Separation technology of hydrogen sulfide and carbon dioxide in acid gas of oil refinery

A technology of carbon dioxide and separation technology, applied in the direction of hydrogen sulfide, separation method, dispersed particle separation, etc., can solve the problems of rare research, difficult separation of hydrogen sulfide and carbon dioxide, etc., achieve high selectivity, low energy consumption of the device, and small loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

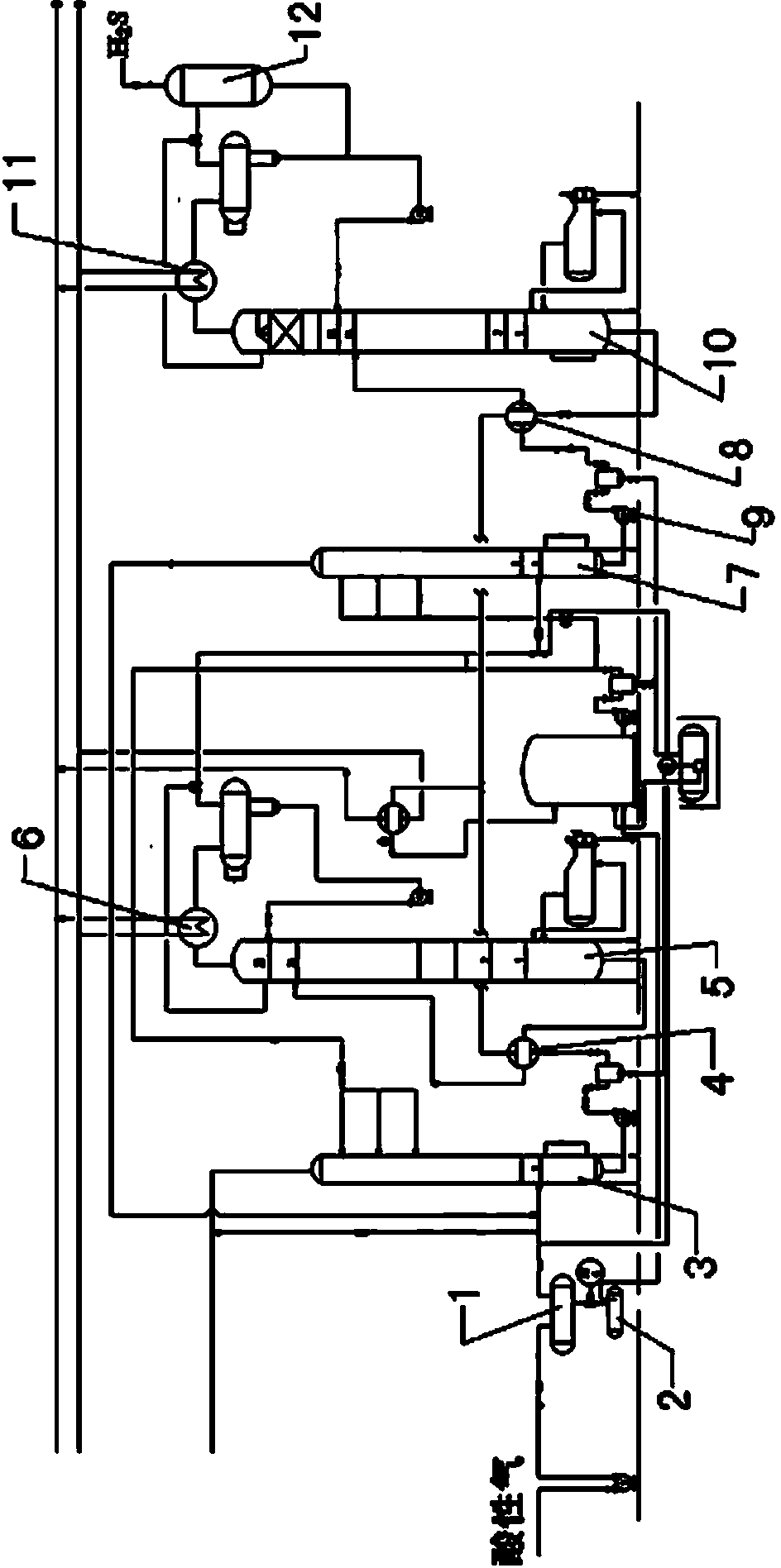

[0020] In conjunction with accompanying drawing, the present invention is further described:

[0021] A technology for separating hydrogen sulfide and carbon dioxide from acid gas in an oil refinery, comprising the following process steps: the acid gas in an oil refinery passes through an acid gas separation tank 1 and an acid water separation tank 2 and then enters a first absorption tower 3, and at the bottom of the first absorption tower 3 Contact with the lean liquid from the upper part of the tower to fully absorb the hydrogen sulfide in the acid gas to form a rich liquid. The rich liquid and the lean liquid enter the first-stage poor-rich heat exchanger 4 for heat exchange and then enter the first regeneration tower 5 for regeneration. The temperature at the bottom of tower 5 is controlled at about 115°C, and the H produced at the top of the first regeneration tower 5 2 After the S gas is condensed by the first condenser 6, the separated liquid phase is used as the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com