Spinning Point Of Spinning Machine And Method For Operation Of Same

A spinning machine, station technology, applied in spinning machine, open end spinning machine, continuous winding spinning machine, etc., can solve the problem of limiting spinning process, affecting the productivity of air-jet spinning machine, errors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

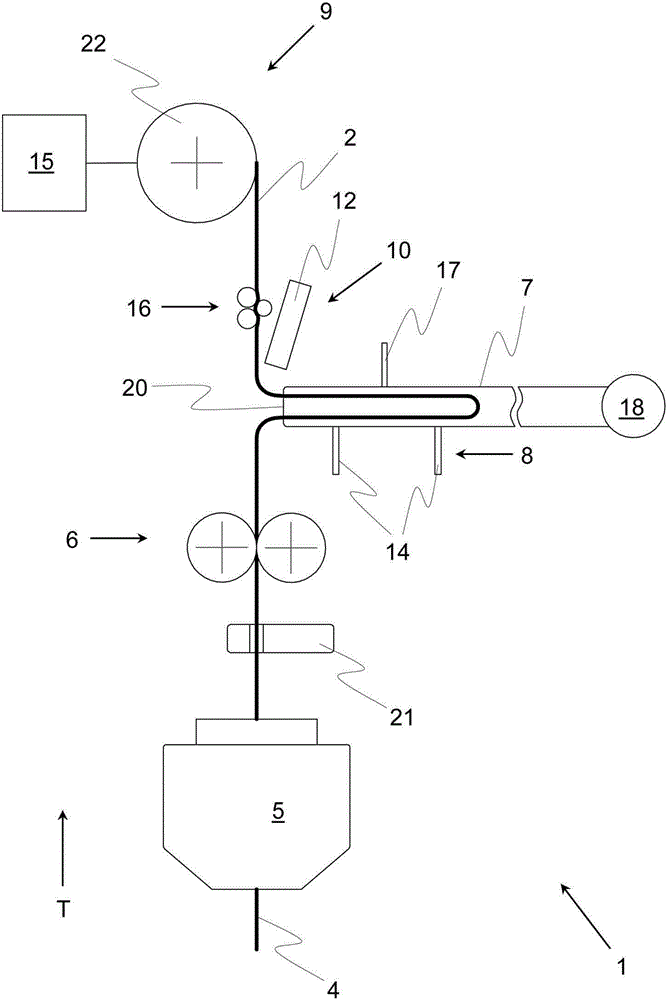

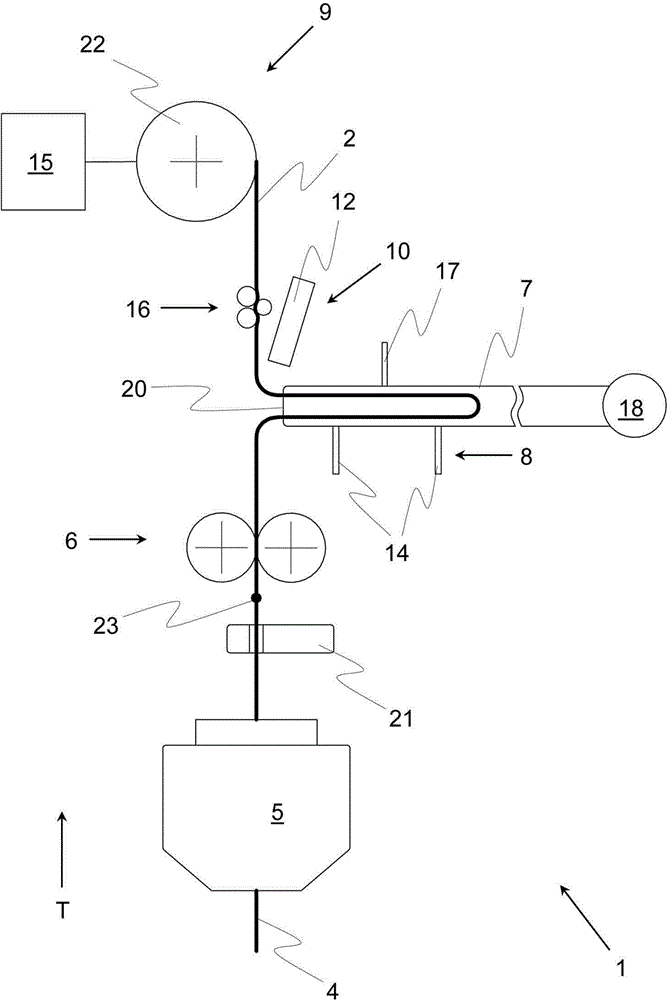

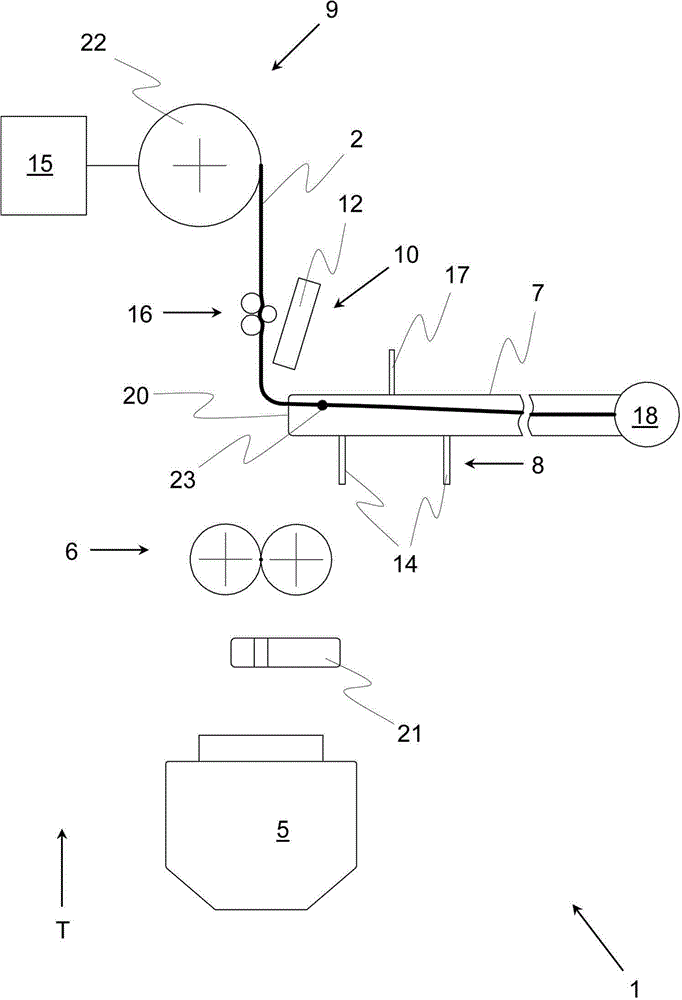

[0038] figure 1 The schematic diagram shows a spinning station 1 of a spinning machine according to the invention, which can be configured, for example, as an air-jet spinning machine or an open-end spinning machine, during the spinning process, during which the yarn 2 is made of composite fibers 4. The composite fibers 4 are generally conveyed here by means of a stretching mechanism (air-jet spinning machine) or a loosening unit (air-jet spinning machine) to a spinning unit 5 (in an air-jet spinning machine) correspondingly known from the prior art in an air swirl chamber, or in an open-end spinning machine, a rotor chamber), and rotates in the spinning unit 5 . In the figures, only the spinning station 1 is shown, but the corresponding spinning machine can of course also comprise a plurality of spinning stations 1 arranged one after the other, for example perpendicular to the drawing, and preferably of similar construction.

[0039] In addition, the shown spinning station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com