating glue, products are strong in engaging force, environment-friendly, water-proof, moisture-proof, antiseptic, mold-proof, inset-proof, termite-proof and capable of eliminating aldehyde. Meanwhile, construction is easy and convenient. Besides, the invention further provides a preparation method of the multifunctional waterproof antiseptic aldehyde-eliminating glue.

Owner:刘川

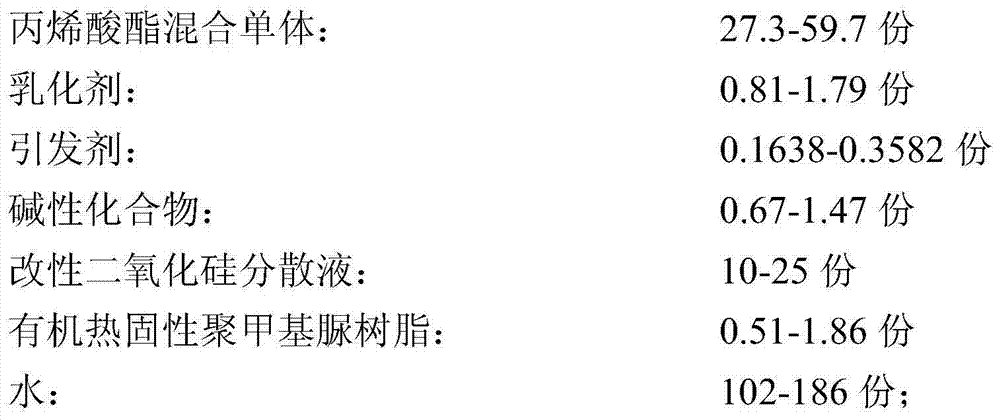

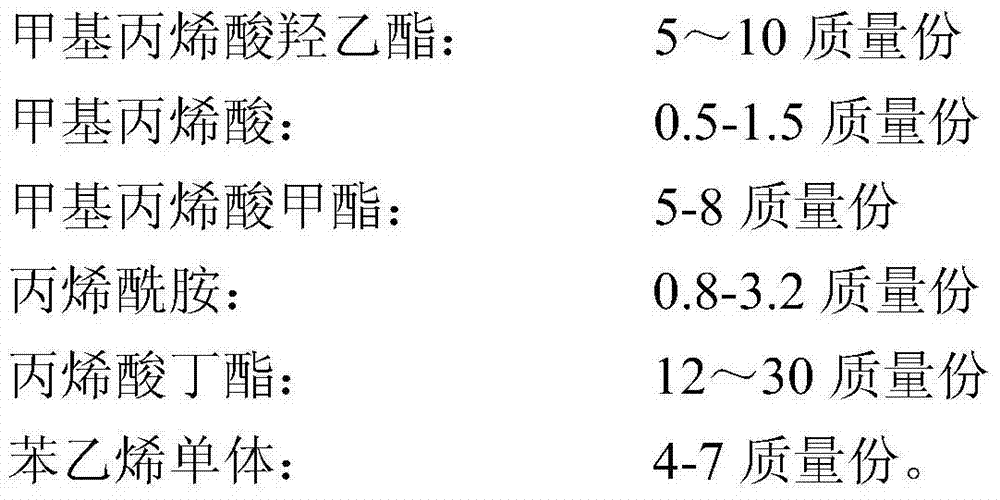

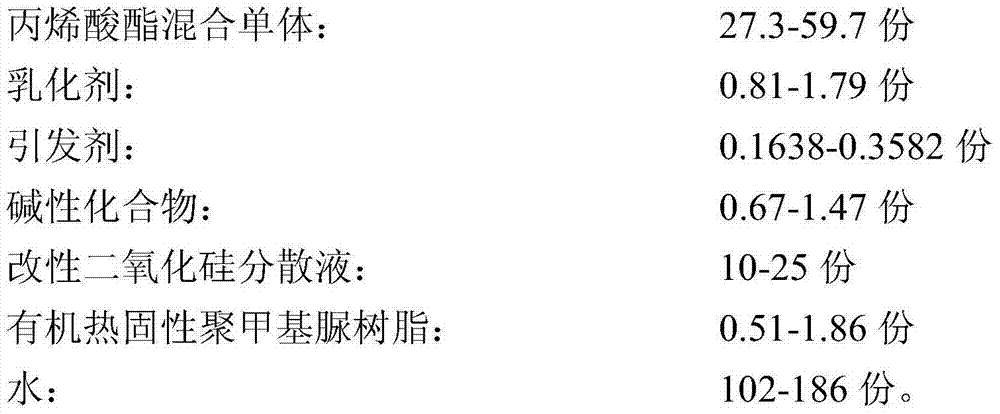

Aqueous multi-functional crylic acid extinction resin and preparation method thereof

The invention discloses an aqueous multi-functional crylic acid extinction resin and a preparation method thereof and belongs to the field of extinction type coatings. The preparation method of the aqueous multi-functional crylic acid extinction resin comprises the following steps: (1) preparing a crylic acid ester mixture monomer; (2) sufficiently mixing water, an emulsifier and a part of the crylic acid ester mixture monomer, heating to 70-90 DEG C, adding an initiator to react for 0.5-1 hour, dropwise adding the rest crylic acid ester mixture monomer within 3-5 hours, adding the rest initiator in different batches, performing heat preservation for 1-3 hours after the dropwise adding, cooling to 45 DEG C, sequentially adding modified silicon dioxide and an organic thermosetting polymethylurea resin with the particle size of 3.5mu m, uniformly stirring, cooling down and discharging so as to obtain the aqueous multi-functional crylic acid extinction resin. The aqueous multi-functional crylic acid extinction resin prepared by the preparation method disclosed by the invention is high in extinction efficiency, excellent in water resistance, acid resistance and alkali resistance, and good in abrasion resistance property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method of polyester acrylate hybrid aqueous dispersion

InactiveCN101824209AAchieve chemical modificationImprove stabilityPolyurea/polyurethane coatingsPolyesterOrganic solvent

The invention relates to a preparation method of polyester acrylate hybrid aqueous dispersion, which belongs to the field of chemical coatings, and the preparation method comprises four steps of synthesizing hydroxyl acrylate resin, preparing an intermediate, preparing polyester acrylate resin and dispersing with deionized water. The preparation method effectively combines the advantages of polyester and acrylic resin, the prepared stable dispersion can be used as the hydroxyl resin component of a dual-component polyurethane coating for preparing a high-performance waterborne dual-component polyurethane coating with hydrophilic polyisocyanate, and a coating film has excellent performance; in addition, the preparation of the dispersion does not use amine as a neutralizer, thereby avoiding the smell caused by the amine and simplifying the process; and only a small amount of cosolvent is adopted in the dispersion, and the content of an organic solvent in the coating is low.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

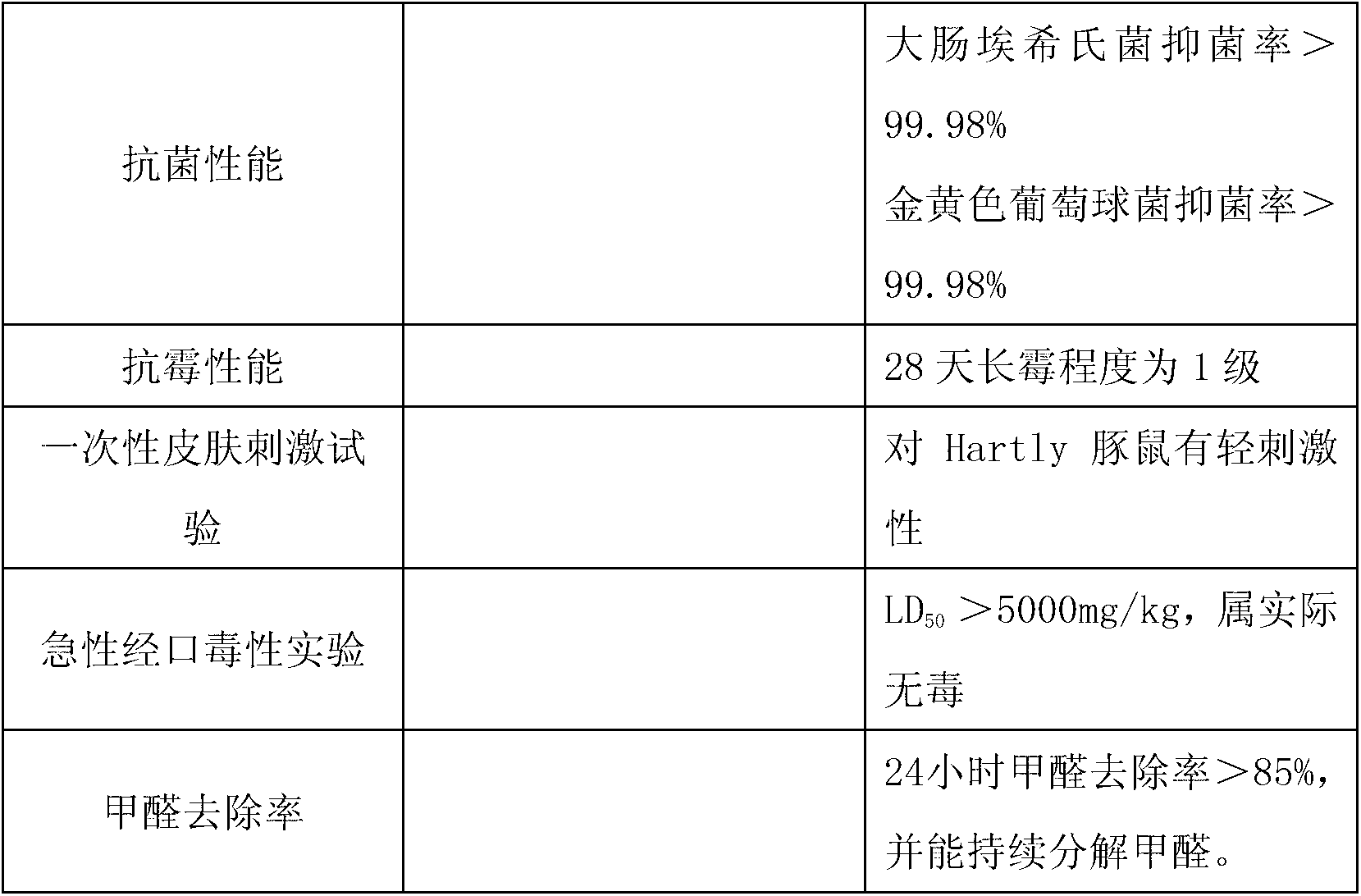

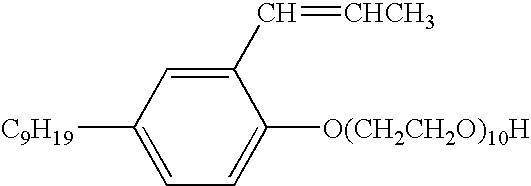

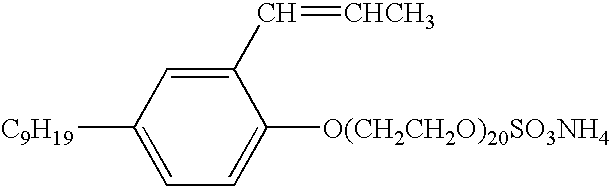

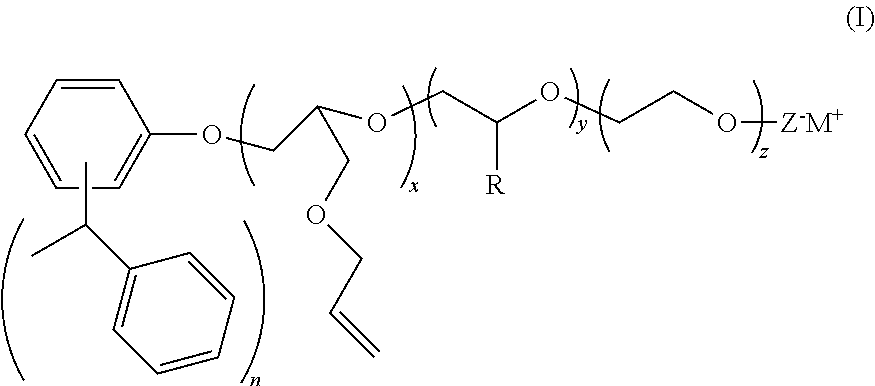

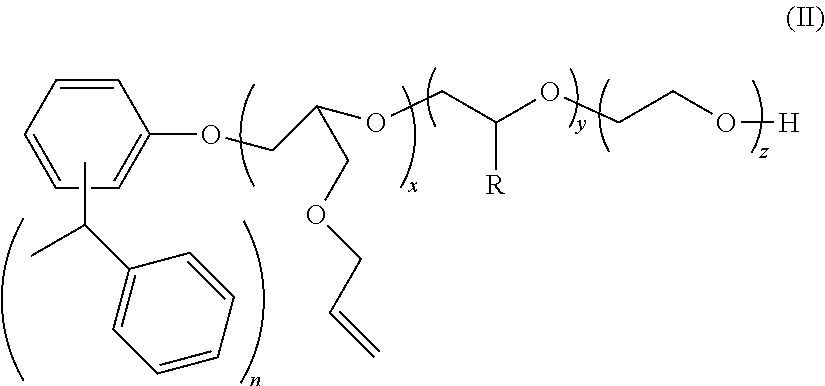

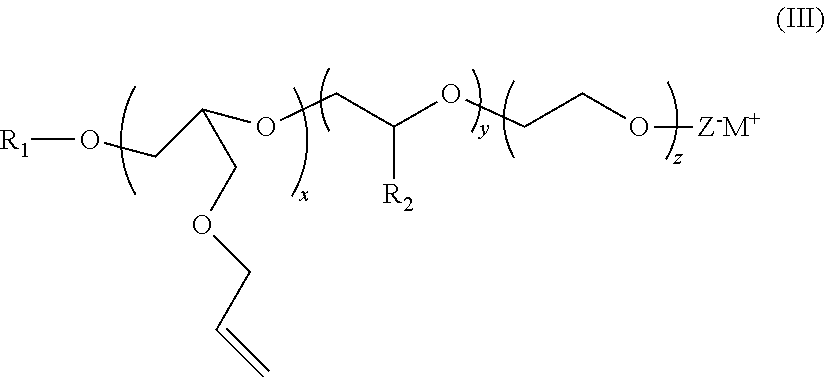

New reactive surfactants for freeze-thaw stable emulsion polymers and coatings thereof

ActiveUS20140114006A1Reduce the amount requiredConvenient coatingOther rubber coatingsPolyether coatingsArylPolymer science

The invention provides aqueous coating composition having freeze thaw stability, comprising: (a) at least one latex polymer derived from at least one monomer and at least one reactive surfactant of the formulaR1O—(CH2CHR2O)x—(CH2CH2O)y—(CH2CHR3O)z—R4 where R1 is either alkyl, aryl, alkylaryl, or aralkylaryl of 8-30 carbon atoms, R2 is —CH2OCH2CH═CH2 (AGE); R3 is either H, CH3, or CH2CH3; R4 is H or —SO3M or —PO3M where M is H or K, Na, NH4, NR4, alkanolamine, or other cationic species and x=2-100; y=4-200 and z=0-50.

Owner:ETHOX CHEM LLC

Method for manufacturing environment-friendly semi-polyurethane leather

InactiveCN102433765ASoft touchFeel comfortableSynthetic resin layered productsTextiles and paperEnvironmental resistanceWater based

The invention discloses a method for manufacturing environment-friendly semi-polyurethane leather. The method is characterized in that: polyvinyl chloride (PVC) is taken as a foam layer, water-base cement is taken as an adhesive layer, and the environment-friendly semi-polyurethane (PU) leather is prepared by a transfer coating method. Water-borne polyurethane replaces the traditional solvent-type polyurethane to serve as a surface layer, a surface treatment layer and an adhesive layer of the semi-polyurethane leather, organic pollution is eliminated from the source, organic solvent resourcesare saved, potential safety hazards are eliminated, and the working environment of workers is improved. The content of volatile organic compounds (VOC) of the finished leather is less than 5mg / kg (ofleather), the finished leather is eco-friendly and meets the requirement of ecological semi-PU leather, and other performance of the finished leather is equal to or superior to that of a solvent-typeproduct.

Owner:SICHUAN UNIV

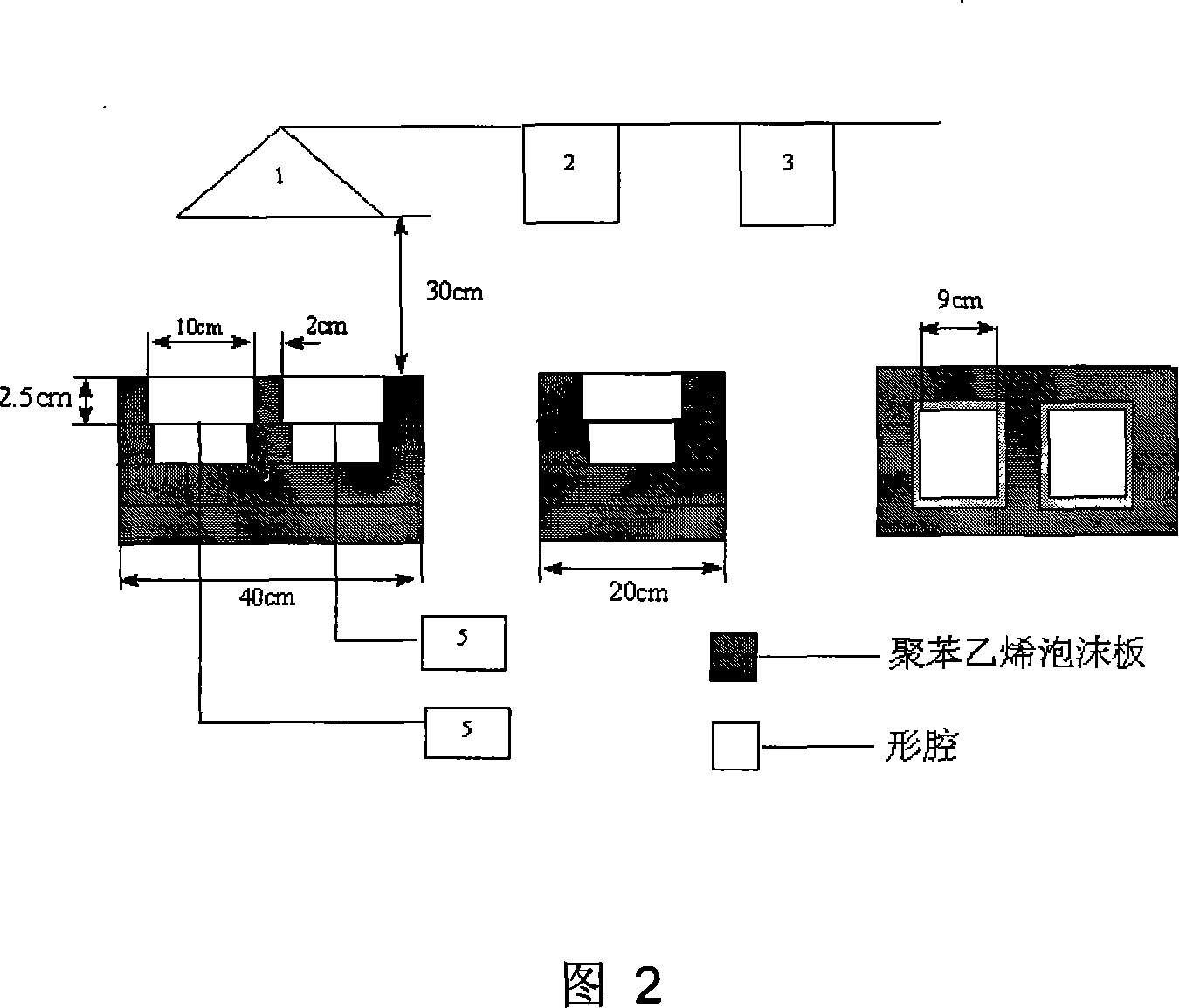

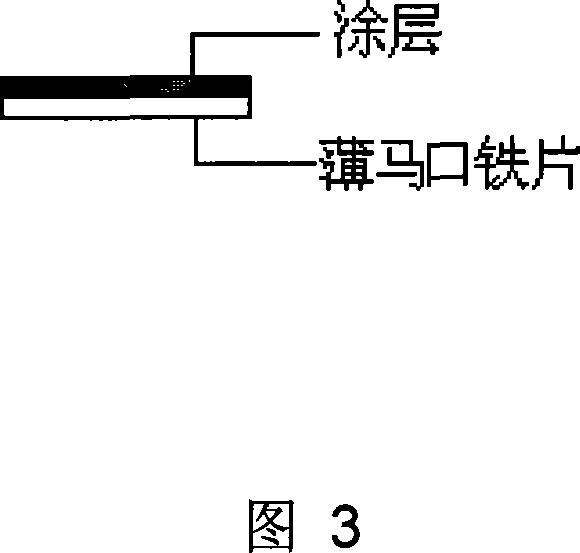

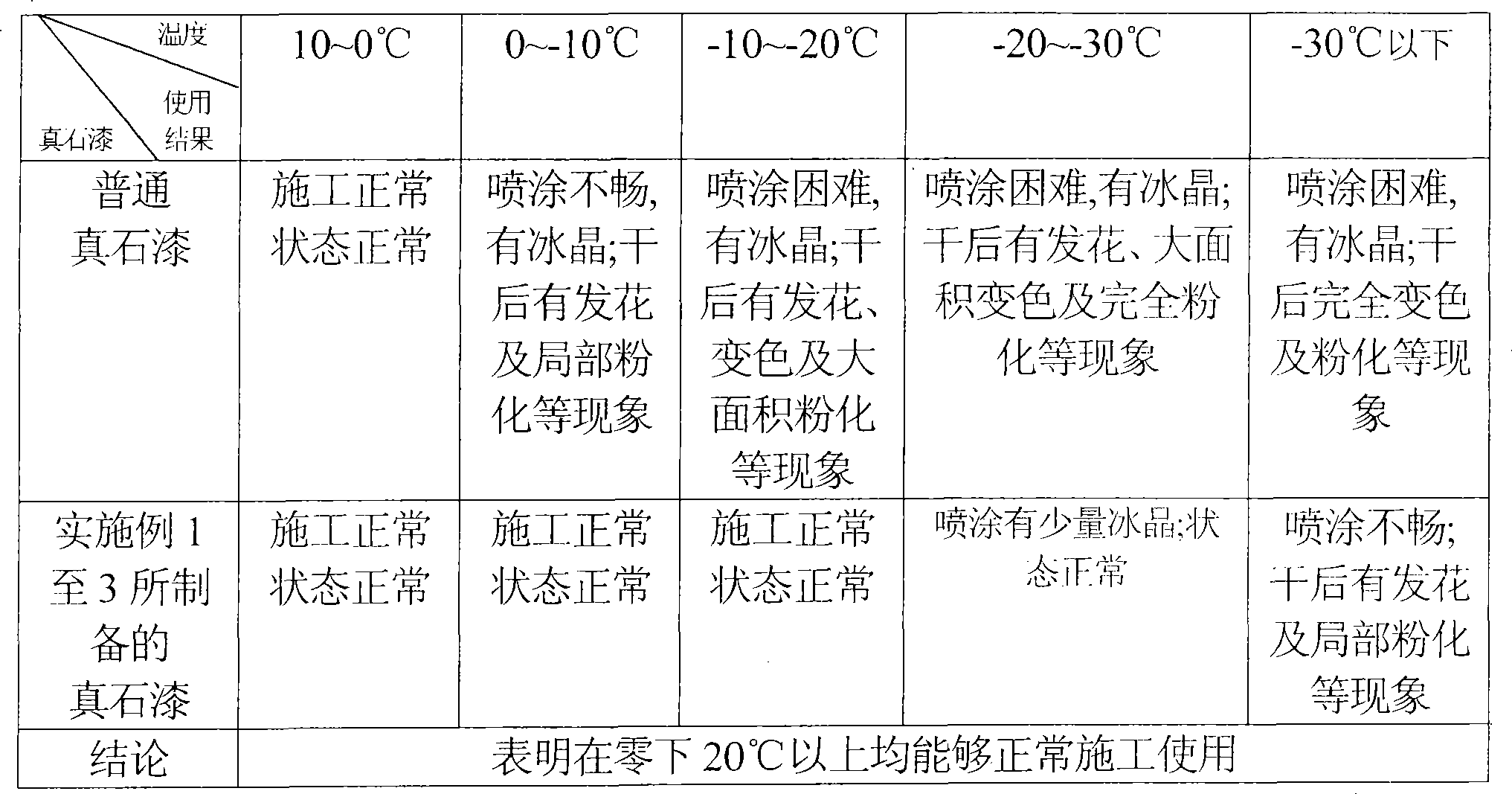

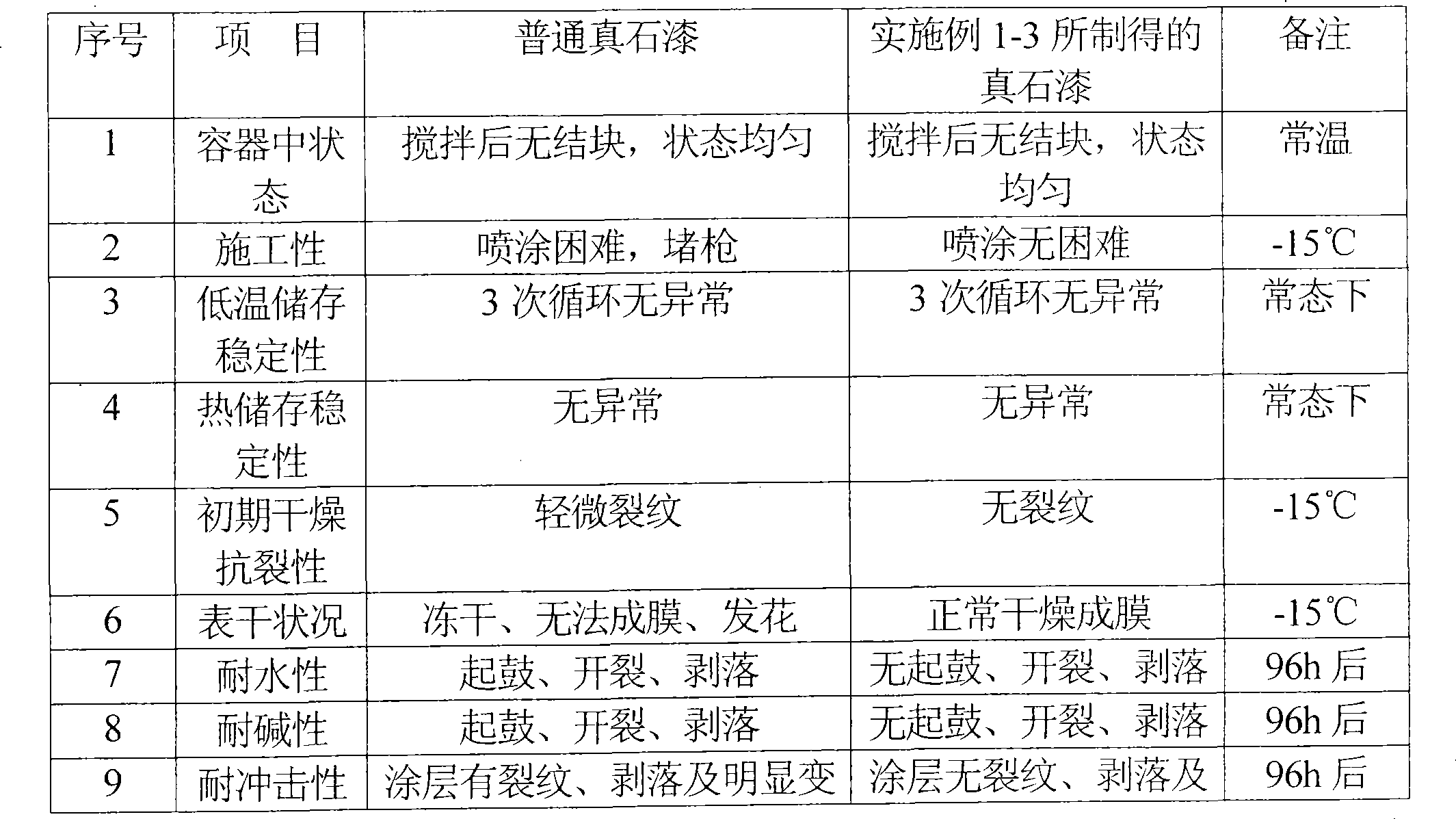

Environment friendly antifreezing stone-like paint and preparation thereof

The invention discloses an environment freeze protection stone paint, which comprises the following raw material components according to the parts by weight: 0.1-5 of fibrin aqueous solution of 1-4% concentration, 0.8-1.2 of glycol, 50-70 of colored sand of 41-80 mesh, 5-25 of colored sand of 81-120, 17-23 of KE025 acrylic emulsion, 0.6-0.9 of alcohol ester-12 addition agent, 0.02-0.06 of foam killer, 0.01-0.1 of thickness agent and 0.02-0.06 of neutralizing agent. Meanwhile, the invention also discloses a preparation method for the stone paint. The stone paint has the environment and freeze protection performance, provides powerful guarantee for being suitable for winter construction, in particular to various severe conditions of winter construction in the northern area of our country.

Owner:许军 +1

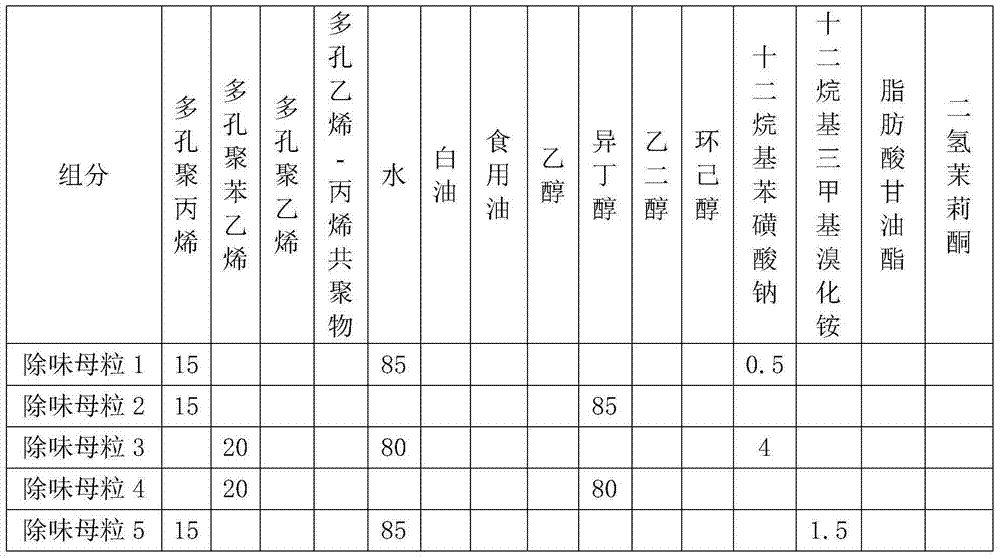

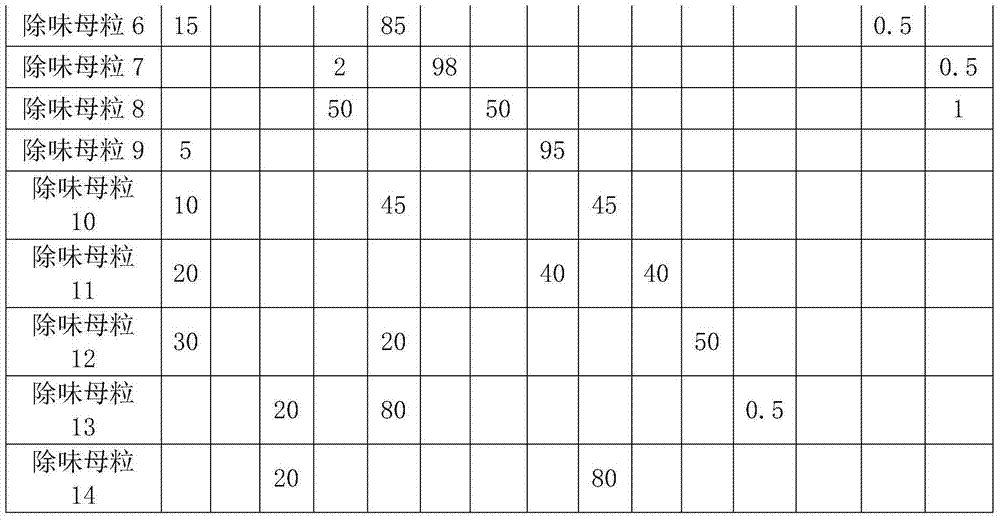

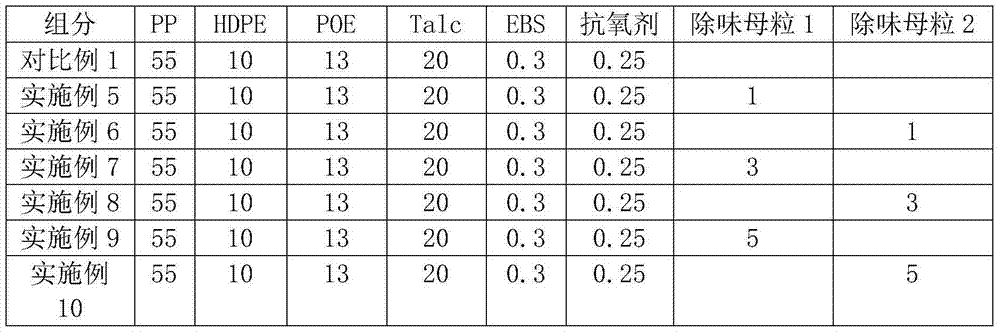

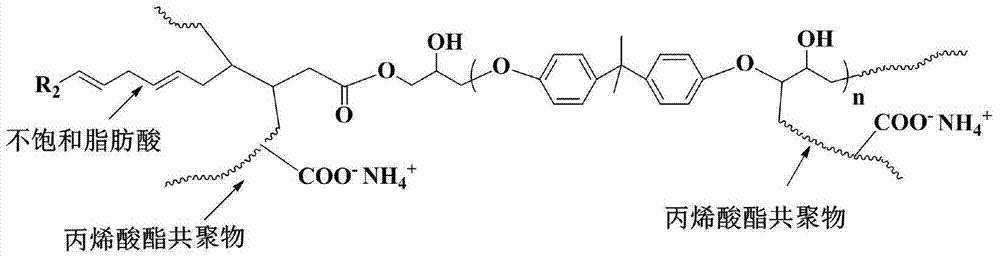

Smell removing master batch as well as preparation method and application thereof

The invention discloses a smell removing master batch, as well as a preparation method and an application thereof. The smell removing master batch is prepared by using a porous polymer bead to adsorb a stripping agent, wherein the mass content of the porous polymer bead in the smell removing master batch is 2-50% and the balance is the stripping agent; and the aperture ratio of the porous polymer bead is greater than 50% and the foaming ratio is 2-45 times. The smell removing master batch prepared by the invention has an obvious effect for removing the VOC and the smell in a modified plastic or a modified elastomer, and greater than 80% of the VOC content can be reduced; besides, the smell removing master batch prepared by the invention is added to a high polymer material similar to the porous polymer bead matrix component to modify, the heterogeneous substance is not introduced so that the smell removing master batch does not have negative effects on the physical property, the appearance and the photo-thermal aging characteristic of the high polymer material.

Owner:HEFEI INNOVATION LIGHTWEIGHT MATERIALS

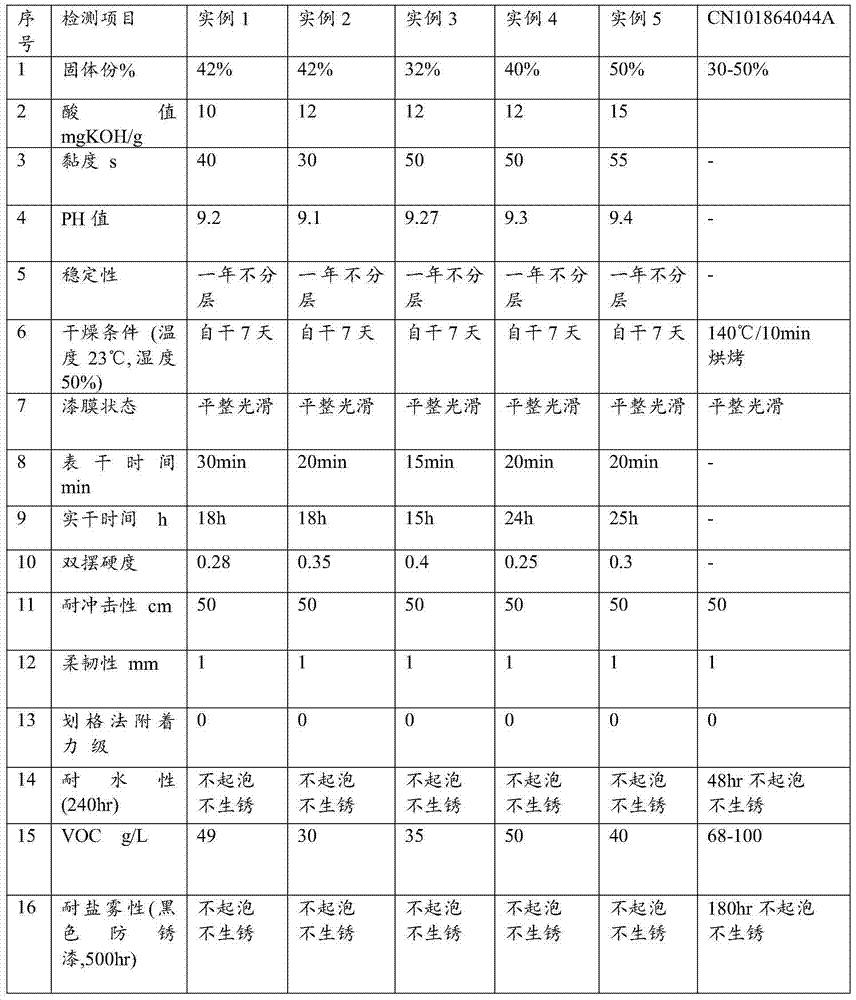

Preparation method for low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin

Belonging to the paint field, the invention relates to a preparation method for a low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin. The method includes: firstly modifying epoxy resin with fatty acid, then conducting modification with acrylic acid and acrylate monomer under the action of an initiator, then adding a neutralizer and a drier, adding water to perform emulsification, and reducing pressure to remove the solvent, thus obtaining a low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin emulsion, which has an acid value of 10-15mgKOH / g, a solid content of 30-50%, and a VOC content of less than 7%. Due to a low acid value, the obtained resin has excellent water resistance, and because of the extremely low VOC content, the emission of pollutants is greatly reduced, and the harm to the human is lowered. In addition, due to high unsaturated fatty acid content and epoxy resin content and adding of the drier, the resin itself can have the characteristics of natural drying at room temperature, excellent anti-rust performance and the like.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Coating composition having a low volatile organic compound content

ActiveUS20080119600A1Same performanceLow VOC contentFibre treatmentMixingSolventVolatile organic compound

A coating composition includes a latex component and an agent for replacing all or part of the volatile coalescing solvent. The agent has the following formula:X(AO)nHwhereinX is a C6 to C16 group selected from the group of linear, chains, branched chains, aromatic rings, and combinations thereof,AO is an alkyleneoxy group selected from the group of ethyleneoxy groups, 1,2-propyleneoxy groups, 1,2-butyleneoxy groups, and combinations thereof, andn is from 3 to 14.The coating composition has a VOC content of less than or equal to 150 g / L. The agent for replacing the volatile coalescing solvent contributes little or nothing to a total VOC level in the coating composition. As such, the coating composition may be formulated to have a VOC content of less than or equal to 150 g / L, which meets or exceeds standards for VOC content in interior and exterior flat and non-flat paints for all sheen ranges, while providing equivalent or superior properties to those provided by volatile coalescing solvents.

Owner:BASF CORP

Non-aqueous slurries used as thickeners and defoamers and method of using slurries in aqueous systems

InactiveUS20060160921A1Increase moistureReduce foamingAntifouling/underwater paintsThixotropic paintsParticulatesSlurry

A low VOC, HAPs free, substantially non-aqueous slurry for use as a rheology modifier in aqueous systems including but not limited to latex paints. The slurry comprises a particulate water-swelling polymer such as hydroxyethyl cellulose, mineral oil carrier liquid, a non-ionic surfactant, a particulate thickening agent, a defoamer, and optionally an amine component.

Owner:THE SHERWIN-WILLIAMS CO

Quick-drying hydroxylated acrylic resin water dispersion and preparation method and use thereof

ActiveCN102161770AGood pigment wettingImprove performancePolyurea/polyurethane coatingsAcrylic resinPrepolymer

The invention relates to quick-drying hydroxylated acrylic resin water dispersion and a preparation method and use thereof, in particular to quick-drying aqueous automobile repair solid color paint prepared from the hydroxylated acrylic resin dispersion. The invention discloses a method for preparing the hydroxylated acrylic resin dispersion, which comprises: A, preparing a prepolymer of hydroxylated acrylic resin; and B, preparing aqueous prepolymer of the hydroxylated acrylic resin. And the invention also discloses a method for preparing quick-drying aqueous automobile repair solid color paint by using the dispersion. The coating of the quick-drying aqueous automobile repair solid color paint is accomplished at a low temperature or even at normal temperature, so the volatile organic compound (VOC) emission in a coating process of an automobile is reduced and energy conservation and emission reduction are realized. Thus, the quick-drying aqueous automobile repair solid color paint can be promoted and used easily.

Owner:广东绚缤材料科技有限公司

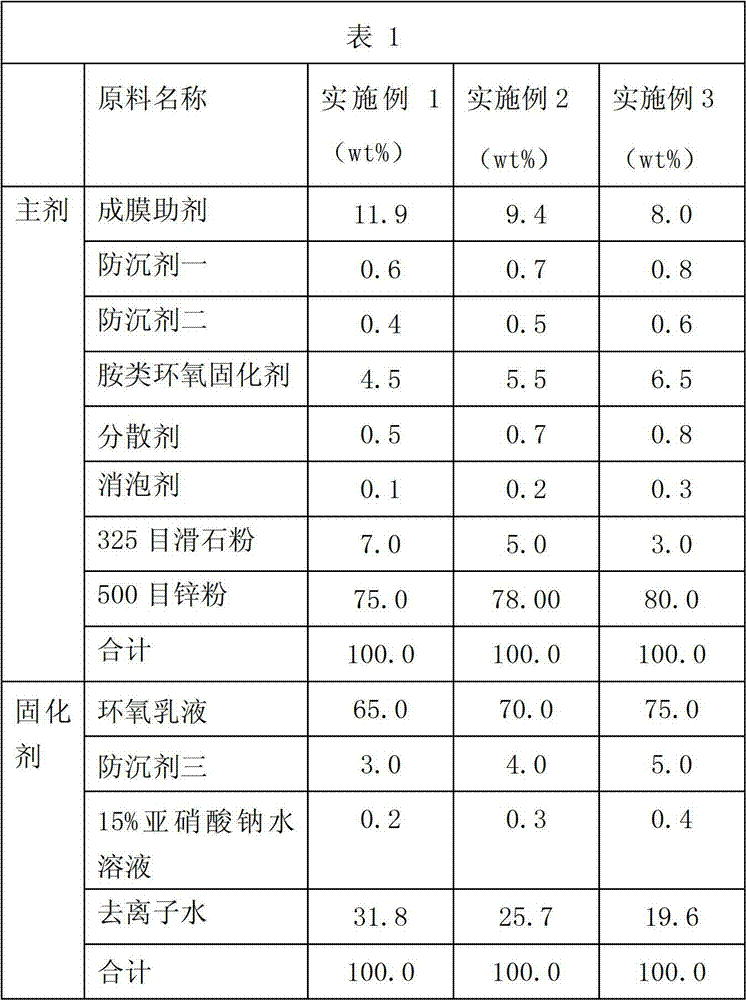

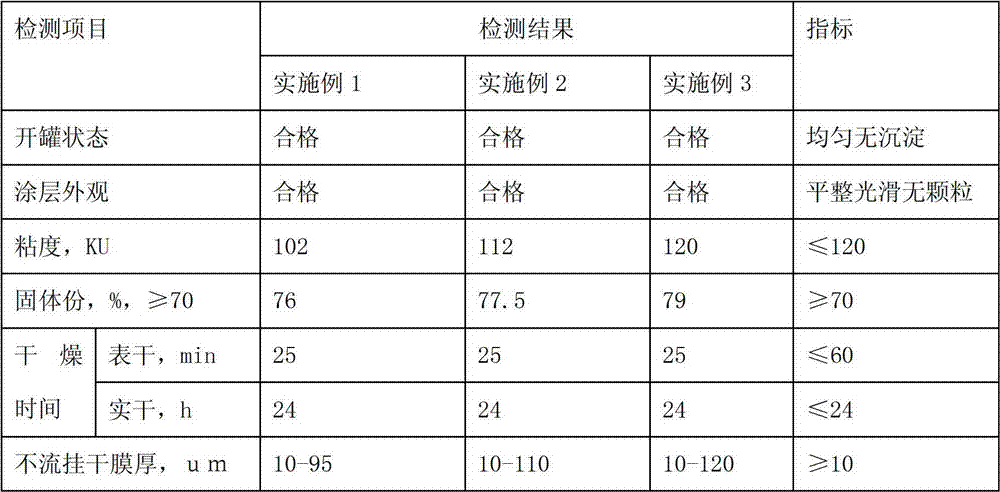

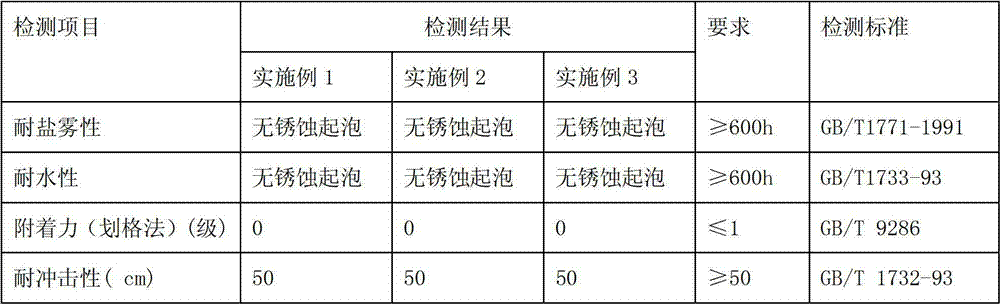

Water-base epoxy zinc-rich priming paint and preparation method thereof

ActiveCN102863874ALow VOC contentSmall smellAnti-corrosive paintsEpoxy resin coatingsSolventEmulsion

The invention discloses a water-base epoxy zinc-rich priming paint and a preparation method thereof. The water-base epoxy zinc-rich priming paint comprises a host and a curing agent according to the weight proportion of 4:1. The host comprises filming auxiliary, a first anti-settling agent, a second anti-settling agent, an amine epoxy curing agent, dispersant, a defoaming agent, filler and zinc powder, and the curing agent comprises epoxy emulsion, a third anti-settling agent, an anti-flash anti-rust agent and deionized water. The preparation method includes steps of preparing the host and the curing agent and proportioning paint by the host and the curing agent according to the weight proportion of 4:1. By taking water as a main dispersion medium, the water-base epoxy zinc-rich priming paint has quite low volatilizable organic content, light smell, low harms on humans, non-combustible property and unique safety in storage, transport and use, safety potential hazards caused by accumulation of a great quantity of harmful solvents are eliminated, harms on physical and psychological health of constructors are reduced to the greatest extent, and further, the requirements of production efficiency of fast paces of a container production line can be met.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com