Patents

Literature

1694results about How to "Improve roundness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

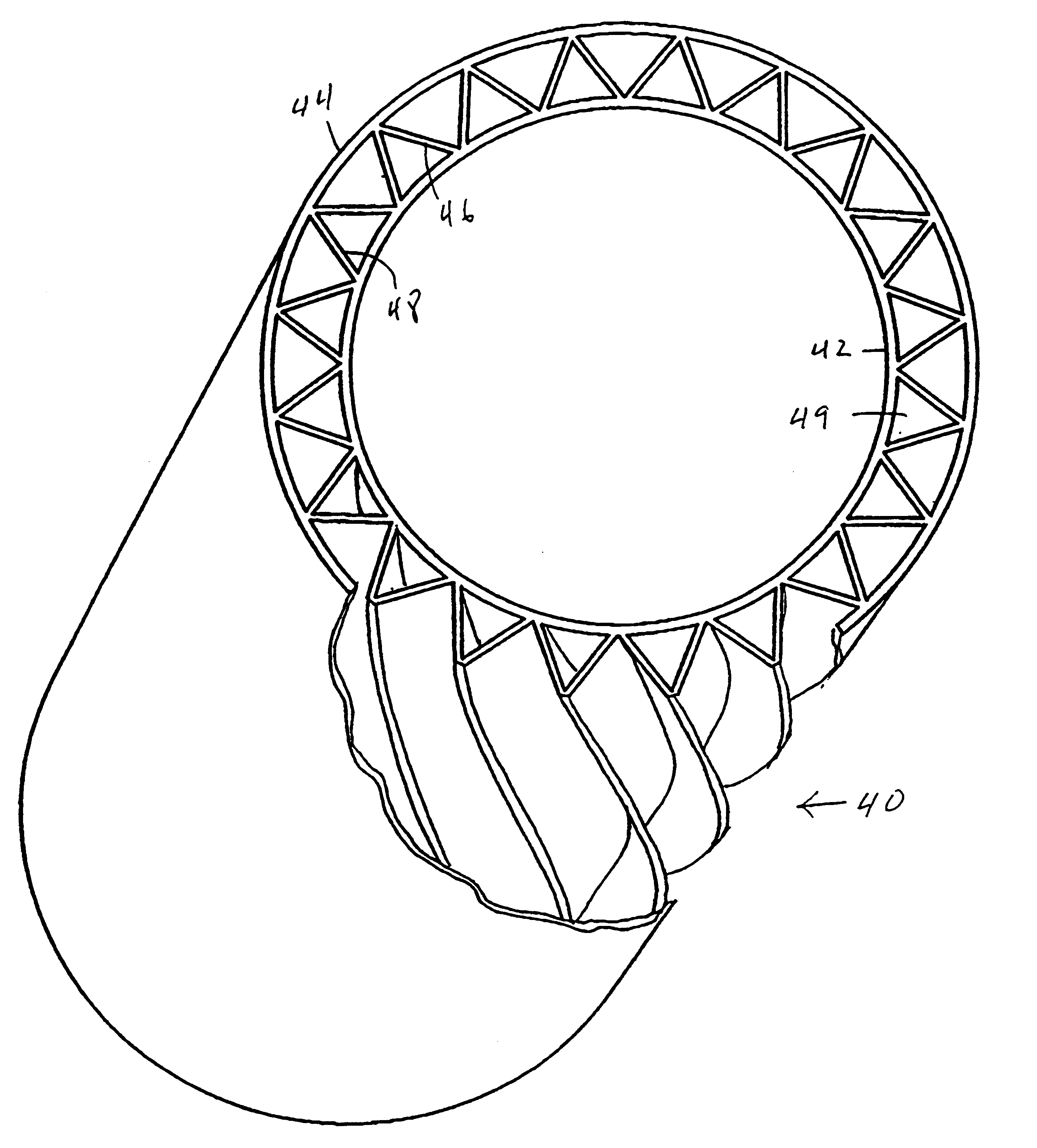

Ribbed core dual wall structure

InactiveUS6405974B1Improve consistencyImprove roundnessHollow wall articlesDomestic articlesEngineeringHelix

An elongated composite tube made up of an inner tube 42 and an outer tube 44 (FIG. 3) with a plurality of elongated helical ribs disposed between the inner tube and the outer tube in a supporting relationship to both. A slinky like toy made from the composite tube is also disclosed, as is a method of making both.

Owner:PROTEUS

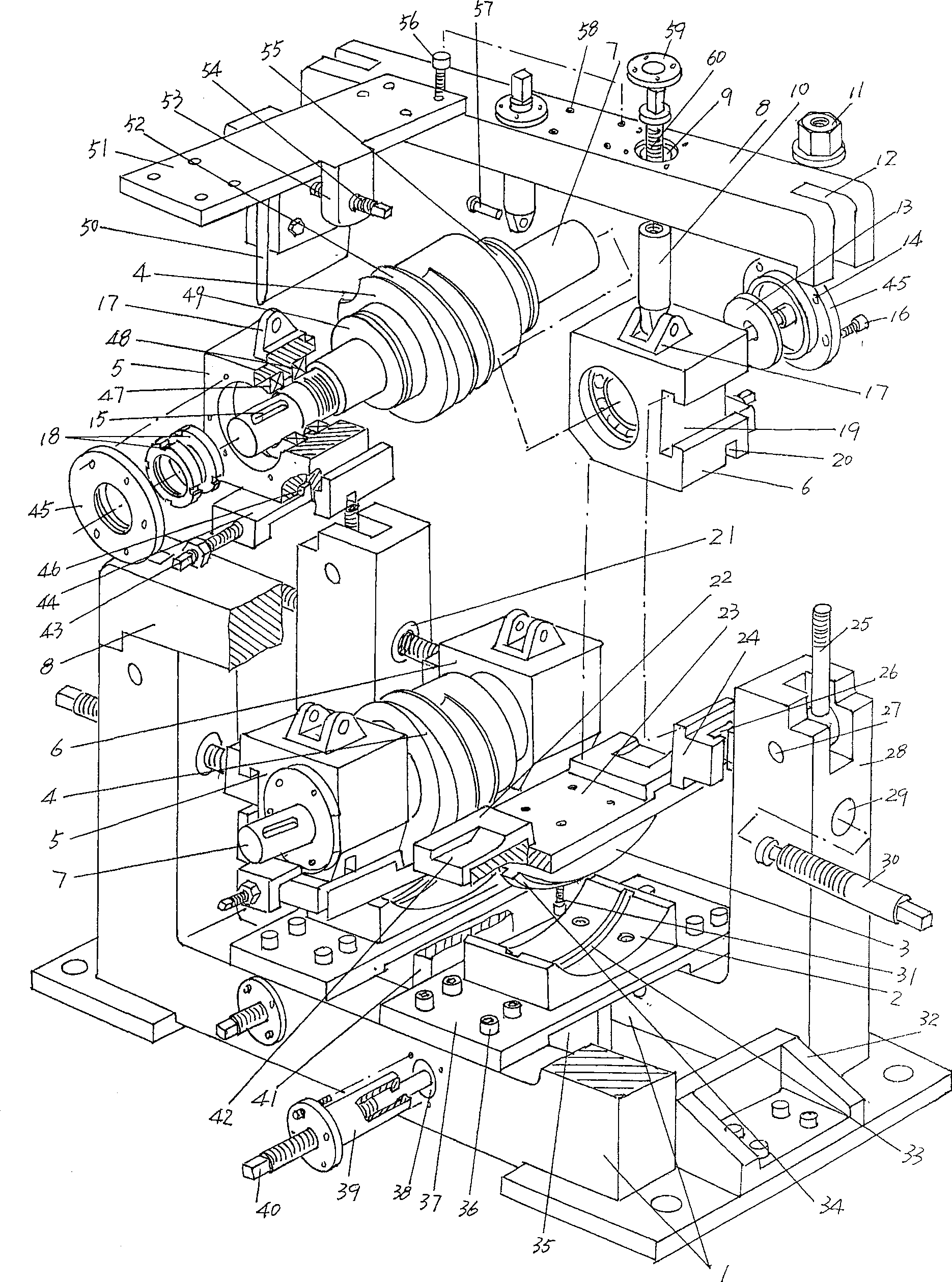

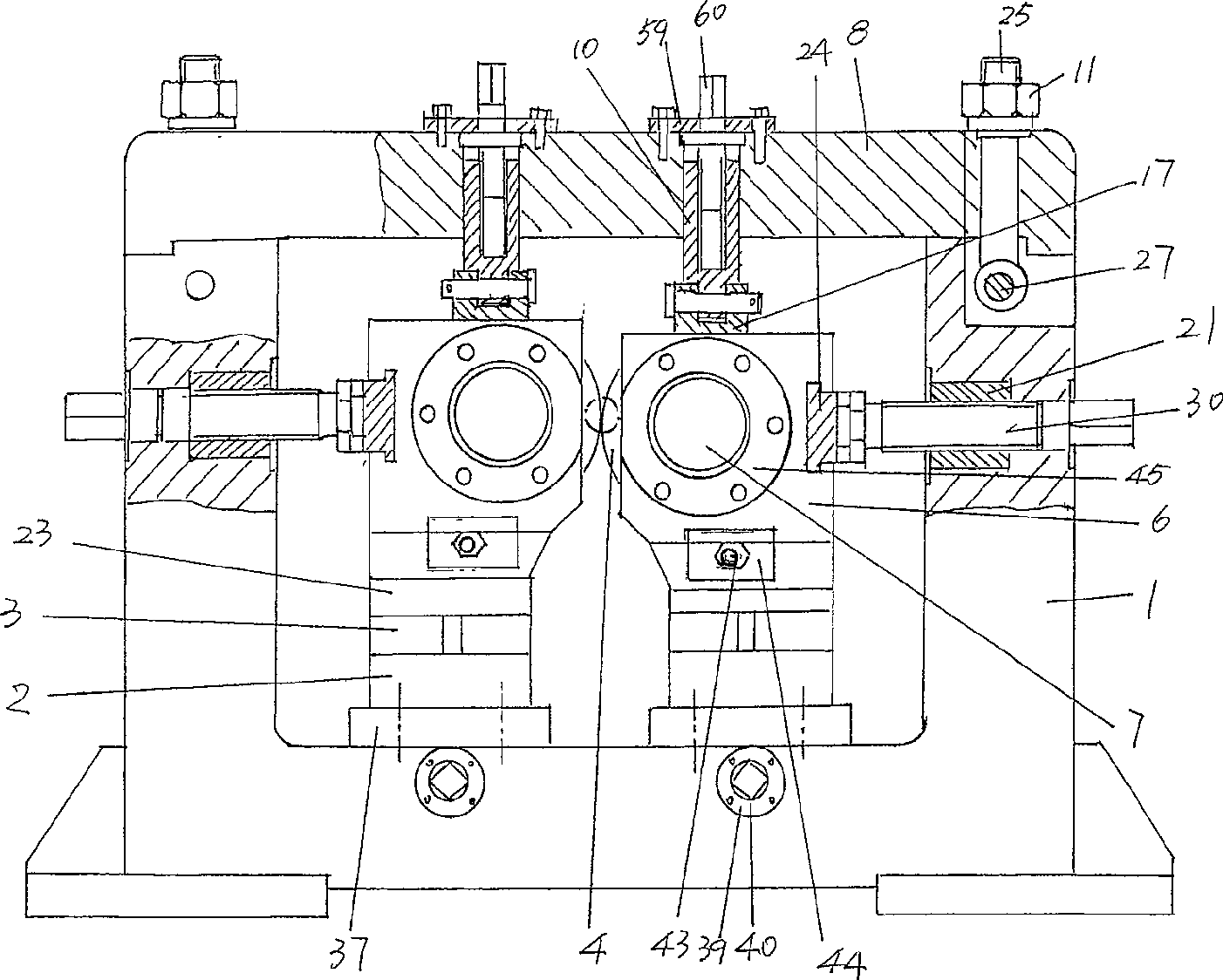

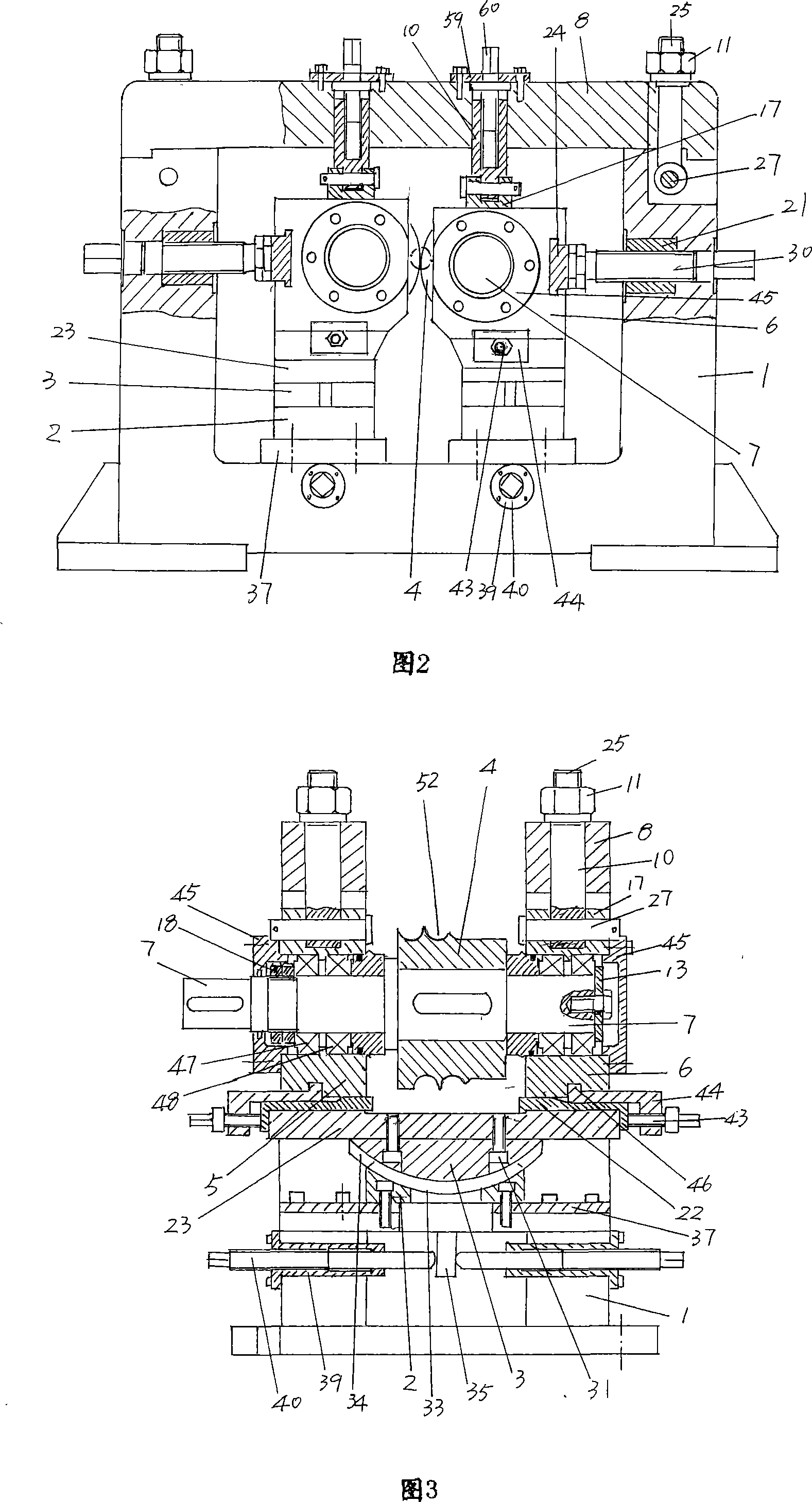

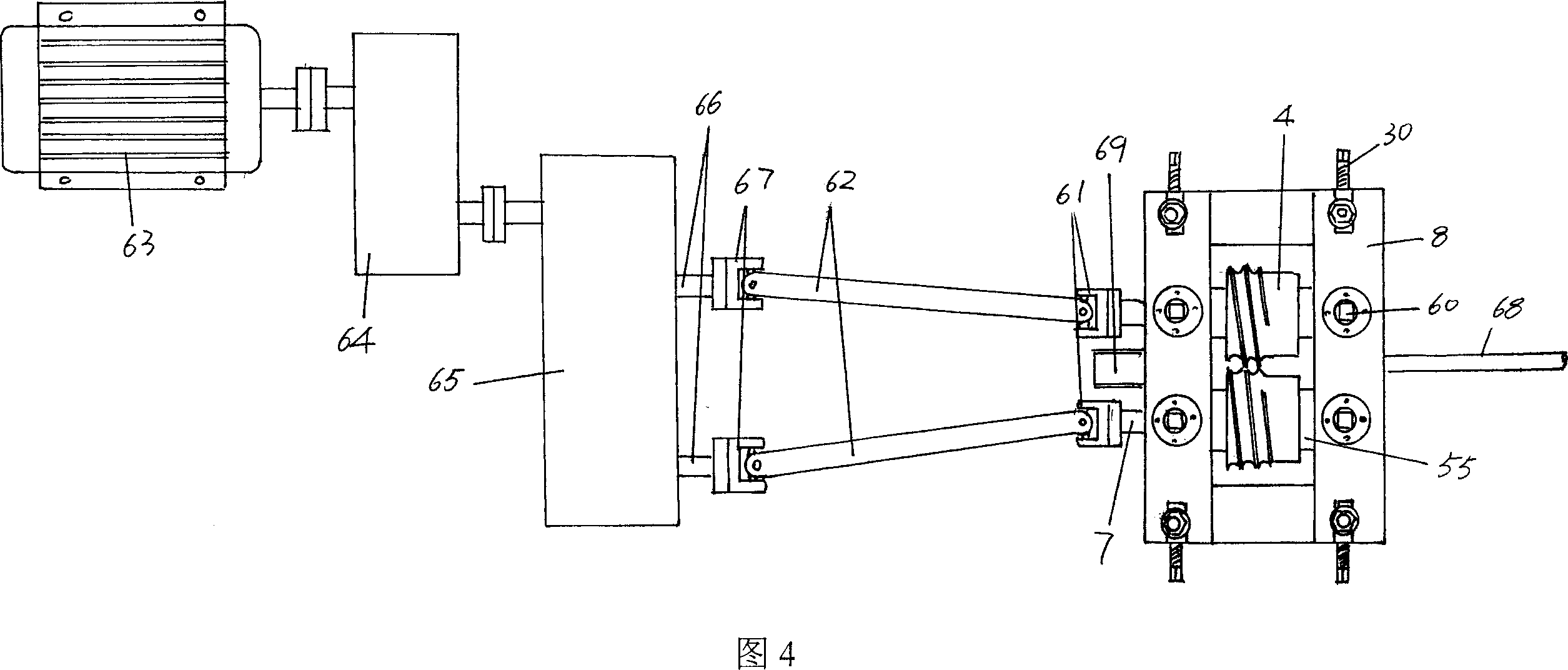

Ball forming mechanism of ball rolling machine

The ball forming mechanism of ball rolling machine for rolling metal rod, especially copper rod, into ball in the required size includes one frame, one pair of rotating drum seats in the lower part of the frame, one pair of rotating drums, one pair of ball forming rollers matching the rotating drums and with spindle set via two bearing seats on the frame. The ball forming process has high efficiency and no material loss, and the formed ball has high sphericity, smooth surface and high density.

Owner:常熟市钢强金属制品厂

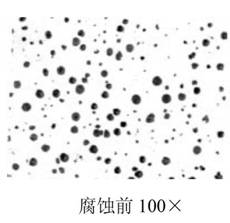

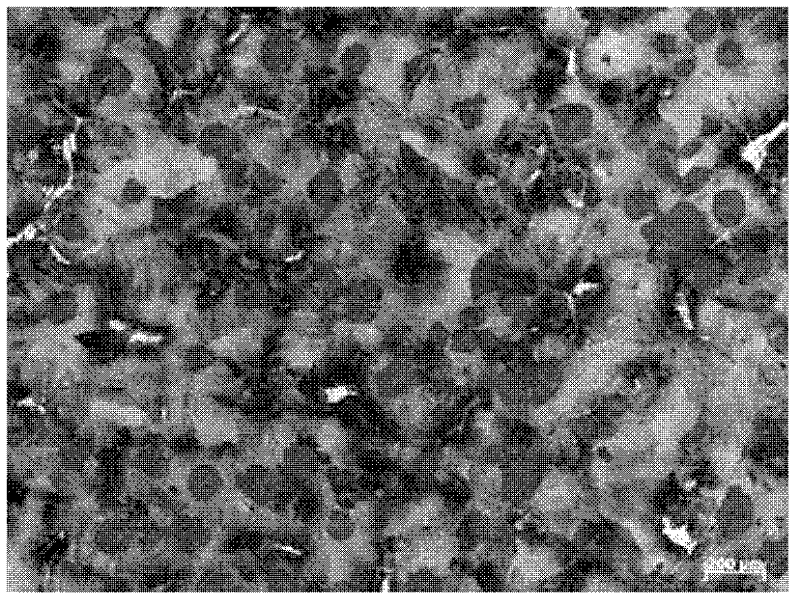

Smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron

ActiveCN102690986AImprove densification performanceImprove roundnessIntermediate frequencyStress relief

The invention relates to a smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron comprises the following chemical components in percentage by mass: 3.5-4.1 percent of C, 1.7-2.2 percent of Si, 0.10-0.25 percent of Mn, not more than 0.035 percent of P, not more than 0.020 percent of S, 0.015-0.030 percent of Re, 0.025-0.045 percent of Mg, 0-0.20percent of Cu, less than 0.1 percent of residual element, and Fe in balancing amount. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron is obtained by mixing furnace materials and carrying out high-temperature smelting in an intermediate-frequency furnace, modularization and inoculation treatment and casting and heat-insulating treatment on the mixed furnace materials. Cast iron products obtained by adopting the smelting method disclosed by the invention obtain normal-temperature mechanical property and low-temperature mechanical property under the cast state conditions; complex medium-thin wall parts are required to be subjected to low-temperature stress relief annealing; and simple medium-thin wall parts are free from being annealed, so that the production cost is greatly reduced, the production period is greatly shortened and the production efficiency is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Production process of honey peach CZ diamond

InactiveCN102838277ANo pollution damagePlay a role in fluxingGlass furnace apparatusGlass productionMachine toolKiln

The invention relates to a production process of a honey peach CZ diamond. The honey peach CZ diamond comprises the following raw materials in parts by weight: 60-70 parts of SiO2, 0.5-1.5 parts of Al2O3, 0.5-2.5 parts of BaO, 1.5-5 parts of ZnO, 1.0-2.5 parts of B2O3, 3-8 parts of K2O3, 8-15 parts of Na2O, 0.5-1.5 parts of CaO, 0.3-1.5 parts of Se and 0.03-0.3 parts of S. The production process comprises the following steps of: smelting by a hot smelting kiln and classifying; discharging to obtain a CZ diamond bead blank; sequentially carrying out fire polishing by a fire polishing furnace, and grinding by a grinding machine; and grinding a plurality of cutting surfaces of the CZ diamond by a multi-faced grinding machine tool and chemically plating to obtain a CZ diamond finished product.

Owner:JIANGSU JINCHENG GRP TECH

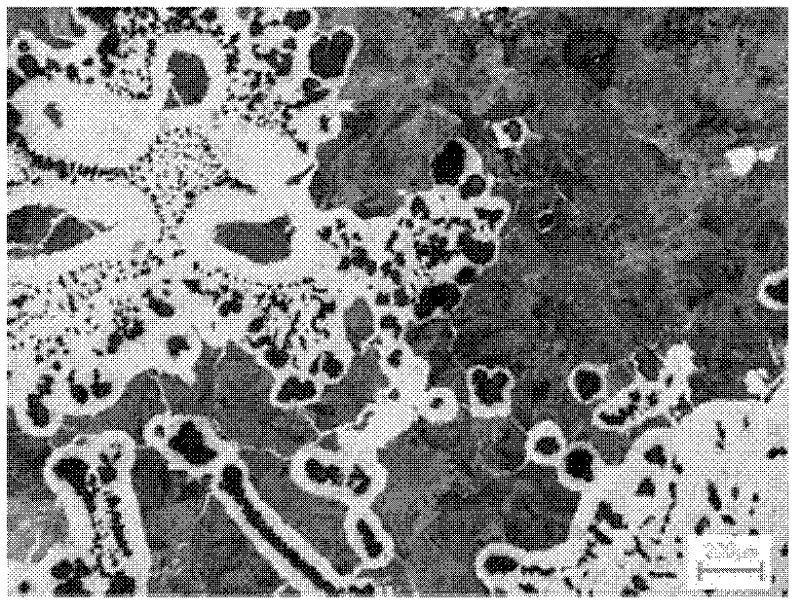

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

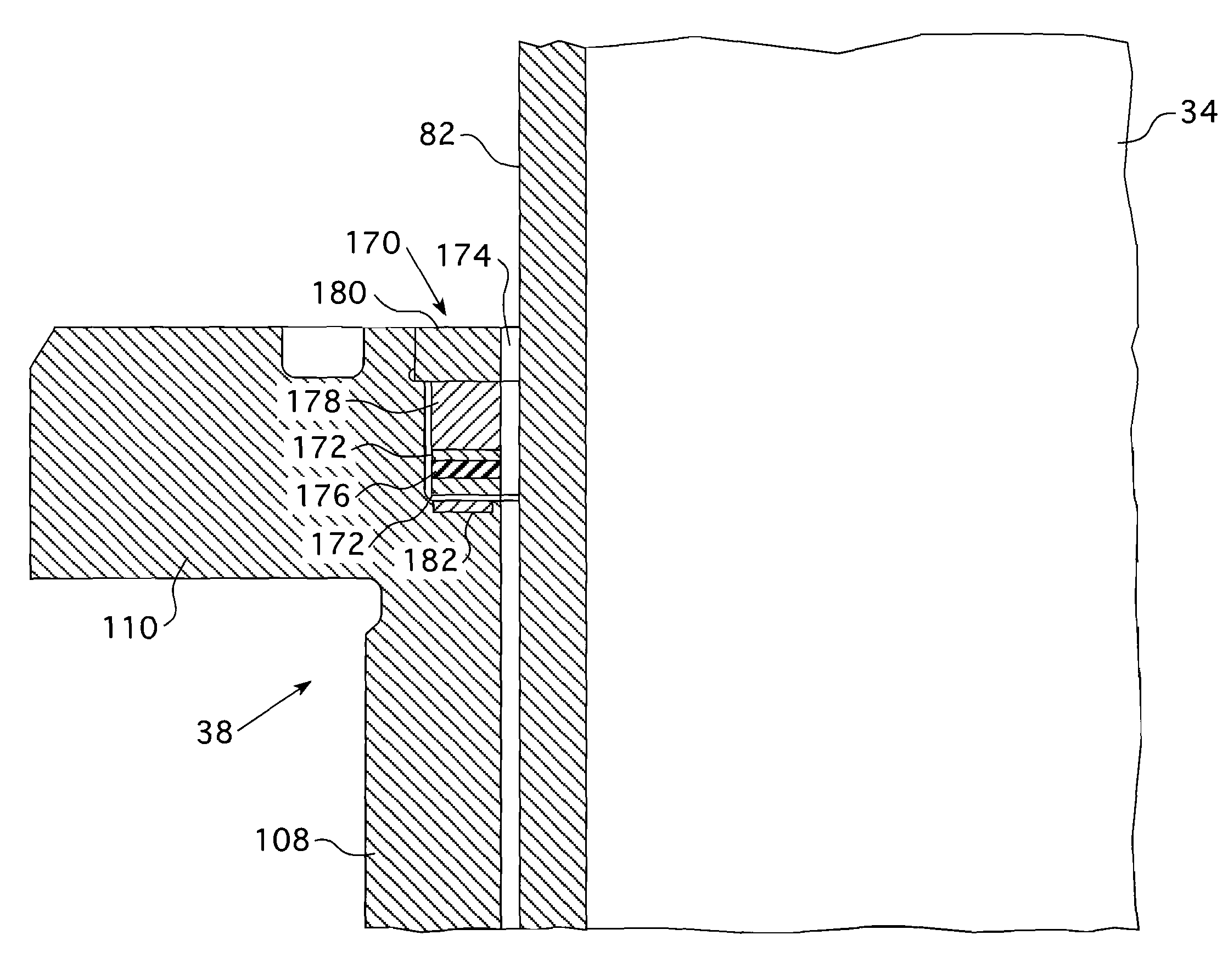

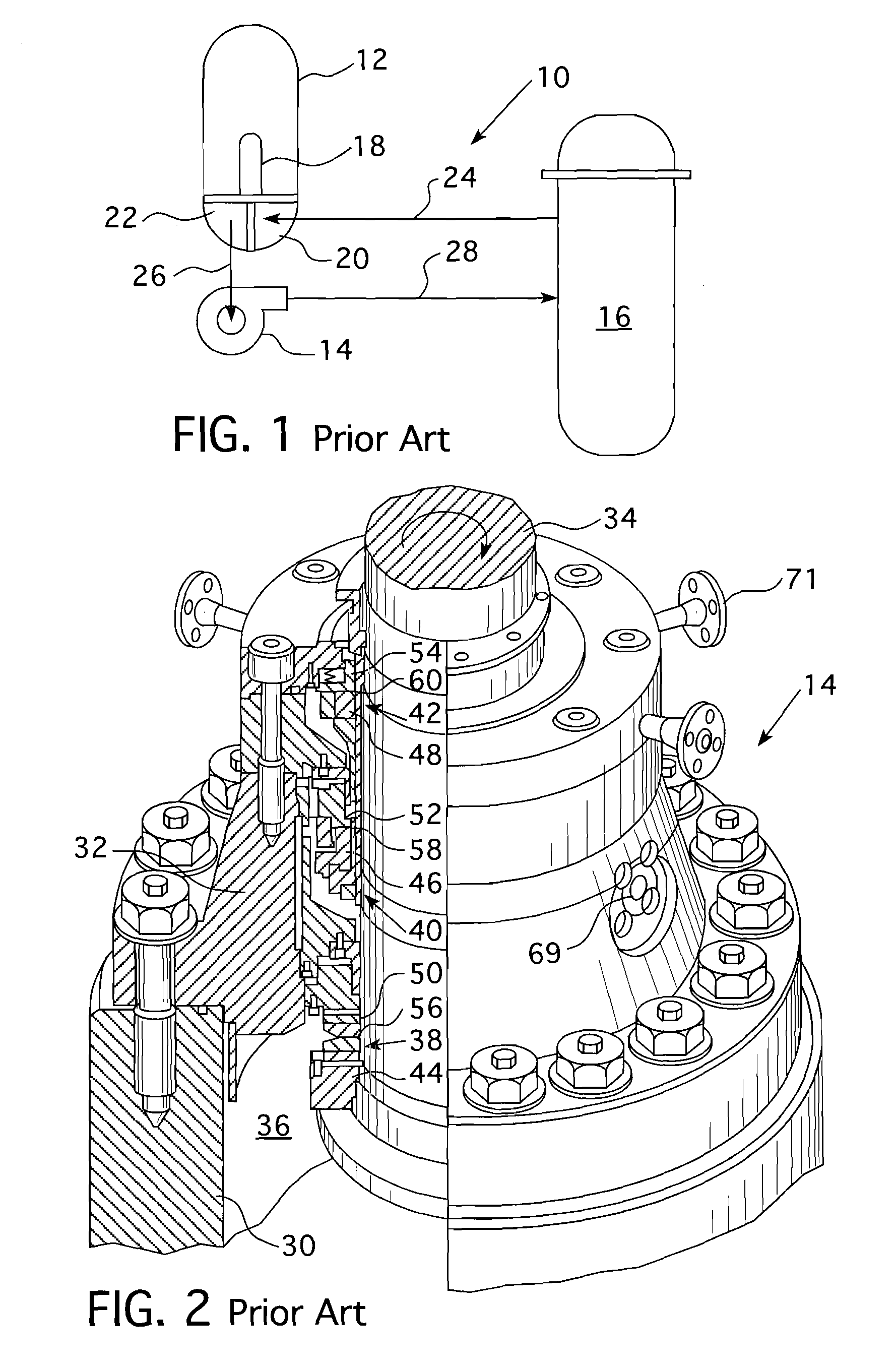

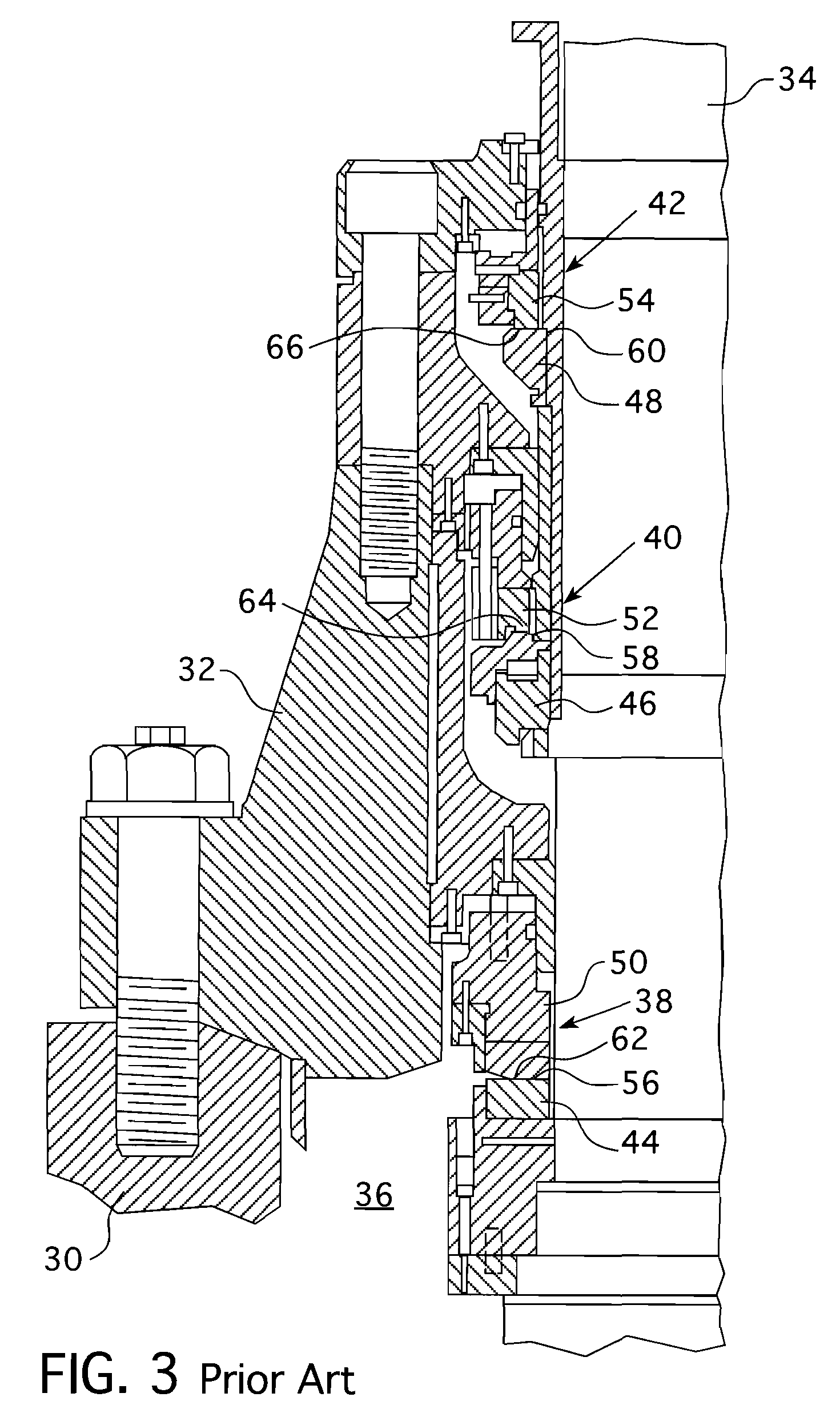

Thermally activated shutdown seals for rotatable shafts

A thermally actuated shutdown seal for a rotating shaft having a narrow annular fluid flow path surrounding the shaft. The seal surrounds the shaft with the annulus therebetween during normal operation and constricts against the shaft when the shaft slows or stops rotating. The annulus is maintained open during normal operation by a spacer interposed between opposing ends of a split ring. When the shaft stops rotating, the temperature of the annulus rises, which actuates removal of the spacer from the split ring constricting the split ring against the shaft blocking the annulus. The blocked annulus causes a pressure differential across the seal which urges a polymer seal ring, downstream of the split ring against the shaft which seals the annulus. In one embodiment, the spacer is formed of a meltable material. In a second embodiment, the spacer is removed from the split ring by a thermally responsive actuator.

Owner:WESTINGHOUSE ELECTRIC CORP

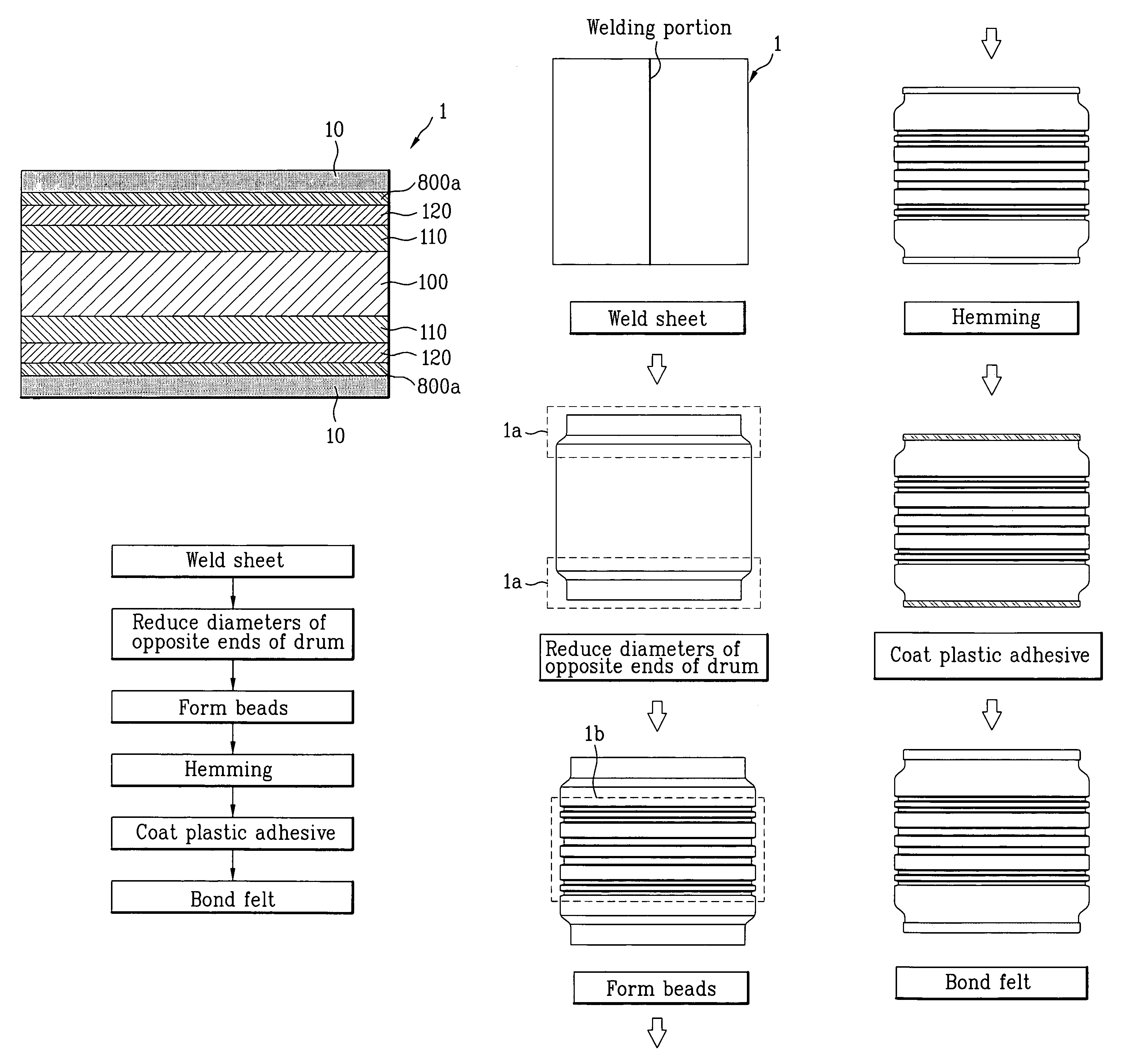

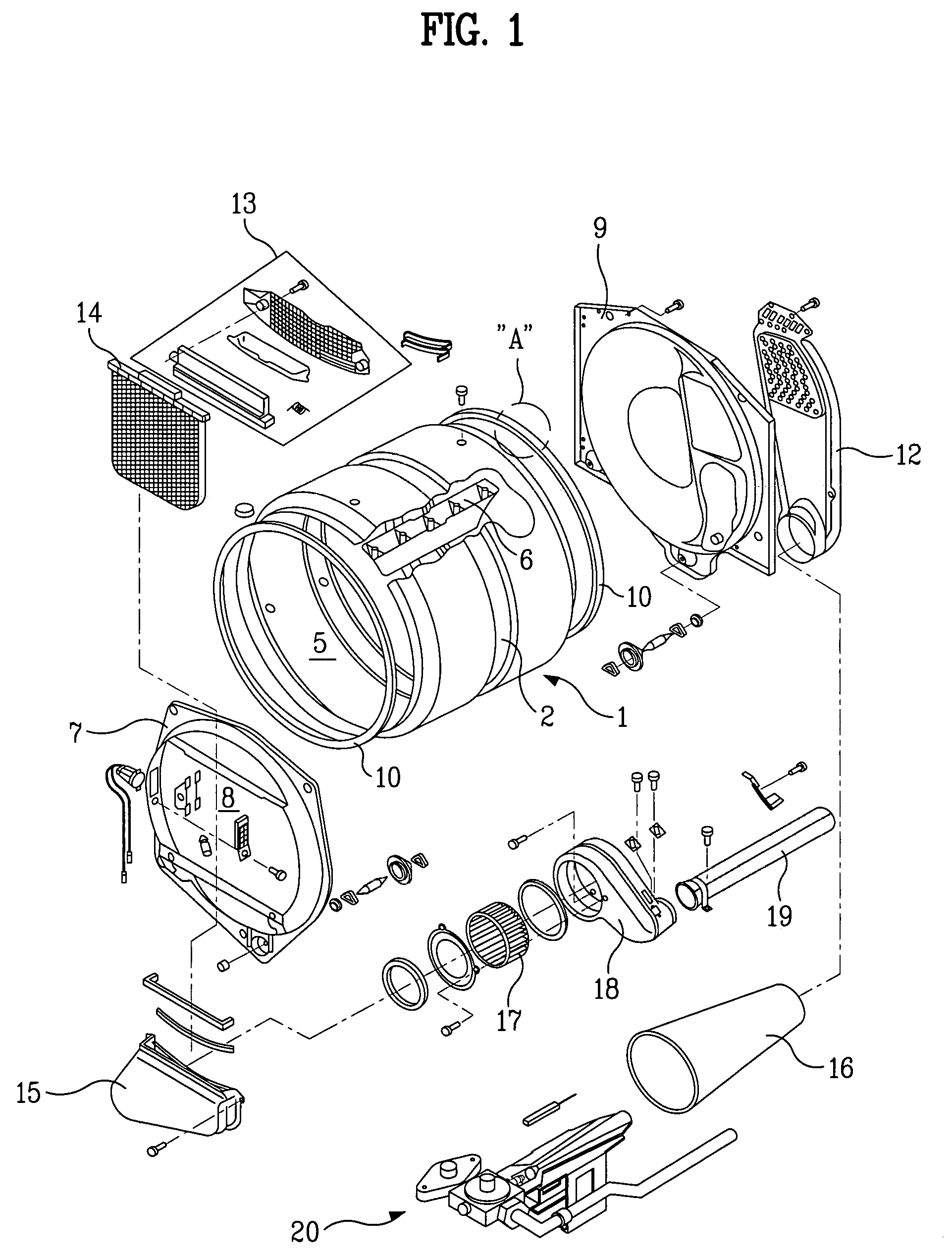

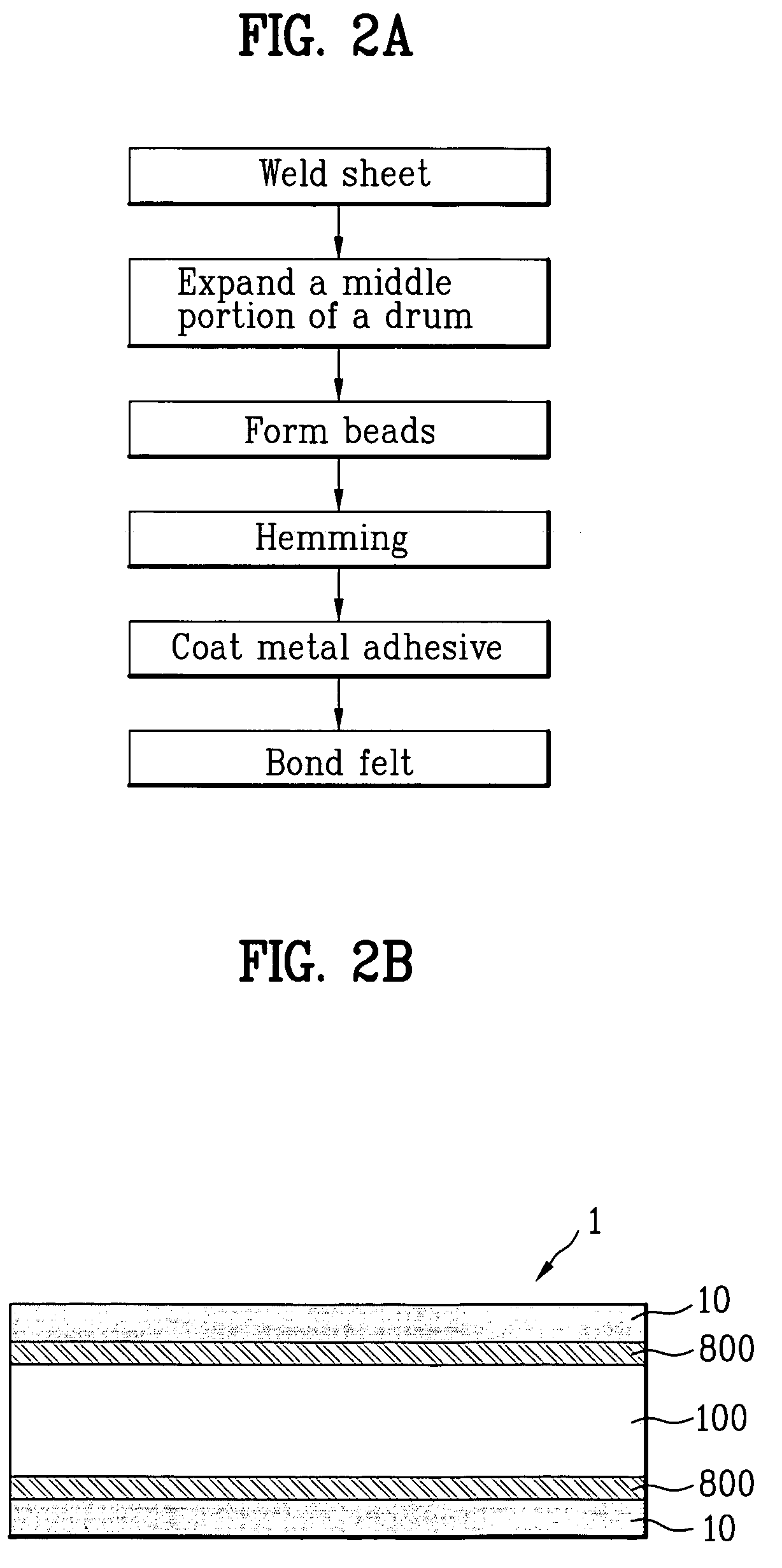

Drum in dryer and method for fabricating the same

ActiveUS7340849B2Low costHigh bonding strengthDrying machines with non-progressive movementsTextiles and paperEngineeringMetal sheet

Owner:LG ELECTRONICS INC

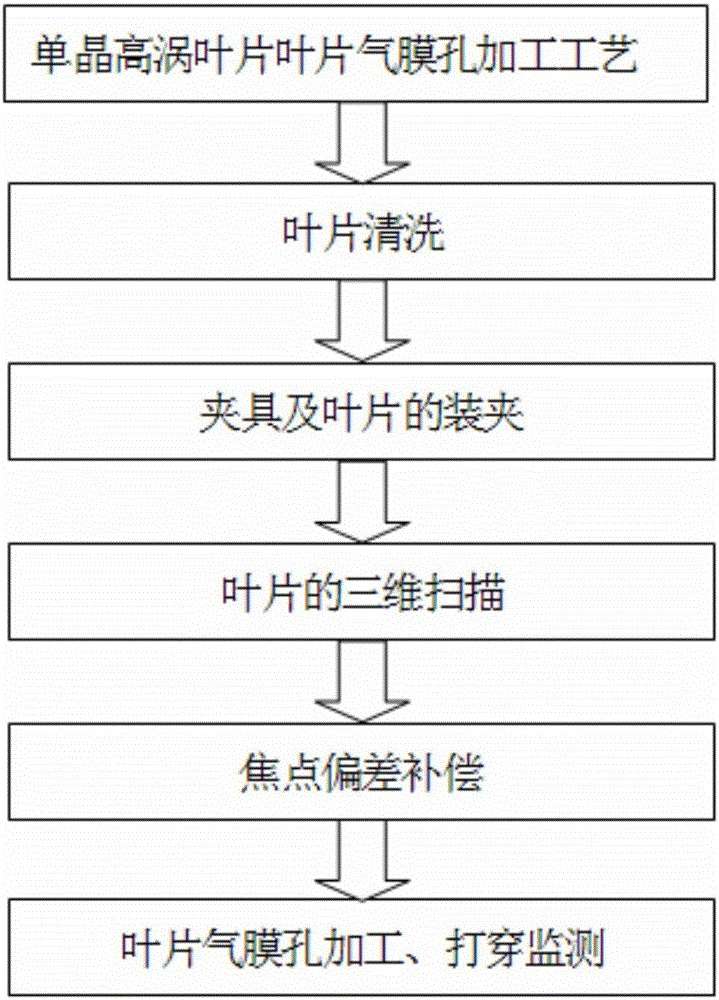

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

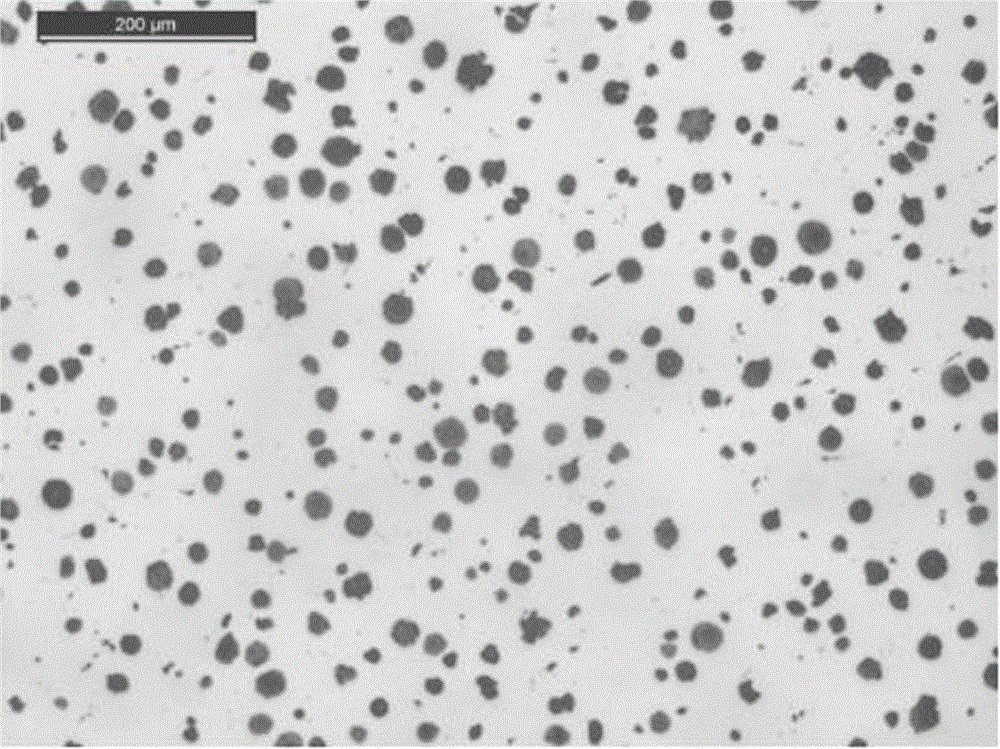

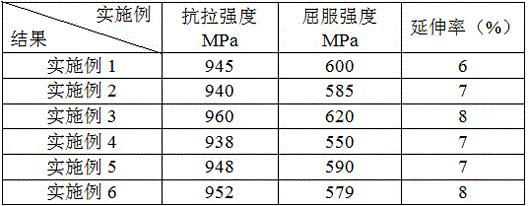

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

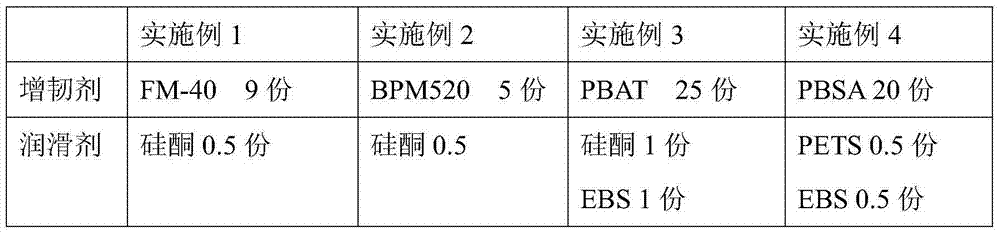

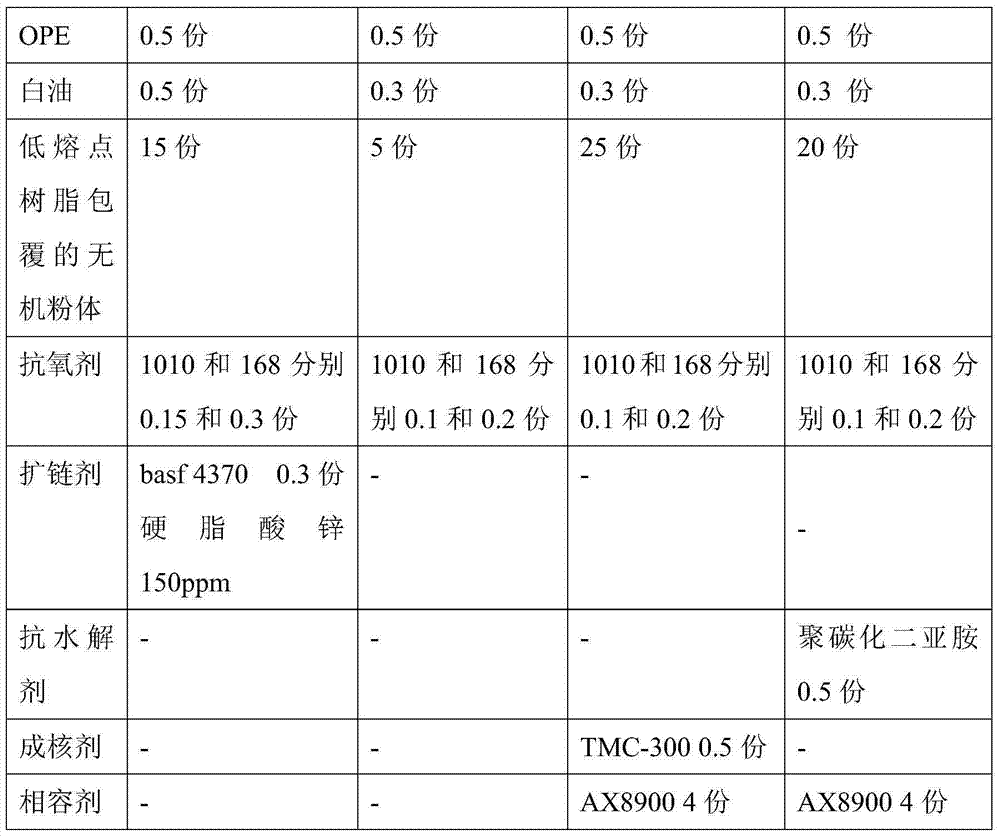

Polylactic acid toughened material for 3D printing and preparation method thereof

ActiveCN104725806AImprove toughnessImprove shrinkageAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention discloses a polylactic acid toughened material for 3D printing, which comprises polylactic acid and the following components in percentage by mass (on the basis of polylactic acid): 5-25% of toughener, 0.5-2.0% of lubricant, 0.5-2.0% of oxidized polyethylene wax, 0.3-1.0% of white oil, 5-25% of low-melting-point resin-coated inorganic powder and 0.3-0.9% of antioxidant. The material prepared by the technical scheme has the advantages of favorable toughness, high extrusion forming regularity and favorable line roundness. The printing proves that the product has the advantages of low shrinkage, no edge lifting, no cracking, high cooling speed and favorable appearance and has wide printing application range.

Owner:SHENZHEN ESUN IND

Ball forming mechanism of ball rolling machine

The ball forming mechanism of ball rolling machine for rolling metal rod, especially copper rod, into ball in the required size includes one frame, one pair of rotating drum seats in the lower part of the frame, one pair of rotating drums, one pair of ball forming rollers matching the rotating drums and with spindle set via two bearing seats on the frame. The ball forming process has high efficiency and no material loss, and the formed ball has high sphericity, smooth surface and high density.

Owner:常熟市钢强金属制品厂

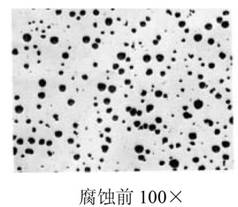

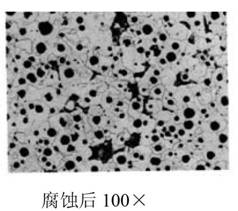

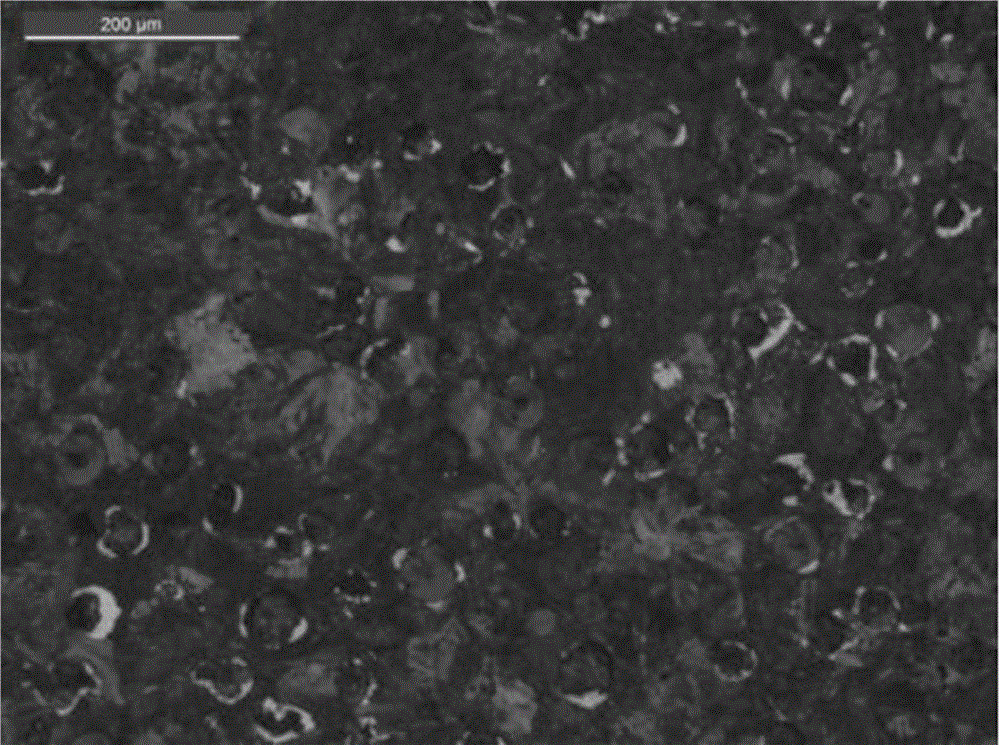

Nodular cast iron and centrifugal composite casting roller

ActiveCN102392178AImprove roundnessDecrease in spheroidizationRollsMetal rolling arrangementsCeriumHardness

The invention relates to nodular cast iron and a centrifugal composite casting roller. The nodular cast iron comprises, by weight, 3.0-3.4% of C, 2.2-2.4% of Si, Mn being less than 0.4, P being less than 0.05, S being less than 0.015, 0.85-0.95% of Ni, 0.3-0.5% of Cu, 0.2-0.3% of Mo, 0.015-0.020% of Sb, 0.01-0.03% of RE, 0.03-0.06% of Mg, and the balance being Fe and impurity elements. Concrete steps comprise: firstly melting base iron, using a cerium-based light RE-Mg nodulizer and an Mg-Ni alloy nodulizer for spheroidising by pouring process; using a long-acting inoculant containing barium and calcium elements for stream inoculation during the casting process while the casting temperature of nodular cast iron is 1430-1450 DEG C, and realizing metallurgy melting with centrifugal casting high chromium cast steel to form a roll core part and a roll neck. According to the obtained roll neck, the nodular cast iron tensile strength is greater than or equal to 550MPa, graphite nodularity reaches 2-3 level, hardness number is HSD35-45, and there is no macroscopic grey spots and bright spots. In addition, the invention also provides the high chromium cast steel centrifugal composite casting roller with the above nodular cast iron as the core part.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

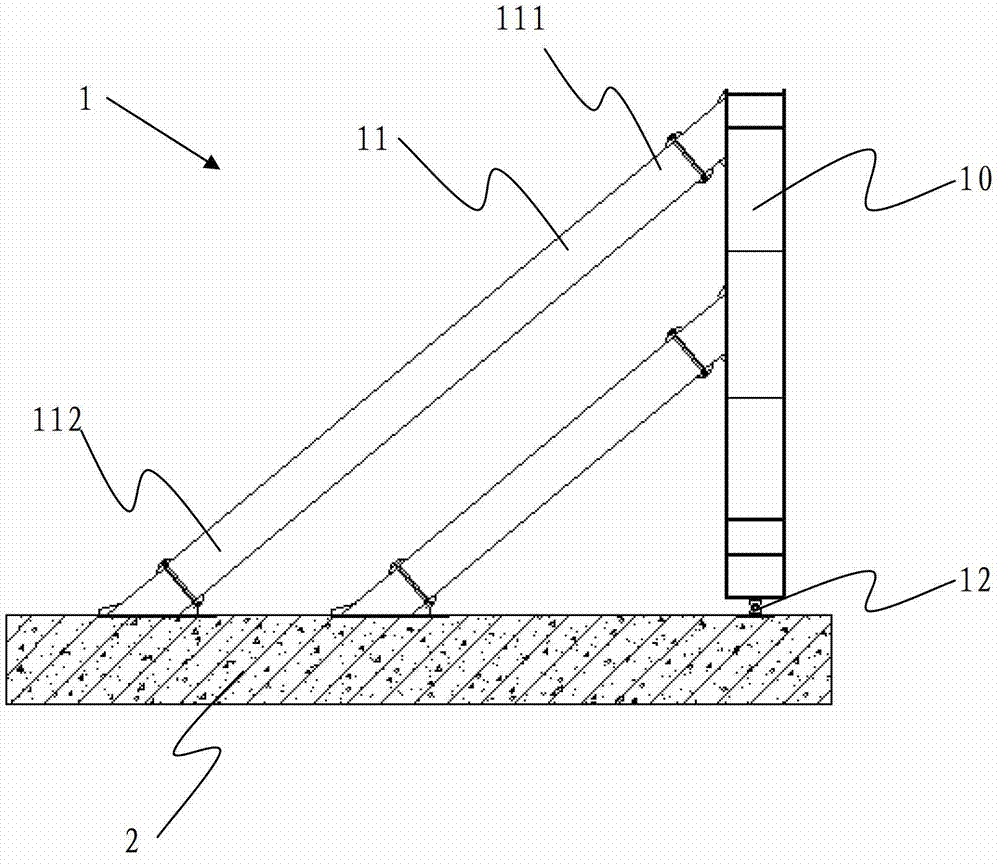

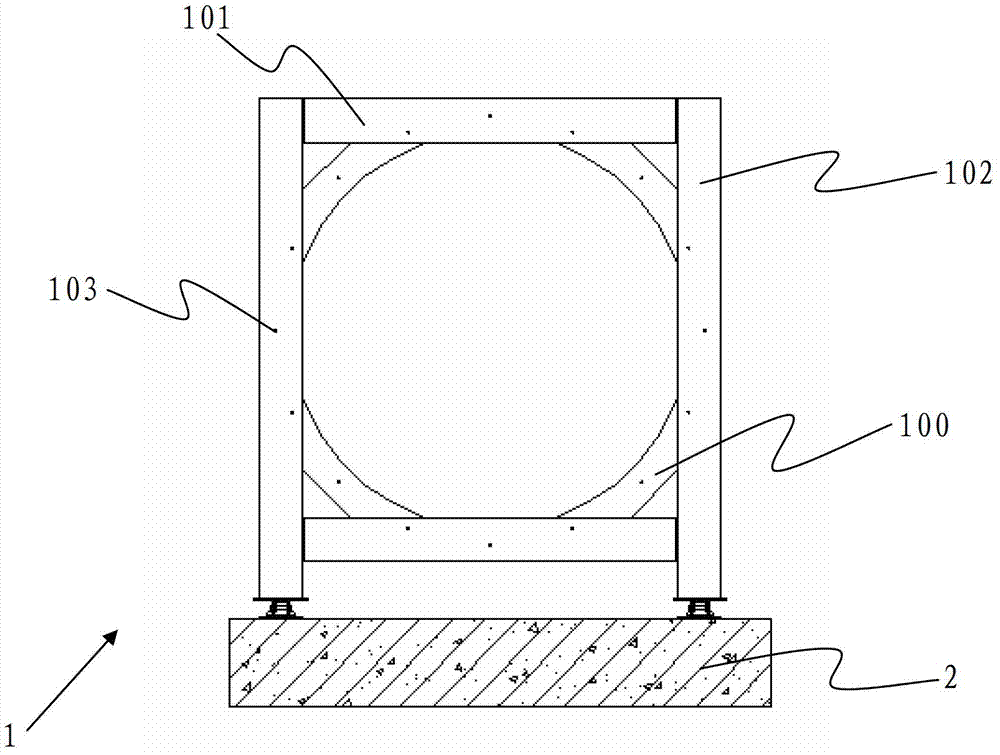

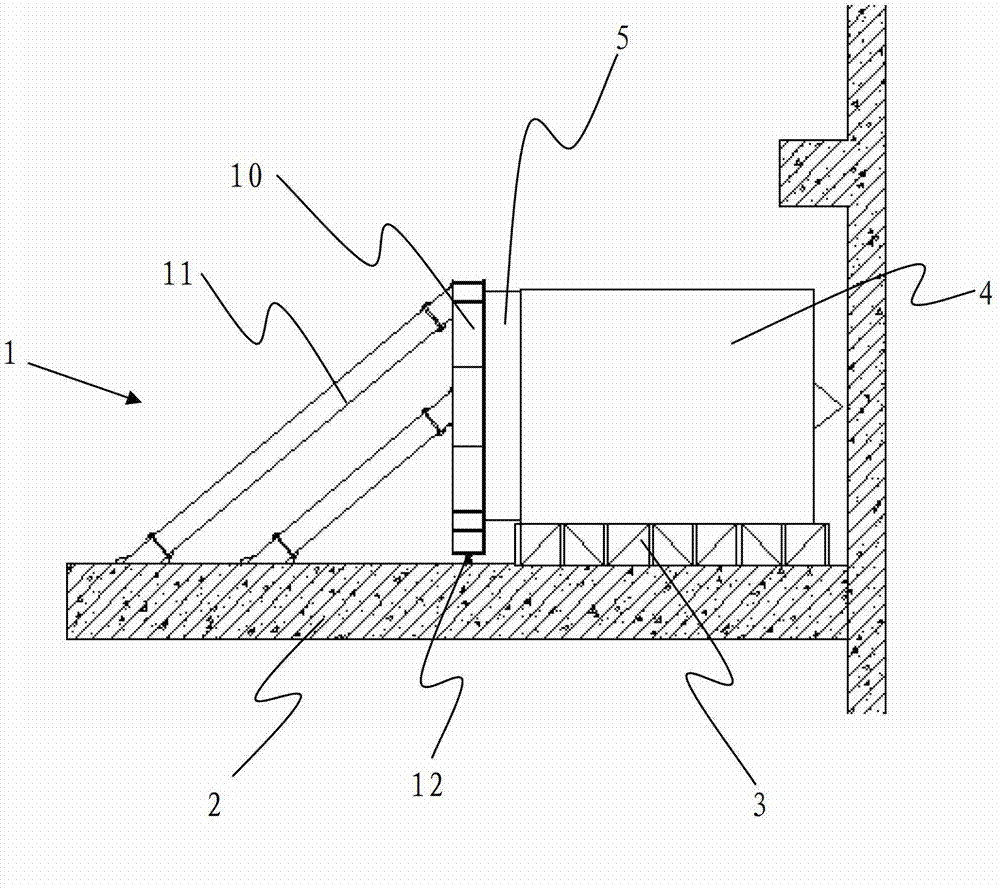

Assembling type reaction frame device for shield launching and propulsion

InactiveCN102758634AEasy to controlGuarantee smooth implementationUnderground chambersTunnel liningEngineeringHinge angle

The invention discloses an assembling type reaction frame device for shield launching and propulsion, and the device is arranged on a bottom plate of a work shaft, wherein the reaction frame device comprises a frame and a plurality of supporting rods; the frame is connected to the bottom plate of the work shaft by a hinge; the first ends of the supporting rods are connected with the frame; the second ends of the supporting rods are connected with the bottom plate of the work shaft; the frame is coaxial to a tunnel portal; the frame further comprises two cross beams and two vertical beams which are mutually connected to form a rectangular frame; the frame also comprises a plurality of reaction ring assembling beams and a plurality of bolt holes; the reaction ring assembling beams are arc-shaped and are respectively connected at the four corners in the rectangular frame; the surfaces of the reaction ring assembling beams and the surface of the rectangular frame form a plane; and the bolt holes are distributed on the surface of the frame and are corresponding to the positions of longitudinal bolt holes of pipe pieces. Since the whole assembling structure can be repeatedly utilized and the position can be freely adjusted, the assembling type reaction frame device is applicable to different types of work shafts.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +1

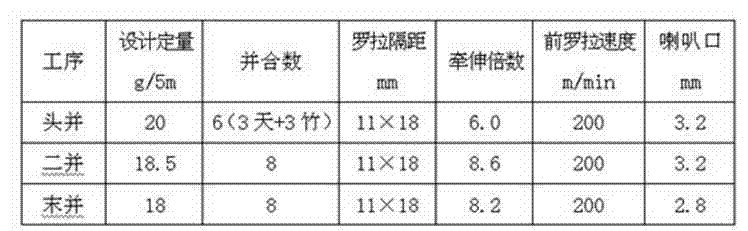

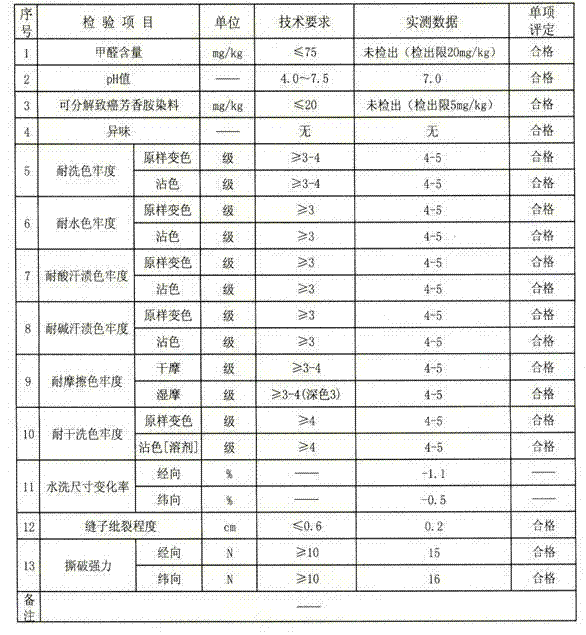

Natural bamboo fiber shirt fabric and manufacture method thereof

The invention provides natural bamboo fiber shirt fabric which has silky gloss, good feel and drapability, and is rich in graceful feeling, antibiosis, moisture-adsorption and ventilating. Warps and wefts of the fabric are both natural fiber / bamboo viscose blended yarns, the blending ratio of the warps and the wefts is 1:1, the warp density is 512 / 10cm, and the weft density is 338.5 / 10cm. A manufacture method of the natural bamboo fiber shirt fabric comprises the following steps: a, blending: opening picking, carding cotton, drawing out, roving and spun yarn; b, drum yarn dying: tube loosening, pretreatment, dying, dehydration and drying, wherein the pretreatment comprises bleaching and enzyme treatment; during bleaching: soda ash is 1-3g / L, hydrogen peroxide is 1-2g / L, the temperature is 95 DEG C, the time is 35-45min; and during the enzyme treatment, HontonezymePA is 1-1.5g / L, pH value is 4.5-5.5, the bath ratio is 1:15, and the time is 25-35min; and during dying, the drum yarn density is 0.33-0.35g / cm<3>, and MegafixB type reactive dying is adopted; c, weaving: winding, warp pulp connection, drawing in or warp tying and weaving; and d, after treatment: singeing, desizing, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

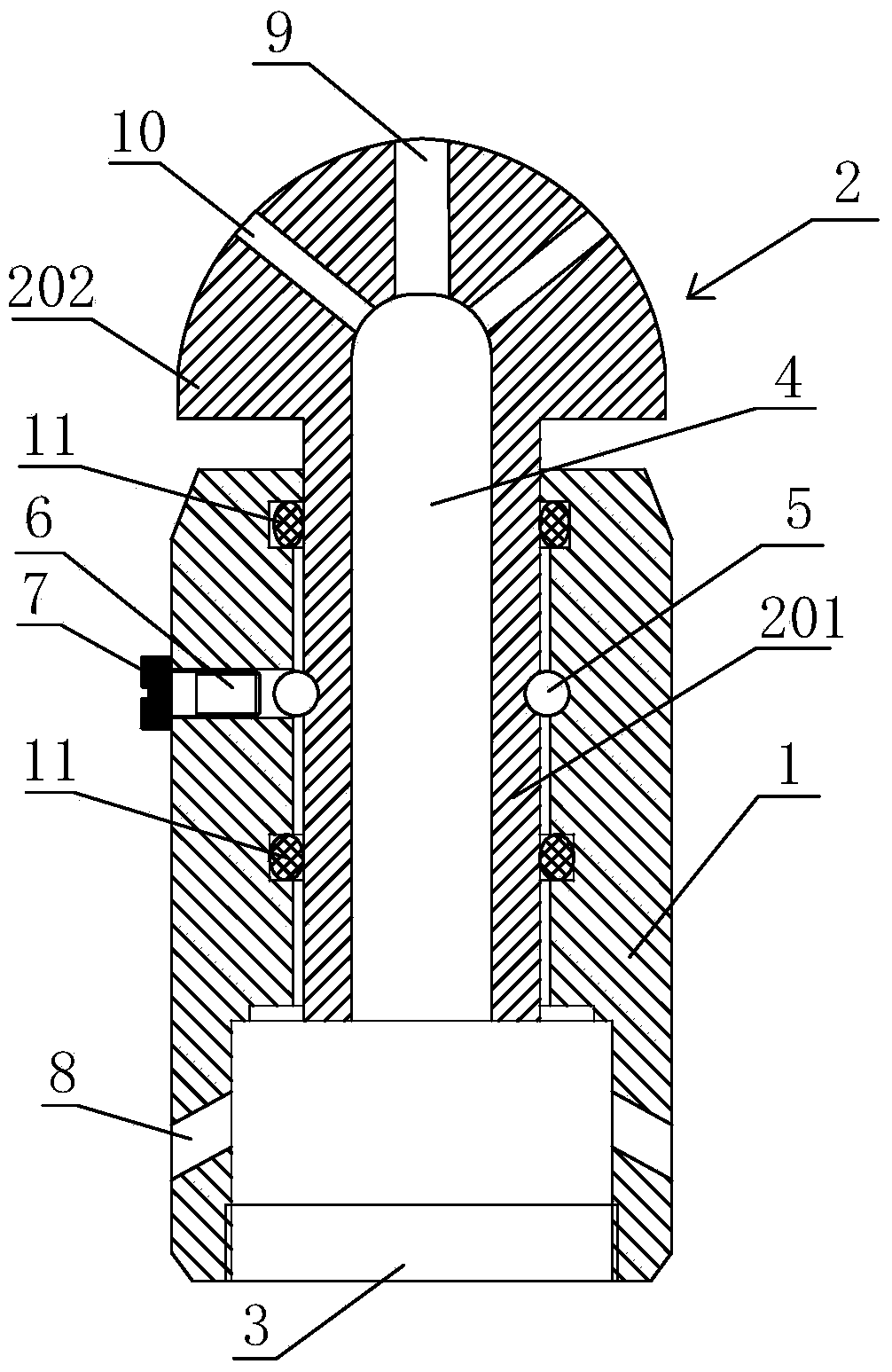

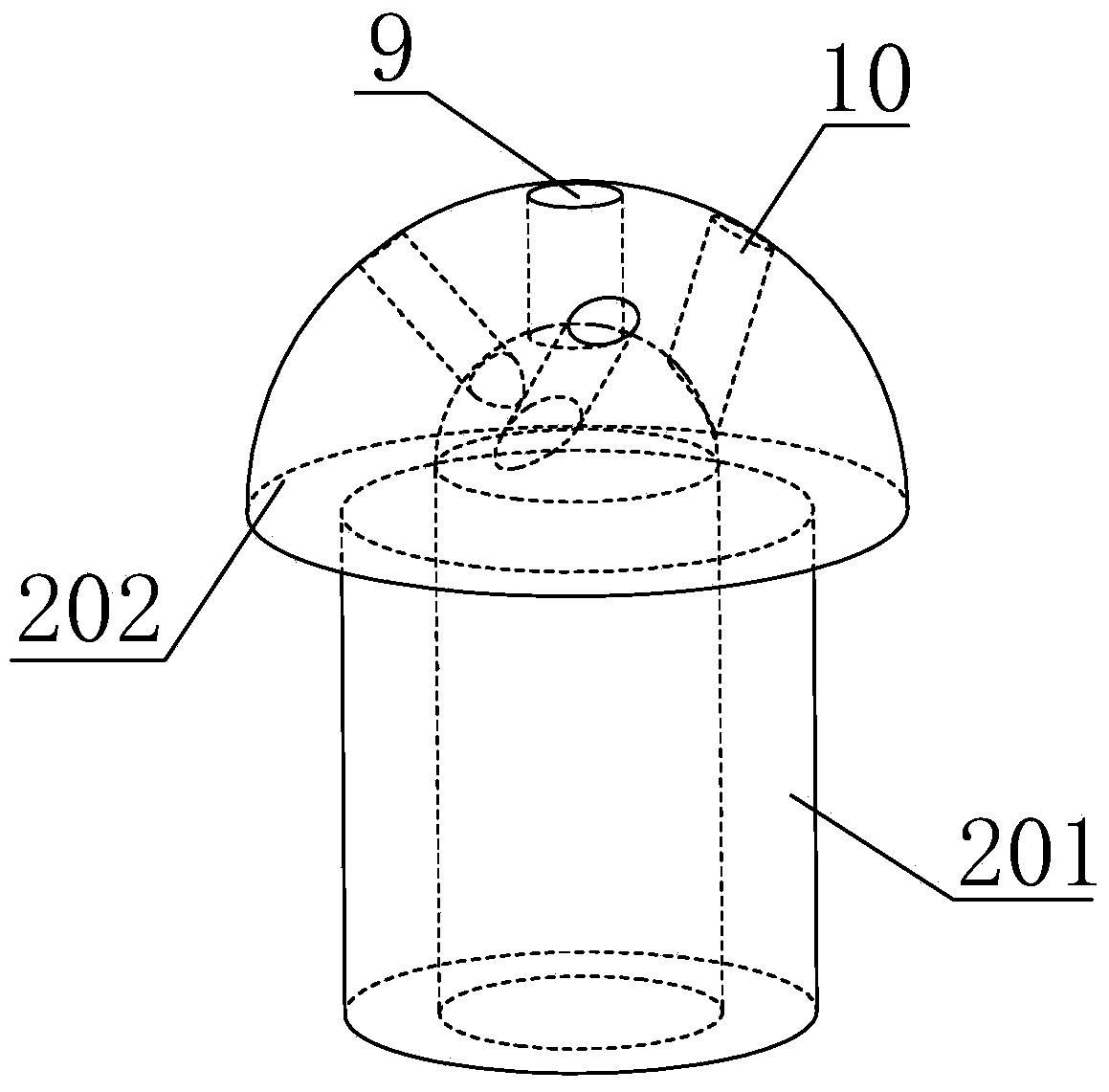

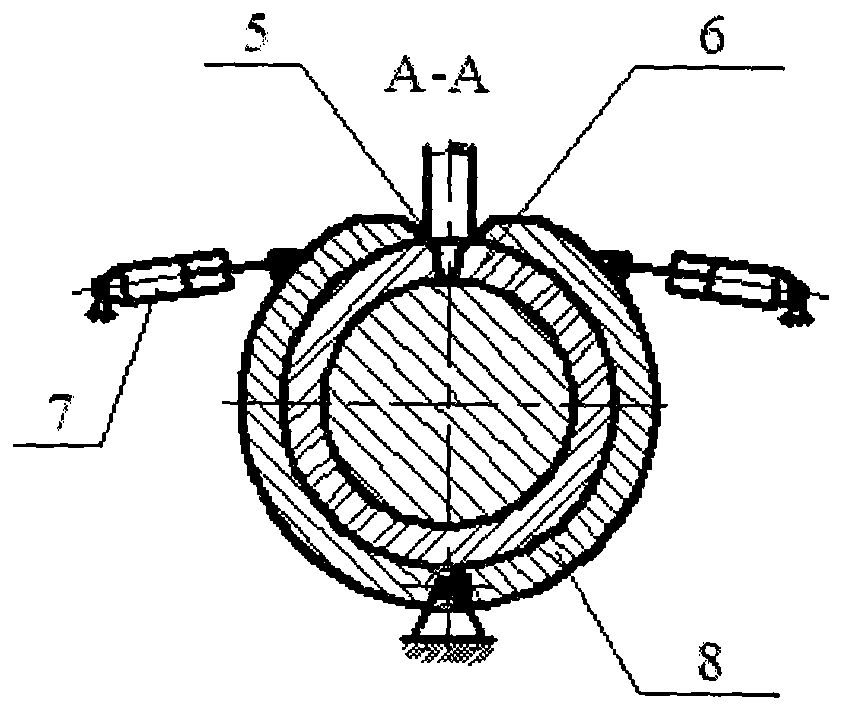

Radial sidetrack drilling rotating self-propelled porous jet flow drill bit

The invention relates to a radial sidetrack drilling rotating self-propelled porous jet flow drill bit, which mainly comprises a casing, a rotating drill bit body, a gear type slide ring type combined seal, an opening sealing screw, steel balls and the like, wherein a water inlet is processed at the tail end of the casing; a backward spray nozzle is processed on the casing; a forward spray nozzle and a center spray nozzle are processed on the rotating drill bit body; semicircular grooves are respectively processed in the casing and the rotating drill bit body; the steel balls are placed in the grooves formed between the casing and the rotating drill bit body; the rotating drill bit body is positioned through the steel balls and can rotate around the self axial line; the gear type slide ring type combined seal is adopted between the rotating drill bit body and the casing; through holes are formed at the lateral side of the casing; the steel balls are placed into the grooves through the through holes; and after the steel balls are placed into the grooves, the through holes are sealed through the opening sealing screws. The radial sidetrack drilling rotating self-propelled porous jet flow drill bit can effectively solve the problems of poor jet flow drill bit reaming capability, poor rock breaking hole smooth roundness, bent tracks of hydraulic jet hoses and the like of the hydraulic jet radial sidetrack drilling tiny drill hole technology, and can be widely applied to the hydraulic jet radial horizontal well technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

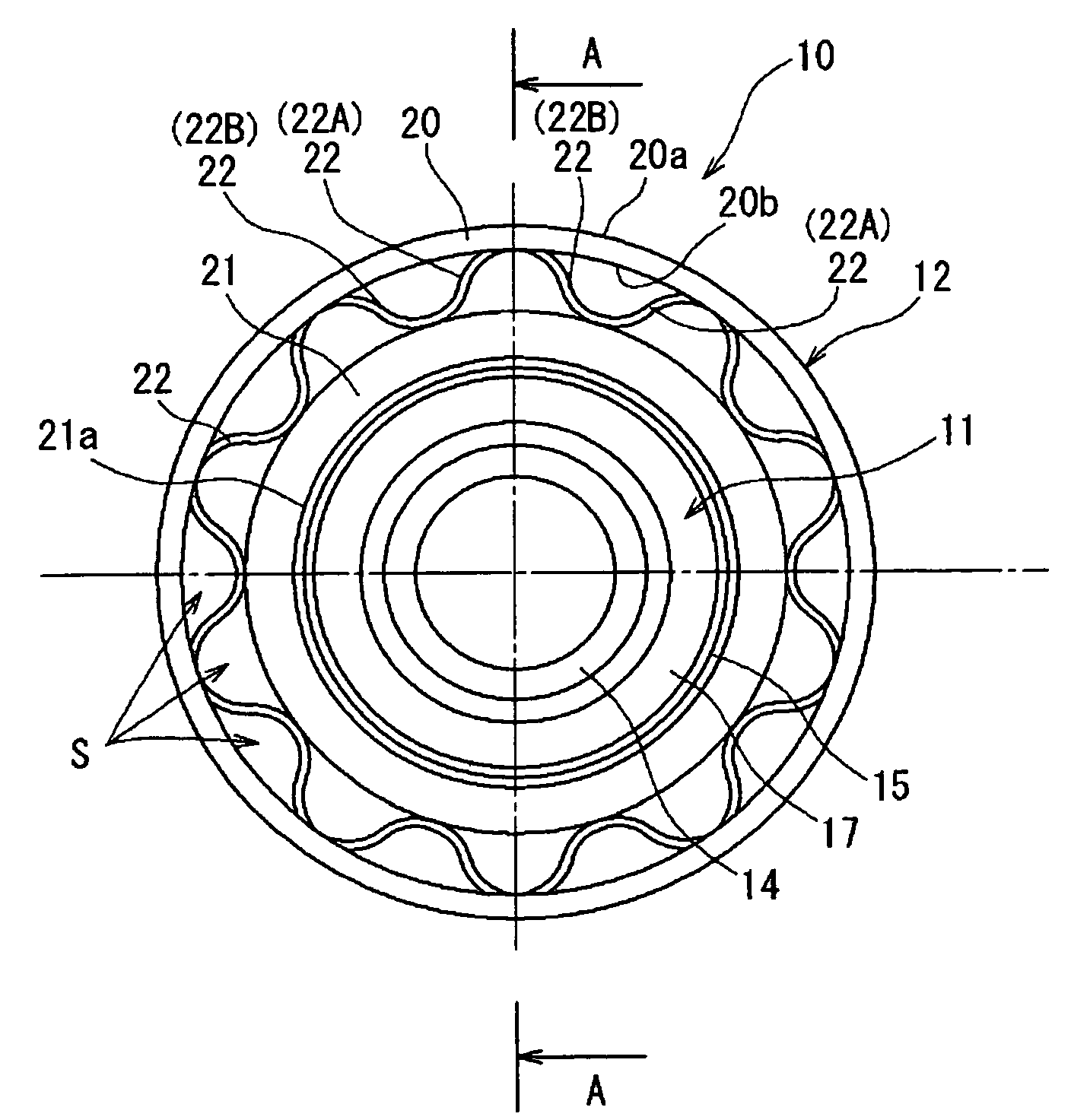

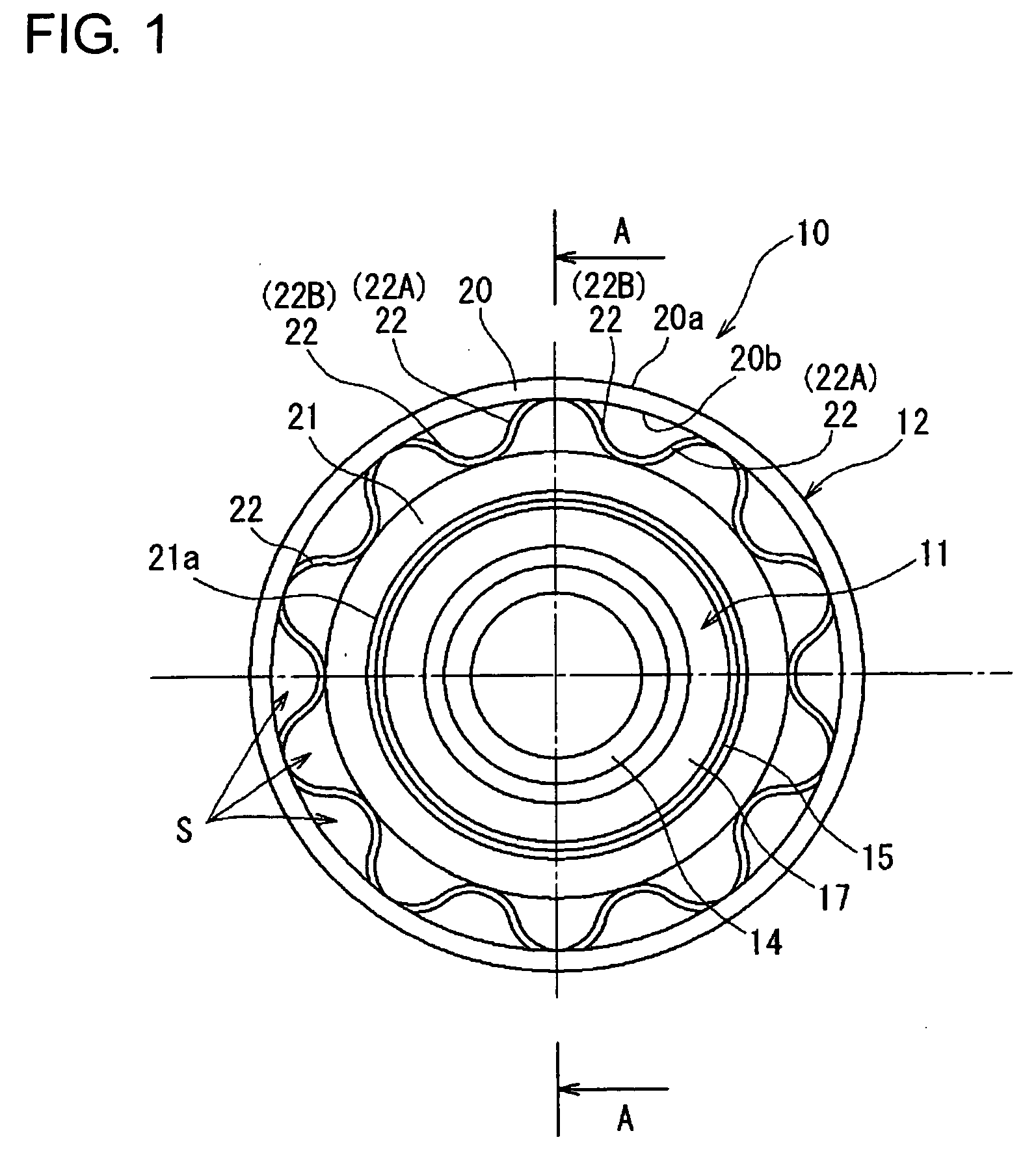

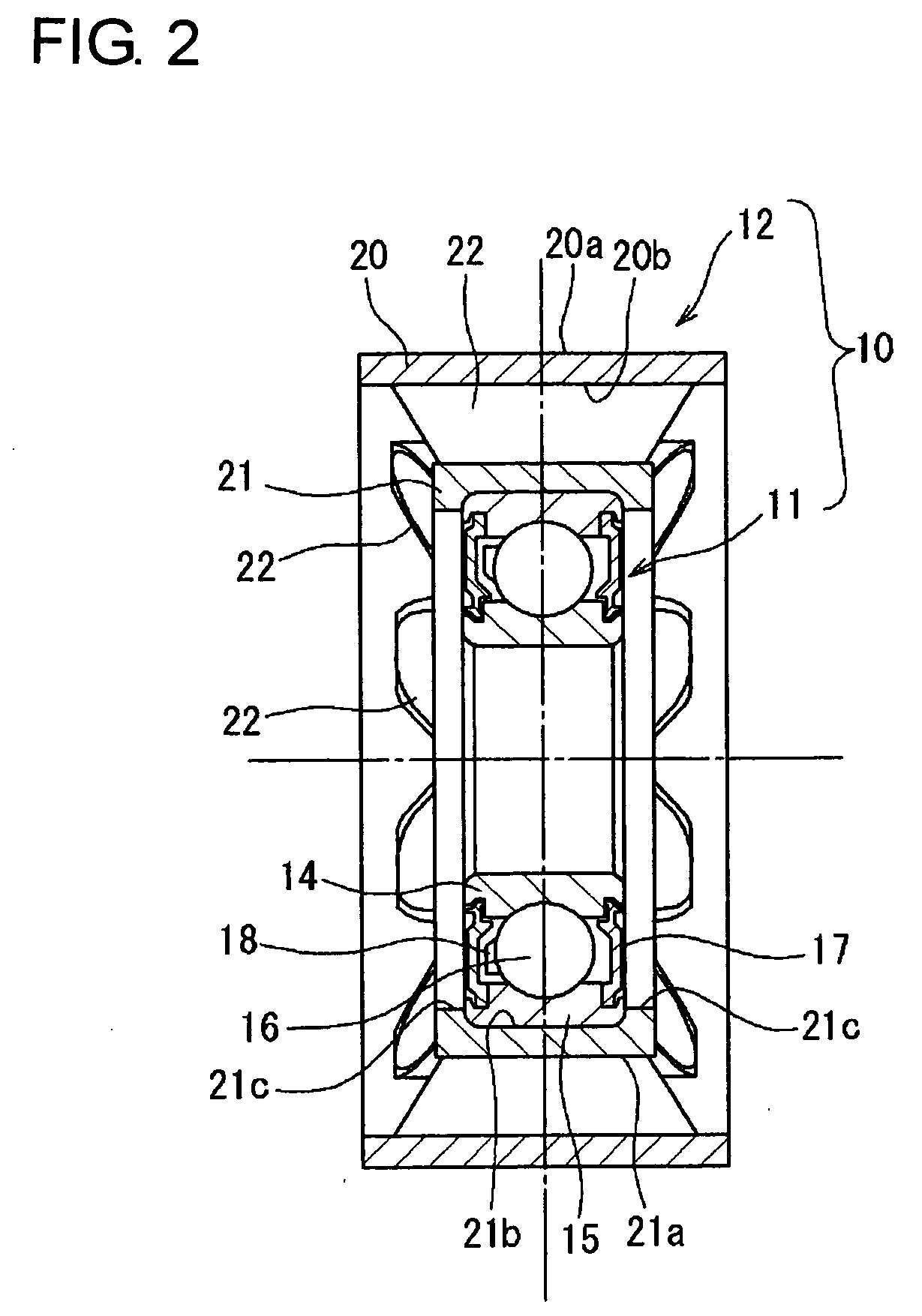

Resin pulley

A resin pulley includes: an outer cylindrical portion having an outer circumferential surface on which a belt is to be wound; an inner cylindrical portion which is disposed radially inwards of and concentrically with the outer cylindrical portion; and a plurality of ribs connecting an inner circumferential surface of the outer cylindrical portion and an outer circumferential surface of the inner cylindrical portion. The outer cylindrical portion, the inner cylindrical portion and the ribs are formed integrally from a resin material, and the ribs are provided in such a manner as to be inclined towards a circumferential direction relative to a radial imaginary line as viewed in an axial direction.

Owner:JTEKT CORP

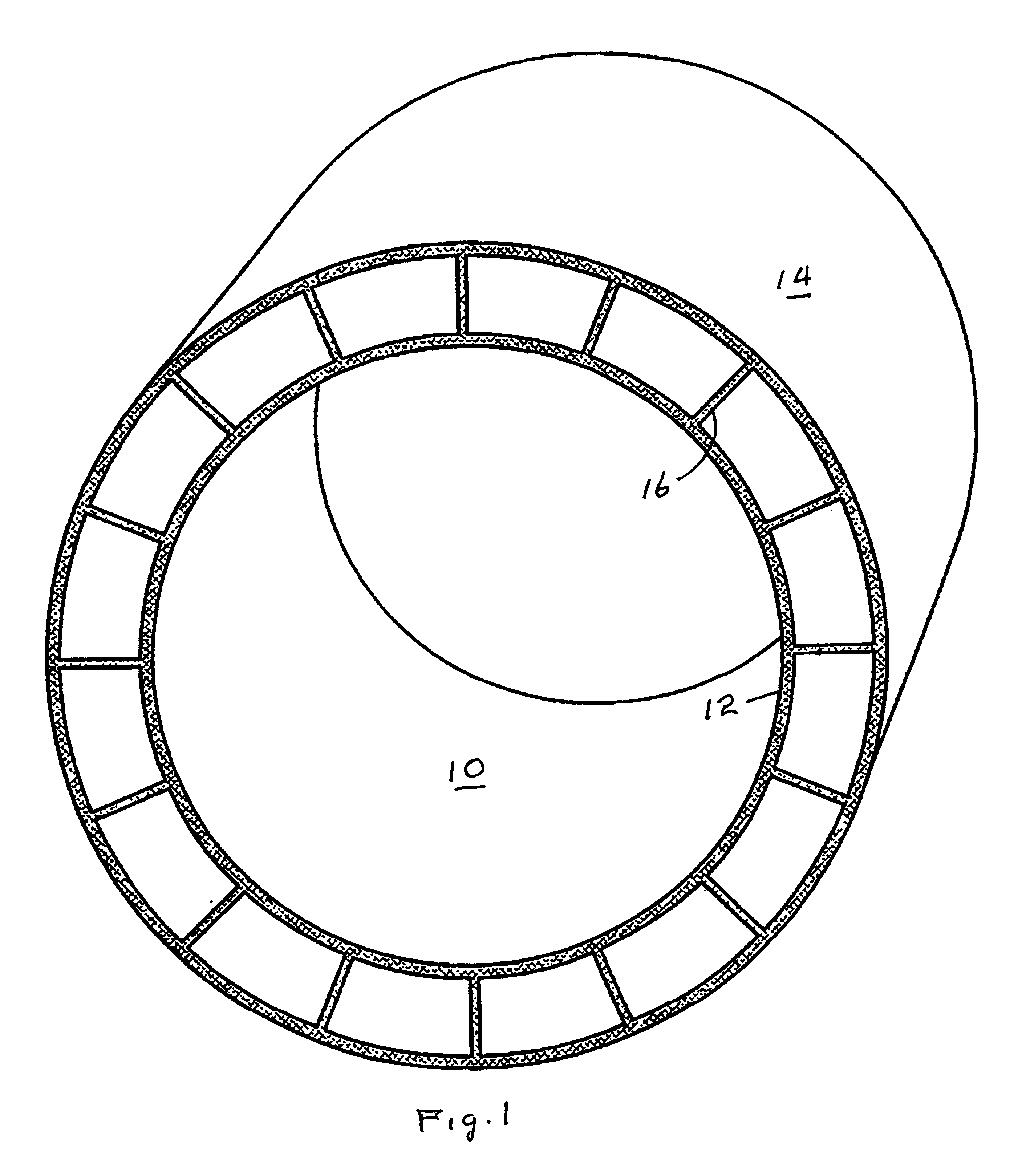

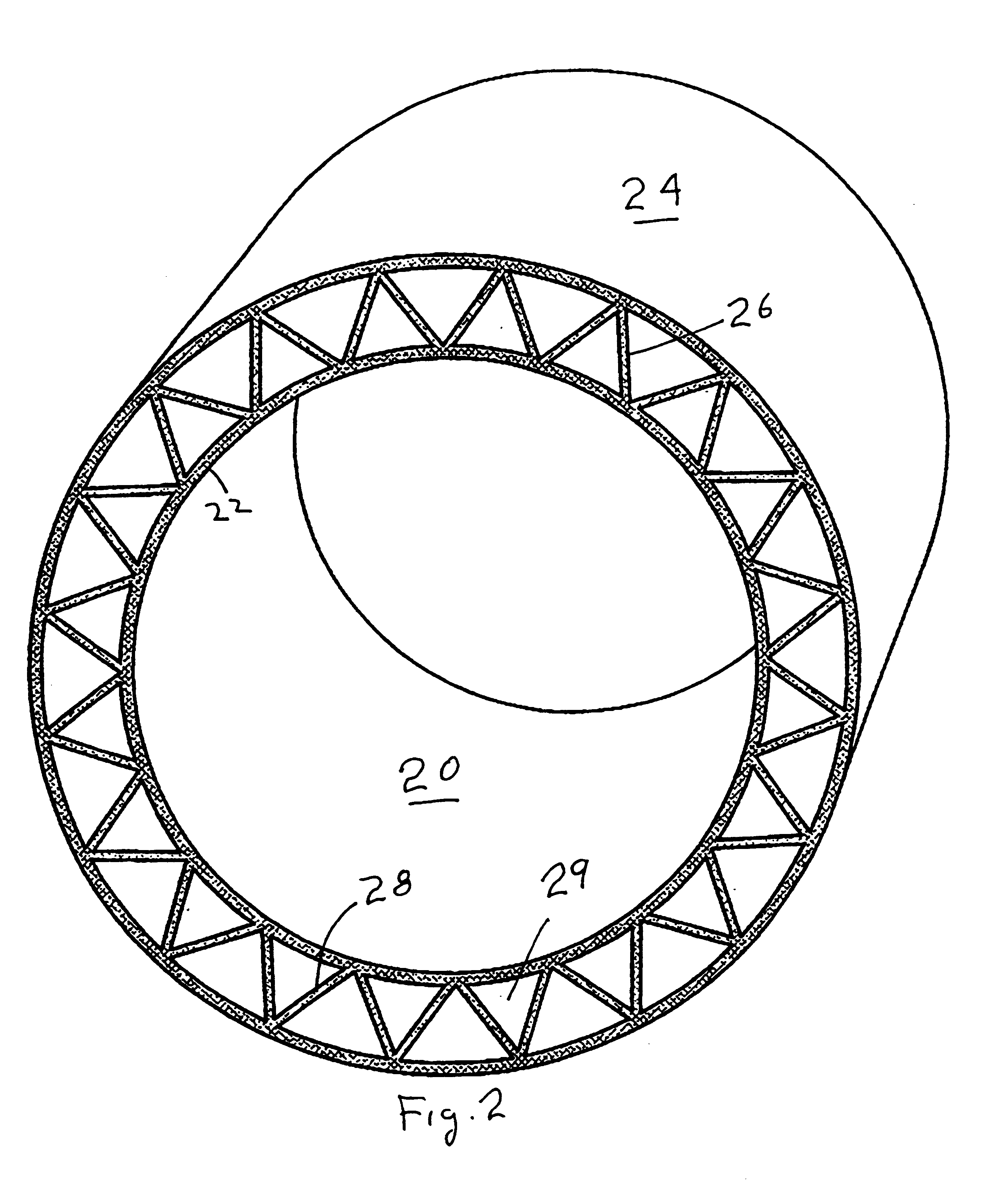

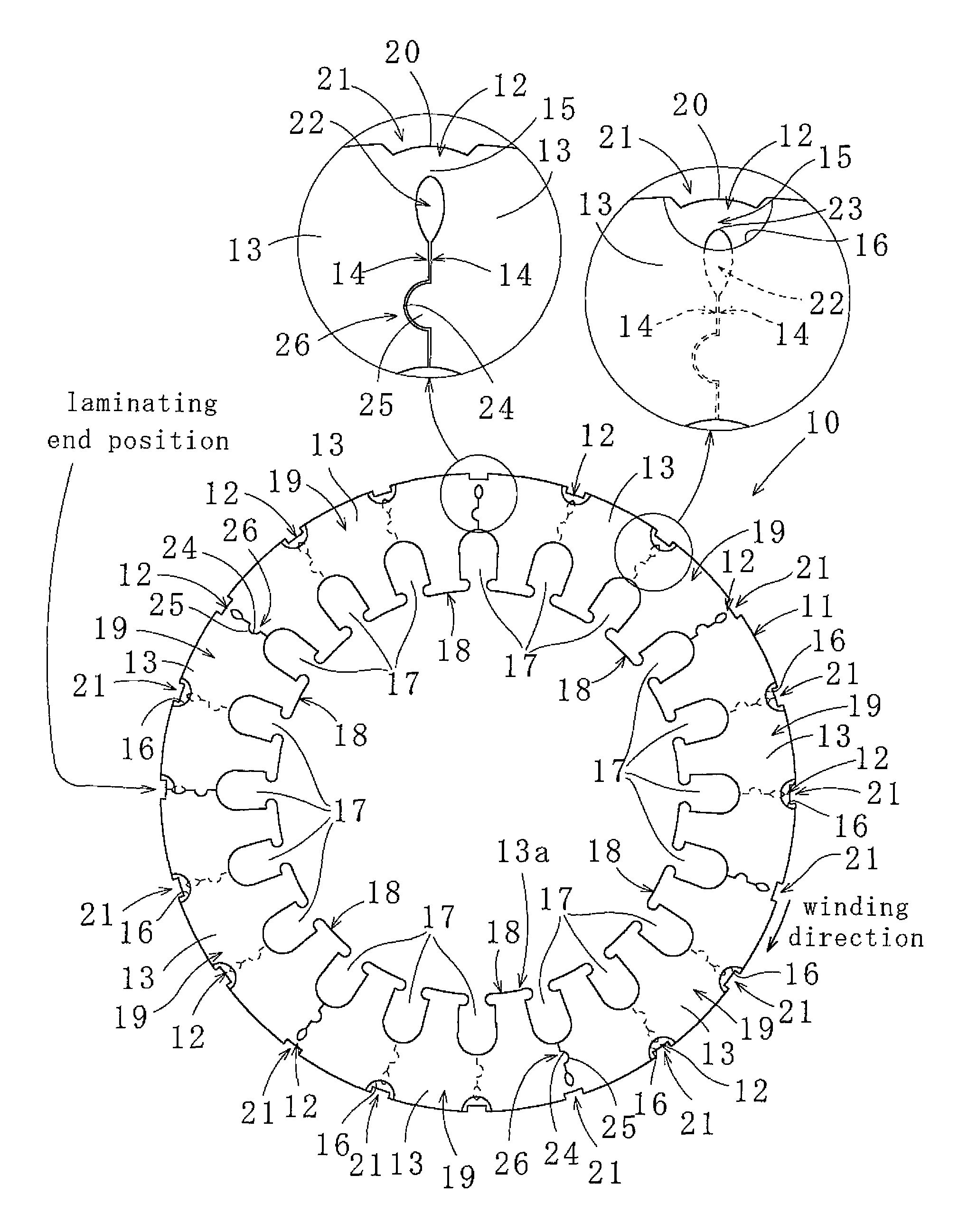

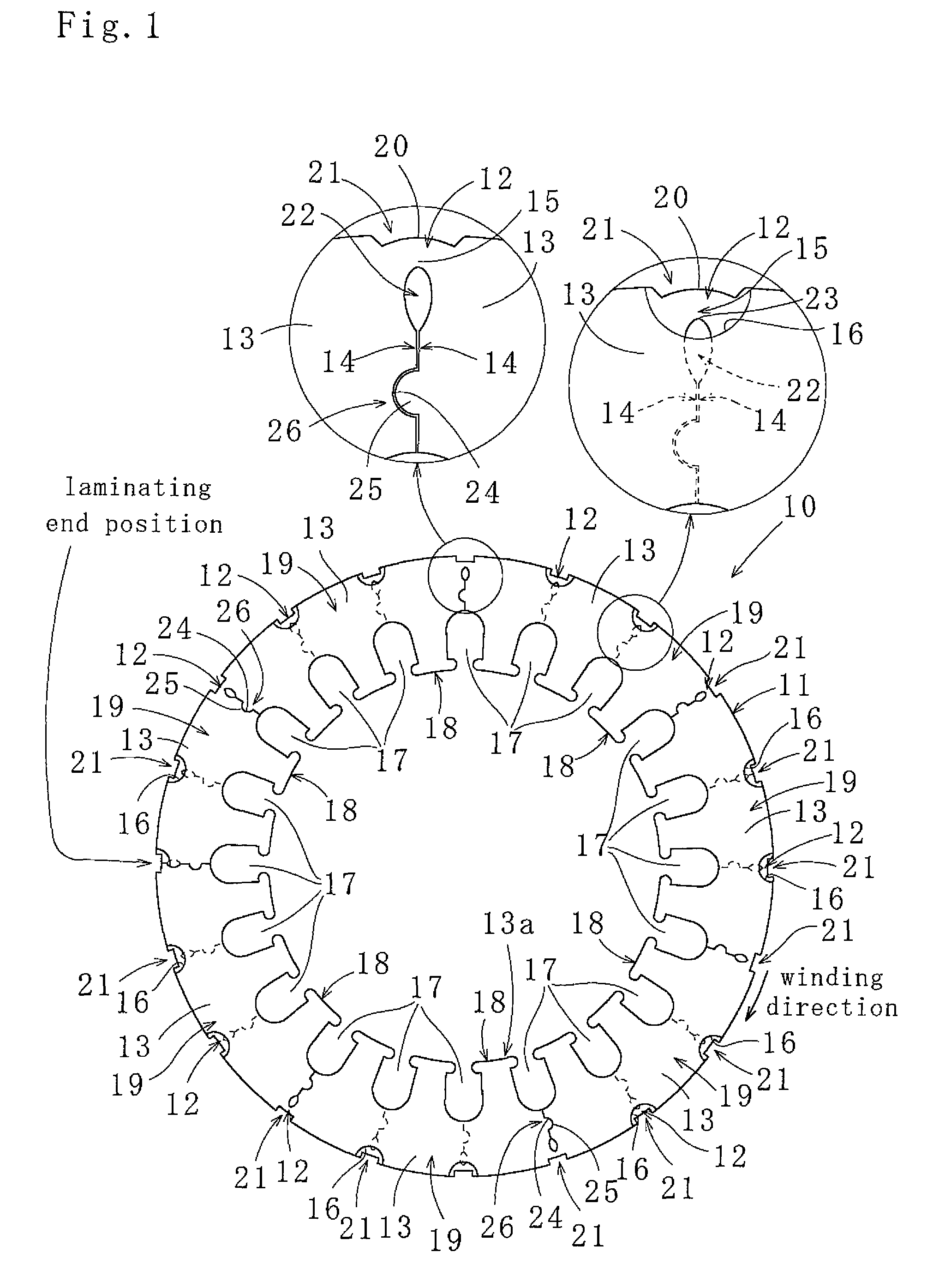

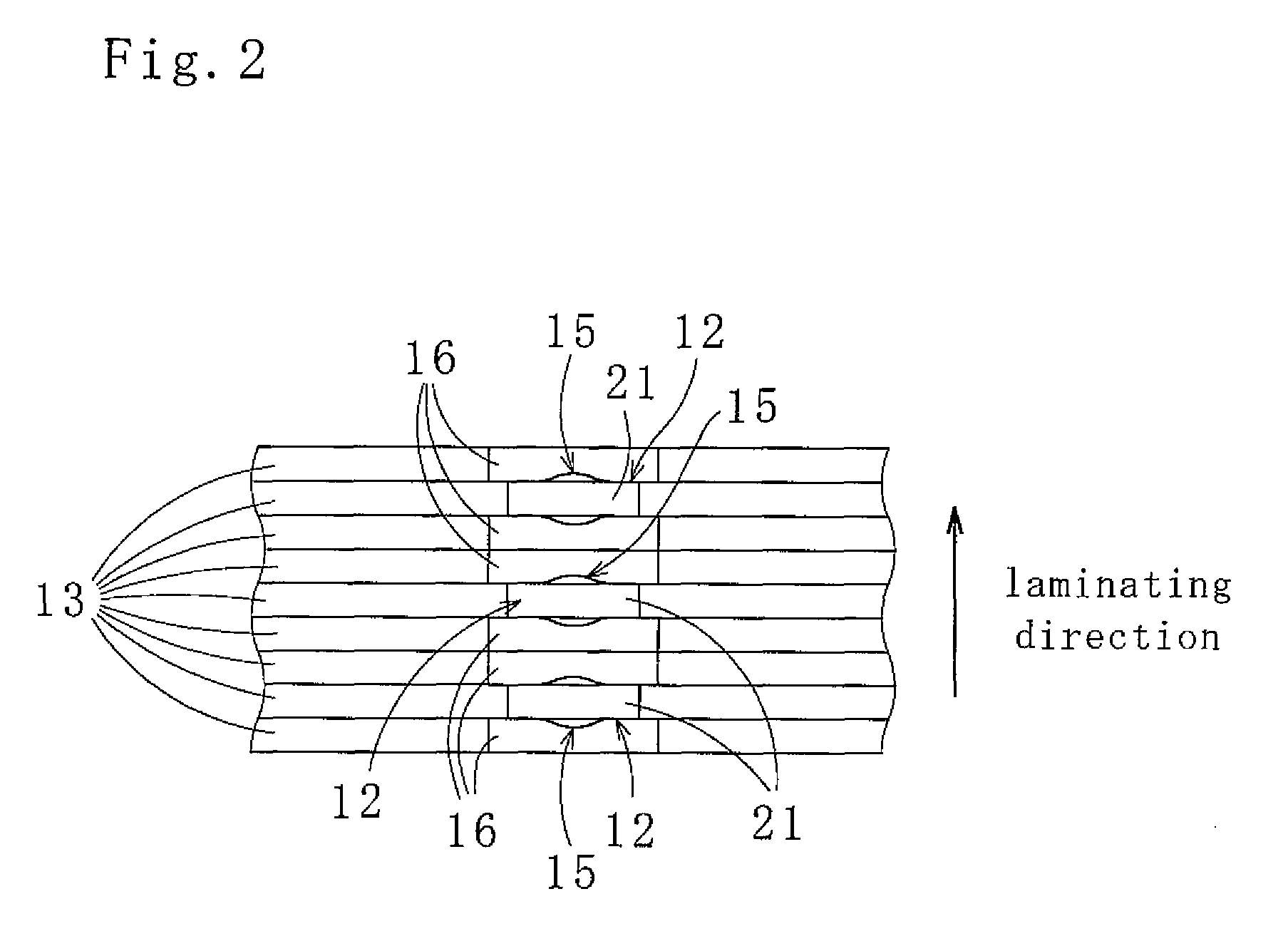

Laminated core and method for manufacturing the same

InactiveUS7777387B2Improve efficiencyImprove magnetic efficiencyMagnetic circuit stationary partsManufacturing dynamo-electric machinesEngineeringMechanical engineering

A laminated core (10) and a method for manufacturing the same formed with multiple continuous segment core pieces (13) wound in a spiral form by bending connecting portions (12) mutually connecting the segment core pieces (13), the connecting portions (12) being formed in an outer peripheral area (11), while the connecting portions (12) of vertically adjacent layers being displaced in a circumferential direction with inner edges or outer edges of the segment core pieces (13) fitted, the laminated core comprising: a concave cutout (21) provided in a radial exterior of each connecting portion (12) to dispose a radially expanded portion (20) within an outer circle of the laminated core (10), the radially expanded portion (20) being formed with each connecting portion (12) expanding radially outward at the time of bending each connecting portion (12); an interior cutout (22) provided in a radial interior of each connecting portion (12) to define a bending position of each connecting portion (12); and a receptacle (16) provided in a radial exterior of each segment core piece (13) to receive an expanded part (15) formed in the thickness direction at the time of bending each connecting portion (12).

Owner:MITSUI HIGH TEC INC

Production method of ultra-large-diameter thin-walled pressure-resistant aluminum alloy pipe

InactiveCN104668306AGood weld strengthGood weld consistencyNon-electric welding apparatusWeld seamConductor Coil

The invention discloses a production method of an ultra-large-diameter thin-walled pressure-resistant aluminum alloy pipe. The production method comprises the steps: (1) feeding, (2) winding or rolling of a reel, (3) performing stirring friction welding, (4) performing solid solution quenching, (5) reshaping, (6) performing aging treatment, and (7) performing pressure resistance test. The aluminum alloy pipe produced by using the method is high in welding seam strength, high in welding seam consistency, high in pipeline roundness and high in internal pipe pressure resistance. According to each series of typical alloys subjected to the method and the process, the minimum yield strength of a pipe welding seam and the allowable internal pipe pressure resistance (applicable to gas and liquid) are as follows: (1) if the alloy is 2XXX, sigma <0.2> is greater than or equal to 290 Mpa, and P (internal pressure) is greater than or equal to 15 Mpa; (2) if the alloy is 6XXX, sigma<0.2> is greater than or equal to 200 Mpa, and P (internal pressure) is greater than or equal to 10 Mpa; (3) if the alloy is 7XXX, sigma<0.2> is greater than or equal to 395 Mpa, and P (internal pressure) is greater than or equal to 20 Mpa.

Owner:郑英

High-strength high-ductility nodular cast iron and manufacturing method thereof

The invention relates to the technical field of nodular cast iron material, in particular to a type of high-strength high-ductility nodular cast iron which contains the following ingredients by weight percent: 3.4-3.8% of C, 2.3-2.7% of Si, 0.3-0.5% of Mn, 0-0.03% of S, 0-0.04% of P, 0.3-0.5% of Cu, 0.02-0.10% of Cr, 0.001-0.005% of Sb, 0.03-0.06% of Mg, 0.01-0.03% of Re and the balance Fe. With the nodular cast iron material disclosed by the invention, a greater quantity of graphite with higher roundness can be obtained, matrix structures with a certain content ratio of ferrite and pearlite can be obtained, and castings with both higher strength and higher elongation under a cast state can be stably produced. The performance of the castings is improved and the using requirements of the castings such as an axle housing of a drive axle of a heavy-duty truck, and a bracket are satisfied.

Owner:SINO TRUK JINAN POWER

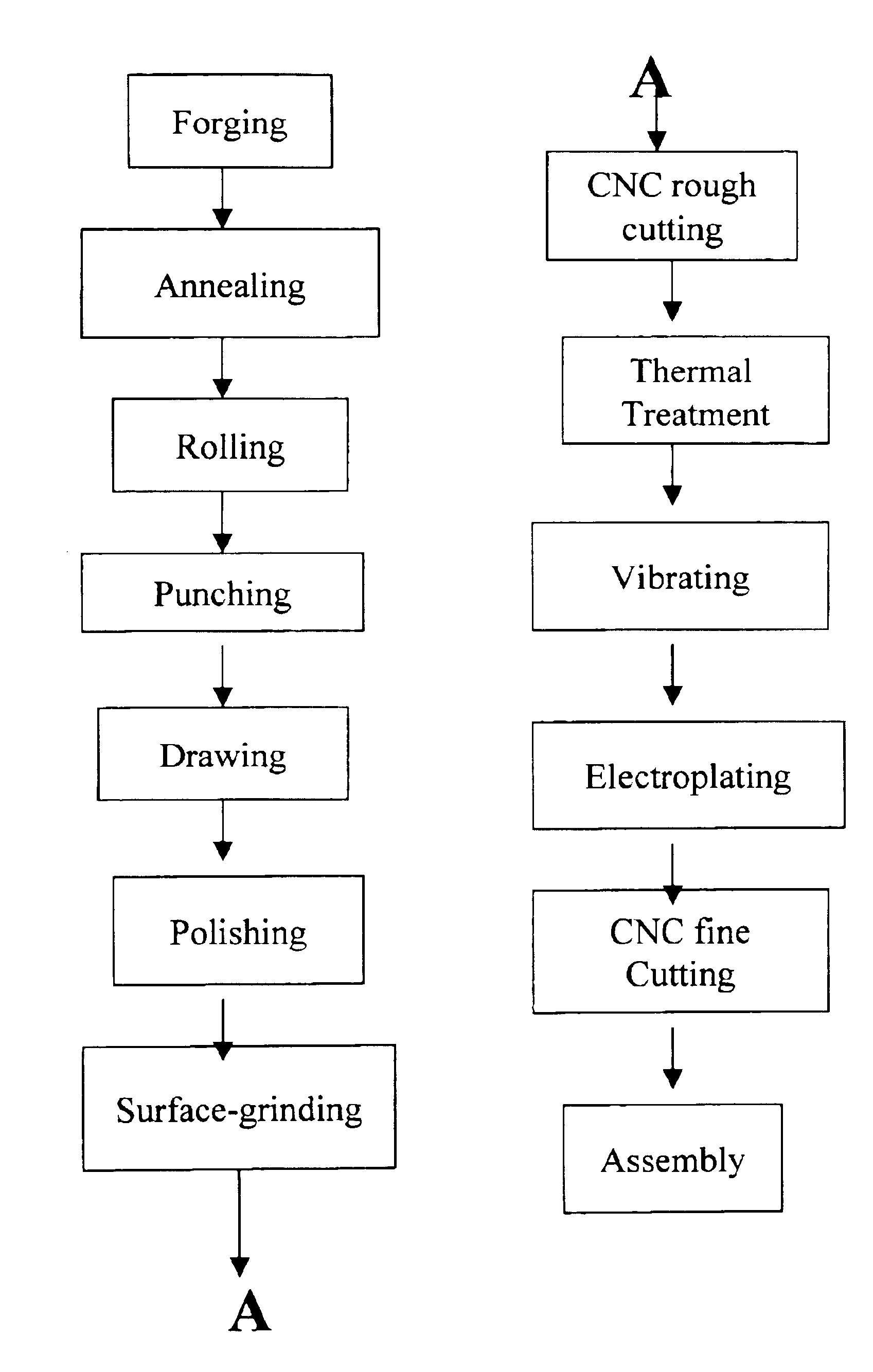

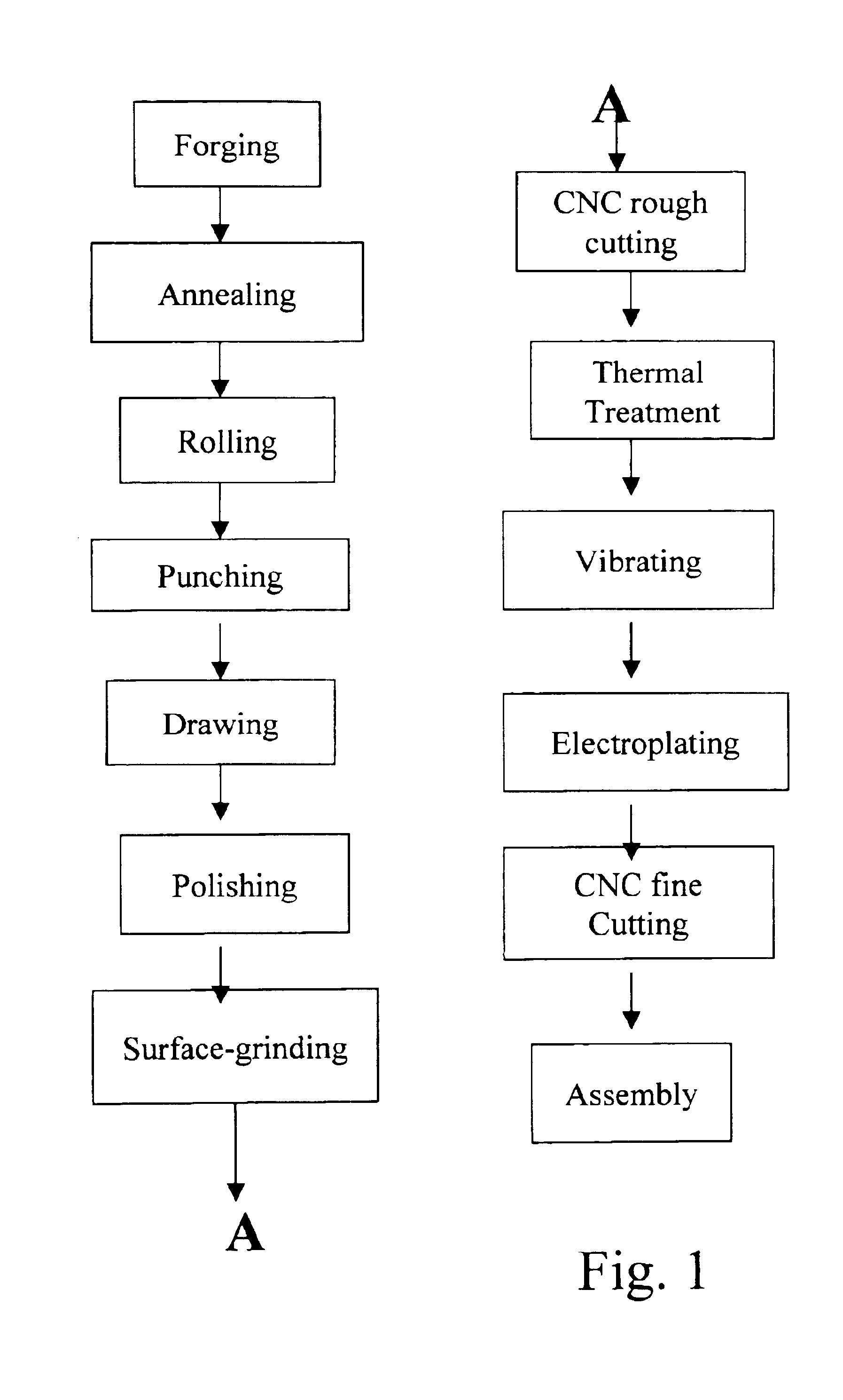

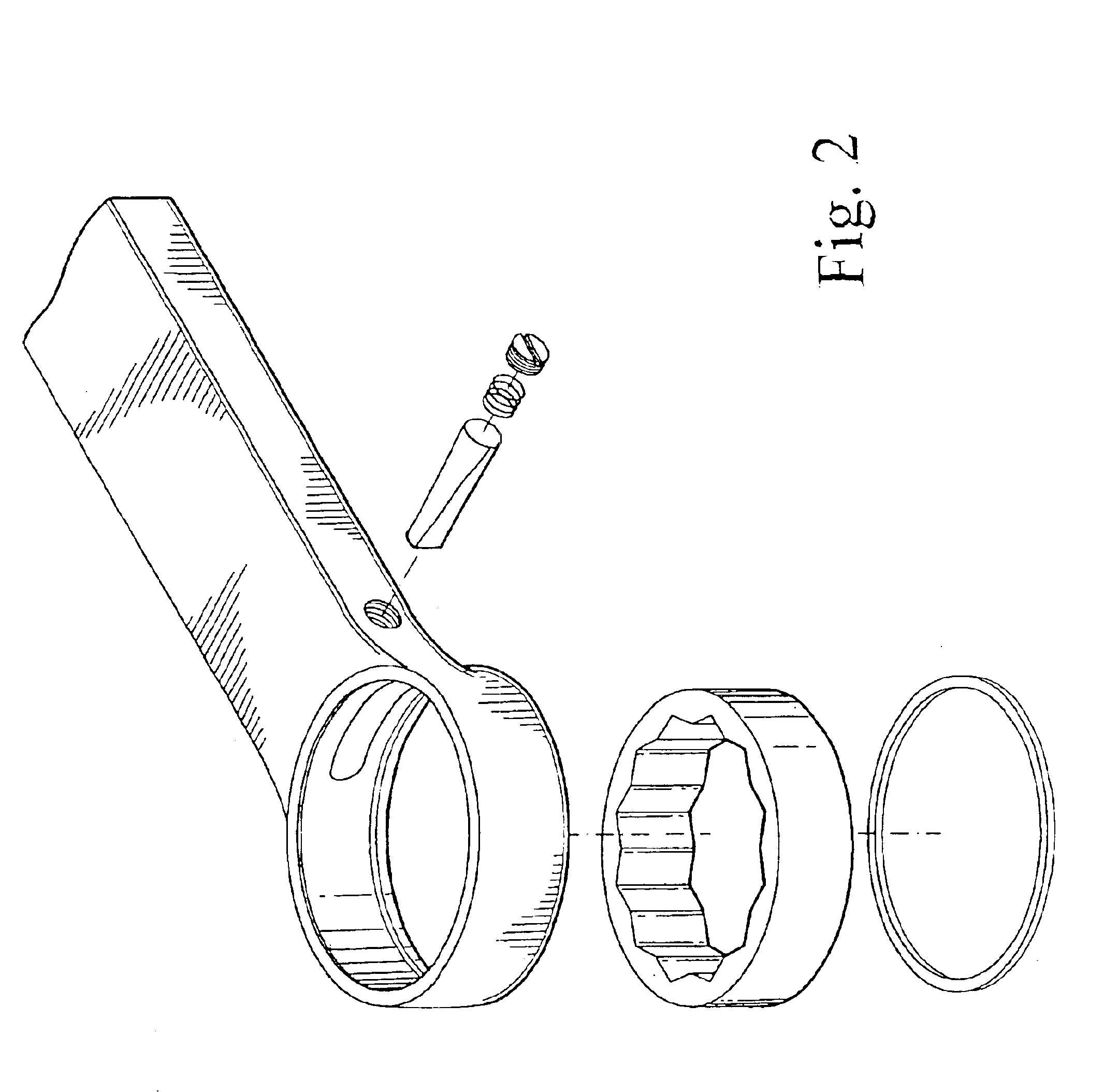

Wrench manufacturing process

A wrench manufacturing process for manufacturing a rotational-tube wrench comprises the steps of forging, annealing, rolling, punching, drawing, polishing, surface grinding, CNC rough cutting, thermal treatment, vibrating, electroplating, CNC fine cutting and assembling. The additional steps of thermal treatment and CNC or MC fine cutting not only enhance the structural toughness of the wrench but also guarantee high degree of roundness for the receptacle space thereof. The CNC or MC fine cutting also provides the inner wall of the receptacle space with fine tool marks so that the confinement strength of a rotational tube without ratchets therein can be significantly enlarged.

Owner:HSIEN CHIN CHING

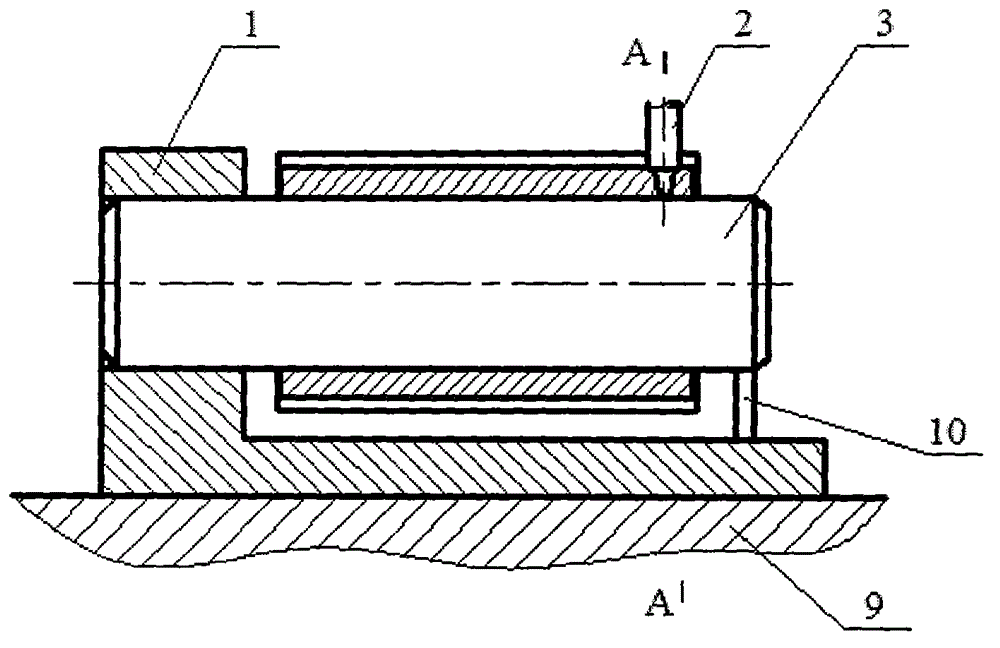

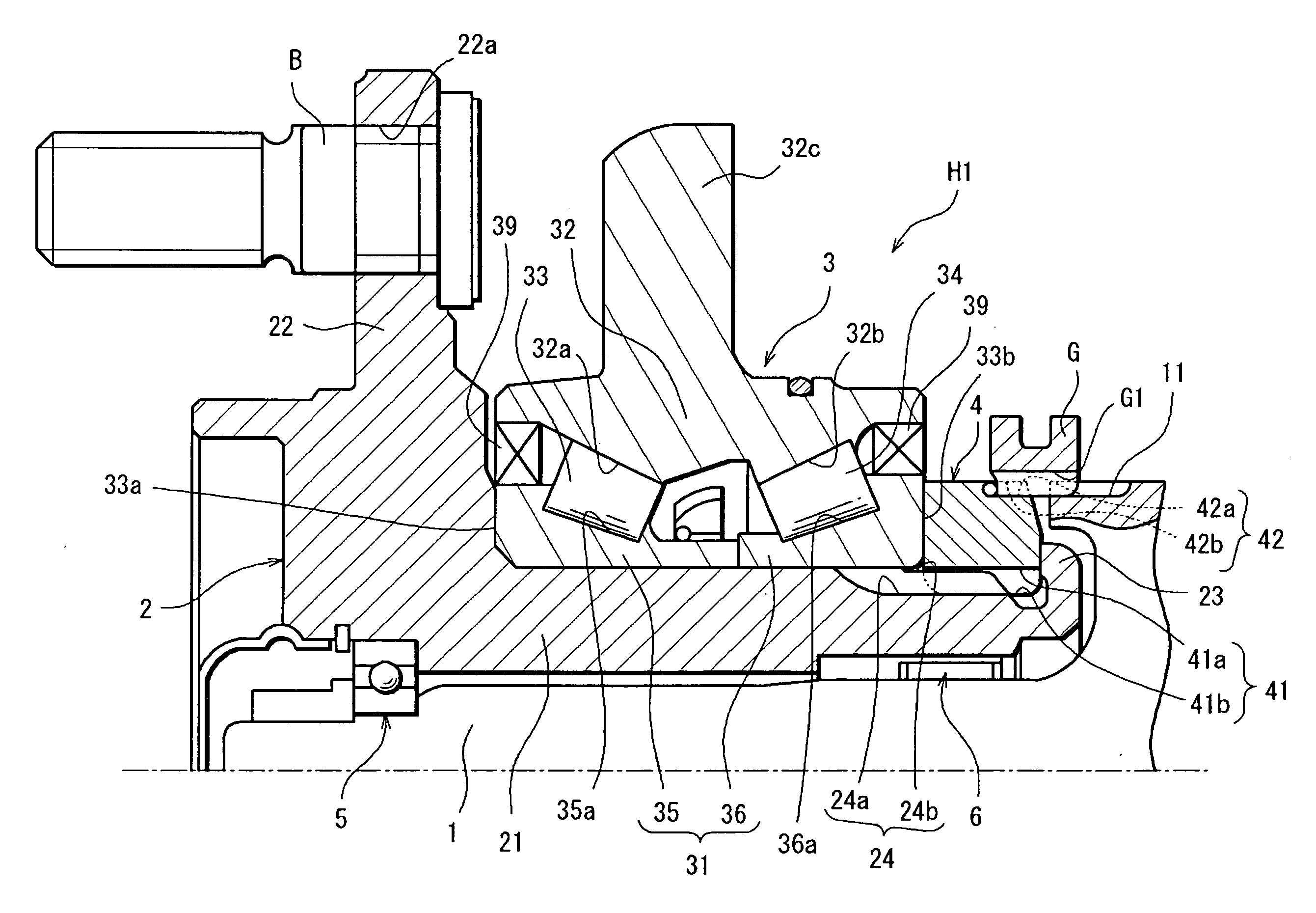

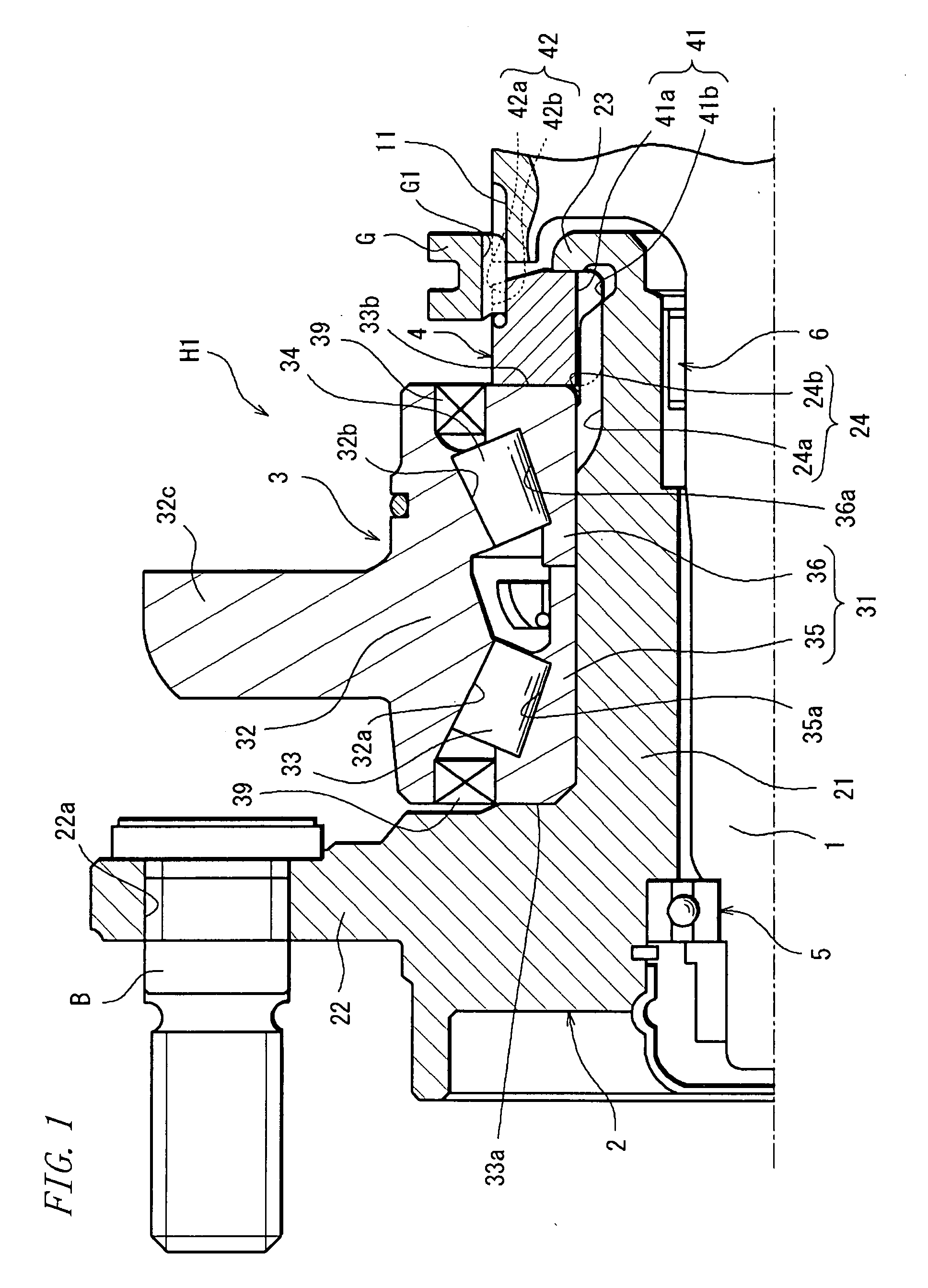

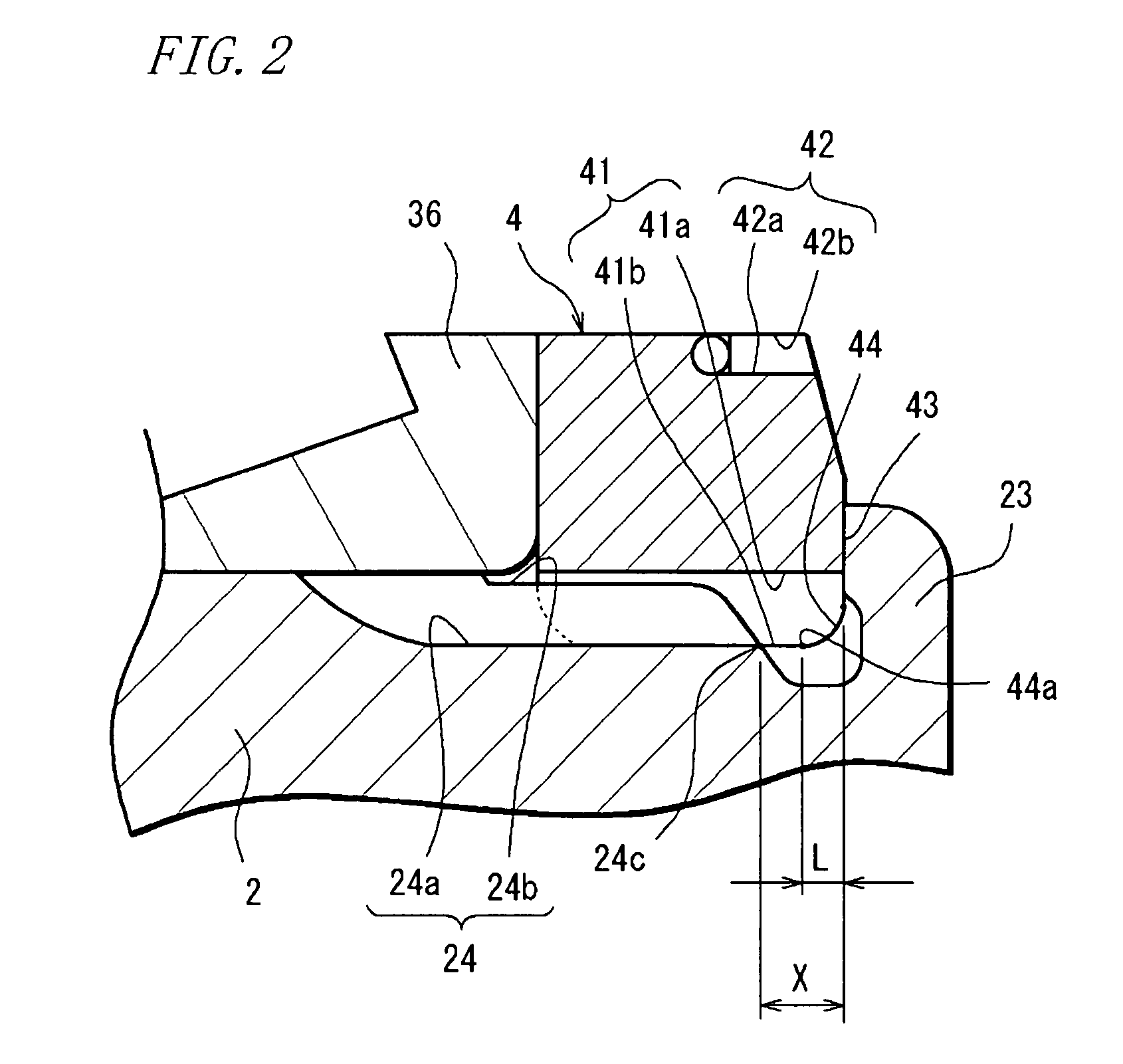

Hub Unit, Rolling Bearing Assembly and Manufacture Method Thereof, as Well as Assembling Apparatus for Rolling Bearing Assebly and Assebly Method Thereof

InactiveUS20070217728A1High-accuracy assembling operationAvoid crackingRolling contact bearingsHubsRolling-element bearingMechanical engineering

A rolling bearing adapted to prevent crack formation in a caulking portion is provided. A rolling bearing assembly includes: a hub shaft having the caulking portion at an axial end thereof, the caulking portion bendably deformed in a radially outward direction; the rolling bearing mounted on an outside surface of the hub shaft; and an annular member spline-engaged with the hub shaft and caulk-fixed to place by the caulking portion. An inner-side axial end of a second male spline formed on the hub shaft is shifted from an inner-side end of the hub shaft toward an outer side far enough to ensure that the second male spline is not susceptible to the plastic deformation of the caulked caulking portion.

Owner:JTEKT CORP

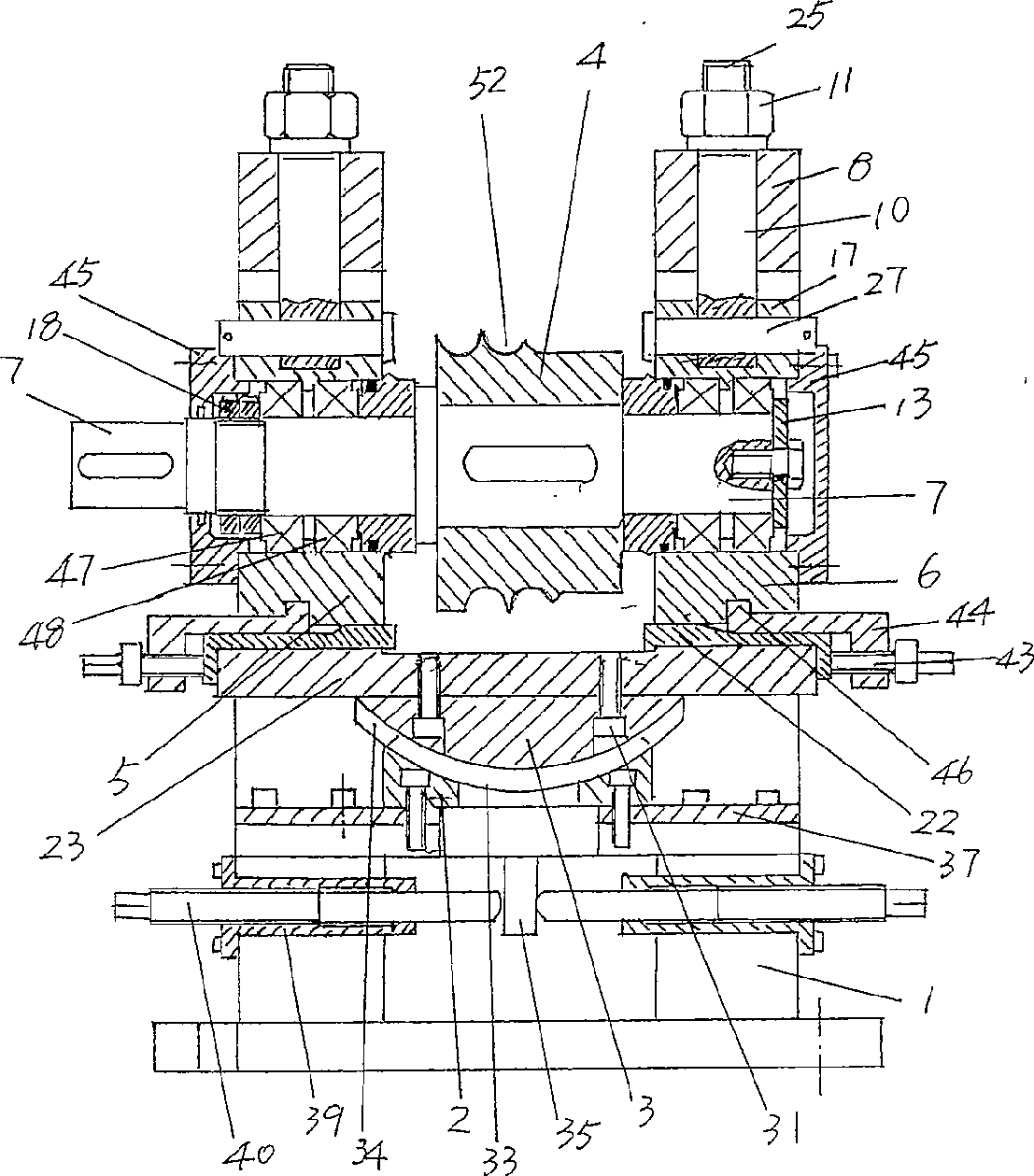

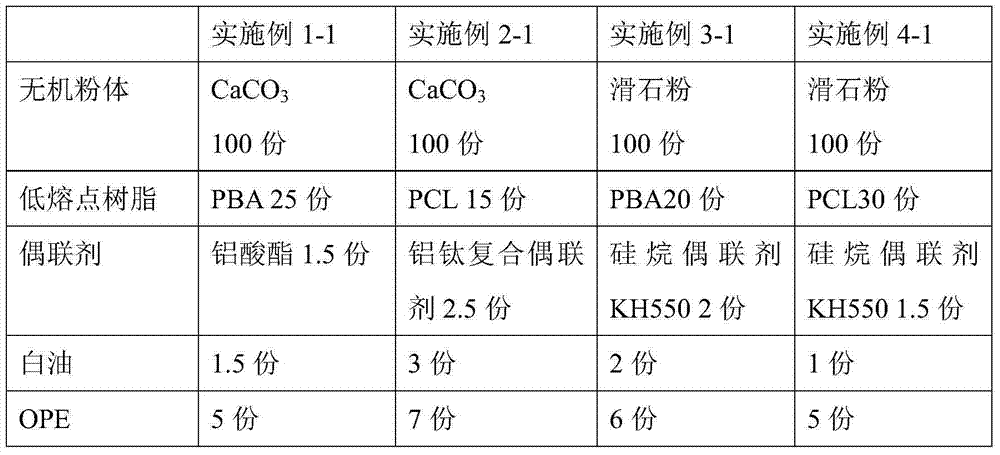

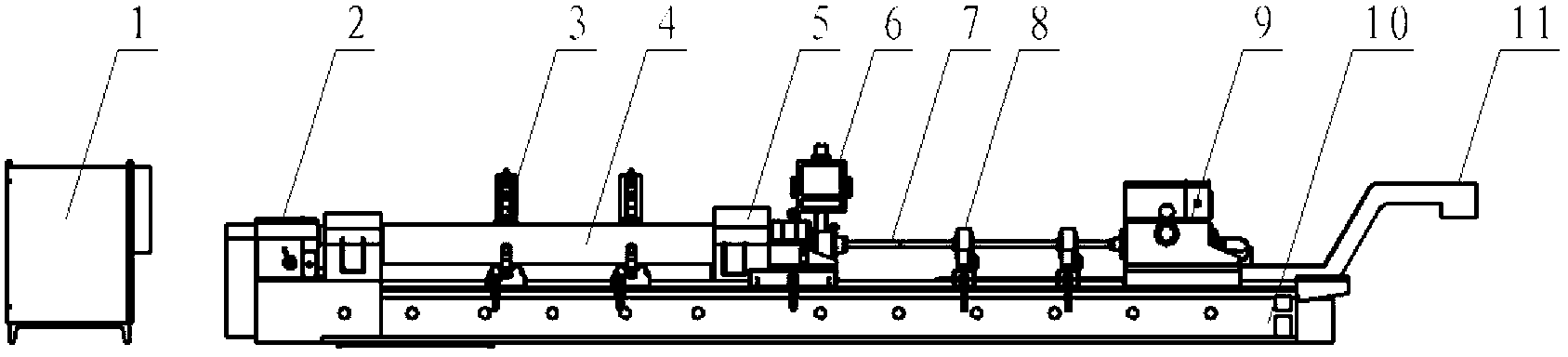

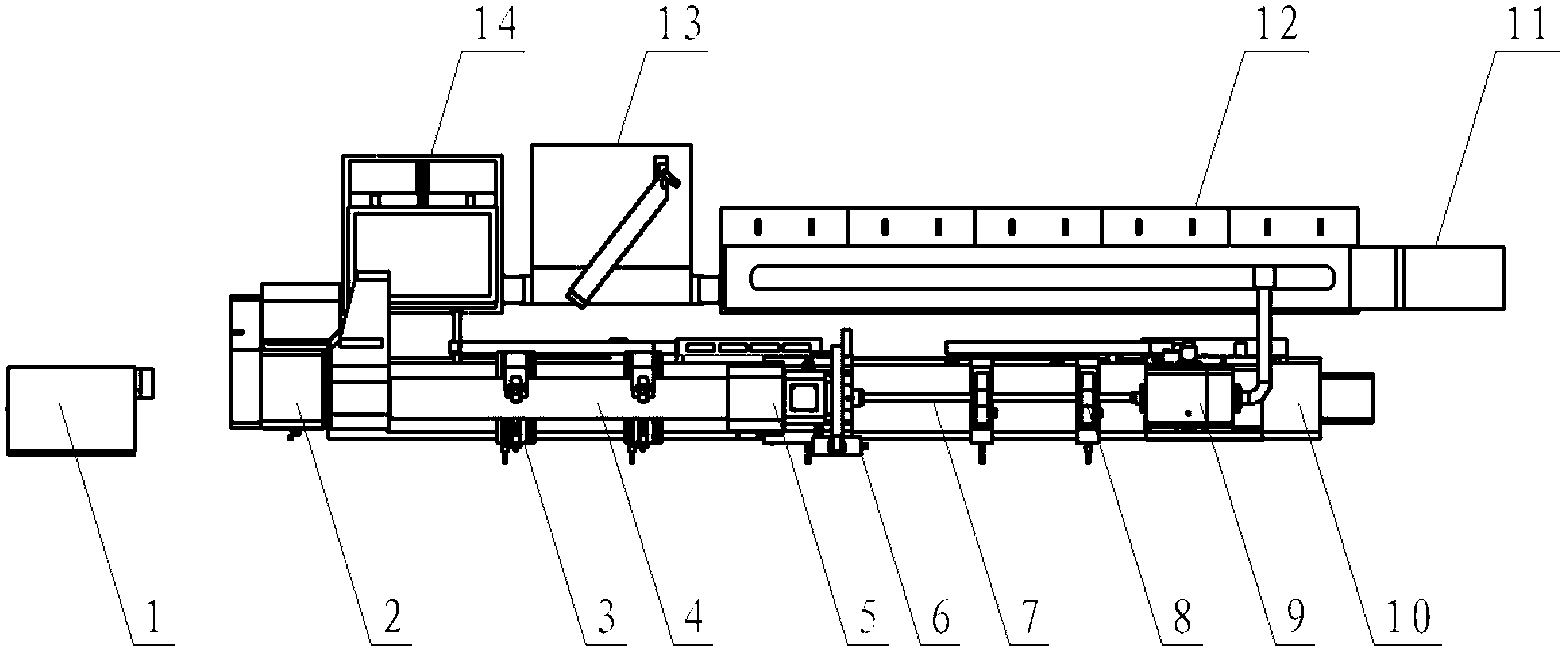

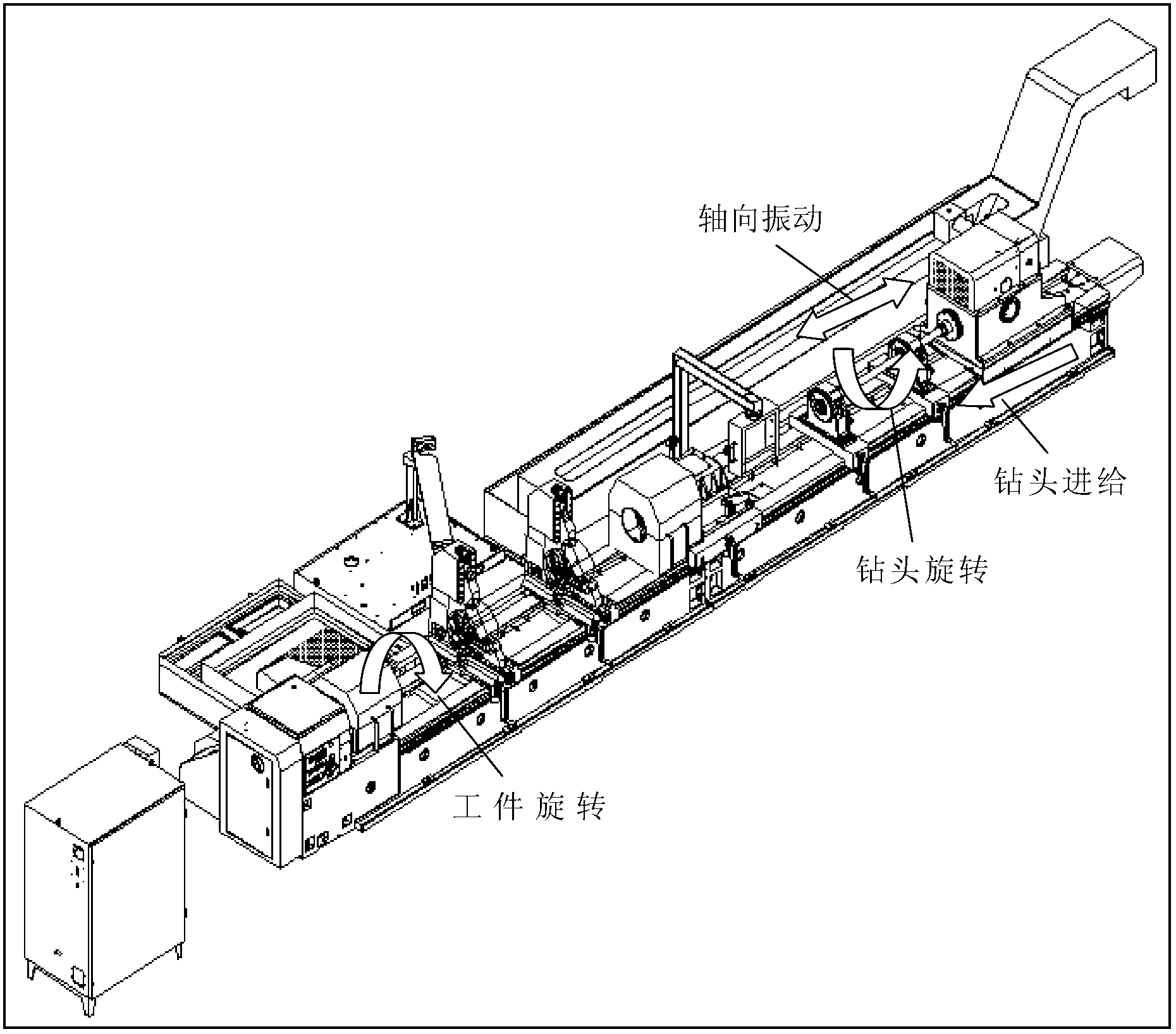

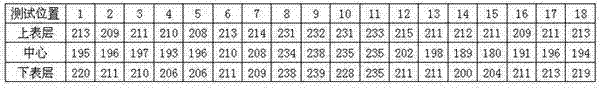

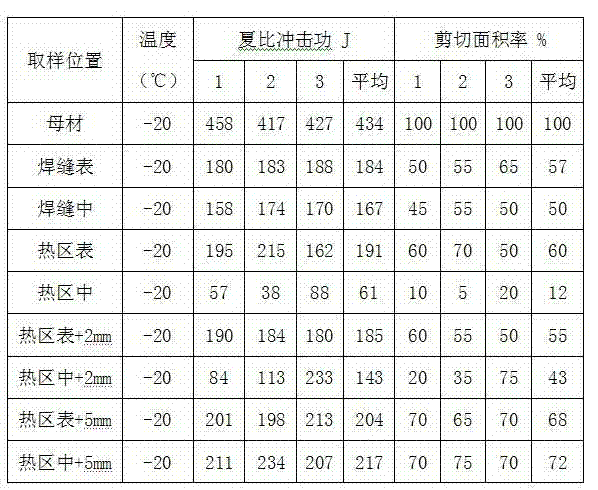

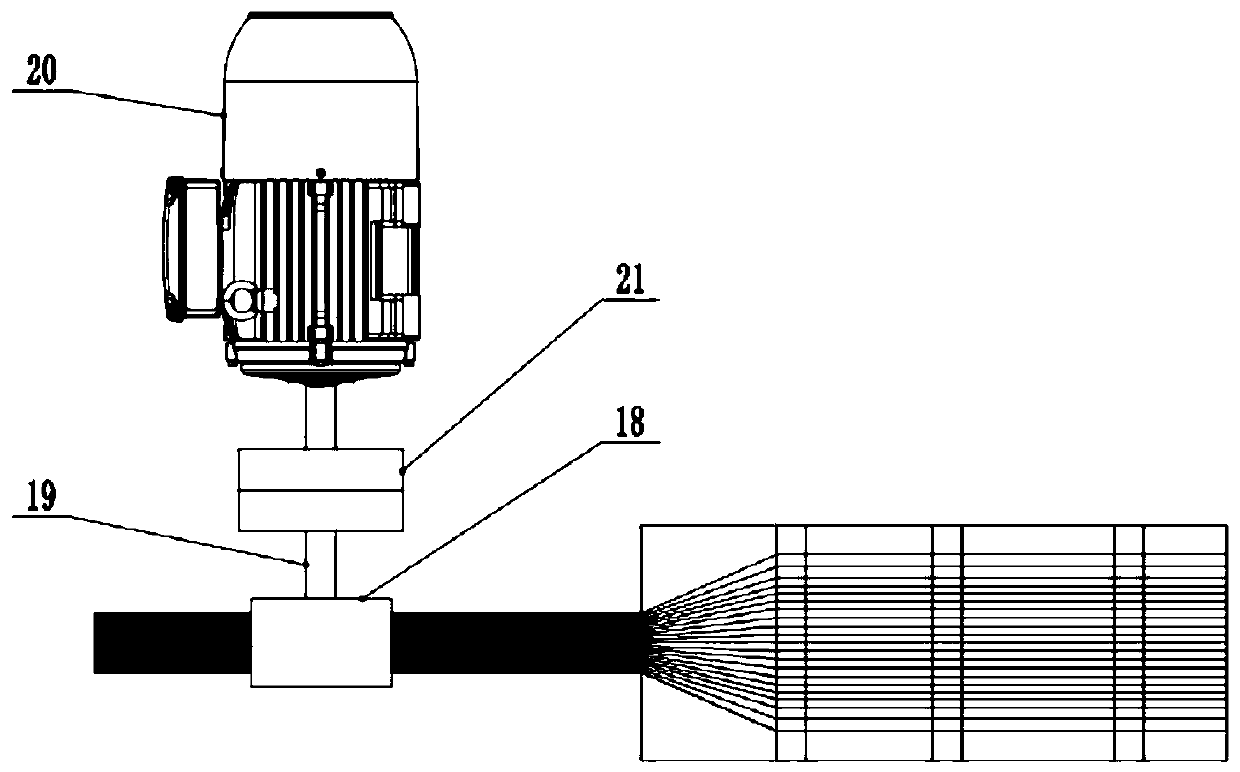

Numerical control vibration deep-hole drilling and boring machining equipment and method

InactiveCN102699375AImprove roundnessImprove straightnessBoring/drilling componentsMaintainance and safety accessoriesNumerical controlAxial vibration

The invention discloses numerical control vibration deep-hole drilling and boring machining equipment, which is characterized by comprising a workpiece arranged on a machine tool body, a drill bit and a drill stem, wherein the workpiece is driven by a main motor to rotate; and the drill bit is driven by the motor to rotate along with the drill stem and is simultaneously driven by a servo reducing motor and a vibration motor to make numerical control feed movement and axial reciprocating vibration. By the deep-hole drilling and boring equipment, the functions of rotating the workpiece and the drill bit in a bidirectional mode and axial vibration drilling can be realized, the severe working conditions and the lubricating effect of a cutting area of the drill bit are improved, the cuttings are automatically controlled, the process range of the equipment is greatly widened, the machining precision indexes of the holes such as roundness and straightness are improved, and the hole machining quality and efficiency are improved further; and moreover, the problem of chip breakage and removal in the prior art is solved, the cuttings can be automatically separated, collected and conveyed, automation of the drilling process is realized, and the equipment can be widely applied to the field of machining of rotary deep-hole parts.

Owner:XIAN UNIV OF TECH

Manufacturing method of X65 pipeline steel longitudinal submerged arc welded pipe for undersea use

ActiveCN102310119AUniform deformationUniform performanceArc welding apparatusUltrasound testMagnetic particle inspection

The invention discloses a manufacturing method of an X65 pipeline steel longitudinal submerged arc welded pipe for undersea use. The manufacturing process of the steel pipe comprises: edge milling, edge prebending, JCO moulding, prewelding, inside welding, outside welding, first ultrasonic inspection, first x-ray inspection, mechanical expanding, hydrostatic test, chamfering, groove machining, second ultrasonic inspection, second x-ray inspection, pipe end magnetic particle inspection and appearance quality inspection. The method of the invention makes each part of the X65 steel grade ongitudinal submerged arc welded pipe with a diameter of phi 762mm and wall thickness of 28.6-30.2mm has uniform deformation and performances in the process of JCO moulding; the method in the invention solves the problem that local heating of the steel pipe during welding results in severely reduced strength and toughness as well as elongation; the method provided in the invention also provides a solution to the problems of increased strength and reduced toughness and uniform elongation caused by work hardening during steel pipe mechanical expanding.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

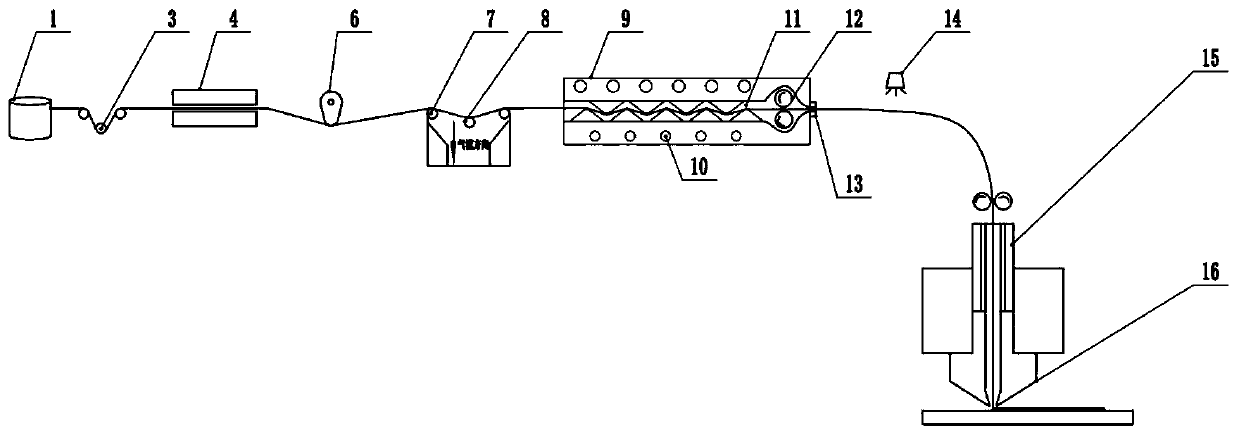

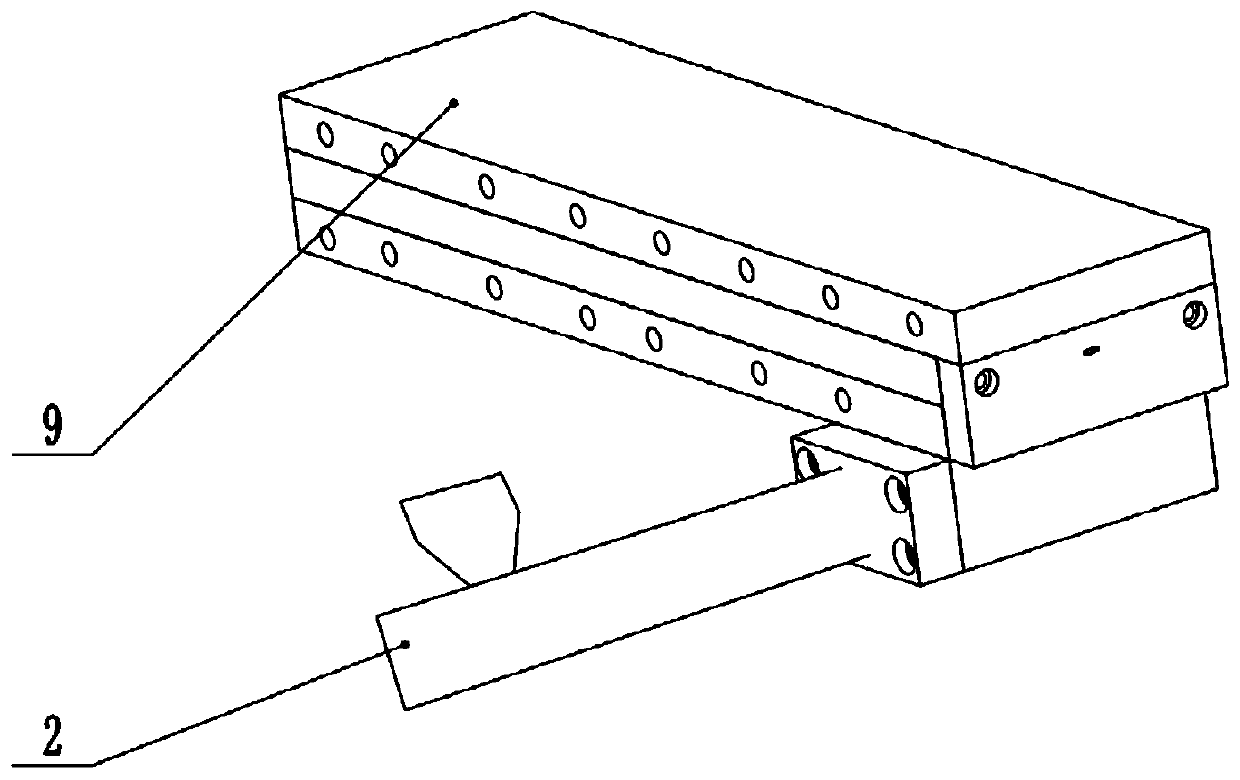

Continuous fiber melt impregnation 3D printing device and process

ActiveCN111186138AHigh molding pressureEnough molding pressure3D object support structuresApplying layer means3d printPolymer science

The invention relates to a continuous fiber reinforced thermoplastic resin melt impregnation 3D printing device and a method, wherein thermoplastic resin is used as a matrix, and continuous glass fiber or carbon fiber is used as a reinforcement. The 3D printing device comprises an extruder, an unwinding roller, a pre-tensioning roller, an infrared radiation device, a gas-assisted swinging device,a wire wetting mold, a cooling device and a 3D printer. A continuous fiber bundle is firstly pre-dispersed by the pre-tensioning roller, the upper surface and the lower surface of the continuous fiberare pre-heated by the infrared radiation device, the pre-heated continuous fiber is unfolded to a certain width under the action of the gas-assisted swinging device, then the pre-heated continuous fiber enters the wire wetting mold, the wetting process of the resin matrix on the fiber bundle is completed under the action of a wave-shaped runner, the fiber bundle is conveyed forwards by the traction of an inner traction roller and passes through a circular shaping die to form continuous fiber prepreg filaments which can be used for 3D printing, and cooling, feeding and printing are carried outto finally obtain the 3D printed product of the continuous fiber reinforced thermoplastic composite material. According to the device and the method, uniform dispersion and full impregnation of the continuous fiber in the resin matrix can be realized, the 3D printing continuous fiber reinforced thermoplastic composite material product with good interface bonding and excellent performance can be prepared, and meanwhile real-time integrated forming of continuous fiber consumables and the 3D printing composite material product can be realized.

Owner:BEIJING UNIV OF CHEM TECH

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

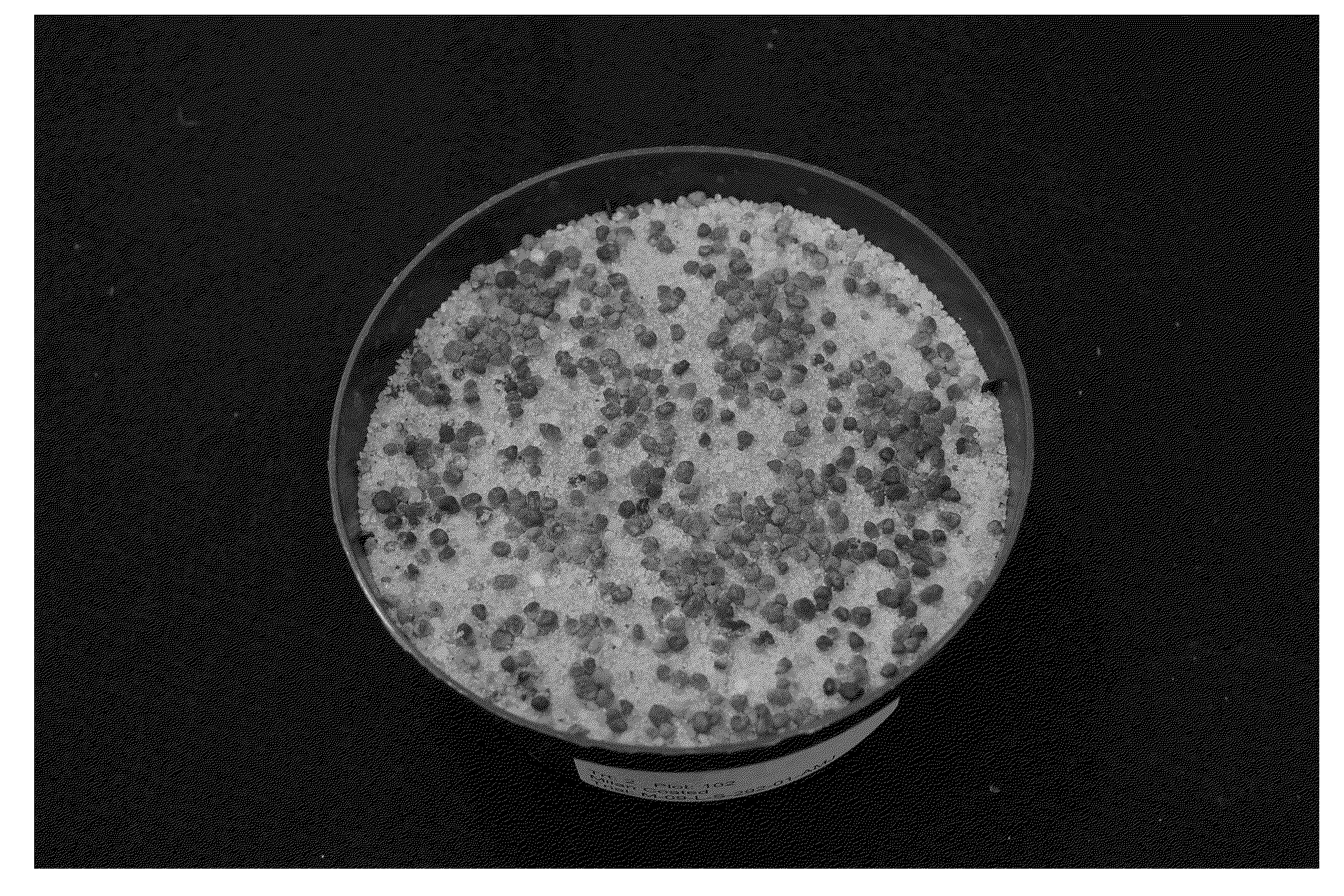

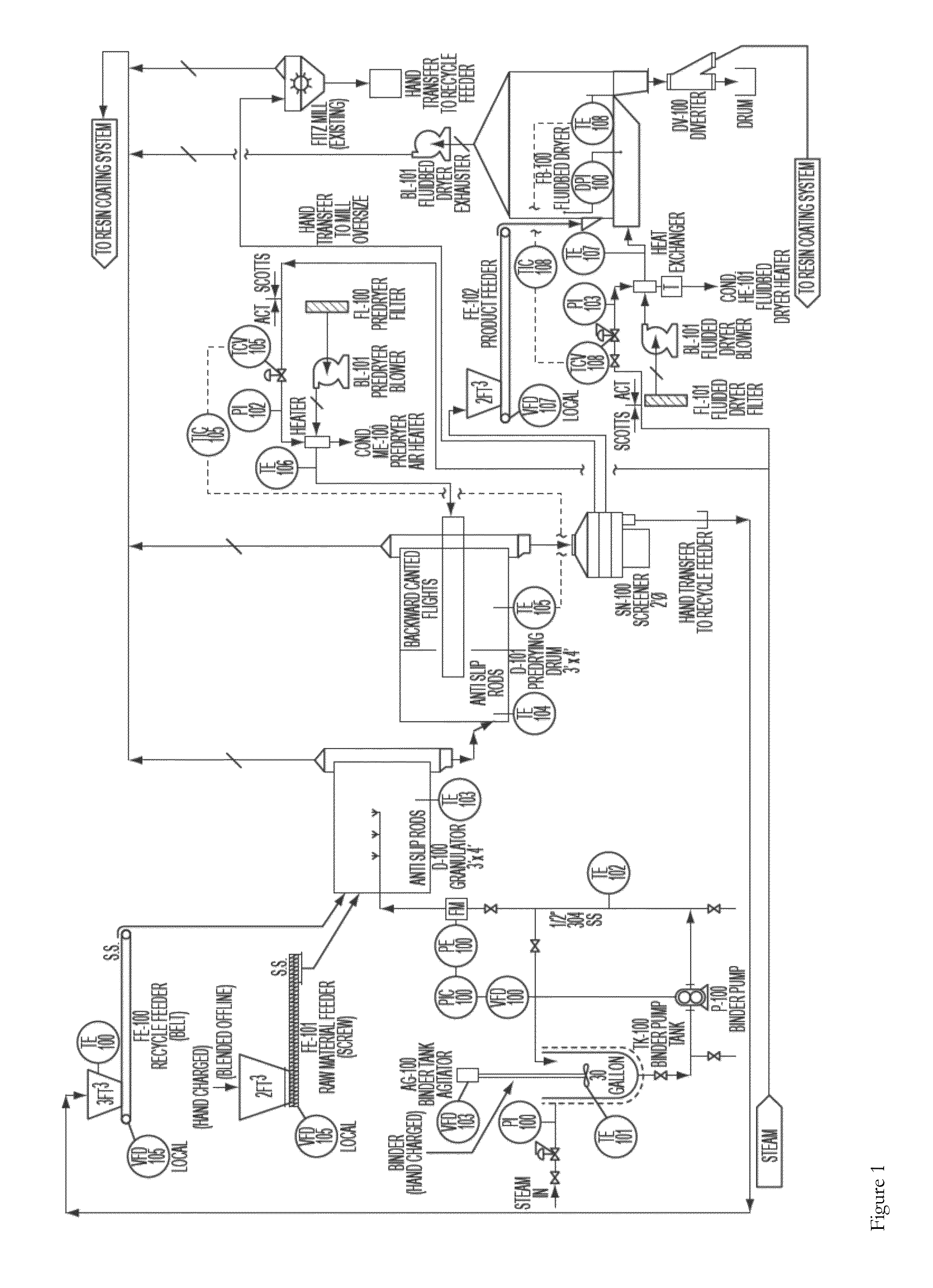

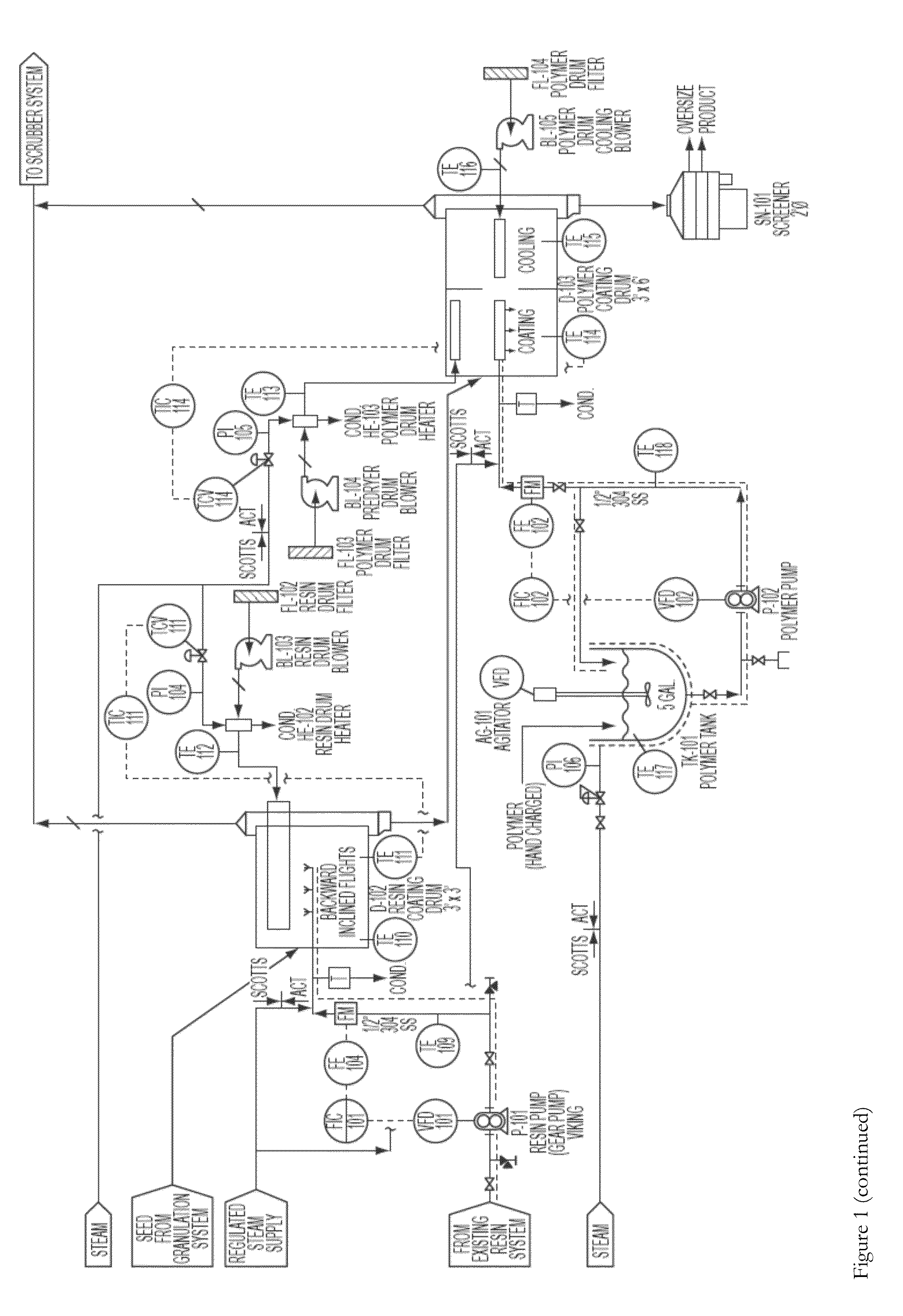

Multi-purpose lignin-carbohydrate binding system

InactiveUS20140235438A1Improve crush resistanceHigh hardnessCalcareous fertilisersBiocideDual purposeGermination

The present invention relates to a novel, dual purpose binder formulation or system. The invention also relates to a process of agglomerating dispersed particles or fines into substantially spherical and crush resistant granules. The invention further relates to a method of covering a seed and binding the seed with a material mixture beneficial for seed germination. The invention also relates to an all-in-one seed agglomerated by the dual purpose binder formulation.

Owner:OMS INVESTMENTS INC

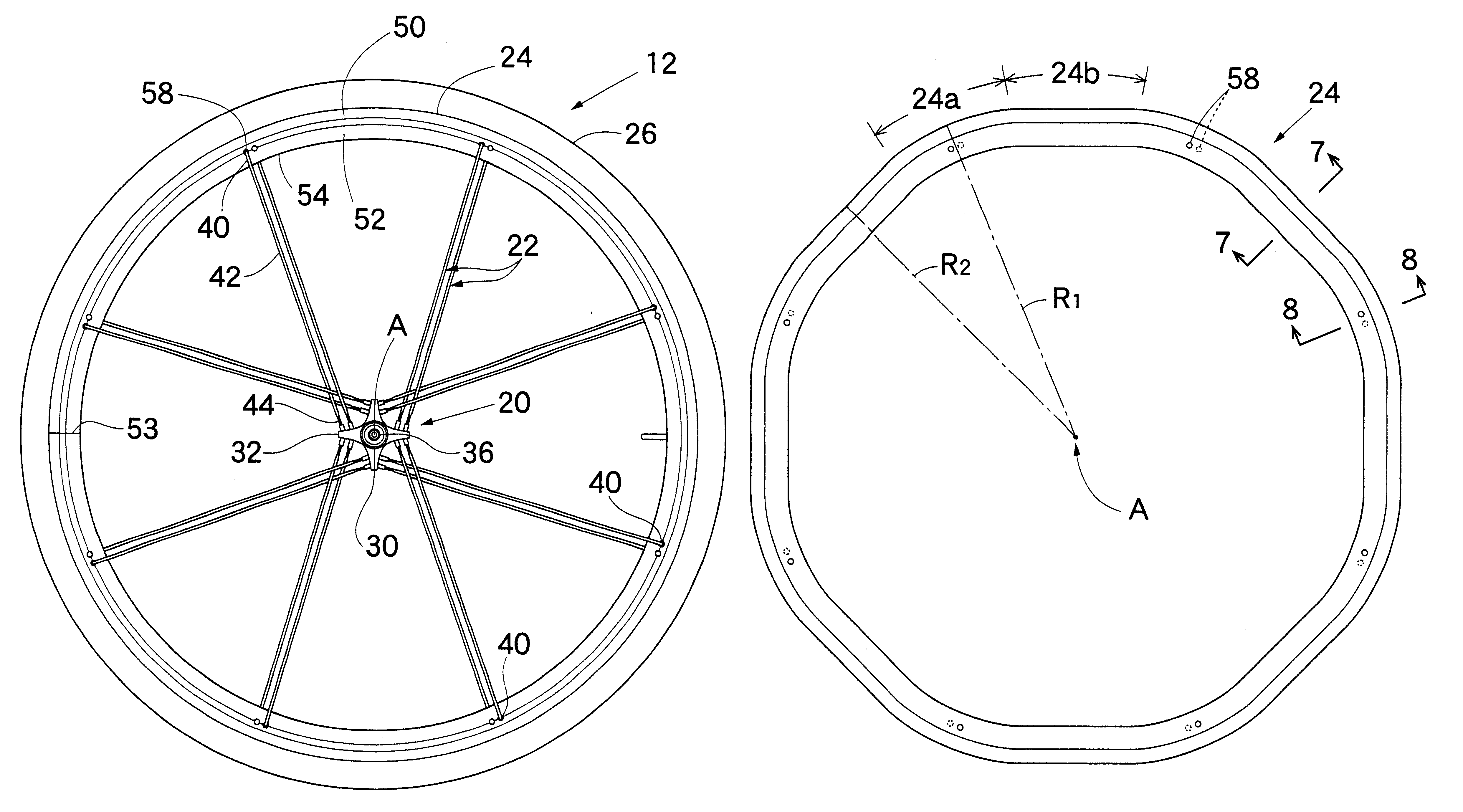

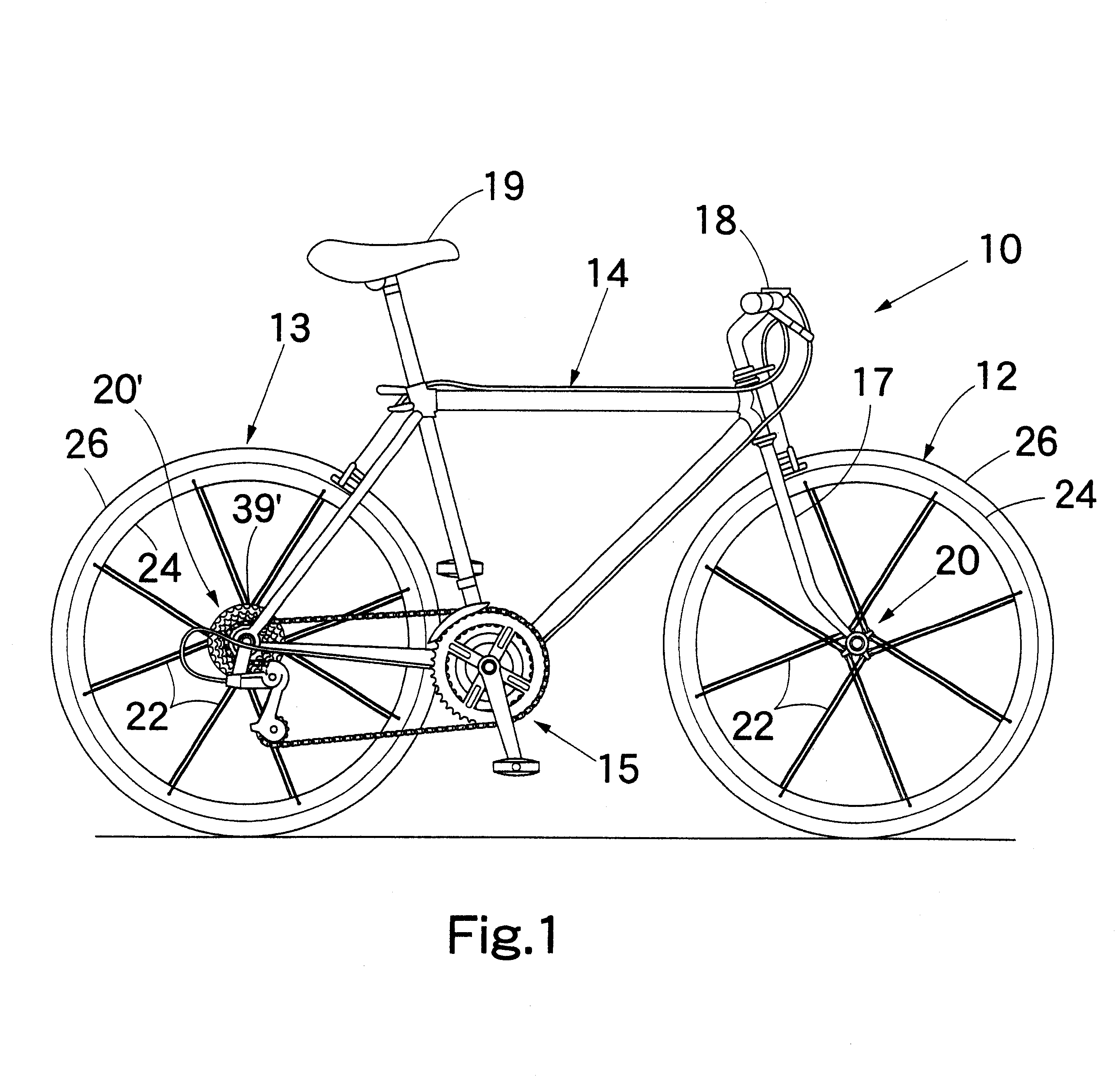

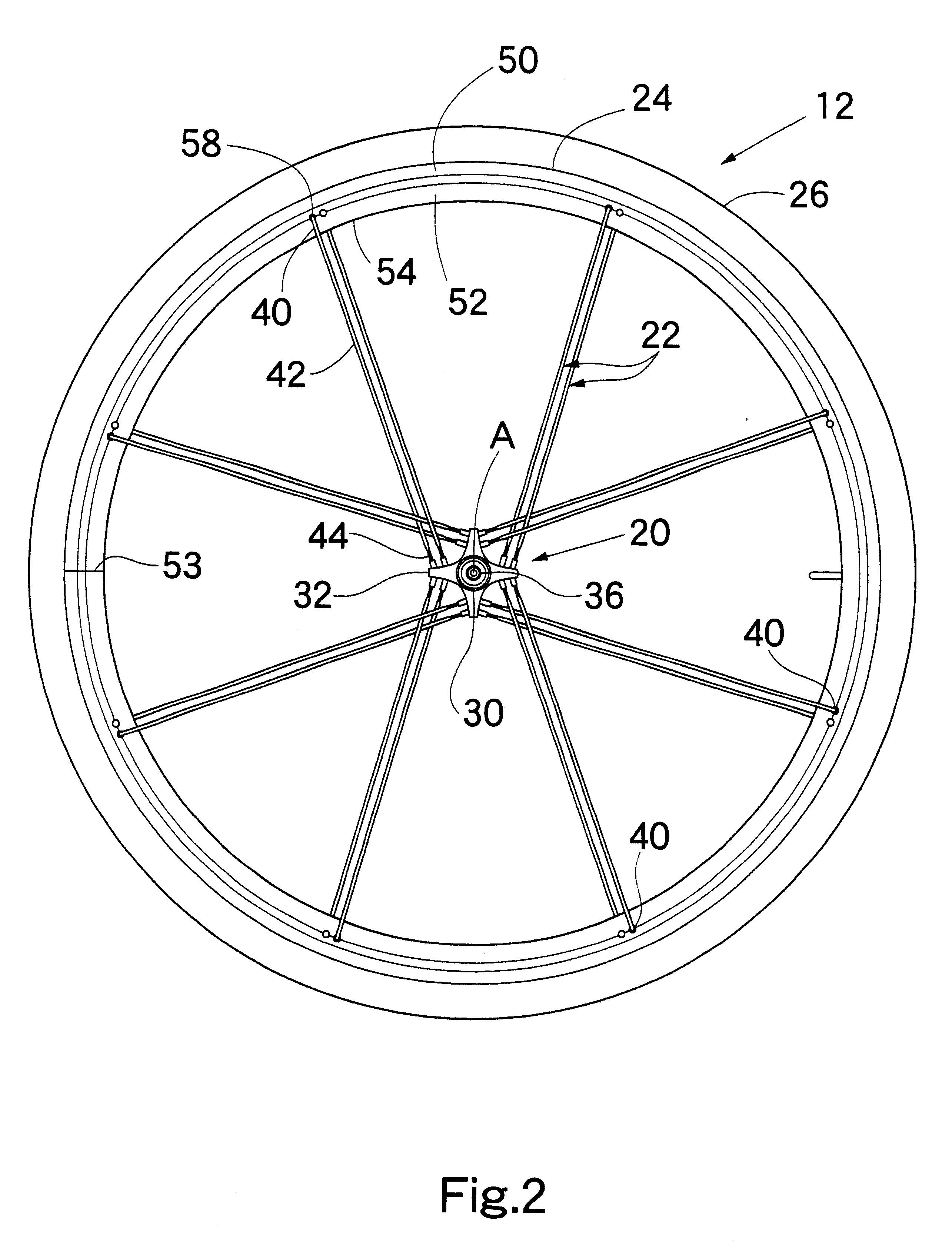

Bicycle rim

InactiveUS6588853B2Improve roundnessWithout cost of manufactureRimsMetal-working apparatusEngineeringMechanical engineering

A bicycle rim includes side portions with an outer portion extending between the side portions to form a pair of outer corners, and a spoke attachment portion. The outer portion includes a pair of ridges spaced from the outer corners. The ridges preferably divide a pair of inclined surfaces. The side portions preferably include a pair of ground braking surfaces with a pair of sloping surfaces extending from the braking surfaces to a pair of outer side surfaces.

Owner:SHIMANO INC

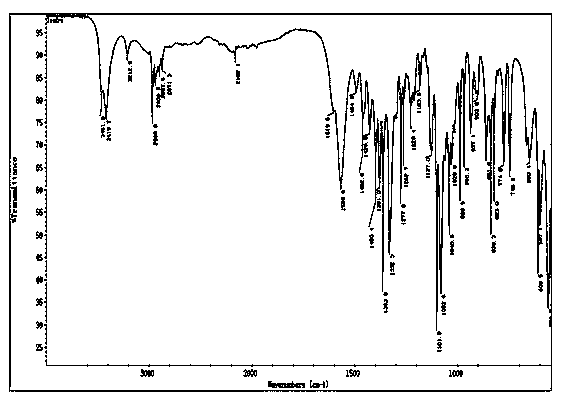

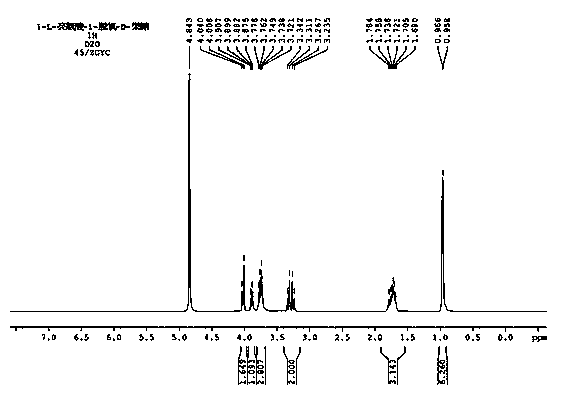

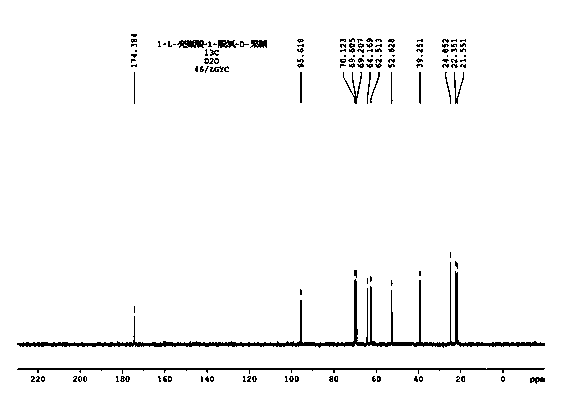

Cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose and preparation method thereof

ActiveCN103349356AReasonable synthetic routeGood physical moisturizing effectSugar derivativesTobacco treatmentFructoseBiochemical engineering

The invention discloses cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose. The structural formula of the cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose is as follows. The invention further discloses a preparation method of the compound. D-mannose is taken as a raw material, and the cigarette aroma enhancement humectant 1-L-leucine-1-deoxidation-D-fructose is successfully synthesized through simple reaction processing. Physical humectant performance tests and inherent sensory quality evaluations show that the humectant has a good physical humectant effect on cigarettes, and can reduce irritation and blended gases of the cigarettes and improve the smoke mellow sense and comfort of the cigarettes.

Owner:CHINA TOBACCO HENAN IND +1

Preparation method of scallop seasoning essence

The invention relates to a preparation method of a scallop seasoning essence, which comprises the following steps of: crushing cleaned scallop aprons, and carrying out blanching denaturation; carrying out enzymolysis, enzyme destruction, concentration, drying and pulverization to obtain scallop apron hydrolysate; adding auxiliary materials comprising HVP(Hydrolyzed Vegetable Protein) powder, yeast extract, L-sulfo-aminolactic acid, xylose, glycine, aminopropionic acid, L-phenylalanine, DL-methionine, salts, purified water, vitamins, glucose, thiamine chloride VB1, I+G, maize starch, onion powder and ginger powder to the scallop apron hydrolysate, carrying out Maillard heat reaction for 40-60 min at 100-125 DEG C; and carrying out cooling, vacuum drying, pulverization, granulation and packaging to obtain the scallop seasoning essence as a finished product. The scallop seasoning essence has delicious and pure taste, pure and thick mouth feel and strong sweet smell, is endowed with the peculiar seafood flavor of scallop and has the characteristics of natural raw materials and various nutrient substances comprising amino acid, peptides and the like. The preparation method has the advantages of reasonable process, convenience for operation, strong operability and easiness of realizing industrial production.

Owner:SHANDONG HOMEY AQUATIC DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com