Hard alloy and double-metal composite technique and device

A cemented carbide and composite process technology, applied in the field of cemented carbide and its bimetal composite material manufacturing process and equipment, can solve the problem that the composite interface cannot form a metallurgical bonding layer, the bonding interface cannot be fully fused, and the cemented carbide is expensive. and other problems, to achieve the effect of promoting material and energy exchange, excellent crystalline structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

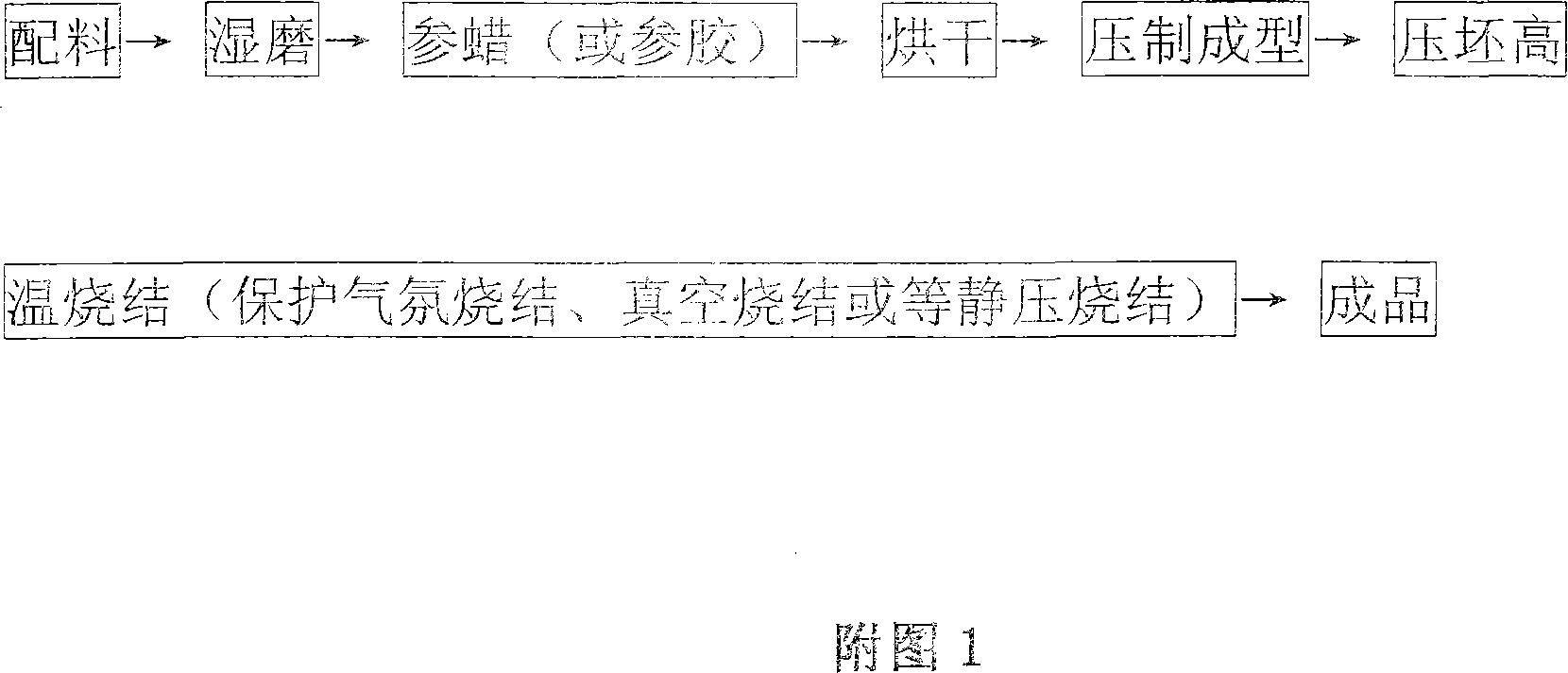

[0021] Embodiment 1: in Fig. 1, 10%-40% high chromium cast iron or improved high chromium cast iron containing following composition and percentage are used as the binding agent of cemented carbide:

[0022] (1) C 1.5-3.8%, Cr 15-27%, remaining Fe;

[0023] (2) C 1.5-3.8%, Cr 15-27%, Ni 0.4-2.5%, remaining Fe;

[0024] (3) C 1.5-3.8%, Cr 15-27%, Co 0.5-3%, Mo 0.4-3%, V 0.2-2%, remaining Fe;

[0025] (4) In the alloy of the above-mentioned components, an appropriate amount of rare earths such as cerium or lanthanum or yttrium and high-chromium cast iron and improved high-chromium cast iron alloys of rare earth alloys can also be added.

[0026] The cemented carbide particles containing the following components and percentages with a content of 90%-60% are used as the hard phase.

[0027] (1) WC particles 100%;

[0028] (2) TiC particles 100%;

[0029] (3) WC particles 70%-90%;

[0030] TiC particles 30%-10%;

[0031] (4) In the above-mentioned cemented carbide particles, ...

Embodiment 2

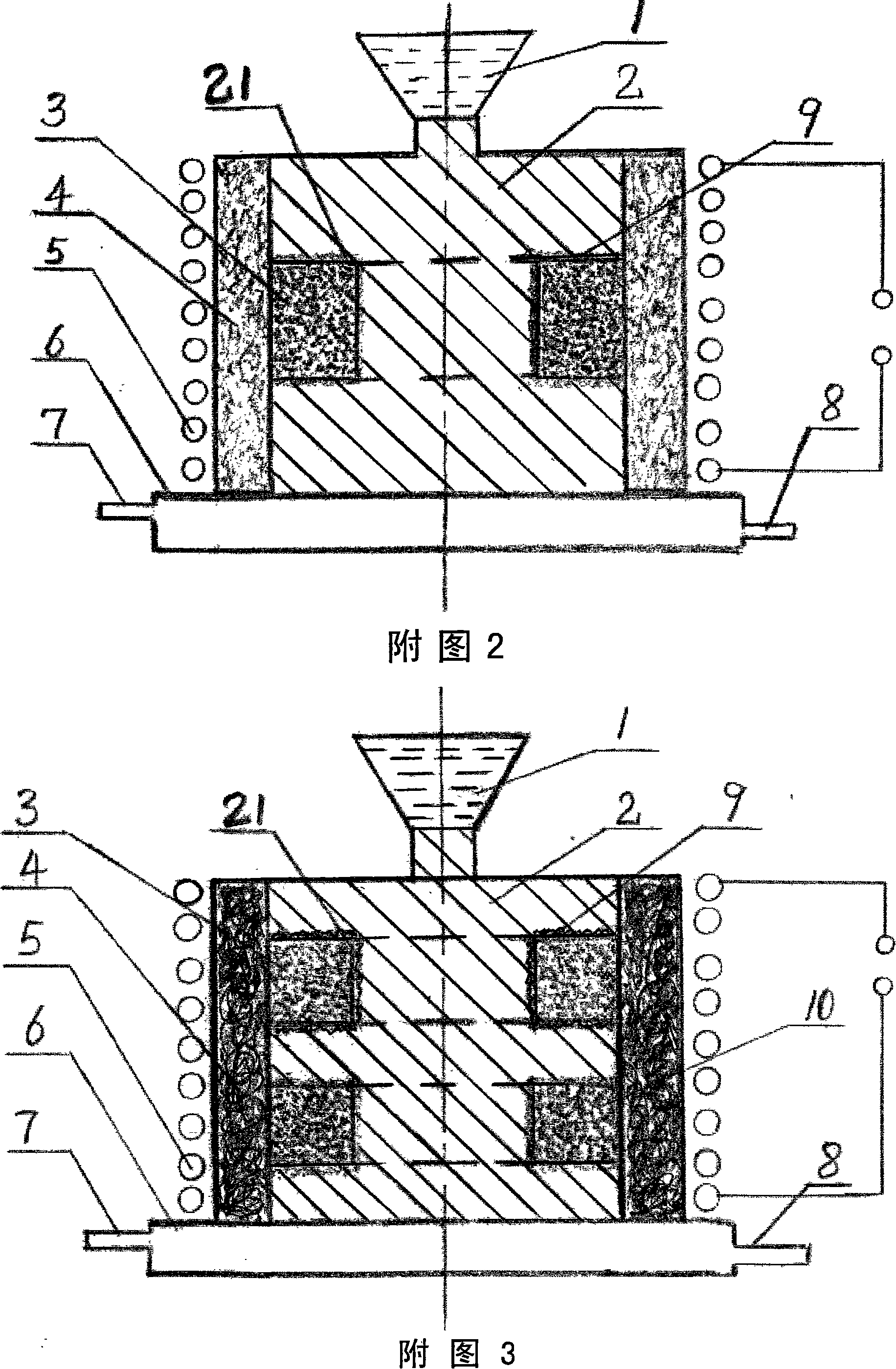

[0034] Embodiment 2: in Fig. 2, this equipment is made of casting mold 4 with refractory material, and electromagnetic induction heater 5 is installed outside casting mold 4, and the bottom of casting mold 4 is connected with water-cooled box base 6, in water cooling A water inlet pipe 8 is installed at the bottom of any side of the box base 6 , an outlet pipe 7 is installed at the top of any side of the water-cooled box base 6 , and a pouring insulation riser 1 is connected at the top of the mold 4 .

[0035] At the beginning of work, any cemented carbide 3 in the above components should be dried after surface cleaning and oxide removal, and a layer of 1-4mm thick cast iron powder 9 or Iron powder containing 2%-10% nickel or iron powder containing 10%-50% WC and other hard alloy particles or iron powder containing 2%-10% nickel or hard alloy particles containing 10%-50% WC Alloy particles, 2%-10% nickel, 2%-15% chromium and 1%-5% molybdenum and iron powder 9 of other alloys (...

Embodiment 3

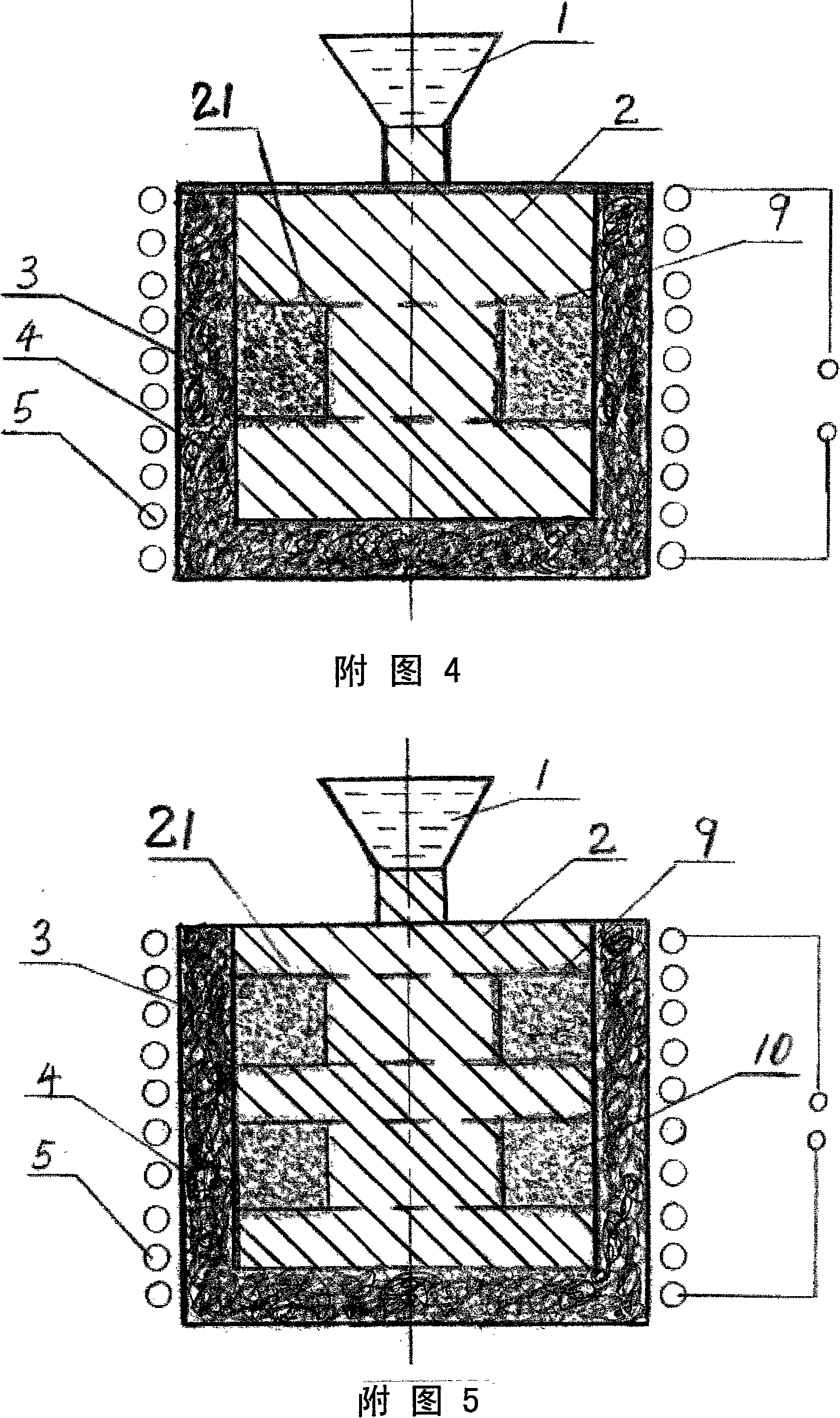

[0037] Embodiment 3: In Fig. 3, the difference from Fig. 2 is that two or more cemented carbides 10 are installed in the mold 4, and the above-mentioned process can be repeated to realize simultaneous compounding of multiple cemented carbides. Other process and equipment are identical with embodiment 2. slightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com