Patents

Literature

812 results about "Steel pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

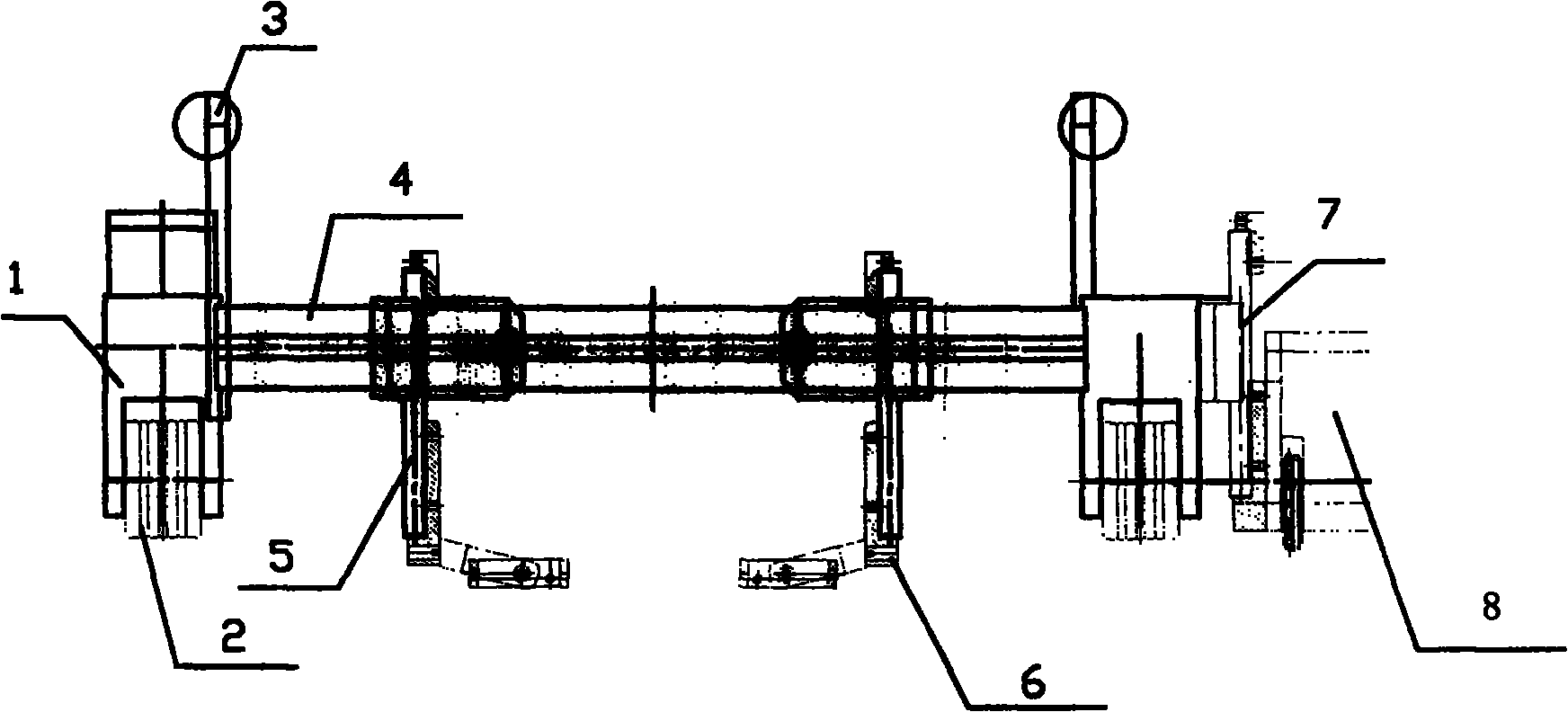

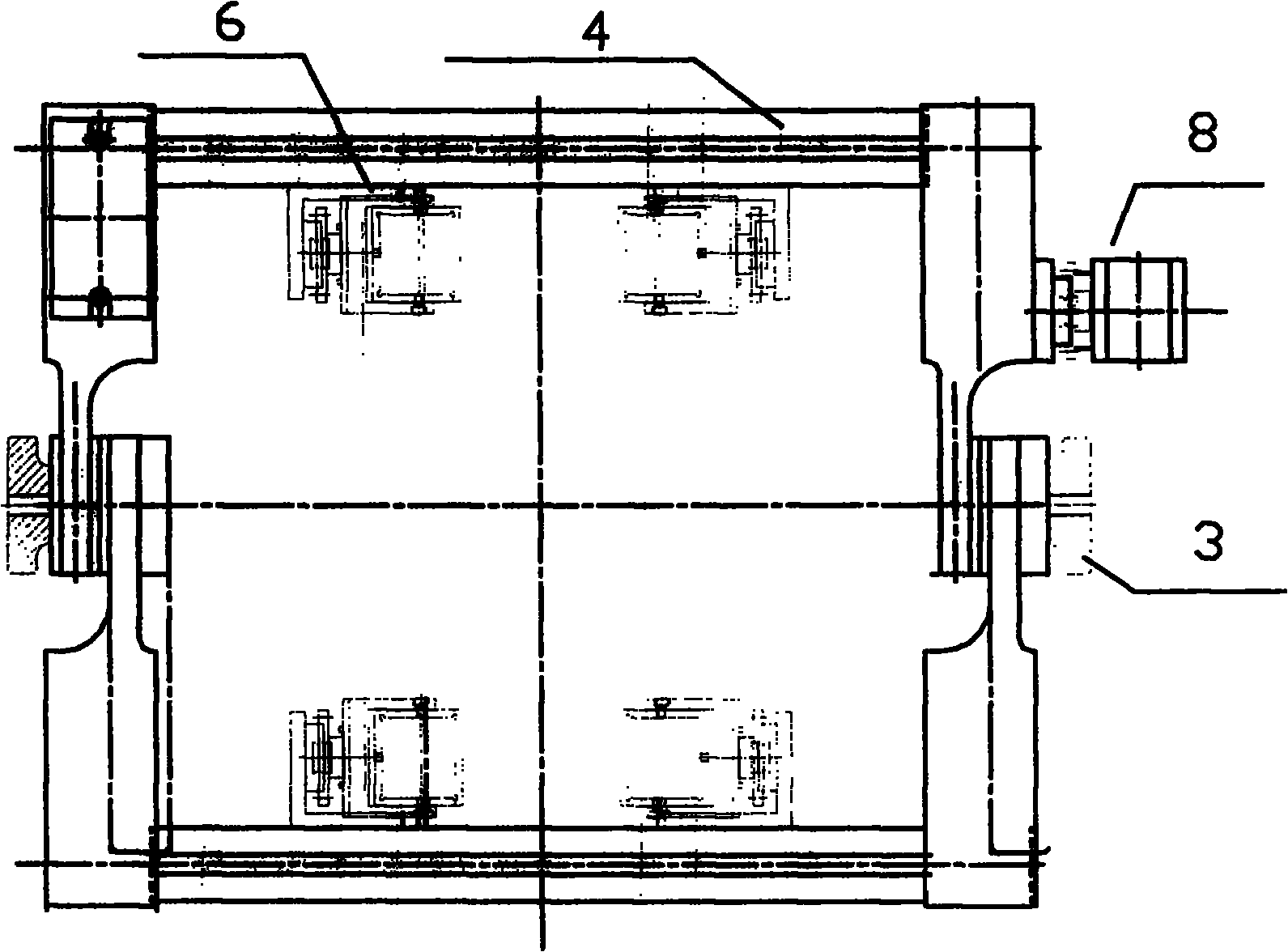

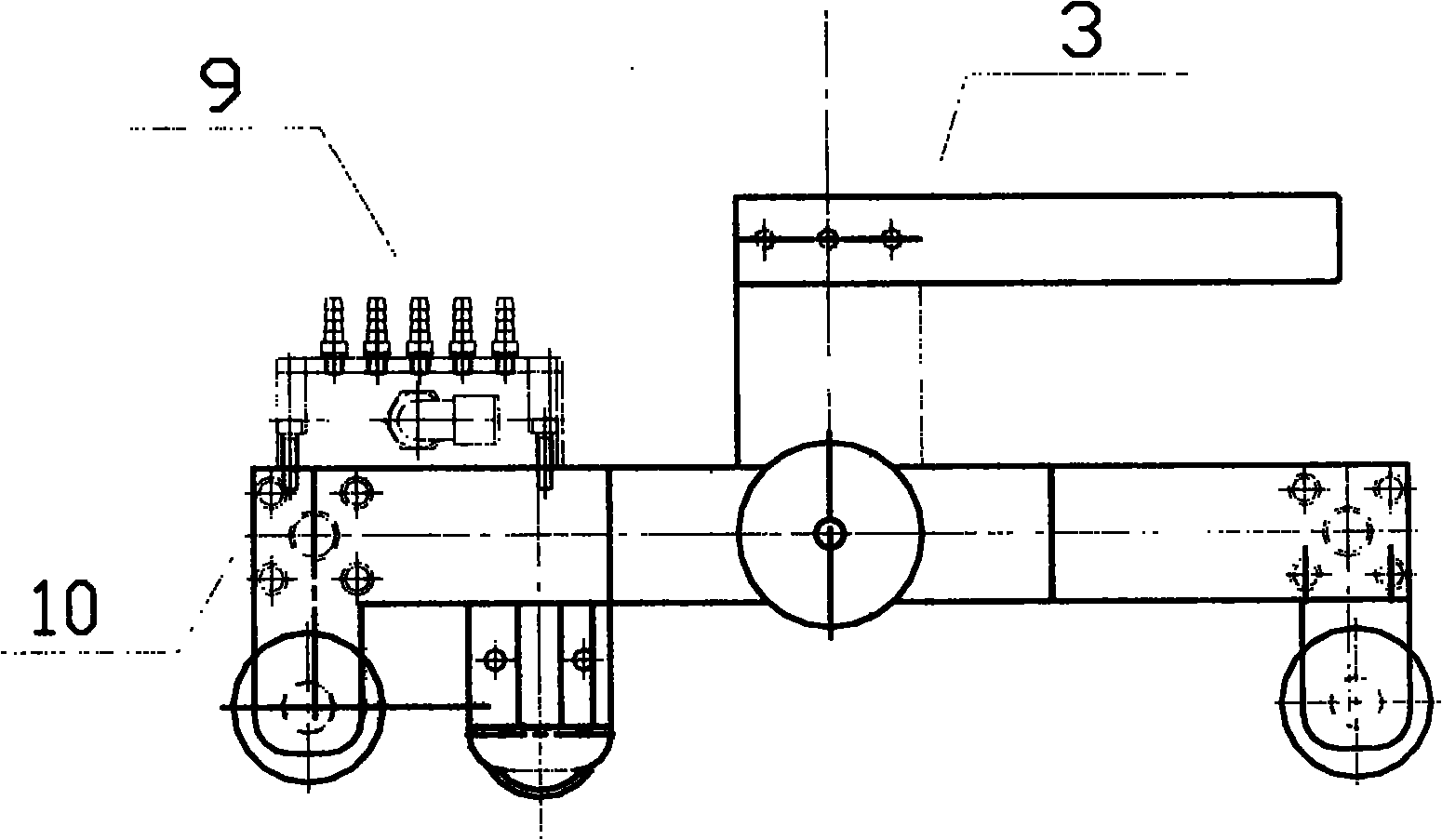

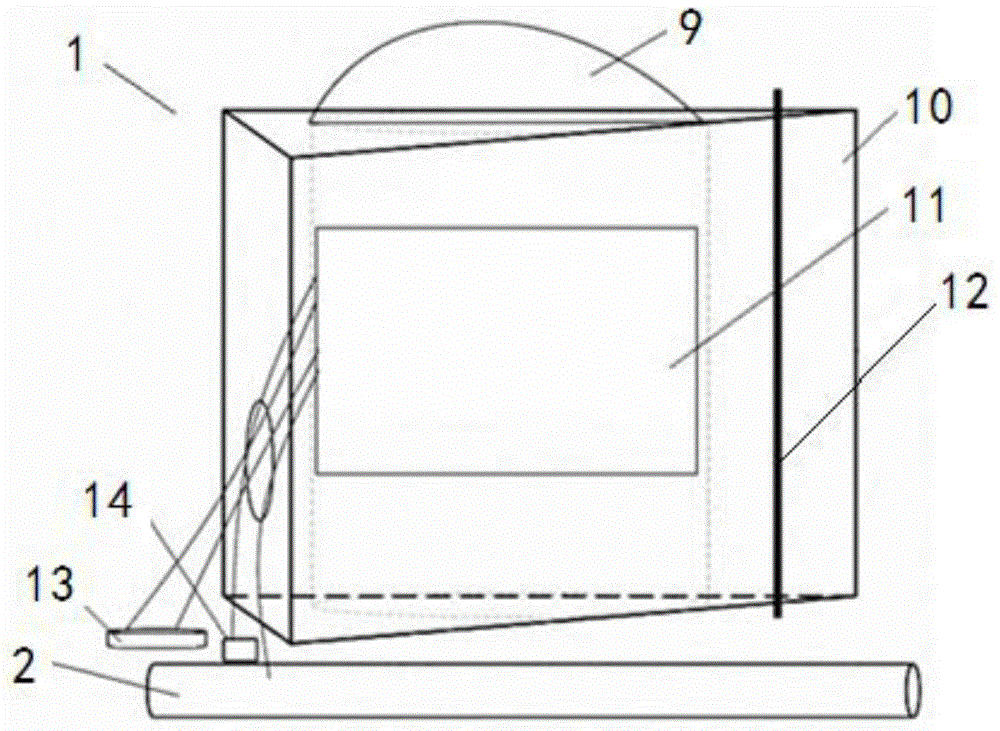

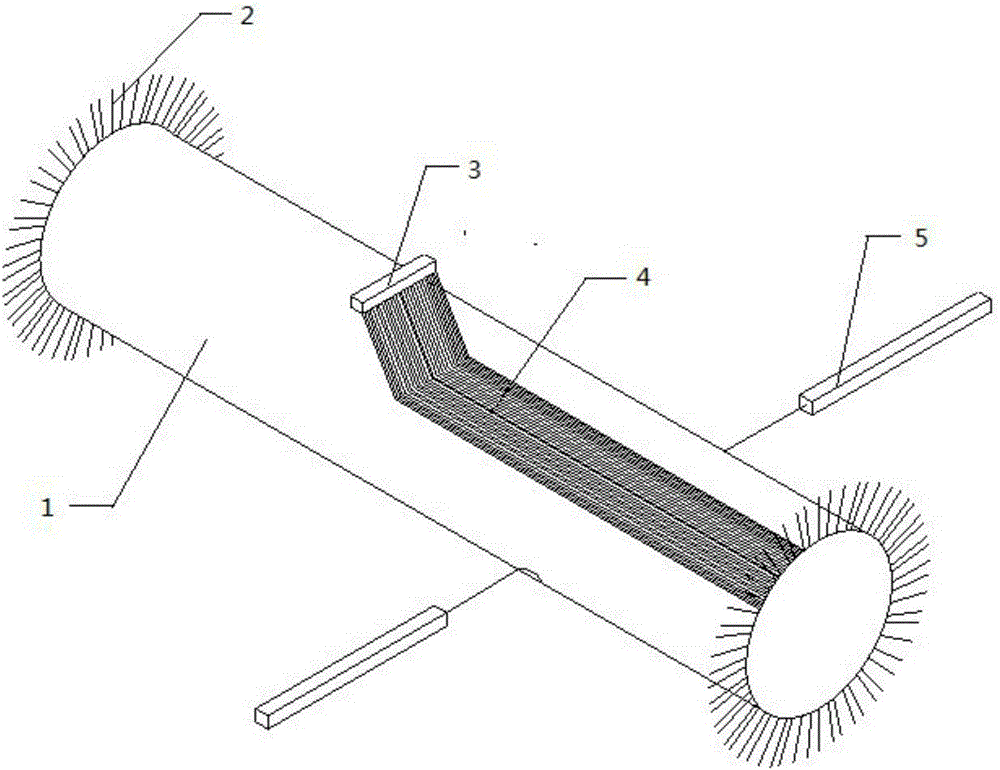

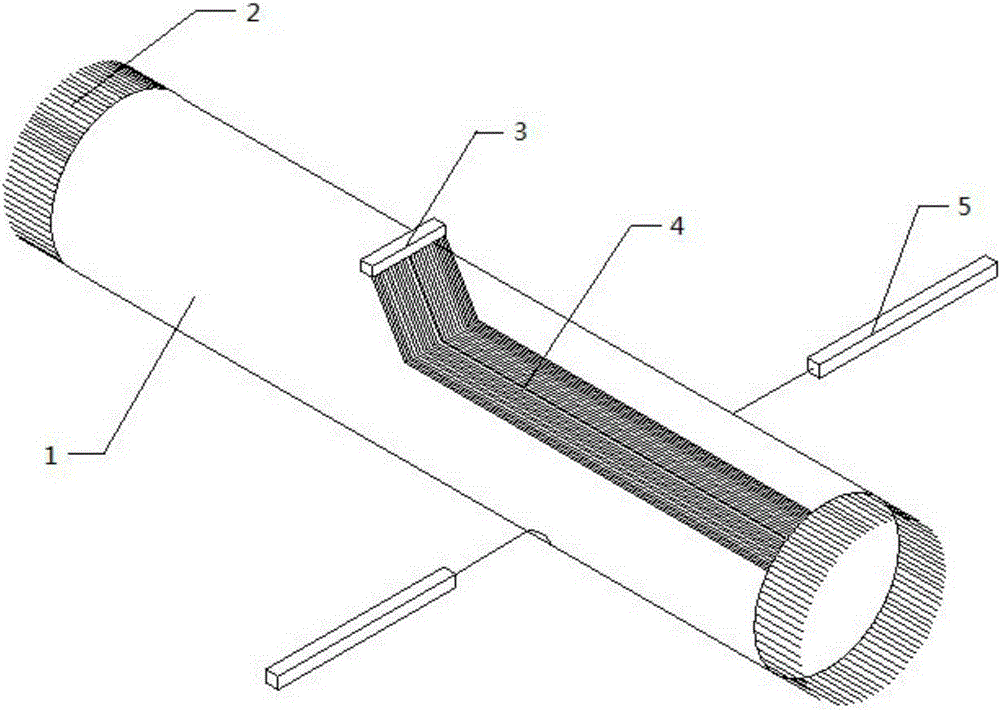

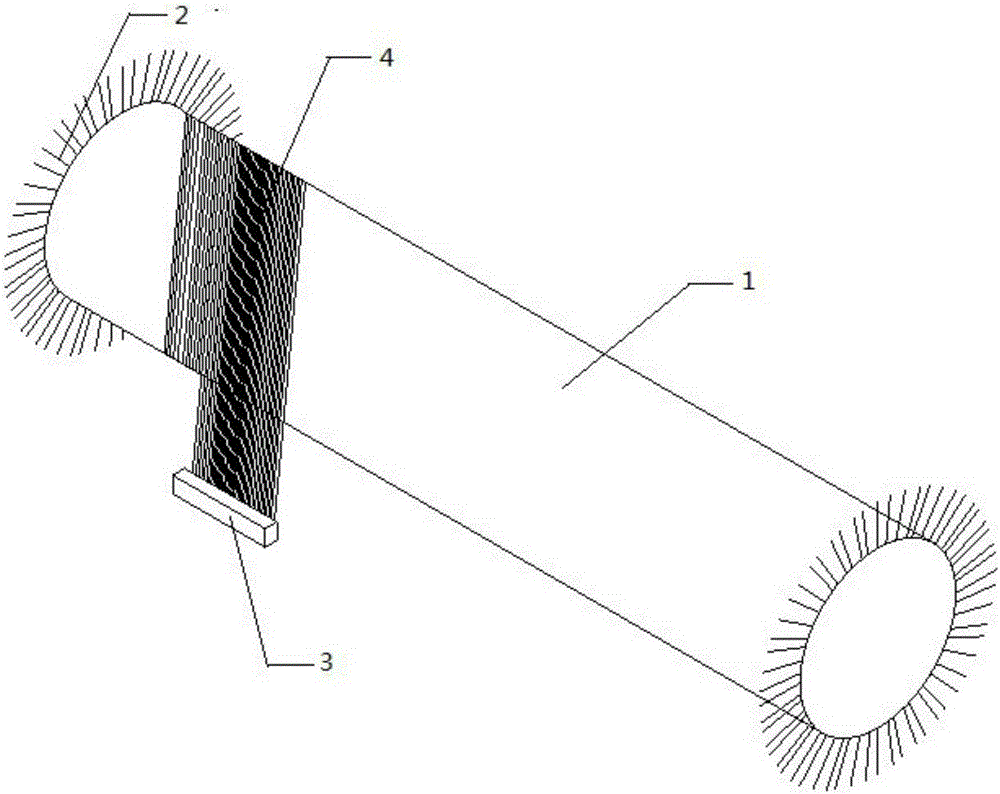

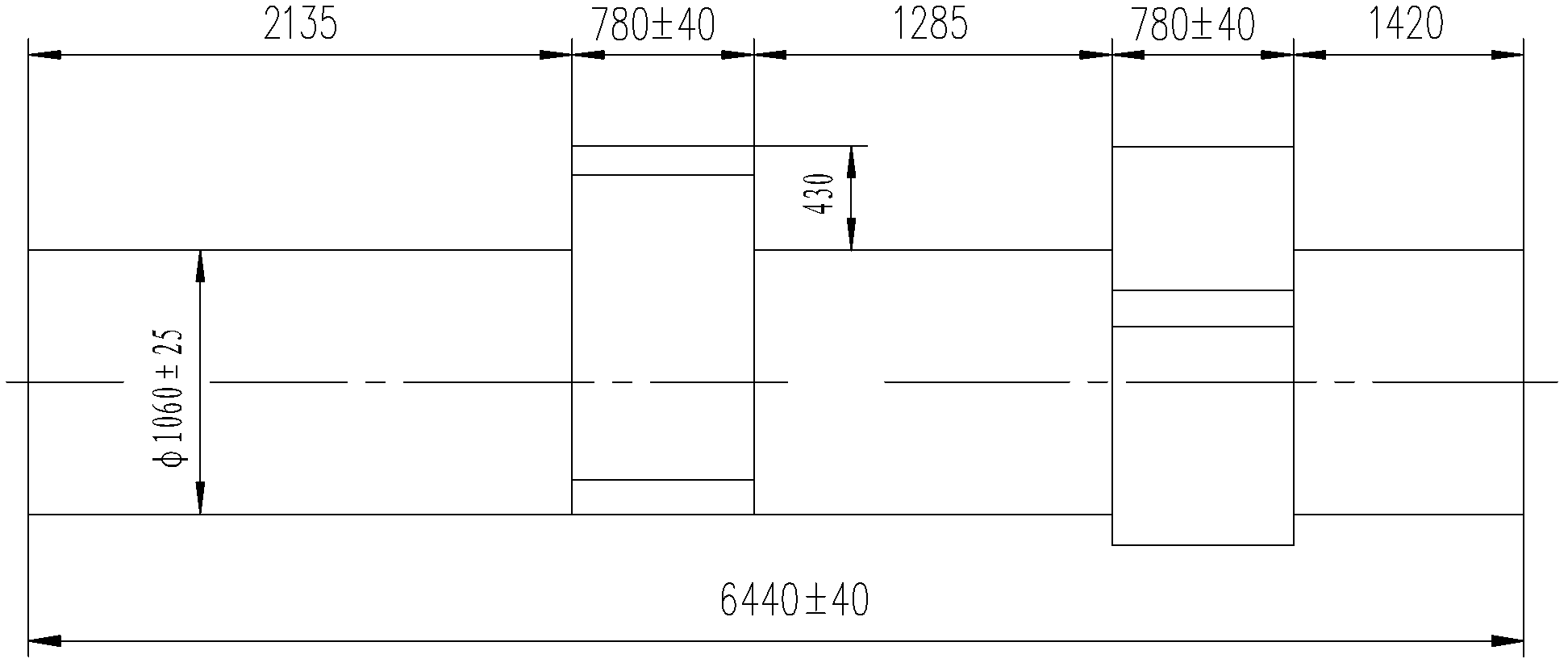

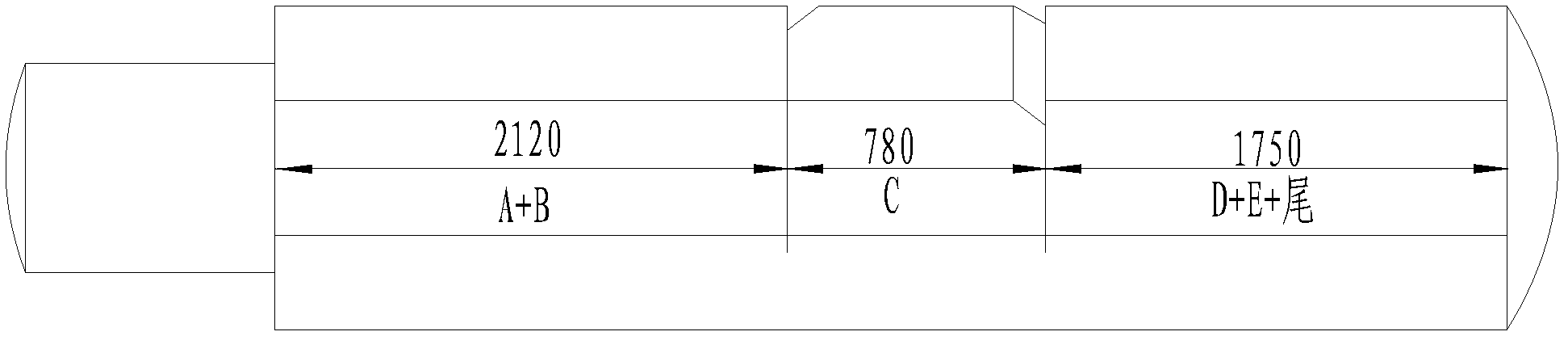

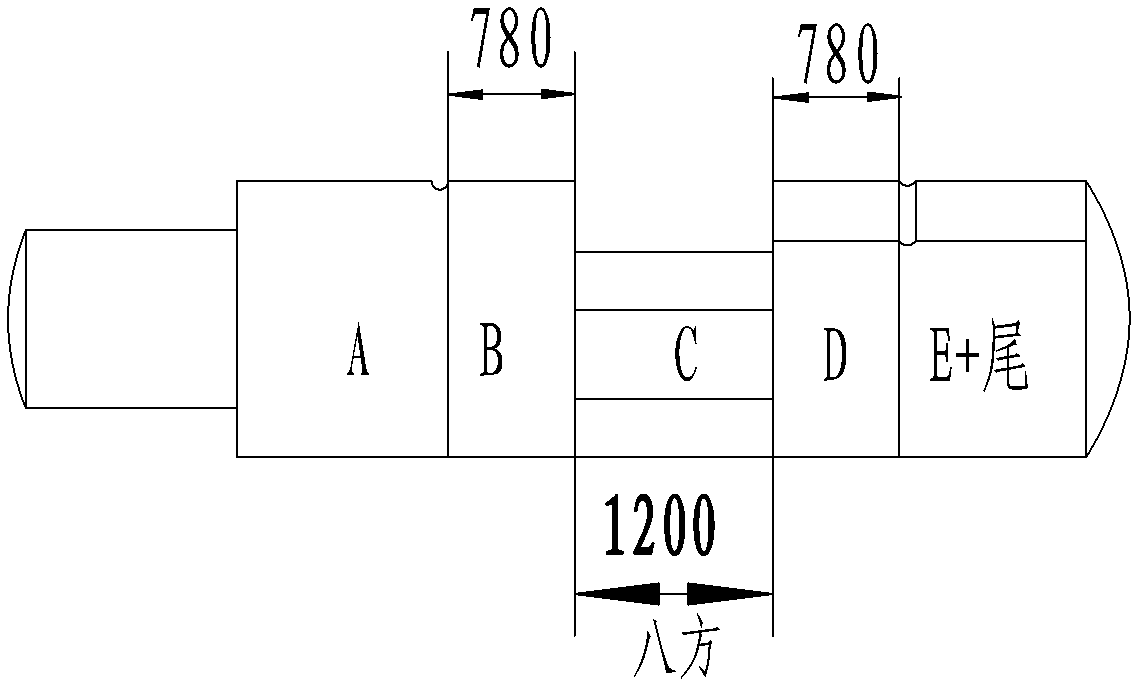

Helical soldering seam manual checking machine

ActiveCN101256173AReliable detectionAccurate detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsSolderingSteel pipeline

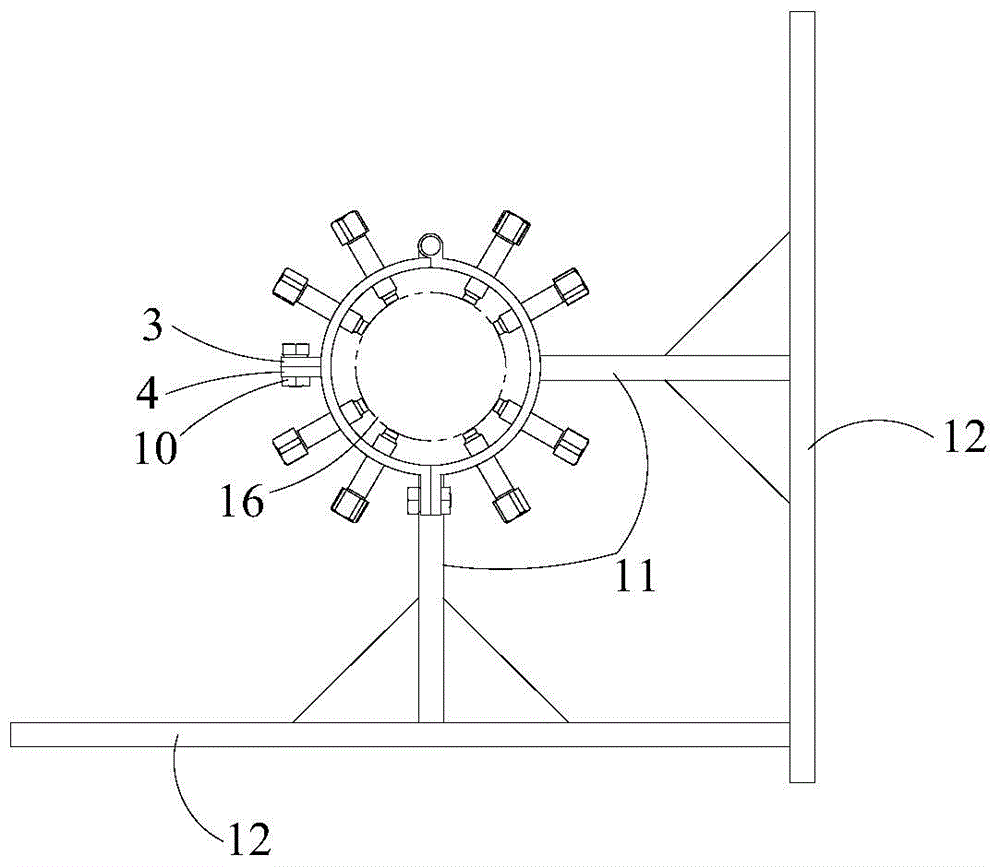

The invention is a spiral weld manual scanner walking on pipelines, which is used for detecting spiral welds of steel pipelines on service with phased array combined with TOFD ultrasonic. The invention relates to the fields of equipment test and pipeline system technology, which are not included in other categories. The invention is composed of a scan rack [1], a probe rack [6], a rolling wheel mechanism and a code device, the rectangle scan rack [1] is equipped with four rolling wheel mechanisms on the four corners, the probe rack [6] is installed on probe rack mobile railways on double sides of the scan rack [1], the code device mechanism is installed on one side out of the scan rack [1]. The scanner can walk on pipelines steadily and reliably, when the scanner detects spiral welds of steel pipelines on service, the probe is parallel to the surface of the pipeline weld accurately all the time and keeps a certain distance with that, in order to provide reliable and accurate tests for detecting spiral welds of steel pipelines on service with phased array combined with TOFD ultrasonic.

Owner:PIPECHINA SOUTH CHINA CO

Submerged arc welding wire for steel pipeline

ActiveCN101104229AEasy to implementLow costArc welding apparatusWelding/cutting media/materialsSheet steelWeld seam

The invention relates to a submerged arc welding wire used on a pipeline steel, which is applied in the submerged arc welding of an X80 high steel grade pipeline steel plate used on high-pressure oil and high-pressure gas conveying pipelines. The chemical components comprise (according to weight percent): C 0.02-0.07; Si 0.10-0.30; Mn 1.80-2.50; P is less than 0.010; S is less than 0.010; Cr 0.10- 0.50; Ti 0.05-0.08; Mo 0.20-0.50; B 0.003-0.004; and the rest is Fe. The welding wire is matched with BGSJ101-G flux and other special flux for pipeline steel welding , and then the best strength and toughness of welding seam can be obtained; the tensile strength ob of welded seam metal is more than or equal to 700MPa. Impact energy AkV of the welded seam metal in the minus 20 DEG C is more than or equal to 150J. And thus, the invention is suitable for the submerged arc welding of the X80 high steel grade pipeline steel plate.

Owner:SHOUGANG CORPORATION +1

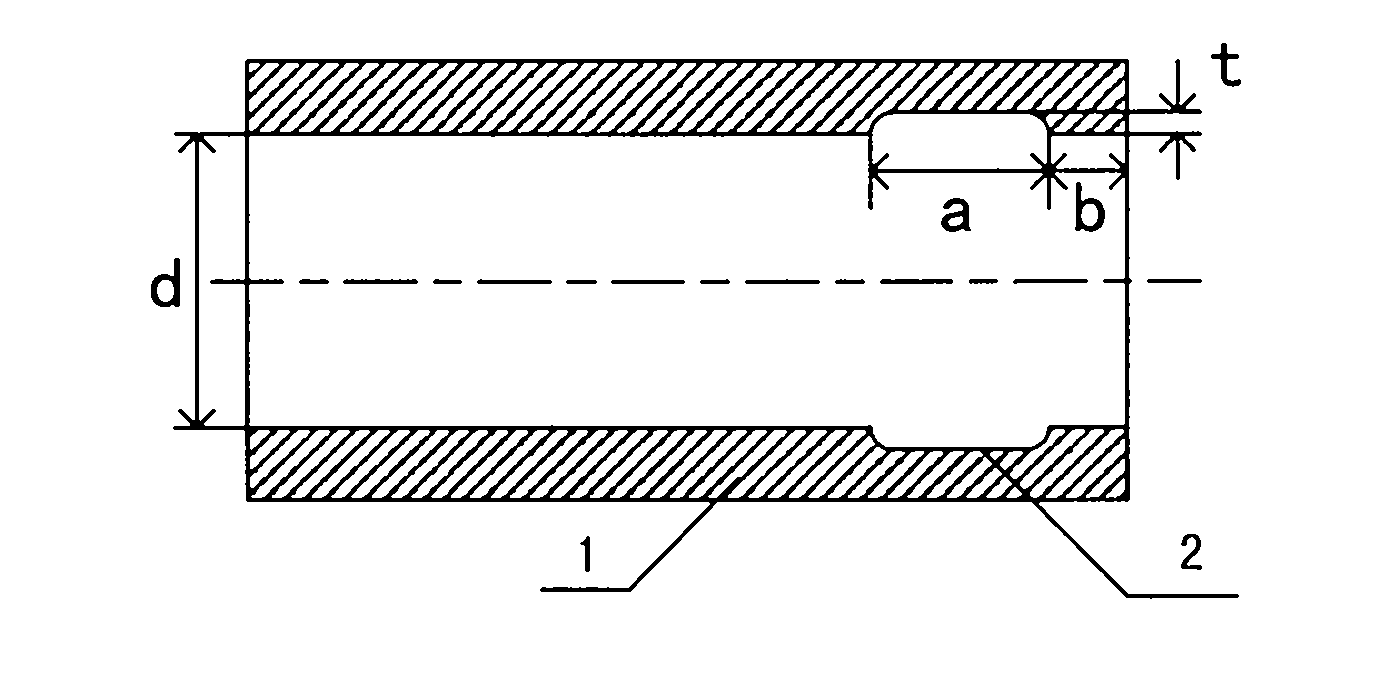

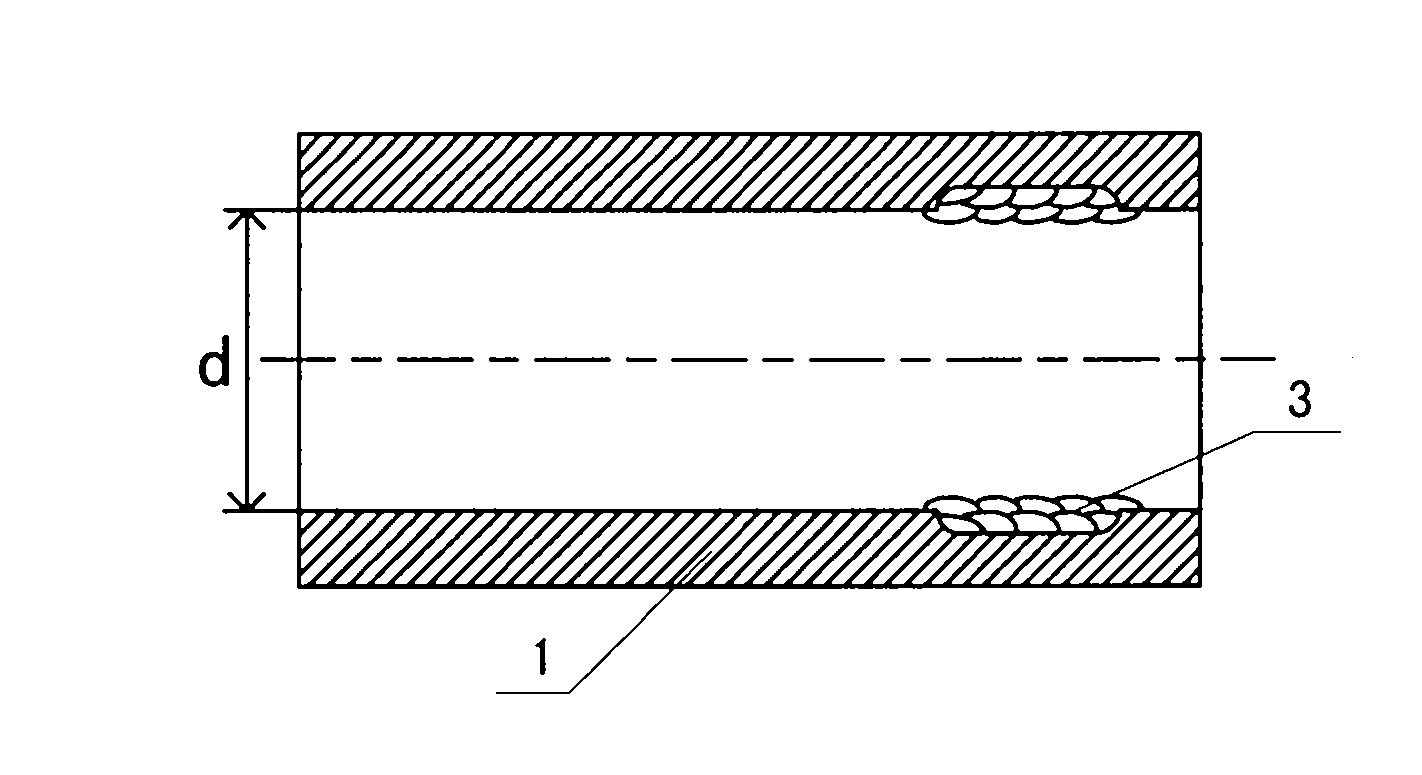

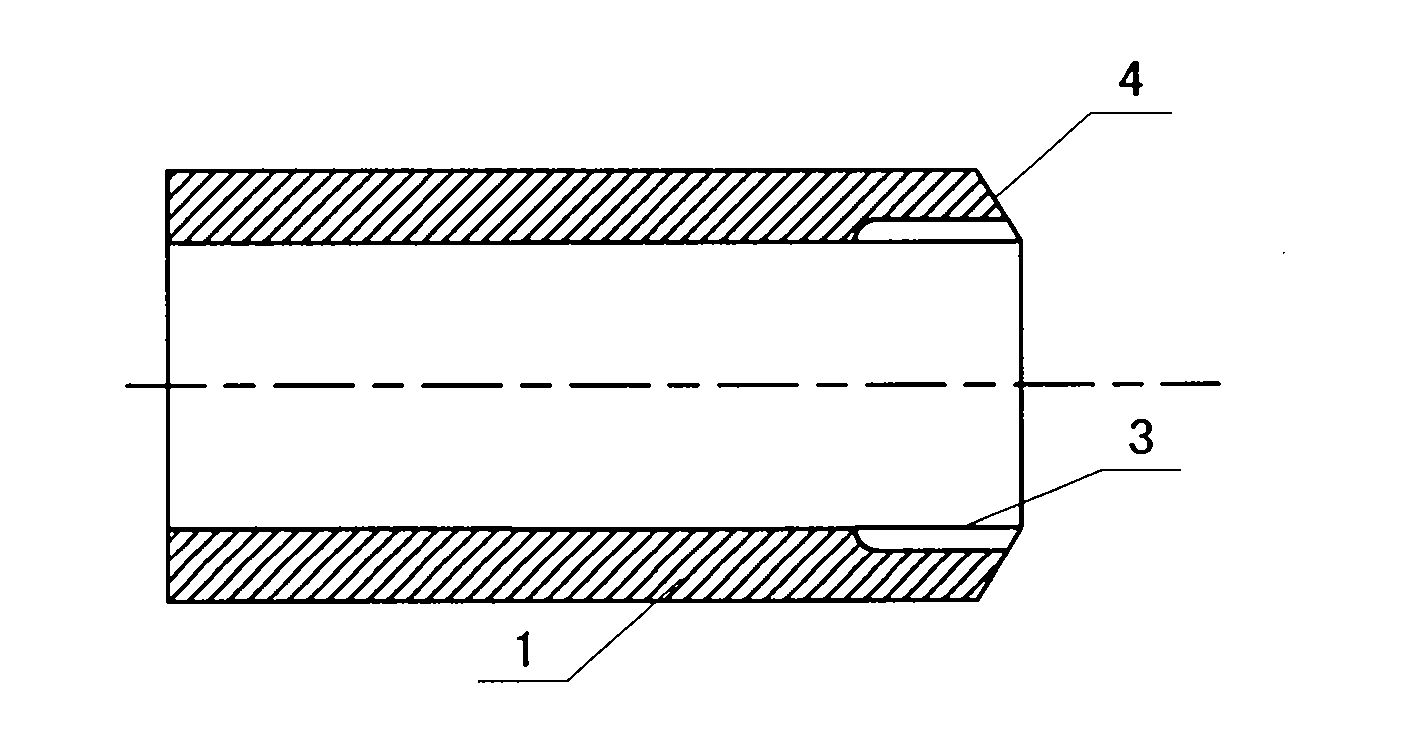

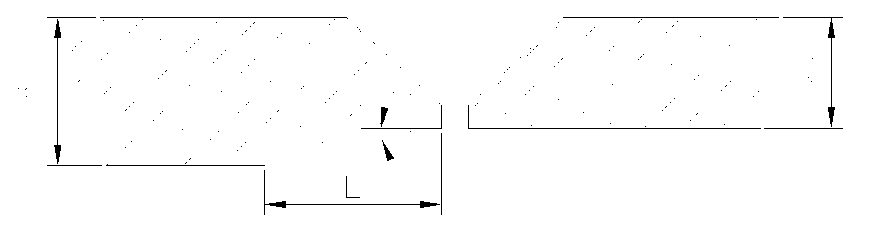

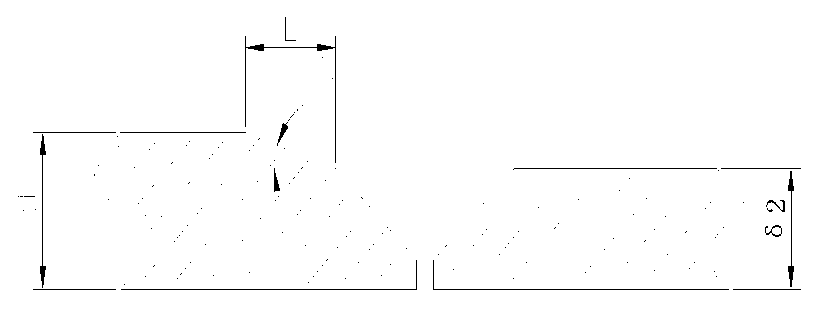

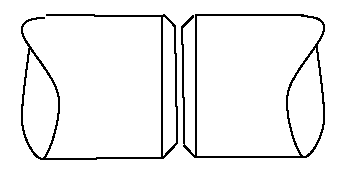

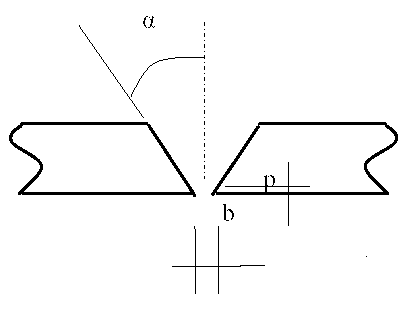

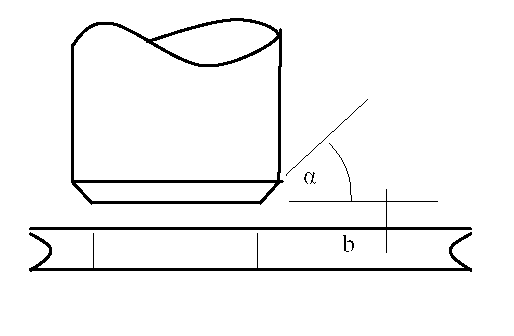

Method for welding anticorrosion steel pipeline with no internal repaired mouth

InactiveCN103008988AReduce the chance of welding defectsRigid enoughArc welding apparatusChemical industryAlloy

The invention provides a method for welding an anticorrosion steel pipeline with no internal repaired mouth, which is applicable to the anticorrosion treatment of a steel pipeline welding connector with an anticorrosion coating in the petroleum industry and the chemical industry. The method is characterized in that a groove with a certain length and depth is machined on a position which is at a certain distance from the end part of the steel pipe, an anticorrosion alloy material is surfaced on the groove, the end part of the surfaced steel pipe is machined into a V-shaped groove, an anticorrosion coating with sufficient thickness is coated on the inner wall of the steel pipe, the anticorrosion coating covers sufficient length of the anticorrosion alloy surfacing layer, then two steel pipes are in butt connection with each other, layering welding is carried out after the two steel pipes are fixed on one point, an argon tungsten-arc welding method is adopted, the anticorrosion alloy material which is identical to that of the surfacing is selected as the filling material, and argon is filled into the pipe to protect the pipe in the welding process. Due to the adoption of the novel technology for welding the anticorrosion steel pipeline with no internal repaired mouth, the corrosion resistance of the inner wall and a weld mouth of the pipeline can be guaranteed, the internal mouth repairing technology on the spot after the welding can be avoided, characteristics such as simplicity in construction and reliability in performance can be realized, and the method is suitable for the real engineering application of the petroleum and chemical industry fields.

Owner:HARBIN INST OF TECH

Heat-recoverable composition and article

Disclosed is an adhesive composition suitable for bonding to a polymeric material and steel. The composition comprises specified proportions of a maleic anhydride-modified propylene-ethylene copolymer resin, a maleic anhydride-modified polyethylene, a polyisobutylene, a terpolymer comprising ethylene, propylene and a non-conjugated diene, and a hydrocarbon resin tackifier. The composition is useful in preparing a heat-recoverable article that is used to provide a protective coating on the joints of a steel pipeline. Also provided is a single sleeve or two-sleeve system for application to the joints of a coated steel pipeline operating at temperatures up to 120° C.

Owner:BERRY PLASTICS CORP

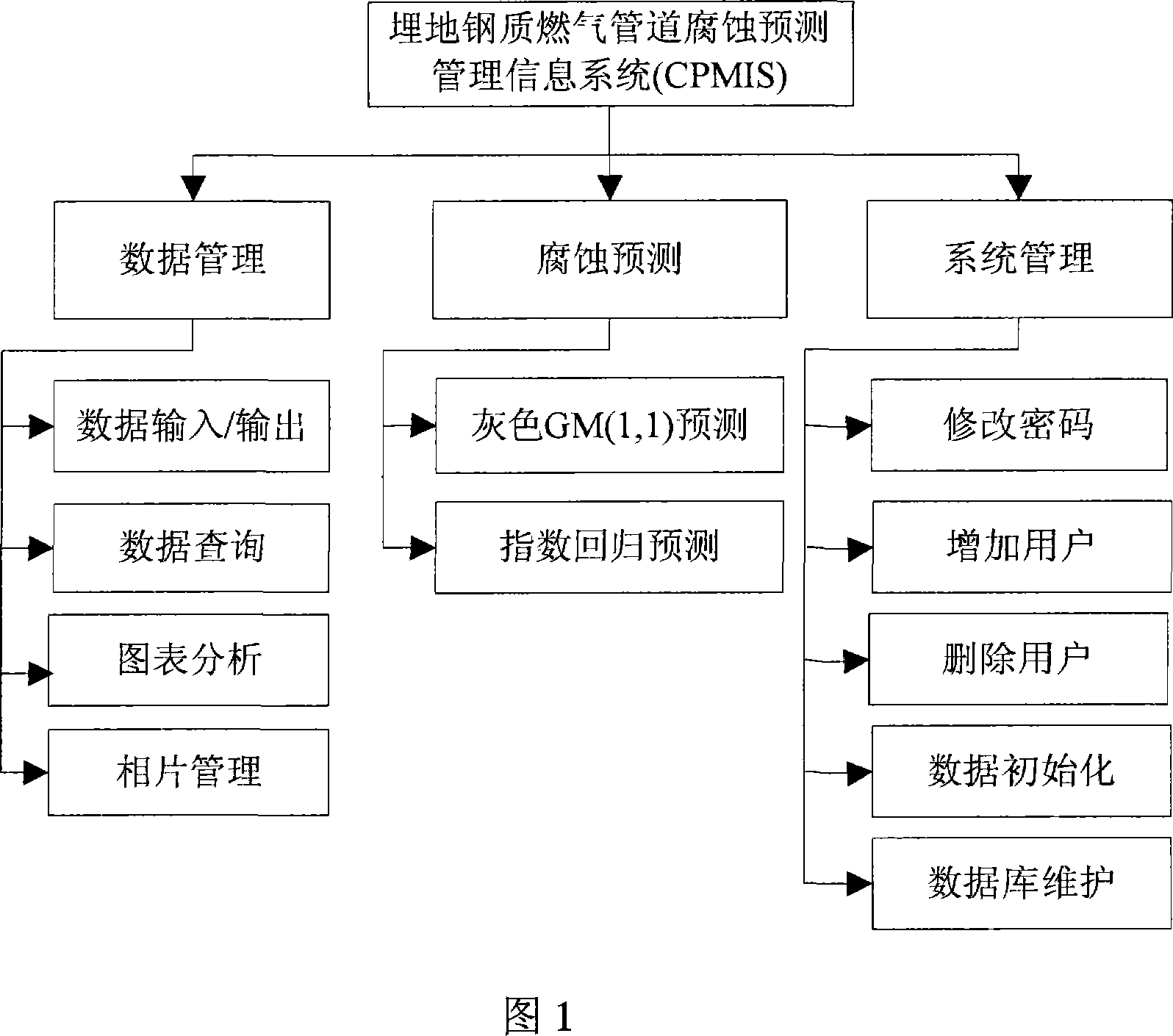

Underground steel gas pipe network pipeline corrosion prediction system

InactiveCN101071098AEfficient managementAccurate estimateWeather/light/corrosion resistancePipeline systemsSystems managementData management

Owner:GUANGZHOU GAS +1

Method for repairing and reinforcing pipeline by means of composite materials

ActiveCN104534221AImprove corrosion resistanceAccelerated corrosionPipe elementsFiberCrack resistance

The invention relates to a method for repairing and reinforcing a pipeline by means of composite materials. The method for repairing and reinforcing the pipeline by means of the composite materials comprises the following steps that S1, defect positioning and working surface creating are conducted on the pipeline to be repaired and reinforced; S2, the surface of the pipeline is treated; S3, defects on the surface of the steel pipeline are filled and leveled up; S4, an anti-stripping coating is painted; S5, adhesion of carbon fiber sheets is conducted; S6, curing and maintenance are conducted, wherein vacuum auxiliary curing is adopted; S7, the hardness of the composite materials is tested and checked, wherein a hardness tester is used for measuring whether a reinforcing layer is qualified or not during checking; S8, a repaired mouth and the reinforcing layer are protected, and the reinforced portion of the steel pipeline is painted with protective paint or is wrapped in a protective layer; S9, an outer protective layer of the steel pipeline is checked and accepted. The method for repairing and reinforcing the pipeline by means of the composite materials has the advantages that the technical processes are simple, operation is convenient, cost is low, and the construction cycle is short; meanwhile, the strength, the crack resistance, the seepage resistance and the corrosion resistance of the wall of the repaired and reinforced pipeline are improved, and the service life of the repaired and reinforced pipeline is prolonged.

Owner:BEIJING FIRMBASE ENG

Hot-rolled wide and thick plate with good ductility and toughness for low temperature pipelines and manufacturing method thereof

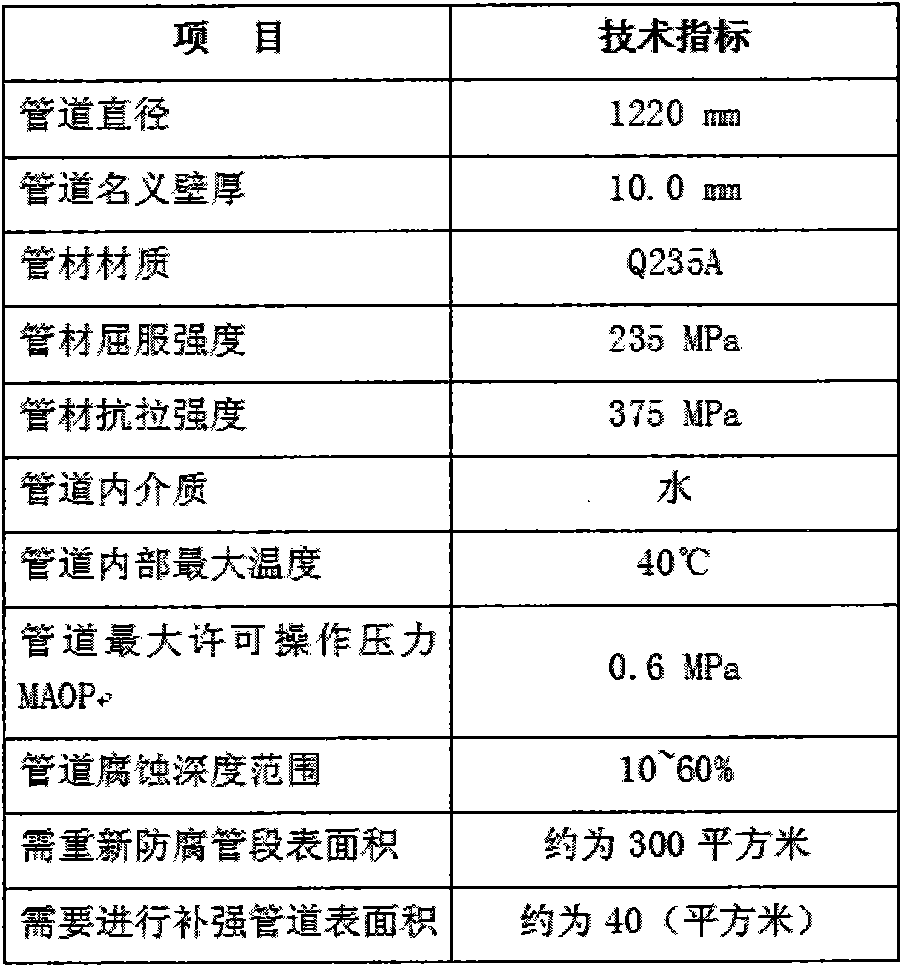

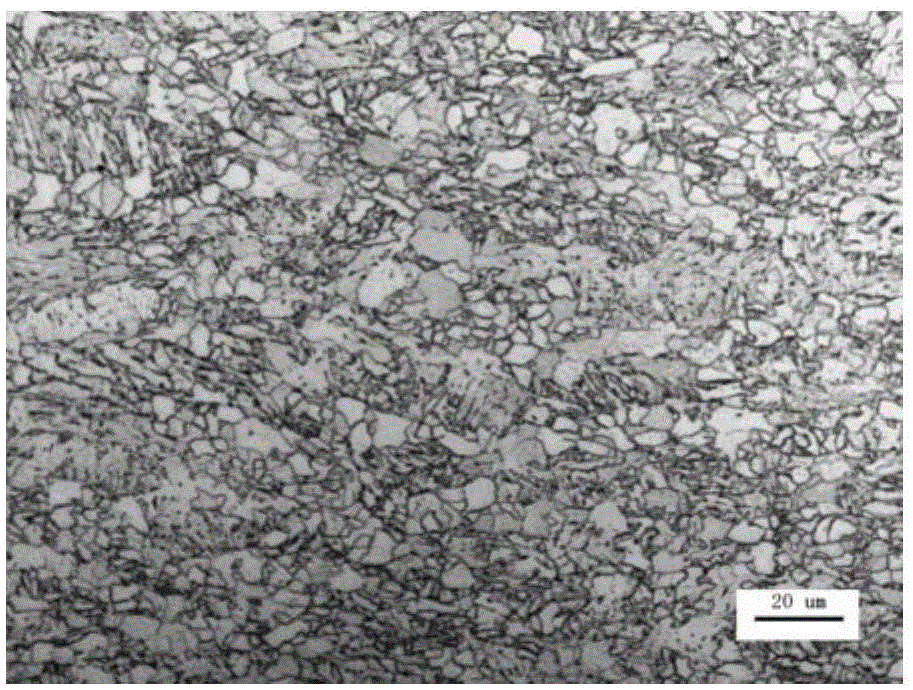

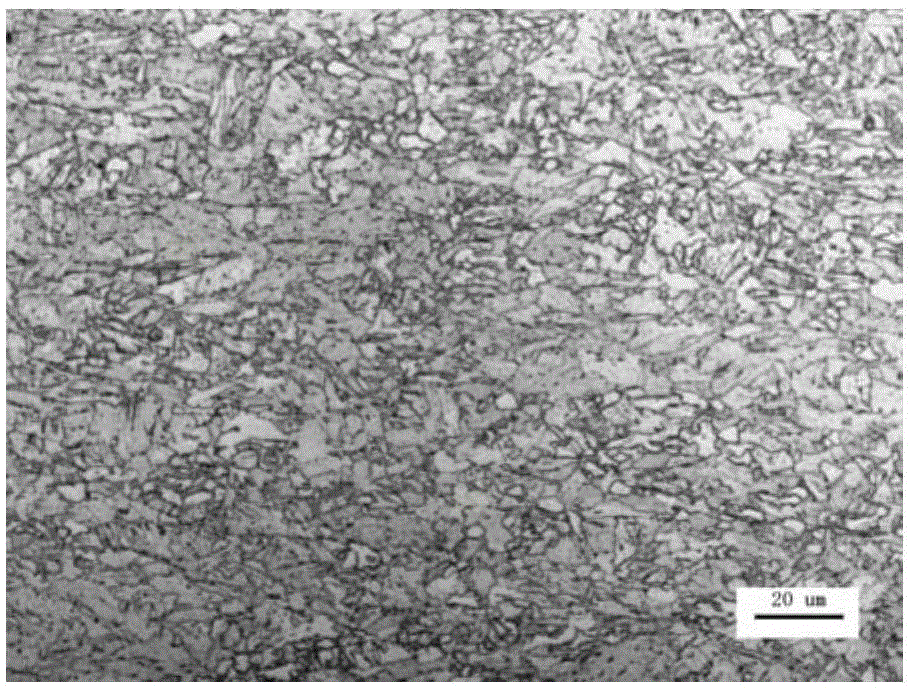

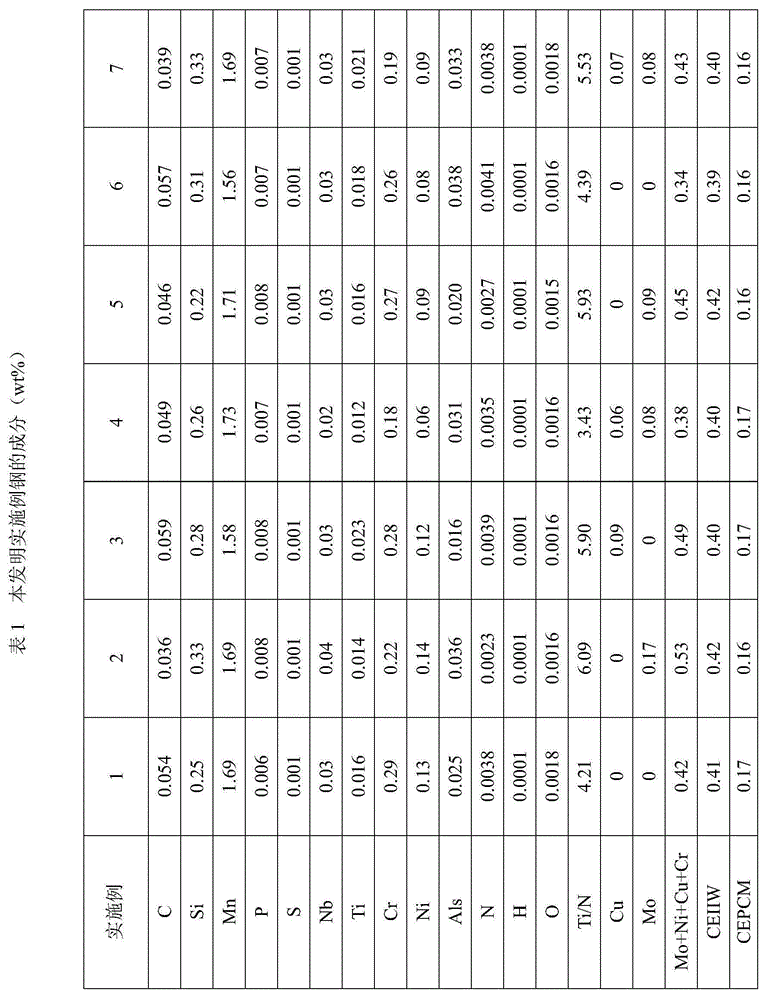

The invention provides a hot-rolled wide and thick plate with good ductility and toughness for low temperature pipelines and a manufacturing method thereof. The steel plate comprises the following components in percentage by weight: 0.035 to 0.060% of C, 0.20 to 0.35% of Si, 1.56 to 1.74% of Mn, 0.01 to 0.04% of Nb, 0.011 to 0.025% of Ti, 0.18 to 0.30% of Cr, 0.06 to 0.15% of Ni, 0.015 to 0.040% of Als, 0 to 0.10% of Cu, 0 to 0.19% of Mo, 0.0020 to 0.0045% of N, not more than 0.009% of P, not more than 0.001% of S, not more than 0.0015% of H, not more than 0.0020% of O, and the balance being iron and inevitable impurities; wherein the total percentage of Mo, Ni, Cu, and Cr is in a range of 0.32 to 0.55%, and the ratio of Ti and N is in a range of 3.42 to 6.10. At the same time, CEIIW is controlled in a range of 0.385 to 0.430%, and CEPcm is controlled in a range of 0.159 to 0.175%. The manufacturing method comprises steps of molten iron pretreatment, converter smelting, external refining, continuous casting, casting blank reheating, rolling, and cooling. The provided wide and thick plate can be used as a raw material to prepare large diameter (not less than 1420 mm) thick wall low temperature steel pipelines, and the ductility and toughness are good.

Owner:ANGANG STEEL CO LTD

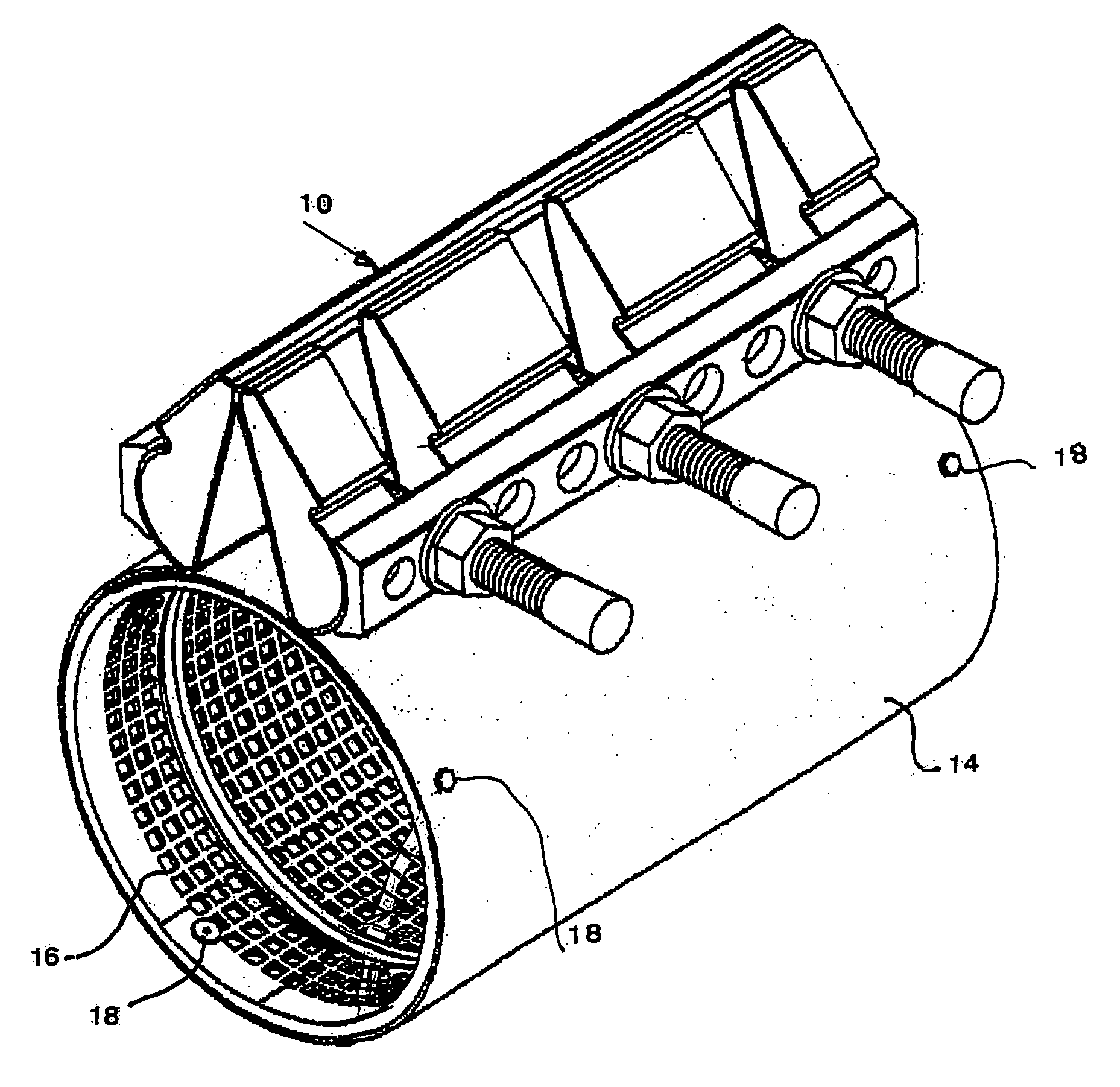

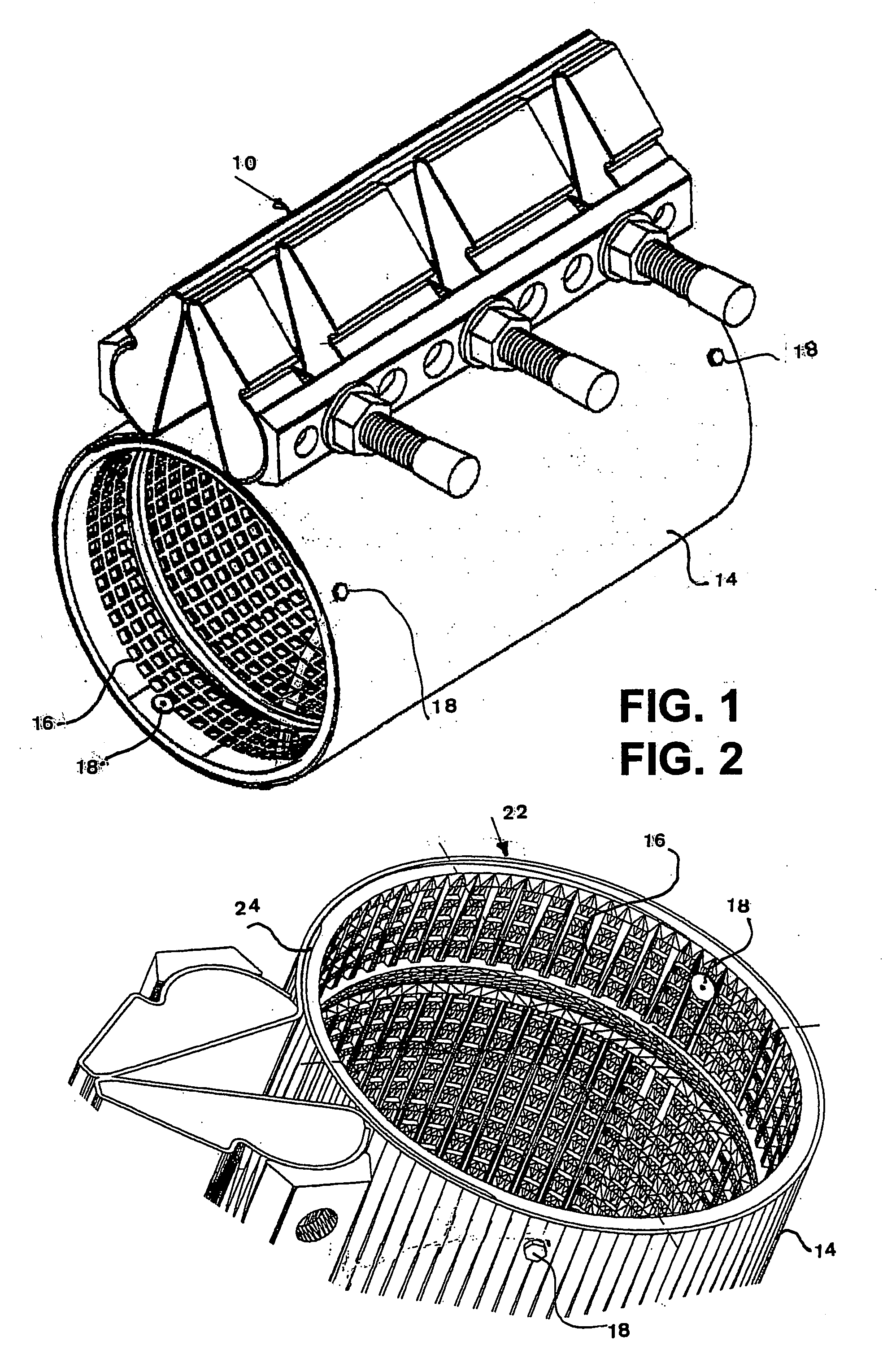

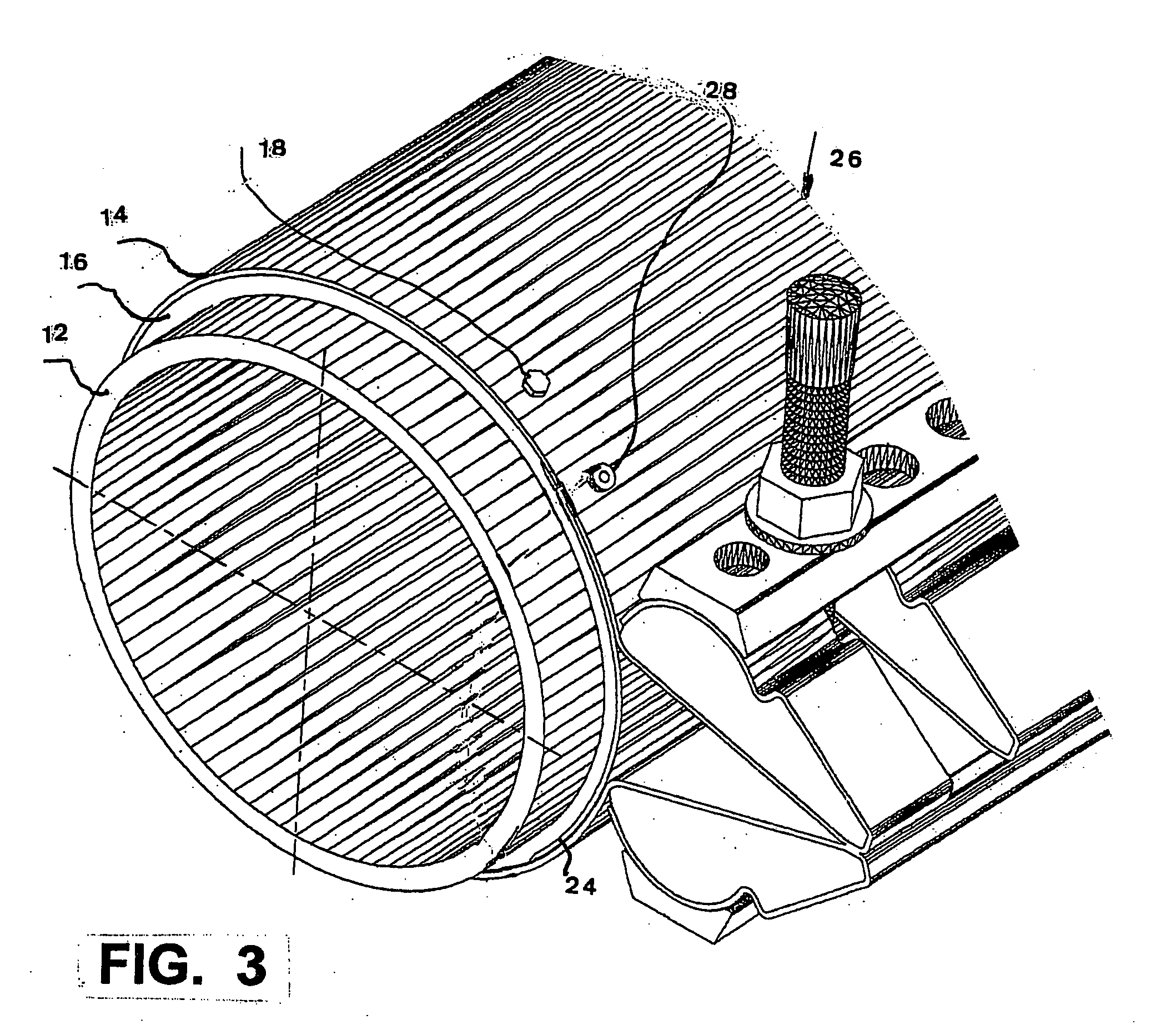

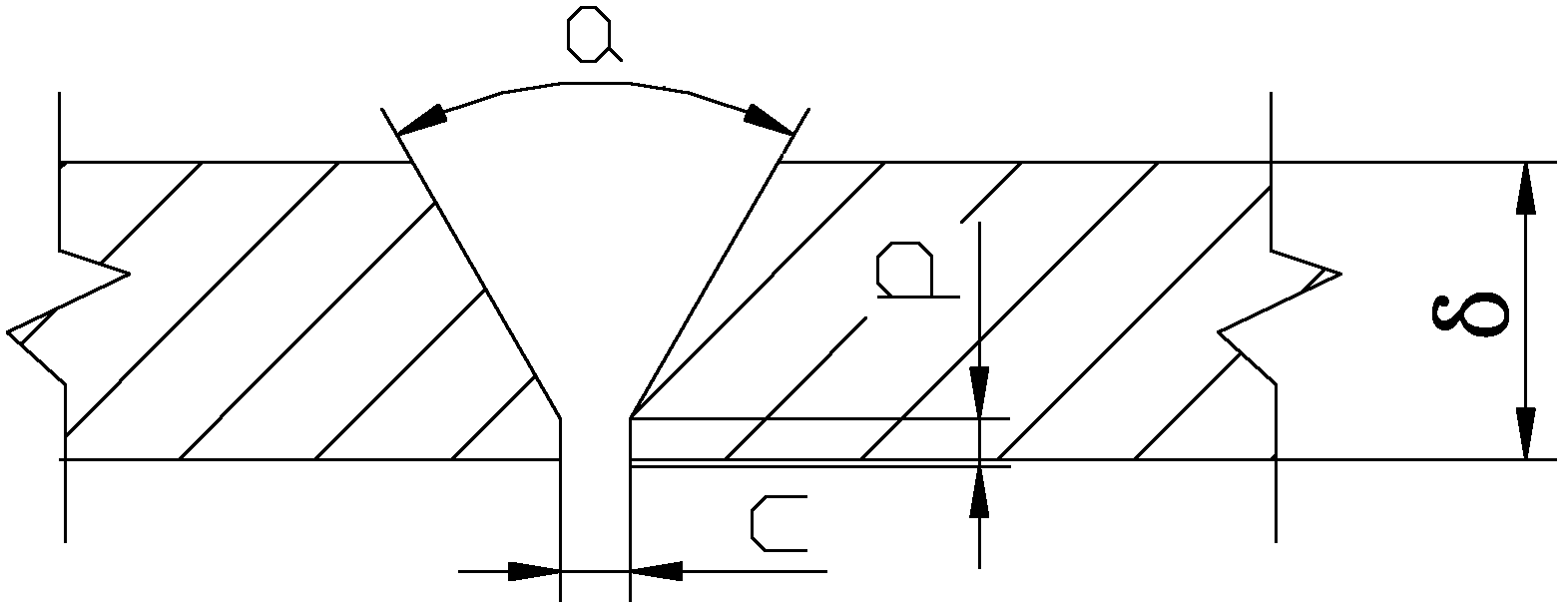

Clamp to anode connection

InactiveUS20040108713A1Secure and robust and inexpensive arrangementSleeve/socket jointsThermal insulationElectricityCoupling

The present invention relates to the corrosion protection of a steel pipeline, and to improvements in pipe clamps useful for this purpose. The invention provides a pipe clamp or coupling which makes electric contact with the pipes on which it is assembled and provides a continuous electrical connection, of the pipes. The pipe clamp according to the invention for sealing by means of a metal clamping band to surround the pipe or a pipe coupling for removably holding extremities of a pair of metallic pipes provided with a flexible inner sleeve disposed inside the clamping band; the inner sleeve is attached to the clamping band by means of metallic fasteners, the metallic fasteners being arranged to contact the metallic pipes when the assembly is tightened, to form a continuous electrical connection of the pipes.

Owner:KRAUSZ IND

Heat-recoverable composition and article

Disclosed is an adhesive composition suitable for bonding to a polymeric material and steel. The composition comprises specified proportions of a maleic anhydride-modified propylene-ethylene copolymer resin, a maleic anhydride-modified polyethylene, a polyisobutylene, a terpolymer comprising ethylene, propylene and a non-conjugated diene, and a hydrocarbon resin tackifier. The composition is useful in preparing a heat-recoverable article that is used to provide a protective coating on the joints of a steel pipeline. Also provided is a single sleeve or two-sleeve system for application to the joints of a coated steel pipeline operating at temperatures up to 120° C.

Owner:BERRY PLASTICS CORP

X80 steel made pipe fittings and manufacture technique thereof

ActiveCN101205594AMeet technical requirementsFurnace typesRigid pipesChemical compositionPipe fitting

The invention relates to a pipeline made of X80 steel and a method for manufacturing the same. The chemical compositions are that: 0.06 to 0.1 percent of C, 0.1 to 0.3 percent of Si, 1.4 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, 0.01 percent of S, 0 to 0.45 percent of Cr, 0 to 0.3 percent of Mo, 0 to 0.3 percent of Cu, 0 to 0.5 percent of Ni, 0.05 to 0.15 percent of Nb, 0 to 0.06 percent of Ti, 0 to 0.06 percent of V, Ceq controlled between 0.36 and 0.44 percent, Pcm controlled between 0.17 and 0.23 percent. The pipeline manufactured with the controlled rolled steel plate of the compositions by means of controlling the forming temperature, hardening heat, drawing temperature, cooling velocity, etc. has low-temperature impact toughness more than 90 J, completely meets the technical requirement on the X80 pipelines and is suitable to be used as X80 steel pipelines for oil and gas pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

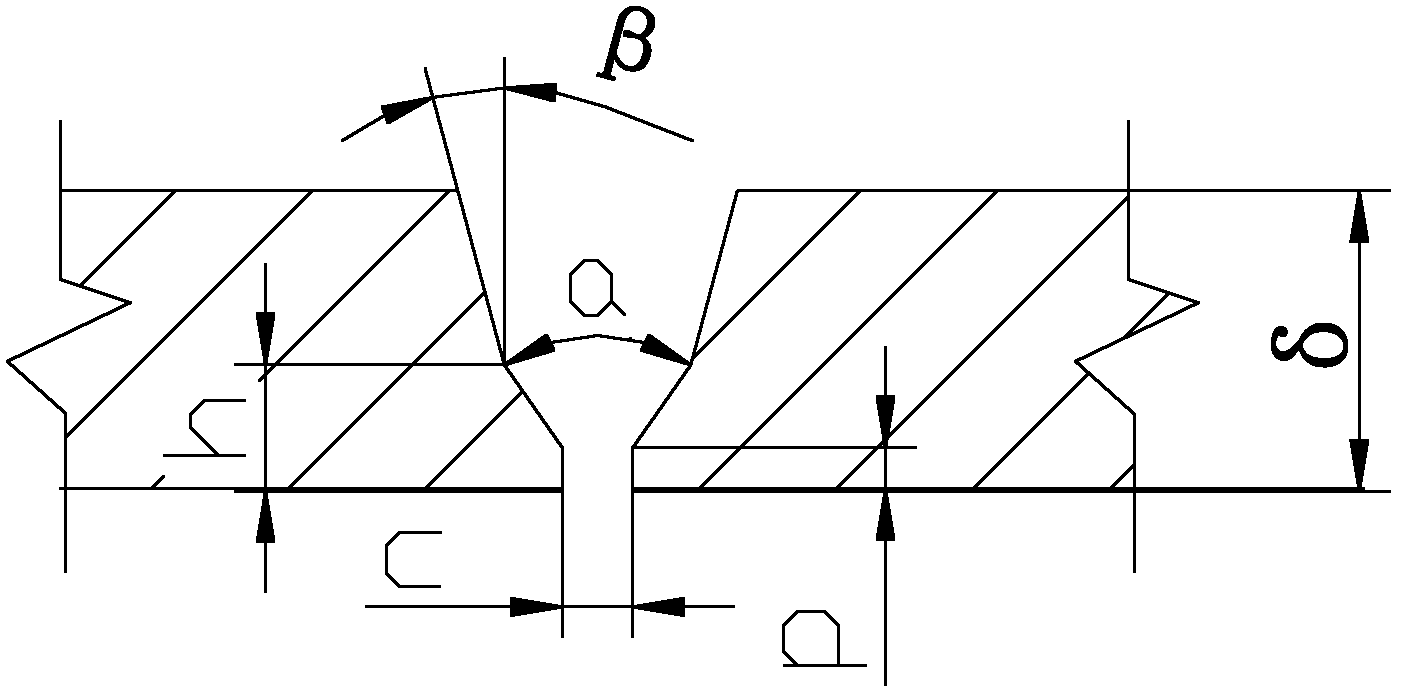

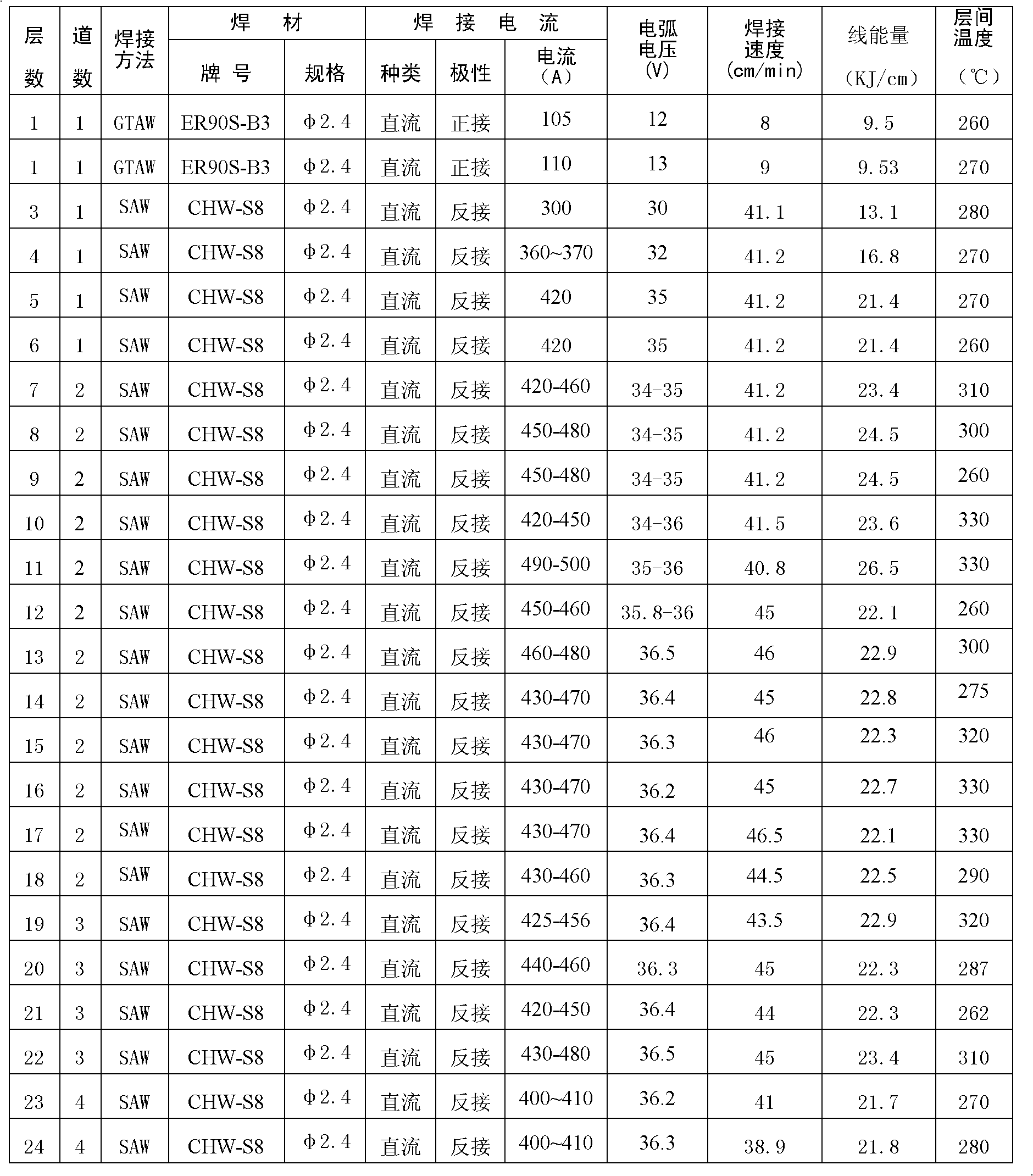

Thick-wall chromium-molybdenum steel pipeline submerged arc welding technology

InactiveCN102248267ABeautiful weld shapeImprove weld seam qualityArc welding apparatusPower flowEngineering

The invention discloses a thick-wall chromium-molybdenum steel pipeline submerged arc welding technology, which is characterized in that an automatic submerged arc welding is used for filling and welding a cover: a pipeline is placed on a rolling tire, an automatic submerged arc welder is used for welding the pipeline, the rolling tire is rotated to drive the pipeline to rotate during welding, and a welding gun is located at a flat welding position and always keeps still; welding parameters are as follows: the welding current is 240-500A, the voltage is 30-36.5V, the welding speed is 36-46.5 cm / min, the extension length of a welding wire is 8-12 mm, and a distance from a tail end of the welding wire to a weld surface is 5-6 mm. The average working efficiency by using the submerged arc welding technology to weld the thick-wall chromium-molybdenum steel pipeline is more than 4-6 times that of the manual welding, the thickness theta of a welding wall is more than the thick-wall pipeline of 30 mm, and the working efficiency is 8-12 times that of the manual welding.

Owner:SINOPEC THE FOURTH CONSTR

Mechanical property measuring device for natural gas hydrates

ActiveCN104406864AHigh measurement accuracyCompact designPreparing sample for investigationMaterial strength using steady shearing forcesVacuum pumpingEngineering

The invention discloses a mechanical property measuring device for natural gas hydrates. The device comprises a data collecting system, a vacuum pumping system, a natural gas pressurization air inlet system and a hydrate reaction still, wherein the hydrate reaction still comprises a reaction still base, an end cover, a force applying rod, a reaction still casing and a reaction bracket, the reaction still casing and the reaction still base are connected through a bolt and are sealed through a sealing ring, the end cover is connected with the reaction still base through a spiral stainless steel pipeline, the force applying rod penetrates in from the top part of the reaction still casing and is sealed through a sealing ring, one end of the force applying rod is propped against the end cover, the other end of the force applying rod is propped against the reaction bracket, a first inlet / outlet and a second inlet / outlet are formed in the end cover, a third inlet / outlet and a fourth inlet / outlet which penetrate through the center of a boss of the reaction still base are formed in the reaction still base, and the four inlets / outlets are connected with the vacuum pumping system and the natural gas pressurization air inlet system. The measuring device can be used for measuring the mechanical property of solids in situ under the conditions of high pressure and low temperature, the usage range of the existing device is expanded, and the measurement accuracy is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

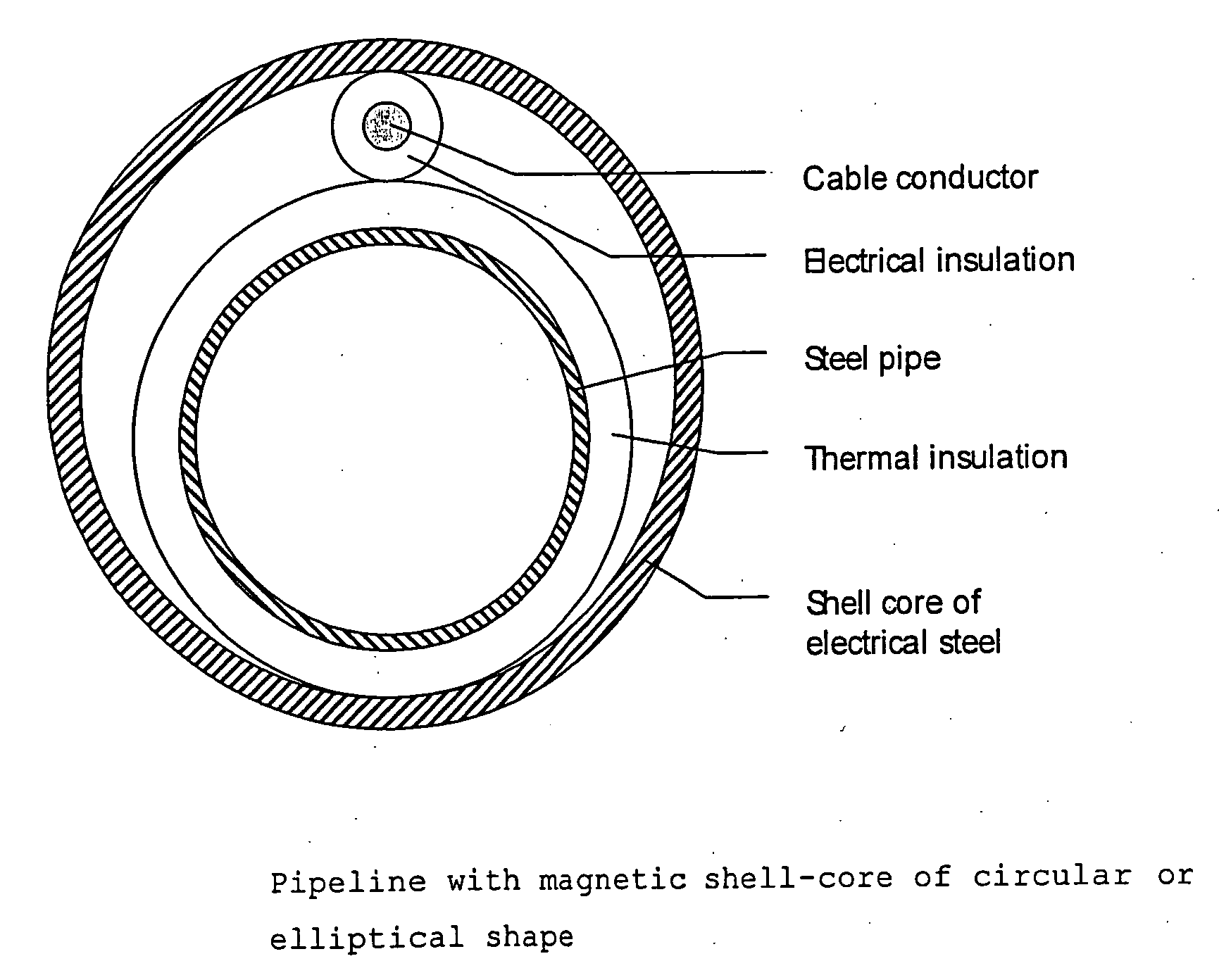

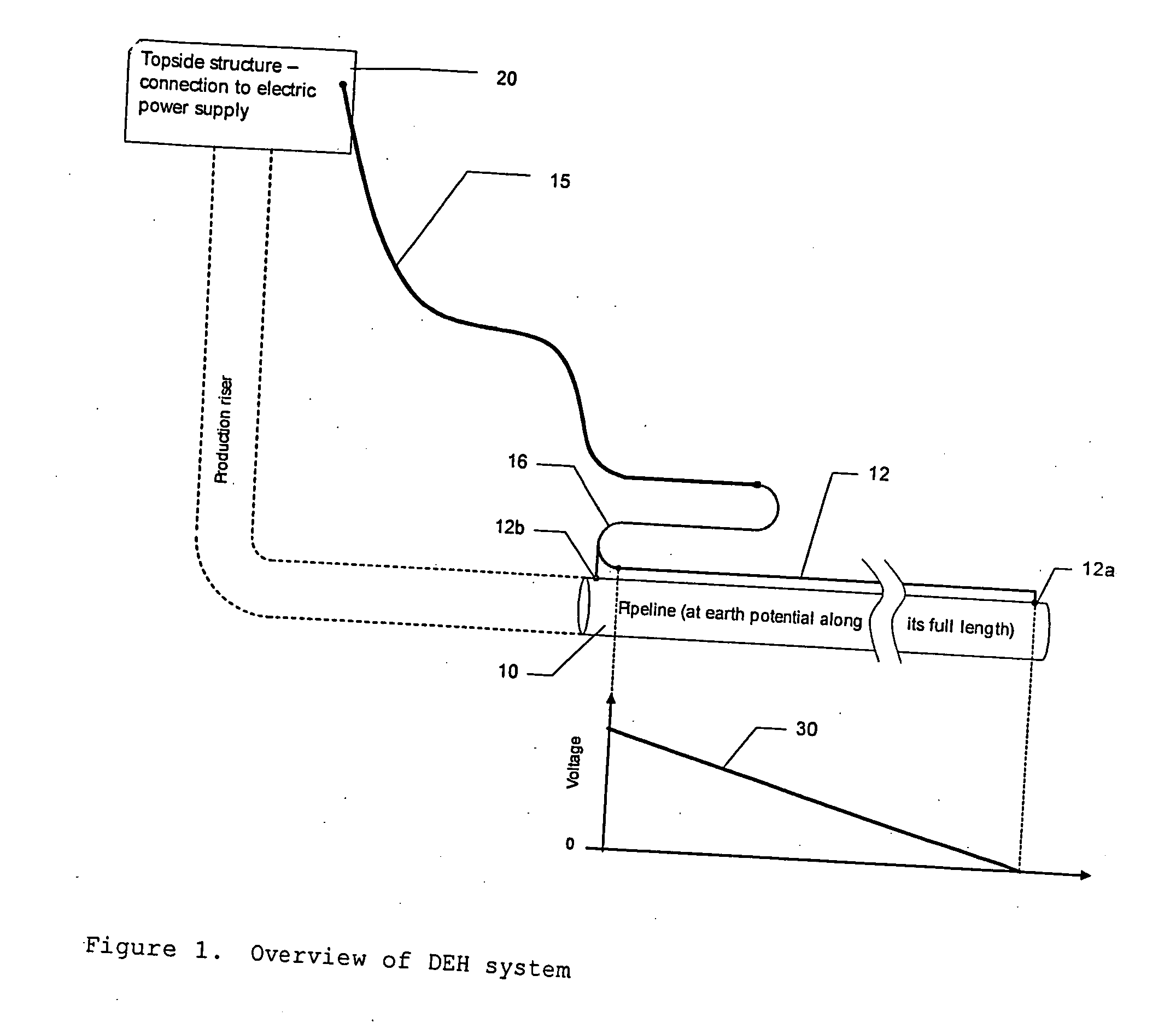

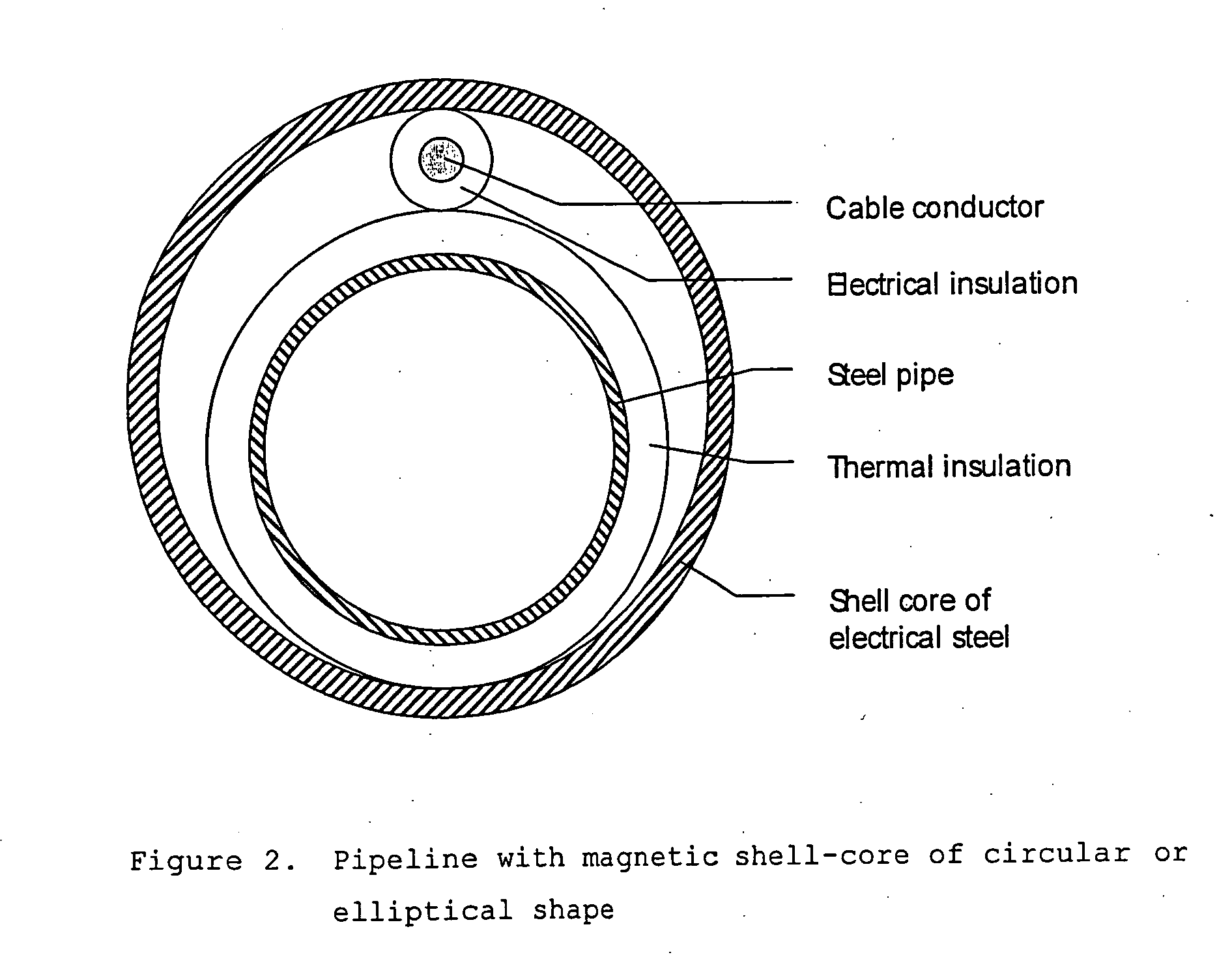

High efficiency direct electric heating system

InactiveUS20090214196A1Improving pipeline current ratioTotal current dropPipe heating/coolingFluid removalElectricityCoupling

A direct electric heating system for subsea steel pipeline with a piggyback cable arranged on the pipeline, where at least one shell-type magnetic core encompasses the pipeline with its piggyback cable. The shell-type magnetic core may be continuously or discretely arranged on the pipeline. The shell-type magnetic core may be applied around the pipeline with piggyback cable. This direct electric heating system improves the pipeline current ratio through introduction of magnetic coupling between piggyback cable and pipeline thus significantly reducing power consumption and current in sea water.

Owner:NEXANS

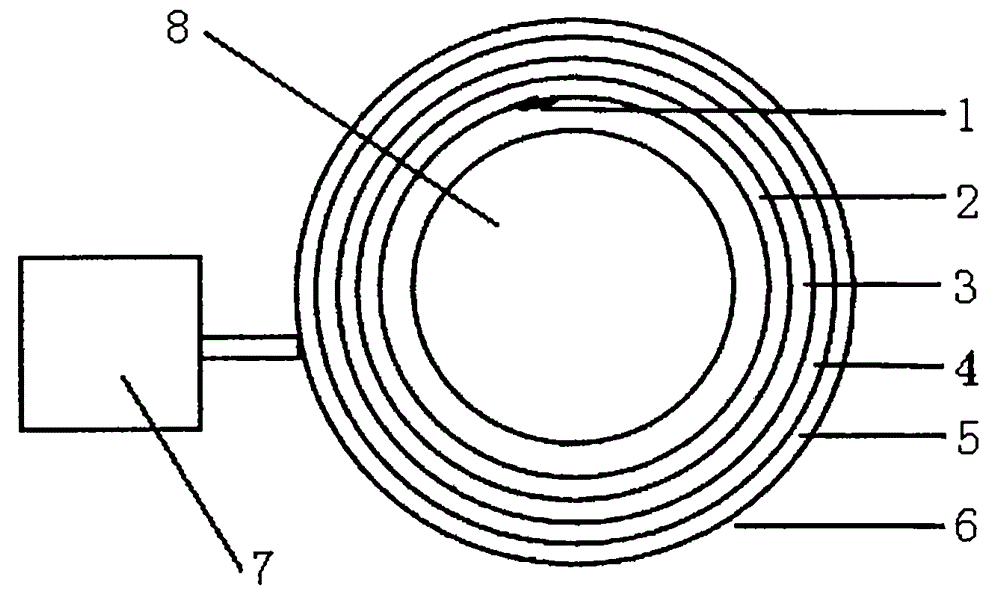

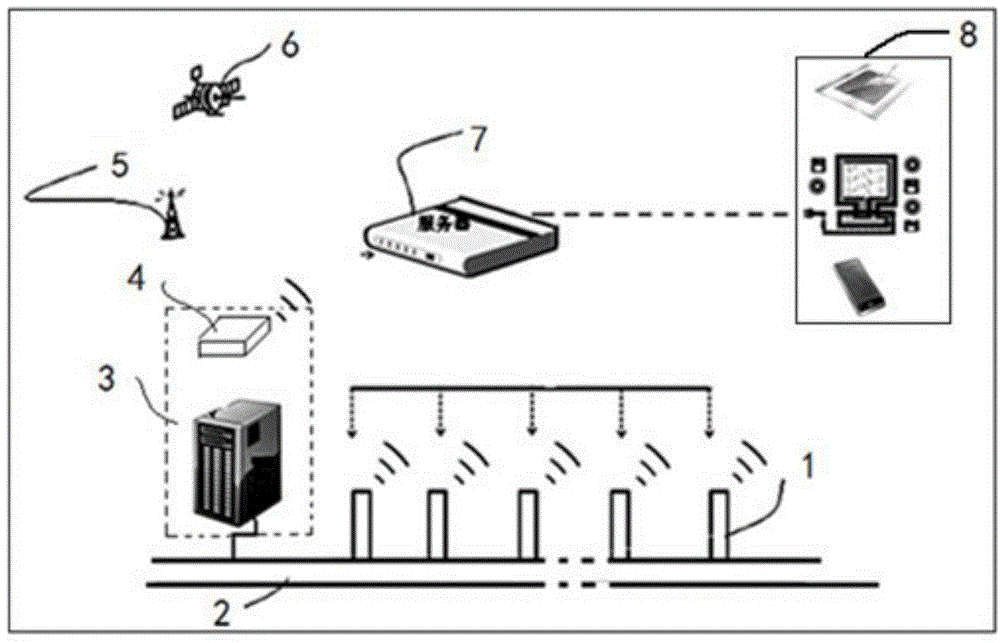

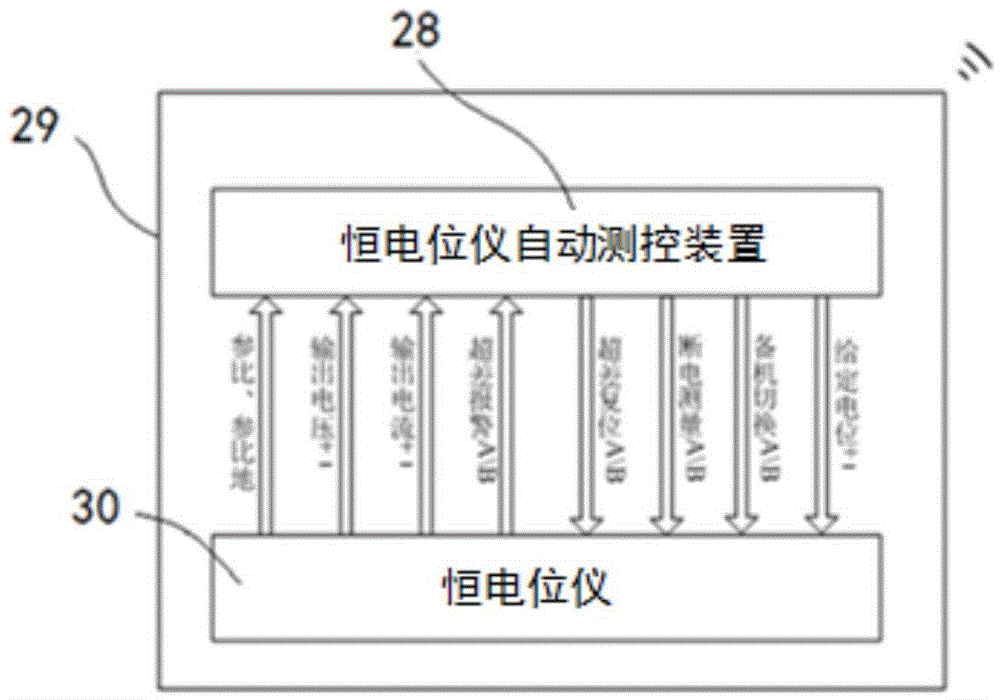

Intelligent remote monitoring and regulating system for cathode protection of underground pipelines

ActiveCN104674229AFunctionalRemotely adjust the frequency of data collectionGeneral Packet Radio ServiceEngineering

An intelligent remote monitoring and regulating system for cathode protection of underground pipelines comprises an intelligent test pole (1) equipped with a polarized probe, a constant potential rectifier (3) equipped with a constant potential rectifier intelligent measurement and control device, a transmission channel formed by electrically connecting the constant potential rectifier (3) and an underground steel pipeline (2) and used for inputting electrical parameters, as well as a monitoring host system comprising a server (7) of a remote monitoring and management system and intelligent terminals such as a computer, a tablet personal computer, a mobile phone and the like which are arranged in a monitoring center, an intelligent collecting processing and transmission system for measured data and control data is formed by a GPRS (general packet radio service) wireless network (5), the server (7) and the monitoring host system (8), and meanwhile, the remote real-time monitoring and detection system with functions of accurate positioning and time service is formed by an intelligent measurement and control device arranged in the intelligent test pole (1) and the constant potential rectifier intelligent measurement and control device matched with the constant potential rectifier (3) through a satellite positioning system (6).

Owner:CHINA SINOPEC PIPELINE STORAGE & TRANSPORTATION CO LTD +1

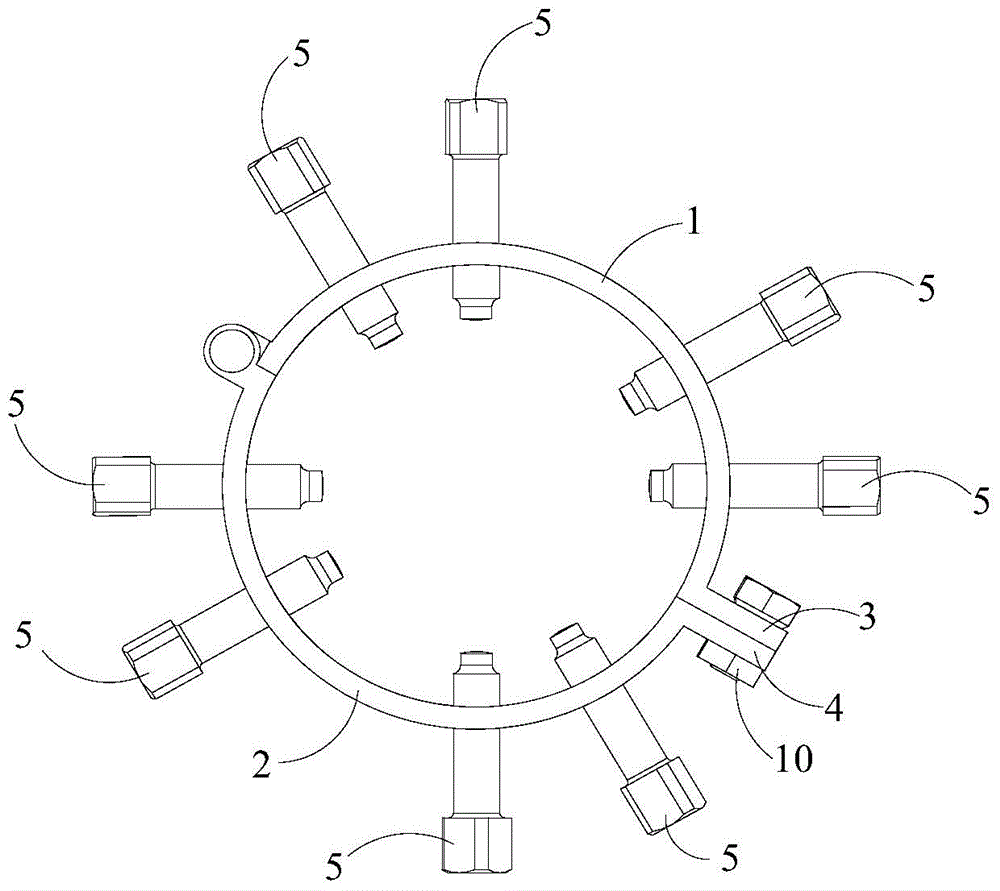

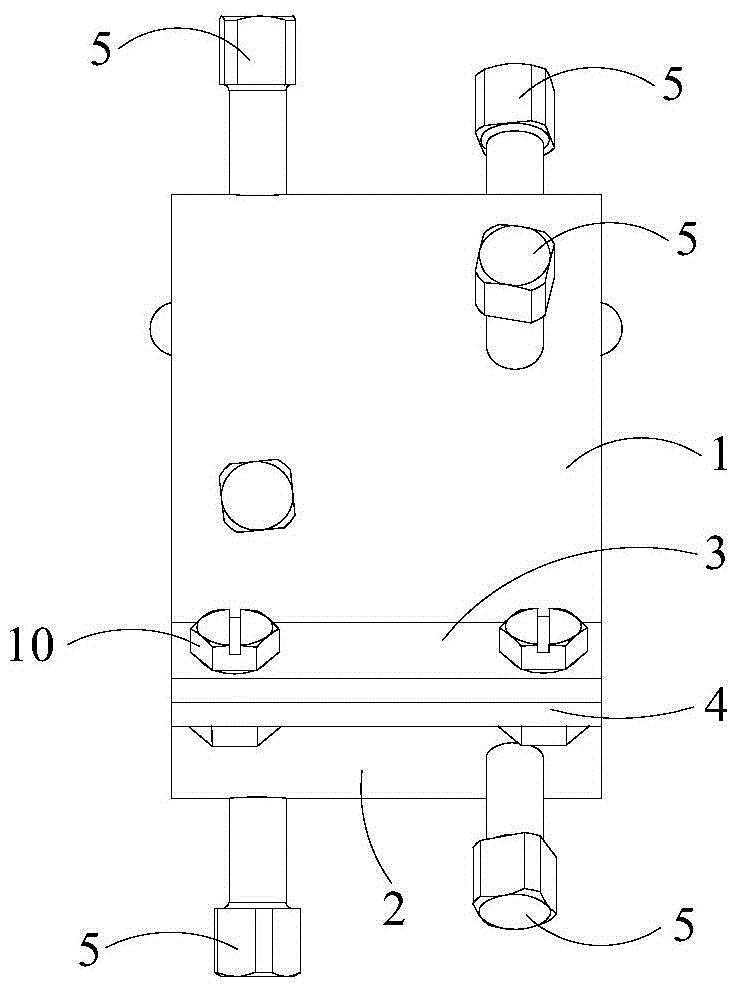

Stainless steel pipeline welding connection method and center-adjustable connection clamp

InactiveCN104551356ASave operating timeAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesStainless steel wireSteel pipeline

The invention discloses a stainless steel pipeline welding connection method and a center-adjustable connection clamp. The stainless steel pipeline welding connection method comprises the following steps: A, performing slope holes in the end parts of two or more stainless steel pipelines; B, coaxially arranging the stainless steel pipelines with the preformed slope holes, and filling the space between the preformed slope holes of the every two adjacent stainless steel pipelines with stainless steel sheets and stainless steel wires; C, coating the section, near the slope hole, of each stainless steel pipeline with a layer of anti-splashing agent for welding and the like before welding to wrap and cover the section, near the slope hole, of the stainless steel pipeline; D, mounting an argon protection device filled with argon in the stainless steel pipeline at the to-be-welded part; E, finishing the welding process, cooling the stainless steel pipeline to lower than 50 DEG C, and dismounting the center-adjustable connection clamp. According to the method, the position welding operation which has to be carried out in a conventional method can be avoided, the damage to base metal due to position welding can be completely avoided, the operation time for pipeline assembly and welding is shortened, and the overall precision of a pipeline product is guaranteed.

Owner:LONGKOU CIMC RAFFLES OFFSHORE +2

Anticorrosive wear-resistant paint for oilfield pipelines

InactiveCN104130662AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to an anticorrosive wear-resistant paint for oilfield pipelines. The paint is characterized by comprising the following components by weight: 25-35 parts of epoxy resin, 5-15 parts of organic silicon resin, 0.5-5 parts of ceramic micropowder, 10-20 parts of nano-graphite powder, 5-15 parts of an epoxy resin curing agent, and 10-20 parts of butanone. The paint provided by the invention can provide a protective coating with high corrosion resistance, wear resistance, high adhesion and impact resistance for various steel pipelines of oilfield.

Owner:西安和泰化工有限公司

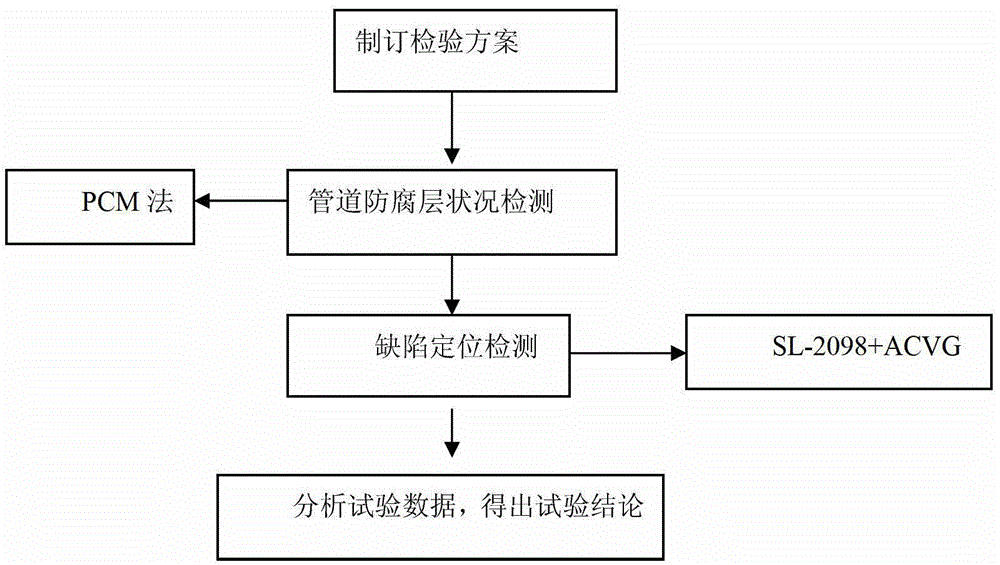

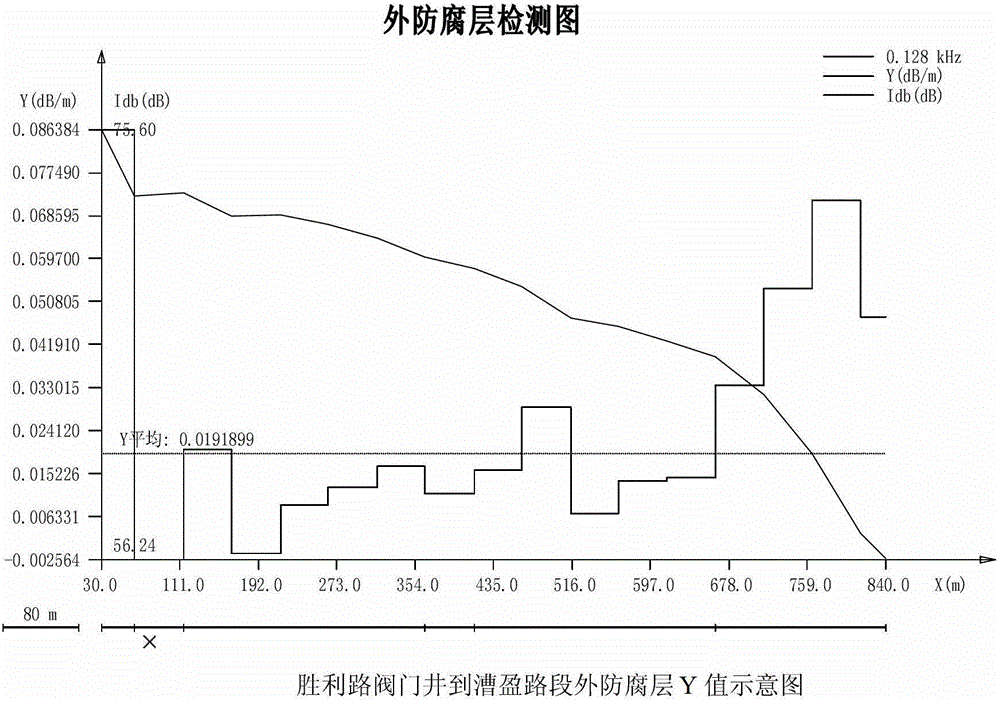

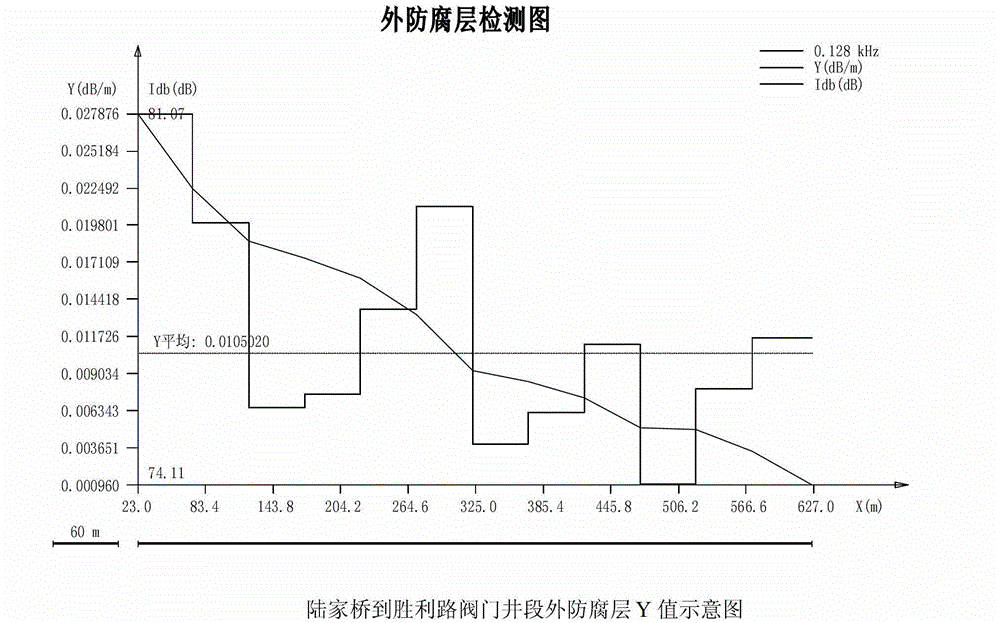

Detecting method of outer anti-corrosion layer of buried fuel gas steel pipeline

InactiveCN103063738AAchieve standardizationMaterial magnetic variablesPower flowPulse-code modulation

The invention relates to the technical field of pipeline inspection, and particularly to a detecting method of an outer anti-corrosion layer of a buried fuel gas steel pipeline. The detecting method is characterized by comprising the following steps: a, dividing a detected pipeline into multiple sections for detection, wherein the distance between detecting points is 50 m; b, connecting two ends of the detected pipeline with insulating flanges; c, applying a low-frequency current signal to the pipeline by using a pipeline signal transmitter of a signal transmission machine, and then detecting the trend of the pipeline on the ground surface and detecting by using a reception machine; and d, transmitting an audio signal to the pipeline by utilizing a transmission machine of a buried pipeline outer anti-corrosion layer detection instrument, connecting an 1000 Hz AC signal with the pipeline, generating an alarm display for an obvious overflow signal by the reception machine when a detector holding the reception machine with a frequency-selective amplifier walks right above the pipeline, and determining the position of the damage of the anti-corrosion layer of the pipeline by the detector based on the audio alarm and the size of the current signal. The two detection technologies, namely, a PCM (Pulse Code Modulation) method and a PEARSON method, are combined for the pipeline detection, so that the detecting method of the outer anti-corrosion layer of the buried fuel gas steel pipeline is excellent in detection precision as well as sensitivity of the outer anti-corrosion layer.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

Manufacturing method for glass steel pipeline in zero-degree winding manner

The invention discloses a manufacturing method for a glass steel pipeline in a zero-degree winding manner. The method sequentially comprises the steps that winding yarn immersed in resin is used for hoop winding, then, a wire guiding head drives the winding yarn to pass multi-tooth comb rings buckled at the two ends of a core die to be axially wound, finally, winding yarn immersed in resin is in hoop winding again to stabilize an axial winding layer, hoop and axial winding is repeated, and pipeline winding with different strength requirements is achieved. Continuous winding of the axial zero degree of the winding yarn and pipelines is achieved, the axial mechanical performance of the pipelines is optimal, and then the high requirement of industrial fields for the axial performance can be met. The required axial strength is achieved, the production cost is reduced to the maximum degree, meanwhile, the pipeline thickness is reduced, and the pipelines are convenient to transport and use.

Owner:HEBEI HAOZHENG NON METALLIC MATERIALS TESTING SERVICES CO LTD

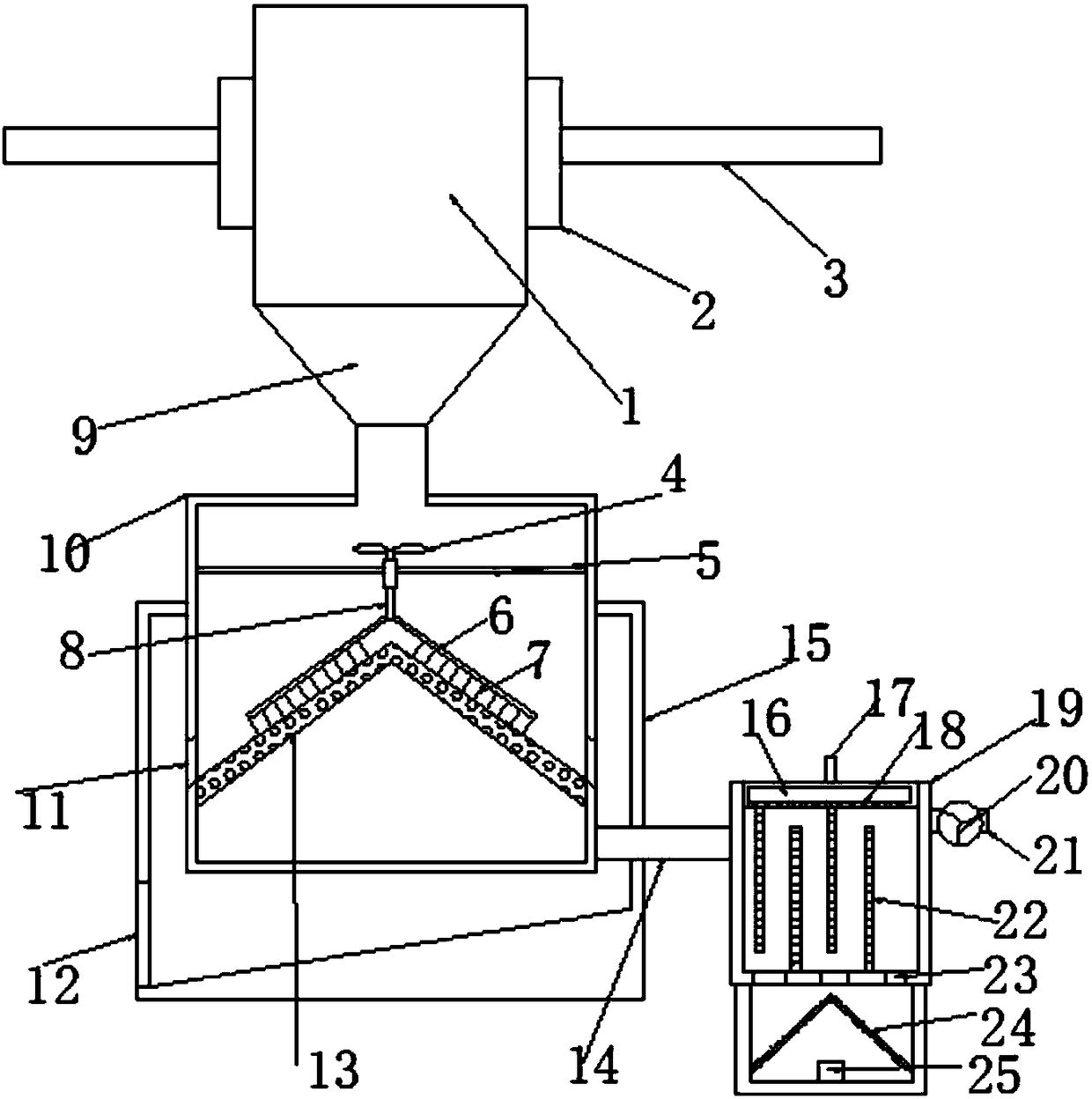

Device for removing rust and then purifying dust for steel pipeline anti-corrosion production line

InactiveCN108159823AAids in washing effectReduce pollutionCombination devicesDispersed particle filtrationEngineeringSteel pipeline

The invention discloses a device for removing rust and then purifying dust for a steel pipeline anti-corrosion production line. The device comprises a rust removal tank, a purifying inner tank, a purifying outer tank and a washing tank, wherein conveying ports are symmetrically formed in the left end and the right end of the rust removal tank, a rust removal pipe penetrates through the left conveying port and the right conveying port, a rust removal mechanism in the rust removal tank removes the rust on a rust removal pipe, a material guide part is arranged at the lower end of the rust removaltank, the lower end of the material guide part is connected with the purifying inner tank, a conical filter screen is arranged in the inner part of the purifying inner tank, filter holes are evenly distributed in the surface of the conical filter screen, the lower end of the conical filter screen is connected and fixed with the inner wall of the purifying inner tank, the conical filter screen isprovided with a residue discharge port in the inner wall of the purifying inner tank, and the tip of the top part of the conical filter screen and a lower port of the material guide part mutually correspond. The device is simple and reasonable in structure, the recycling of water is realized, the exhaust gas is effectively purified, the environment pollution caused by the device is reduced, the air quality is guaranteed, and the practicality of the device is strong.

Owner:姬文亮

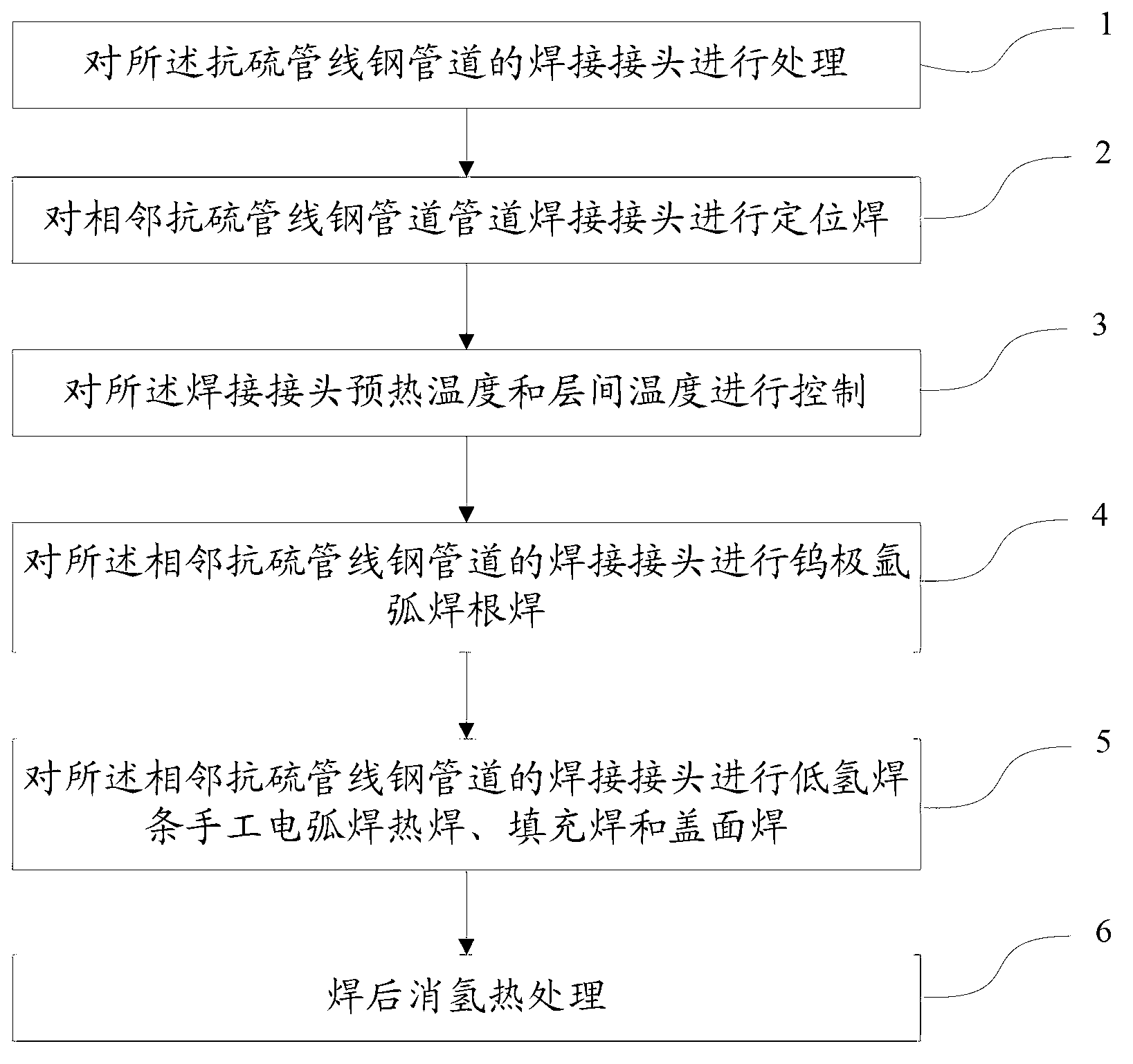

Welding method of oil gas transmission antisulphour steel pipelines

InactiveCN103286414AExcellent corrosion resistance and crack resistanceSafe and stable operationArc welding apparatusTubular articlesCrack resistanceSteel pipeline

The invention discloses a welding method of oil gas transmission antisulphour steel pipelines, which comprises the steps of: 1, treating welding joints of the antisulphour steel pipelines, 2, conducting positioned welding on the welding joints of the adjacent antisulphour steel pipelines, 3, controlling preheating temperature and interlayer temperature of the welding joints, 4, conducting argon tungsten-arc root welding on the welding joints of the adjacent pipelines, 5, conducting manual arc hot welding, filling welding and cosmetic welding on the welding joints of the adjacent pipelines with low-hydrogen electrodes, and 6, conducting post-welding hydrogen removal heat treatment on the welding joints. According to the welding method, since the argon tungsten-arc root welding is combined with the manual arc hot welding, filling welding and cosmetic welding with the low hydrogen electrode, the welding joints with good corrosion resistance and crack resistance can be obtained by effectively controlling the welding parameters, preheating temperature and post-welding heat treatment temperature; the oil gas pipelines can operate stably and safely in service under a sulphated working condition; and the welding method has an active significance in the development of a sulphated oil and gas field.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

30CrMo heat resistant steel pipeline welding construction method

InactiveCN104551337AAvoid flowAvoid crackingWelding/soldering/cutting articlesMetal working apparatusWeld seamThick wall

The invention relates to a 30CrMo heat resistant steel pipeline welding construction method, in particular to the 30CrMo heat resistant steel pipeline welding construction method which is applied to the high pressure pipeline welding filed. The 30CrMo heat resistant steel pipeline welding construction method is high in welding quality and can effectively guarantee a hydraulic pipeline system after welding to safely bearing the working pressure. The 30CrMo heat resistant steel pipeline welding construction method comprises the following steps of cleaning a to-be-welded pipeline; preheating the to-be-welded pipeline, wherein the preheating method before welding can effectively prevent hydrogen-induced delayed crack. According to the 30CrMo heat resistant steel pipeline welding construction method, a backing welding seam during pipeline welding is easy to generate welding defects, meanwhile thick-wall pipe welding defects are difficult to repair, so that nondestructive examination of the weld joint is achieved after backing welding is achieved, filling and screen welding are performed when the welding has no repair defects, and the defect that gaps of a sealing surface of a high pressure pipeline are uneven can be eliminated through the grinding technology.

Owner:ZHONGYU YUANFA INT CONSTR GRP

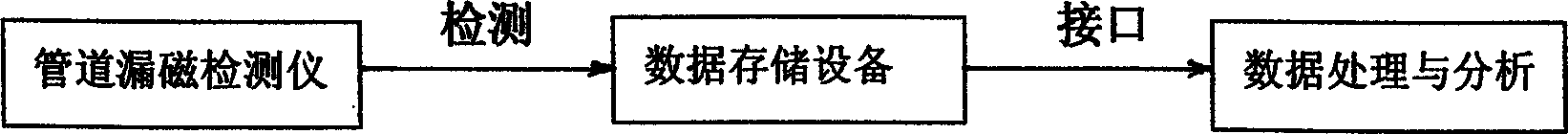

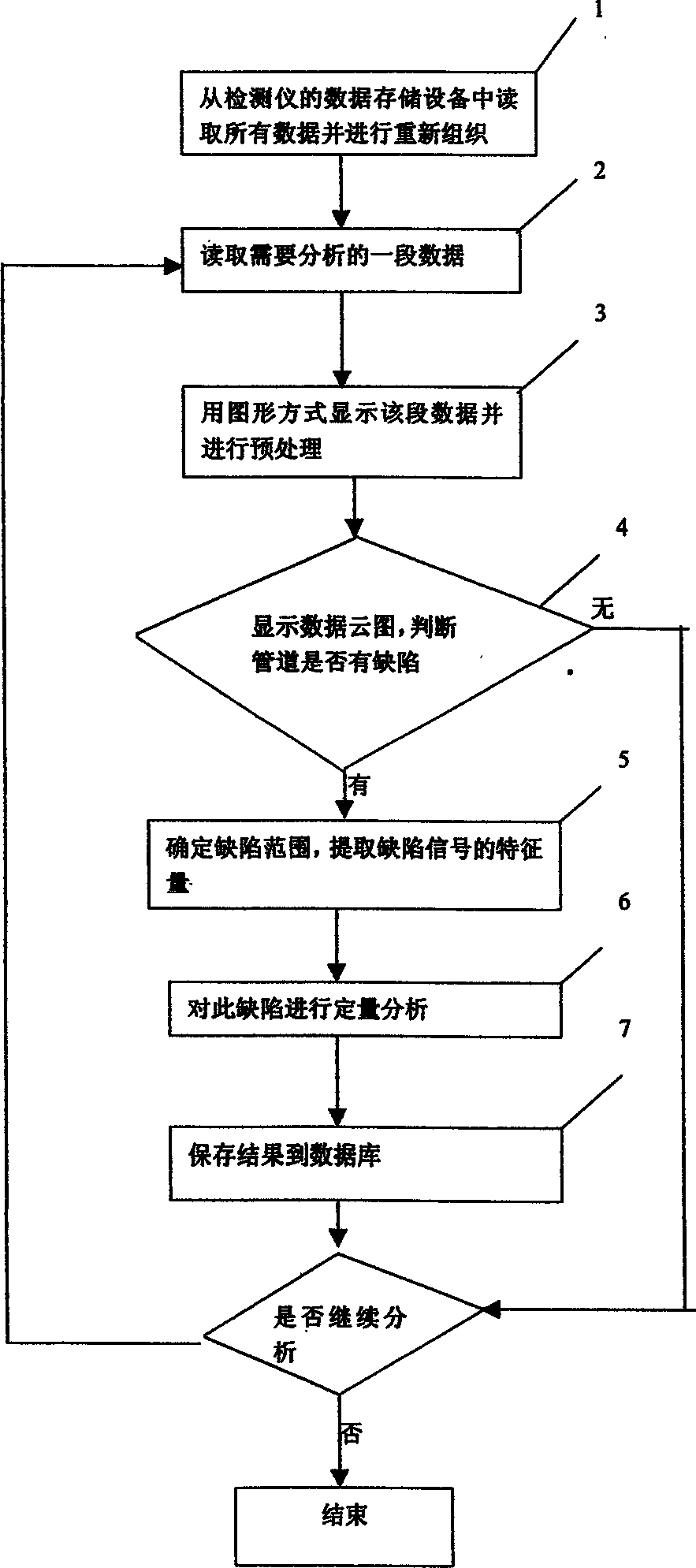

Analysing method for detection data of pipeline defect leaking magnet

InactiveCN1458442AImprove analysis efficiencyImprove analysis accuracyPipeline systemsEngineeringData memory

The present invention discloses analysis and processing method of magnetic leakage detecting data of steel pipeline defect with high signal efficiency and accuracy. The technological scheme includesthe following steps: reading all data from the data memory of pipeline defect magnetic leakage detector and re-organizing; reading one section of the data for analysis; graphically displaying the data and pre-treatment; judging whether to exist defect based on data nephogram; if any, determining the defect range, analyzing quantitatively and recording the results. The present invention is used in defect analysis of oil-gas pipeline, and has high analysis efficiency and accuracy.

Owner:TIANJIN UNIV

Benzene hydrogenation engineering heat resistant steel pipeline welding method

The invention provides a benzene hydrogenation engineering heat resistant steel pipeline welding method. By using a TIG pulsating welder, a pearlite heat resistant steel with a band number of 12 Cr2Mo is welded through manual argon tungsten-arc welding; the supply state of the heat resistant steel is that the heat resistant steel is annealed at 730-750 DEG C; and the welding method is characterized by comprising the following steps: (a) pipe section cutting and groove preparation, (b) providing an argon shield device, (c) preheating before welding, (d) welding and (e) heat treatment after welding. The benzene hydrogenation engineering heat resistant steel pipeline welding method provided by the invention has the advantages of reasonable construction step design, simplicity in operation and safe and reliable welding quality, and the engineering construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Steel pipeline corrosion proof reinforcing method

The invention relates to a method for reinforcing and antisepticising steel pipeline, comprising the following steps of: processing the surface of steel pipeline to be reinforced and antisepticised, preparing epoxy ethylene resin and resin mortar, using the mortar to fill and block the crack and perforation part of the pipeline, sticking bidirectional carbon fiber cloth on the patching part, finally winding and sticking the unidirectional carbon fiber cloth on the pipeline in circularity when the surface of the pipeline is being coating by the prepared resin, the direction of the carbon filament should be right angle of 90 degrees with the axes of the pipeline, and then winding and brushing, recoating a layer of resin surface layer after the surface of the resin gel is dry. The invention has the advantages that the adopted carbon fiber epoxy ethylene resin composite material system has the excellent performances of high strength, light weight, corrosion resistance and humidity resistant, evident dual effect of reinforcing and antisepticising, and practical and reliable method for patching crack and perforation, which can greatly prolong the service life of the pipeline.

Owner:上海华夏化工材料有限公司

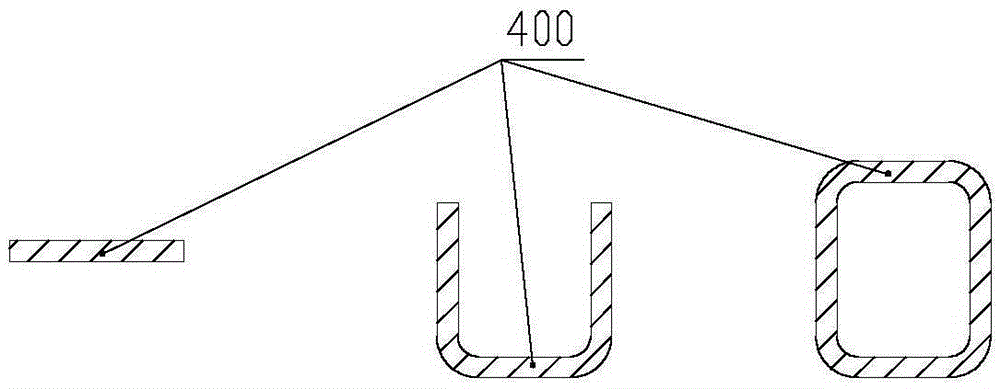

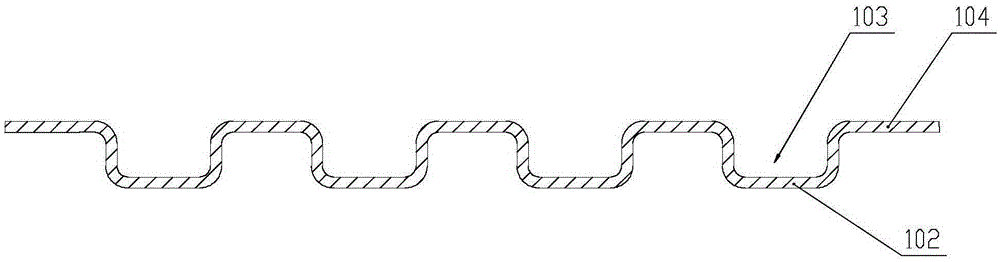

Prefabricated assembled steel-concrete composite structure pipeline and manufacturing method thereof

The invention discloses a prefabricated assembled steel-concrete composite structure pipeline and a manufacturing method thereof. The pipeline comprises a pipe body formed by assembling unit sheets with radians in the circumferential direction; the adjacent unit sheets are connected through side flanges, and the head end and the tail end of each unit sheet are each provided with an end face flange matched with the unit sheet in section shape; meanwhile, the surfaces of the unit sheets extend outwards to form protruding ribs consistent with the unit sheets in radian, grooves are formed by the unit sheets and the protruding ribs, and blocking steel strips are arranged; cavities are formed by the grooves and the blocking steel strips and filled with concrete. Due to the fact that the steel pipeline is formed by assembling the unit sheets, the unit sheets can be transported in a stacked mode, the transportation expense is reduced, and the construction period is shortened; bolt holes and bolts do not exist in the pipe body, and safety is improved; a flushing-preventing metal layer is arranged at the inner bottom of the pipeline, corrosion resistance and abrasion resistance are improved, and therefore the service life is prolonged; the adaptability to deformation of the pipe body is good, and steel pipeline damage caused by differential settlement of a foundation can be avoided.

Owner:NANJING LIANZHONG CONSTR ENG TECH

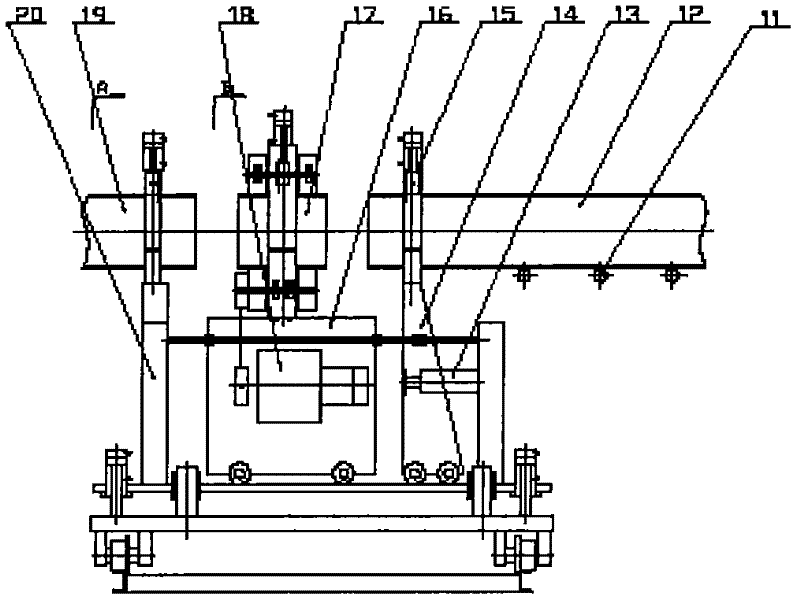

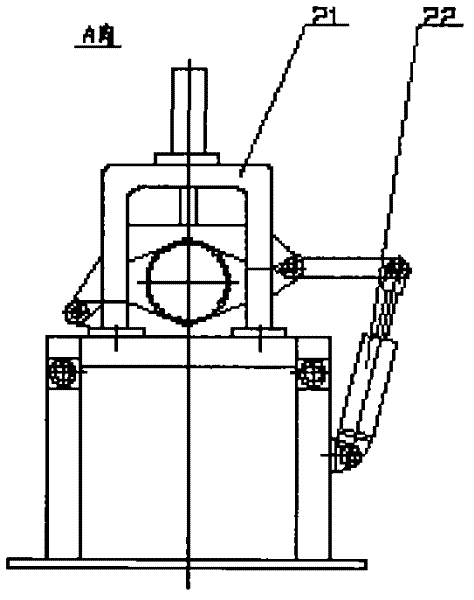

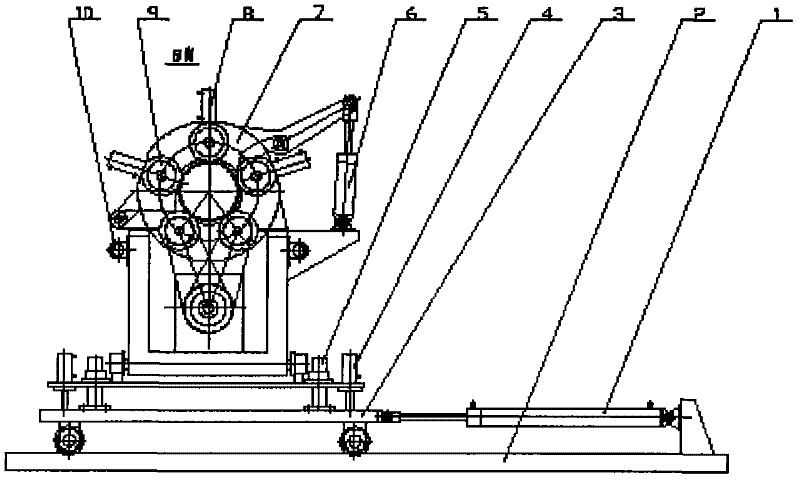

Steel pipeline friction-welding device

ActiveCN102500913AQuality improvementImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingProgrammable logic controller

The invention relates to a steel pipeline friction-welding device. A programmable logic controller (PLC) device is respectively connected with an oil cylinder 1, an oil cylinder 4, an oil cylinder 6, an oil cylinder 8, an oil cylinder 13, an oil cylinder 22 and an oil cylinder 15 through a magnetic valve. The oil cylinder 1 is connected with a trolley, a rail is arranged under the trolley, the oil cylinder 4 is connected with an engine base plate, the oil cylinder 6 is connected with a clamp 7, and the clamp 7 is connected with a clamp base. The oil cylinder 8, a friction wheel and the oil cylinder 13 are connected with a movable clamping frame, the movable clamping frame is connected with the oil cylinder 15, and the oil cylinder 22 is connected with a fixed clamping frame. The fixed clamping frame 20 is connected with a clamp 21, the trolley 3 is installed on the engine base plate, and the movable clamping frame is connected with an upset forging vertical seat through the oil cylinder 13. The PLC device is connected with a pressure sensor, a temperature sensor and a power device. The power device is connected with the clamp 7. By means of the steel pipeline friction-welding device, the fact that weld joint strength is equal to strength of a matrix material in respect of welding quality can be achieve, welding efficiency is high, the quality is stable, and consistency is good.

Owner:QINGDAO DACANG CORROSION PREVENTION CO LTD

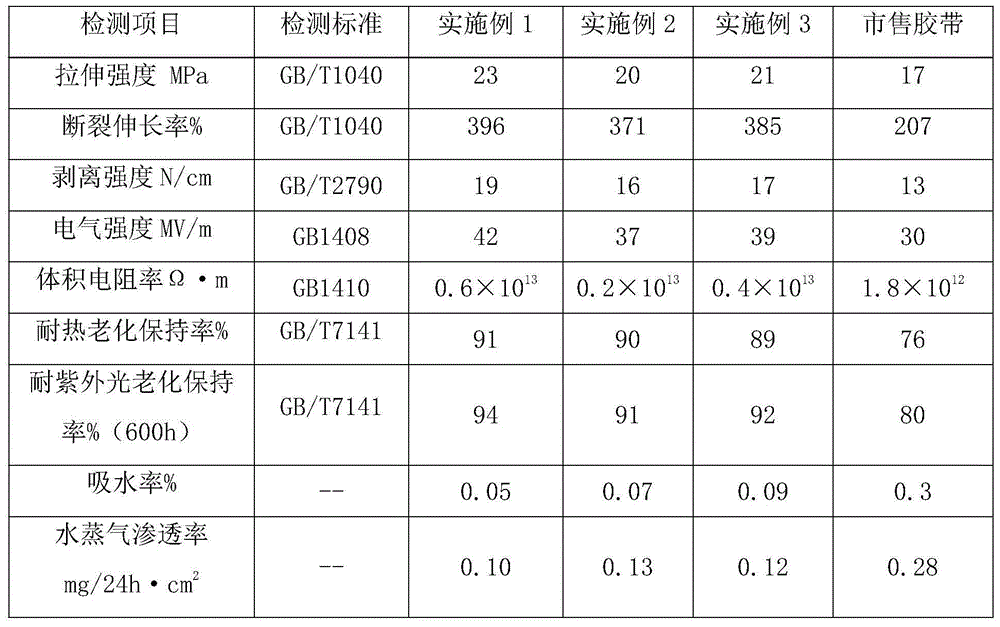

Cold pressure-sensitive adhesive tape for pipeline anticorrosion

InactiveCN103602273AAvoid pollutionSimple construction processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantEngineering

The invention provides a cold pressure-sensitive adhesive tape for pipeline anticorrosion. The cold pressure-sensitive adhesive tape can be directly used in the steel pipeline anticorrosion without a primer. The cold pressure-sensitive adhesive tape comprises a base film layer and a pressure-sensitive adhesive layer, wherein the base film layer is a high-density polyethylene sheet, and has a thickness of 0.1-0.3mm; and the pressure-sensitive adhesive layer comprises, by weight, 40-55 parts of butyl rubber, 20-35 parts of polyisobutylene, 10-25 parts of a tackifying resin, 1-8 parts of a plasticizing system, 0.1-1 part of an antioxidant, and 3-6 parts of an inorganic filler, wherein the tackifying resin is one or more of rosin glyceride, a C5 petroleum resin and a terpene resin. The cold pressure-sensitive adhesive tape can be directly used in the steel pipeline anticorrosion without a primer, so the pollution of benzene or gasoline organic solvents in the primer to the environment is avoided, and the construction technology is simplified, thereby the cold pressure-sensitive adhesive tape can be adapted to the anticorrosion of many types of pipelines.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Forging process of main stainless-steel pipeline for nuclear power

ActiveCN102825207AShorten production timeGuaranteed design size requirementsEngine componentsElectricityNuclear power

The invention relates to a forging process of a main stainless-steel pipeline for nuclear power. The forging process is characterized in that a 316LN electroslag ingot blank is adopted; heat cleaning is carried out on surface cracks in time in the forging process, and a forging ratio is guaranteed to be more than 4; construction members needed by the forging process comprise a hot leg L001A, a hot leg L001B, a cold leg A, a cold leg B, a cold leg C, a cold leg D, a wave pipe I, a wave pipe II, a wave pipe III, a wave pipe IV and a wave pipe VII; and the forging process of the construction members is grouped into the hot leg L001A, the hot leg L001B, a cold leg group, a wave pipe group including the wave pipes I, II and V, and a wave pipe group including the wave pipes III and IV. Compared with the prior art, the process disclosed by the invention has the beneficial effects of reducing the production heating number of a forge piece to a great extent, improving the production efficiency, guaranteeing the design size requirements on the forge piece, overcoming the heat crack tendency of the surface of the blank and improving the surface quality of the main pipeline through the timely heat cleaning in the forging process, and realizing the 100% localization of key equipment of the nuclear power.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

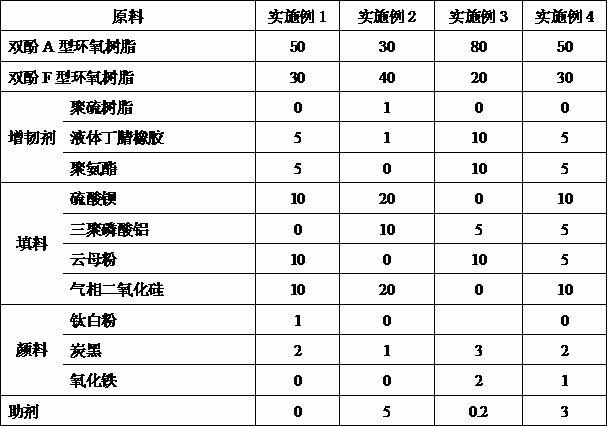

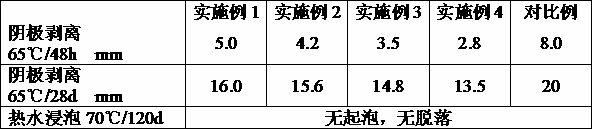

Solvent-free epoxy primer for corrosion protection of 3 polypropylene (PP) at craters of steel pipelines

InactiveCN102367354AReduce pollutionIncrease productivityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses a solvent-free epoxy primer for corrosion protection of 3 PP at craters of steel pipelines. The primer comprises, by mass, 50 to 80% of component A and 20 to 50% of component B, wherein, the component A comprises, by weight, 30 to 80 parts of a bisphenol A type epoxy resin, 20 to 40 parts of a bisphenol F type epoxy resin, 2 to 20 parts of a flexibilizer, 15 to 50 parts of a filling material and 1 part to 5 parts of pigments, and the component B is a polyamide epoxy hardener. According to the invention, the solvent-free epoxy primer for corrosion protection of 3 PP at craters of steel pipelines ensures good bond performance, i.e., high bonding strength, between the primer and PP, and good bond performance between 3 PP and a hot melt adhesive as well.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

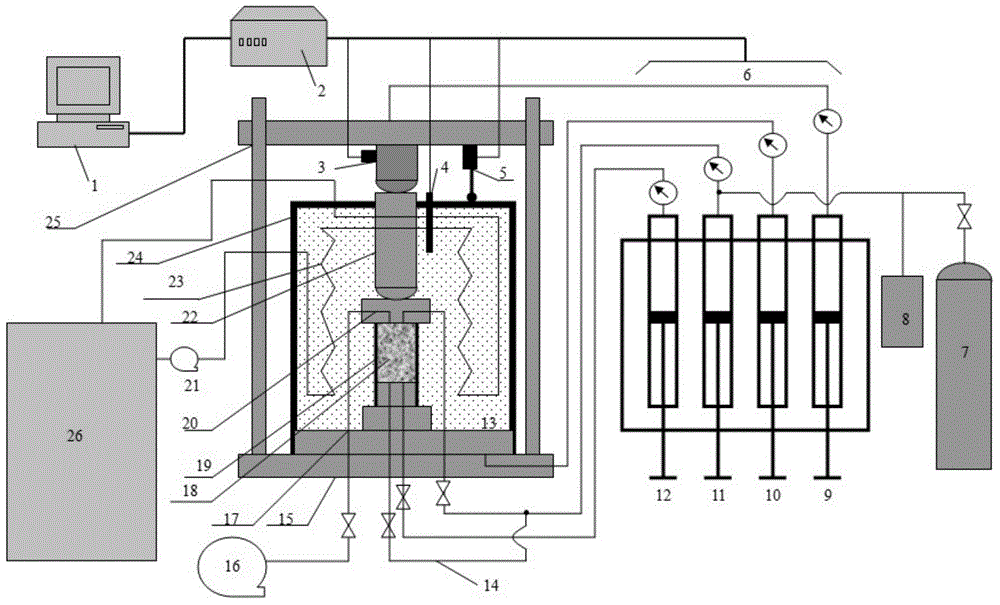

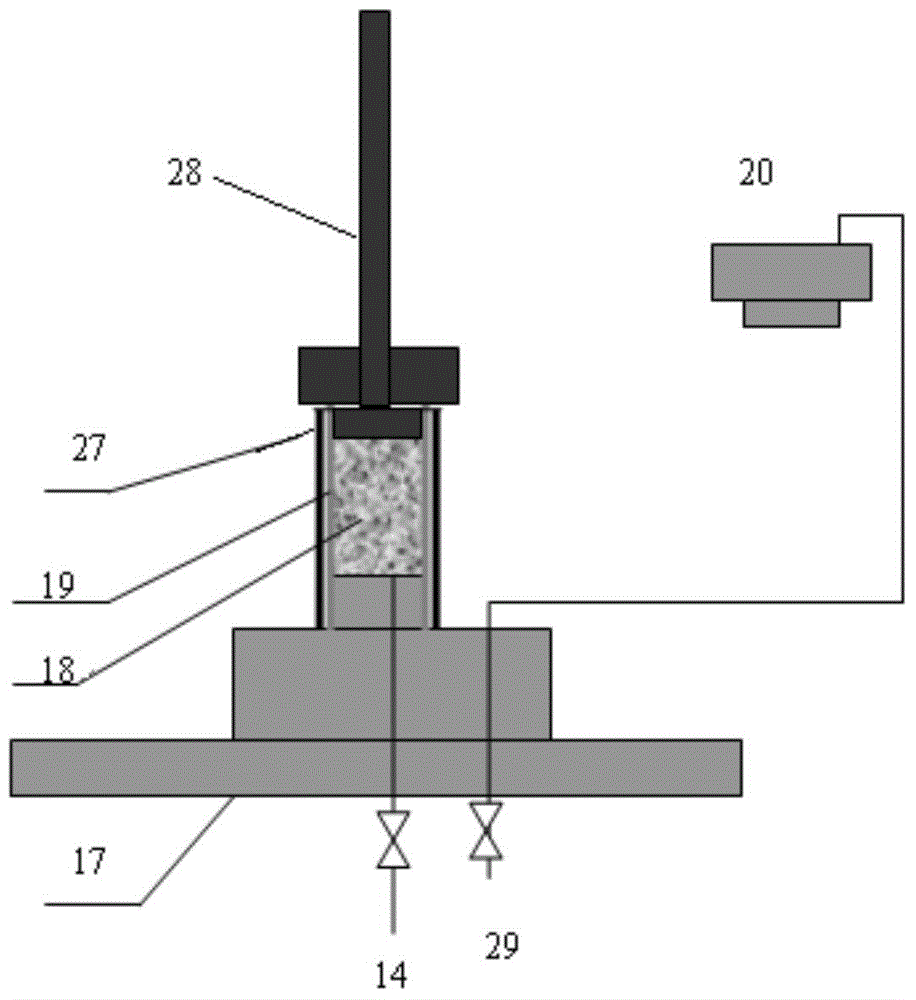

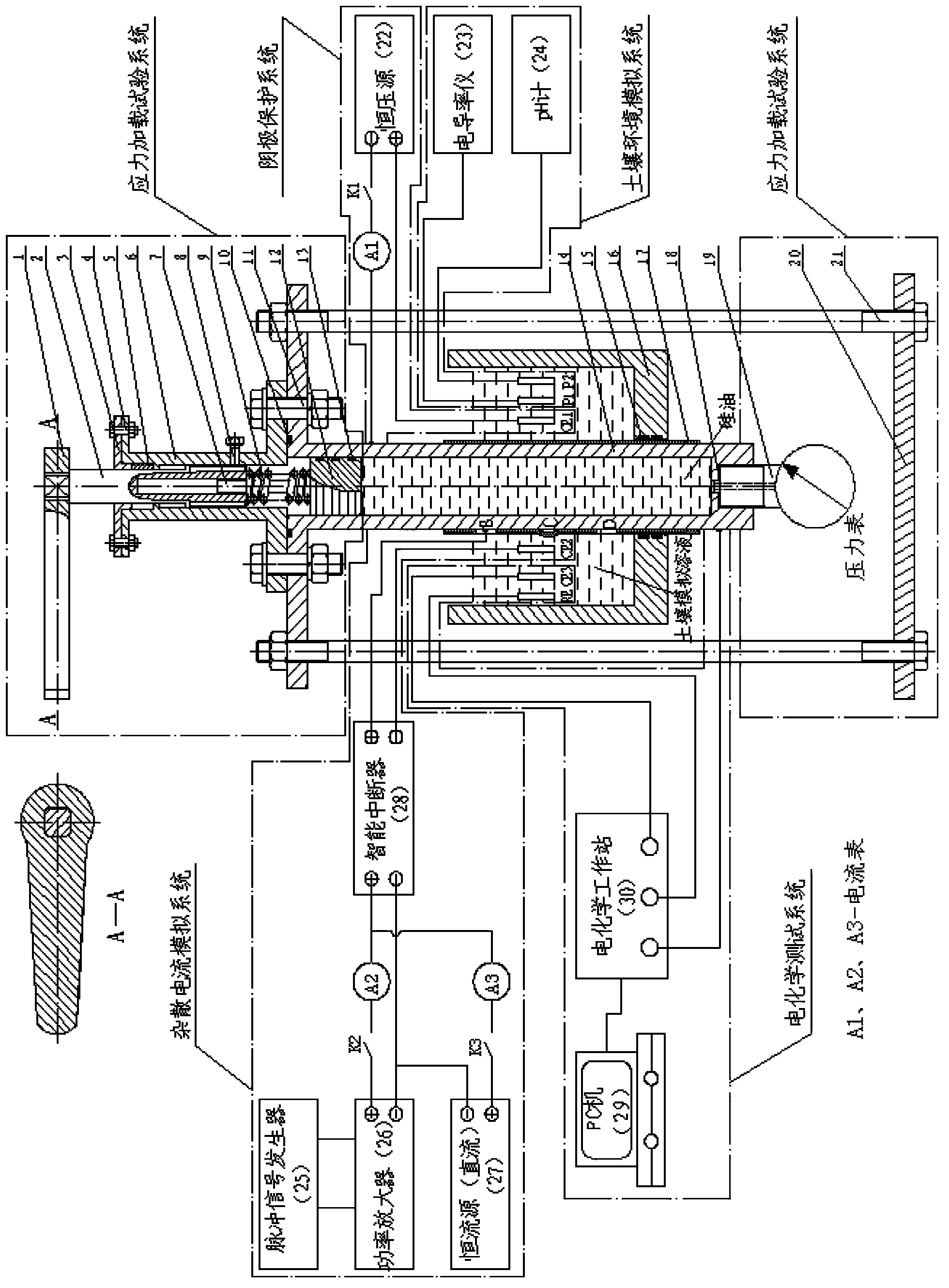

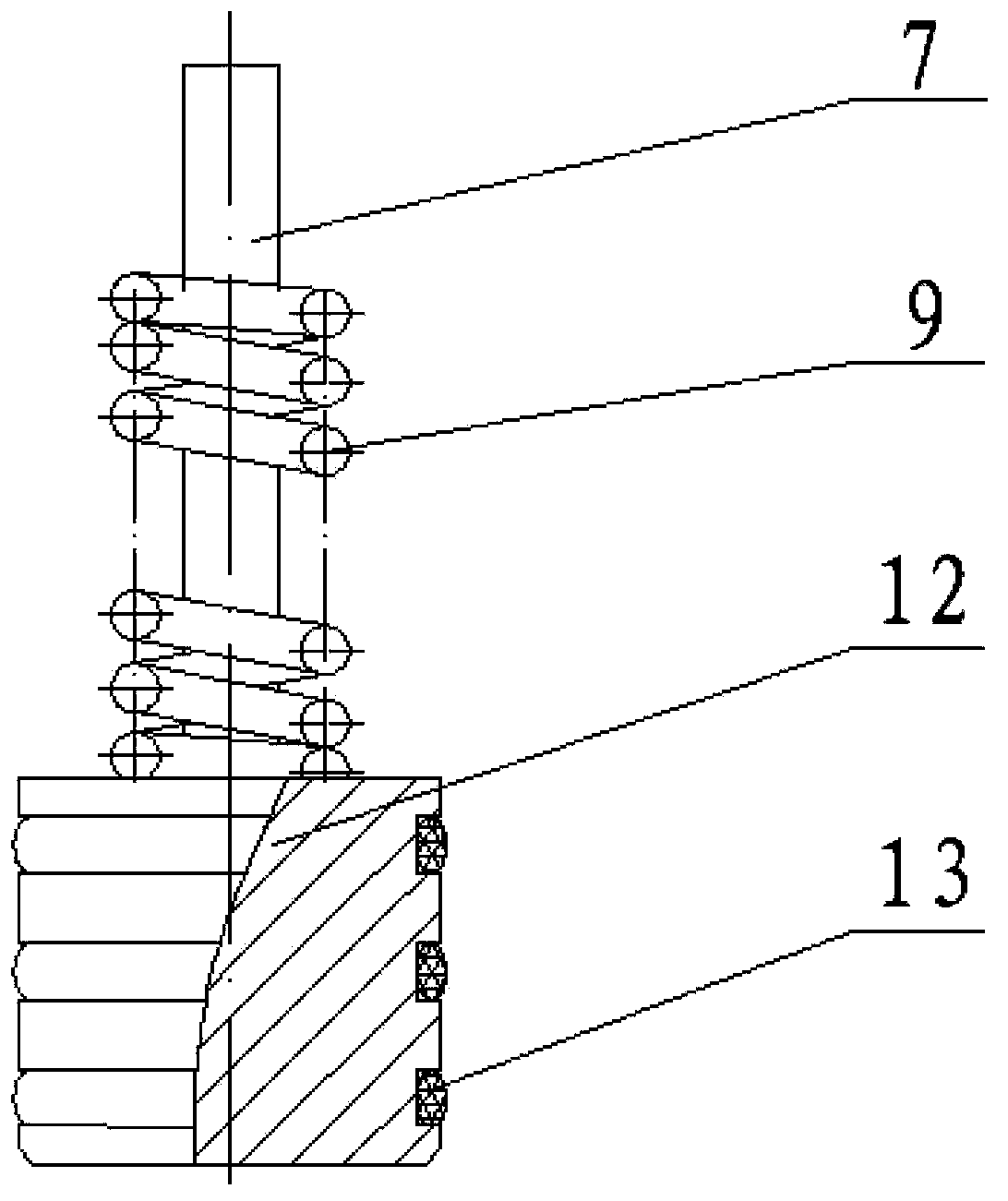

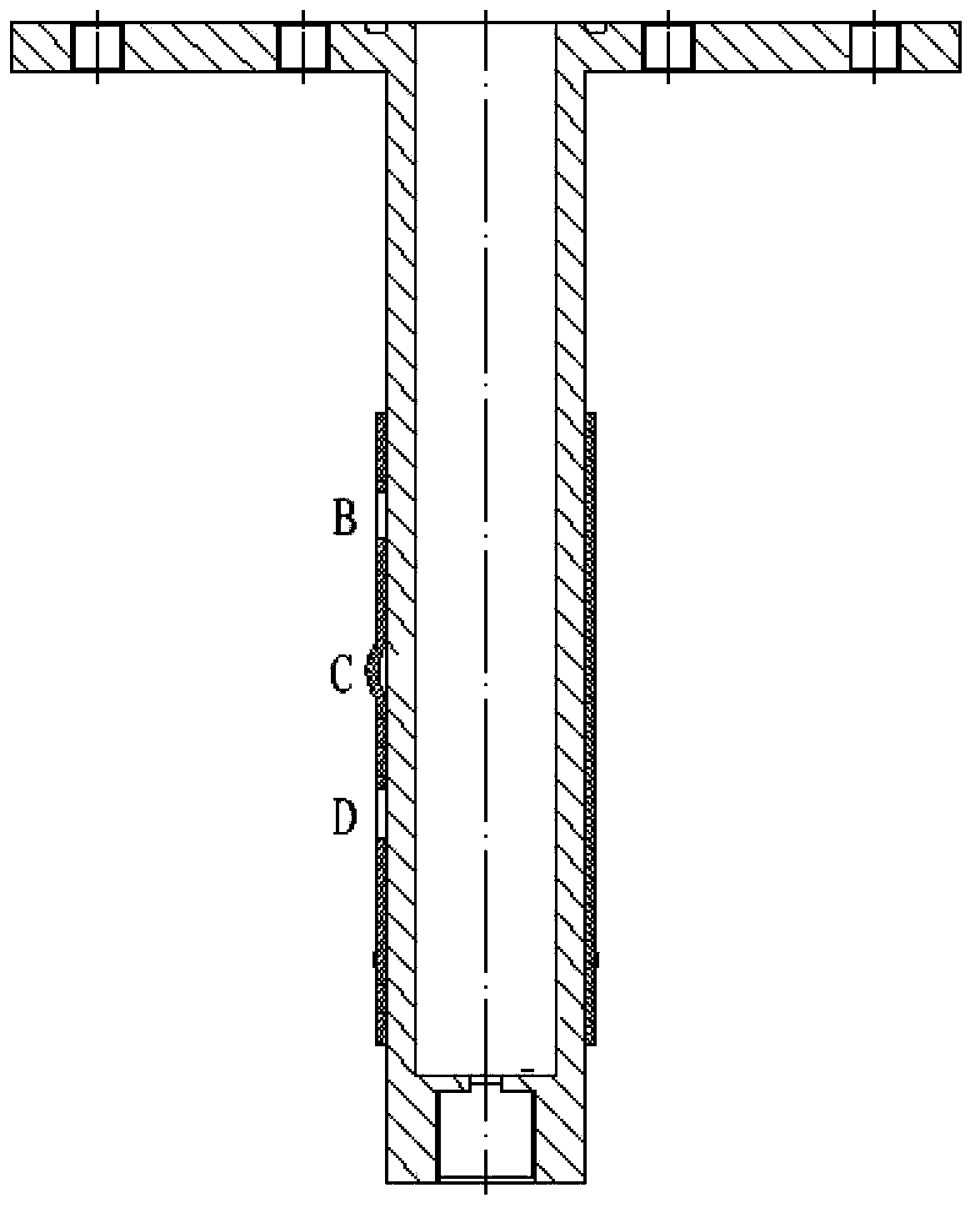

Buried steel pipeline coating stripping and corrosion test system under stress and stray current coupling effect

The invention relates to a buried steel pipeline coating stripping and corrosion test system under a stress and stray current coupling effect, and belongs to the field of pipeline corrosion and coating stripping detection. The test system comprises a stress loading test system, a soil environment simulation system, a stray current simulation system, a cathode protection system, and an electrochemistry test system. With the test system, actual working conditions of a buried steel pipeline can be simulated, corrosion law experiments under different influence factors (soil resistivity / conductivity, soil pH value, different stress levels, stray current types / intensity, damage area / stripping area, and the like) can be performed on pipelines, a pipeline cathode stripping experiment and an experiment of stripping produced on a coating damage position due to stray current inflow can be performed, and an experiment of underlayer corrosion caused by pipeline cathode stripping and an experiment of corrosion (including stray current corrosion) caused by coating damage can be performed. The method can be suitable for buried steel pipeline coating stripping and corrosion detection laboratory researches and preliminary studies of pipeline production enterprises.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com