Patents

Literature

938 results about "Threshing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A threshing machine or a thresher is a piece of farm equipment that threshes grain, that is, it removes the seeds from the stalks and husks. It does so by beating the plant to make the seeds fall out.

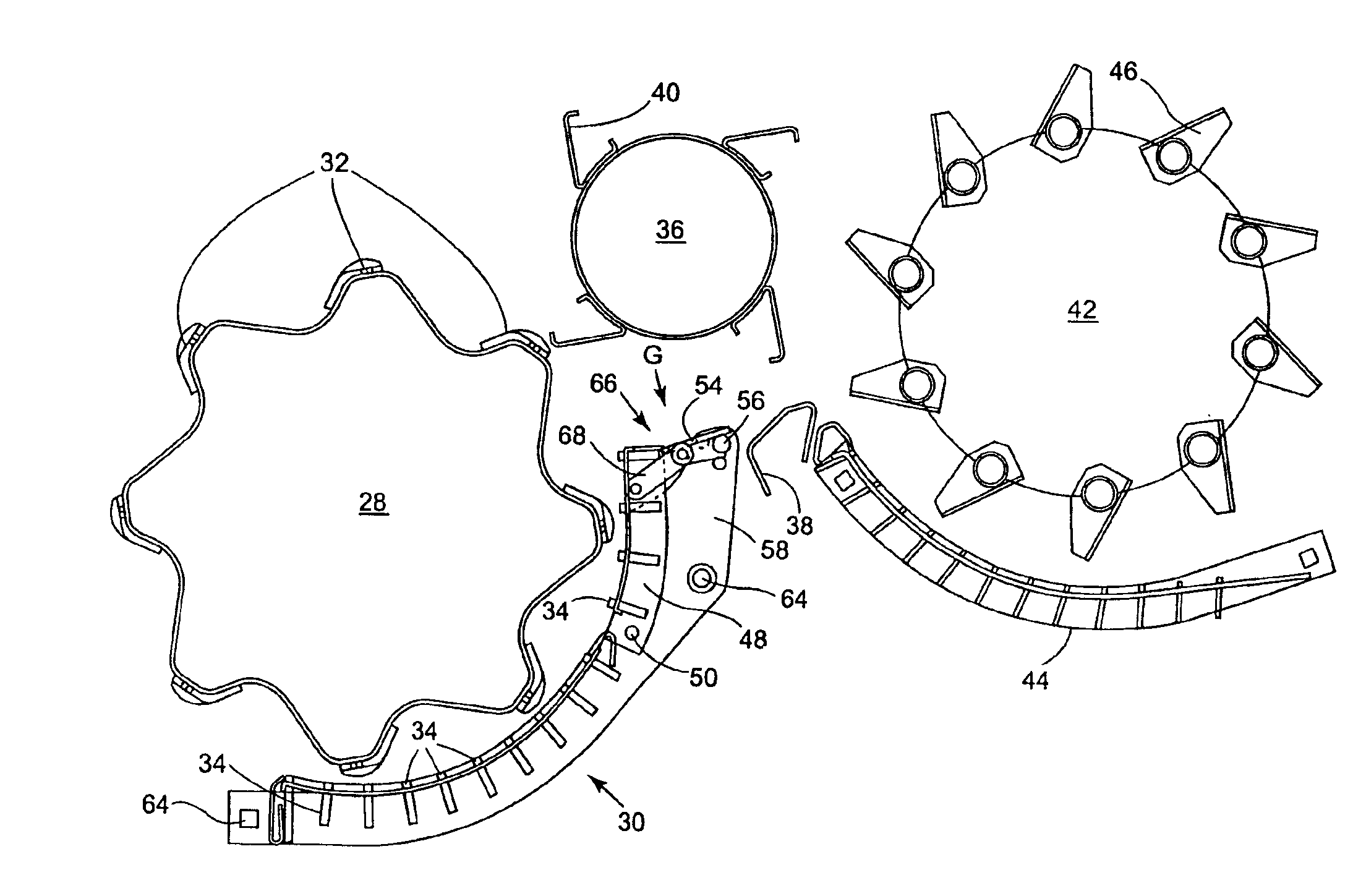

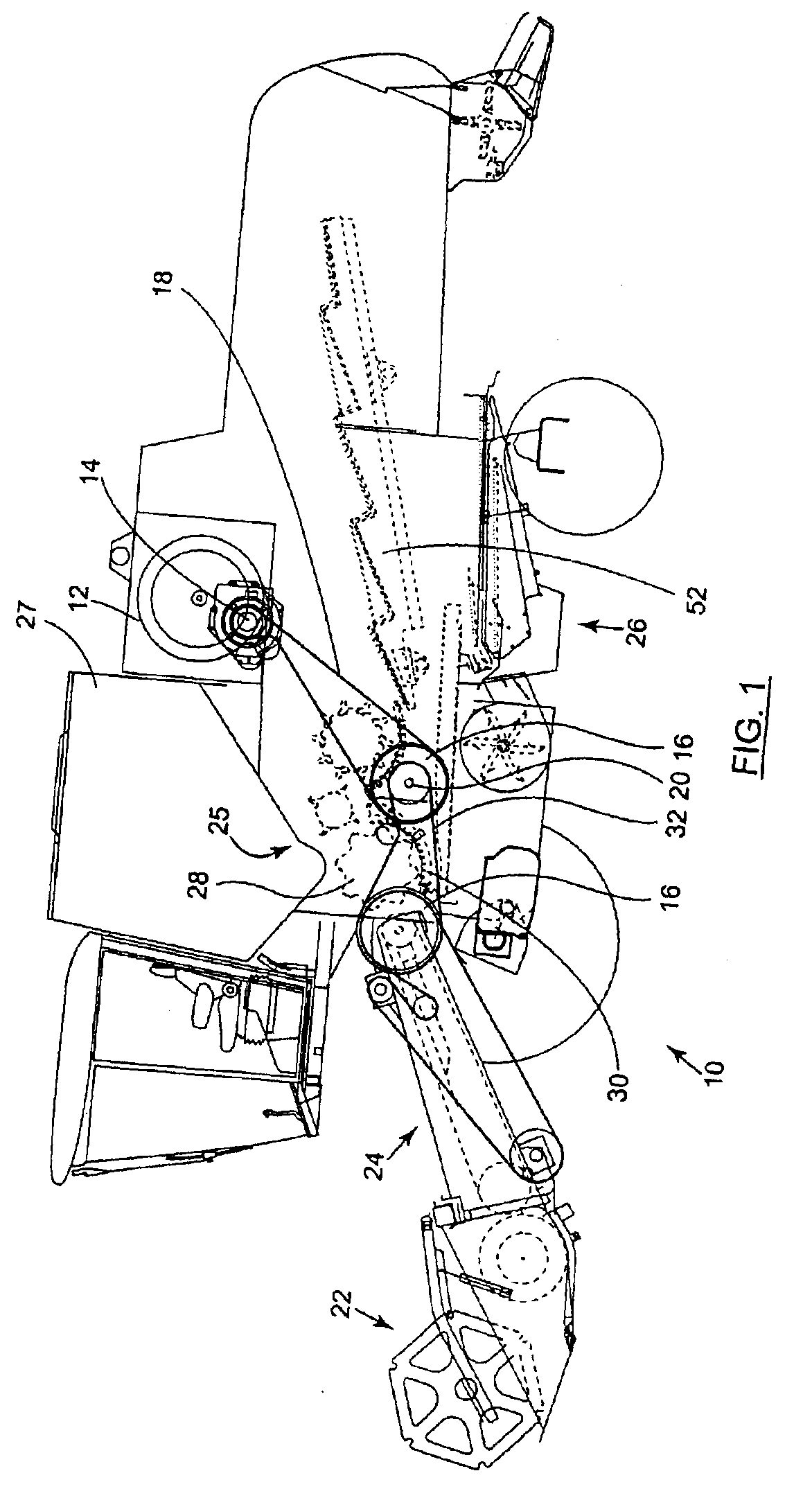

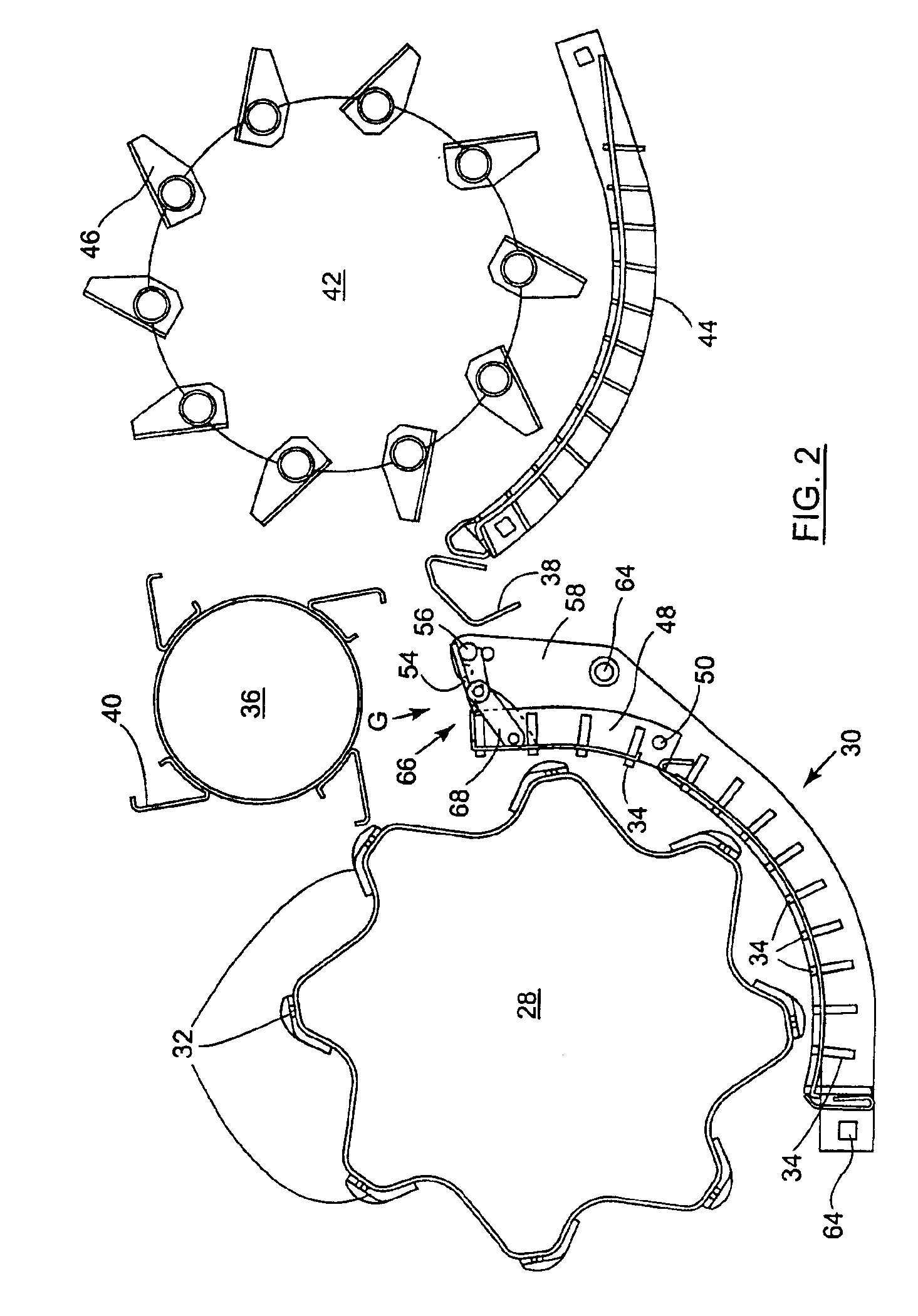

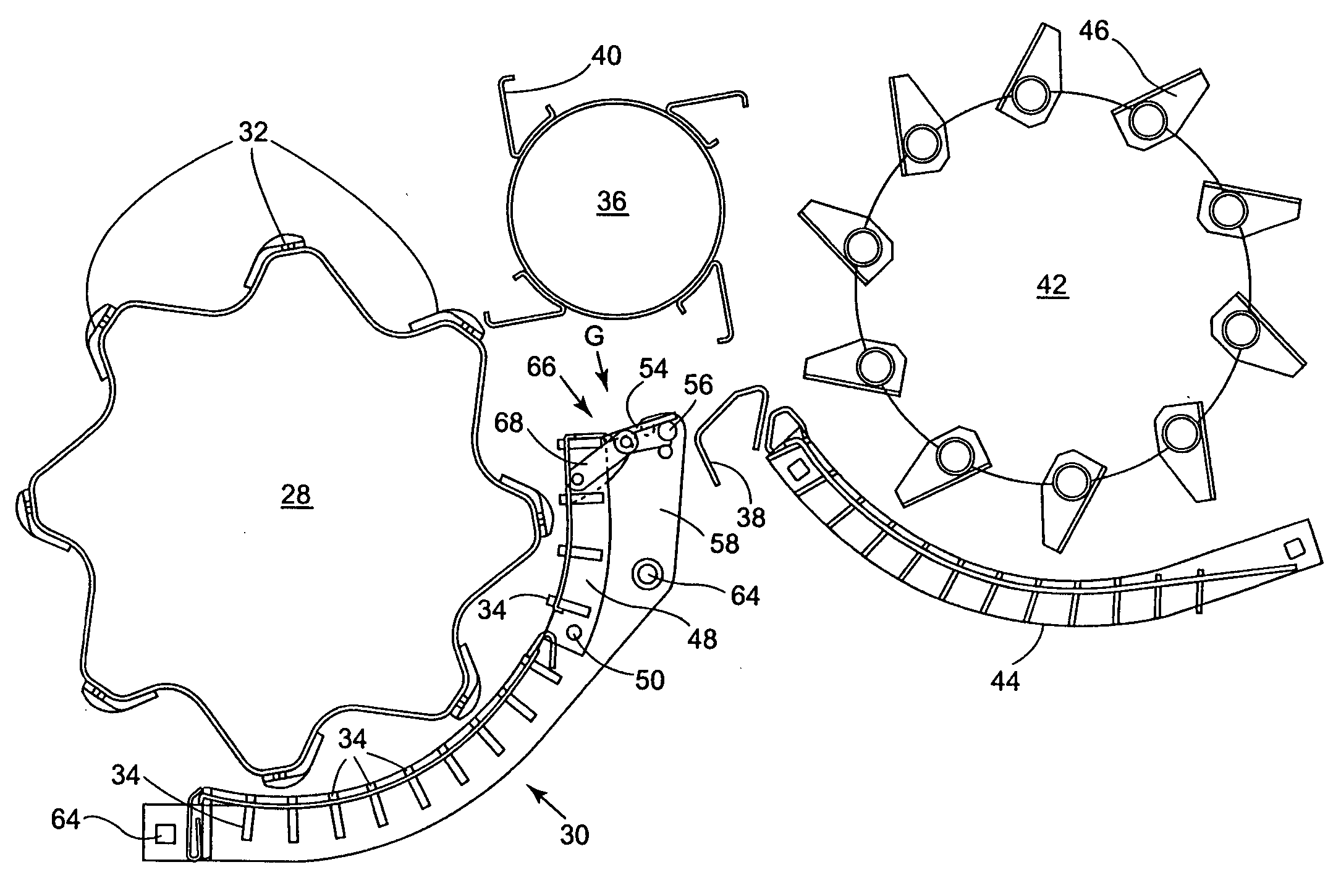

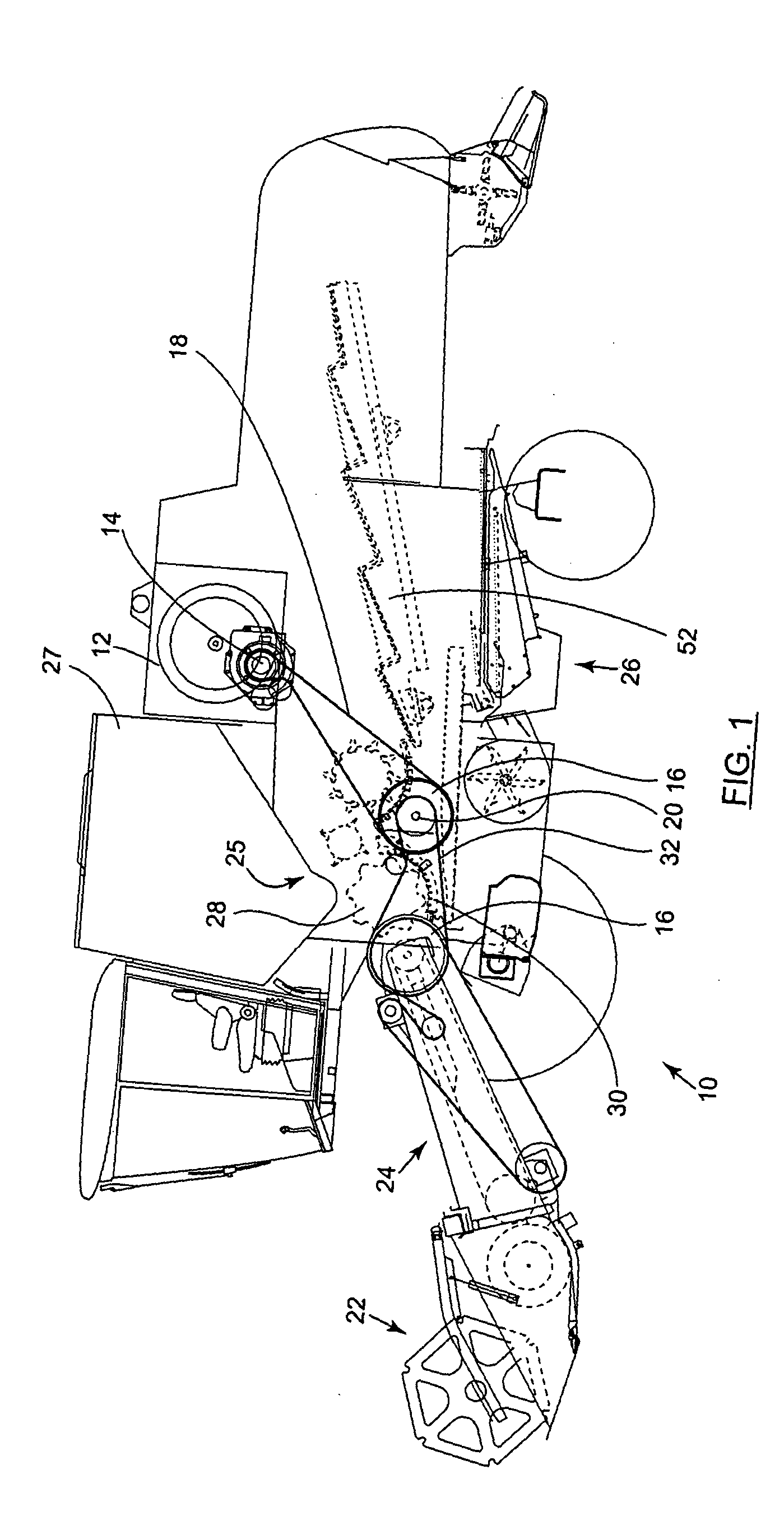

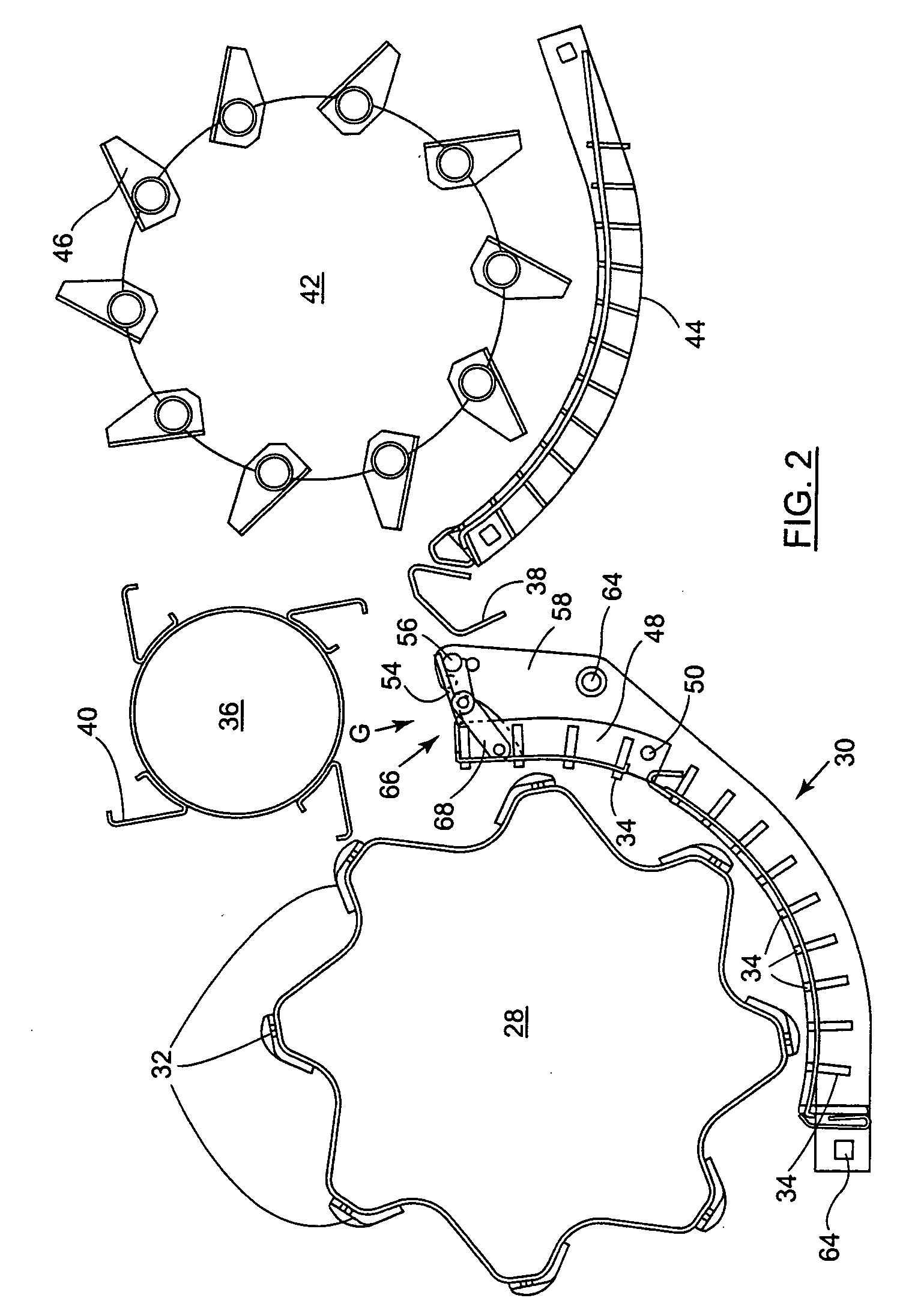

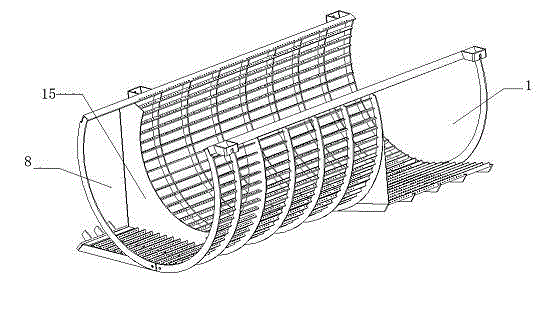

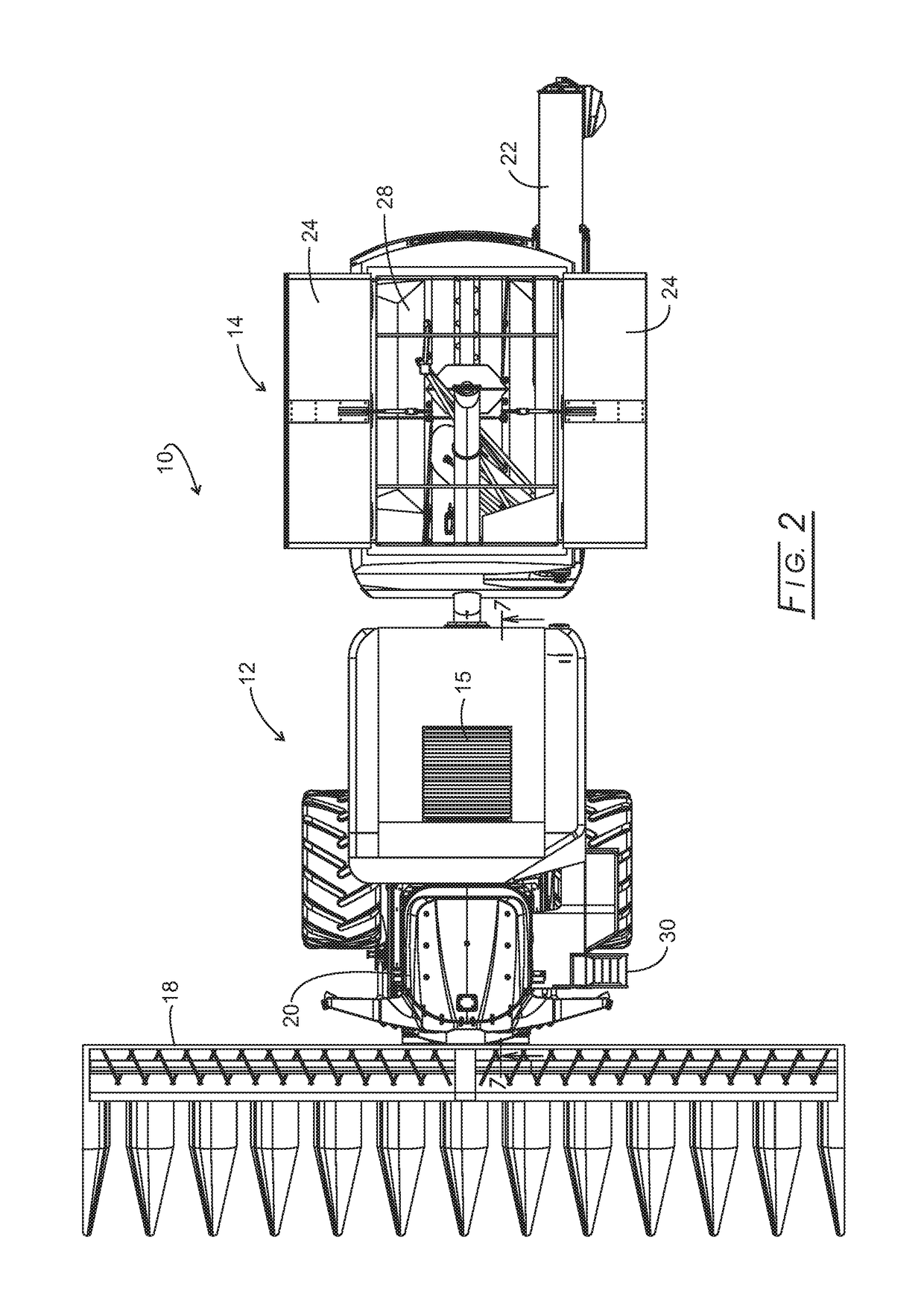

Threshing machinery concave arrangements

A concave arrangement is disclosed for a threshing machine such as a combine harvester 10. The arrangement includes a concave 30 having a moveable rear portion 48 that is adapted to vary the break-over angle presented to straw passing downstream. A flap member 54 is provided that moves jointly with the moveable rear portion 48 and ensures that a gap G between the moveable portion 48 and a later processing stage such as a beater apparatus is kept substantially closed. Variation of the break-over angle influences the length of the straw leaving the threshing machine and the loading of the further separation and cleaning mechanisms.

Owner:BLUE LEAF I P INC +1

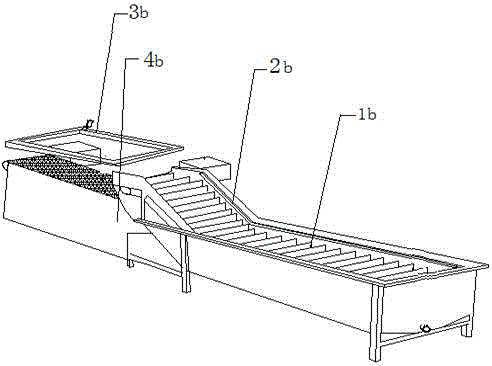

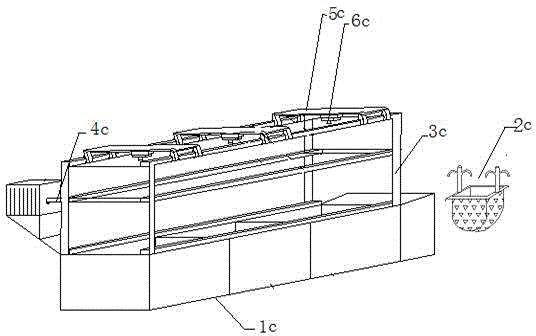

Tobacco leaf threshing and destemming technical method and special equipment thereof

ActiveCN102813277AHigh separation purityReduced stalk rateTobacco treatmentGas current separationProcess engineeringLighting spectrum

The invention provides a tobacco leaf threshing and destemming technical method and a special equipment of the tobacco leaf threshing and destemming technical method. The invention is characterized in that the threshing and destemming technology is a three-section type threshing, destemming and leaf-stem separating process, the leaf-stem separating processes of the first stage and second stage threshing sections all adopt the assembled classification in the manner of light spectrum destemming and wind separating, i.e. the last-stage wind separating devices of the first threshing section and the second threshing section adopt high-wind speed wind separation, the all free purified leafs and some leafs with stems are selected from the upstream material, the leafs with stems and the purified leafs in the upstream material are further finely separated from each other by the light spectrum destemming, and the separated leafs with stems are charged into the nest-stage leaf threshing machine. The method has the advantages that 1) the leaf-stem separating purity can be improved, and the stem containing rate in the leafs of the output leafs and the leaf containing rate in the stems of the tobacco stems can be reduced; 2) a threshing and destemming flow path can be effectively simplified by the three-threshing seven-wind separating technology, so that a processing link can be reduced; 3) the threshing times can be reduced, so that the structures of the threshed tobacco leafs and tobacco stems can be improved; and 4) a wind separation unit is reduced, so that the gas use amount can be reduced, and the energy consumption of the system can be reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

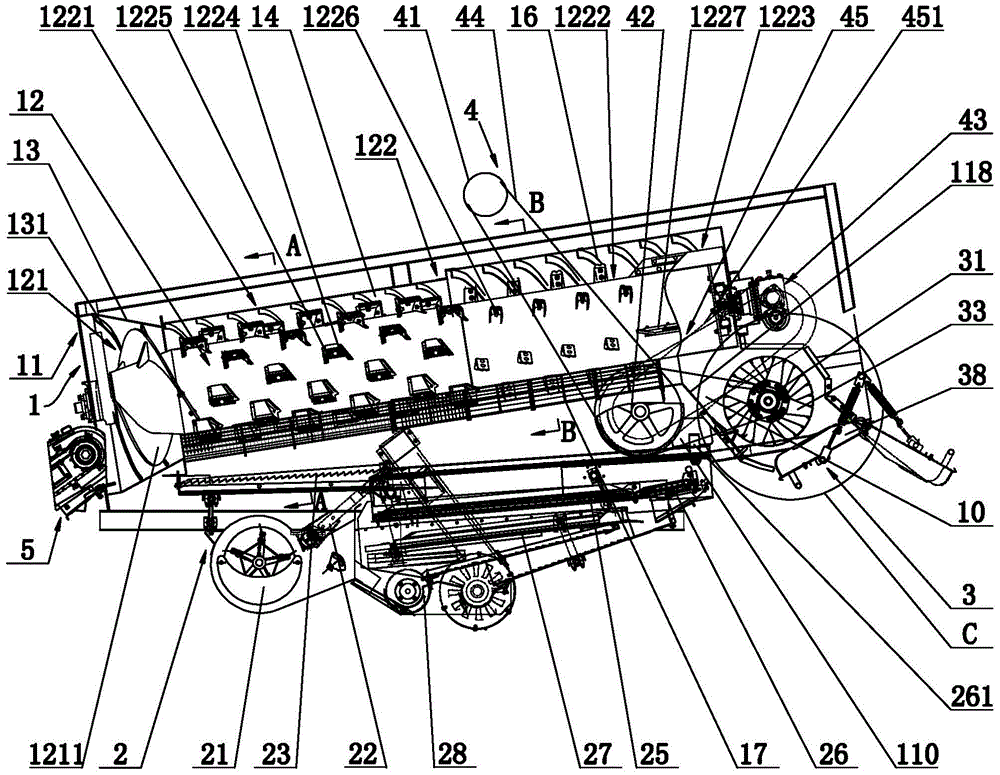

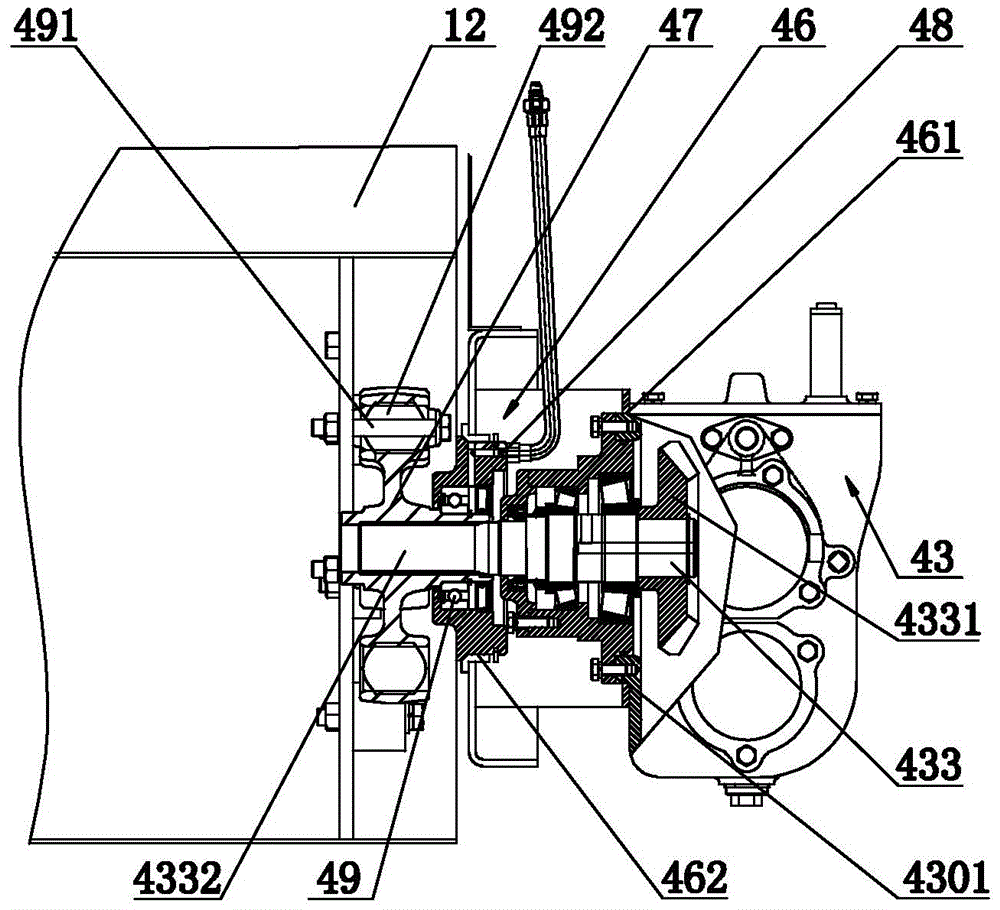

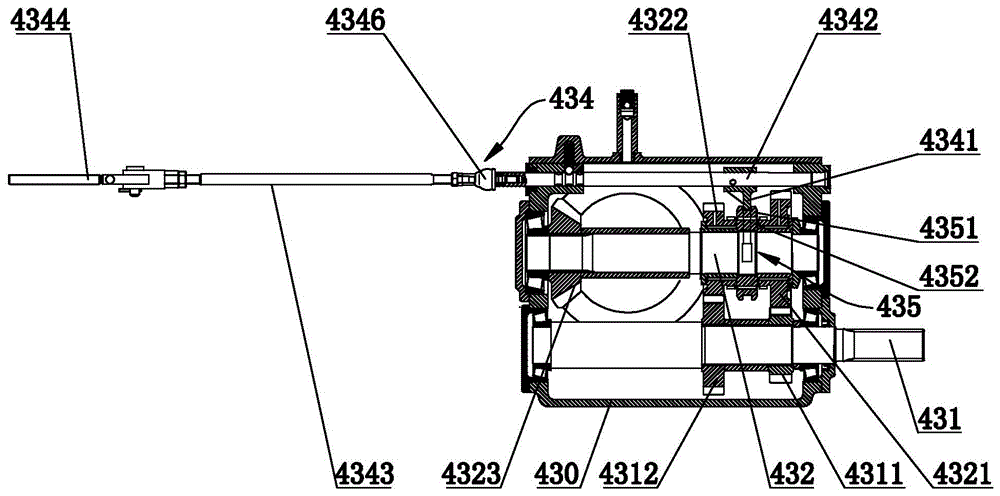

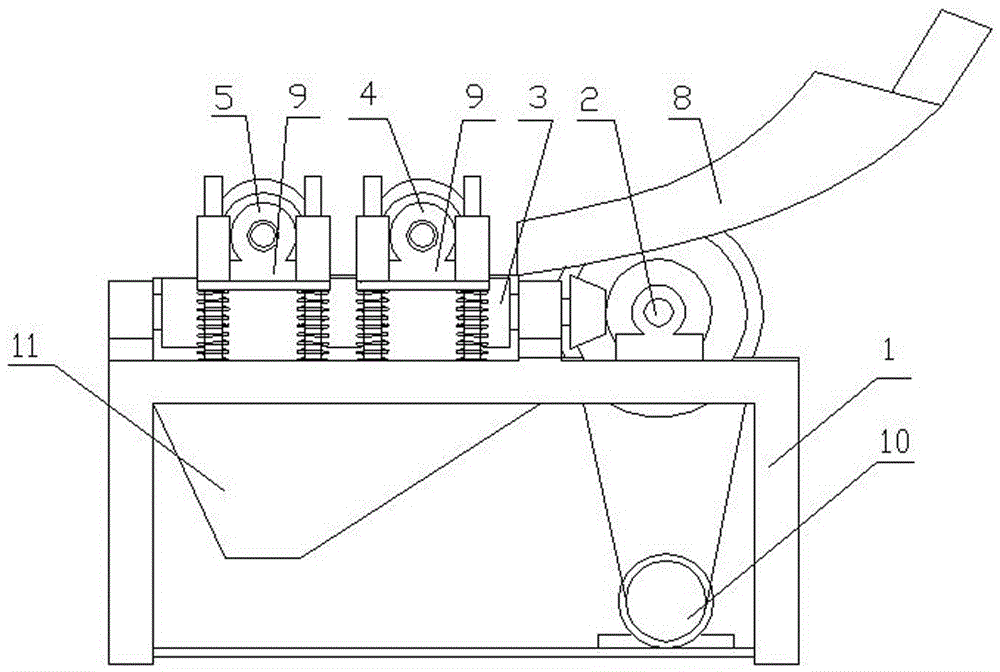

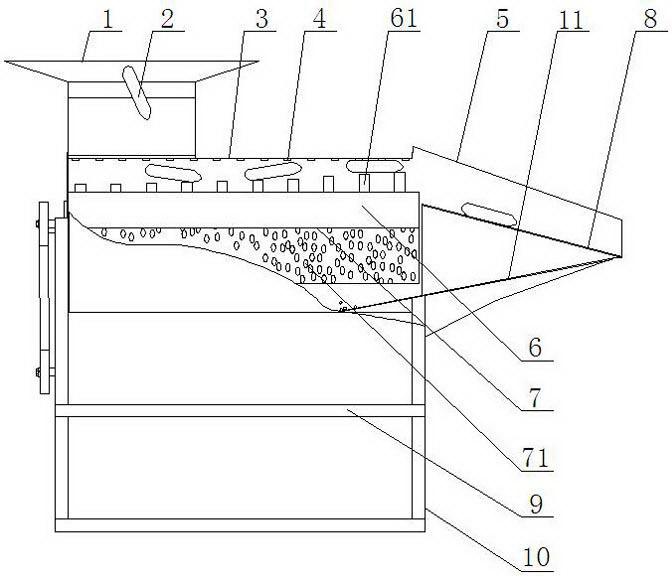

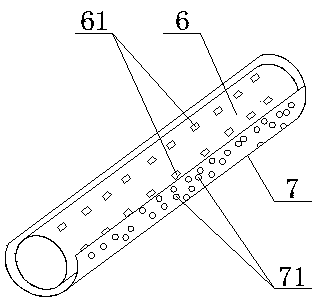

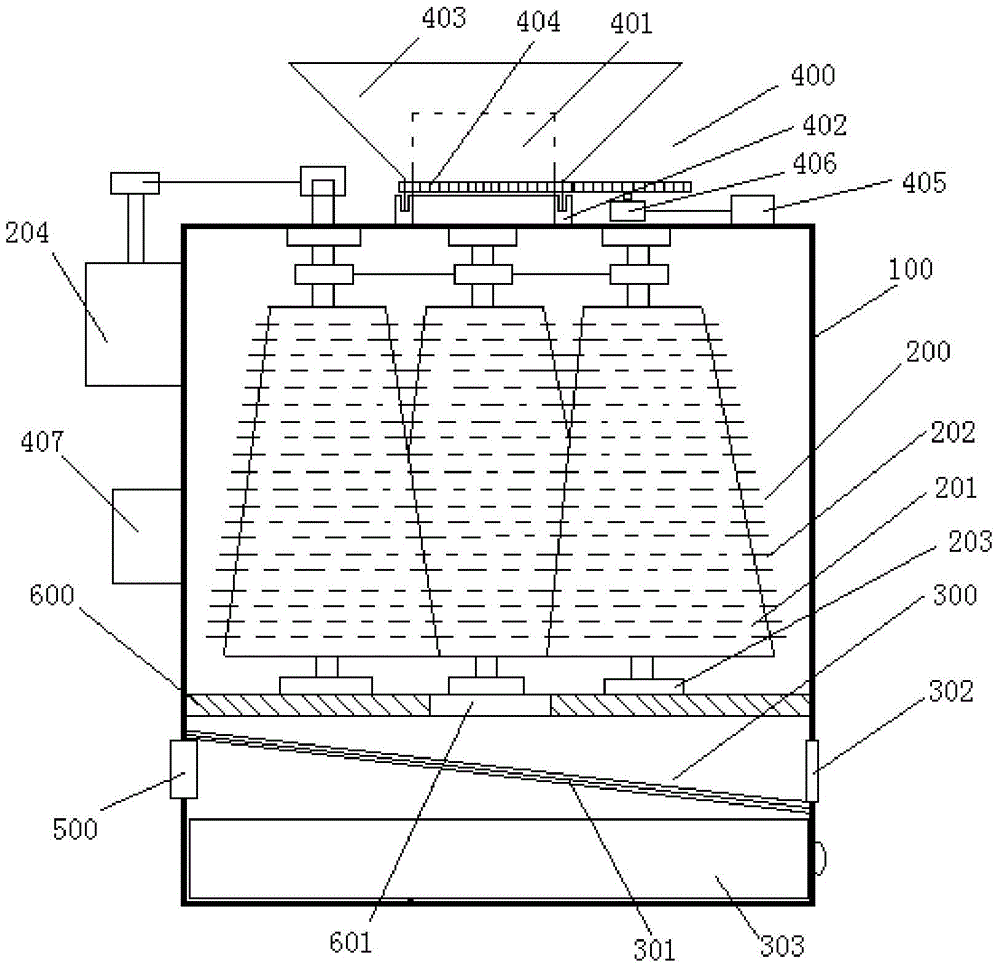

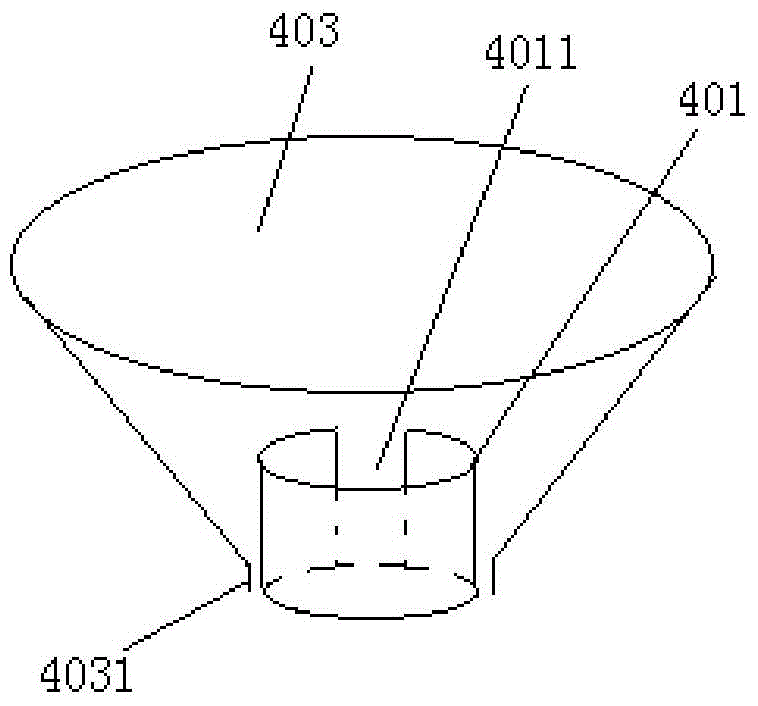

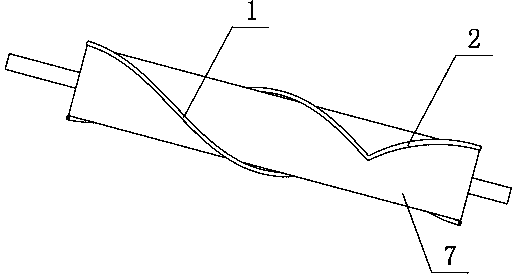

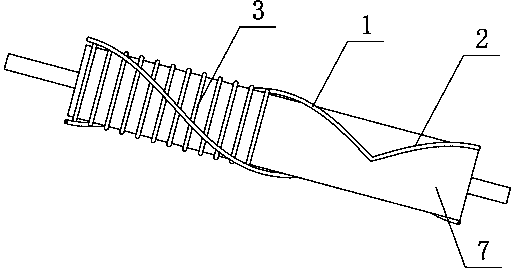

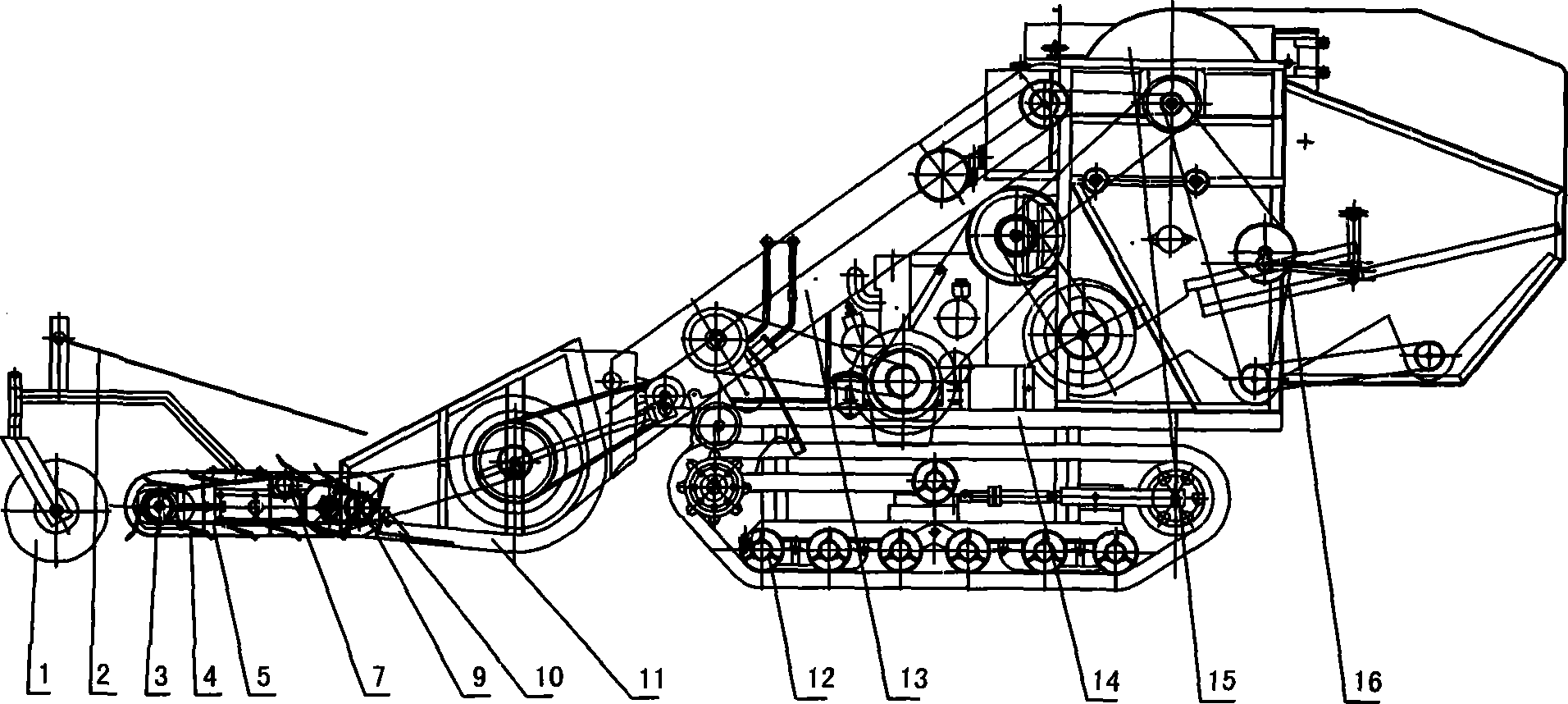

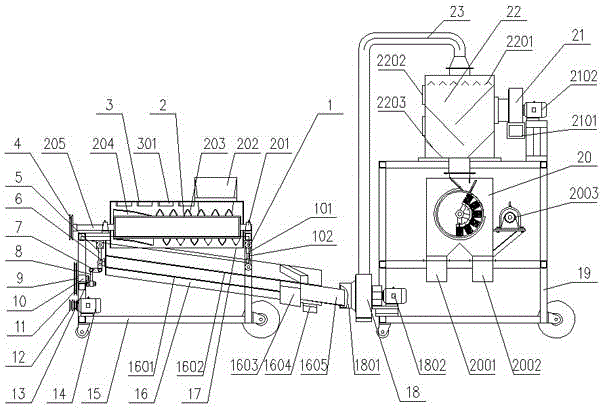

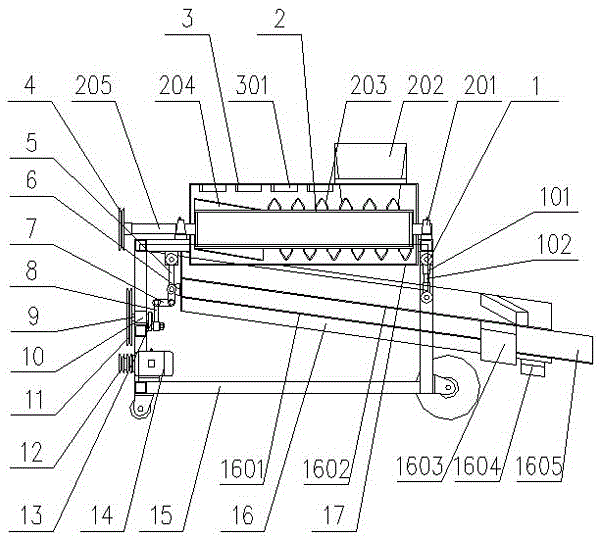

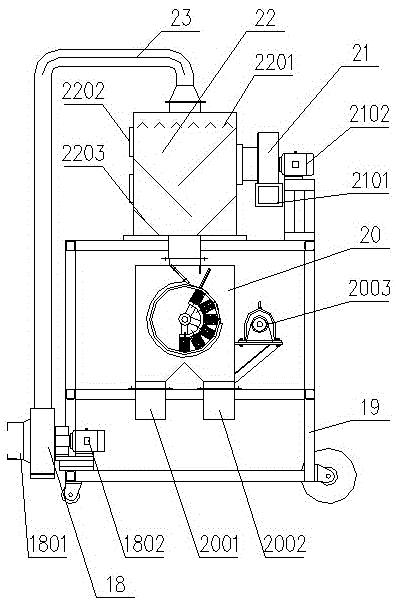

Threshing cleaning device of longitudinal-axial-flow combine harvester

ActiveCN105123147ALarge field return functionAchieve bothCrop conditionersMowersPulp and paper industryCombine harvester

The invention discloses a threshing cleaning device of a longitudinal-axial-flow combine harvester, and belongs to the technical field of combine harvesters. The threshing cleaning device comprises a threshing separating device, a cleaning device body and a stalk chopper. The threshing separating device comprises a threshing machine body and a longitudinal-axial-flow roller driven by a power device. The longitudinal-axial-flow roller comprises a feeding-in part and a roller body part, and the roller body part sequentially comprises a threshing section, a separating section and a weed-discharging section. A feeding-in shell is fixed to the portion, corresponding to the feeding-in part, of the threshing machine body, a threshing section roller cover is arranged on the upper portion, corresponding to the threshing section, of the threshing machine body, and a threshing section concave plate is arranged on the lower portion, corresponding to the threshing section, of the threshing machine body. A separating section roller cover is arranged on the upper portion, corresponding to the separating section, of the threshing machine body, a separating section concave plate is arranged on the lower portion, corresponding to the separating section, of the threshing machine body, and the diameter of the separating section roller cover is larger than that of the threshing section roller cover. The feed quantity is large in harvesting, the function of returning stalks to the field is achieved, working efficiency is improved, kinds of crops are harvested, and the requirements for earnings of a user are met.

Owner:LOVOL HEAVY IND

Threshing machinery concave arrangements

A concave arrangement is disclosed for a threshing machine such as a combine harvester 10. The arrangement includes a concave 30 having a moveable rear portion 48 that is adapted to vary the break-over angle presented to straw passing downstream. A flap member 54 is provided that moves jointly with the moveable rear portion 48 and ensures that a gap G between the moveable portion 48 and a later processing stage such as a beater apparatus is kept substantially closed. Variation of the break-over angle influences the length of the straw leaving the threshing machine and the loading of the further separation and cleaning mechanisms.

Owner:BLUE LEAF I P INC +1

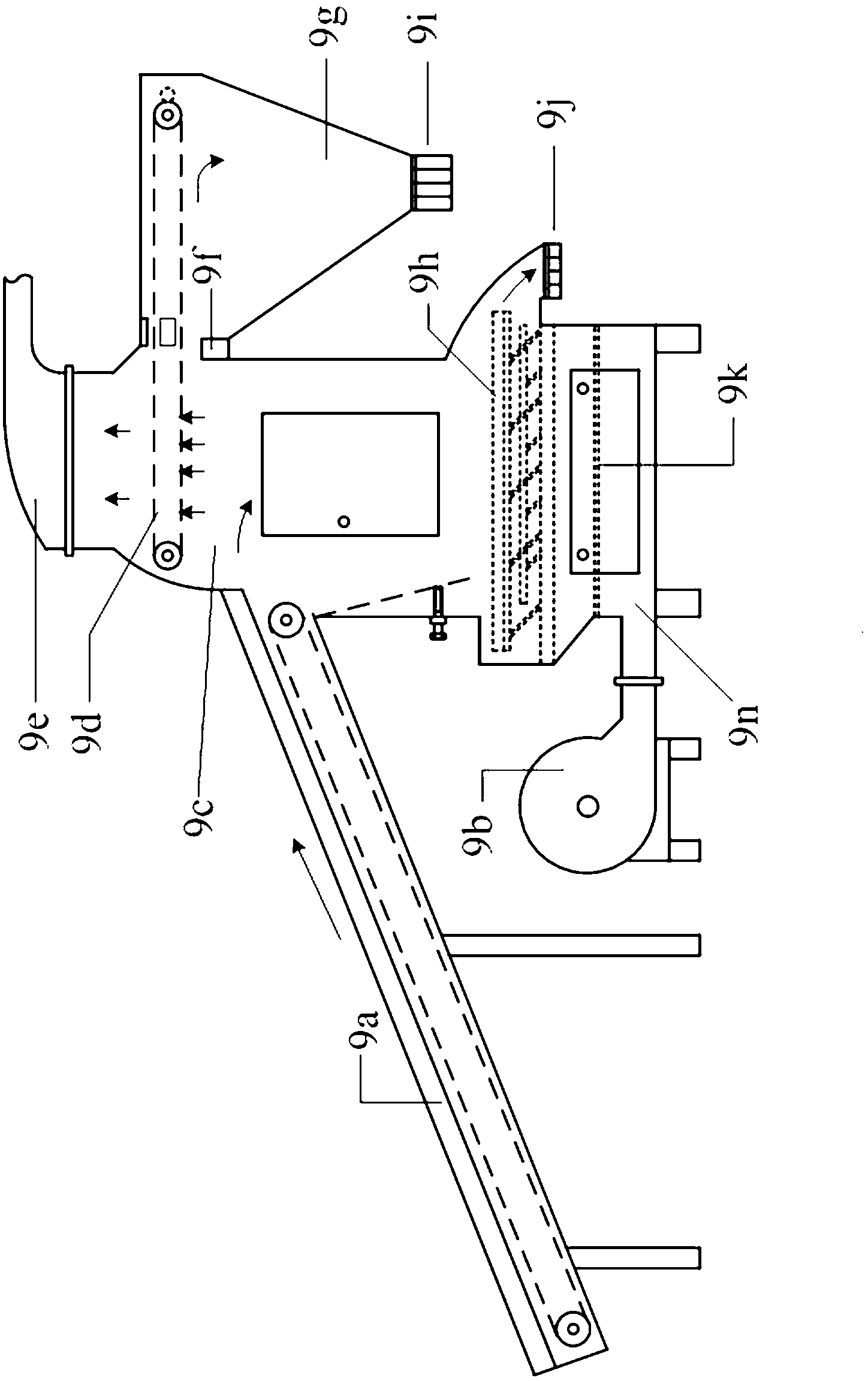

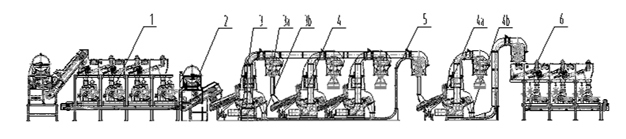

Sweet corn grain production line and sweet corn grain production process

InactiveCN104799172AImprove qualityGuaranteed freshSeed preservation by freezing/coolingFood preparationProduction lineAgricultural science

The invention discloses a sweet corn grain production line and a sweet corn grain production process. The sweet corn grain production line comprises a withering system, a peeling machine, a threshing machine, a sweet corn grain uniform spreading and selection device, a sweet corn grain processing rinsing machine, a sweet corn grain processing blanching device, a cooling system, a sweet corn grain processing draining device, a quick-freezing system, a sweet corn grain selection mechanism, a sweet corn grain processing last-stage metal detection mechanism, a packaging mechanism and a metal detector, which are sequentially arranged in the material conveying direction. The sweet corn grain production process comprises the steps of raw material acceptance check, withering, peeling, threshing, selection, rinsing, blanching, cooling, draining, quick-freezing, selection, gold detection before packaging, packaging, gold detection after packaging and warehousing. By adopting the sweet corn grain production line and the sweet corn production process, the sweet corn grains with good quality can be produced, the freshness of the corn grain can be guaranteed, the nutrition of the corn can be prevented from being lost, the automation degree is high in the processing process, the labor intensity can be alleviated, and the streamline operation can be realized.

Owner:HENAN KEXI FOOD

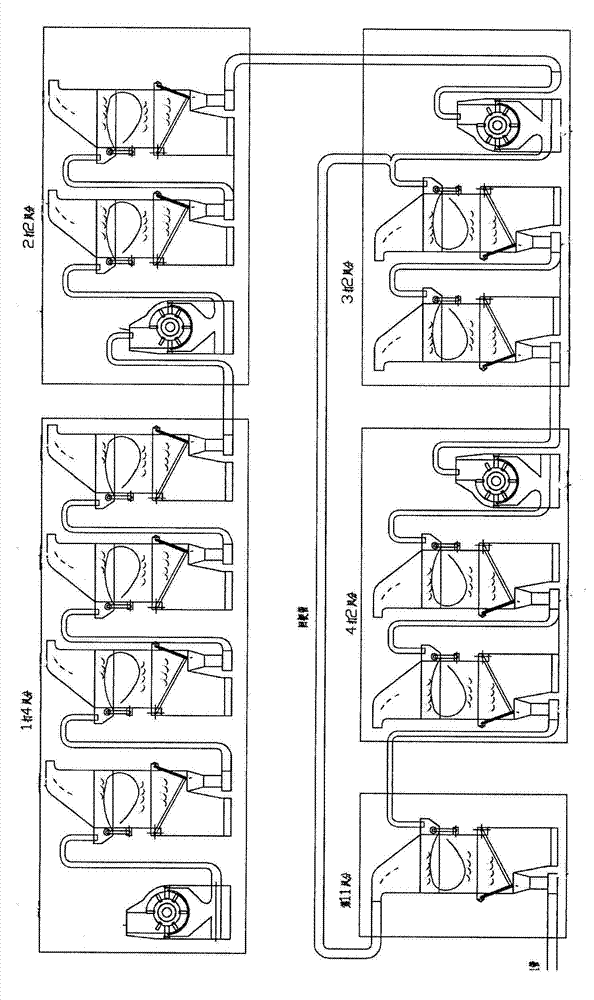

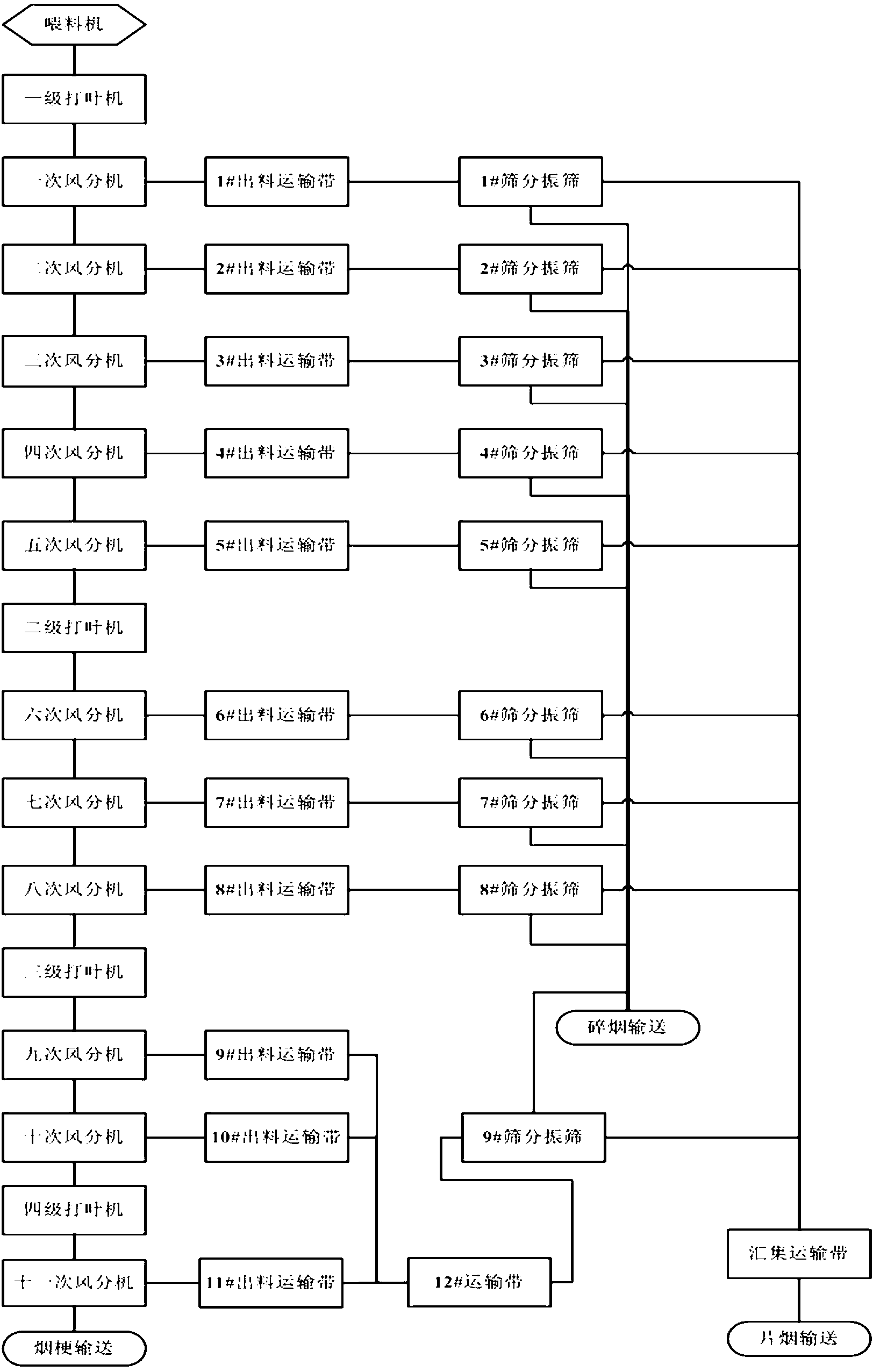

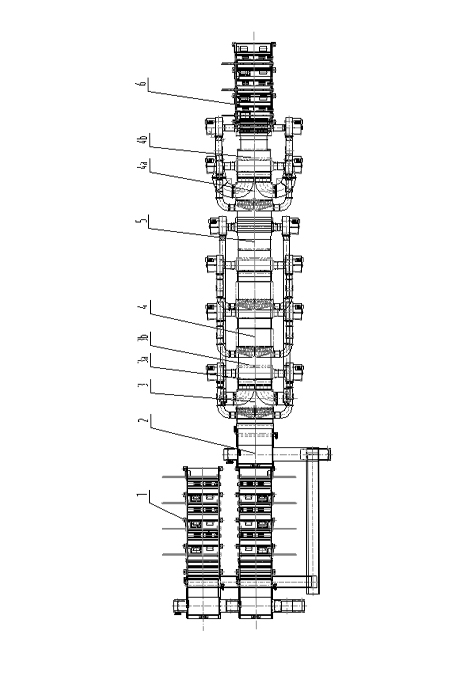

High-efficiency energy-saving threshing air separation new process and equipment

ActiveCN103263075AReduce the temperatureReduce drynessTobacco treatmentGas current separationAir separationMechanical engineering

The invention relates to a high-efficiency energy-saving threshing air separation new process and equipment, and particularly relates to a threshing redrying process which carries out air separation on tobacco flakes and tobacco stalks and belongs to a tobacco processing industry and the technical field of equipment. The threshing redrying process sequentially comprises the following steps of: a scraping plate feeding machine, a bin type feeding machine, a proportional distributor, a first-level threshing machine set, a conveying belt, a first-level air separation machine set (double-bin air separator), a stalky leaf conveying belt, a second-level threshing machine set, the conveying belt, a second-level air separation machine set (three-bin air separator), the stalky leaf conveying belt, a third-level threshing machine set, the conveying belt, a third-level air separation machine set (three-bin air separator), the stalky leaf conveying belt, a fourth-level threshing machine set, the conveying belt and a fourth-level air separation machine set (three-bin air separator), wherein the first-level air separation machine set is provided with an air pressure type double-bin air separator which only separates qualified tobacco flakes; and the second-level air separation machine set, the third-level air separation machine set and the fourth-level air separation machine set are provided with air pressure type three-bin air separators which can separate qualified tobacco flakes and tobacco stalks.

Owner:HONGTA TOBACCO GRP

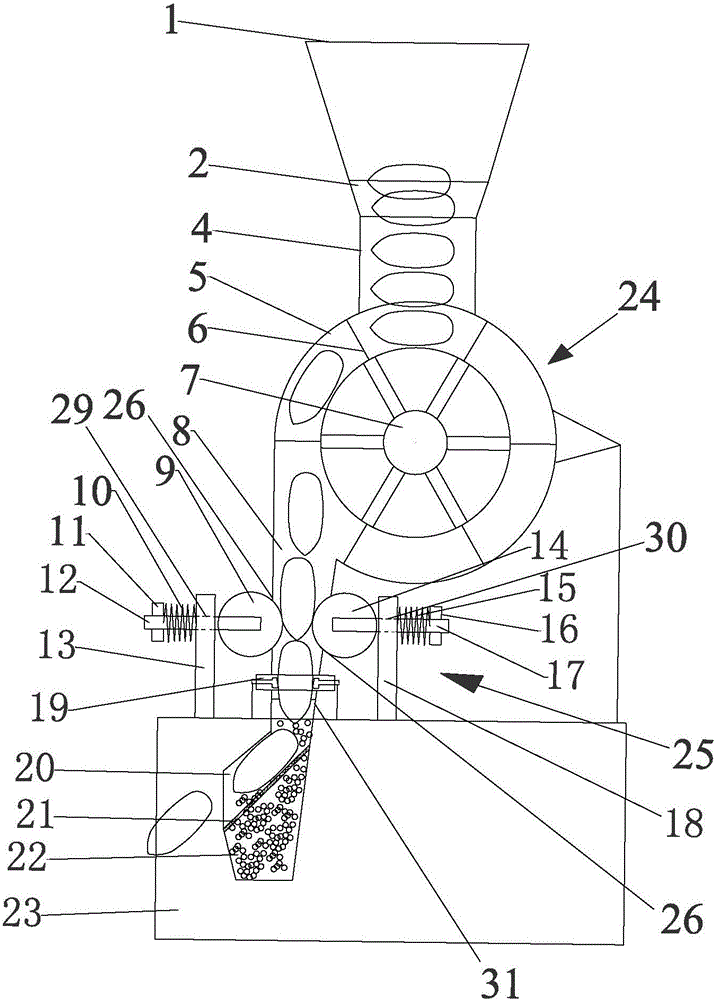

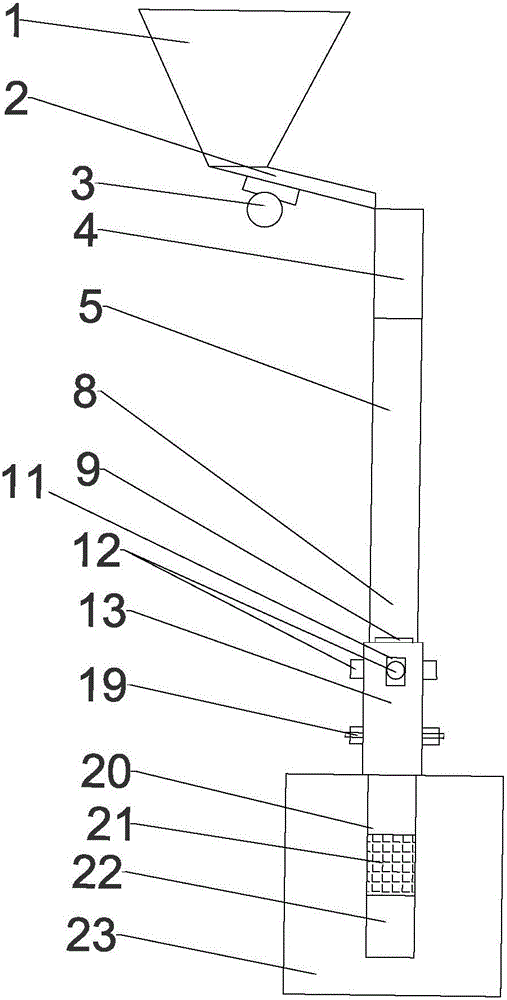

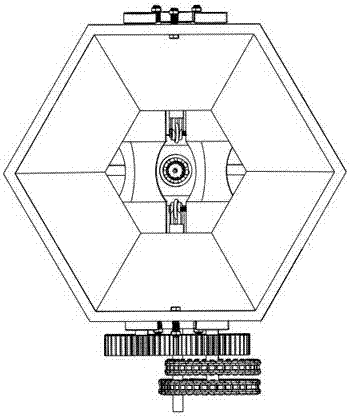

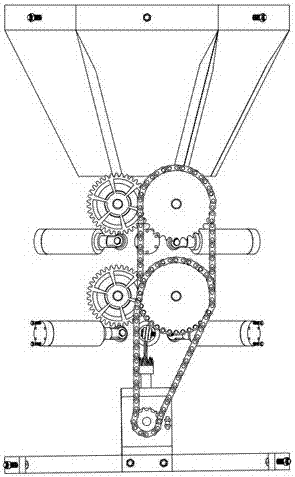

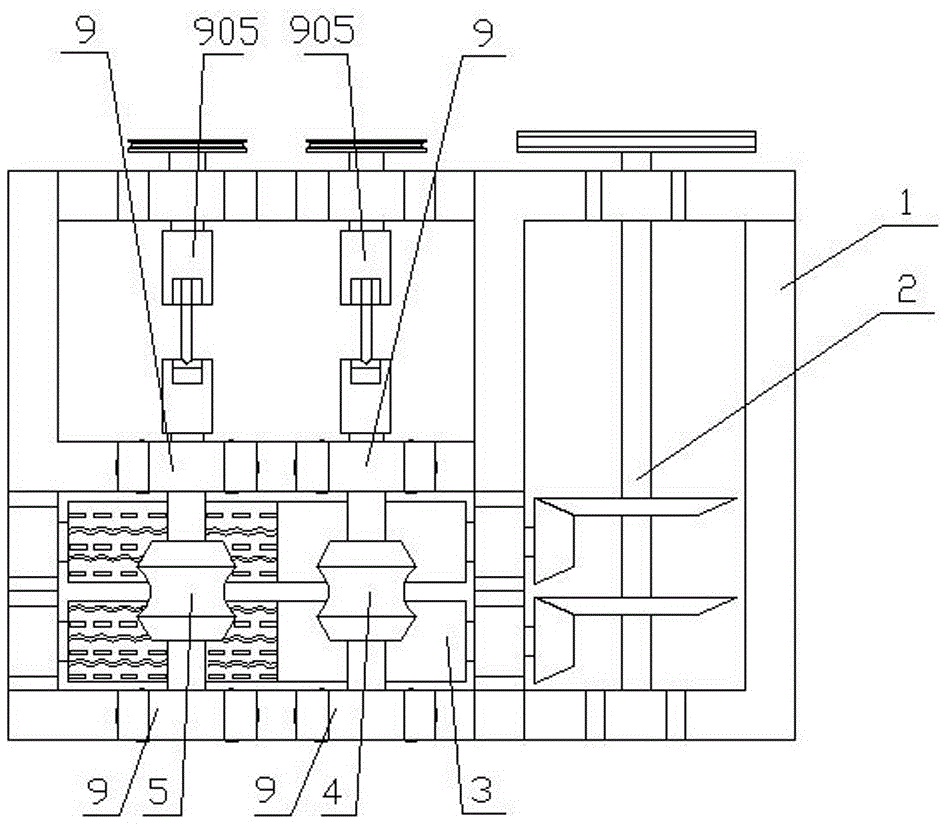

Axial shearing corn threshing machine and corn threshing method

The invention discloses an axial shearing corn threshing machine, which comprises a material bin, a rolling plate, a buffering bin, a base, an impeller feeding device, a self-adaptive double-roller conveyance device and a self-adaptive annular axial threshing device, wherein the output end of the material bin is connected with the input end of the buttering bin through the rolling plate, the output end of the buffering bin is connected with the input end of the impeller feeding device, a discharging hole of the impeller feeding device is fixedly communicated with the top surface of a threshing device shell, and two roller operation through holes, including a left roller operation through hole and a right roller operation through hole, are formed in the discharging hole, a left conveyance roller and a right conveyance roller of the self-adaptive double-roller conveyance device are respectively placed in the left roller operation through hole and the right roller operation through hole and can synchronously and relatively rotate in the corresponding roller operation through holes. The axial shearing corn threshing machine can ensure the completion of corn cobs in a corn ear threshing process.

Owner:HUBEI UNIV OF TECH

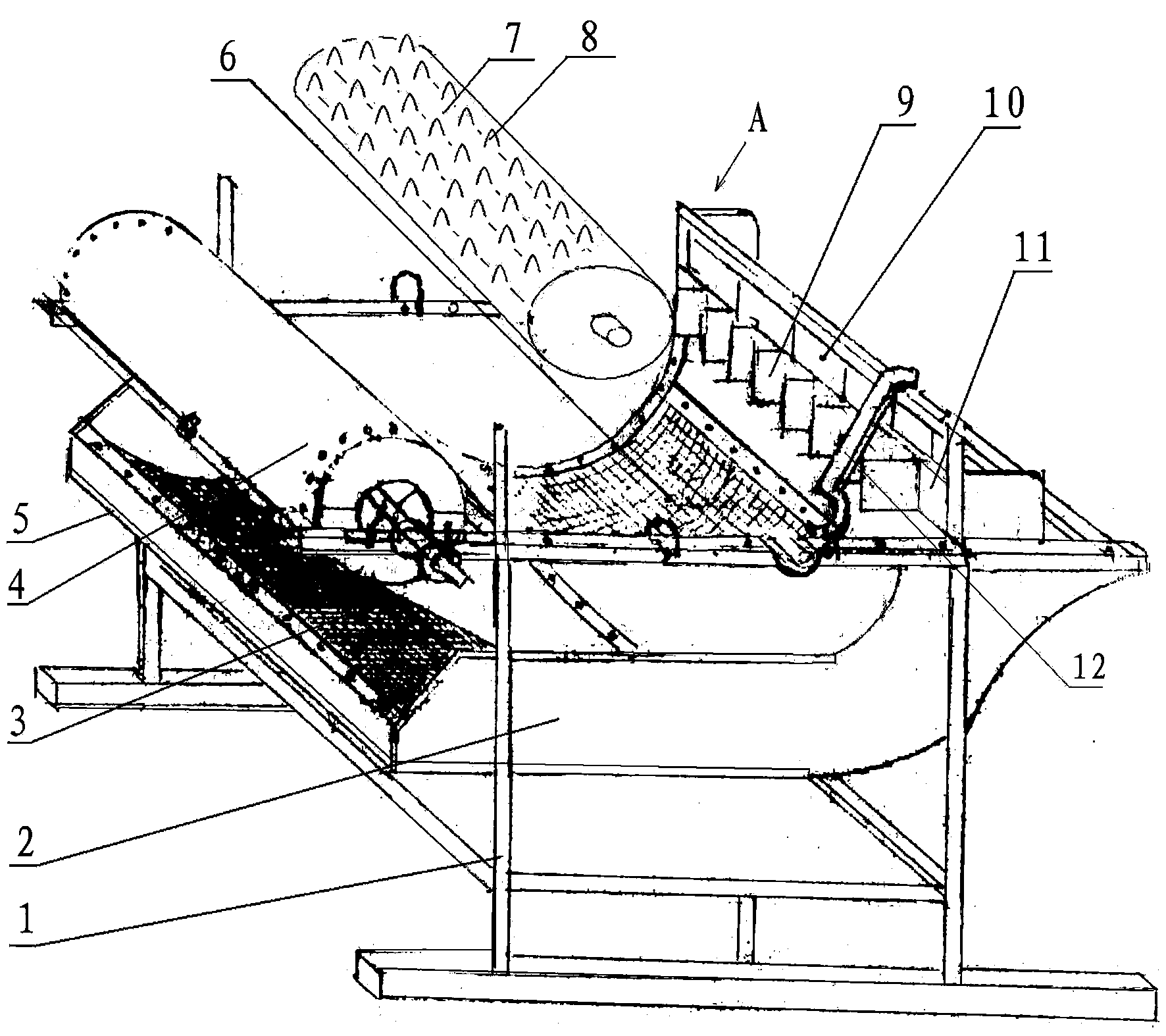

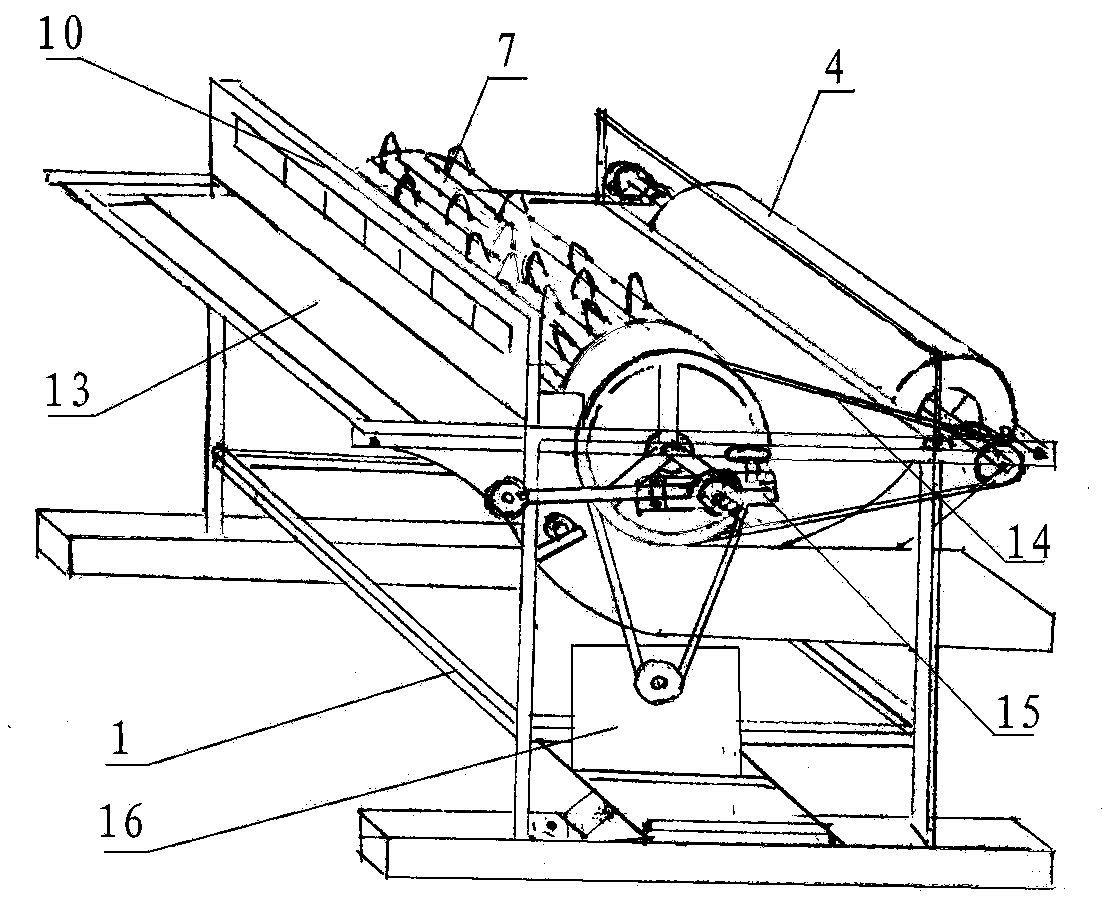

Combine-harvester for rapes, rice and wheats

The invention discloses a combine-harvester for rapes, rice and wheats. The combine-harvester for the rapes, the rice and wheats is capable of combining the functions of harvesting, threshing and grading of the rices and wheats and the rapes into a whole. The combine-harvester for the rapes, the rice and wheats comprises a rack, an actuating mechanism, a panicle-inlet mechanism, a threshing mechanism and a grain-shell separating mechanism, wherein the panicle-inlet mechanism is installed on the rack, the threshing mechanism is located at the back of the threshing mechanism, and the grain-shell separating mechanism is connected with a grain outlet of the threshing mechanism. The grain-shell separating mechanism comprises a vibrating grading sieve, a shell-blowing fan and a shell outlet, the vibrating grading sieve is composed of a vibrating grading sieve basket, an upper-layer sieve-piece angle-adjustable sieve and a lower-layer net-shaped sieve, wherein the upper-layer sieve-piece angle-adjustable sieve and the lower-layer net-shaped sieve are installed on the vibrating grading sieve basket. According to the combine-harvester for the rapes, the rice and wheats, due to the fact that the sieve-piece angle-adjustable sieve is added on the vibrating grading sieve basket, on one hand, impurities can be further graded, on the other hand, the sizes of sieve openings can be controlled by adjusting angles of sieve pieces, and the combine-harvester for the rapes, the rice and wheats is capable of achieving the grading of the rice and wheats and the rapes.

Owner:四川天顺祥农机有限公司

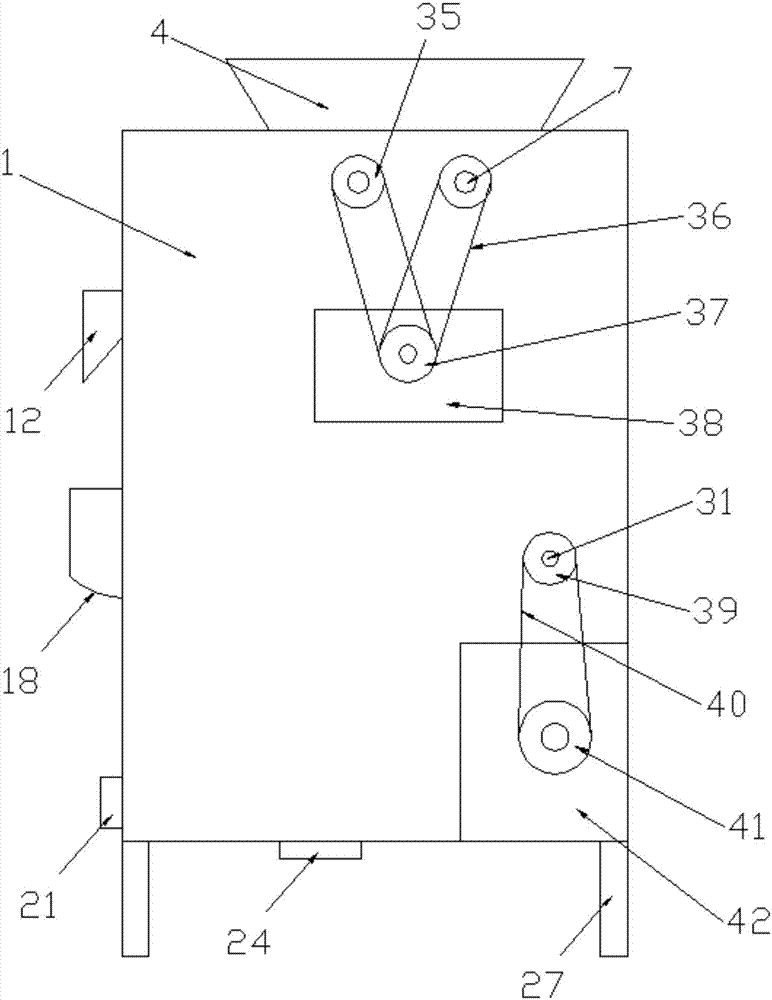

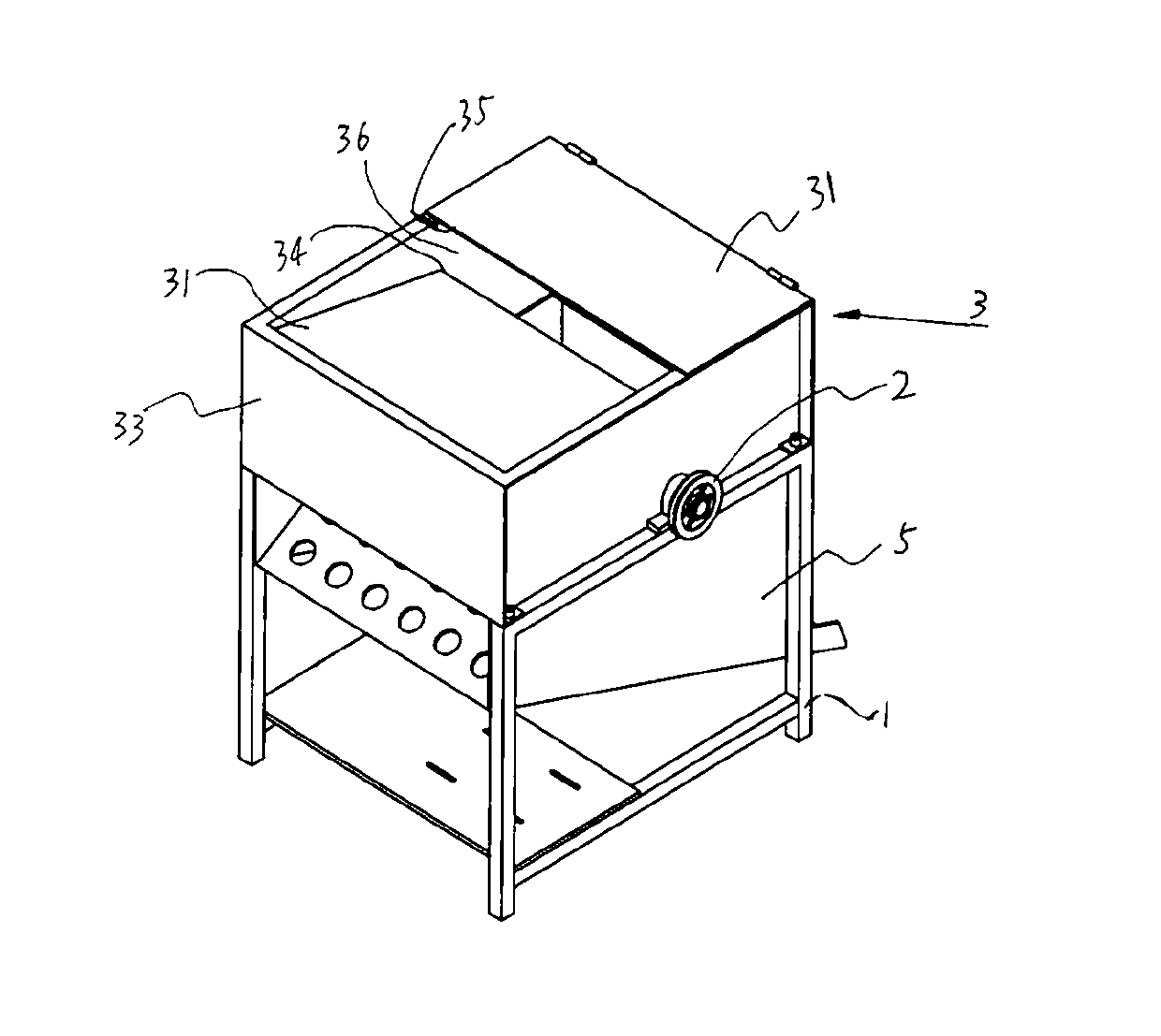

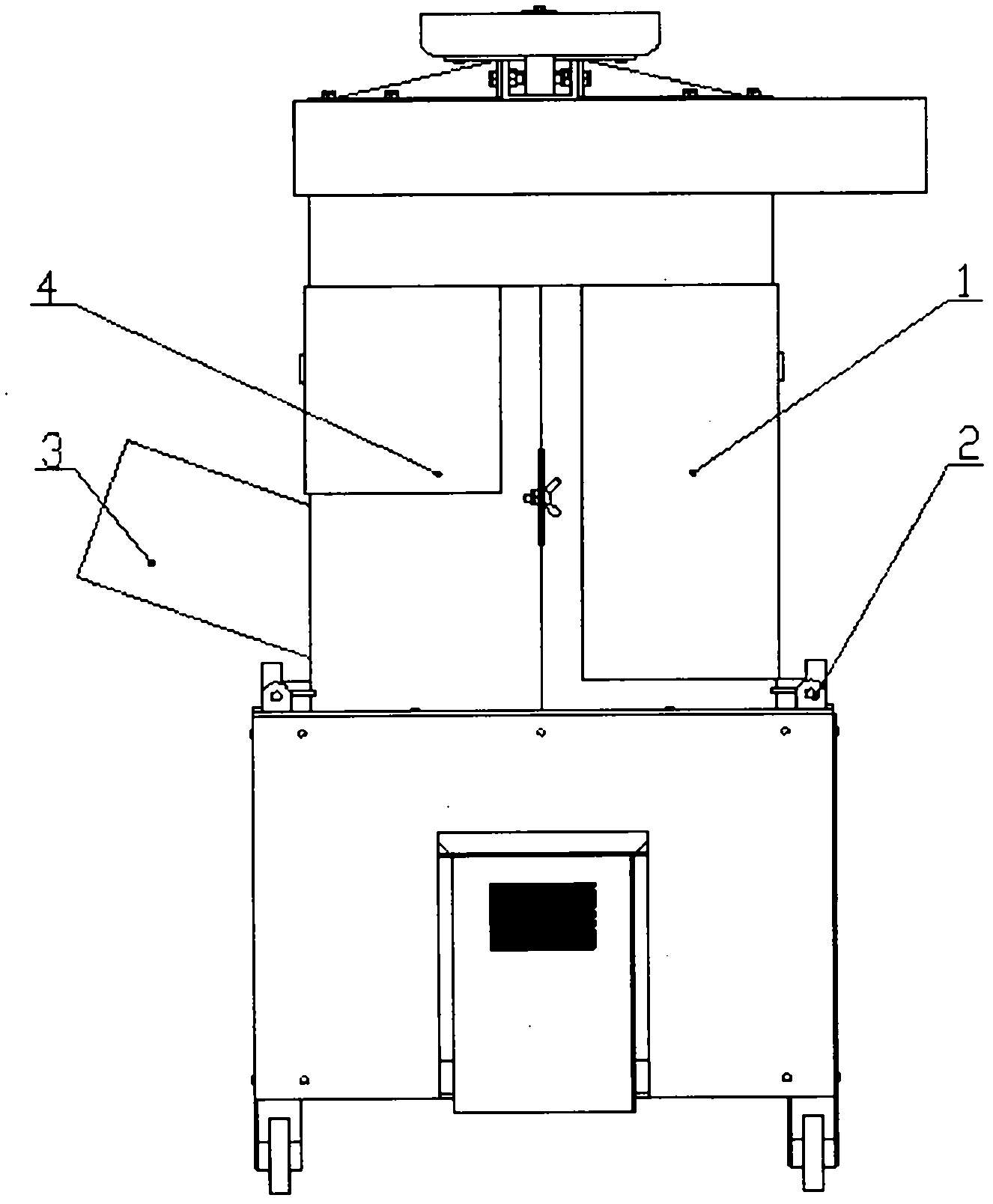

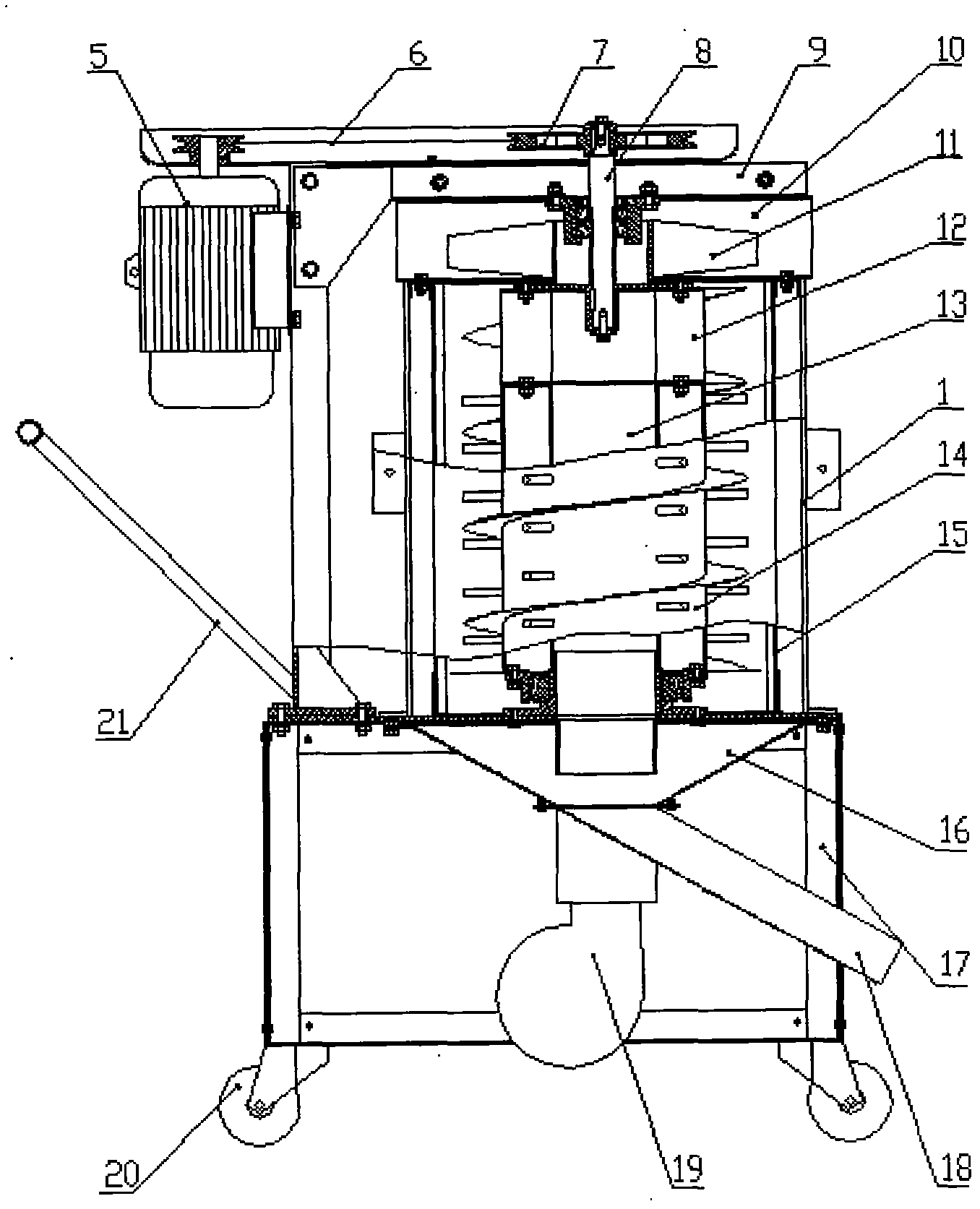

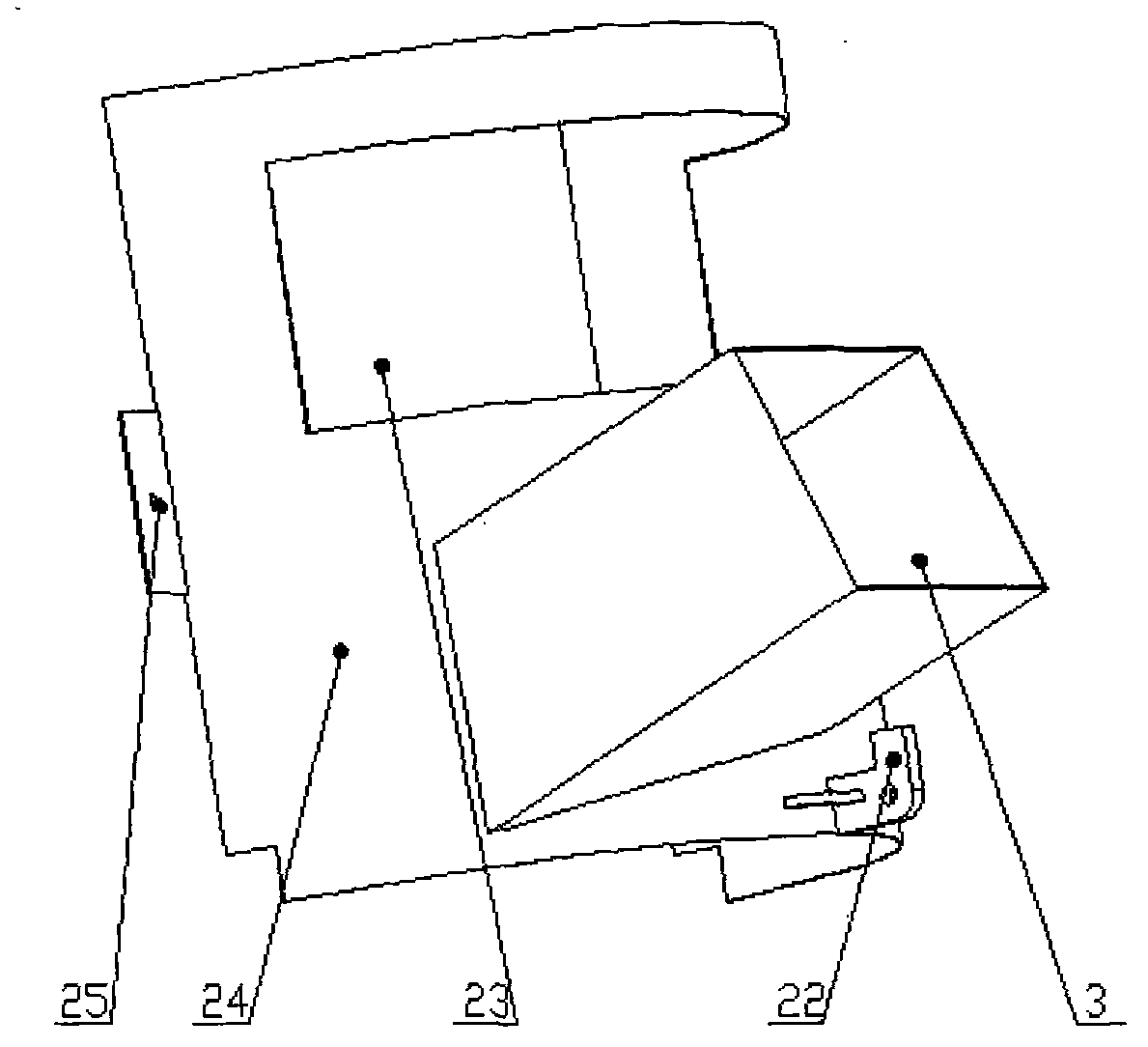

Threshing machine

The invention discloses a threshing machine. The threshing machine comprises a machine frame, a cover body at the top of the machine frame and a tool rest at the rear of the machine frame, wherein the cover body is located on an opening in front of the machine frame, a plurality of cutters with cutting edges forward are abreast and evenly arranged on the tool rest, a threshing roller is installed on the machine frame, a plurality of teeth used to brush away grains are evenly arranged on the threshing roller, two layers of screens are installed below the threshing roller, a draught fan is installed on one side of a space between the two layers of the screens, an opening of the draught fan faces the screen on the upper layer, a collection plate used to receive the grains is arranged right below the screen on the lower layer, a discharging hopper is arranged on one side of the collection plate, a vibration device is arranged on one side of each of the screens and the collection plate, and the threshing roller, the draught fan and the vibration devices are all connected with power machines through power transmission devices. The threshing machine can thoroughly thresh the grains on harvested paddy rice and separate the grains from stalks and impurities.

Owner:韦少付

Grain threshing machine having efficient impurity removing function

The invention discloses a grain thresher with high-efficiency impurity removal function, which comprises a casing, a feeding hopper is arranged on the top of the casing, threshing rollers are arranged symmetrically on the left and right corresponding to the lower end of the feeding hopper in the casing, and the threshing rollers are set On the roller shaft set in the casing, the roller shaft protrudes out of the casing, and a roller shaft driving mechanism is arranged outside the casing, and a deflector is arranged under the corresponding feeding hopper in the casing, and the deflector is high on the left and low on the right Inclined setting; the left end of the deflector plate is fixedly connected with a sieve plate, the sieve plate is arranged at a downward slope to the left, the other end of the sieve plate is fixed on the left side wall of the housing, and a The first miscellaneous outlet, the upper part of the sieve plate is fixed below the top wall of the housing through a suspender, and the first winch is arranged above the deflector. The present invention provides a grain thresher with an efficient miscellaneous removal function; The invention ingeniously arranges a multi-stage impurity removal mechanism. After threshing, the grains are multi-layered and high-precision impurity removal to obtain clean grains.

Owner:郑州味觉信息技术有限公司

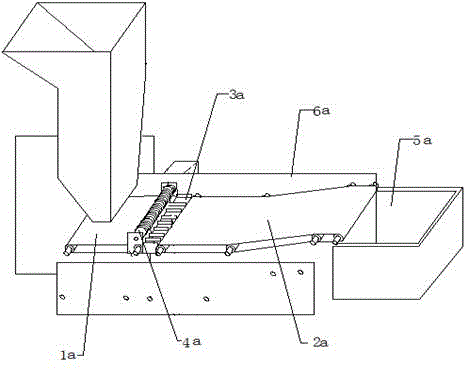

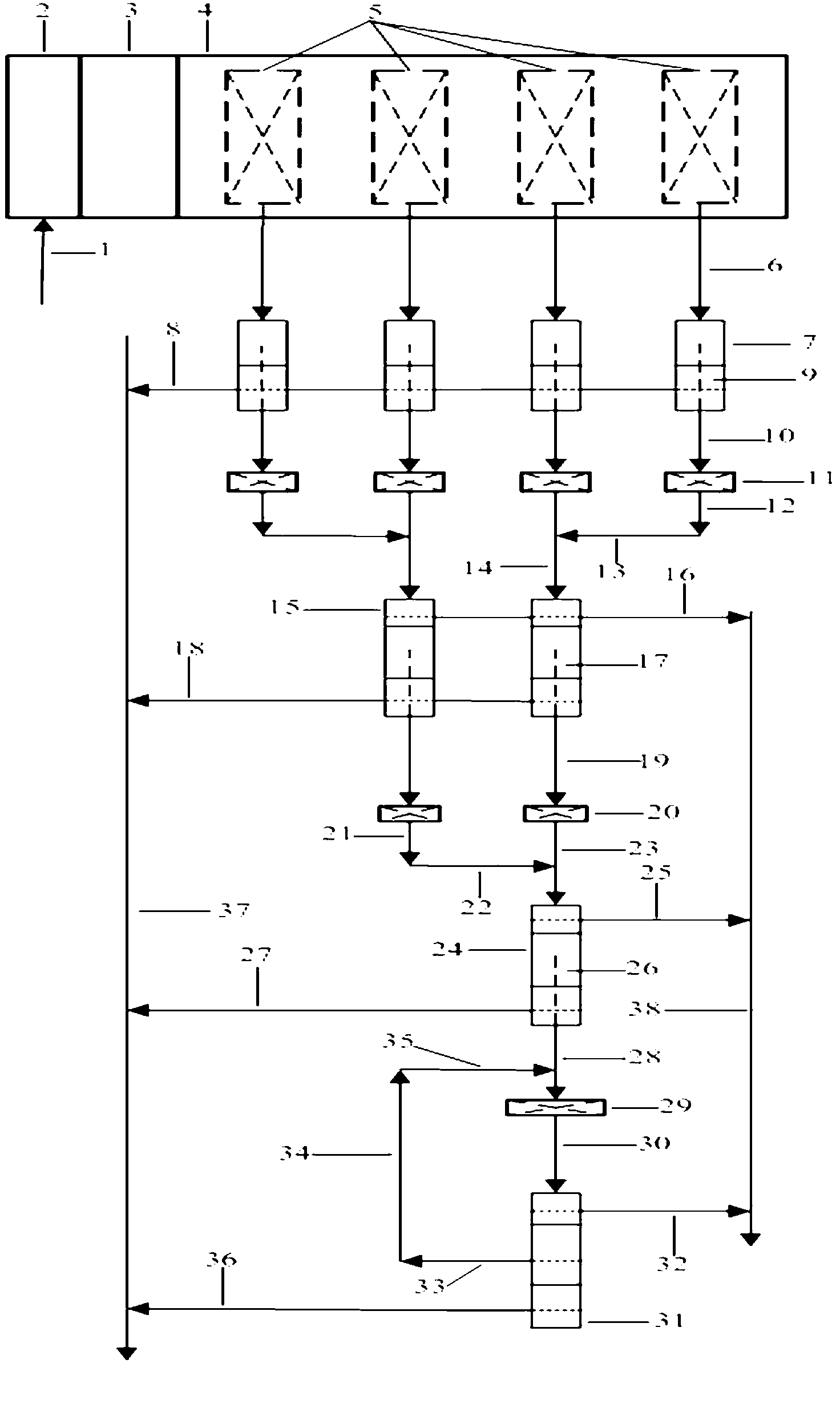

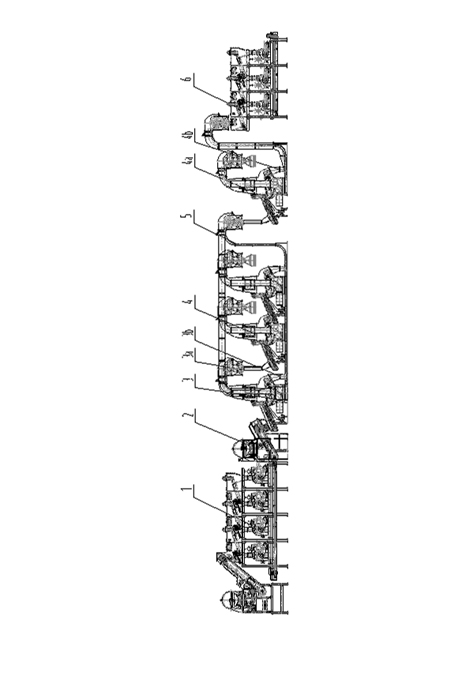

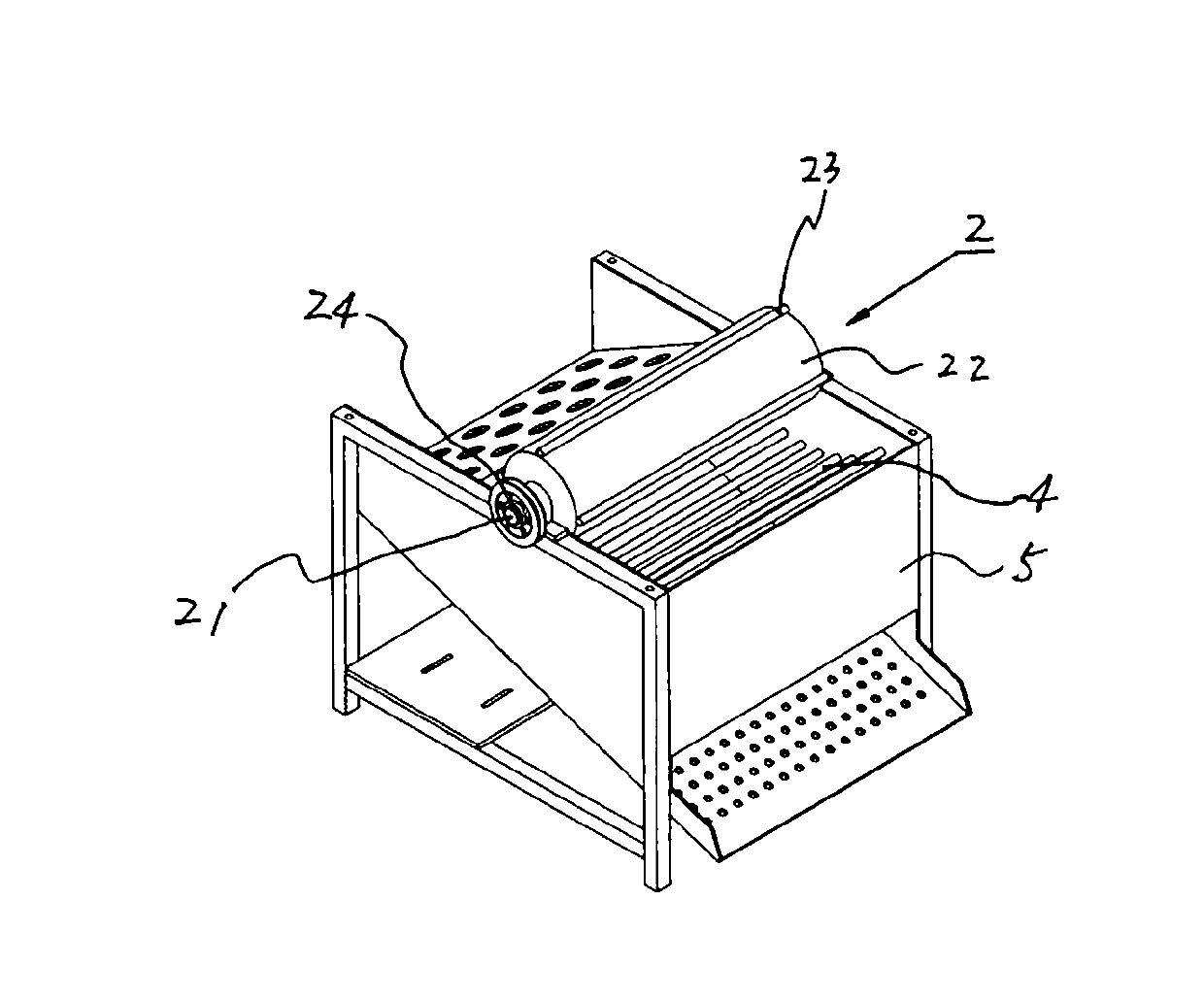

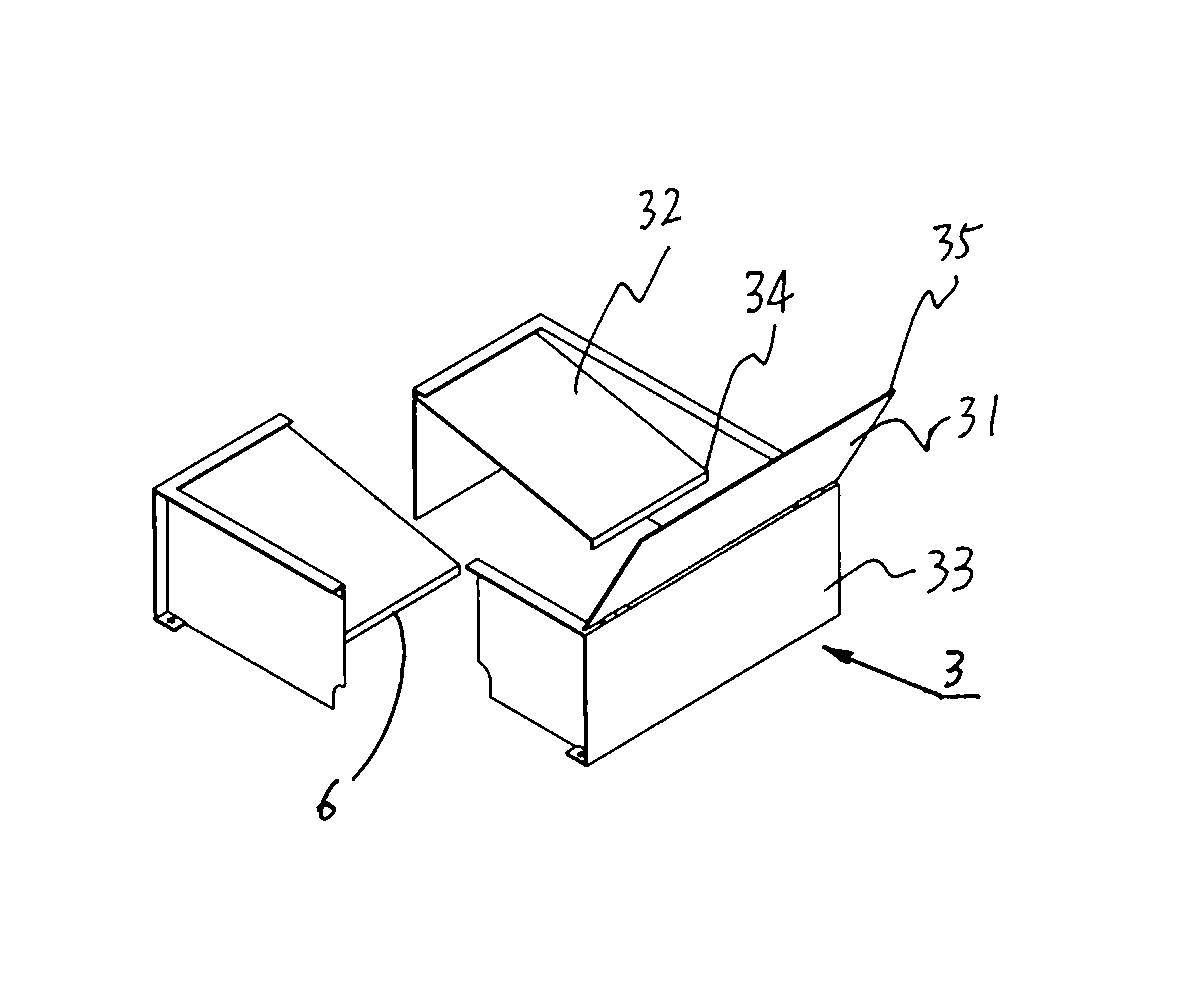

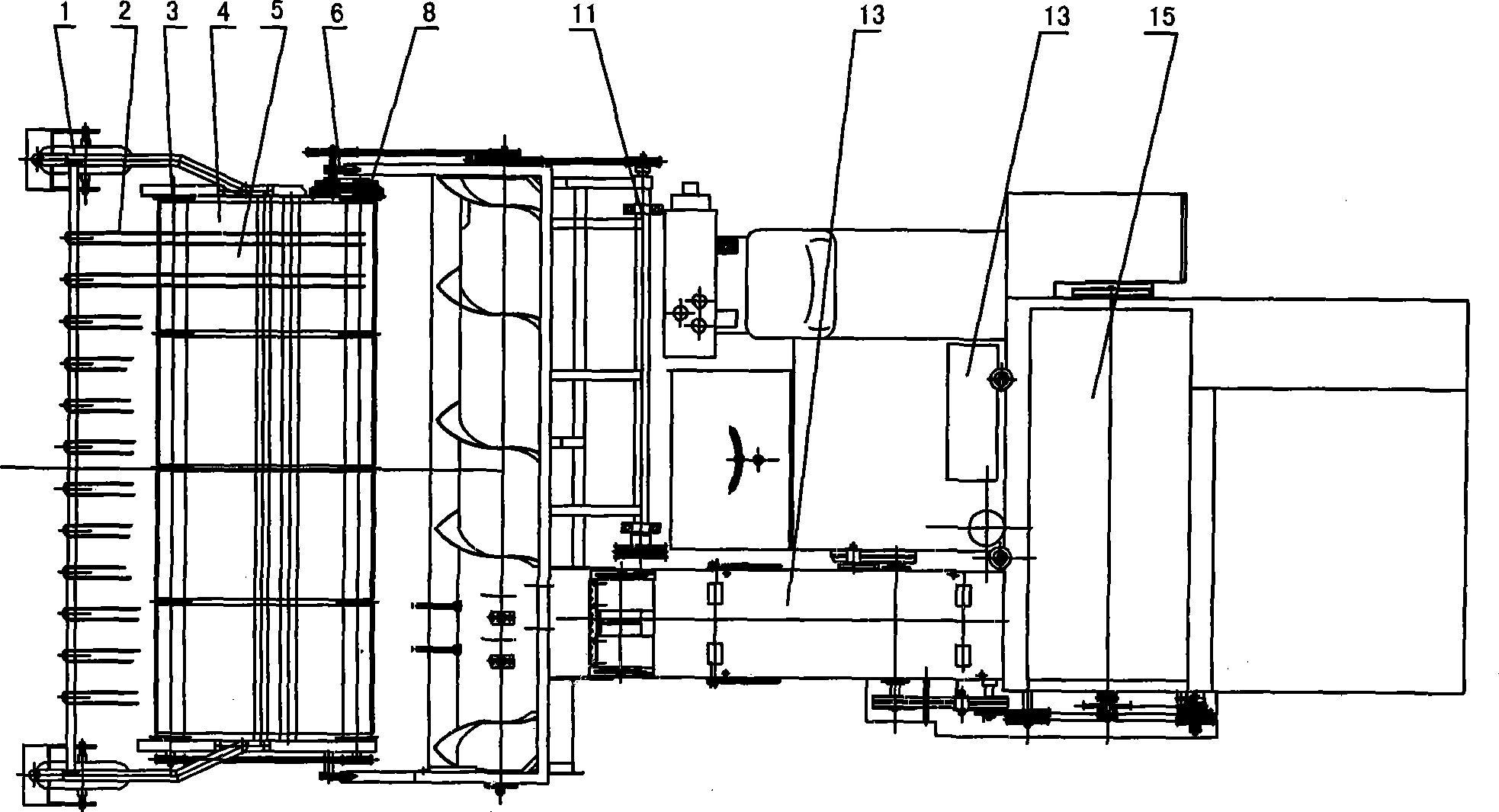

Divided winnowing method and system for tobacco leaf threshing

ActiveCN102048237AShorten delivery timeShorten the conveying distanceTobacco preparationProcess engineeringMutual influence

The invention relates to a divided winnowing method and system for tobacco leaf threshing. The winnowing system consists of a leaf threshing machine (1), a primary-selection winnowing unit (3), a multi-stage fine-selection air distributing unit (4) and a secondary leaf threshing machine (6) that are sequentially arranged, wherein the leaf threshing machine and the primary-selection winnowing unitare connected via auxiliary communicated conveying equipment (2), a blanking hole (3a) of a blanking device of the primary-selection winnowing unit is arranged above a feeding device of the multi-stage fine-selection air distributing unit, and the part between the discharge hole (3b) of the primary-selection winnowing unit and the secondary leaf threshing machine is connected with a collecting air blowing pipeline (5) or a conveyor. By virtue of the winnowing system, materials obtained after leaves are threshed can be reasonably divided and winnowed, lighter materials and heavier materials are effectively separated so as to avoid the mutual influence caused by mixing different materials during winnowing, the load entering a winnowing classifier is reduced, the winnowing precision of the fine-selection air distributing unit is improved, the stalk-content index in leaves is reduced, the leaf threshing effect is enhanced, the breakage of tobacco leaves is lowered, and the resource waste is reduced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

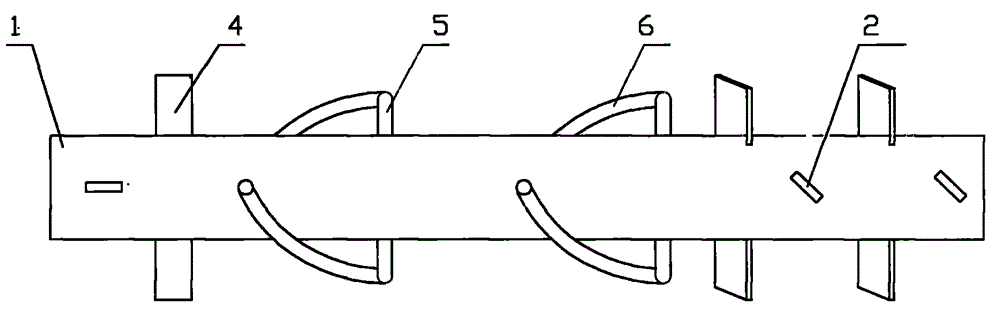

Corn threshing machine

InactiveCN102783316AImprove work efficiencyHigh outputThreshersAgricultural scienceAgricultural engineering

The invention relates to a corn threshing machine. A corn feeding assembly is installed above a threshing drum; an arc-shaped limiting sieve is installed below the threshing drum; and a limiting component for limiting position of a corncob in a threshing process is arranged between the corn feeding assembly and the threshing drum. The corn threshing machine can continuously feed the corncobs from the corn feeding assembly into the threshing drum and quickly thresh the corncobs and has a very high working efficiency.

Owner:桓仁弘兴农机制造有限公司

Threshing machine capable of compressing tree leaves

InactiveCN107258345AEfficient compressionSolve the problem of occupying the internal storage space of the leaf topperRoad cleaningPressesEngineeringThreshing machine

The invention discloses a leaves-threshing machine capable of compressing leaves, comprising a workbench, a support frame is fixedly connected to the right side of the top of the workbench, a support platform is fixedly connected to the top of the support frame, and a support platform is fixedly connected to the top of the support platform. The top is fixedly connected with a suction fan, the right side of the top of the suction fan is connected with a first connecting pipe, the bottom of the first connecting pipe is connected with a suction cover at the end far away from the suction fan, and the bottom of the left side of the suction fan is connected with There is a second connecting pipe, the left side of the second connecting pipe communicates with a protection box, and the top of the inner cavity of the protection box is fixedly connected with a cylinder. The present invention can effectively compress the leaves by setting the air cylinder, the first connecting rod, the support rod, the cushion block, the pressing plate, the fixed block, the roller and the chute, so that the compression effect is better and solves the problem of existing leaf beating problems. When the machine finishes collecting the leaves, the problem of occupying the internal storage space of the leaf topper improves the practicability of the leaf topper.

Owner:陈德忠

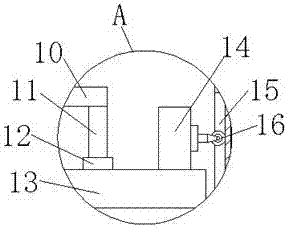

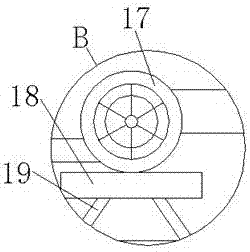

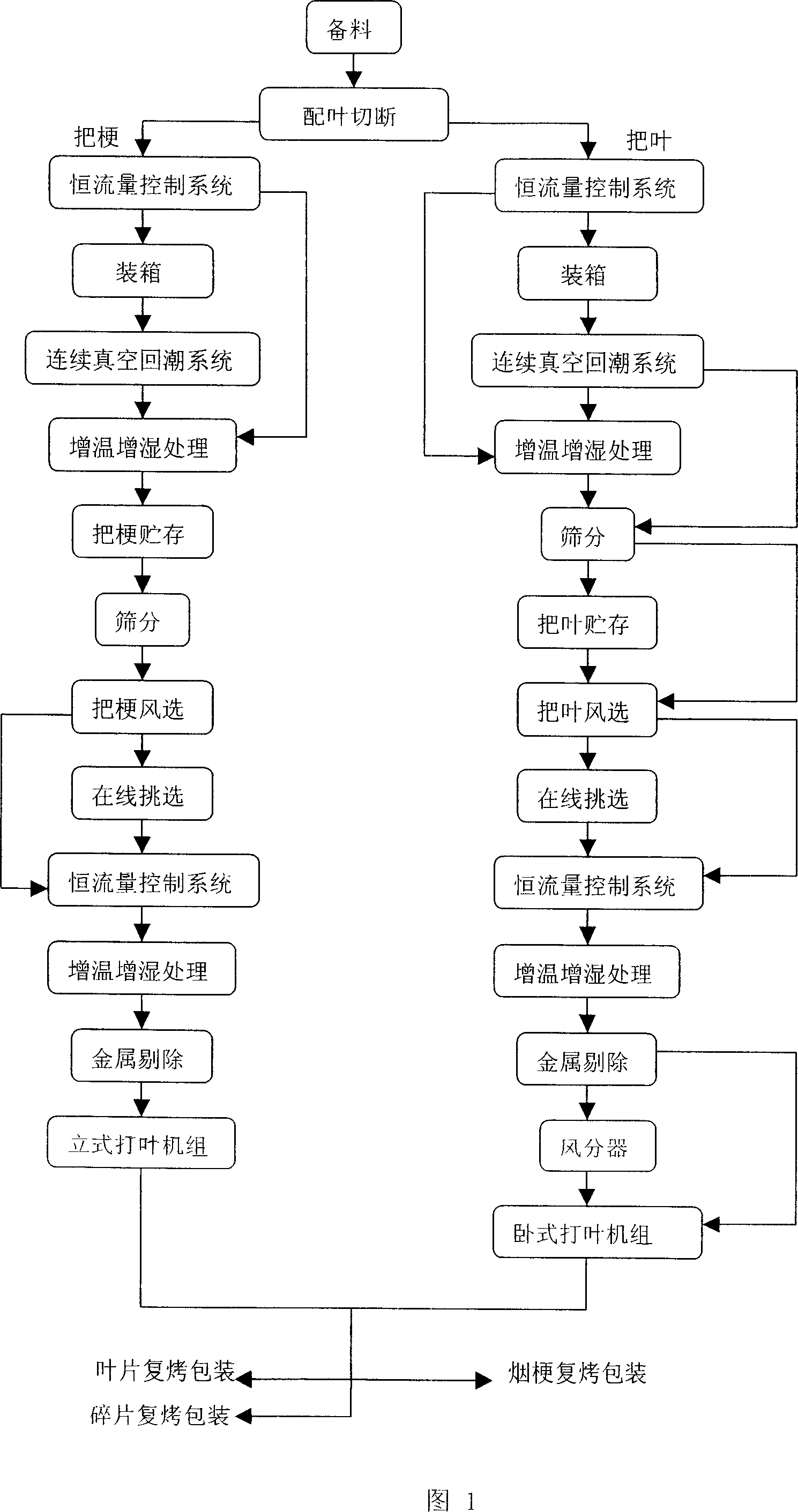

Tobacco stem-leaf separating and re-curing process

InactiveCN1973698AExcellent indicatorsReduce loadTobacco preparationTobacco treatmentMetal impuritiesEngineering

The tobacco stem-leaf separating, threshing and re-curing process includes the separation between tobacco stem and tobacco leaf and the following separated tobacco stem and tobacco leaf treating steps: 1. feeding to constant flow rate controlling system; 2. tobacco stem material temperature and humidity increasing treatment and storing; and tobacco leaf material vacuum remoistening and / or temperature and humidity increasing treatment; 3. sieving out silt; 4. wind separating out other impurity; 5. feeding to constant flow rate controlling system; 6. the last temperature and humidity increasing treatment; 7. eliminating metal impurity; and 8. separating tobacco stem from tobacco leaf in a vertical threshing machine and a horizontal threshing machine, and final separated re-curing and packing of tobacco stem and tobacco leaf. The present invention treats tobacco stem and tobacco leaf separately to reach ideal treating effects.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

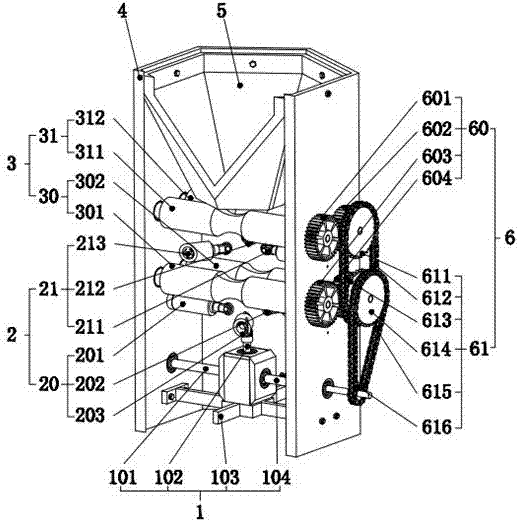

Corn cob crushing device and corn harvesting device

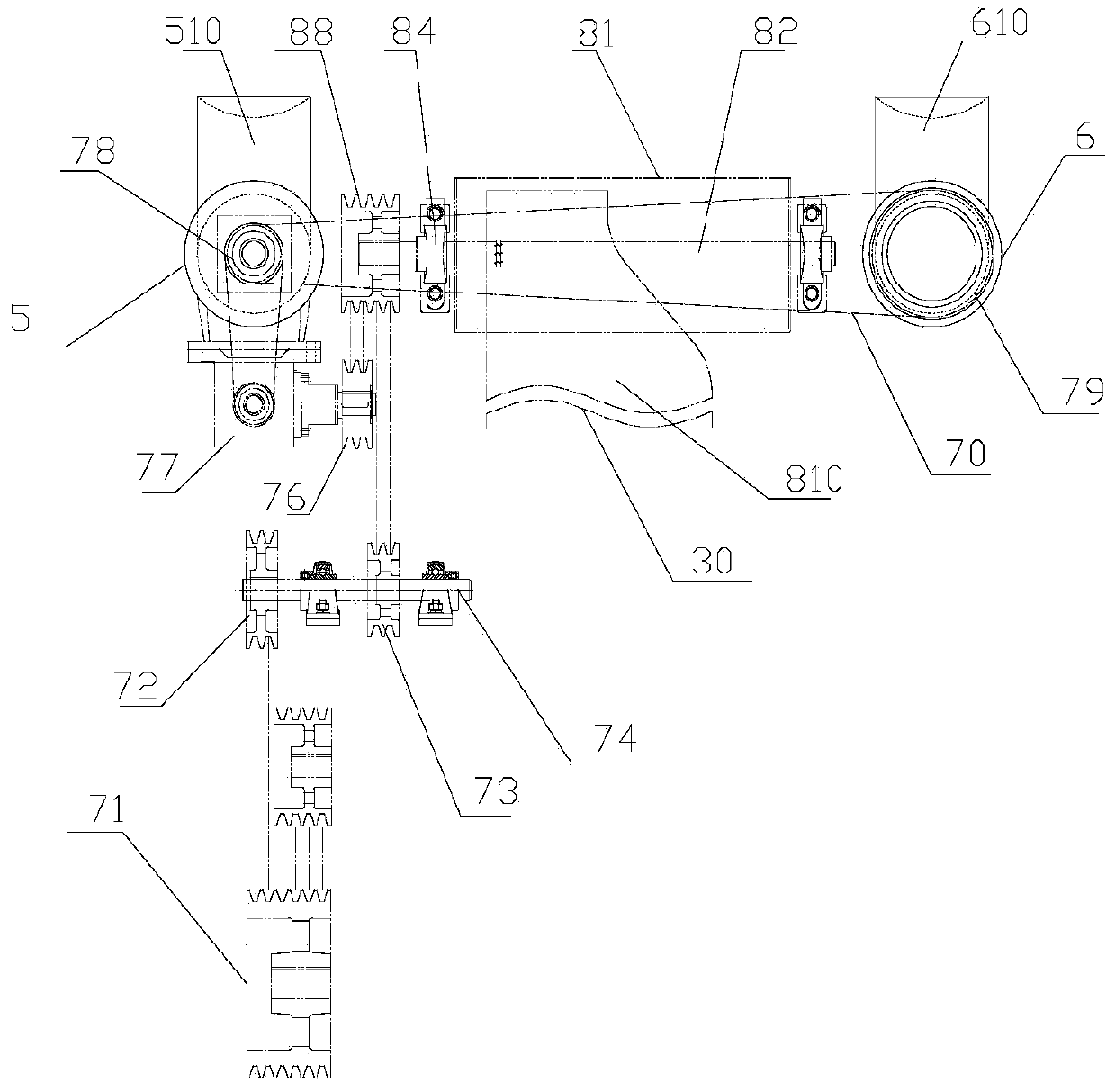

ActiveCN106937557ASolve the problem that the grain cannot be harvested directlyReduce the waste of manpower and material resourcesMowersThreshersGear wheelEngineering

The invention discloses a corn cob crushing device and a corn harvesting device. The corn cob crushing device comprises a rack, a receiving hopper, a clamp conveying mechanism, an elastic locating mechanism, a transmission mechanism and a corn cob crushing mechanism positioned at the lower end in the rack, wherein the receiving hopper is fixed at the upper part in the rack; the clamp conveying mechanism and the elastic locating mechanism are positioned at the middle part in the rack; the transmission mechanism is positioned outside the whole machine; the corn cob crushing mechanism comprises a power output shaft, a corn cob crushing drill, a transmission case rack, a power input shaft and bevel gears, wherein the transmission case rack is fixed in the lower end of the rack; the power output shaft is installed on the rack and the transmission case rack which are positioned at the side opposite to the transmission mechanism, and is meshed with the power input shaft and the corn cob crushing drill by the bevel gears; the power input shaft is installed on the transmission case rack and the rack which are positioned at the side where the transmission mechanism is arranged; an auger bit is arranged in the center of the corn cob crushing drill. The corn cob crushing device can realize the corn cob crushing process of internal corn threshing and provide kernel-core conjugate for a threshing machine, and is reliable in work, low in damage and high in efficiency.

Owner:ZHEJIANG UNIV

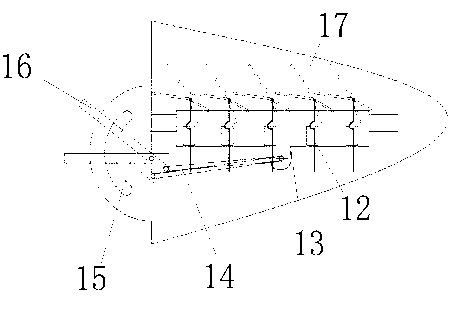

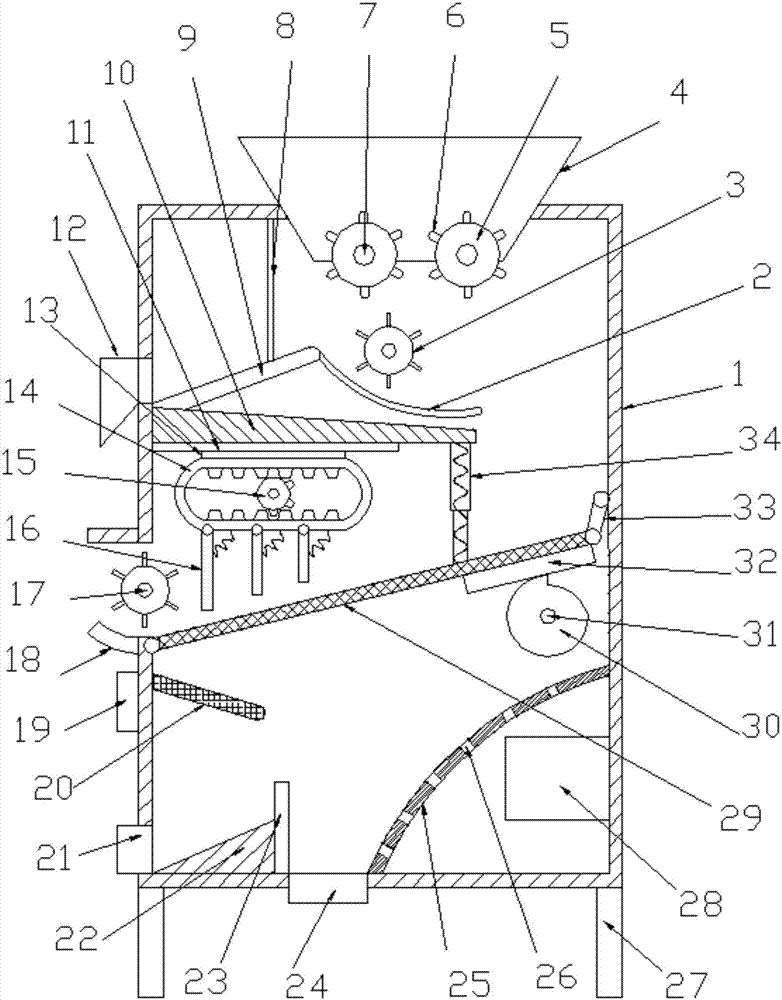

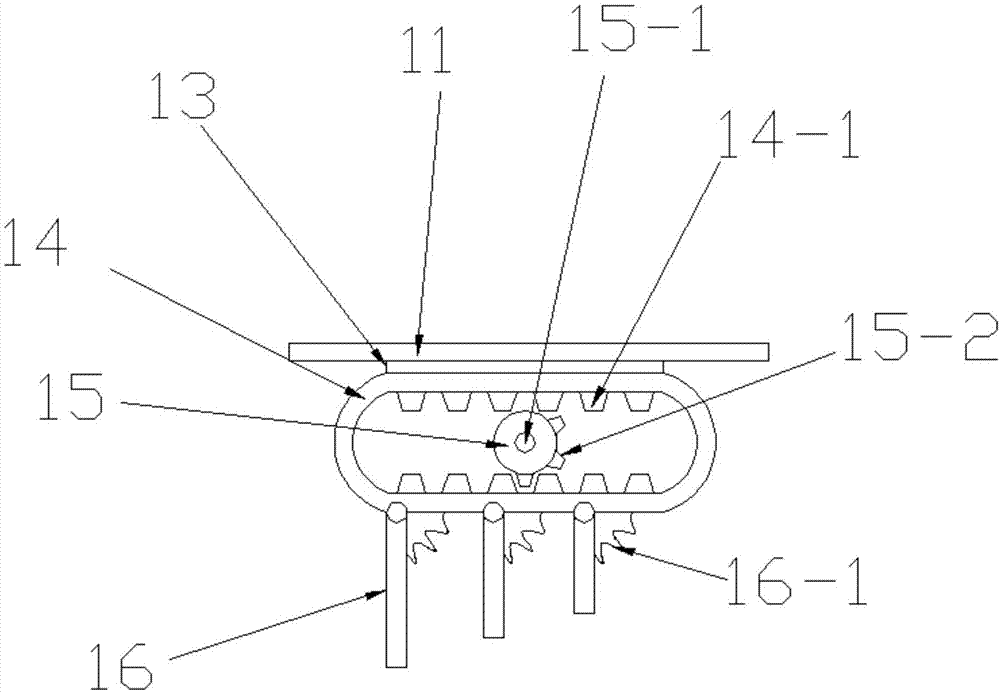

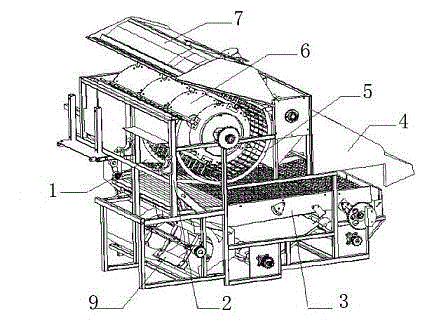

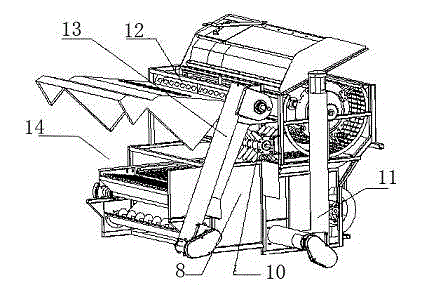

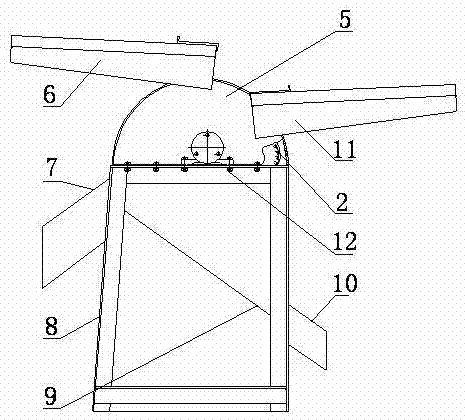

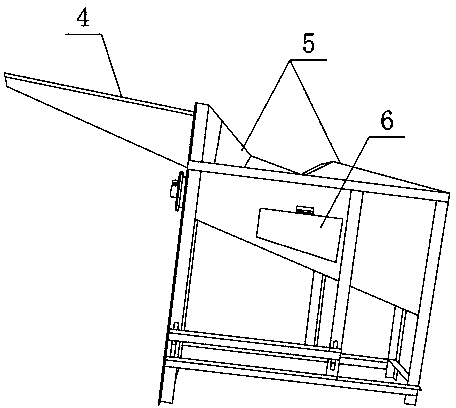

Threshing and sorting system for combined harvester

InactiveCN102714984AEnhanced feedingImprove work efficiencyMowersThreshersCombine harvesterThreshing machine

The invention discloses a threshing and sorting system for a combined harvester. A crop feeding port (1) is positioned at the upper-left front part of a thresher room (2); the length of the cross section of the crop feeding port (1) is larger than 540 mm; a weed discharge port (8) is positioned at the lower-right rear part of the thresher room (2); a threshing drum is mounted at the front upper part of the thresher room; a drum cover (7) is positioned above the threshing drum (6); a sorting vibration sieve (3) is positioned below the threshing drum (6) and a concave plate sieve (5); a blower (9) is positioned at the lower front part of the sorting vibration sieve (3); a main auger (11) is positioned at the rear part of an air outlet (18) and below the sorting vibration sieve (3); a rethreshing device (12) is positioned at the rear part of the threshing drum (6) and above the sorting vibration sieve (3); a stem cutting device (10) is positioned at the weed discharge port (8); and a thresher tail hood (4) is positioned at the upper rear part of the thresher room (2).

Owner:HUNAN LONGZHOU FARM EQUIP HLDG CO LTD

Floating directional feeding type corn bionic threshing machine

InactiveCN106489443AGood threshing effectGuaranteed rotation workThreshersAgricultural engineeringBreakage rate

The invention relates to the field of agricultural machinery, in particular to a floating directional feeding type corn bionic threshing machine. The floating directional feeding type corn bionic threshing machine comprises a machine frame, wherein two differential rollers, a dispersing roller and a threshing roller are arranged on the machine frame; a dispersing area for destroying a corn particle integrated arrangement structure on corn ears and a threshing area for completely stripping the corn particles from the corn ears are formed between the dispersing roller and the threshing roller as well as the two differential rollers correspondingly; a feeding device which is used for conveying the corn ears to the dispersing area one by one along the axial direction between the two differential rollers is arranged on one side, provided with the dispersing area, of the machine frame; height floating adjusting devices are arranged between each of roller shafts of the dispersing roller and the threshing roller as well as the machine frame; and the height floating adjusting devices perform floating adjustment on the height of the dispersing roller and the height of the threshing roller according to the diameter difference of the corn ears which enter the dispersing area and the threshing area. The floating directional feeding type corn bionic threshing machine has the advantages of extremely low breakage rate, high threshing rate and avoidance of corncob breakage, and is suitable for subsequent processing after the corn ears are picked.

Owner:HENAN UNIV OF SCI & TECH

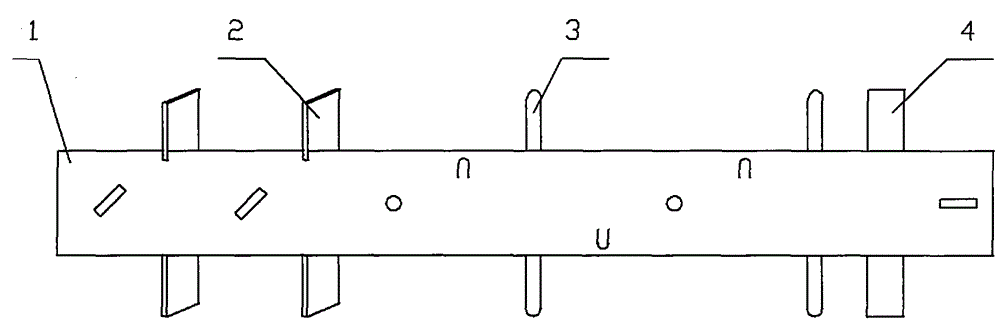

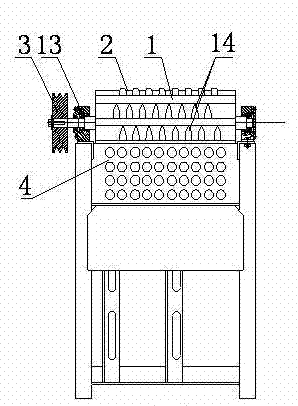

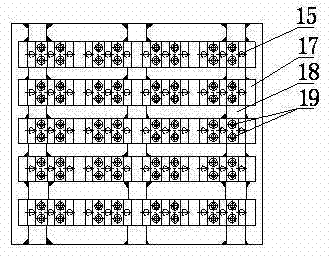

Corn threshing roller set and corn threshing machine

The invention relates to a corn threshing roller set and a corn threshing machine. The corn threshing roller set is composed of a plurality of threshing rollers arranged side by side, driving end of first and second threshing rollers are provided with a pushing board, driven ends of the first and second threshing rollers are provided with a plurality of stirring plates, a roller core body is provided with a plurality of threshing rods. A driven end of a third threshing roller is provided with a pushing board, a driving end of the third threshing roller is provided with a stirring plate, the body of the third threshing roller is provided with threshing ribs. The corn threshing machine comprises a machine body, a power device, a feed device and a plurality of threshing chambers arranged side by side, each threshing machine is composed of an upper cover and a screen mesh, two ends of the first threshing chamber communicate with two ends of the second threshing chamber, and pushing tails of other threshing chambers communicate with pushing heads of next adjacent threshing chambers. The corn threshing roller set and the corn threshing machine are high in work efficiency, corn grains and cobs will not be severely broken, and the threshing rate is high.

Owner:杜红军

Multi-functional bionic corn thresher

InactiveCN102369821AReduce breakage rateImprove cleaning rateThreshersAgricultural engineeringStructural engineering

The invention discloses a multi-functional bionic corn thresher which comprises a rack, a threshing cylinder, a threshing sieve, a sieve plate and a belt pulley, wherein the belt pulley is connected with the threshing cylinder; the rack is composed of an upper shell and a lower frame which are matched, and the upper shell is provided with a first feed inlet and a second feed inlet; the axial circumferential surface of the threshing cylinder is provided with a chicken beak-shaped kernel driving lever; and the threshing sieve is provided with a chicken beak-shaped threshing lever. The corn thresher disclosed by the invention can satisfy the threshing needs of corn kernels with different uses; and according to the principle of bionics, a threshing unit (such as teeth or striking ribs) on the cylinder is designed into the shape of a wedge-shaped beak part of a chicken, so that an effect of loosing clusters and then threshing the clusters can be achieved, thereby greatly reducing the damages on corn kernels during threshing.

Owner:HENAN UNIV OF SCI & TECH

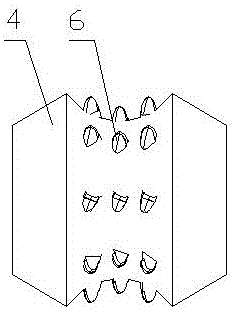

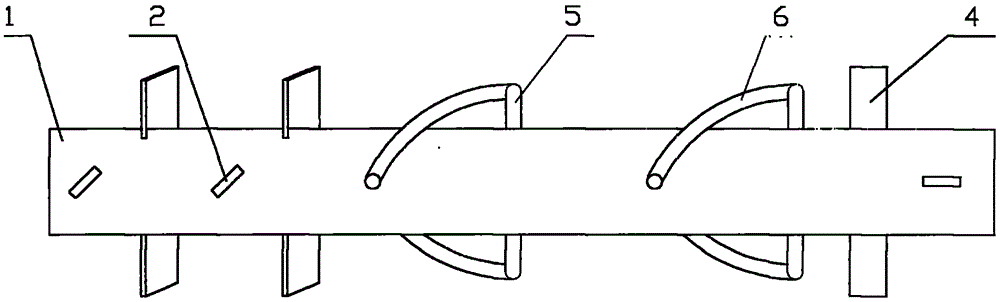

Flexible differential corn threshing machine

InactiveCN103999642AAchieve multiple threshingReduce breakage rateThreshersEngineeringThreshing machine

A flexible differential corn threshing machine comprises a machine frame, a threshing chamber, a feeding hopper, a cob discharging hopper and a lower sliding plate arranged on the machine frame. A threshing cylinder and an annular concave plate arranged on the periphery of the threshing cylinder are arranged inside the threshing chamber. The upper portion of the annular concave plate is provided with an opening extending in the axial direction. A guiding line is arranged on the inner wall of the upper portion of the threshing chamber. A plurality of rows of spike teeth are evenly arranged on the peripheral face of the threshing cylinder at intervals in the axial direction. Each row of spike teeth are arranged in a staggered mode so as to be distributed in the spiral direction consistent with the spiral direction of the guiding line along the peripheral face of the threshing cylinder. According to the set height of the spike teeth, corn ears can be extruded between the spike teeth and the annular concave plate when pushed to move forwards, and therefore threshing is achieved. Kernels obtained through threshing are discharged through concave plate holes formed in the annular concave plate. The peripheral face of the threshing cylinder and the spike teeth are sleeved with rubber sleeves. According to the flexible differential corn threshing machine, repeated threshing of the corn ears is achieved, the ears are abraded through the spike teeth and the annular concave plate, differential threshing is formed, the threshing efficiency is improved, and the corn kernel damage rate is reduced.

Owner:HENAN UNIV OF SCI & TECH

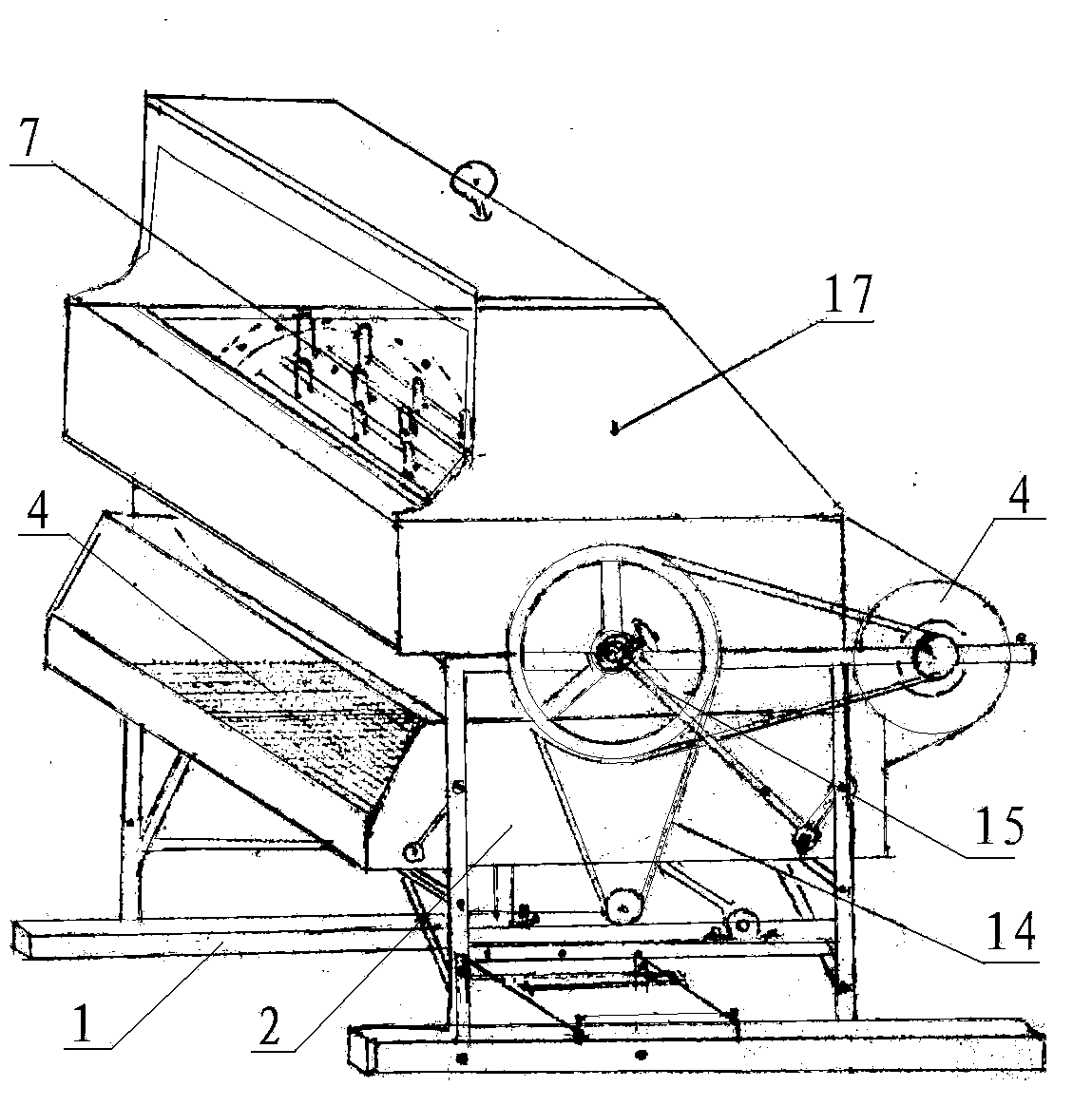

Rape threshing machine

The invention discloses a rape threshing machine which comprises a machine frame, a driving system, as well as a threshing system and a cleaning and selecting system which are arranged inside the machine frame, wherein the cleaning and selecting system is arranged below the threshing system; the threshing system comprises a main shaft and a threshing roller, the main shaft is mounted on the machine frame, the main shaft drives the threshing roller to rotate, the cleaning and selecting system comprises a shake slide plate, a slide plate hoisting rod, a vibration sieve box, a sieve box hoisting rod, a crank shaft, a grain receiving plate and a blower, the slide plate hoisting rod and the sieve box hoisting rod are both hinged to the interior of the machine frame, one end of the shake slide plate is connected onto the machine frame in a hanging manner through the slide plate hoisting rod, and the other end of the shake slide plate is hinged to the sieve box hoisting rod through a hinge; one end of the vibration sieve box is connected onto the machine frame in the hanging manner through the slide plate hoisting rod, and the end meanwhile is hinged to the shake slide plate, and other end of the vibration sieve box is connected with the crank shaft installed on the machine frame; the grain receiving plate is arranged below the vibration sieve box, and fixed on the machine frame. According to the invention, a whole-feed axial-flow type threshing system is adopted, so that the threshing time is prolonged, the threshing is more thorough and the threshing loss is reduced.

Owner:HUNAN AGRICULTURAL UNIV

Corn threshing machine

The invention discloses a corn threshing machine comprising a housing, a threshing unit arranged in the housing, and a kernel and core separation device arranged in the housing. The kernel and core separation device is arranged below the threshing unit. A sound insulation layer is arranged in a shell layer of the housing; and the thickness of the sound insulation layer is the half of the thickness of the shell layer. The corn threshing machine also includes a corncob feeding device arranged at the top of the housing. The corncob feeding device contains a feeding cylinder and a rotation cylinder. The feeding cylinder connected with the inner cavity of the housing is fixed at the top of the housing and is protruded outwardly; and the rotation cylinder connected with the feeding cylinder in a rotation mode is in transmission connection with a first power unit. Multiple corncob that are going to be processed by threshing are laid on the inner wall of the rotation cylinder in a loop mode. According to the invention, on the basis of improvement of the existing corncob feeding device, the corn threshing machine has the automatic feeding function; and with the sound insulation layer at the housing, noises caused during the equipment running processing can be effectively reduced.

Owner:秦朝东

Industrial processing method for fresh and tender wheat food without additives

The invention relates to an industrial processing method for fresh and tender wheat food without additives, which is mainly characterized in that by taking wheat which is planted in a pollution-free mode and is in the milk ripe stage as a processing object, ears of wheat are harvested and are frozen by utilizing a refrigeration storage quickly, so that the ears of the wheat are refrigerated at low temperature under the condition of no antistaling agent to retain freshness; and the ears of the wheat are threshed by utilizing a thresher under the freezing condition and are processed under the condition of no food additives to obtain green, healthy and safe fresh and tender wheat food which is full of nutriments. By the industrial processing method, the nutrition of the fresh and tender wheat is reserved to a maximum degree, the nutrients of the obtained food are easy to absorb by human bodies, and the food has excellent colors, fragrance, tastes and functionality and is suitable for vast people; the food is prevented from being polluted, the influence of the food additives on the nutrition and safety of the food is avoided, and a new path for the comprehensive utilization and deep processing of the wheat is opened up; and the industrial processing method has a great strategic significance for wheat production, development of food industry, the improvement on the health condition of current population and progressing of agricultural industry.

Owner:边永启

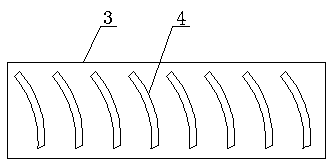

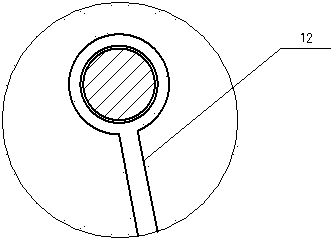

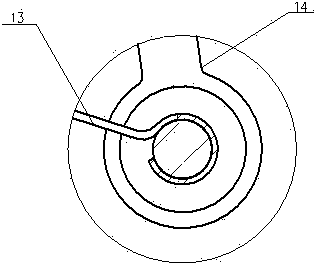

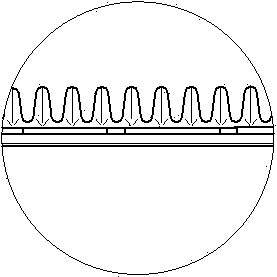

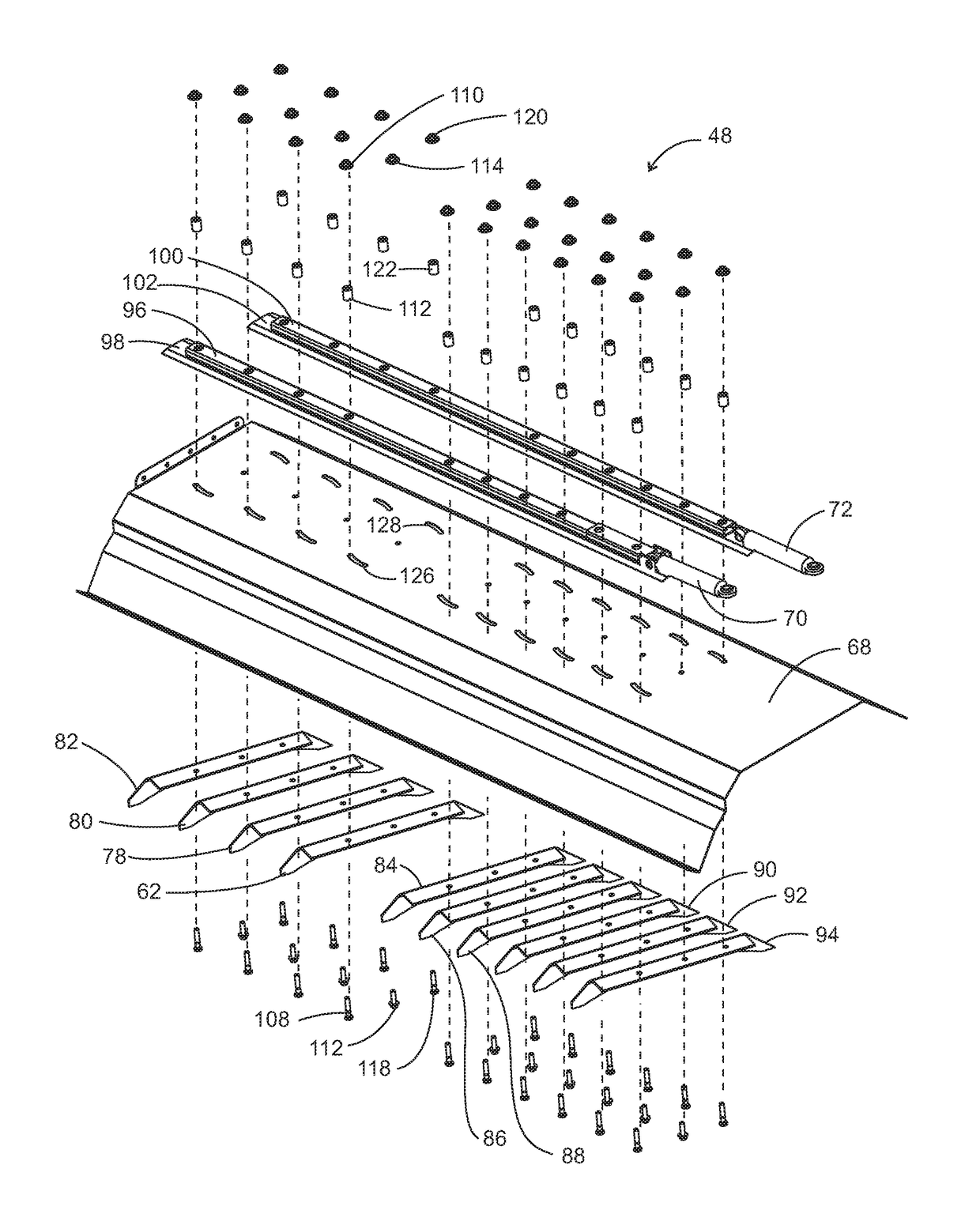

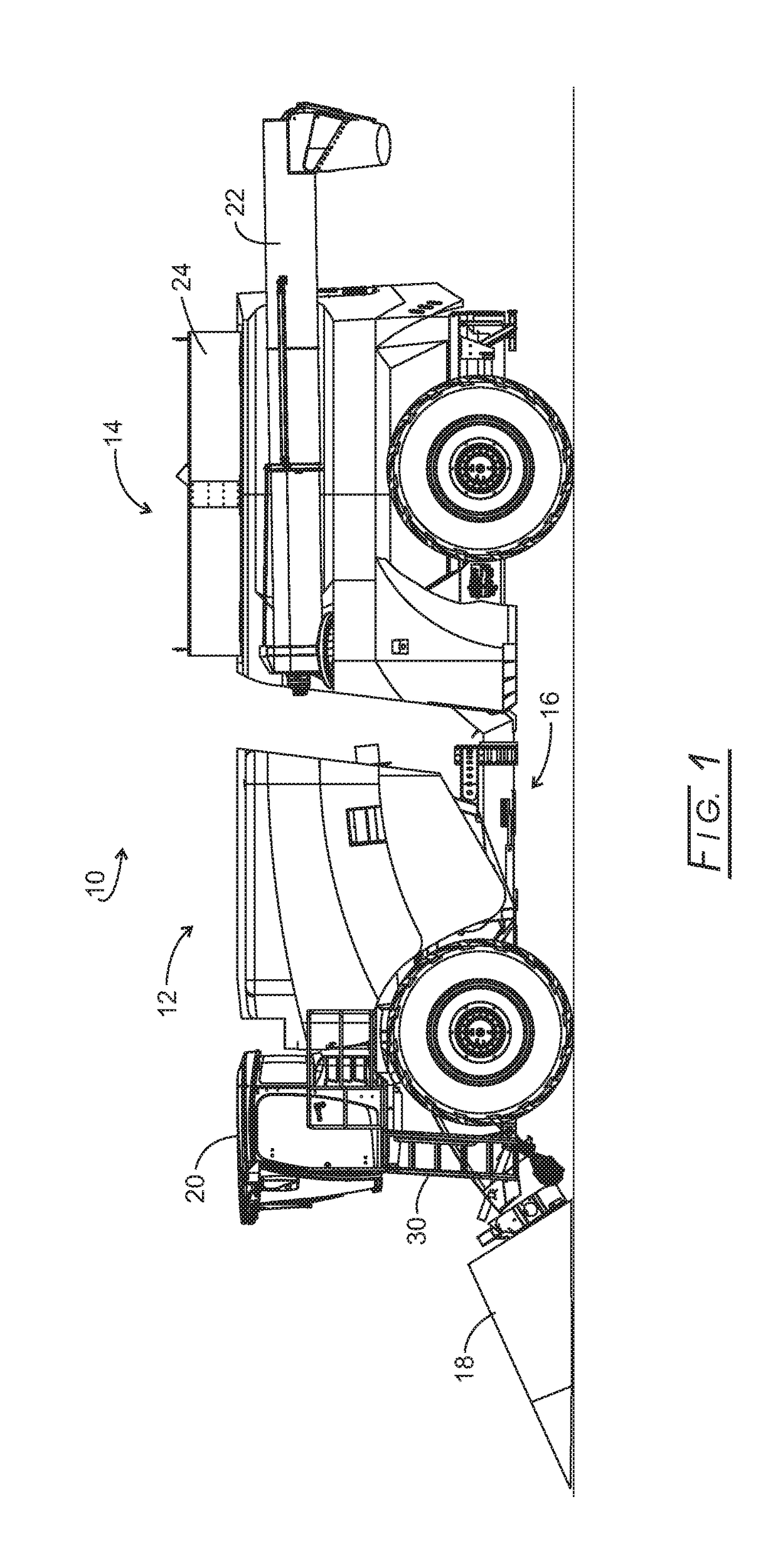

Adjustable Top Cover Vanes for Controlling Crop Flow in a Rotary Thresher

ActiveUS20180153104A1Promoting and retarding flow of materialAgricultural vehiclesMowersEngineeringMechanical engineering

Disclosed is a harvesting combine rotor cage top cover assembly that includes an overhead roof formed from a substantially horizontal flat section and downwardly angled side sections. A series of substantially parallel vanes are located beneath the overhead roof. Each vane is formed from a substantially flat top section located against the roof horizontal flat section and downwardly laterally extending legs being angled on their sides and having an arcuate bottom. The sides of the vanes are rotatable about a central pivot for promoting or retarding the flow of material in the rotor cage.

Owner:TRIBINE IND

Corn thresher capable of carrying out deflecting threshing

ActiveCN103931358AShorten the lengthReduce non-threshing operation sectionThreshersAgricultural engineeringStructural engineering

The invention discloses a corn thresher capable of carrying out deflecting threshing. The corn thresher comprises a feeding port, a threshing barrel, a bin shell, a corn kernel discharge port and a corncob discharge port, the threshing barrel is obliquely arranged, at least one layer of threshing ribs is arranged on the threshing barrel, each threshing rib comprises an upper threshing rib segment and a lower threshing rib segment, the upper threshing rib segments and the lower threshing rib segments are all spiral threshing ribs and are opposite in spiral direction, the spiral direction of the upper threshing rib is opposite to the rotating direction of the threshing barrel, and the spiral direction of the lower threshing rib segments is identical to the rotating direction of the threshing barrel. The corncob discharge port is formed in the side face corresponding to the connecting positions of the upper threshing rib segments and the lower threshing rib segments. The motion track of corn cobs entering a threshing bin is limited by arranging the deflecting ribs, the height of the threshing bin is changed by changing the barrel diameter of the threshing barrel or the double-layer ribs, and therefore the corn cobs can be fully threshed in different spaces of the threshing bin, the threshing performance can be greatly improved, and the non-threshing work sections of the threshing bin are reduced.

Owner:李禄海

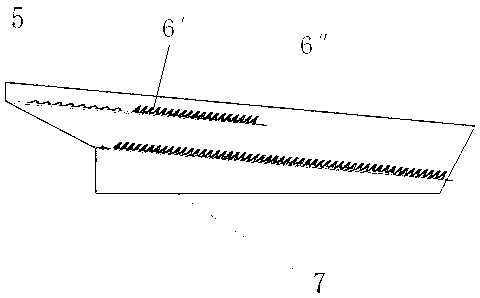

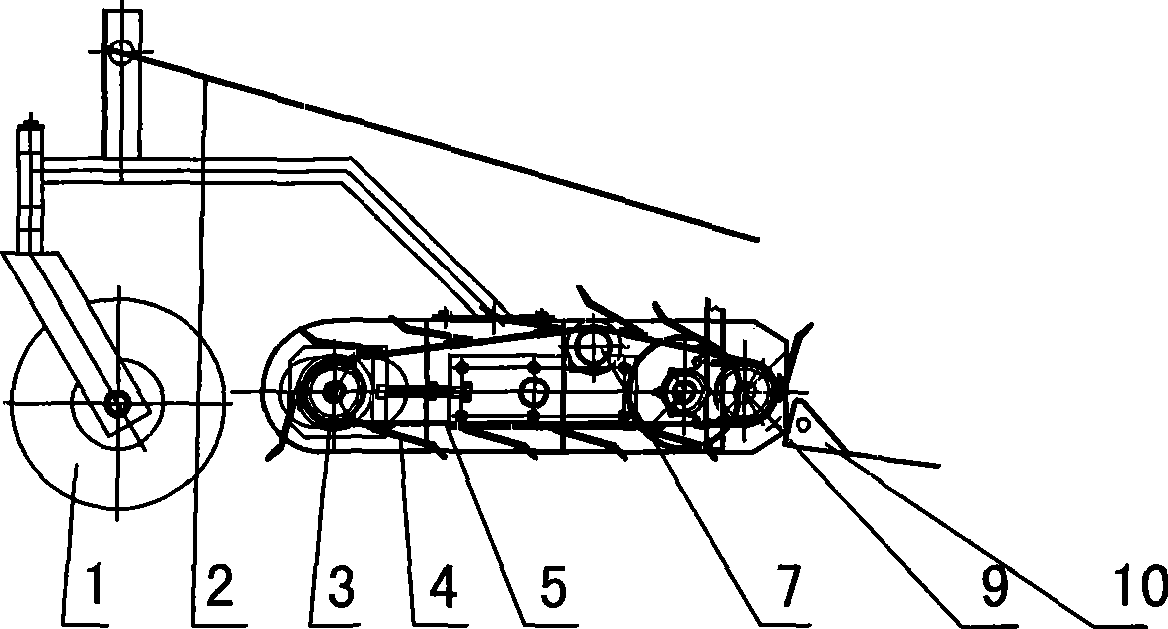

Cole gathering and threshing mill

InactiveCN101366335AGuaranteed Harvest QualityImprove work efficiencyLoadersThreshersDevice formAgricultural engineering

The invention relates to a rapeseed picking thresher, which belongs to the technical field of agricultural machinery. The thresher comprises a traction drive thresher, wherein the front part of the traction drive thresher is provided with a header feeding device; grain picking devices are hung on two sides of the front end of the header feeding device through a hitching device; each grain picking device is an independent unit type picking device which consists of a copying land wheel and a belt-type picking mechanism; the copying land wheel is positioned in front of the belt-type picking mechanism; the copying land wheel and the hitching device form front and back supports for the belt-type picking mechanism; the belt-type picking mechanism is formed by a toothed belt wound on a driving roll shaft and a driven roll shaft; and elastic conveying deflector teeth are alternately distributed on the toothed belt. The rapeseed picking thresher can complete picking and threshing rapeseeds in a mechanized mode, so as to change the prior manual reaping mode, lay a foundation for realizing the segmented reaping of rapeseeds, effectively guarantee the reaping quality of rapeseeds and improve operation efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

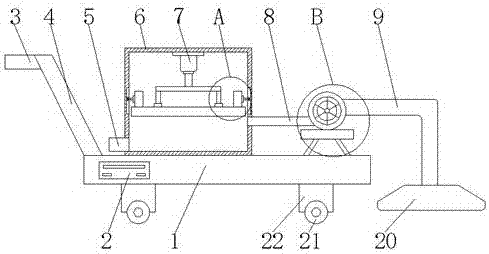

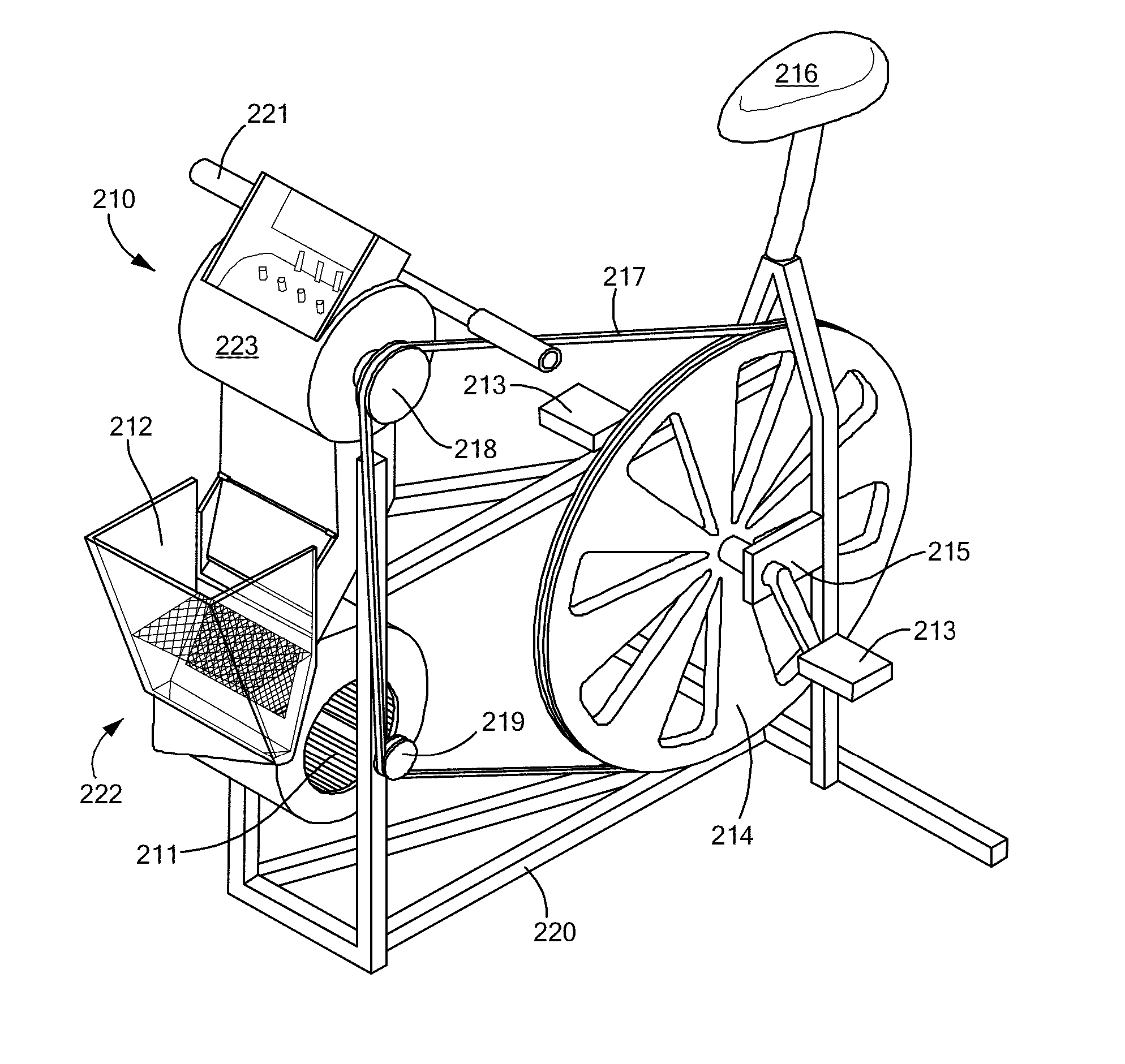

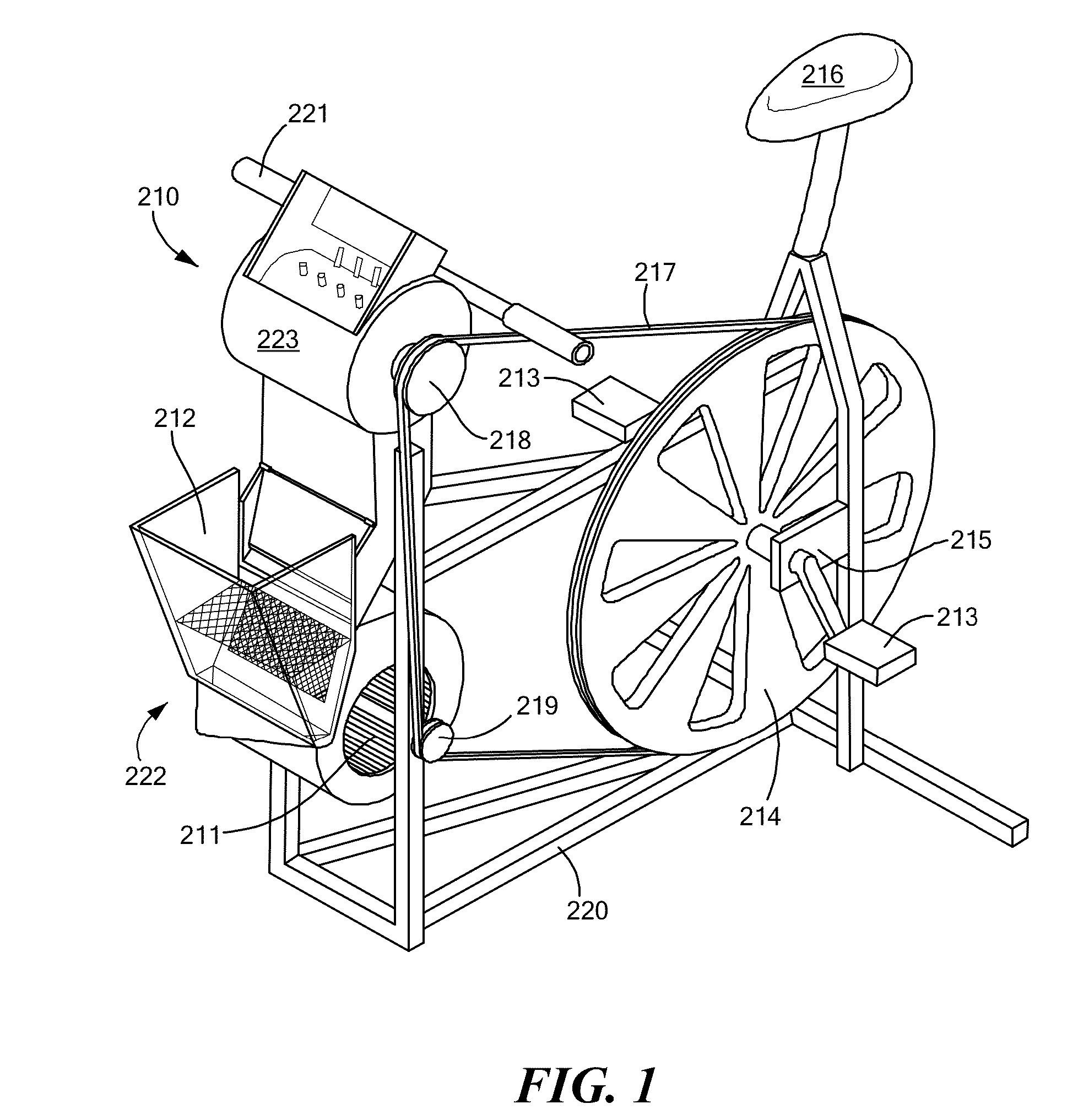

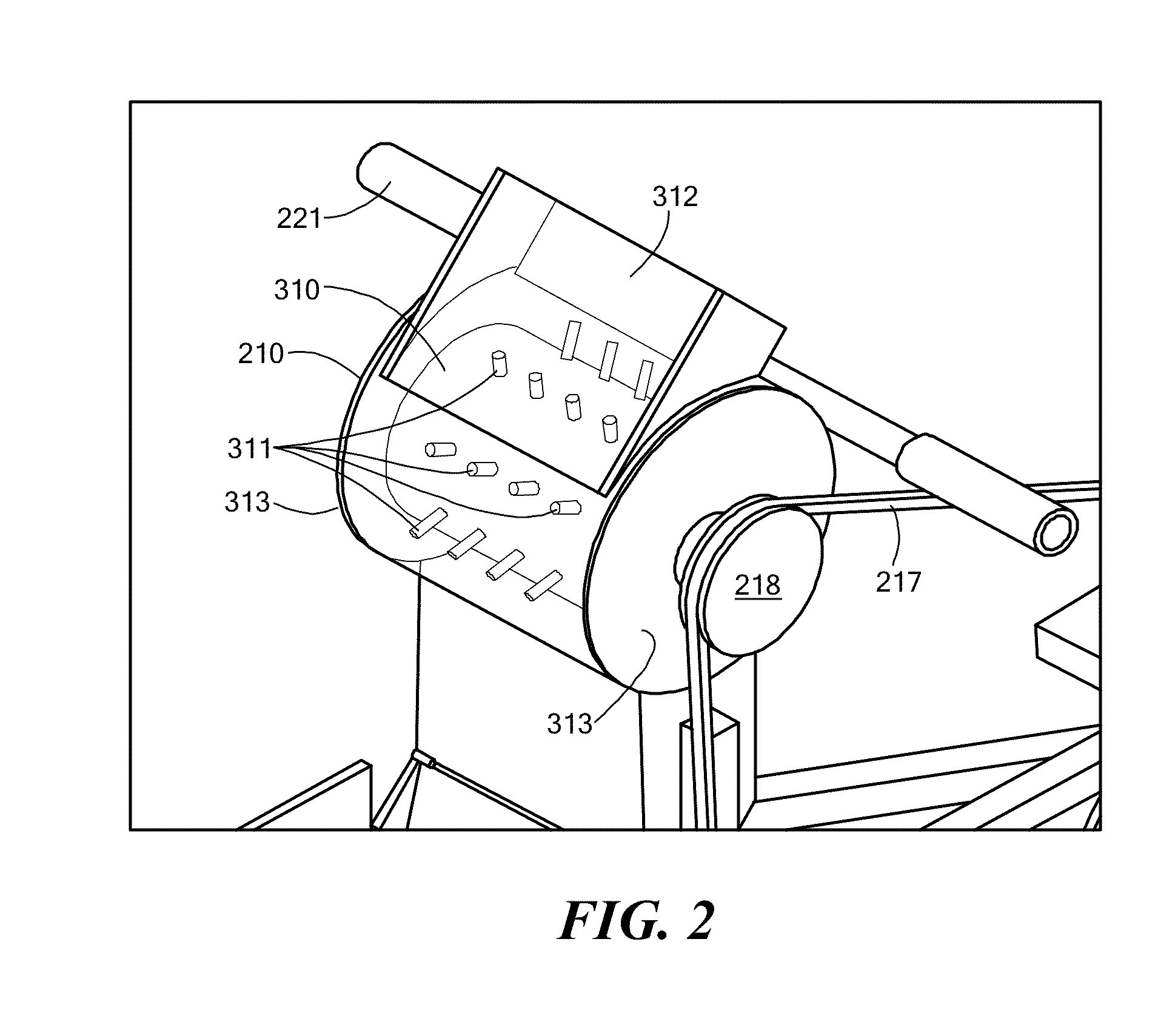

Pedal-Operated Threshing Machine

A pedal-driven machine and methods for processing grain using the physical exertions of a single individual. The single individual feeds a panicle of grain into a thresher, drives the thresher to thresh the grain, winnows the threshed grain with a winnower, and collects the threshed grain, all concurrently. The panicle may be withdrawn from the thresher after being threshed without the panicle having passed entirely through the thresher. The machine that enables the foregoing processing by a single individual has a pedaling mechanism for driving both the thresher and the winnower via a single drive member.

Owner:TEEN TECH A NJ NONPROFIT CORP

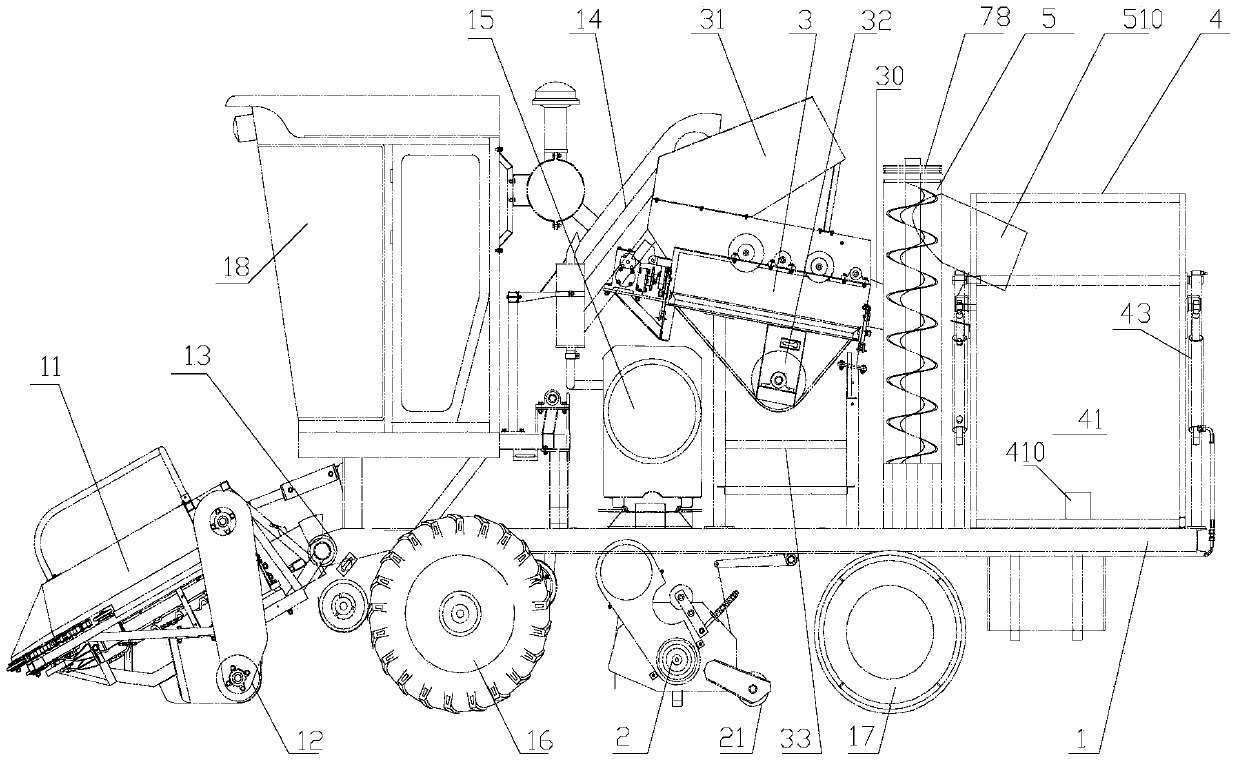

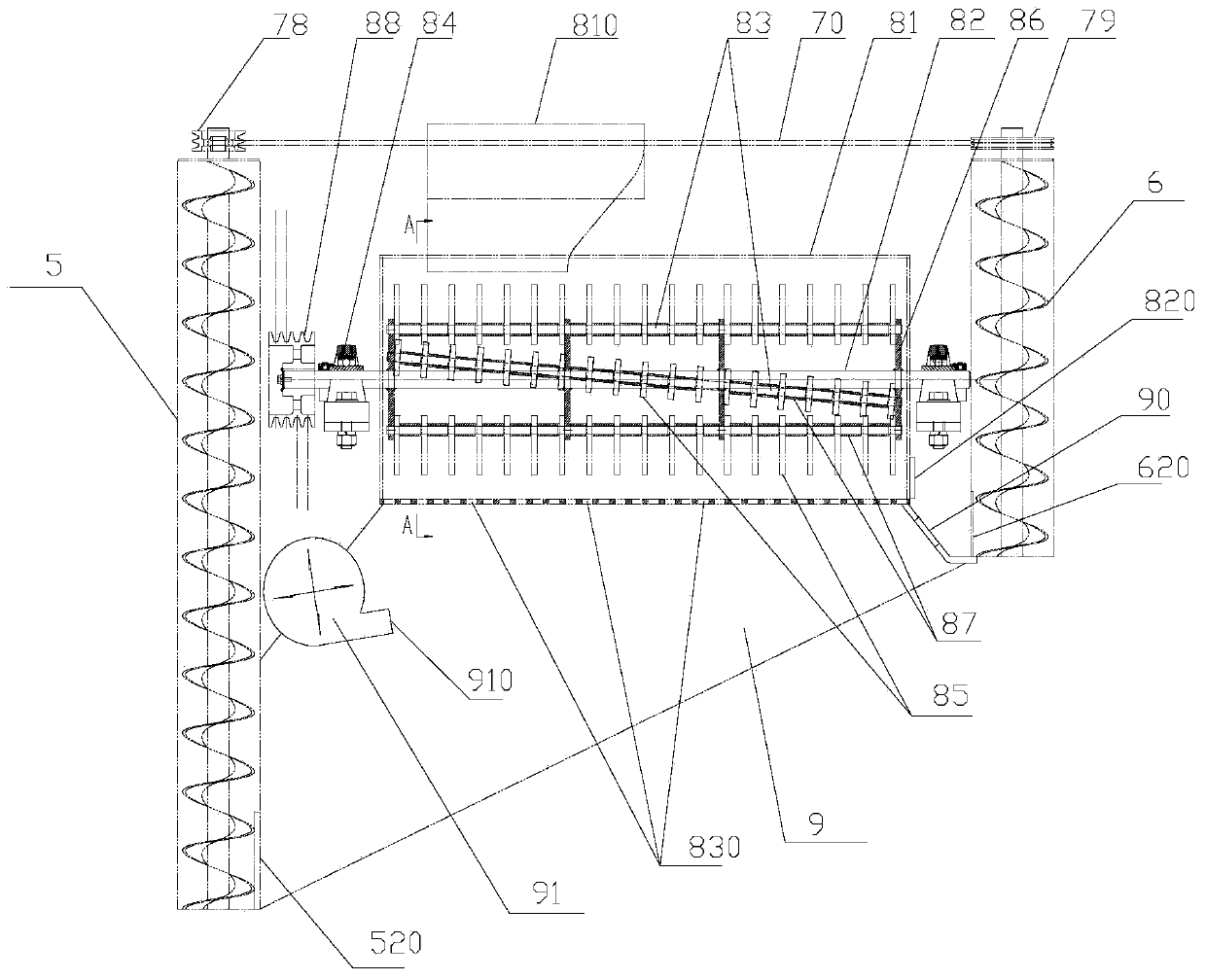

Self-propelled shelled corn and corncob classification harvester

InactiveCN103548483AIncrease the level of mechanizationIncrease productivityMowersSteering wheelDrive wheel

The invention provides a self-propelled shelled corn and corncob classification harvester, which comprises a chassis, a cab, a diesel, a barn, driving wheels, steering wheels, a header, a small elevator, a big elevator, a front chopper, a peeling machine, a threshing machine, a shelled corn packing auger and a corncob packing anger, wherein the threshing machine is positioned above the chassis between the peeling machine and the barn and is used for peeling shelled corns on the corncob and separating the shelled corns from the corncob; the corncob discharging hole of the peeling machine is in butt joint with the corncob feeding hole of the threshing machine; the shelled corn packing auger is used for upwards conveying the shelled corns; the corncob packing anger is used for upwards conveying the corncob; a vertical clapboard is arranged in the barn to divide the barn into a shelled corn cabin and a corncob cabin; the shelled corns are fed into the shelled corn cabin via the shelled corn packing auger; the corncob is fed into the corncob cabin via the corncob packing anger. According to the self-propelled shelled corn and corncob classification harvester disclosed by the invention, the effect of one machine with multiple functions of stripping, peeling and threshing corn as well as classifying, storing and transporting the shelled corns and corncobs can be achieved.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Oily peony seed threshing and sorting device and process

ActiveCN105594385AImprove threshing and sorting efficiencyGood threshing and sorting effectThreshersEngineeringCentrifugal fan

An oily peony seed threshing and sorting device comprises a threshing and screening device and a winnowing and magnetic separating device. The threshing and screening device comprises a threshing machine frame, a threshing roller and a motor. The threshing roller is installed on the threshing machine frame through bearings at the two ends of a roller shaft. A roller cover is arranged at the upper portion of the threshing roller. A feed port is formed in one side of the upper portion of the roller cover. A concave plate screen is arranged below a discharge port of the threshing roller. A vibration screen is arranged below the concave plate screen. A shell material outlet and a seed outlet are formed in the tail end of the vibration screen. A seed outlet of the threshing and screening device is connected with a feed port of a centrifugal fan. The oily peony seed threshing and sorting device has the advantages that a special and systematic device for threshing and sorting oily peony seeds is provided, the threshing and sorting efficiency of oily peony seeds can be effectively improved, the threshing and sorting effect is good, and the requirement for large-scale production is met.

Owner:HENAN UNIV OF SCI & TECH

Vertical type axial flow threshing machine specially designed for breeding soybeans

The invention provides a vertical type axial flow threshing machine specially designed for breeding soybeans, and belongs to the field of farm machinery. The threshing machine consists of a machine frame, a cantilever beam, a visual combined cover, a threshing cylinder, a blade type cleaning cylinder, a stalk-discharging fan, a centrifugal fan, a feed inlet, a material collecting port and a seed outlet, wherein the visual combined cover is hinged on both ends of the machine frame and can be freely opened and closed, and organic glass is fixedly arranged on the surface of the cover; and the threshing cylinder, the blade type cleaning cylinder and the stalk-discharging fan are fixedly connected in sequence, and a cleaning air channel is arranged in the middle of the threshing cylinder. The machine can complete the operation of threshing, separating and cleaning at the same time, has the characteristics of small volume, light weight, reasonable structure, convenient and quick cleaning, high maneuverability and the like, and can meet the requirements of the accurate yield measurement in scientific research and production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com