Patents

Literature

210 results about "Process selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

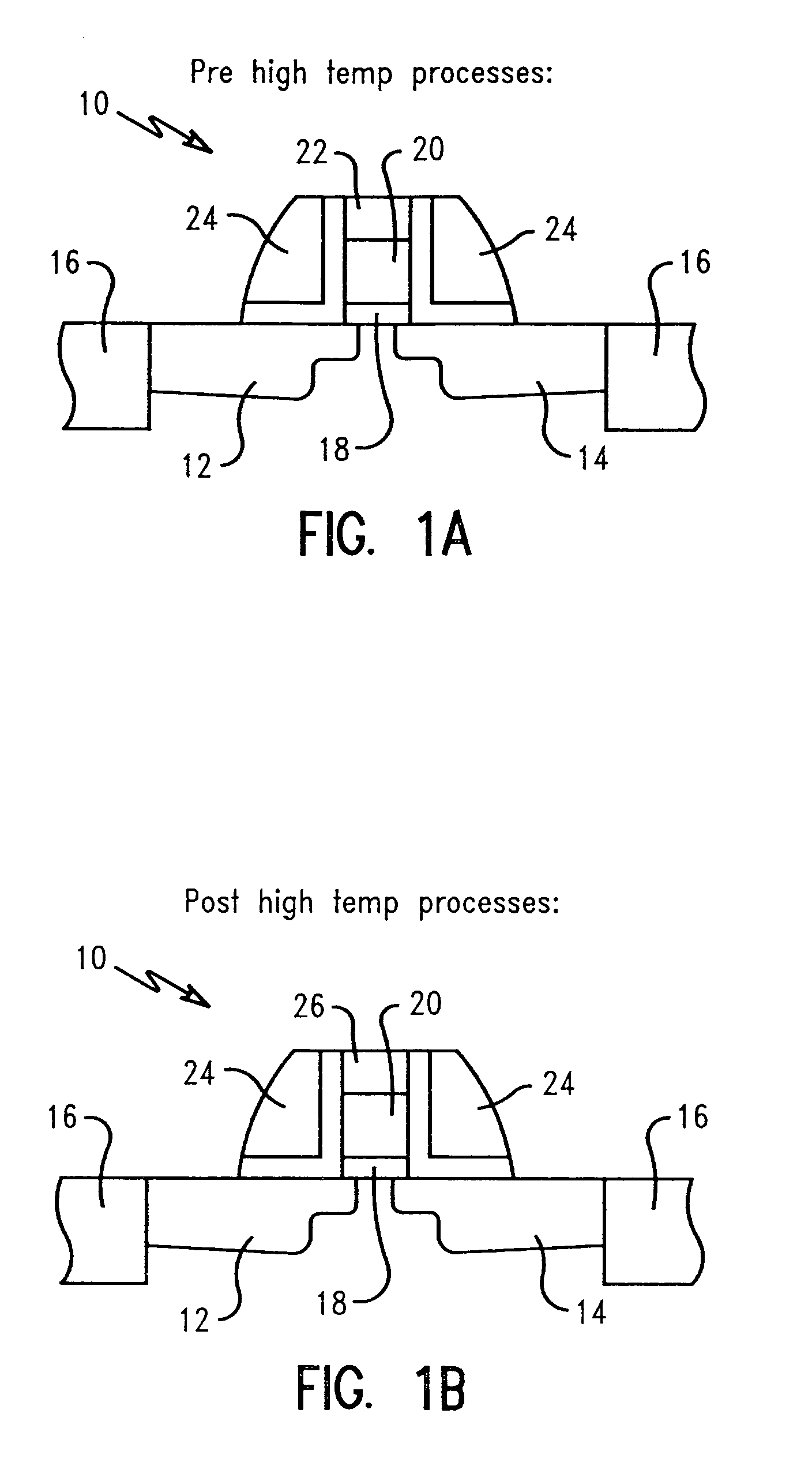

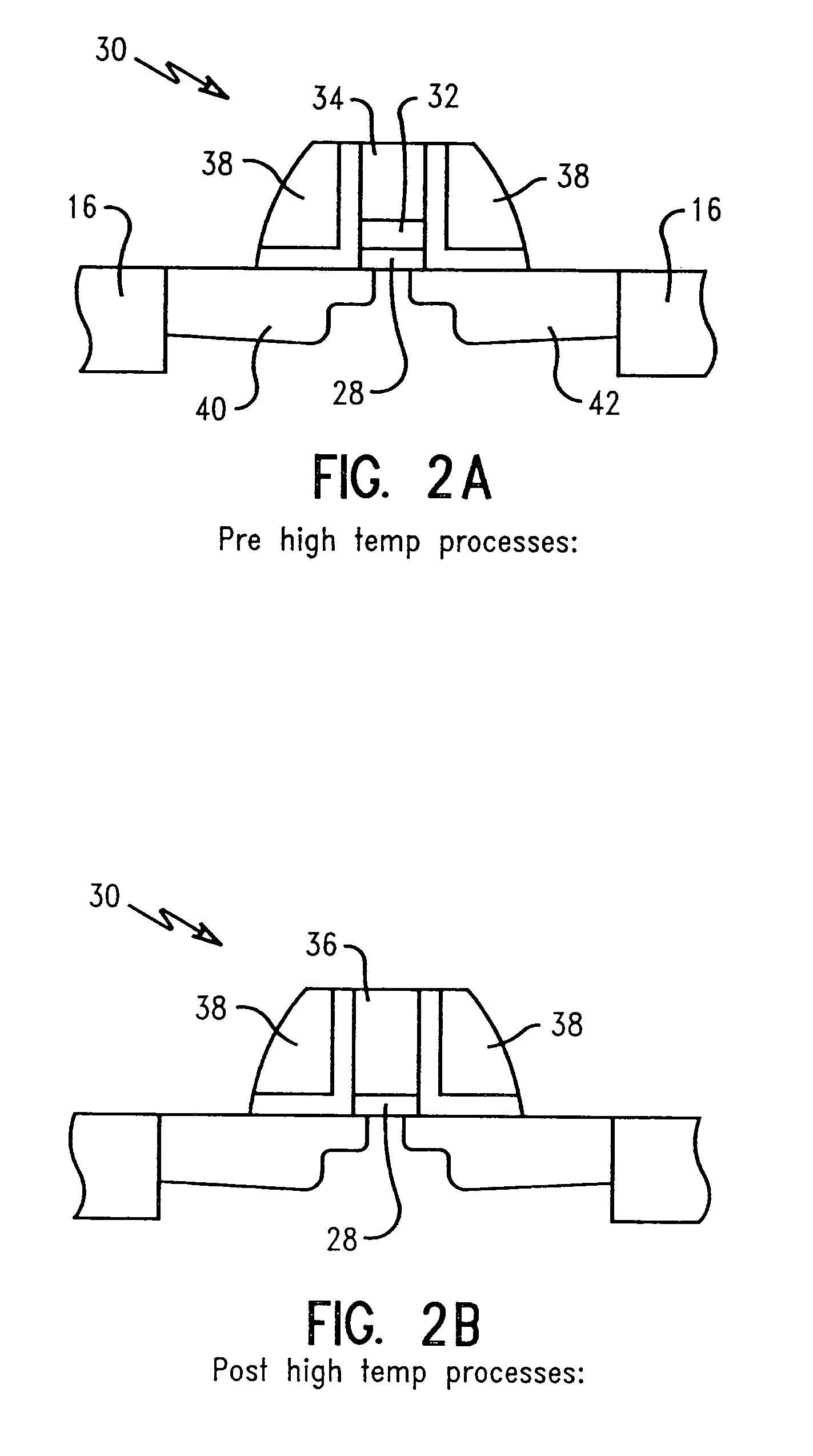

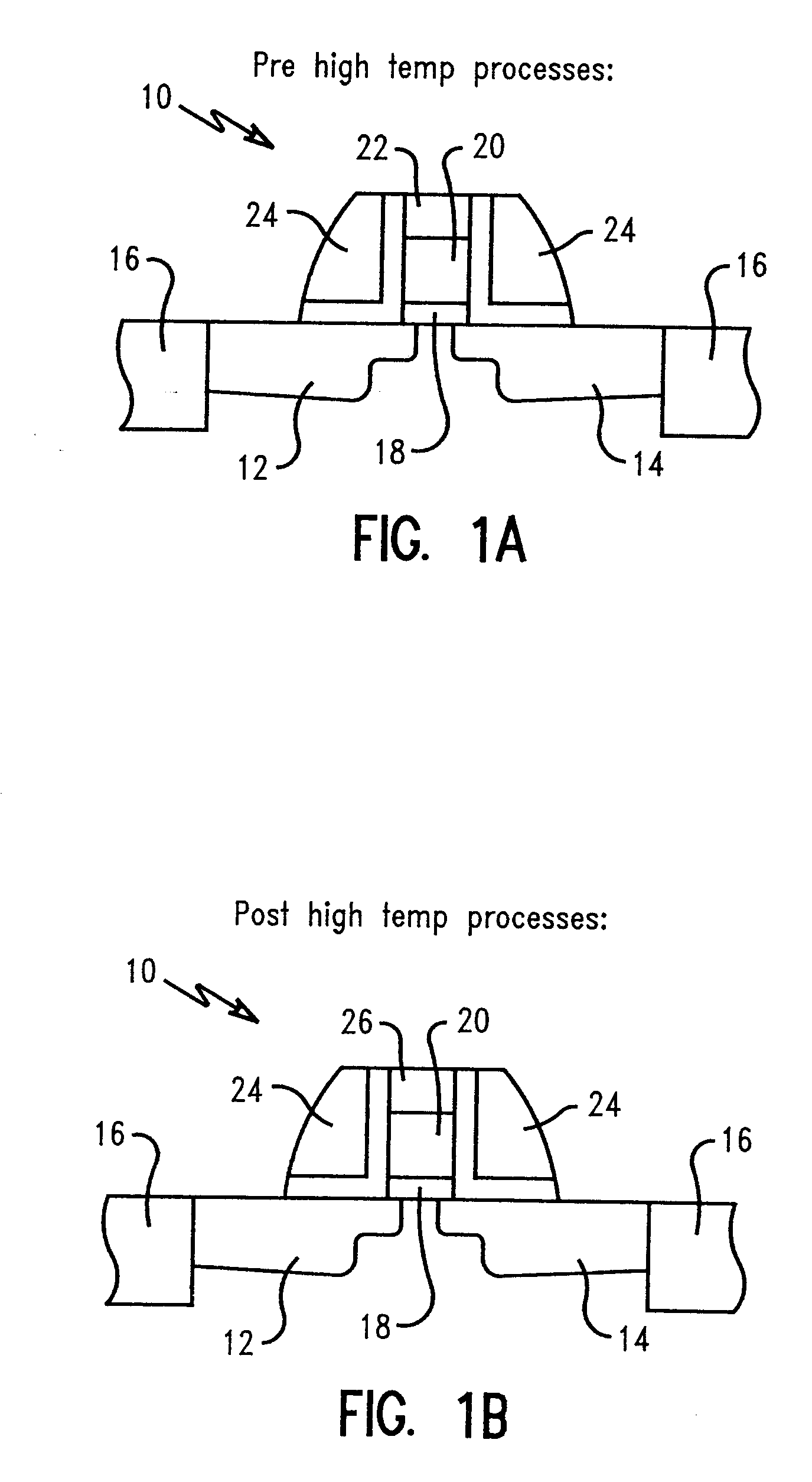

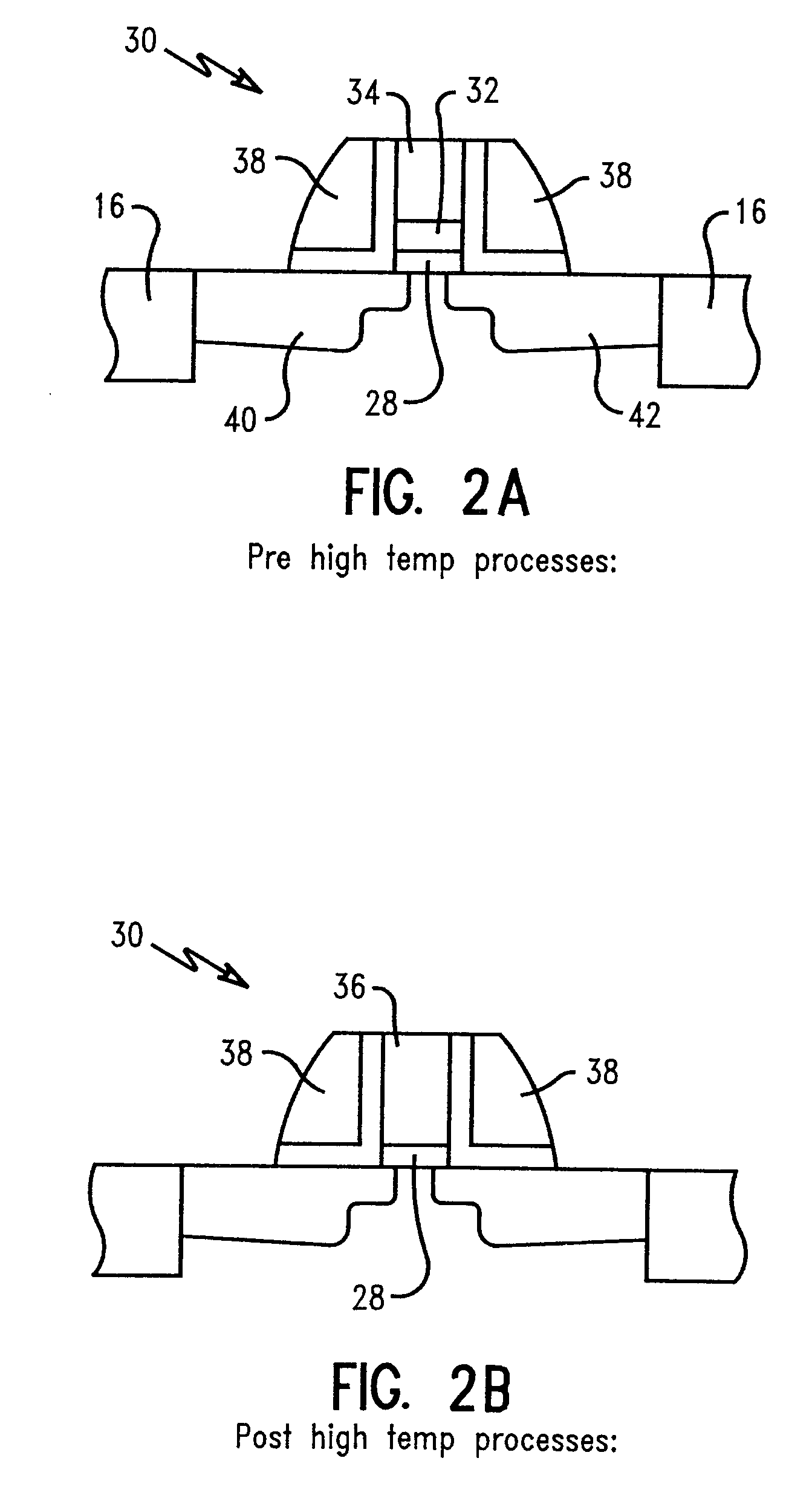

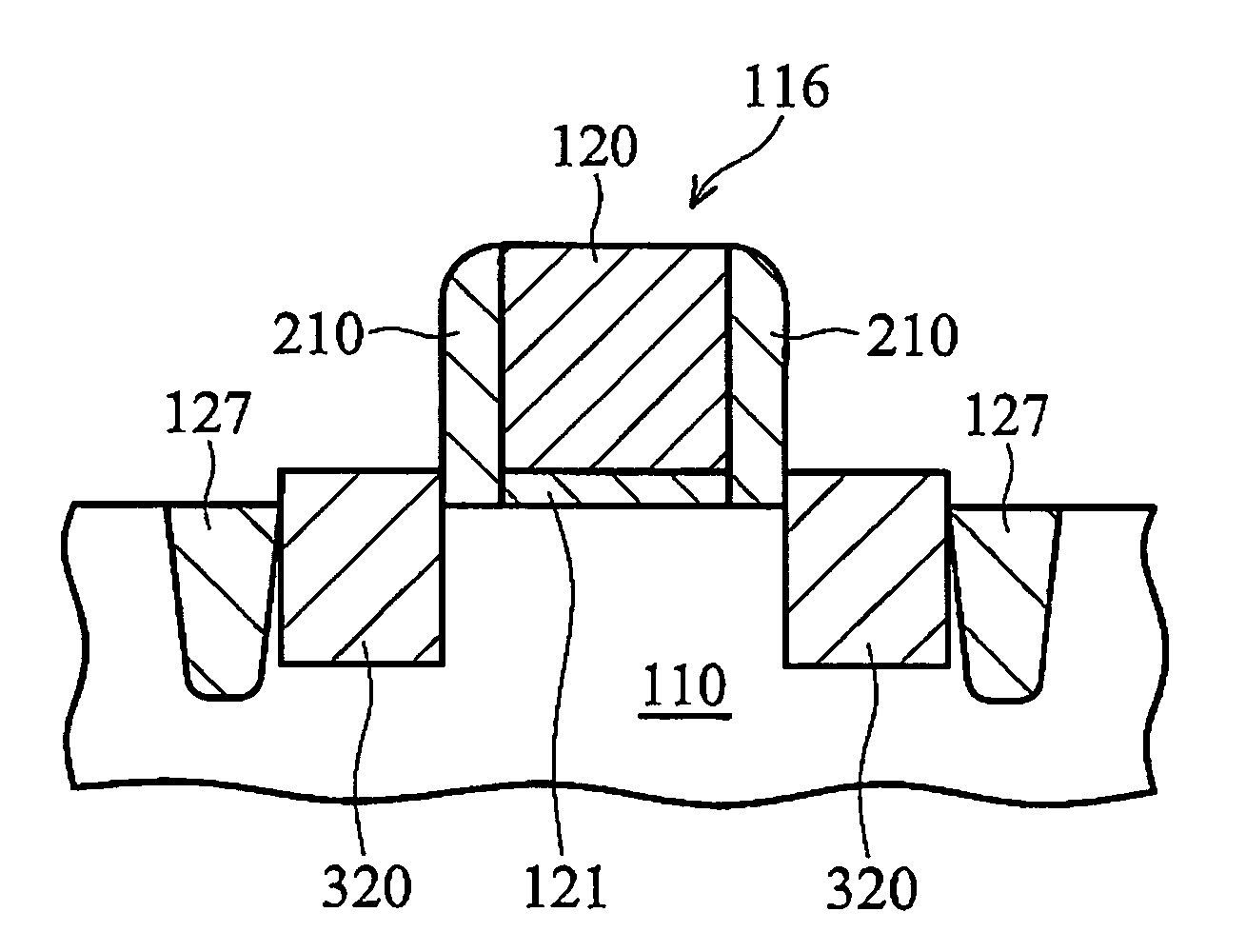

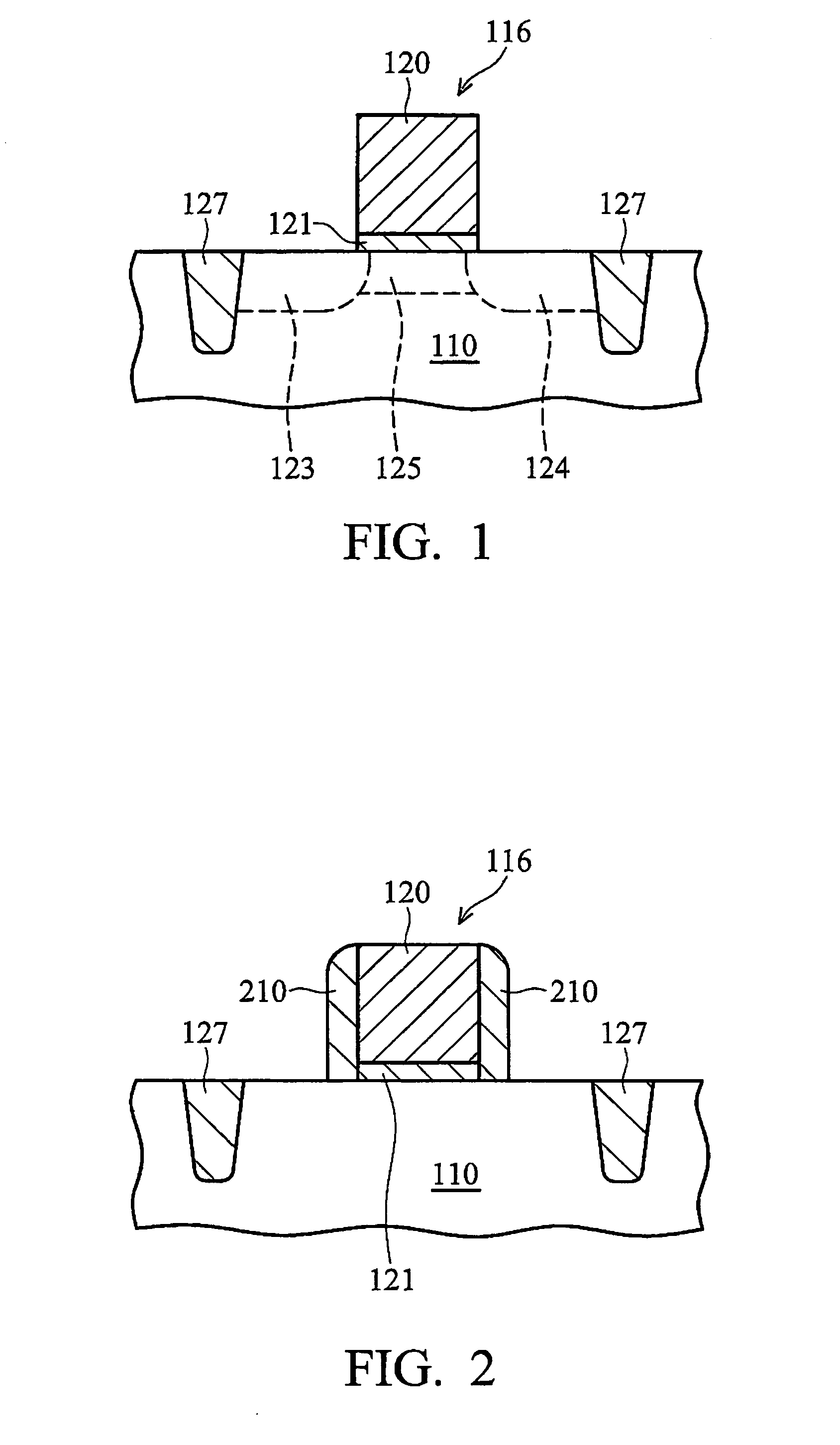

SiGe selective growth without a hard mask

InactiveUS20080083948A1Semiconductor/solid-state device manufacturingSemiconductor devicesTensile strainCharge carrier mobility

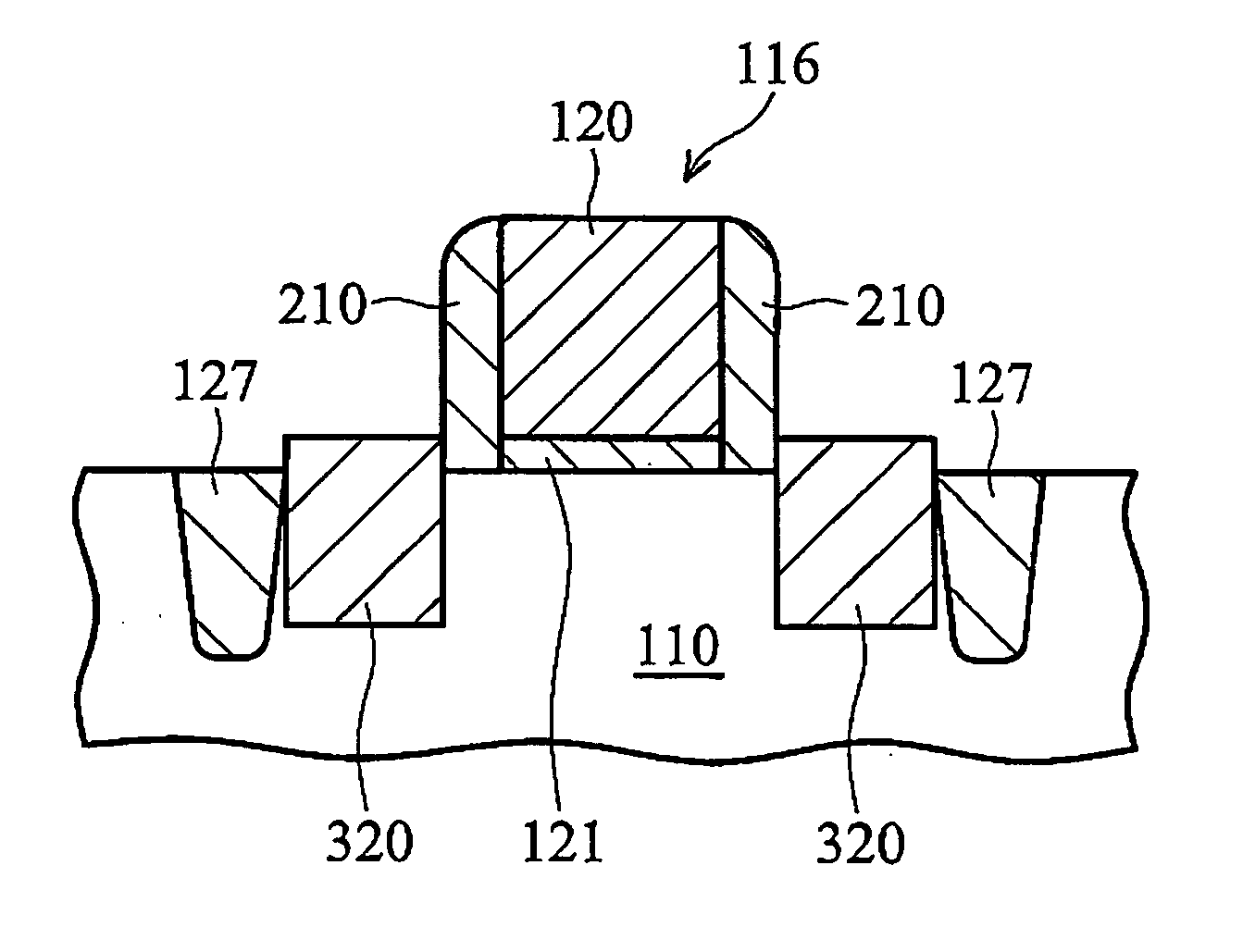

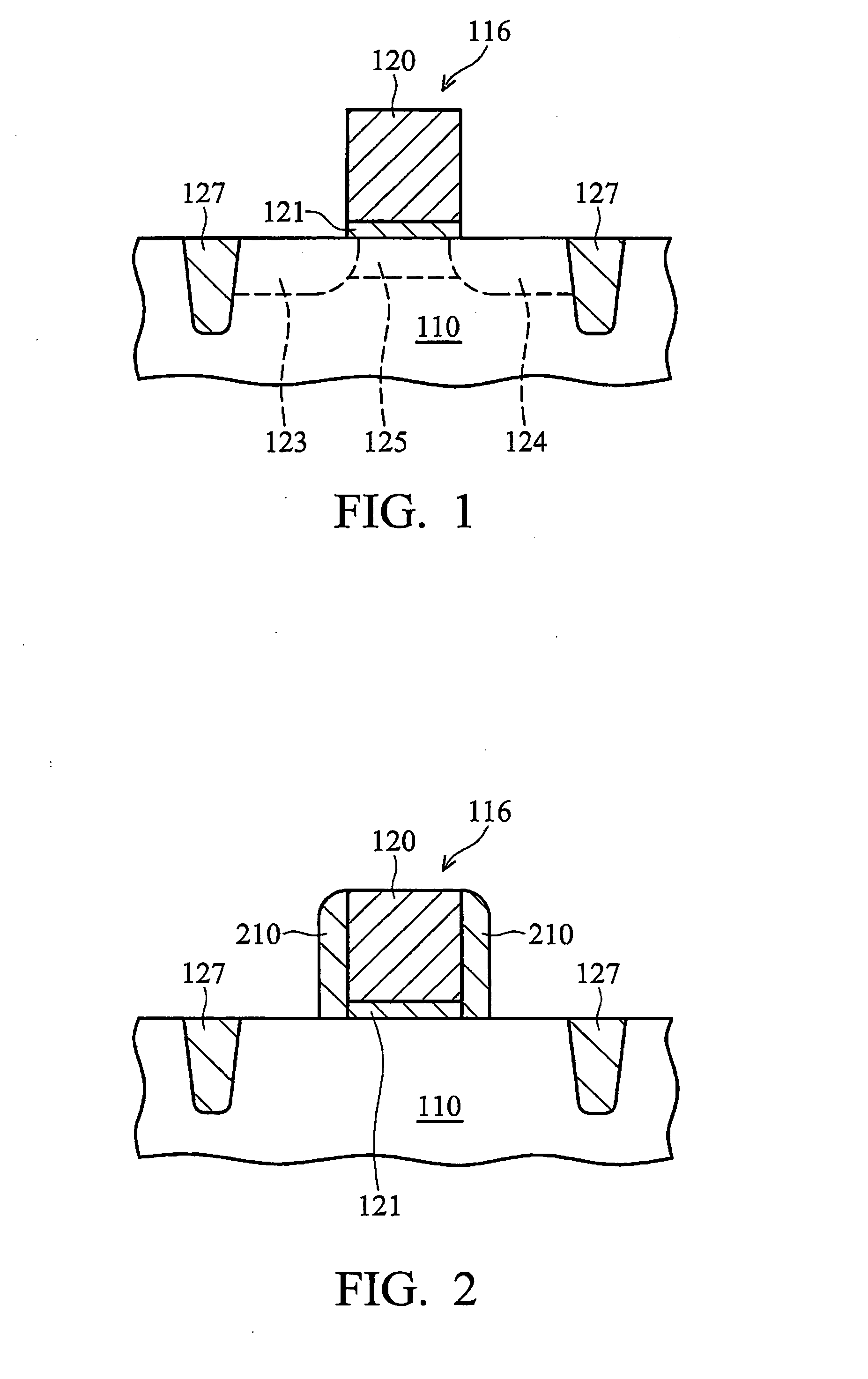

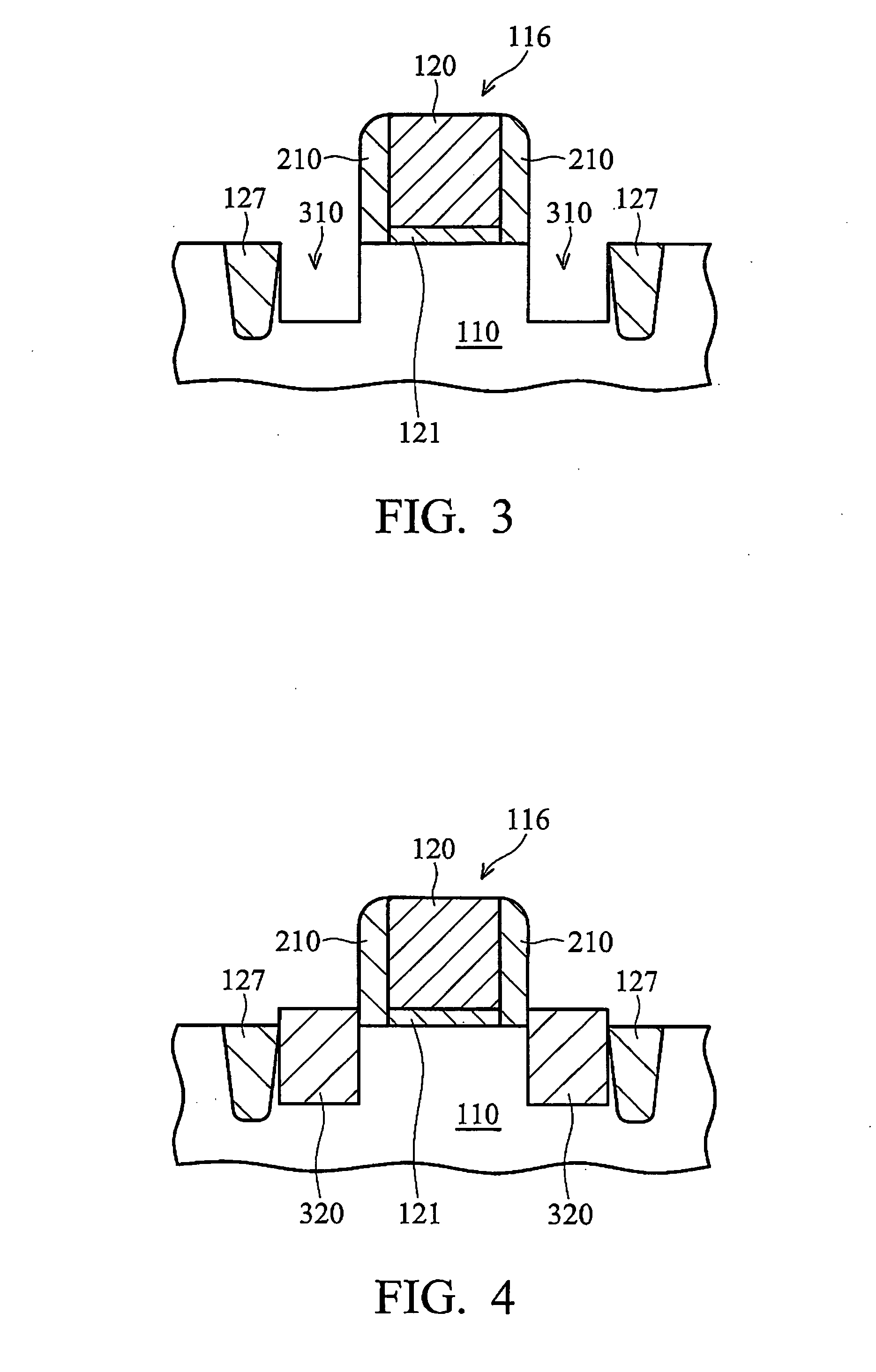

MOS transistors having localized stressors for improving carrier mobility are provided. Embodiments of the invention comprise a gate electrode formed over a substrate, a carrier channel region in the substrate under the gate electrode, and source / drain regions on either side of the carrier channel region. The source / drain regions include an embedded stressor having a lattice spacing different from the substrate. In a preferred embodiment, the substrate is silicon and the embedded stressor is SiGe or SiC. An epitaxy process that includes using HCl gas selectively forms a stressor layer within the crystalline source / drain regions and not on polycrystalline regions of the structure. A preferred epitaxy process dispenses with the source / drain hard mask required of conventional methods. The embedded SiGe stressor applies a compressive strain to a transistor channel region. In another embodiment, the embedded stressor comprises SiC, and it applies a tensile strain to the transistor channel region.

Owner:TAIWAN SEMICON MFG CO LTD

METAL GATE STRESS FILM FOR MOBILITY ENHANCEMENT IN FinFET DEVICE

A CMOS FinFET semiconductor device provides an NMOS FinFET device that includes a compressive stress metal gate layer over semiconductor fins and a PMOS FinFET device that includes a tensile stress metal gate layer over semiconductor fins. A process for forming the same includes a selective annealing process that selectively converts a compressive metal gate film formed over the PMOS device to the tensile stress metal gate film.

Owner:TAIWAN SEMICON MFG CO LTD

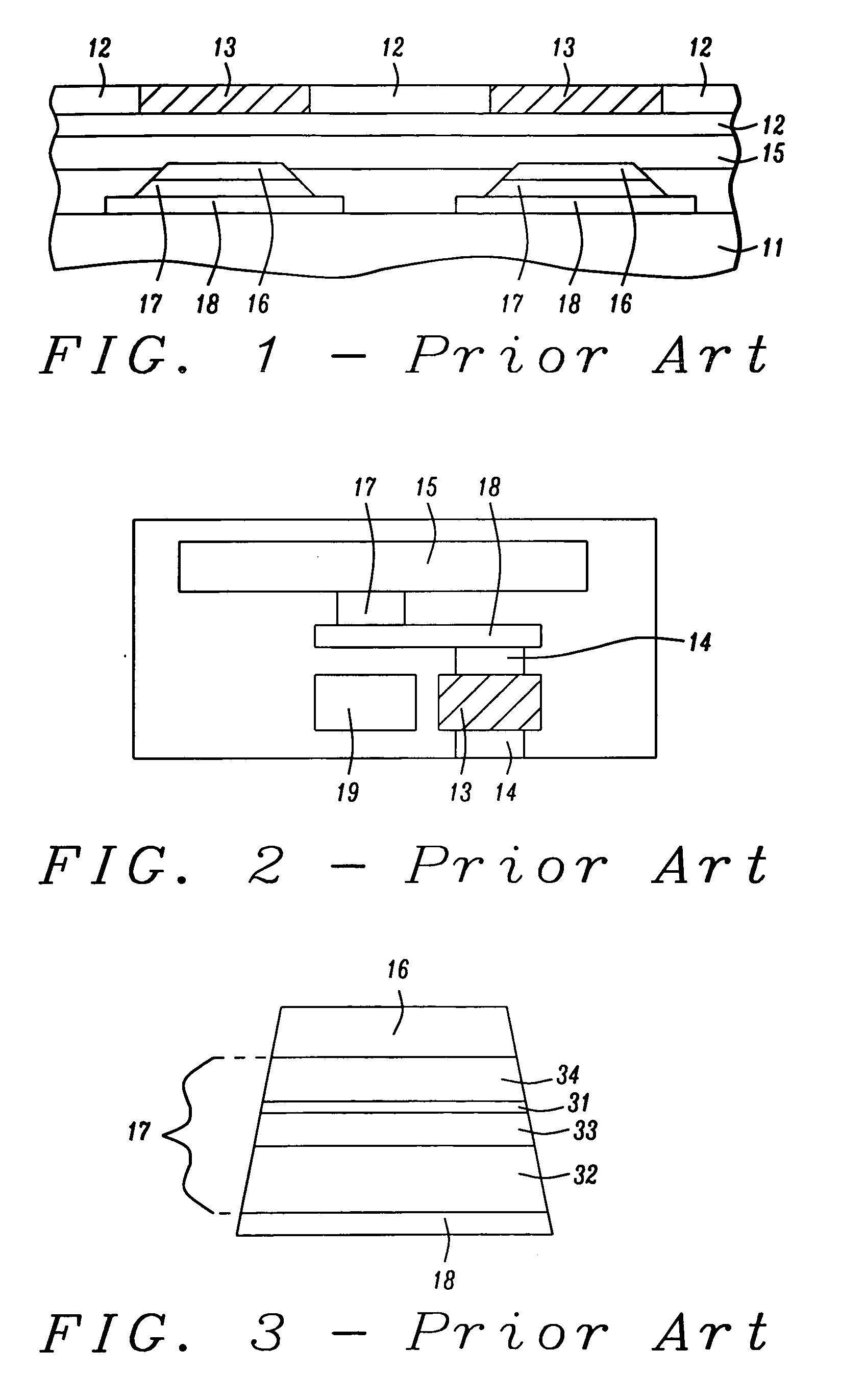

Structure and fabrication of an MRAM cell

InactiveUS20070054450A1Minimal thicknessMinimizing the bit line to free layer distanceSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentState of artDielectric

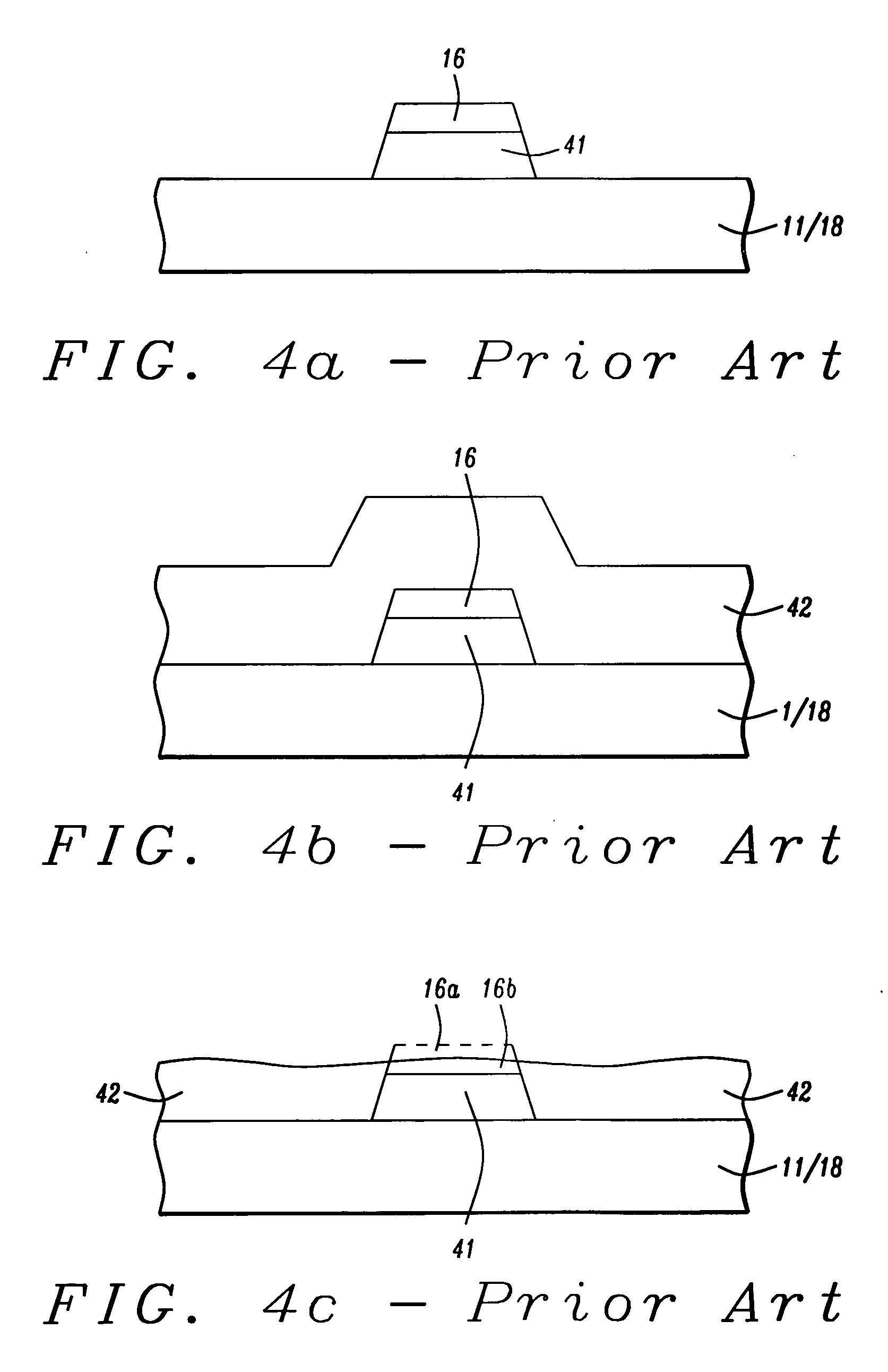

MTJ stacks formed using prior art processes often fail because of shorts between the pinned layer and the top electrode. This problem has been overcome by depositing a protective layer on the MTJ sidewalls followed by an inter-layer dielectric. Then planarizing until the protective layer is just exposed. Finally, an etching (or second CMP) process is used to selectively remove the protective layer from the top surface of the cap layer.

Owner:HEADWAY TECH INC

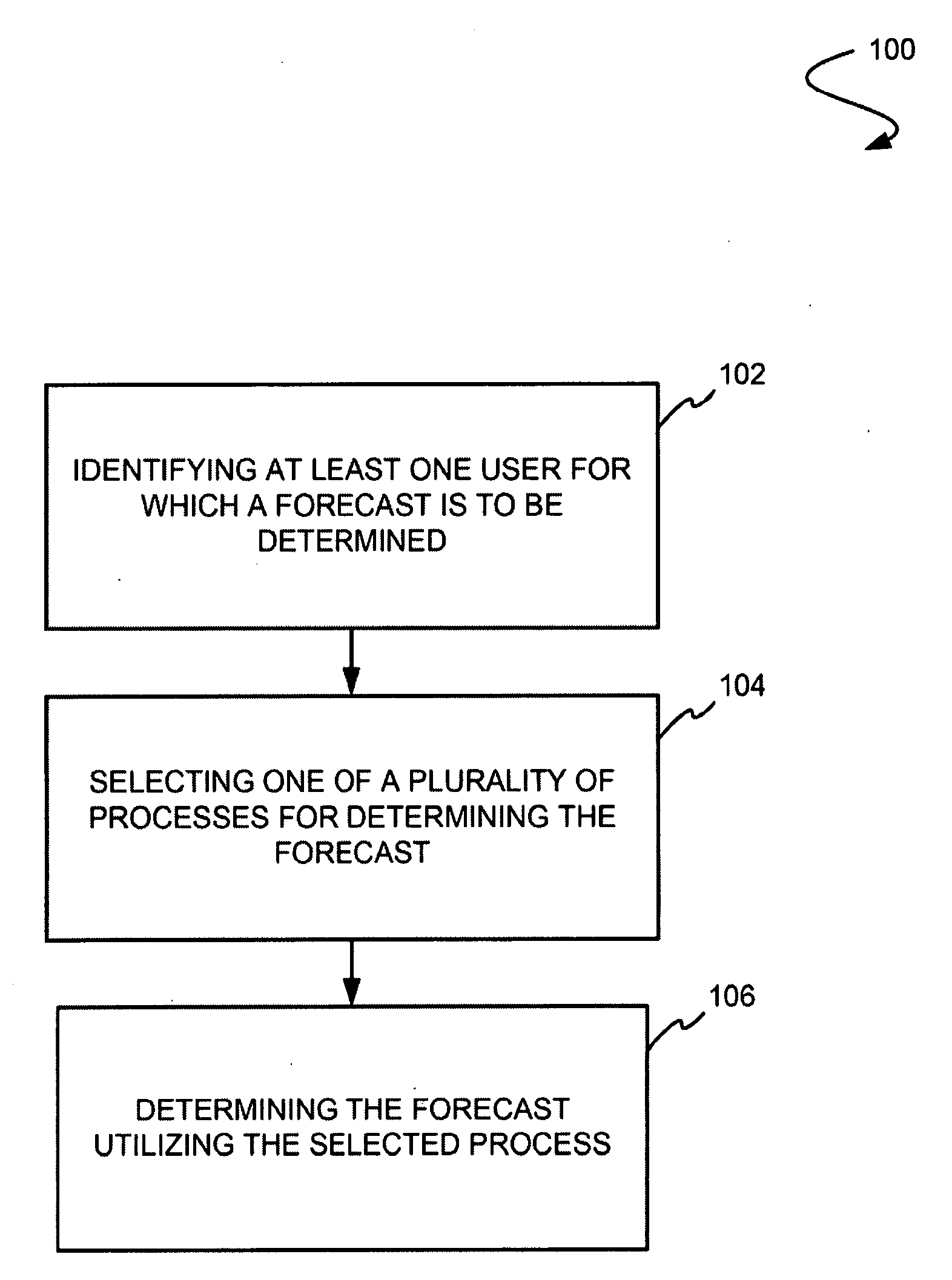

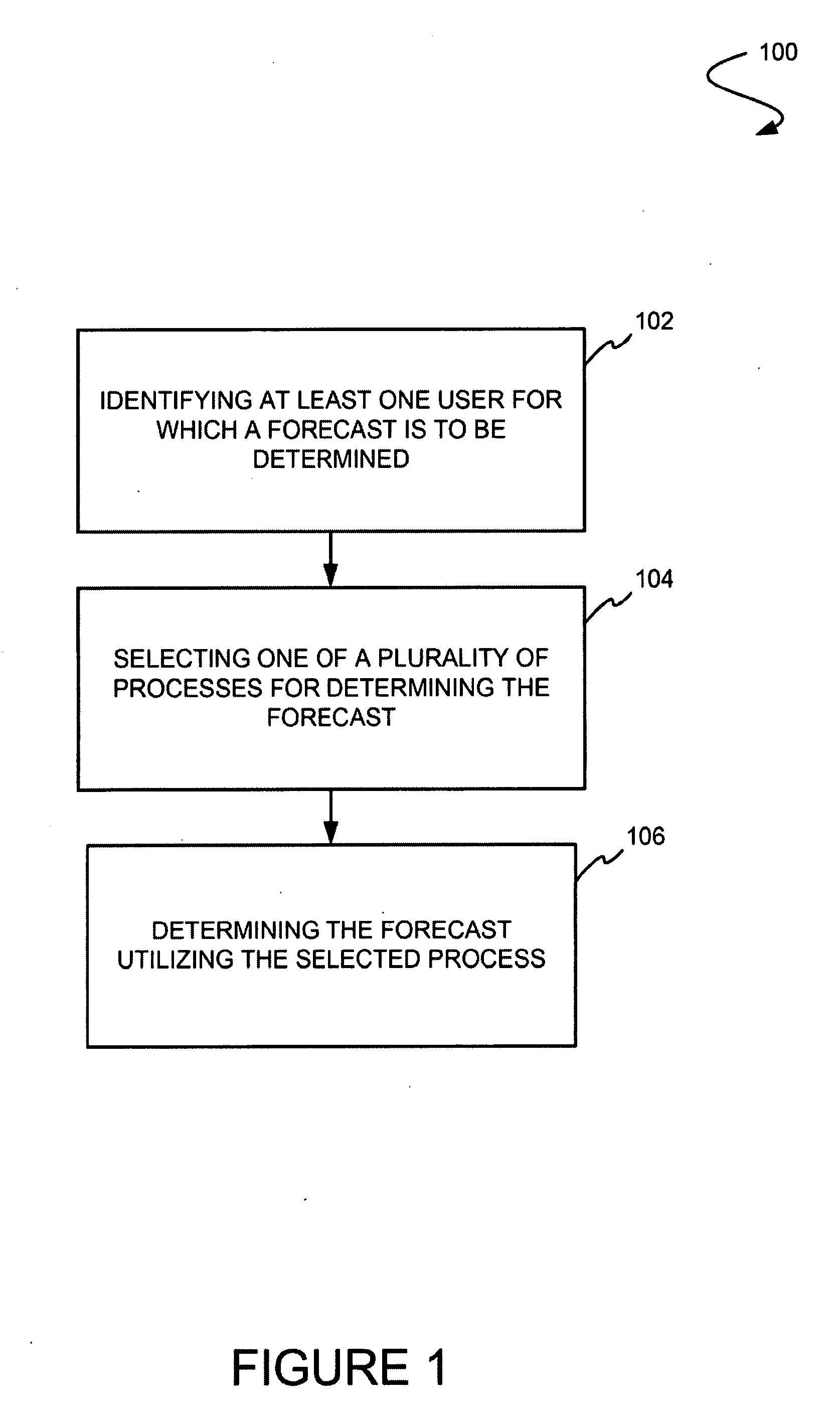

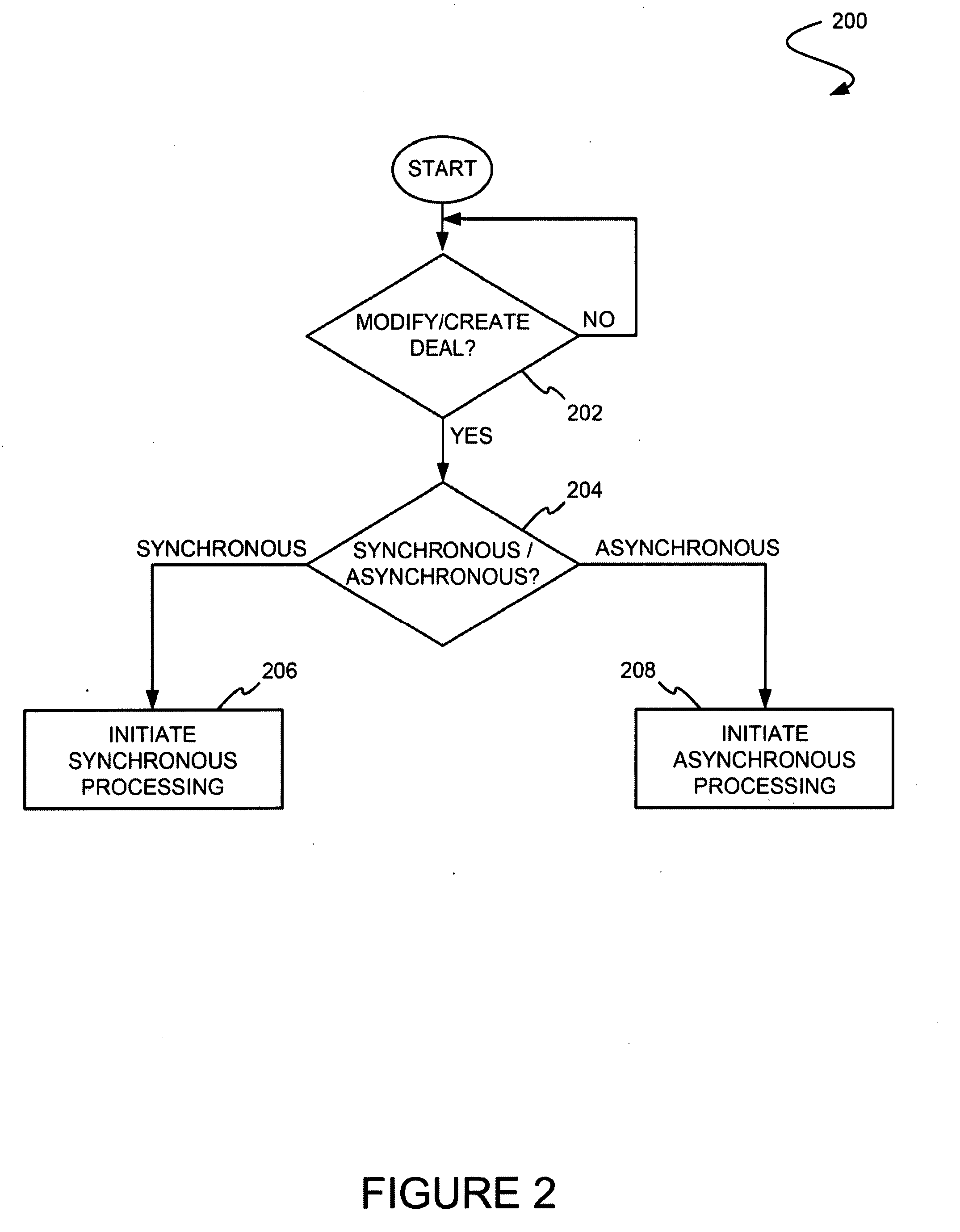

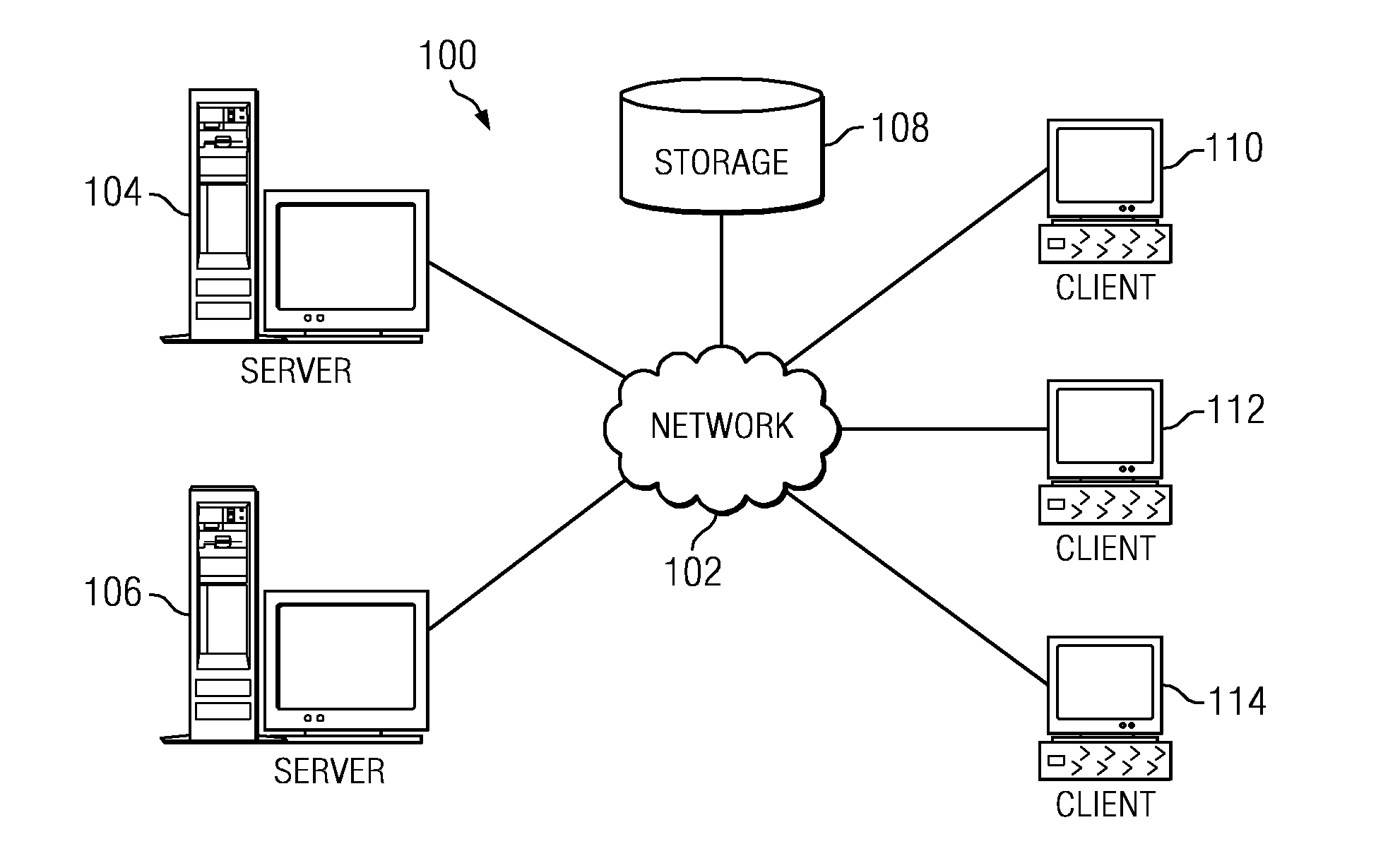

Method and system for selecting a synchronous or asynchronous process to determine a forecast

In accordance with embodiments, there are provided mechanisms and methods for selecting a synchronous or asynchronous process to determine a forecast. These mechanisms and methods for such synchronous / asynchronous process selection can enable embodiments to determine forecasts for multiple users (e.g. with hierarchical relationships, etc.) over an arbitrary time interval. The ability of embodiments to provide forecasts that involve such a large amount of data in an effective way can enable forecasting that was otherwise infeasible due to resource limitations.

Owner:SALESFORCE COM INC

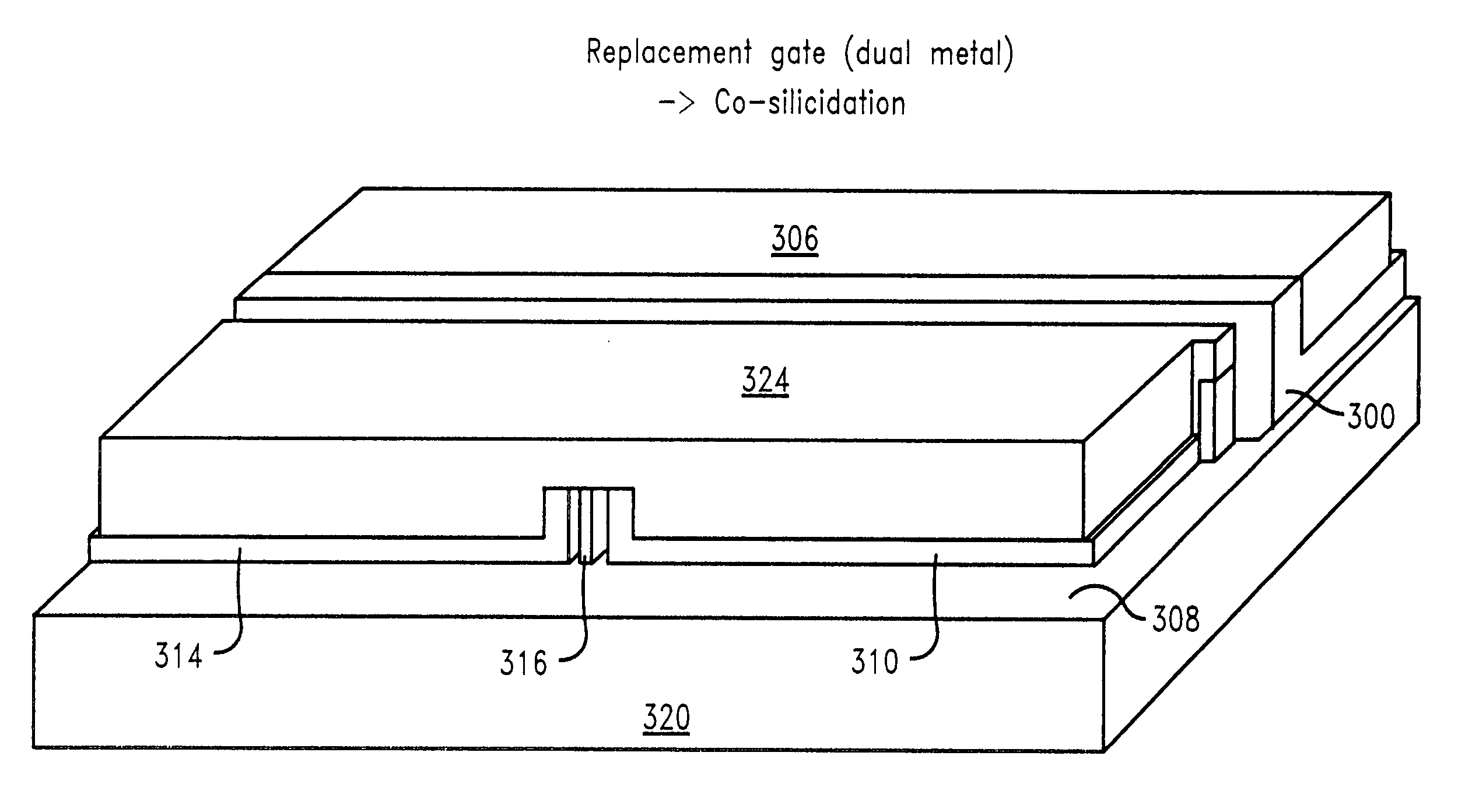

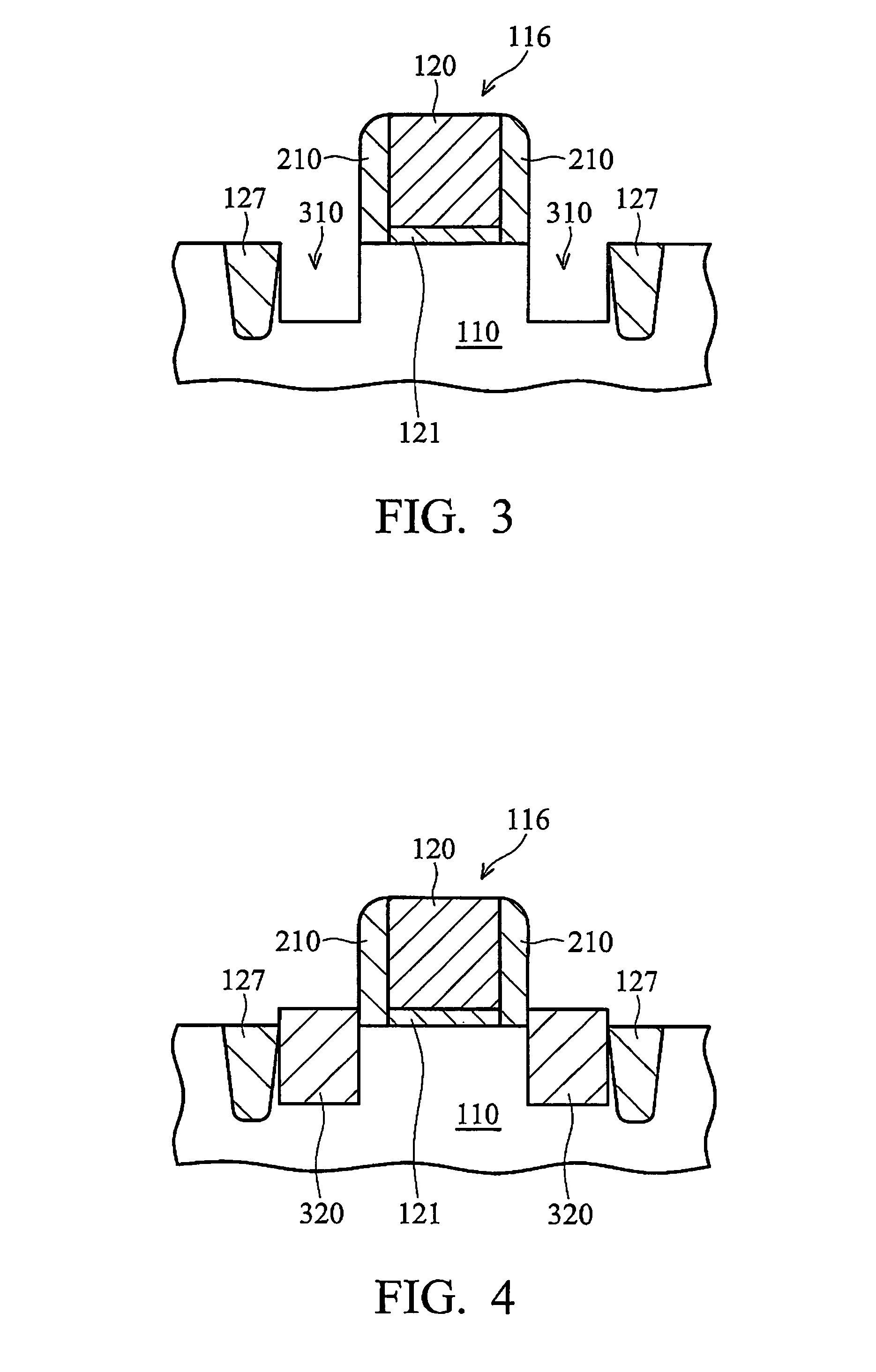

Process options of forming silicided metal gates for advanced CMOS devices

Silicide is introduced into the gate region of a CMOS device through different process options for both conventional and replacement gate types processes. Placement of silicide in the gate itself, introduction of the silicide directly in contact with the gate dielectric, introduction of the silicide as a fill on top of a metal gate all ready in place, and introduction the silicide as a capping layer on polysilicon or on the existing metal gate, are presented. Silicide is used as an option to connect between PFET and NFET devices of a CMOS structure. The processes protect the metal gate while allowing for the source and drain silicide to be of a different silicide than the gate silicide. A semiconducting substrate is provided having a gate with a source and a drain region. A gate dielectric layer is deposited on the substrate, along with a metal gate layer. The metal gate layer is then capped with a silicide formed on top of the gate, and conventional formation of the device then proceeds. A second silicide may be employed within the gate. A replacement gate is made from two different metals (dual metal gate replacement) prior to capping with a silicide.

Owner:GLOBALFOUNDRIES INC

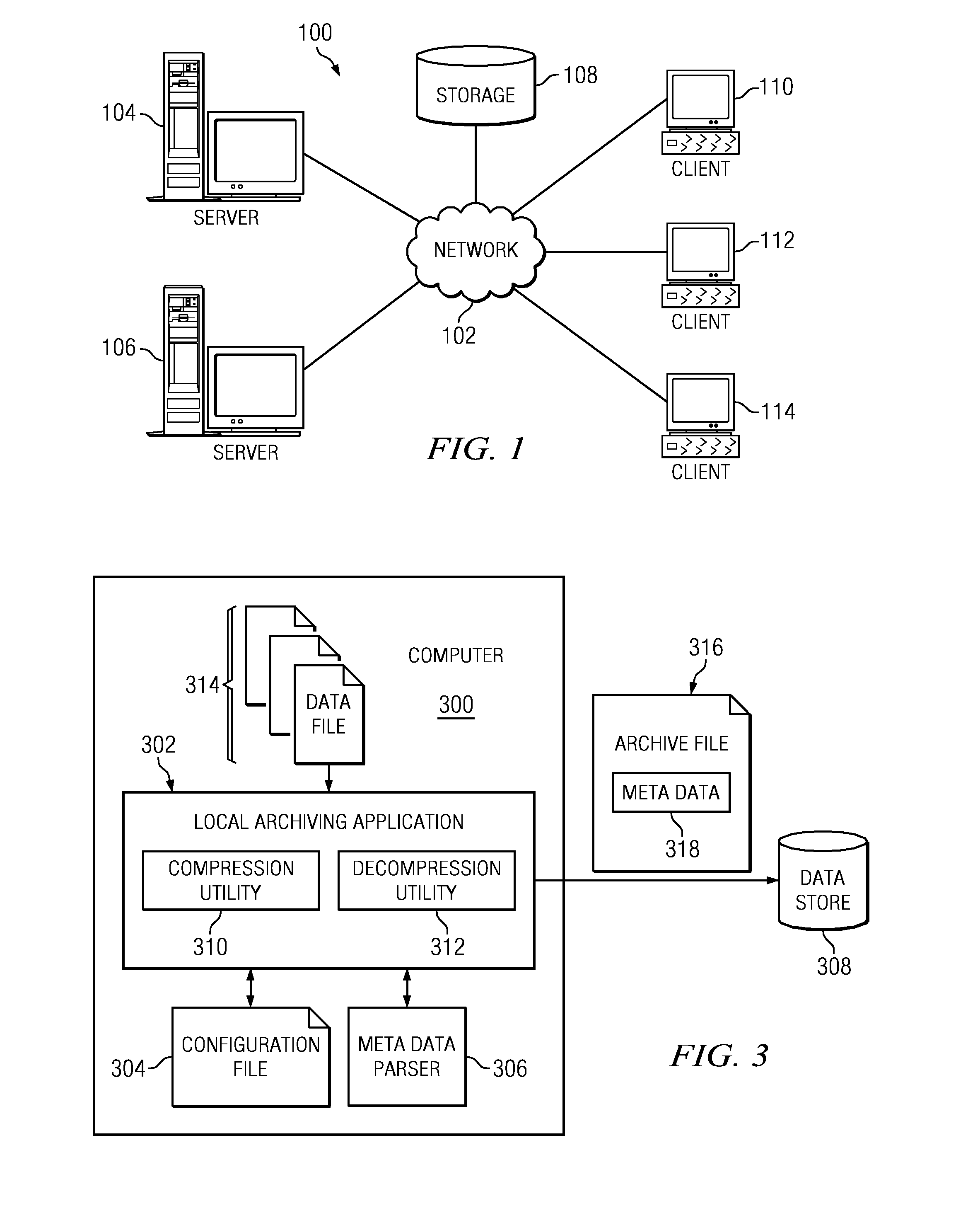

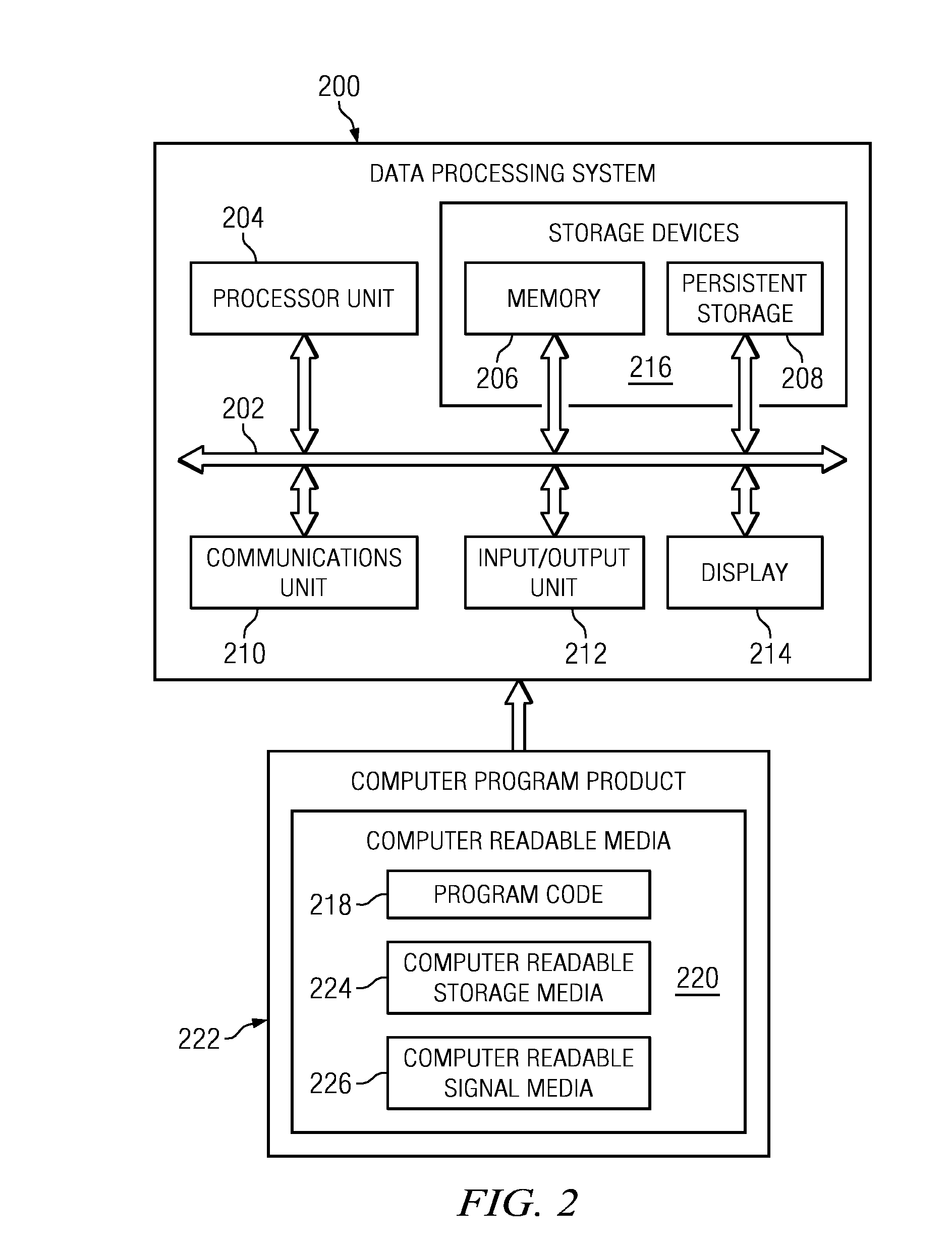

Optimal Compression Process Selection Methods

A mechanism for determining an optimal compression technique for each data file when creating a computer archive file from a set of data files. A local archiving application receives an instruction to archive a set of data files and determines the file type and size of a data file in the set of data files. An optimal compression method for the data file is selected based on the file type and size of the data file. The archiving application compresses the data file using the optimal compression method. The archiving application updates meta data associated with the compressed file to include a meta compression format identifier of the optimal compression method used to compress the data file. The archiving application then repeats the determining, selecting, compressing, and updating for each data file in the set of data files to create an archive of the set of data files.

Owner:KYNDRYL INC

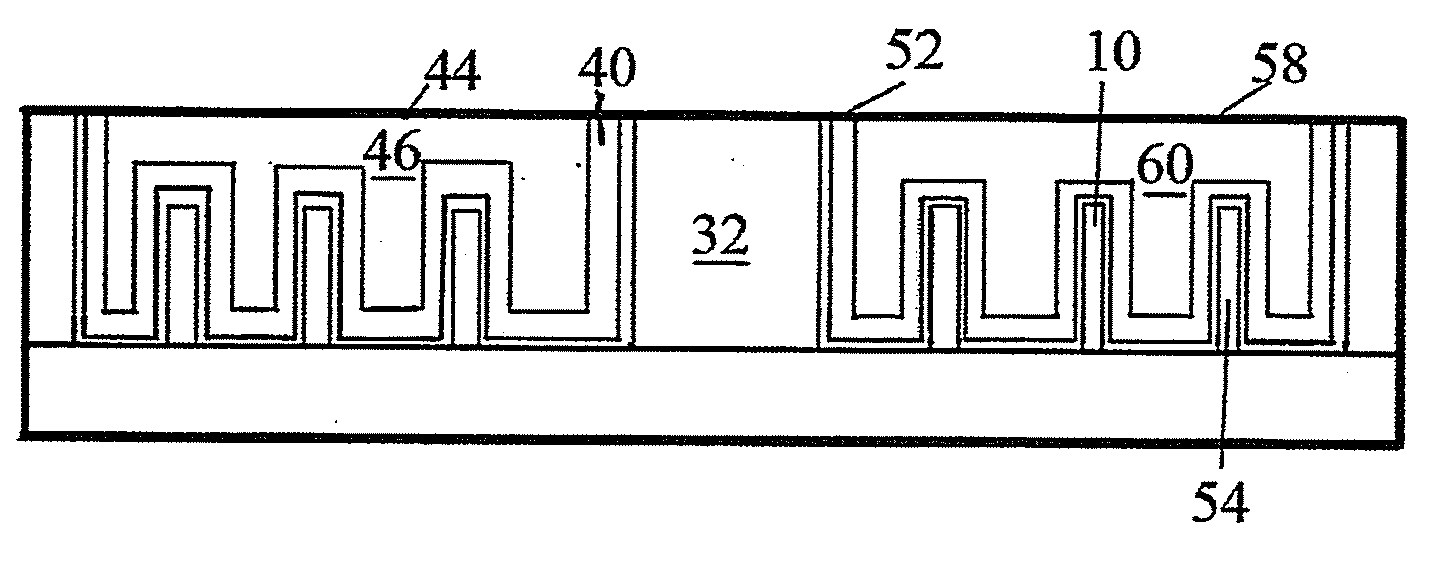

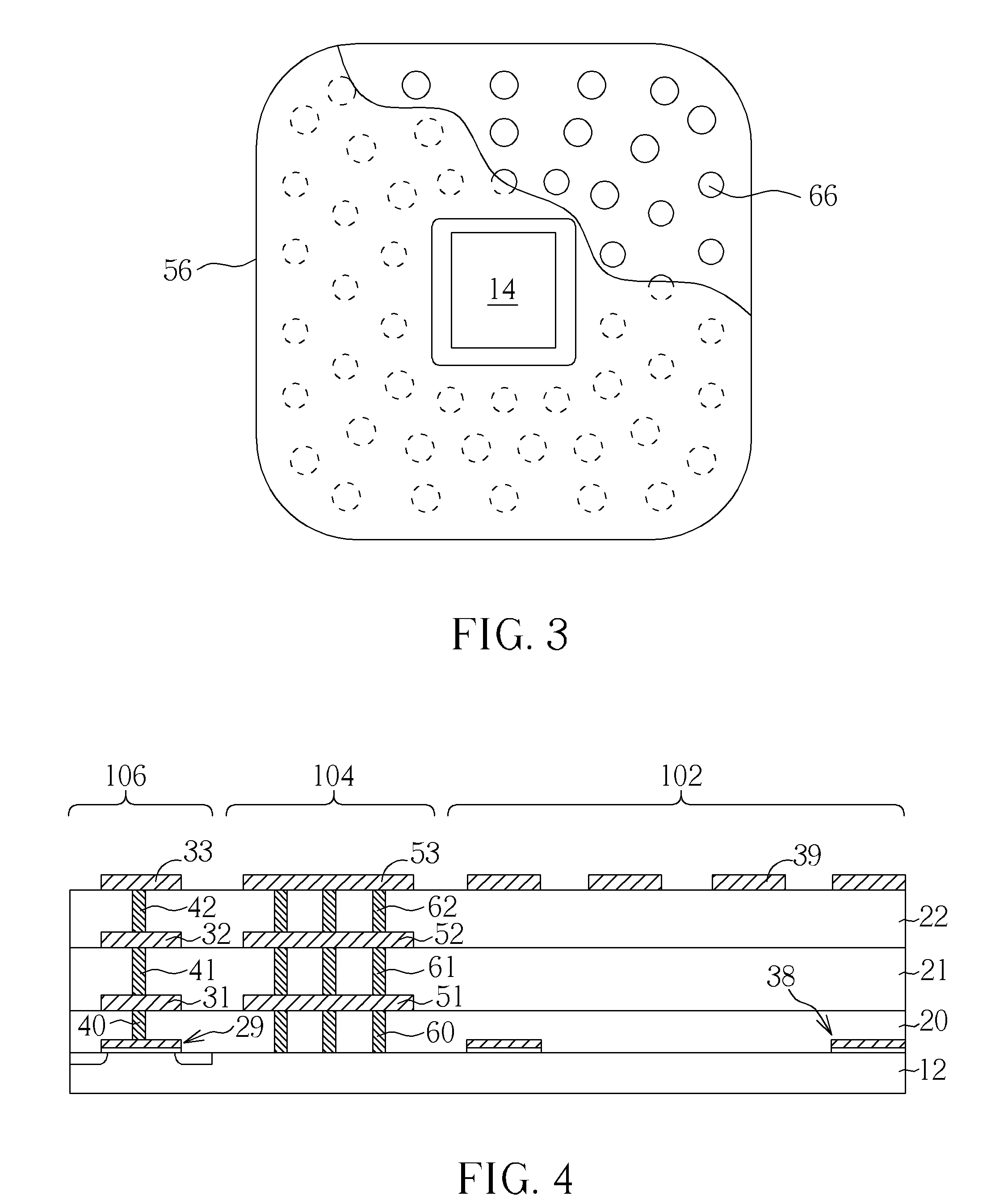

Integrated structure for MEMS device and semiconductor device and method of fabricating the same

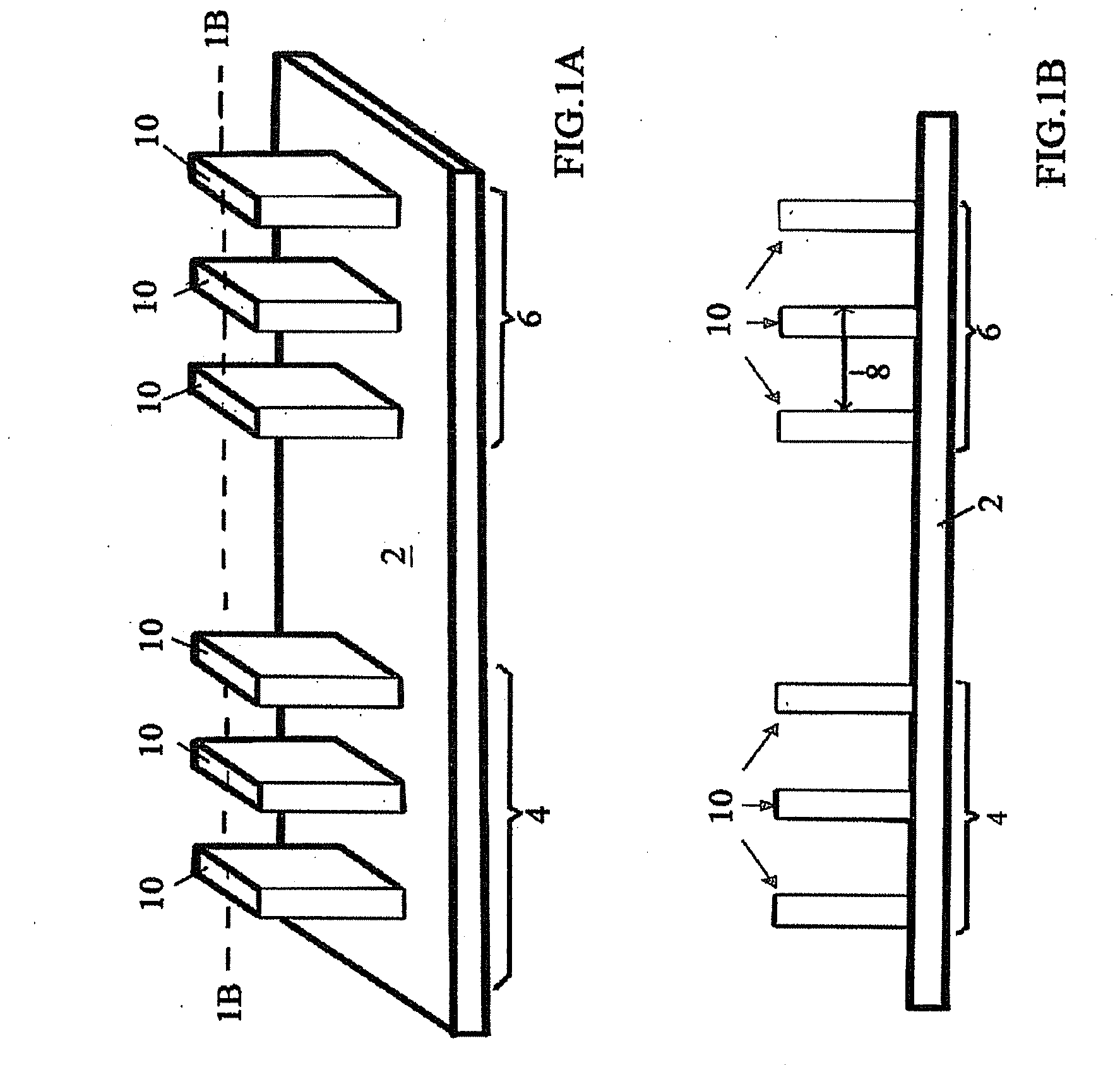

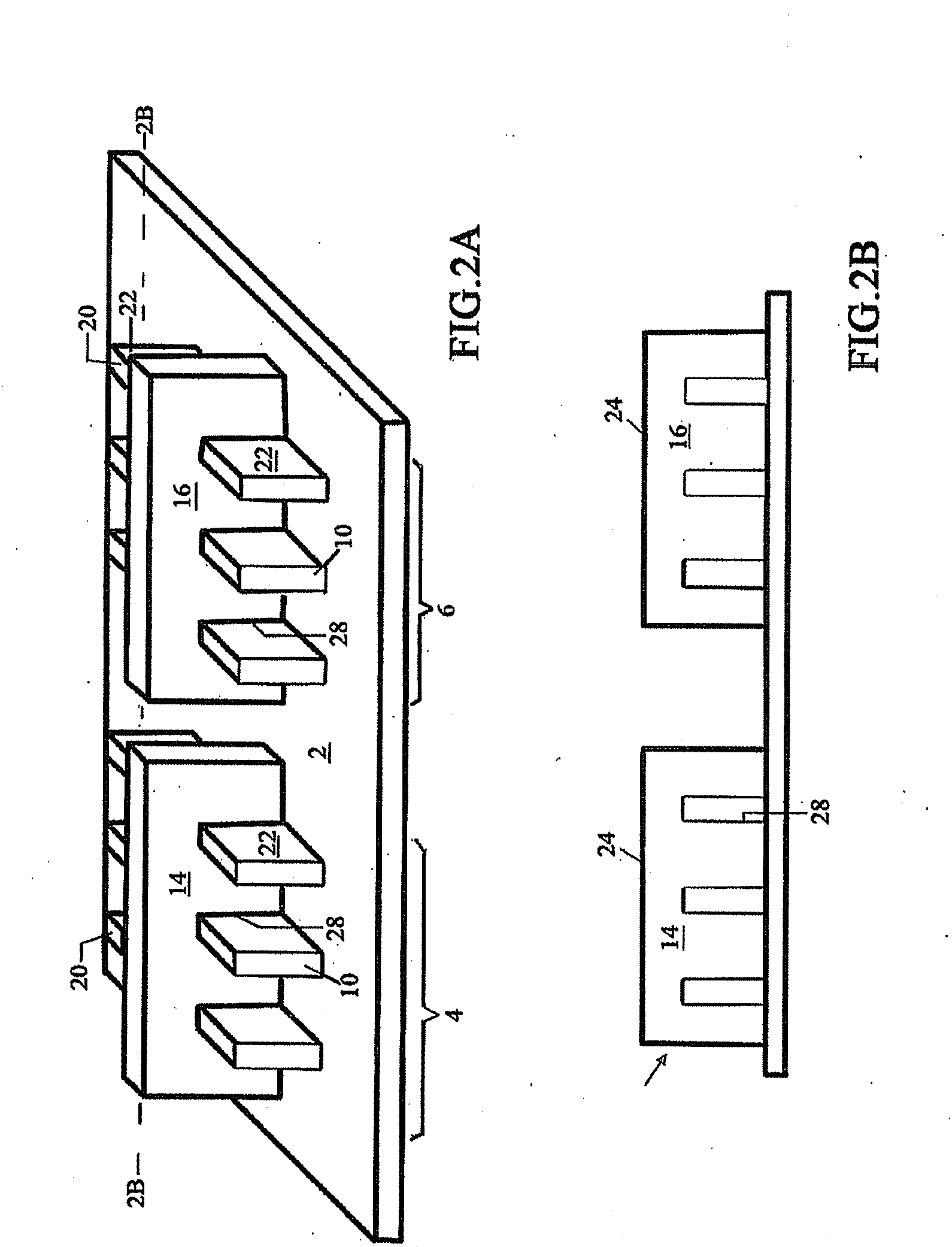

ActiveUS20090243004A1Avoid corrosionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringStops device

The present invention relates to an integrated structure for a MEMS device and a semiconductor device and a method of fabricating the same, in which an etch stopping device is included on a substrate between the MEMS device and the semiconductor device for protecting the semiconductor device from lateral damage when an oxide releasing process is performed to fabricate the MEMS device. The etch stopping device has various profiles and is selectively formed by an individual fabricating process or is simultaneously formed with the semiconductor device in the same fabricating process. It is a singular structure or a combined stacked multilayered structure, for example, a plurality of rows of pillared etch-resistant material plugs, one or a plurality of wall-shaped etch-resistant material plugs, or a multilayered structure of a stack of which and an etch-resistant material layer.

Owner:MARLIN SEMICON LTD

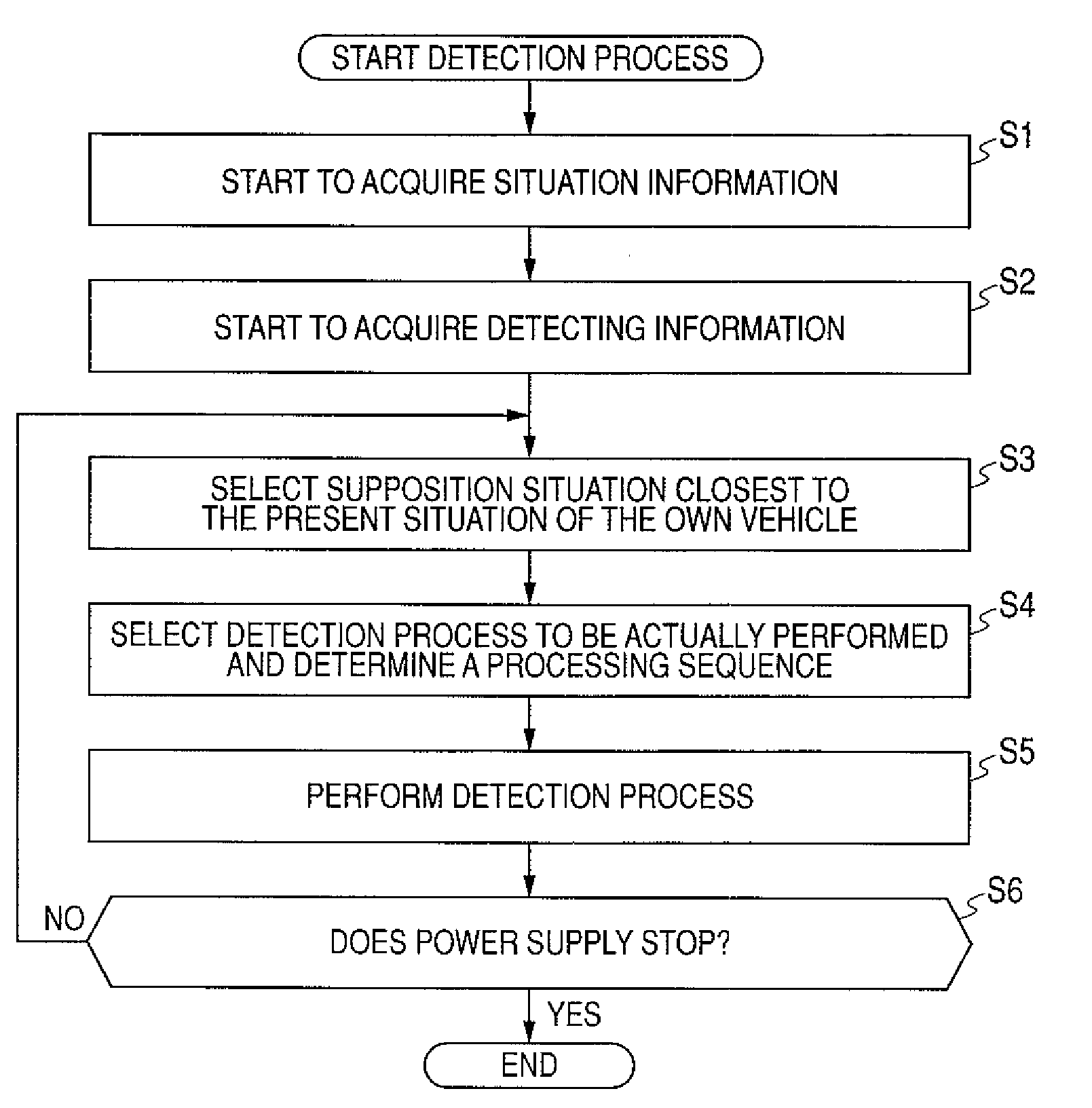

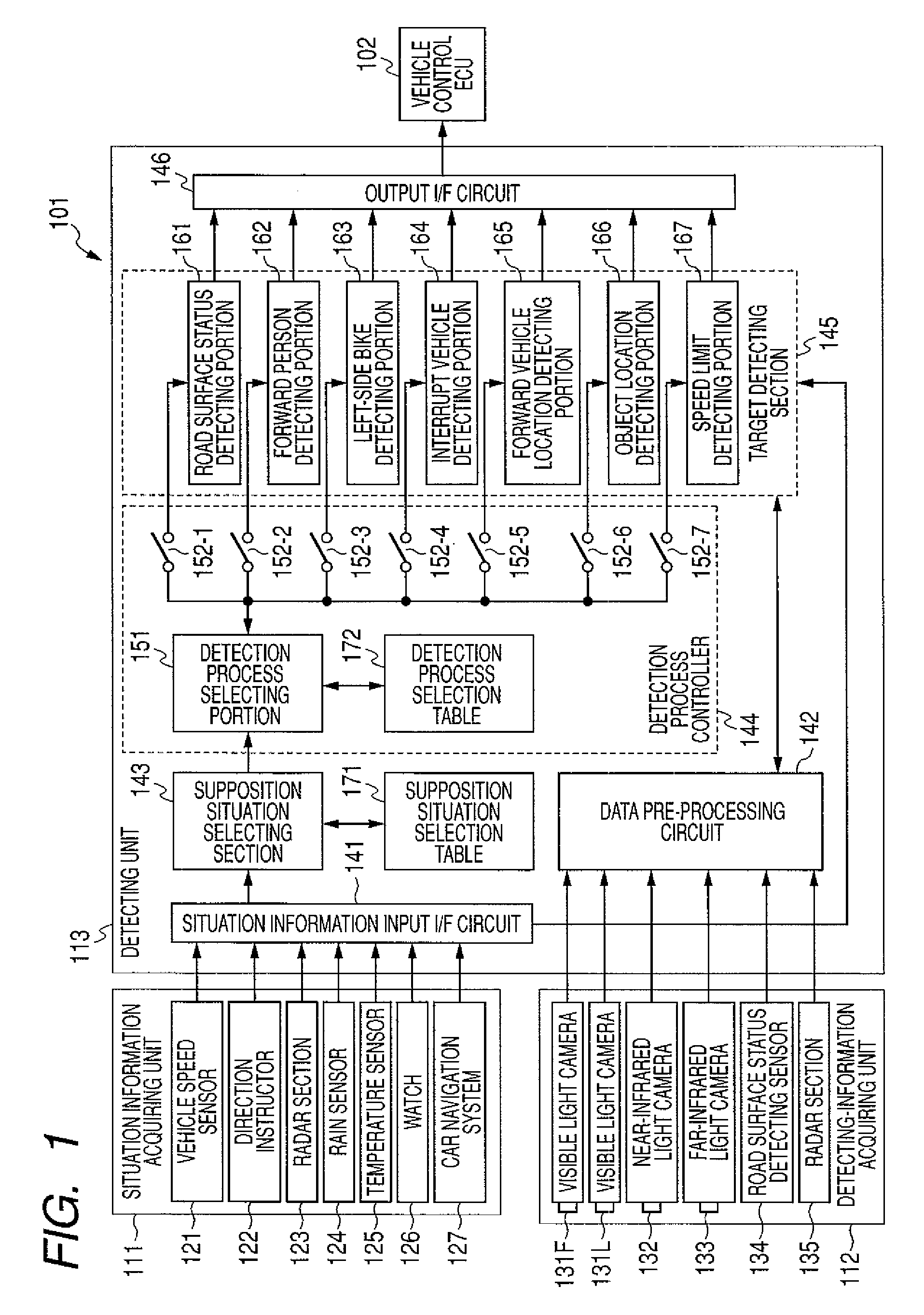

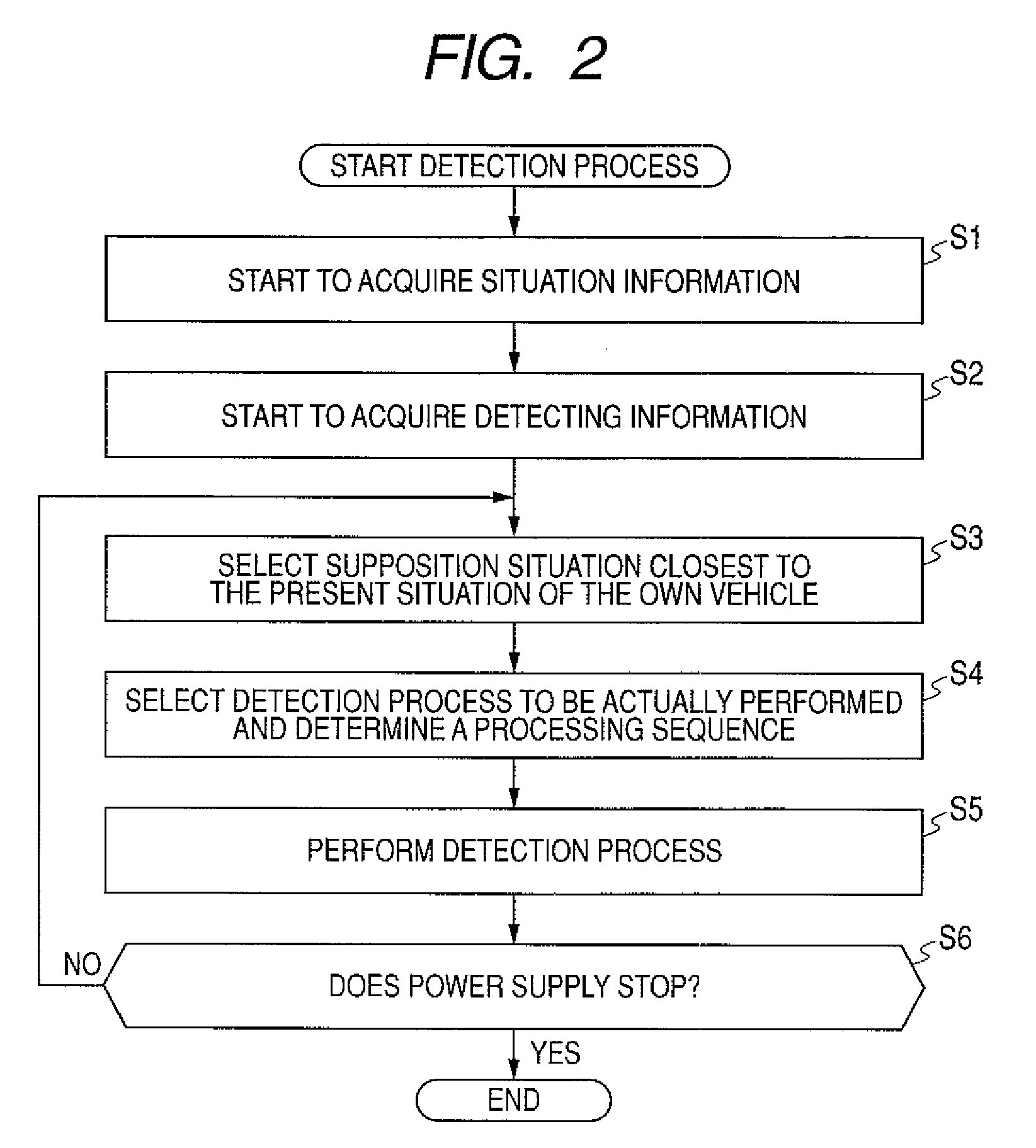

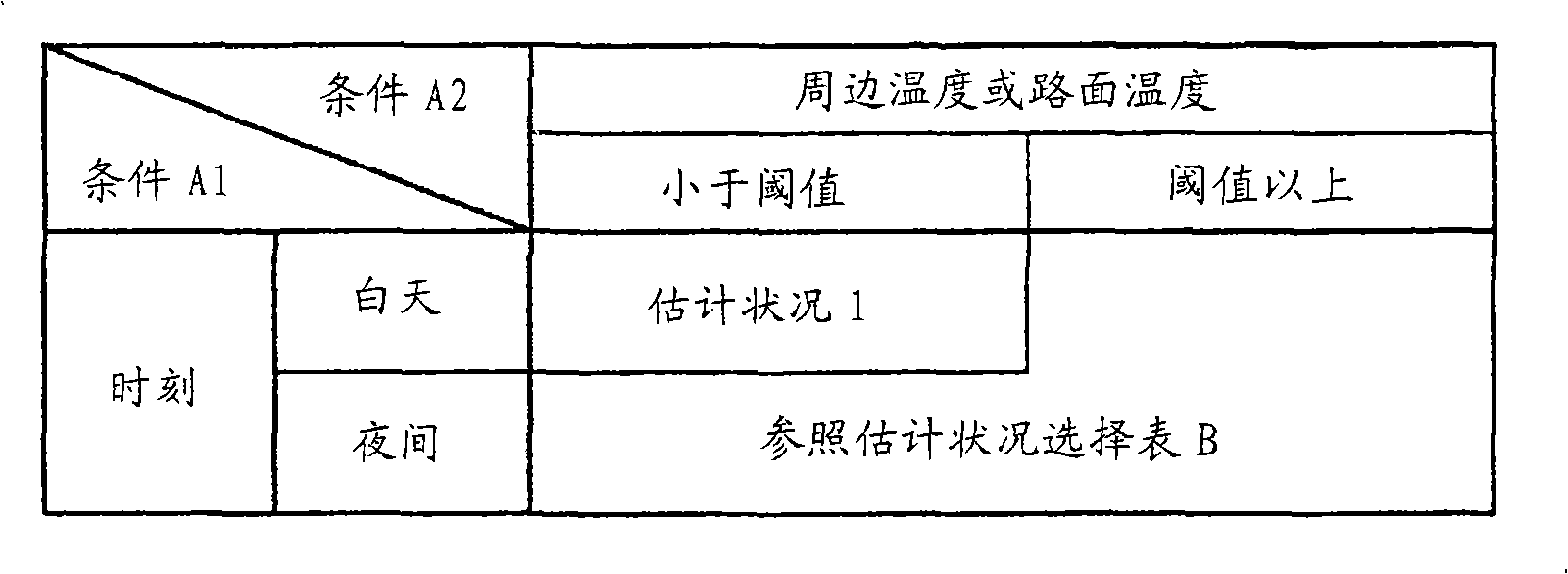

Detecting device, detecting method, and program

InactiveUS20090018711A1Efficient detectionEffectively detect information requiredDigital data processing detailsAnti-collision systemsImaging processingIn vehicle

Information necessary to control a vehicle is to be effectively detected in accordance with a situation. A supposition situation selecting section selects a supposition situation closest to the present situation of an own vehicle from a plurality of pre-supposed supposition situations on the basis of situation information acquired from a situation information acquiring unit and a supposition situation selection table through a situation information input I / F circuit. A detection process selecting portion selects a detection process to be actually performed from detection processes which can be performed by each detecting portion of a target detecting section on the basis of the selected supposition situation and a detection process selection table. The invention is applicable to an in-vehicle image processing device.

Owner:ORMON CORP

Process options of forming silicided metal gates for advanced CMOS devices

InactiveUS20050064690A1Minimizes gate dielectric attackMinimize damageSemiconductor/solid-state device manufacturingCMOSGate dielectric

Silicide is introduced into the gate region of a CMOS device through different process options for both conventional and replacement gate types processes. Placement of silicide in the gate itself, introduction of the silicide directly in contact with the gate dielectric, introduction of the silicide as a fill on top of a metal gate all ready in place, and introduction the silicide as a capping layer on polysilicon or on the existing metal gate, are presented. Silicide is used as an option to connect between PFET and NFET devices of a CMOS structure. The processes protect the metal gate while allowing for the source and drain silicide to be of a different silicide than the gate silicide. A semiconducting substrate is provided having a gate with a source and a drain region. A gate dielectric layer is deposited on the substrate, along with a metal gate layer. The metal gate layer is then capped with a silicide formed on top of the gate, and conventional formation of the device then proceeds. A second silicide may be employed within the gate. A replacement gate is made from two different metals (dual metal gate replacement) prior to capping with a silicide.

Owner:GLOBALFOUNDRIES INC

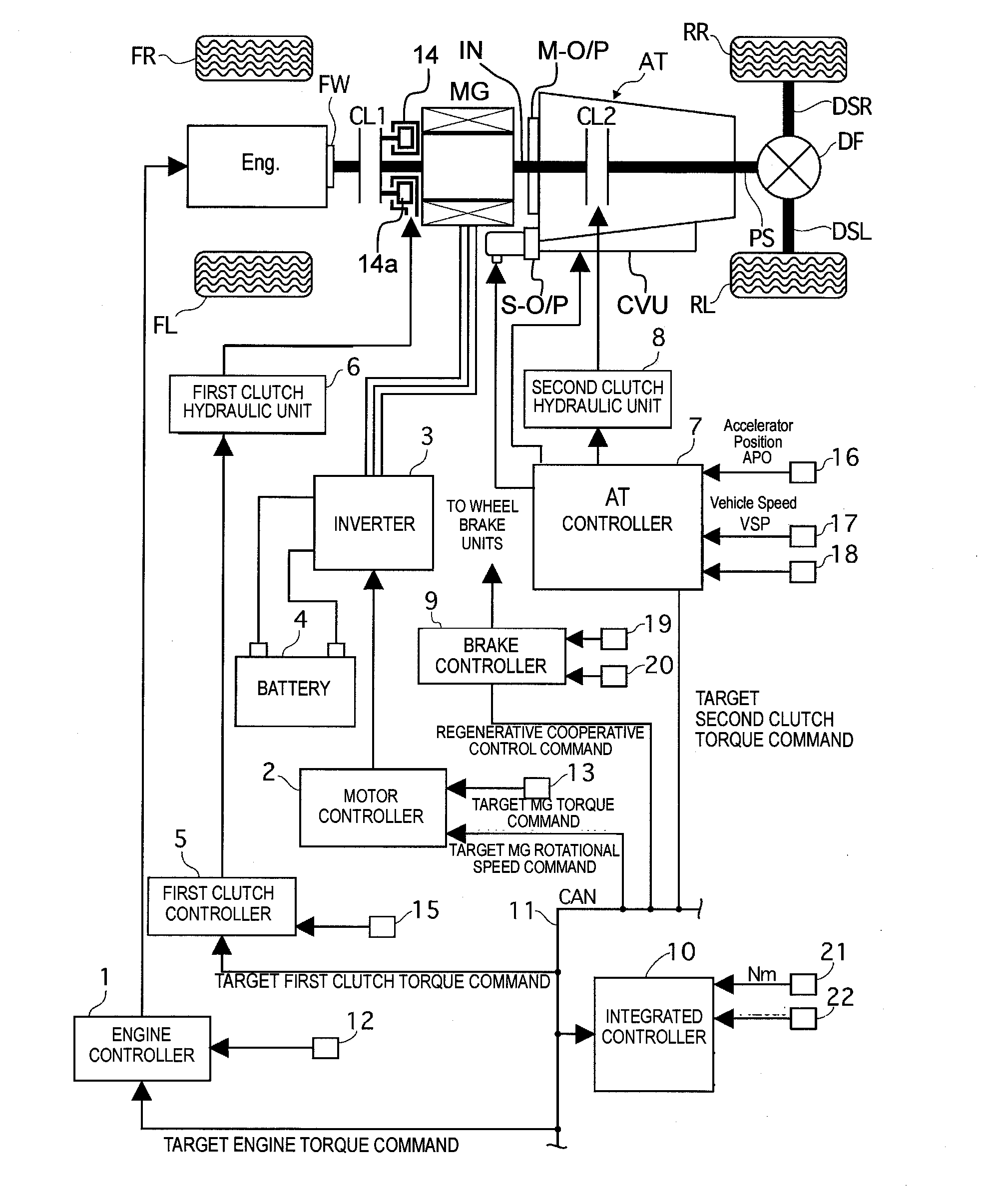

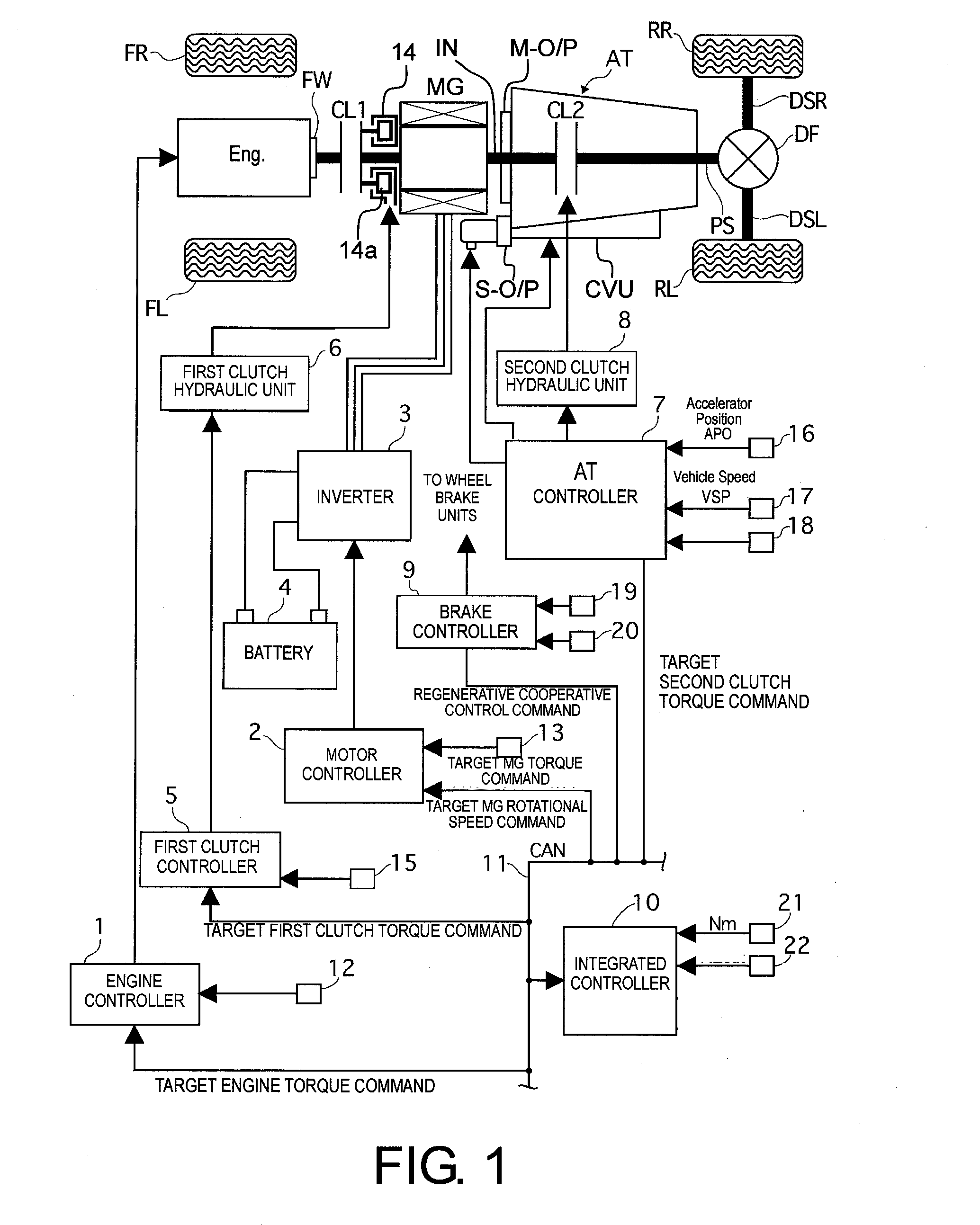

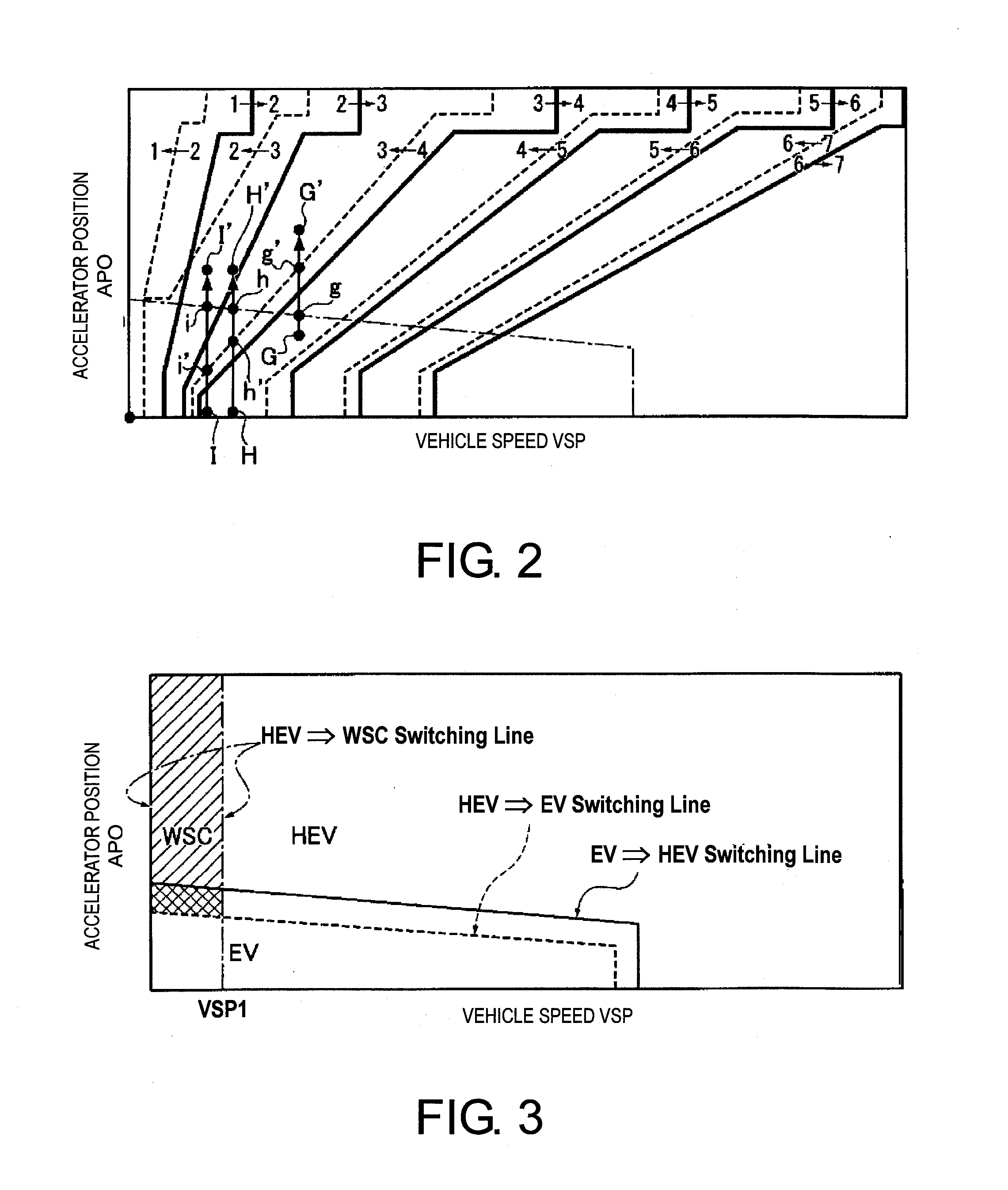

Hybrid vehicle control device

ActiveUS20130297136A1Hybrid vehiclesDigital data processing detailsAutomatic transmissionControl theory

A hybrid vehicle control device is provided with an engine, a motor / generator, a first clutch, an automatic transmission, a second clutch, and a controller having a simultaneous process selection control section. The simultaneous process selection control section performs engine startup control and downshift control in parallel in cases where the torque outputtable by the motor subsequent to downshifting during overlap of an engine startup request and a downshift request is equal to or greater than the engine startup torque, or performs engine startup control first then downshift control in cases where the torque outputtable by the motor subsequent to downshifting is less than the engine startup torque.

Owner:JATCO LTD +1

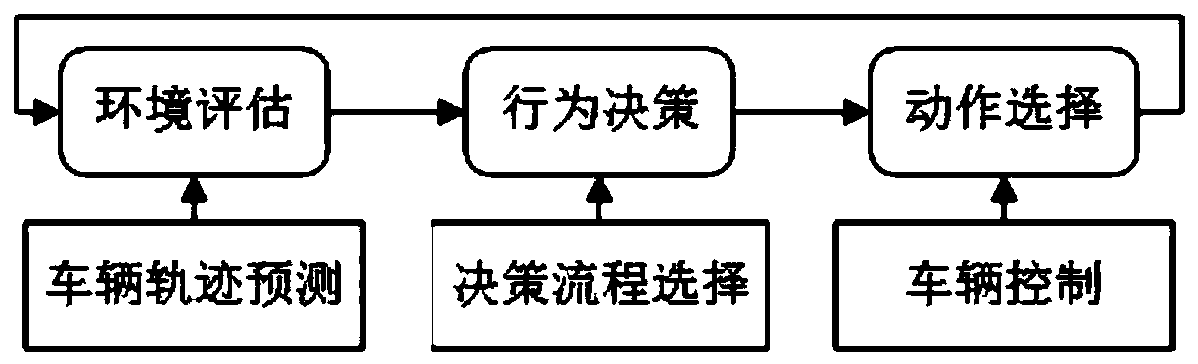

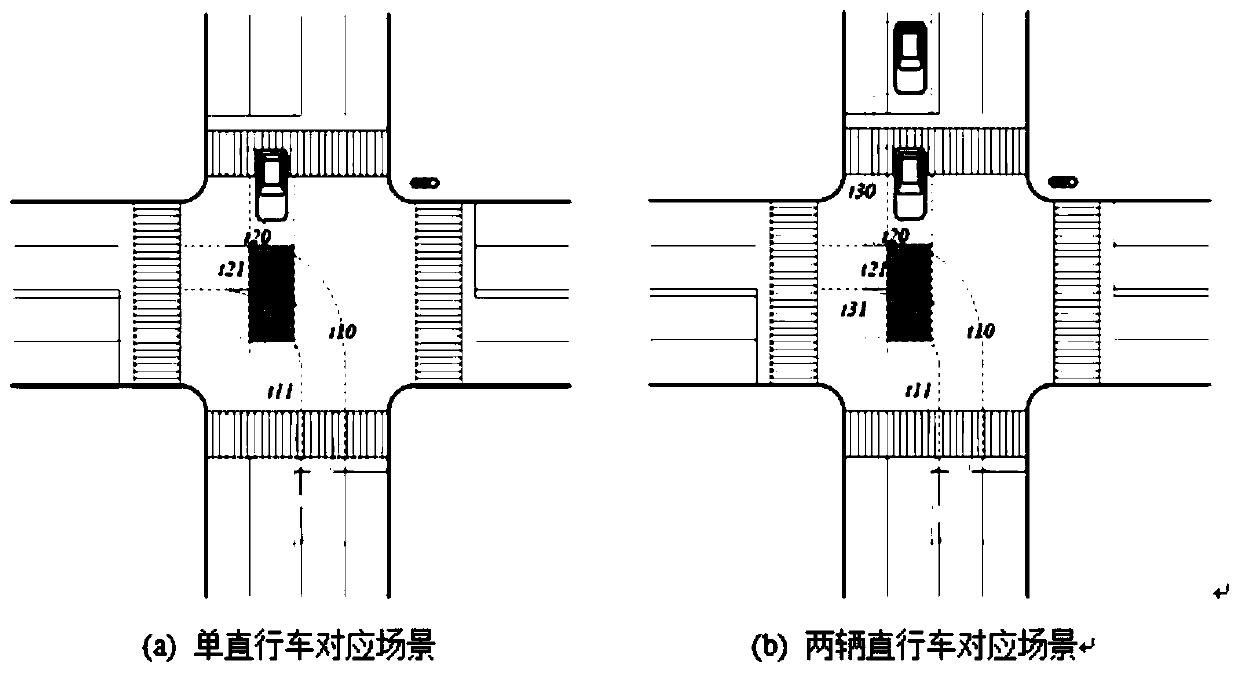

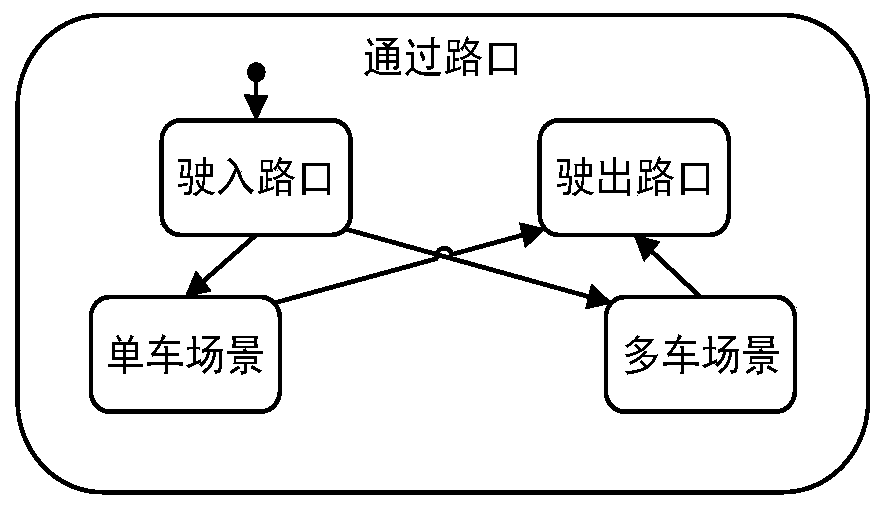

Unmanned vehicle urban intersection left turn decision-making method based on conflict resolution

ActiveCN110298122AImprove rationalityImprove adaptabilityControlling traffic signalsForecastingDecision modelVehicle driving

The invention discloses an unmanned vehicle urban intersection left-turn decision-making method based on conflict resolution. The method comprises the steps of track prediction for straight vehicles at an intersection, decision-making process selection of a behavior decision-making module corresponding to different scenes, and vehicle control parameter selection corresponding to an action selection module. According to the invention, the decision-making framework of the left turn of the unmanned vehicle at the intersection is divided into environment assessment, behavior decision-making and action selection; prediction of intersection straight driving motion tracks is realized by using a Gaussian process regression model, decision-making processes under different left-turn scenes are formulated, and an unmanned vehicle driving action selection method considering multiple factors is provided; and the decision-making process of the left turn of the unmanned vehicle at the intersection isstructured and clarified, so that the reasonability and the adaptability of the decision-making model are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

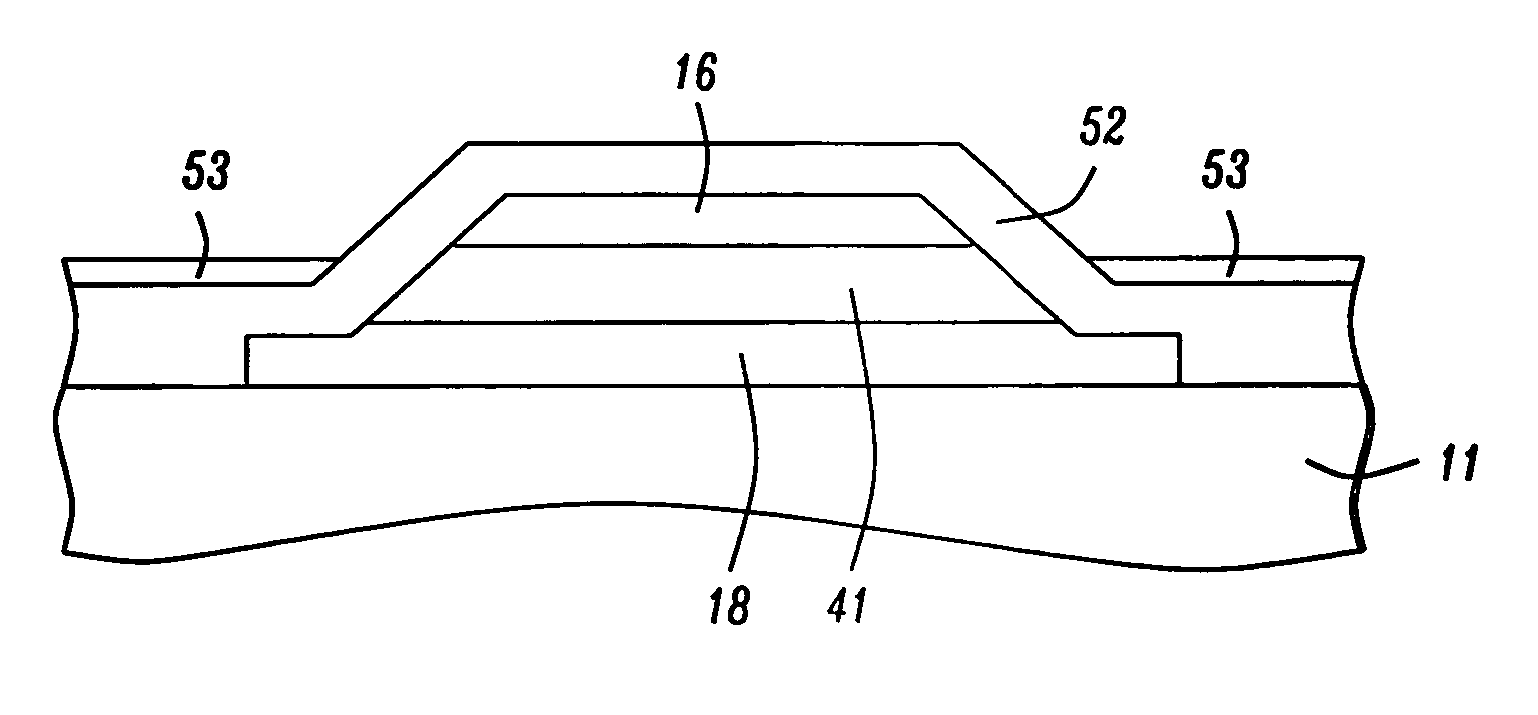

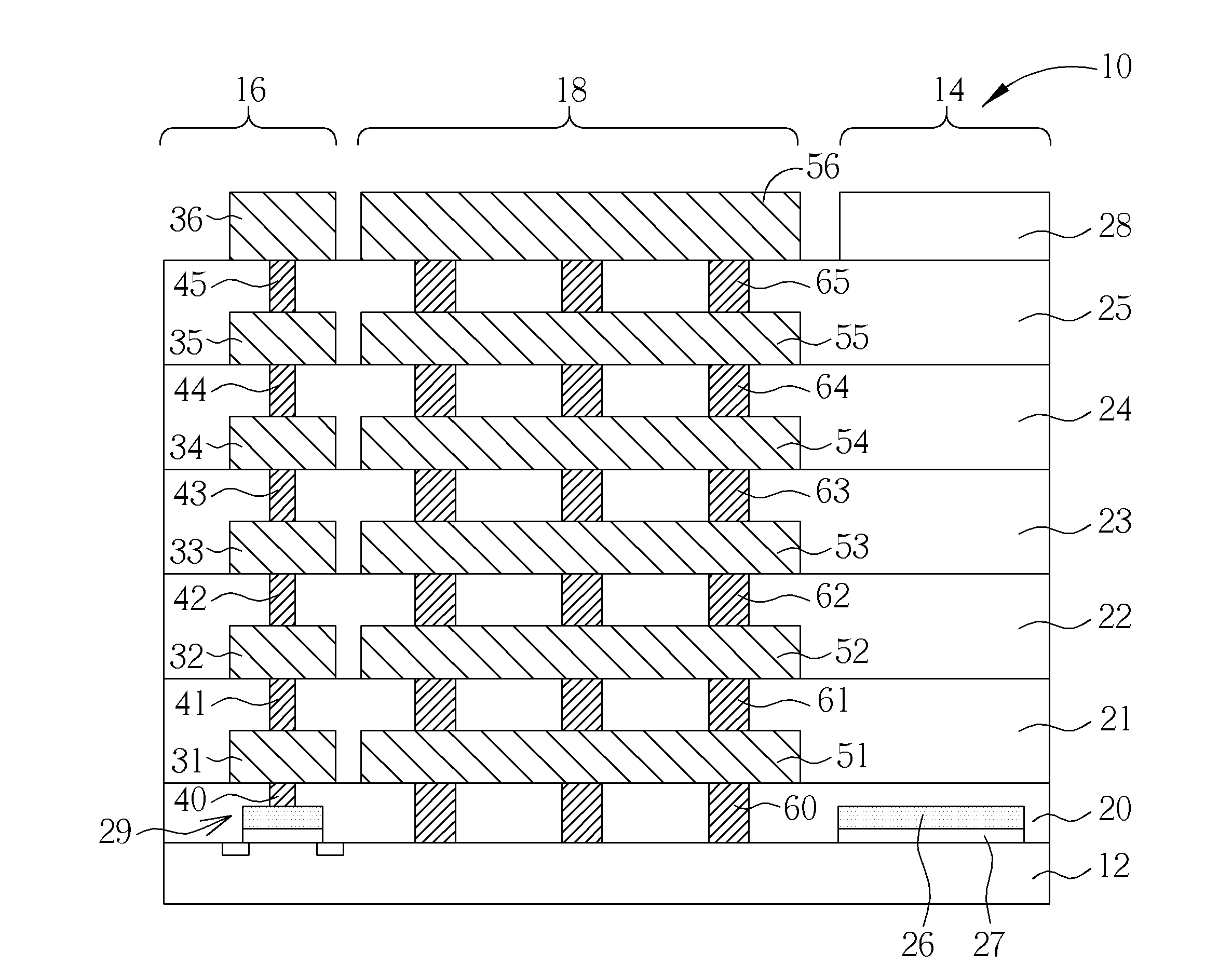

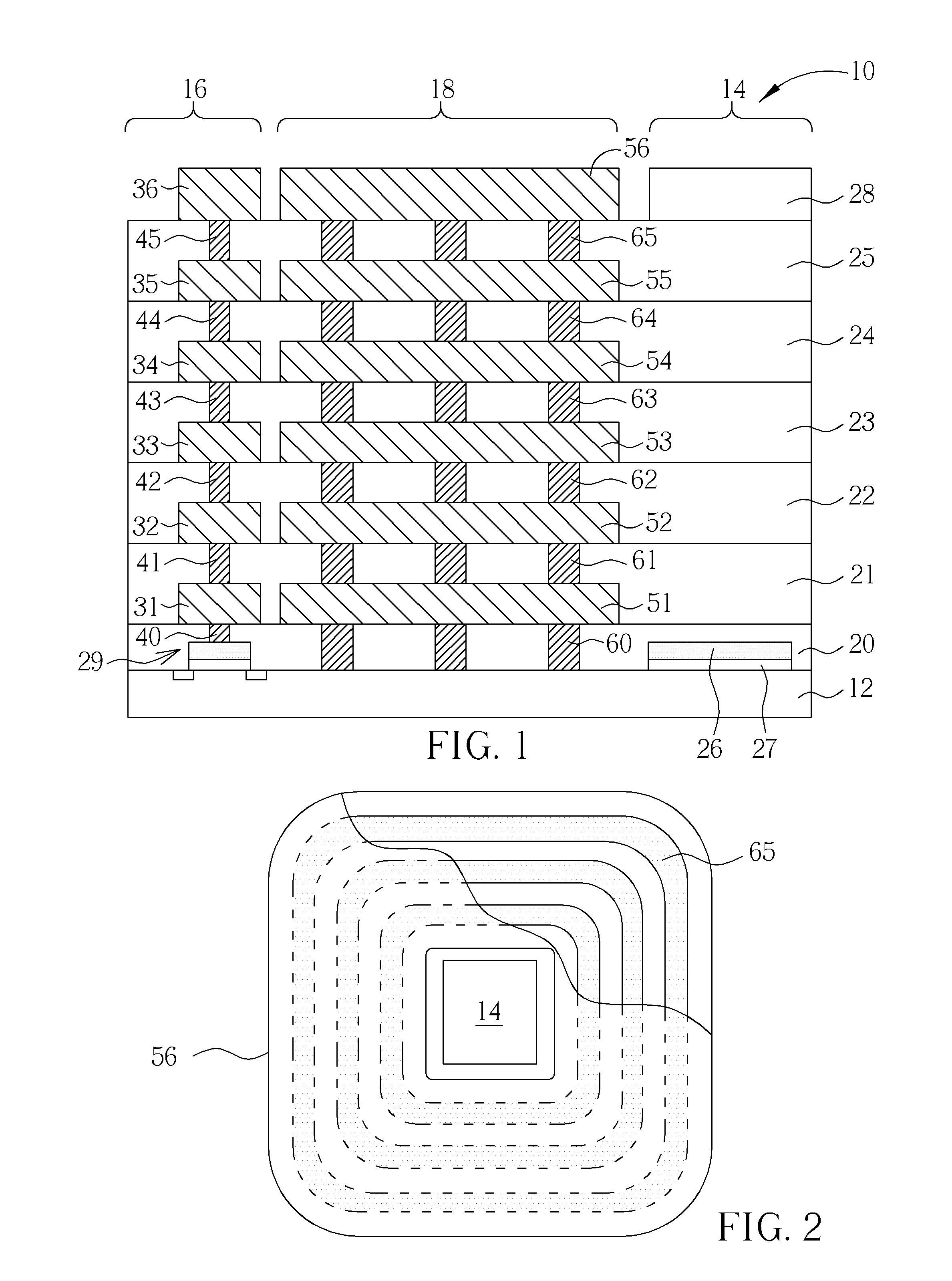

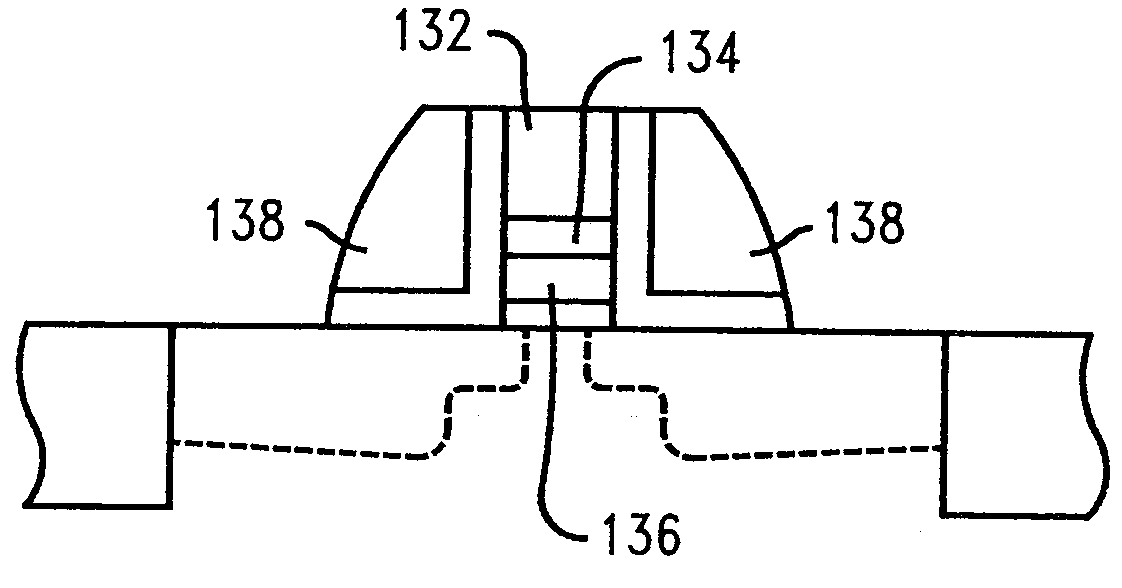

SiGe selective growth without a hard mask

InactiveUS7494884B2Semiconductor/solid-state device manufacturingSemiconductor devicesTensile strainCharge carrier mobility

MOS transistors having localized stressors for improving carrier mobility are provided. Embodiments of the invention comprise a gate electrode formed over a substrate, a carrier channel region in the substrate under the gate electrode, and source / drain regions on either side of the carrier channel region. The source / drain regions include an embedded stressor having a lattice spacing different from the substrate. In a preferred embodiment, the substrate is silicon and the embedded stressor is SiGe or SiC. An epitaxy process that includes using HCl gas selectively forms a stressor layer within the crystalline source / drain regions and not on polycrystalline regions of the structure. A preferred epitaxy process dispenses with the source / drain hard mask required of conventional methods. The embedded SiGe stressor applies a compressive strain to a transistor channel region. In another embodiment, the embedded stressor comprises SiC, and it applies a tensile strain to the transistor channel region.

Owner:TAIWAN SEMICON MFG CO LTD

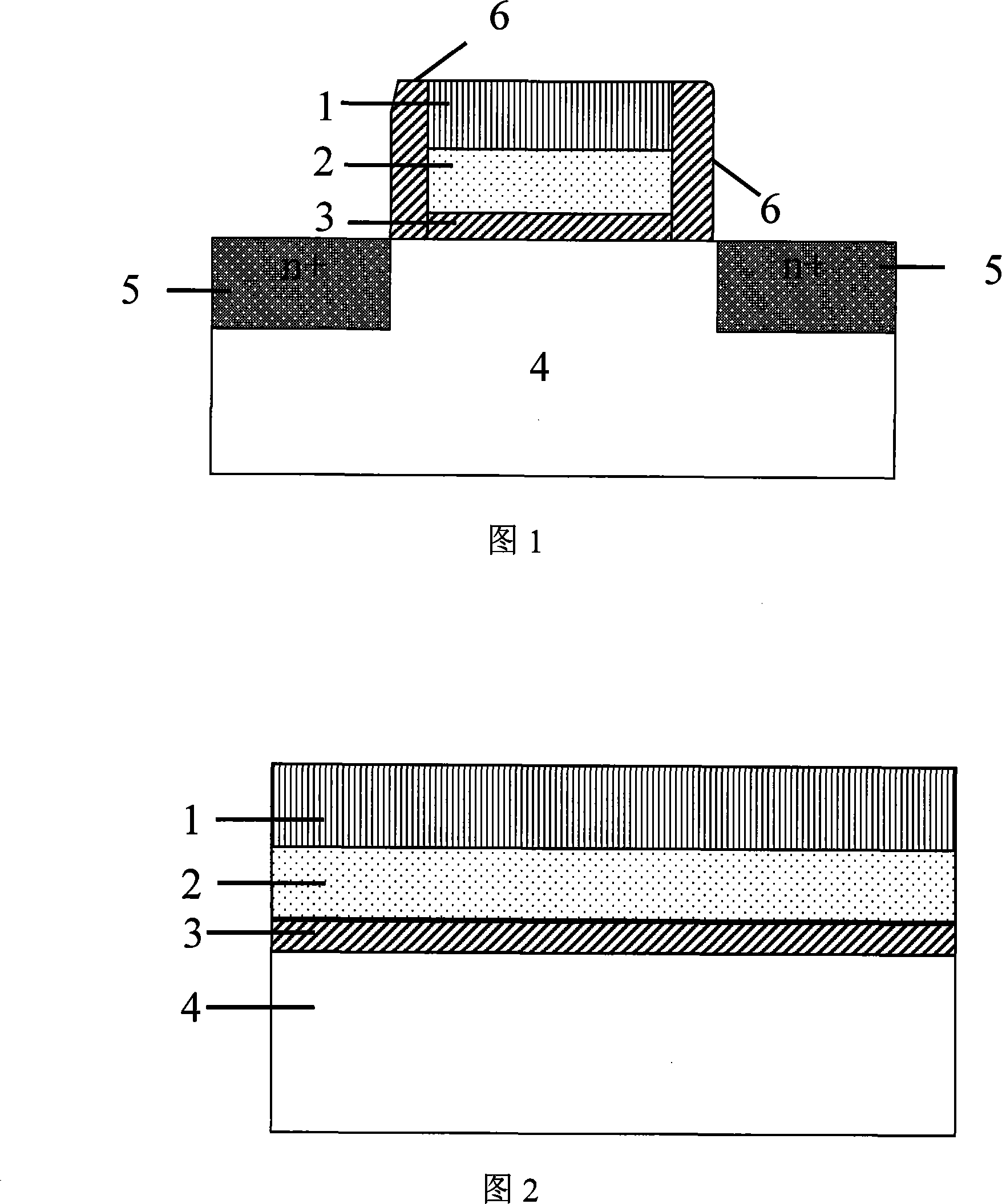

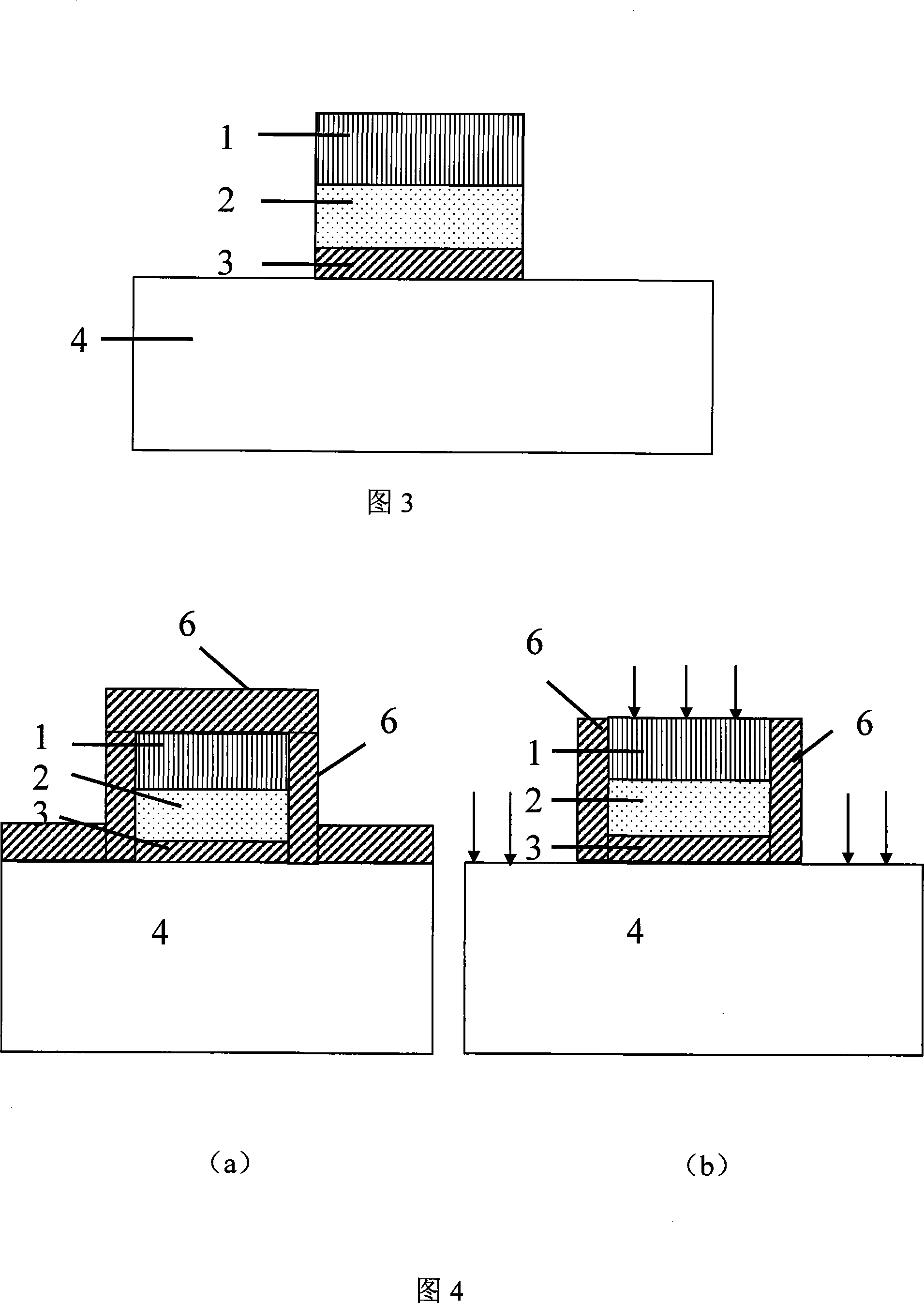

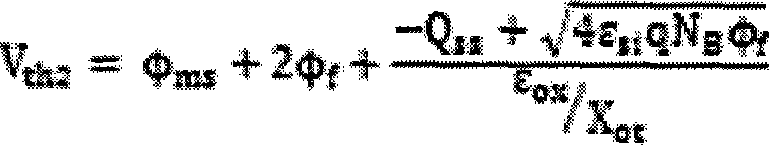

Field-effect tranisistor realizing memory function and method of producing the same

InactiveCN101179095AImprove reliabilityMeet functional applicationsSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyField-effect transistor

The invention provides a field effect transistor that achieves the storage function and the preparation method, which belongs to the filed of semiconductor integrated circuit and manufacturing technology. The transistor comprises a source region, a drain region and a control grid, wherein the control grid utilizes a grid stepped construction which comprises a bottom layer of a tunneling oxidizing layer, an interface layer of a resistance-varying material layer and a top layer of a conductive electrode layer. The field effect transistor obtains an electrically programmable multi-threshold function, the source and drain currents of which are different when a same reading voltage is imposed on the grid, thereby achieving the information storage on two different states or other functions. Utilizing the invention, a plurality of devices and circuits with new functions, high performance and high reliability can be composed, thereby meeting the application of different circuit functions. Meanwhile the invention can adopt the compatibility with the CMOS technology of the conventional PN source or drain junction structure, and can also adopt the compatibility with the CMOS technology of the Schottky source or drain junction structure, with a greater flexibility in technology selection.

Owner:PEKING UNIV

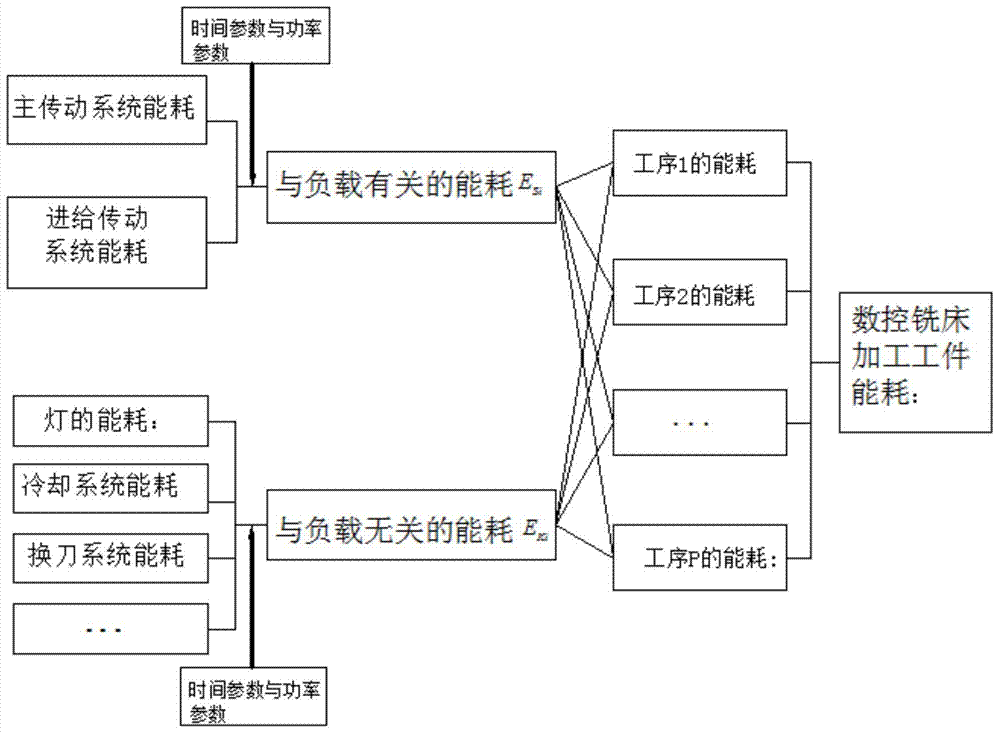

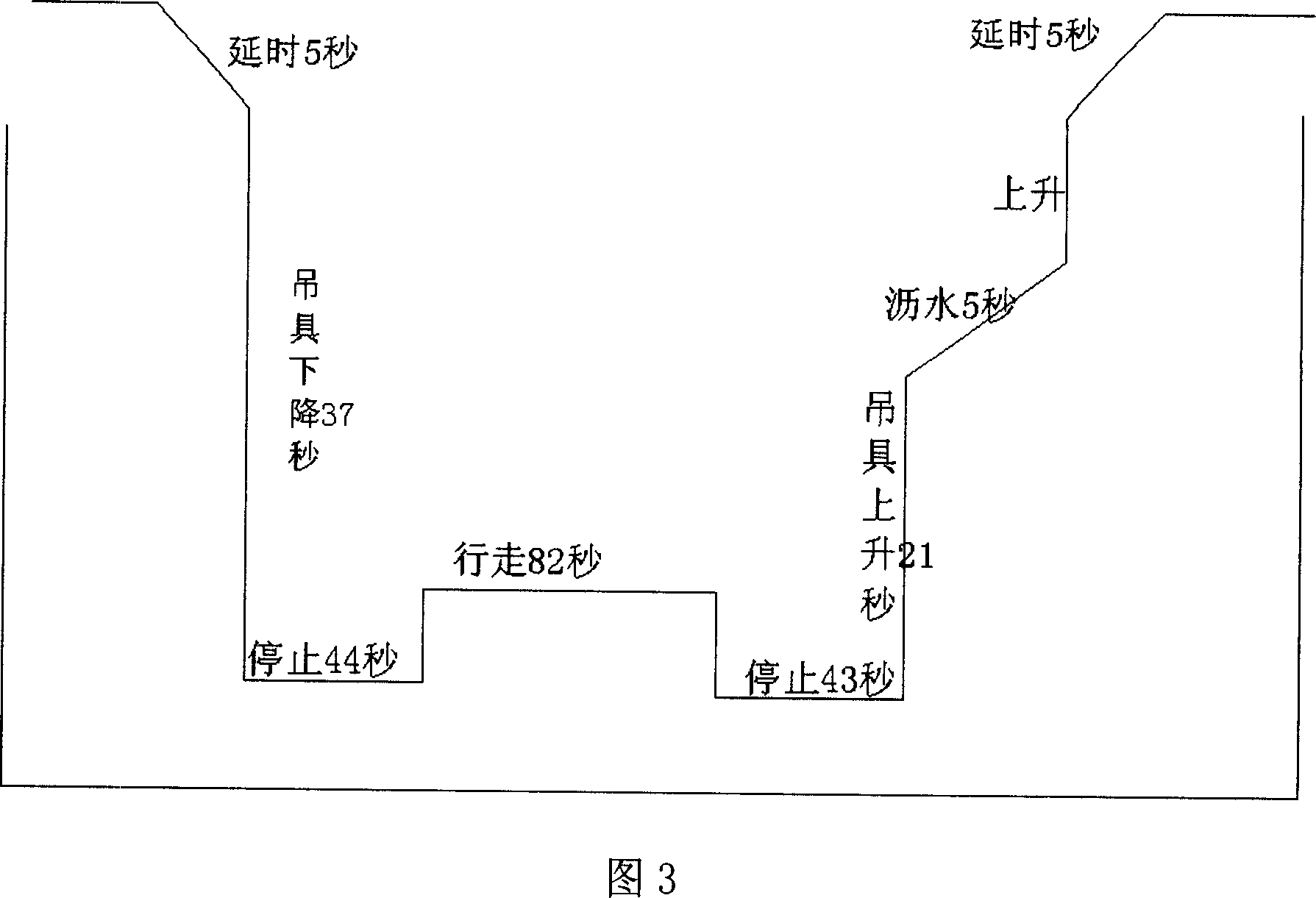

Method for predicting energy consumption of CNC milling machine based on time parameters

ActiveCN103941644ACalculate energy consumptionHigh feasibilityProgramme controlComputer controlWork timeTransmission system

The invention discloses a method for predicting the energy consumption of a CNC milling machine based on time parameters. The method includes the steps that (a) an energy consumption prediction model is established for the machining process of the CNC milling machine; (b) the no-load power, the additional power, the cutting power and the feeding power of a feed shaft of each component process are detected, and meanwhile the time parameters including the idle time of a main transmission system, the milling time and the working time of the feed shaft are acquired respectively through NC codes; (c) all the obtained power parameters and the obtained time parameters are substituted into the energy consumption prediction model, and the overall energy consumption prediction technological process is correspondingly executed. By the adoption of the method, the energy consumption prediction process of the CNC milling machine can be rapidly and accurately realized only by inputting the cutting data and the time parameters of each process, the method is high in feasibility, and optimization and support can be provided for solving a series of problems of process selection, energy consumption prediction, energy consumption evaluation, energy saving and emission reduction of the machine and the like in workpiece machining process of the CNC milling machine.

Owner:重庆亿如电子有限公司

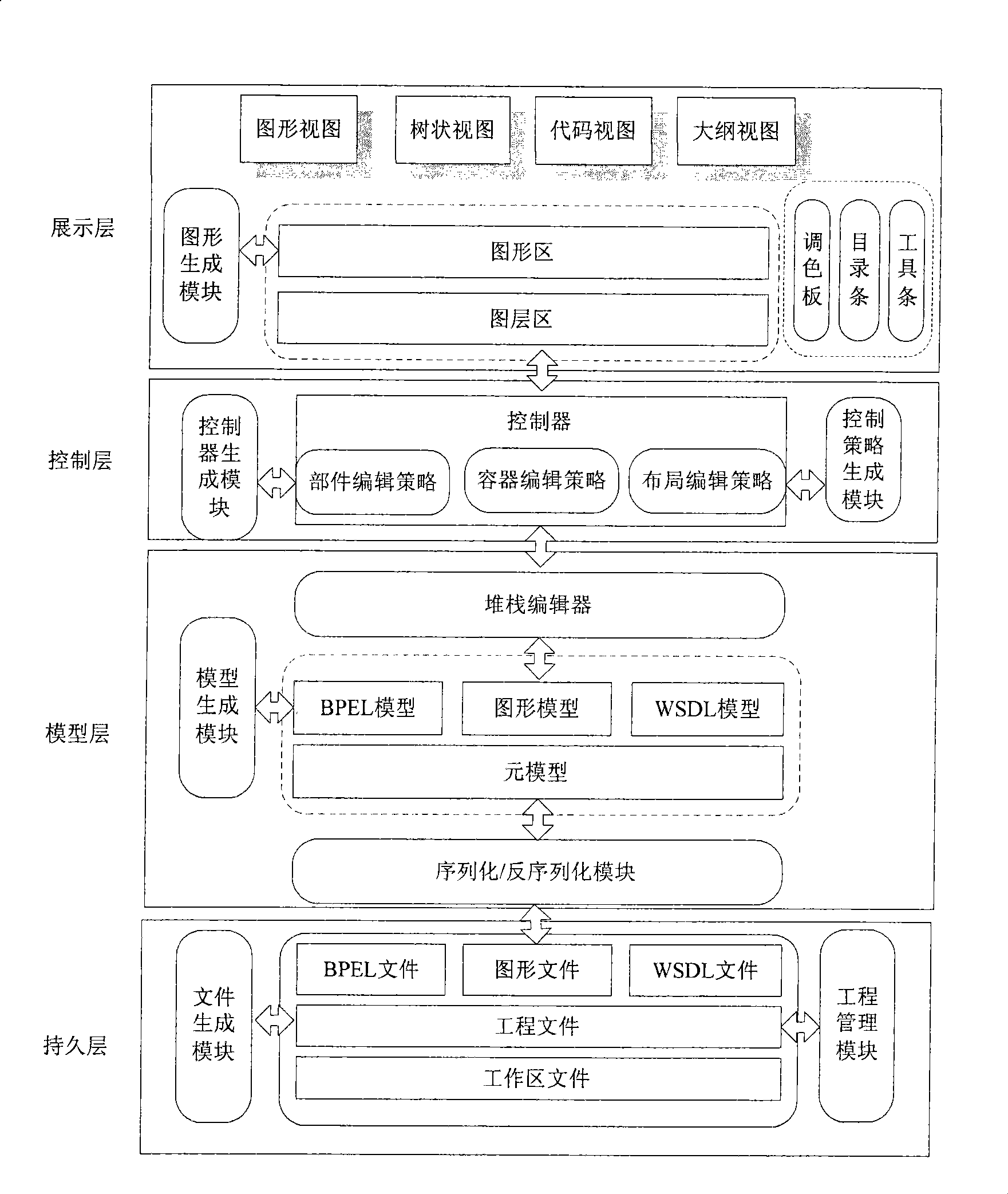

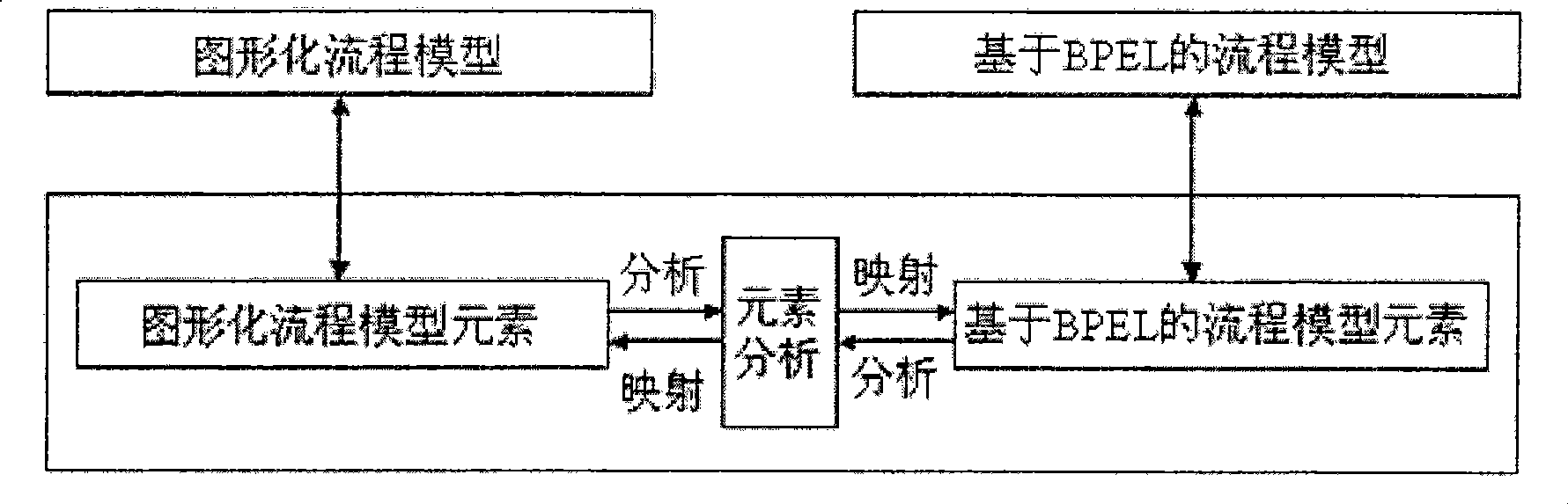

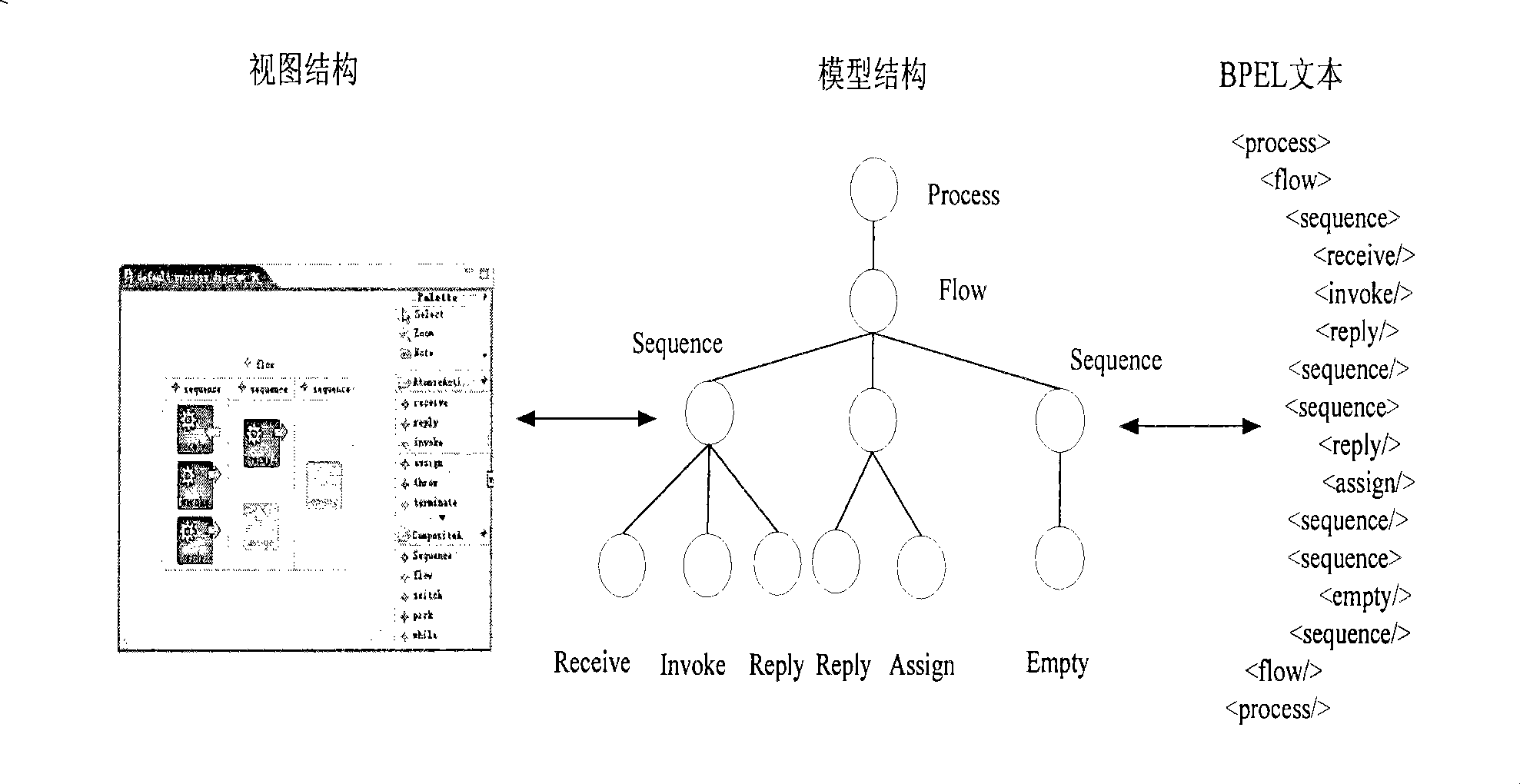

BPEL visual model building system based on GMF

InactiveCN101364176AImprove scalabilityCorrect and flexible conversionSpecific program execution arrangementsMapping algorithmSimulation

The invention relates to a GMF-based BPEL visual modeling system. The system is characterized in that: (1), the overall frame of the visual modeling system is designed based on the GMF technology by adopting an MVC design pattern; (2), the mapping algorithm of a BPEL view and a text is realized; (3), the multiple view synchronous design is realized; (4), the algorithm of structured active extension and contraction is realized; (5), a stack editor for re-do and un-do to a user operation is realized; (6), an automatic layout algorithm is designed to realize the active hierarchical layout during the modeling process and embody the process concept; (7), a connecting layout algorithm is designed to perform the automatic connecting branching to the structured activity in a BPEL process and embody the process selection concept; and (8), a controller-control strategy-control command mode, which can listen in and respond active operations in time, realize the random inserting of a sub-activity into the parent system, and delete and insert the prompt lines, is designed. The system has strong extended performance, and is a practical BPEL modeling tool with artistic interface.

Owner:BEIHANG UNIV

Separation technology of hydrogen sulfide and carbon dioxide in acid gas of oil refinery

InactiveCN103446849AHigh selectivityImprove stabilityHydrogen sulfidesDispersed particle separationSeparation technologyGas phase

The invention relates to a separation technology of hydrogen sulfide and carbon dioxide in acid gas of an oil refinery. According to the technical scheme, the separation technology comprises the following processing steps that the acid gas of the oil refinery flows through an acid gas separating tank and an acid water separating tank and then enters a first absorbing column; the acid gas at the bottom part of the first absorbing column is in contact with barren liquor from the upper part of the column, thus hydrogen sulfide in the acid gas can be fully absorbed to generate rich liquor; the rich liquor and barren liquor enter a first-grade rich-barren heat exchanger to exchange the heat and then enter a first regenerating column to regenerate; H2S gas generated at the top of a second regenerating column is condensed through a second condenser and then flows into a separating tank; a separated liquid phase is used for backflow in the top of the regenerating column; and a gas phase, namely, H2S gas, is used as sodium hydrosulfide to prepare some of raw materials. The separation technology has the beneficial effects that a methyldiethanolamine extracting agent at a concentration of 50% is selected; and compared with other extracting agents, the methyldiethanolamine extracting agent has relatively high selectivity and stability, causes a very little loss, and is low in energy consumption of devices.

Owner:SHANDONG KENLI PETROCHEM GRP

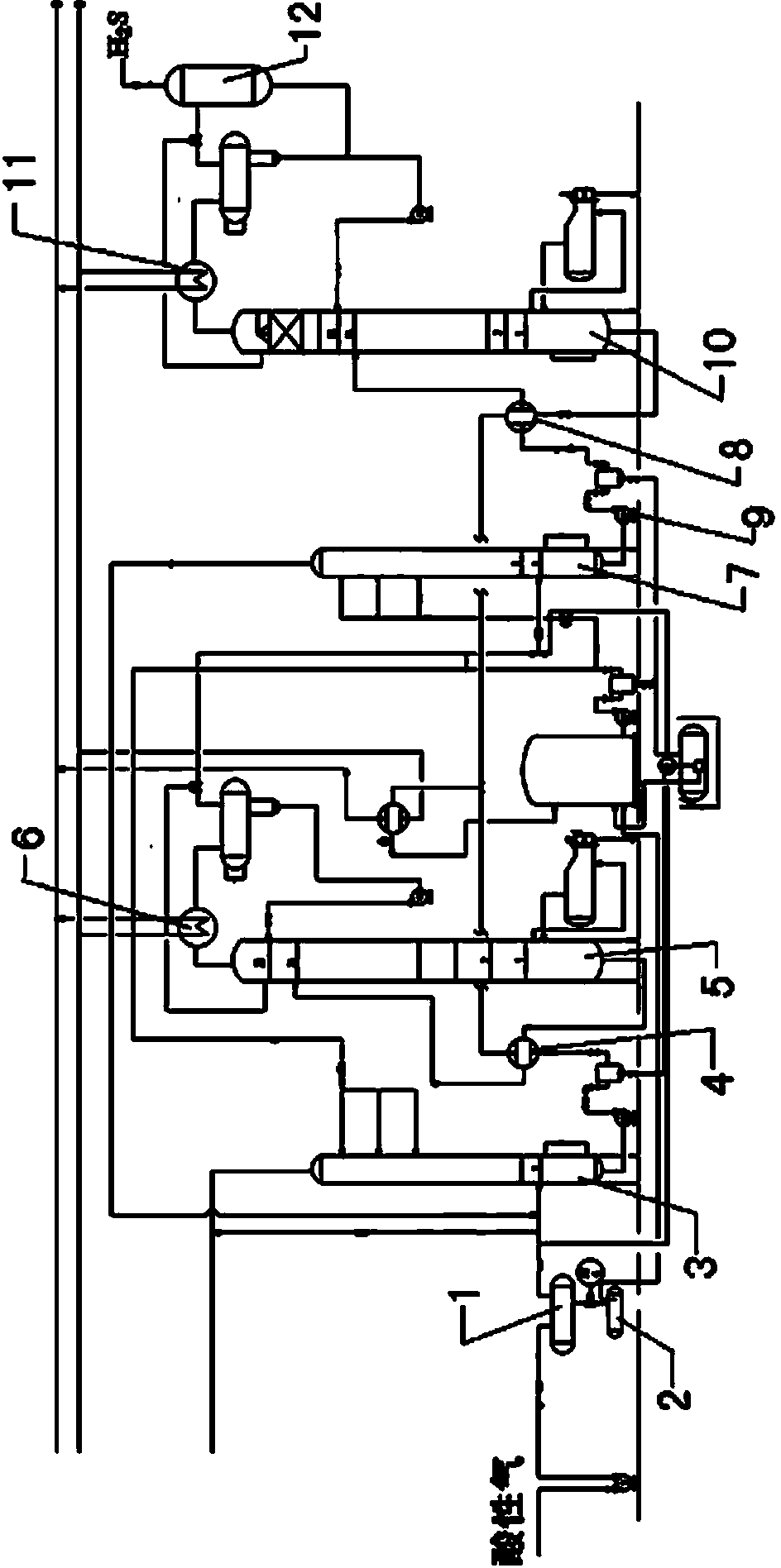

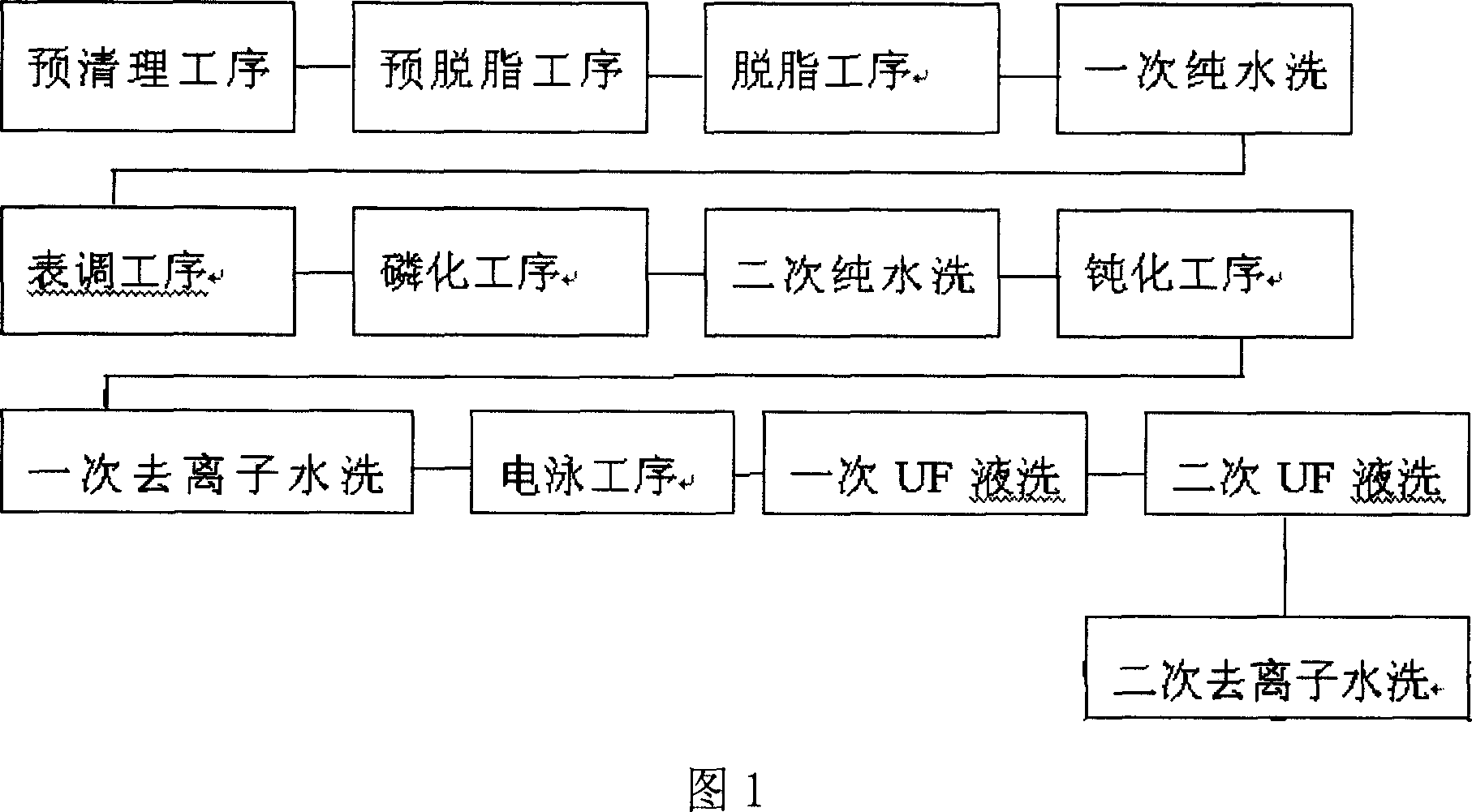

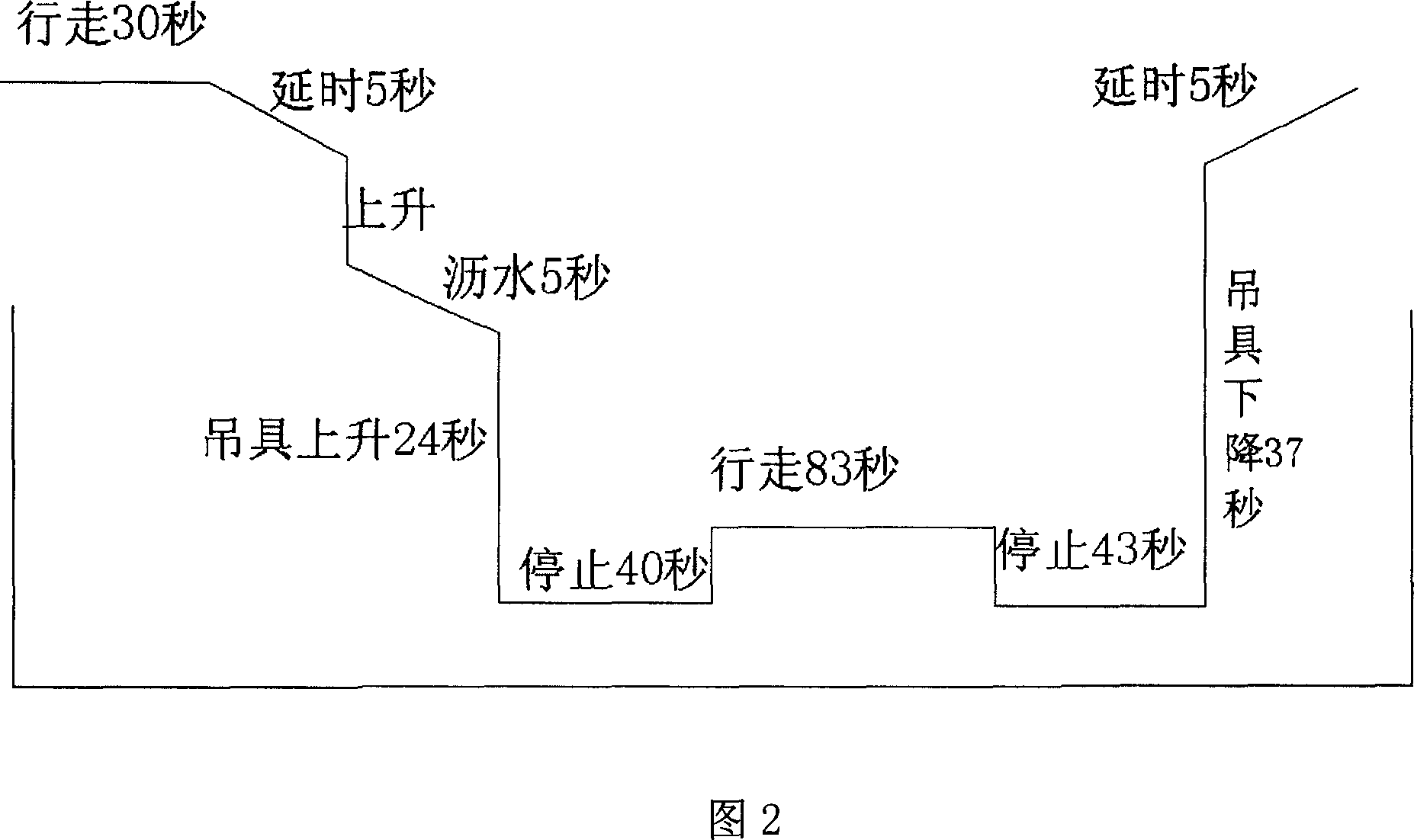

Manufacturing technique for painting dressing automobiles

ActiveCN1958174AShorten painting production cycleCooperate effectivelyLiquid surface applicatorsMetallic material coating processesHigh volume manufacturingElectrophoresis

A coating technology for car includes such steps as cleaning surface, pre-removing oil, removing oil, washing with purified water, conditioning surface, phosphorizing, washig with purified water again, passivating, washing with deionized water, electrophoresis, washing with UF solution twice, and washing with deionized water again.

Owner:CHERY AUTOMOBILE CO LTD

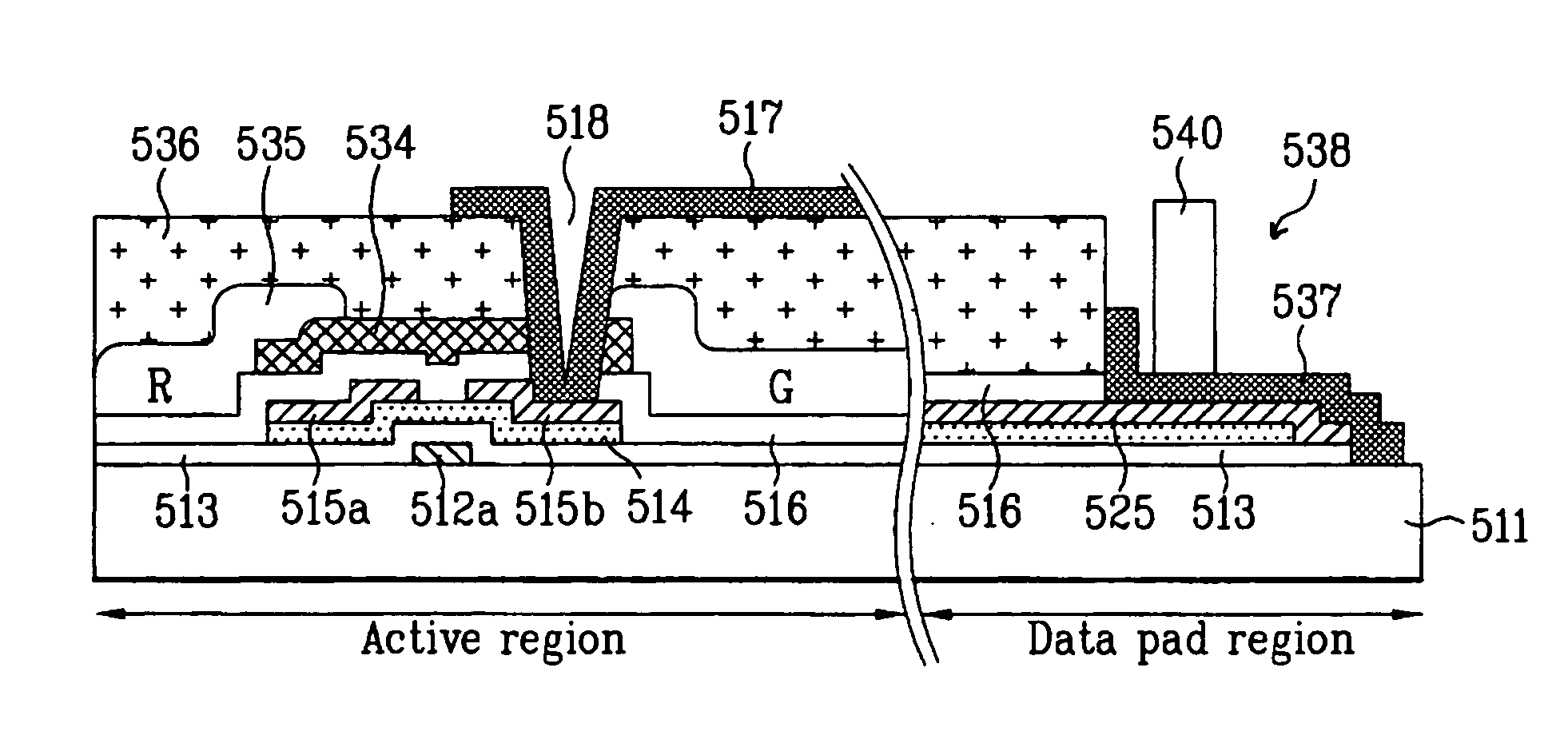

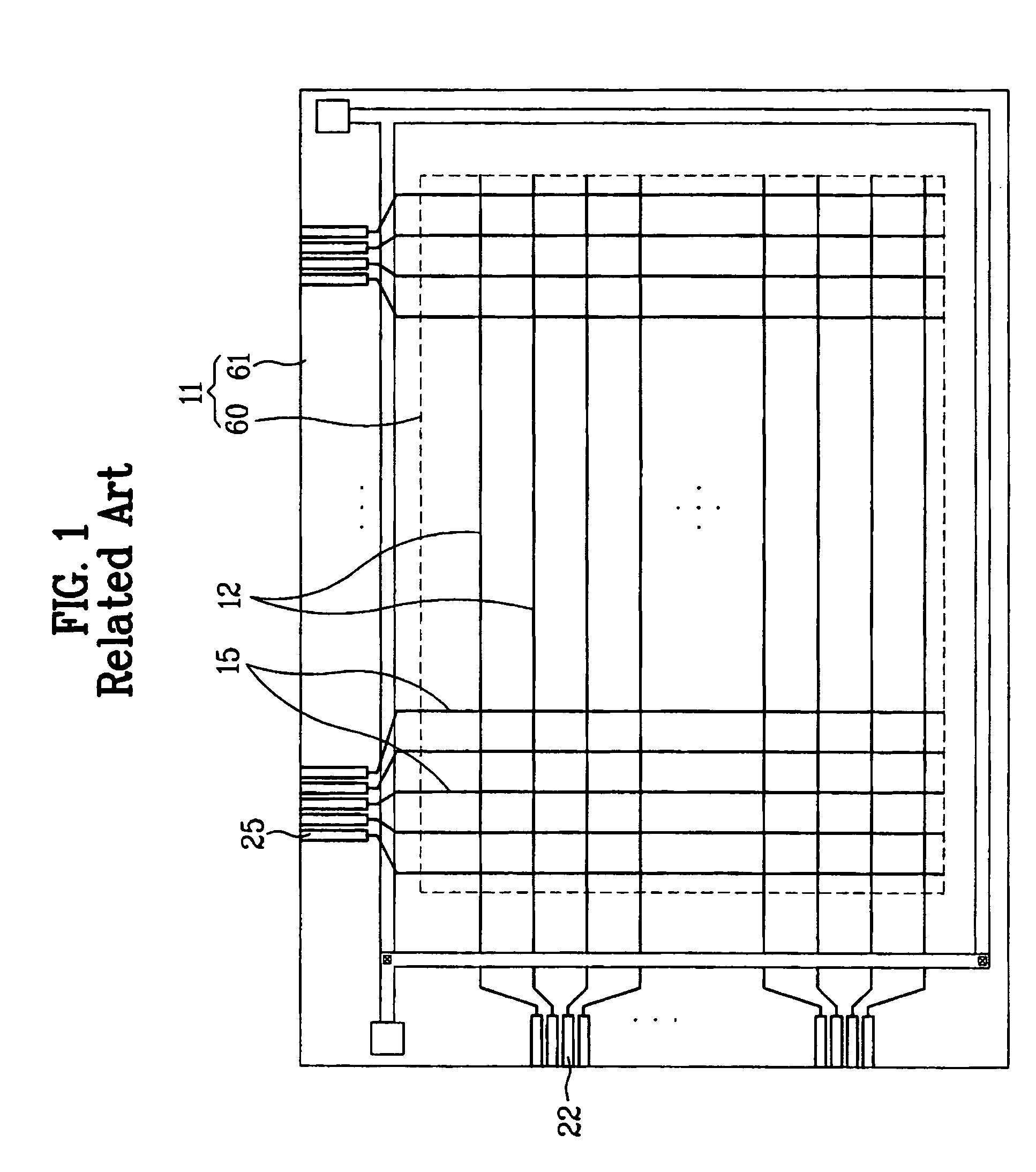

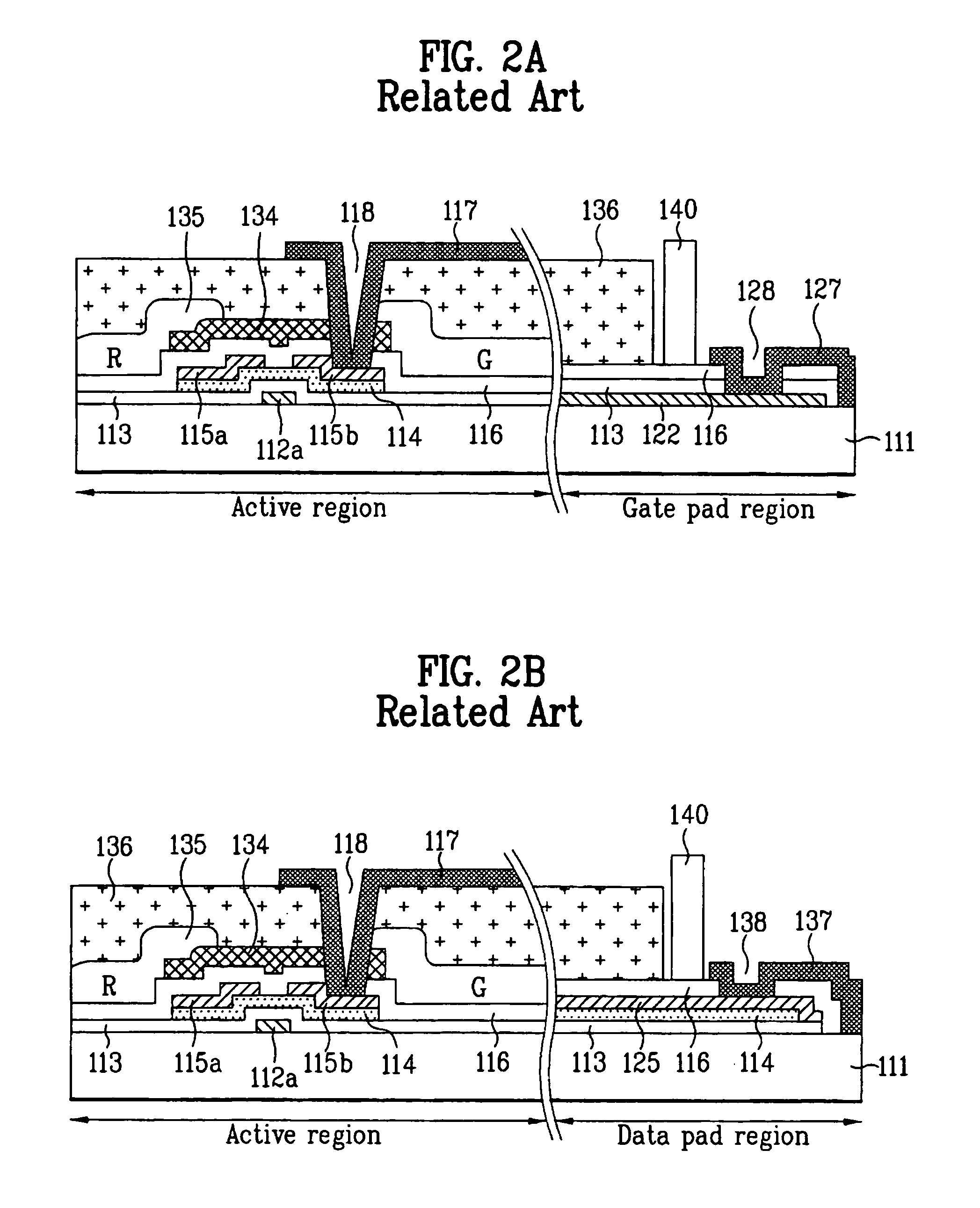

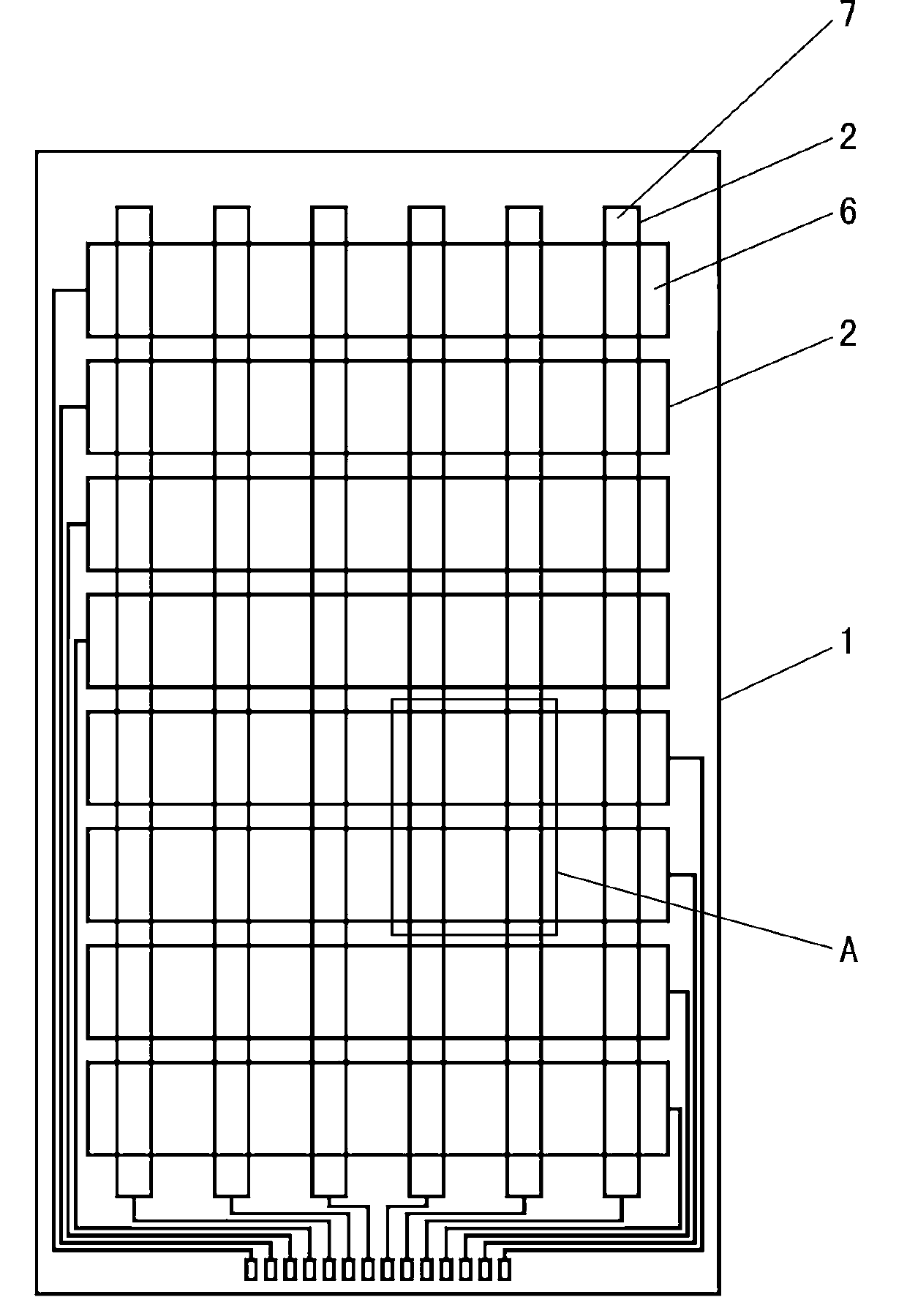

Liquid crystal display device and method for fabricating the same

ActiveUS20050219433A1Simple manufacturing processReduce processing stepsTransistorOrnamental textile articlesLiquid-crystal displayEngineering

An LCD device and a method for manufacturing the same is disclosed in which the manufacturing process is simplified by etching an overcoat layer and a lower insulating layer at the same time. Disclosed is a method for manufacturing the LCD device that includes forming a thin film transistor (TFT) on an active region of a substrate, forming a gate pad region and data pad region, and forming a passivation layer on the entire surface of the substrate. The manufacturing method further includes forming an overcoat layer and selectively etching the overcoat layer. Contact holes for the pixel electrode, the gate pad, and the data pad are formed by selectively etching the overcoat layer, the passivation layer, and the gate insulating layer though one process.

Owner:LG DISPLAY CO LTD

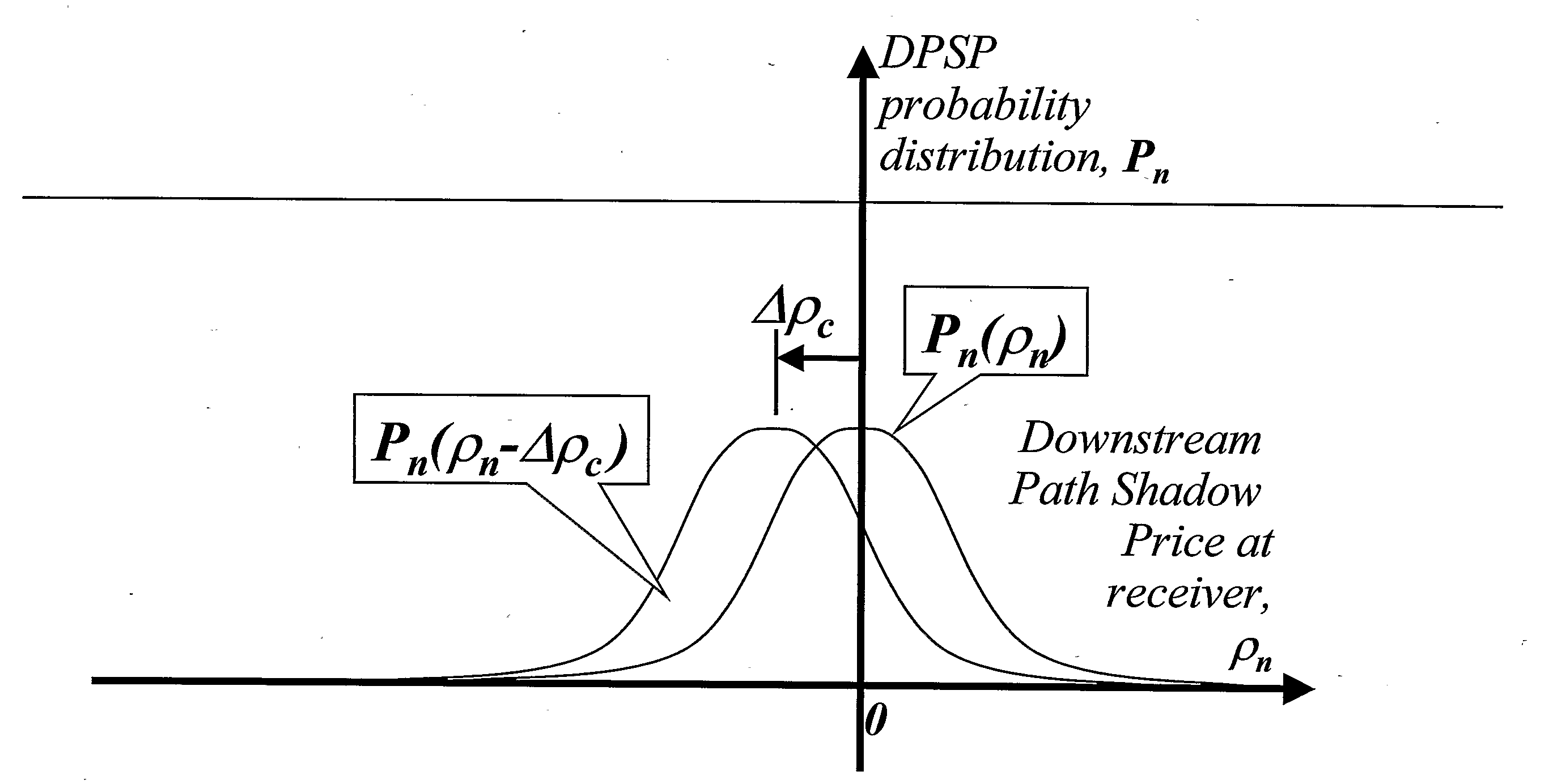

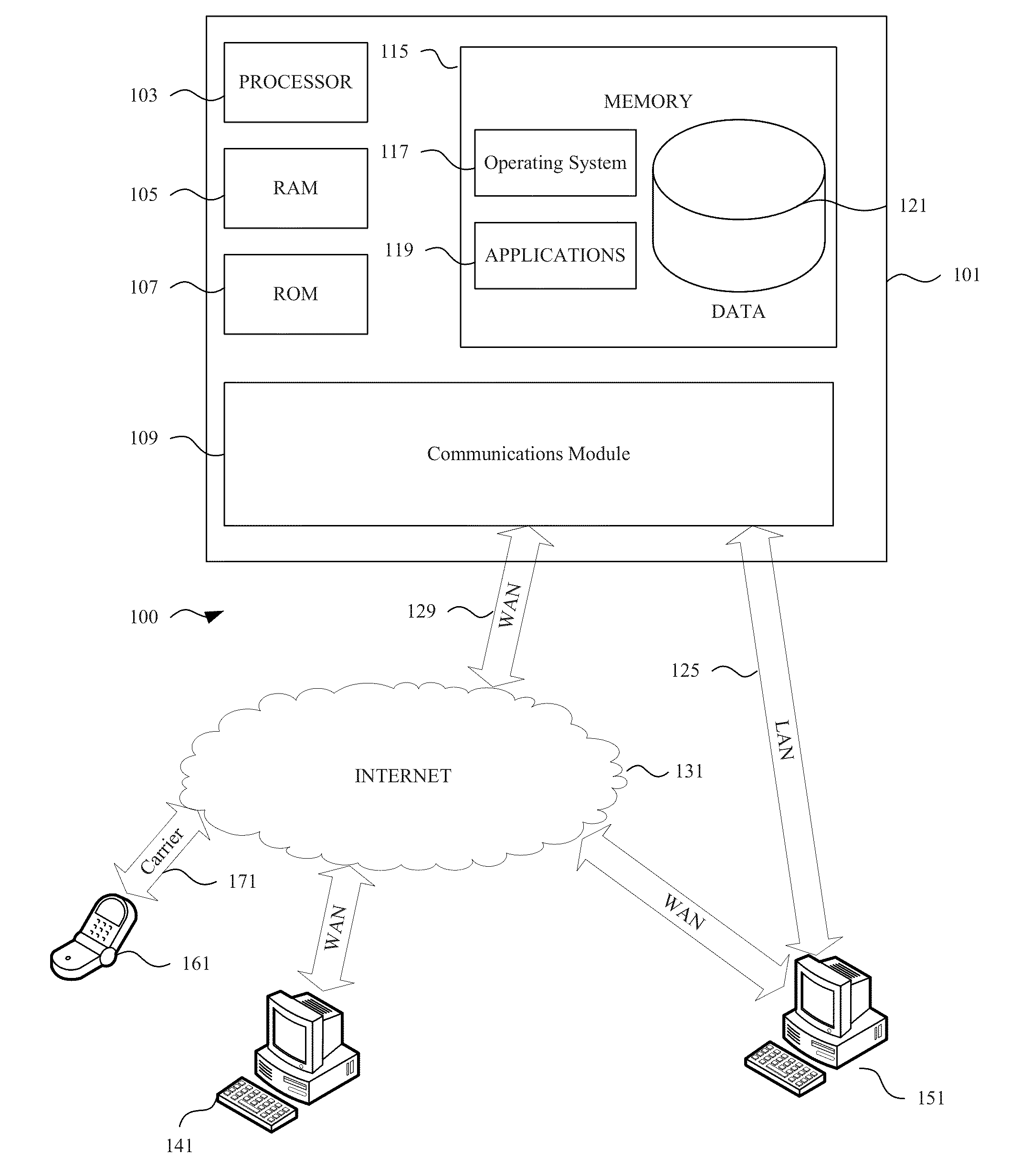

Processing of Data in Networks

ActiveUS20080091766A1Data switching by path configurationMultiple digital computer combinationsData miningProcess selection

A processing node for processing data items in a data network, comprising means for receiving data items, means for receiving characterisation metrics associated with the data items and identifying characteristic values in respect thereof, and a process selection means, said process selection means comprising means for deriving a collective value from characteristic values associated with a plurality of the data items, means for comparing characteristic values associated with a plurality of the data items with a predetermined target value, means for subjecting data items in respect of which the characteristic values are on a first side of the predetermined target value to a first process, means for selecting at least some of the data items in respect of which the characteristic values are on a second side of the predetermined target value, and means for subjecting the selected data items to a second process which is different from the first process.

Owner:BRITISH TELECOMM PLC

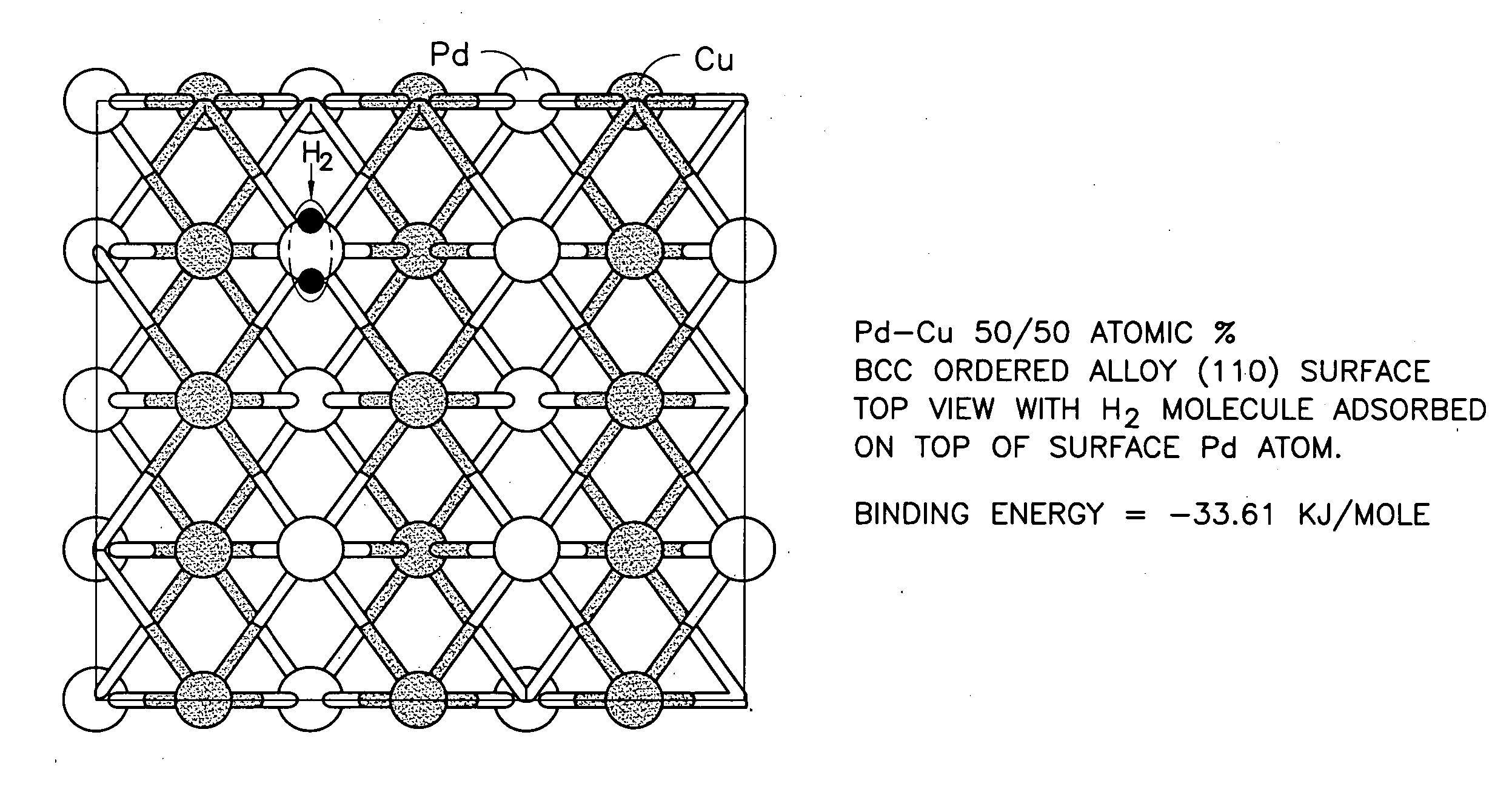

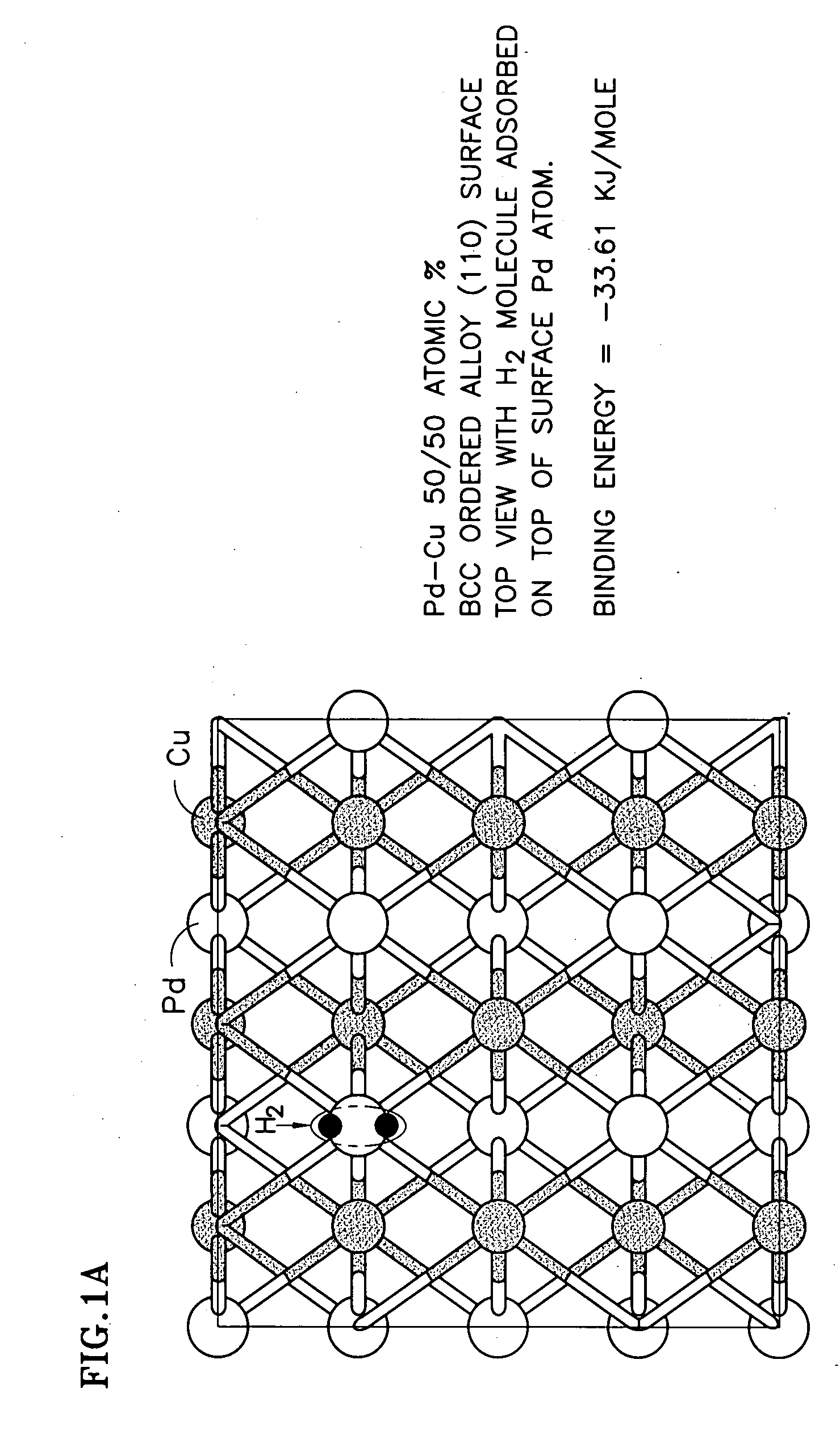

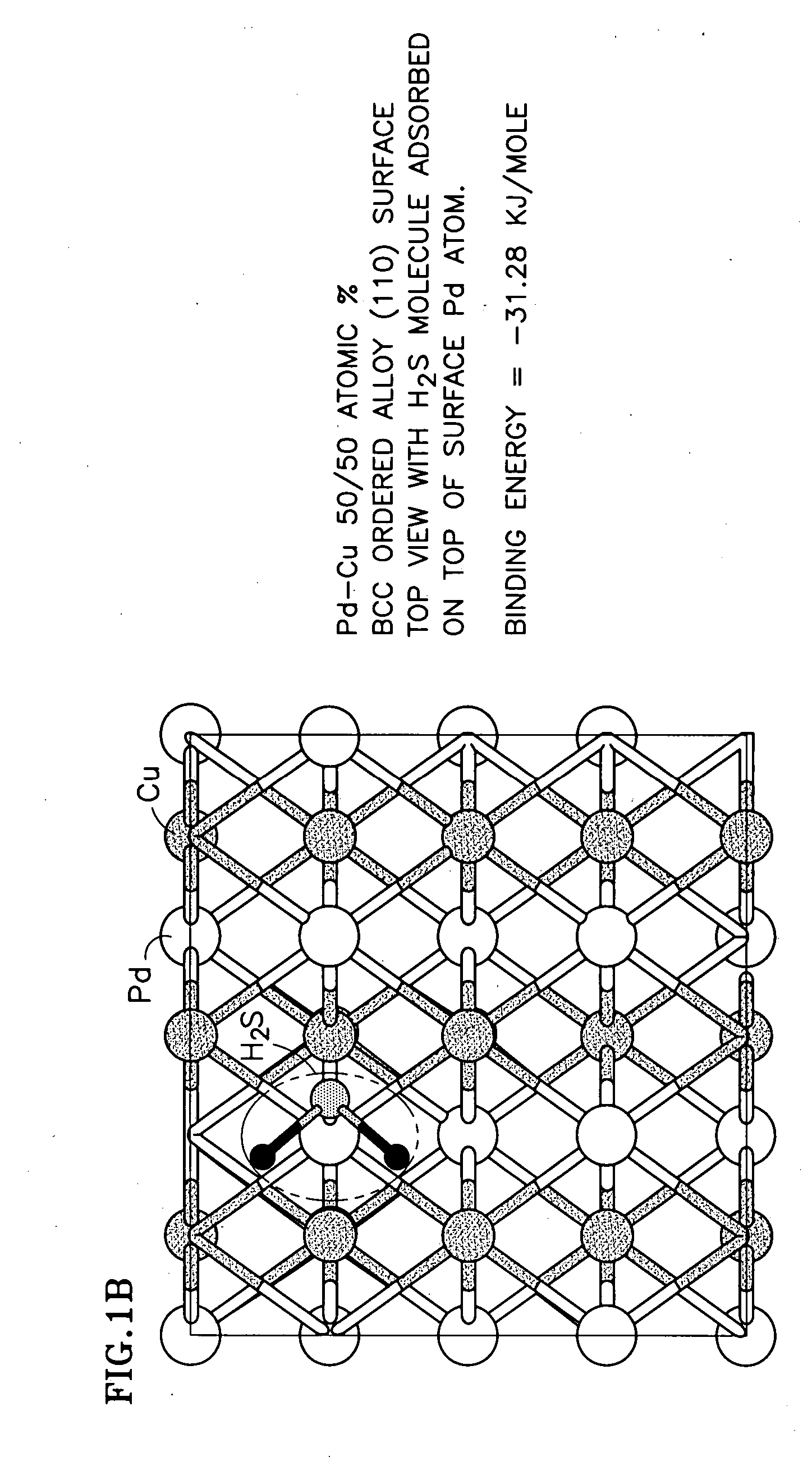

Duarable Pd-based alloy and hydrogen generation membrane thereof

InactiveUS20070240566A1High H permeanceCost-effective provisionSemi-permeable membranesMembranesBinary alloyHydrogen

A durable Pd-based alloy is used for a H2-selective membrane in a hydrogen generator, as in the fuel processor of a fuel cell plant. The Pd-based alloy includes Cu as a binary element, and further includes “X”, where “X” comprises at least one metal from group “M” that is BCC and acts to stabilize the β BCC phase for stability during operating temperatures. The metal from group “M” is selected from the group consisting of Fe, Cr, Nb, Ta, V, Mo, and W, with Nb and Ta being most preferred. “X” may further comprise at least one metal from a group “N” that is non-BCC, preferably FCC, that enhances other properties of the membrane, such as ductility. The metal from group “N” is selected from the group consisting of Ag, Au, Re, Ru, Rh, Y, Ce, Ni, Ir, Pt, Co, La and In. The at. % of Pd in the binary Pd—Cu alloy ranges from about 35 at. % to about 55 at. %, and the at. % of “X” in the higher order alloy, based on said binary alloy, is in the range of about 1 at. % to about 15 at. %. The metals are selected according to a novel process.

Owner:UNITED TECH CORP

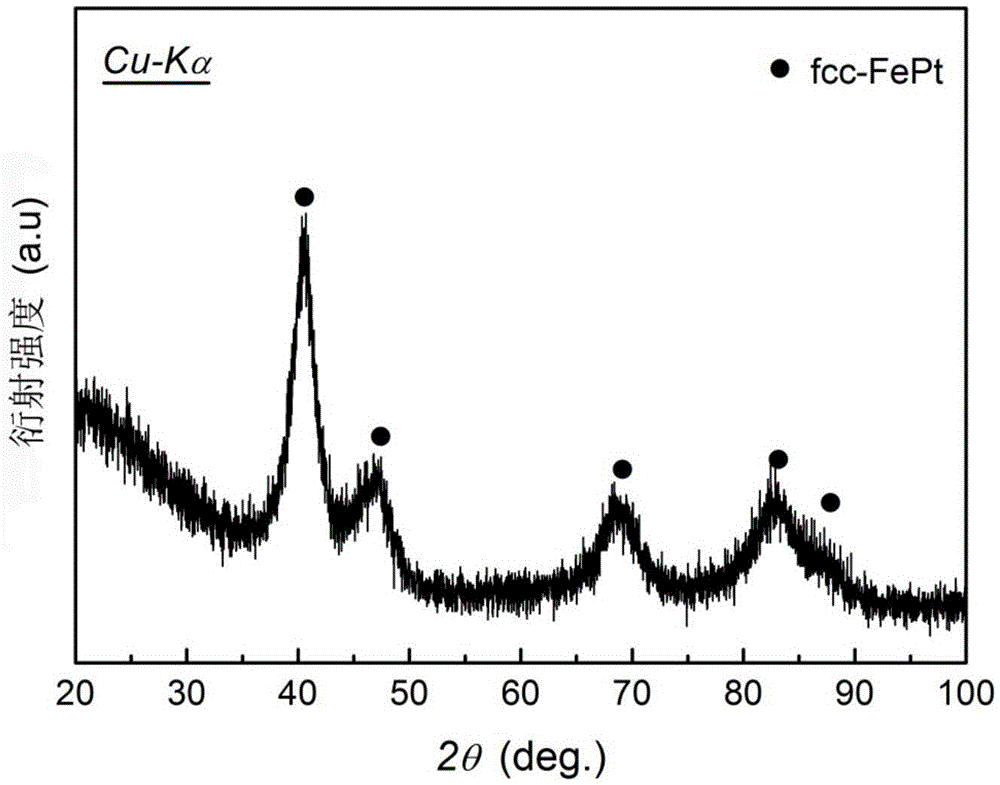

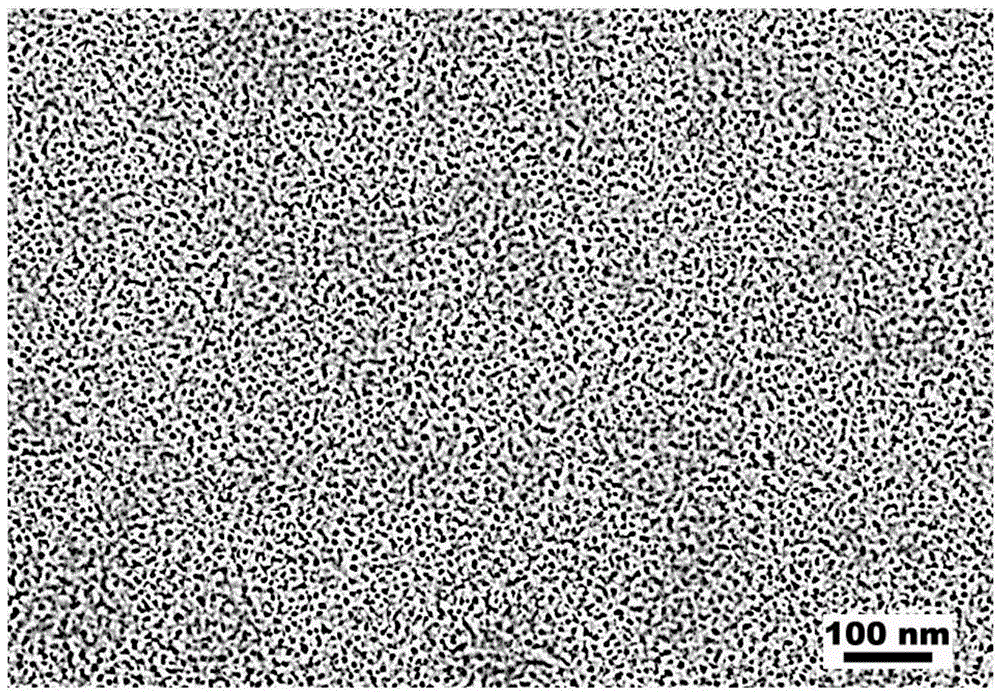

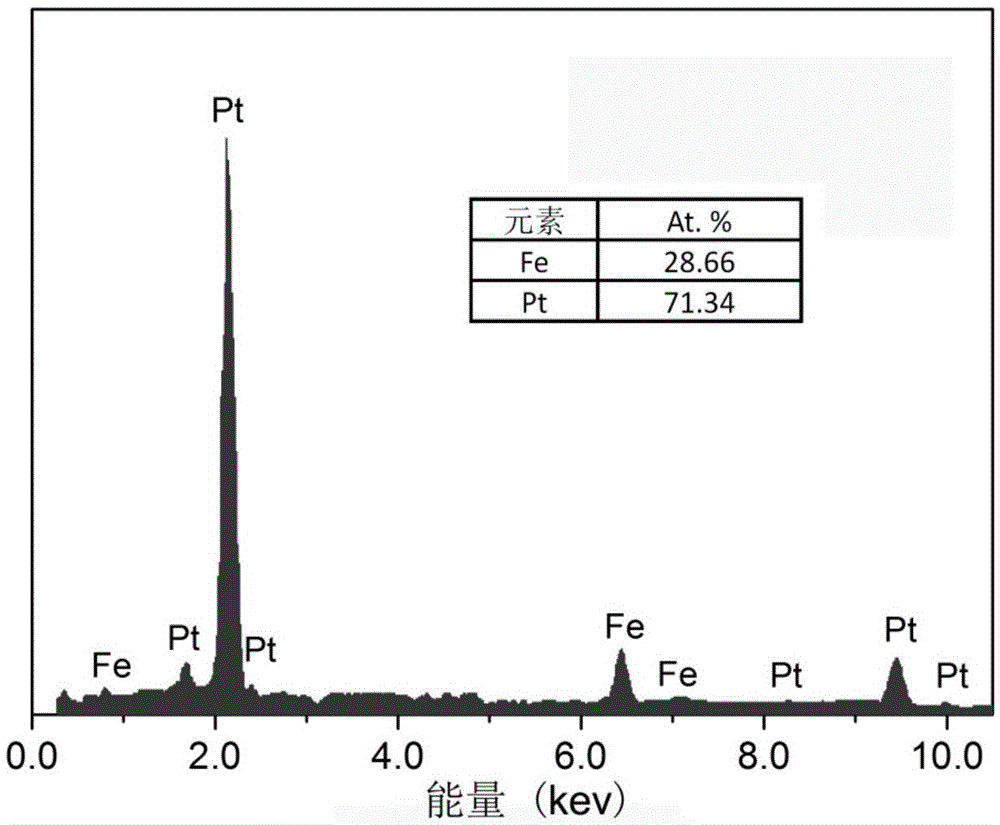

Preparation method of magnetic nano porous Fe-Pt alloy with electro-oxidation catalytic performance

InactiveCN105648478AGood electro-oxidation catalytic performanceHigh catalytic activityNanotechnologyElectric arc furnaceCO poisoning

The invention provides a preparation method of magnetic nano porous Fe-Pt alloy with electro-oxidation catalytic performance and belongs to the technical field of new materials. An electric arc furnace or induction melting furnace is used for preparing Fe-Pt-(B, Si) system alloy master alloy ingots, and a precursor alloy strip with an amorphous or amorphous / nanocrystalline structure is prepared through a single-roller melt-spinning method; and precursor alloy is used as a working electrode, elements such as Fe, B and / or Si in the alloy are selectively etched off through a dealloying process in a room-temperature and acid environment, and the nano porous Fe-Pt alloy with the pore size ranging from 3 nm to 18 nm and the pore wall thickness ranging from 5 nm to 22 nm is obtained. According to the preparation method, the process is simple, the procedure is short, and high efficiency and energy conservation are achieved. The obtained magnetic nano porous Fe-Pt alloy is uniform and controllable in pore size, has good catalytic activity and anti-CO-poisoning capacity for an electro-oxidation reaction in methyl alcohol and other substances in acid liquid, is easy to recycle and serves as a catalyst for an anodic reaction in fuel cells such as acidic methanol.

Owner:DALIAN UNIV OF TECH

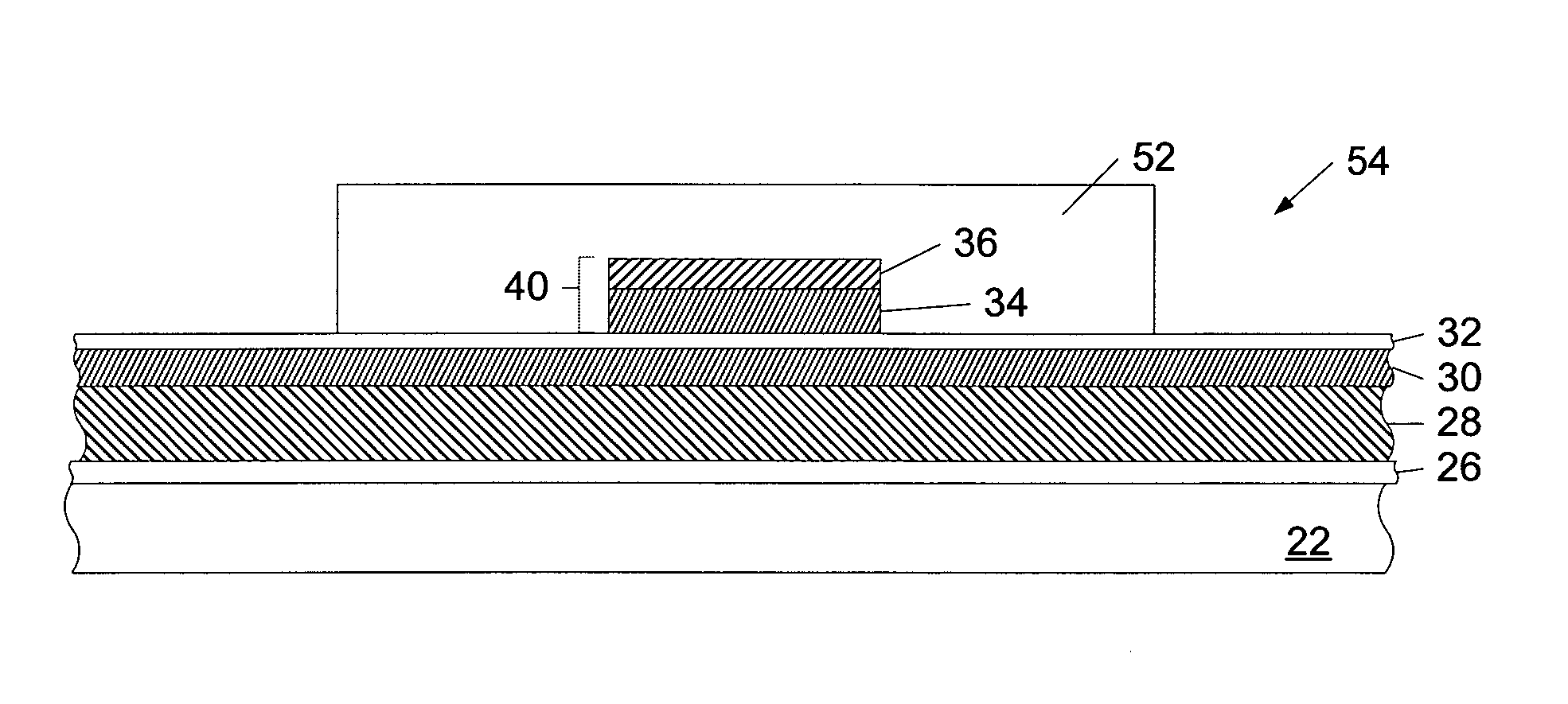

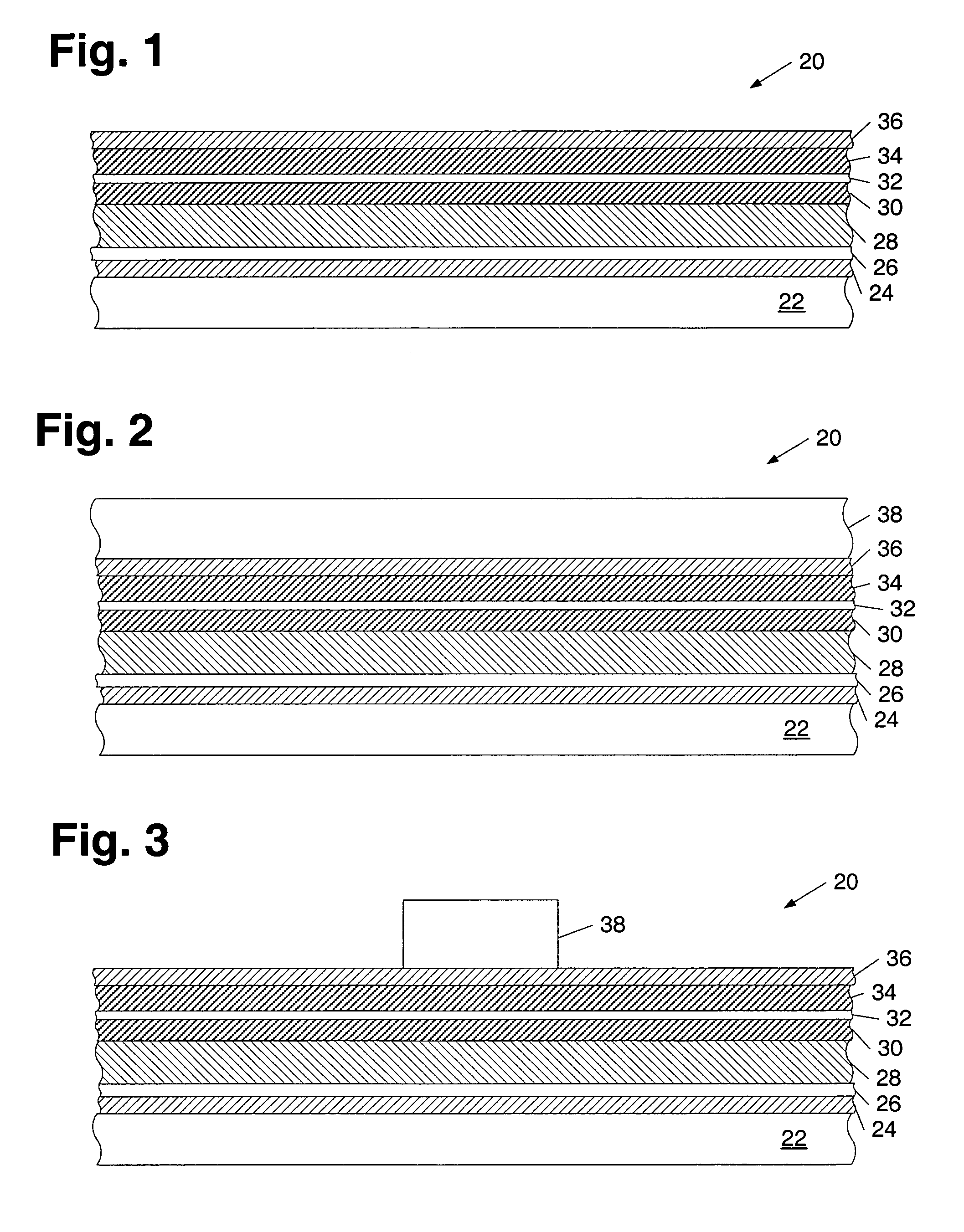

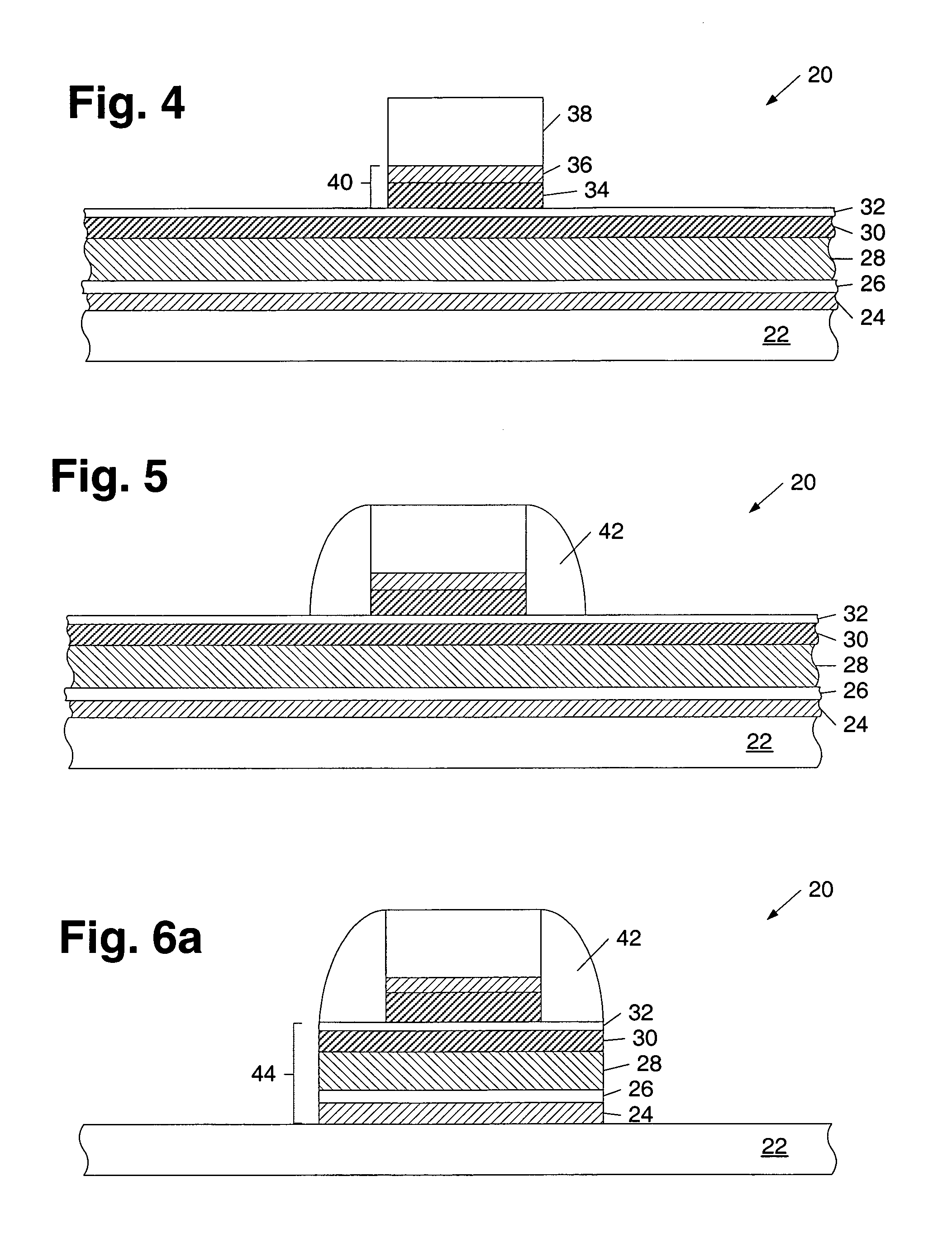

Metal etch process selective to metallic insulating materials

InactiveUS6972265B1Relieve pressureReduce exposureSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentResistOxygen plasma

A method is provided which includes patterning one or more metal layers arranged above a metal insulating layer and terminating the patterning process upon exposure of the metal insulating layer. In particular, the method may be adapted to be more selective to the metal insulating layer than the one or more metal layers. In general, such an adaptation may include exposing the semiconductor topography to an etch chemistry comprising hydrogen bromide. In some cases, the etch chemistry may further include a fluorinated hydrocarbon. In yet other embodiments, the method may further or alternatively include using a reactive ion etch process, etching at a relatively low temperature, using a resist mask, and / or using an etch chemistry substantially absent of an oxygen plasma. In this manner, the method may, in some embodiments, include patterning the one or more metal layers using a reactive ion etch process substantially absent of an oxygen plasma.

Owner:MONTEREY RES LLC

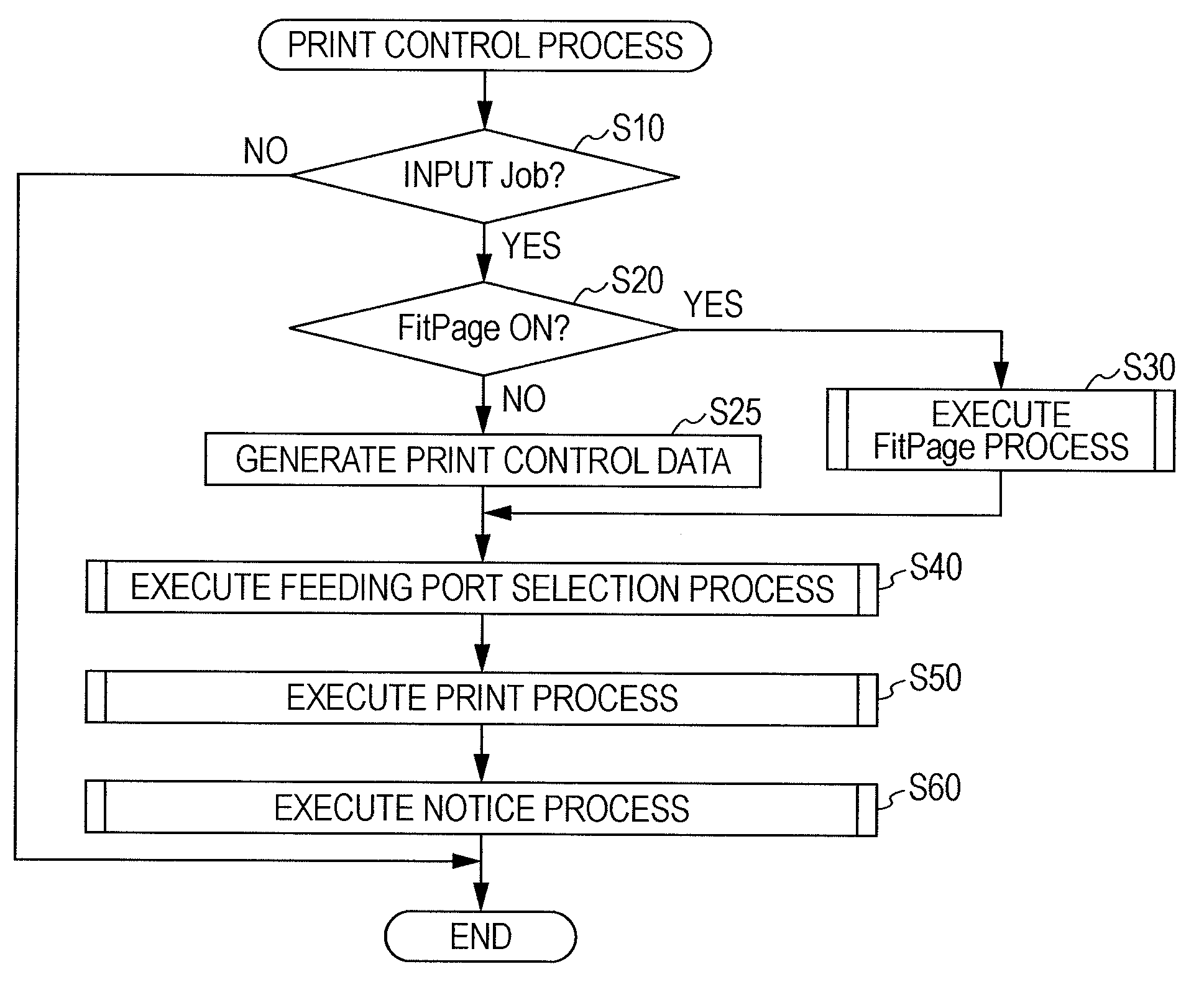

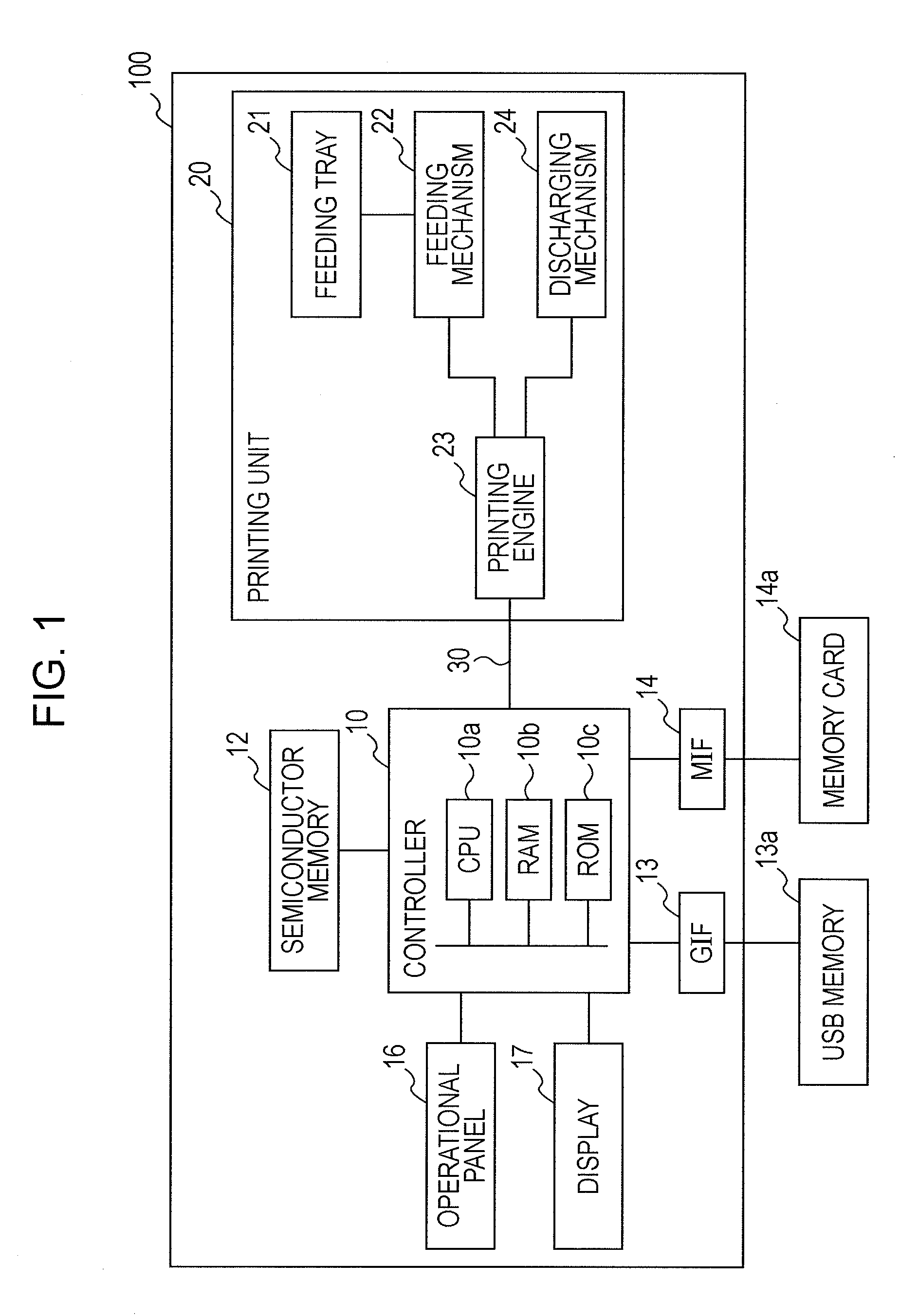

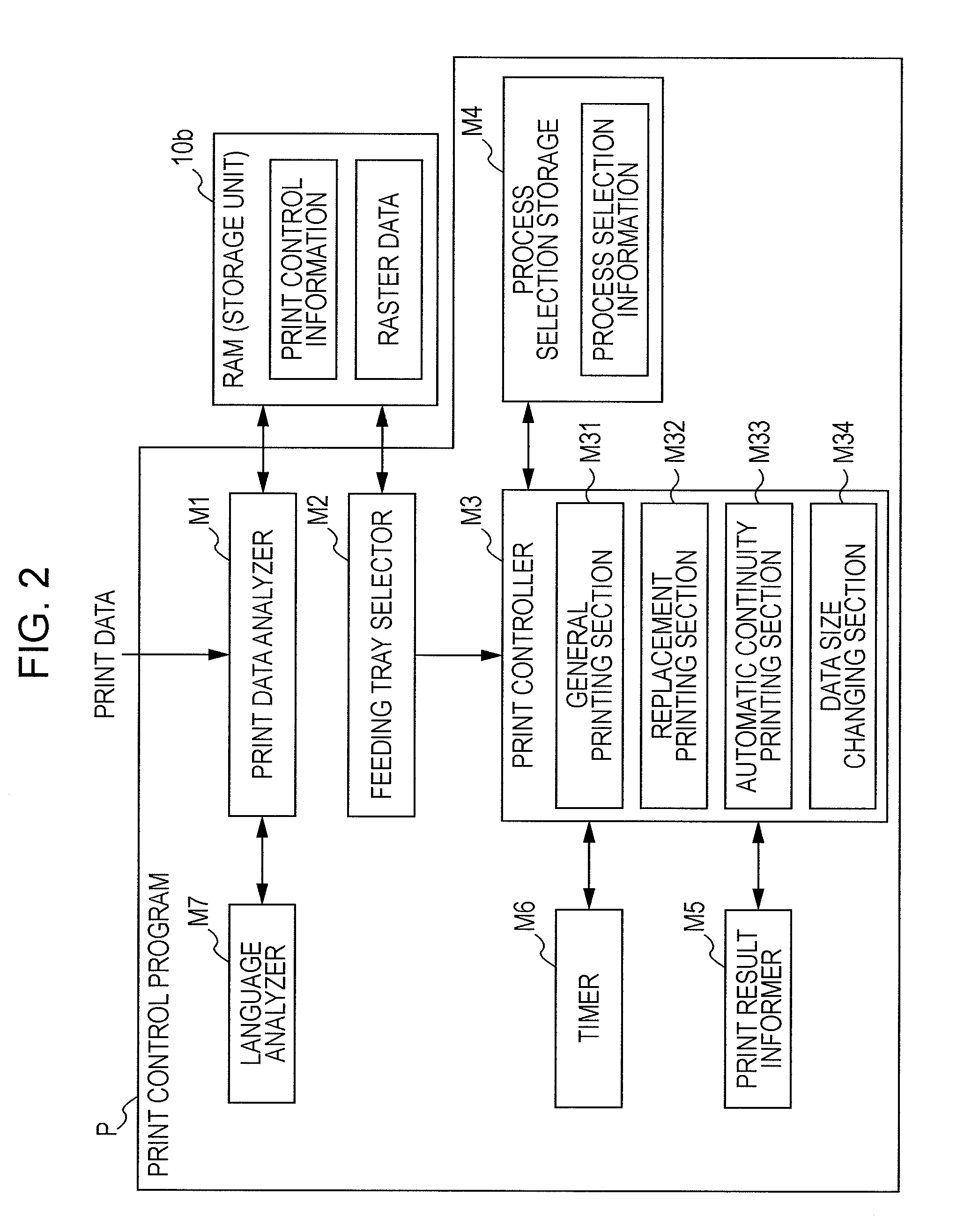

Printing apparatus

ActiveUS20100178067A1Reduce downtimeElectrographic process apparatusStorage cellIndustrial engineering

A printing apparatus including one or more feeding units includes: a sheet size determining unit which determines a sheet size of a sheet, on which print data are printed, in predetermined order; a print control unit which stores a designated size, which is the sheet size determined by the sheet size determining unit, in a storage unit; a feeding unit selector which selects the feeding unit on the basis of the designated size; and a process selection information storing unit which stores process selection information used to designate a process executed by the print control unit.

Owner:SEIKO EPSON CORP

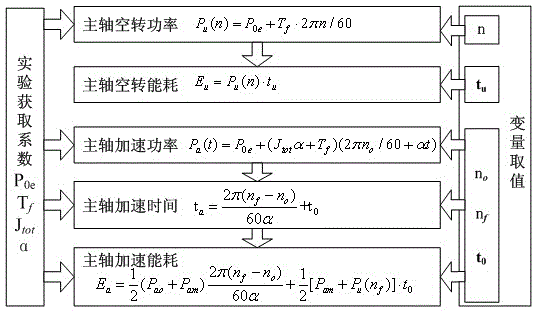

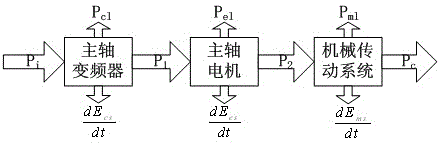

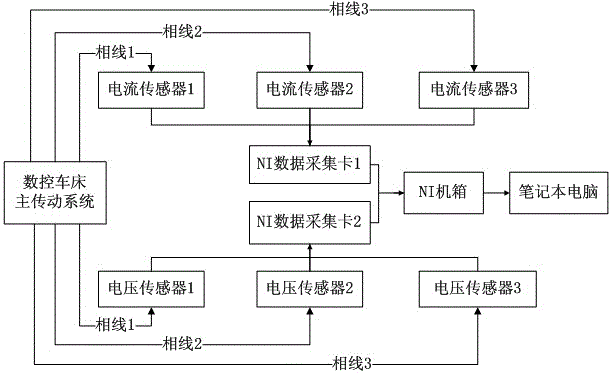

Non-cutting energy obtaining method for main transmission system of numerically controlled lathe

InactiveCN102744649AThe experimental method is simpleEasy to operateMeasurement/indication equipmentsFriction torqueRegression analysis

The invention discloses a non-cutting energy obtaining method for a main transmission system of a numerically controlled lathe. A power and energy consumption value in main shaft idle operation and main shaft acceleration can be calculated according to an established main shaft idle operation and main shaft acceleration power and an energy consumption model, and coefficient values (which are obtained through experiments) of a main transmission system frequency converter, a main shaft motor no-load power Poe, a main shaft idle operation friction torque Tf, a main transmission system rotational inertia Jtot, a main shaft angle acceleration alpha and other models. The invention provides a method for obtaining relevant coefficients through the experiments; and the method comprises the steps of: obtaining the coefficients Poe and Tf through regression analysis on main shaft idle operation power data, and obtaining the coefficients Jtot and alpha through the analysis on the data such as main shaft starting power and time. The method can be used for machine tool use environment influence evaluation, mechanical machining process energy consumption calculation, machine tool and process selection based on the minimum energy consumption; and the successful execution on energy conservation and consumption reduction during mechanical manufacturing is promoted smoothly.

Owner:ZHEJIANG UNIV

Automatic Deployment, Configuration, and Lifecycle Management of Applications and Infrastructure Components

Apparatuses, computer readable media, methods, and systems are described for automatic deployment of applications and infrastructure components, which may include processing selection of an operating system, processing selection of a stack, creating a stencil based on the operating system and the stack, and publishing the stencil.

Owner:BANK OF AMERICA CORP

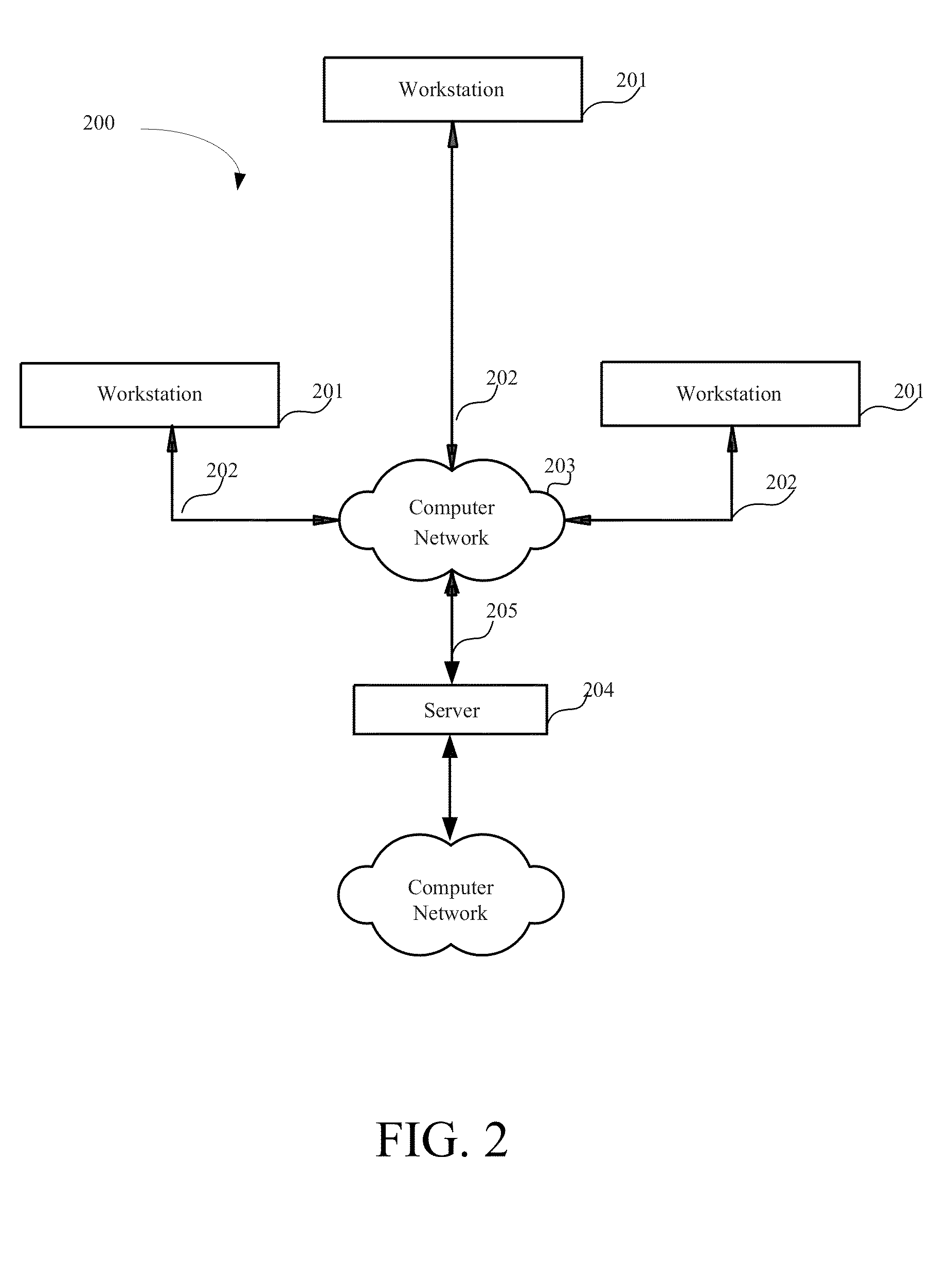

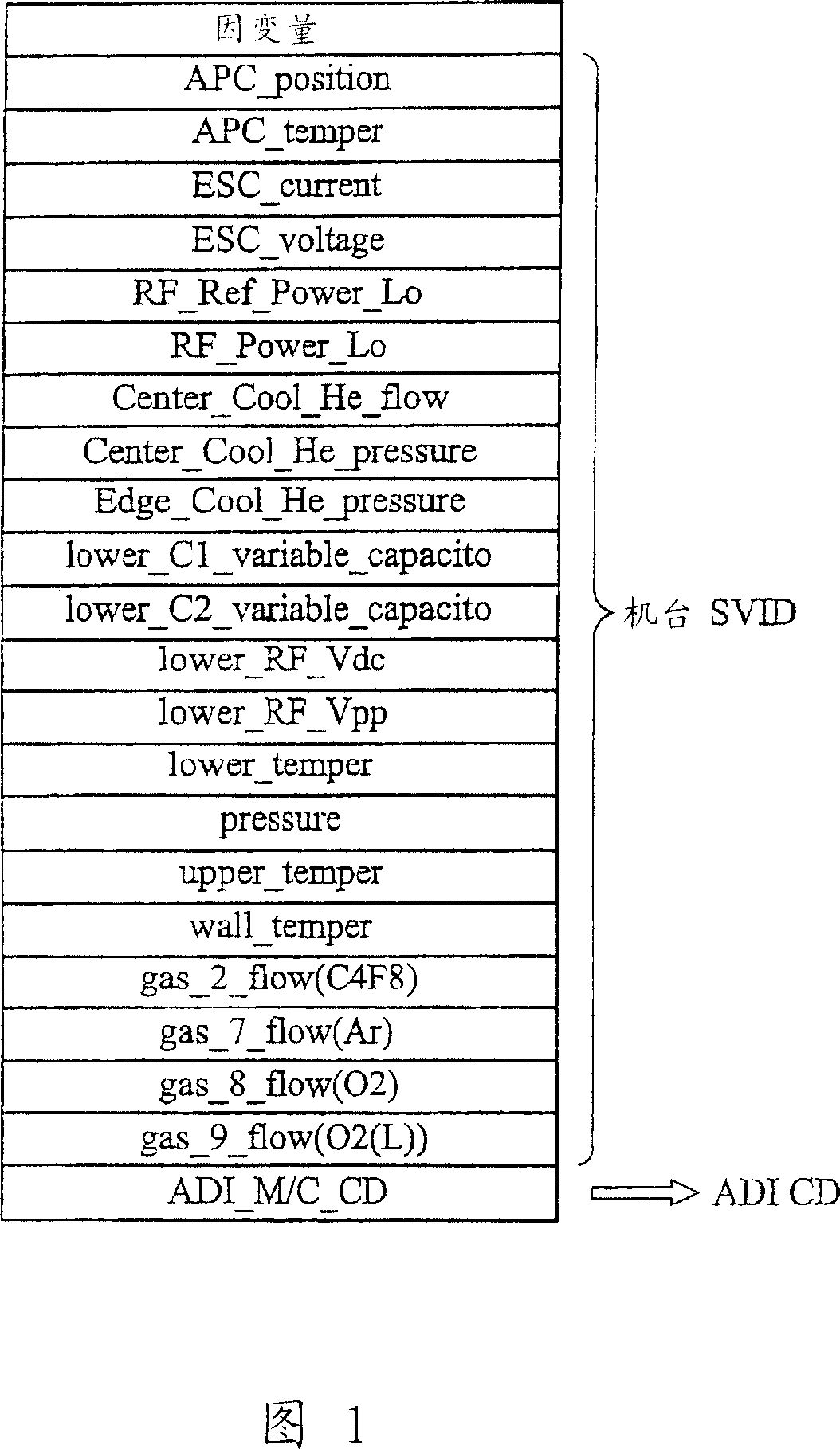

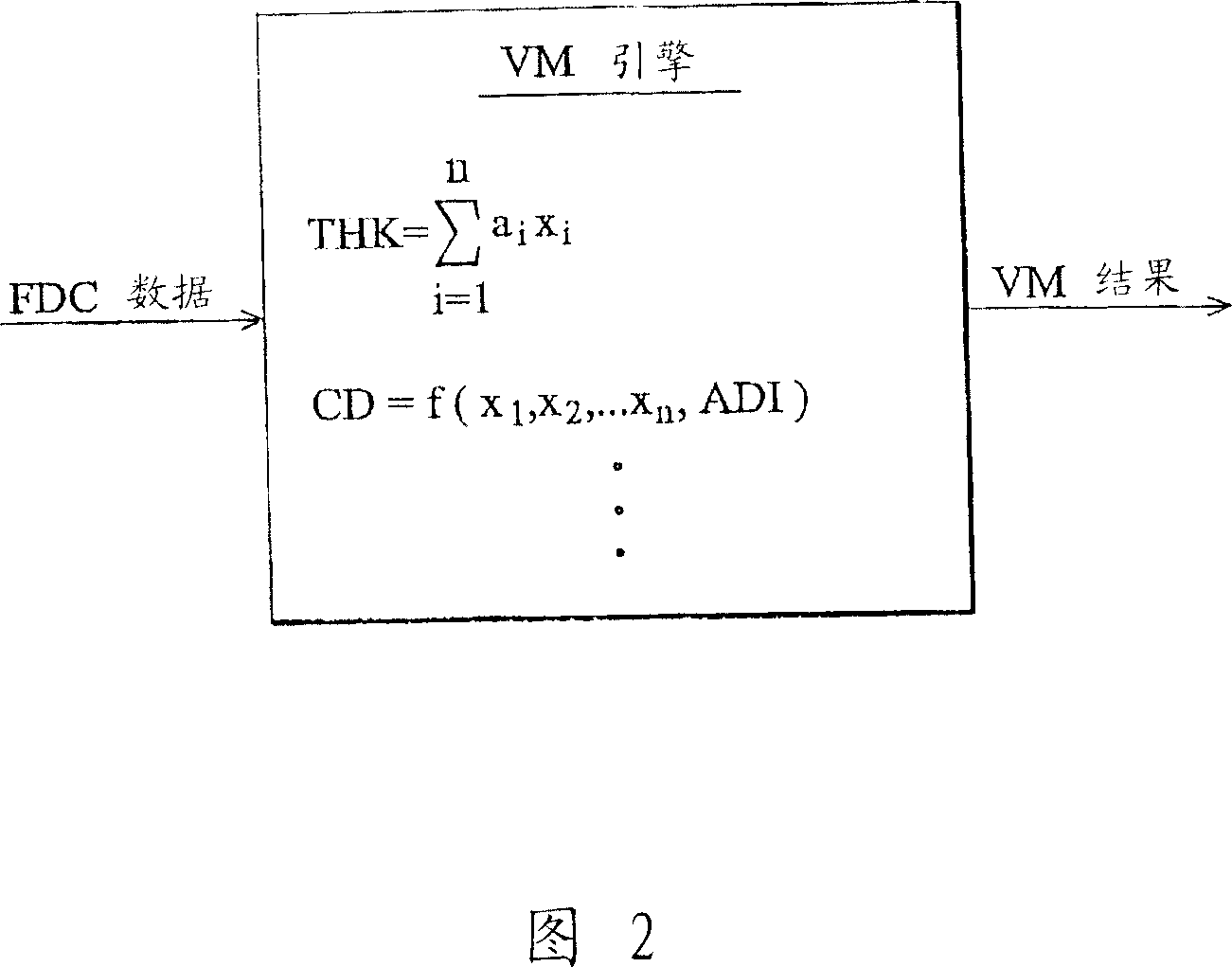

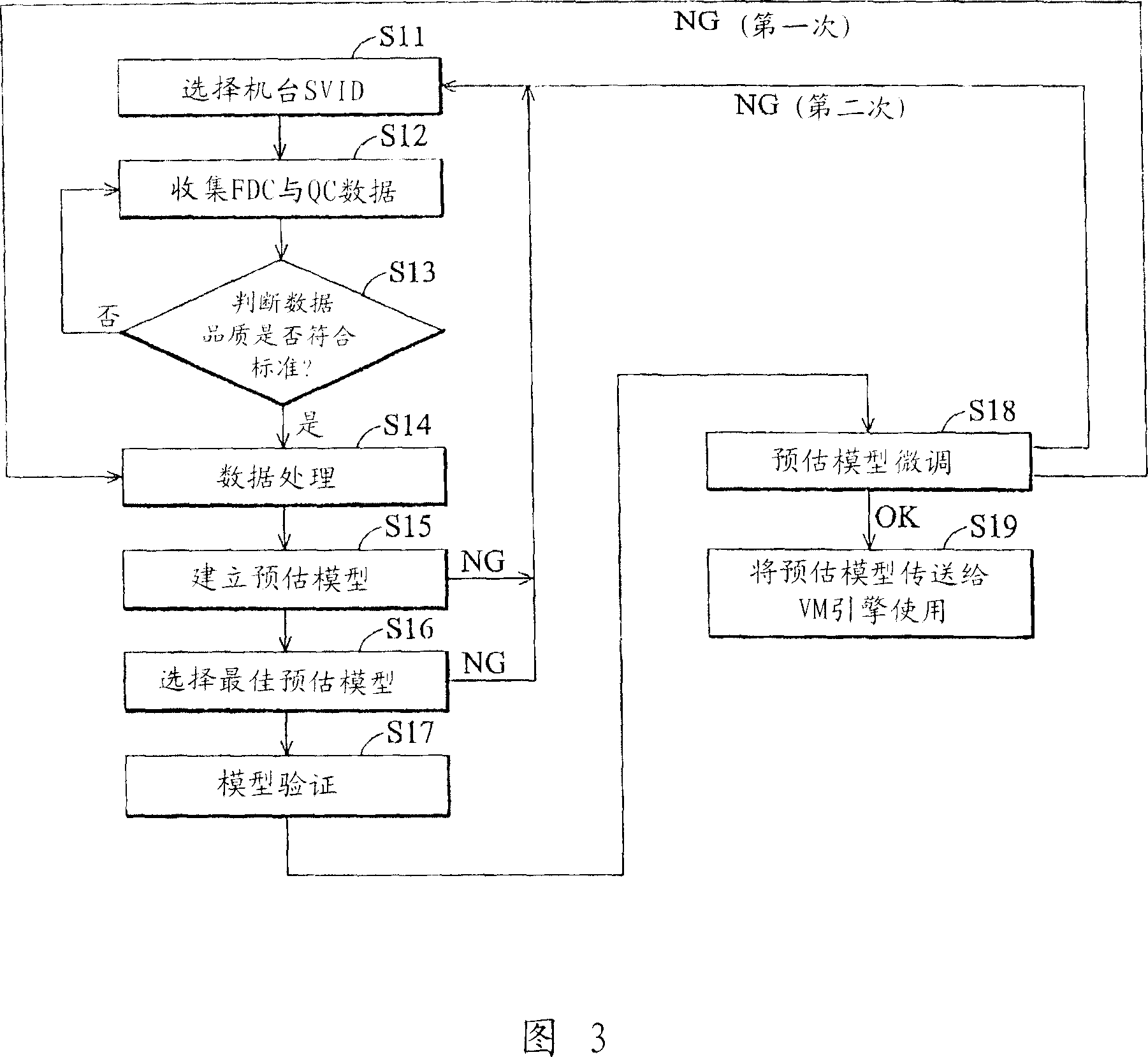

Virtual measurement prediction generated by semi-conductor, method for establishing prediction model and system

The present invention discloses a method for creating a pre-estimation model. The method is to choose the varying detecting value of a plurality of real time technique states, and collect error detecting and categorical data as well as quality control data according to different techniques. The data control quality is judged whether the data control quality measures up to standard. When the data control quality does not measure up to standard, the error detecting and categorical data and the quality control data are recollected, or the sampling frequency is trimmed. When the data control quality measures up to standard, the error detecting and categorical data and the quality control data are processed. A plurality of pre-estimation models is created according to the data processing result, an optimum pre-estimation model is chosen according to a pertinence indicating hand to validate the pre-estimation model, and optimum pre-estimation model is trimmed. When the trimming is finished and the optimum pre-estimation model is in the optimum state, the optimum pre-estimation model is delivered to a dummy measure engine.

Owner:POWERCHIP SEMICON CORP

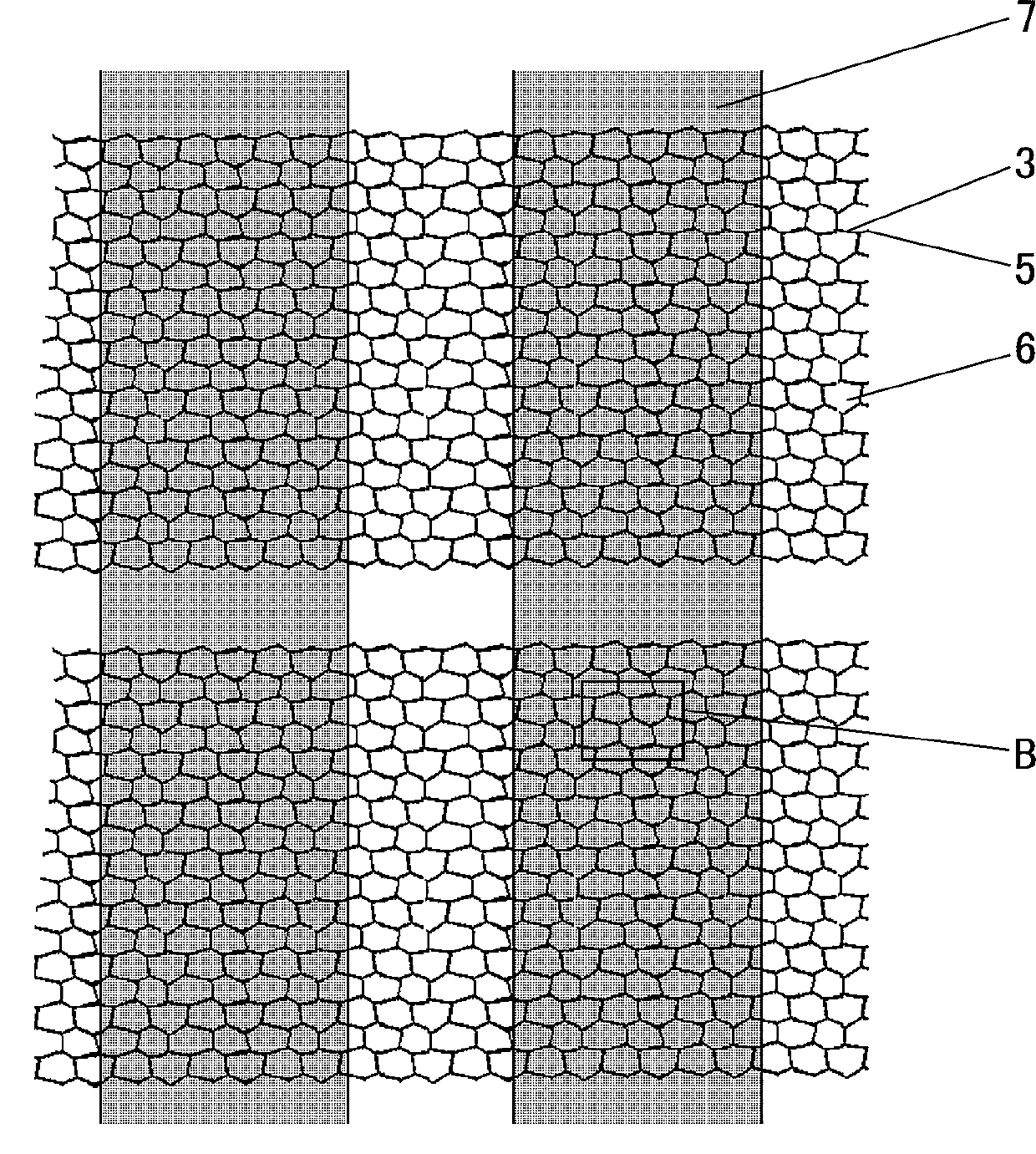

Capacitive touch screen and manufacturing method thereof

ActiveCN103123564AGuaranteed electrical conductivityGuaranteed light transmissionInput/output processes for data processingCapacitanceEngineering

The invention relates to a capacitive touch screen and a manufacturing method thereof. The capacitive touch screen comprises at least one rigid transparent base plate, and is characterized in that at least one surface of each base plate is provided with an electrode arrangement area, each electrode arrangement area is provided with a plurality of grooves, conductive nano-powder is filled in the grooves, the conductive nano-powder in the grooves is connected to form conductive fine wires, and the conductive fine wires form inductive electrodes of the capacitive touch screen in a netted and tiled mode. The inductive electrodes of the capacitive touch screen are manufactured through the method that the grooves are arranged and the conductive nano-powder is embedded into the grooves to form the conductive fine wires, the method that film coating is carried out on the base plate at high temperature does not need to be adopted, and therefore the capacitive touch screen has high flexibility in material, structure and technological selection, and manufacturing cost of the capacitive touch screen is further reduced.

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD

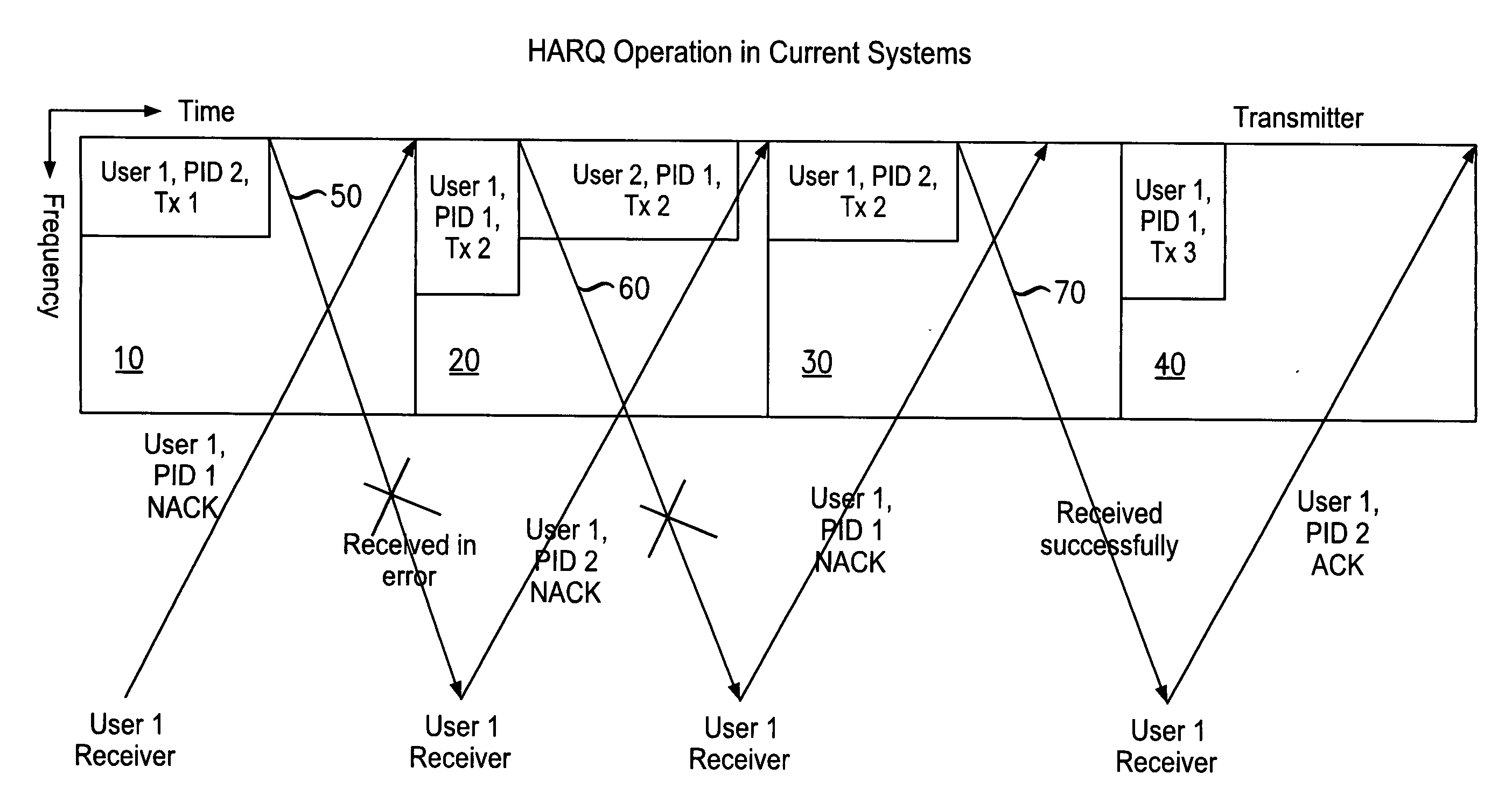

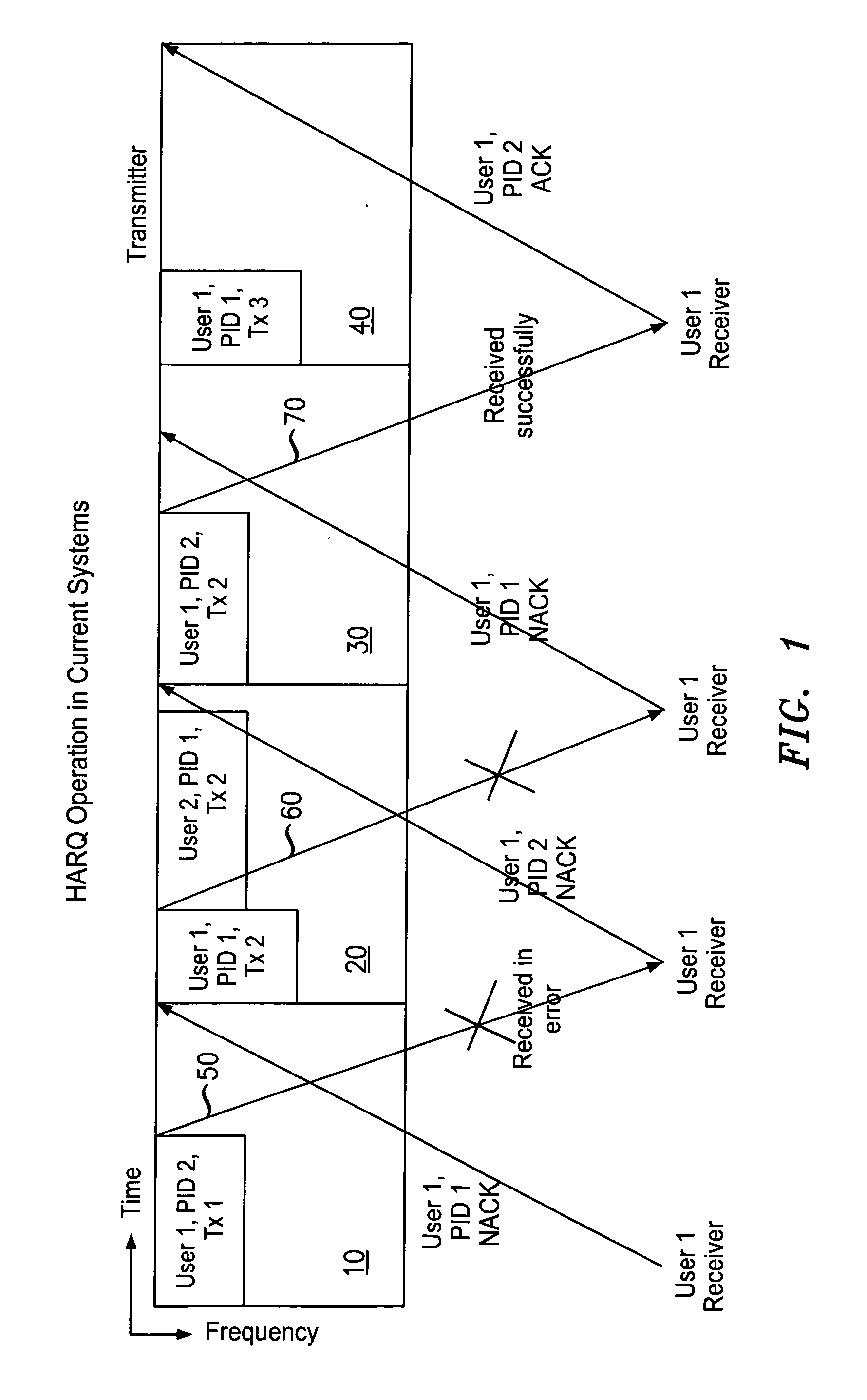

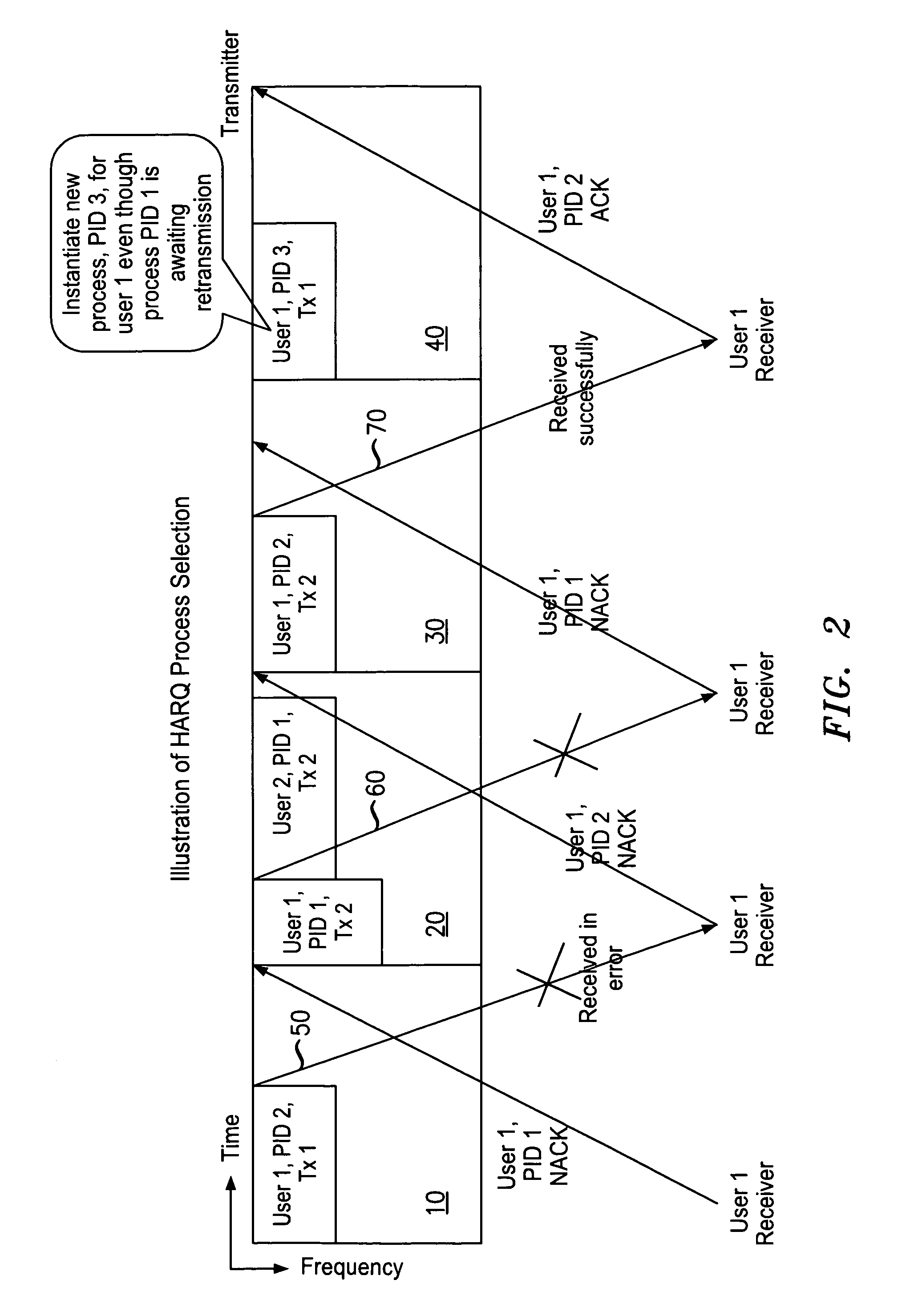

Method and apparatus of HARQ process selection

InactiveUS20100218065A1Improve efficiencyError prevention/detection by using return channelTransmission systemsDistributed computingProcess selection

A method for implementation of HARQ between a transmitting node and a receiving node in a communication network is provided. HARQ processes may be selected from a list for instantiation according to a policy that may deviate from strict first-in, first-out processing of packets. The greater flexibility that this affords may lead to improved efficiency in the use of transmission resources.

Owner:ALCATEL LUCENT SAS

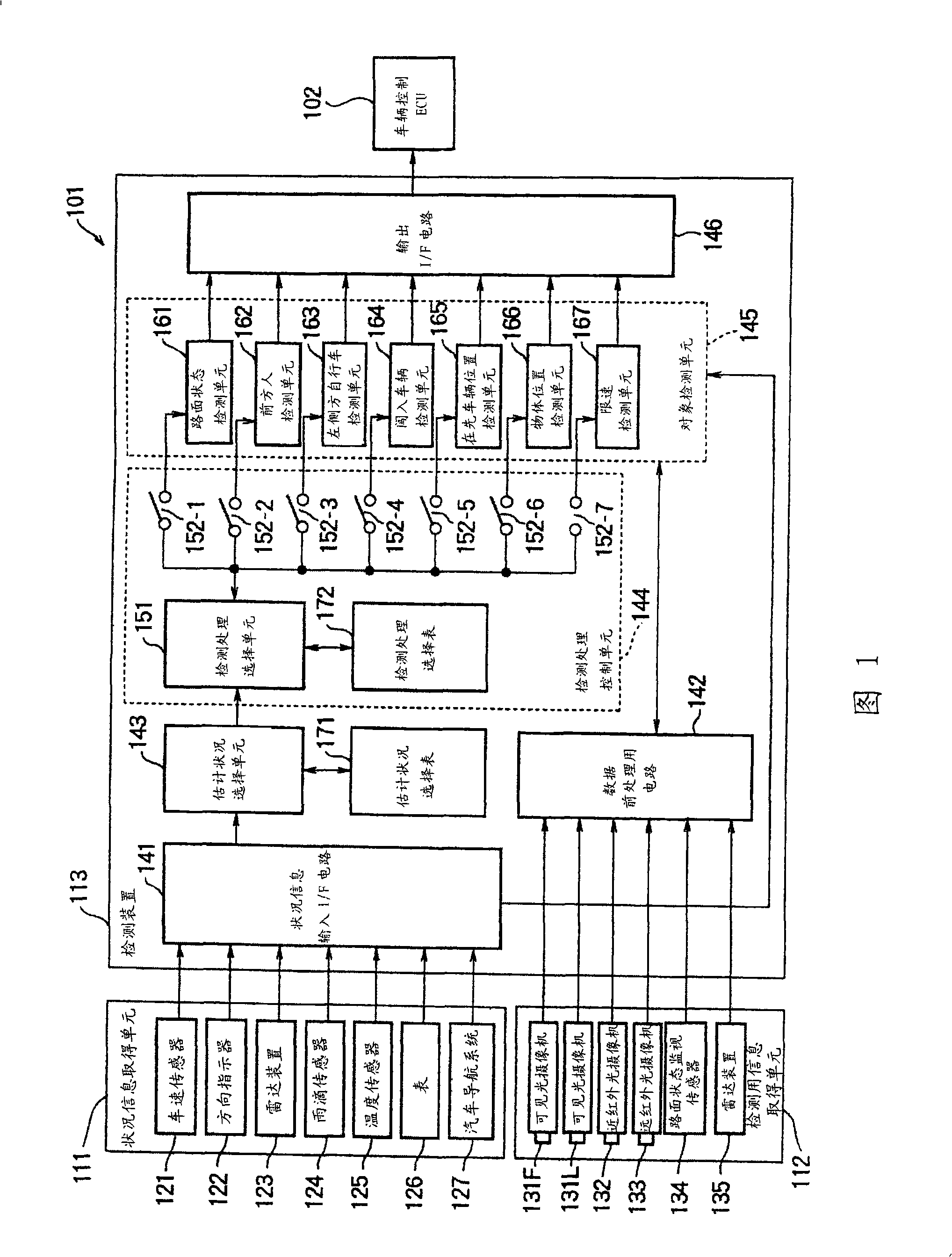

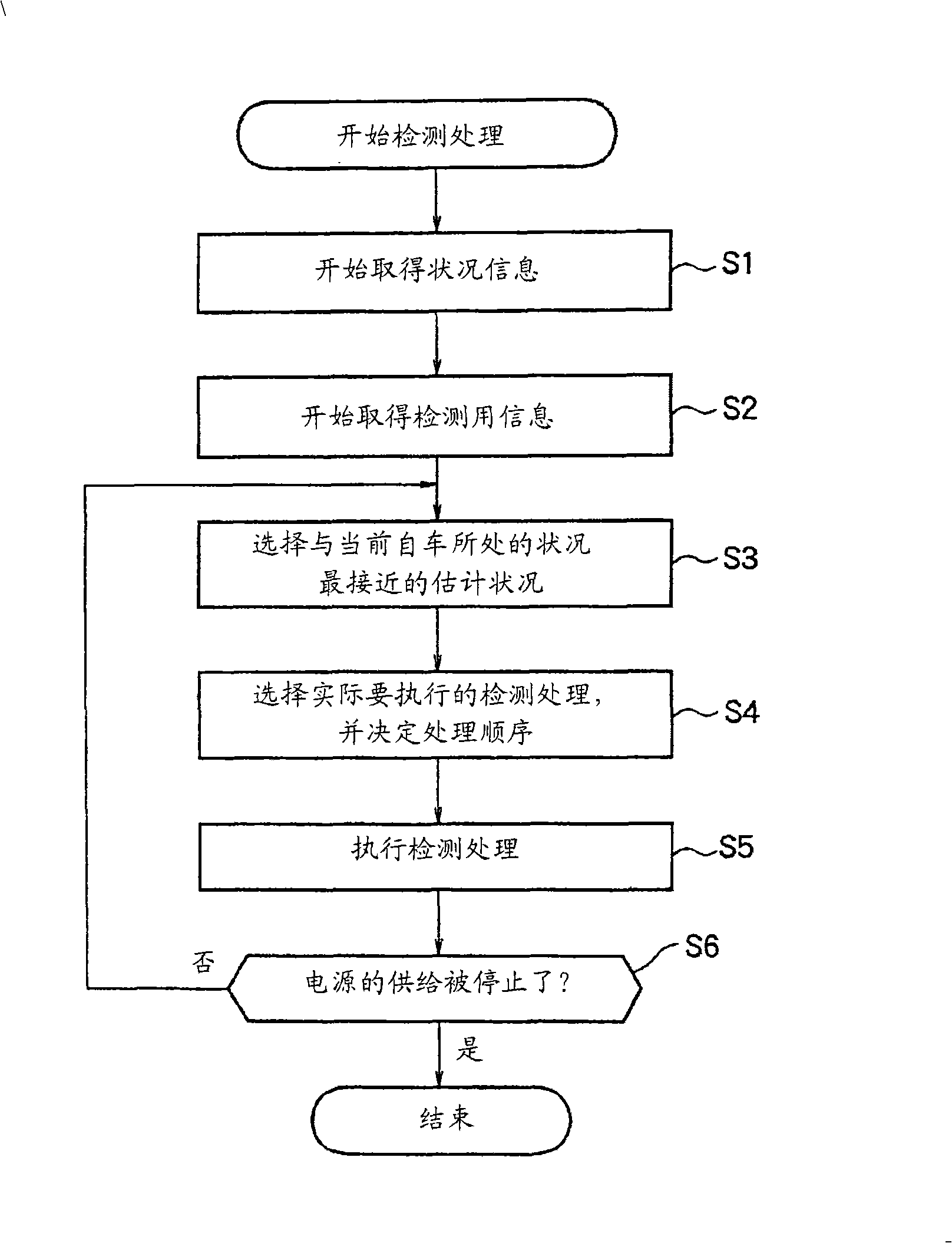

Surroundings detecting device, method and program

InactiveCN101342892AEfficient detectionPedestrian/occupant safety arrangementAnti-collision systemsImaging processingIn vehicle

Information necessary to control a vehicle is to be effectively detected in accordance with a situation. A supposition situation selecting section selects a supposition situation closest to the present situation of an own vehicle from a plurality of pre-supposed supposition situations on the basis of situation information acquired from a situation information acquiring unit and a supposition situation selection table through a situation information input I / F circuit. A detection process selecting portion selects a detection process to be actually performed from detection processes which can be performed by each detecting portion of a target detecting section on the basis of the selected supposition situation and a detection process selection table. The invention is applicable to an in-vehicle image processing device.

Owner:ORMON CORP

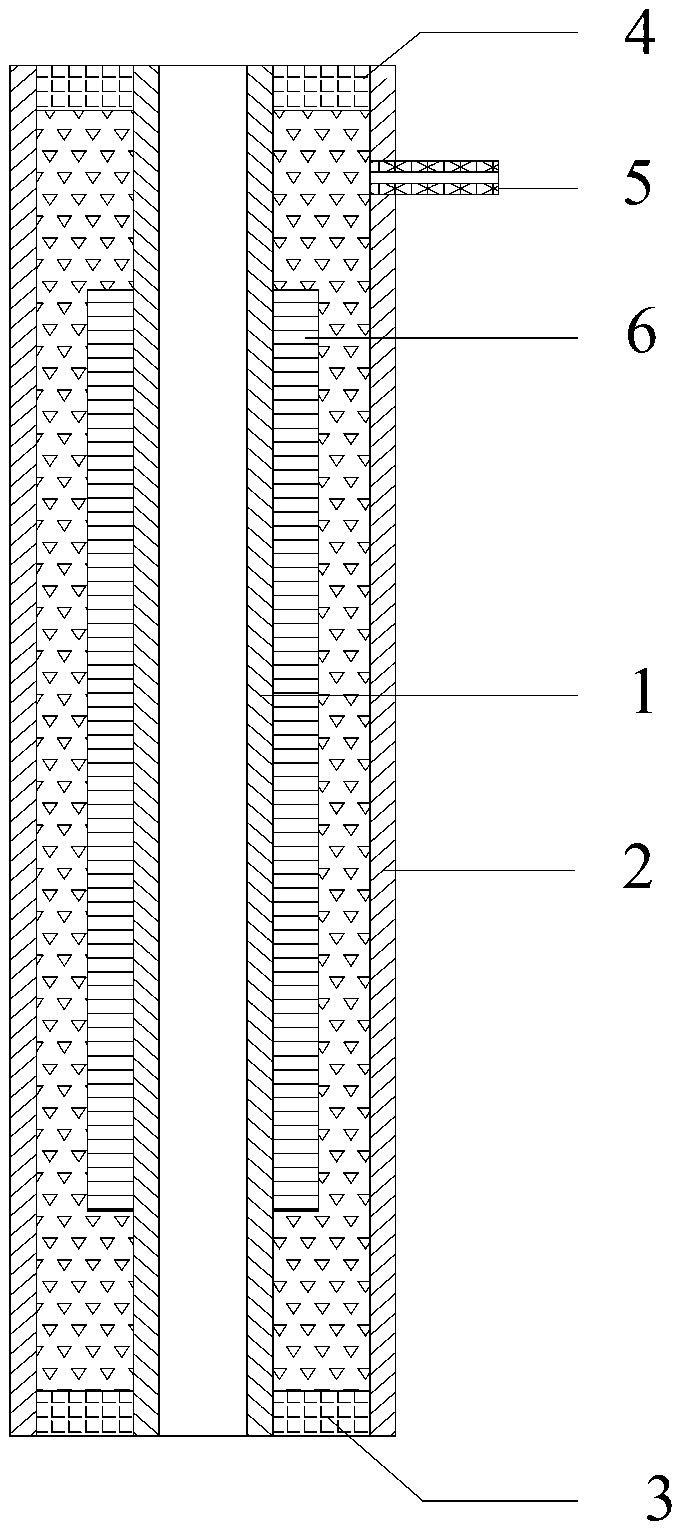

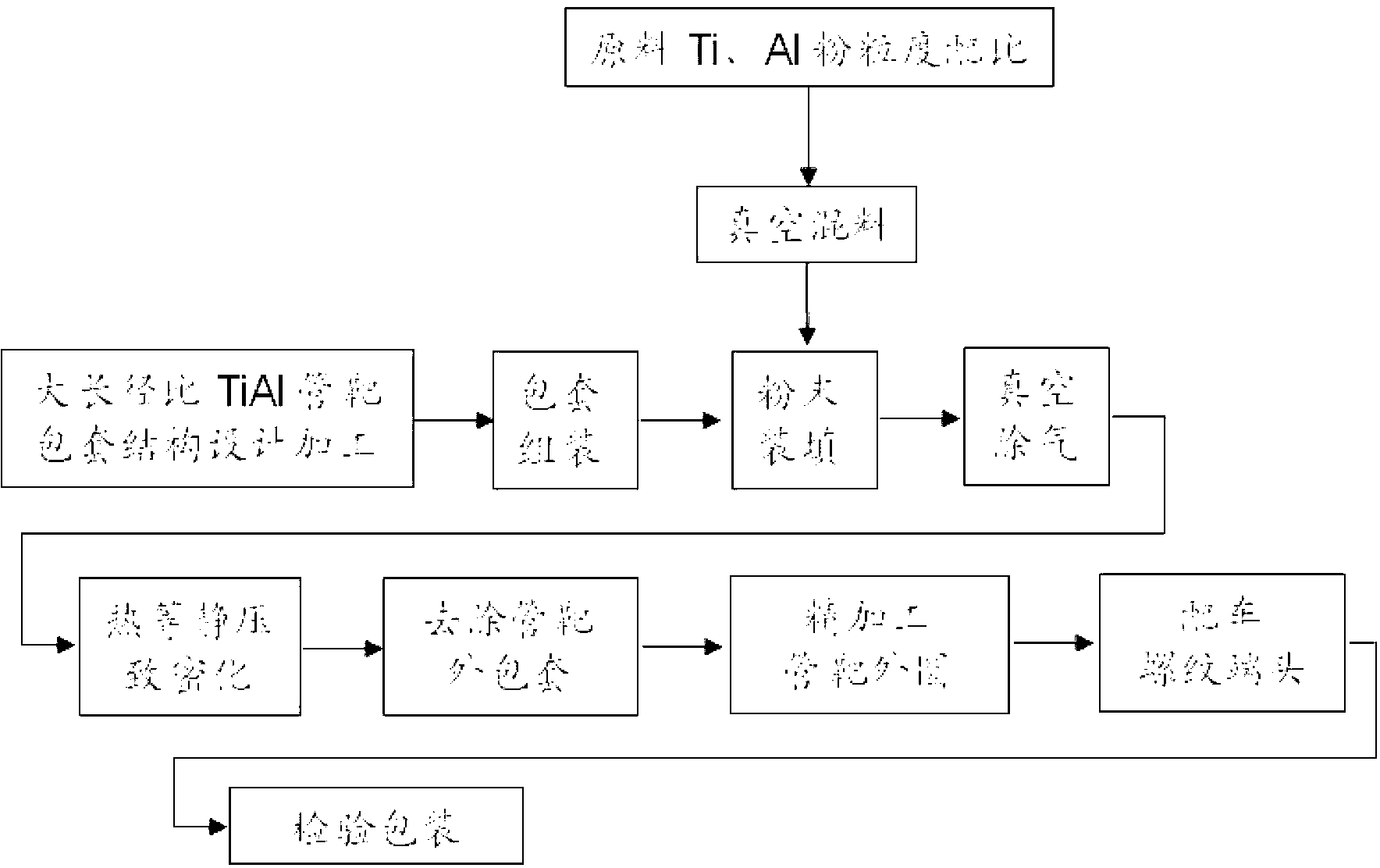

Forming method of TiAl pipe target material in large length-diameter ratio

ActiveCN103071791AGood welding performanceRealize the bindingVacuum evaporation coatingSputtering coatingLeg lengthDiameter ratio

The invention relates to a forming method of TiAl pipe target material in a large length-diameter ratio. The forming method comprises the following steps of (1) assembling of a sheath die; (2) packing and sealing welding of raw materials of Ti powder and Al powder; (3) vacuum heat degassing; (4) densification forming of hot isostatic pressure; (5) removing of the sheath die; and (6) product fine processing. According to the forming method disclosed by the invention, the structure of the sheath die is subjected to innovation design, excellent welding performance of the sheath die is ensured, the whole binding of the TiAl target material and a back pipe is realized, and segregation-free Ti and Al mixed powder which is uniform in composition is prepared through the optimization selection of raw material powder size and the vacuum material mixing; the powder packing density and the uniformity of the pipe target material are ensured by adopting a special powder packing technology; and the density and the straightness of the TiAl pipe target material after pressing forming can be ensured through optimized technological selection of the vacuum heat degassing and the densification forming.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com