Adaptive controlling device for size of threshing roller cavity of corn threshing machine

An adaptive adjustment, threshing roller technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of low threshing effect and threshing efficiency, complex structure, and inability to change automatically, so as to meet the requirements of self-adaptive and efficient threshing , Easy to enter, and ensure the effect of the same size of the entrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be further detailed in combination with examples and drawings:

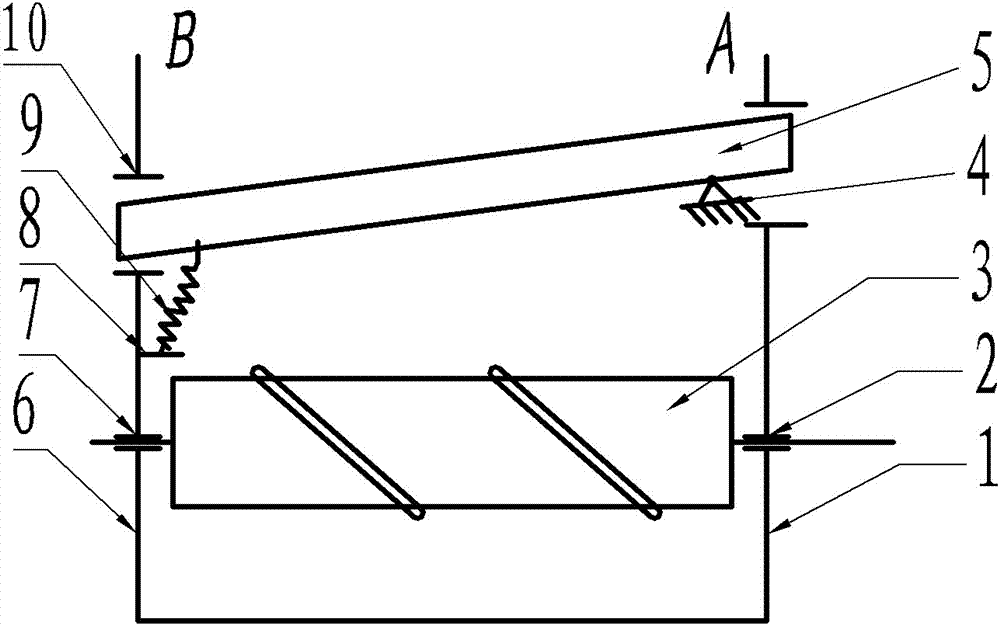

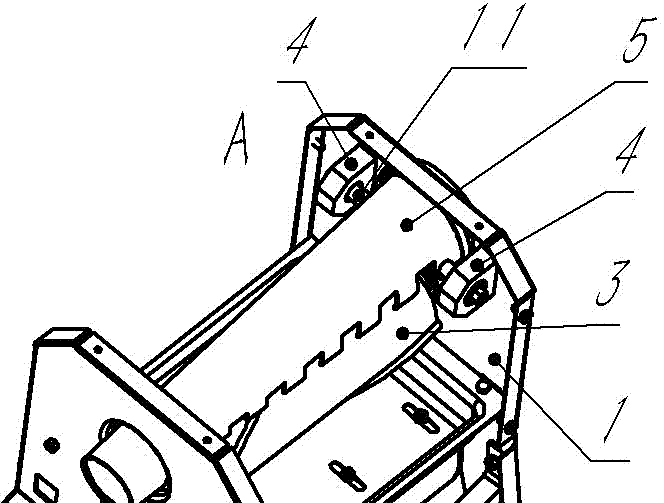

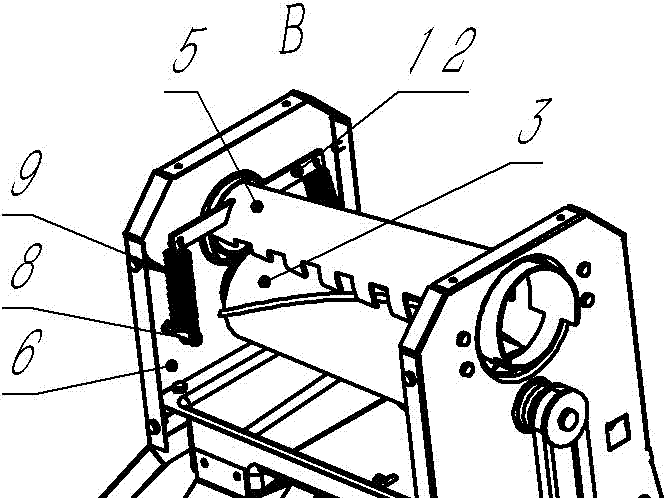

[0026] Such as figure 1 , figure 2 , image 3 As shown, the adaptive adjusting device for the size of the threshing roller cavity of the corn thresher of the present invention is mainly composed of the front side plate 1, the rear side plate 6, the threshing roller 3, the threshing tube 5, the vertical shaft 11, and the front side rotating hinge of the threshing tube 4. The rear side of the threshing tube is composed of a tension spring 9, a bearing before the threshing roller rotates, a bearing 7, a tension spring fixing rod 8 and a tension spring connecting rod 12 after the threshing roller rotates.

[0027] The threshing roller 3 is fixed on the front side plate 1 and the rear side plate 6 through the front bearing 2 and the rear side plate 6 after the threshing roller rotates. The threshing roller 3 can be driven by the outside under the support of the front sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com