Strip steel quality forecasting, furnace condition early-warning and fault diagnosis method based on partial least square

A partial least squares and quality prediction technology, which is applied in the fields of furnace condition early warning and fault diagnosis, and strip steel quality prediction, can solve problems such as time lag, limiting the qualified rate of strip steel product quality, and difficulty in finding fault factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

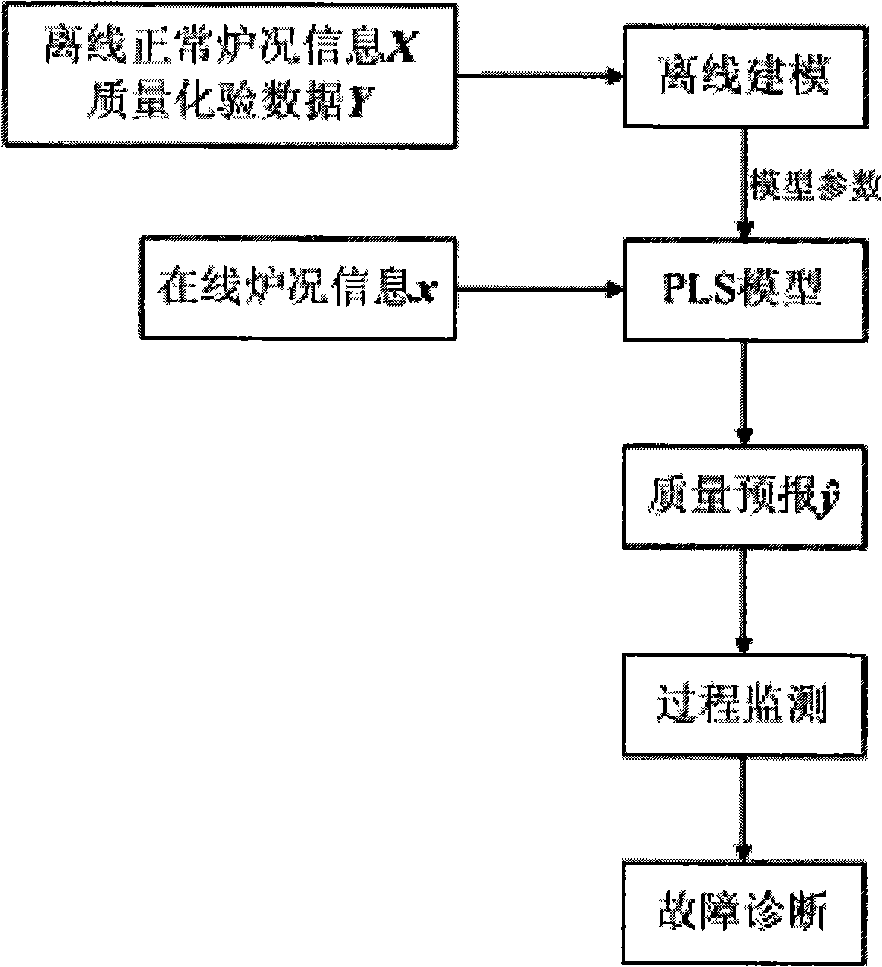

[0137] Such as figure 1 Shown, below is that the present invention is further described, comprises six steps:

[0138] 1. Model Selection

[0139] There are mainly two types of quality prediction model structures: single-model structure and multi-model structure; the complexity of the actual annealing process and the diversity of strip steel specifications are considered in the modeling, and the analysis shows that different steel types (degree of quenching and tempering) affect the process The operating conditions have different requirements, which directly or indirectly affect the quality of the strip steel, that is, different model structure relationships under different working conditions. Using a single model structure to describe the relationship between quality and process variables under different working conditions will result in defects such as large model structure, overfitting of data relationships, and low prediction accuracy. Therefore, this project adopts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com