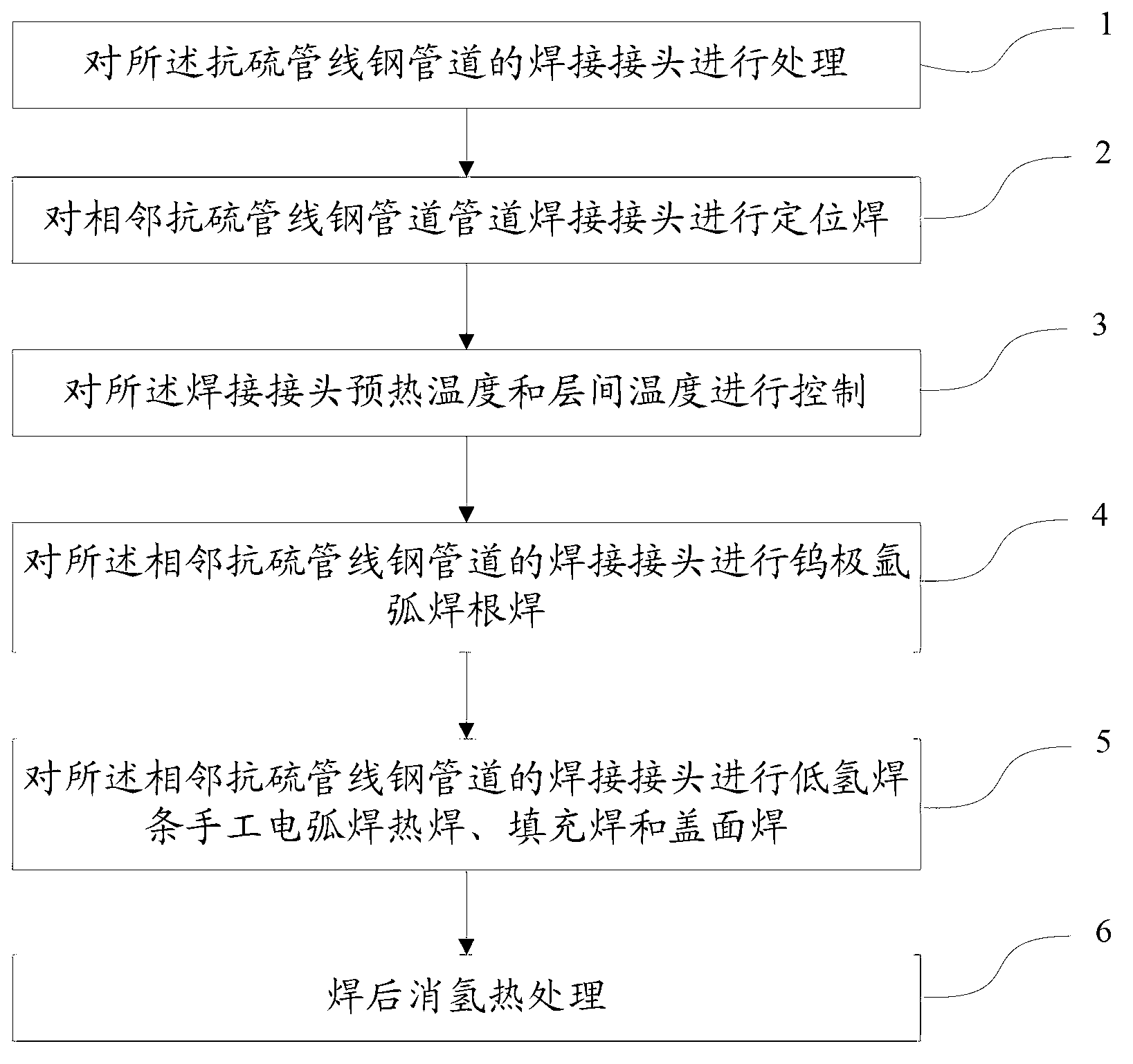

Welding method of oil gas transmission antisulphour steel pipelines

A welding method and pipeline steel technology, applied in welding equipment, tubular objects, arc welding equipment, etc., can solve problems such as poor welding quality, and achieve the effect of ensuring smooth and safe operation, excellent corrosion resistance and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0049] The following embodiments of the present invention will describe the embodiments of the present invention from the perspective of specific test pieces, specifically as follows:

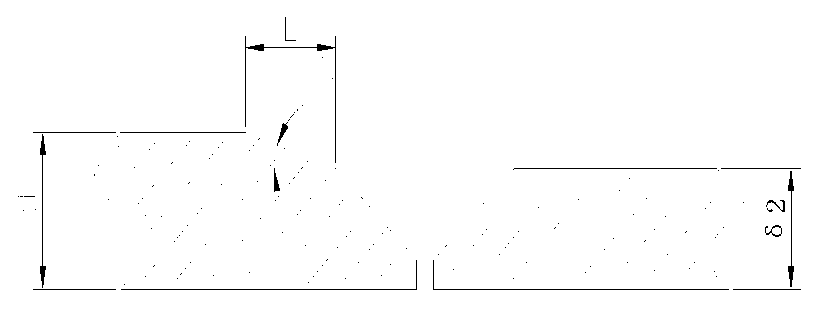

[0050] Test piece: APL Spec5L PSL2 grade X52QS seamless anti-sulfur pipeline steel pipe commonly used in sulfuric acid oil and gas fields, size specifications: outer diameter 219.1mm, wall thickness 25.4mm.

[0051] Times Inverter WS-400 welding machine is used to carry out the combined welding process of argon tungsten arc welding (GTAW) root welding + low hydrogen electrode manual arc welding (SMAW) heat welding, filling welding and cover welding. The specific operation steps are as follows :

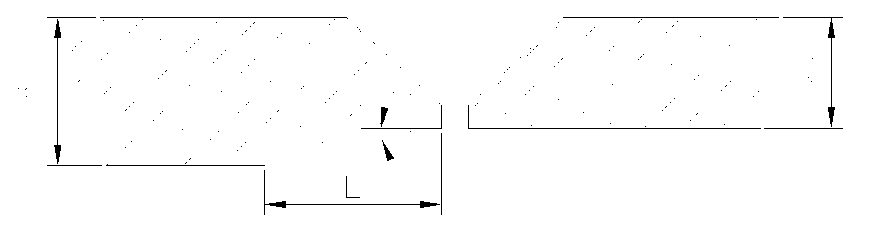

[0052] 1. Process the welded joints of the sulfur-resistant pipeline steel pipes; adopt standard V-groove butt joints, with a groove angle of 60°, a blunt edge size of 1.5 mm, and a root gap of 2.0 mm; remove the groove surface of the pipe end before welding Rust, slag, oil and other harmful substance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com