Patents

Literature

241results about How to "For subsequent use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

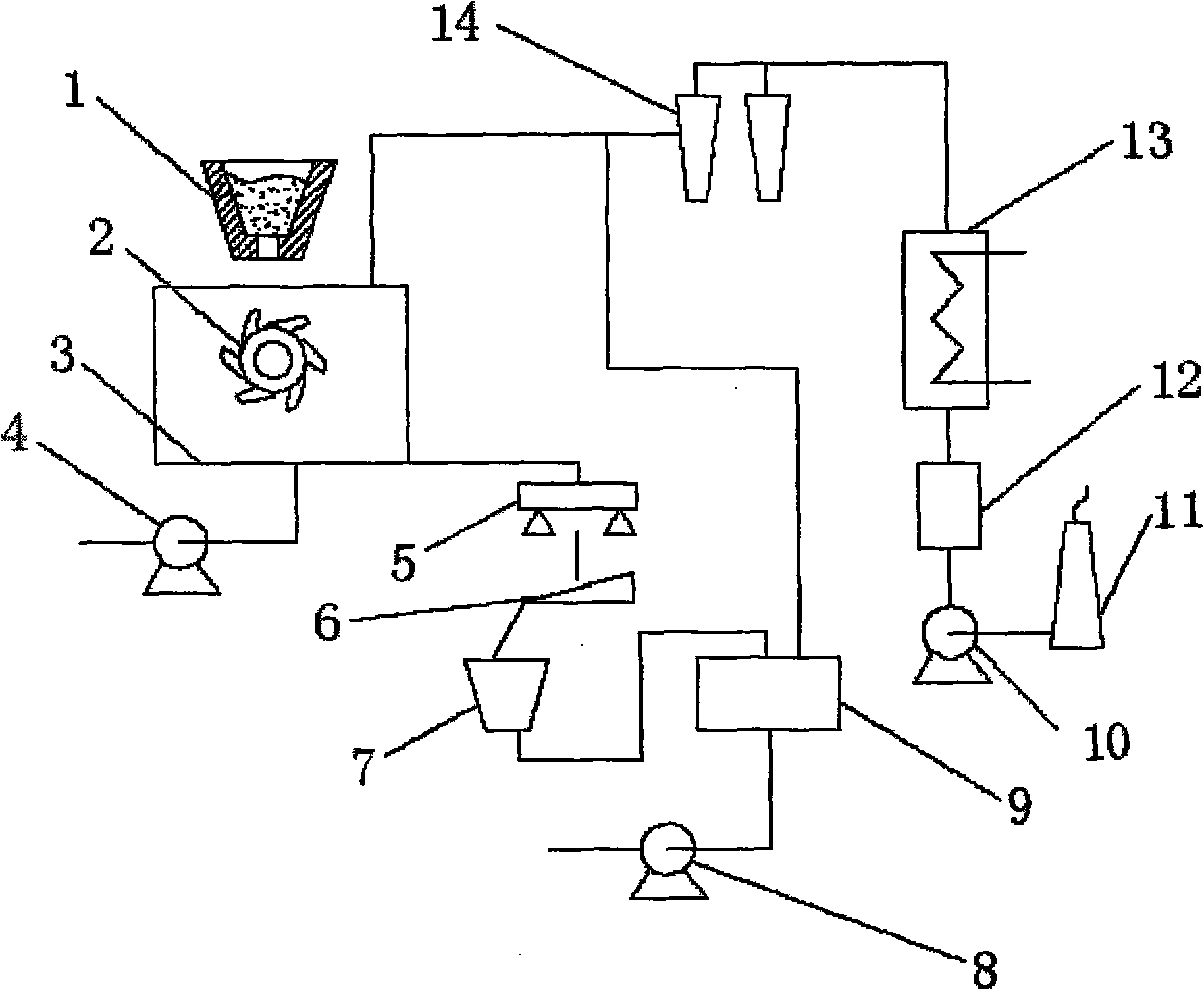

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

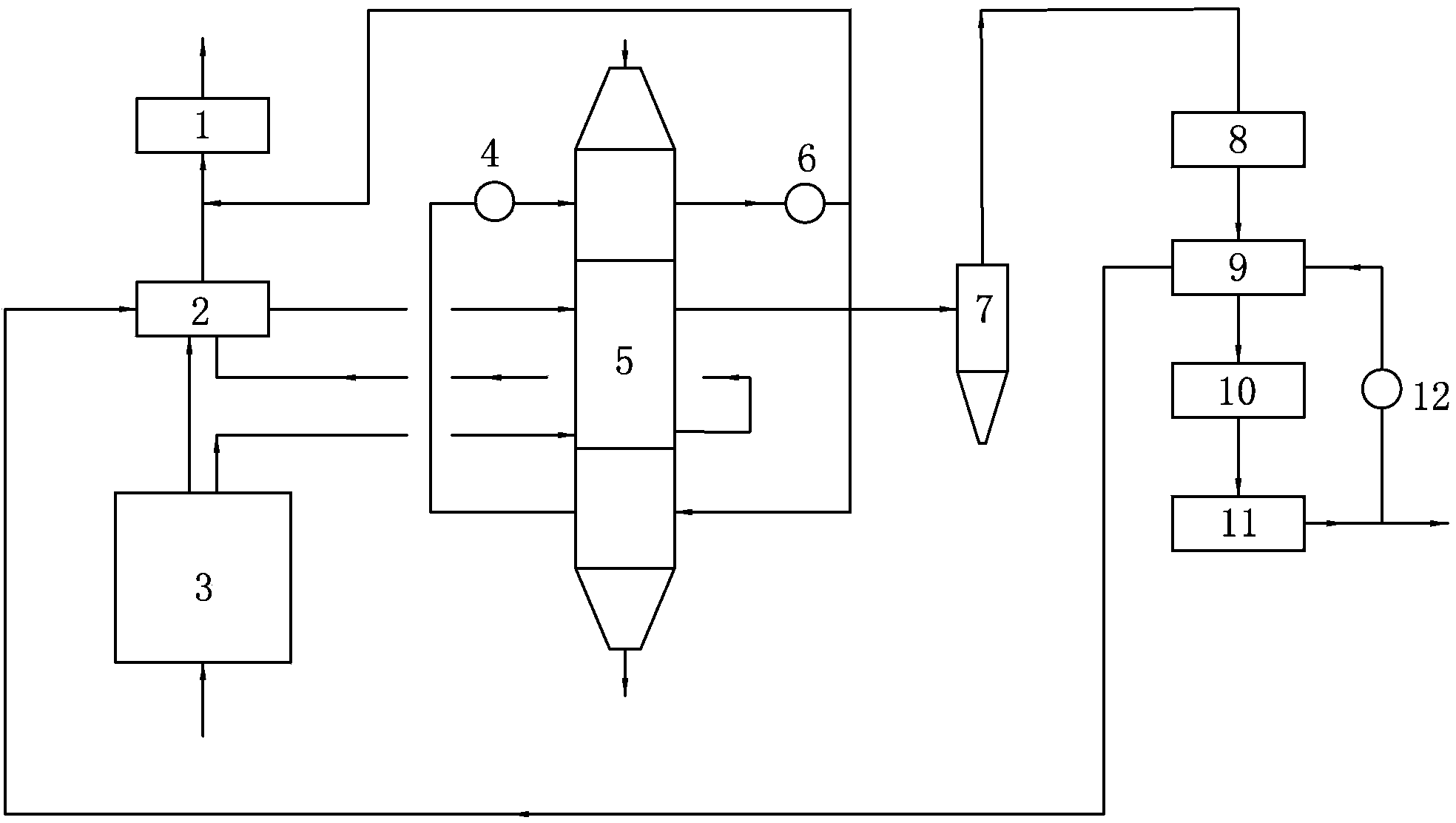

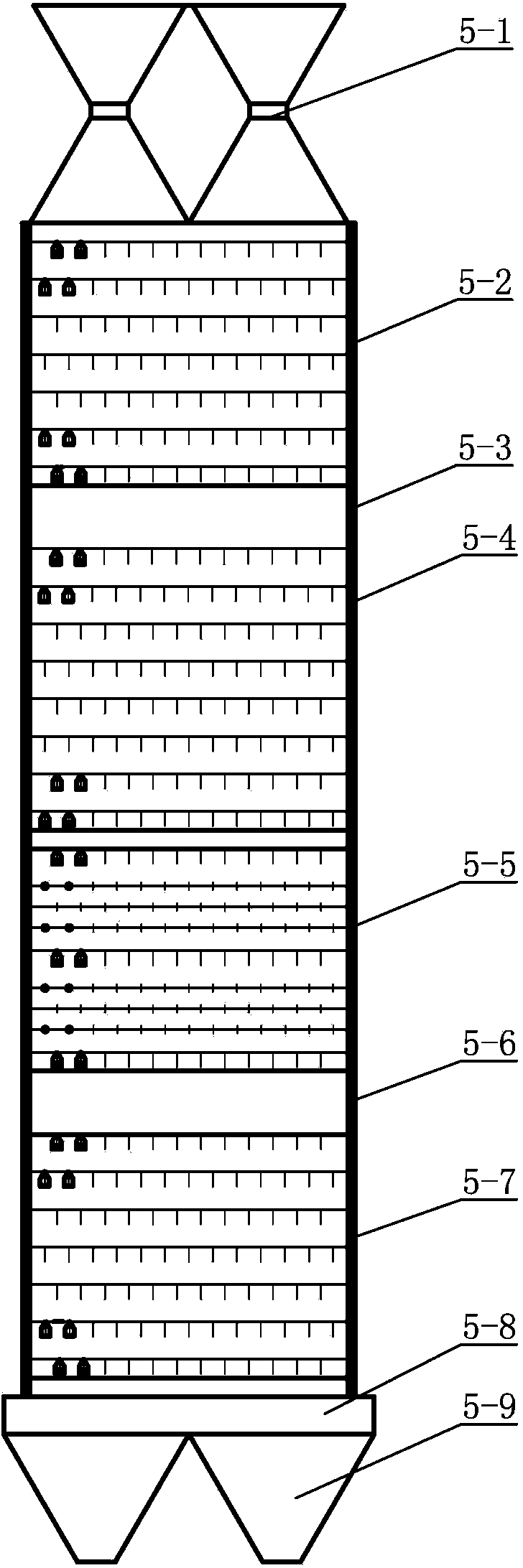

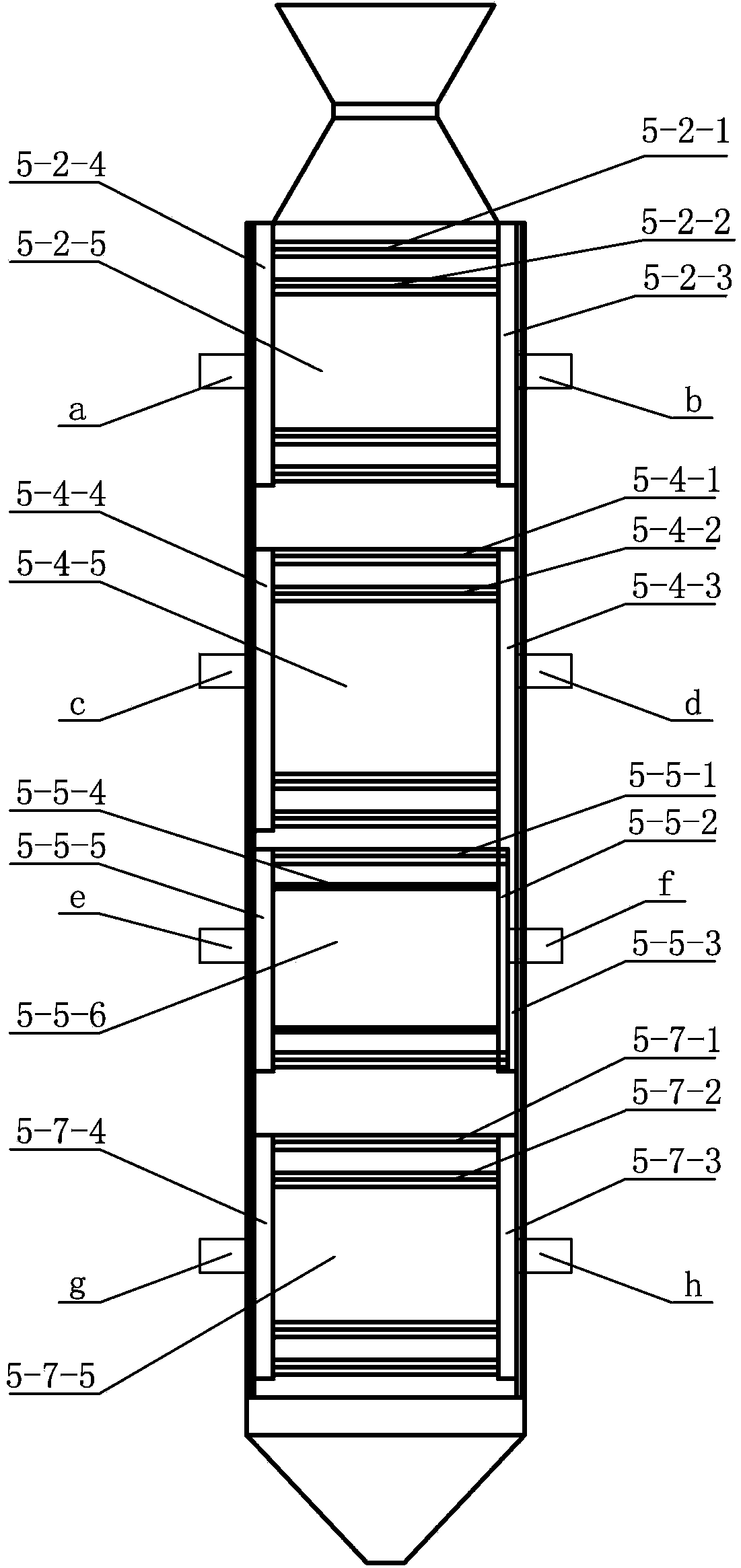

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

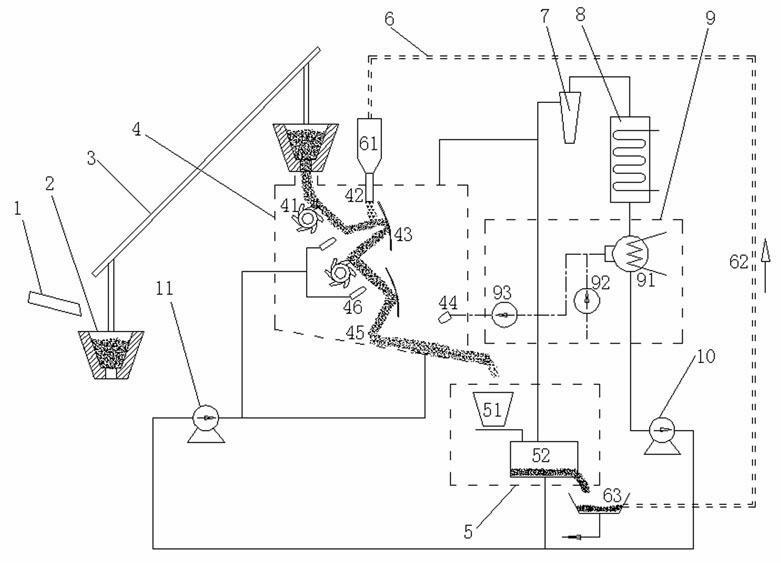

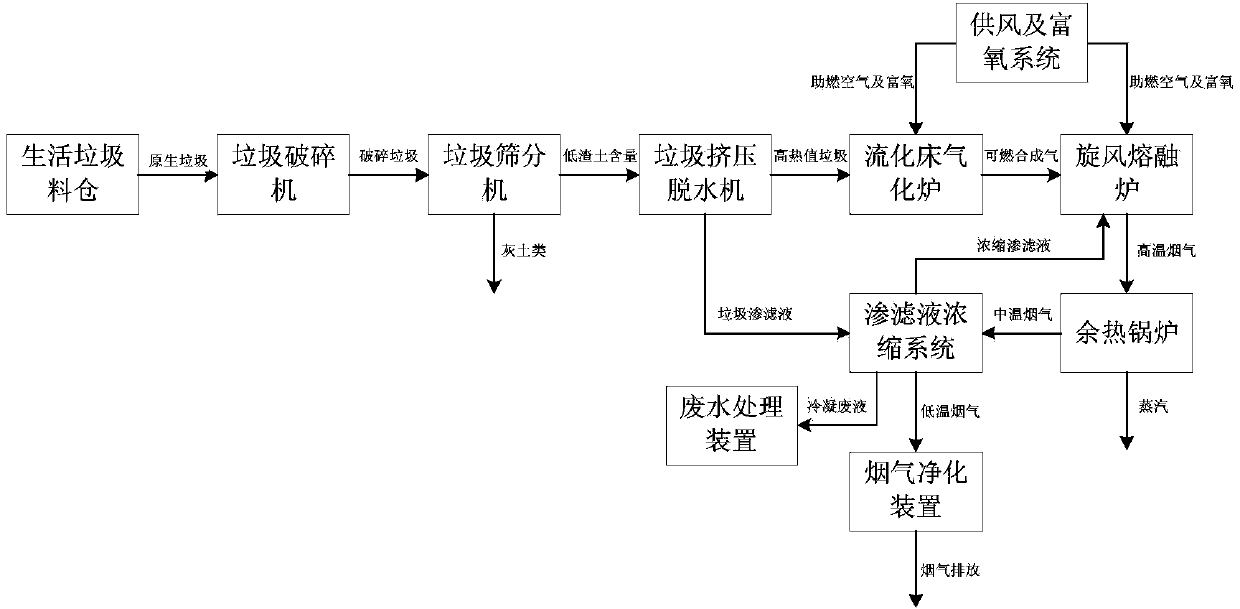

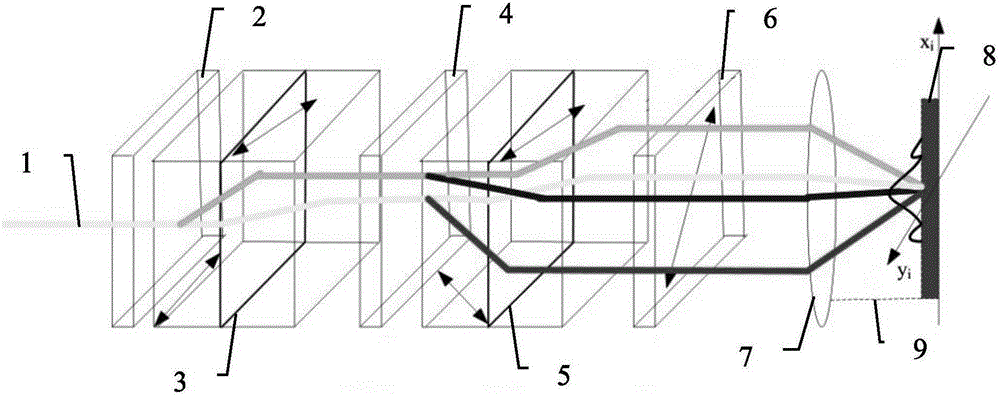

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

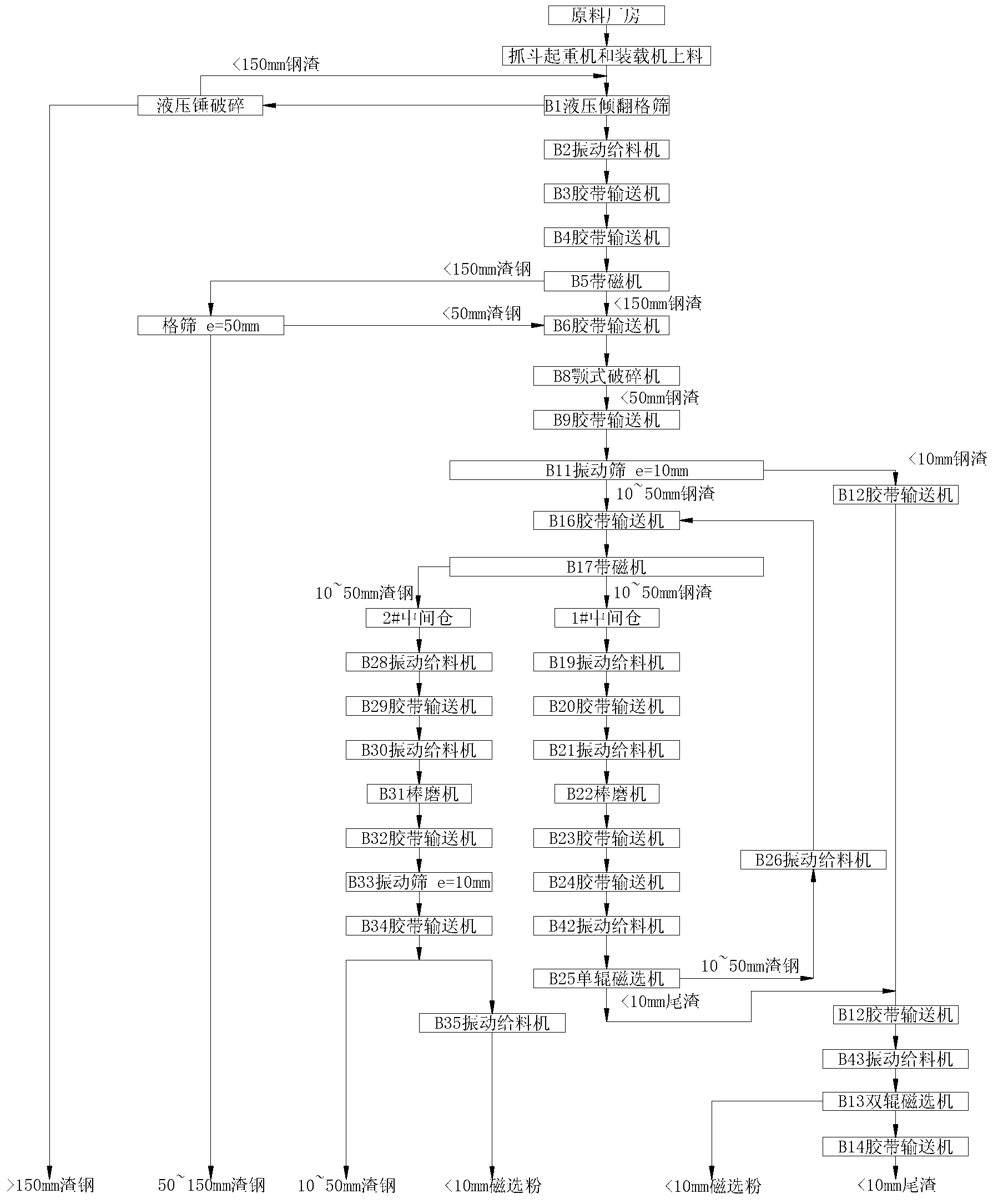

Steel slag treating technology

ActiveCN103290153AIncrease added valueFor subsequent useRecycling and recovery technologiesSteelmakingClosed loop

The invention relates to a steel slag treating technology which can be used for treating steel slag after which is stabilized by adopting a hot and stuffy method. According to the technology, the steel slag is treated by the procedures of screening, crushing, magnetic separation, purification and the like through utilizing the mode of combining an open loop and a closed loop circulation to obtain five high-value-added high-quality products, namely first-type bulk slag steel with the grade of more than or equal to 80% and particle size of 150mm, a second-type bulk slag steel with the grade of more than or equal to 80% and particle size of 50-150mm, slag steel with grade of more than or equal to 85% and particle size of 10-50mm, magnetic separation powder with grade of more than or equal to 42% and particle size of 10mm, and metal iron content (2% of tailings with the particle size of 10mm), wherein the first-type bulk slag steel and the second-type bulk slag steel and the slag steel with the grade of more than or equal to 85% can be returned for steelmaking, the magnetic separation powder can be used for sintering, and the tailings can be used for producing steel slag micropowder as high-activity admixture of cement and concrete and the like. Through the technology, the zero emission of the steel slag can be realized, the defects that the steel slag stored occupies a large area and pollutes the environment can be solved, and the economic benefits of a steel mill can be increased.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

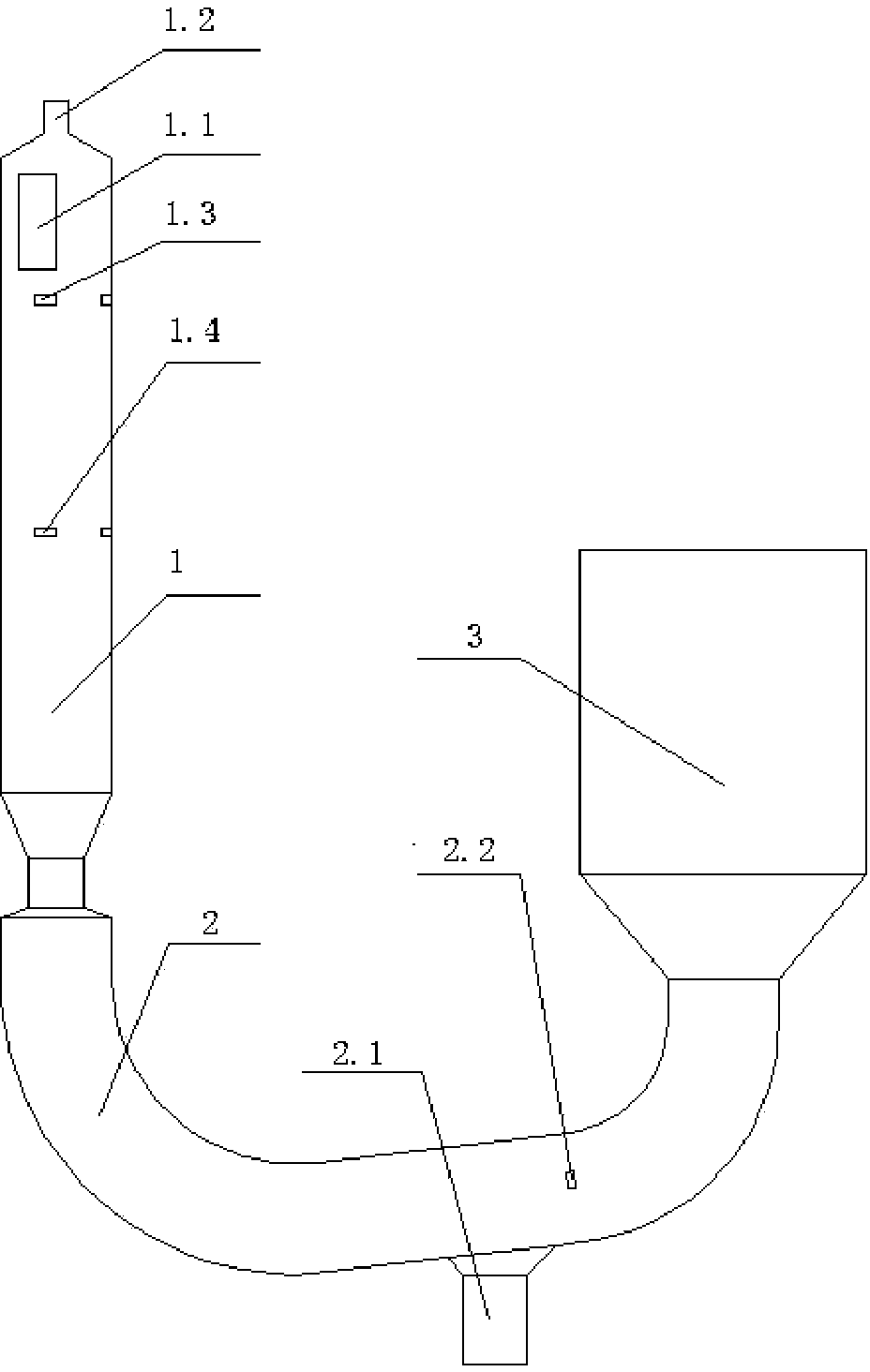

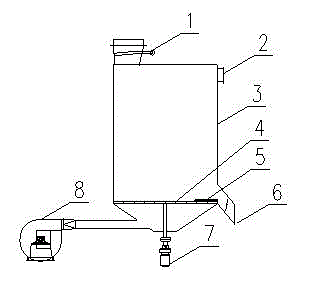

Recovery method of steel slag residual heat and system thereof

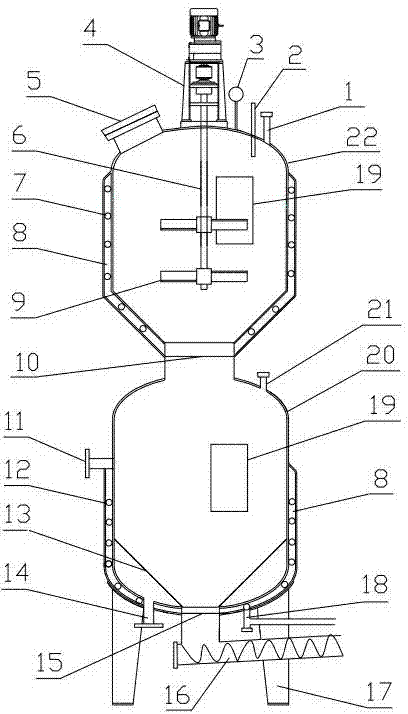

ActiveCN101551199AReduce consumptionEliminate pollutionProcess efficiency improvementWaste heat treatmentRecovery methodFluidized bed

The invention discloses a recovery method of steel slag residual heat and system thereof. The system is composed of a steel slag flow distributor, a water-cooling granulation wheel, a first fluidized bed, a weigher, a vibration sieve, a hot slag particles bunker, a second fluidized bed, a dedusting device, a blower and a residual heat boiler in sequence. The method is that, pouring high-temperature liquid slag into the steel slag flow distributor, the steel slag flown out of the steel slag flow distributor falling onto the water-cooling granulation wheel and being crushed and throwing out to fall into the first fluidized bed for exchanging heat with air, hot slag particles discharged from the first fluidized bed is stored in the hot slag particles bunker after going through the weigher and the vibration sieve, and discharging when the temperature is cooled to 350 DEG by a heat exchanger of the second fluidized bed. High-temperature air discharged from the first fluidized bed and the second fluidized bed enters the residual heat boiler for exchanging heat after dedusting. The invention can reduce energy consumption in steel production, graining effect of the steel slag is good, which is benefit for following degradation of free CaO and magnetic separation of wasted steel.

Owner:HANGZHOU BOILER GRP CO LTD

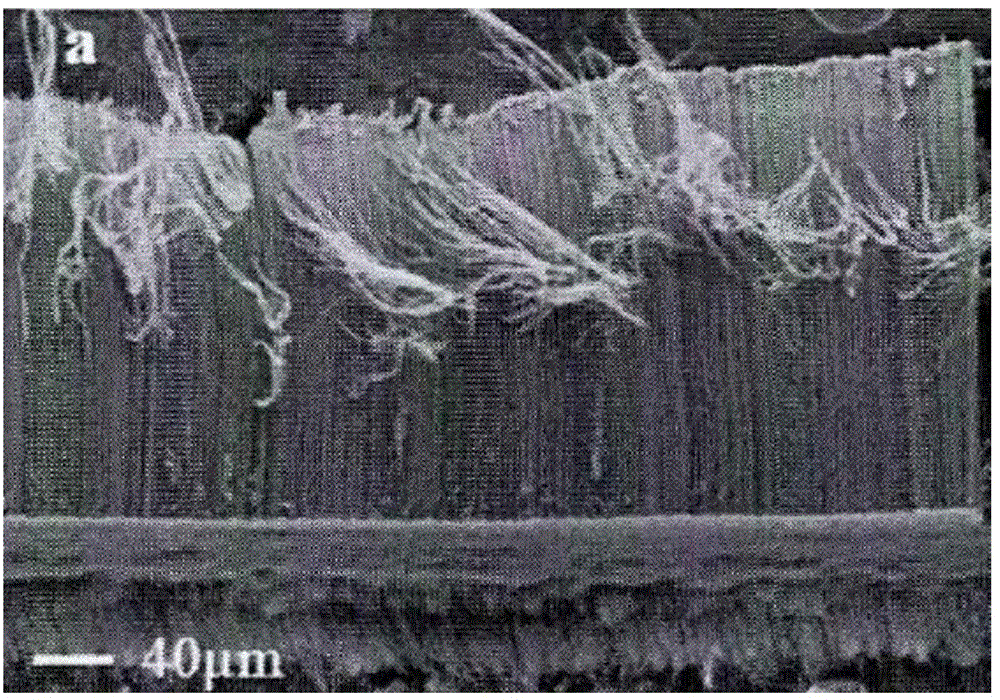

Method for directly growing carbon nano tube array on fiber substrate

ActiveCN104310372AIncrease coverageReduce interdiffusionMaterial nanotechnologyPre treatmentCarbon nanotube

The invention provides a method for directly growing a carbon nano tube array on a fiber substrate. The method comprises the following steps: (1) pre-treating the fiber substrate; (2) attaching a catalyst precursor on the surface of the substrate obtained in the step 1, wherein the catalyst comprises transitional metal elements such as Fe, Co, Ni, Cu, Au, Pt, Mo or Ag; (3) putting the substrate obtained in the step (2) in a reaction furnace, heating the substrate to a first temperature and maintaining for a preset time, and introducing inert gas to remove organic matters in the catalyst precursor; (4) heating to a second temperature and maintaining for a preset time, continuously introducing inert gas, introducing mixed gas of reductive gas and carbon source gas, maintaining the pressure in the reaction furnace, and growing high-density carbon nano tubes on the surface of the substrate; and (5) after reaction, stopping introduction of the reductive gas and carbon source gas, and continuously introducing inert gas till the temperature is reduced to room temperature.

Owner:4MICRO TECH COMPANY

Arsenic-polluted place soil restoration stabilizer

InactiveCN104004520AGood stabilization effectFacilitate processing and subsequent utilizationContaminated soil reclamationOrganic fertilisersNutrientPolluted soils

The invention belongs to the technical field of polluted soil treatment and restoration and discloses an arsenic-polluted place soil restoration stabilizer. The arsenic-polluted place soil restoration stabilizer is characterized in that bentonite mass is 1-5% arsenic-polluted soil mass, calcium sulfate mass is 0.1-1% arsenic-polluted soil mass, a mole ratio of iron powder to arsenic in polluted soil is in a range of 3: 1 to 10: 1, plant ash mass is 2-8% arsenic-polluted soil mass, bentonite is dried in the air, crushed and sieved by a sieve of 100-200 meshes, iron powder fineness is in a range of 100-200 meshes, the arsenic-polluted place soil restoration stabilizer is added into the arsenic-polluted soil, then the mixture is subjected to dry stirring for full mixing and then is added with water so that soil water content is in a range of 30-35% and then the mixture is subjected to stirring. The arsenic-polluted place soil restoration stabilizer utilizes cheap and easily available raw materials, has good stabilization effects, substantially does not change a polluted soil pH value, can supply nutrients for polluted soil and is conducive to soil treatment and follow-up utilization.

Owner:上海纺织建筑设计研究院有限公司

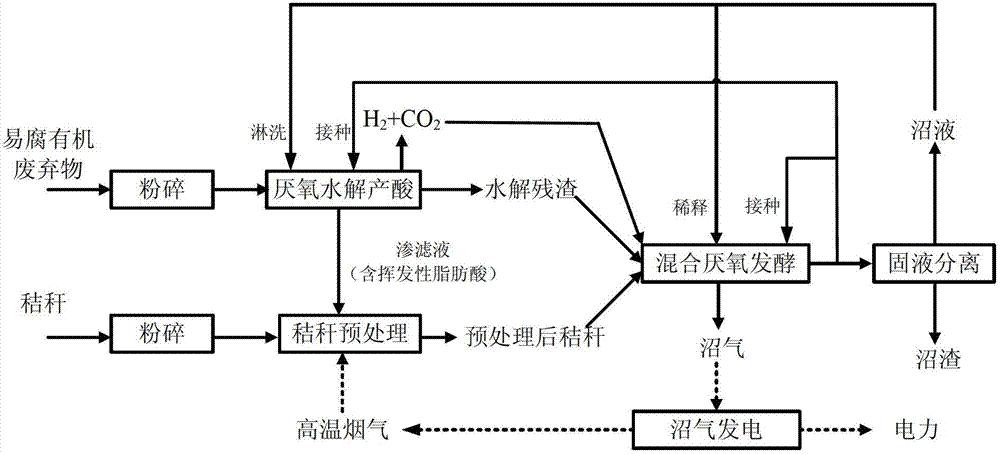

Method for producing methane through combination of perishable organic wastes and straws

ActiveCN102757980AImprove fermentation effectAvoid "acidosis"Waste based fuelFermentationStrong acidsMethane fermentation

The invention discloses a method for producing methane through combination of perishable organic wastes and straws. The method comprises the following steps: step 1, collecting the perishable organic wastes and the straws, and respectively crushing; step 2, filling the crushed perishable organic wastes on percolation fillings of a solid percolation bed, adding fermenting methane inoculants, and carrying out anaerobic hydrolysis to produce acid so as to form percolate; step 3, collecting the percolate discharged from the bottom of the solid percolation bed, adding the percolate and the crushed straws into a straw pretreatment reactor, heating, soaking and pre-treating; and step 4, collecting a mixture of hydrolysis acid production residues, and pre-treated straws and percolate, adding the mixture into a methane fermentation reactor, and carrying out hybrid anaerobic fermentation to produce the methane. According to the invention, acid poisoning of the perishable organic wastes, which is easy to happen in the conventional anaerobic fermentation process, and abrasion of equipments and pipelines in the conventional strong acid / strong alkali pretreatment can be avoided, the pretreatment cost of the straws is reduced, the method is beneficial for subsequent utilization of methane residues, and the fermentation performance of the methane is improved.

Owner:深圳市海吉星环保有限责任公司

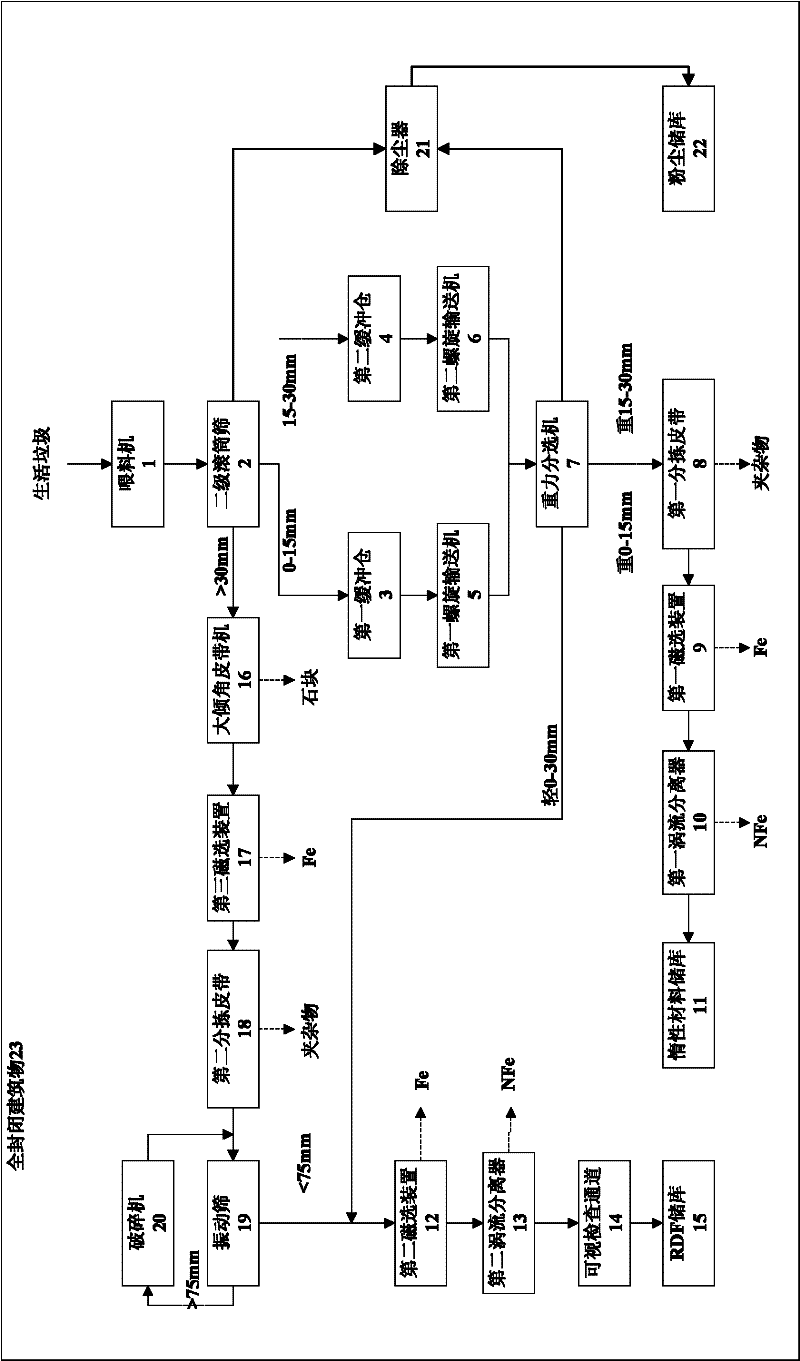

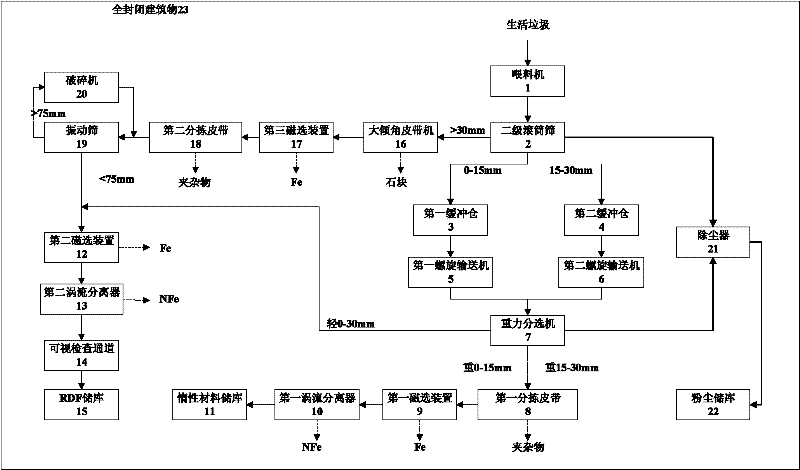

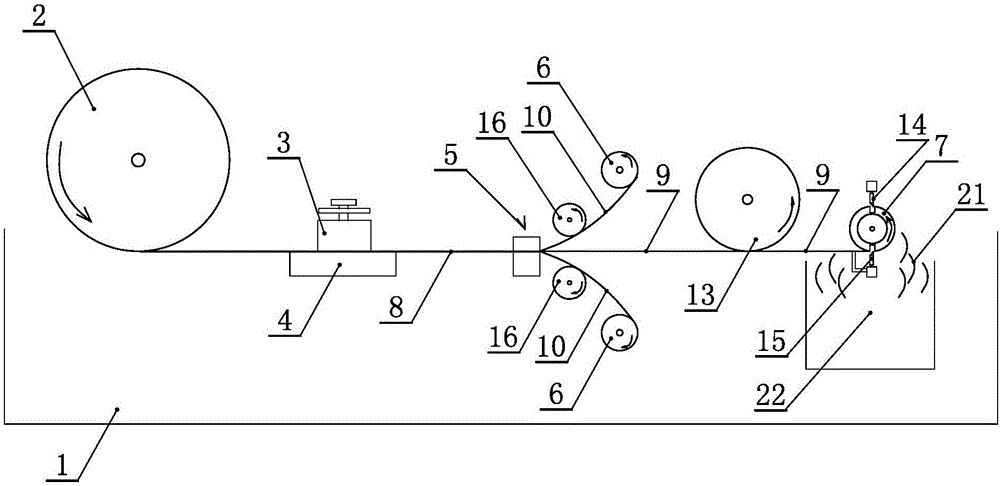

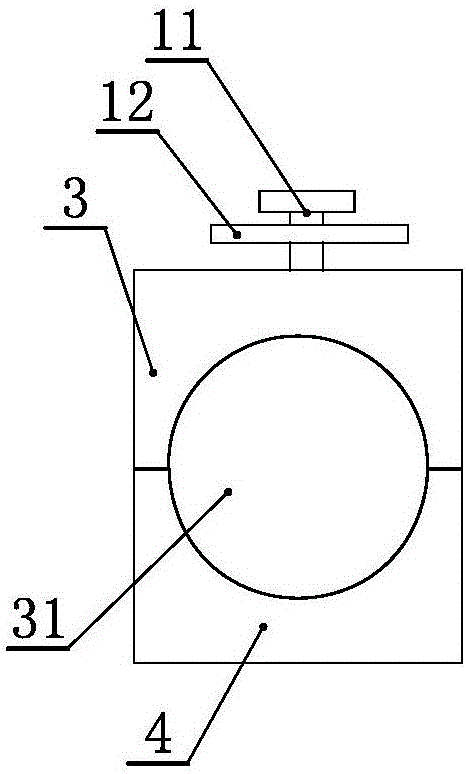

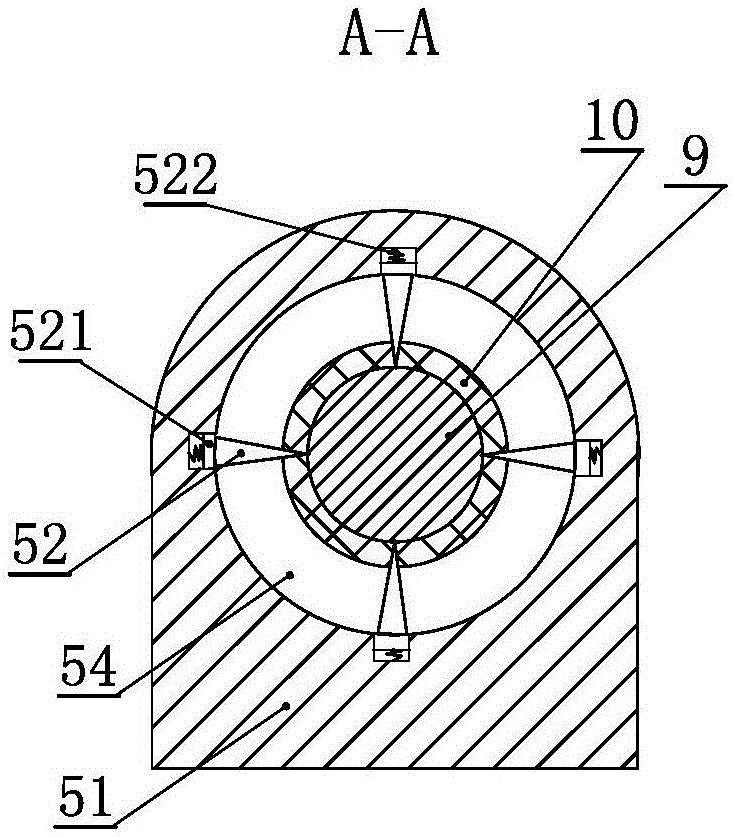

Municipal waste separation system

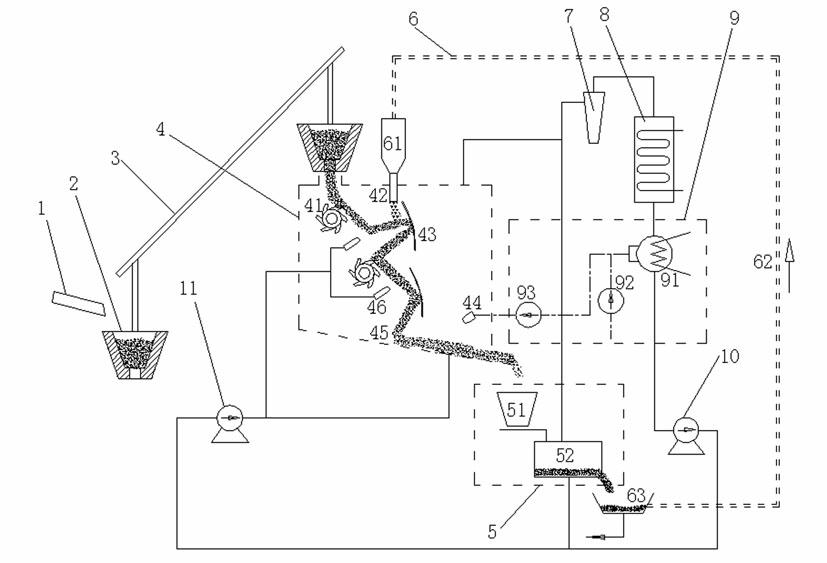

ActiveCN102189094AEfficient separationImprove working environmentSolid waste disposalSolid separationHazardous substanceEngineering

The invention relates to a municipal waste separation system. The municipal waste separation system is characterized by comprising a feeding machine, a secondary rotary screen, a first buffer bin, a second buffer bin, a first spiral conveyer, a second spiral conveyer, a gravity separator, a first sorting belt, a second sorting belt, a first magnetic separation device, a second magnetic separationdevice, a third magnetic separation device, a first vortex separation device, a second vortex separation device, an inert material storage hall, a resource description framework (RDF) storage hall, alarge-inclination-angle belt machine, a vibrating screen and a crushing machine. The separation system has high sorting efficiency, and can effectively separate combustible substances, insert components, ferrous metal / non-ferrous metal, and harmful substances in the pre-crushed and dried municipal waste to facilitate subsequent comprehensive utilization. The separation process is totally closed,remote operation and control is performed by using a computer, waste is not required to be directly contacted, the working environment of workers is improved, mechanization and automation are realized, and efficiency is improved.

Owner:华新环境工程有限公司

Metal line inner core recycle device of power supply and utilization cable

InactiveCN106205894AQuick splitEasy to separateBasic electric elementsElectronic waste recyclingMetal stripsEngineering

A metal line inner core recycle device of a power supply and utilization cable comprises a base, a feeding part, limitation parts, a cutting part, an outer skin recycle part, an inner core winding part, an inner core recycle part and a cut part inner core recycle box, wherein the feeding part is a feeding wheel, a cable is wound around the feeding wheel, the limitation parts are limitation rings arranged vertically, a cutting knife is arranged on the cutting part and is used for cutting the cable to a plurality of strips, an inner core and an outer skin which are cut and separated are respectively wound the inner core winding part and the outer skin recycle part, and the inner core on the inner core winding wheel is wound the inner core recycle wheel and is cut to achieve fixed length recycle of metal strips. By the device, the inner core and the outer skin of a waste cable are rapidly cut, and the fixed length mass production and recycle of the inner core of the cable become possible. The device is high in automation, a separation effect of the inner core and the outer skin is good, the inner core and the outer skin are simultaneously and orderly wound during the separation process, and subsequent utilization is facilitated.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Device and method for pyrolyzing pea coal by utilizing internally heated vertical furnace

ActiveCN103468292AAvoid secondary crackingHigh yieldIndirect and direct heating destructive distillationCycloneRecuperator

The invention relates to a device and method for pyrolyzing pea coal by utilizing an internally heated vertical furnace. The device comprises an internally heated vertical furnace, wherein a feed hopper, a drying section, a first transition section, a pyrolysis section I, a pyrolysis section II, a second transition section, a cooling section, a discharge valve and a discharge hopper are arranged on the internally heated vertical furnace sequentially from top to bottom, wherein the drying section is communicated with a dry steam circulating fan and a high-temperature steam circulating fan; the dry steam circulating fan is communicated with the cooling section; the pyrolysis section I is communicated with a coal gas heat exchanger and a micro-cyclone dust collector; the micro-cyclone dust collector is communicated with a quencher; the quencher is communicated with a raw gas heat exchanger; the raw gas heat exchanger is communicated with a coal gas heat exchanger and a horizontal water-tube cooler; the horizontal water-tube cooler is communicated with an electrical tar precipitator; the pyrolysis section II is communicated with a combustion furnace and the micro-cyclone dust collector; the combustion furnace is communicated with the coal gas heat exchanger. The device and method are easy to operate, high in heat efficiency, environment-friendly and high in carbocoal quality, and the coal gas can be recycled.

Owner:陕西凯德利能源科技有限公司

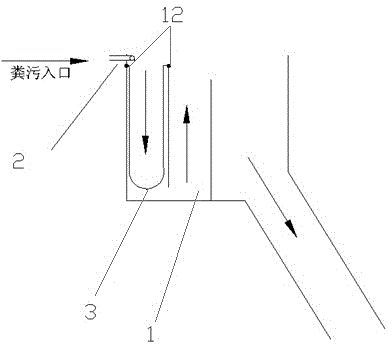

Kitchen waste hydrothermal three-phase separation system

ActiveCN103480632AFully realize hydrolysisEvenly heatedWaste processingSolid waste disposalThree-phaseVaporization

The invention relates to the technical field of treatment of kitchen waste, in particular to a kitchen waste hydrothermal three-phase separation system. In the kitchen waste hydrothermal three-phase separation system, a heating device is arranged on the outer wall of a hydrothermal reactor tank body and is a conduction oil coil pipe; the conduction oil coil pipe is clung to the side wall of a hydrothermal reactor to provide thermal energy for the kitchen waste, and the interior of the hydrothermal reactor is heated evenly; a thermal energy recovery device is arranged on a three-phase separator, and comprises a thermal energy recovery coil pipe arranged on the outer wall of a three-phase separator tank body, and a thermal energy recovery guide pipe connected with the thermal energy recovery coil pipe. According to the invention, the kitchen waste is heated by the conduction oil, so that the energy can be saved and the cost can be reduced; the kitchen waste is heated under a water condition to realize full hydrolyzation, and is discharged through jet explosion, so that the hydrolyzation is performed more thoroughly, and the subsequent utilization is facilitated. The three-phase separator integrates the functions of explosion bearing, flash vaporization and three-phase separation, and an outer water coil pipe is arranged for recovery of the thermal energy, so that the recycling of the thermal energy is realized, and the kitchen waste cannot be blocked at the same time.

Owner:SOUTH CHINA AGRI UNIV

A kind of positive electrode of lithium ion battery and preparation method thereof

ActiveCN103715394BImprove bindingLight in massCell electrodesCell component detailsCarbon nanotubePole piece

The invention discloses a lithium ion battery anode and a preparation method thereof. The anode utilizes a carbon nano pipe film formed by a carbon nano pipe macroscopic pipe as a current collector, and an anode material layer is formed on the carbon nano pipe film. Compared with the traditional aluminum foil current collector anode, the lithium ion battery anode has the advantages that the weight of the lithium ion battery anode prepared by the method is light, and the anode material layer and the current collector are firmly combined. The preparation method comprises the following steps of preparing a high strength carbon nano pipe on a glass substrate by utilizing a carbon nano pipe macroscopic pipe continuum generated by a reactor port, generating the anode material layer on the carbon nano pipe film layer, separating the carbon nano pipe film layer with the anode material layer from and the glass substrate, and mounting a pole ear on a pole piece. Under the same size, the carbon nano pipe film is far lighter than the aluminum foil, the weight of the saved part can be replaced by the anode material, and the capacity of the battery is 15%-50% higher than that of a battery which takes the aluminum foil as an anode current collector. The lithium ion battery anode is low in cost, high in generation efficiency, simple in equipment, capable of realizing semicontinuous operation and suitable for mass production.

Owner:北京旭江科技有限公司

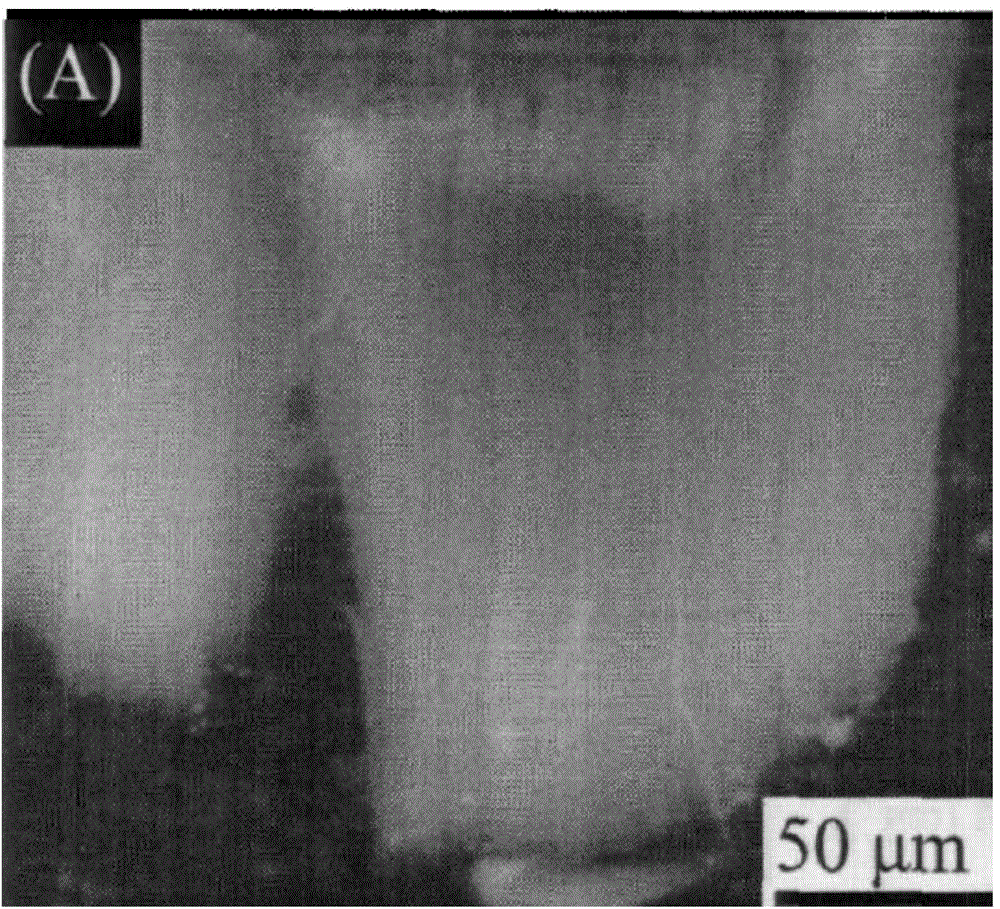

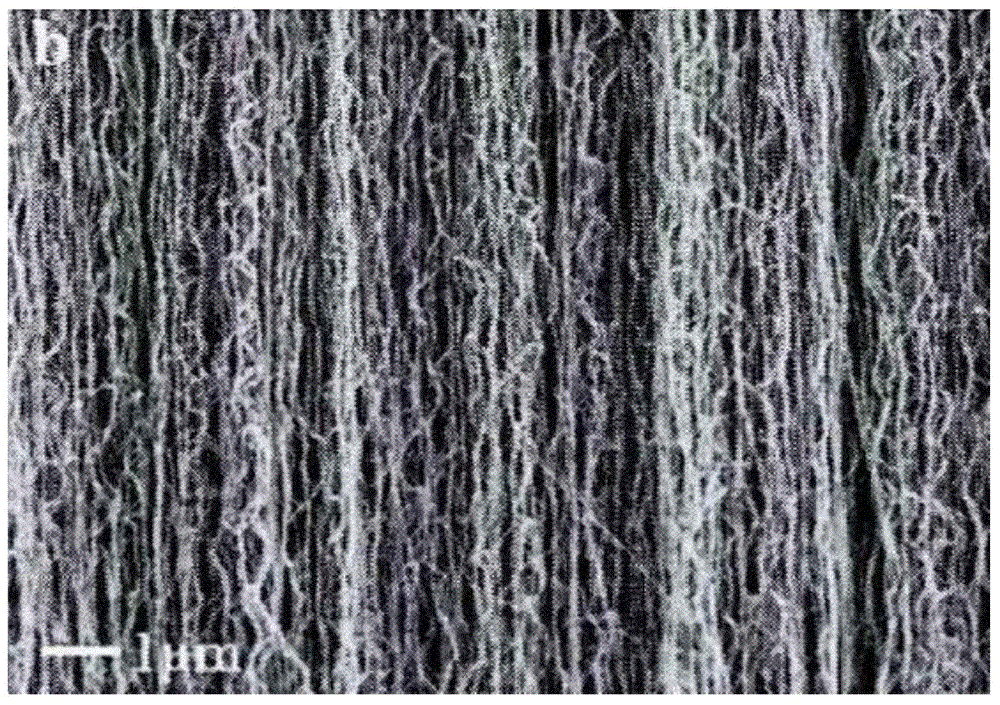

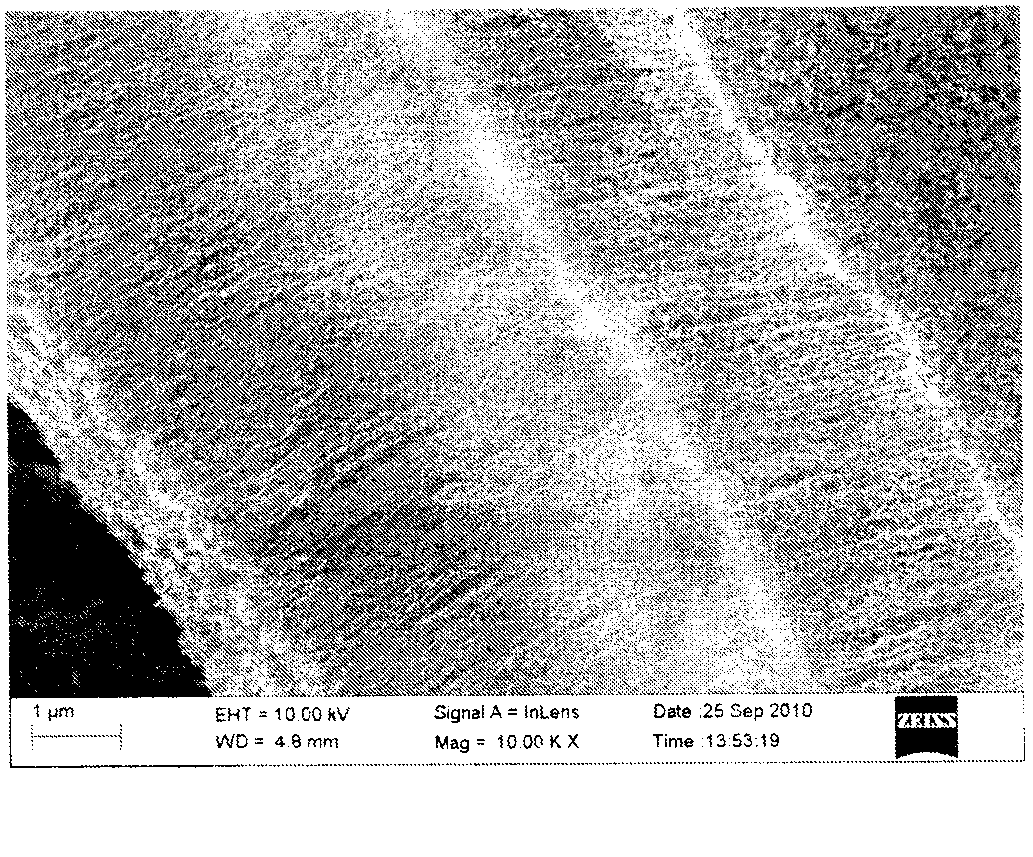

Preparation method for directly growing high density carbon nanotube array on carbon fiber paper base bottom

InactiveCN103253647ASimple methodEasy to controlMaterial nanotechnologyCarbon compoundsFiberCarbon fibers

The invention discloses a preparation method for directly growing high density carbon nanotube array on carbon fiber paper base bottom. The method is a chemical vapor deposition method. Firstly, iron (Fe), cobalt (Co) and nickel (Ni) element containing sol is prepared and coated on carbon fiber paper after pretreatment. The carbon fiber paper base bottom formed with catalyst precursor is placed in the vacuum furnace chamber, and the substrate is heated to a first temperature and maintained for a predetermined time; with the protection gas, the reduction gas is let into the reacting furnace, and the substrate formed with catalyst precursor is heated to a second temperature and maintained for a predetermined time; the mixture of protection gas and carbon source gas is let into the reacting furnace, and is heated to a third temperature, and the high density carbon nanotube array is grown on the surface of the substrate catalyst. The carbon nanotube array can be directly grown on the carbon fiber paper base bottom according to the method, and can be used as electrode material of green energy storage device fuel cell and super capacitor.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Stainless steel pickling waste water resource recycling method

ActiveCN105060599AReduce dosageImprove recycling efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodEvaporation

The invention discloses a stainless steel pickling waste water resource recycling method. The method includes the steps of firstly, conducting reduced pressure evaporation on mixed acid of hydrofluoric acid and nitric acid so that acid recycling can be achieved; secondly, separating out and recycling iron in the solution; thirdly, gathering diluted acid, nickel and chromium in a circulating mode; fourthly, recycling diluted acid through a film method; fifthly, conducting neutralization and iron recycling; sixthly, separating nickel and chromium and recycling nickel; seventhly recycling chromium. By means of the method, efficient recycling of valuable metal resources such as nitric acid, hydrofluoric acid, iron, chromium and nickel is achieved, purified water can stably reach the standard, and the method is remarkable in economic benefit.

Owner:CENT SOUTH UNIV

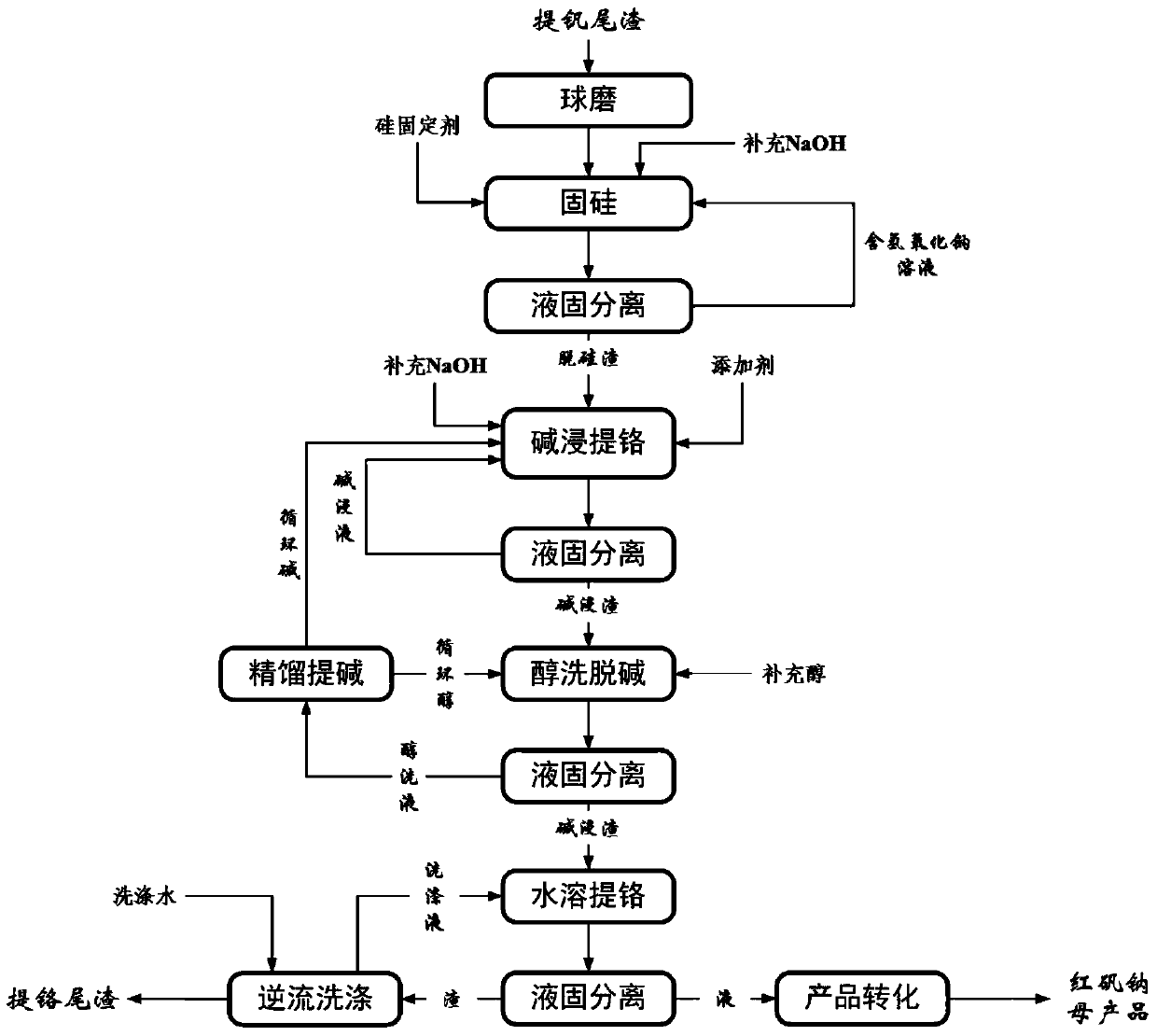

Clean process method for efficiently extracting chromium in extracted vanadium tailings

ActiveCN104195346AFor subsequent useImprove resource utilizationProcess efficiency improvementSiliconMaterials science

The invention discloses a clean process method for efficiently extracting chromium in extracted vanadium tailings. For the extracted vanadium tailings, a silicon fixing agent is added while silicon is leached with low-concentration sodium hydroxide; the silicon is converted into an inert compound in the alkaline leaching and chromium extracting process; the inert compound is subjected to alkaline leaching and chromium extracting to obtain sodium chromate alkali solution with lower silicon content and iron-enriched tailings, so that high-efficiency extraction of the chromium in the extracted vanadium tailings and comprehensive utilization of valuable components are realized. According to the clean process method disclosed by the invention, the high-efficiency extraction of the chromium in the extracted vanadium tailings can be realized, the extraction rate of the chromium is larger than 85 percent, and the content of the silicon in the obtained sodium chromate alkali solution is lower.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Absorbent for circularly absorbing sulfur dioxide gas in tail gas of natural gas and application of absorbent

ActiveCN107019996ALarge absorption capacityReduce desorption energy consumptionDispersed particle separationAbsorption capacityDesorption

The invention discloses an absorbent for circularly absorbing sulfur dioxide gas in tail gas of natural gas and an application of the absorbent. The absorbent comprises the following components in percentage by mass: 30-60wt% of cyclic tertiary amine compounds, 5-10wt% of a desulfurization fortifier, 10-30wt% of a latent solvent, 0.5-3wt% of an activating agent, 1-2wt% of an antioxidant, 0.5-2wt% of a corrosion inhibitor and the balance of water. The application refers to applying the absorbent to removal of the sulfur dioxide gas in the tail gas of the natural gas at an absorption temperature of 20-70 DEG C. According to the invention, by utilizing the structure characteristics of the cyclic tertiary amine compounds which are high in sulfur dioxide absorption capacity and low in desorption energy consumption, and adding corresponding auxiliary agents at the same time, the absorption of absorption liquid to sulfur dioxide has high efficiency and specificity; and the absorbent can selectively remove SO2 from the tail gas of the natural gas, so as to greatly reduce the gas purification cost, and facilitate follow-up utilization of recycled acid gas.

Owner:CHINA PETROLEUM ENG CORP LTD +2

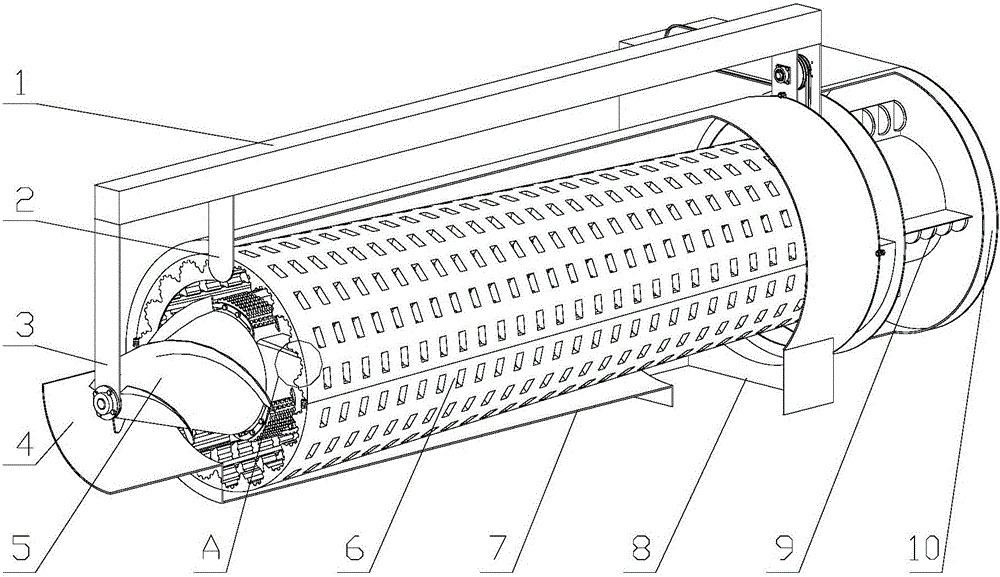

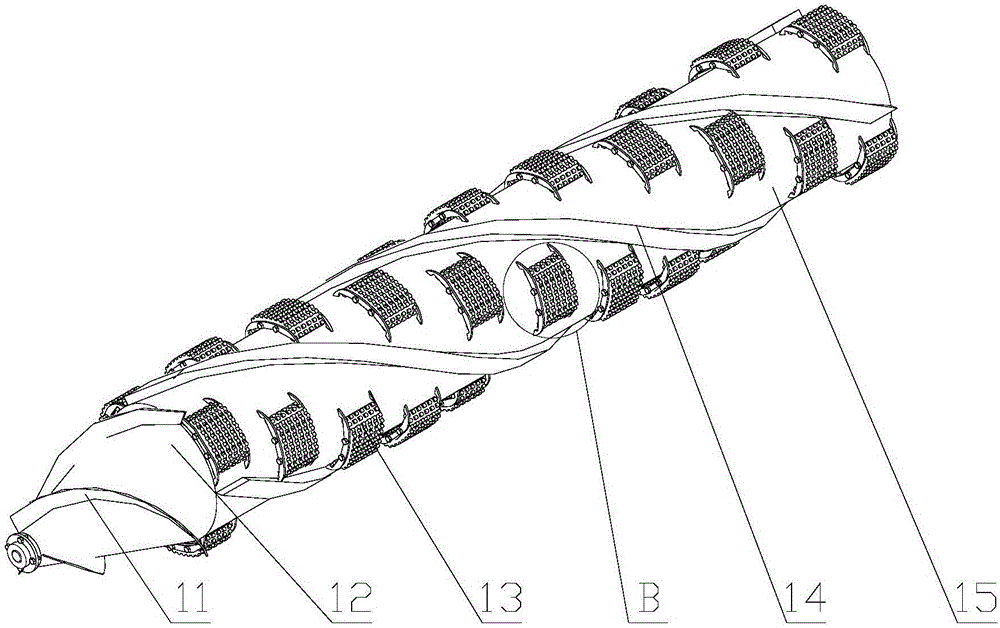

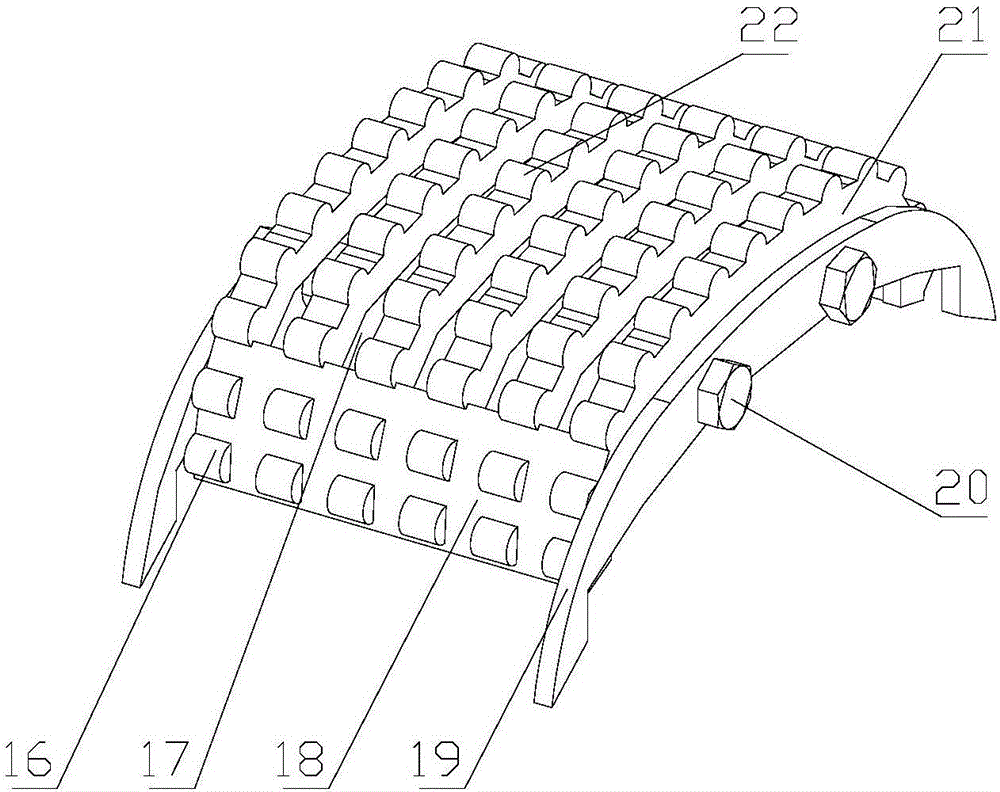

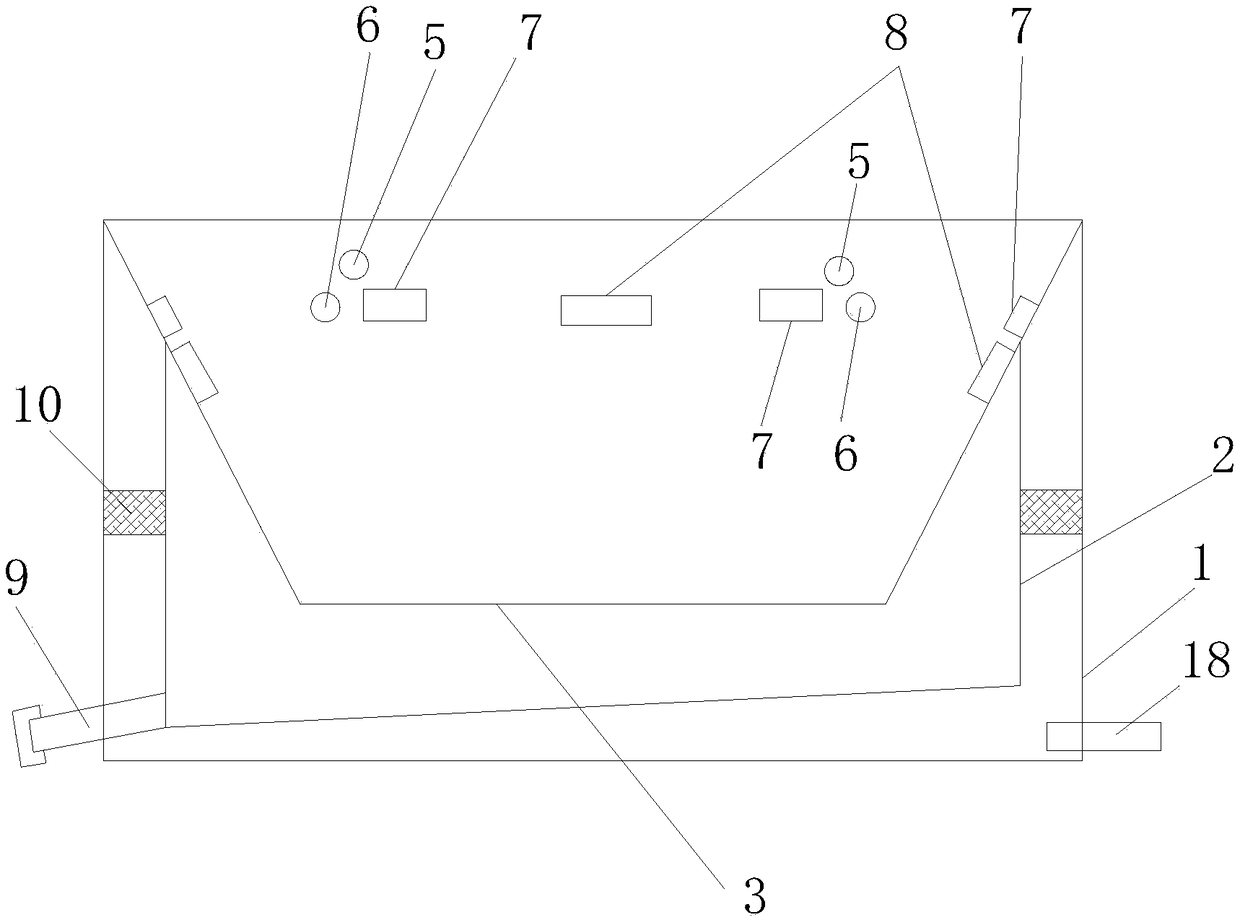

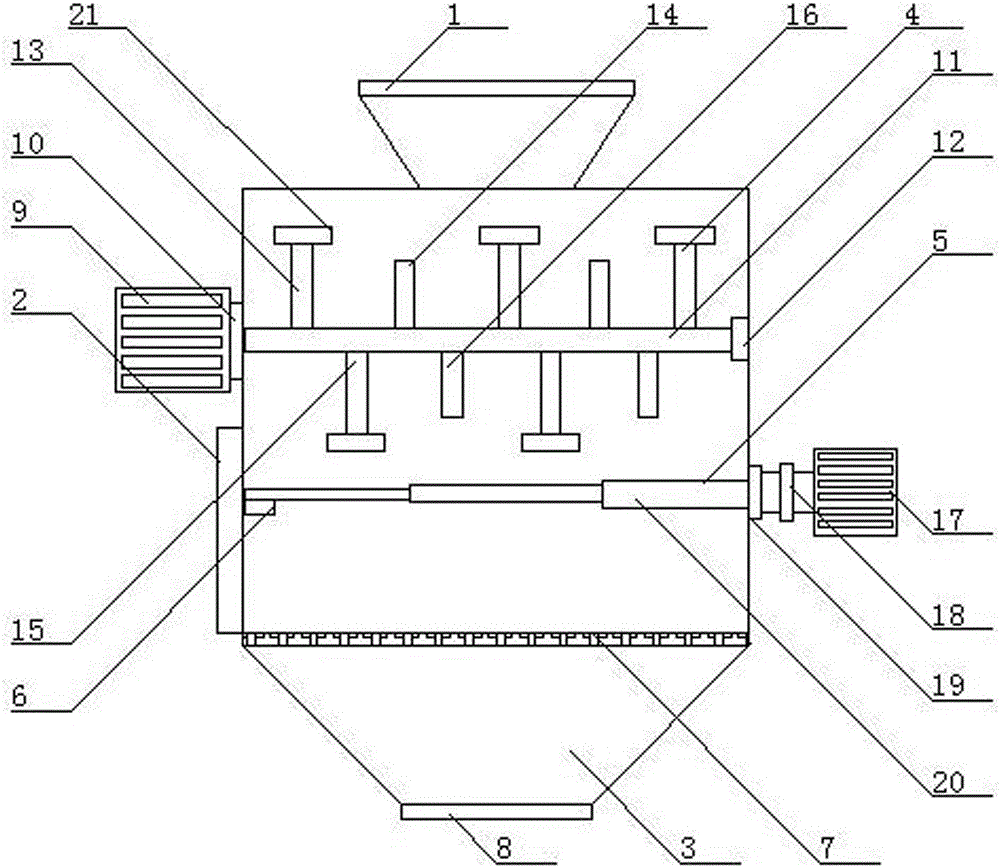

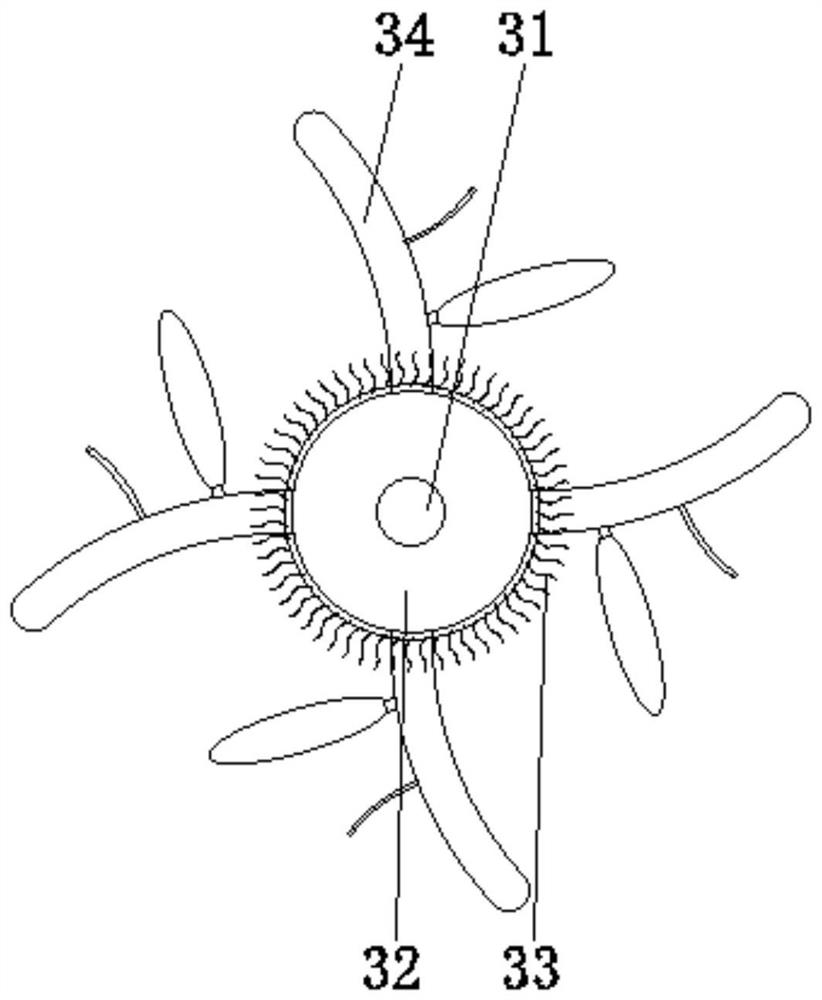

Axial rheological gap bionic corn threshing device

The invention discloses an axial rheological gap bionic corn threshing device. The axial rheological gap bionic corn threshing device comprises a machine frame, a threshing roller, a concave plate sieve, a machine cover and a corncob recycling mechanism, wherein the machine cover is fixed at the lower part of the machine frame; the concave plate sieve is fixed in the machine cover; the threshing roller is fixed in the concave plate sieve; the corncob recycling mechanism is fixed ar the back part of the machine cover; the cylindrical threshing roller and the conical concave plate sieve jointly form threshing gaps which are continuously changed from big to small to promote that corn ears are subjected to effective threshing action all the time; and threshing teeth on the outer surface of a bionic threshing bridge and threshing columns which are distributed on the inner surface of the concave plate sieve in a copying arc form jointly form the threshing functional surface, microscopic threshing moment is applied to corn grains, and the removed corn grains are separated out timely through a grain leaking groove in the surface of the bionic threshing bridge and a separating port in the surface of the concave plate sieve. The axial rheological gap bionic corn threshing device has high threshing efficiency and few crushed grains, and can synchronously collect the corncobs.

Owner:SHANDONG JUMING MASCH CO LTD

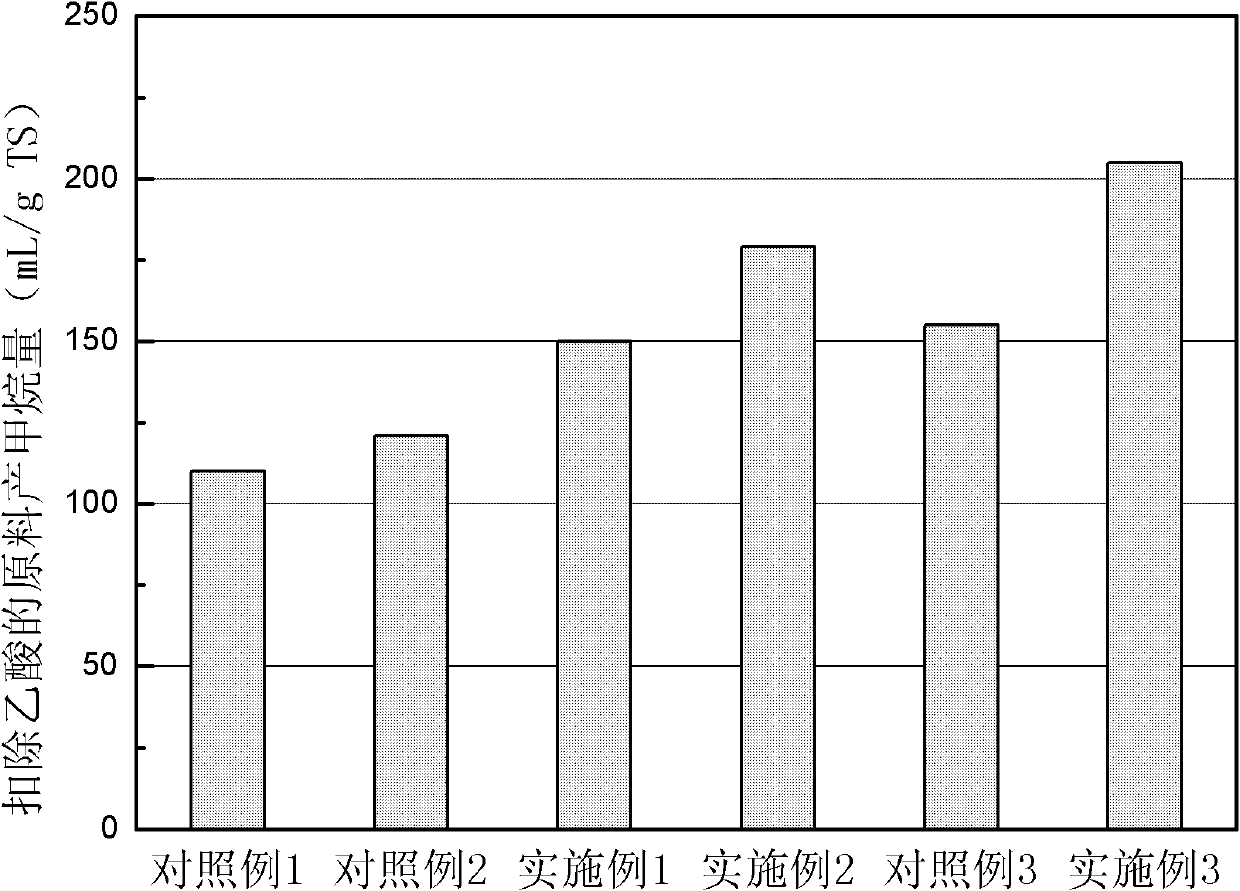

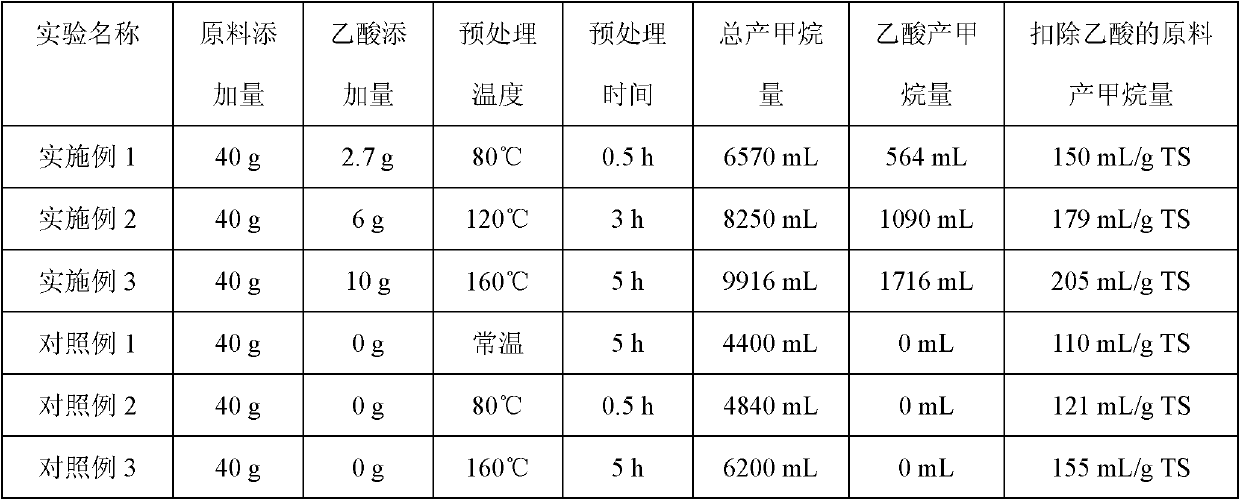

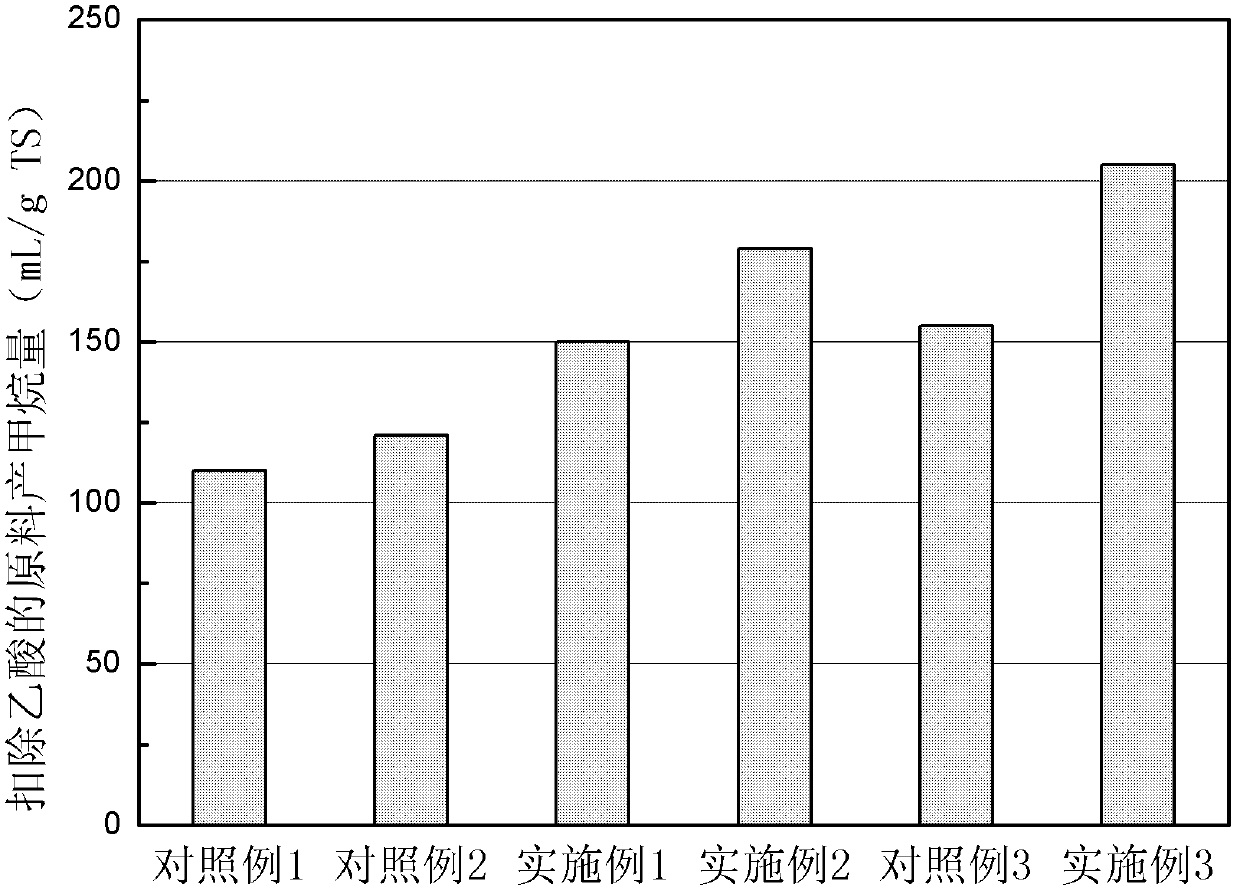

New method for pre-treating raw materials for fermenting wheat straw biogas

InactiveCN102604999AAvoid corrosionIncrease productionWaste based fuelFermentationVolatile fatty acidsMixed materials

The invention discloses a new method for pre-treating raw materials for fermenting wheat straw biogas. The method comprises the following steps of: crushing a wheat straw raw material; adding the crushed wheat straw raw material into a pre-treating reactor; adding a volatile fatty acid or organic waste water which contains the volatile fatty acid into the reactor in the mass ratio of the volatile fatty acid to dry wheat straws being 1:(4-15); adding water into the pre-treating reactor to adjust the mass concentration of the dry wheat straws to 8 to 15 percent; uniformly stirring the mixed materials; and after sealing the pre-treating reactor, pre-treating the materials for 0.5 to 5 hours by heating and soaking the materials, and controlling the temperature of the pre-treatment to be between 80 and 160 DEG C, thus obtaining the pre-treated raw materials. Corrosion to equipment and pipes can be avoided, the loss caused when organics are dissolved is avoided, the accumulation of alkali-metal ions which are introduced in a large amount is reduced, anaerobic fermentation inhabitation and environmental pollution are avoided, the subsequent utilization of biogas residues is facilitated, and the pretreatment cost for unit biogas yield can be reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

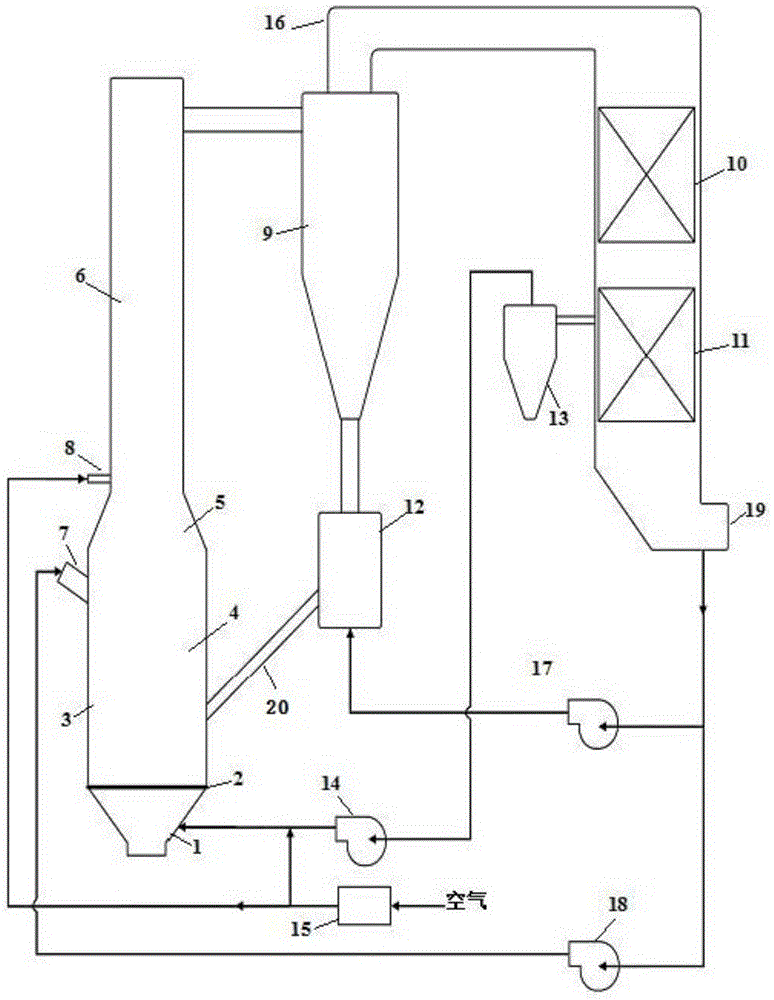

Oxygen-enriched combustion device and method of solid fuel circulating fluidized bed

InactiveCN105698163AReduce carbon contentImprove combustion efficiencyFluidized bed combustionStaged combustionCycloneNitric oxide

The invention discloses an oxygen-enriched combustion device and method of a solid fuel circulating fluidized bed and belongs to the field of clean utilization of solid fuel. The device mainly comprises an air chamber, an air distribution device, a furnace hearth, a high-temperature cyclone separator, a return feeder, a heat exchanger, a coal economizer, a medium-temperature cyclone separator and a secondary air distribution pipe, wherein the furnace hearth is composed of a lower dense-phase bubble or turbulence strongly mixing area with a large sectional area and an upper dilute-phase quick or pneumatic conveyed quasi plug-flow area with a small sectional area. According to the method, combustion of solid fuel is achieved by adopting oxygen-enriched combustion zone control and regulation and multi-stage air distribution in the oxygen-enriched combustion device of the circulating fluidized bed, wherein the primary air is oxygen and recycled exhaust gas mixed air, the secondary air is oxygen, and the recycled exhaust gas includes fuel spreading air and vibrating air. The oxygen-enriched combustion device and method can overcome the defects of the prior art; the CO2 concentration of exhaust gas generated after combustion of solid fuel is made to be above 80%, so that storage or utilization after combustion is facilitated; and meanwhile, emission of nitric oxide and sulfur oxide is reduced, and accordingly the oxygen-enriched combustion device and method have the broad application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Chemical conditioning method of dehydration pretreatment of activated sludge

InactiveCN101693593AWon't breakReduce odorSludge treatment by de-watering/drying/thickeningActivated sludgeTreatment costs

The invention discloses a chemical conditioning method of the dehydration pretreatment of activated sludge, which is characterized by comprising the following steps: transferring the activated sludge with the water ratio of 90-97 percent, which is preliminarily concentrated, into a mixing vessel, adding fully-dissolved ferrous chloride solution while continuously stirring for 3-5 minutes, adding calcined lime while continuously stirring, and then filtering and dehydrating, wherein the dry basis weight ratio of the sludge, the ferrous chloride and the calcined lime is 60: 1.6-3.0: 8-15. The invention has the advantages: 1. generated odor and ammonia gas can be greatly reduced; 2. the treatment cost is lower than that of the treatment methods adopted at present; and 3. as the ferric chloride is taken as the dehydration auxiliary agent for treating the sludge, the organic matter content of the produced sludge is improved by about 10 percent compared with that of the sludge produced by taking ferric salts and calcium oxide as dehydration auxiliary agents.

Owner:连小美

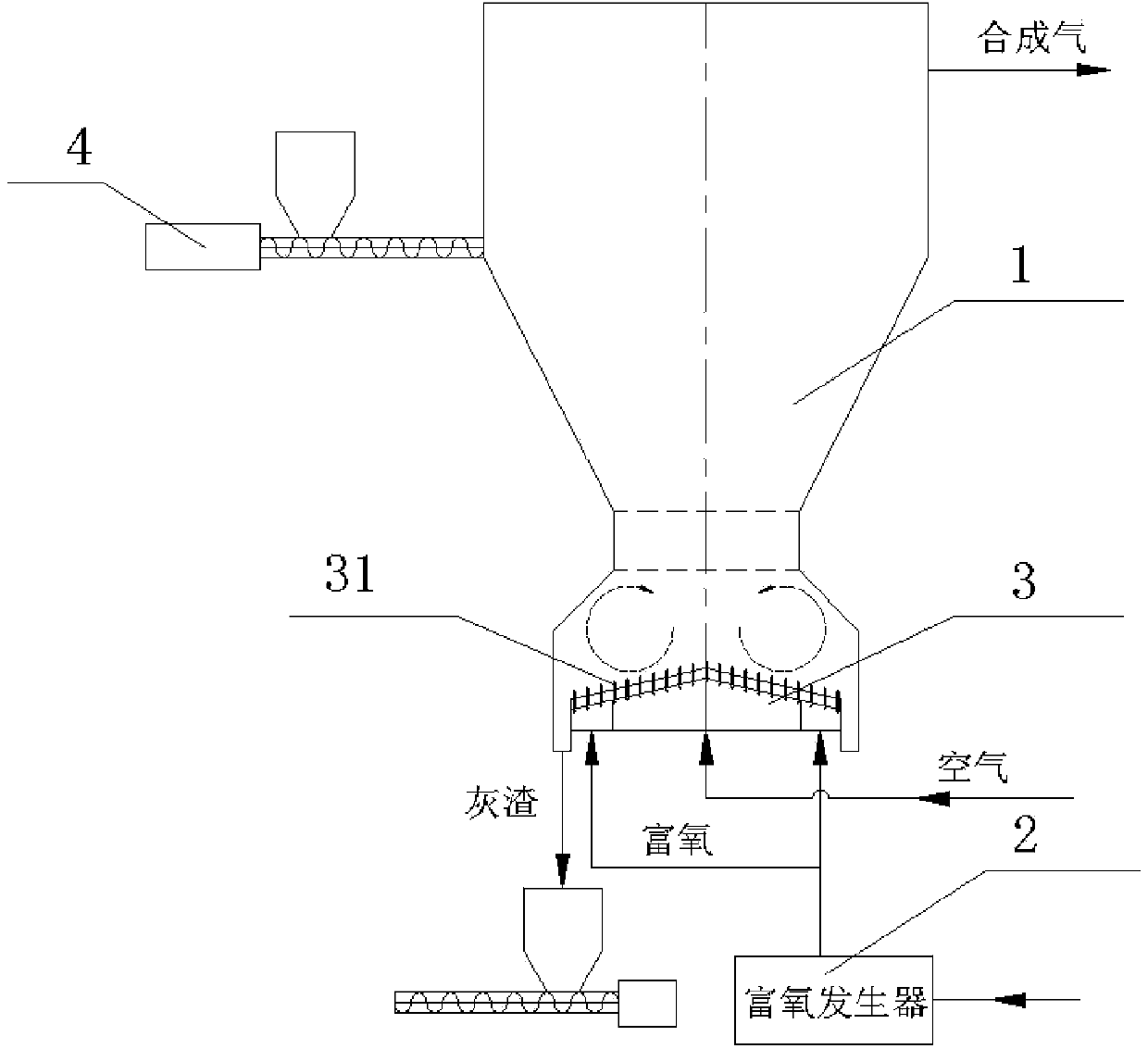

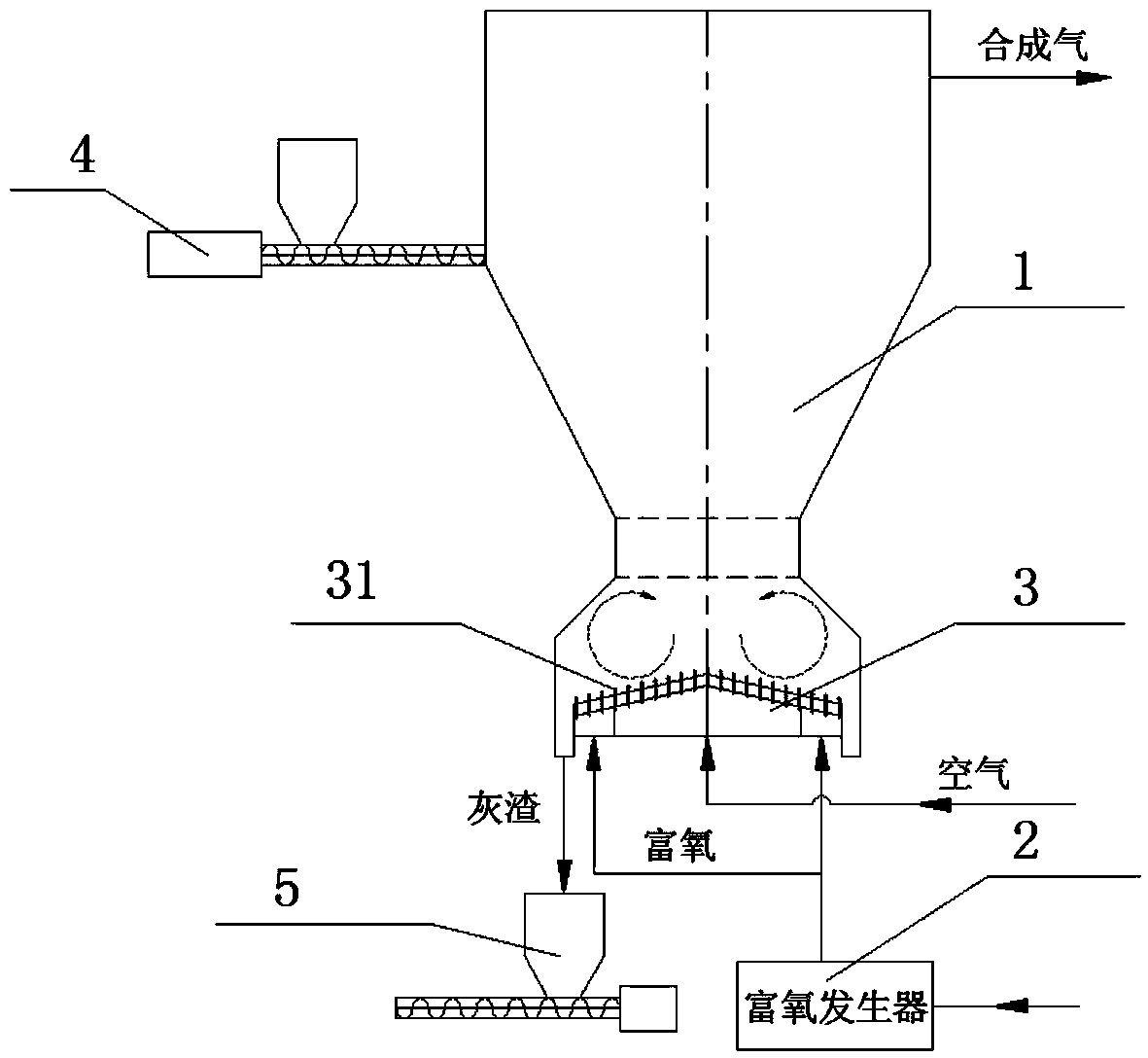

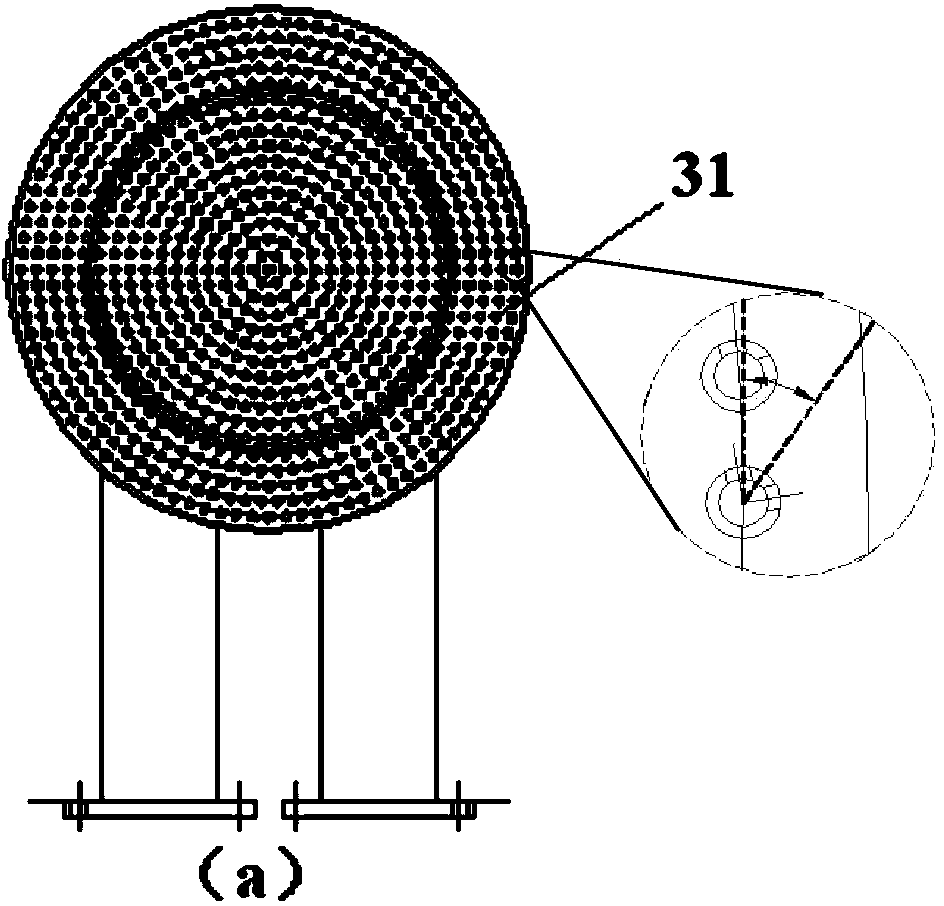

Internal circulating fluidized-bed oxygen-enriched gasification device

ActiveCN103471104AHigh calorific valueGood use effectIndirect carbon-dioxide mitigationIncinerator apparatusFluidized bedSlag

The invention provides an internal circulating fluidized-bed oxygen-enriched gasification device. The device comprises a gasifier body, a rich oxygen generation device, a multi-air-chamber air distribution device, a feeding device and a deslagging device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; the dense-phase region is connected with the dilute-phase region through a throat region; the multi-air-chamber air distribution device which is provided with directional wind caps is arranged at the bottom of the dense-phase region and is connected with the rich oxygen generation device; an outlet of the feeding device is arranged at the junction of the dense-phase section and the dilute-phase section; a slag outlet is arranged at a gap of the multi-air-chamber air distribution device and the gasifier body at the bottom of the dense-phase section; the deslagging device is arranged below the slag outlet. The system can efficiently realize pyrolysis and gasification of waste solid organic matters such as garbage and biomass, and has the advantages of high gasification speed, high conversion efficiency, less deslagging carbon residue, easiness in control over pollutants and the like.

Owner:XI AN JIAOTONG UNIV

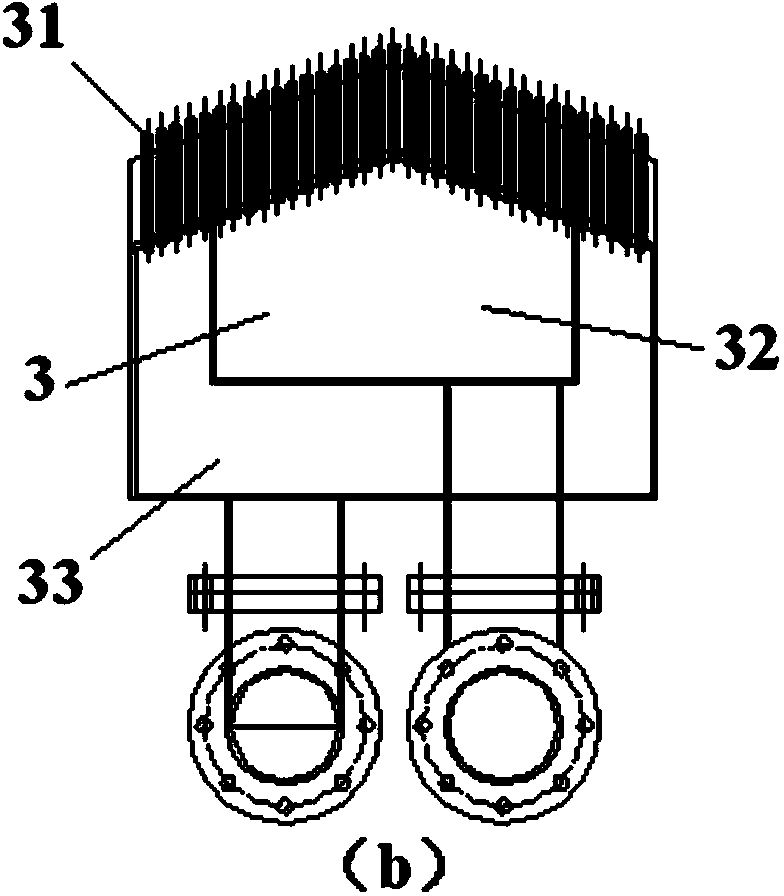

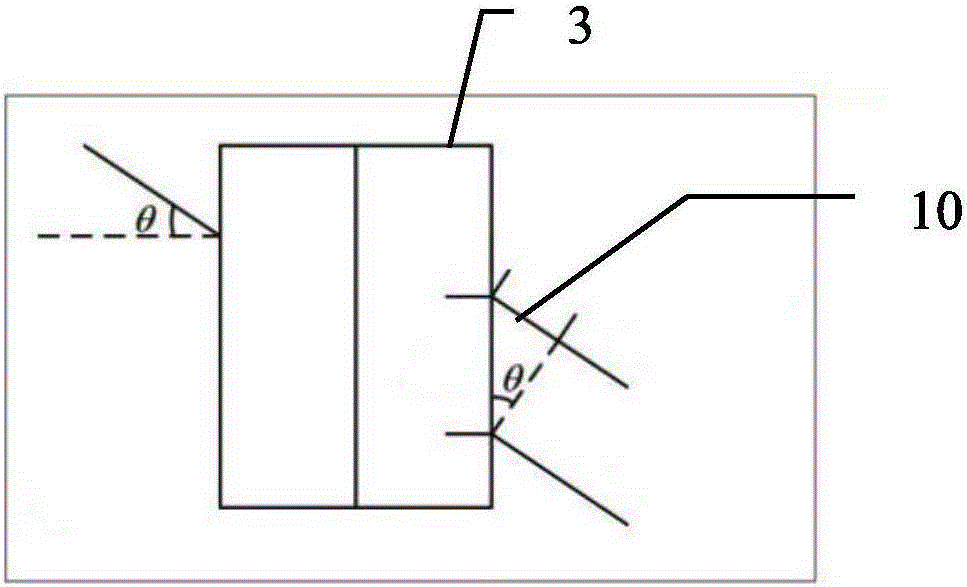

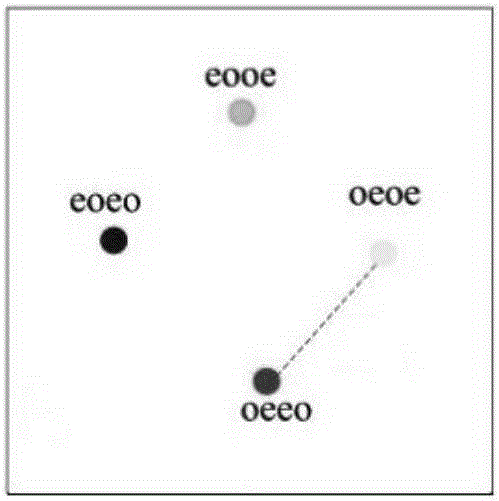

Bi-mode full polarization imaging polarization measurement method

ActiveCN106197670AEliminate crosstalkImprove spatial resolutionLight polarisation measurementOptoelectronicsPolarizer

The present invention relates to the field of polarization imaging, and more particularly to a bi-mode full polarization imaging measurement method, comprising the use of a snapshot mode or a time division mode to conduct full polarization imaging measurement to a target. The method is technically performed as follows: an incident light passes sequentially in its transmission direction the coaxially arranged elements of a filter, a first modified Sava-type polarizer, a half-wave plate, a second modified Sava-type polarizer and a polarizer, and is then converted into four parallel beams of linearly polarized light, followed by a process of imaging for a first interference pattern of the incident light which forms S0 ~ 3 images of the incident light after demodulation. Through the 90-degree horizontal rotation of the polarizer along the plane where the polarizer is located and another process of imaging, a second interference pattern of the incident light can be available. The adding of the first interference pattern and the second interference pattern forms a full resolution S0 image that eliminates crosstalk targets. The images S1-S3 are obtained through the demodulation of the differential image of the first interference pattern and the second interference pattern. The polarization direction angle of the polarizer is 22.5 degrees. The present invention provides a bi-mode polarization measurement method for selecting different modes of full polarization imaging for different requirements of different targets.

Owner:GUANGXI TEACHERS EDUCATION UNIV

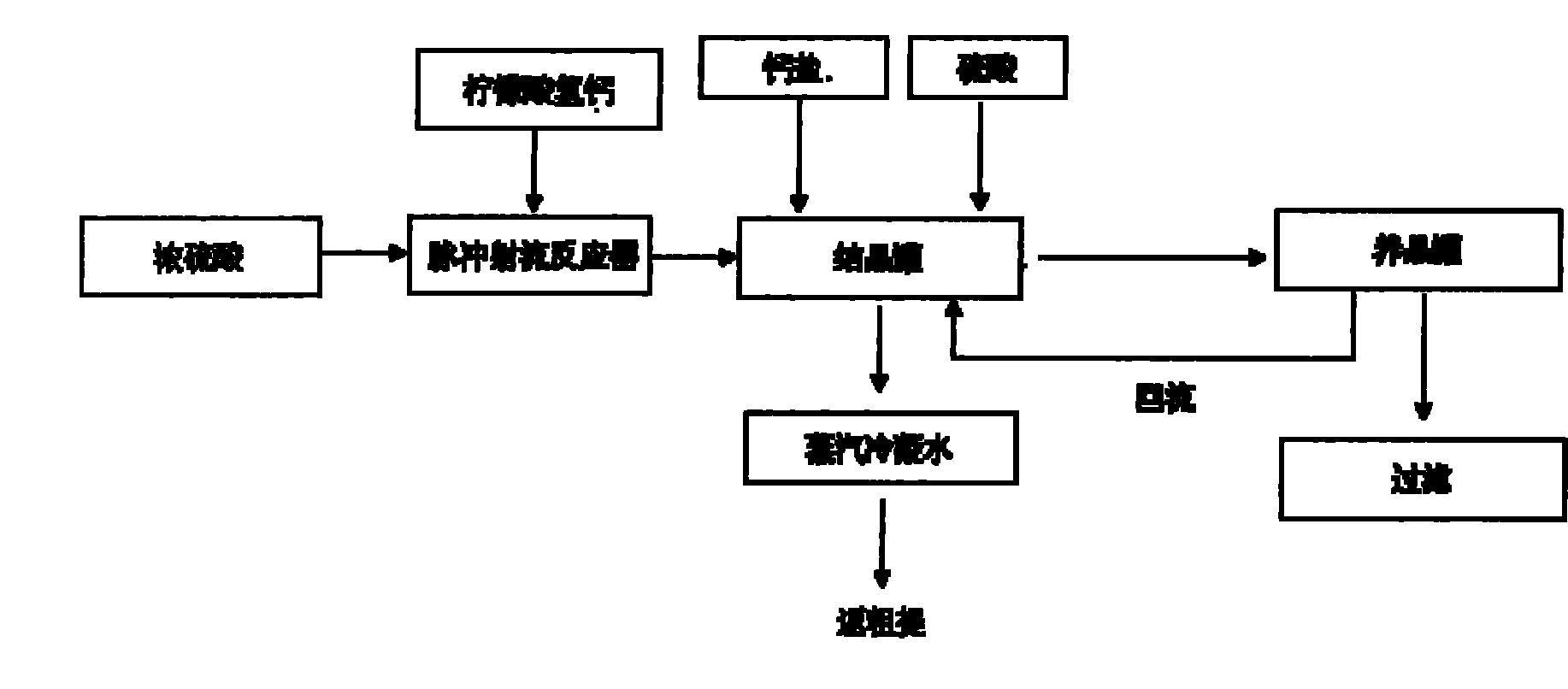

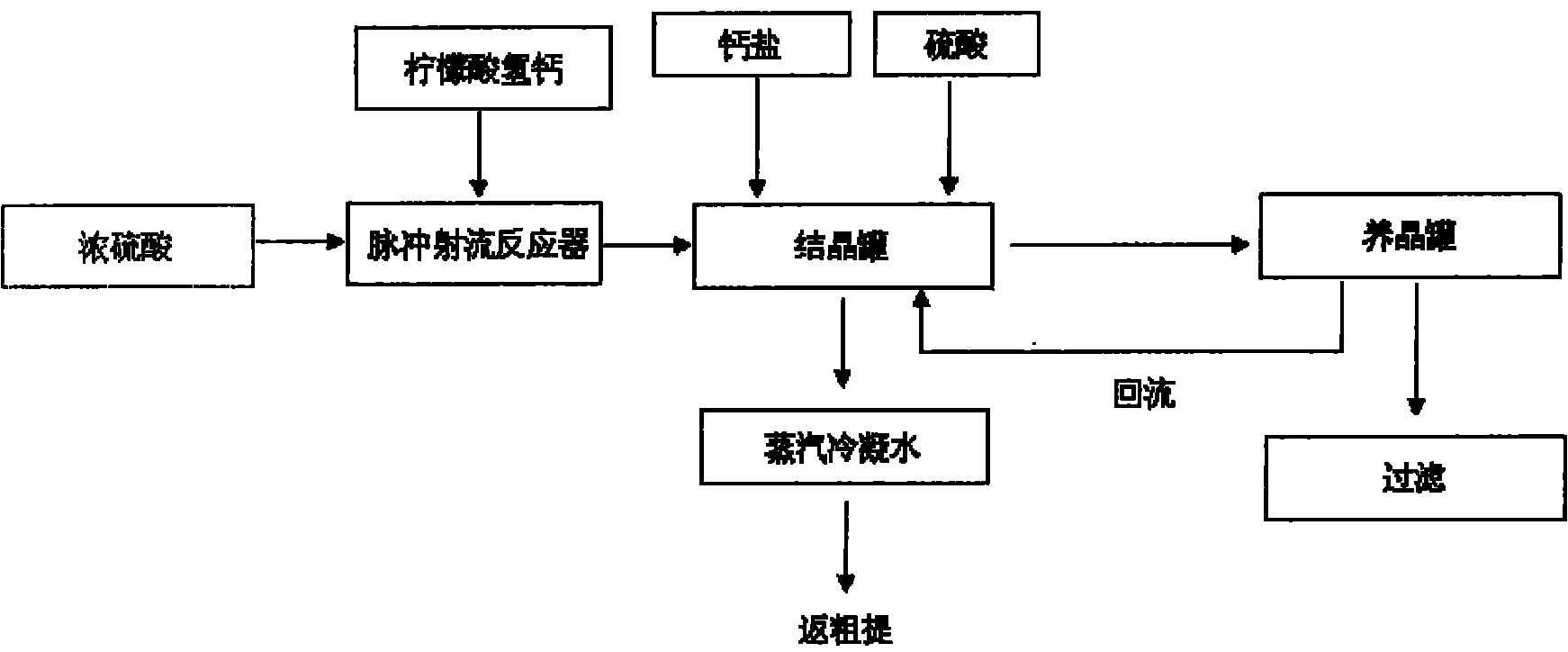

Continuous acidolysis process for calcium hydrogen citrate

ActiveCN102060691AHigh degree of automationContinuous stable operationPreparation from carboxylic acid saltsCarboxylic compound separation/purificationMagmaCITRATE ESTER

The invention relates to a continuous acidolysis process for calcium hydrogen citrate. The process mainly the following steps of: 1, respectively feeding calcium hydrogen citrate and concentrated sulfuric acid into a pulse jet reactor through pipelines for finishing an instantaneous acidolysis reaction in the reactor; 2, performing fine adjustment on the pH value of reaction solution in a crystallizer and finishing a crystallization process; and 3, finishing coarse-fine granule grading of the magma liquid in a maturing tank, and making the magma liquid enter a filtering process to finish solid-liquid separation. The process has the advantages of thorough reagent reaction, high automation degree, high acidity of acidolysis liquid, good crystal form of byproducts such as calcium sulphate, controllable granularity and the like.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

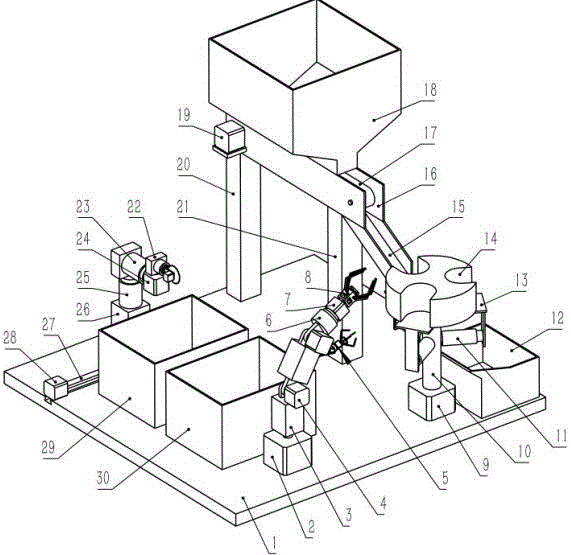

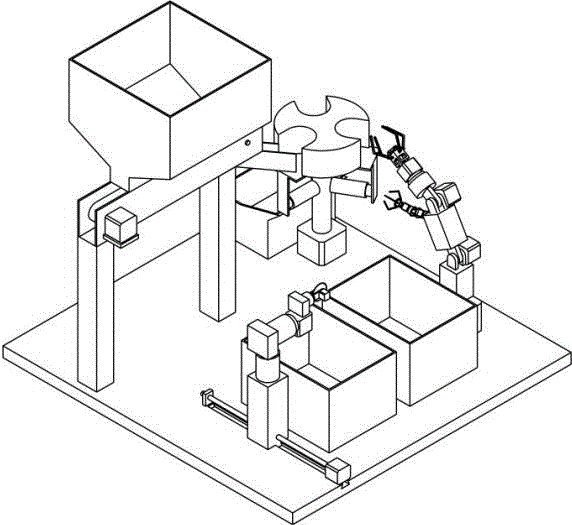

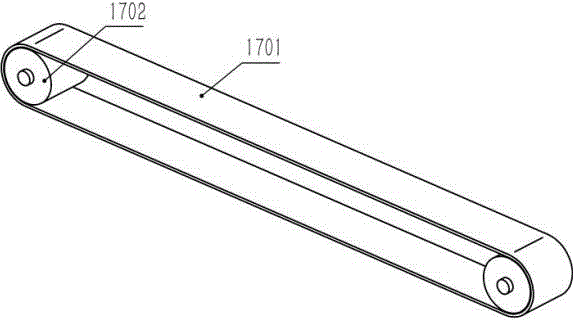

Intelligent screening, pit removing and peach cutting robot

InactiveCN107520888AIntegrity guaranteedFor subsequent useFruit stoningSortingControl theoryStepper motor

The invention discloses an intelligent screening, pit removing and peach cutting robot. The robot comprises a baseplate, a first stepper motor, two connecting columns, two first servo motors, a mechanical arm, a first extension cylinder, a second servo motor, a large mechanical jaw, a second stepper motor, a first support column and the like. The robot has the following advantages: fruits are screened through an unique rotating table and a fruit quality detector arranged thereon, so that the product quality is guaranteed, and a cutter is protected; peaches are grabbed through large and small mechanical jaws; one halves of the peaches are firstly cut off by using the cutter; and then, the other halves are cut off, so that the pit completeness can be kept, and subsequent utilization of pits is achieved.

Owner:CHIC AHCOF ANHUI FOODS

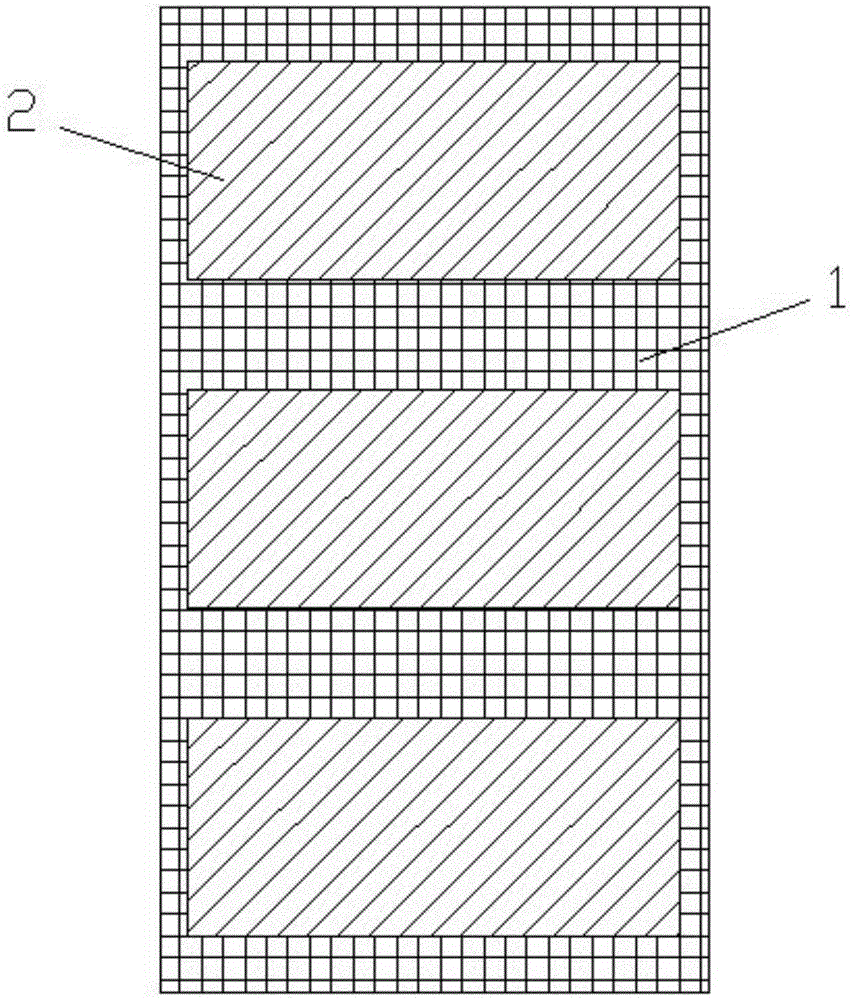

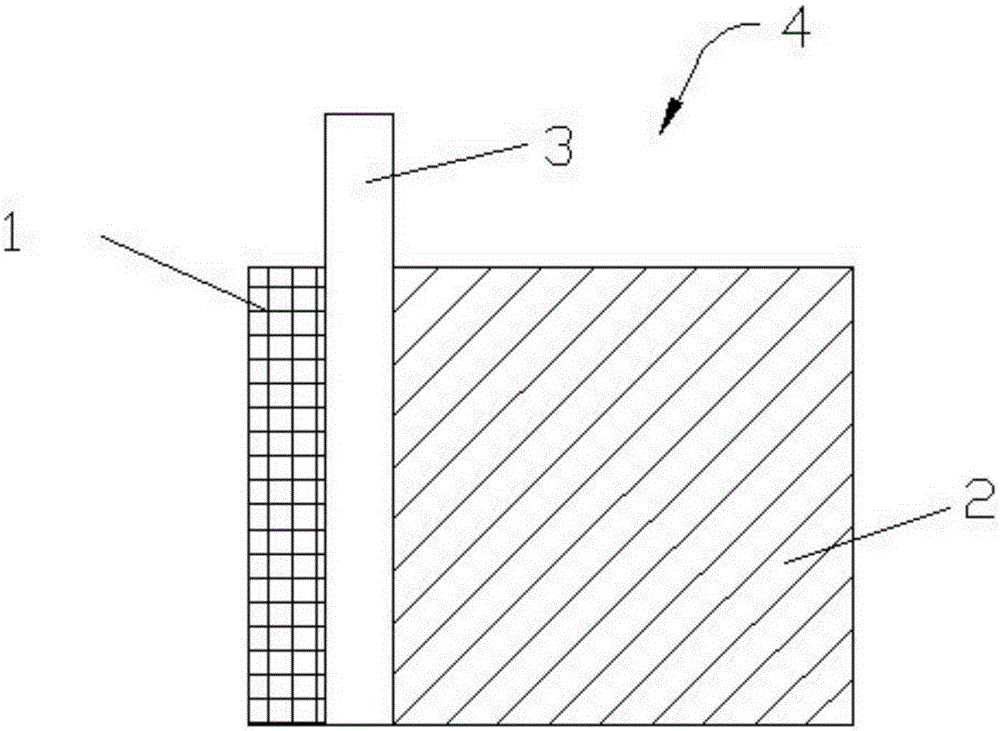

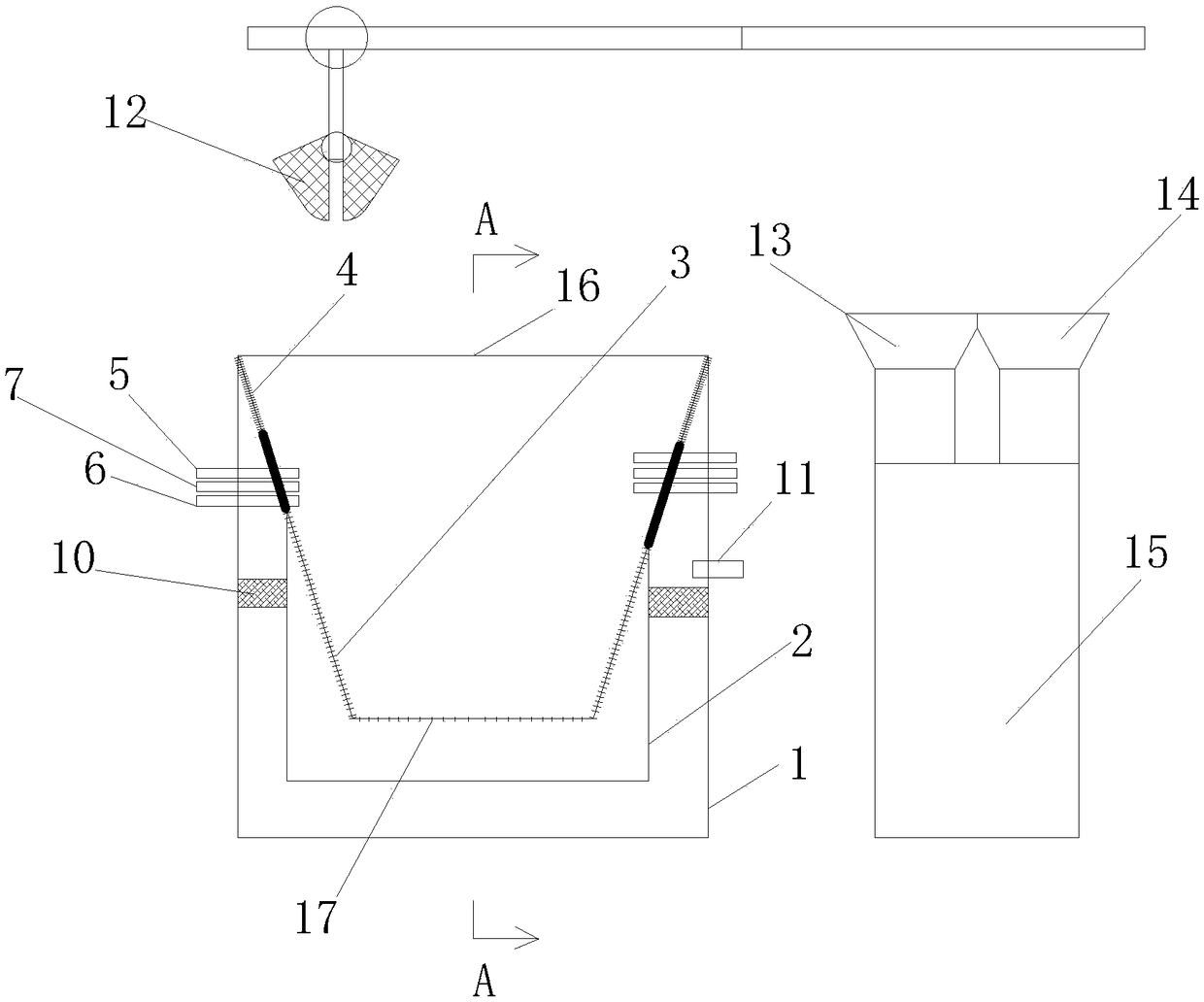

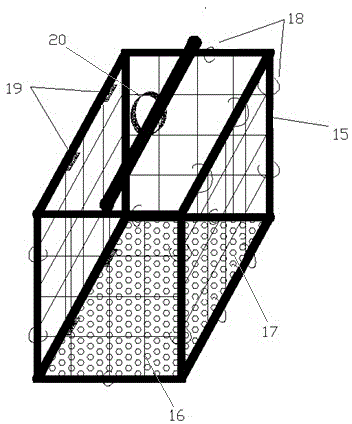

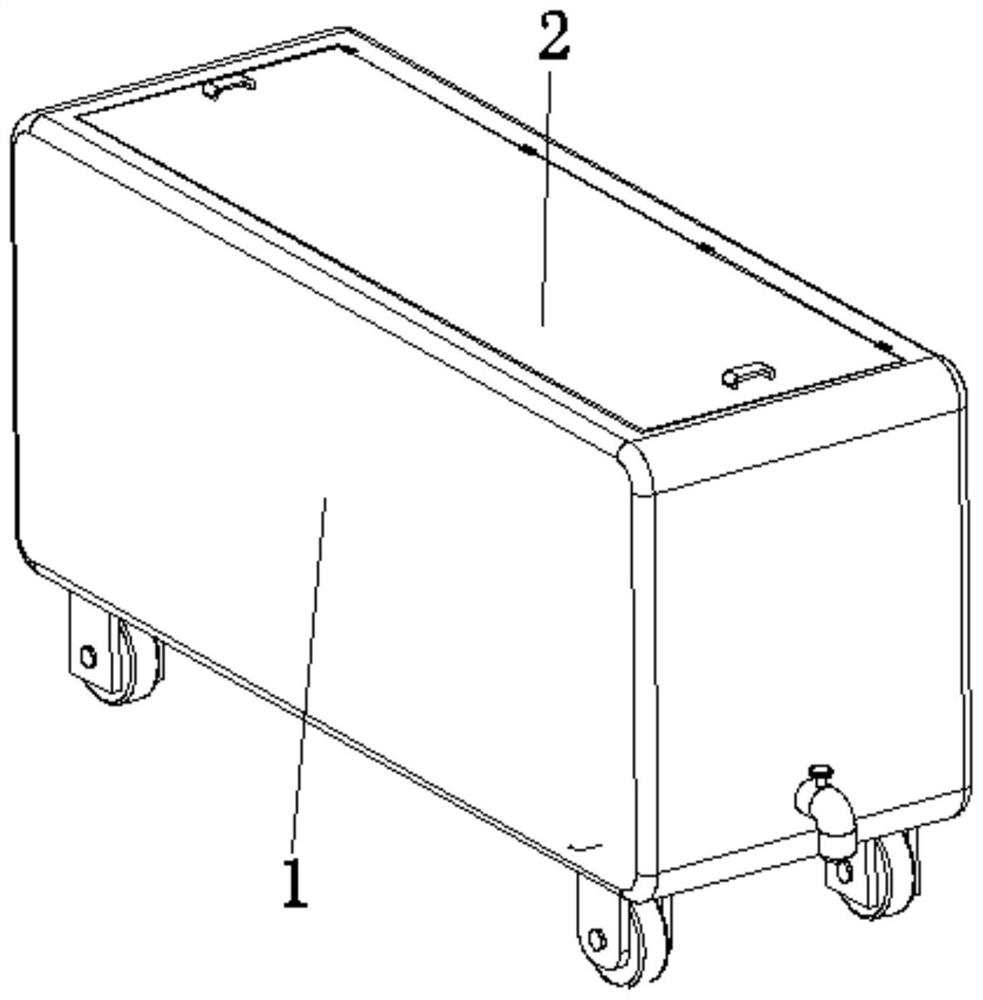

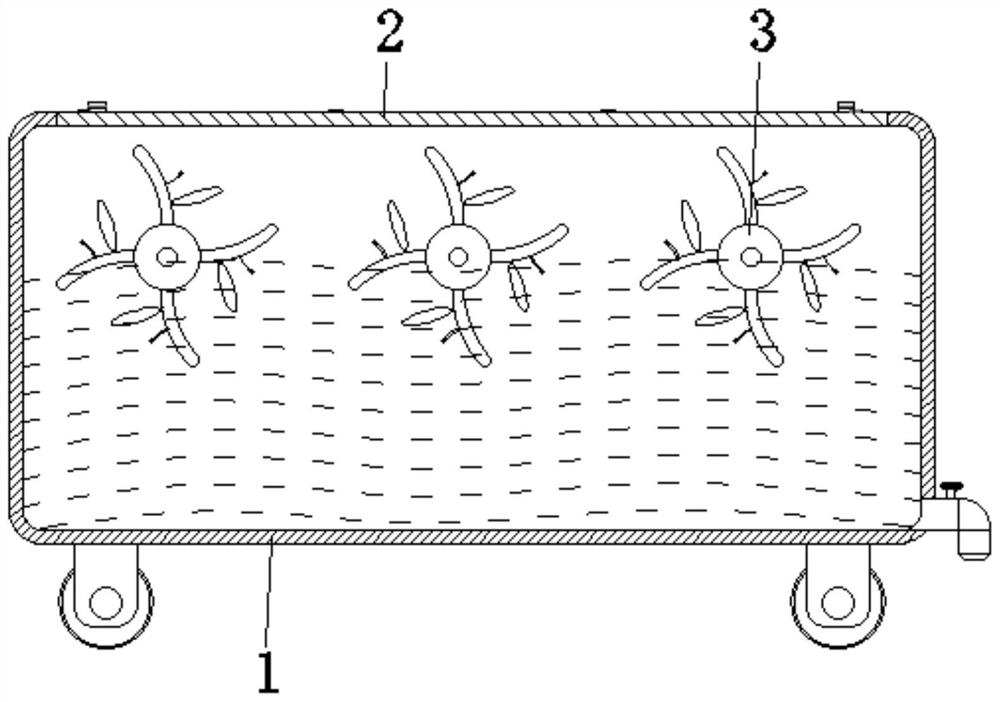

Separating and cleaning device for film-type plastic and fabrics

ActiveCN108080336AEfficient removalEfficient separationCleaning using liquidsWet separationVolumetric Mass DensityEngineering

The invention discloses a separating and cleaning device for film-type plastic and fabrics. The separating and cleaning device comprises a cuboid outer pool (1) which is internally provided with a sediment collecting pool (2), and the sediment collecting pool (2) is internally provided with a main separating pool (3). The main separating pool (3) is of a flaring structure, wherein the lower portion of the side wall and the bottom wall of the structure are provided with screen holes (17). The upper edge of the sediment collecting pool (2) is connected with the middle of the main separating pool(3), and the main separating pool (3) is connected with the outer pool (1) through a filter screen (4) on the upper portion of the side wall of the main separating pool (3). According to the separating and cleaning device, through a triple nested pool body structure, the fabrics and the plastic can be effectively separated and recovered through the principle that the hydrophilicity and density ofthe fabrics and the plastic are different, and floating oil contamination, sedimentary sediment and the like mixed in the film-type plastic and the fabrics can further be effectively removed to achieve the cleaning function.

Owner:ZHEJIANG MEDICAL COLLEGE

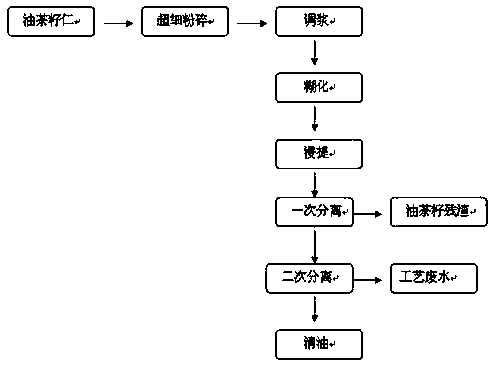

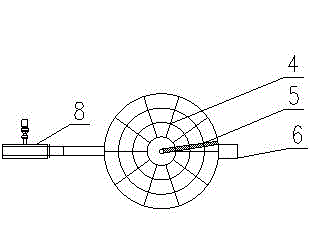

Method for extracting camellia oleosa seed oil by weak acid aqueous solution

ActiveCN103351945ASimple production processEasy to operateFatty-oils/fats productionCamellia oleiferaHigh energy

The invention relates to an edible oil production and processing technology, in particular to a method for extracting camellia oleosa seed oil by weak acid aqueous solution. The technical scheme adopted by the invention is that camellia oleosa seeds are taken as raw materials, and are added in the weak acid aqueous solution for slurry mixing after being subjected to superfine grinding, the constant temperature mixing and extracting are carried out on slurry after the slurry is gelatinized for a period of time, and the obtained extract liquid is subjected to two-step centrifugal separation to obtain the camellia oleosa seed oil. The camellia oleosa seed oil is clear, transparent, light yellow, and even golden yellow, does not contain benzo(a)pyrene, has no residual organic solvent, and can reach the national-level camellia oil edible safety standard without refining or after being subjected to simple refining. According to method, the production technology is simple, biological enzyme is not used during the production process, the processing temperature is low, the production cost of the camellia oleosa seed oil is lowered, so that the method is suitable for industrial large-scale production; meanwhile, the problems of low camellia oleosa seed oil yield, high energy consumption, existence of residual organic solvent, serious active nutritional ingredient loss and the like in a conventional production method are solved.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

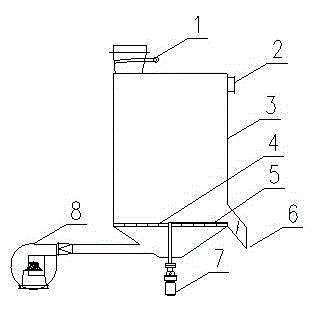

Ash cooling device for garbage burning

The invention discloses an ash cooling device for garbage burning, which comprises parts for controlling ash entering, cooling and ash discharging; according to the ash cooling device, the cooling of ash is realized, and the heat energy of hot ash can be used for heating air so as to dry and burn garbage; and by the adoption of the device, the dry-process cooling and the discharging of ash during garbage burning are realized, harmlessness of ash and reasonable utilization of heat energy during garbage burning are realized, a variety of disadvantages caused by water-cooled deslagging are avoided, and the device is an energy-saving, safe and environment-friendly ash cooling device for garbage burning in the field of garbage treatment.

Owner:NANJING KISEN INT ENG

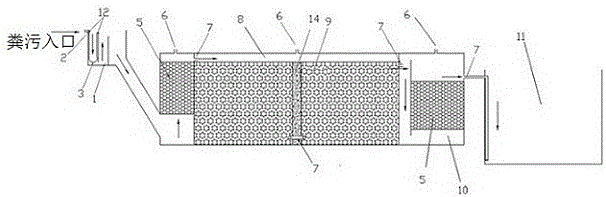

Apparatus for producing biogas by utilizing rural multivariate organic waste

InactiveCN103602580ASimple processEasy to operateGas production bioreactorsWaste based fuelWaste processingOutput compare

An apparatus for producing biogas by utilizing rural multivariate organic waste comprises a pretreatment pool, a wastewater anaerobic fermentation pool, a straw bed reactor, a biogas slurry deep fermentation pool and a biogas slurry storage pool which are in series connection, wherein the tops of the wastewater anaerobic fermentation pool, the straw bed reactor and the biogas slurry deep fermentation pool are provided with gas outlets, the wastewater anaerobic fermentation pool and the biogas slurry deep fermentation pool employs an AF technology, the pretreatment pool is inside provided with a collection mesh bag, and straw cases are filled with straw. The advantages comprise that: the apparatus has the characteristics of being wide in fermentation raw material adaptation scope, little in one-time investment, simple and convenient in operation, low in operation, management and protection costs, good and stable in biogas generating effect, and the like; the apparatus has substantially improved volume biogas output compared with conventional methods, the fermentation raw materials can be directly charged without additional pretreatment, and the apparatus is accord with the demand on rural multivariate waste processing and the present situation of shortage of rural labor force, and has extremely good popularization utilization value.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Magnetic separating device for rice processing

InactiveCN106513167AQuality assuranceImprove adsorption capacityMagnetic separationGrain millingMetal adsorptionMagnetic separator

The invention discloses a magnetic separating device for rice processing. The magnetic separating device comprises a machine body; a feeding funnel is arranged in the middle of the top end of the machine body; a clearing door is arranged at the lower end at the left side of the machine body; a tapered discharge hopper is arranged at the bottom end of the machine body; a stirring magnetic separator is arranged at the upper end inside the machine body; a telescopic baffle plate mechanism is arranged at the middle lower end inside the machine body; a fixed blocking part is arranged at the middle lower end at the left side inside the machine body; and a metal adsorption net is arranged at the lower end inside the machine body. The magnetic separating device for rice processing solves the problems that magnetic separating equipment in the prior art is generally not good in magnetic separating effect, is low in working efficiency and is inconvenient to use; a stirring magnetic-separating design is adopted to carry out magnetic separating processing while stirring; and the metal adsorption net is arranged, so that dual adsorption effects are achieved, rice can be quickly and comprehensively subjected to magnetic separating processing, the magnetic separating effect is better, and magnetic separating efficiency is extremely high.

Owner:HARBIN MIMI RICE IND TECH CO LTD

Plastic cleaning equipment

InactiveCN112808692AAdaptableReduce limitationsPlastic recyclingCleaning using toolsStructural engineeringBrush device

The invention discloses plastic cleaning equipment comprising a cleaning box, a top cover and cleaning devices, the top cover is rotationally connected to the center of the top of the cleaning box, the cleaning devices are rotationally connected to the positions, close to the top cover, between the two corresponding sides of the inner wall of the cleaning box, and the cleaning devices are evenly distributed in the cleaning box. A roller is fixed to the center of the surface of a driving rotating shaft and located in the cleaning box, cleaning brushes are fixed to the surface of the roller and evenly distributed on the surface of the roller, and a brushing device is fixed to the surface of the roller. According to the plastic cleaning equipment, the purposes of pressing down and cleaning are achieved, flaky floating plastic chips are pressed down to make full contact with water, rise through the buoyancy of the flaky floating plastic chips and are combined with the cleaning equipment for rapid cleaning, smooth completion of cleaning work is facilitated, adaptability is high, limitation is reduced, and the cleaning efficiency and the use performance are improved.

Owner:见才福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com