Patents

Literature

1304 results about "Metal detectors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

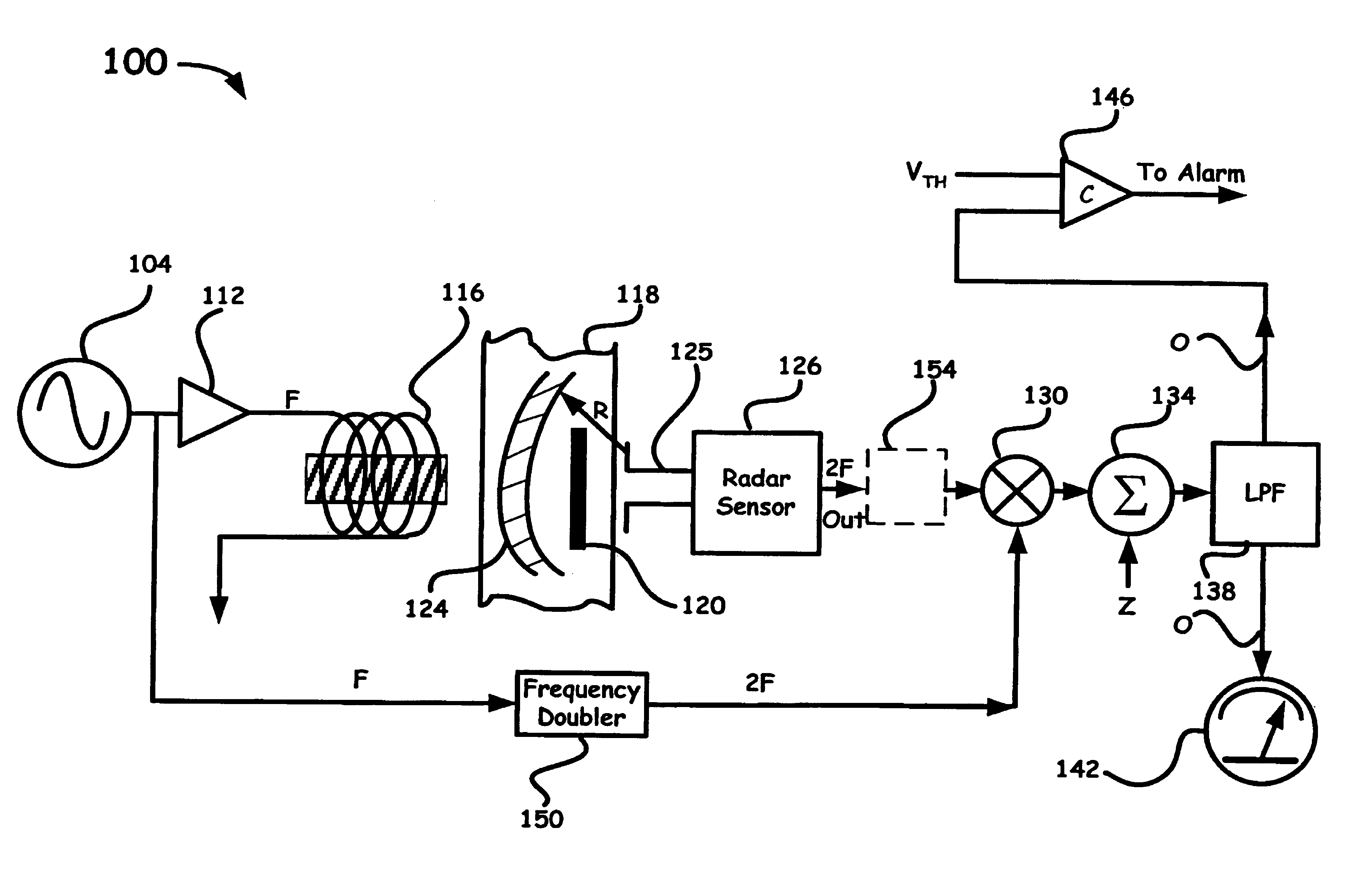

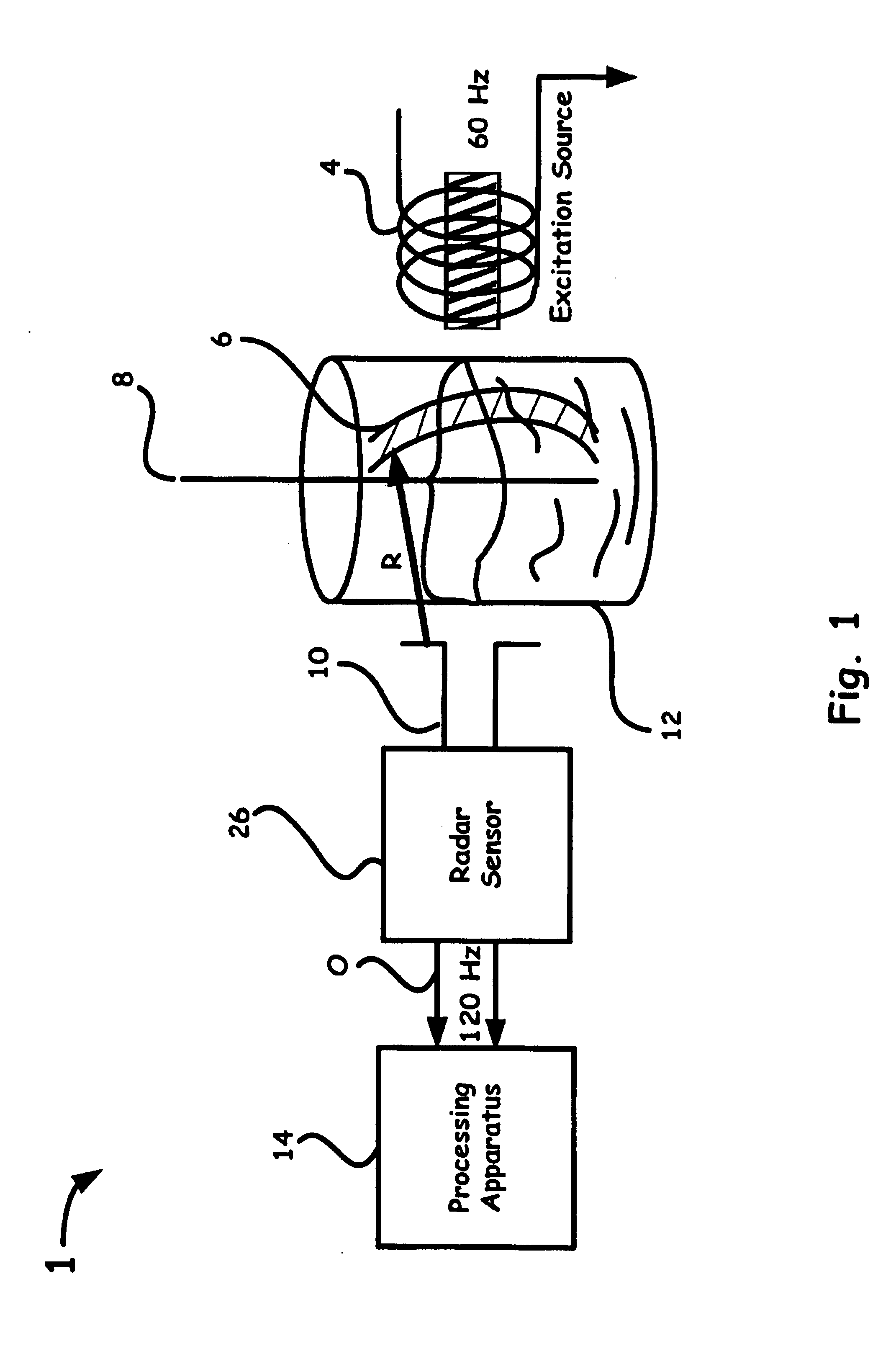

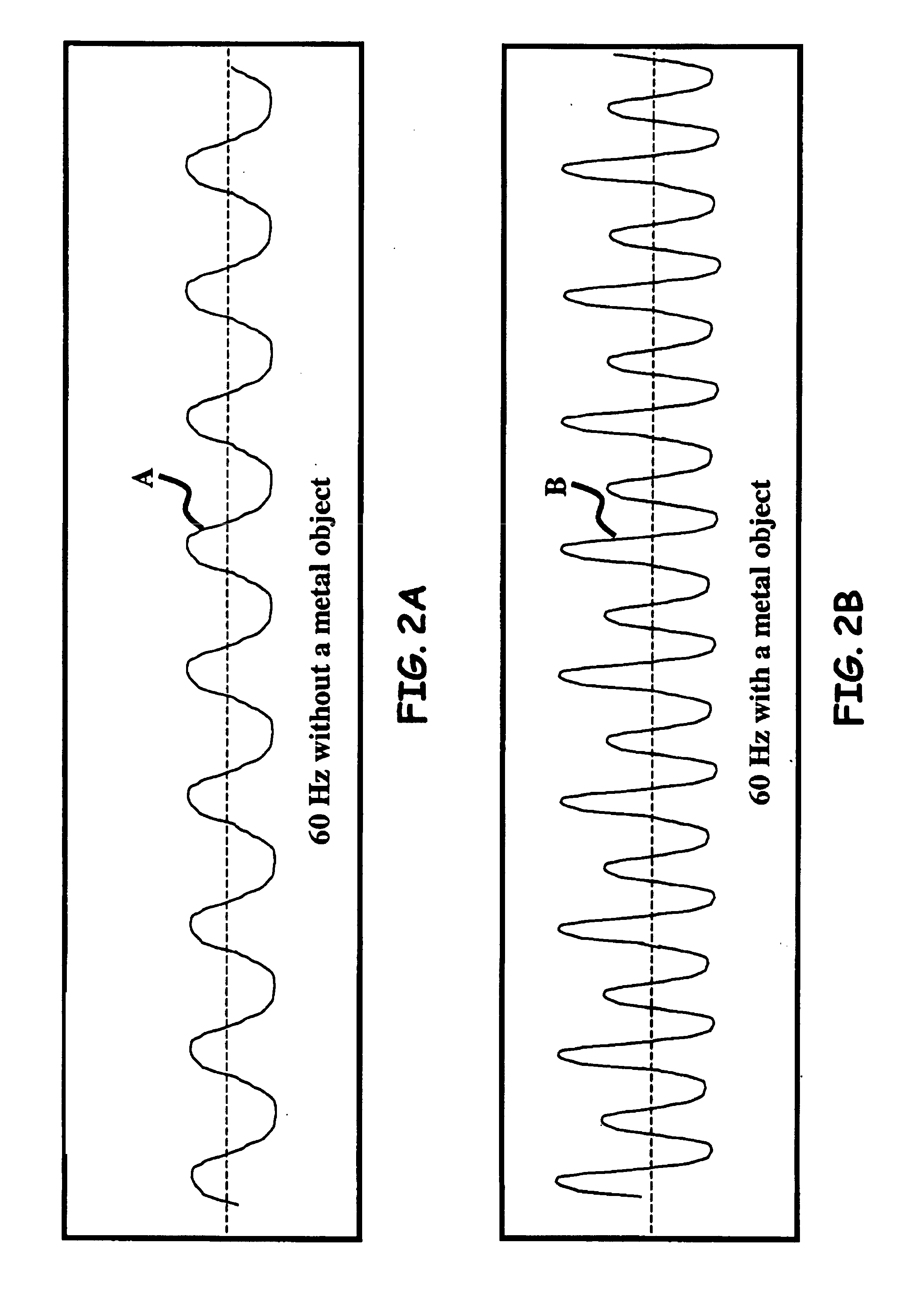

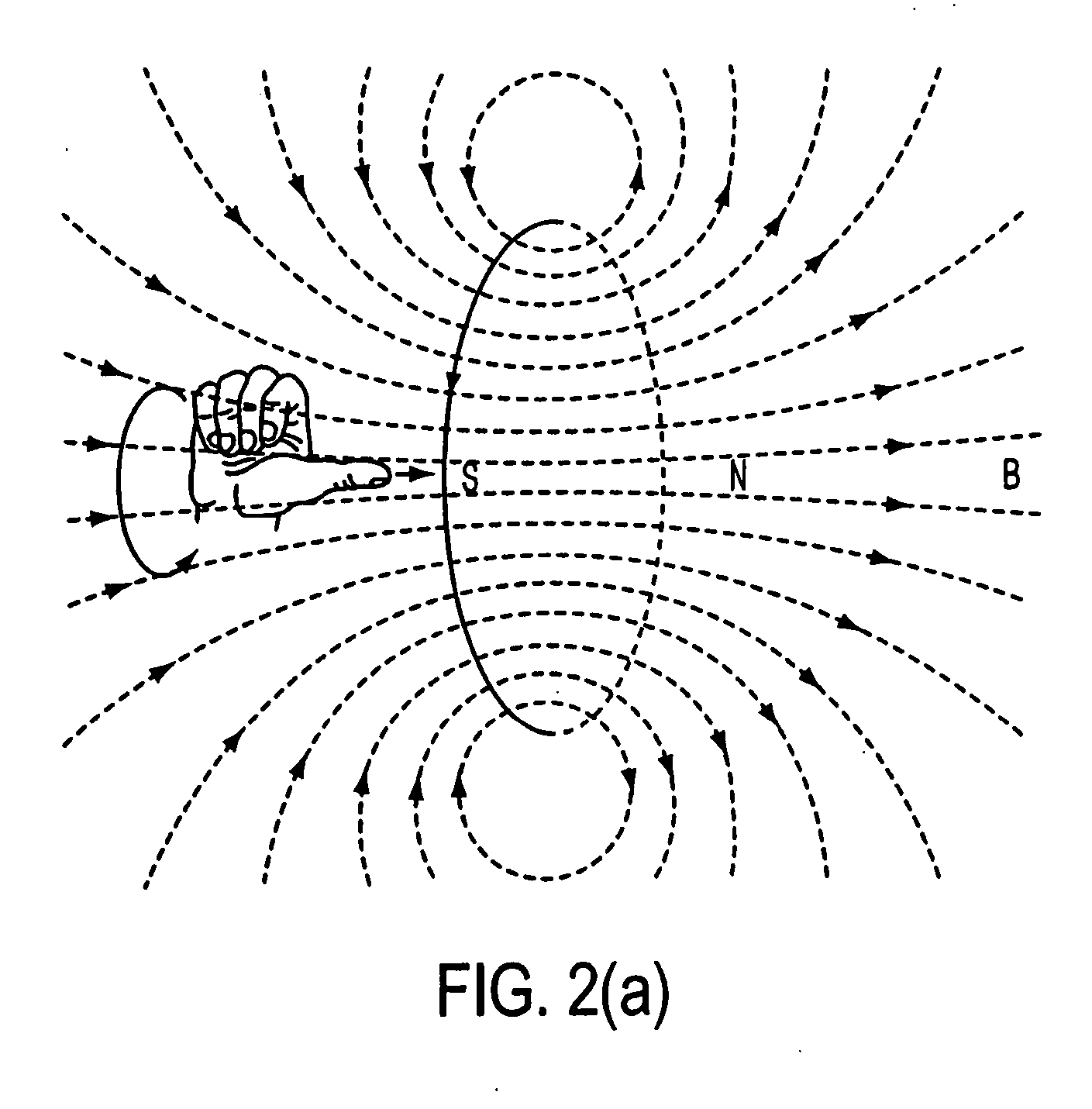

Magneto-radar detector and method

A varying magnetic field excites slight vibrations in an object and a radar sensor detects the vibrations at a harmonic of the excitation frequency. The synergy of the magnetic excitation and radar detection provides increased detection range compared to conventional magnetic metal detectors. The radar rejects background clutter by responding only to reflecting objects that are vibrating at a harmonic excitation field, thereby significantly improving detection reliability. As an exemplary arrangement, an ultra-wideband micropower impulse radar (MIR) is capable of being employed to provide superior materials penetration while providing range information. The magneto-radar may be applied to pre-screening magnetic resonance imaging (MRI) patients, landmine detection and finding hidden treasures.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

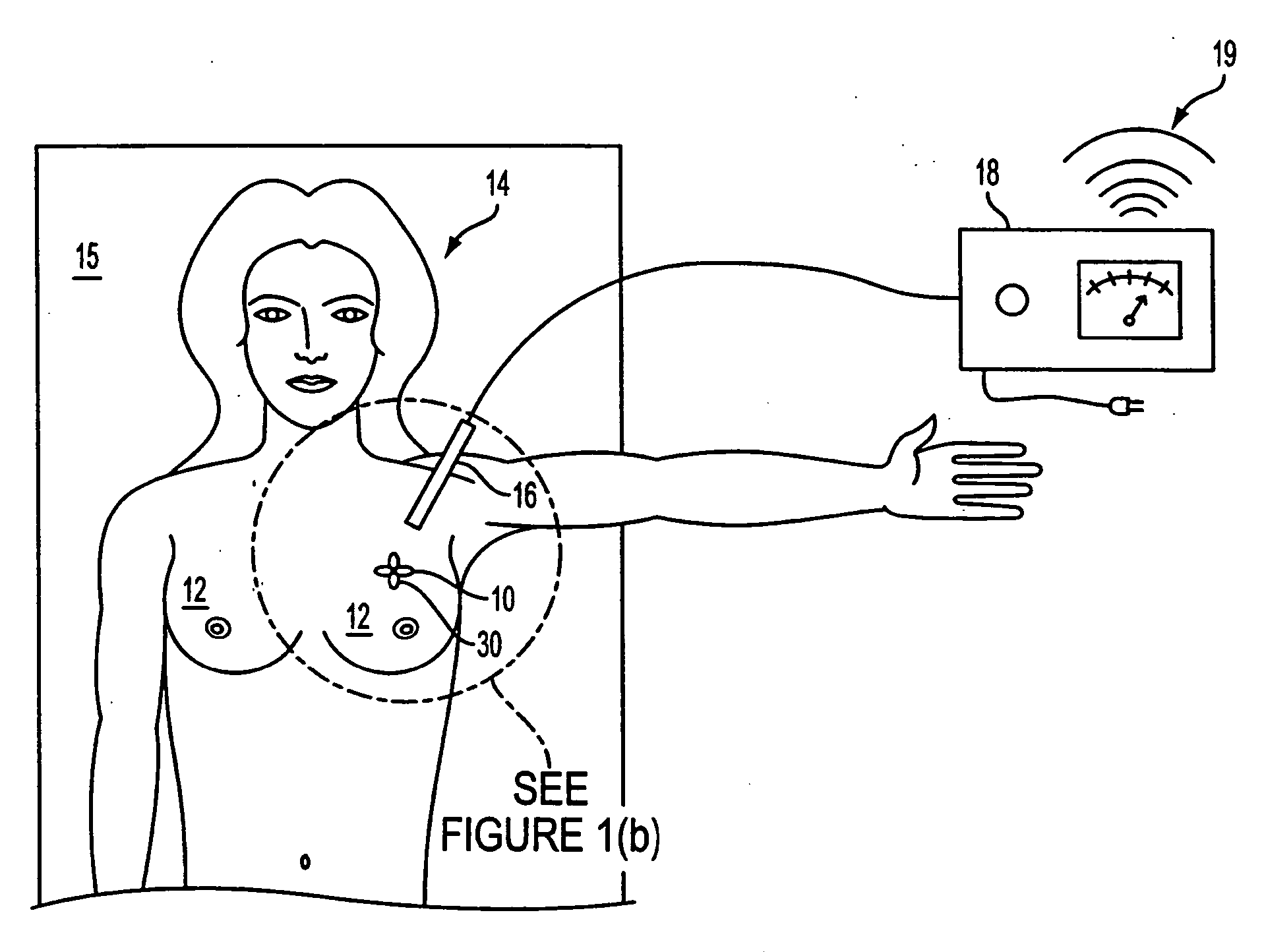

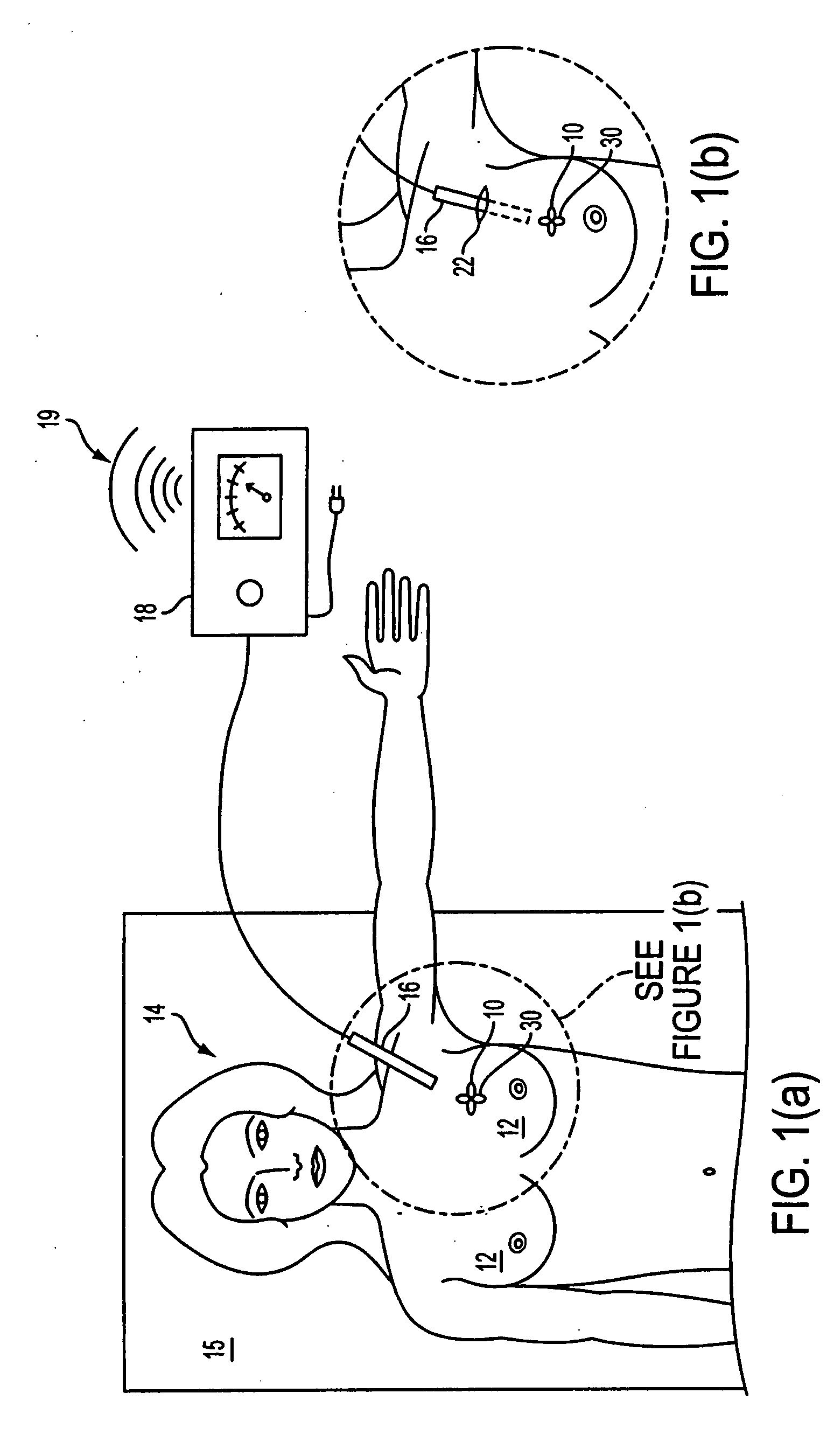

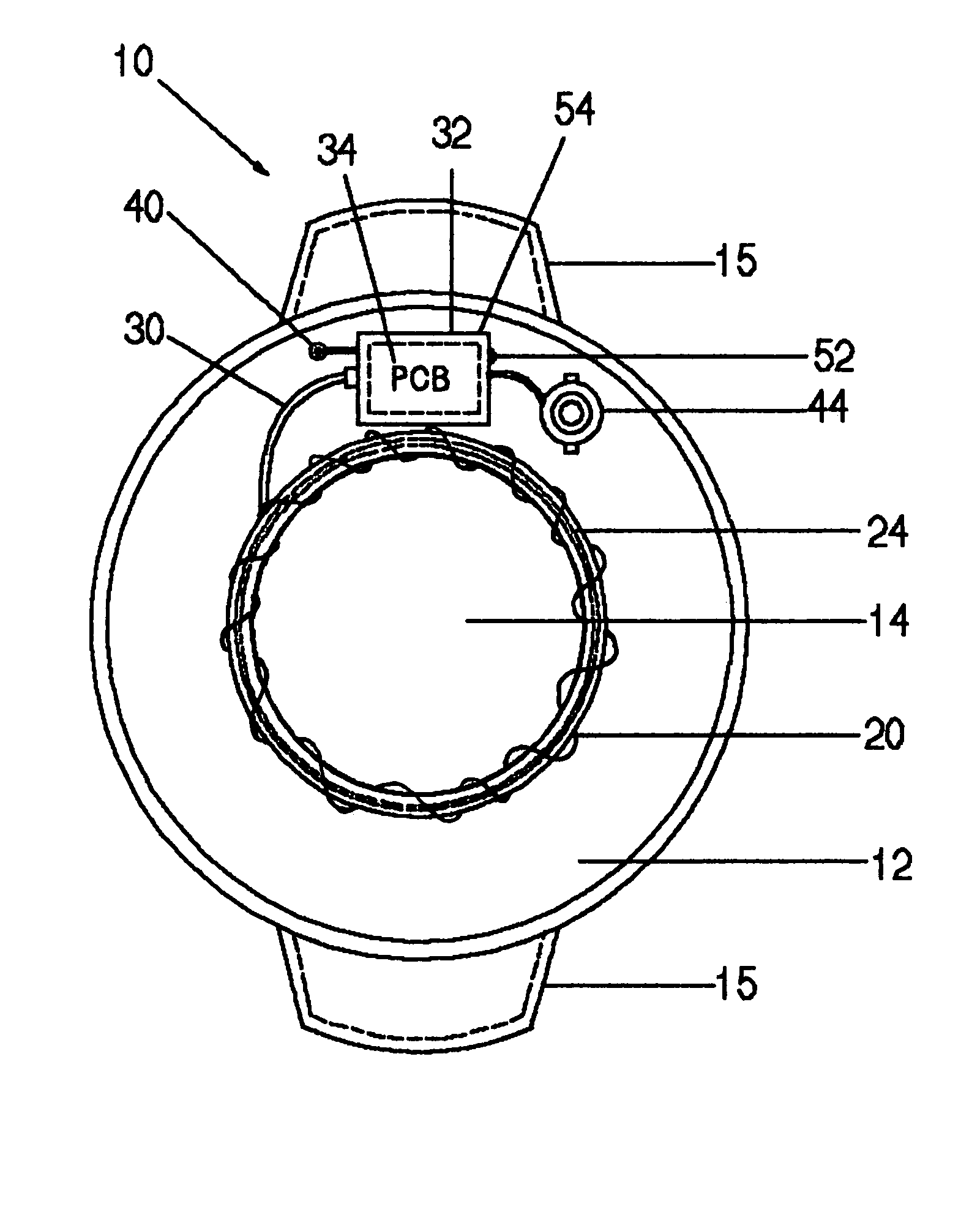

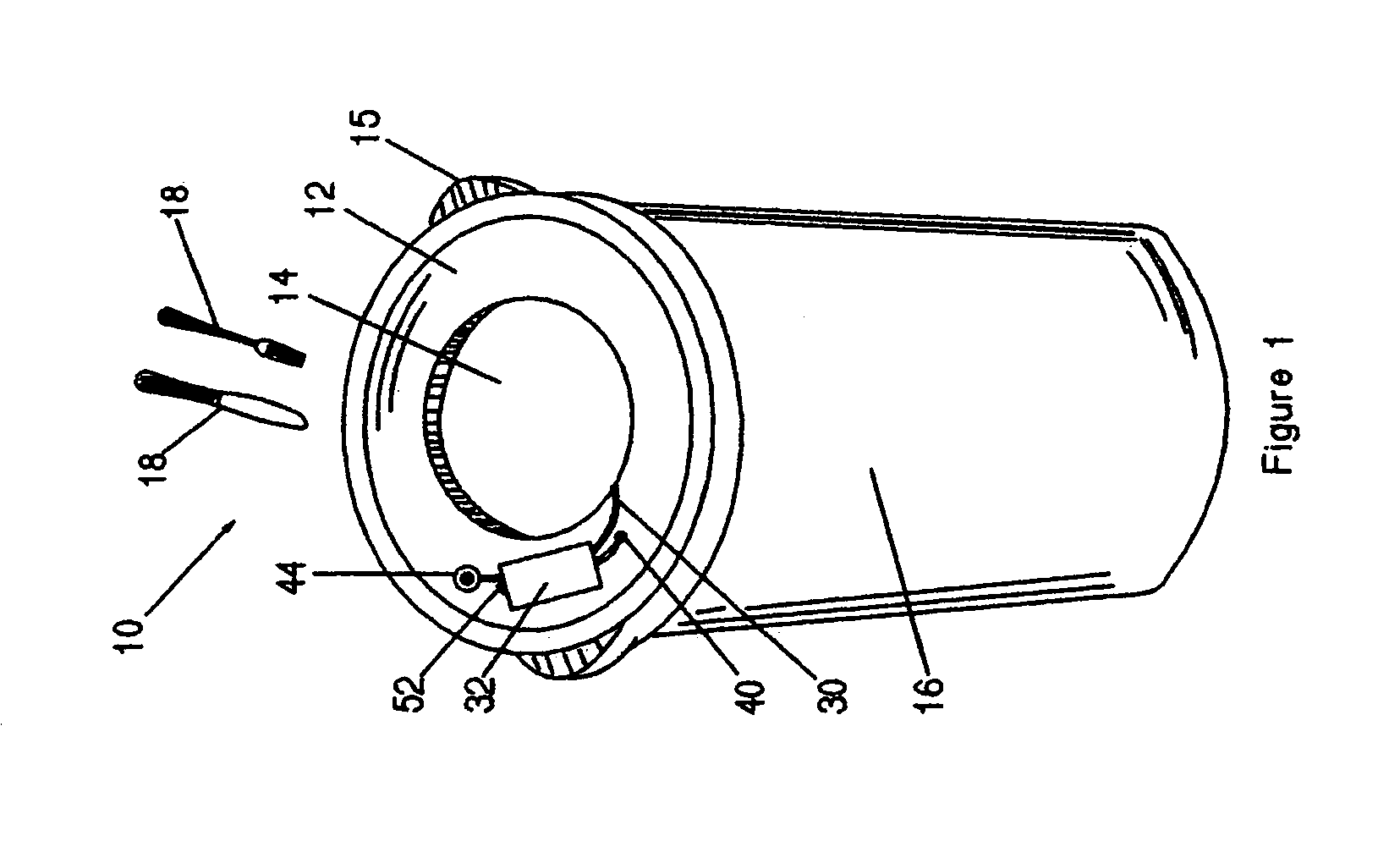

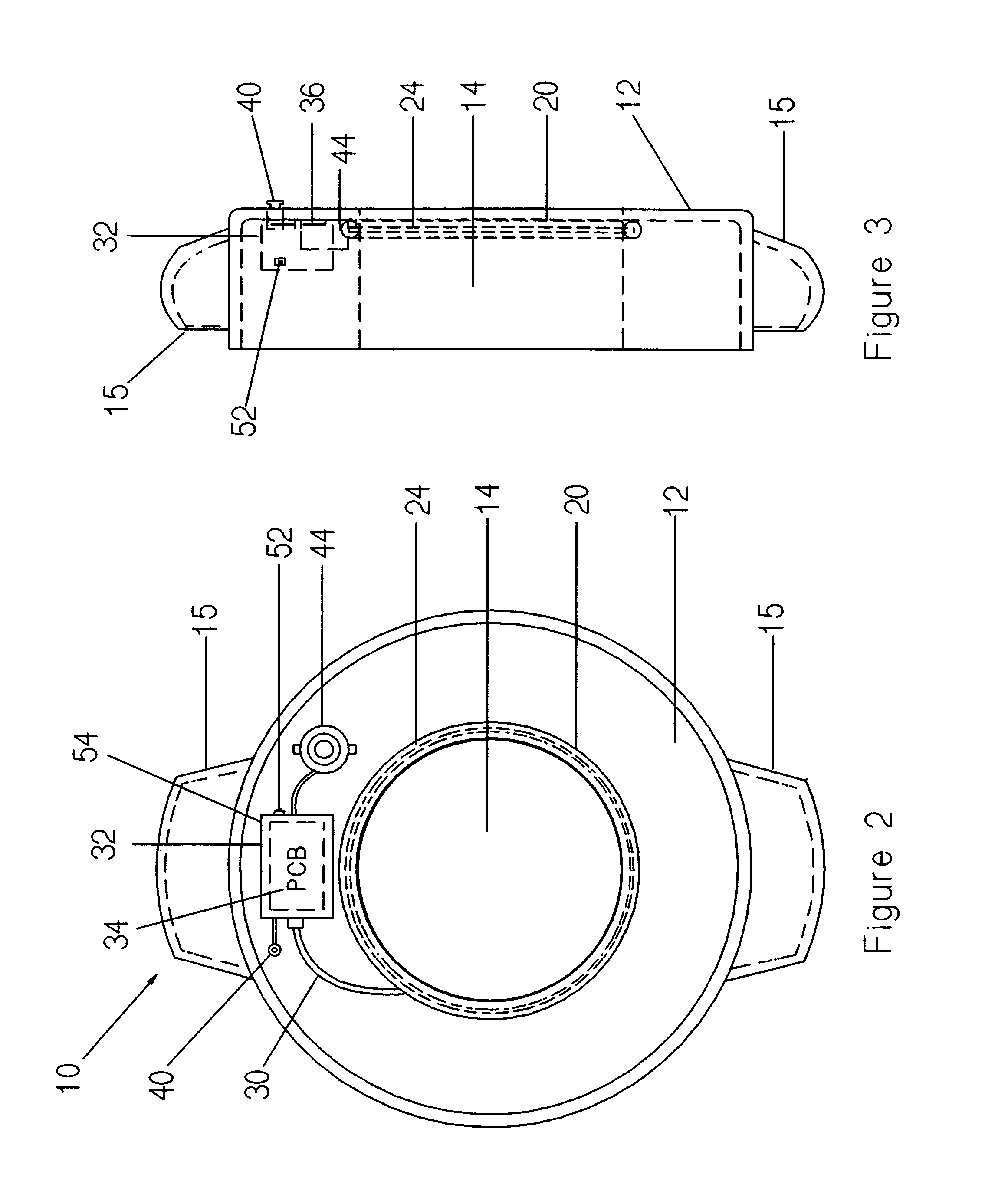

Tissue Marking Devices and Systems

InactiveUS20080097199A1Maximize detectabilitySurgeryVaccination/ovulation diagnosticsElectron orbitalClosed loop

A marker for marking a site within the body of a mammalian patient is positioned within the tissue of a patient. The marker may be placed in the first instance by a needle or the like or placed where a tissue sample has been removed. The marker has a plurality of loops each at various angles to the other such that when positioned within the patient, one of the loops is positioned orthogonal to a magnetic field of a metal detector. Various shapes of markers may be used, including electron orbital shapes, chains of loops or barbells. Barbs or other anchoring elements may be used to stabilize the marker's position. Normal delivery techniques as needles, catheters or cannulas may readily position the marker within the patent. By having the marker so designed and positioned, at least one of the closed loops is detectable by a metal detection beam of a metal detection device.

Owner:MULLEN DAVID

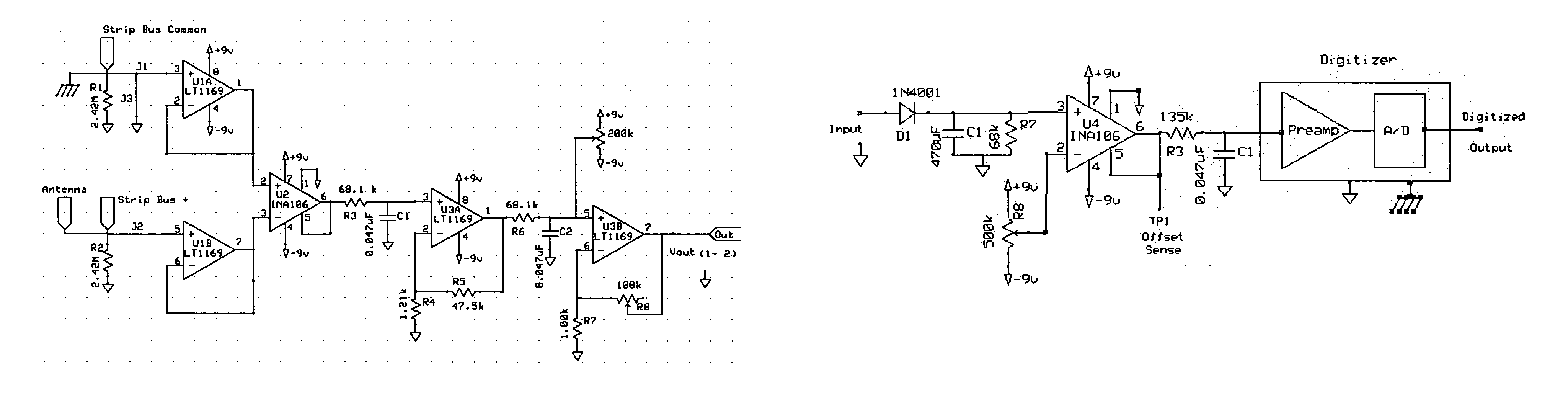

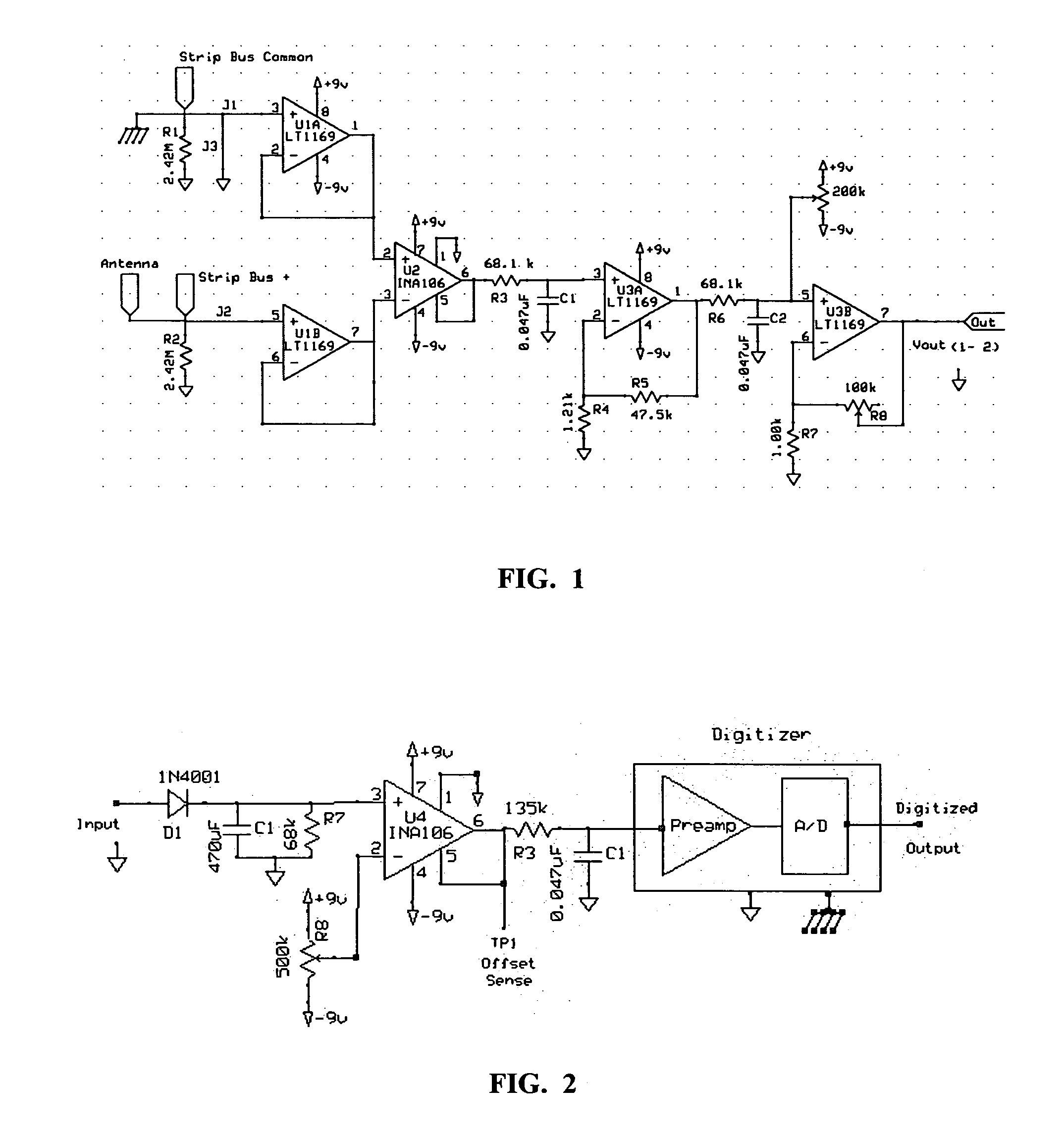

Method and apparatus for detecting charge and proximity

InactiveUS20060092022A1Possible to detectInput/output for user-computer interactionResistance/reactance/impedenceEngineeringObstacle avoidance

A method and apparatus is invented that provides unambiguously detection of the charge and proximity to an object. The method and apparatus are passive and function by using the background electric fields from electrical power wiring and equipment. The invention is useful for detecting plastic and other charged objects concealed by nonconductive covering materials. Applications of this lead to plastic detectors to scan people and cargo for dangerous dielectric items similar to metal detectors. It is also useful to warn of hazards due to static electricity buildup on objects or individuals. The technology also offers touchless control capability of computers, apparatus, and games, with plastic objects such as pointers, styluses, swords, sticks, and wands. The sensors are able to detect motion while discerning between proximity to bodies with dielectric or plastic objects. It is also useful for providing people, robots, and machines with obstacle avoidance, and vision capabilities. Medial imaging possibilities also exist with the technology of this invention.

Owner:CEHELNIK THOMAS G

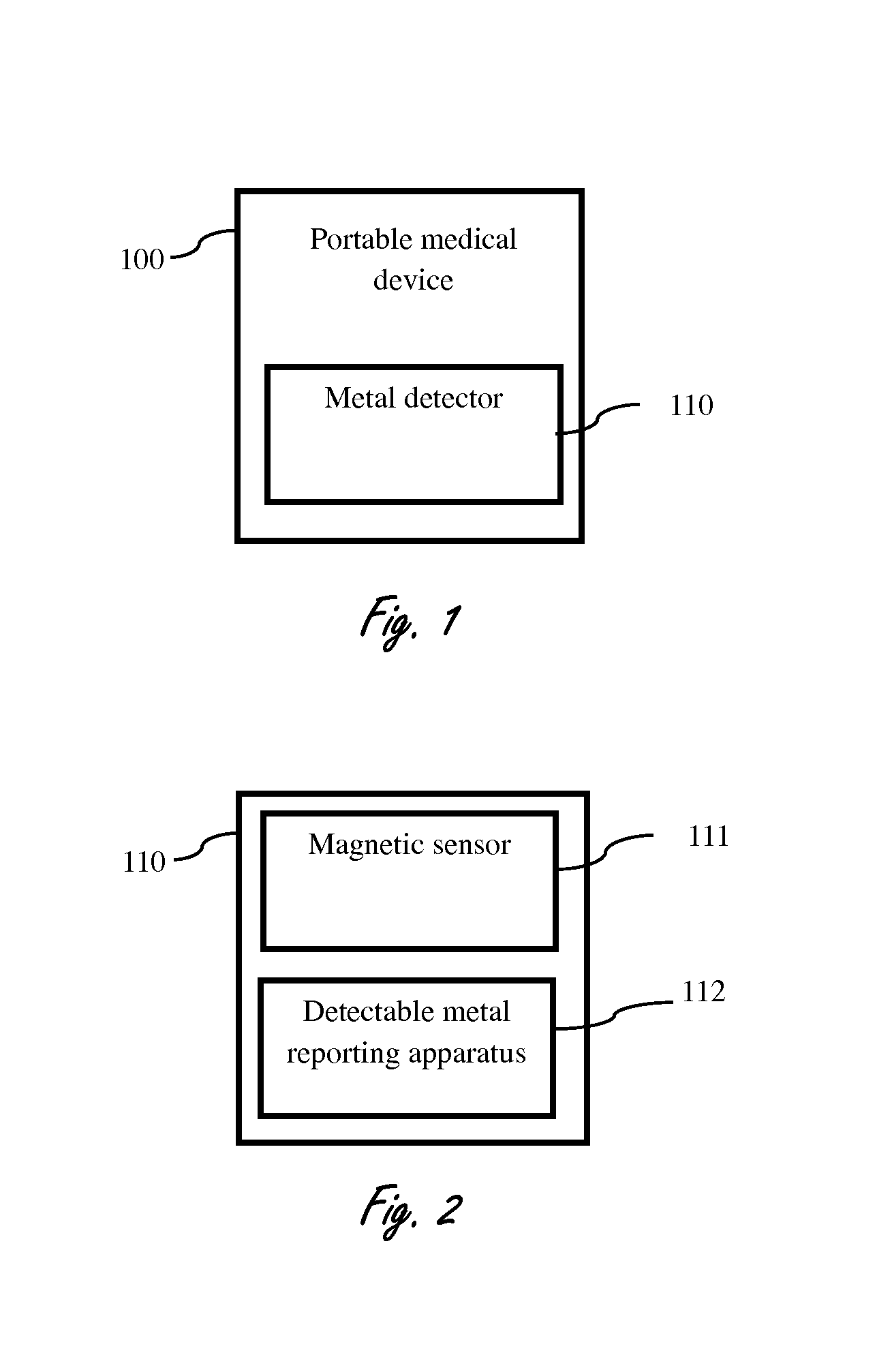

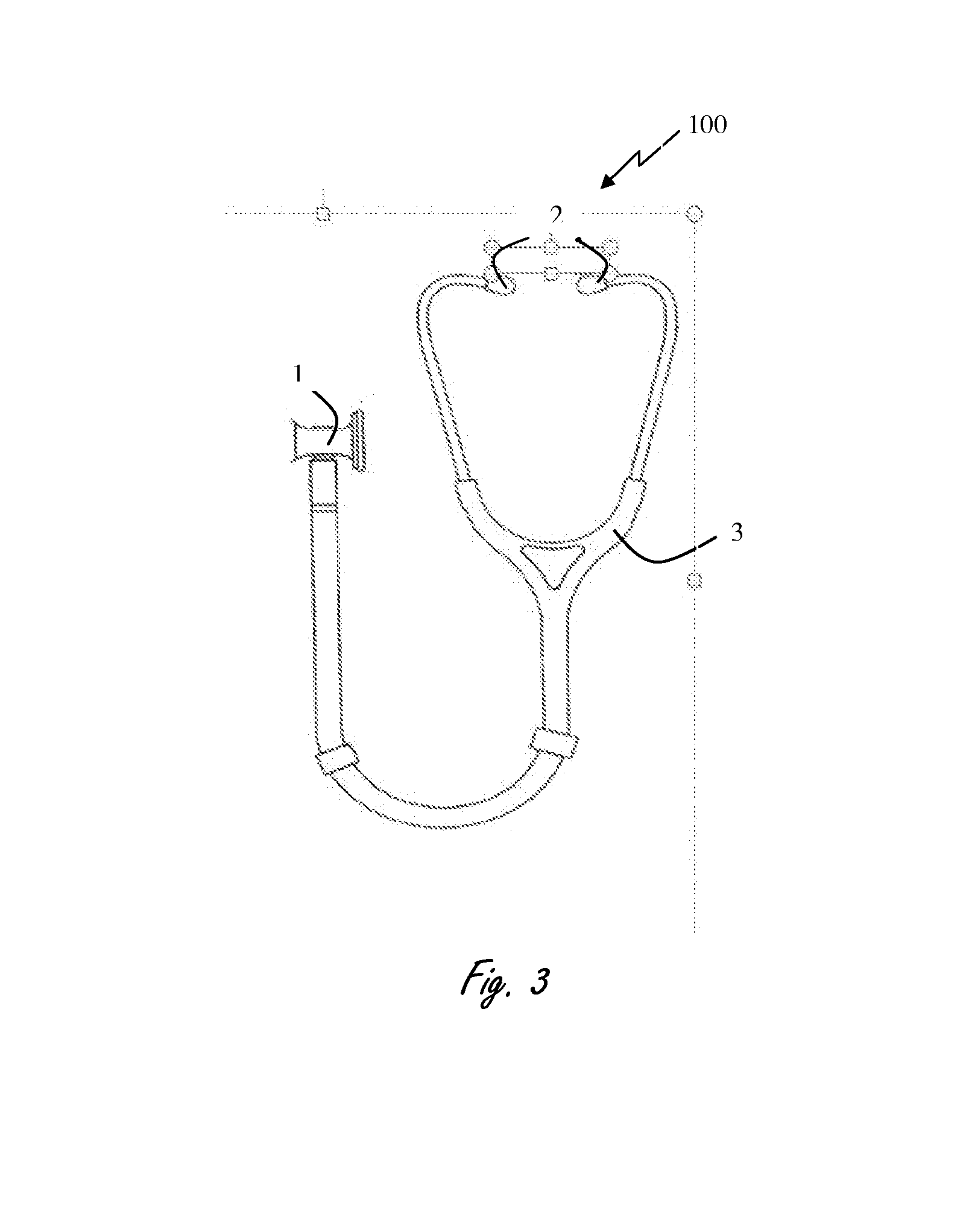

Integrated metal detector-portable medical device

An integrated metal detector-portable medical device adapted to identify metals in a human body, where the metal detector is in connection with the portable medical device. The metal detector includes: at least one transmitting means adapted to generate a second magnetic field so as to induce a magnetic field generated by a metal; at least one sensor adapted to detect a magnetic field generated by the metals to be detected; and at least one signaling means adapted, upon detection of a magnetic field, to alert the identification of metals, if the intensity of a magnetic field is above a predetermined value.

Owner:ASPECT IMAGING

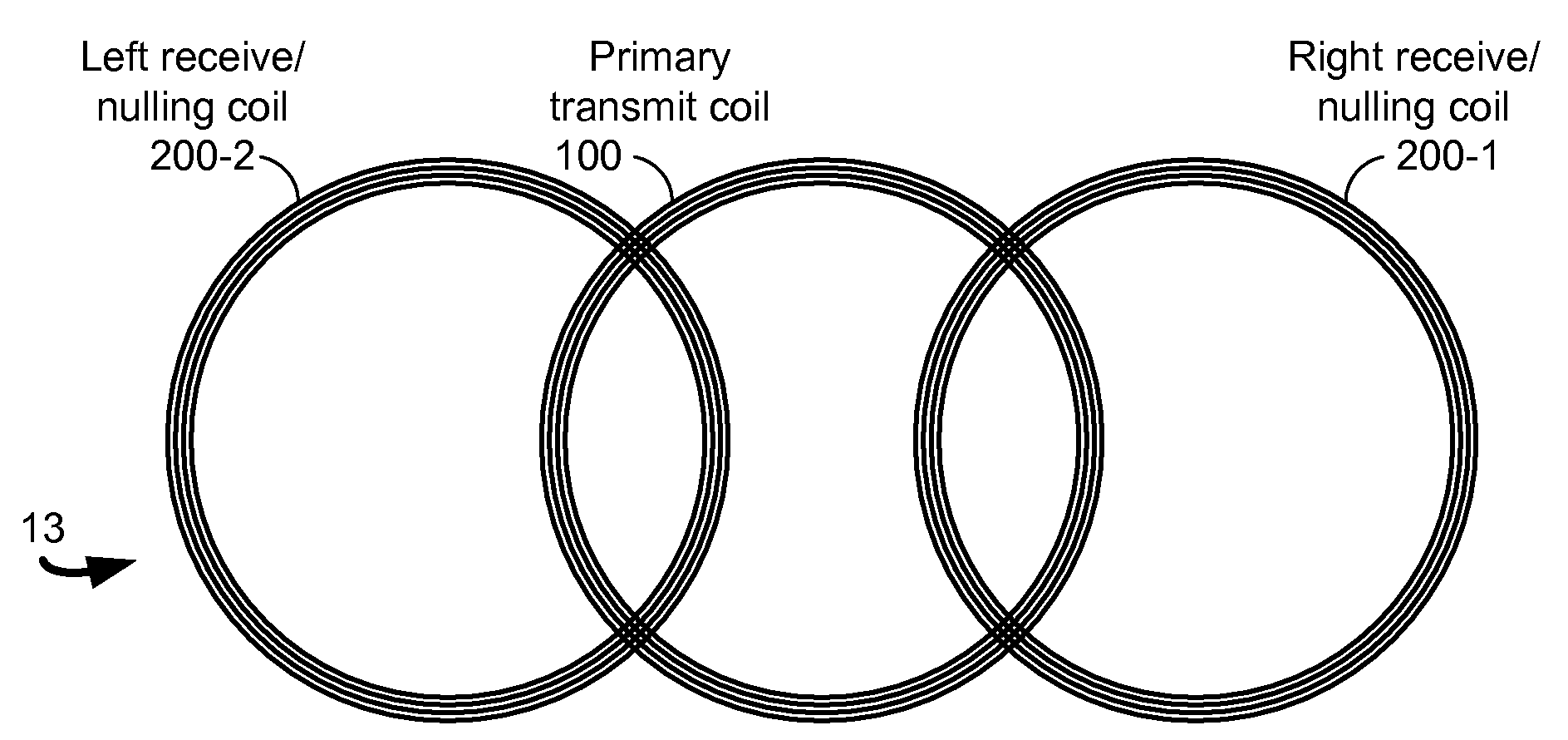

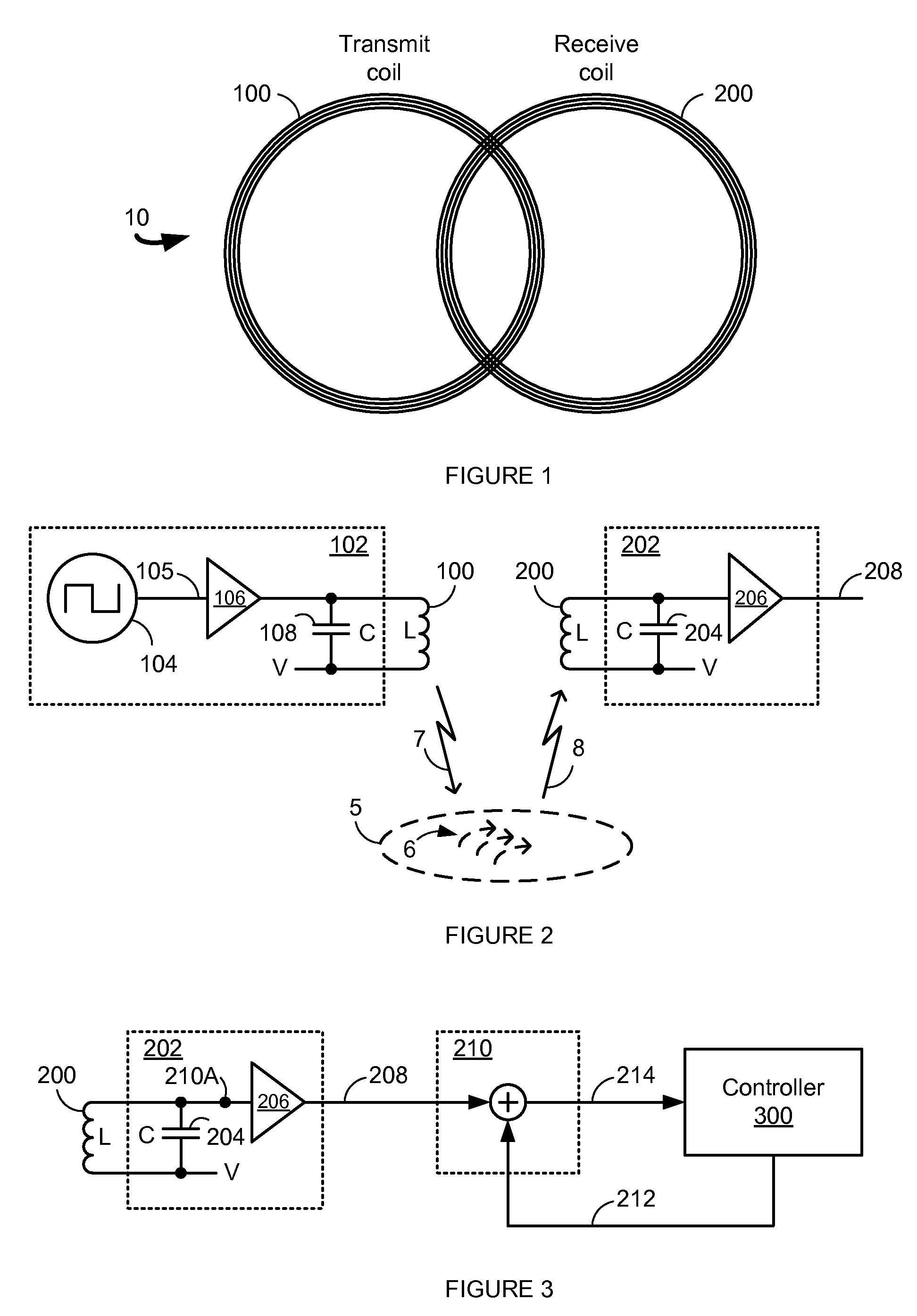

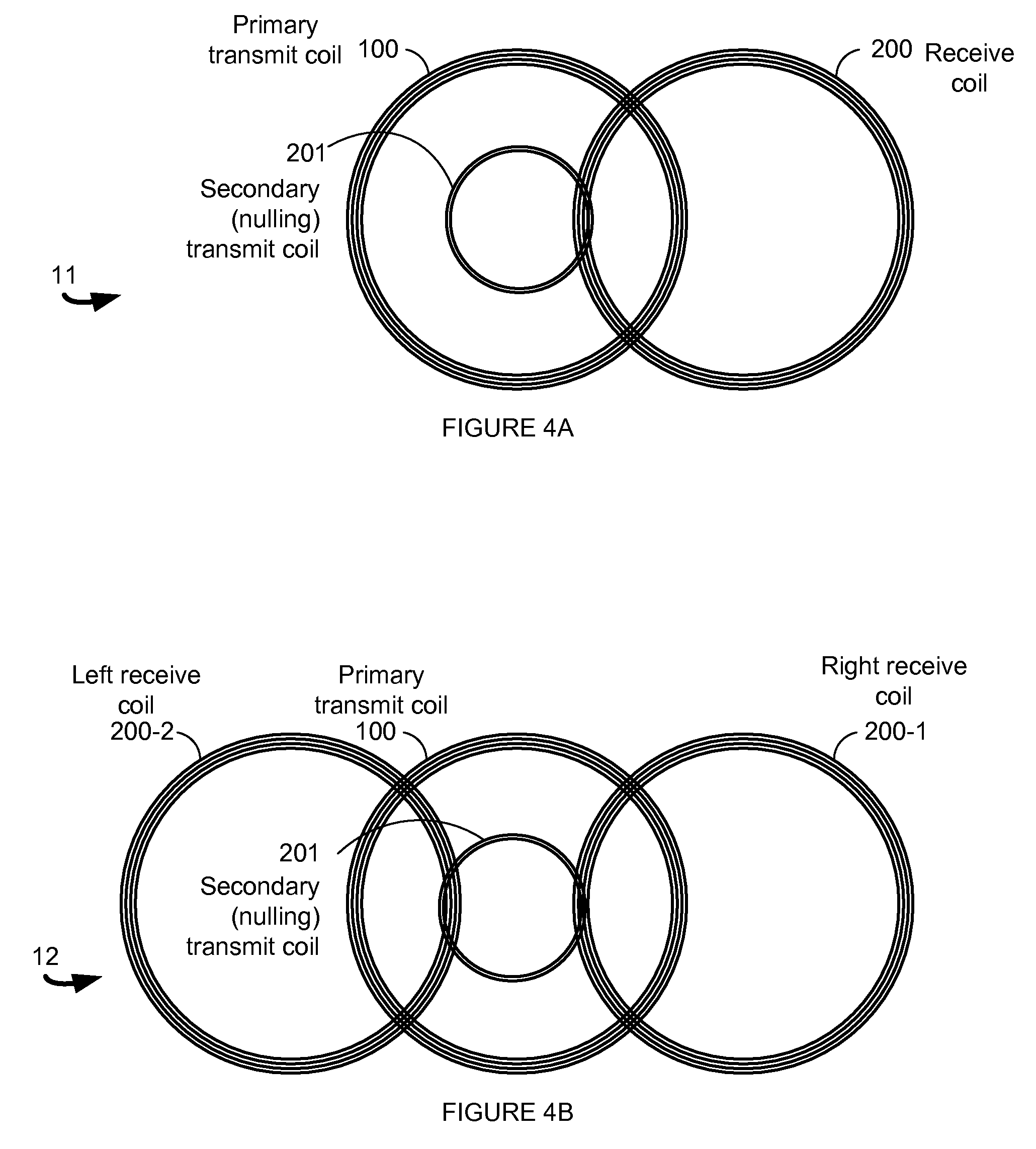

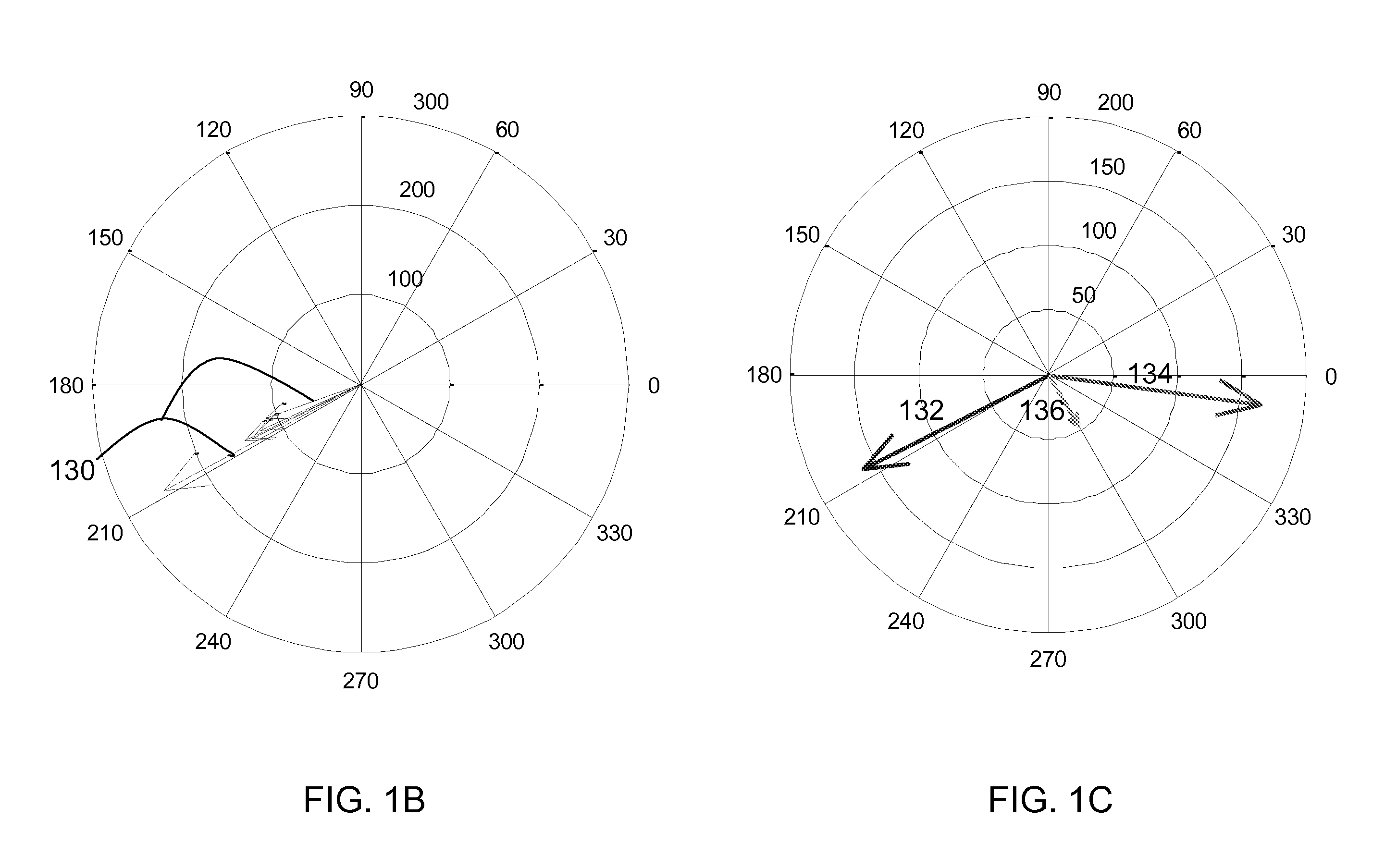

Gradiometric Directional Metal Detector

InactiveUS20080297158A1Magnetic property measurementsElectric/magnetic detectionMetal detectorsAtomic physics

An implementation of a direction finding and magnetic nulling metal detector is provided. Some embodiments of the present invention provide for a metal detector having multiple resonant circuits and associated coils for transmitting a primary transmit signal, transmitting a magnetic nulling signal, and receiving a receive signal. A controller includes logic to process the generate the transmit signals and to process the received signal in order to determine a gradient vector along one or two dimensions, a depth and whether or not a metal object is ferrous.

Owner:ZIRCON

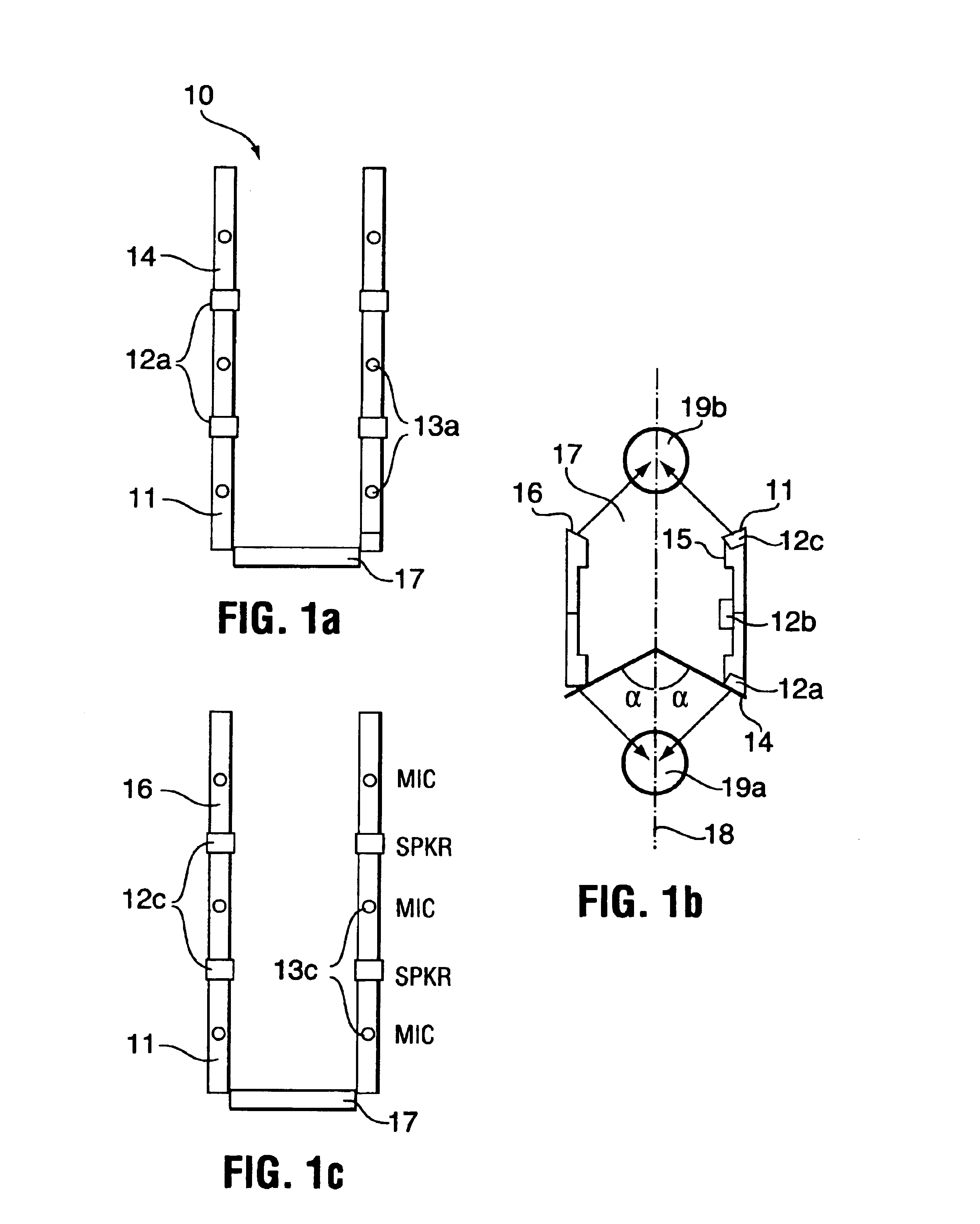

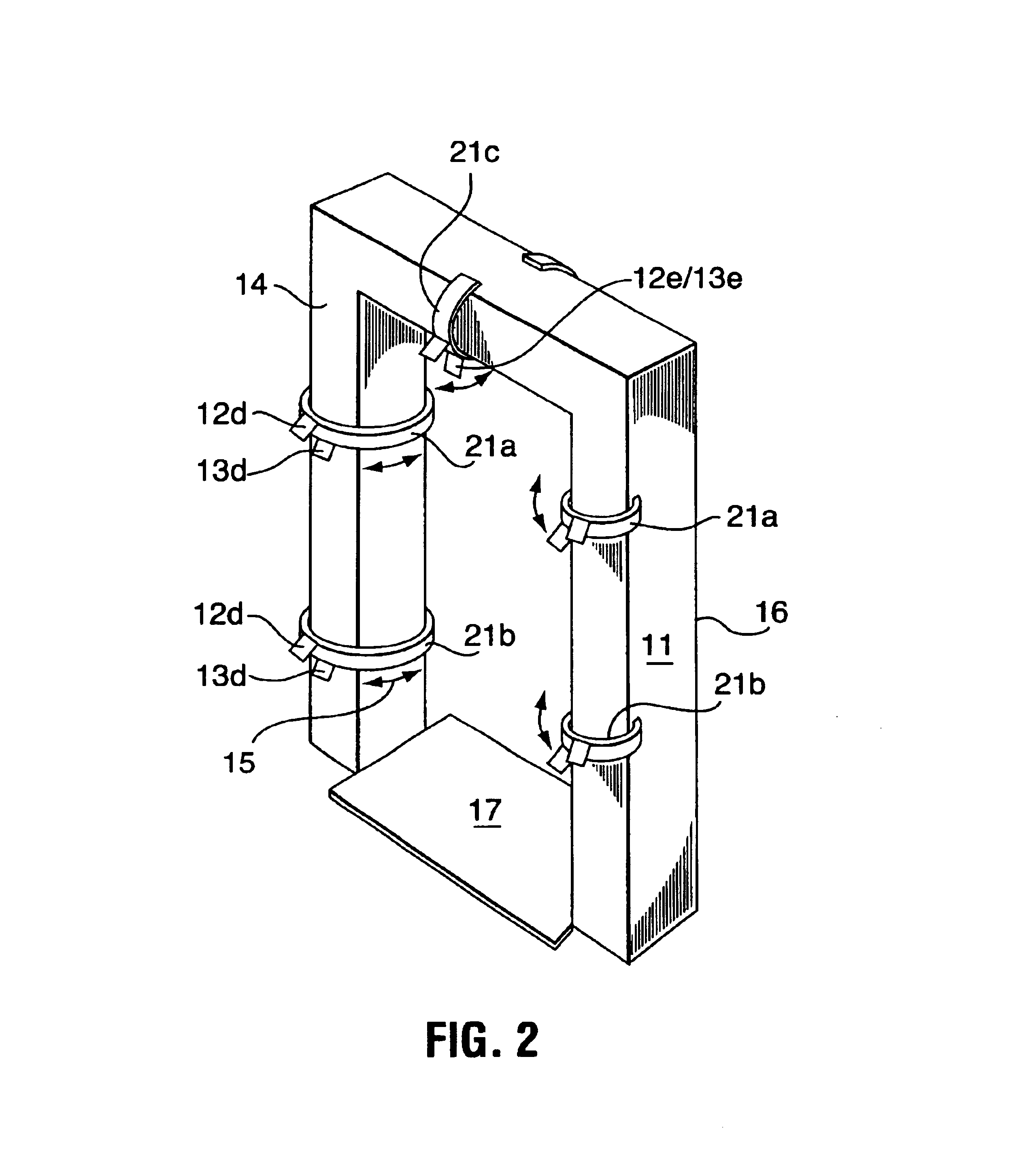

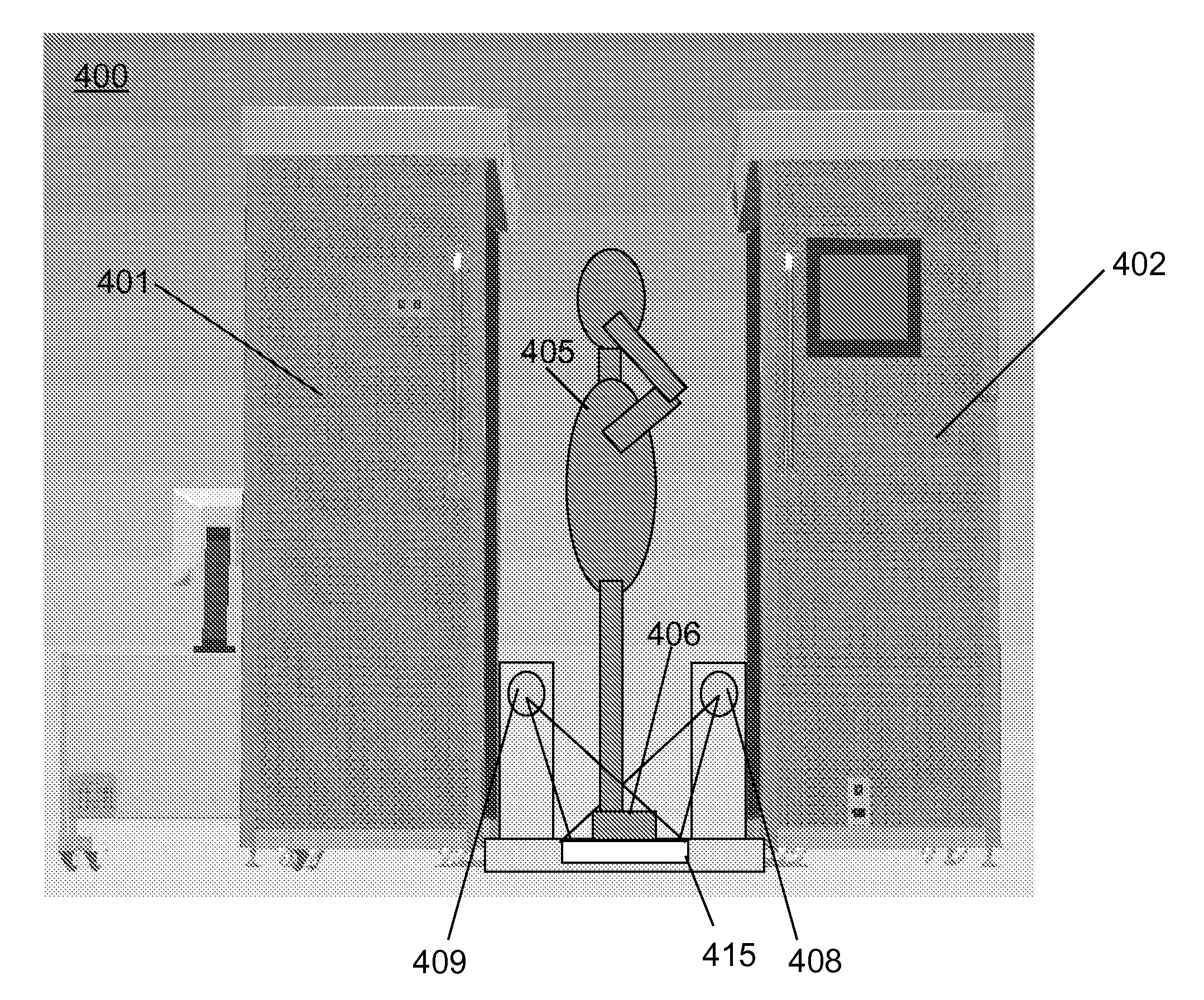

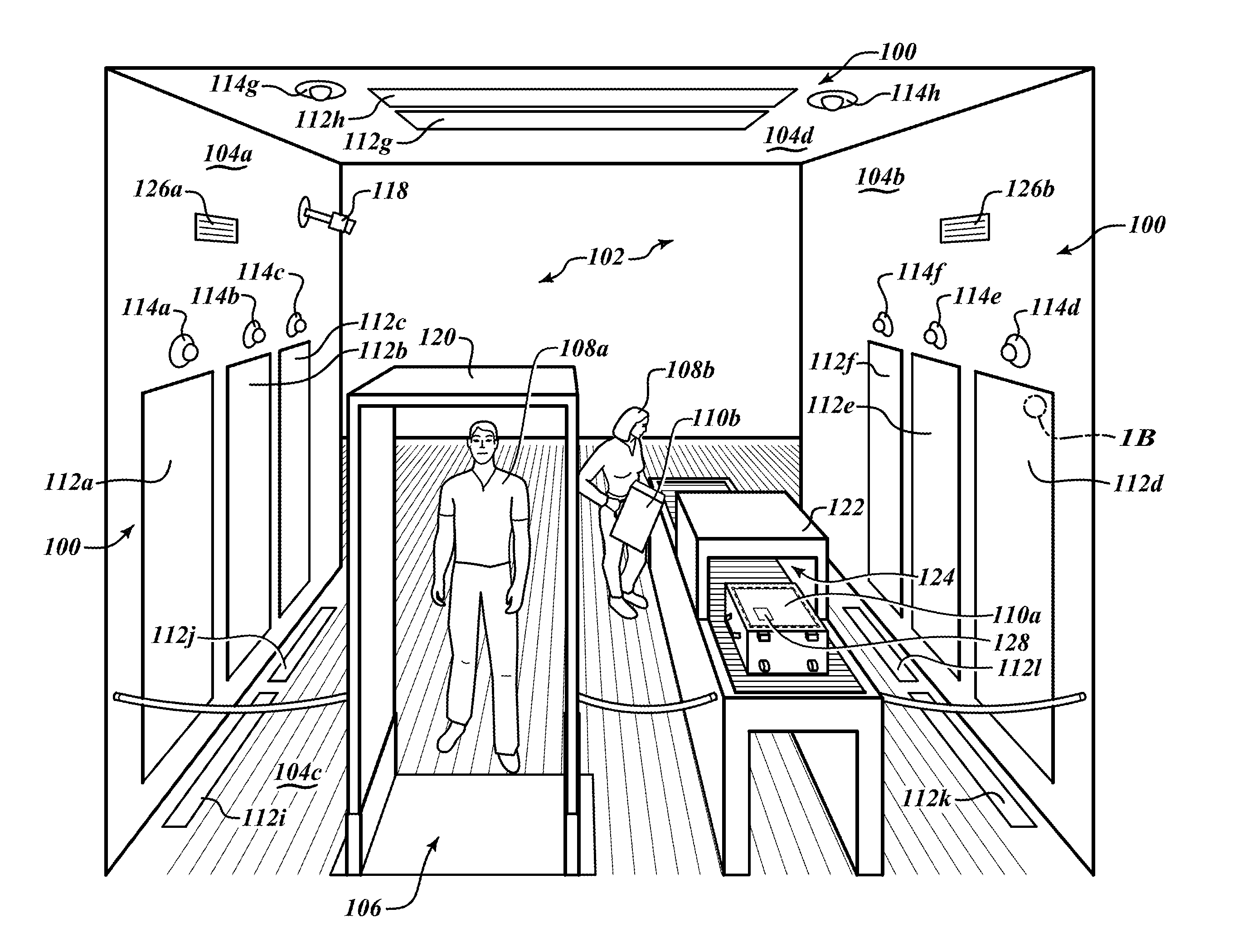

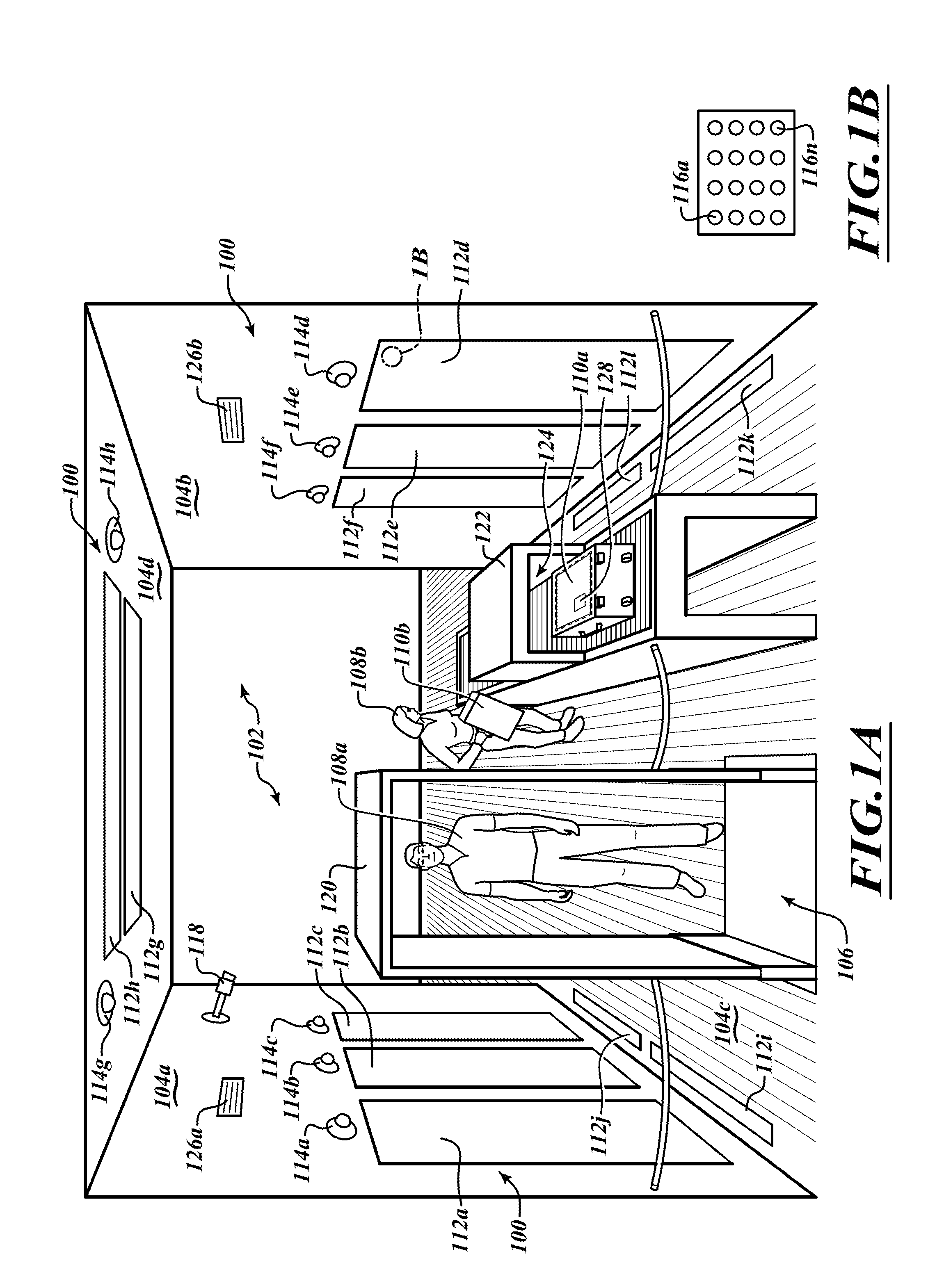

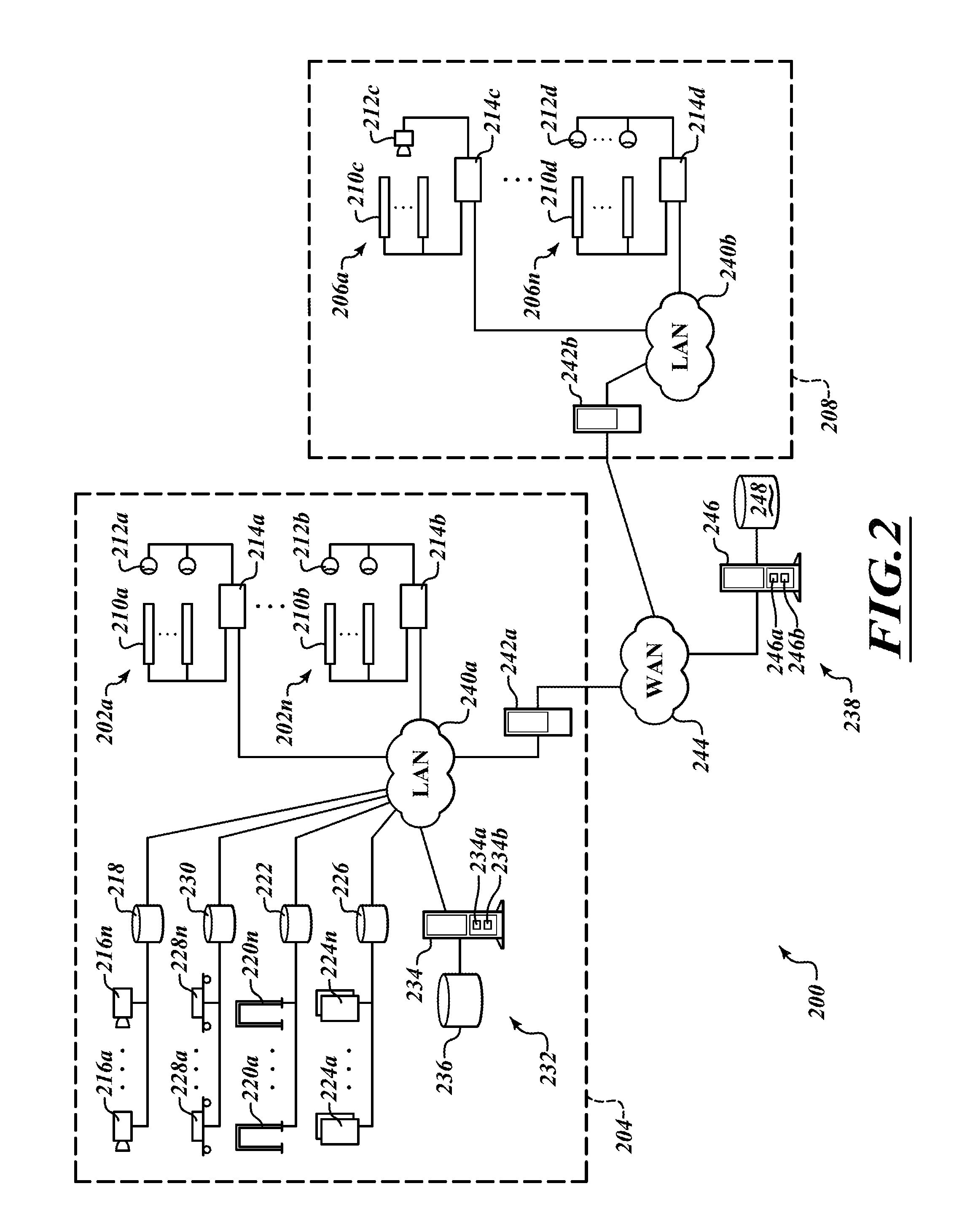

Acoustic portal detection system

InactiveUS6870791B1Rapidly and efficiently and non-invasively scanningImprove securityPhotographyAcoustic wave reradiationPublic placeCombined use

Airports and other public places require security measures for the screening of human subjects for illicit objects and materials concealed from view beneath clothing. However, at present most of such screening processes involve only metal detectors, which are inherently incapable of detecting non-metallic illicit objects and materials. For this reason, there remains a strong need for novel systems and methods that can detect all types of materials. The present invention provides for a portal detection system that is configured for safe, rapid, and non-invasive scanning of human subjects. For this purpose, the portal detection system utilizes acoustic technology to achieve this end. The portal detection systems of the present invention may optionally be used in conjunction with conventional metal detection means. The invention encompasses portal detection systems, their use in scanning human subjects, and corresponding methods of scanning human subjects for illicit objects and substances.

Owner:CAULFIELD DAVID D +2

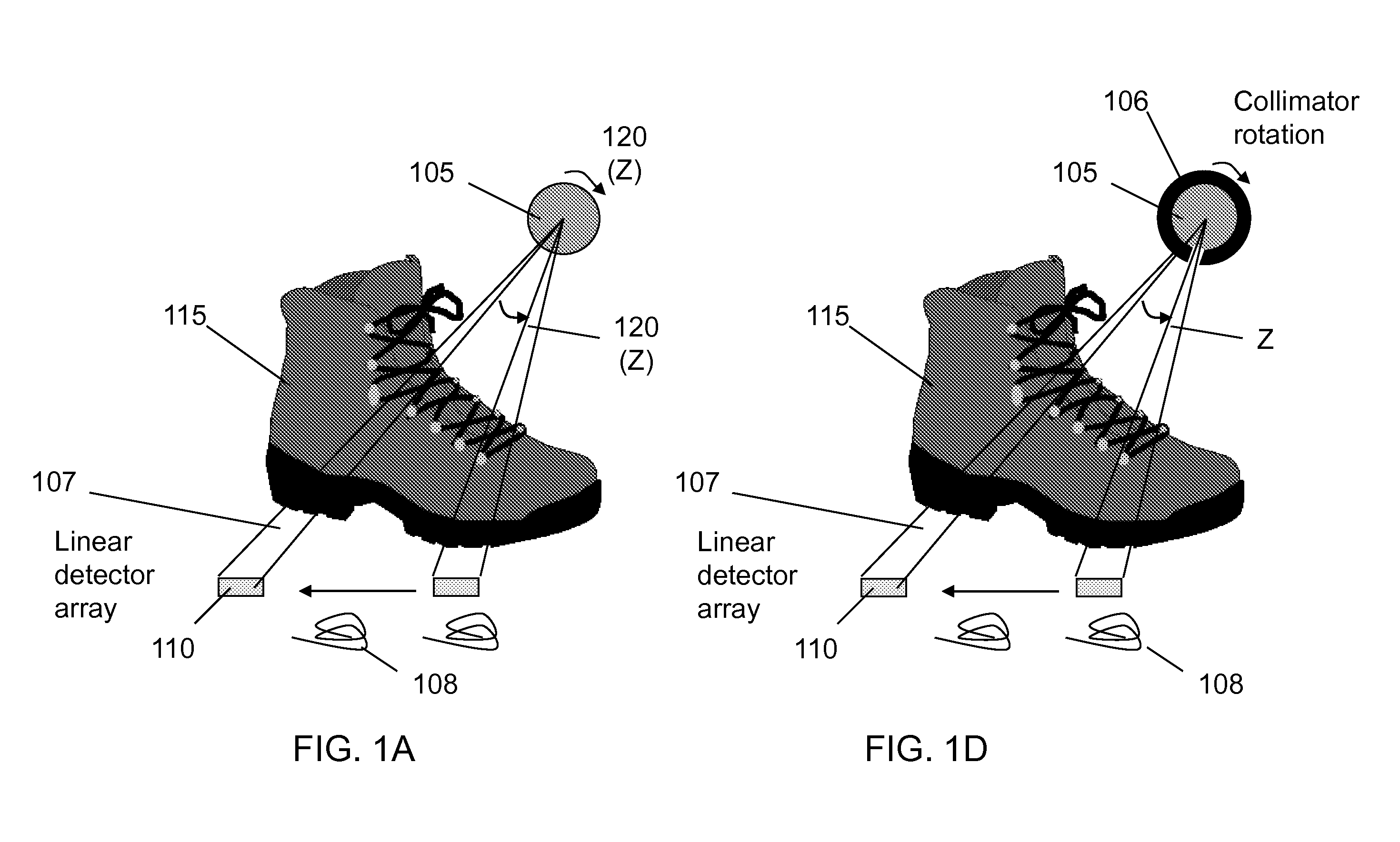

X-Ray-Based System and Methods for Inspecting a Person's Shoes for Aviation Security Threats

ActiveUS20110129063A1Electric/magnetic detectionMaterial analysis by transmitting radiationX-rayDetector array

The present application discloses a system for scanning a shoe for illegal materials. The system includes an X-ray source for projecting a beam of X-rays onto the shoe, a detector array for detecting X-rays transmitted through the shoe and at least one metal detector coil for detecting metals within the shoe. The system produces a radiographic image of the shoe by processing the detected X-rays and data obtained from the at least one metal detector coil. Other embodiments are directed toward other screening technologies, including millimeter wave screening technologies.

Owner:RAPISCAN SYST INC (US)

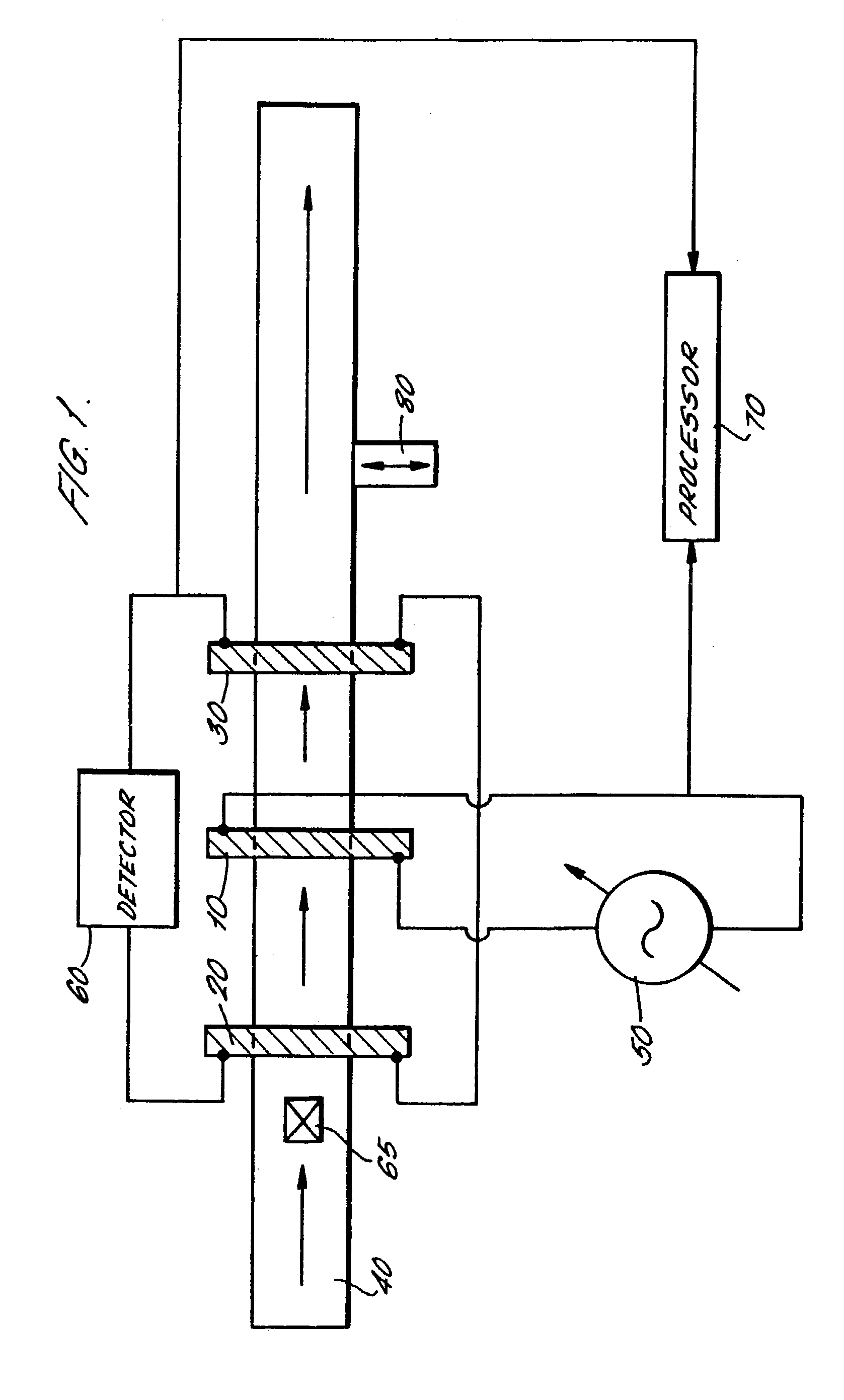

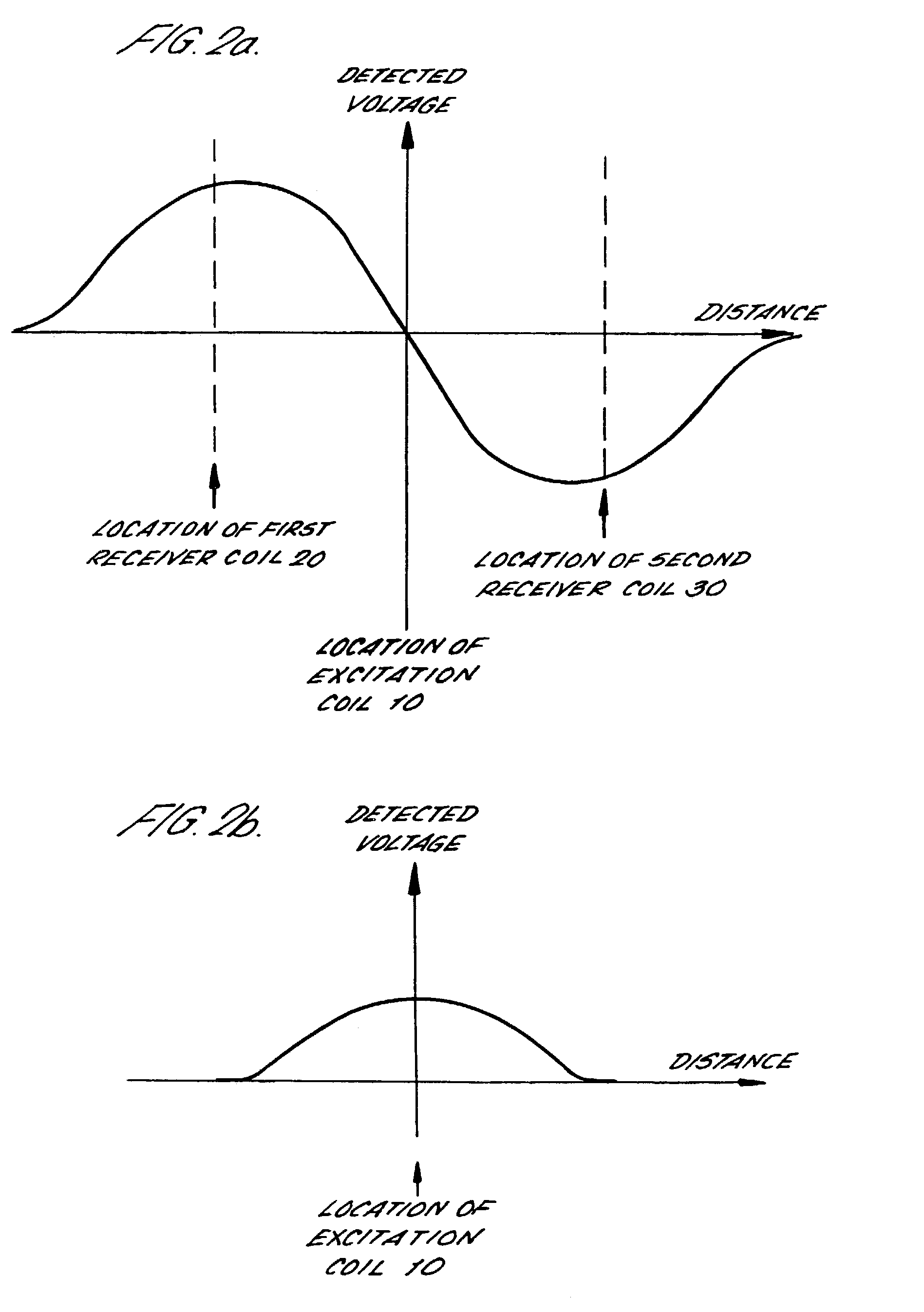

Metal detector

InactiveUS7061236B2Reducing contaminant detection problemHigh sensitivityMagnetic property measurementsBurglar alarm by hand-portable articles removalReceiver coilConveyor belt

A metal detector has a circular excitation coil (10) through which foodstuffs to be tested (65) pass, on a conveyor belt (40). The excitation coil (10) is excited by a stable oscillator (50) and the lines of flux generated by the excitation coil (10) link two receiver coils (20, 30) equidistantly spaced either side of the excitation coil (10). As a foodstuff (65) having a foreign ferromagnetic or electrically conductive object therein passes through the receiver coils (20, 30), a voltage is induced in them. This induced voltage is phase compensated. The change in amplitude or frequency of the oscillator (50) as the foodstuff (65) moves through the excitation coil (10) is also passed to the processor (70) which removes the artifacts from the detector signal caused by the volume of the foodstuff (65) itself. The resultant signal, which was previously swamped by the effect of the volume of the foodstuff itself, can then be detected and the foodstuff can be removed from the conveyor (40).

Owner:THERMO ELECTRON A DE

Ferrous metal detector with alarm

InactiveUS7296683B1Extend battery lifeIncrease the number ofMagnetic property measurementsRefuse receptaclesAudio power amplifierTRIAC

Owner:VALLELONGA SR KENNETH M +1

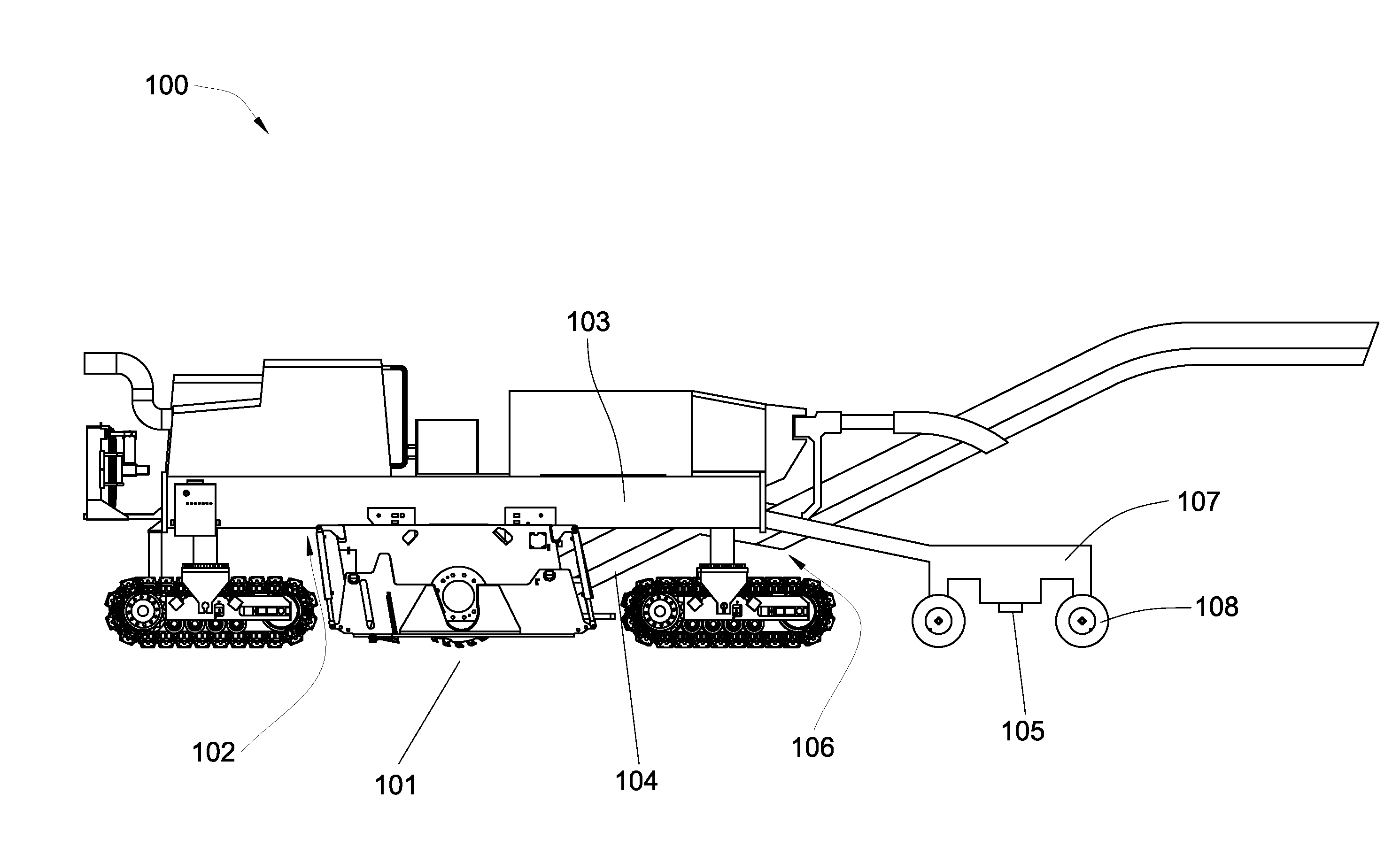

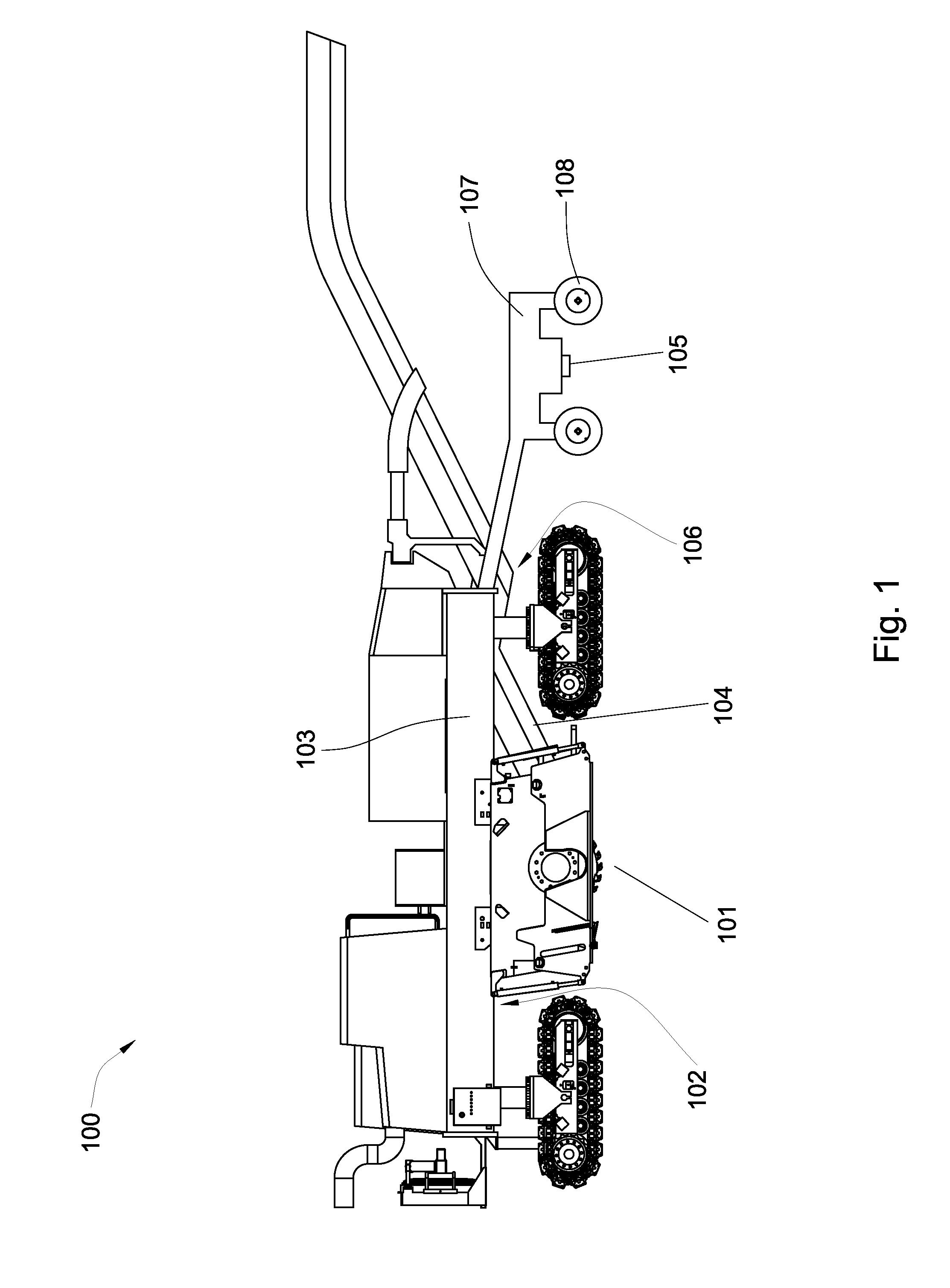

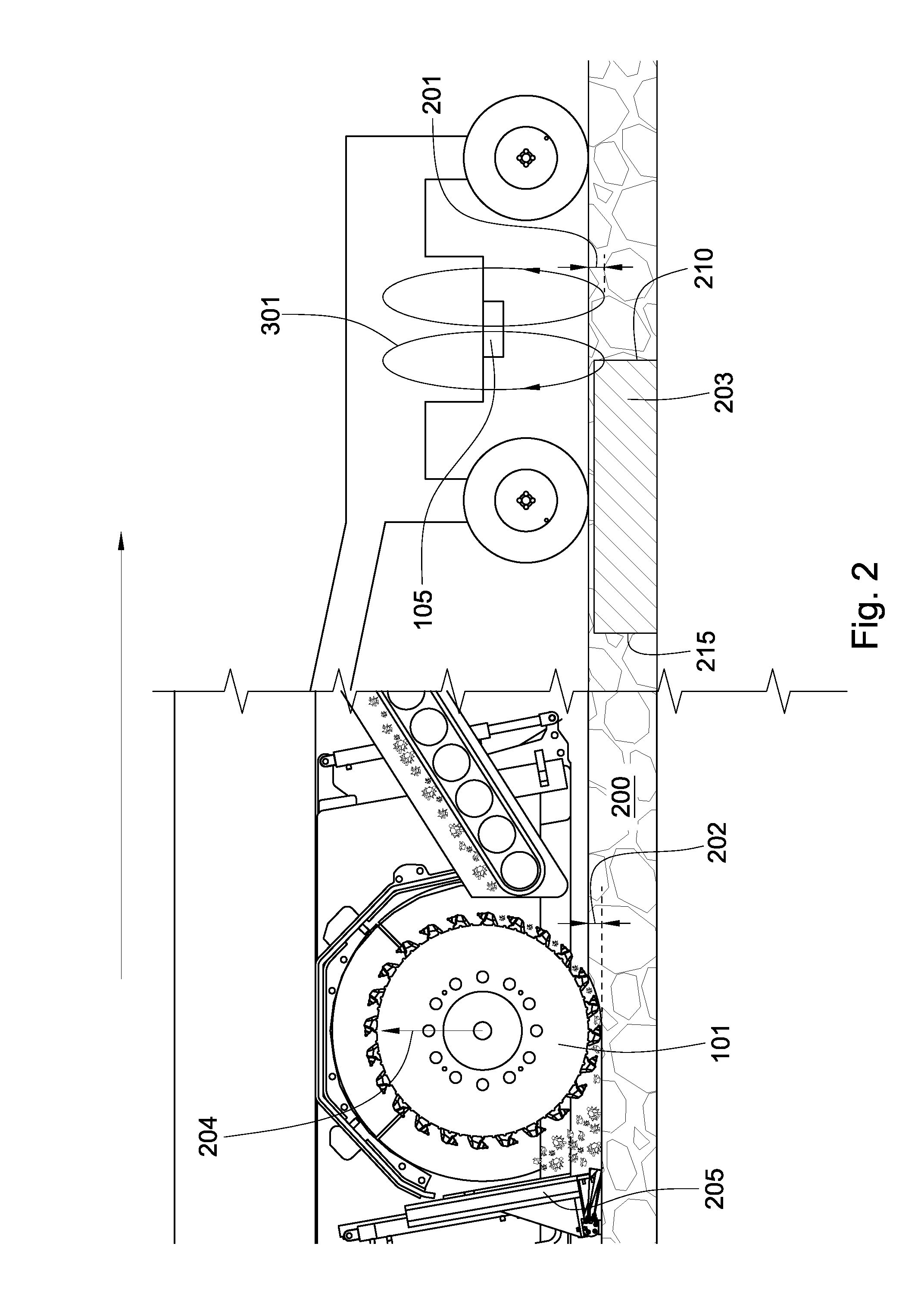

Metal Detector for an Asphalt Milling Machine

A milling machine for milling a paved surface has milling tools connected to an underside of a body of the machine. At least one ferrous metal detector is attached to a front end of the machine. Electronic equipment is disposed within the machine and is in communication with the metal detector, the equipment being adapted to interpret feedback from the detector.

Owner:NOVATEK IP

Hybrid-technology metal detector

InactiveUS20070046288A1Efficient separationOut of balanceBurglar alarm electric actuationElectric/magnetic detection for transportTransmitter coilTarget signal

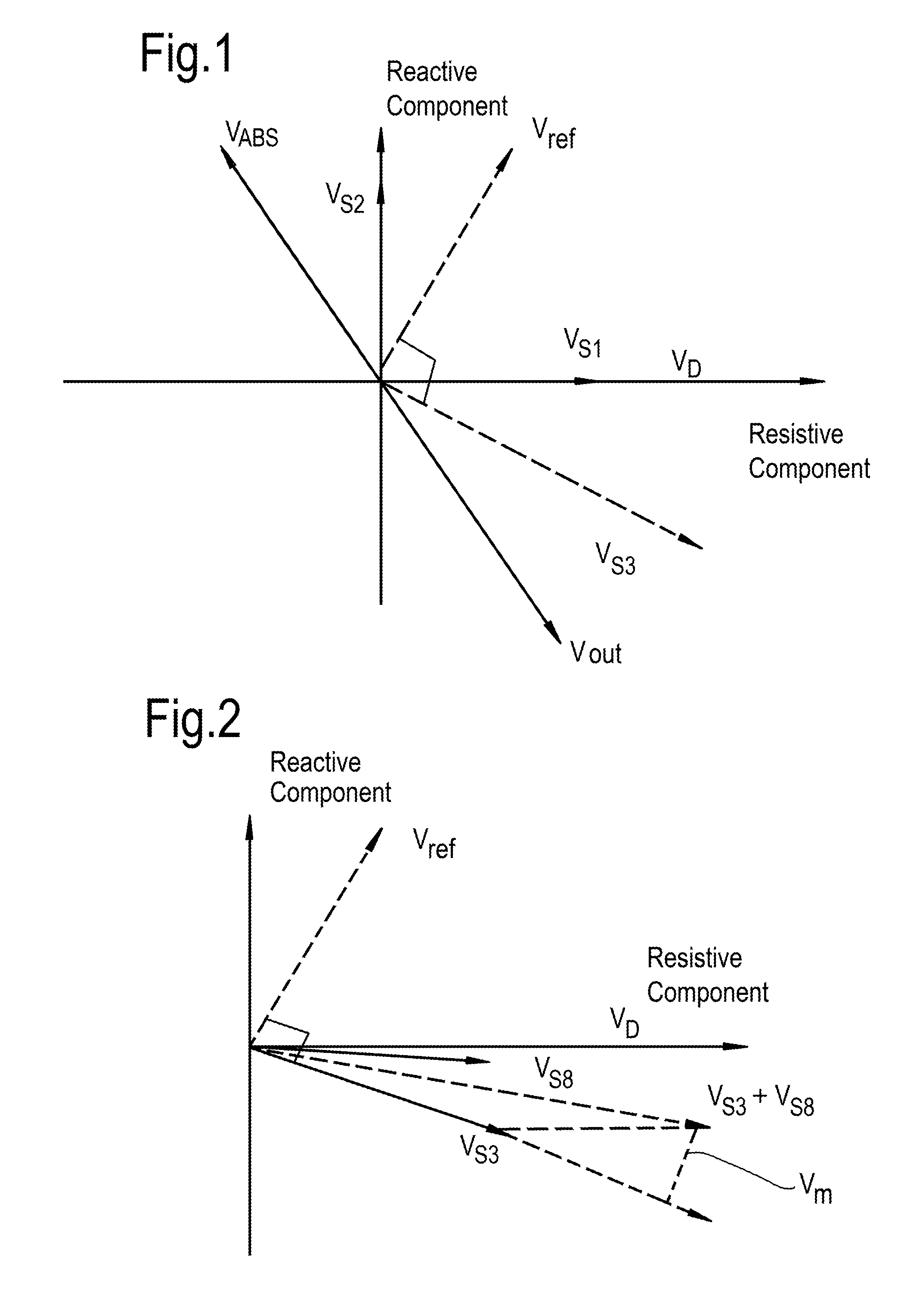

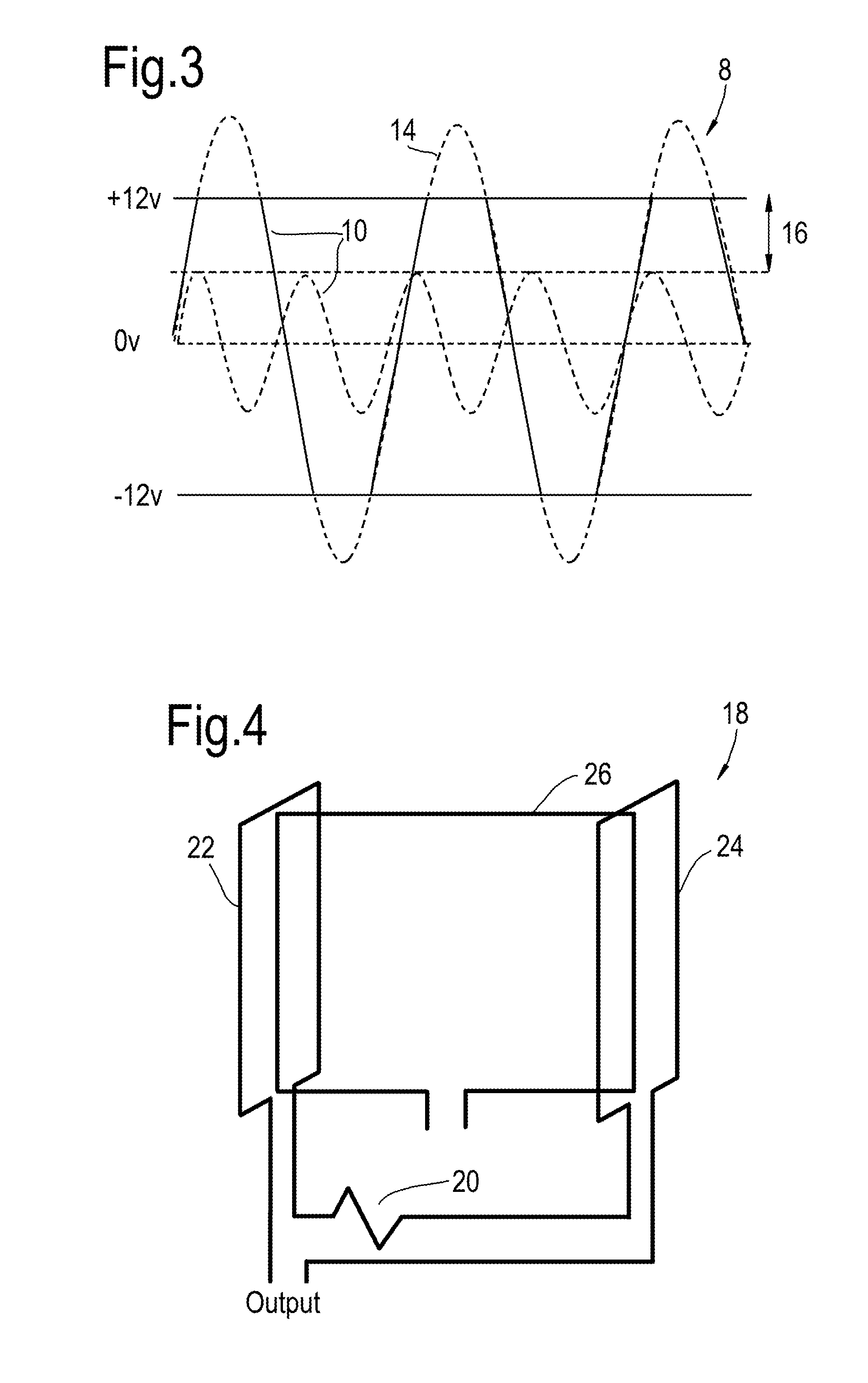

A hybrid-technology metal detector, using pulse-induction and sine-wave excitation of the transmitter coil alternately, in rapid succession. The energy stored in the transmitter coil, in the pulsed mode, is used to shock-excite a high-Q circuit formed by the coil and a parallel capacitor into oscillations in the sine-wave mode. The multiplicative action of the circuit Q causes high currents to flow in the transmitter coil, causing high fluxes to be impressed on the searched area, with increased sensitivity as a result. Using a linear coil-current ramp to assess and minimize the coupling between the transmitter and receiver coils permits effective separation of the reactive and resistive components of the target signals, making accurate identification of targets possible.

Owner:DIENCO

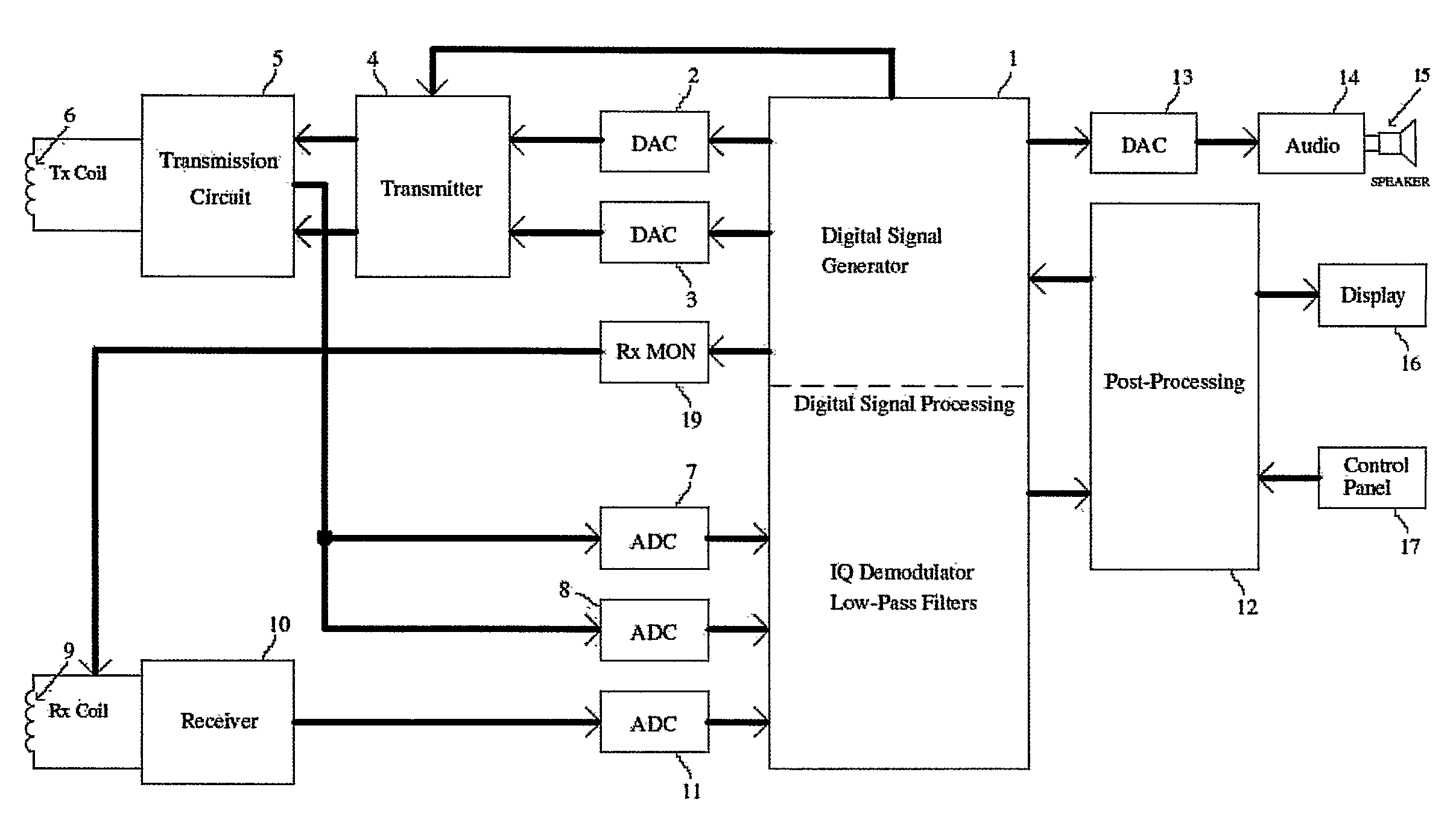

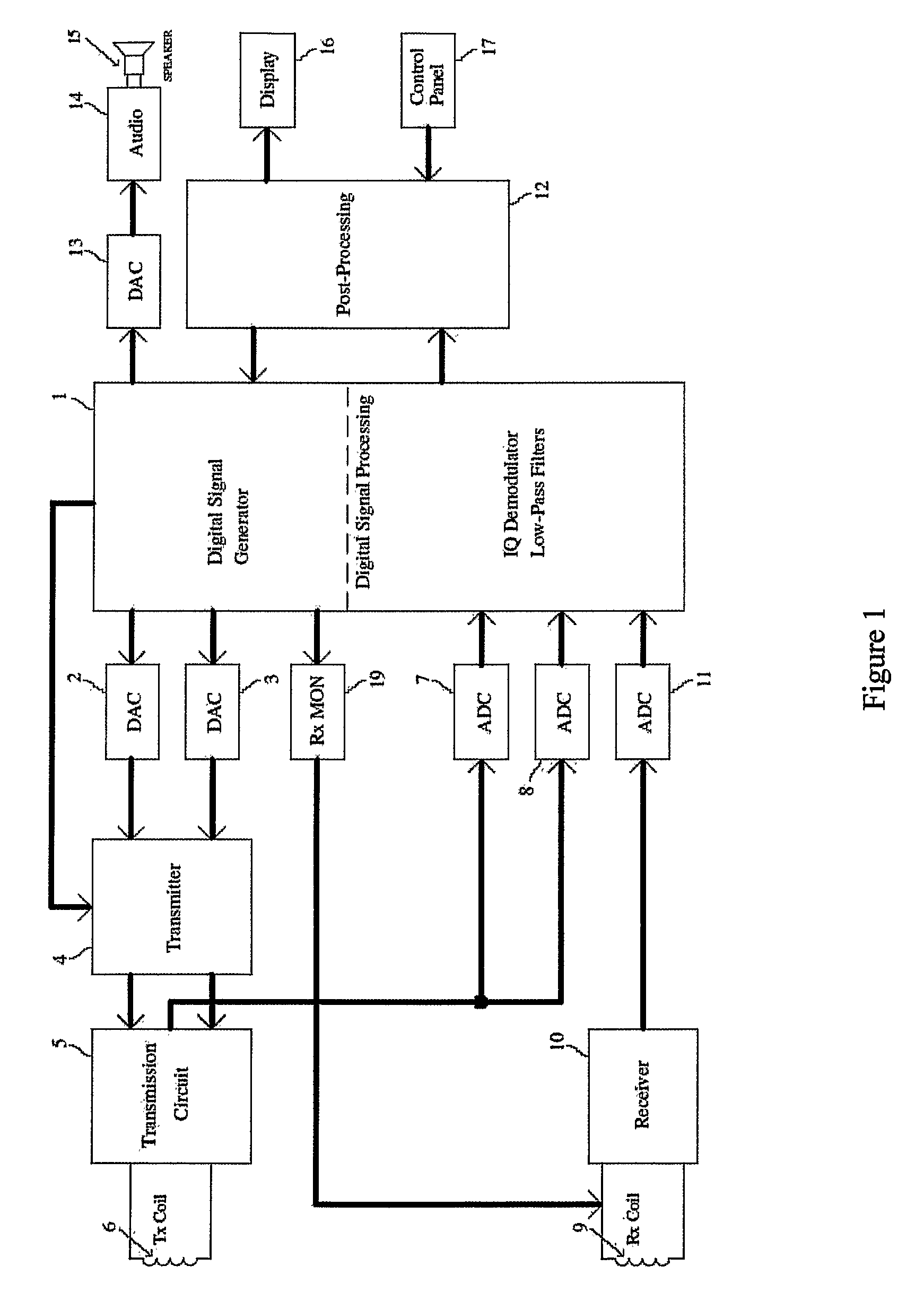

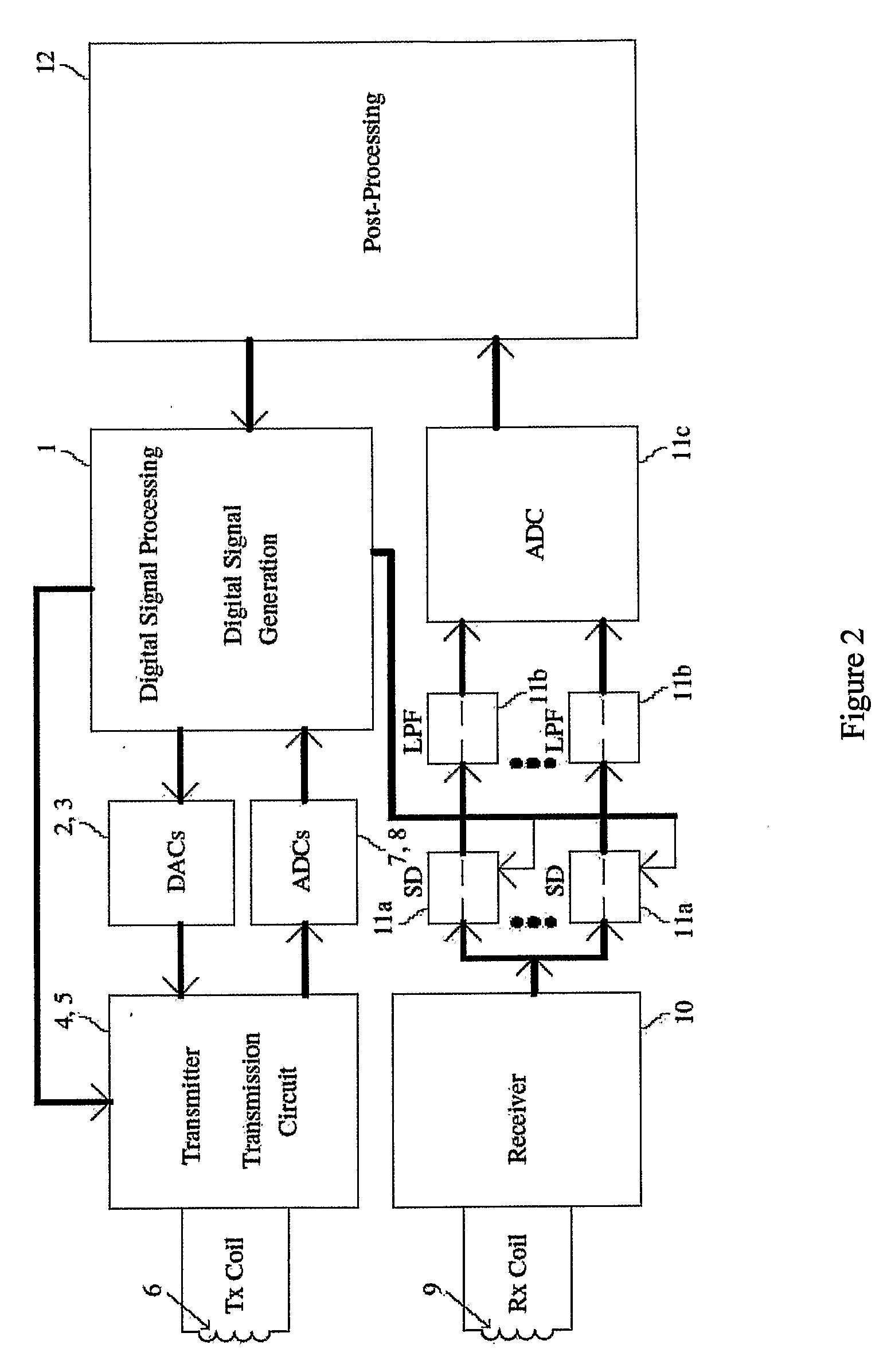

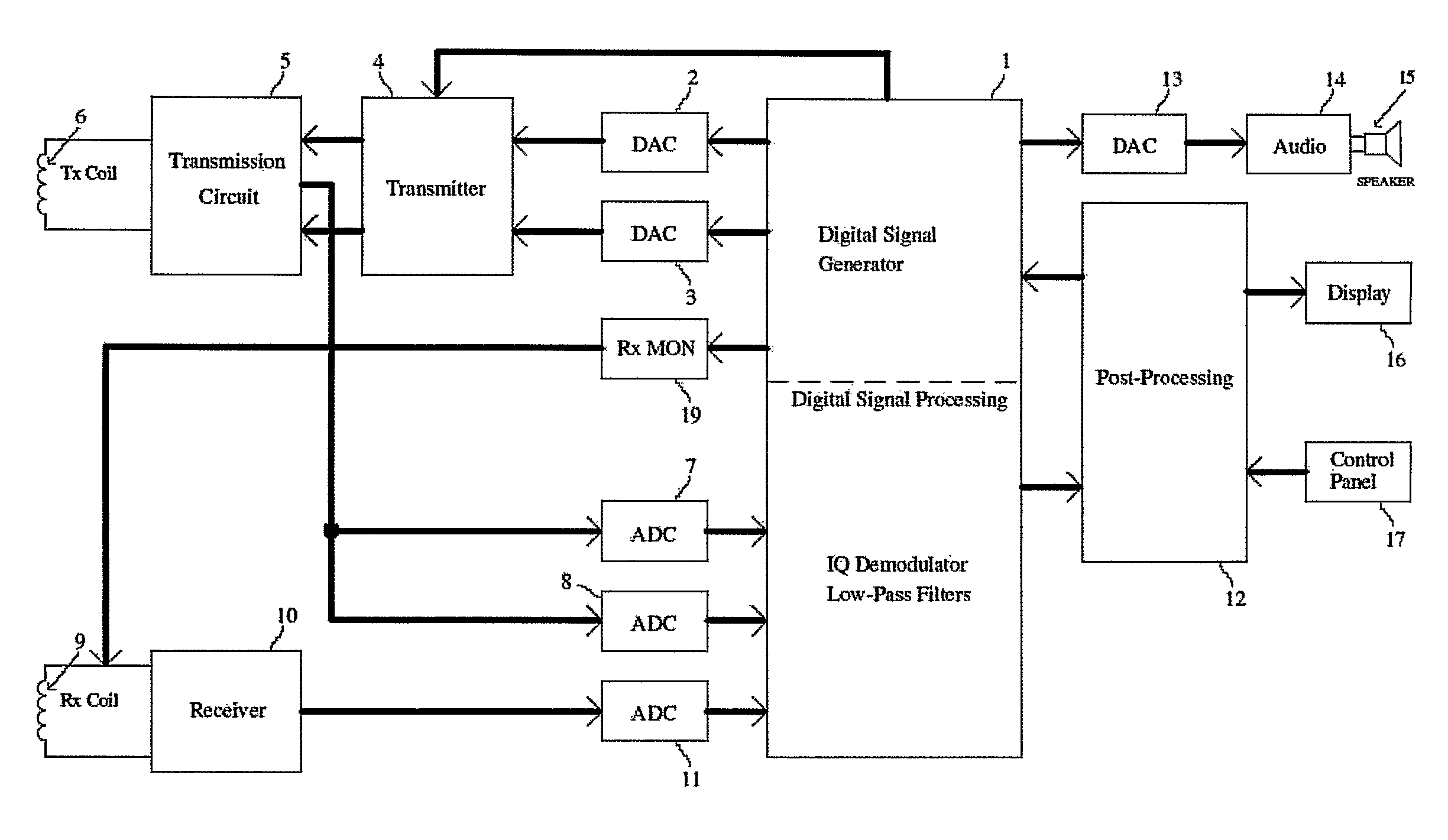

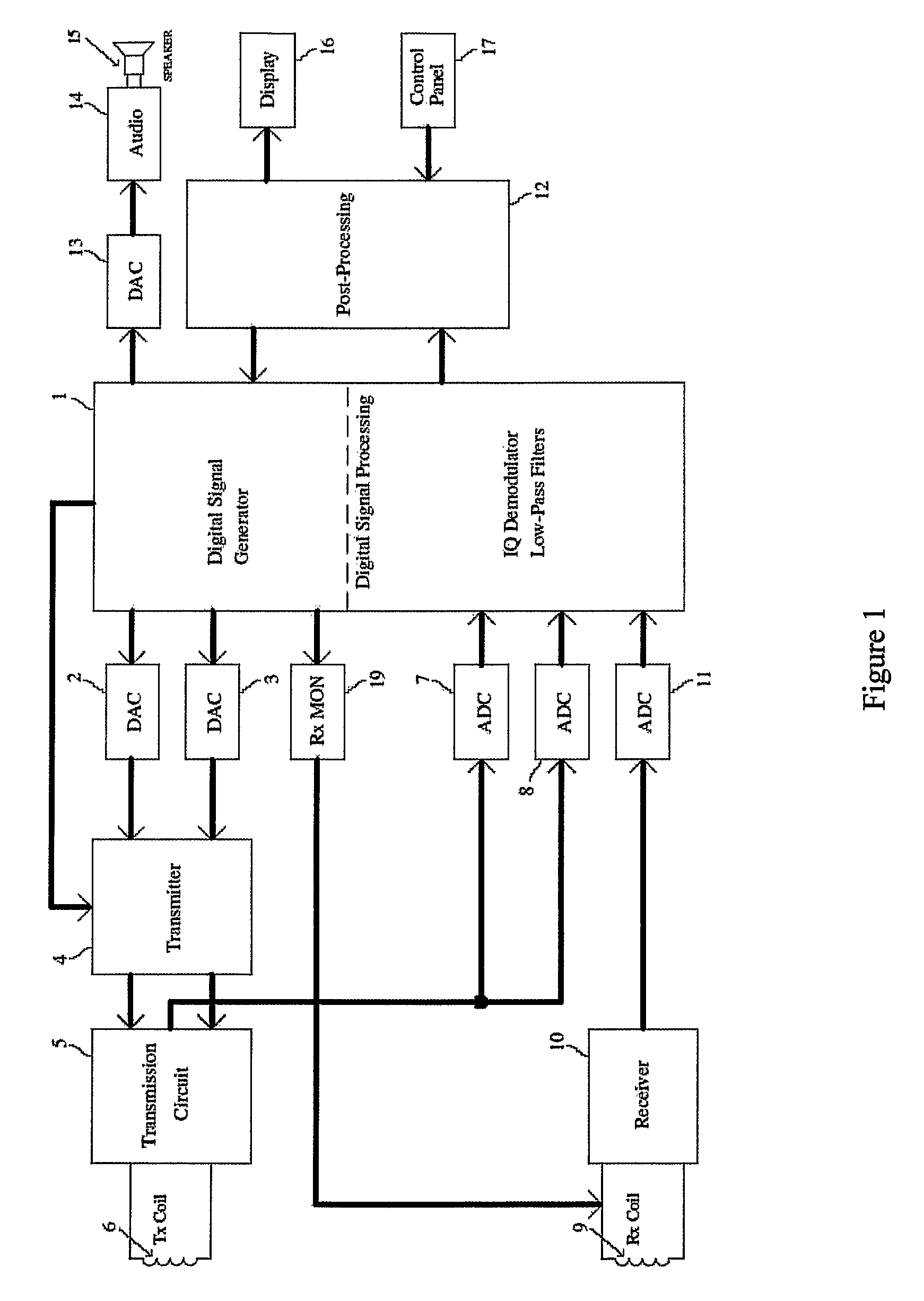

Method and Apparatus for Metal Detection Employing Digital Signal Processing

ActiveUS20070296415A1Easy to detectImprove discriminationMagnetic property measurementsMaterial magnetic variablesDigital signal processingPhase shifted

This invention relates to a metal detector using multiple frequency signals generated and processed digitally. The detector transmits sinusoidal signals using a multiple frequency resonator or square waves, with optional modulation. The operation of the transmitter is continuously monitored to allow for tuning, detection of abnormal conditions and correction of phase shifts.

Owner:MINELAB ELECTRONICS

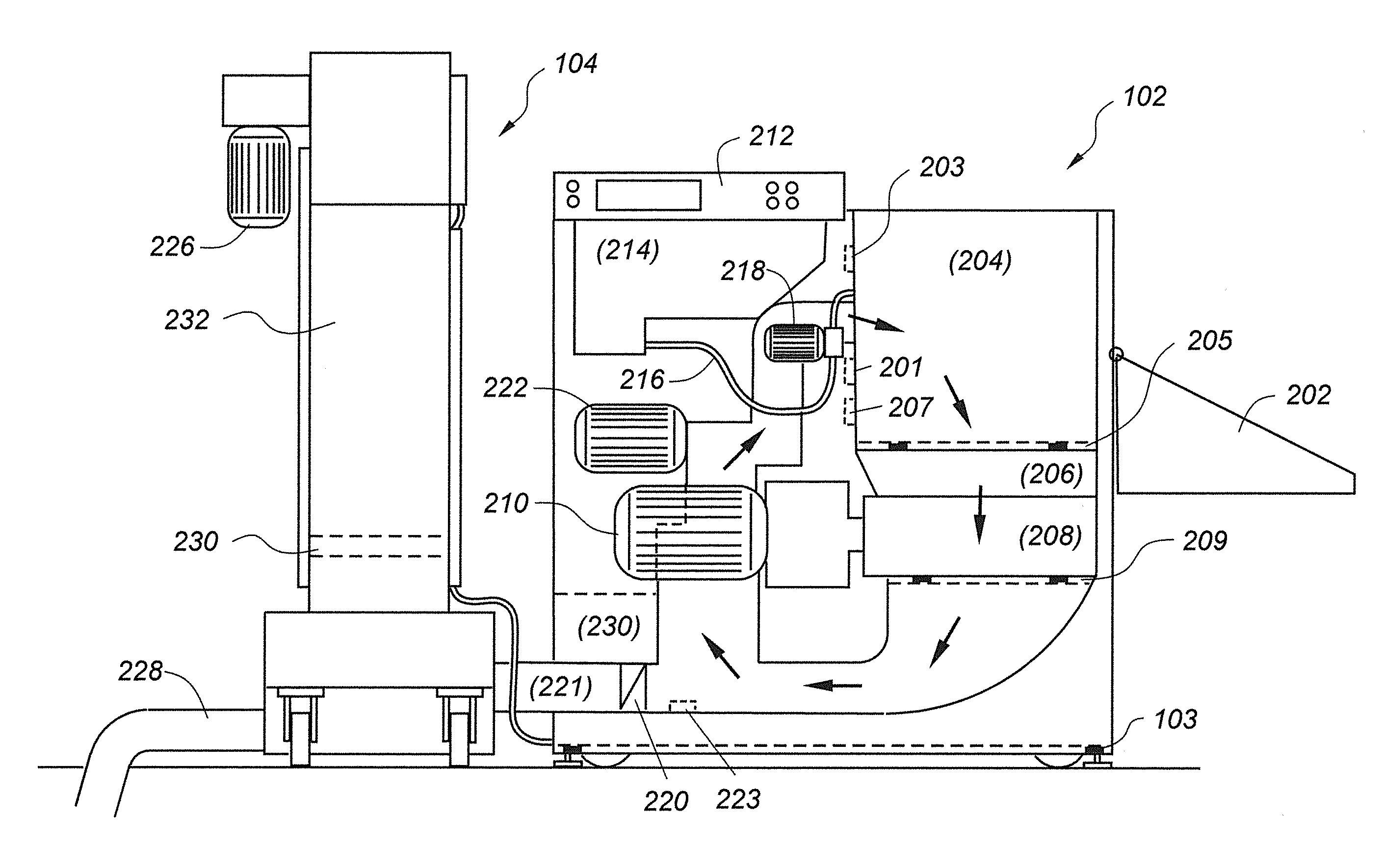

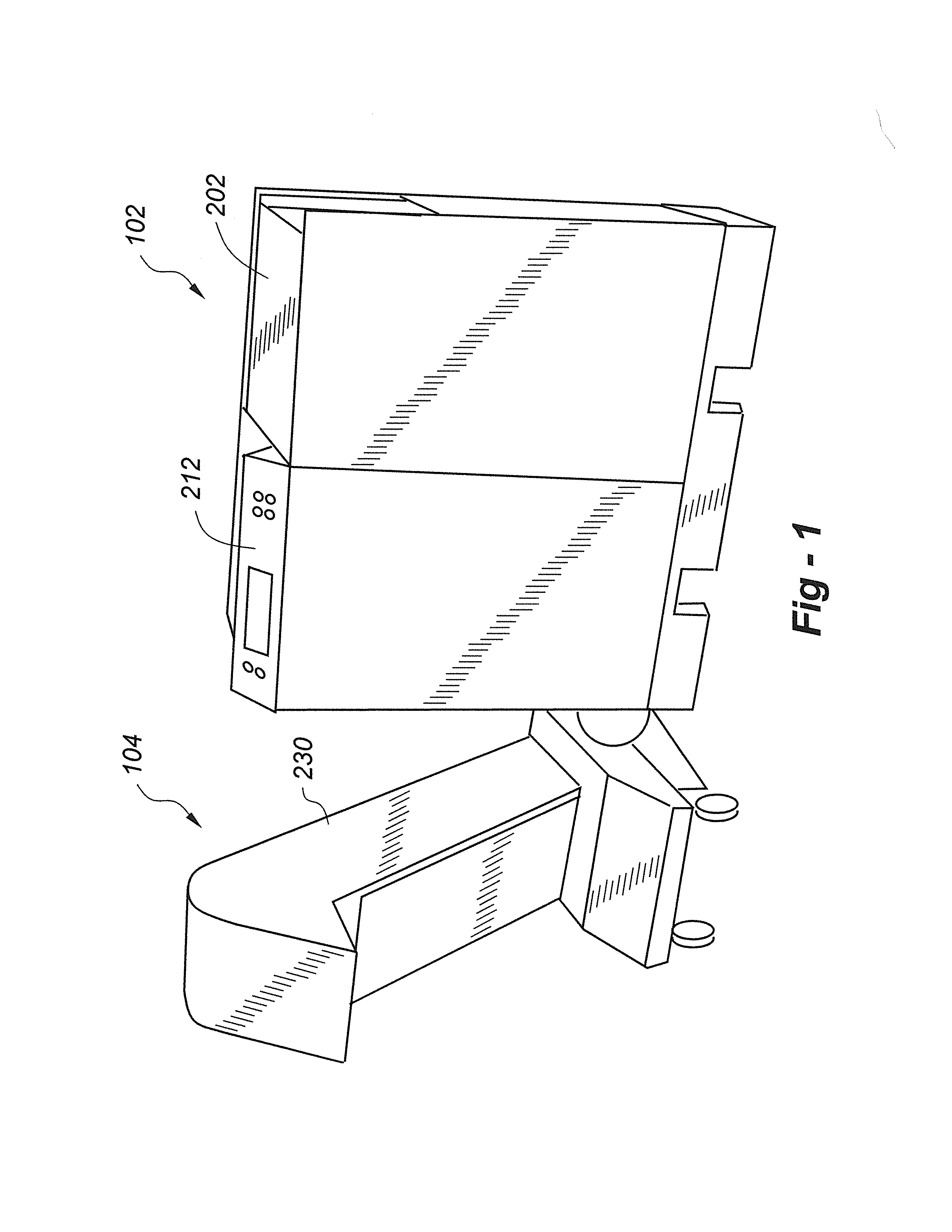

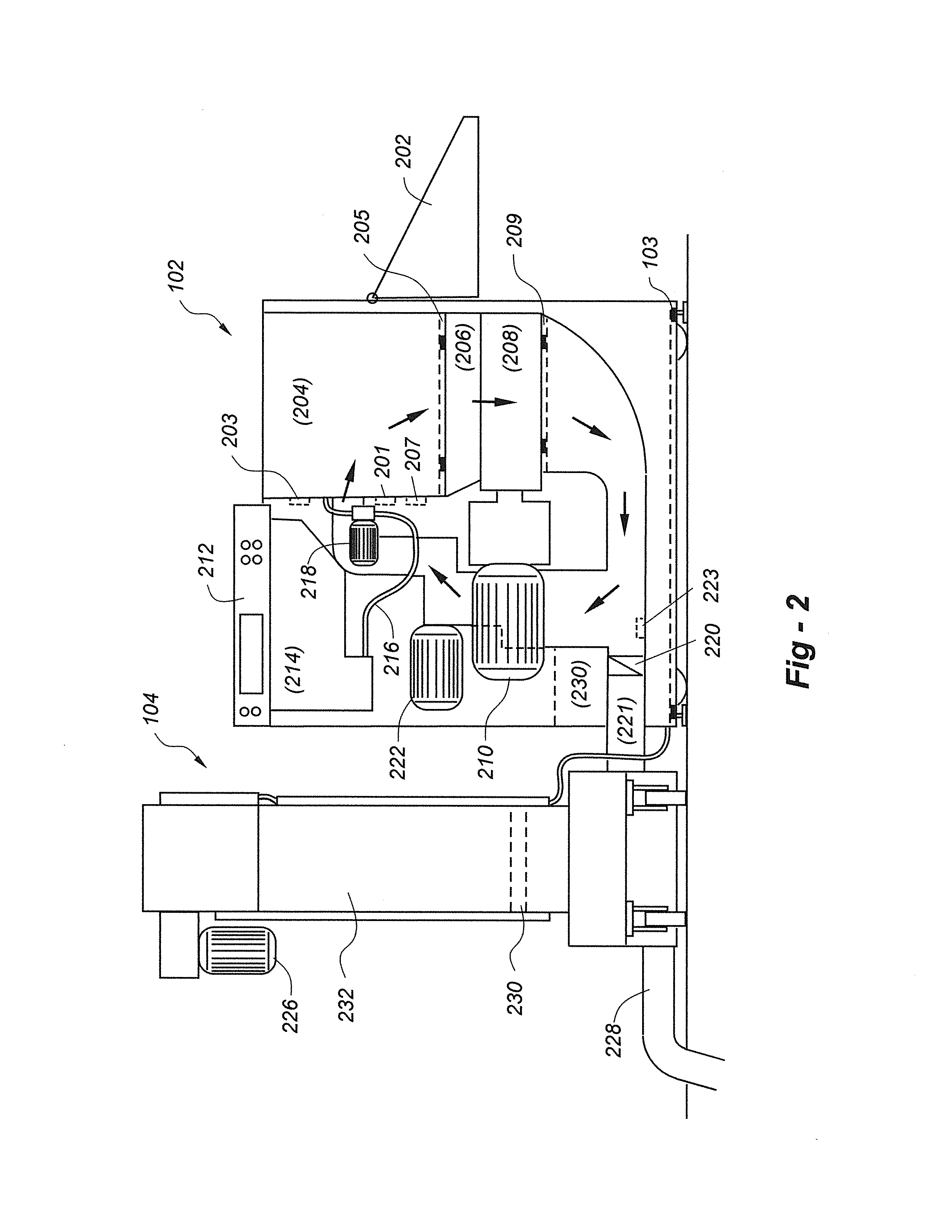

Integrated medical waste management system and operation

InactiveUS20130175373A1Promote degradationGas current separationSolid waste disposalTelecommunications linkDisinfectant

An integrated medical waste management and treatment system may include sensors, interlocks, communications links and / or other features for determining if the waste itself, the decontaminating disinfectant used in the process, or the status of the system are consistent with recommended or authorized system operation. System operation may be terminated if a condition inconsistent with recommended or authorized system operation is detected. Such compliance apparatus may include an electronic scale for determining the weight of the waste loaded into the receiver compartment, a metal detector, or a sensor for determining if the decontaminating disinfectant is a recommended or authorized disinfectant. A communications link may be provided one or more systems to transmit information to a central station to deliver updates or commands associated with the recommended or authorized operation of each system.

Owner:STERIMED MEDICAL WASTE SOLUTIONS UK

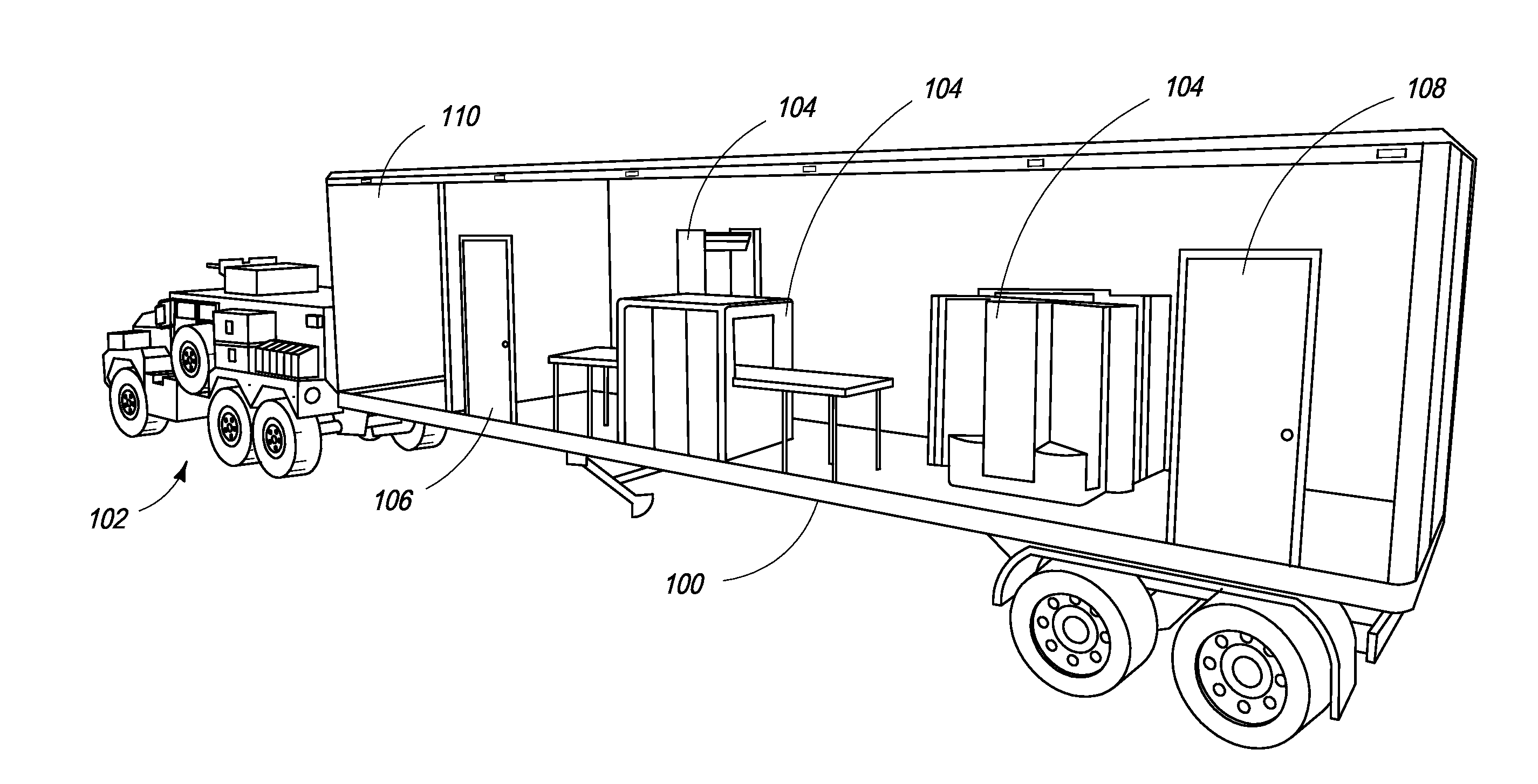

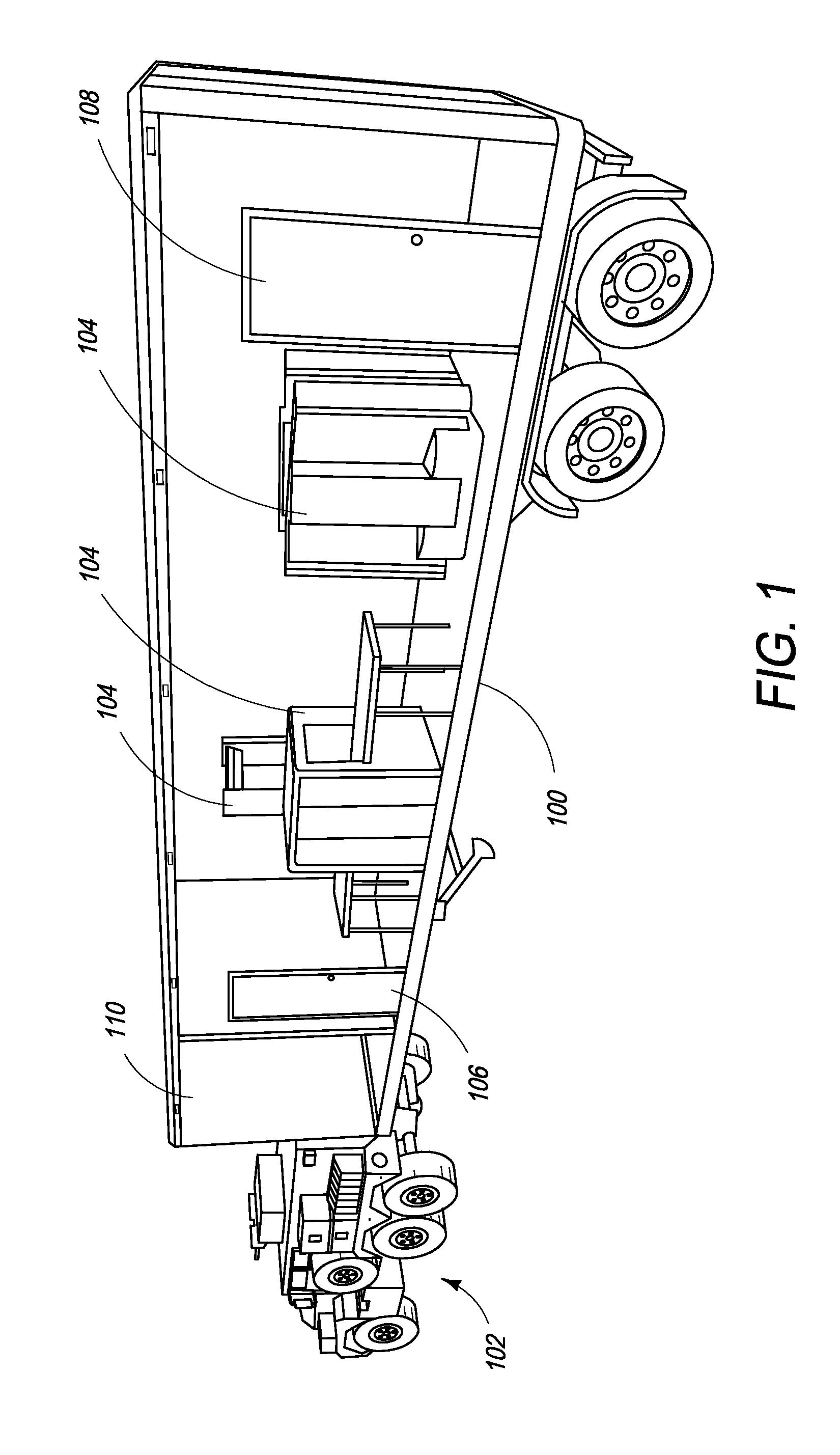

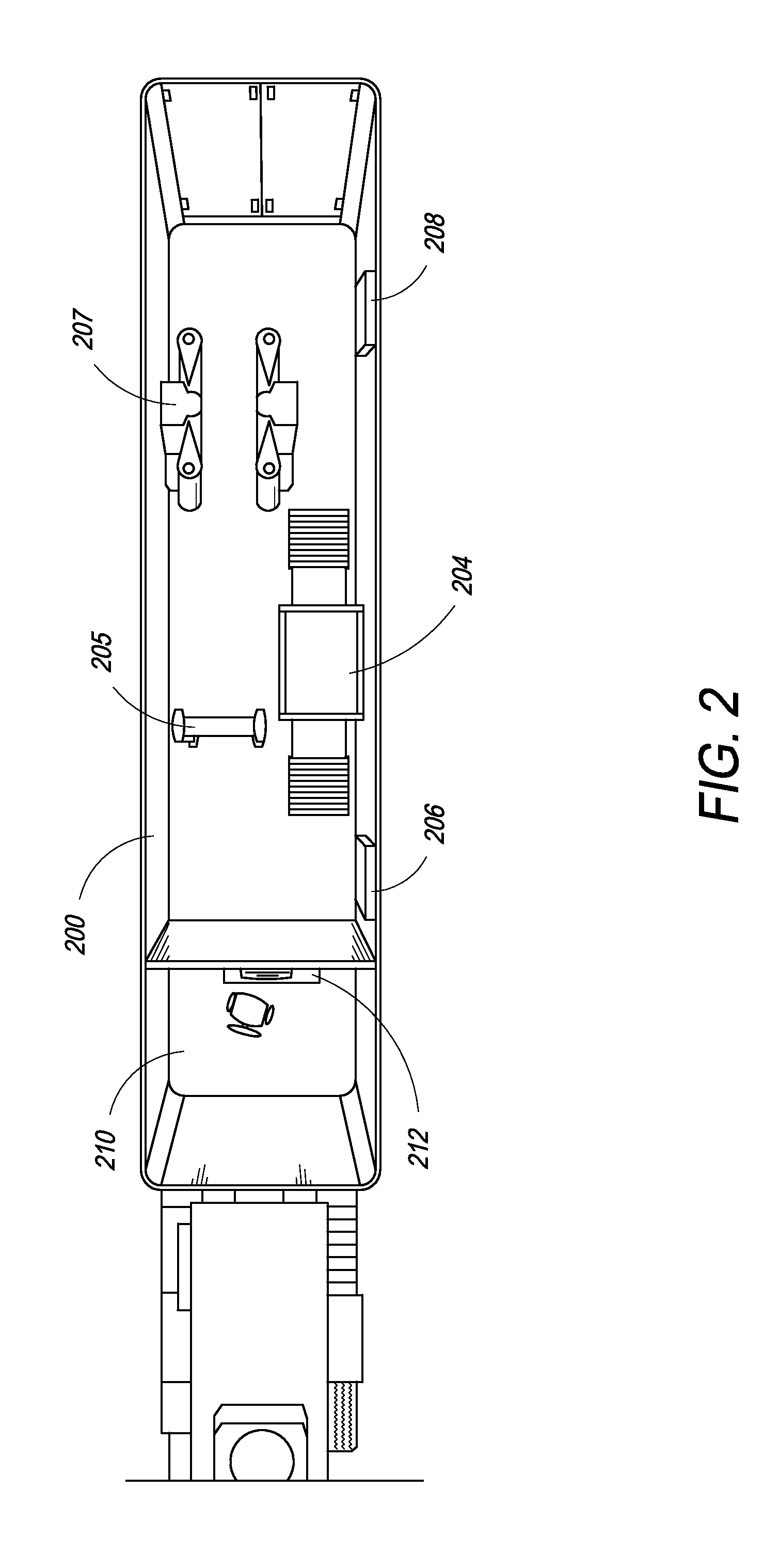

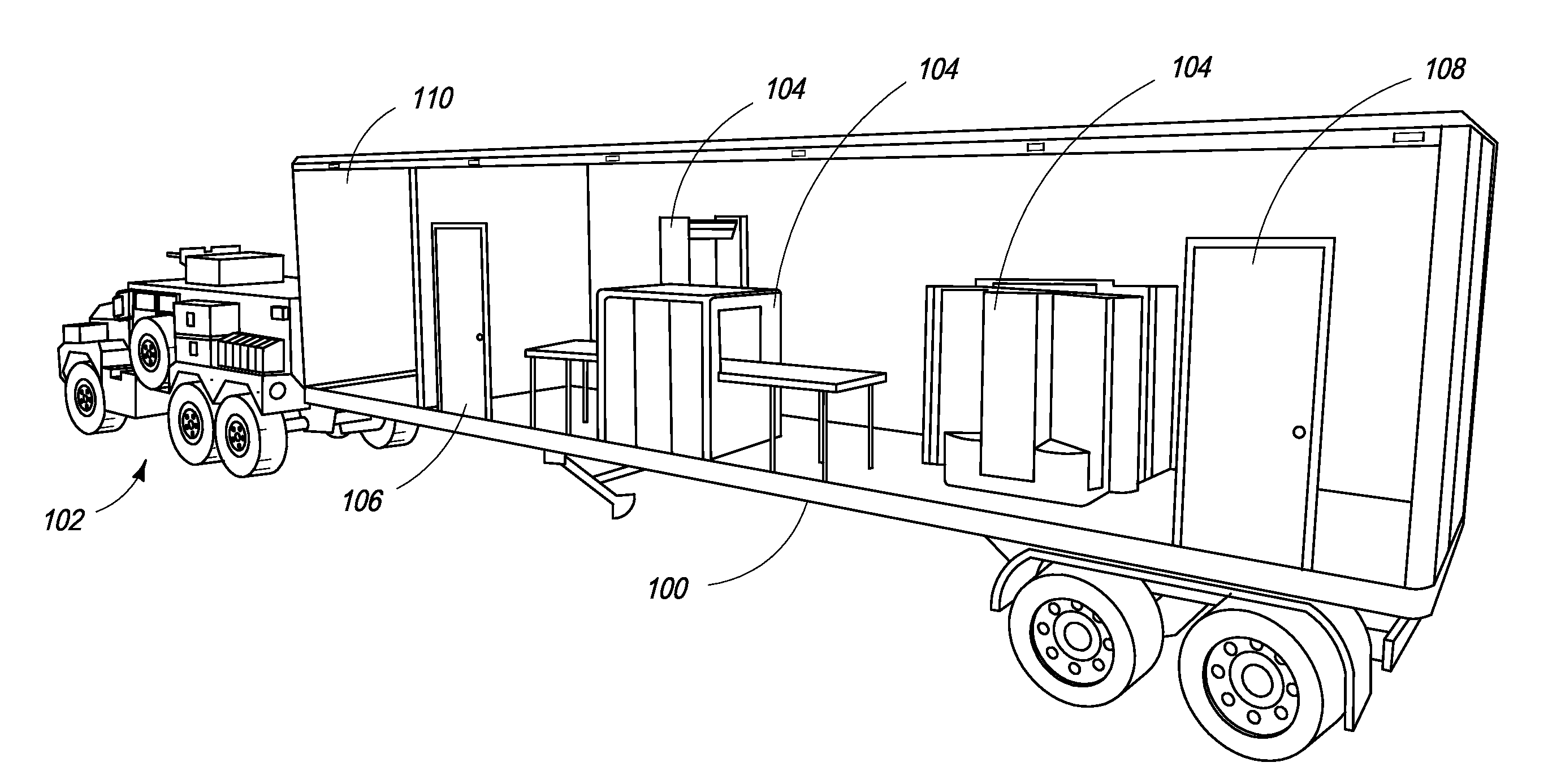

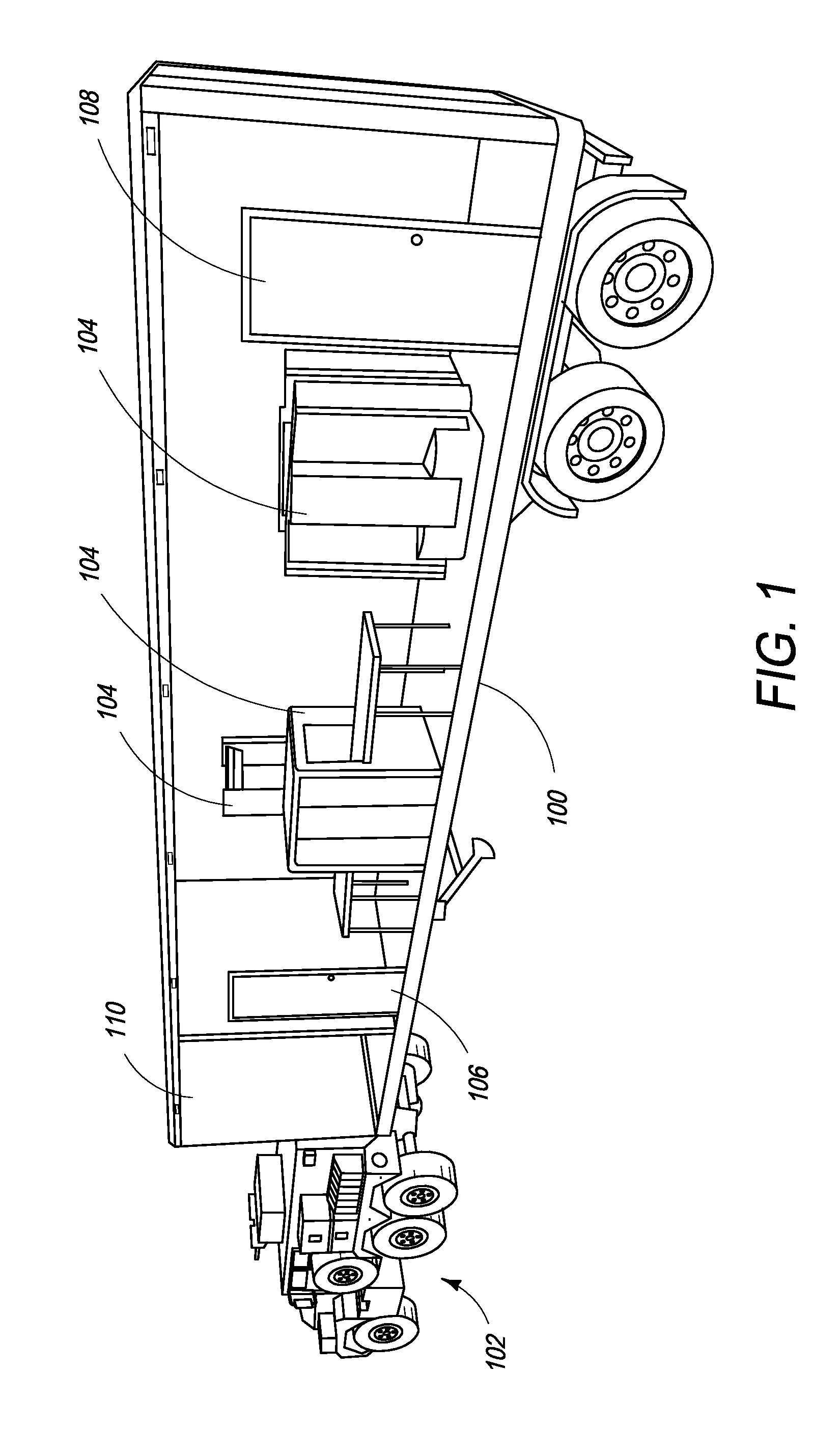

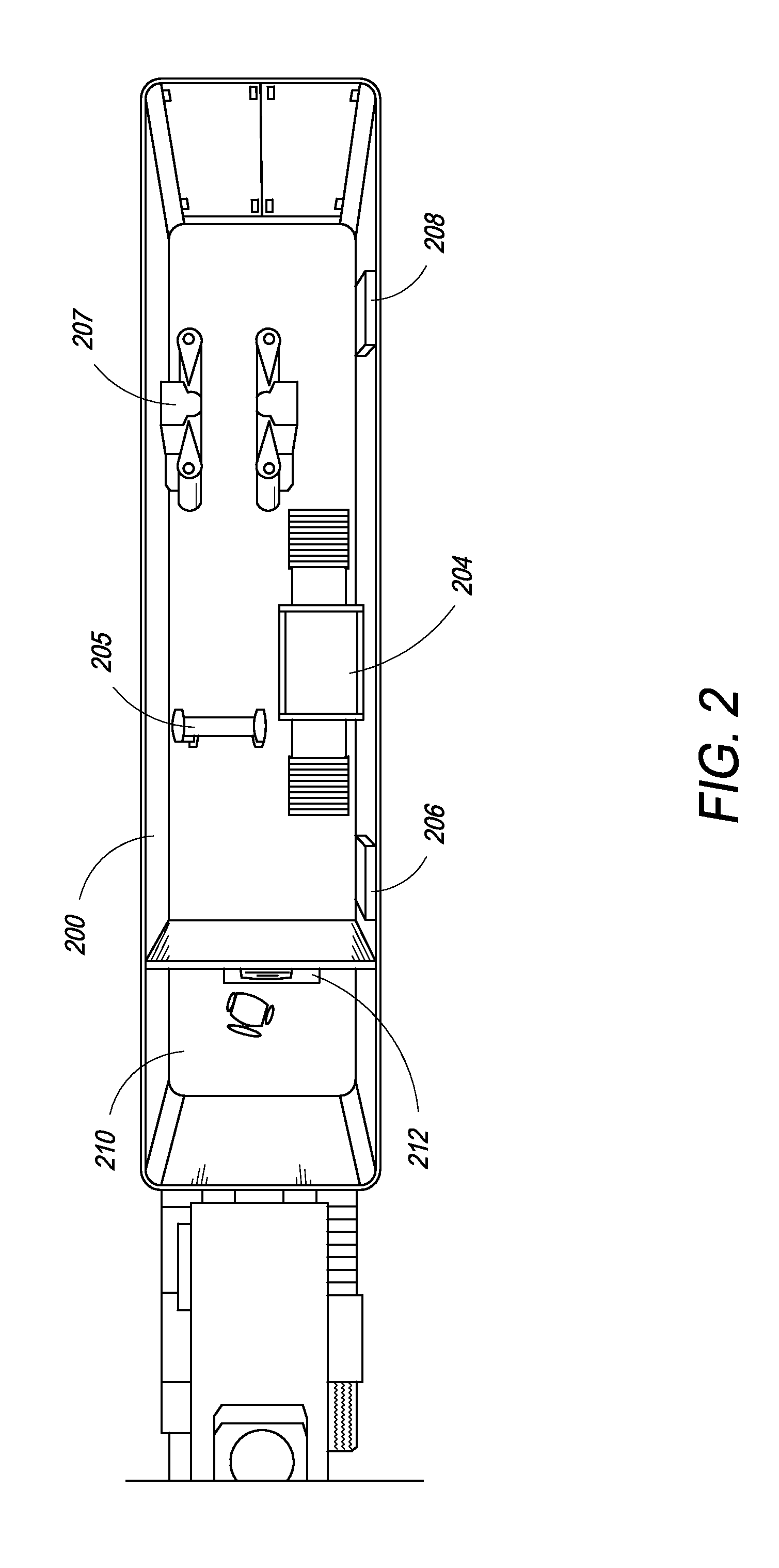

Integrated portable checkpoint system

InactiveUS8731137B2Electric/magnetic detectionMaterial analysis by transmitting radiationX-rayEngineering

The present specification discloses a portable system for inspecting objects. The system includes a housing adapted to be carried by a vehicle, which houses a metal detector and an X-ray scanner and further includes a deployable boom positioned on a top surface of the housing. Operationally, the system is transported to a location, persons or objects are inspected by the metal detector or X-ray scanner and the boom is deployed to inspect external cargo. The integrated portable checkpoint system provides security screening and inspection equipment with increased operational capabilities in one fully integrated package.

Owner:RAPISCAN SYST INC (US)

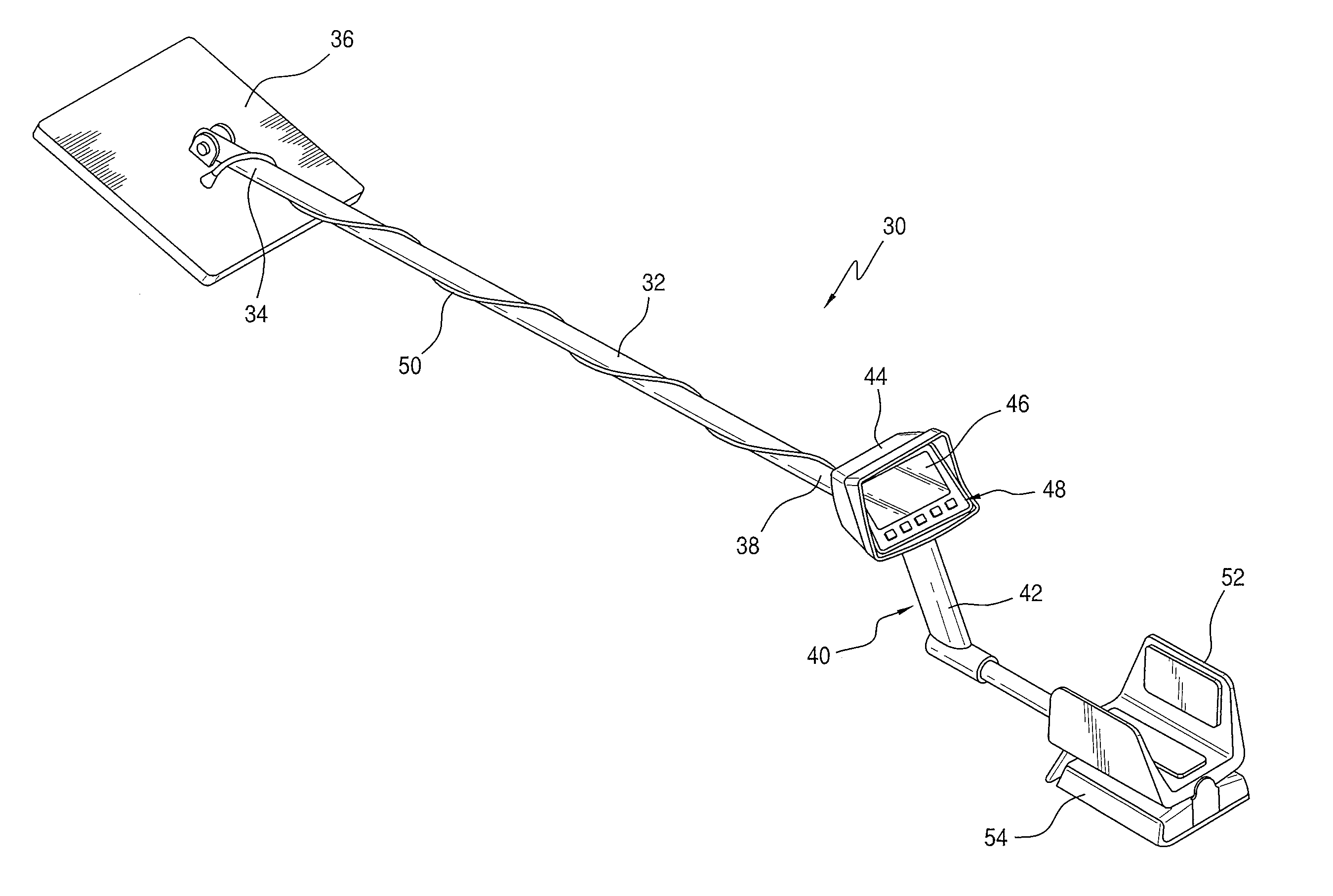

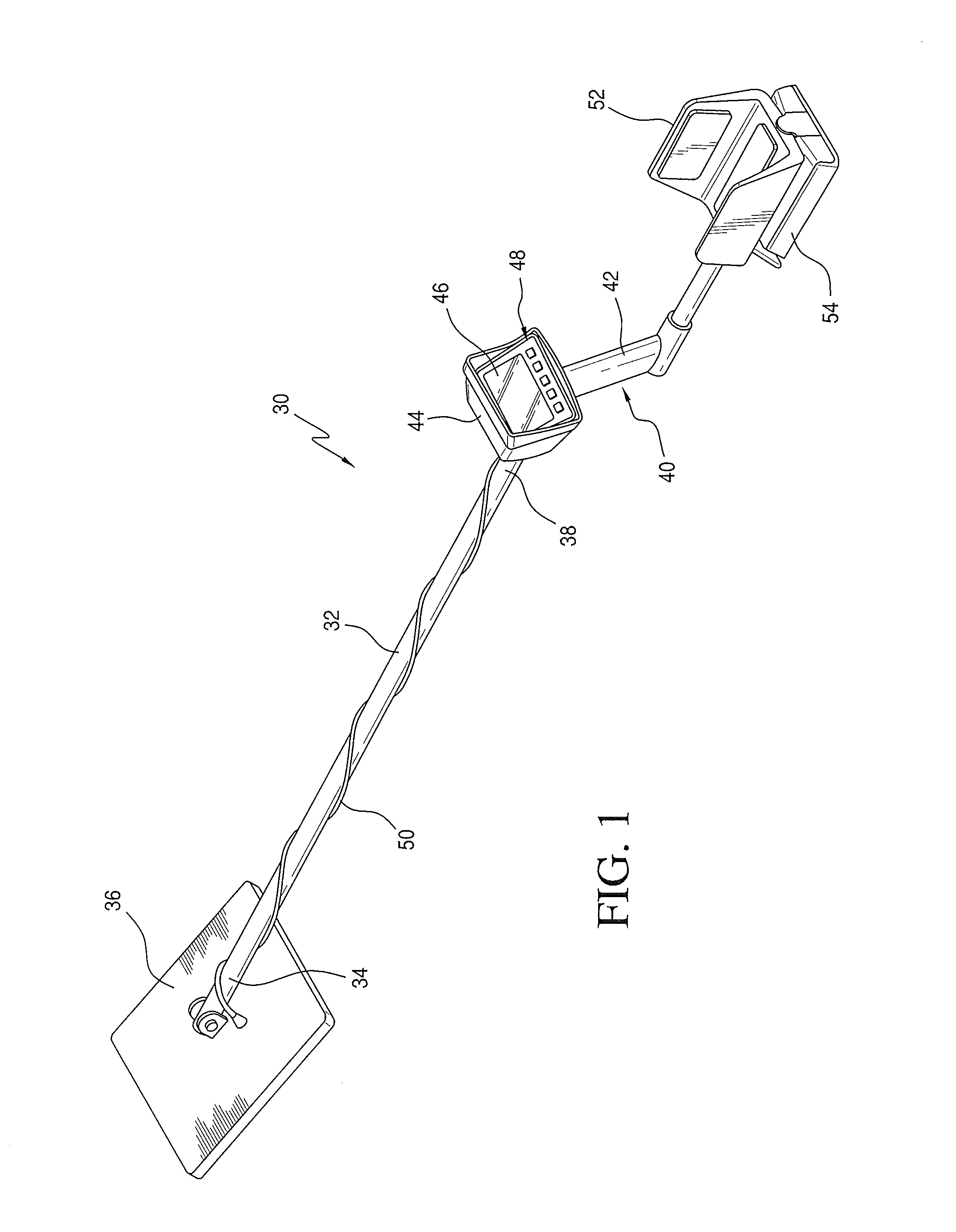

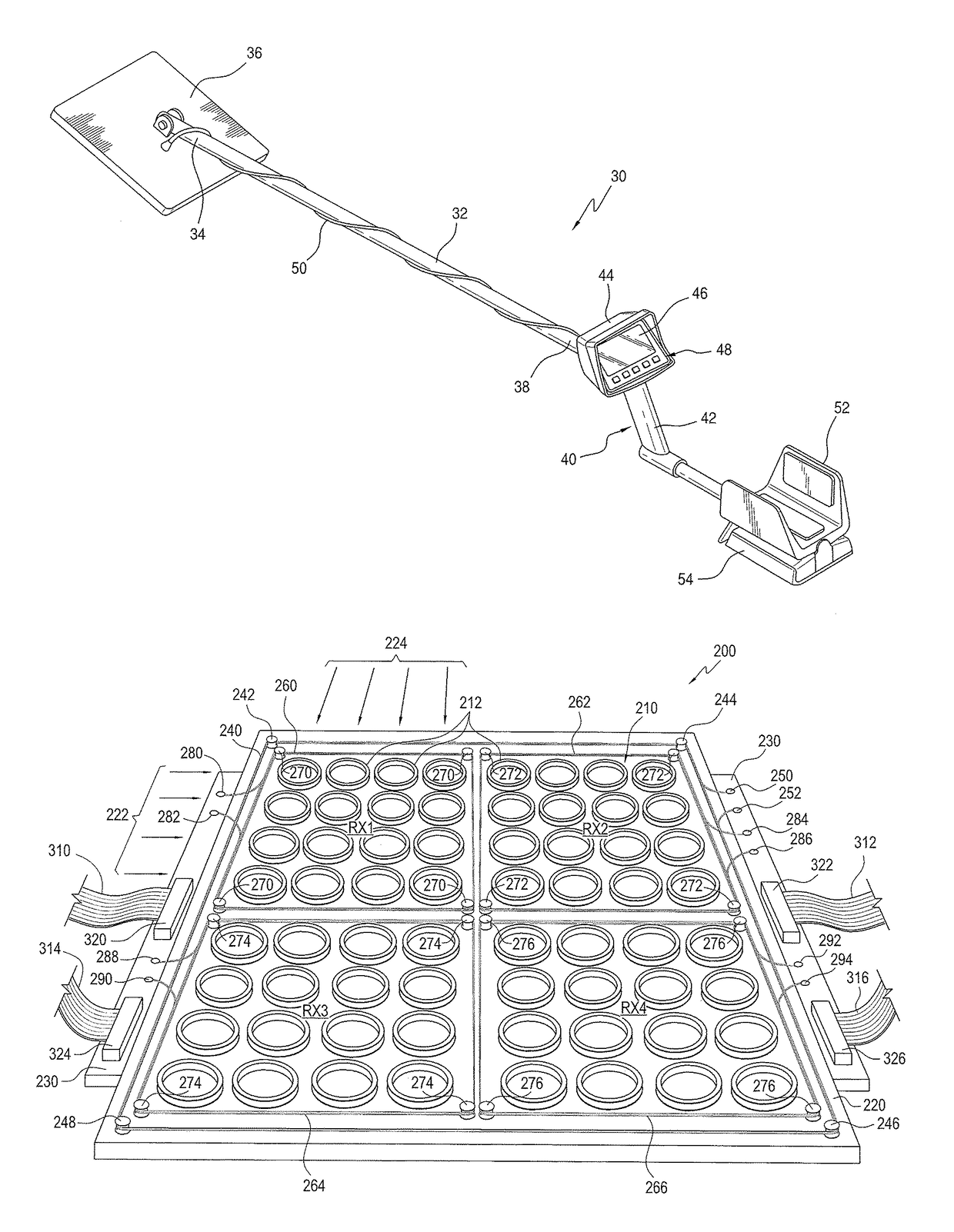

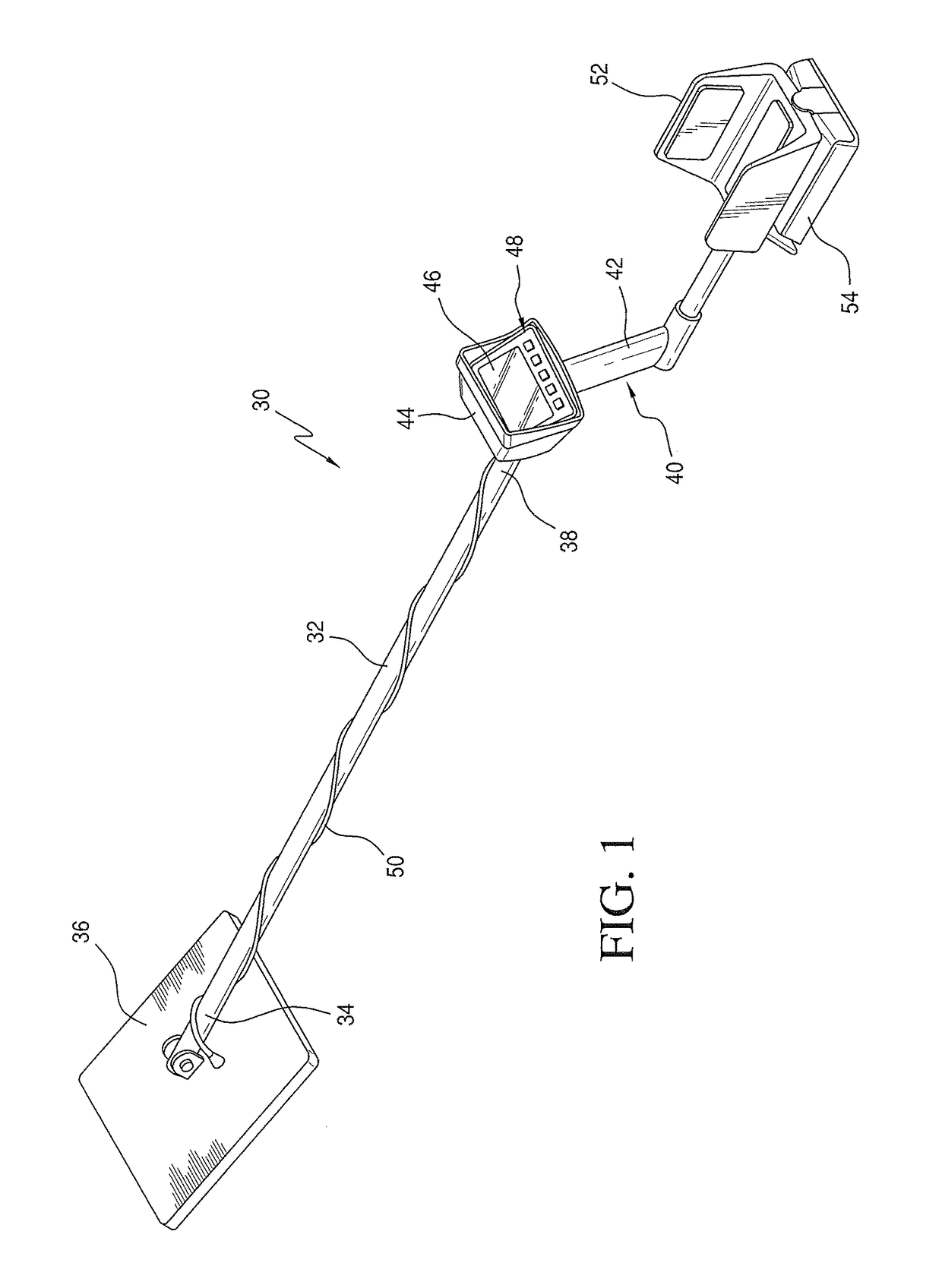

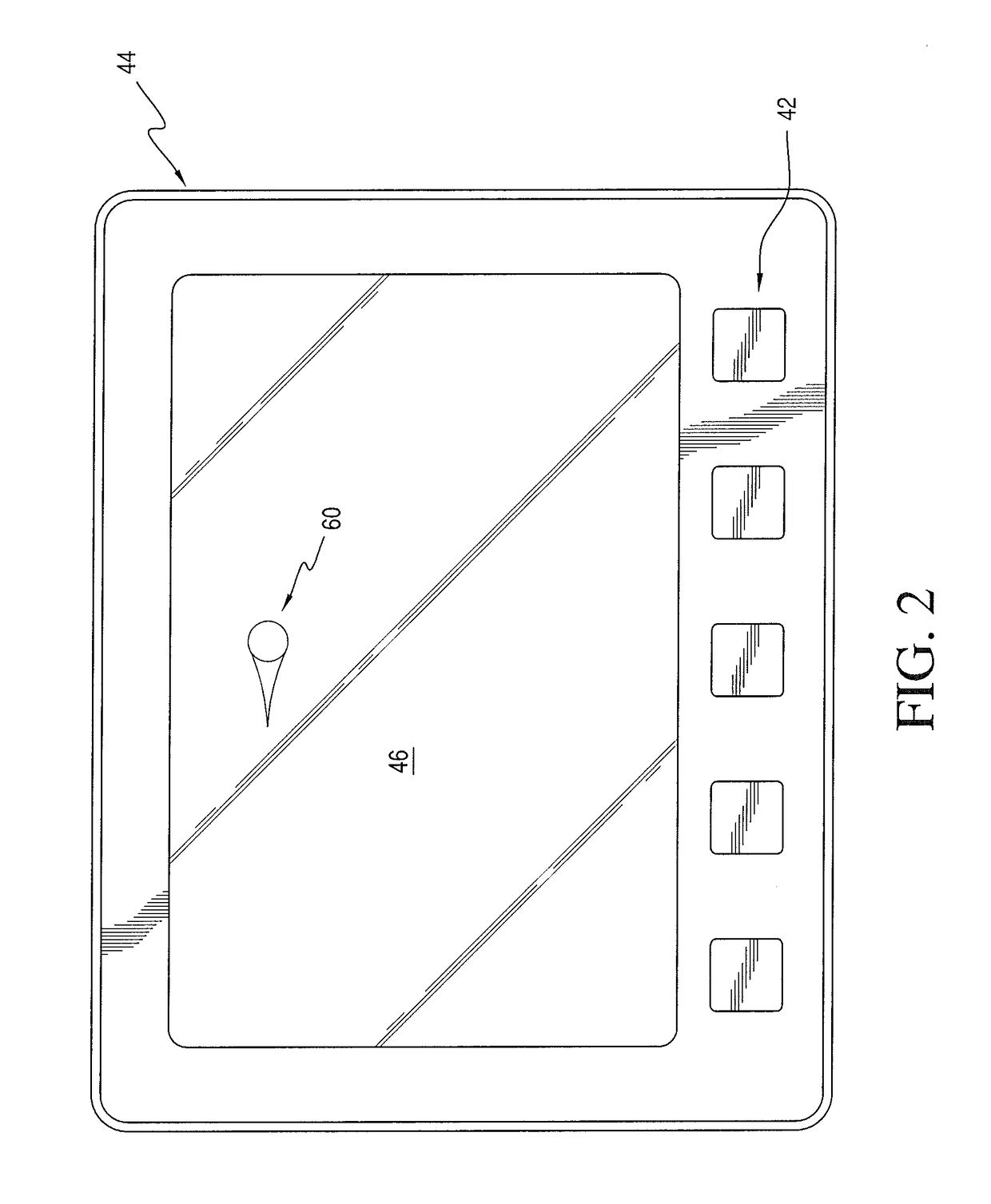

Metal Object or Feature Detection Apparatus and Method

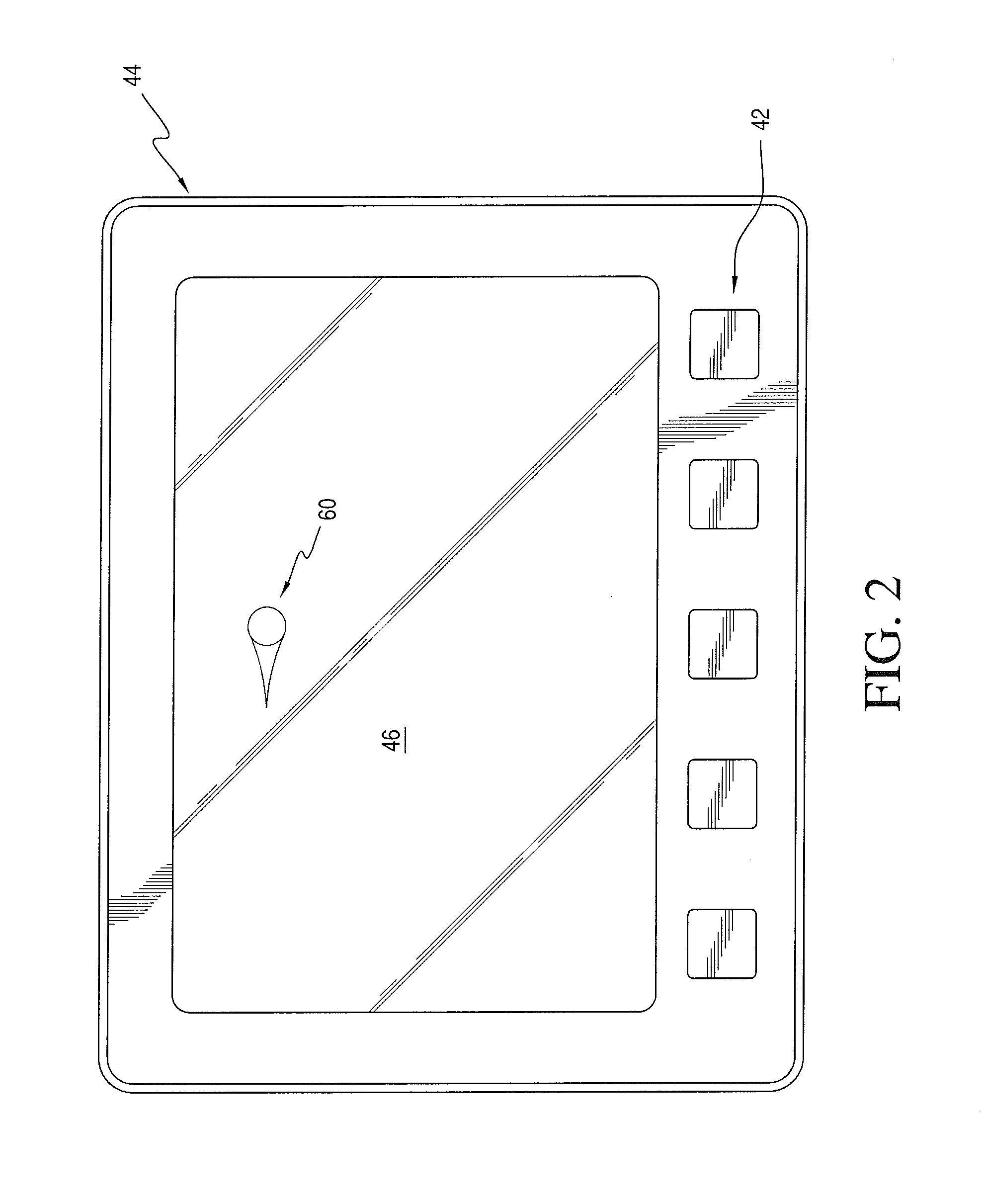

ActiveUS20140218036A1Accurate displayElectric/magnetic detectionAcoustic wave reradiationDisplay deviceReceiver coil

A metal detector system 30 for sensing target (e.g., metal) objects within soil or other strata includes a pickup head 36 carrying an excitation coil configured to generate an excitation signal to energize a target object 400 and uses a 2-D (e.g., planar, rectangular) array of pixel-receive coils configured within the pickup head to receive electro-magnetic energy from the energized target object. As the user moves the pickup head across the strata's surface, the pixel-receive coils sense relative motion between each pixel-receive coil and the energized target object, where motion is detectable as individually sensed changes in received signal levels among the pixel-receive coils. The metal detector system also includes a 2-D display 46 which depicts or visually represents the 2-D array of pixel-receive coils and generates a changing display of any sensed moving target object 60 in response to sensed changes in received signal levels among the pixel-receive coils.

Owner:FRY TERRY

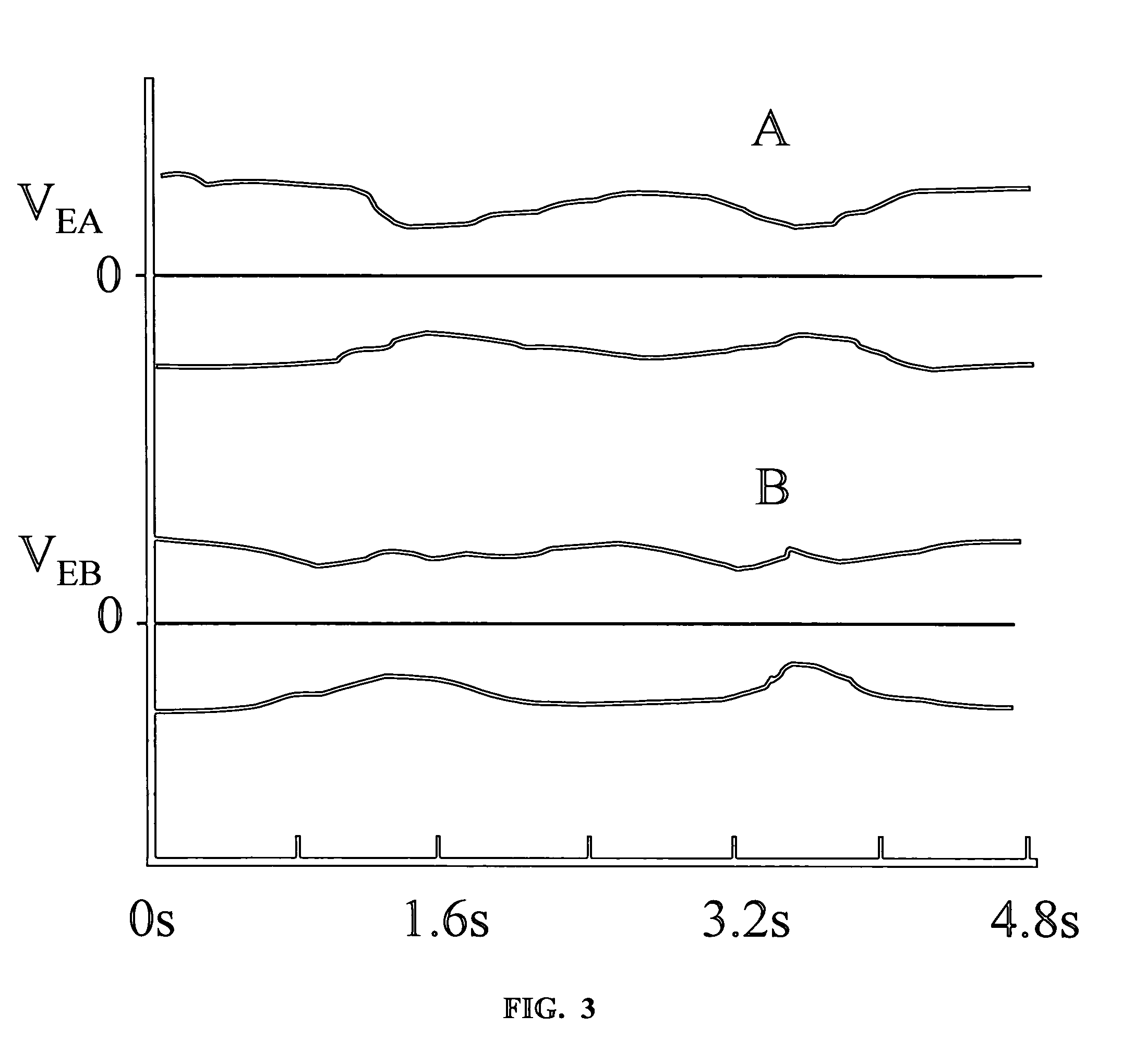

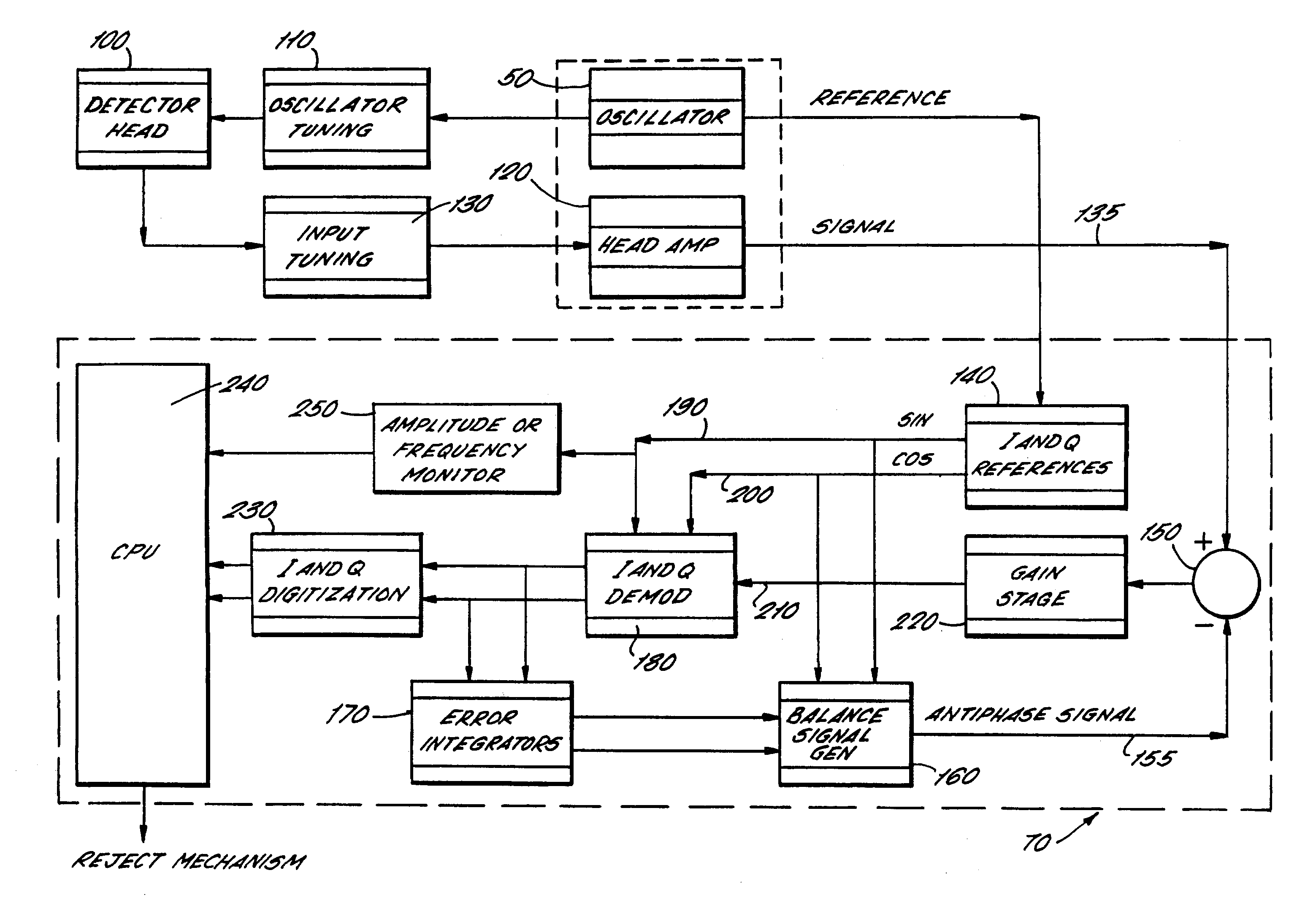

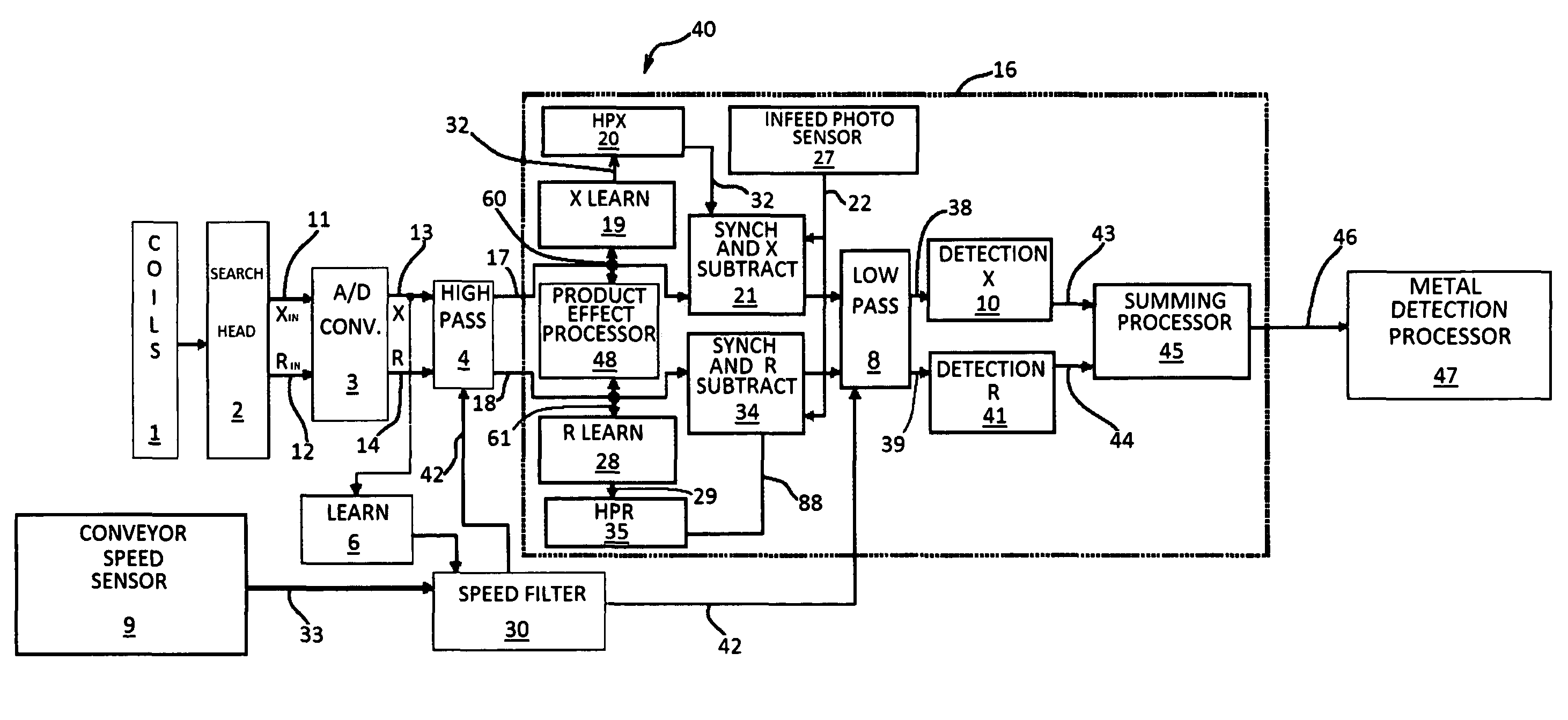

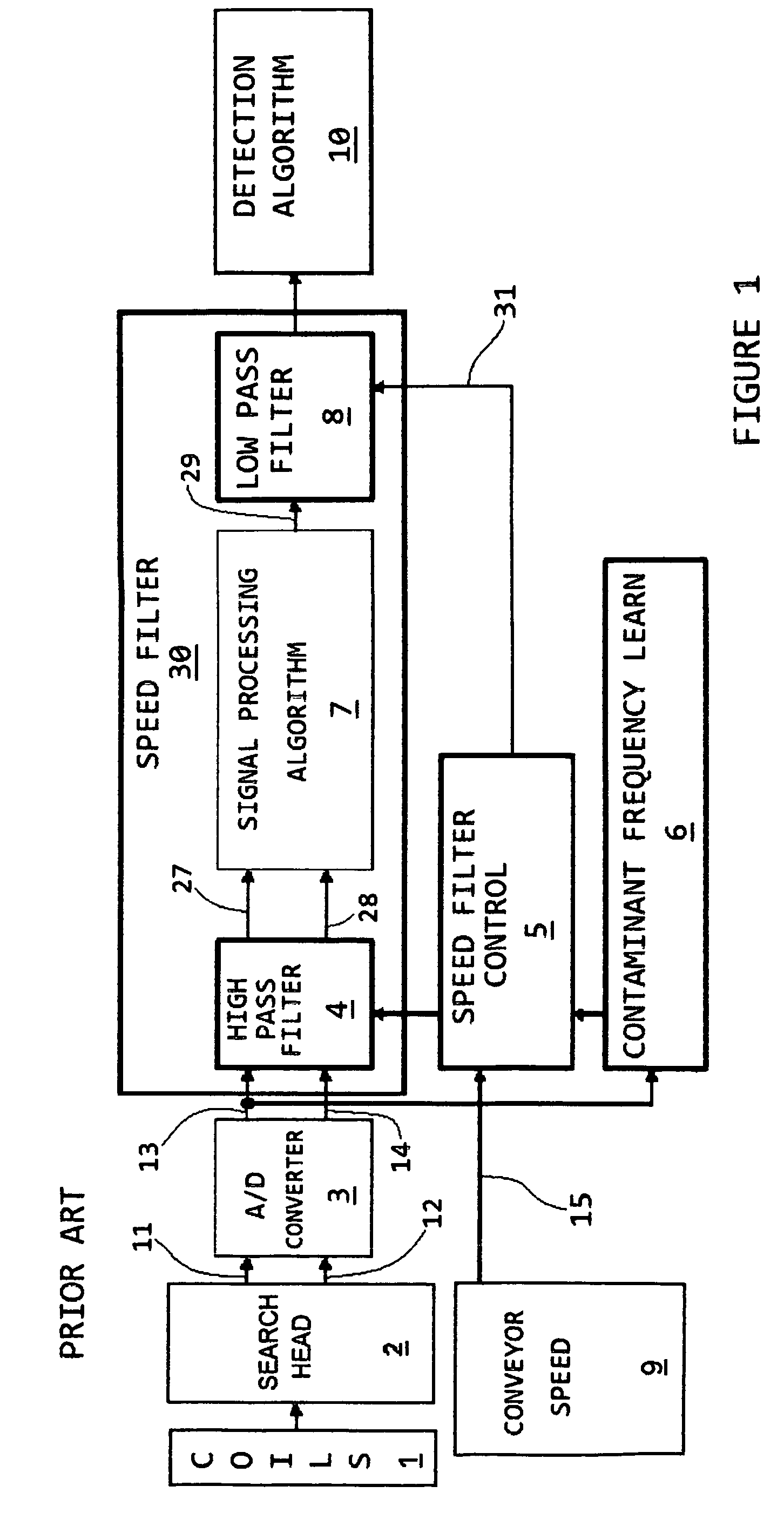

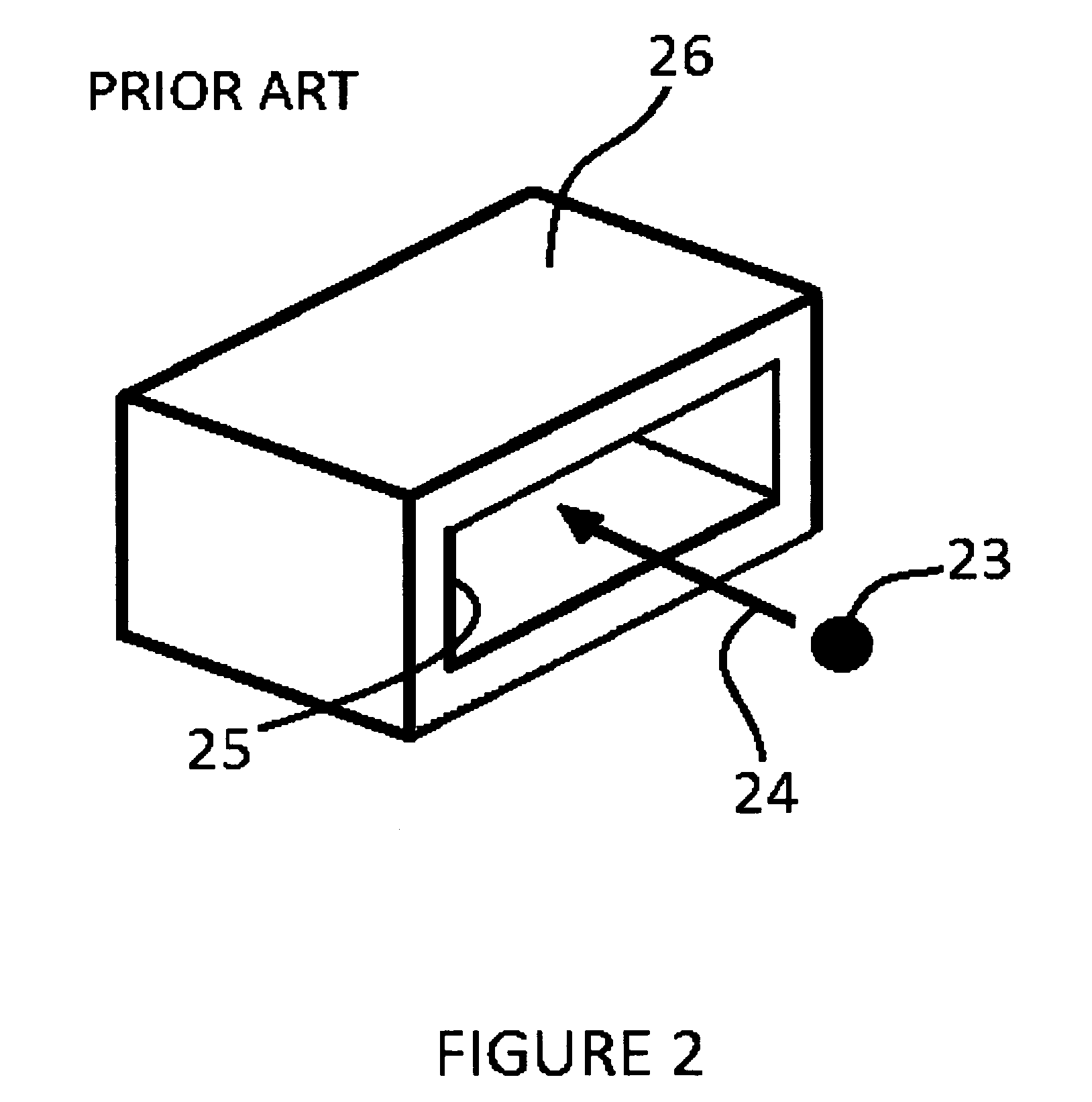

Apparatus and method for automatic product effect compensation in radio frequency metal detectors

ActiveUS8207731B2Good compensationImproves simultaneous sensitivityMagnetic property measurementsTesting foodEngineeringRadio frequency

A metal detector used for identifying contaminants in packages on a conveyor. The detector includes coils a search head and an analog to digital converter generating a reactive signal and a resistive signal in response to the presence of a contaminant. During a learning mode a sample product passes through the metal detector providing a representative product effect signal which is stored by the reactive learn memory and the resistive learn memory. The learn memory values provide a reference value subtracted from each product signal during a normal production cycle, canceling the product effect caused by contaminants in individual packages. The product effect is monitored during successive cycles composed of a series of packages undergoing normal inspection by the metal detector. A tracking processor averages the product effect signal produced by the individual packages and continuously updates a product effect trend signal that is subtracted from each product signal.

Owner:THERMO FISHER SCIENTIFIC INC

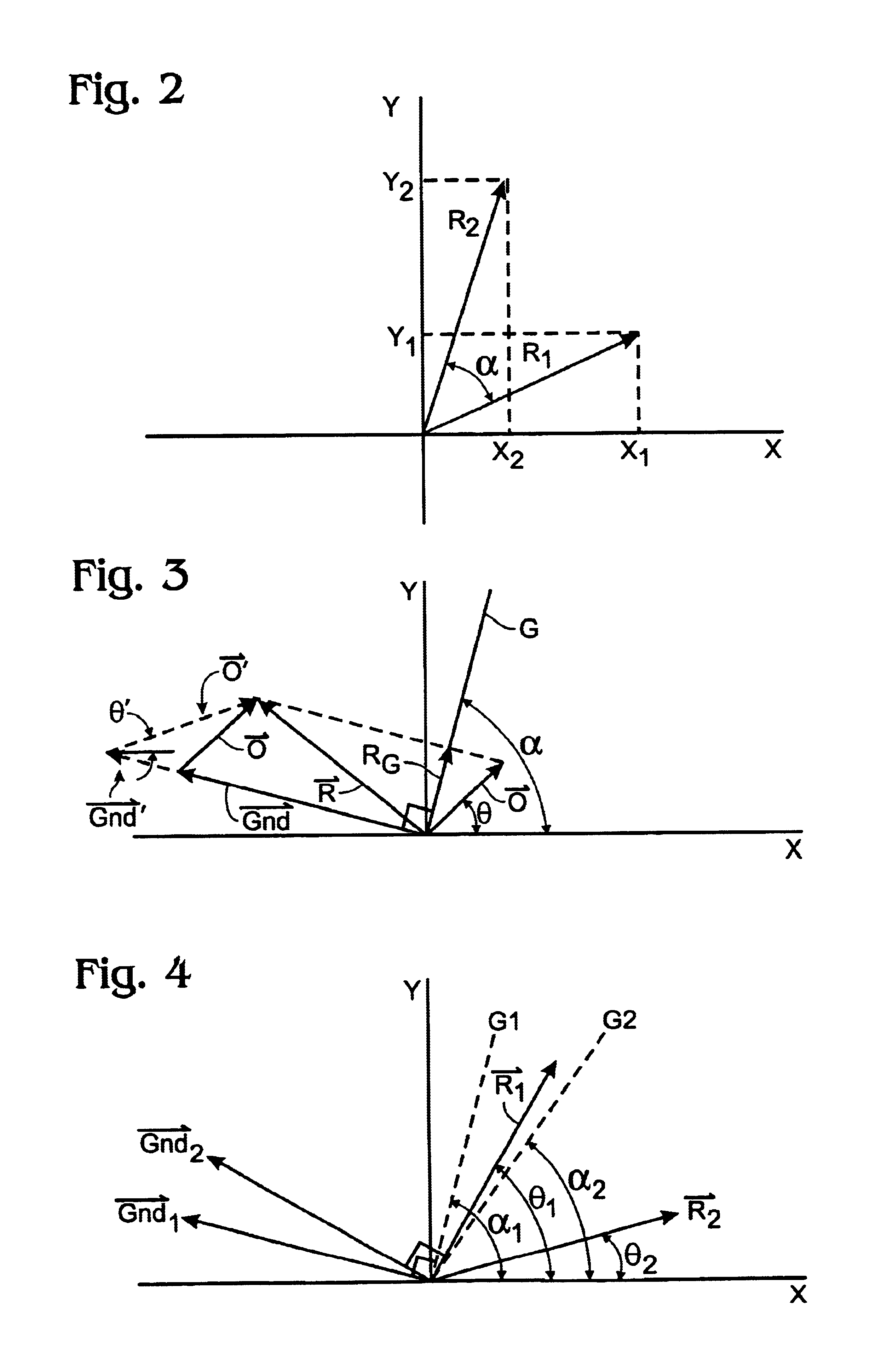

Metal detector employing static discrimination

InactiveUS6911823B2Cancellation effectImprove discriminationElectric/magnetic detectionSpecial data processing applicationsDouble frequencyMetal detectors

A metal detector employing static discrimination. Within the scope of the invention is a two-frequency method and apparatus for discriminating between metal objects and ground. Also within the scope of the invention is a three-frequency method and apparatus for discriminating between ferrous and non-ferrous metal objects. The methods and apparatus do not require movement of the search head of the metal detector.

Owner:GARRETT ELECTRONICS

Area surveillance systems and methods

InactiveUS20140063239A1Color television detailsClosed circuit television systemsReference sampleFrequency spectrum

A spectral analysis surveillance system includes sources or emitters which emit various wavelengths of electromagnetic radiation or energy into a space under surveillance, and a sensor which produce signals indicative of electromagnetic energy returned by people and other objects in the space. The electromagnetic radiation may fall in the visible portion of the electromagnetic spectrum yet the energy is emitted to appear as either white light or a single color. Returned energy is analyzed against reference samples. The spectral analysis surveillance system may be part of an integrated surveillance system including other components, for example metal detectors, baggage X-ray scanners, full body imagers, etc., and may provide surveillance of private or public locations, for instance airports.

Owner:VISUALANT

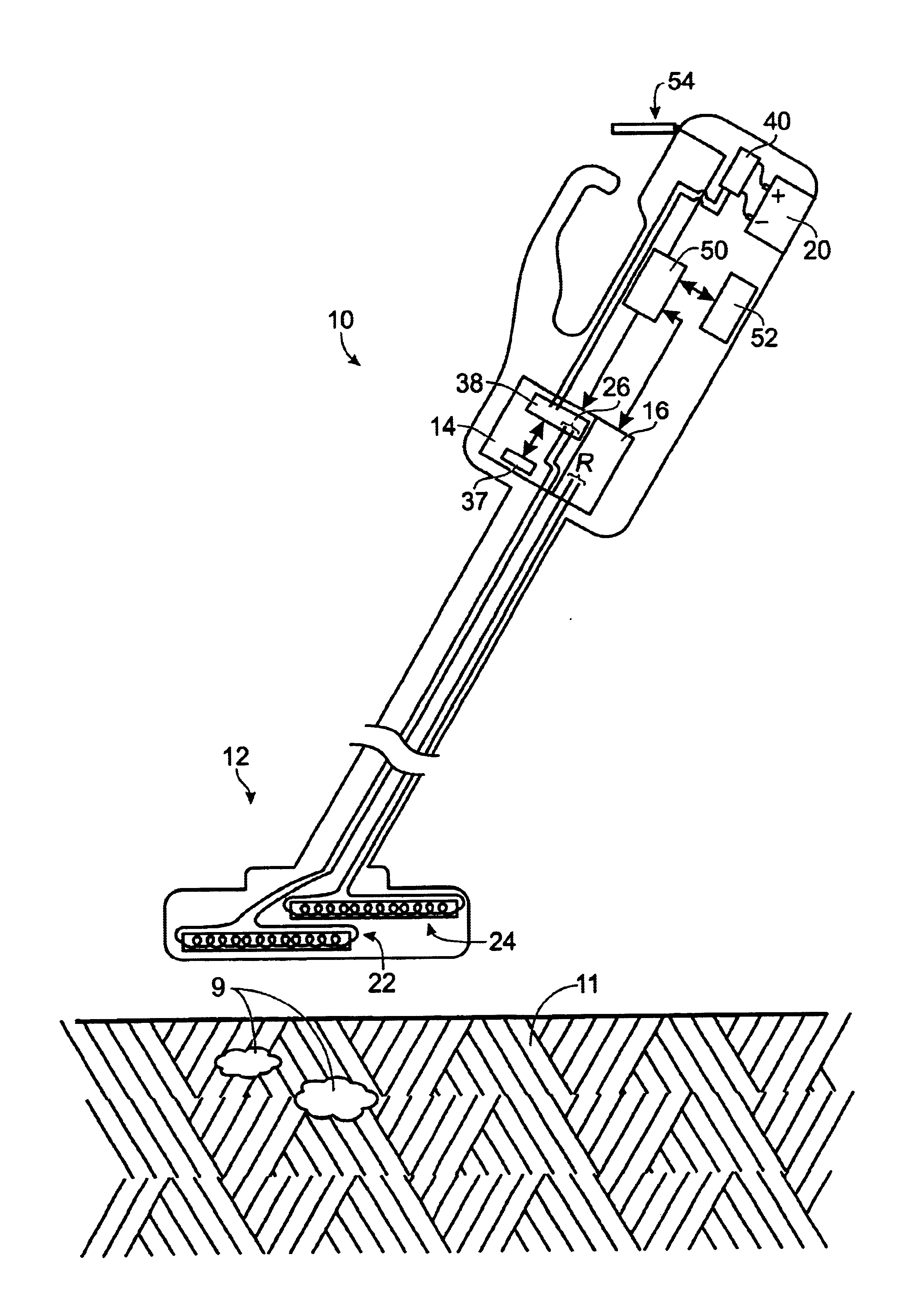

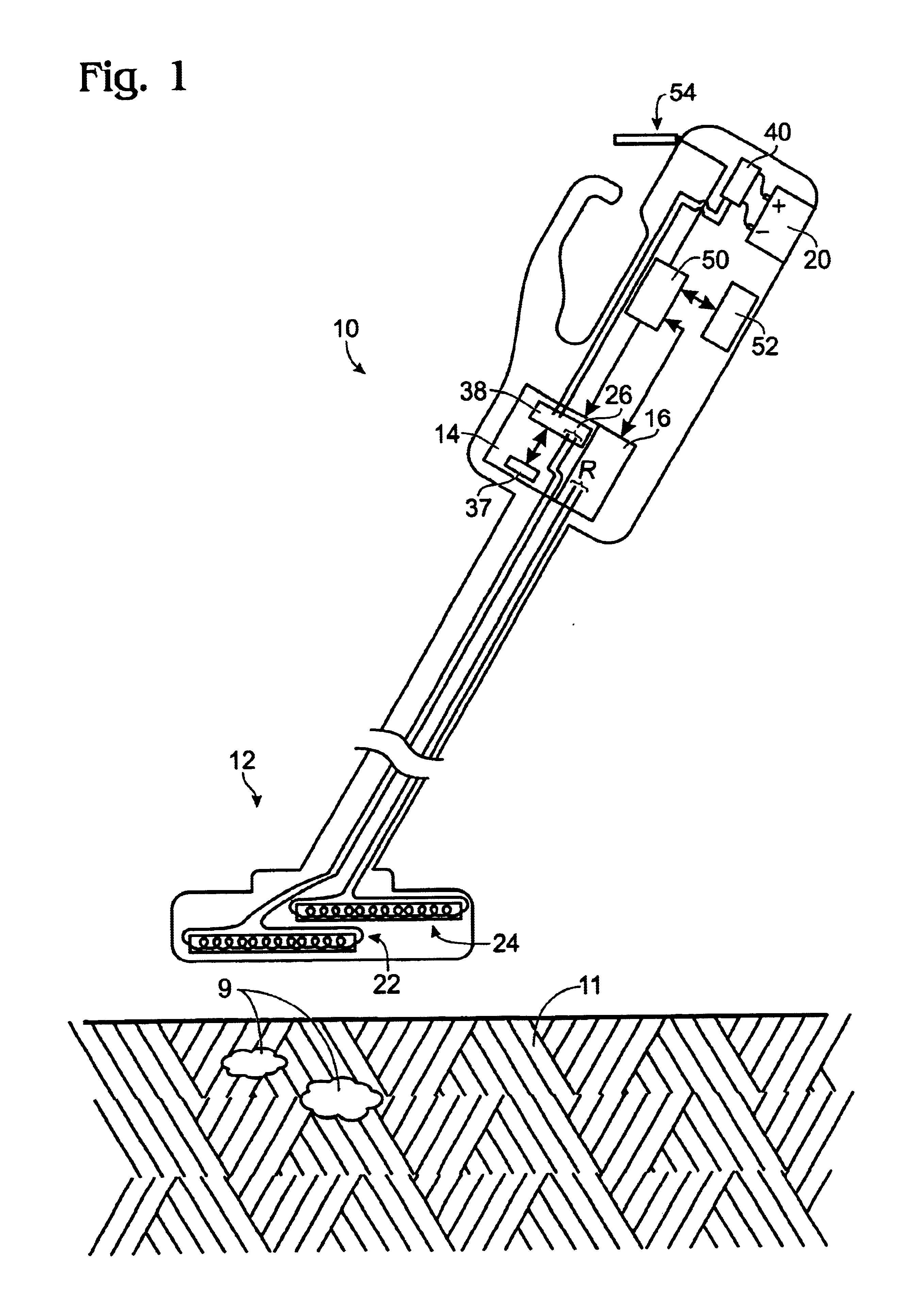

Metal object or feature detection apparatus and method

ActiveUS9664809B2Accurate displayElectric/magnetic detectionAcoustic wave reradiationDisplay deviceRelative motion

A metal detector system 30 for sensing target (e.g., metal) objects within soil or other strata includes a pickup head 36 carrying an excitation coil configured to generate an excitation signal to energize a target object 400 and uses a 2-D (e.g., planar, rectangular) array of pixel-receive coils configured within the pickup head to receive electro-magnetic energy from the energized target object. As the user moves the pickup head across the strata's surface, the pixel-receive coils sense relative motion between each pixel-receive coil and the energized target object, where motion is detectable as individually sensed changes in received signal levels among the pixel-receive coils. The metal detector system also includes a 2-D display 46 which depicts or visually represents the 2-D array of pixel-receive coils and generates a changing display of any sensed moving target object 60 in response to sensed changes in received signal levels among the pixel-receive coils.

Owner:FRY TERRY

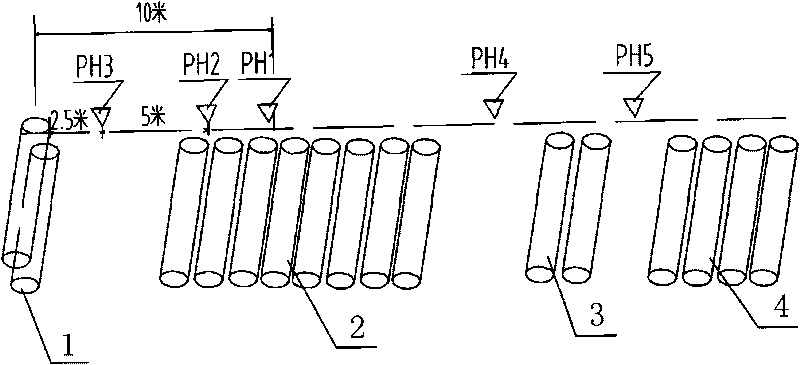

Continuous casting-direct rolling device for producing rod wire and section bar and method

ActiveCN104550237AReduce energy consumptionEmission reductionMetal rolling arrangementsProduction lineThermal energy

The invention relates to a continuous casting-direct rolling device for producing a rod wire and a section bar. The device comprises a continuous casting machine, a casting blank cutting device, a after-cutting roller way, a quick heat-insulating roller way and a steel rolling production line, wherein the continuous casting machine is arranged as a one-machine one-flow or multi-machine multi-flow continuous casting machine; the roller way width of the quick heat-insulating roller way is gradually reduced along the direction from the continuous casting machine to the steel rolling production line till a single casting blank can pass; a plurality of hot metal detectors, a pyrometer and a heat-insulating device are arranged on the quick heat-insulating roller way; the device further comprises a casting blank unloading device; the casting blank unloading device can be selectively arranged in front of the quick heat-insulating roller way or the steel rolling production line. The invention further provides a continuous casting-direct rolling method for producing the rod wire and the section bar. According to the invention, a traditional heating furnace is cancelled and the metallurgy thermal energy of a continuous casting blank is fully utilized, so that the energy consumption and the discharging in the production of the rod wire and the section bar are greatly reduced; the technological process is simplified, the equipment investment of a heating furnace area is reduced, and the cost is lowered; the oxidation burning loss of the billet is reduced and the yield is increased.

Owner:WISDRI ENG & RES INC LTD

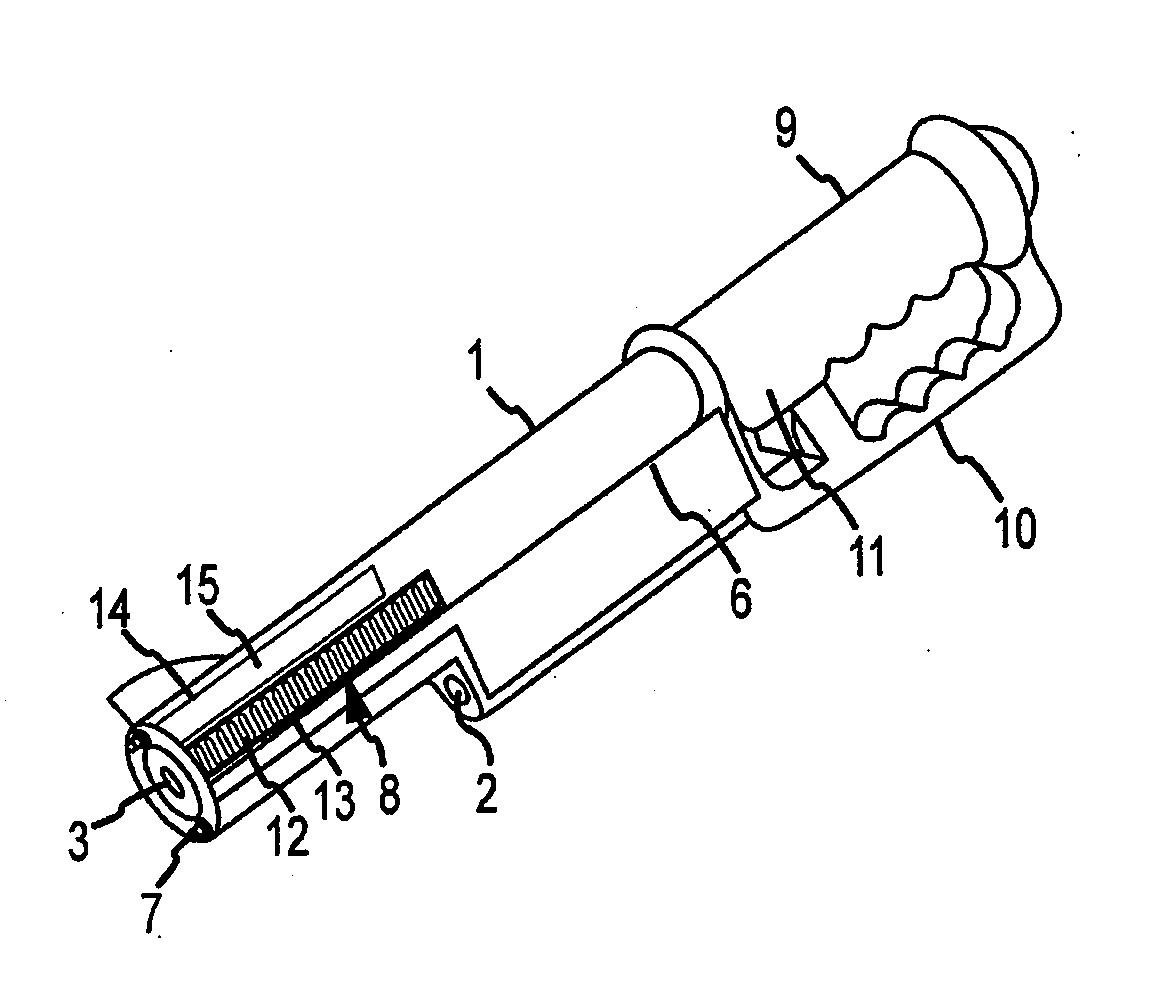

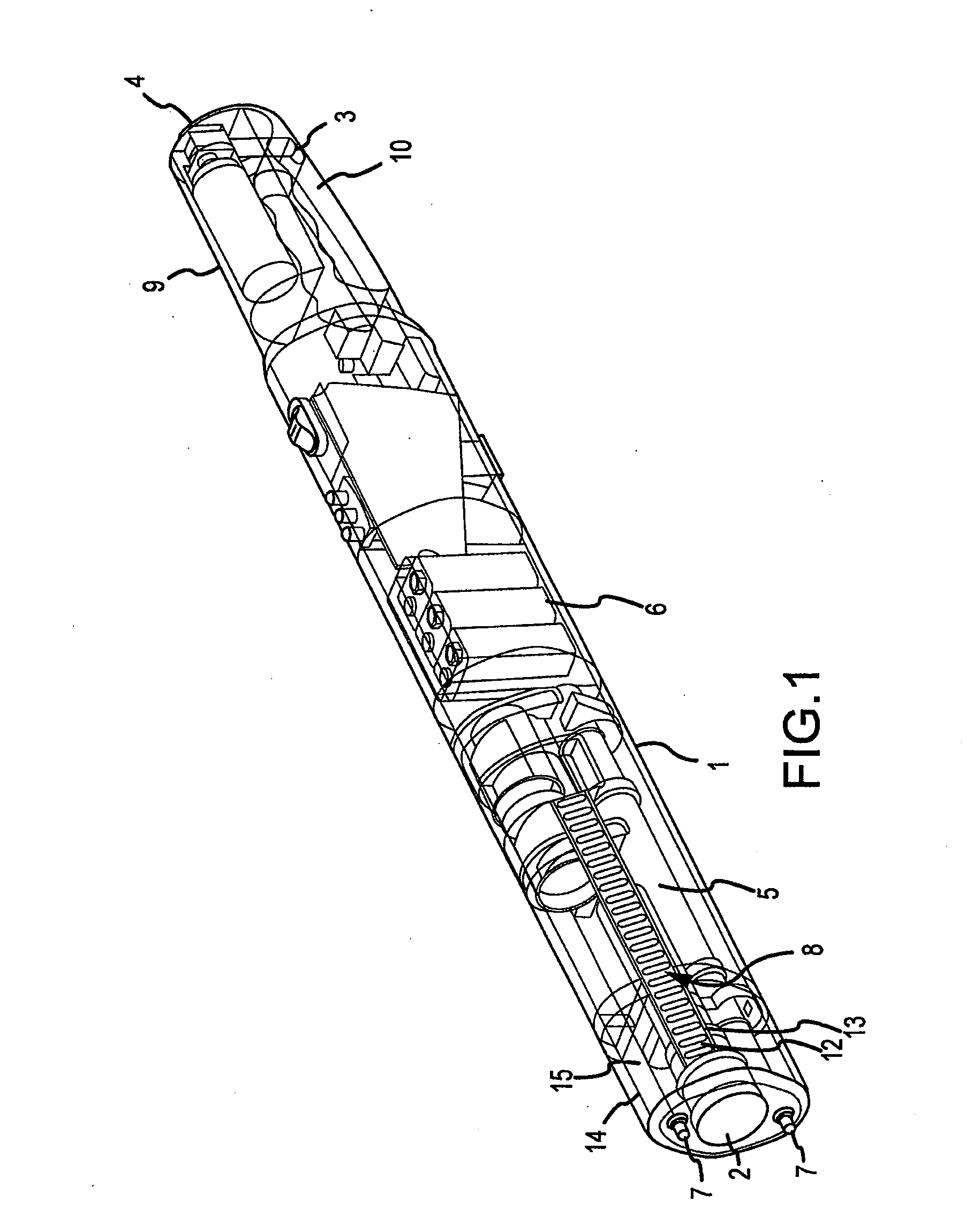

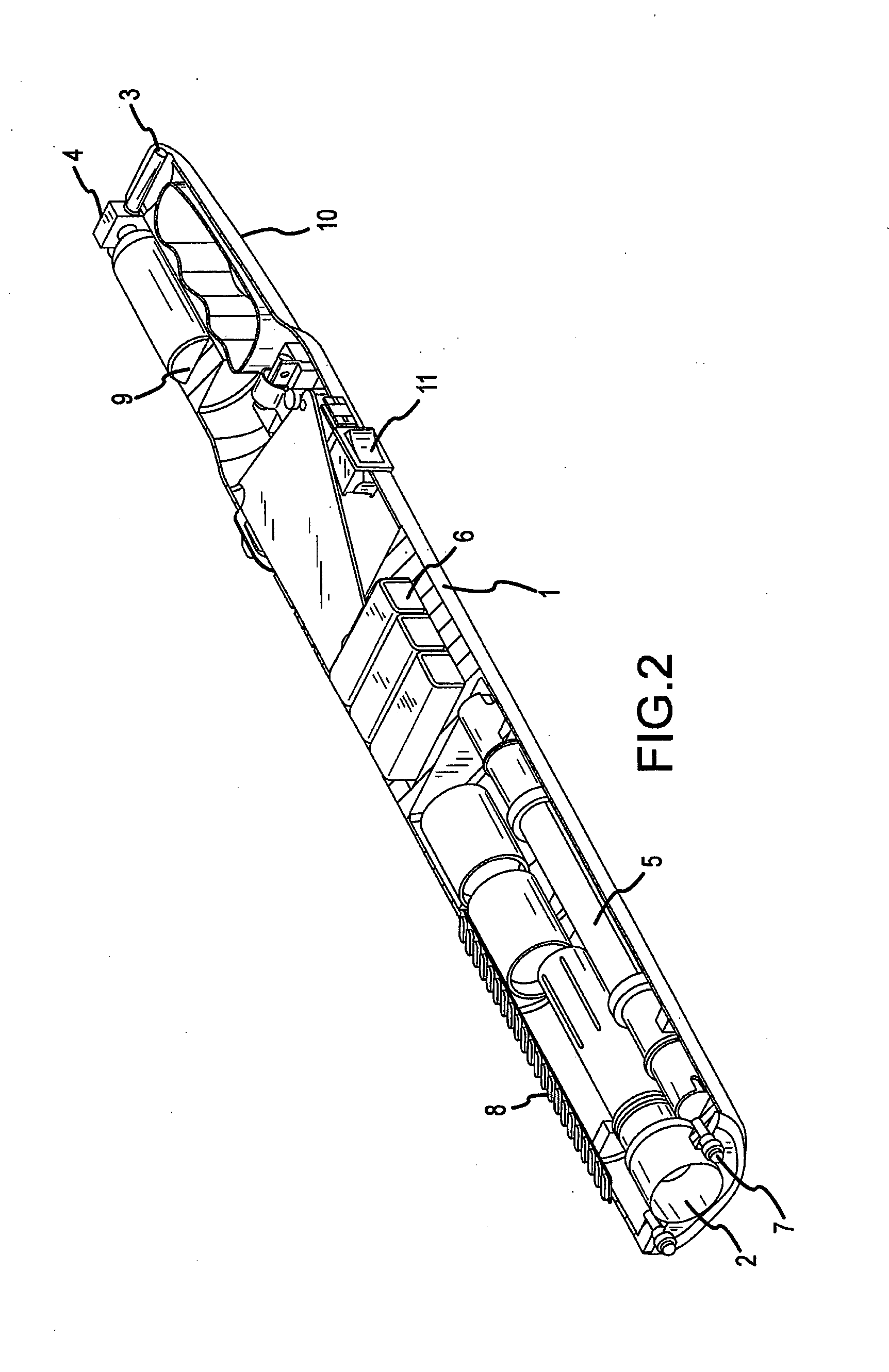

Multifunction security device

InactiveUS20100304874A1Reduce expensesLost agilityAmmunition projectilesWalking sticksBiomedical engineeringMetal detectors

The present invention is directed to an apparatus for providing law enforcement and private citizens with a single device that integrates law enforcement tools and mechanisms for the application of force. An exemplary device features a metal detector, a light emitting source optionally having a strobe feature, an electric stun system, and a debilitating spray dispensing system. Some embodiments of the present invention include an electric stun system comprising a plurality of probes mounted to the distal terminus of the shaft and configured to protrude from the shaft, a plurality of plates configured longitudinally along the outer surface of the shaft, and a stun system switch disposed on the shaft. Some embodiments of the present invention include the debilitating spray dispensing system comprising at least one nozzle and a dispensing switch disposed on the handle. Some embodiments of the present invention include a handle comprising an ergonomic grip and a guard.

Owner:ABATEMARCO MICHAEL R

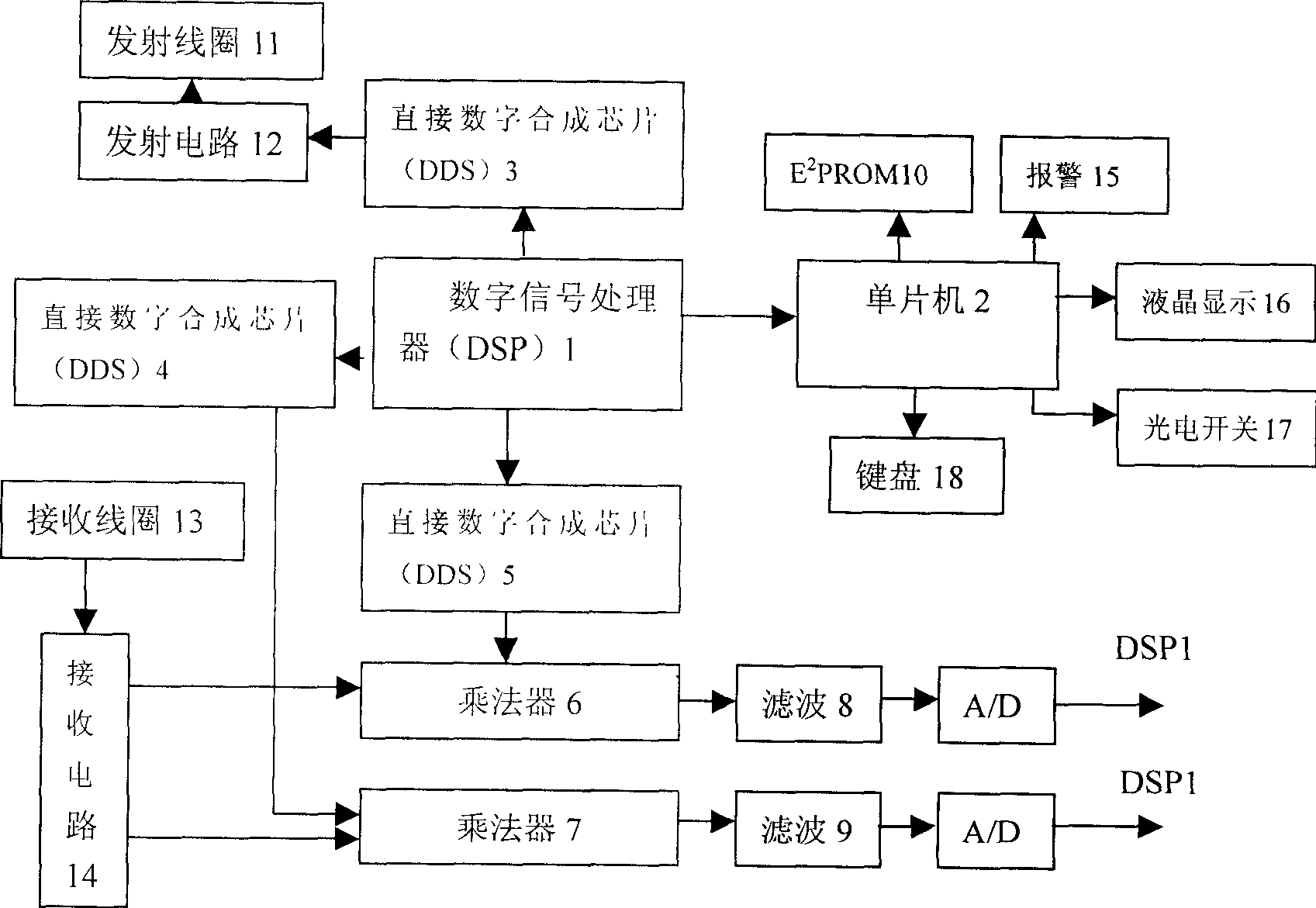

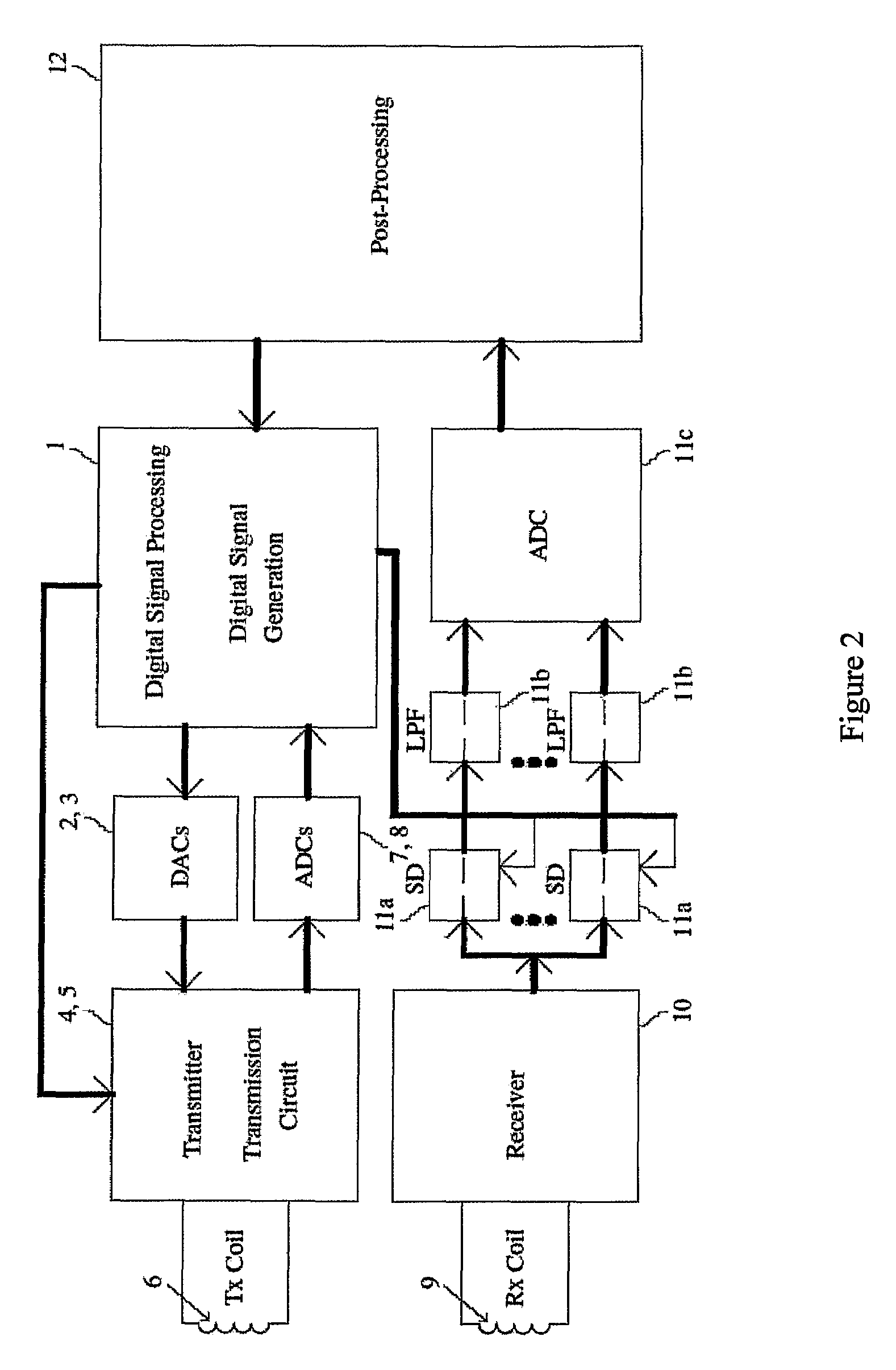

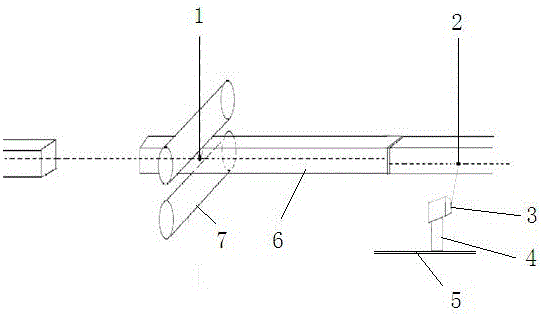

Intelligent metal detector

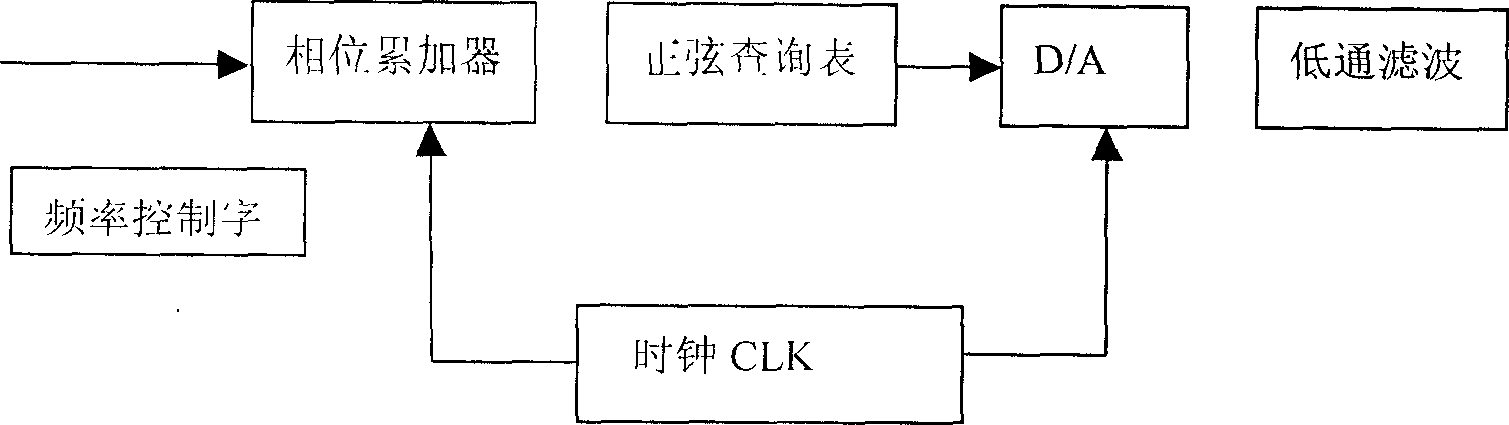

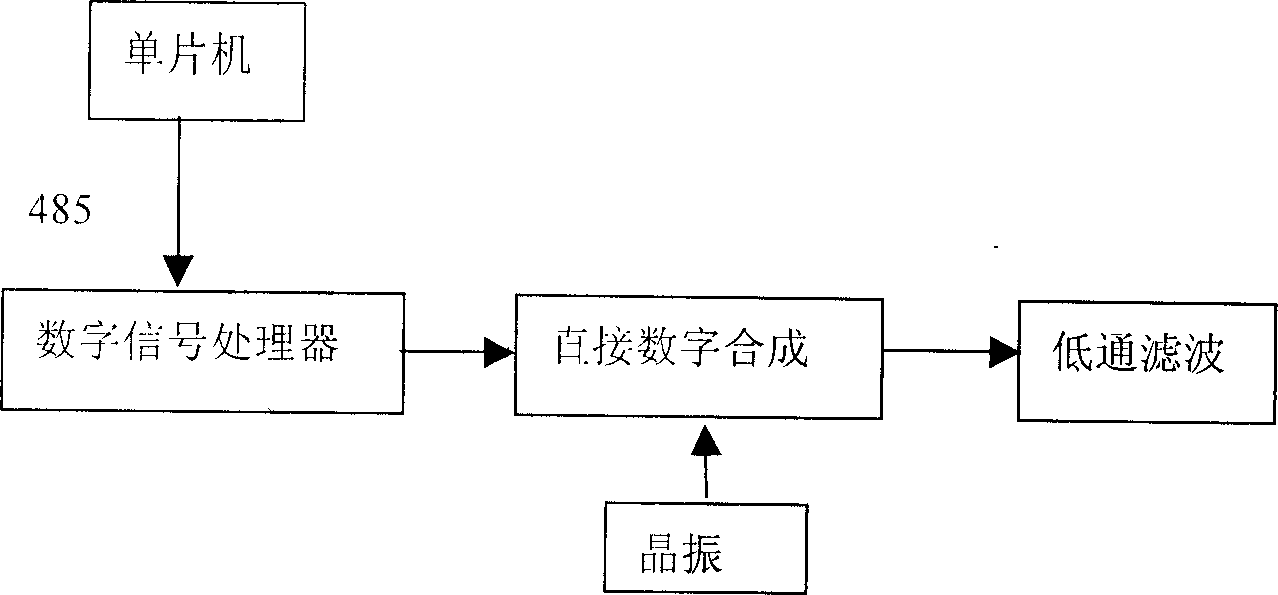

InactiveCN1603802AEasy to set upIntelligentMaterial analysis using microwave meansDigital signal processingMicrocontroller

It is a metal probe in lossless electromagnetism measurement technique field. The digital signal processor generates two paths of signals through two direct digital systemization chips into two multipliers that get two paths of separation signals through two low-pass filters. The data through the A / D conversion is sent to the digital signal processor for analysis and judgments. The human and machine dialogue system comprises single machines communicated with digital signal serial processors.

Owner:SHANGHAI JIAO TONG UNIV +1

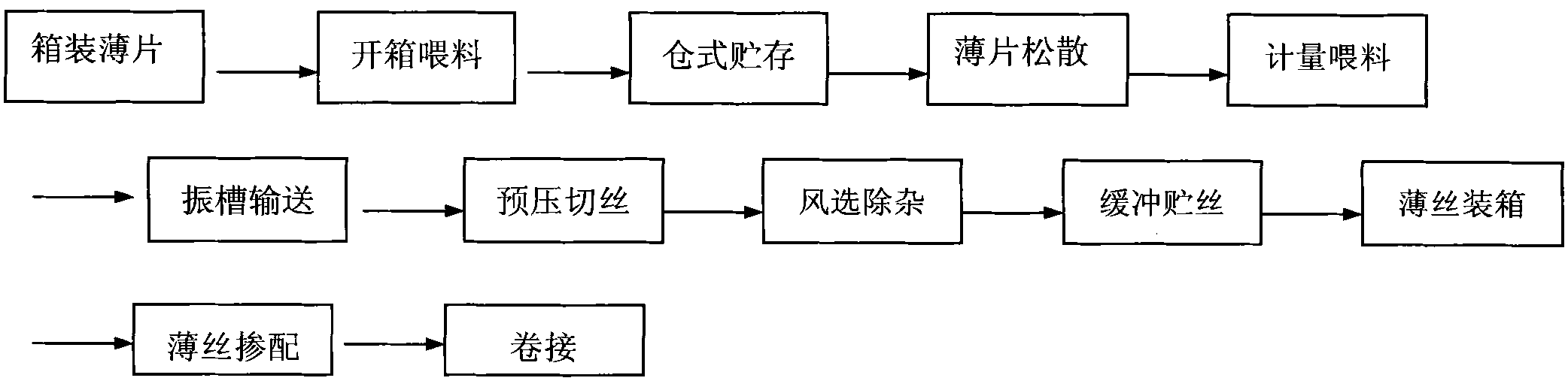

Method and equipment for manufacturing cigarettes by filamentization of tobaccos reconstituted by papermaking process

ActiveCN102008122AIncrease forming timeHigh densityTobacco preparationMechanical crushingPapermaking

The invention relates to the manufacturing field of cigarettes, in particular to a method for manufacturing cigarettes by the filamentization of tobaccos reconstituted by a papermaking process. The method comprises the following steps of: (1) scattering boxed finished reconstituted tobaccos, and storing the scattered reconstituted tobaccos in a bin cabinet; (2) lifting the reconstituted tobaccos in the bin cabinet, and controlling the flow of the reconstituted tobaccos by using an electronic belt scale; (3) conveying the reconstituted tobaccos to a reversible belt by a high-position vibrationgroove with a metal detector; (4) after the reconstituted tobaccos on the reversible belt falls off the conveying vibration groove, prepressing the reconstituted tobaccos by a prepressing device, andallowing the reconstituted tobaccos to enter a tobacco filament cutter; (5) winnowing the reconstituted tobaccos to remove dust, allowing the reconstituted tobaccos to enter a buffering cabinet, and metering and boxing for blending; and (6) mixing the boxed reconstituted tobaccos and cut tobaccos directly by a blending filament mixing system, perfuming, storing and rolling to form the cigarettes of finished products. The reconstituted tobaccos are blended directly without undergoing a high-strength processing process, so resource waste caused by mechanical crushing in the process of blending the reconstituted tobaccos is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

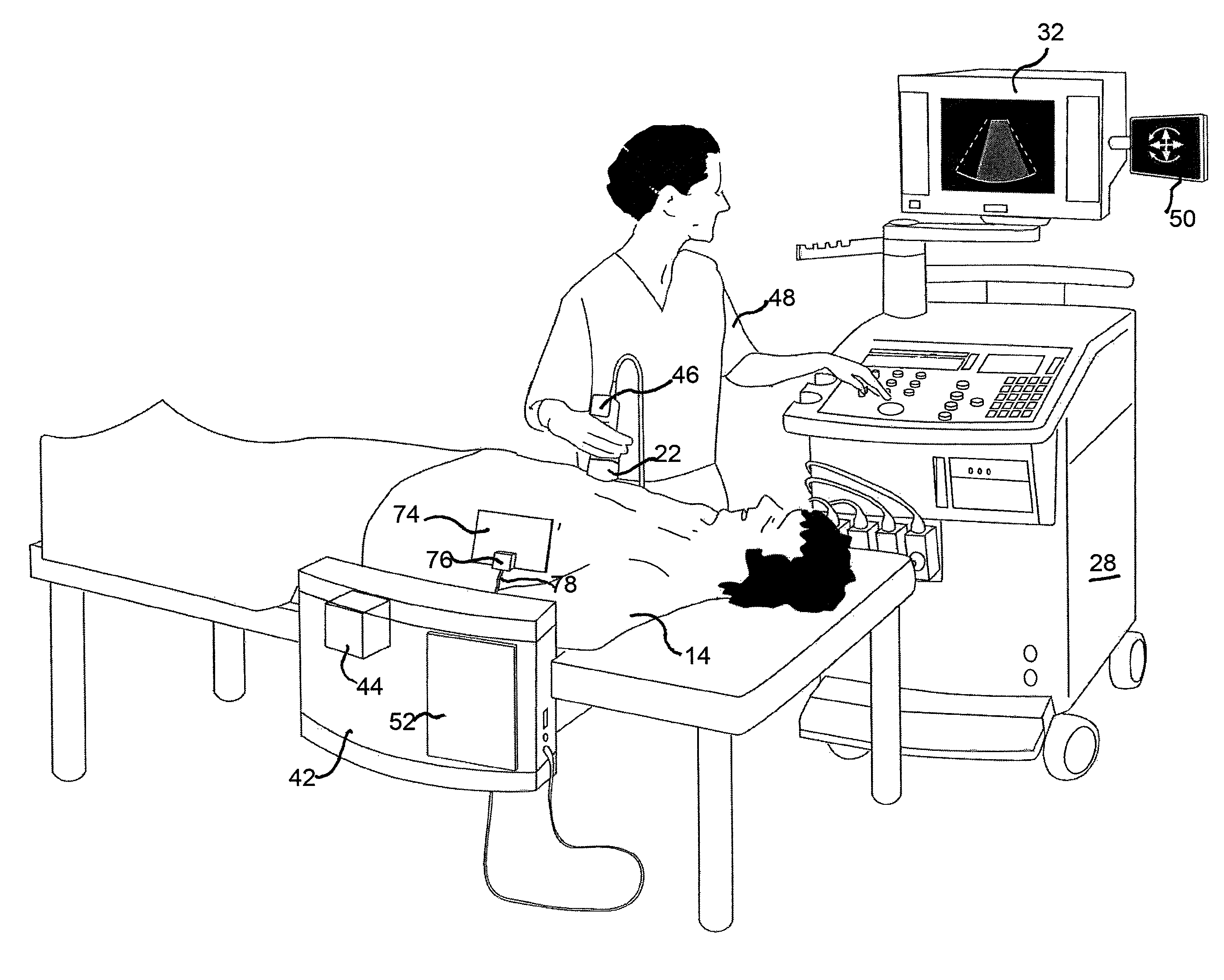

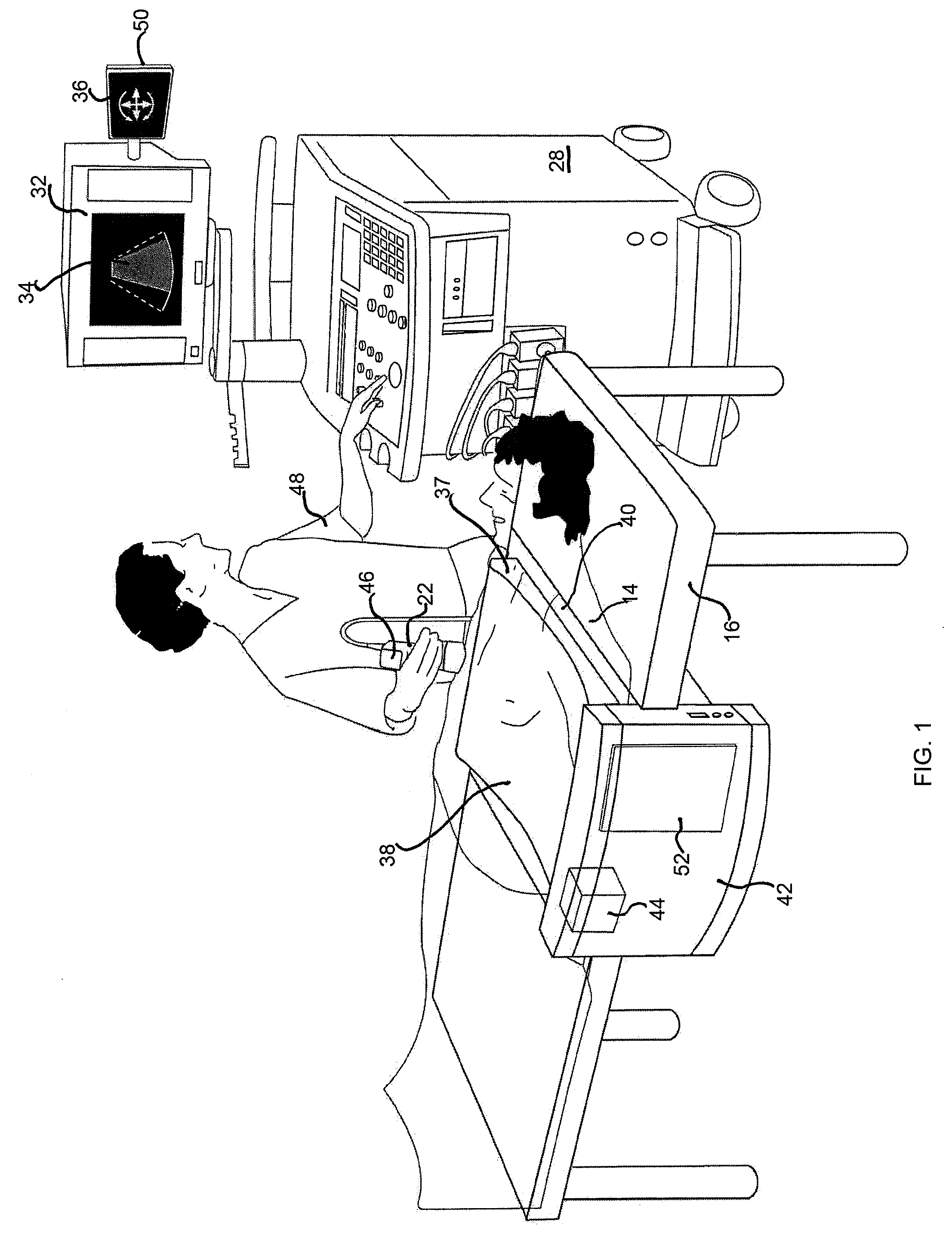

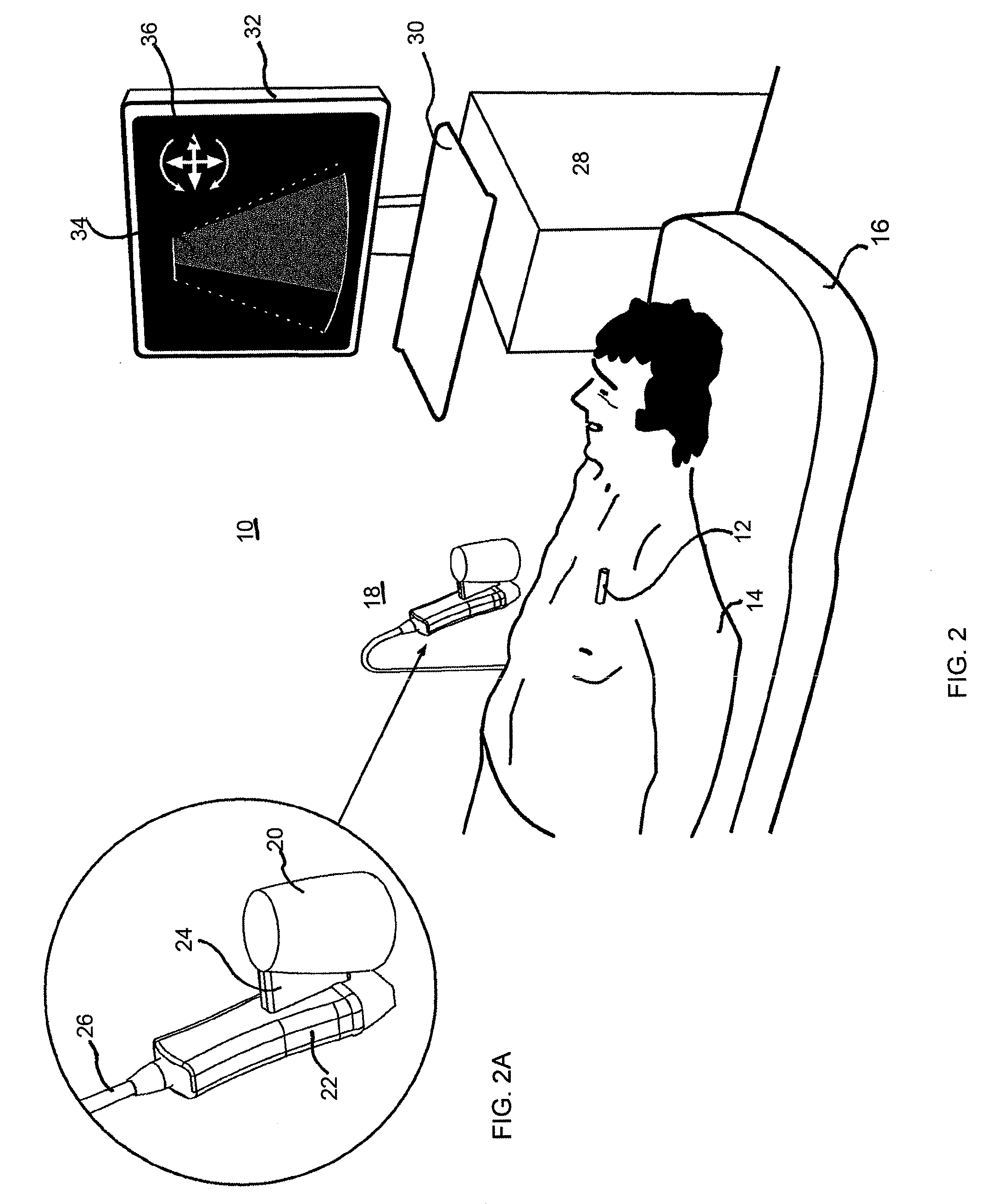

Location tracking of a metallic object in a living body using a radar detector and guiding an ultrasound probe to direct ultrasound waves at the location

ActiveUS8352015B2Facilitates direct vascular flow measurementPrecise determinationDiagnostic probe attachmentBlood flow measurement devicesDiagnostic Radiology ModalityEcg gating

A method and apparatus are provided for determining and tracking location of a metallic object in a living body, and then directing a second modality such as ultrasound waves to the determined location. The metal detector may be a radar detector adapted to operate on a living body. The adaption may include disposing a transfer material having electromagnetic properties similar to the body between the radar detector and the living body, ECG gating the radar detector, and / or employing an optimal estimator with a model of expected stent movement in a living body. Applications include determination of extent of in-stent restenosis, performing therapeutic thrombolysis, or determining operational features of a metallic implant.

Owner:ZOLL MEDICAL ISRAEL LTD

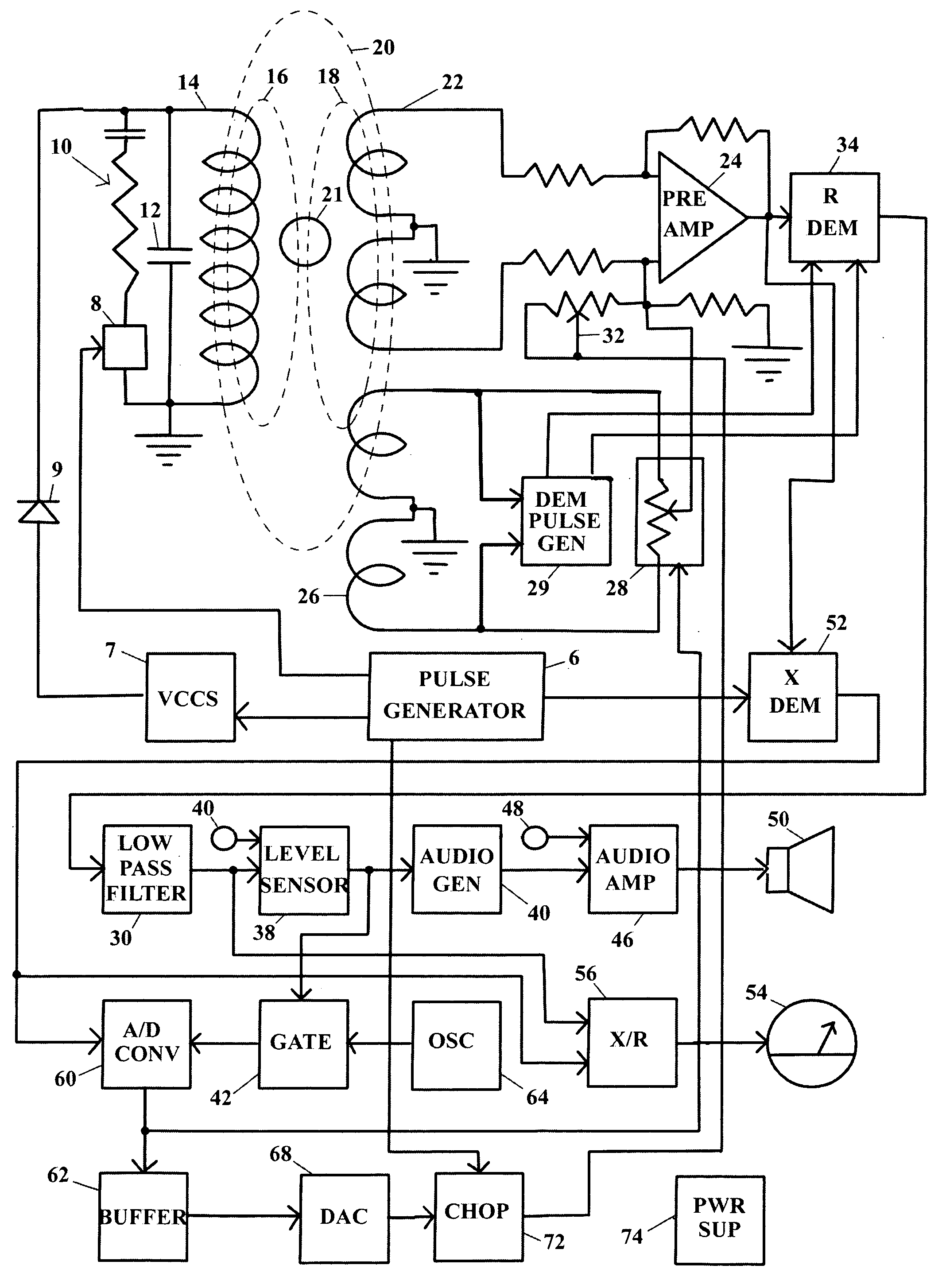

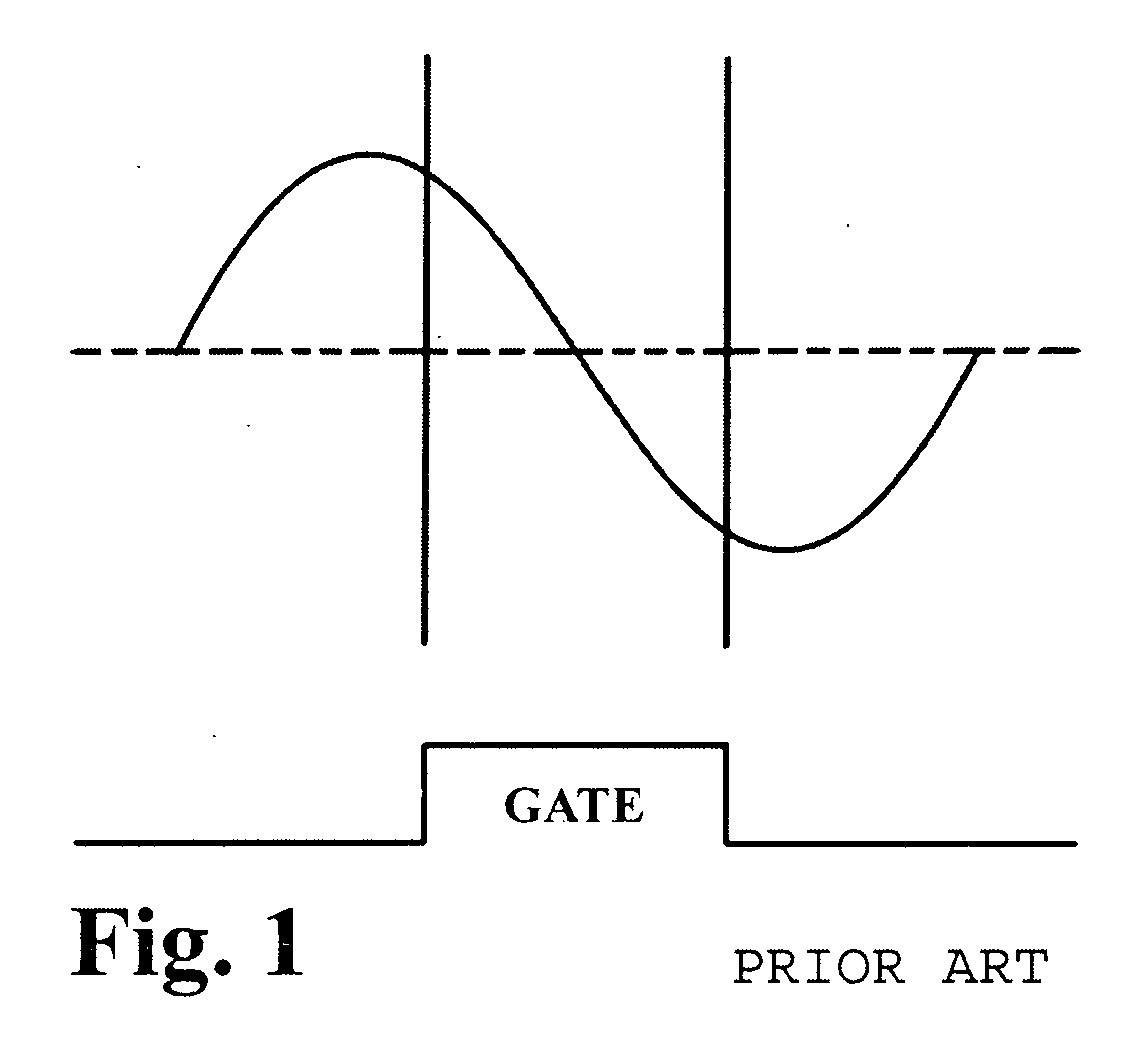

Method and apparatus for metal detection employing digital signal processing

ActiveUS7432715B2Improve practicalityMagnetic property measurementsElectric/magnetic detection for transportDigital signal processingResonance

A metal detector employing digital means for the generation of highly quality reference signals used for transmission and demodulation and capable of continuously monitoring the parameters of the transmitting and receiving coils. Using the monitored signals and calibration of the measurements paths in both amplitude-frequency and phase-frequency, the effects of the targets and magnetic and / or conductive grounds on the transmitting and receiving coils are greatly reduced, leaving the received signals substantially free of instrumental effects. Methods of ground tracking and filtering are described to separate target information from the ground plus-target receive signals. Single-and multi-frequency operation, with or without modulation for both sinusoidal and square wave transmission, is described, as are means to detect abnormal situations and to find and operate at resonance.

Owner:MINELAB ELECTRONICS

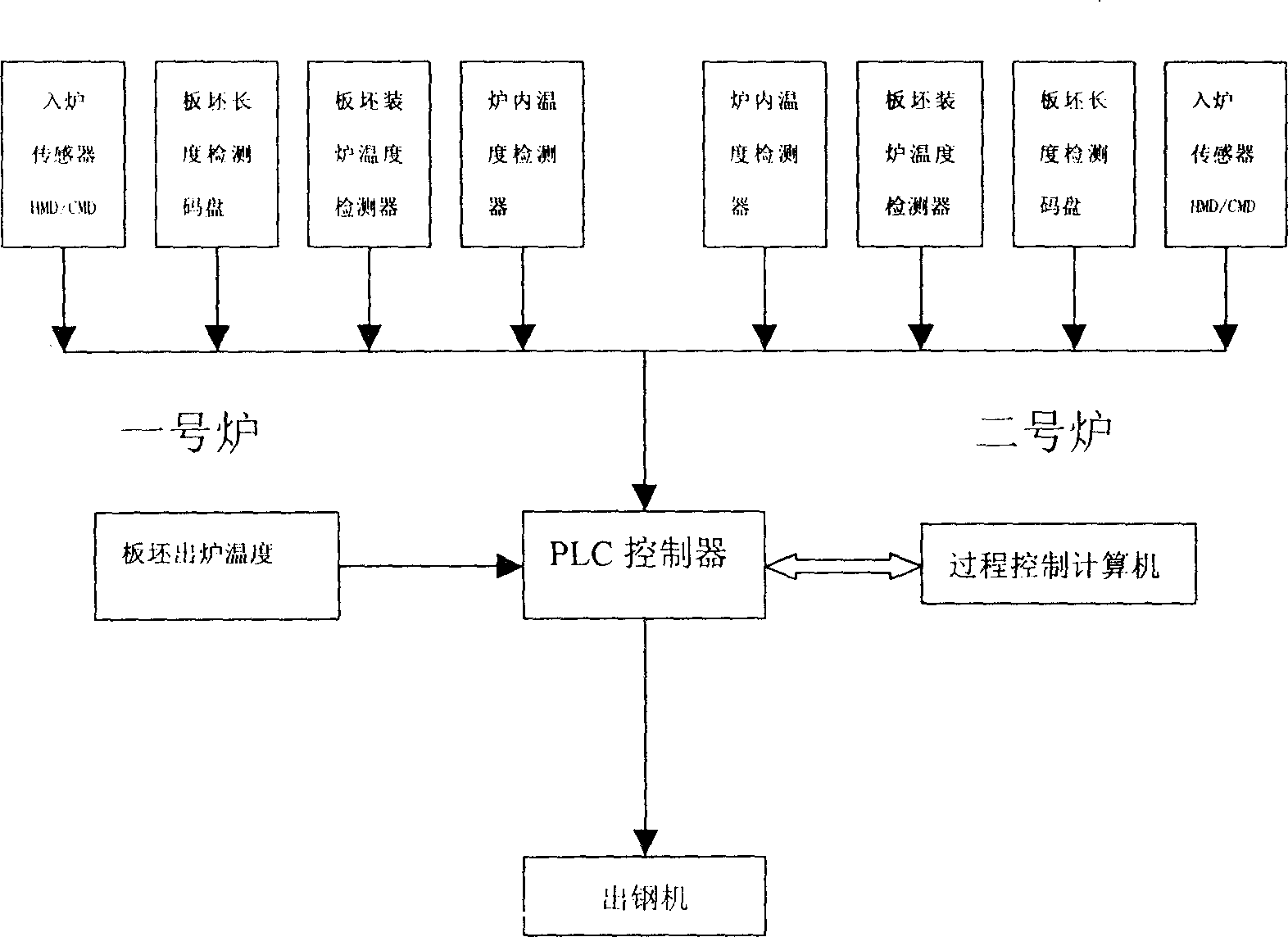

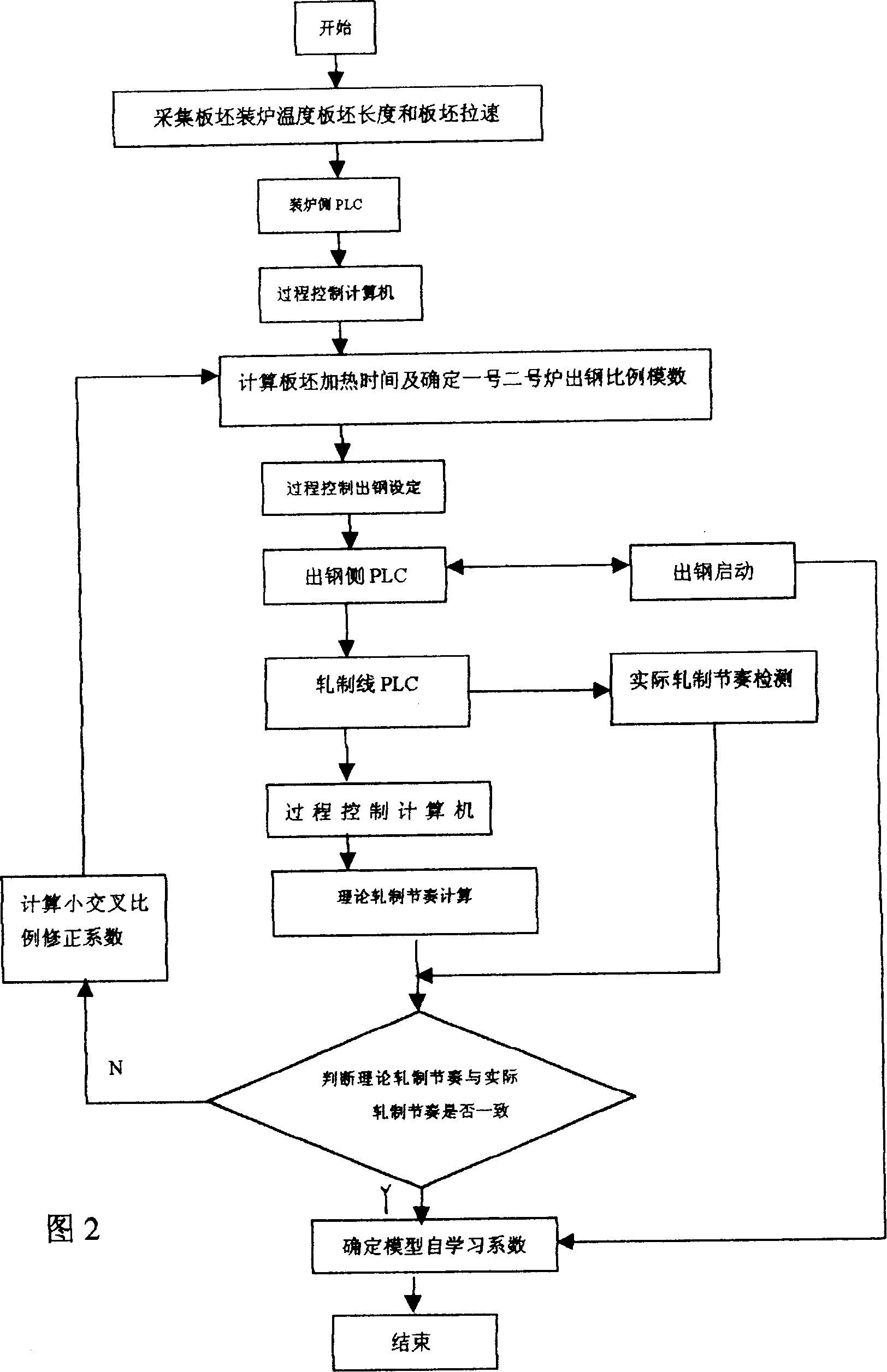

Small cross steel tapping control method for continous steel billet neating furnace

InactiveCN1483985AThe calculated value is accurateHigh thickness accuracyCrucible furnacesSlab pullEngineering

The present invention discloses a small-cross tapping control method of continuous cast billet heating furnace, and is characterized by that at charging side of two heating furnaces a furnace-charging sensor, slab length detection disk and slab furnace-charging temp. detector are mounted, in the interior of the furnace a detector is mounted and at tapping hole a heat metal detector is mounted. The slab length signal, billet furnace-charging temp. signal and slab pulling speed signal are transferred into PLC and process control computer, and the computer can be used for making operation and comparison so as to obtain the optimized tapping modulus of two furnaces and can implement slab small-cross tapping control of two heating furnaces.

Owner:ANGANG STEEL CO LTD

Integrated portable checkpoint system

InactiveUS20120148020A1Electric/magnetic detectionMaterial analysis by transmitting radiationComputer hardwareSecurity check

The present specification discloses a portable system for inspecting objects. The system includes a housing adapted to be carried by a vehicle, which houses a metal detector and an X-ray scanner and further includes a deployable boom positioned on a top surface of the housing. Operationally, the system is transported to a location, persons or objects are inspected by the metal detector or X-ray scanner and the boom is deployed to inspect external cargo. The integrated portable checkpoint system provides security screening and inspection equipment with increased operational capabilities in one fully integrated package.

Owner:RAPISCAN SYST INC (US)

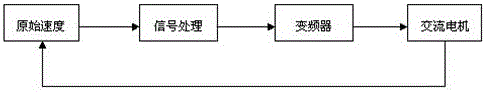

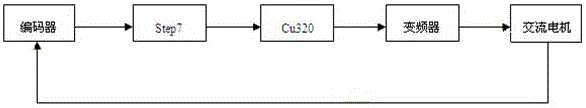

Device and method for shortening continuous tapping time interval of rolled steel production line

ActiveCN106670241ANo false signalAvoid sensor placement challengesRoll mill control devicesMetal rolling arrangementsProduction lineLow speed

The invention discloses a device and a method for shortening a continuous tapping time interval of a rolled steel production line, belongs to the technical field of rolled steel production line equipment and processes, and is used for shortening the continuous tapping time interval of the rolled steel production line. A heat metal detector is placed in front of a first rolling mill from the center line of a roller of the first rolling mill by a length of a whole section of steel blank; and steel tail signals monitored by the heat metal detector are used for replacing steel containing signals when engaging in the rolling mill. When the head part of the latter steel blank is rightly engaged in the first rolling mill, an alternating-current main motor of the first rolling mill starts to decelerate. The reasonable steel separation distance is guaranteed by dint of the continuously quickened rolling speed of a downstream frame, the low-speed continuous time and the low-speed rate setting. The safe steel separation is realized by using the first rolling mill as a steel separation point, so that the normal operation of subsequent key equipment is guaranteed, and the effects of shortening the steel blank rolling interval time, improving the production efficiency and largely reducing the energy consumption are achieved under the precondition of not influencing the production process.

Owner:张家口宣钢机电工程有限公司

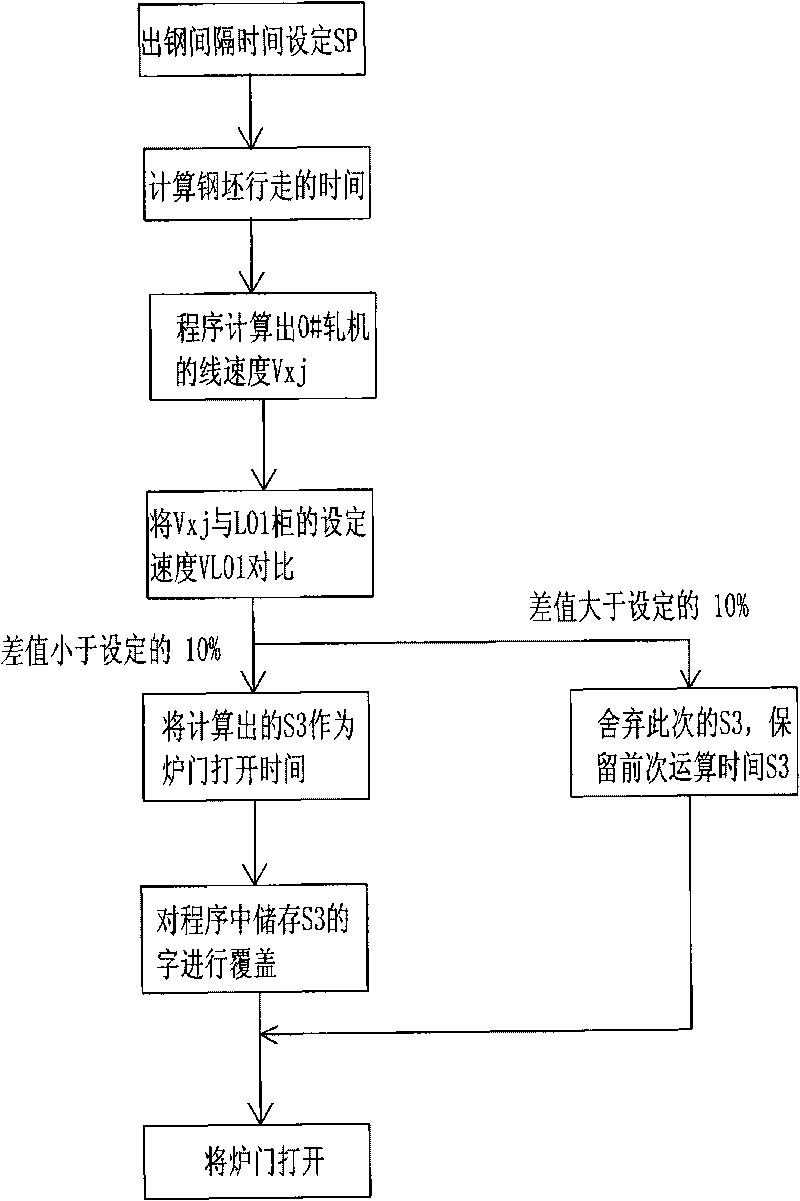

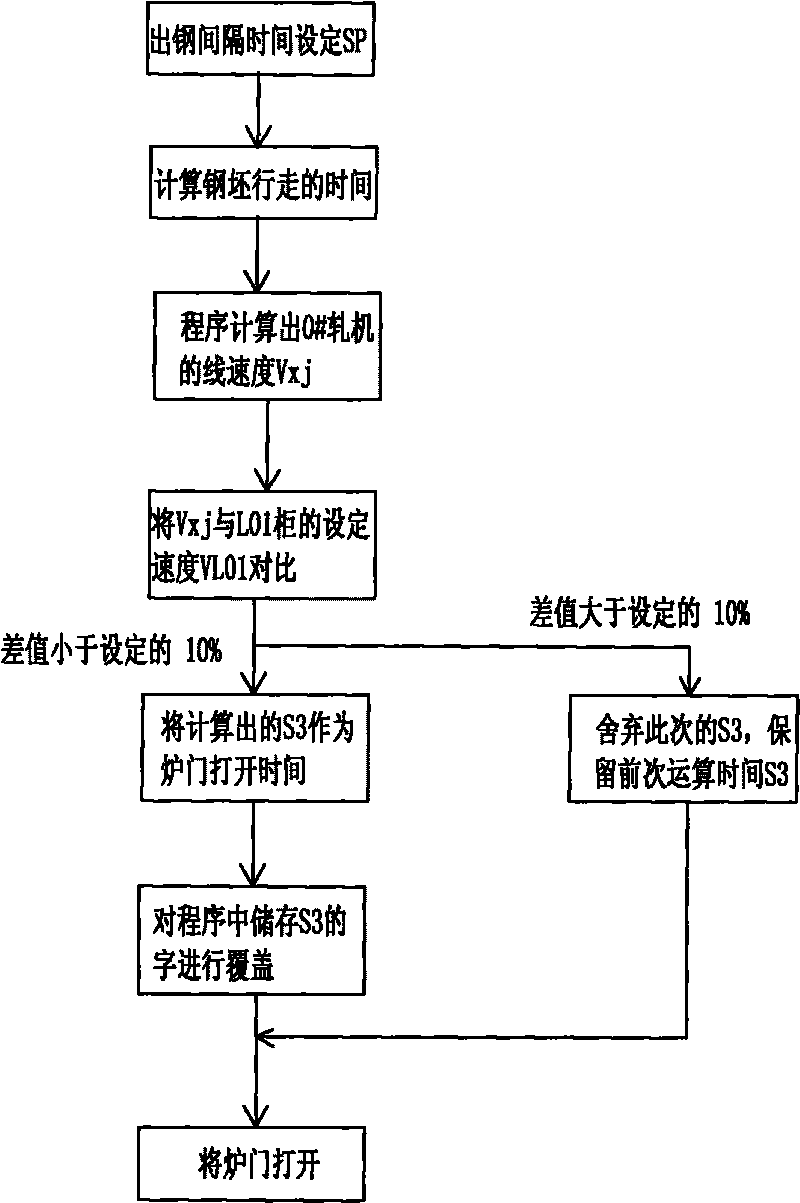

Method for controlling automatic equidistant steel tapping of heating furnace

InactiveCN101701287AEasy to controlReduce pile of steelHeat treatment process controlStrip millHeating furnace

The invention relates to a method for controlling automatic equidistant steel tapping of a heating furnace, comprising the following steps of: setting steel tapping intervals; obtaining the time that billet is conveyed to the outlet of a heat insulating roller bed according to the distance from the head of the billet in the heating furnace to a hot metal detector at the outlet of the heat insulating roller bed and the speed of the roller bed; calculating the line speed of the billet in a 0# rolling mill; calculating the time that the tail of the billet is separated from the hot metal detector at the outlet of the heat insulating roller bed and enters the 0# rolling mill; calculating the time S3 when the furnace door of the heating furnace is opened; comparing the speed of the billet in the rolling in actual production with the linear speed of the billet in the 0# rolling mill, wherein if the difference is smaller than or equal to 10% of the linear speed of the billet in the 0# rolling mill, S3 is used as the time that the furnace door is opened, and if the difference is greater than 10% of the linear speed of the billet in the 0# rolling mill, the time S3of opening the furnace door calculated previously is retained. The invention can avoid repeat steel heaping and reduce delay of machine halt, thereby the dimensional accuracy of the product is improved, and the hour yield of roll line production is improved greatly.

Owner:NANJING IRON & STEEL CO LTD

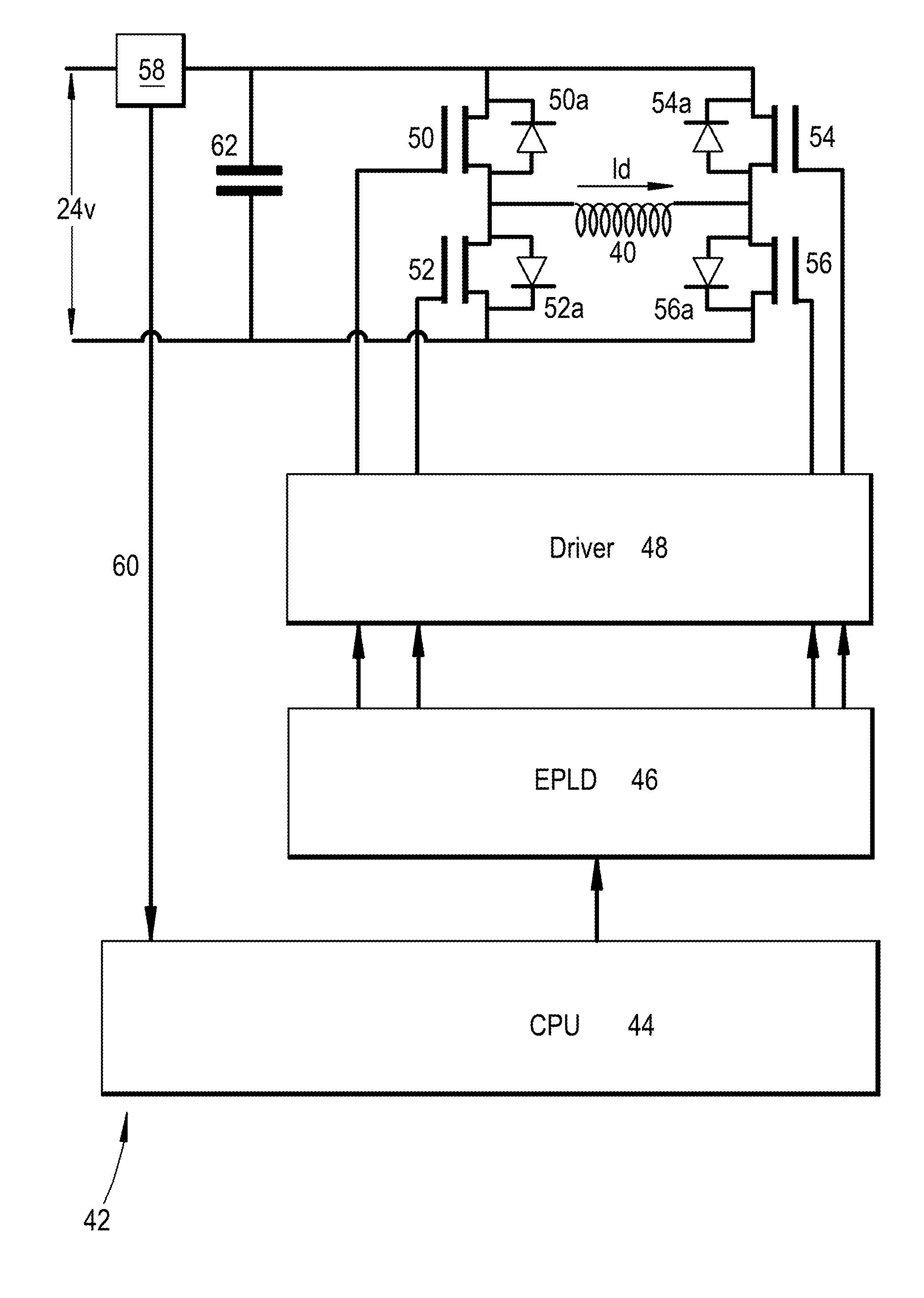

Metal detector

ActiveUS20150234075A1Reduce complicationsGreat range of operational frequencyMagnetic measurementsTesting foodDriver circuitEngineering

A method of operation of a metal detector having a driver circuit for establishing an alternating magnetic field in a coil system so as to generate an output signal at a given frequency, the method comprising the steps ofa. generating an adjustable balance signal;b. combining the adjustable balance signal with the output signal of the detector.c. varying the adjustable balance signal so as to provide a compensated signal.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com