Method for controlling automatic equidistant steel tapping of heating furnace

A heating furnace and equidistant technology, applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of low machine-time output, high labor intensity, and delayed production, so as to improve product dimensional accuracy and avoid repeated stacking of steel. , the effect of reducing downtime delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

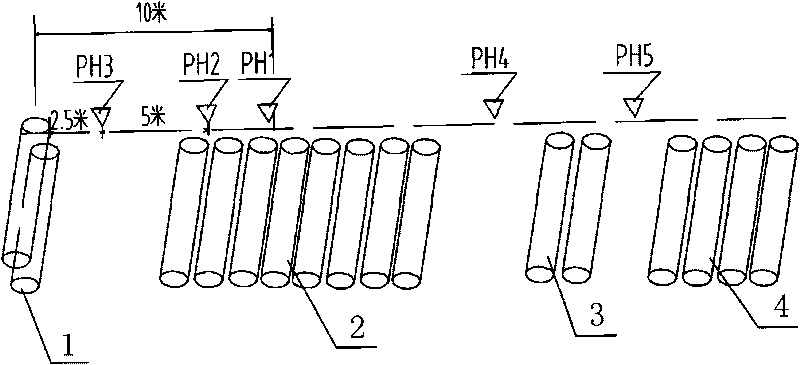

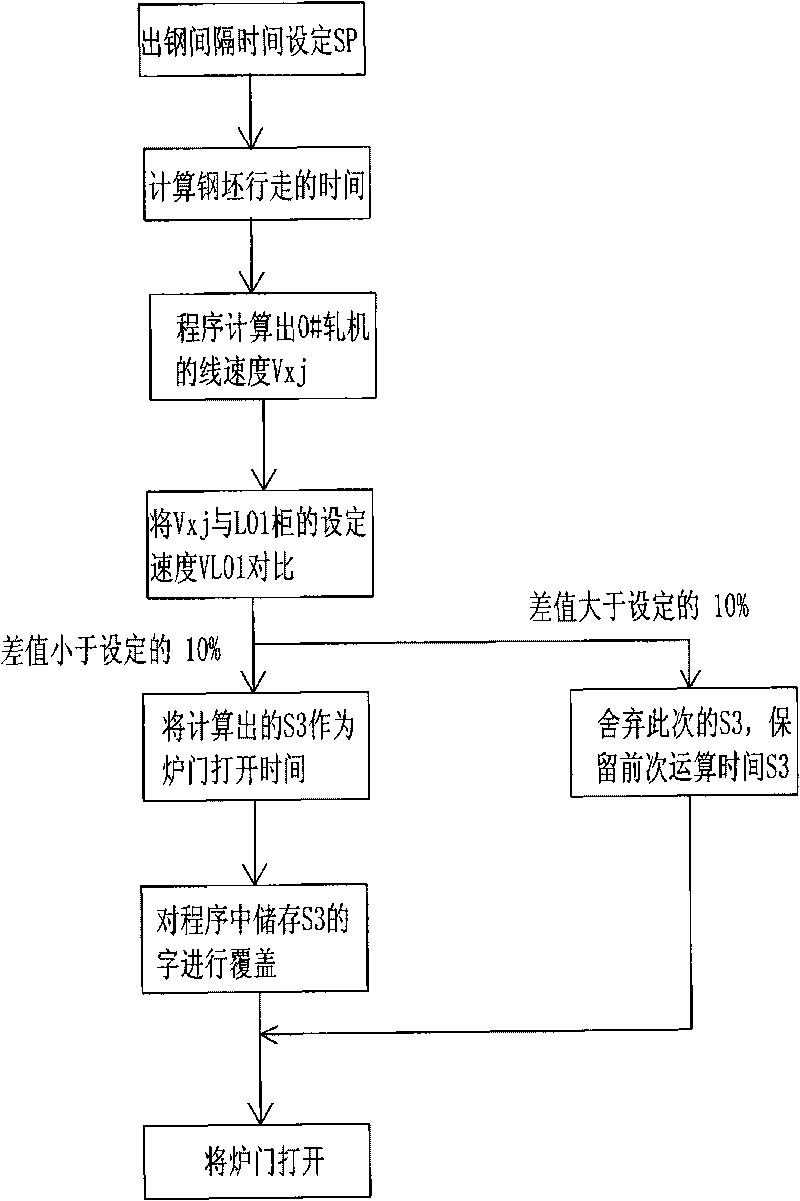

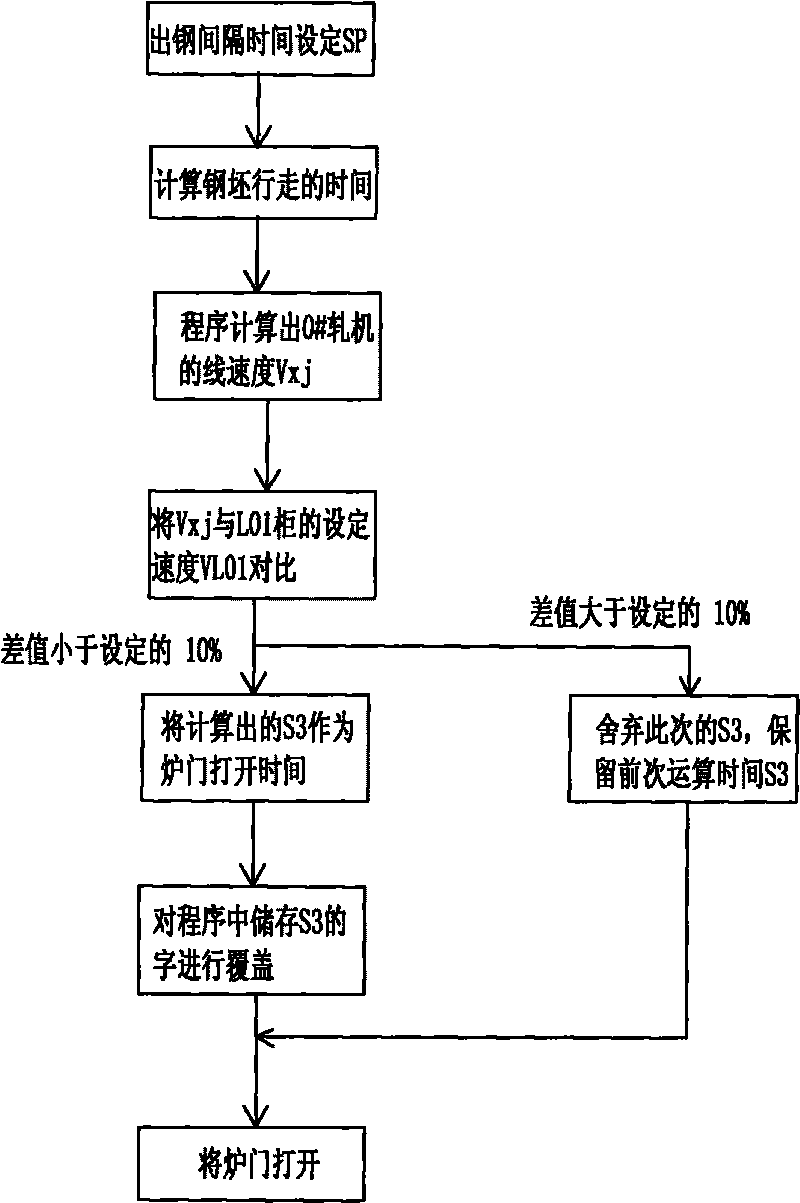

[0018] The invention relates to a method for controlling automatic equidistant steel tapping of a heating furnace, which includes transmission equipment and electrical signal detection equipment. Composed of 0# rolling mill 1, the electrical signal detection equipment consists of a hot metal detector at the outlet of the heating furnace, a pyrometer at the entrance of the heat preservation roller table, a hot metal detector PH2 at the exit of the heat preservation roller table (7.5 meters away from the 0# rolling mill), and a 0# rolling mill entrance The hot metal detector PH3 (2.5 meters away from the 0# rolling mill), the hot metal detector PH1 (10 meters away from the 0# rolling mill) and the billet speed control cabinet at the 0# rolling mill are composed of the following steps:

[0019] (1) Set the tapping interval SP according to the steel rolling process, which is set to 3 seconds;

[0020] (2) The distance L1 between the head of the billet in the heating furnace and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com