Patents

Literature

1224 results about "Steel quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

QUALITY OF STEEL. Quality of steel should be seen as an inherently quantifiable attribute that is used to determine a steel’s ability to perform its designed function without limitation due to internal flaws or large variances in microstructure or homogeneity.

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

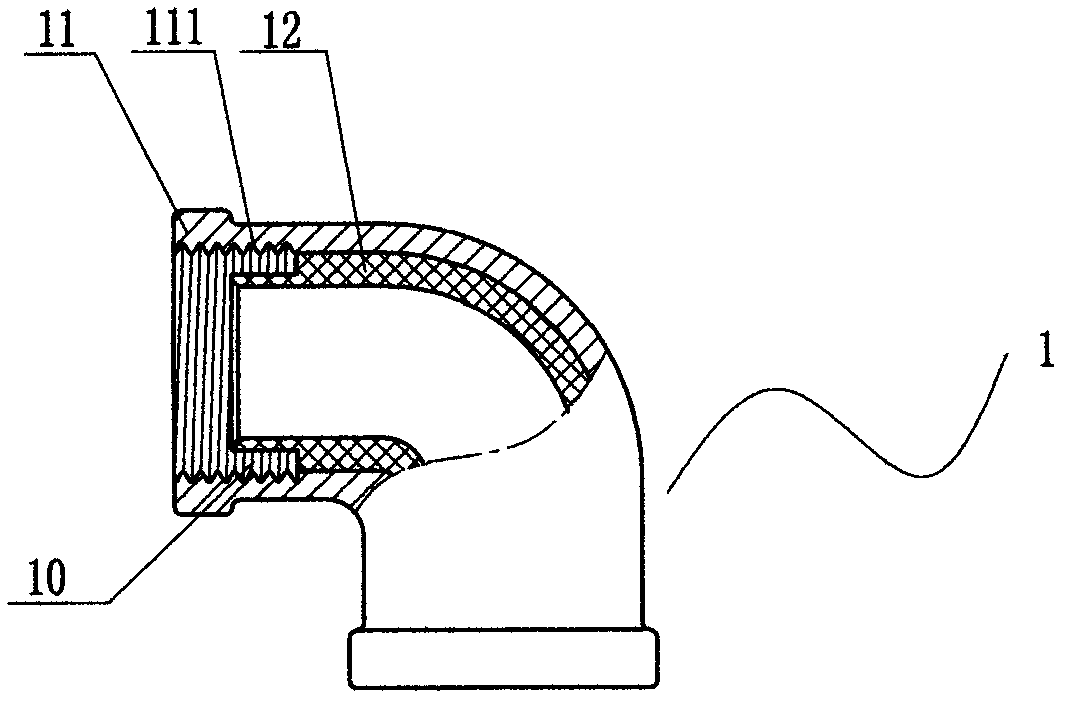

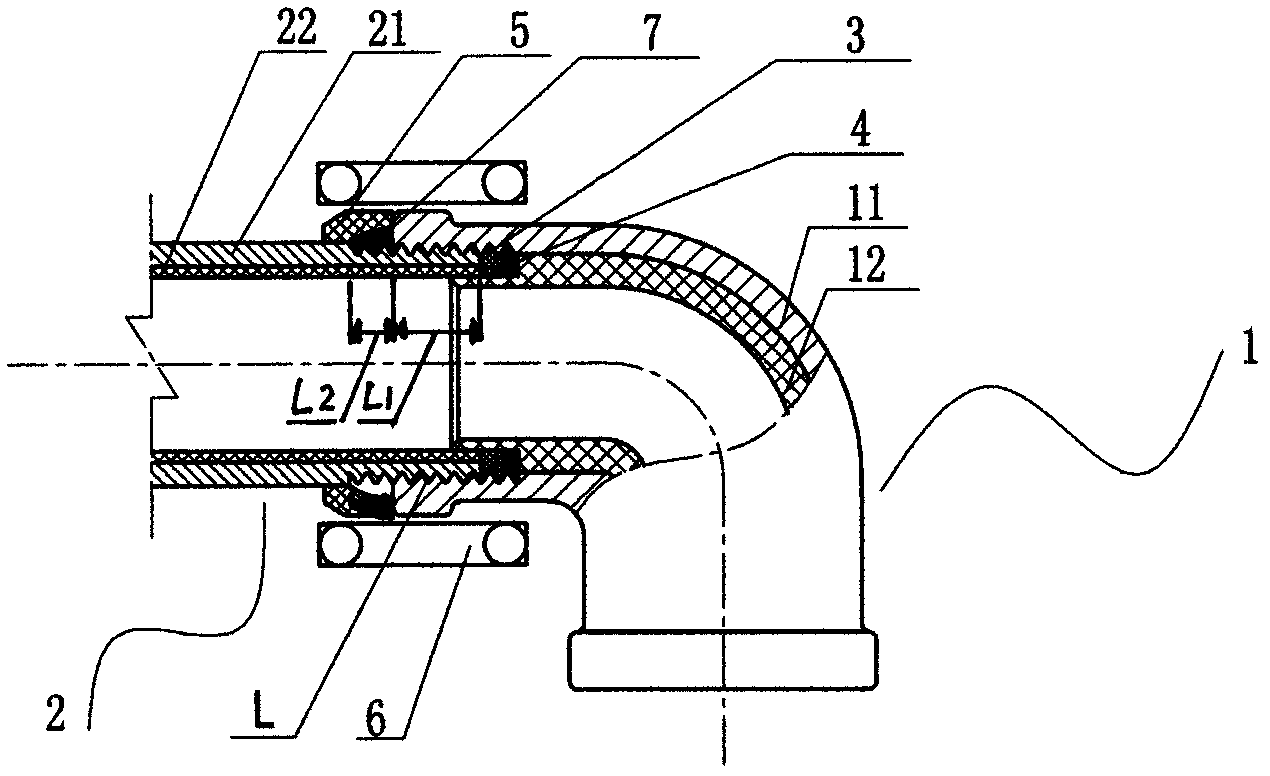

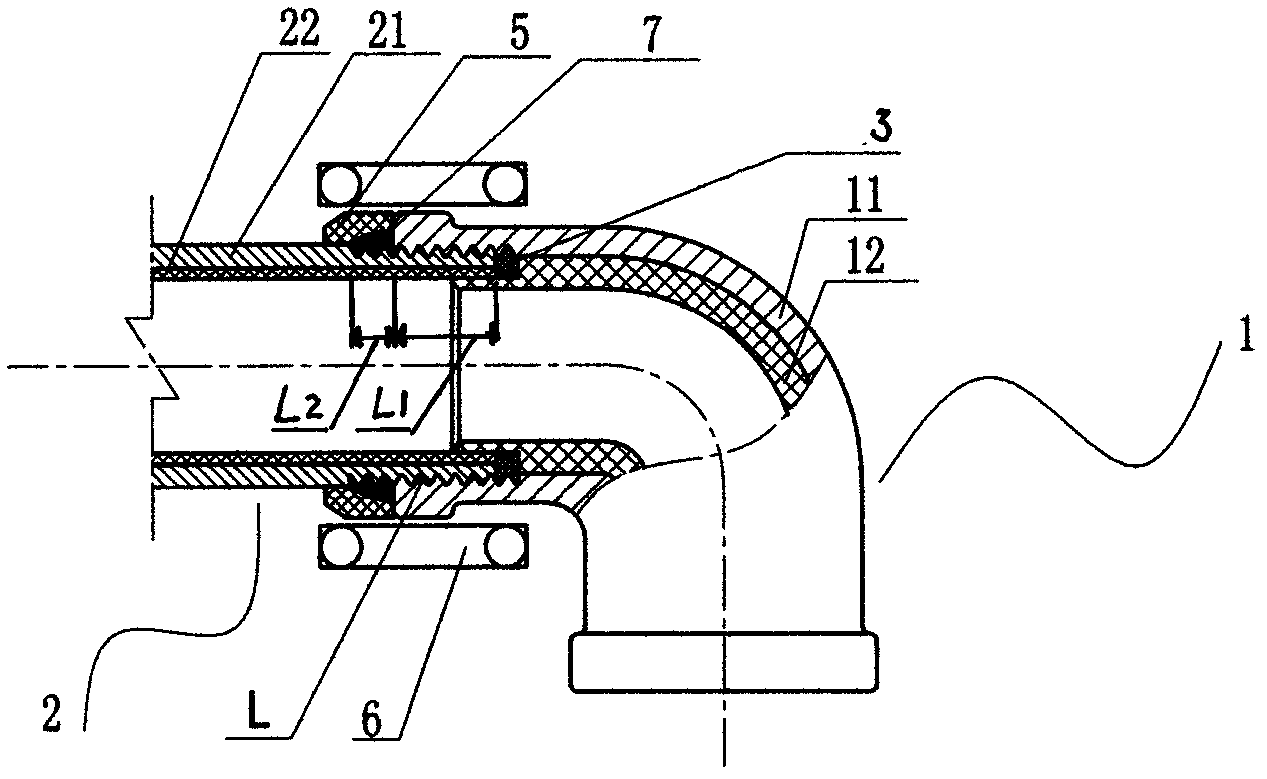

Full corrosion-resistant connection structure of steel lining plastic composite pipeline

InactiveCN102359697AReduce the chance of secondary pollutionEliminate interface rustCorrosion preventionPipe protection against corrosion/incrustationPipe fittingHot-melt adhesive

The invention discloses a full corrosion-resistant connection structure of a steel lining plastic composite pipeline, and belongs to the technical field of connection of the steel lining plastic composite pipeline. The structure comprises a corrosion-resistant ring sleeved on a non-meshing section of an external thread of a steel outer layer, a steel lining plastic composite pipe fitting consisting of a steel outer ring part and a plastic inner ring part, and a composite pipe consisting of the steel outer layer with the external thread, and a plastic inner layer, wherein the external thread consists of a meshing section and the non-meshing section; an annular cavity of which the inner wall is provided with an internal thread section is formed between the steel outer ring part and the plastic inner ring part; the pipe is in threaded connection with the pipe fitting; a solid hot melt adhesive is arranged in the annular cavity; when an alternating magnetic field is formed at the periphery of the joint of the pipe fitting and the pipe, the solid hot melt adhesive is in thread engagement with the steel outer ring part and in sealed connection with the end faces of the steel outer layer and the plastic inner layer; and the corrosion-resistant ring is in sealed connection with the non-meshing section of the pipe. After the scheme is adopted, the problem that the threads of the pipe and the pipe fitting are easily corroded and rusted is solved, and a full corrosion-resistant threaded connection effect is achieved.

Owner:HUAHUI CONSTR GROUP

Weather-resistance bridge high-strength steel plate and production method thereof

The invention discloses a weather-resistance bridge high-strength steel plate and a production method thereof. The weather-resistance bridge high-strength steel plate is prepared from the following components in percentage by weight: less than or equal to 0.11 percent of C, 0.30 to 0.50 percent of Si, 1.10 to 1.35 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.006 percent of S, 0.25 to 0.40 percent of Ni, 0.04 to 0.08 percent of V, 0.025 to 0.045 percent of Nb, 0.010 to 0.040 percent of Alt, 0.45 to 0.70 percent of Cr, 0.25 to 0.40 percent of Cu, 0.02 to 0.08 percent of Mo, 0.015 to 0.025 percent of Ti, less than or equal to 0.015 percent of N and the balance of Fe and inevitable impurities. The invention also relates to a production method of the weather-resistance bridge high-strength steel plate. The steel plate has excellent obdurability matching, high yield strength, high weather resistance and high cold-workability. The steel quality is purer, and the maximum thickness of the steel plate is up to 90 millimeters. The weather-resistance bridge high-strength steel plate is mainly used for manufacturing ocean platform and large sea-crossing bridge structural parts.

Owner:WUYANG IRON & STEEL +1

Wear-resistant and high temperature-resistant powder coating for preventing corrosion of inside and outside of steel pipeline

ActiveCN101899253AImprove wear resistanceImprove high temperature resistanceRubber derivative coatingsAnti-corrosive paintsSteel qualityCorrosion

The invention discloses a wear-resistant and high temperature-resistant powder coating for preventing corrosion of inside and outside of a steel pipeline. The coating comprises the following components in part by weight: 60 to 80 parts of epoxy resin E-12, 10 to 20 parts of WT800 pure organic silicon resin, 8 to 10 parts of terminal amino group rubber resin, 18 to 24 parts of phenol curing agent, 0.6 to 0.8 part of catalyst 2-methylimidazole, 10 to 16 parts of leveling agent acrylicpolymer, 0.6 to 0.8 part of defoaming agent, 10 to 15 parts of titanium dioxide, 20 to 40 parts of silicon carbide, 15 to 30 parts of wollastonite powder, 2 to 4 parts of sericite, 3 to 5 parts of graphite, 3 to 5 parts of pigment and 2 to 4 parts of dibutyl phthalate. The coating has the advantages of excellent anticorrosion effect, and high wear-resisting property and resistance to high temperature, and is an anti-corrosive material with a simple and convenient anti-corrosive process and low cost.

Owner:HEILONGJIANG EAIEN NEW MATERIAL TECH DEV CO LTD

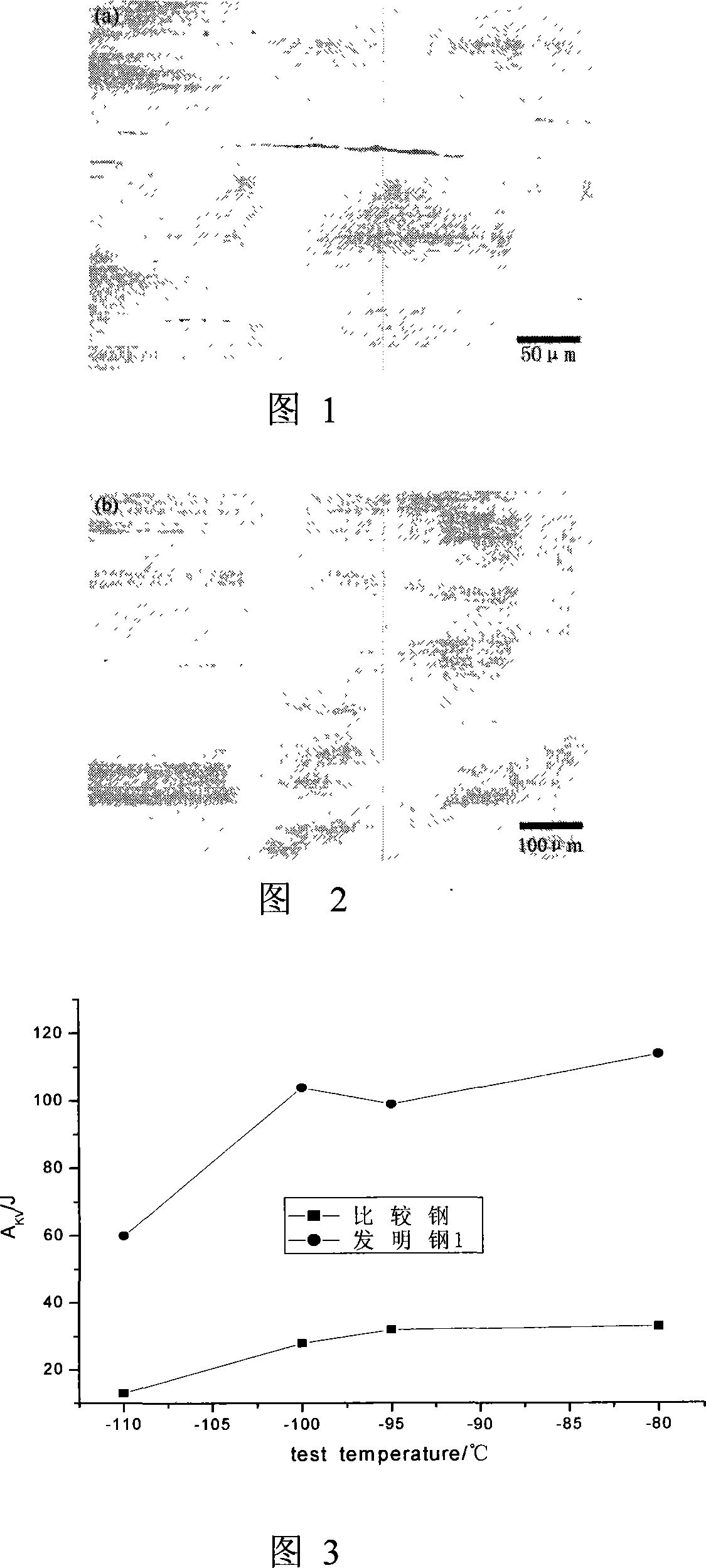

High ductility negative 110 degree low-temperature steel and manufacturing method thereof

InactiveCN101235466AStable and excellent low temperature toughnessExcellent -110℃ low temperature toughnessMetal rolling arrangementsReduction rateToughness

The invention relates to high toughness -110 DEG C low temperature steel and a method for manufacturing the low temperature steel, the steel is composed of components with following weight percent: C 0.02-0.12, Si 0.10-0.35, Mn 0.30-0.80, P<=0.015, S<=0.010, Ni 3.20-3.80, Ti 0.005-0.05a and Al 0.005-0.10, the low temperature steel also comprises two or more than two of Nb<=0.050, V<=0.10, Cu<=2.0, Mo<=0.50, Zr<=0.040 and RE<=0.020, and allowance is Fe. The method for manufacturing comprises: coating anti-oxidation coating on the surface of casting billets and controlling proper technological parameter such as the initial rolling temperature of steel, the controlled rolling accumulated reduction rate, each operation secondary reduction rate for last three operations, the finish rolling temperature, the normalizing heat preservation temperature, the heat preservation time, the tempering heat preservation temperature and the like. The method has the advantages of pure steel quality, stable organization, stable and excenlent-110DEG C low temperature toughness, simple technique and low cost, and is beneficial for extending and applying.

Owner:武汉钢铁有限公司

Method for producing sulfur free cutting and non-hardened and tempered steel

InactiveCN1667129AQuality improvementIncrease reflectionManufacturing convertersProcess efficiency improvementSystems researchOxygen content

This invention relates to manufacturing method of sulfurous free machining non- quenched and tempered steel. Desulfurization operation is not used in convertor, residue consumption is reduced, and convertor few residue smelting technology is realized. Appropriate deoxidizer and deoxidation technique is selected and high sulfur steel sulfide inclusion is controlled efficiently to make it tiny, uniform distributing, it realizes innocent treatment of high sulfur steel sulfide inclusion. Sulfur element absorptivity, narrow composition control and inclusion removal is ensured by refining technique and residue system research. The contradiction of reducing oxygen content and ensuring sulfur content is solved and high sulfur steel continuous casting low control problem. Sulfur in steel can be stably controlled to 0.040~0.060% by this invention, the history domestic convertor-refinery-continuous casting-binding and cold control technique can not produce sulfurous free machining non- quenched and tempered steel is changed. The steel quality is good and reaches to convertor-refinery-molded casting-binding and cold control technique level. It has been mass produced, and has good reflection from consumer.

Owner:SHOUGANG CORPORATION

Steel plate for large-thickness hydrogen-contacting equipment and its production technology

InactiveCN101368251AExcellent resistance to hydrogen corrosionHigh strengthRoll force/gap control deviceTemperature control deviceSheet steelHydrogen

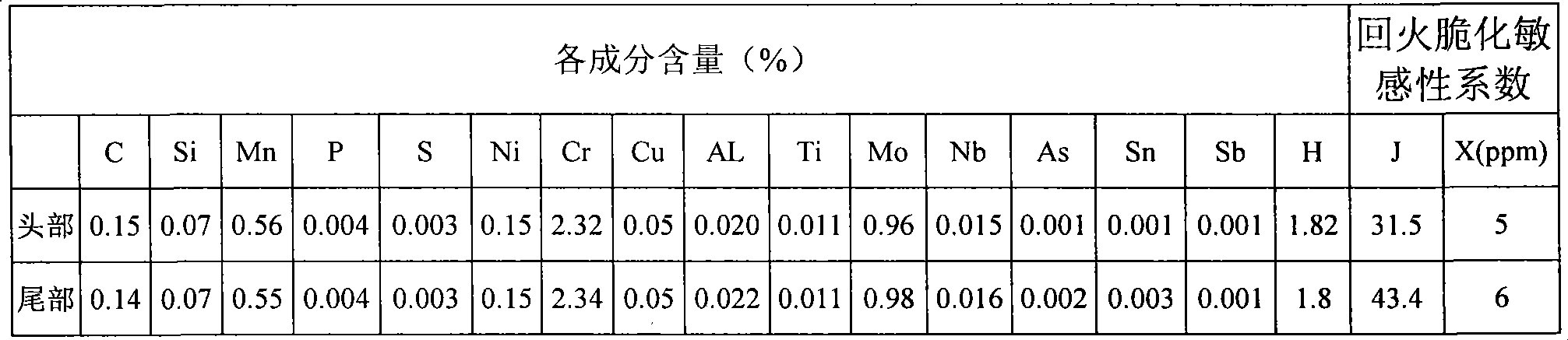

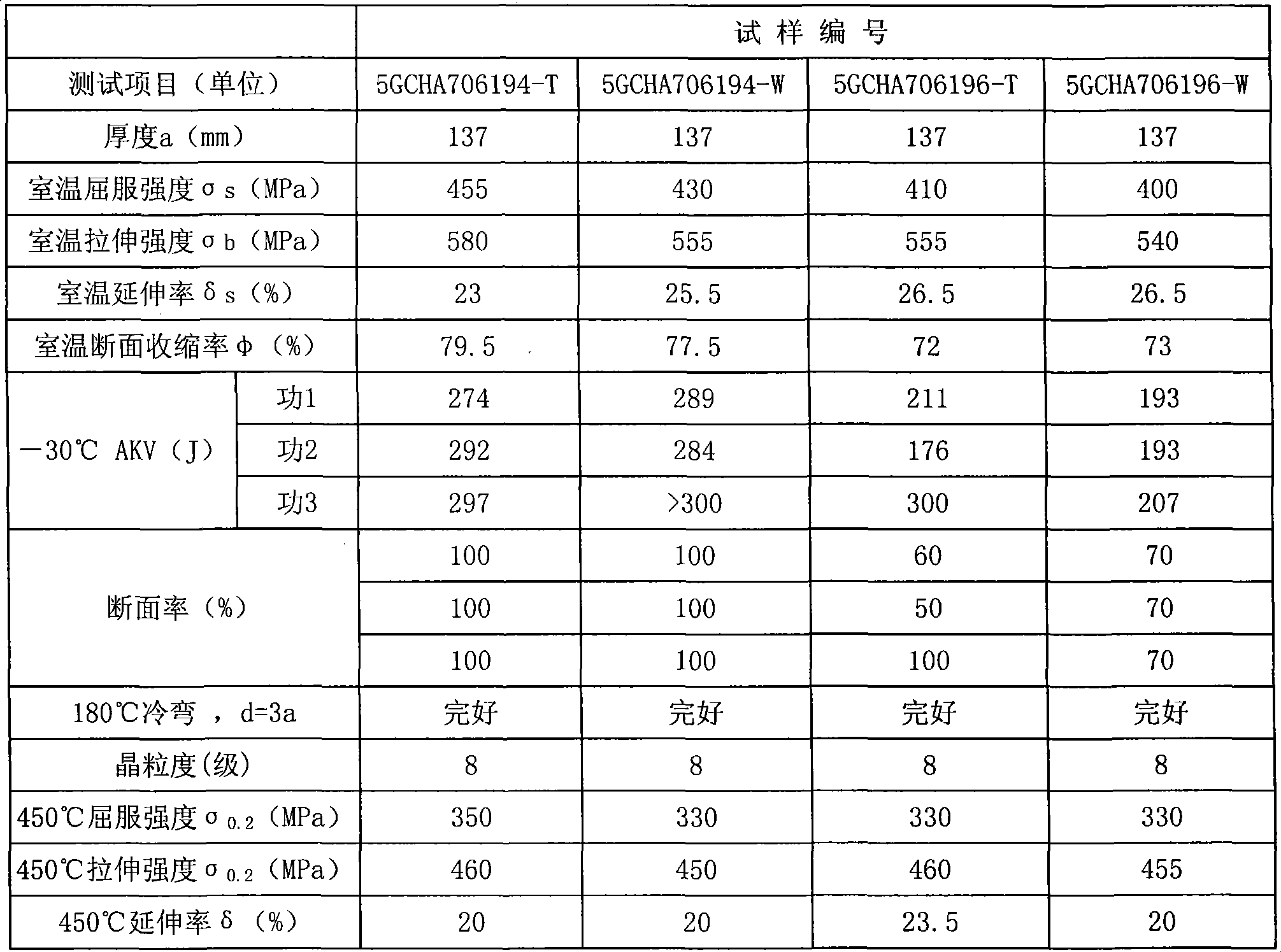

The invention relates to a steel plate used for a large-thickness hydro-device which belongs to the technical field of steel-making. Counted by weight percentage, the steel plate consists of the following elements: 0.13 to 0.15 percent of C, equal to less than 0.10 percent of Si, 0.50 to 0.60 percent of Mn, equal to or less than 0.008 percent of P, equal to or less than 0.007 percent of S, 0.14 to 0.18 percent of Ni, 2.30 to 2.50 percent of Cr, equal to or less than 0.15 percent of Cu, 0.95 to 1.10 percent of Mo, 0.015 to 0.020 percent of Nb, 0.010 to 0.020 percent f Ti, 0.020 to 0.045 percent of Al, equal to or less than 0.016 percent of As, equal to or less than 0.015 percent of Sn, equal to or less than 0.003 percent of Sb and the rest is Fe as well as unavoidable impurities. The delivery state of the steel plate is normalizing plus annealing; the quality of the steel is pure; the capacity for resisting the corrosion of hydrogen is excellent; besides, the steel plate has excellent weldability and comprehensive mechanical properties.

Owner:WUYANG IRON & STEEL

Easy-weld hardening high-strength steel plate and production method thereof

InactiveCN101096735AMeeting the demands of growing usageReduce manufacturing costRoll force/gap control deviceTemperature control deviceChemical compositionSheet steel

The invention relates to an easily welded, hardened and tempered high-intensity steel plate and its producing method, which comprises the following part: C<=0.15%, 0.15%-0.50% Si, 0.80%-1.80% Mn, P<=0.02%, S<=0.01%, Mn<=0.6%, Nb<=0.07%, B<=0.003%, Ni<=1.20%, Cr<=0.80%, Ti<=0.03%, V<=0.08%, the rest Fe and unavoidable impurity. The invention smelts with the electric furnace, which is provided with the low quantity P, S and the pure steel, gets the users' favor, has the low cost and the market competitive ability, solves the problem of big crystal grain and low dynamic ductility, and is fit for producing the high-intensity steel with low draught pressure rolling mill in the other steel factory. The invention also reduces the labor strength, which saves the time of the work, improves the availability ratio of the material, and reduces the leveling expense of making the steel plate.

Owner:WUYANG IRON & STEEL

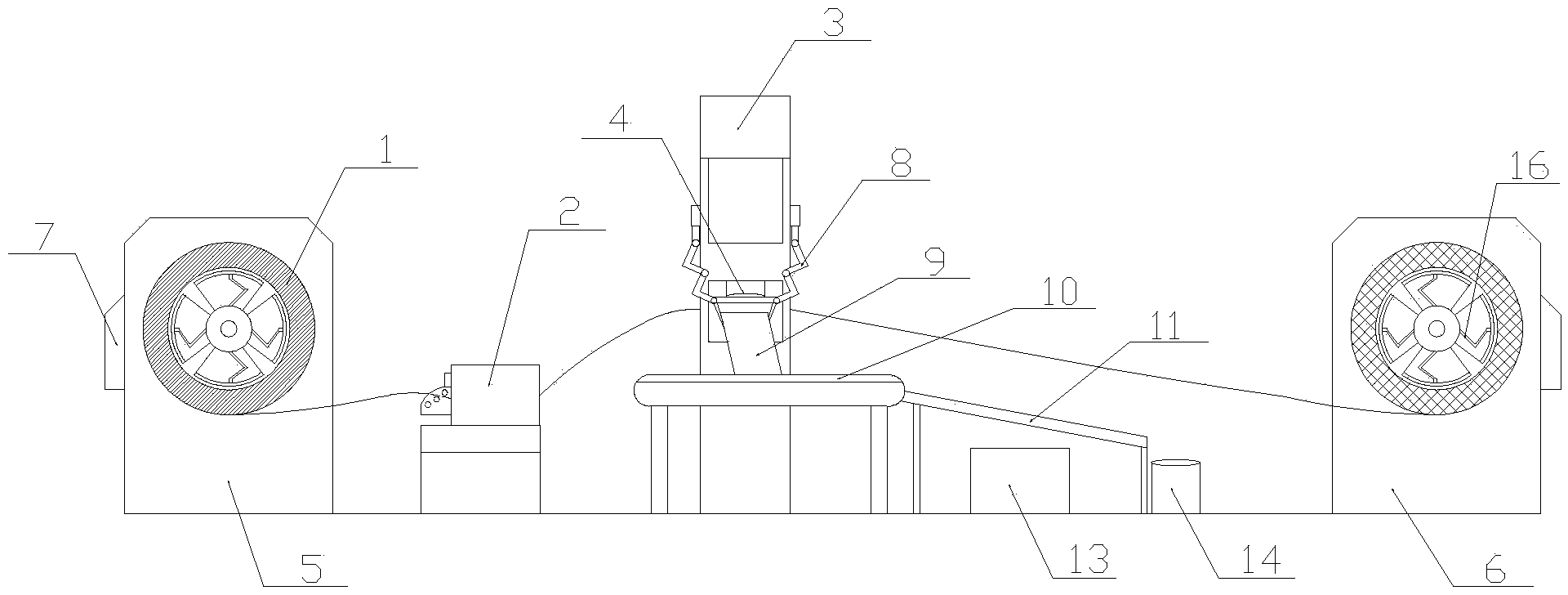

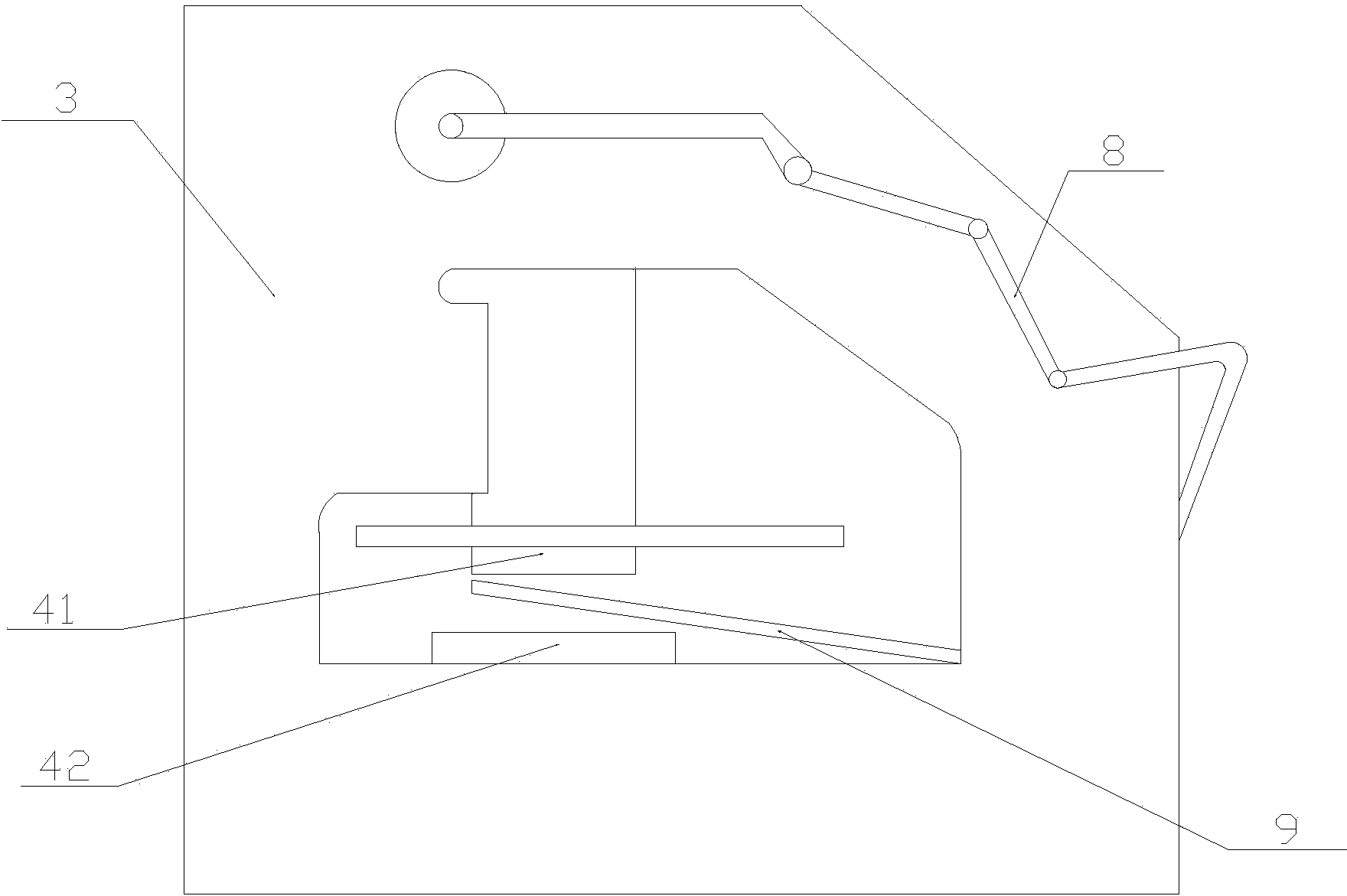

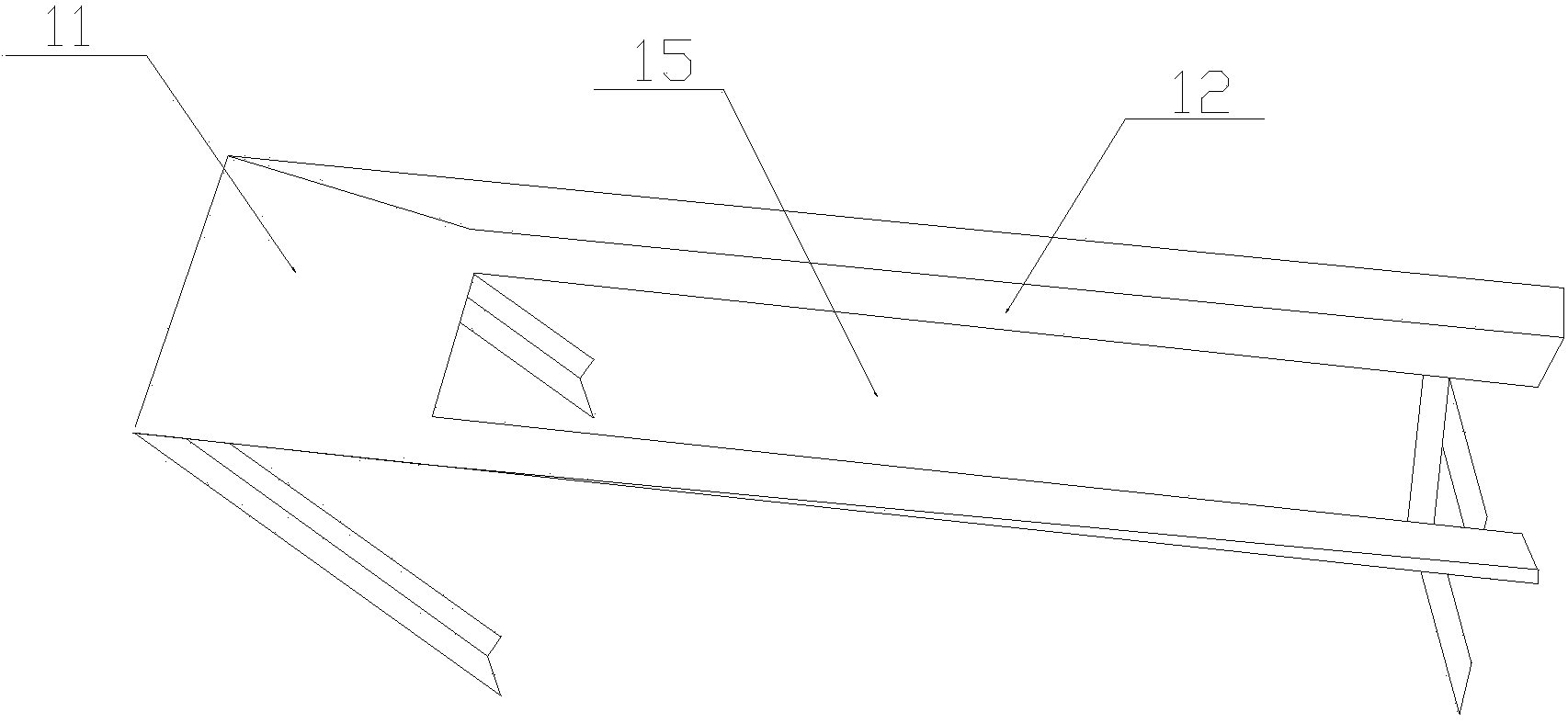

Automatic efficient motor stamped steel device and punching technology thereof

InactiveCN103962443AReduce trimmingSave materialMetal-working feeding devicesManufacturing stator/rotor bodiesSteel qualitySteel plates

The invention relates to the technical field of motor stator core manufacturing, in particular to an automatic efficient motor stamped steel device and a punching technology thereof. The automatic efficient motor stamped steel device comprises a silicon steel plate material coil, a deflection material conveying device, a customized punching machine, a one-time finished product punching die, an automatic finished product sorting mechanism, an automatic numerical-controlled discharging device and a waste recycling device. The punching machine of the improved structure can enable the material coil to freely swing without being uncoiled, and the sorting device can be additionally arranged; the punching die of the improved structure manufactures motor stamped steel finished products through one-time punching, and the automatic finished product sorting mechanism can automatically sort stamped steel. The punching technology of the automatic efficient motor stamped steel device comprises the steps that the overall coil is conveyed automatically, motor stamped steel finished products are manufactured, stator stamped steel and rotor wafers are automatically separated and sorted. The technology has the advantages that processes are few, the stamped steel finished products are smooth, and stamped steel quality is high.

Owner:江苏环球特种电机有限公司

Method for controlling and treating bottom roller dross of carbon sleeve furnace

ActiveCN101906529AReduce running speed varianceReduce nodulationFurnace typesHeat treatment process controlDrossDew point

The invention discloses a method for controlling and treating bottom roller dross of a carbon sleeve furnace. The possibility of dross occurrence is reduced by effective preventive measures for controlling the brushing current of a brush roller, reducing the use of a severely-oxidized transition strip, controlling appropriate furnace pressure, dew point and hydrogen content according to the difference of process speeds and process temperatures, periodically adjusting the rotating speed of a furnace roller, reducing running speed difference between the furnace roller and band steel, controlling the temperature raising and lowering rates of process temperature transformation during steel transformation and the like. Simultaneously, different treatment methods are used according to different dross states, so that treatment time is shortened greatly. The problems of long treatment time, single treatment method, no distinguished treatment according to different dross states, grinding of all furnace bottom rollers during treatment, damage to the furnace bottom rollers without dross, effect on service life and the like are solved, the plate surface quality of a cold-rolled and annealed product is enhanced and product percent of pass is increased.

Owner:ANGANG STEEL CO LTD

Production technique method of double-liquid bimetal composite casting hammer type hammerhead

The invention provides a producing method for a double-fluid bimetal complex casting hammer type hammerhead. Two casting systems are used. Firstly, low-alloy steel or common cast steel are cast at the cast steel gate, when the molten steel reaches the complex boundary or is a little lower than that, according to the size of the cast, after spacing 3-120 seconds, high-chromium cast iron or high alloy steel are cast into the high-chromium cast iron gate, and chill material is placed at the cast steel part of the steel and iron connection position, to ensure the crystal boundary surface and the base body to have a certain temperature gradient, a certain thickness and a intact boundary surface. Since the hammerhead is made of high-chromium cast iron, the hammer handle is made of low-alloy steel or common cast steel, wearing resistance property of high-chromium cast iron and strong toughness of hammer handle steel are both utilized, so that the use characteristic of the hammerhead is optimized.

Owner:荣守范 +1

Large-thickness steel plate for oceaneering and production method thereof

The invention belongs to the technical field of steel and iron, and in particular discloses a large-thickness steel plate for oceaneering and a production method thereof. The large-thickness steel plate for oceaneering comprises the following components in percentage by weight: 0.07-0.09 percent of C, 0.15-0.40 percent of Si, 1.40-1.50 percent of Mn, not more than 0.012 percent of C, not more than 0.005 percent of S, 0.60-0.70 percent of Ni, 0.030-0.040 percent of Nb, 0.020-0.045 percent of Al, 0.13-0.17 percent of Mo, 0.04-0.05 percent of V, 0.012-0.020 percent of Ti and the balance of Fe and inevitable impurities. The large-thickness steel plate for oceaneering has the advantages of pure steel quality, good low-temperature impact toughness, high thickness (Z direction) tensile cross section contractibility rate, large thickness, high strength, good low-temperature aging impact toughness and low product cost. The large-thickness steel plate for oceaneering, provided by the invention,is suitable for use of large-thickness structures for oceaneering.

Owner:WUYANG IRON & STEEL +1

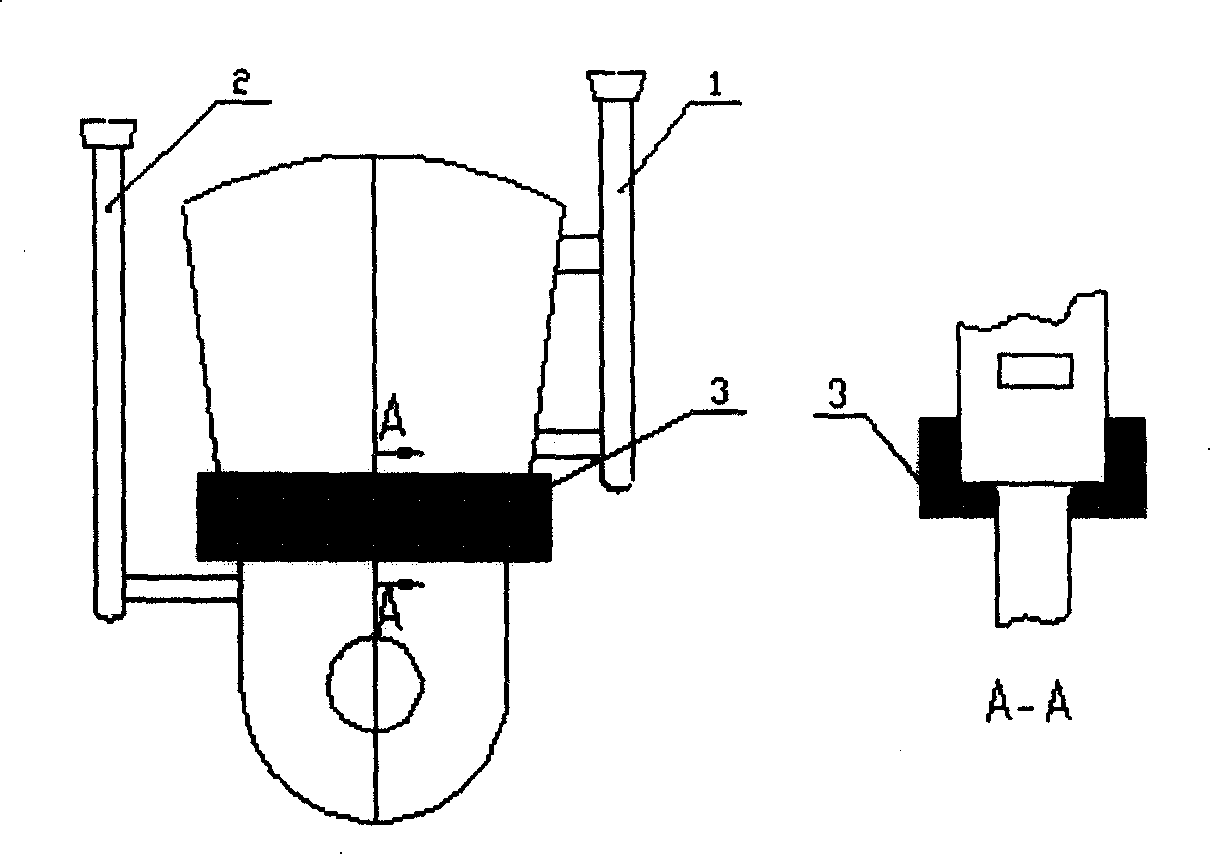

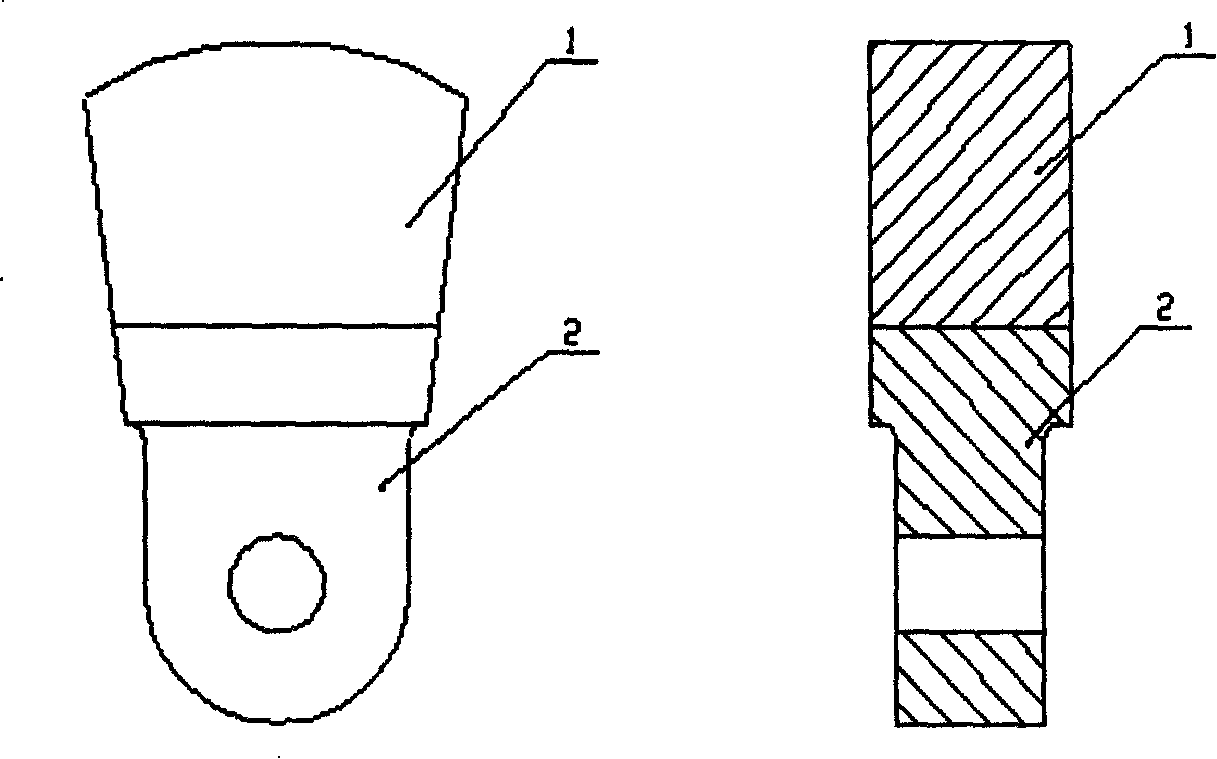

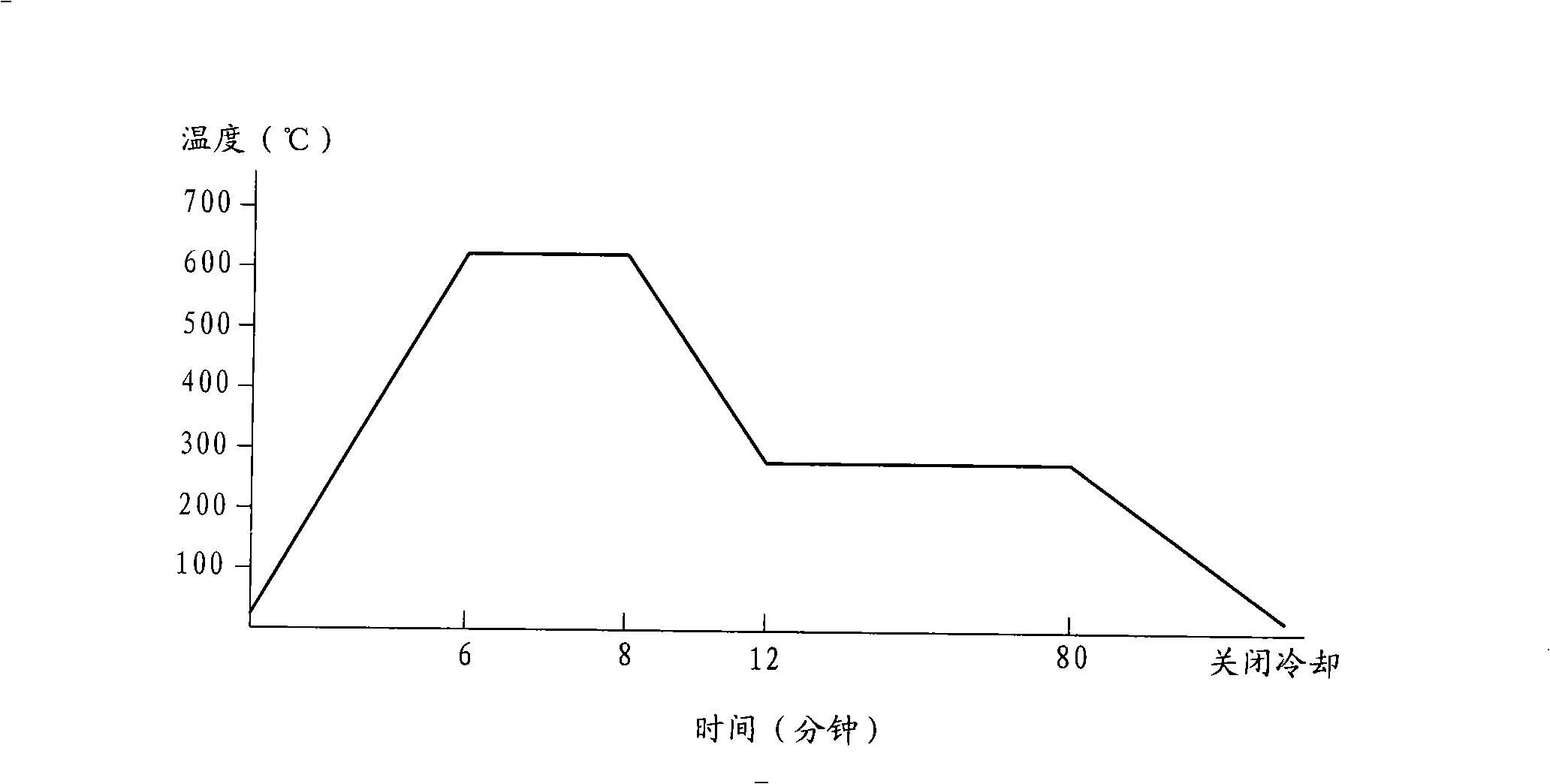

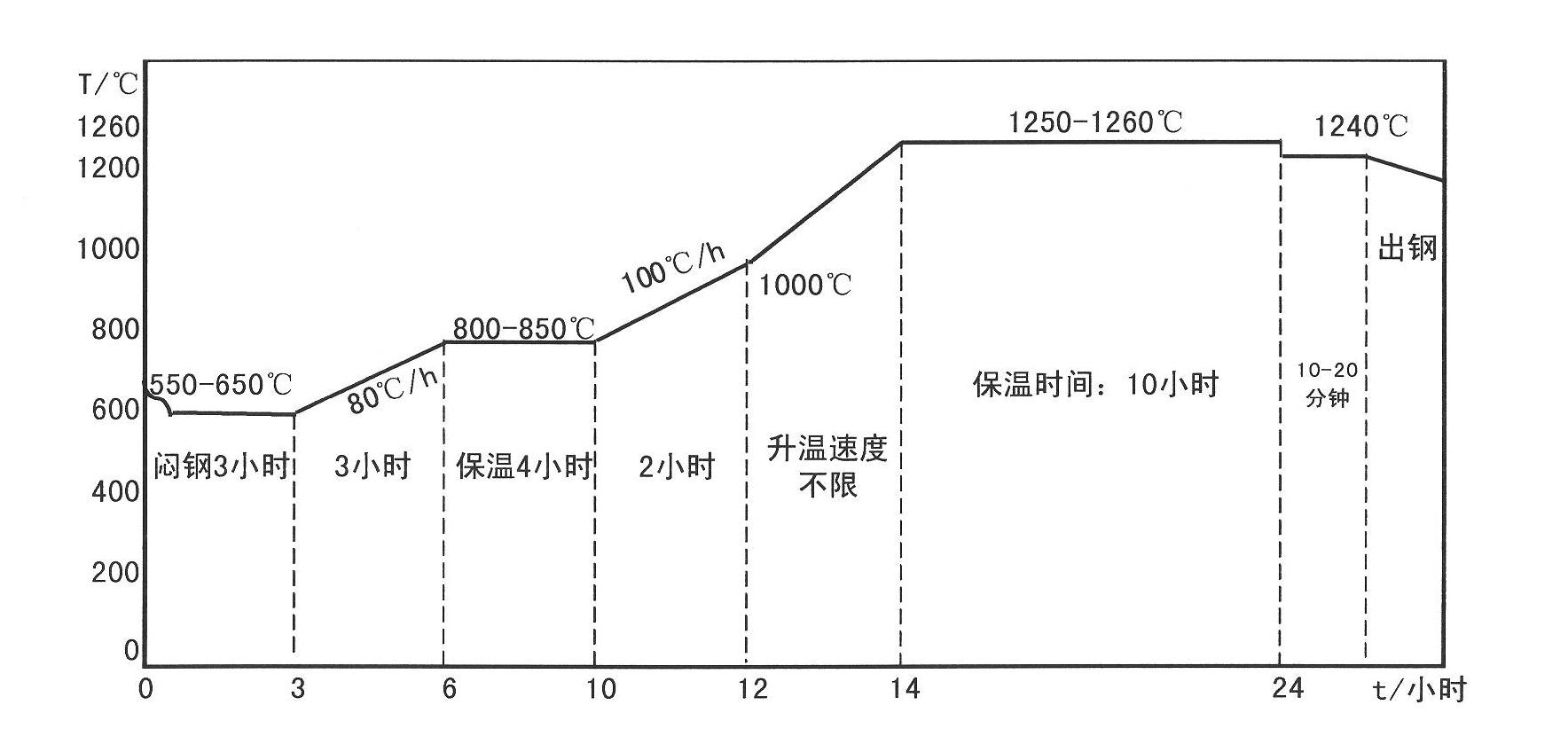

Welding method and silver based metal for hard-alloy heavy type cutting tools

InactiveCN101342626ALow melting pointEasy to breedOther manufacturing equipments/toolsWelding/cutting media/materialsAlloyEngineering

The invention discloses a welding method of heavy type hard-alloy cutting tool and silver based solder thereof. The welding method and the silver based solder can effectively avoid the welding crack during welding process, and consequently assure the welding quality of the heavy cutting tool. The welding method comprises the following procedures: surface treatment of the welding area, removal of oil, purities and rust-spotting, and enabling the welding surface to have the certain roughness; coating the welding flux and the silver based solder on the welding surface of hard-holly blade and steel substrate, putting the welding material into a vacuum heating furnace, and counterweighing the welding material with a metal block; filling inert gas into the vacuum heating furnace and heating up to 600 to 640 DEG C and insulating; decreasing to 280 to 300 DEG C and insulating, and finally decreasing to the room temperature for completing the welding process. The composition of the silver based solder in weight percentage is as follows: 40 to 50 percent of Argentum, 20 to 30 percent of Copper, 18 to 25 percent of Zinc, 1 to 3 percent of Stannum, 1 to 3 percent of Nickel and impurities.

Owner:王朝

High-tensile quenched and tempered steel plate for large-thickness structures and production method thereof

InactiveCN102080185AGood lamellar tear resistanceImprove low temperature toughnessRoll force/gap control deviceTemperature control deviceChemical compositionSheet steel

The invention discloses a high-tensile quenched and tempered steel plate for large-thickness structures and a production method thereof, wherein the high-tensile quenched and tempered steel plate comprises the following chemical compositions in percentage by weight: less than or equal to 0.19% of C, less than or equal to 0.50% of Si, 1.00-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, less than or equal to 0.20% of microalloying elements (Nb+V+Ti+Ni), less than or equal to 0.050% of Als, and the balance of Fe and residual elements. By reasonably taking a chemical composition design on composite multicomponent microalloying elements and adopting an LF+VD (ladle refining + vacuum degassing)process, the purity of the steel plate is ensured, and the sum of levels of various inclusions is not more than 3.0; and by utilizing a thermo mechanical control process and adopting normalizing treatment, the grain fineness number of the steel plate reaches level 9.0-10.0; by means of the effective implementation of the measures, the extra-thick steel plates (thickness: greater than or equal to 100mm) for high-rise buildings with guaranteed flaw detection and mechanical properties are produced successfully.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

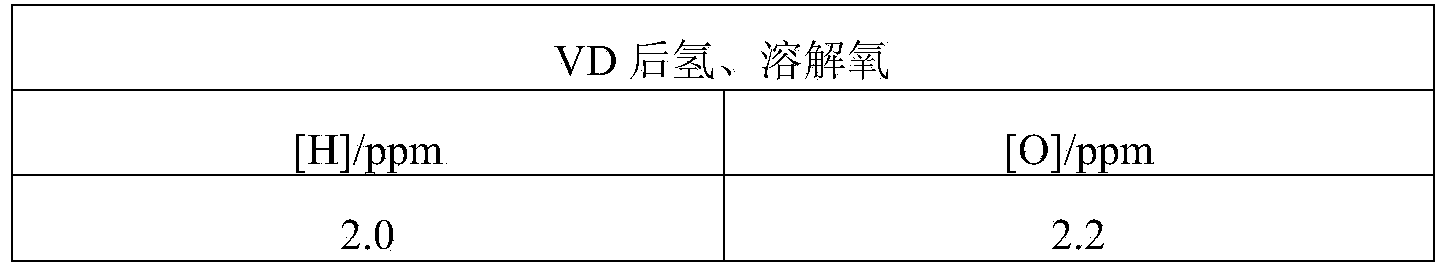

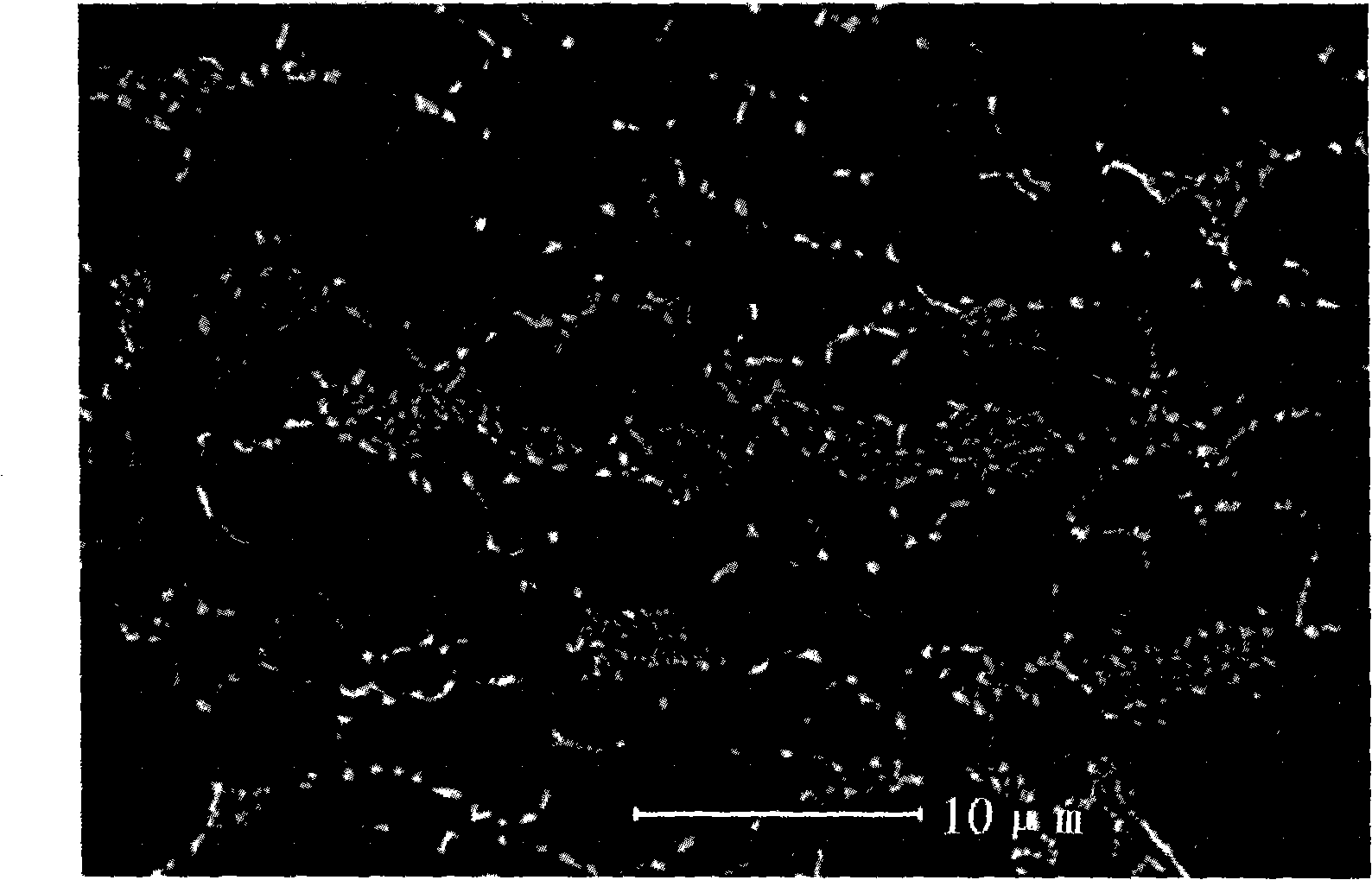

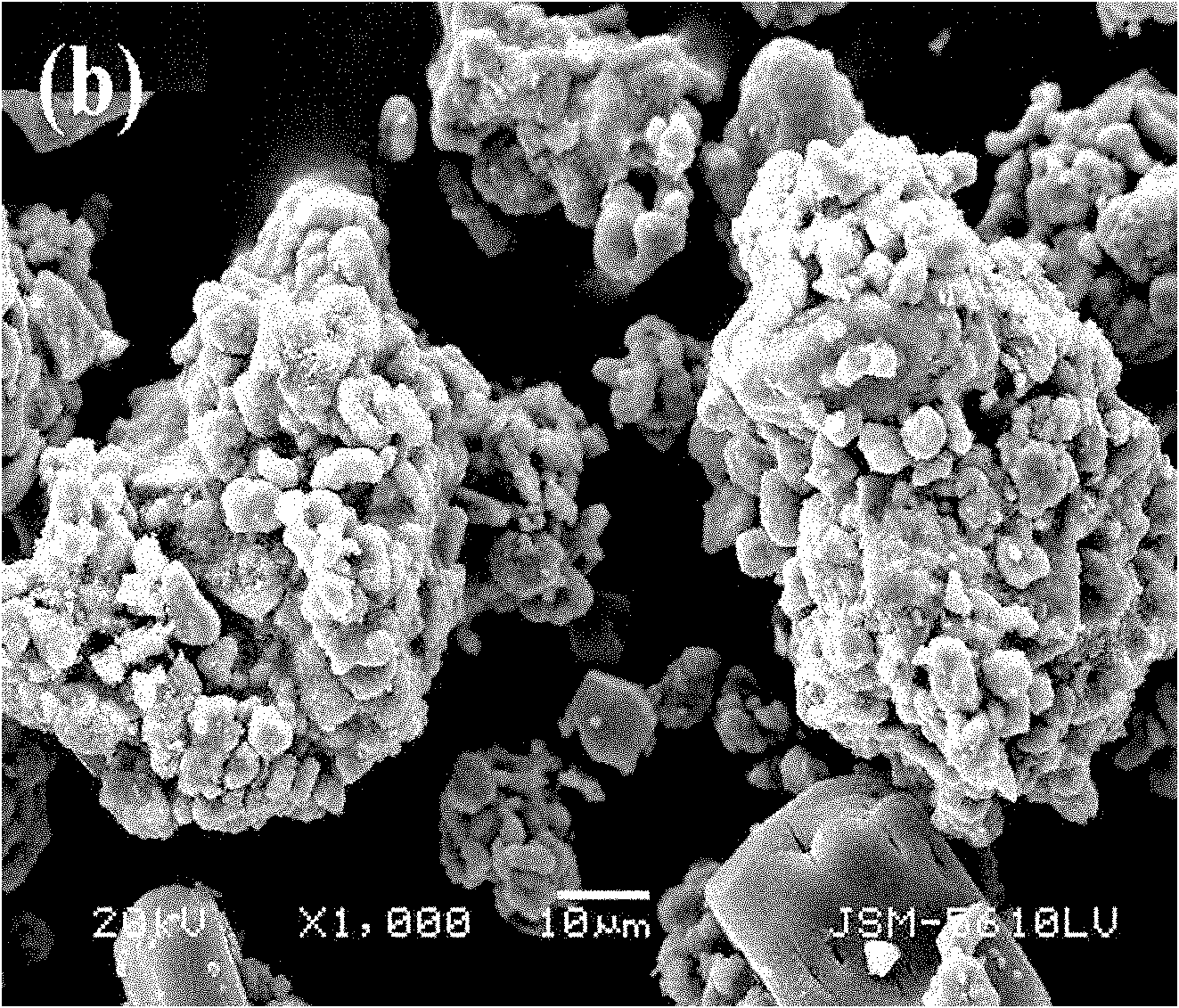

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

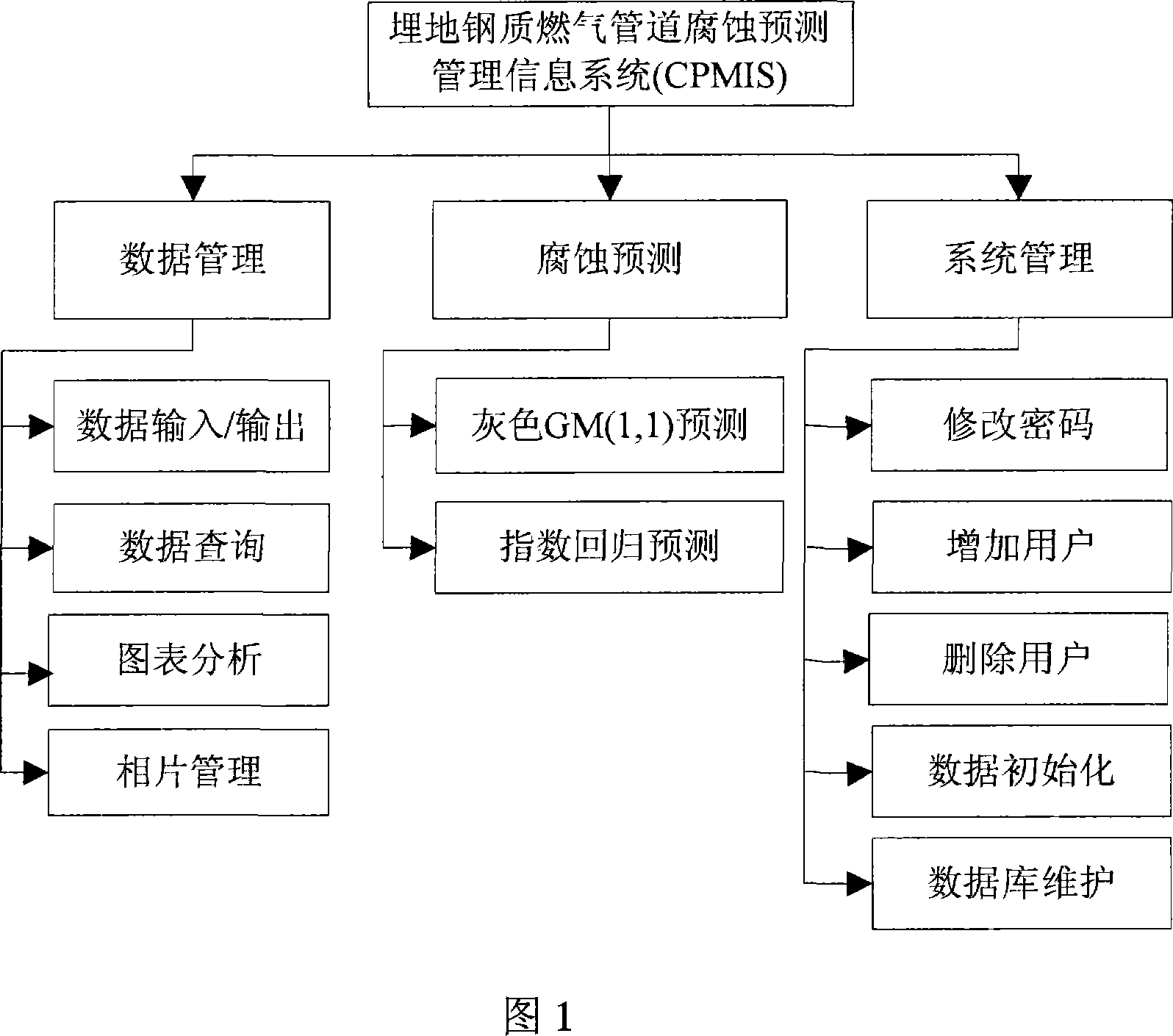

Underground steel gas pipe network pipeline corrosion prediction system

InactiveCN101071098AEfficient managementAccurate estimateWeather/light/corrosion resistancePipeline systemsSystems managementData management

Owner:GUANGZHOU GAS +1

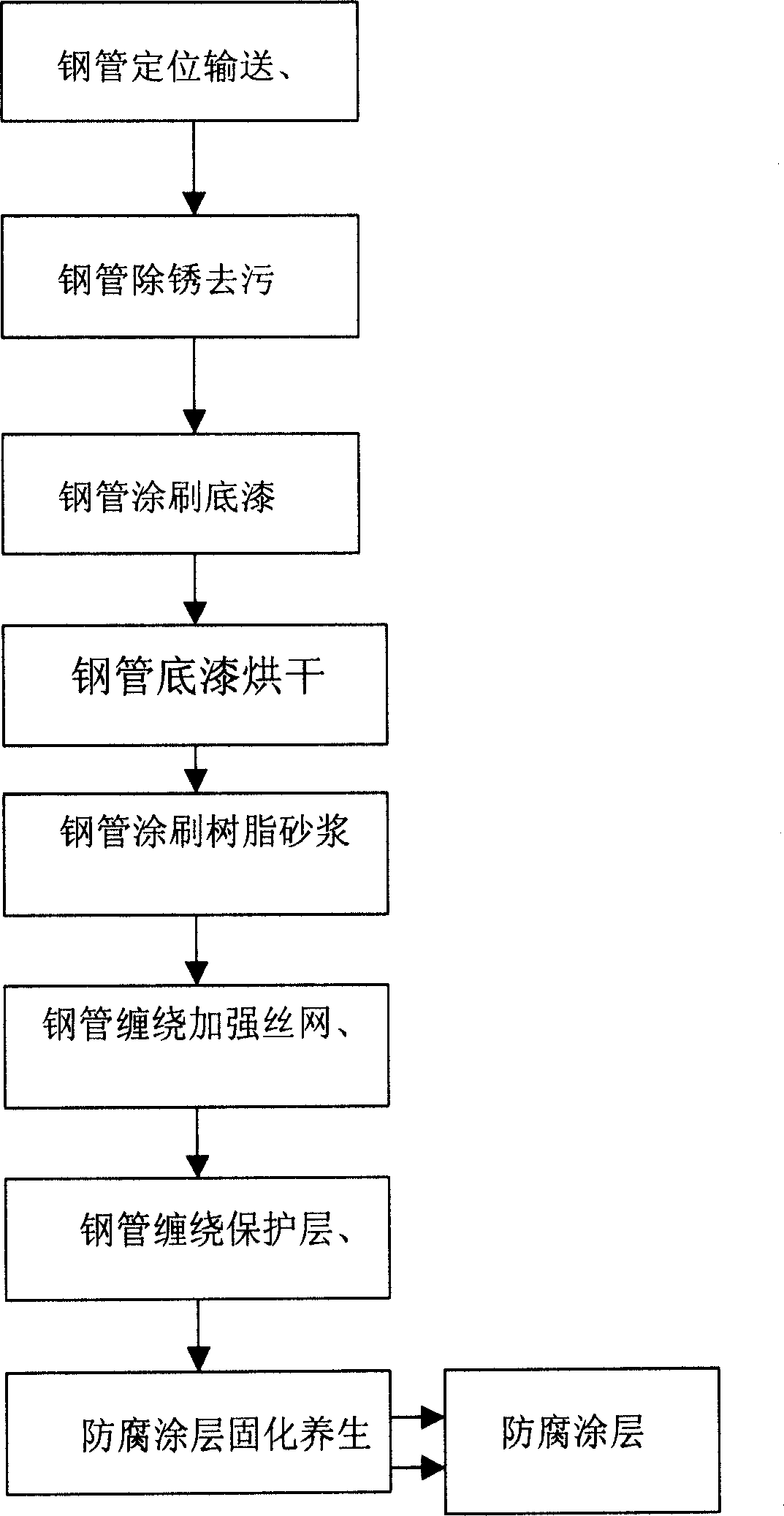

Prepn process of outer anticorrosive coating for steel pipe

InactiveCN1672809AHigh mechanical strengthHigh bonding strengthPretreated surfacesSpecial surfacesWinding machineProduction line

The present invention is the preparation process of outer anticorrosive coating for steel pipe. In the mechanized production line comprising pipe feeding machine, pre-heating machine, shot peeling machine, material mixing machine, spraying machine, glue extruding and painting machine, winding machine and stoving machine, outer anticorrosive coating with resin mortar layer and high strength net layer may be formed through the steps of steel pipe locating and conveying, derusting and decontaminating, painting primer, stoving primer, painting resin mortar, winding reinforcing net, winding protecting layer, curing the anticorrosive coating, etc. The outer anticorrosive coating has high mechanical strength, high anticorrosive performance, stable quality, simple operation and other advantages. The present invention may be used in anticorrosion of various kinds of steel pipe.

Owner:张炼

Composite board produced with waste and old plastic and coal ash, and producing method thereof

The invention discloses a composite board made from waste plastics and fly ashes and a method for producing the same. The composite board is prepared from the waste plastics and the fly ashes according to certain weight ratio. The main raw materials for producing the composite board comprise the waste plastics and the fly ashes, wherein the waste plastics are discarded in industrial production and in human life and comprise waste polypropylene plastic, waste polyethylene plastic, waste polystyrene plastic and waste polyvinyl chloride plastic and the like, and the fly ashes are discharged by coal-fired power plants and the chemical industry; the main raw materials are manufactured into the composite board through crushing and hot pressing; the manufactured composite board meets the national standards for construction templates, not only reduces the environmental pollution caused by industrial fly ashes and plastic wastes, but also can be applied to replacing wooden construction templates or steel construction templates widely used in the prior building operations, and not only has the advantages of low production cost, light weight, high strength, impact resistance, and easy demoulding, but also 'turns harmful into beneficial and changes waste into valuable', and significantly speeds up the process of recycling wastes in China.

Owner:GUIZHOU UNIV

Method for controlling tapping nitrogen content of converter

ActiveCN102978330AReduce carbon contentQuality improvementManufacturing convertersMolten steelDeoxygenation

The invention relates to a method for controlling the tapping nitrogen content of a converter. Requirements for molten iron are as follows: P is less than or equal to 0.150%, T is more than or equal to 1250 DEG C, the sulphur content is lower than 0.015%, and the hot metal ratio is increased by 85-90%; 30-40kg / t iron ore is added in the blowing period of the converter; terminal control comprises is as follows: C is 0.08-0.12%, P is less than or equal to 0.015%, S is less than or equal to 0.020% and T is 1650-1690 DEG C; steel ladle bottom argon blowing is carried out in advance, argon blowing is carried out in the whole tapping course, the bottom argon blowing amount is reduced and soft blowing is carried out under the condition that a molten steel liquid level is not exposed in a tapping process; and a two-step deoxygenation method is adopted in the tapping process. According to the method provided by the invention, no new equipment is required to be added and the equipment is not required to be modified, and the nitrogen content is 25ppm after tapping of the converter is reduced while the cost is not increased, so that the nitrogen content of the finished product is reduced and the steel quality is improved.

Owner:NANJING IRON & STEEL CO LTD

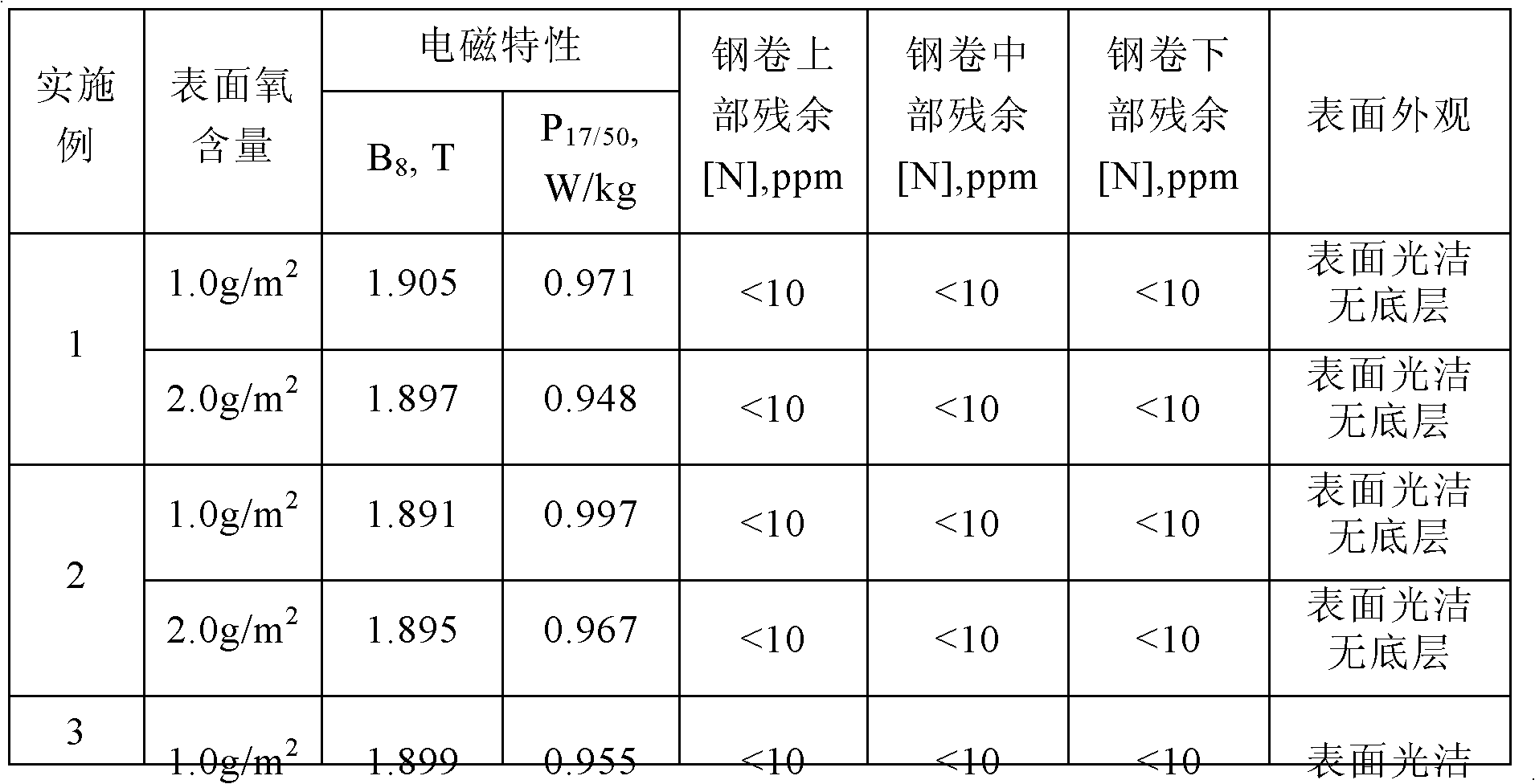

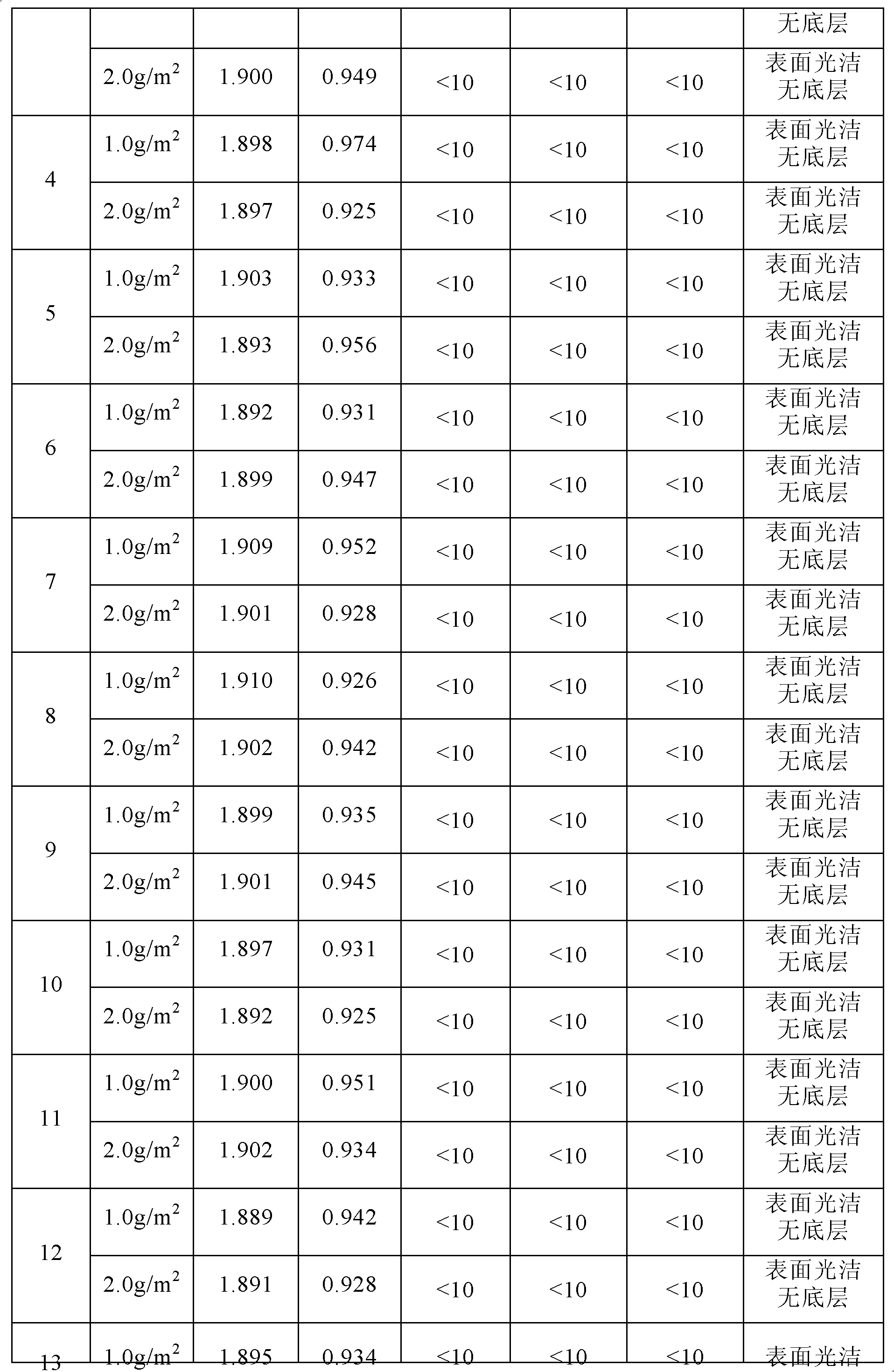

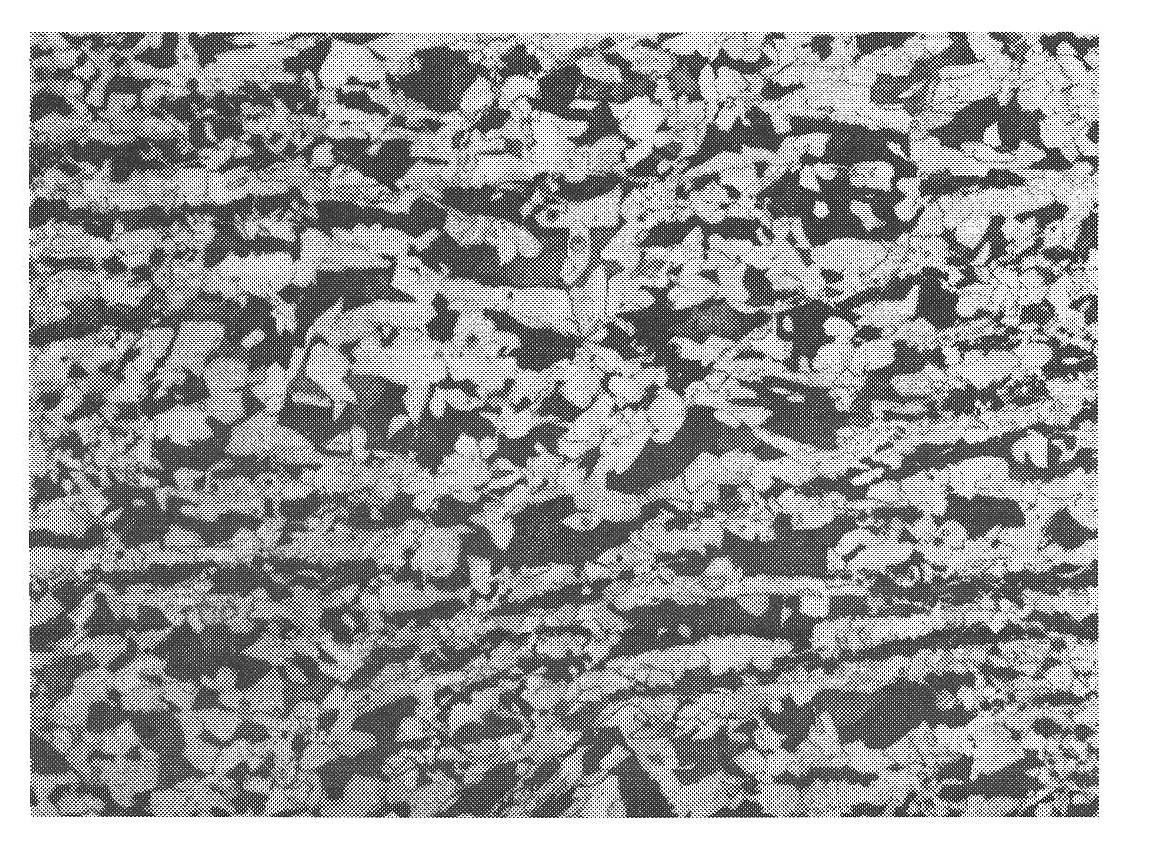

Manufacturing method of mirror surface oriented silicon steel with good magnetic performance and annealing parting agent

ActiveCN103014285AStrong magnetismFlat surfaceFurnace typesHeat treatment furnacesCorrosion reactionMetal chloride

The invention discloses a manufacturing method of mirror surface oriented silicon steel with good magnetic performance and an annealing parting agent. The manufacturing method comprises the following steps of: 1) smelting; 2) hot rolling and normalizing; 3) cold rolling; 4) decarbonization and nitriding; and 5) parting agent coating and high-temperature annealing. The annealing parting agent comprises the following components in parts by mass: 65-96 parts of Al2O3 powder, 2-15 parts of silicate powder with a particle size of 0.1-100 microns, 1-10 parts of alkaline earth metal oxide and 1-10 parts of metal chloride. According to the invention, through the annealing parting agent consisting of Al2O3 powder, silicate powder, alkaline earth metal oxide and metal chloride, a glass film bottom layer is not formed on the surface of a steel plate in a high-temperature annealing process, and the steel can be effectively purified; and meanwhile, the embedded oxide on the near surface of a substrate is removed through the corrosion reaction of chloride so as to obtain a product with a smooth and clean surface and stable magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

High-grade wear-resistant steel plate and production method thereof

InactiveCN101748346AGuaranteed hardenabilitySolve the coarse and uneven grain sizeRoll mill control devicesElectric furnaceWear resistantQuenching

The invention discloses a high-grade wear-resistant steel plate. The steel plate comprises the following components in percentage by mass: less than or equal to 0.26 percent of C, less than or equal to 0.50 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.30 percent of Ni, less than or equal to 1.50 percent of Cr, less than or equal to 0.06 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.03 percent of Ti, less than or equal to 0.50 percent of Mo, less than or equal to 0.08 percent of V, less than or equal to 0.004 percent of B, and the balance of Fe and inevitable impurities. A method for producing the steel plate comprises smelting, casting, heating, rolling, straightening, shot blasting, quenching, heat treatment, cutting and other process steps. The steel plate has the advantages of steel purity, high strength, high hardness, good low temperature toughness, good weldability, good processability, good cold bending property, large steel plate thickness, good plate cut, little noble metal added to the steel plate and low cost. The steel plate can be widely used in the industry of manufacturing mining, engineering, metallurgical and other machinery with broad application prospects.

Owner:WUYANG IRON & STEEL +1

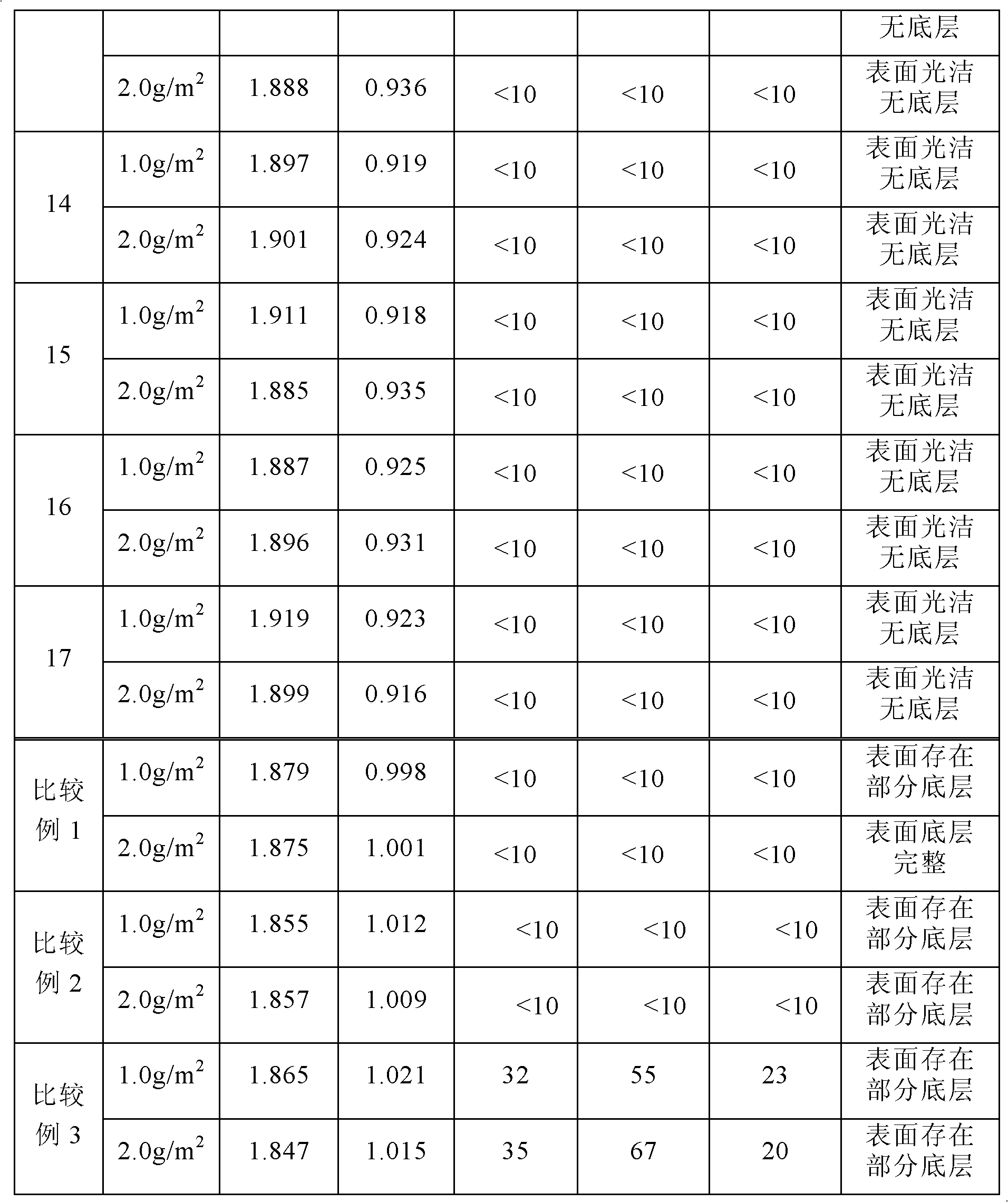

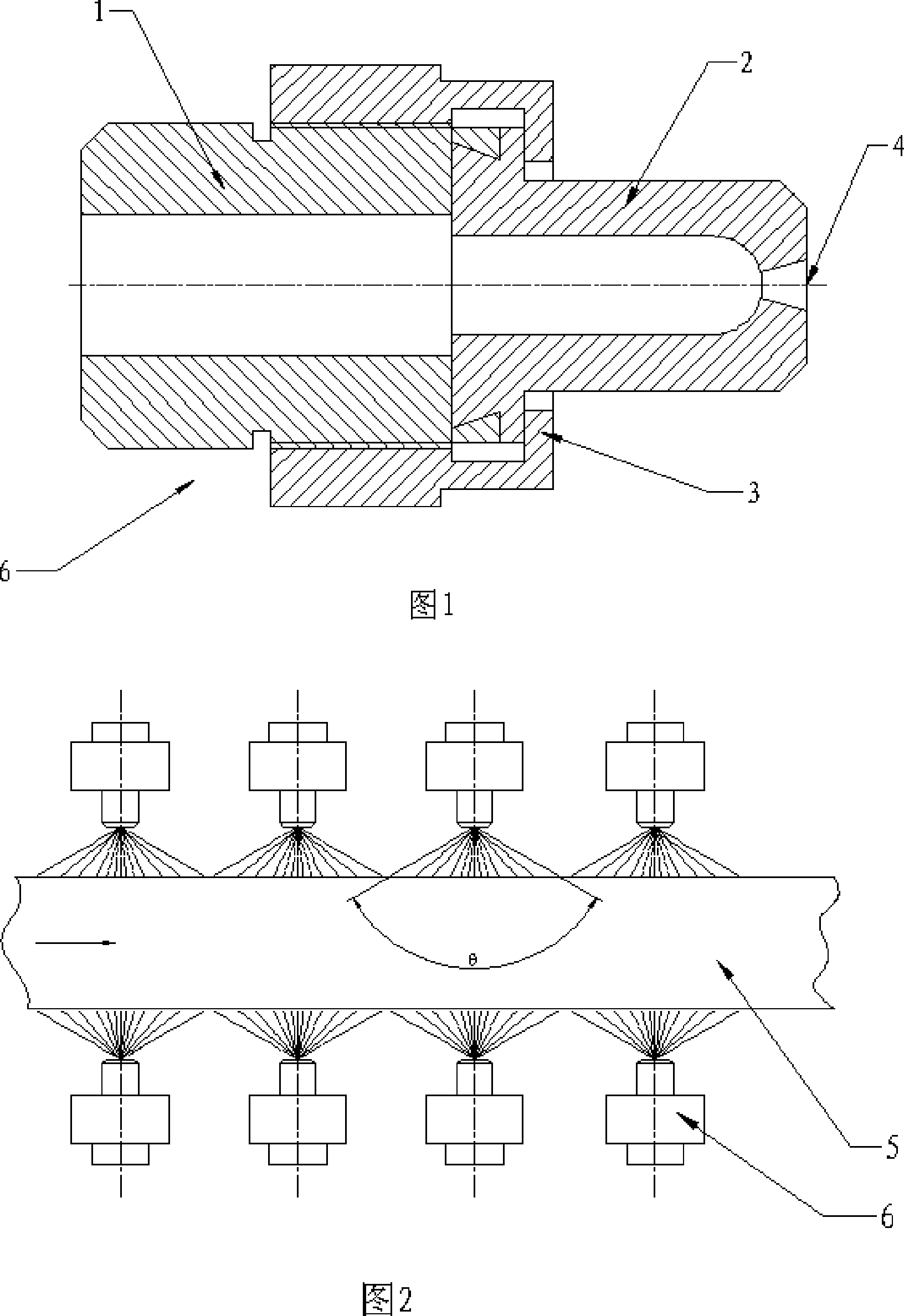

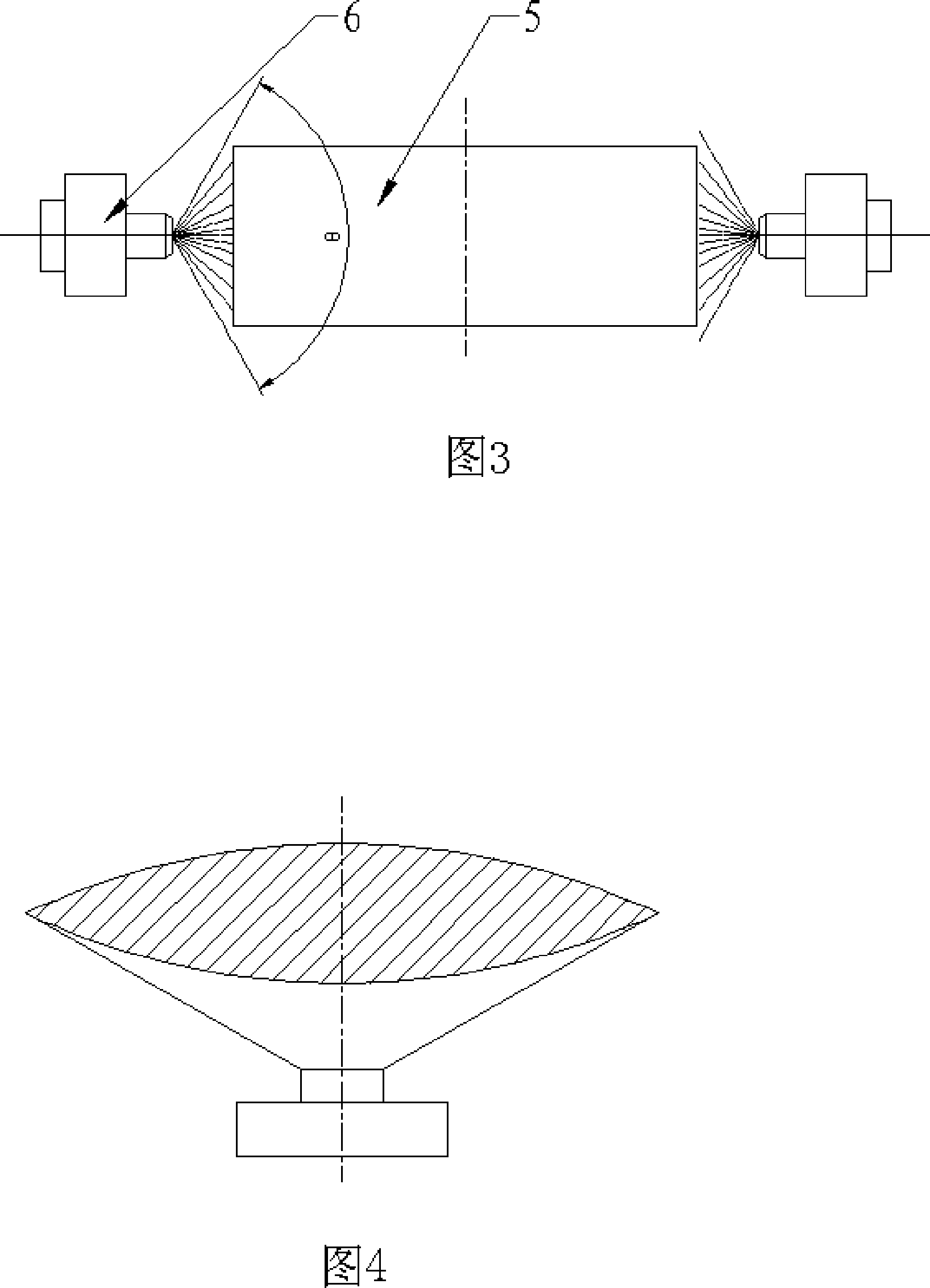

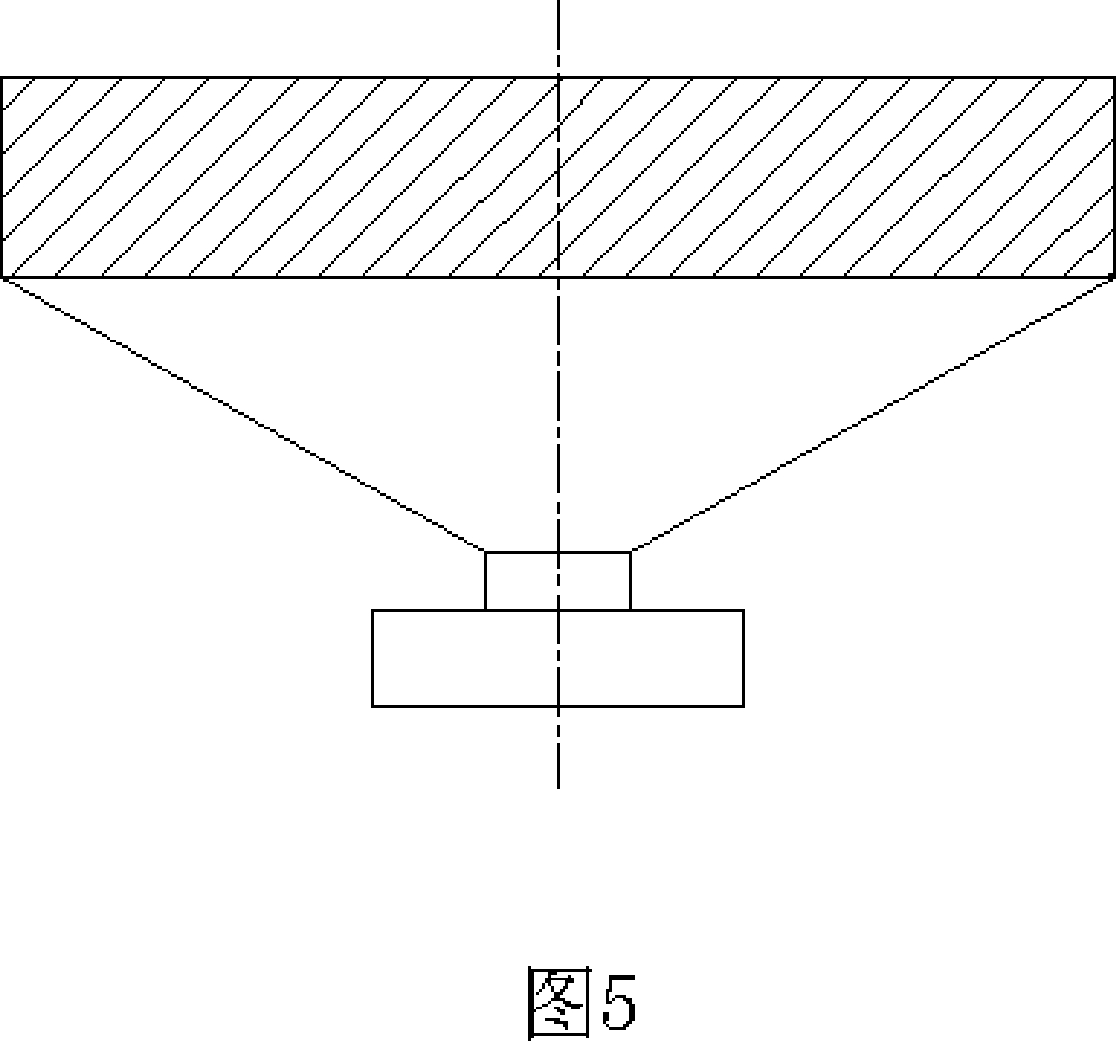

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

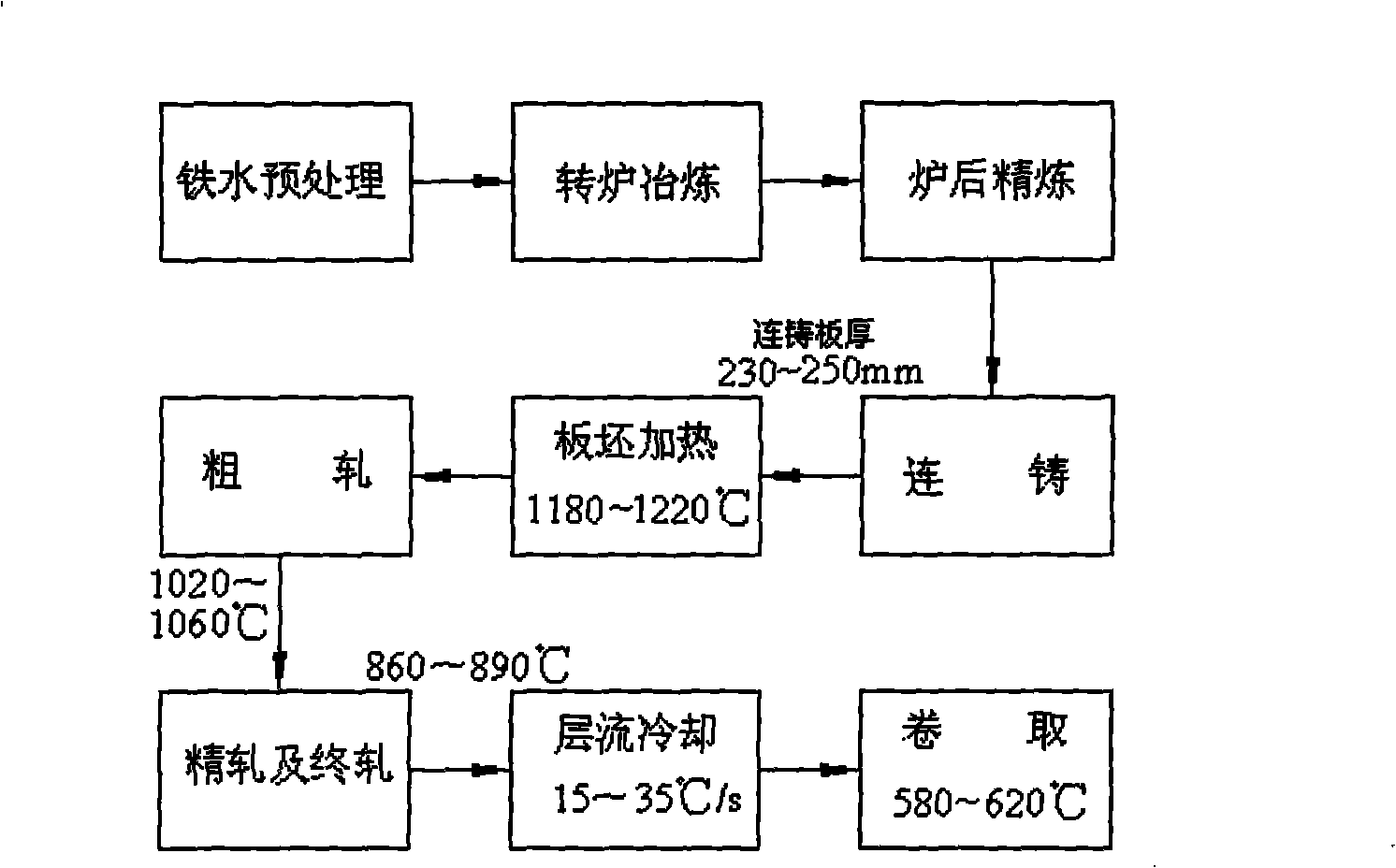

High-strength hot rolled steel plate and manufacturing method thereof

ActiveCN101280390APure steelImprove performanceTemperature control deviceManufacturing convertersManganeseUltimate tensile strength

The invention discloses a high strength hot rolled structure steel plate, which belongs to the technical field of the metal structure material. In the invention, an Nb microalloying element is added into low carbon and high manganese clean steel, and also Ca in minute quantities is added. Simultaneously, the invention also discloses the manufacturing method of the steel plate, the manufacturing method comprises the steps that the converter smelting and refining, continuous caster protecting casting, and rolling control and cooling control process is adopted, through the thinning strengthening and precipitation strengthening of the crystal grain, the hot tandem rolled coiled sheet with pure steel quality, good combined property and uniform and fine grain size can be obtained, the steel plate not only has high strength, but also has very high toughness and superior cold forming performance, and the structure requirement of the vehicle can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

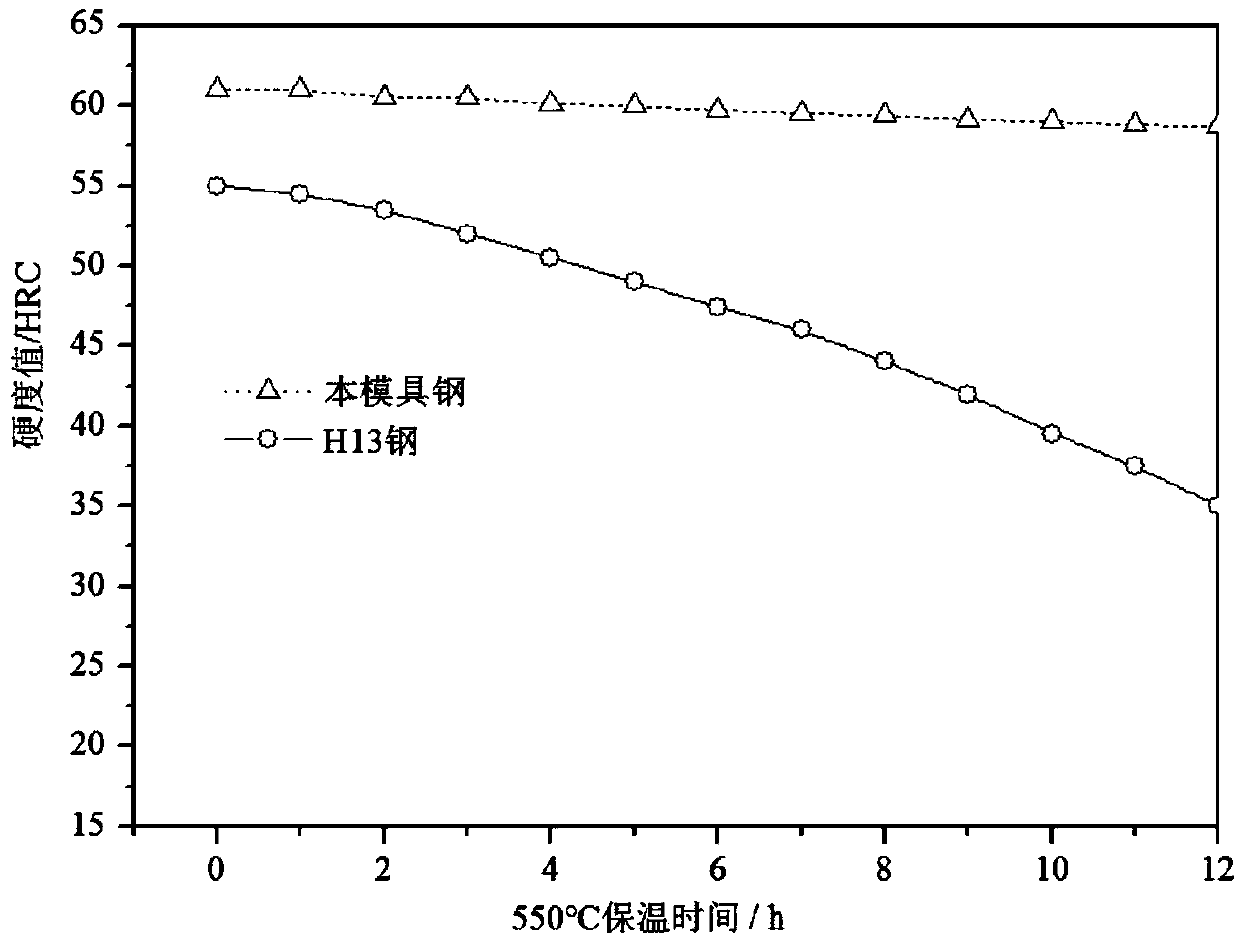

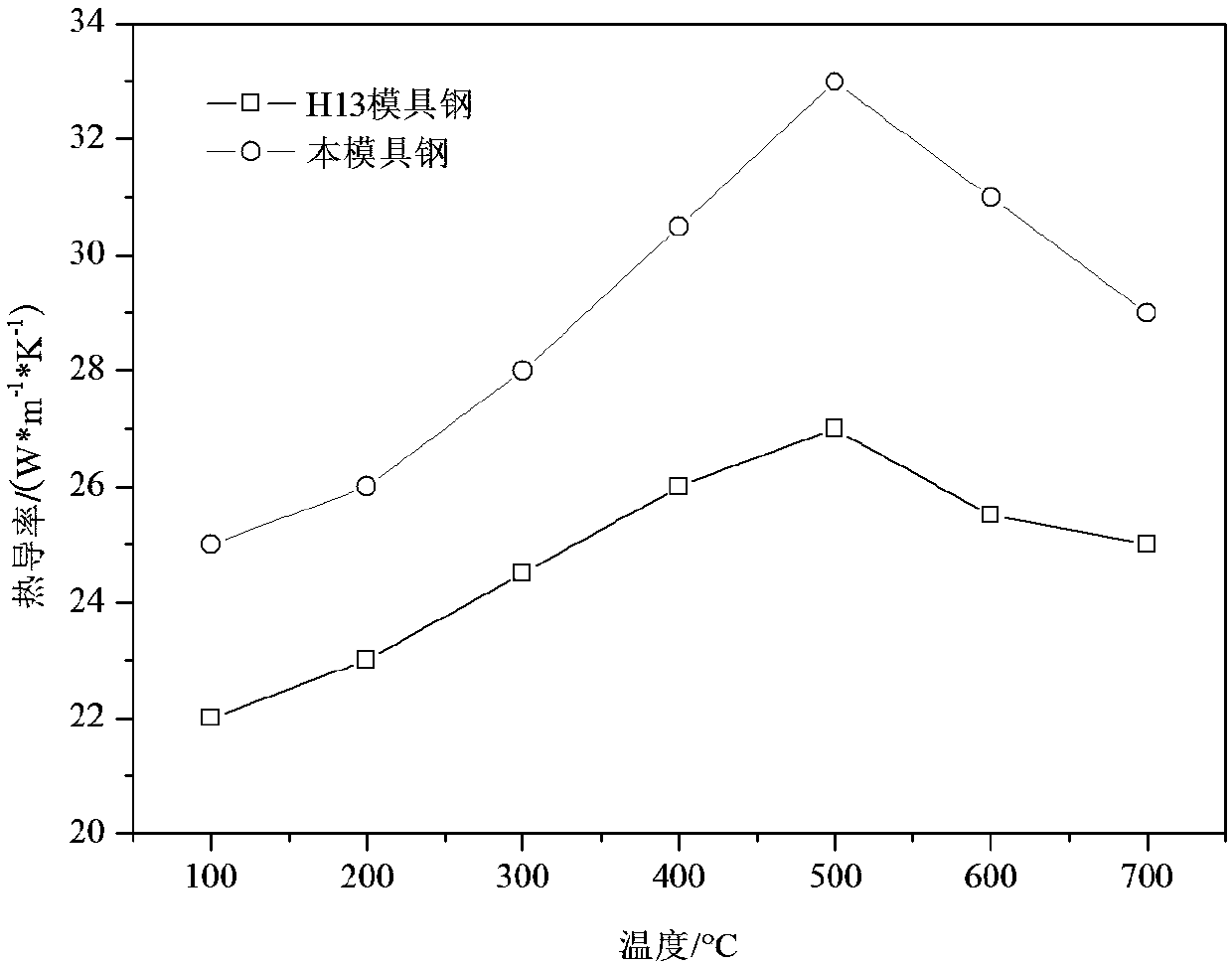

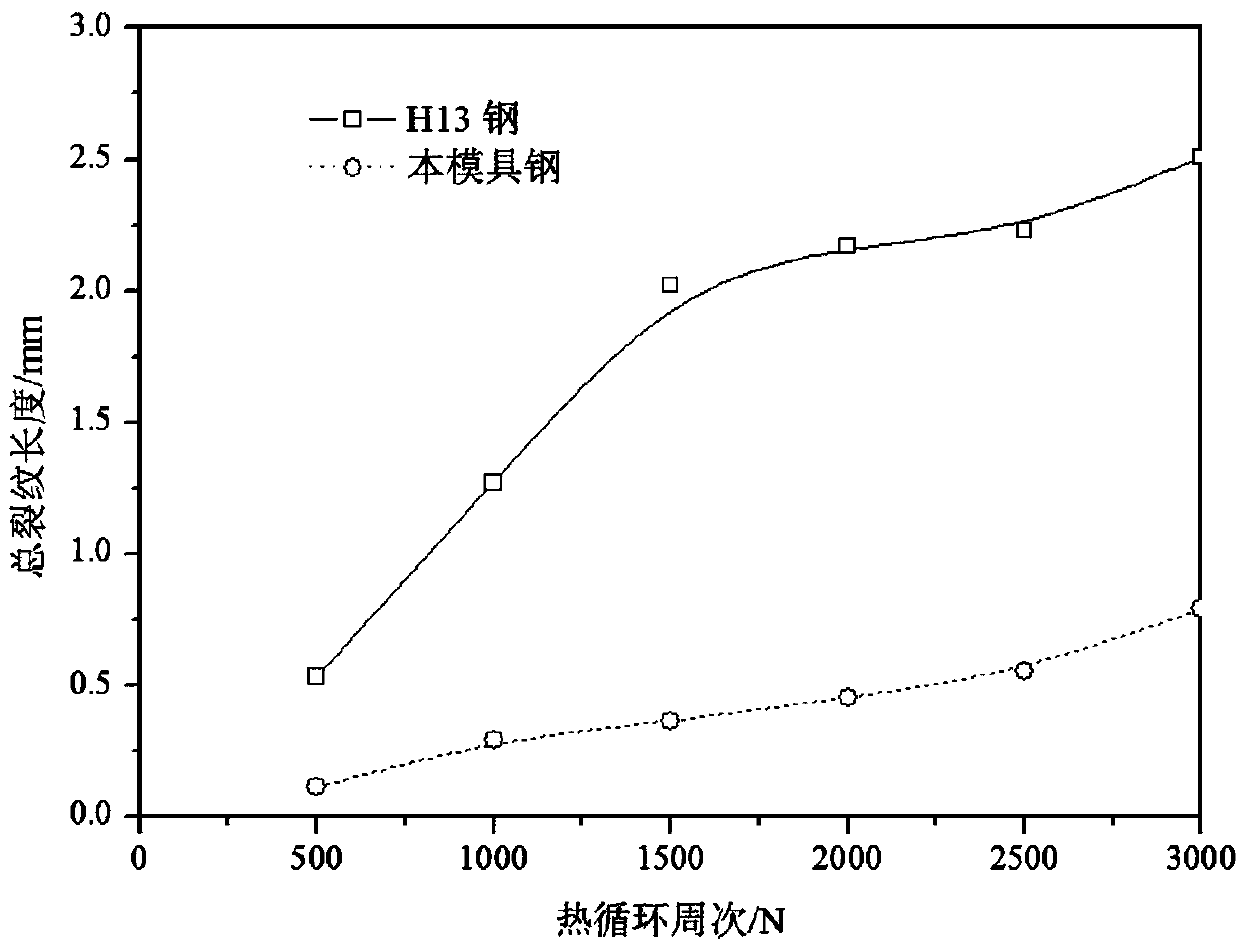

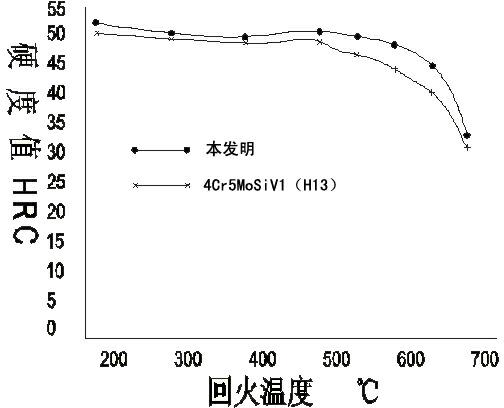

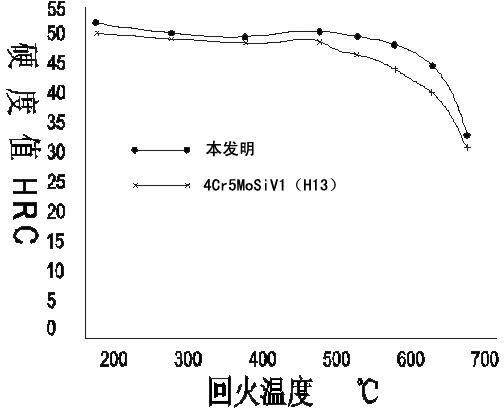

Hot work die steel high in comprehensive performance and preparation method of hot work die steel

The invention discloses hot work die steel high in comprehensive performance and a preparation method of the hot work die steel. The hot work die steel comprises the components of, by weight percentage, 0.25-0.35% of C, 0.6-0.8% of Si, 0.8-1.0% of Mn, 3.75-4.5% of Cr, 1.0-1.65% of Mo, 0.01-0.03% of Y, 0.02-0.05% of Ir, 0.01-0.03% of Sr, 0.2-0.6% of V, less than or equal to 0.03% of P, less than orequal to 0.03% of S and the balance Fe. The preparation method comprises the following steps of (1) smelting, (2) refining, (3) VD vacuum degassing, (4) casting, (5) electroslag remelting, (6) forging, (7) annealing and (8) double refining, thereby obtaining the hot work die steel finally. The hot work die steel has good thermostability and can maintain high rigidity under the condition of 700 DEG C, and the rigidity is above HRC45. The prepared hot work die steel has high high-temperature strength, and has relatively high rigidity, and excellent impact toughness and tempering (thermal fatigue) resistance. The hot work die steel has the advantages of optimization in matching ratio, purity in steel quality, structure uniformity, high strength, high toughness, good tempering resistance andthe like, therefore, the service life of the hot work die steel is prolonged.

Owner:CHONGQING UNIV OF ARTS & SCI

Manufacturing method of low-yield-ratio carbon-manganese low-temperature steel

InactiveCN108220784AReduce manufacturing costReduce the ductile-brittle transition temperatureYield ratioMaterials science

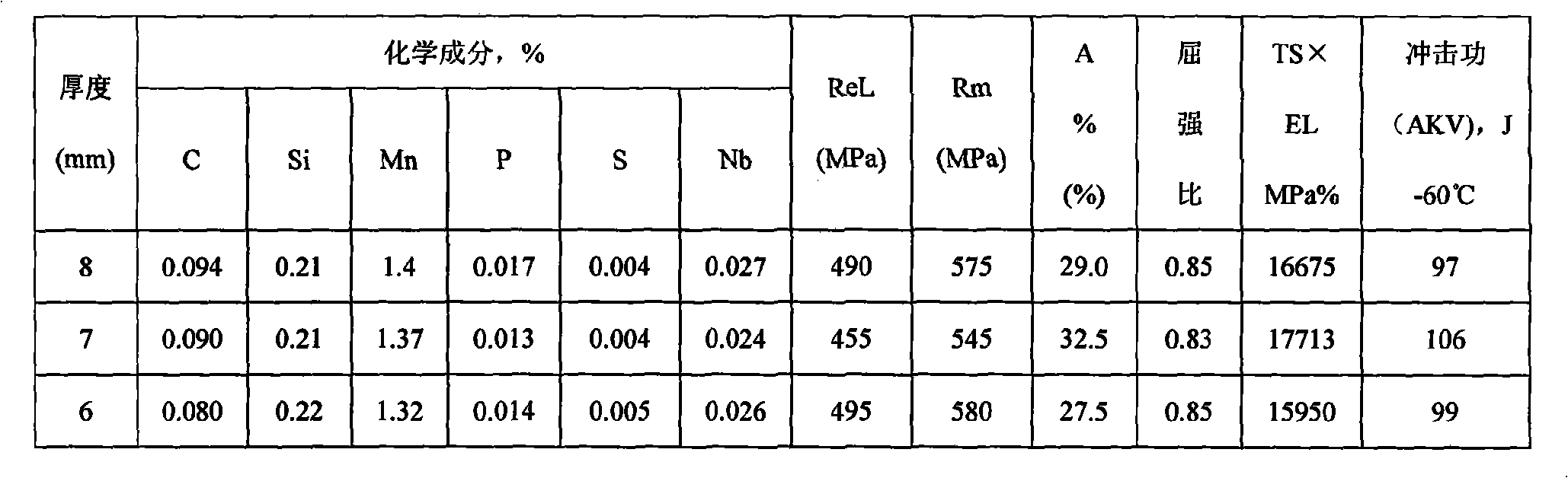

The invention discloses a manufacturing method of low-yield-ratio carbon-manganese low-temperature steel. The chemical components of the low-yield-ratio carbon-manganese low-temperature steel comprises, by weight, 0.05-0.09% of C, 0.10-0.40% of Si, 1.30-1.50% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, less than or equal to 0.010% of Nb, 0.030-0.060% of Al, and thebalance Fe and inevitable impurities. By adopting the design of low-carbon, high-manganese and high-aluminum components, fine quasi-polygonal ferrites and a few acicular ferrites and pearlitic structures through cooperation of the dynamic soft reduction control technology during the continuous casting process and high-temperature heavy reduction and fast cooling control process after rolling during the rolling process. Compared with steel for liquefied petroleum gas tankers, the low-yield-ratio carbon-manganese low-temperature steel has the characteristics of being pure in steel quality, lowin yield ratio, high in toughness and excellent in low-temperature welding performance. The ductile-brittle transition temperature of a steel plate in the thickness direction is lower than minus 80 DEG C, and the postwelding welding performance at minus 70 DEG C is excellent. Moreover, there is no need to add microalloy elements such as Cu and Cr, and the manufacturing cost is low.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Copper-plated carbon nanotube reinforced pantograph pan material and preparation method thereof

InactiveCN102031439ACompact structureImprove performancePower current collectorsCopper platingHydrogen

The invention provides a copper-plated carbon nanotube reinforced pantograph pan material and a preparation method thereof. The material comprises the following raw materials: Cu, CNTs, Ti3SiC2 and TiB2 in a volume ratio of (65-90):(1-20):(2-30):(1-20). The preparation method comprises the following steps of: uniformly mixing the four raw materials and glycerol, baking the mixture, loading the mixture into a steel mould, cold molding, placing the mixture in a high-temperature furnace under the protection of hydrogen, raising the temperature to 700 to 900 DEG C, preserving heat for 5 to 30 minutes, taking out the sample, cold molding again, sintering the sample at the temperature of between 800 and 900 DEG C for the second time and preserving heat for 30 to 60 minutes. The method has a simple process; the performance of the pantograph pan material can be greatly improved by the traditional equipment; and the prepared pantograph pan material has the advantage of relatively low cost.

Owner:WUHAN UNIV OF TECH

Super-thick Q390GJC-Z35 steel plate for high-rise buildings and production method thereof

ActiveCN102061424AMeet development requirementsManufacturing convertersProcess efficiency improvementChemical compositionSheet steel

The invention discloses a super-thick Q390GJC-Z35 steel plate for high-rise buildings and a production method thereof. The super-thick Q390GJC-Z35 steel plate comprises the following chemical compositions in percentage by mass: less than or equal to 0.19 percent of C, less than or equal to 0.50 percent of Si, 1.00 to 1.60 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.20 percent of microalloyed elements (Nb+V+Ti+Ni), less than or equal to 0.050 percent of Als and the balance of Fe and residual elements. By reasonably designing the chemical compositions of multiple composite microalloy elements, the cleanliness of steel is ensured by a low frequency (LF)+vacuum degassing (VD) process, the level of the sum of various inclusions does not exceed 3.0, the grain size of the steel reaches 9.0-10.0 level through control rolling and control cooling and normalizing treatment, and the super-thick steel plate for the high-rise buildings, which has the thickness of more than or equal to 100mm and ensures flaw detection and mechanicals properties, is produced successfully through the effective implementation of the measures.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

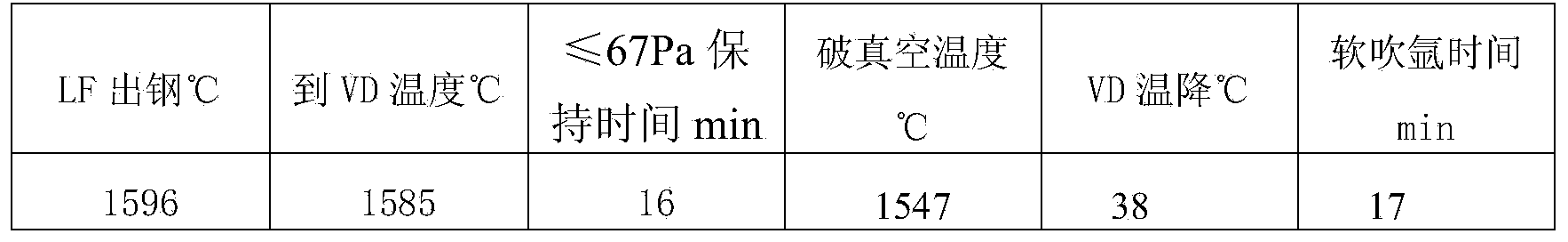

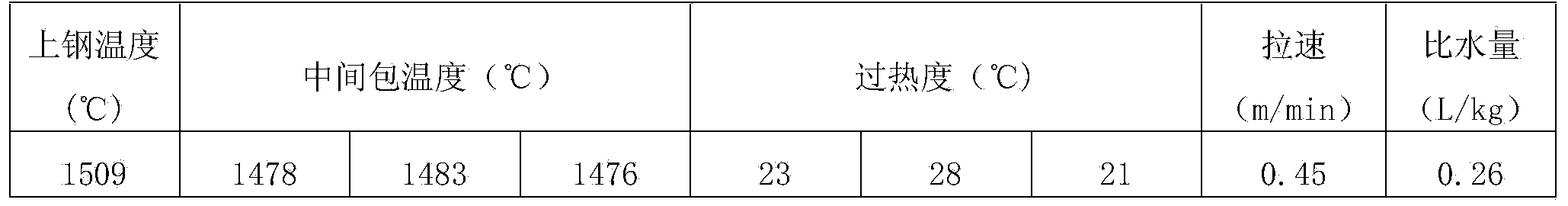

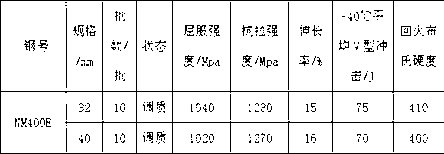

Production process of wear-resistant steel NM400E medium plate

The invention discloses a production process of a wear-resistant steel NM400E medium plate. The production method disclosed by the invention comprises the steps of converter smelting, LF (Ladle Furnace) refining, vacuum refining, pouring, casting blank heating, rolling, slow cooling, heat treatment and the like. According to the invention, the cleanliness of the steel is guaranteed through reasonable chemical component design and processes of LF and VD (vacuum degassing); and high-strength NM400E steel with the thickness of 30-40 mm is successfully developed through the effective implementation of processes such as heating, rolling and thermal refining, wherein the yield strength of the steel is controlled at 1000-1100MPa, the tensile strength is controlled at 1200-1300MPa, the elongation is controlled at 13-17%, the V type impact energy at the temperature of minus 40 DEG C is controlled at 60-80J and the brinell hardness in a high-temperature tempering state is 380-420.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

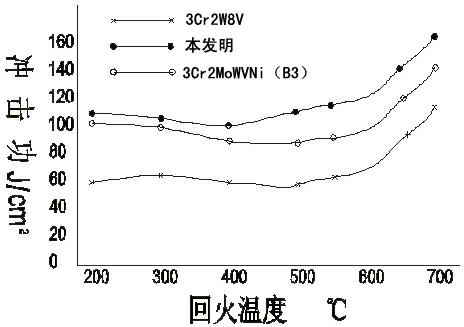

B3R hot work die steel with high strength and toughness and resistance to tempering, and preparation process thereof

The invention provides 4Cr3MoWVNi (B3R) hot work die steel with high strength and toughness and resistance to tempering, and a preparation process thereof. Raw materials for preparing the B3R hot work die steel comprise, by weight, C 0.35 to 0.42%, Si 0.15 to 0.35%, Mn 0.3 to 0.5%, Cr 2.50 to 3.50%, Mo 1.00 to 1.50%, W 0.50 to 0.80%, V 0.50 to 0.80%, Ni 1.45 to 1.85%, S 0.003 to 0.010% and P 0.008 to 0.018%, with the balance being Fe. The preparation process comprises the following steps: smelting at intermediate frequency--remelting (refining) of electroslag-diffusion hydrogen of electroslagingots, annealing treatment of electroslag ingots--forging--annealing of forging stocks--rough machining--vacuum heat treatment, and secondary tempering so as to obtain the novel product of die steel. The hot work die steel prepared in the invention has high Rockwell hardness, excellent impact toughness and tempering (thermal fatigue) resistance, and the advantages of optimized collocation of components, pure steel quality, a uniform structure, high strength, strong toughness, good tempering resistance, etc.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

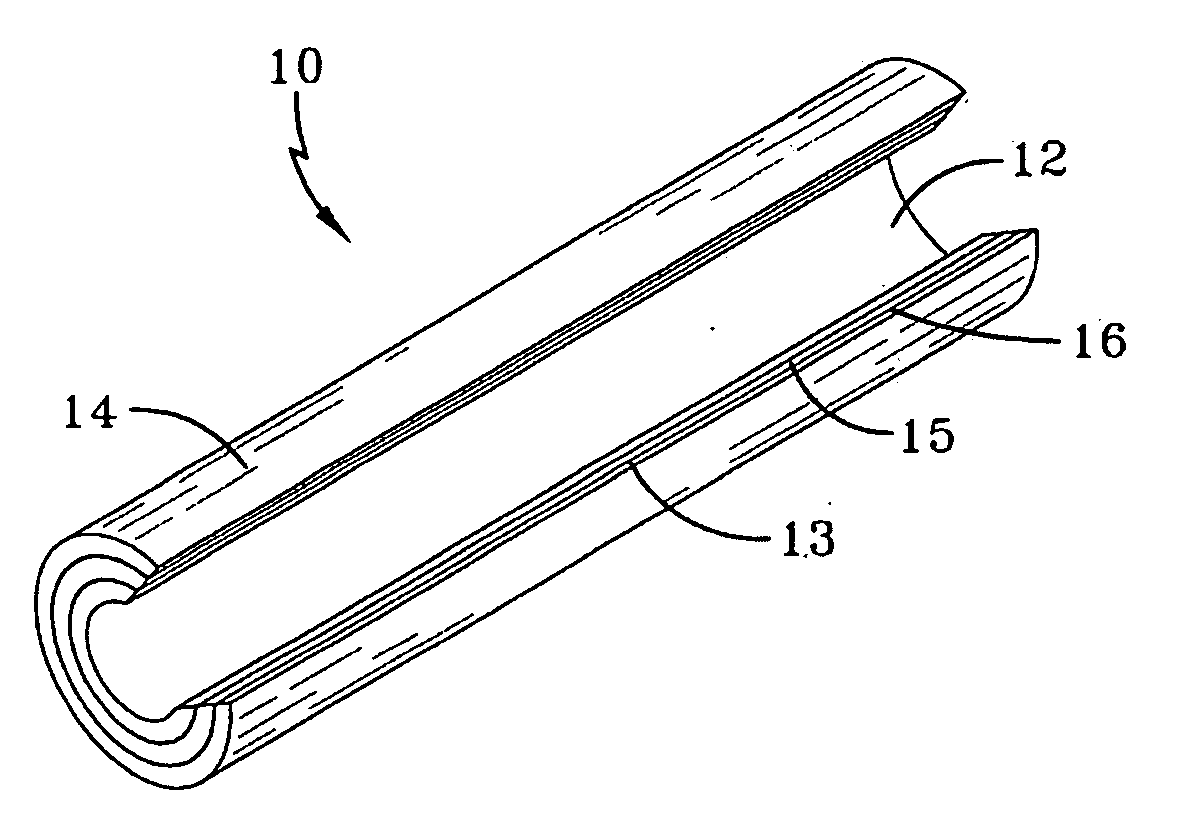

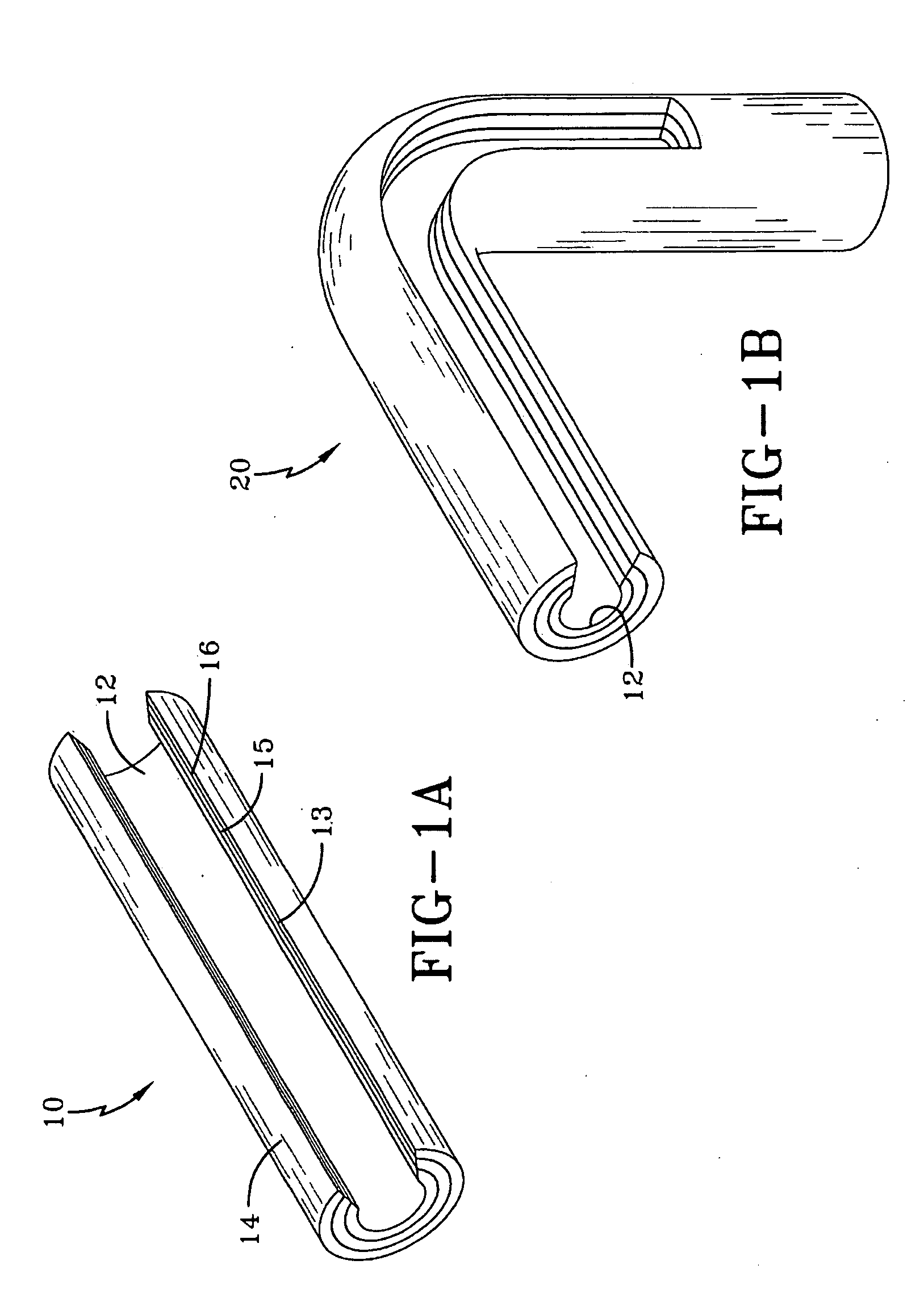

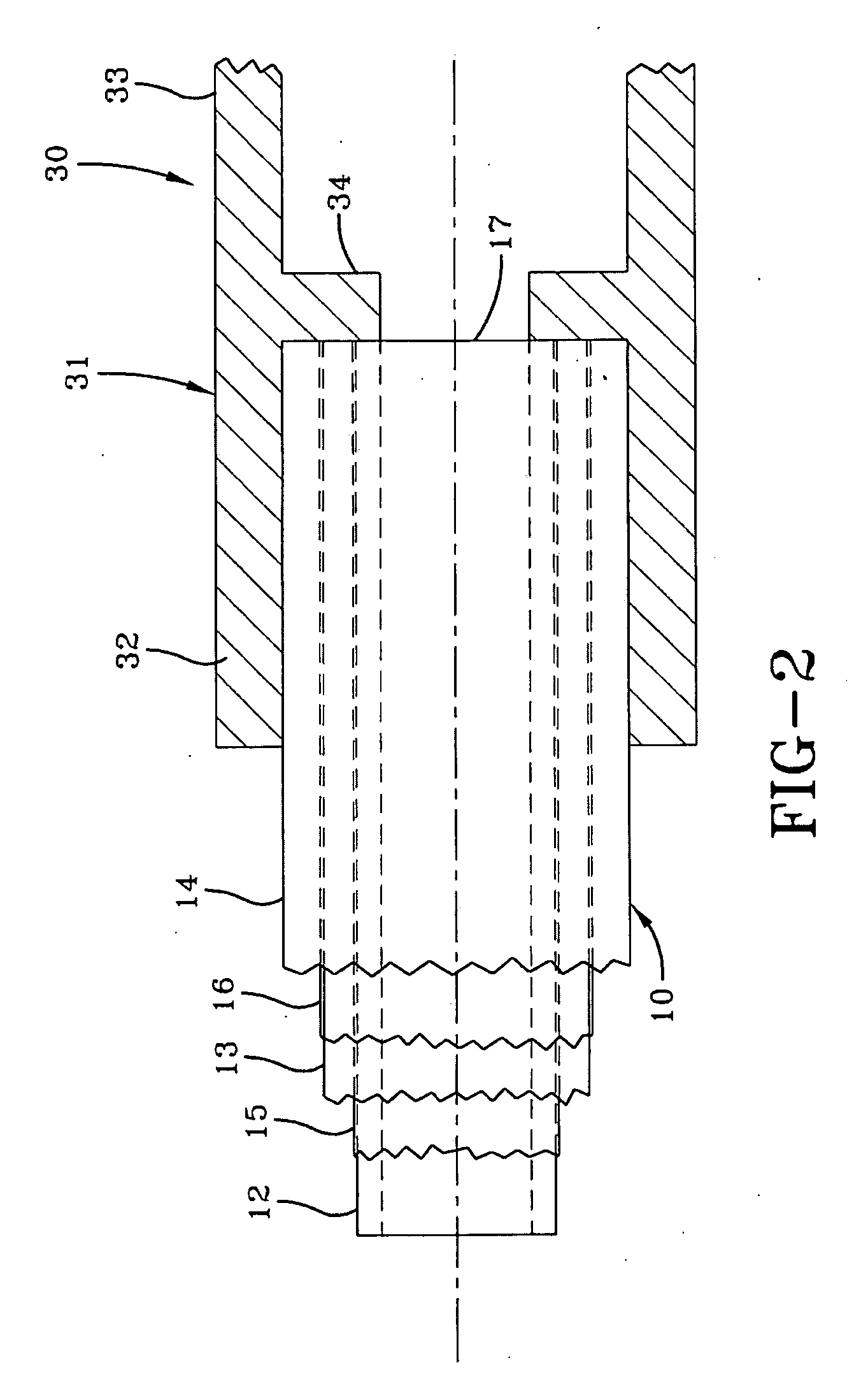

PVC/CPVC Composite Pipe With Metal Interlayer And Process For Making It

InactiveUS20090139661A1Reduce oxidationReduced strengthSynthetic resin layered productsLaminationBi layerAdhesive

A composite pipe has a metal conduit sandwiched between inner and outer conduits of PVC / CPVC, each of which are adhesively secured to the interlaying metal conduit with a dried, solvent-free thin layer of a thermosetting bilayer adhesive which provides a bond with the metal, which bond fails in cohesive failure. Narrowly defined limits on the thickness of each conduit are found to provide a bendable composite pipe with an aluminum interlayer; and to provide a rigid non-bendable composite pipe with a steel interlayer. Making the composite pipe which meets required ASTM and NSF test considerations requires unexpectedly critical process steps. A process for making the pipe is disclosed, as are PVC / CPVC fittings which allow lengths of pipe to be solvent-cemented in them so as to seal the terminal ends of the pipe against infusion of fluid under pressure in the pipe, thus preventing delaminaton.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com