Patents

Literature

6869results about How to "Improve fire performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-free expansion type fire-proof epoxy coating and its preparation method

The invention discloses the inflatable fire-resisting paint, comprising A and B. The A comprises epoxide resin, modified resin, catalyst, foamable agent, fire retarding agent, fluxing agent, color filler and smog inhibiting agent, and the B comprises color filler, curing agent and auxiliary agent. The fire-resisting paint has the advantages of good heat-insulating property, adhesion force and intensity. The coating has good water resistance, acid- alkali resistance, corrosion resistance and tenacity, and is not easy to drop. The paint can be used in rolled steel and aluminum products, especially the fireproof situation of oil factories.

Owner:MARINE CHEM RES INST

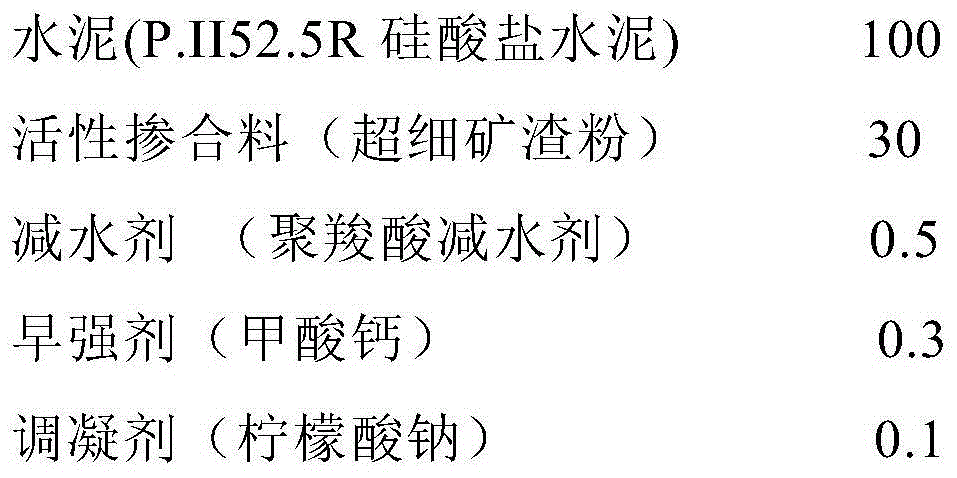

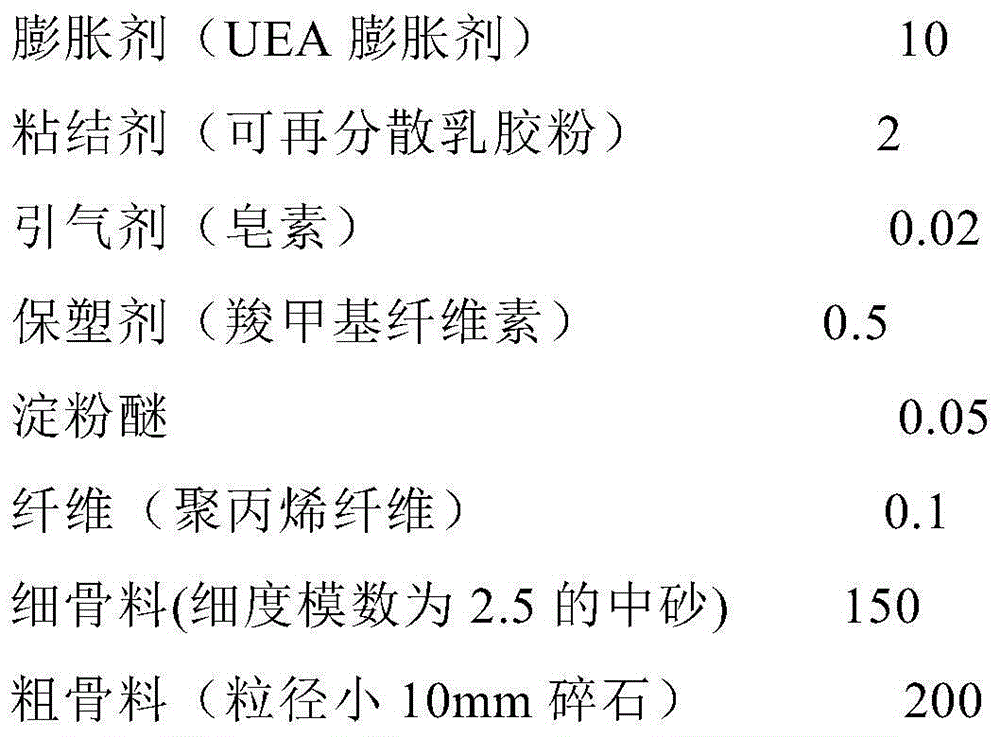

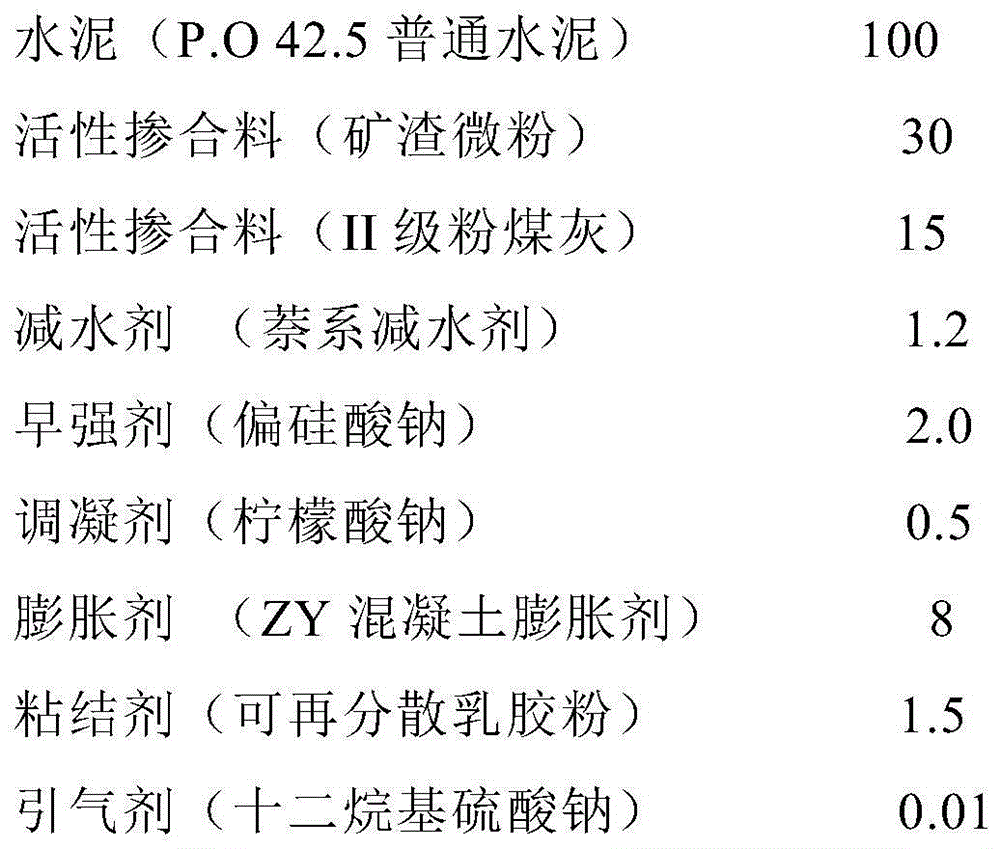

3D printing cement-based material and preparation method thereof

The invention relates to a 3D printing cement-based material and a preparation method thereof. The 3D printing cement-based material is composed of a powder form gelling material and an aggregate, the powder form gelling material is composed of cement, an active admixture, a water reducer, a hardening accelerator, an adjustable solidification agent, an expanding agent, a binder, an air-entrainer, a plasticity-maintaining agent, a water repellent, starch ether, a powder filling material and fiber, and the aggregate is composed of a fine aggregate and a crude aggregate. Compared with prior art, the 3D printing cement-based material has the advantages of good work performance, constructability performance, mechanical property and endurance performance.

Owner:TONGJI UNIV

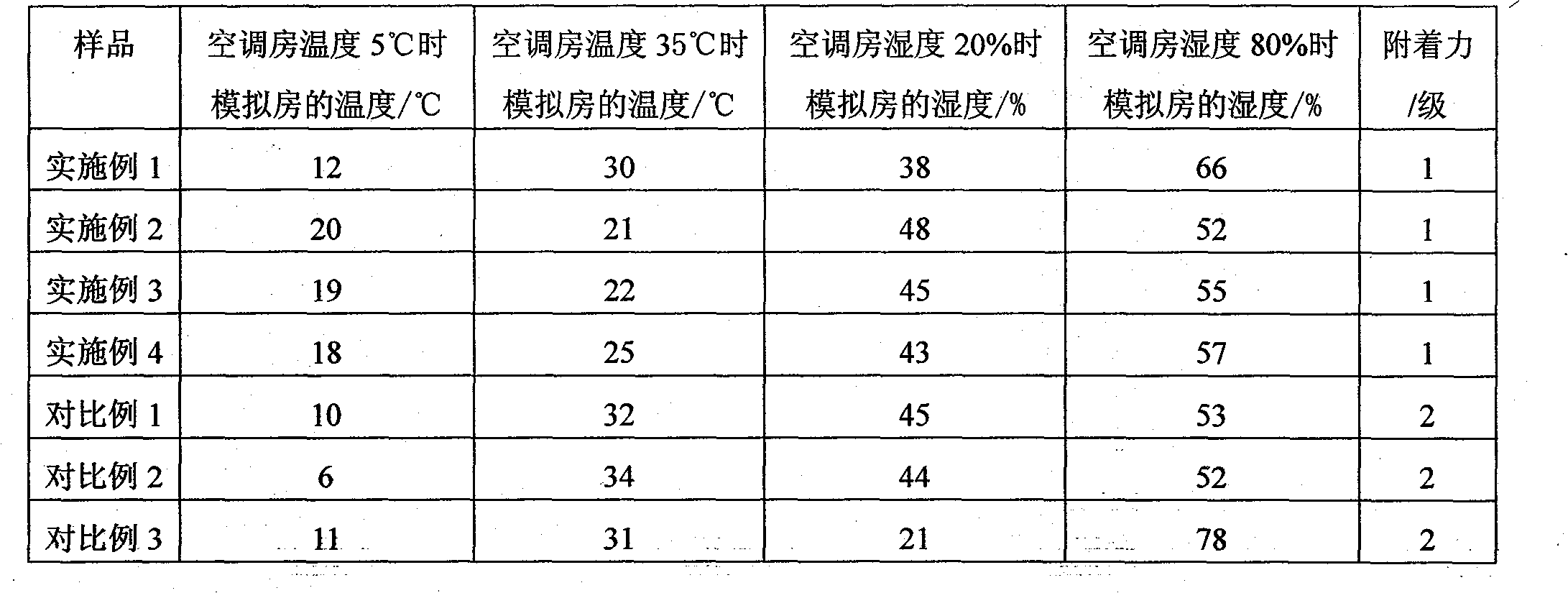

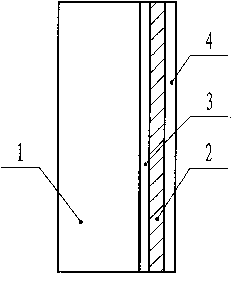

Temperature adjusting humidity adjusting coating and preparation method thereof

InactiveCN103159437ALower room temperatureTurn up the room temperatureEnvironmental resistanceThermal insulation

The invention relates to temperature adjusting humidity adjusting coating and a preparation method thereof. The temperature adjusting and humidity adjusting coating comprises thermal insulation undercoat, phase transition energy storage intermediate coat and heat conduction humidity adjusting finish. The undercoat insulates heat, and the phase transition energy storage intermediate coat transmits indoor energy through the finish and stores energy through the phase transition, and thereby effectively adjusting indoor temperature. The phase transition energy storage intermediate coat and the humidity adjusting function of the finish impart the whole coating temperature adjusting and humidity adjusting function. In addition, the temperature adjusting and humidity adjusting coating has the advantages of being fireproof, waterproof, antifouling, mechanical, capable of eliminating peculiar smell, sterilizing, insulating heat, removing sound, protecting environment and the like. The temperature adjusting and humidity adjusting coating is applicable to various kinds of constructional coating.

Owner:LUNAN RES INST OF COAL CHEM

Extended coverage ordinary hazard sprinkler system

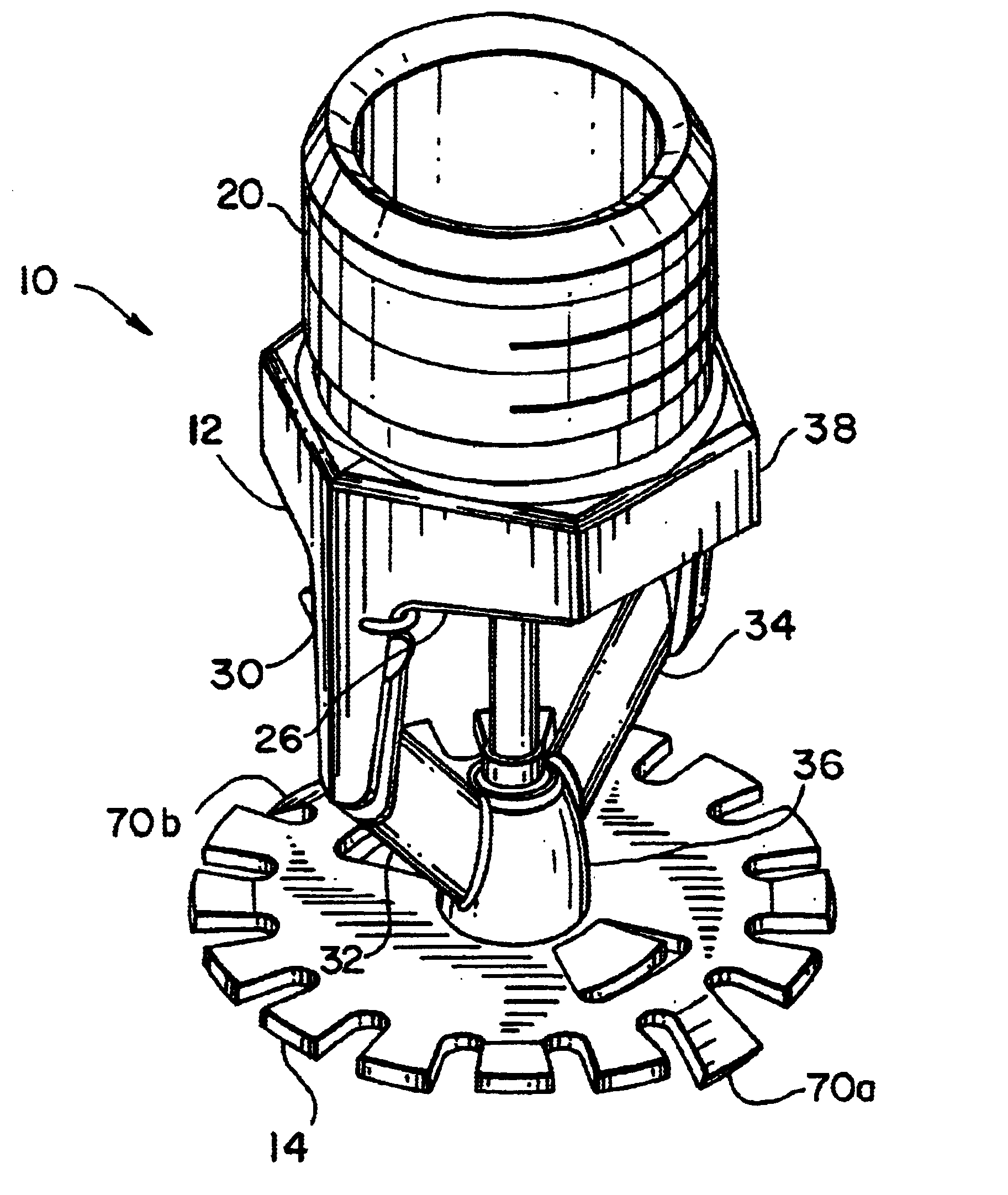

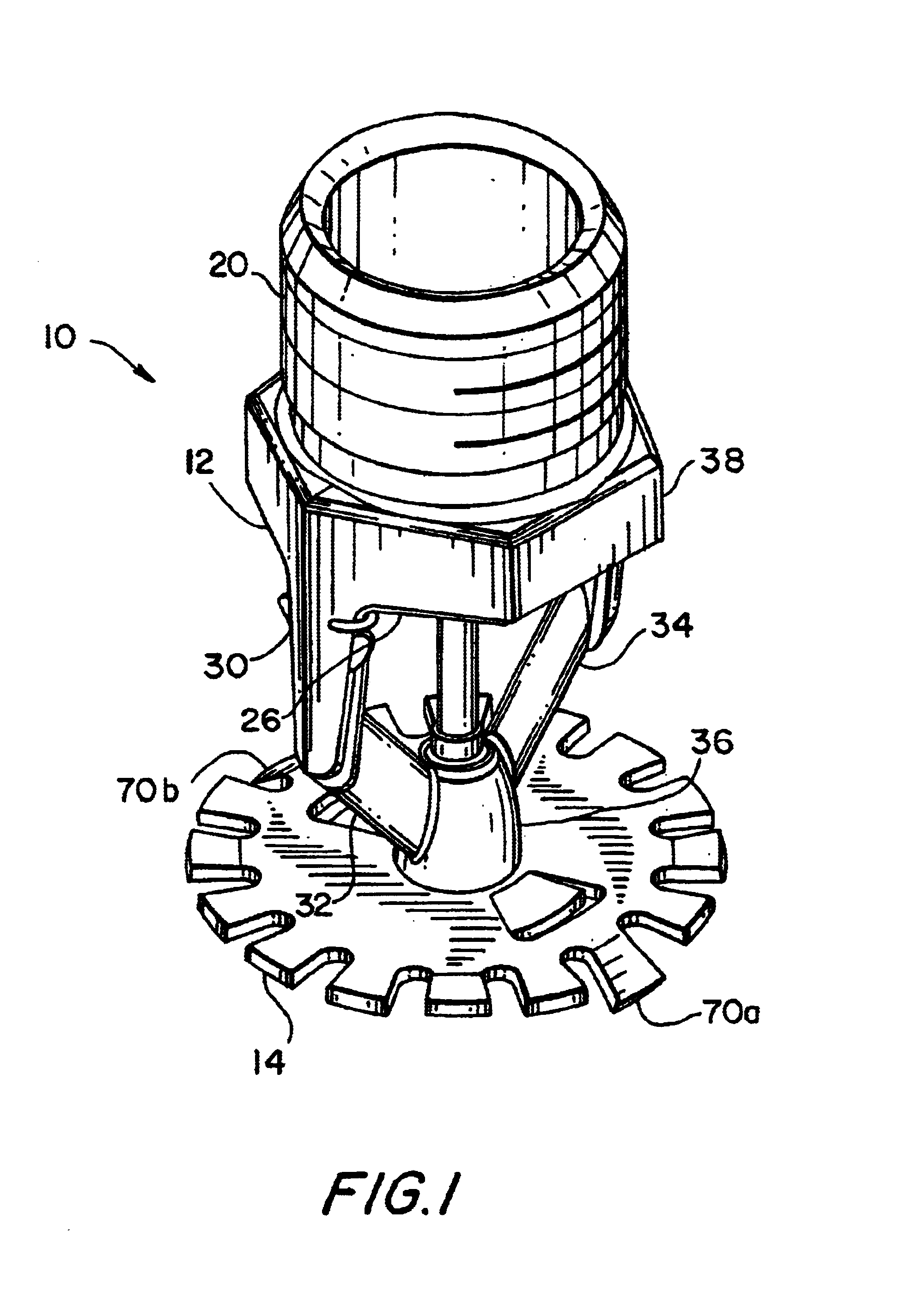

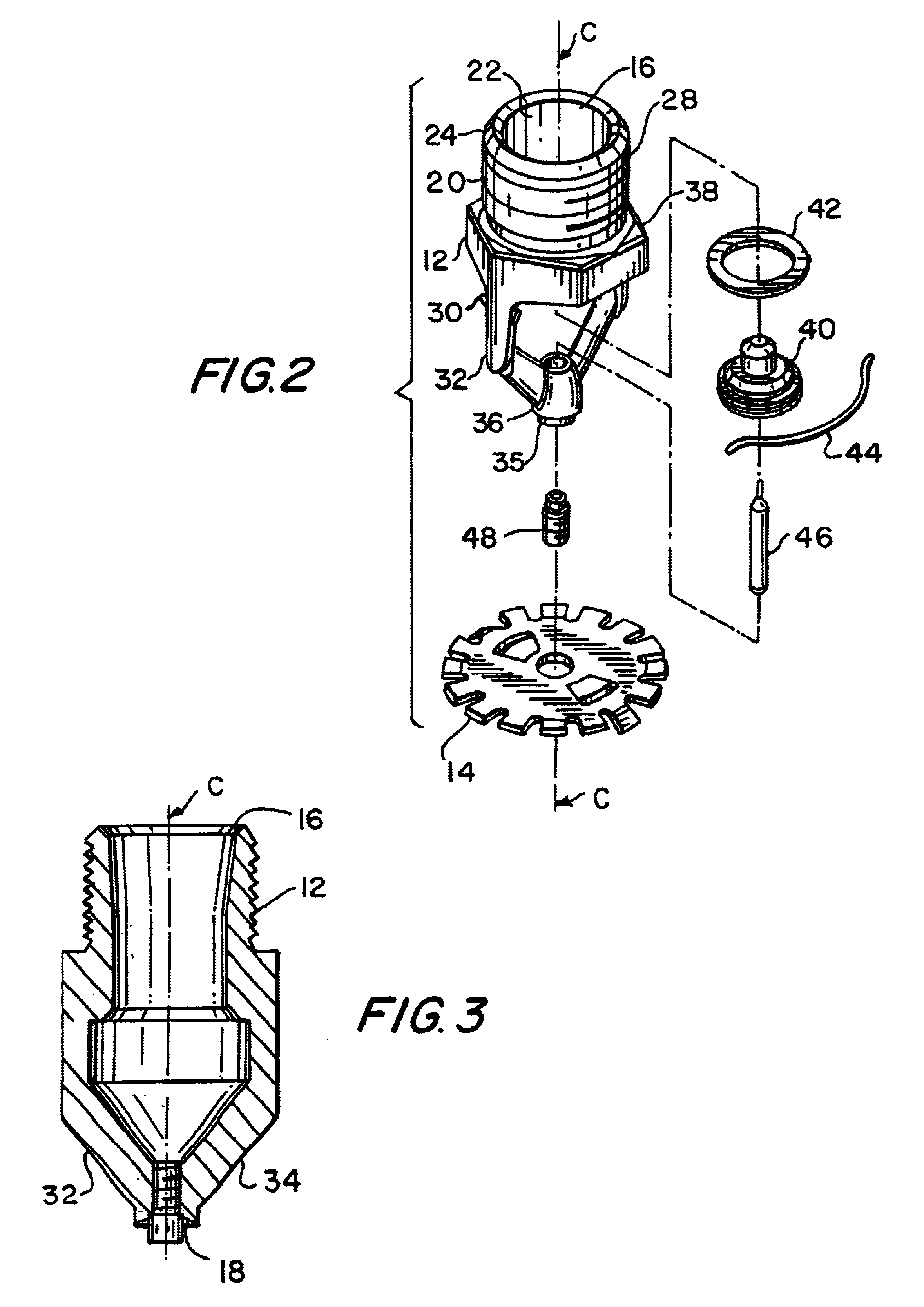

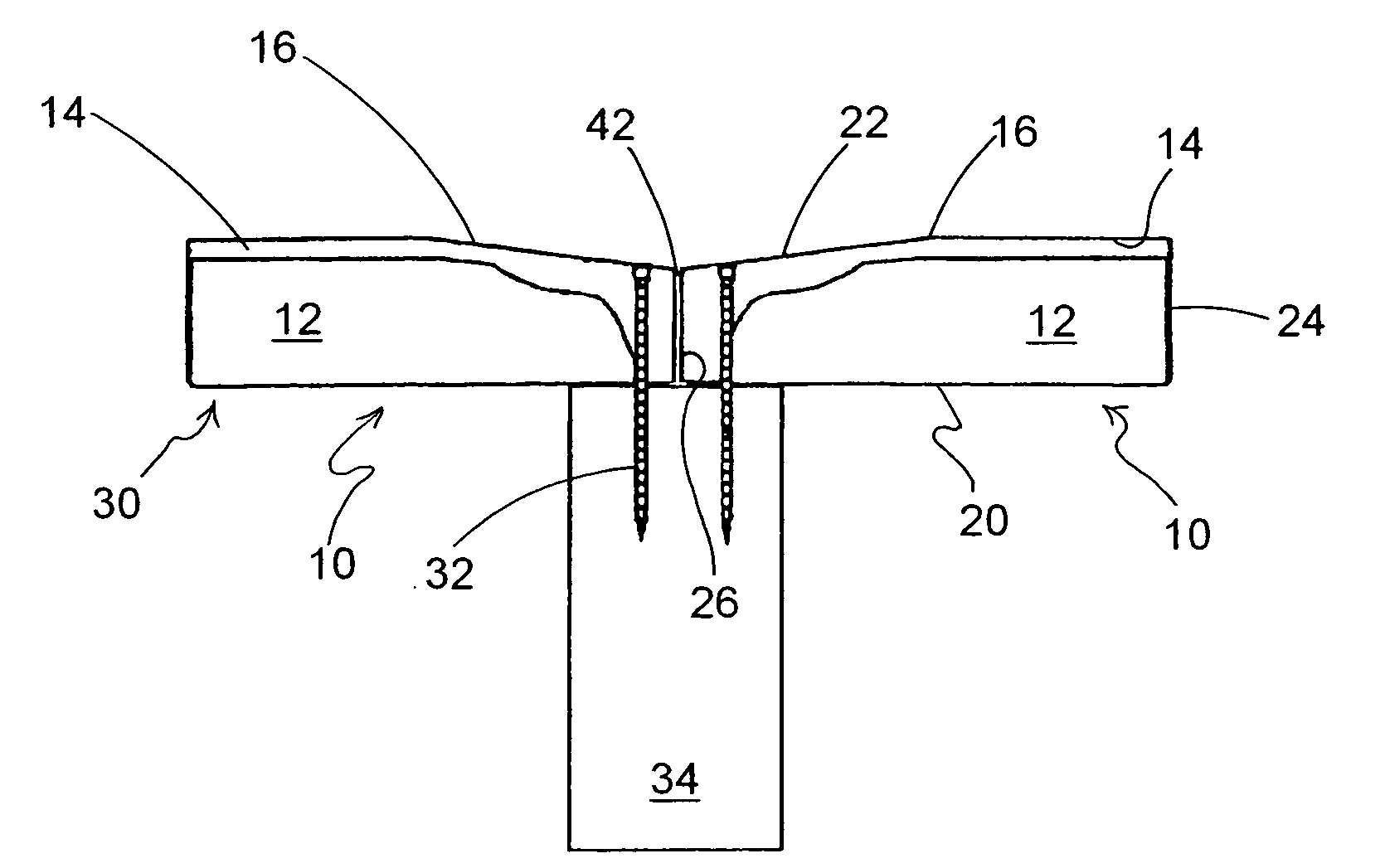

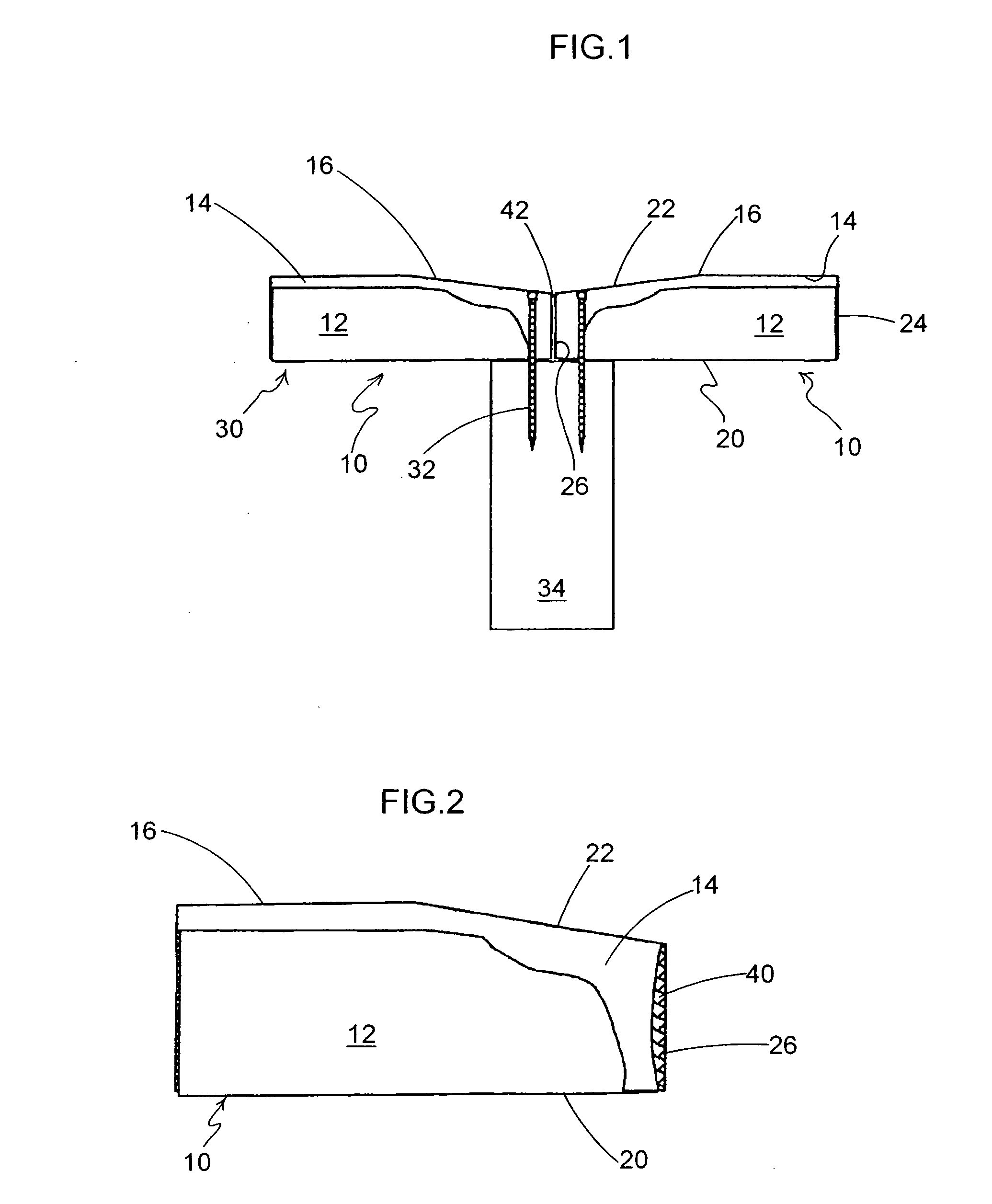

InactiveUS6854668B2Avoid difficultyImprove fire performanceSpray nozzlesFire rescueExtended coverageSprinkler system

A sprinkler discharges a column of water downwardly onto a deflector that has a plurality of peripheral tines with a respective non-radial tapered notch separating each adjacent pair of tines. Opposed cutouts with tabs in the central portion of the deflector combine with the notches and with depressed peripheral tabs to produce a predetermined spray pattern.

Owner:VICTAULIC

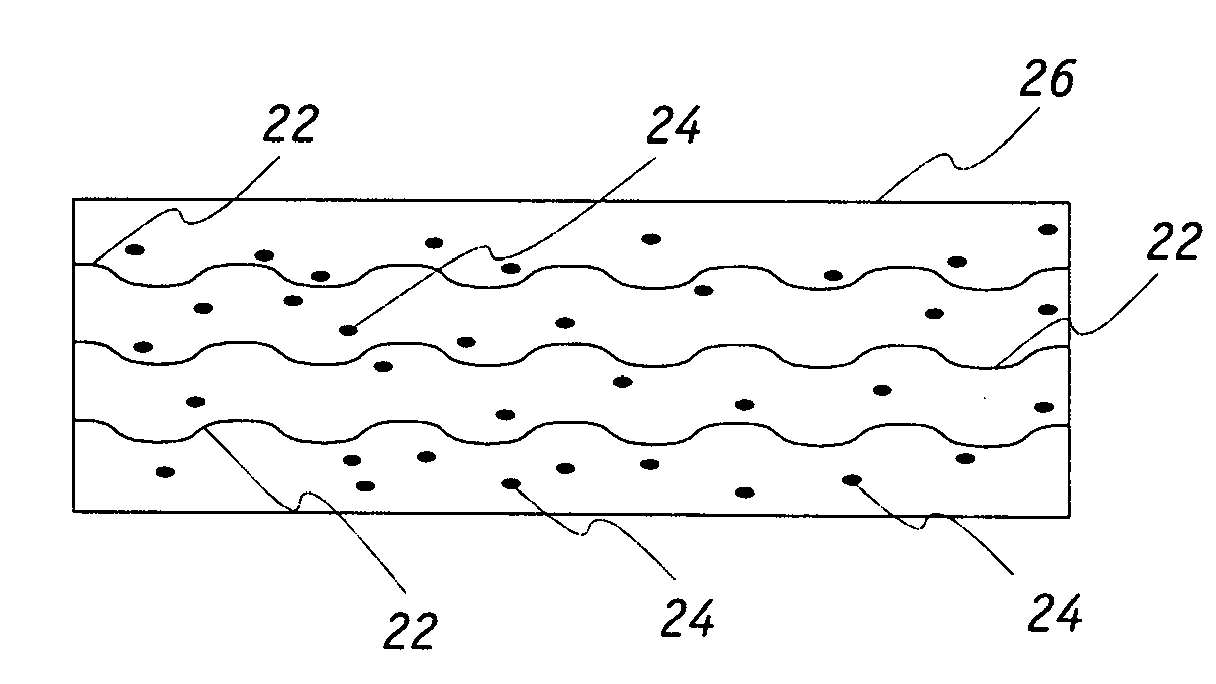

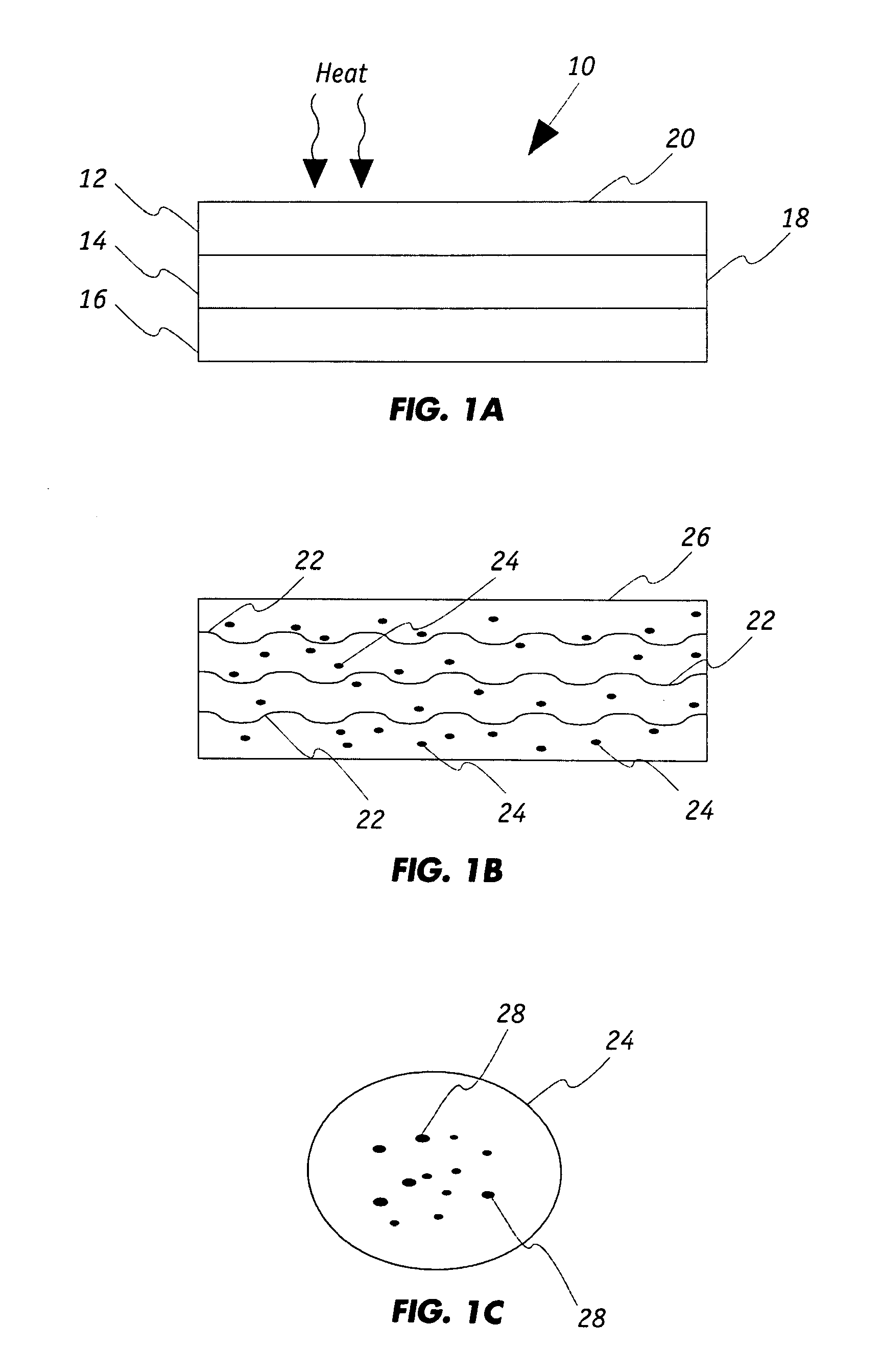

Fire-resistant gypsum panel

InactiveUS20080087366A1Improve fire resistanceImprove fire performanceConstruction materialCovering/liningsFire protectionSlurry

A method of continuously forming a multilayer panel includes making a gypsum slurry, then dividing the gypsum slurry into at least a primary gypsum slurry and a secondary gypsum slurry. An additive slurry having water and an intumescent material is created, then added to the secondary gypsum slurry to make an expandable layer slurry that is spread over at least a portion of a facing material. The primary gypsum slurry is distributed over the secondary gypsum slurry over the facing material and the expanding layer slurry to form a core. Optionally, another layer, an edge coating, is applied to the expanding layer for additional fire protection. The edge coating includes a second intumescent material. During a fire, the expanding layer expands to increase the thickness of the fire exposed gypsum panel and the edge coating expands to seal the gap between adjoining gypsum panels.

Owner:UNITED STATES GYPSUM CO

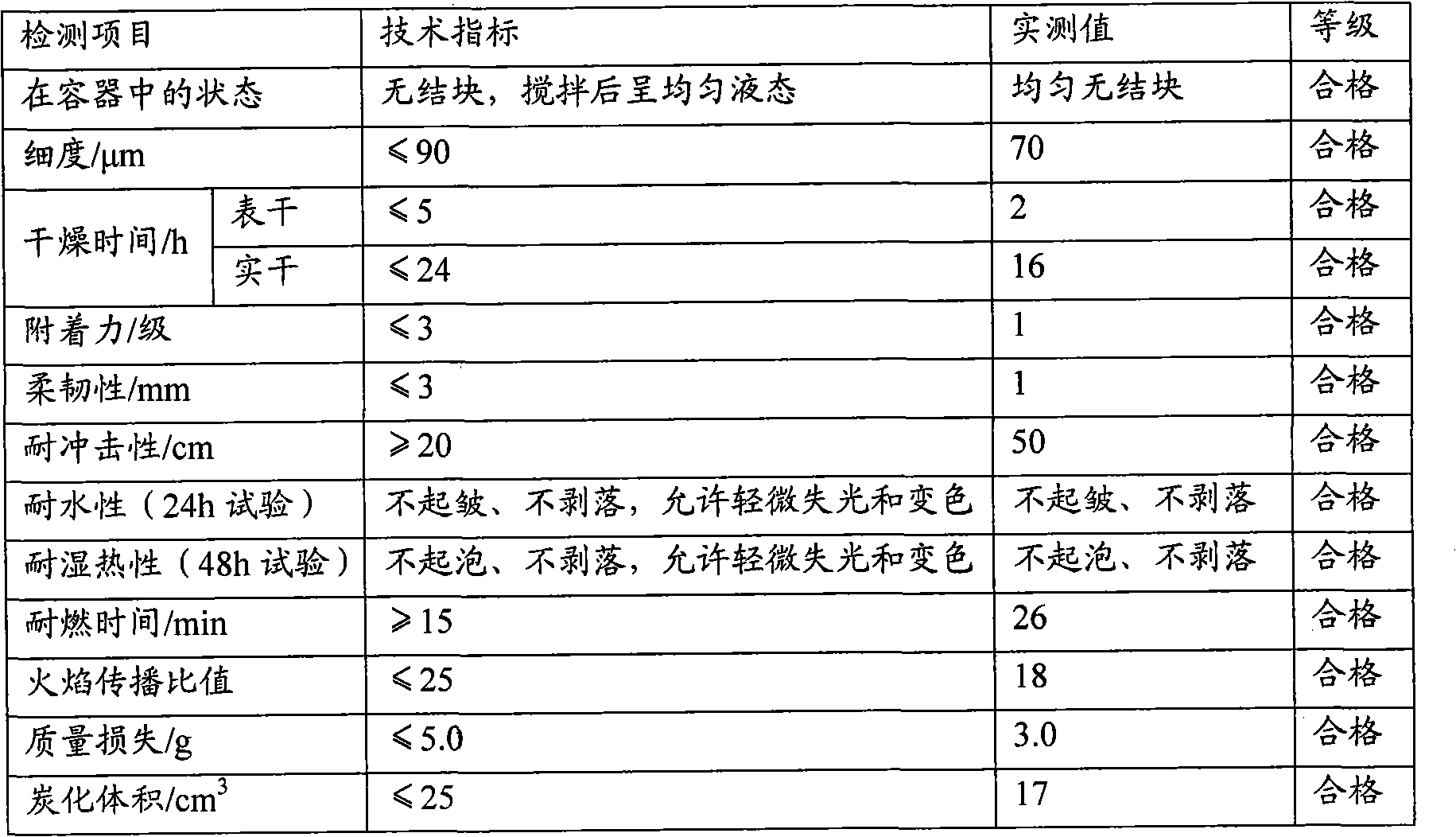

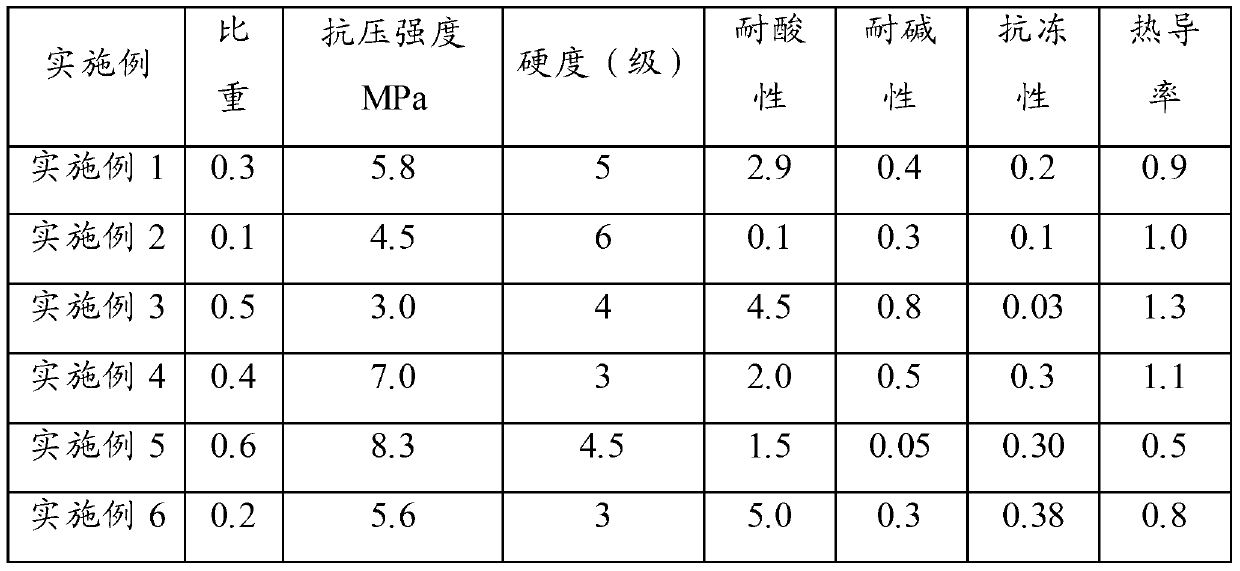

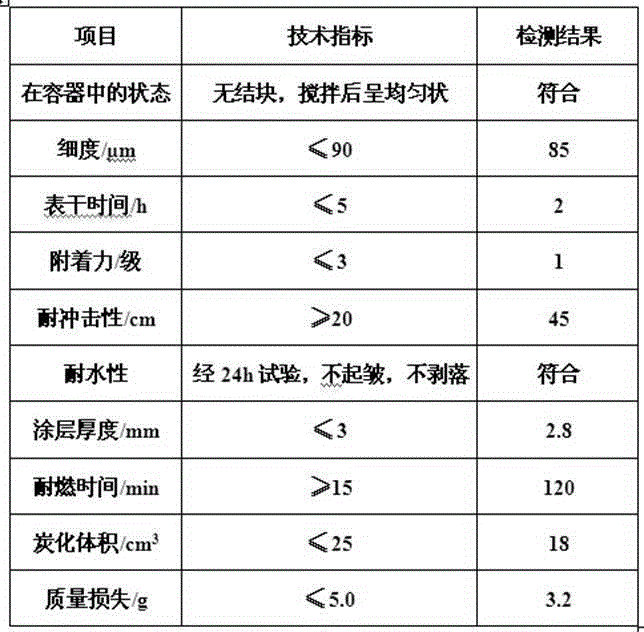

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

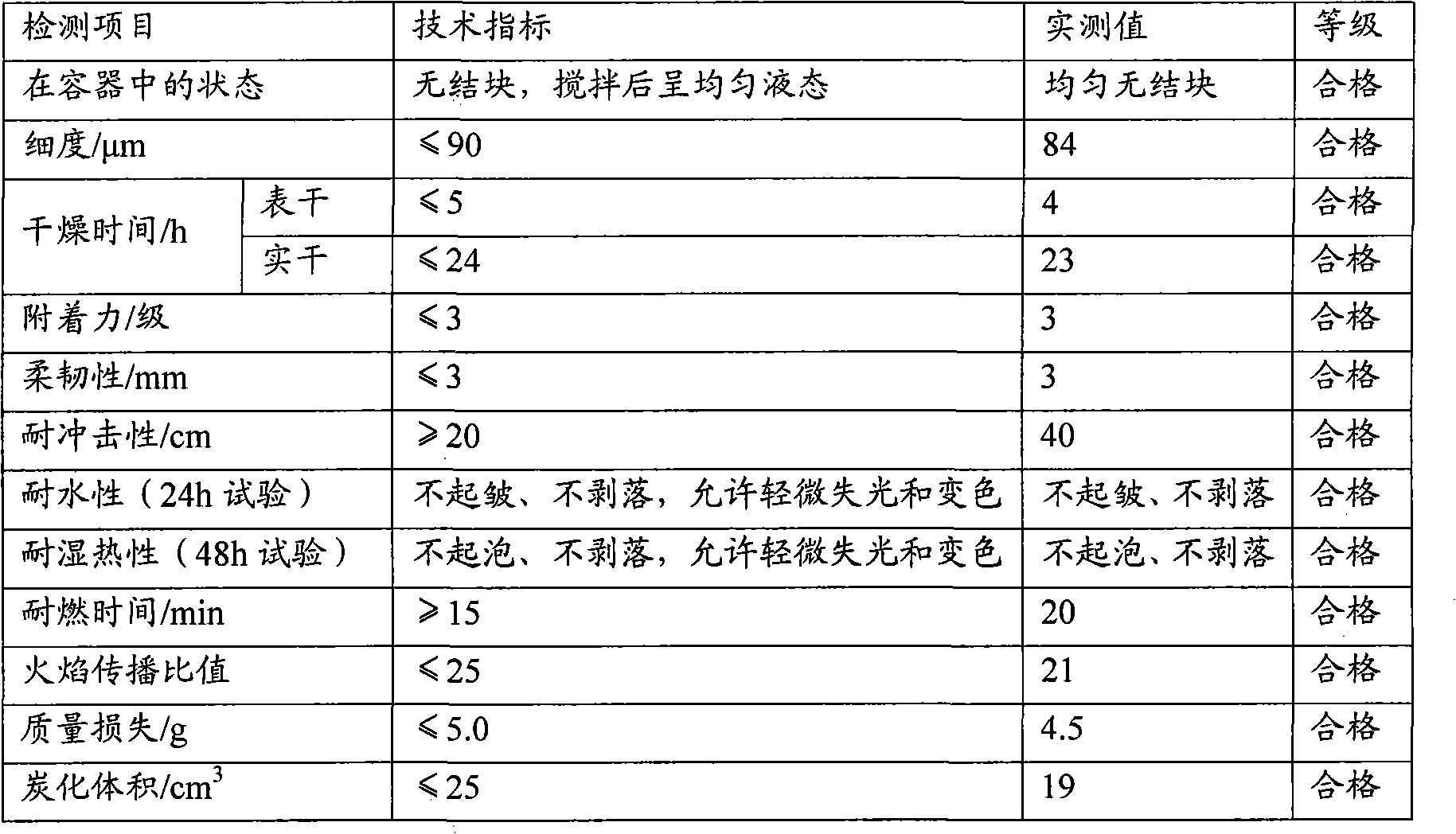

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

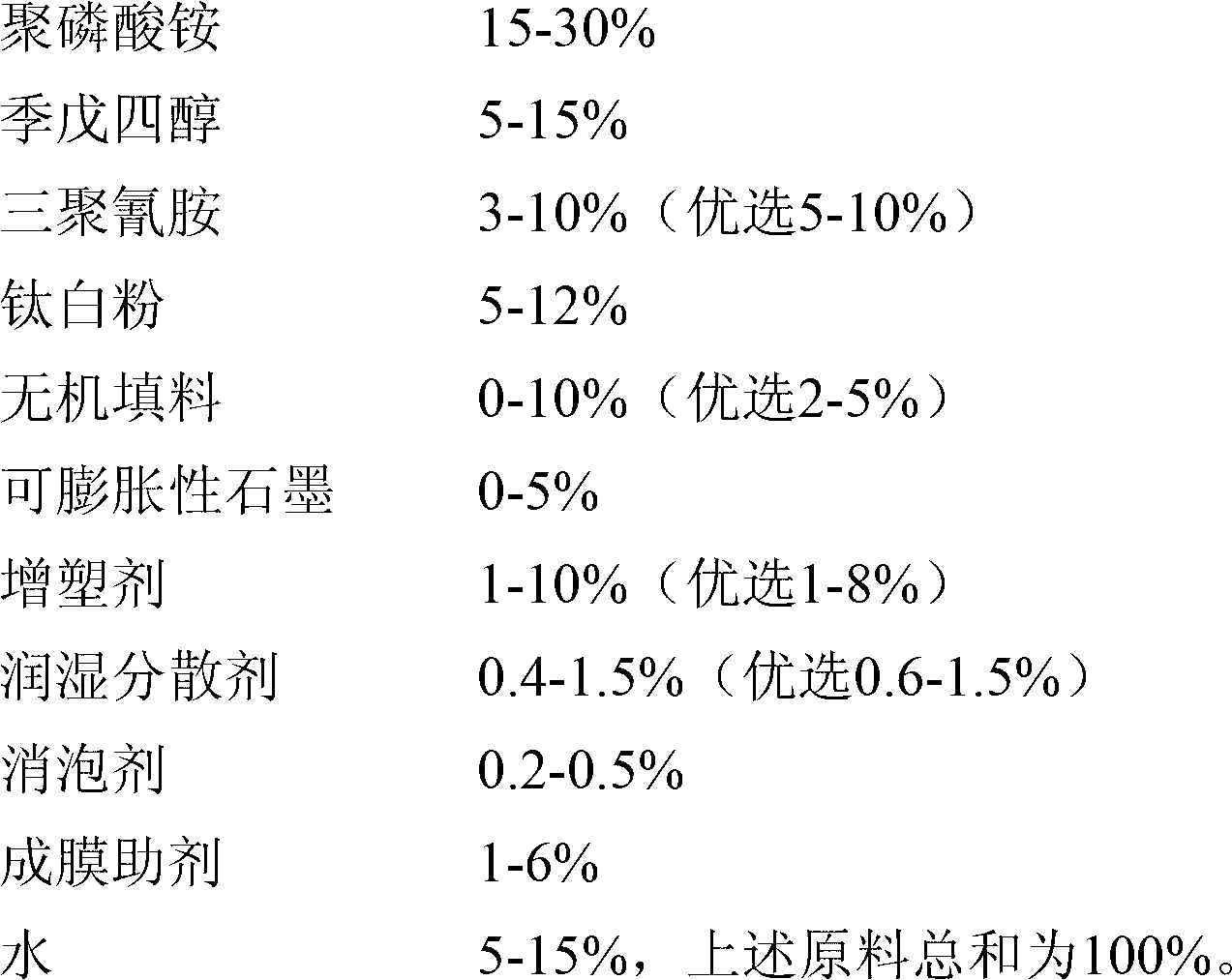

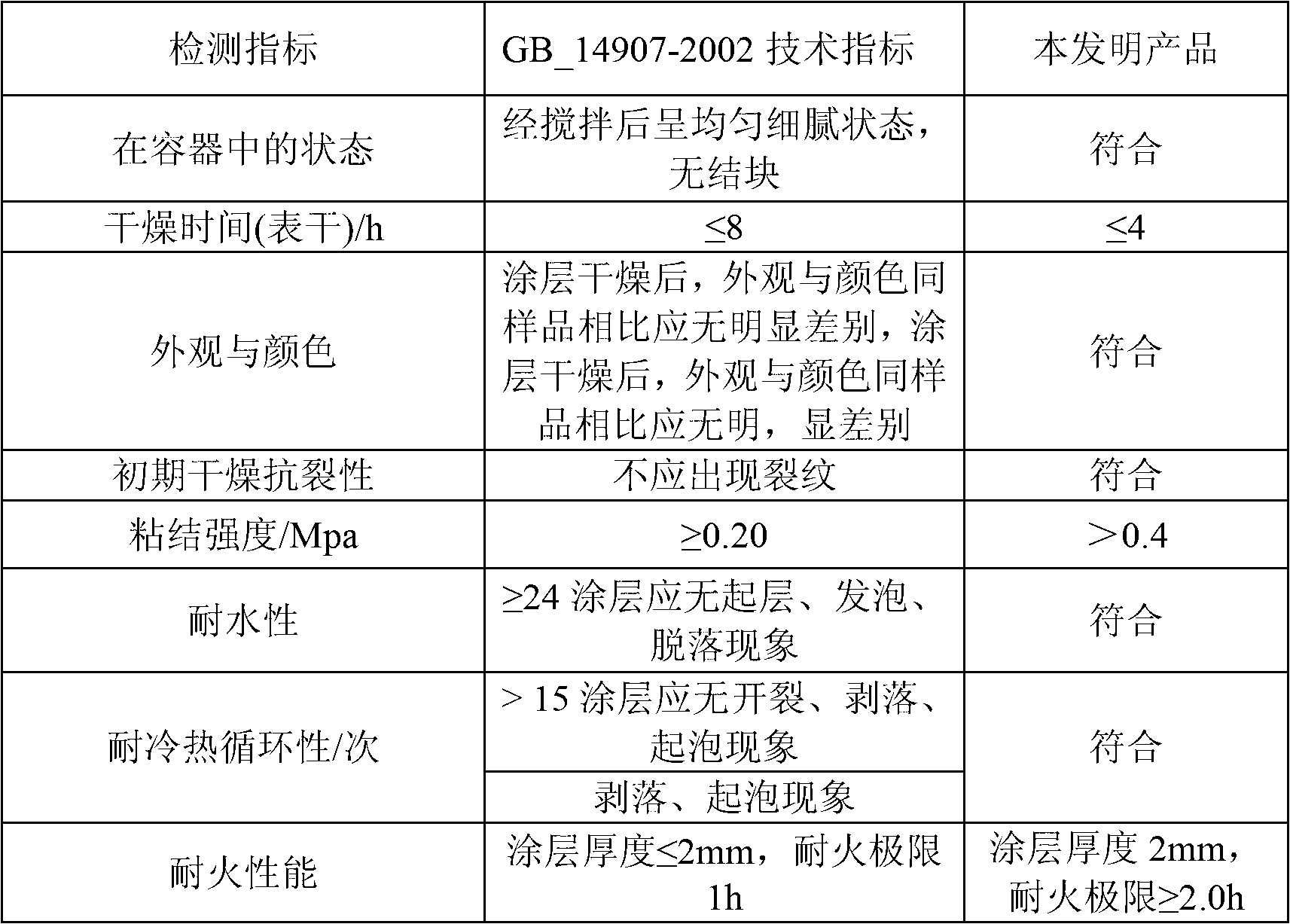

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

Fire-resistant gypsum panel

InactiveUS7776170B2Improve fire resistanceImprove fire performanceConstruction materialCovering/liningsFire protectionSlurry

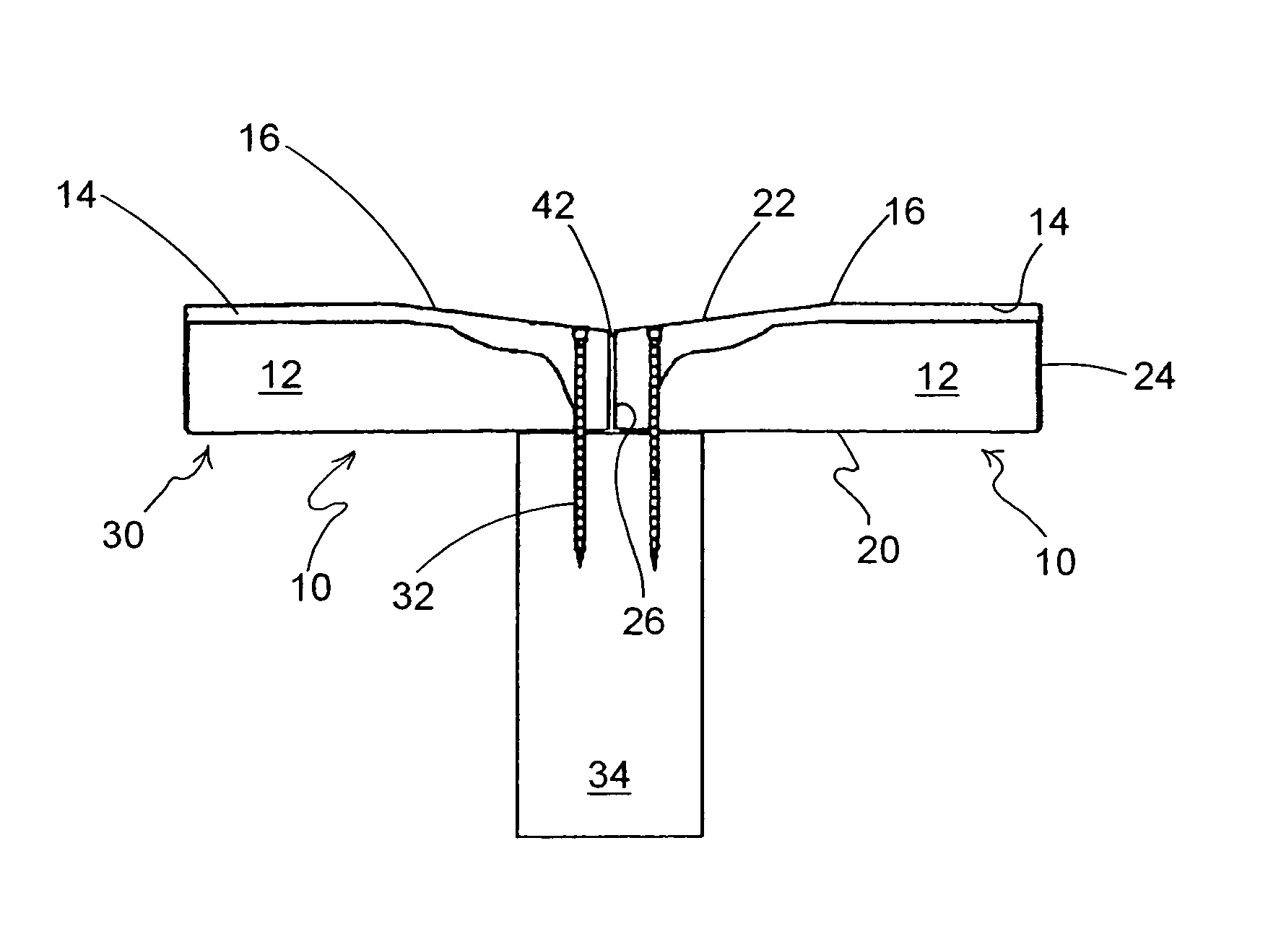

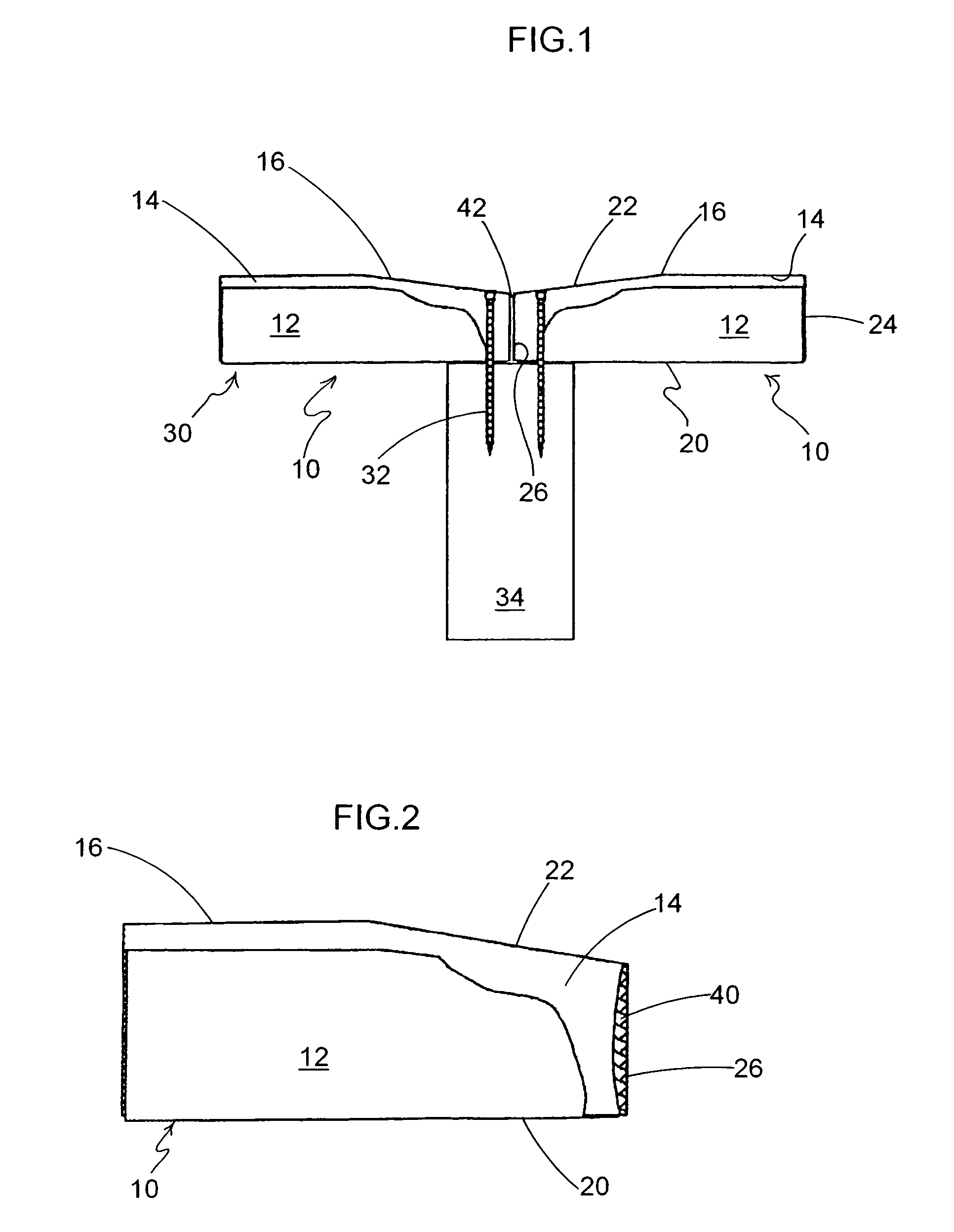

A method of continuously forming a multilayer panel includes making a gypsum slurry, then dividing the gypsum slurry into at least a primary gypsum slurry and a secondary gypsum slurry. An additive slurry having water and an intumescent material is created, then added to the secondary gypsum slurry to make an expandable layer slurry that is spread over at least a portion of a facing material. The primary gypsum slurry is distributed over the secondary gypsum slurry over the facing material and the expanding layer slurry to form a core. Optionally, another layer, an edge coating, is applied to the expanding layer for additional fire protection. The edge coating includes a second intumescent material. During a fire, the expanding layer expands to increase the thickness of the fire exposed gypsum panel and the edge coating expands to seal the gap between adjoining gypsum panels.

Owner:UNITED STATES GYPSUM CO

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

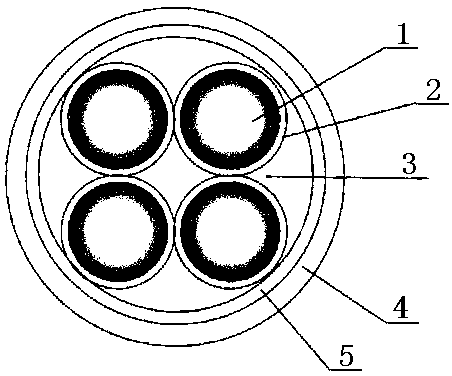

Fireproof and flame retardant mineral compound filling material and cable containing the same

ActiveCN103102134ANo harmImprove fire performanceInsulated cablesInsulated conductorsPolymer scienceFirming agent

The invention relates to a fireproof and flame retardant mineral compound filling material for cables. The filling material comprises a silicon-containing binder; an inorganic flame retardant compound; and a mineral compound. The filling material also can include a silicate modifier, a silicate curing agent and a pigment. Being free of any flammable substance, the fireproof and flame-retardant mineral compound filling material provided in the invention has an excellent fireproof effect, can lose moisture and absorb a lot of heat so as to achieve the flame retardant effect. With good flexibility, the fireproof and flame retardant mineral compound filling material has no hazard to the nature after it is abandoned.

Owner:上海宏胜电线电缆有限公司 +1

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

Nano porous concrete taking thixotropic colloid as template agent and preparation method

InactiveCN105294141AHas a three-dimensional network microporous structureNo pollution in the processCeramicwareBrickThixotropy

The invention relates to porous concrete and a preparation method thereof, in particular to novel nano porous concrete which is prepared by taking thixotropic colloid as a template agent to form a uniform-water-phase three-dimensional network nano porous structure and adding cementing materials, fine aggregate, coarse aggregate, an admixture and an additive. The nano porous concrete has the characteristics of being light, high in strength and low in heat conductivity, can be prefabricated into bricks, building blocks, plates, and assembly type stairs, wallboards, balcony slabs and roof panel parts in a factory, can be also cast on a construction site, and further can be prepared into mortar, thereby having remarkable practical significance on promotion of development of housing industrialization and green building concrete material in our country.

Owner:浙江圣润纳米科技有限公司

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

Foaming type inorganic heat insulation plate, preparation method thereof and heat insulation layer thereof

InactiveCN101798850ALow thermal conductivityImprove insulation effectSolid waste managementCeramic shaping apparatusFiberCellulose

The invention relates to a foaming type inorganic heat insulation plate, a preparation method thereof and a heat insulation layer thereof, which belongs to the technical field of a heat insulation plate and a heat insulation layer, and provides a foaming type inorganic heat insulation plate with high efficiency and energy saving, a preparation method thereof and a heat insulation layer thereof. The heat insulation plate is prepared from the following raw materials in parts by weight: 10-55 parts of composite light weight admixture, 10-55 parts of cement, 5-30 parts of lime, 3-20 parts of plaster, 1-10 parts of wollastonite, 10-55 parts of water glass, 10-60 parts of foam body which is foamed by a foaming machine through a foaming agent, 3-20 parts of fly ash, 0.1-3 parts of gel powder, 0.05-2 parts of cellulose ether, 0.01-2 parts of glauber salt, 0.1-3 parts of water reducing agent, 0.1-2 parts of hydrophobic agent, 0.01-1 part of mekarlon, 1-10 parts of bone glue, 5-30 parts of emulsion, 4-12 parts of waste slag, 1-45 parts of water and 0.02-1 part of aluminum powder. The invention is applied to the technical field of heat insulation materials.

Owner:太原思科达科技发展有限公司

Fire resistant flexible ceramic resin blend and composite products formed therefrom

InactiveUS20100304152A1Improve fire performanceConducive to lightweightSynthetic resin layered productsCellulosic plastic layered productsAdhesiveComposite laminates

High heat resistant elastic composite laminates, sealants, adhesives, and coatings developed from a resin blend. The resin blend is made up of methyl and optionally phenyl silsequioxane resins selected to produce silanol-silanol condensation silicone polymers formed in a slowly evolving reaction mass containing submicron boron nitride, silica and boron oxide fillers. The required ratio of submicron boron nitride to silica has been discovered for assuring the formation of a high temperature resistant elastic composite blend that will form intermediate flexible ceramic products up to 600 deg C., then continue to form preceramic then dense ceramic products from 600 to 1000 deg C. The thermal yield of the composite is generally greater than 90 wt. % at 1000 deg C. Composite products with different levels of heat transformation can be fabricated within the same product depending upon the thickness of the layers of reinforcement.

Owner:FLEXIBLE CERAMICS

Composite plate material of foam microcrystalline glass and pure microcrystalline glass and manufacturing method of composite plate material

The invention provides a composite plate material of foam microcrystalline glass and pure microcrystalline glass. The composite plate material comprises a base body and a decoration surface, wherein the base body is made of a foam microcrystalline glass mixed material; the thickness of the base body is 50mm to 500mm; the decoration surface covers the surface of the base body and is made of pure microcrystalline glass granules; the thickness of the decoration surface is 3mm to 30mm. The invention also provides a manufacturing method of the composite plate material. The composite plate material of the foam microcrystalline glass and the pure microcrystalline glass, provided by the invention, can simultaneously replace a building material and a decoration material, and is small in specific gravity, high in strength, fireproof and corrosion-resistant; environment products which are difficultly handled in a natural environment and industrial wastes which are difficultly treated currently can be consumed; the environment stress is reduced.

Owner:北京晶雅石科技有限公司

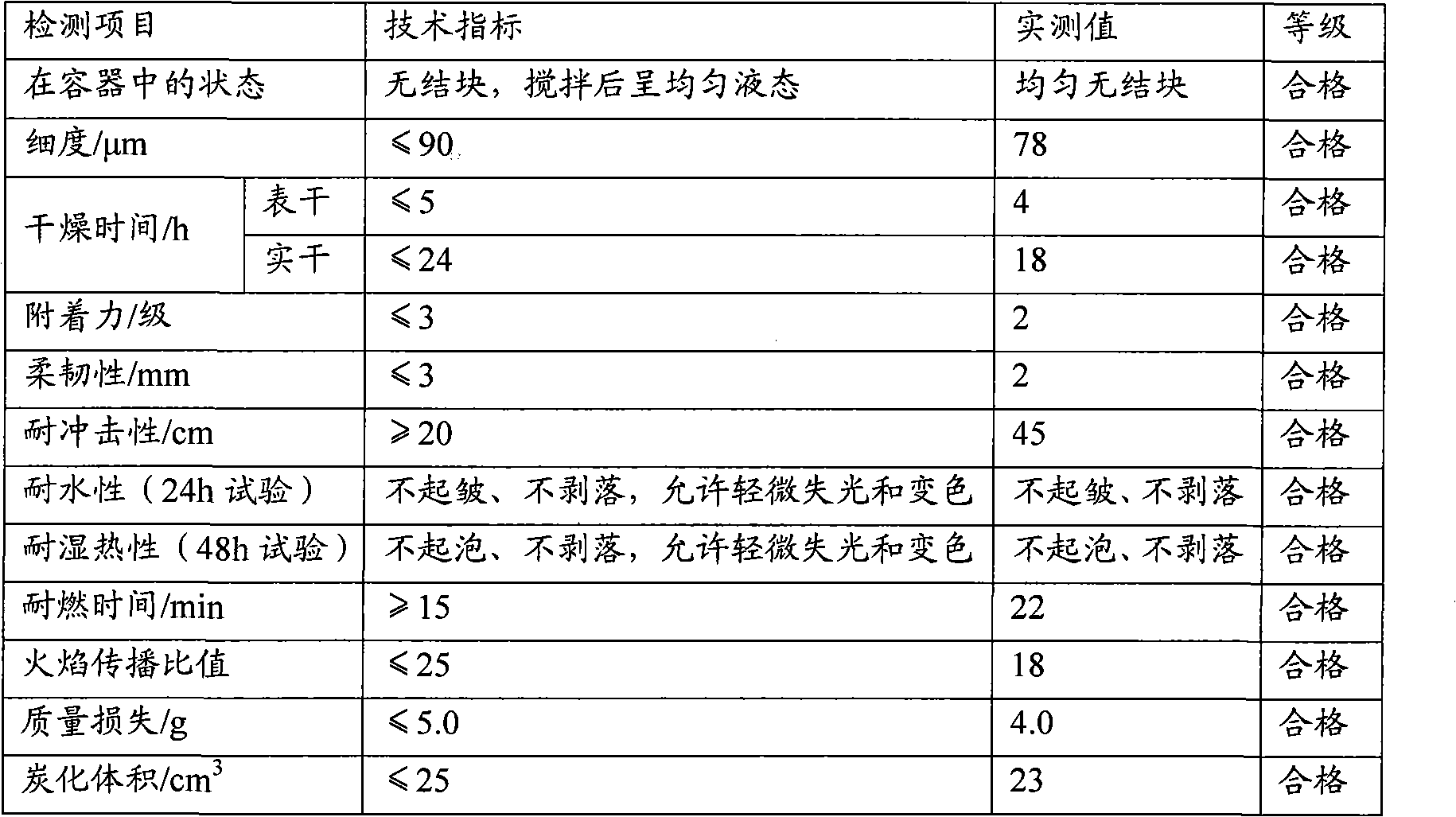

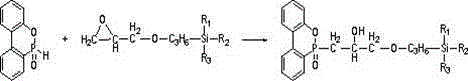

Poly(propylene carbonate)-based polyurethane fireproof coating and preparation method thereof

ActiveCN102241942AImprove hydrolysis resistanceImprove fire performanceFireproof paintsPolyurea/polyurethane coatingsSilane couplingFlame resistance

The invention relates to a poly(propylene carbonate)-based polyurethane fireproof coating and a preparation method thereof. The poly(propylene carbonate)-based polyurethane fireproof coating is prepared from 100 parts of poly(propylene carbonate) which is the polymer of carbon dioxide and propylene oxide, 15-30 parts of aromatic diisocyanate, 0.1-0.2 part of catalyst, 0-3 parts of non-ionic chainextender containing active hydrogen, 2-8 parts of active-hydrogen-containing ionic chain extender capable of forming a hydrophilic group, 1-6 parts of neutralizer, 1-10 parts of silane coupling agent, 200-350 parts of adjuvant, 40-140 parts of flame retardant, 10-50 parts of bentonite and 1-3 parts of dispersant. The fireproof coating has the advantages of good water resistance, strong adhesion force, flame retardance reaching one level, superior fireproof performance, strong integrated application capability and bright application prospect, and can be applied to the surface coating of wood, steel and other substrates.

Owner:JIANGSU ZHONGKE JINLONG CHEM

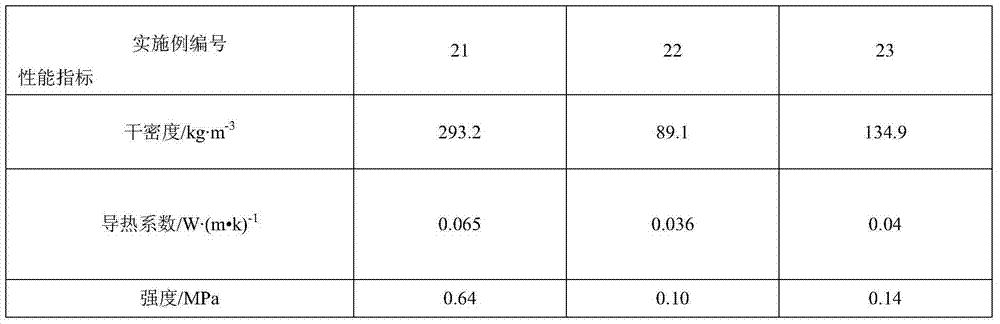

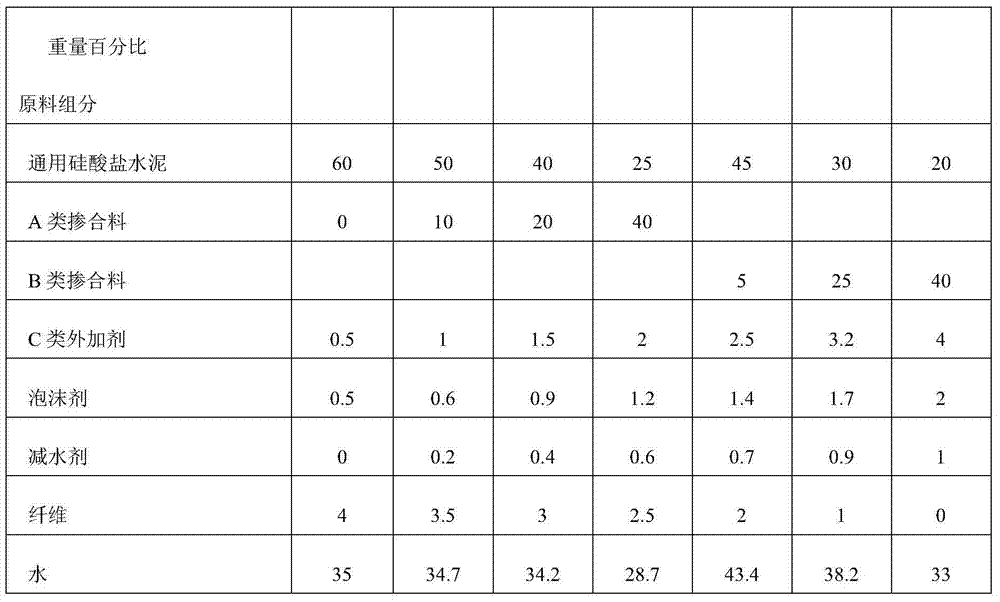

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

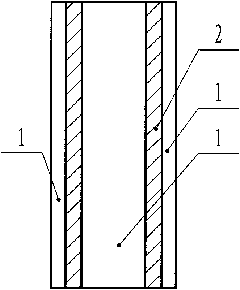

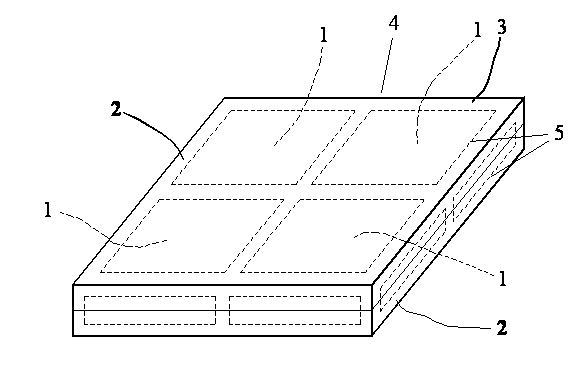

Building wall insulation composite board and preparation method thereof

ActiveCN103104046AReasonable structural designImprove fire performanceClimate change adaptationPolyureas/polyurethane adhesivesBuilding energyThermal insulation

The invention relates to a building wall insulation composite board and a preparation method of the building wall insulation composite board, and belongs to the technical field of building energy-saving insulation materials and preparation methods. A wall insulation hard foam polyurethane composite board comprises inner cores, protective layers coated on the peripheries of the inner cores and interface layers coated on the upper surfaces and the lower surfaces of the protective layers in an attached mode. The inner cores are vacuum insulation boards. The preparation method of the wall insulation hard foam polyurethane composite board comprises preparation of interface coiled materials: coating prepared flame-retarded polymer mucilage on base materials to produce the interface coiled materials, and manufacturing of the protective layers and the wall insulation hard foam polyurethane composite board. The insulation composite board has good thermal insulation performance, waterproof performance and heat insulation performance, can satisfy 65% requirements of building energy efficiency very well, is high in bonding strength and convenient to construct and operate, greatly increases overall fireproof performance of the whole wall heat-insulation system after being arranged on a wall, and can be widely applied to the inner portions of walls, outer walls, and roof covering thermal insulation systems, heat insulation systems and waterproof systems.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

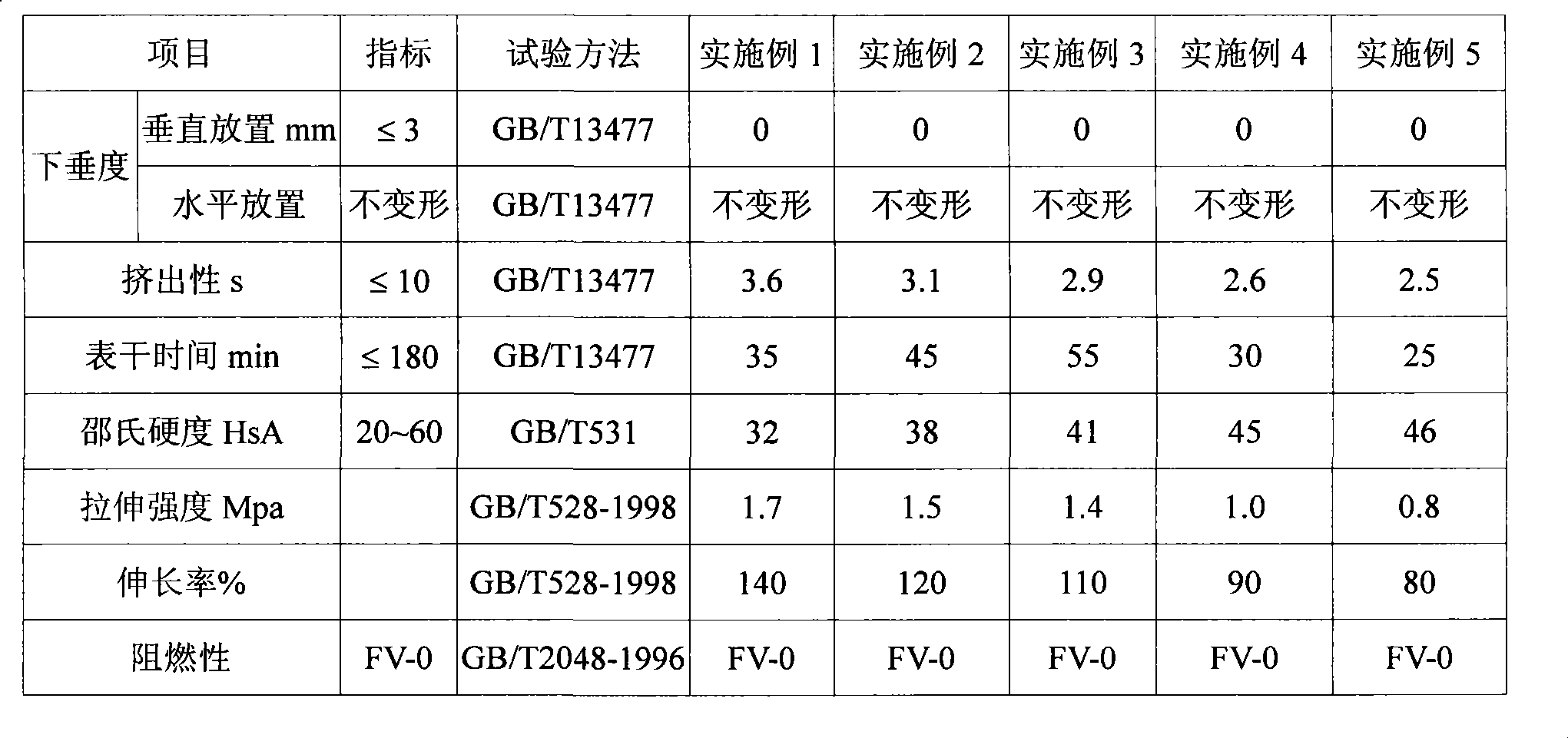

Expansion flame-proof organosilicon fluid sealant and method of producing the same

InactiveCN101368080AEnsure the safety of personnel and propertyGood fire performanceOther chemical processesAdhesivesOrganosiliconPlasticizer

The invention relates to an expansion flame retardant organosilicon sealant and a manufacturing method thereof. The sealant comprises the following components by weight portion: 100 portions of Alpha, Omega-dihydroxyl polysiloxane; 5 to 30 portions of plasticizer; 20 to 100 portions of filler; 50 to 150 portions of inorganic flame retardant; 5 to 30 portions of expansion fire retardant; 1 to 30 portions of cross-linking agent; 0.1 to 1 portion of catalyzer; 1 to 5 portions of viscosity increaser and 0.1 to 5 portions of inorganic pigment. The manufacturing method comprises the following steps: the Alpha, Omega-dihydroxyl polysiloxane, the filler, the inorganic flame retardant and the expansion fire retardant are dehydrated at 80 to 150 DEG C in a vacuum triple motion agitator, and are mixed for 0.5 to 2 hours before the mixture is cooled to the room temperature; the silane cross-linking agent, the viscosity increaser, the catalyzer and the plasticizer are added and mixed for 0.5 to 2 hours. The expansion flame retardant organosilicon sealant has excellent mechanical property, fire retardancy, adhesion and storage stability, which is primarily used as a sealant in devices that cables are threaded through on watercrafts as well as used for closing off various openings formed in the way that cables, air conduits, oil tubes and so on pass through walls, bulkheads, floor slabs, decks and so on in buildings or power supply systems.

Owner:陈栋梁 +1

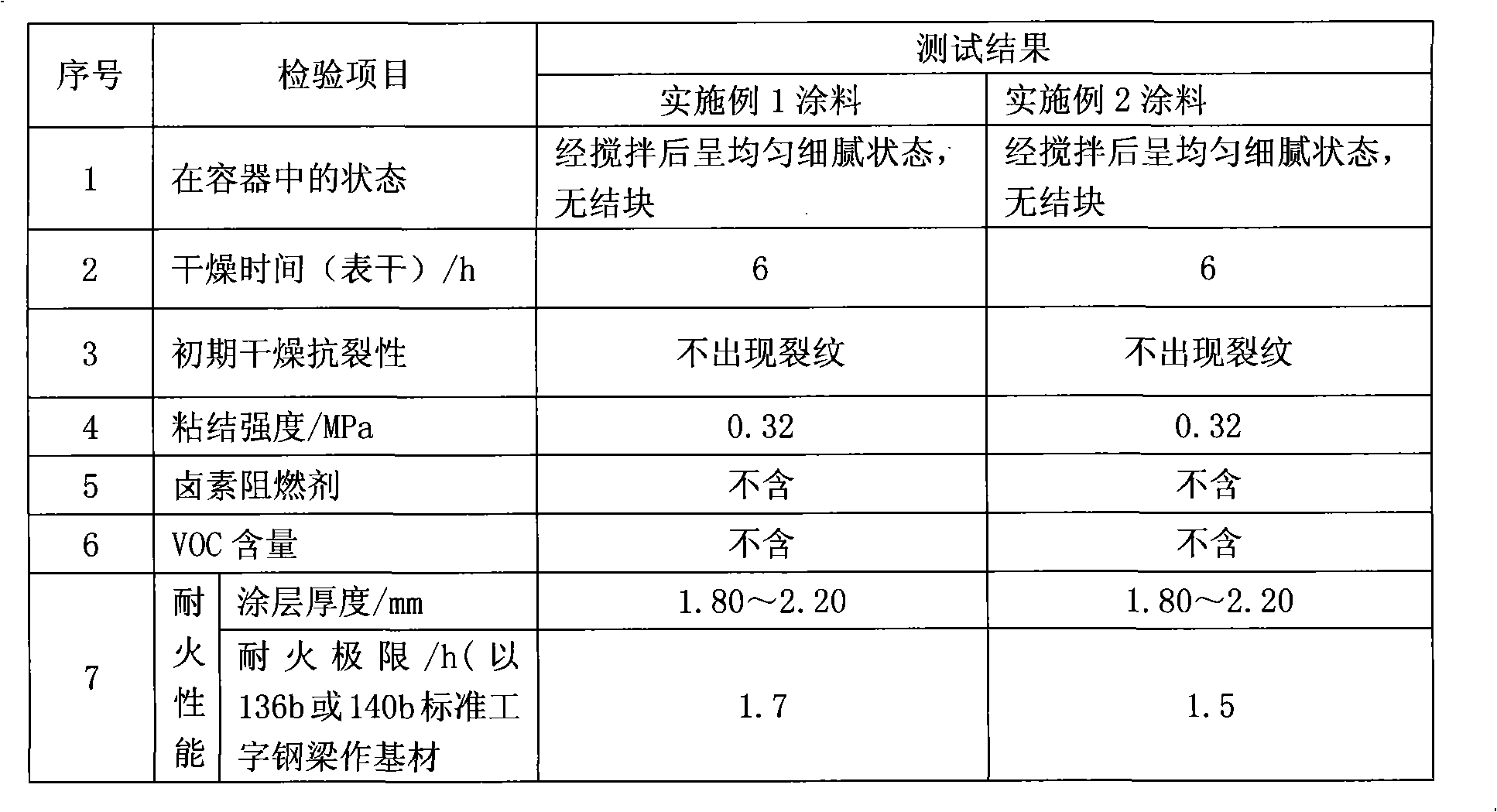

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

Fire resistant material

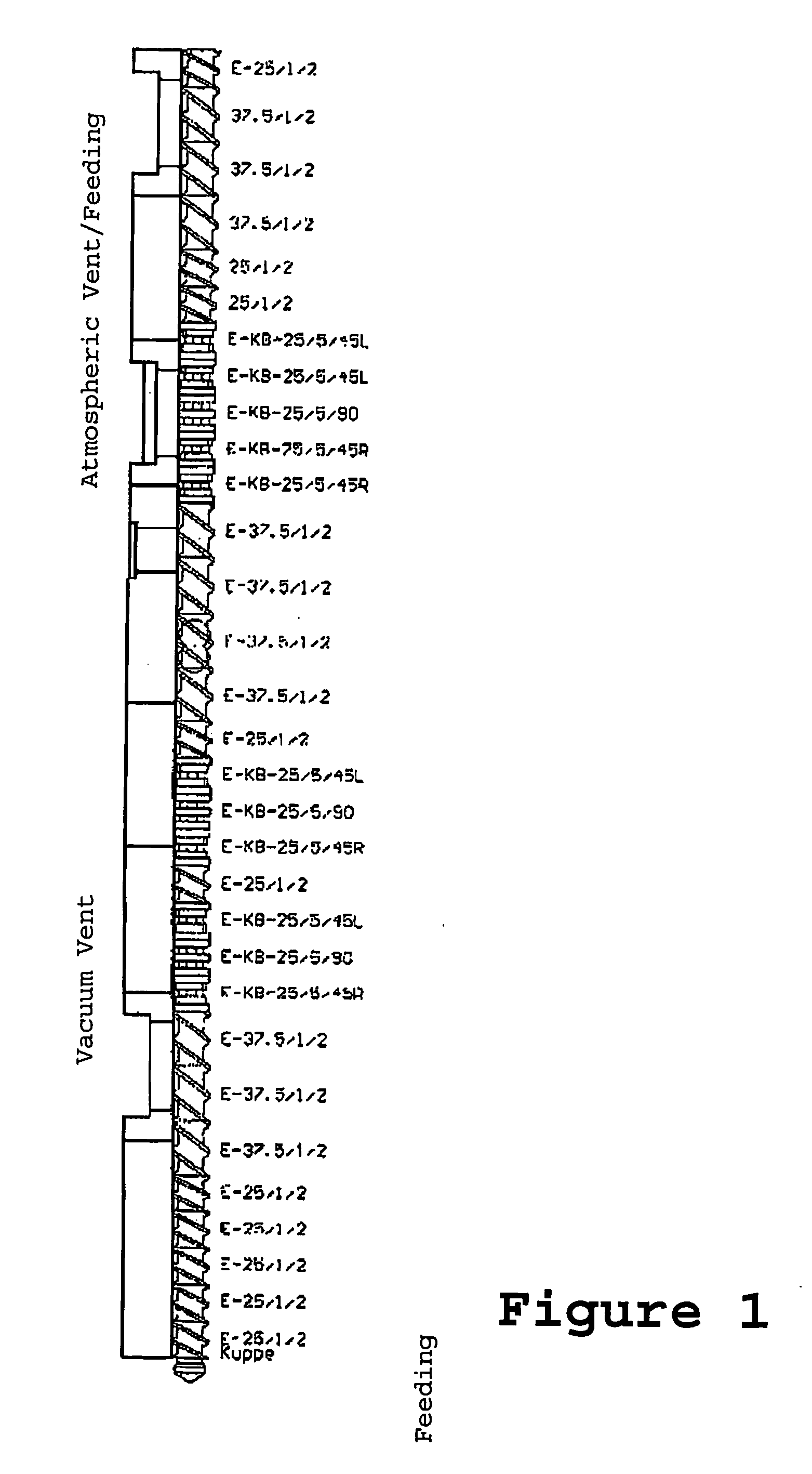

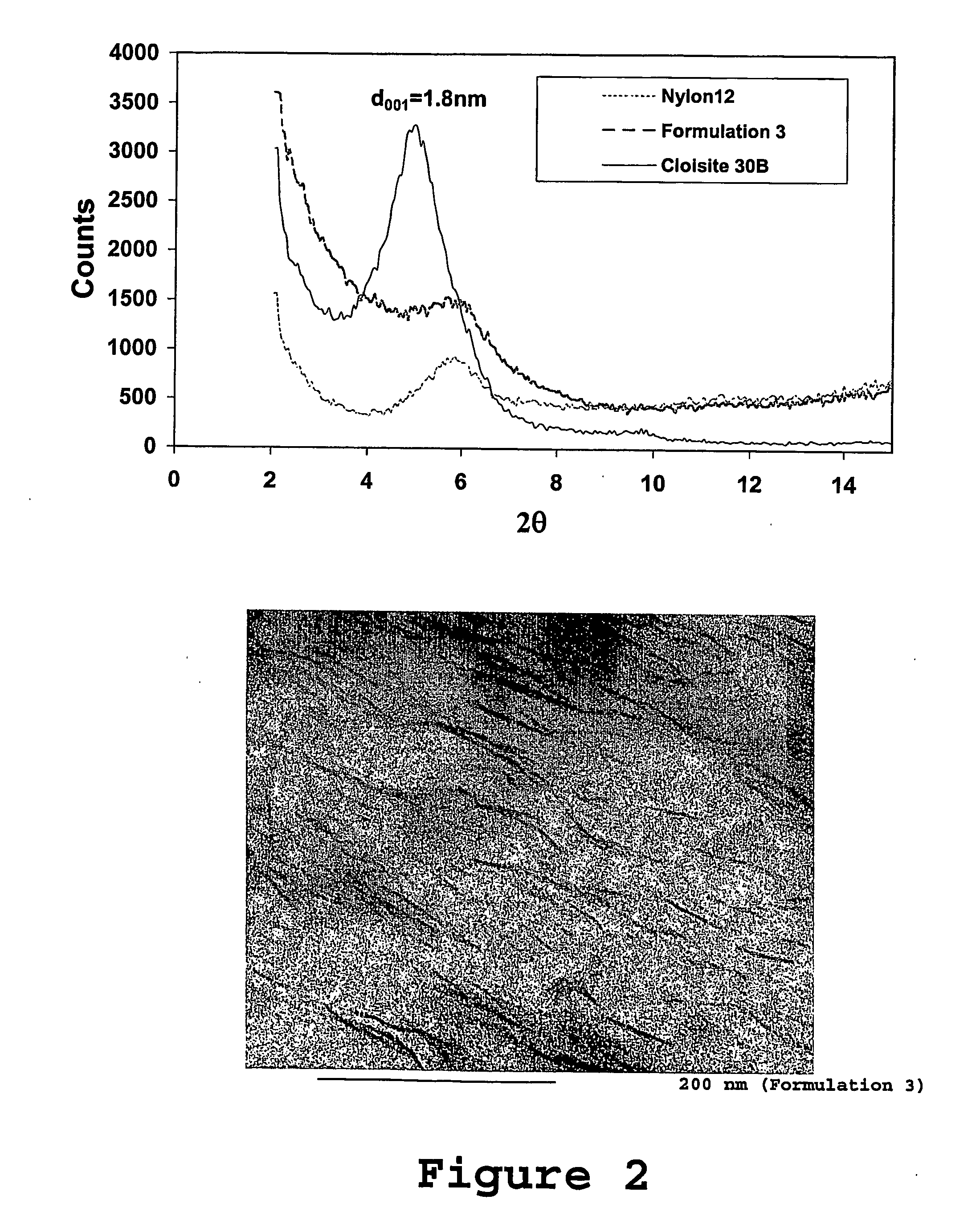

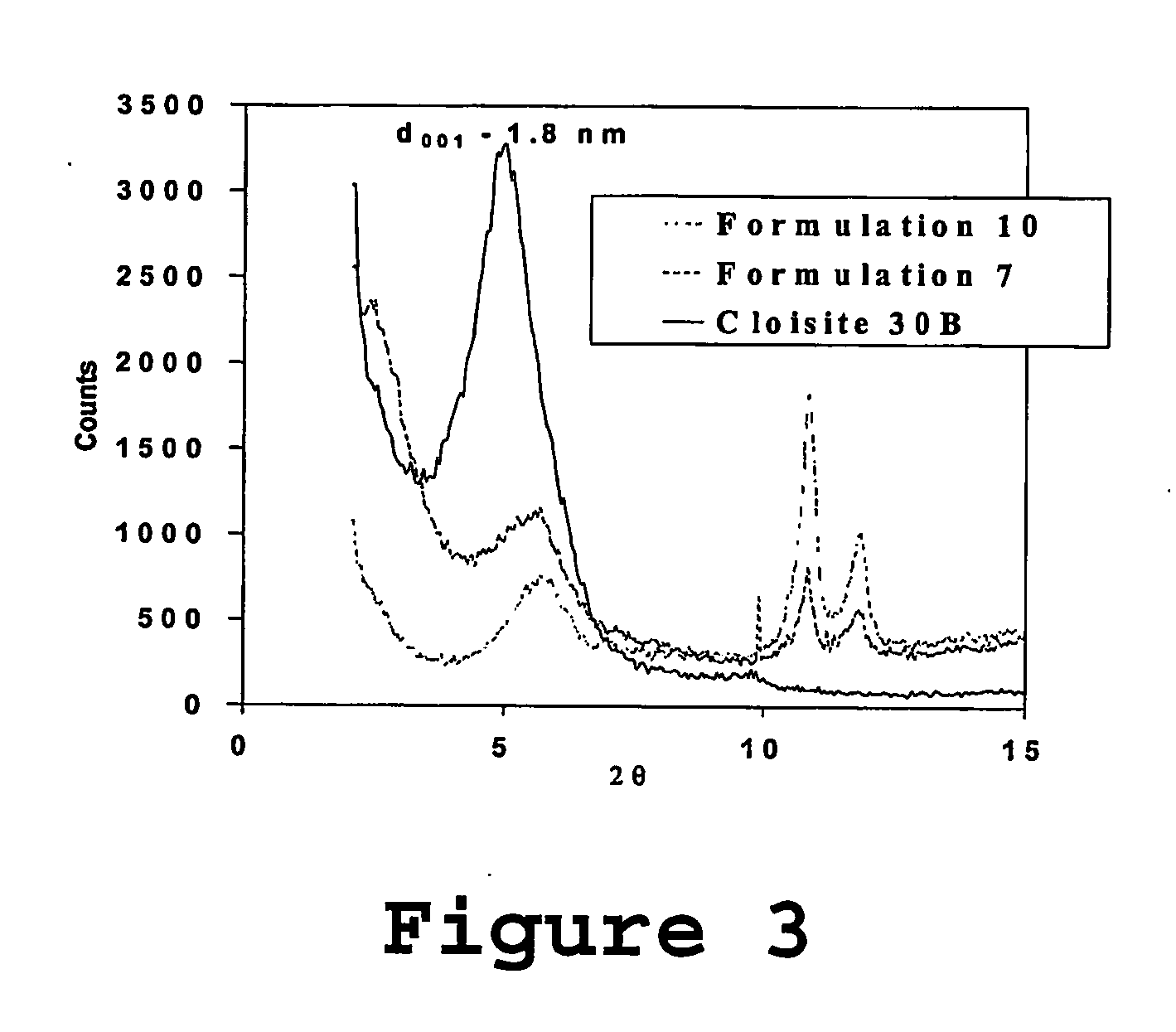

InactiveUS20070194289A1Improve compatibilityImprove rheologySilicon compoundsTextile shapingPolyamideMaterials science

The present invention relates to inorganic-organic hybrids (IOHs), methods for their preparation and their use as fire resistant materials or components of fire resistant materials. More specifically, the invention relates to polyamide fire resistant formulations containing IOHs which have application in the production of fire resistant articles or parts thereof for use in the transportation, building, construction and electrical or optical industries.

Owner:THE BOEING CO

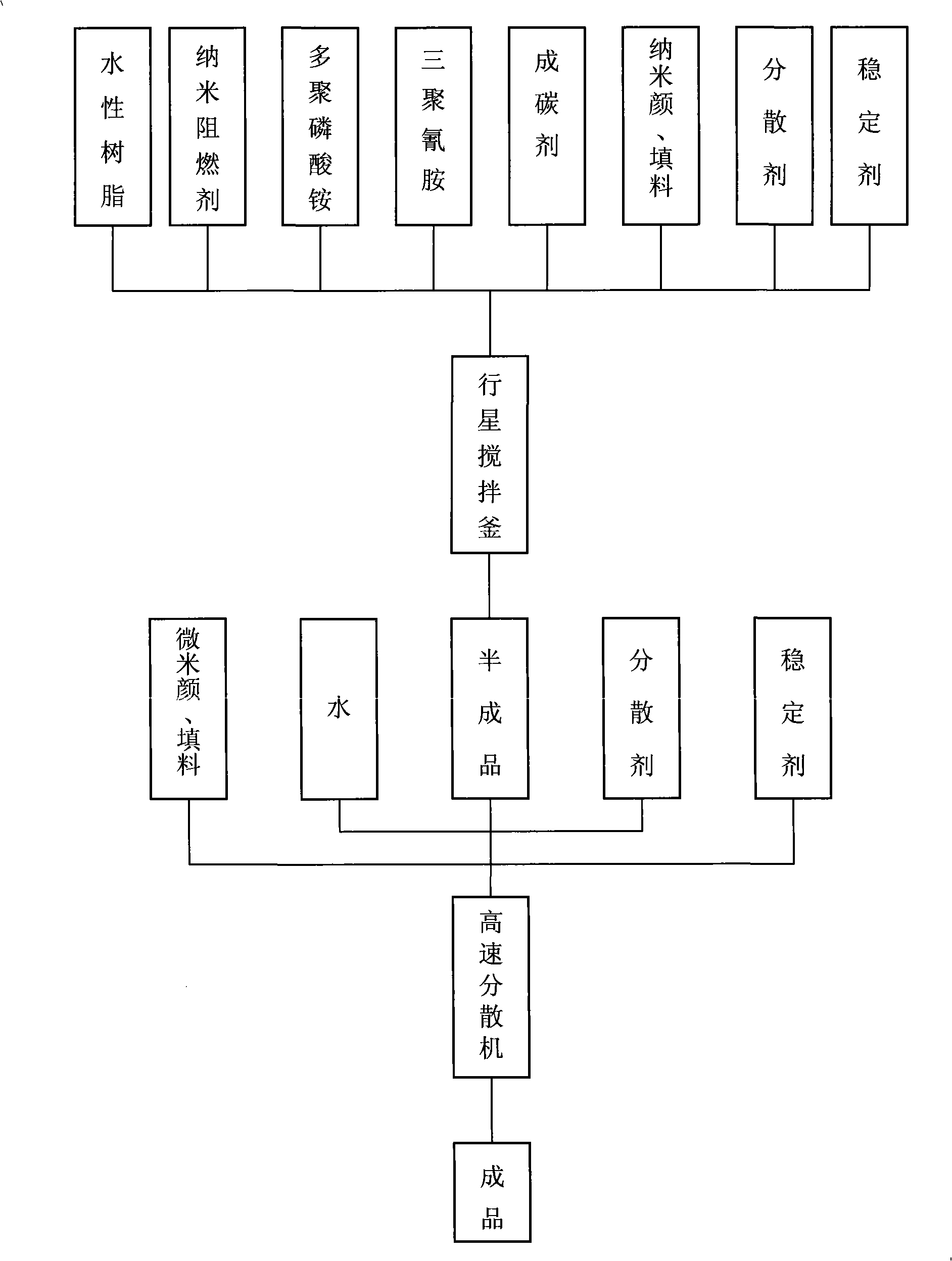

Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

InactiveCN101280142AImprove fire performanceLow VOC contentFireproof paintsEmulsion paintsPolymerStabilizing Agents

The invention is environmental-friendly waterborne nanometer fireproof flame-retardant coating and the preparation method, which belong to the fireproof flame-retardant coating manufacturing industry. The flame-retardant coating is obtained through the compounding of two types of flame-retardant agents, waterborne resin, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and filler, micrometer pigment and filler and other auxiliary agent; the flame-retardant coating contains no organic agent and halogen flame retardant, low VOC content, good fireproof property, good physical and chemical properties; the composition of the flame-retardant coating is as follows: the content of waterborne resin is 10-90%; the content of phyllo-silicate nanometer flame retardant which contains phosphor, nitrogen organic intercalation is 1-50%; the content of nanometer magnesium hydroxide flame retardant wrapped by polymer is 1-50%; the content of ammonium polyphosphate is 1-30%; the content of melamine is 1-20%; the content of carbon-forming agent is 1-30%; the content of nanometer pigment and filler is 0.1 to 30%; the content of micrometer filler is 0.1 to 60%; the content of dispersant is 0.1 to 10%; the content of stabilizer is 0.1 to 10%; the content of water is 0.1 to 50%; the content of micrometer pigment is proper; firstly, waterborne resin, nanometer flame retardant, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and fillers, dispersant and stabilizer are put into a planet stirring reactor for stirring and even dispersion; micrometer pigment and filler, water, dispersant and stabilizer are added to the discharged mixture and then put into a high-speed dispersion machine for even dispersion so that the product is obtained.

Owner:中山市孙大化工科技有限公司

High water absorption resin water suction gel fire extinguisher and its application

InactiveCN1557516AImprove water retentionImprove fire extinguishing effectFire extinguisherFiberOrganic solvent

The present invention is water absorbing gel fire extinguishing agent of high-hydroscopicity resin and its application, and aims at raising water-maintaining and fire extinguishing performance and saving water. The present invention features that high-hydroscopicity resin comprising synthetic resin, starch and fiber as the kernel components is mixed with water to form the fire extinguishing agent, which is used via traditional fire nozzle. When used, the high-hydroscopicity resin may be mixed with great amount of water for half an hour to create water absorbed gel sprayed with fire nozzle to the fire; or the high-hydroscopicity resin powder may be mixed with great amount of water and sprayed to the fire to form fire extinguishing gel in 15-60 sec; or the high-hydroscopicity resin may be mixed with some organic solvent and sprayed together with water to the fire; or fine high-hydroscopicity resin powder may be spread and water is sprayed to form fire extinguishing gel.

Owner:ZHEJIANG UNIV

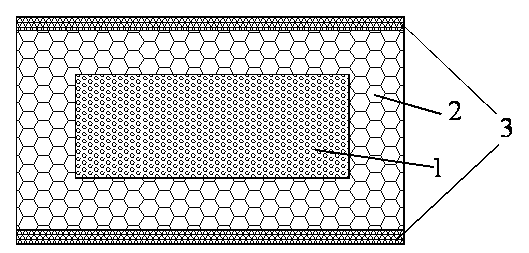

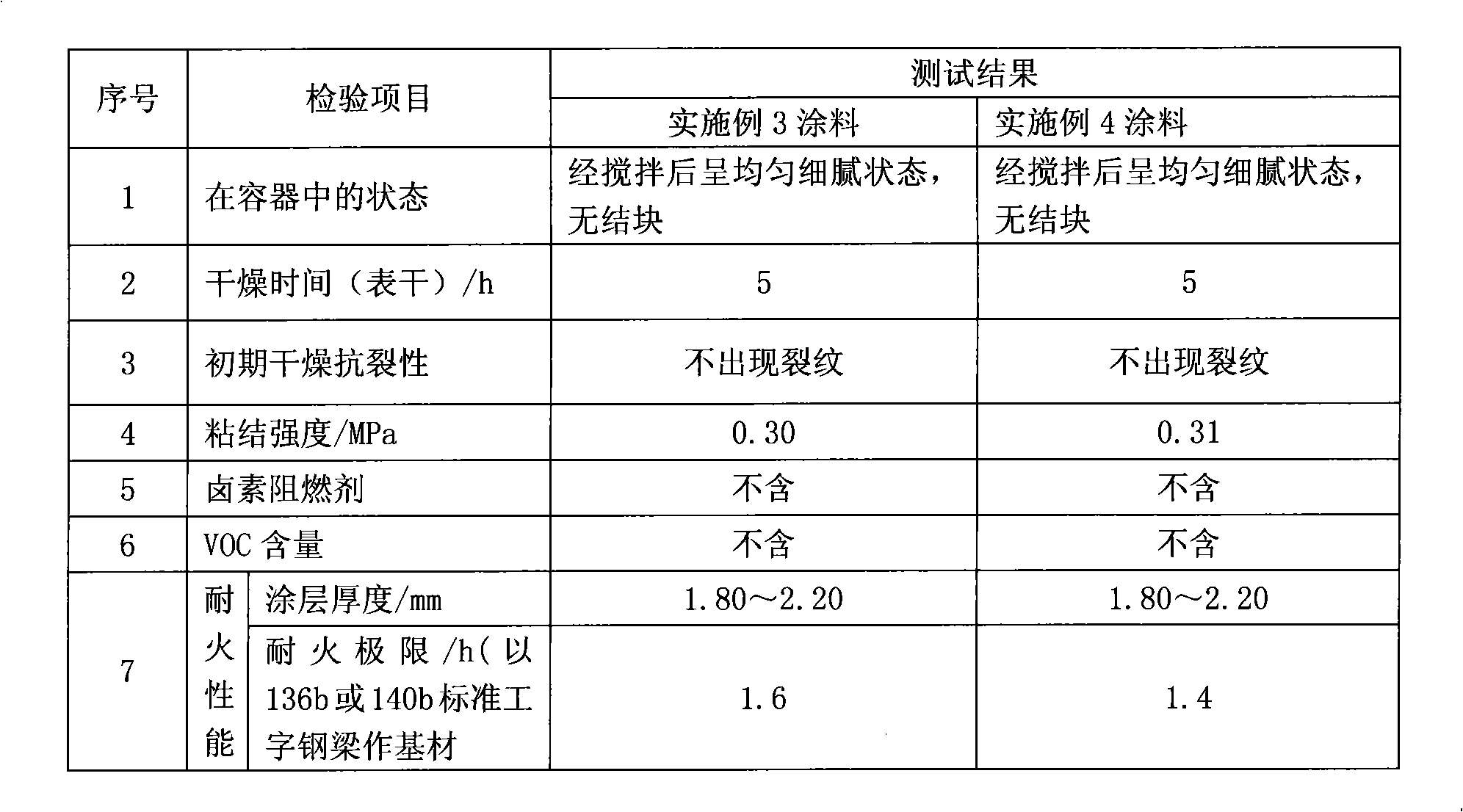

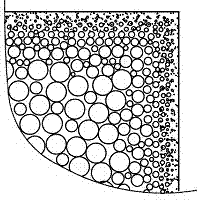

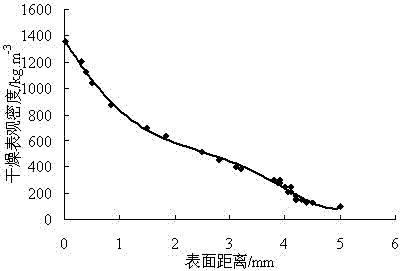

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

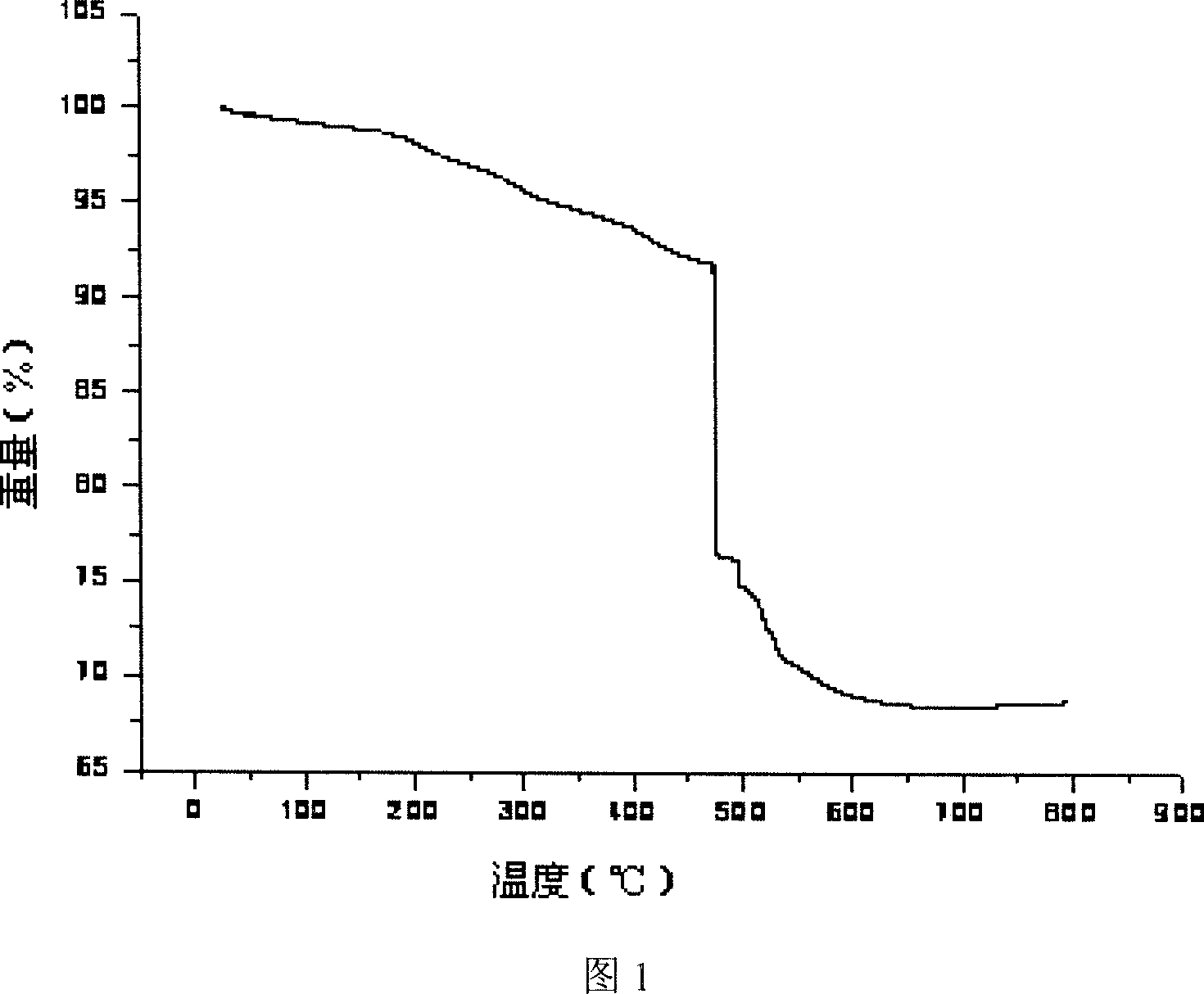

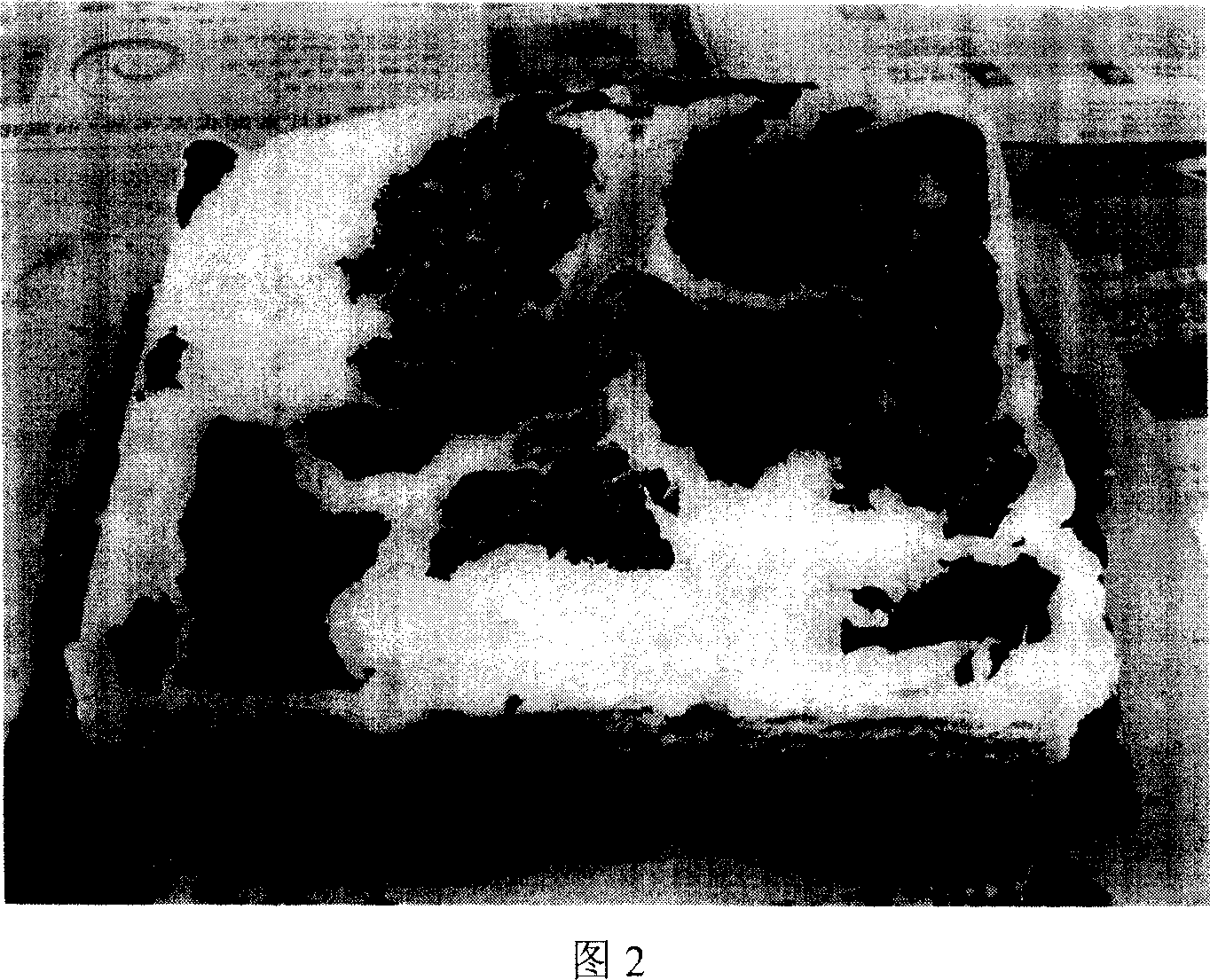

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

Super thin no-halogen less-smoke fire proof organic-inorganic composite paint and its prepn process

InactiveCN1974695AImprove heat resistanceImprove fire performanceFireproof paintsEpoxy resin coatingsHalogenFoaming agent

The present invention relates to one kind of super thin no-halogen less-smoke fireproof organic-inorganic composite paint and its preparation process. The composite paint is compounded with heat resistant organic and inorganic nanometer hybridized resin, organic resin, heat resistant pigment, heat resistant filler, carbon forming agent, foaming agent, catalyst, assistant, etc. In case of fire, the components of the paint synergy to swell, foam, isolate oxygen, delay heat transfer and inhibit fire spread. The fireproof paint may be used to form coating of controllable thickness in 0.2-2 mm, has fire resisting limit of 30-200 min, excellent heat resisting performance, excellent fire retarding performance, high fireproof performance, high anticorrosion performance and other advantages.

Owner:FUDAN UNIV

Aqueous ultrathin expansion-type fireproof coating for steel structure and preparation method thereof

ActiveCN104130671AImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsPolymer sciencePentaerythritol

The invention discloses an aqueous ultrathin expansion-type fireproof coating for a steel structure and a preparation method thereof, and belongs to the technical field of fireproof coatings. The aqueous ultrathin expansion-type fireproof coating comprises, by mass, 10-35 parts of a modified aqueous epoxy emulsion, 1-8 parts of a curing agent, 5-15 parts of a styrene-acrylic emulsion or a silicone-acrylic emulsion, 10-20 parts of ammonium polyphosphate, 6-12 parts of melamine, 8-16 parts of pentaerythritol, 5-15 parts of a fire retardant, 5-15 parts of a pigment and a filling material, 2-8 parts of an assistant and 15-35 parts of water. The aqueous ultrathin expansion-type fireproof coating has the characteristics of low raw material cost, simple preparation process and environmental friendliness.

Owner:沈阳泰丰化工有限公司

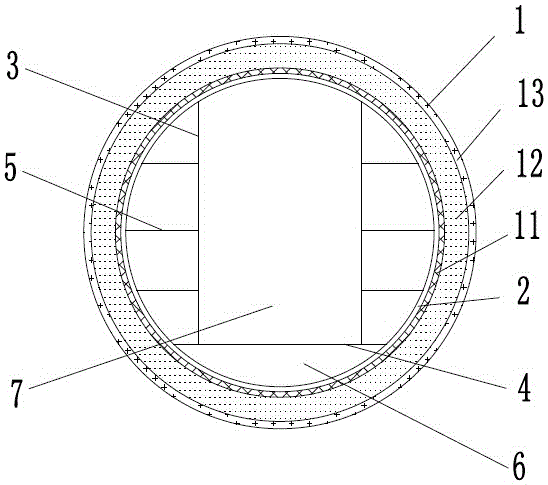

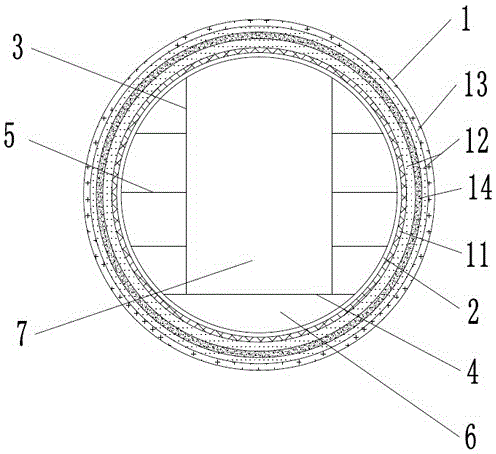

Prefabricated bamboo composite pipe gallery and manufacturing method thereof

InactiveCN105042213AReduce manufacturing costEnergy saving and environmental protection in the production processUnderwater structuresRigid pipesEngineeringWater soluble

The invention discloses a prefabricated bamboo composite pipe gallery, which is formed by connecting a plurality of prefabricated pipe joints, wherein each pipe joint comprises a pipe body, a force bearing mechanism, vertical supporting beams, a horizontal supporting beam and pipeline supports; the pipe body radially comprises a liner layer, a structure layer and an outer protection layer from inside to outside in sequence; the liner layer comprises flame-retarded resin and flame-retarded fabrics; the structure layer at least comprises a plurality of bamboo skin layers which are bonded with water soluble resin; the outer protection layer at least comprises flame-retarded resin; and the force bearing mechanism is fixed to the inner surface of the pipe body. The invention also discloses a method of manufacturing the prefabricated bamboo composite pipe gallery. The method comprises the manufacturing of the pipe body. The preparation method of the pipe body comprises the steps: (1) the liner layer is manufactured; (2) the structure layer is manufactured; and (3) the outer protection layer is manufactured. According to the invention, bamboo is utilized to manufacture a prefabricated pipe gallery, so that the intensity is good, the weight is light, the cost is low, the impermeability is good, the antiknock characteristic is strong, the construction is convenient, and the technical problems that the existing comprehensive pipe gallery consumes too many materials, the construction project amount is large, the construction period is long and the construction cost is high are solved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com