Patents

Literature

6257results about "Heat treatment process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

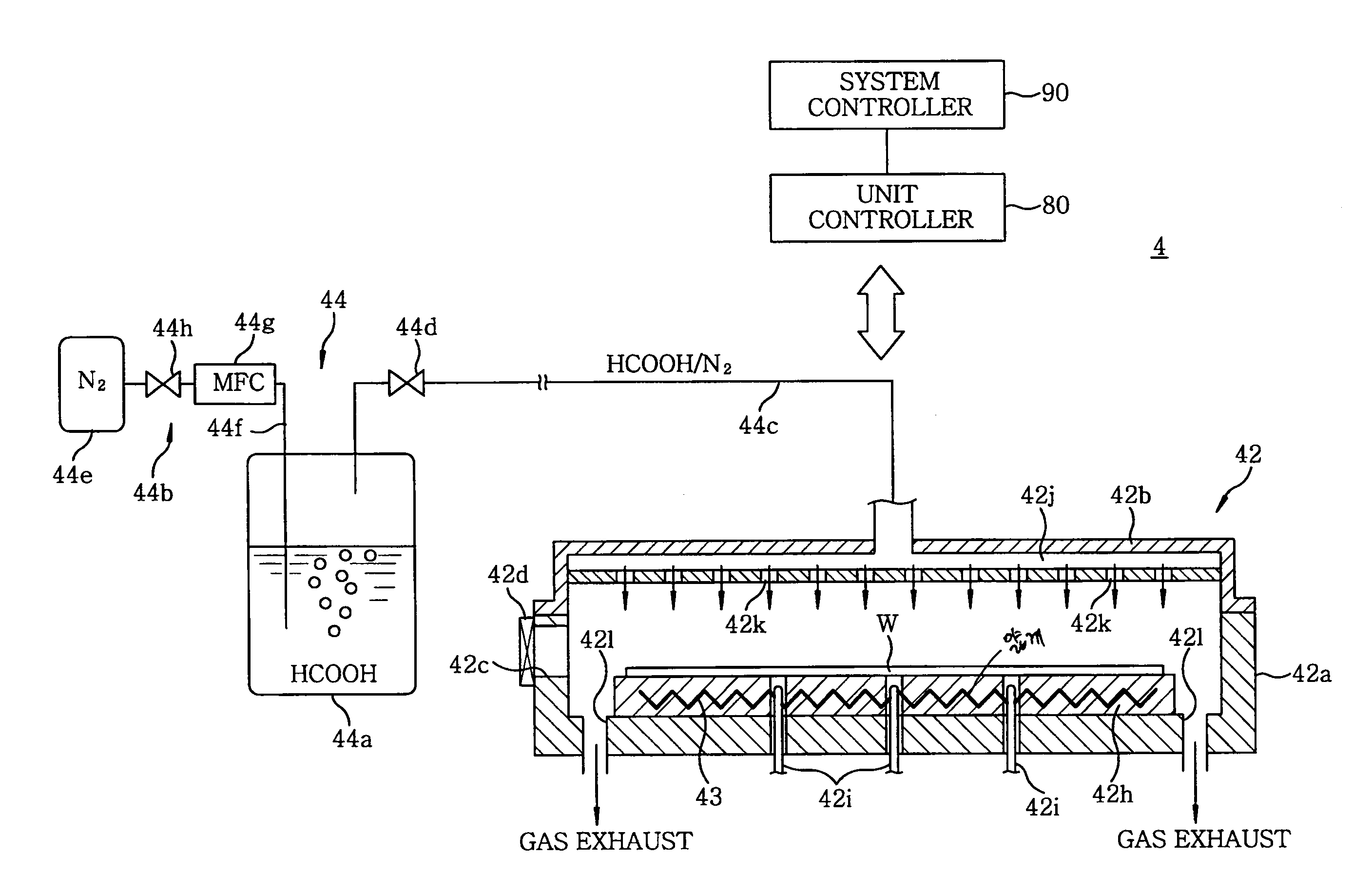

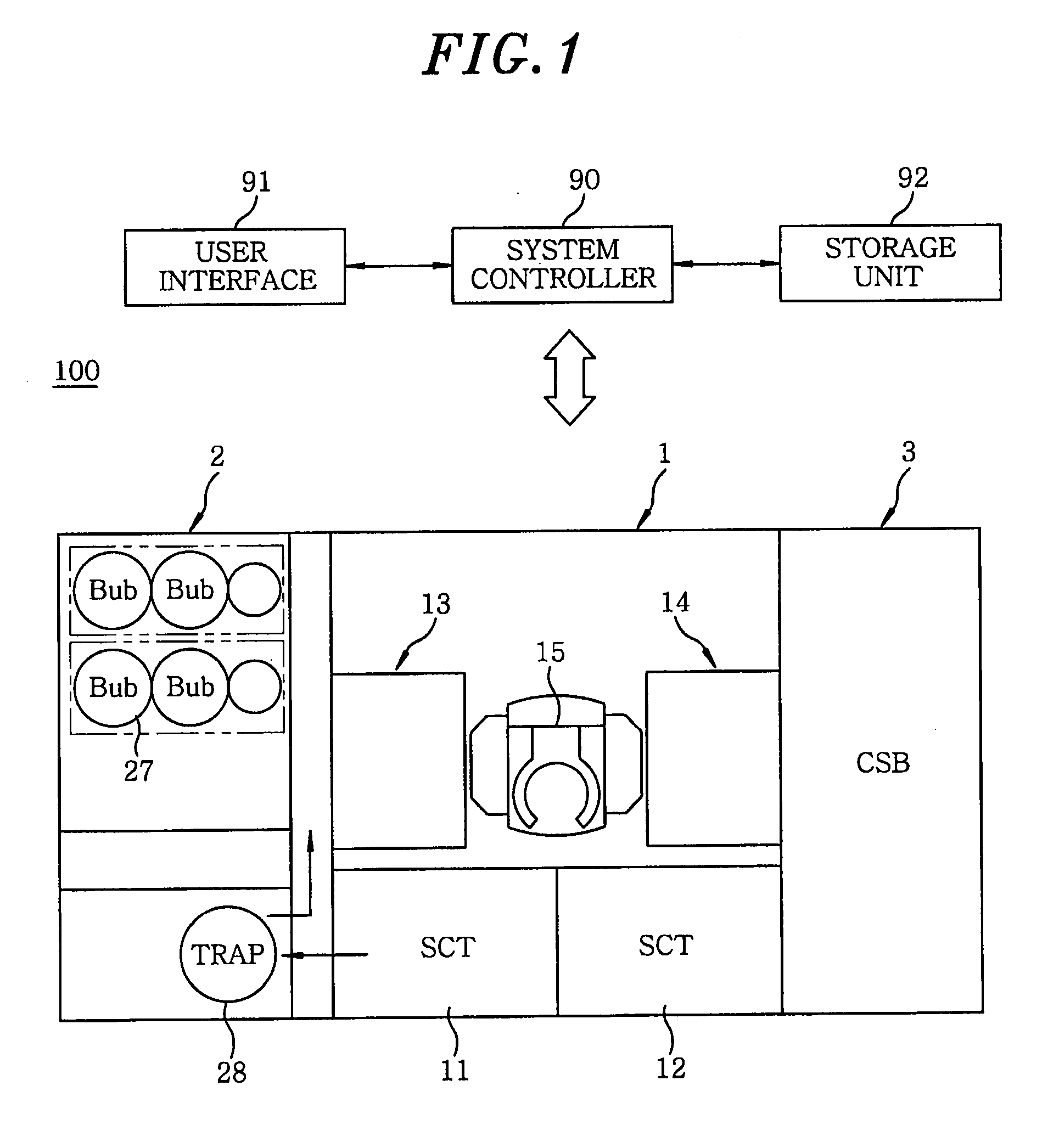

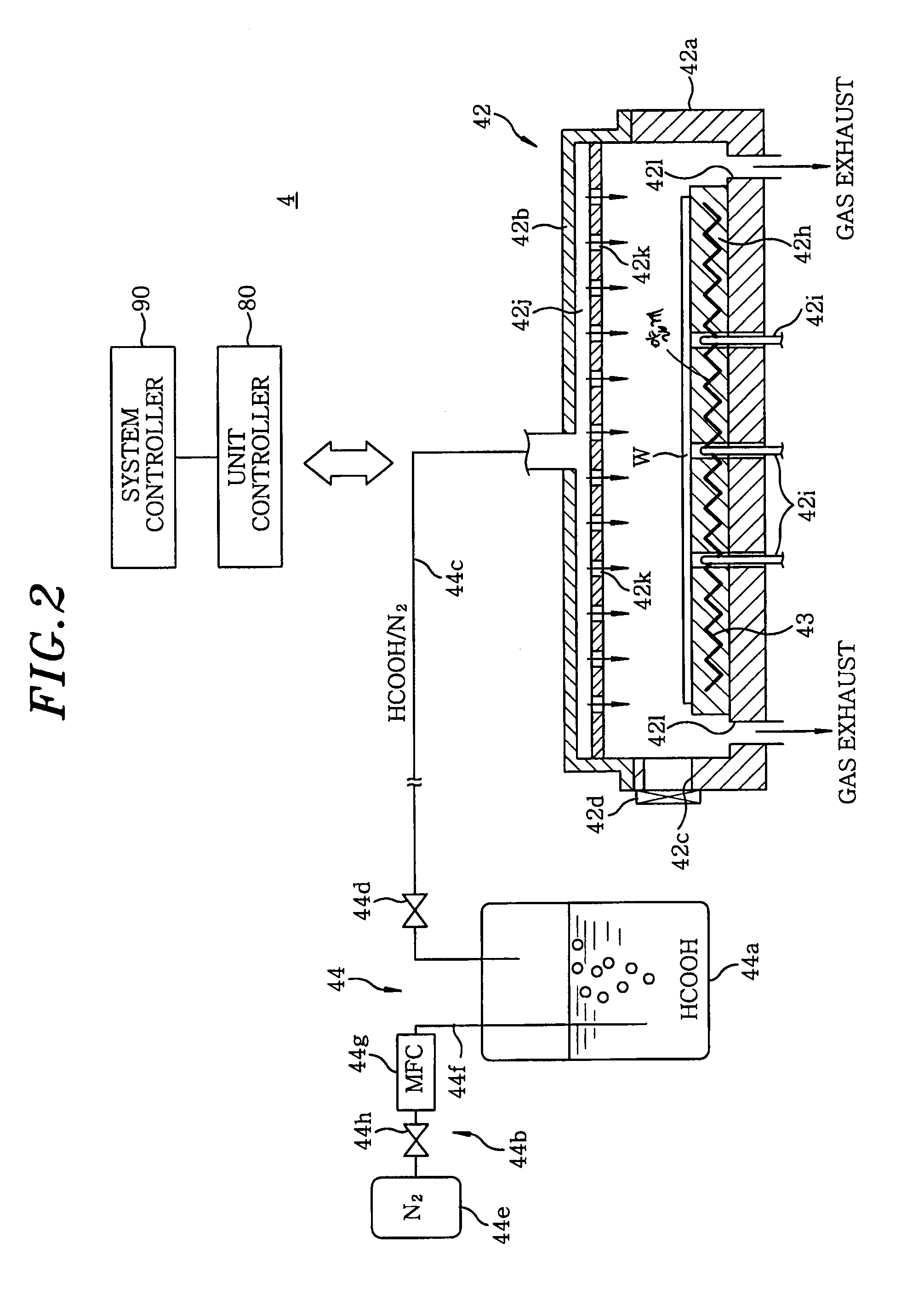

Heat treatment method, heat treatment apparatus and substrate processing apparatus

InactiveUS20090163038A1Improve reducibilityEfficient removalSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingEngineeringHeat treated

Disclosed is a heat treatment unit 4 serving as a heat treatment apparatus, which includes a chamber 42 for containing a wafer W on which a low dielectric constant interlayer insulating film is formed, a formic acid supply device 44 for supplying gaseous formic acid into the chamber 42, and a heater 43 for heating the wafer W in the chamber 42 which is supplied with formic acid by the formic acid supply device 44.

Owner:TOKYO ELECTRON LTD

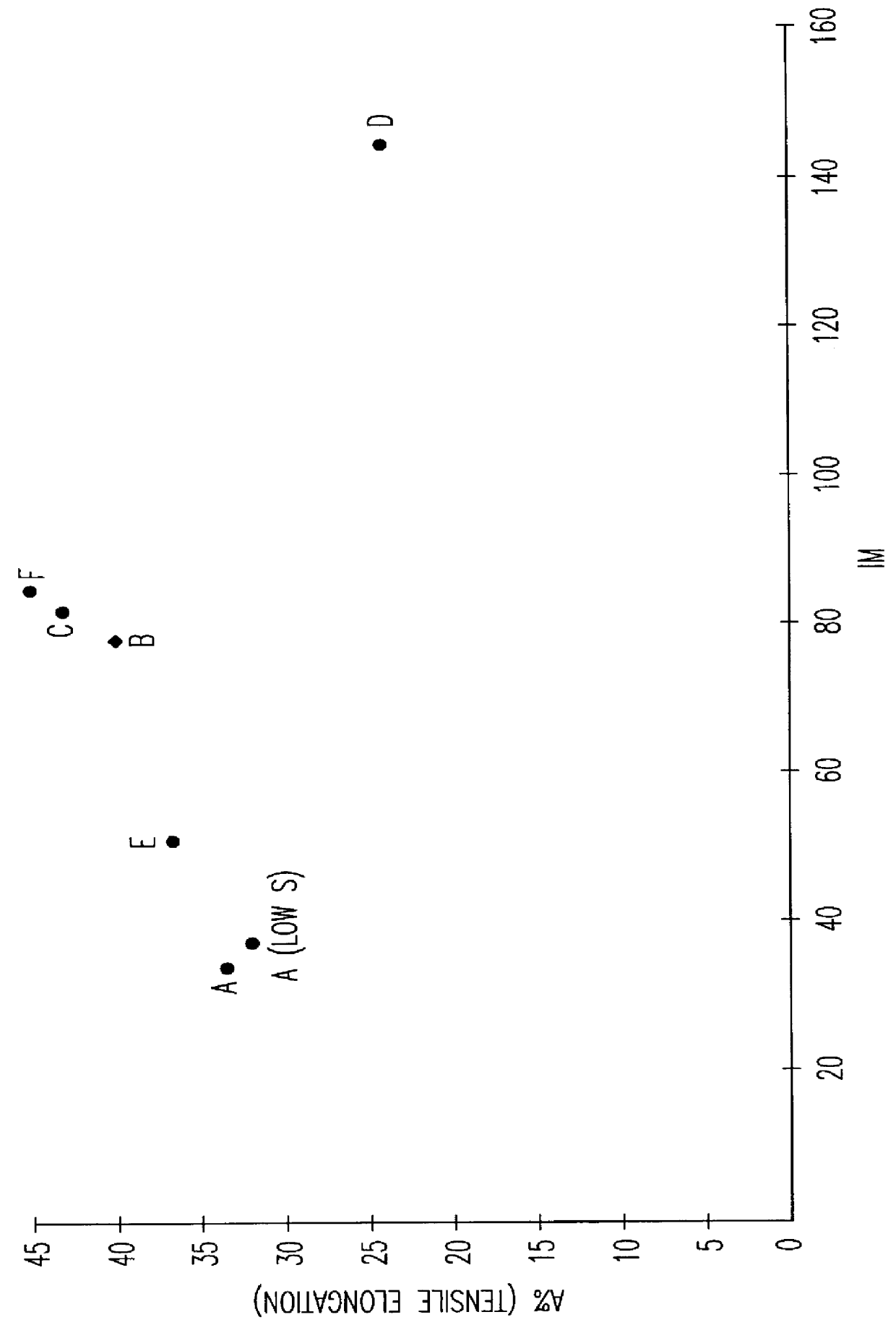

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

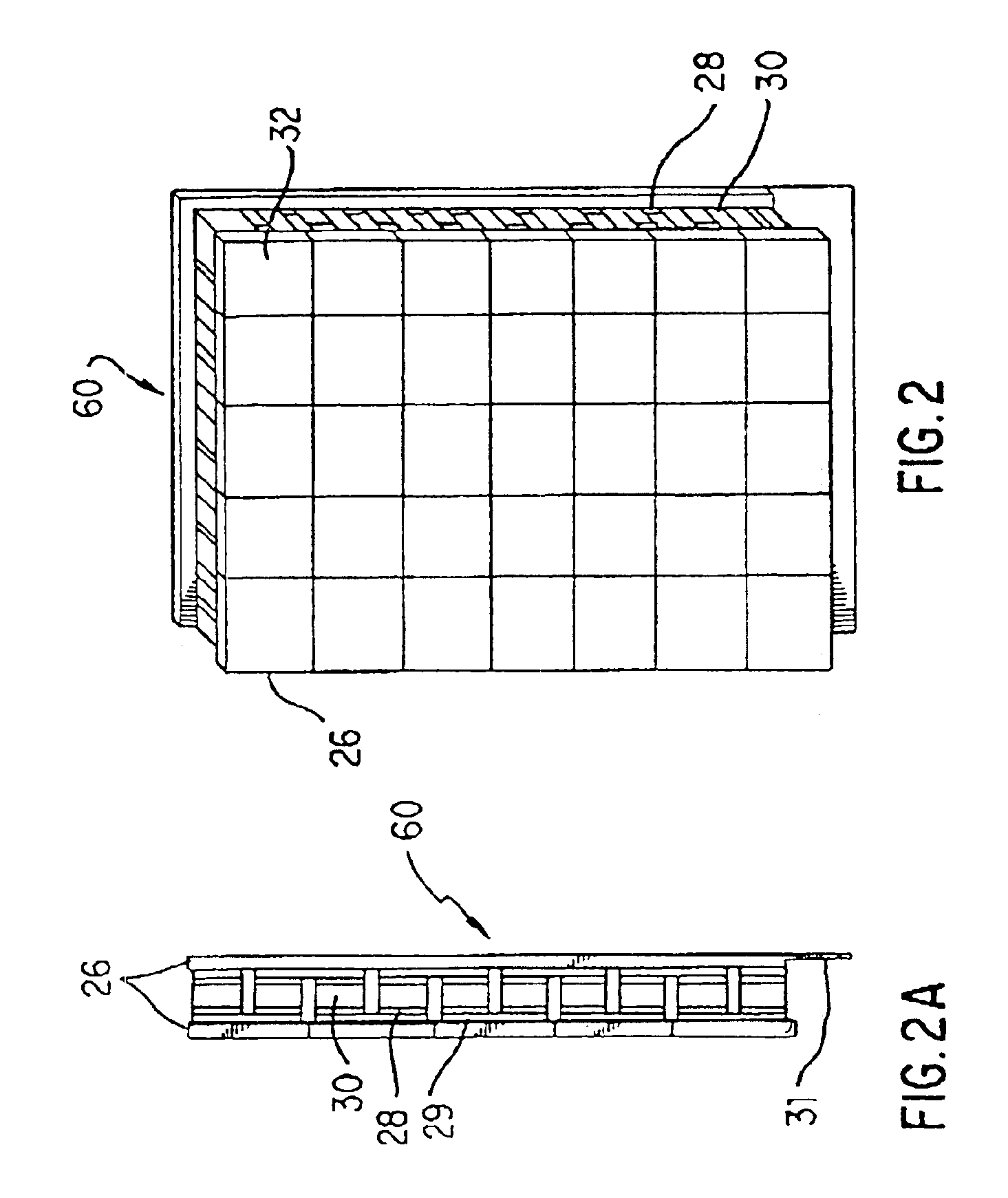

Thermal cycler for PCR

InactiveUS7133726B1Limit heat conductionMinimize thermal non-uniformityHeating or cooling apparatusThermoelectric device with peltier/seeback effectThermal isolationEvaporation

An instrument for PCR comprising an assembly, a heated cover, and a computer. The assembly can include a sample block, Peltier devices, and a heat sink, clamped together. The sample block temperature can be changed by controlling the Peltier devices with the computer. A perimeter heater can be used to in prove thermal uniformity. A heated platen can push down onto tube caps to apply a minimum force for seating the tubes. The force can be applied about the periphery of the tube caps to prevent distortion of the caps. The platen can be heated to provide thermal isolation and prevent evaporation from the surface of the sample. The software can include diagnostics to compensate for variation in thermoelectric coolers such that all instruments can perform identically.

Owner:APPL BIOSYSTEMS INC

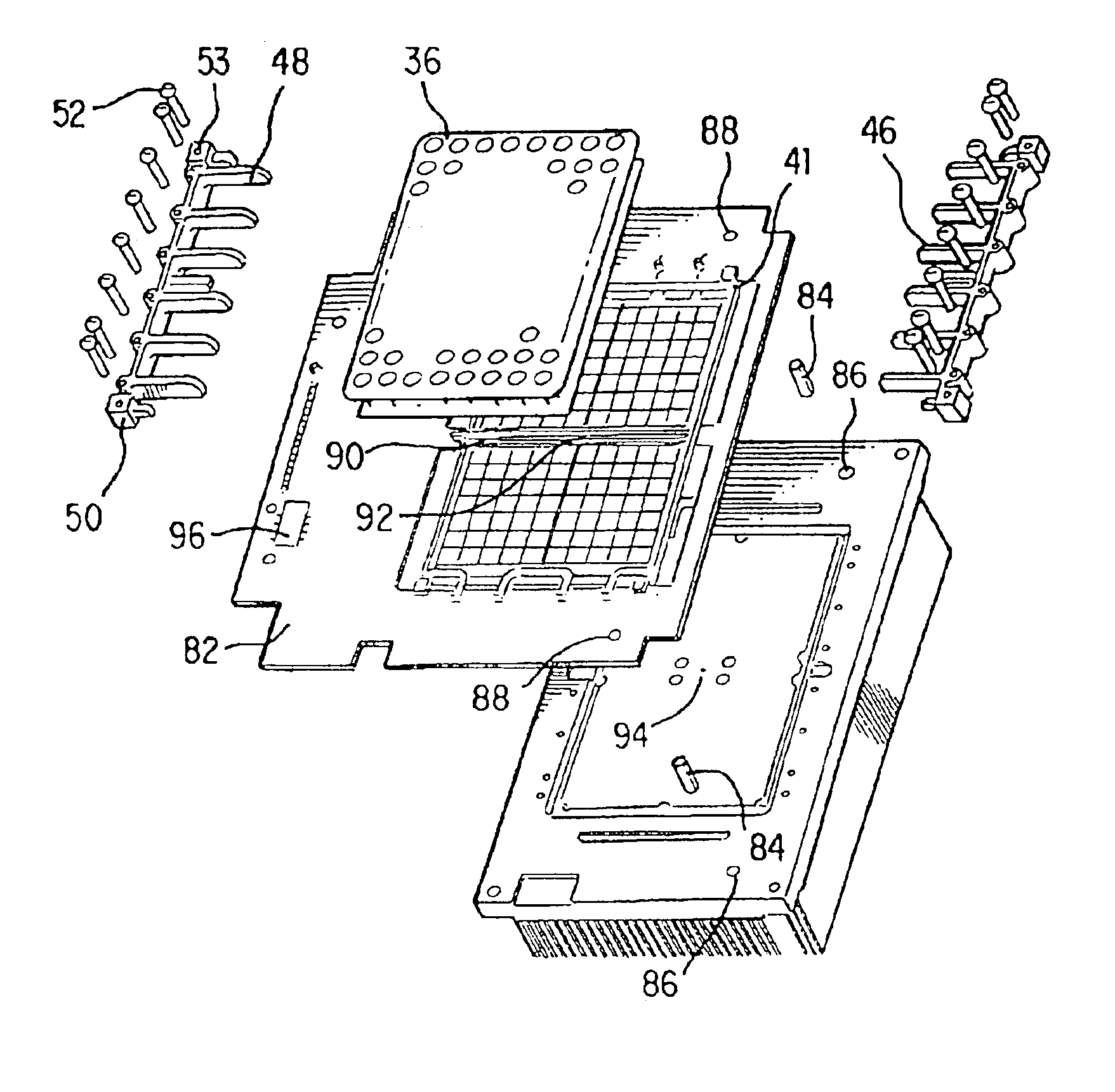

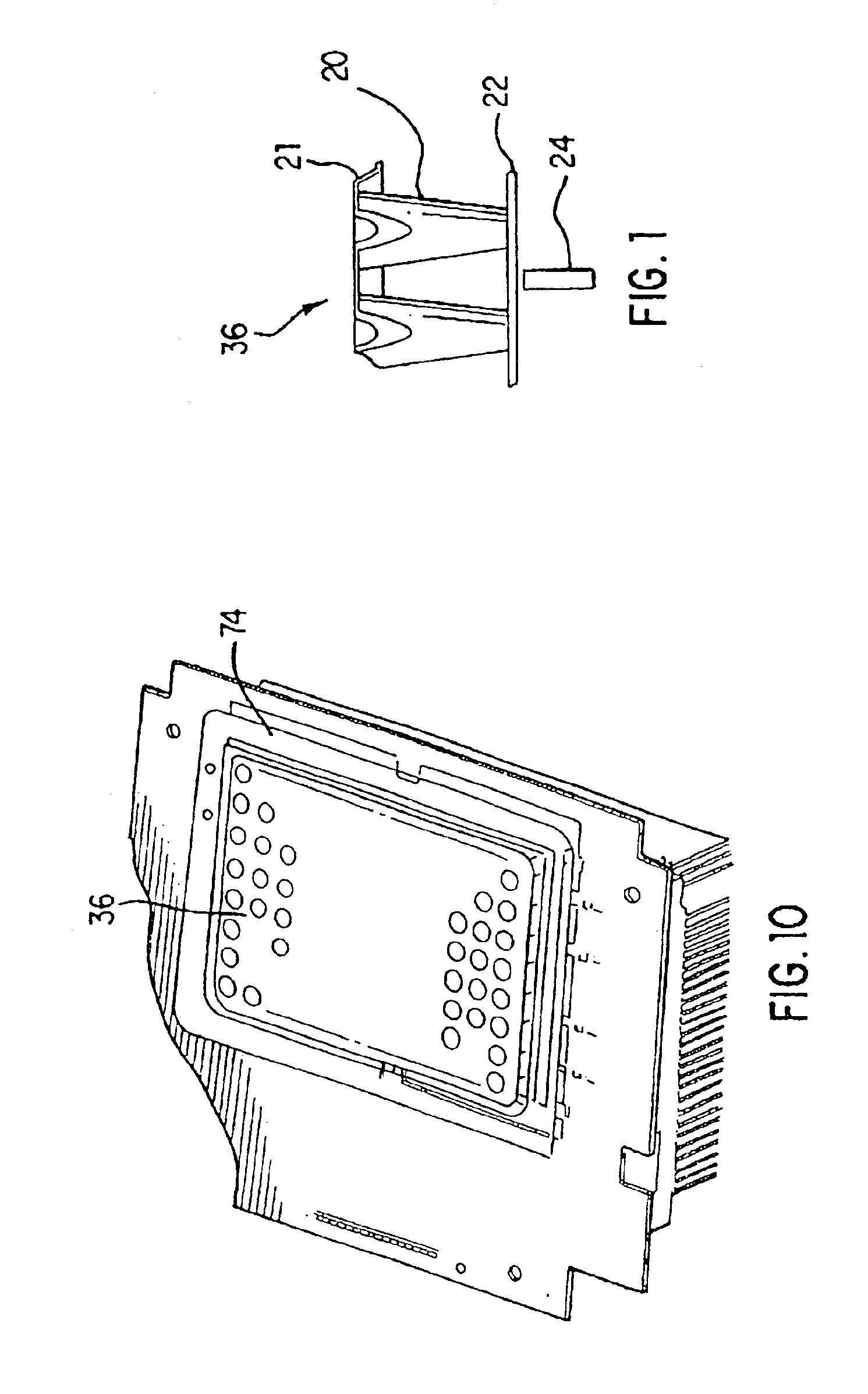

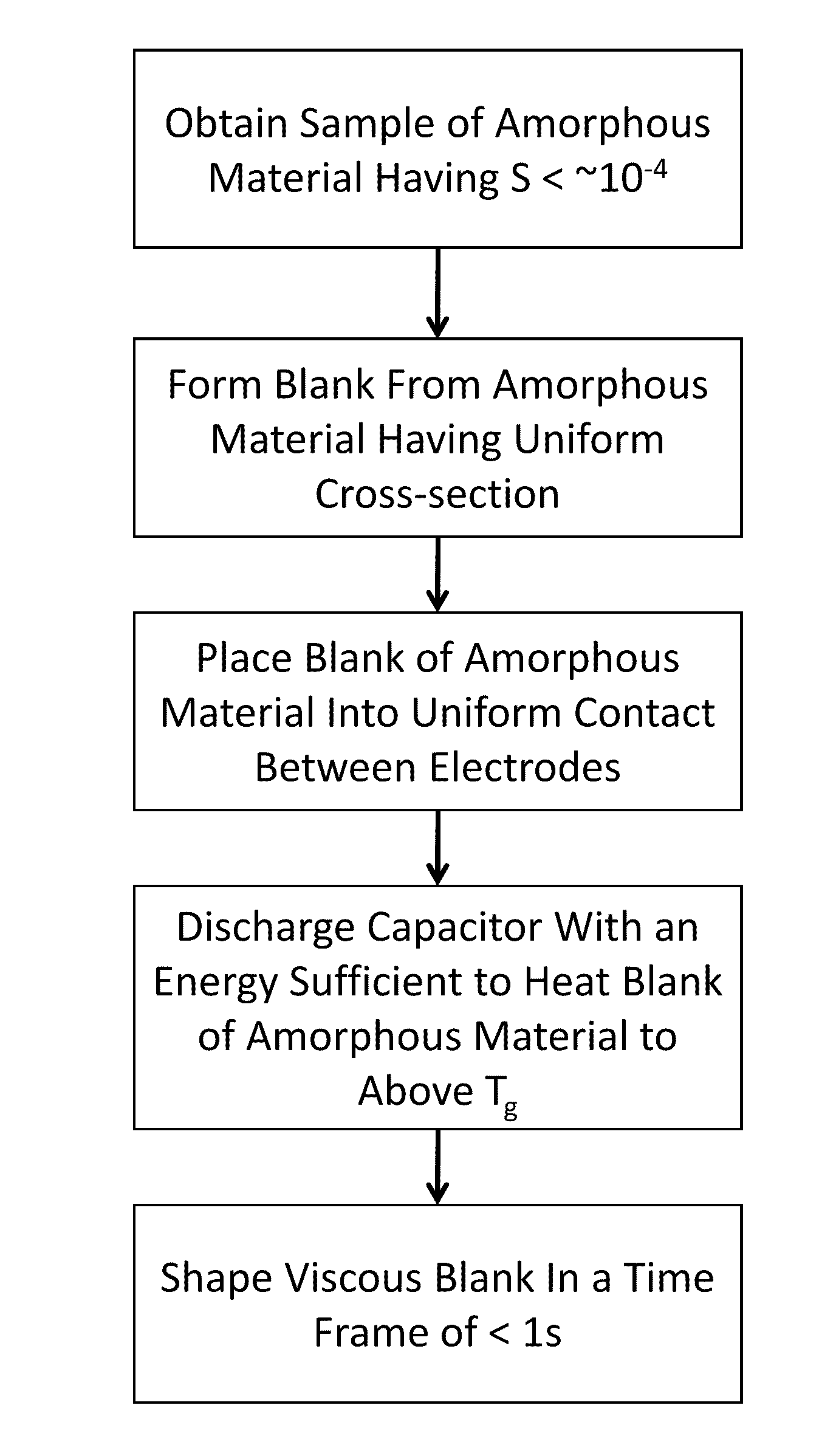

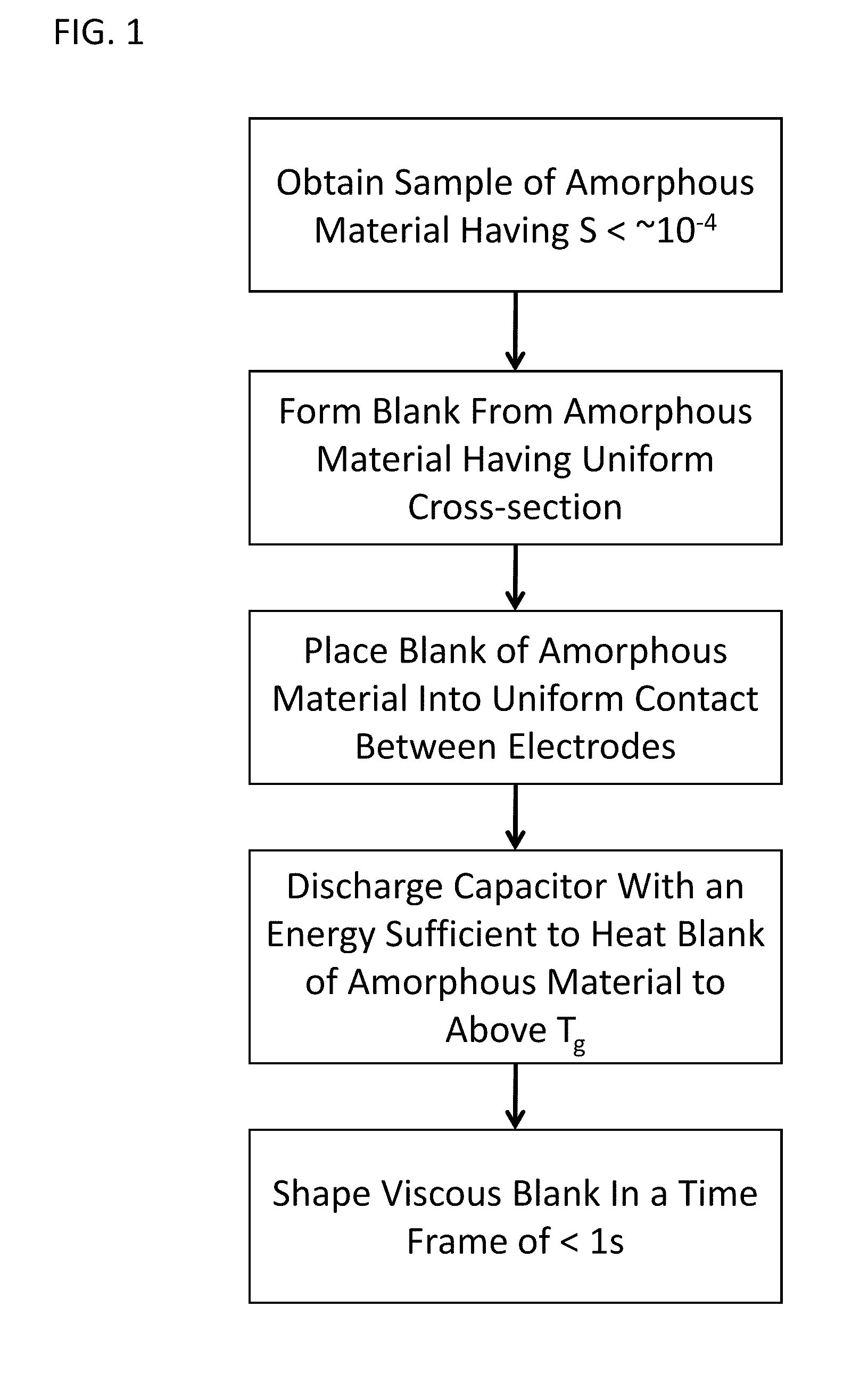

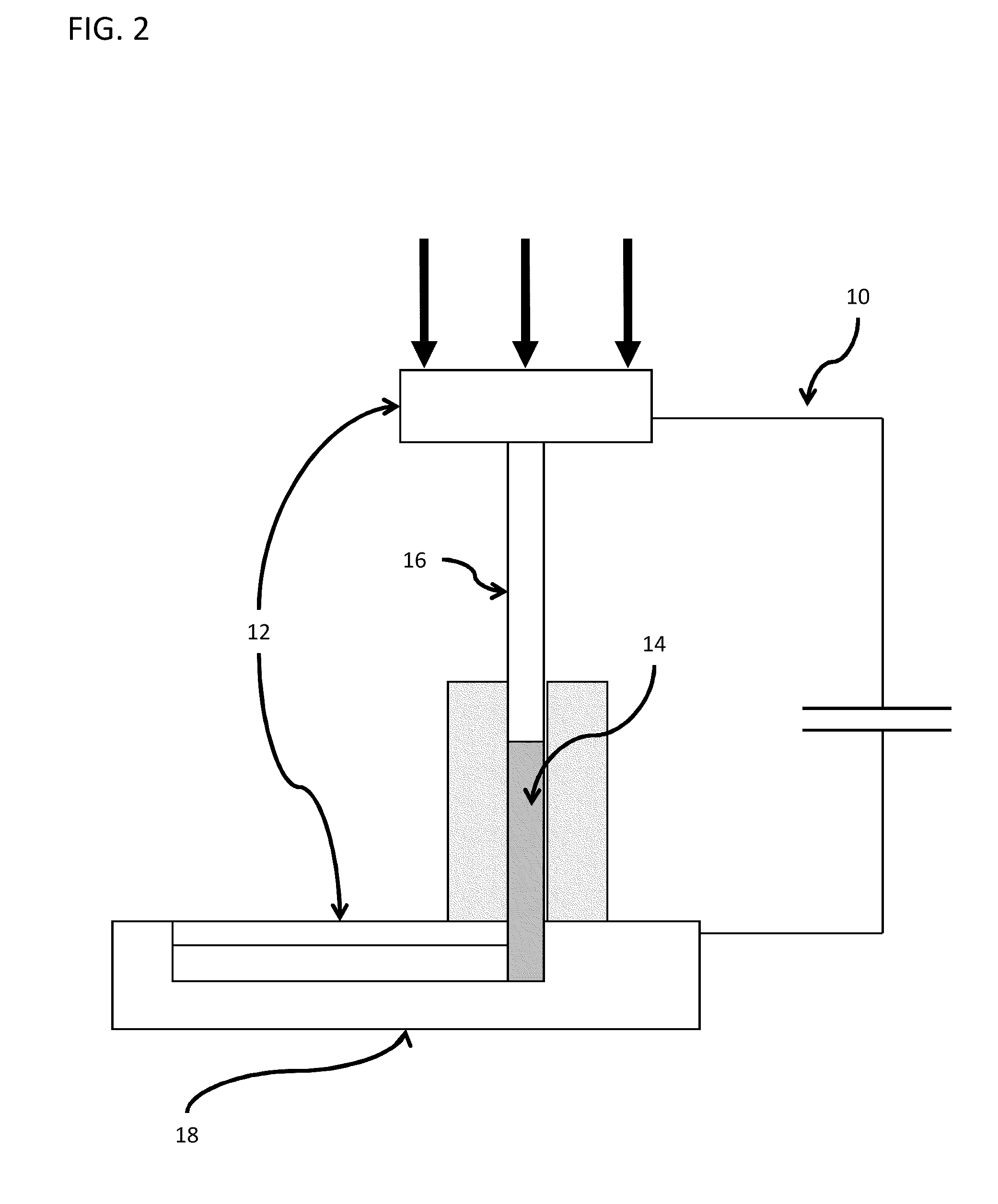

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

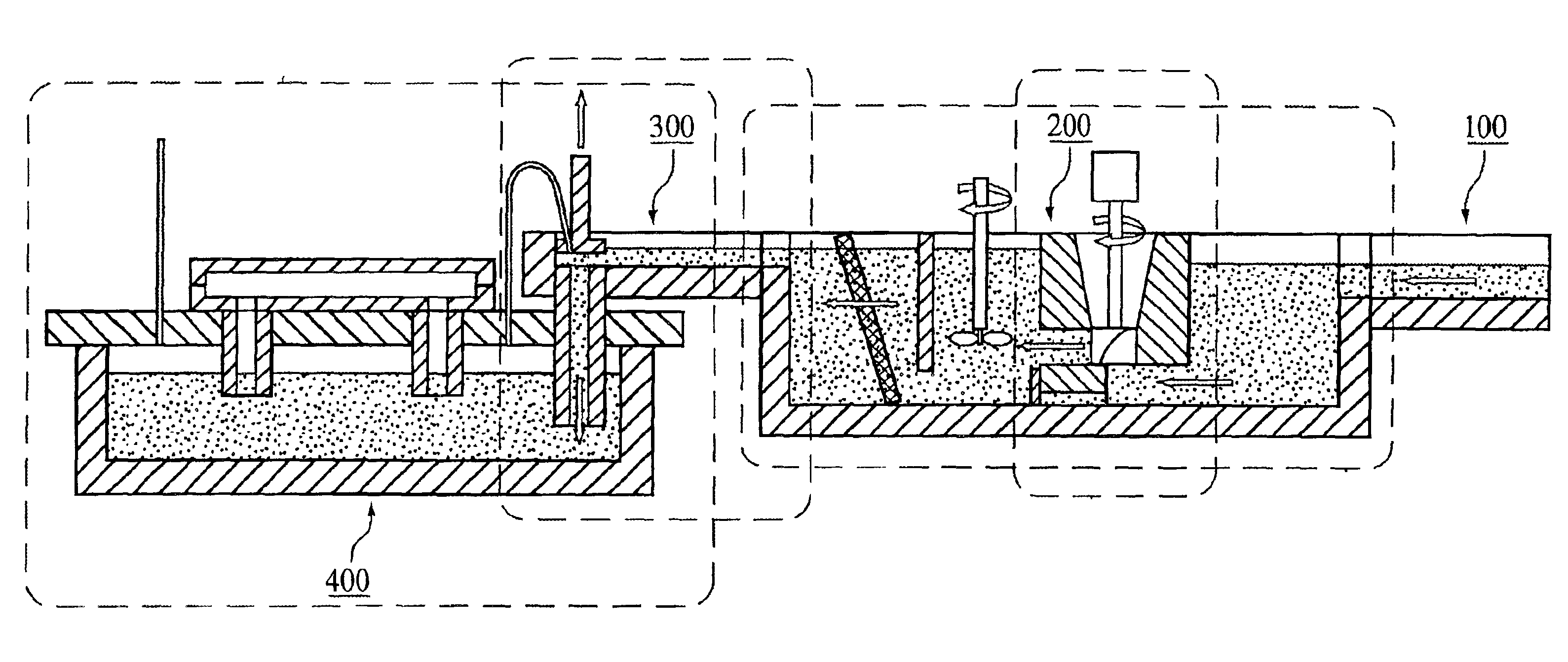

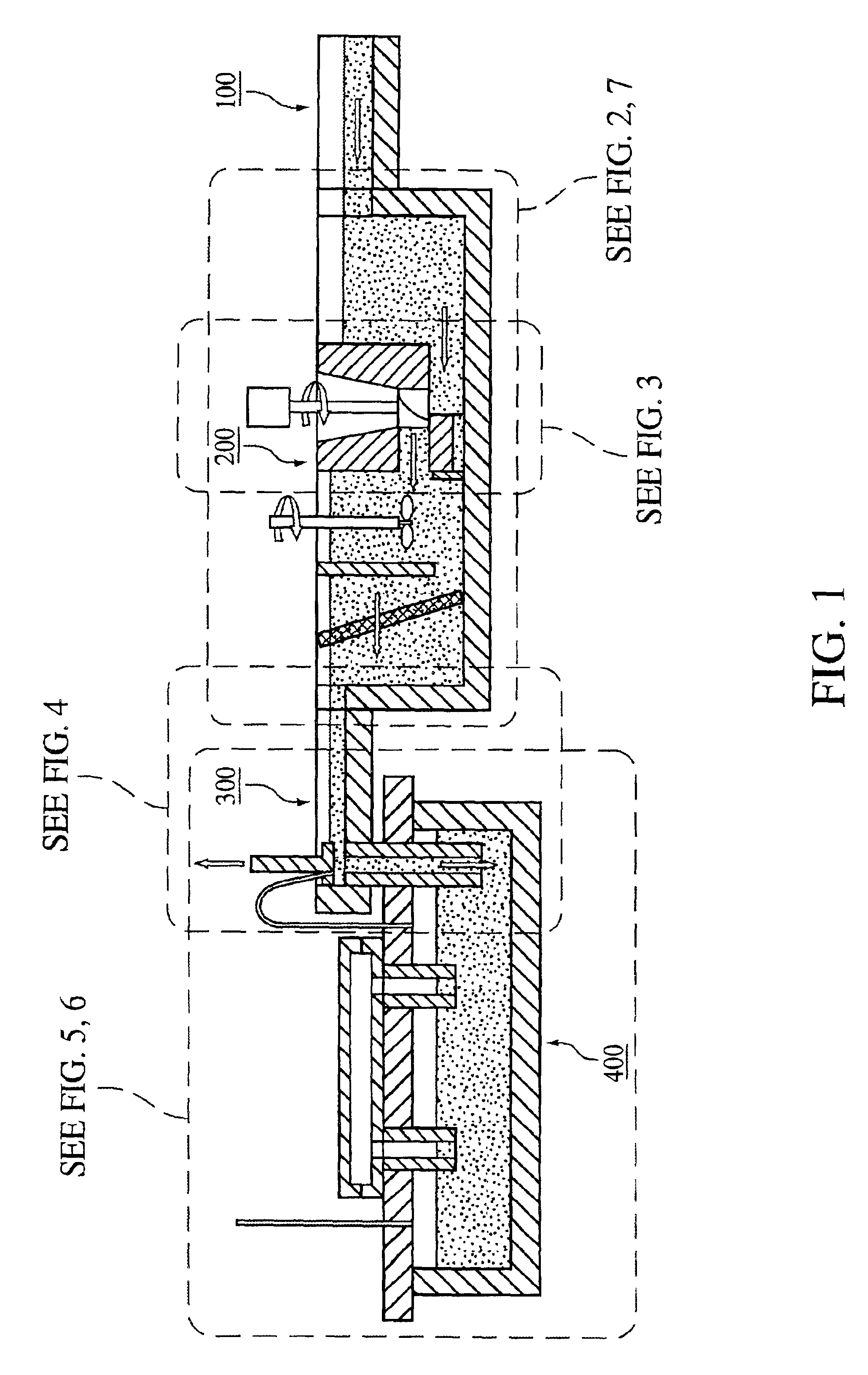

Overflow transfer furnace and control system for reduced oxide production in a casting furnace

InactiveUS6902696B2Reduce productionReduce in quantityLiquid transferring devicesManufacturing convertersControl systemMolten metal

An apparatus for transferring molten metal from a melting furnace to a casting furnace is provided. A sensing and control system for the transfer of molten metal from a transfer furnace to a casting furnace is also described. The combination of the transfer apparatus with the sensing and control system provides for the introduction of reduced oxide molten metal into a casting furnace.

Owner:SHIPSTON ALUMINUM TECH MICHIGAN

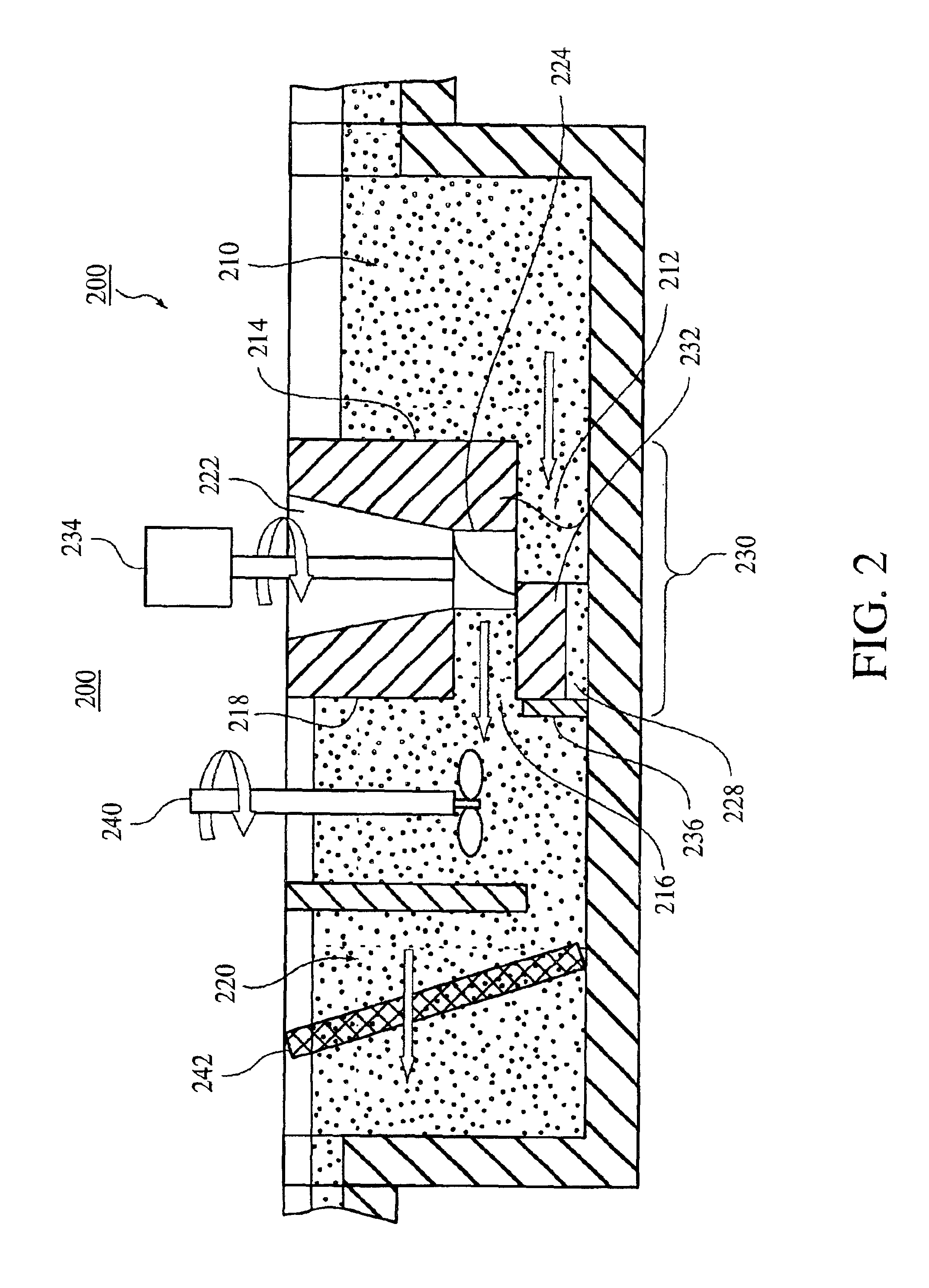

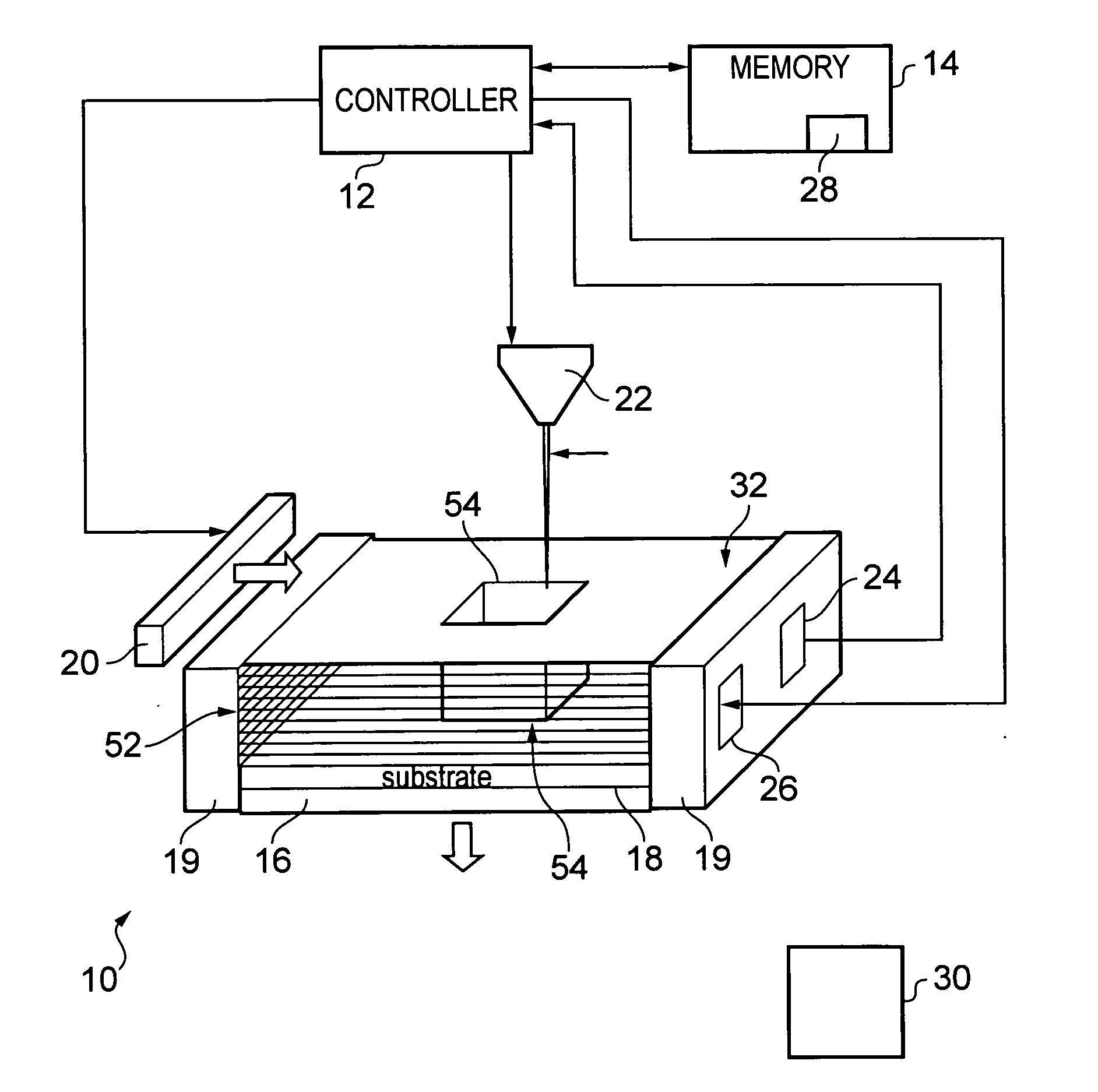

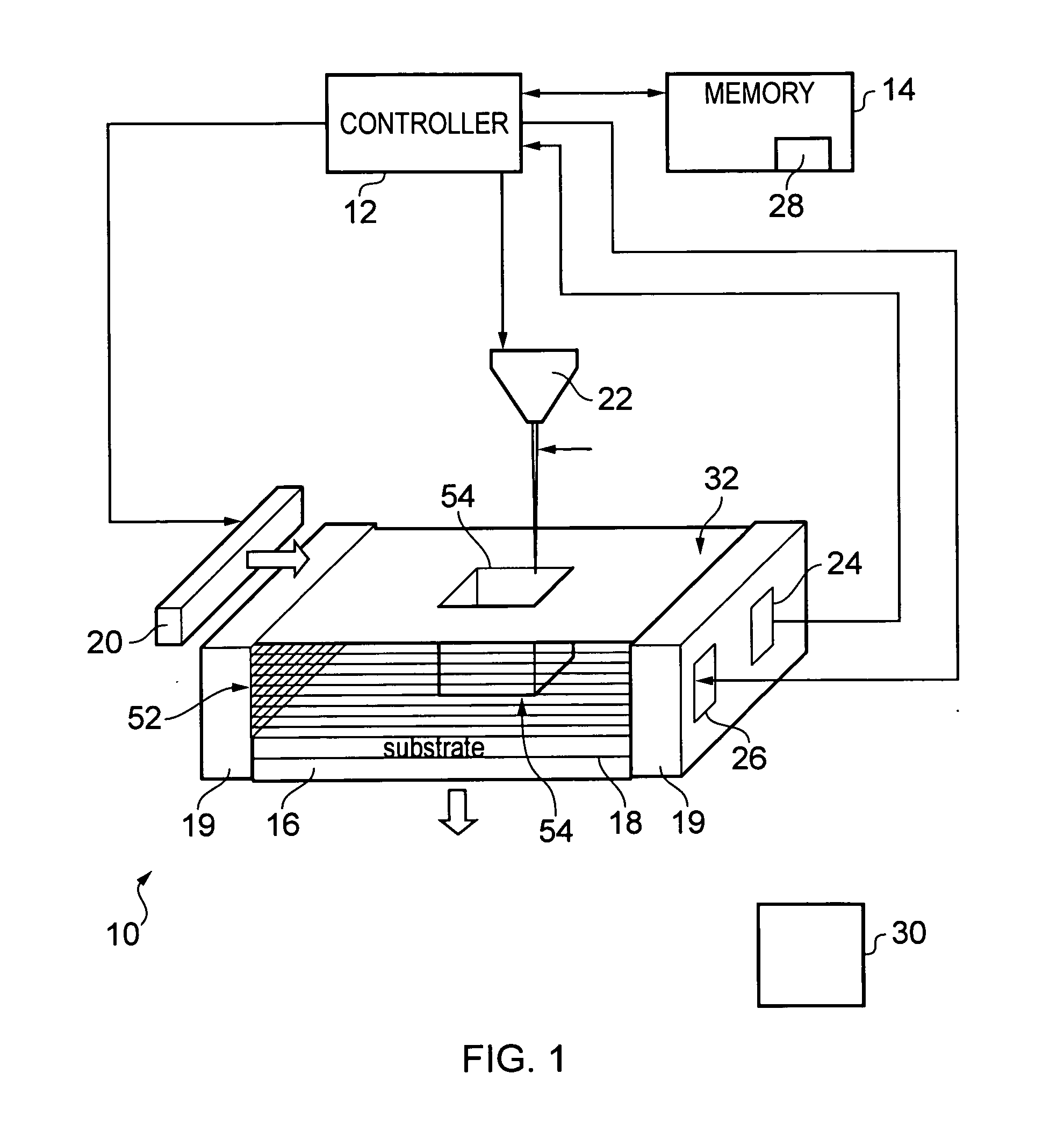

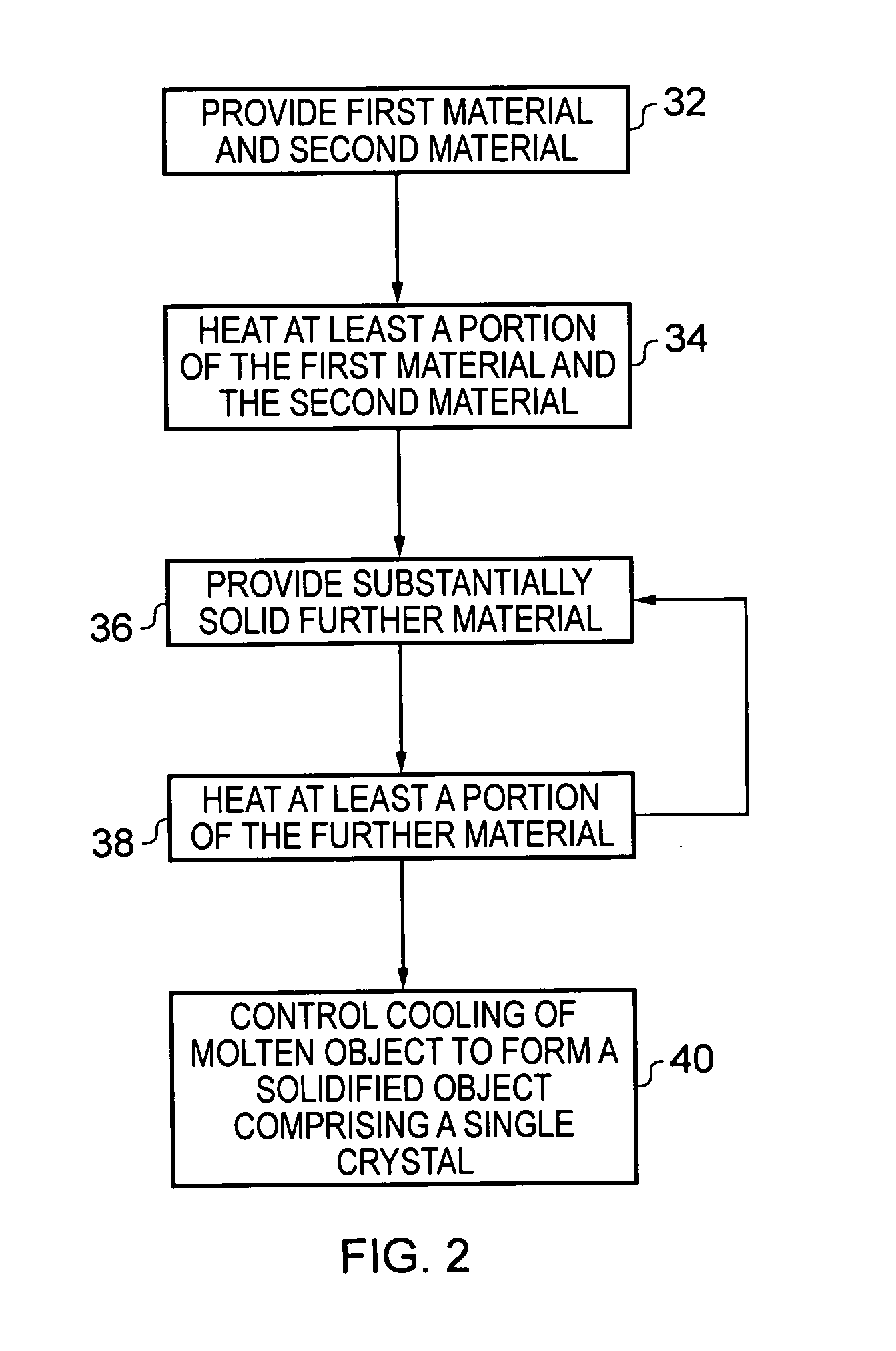

Method, apparatus, computer readable storage medium and computer program for forming an object

InactiveUS20110042031A1Polycrystalline material growthAdditive manufacturing apparatusComputer programFreezing point

A method for forming an object, including providing at least a first material having a melting point at a first temperature and a second material having a melting point at a second temperature; heating at least a portion of the first and second materials above the first and second temperatures to form a substantially molten alloy, the molten alloy having a solidifying point at a third temperature, the third temperature being less than the first temperature and the second temperature; and providing substantially solid further material to at least a portion of the molten alloy, the further material having a melting point at a temperature greater than the third temperature.

Owner:UNIV OF SHEFFIELD

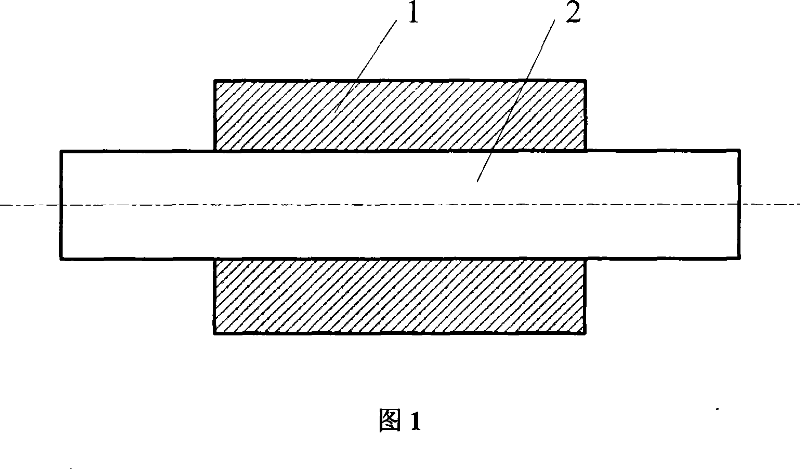

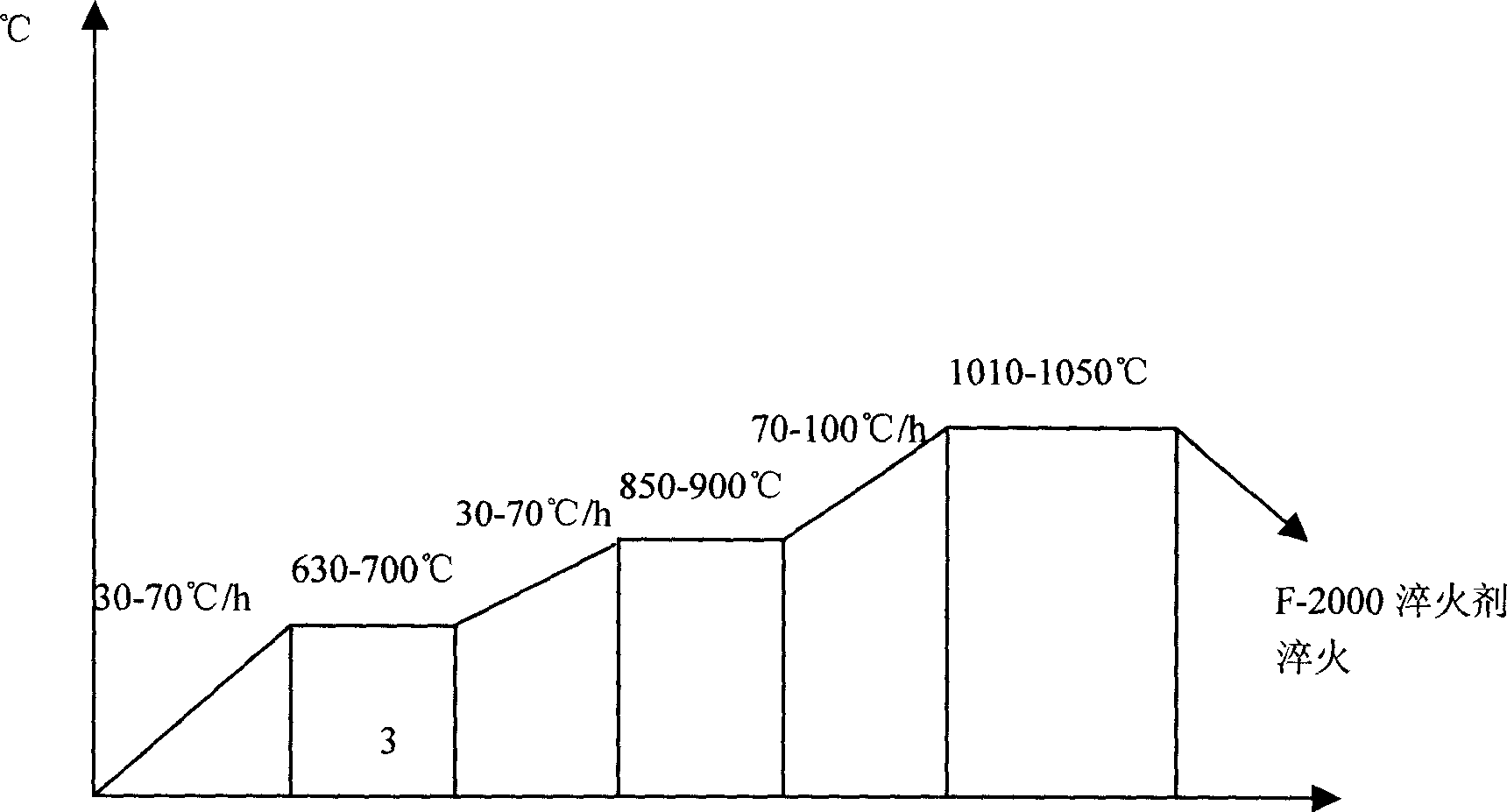

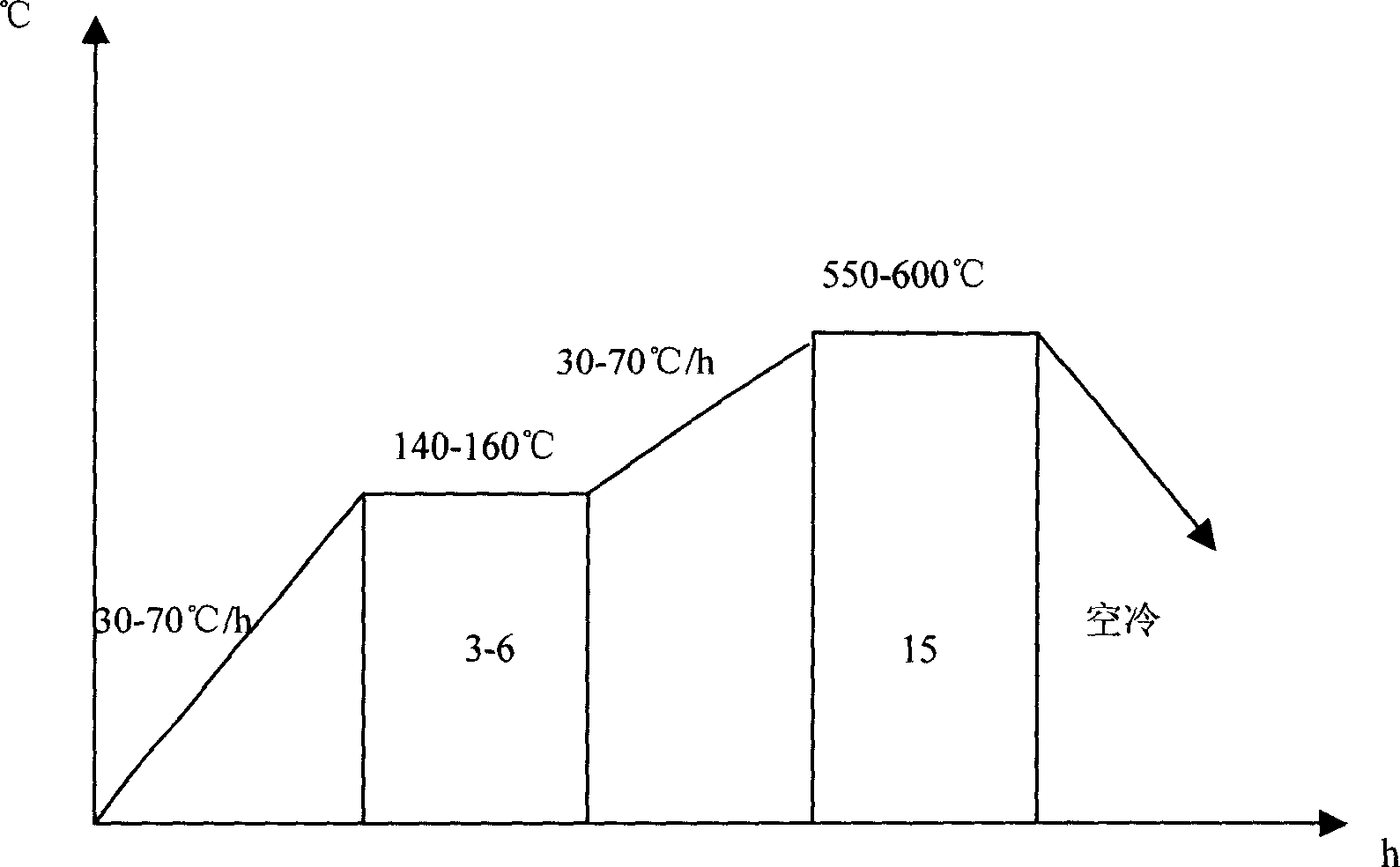

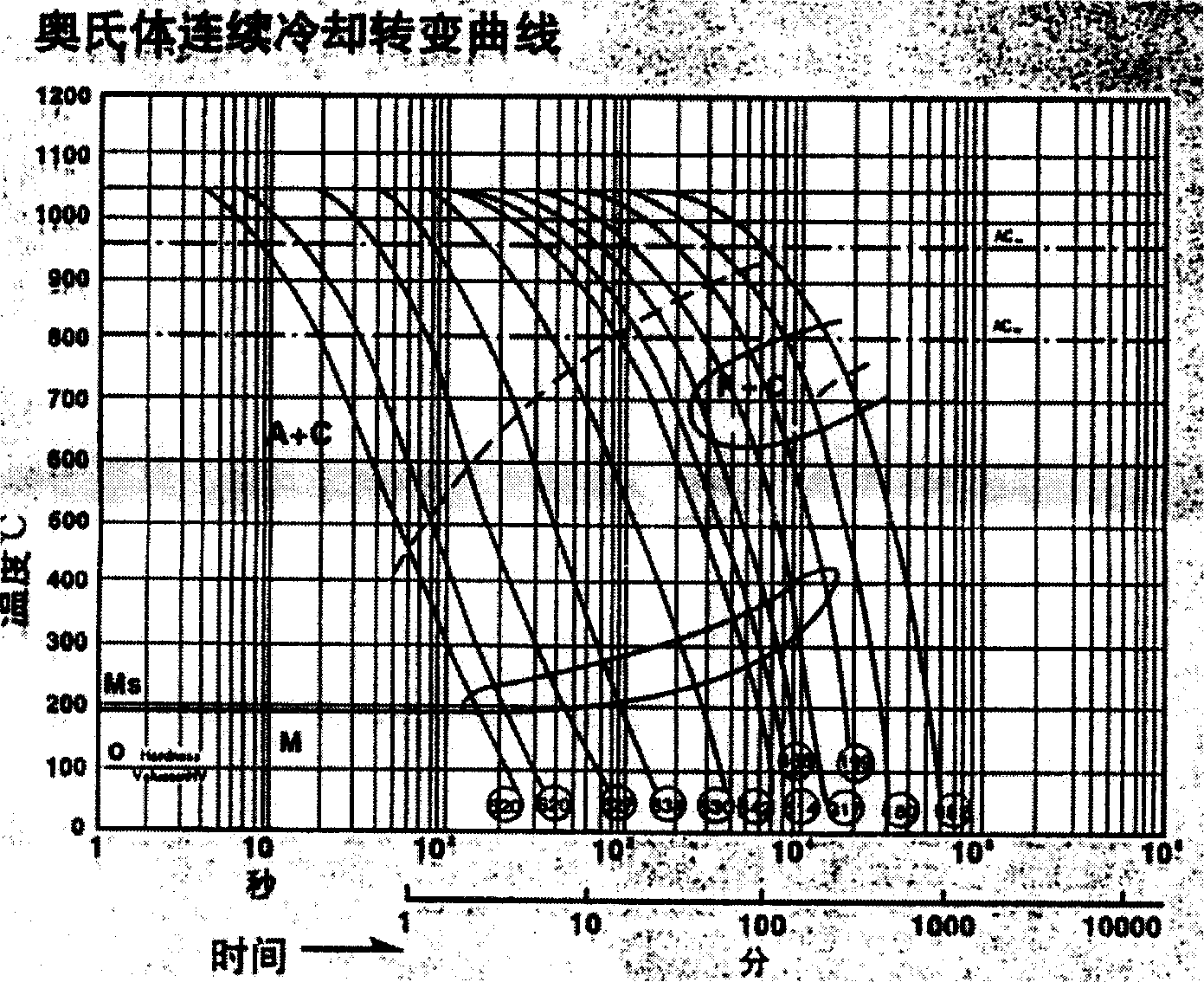

High-carbon high-high-vanadium high-speed steel composite roller and heat treatment method thereof

InactiveCN101037760ASimple production processImprove wear resistanceFurnace typesHeat treatment process controlChemical compositionHigh-speed steel

The invention discloses a high-carbon high-vanadium high-speed-steel complex roll. The outer layer of the high-carbon high-vanadium high-speed-steel complex roll comprises, based on weight percent, C: 1.8%-3.0%, V: 3.0%-6.0%, Cr: 4.0%-6.0%, Mo: 3.0%-6.0%, W: 1.0%-3.0%, Nb: 1.0%-5.0%, Co: 1.0%-5.0%, Si: <1.0%, Mn: <1.5%, P: <0.04%, S: <0.04%; Y: 0.05%-0.20%, Ti: 08%-0.25%, Mg: 0.03%-0.12%, Zr: 0.04%-0.18%, Te: 0.02%-0.12%, the residuel of Fe, the total of 100%. The roll is produced by smelting using electric furnace, casting and forming using centrifugal casting, heat treatment comprising quenching and tempering treatment. The high-speed-steel roll has high rigidity and strength, good toughness and wear resistance, and good anti-thermal fatigue, without roll breakage and desquamation in use. The application of the inventive roll can reduce the consumption of roll, improve the work rates of roll, prolong roll changing cycle, improve the surface quality of roll, with good economic and social effect.

Owner:XI AN JIAOTONG UNIV

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

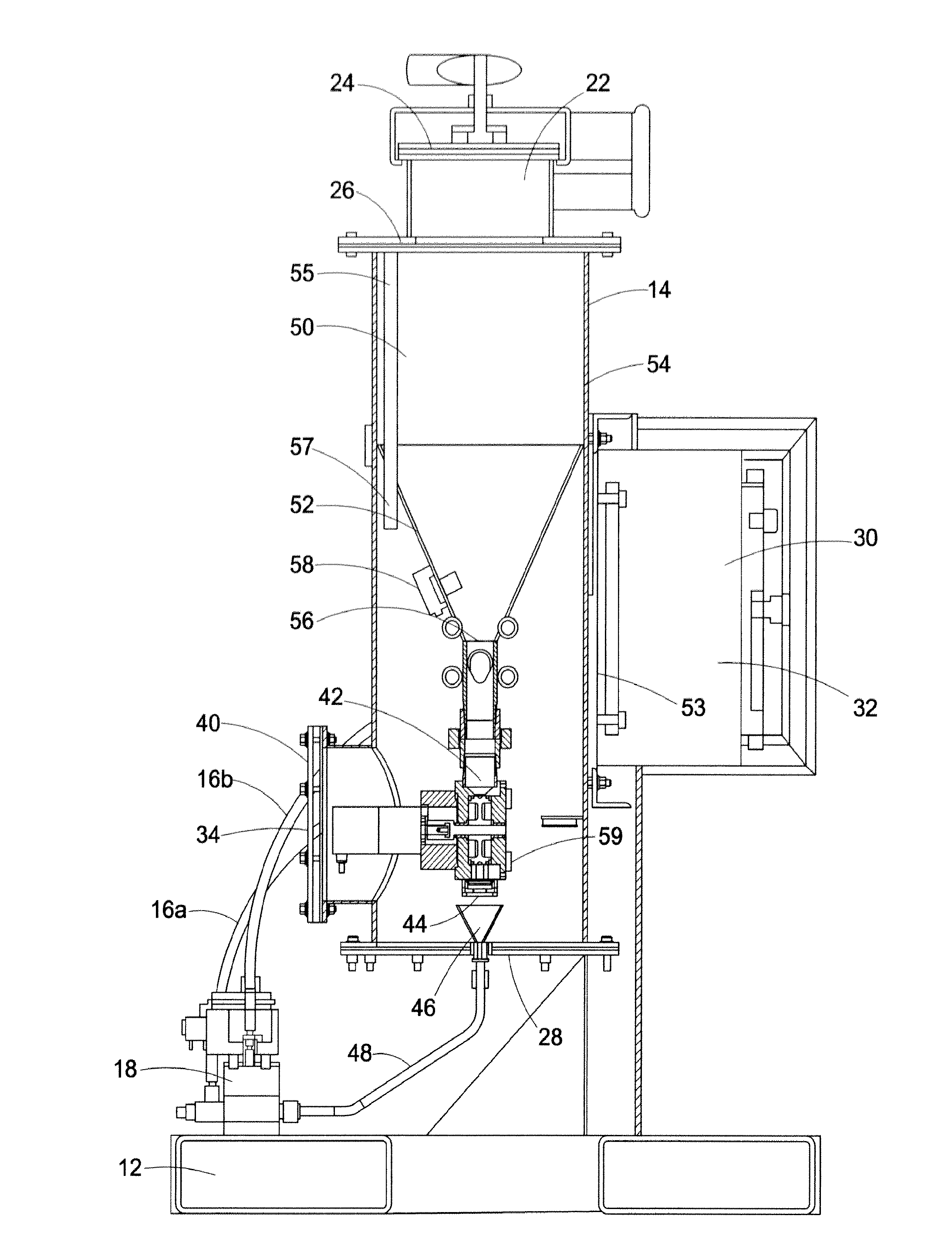

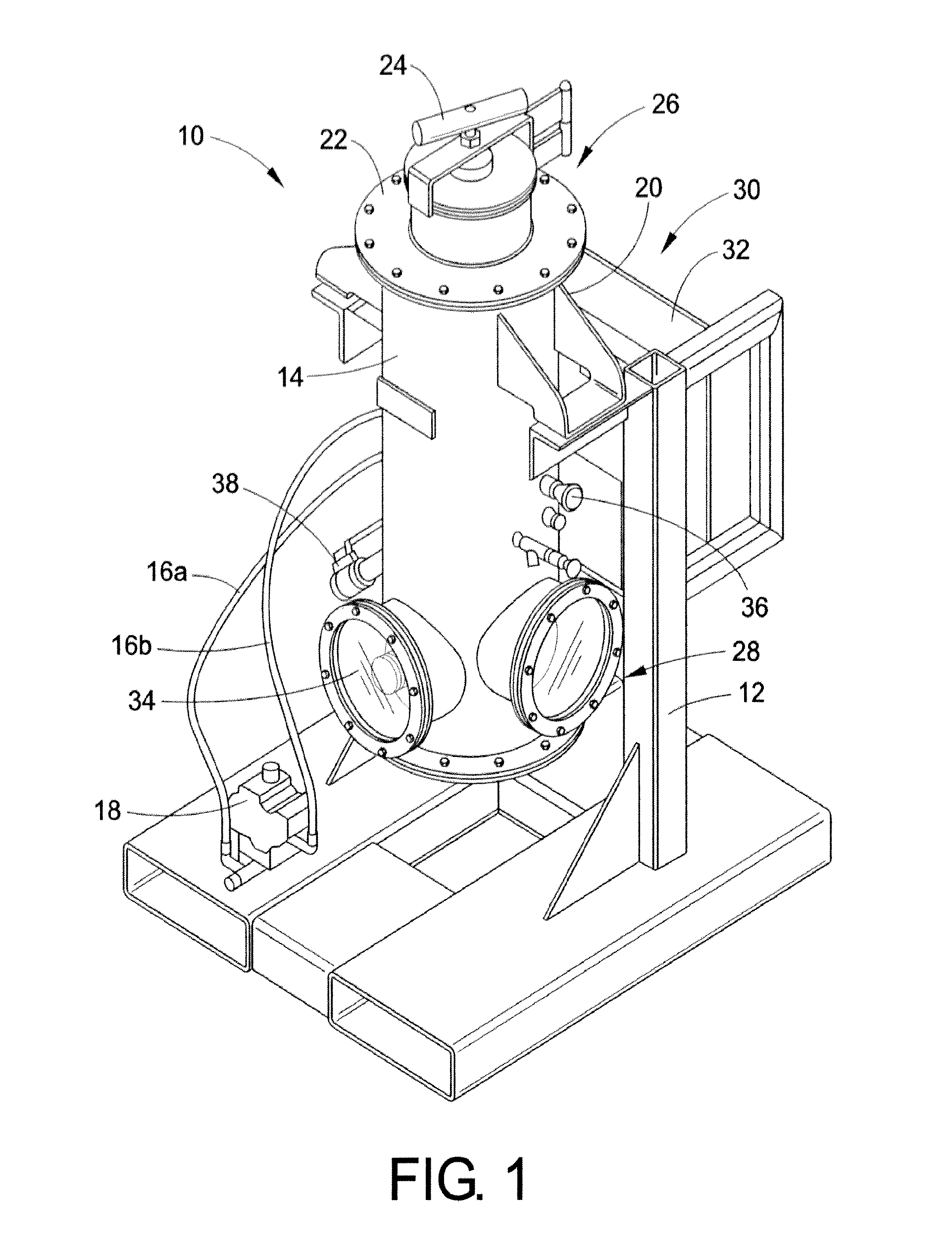

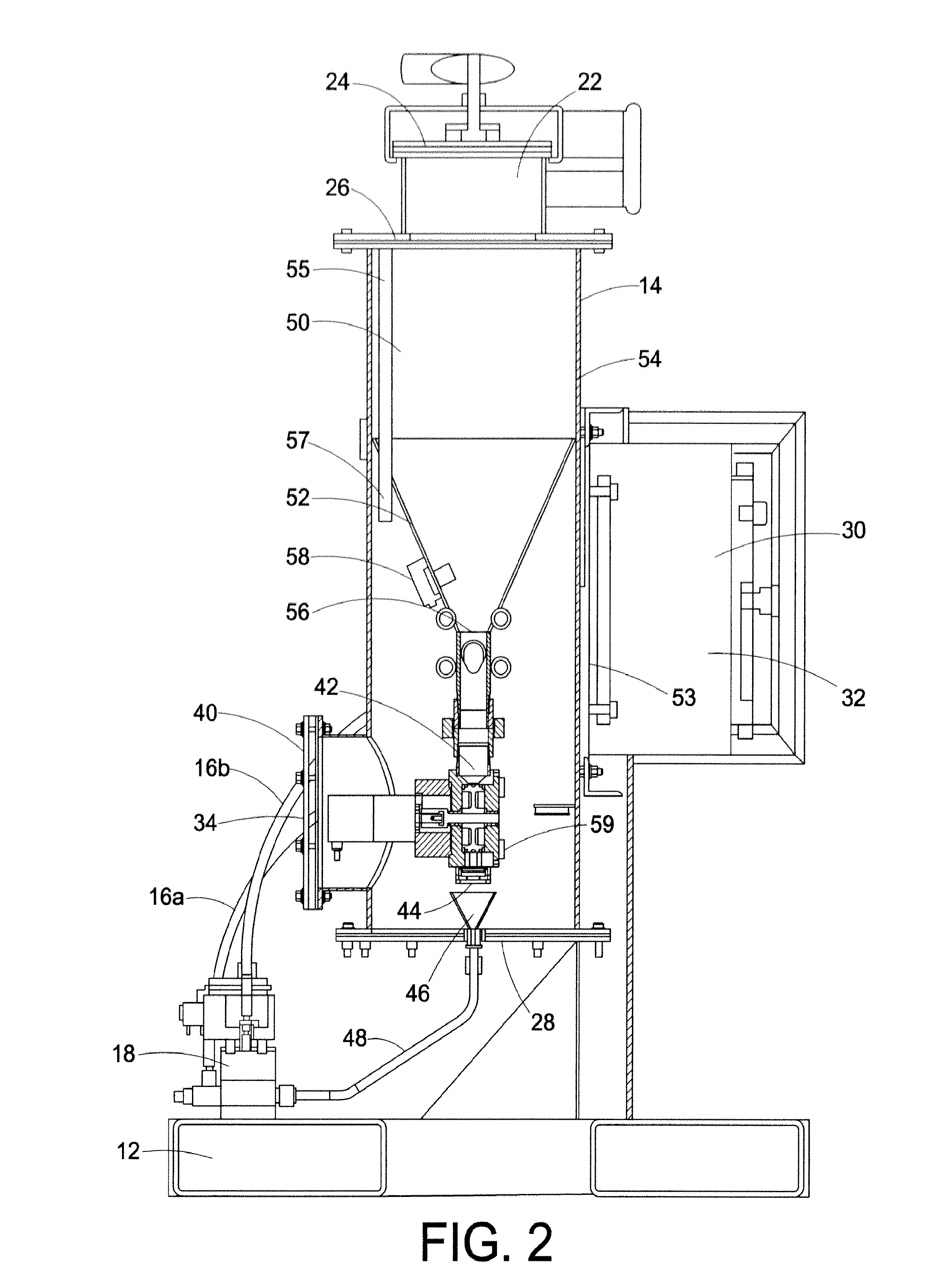

Flux injection assembly and method

ActiveUS20140083253A1Safely store and measureAvoid pollutionCharge manipulationBlast furnace detailsEngineeringInjector

A flux injector apparatus and method adapted to distribute a predetermined amount of flux to an associated pool of molten aluminum. The flux injector apparatus includes a pressurized tank adapted to store and feed the flux under pressure. A feed mechanism operative to discharge a predetermined amount of flux to an outlet and a controller for monitoring and operating the apparatus. The feed mechanism includes a housing having an inner wall defining a cavity with an inlet and an outlet. A feed wheel is positioned within the cavity and operative to receive a predetermined amount of flux from the inlet, translate the flux within the cavity and discharge the predetermined amount of flux through the outlet of the pressurized tank.

Owner:PYROTECK INC

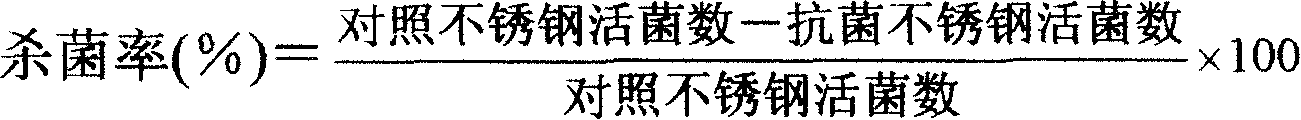

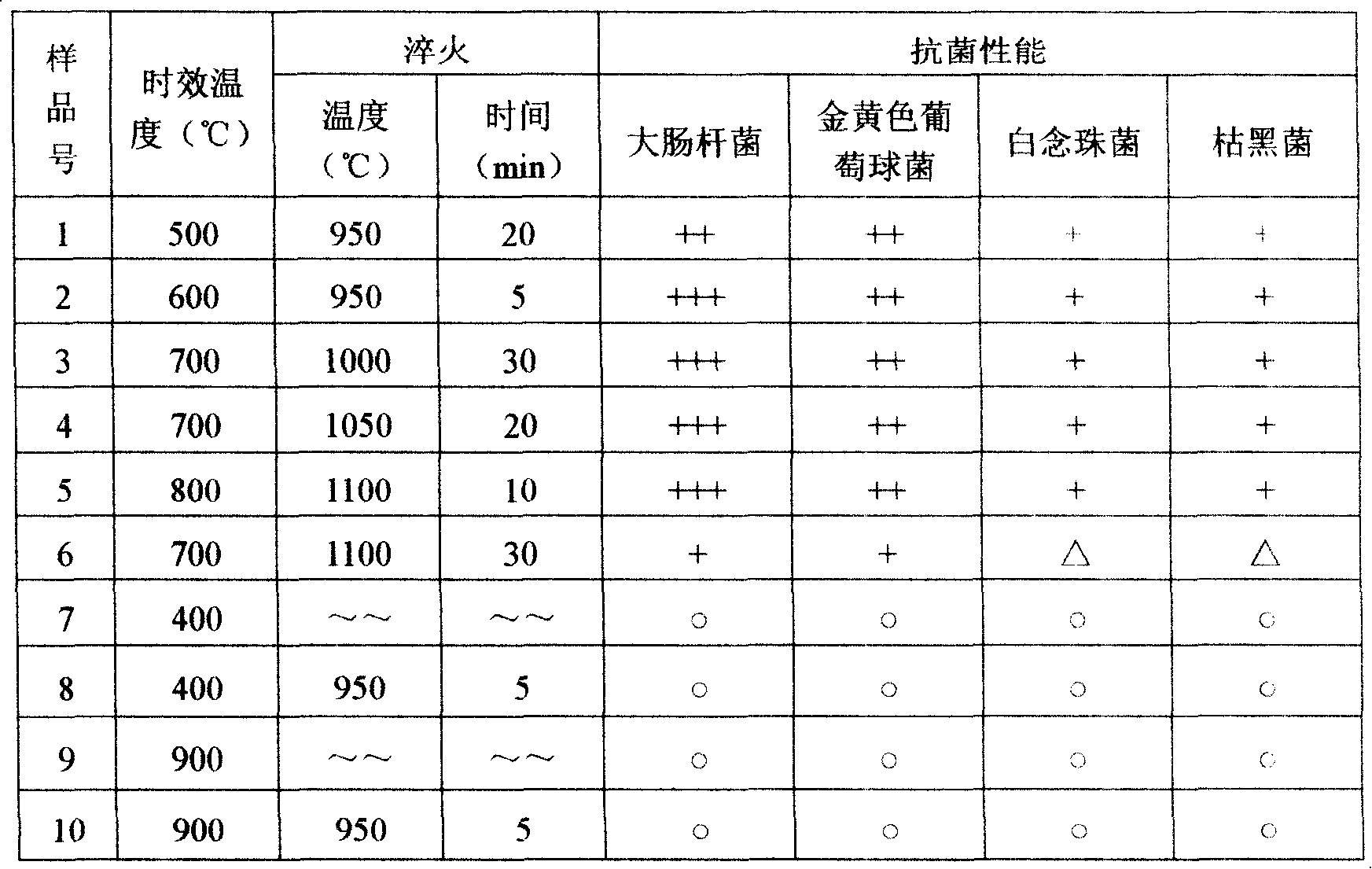

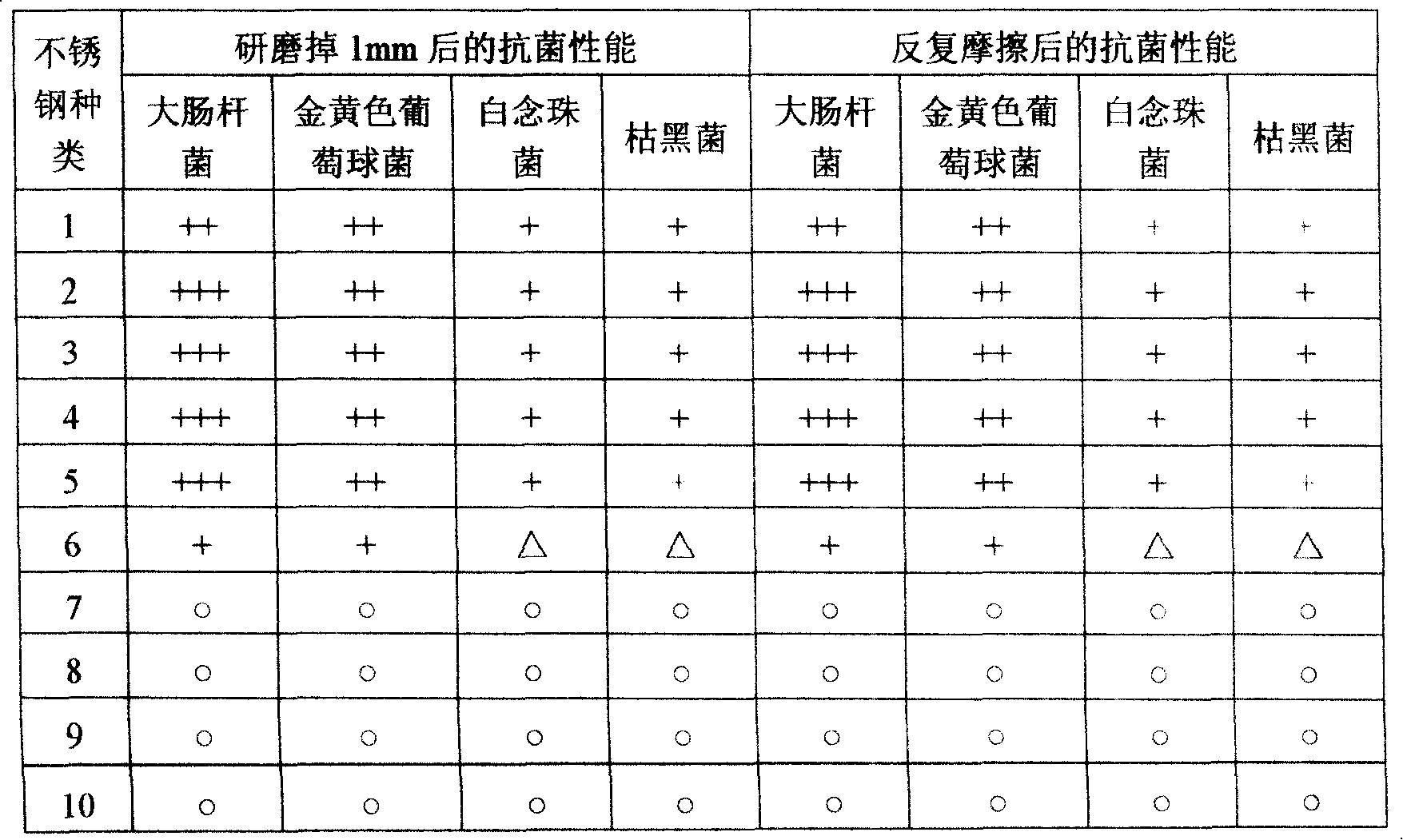

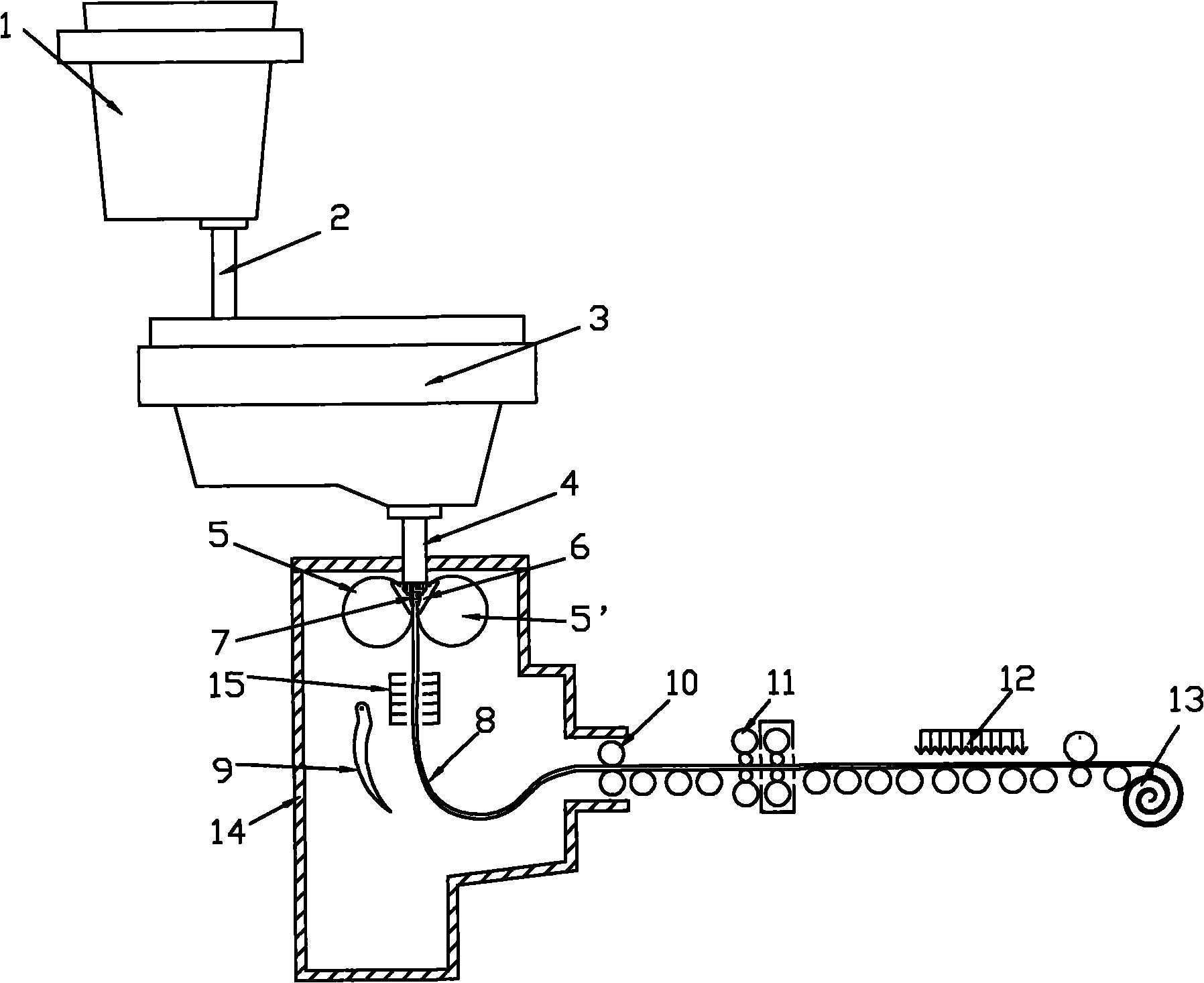

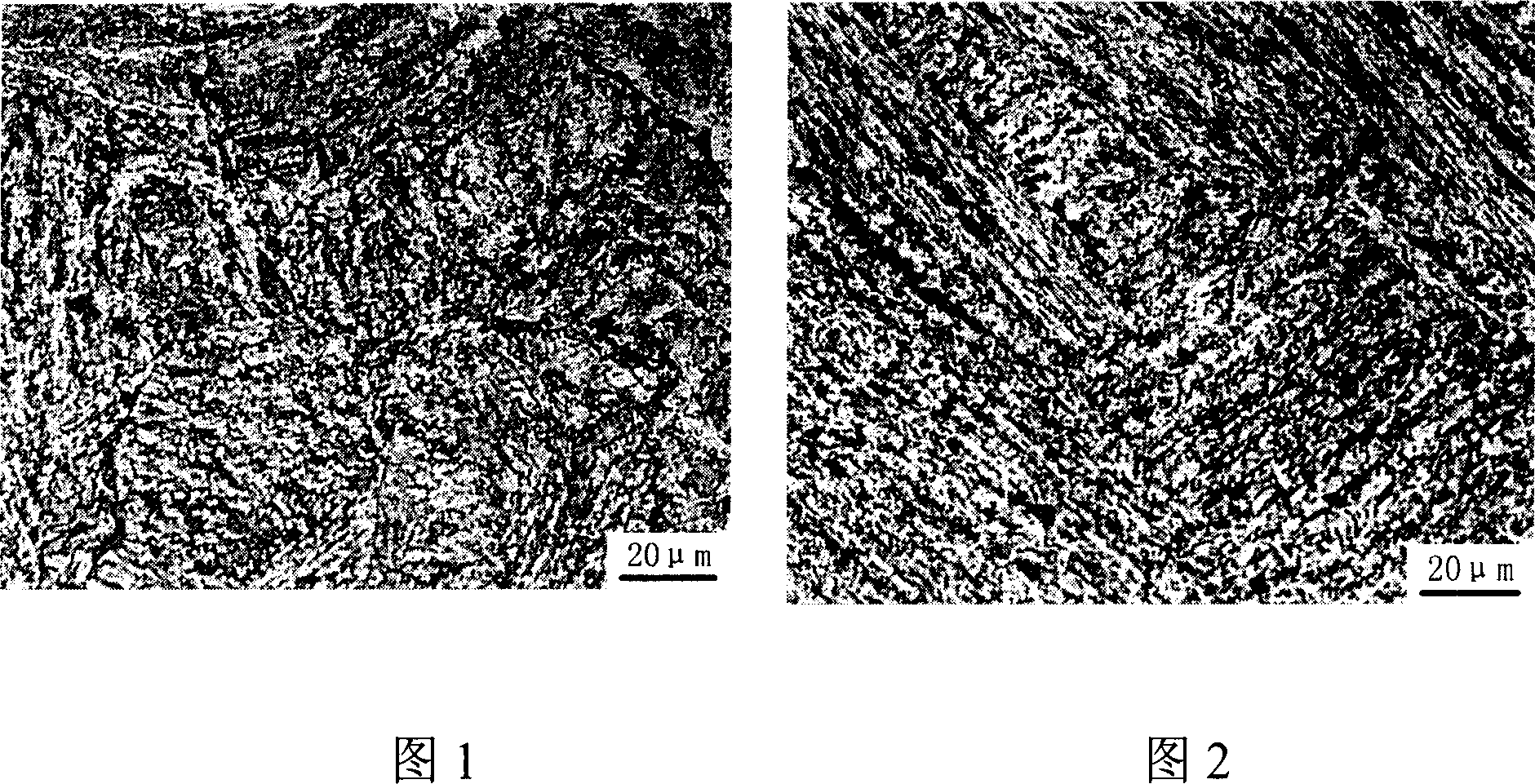

Martensitic antibiotic stainless steel and thermal treatment method thereof

ActiveCN101205592AImprove mechanical propertiesAntibacterial property does not decreaseHeat treatment process controlProcess efficiency improvementChemical compositionThermal treatment

The invention discloses martensite antibacterial stainless steel, the weight percentage compositions of which are: 0.05 to 1.0 percent by weight of C, less than or equal to 3 percent by weight of Si, less than or equal to 1.5 percent by weight of Mn, 10 to 30 percent by weight of Cr, less than or equal to 1 percent by weight of Ni, 0.5 to 5 percent by weight of Cu, less than or equal to 1 percent by weight of Nb, less than or equal to 1 percent by weight of Ti, uniformly dispersed nano-precipitation phases epsilon-cu, and the balance Fe and unavoidable impurities. The invention also discloses a hot treatment method of the martensite antibacterial stainless steel, which comprising the following steps of: firstly, performing hot rolling and cold rolling, followed by antibacterial treatment on the martensite antibacterial stainless steel to making an antibacterial part of the martensite antibacterial stainless steel; and then performing quenching and tempering sequentially. The invention has a broad spectrum antibacterial property, rapid sterilization property and a long-lasting antibacterial property, maintains good mechanical performance of the materials and has significant economic and social value.

Owner:华南生物医用材料(深圳)有限公司

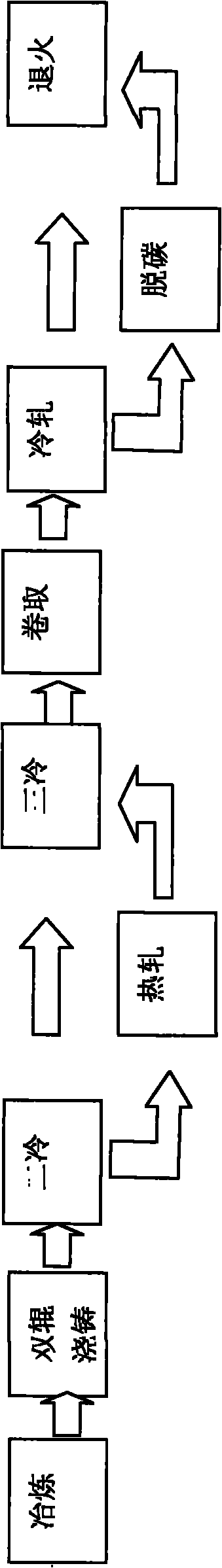

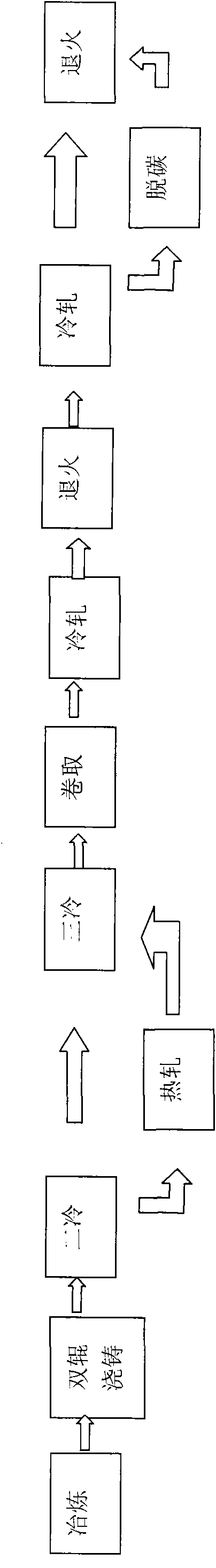

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

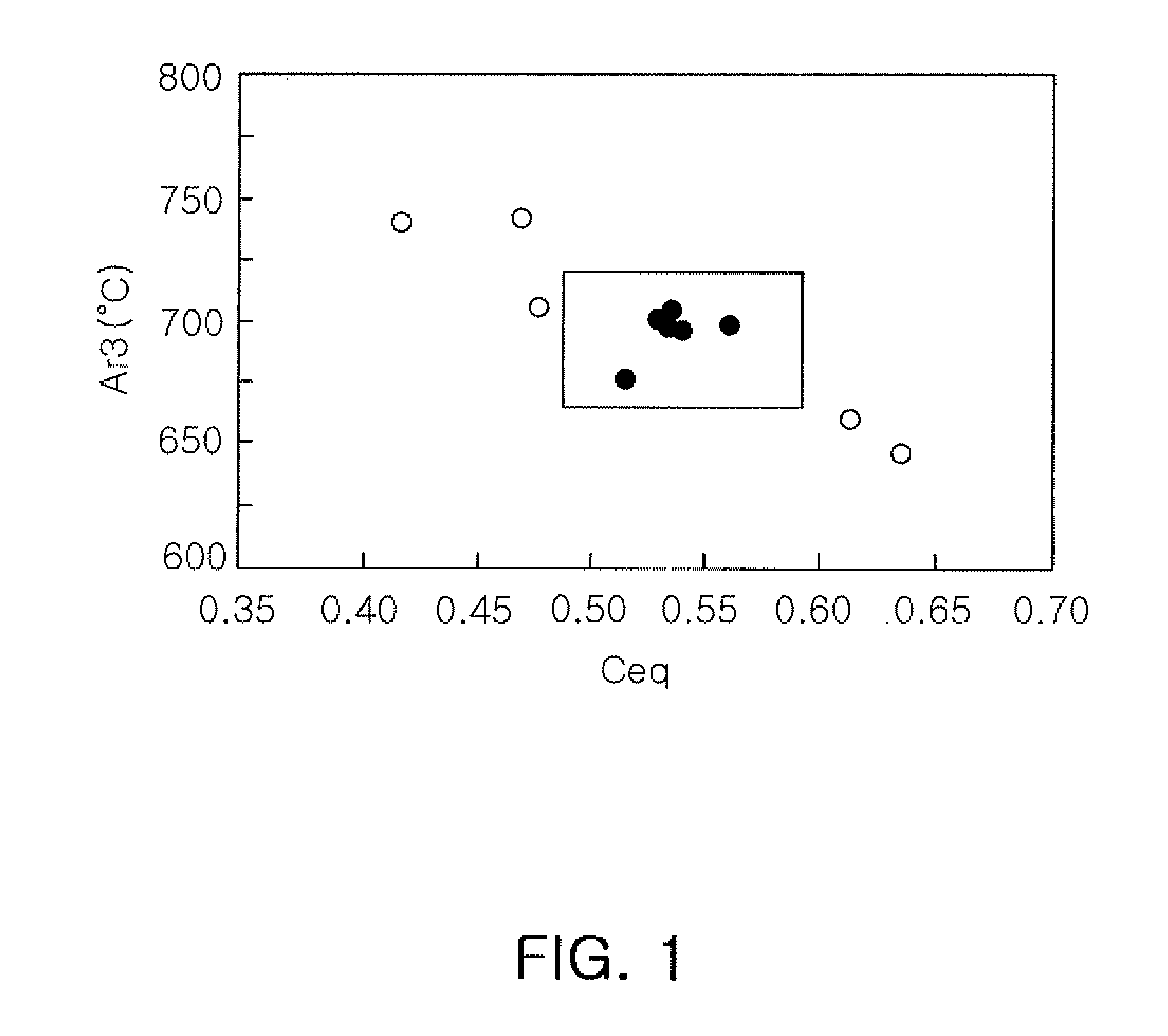

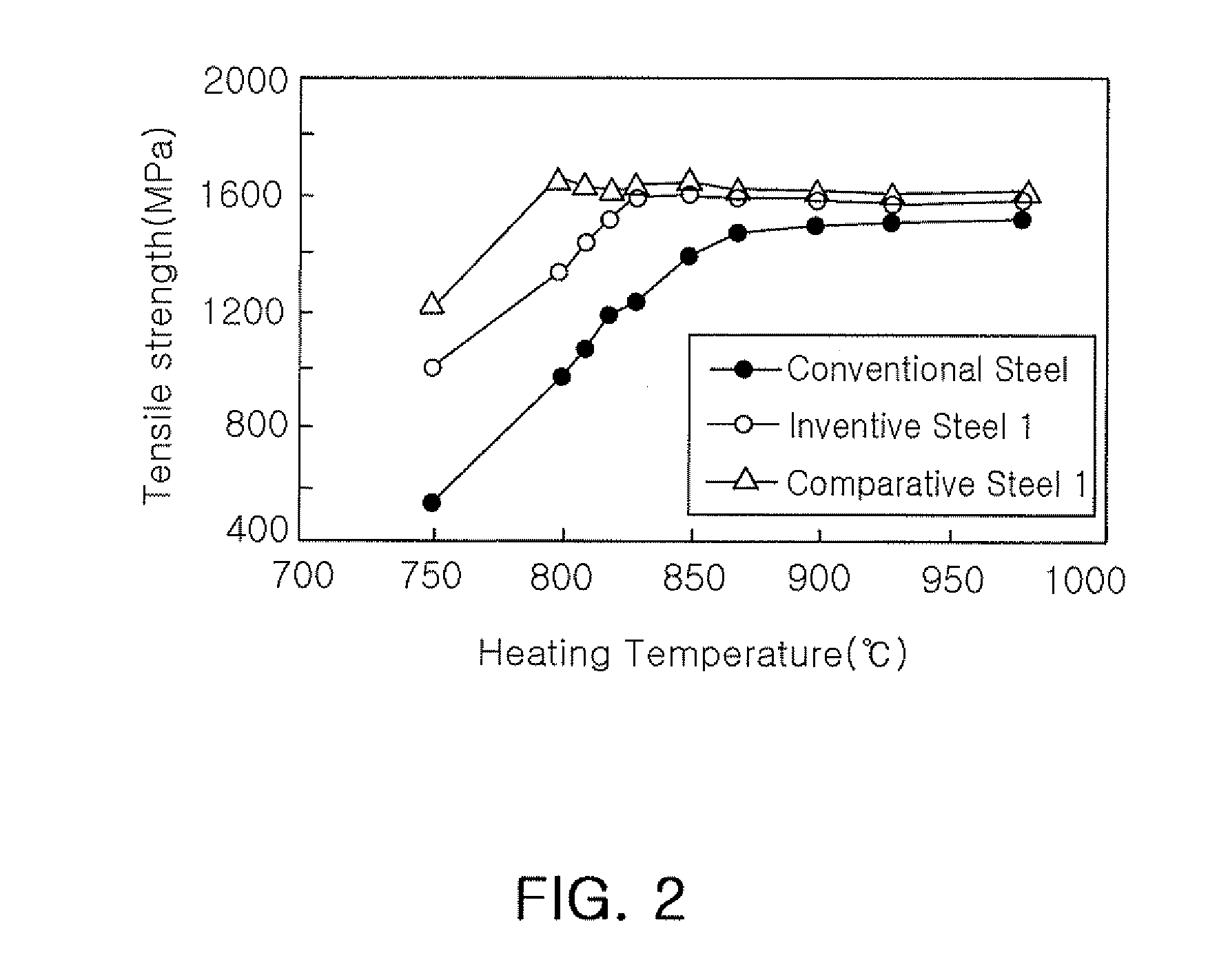

Steel sheet for hot press forming having low-temperature heat treatment property, method of manufacturing the same, method of manufacturing parts using the same, and parts manufactured by the same

ActiveUS20090238715A1Reduced strengthHigh yield strengthMetal rolling stand detailsFurnace typesManganeseHeat treated

A steel sheet for forming having low-temperature heat treatment property, in which heat treatment is performed within a range of lower temperature than a conventional steel sheet in the event of hot press forming or post-heat treatment after cold forming, a method of manufacturing the same, and a method of manufacturing parts using the same. The steel sheet has a composition of, by weight, carbon (C): 0.15 to 0.35%, silicon (Si): 0.5% or less, manganese (Mn): 1.5 to 2.2%, phosphorus (P): 0.025% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.01 to 0.05%, nitrogen (N): 50 to 200 ppm, titanium (Ti): 0.005 to 0.05%, tungsten (W): 0.005 to 0.1%, and boron (B): 1 to 50 ppm, wherein Ti / N: less than 3.4, where Ti / N is the atomic ratio of the corresponding elements, Ceq expressed by the following formula ranges from 0.48 to 0.58, and temperature Ar3 ranges from 670° C. to 725° C. Wherein Ceq=C+Si / 24+Mn / 6+Ni / 40+Cr / 5+V / 14 where C, Si, Mn, Ni, Cr and V indicate the contents (wt %) of the respective elements.

Owner:POHANG IRON & STEEL CO LTD

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

High-strength weathering steel and method of manufacturing same

InactiveCN1970818AReduce control requirementsUniform microstructureRoll mill control devicesHeat treatment process controlSolubilityMetallurgy

The invention discloses a high-strength weatherabile steel and manufacturing method in the low-alloy steel making domain, which is characterized by the following: adding low-carbon and Cu-Cr-Ni-Mo-Nb into two or more composite additives; controlling carbon content with maximum solubility in the alpha-Fe at 0.0218% under normal temperature; reducing carbon-permeating evolution; affirming main control tissue evenly.

Owner:武钢集团有限公司 +1

Built up welding technique of restoring roller for shape bar

InactiveCN101003104AReduce manufacturing costArc welding apparatusFurnace typesEngineeringMechanical engineering

A build-up welding technology for repairing the rolling roller of section includes such steps as pre-turning, defect inspection, pre-heating, welding transition layer with flux-cored wire SN-YD1031 and flux SSF, welding working layer with flux-cored wire SN-YD285 and flux HJ107, heat treating, turning, and inspection.

Owner:攀枝花钢城集团有限公司协力分公司

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

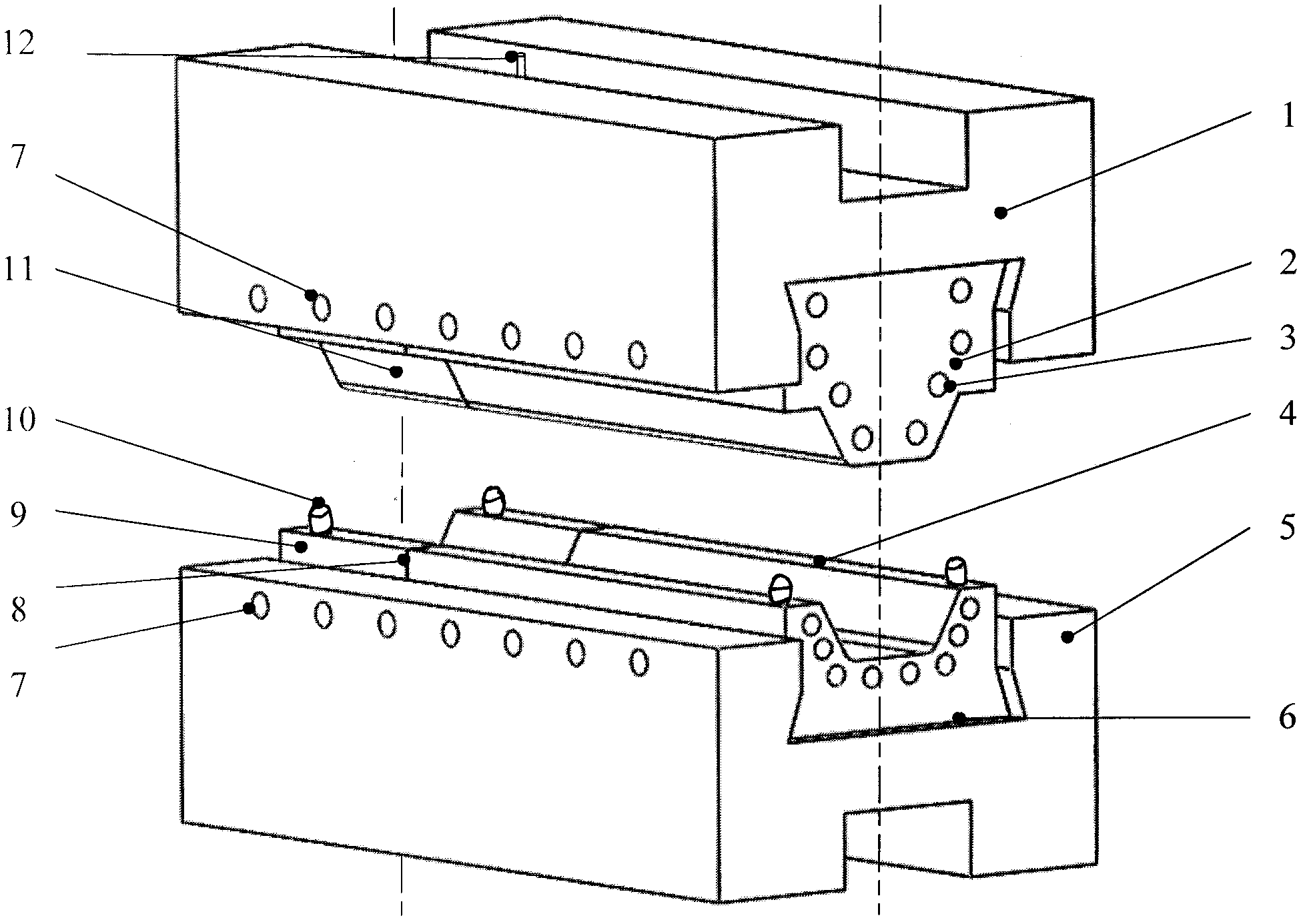

High-temperature splicing and quenching forming process and device of ultrahigh-strength steel

InactiveCN102304612ALess investmentReduce production processHeat treatment process controlHardnessUltimate tensile strength

The invention discloses a high-temperature splicing and quenching forming process of ultrahigh-strength steel. The process is characterized in that heat transfer with different degrees is performed in different regions of a part in forming and in-mold cooling processes, thus the strength and hardness are distributed according to requirements and the random splicing of the high strength and energyabsorption property of the material is achieved. At the same time, the invention also discloses a device for the process. The male mold and female mold of the device are formed by splicing one and more than one insert according to the requirement, and the male mold and the female mold are combined in five different combination modes. The process and device can ensure that the part has different mechanical properties in the different regions after one-time hot forming is finished, and can be applied to the production of automobile anti-collision parts (such as anti-collision beams, pillars A, pillars B, automobile body floor passageway and the like).

Owner:SHANDONG JIANZHU UNIV

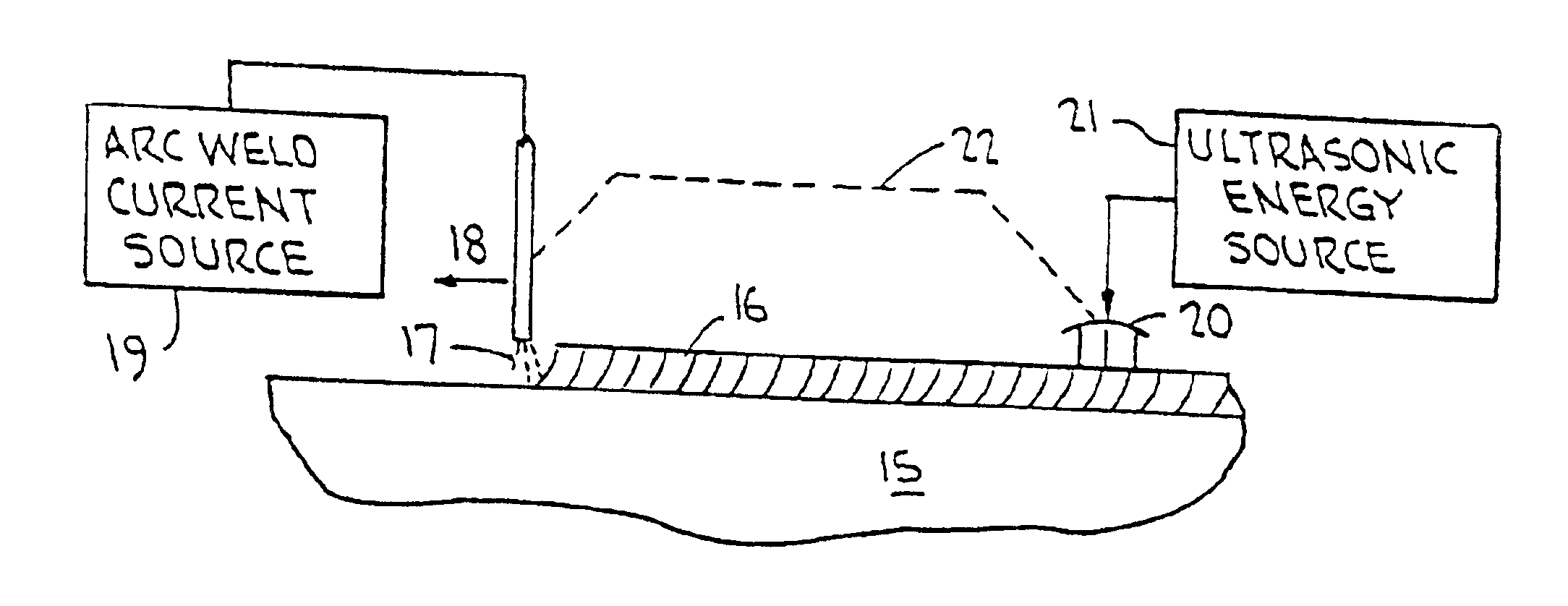

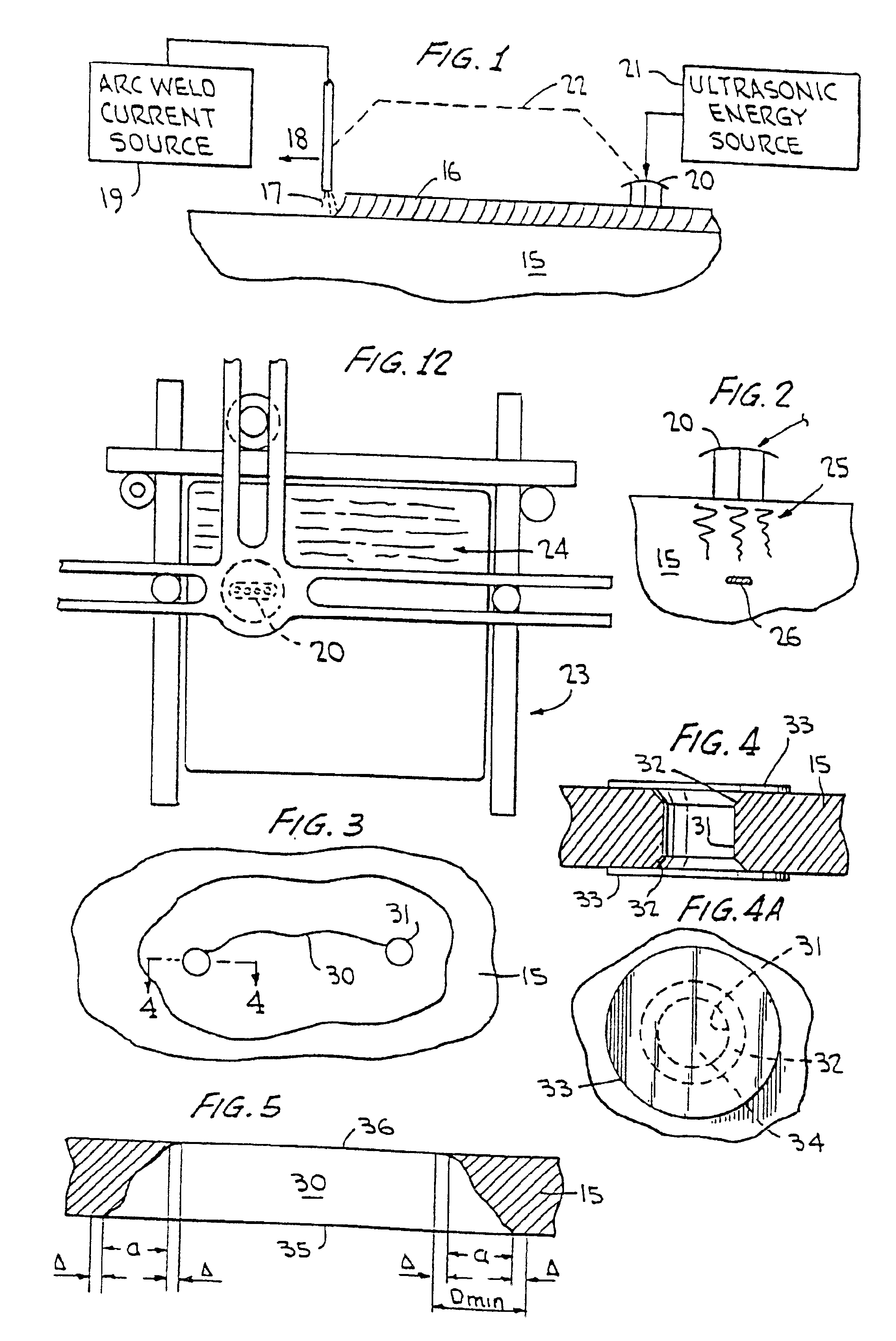

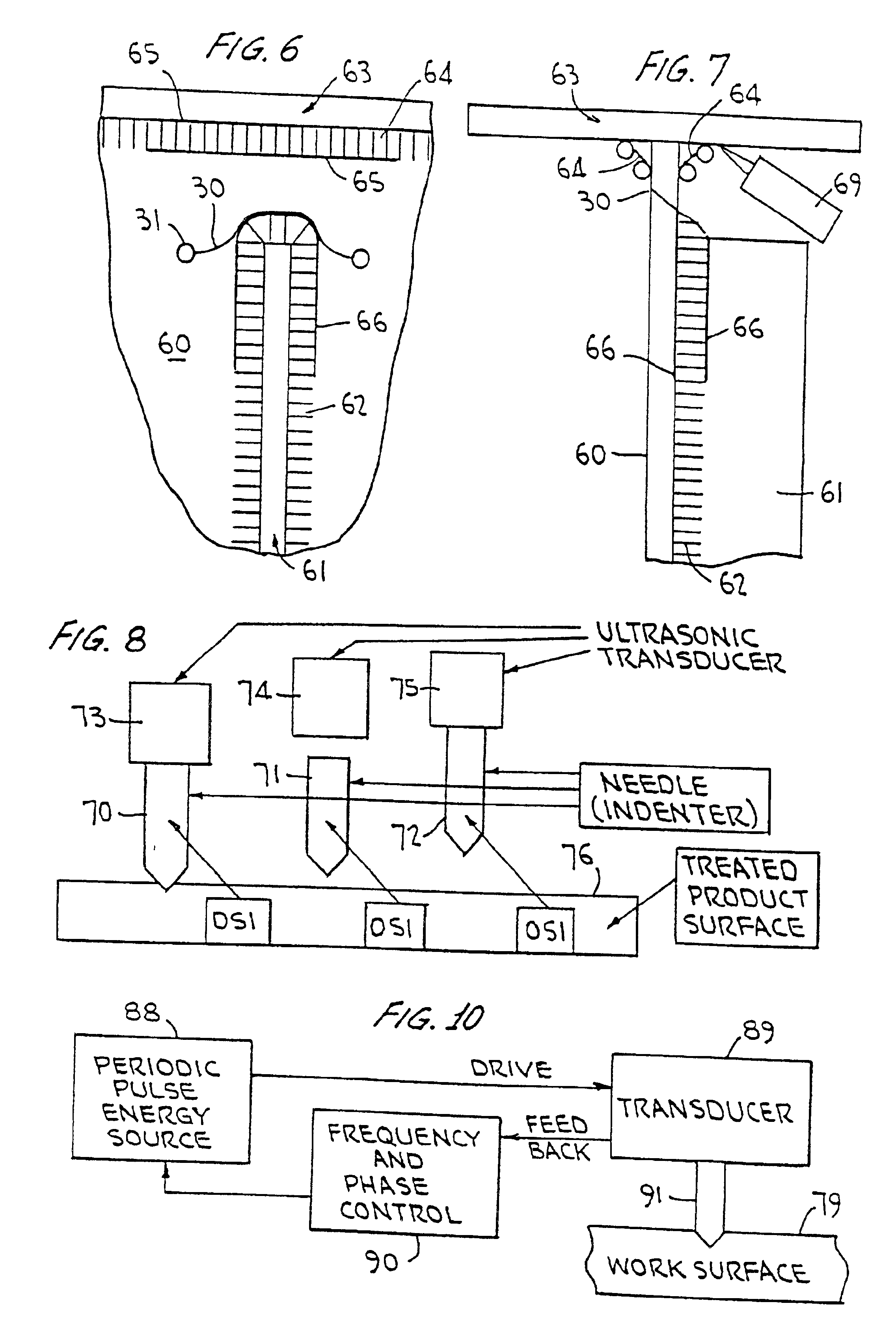

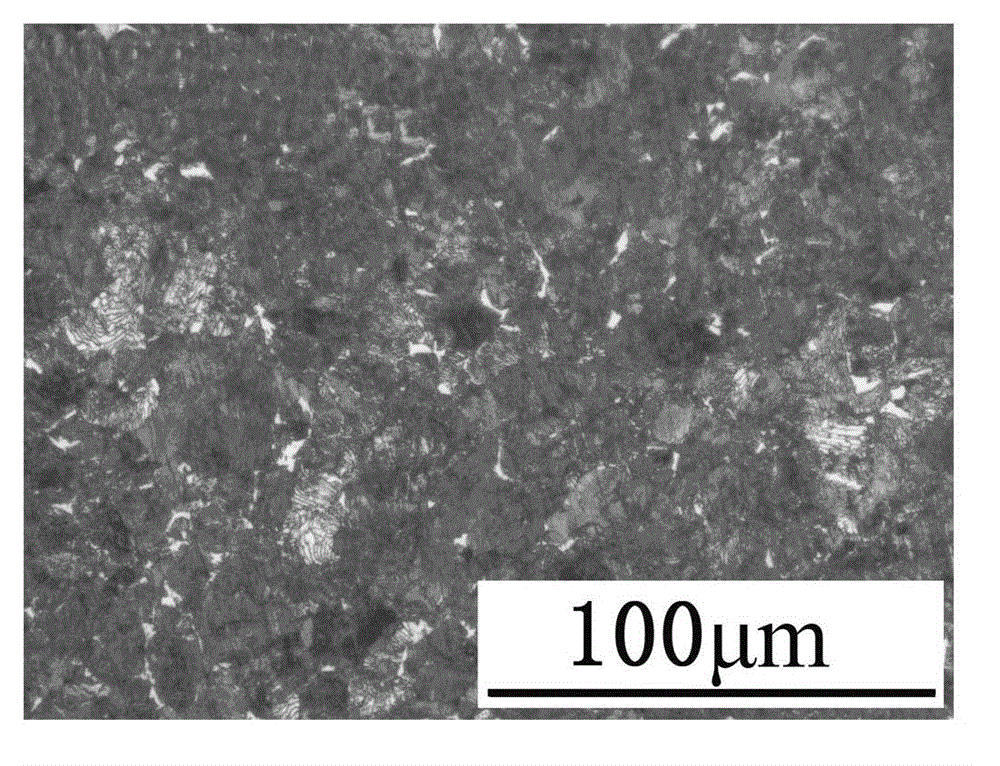

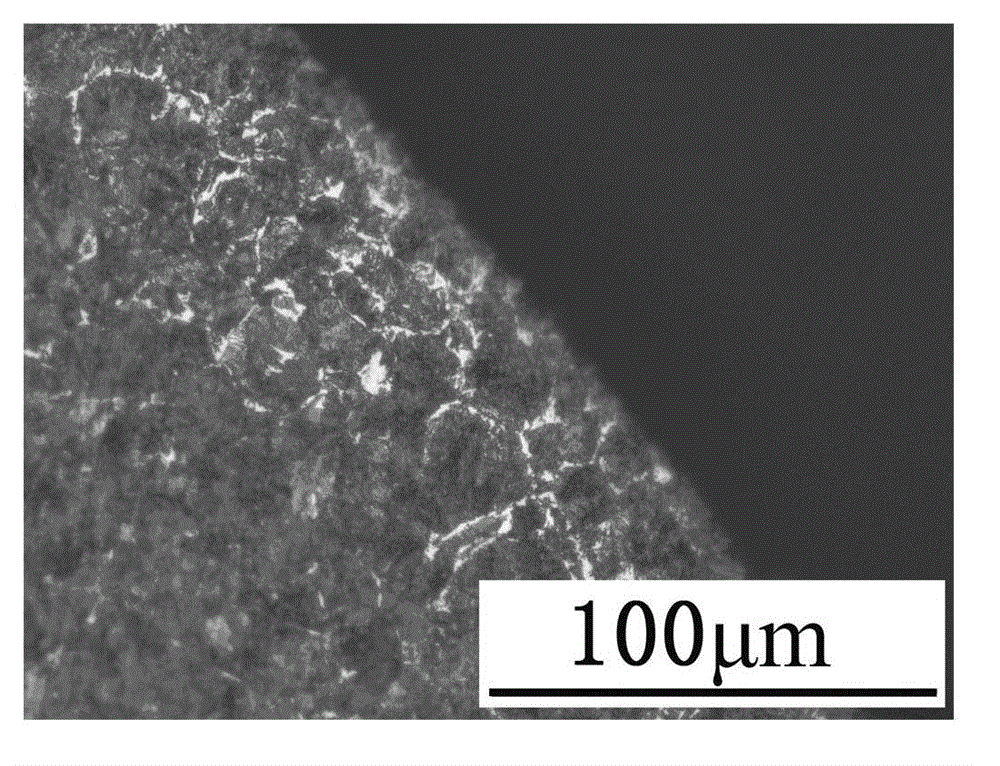

Ultrasonic impact methods for treatment of welded structures

InactiveUS6843957B2Improve corrosion fatigue strengthIncreased durabilityBlast furnace detailsHigh frequency current welding apparatusUltrasonic sensorEngineering

This invention provides methods of treatment for work products of materials such as steel, bronze, plastic, etc. and particularly welded steel bodies by pulse impact energy, preferably ultrasonic, to relax fatigue and aging and extend expectant life. The treatment may occur (a) at original production, (b) during the active life period for maintenance or (c) after failure in a repair stage. The ultrasonic treatment improves the work product strength. In welded products residual stress patterns near the weld sites are relaxed and micro-stress defects such as voids and unusual grain boundaries are reduced. The basic method steps are non-destructive in nature, inducing interior pulse compression waves with ultrasonic transducers and accessory tools impacting an external product surface with enough impulse energy to heat and temporarily plasticize the metal interior and relax stresses. The nature of the work product interior structure being treated is determined by sensing the mechanical movement at the impact surface of the work body to produce feedback frequency and phase signals responsive to input impact signals. These signals automatically conform driving pulse energy frequency and phase to the input transducers to match the mechanical resonance frequency of the working transducers and increase efficiency of energy transfer. Such feedback signals also are available for automated procedures which can improve product quality and consistency.

Owner:PROGRESS RAIL SERVICES

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

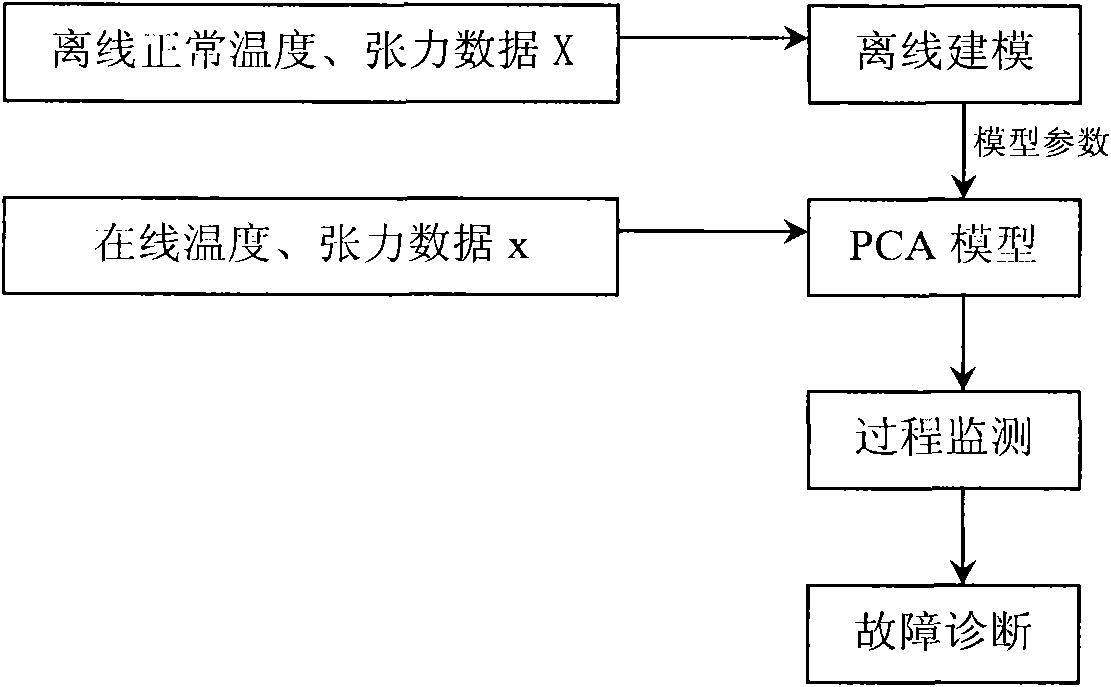

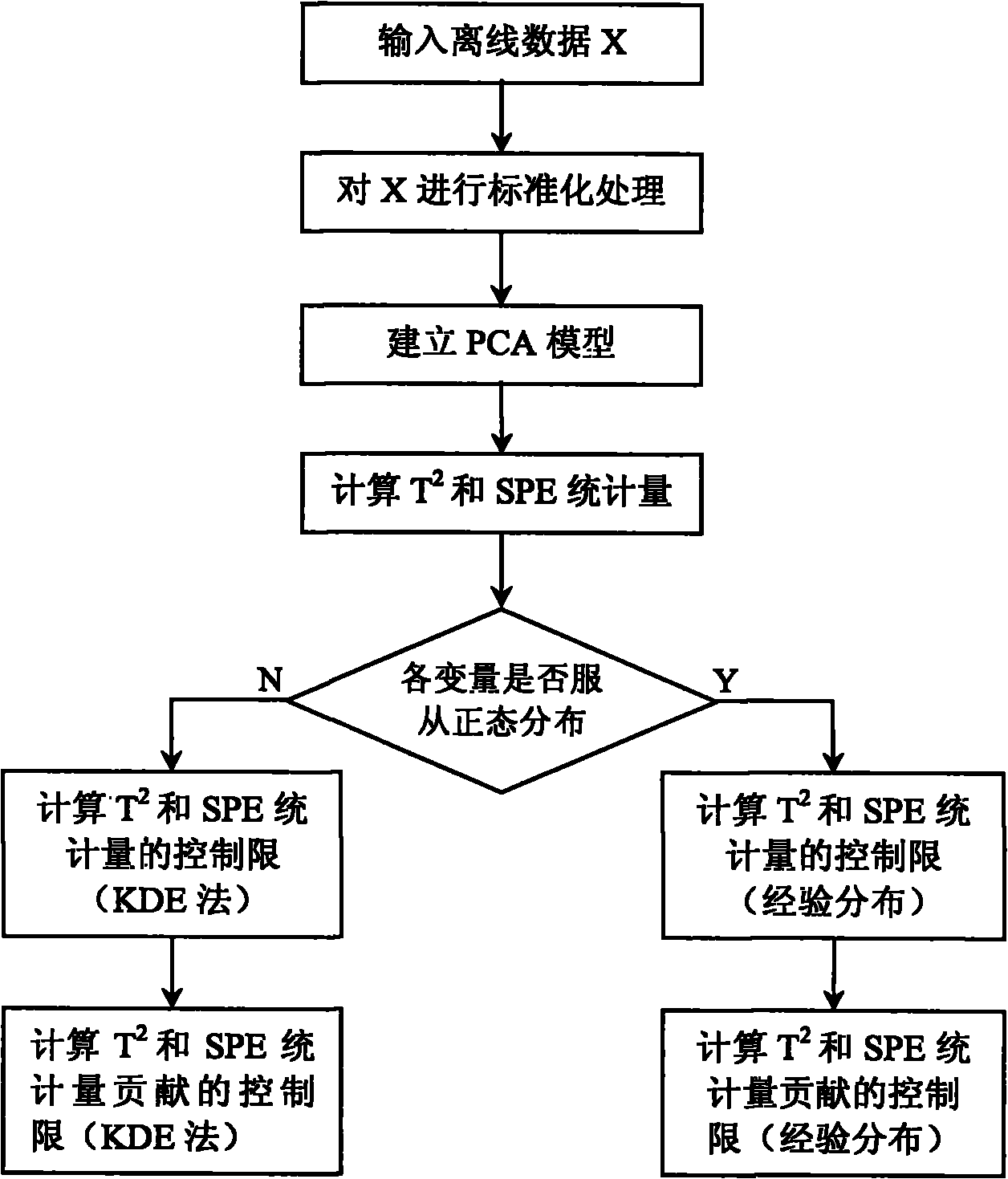

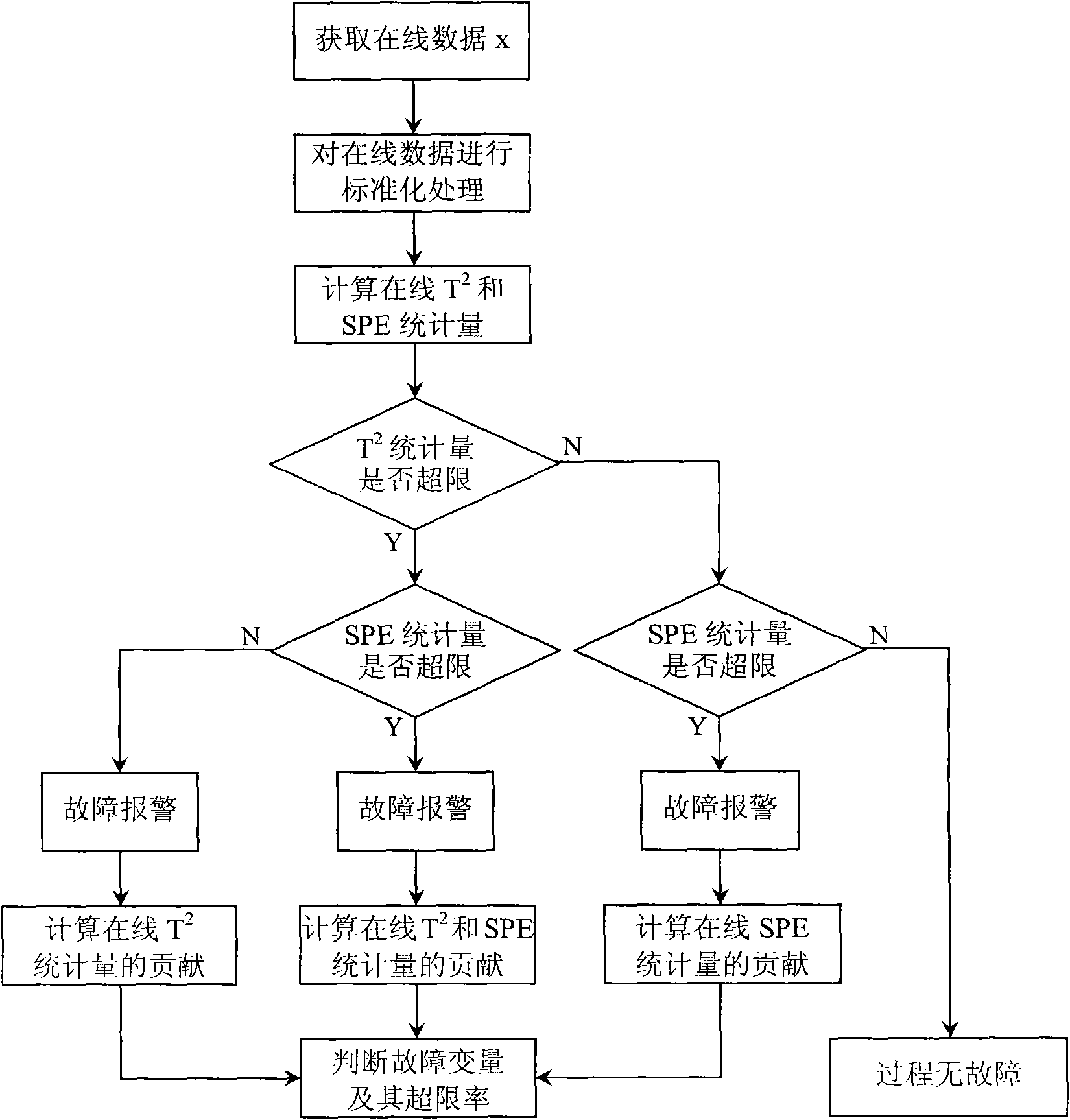

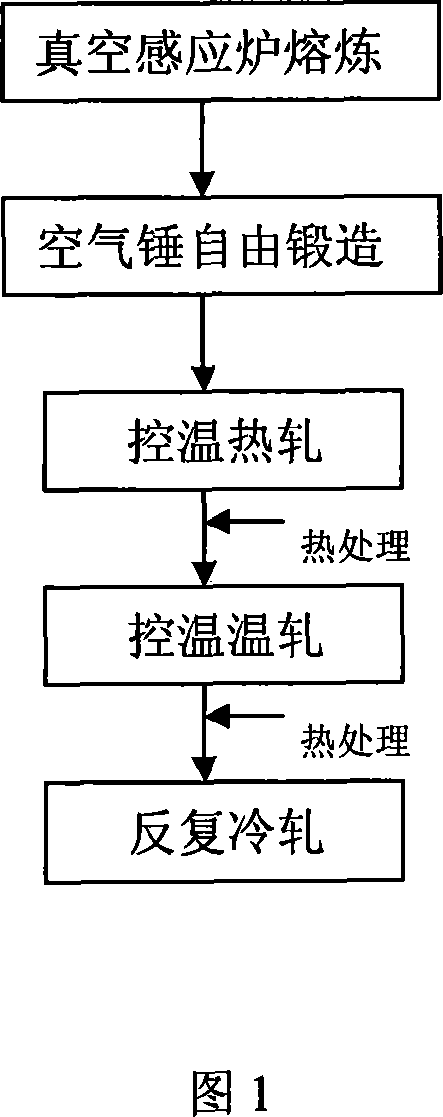

PCA (Principle Component Analysis) model based furnace temperature and tension monitoring and fault tracing method of continuous annealing unit

InactiveCN101899563AClear structureClear relationshipHeat treatment process controlFurnace temperatureOnline model

The invention relates to a fault monitor and diagnosis method of a continuous annealing unit, in particular to a PCA (Principle Component Analysis) model based furnace temperature and tension monitoring of a continuous annealing unit, mainly comprising the following steps of firstly, according to process variable data obtained in the field, and establishing a temperature and tension monitor modelby utilizing a principle component analysis PCA method; secondly, establishing an off-line model and calculating the T2 statistics quantity and the SPE statistics quantity as well as contributed control limits thereof by utilizing the data, obtained in step one, when process variable is in a normal work condition; thirdly, applying an on-line model, calculating the T2 statistics quantity and the SPE statistics quantity of current data, monitoring whether a current state is normal or not according to information supplied by the off-line model, and giving alarm signals if abnormal; fourthly, determining a leading variable which causes a fault by utilizing contribution of the T2 statistics quantity and contribution of the SPE statistics quantity. The invention monitors the furnace temperature and tension in real time in the production process and traces back a fault reason for leading to system abnormality when the abnormality occurs.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

Leveler roll and manufacturing process thereof

ActiveCN101153377AReduce contentChange sizeIncreasing energy efficiencyFurnace typesStrip steelMachining

The invention relates to a straightening roll and the manufacturing process thereof, wherein, the composition of the roll includes 0.60wt percent to 1.10wt percent of C, 0.20wt percent to 1.0wt percent of Si, 0.20wt percent to 0.60wt percent of Mn, 0.20wt percent to 1.00wt percent of Ni, 4.00wt percent to 6.00wt percent of Cr, 0.20wt percent to 1.00wt percent of Mo, 0.10wt percent to 0.50wt percent of V, less than or equal to 0.02wt percent of P, less than or equal to 0.02wt percent of S and the rest, Fe and other inevitable impurities; the manufacturing process of the roll includes: electric furnace smelting to secondary refining to ingot casing to electrode rolling to electrode rough machining to electroslag remelting to ingot casing to hydrogen diffusion annealing to forging to conditioning treatment to ultrasonic flaw detection and microscopic and macroscopic test to rough machining to quenching and tempering heat treatment to semifinishing to final heat treatment to finish machining to finished product. The invention increases the service life of the straightening roll and the surface quality of strip steel and eliminates the bottleneck in straightening high strength plate during production.

Owner:BAOSHAN IRON & STEEL CO LTD

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

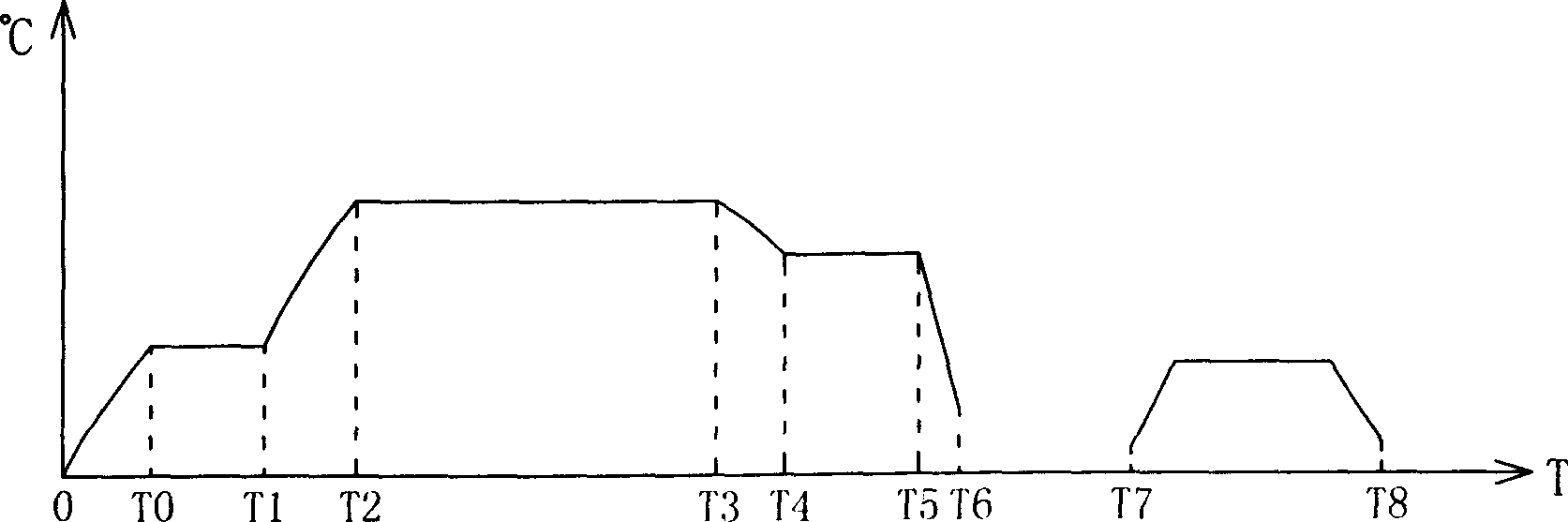

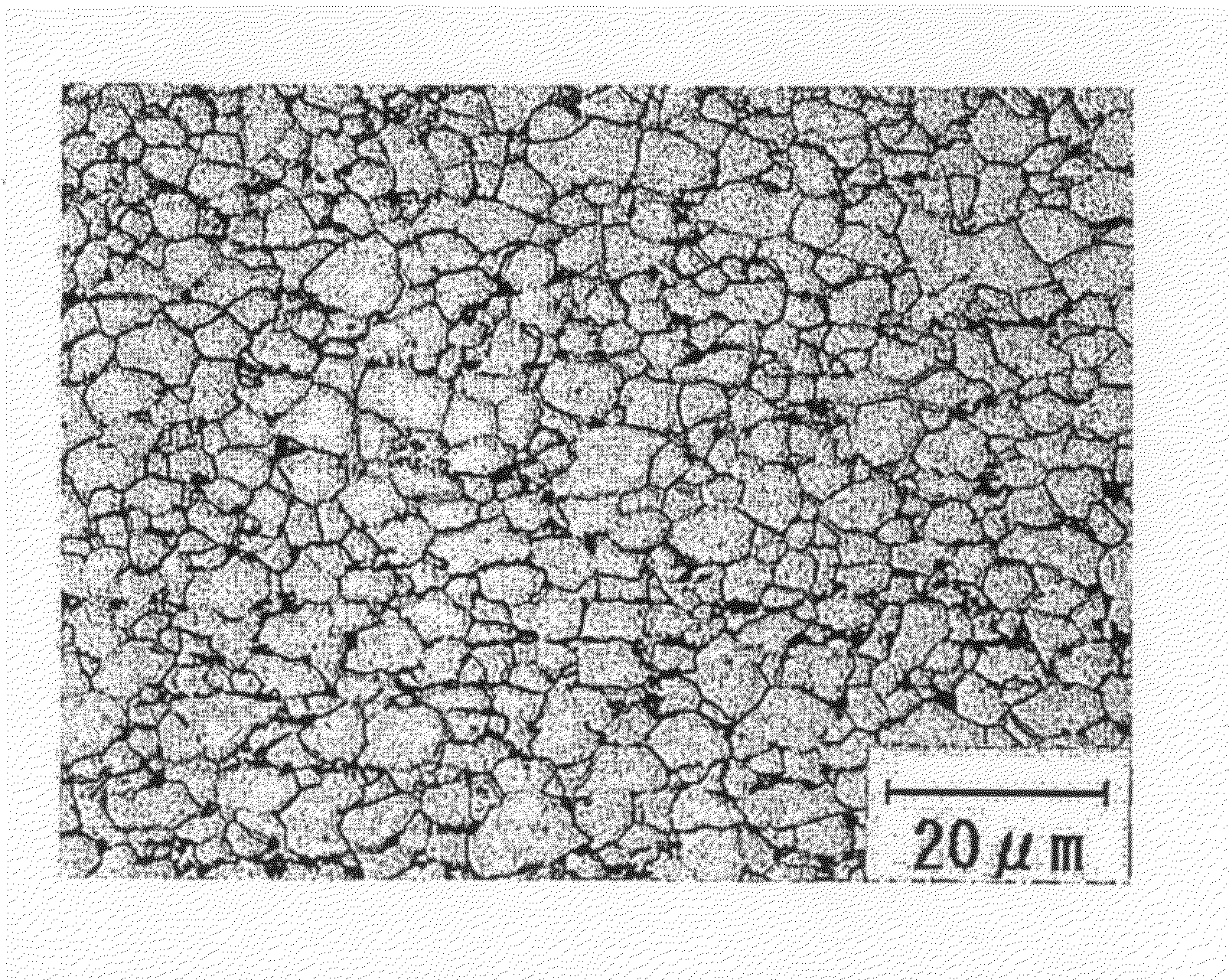

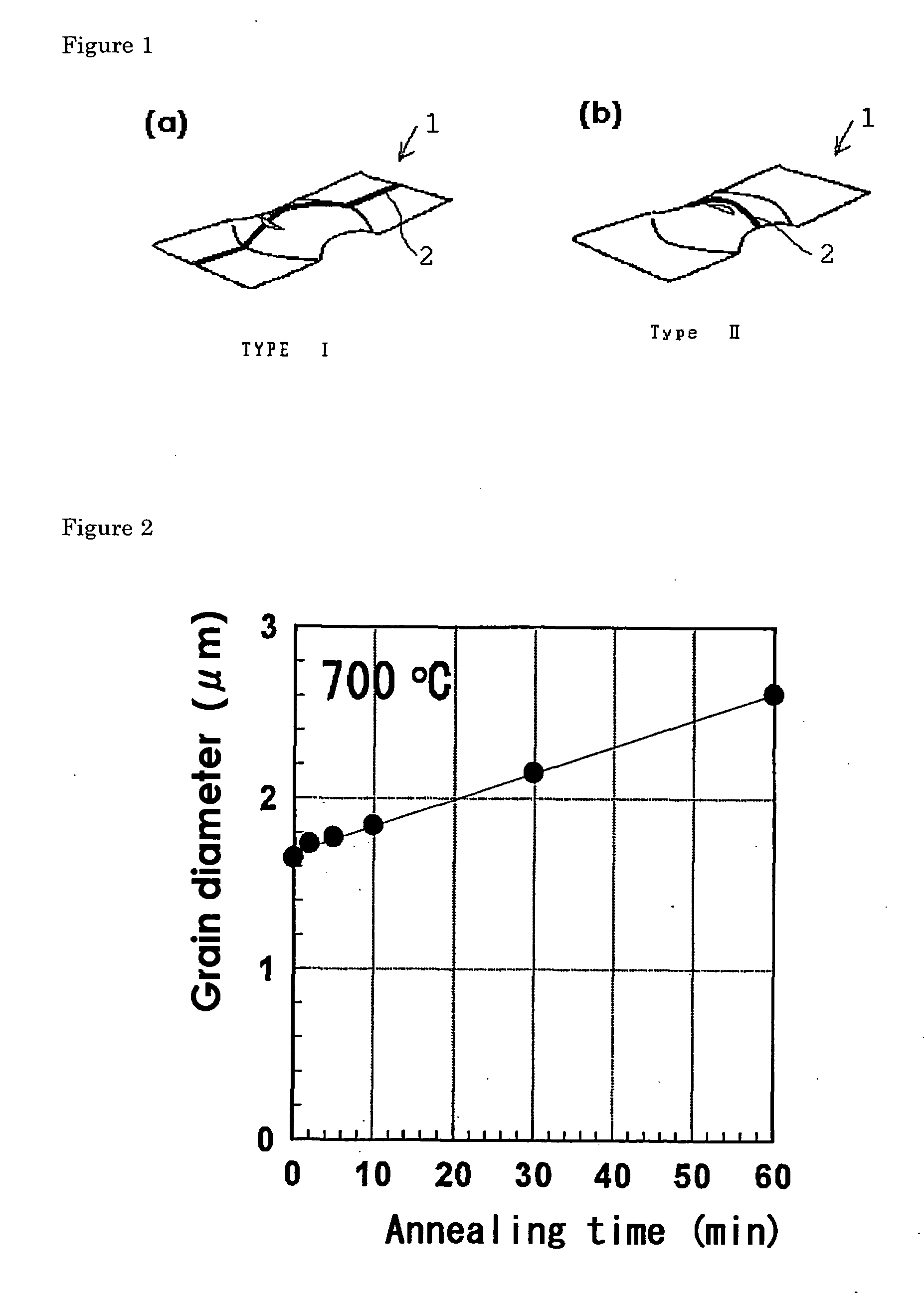

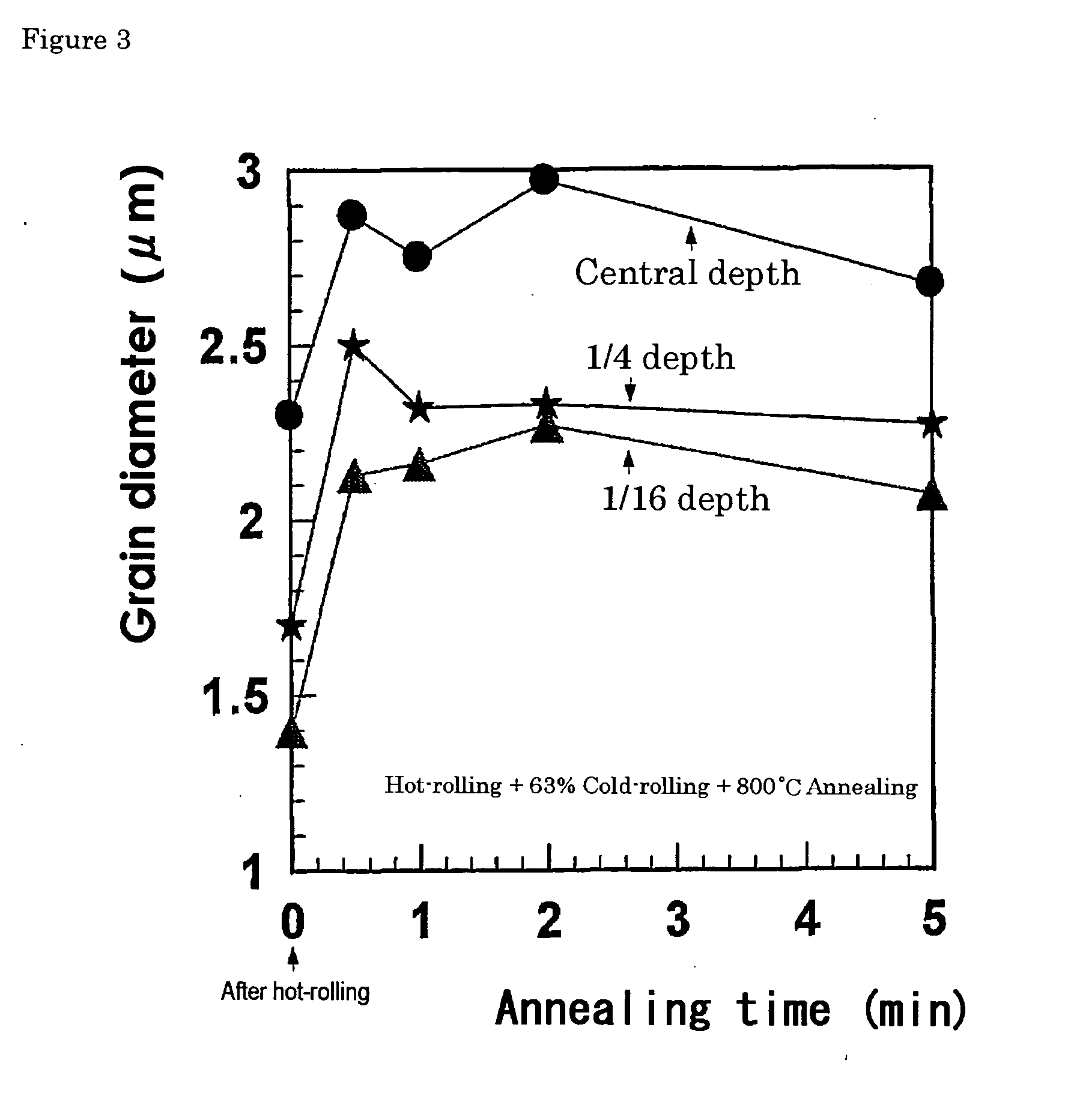

Hot-rolled steel sheet and cold-rolled steel sheet and manufacturing method thereof

InactiveUS20080202639A1Excellent mechanical propertiesLower transition temperatureHot-dipping/immersion processesFurnace typesMaterials scienceRaw material

A steel sheet excellent in mechanical strength, workability and thermal stability and suited for use as a raw material in such fields of manufacturing automobiles, household electric appliances and machine structures and of constructing buildings, and a manufacturing method thereof. are provided.The steel sheet is a hot-rolled steel sheet of carbon steel or low-alloy steel, the main phase of which is ferrite, and is characterized in that the average ferrite crystal grain diameter D (μm) at the depth of ¼ of the sheet thickness from the steel sheet surface satisfies the relations respectively defined by the formulas (1) and (2) given below and the increase rate X (μm / min) in average ferrite crystal grain diameter at 700° C. at the depth of ¼ of the sheet thickness from the steel sheet surface and said average crystal grain diameter D (μm) satisfy the relation defined by the formula (3) given below:1.2≦D≦7 formula (1)D≦2.7+5000 / (5+350·C+40·Mn)2 formula (2)D·X≦0.1 formula (3)wherein C and Mn represent the contents (in % by mass) of the respective elements in the steel.

Owner:NIPPON STEEL CORP

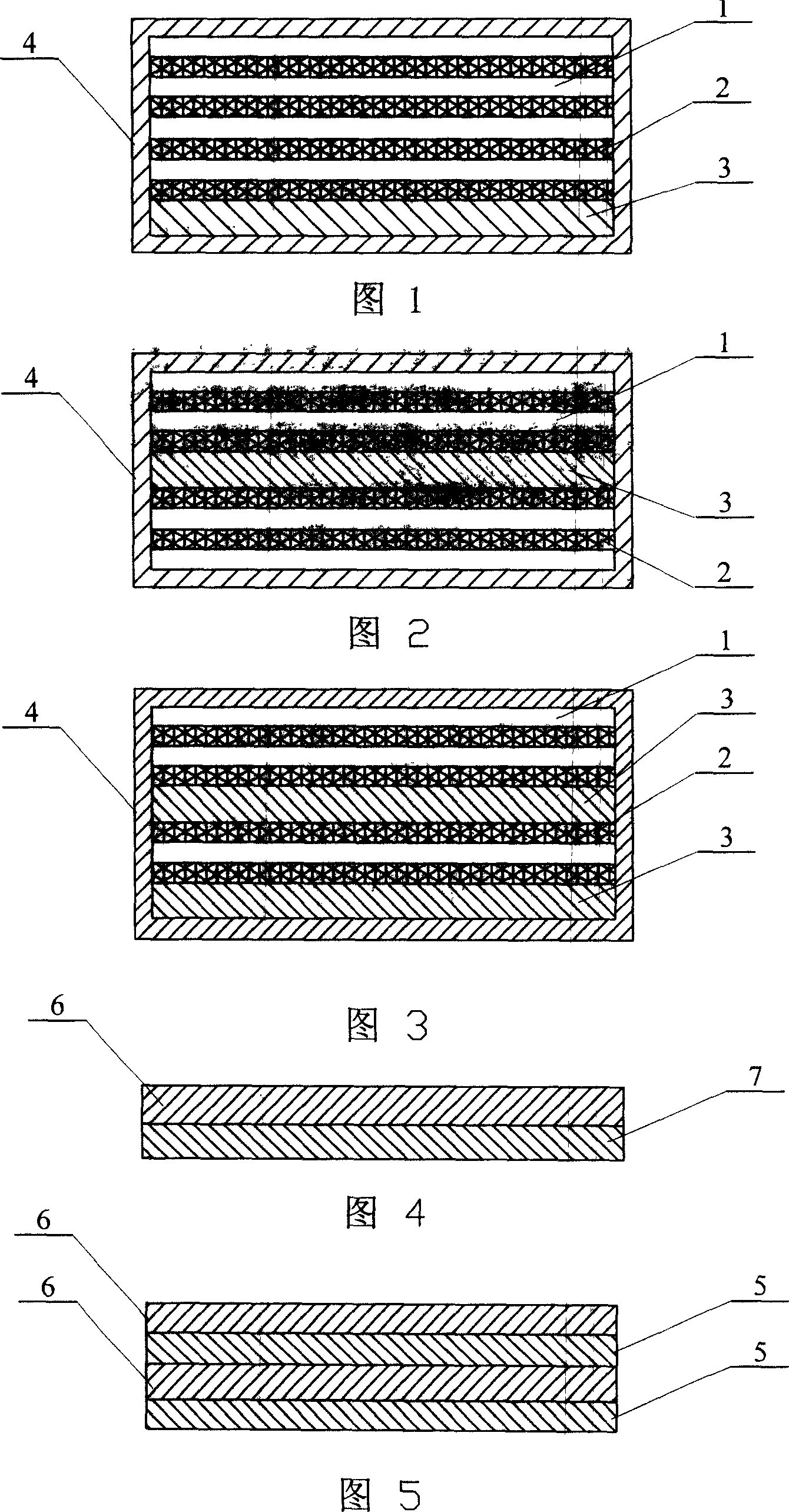

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

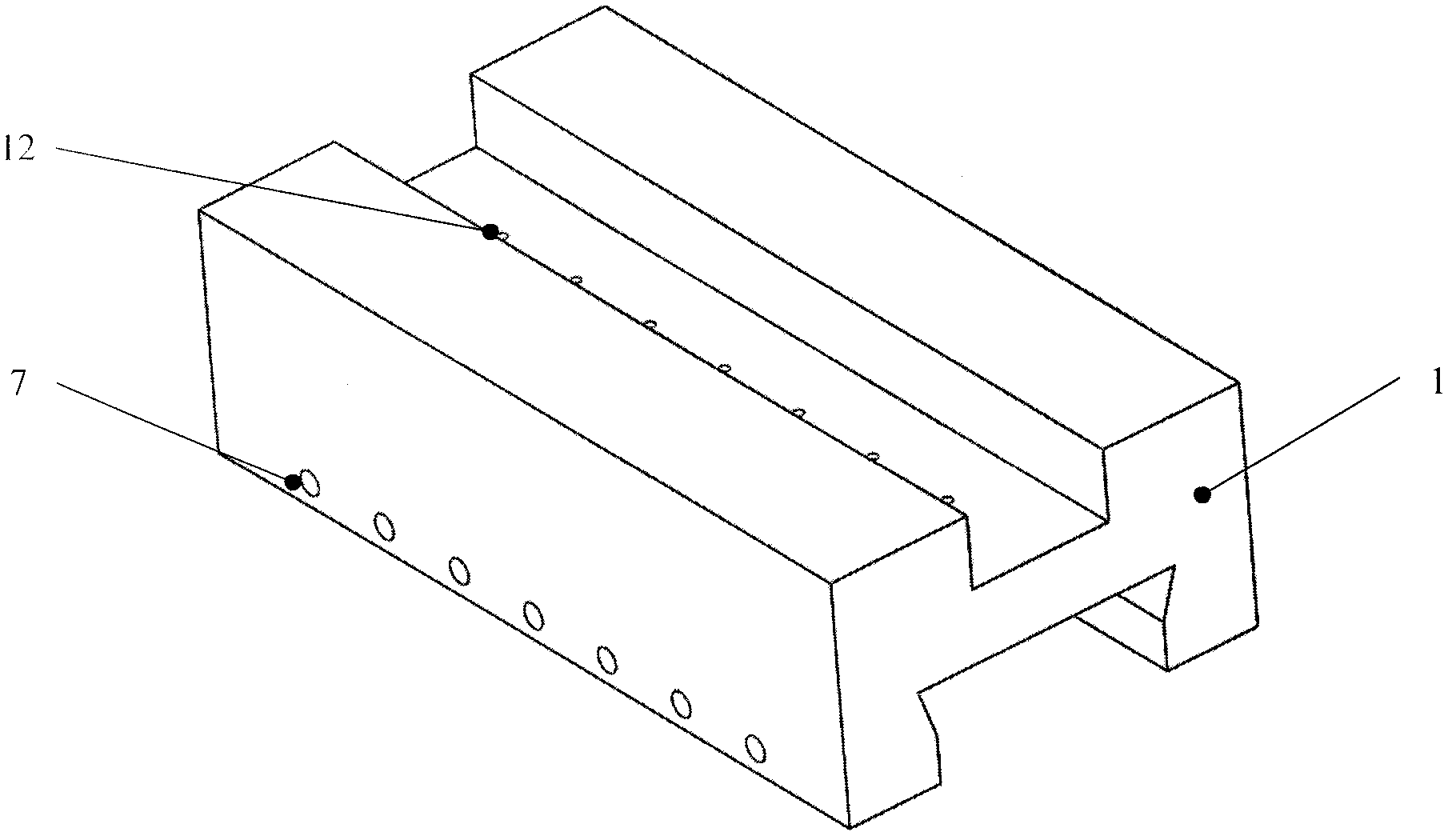

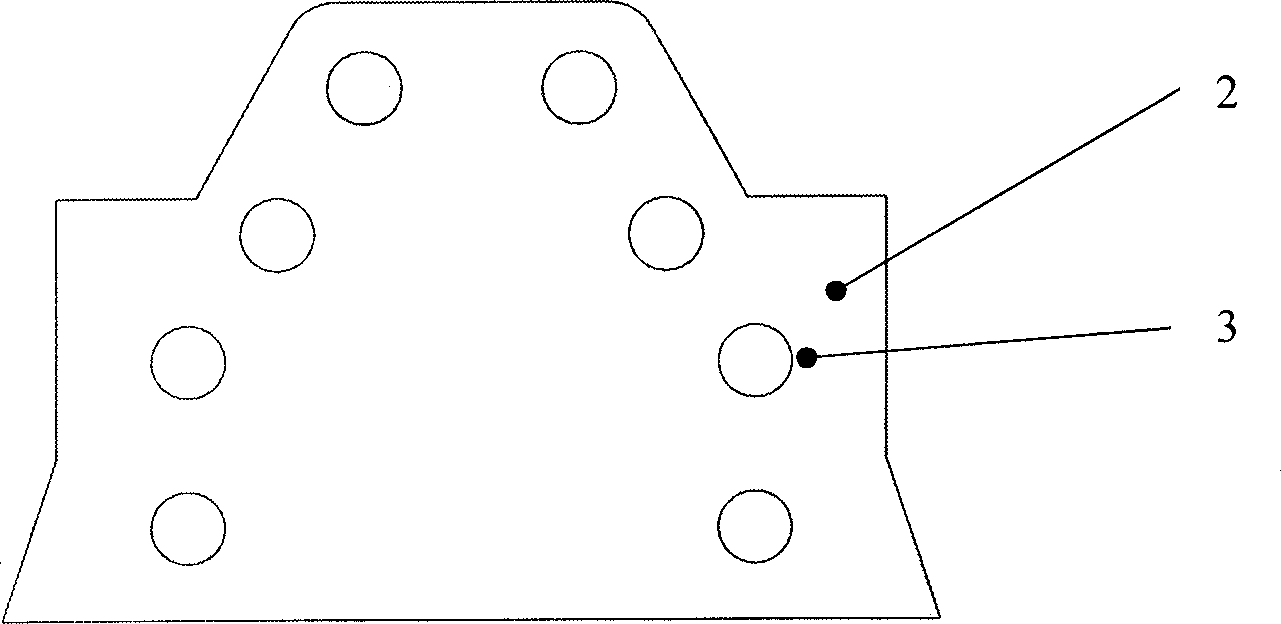

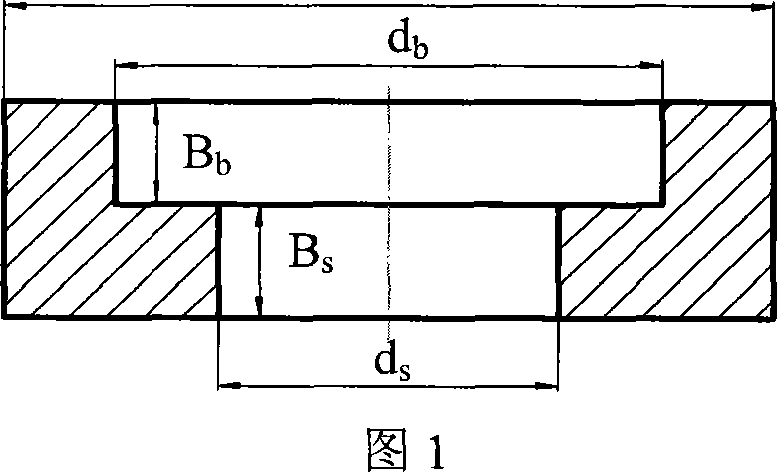

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

Super-thick non-hardening plastic mold steel and method for manufacturing the same

ActiveCN101096743ARealize non-temperedEliminate quenching and temperingHeat treatment process controlHardnessImpurity

The invention discloses a hyper-thick non-modified plastic die steel, which comprises the following parts: 0.20-0.32% C , 0.20-0.80% Si , 1.80-2.50% Mn, 0.80-1.50% Cr, 0.20-0.60% Mo, 0.08-0.20% V, 0.0010-0.0030% B, 0.02-0.06% Ti , not more than 0.035% P, not more than 0.035% S, ferric and inevitable impurity, wherein the structure condition is bainite. The invention ensures the hardness HRC30-36 of bainite structure and pre-hardening plastic die steel, which controls the cooling speed after forging with thickness over 300mm.

Owner:宝武特种冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com