Patents

Literature

48results about How to "Efficient threshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

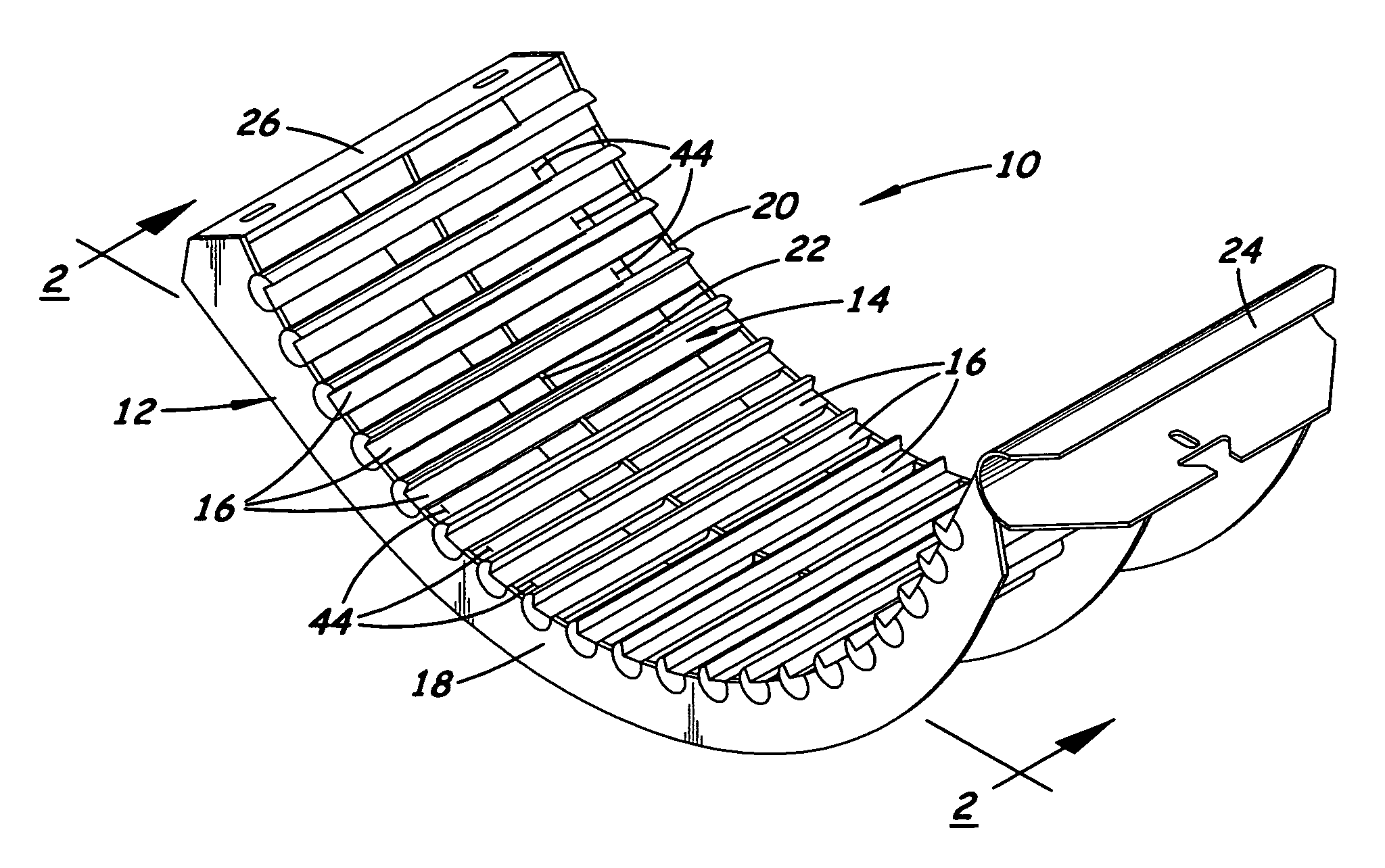

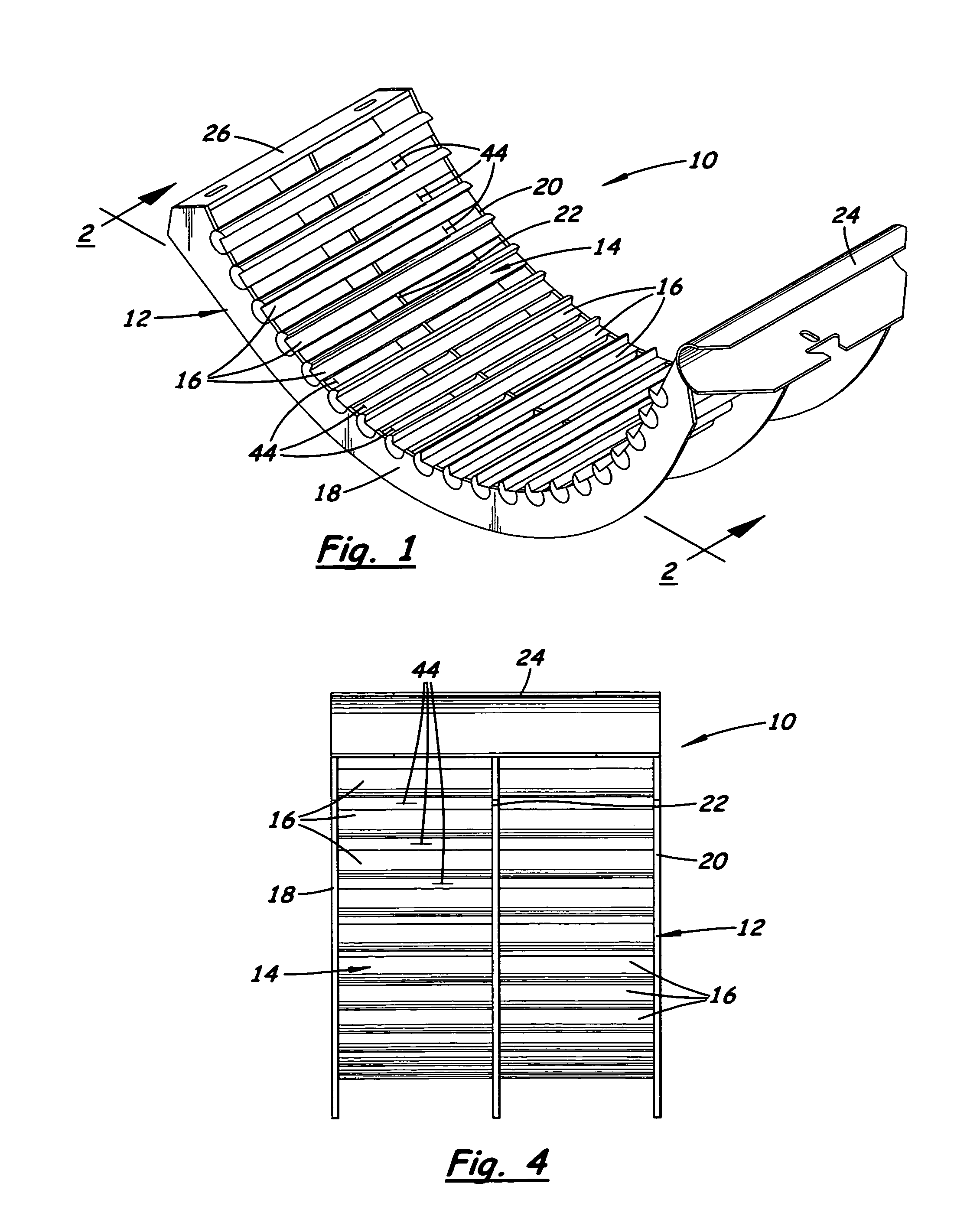

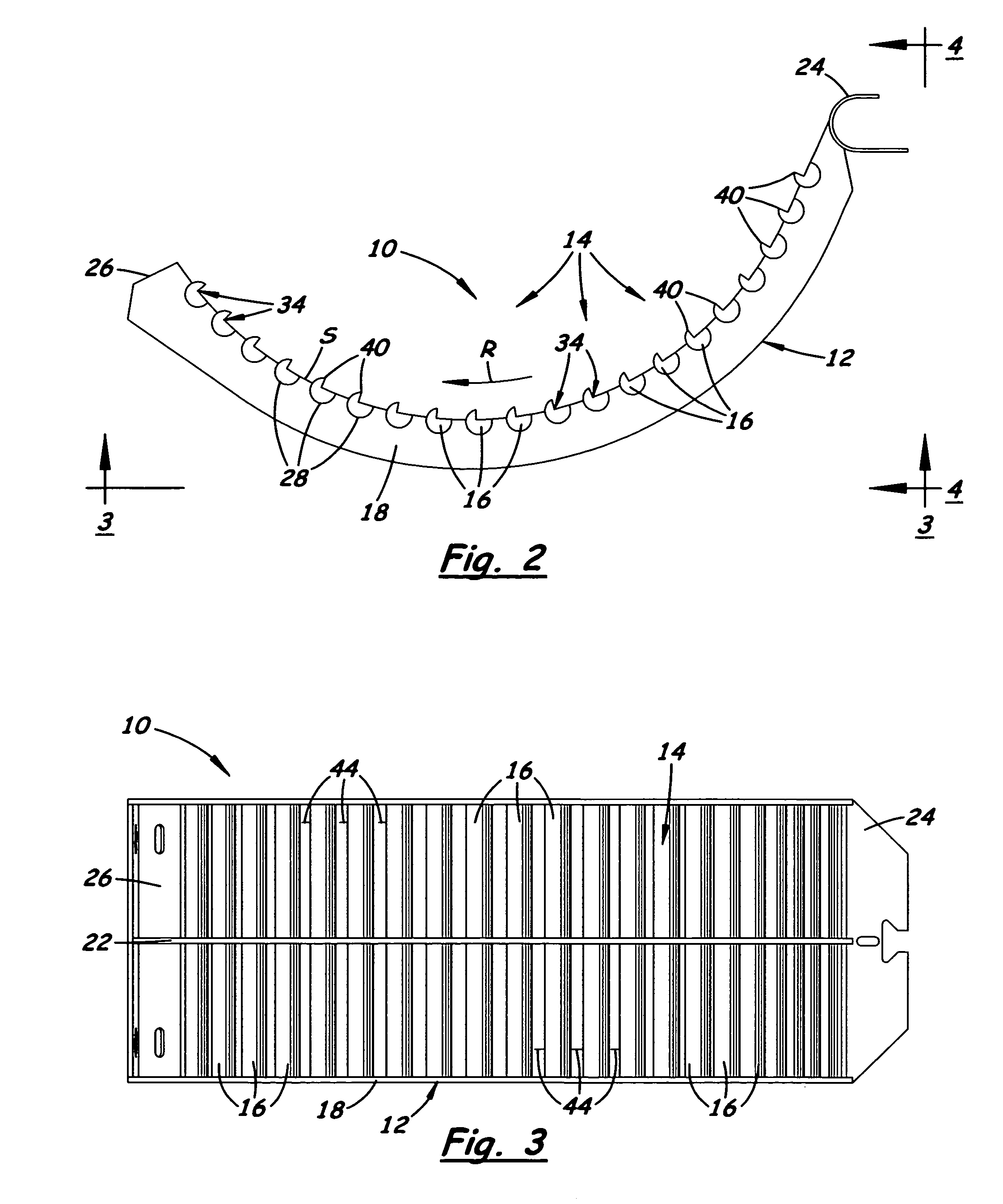

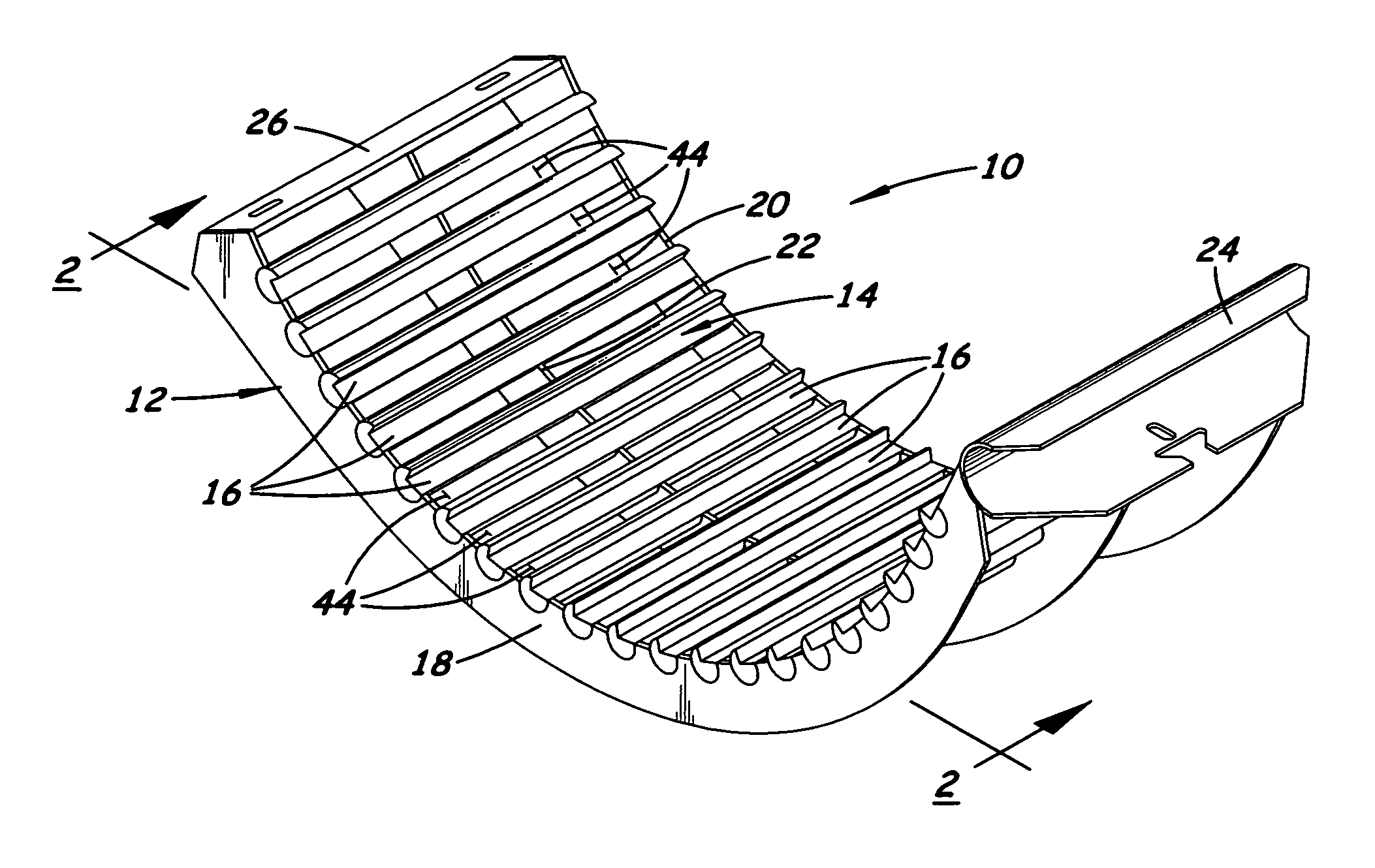

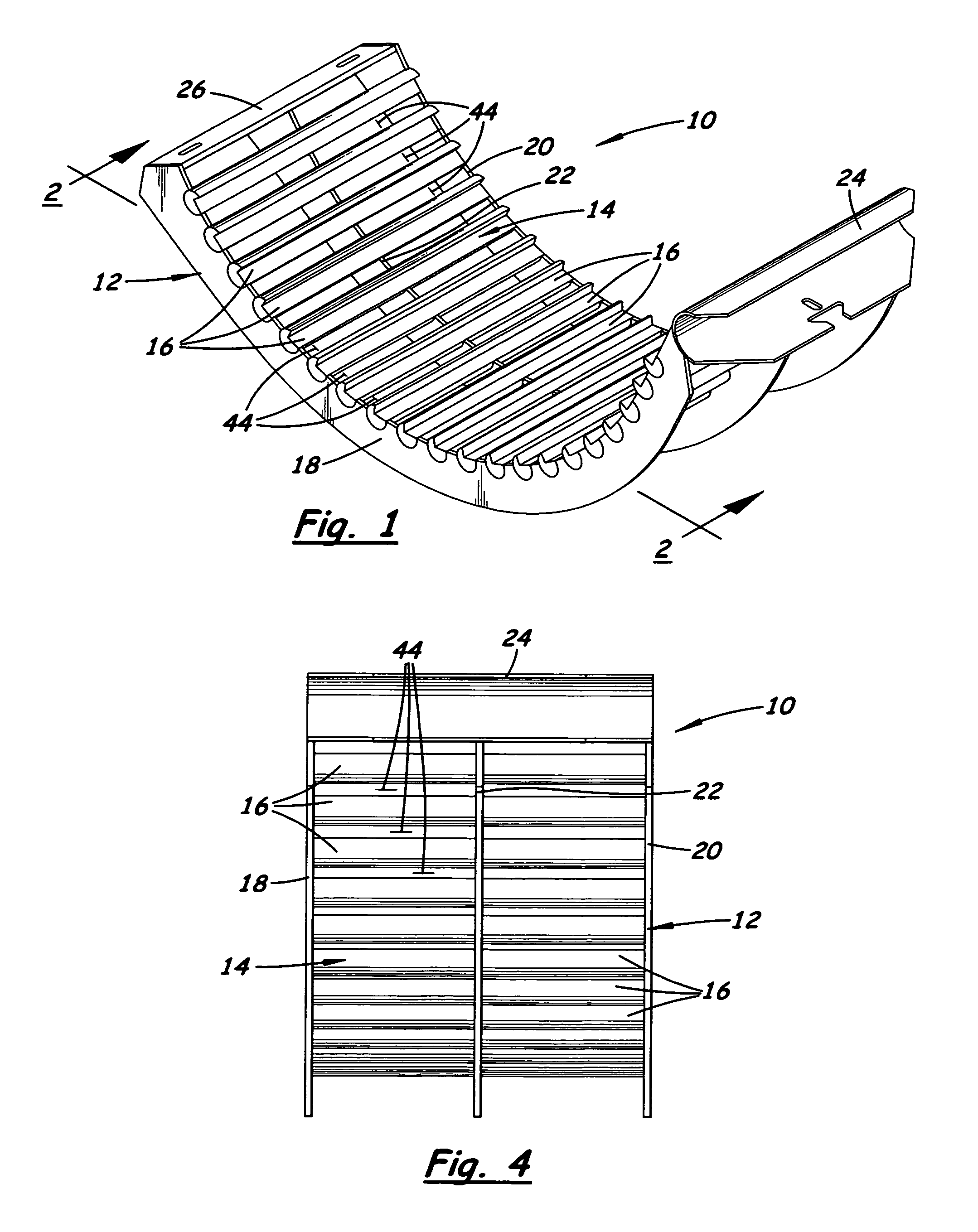

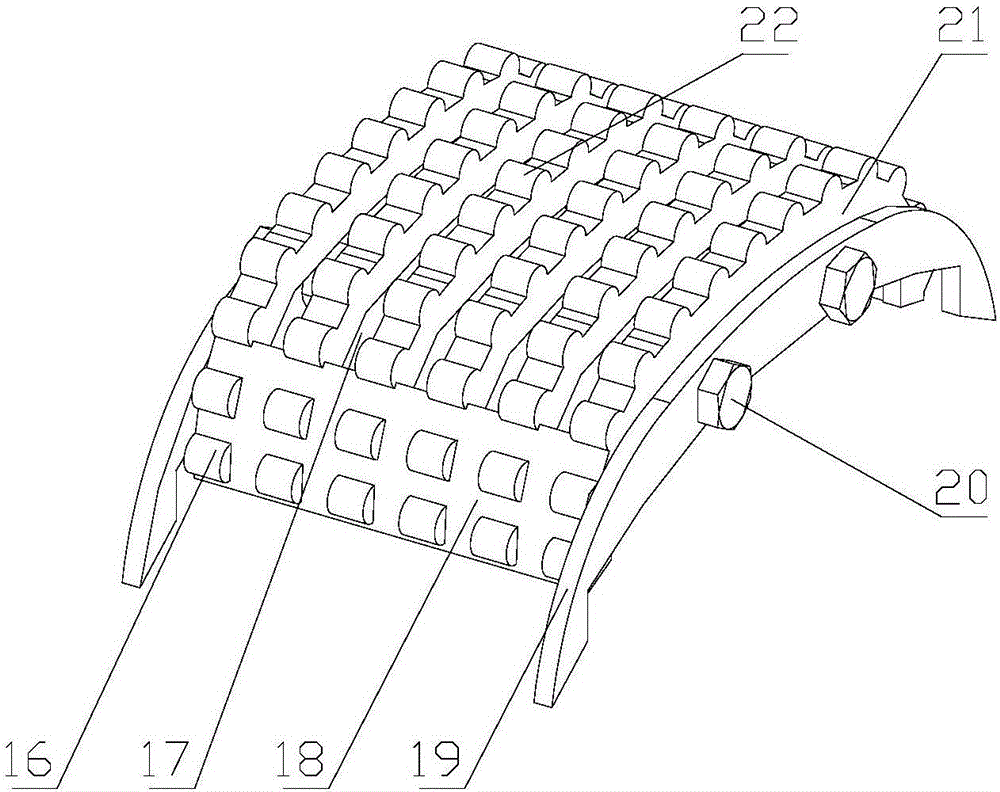

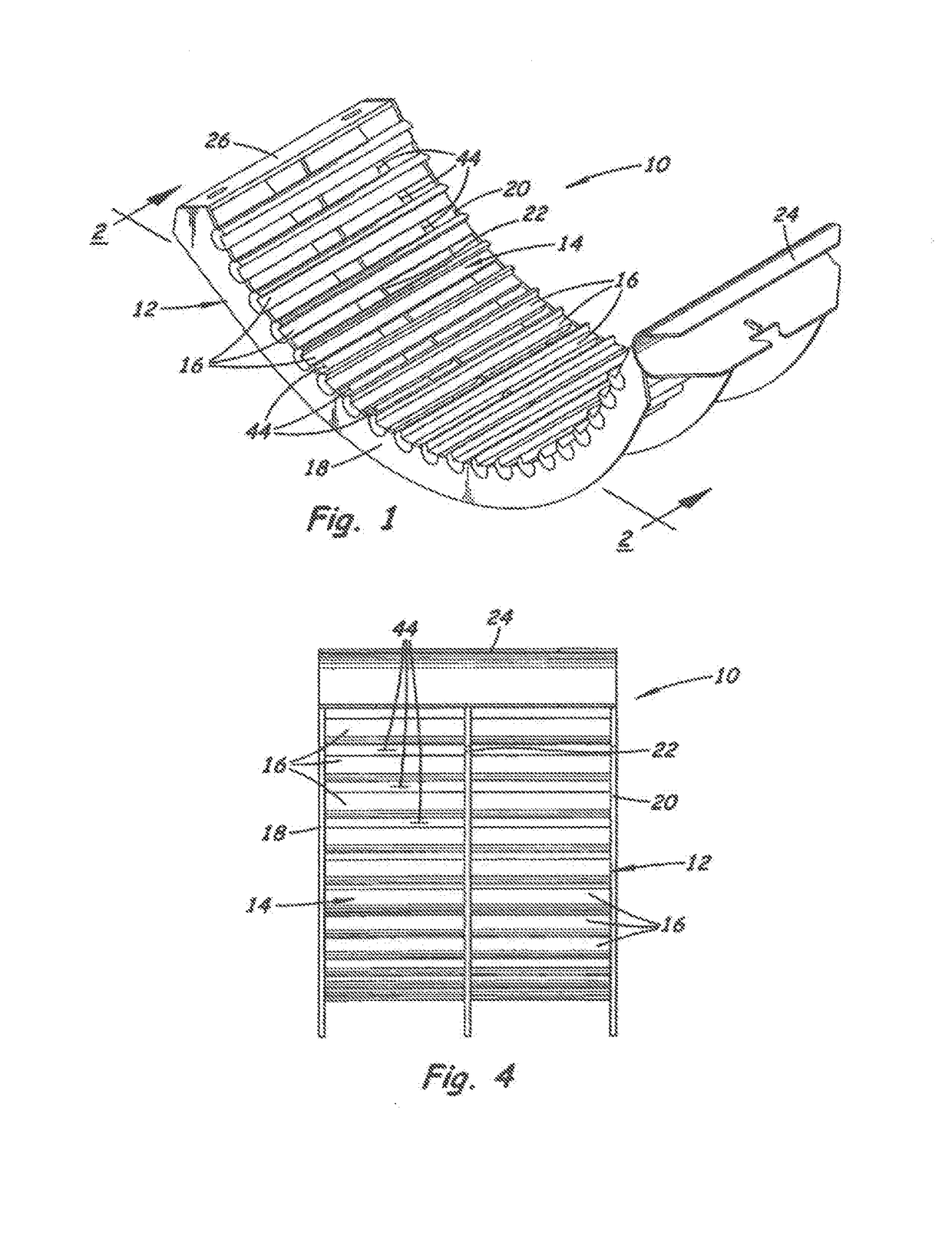

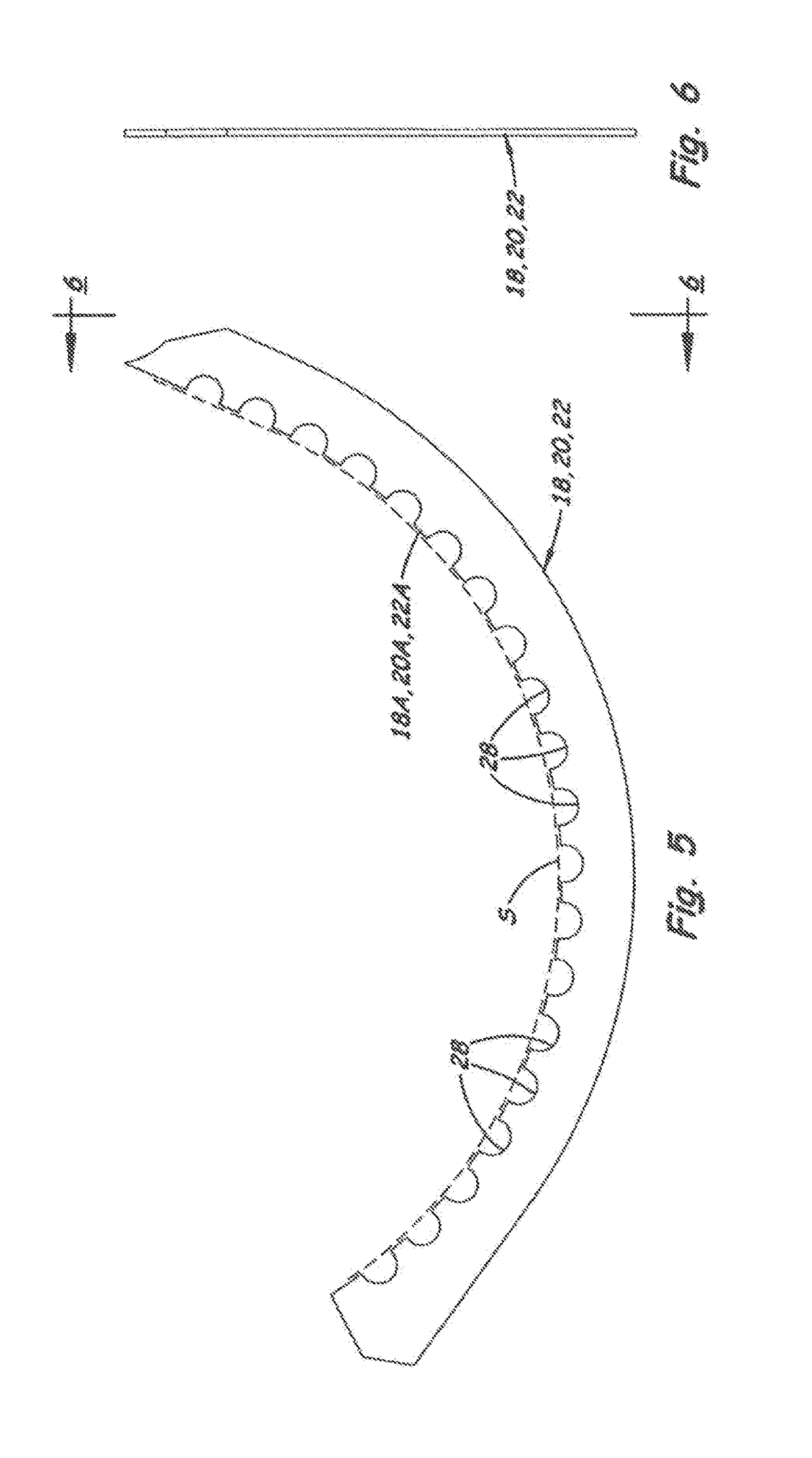

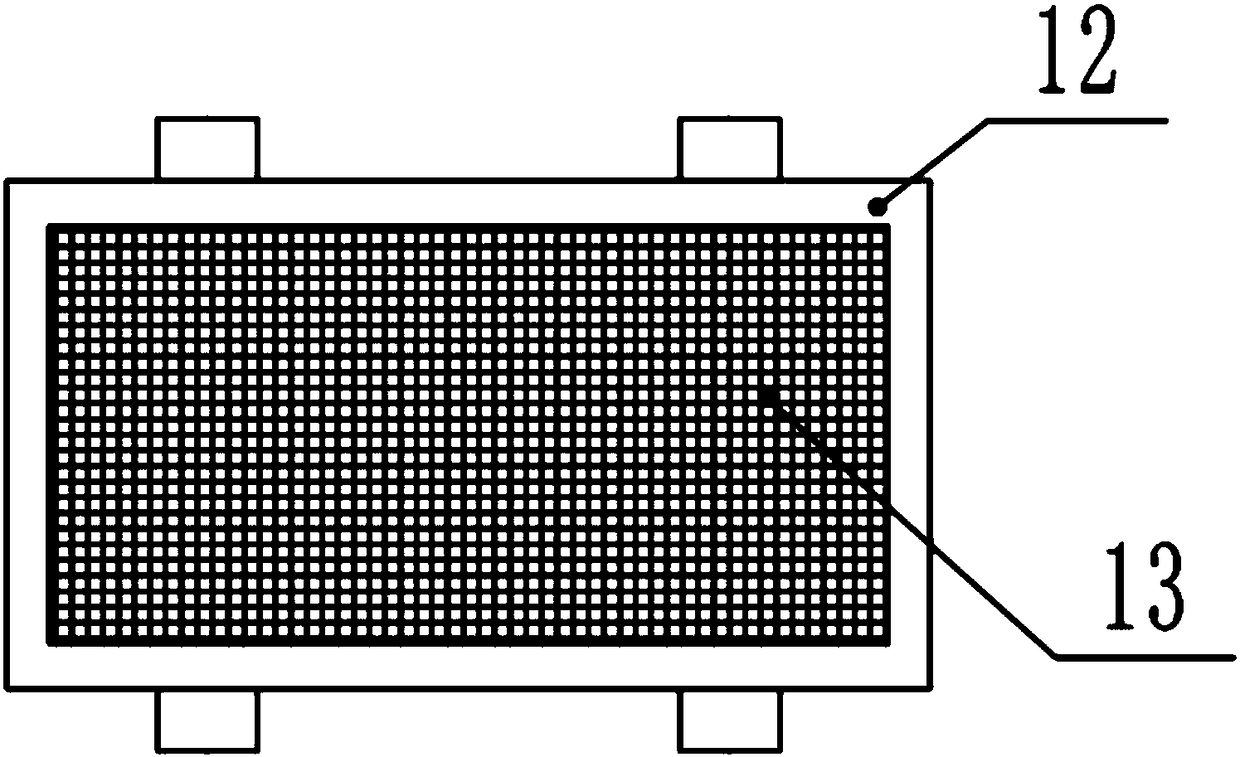

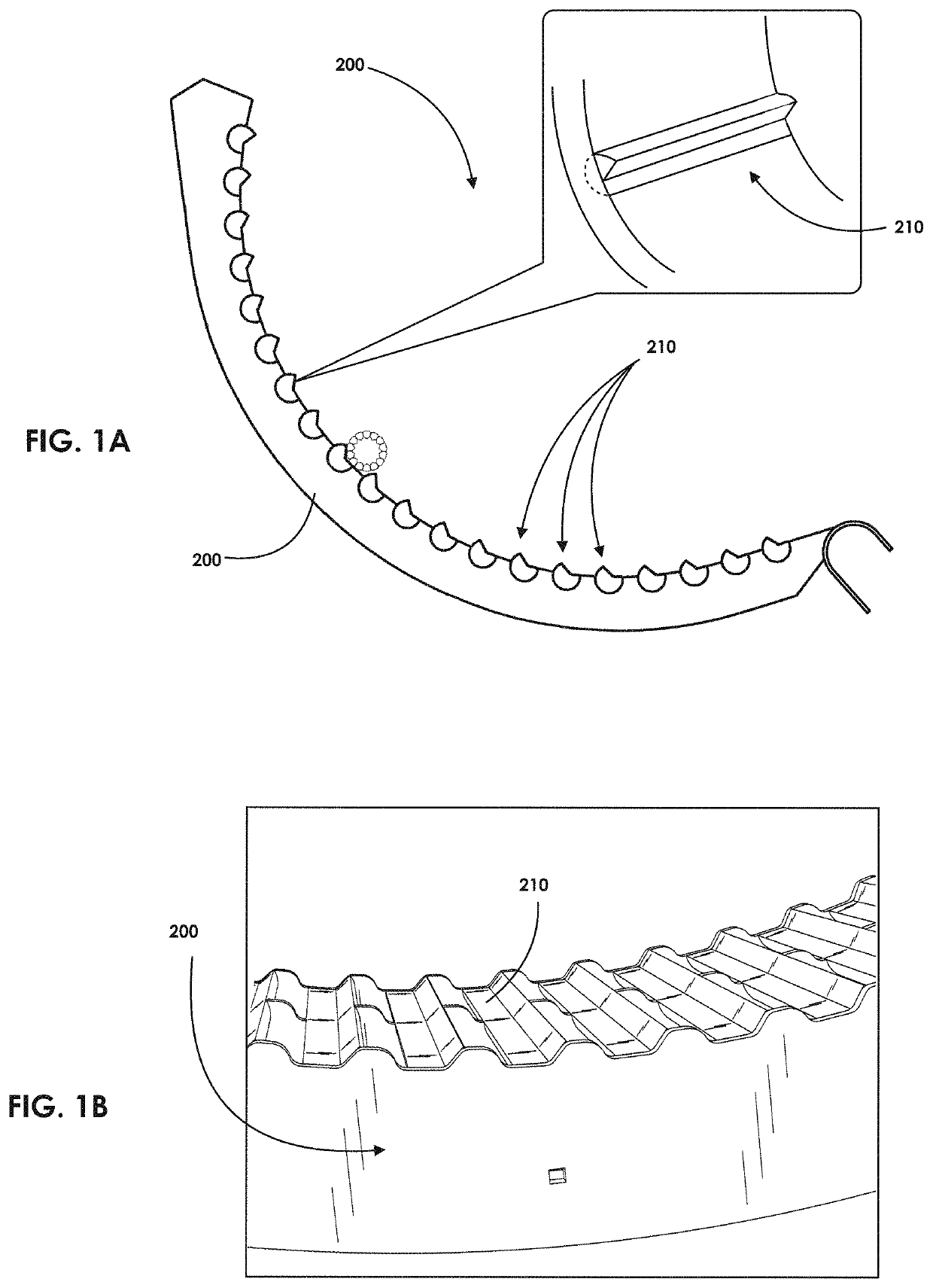

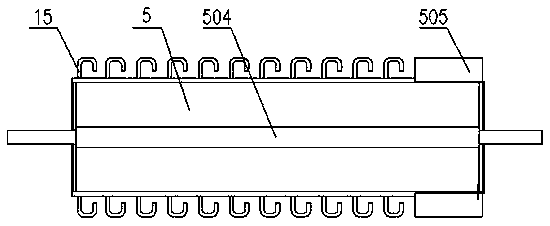

Concave with an array of longitudinally notched spaced apart threshing elements

A concave includes a frame and an array of threshing elements supported by the frame, the threshing elements being spaced apart and extending generally parallel to one another. The threshing elements are configured in the form of round bars each having formed on an upper portion thereof disposed adjacent to an upper portion of the frame a longitudinally-extending notch respectively defining an aggressive threshing edge. The spaced apart relationship and round configuration of the threshing elements reduce plugging of the concave. The threshing edges facing in a direction opposite to the direction of crop material flow restrict crop material flow and thereby enable more effective threshing.

Owner:CSM CORP

Longitudinally notched threshing element for an agricultural combine threshing concave

Owner:CSM CORP

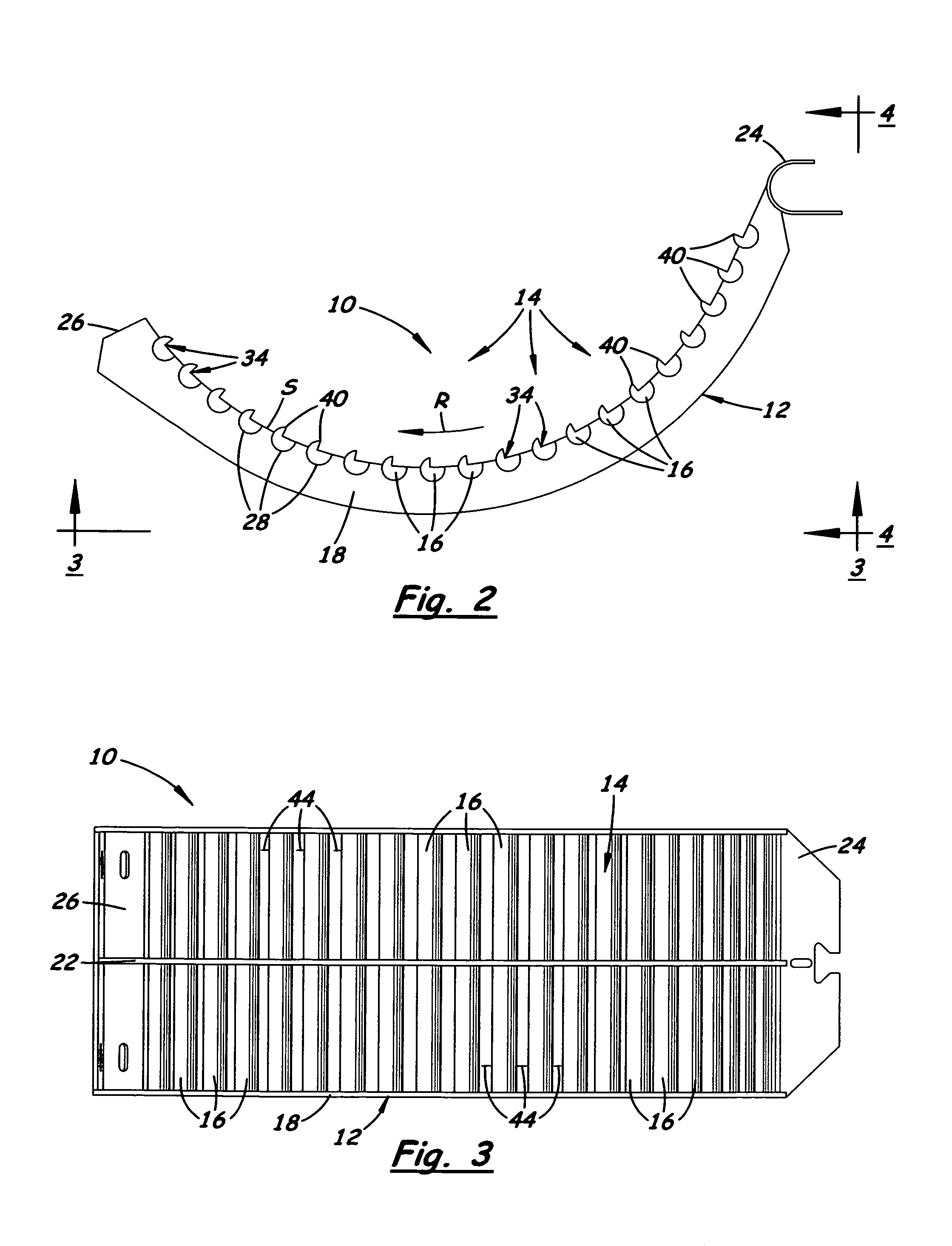

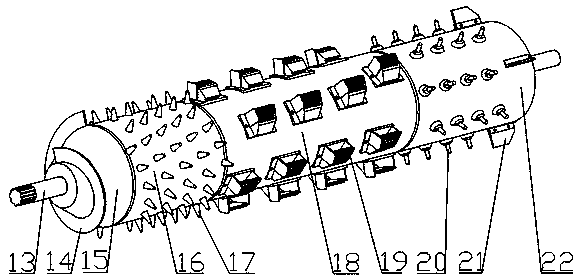

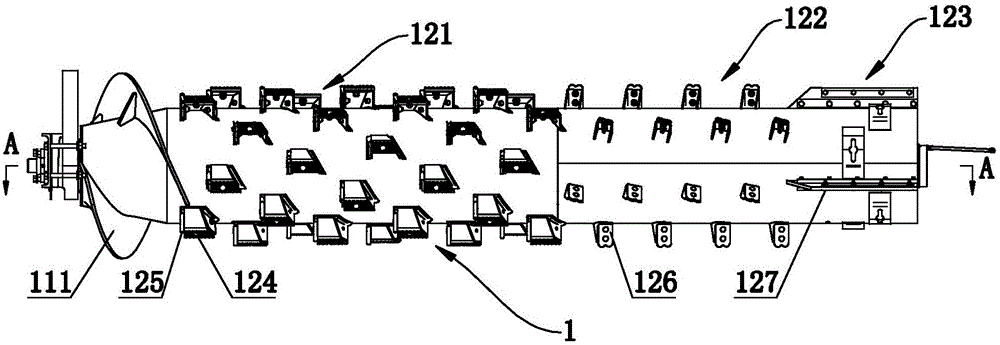

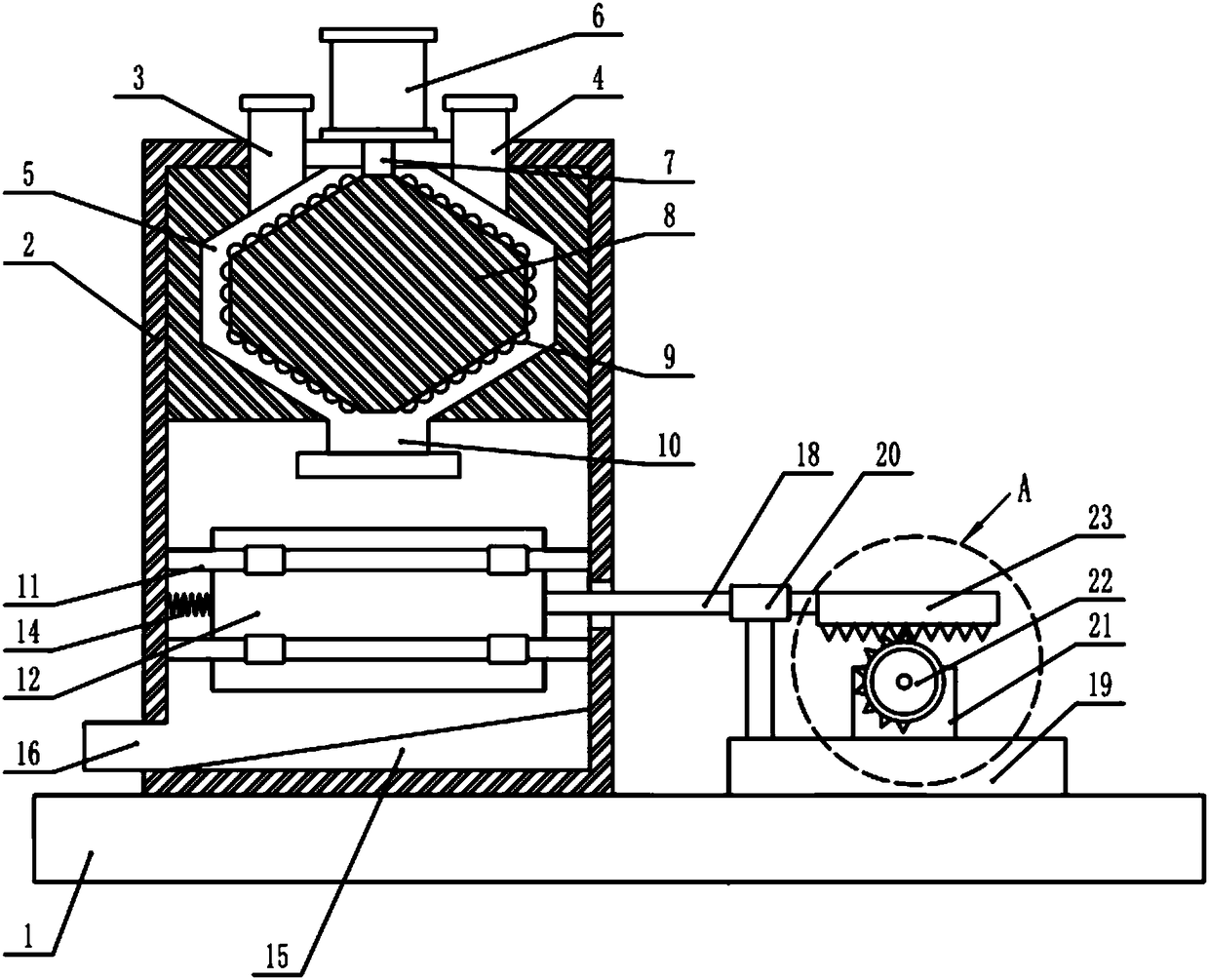

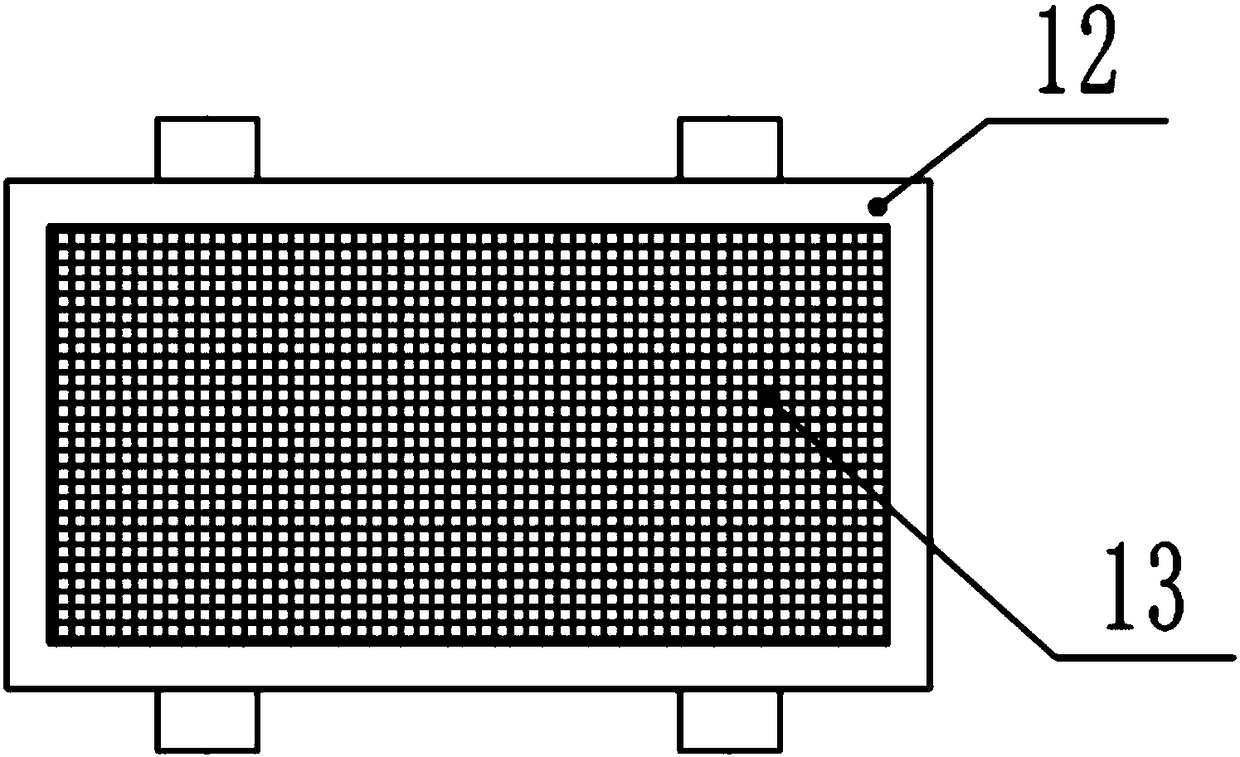

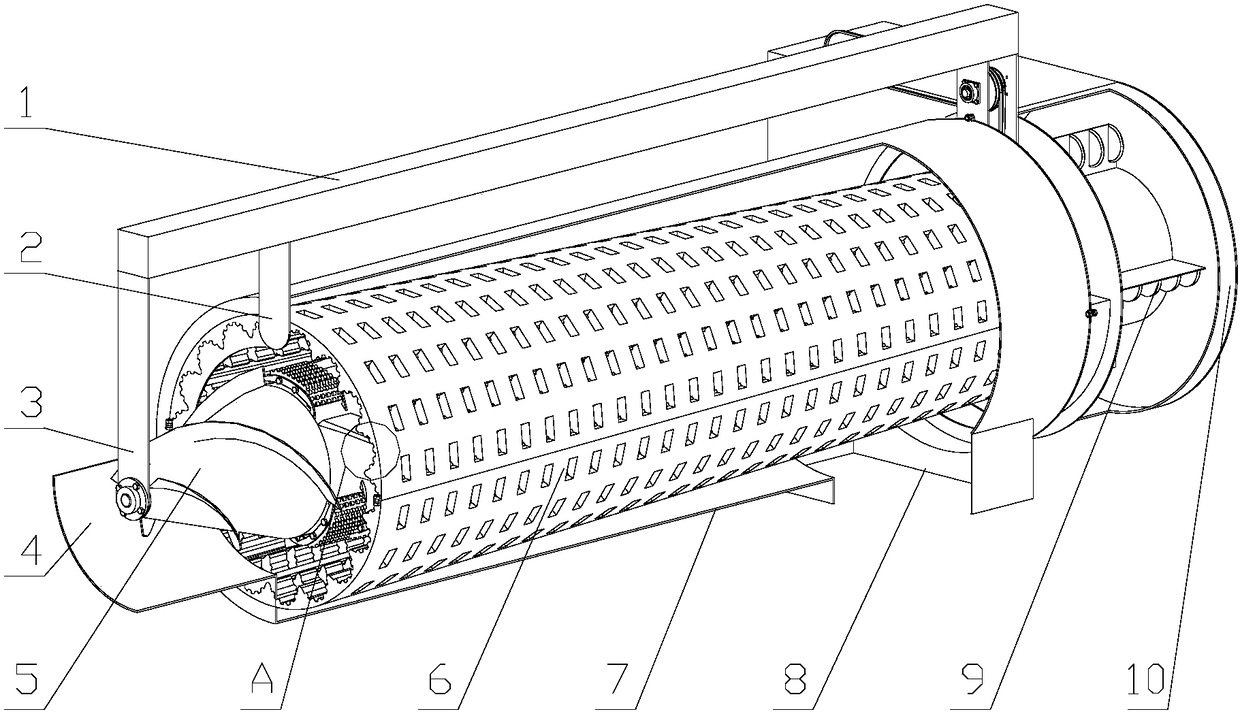

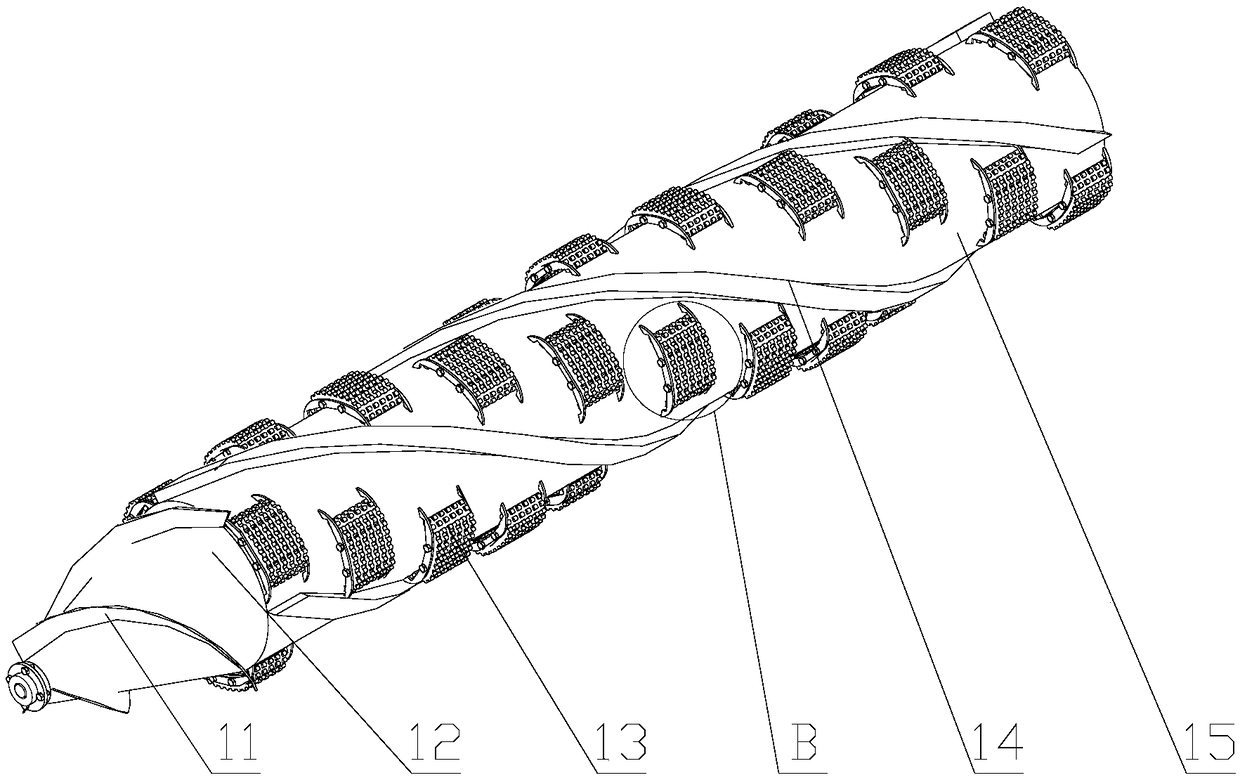

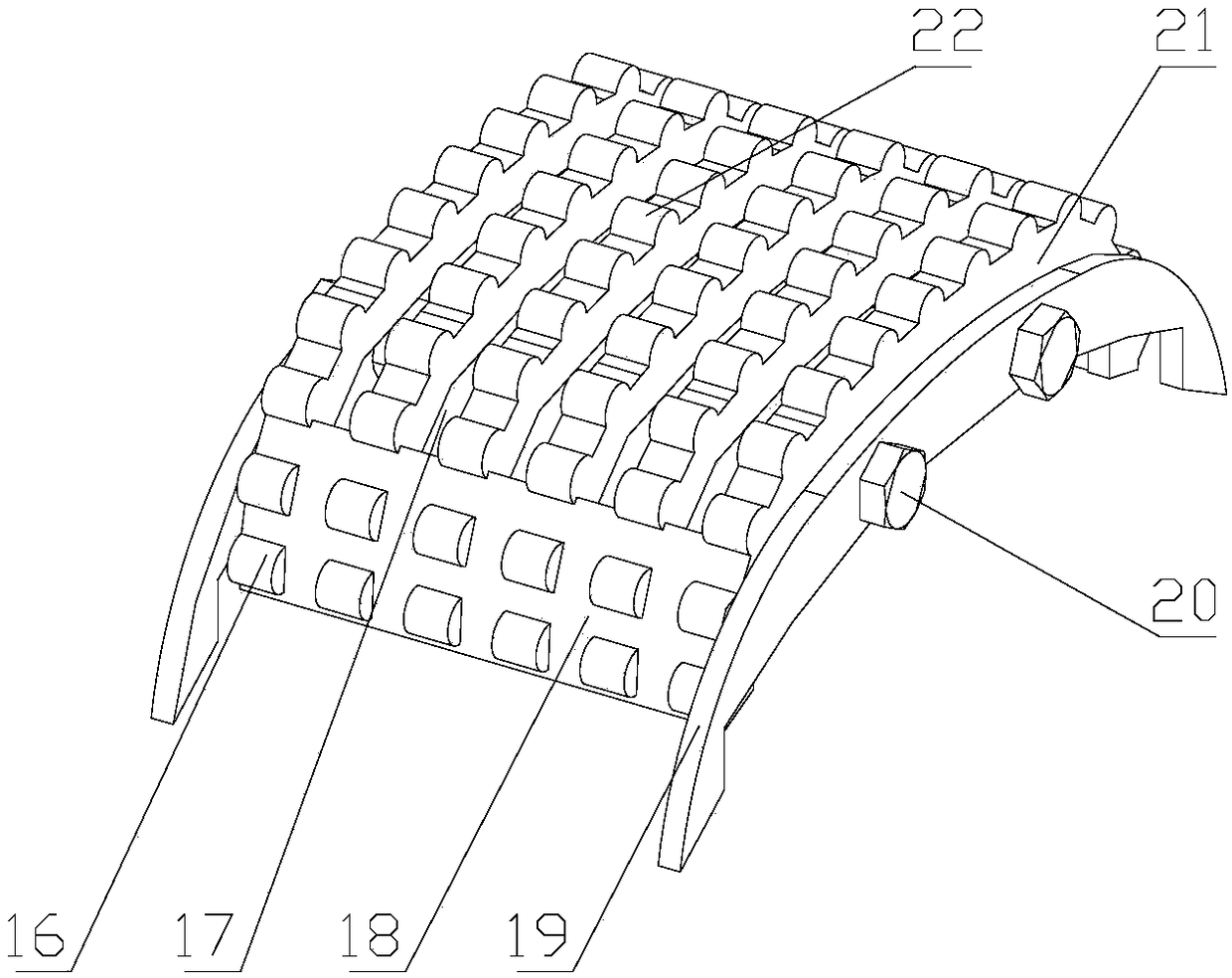

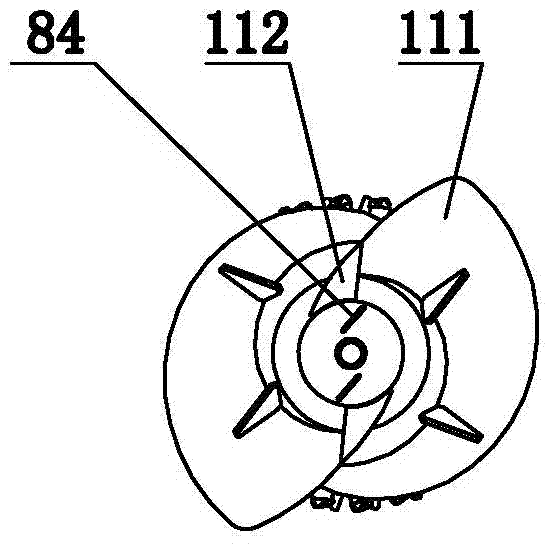

Axial rheological gap bionic corn threshing device

The invention discloses an axial rheological gap bionic corn threshing device. The axial rheological gap bionic corn threshing device comprises a machine frame, a threshing roller, a concave plate sieve, a machine cover and a corncob recycling mechanism, wherein the machine cover is fixed at the lower part of the machine frame; the concave plate sieve is fixed in the machine cover; the threshing roller is fixed in the concave plate sieve; the corncob recycling mechanism is fixed ar the back part of the machine cover; the cylindrical threshing roller and the conical concave plate sieve jointly form threshing gaps which are continuously changed from big to small to promote that corn ears are subjected to effective threshing action all the time; and threshing teeth on the outer surface of a bionic threshing bridge and threshing columns which are distributed on the inner surface of the concave plate sieve in a copying arc form jointly form the threshing functional surface, microscopic threshing moment is applied to corn grains, and the removed corn grains are separated out timely through a grain leaking groove in the surface of the bionic threshing bridge and a separating port in the surface of the concave plate sieve. The axial rheological gap bionic corn threshing device has high threshing efficiency and few crushed grains, and can synchronously collect the corncobs.

Owner:SHANDONG JUMING MASCH CO LTD

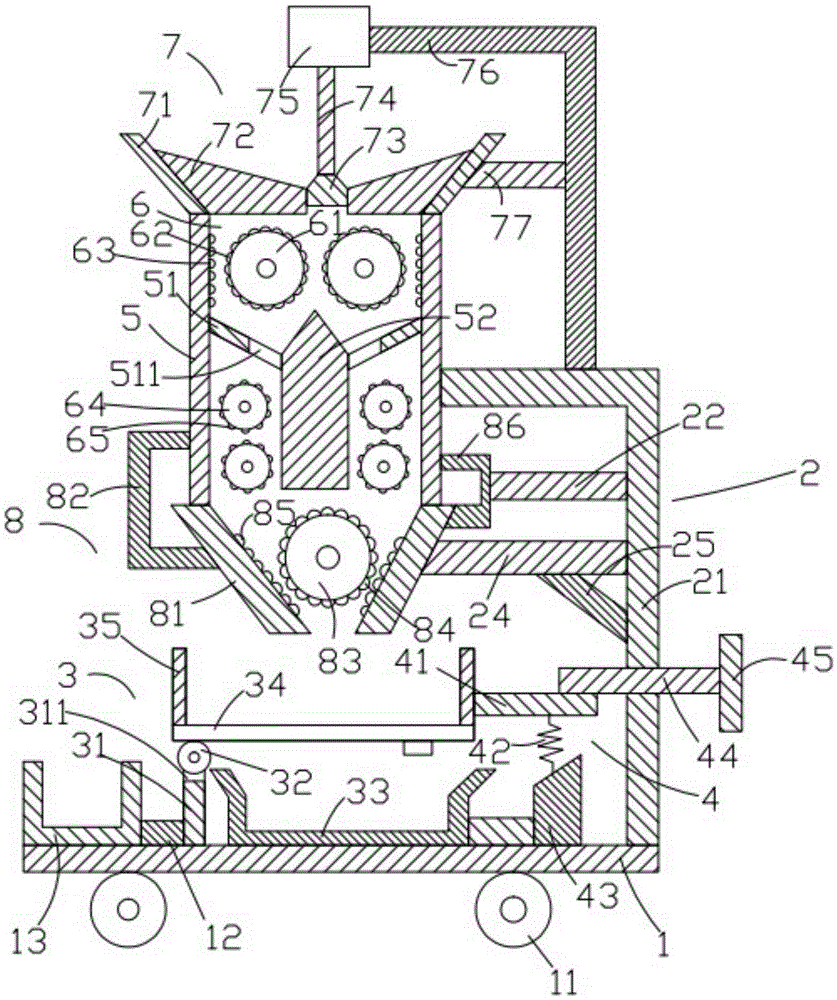

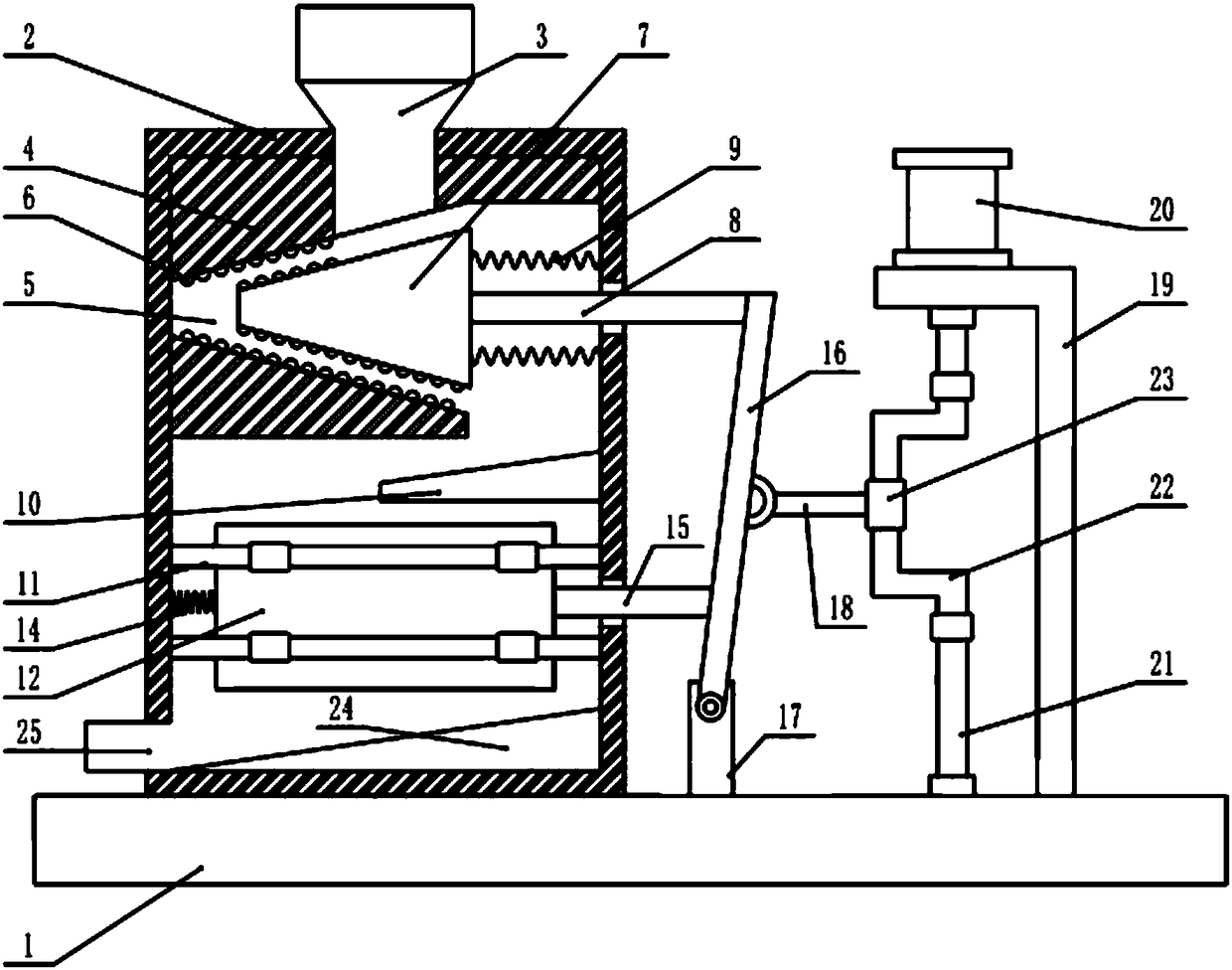

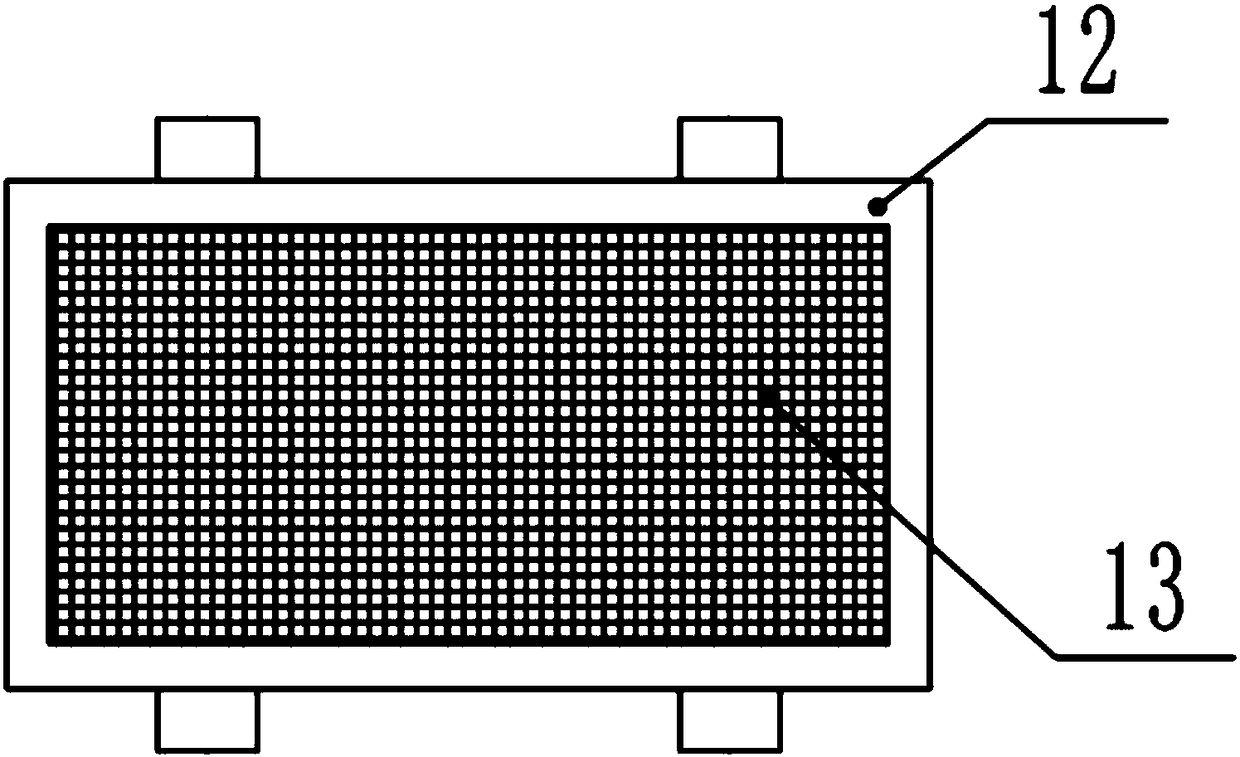

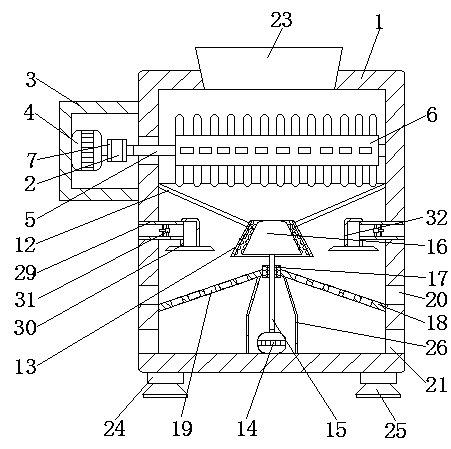

Corn thresher

The invention discloses a corn thresher. The corn thresher comprises a bottom plate, a support device, a collecting device, a fastening device, a frame, a first rubbing device, a feeding device and a second rubbing device. The bottom plate is provided with a first collecting box and a first fixing block; the support device comprises a first support, a first cross bar, a second cross bar and a first inclined bar; the collecting device comprises a first supporting rod, a first rotating shaft, a second collecting box, a first filter screen, a baffle ring and a vibrator; the fastening device comprises a first fastening rod, a first spring, a second fixing block, a second fastening rod and a gripping rod; a second inclined bar and a distributing block are provided inside the frame; the first rubbing device comprises a first roller, a first lug, a second lug, a second roller and a third lug; the feeding device comprises a feeding hopper, a centralizing block, a moving block, a pushing rod, a cylinder, a first fixing rack and a third cross bar; and the second rubbing device comprises a discharging hopper and a second fixing rack. The corn thresher provided by the invention can be used for threshing corn effectively, and is high in threshing efficiency.

Owner:重庆潼双机械制造有限公司

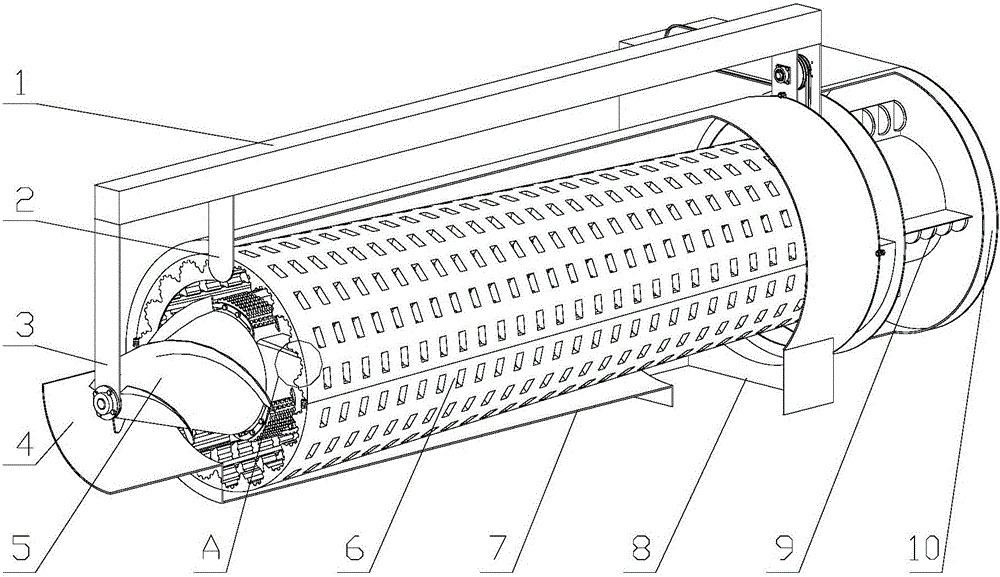

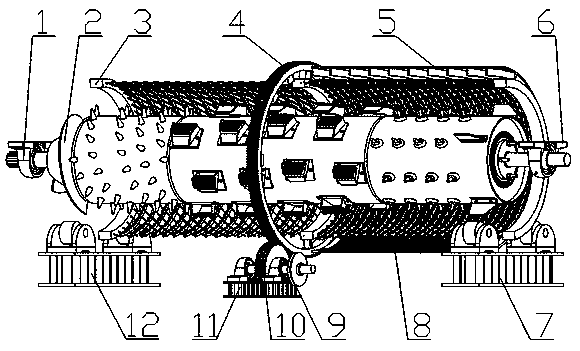

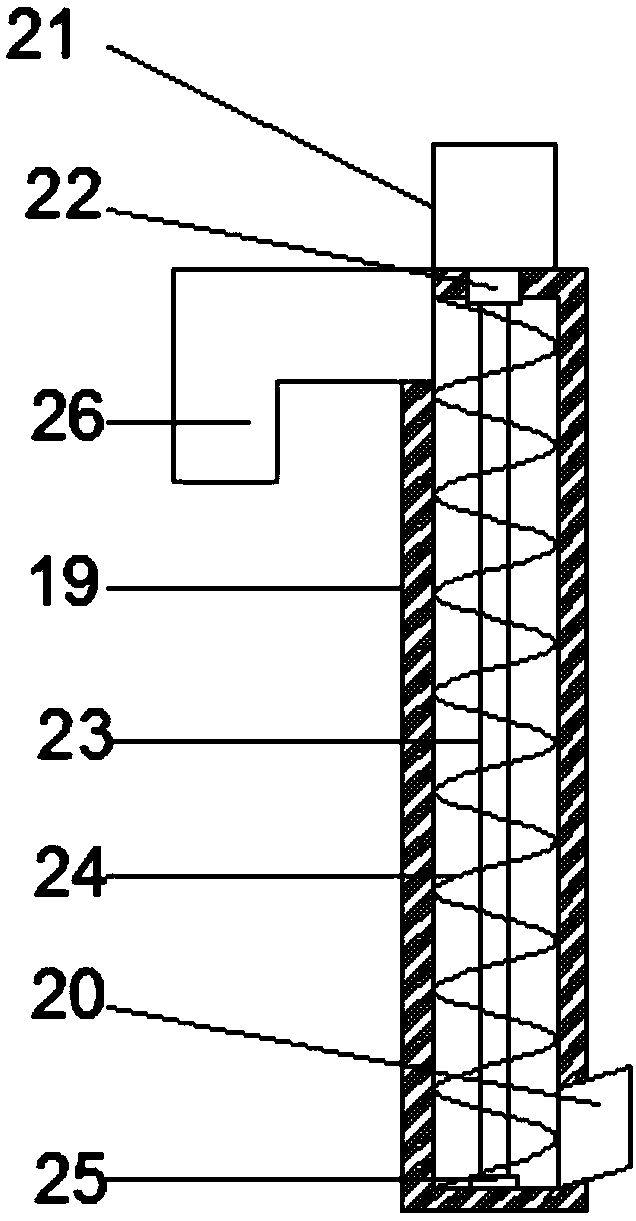

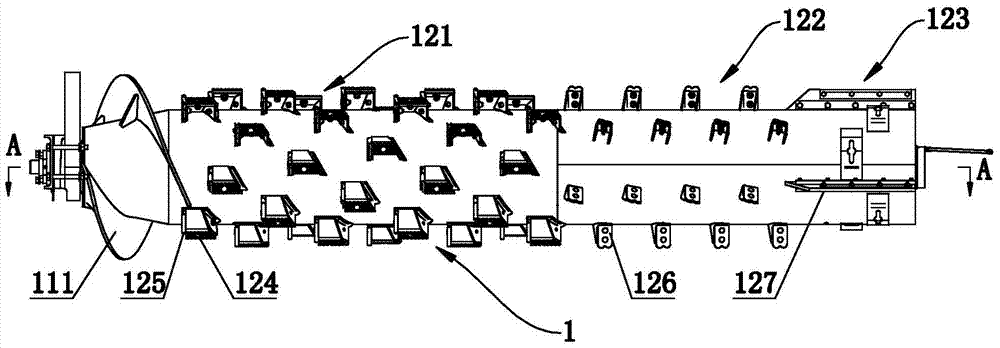

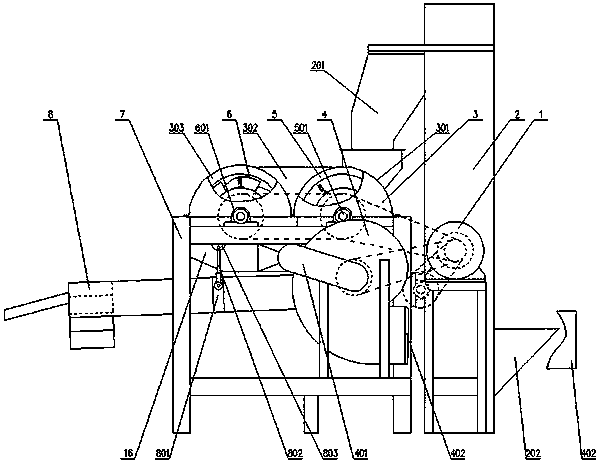

Longitudinal axis flow nested differential type corn threshing device

A longitudinal axis flow nested differential type corn threshing device comprises a front bearing seat, a threshing roller, a cylindrical concave plate screen, a concave plate screen gear ring, an upper flow guide cover, a rear bearing seat, a rear support, a lower cleaning screen, a belt wheel, a concave plate screen driving gear, a middle support and a front support; the threshing roller comprises a transmission shaft, a conical cylinder, a coarse threshing roller, a fine threshing roller, a crushing and guiding roller and a differential mechanism; the differential mechanism comprises a stargear, a star gear fixing seat, a fixed connecting rod, a first bearing, a flat key, a threshing roller driving gear, a second bearing, a transmission shaft fixing seat, a fixing rod, a fixed baffle plate, a blocking plate, a star gear support and a roller gear ring; the transmission ratio of the threshing roller driving gear and the star gear is different from the transmission ratio of the star gear and the roller gear ring, the rotation speeds of the coarse threshing roller, the fine threshing roller and the crushing and guiding roller are different, and the rotation directions thereof are same. The threshing efficiency and quality are improved, the damage and loss of corn grains can be reduced, and the winding and blocking of impurities such as straws are reduced.

Owner:JILIN UNIV

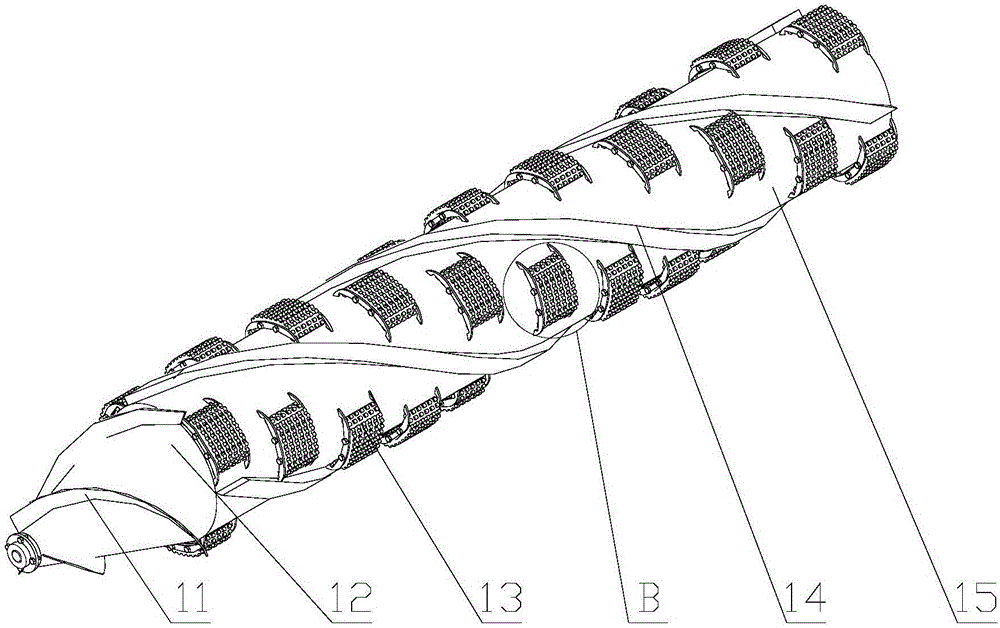

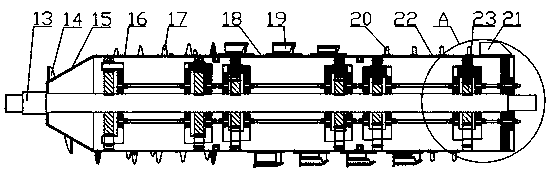

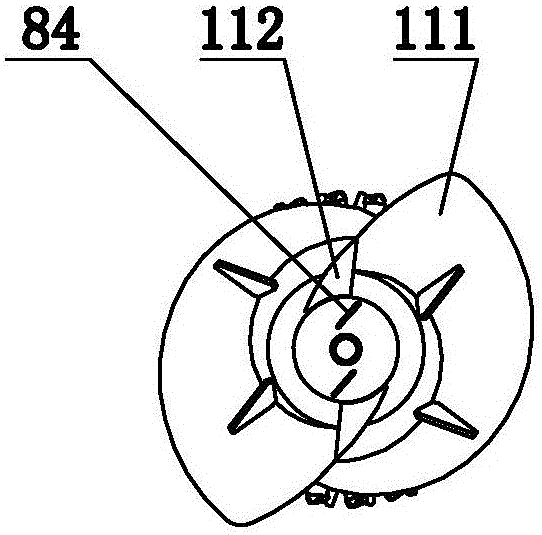

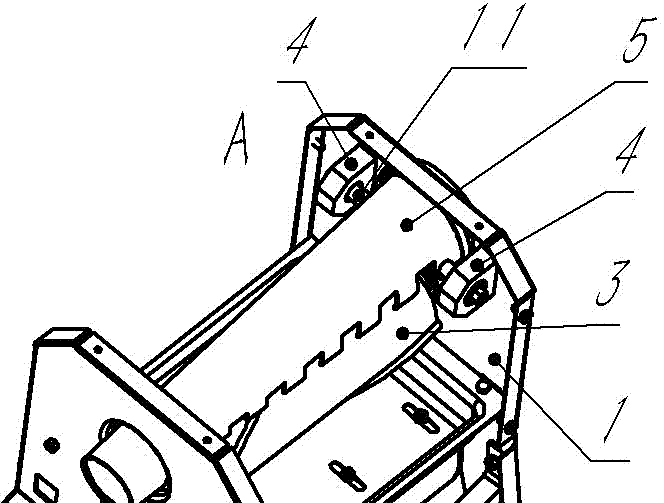

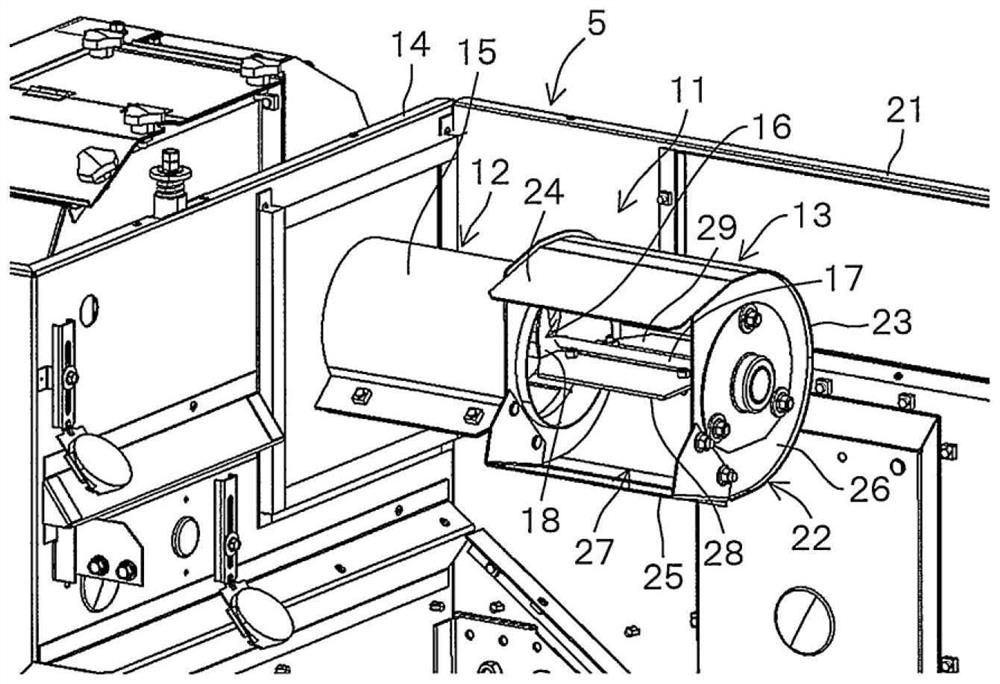

Longitudinal-axial-flow roller

The invention discloses a longitudinal-axial-flow roller, and belongs to the technical field of combine harvester threshing separating devices. The longitudinal-axial-flow roller comprises a roller body, a roller front shaft, a power input shaft, a roller front support and a roller rear support. The roller body comprises a feeding-in part and a roller body part, and an anti-tangling element is arranged between the roller front support and the feeding-in part and comprises a guiding crescent moon, a wedge-shaped roller front cover, a roller front cover seal cover and roller front protrusions wherein the guiding crescent moon and the wedge-shaped roller front cover are fixed to the roller front support, the guiding crescent moon comprises a disc and a guiding plate, one end of the disc is fixedly installed on the roller front support, and an opening is formed in the other end of the disc. The disc penetrates through an installing hole in the roller front cover, the roller front cover seal cover is fixed to the roller front cover, and the roller front protrusions are fixed to the front end face of the feeding-in part and located inside the opening. In harvesting, the roller front shaft is not likely to be tangled with weeds, working efficiency is high, kinds of crops are harvested without replacing the roller, and the requirements for earnings of a user are met.

Owner:LOVOL HEAVY IND CO LTD

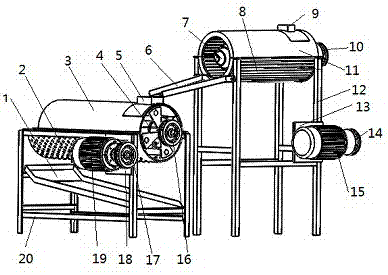

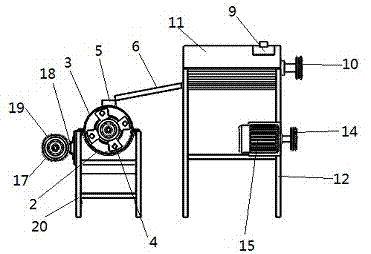

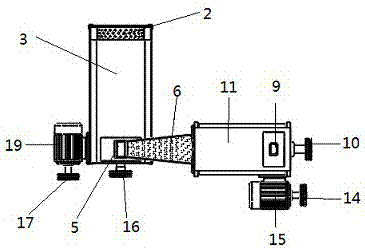

Novel corn husking and threshing device

InactiveCN106856883ASimple structureReduce resistanceHarvestersThreshersAgricultural engineeringSlide plate

The invention discloses a novel corn husking and threshing device, and belongs to the technical field of machine manufacturing. The novel corn husking and threshing device comprises a grain recovery slide plate, a threshing concave plate, a threshing machine cover, a threshing roller, a first feed hopper, a connecting sieve, a husking roller, a husking concave plate, a second feed hopper, a first driven belt wheel, a husking machine cover, a first rack, a first motor support, a first driving belt wheel, a first motor, a second driven belt wheel, a second driving belt wheel, a second motor support, a second motor and a second rack. The novel corn husking and threshing device is characterized in that the husking concave plate is connected to the first rack through welding, and the husking machine cover is connected to the husking concave plate through thread connection; the threshing concave plate is connected to the second rack through welding, and the threshing machine cover is connected to the threshing concave plate through thread connection. The novel corn husking and threshing device is simple in structure, low in cost and good in work effect.

Owner:UNIV OF JINAN

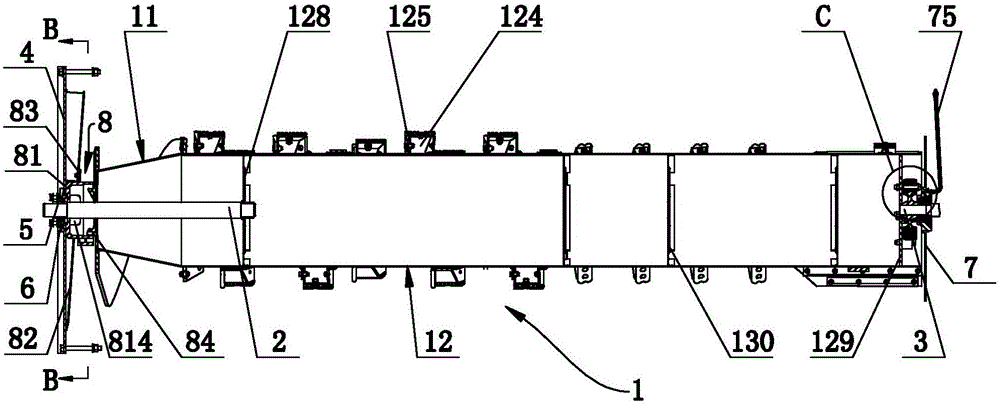

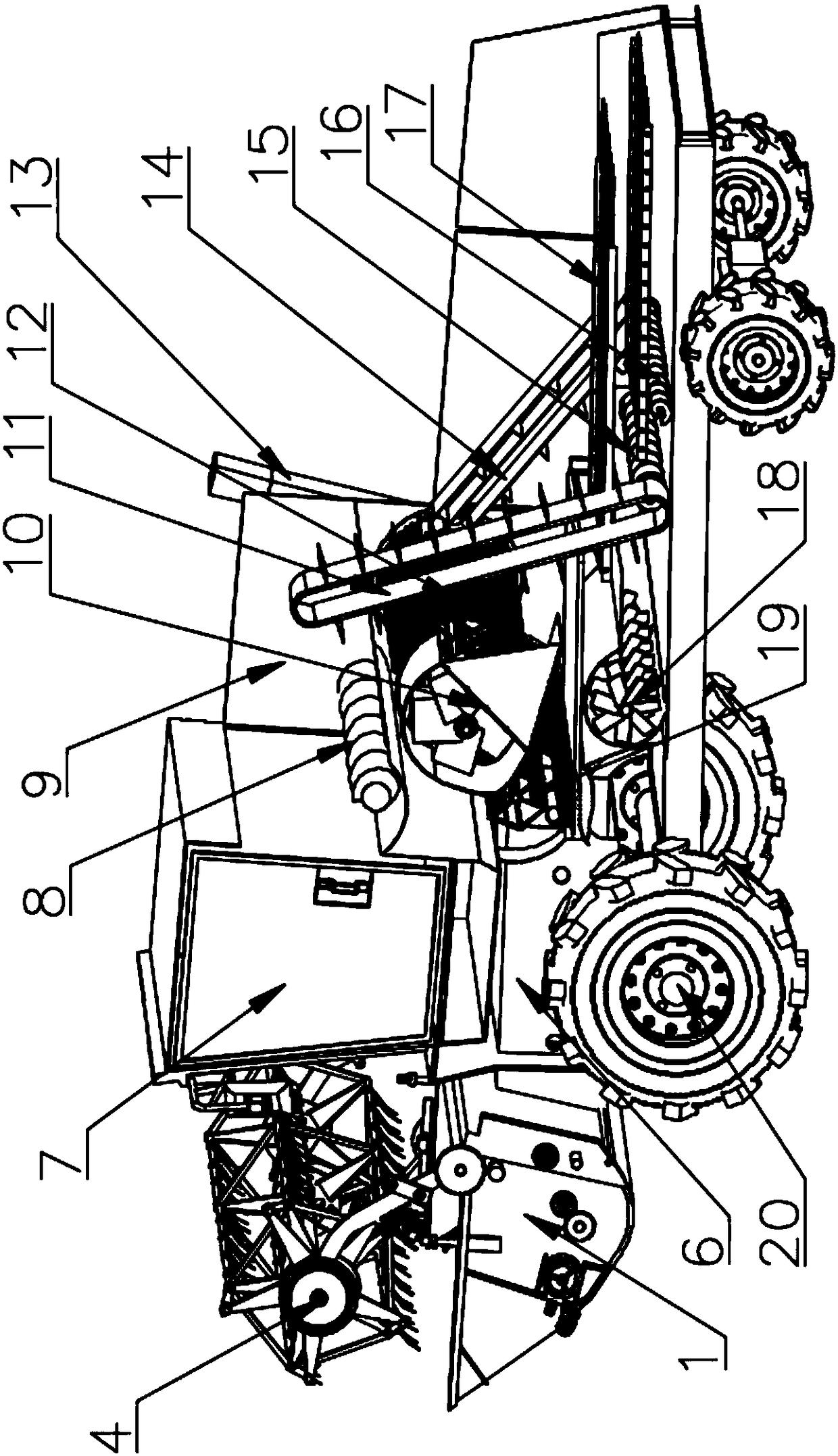

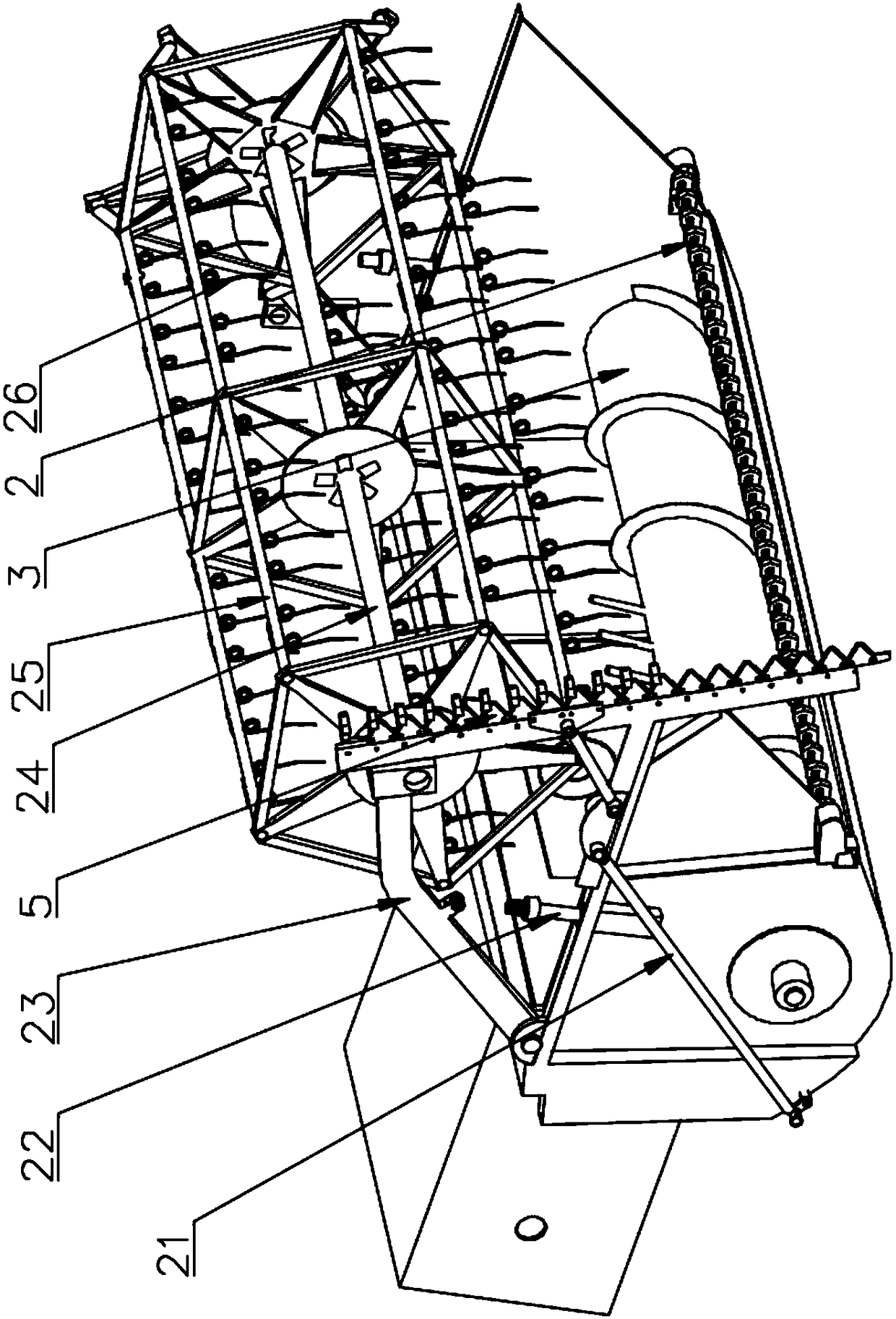

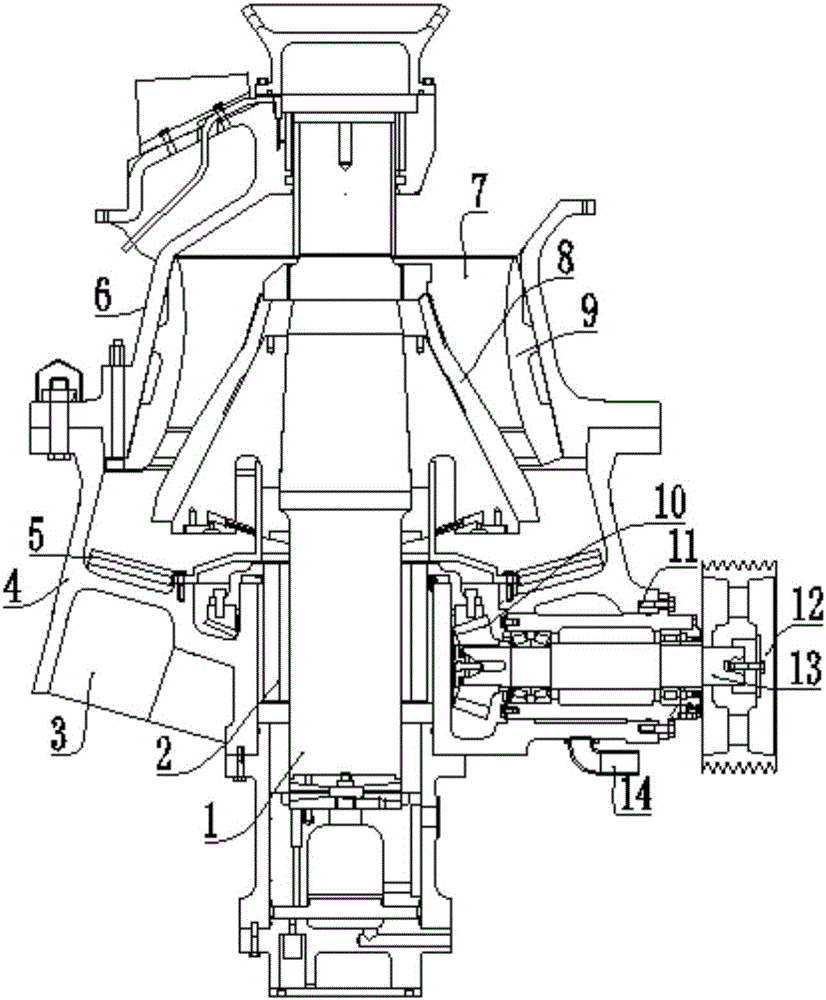

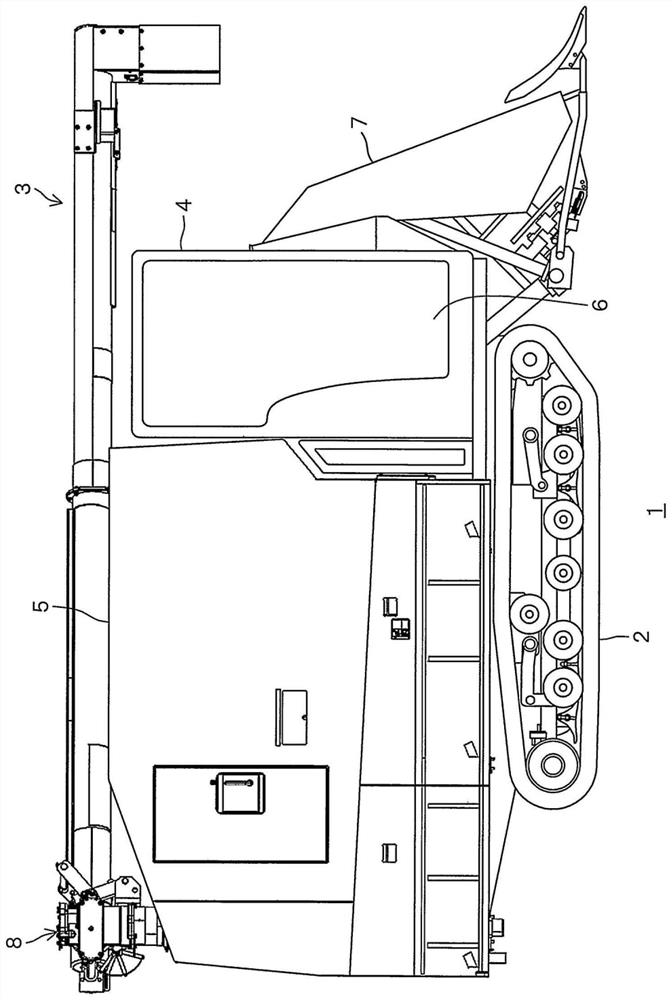

Oilseed rape combine harvester

The invention discloses an oilseed rape combine harvester, which comprises a machine body, a gap bridge arranged on the machine body, a lifting header component hinged on the machine body, located atthe front end of the gap bridge and used for dividing and cutting a plant, a divider conveying packing auger component in the middle of the divider component, a liftable rice pulling component arranged at the upper part of the divider component, a link target component arranged in the gap bridge, a threshing component arranged on the machine body and located behind the gap bridge, a sorting component arranged on the machine body and located at the lower part of the gap bridge, a divider lifting component arranged at the front end of the machine body, and a rice pulling lifting component for adjusting the rice pulling component; the divider conveying packing auger component comprises a divider conveying packing auger, and the divider component comprises a divider framework, the divider conveying packing auger is rotationally arranged in the middle of the divider framework; the front end of the divider framework is hinged with a cross cutter in parallel to the center line of the dividerconveying packing auger component and a vertical cutter component perpendicular to the center line of the divider conveying packing auger.

Owner:GANSU AGRI UNIV

Concave threshing bars for use in an agricultural harvester

A concave includes a frame and an array of threshing elements supported by the frame, the threshing elements being spaced apart and extending generally parallel to one another. The threshing elements each have formed on an upper portion thereof disposed adjacent to an upper portion of the frame a longitudinally-extending notch respectively defining an aggressive threshing edge. The threshing edges faces a direction opposite to the direction of rotation of a harvester rotor. The notch is recessed into the bar and disposed adjacent to the upper portions of the opposite members of the frame and facing opposite to a direction of movement of the rotor. The notch has a channel along an outer edge of the notch, the channel being filled with filler material having a differing hardness than a hardness of the bar.

Owner:CSM CORP

Kneading threshing device

The invention relates to a kneading threshing device which comprises a bottom plate, a roller device, a feeding device, a threshing structure and an air cylinder device, wherein the roller device comprises a first bracket, a first vertical rod, a roller, first bumps, a first slanting pole, a first transverse rod and a baffle plate, wherein the feeding device comprises a first supporting rod, a first feeding pipe, a second feeding pipe, a feeding hopper, a first fixed bracket, a first fixed block, a second transverse rod and a third slanting pole; the threshing structure comprises a supporting block, a threshing plate, second bumps and first springs; the air cylinder device comprises an air cylinder, a pushing rod, a transverse plate, second vertical rods, second springs, first cushion blocks, second cushion blocks and third springs; a second groove is formed on the upper surface of the supporting block, the threshing plate is in a hemicyclic shape, each of the second bump is semispherical, each of the second bump is fixedly connected with the inner surface of the threshing plate, the two first springs are located on the left and right sides, respectively, and the first springs are inclined. The kneading threshing device provided by the invention can be used for effectively threshing seeds and is high in threshing efficiency.

Owner:海门华夏时丽网络科技服务有限公司

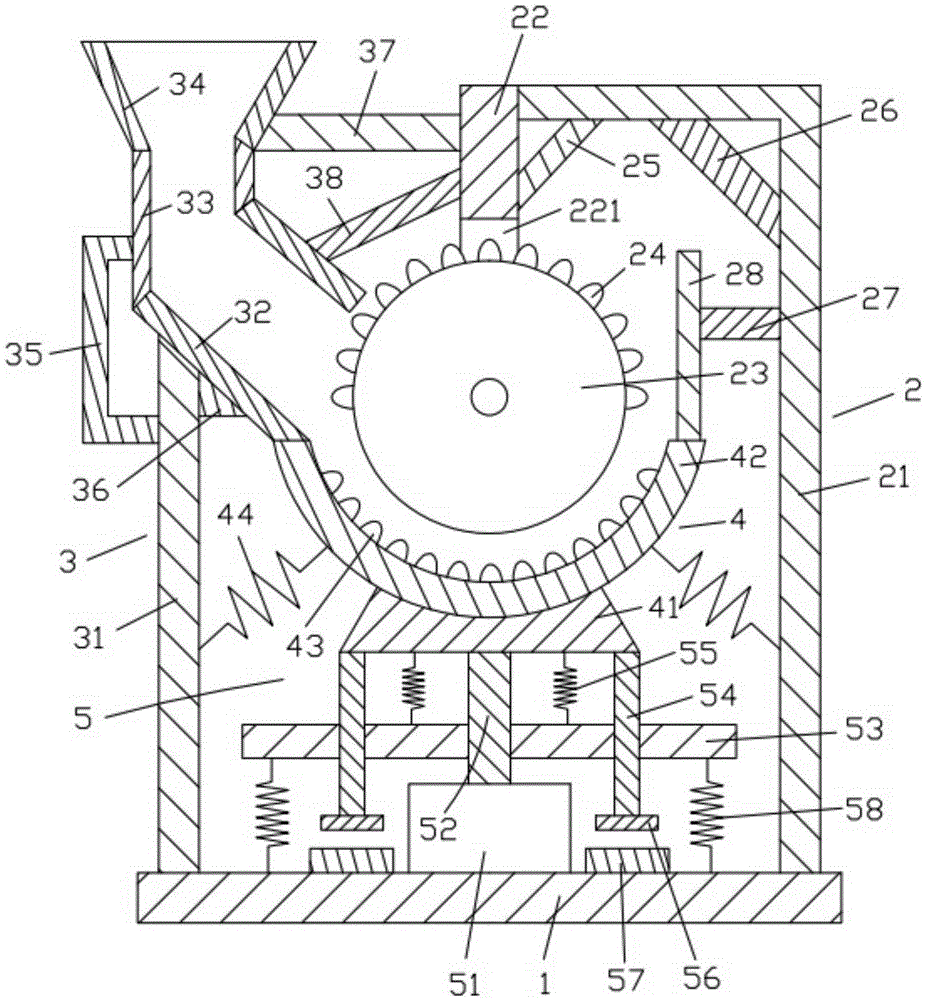

Rotary-threshing-type sunflower seed threshing and screening device

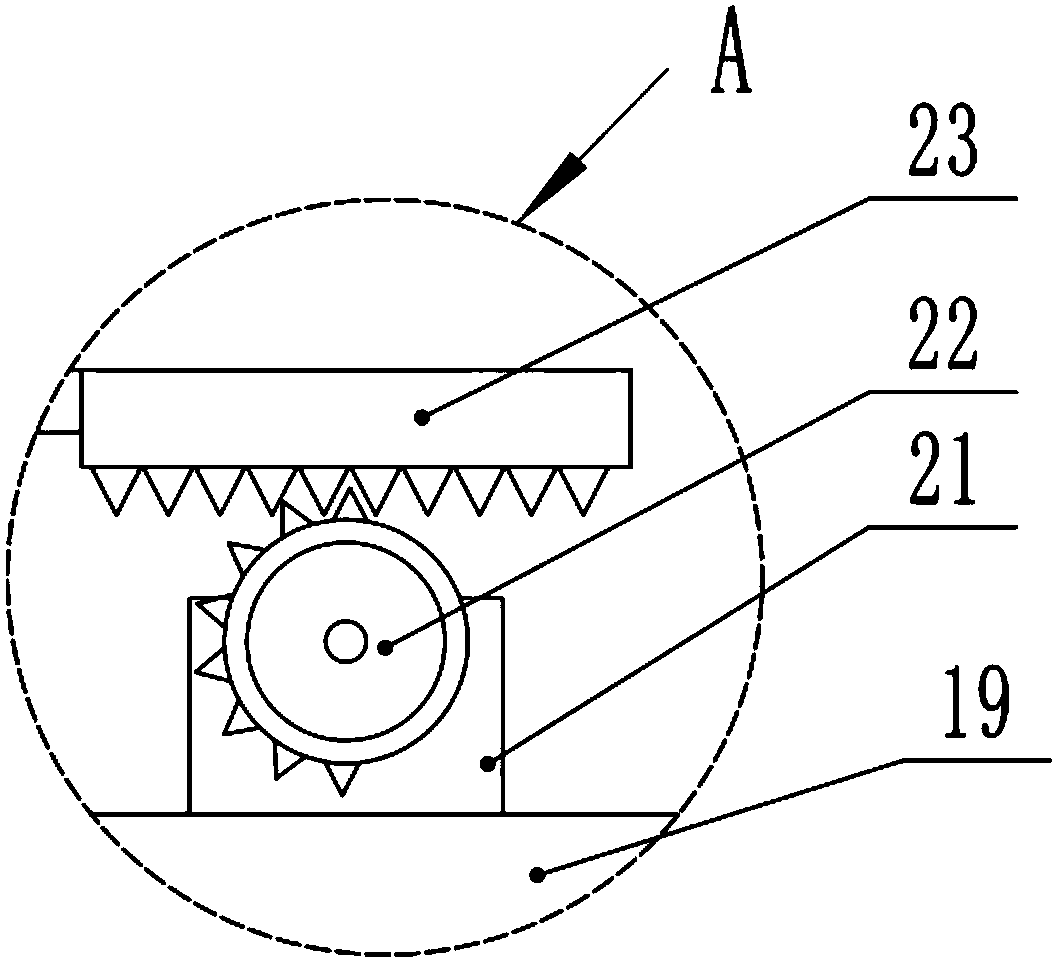

The invention discloses a rotary-threshing-type sunflower seed threshing and screening device. The device comprises a base, a threshing box, a rotating motor, a thresher and a screening box, wherein the threshing box is arranged on the base, a threshing chamber is formed inside the threshing box, the thresher is fixedly connected to the lower end of an output shaft of the rotating motor through acoupling, at least two sets of supporting sliding bars are arranged, and the screening box is mounted on the supporting sliding bars in a slidable manner. Sunflower seeds are threshed through threshing bulges on the thresher, and a threshing stroke is longer due to the bent threshing chamber compared with the ordinary threshing device, so that the threshing is more efficient, the threshing effectis improved, and the purity of the sunflower seeds is guaranteed; and a special-shaped gear is driven to be matched with a gear rack through a driving motor, so that the screening box is driven to move left and right, the screening speed of the sunflower seeds is greatly accelerated, and the working efficiency is greatly increased.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

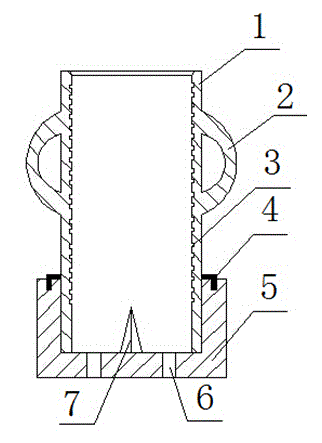

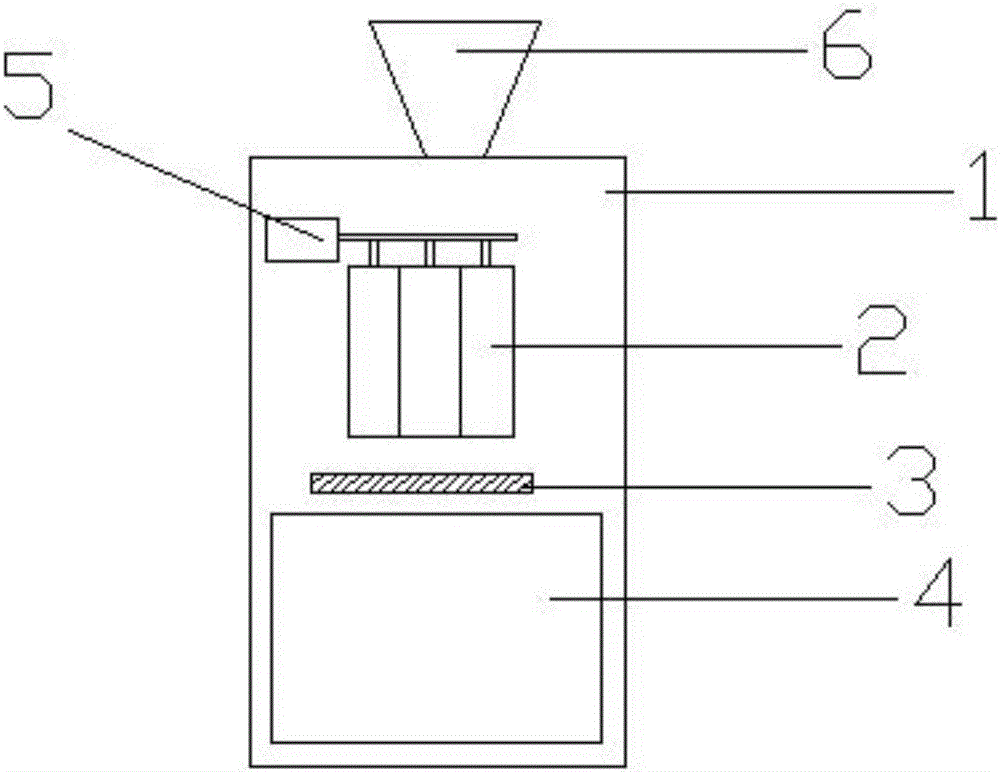

Corn threshing device

InactiveCN104094737AEfficient threshingSimple structural designThreshersHand equipmentsEngineeringScrew thread

The invention discloses a corn threshing device, and relates to the field of agricultural processing mechanical devices. The corn threshing device comprises a threshing barrel and a base. The threshing barrel is a cylindrical barrel, thread grooves are formed in the inner side of the threshing barrel by means of machining, handles are arranged at the upper end of the outer side of the threshing barrel, and a slide bar is arranged at the lower end of the threshing barrel; the base is of a 'concave' structure, a circular groove which is used for being connected with the slide bar is formed in the upper surface of the base by means of machining, and discharge holes are formed in the lower surface of the base; a fixing cone is arranged at the bottom of the inner side of the base; the lower end of the threshing barrel is arranged in the base. The corn threshing device has the advantages that the corn threshing device is simple in structural design and convenient to use, a corn cob can be fixed onto the fixing cone, then the threshing barrel can be turned by the aid of the handles, and the corn cob can be effectively threshed by the thread grooves; corns can be prevented from being pulverized, the labor intensity can be greatly reduced, and the threshing efficiency can be improved.

Owner:丁玉清

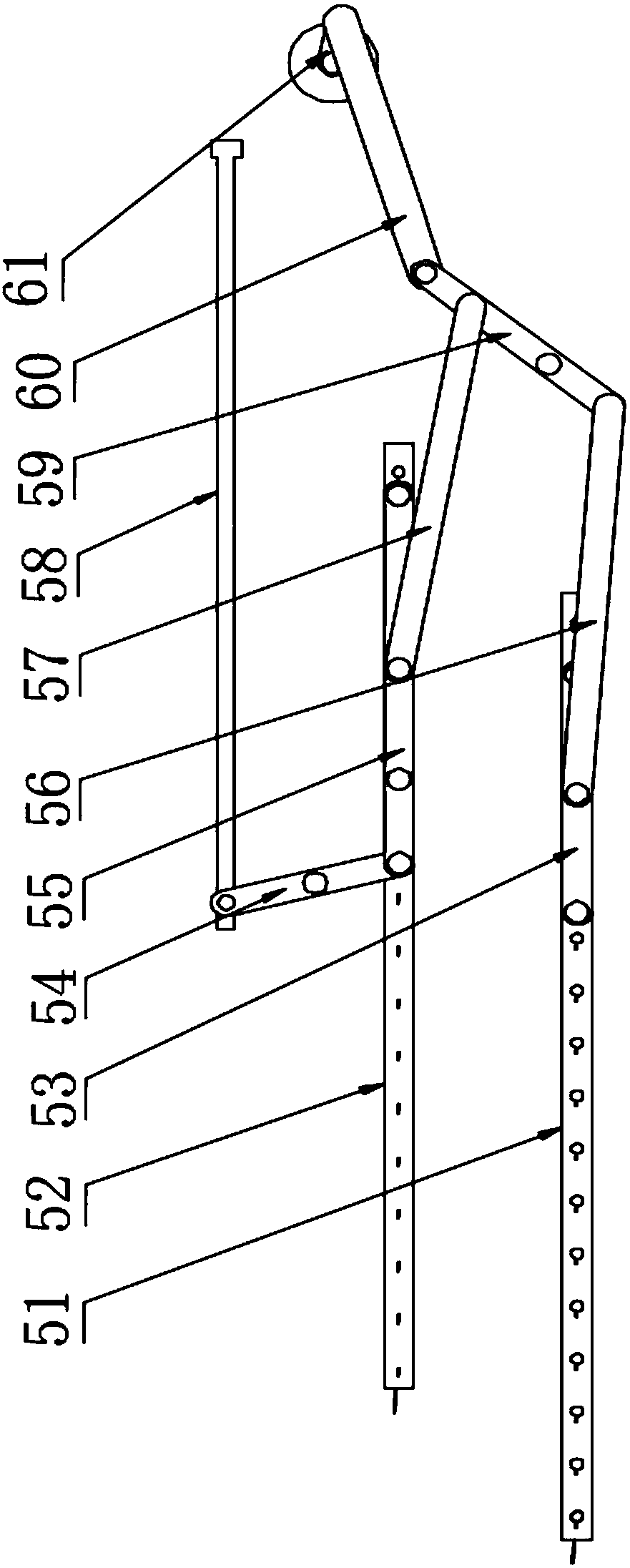

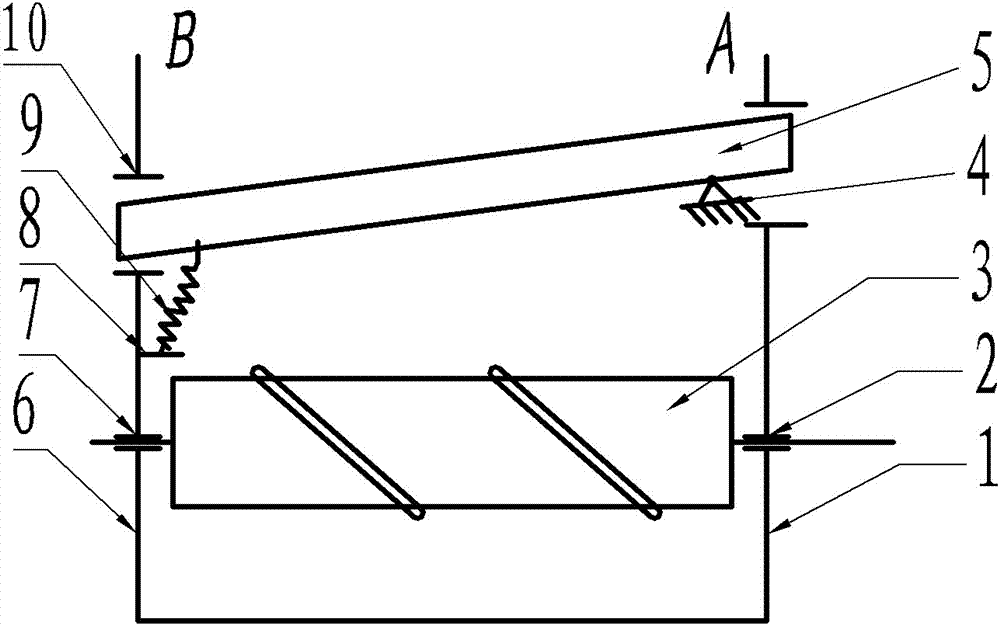

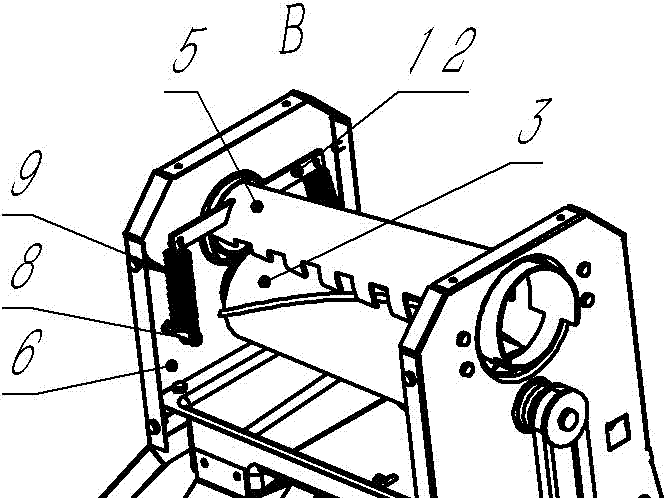

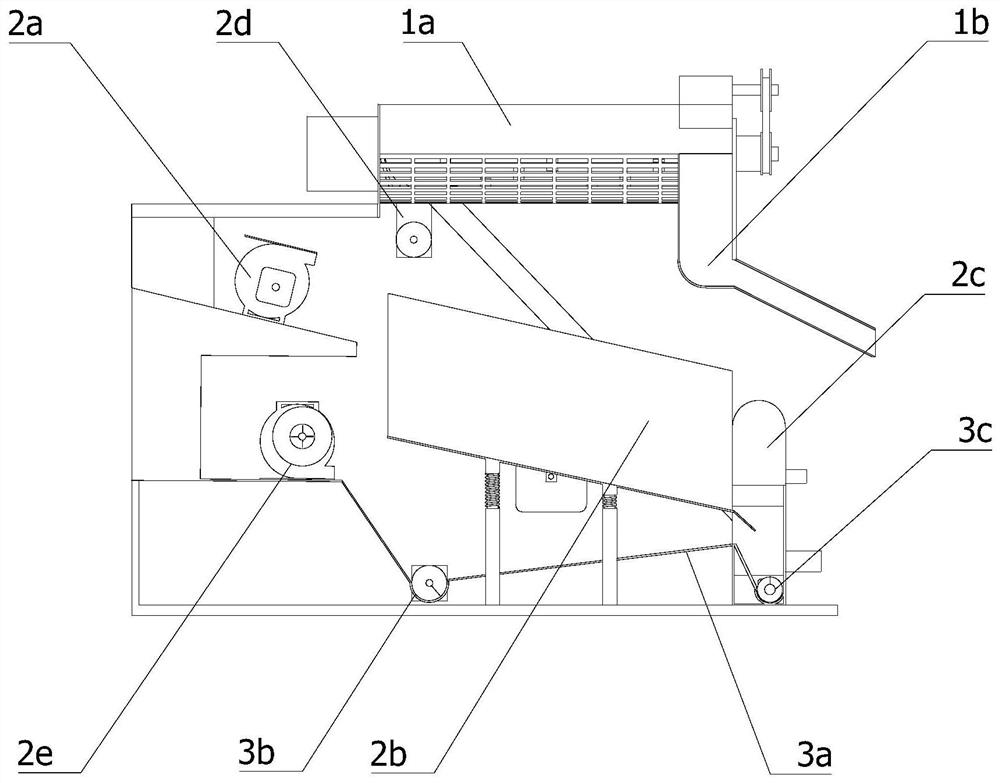

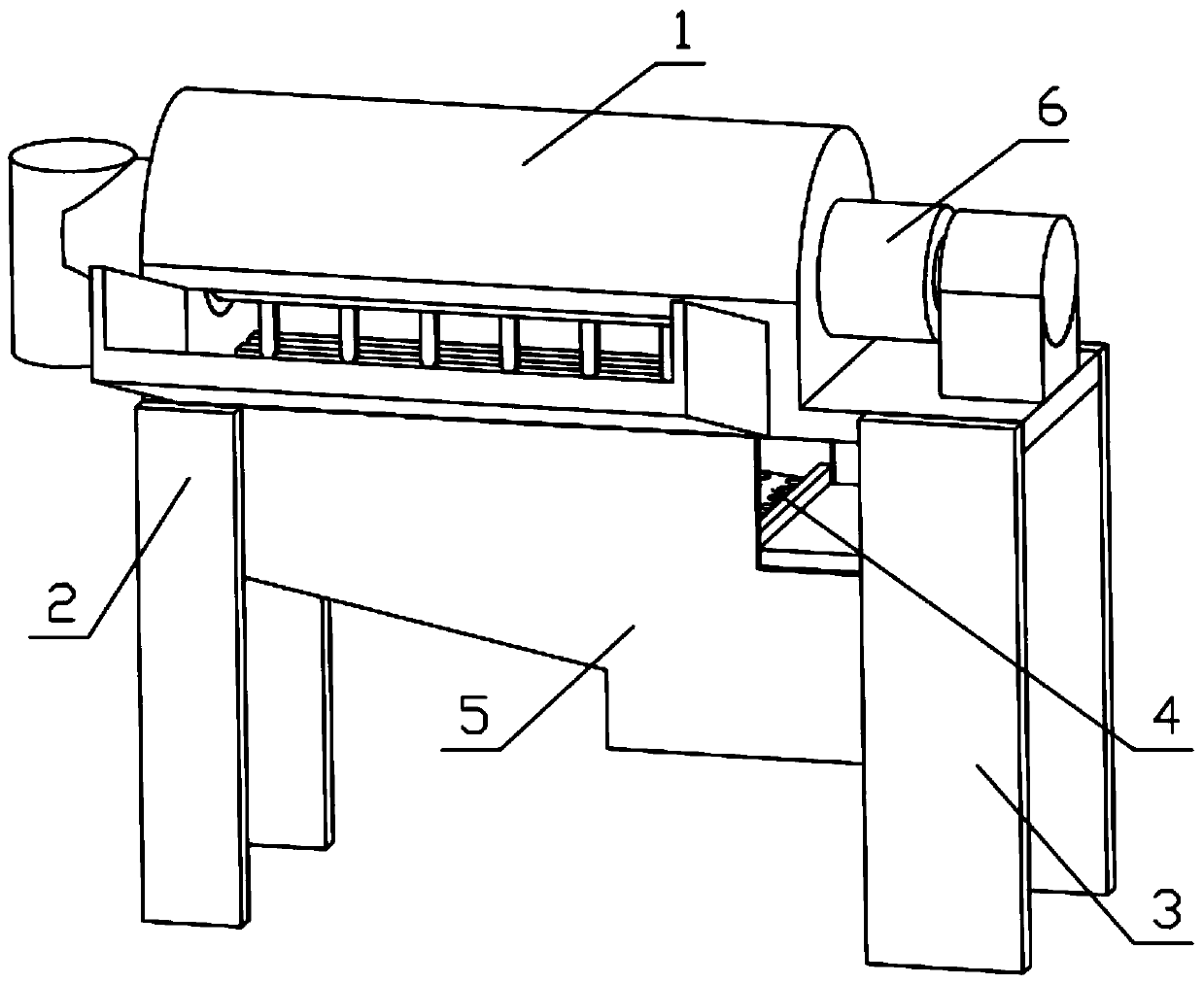

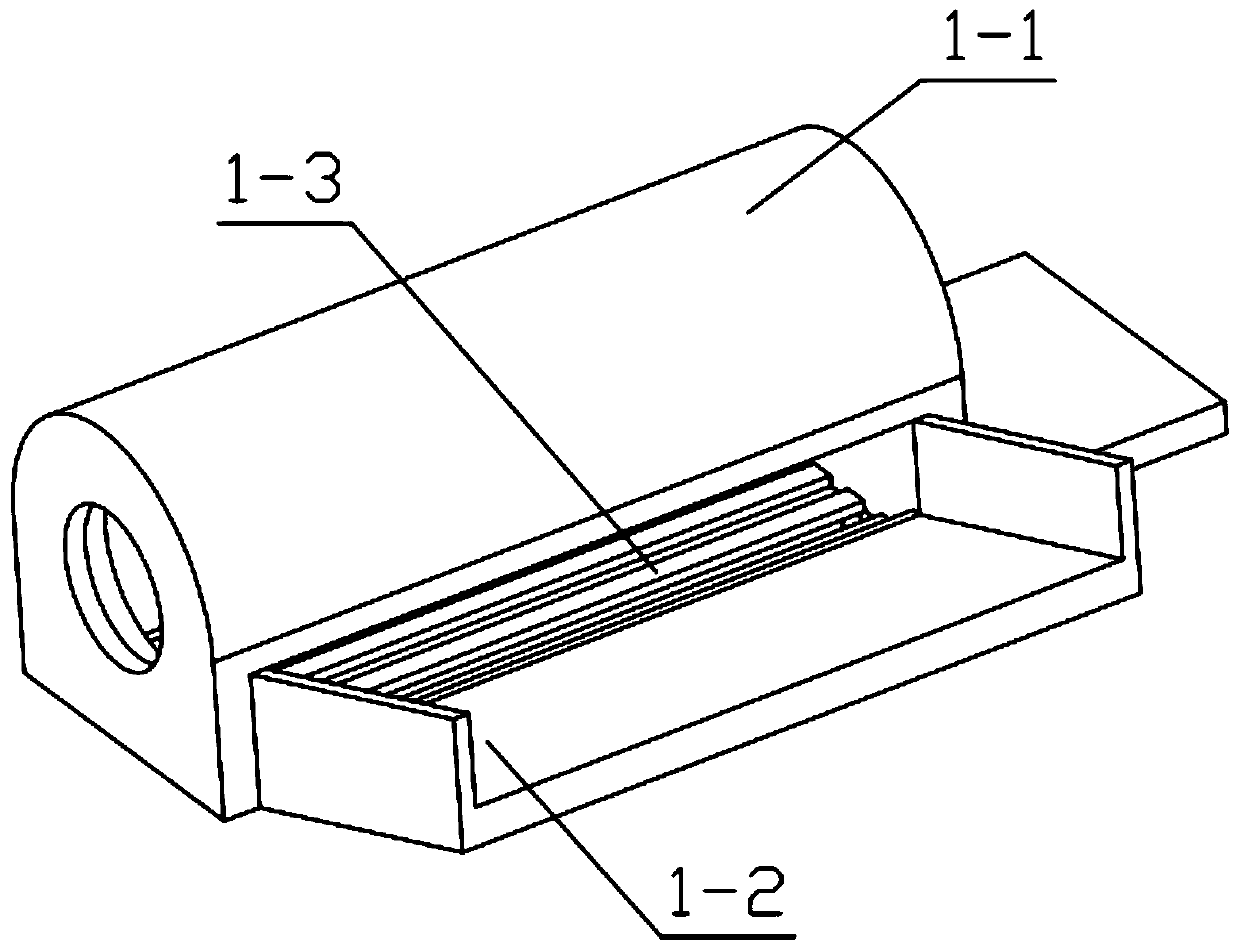

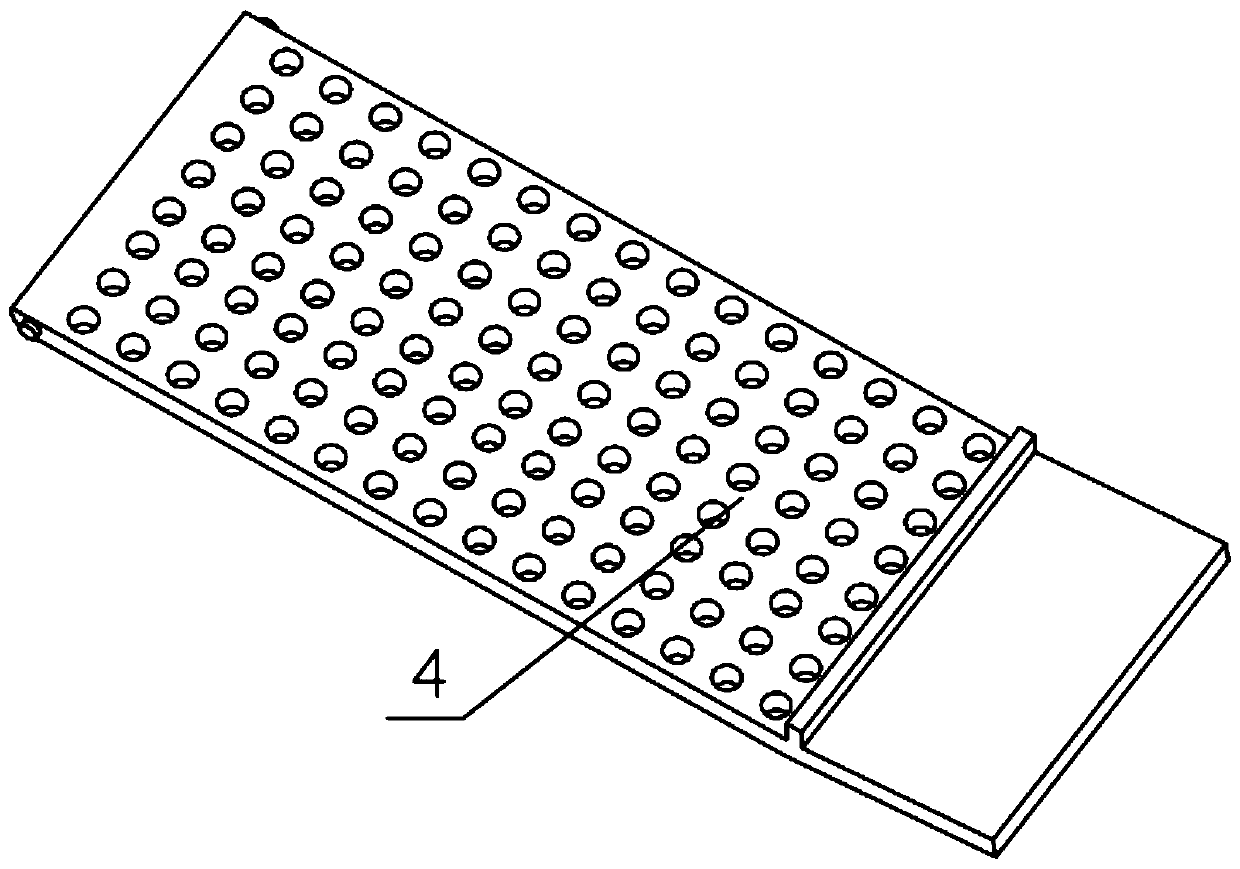

Adaptive controlling device for size of threshing roller cavity of corn threshing machine

The invention discloses an adaptive controlling device for the size of a threshing roller cavity of a corn threshing machine. The adaptive controlling device mainly comprises a front side plate, a rear side plate, a threshing roller, a threshing tube, a threshing tube front rotating hinge, a threshing tube rear tension spring and a tension spring fixing rod, wherein the threshing roller is fixed between the front side plate and the rear side plate and only can perform principal rotating motion; and the front end of the threshing tube is fixedly connected with the front side plate through the threshing tube front rotating hinge, so that the threshing tube only can rotate around the hinge, and the rear side of the threshing tube moves away from the threshing roller or moves towards the threshing roller. The rear side of the threshing tube is close to the threshing roller under the effect of a downward pretension force of the threshing tube rear tension spring, and stays on the lower side of a large through hole reserved in the rear side plate when the threshing tube is in a normal state. When the adaptive controlling device works, a cob can upward jack the threshing tube so that the threshing tube rotates around the hinge; and a gap between the rear side of the threshing tube and the threshing roller is controlled adaptively. By the adaptive controlling device for the size of the threshing roller cavity of the corn threshing machine, the size of an inlet of the threshing machine is unchanged, and requirements of adaptive high-efficiency threshing of the corn threshing machine on cobs with different sizes are met.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Agricultural thresher

InactiveCN106034572AEfficient threshingAutomatic centralized collectionThreshersAgricultural engineeringThreshing machine

Owner:安庆育朴机械技术开发有限公司

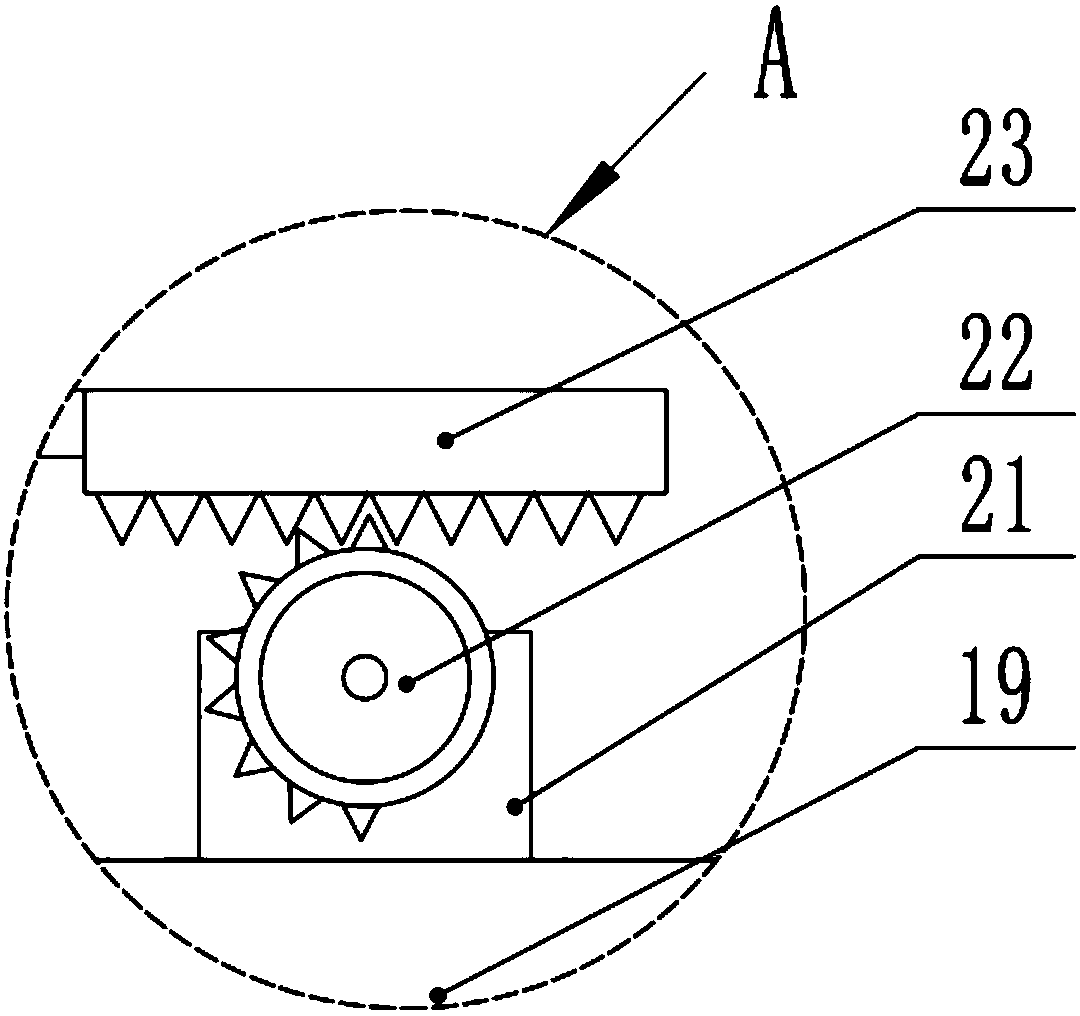

Gear matched type threshing and screening device for sunflower seeds

The invention discloses a gear matched type threshing and screening device for sunflower seeds. The gear matched type threshing and screening device comprises a base, a threshing tank, a conical threshing barrel, a threshing head and a screening tank. The threshing tank is arranged on the base, the conical threshing barrel is horizontally arranged inside the threshing tank, a threshing cavity is arranged inside the conical threshing barrel, the threshing head is arranged inside the threshing cavity, and the screening tank is slidably mounted on at least two groups of support slide bars. The gear matched type threshing and screening device has the advantages that rubbing effects can be realized by threshing protrusions on the threshing head and threshing protrusions inside the threshing cavity, and accordingly threshing can be carried out for the sunflower seeds; the gear matched type threshing and screening device with V-shaped grinding cavities is long in threshing stroke as comparedwith common threshing devices, accordingly, effective threshing can be carried out, threshing effects can be improved, and the purity of the sunflower seeds can be guaranteed; a second connecting rodcan be driven by a third connecting rod to move in the left-right directions, accordingly, the screening tank can be driven to move in the left-right directions, the sunflower seed sieving speeds canbe greatly increased, and the work efficiency can be greatly improved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Cereal threshing device

The invention discloses a cereal threshing device which comprises a threshing chamber, a threshing cylinder assembly, a first conveyor belt, a conveying barrel and a bagging port, the threshing cylinder assembly is arranged in the middle portion in the threshing chamber, and a fixed conveyer is arranged in the middle portion of the right sidewall of the threshing chamber and one right of the threshing cylinder assembly. During work, a first motor drives a second gear to rotate, first and third gears cooperate with each other to drive first and second conveyor belt assemblies to rotate, and thus, a worker can place crop straws between the first and second conveyor belt assemblies in an emptying port with cereals facing the threshing cylinder assembly, high efficiency threshing of the cerealis realized, threshing can be carried out without holding the straws by people, and the worker is safer; and the worker can place a bag under the bagging port to bag the cereals, and the labor intensity of manual cereal collection is reduced.

Owner:全椒县汊河农机服务专业合作社

Crankshaft connecting rod type sunflower seed threshing and screening device

The invention discloses a crankshaft connecting rod type sunflower seed threshing and screening device comprising a base, a threshing box, a conical threshing cylinder, a threshing head and a screening box; the base is provided with the threshing box; the conical threshing cylinder is horizontally arranged in the threshing box; a threshing cavity is arranged inside the conical threshing cylinder;the threshing head is arranged inside the threshing cavity; and at least two groups of supporting sliding rods are arranged and are slidably provided with the screening box. Sunflower seeds are threshed by mutual friction between threshing bulges on the threshing head and threshing bulges inside the threshing cavity; compared with a common threshing device, the crankshaft connecting rod type sunflower seed threshing and screening device has the advantages that the threshing stroke is longer due to the adoption of a V-shaped grinding cavity, so that the threshing is more effective, the threshing effect is improved, and the purity of the sunflower seeds is guaranteed; and a third connecting rod drives a second connecting rod to move left and right, so that the screening box is driven to moveleft and right, and furthermore, the screening speed of the sunflower seeds and the work efficiency are greatly increased.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Full-automatic corn thresher for processing agricultural products

The invention discloses a full-automatic corn thresher for processing agricultural products. The full-automatic corn thresher comprises a vertical shaft, a smashing device, a large conical gear and a horizontal shaft. A driving gear is arranged at the side edge of the vertical shaft, a small conical gear is arranged at the side edge of the driving gear and arranged on the horizontal shaft, a corn-kernel discharging pipe is arranged below the horizontal shaft, a V-shaped belt wheel is arranged at the side edge of the horizontal shaft, a sealing ring is arranged outside the horizontal shaft, a lower machine frame is arranged on the sealing ring, a corncob discharging pipe is arranged below the lower machine frame, the smashing device is arranged on the lower machine frame, and the large conical gear is arranged on the driving gear. The full-automatic corn thresher has the advantages that corn kernels are effectively and efficiently threshed through the large conical gear and a fixing jaw plate, working efficiency is improved, and using is convenient.

Owner:张旭光

Agricultural threshing machine

InactiveCN108271537AHigh threshing rateImprove threshing speedThreshersAgricultural engineeringThreshing machine

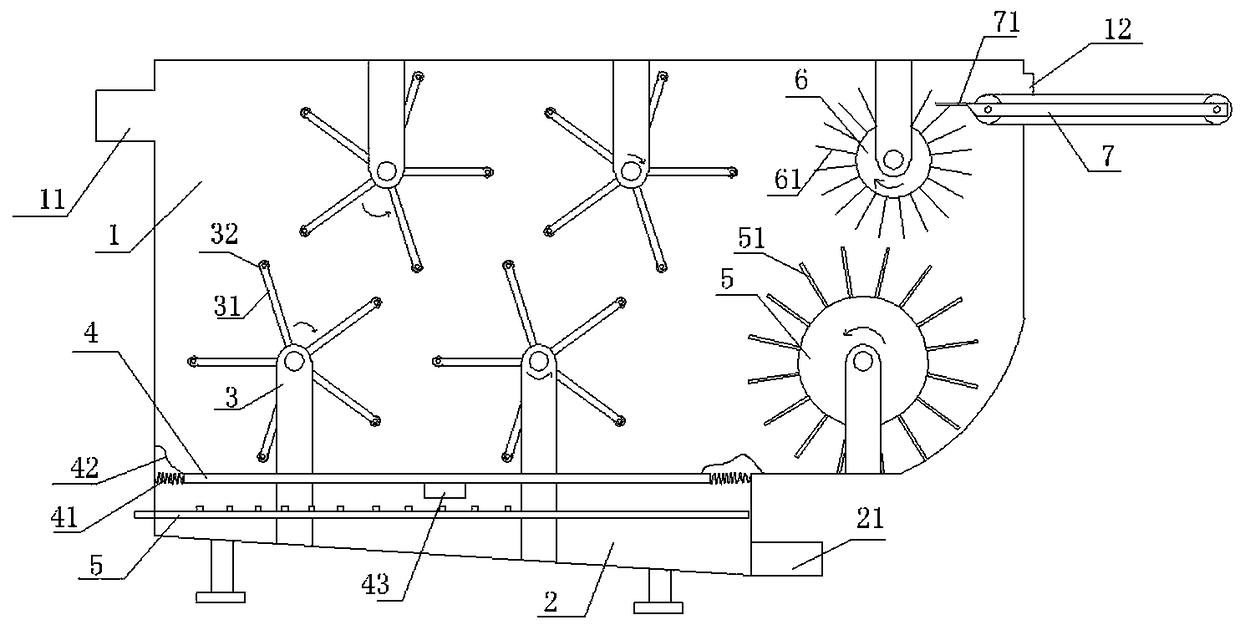

The invention relates to an agricultural threshing machine which comprises a chamber. The chamber is internally partitioned into an upper threshing chamber and a lower discharging chamber by a vibrating screen in horizontal arrangement. The left top and the right top of the threshing chamber are provided with a feeding port and a waste outlet respectively. The bottom wall of the discharging chamber is inclined, and the bottommost end of the bottom wall of the discharging chamber is provided with a discharging port. A plurality of groups of upper and lower threshers are arranged in the threshing chamber, a frame of each upper thresher is connected with the top wall of the threshing chamber, the bottom of a frame of each lower thresher is connected with the bottom wall of the discharging chamber while the top penetrates a notch reserved in the vibrating screen, each frame is connected with a rotating shaft driven by a motor, each rotating shaft is radially provided with a plurality of swing arms, and a threshing drum is arranged at the top of each swing arm. A conveying belt is horizontally arranged at the waste outlet and provided with a straw receiving fork horizontally arranged atthe end of a frame in the chamber, a straw raising drum is arranged on the lateral side of the conveying belt and driven by a motor, a body of the straw raising drum is provided with a plurality of fork rods, and the fork rods and the straw receiving fork are staggered. The agricultural threshing machine has advantages of simple structure, great threshing effects and high efficiency.

Owner:登封市绿奥农林科技有限公司

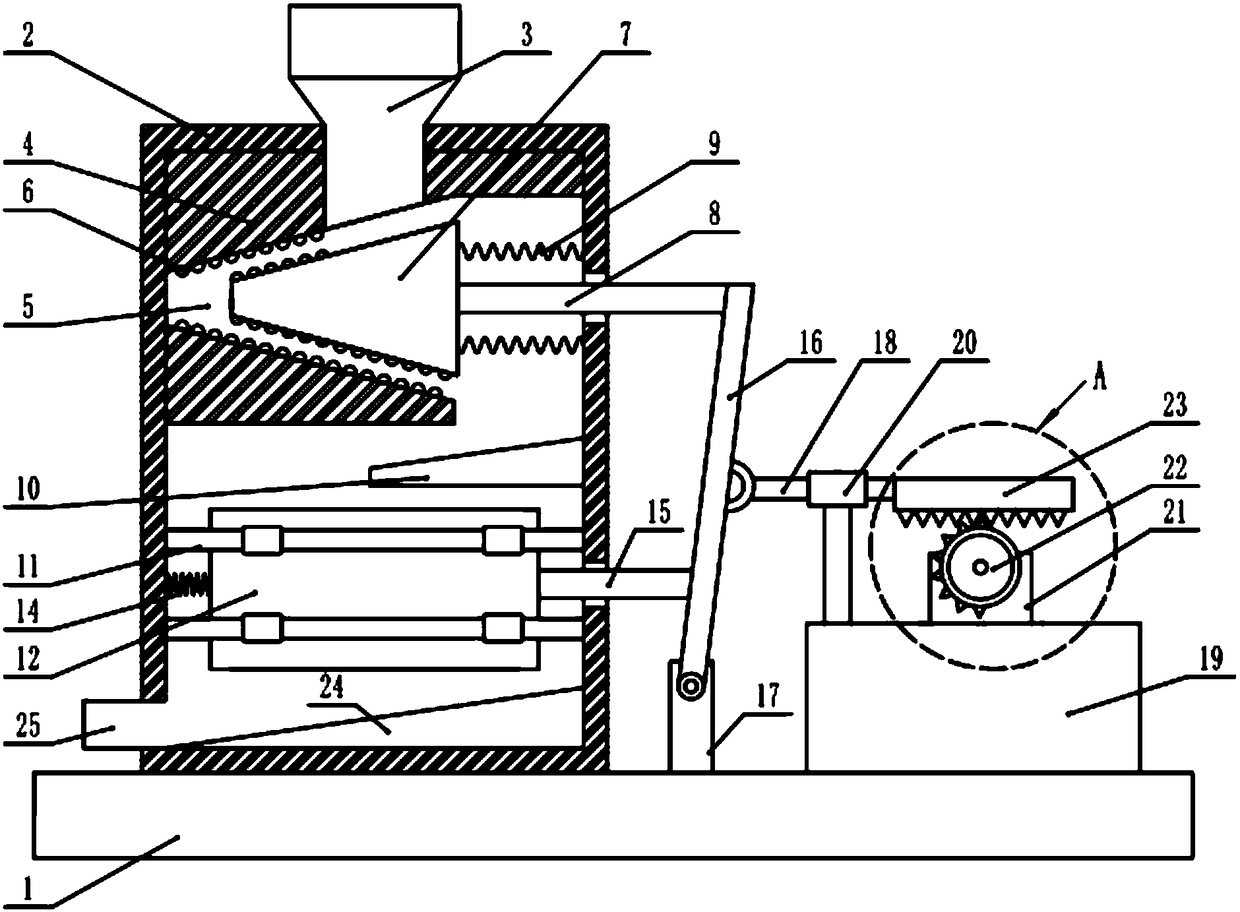

Efficient corn thresher

InactiveCN109168648ASolve low work efficiencyEfficient threshingThreshersPower beltArchitectural engineering

The invention discloses an efficient corn thresher, which comprises a box body and a power belt. The left side of the box body is fixed with a cover body, the left side of the inner cavity of the cover body is fixed with a first motor, the output end of the first motor is fixed with a first rotating rod, the right end of the first rotating rod runs through the cover body and the box body in turn and is fixed with a first threshing rod, and the right side of the first threshing rod is movably connected with the inner wall of the box body through a bearing. Through arranging the first motor, thefirst rotating rod, the first threshing rod, a first belt pulley, a second rotating rod, a second threshing rod, a second belt pulley, an auxiliary threshing rod, a funnel and a threshing tube for matched use, the problem of low working efficiency of the existing corn thresher is solved. The efficient corn thresher disclosed in the invention has the advantages that efficient threshing is achieved; the working efficiency is improved; the use cost is reduced; the labor is saved, and use by people is facilitated.

Owner:许昌泰禾农业科技发展有限公司

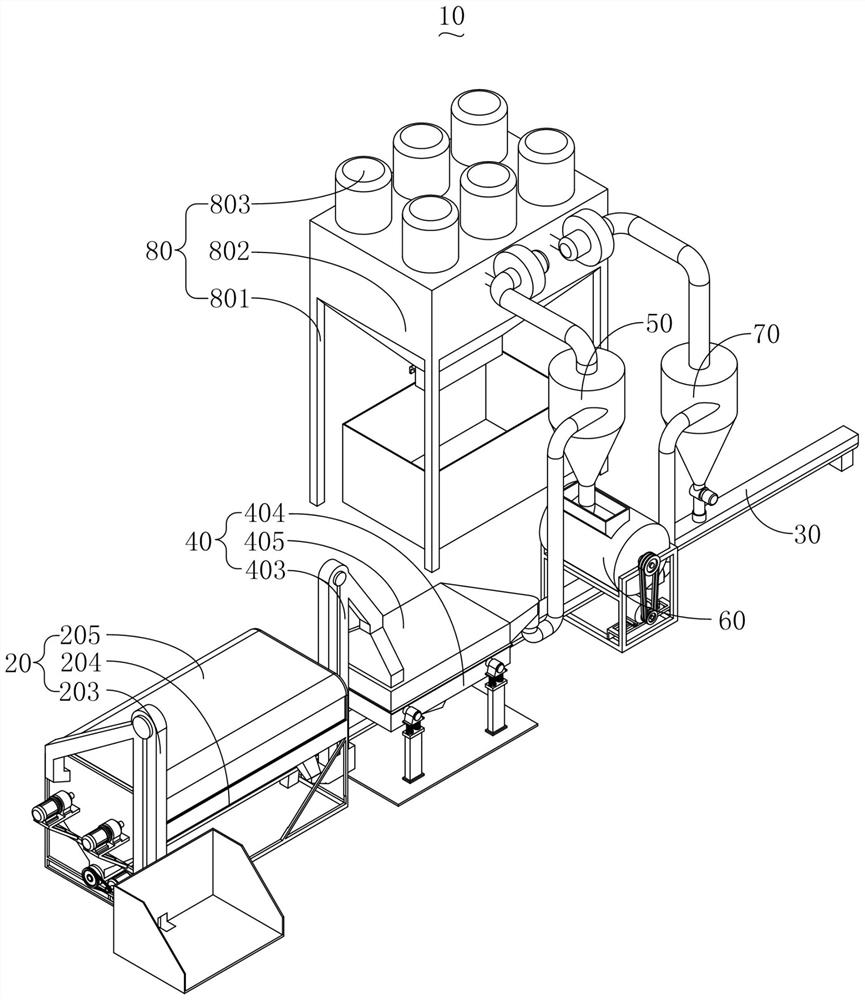

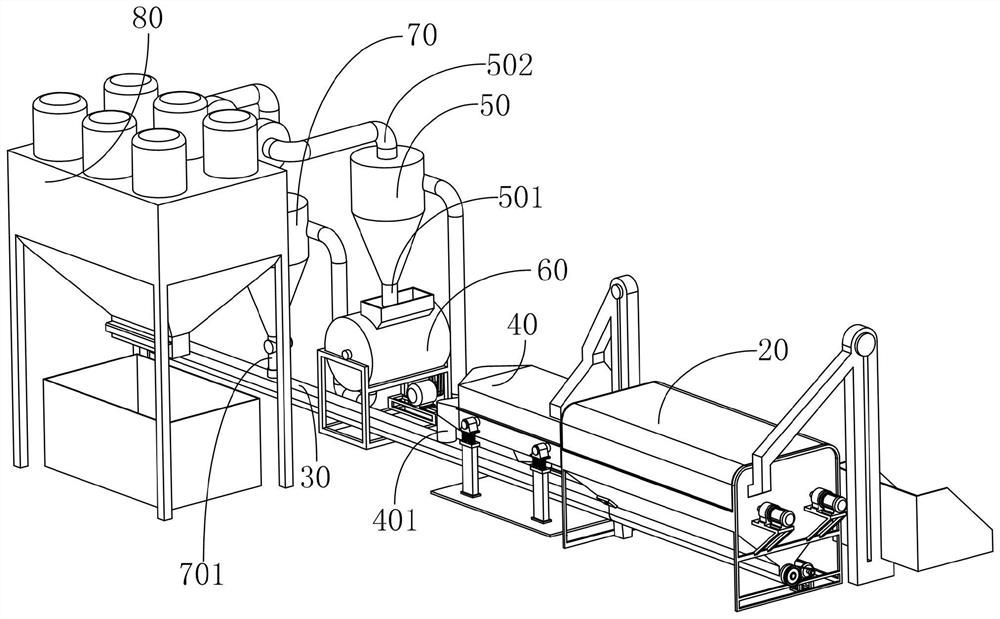

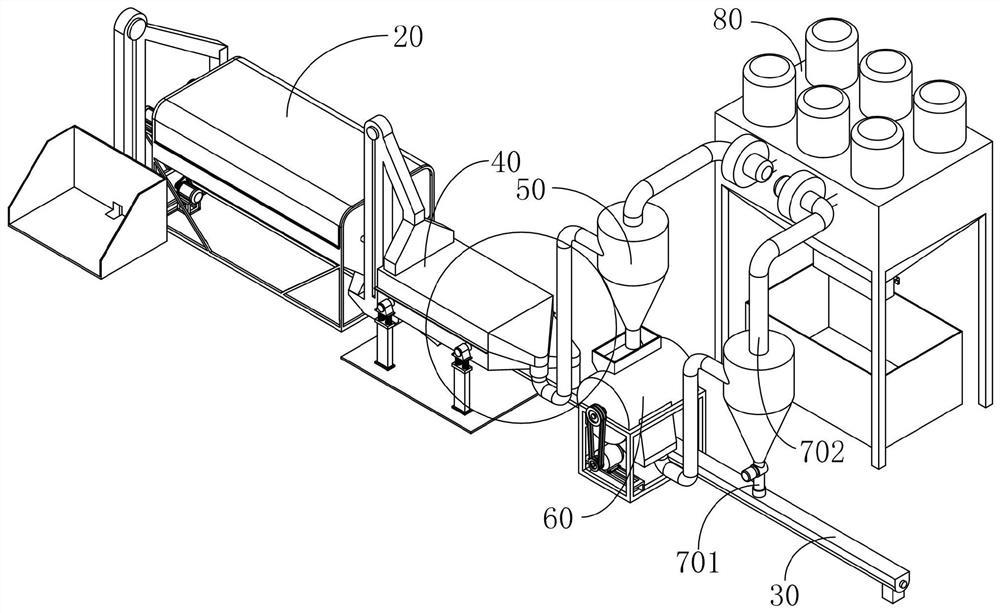

Unhulled rice threshing device

PendingCN111631024AImprove efficiencyShort time spentThreshersAgricultural engineeringAgricultural science

The invention relates to an unhulled rice threshing device. The unhulled rice threshing device comprises a cylindrical sieve device, an unhulled rice conveying device, a vibrating sieve device, a first cyclone separation device, an unhulled rice thresher, a second cyclone separation device and a straw recovering device, wherein the cylindrical sieve device is provided with a first unhulled rice discharge opening and a first sundry discharge opening; the vibrating sieve device is provided with a second unhulled rice discharge opening and a second sundry discharge opening, the second unhulled rice discharge opening communicates with a feed opening of the unhulled rice conveying device, and the second sundry discharge opening communicates with a feed opening of the first cyclone separation device; the first cyclone separation device is provided with a third unhulled rice discharge opening and a third sundry discharge opening, the third sundry discharge opening communicates with a feed opening of the straw recovering device, and the third unhulled rice discharge opening communicates with a feed opening of the unhulled rice thresher; and the second cyclone separation device is providedwith a fourth unhulled rice discharge opening and a fourth sundry discharge opening, the fourth unhulled rice discharge opening communicates with a feed opening of the unhulled rice conveying device,and the fourth sundry discharge opening communicates with a feed opening of the straw recovering device.

Owner:NINGXIA ZHONGHANG ZHENGFEI SAIWAIXIANG HALAL FOOD CO LTD

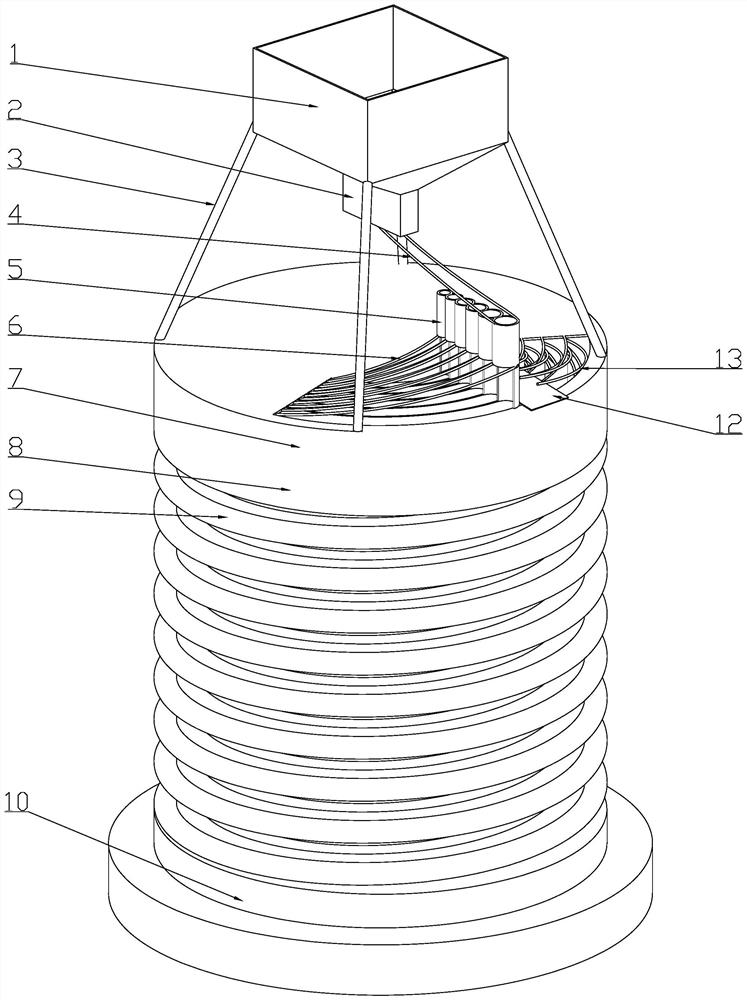

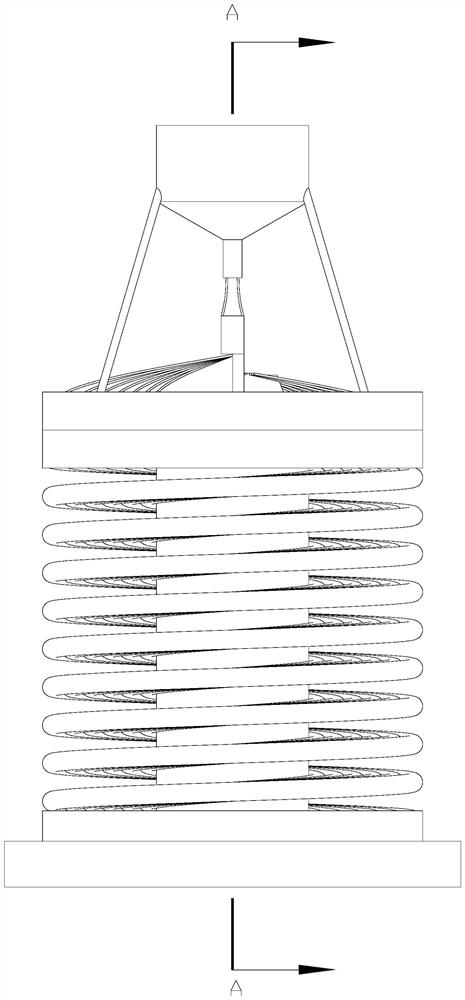

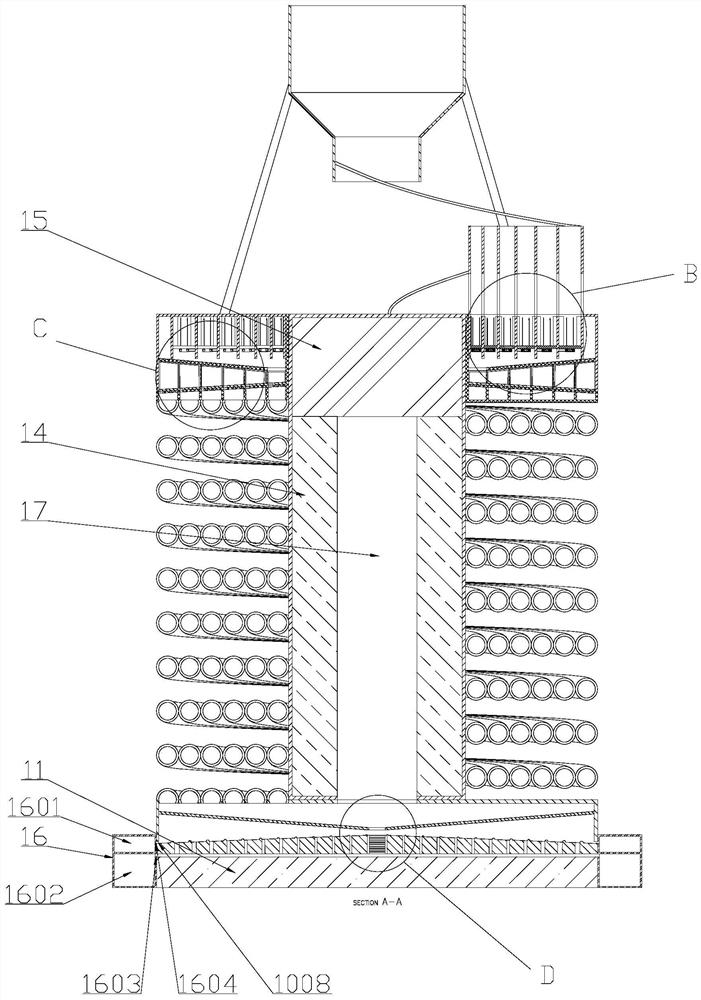

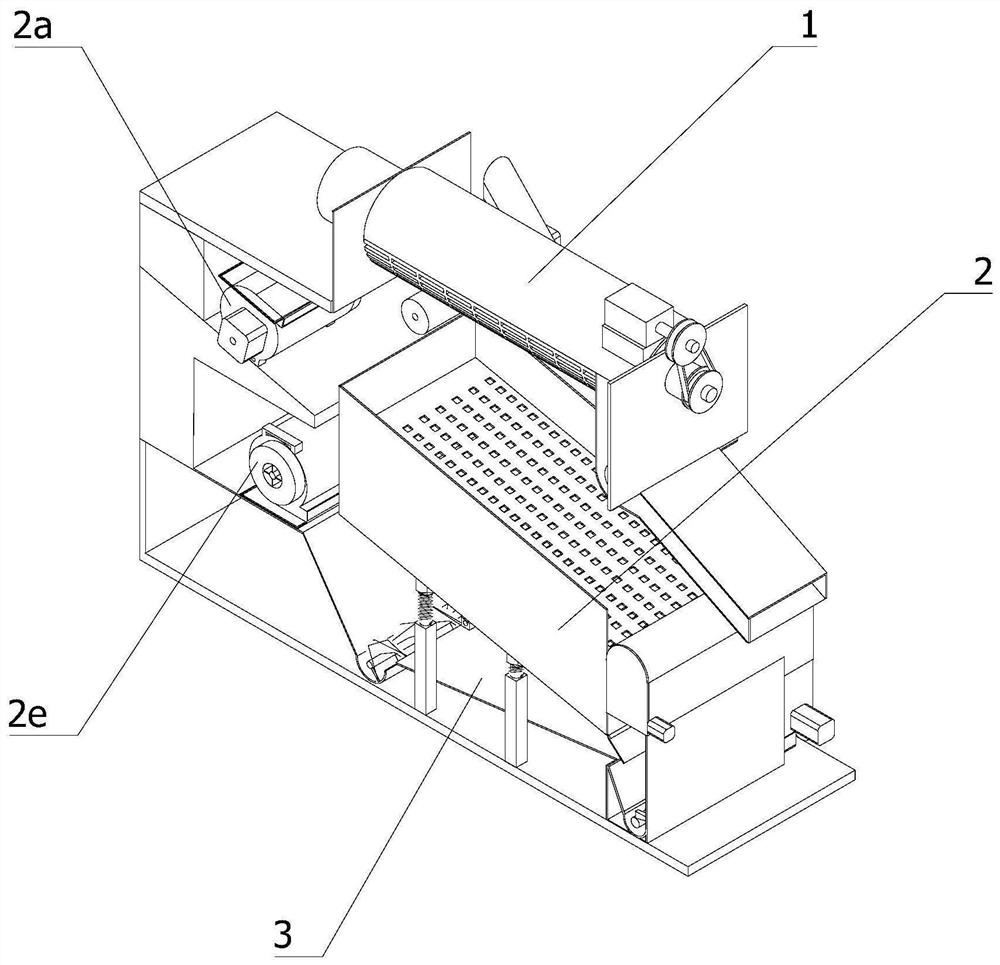

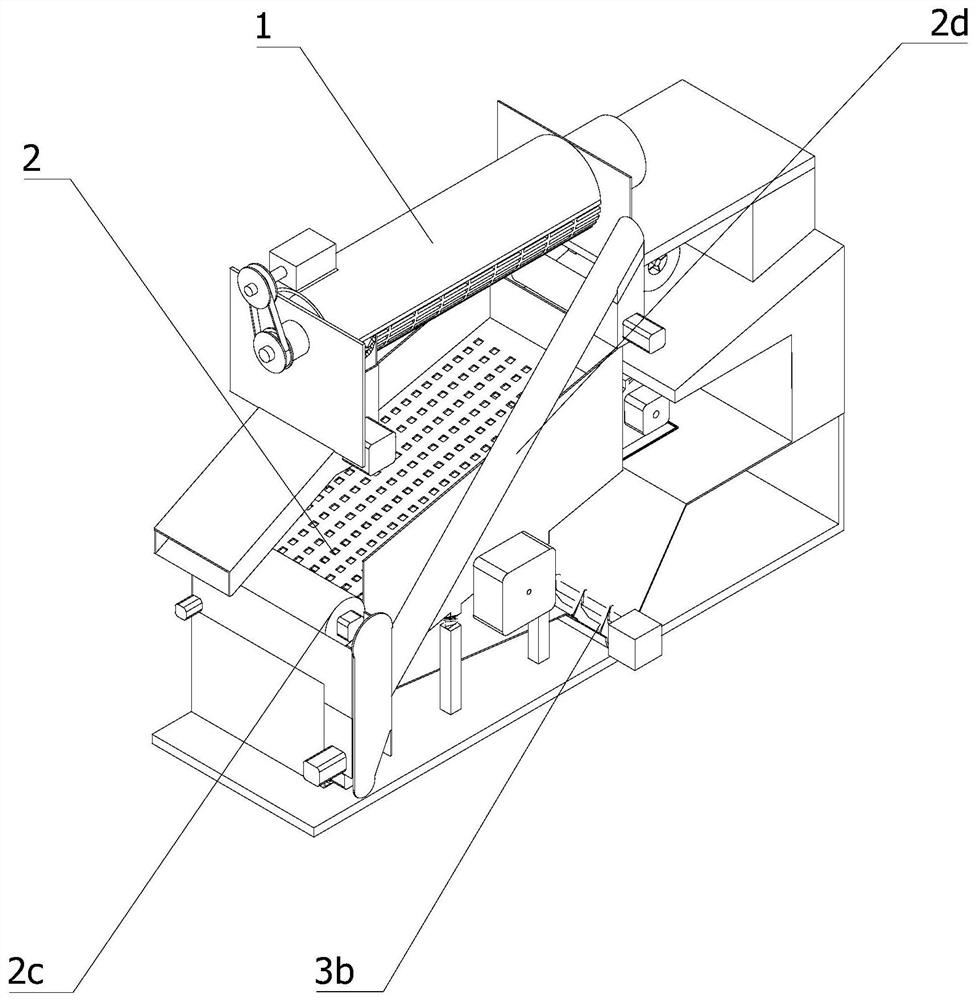

Refined corn flour processing equipment and corn processing method

PendingCN114158359AThrift threshingEfficient threshingGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention belongs to the field of agricultural product fine processing, and particularly relates to refined corn flour processing equipment and a corn processing method.The refined corn flour processing equipment comprises a feeding box, a discharging opening is formed in the lower portion of the feeding box, the feeding box and the discharging opening are fixed through four supporting frames, the discharging opening is provided with two sorting guide rails, and the sorting guide rails are downwards connected with sorting feeding openings; a threshing mechanism is connected below the sorting feed inlet, a press-in rail and a separation rail are connected between the sorting feed inlet and the threshing mechanism, a sorting mechanism is arranged below the threshing mechanism, a ventilator is arranged at the center of circle of the middle of the threshing mechanism, a dryer is arranged below the ventilator, and a plurality of spiral pipelines are arranged on the outer side of the dryer and located below the sorting mechanism. A plurality of small protrusions are arranged in the spiral pipeline, a peeling and sorting mechanism is arranged below the drying mechanism, a grinding mechanism is connected below the peeling and sorting mechanism, and a collecting box is arranged on the outer side of the grinding mechanism. According to the invention, direct production from corn cobs to corn flour is realized more efficiently and quickly.

Owner:王志民

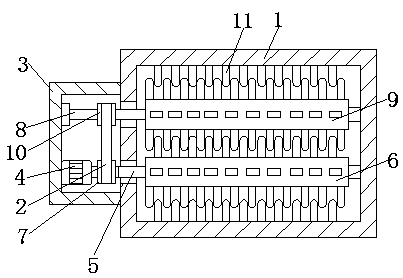

High-throughput threshing and cleaning device for combine harvester

InactiveCN113767762AFunction to solve loop filteringIncrease the net off rateThreshersAgricultural engineeringThreshing

The invention discloses a high-throughput threshing and cleaning device for a combine harvester, relates to the technical field of agricultural equipment, and solves the technical problem about how to carry out cyclic screening in the threshing and cleaning device. The high-throughput threshing and cleaning device comprises a threshing device, a cleaning device and a grain conveying device; the cleaning device comprises a first fan, a double-layer screen cloth vibrating screen, a separating device, a first conveying device and a second fan; the double-layer screen cloth vibrating screen is located between the threshing device and the grain conveying device, a first screen cloth waste outlet of the double-layer screen cloth vibrating screen communicates with a feeding port of the separating device, and the first conveying device communicates with a feeding port of the double-layer screen cloth vibrating screen and a discharging port of the separating device; the first fan is used for outputting high-speed airflow towards the outside of the threshing and cleaning device between the double-layer screen cloth vibrating screen and the threshing device; and the second fan is used for outputting high-speed airflow towards the outside of the threshing and cleaning device between the double-layer screen cloth vibrating screen and the grain conveying device, so that high throughput is achieved while high-quality screening of crops is realized.

Owner:JINHUA VOCATIONAL TECH COLLEGE

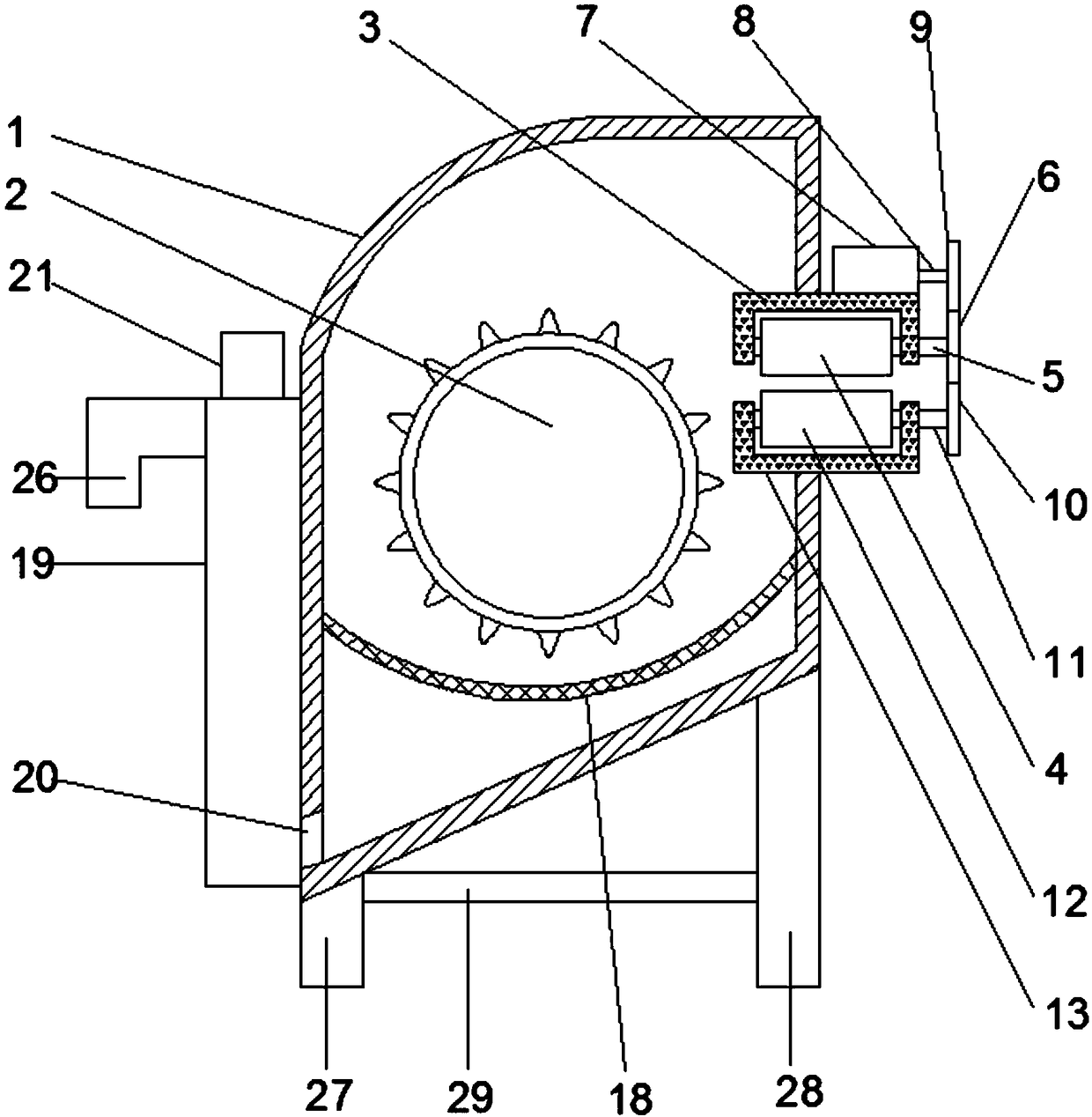

Agricultural machinery for threshing various crops

InactiveCN111373934AEfficient threshingPromote repairThreshersAgricultural scienceAgricultural engineering

The invention relates to an agricultural machinery device, in particular to an agricultural machinery for threshing various crops. The agricultural machinery for threshing various crops comprises a feeding sealed casing, front supporting legs, rear supporting legs, a cereal filter plate and a bottom end sealed casing, wherein the feeding sealed casing is fixedly connected with the bottom end sealed casing; the bottom end sealed casing is fixedly connected with the front supporting legs; the feeding sealed casing is fixedly connected with the rear supporting legs; the cereal filter plate is rotatably mounted on a groove in the bottom end sealed casing; and the threshing mechanism is mounted on the feeding sealed casing. According to the agricultural machinery for threshing various crops disclosed by the invention, a manner of multi-tooth swinging is adopted, so that the working efficiency of the threshing machine is improved, and seeds are separated from straws; and the agricultural machinery for threshing various crops has the function of screening, and can effectively separate the straws and impurities from the seeds.

Owner:任莉颖

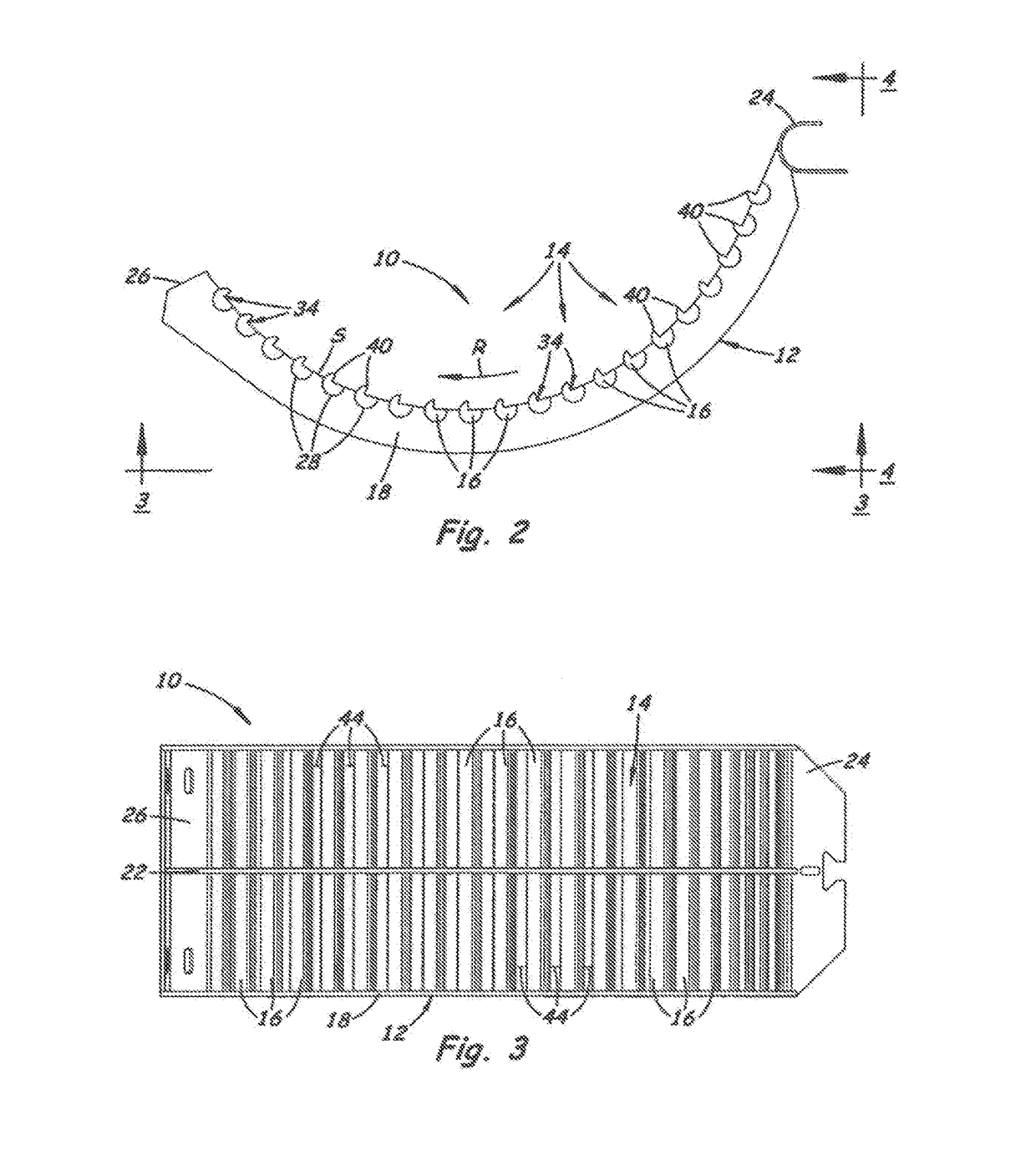

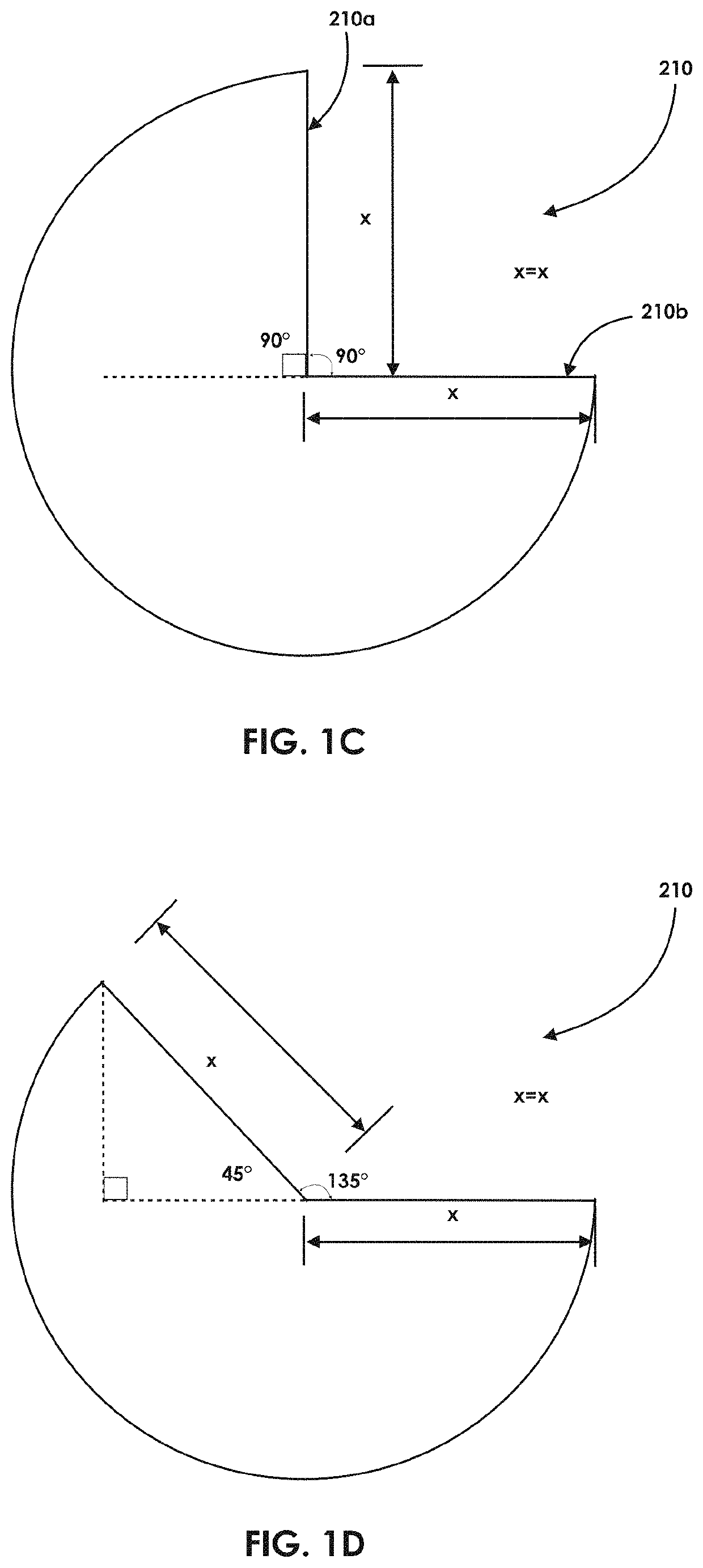

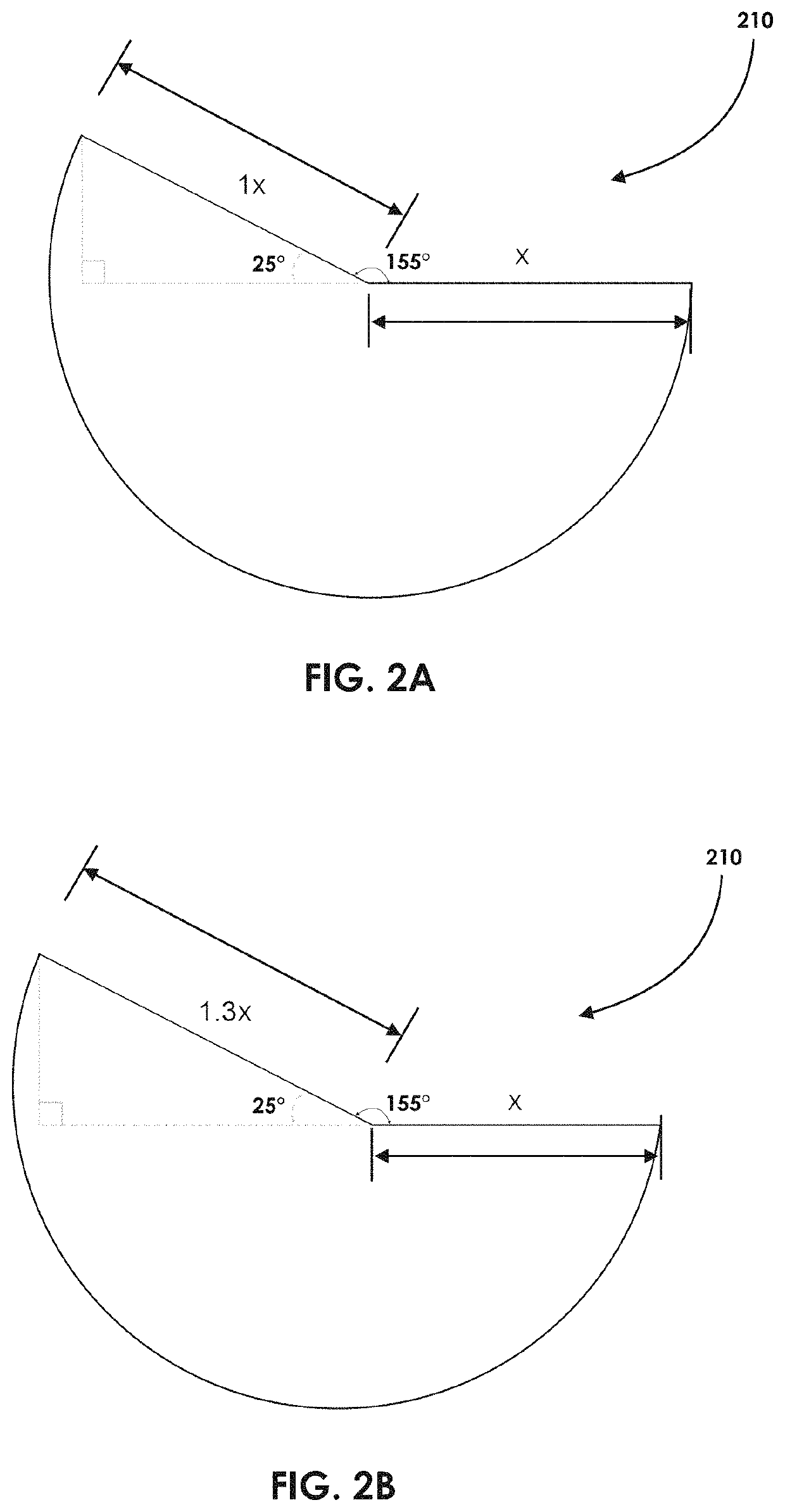

Combine harvester concave threshing bar

ActiveUS11464169B2Least amount of grain damageEfficient threshingThreshersAntineoplastic agentsAgricultural engineeringStructural engineering

A threshing concave assembly is disclosed having a threshing concave bar wherein the threshing bar is comprised of two threshing surfaces having a dihedral angle relationship relative to each other. In addition, in another aspect the threshing bar can be comprised of two dihedral surfaces whereby one surface face has about 130% greater surface area than its adjacent surface face. Alternatively, one surface face of the threshing bar can be 1.3x wider than its adjacent surface face. In another aspect the threshing bar can be comprised of two dihedral surfaces whereby one surface face has about a 170% greater surface area than its adjacent surface face.

Owner:ROBERTSON BRIAN G

Axial rheological gap bionic corn threshing device

The invention discloses an axial rheological gap bionic corn threshing device. The axial rheological gap bionic corn threshing device comprises a machine frame, a threshing roller, a concave plate sieve, a machine cover and a corncob recycling mechanism, wherein the machine cover is fixed at the lower part of the machine frame; the concave plate sieve is fixed in the machine cover; the threshing roller is fixed in the concave plate sieve; the corncob recycling mechanism is fixed ar the back part of the machine cover; the cylindrical threshing roller and the conical concave plate sieve jointly form threshing gaps which are continuously changed from big to small to promote that corn ears are subjected to effective threshing action all the time; and threshing teeth on the outer surface of a bionic threshing bridge and threshing columns which are distributed on the inner surface of the concave plate sieve in a copying arc form jointly form the threshing functional surface, microscopic threshing moment is applied to corn grains, and the removed corn grains are separated out timely through a grain leaking groove in the surface of the bionic threshing bridge and a separating port in the surface of the concave plate sieve. The axial rheological gap bionic corn threshing device has high threshing efficiency and few crushed grains, and can synchronously collect the corncobs.

Owner:SHANDONG JUMING MASCH CO LTD

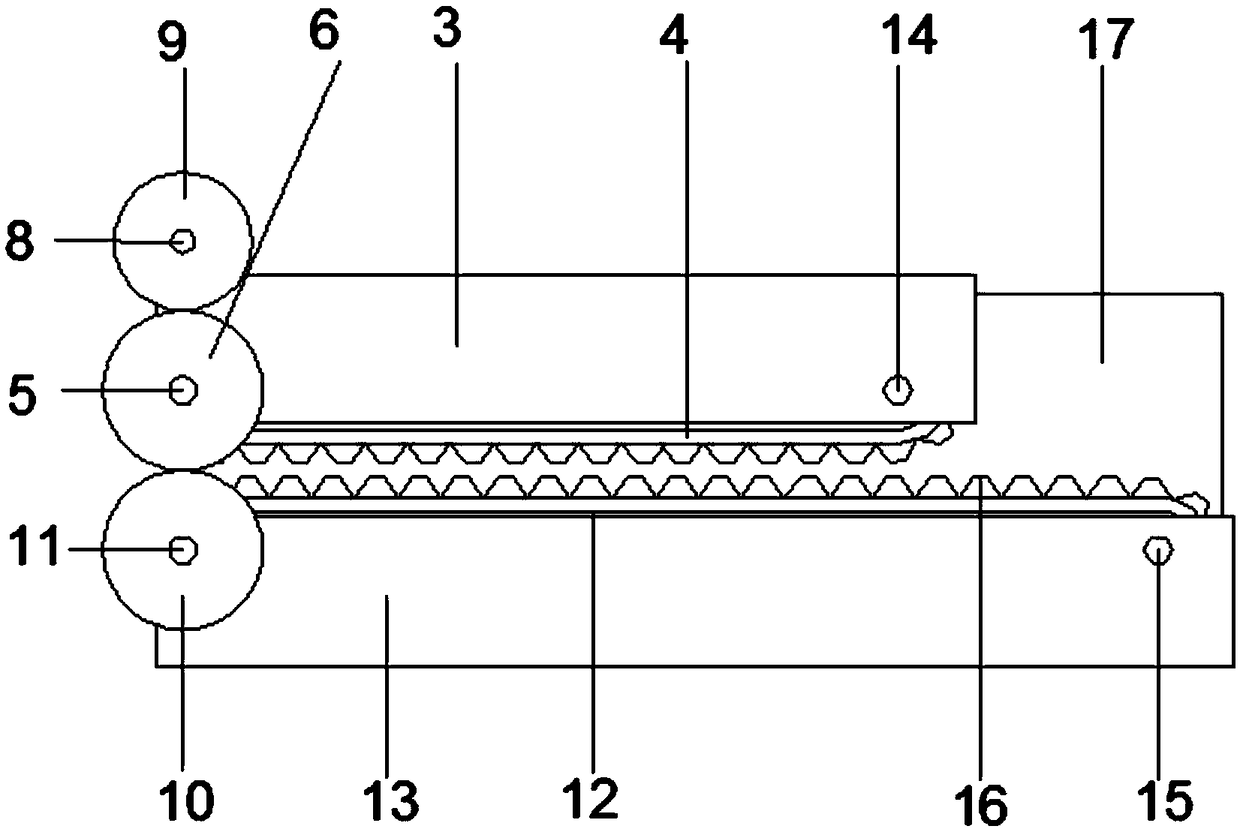

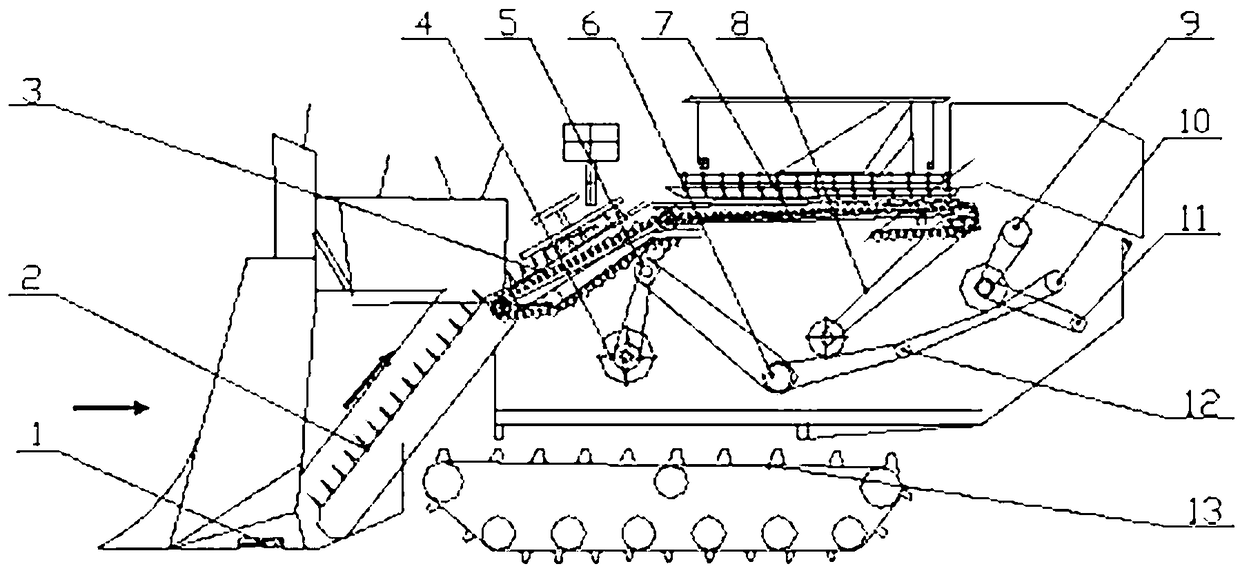

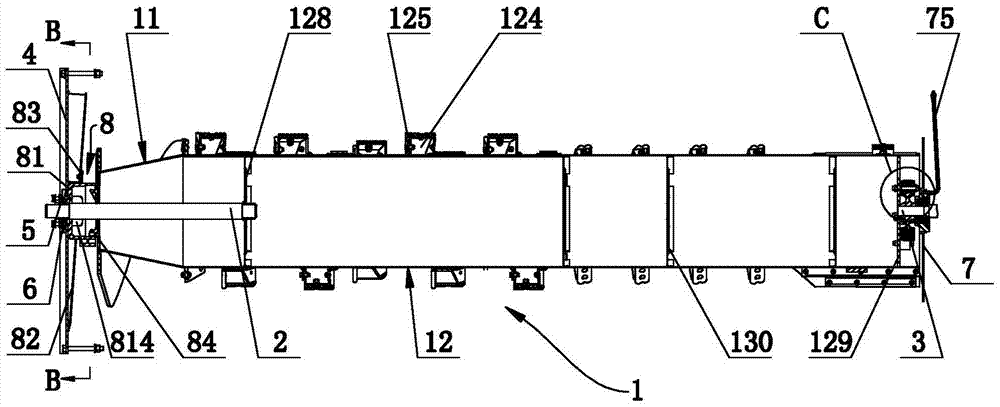

Novel flat threshing combine harvester

InactiveCN108076788AEasy to transportSimple structureMowersThreshersManufacturing technologyEngineering

A novel flat threshing combine harvester is mainly composed of a header device, a threshing device, a cleaning device, a grain collecting device, a grass cutting and discharging device, a diesel engine and a running gear; the header device uses a L-shaped header for conveying so that the manufacturing technology is simple; grains can be recovered by a granule recovery tank during transverse conveying process the fallen grains can be directly conveyed to a threshing cylinder by means of an inclined recovery tank chain; rice can be tightly clamped by a clamping star-wheel during cutting and thenbe conveyed to the transverse conveying chain; traditional roller threshing device is replaced by the flat threshing device; arch-shaped teeth are uniformly distributed on a surface of a flat deviceso that the effective threshing area is large and the grains at the bottom ears of crops can be easily threshed and relatively short rice can also be threshed. The invention has the advantages of simple structure, convenient disassembly and maintenance, high work efficiency, reliable performance, facilitates the transportation of rice, more efficient threshing, and saves cost.

Owner:吴丽娜

Vertical axial flow drum

The invention discloses a longitudinal axial flow drum, which belongs to the technical field of combine harvester threshing and separation devices, and comprises a drum body, a drum front shaft, a power input shaft, a drum front bracket and a drum rear bracket, and the drum body includes a feeding part and a drum The body, the anti-winding element is provided between the front support of the roller and the feeding part, and the anti-winding element includes: a material guide crescent and a wedge-shaped roller front cover fixed on the front support of the roller, and the material guide crescent includes Disc and material guide plate, one end of the disc is fixedly installed on the front support of the drum, and the other end has an opening; the disc passes through the installation hole of the front cover of the drum; it is fixed on the front of the drum The front cover cover of the drum on the cover; the front protrusion of the drum fixed on the front end face of the feeding part, and the front protrusion of the drum is located in the opening. During the harvesting operation, the front axle of the drum is not easy to entangle the grass, and the working efficiency is high, which realizes the simultaneous harvesting of various crops, and does not need to replace the drum, which meets the user's profit demand.

Owner:LOVOL HEAVY IND CO LTD

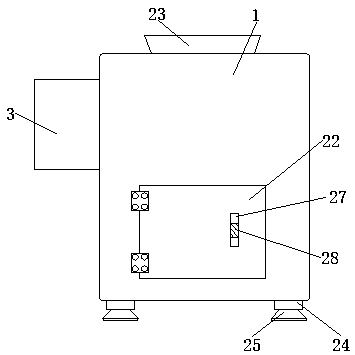

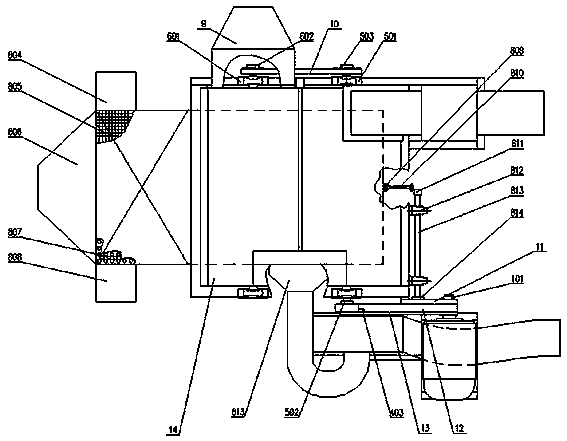

Device for pod and impurity removing of oil peony

PendingCN109769482AReduce breakage rateImprove pod removal rateThreshersPulp and paper industryUltimate tensile strength

The invention relates to a device for pod and impurity removing of an oil peony, and belongs to the field of agricultural product processing machinery. The device comprises a rack, a material hoist for conveying oil peony fruit pods without pod removing, a primary pod removing roller and a secondary pod removing roller arranged in parallel on the rack, vibrating screens for screening and a centrifugal fan for sucking off dust and debris, cover casings are arranged above the primary pod removing roller and the secondary pod removing roller, concave plates are arranged under the primary pod removing roller and the secondary pod removing roller, guiding hoppers are arranged below the concave plates, and the vibrating screens are arranged below the concave plates. The device can reduce the labor intensity, improve the production efficiency, facilitate the pod removing of the oil peony fruit pods and the removing of mixed sandstone, weeds, wood chips and the like, improve the pod removing rate and reduce peony kernel damage.

Owner:HENAN UNIV OF SCI & TECH

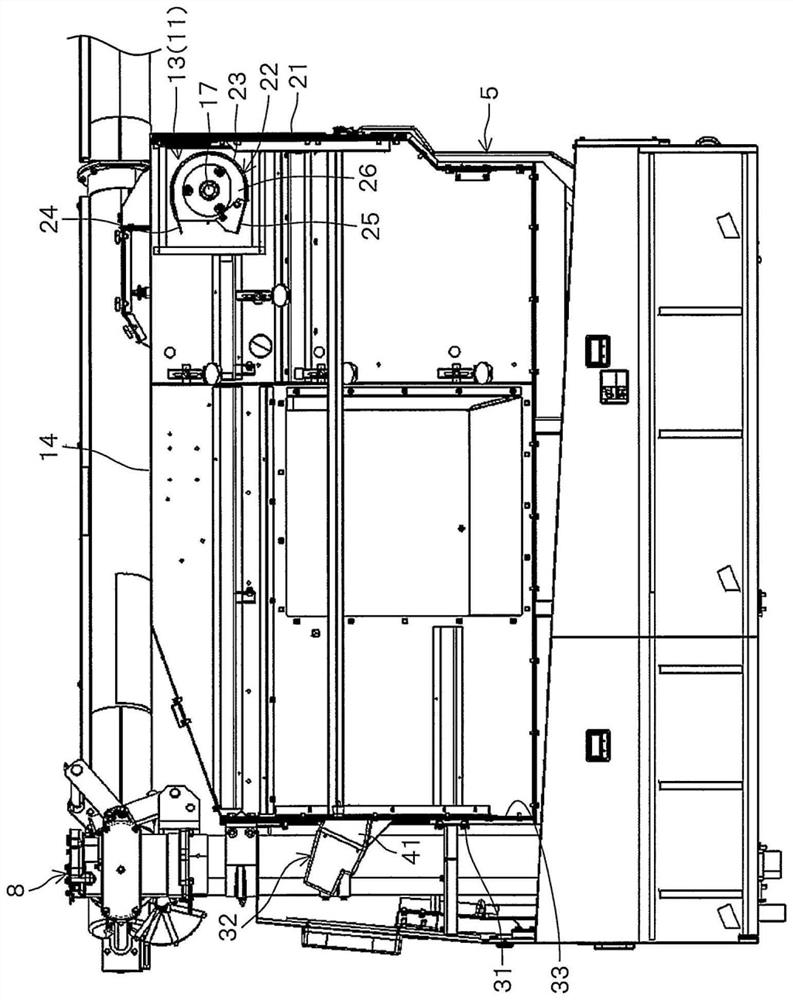

Combine harvester

PendingCN113853928AEfficient receptionEffective cutMowersThreshersAgricultural engineeringEnvironmental geology

The present invention provides a combine harvester in which a moisture sensor can satisfactorily receive grains scattered from a discharge port. A discharge part having a discharge port opened rearward is disposed at the upper part of the front end in a grain tank (5) for storing grains. When the rotating blade arranged in the discharge part rotates in the direction of passing through the discharge port from bottom to top, the grains are swept by the rotating blade and fly into the grain tank (5) from the discharge port. A moisture sensor (32) for receiving the grains and detecting the moisture content of the grains is arranged on the rear surface (33) in the grain tank (5) at a position which is higher than the center in the vertical direction and lower than the discharge port and at a position which is closer to the right side than the center in the left-right direction.

Owner:KUBOTA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com