Metal line inner core recycle device of power supply and utilization cable

A cable and metal wire technology, which is applied in the field of metal wire inner core recycling devices, can solve the problems of difficult cable recycling, different waste cables, easy cuts, etc., and achieves convenience for subsequent use, high degree of automation, and separation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

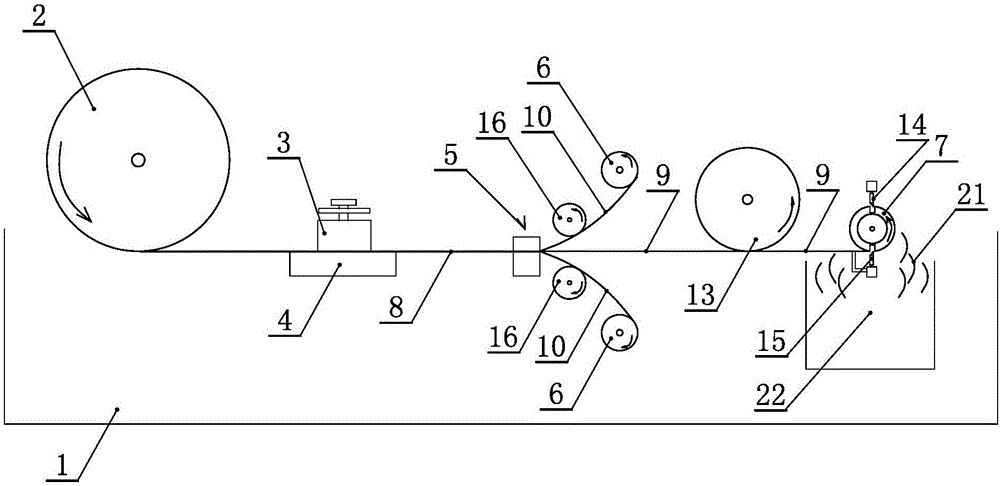

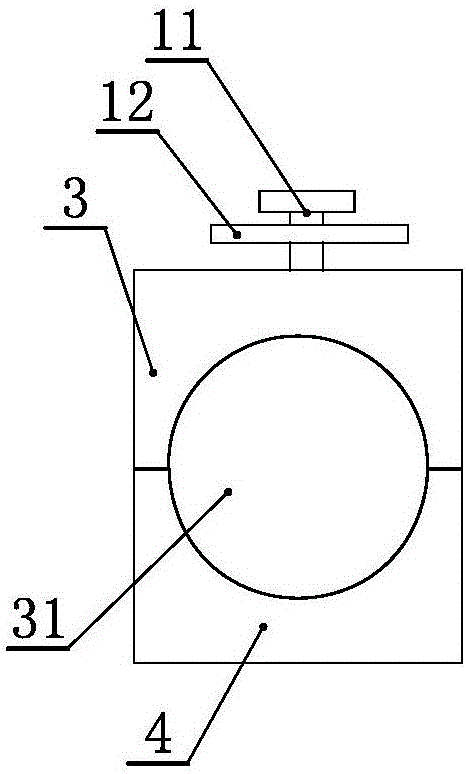

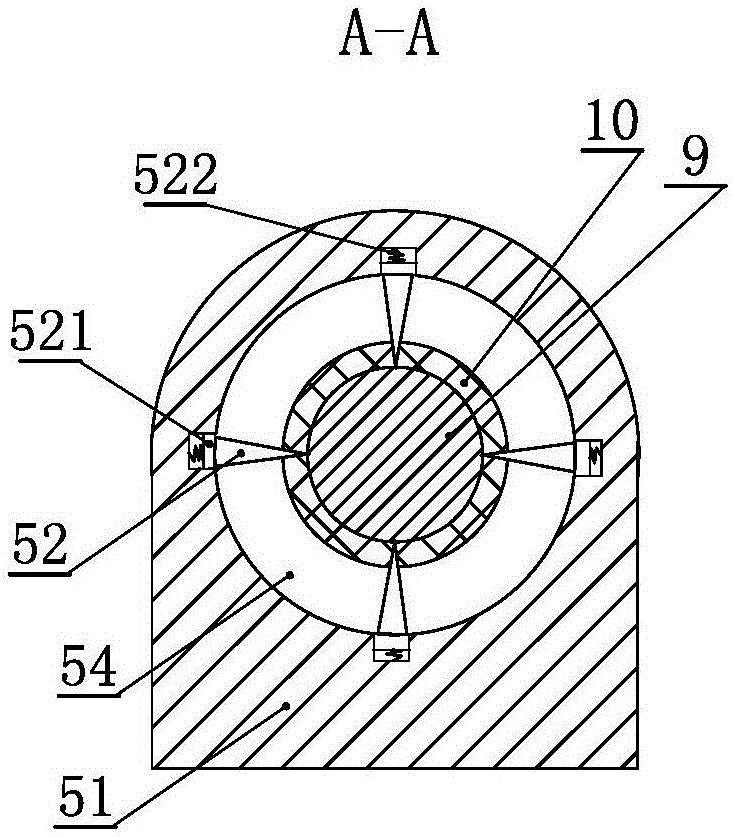

[0038] The following is attached Figure 1-Figure 10 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0039] like figure 1 As shown, the invention includes a base 1, a feeding part, a limiting part, a cutting part 5, an outer skin recycling part, an inner core retracting part, an inner core recycling part, a cutting part and an inner core recycling box. And the feeding part, the limiting part, the cutting part 5, the outer skin recovery part, the inner core retraction part, the inner core recovery part, and the cutting part are arranged in sequence from left to right on the base.

[0040] Wherein the base 1 is a support plate arranged horizontally, and the base is fixed on the ground through anchor bolts. A feeding component is fixed on the left side of the upper surface of the base.

[0041]The feeding part includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com