Patents

Literature

2747 results about "Ductile iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

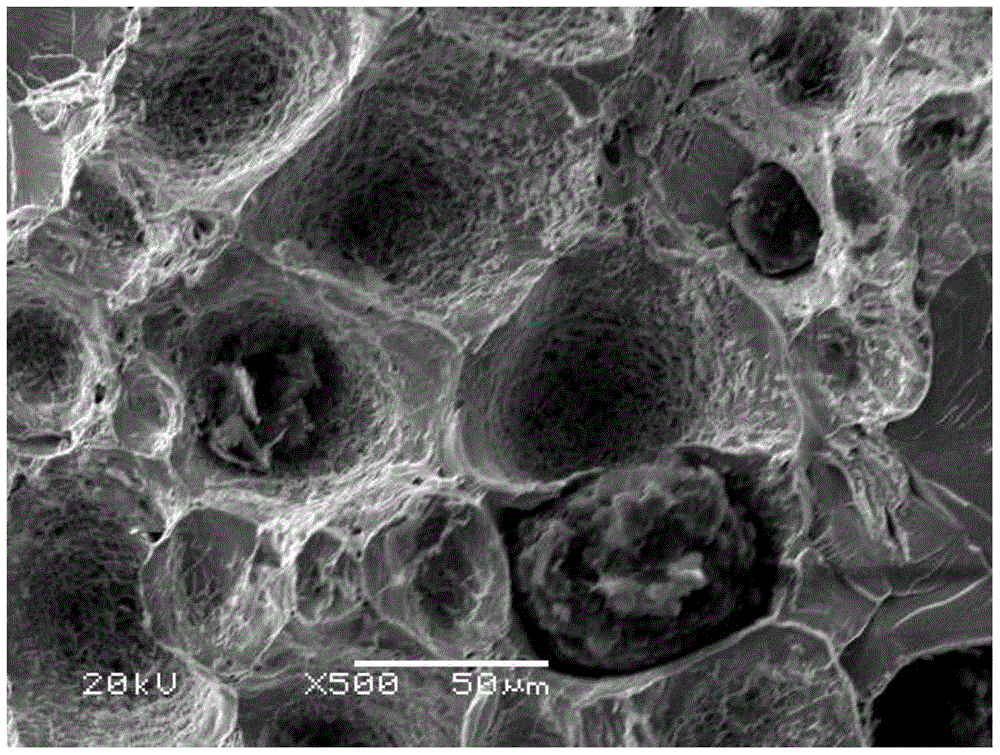

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spheroidal graphite cast iron and SG iron, is a type of graphite-rich cast iron discovered in 1943 by Keith Millis. While most varieties of cast iron are weak in tension and brittle, ductile iron has much more impact and fatigue resistance, due to its nodular graphite inclusions.

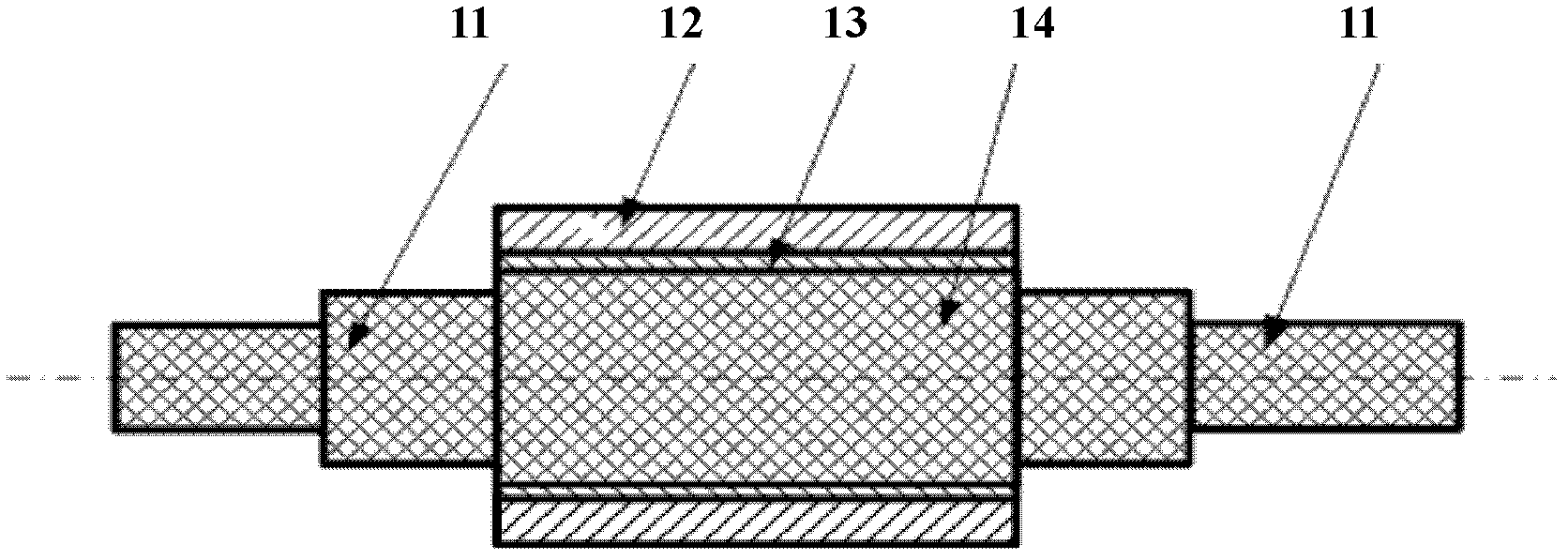

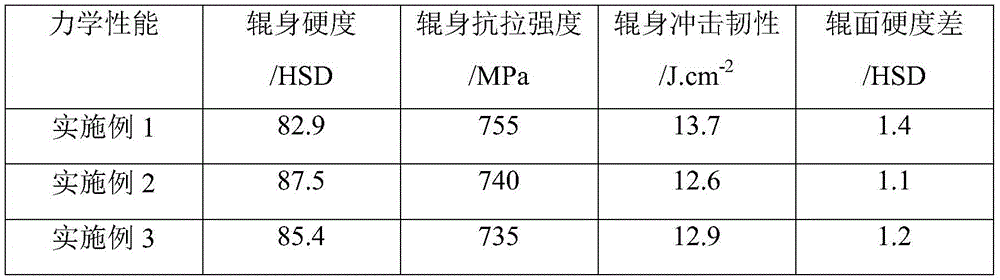

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

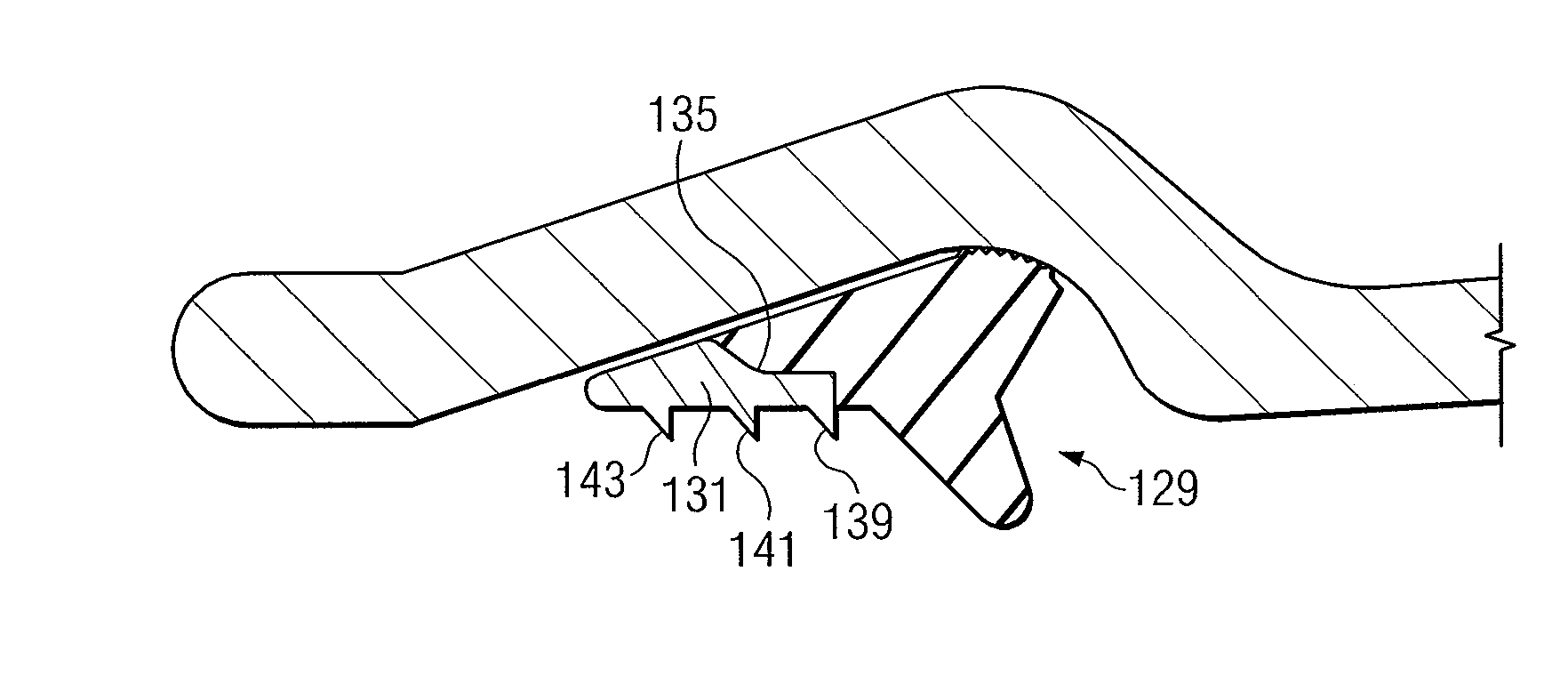

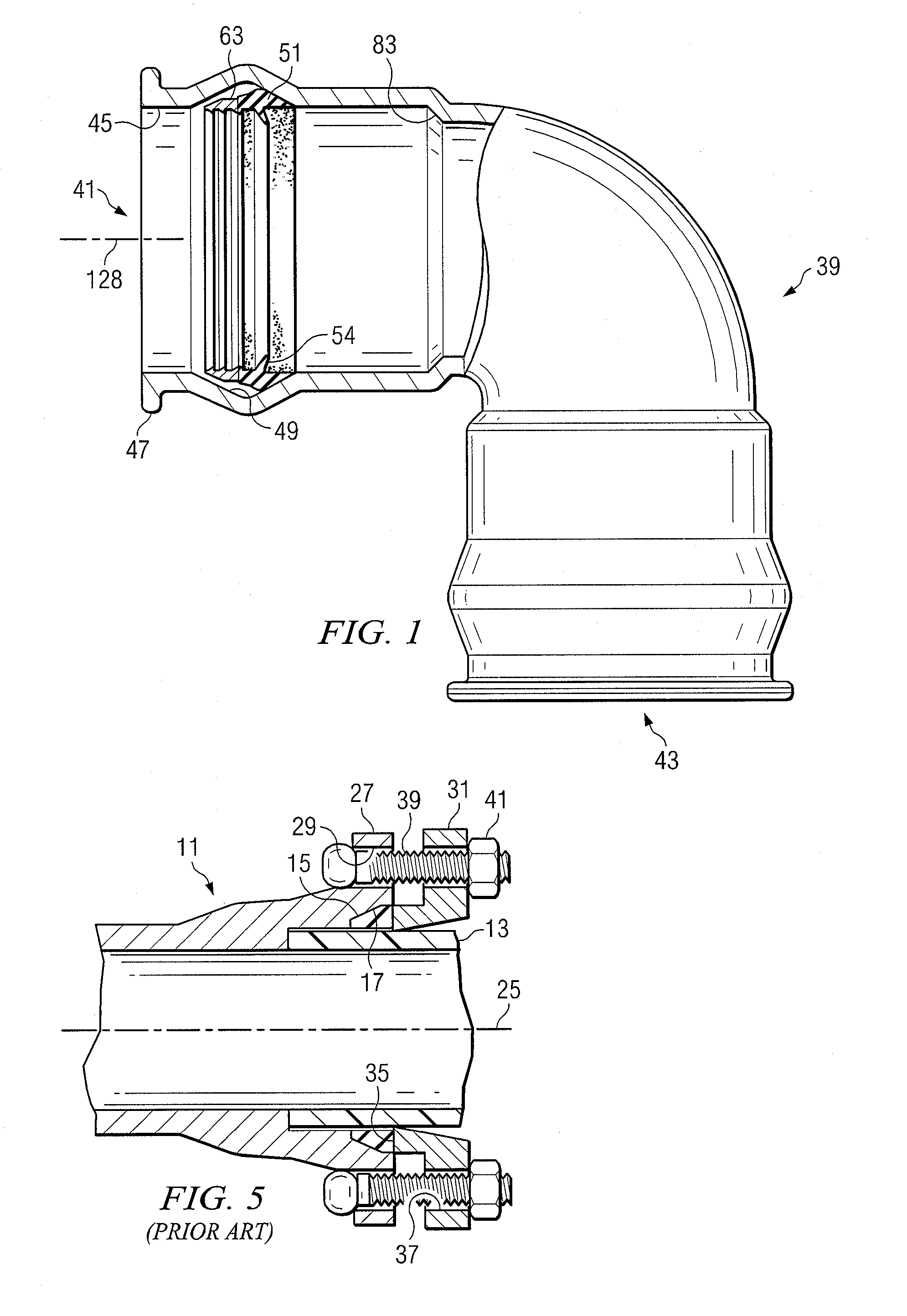

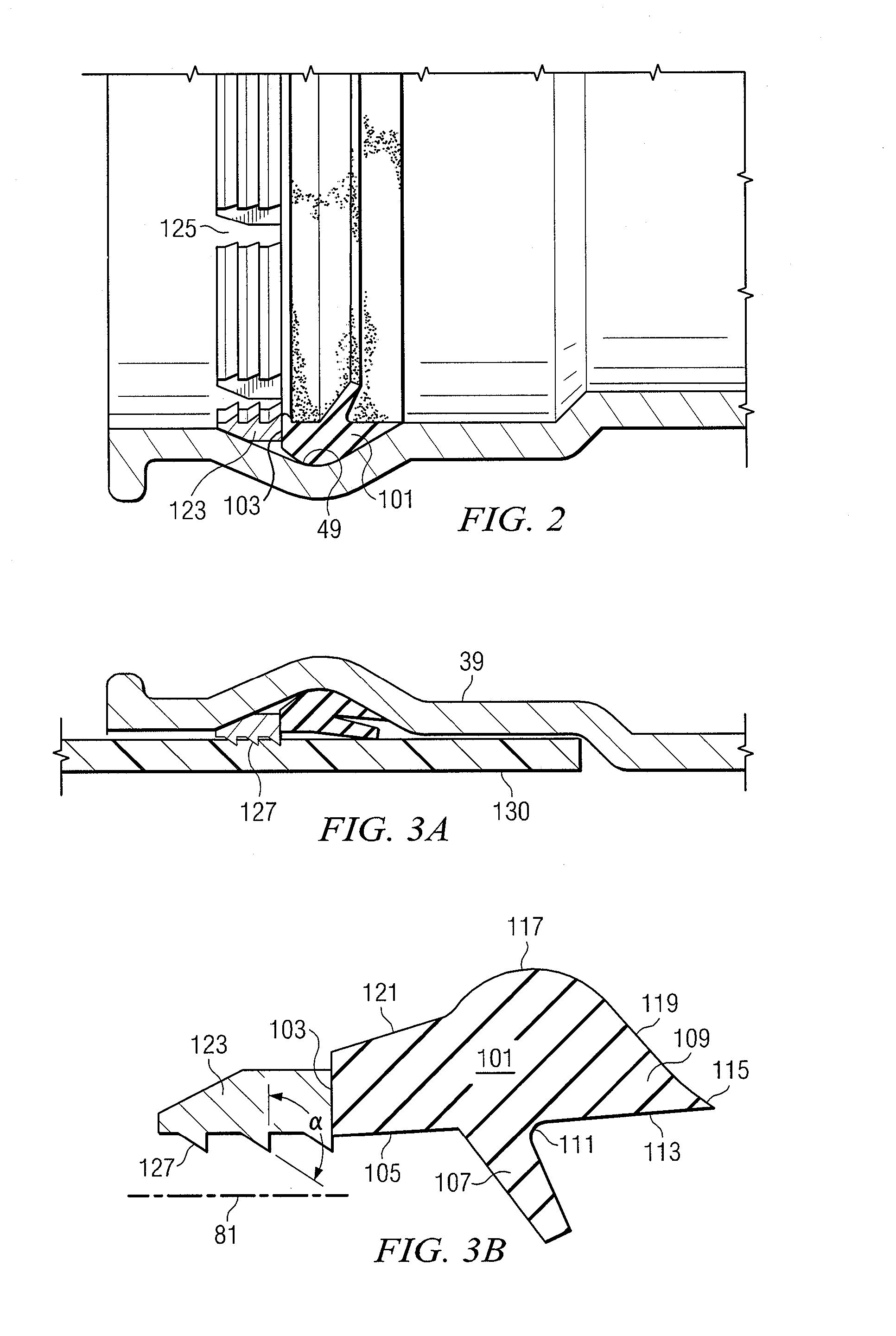

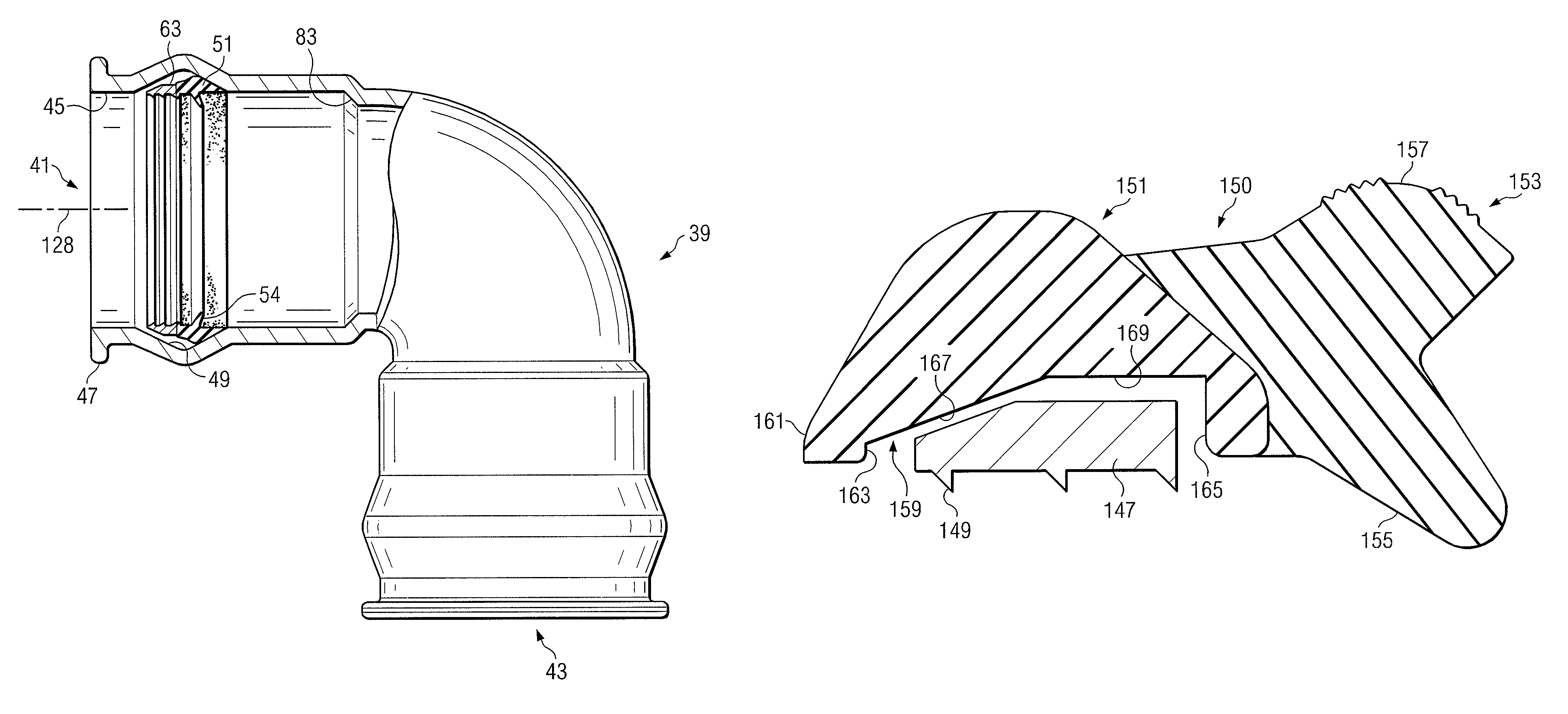

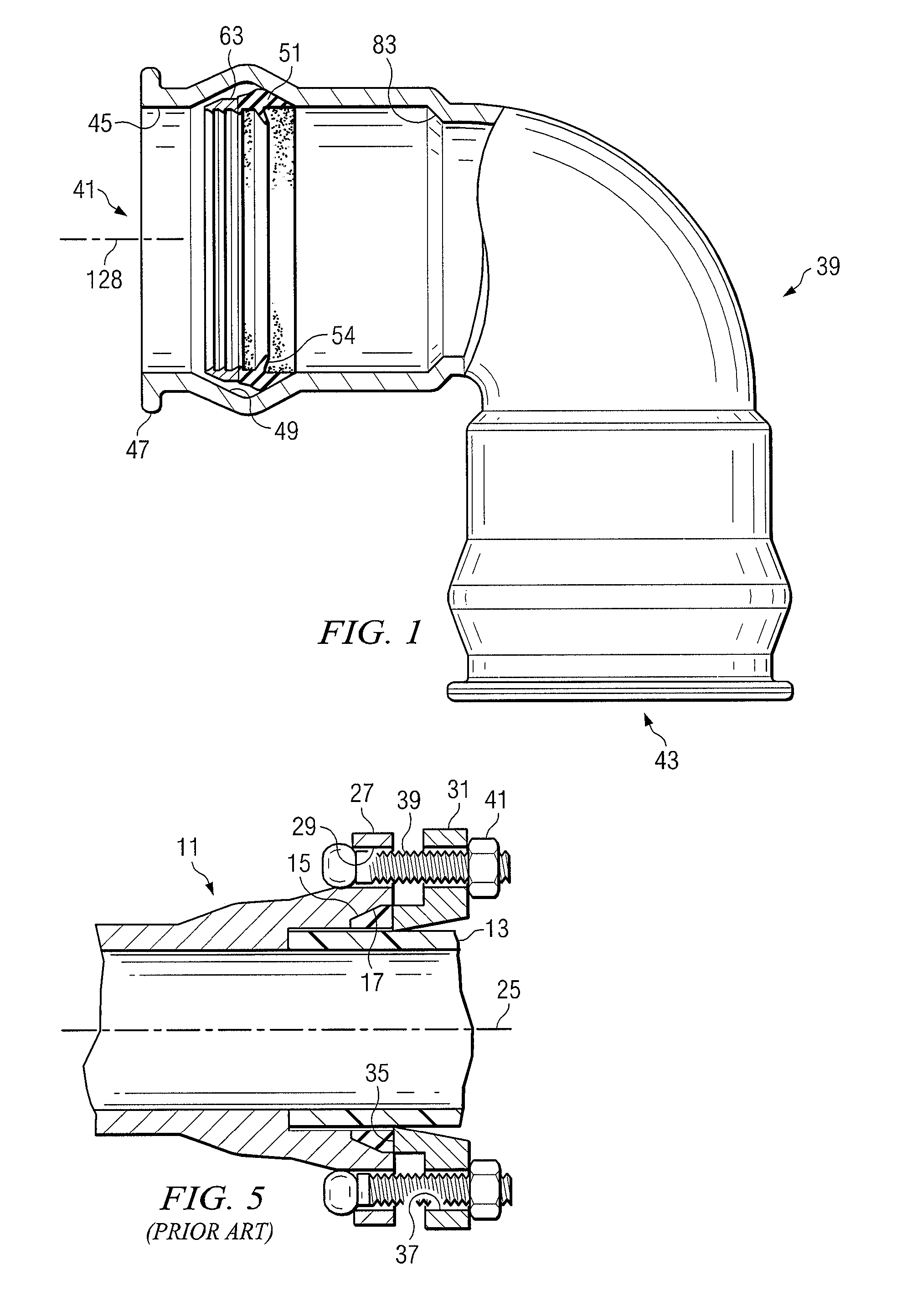

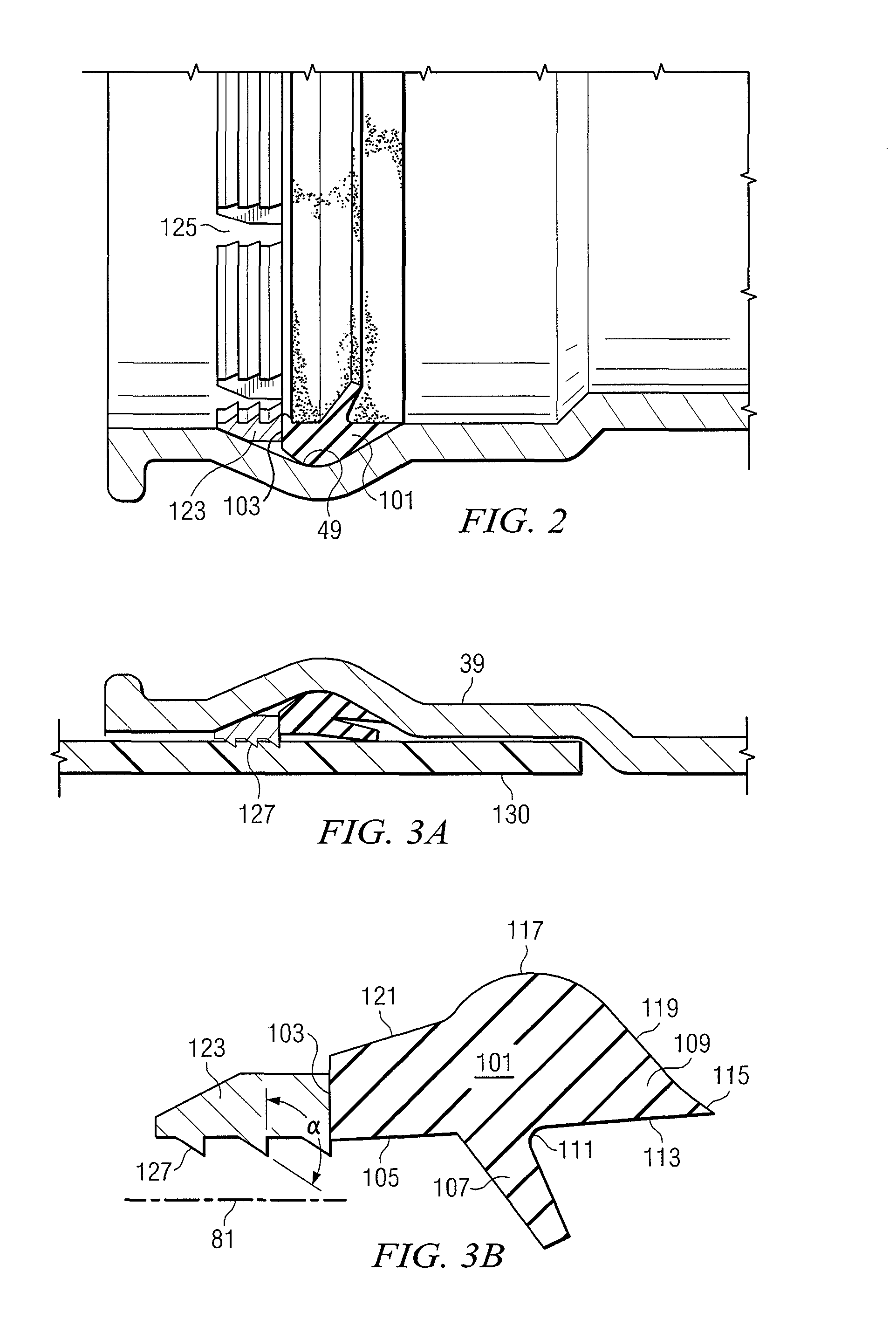

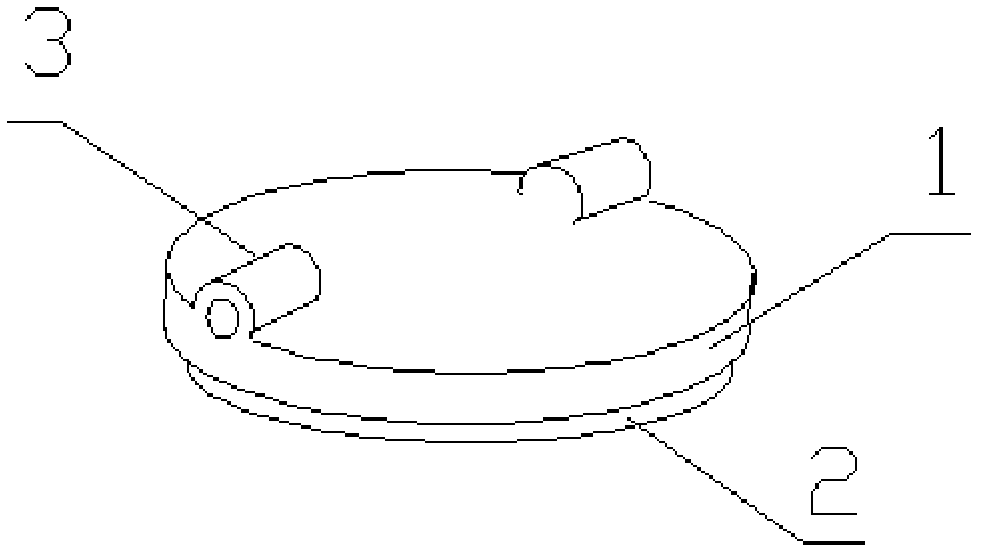

Self restrained ductile iron fitting

A combination sealing and restraint system for an as-cast ductile iron fitting is shown for both sealing and preventing separation of an iron pipe fitting and a mating male pipe. A ring-shaped body is installed within a mating groove provided in a mouth region of the as-cast fitting after the fitting has been cast at the manufacturing plant. The ring-shaped body carries a gripping member with teeth on an inner surface thereof which are initially angled away from an outer surface of a mating male pipe. The teeth are forced into engagement with the exterior surface of the mating male pipe as the pipe joint at the fitting is assembled. The teeth are oriented to allow movement of the male pipe in a first direction relative to an end opening of the fitting during assembly, but to resist movement in a opposite direction after the fitting joint has been assembled. The ring-shaped body also includes a relatively flexible portion formed of an elastomer which forms a sealing member with the mating male pipe.

Owner:S & B TECHN PRODS

Shield type coating composition and preparation process of coating thereof

InactiveCN101817058APrevent sulfidation defectsGuaranteed qualityFoundry mouldsFoundry coresPowder mixtureCarrier fluid

The invention discloses a shield type coating composition, comprising a fire-proof powder mixture, a suspending agent, a binder and a carrier fluid, wherein the fire-proof powder composition consists of high temperature resistant components and functional components, and has a particle size of 200-325 meshes. The invention selects a reasonable fire-proof powder composition to prepare the shield type sand coating, thus achieving good sand burning resistance, and preventing the defects of recarburization on extra-low-carbon stainless steel piece surface and desulphurization on nodular cast iron piece surface, thereby realizing the aim of ensuring casting quality.

Owner:深圳市景鼎现代科技有限公司

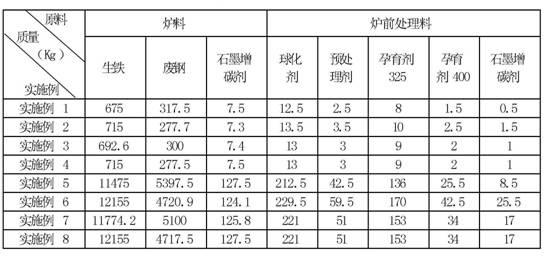

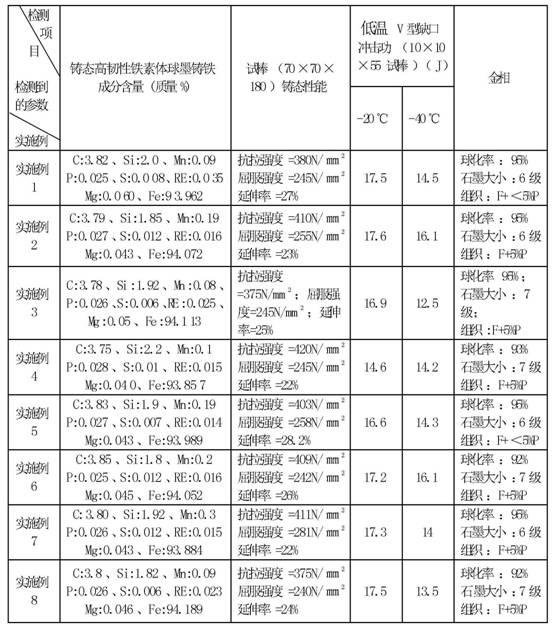

As-cast high-toughness ferrite nodular iron and production method thereof

The invention discloses as-cast high-toughness ferrite nodular iron, which comprises the following components: 3.75 to 3.85 mass percent of C, 1.8 to 2.2 mass percent of Si, 0.08 to 0.3 mass percent of Mn, less than 0.03 mass percent of P, less than 0.015 mass percent of S, 0.015 to 0.035 mass percent of RE, 0.04 to 0.06 mass percent of Mg and the balance of iron and inevitable micro impurities. The as-cast high-toughness ferrite nodular iron has high toughness, high ferrite content, high spheroidization and high low-temperature performance and is particularly suitable for making wind and power castings. The invention also discloses a production method of the nodular iron, which comprises the following steps: smelting pig iron, waste steel and graphite carburetant; and adding a nodulizer,a pretreating agent and an inoculant for before-furnace treatment. The product cost is low and the production period is short.

Owner:衡阳中钢衡重铸锻有限公司

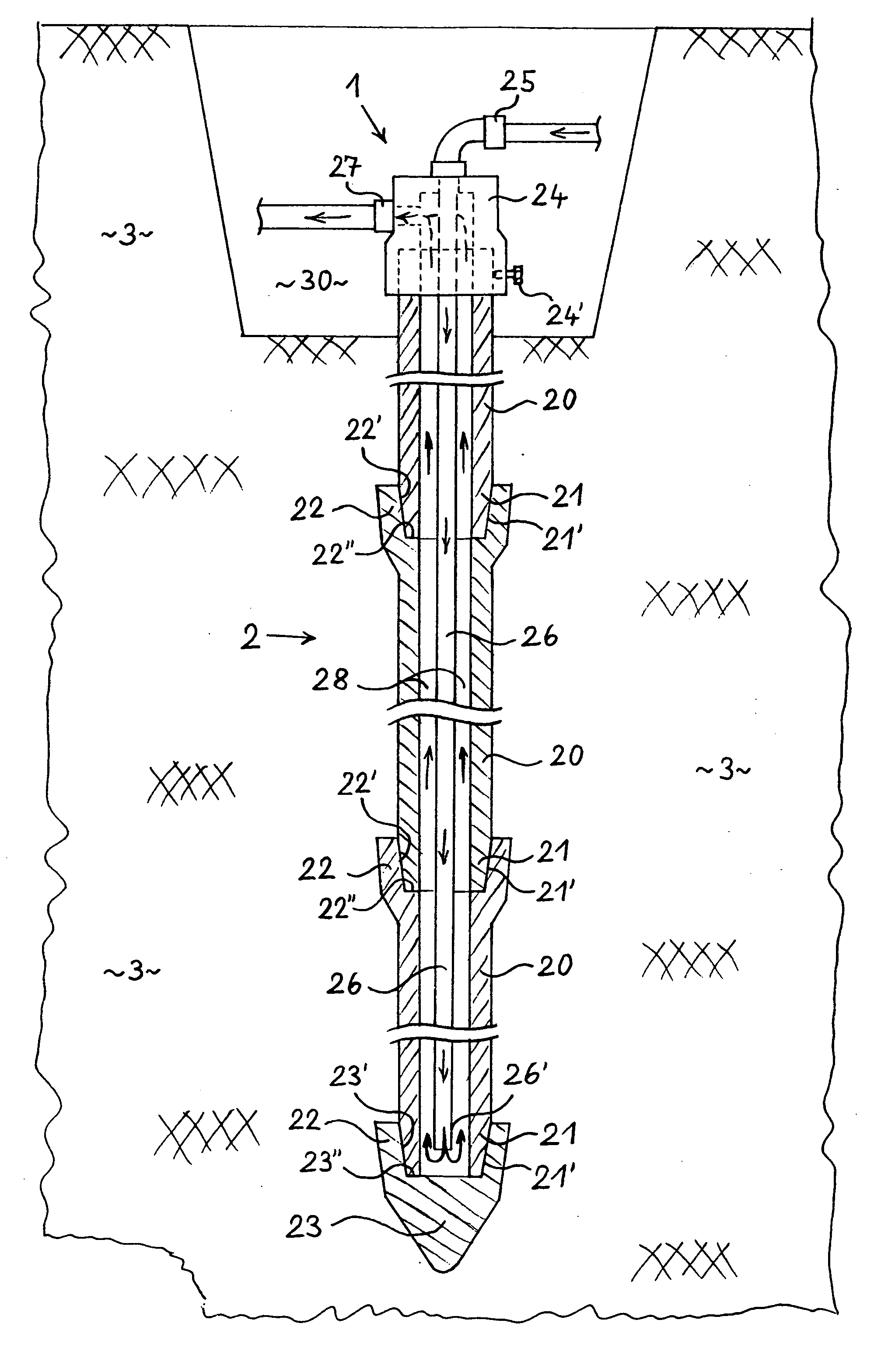

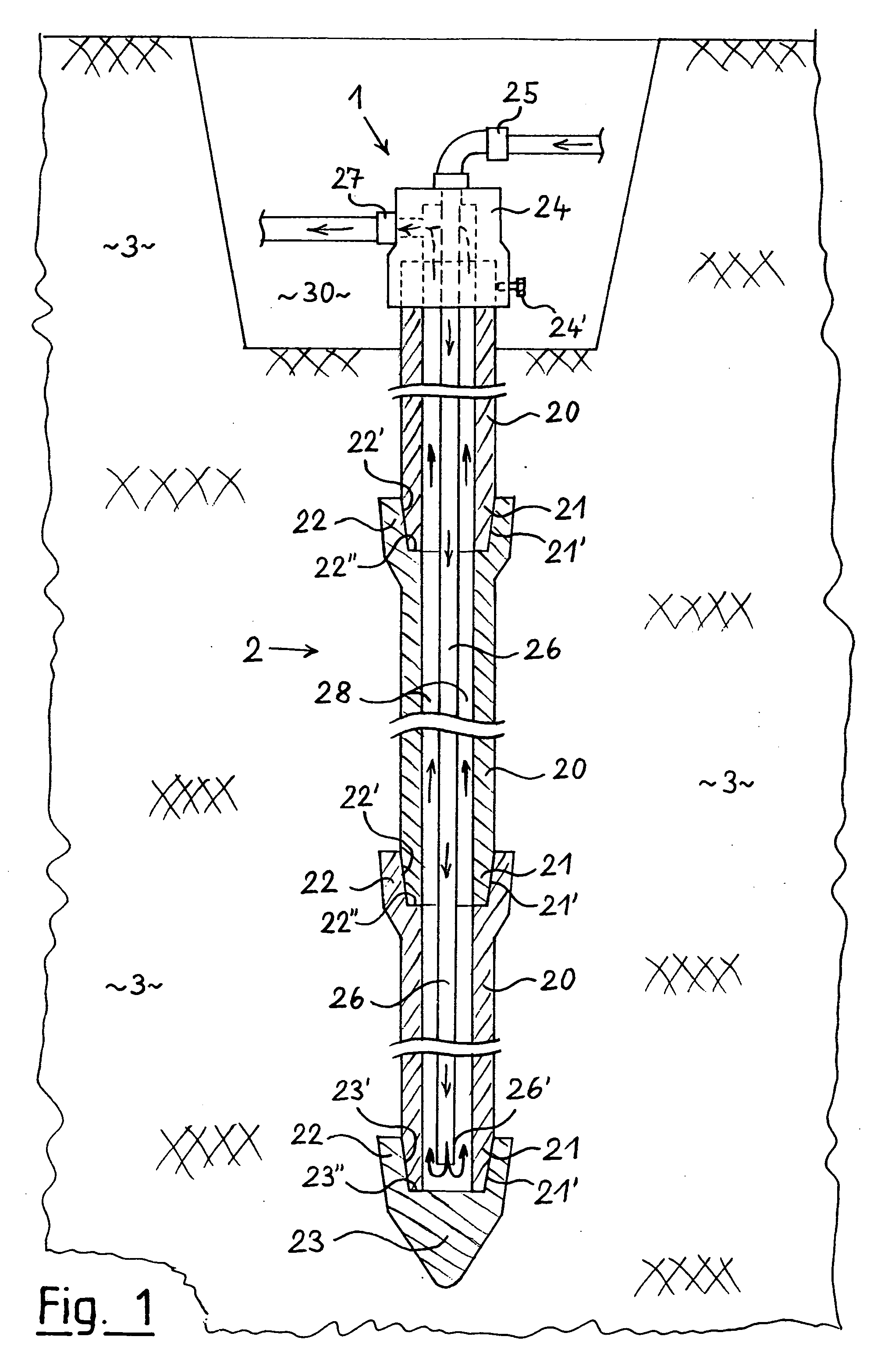

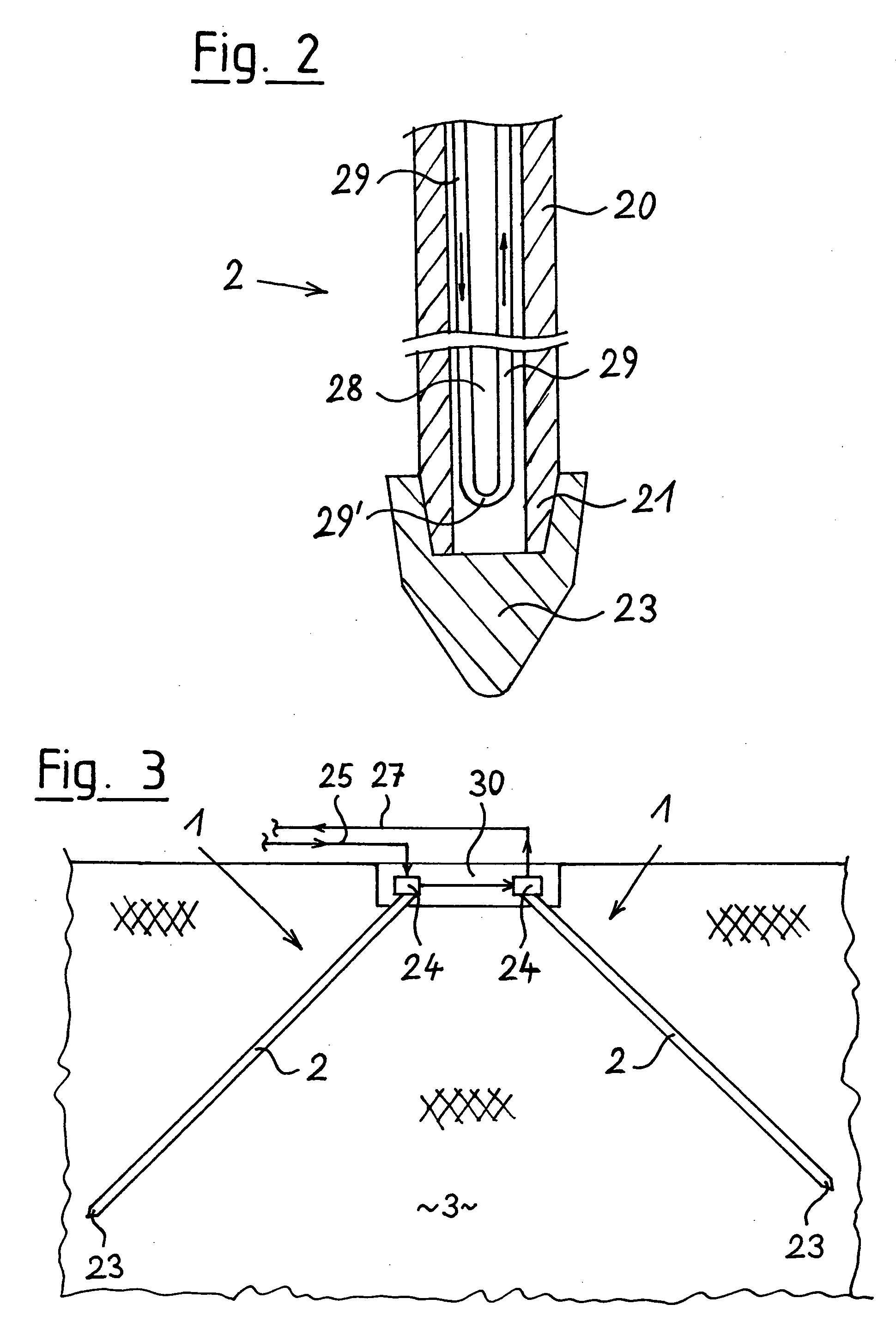

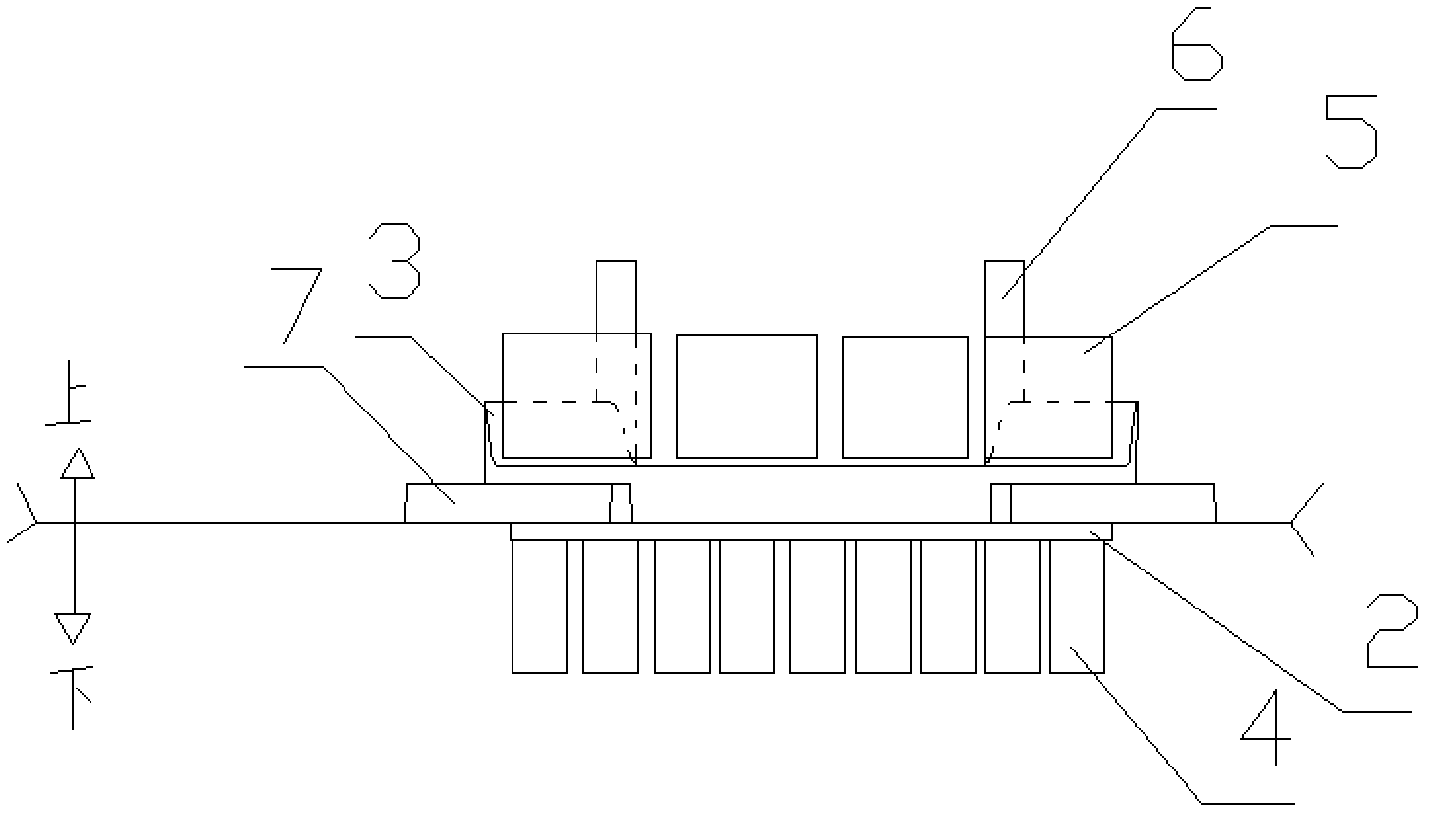

Heat source or heat sink unit with thermal ground coupling

InactiveUS20050061472A1Avoid corrosion damageAvoid introducingOther heat production devicesGeothermal energy generationCouplingEngineering

The invention relates to a heat source or a heat sink unit with thermal ground coupling, comprising at least one ground probe arranged in the earth, whereby each earth probe is a probe tube made from several pile tube segments. An open dip tube or a U-shaped tube loop is arranged in the probe tube at the open lower end thereof. Said unit is characterized in that each pile tub segment is made from ductile cast iron, the pile tube segments re embodied such as to plug into each other at the ends thereof and each pile tube segment comprises, at the one end thereof, a conical outer circumference and, at the other end thereof, a sleeve embodied with a shoulder stop having a matching conical internal circumference, whereby the diameter thereof and the cone angle are such that on driving in the pile tube segments a positive and sealed connection between the pile tube segments is generated.

Owner:WATERKOTTE WARMEPUMPEN

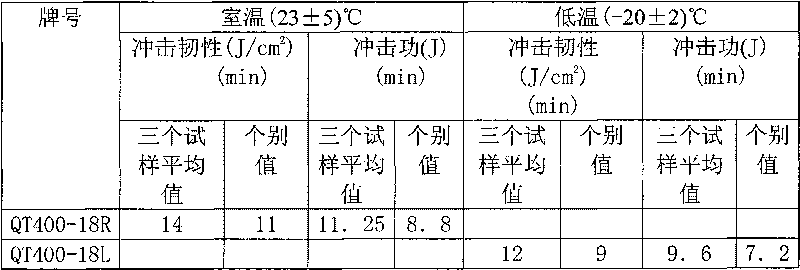

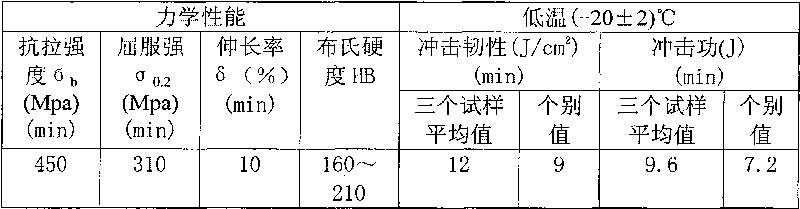

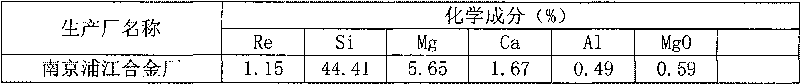

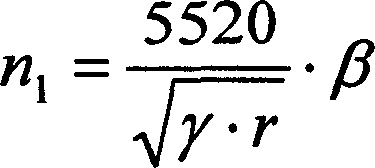

Method for producing low-temperature impact resistance high-strength nodular cast iron

ActiveCN101760689AIncrease the level of nodularityImprove impact performanceProcess efficiency improvementHigh intensityDuctile iron

The invention discloses a method for producing low-temperature impact resistance high-strength nodular cast iron, which comprises processes of material preparing, smelting, desulfurizing, molten iron adjusting and spheroidizing. The method is characterized in that: in the material preparing process, based on 100 percent, base iron accounts for 30 to 70 percent, steel scarp accounts for 10 to 20 percent, and recirculated iron accounts for 10 to 60 percent; other additives are added based on the total weight of the base iron, the steel scarp and the recirculated iron, wherein spheroidizing agent accounts for 1.6 to 2.0 percent, inoculant accounts for 0.4 to 0.6 percent, desulfurizer accounts for 1.2 to 1.8 percent, and carburant accounts for 1 to 3 percent; furthermore, 0.15 to 0.50 percent of Cu is added. On the premise of ensuring low temperature impact performance, the nodular cast iron improves strength,, meets the requirement that the nodular cast iron of the mark has higher low-temperature impact resistance and high normal-temperature strength, and can be widely used for manufacturing important high-strength cast of vehicles, locomotive, draught fans and engineering machinery used in low temperature environment and manufacture of cast having strict requirement on fatigue strength.

Owner:山东汇金股份有限公司

Compound high speed steel roll and its making process

InactiveCN1846887AImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

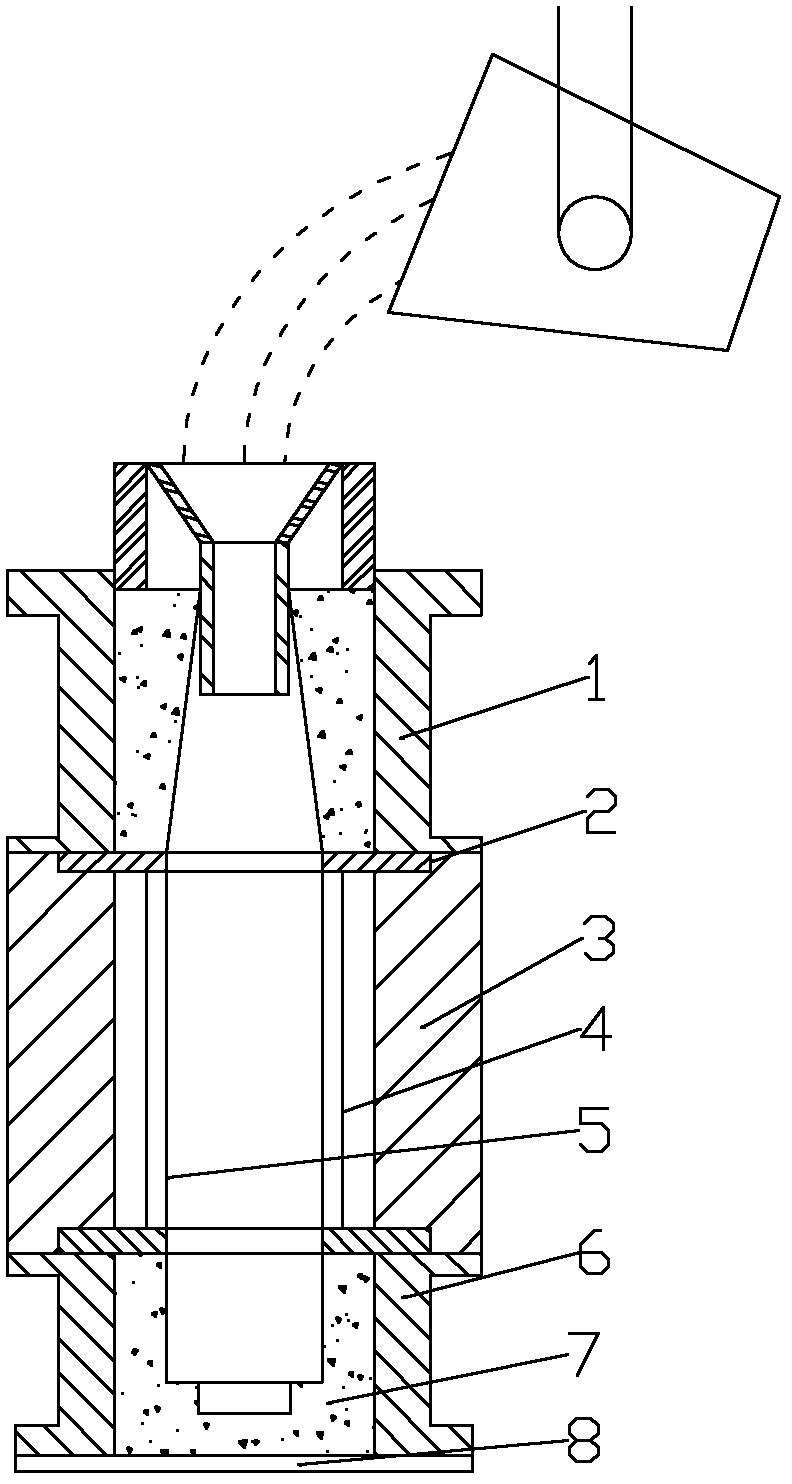

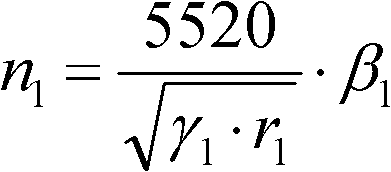

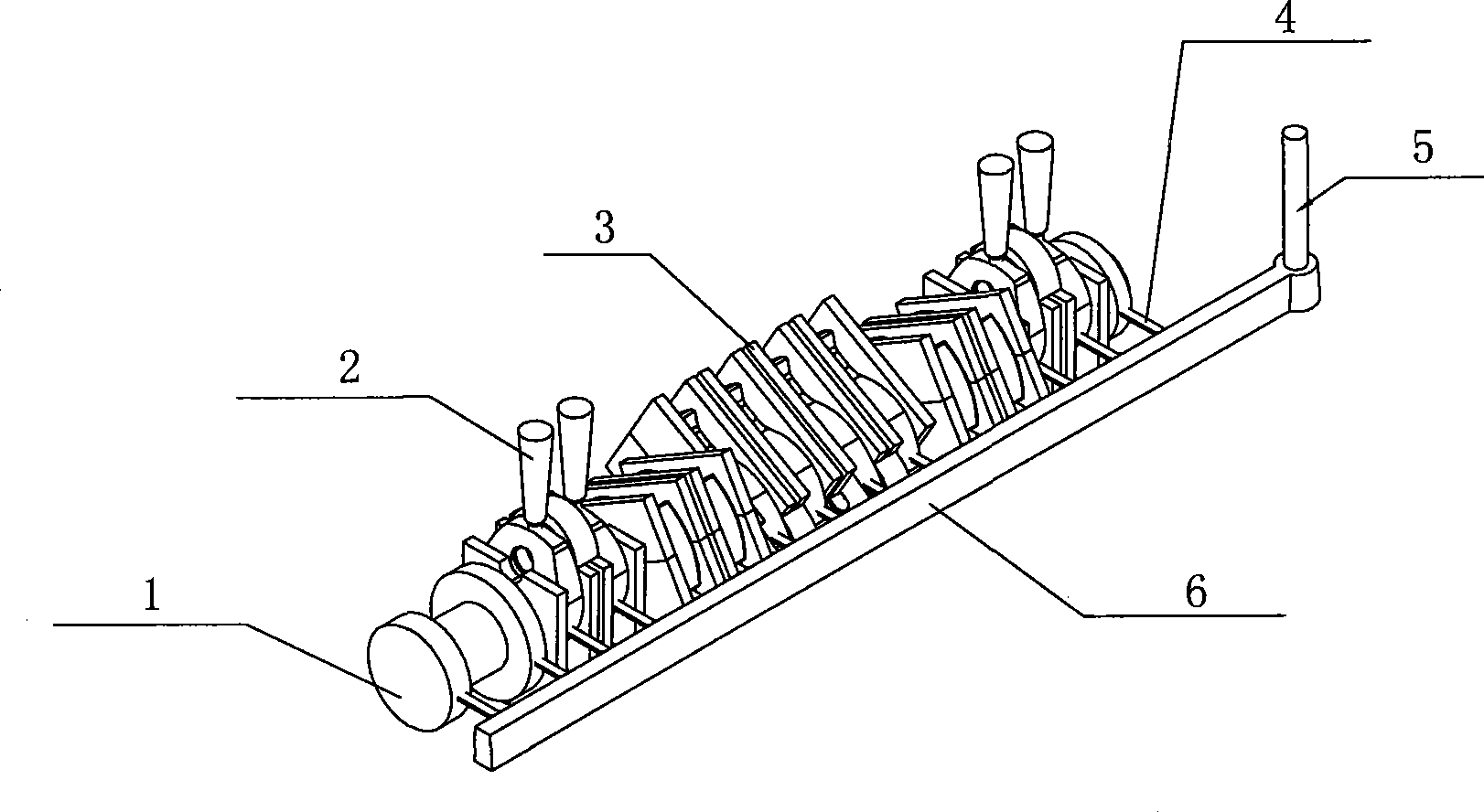

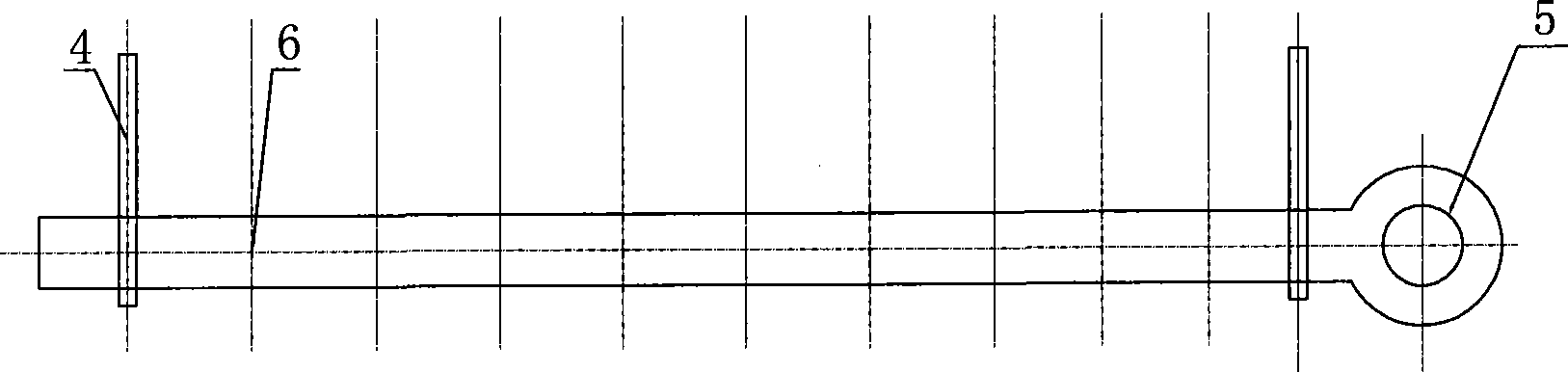

High-speed steel composite roller and casting method thereof

The invention belongs to the field of steel rolling manufacture, specifically is a high-speed steel composite roll for strip mill in steel rolling industry and casting method thereof. The outer layer of the composite roll is made of high-speed steel, the middle layer is made of ductile cast iron base iron or graphite semisteel, the core is made of ductile cast iron. The invention employs centrifugal compound foundry technique, the roll is moulded by three times of casting. Constant centrifugal rotating speed is kept in centrifuge, the metal material of the outer layer and the middle layer are mould cast, and then the metal of the roll core is statically cast to form the final product. Compared with former dual-layer or other three-layer composite high-speed steel rolling rolls, the three layers of metal of the high-speed steel composite roll of the invention are well combined and have high strength; the optimal selection of the material of the middle layer improves the strength of the bonding layer, the carbide affecting the binding performance in the middle layer is reduced, the spreading of alloy element in the outer layer high-speed steel to the core, which affects the core material performance, is also effectively avoided by the middle layer, cracking and dropping off of the working layer in hot processing and rolling process are prevented as well.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

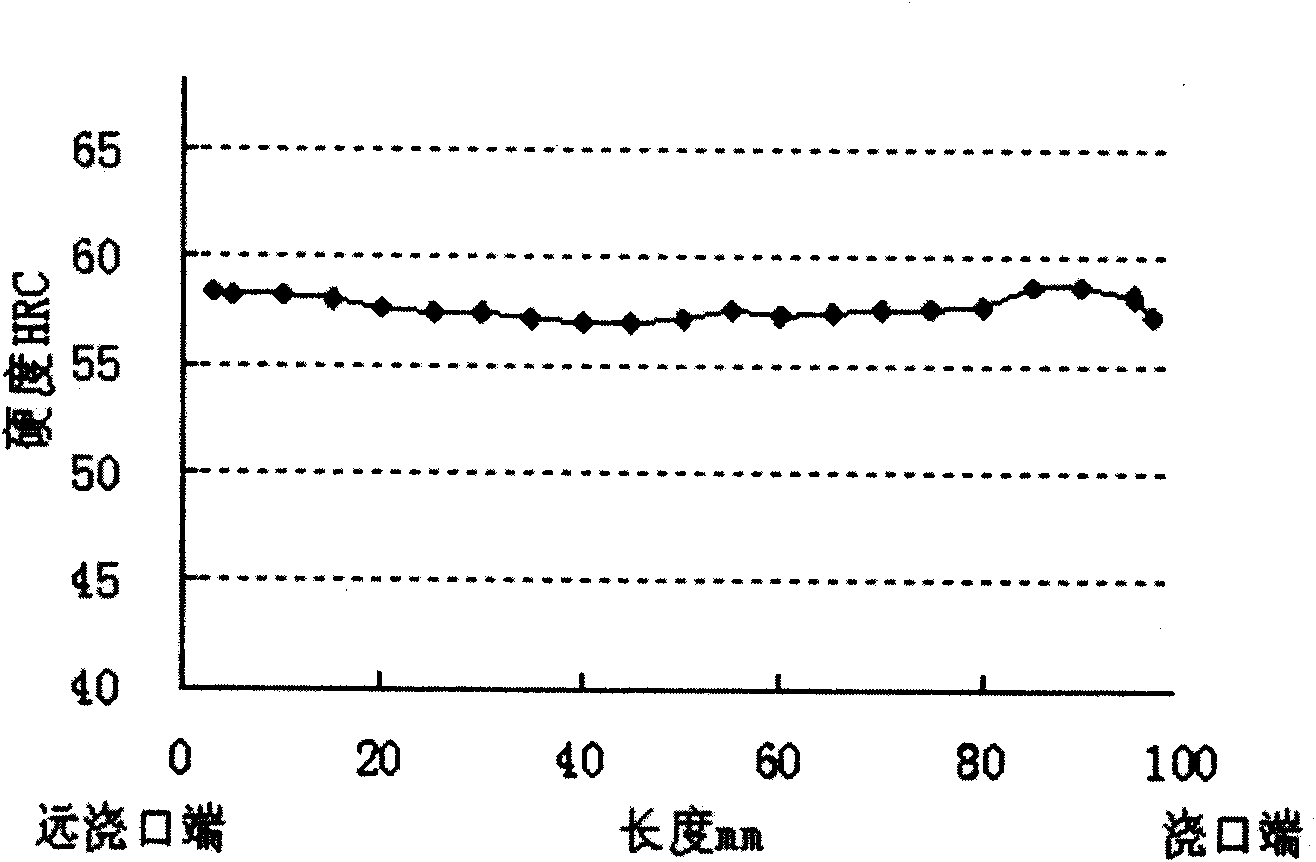

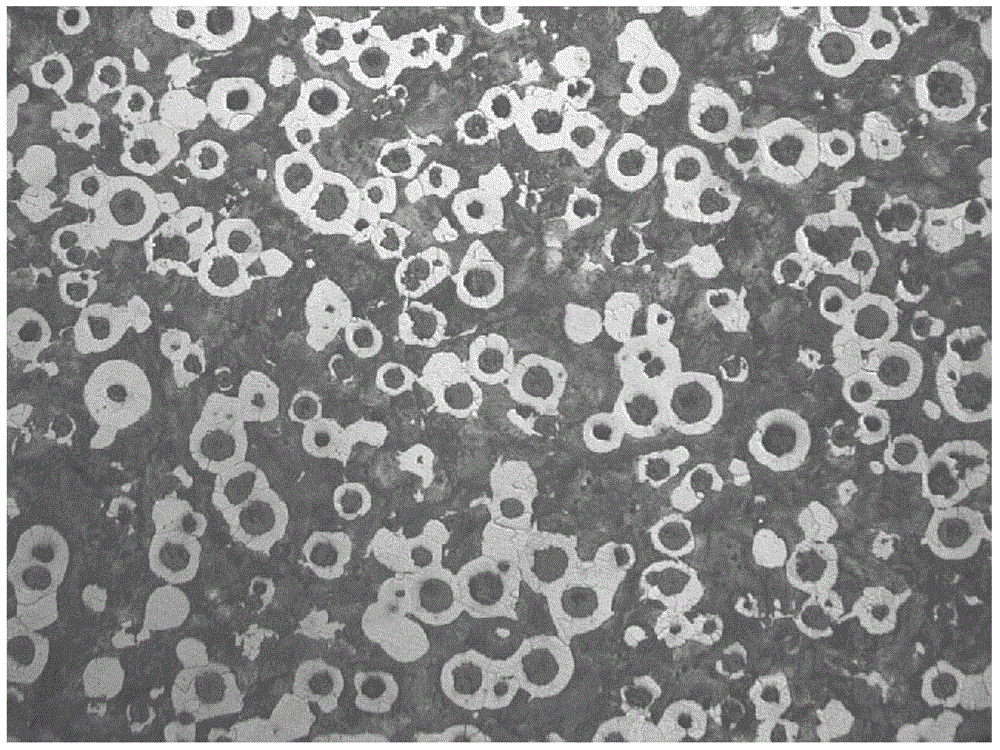

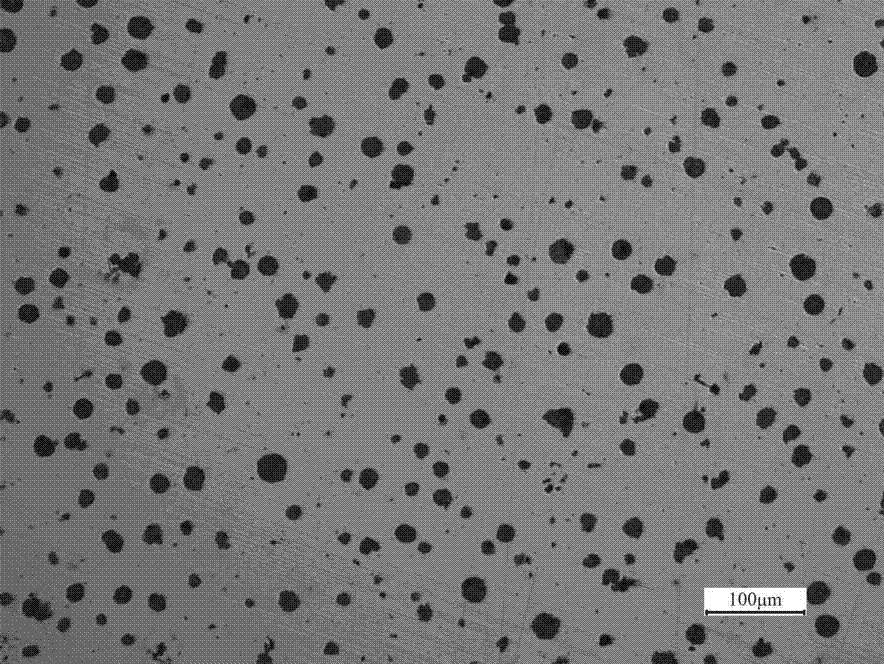

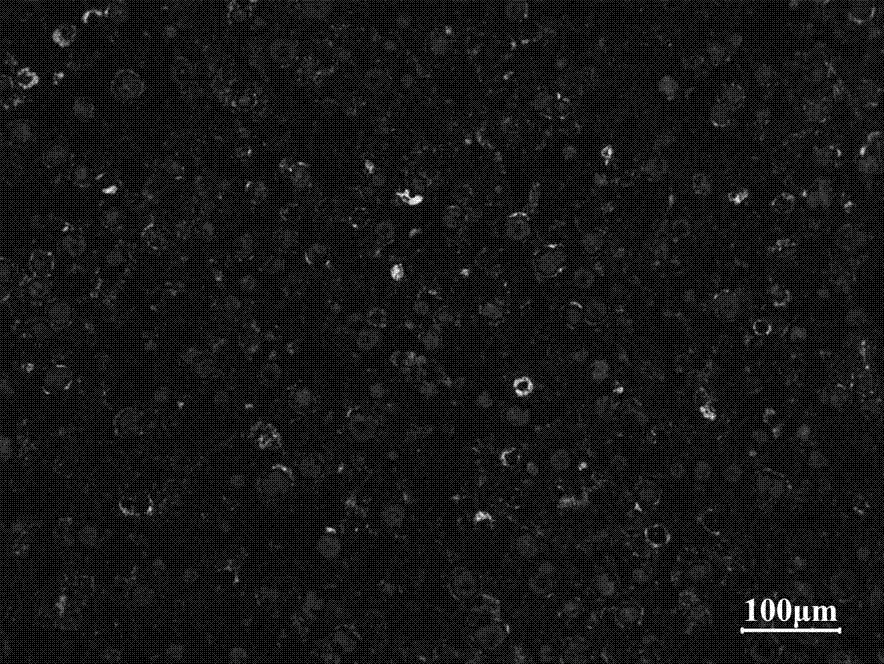

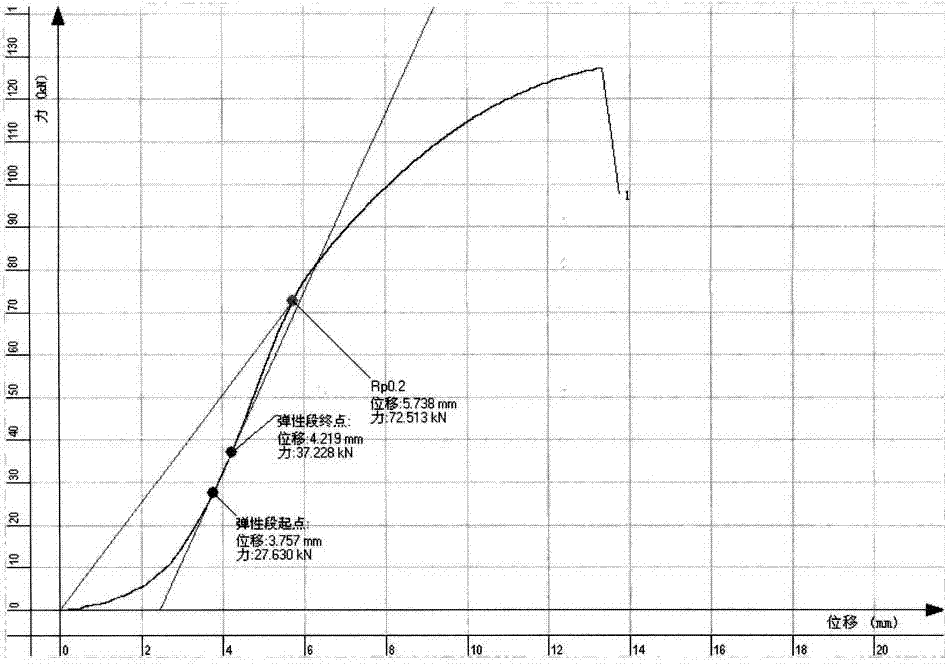

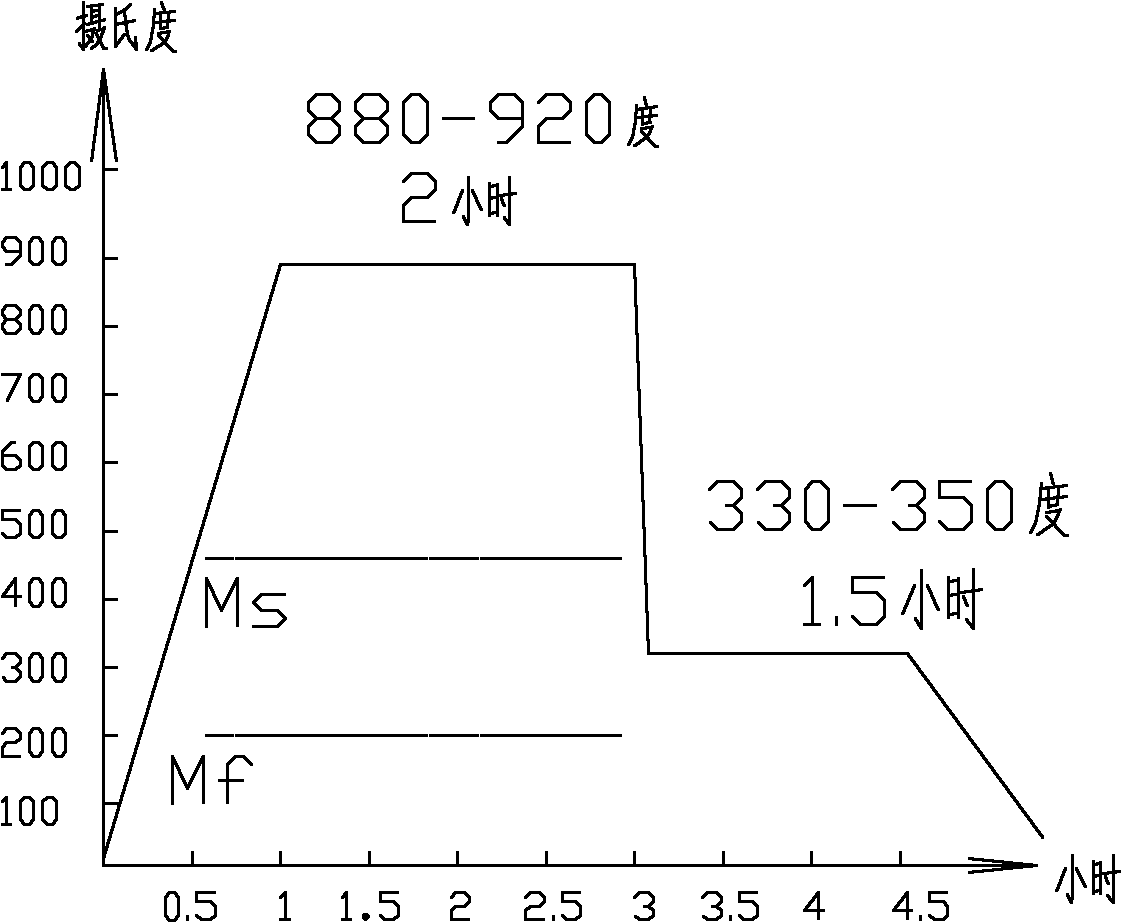

Carbide-containing ausferrite spheroidal graphite cast iron grinding ball and manufacturing method thereof

The invention discloses a carbide-containing ausferrite spheroidal graphite cast iron grinding ball and a manufacturing method thereof, relating to a cast iron alloy containing spheroidal graphite. The grinding ball comprises the following chemical elements in percentage by mass: 3.3 to 3.7 percent of C, 2.4 to 3.3 percent of Si, 2.5 to 3.6 percent of Mn, 0.6 to 1.5 percent of Cr, less than 0.08 percent of P, less than 0.025 percent of S, 0.03 to 0.05 percent of Mg, 0.02 to 0.04 percent of Re and the balance of Fe. The preparation method of the grinding ball comprises the following steps of: (1) raw material preparation and smelting; (2) spheroidization and inoculation; and (3) isothermal quenching heat treatment. In the invention, a certain quantity of carbides and graphite balls are formed in a grinding ball casting-state structure by utilizing a sand lined metal casting technology; and an ausferrite base body with excellent comprehensive mechanical property is obtained by adopting an isothermal quenching technology; and as a certain quantity of carbides are distributed in the ausferrite base body, the carbide-containing ausferrite spheroidal graphite cast iron grinding ball has high wear resistance and toughness.

Owner:HEBEI UNIV OF TECH +1

Smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron

ActiveCN102690986AImprove densification performanceImprove roundnessIntermediate frequencyStress relief

The invention relates to a smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron comprises the following chemical components in percentage by mass: 3.5-4.1 percent of C, 1.7-2.2 percent of Si, 0.10-0.25 percent of Mn, not more than 0.035 percent of P, not more than 0.020 percent of S, 0.015-0.030 percent of Re, 0.025-0.045 percent of Mg, 0-0.20percent of Cu, less than 0.1 percent of residual element, and Fe in balancing amount. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron is obtained by mixing furnace materials and carrying out high-temperature smelting in an intermediate-frequency furnace, modularization and inoculation treatment and casting and heat-insulating treatment on the mixed furnace materials. Cast iron products obtained by adopting the smelting method disclosed by the invention obtain normal-temperature mechanical property and low-temperature mechanical property under the cast state conditions; complex medium-thin wall parts are required to be subjected to low-temperature stress relief annealing; and simple medium-thin wall parts are free from being annealed, so that the production cost is greatly reduced, the production period is greatly shortened and the production efficiency is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

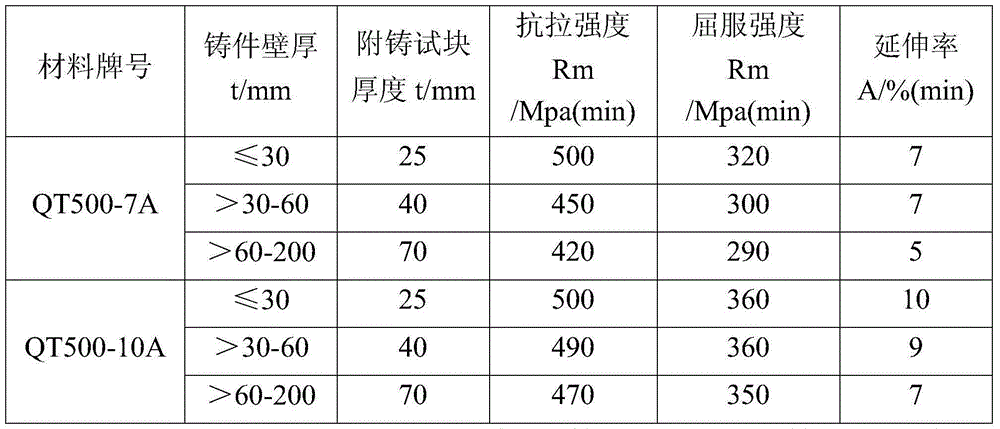

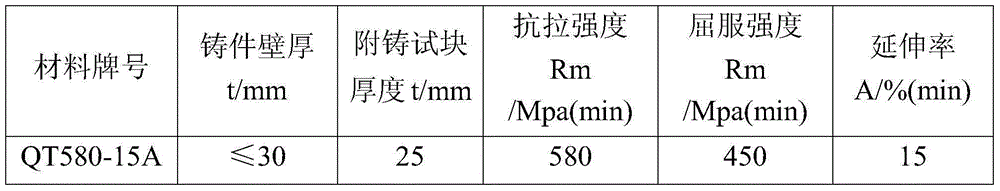

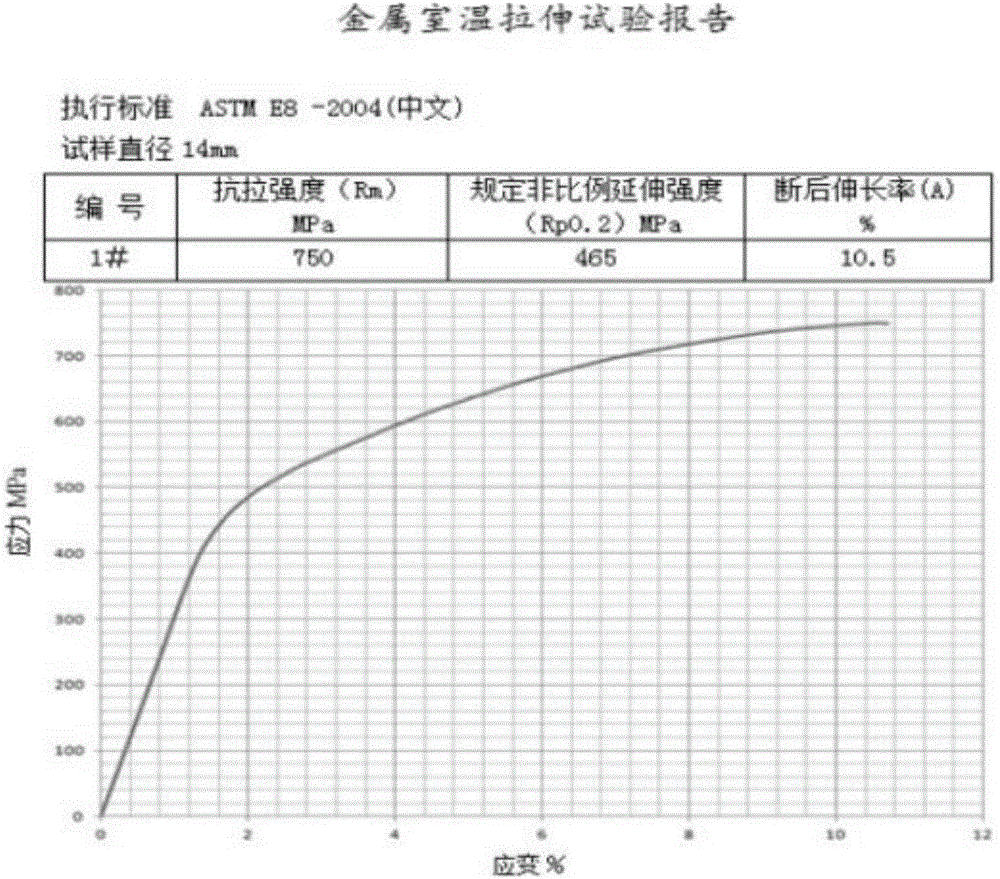

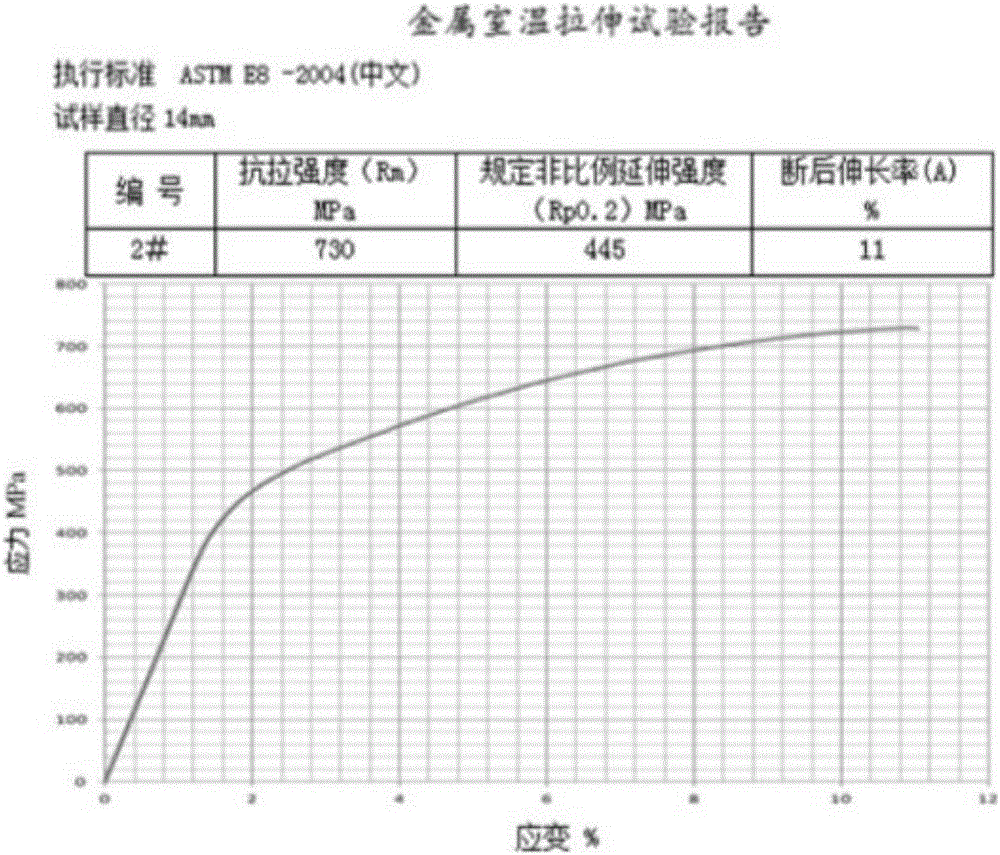

Large-section cast ferrite nodular cast iron and preparation method thereof

The invention belongs to the technical field of nodular cast irons, concretely relates to control and casting production of a nodular cast iron material, and especially relates to a large-section cast ferrite nodular cast iron QT580-15A and a preparation method thereof. Performances of a separately cast test block with the wall thickness being greater than 60mm and an attached test block with the thickness of 70mm respectively meet requirements (separate cast: the tensile strength is not smaller than 580MPa, the yield strength is not smaller than 450MPa, and the elongation is not smaller than 15%; and attached cast: the tensile strength is not smaller than 530MPa, the yield strength is not smaller than 400MPa, and the elongation is not smaller than 12.5%) through selecting raw materials, controlling the components of molten iron, optimizing a nodulizer, a covering agent and a technology, determining an inoculant and the technology, and controlling the addition amount and the addition method of trace alloy elements.

Owner:JIANGSU JIXIN WIND ENERGY TECH

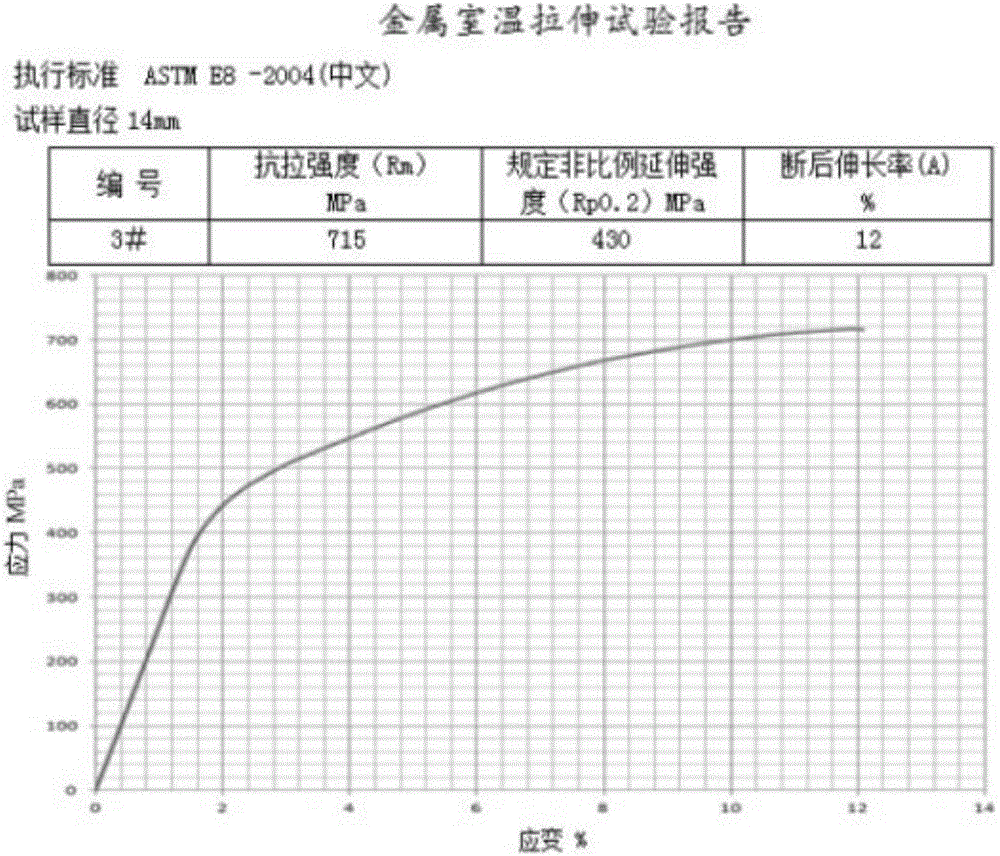

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

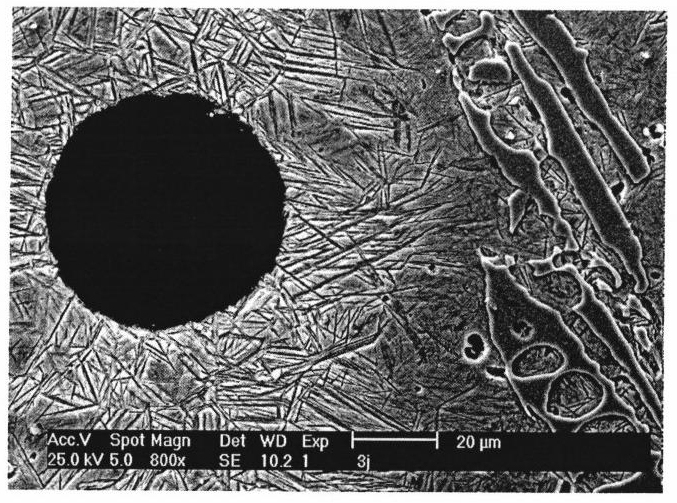

Nodular graphite cast iron crankshaft of diesel engine and its non-feedhead casting process

ActiveCN101429615APrevent shrinkage and shrinkage defectsImprove product qualityDuctile ironHeavy load

The invention discloses a diesel nodular cast iron crankshaft, which comprises the following components in mass percentage: 3.80 to 3.90 percent of w(C), 2.10 to 2.40 percent of w(Si), more than 0 and less than or equal to 0.30 percent of w(Mn), more than 0 and less than or equal to 0.060 percent of w(P), more than 0 and less than or equal to 0.020 percent of w(S), 0.60 to 0.80 percent of w(Cu), 0.20 to 0.30 percent of w(Mo), 0.020 to 0.040 percent of w(RE), 0.030 to 0.050 percent of w(Mg), and the balance being Fe. The nodular cast iron crankshaft can bear heavy load and constantly changing bending moment and torque actions, and has good mechanical property. The invention also provides a feederless casting process for the crankshaft, and cast parts produced by the casting process do not have the defect of shrinkage porosity at the root part and have reliable mechanical property and high yield.

Owner:GUANGZHOU DIESEL ENGINE FACTORY

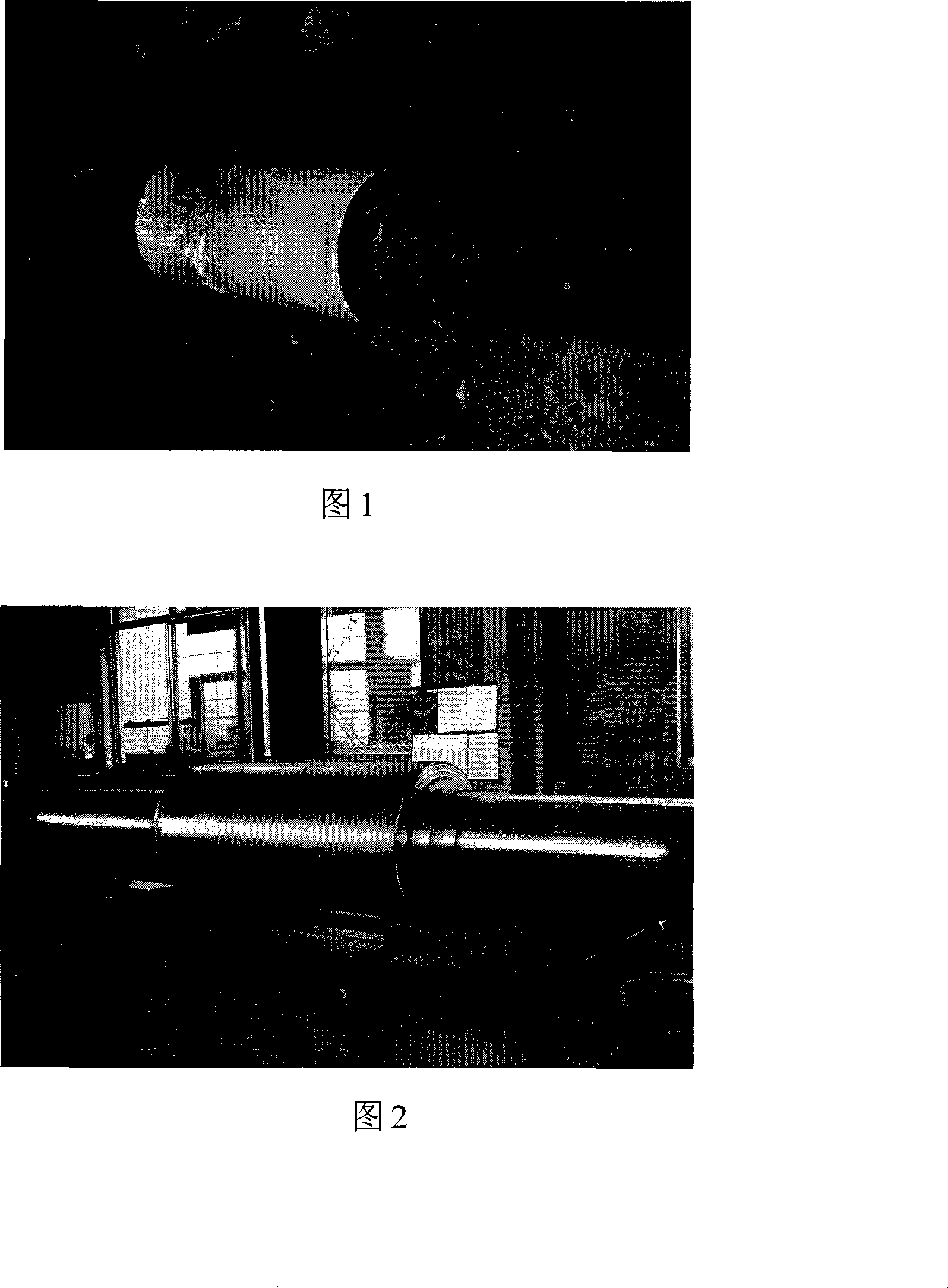

Overlaying welding technology of ductile cast iron roller

ActiveCN101543926ASolve the problem of repairing welding defects such as small and medium cracksAvoid Weld CrackingWelding/soldering/cutting articlesWelding accessoriesEconomic benefitsDuctile iron

The invention relates to an overlaying welding technology of an iron casting, in particular to an overlaying welding technology of a ductile cast iron roller. The technology comprises the following steps: (1), post-welding preparation: a, detecting cracks; b, controlling a welding material; and c, selecting a welding beveling; (2), welding: a, preheating the beveling within a range of 120mm to 180mm at a temperature range of 130 DEG C to 170 DEG C; b, adopting a DC reverse-connected arc welding machine for welding, using welding rods with the diameter of 3.2mm for welding a first-layer welding line and using welding rods with the diameter of 4mm for welding lines on subsequent layers; and (3), post-welding detection. The invention adopting the technologies, such as small currents, a plurality of stages, sectional welding, welding line hammering after welding, cooling speed reduction, and the like prevents welding line cracks and fusion region cracks from generating, prolongs the service life of products, obtains favorable economic benefits and solves the problems for the overlaying welding of mid-small cracks, and the like on the surface of the ductile cast iron roller.

Owner:CHANGZHOU HAIJIE METALLURGICAL MACHINERY MFG

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

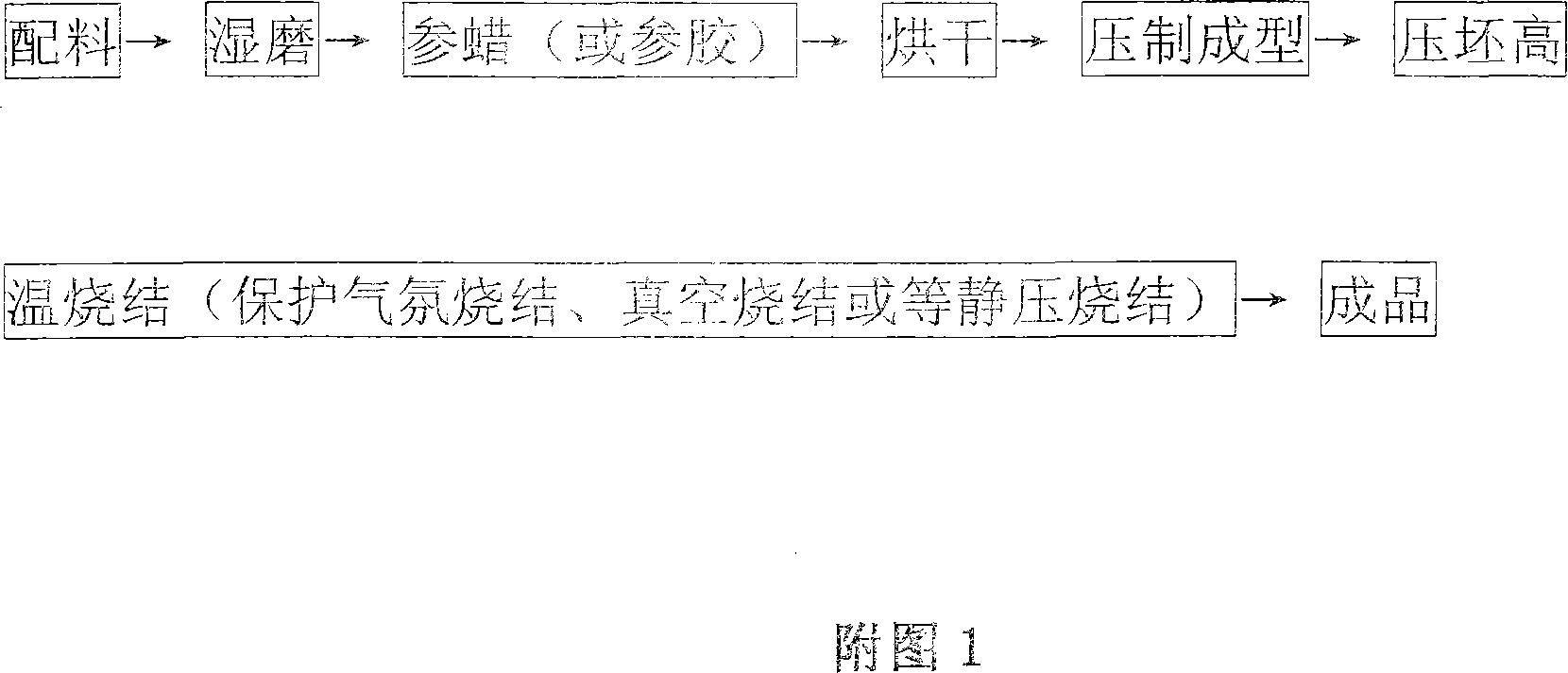

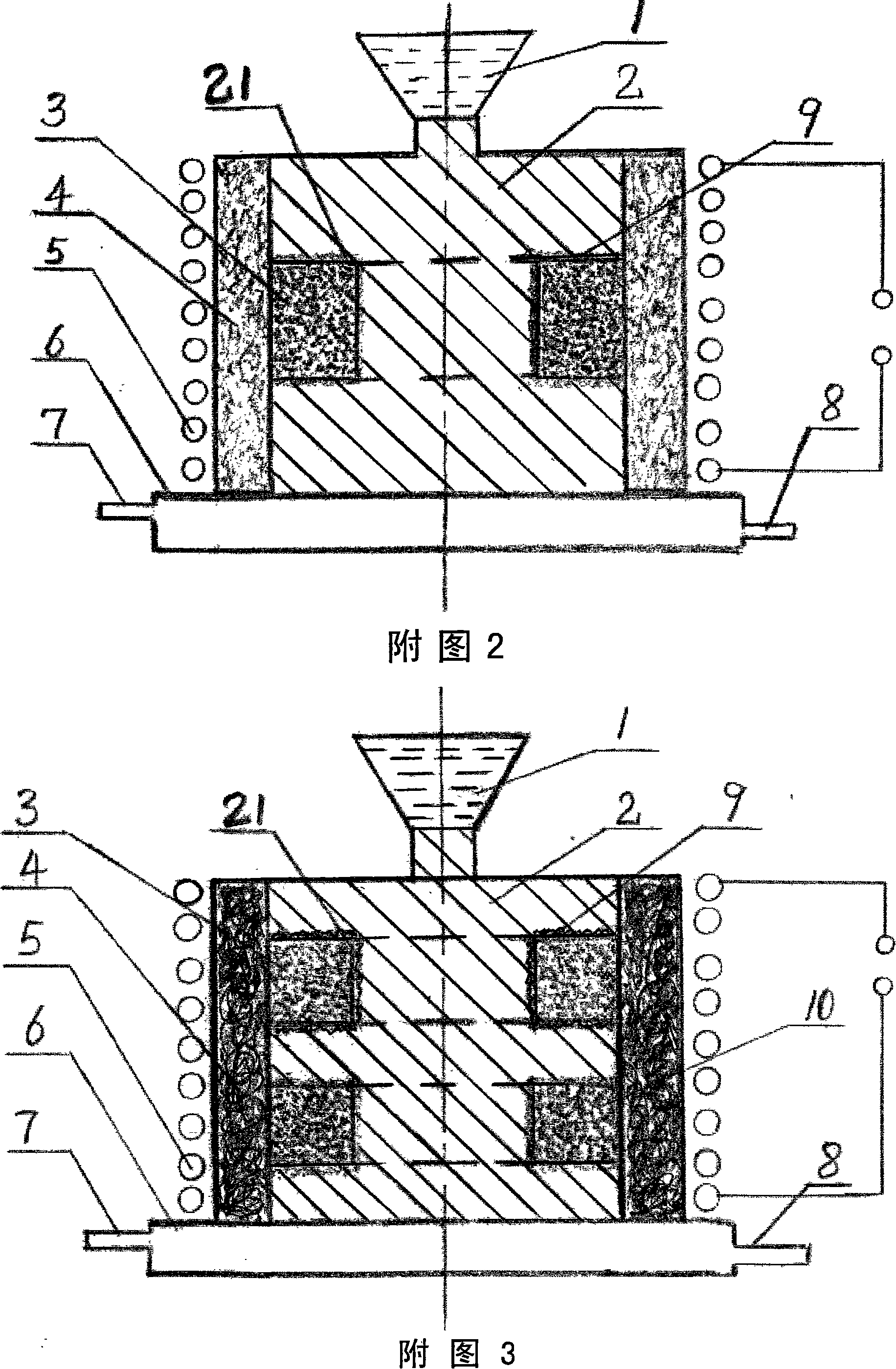

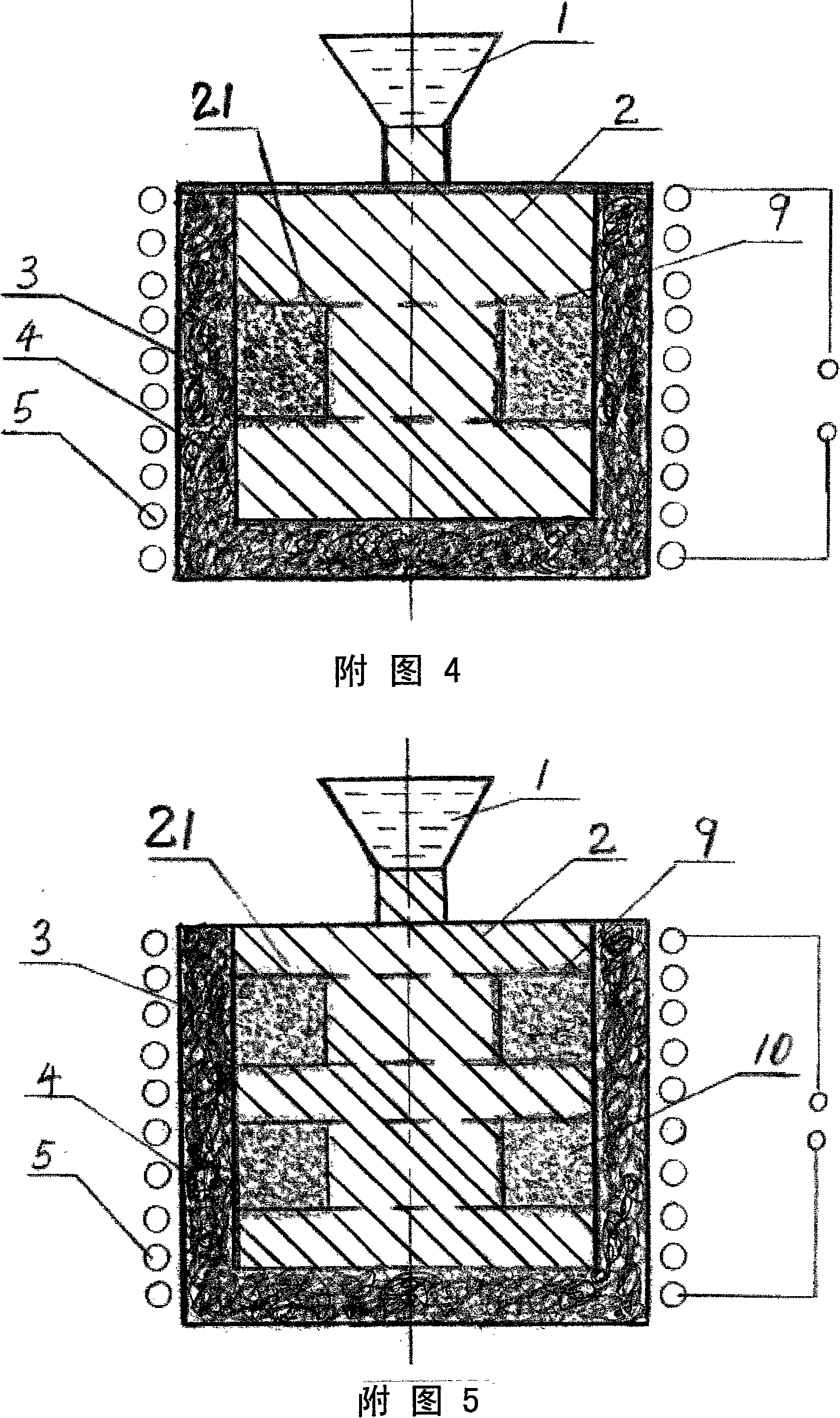

Hard alloy and double-metal composite technique and device

The utility model relates to a composite art and apparatus for hard alloy and bimetal, wherein the hard alloy is made of C with the content from 1.5 to 3.8 percent, Cr with the content from 15 to 27 percent, high chromium foundry iron with the content Fe used as binder, WC or TIC particles by the powder metallurgy technique, wherein the C and Cr are both accounted for 10-40 percent, the rest is the high chromium foundry iron, the WC or the TIC has the content from 90 to 60 percent. The hard alloy proceed composite casting with the C with the content from 1.5 to 3.8 percent, the Cr with the content from 15 to 25 percent, the rest high chromium foundry iron and spheroidal graphite cast iron in the mould provided with an electro-magnetism induction heater outside. The recombination of two materials is achieved by directly heating to the hard alloy and base metal liquid via the induction heater in the process of casting. The hard alloy produced by the invention has better wetting property and less bulking difference to the base metal, and is capable of achieving good recombination with the base metal. The invention has the advantages of simple recombination technique, easy achievement of technique, good property of the recombination products and low manufacturing costs.

Owner:丁家伟 +1

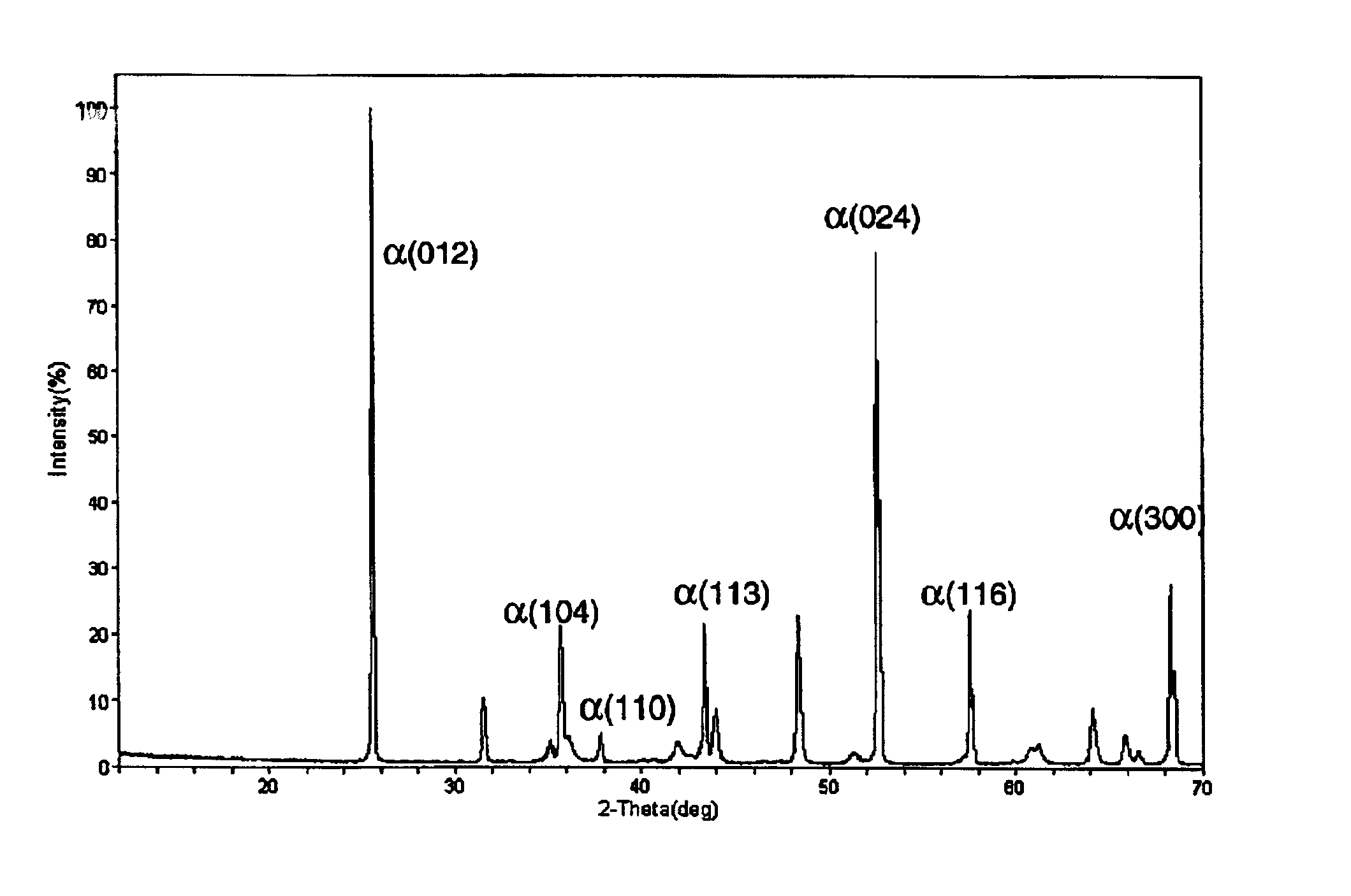

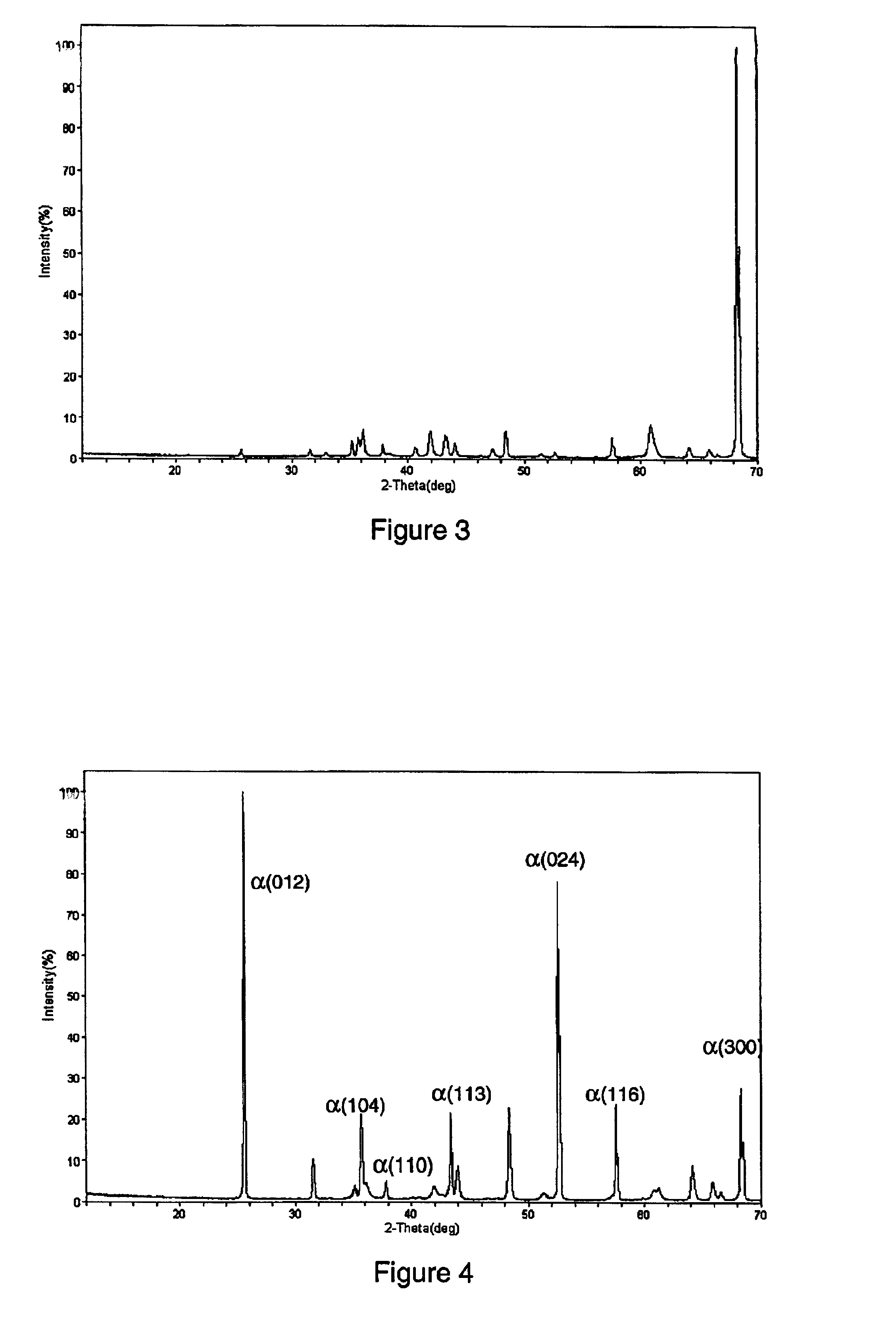

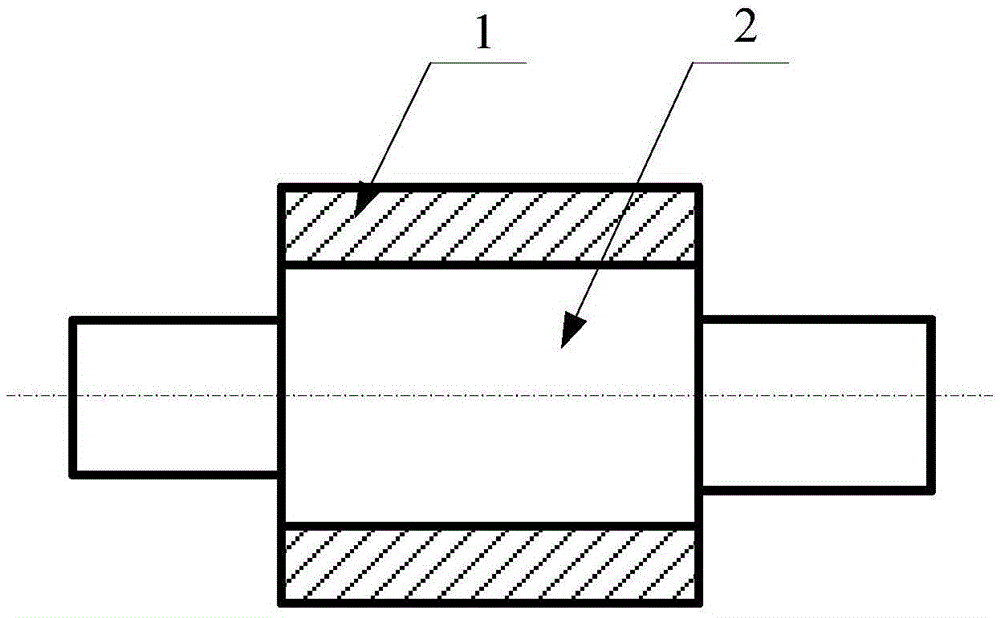

Alpha-alumina coated cutting tool

A coated cutting tool is composed of one or more layers of refractory compounds of which at least one layer is single-phase α-alumina with a pronounced columnar grain-structure and strong texture in the [300]-direction. The alumina layer is preferably deposited by CVD (Chemical Vapor Deposition) and the preferred microstructure and texture are achieved by adding a second metal halide, and a texture modifying agent, to the reaction gas. When coated cemented carbide cutting tools according to the invention are used in the machining of steel or cast iron, several important improvements compared to prior art have been observed, particularly in the machining of nodular cast iron.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Low-temperature impact resistant as-cast ductile iron with big section and production method thereof

The invention discloses a large-section as-cast magnesium iron with low-temperature impact resistance and a production method thereof. Compared with the magnesium iron produced by the prior art, the large-section as-cast magnesium iron with the low-temperature impact resistance has high low-temperature impact ductility and high elongation, does not contain Ni and can meet the requirement of a large-section magnesium iron casting which has special requirements for resisting the temperature of minus 20 DEG C to minus 40 DEG C; the large -section as-cast magnesium iron with the low-temperature impact resistance produced by the method takes the plain cast iron as a raw material, has high ductility, the mechanical properties of the large-section as-cast magnesium iron meets or is superior to the requirements of GJS400-18-LT designtion in EN1563 standard.

Owner:辽宁隆达集团百星达铸造有限责任公司

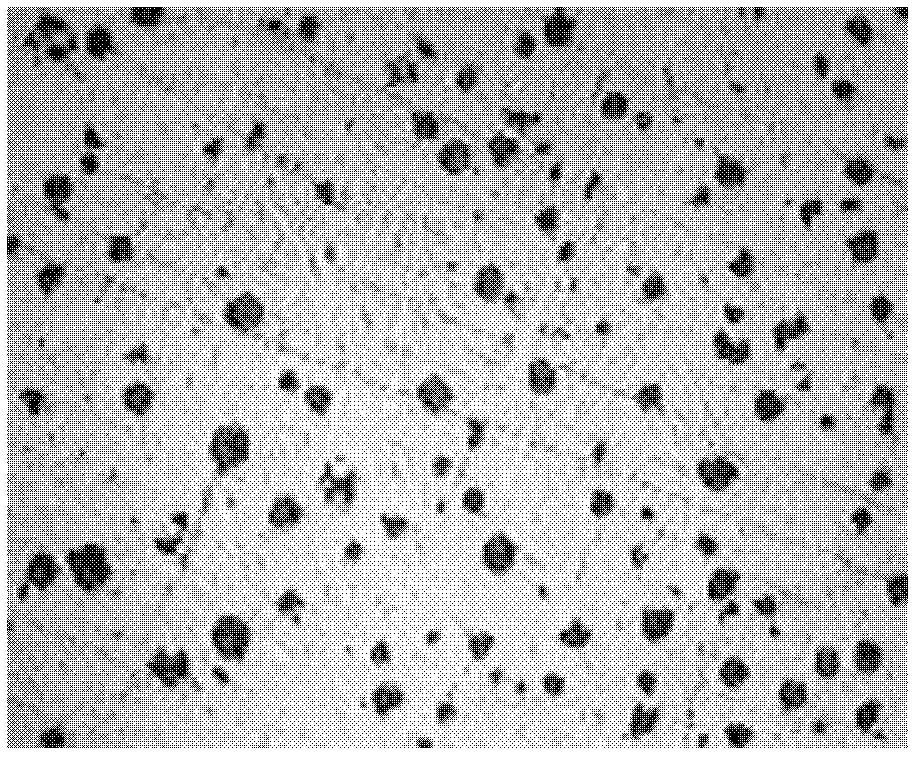

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

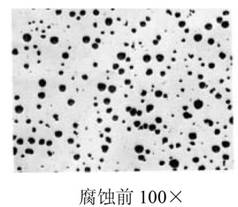

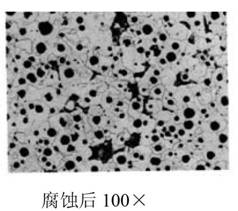

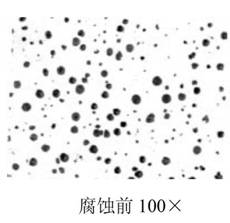

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

Abrasion-resistance high-speed steel composite roller and preparation method thereof

The invention discloses an abrasion-resistance high-speed steel composite roller and a preparation method thereof, and belongs to the technical field of rollers. The composite roller forms a whole through roller body high-speed steel and roller core nodular cast iron by means of centrifuge composite casting. The roller body molten steel is controlled to comprise, by mass, 1.5%-2.4% of C, 3.5%-6.0% of Cr, 3.5%-6.0% of Mo, 3.5%-6.0% of V, 1.5%-3.5% of W, 0.6%-1.2% of Nb, 0.5%-1.2% of Ni, 0.3%-0.8% of Si, 0.3%-0.8% of Mn, 0-0.04% of S, 0-0.04% of P and the balance Fe. The roller body molten steel is deoxidized, external-furnace modification treatment is conducted on the molten steel through multi-element micro-alloy wires, and then pouring is conducted on a centrifugal machine to form the roller; the roller core is made of nodular cast iron, tempering is conducted on the roller after quenching, and therefore the characteristics of being high in hardness, high in toughness, good in abrasive resistance and the like are realized, and an excellent using effect is achieved.

Owner:安徽环渤湾高速钢轧辊有限公司

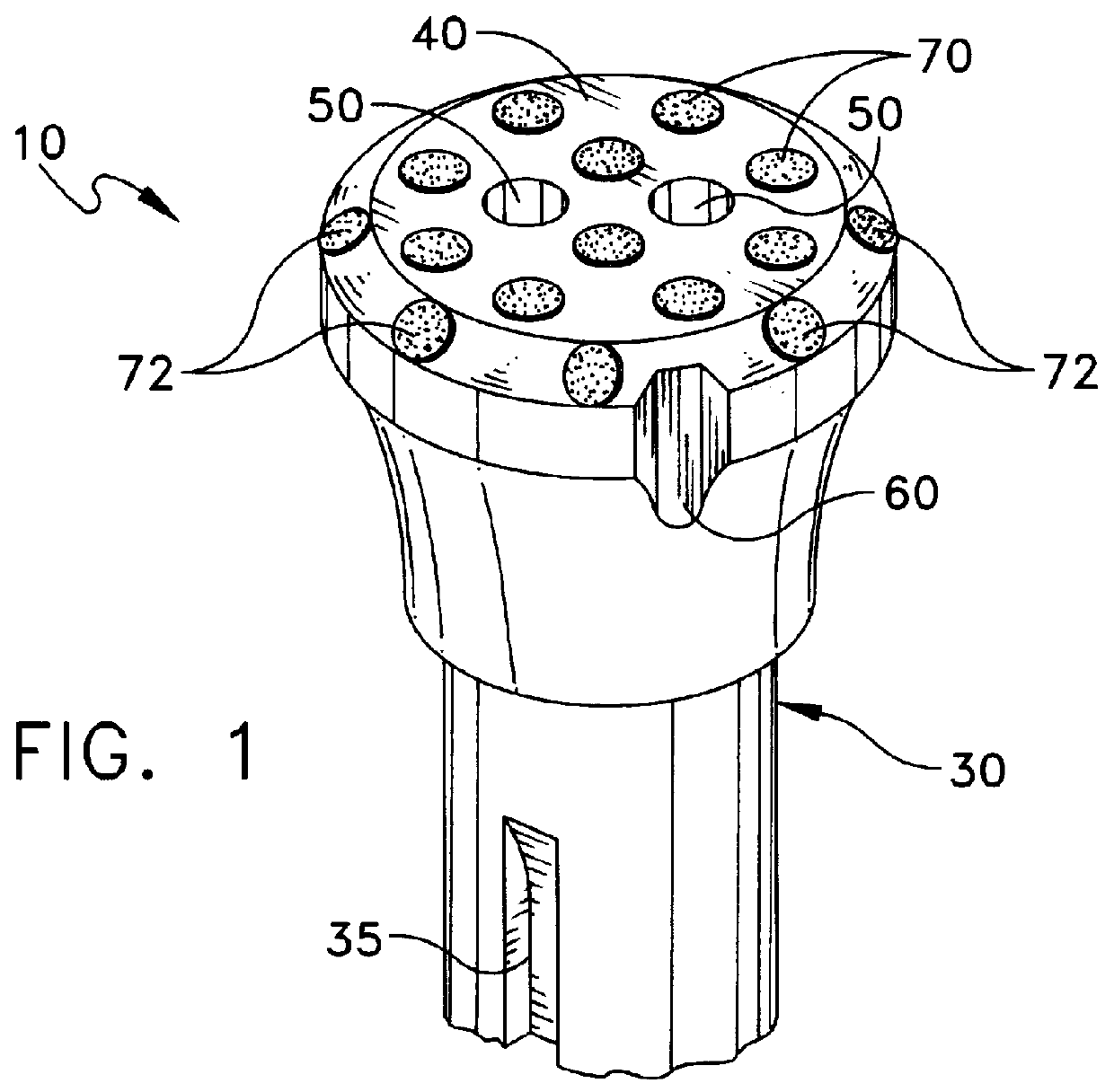

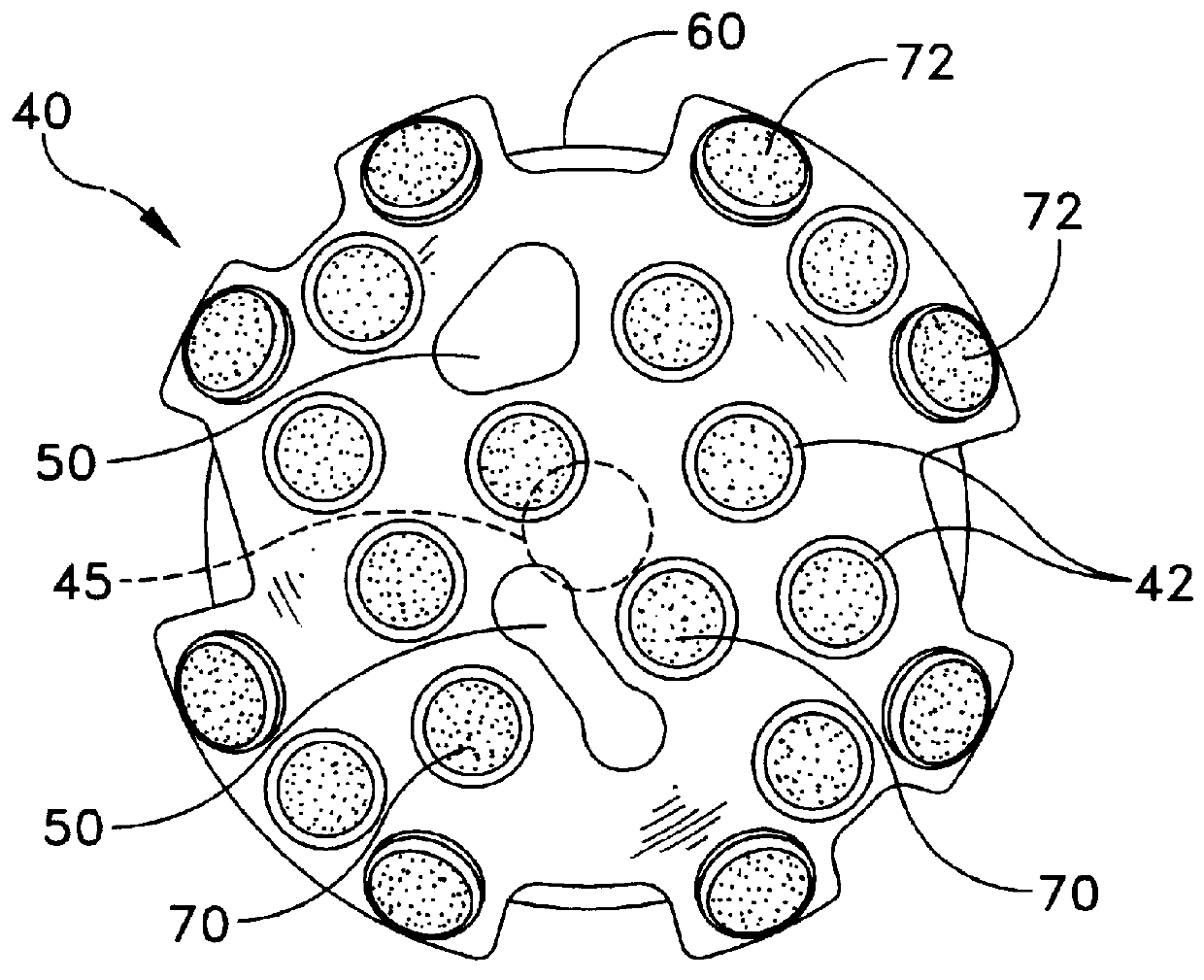

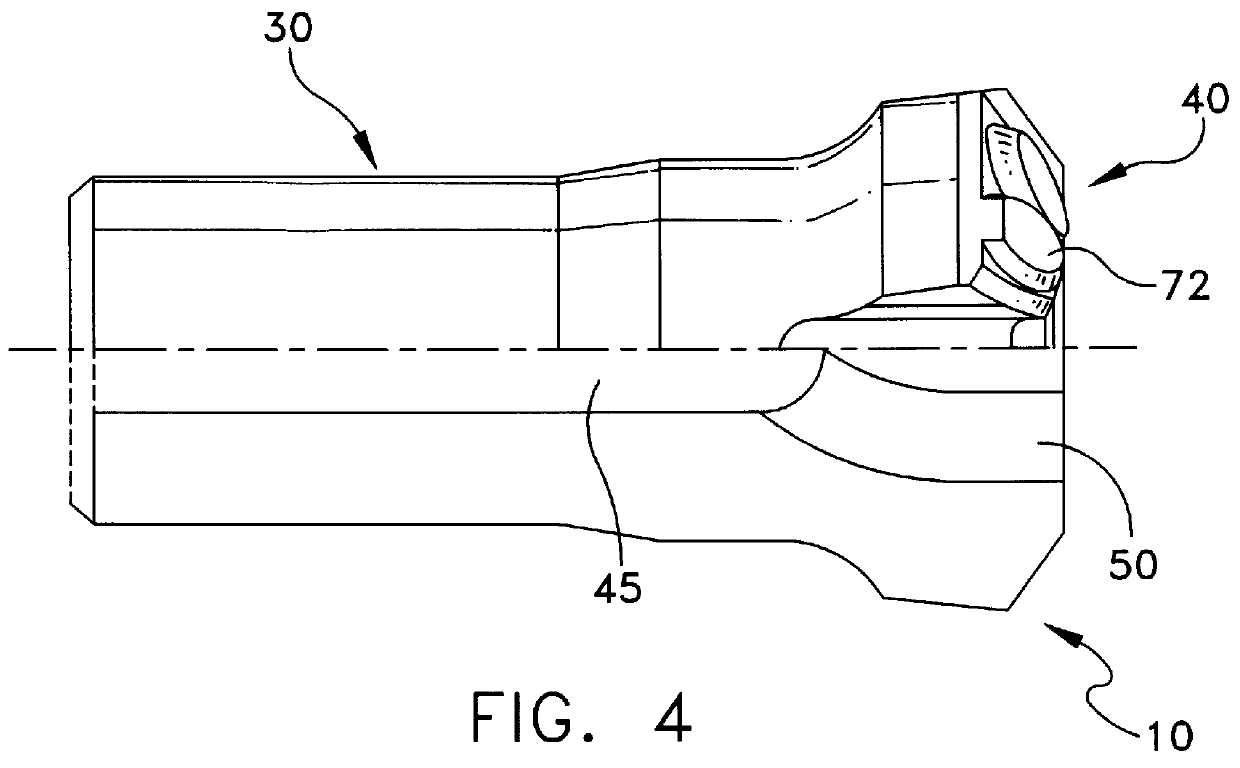

Rock drill

InactiveUS6039127AConvenience to mergeEasy to disassembleDrill bitsDrilling machines and methodsDuctile ironDrill bit

A rock drilling bit for drilling bores in rock, more particularly to a percussion rock drilling bit. Specifically, a rock drilling bit having hard material cutting inserts affixed to an austempered ductile iron (ADI) drill body, and a method of drilling rock using said bit.

Owner:LOUDON ENTERPRISES

Composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof

The invention relates to a composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof, belonging to the technical field of the steel rolling. The composite roll comprises a roll external layer and a roll core. The chemical components of the materials of the roll external layer in terms of the percentage by weight are as below: 25-28 of alloy scrap iron of a high-nickel-chromium infinite chilled iron roll, 28-30 of carbon ferrochrome, 1.5-2.5 of mid-carbon ferromanganese, 2.5-3.5 of ferroboron, 0.5-0.8 of silicon-calcium-barium alloy, 0.2-0.4 of aluminum, 0.3-0.5 of ferrotitanium, 0.2-0.4 of rare earth ferrosilicon, 0.10-0.15 of zinc, 0.15-0.18 of magnesium and the balance of low-carbon waste steel sheet. The roll core is high-strength alloy cast iron or low-alloy ductile cast iron. The roll external layer and the roll core are formed through centrifugal composite casting. The roll has low production cost, contains a small number of impurities and has high degree of purity; the hardenability, the mechanical performance and the thermal fatigue of the roll can be improved; and the roll has long service life and low production cost.

Owner:江苏环立板带轧辊有限公司

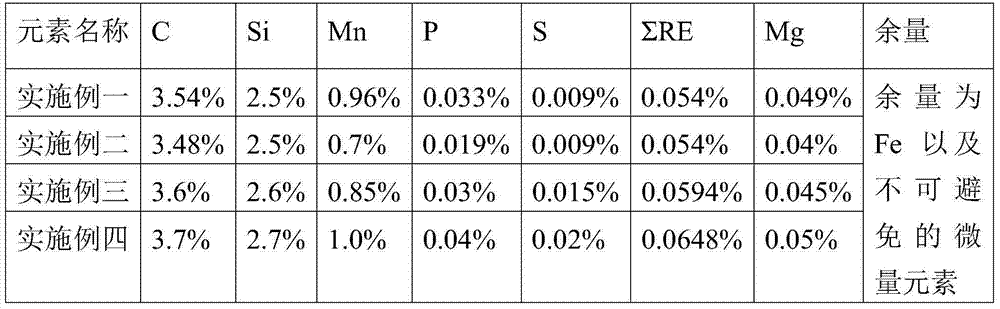

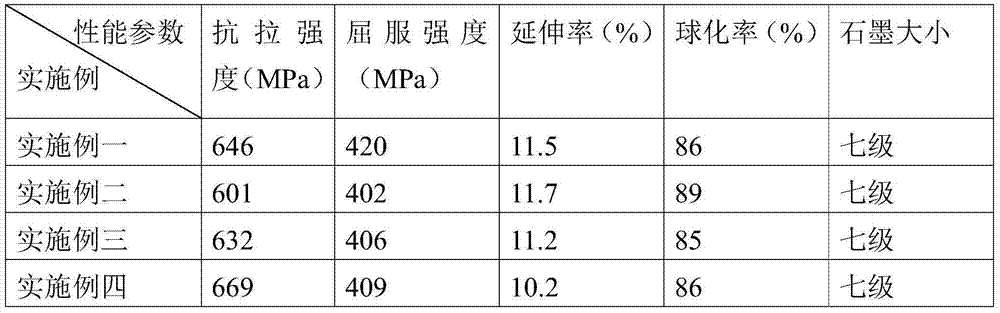

High-strength high-toughness ductile cast iron 600-10 and production method thereof

The invention discloses a high-strength high-toughness ductile cast iron 600-10 and belongs to the technical field of cast iron metallurgy. The high-strength high-toughness ductile cast iron 600-10 comprises the following elements in percentages by mass: 3.48%-3.7% of C, 2.5%-2.7% of Si, 0.7%-1.0% of Mn, 0.019%-0.04% of P, 0.009%-0.02% of S, 0.054%-0.0648% of the sum of the rare earth elements, 0.04%-0.05% of Mg and the balance of Fe and unavoidable trace elements. The invention also discloses a production method of the high-strength high-toughness ductile cast iron 600-10. The high-strength high-toughness ductile cast iron 600-10 disclosed by the invention has the advantages of high strength and good toughness, the high-strength high-toughness ductile cast iron 600-10 is easily shaped and has other characteristics and the casting process is simple.

Owner:DALIAN JINZHOU MAOLONG IND

Self restrained ductile iron fitting

A combination sealing and restraint system for an as-cast ductile iron fitting is shown for both sealing and preventing separation of an iron pipe fitting and a mating male pipe. A ring-shaped body is installed within a mating groove provided in a mouth region of the as-cast fitting after the fitting has been cast at the manufacturing plant. The ring-shaped body carries a gripping member with teeth on an inner surface thereof which are initially angled away from an outer surface of a mating male pipe. The teeth are forced into engagement with the exterior surface of the mating male pipe as the pipe joint at the fitting is assembled. The teeth are oriented to allow movement of the male pipe in a first direction relative to an end opening of the fitting during assembly, but to resist movement in a opposite direction after the fitting joint has been assembled. The ring-shaped body also includes a relatively flexible portion formed of an elastomer which forms a sealing member with the mating male pipe.

Owner:S & B TECHN PRODS

Nodular cast iron cylinder sleeve and manufacturing method thereof

The invention relates to a nodular cast iron cylinder sleeve and a manufacturing method of the nodular cast iron cylinder sleeve. The nodular cast iron cylinder sleeve comprises the following chemical ingredients in percent by mass: 3.6-3.9% of carbon, 2.0-2.3% of silicon, 0.7-0.9% of manganese, not greater than 0.08% of phosphorus, not greater than 0.02% of sulphur, not greater than 0.08% of chromium, 0.3-0.5% of molybdenum, 0.9-1.1% of nickel, 0.1-0.2% of copper, and the balance of Fe. The material proportioning of the nodular cast iron cylinder sleeve and the preparation method of the nodular cast iron cylinder sleeve can meet the requirement of high explosion pressure on an engine at present and in future; moreover, the cost is low.

Owner:YANGZHOU WUTINGQIAO CYLINDER LINER

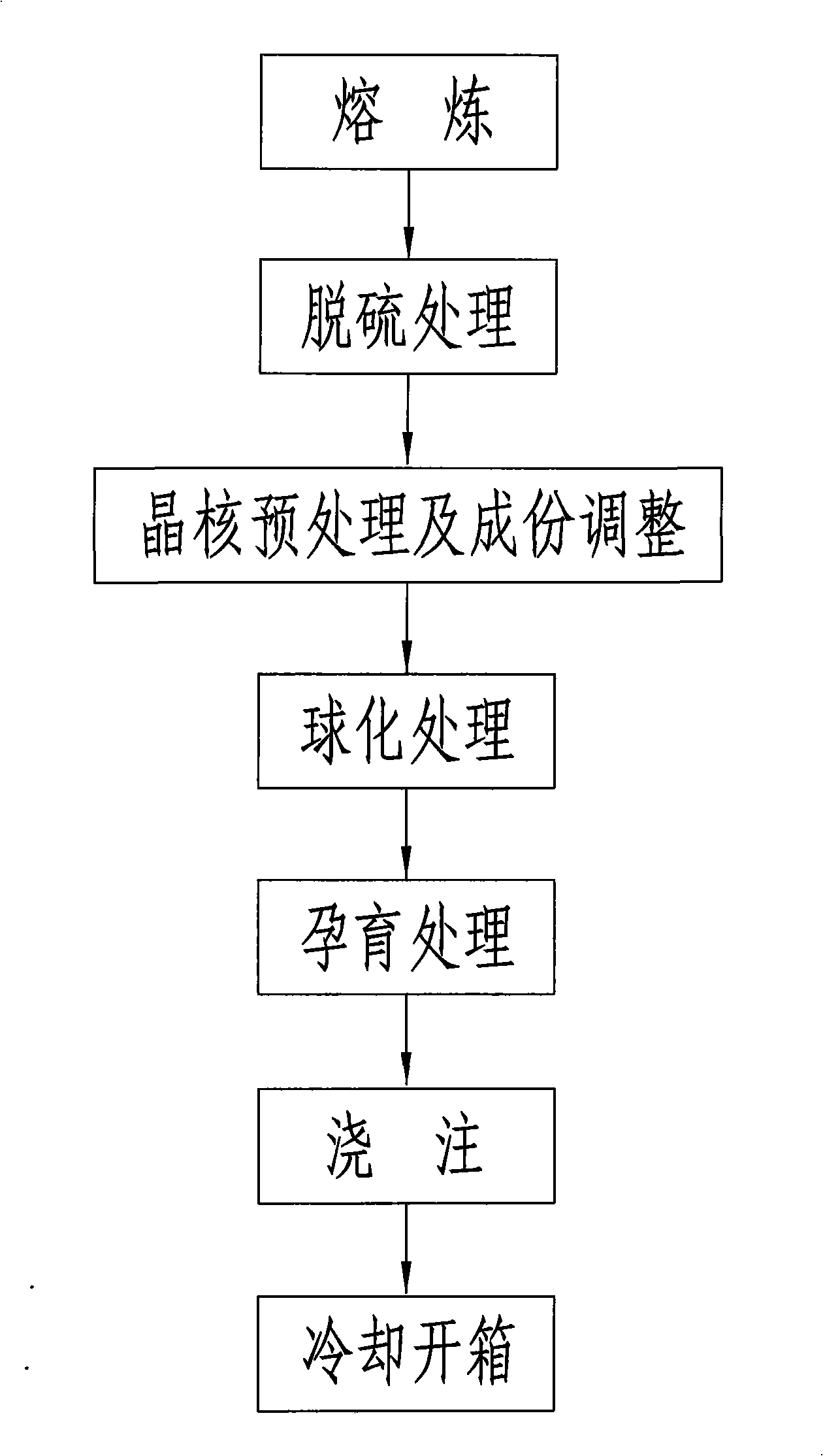

Smelting technique for cast of wind energy apparatus

InactiveCN101407884AHigh nodularityMeet mechanical performance requirementsSmelting processLiquid iron

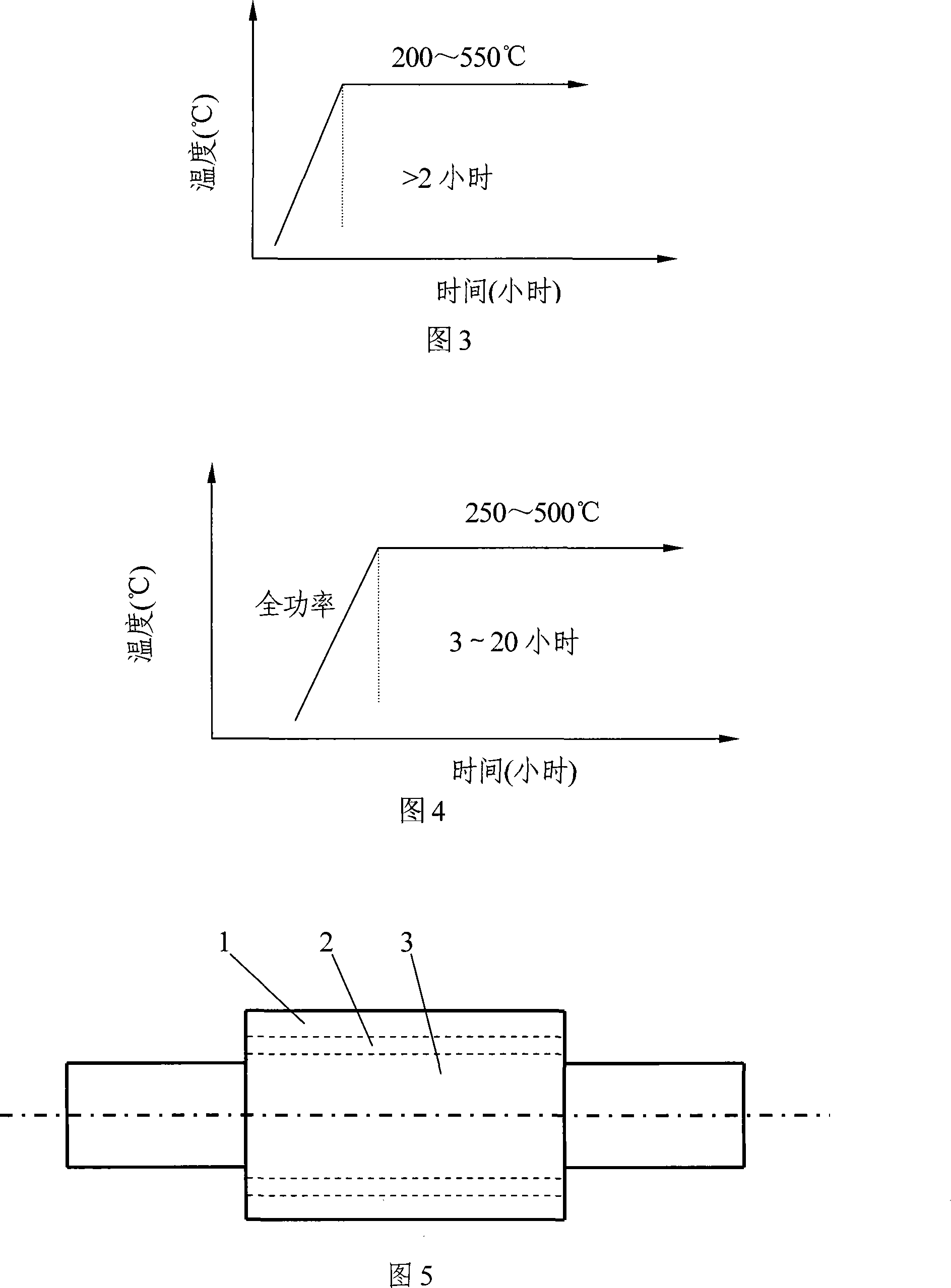

The invention discloses a smelting process of castings of wind energy equipment, which is suitable for the smelting production of castings of wind energy equipment with the wall thickness of 60 to 200mm and includes the following steps: a. new pig iron, scrap steel and carburants with special requirements are sent into a melting electric furnace for smelting; b. high temperature liquid iron is subjected to desulfurization treatment by a desulfurization agent; c. the desulfurized liquid iron is returned into a heat insulation electric furnace for component adjustment, and the carburant is added for carrying out pre-treatment of crystal nucleus to graphite in the liquid iron; d. spheroidization treatment is carried out to the liquid iron; e. an inoculant is added into the liquid iron for inoculation; f. the liquid iron is poured to casting sand mold; and g. the castings are naturally cooled to 500 to 550 DEG C for unpacking after finishing pouring. The smelting process of castings of wind energy equipment can increase the spheroidization efficiency of ductile iron castings used by the wind energy equipment, which causes the castings to have good intensity of tension, extensibility and high impact ductility in low temperature environments, thus meeting the requirements on the castings used by the wind energy equipment.

Owner:CHANGZHOU ZHUORUN WIND POWER EQUIP

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

High-strength low stress cast nodular cast iron with high elasticity modulus and manufacturing method thereof

The invention discloses a high-strength low stress cast nodular cast iron with high elasticity modulus. The nodular cast iron comprises the following components by mass percent: 3.7-3.9% of C, 2.0-2.2% of Si, 4.50-4.65% of CE, 0.5-0.6% of Mn, less than or equal to 0.03% of P, less than or equal to 0.02% of S, 0.03-0.06% of Mg, 0.01-0.02% of RE, 0.5-0.7% of Cu, and 0.05-0.06% of Sn. A manufacture method of the nodular cast iron is characterized by high temperature pure iron liquid of base iron, compound alloying and accurate addition; according to the microscopic structure of the manufactured nodular cast iron, the content of pearlite is more than or equal to 95%, the nodularity is more than or equal to 90%, spherulitic graphite number in unit area is 200-380 / mm<2>, the yield strength is over 400MPa, the strength of extension is over 700MPa, the elastic modulus is more than 170GPa, the hardness HB is 190-250, the elongation is more than 3%, the casting inner stress is less than or equal to 50MPa, namely, with high carbon equivalent and high silicon-carbon ratio, the nodular cast iron has excellent performances such as high strength, high elasticity modulus and low stress, thus meeting the technical requirement of casting of machine tools.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

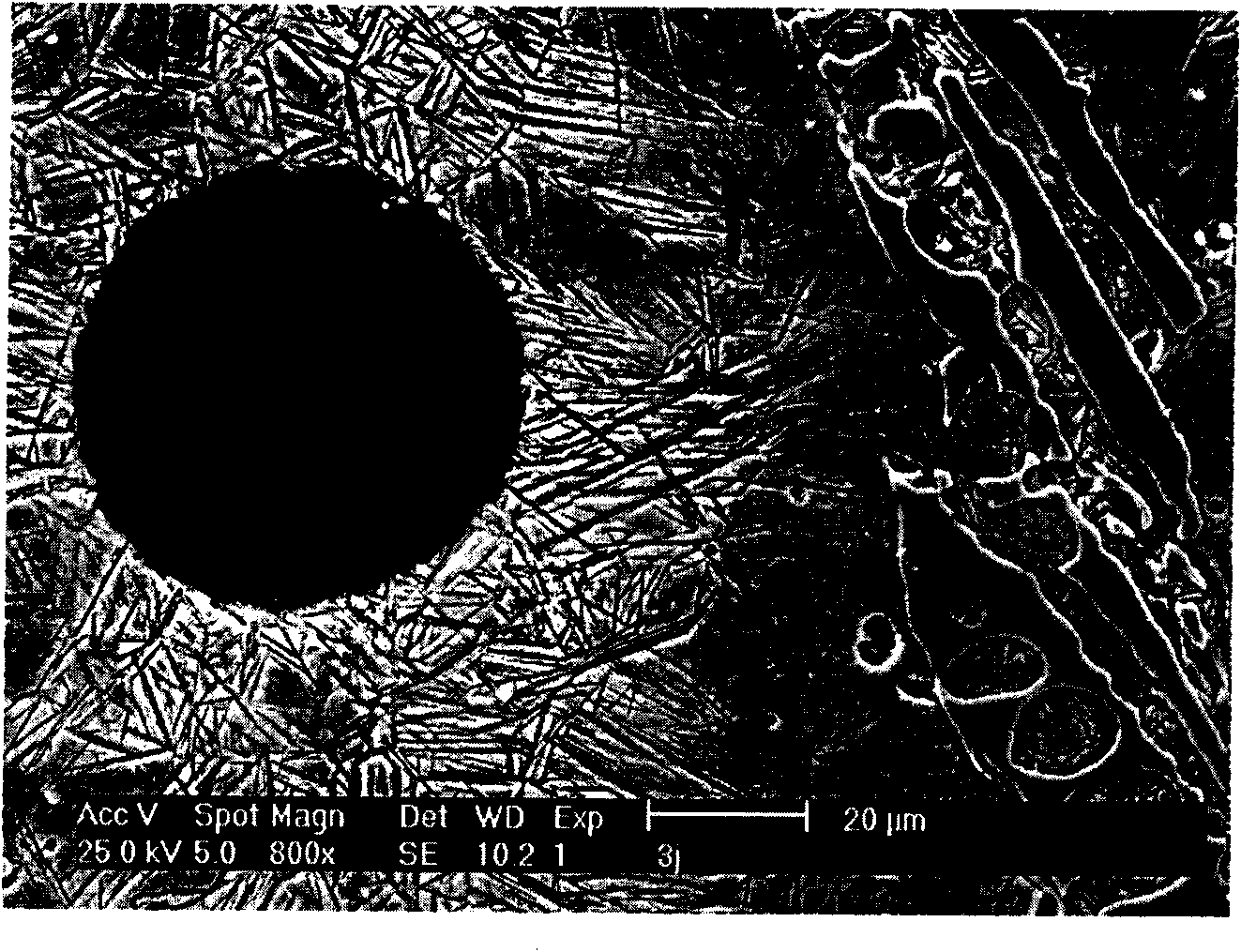

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com