Patents

Literature

2553 results about "Gas transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas transmission system is a link between gas fields and gas consumers. A gas transmission system is the basis of the Unified Gas Supply System (UGSS) of Russia.

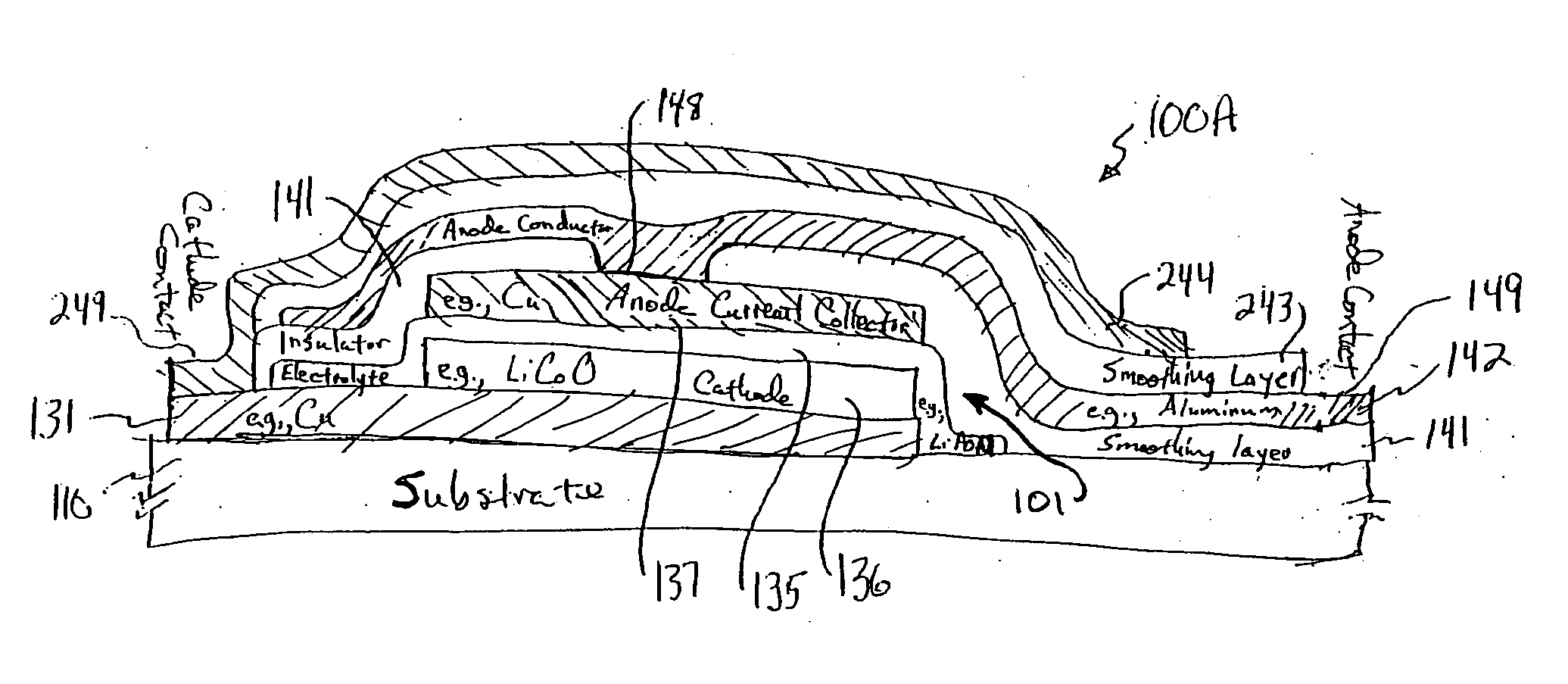

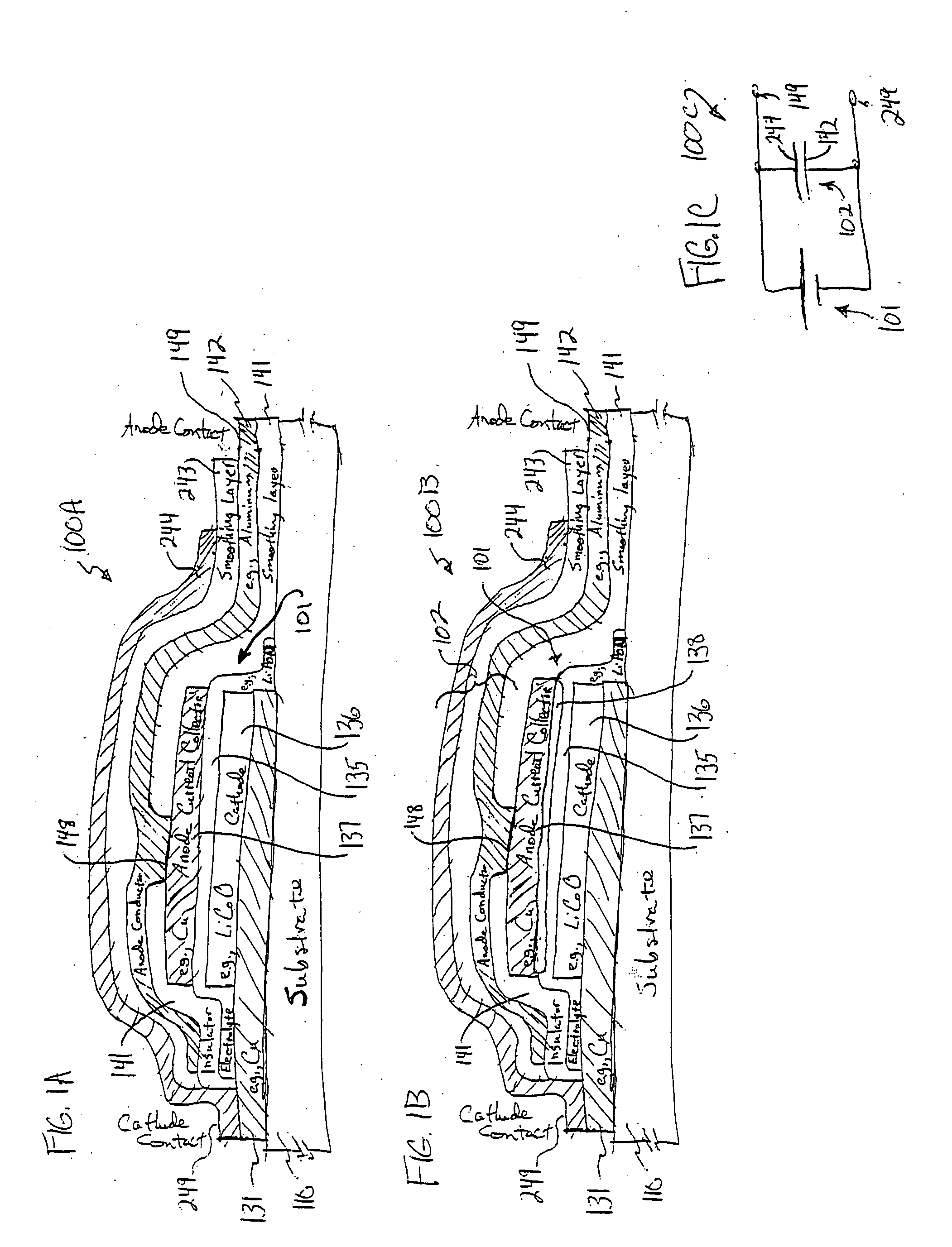

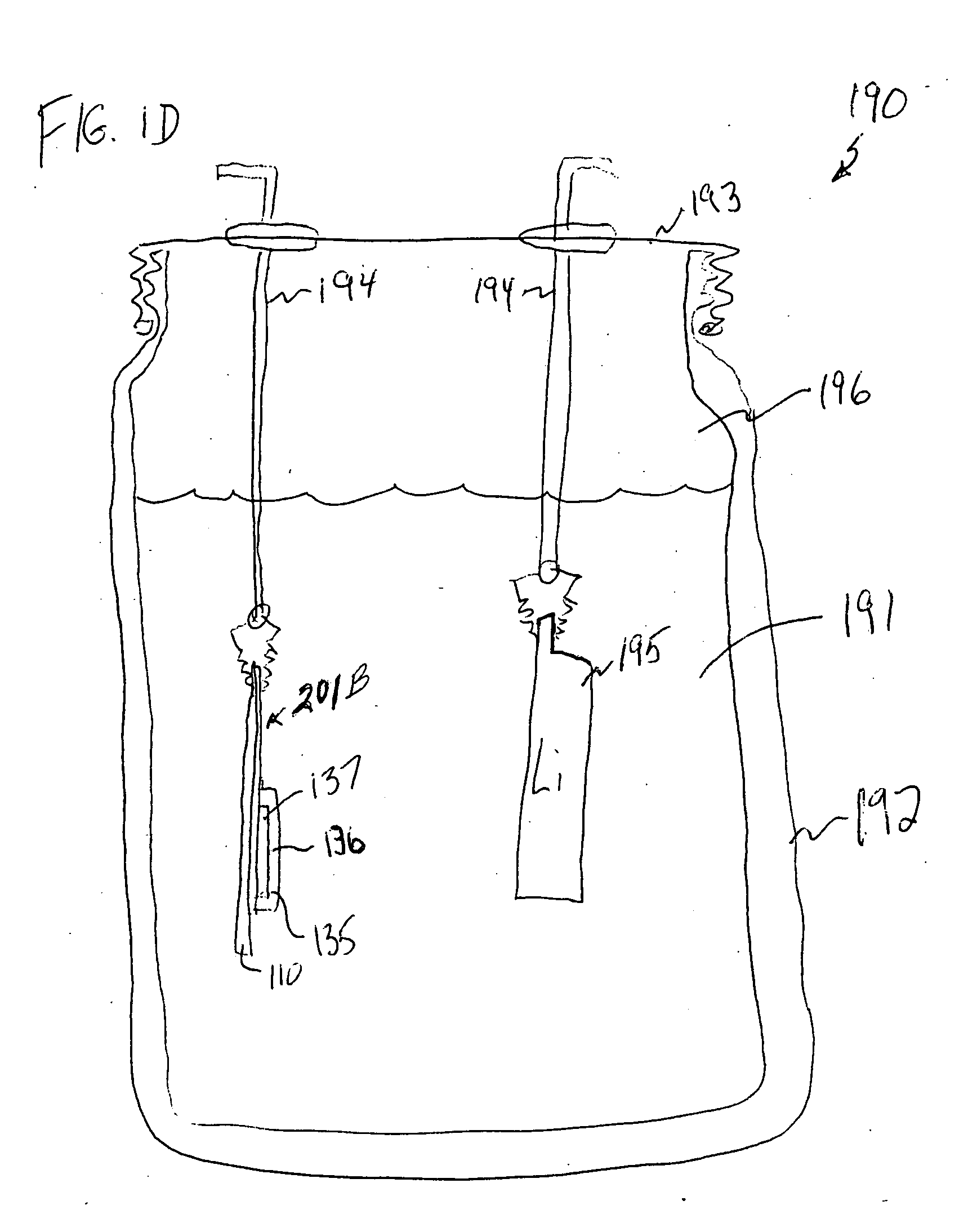

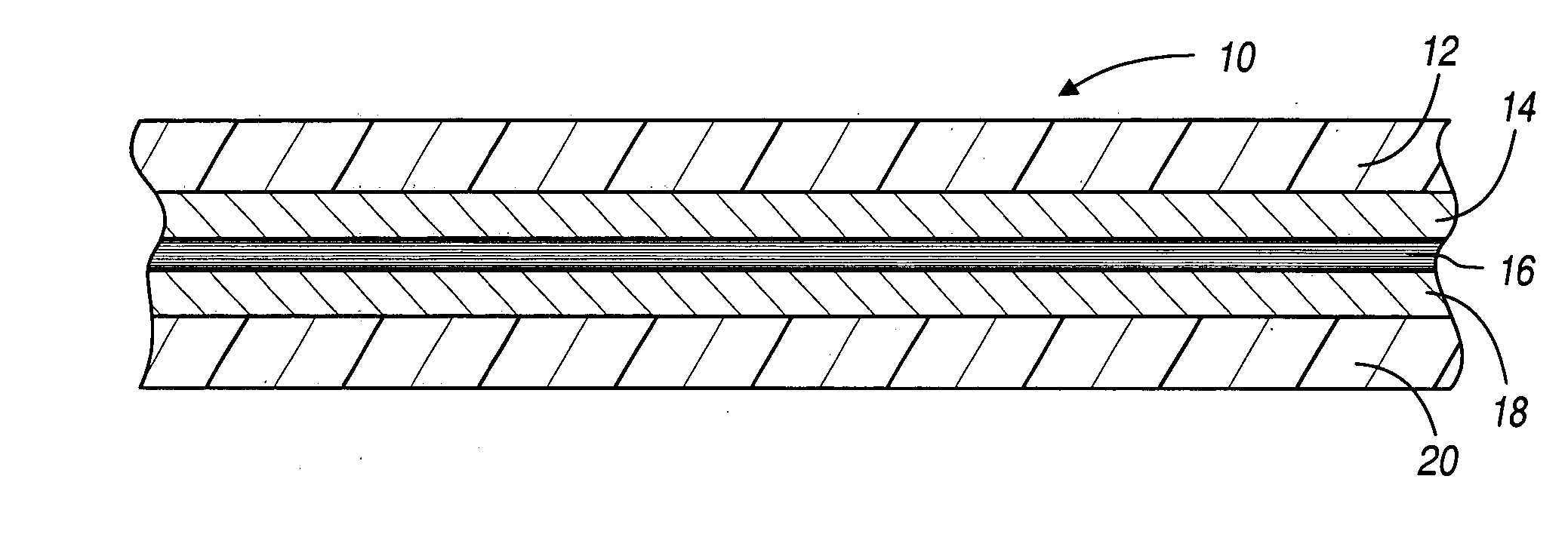

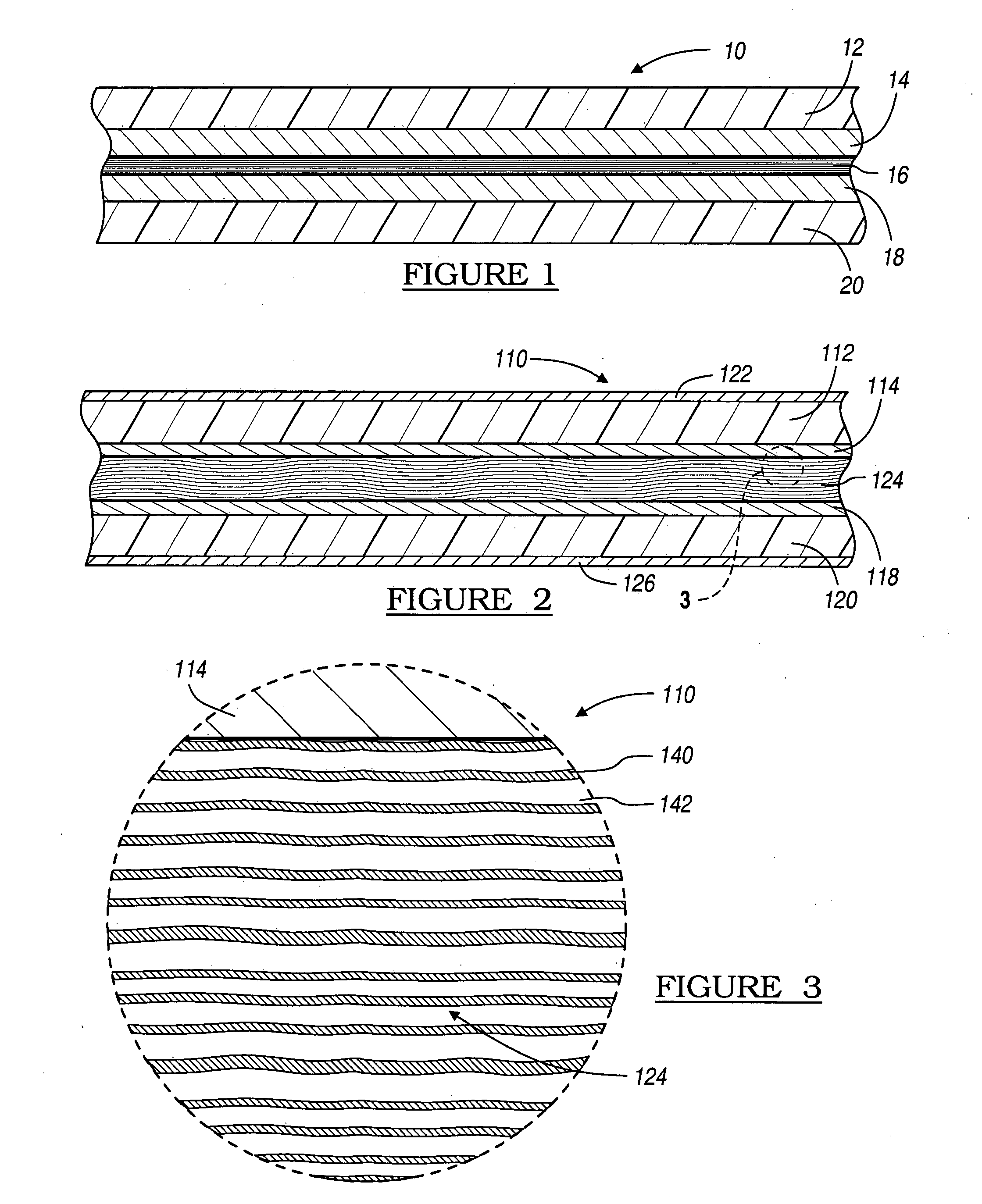

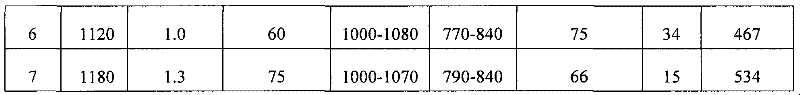

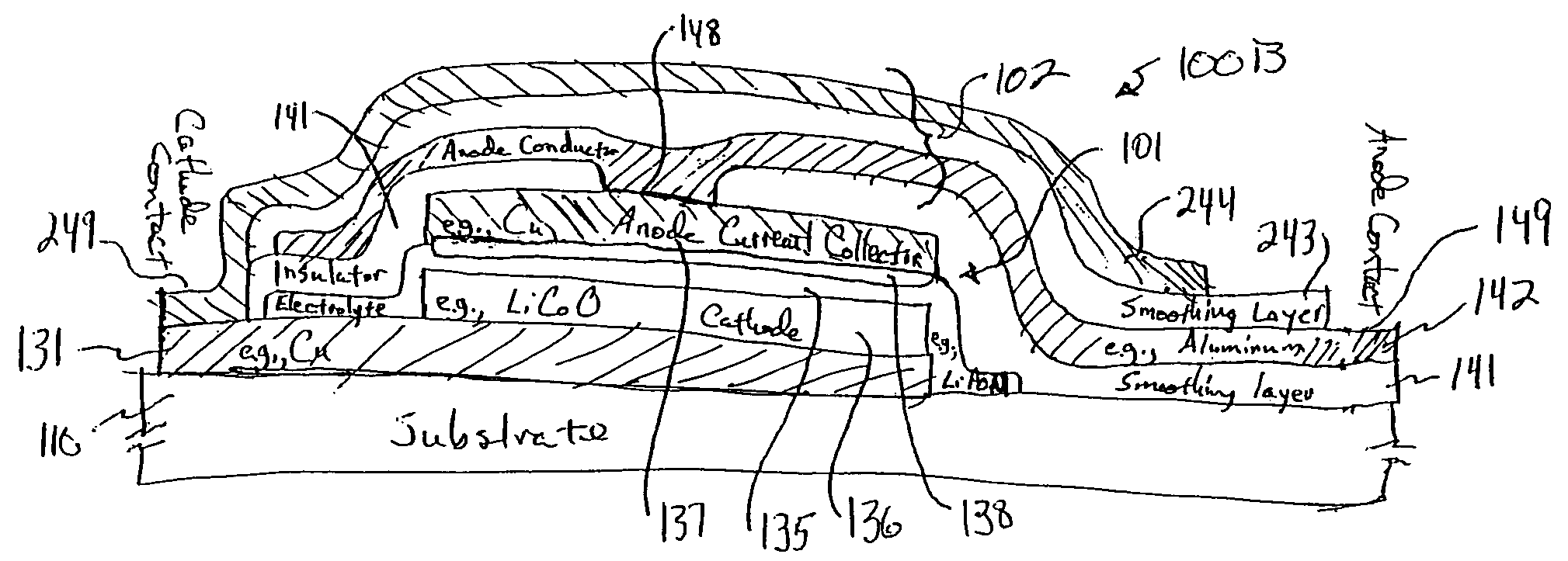

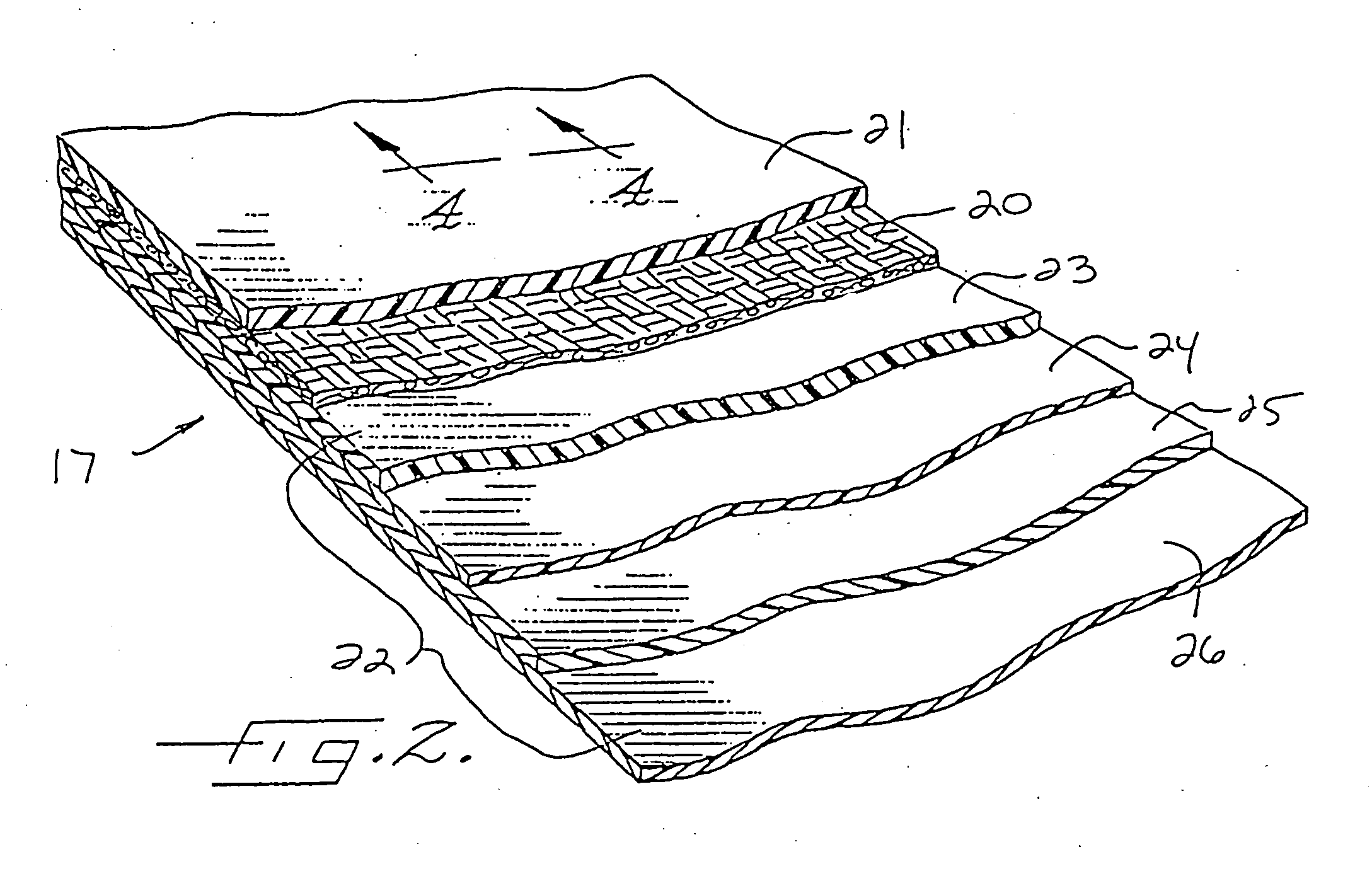

Layered barrier structure having one or more definable layers and method

InactiveUS20050147877A1Reduce transmissionLow rateFuel and primary cellsElectrode manufacturing processesDielectricLithium compound

A system provides an environmental barrier also useful for providing a circuit, for example, one having a thin-film battery such as one that includes lithium or lithium compounds connected to an electronic circuit. An environmental barrier is deposited as alternating layers, at least one of the layers providing a smoothing, planarizing, and / or leveling physical-configuration function, and at least one other layer providing a diffusion-barrier function. The layer providing the physical-configuration function may include a photoresist, a photodefinable, an energy-definable, and / or a maskable layer. The physical-configuration layer may also be a dielectric. A layered structure, including a plurality of pairs of layers, each pair including a physical configuration layer and a barrier layer with low gas-transmission rates, may be used in reducing gas transmission rate to beyond currently detectable levels.

Owner:CYMBET CORP

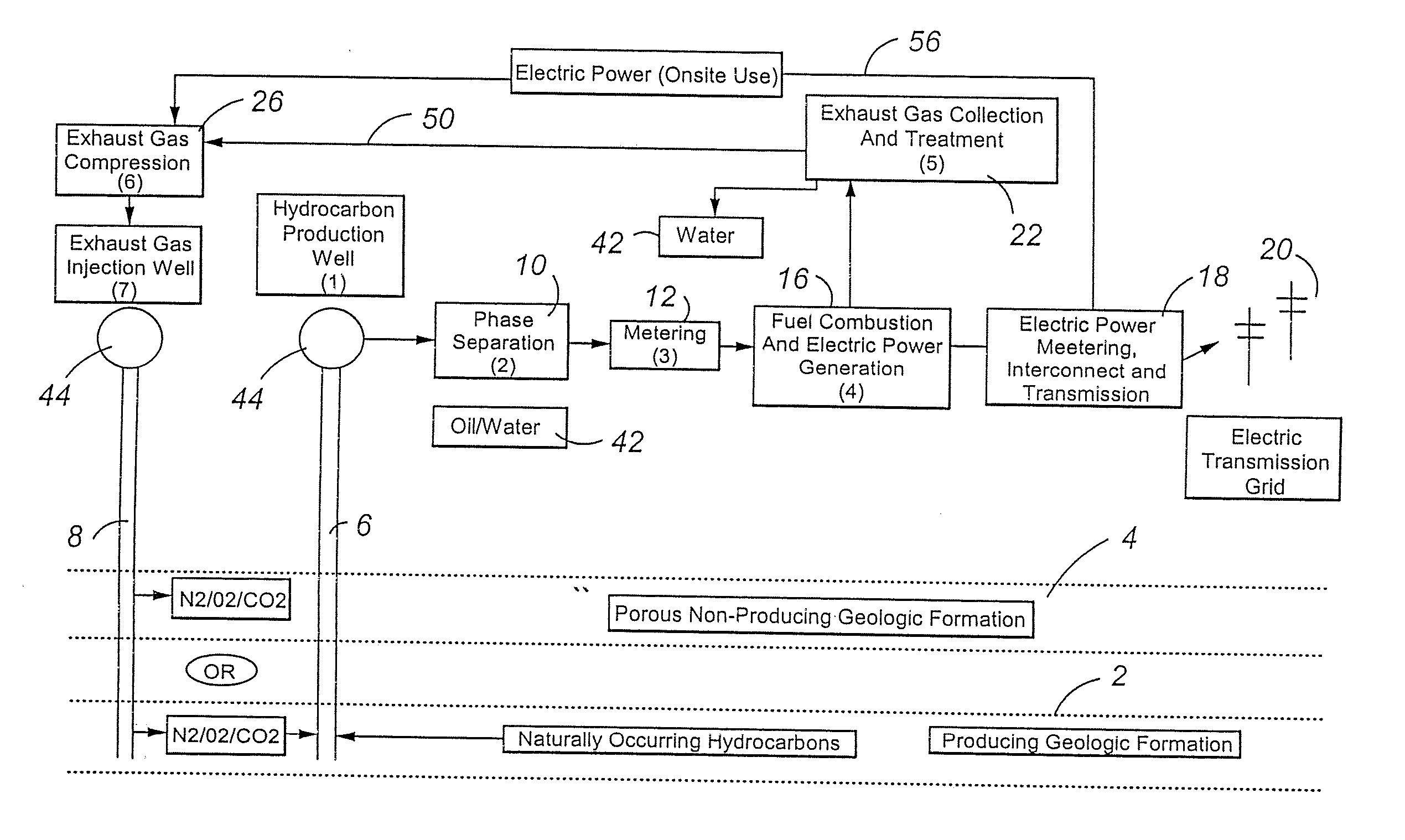

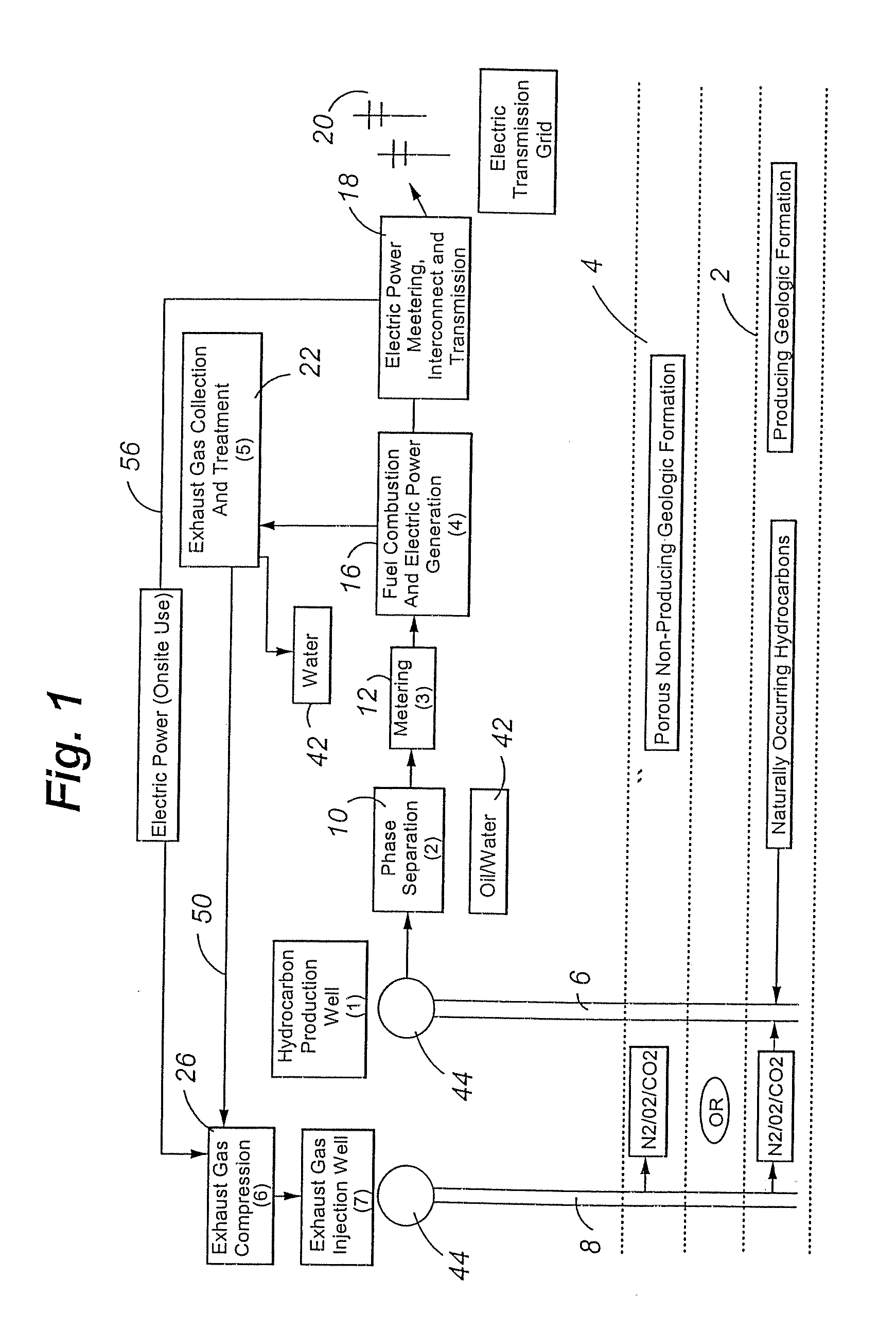

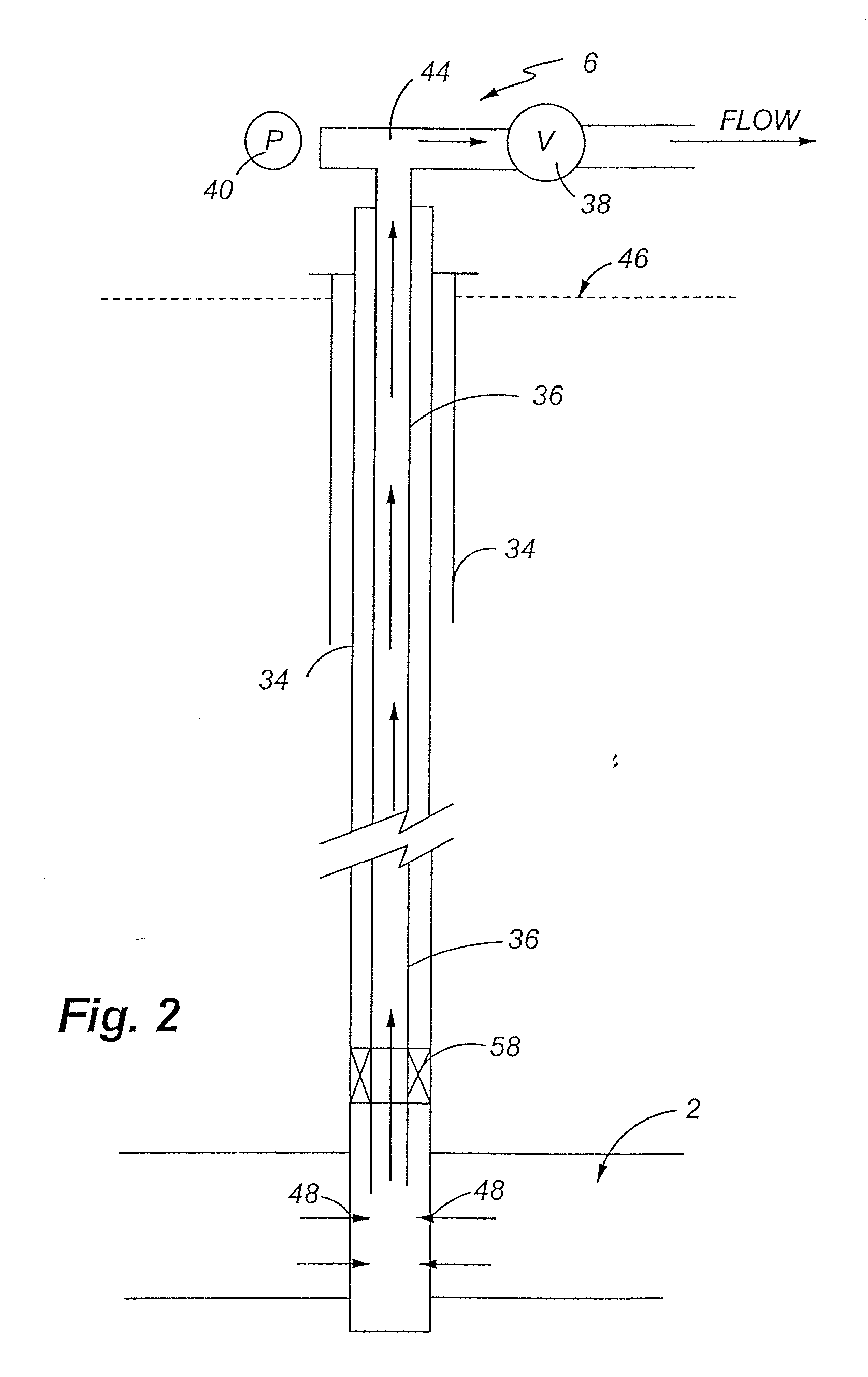

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20080017369A1Cost effectivePollution free energyFluid removalThermal energyHydrocotyle bowlesioides

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. The present invention further relates to managing and supplying this electrical energy to at least one of a variety of subprocesses for producing a fuel product, such as hydrogen or ethanol. Alternatively, electrical power can be generated from a non-hydrocarbon source such as thermal, solar, wind or other power source to produce electrical energy, which in turn may be used to produce fuel products or other forms of usable energy. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

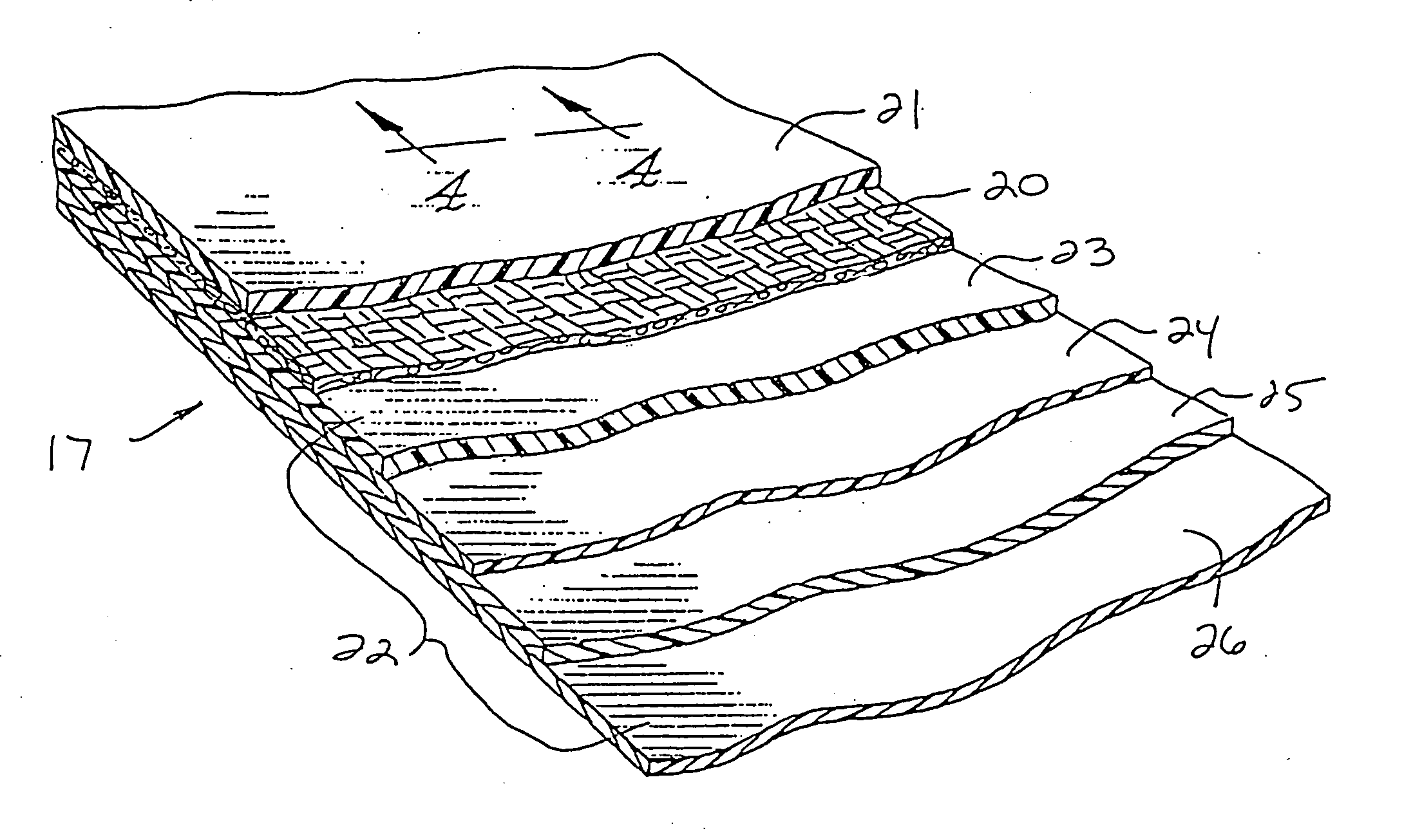

Membranes with fluid barrier properties and articles containing such membranes

InactiveUS20050031816A1Increases ability of to preventReduce reboundMaterial nanotechnologySolesElastomerPlatelet

A membrane comprising at least one elastomeric material, at least one polymeric fluid barrier material, and a laminar nano-filler having an average platelet thickness of up to about 10 nanometers and an average aspect ratio of at least about 200 provides desirable appearance and low gas transmission characteristics. The membrane may be a single layer, but preferably the membrane includes at least one layer of an elastomeric material and at least one layer of a polymeric barrier material, in which the elastomeric material layer and / or the polymeric barrier material layer comprises the laminar nano-filler.

Owner:NIKE INTERNATIONAL LTD

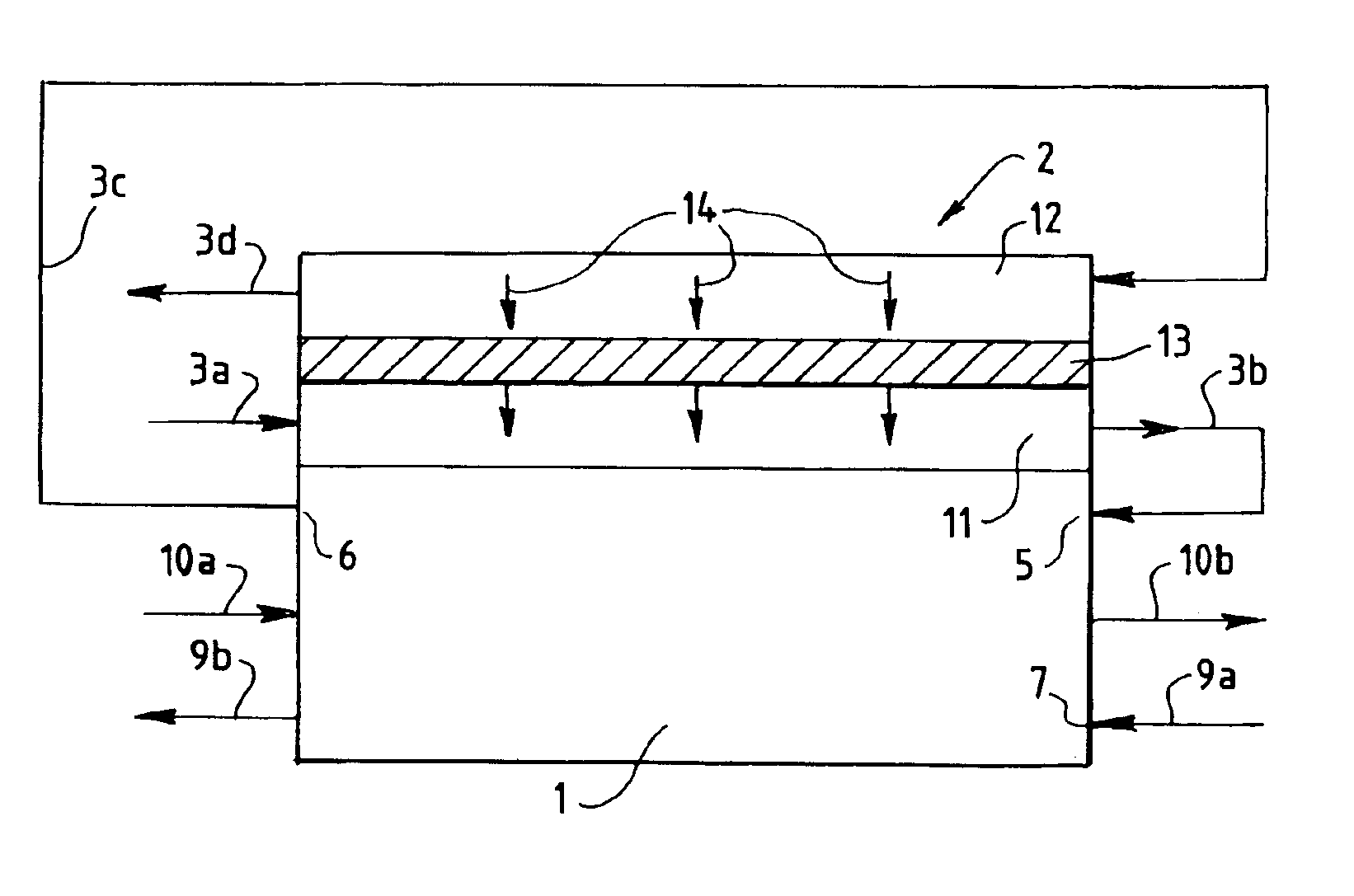

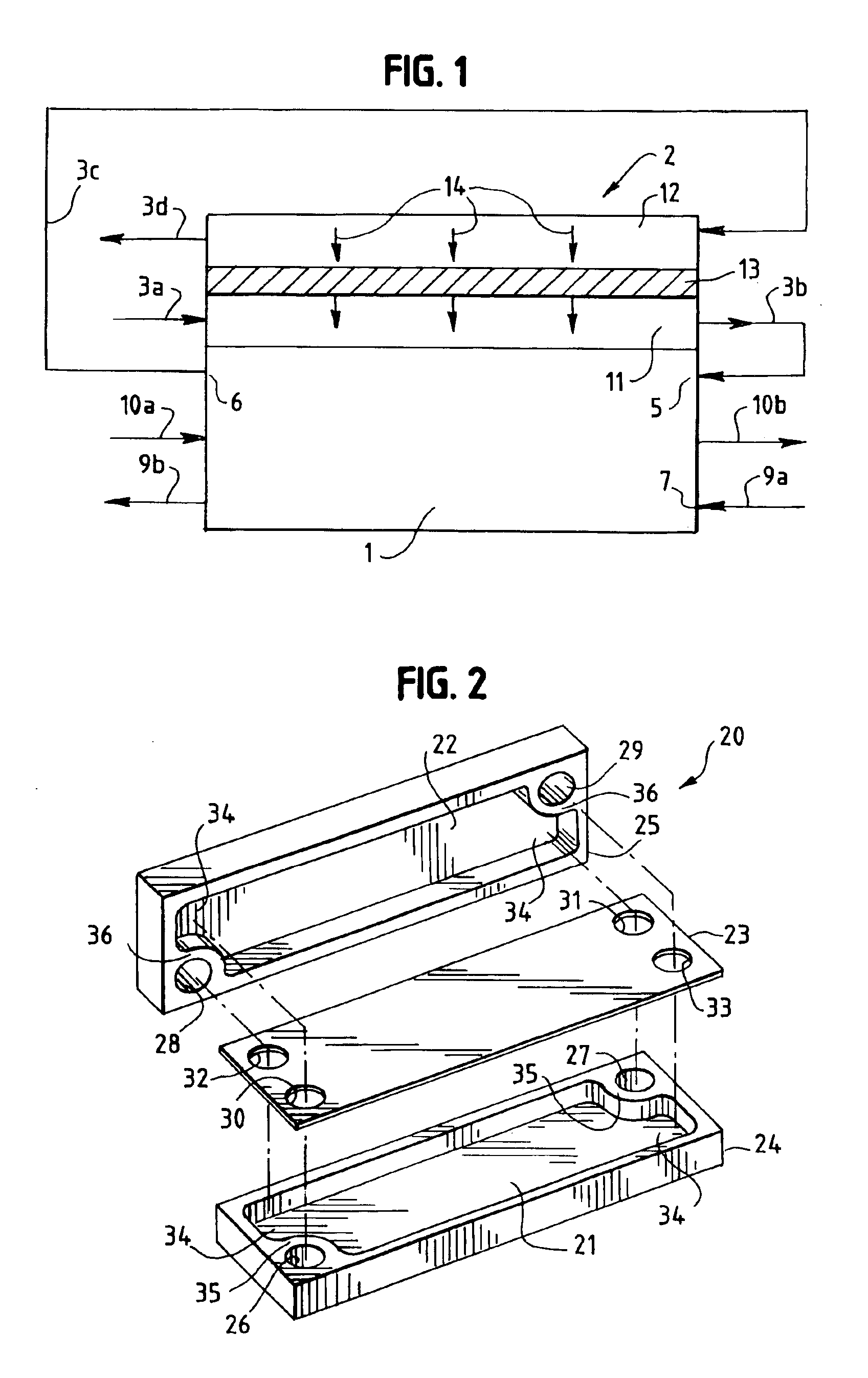

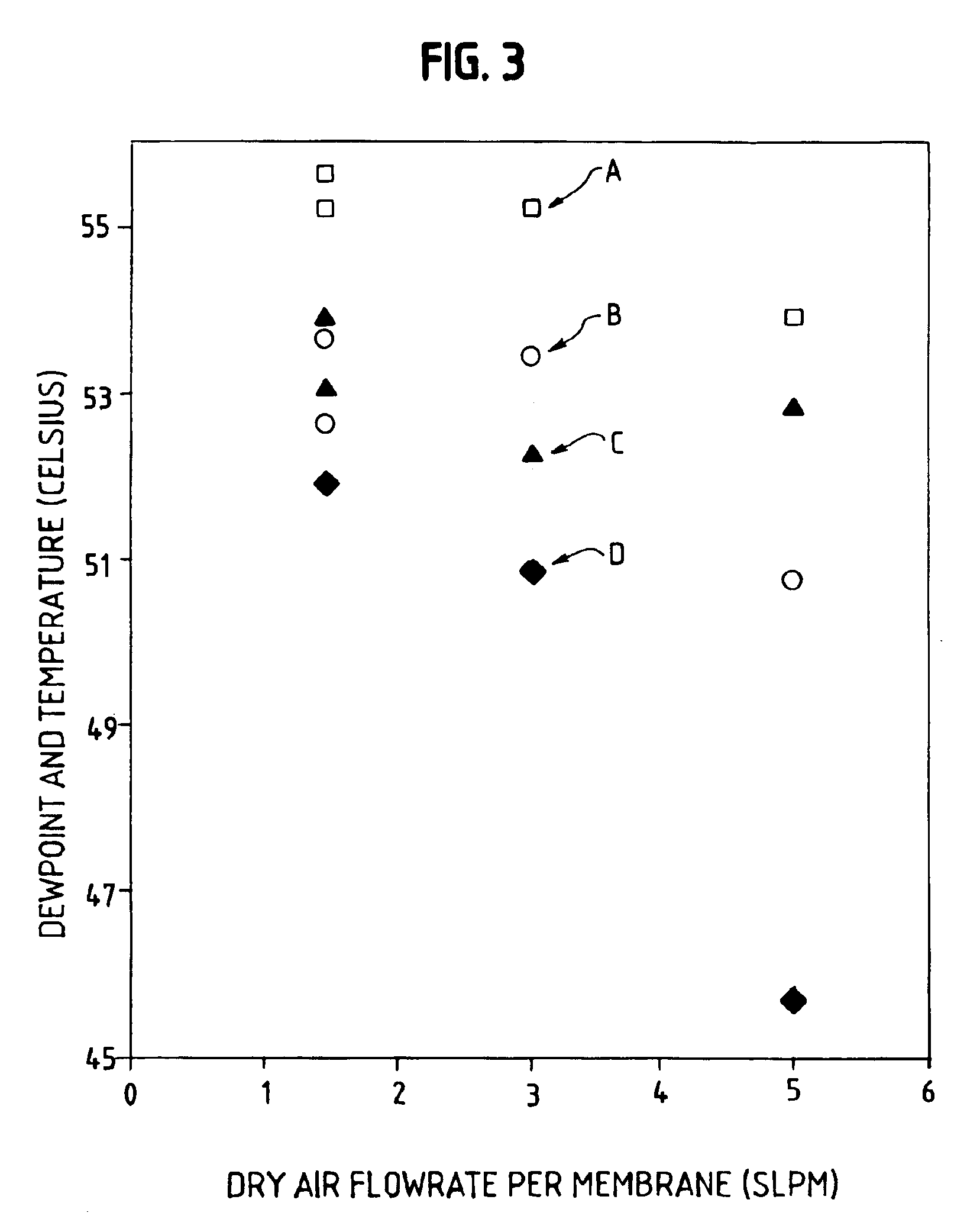

Membrane exchange humidifier for a fuel cell

InactiveUS6864005B2Simpler humidifier constructionFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsLiquid water

Owner:BDF IP HLDG

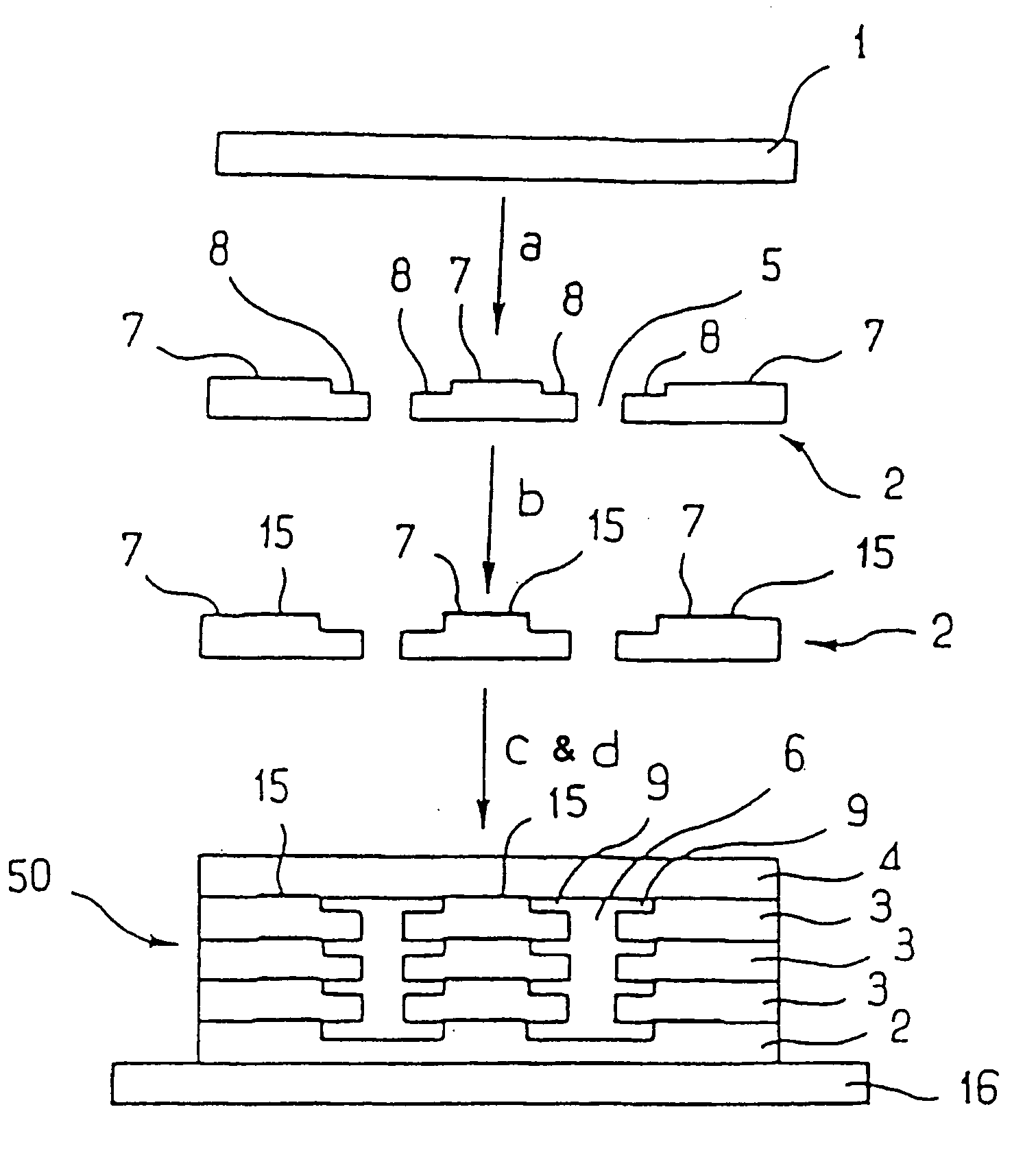

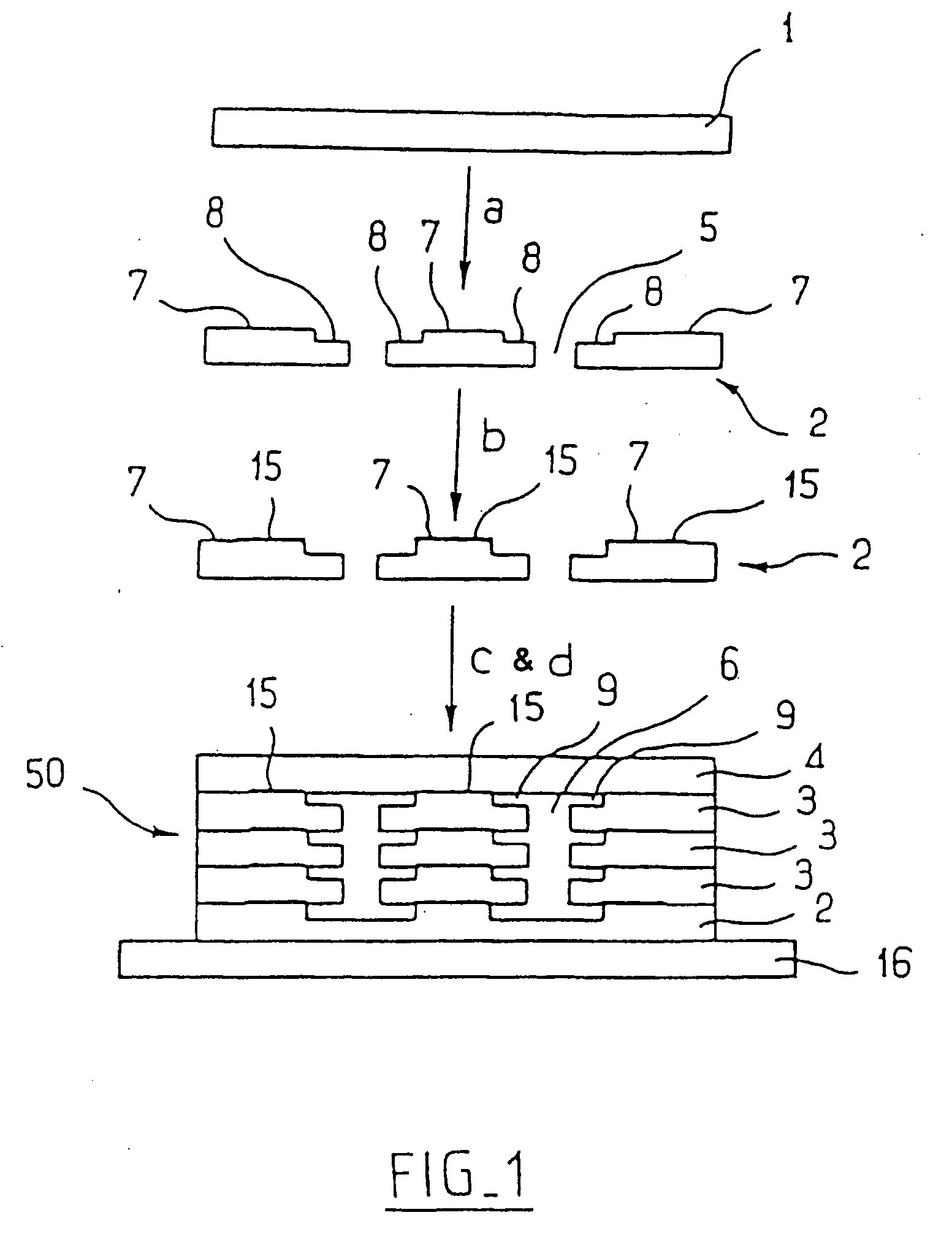

Heat exchanger device using a two-phase active fluid, and a method of manufacturing such a device

InactiveUS20050022978A1High degree of compactness and performanceLittle riskLayered productsSemiconductor/solid-state device detailsCapillary channelEngineering

Owner:ATMOSTAT ETUD & RECH

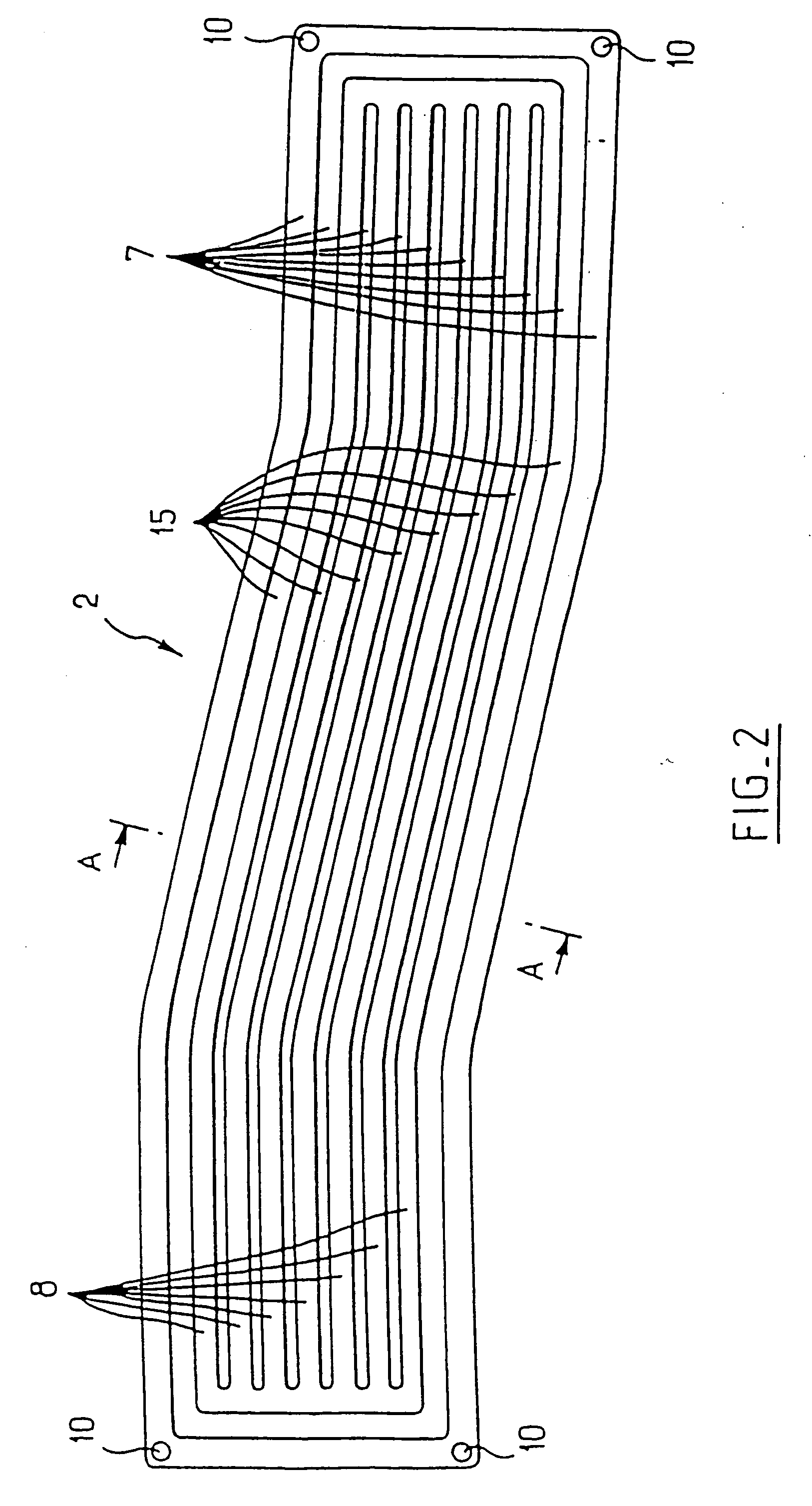

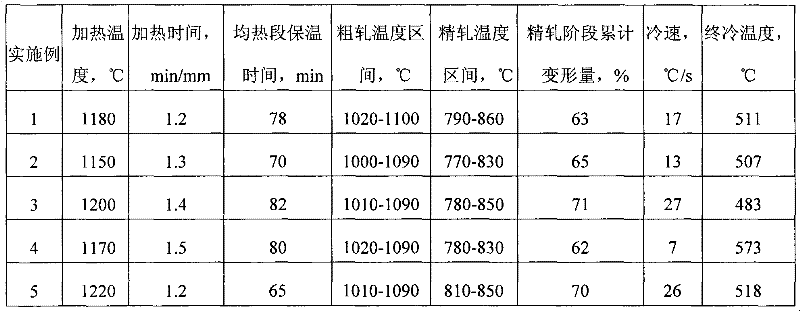

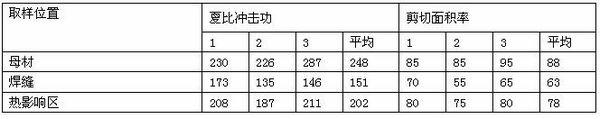

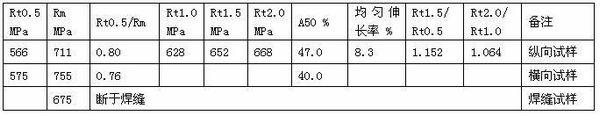

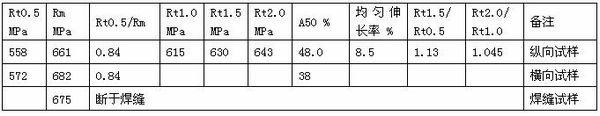

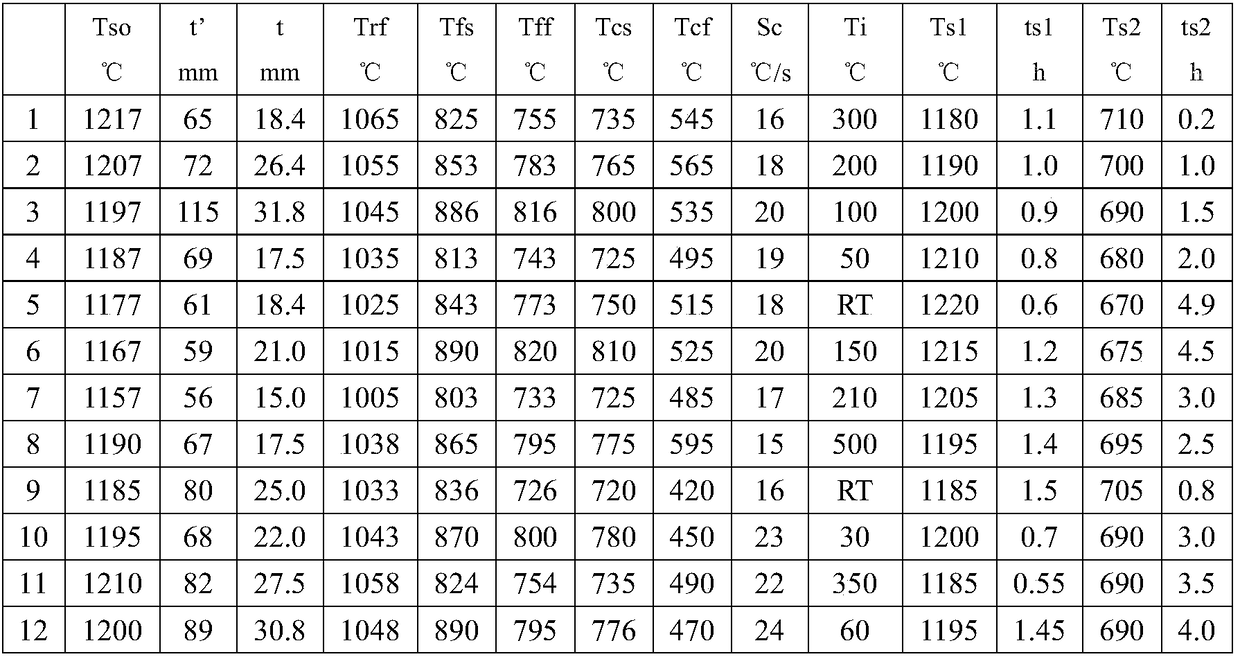

Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

ActiveCN102409224AGuaranteed toughnessSuitable for solderabilityRoll mill control devicesMetal rolling arrangementsHydrogenChemical composition

The invention provides a hot rolled steel plate with excellent low-temperature toughness for a thick submerged pipeline and a production method of the hot rolled steel plate. The hot rolled steel plate comprises the following chemical components by weight percentage: 0.02%-0.07% of C, 0.15%-0.40% of Si, 1.0%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.003% of S, less than or equal to 0.06% of Nb, less than or equal to 0.025% of Ti, less than or equal to 0.06% of V, less than or equal to 0.20% of Mo, less than or equal to 0.25% of Cu, 0.10%-0.30% of Ni, less than orequal to 0.25% of Cr, less than or equal to 0.008% of N, 0.010%-0.040% of Al, more than or equal to 2 of Al / N and the rest Fe and inevitable impurities. According to the steel for the submerged pipeline with the thickness being over 28mm, disclosed by the invention, the transversal and longitudinal bending strength can reach over 480MPa or 510MPa, the transversal and longitudinal tensile strengthcan reach over 560MPa or 600 MPa, the transversal impact toughness at the temperature of 60 DEG below zero is larger than or equal to 400 J, the transversal DWTT (Drop-Weight Tear Test) shearing areaat the temperature of 25 DEG C below zero is larger than or equal to 85%, simultaneously, the corrosion resistant of the steel plate is excellent, and the result of a 96-hour HIC (Hydrogen Induced Cracking) test conforms to the requirements of the standard 0284 of the NACE (National Association of Corrosion Engineers). The hot rolled steel plate is suitable to be as a raw material for manufacturing a pipeline for submerged oil and gas transmission.

Owner:ANGANG STEEL CO LTD

Layered barrier structure having one or more definable layers and method

InactiveUS7494742B2Reduce transmissionReduce reduction reactionFuel and primary cellsElectrode manufacturing processesDielectricDiffusion barrier

A system provides an environmental barrier also useful for providing a circuit, for example, one having a thin-film battery such as one that includes lithium or lithium compounds connected to an electronic circuit. An environmental barrier is deposited as alternating layers, at least one of the layers providing a smoothing, planarizing, and / or leveling physical-configuration function, and at least one other layer providing a diffusion-barrier function. The layer providing the physical-configuration function may include a photoresist, a photodefinable, an energy-definable, and / or a maskable layer. The physical-configuration layer may also be a dielectric. A layered structure, including a plurality of pairs of layers, each pair including a physical configuration layer and a barrier layer with low gas-transmission rates, may be used in reducing gas transmission rate to beyond currently detectable levels.

Owner:CYMBET CORP

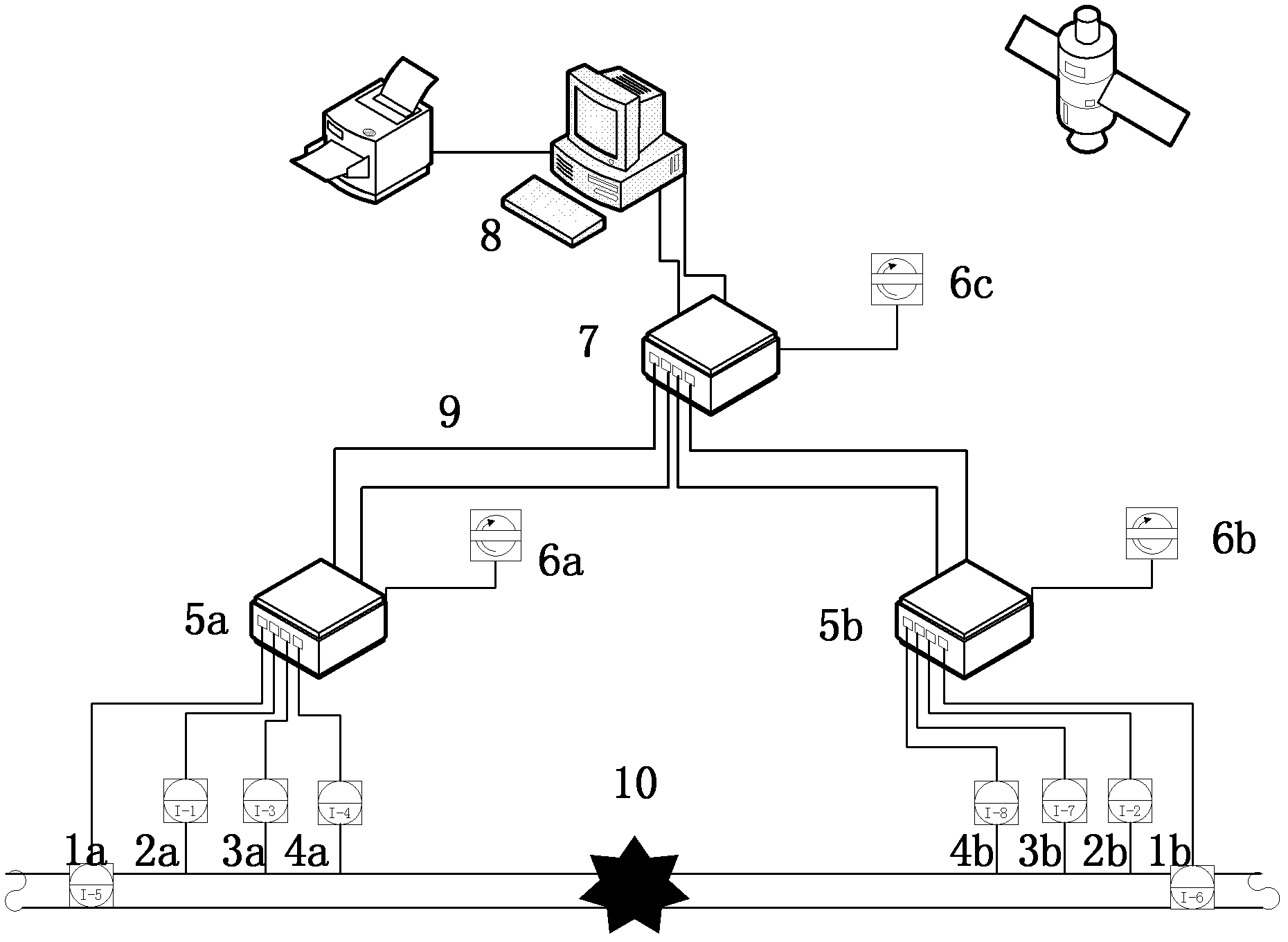

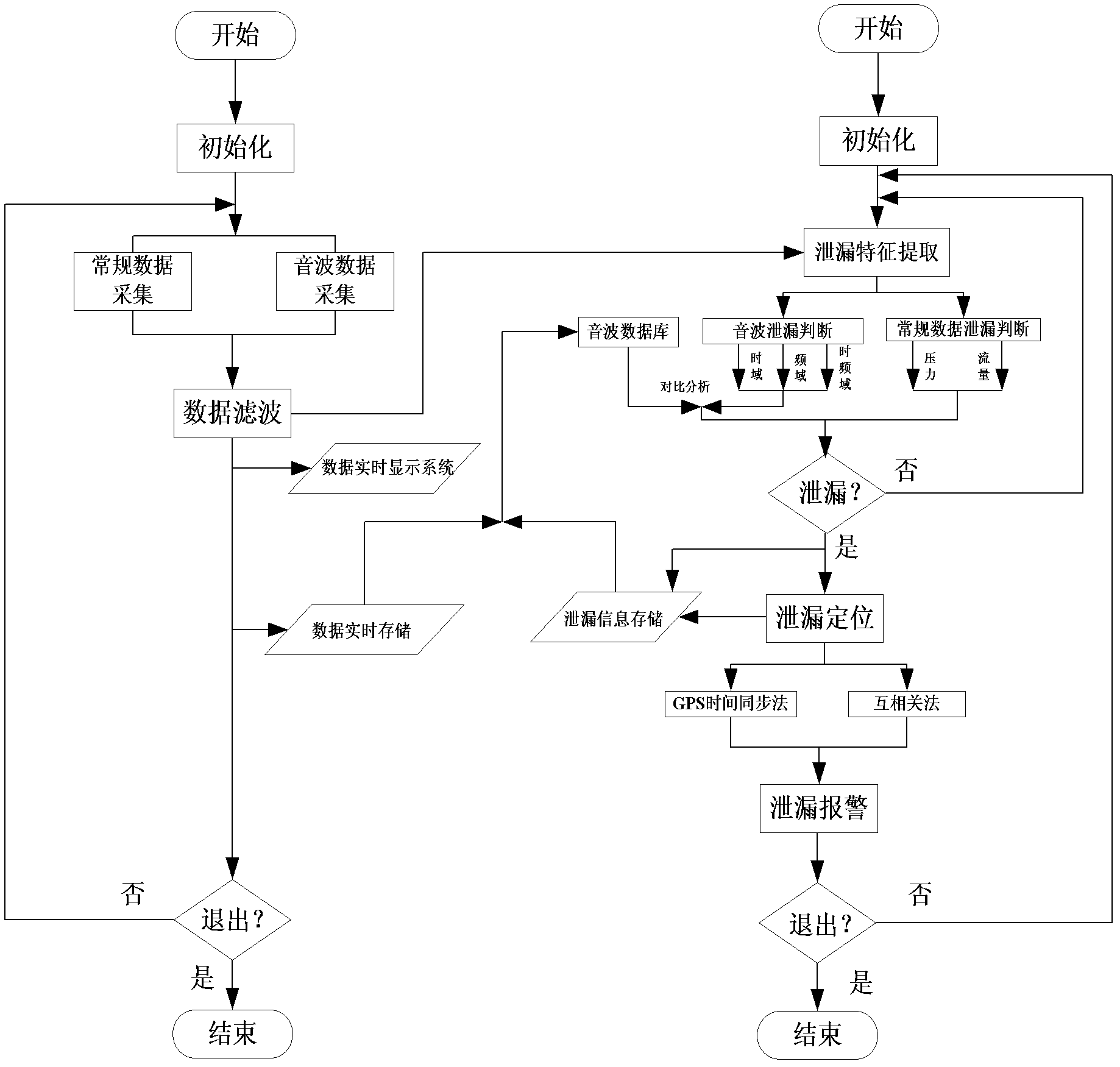

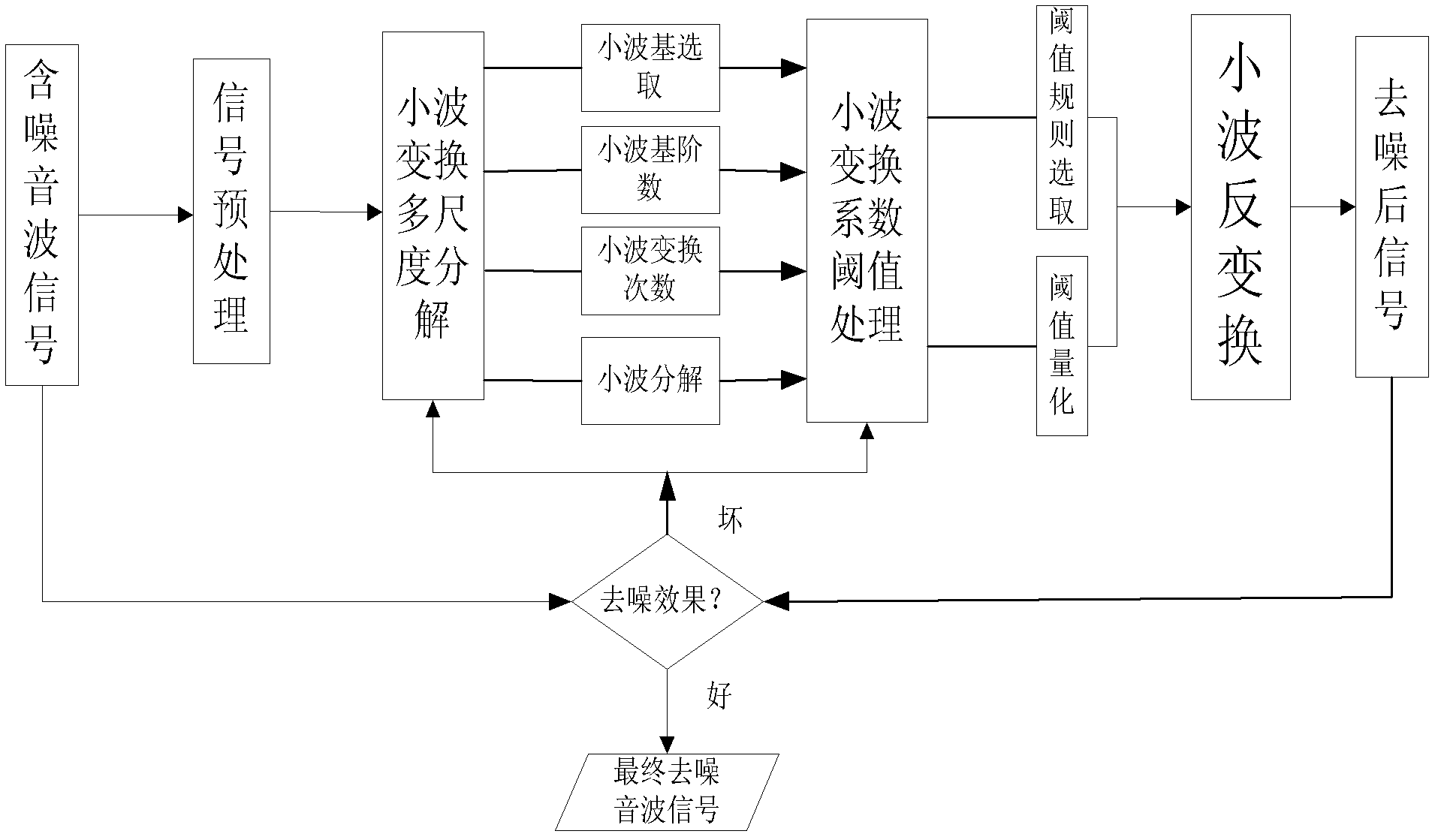

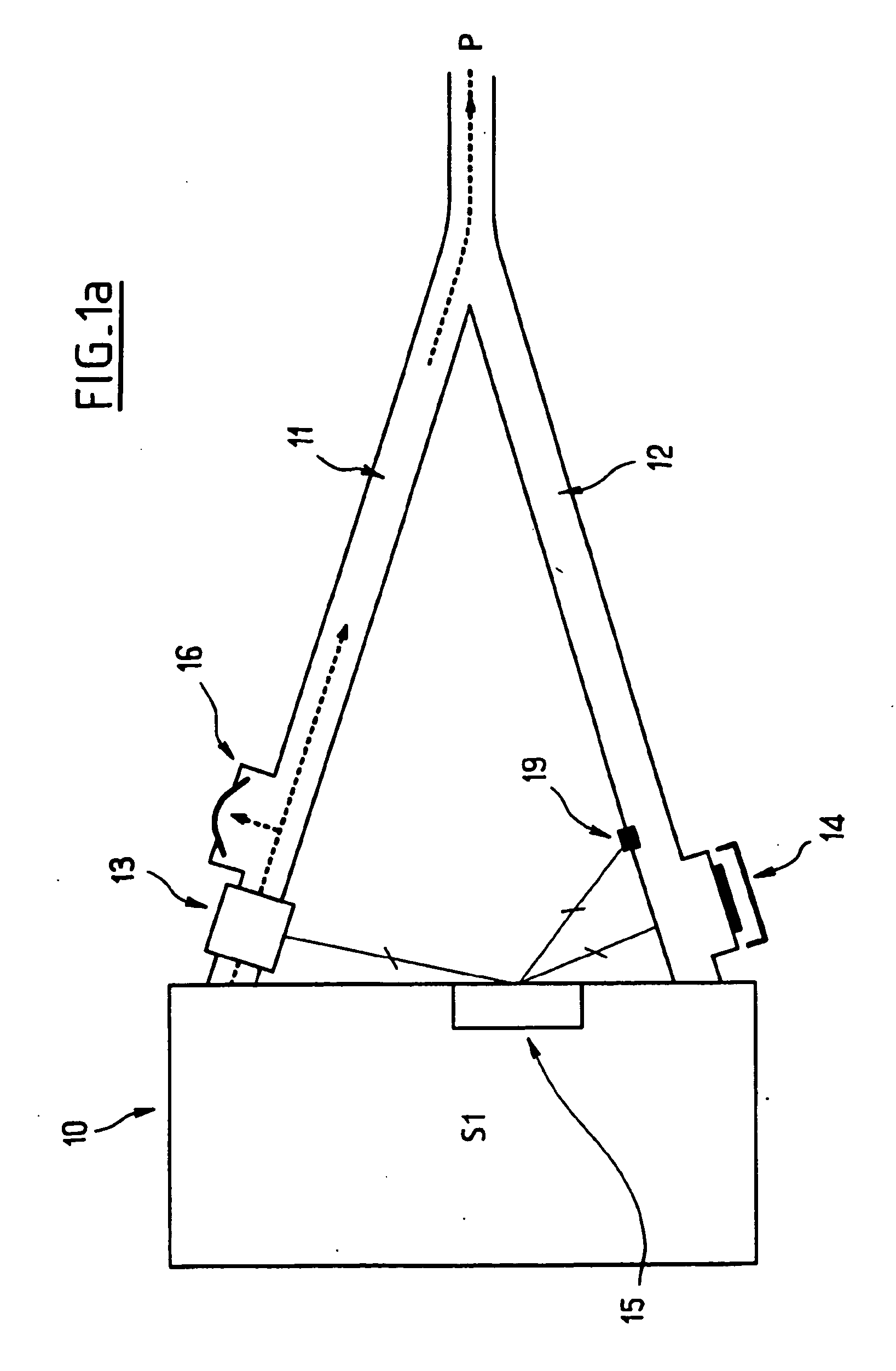

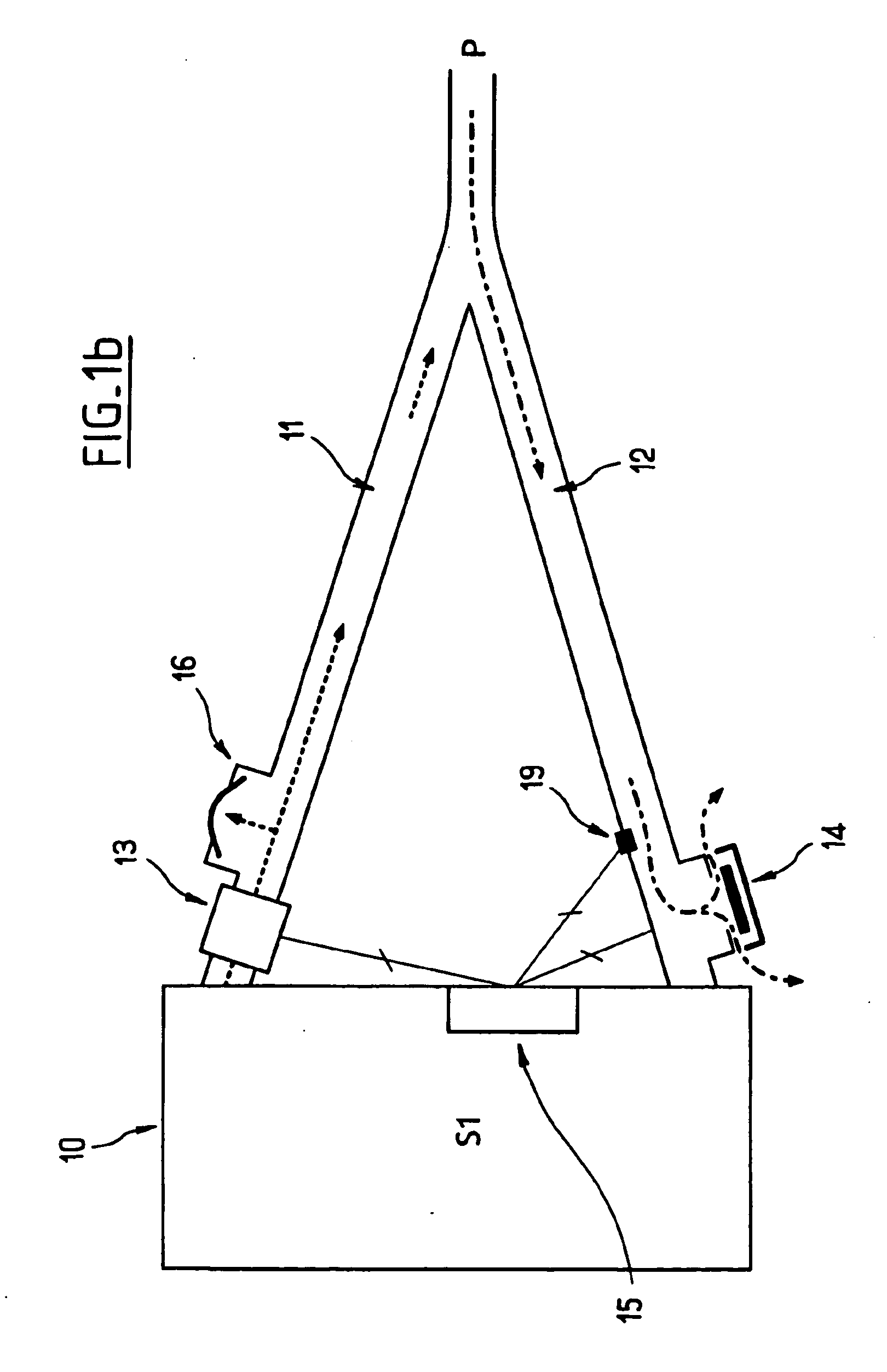

Device and method for detecting and positioning leakage of gas transmission pipeline based on conventional data and sound wave signals

InactiveCN102563361ADetermining the speed of propagationPrecise positioningPipeline systemsData acquisitionGlobal Positioning System

The invention discloses a device and a method for detecting and positioning leakage of a gas transmission pipeline based on conventional data and sound wave signals. The detecting device comprises a sensor group, a field data acquisition processor, a global positioning system (GPS) receiver, a communication network, a central data gathering processor and a monitoring host. The detecting method comprises the following steps of: respectively acquiring sound wave data and traffic, pressure and temperature conventional data of the upstream and the downstream of the pipeline, filtering background noise from the sound wave data by using wavelet transform, respectively identifying a time domain, a frequency domain and time and frequency domain characteristics of the sound wave signals by combining the conventional data to remove external interference and realize leakage signal characteristic extraction, performing leakage positioning by adopting an improved positioning method based on a related analysis method and a GPS synchronous time method, and giving a theoretical installation distance of sound wave sensors according to a propagation model of the sound wave signals. An interface can be established between the conventional data and a field supervisory control and data acquisition (SCADA) system, and only the sound wave sensors are arranged on the upstream and the downstream of the pipeline, so that the invention has the advantages of low investment, high equipment sensitivity and strong adaptability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pre-filled package containing unit dose of medical gas and method of making the same

InactiveUS6866142B2Extended shelf lifeMinimize gas leakageDiagnosticsSurgical needlesProcess engineeringProduct gas

A unit dose, gas-filled syringe is provided which is filled with gas and packaged in a gas barrier material prior to use to increase shelf-life, that is, to minimize gas leakage and dilution of the contents of the syringe. The syringe is filled with a selected gas and sealed inside a container made from a high gas barrier material. The container is also filled with the selected gas. The container material is selected to have a gas transmission rate sufficient to prevent the selected gas from diffusing out of the container into the atmosphere. The volume of gas in the container is greater that atmospheric pressure to prevent atmospheric contaminants from entering the container and syringe.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

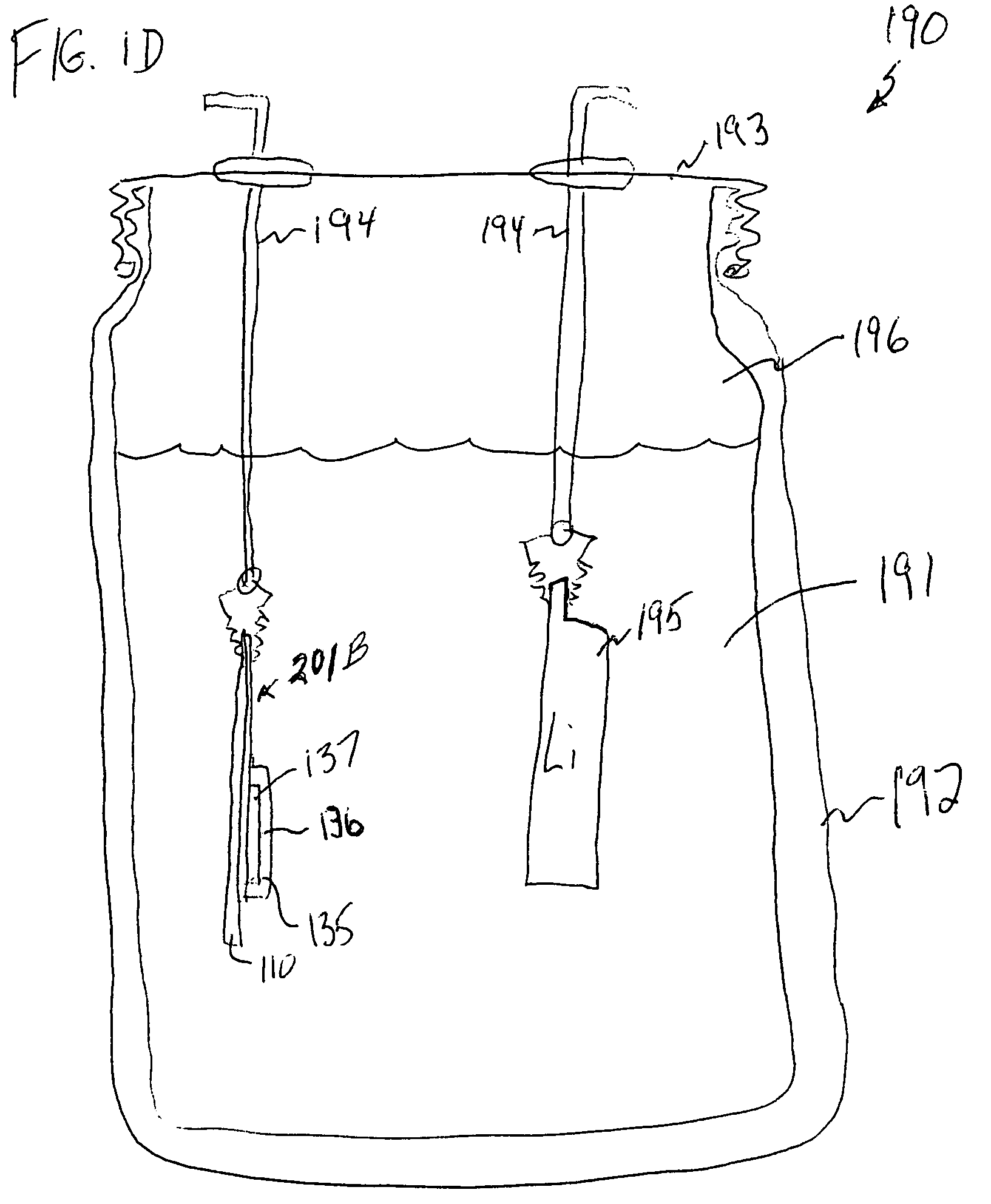

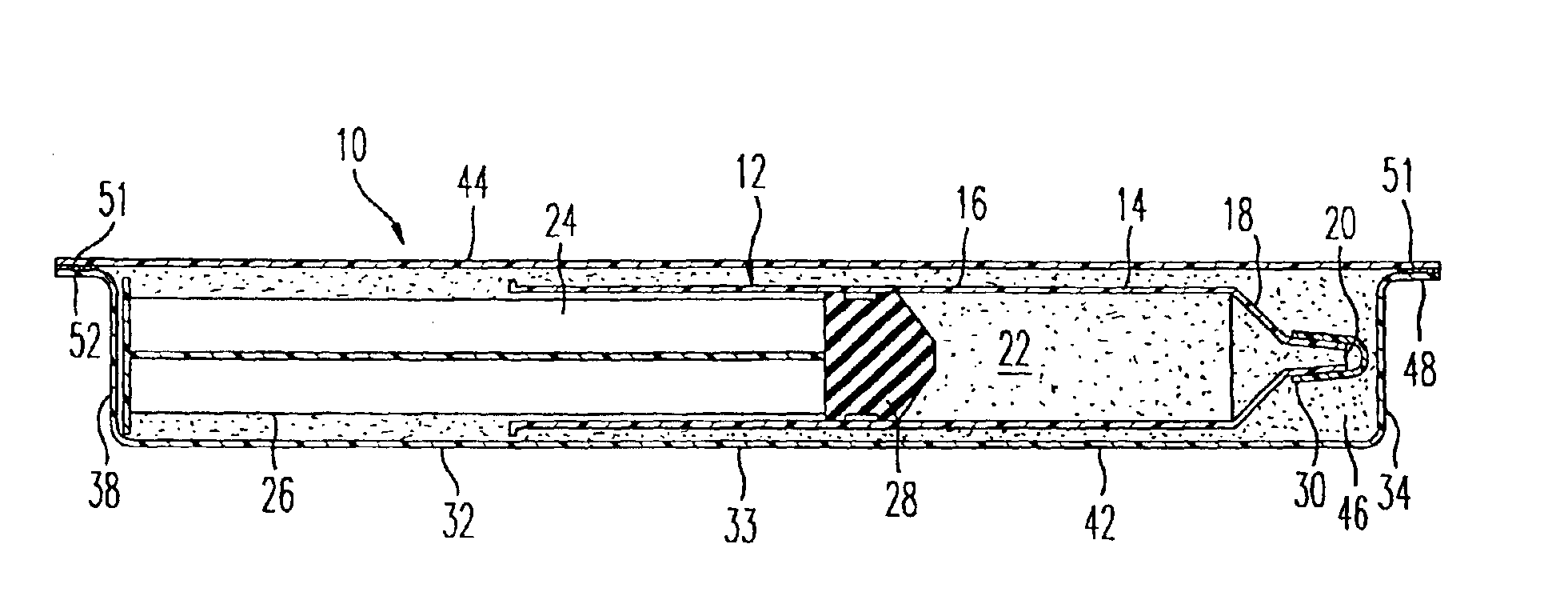

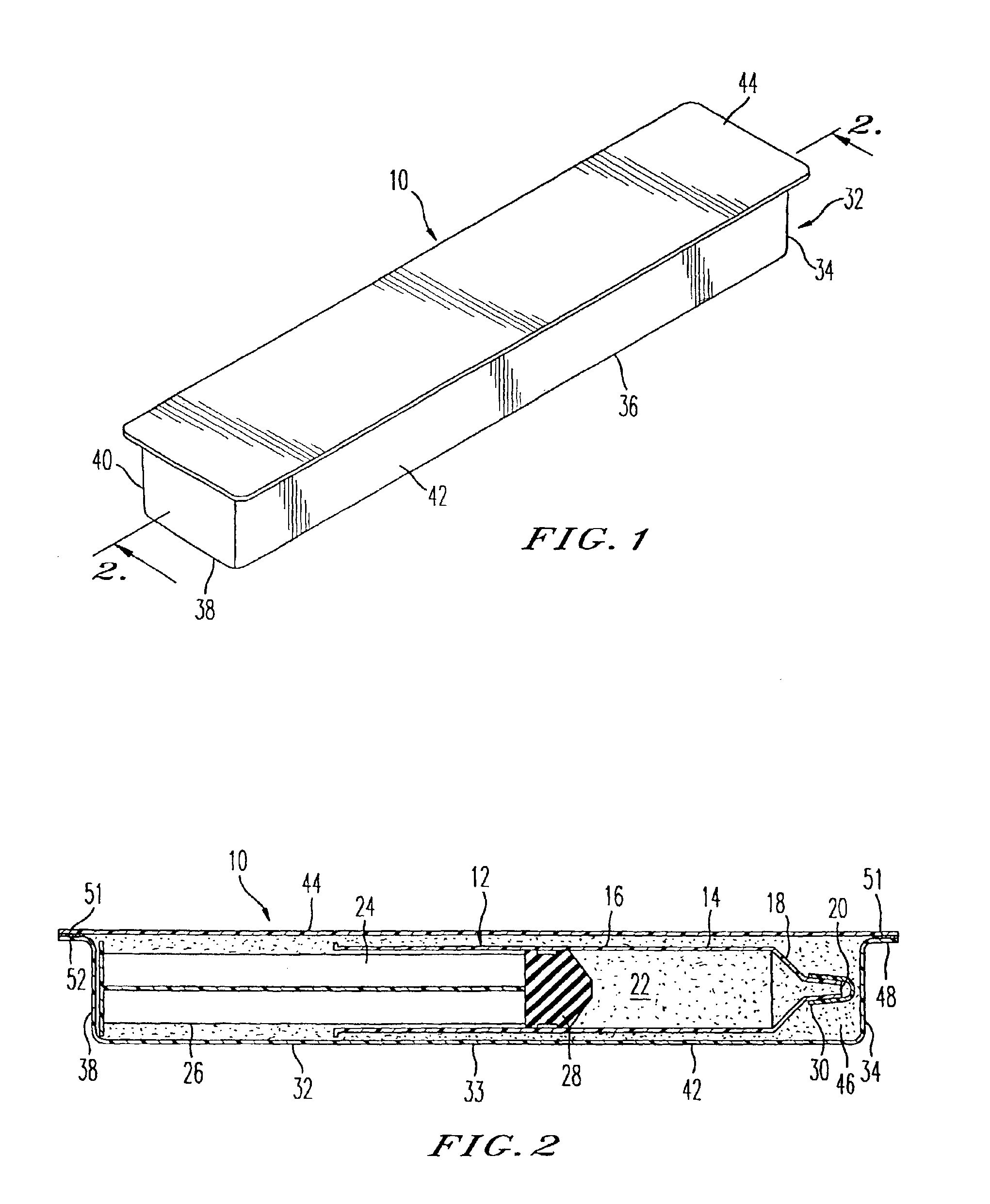

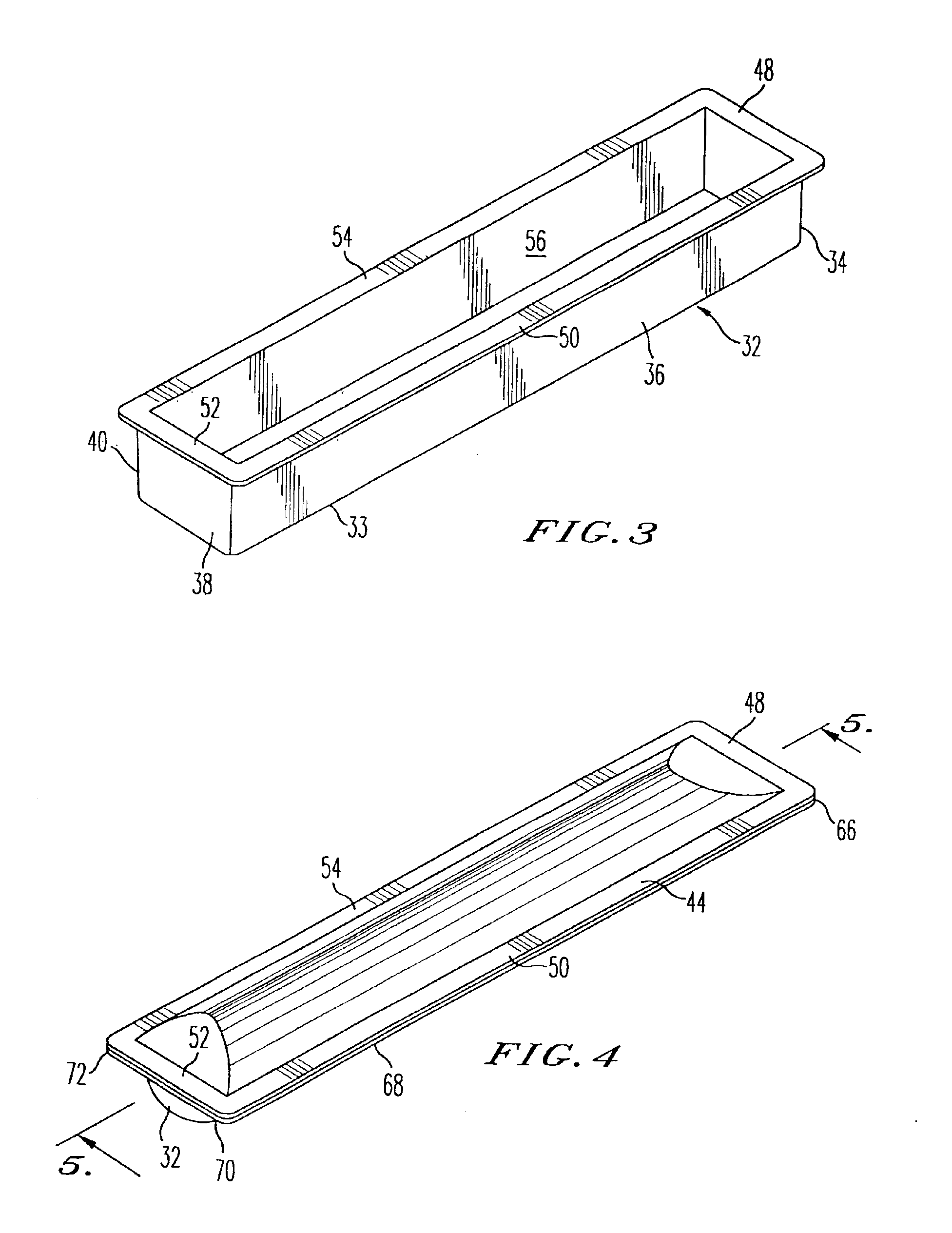

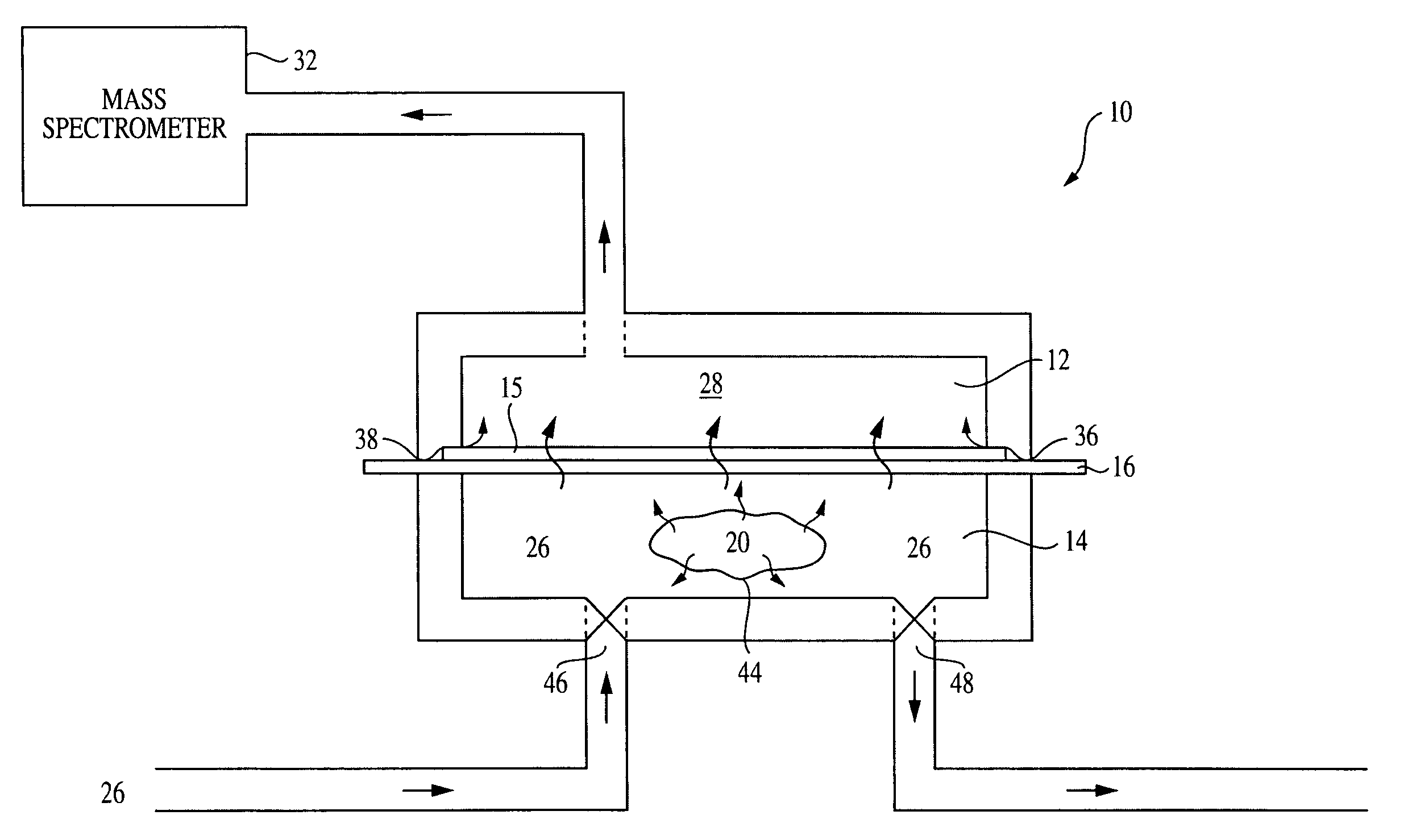

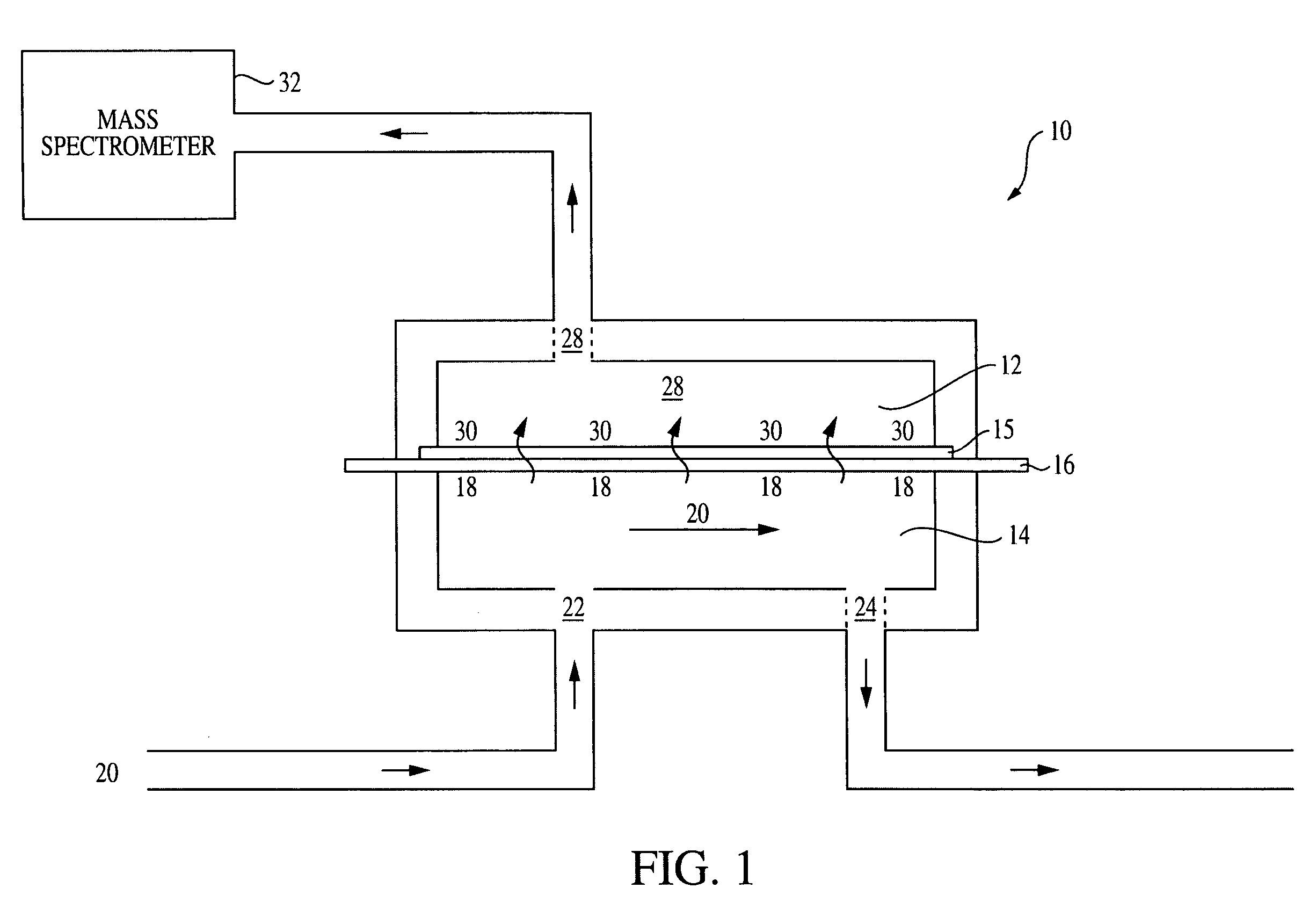

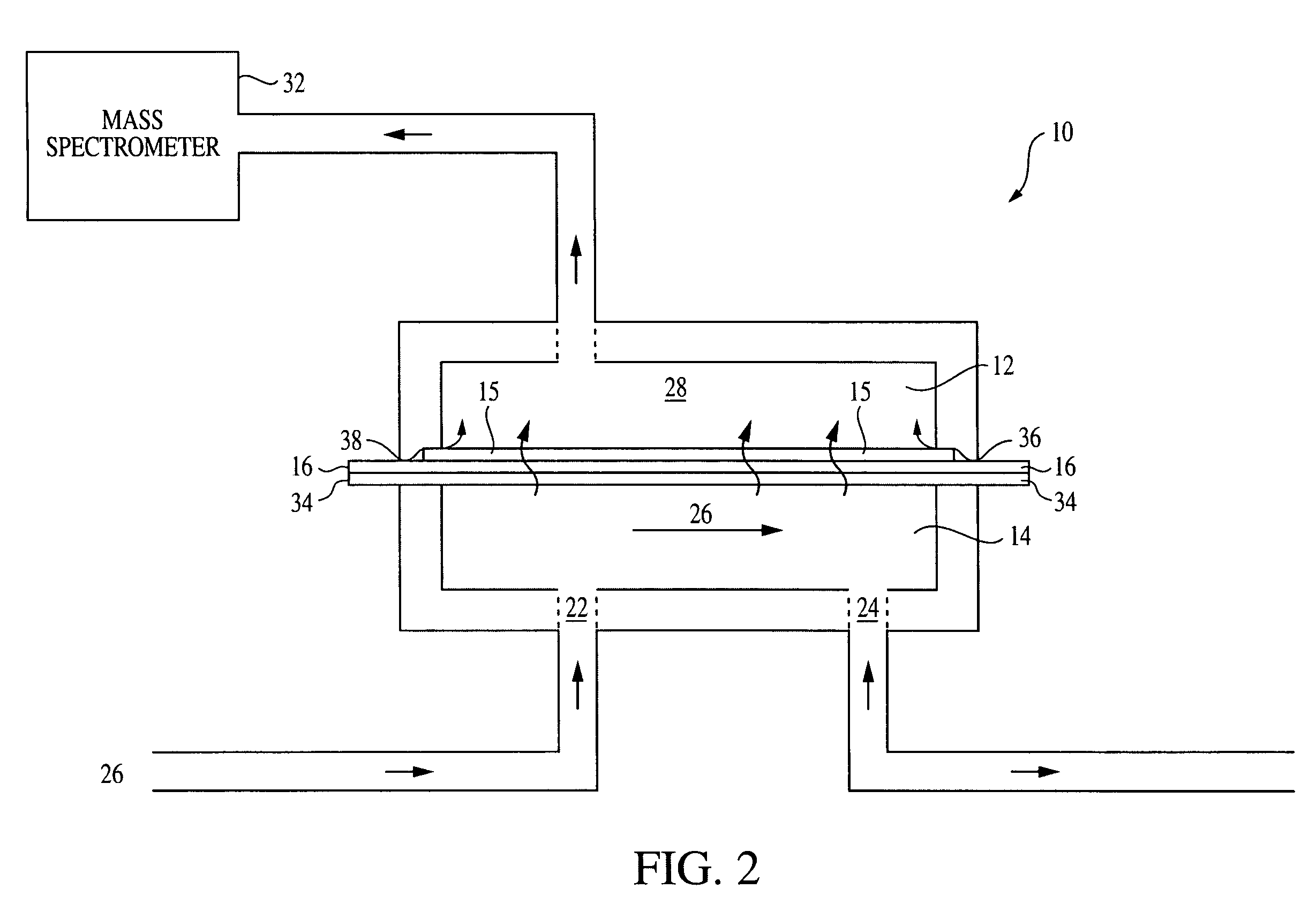

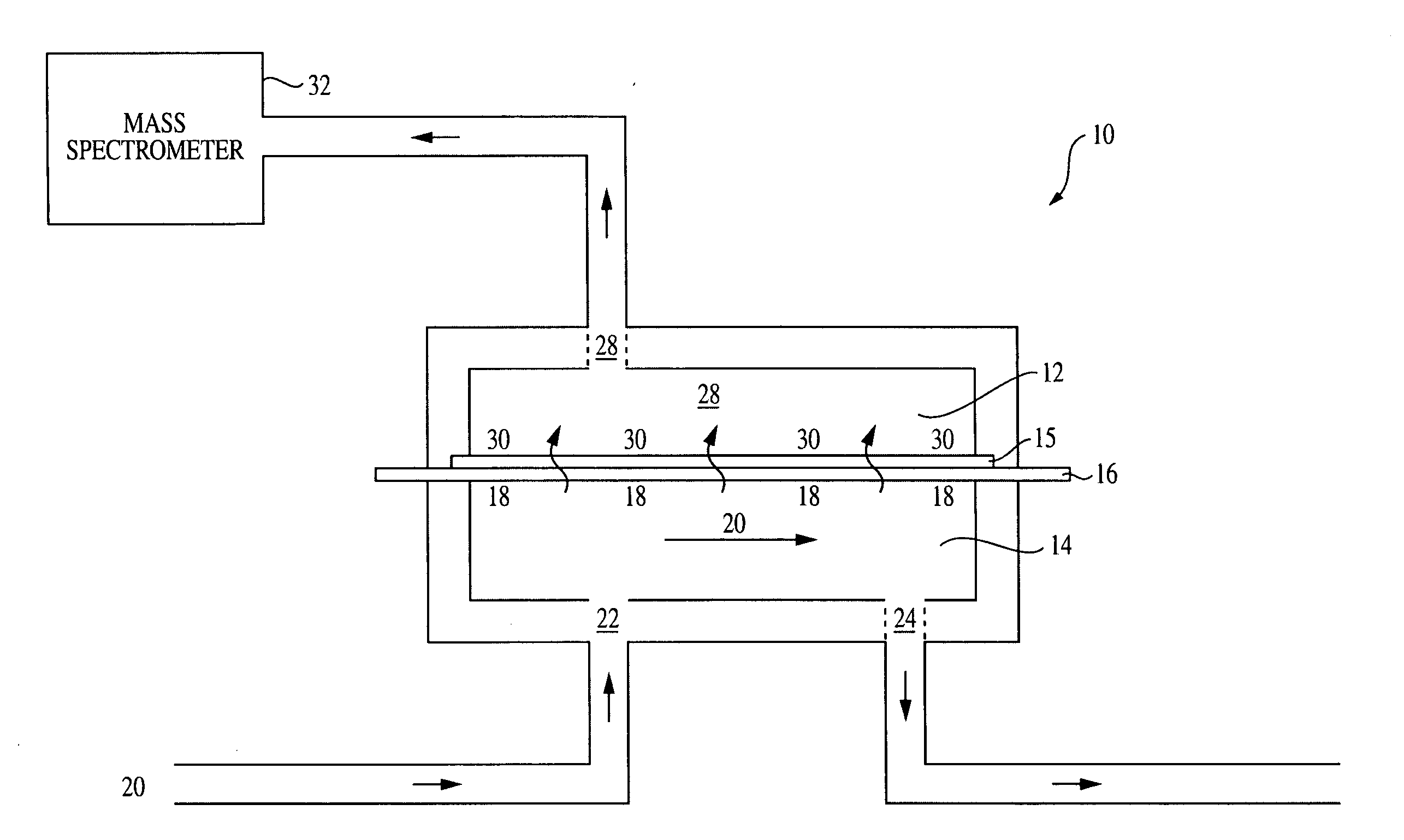

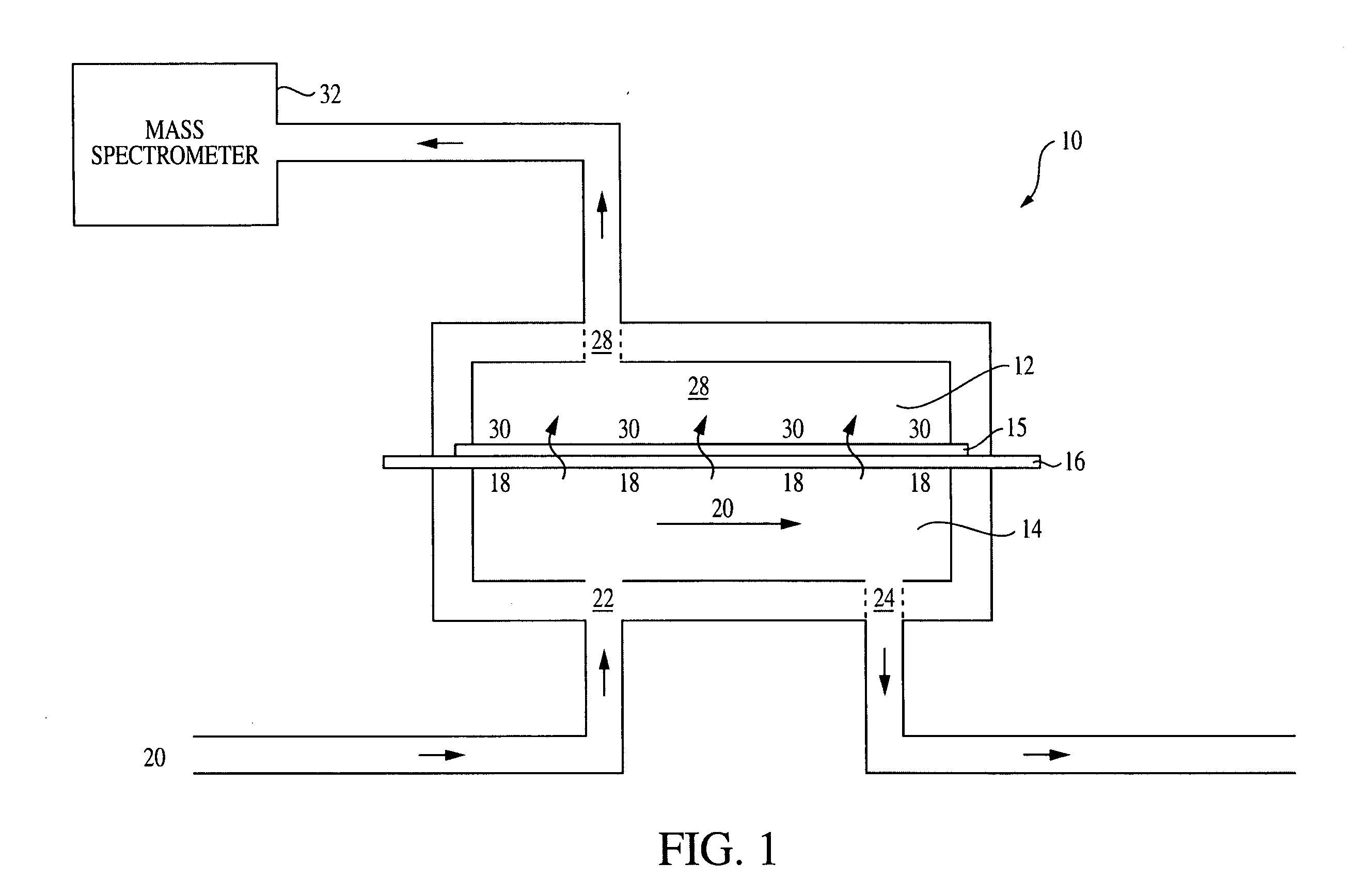

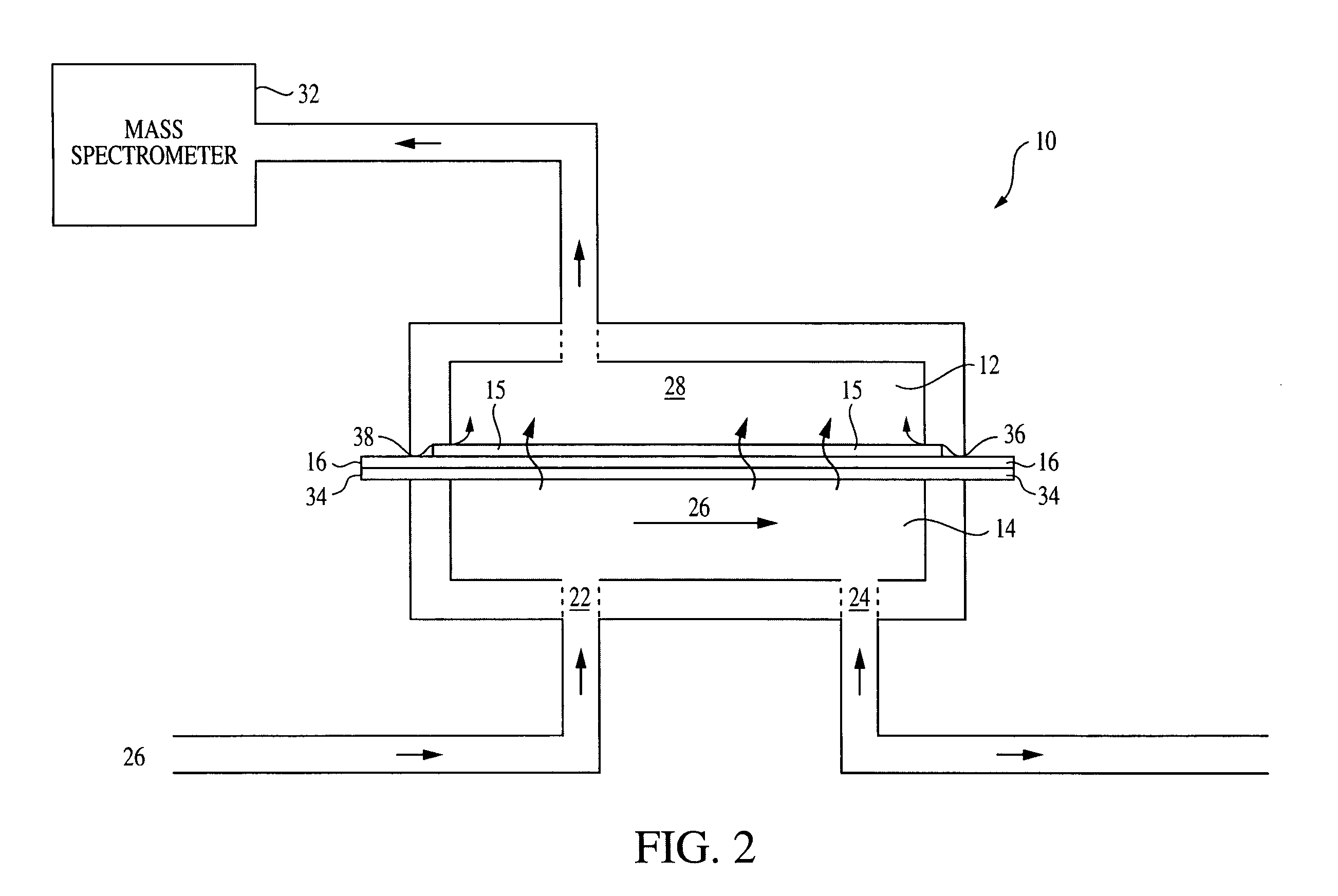

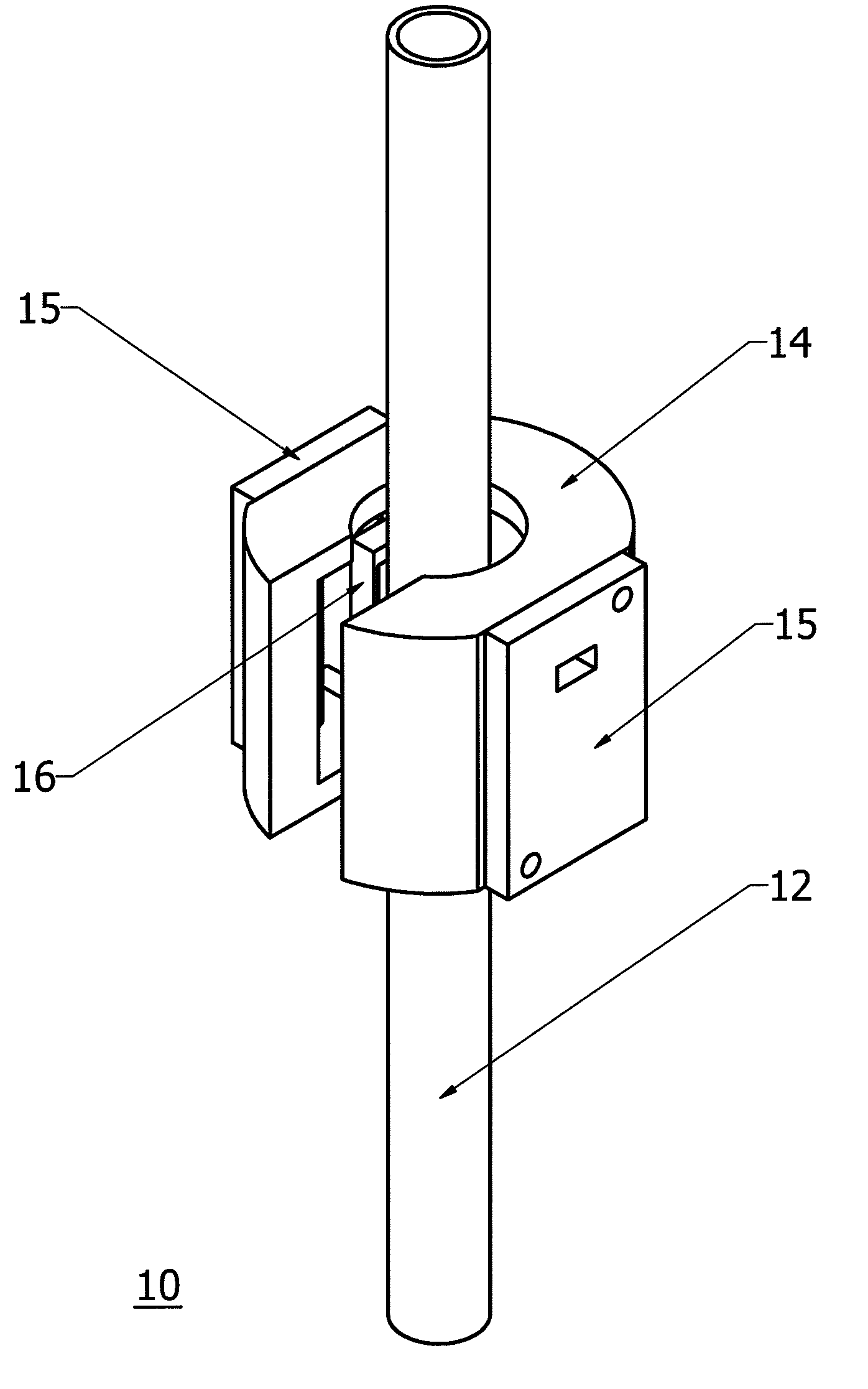

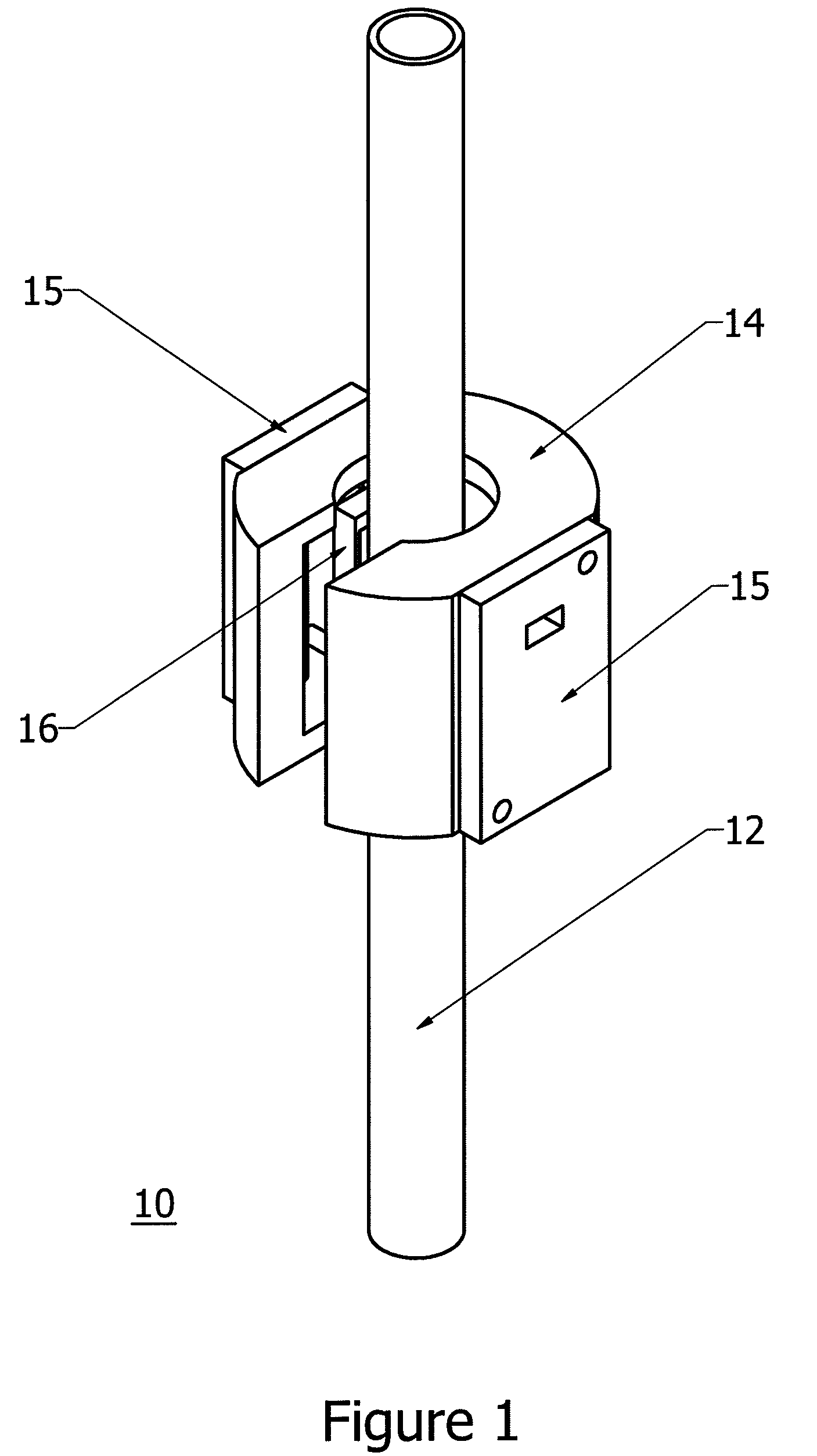

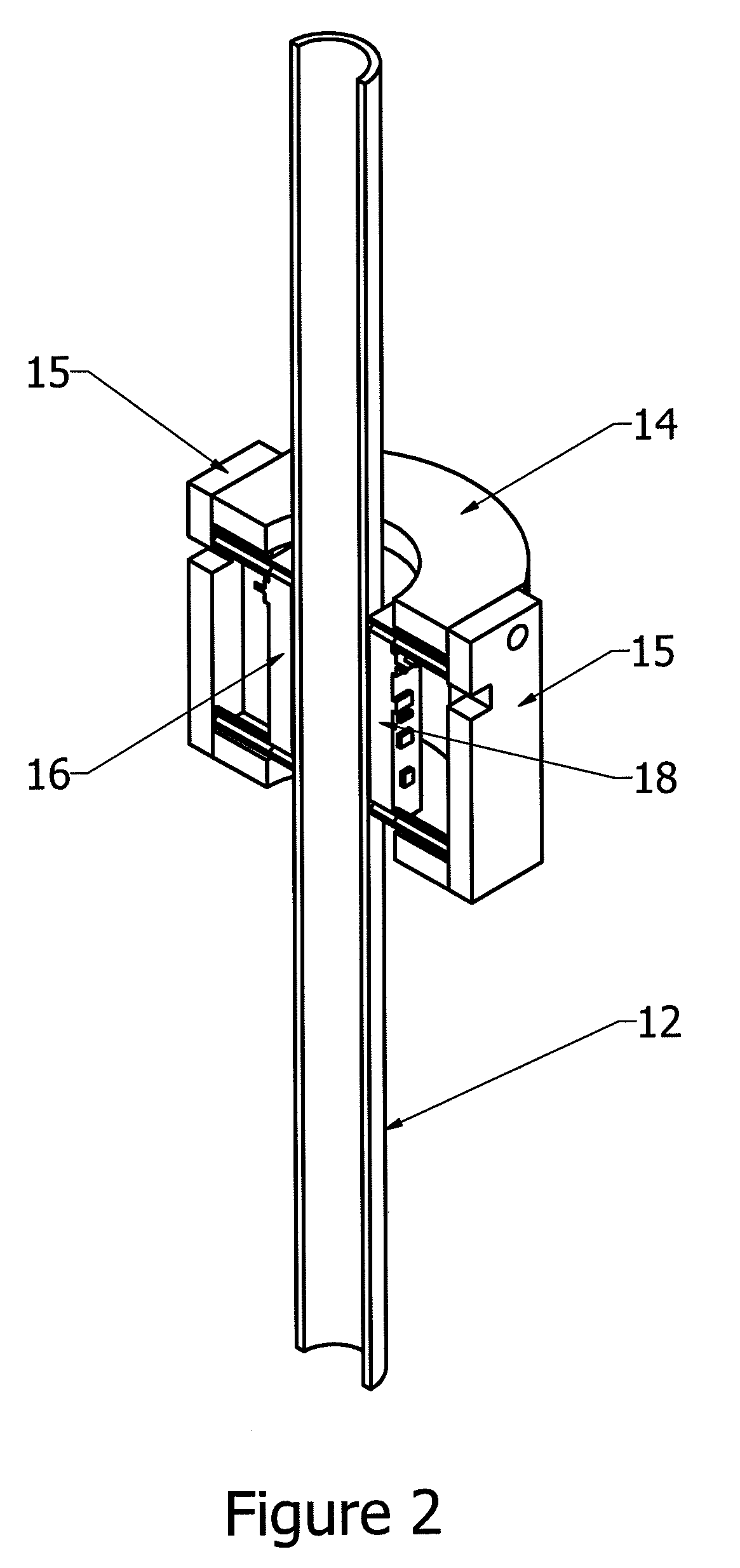

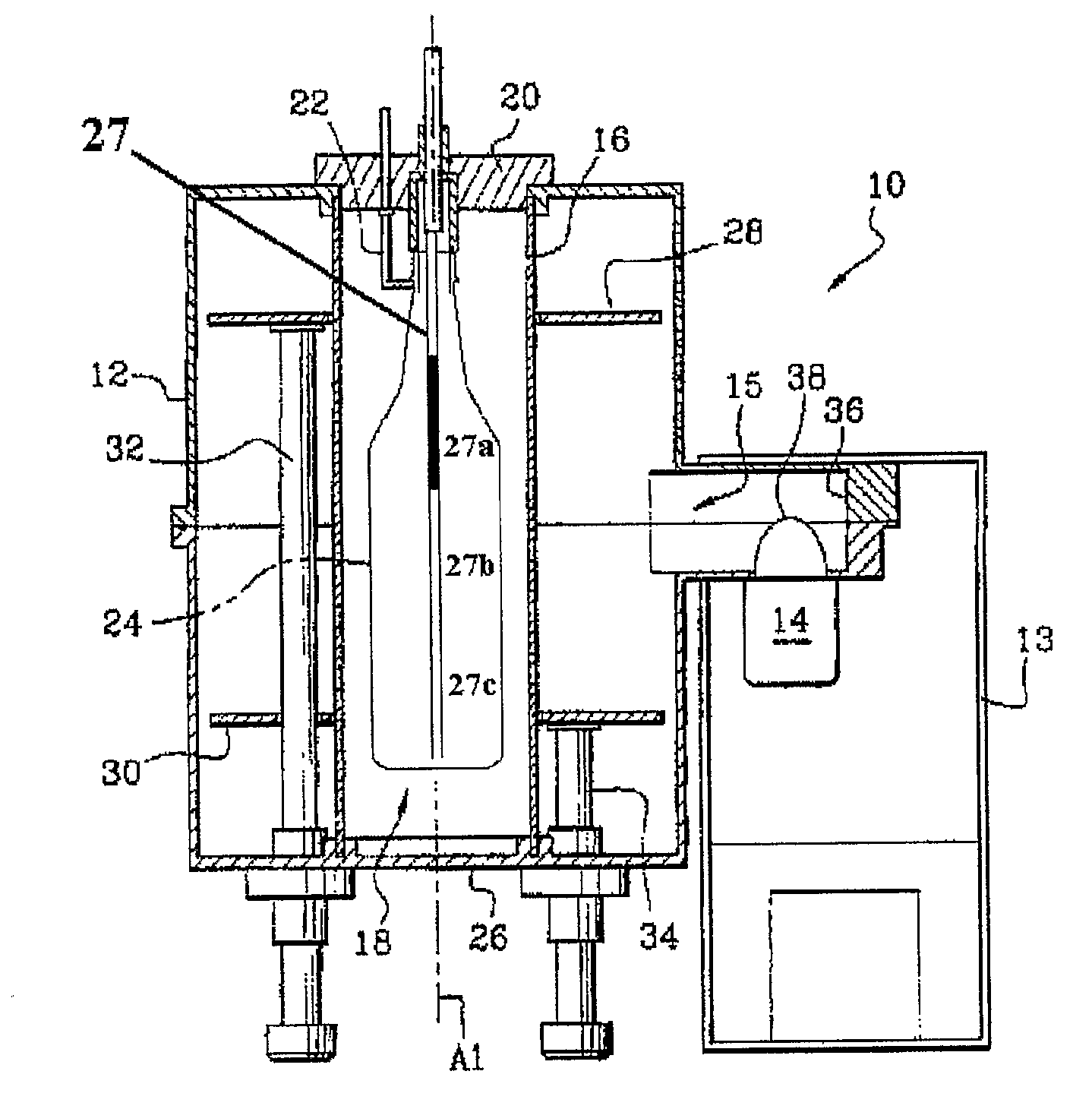

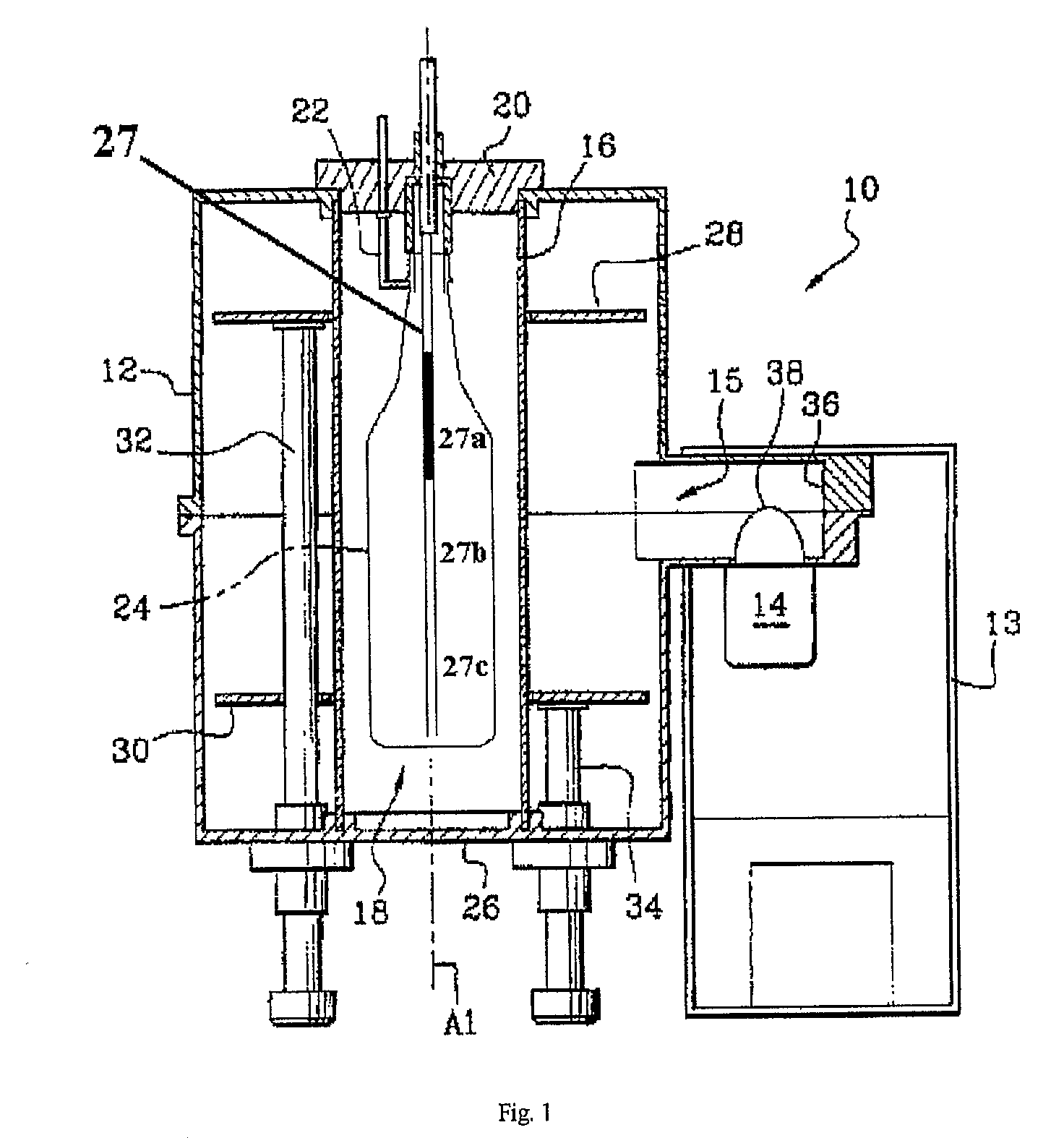

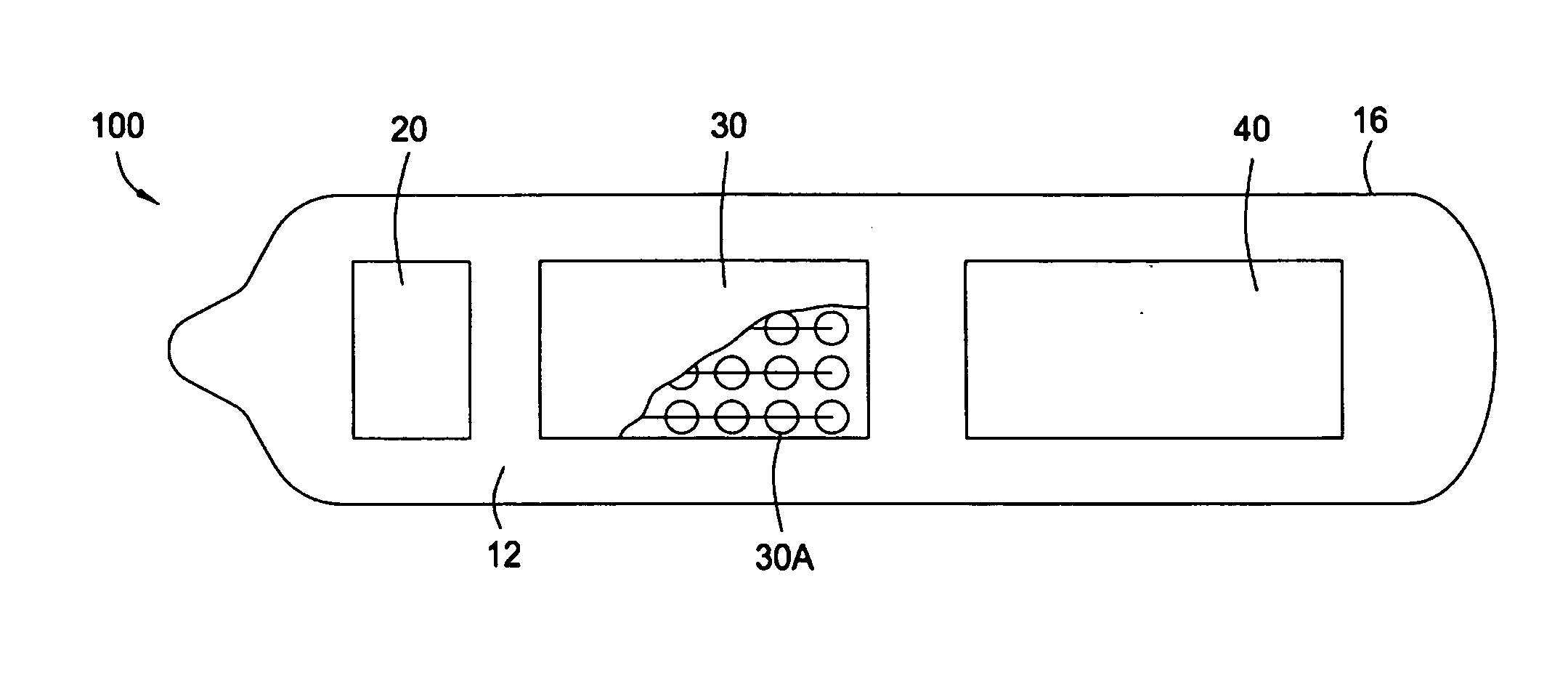

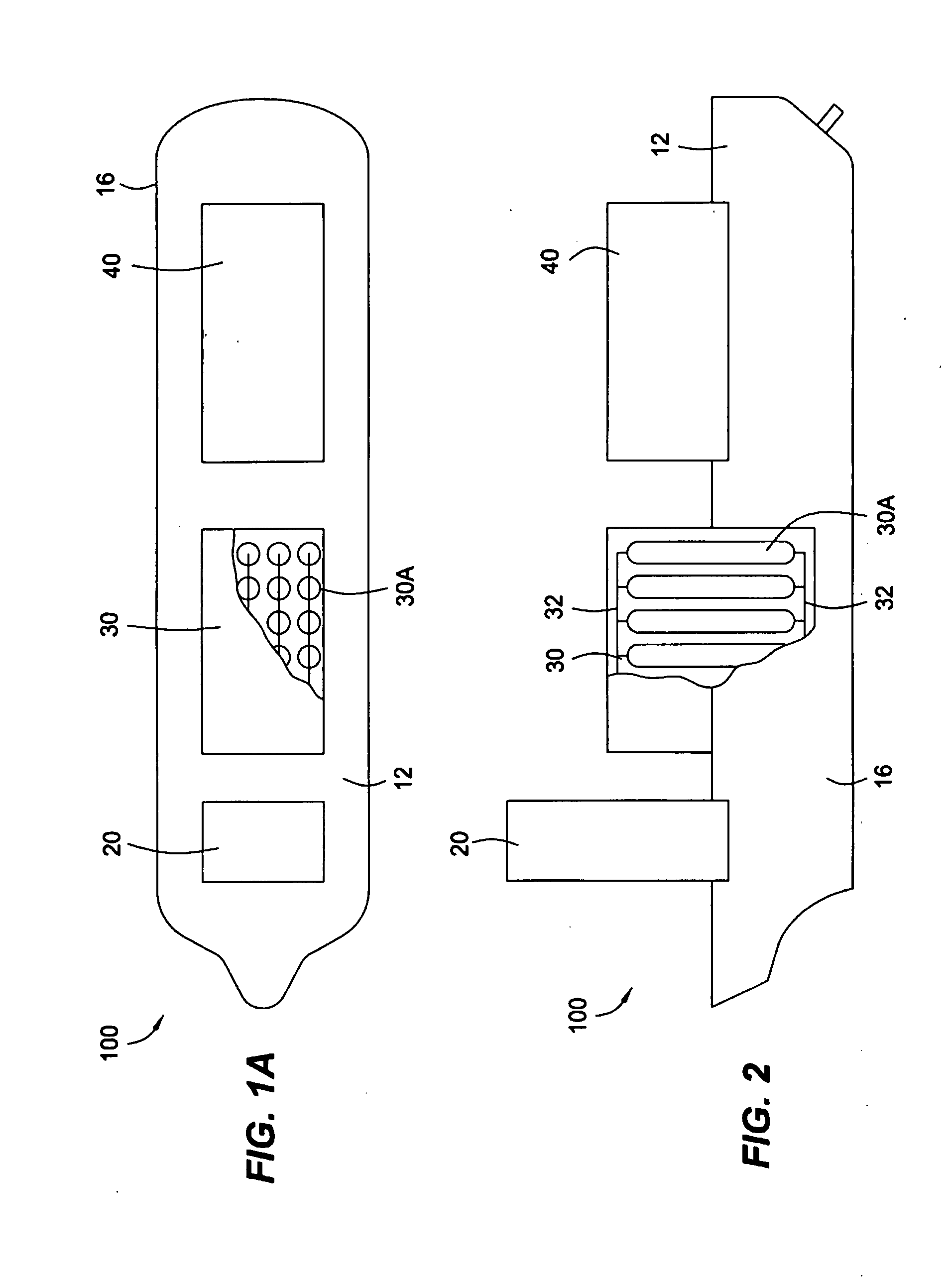

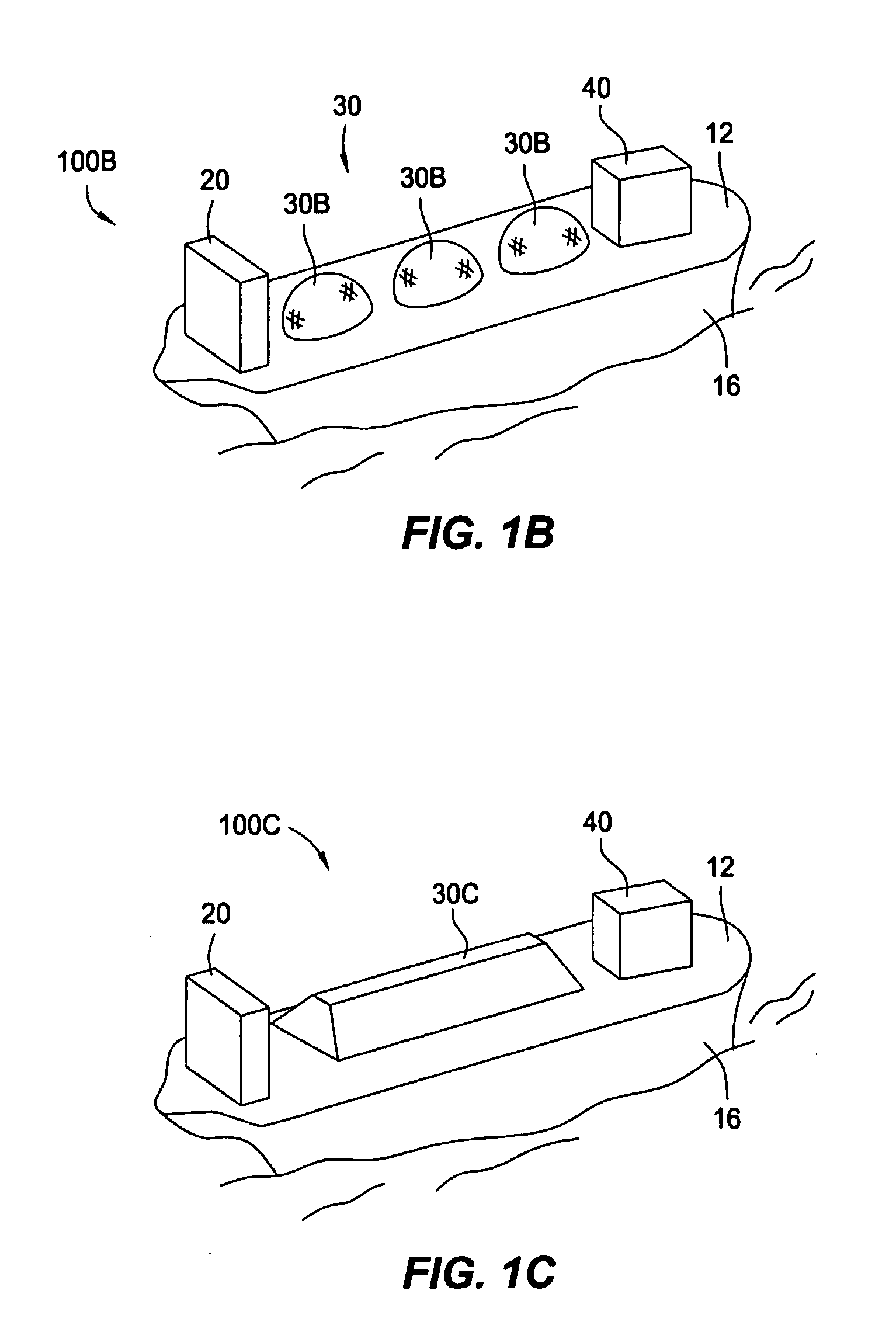

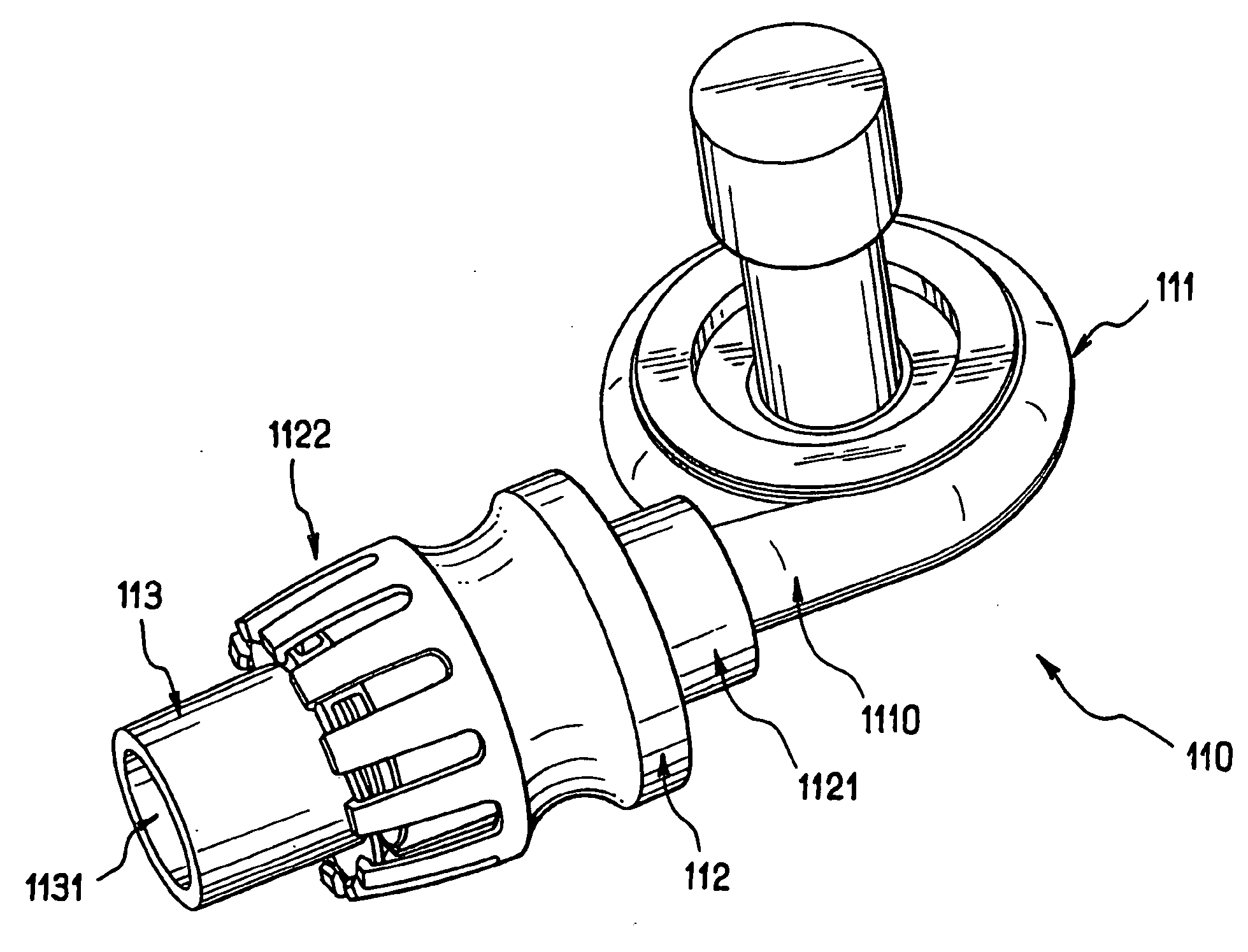

Method and apparatus for measuring gas transmission rates of deformable or brittle materials

ActiveUS6981403B2High precisionParticle spectrometer methodsPermeability/surface area analysisDiffusionProduct gas

Provided are an apparatus and a method for measuring gas transmission rates and nanoleaks of deformable and brittle materials. The apparatus includes a test chamber having an upper and lower diffusion cells that when closed form a chamber wall seal, a gas inlet and a gas outlet in fluid communication with the lower diffusion cell, the upper diffusion cell being fluidly connected to a high-vacuum mass spectrometer. The method of measuring gas transmission rates and nanoleaks includes placing a sealed package containing the test gas in the lower diffusion cell, closing the upper and lower diffusion cells, flushing the lower diffusion cell with a source of a second gas other than the test gas, closing off the source of the second gas; and measuring the leak rate of the sealed package.

Owner:MODERN CONTROLS

Method and apparatus for measuring gas transmission rates of deformable or brittle materials

ActiveUS20050092068A1Apparent advantageHigh precisionParticle spectrometer methodsPermeability/surface area analysisTest roomEngineering

Provided are an apparatus and a method for measuring gas transmission rates and nanoleaks of deformable and brittle materials. The apparatus includes a test chamber having an upper and lower diffusion cells that when closed form a chamber wall seal, a gas inlet and a gas outlet in fluid communication with the lower diffusion cell, the upper diffusion cell being fluidly connected to a high-vacuum mass spectrometer. The method of measuring gas transmission rates and nanoleaks includes placing a sealed package containing the test gas in the lower diffusion cell, closing the upper and lower diffusion cells, flushing the lower diffusion cell with a source of a second gas other than the test gas, closing off the source of the second gas; and measuring the leak rate of the sealed package.

Owner:MODERN CONTROLS

Systems and methods for detecting the presence and/or absence of a solid liquid or gas

InactiveUS7482818B2Limiting spurious emissionImprove abilitiesResistance/reactance/impedenceMaterial analysis by electric/magnetic meansEnergy transferPhysical space

Systems and methods are described for detecting the presence and / or absence of a solid, liquid or gas which utilize an RF energy emitter and RF energy detector for determining whether a solid, liquid or gas is present within a defined physical space. More specifically, an RF energy emitter is provided at a first side of a solid, liquid or gas transmission channel and an RF energy receiver / detector is provided at an opposite side of the solid liquid or gas fluid channel. The RF energy emitter either continuously or periodically emits RF energy which in the preferred exemplary embodiment is in the high-frequency or more preferably ultrahigh frequency signal range. The amount of detected RF energy transferred across the channel is used in determining the presence and / or absence of a solid, liquid or gas.

Owner:GREENWALD TECH

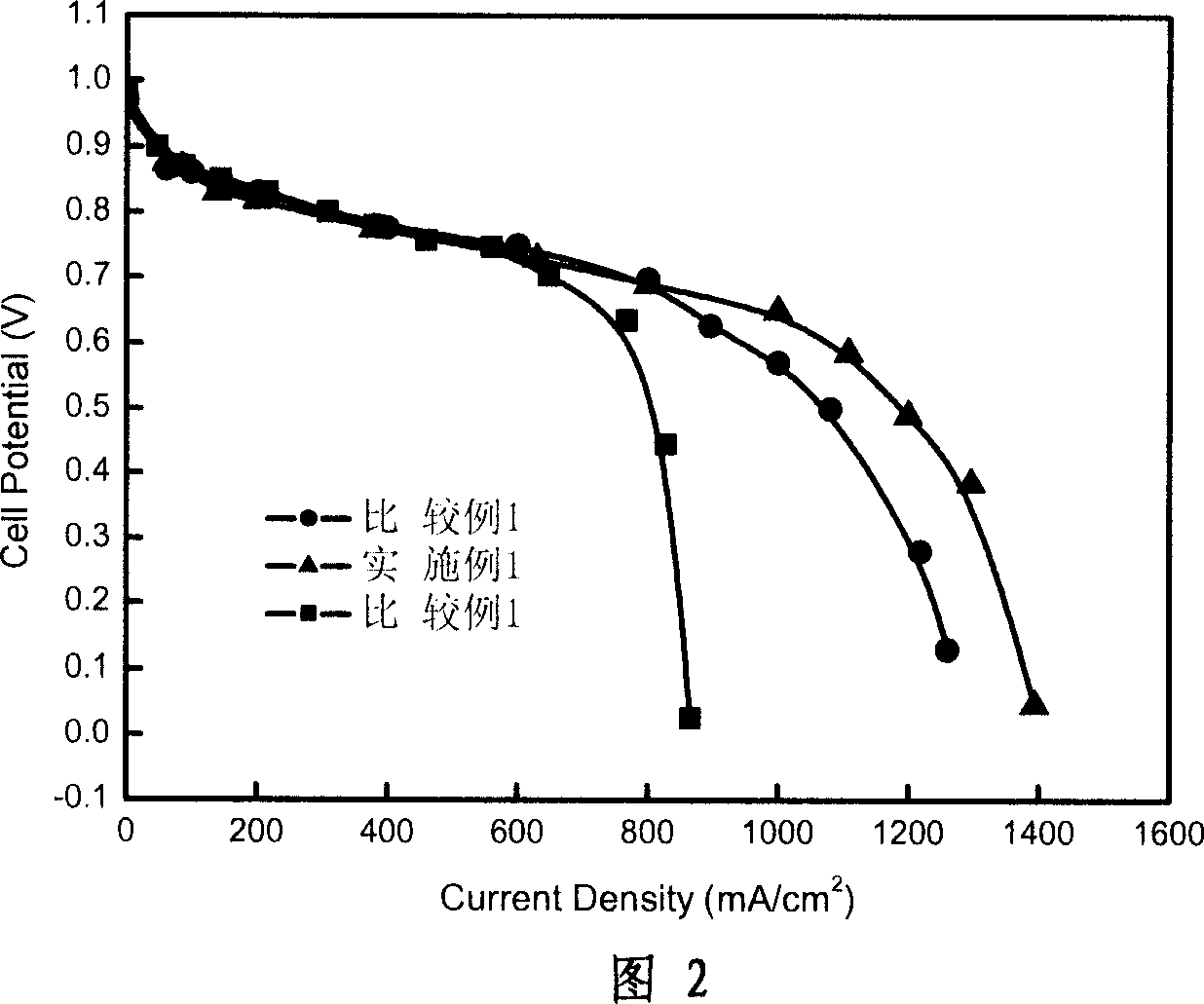

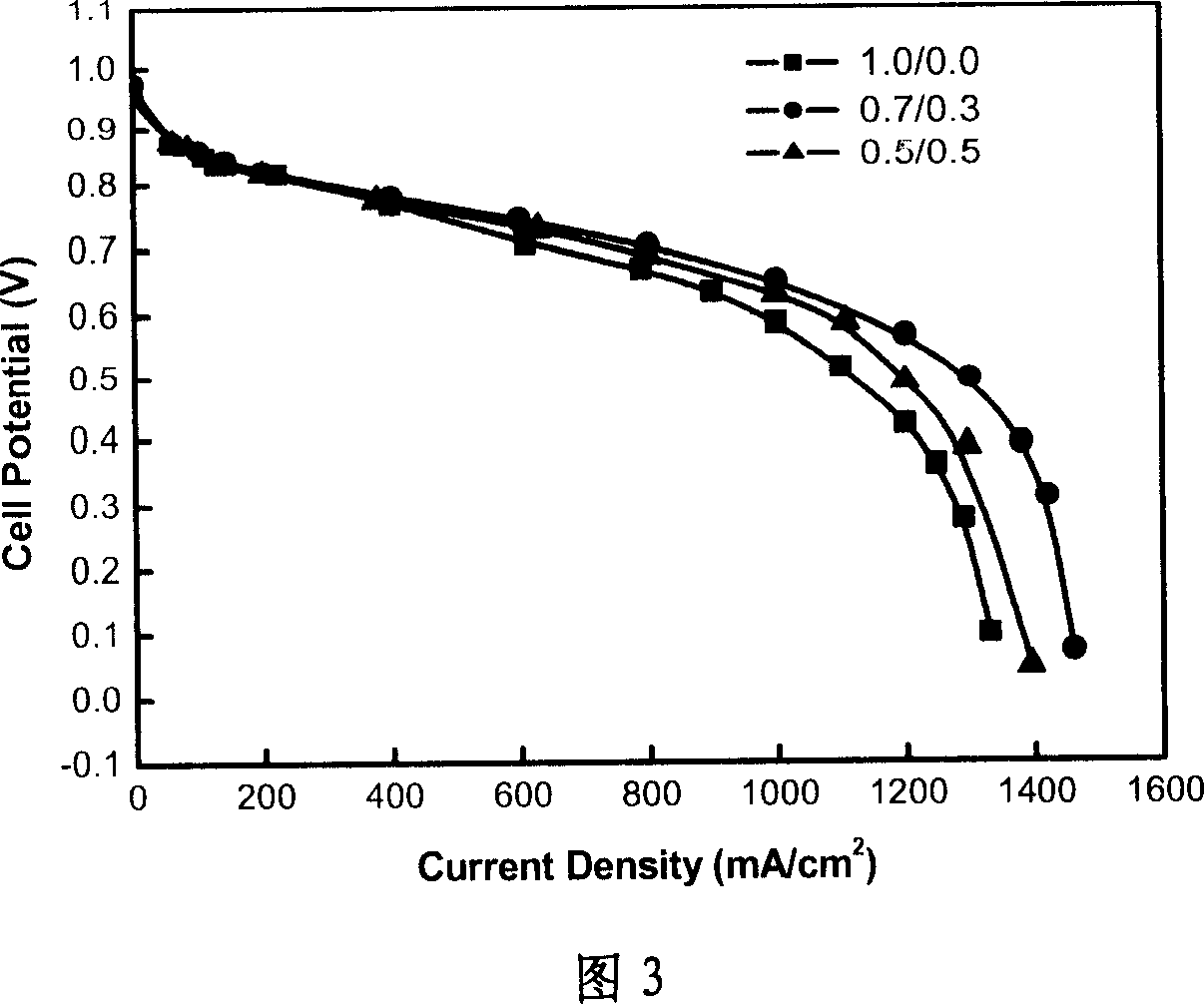

Gas diffusion layer for low temp fuel cell and preparing process thereof

ActiveCN1949570AImprove mass transfer effectNot easy to coagulateCell electrodesFuel cell detailsFuel cellsLiquid water

The invention relates to a low-temperature fuel cell, concretely a gas diffusion layer for low-temperature fuel cell and the preparing method thereof, where the gas diffusion layer is composed of substrate layer and microporous laye, and the microporous layer is mixed of two or more conductive carbon materials. And the preparing method: taking and mixing two or more conductive carbon materials in proportion into composite conductive material, uniformly diffusing the composite condutive material and hydrophobic agent in solvent to form plup; uniformly arranging the pulp on one or two sides of a hydrophobic processed porous conductive substrate; finally forming the gas diffusion layer by thermal treatment. Because of preparing microporous layer by compositive conductive material, it forms a double-function hole structure beneficial to reacting gas transmission and liquid water transmission, improving battery performances.

Owner:SUNRISE POWER CO LTD

Electric welding rod for hand welding X80 grade steel oil, gas transmission pipe

ActiveCN101362257AHas tensile strengthHas a shock valueWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to an electric welding rod used for manual welding. The electric welding rod comprises core welding-wires containing the following chemical compositions (wt%): 0.020-0.100 of C, 0.350-0.550 of Mn, 0.015-0.030 of Si, 0.005-0.015 of P, 0.002-0.005 of S, 0.01-0.20 of Cr, 0.01-0.30 of Ni, 0.01-0.20 of Cu, 98.675-99.47 of Fe, and the residue of impurity; the electrode coating comprises the following compositions: 28-38 of marble powder, 16-28 of fluorite powder, 2-8 of feldspar powder, 2-7 of white titanium pigment, 4-8 of electrolytic manganese, 3-7 of ferrosilicon powder, 6-9 of ferrotitanium powder, 0.5-2 of ferromolybdenum powder, 3-8 of nickel powder, 10-25 of iron power and 5-8 of other elements. The chemical compositions, the performance and the structure of the welding seam of a grade X80 steel pipe welded by using the electric welding rod are closer to the pipe body, and without heat treatment, the welding seam can meet the requirements on technical indicators such as high strength, high toughness, low hardness and the like of the grade X80 steel pipe used for oil and natural gas transferring; the electric welding rod overcomes the defaults in the prior art that the welding seam is required to be heat-treated after welding, the quality is poor, and engineering accidents are easy to happen when in use and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Process for Plasma Coating

InactiveUS20070281108A1Effective barrier against gas transmissionImprove barrier propertiesElectric discharge tubesChemical vapor deposition coatingPolyolefinPlasma coating

The present invention describes a method for plasma coating the inside surface of a polyolefin or a polylactic acid container to provide an effective barrier against gas transmission. The method provides a way to deposit rapidly and uniformly very thin, adherent and nearly defect-free layers of polyorganosiloxane and silicon oxide (or amorphous carbon) on the inner surface of the container to achieve more than an order of magnitude increase in barrier properties.

Owner:WEIKART CHRISTOPHERM +1

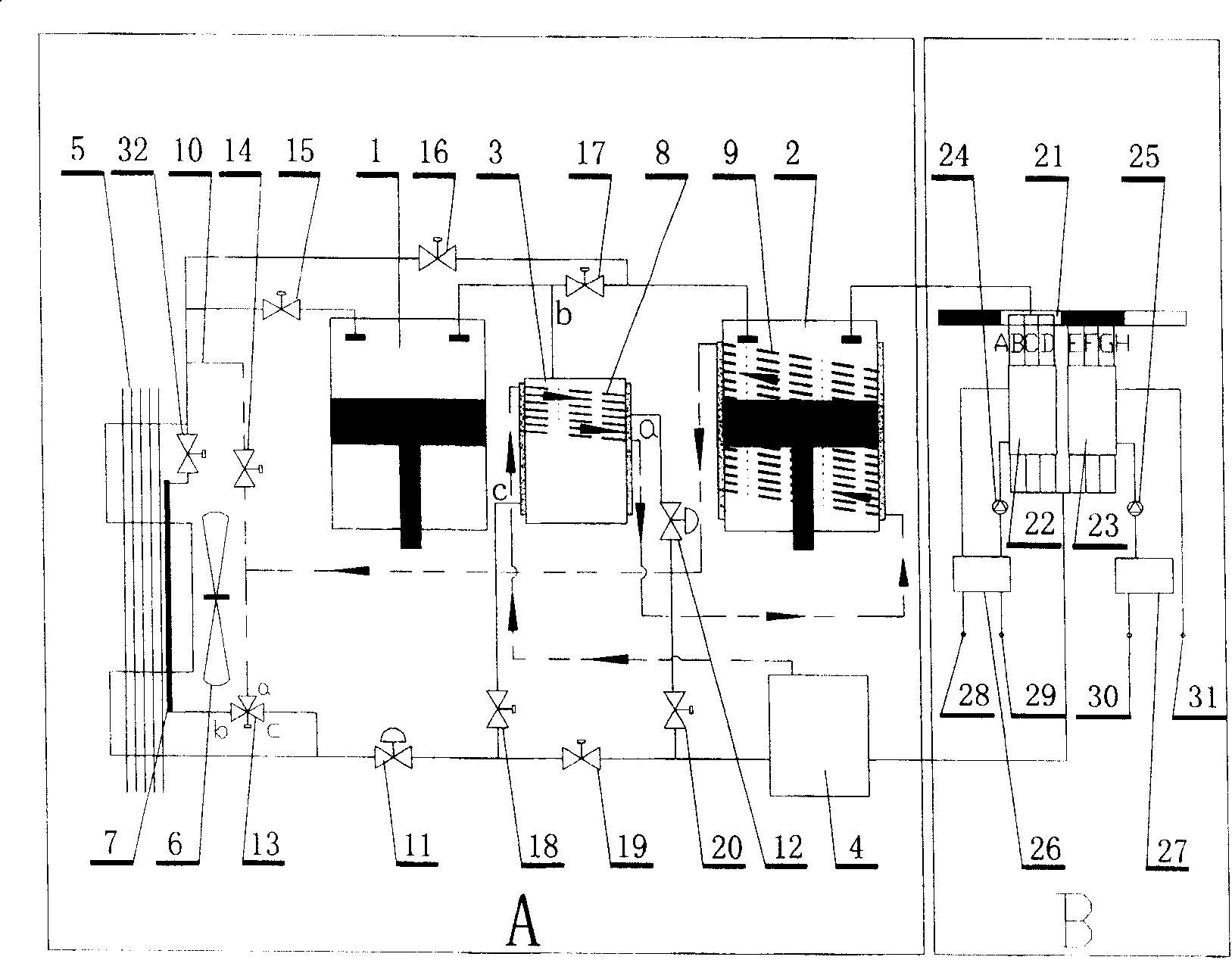

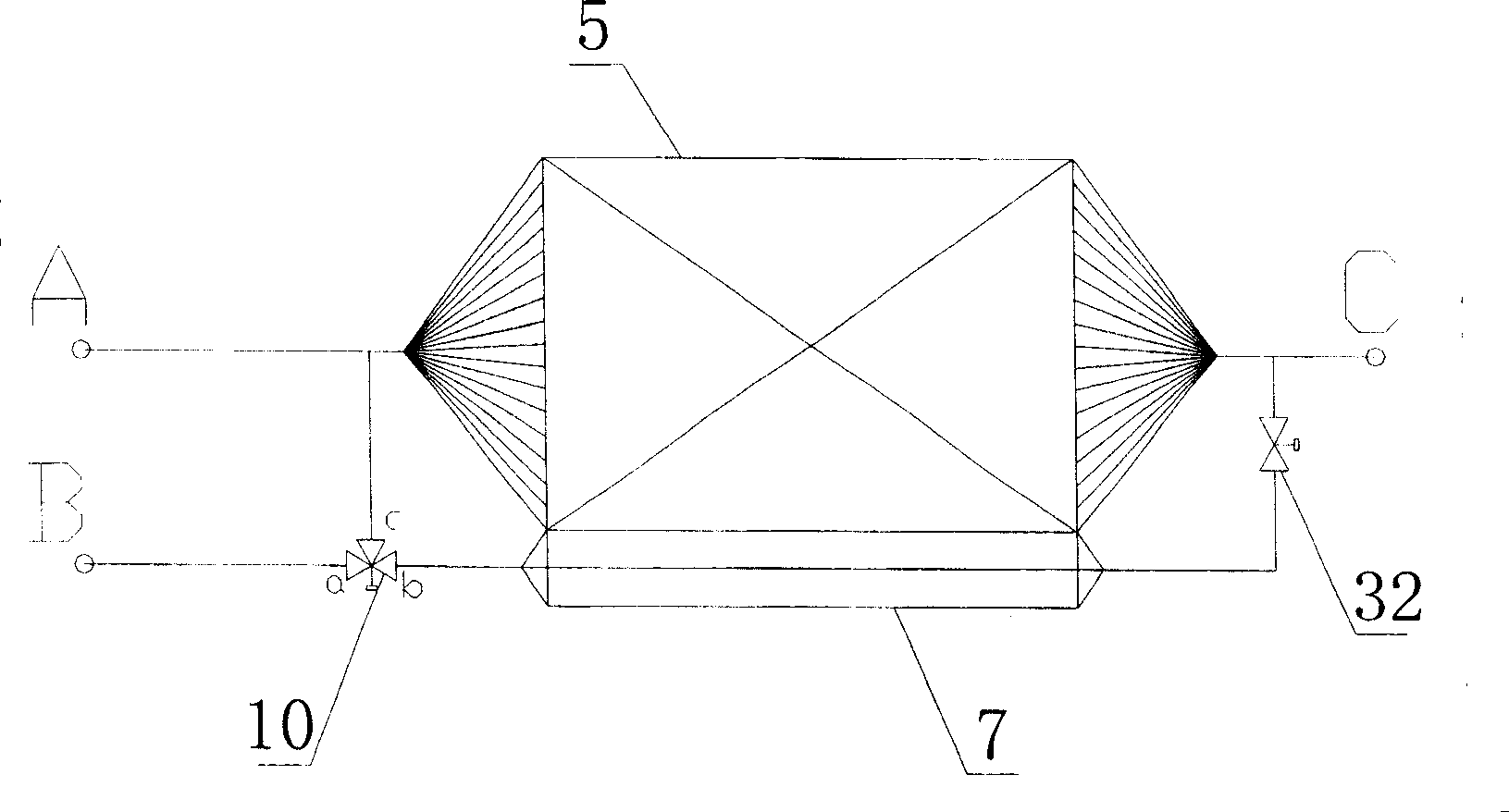

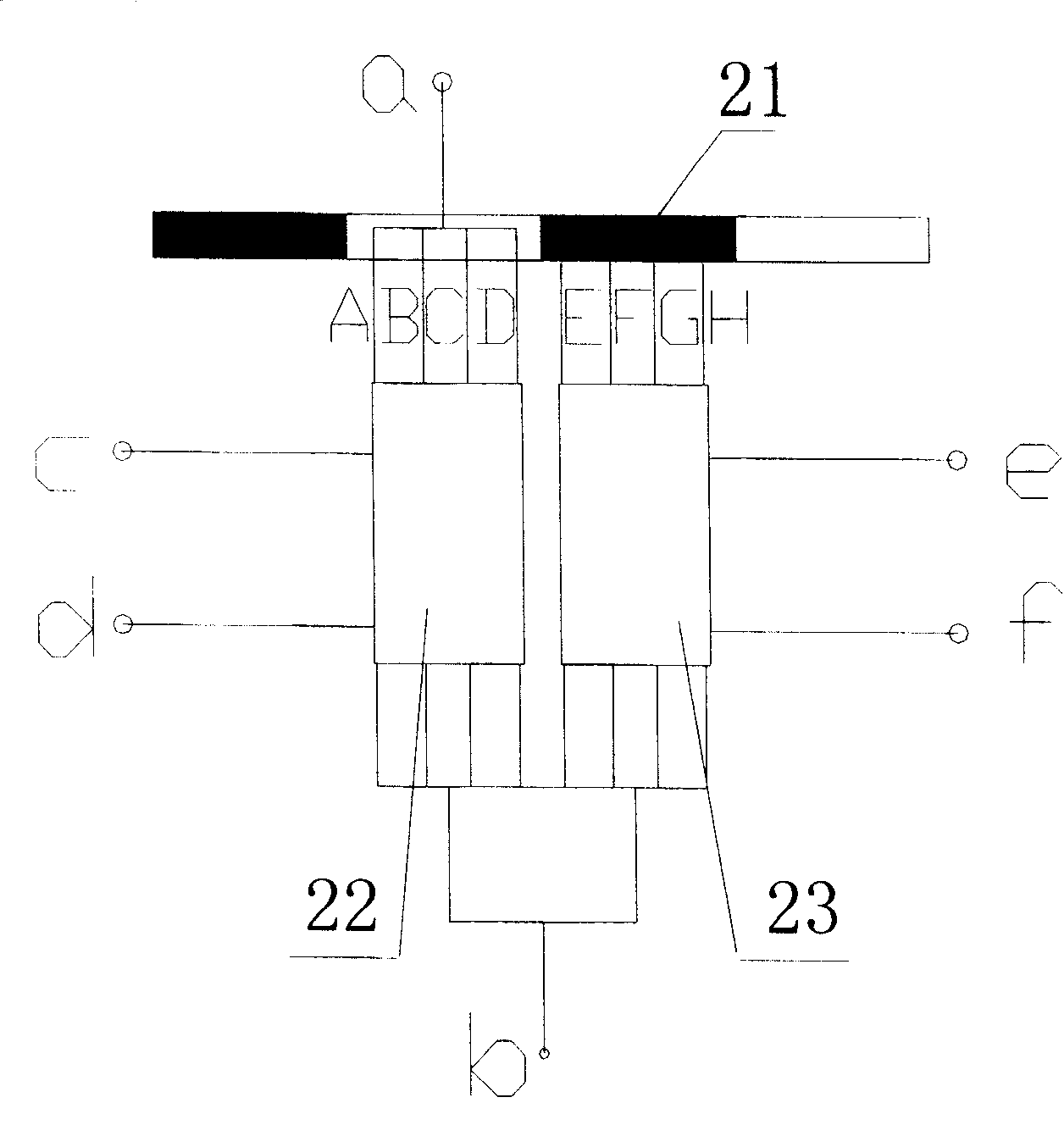

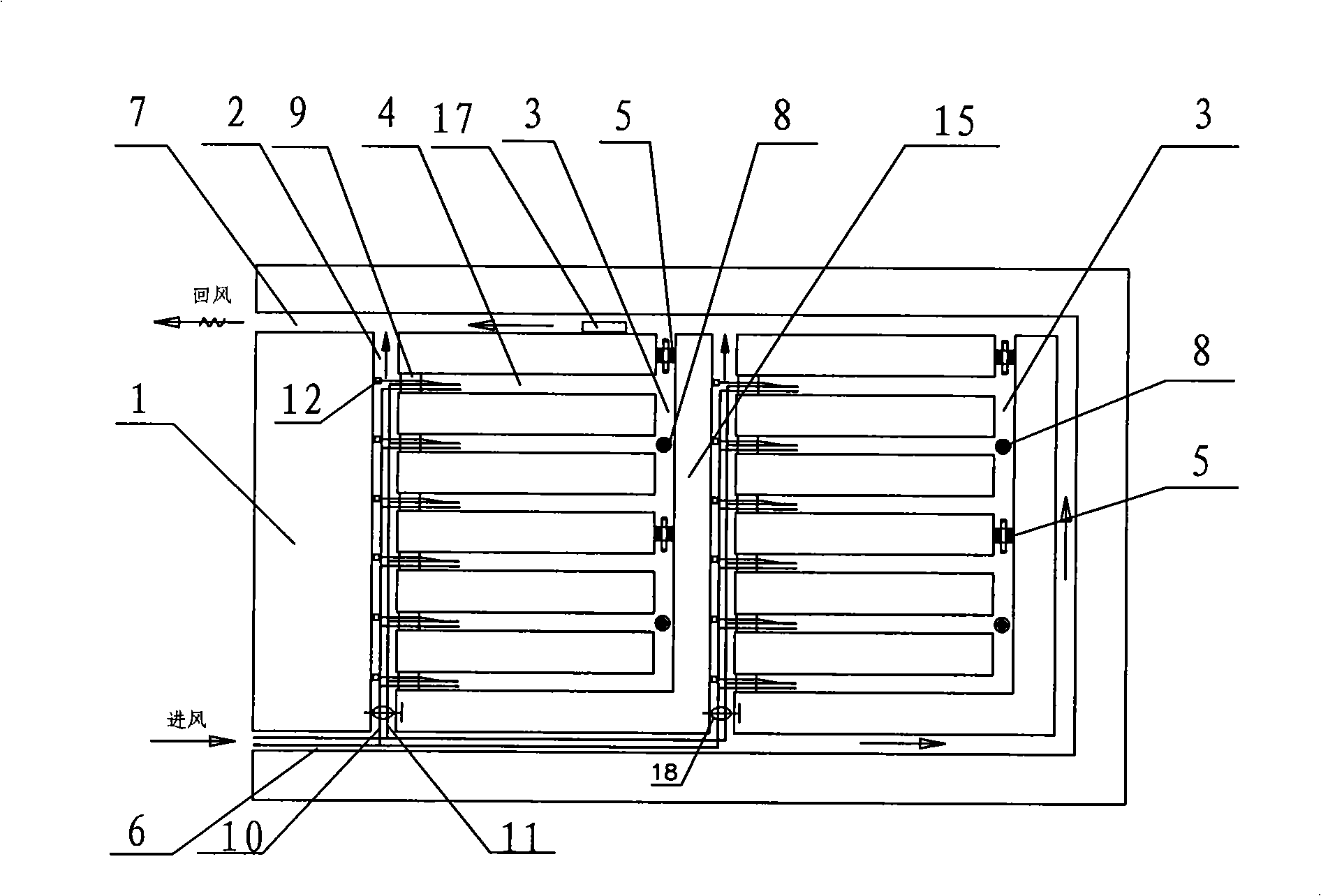

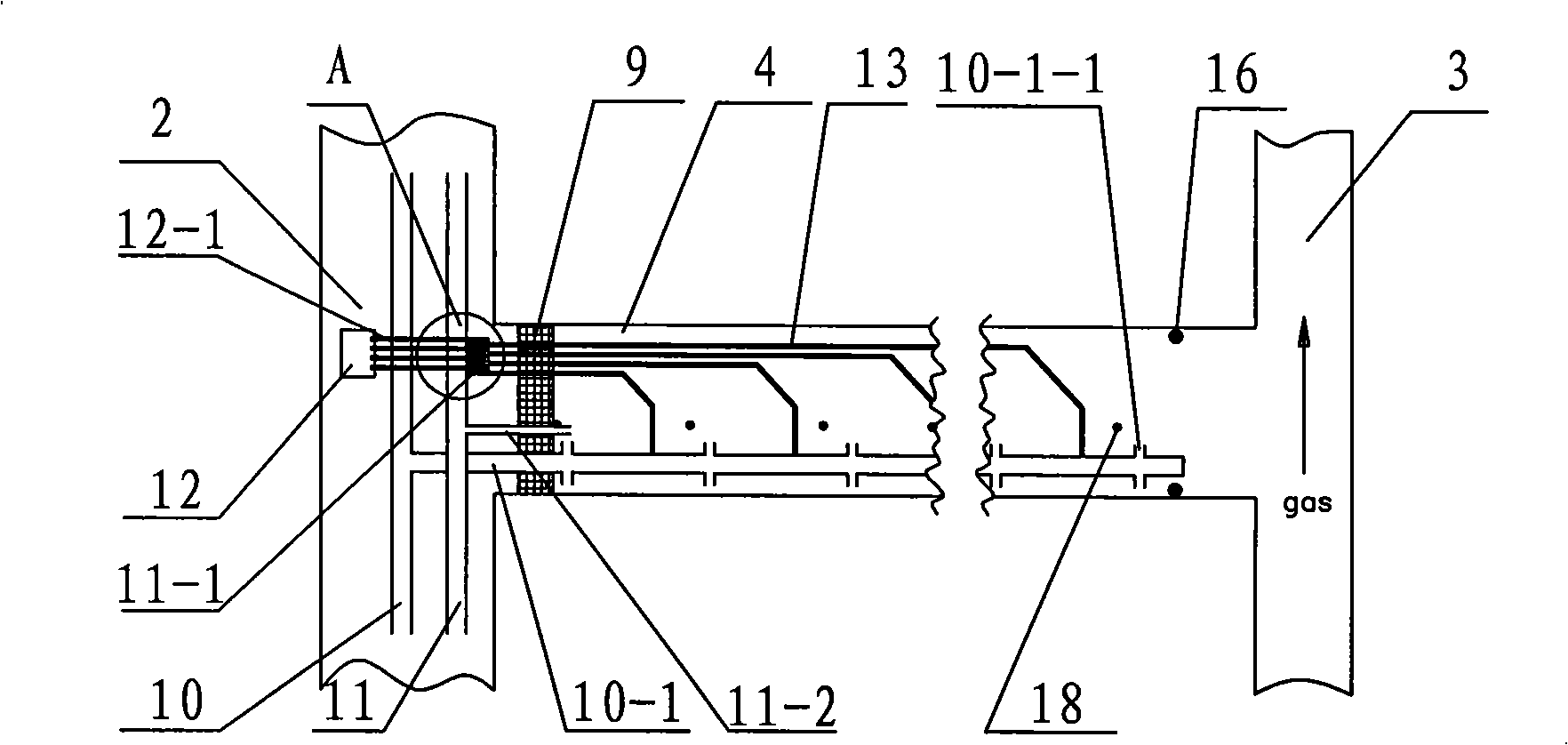

Domestic air source heat pump heating system and apparatus for coldness area

InactiveCN101457949ALower oil temperatureReduce exhaust temperatureHeat pumpsEnergy efficient heating/coolingBusiness efficiencyFlash-gas

The invention discloses a household air source heat pump heating system in cold area and a device thereof, and relates to a heat pump system which uses the air source for running steadily under the low-temperature environment and supplying the interior with the needed heat and healthy hot water and a device thereof. The device comprises parts such as a low pressure frequency compressor, a high pressure compressor, an outdoor heat exchanger, a flash evaporator, a reservoir, a defrosting coil, a flash gas overheating coil, a compressor heat radiating recovery coil, a low pressure air supply pressurization line, a sub-thermal converter, a multi-head efficient spiral heat exchanger, a thermal expansion valve, and the like, which are connected by a pipeline. The invention is characterized in that the system comprises a flash evaporator component, a flash gas overheating coil, a compressor heat radiating recovery coil, and a low pressure air supply pressurization line. When in heat operation under low-temperature working condition, based on the two-stage compression cycle which is incompletely cooled between two stages of throttles, the invention uses the flash gas overheating coil, the compressor heat radiating recovery coil, and the low pressure air supply pressurization line for recovering the heat radiating capacity of a compressor, realizes the overheating of the flash gaseous working substance, enhances the gas transmission capacity of the compressor, and further improves the heat and the energy efficiency ratio of a heat pump system. Meanwhile, the defrosting coil is added to the bottom part of the heat exchanger device, so the frosting problem of the outdoor heat exchanger of the heat pump is solved. The invention can realize the mutual switch among a single heating operating mode in winter, a heating and healthy hot water united operating mode in winter, and a healthy hot water single operating mode during a non-heating period.

Owner:DALIAN ZHONGXING TECH DEV

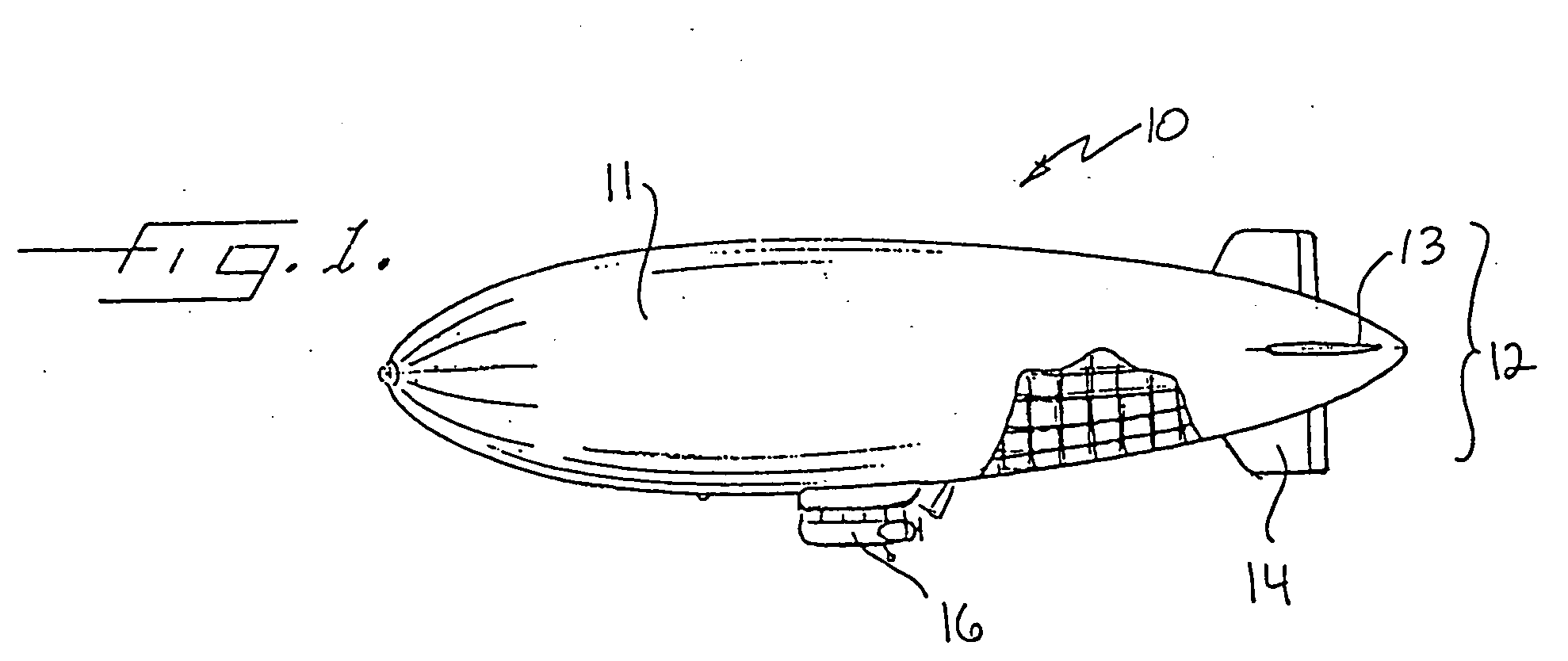

Lng Transportation Vessel and Method For Transporting Hydrocarbons

A vessel for transporting liquefied natural gas is provided. The vessel generally includes a gas transfer system for on-loading and off-loading natural gas to and from the vessel at essentially ambient temperature. The vessel further includes a gas processing facility for selectively providing liquefaction and regasification of the natural gas. The vessel also includes a containment structure for containing the liquefied natural gas during transport. The vessel may be a marine vessel or a barge vessel for transporting LNG over water, or a trailer vessel for transporting LNG overthe-road. A method for transporting LNG is also provided, that provides on-loading of natural gas onto a vessel, condensing the natural gas, storing the gas on the vessel in liquefied form, transporting the gas to an import terminal, vaporizing the gas, and off-loading the gas at the terminal.

Owner:BOWEN RONALD R +3

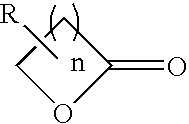

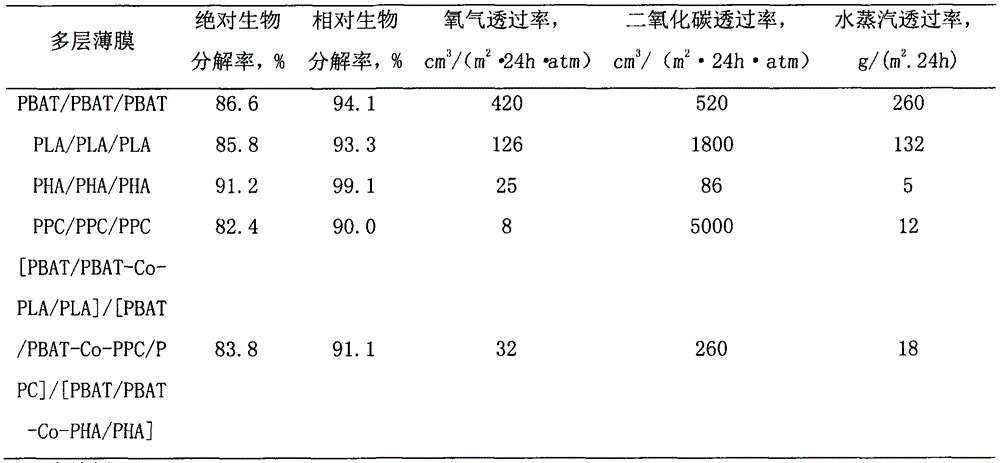

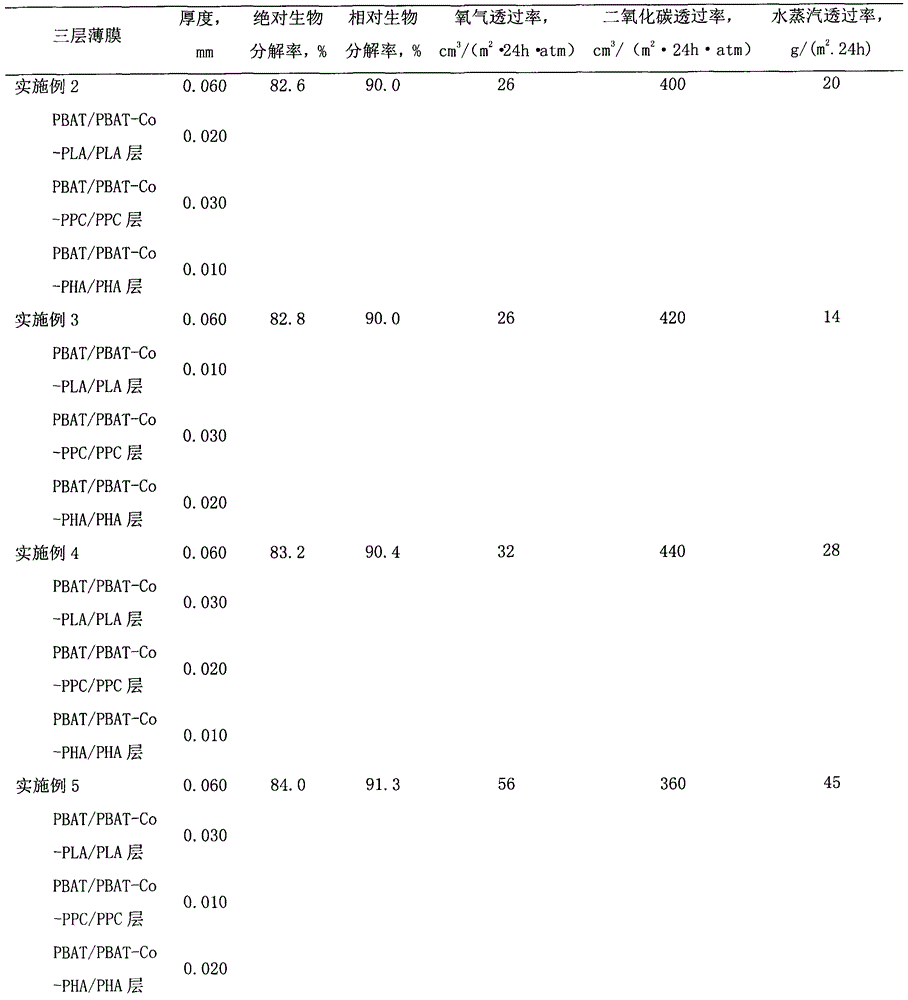

Biodegradable multilayer material with adjustable gas transmission rate and preparation method and applications thereof

ActiveCN104691067AStable physical propertiesNot easy to layerFlexible coversWrappersWater vaporOxygen

The invention relates to a biodegradable multilayer material, which can be a thin film material or a sheet material. The biodegradable multilayer material at least comprises one of an adipic butanediol terephthalate copolymer (PBAT) / PBAT-chain extender-polypropylene carbonate (PBAT-Co-PPC) / PPC blend layer, a PBAT / PBAT-chain extender-polylactic acid (PBAT-Co-PLA) / PLA blend layer and a PBAT / PBAT-chain extender-polyhydroxyalkanoate (PBAT-Co-PHA) / PHA blend layer, and blend resins are respectively prepared through twin-screw reactive extrusion. The multilayer material is produced by using extrusion and coextrusion methods, has a function that the transmission rates of oxygen, carbon dioxide and water vapor can be adjusted, and can be applied to the packaging field and the agriculture field, and especially applied to food packaging, pharmaceutical packaging, and ground film mulching.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Industrial flue gas purification, desulfurization and denitrification integrated device and working method thereof

ActiveCN102489129AReduce usageEfficient removalAmmonium nitratesDispersed particle separationParticulatesSulfur dioxide

The invention discloses an industrial flue gas purification, desulfurization and denitrification integrated device and a working method thereof. A section of pretreatment flue is additionally arranged on a flue in front of an absorption tower, and the outlet of the pretreatment flue is connected to the inlet flue of the absorption tower in a downward gradient mode; an ozone spraying device and a pre-spraying device are arranged in the pretreatment flue from the inlet in turn; and the ozone spraying device is connected with an ozone generator through a gas transmission pipeline and converts SO2 into SO3 sulfide which is freely soluble in water, the pre-spraying device absorbs SO3 which is freely soluble in water and converts the SO3 into H2SO4, namely sulfuric acid, and flue gas is cooled simultaneously, so that the aim of removing nitrogen oxide and sulfur dioxide is fulfilled. The device can efficiently remove the nitrogen oxide, has an obvious effect of removing particulate matters such as the sulfur dioxide, dust and the like, and is desulfurization and denitrification equipment with a wide application prospect.

Owner:山东中玻节能环保发展有限公司

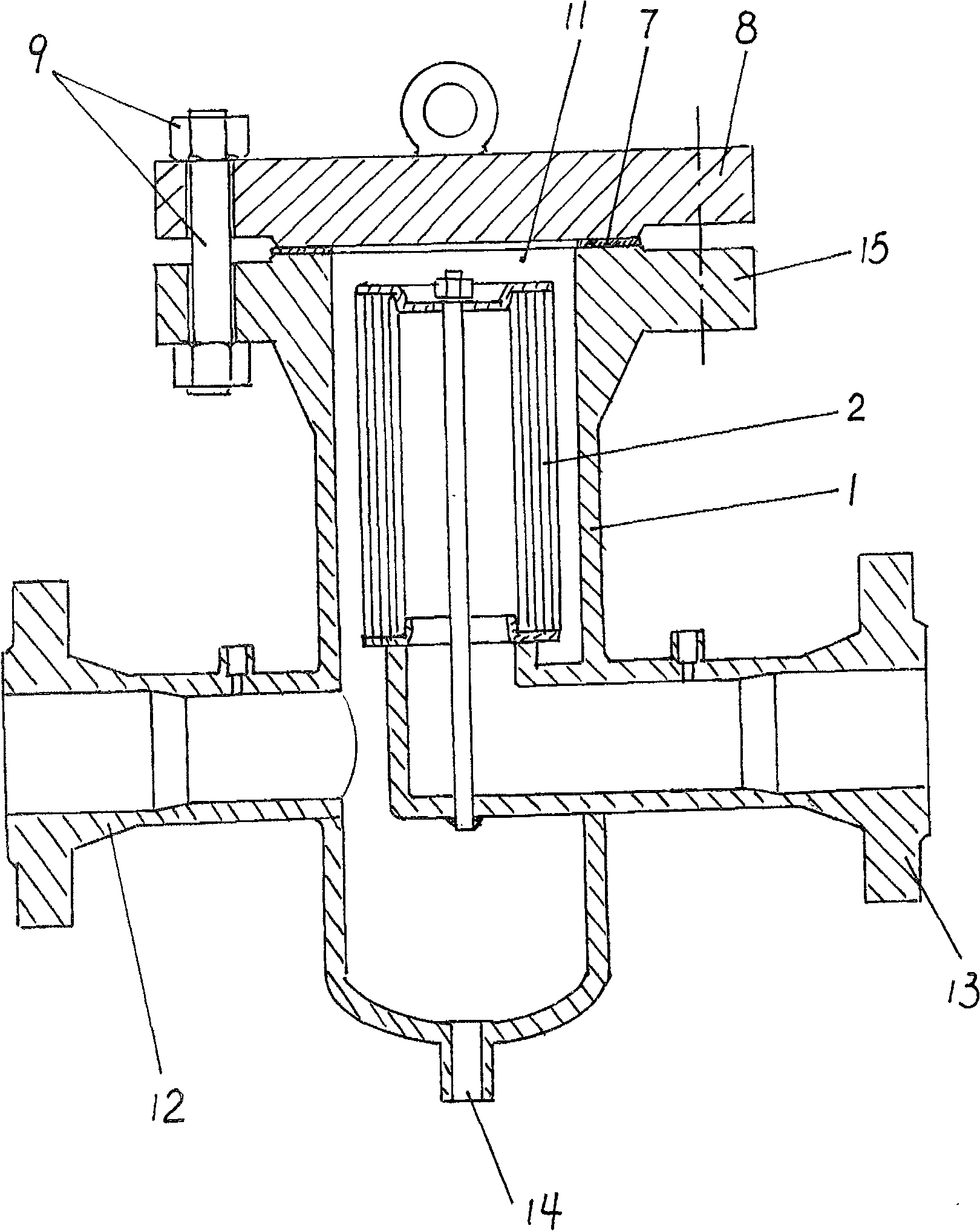

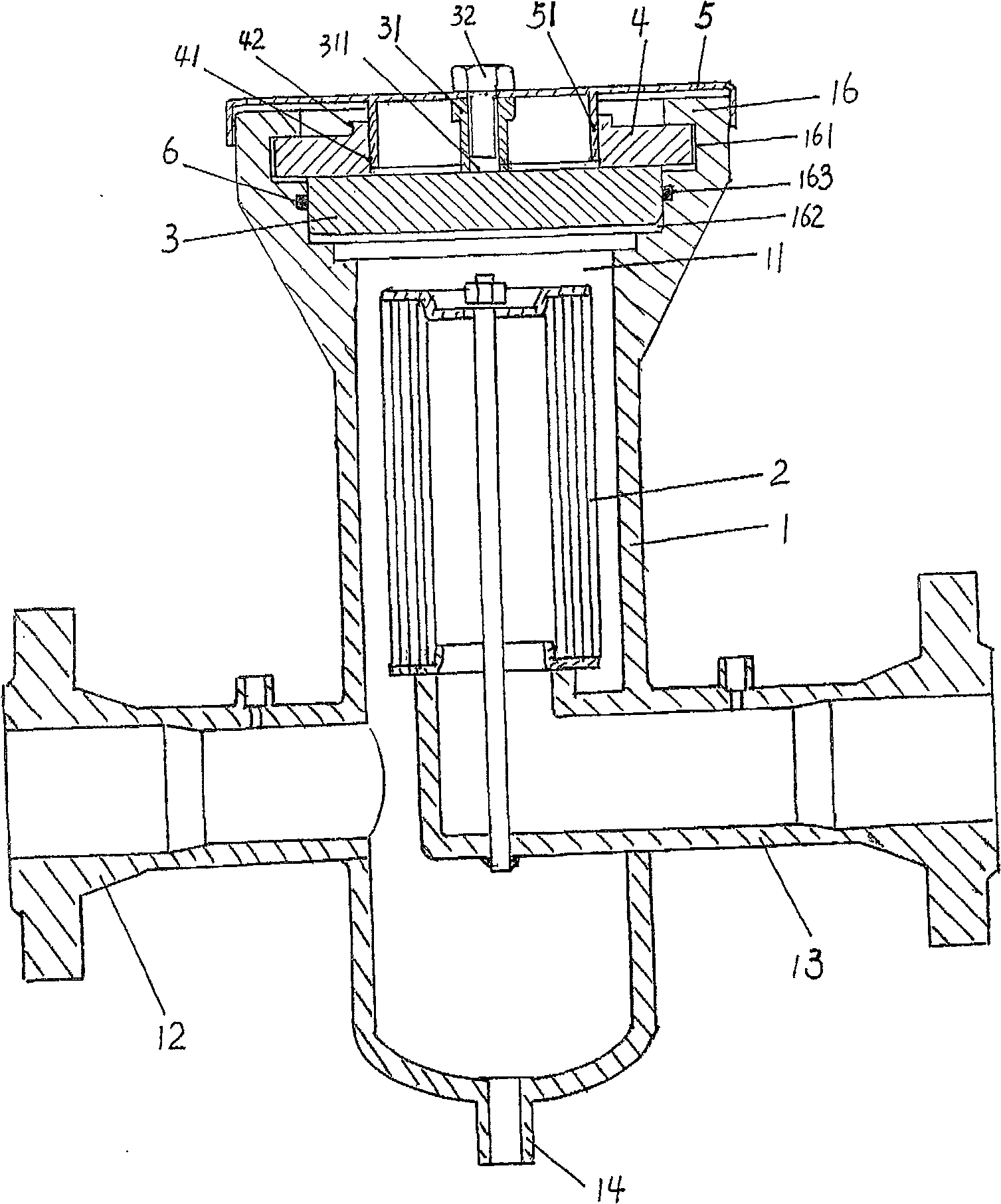

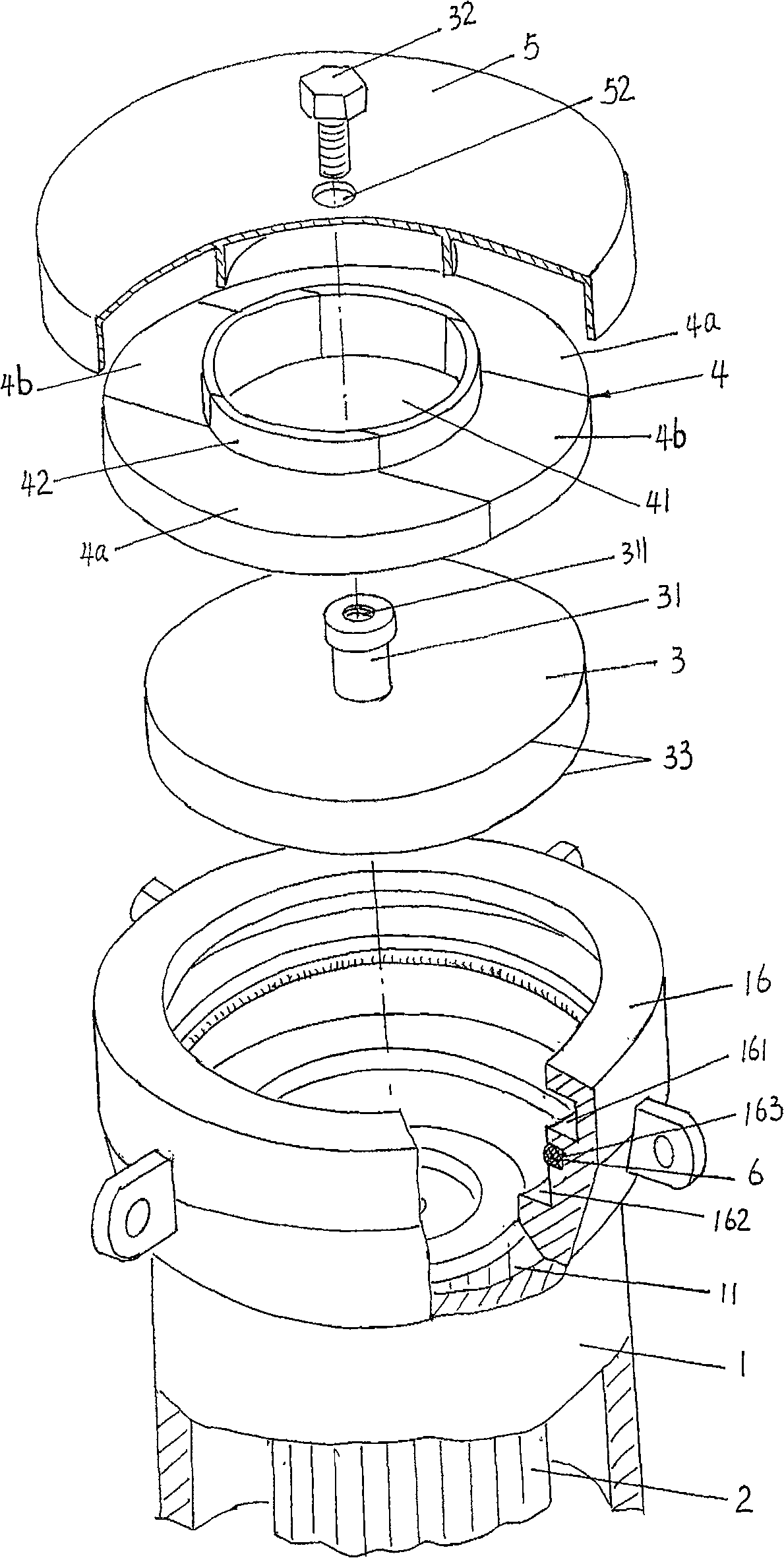

Natural gas filter

InactiveCN100535501CPrevent air leakageReduce incidenceDispersed particle filtrationPipe elementsFiltrationOutfall

The utility model relates to a natural gas filter, which belongs to a filtering device for natural gas pipelines in petroleum gathering and transportation projects such as natural gas fields, gas transmission and distribution pressure regulation systems, and city gate stations. It includes a cylinder with an opening on the top, a filter element placed in the cylinder, and a sealing mechanism for sealing the opening. The cylinder is provided with a raw material gas inlet, a purified gas outlet, and a sewage outlet. The filter element is The upper end is close to the opening, and the lower end of the filter element is connected to the outlet of the purified gas. The characteristic is that the sealing mechanism includes a high neck extending on the top of the cylinder, a sealing cover, a quarter ring, a protective cover, and fixing screws. Advantages: opening and closing the container becomes fast, convenient, time-saving, labor-saving and cost-saving; the sealing mechanism has a self-locking structure, which uses the pressure of its own natural gas in the container to lift the sealing cover, and the sealing cover and the high neck The space is sealed by an O-ring, and the four-part ring lifts the cover to meet the requirements of self-locking sealing. The sealing performance is good, which can prevent the container from leaking and reduce the incidence of accidents.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

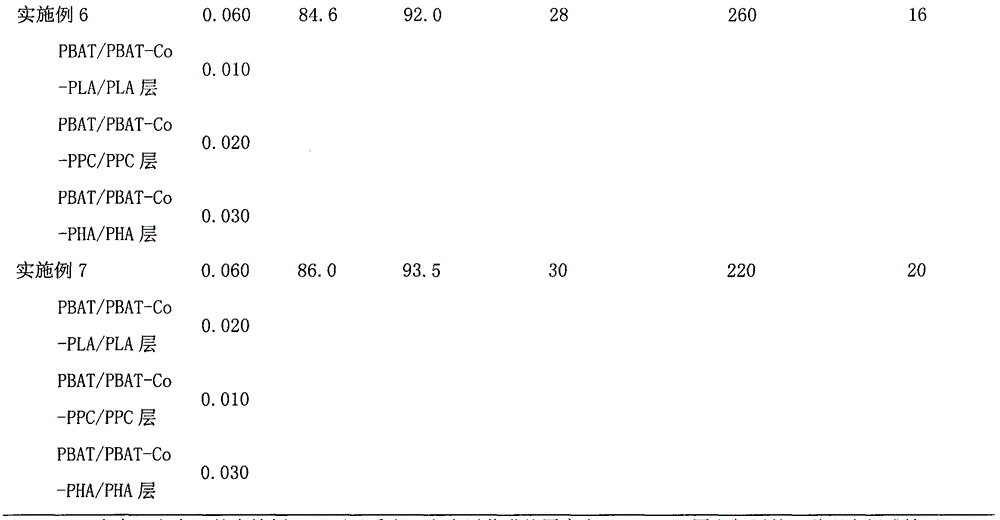

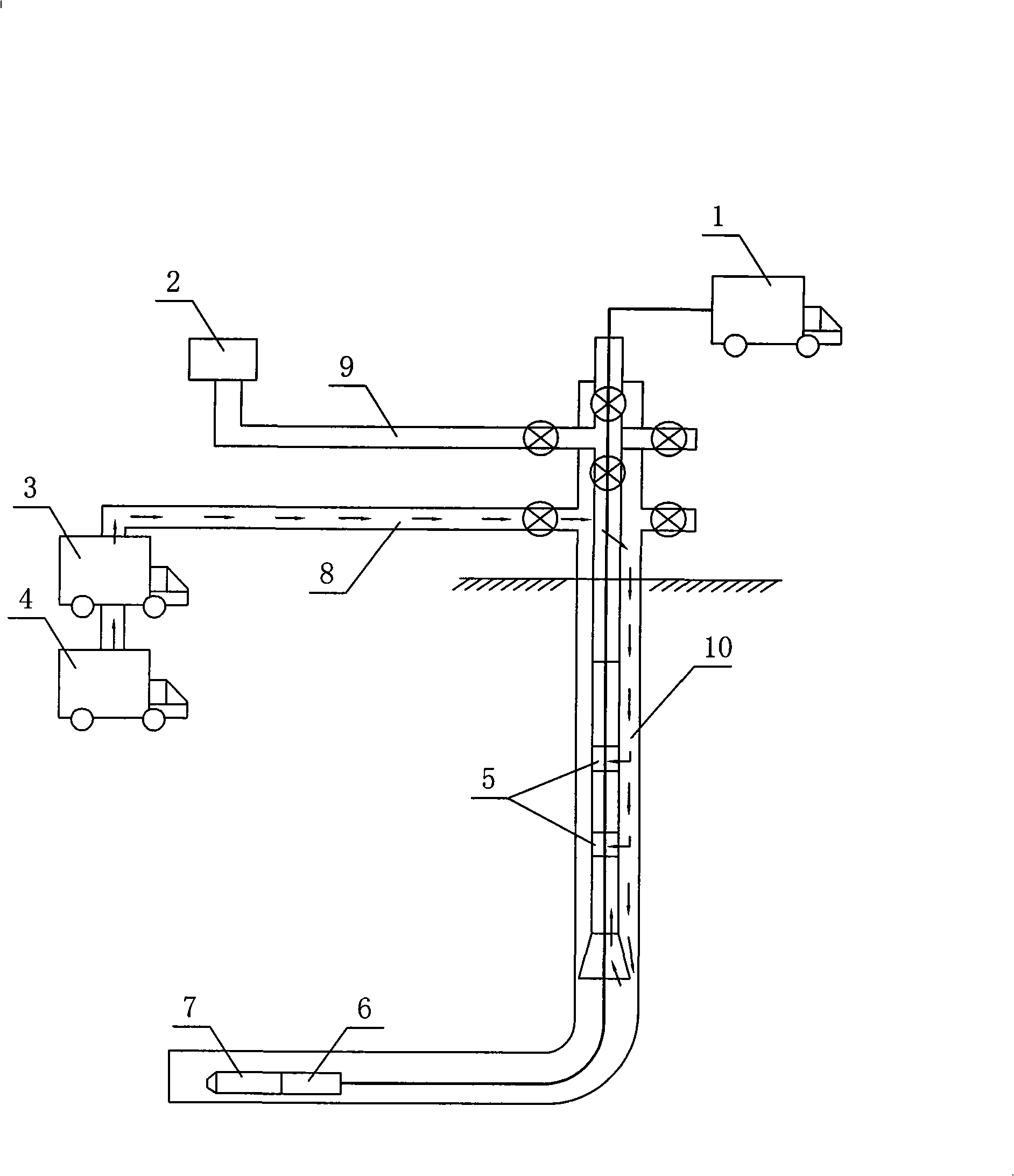

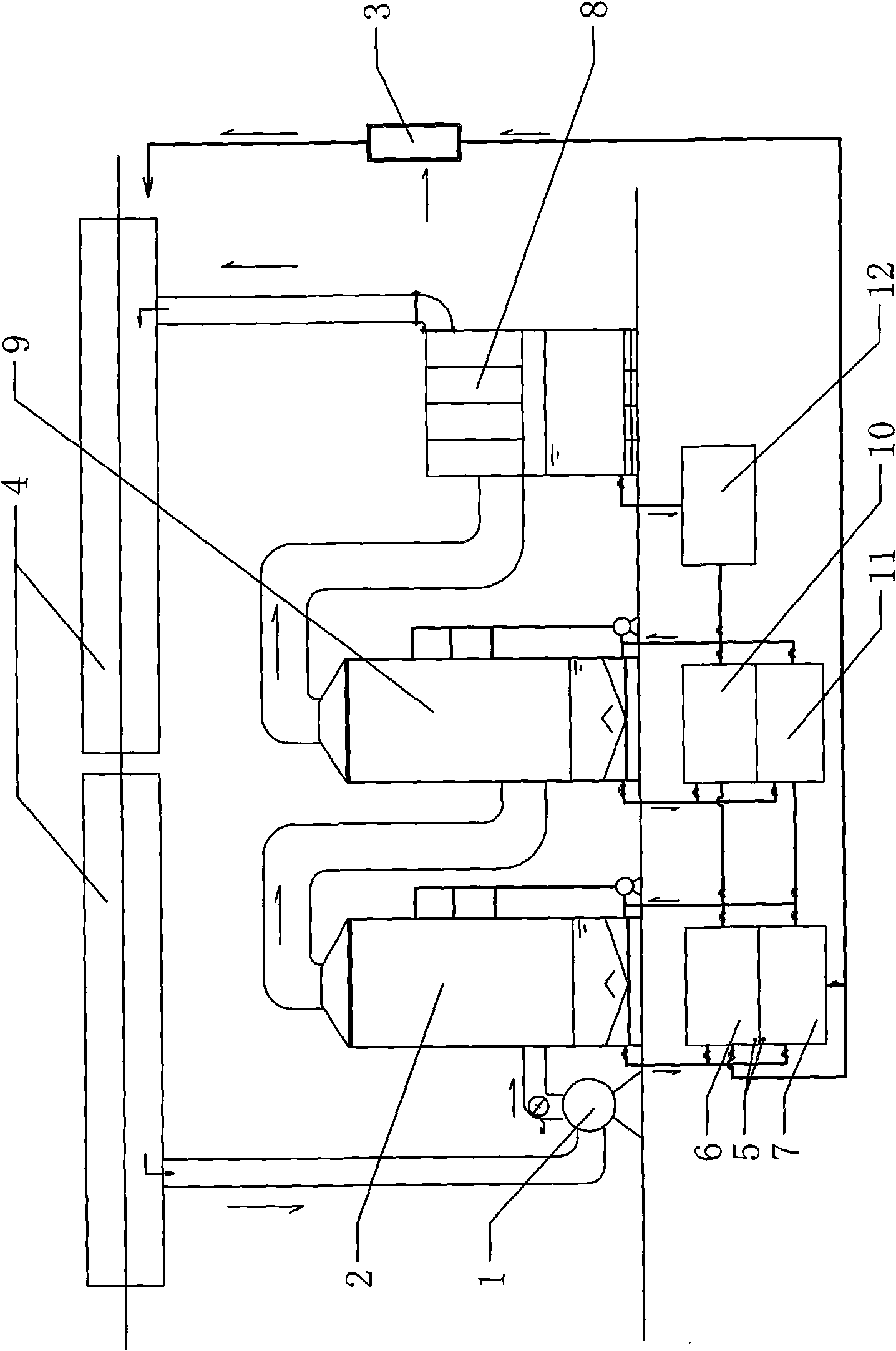

Gas lift method production fluid section plane test technique of mechanical mining horizontal well

InactiveCN101403292ASmall footprintImplement output profile testingSurveyFluid removalLine tubingSection plane

The invention relates to a produced fluid profile logging technique method of a mechanical recovery horizontal well by a pneumatic lifting method, aiming at solving the problem that the existing horizontal well can not carry out profile testing in normal production state. The method is characterized in that: a. a pneumatic lifting production string (10) is put into the well, and a gas transmission line (8) and a pipe laying (9) are connected; b. a tester (7) and a traction apparatus (6) are put into the well by the pneumatic lifting production string (10); and c. a nitrogen gas generation locomotive (4) and a compressing locomotive (3) are started for carrying out oil extraction, and a cable is lifted up to carry out testing when the oil extraction production is stable. The produced fluid profile logging technique method of the mechanical recovery horizontal well by the pneumatic lifting method can leave enough testing channel for the tester, thereby finally realizing the produced fluid profile testing of the horizontal well in normal production state.

Owner:DAQING OILFIELD CO LTD

High strength lightweight composite fabric with low gas permeability

Owner:WARWICK MILLS INC

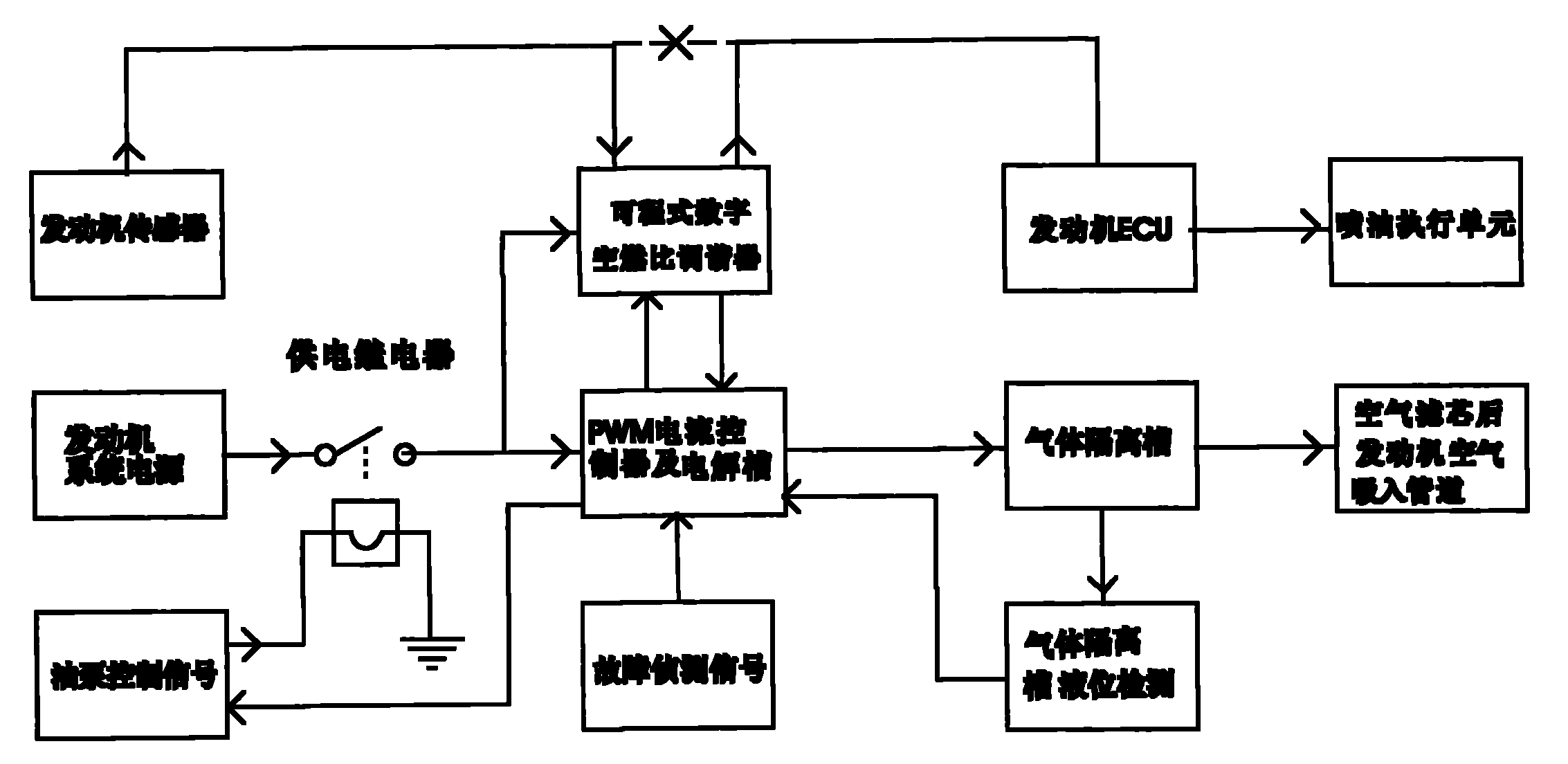

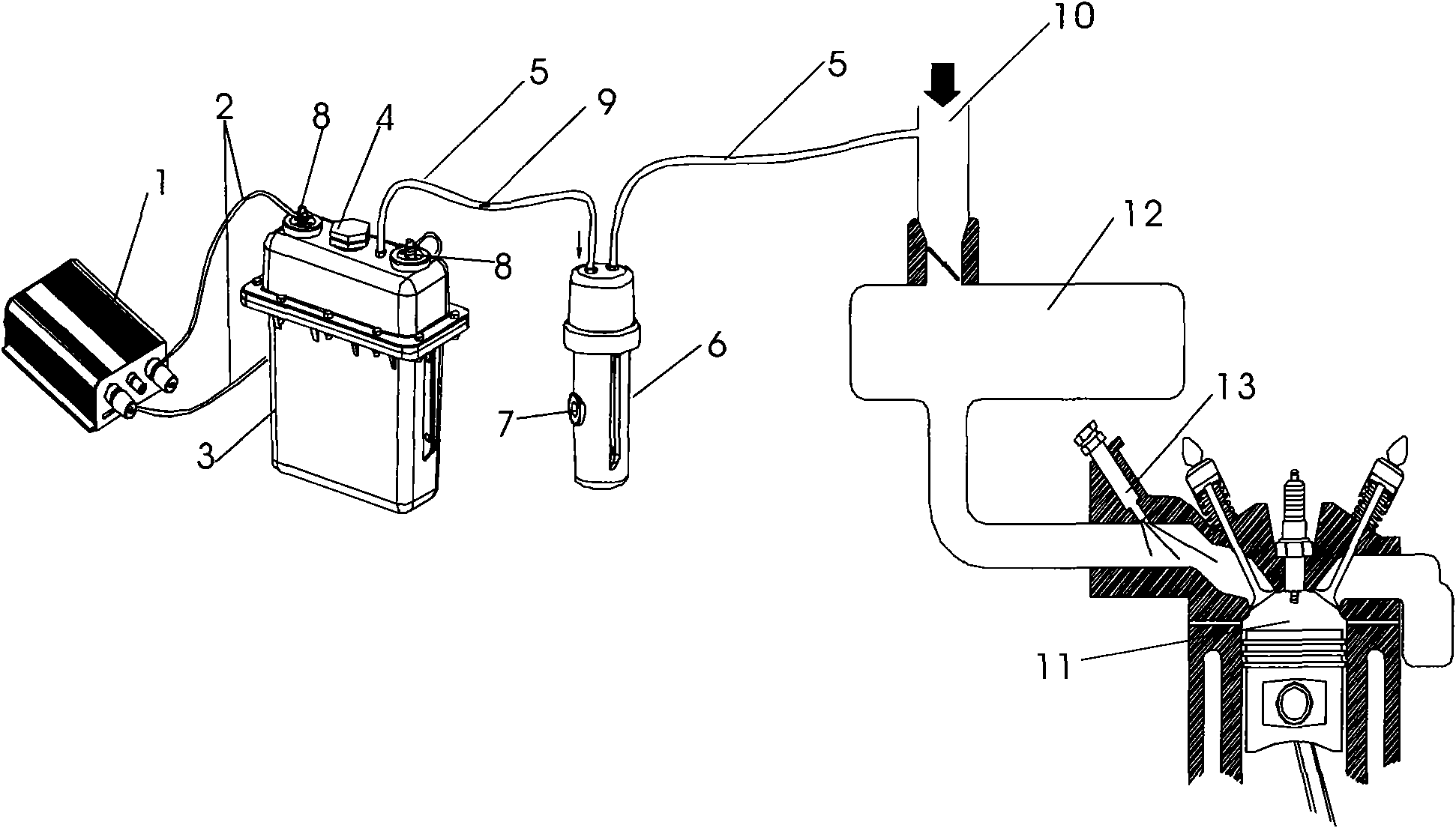

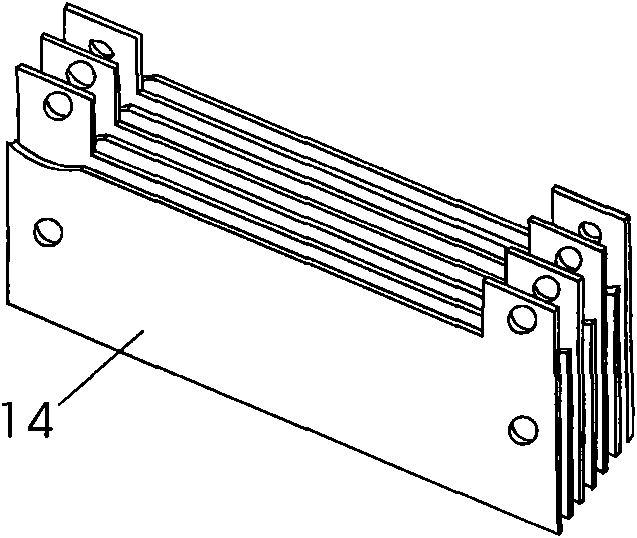

Hydrogen and oxygen combustion-supporting energy-saving intelligent control system device for internal combustion engine

InactiveCN101813040AWith intelligent automatic control performanceBurn fullyElectrolysis componentsElectrical controlHydrogenExternal combustion engine

The invention discloses a hydrogen and oxygen combustion-supporting energy-saving intelligent control system device for an internal combustion engine. The device comprises an engine sensor, a power supply, an electrolytic bath, a PWM current controller and a power supply relay. A hydrogen and oxygen combustion-supporting gas produced by the electrolytic bath is connected to an engine air suction pipeline through a hydrogen and oxygen gas transmission passage. The device is characterized by also comprising a programmable digital air-fuel ratio tuner; the signal output end of the engine sensor is connected with the input end of the programmable digital air-fuel ratio tuner, and the output end of the programmable digital air-fuel ratio tuner is connected with the input end of an engine ECU; the power supply end of the PWM current controller is connected to the power supply relay at the power supply output end, and the output end of the PWM current controller is connected with two electrodes of the electrolytic bath; and the programmable digital air-fuel ratio tuner is connected with the power supply relay. The device can improve the power of the engine, achieves the effects of energy conservation and emission reduction, and is safe and reliable.

Owner:王勇

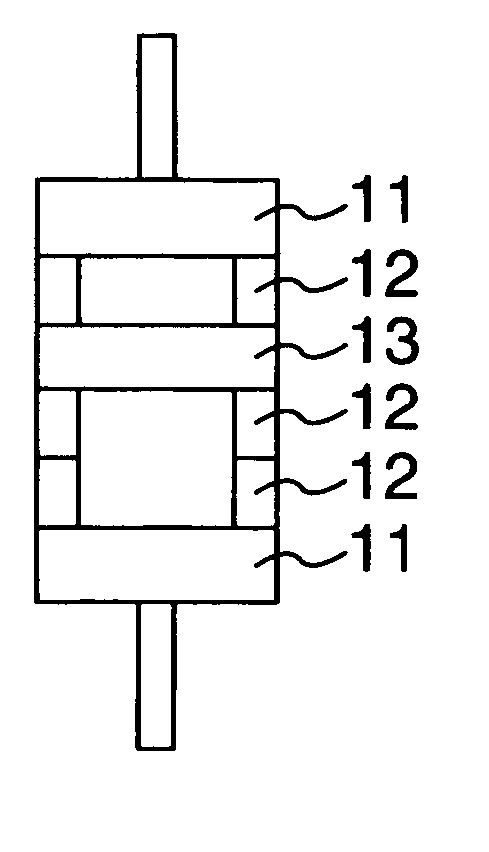

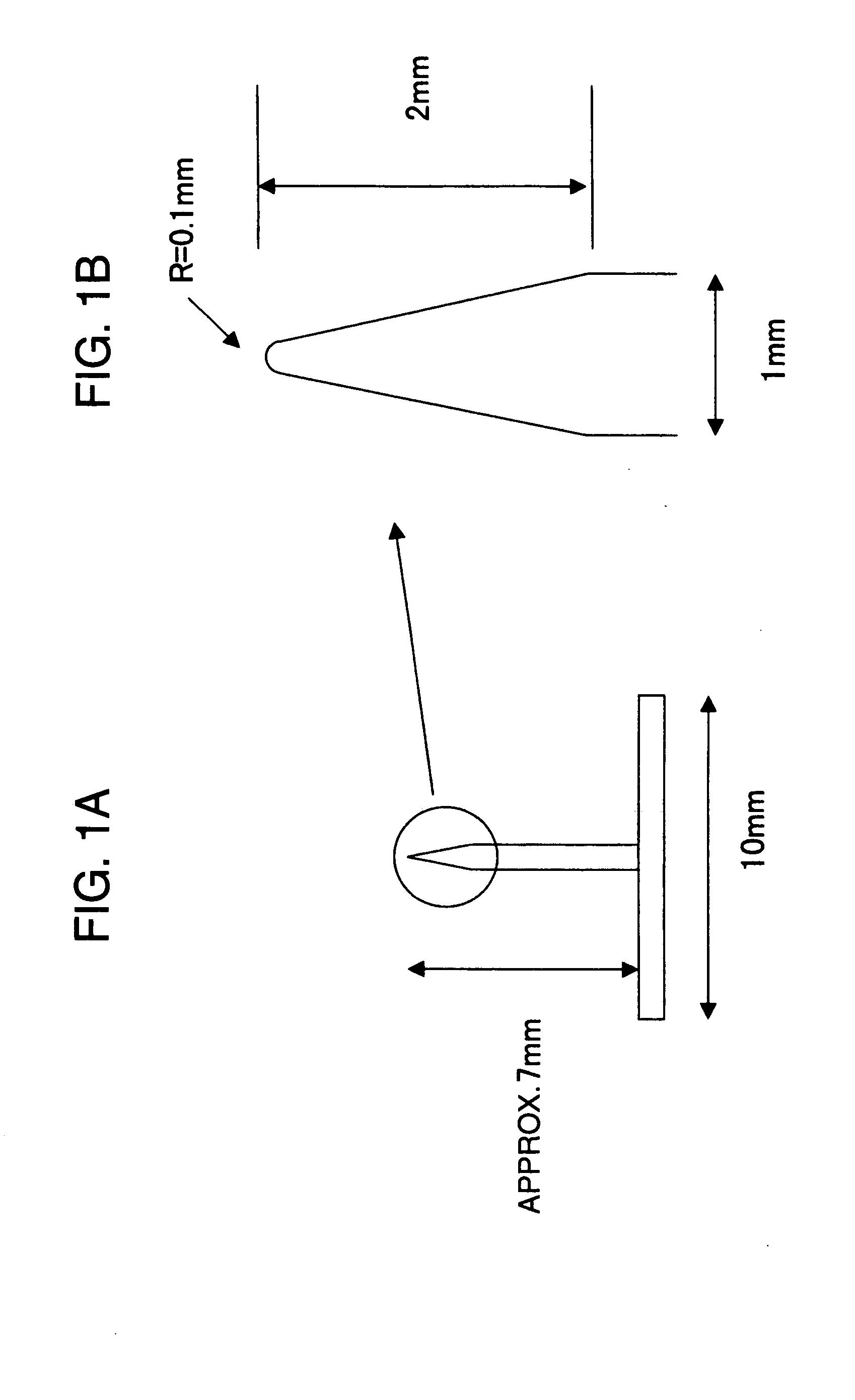

Method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipe

The invention discloses a method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipes, which is applied to the manufacture of special welding pipes for oil and gas transmission. In the method, a controllable rolled steel plate is used, wherein the controllable rolled steel plate has a ferrite-bainite double-phase metallurgical microstructure and contains the following chemical components: 0.04 to 0.07 percent of C, 1.60 to 1.85 percent of Mn, 0.15 to 0.30 percent of Si, not more than 0.003 percent of S, not more than 0.010 percent of P, 0.15 to 0.30 percent of Ni, not more than 0.020 percent of Ti, 0.015 to 0.040 percent of Al, 0.010 to 0.065 percent of Nb, not more than 0.006 percent of N, not more than 0.30 percent of Cu, 0.10 to 0.25 percent of Cr, and not more than 0.0005 percent of B. The method comprises the following steps: (1) milling edges of the steel plate; (2) pre-bending bended edges; (3) performing JCO forming; (4) pre-welding joint seams; and (5) performing finish-welding on the inner and the outer sides of the joint seams. The method is applied to the manufacture of large-deformation-resistant welding pipes which are used in seismic belts, frozen soil areas, landslide area and other areas with high risk of deformation. The method has the advantages as follows: in the JCO forming process, the local deformation amounts and straight edge sizes of the steel plate in different rolling passes are analytically acquired according to the width, thickness and strength of the steel plate and the size of a die so as to determine the rolling passes and ensure uniform deformation at all parts of the steel plate after forming; and in the diameter expansion process, the minimum diameter expansion amount is determined according to the size and shape of the formed steel pipe, so as to ensure the size, shape and physiochemical properties of the steel pipe after diameter expansion.

Owner:CNPC BOHAI EQUIP MFG +2

Polyolefin microporous membrane and method of evaluating the same

The invention relates to a microporous membrane, which is provided with high safety even under a condition that the interior temperature of a battery becomes high, and which has high permeability and high mechanical strength at the same time. The polyolefin microporous membrane is characterized by a membrane thickness of 5 to 50 μm, a void content of 30 to 60%, a gas transmission rate of 40 to 300 sec / 100 cc / 20 μm, a piercing strength of not less than 2.5 N / 20 μm and a break through temperature of not lower than 110° C. The separator in accordance with the present invention is used to exhibit high safety under a high temperature condition as well as high permeability, and therefore it is particularly useful as a separator for miniaturized high capacity batteries of a non-aqueous electrolytic solution type.

Owner:ASAHI KASEI CHEM CORP

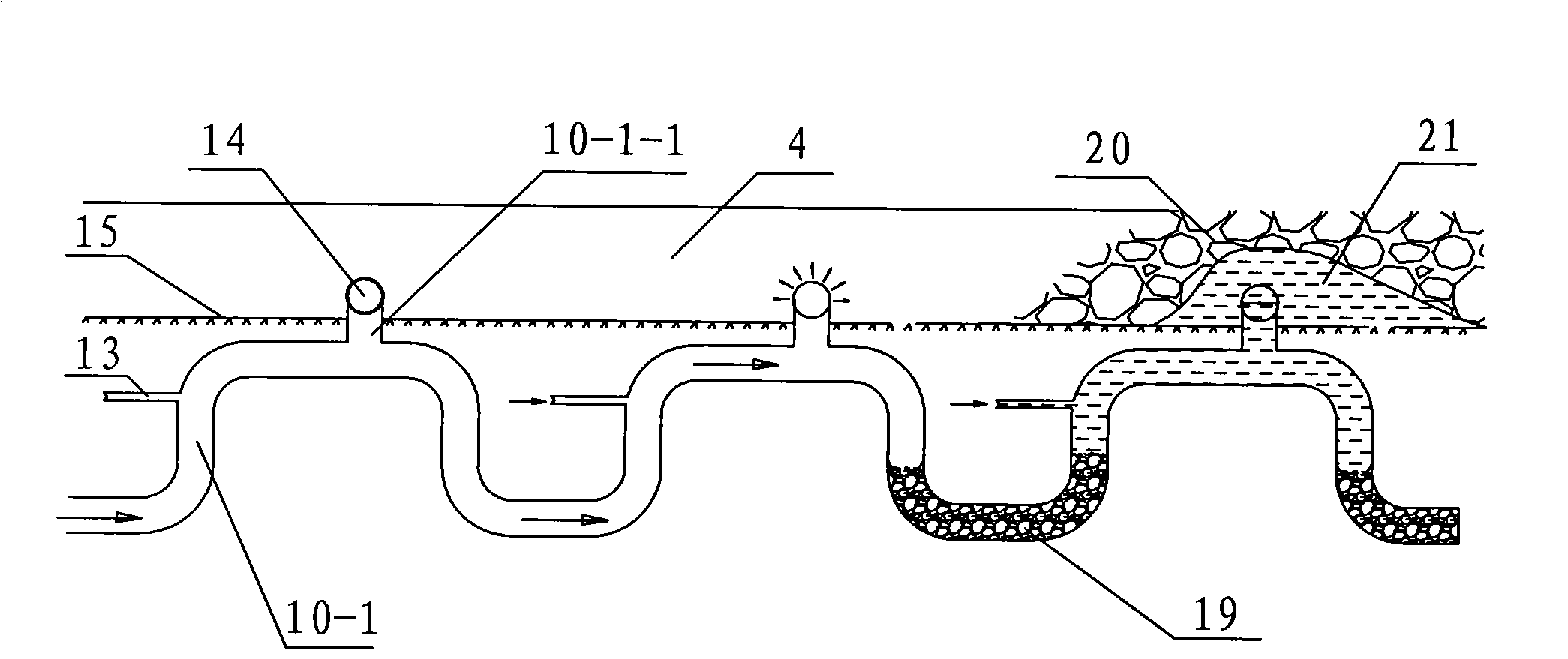

Underground coal gasification system and producing process

InactiveCN101315026AMaximize miningAchieve paddingConstructionsCoal gasificationProcess engineeringControl area

The invention relates to an underground coal gasification system and a production process thereof. The system comprises an air course and a gas transmission course which are arranged in a coal seam, a plurality of gasification channels are arranged in the coal seam, the two mutually parallel ends of each gasification channel respectively communicate with the air course and the gas transmission course, and a water drainage closed wall is arranged in the gas transmission course; and the both ends of the air course are respectively connected with an intake airway and a return airway of a mine system. The gasification process comprises the following steps: igniting; judging whether the burning point is required to be moved forward; moving the burning point of the coal seam backwards; plugging a gas passage of a combustion-supporting gas injection branch pipe which is disabled, and filling a burning control area with paste. The coal underground gasification system and the production process have the advantages that the coal seam can be mined to the utmost extent; the leakage of the combustion-supporting gas to the burning control area can be thoroughly cut off when the secure retraction during the coal underground gasification process is realized; the problem that the gasification agent is short-circuited because a passage is formed due to the collapsing of the coal seam floors in the gasification channel and the earlier period gasification area can be solved in the later period of the underground coal gasification, the gas production is secure and reliable, and the gasification rate is high.

Owner:中矿天晟能源科技有限公司

Breathing assistance device comprising a gas regulating valve and associated breathing assistance method

ActiveUS20090314294A1Simple configurationReduce in quantityRespiratorsOperating means/releasing devices for valvesEngineeringCatheter

The invention relates to a breathing assistance device for a patient, the device including: a source of respiratory pressurised gas; a gas transmission duct comprising a distal end coupled to said source and a proximal end coupled to the patient; a gas regulating valve interposed in the gas transmission duct at a proximal location, comprising a leakage orifice and an obstruction means capable of varying the opening of the leakage orifice upon signal of controlling means and allowing a bidirectional gas flow through the leakage orifice in both expiration and inspiration phases.

Owner:RESMED PARIS

Nbc nanoparticle reinforced X80 plastic pipe steel plate and production method thereof

The invention provides an Nbc nanoparticle reinforced X80 plastic pipe steel plate and a production method of the Nbc nanoparticle reinforced X80 plastic pipe steel plate. The steel plate comprises, by weight percentage, 0.06%-0.12% of C, 0.10%-0.30% of Si, 0.60%-1.40% of Mn, 0.07%-0.15% of Nb, 0.001%-0.004% of N, 0.01%-0.04% of Ti, 0.025%-0.045% of Al, not larger than 0.010% of P, not larger than0.005% of S, not larger than 0.30% of Cu, not larger than 0.30% of Mo, 0.12%-0.30% of Cr, 0.12%-0.30% of Ni and the balance Fe and inevitable impurity elements. The production method comprises the steps of material preparation, converter or electric furnace smelting, secondary refining, casting, slab reheating, controlled rolling and controlled cooling. By the adoption of the produced steel plate, the safety of oil and gas transmission pipelines laid in geological complex areas is ensured, and the purposes of high-pressure transportation of natural gas and oil and the like are met.

Owner:ANGANG STEEL CO LTD

Improved device for recovering, processing and recycling acidic waste gas

ActiveCN101601957AMeet environmental protection requirementsSave resourcesDispersed particle separationDirt cleaningProduction lineExhaust fumes

The invention provides an improved device for recovering, processing and recycling acidic waste gas, which can recover and process the acidic gas to enable the acidic gas to be continuously recycled in a pickling line to ensure that the waste gas can not be discharged into the atmosphere, thereby achieving the purpose of zero draining of the waste gas. The improved device for recovering, processing and recycling acidic waste gas comprises a blower and a waste gas absorber, wherein the waste gas absorber comprises a waste gas absorbing tower and a recovering tank, wherein a gas transmission pipeline of the blower is connected with the waste gas absorbing tower; the recovering tank is connected with a pipeline at the lower part of the waste gas absorbing tower and is connected with a pipeline of a mixing device; and the mixing device is connected with the pickling line.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com