Combined jet fish pump

A combined and jet technology, applied in fishing, application, animal husbandry, etc., can solve the problems of low efficiency of jet fish suction pump, small water flow rate of ejector suction pipe, etc., and achieve simple structure, small fish body damage and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

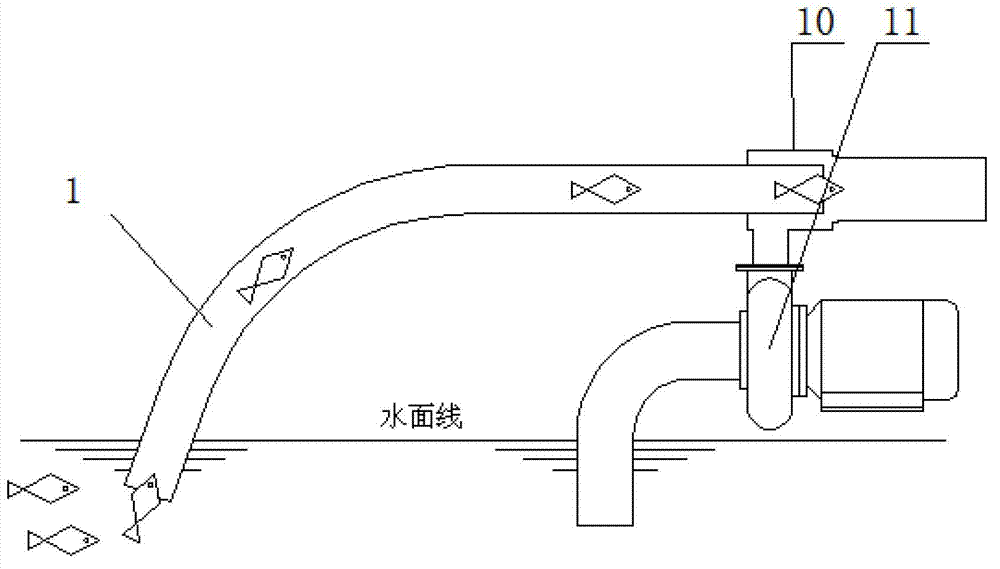

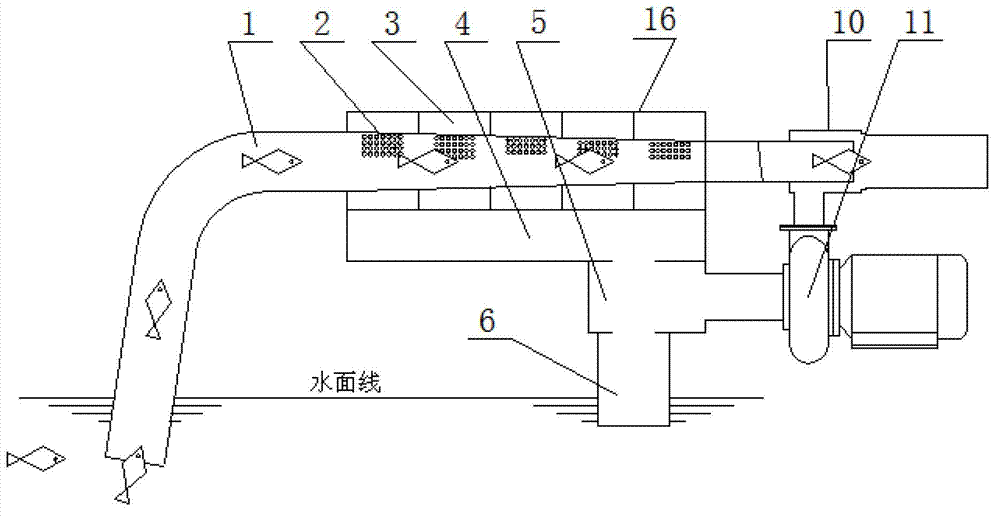

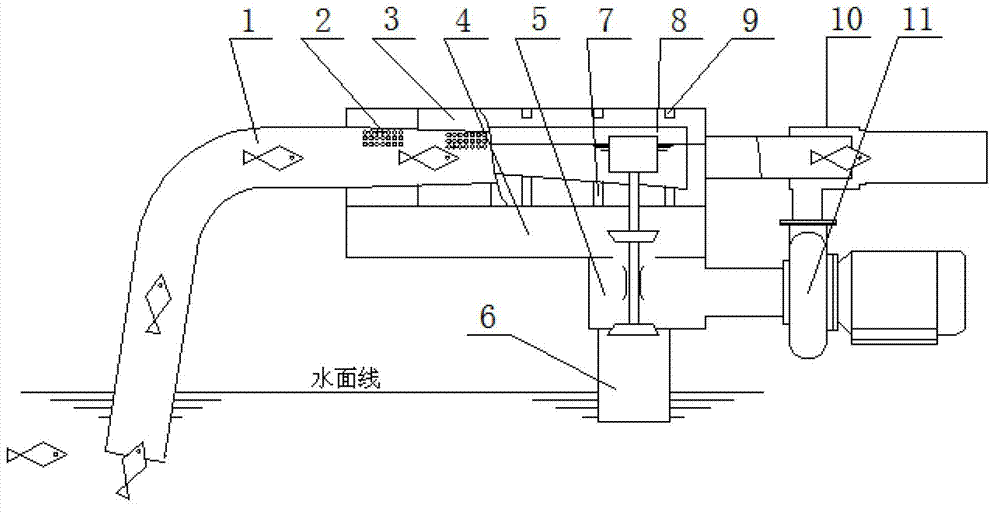

[0026] Such as Figure 2~3 As shown, the present invention provides a combined jet fish suction pump device, comprising a hydrophobic cone 2, a jet 10, a water pump 11, the large end of the hydrophobic cone 2 is a fish suction port, and the small end is connected to the suction port of the jet 10 , the discharge port of the water pump 11 is connected to the ejector chamber of the ejector 10, the water inlet of the water pump 11 is connected to the converter box (5), and also includes a water transfer adjustment water tank group set on the outside of the hydrophobic conical tube, and the water transfer adjustment tank group includes a hydrophobic Box 3, flow stabilization box 4, flow conversion box 5, and outer water pipe 6; the drainage box 3 is in the shape of a rectangular strip, and the inside of the drainage box 3 is separated by water baffles along the center line of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com