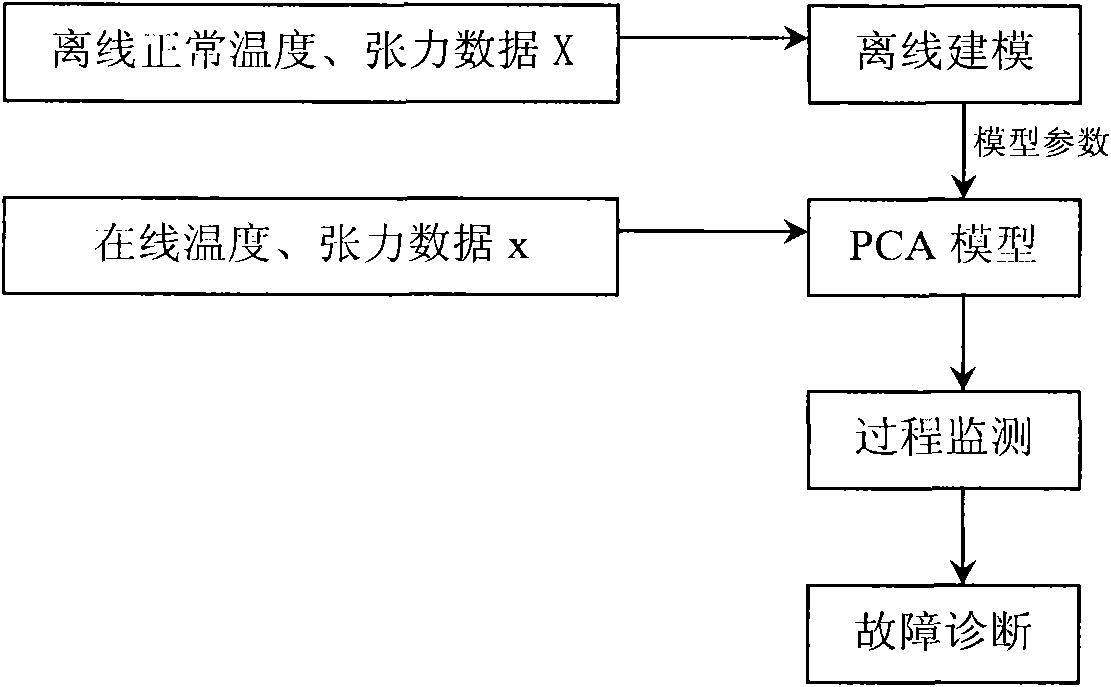

PCA (Principle Component Analysis) model based furnace temperature and tension monitoring and fault tracing method of continuous annealing unit

A furnace temperature and model technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve problems such as difficult monitoring and fault diagnosis, large number of process variables, and inability to guarantee product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

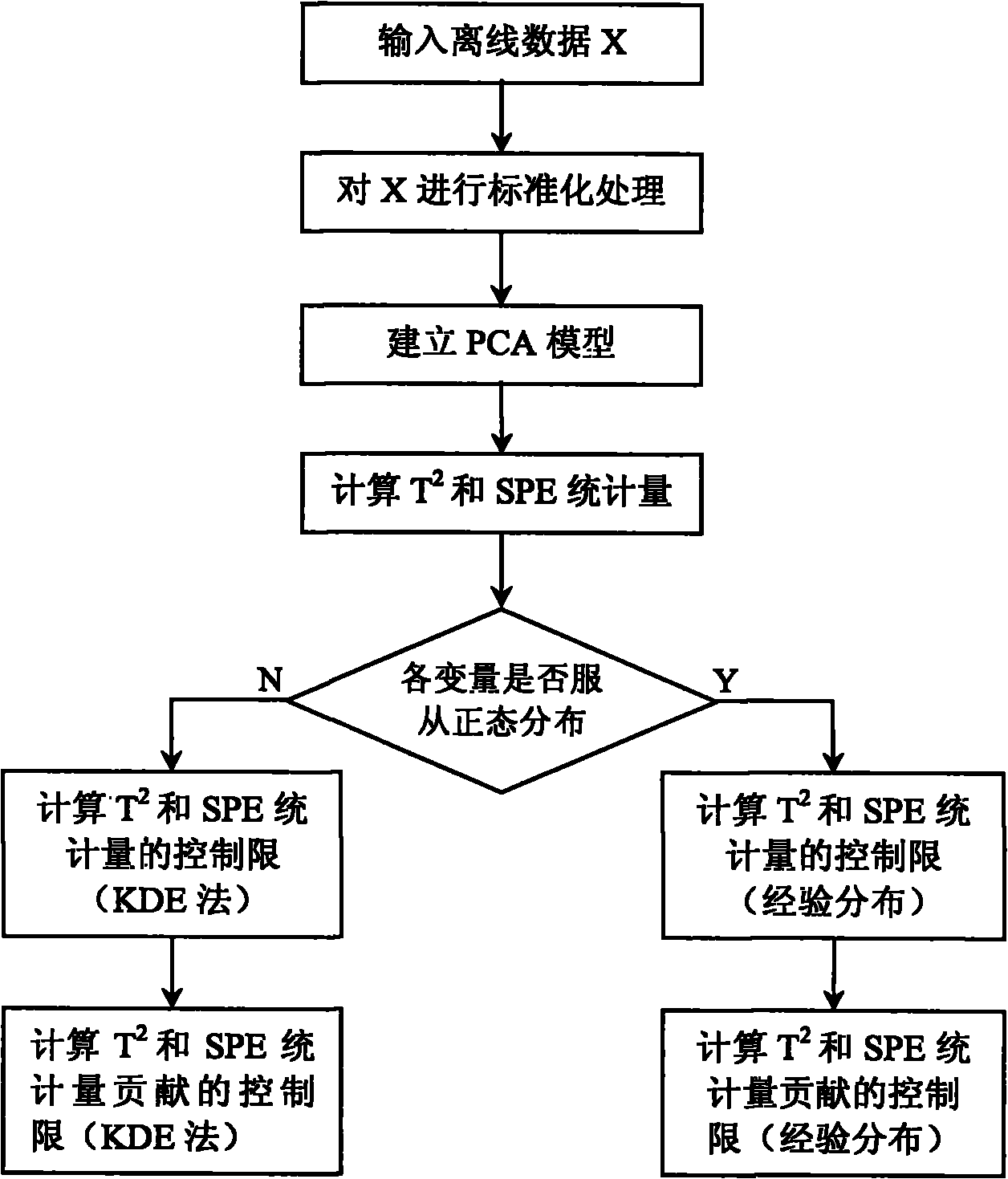

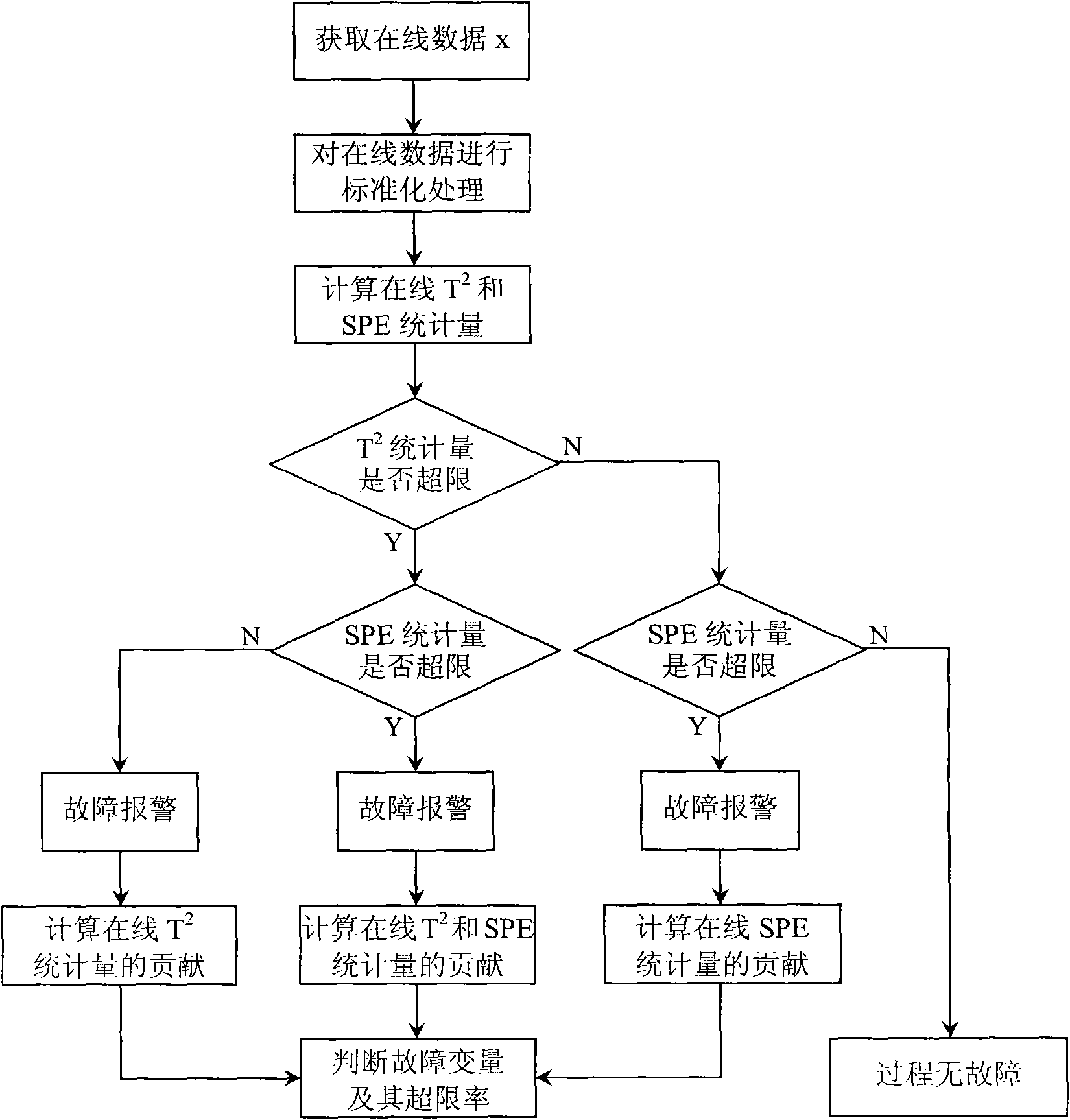

Method used

Image

Examples

Embodiment 1

[0188] Embodiment 1: Process monitoring and fault diagnosis of continuous annealing unit temperature

[0189] variable selection

[0190] According to the knowledge of the annealing mechanism, 32 process variables are selected for the establishment of the temperature model, including: plate temperature of each section, furnace temperature of each section, speed, thickness, and width of the central section.

[0191] data collection

[0192] For the modeling data of the temperature monitoring model based on PCA, the quenching and tempering degree of the steel strip is selected as T-3CA, and the normal production data of the annealing unit is used for one month, and the field data collection frequency is 1 second / time.

[0193] In practical applications, the process data comes from the field, and is affected by factors such as the accuracy and reliability of the measuring instrument and the field measurement environment, and inevitably has various measurement errors. The use of...

Embodiment 2

[0203] Embodiment 2: Process monitoring and fault diagnosis of tension in continuous annealing unit

[0204] variable selection

[0205] According to the knowledge of the annealing mechanism, 22 process variables are selected for the establishment of the tension model, including tension and process variables related to tension: 19 tension measuring points, central section speed, thickness, and width.

[0206] data collection

[0207] The quenching and tempering degree of the PCA-based tension monitoring model is selected as T-4CA, the normal production data of the annealing unit is used for 10 days, and the field data collection frequency is 1 second / time. Taking the average, we get 30,000 modeling samples.

[0208] model training

[0209] The above effective modeling data is sent to the PCA tension monitoring and fault diagnosis offline model, and the model parameters are obtained through training.

[0210] model validation

[0211] In order to verify the reliability of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com