Patents

Literature

118results about How to "Neatly wound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

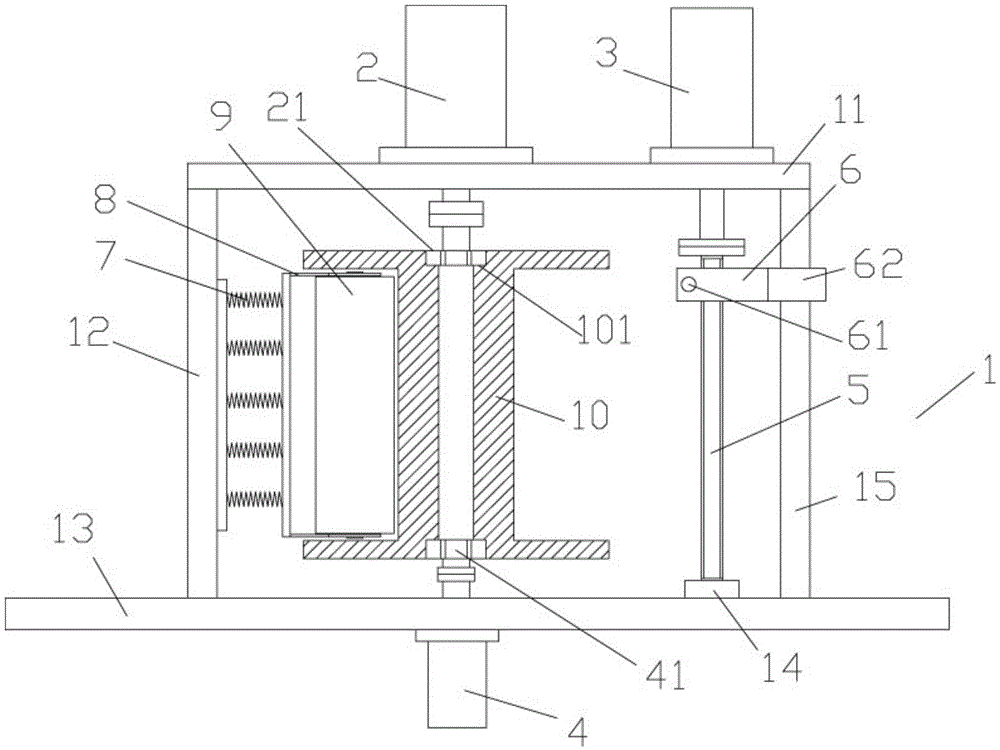

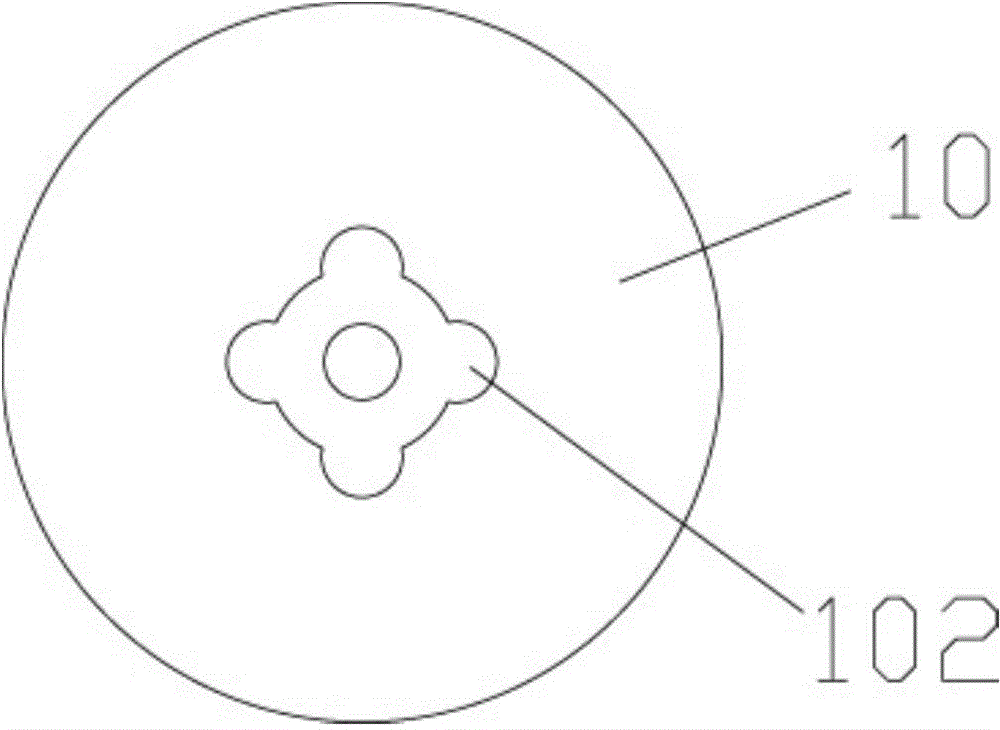

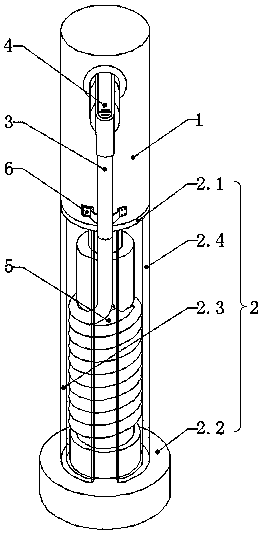

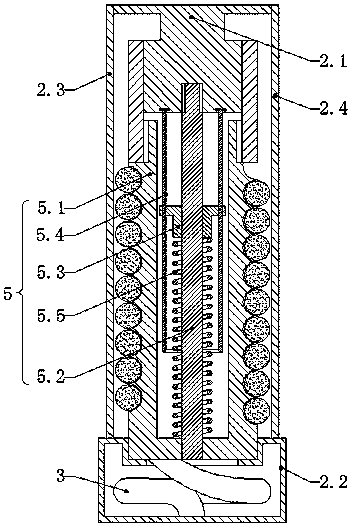

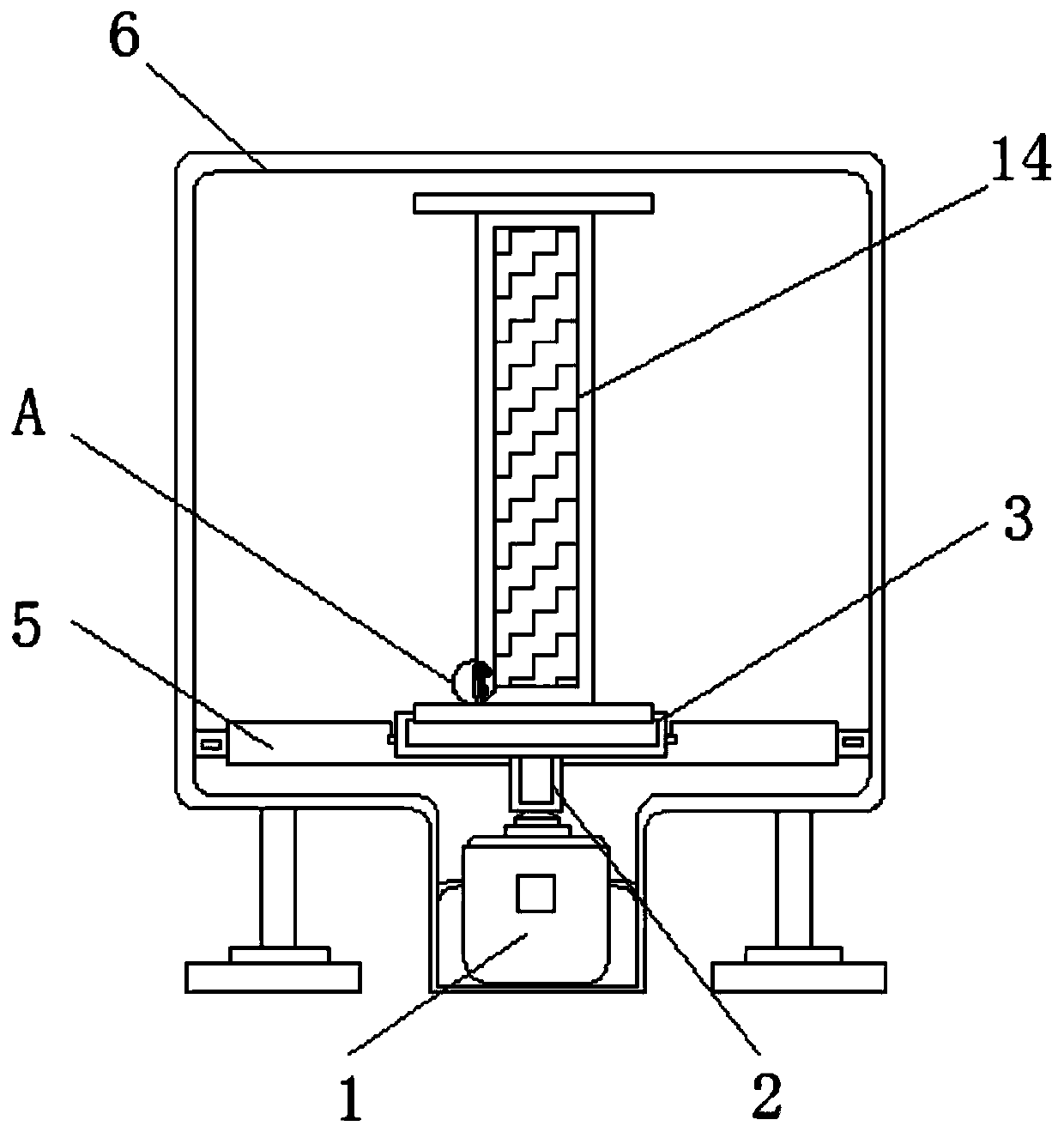

High-precision winding device of enameled wires

The invention discloses a high-precision winding device of enameled wires. The high-precision winding device comprises a frame. The frame comprises an upper support plate, a middle connecting rod and a base plate, wherein the lower end of the middle connecting rod is fixed on the base plate, the upper end of the middle connecting rod is fixed on the upper support plate, a master drive motor and a slave drive motor are fixed on the upper plane of the upper support plate, a lifting air cylinder is fixed at the bottom of the base plate, the push rod of the lifting air cylinder extends out of the upper plane of the base plate, a lower limit block is hinged to the push rod, the output shaft of the master drive motor penetrates out of the lower plane of the upper support plate, an upper limit block is fixed on the output shaft through a coupler, a groove is formed in each of the upper end and the lower end of a winding reel, and the upper limit block and the lower limit block are respectively inserted into the corresponding grooves of the winding reel; a buffer spring is fixed on the middle connecting rod, a hinge rack is fixed at the other end of the buffer spring, a forced-contact roller is hinged to the hinge rack, and the forced-contact roller is close to the middle lateral wall of the winding reel. By the high-precision winding device guide winding of the enameled wires can be achieved, and friction among the enameled wires can be reduced.

Owner:SUZHOU SHENGLI WIRE

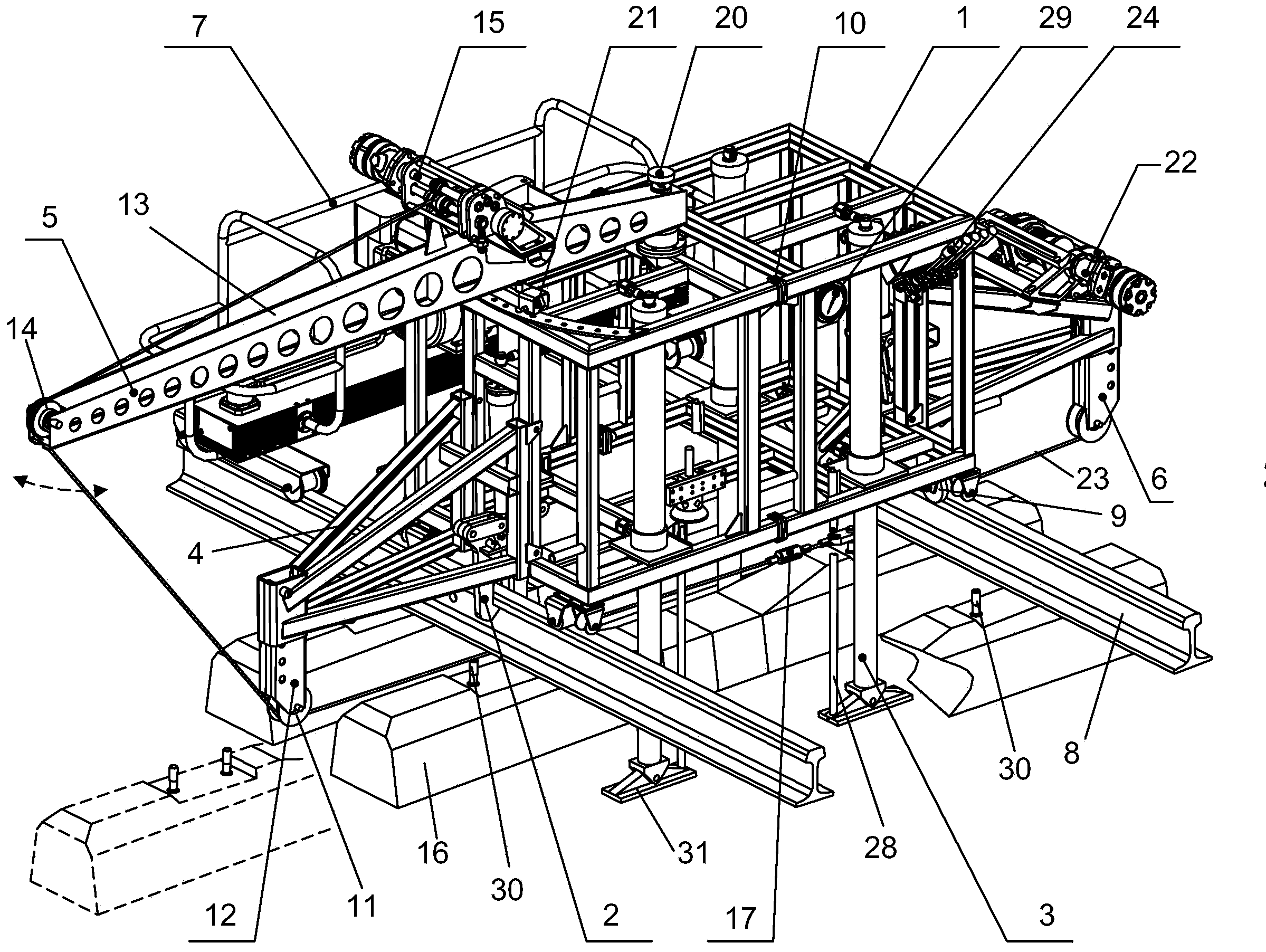

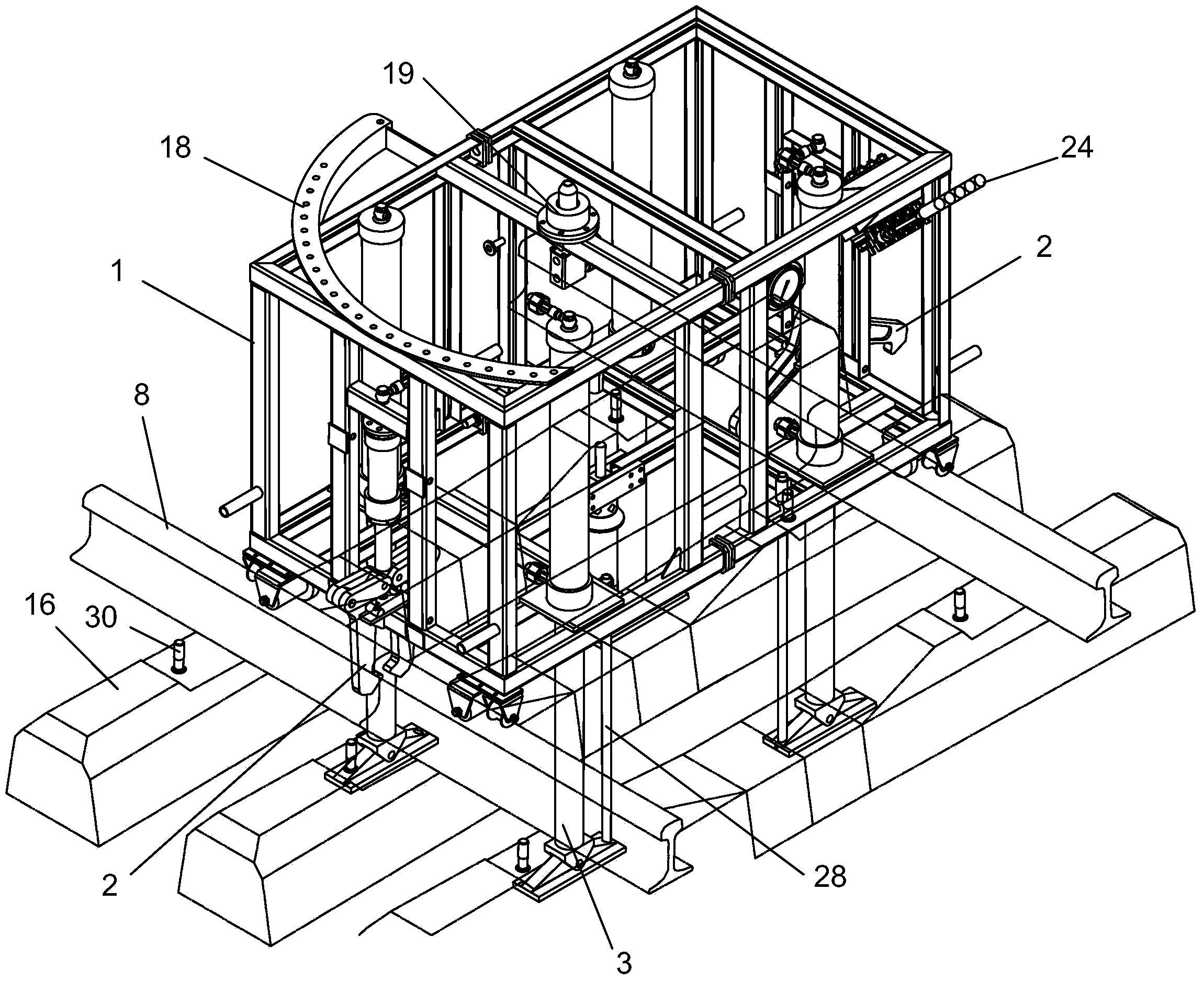

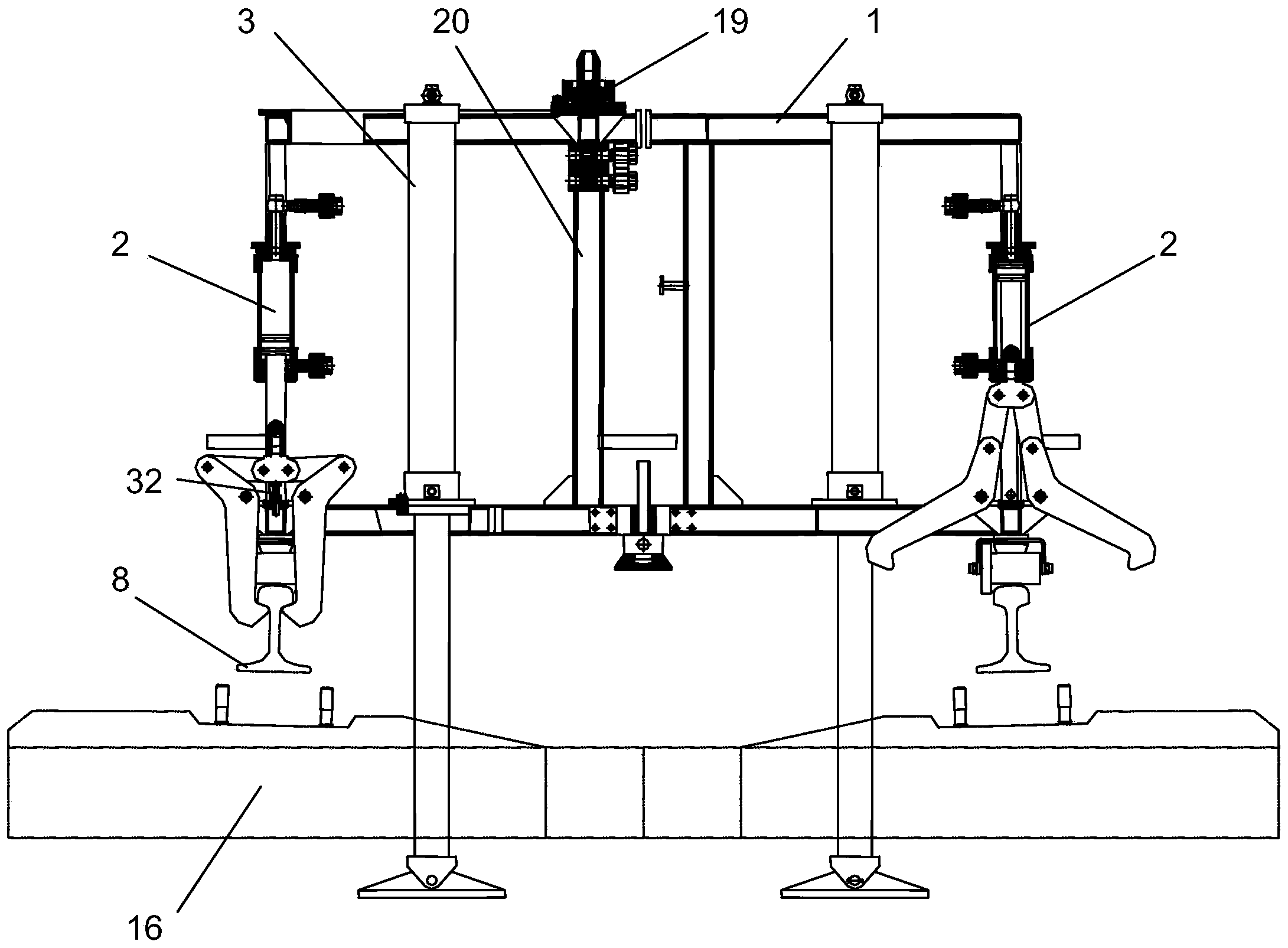

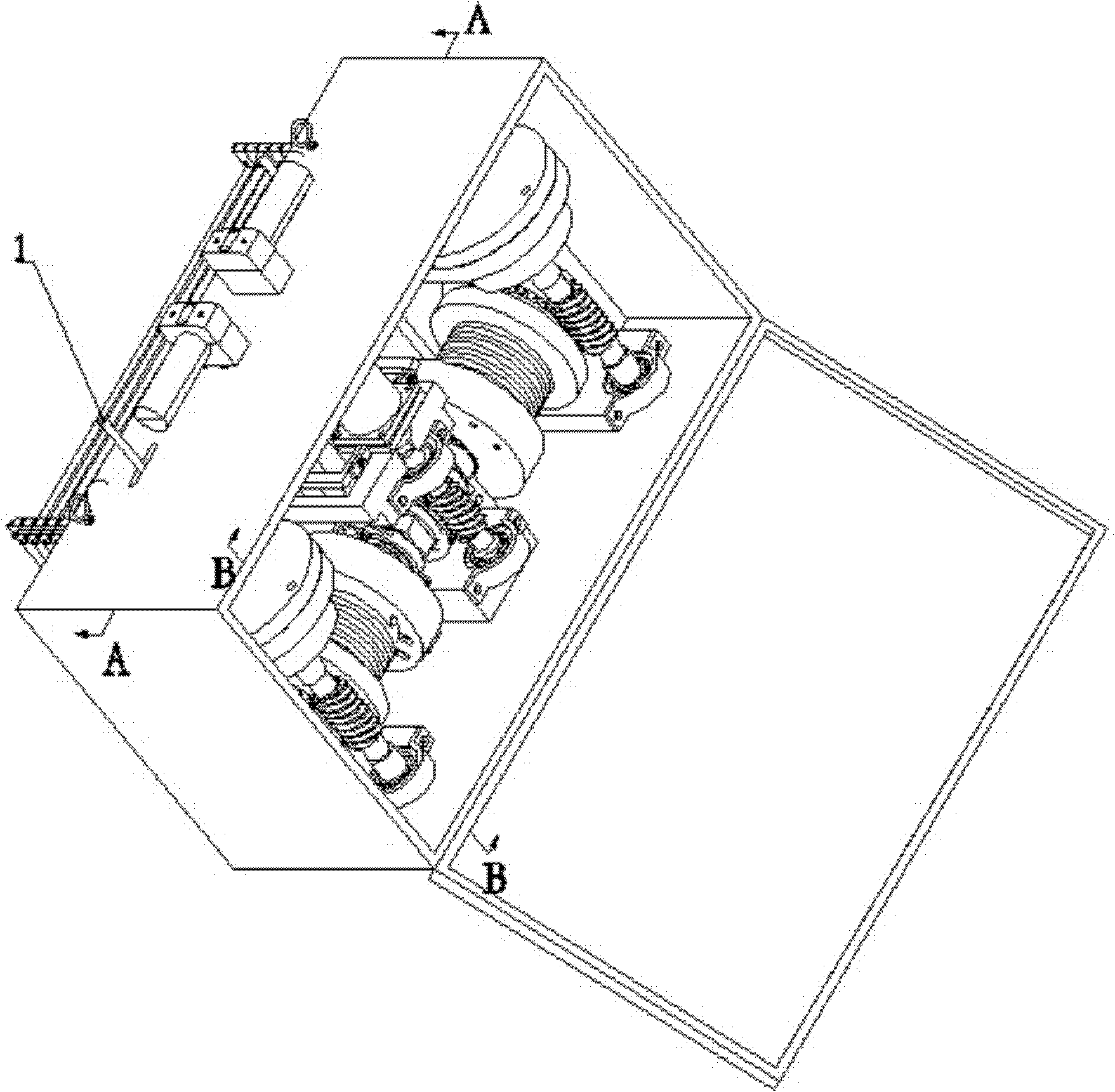

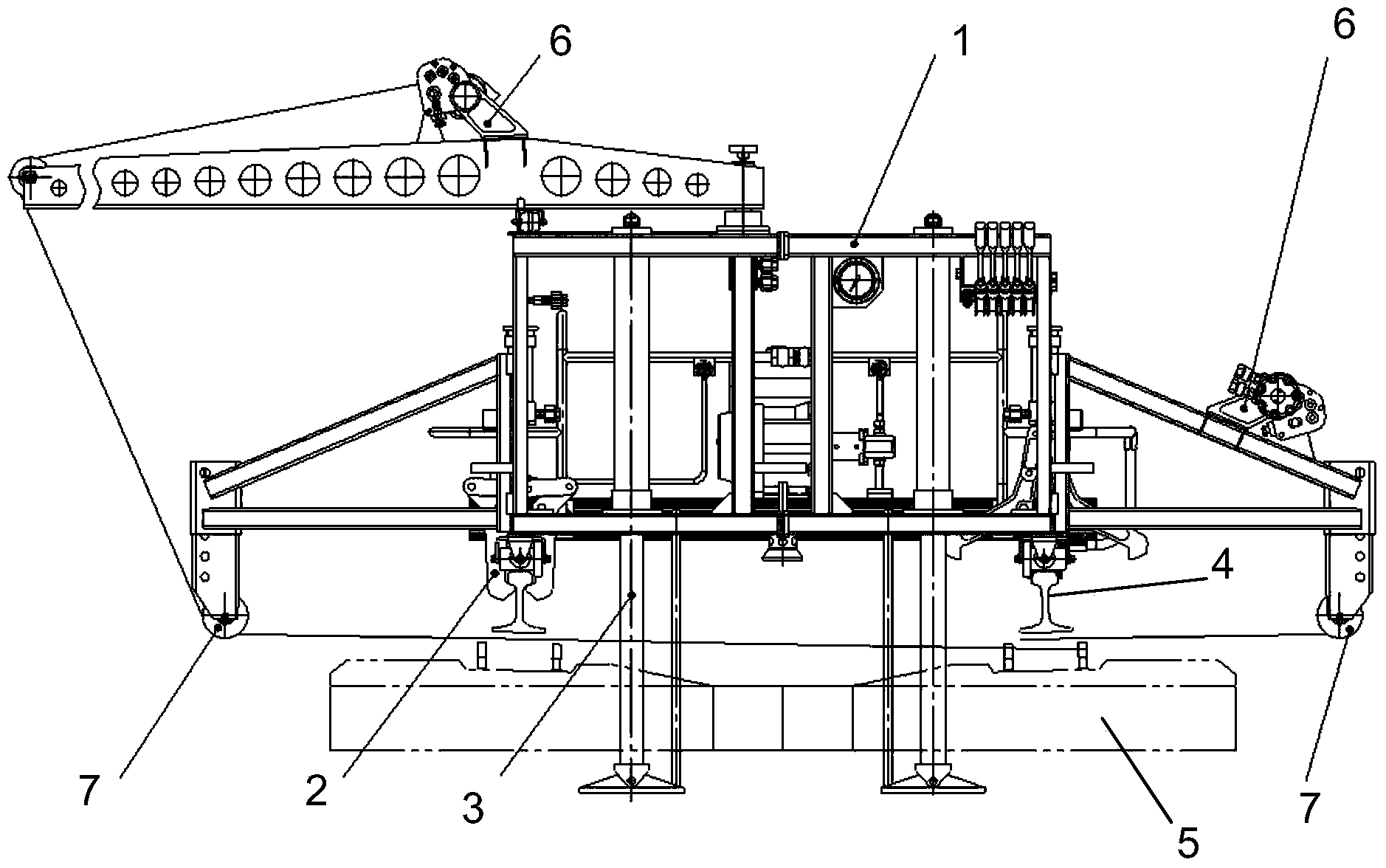

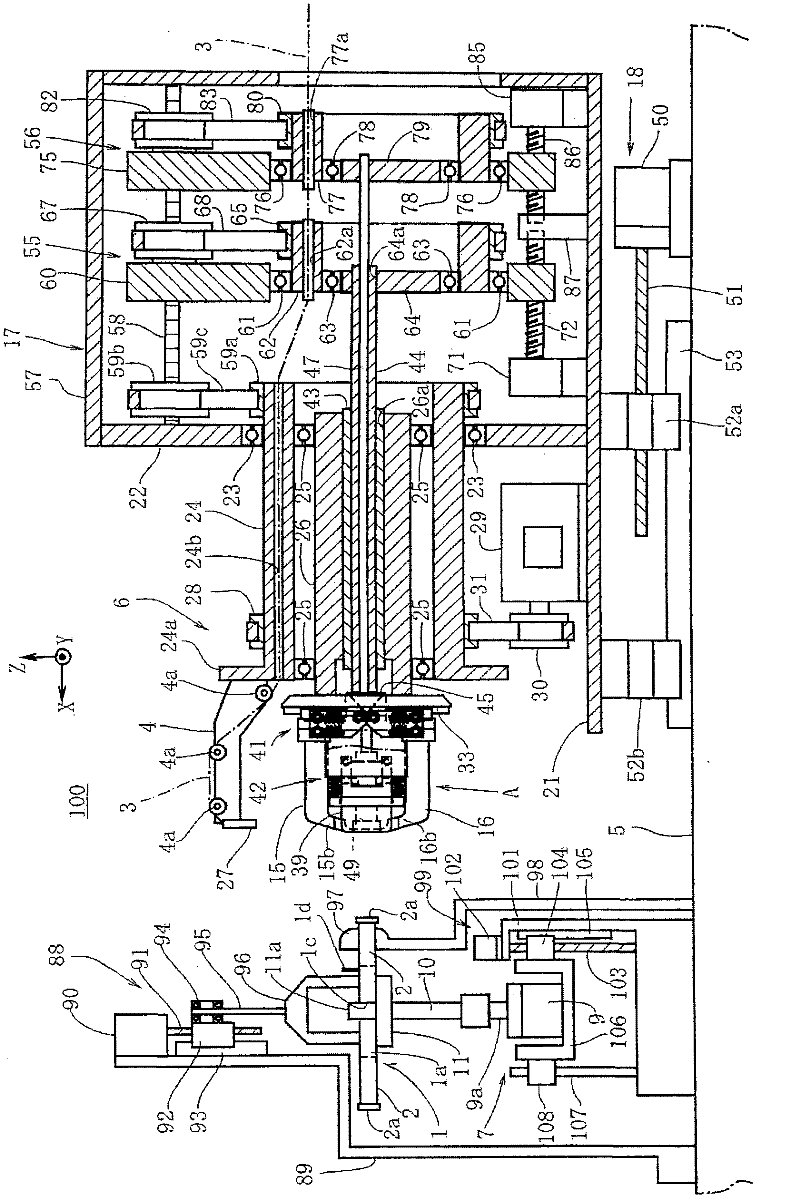

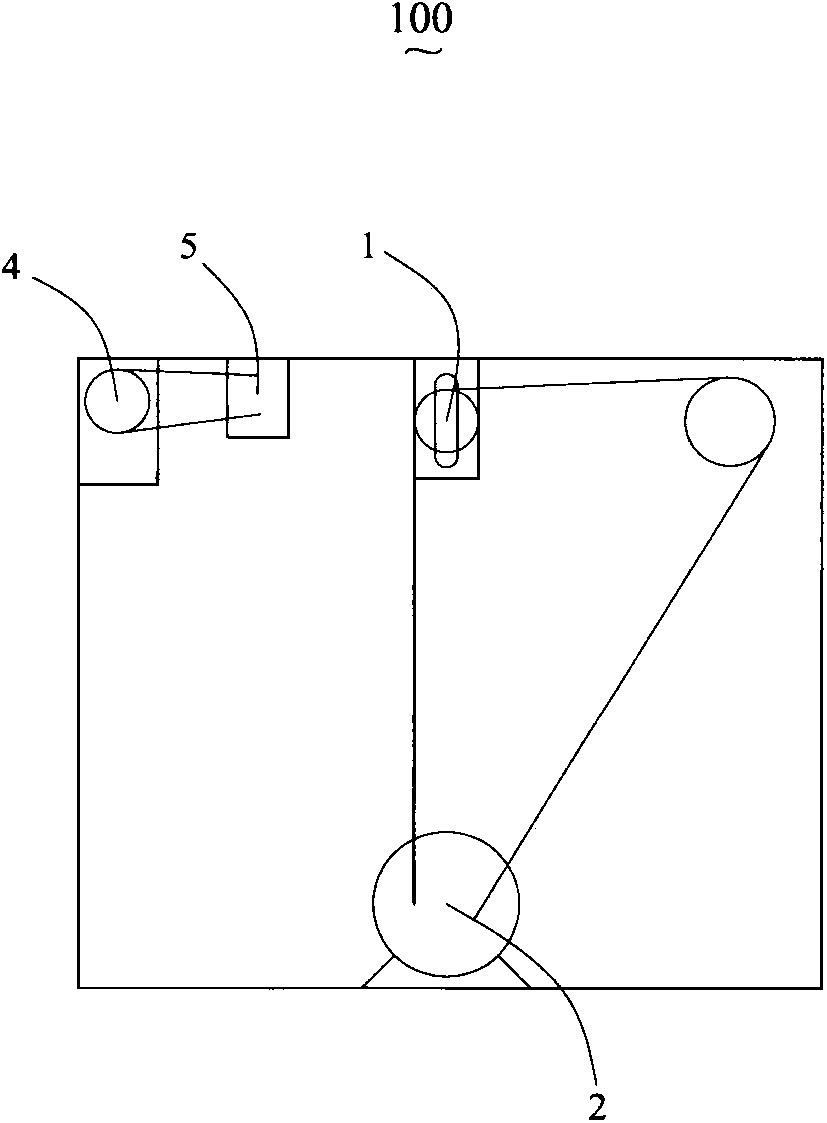

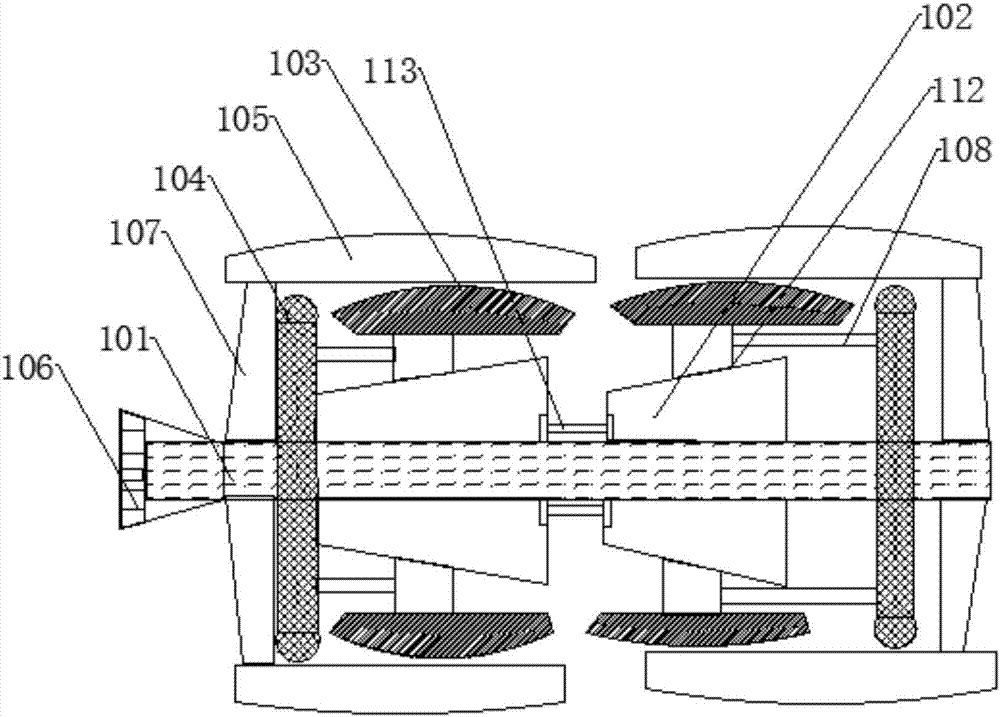

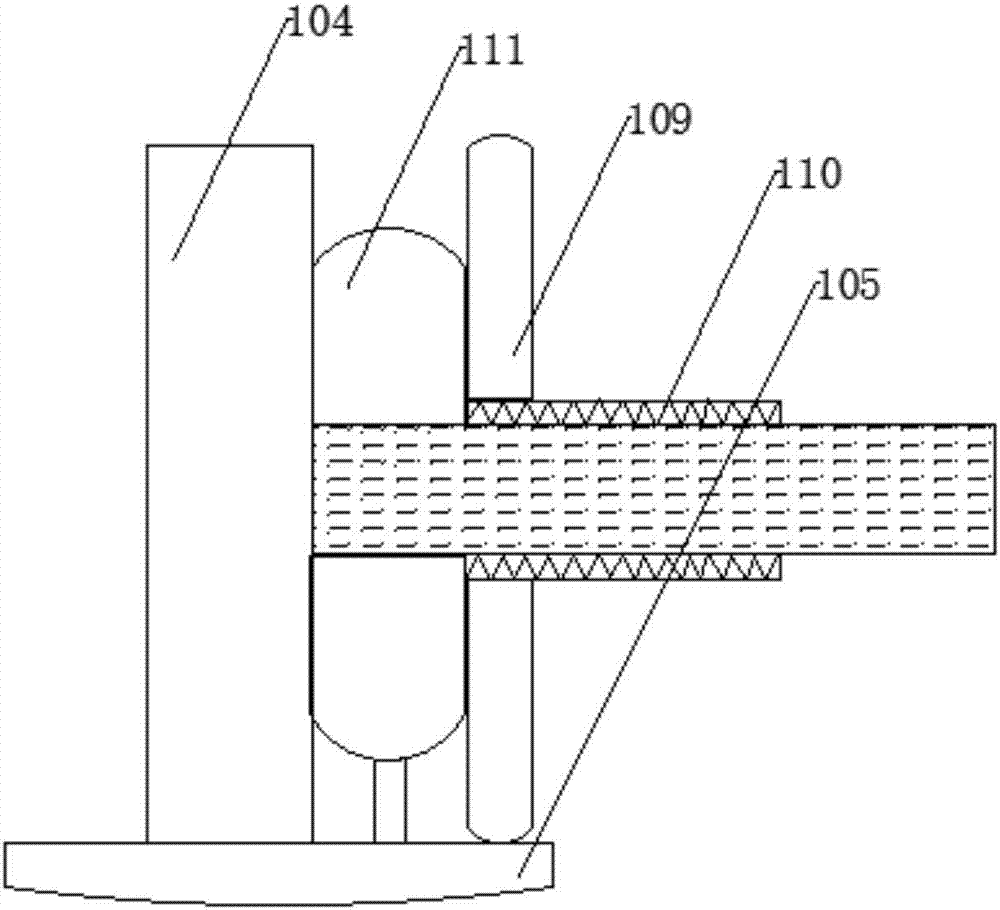

Hydraulic sleeper replacement machine and hydraulic sleeper replacement method

ActiveCN103669133AReduce labor intensityImprove work efficiencyRailway track constructionControl engineeringHydraulic pump

The invention discloses a hydraulic sleeper replacement machine. The hydraulic sleeper replacement machine comprises a main machine frame, track lifting claws, track lifting oil cylinders, an unpowered pulley support, a hydraulic lifting device, a powered pulley support, a hydraulic pump station and the like. The invention further discloses a hydraulic sleeper replacement method. According to the hydraulic sleeper replacement method, a sleeper can be pulled out and replaced through hydraulic control of the hydraulic lifting device and steel wire rope hoisting. The hydraulic sleeper replacement method is suitable for replacement of sleepers of ballasted railways and can relive labor intensity and improve working efficiency.

Owner:上海瑞纽机械股份有限公司

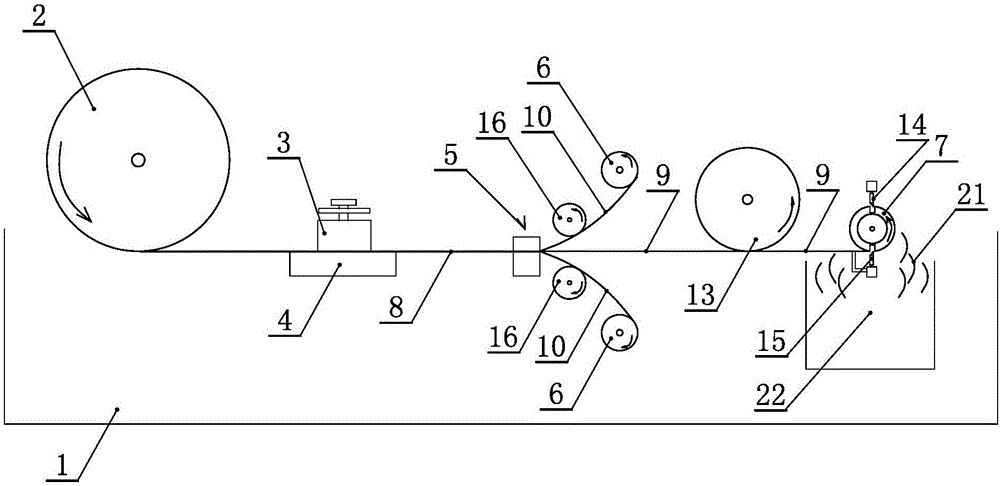

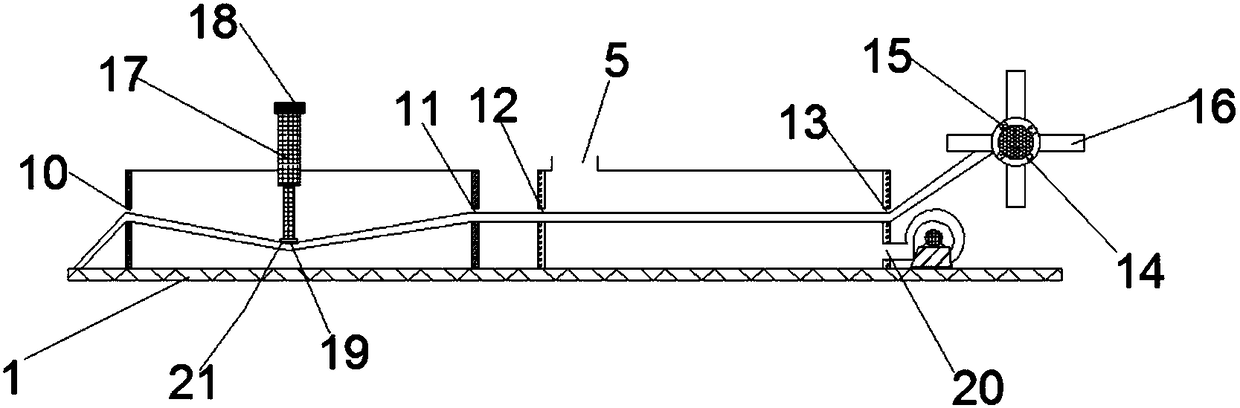

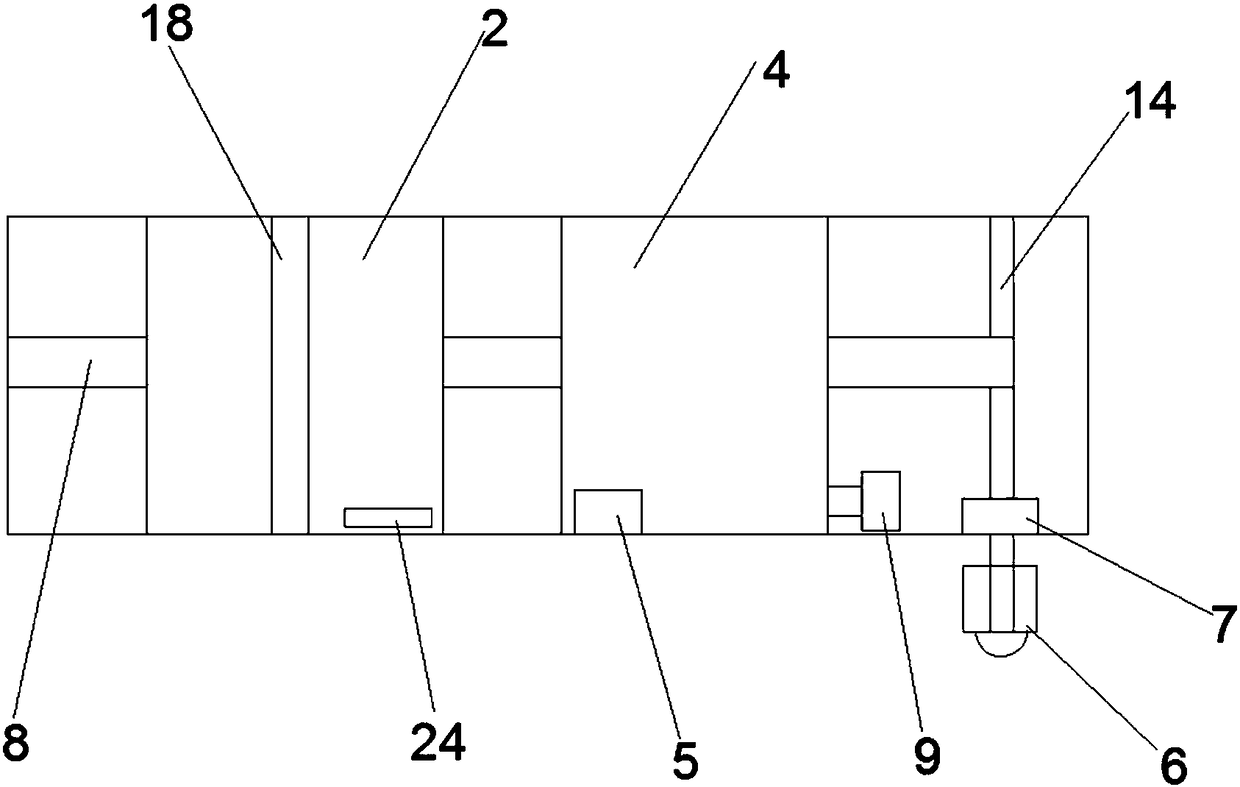

Metal line inner core recycle device of power supply and utilization cable

InactiveCN106205894AQuick splitEasy to separateBasic electric elementsElectronic waste recyclingMetal stripsEngineering

A metal line inner core recycle device of a power supply and utilization cable comprises a base, a feeding part, limitation parts, a cutting part, an outer skin recycle part, an inner core winding part, an inner core recycle part and a cut part inner core recycle box, wherein the feeding part is a feeding wheel, a cable is wound around the feeding wheel, the limitation parts are limitation rings arranged vertically, a cutting knife is arranged on the cutting part and is used for cutting the cable to a plurality of strips, an inner core and an outer skin which are cut and separated are respectively wound the inner core winding part and the outer skin recycle part, and the inner core on the inner core winding wheel is wound the inner core recycle wheel and is cut to achieve fixed length recycle of metal strips. By the device, the inner core and the outer skin of a waste cable are rapidly cut, and the fixed length mass production and recycle of the inner core of the cable become possible. The device is high in automation, a separation effect of the inner core and the outer skin is good, the inner core and the outer skin are simultaneously and orderly wound during the separation process, and subsequent utilization is facilitated.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

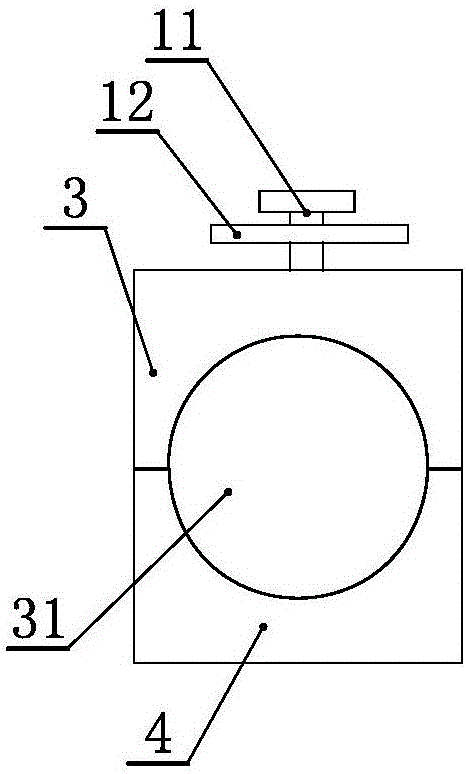

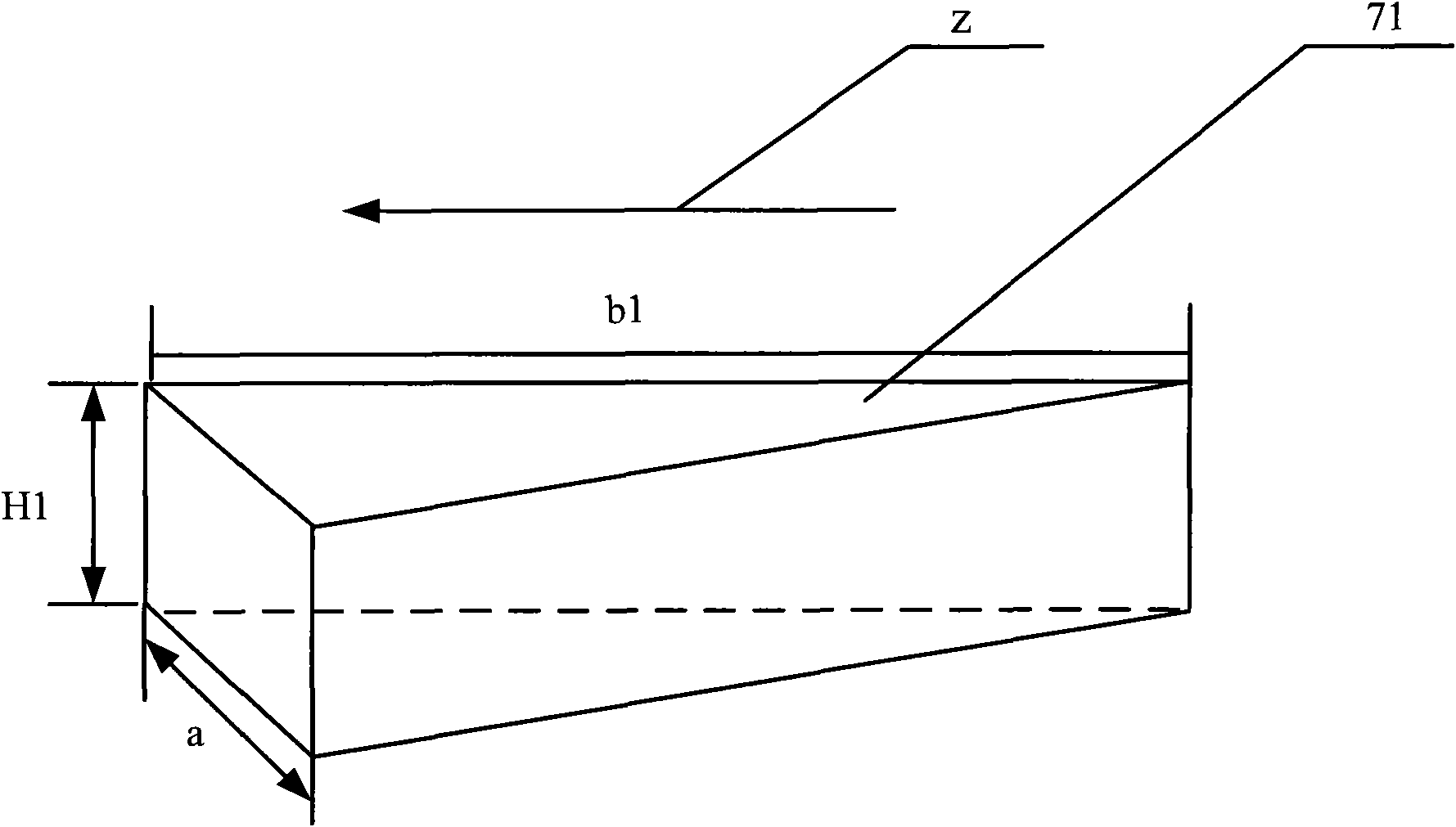

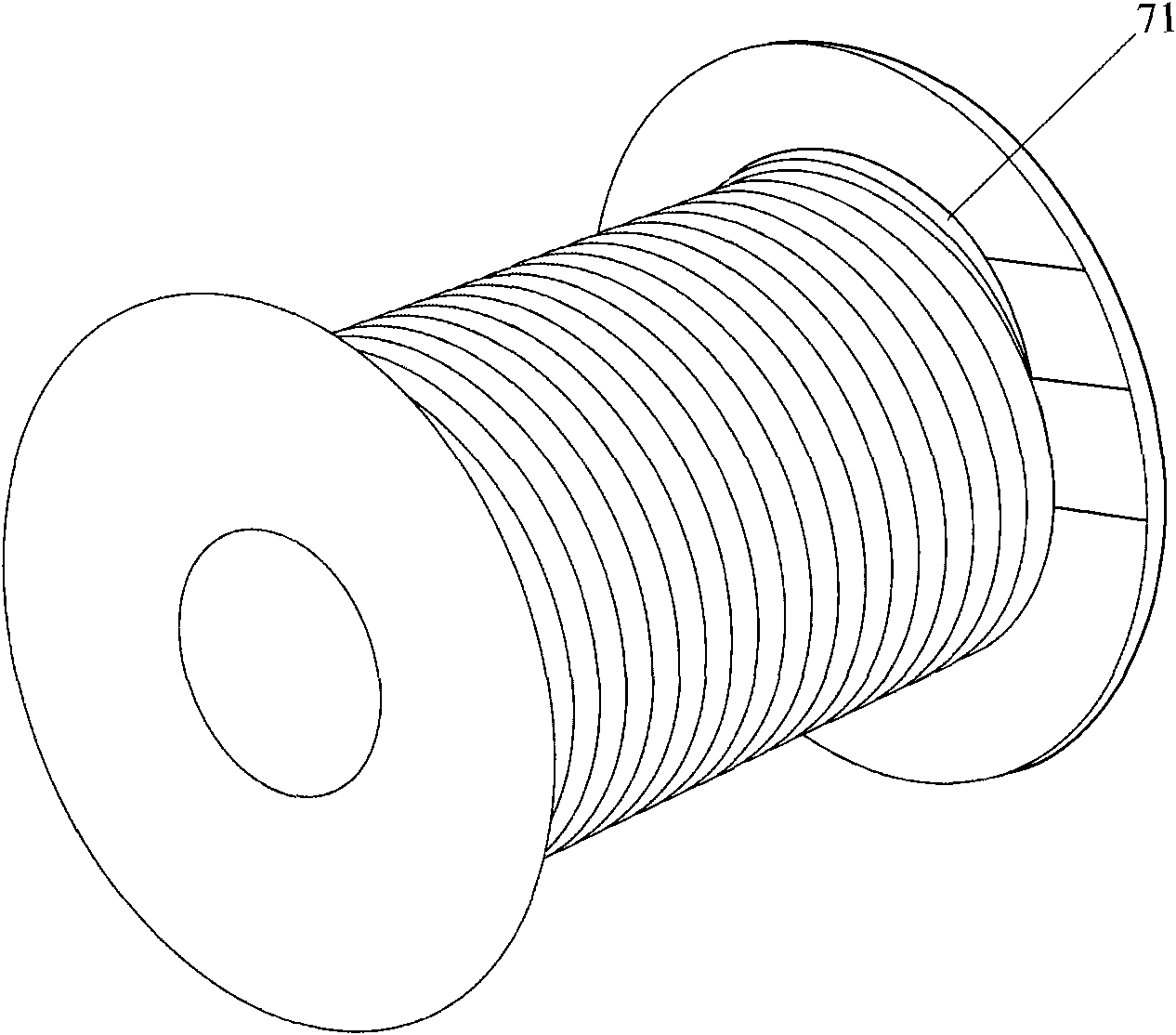

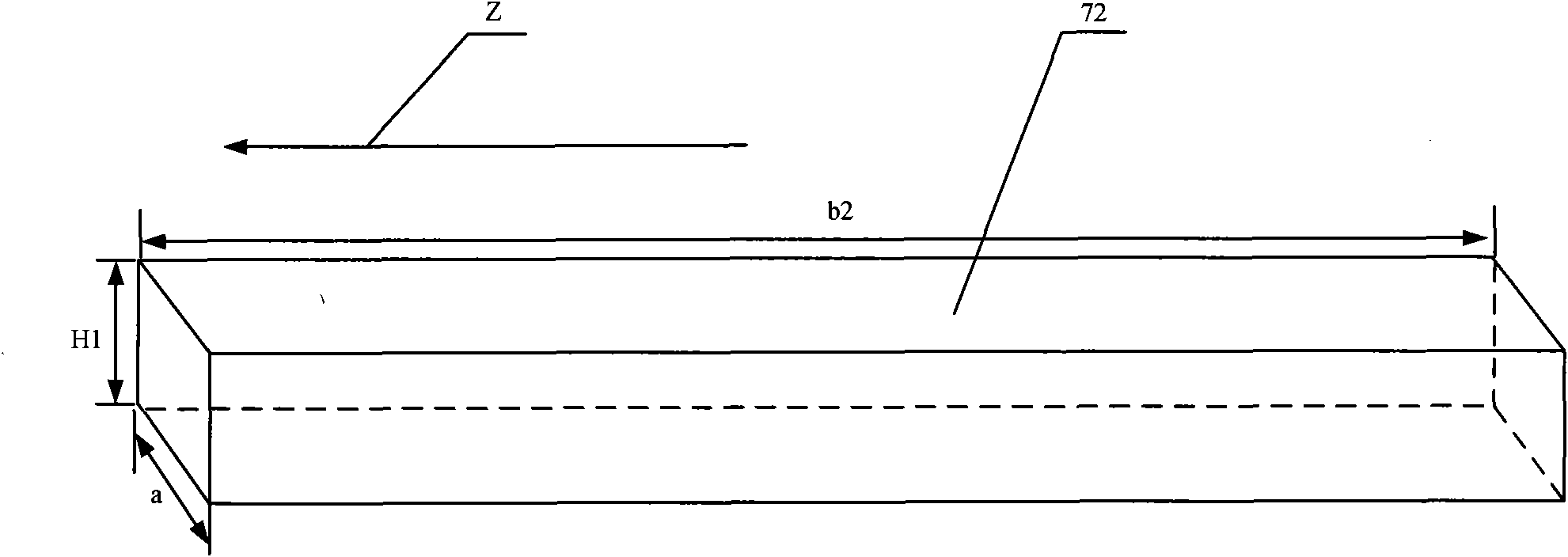

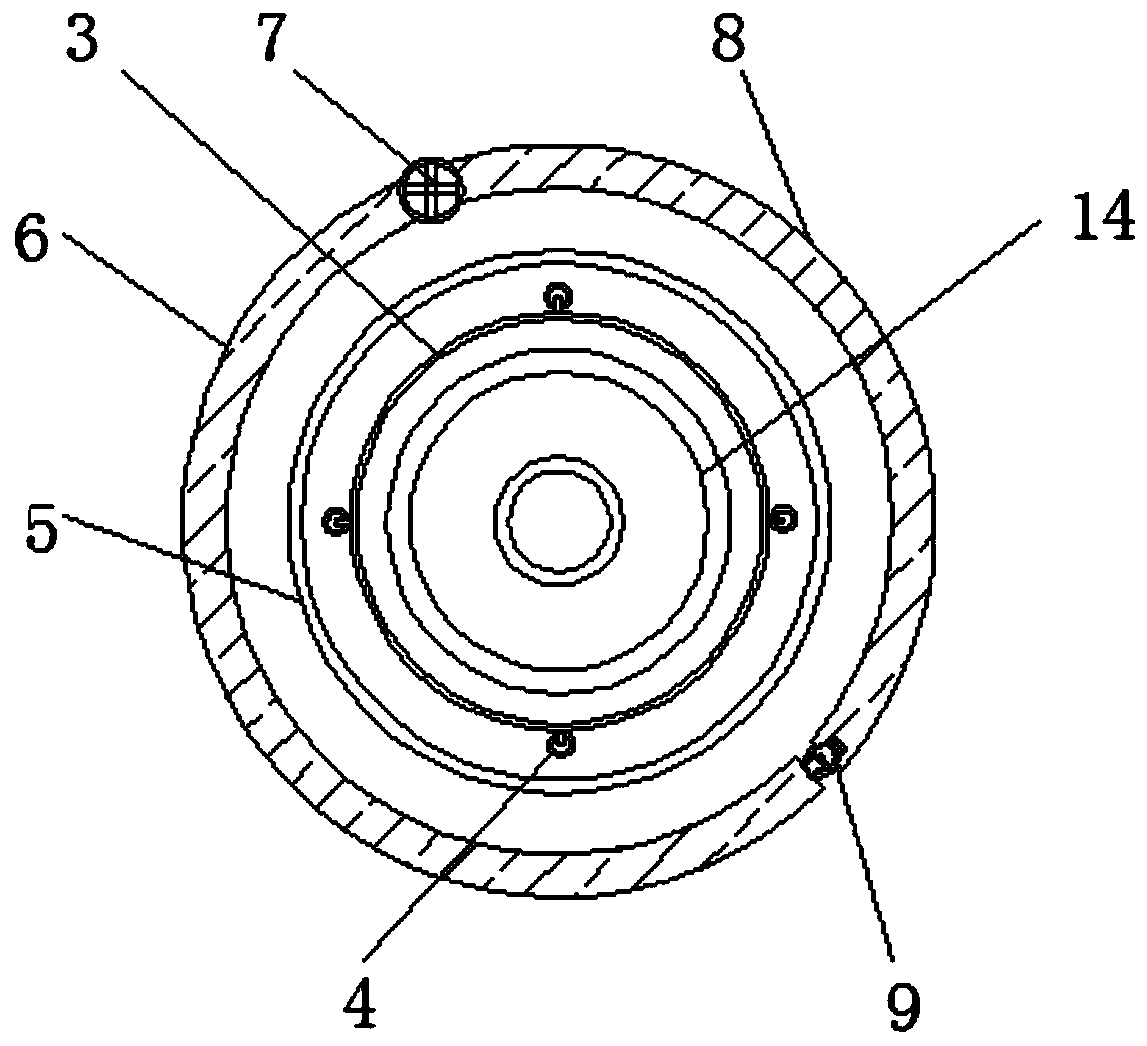

Drum with broken line grooves

The invention relates to a drum with broken line grooves. The first section of a rope outlet side boss corresponds to a first oblique line groove, axial width is gradually increased to half pitch from 0, and radial thickness is the height of a layer of steel wire rope; the second section of the rope outlet side boss corresponds to a first straight line groove, axial width is half pitch, and radial thickness is the height of a layer of steel wire rope; the third section of the rope outlet side boss corresponds to a second oblique line groove, axial width is gradually increased to one pitch from half pitch, and radial thickness comprises two stepped parts; the first section of a non-rope outlet side boss corresponds to the first oblique line groove, axial width is gradually reduced to 0 from half pitch, and radial thickness is the height of a layer of steel wire rope; the second section of the non-rope outlet side boss corresponds to the second oblique line groove, axial width is gradually reduced to half pitch from one pitch, and radial thickness is gradually increased to the height of a layer of steel wire rope from 0; the third section of the non-rope outlet side boss correspondsto a second straight line groove, axial width is half pitch, and radial thickness is the height of a layer of steel wire rope. The drum with the broken line grooves makes the steel wire rope regularly wound.

Owner:北京京城重工机械有限责任公司

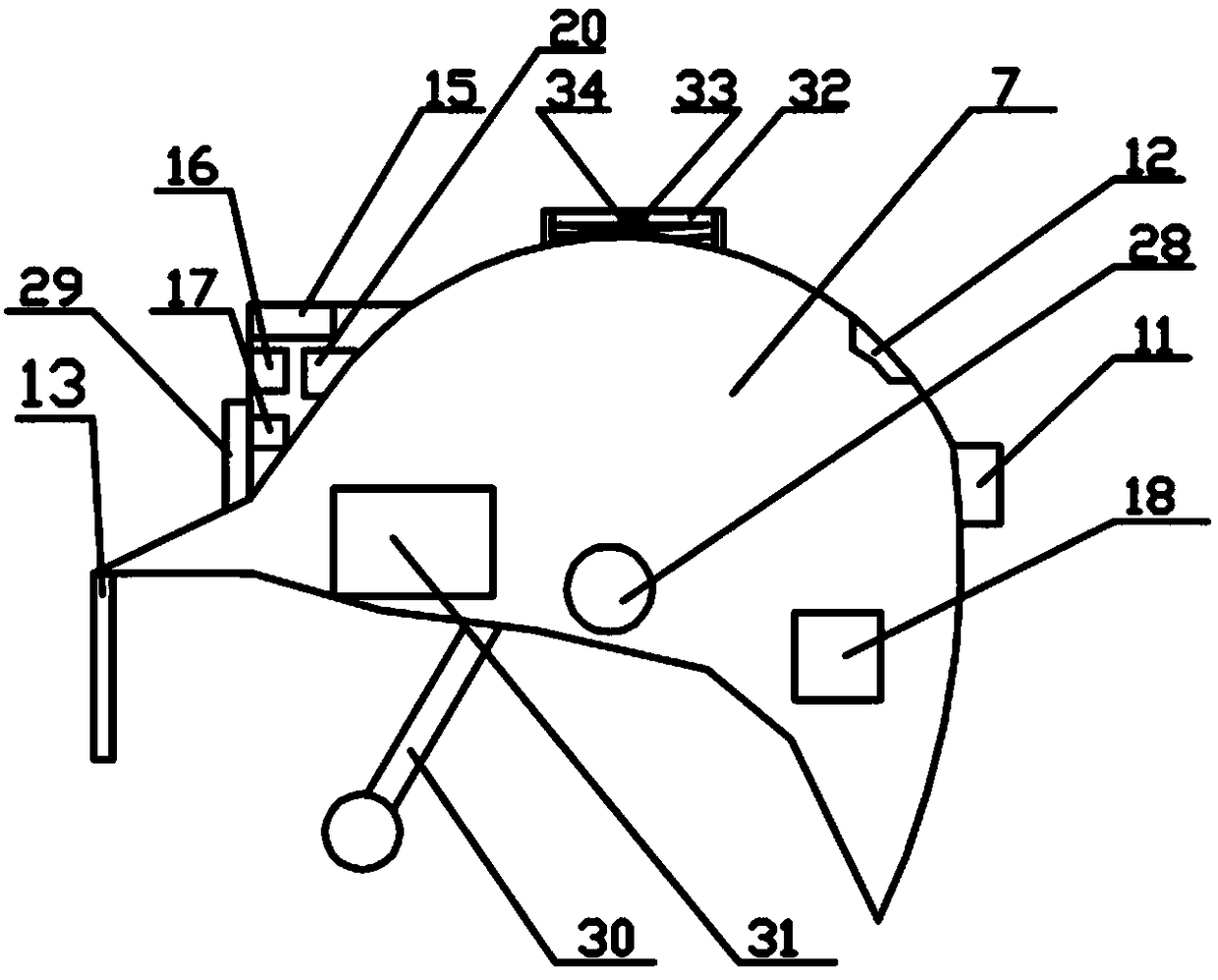

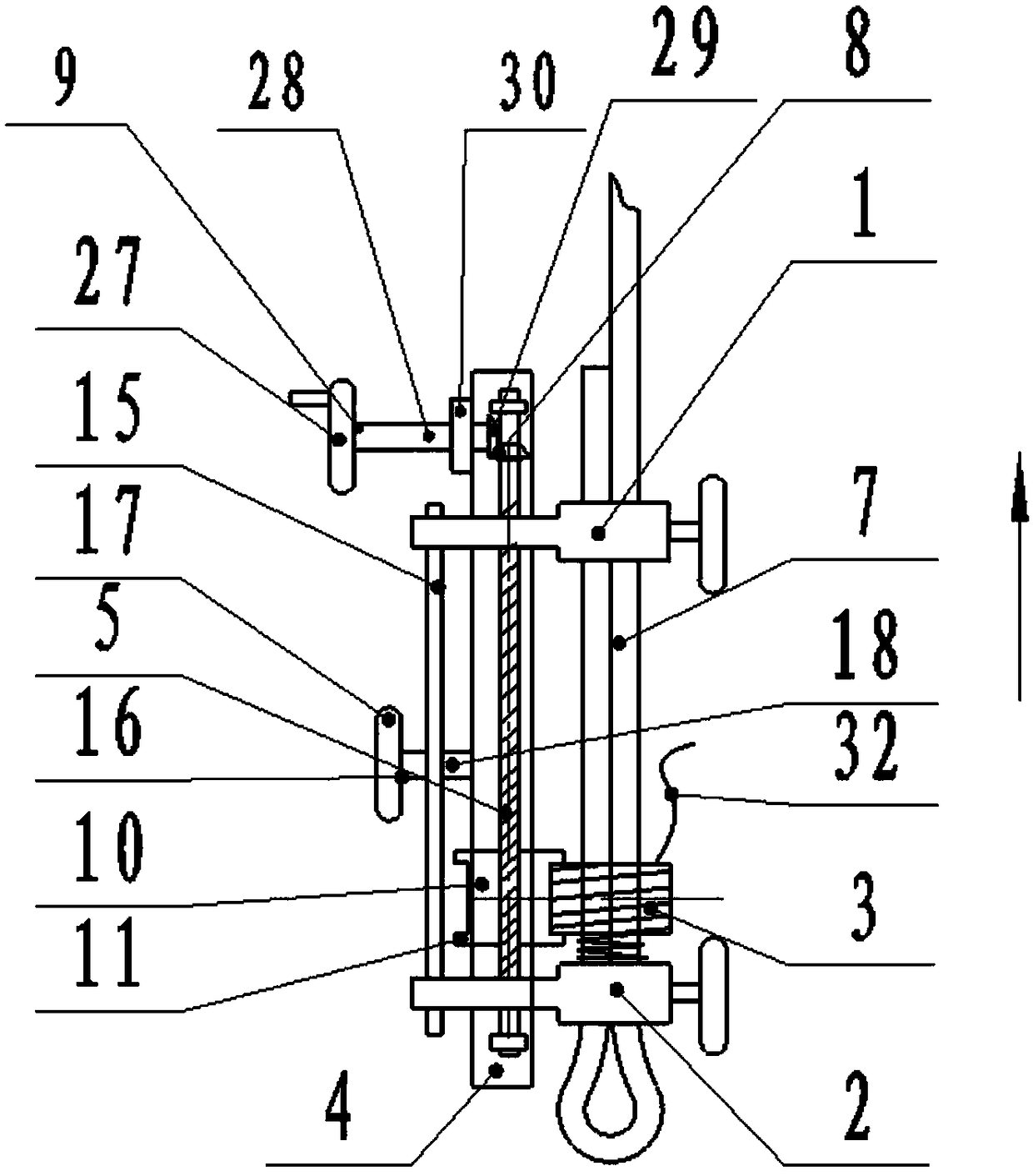

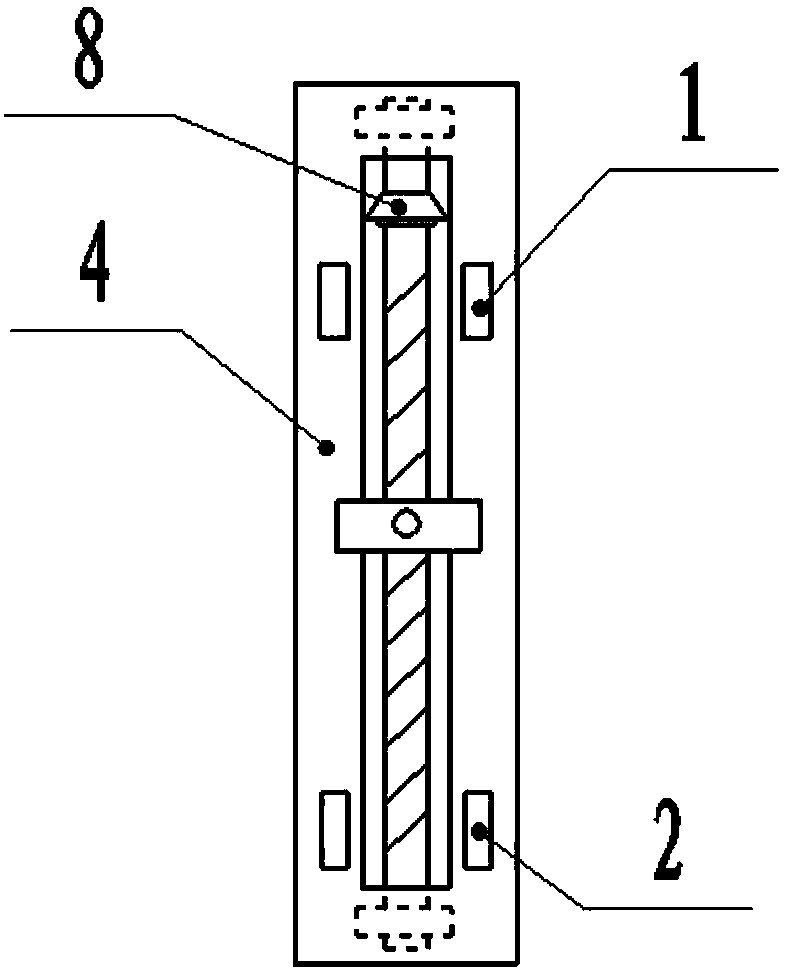

Adjustable high-rise escape device

The invention relates to an adjustable high-rise escape device, which is applied to temporary self rescue occasions when a high-rise emergency and a disaster occur, and comprises a metal structural box body. The adjustable high-rise escape device is characterized in that the box body is internally provided with a safety arrestment part, a guide rope part, a collecting rope part and a lifting and dropping slide part, a manual force adjusting telescopic link and a centrifugal clutch automatic force adjusting device are matched for arrestment, the guide rope part is internally provided with an automatic sequencing and winding mechanism for controlling a lifting and dropping rope, the collecting rope part is internally provided with an electric recovery unit, and the lifting and dropping slide is internally provided with a telescopic slide suitable for an escaper to stand on. The adjustable high-rise escape device is adjusted to drop with constant speed through a manual method or an automatic method by utilizing worm wheel and worm bar transmission and utilizing the weight of the escaper to generate dropping power, and is driven by a motor to return to a rescue site, thereby the quick and continuous escaping effect is realized. The invention has the advantages of strong sense of security of the escaper, small volume, easy storing, light weight as well as convenient conveying and installation in escaping.

Owner:WUHAN TEXTILE UNIV

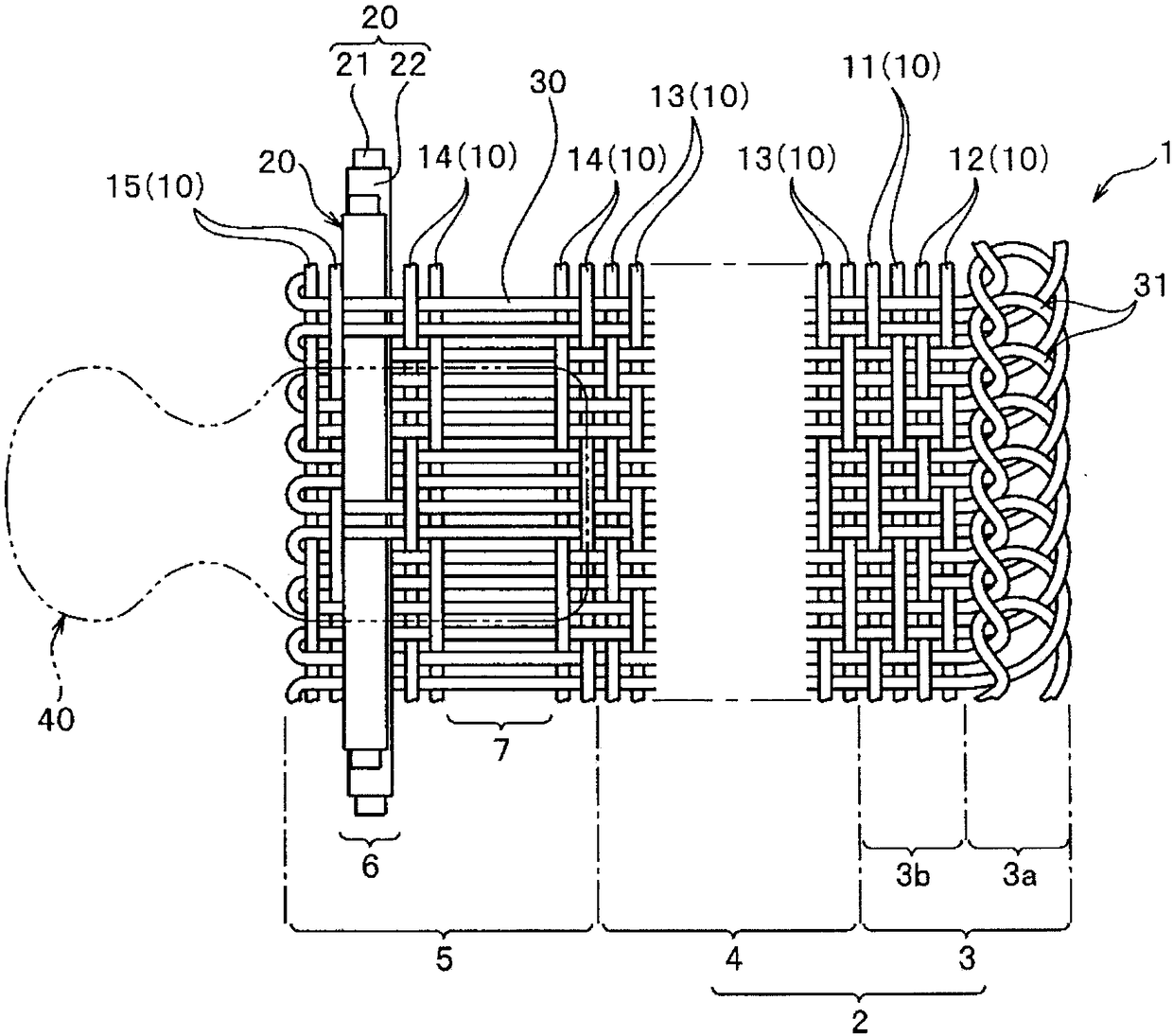

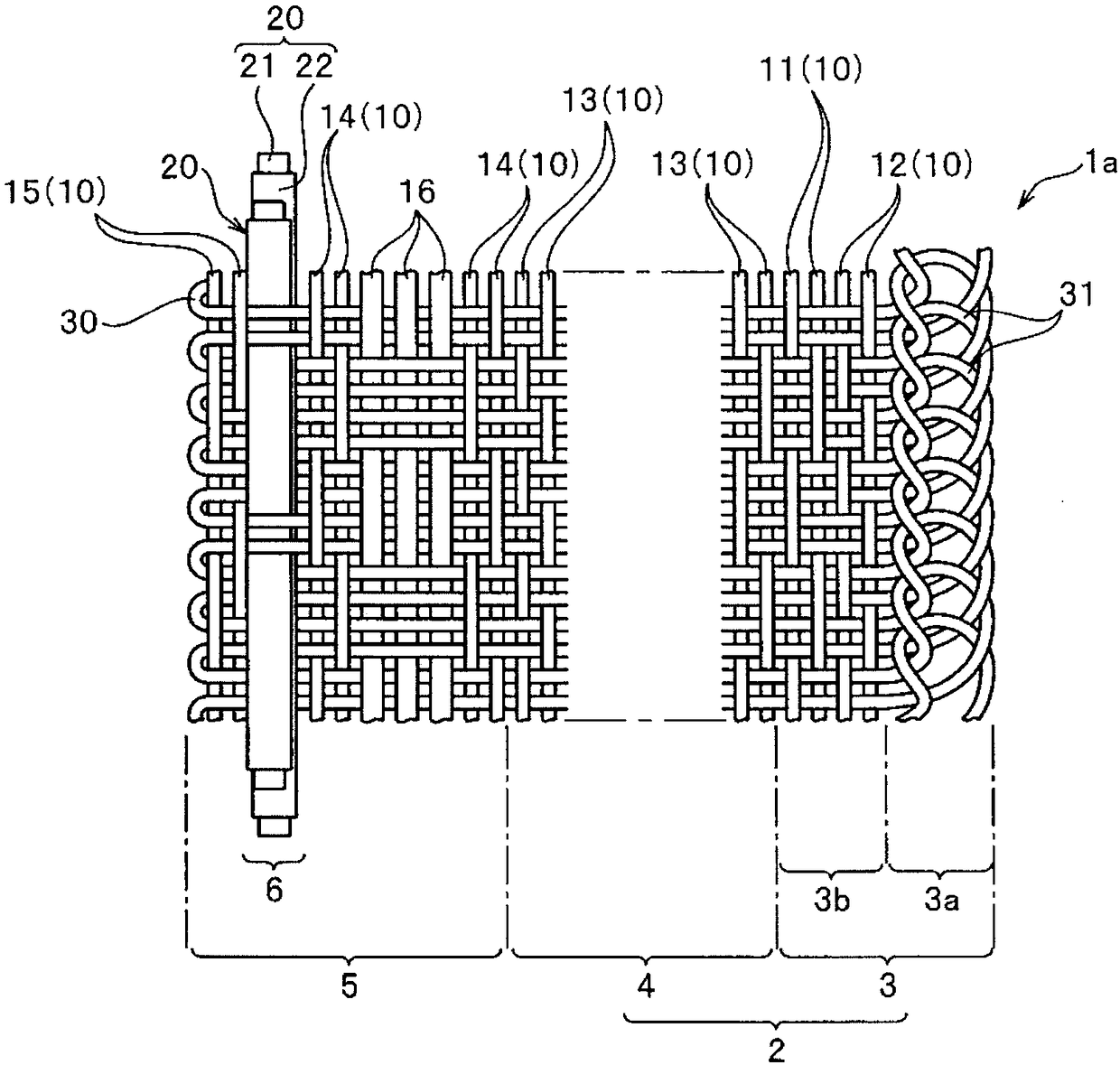

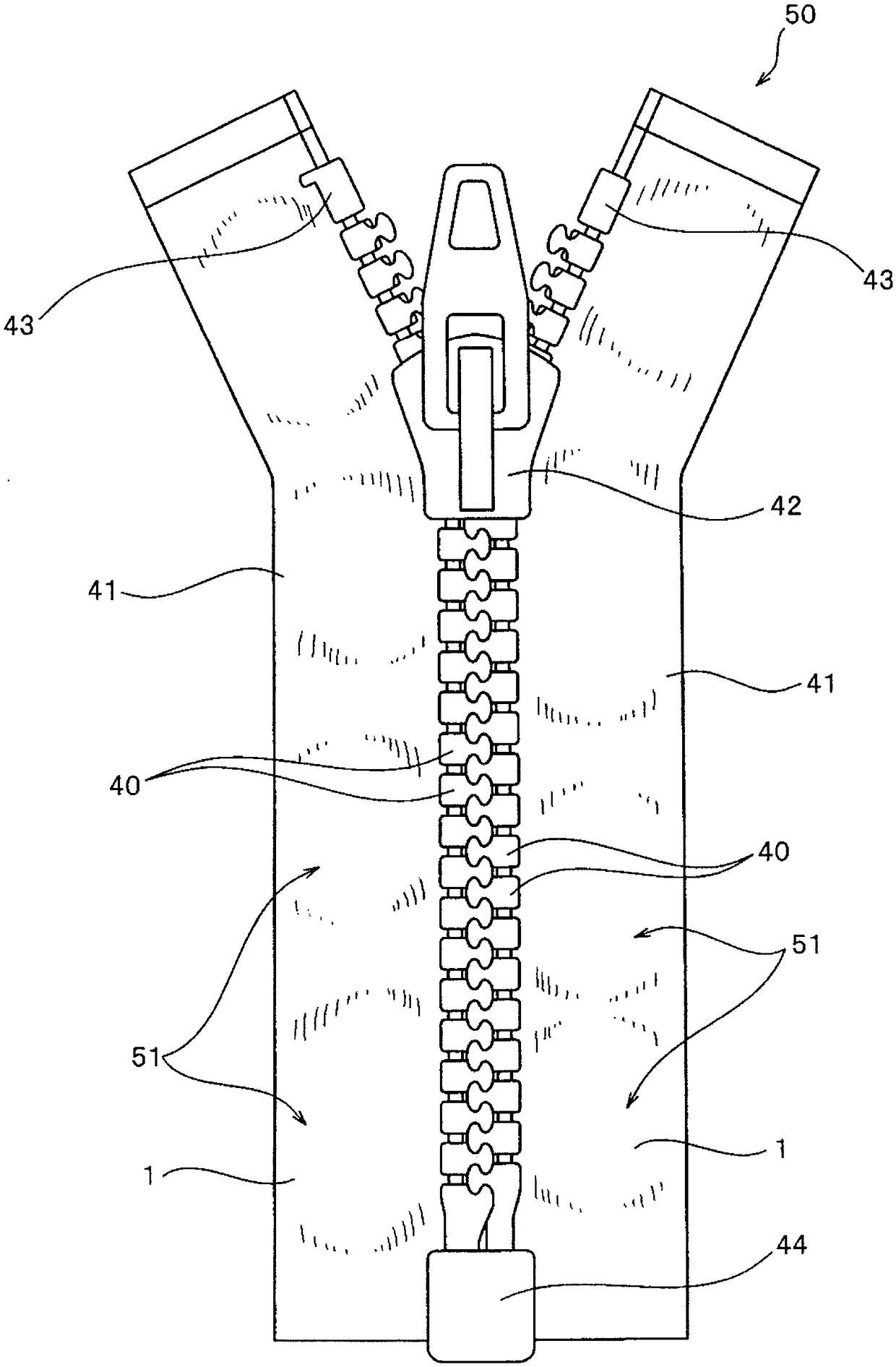

Zipper belt and zipper chain belt

The invention provides a zipper belt and a zipper chain belt, which can prevent reverse wrinkles when a zipper is woven to a product. Moreover, the problems caused by wrinkles in the zipper in the steps such as dyeing, delivering, injection moulding, and the like, are solved. The provided zipper belt (1,1b) comprises a belt main body (2) and a chain installation part (5) provided with a core rope(20). The belt main body (2) comprises an ear part (4) containing a plurality of warps (10) and a basic part (4) arranged between the ear part (3) and the chain installation part (5). The warps (10) of the basic part (4) are arranged in a more released state, compared with the at least one of the warps of the ear part (3) and the core rope (20).

Owner:YKK CORP

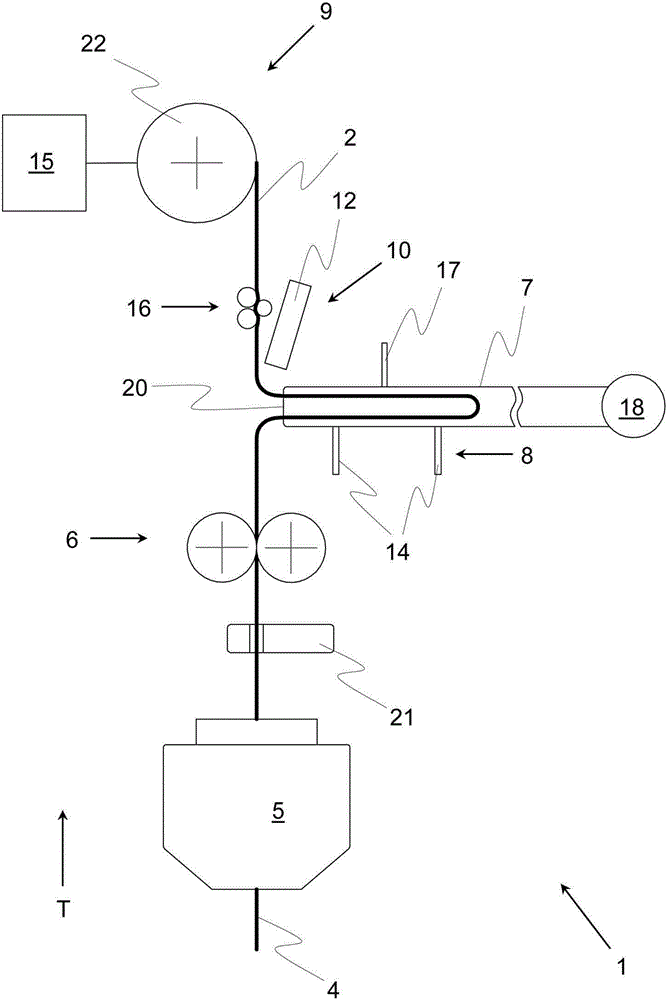

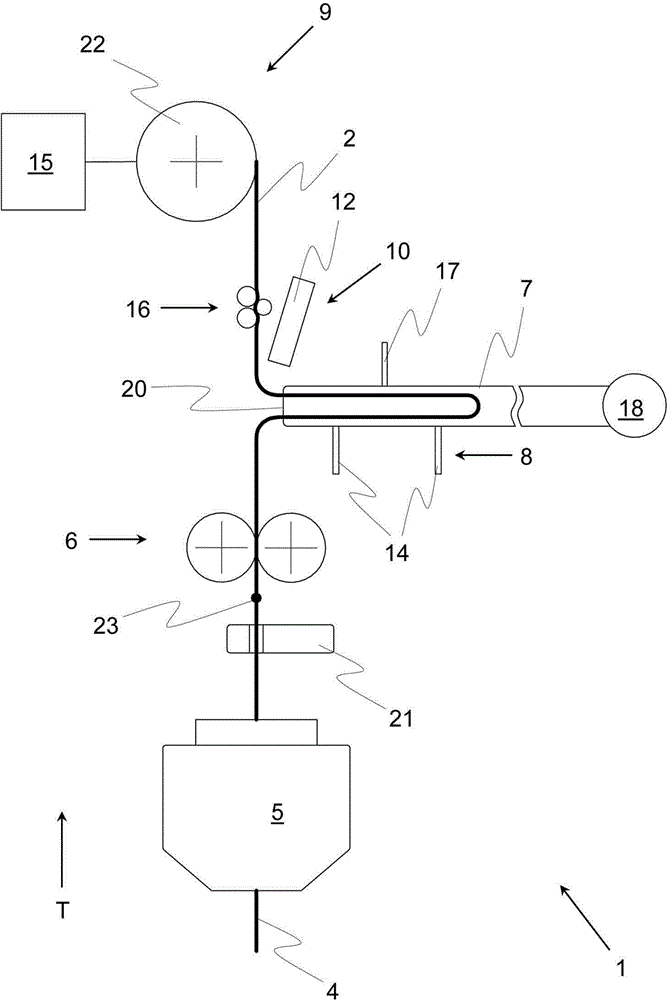

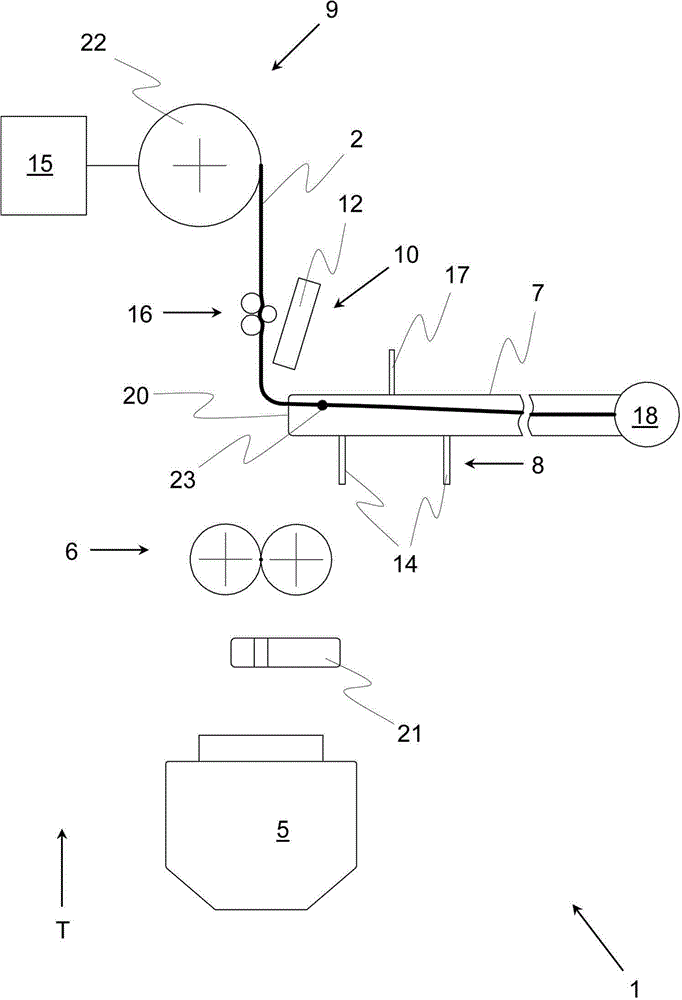

Spinning Point Of Spinning Machine And Method For Operation Of Same

ActiveCN104060350AImprove suction effectActive interruption of productionPiercing arrangementsFilament handlingYarnEngineering

The invention relates to a spinning point (1) of a spinning machine, whereas the spinning point (1) includes a spinning unit (5), a drawing-off device (6) for the yarn (2) downstream of the spinning unit (5) in the direction of transport (T) and a yarn accumulator (7) downstream of the drawing-off device (6) for the intermediate accumulation of a section of yarn, whereas the yarn accumulator (7) is allocated a sensor system (8) for monitoring the filling level of the yarn accumulator (7), whereas the spinning point includes a spooling device (9) for the yarn (2) downstream of the yarn accumulator (7), along with a return unit (10), with the assistance of which an end of the yarn (11), which is found within the yarn accumulator (7) after a yarn break, is able to be returned in the area of the spinning point (1). What is also proposed is a method for the operation of a spinning point (1), characterized in that its spooling device (9) is stopped in such a manner that, after the stop of the spooling device (9), an end section of the yarn (2) remains within the yarn accumulator (7), that, subsequent to this, a part of the yarn (2) is separated with the assistance of a yarn separation unit (17) internal to the spinning point, and that the end of the yarn (11) that newly arises in this manner is returned with the assistance of a return unit (10) internal to the spinning point in the area of the spinning point (1), and that a spinning process is then carried out.

Owner:MASCHINENFABRIK RIETER AG

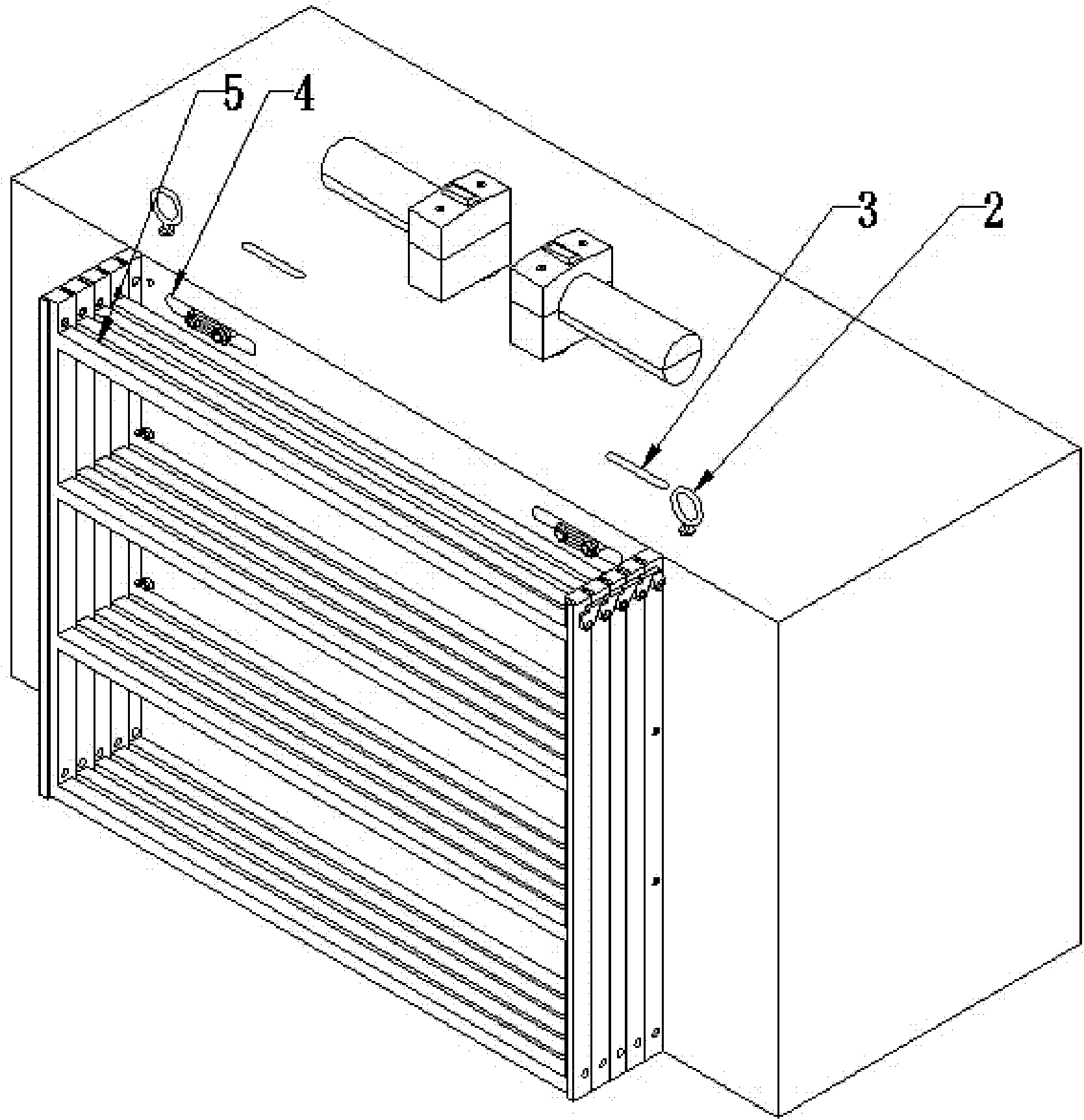

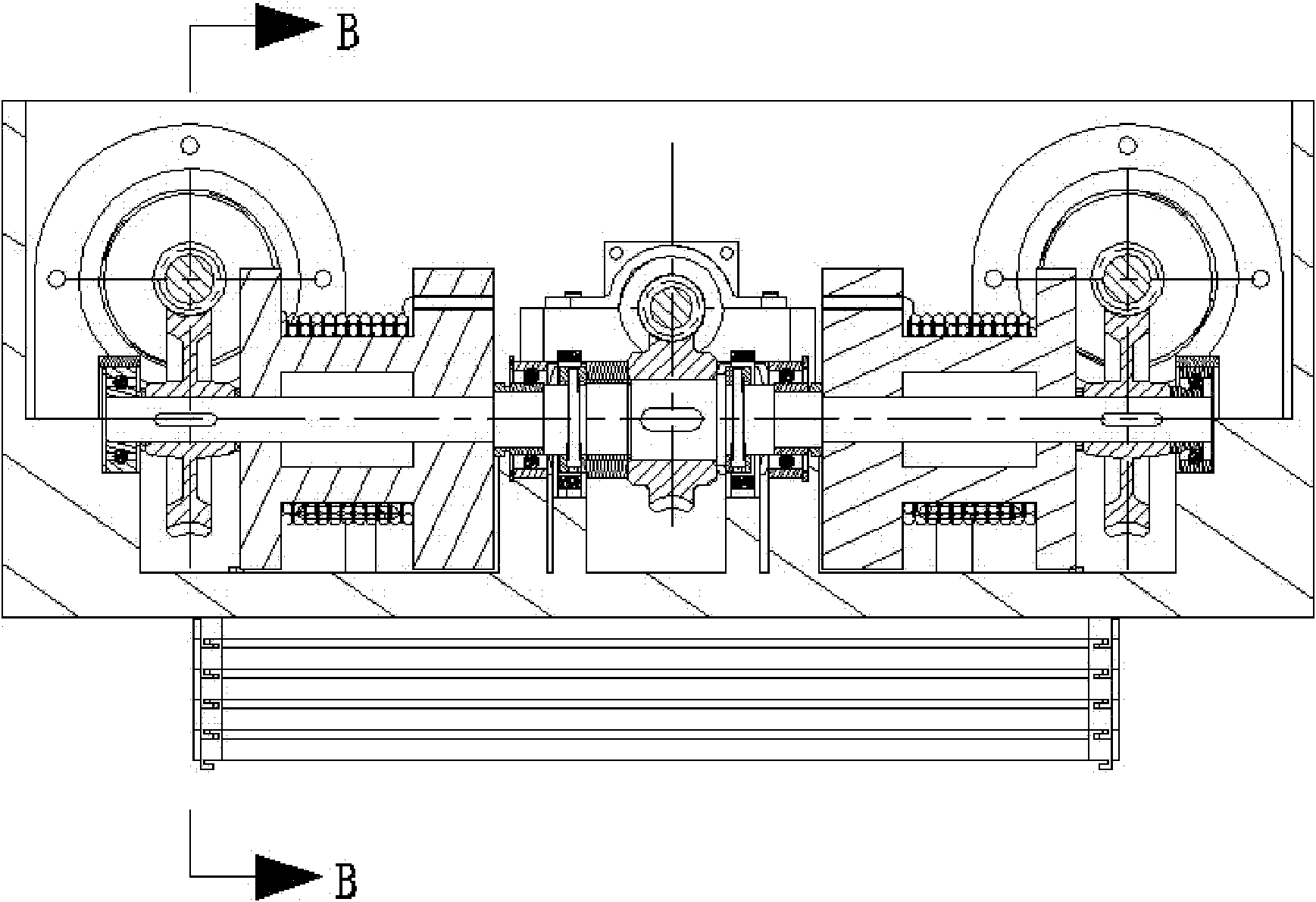

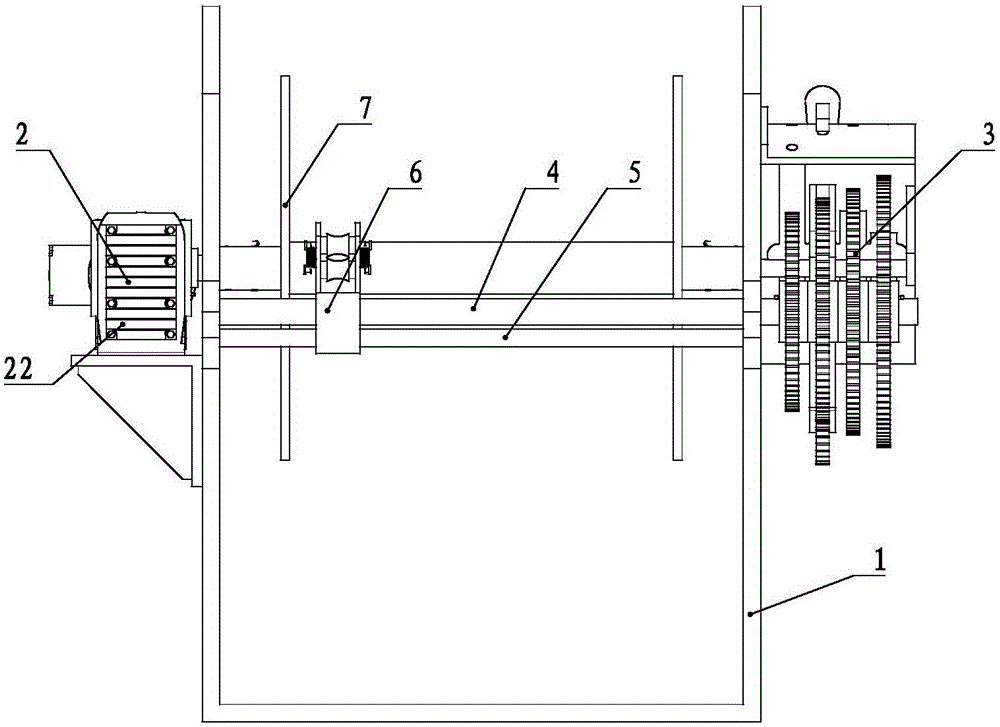

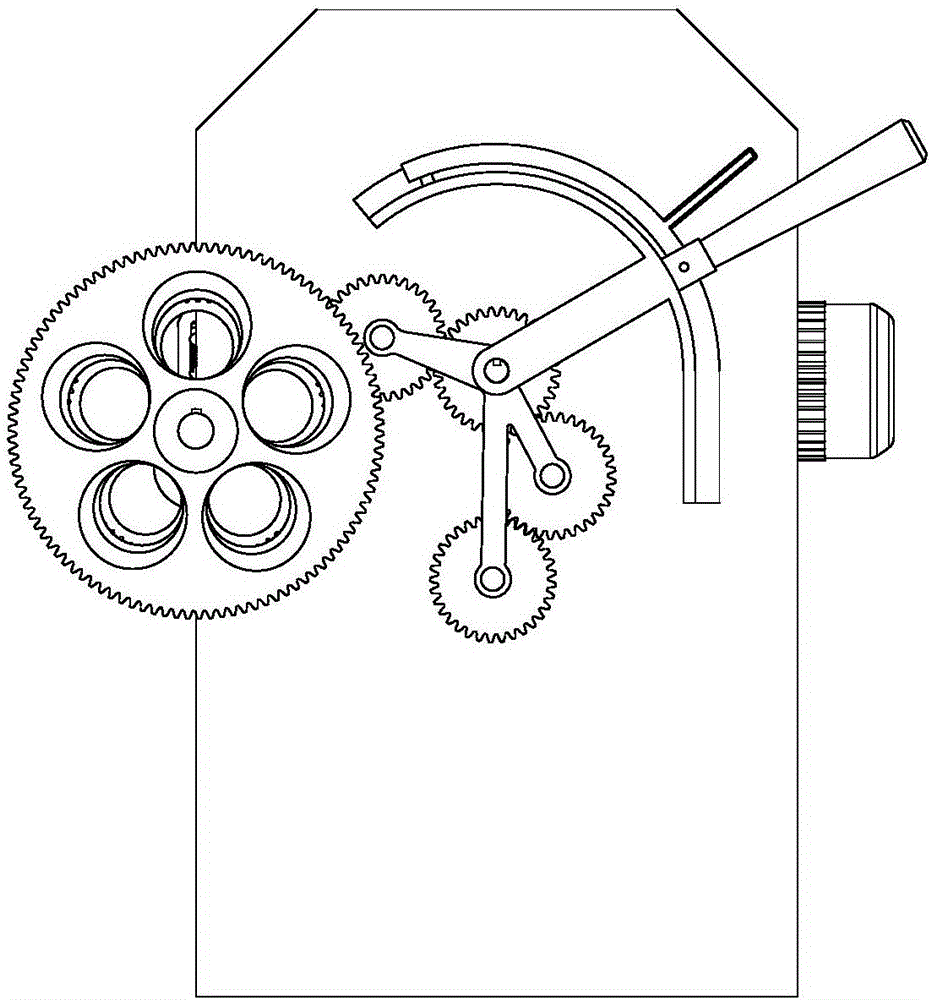

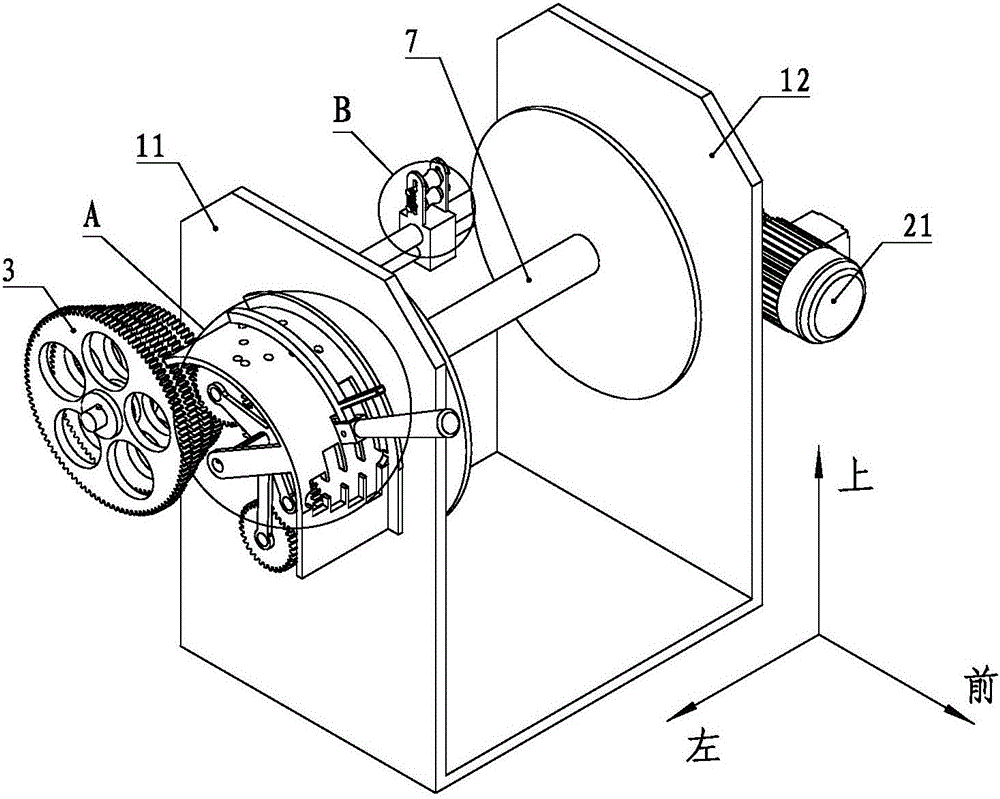

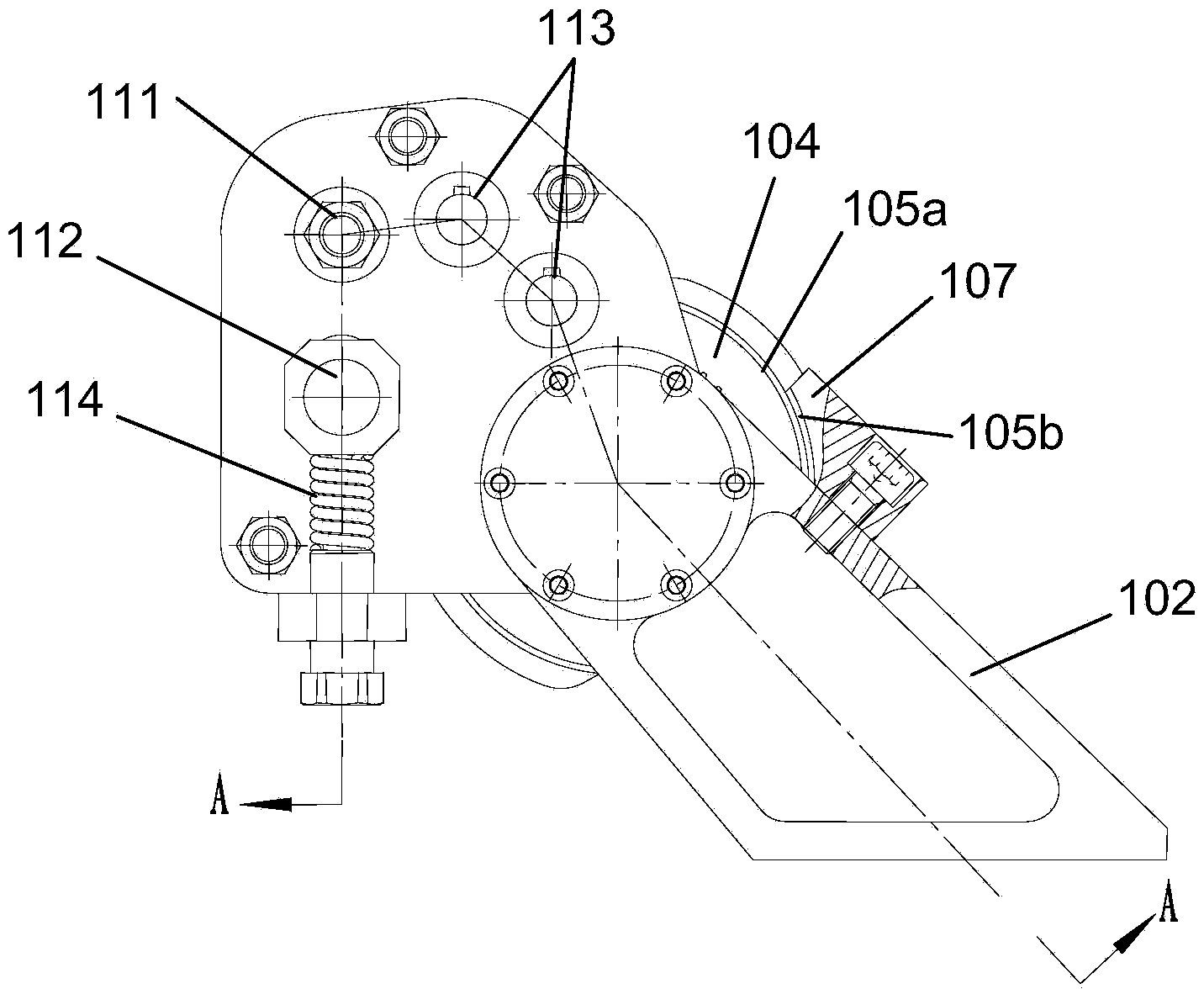

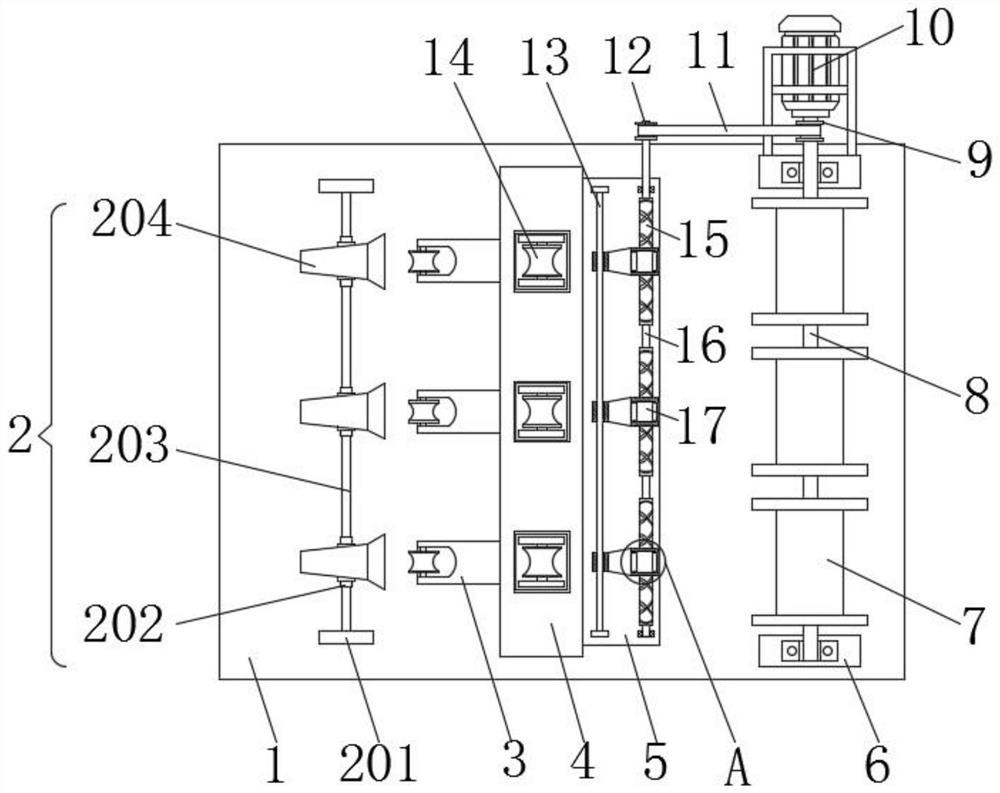

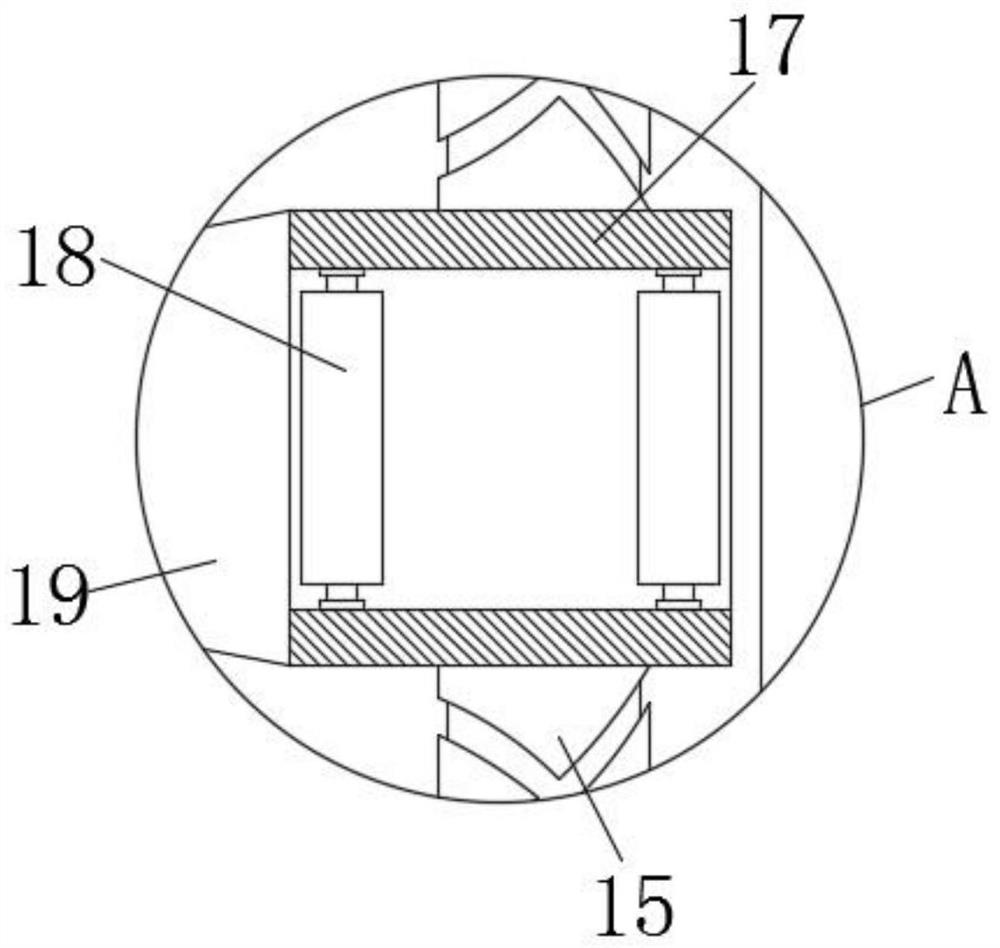

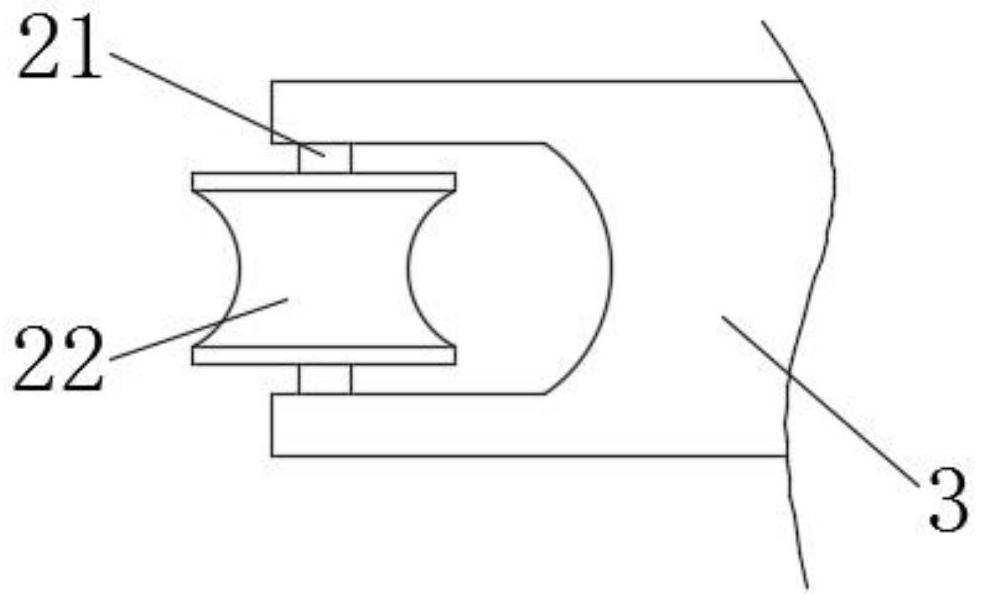

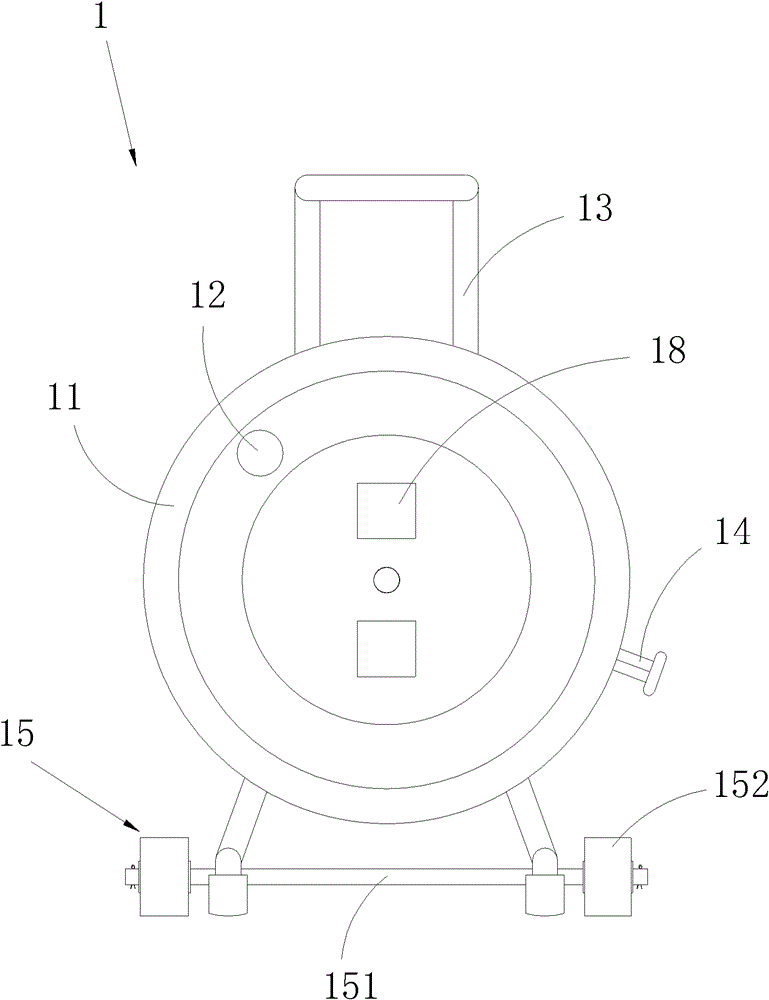

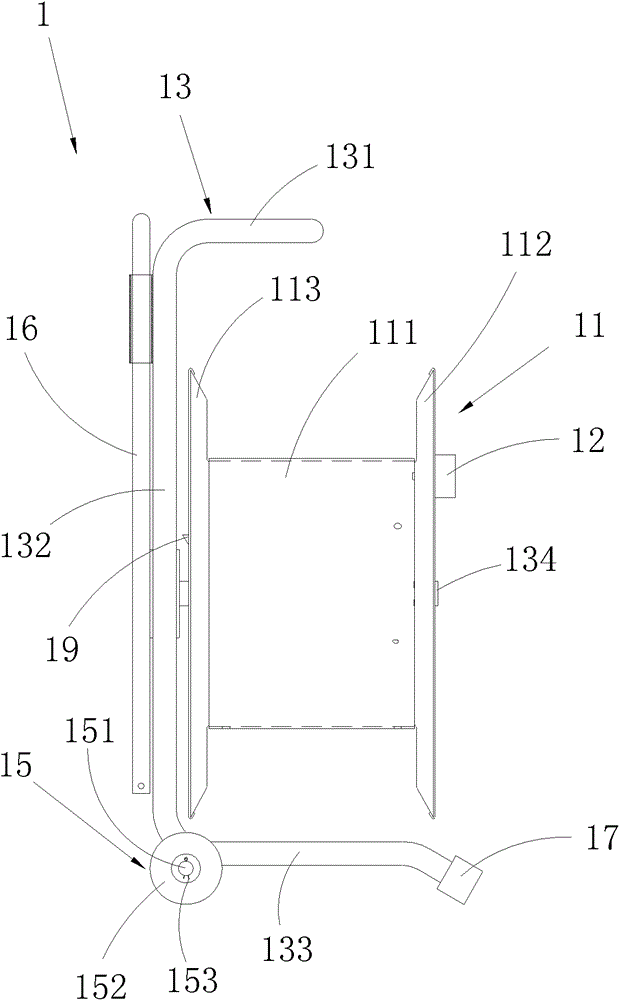

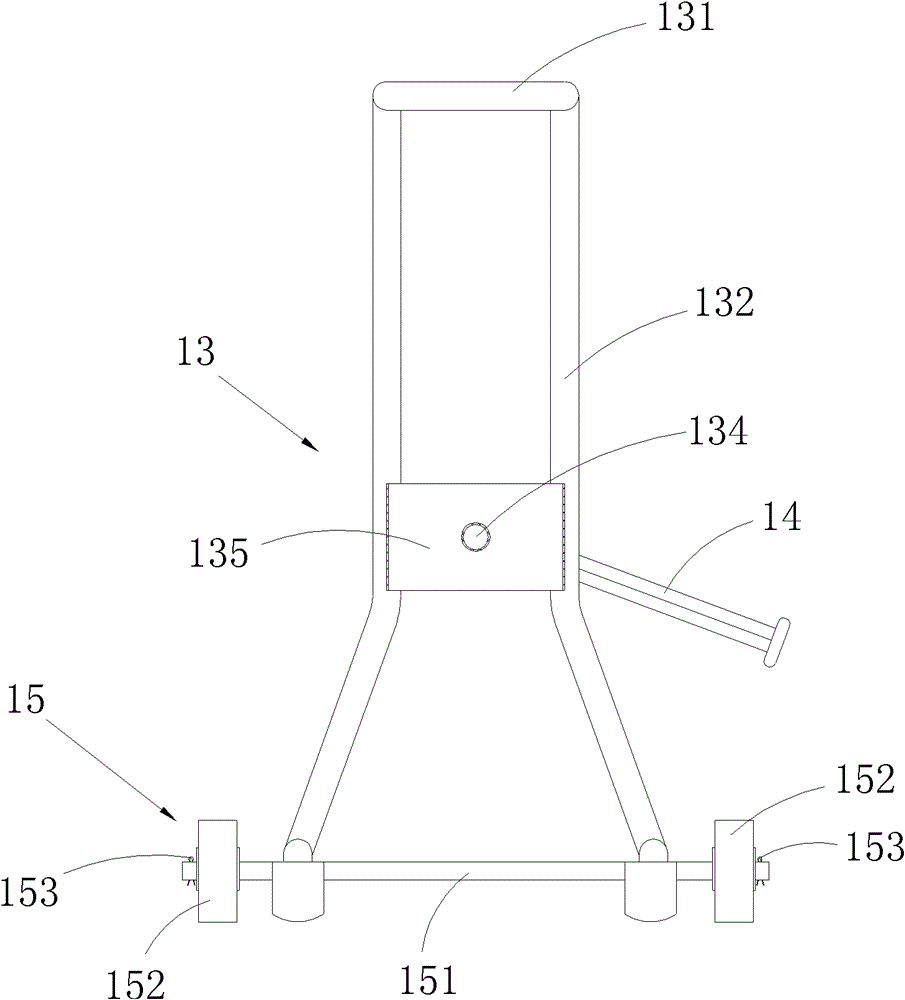

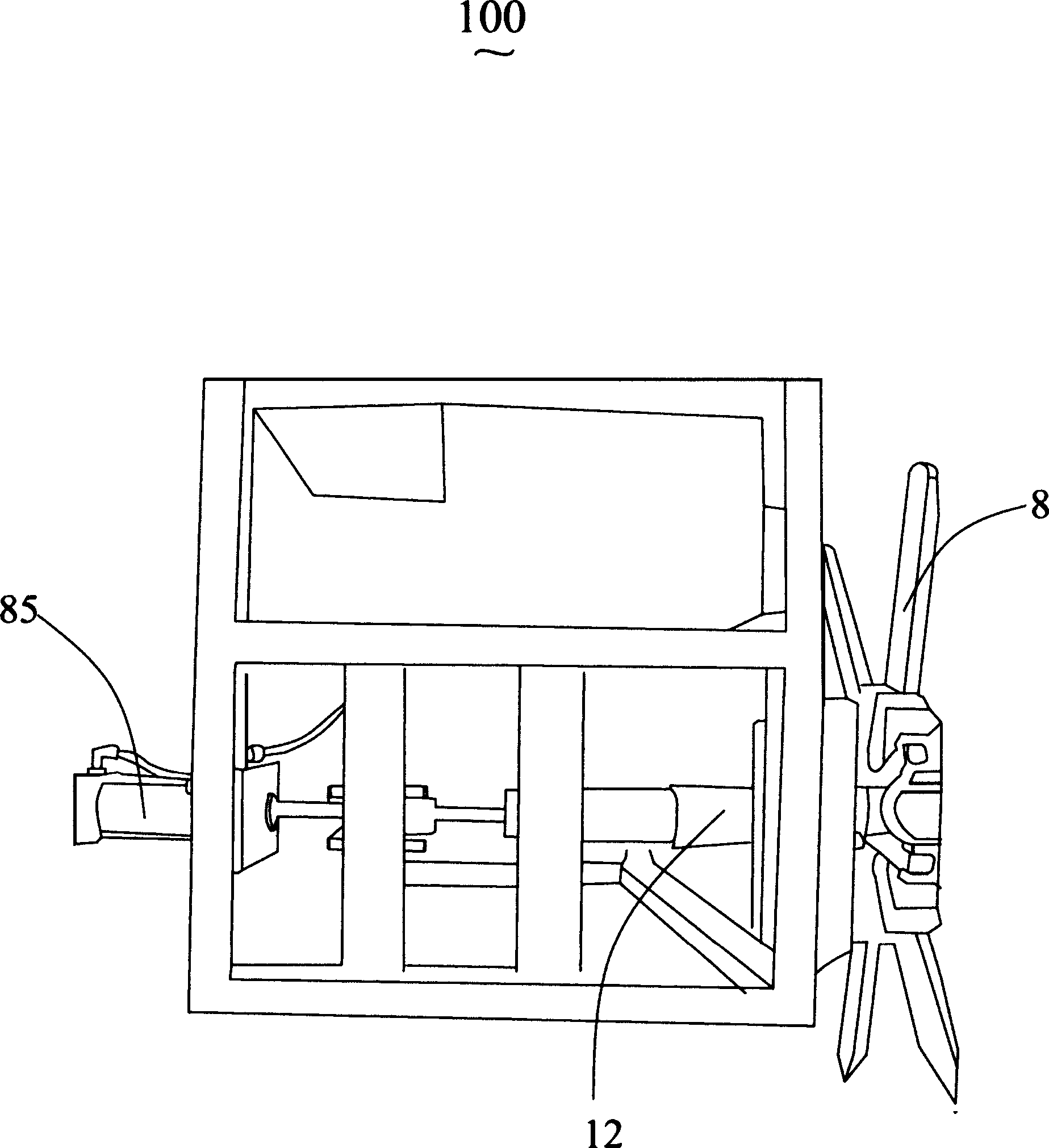

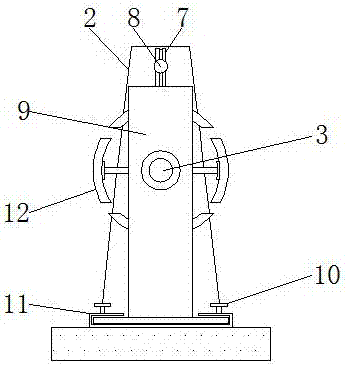

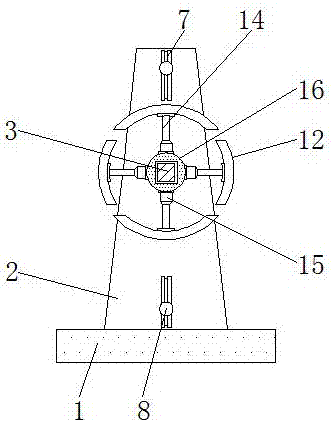

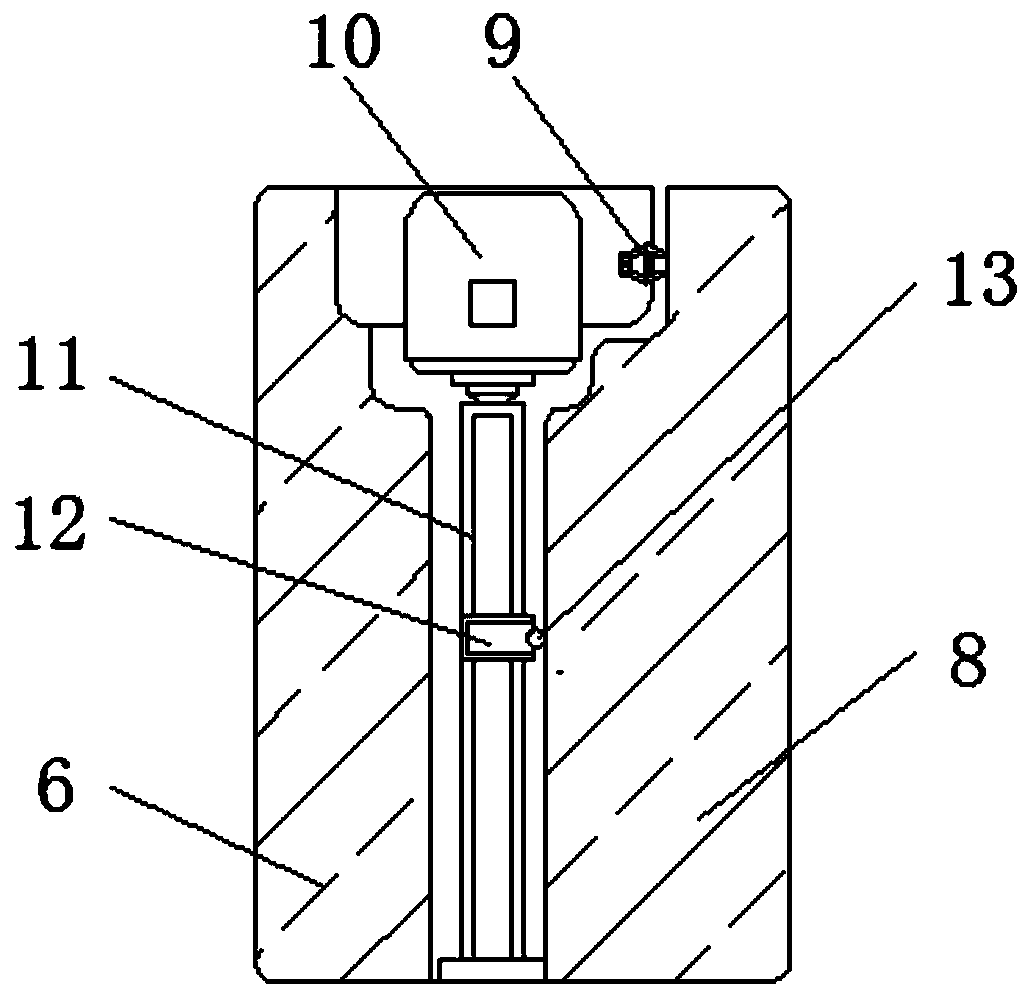

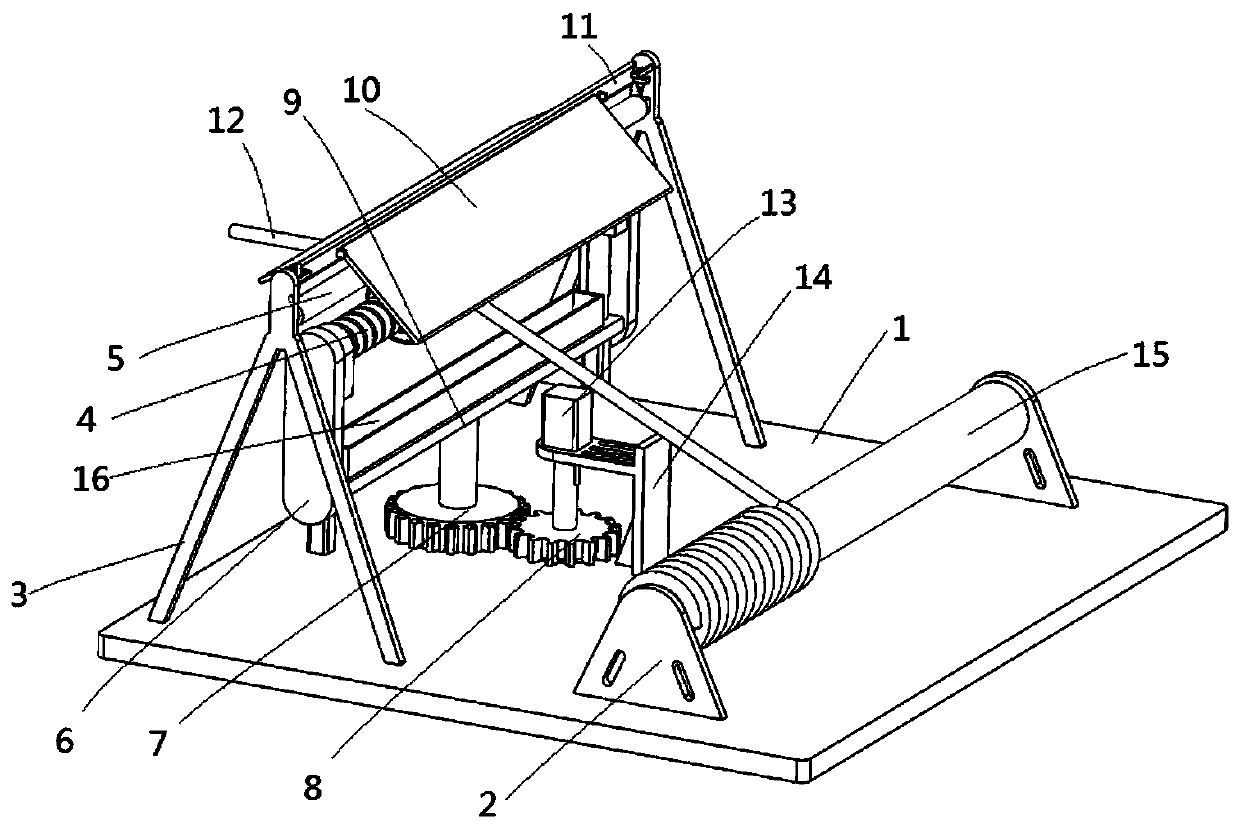

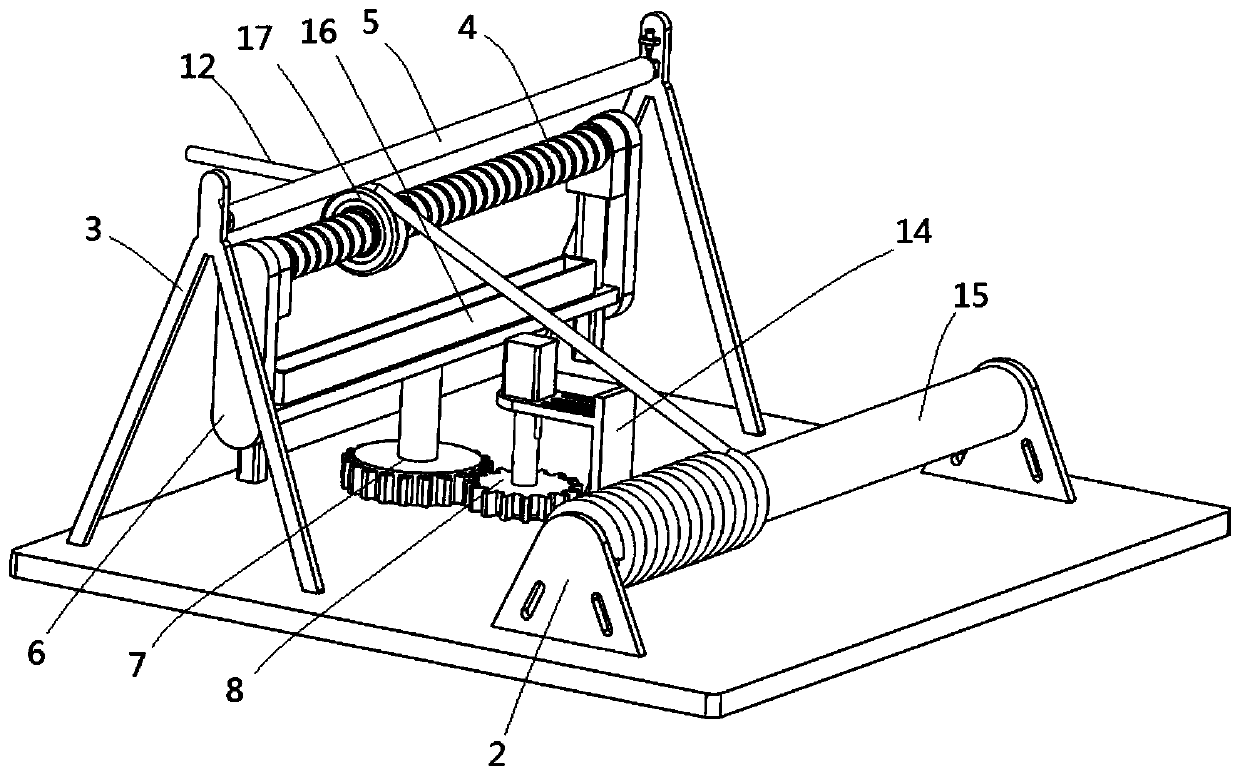

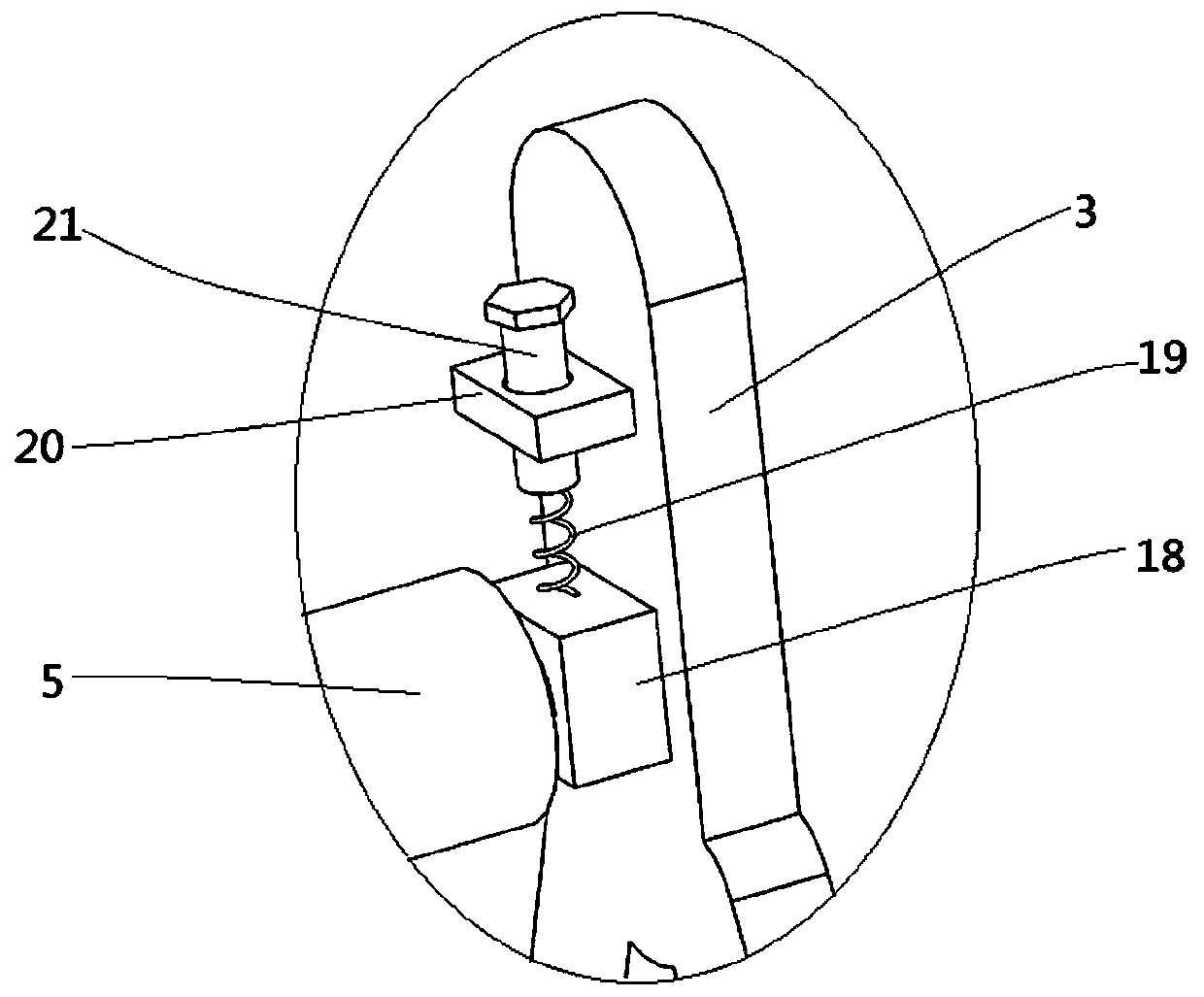

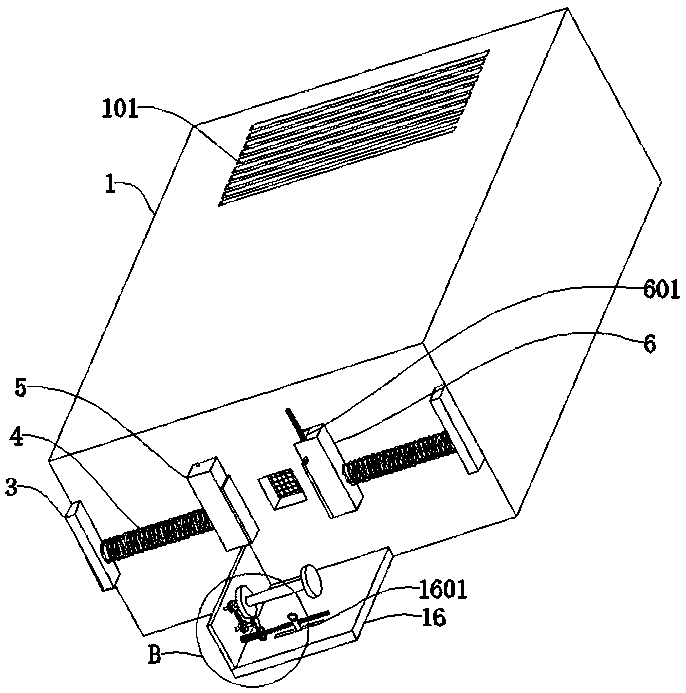

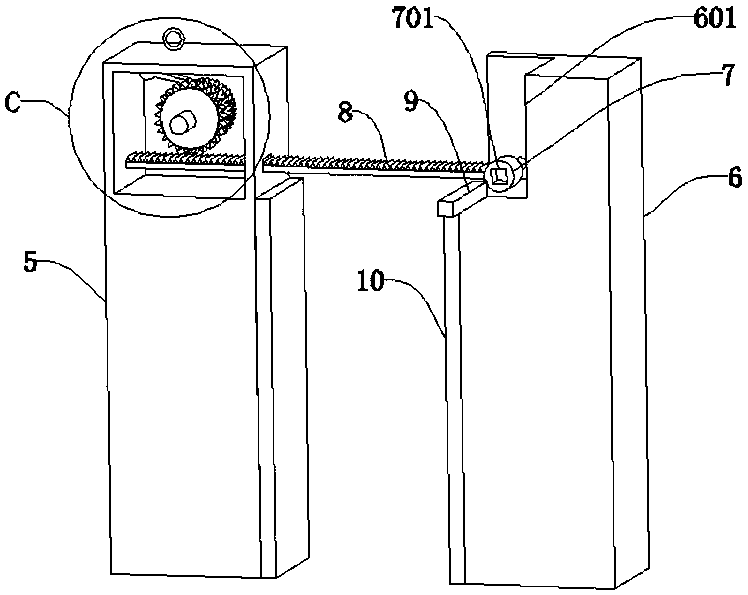

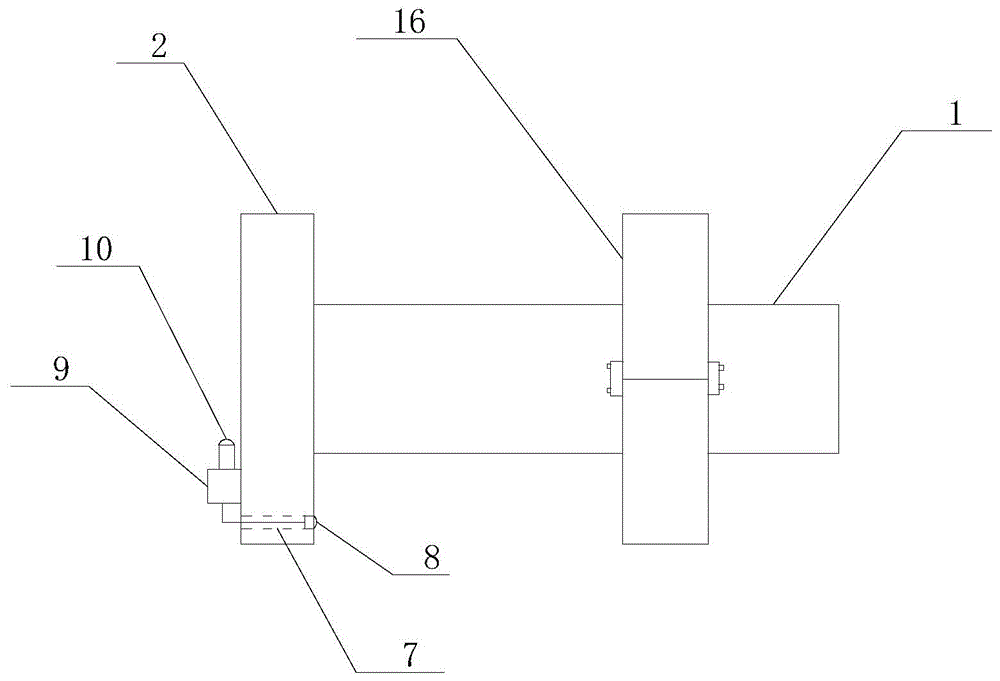

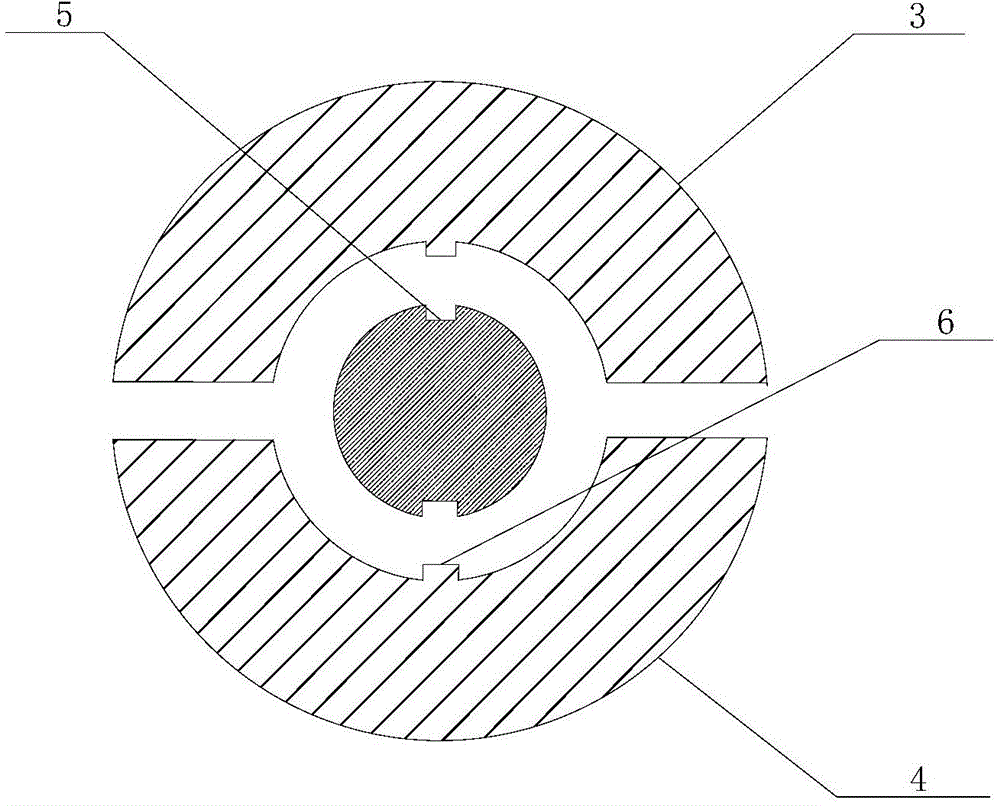

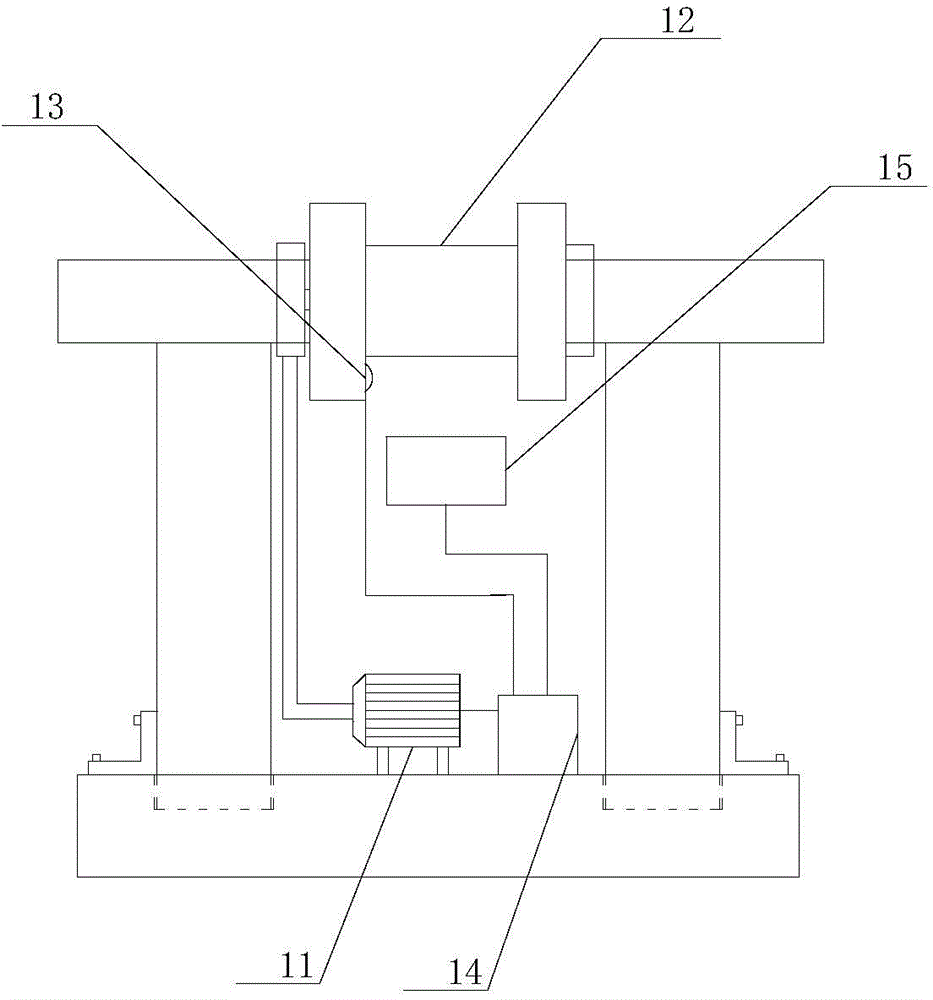

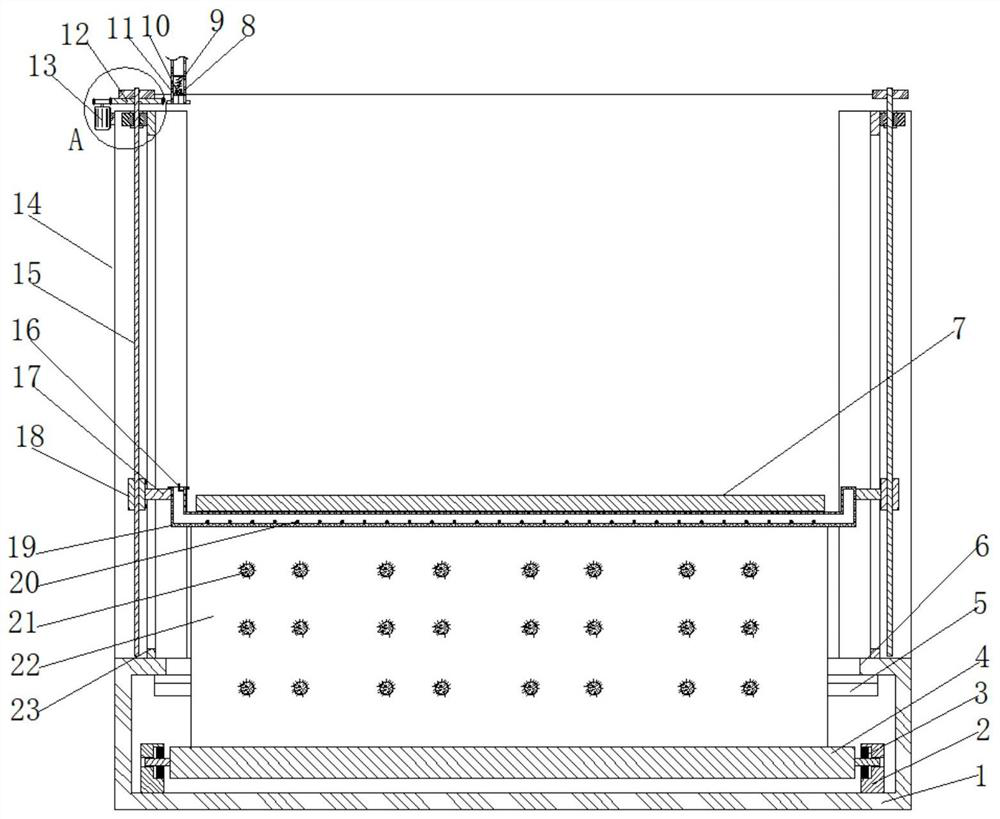

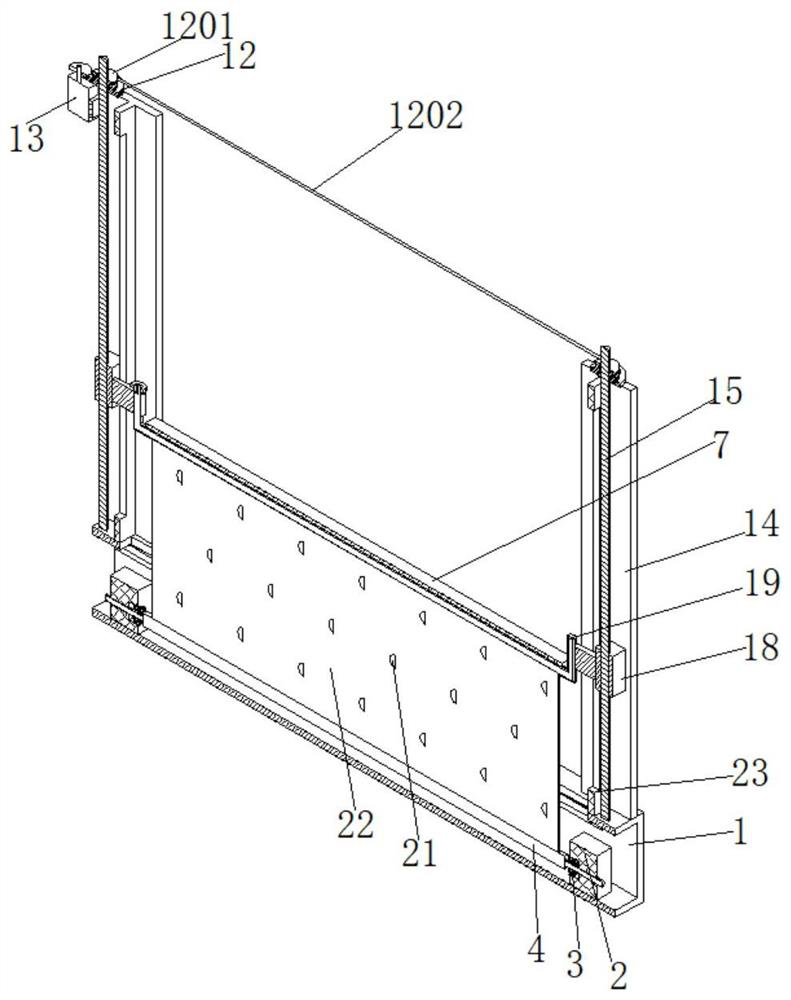

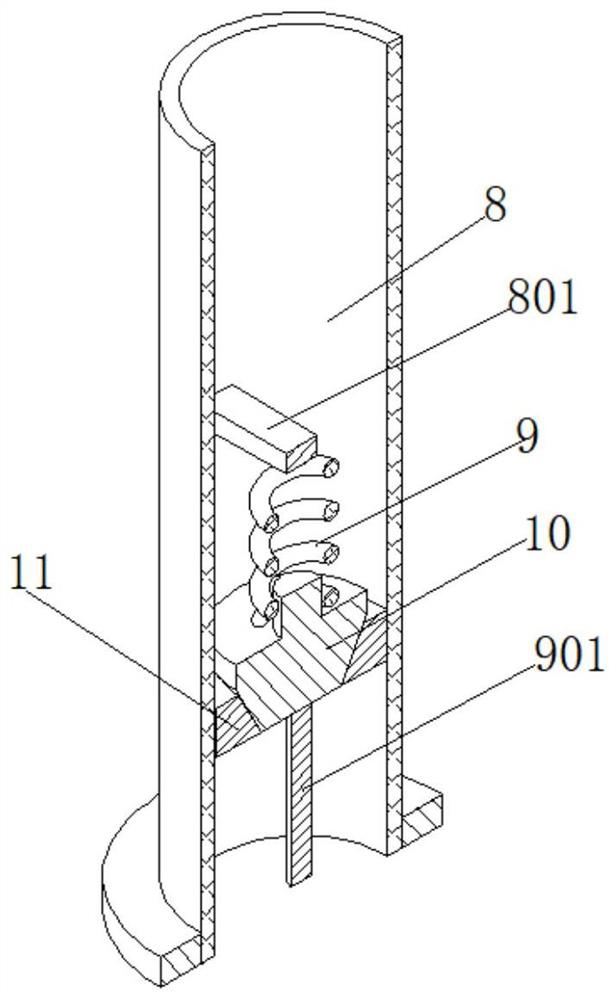

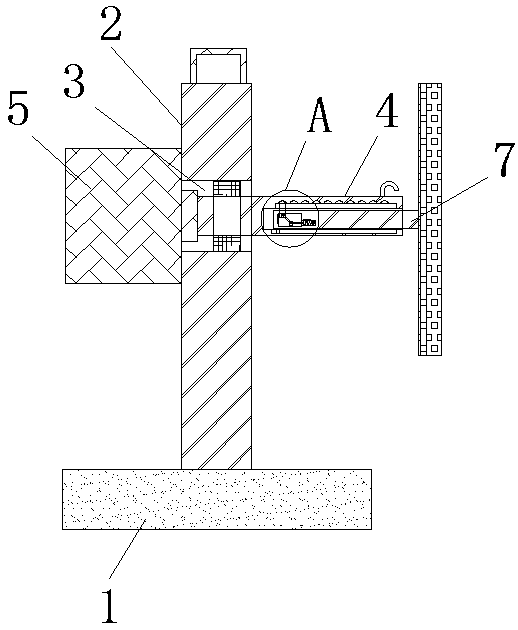

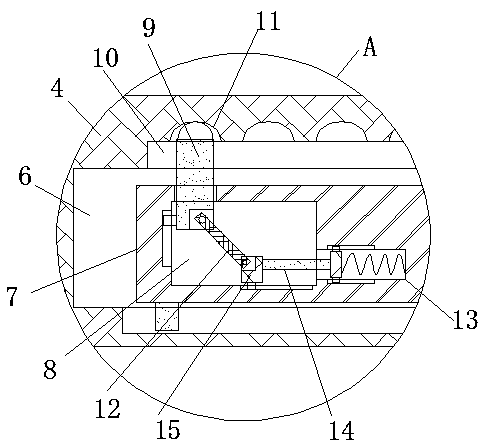

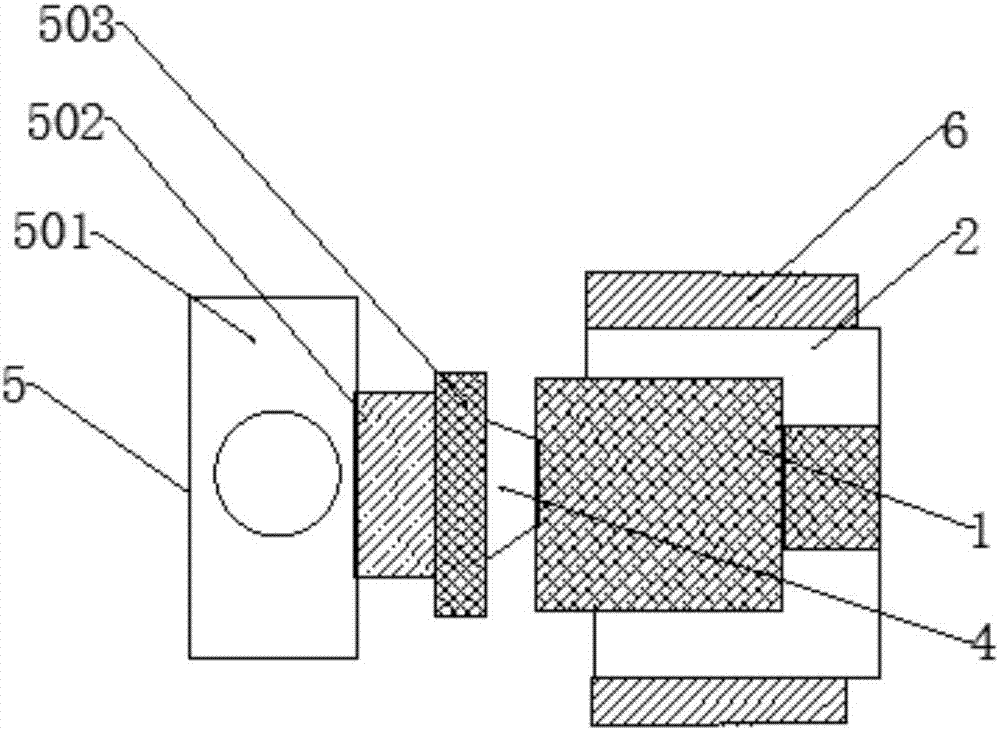

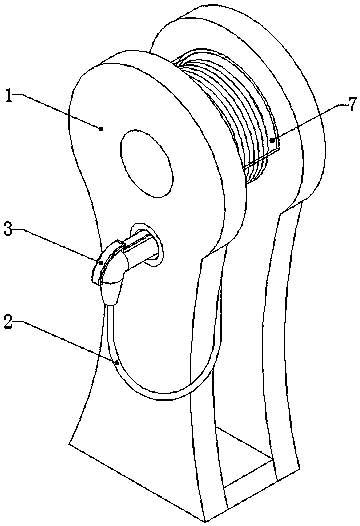

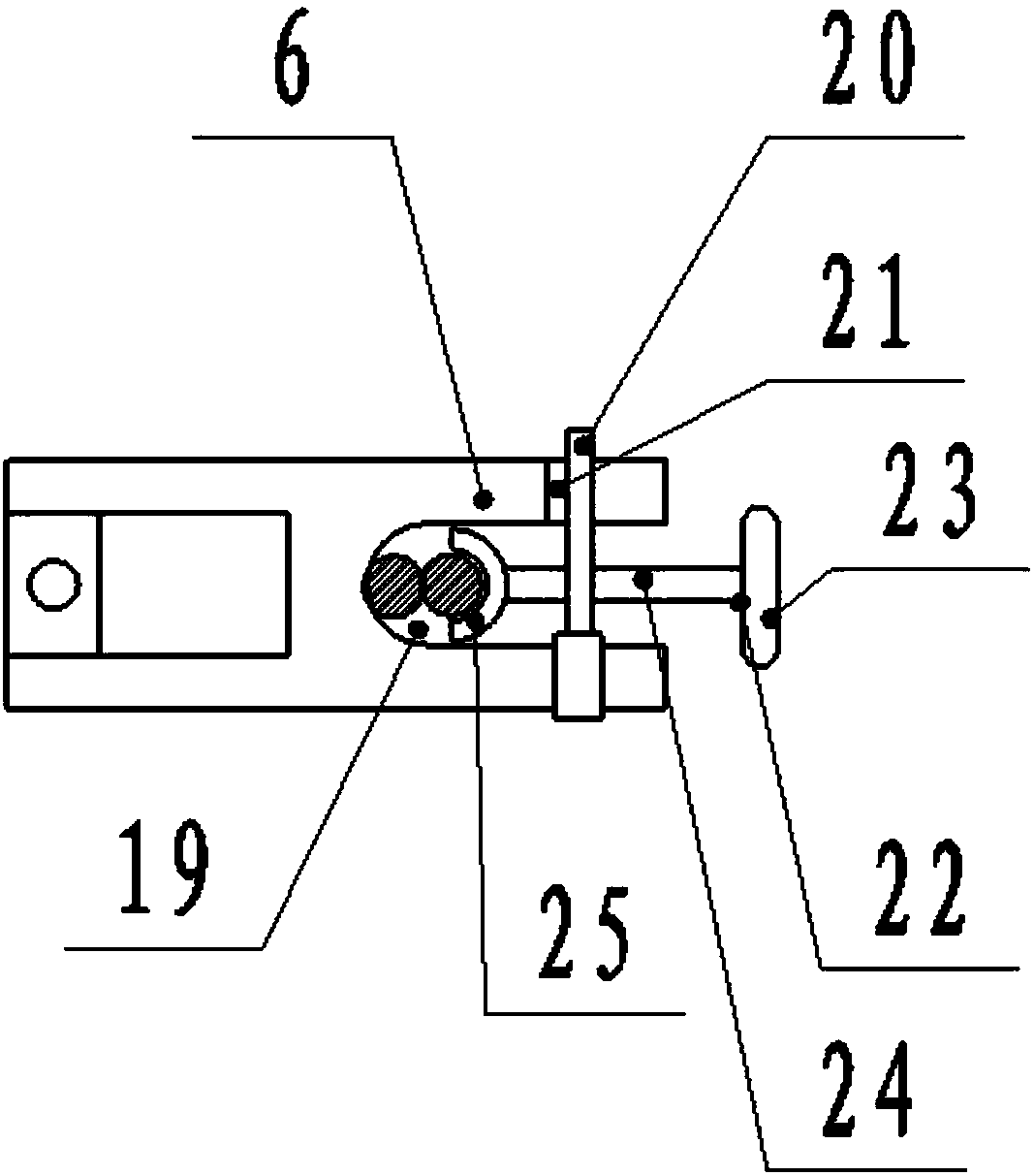

Grounding wire winding device adapted to various specifications of grounding wires

ActiveCN106516875ANeatly woundEasy to assemble and disassembleFilament handlingEngineeringConductor Coil

The invention discloses a grounding wire winding device adapted to various specifications of grounding wires. The device comprises a left vertical plate, a right vertical plate, a driving mechanism arranged on the right vertical plate and a gear shifting mechanism arranged on the left vertical plate, wherein a screw rod and a guide pillar are located between the left vertical plate and the right vertical plate and are respectively arranged on the rear sides of the left vertical plate and the right vertical plate; two ends of the screw rod are rotatably connected with the left vertical plate and the right vertical plate through a bearing assembly respectively; two ends of the guide pillar are fixedly connected with the left vertical plate and the right vertical plate respectively; a guide mechanism is arranged on the screw rod and the guide pillar; a dumbbell-shaped winding roller is arranged between the left vertical plate and the right vertical plate; the left end of the winding roller is connected with the gear shifting mechanism; the right end of the winding roller is connected with a driving mechanism. The device is capable of ensuring that the grounding wires are wound regularly in the processes of winding and unwinding the grounding wires, and can be adapted to different specifications of grounding wires.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

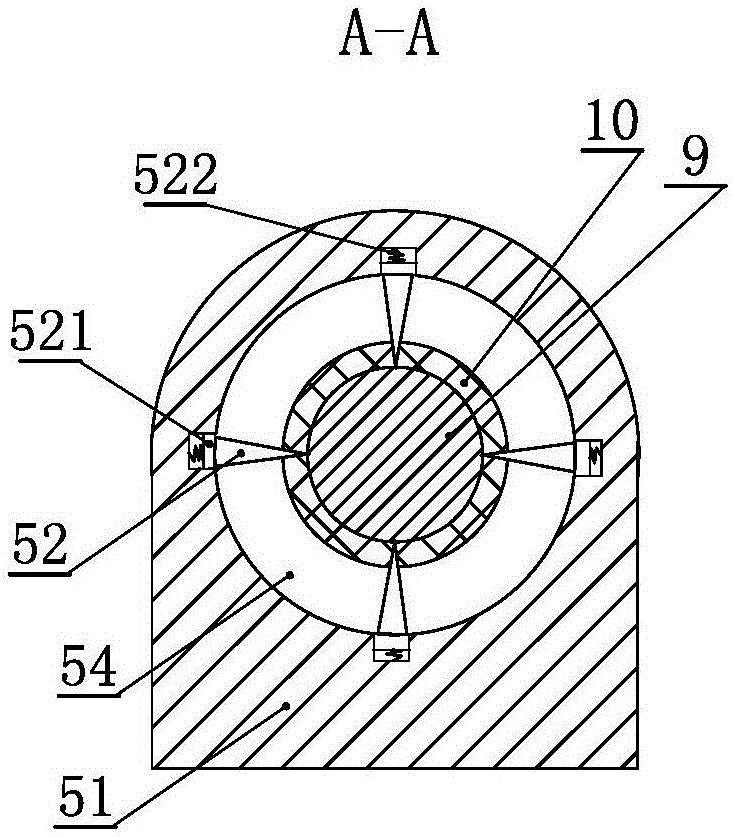

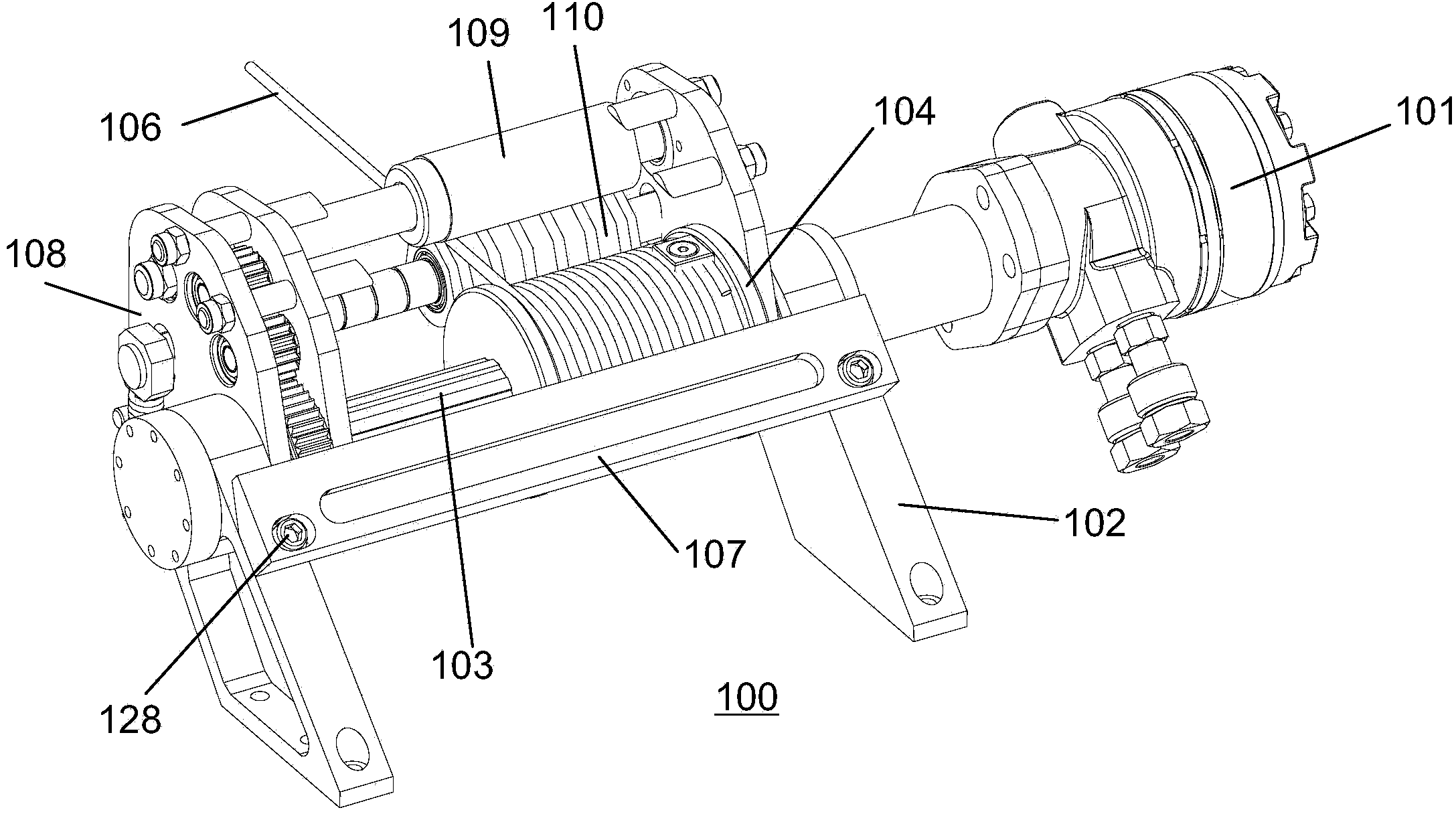

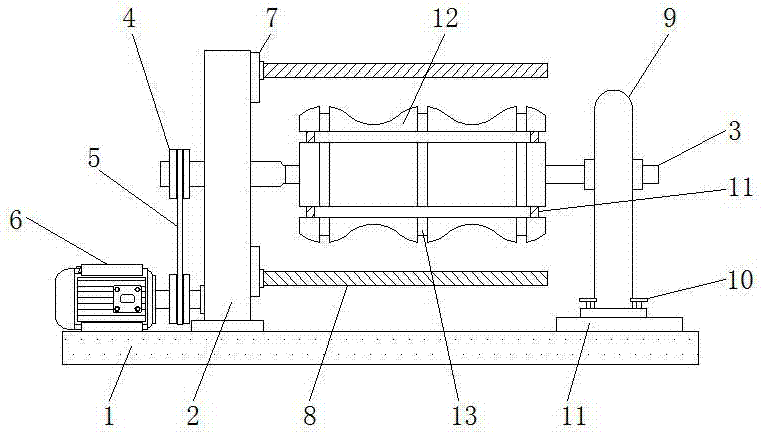

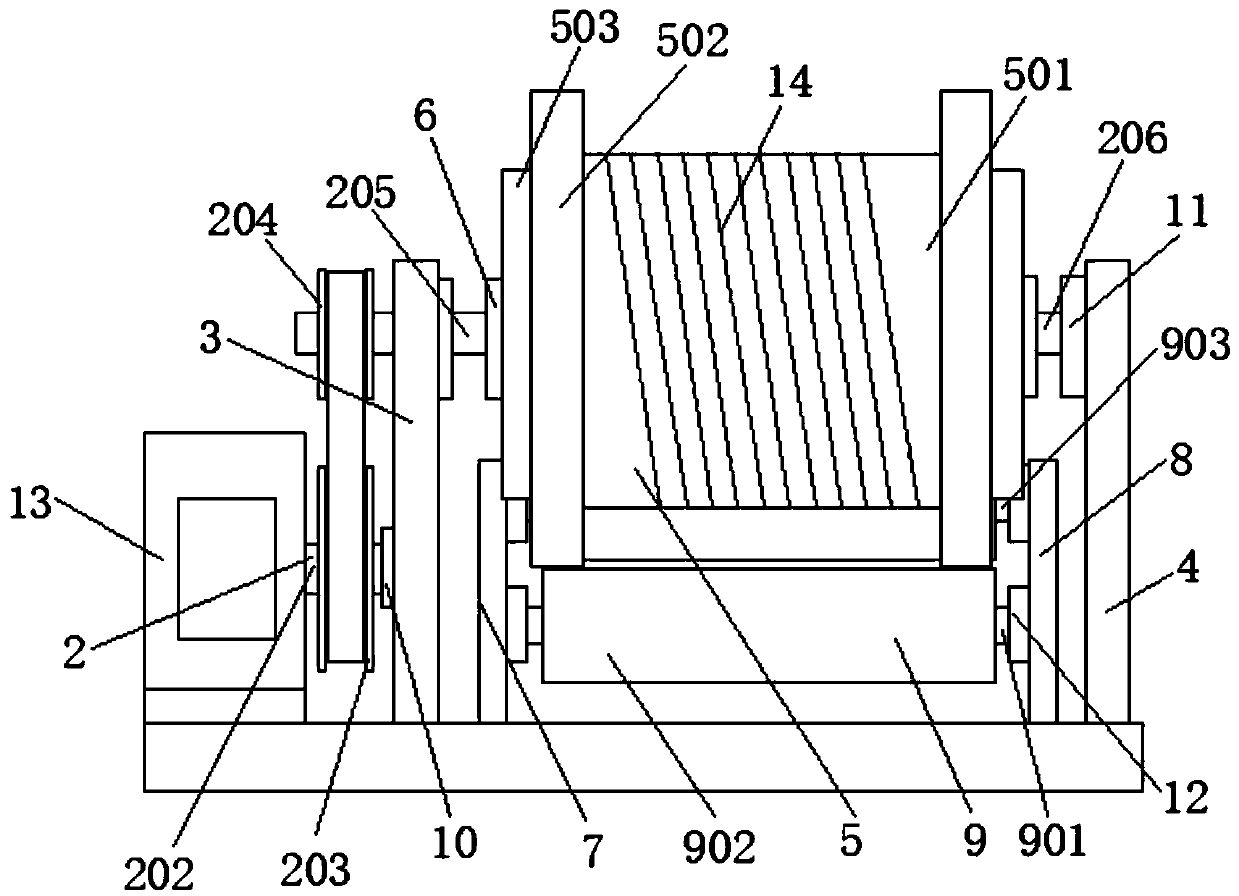

Steel wire rope winding device

The invention discloses a steel wire rope winding device which comprises a power part, a fixing frame, a spline shaft, a steel wire rope reel, a nut plate, a rotary frame, a rope guiding wheel and a rope pressing wheel. The spline shaft is arranged on the fixing frame and connected with the power part, and the steel wire tope reel is movably arranged on the spline shaft in a sleeved mode. Due to the fact that the reel is meshed with the nut plate and can move along the spline shaft, when a steel wire rope is wound into or unwound out of a pulley and the reel, declination is completely avoided, in other words, the declination angle of the steel wire rope is zero degree, and therefore even if limitation of the structural size exists, for example, the center distance between the reel and the pulley is quite small, the phenomenon that due to the excessively-large declination angle of the steel wire rope, the steel wire rope is impacted and rubbed with the lateral side of a rope groove or the steel wire rope jumps out of the groove can be avoided.

Owner:上海瑞纽机械股份有限公司

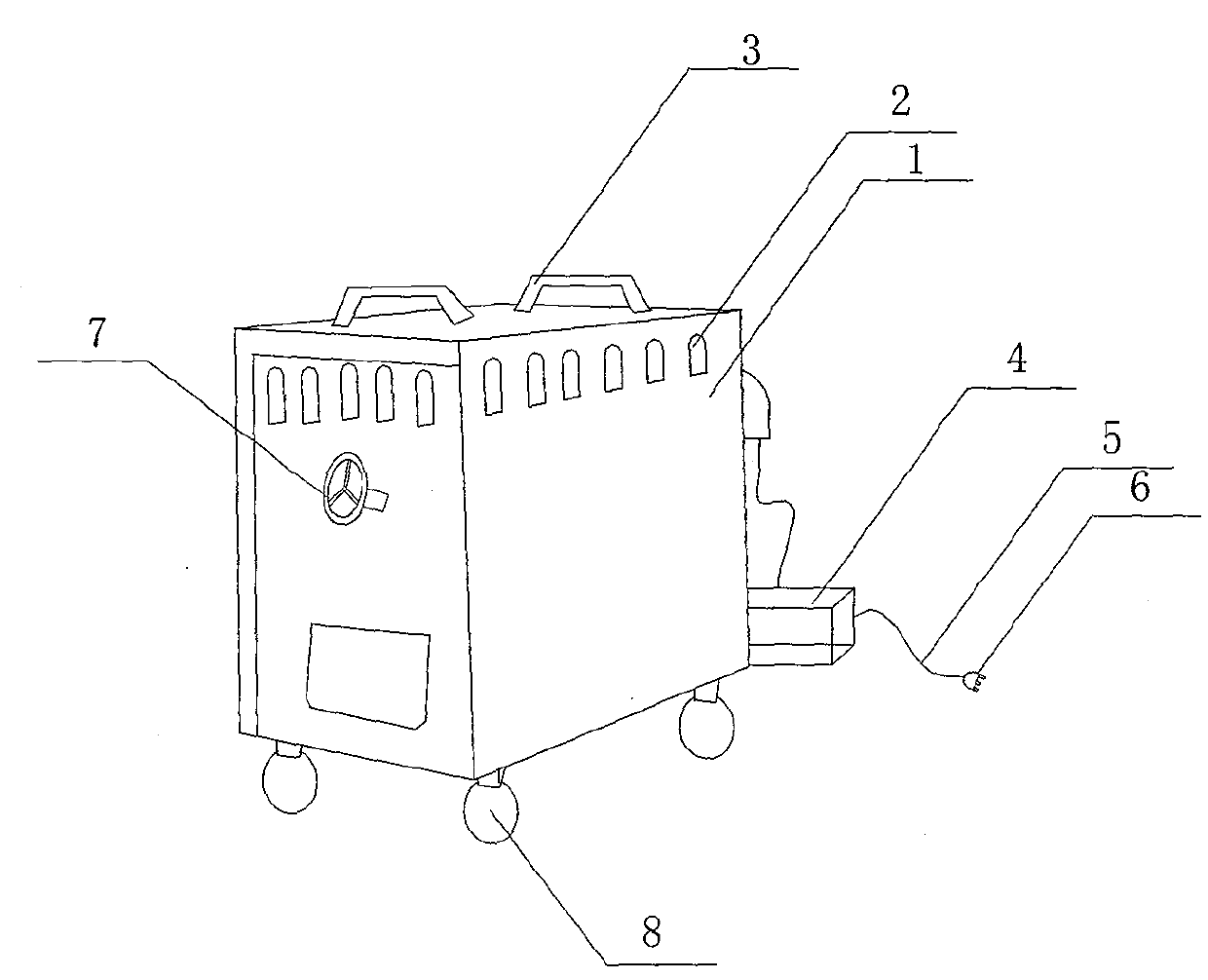

Novel electric welding machine

InactiveCN103464864ASimple structureReasonable designWelding/cutting auxillary devicesAuxillary welding devicesElectric energyElectricity

A novel electric welding machine relates to the technical field of electric welding machines. Handles are arranged on the top of an electric welding machine housing, moreover, a plurality of heat-dissipating holes are evenly formen in the four outer walls of the upper end of the electric welding machine housing, one side of the electric welding machine housing is connected with an electricity-saving protector, which is connected with a plug through a wire, furthermore, a winding handwheel is fixed on the outer wall of the electric welding machine housing, rollers are arranged on the four corners of the bottom of the electric welding machine housing, the middle of the bottom plate of the electric welding machine housing is provided with a through hole, and a cooling fan is fixed under the through hole. The structure of the novel electric welding machine is simple, and the design is reasonable; since the fan is arranged on the bottom, wind flow can upwardly dissipate out internal temperature via the heat-dissipating holes according to the natural wind flow law, so an optimal heat dissipation effect is achieved; moreover, since the electricity-saving protector is added, power can be automatically supplied when the novel electric welding machine operates, and can be cut off when the novel electric welding machine does not operate, and thereby electricity is saved; since the device for winding a welding wire is also arranged, the welding wire can be wound in order, and thereby the novel electric welding machine is more convenient to use.

Owner:NINGBO YINZHOU PINDA APPLIANCE SOLDER

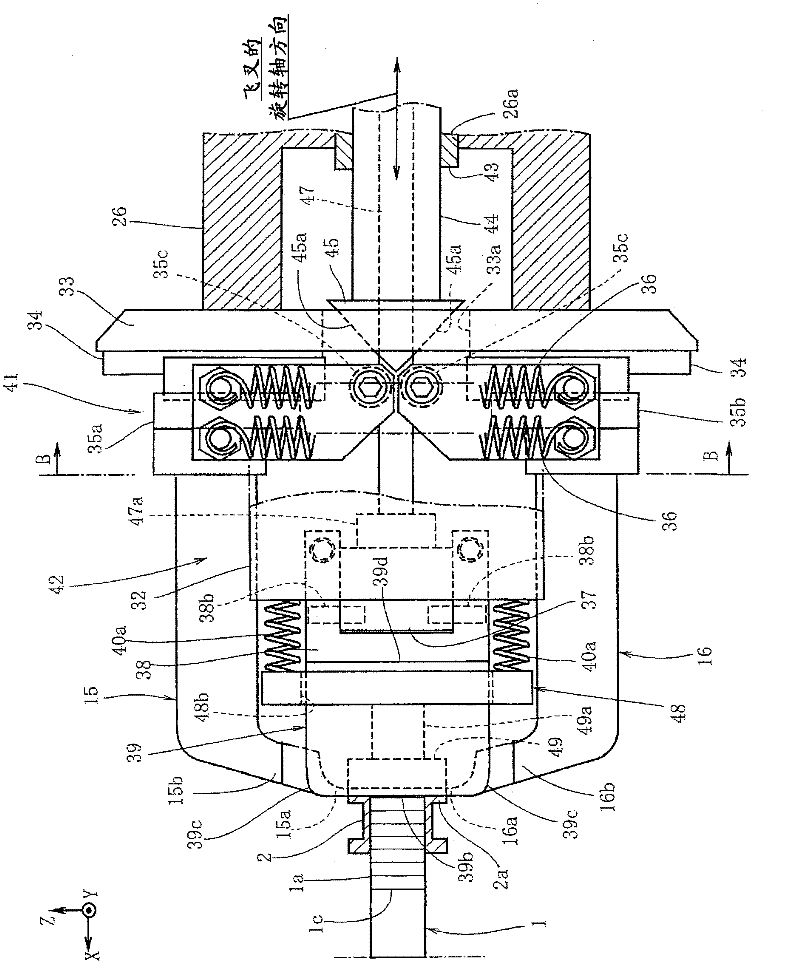

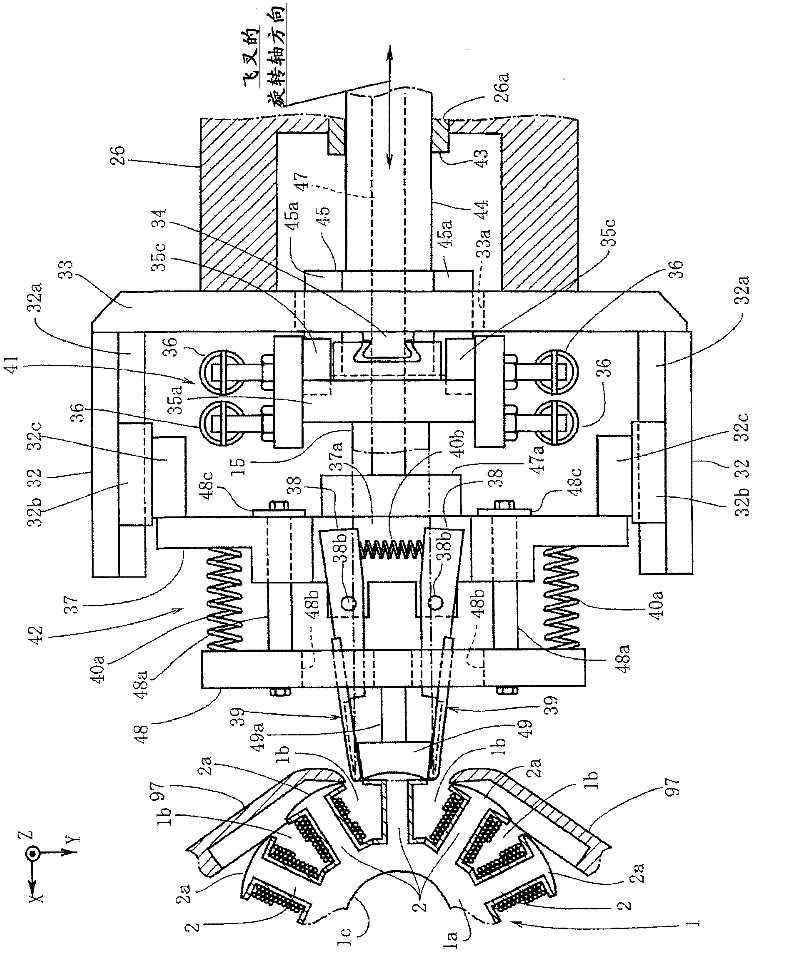

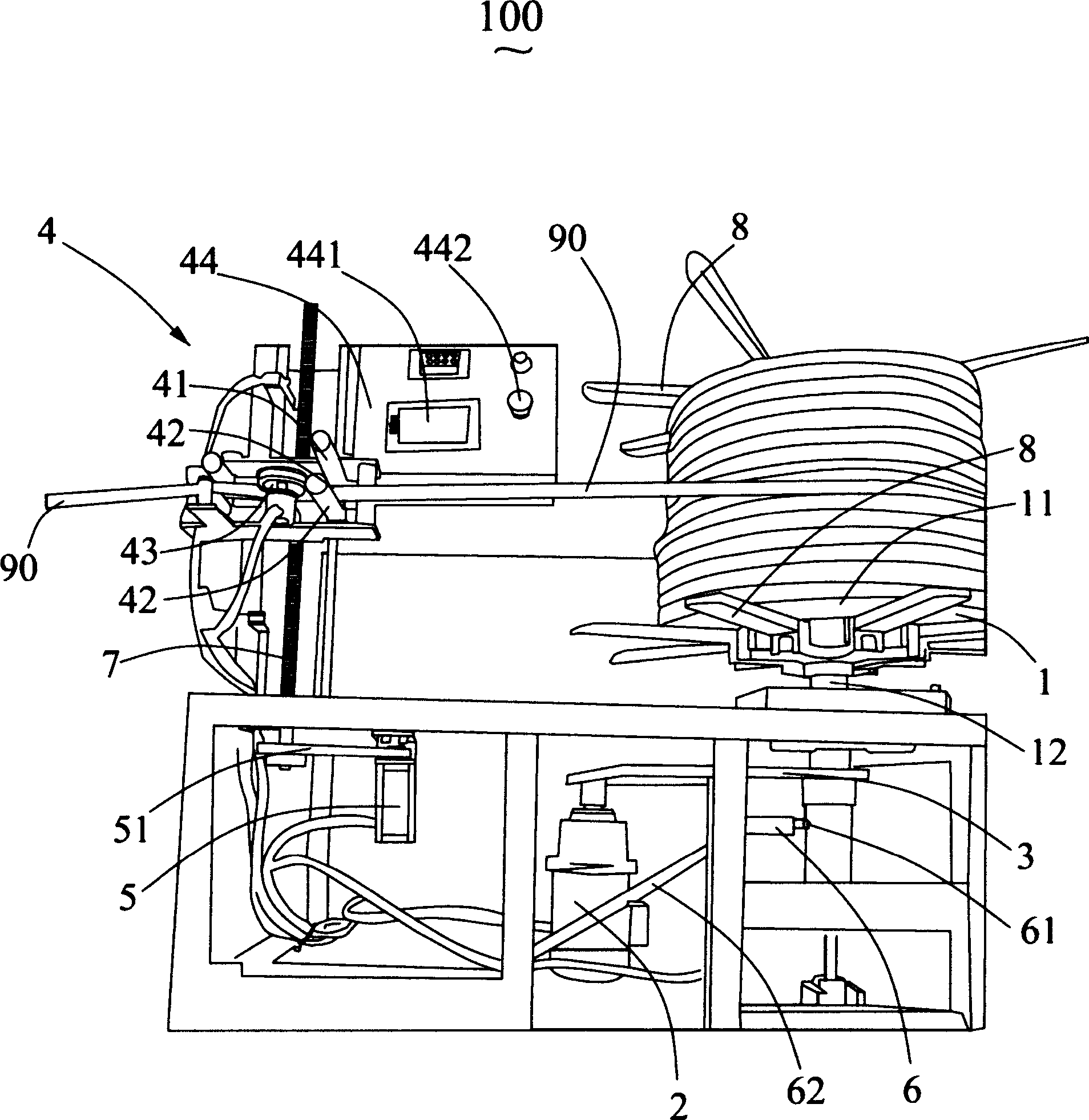

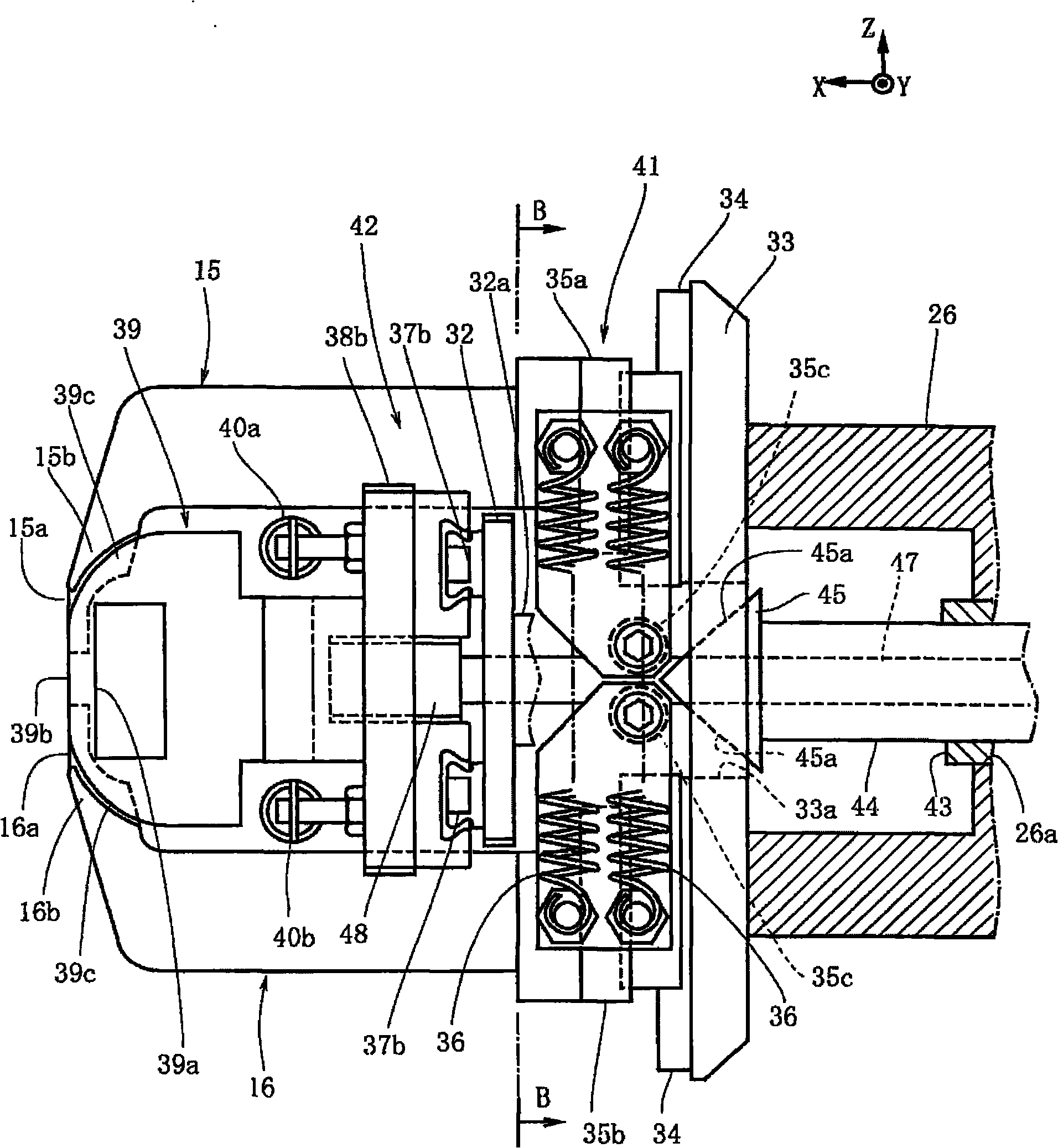

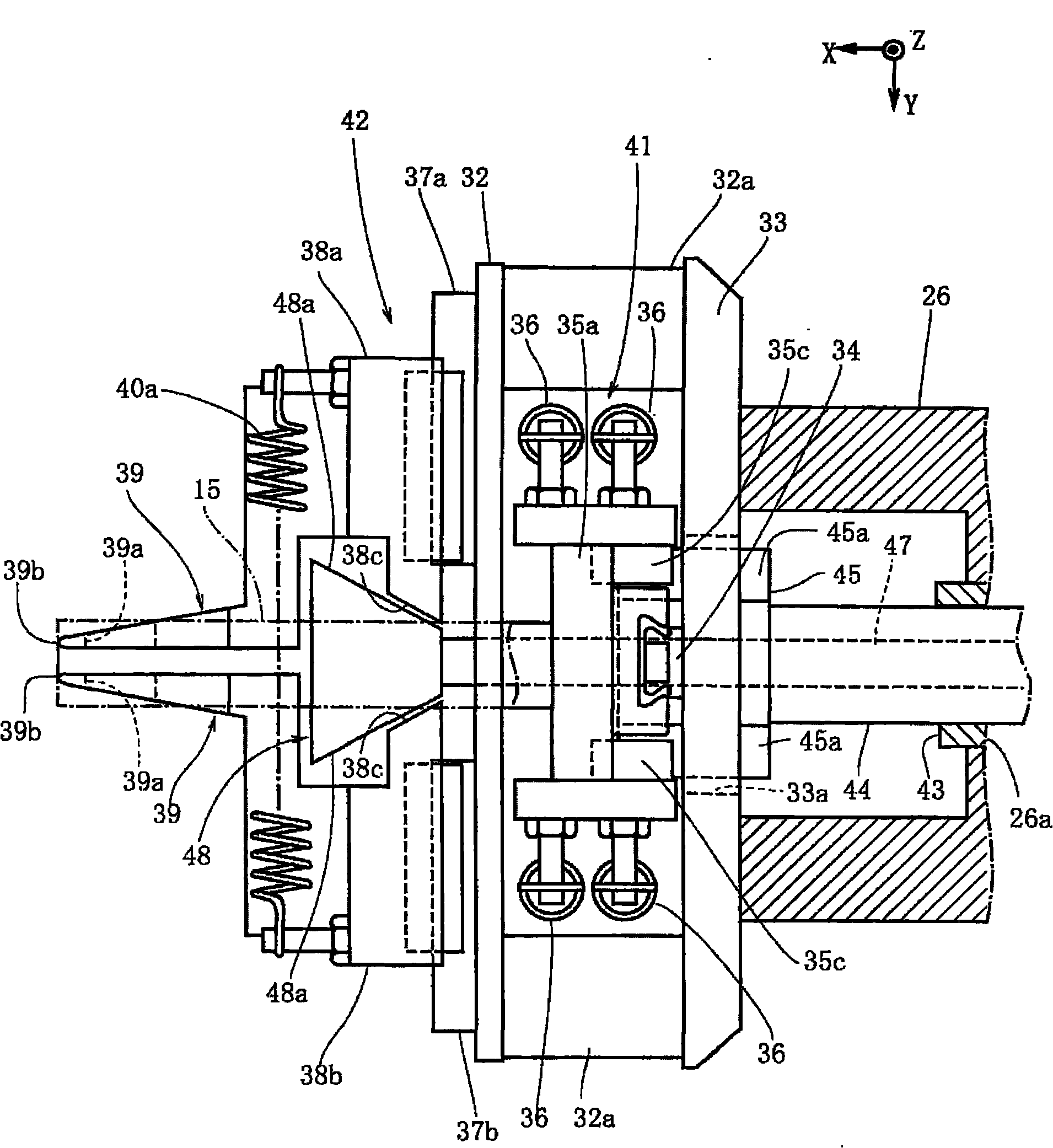

Winding machine and winding method

InactiveCN102570739AWinding firmlyEnter fullyManufacturing dynamo-electric machinesWinding machineMagnetic poles

The invention provides a winding machine and a winding method. When the winding the performed on the first layer and the second layer, a top end of a side plate completely enters into the inner circumferential side of a magnetic pole and the wire is stably and regularly wound on the magnetic pole. The winding machine comprises: a flying fork capable of rotating around the magnetic pole of multi-pole armature and simultaneously leading out the wire and winding the wire relative to the magnetic pole; a pair of central winding molds configured to axially clamp the magnetic pole from the multi-pole armature and guide the wire led out from the flying fork to the magnetic pole; a pair of side plates configured to axially clamp the magnetic pole from the multi-pole armature and guide the wire led out from the flying fork to the magnetic pole. The pair of the side plates are configured to incline relative to a rotation shaft of the flying fork in the way of closing to the inner circumferential side of the multi-pole armature and change the inclined angle relative to the rotation shaft of the flying fork, therefore the top interval between the inner circumferential side of a magnetic pole and the side plate is changed.

Owner:NITTOKU ENG CO LTD

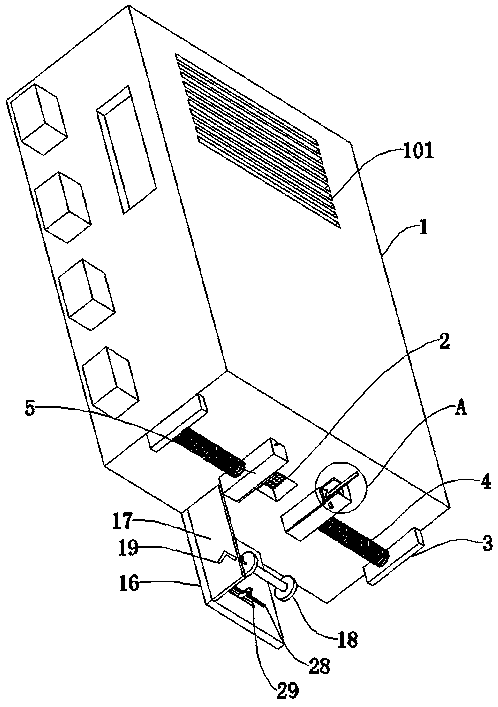

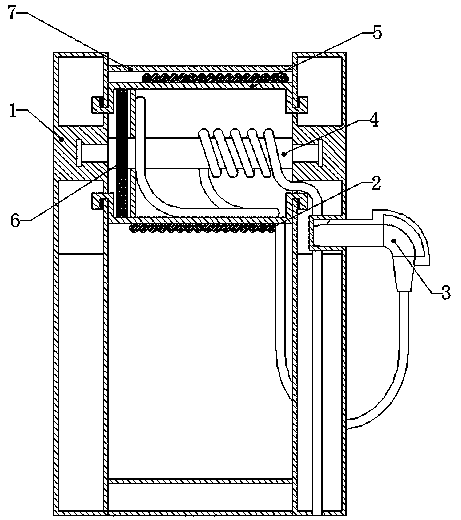

Charging pile with take-up structure

PendingCN108544964AEasy adjustment of release lengthAvoid wear and tearCharging stationsElectric vehicle charging technologyElectrical equipment

The invention discloses a charging pile with a take-up structure and relates to the technical field of electrical equipment. The charging pile with the take-up structure comprises a main shell, a cable and a charging gun which is movably inserted in the main shell; a take-up chamber is formed in the main shell; a cable outlet in communication with the take-up chamber is formed in the main shell; atake-up post assembly capable of rotating around the axis of the take-up post assembly and used for taking up and paying off the cable is arranged in the take-up chamber; one end of the cable is connected with the charging gun; the other end of the cable penetrates through the cable outlet and is wound on the take-up post assembly; and one end, wound on the take-up post assembly, of the cable penetrates through the take-up post assembly and is fixed at the bottom of the main shell. According to the charging pile with the take-up structure, by arranging the take-up post assembly, the length ofthe cable is adjusted and the cable is stored and recovered; the structure is simple and practical; and wear and electric leakage of the cable are effectively avoided.

Owner:成都特来电新能源有限公司

Intelligent classified winding device and method for cable production

The invention discloses an intelligent classified winding device and method for cable production. The device comprises a base; one side of the top of the base is provided with a cleaning assembly; the middle part of the top of the base is provided with a pressure reduction bin body; the top of one side of the pressure reduction bin body is uniformly provided with three groups of support frames A and support frames B; the supporting frames A are located over the supporting frames B; and a connecting shaft C is arranged on the inner side of one end of each supporting frame A and the inner side of one end of the corresponding supporting frame B. Through mutual cooperation of a transmission shaft B, coil springs, wire spools, pulleys A, supporting rods, pressing blocks, sliding blocks, sliding grooves, pressing switches, springs and limiting plates, under the condition that the cable encounters instantaneous jamming or tension increase during emergent winding, the tension generated on a cable can be absorbed and relieved; and the stability of the structure of the winding device is also protected while the cable is protected from being snapped, so that the service life of the device is prolonged, and the safety is improved.

Owner:欧耐特线缆集团有限公司

Wire spool device

InactiveCN102801061APrevent random movementNeatly woundFlexible lead accommodationPortable powerEngineering

The invention relates to the technical field of portable power source devices, and discloses a wire spool device. The wire spool device comprises a support, a wire spool group which can be rotatablely connected to the support and is used for winding electric wires, and a wire bundling piece which can be pressed against the electric wires during wire winding and wire spreading, wherein one end of the wire bundling piece is fixedly connected to the support, and the other end of the wire bundling piece is arranged on the outer side of the wire spool group. When the wire spool group of the wire spool device is used for winding or spreading wires, the wire bundling piece can be pressed against the electric wires to prevent the moving electric wires from random serial movement, so that the electric wires are neatly wound in the wire spool group, wire spreading can be conveniently performed, and the operation is simple.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Winding machine

The invention discloses a winding machine which comprises a winding wheel, a main motor driving the winding wheel to rotate and a chain connected between the main motor and the winding wheel in a transmission mode. The winding wheel is provided with a reel for a pipe to wind on and a winding shaft at least partially arranged in the reel, the main motor drives the winding shaft to rotate through the chain to further drive the reel to rotate along the axis, and the reel rotates along the axis to automatically wind the pipe on the reel. The winding machine further comprises a cycloid device, a driving motor driving the cycloid device to move transversely and a sensor probe used for detecting rotating of the winding wheel. The cycloid device is used for neatly winding the pipe on the winding wheel. By means of the winding machine, the pipe can be neatly wound on the winding wheel.

Owner:象山科迪液压机械制造有限公司

Fire hose cleaning device

Owner:HENAN CHANGMING HANGBIAO ELECTROMECHANICAL EQUIP CO LTD

Steel wire winding machine capable of avoiding wire disorder

InactiveCN107500052APrevent messy linesEasy to disassembleFilament handlingWinding machineConductor Coil

The invention discloses a steel wire winding machine capable of avoiding wire disorder. The steel wire winding machine comprises a fixed base, limiting rods and wire winding plates. A main support plate is mounted on the upper end face of the fixed base. Transmission wheels are mounted at one end of a rotary shaft. One end of each limiting rod is connected with the main support plate through a first sliding rail. The other end of the rotary shaft is connected with an auxiliary support plate. The wire winding plates are located on the outer side of the rotary shaft, and a wire clamping groove is formed in the surface of each wire winding plate. The inner surface of each wire winding plate is connected with a fixed sleeve through a supporting column. The fixed sleeves are fixed to a mounting ring, and the mounting ring is connected with the rotary shaft. According to the steel wire winding machine capable of avoiding wire disorder, the number of coiled steel wires can be adjusted conveniently and fast, the steel wires can be conveniently wound more orderly in the steel wire winding process, the phenomenon of wire disorder is effectively avoided, the steel wires can be fixed stably, conveniently and fast through the wire clamping grooves, the steel wires can be demounted conveniently and fast, and the wires are taken more conveniently.

Owner:江阴市新华橡塑机械有限公司

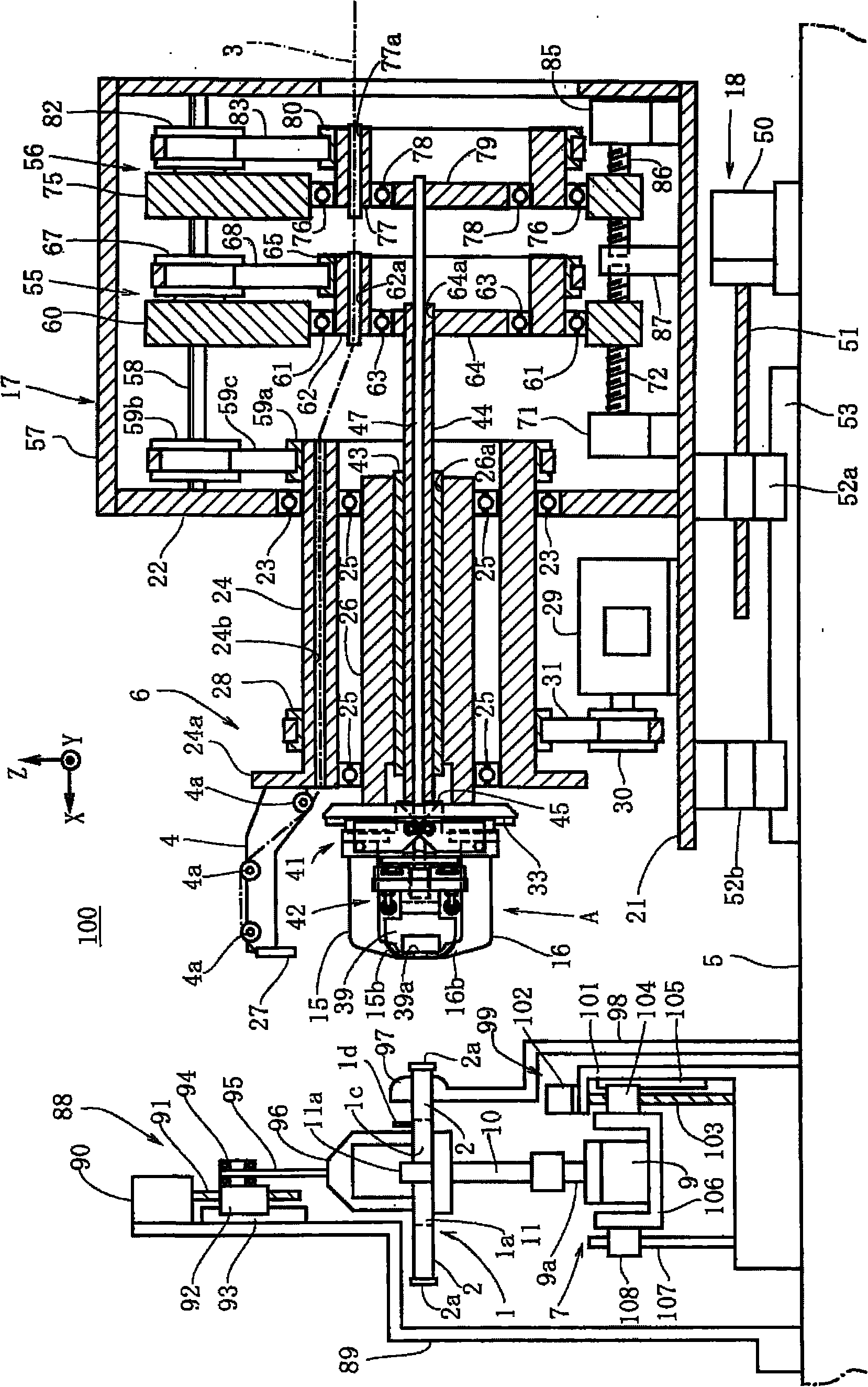

Winding machine and winding method

ActiveCN102270906ANeatly woundAvoid enteringManufacturing dynamo-electric machinesWinding machineEngineering

The invention provides a coil winding device and a coil winding method, wherein coils can be stably and evenly wound on a multi-polar armature even with multiple poles. The coil winding device comprises a flying fork for winding coils on a pole; a pair of central winding dies for guiding coils derived from the flying fork to the pole; a first movement mechanism for moving the pair of central winding dies in a mutually separated or approached manner; a pair of side plates arranged to clamp the pole from the circumferential direction of the multi-polar armature. The top edges of side plates are in the same plane with the top edge of the central winding dies. Along with the rotation of the flying fork, the side plates move toward the radial direction of the multi-polar armature together with the central winding dies; and a second movement mechanism for moving the pair of side plates in the circumferential direction of the multi-polar armature in a mutually separated or approached manner. The side plates are formed with openings. A flange part formed on the protruding end of the pole can enter the opening so as to form a covering part for covering the side edge of the side plates on the central winding dies.

Owner:NITTOKU ENG CO LTD

Spun yarn winding device for textile machine

The invention discloses a spun yarn winding device for a textile machine. The spun yarn winding device comprises a rotary motor and a lead screw. The upper portion of the rotary motor is connected with a rotary roll, and a rotary table is fixedly mounted on an upper end opening of the rotary roll. Rotary wheels are fixedly mounted on the left side and the right side of the rotary table, and the outer sides of the rotary wheels are movably connected with a base. A device left shell is fixedly mounted on the outer side of the base, and the side surface of the device left shell is movably connected with a rotary shaft. A device right shell is fixedly mounted on the right side of the rotary shaft, and a buckle is fixedly mounted on the side face of the device right shell. A servo motor is arranged on the left side of the buckle, and the lead screw is mounted below the servo motor. The outer surface of the lead screw is movably connected with a workbench, and a yarn passing hole is formed in the workbench. A fixed pile is fixedly mounted below a spring. The spun yarn winding device for the textile machine mainly has the beneficial effects that spun yarn is vertically tiled outside a coiling block, so that the spun yarn is wound more smoothly, and then the phenomenon of spun yarn knotting is avoided.

Owner:海安县新华伦纺织有限公司

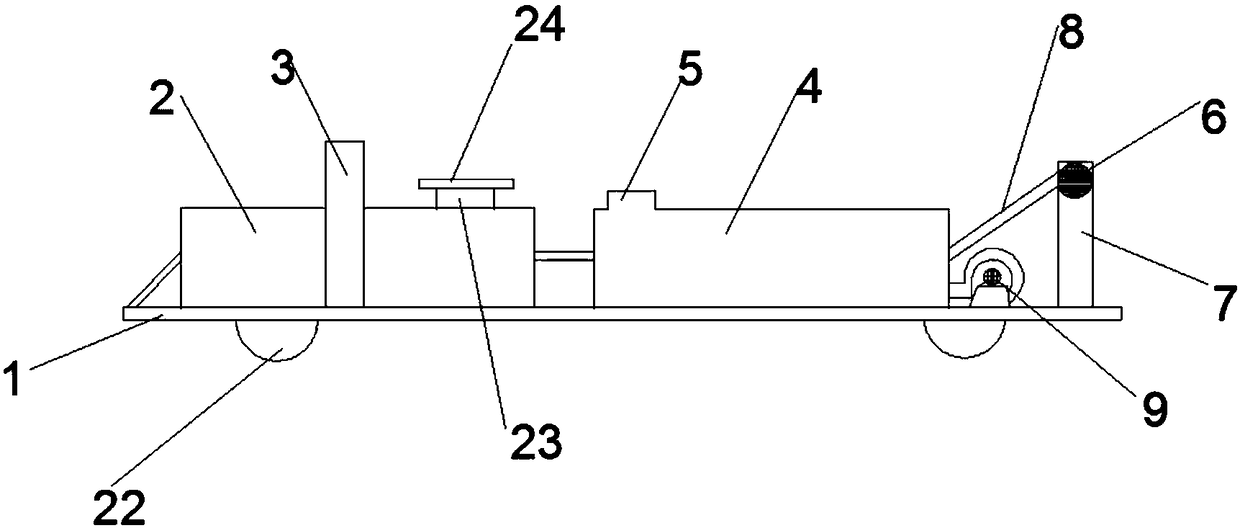

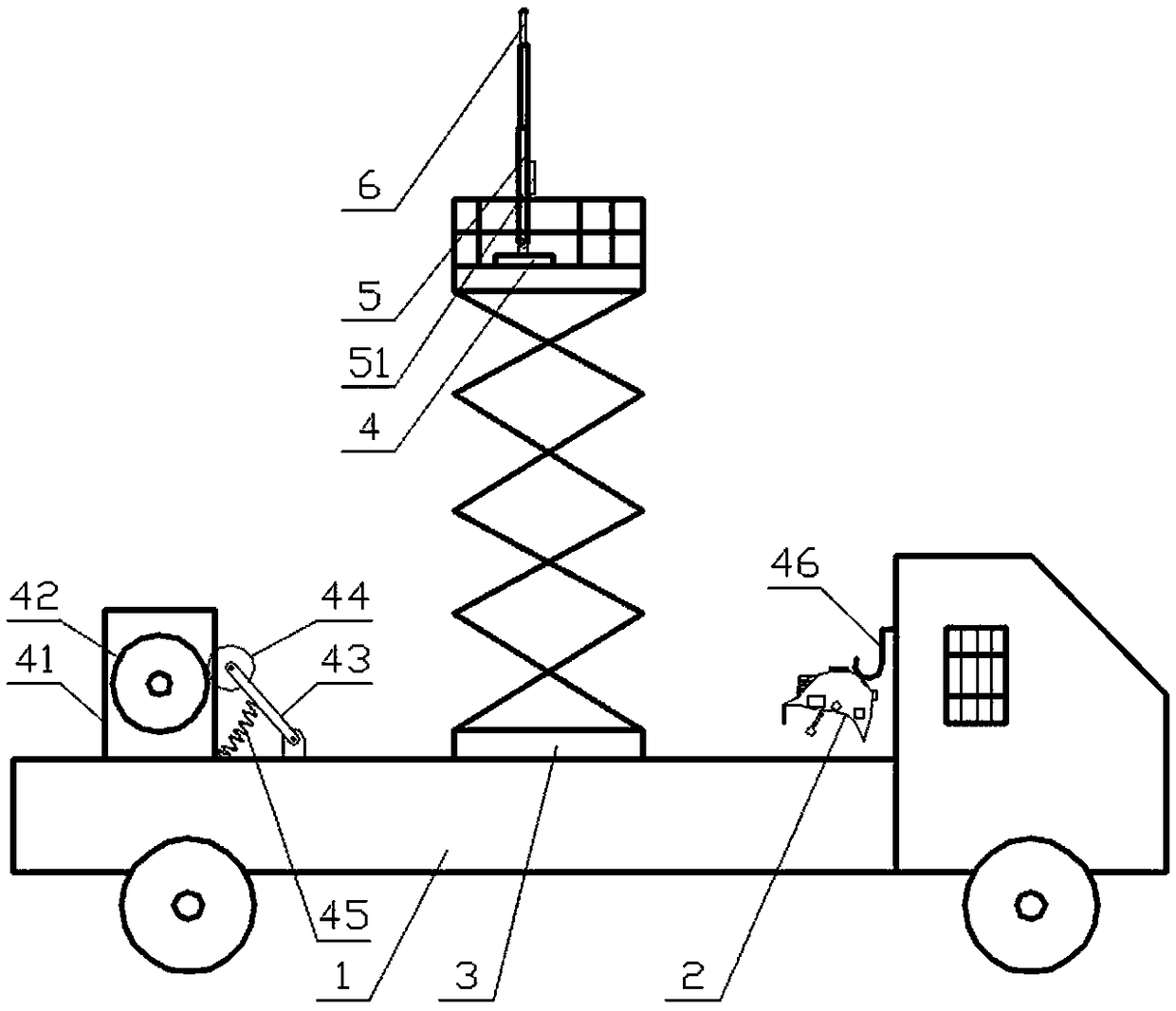

Electric power cable comprehensive repairing car

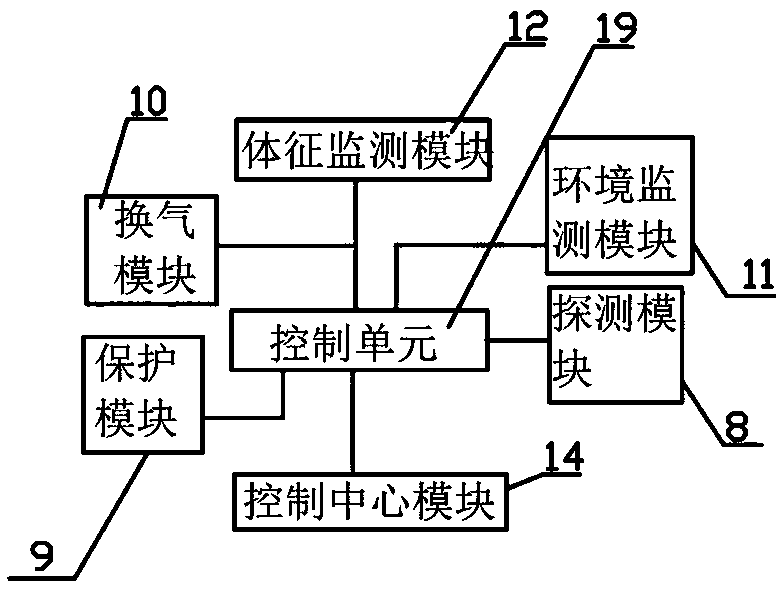

InactiveCN108275059AAvoid entering the phenomenon of strong electric fieldEffective record operationItem transportation vehiclesHelmetsPower cableSlewing bearing

The invention discloses an electric power cable comprehensive repairing car. The car comprises a car body, a waster cable recycling mechanism arranged on the left side of the upper portion of the carbody, a branch removing mechanism arranged on the right side of the upper portion of the car body and a monitoring and protecting mechanism cooperating with the branch removing mechanism; the branch removing mechanism comprises a lifting platform arranged on the right side of the upper portion of the car body, the upper portion the lifting mechanism is provided with a slewing bearing, the upper portion of the slewing bearing is hinged with an automatic telescopic rod, the upper end of the automatic telescopic rod is provided with an electric saw, and the automatic telescopic rod is provided with a handle used for manual operation. According to the electric power cable comprehensive repairing car, not only can branch barriers beside the power cable be removed, but also waste power cables can be automatically recycled to reduce the labour intensity, the work processes can be recorded at the same time, phenomenons which can occur can be prejudged through a remote platform, the misoperation of repairing workers can be avoided, and the safety is greatly improved in the repairing process.

Owner:ZHENGZHOU SIBIAN TECH CO LTD

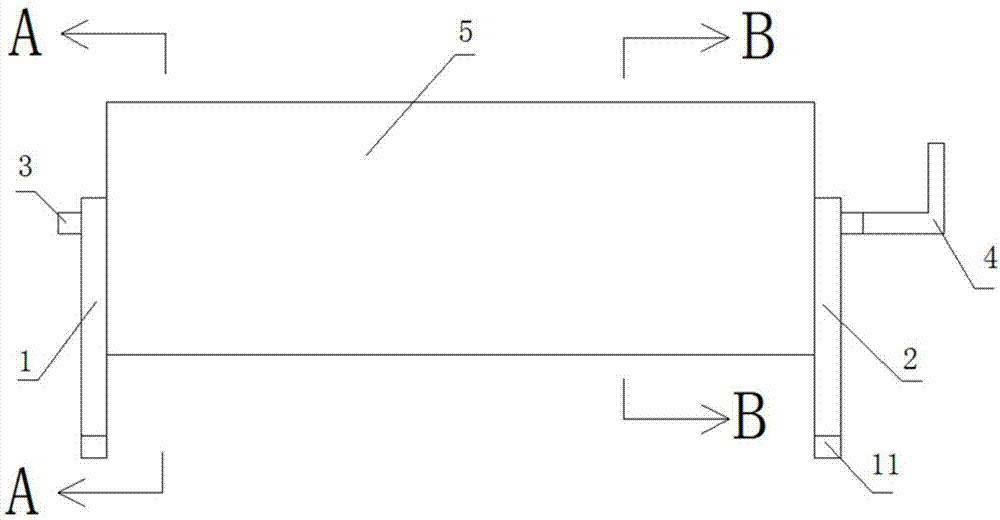

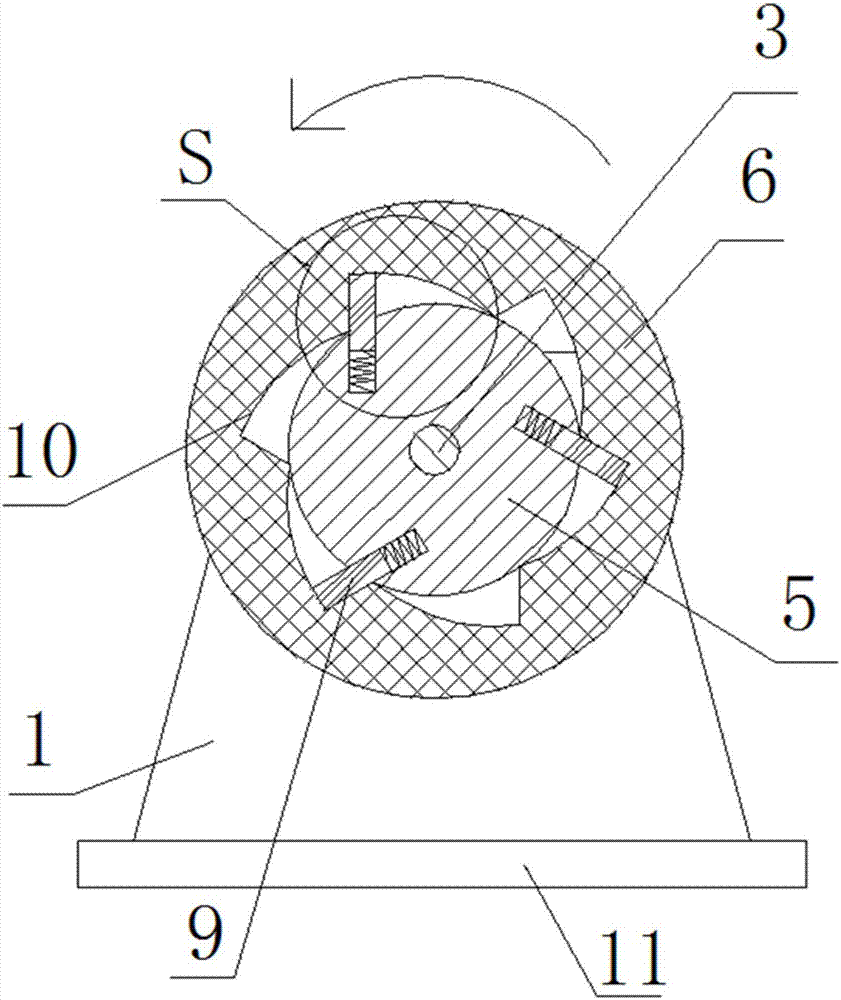

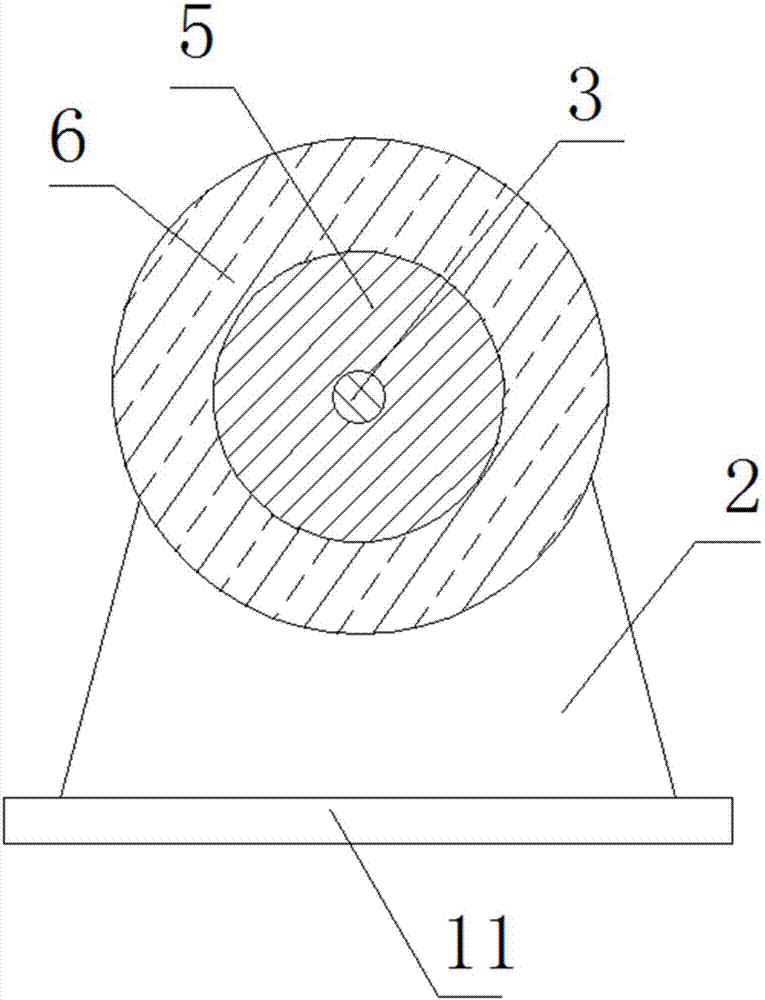

Cable take-up device

The invention provides a cable take-up device. The cable take-up device comprises a first vertical plate and a second vertical plate which are arranged oppositely; a rotating shaft is rotatably arranged between the first vertical plate and the second vertical plate; a power device connected with the rotating shaft is arranged on the outer side of the second vertical plate; a rotating cylinder rotating along with the rotating shaft is arranged outside the rotating shaft in a sleeving way; a winding reel is rotatably arranged outside the rotating cylinder in a sleeving way; three guide grooves are distributed on the outer wall of the rotating cylinder on the first vertical plate side circumferentially and uniformly; springs and pawls are arranged in the guide grooves; one end of each springis connected with the bottom wall of each guide groove and the other end of the spring is connected with the pawl; six inner ratchet wheels matched with the pawls are arranged in the winding reel; andone end of each pawl is fixedly connected with the spring and the other end of the pawl extends into each inner ratchet wheel and is matched with the inner ratchet wheel. The cable take-up device canguarantee the tidy winding effect of the cable during forward rotation winding and also can prevent reversed rotation of the winding reel and guarantee that winding is not returned, and the cost is controlled.

Owner:重庆华旗线缆有限公司

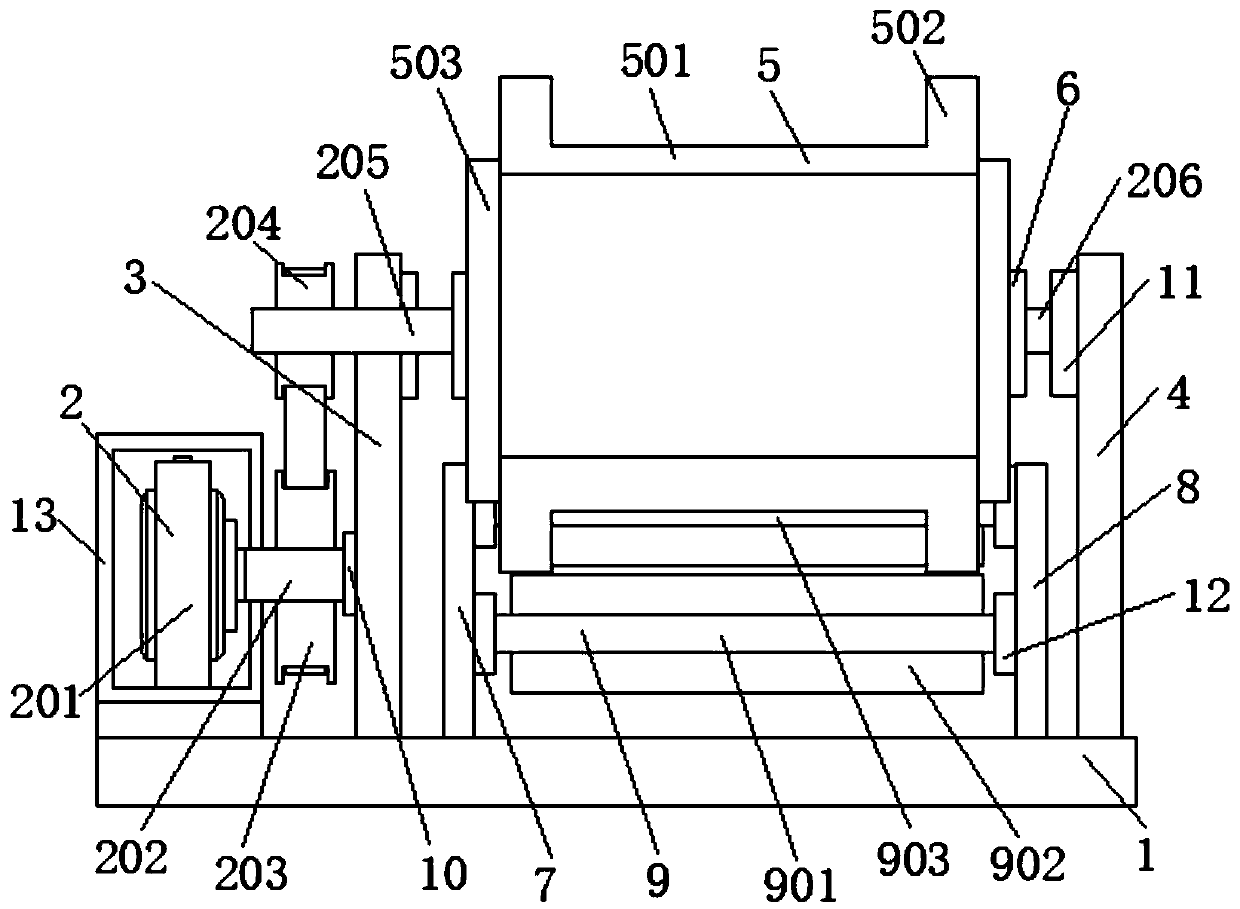

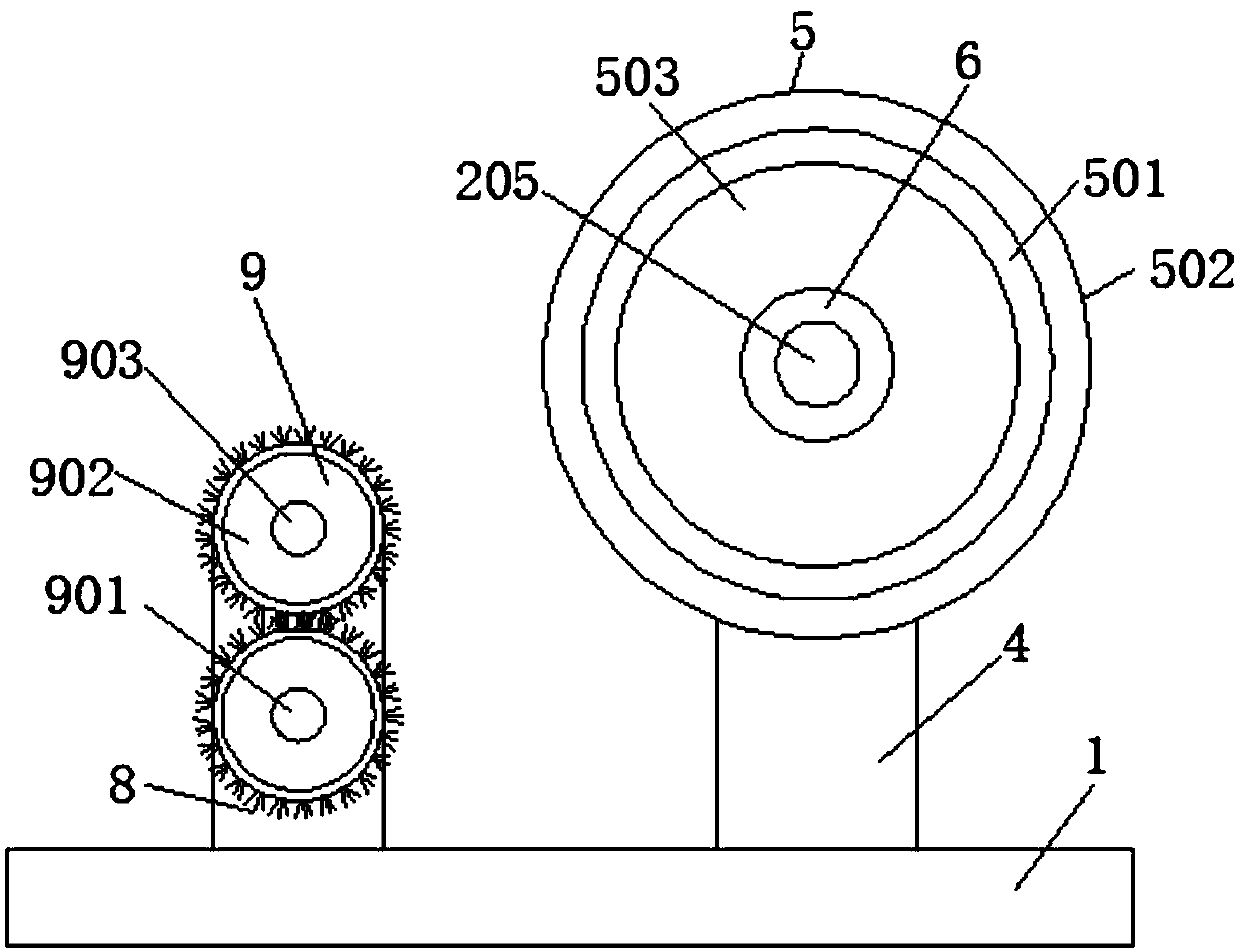

Automatic coil winding system for motor production

ActiveCN111463975ANeatly woundIncrease frictionManufacturing dynamo-electric machinesPhysicsElectric machinery

The invention discloses an automatic coil winding system for motor production. The winding device comprises a bottom plate, and a winding driving mechanism, a winding guide mechanism and a pressing mechanism which are mounted on the bottom plate, the winding guide mechanism comprises a rotary disc rotationally arranged on the top face of the bottom plate, a power mechanism driving the rotary discto rotate, transverse plates arranged above the rotary disc, side plates fixed to the two ends of the two transverse plates, a guide rod which is fixed between the two side plates and a guide disc which is movably sleeved with the guide rod; the upper part of the rotary disc is connected to the transverse plates through a longitudinal rotating shaft; internal threads are formed in the annular inner wall of the guide disc, external threads are formed in the outer wall of the guide rod, the guide disc is spirally connected with the guide rod, a wire groove of the guide disc is used for conveyingwound wires, the pressing mechanism is used for extruding the wound wires to make contact with the wire groove, and the winding driving mechanism is used for driving the wound wires to be conveyed. Winding is convenient, the winding can be wound on the rotor in order, and the working efficiency is improved.

Owner:LUAN QIANGLI MOTOR CO LTD

Multifunctional data converter

ActiveCN110739586ASolve the problem of easy entanglementPlay a protective effectComputer periphery connectorsFlexible lead accommodationConvertersData translation

The invention discloses a multifunctional data converter, and belongs to the technical field of data communication. The multifunctional data converter comprises a converter body. One end of two groupsof first springs far away from the partition plate is respectively connected with a first pressing block and a second pressing block. A rack plate is connected on the side wall of a rotating shaft. Alimiting component is connected on the rod wall of the rotating rod. A winding shaft is connected on the one end of a rocking handle near the jack. A screw rod is connected on the one end of a reciprocating mechanism far away from a first cross rod. A threading block is connected on the rod wall of the screw rod in a threaded way. The first springs can drive the first pressing block and the second pressing block to move toward each other to clamp the plug, the limiting component can limit and fix the first pressing block and the second pressing block, the rocking handle is rotated to drive the winding shaft to wind up the data line and the reciprocating mechanism drives the threading block to be unable to move so that the data line is evenly rolled up, and thus the problem that the data line is excessively long and liable to wind together can be solved and the stability of the connection between the data line and the data converter can be improved.

Owner:SHANDONG QINCHENG INFORMATION TECH CO LTD

Adjustable textile machine winding device

The invention relates to an adjustable textile machine winding device. The adjustable textile machine comprises a transverse rod, a first retaining plate and a second retaining plate which are arranged at the left end and the right end of the transverse rod. The first retaining plate is fixedly connected with one end of the transverse rod. The second retaining plate comprises an upper half retaining plate and a lower half retaining plate. The other end of the transverse rod is provided with a plurality of sets of grooves which correspond with one another in the vertical direction. The upper half retaining plate and the lower half retaining plate are correspondingly provided with projections which are adapted with the grooves. The second retaining plate is arranged at the other end of the transverse rod through cooperation between the projections and the grooves. The lower half retaining plate is fixed on the upper half retaining plate through a positioning board strip. The edge of the first retaining plate is provided with a through hole in which an infrared sensor and a controller are arranged, wherein the controller is connected with the infrared sensor and is arranged outside the first retaining plate. The controller is connected with an alarm. According to the adjustable textile machine winding device, the transverse width of the winding device can be adjusted according to the dimension of cloth. Furthermore the adjustable textile machine winding device has a function of performing alarm when the amount of winding cloth reaches a maximal winding amount of the winding device.

Owner:无锡雅西机电配件厂

Fire isolation device for logistics park security and protection

InactiveCN112043990AImprove fire performancePrevent crushingFire rescueBoring toolsLogistics managementFireproofing

The invention belongs to the technical field of logistics security and protection, and particularly relates to a fire isolation device for logistics park security and protection. Aiming at the problemthat most of existing fire isolation devices are arranged in advance in a park and occupy a large space to reduce the smoothness of the logistics park, the invention provides the following scheme that the fire isolation device comprises a base with a cuboid structure, and a cavity is formed in the base; the base is buried underground; bearing pedestals are fixedly arranged at the positions, closeto the two ends, of the inner wall of the bottom of the base, and symmetrical tapered roller bearings are embedded in the opposite ends of the two bearing pedestals respectively; a same winding roller is rotationally connected between the two tapered roller bearings, and fireproof cloth is wound around the outer wall of the circumference of the winding roller; cotton cloth is fixedly arranged onthe two opposite sides of the fireproof cloth; and a strip-shaped hole matched with the fireproof cloth in width is formed in the middle part of the upper surface of the base. The two sides of the fireproof cloth can be cooled by spraying water while fire is isolated, and the fireproofing grade of the same material is increased.

Owner:宣城市宣之彩计算机科技有限公司

Threading construction device for electrical installation in building

InactiveCN108512133ANeatly woundEasy to wrapApparatus for laying cablesArchitectural engineeringBuilding construction

The invention discloses a threading construction device for electrical installation in a building. The device comprises a pedestal, wherein a fixed base is perpendicularly and fixedly installed at thecenter position of the top of the pedestal, a through hole is formed in one side of the fixed base, a first rod is rotationally installed in the through hole, a motor is fixedly installed on one sideof the fixed base, the output shaft of the motor stretches into the through hole and is fixedly connected with the first rod, one end, far away from the motor, of the first rod stretches out of the through hole and is provided with a sliding chute, a second rod is installed in the sliding chute in a sliding manner, one end of the second rod stretches out of the sliding chute, a cavity positionedin the sliding chute is formed in the second rod, a claming rod is installed in the cavity in a sliding manner, the top end of the clamping rod stretches out of the second rod, and a positioning slotis formed in the inner wall of the top of the sliding chute. The threading construction device provided by the invention is simple in structure and strong in practicability, so that cables can be conveniently, quickly and orderly wound on the first rod and the second rods, and the position of the second rod can be randomly adjusted, so as to be convenient for people to use.

Owner:方亚琴

Automatic cable rolling mechanism for new energy automobile charging pile

InactiveCN107986110AReduce machining accuracyLow costCharging stationsElectric vehicle charging technologyDrive wheelCoupling

The invention discloses an automatic cable rolling mechanism for a new energy automobile charging pile. The automatic cable rolling mechanism comprises a rolling shaft. The outer surface of the rolling shaft is in cup joint with a winding barrel. A winding groove is chiseled in the surface of the winding barrel. The tail end of a reel of the rolling shaft is in cup joint with a coupling gear, andthe other end of the coupling gear is in cup joint with a both-way transmission mechanism. The rolling shaft comprises a main shaft, the front end part of the main shaft is in cup joint with inner conical sleeves at equal intervals, and the outer surfaces of the inner conical sleeves are provided with arc small bulging tiles. The parts, at the two ends of the inner conical sleeves, of the main shaft are in cup joint with supporting discs. The parts between the supporting discs and the small bulging tiles are in cup joint with large bulging tiles. The tail end of the main shaft is further in cup joint with a bevel gear. The both-way transmission mechanism comprises a drive motor, an output shaft of the drive motor is in cup joint with an output flange, the other end of the output flange isin cup joint with a driving wheel disc, and the driving wheel disc is in cup joint with the tail end of the rolling shaft through a driving chain. By means of the automatic cable rolling mechanism, automatic automobile charging pile cable rolling operation can be rapidly achieved, the winding efficiency is high, and the wound cable is twisted tidily and tightly without loosening.

Owner:安徽匠桥财务咨询服务有限公司

Charging pile with cable stored conveniently

PendingCN108439089AAvoid wear and tearPrevent beingCharging stationsElectric vehicle charging technologyConductor CoilElectrical equipment

The invention discloses a charging pile with a cable stored conveniently, and relates to the technical field of electrical equipment. The charging pile comprises a support, the cable, a charging gun movably inserted into the support, a wire winding shaft and a wire winding cylinder on the periphery of the wire winding shaft; the wire winding cylinder is provided with a wire winding cavity, the twoends of the wire winding cylinder are connected with the support through bearings, and the two ends of the wire winding shaft extend out of the wire winding cavity and are fixedly connected with thesupport; a volute spiral spring is further arranged in the wire winding shaft, and the two ends of the volute spiral spring are fixedly connected with the wire winding shaft and the wire winding cylinder respectively; and one end of the cable is connected with the charging gun, the other end of the cable is wound around the wire winding cylinder, penetrates through the wire winding cylinder and extends into the wire winding cavity, the end, extending into the wire winding cavity, of the cable is wound around the wire winding shaft, and the end, wound around the wire winding shaft, of the cableextends out of the wire winding cavity to be fixed in the support. The charging pile has the advantages that the length of the cable can be adjusted, the cable can be stored and recycled, the structure is simple and practical, and the cable electric leakage caused by abrasion of the cable can be effectively avoided.

Owner:成都特来电新能源有限公司

Pole stay wire connector binding device and method for electrical engineering installation

ActiveCN108331424AImprove efficiencyReduce labor intensityTowersBuilding material handlingEngineeringMechanical engineering

The invention discloses a pole stay wire connector binding device and method for electrical engineering installation. The pole stay wire connector binding device comprises a first stay wire connectorclamping element, a second stay wire connector clamping element, a tying binding machine, a binding frame plate and a transmission lead screw. The front ends of the first stay wire connector clampingelement and the second stay wire connector clamping element are correspondingly inserted into two end portions of the binding frame plate, and the rear ends of the first stay wire connector clamping element and the second stay wire connector clamping element are clamped on two ends of the parts which needs to be bound of stay wire connectors by arranging clamping structures. The transmission leadscrew is arranged on the binding frame pate, a lead screw umbrella-shaped tooth is arranged at the upper end of the transmission lead screw, and a binding hand wheel device which is matched with leadscrew umbrella-shaped tooth and used for controlling the rotation of the transmission lead screw is arranged; and the tying binding machine can be rotated and moved forwards and backwards through simple operation, and stay wire binding can be easily completed. Compared with manual binding, the efficiency is increased by more than 5 times, the labor intensity is reduced, and the binding quality isimproved.

Owner:HEFEI HONGGUANG ELECTRIC CO LTD

Optical fiber cable rolling device

InactiveCN109592491ANeatly woundEasy to operateFilament handlingMechanical engineeringOptical fiber cable

The invention discloses an optical fiber cable rolling device. A bottom plate is included. A protection cover is arranged on one side of the top of the bottom plate. A rotation mechanism is arranged in the protection cover. A first supporting plate is arranged on one side of the protection cover. The side, away from the protection cover, of the top of the bottom plate is provided with a second supporting plate. The top end of the side, close to the second supporting plate, of the first supporting plate is provided with a roller assembly, and fixing blocks are arranged on the two sides of the roller assembly. Through an arranged groove, optical fiber cable winding is more tidy, operation is simpler, and work difficulty is lowered; and the diameter of a first wheel is set to be two times ofthe diameter of a second wheel, so that the second wheel rotates with the two-time rotation speed, more labor is saved in the process of optical fiber cable rolling through the optical fiber cable rolling device, the work efficiency is improved, and the usage effect of the optical fiber cable rolling device is better.

Owner:衡阳市光纤技术产学研管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com