Patents

Literature

474results about How to "Improve suction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

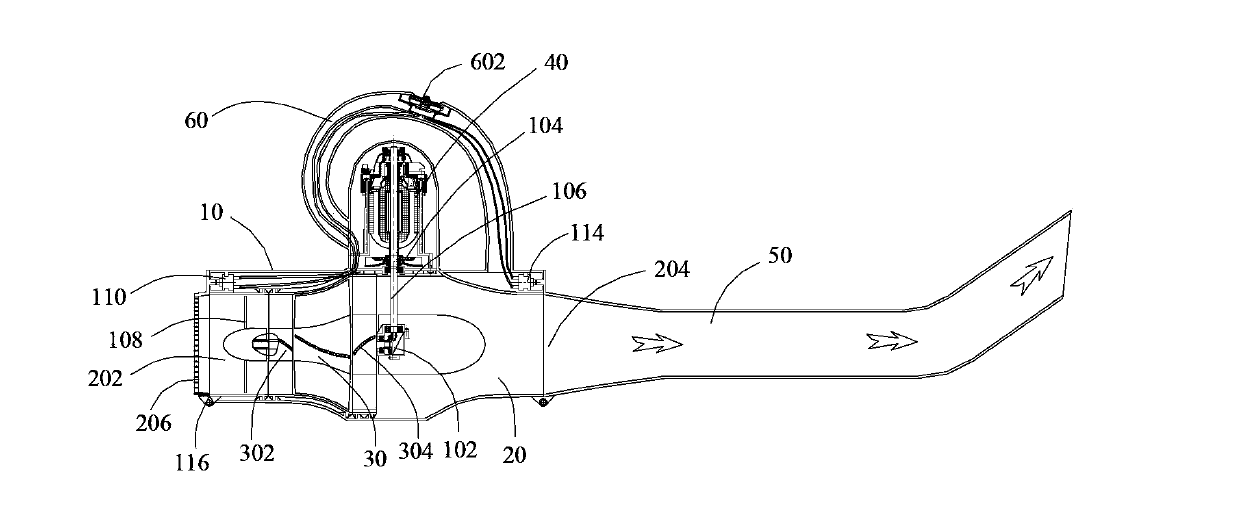

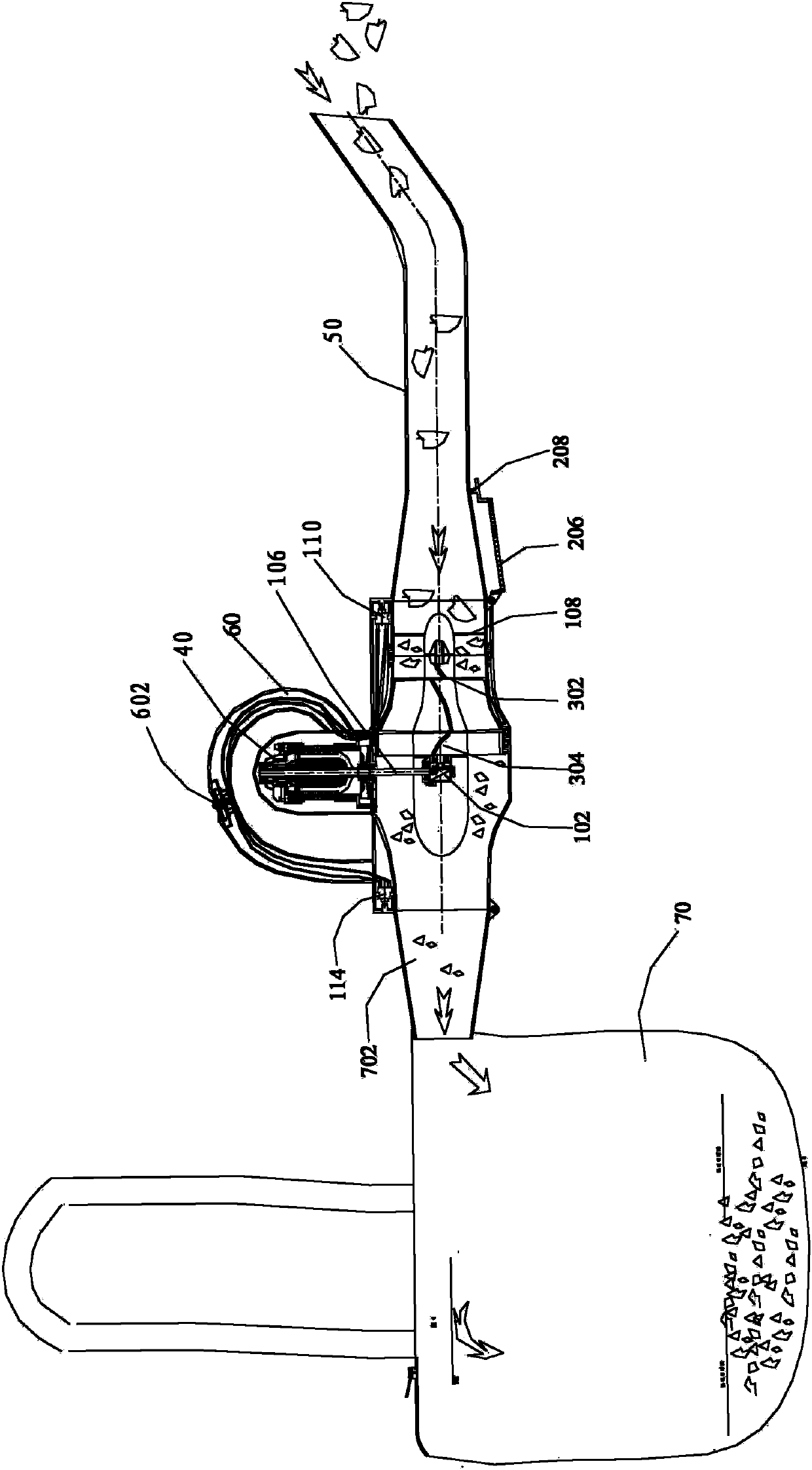

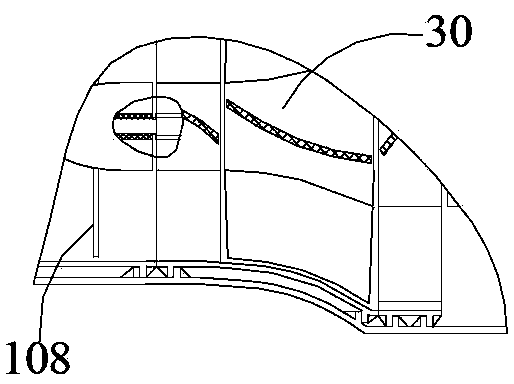

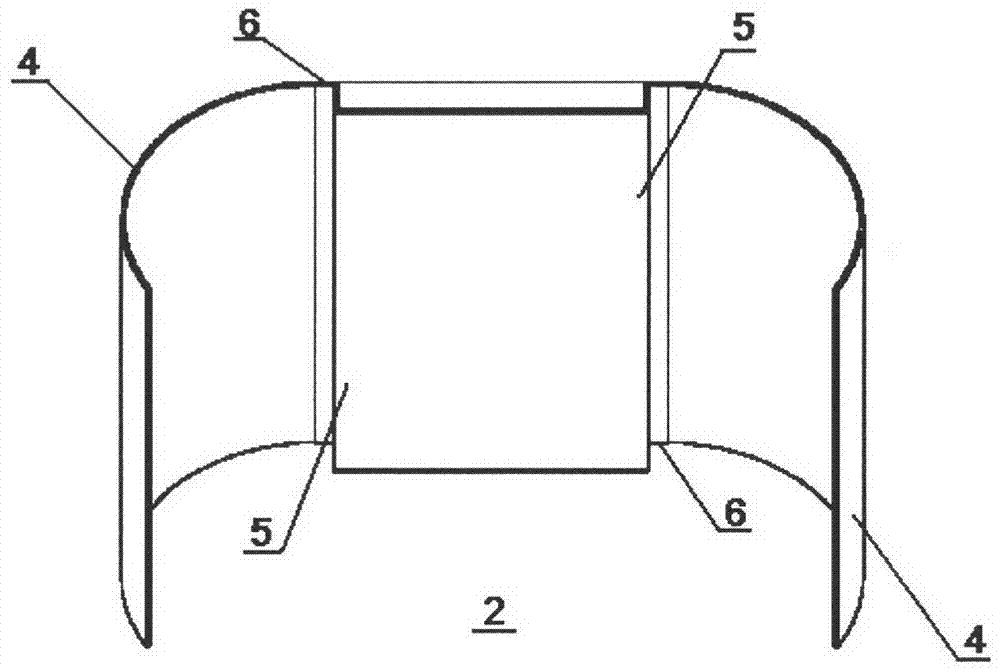

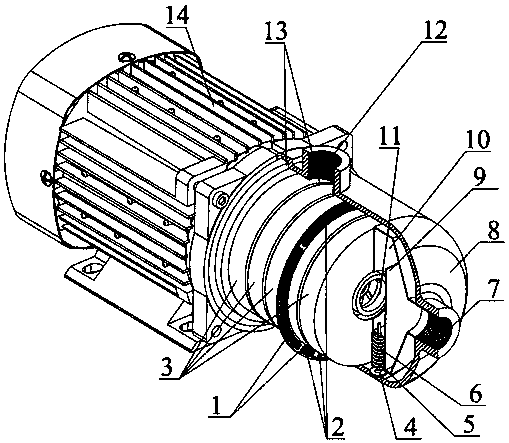

Blower-vacuum

The invention discloses a blower-vacuum. The blower-vacuum comprises a main machine shell and a motor arranged on the main machine shell, an air cavity is formed inside the main machine shell and an axial fan is axially arranged inside the air cavity; the motor is connected through a transmission mechanism and drives the axial fan; a smashing mechanism is formed between an air inlet of the air cavity and the axial fan. An axial fan of a large air volume is utilized, due to the fact that axial fan is axially arranged inside the air cavity and the central axis of the air cavity is linear, effects of air blowing and suction are enhanced and the air utilization rate is improved; meanwhile, leaves and dust are smashed by the smashing mechanism before being sucked into the air cavity, the volumes of the leaves and the dust become smaller and accordingly axial fan blocking caused by relatively large volumes of the sucked leaves or dust can be avoided, and the work efficiency of the blower-vacuum is improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

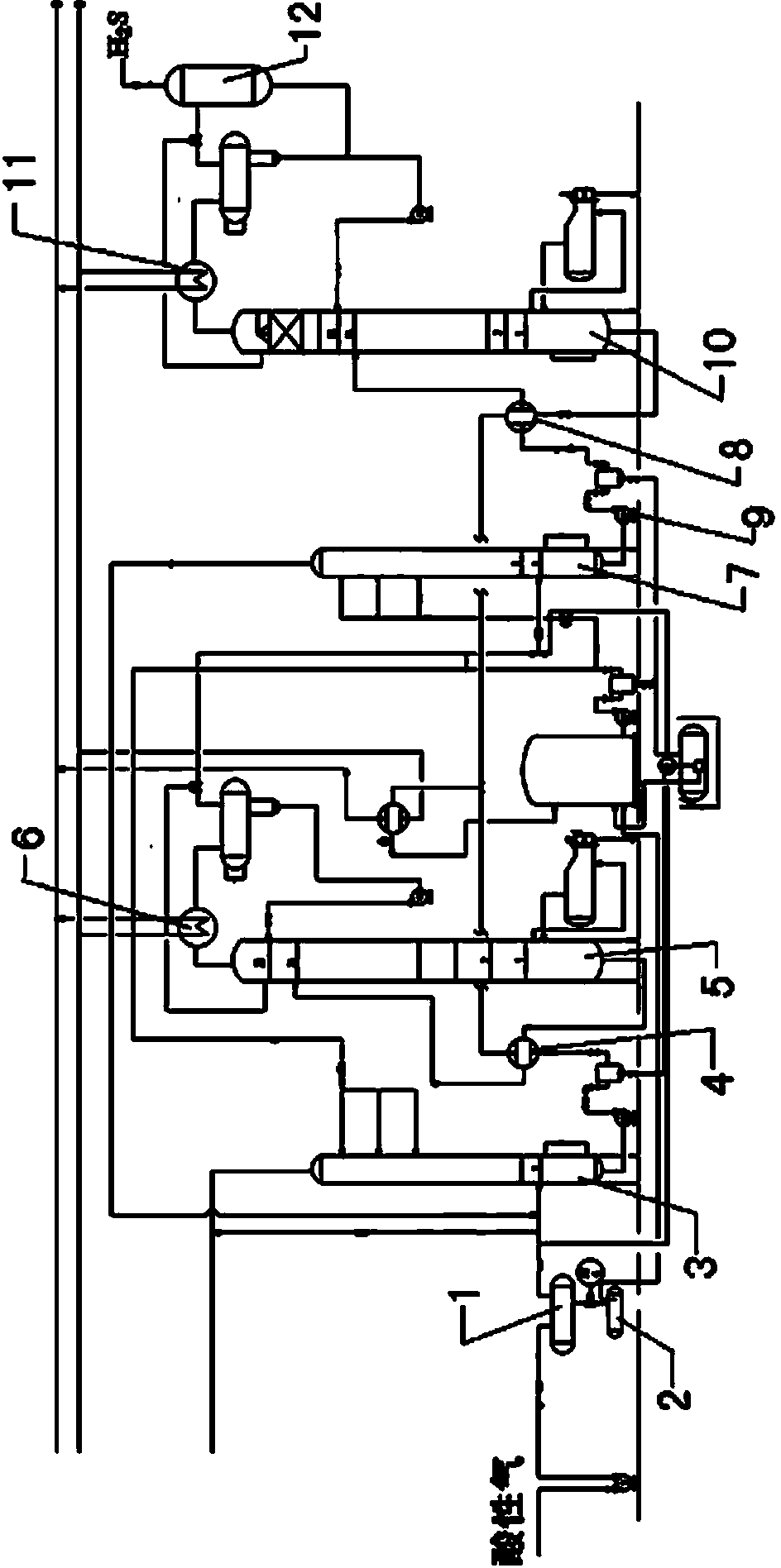

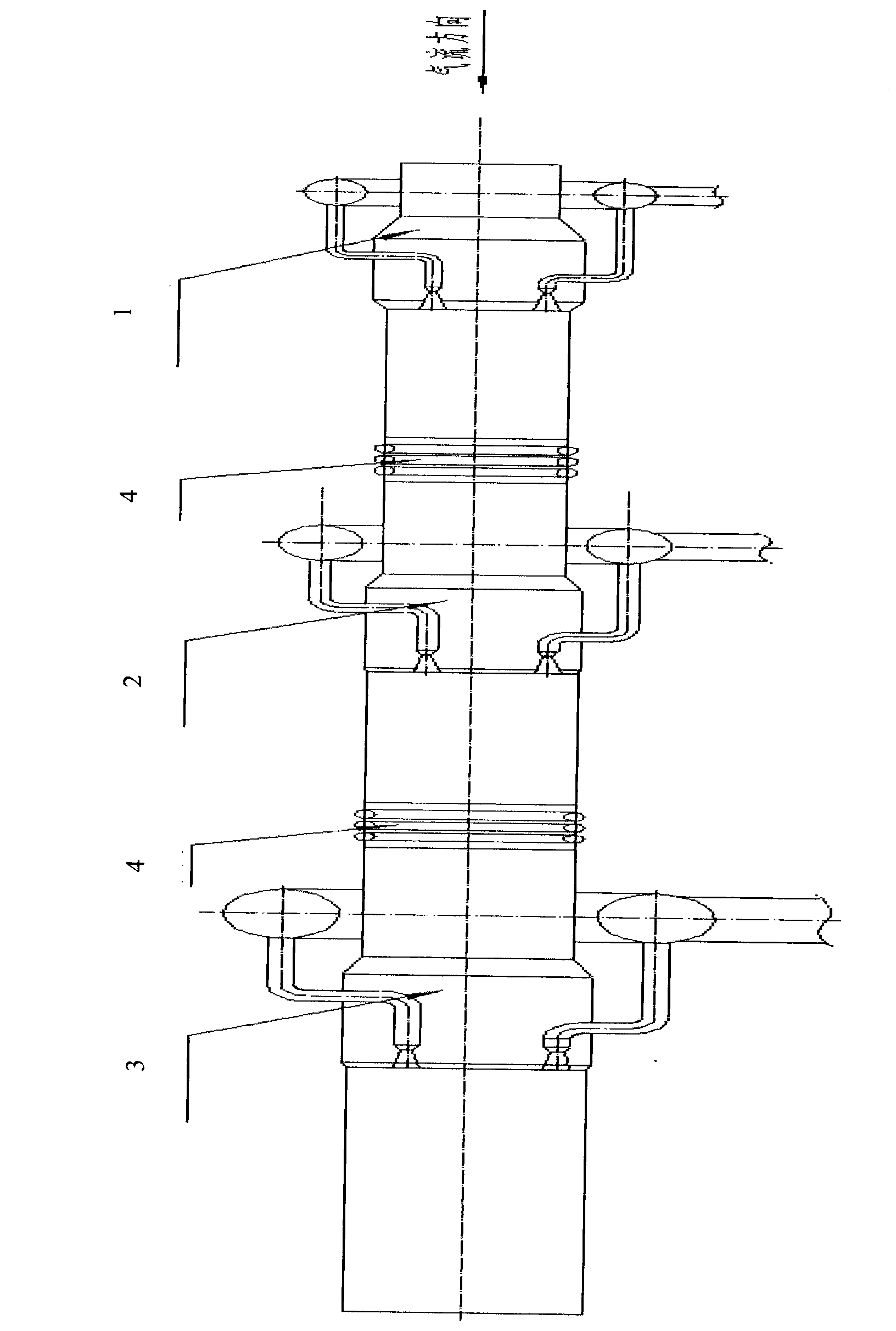

Separation technology of hydrogen sulfide and carbon dioxide in acid gas of oil refinery

InactiveCN103446849AHigh selectivityImprove stabilityHydrogen sulfidesDispersed particle separationSeparation technologyGas phase

The invention relates to a separation technology of hydrogen sulfide and carbon dioxide in acid gas of an oil refinery. According to the technical scheme, the separation technology comprises the following processing steps that the acid gas of the oil refinery flows through an acid gas separating tank and an acid water separating tank and then enters a first absorbing column; the acid gas at the bottom part of the first absorbing column is in contact with barren liquor from the upper part of the column, thus hydrogen sulfide in the acid gas can be fully absorbed to generate rich liquor; the rich liquor and barren liquor enter a first-grade rich-barren heat exchanger to exchange the heat and then enter a first regenerating column to regenerate; H2S gas generated at the top of a second regenerating column is condensed through a second condenser and then flows into a separating tank; a separated liquid phase is used for backflow in the top of the regenerating column; and a gas phase, namely, H2S gas, is used as sodium hydrosulfide to prepare some of raw materials. The separation technology has the beneficial effects that a methyldiethanolamine extracting agent at a concentration of 50% is selected; and compared with other extracting agents, the methyldiethanolamine extracting agent has relatively high selectivity and stability, causes a very little loss, and is low in energy consumption of devices.

Owner:SHANDONG KENLI PETROCHEM GRP

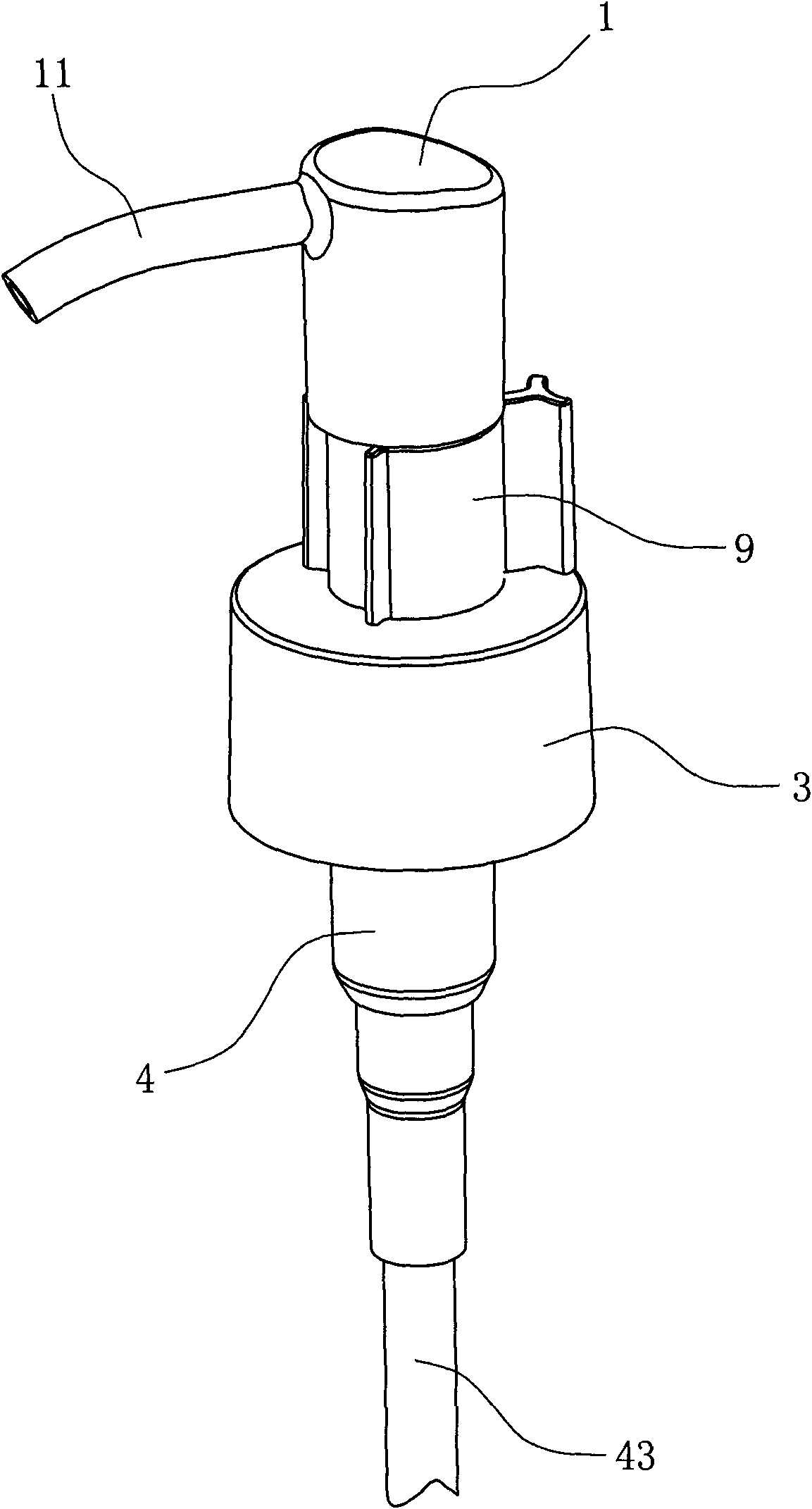

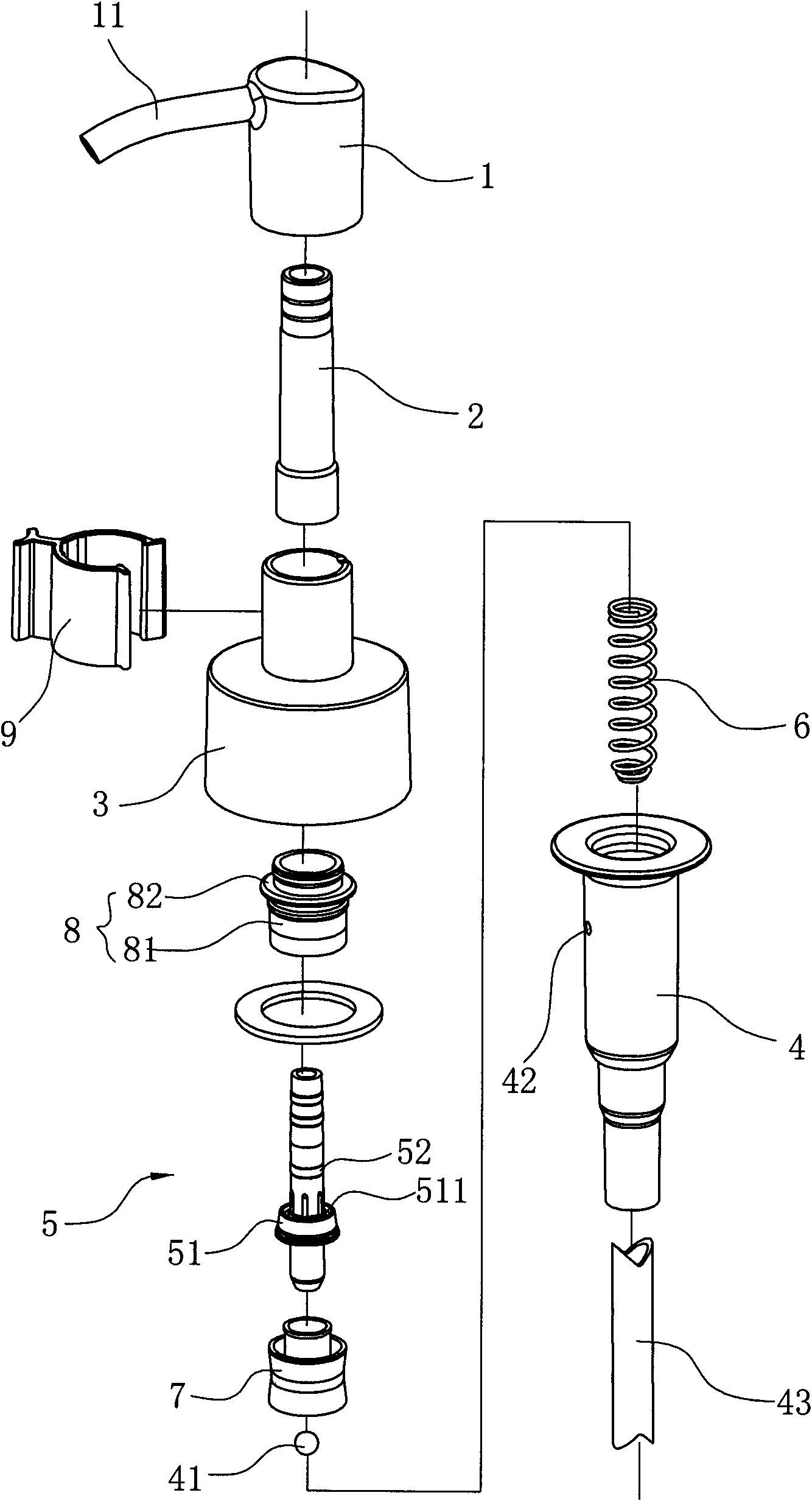

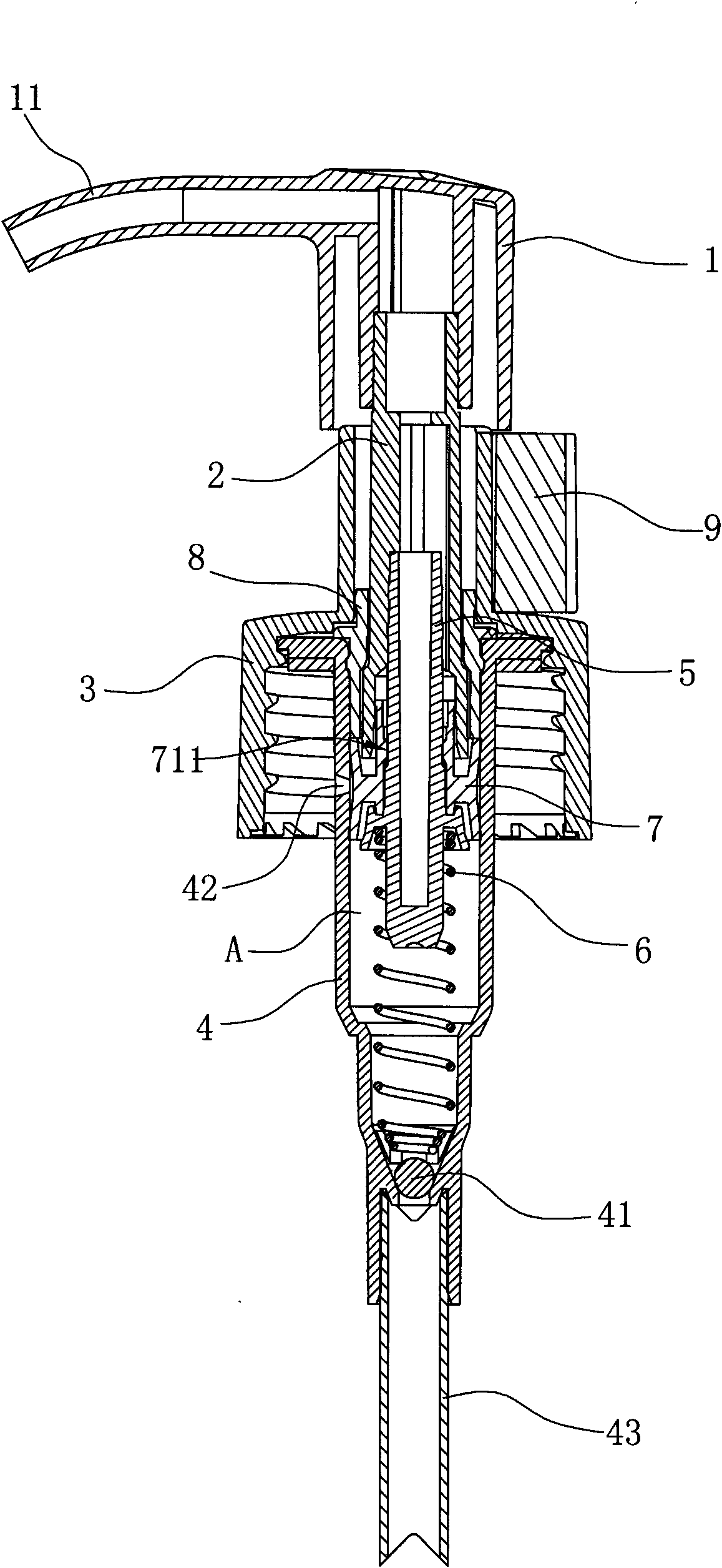

Pressing type emulsion spray nozzle

The invention discloses a pressing type emulsion spray nozzle, which comprises a head cap, a valve rod, a bottle cap and a pump assembly, and is characterized in that: a piston is arranged in a pump body and comprises a shaft neck and a sealing ring projecting outwards radially along the outer wall of the shaft neck; a circle of annular groove with an upward opening is formed on the outer wall of an ejector rod, and can be in splicing fit with the bottom edge of the shaft neck of the piston to realize sealing between the ejector rod and the piston; the piston is provided with a rib on the inner wall of the shaft neck; and the ejector rod is provided with a circle of circumferential convex ring, which can be tightly pressed against the rib, on the upper part of the annular groove. Compared with the prior art, the spray nozzle has the advantages that: the inner wall of the piston is provided with the rib and the outer wall of the ejector rod is provided with the convex ring, so that the piston can still move upwards along with the ejector rod under the action of friction between the rib and the convex ring in the resetting process of the ejector rod, a liquid absorption channel between the piston and a top plate can continually keep open, and emulsion left in the spray nozzle can be absorbed back into the pump body.

Owner:YUYAO SUN RAIN SPRAYER

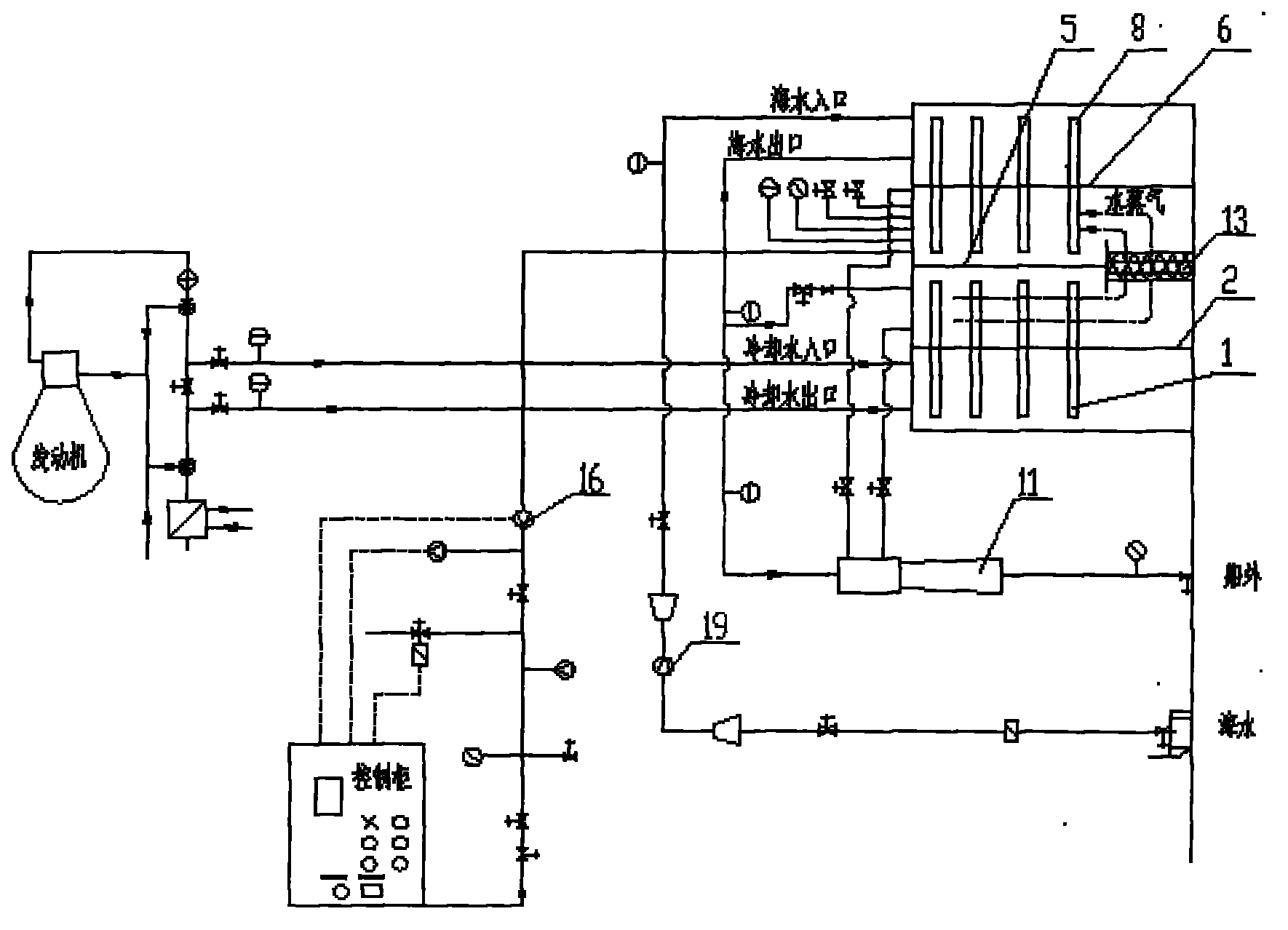

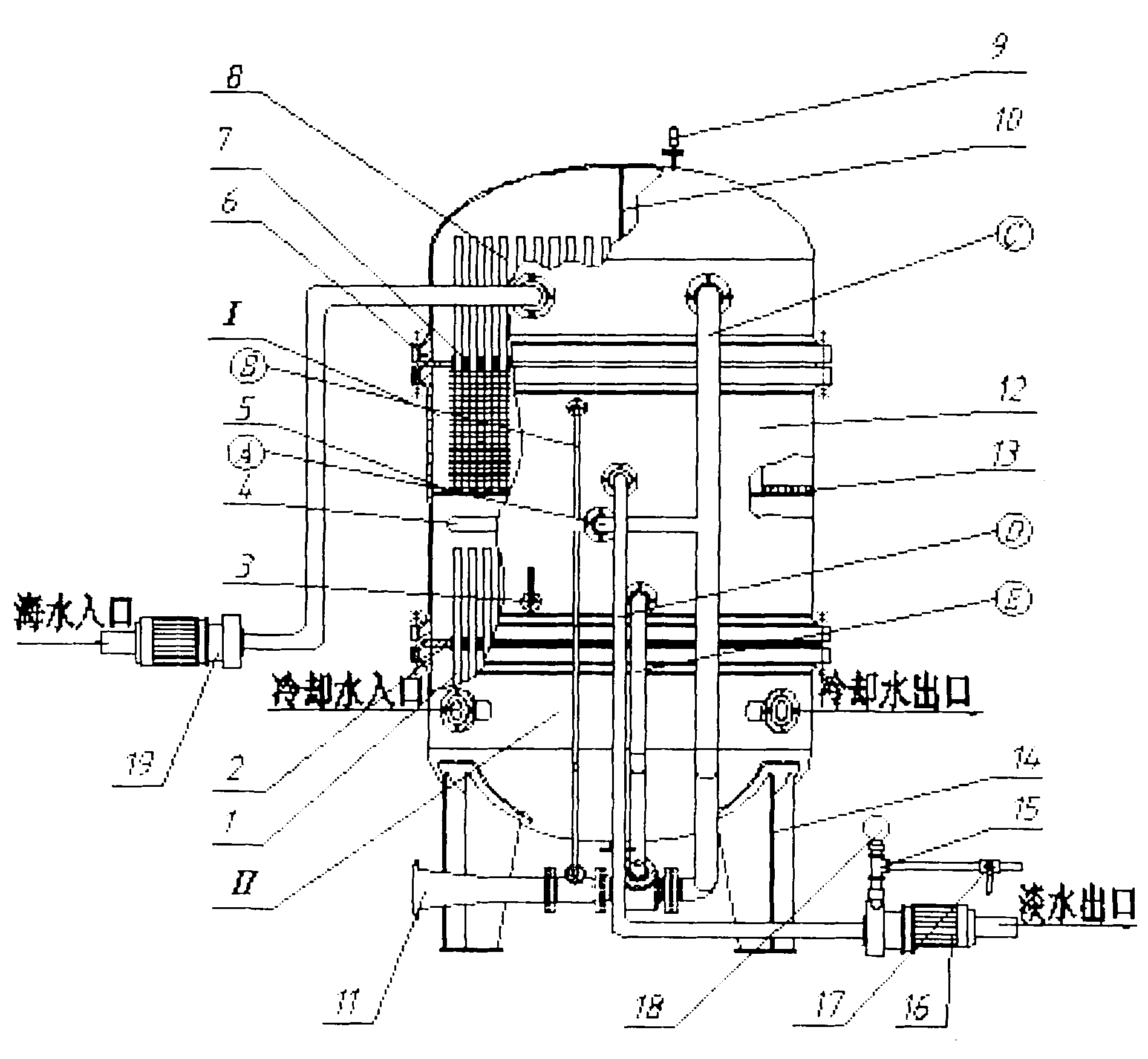

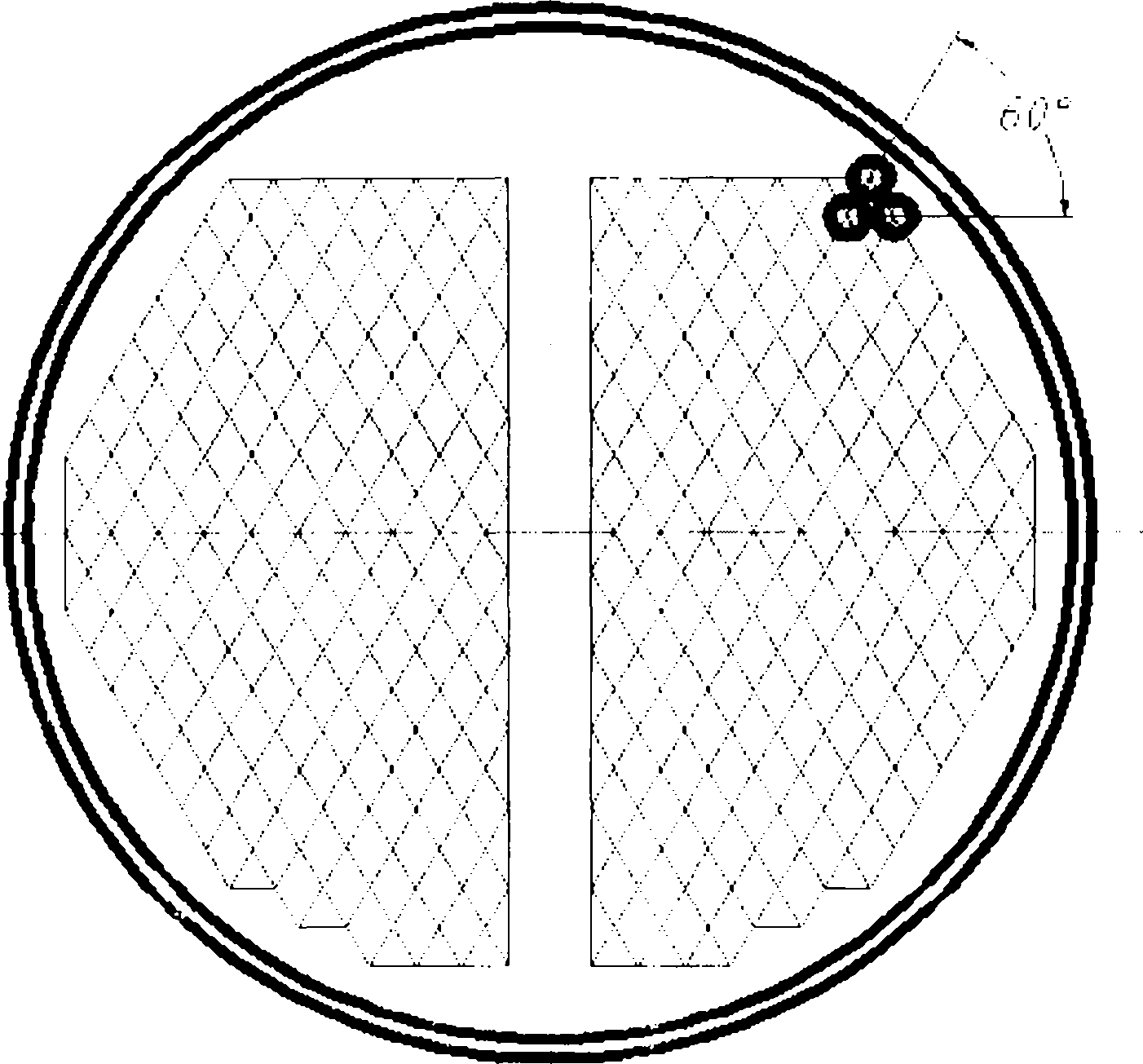

Marine heat pipe type seawater desalination device

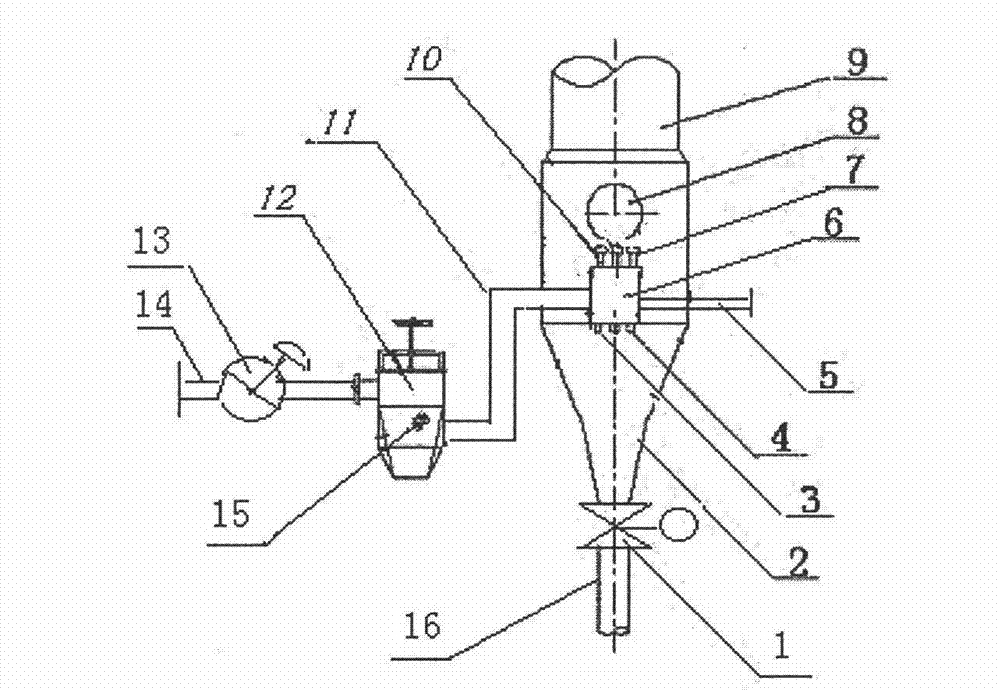

InactiveCN103449548AImprove cooling effectIncrease profitGeneral water supply conservationSeawater treatmentBoiling pointWater cycling

The invention belongs to the field of seawater desalination, and particularly relates to a marine heat pipe type seawater desalination device. The marine heat pipe type seawater desalination device is composed of a pressure gage, a liquidometer, heat pipes, a liquid distributor, a baffling plate, a snuffle valve, a cylinder body, a support, a one-way valve, a fresh water pump, a jet flow vacuum pump, a seawater pump, a partition plate, a demister and connecting pipelines. The marine heat pipe type seawater desalination device provided by the invention fully utilizes the advantage that the heat conductivity coefficient of a gravity heat pipe is high, adopts the heat of the cooling water of a ship engine as a heat source, and can greatly reduce the seawater boiling point under the vacuum environment created by the jet flow vacuum pump driven by a centrifugal pump; the seawater is distilled under the lower boiling point, thus the seawater desalination device provided by the invention has the advantages that the manufacture is simple, the structure is compact, the material consumption is less, the dual purposes that the cooling water of the ship engine is recycled and fresh water of a ship body is autarkical are achieved, the maintenance is convenient, the cost is low, the service life is long, and the installation space is small.

Owner:QINGDAO UNIV OF SCI & TECH

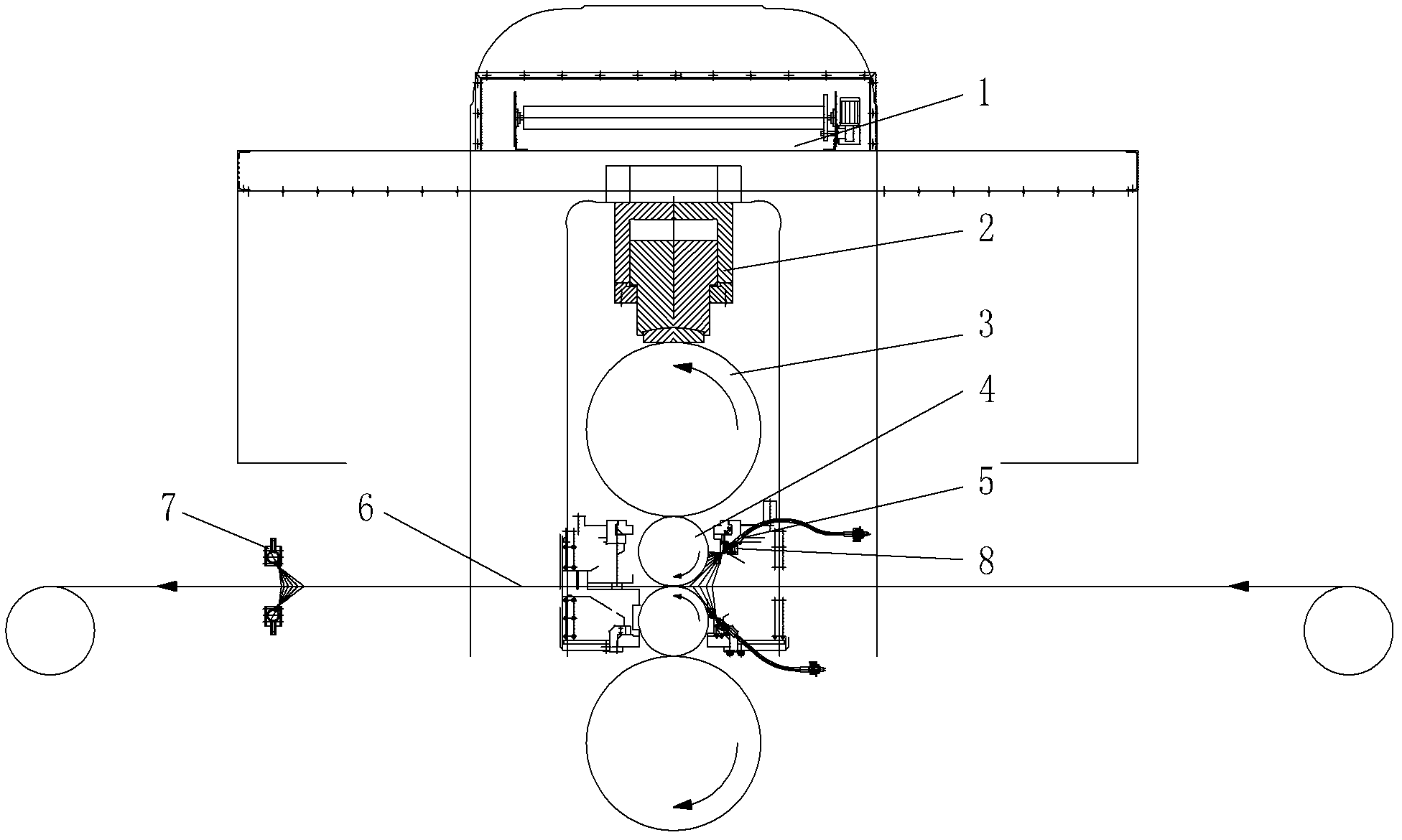

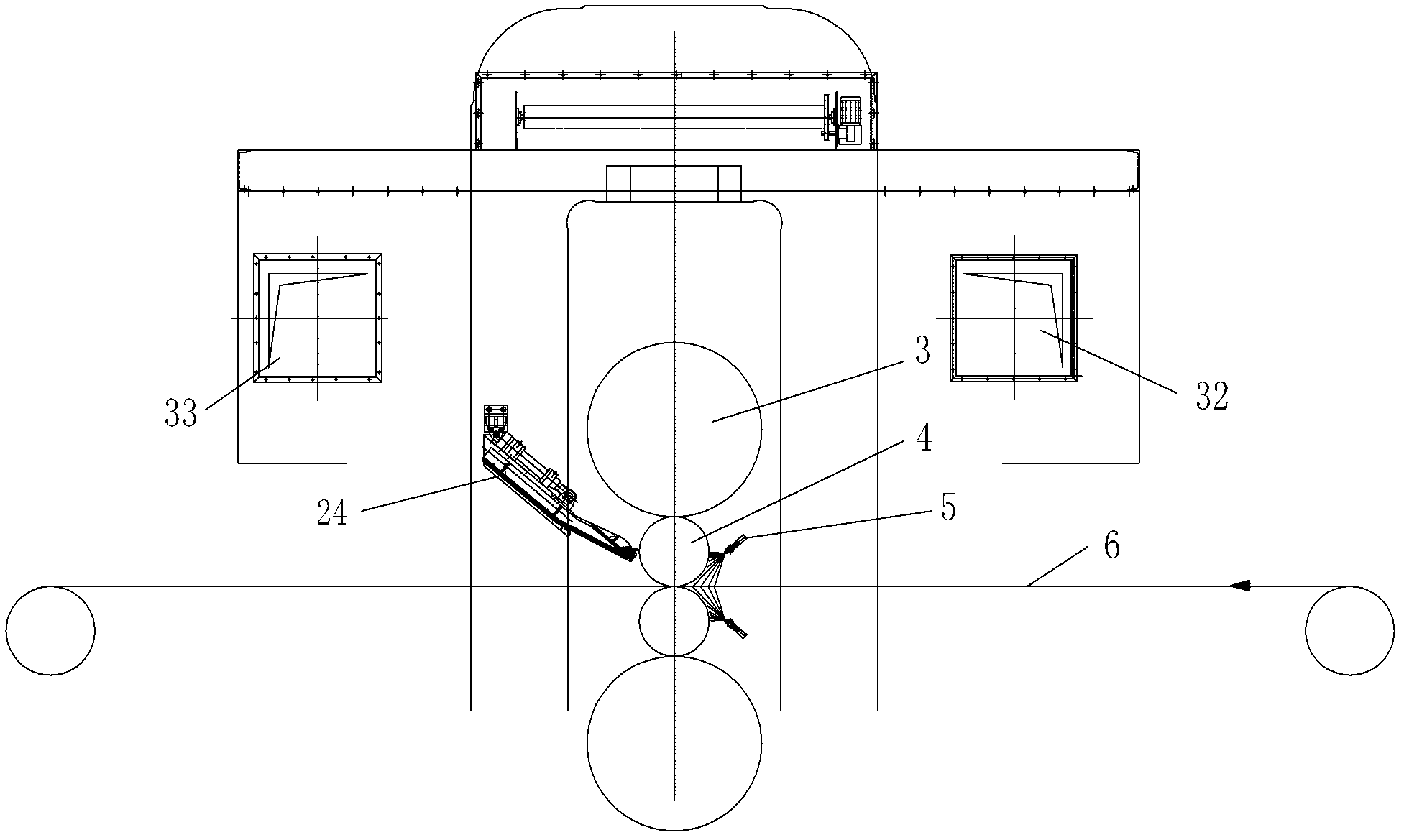

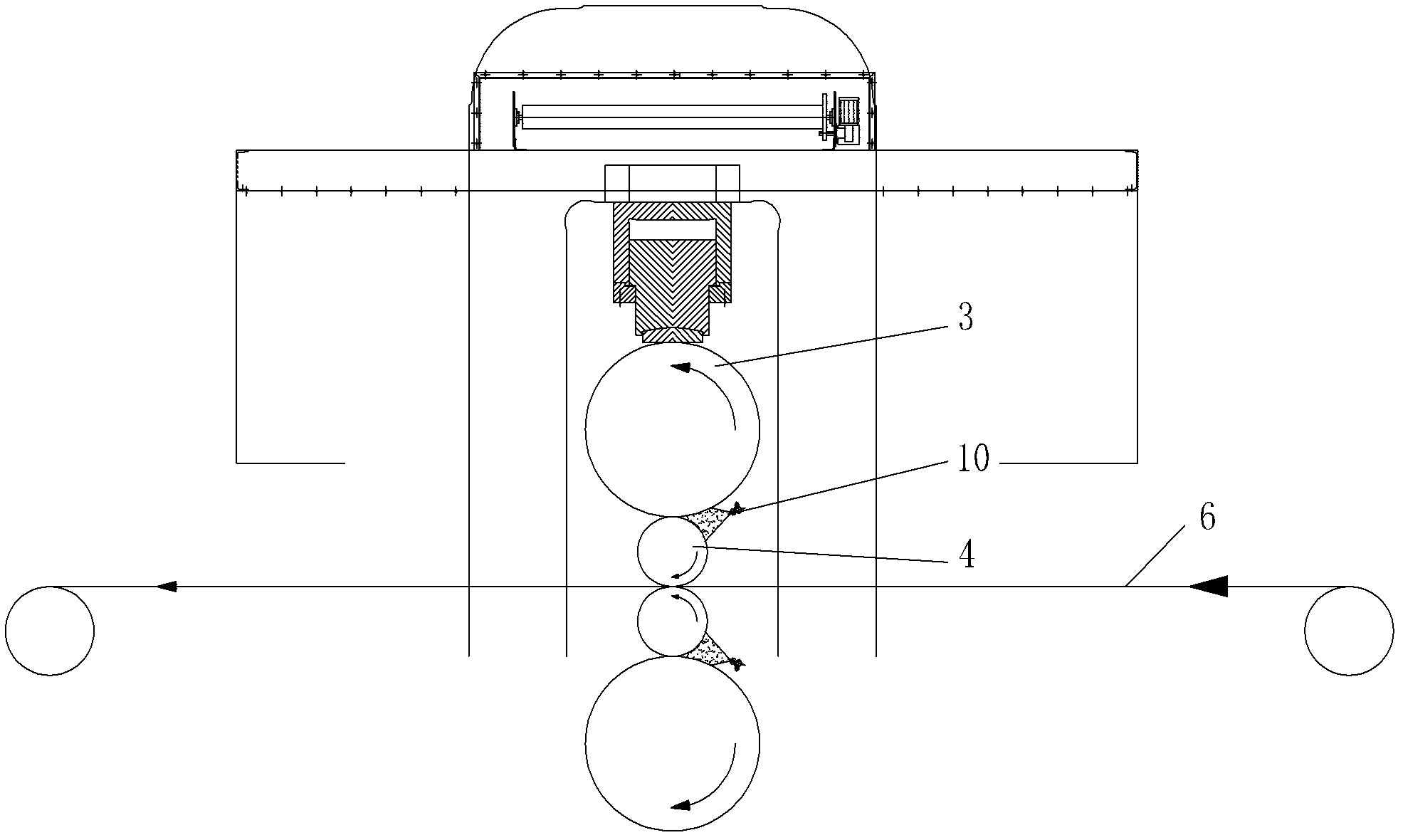

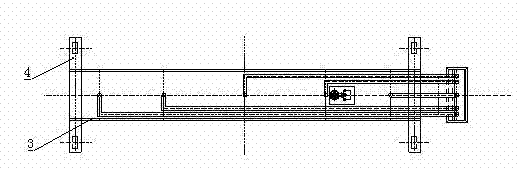

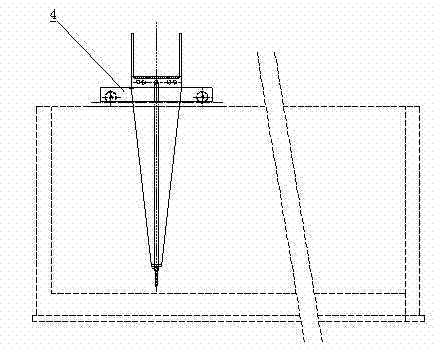

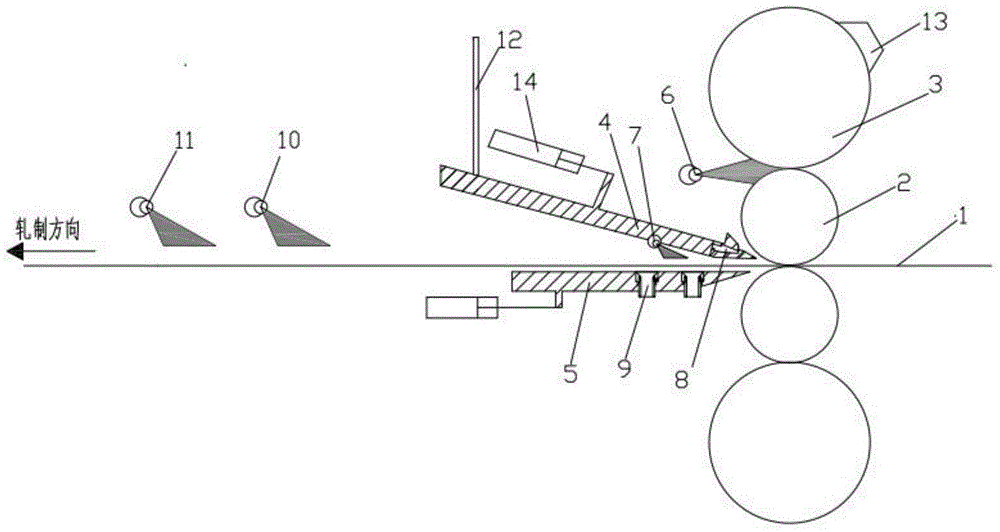

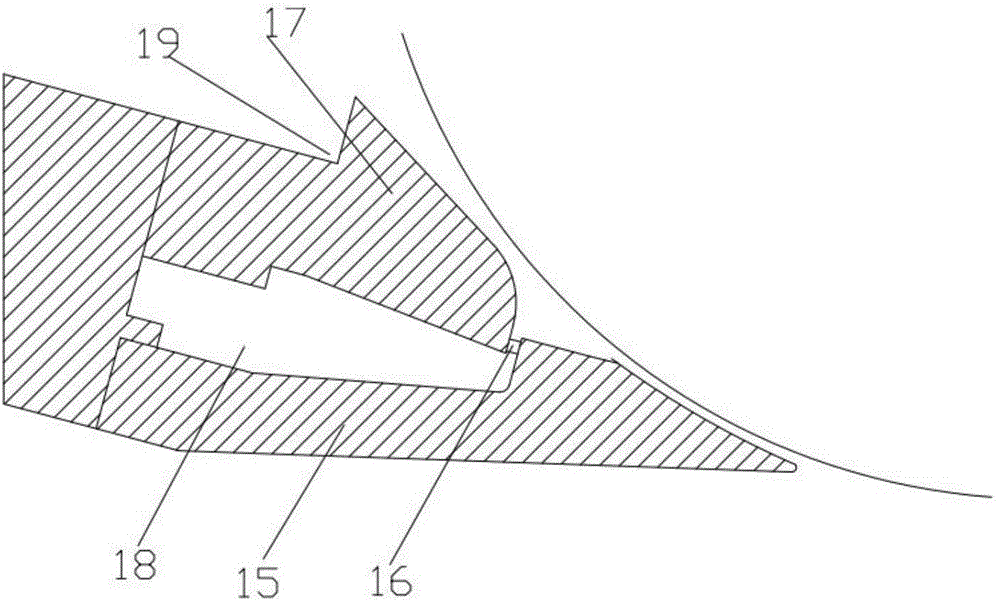

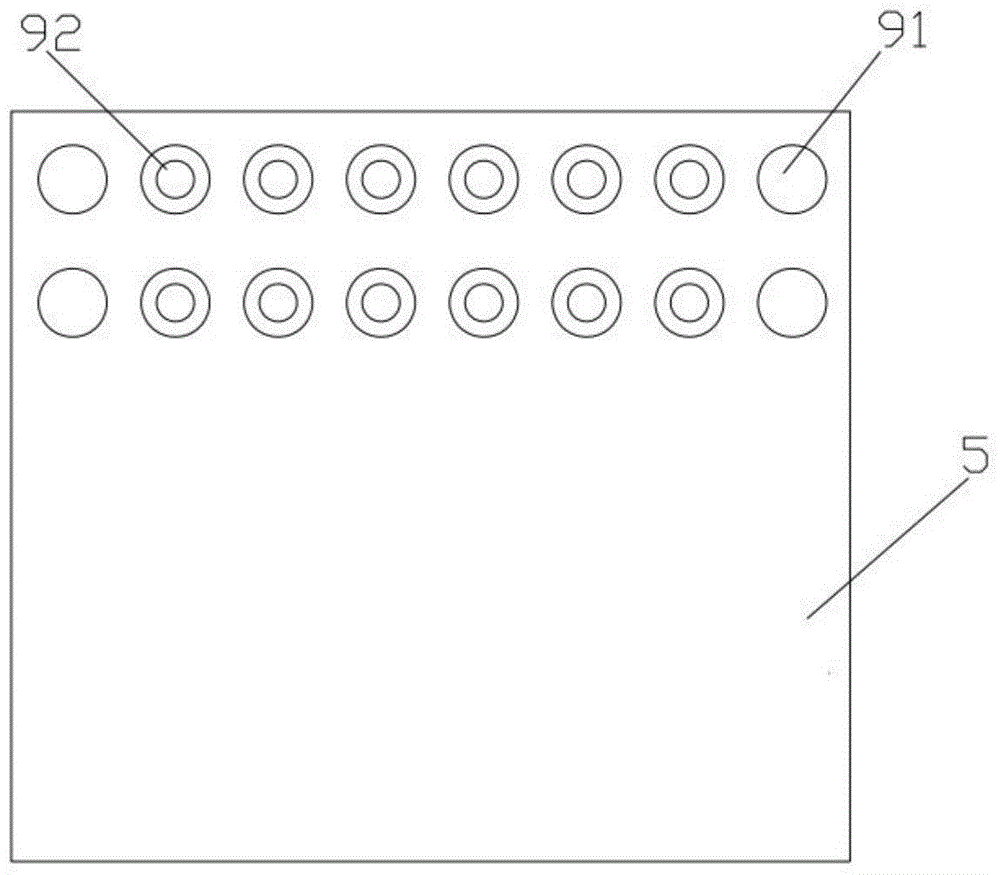

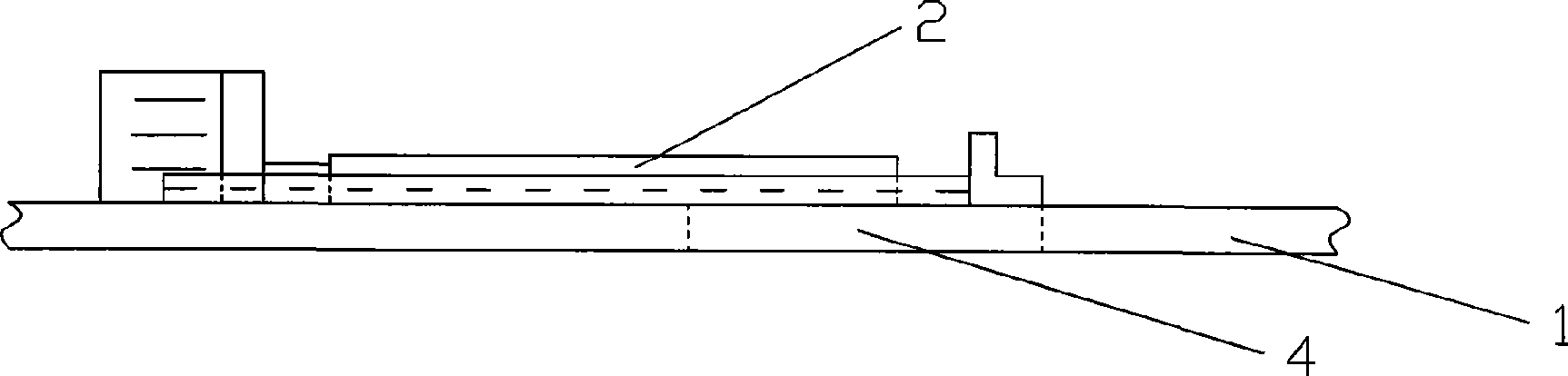

Water mist skin leveling system in cold rolling wet skin leveling production

ActiveCN102284519ASolve the problem of residual smooth spotsReduce consumptionWork treatment devicesMetal rolling arrangementsEngineeringStrip steel

The invention relates to a system for performing a leveling production by means of water mist leveling. A water mist leveling system in a cold-rolling wet leveling production, which is characterized by being composed of a water mist leveling-spraying device and a water mist leveling and suction dust removal system, wherein the water mist leveling-spraying device comprises a water mist leveling-spraying beam, a telescoping mechanism and a leveling mist spraying device; the leveling mist spraying device is fixed on the water mist leveling-spraying beam; the water mist leveling-spraying beam is connected with a connection cross beam via the telescoping mechanism, and the both ends of the cross beam are fixed on the frame of a wet leveling mill respectively; the water mist leveling and suction dust removal system comprises an anti-wrapping guide plate and an inlet side air suction tube; the lower port of the anti-wrapping guide plate is a first air suction opening; the inlet side air suction tube is disposed at the inlet side of the wet leveling mill, and the lower port of the inlet side air suction tube is a second air suction opening. The system can increase the quality of strip steel surface and decrease the production energy consumption.

Owner:WISDRI ENG & RES INC LTD

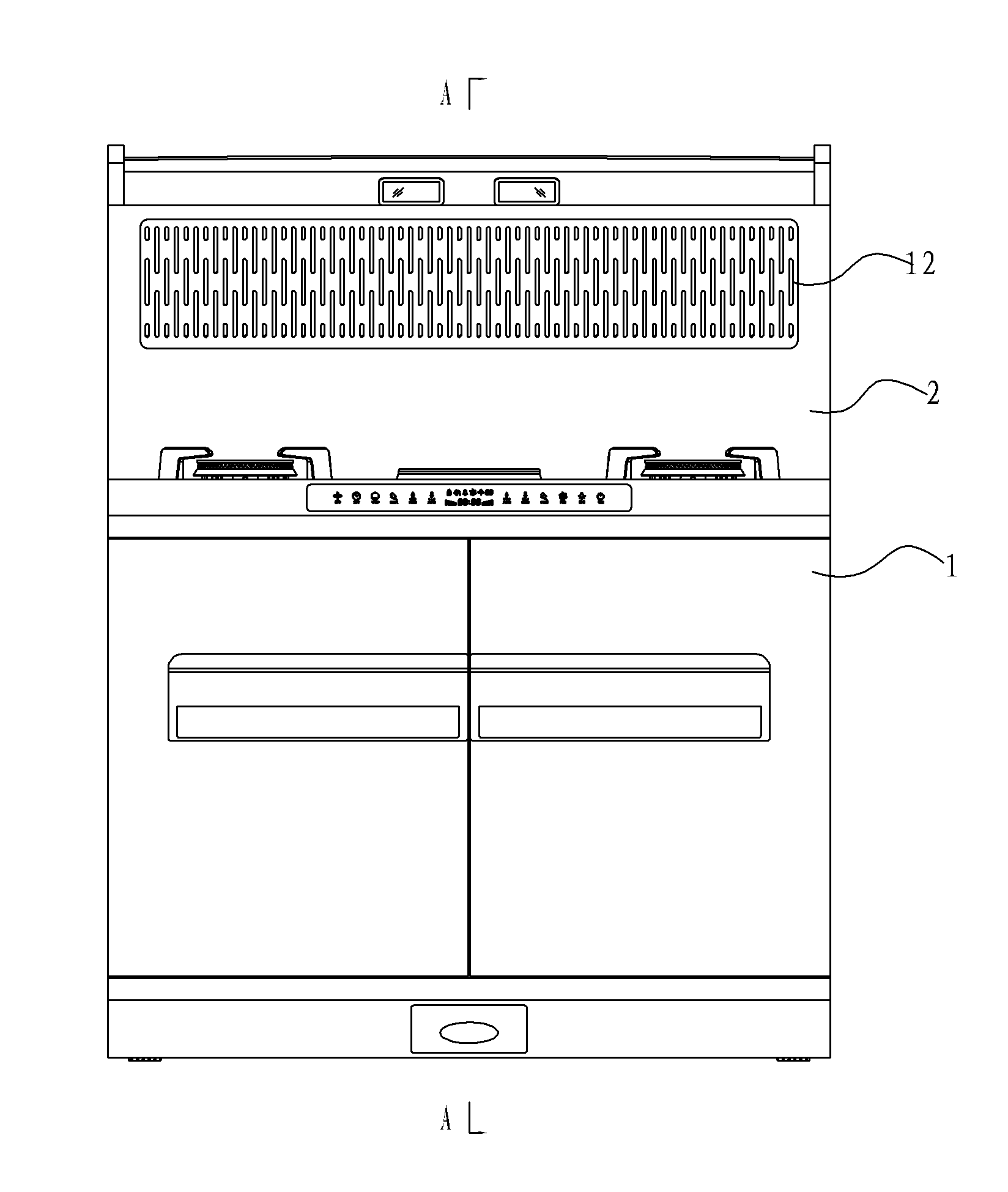

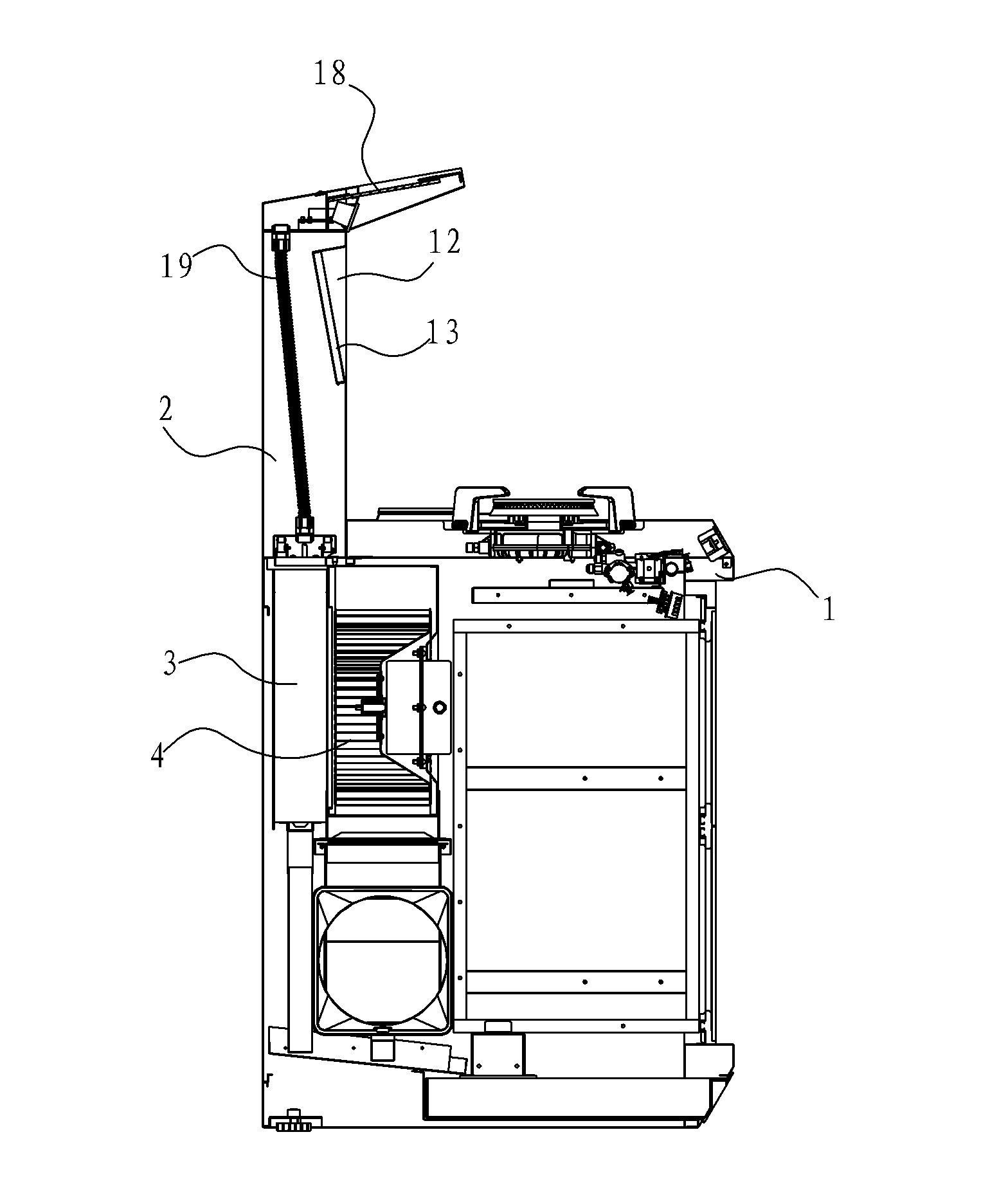

Integrated oven

ActiveCN102121719AAvoid corrosionDischarge in timeDomestic stoves or rangesLighting and heating apparatusTurbinePollution

The invention discloses an integrated oven, comprising an oven table, an air suctioning baffle, a burning system and an air channel, wherein the air suctioning baffle is arranged at the upper part of the oven table; the burning system is arranged below the oven table; the air channel is communicated with the air suctioning opening of the air suctioning plate; the air channel comprises an air suctioning chamber, a turbine fan, an air outlet elbow and an air outlet pipe which are connected in sequence; a first oil collecting nozzle is arranged at the outer wall of the bottom side of the air outlet elbow; an inclined oil collecting plate is arranged below the first oil collecting nozzle; the lowest part of the oil collecting plate is provided with a gap; and a drawer-type oil collecting disc is arranged below the gap. In the integrated oven disclosed by the invention, the whole structure is simple, and since the first oil collecting nozzle, a second oil collecting nozzle and a third oil collecting nozzle are arranged, the capability of timely discharging and collecting oil stains formed in the air channel is guaranteed, and the corrosion of the oil stains to pipelines and the pollution of the oil stains to the environment are prevented. In addition, as an air curtain mechanism is arranged, the diffusion of oily smoke is prevented and further the air suctioning effect of the integrated oven is improved.

Owner:浙江优格实业有限公司

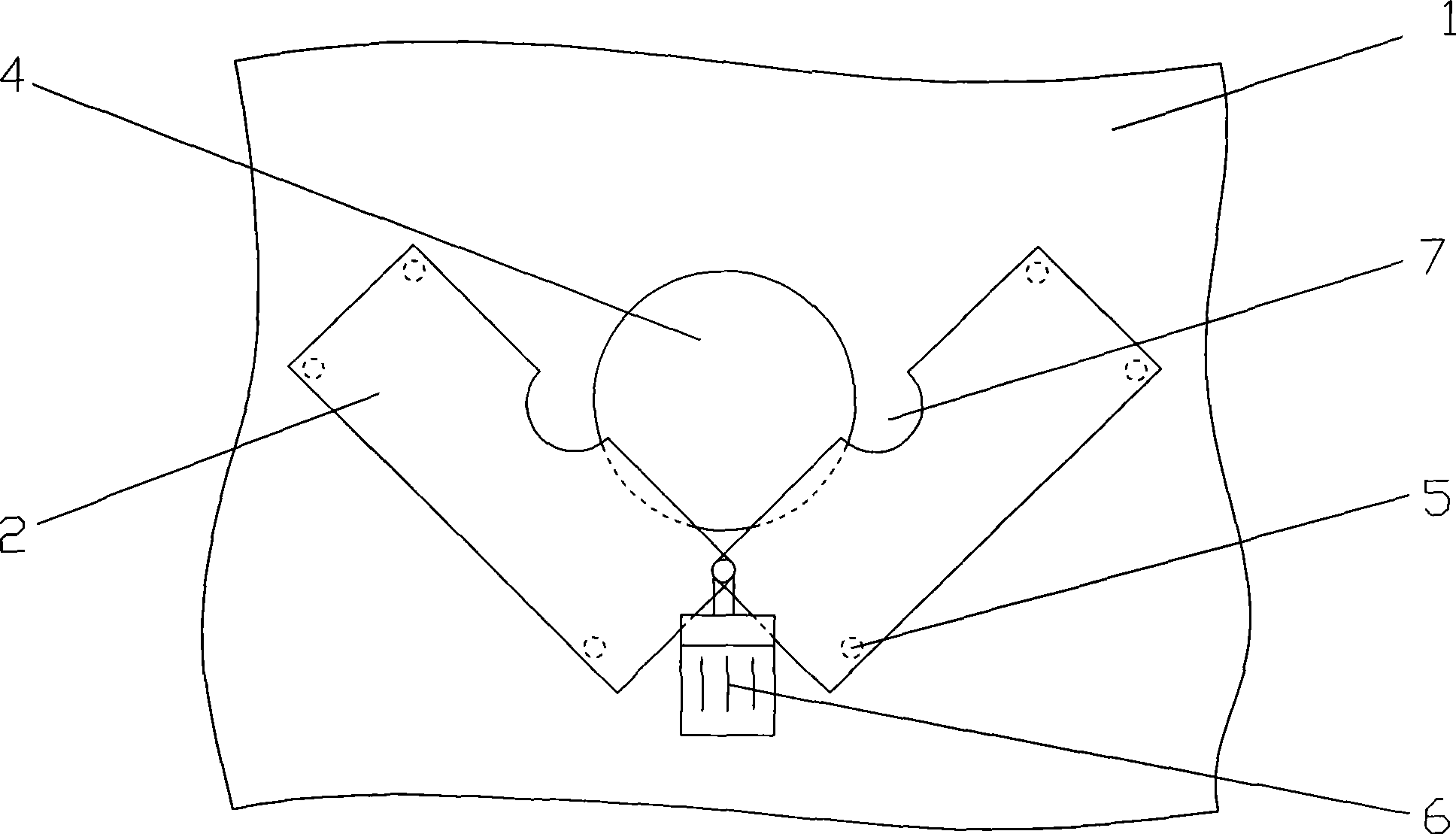

Baffle-rotary lampblack absorber capable of adjusting area of air suction port

InactiveCN101520204AHigh strengthUniform size variationDomestic stoves or rangesLighting and heating apparatusRotational axisSize change

The invention relates to a baffle-rotary lampblack absorber capable of adjusting the area of an air suction port, which comprises a casing, a blower, an air inlet and an air outlet. The baffle-rotary lampblack absorber capable of adjusting the area of the air suction port is characterized in that the air inlet is provided with an adjustable device which comprises at least one wind shield and a rotating shaft, wherein the wind shield and the rotating shaft are movably connected, and the wind shield and the casing are movably connected by a connecting device. In the invention, as the adjustable device is arranged on the air inlet, a user can manually or automatically move the wind shield of the air inlet according to amount of lampblacks and needs; the structural design of a rotary baffle is adopted, so the size of the air inlet can be conveniently and rapidly adjusted, thereby not only saving the energy resource and being beneficial to environment protection, but also enhancing the air suction strength under the situation of not changing the power of the lampblack absorber; the size change of the air suction port of the movable baffle is even on the structural design, thereby the adjustment is convenient; and meanwhile, the invention has constant air suction central point, effectively improves the air suction ratio and achieves the sound air-suction effects of sucking in dense smoke in time and purifying room air during the air suction process.

Owner:HANGZHOU LIUYI TECH

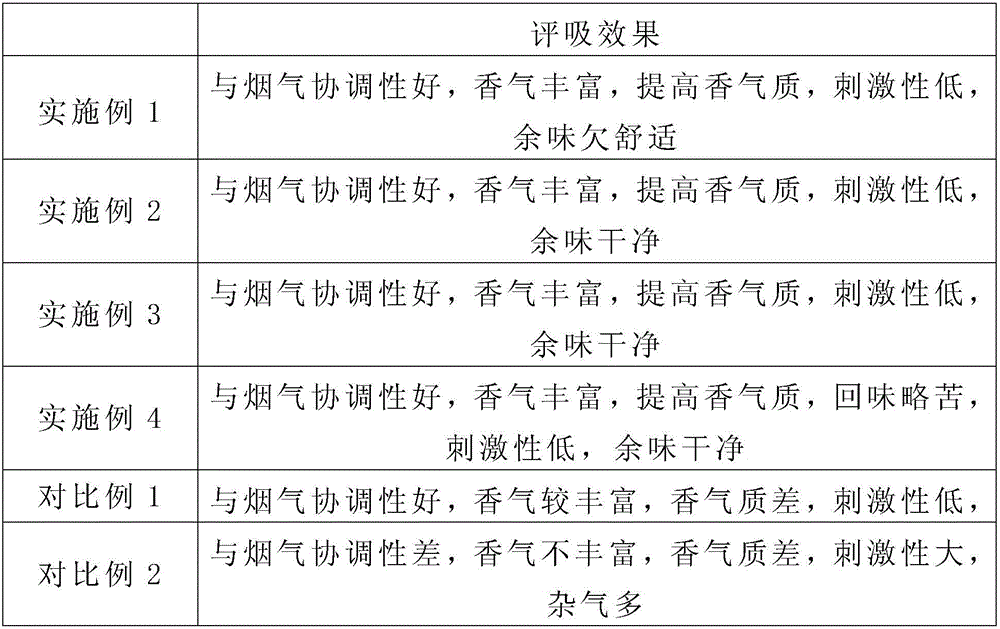

Preparation method of cigarette coffee extract

The invention provides a preparation method of a cigarette coffee extract. The preparation method comprises the following steps of adding coffee beans into a baking machine, baking for 10 to 15min at the temperature of 160 to 220 DEG C, crushing, adding ethanol with the concentration of 40% to 70%, soaking, carrying out ultrasonic extraction for 1 to 3 times, concentrating extracting liquid by vacuum at low temperature, further filtering by ceramic film equipment with hole diameter of 30 to 50nm, and concentrating, so as to obtain the cigarette coffee extract. The preparation method has the advantages that the coffee extract can be extracted and separated at low temperature; the original flavor of the extract is furthest maintained; the smoking evaluation effect of the coffee extract in cigarette is improved; compared with a common coffee extract, the coordination between the prepared extract and the cigarette flavor is good, rich fragrance is realized, the fragrance quality is high, the irritation is low, and the residual flavor is clean.

Owner:HUBEI CHINA TOBACCO IND

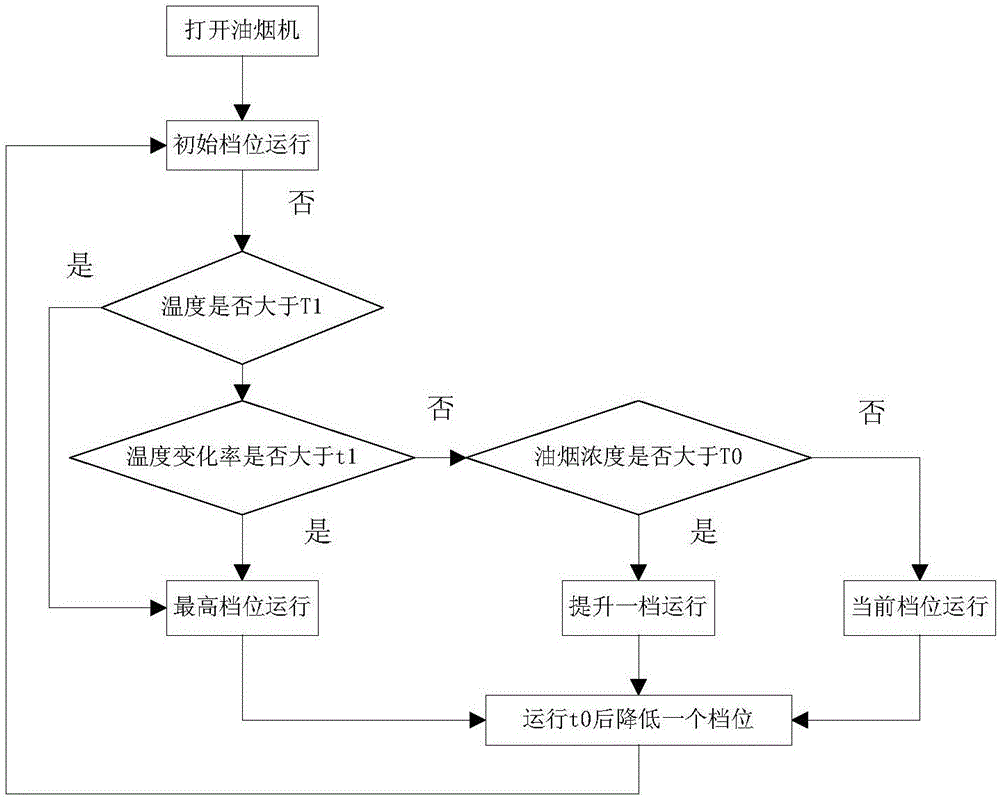

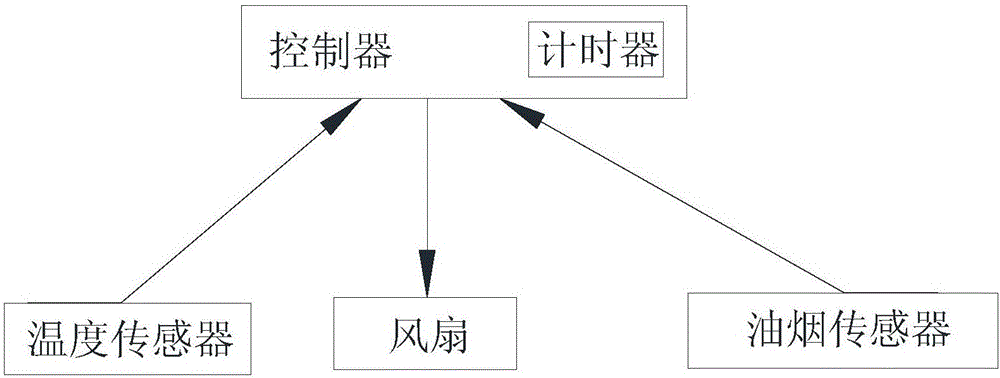

Control method and control system for automatically controlling gears of range hood, and range hood

InactiveCN106196208APromote absorptionHigh control reliabilityDomestic stoves or rangesLighting and heating apparatusAutomatic controlControl system

The invention provides a control method and control system for automatically controlling gears of a range hood, and the range hood. According to the control method for automatically controlling the gears of the range hood, after the range hood is started, the range hood works at the initial gear; if temperature information detected by a temperature sensor exceeds a temperature information threshold value or cooking fume concentration detected by a cooking fume sensor exceeds a cooking fume concentration threshold value T0, upshift operation is carried out on the range hood based on the initial gear, otherwise, the range hood keeps at the initial gear; and when the time that the range hood keeps at any gear exceeds the gear keeping time t0, downshift operation is carried out on the range hood based on the current exhausting gear until the lowest gear is reached. According to the control method, scene judgment is accurate, the cooking fume exhausting effect is good, pollution of cooking fume to the cooking fume sensor is lowered, and the sucking effect and control reliability of the range hood are improved.

Owner:GUANGDONG MACRO GAS APPLIANCE

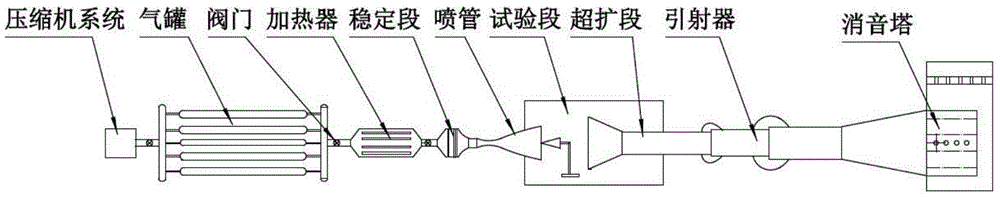

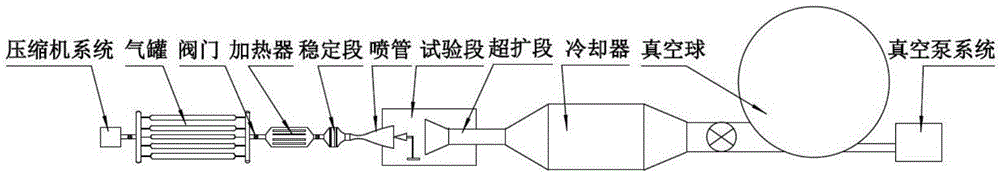

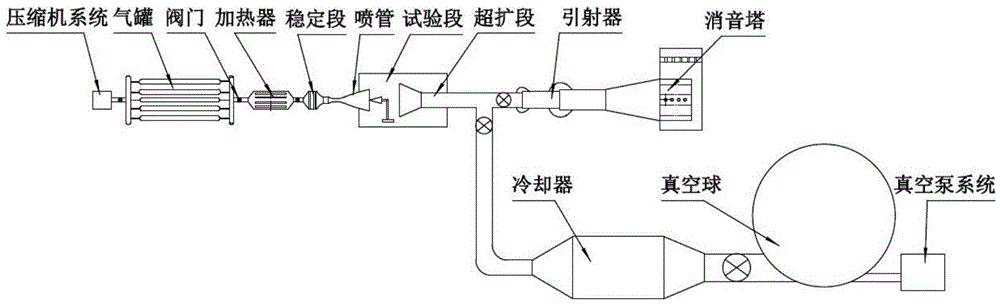

Energy-saving environment-friendly layout of large-scale routine hypersonic wind tunnel

ActiveCN105628331ASolve the problem of high exhaust noise and waste heat wasteReduce the impactAerodynamic testingTest segmentEngineering

The invention provides an energy-saving environment-friendly layout of a large-scale routine hypersonic wind tunnel. The system comprises a gas tank, a heater, a stabilization segment, a jet pipe, a test segment, an ultra-expanding segment and a heat exchanger, wherein the stabilization segment, the jet pipe, the test segment and the ultra-expanding segment are successively connected to form a major test wind tunnel assembly, the heat exchanger comprises an intermediate channel and a peripheral channel encircling the intermediate channel, an outlet of the ultra-expanding segment communicates with the intermediate channel of the heat exchanger, the gas tank communicates with the peripheral channel of the heat exchanger, and high-pressure gas in the gas tank is sent into the heater via the peripheral channel of the heat exchanger by means of a gas pipeline, then is sent into the stabilization segment after passing through the heater and is discharged through flowing through the intermediate channel of the heat exchanger after being tested in the major assembly of a test wind tunnel. According to the invention, energy consumption is reduced, the operation cost is decreased, at the same time, the influence on the environment is reduced, and the problems of large exhaust noise and waste of afterheat of a conventional hypersonic wind tunnel can be solved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Suction catheter for thrombolysis and suction of thrombotic substance

InactiveCN105920720AEasy to handleAvoid the disadvantages of insufficient concentrationCatheterIntravenous devicesAspiration catheterThrombolysis

The invention relates to a suction catheter for thrombolysis and suction of thrombotic substance. The suction catheter comprises a central catheter, one end of the central catheter is connected with a suction connecting tube and an administration tube respectively, a liquid outlet of the suction connecting tube is connected with a middle tube, a liquid suction connecting head is arranged at each of two ends of the middle tube, the other end of the suction connecting tube is connected with a two-way valve, a liquid outgoing port end of the two-way valve is connected with a catheter joint, the other end of the catheter joint is connected with a rear-end suction catheter which is connected with a suction pump, a liquid incoming port end of the administration tube is connected with an administration one-way valve, and the other end of the administration one-way valve is connected with an administration injector. The suction catheter has the advantages of simple structure, convenience in operation, low manufacturing cost and convenience in clinical use.

Owner:HENAN YADU IND

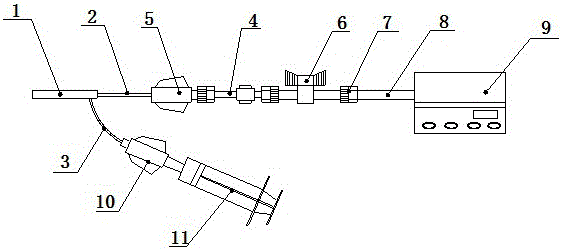

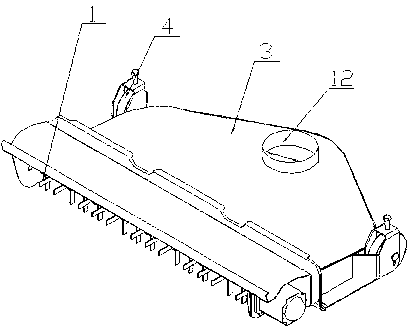

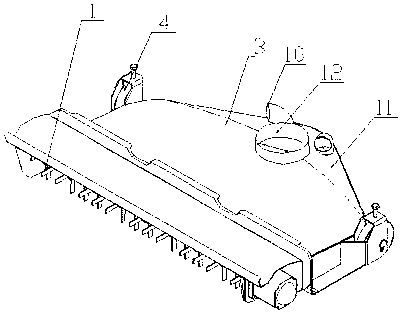

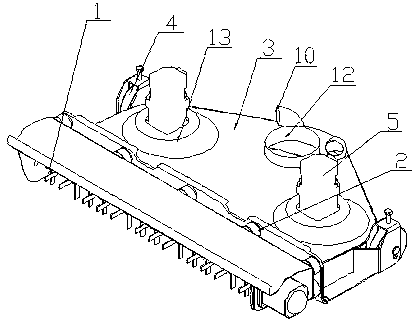

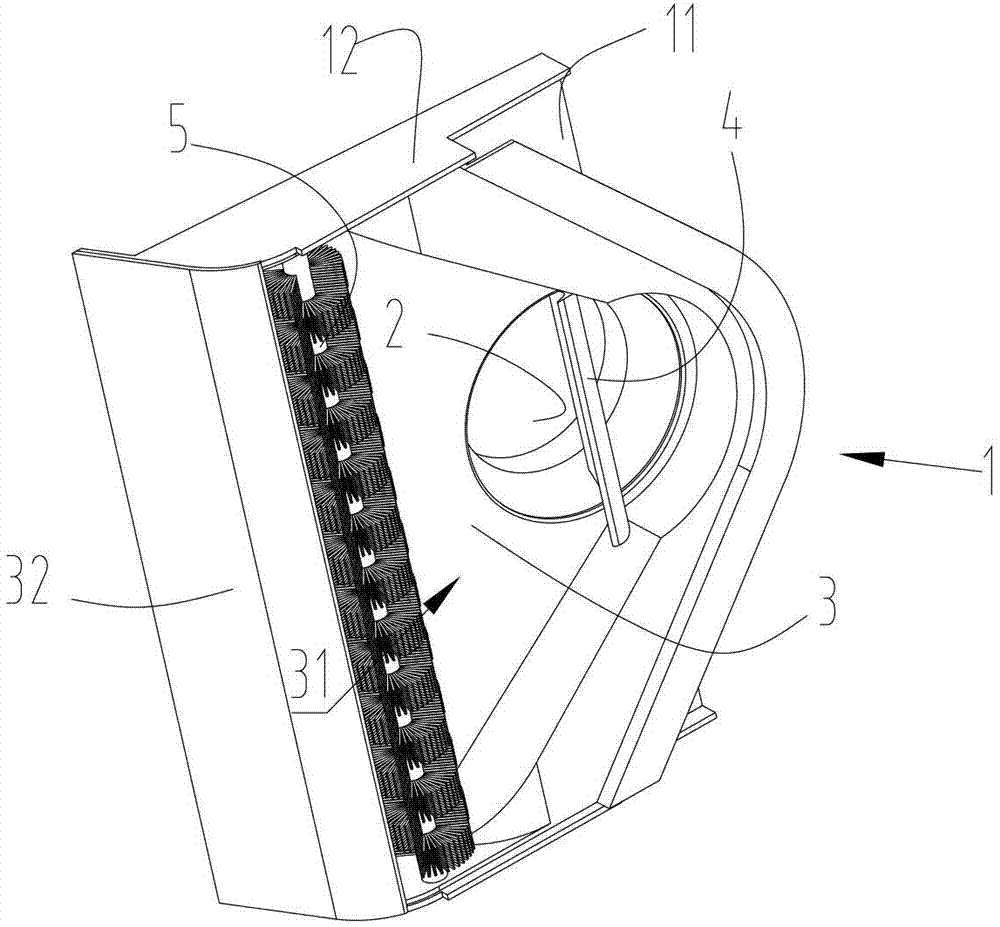

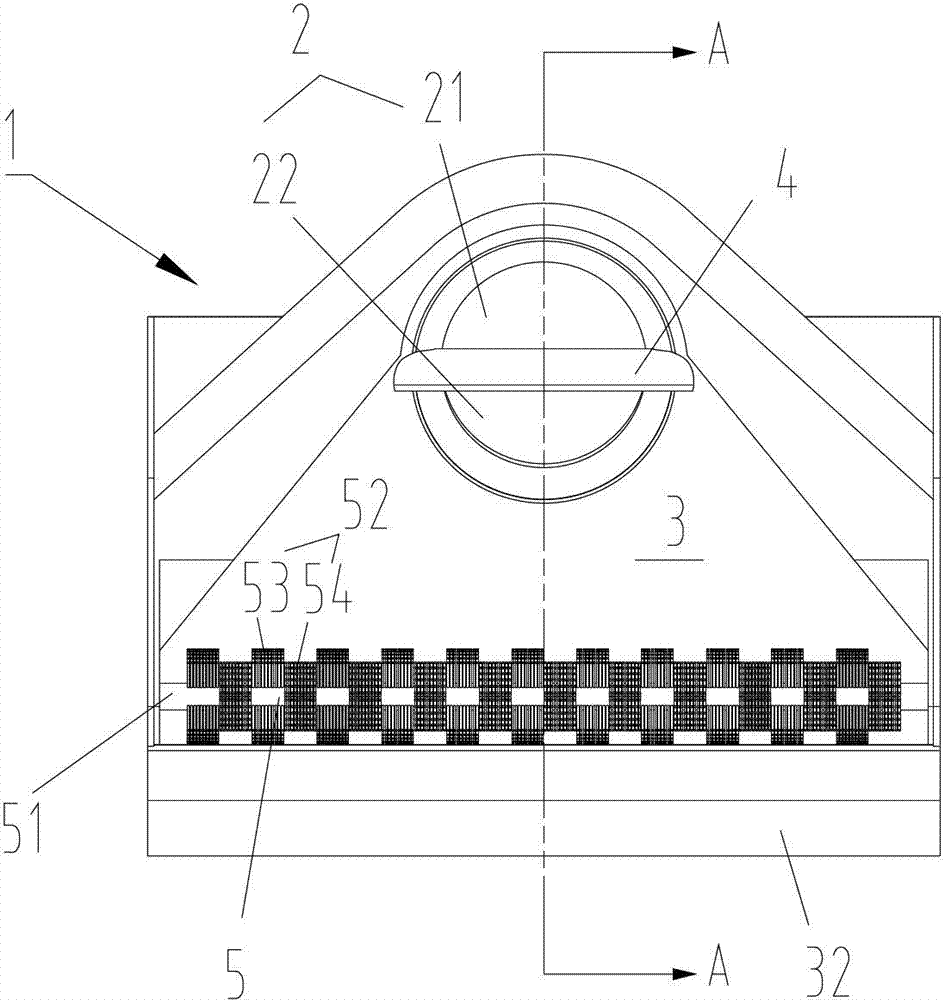

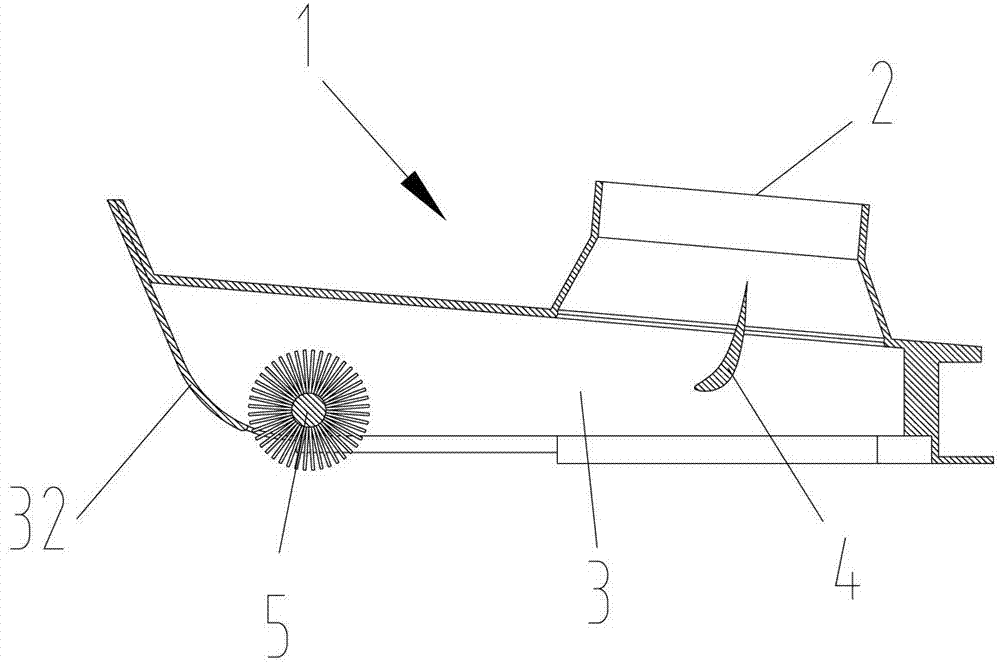

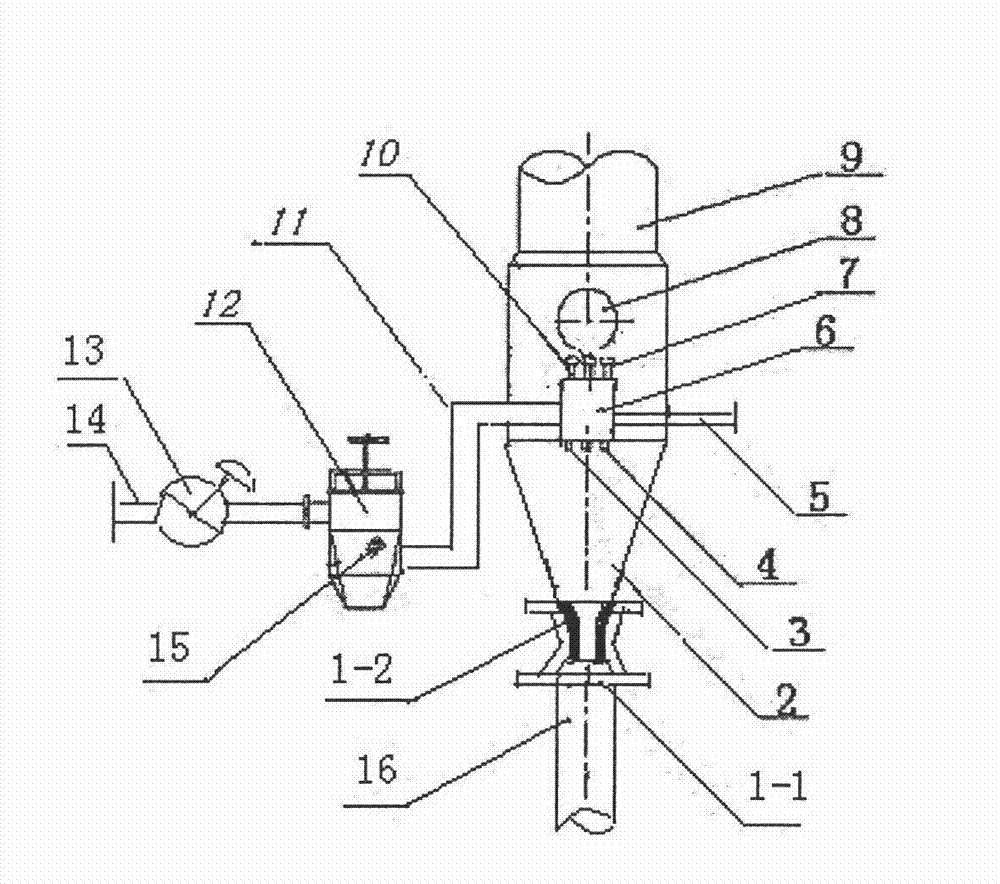

Ultra-wide garbage grinding and collecting device

The invention discloses an ultra-wide garbage grinding and collecting device. The device comprises a suction port body, casters and a suction port, wherein a garbage grinding device is installed on the front part of the suction port body, a reverse blowing cavity is formed behind the sucking port in the sucking port body and is provided with a reverse blowing port which is communicated with an external dust absorbing fan, conical barrels are symmetrically arranged on the left side and the right side in front of the sucking port body, and sucking port sweepers are installed in the conical barrels and on a sweeper motor. The device has the characteristics of suitability for thoroughly sweeping different pavements, capability of grinding and collecting larger garbage, large garbage collecting working surface, high cleaning efficiency, low energy consumption and convenience in sweeper changing.

Owner:YANTAI HAIDE SPECIAL VEHICLE

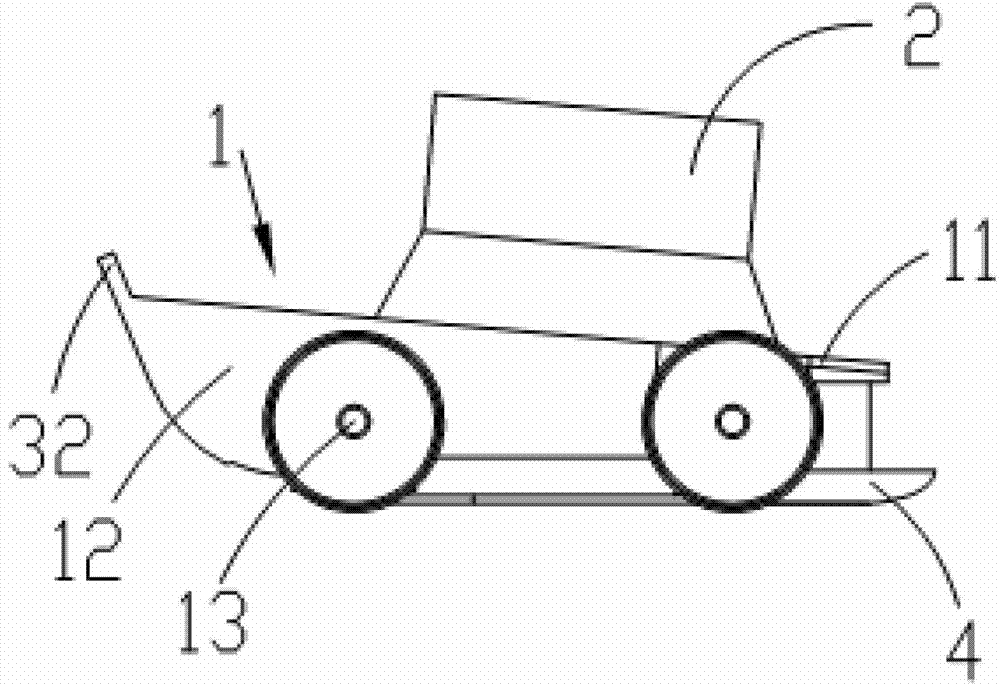

Cleaning nozzle and cleaning trolley

The invention discloses a cleaning nozzle. The cleaning nozzle comprises a nozzle body capable of moving along an object to be cleaned. The nozzle body is provided with an air inlet. A gas gathering area around the air inlet is formed on the lower side of the nozzle body. An opening where gas mingled with garbage passes through is arranged at the front end of the gas gathering area. Gas around the nozzle can enter into the gas gathering area all around and enters into the air inlet. A rib capable of guiding gas mingled with garbage to enter into the air inlet is arranged below the air inlet. The length direction of the rib is vertical to the front and back direction of the nozzle body, and the air inlet is divided into a front air inlet and a back air inlet. The invention further provides a cleaning trolley which uses the cleaning nozzle. As the rib arranged below the air inlet can guide gas mingled with garbage entered from the opening of the front gas gathering area into a nose air intake, the suction efficiency of the nozzle is high and the practicality is great.

Owner:ZOOMLION HEAVY IND CO LTD

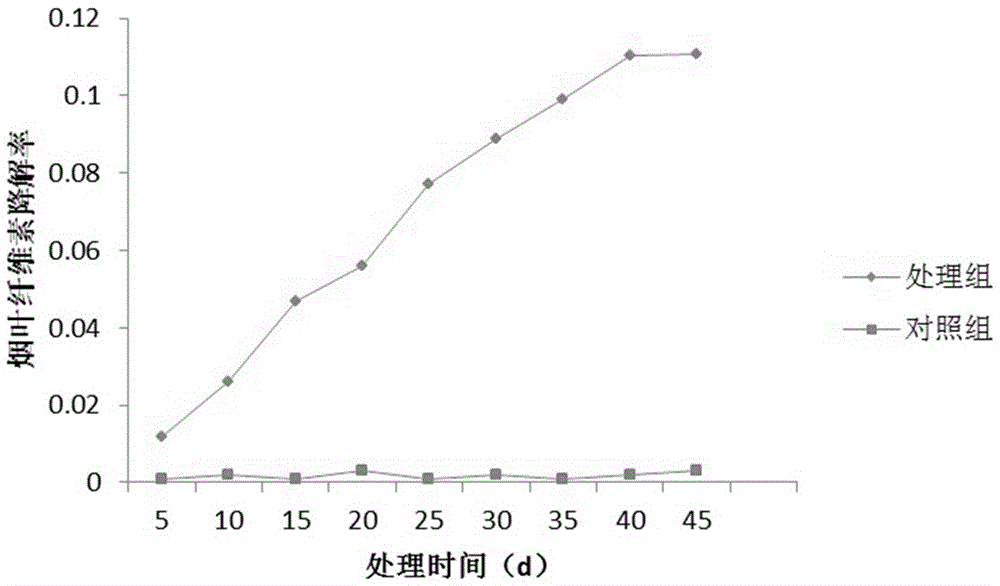

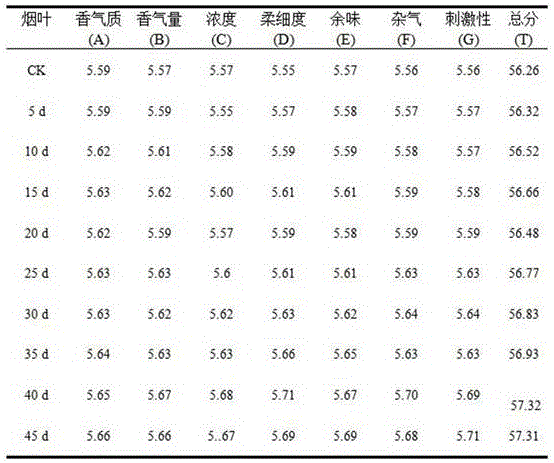

Application of bacillus subtilis to degradation of cellulose in tobacco products

ActiveCN106723311AImprove the level ofProlong the aging processTobacco treatmentCelluloseNicotiana tabacum

The invention belongs to the technical field of tobacco preparation, in particular to application of a bacillus subtilis xp bacterial strain to degradation of cellulose in tobacco products. The bacillus subtilis xp bacterial strain is currently preserved in the China Center For Type Culture Collection, and a preservation number is CCTCC NO:M 2011452. The bacillus subtilis xp bacterial strain is used for reducing the cellulose content of the tobacco products. In application, the bacillus subtilis xp bacterial strain is made into a bacterial agent, the bacterial agent is uniformly sprayed to surfaces of the tobacco products according to a tobacco product mass ratio of 1.2%, and then storage for mellowing is performed for 40-50d under conditions that the temperature is 30-35DEG C, and humidity is 55-65%. By selection of the specific bacillus subtilis bacterial strain, effectiveness in reduction of the cellulose content of the tobacco products can be proved, tobacco grade is raised, and a tobacco mellowing process is accelerated while mellowing effects are guaranteed.

Owner:CHINA TOBACCO HENAN IND

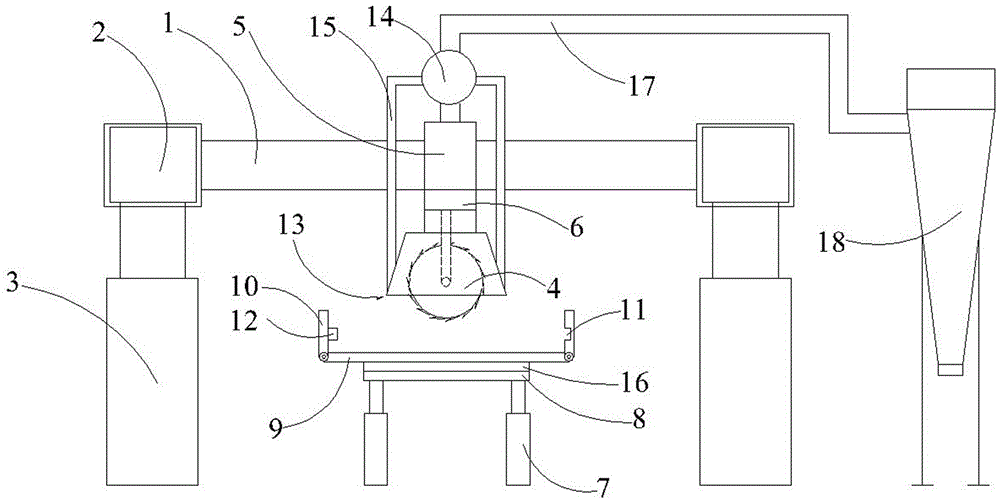

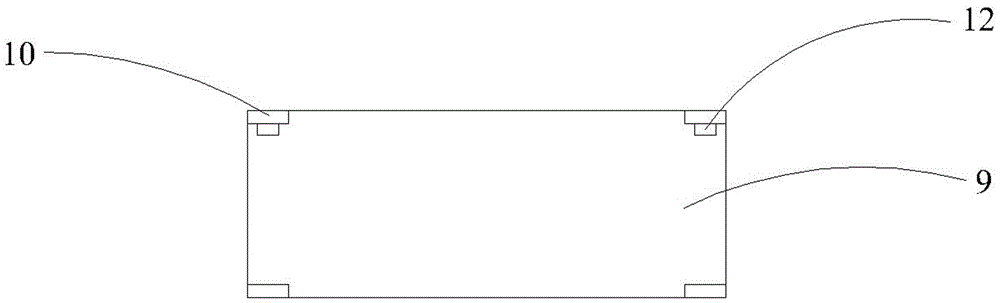

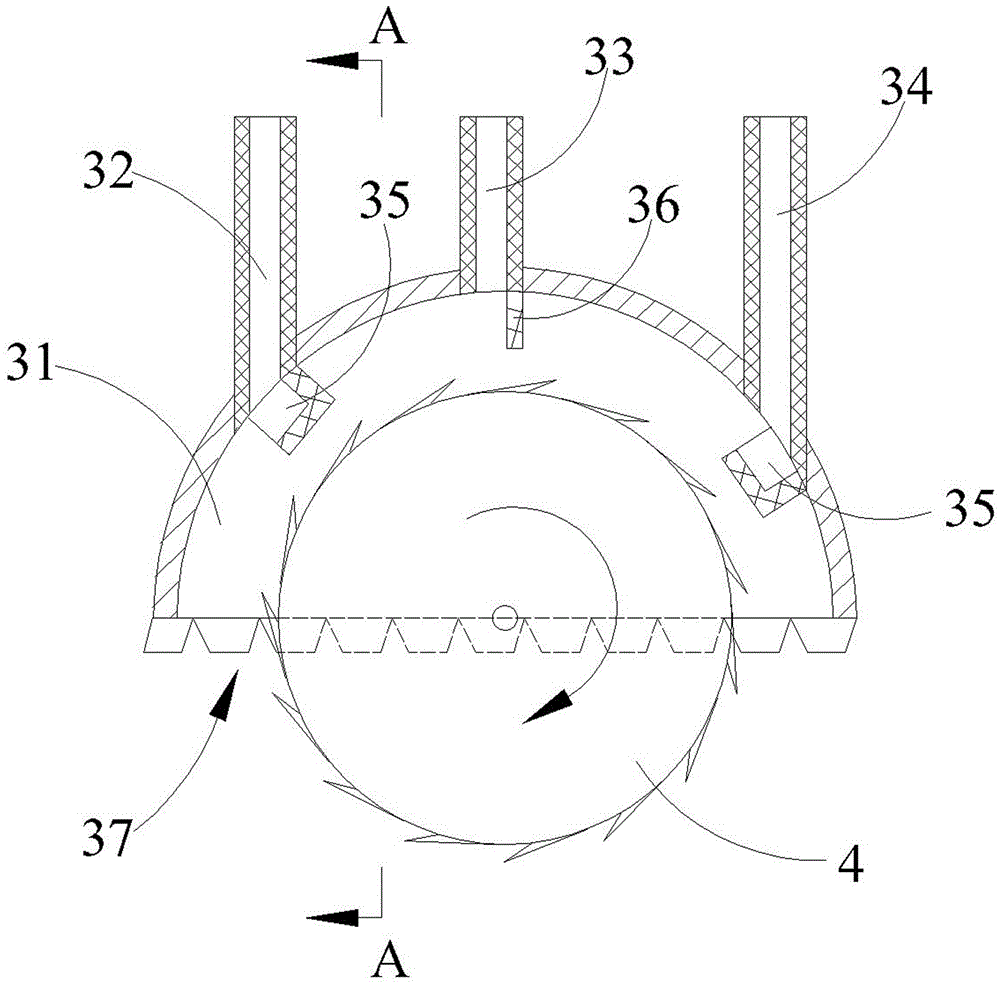

Wallboard cutting saw

PendingCN105619621AExpand the scope of applicationPurify the operating environmentWorking accessoriesStone-like material working toolsElectric machineryWall plate

The invention relates to a wallboard cutting saw. The wallboard cutting saw comprises a support, a cutting device, a dedusting device and a wallboard fixing table. The support comprises a cross rail, sliding rails and stand columns, wherein the two ends of the cross rail are sleeved with the sliding rails correspondingly, and the stand columns are arranged at the bottoms of the sliding rails. The two sliding rails are parallel to each other, and the cross rail can move along the sliding rails. The cutting device comprises a base, a saw blade and a motor used for driving the saw blade to rotate. The cross rail is sleeved with the base. The motor is fixedly connected with the base. The wallboard fixing table comprises hydraulic rods, a supporting plate, a turntable bearing and a fixing plate, wherein the number of the hydraulic rods is four, and the four hydraulic rods are connected with the four vertex angles of the bottom of the supporting plate in a hinged mode correspondingly. The dedusting device comprises a dust hood, a suction fan, a cyclone separator and an air pipe, wherein the dust hood is arranged above the saw blade, and the air pipe is connected with the dust hood and the suction fan. The top of the dust hood is fixedly connected with the bottom of the base. An outlet of the suction fan is connected with the cyclone separator through an exhaust pipeline. The wallboard cutting saw is convenient to operate, high in cutting precision and good in dust collection effect.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

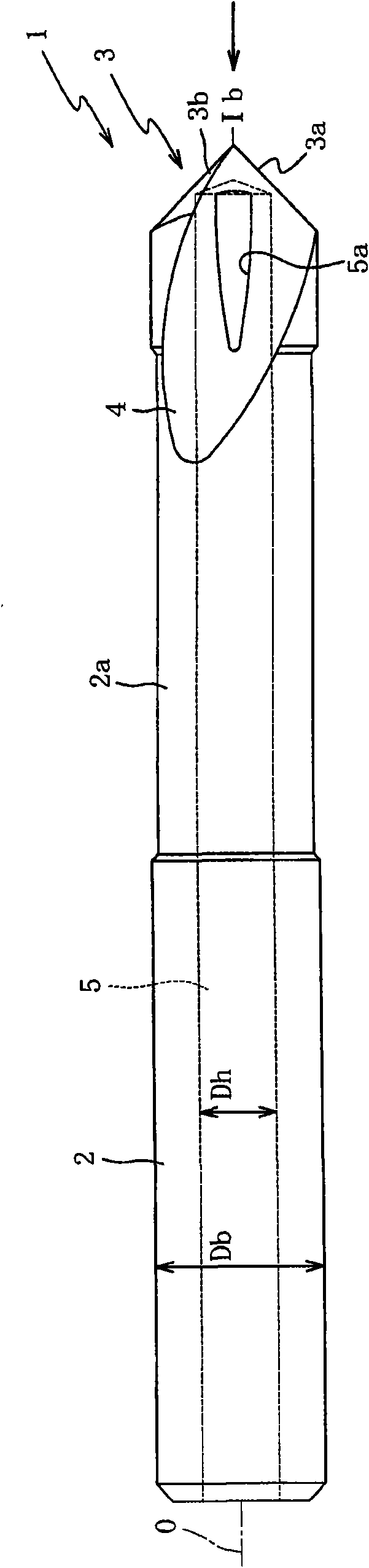

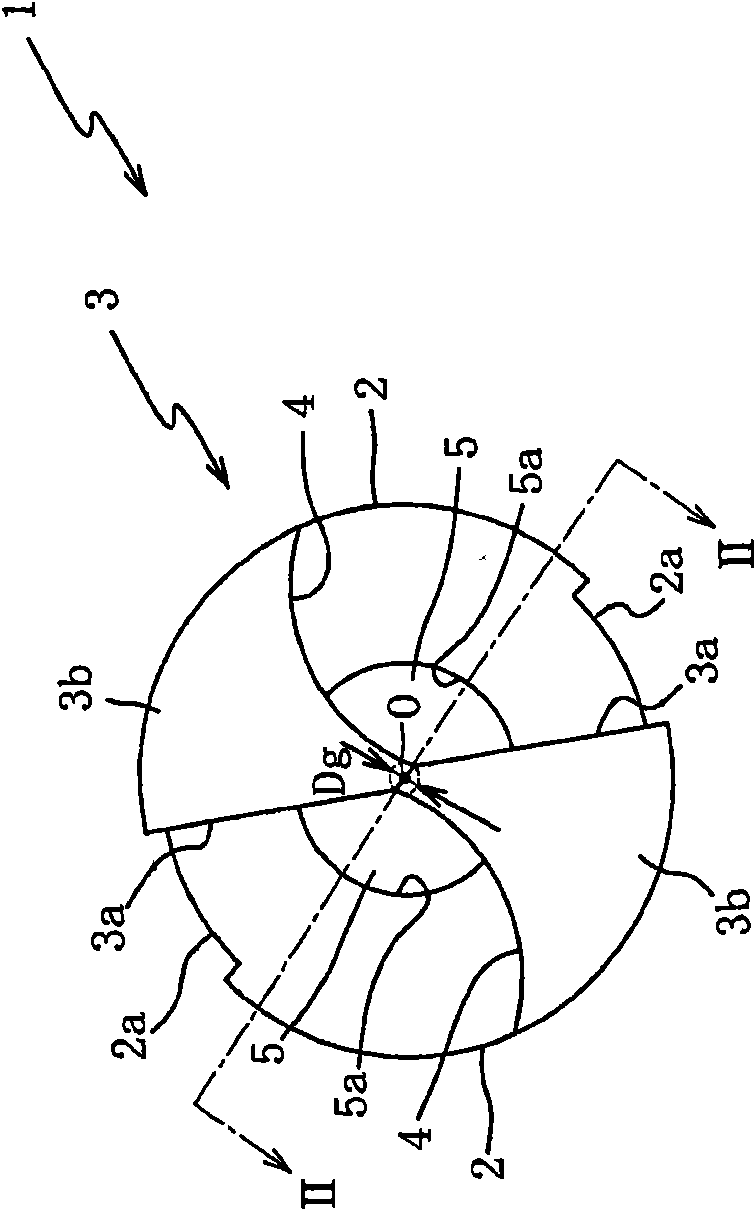

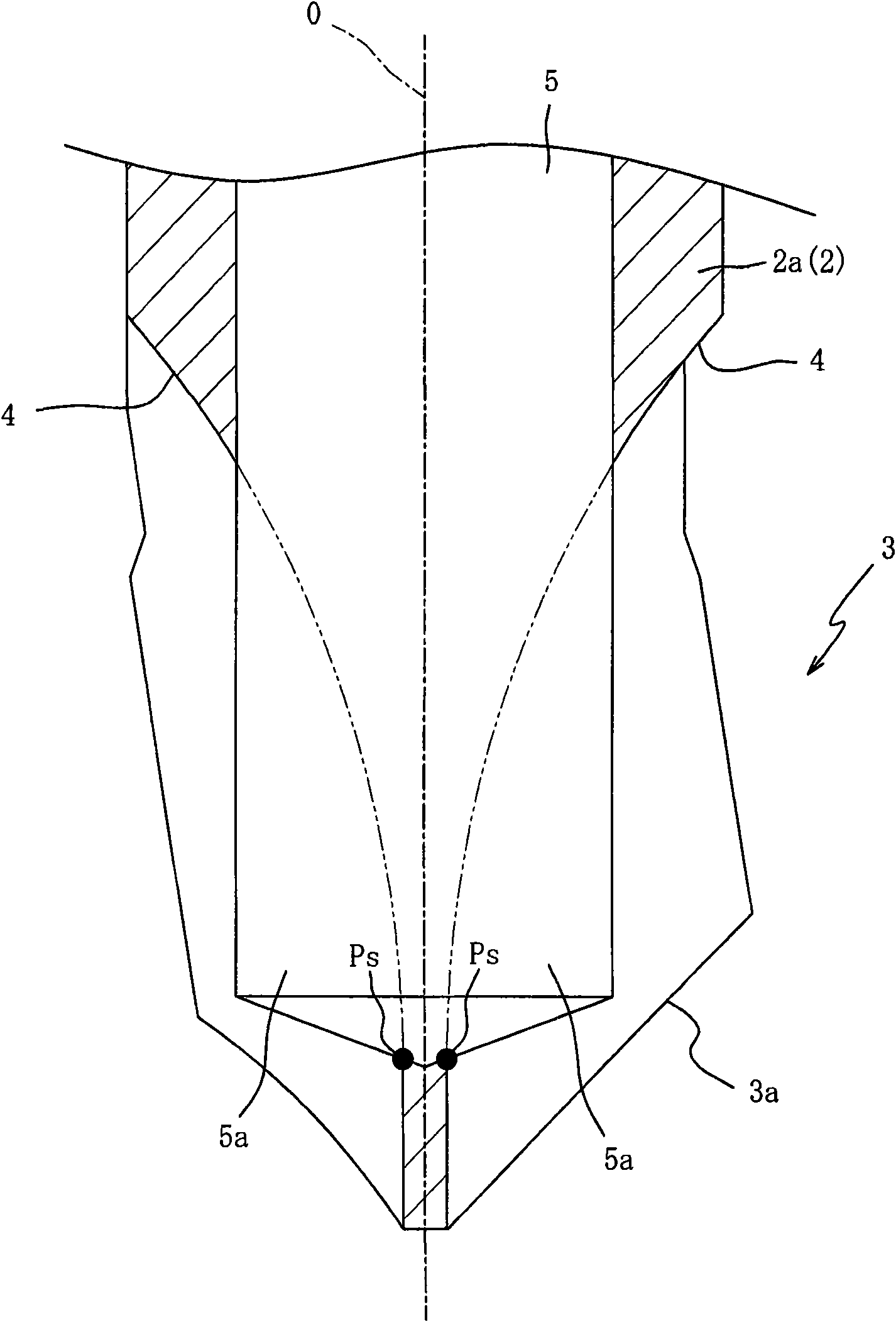

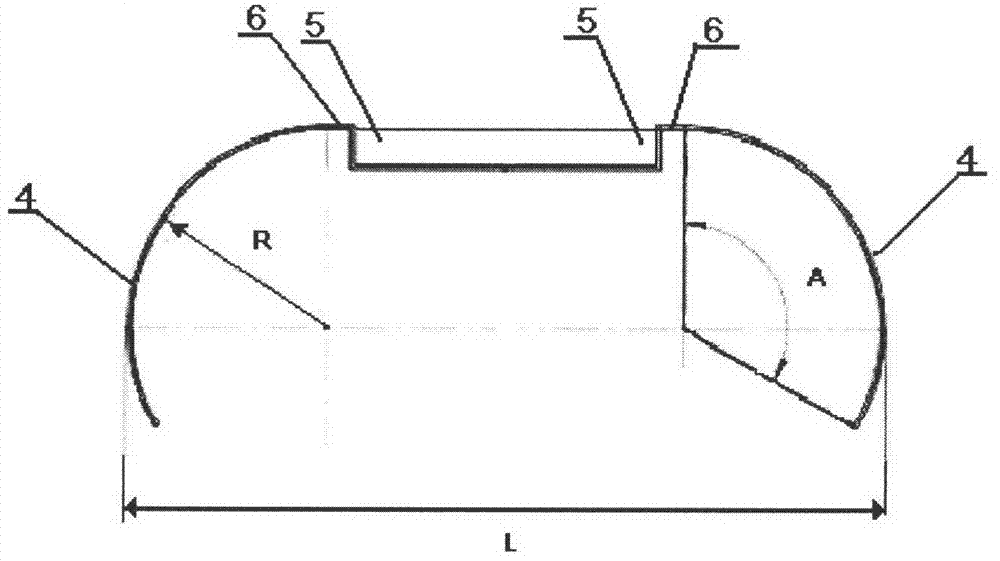

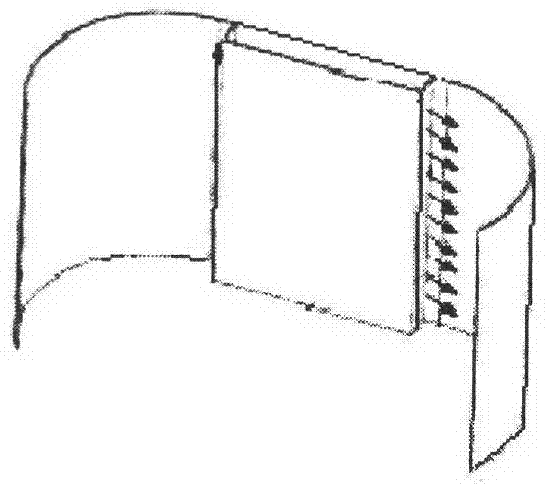

Drill

ActiveCN101528394AAvoid pollutionReduce processing costsTransportation and packagingMetal working apparatusEngineeringDrill

The present invention provides a drill that by forcibly suctioning and discharging of chips, attaining not only prevention of environmental pollution but also simplification of cleaning operation. Drill (1) has air suction hole (5) provided with aperture (5a). Accordingly, by air suctioning through the air suction hole (5), any chips generated at cutting processing can be forcibly suctioned from the aperture (5a). Thus, as the chips can be discharged without the use of cutting liquid, there can be attained prevention of environmental pollution. Further, as not only can the chips be forcibly suctioned from the aperture (5a) but also the chips having been suctioned from the aperture (5a) can be discharged through the air suction hole (5), scattering of the chips on the workpiece can be avoided to thereby attain simplification of cleaning operation.

Owner:OSG

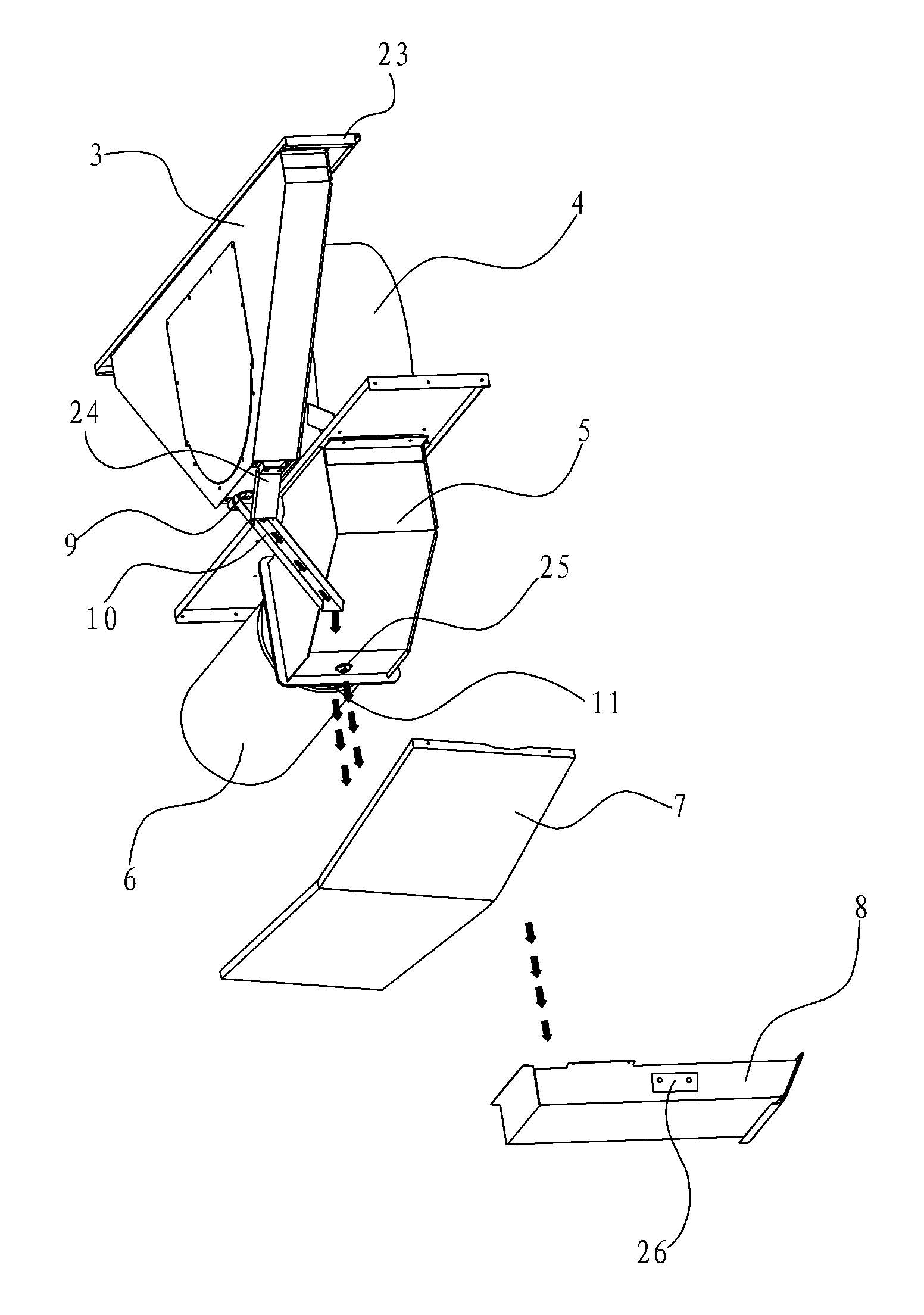

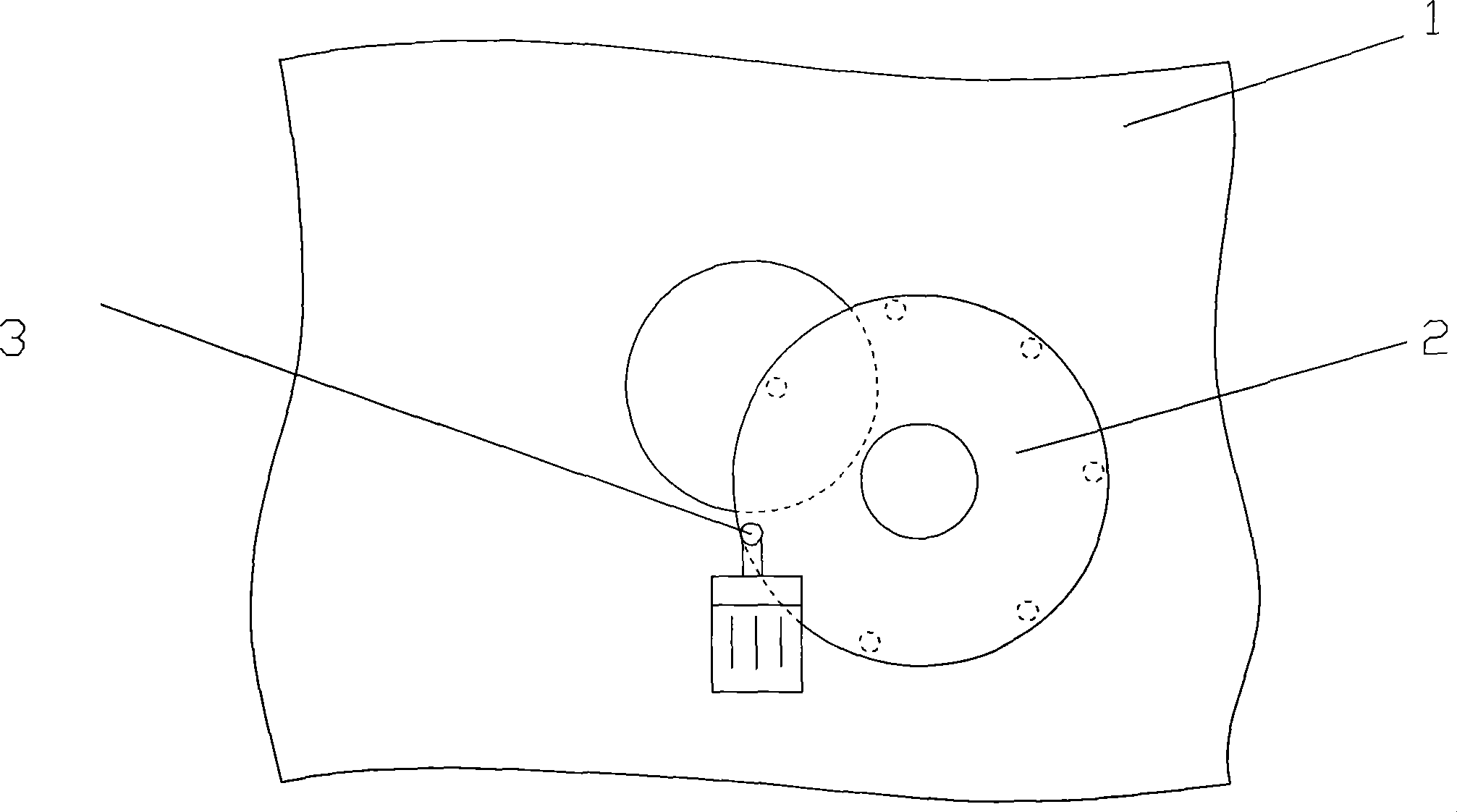

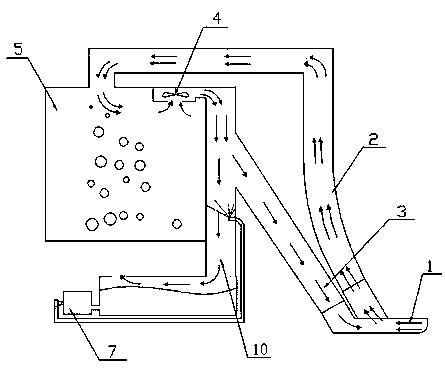

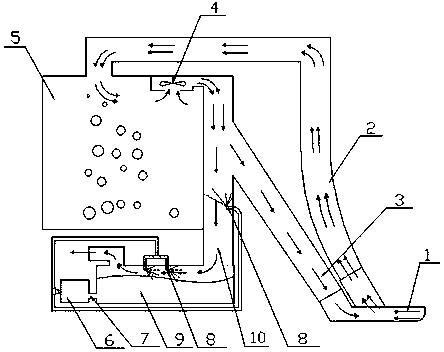

Whirlwind generating device and range hood provided with same

InactiveCN102954515AReduce escapeImprove suction effectDomestic stoves or rangesLighting and heating apparatusExhaust fumesCooker

The invention provides a range hood. The range hood comprises a fan system, an exhaust fume collecting hood and wind inlets communicated with the fan system, wherein the wind inlets are arranged on the exhaust fume collecting hood. The range hood also comprises a whirlwind generating device, wherein the whirlwind generating device is arranged between a cooker panel and the exhaust fume collecting hood and comprises hood body parts and airflow jet parts; the airflow jet parts are used for jetting airflow toward the hood body parts; and the hood body parts are used for guiding airflow directions when the fan system and the airflow jet parts are simultaneously started and then generating whirlwind airflow flowing toward the wind inlets. As the whirlwind airflow can be generated, the oil fume suction of the range hood is obviously increased, thus oil fume escape can be reduced and the oil fume suction effect can be promoted. Besides, as the whirlwind effect can be generated, the user experience can be promoted.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

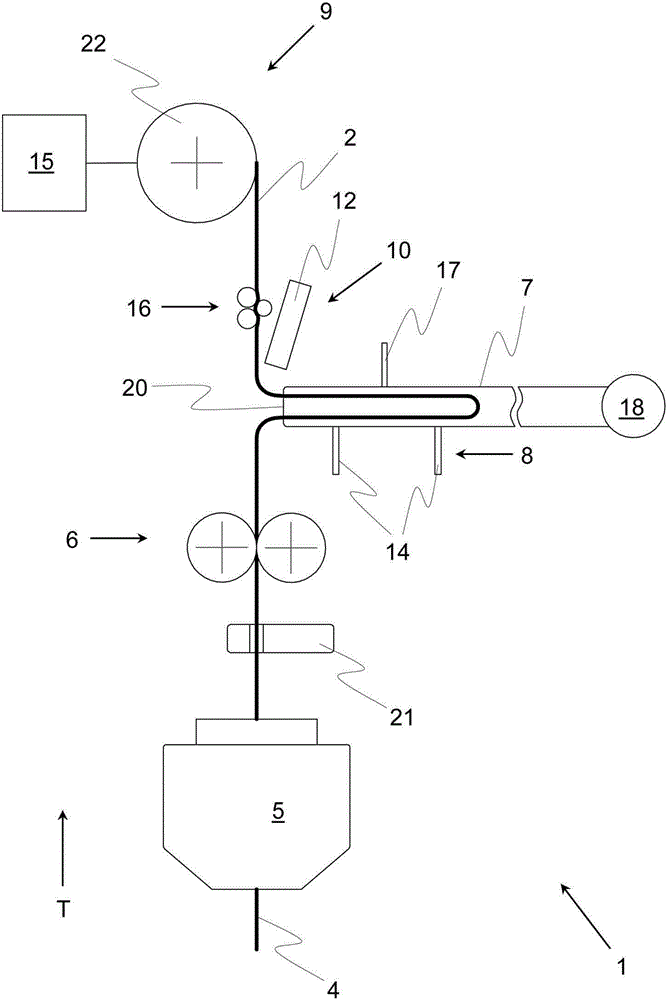

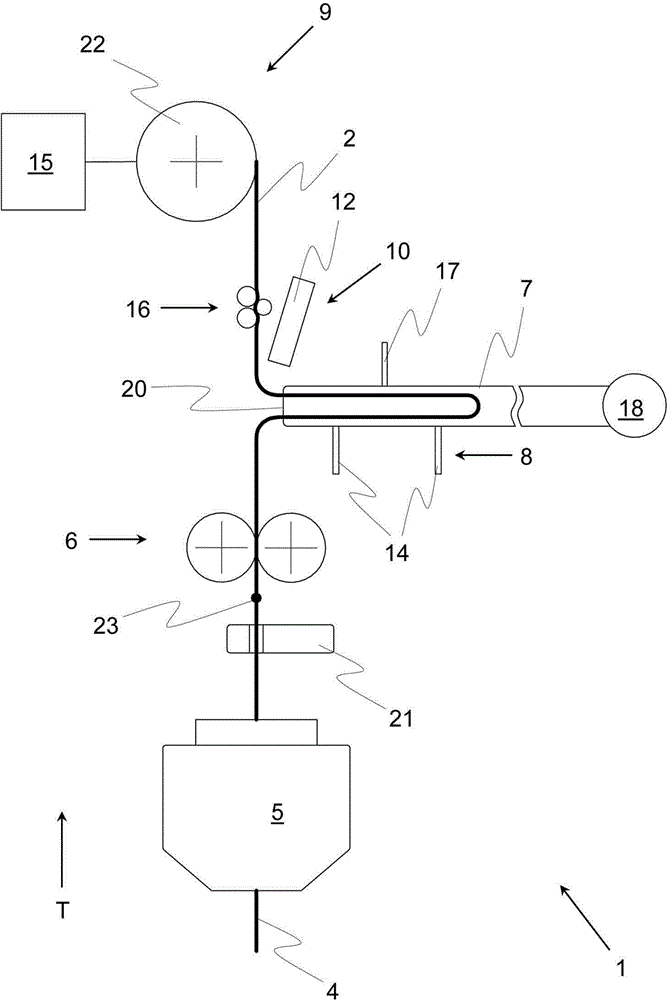

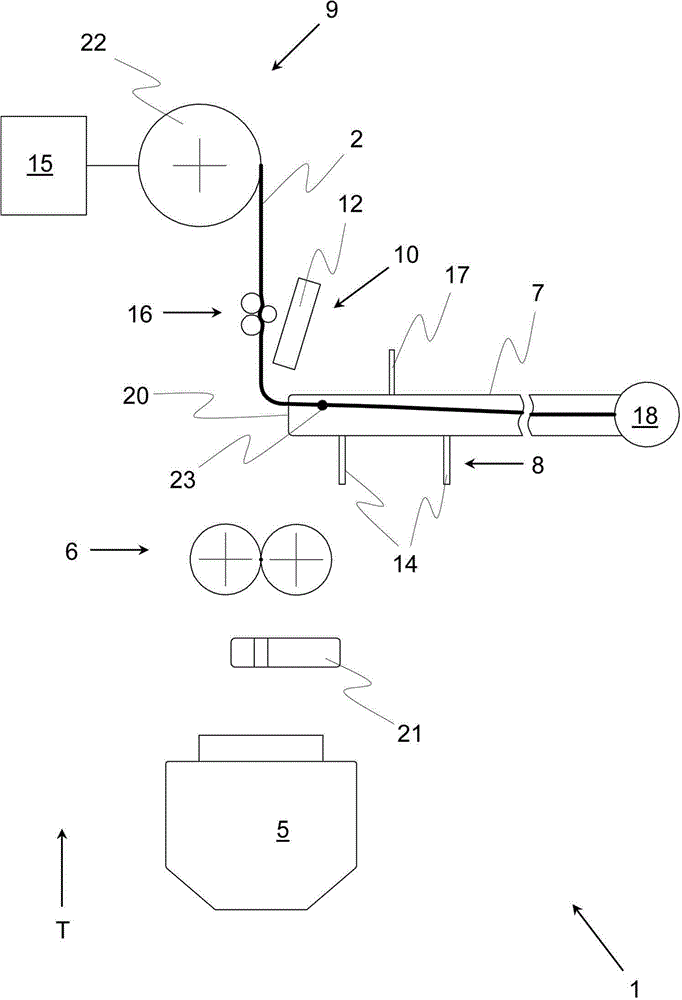

Spinning Point Of Spinning Machine And Method For Operation Of Same

ActiveCN104060350AImprove suction effectActive interruption of productionPiercing arrangementsFilament handlingYarnEngineering

The invention relates to a spinning point (1) of a spinning machine, whereas the spinning point (1) includes a spinning unit (5), a drawing-off device (6) for the yarn (2) downstream of the spinning unit (5) in the direction of transport (T) and a yarn accumulator (7) downstream of the drawing-off device (6) for the intermediate accumulation of a section of yarn, whereas the yarn accumulator (7) is allocated a sensor system (8) for monitoring the filling level of the yarn accumulator (7), whereas the spinning point includes a spooling device (9) for the yarn (2) downstream of the yarn accumulator (7), along with a return unit (10), with the assistance of which an end of the yarn (11), which is found within the yarn accumulator (7) after a yarn break, is able to be returned in the area of the spinning point (1). What is also proposed is a method for the operation of a spinning point (1), characterized in that its spooling device (9) is stopped in such a manner that, after the stop of the spooling device (9), an end section of the yarn (2) remains within the yarn accumulator (7), that, subsequent to this, a part of the yarn (2) is separated with the assistance of a yarn separation unit (17) internal to the spinning point, and that the end of the yarn (11) that newly arises in this manner is returned with the assistance of a return unit (10) internal to the spinning point in the area of the spinning point (1), and that a spinning process is then carried out.

Owner:MASCHINENFABRIK RIETER AG

Wet dust suppressor for use at circulating air outlet of road sweeping equipment

The invention discloses a wet dust suppressor for use at a circulating air outlet of road sweeping equipment. The wet dust suppressor comprises a suction nozzle, a suction tube, a back-blowing tube, a fan and a refuse box. An air passage used for discharging part of dust-bearing air is connected to the back-blowing tube and is provided with a spray dedusting and water recycling unit. The wet dust suppressor has the advantages that secondary pollution by raised dust occurring in cleaning operation of the road sweeping equipment is avoided, dedusting is effective, circulating water is utilized, and spray dedusting is effective.

Owner:YANTAI HAIDE SPECIAL VEHICLE

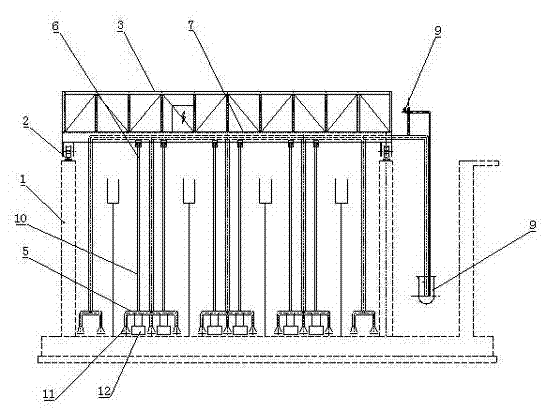

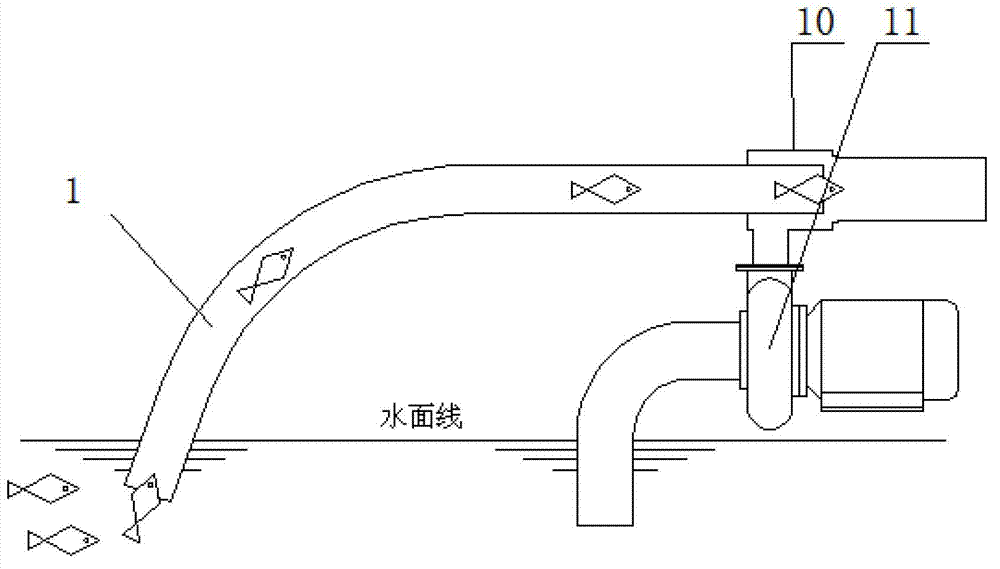

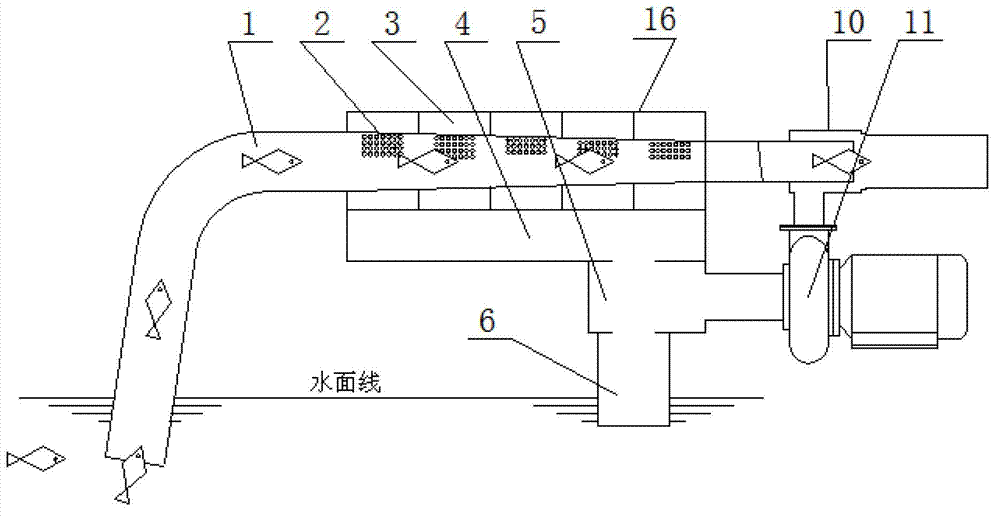

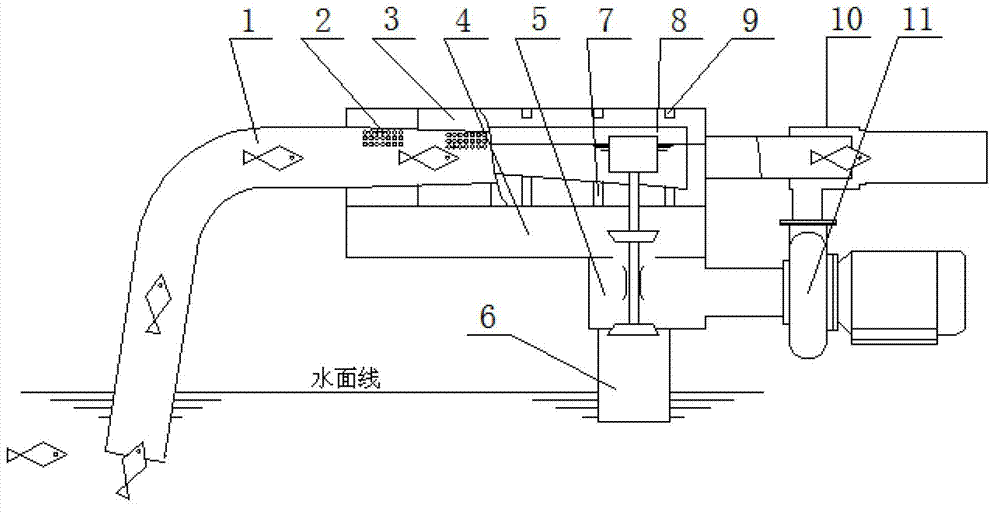

Siphon type suction dredge

InactiveCN102886162AEasy to suck mudReduce the required powerSettling tanks feed/dischargeSiphonVacuum pumping

The invention relates to a siphon type suction dredge. The siphon type suction dredge comprises a working bridge, guide rails, a driving device, sludge suction nozzles, underwater sludge suction pipes and overwater sludge discharge pipes, wherein the working bridge stretches across the guide rails; and the driving device is arranged on the working bridge. The innovation is that: the bottom of a pool is provided with a plurality of transverse sludge suction pipes which are connected with the underwater sludge suction pipes and the overwater sludge discharge pipes, the tail ends of the overwater sludge discharge pipes are connected into a water sealing cylinder, and the overwater sludge discharge pipes are also connected with a vacuum-pumping system; and a plurality of sludge suction nozzles are arranged on each transverse sludge suction pipe, and a rhombic scraper is arranged between the adjacent sludge suction nozzles. The working bridge does reciprocating motion along the guide rails; after the vacuum-pumping system is started, sludge enters the transverse sludge suction pipes, the underwater sludge suction pipes and the overwater sludge discharge pipes through the sludge suction nozzles under negative pressure, and then falls into the water sealing cylinder; the sludge is divided toward two sides and is pushed to positions in front of the sludge suction nozzles by utilizing the forward movement of the rhombic scrapers, so that the sludge suction nozzles can suck the sludge conveniently, and the siphon type suction dredge has a good sludge suction effect; and meanwhile, the resistance when the working bridge moves forwards is reduced, so that the power and energy consumption of the driving device can be correspondingly reduced.

Owner:NANTONG BEICHEN MACHINERY EQUIP MFGCO

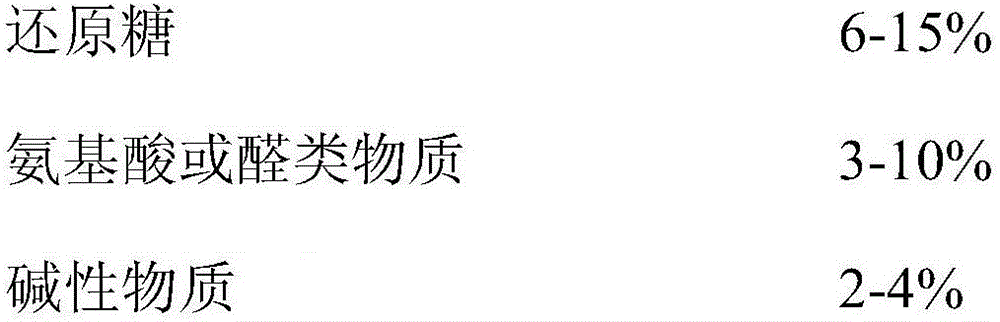

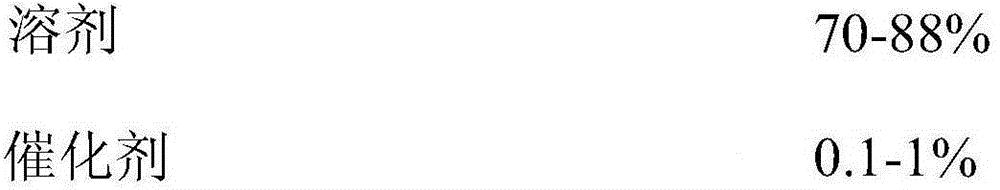

Formula of Amadori reactive flavor, preparation method of Amadori reactive flavor and use of Amadori reactive flavor

ActiveCN106520368AGreat tasteImprove fullnessTobacco preparationEssential-oils/perfumesSolventSide reaction

The invention provides a formula of an Amadori reactive flavor, a preparation method of the Amadori reactive flavor and a use of the Amadori reactive flavor. The preparation method comprises that reducing sugar, amino acids or an aldehyde substance as a raw material undergo a reflux reaction in a solvent with a drying agent in a basic environment to produce Schiff bases of the amino acid and reducing sugar, after the reaction, N-substituted glycosylamine is subjected to Amadori rearrangement to form an Amiadori reactant in the presence of a catalyst, the reactant is subjected to vacuum concentration to form a crude product, the crude product is subjected to recrystallization, and the crystals are dried to form an Amadori reactive mixture. The preparation method has the advantages of simple operation, low cost and high yield, prevents the dark brown viscous material which is produced from the reducing sugar and amino acid and is difficult to treat, and has les side reaction. The reaction product can be used in cut tobacco, cut stems, tobacco sheets and cigarette papers, improve the taste of cigarettes, increase the aroma of tobacco sheet cigarettes and improve the smoking effects.

Owner:HUBEI CHINA TOBACCO IND

Super absorbent dust-free wiping cloth and manufacturing method thereof

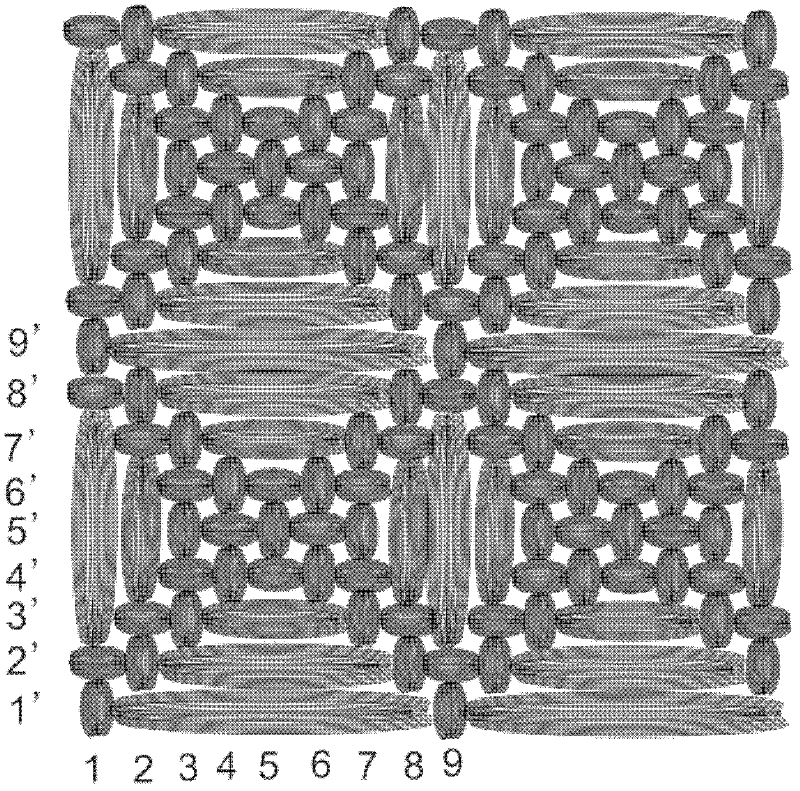

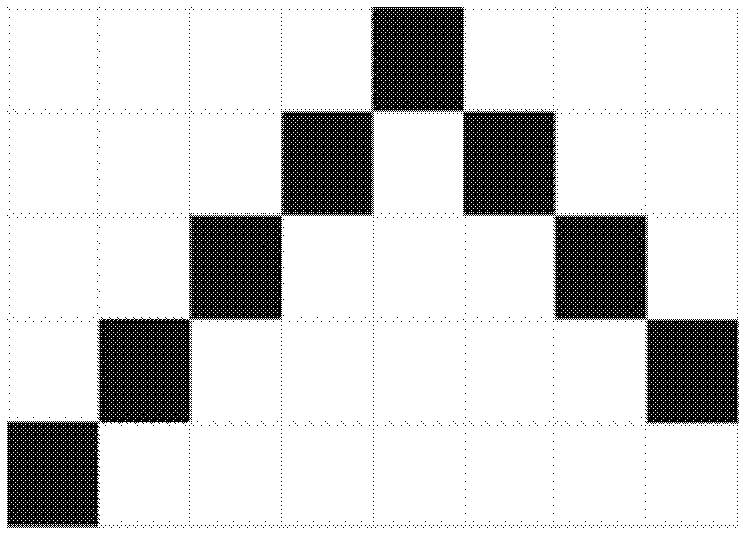

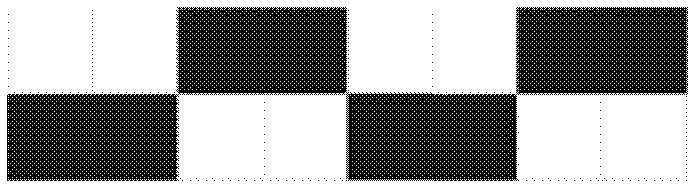

InactiveCN102505253ALoose arrangementLarge specific surface areaCarpet cleanersFloor cleanersSuper absorbentLaser cutting

The invention discloses a super absorbent dust-free wiping cloth and a manufacturing method thereof. The wiping cloth is formed by interweaving warps and wefts and is characterized in that the dust-free wiping cloth is formed by circularly arranging square concave weave repeat units formed by interweaving the warps and the wefts along the warp direction and the weft direction respectively; at least one of the warp and the weft is formed by superfine fiber filaments; and in one weave repeat unit, the warps and the wefts are respectively arranged stepwise and upward in sequence from the central lowest point, and the floating length of the adjacent warps and the adjacent wefts on the steps increases in sequence to form concavo-convex patterns which are piled up alternately from low to high and have four high sides and low middle. The manufacturing method comprises the steps of beaming, drafting and reeding, weaving, weight reducing, tenter setting, laser cutting and packaging, thereby obtaining the super absorbent dust-free wiping cloth. The super absorbent dust-free wiping cloth has soft handfeel, good wiping effect and super absorbency and can be used in a dust-free room with a higher cleanliness requirement. The manufacturing method is simple and can be used for manufacturing the high-quality dust-free wiping cloth.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Full automatic control water jet condenser with characteristics of concentric diameter changing throat part, temperature control, constant water pressure and adjustable nozzles

InactiveCN103074453AGood effectStable high vacuumSugar juice boiling/evaporationAutomatic controlSpray nozzle

The present invention discloses a full automatic control water jet condenser with characteristics of a concentric diameter changing throat part, temperature control, constant water pressure and adjustable nozzles, wherein the full automatic control water jet condenser is used in sugar refineries. The full automatic control water jet condenser is characterized in that part of spray nozzles and jet nozzles arranged in a water chamber are nozzles provided with a pneumatic opening and closing control device, a throat part of the condenser is provided with a concentric diameter changing throat part device, and the pneumatic opening and closing controlled nozzles and the concentric diameter changing throat part device can jointly act and perform adjustment control according to a water temperature and a water supply amount of water entering the condenser water chamber. According to the present invention, a pressure transmitter for detecting a vacuum degree of a container (a sugar boiling tank or an evaporation tank), a temperature transmitter for detecting a temperature of a material (a syrup and a sugar paste) inside the container, and a pressure transmitter for detecting water pressure inside the water chamber jointly adjust and control an opening degree of an automatic control water inlet valve, such that the condenser can achieve a high vacuum degree under a normal production condition, and can achieve a preset vacuum degree and a preset material temperature during production condition changing, wherein the existing wet type water jet condensers used in sugar refineries at home and abroad do not have the advantages of the condenser of the present invention.

Owner:NANNING MAST SUGAR MACHINE EQUIP MFG CO LTD

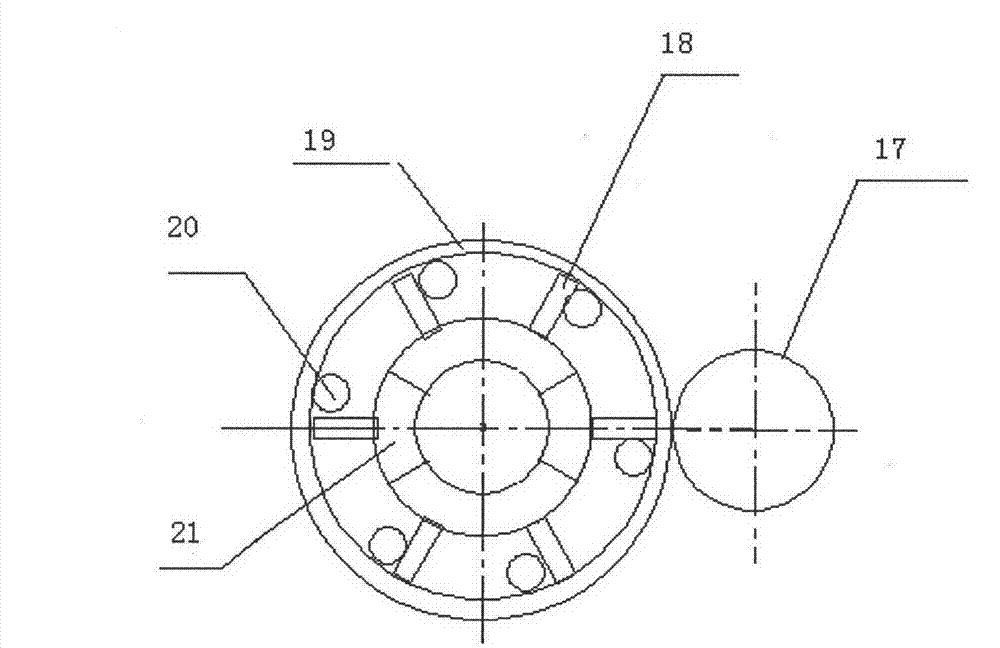

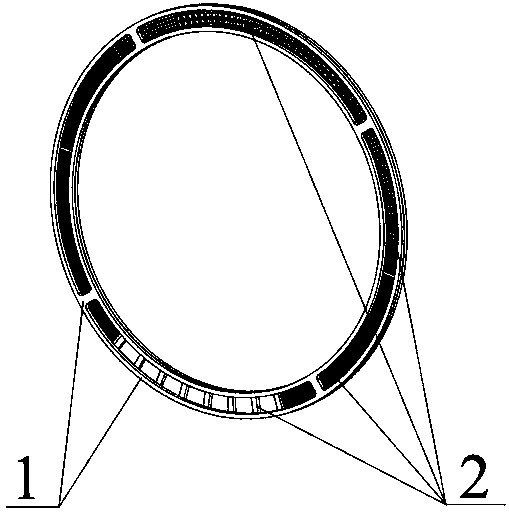

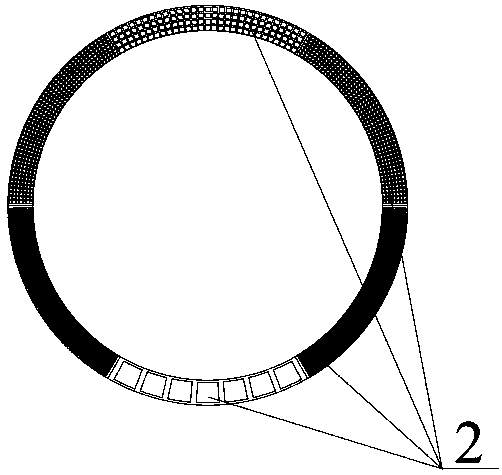

Self-suction multiple-stage centrifugal pump with variable-scale separation net

ActiveCN108050076AReduce bubble volume concentrationIncrease kinetic energyPump componentsPriming pumpEngineeringPressure difference

The invention discloses a self-suction multiple-stage centrifugal pump with a variable-scale separation net. The self-suction multiple-stage centrifugal pump comprises the variable-scale annular separation net and an annular net frame. The variable-scale separation net and the net frame are closely attached together to be mounted between a centrifugal pump outlet and a backflow hole and are closeto the centrifugal pump outlet. The scales of grids, in the circumferential direction of the separation net, of the separation net change constantly. According to the specific change rule, smaller-scale and closer separation nets are distributed in areas high in bubble concentration and axial speed, bubble backflow is stopped, and bubble floating is accelerated; and larger-scale and sparser separation nets are distributed in areas small in bubble concentration and low in axial speed, backflow flowing resistance of the self-suction stage is reduced, and self-suction is accelerated. According tothe self-suction multiple-stage centrifugal pump, turbulent flow in a pump casing cavity at different rotating speeds is fully rectified, flowing uniformity is obviously enhanced after the flow passes through the variable-scale separation net, the fluid speed is reduced, and pressure is enhanced; and fluid kinetic energy can be converted into pressure potential energy better, and the pressure difference between an inlet cavity and an impeller inlet is increased.

Owner:台州天计流体科技有限公司

Coating liquid for tobacco sheet cigarette paper

ActiveCN105040518AIncrease contentProduct quality, safety and stabilityNon-fibrous pulp additionPaper/cardboardMaillard reactionIrritation

The invention discloses a coating liquid for tobacco sheet cigarette paper. The coating liquid is prepared from a toner, a combustion improver and a spice, wherein the toner is prepared by the following steps: (1) adding water to tobacco leaf waste, decocting, extracting, adding saccharomycetes and protease to an extracted liquid for fermentation, concentrating the fermented liquid, adding ethanol, standing, taking a supernatant liquid, recovering the ethanol and carrying out vacuum concentration to form clear paste; and (2) adding hot water, revertose and amino acid to the clear paste, carrying out maillard reaction, ending the reaction, and concentrating a reaction liquid, so as to obtain the coating liquid. According to the coating liquid disclosed by the invention, the wood gas, the offensive odor and the oral irritation of the tobacco sheet cigarette paper can be reduced; the fragrance of the tobacco sheet cigarette paper can be increased; the smoke panel test result is improved; and meanwhile, the cigarette paper can also be dyed by the coating liquid instead of a natural pigment.

Owner:HUBEI CHINA TOBACCO IND

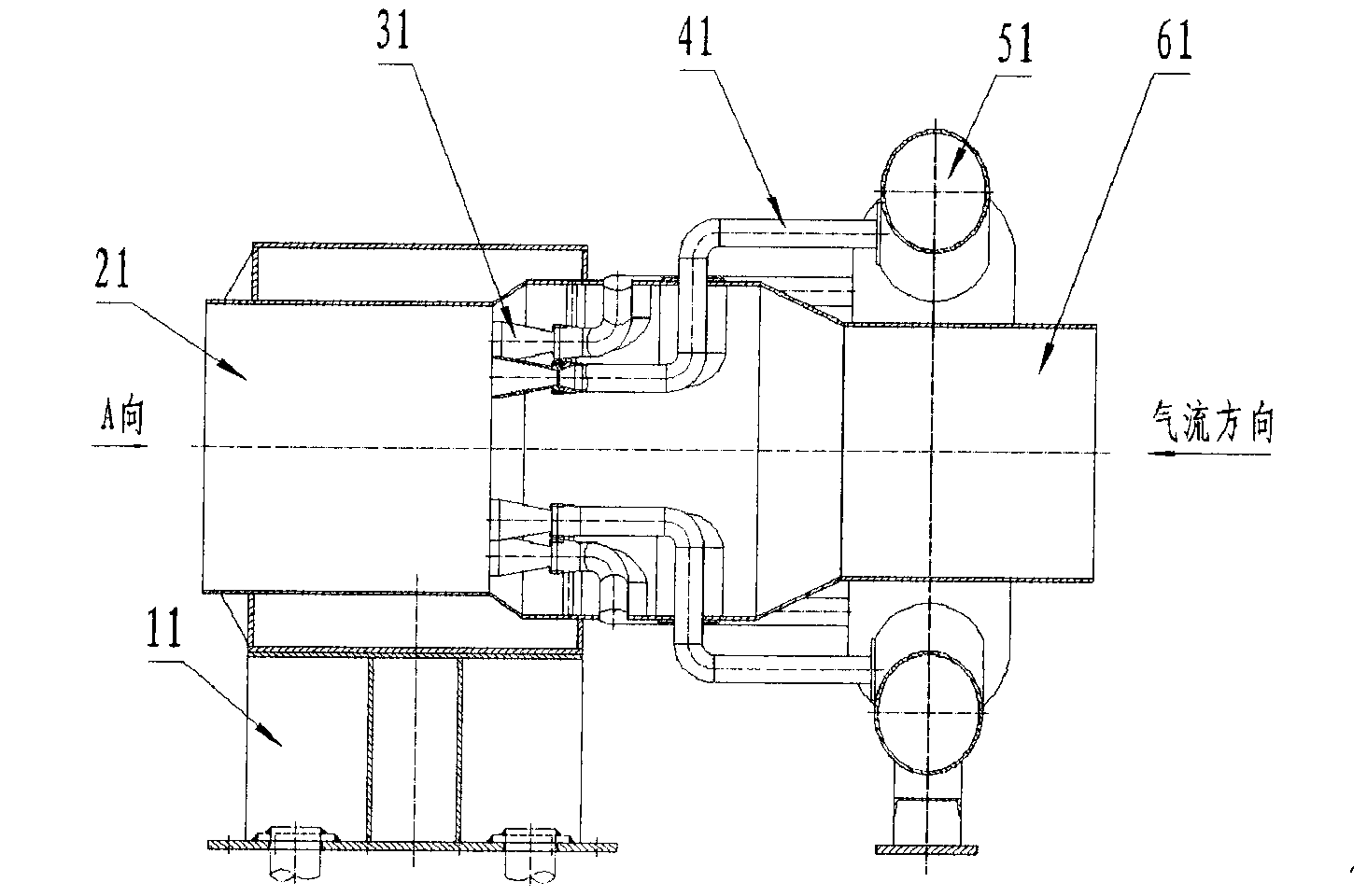

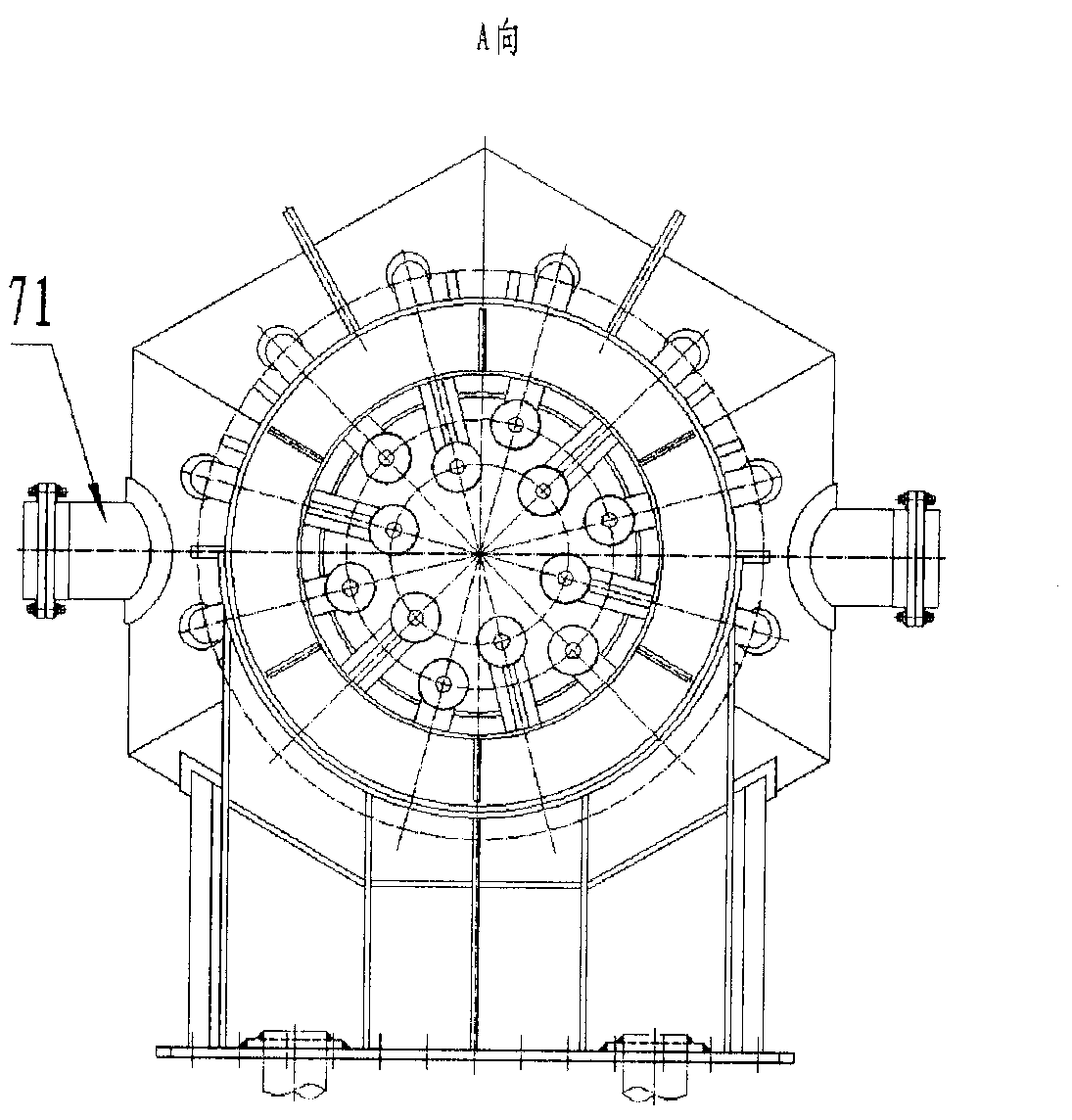

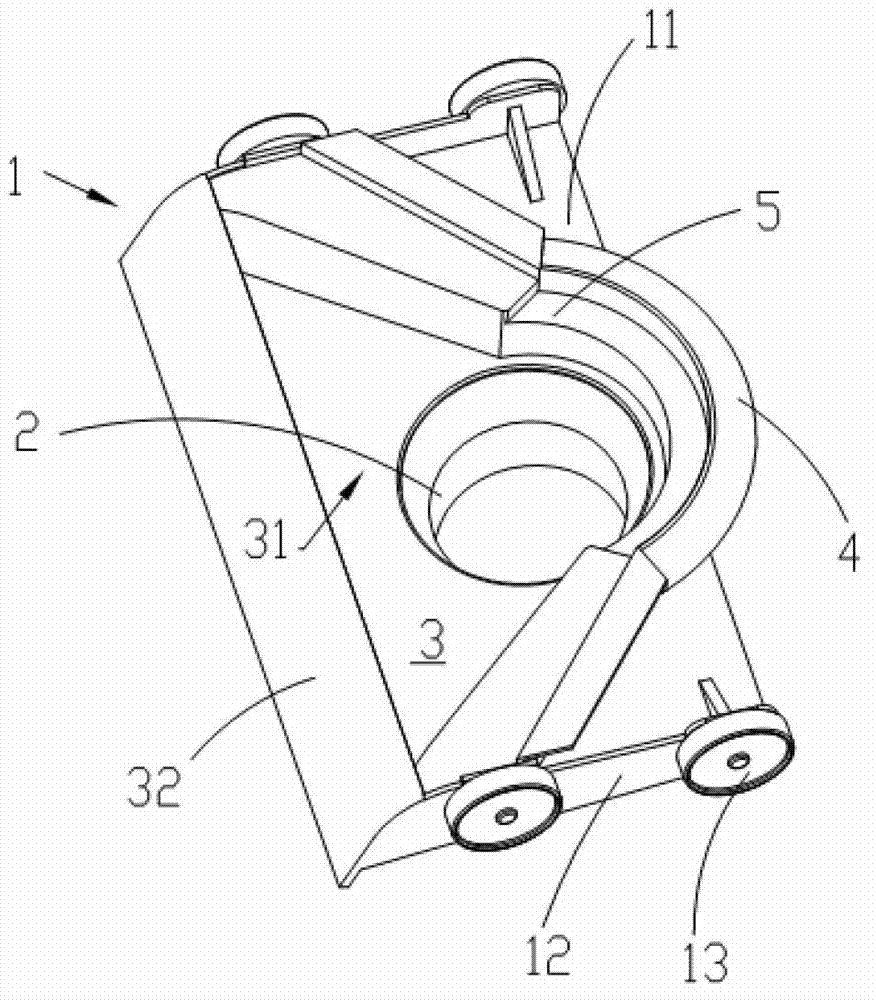

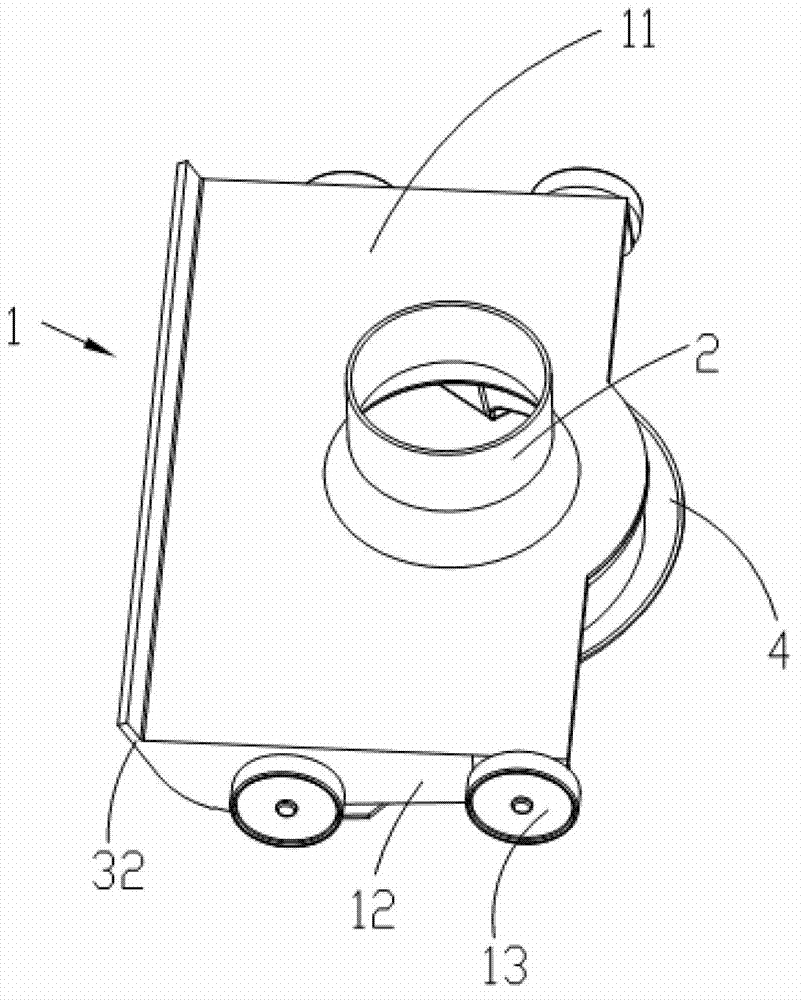

Three-level multi-spray-pipe central ejector

ActiveCN103016425AIncrease contact surfaceEnhance blending abilityJet pumpsMachines/enginesThree levelAirflow

The invention discloses a three-level multi-spray-pipe central ejector, which comprises a first-level multi-spray-pipe central ejector (1), a second-level multi-spay-pipe central ejector (2) and a third-level multi-spray-pipe central ejector (3), wherein the first-level multi-spray-pipe central ejector (1), the second-level multi-spray-pipe central ejector (2) and the third-level multi-spray-pipe central ejector (3) are sequentially connected with one another in serial along the flowing direction of main airflow, and an expansion joint (4) is respectively arranged between the first-level multi-spray-pipe central ejector and the second-level multi-spray-pipe central ejector and between the second-level multi-spray-pipe central ejector and the third-level multi-spray-pipe central ejector. The three-level multi-spray-pipe central ejector has the advantages of good pumping effect and convenience in machining and manufacturing.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Cleaning suction nozzle and cleaning vehicle

The invention discloses a cleaning suction nozzle which comprises a suction nozzle main body capable of moving along an object to be cleaned. The suction nozzle main body is provided with an air inlet, an air gathering area surrounding the air inlet is formed on the lower side of the suction nozzle main body, an opening is arranged at the front end of the air gathering area, air with garbage passes through the opening, air surrounding the suction nozzle can enter the air gathering area from the periphery of the suction nozzle and then enters the air inlet, a front baffle is arranged at the front of the opening, and a groove which is recessed forwards is formed on a first side surface, which faces the air gathering area, of the front baffle. The invention further discloses a cleaning vehicle using the cleaning suction nozzle. Because the air gathering area is formed on the lower side of the suction nozzle main body, the front baffle is arranged at the front end of the air gathering area, and the groove which is recessed forwards is formed on the first side surface, which is opposite to the air gathering area, of the front baffle, air vortex can be strengthened, suction force of the air inlet is increased, and the cleaning efficiency of the cleaning vehicle using the suction nozzle is high.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Combined jet fish pump

The invention relates to a combined jet fish pump comprising a water delivery regulating box group which is sleeved outside a drain conical pipe and comprises a drain tank, a steady flow box and a variable flow box respectively, wherein the interior of the drain tank is respectively separated by water separating plates along the shaft axis of the drain conical pipe; drain holes are arranged on the wall of the drain conical pipe; an overflow opening is respectively arranged at the lower part of each water separating box; the downward side of the steady flow box is communicated with the variable flow box; the downward side of the variable flow box is communicated with an outer water pipe; an upper valve port is arranged between the steady flow box and the variable flow box; a lower valve port is arranged between the variable flow box and the outer water pipe; a two-way valve rod penetrates in the upper and the lower valve ports; when the valve rod moves downwards, the upper valve port is closed and the lower valve port is opened; when the valve rod moves upwards, the upper valve port is opened and the lower valve port is closed; the two-way valve rod moves up and down along with the height variation of a floating body in the steady flow box; and the variable flow box is connected with a water suction port of a water pump. The combined jet fish pump disclosed by the invention is simple in structure and has the advantages that the suction ability is increased by about 4 times; the density of fish and water pumped for a jet device in the box is increased through draining; and the working efficiency is increased for the fish pump.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

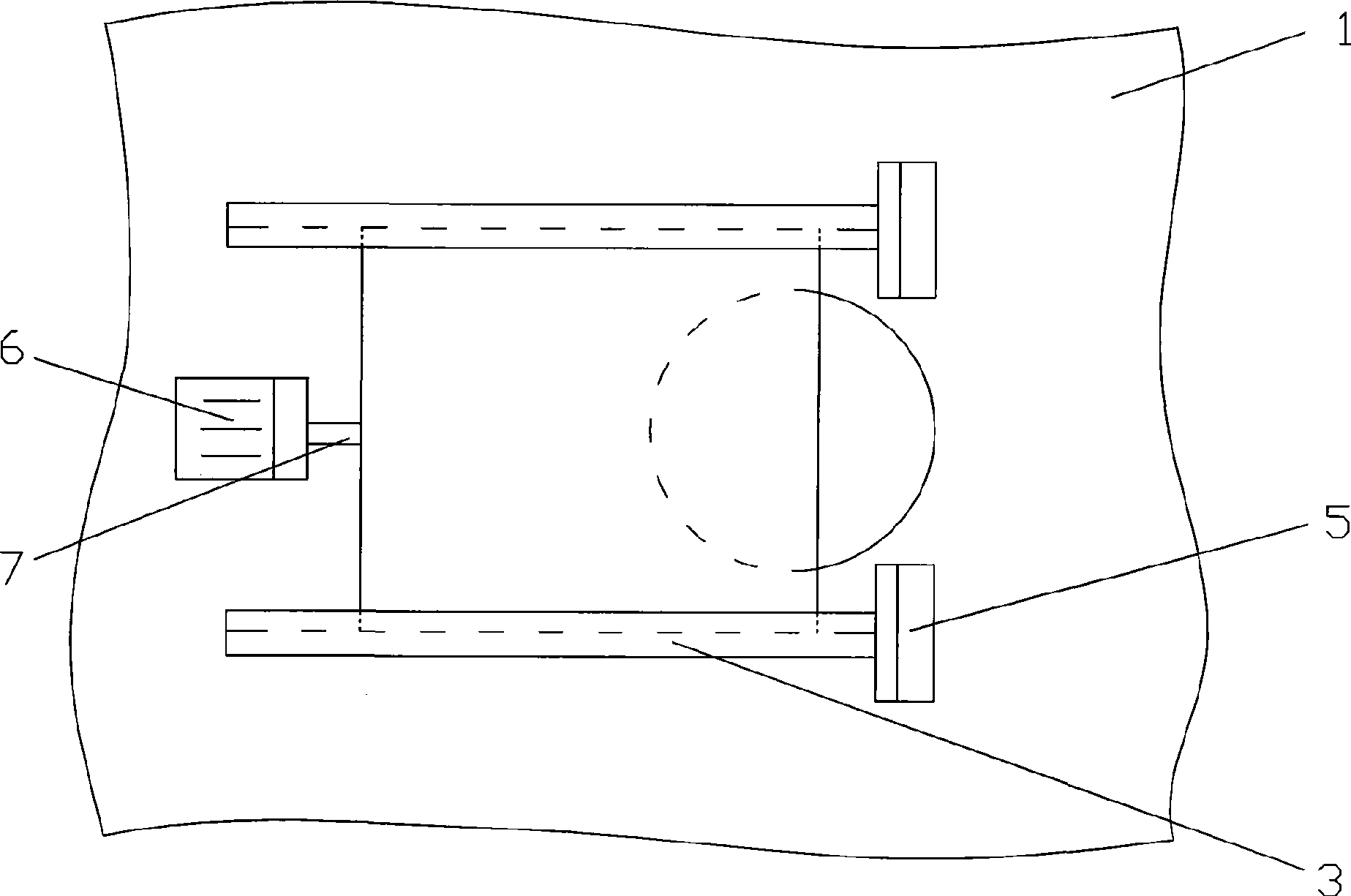

Device and method for removing emulsion on surfaces of cold-rolled steel strips

InactiveCN104646440AImproves the effectiveness of peeling emulsionsSolve the shortcomings of suctionWork treatment devicesMetal rolling arrangementsEmulsionWhole body

The invention discloses a device and a method for removing emulsion on surfaces of cold-rolled steel strips. The device comprises an upper working roller, an upper support roller seam purging mechanism, a steel strip upper surface emulsion sealing mechanism, an upper working roller surface emulsion removing mechanism, a steel strip lower surface emulsion removing mechanism, a steel strip upper surface purging mechanism and an upper support roller surface emulsion removing mechanism. The method is mainly characterized by reasonably controlling the sequence of opening and closing an emulsion injecting system and an emulsion removing device; a plurality of removing methods synergistically cooperate to form a whole body; the effect of removing the emulsion on the surfaces of the steel strips on the outlet side of a rolling mill is further improved; meanwhile, the residues of the emulsion in special parts of heads, tails, sides and the like of the steel strips can be removed; the surface quality of the finished steel strips can be improved.

Owner:SHANDONG IRON & STEEL CO LTD

Lampblack absorber with area-adjustable air inlet of movable deflector type

InactiveCN101532696ATimely inhalationSave energyDomestic stoves or rangesLighting and heating apparatusIndoor airComputer engineering

Owner:HANGZHOU LIUYI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com