Patents

Literature

7455 results about "Cast iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its colour when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing.

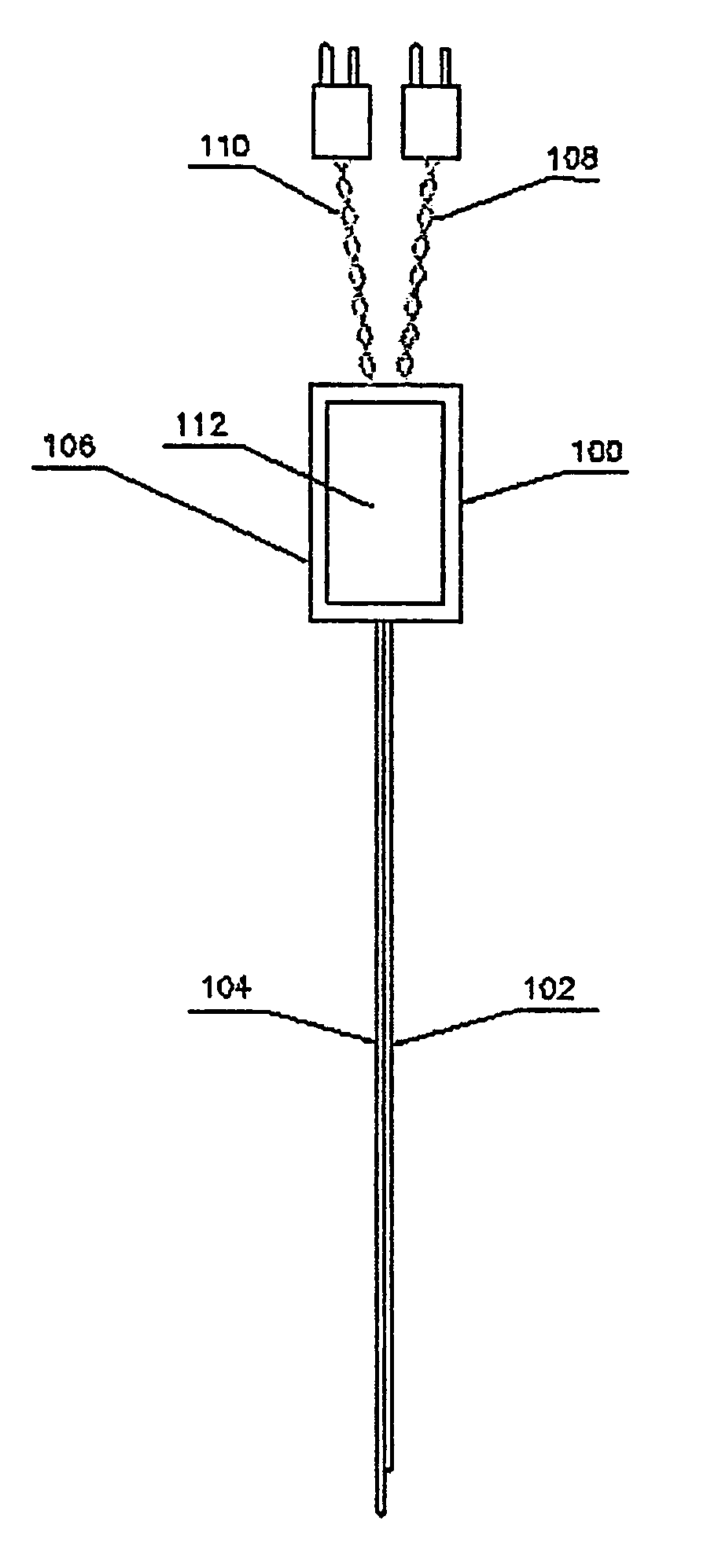

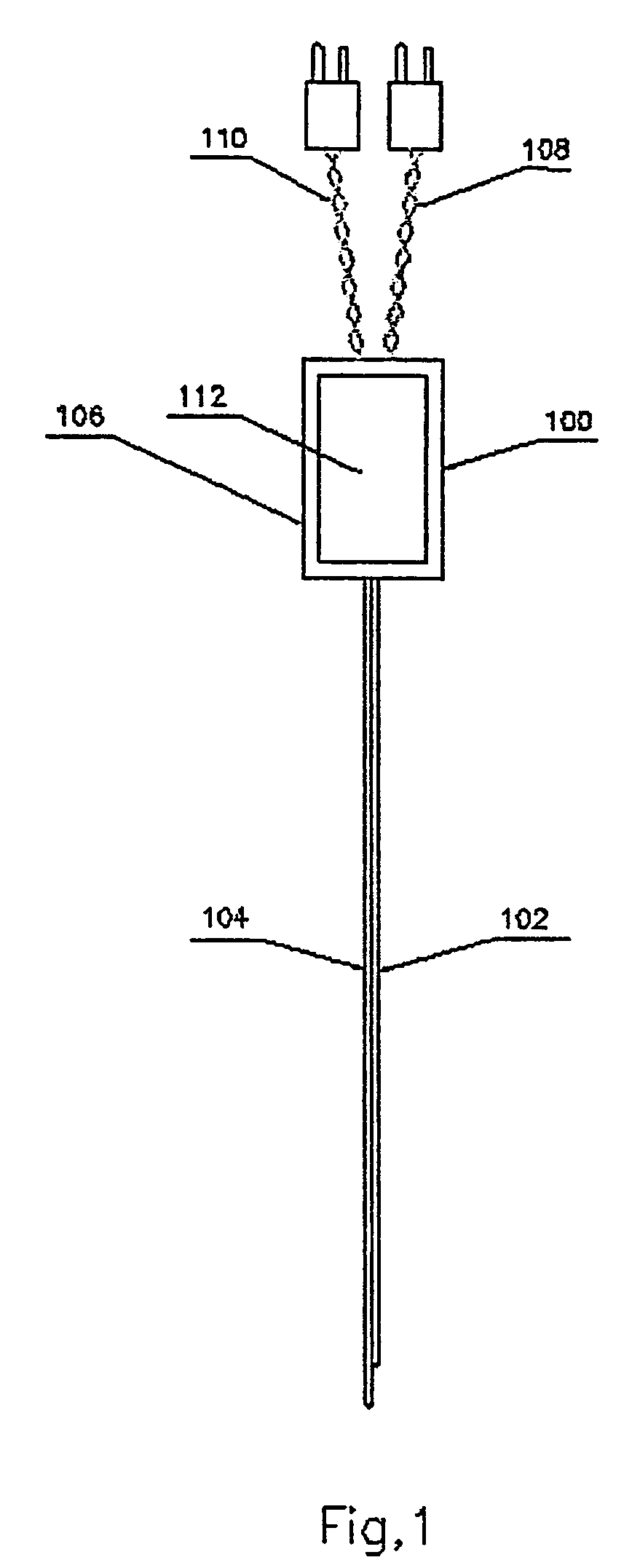

Method and a device for thermal analysis of cast iron

InactiveUS7168852B2Improve accuracyEliminate sourceThermometer detailsWithdrawing sample devicesCooling curveComputer module

Owner:SINTERCAST

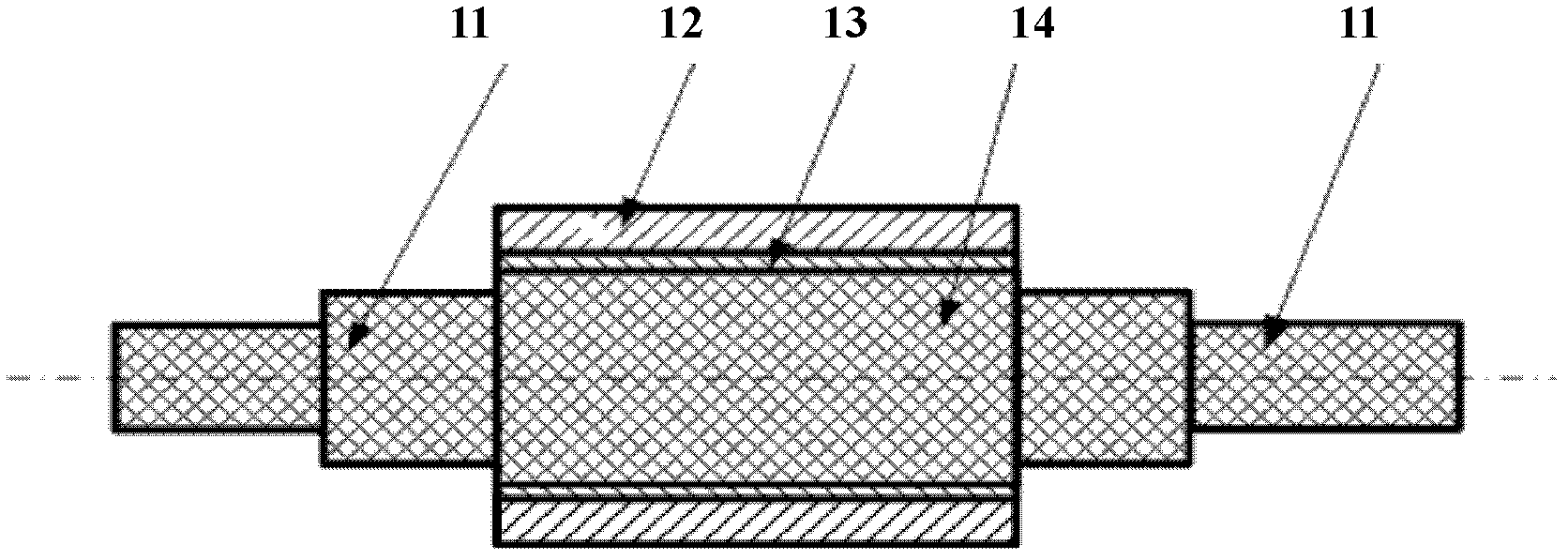

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

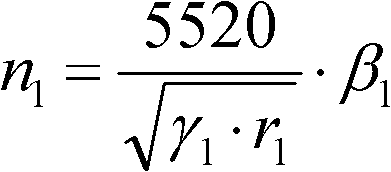

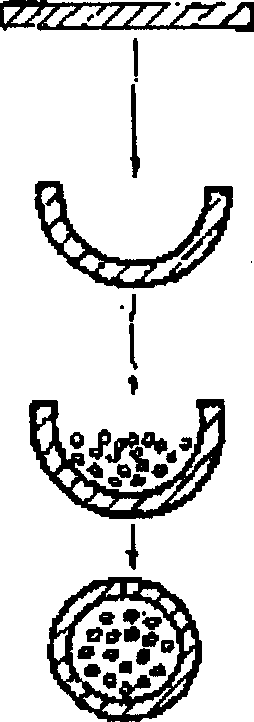

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

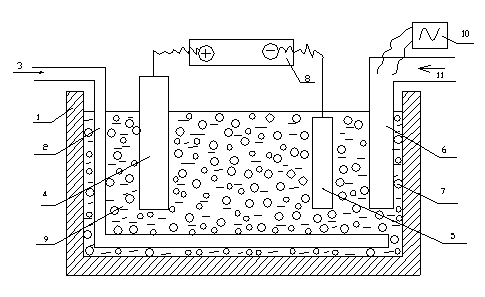

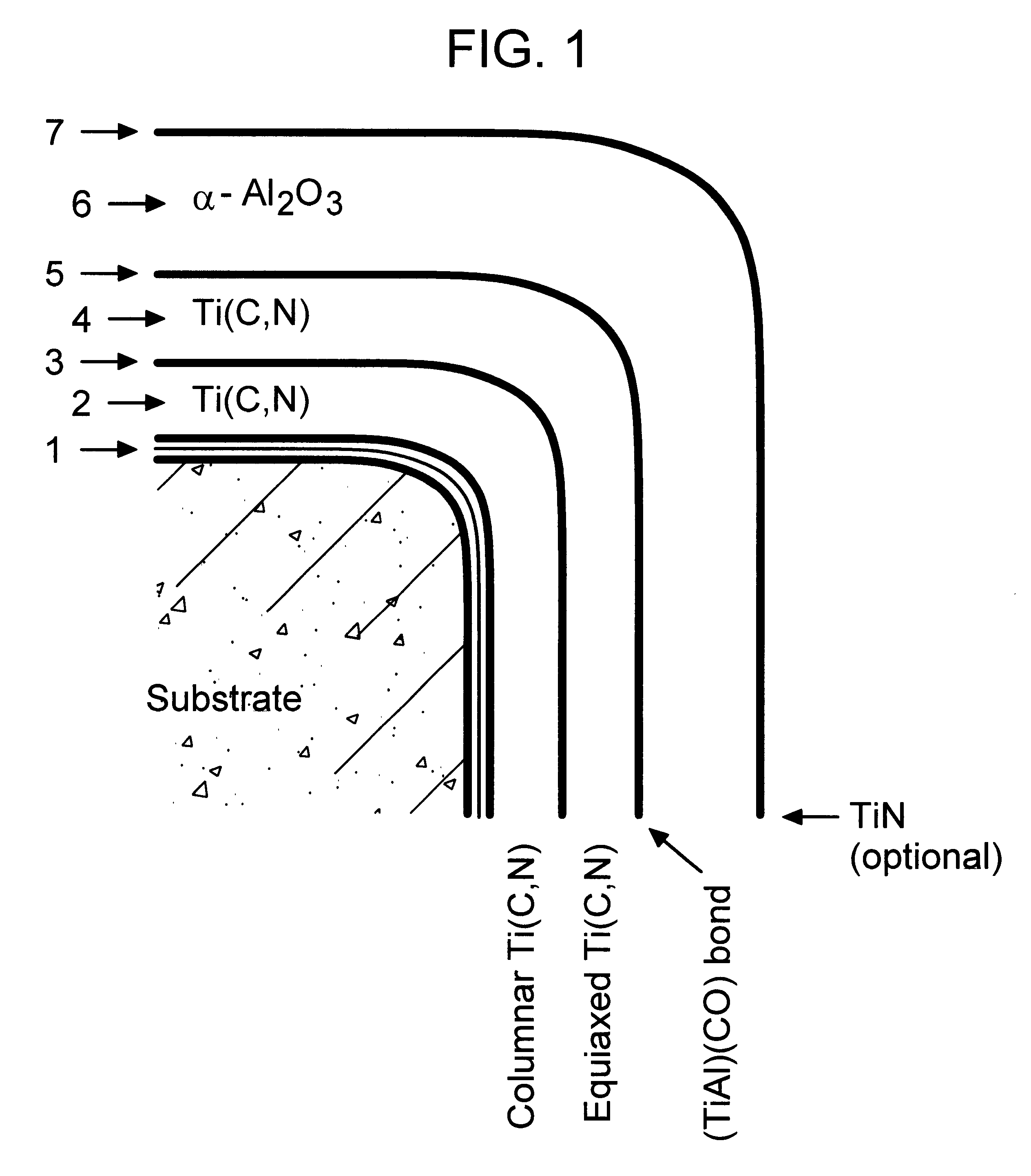

Coated cutting insert

The present invention discloses a coated cutting insert particularly useful for dry milling of grey cast iron. The insert is characterized by a WC-Co cemented carbide substrate and a coating including an innermost layer of TiCxNyOz with columnar grains and a top coating of a fine grained alpha-Al2O3 layer.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

High anticrack, wear-resistance, high-cr cast iron cored solder wire for huild-up welding

The present invention relates to a high-anticracking high-chrome cast iron type hardfacing flux-cored welding wire. Its flux core composition includes (by wt%) 43-70% of chromium carbide, 10-25% of ferrovanadium, 1-5% of 75# ferro-silicon, 3-8% of metal manganese, 1-3% of alumino-magnesium alloy, 2-5% of ferro-boron, 2-6% of ferro-titanium, 1-5% of ferro-niobium and 2-8% of ferro-molybdenum.

Owner:BEIJING UNIV OF TECH

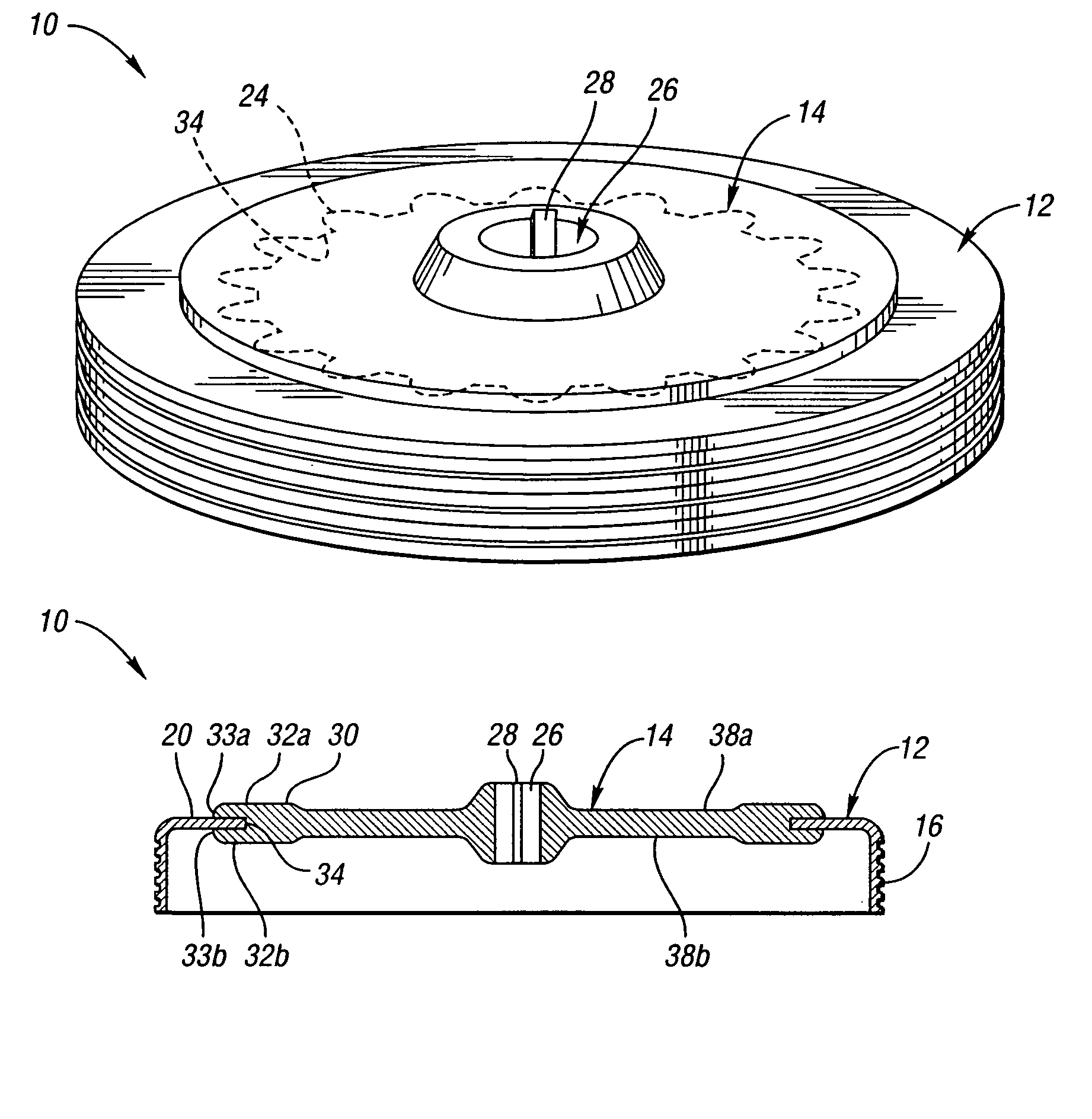

Pulley assembly and method

InactiveUS20070142149A1Prevent rotationLight volumePortable liftingGearing elementsEngineeringCast iron

The apparatus of the present invention provides an improved pulley assembly. The pulley assembly includes a ring portion having a frictional surface and a radially inner ring flange defining a plurality of ring teeth. The pulley assembly also includes a hub integrally formed onto the ring portion. The hub has a peripheral hub flange that includes a top portion and a bottom portion configured to trap the ring flange therebetween. The hub flange is also configured to engage the ring teeth and thereby prevent rotation of the hub relative to the ring portion. The ring portion is preferably composed of a first material such as steel or cast iron, and the hub is preferably composed of a second material such as aluminum or magnesium that is lighter by volume than the first material. Accordingly, the overall weight of the pulley assembly is less than that of a comparable pulley assembly composed entirely of steel or cast iron.

Owner:GM GLOBAL TECH OPERATIONS LLC

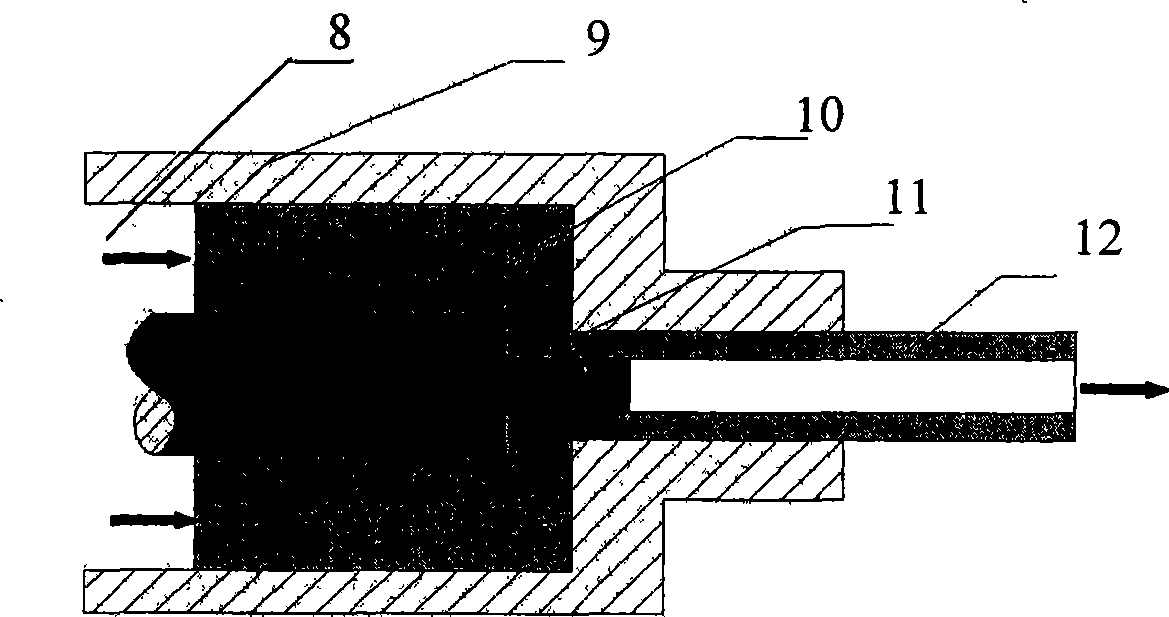

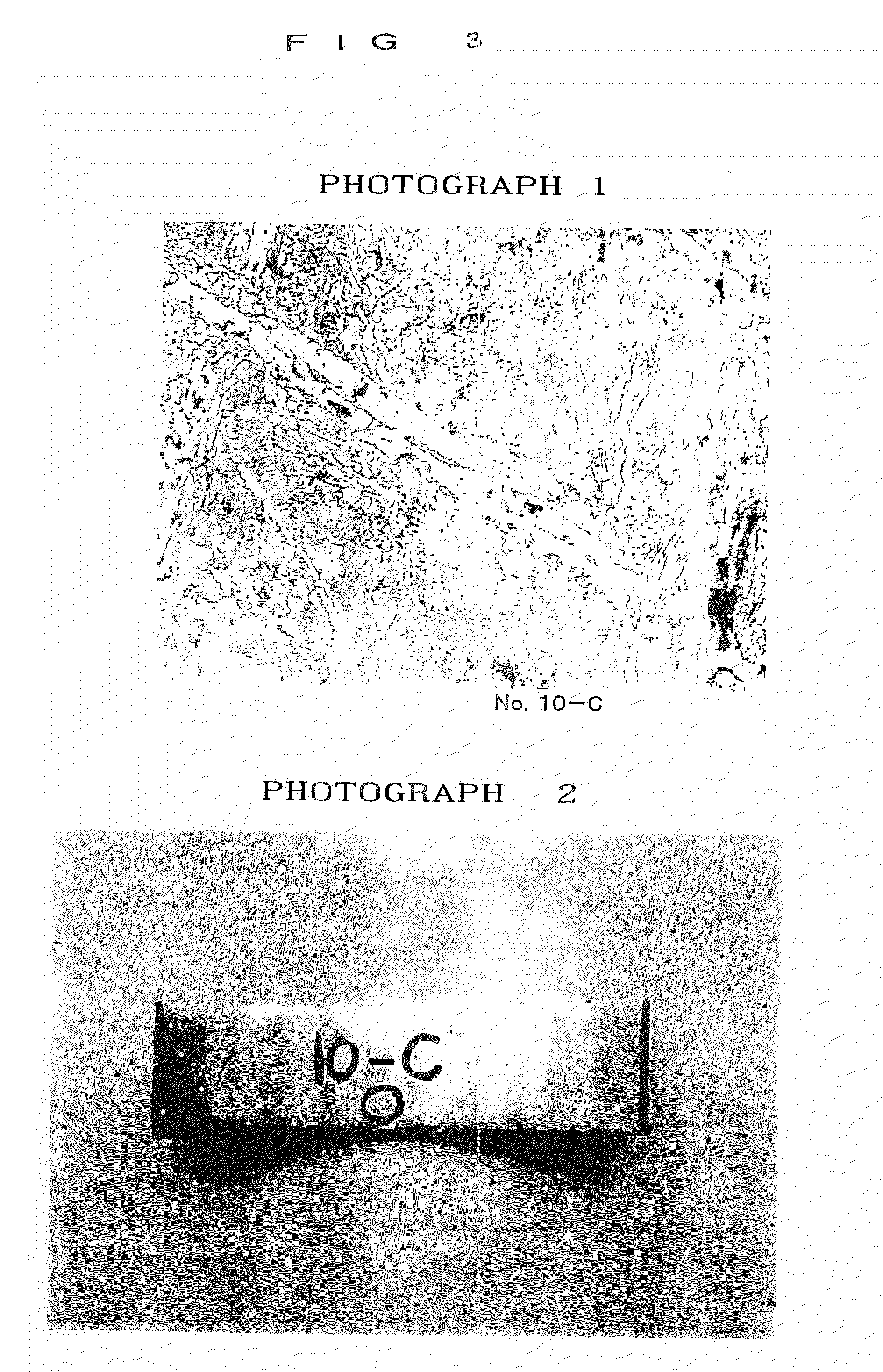

High-silicon aluminum alloy cylinder sleeve material and preparation method thereof

InactiveCN101457318AImprove mechanical propertiesImprove tribological propertiesRefining (metallurgy)Manufacturing technology

The invention discloses a high silicon aluminum alloy cylinder sleeve material and a manufacturing method thereof., Ingredients of the material by weight percent are as follows: Si: 18.0%-25.0%; Fe: 3.5%-6.0%; Ni: 1%-2%; Cu: 1.5%-3.0%; Mg: 0.5%-1.0%; Mn: 0.5%-1.5%; V: 0.1%-0.5%; Sr: 0.05%-0.15%; and the balance of Al. The manufacturing method thereof comprises the following steps: 1, composition design and accurate mixture which uses an intermediate alloy for quantitative mixture; 2, smelting, covering and refining; 3, injection deposition; 4, extrusion processing; 5, heat treatment; 6, mechanical processing and honing processing. The material and the manufacturing method lead the high silicon aluminum alloy products to have high comprehensive mechanical property characteristics which are superior to mechanical property characteristics of cast iron cylinder sleeve material, have frictional property which are superior to frictional property of steel and cast iron cylinder sleeve material, and have great compatibility with thermophysical property of aluminum piston alloy material, thereby obviously narrowing the gap for cylinder matching. The manufacturing method is characterized in that: the manufacturing process of injection deposition is employed, which serves as a primary means in manufacturing the high silicon aluminum alloy, is superior to the powder metallurgy process and the die-casting process, and can use conventional processing equipment and process conditions.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Vermicular cast iron cylinder liner and preparation method thereof

The inventions relates to a vermicular graphite cast iron cylinder sleeve and a method for preparing the same. The weigh percentage chemical compositions of the vermicular graphite cast iron cylinder sleeve to the vermicular graphite cast iron cylinder sleeve are: 3.4 to 3.8 percent of carbon, less than or equal to 0.05 percent of sulfur, 1.8 to 2.6 percent of silicon, less than or equal to 0.50 percent of phosphor, 0.5 to 1.0 percent of manganese, 0.2 to 0.5 percent of chrome, 0.2 to 0.5 percent of copper and the balance of Fe. The vermicular graphite cast iron cylinder sleeve has good friction alleviation property, high tensile strength and fatigue strength. The property is superior to the prior alloy gray cast iron cylinder sleeve, can fully fulfill the requirements of the modern high-speed, highly-intensified, high-performance, low-exhaust, long service life and high-power internal-combustion engine, reduces the production cost, and has ratio of quality to price and simple preparation technology.

Owner:ZYNP GRP

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

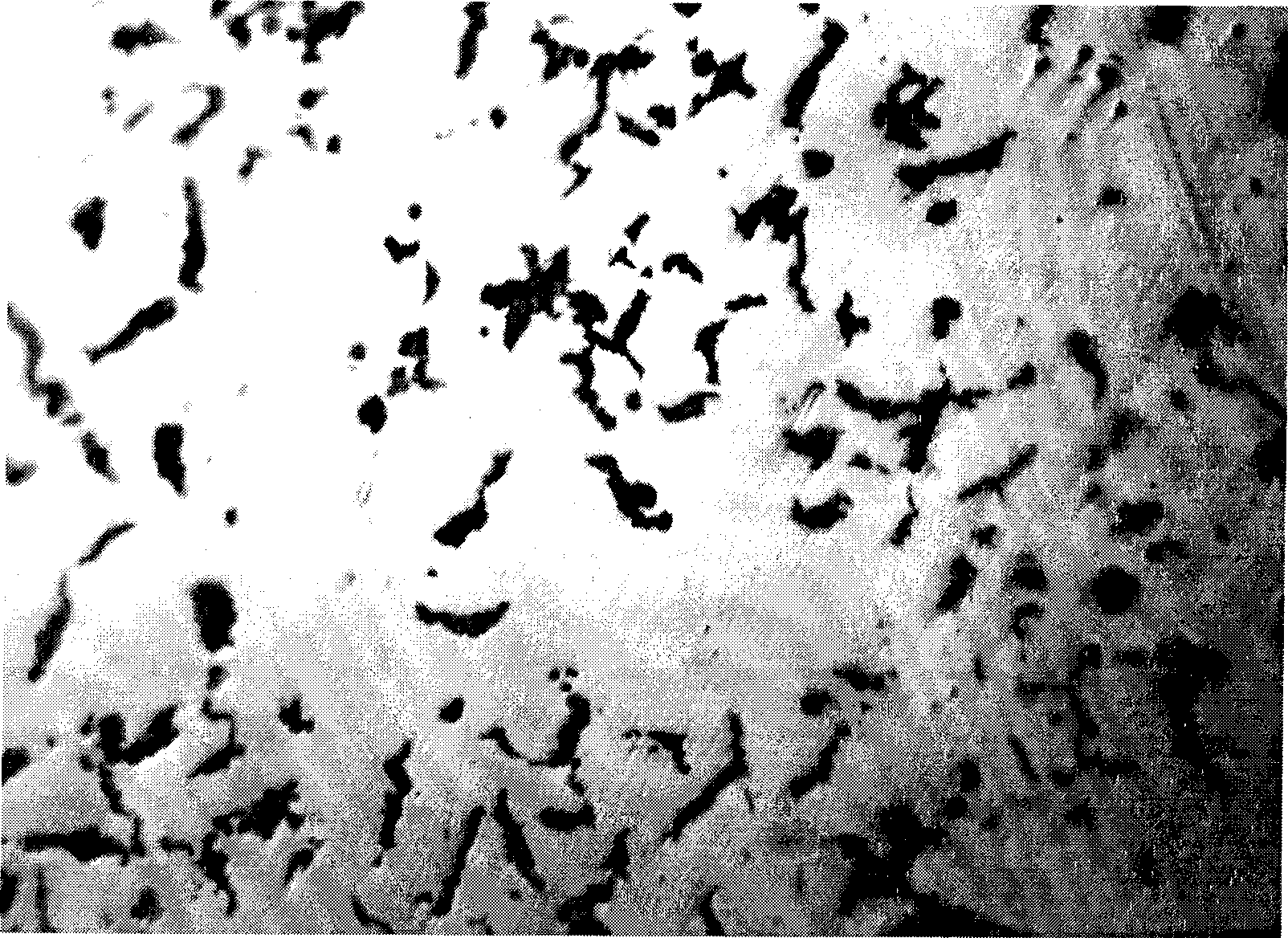

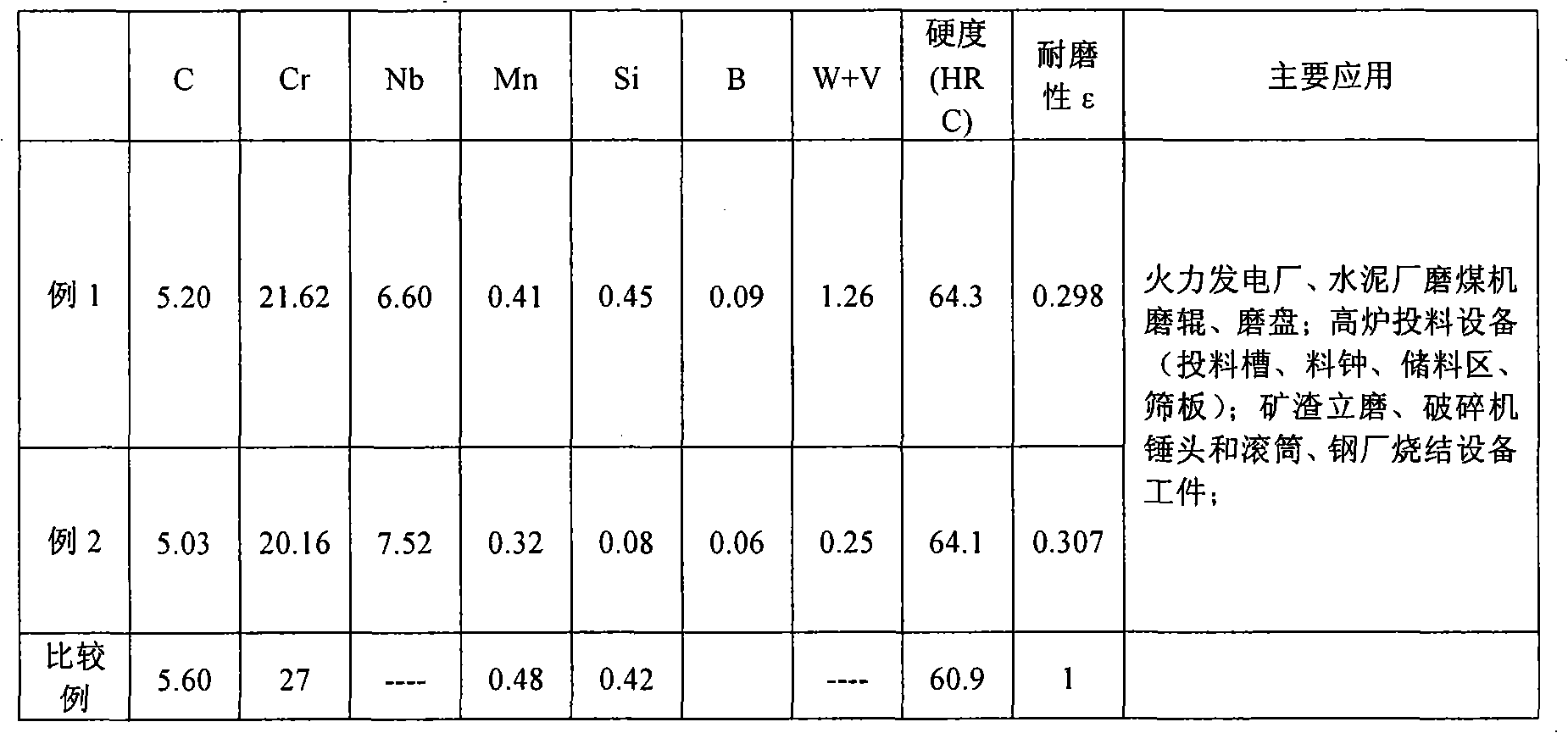

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Boron-containing high-chromium abrasion-proof cast iron and preparation method thereof

InactiveCN101260497AImprove hardenabilityReduce manufacturing costProcess efficiency improvementWear resistantCerium

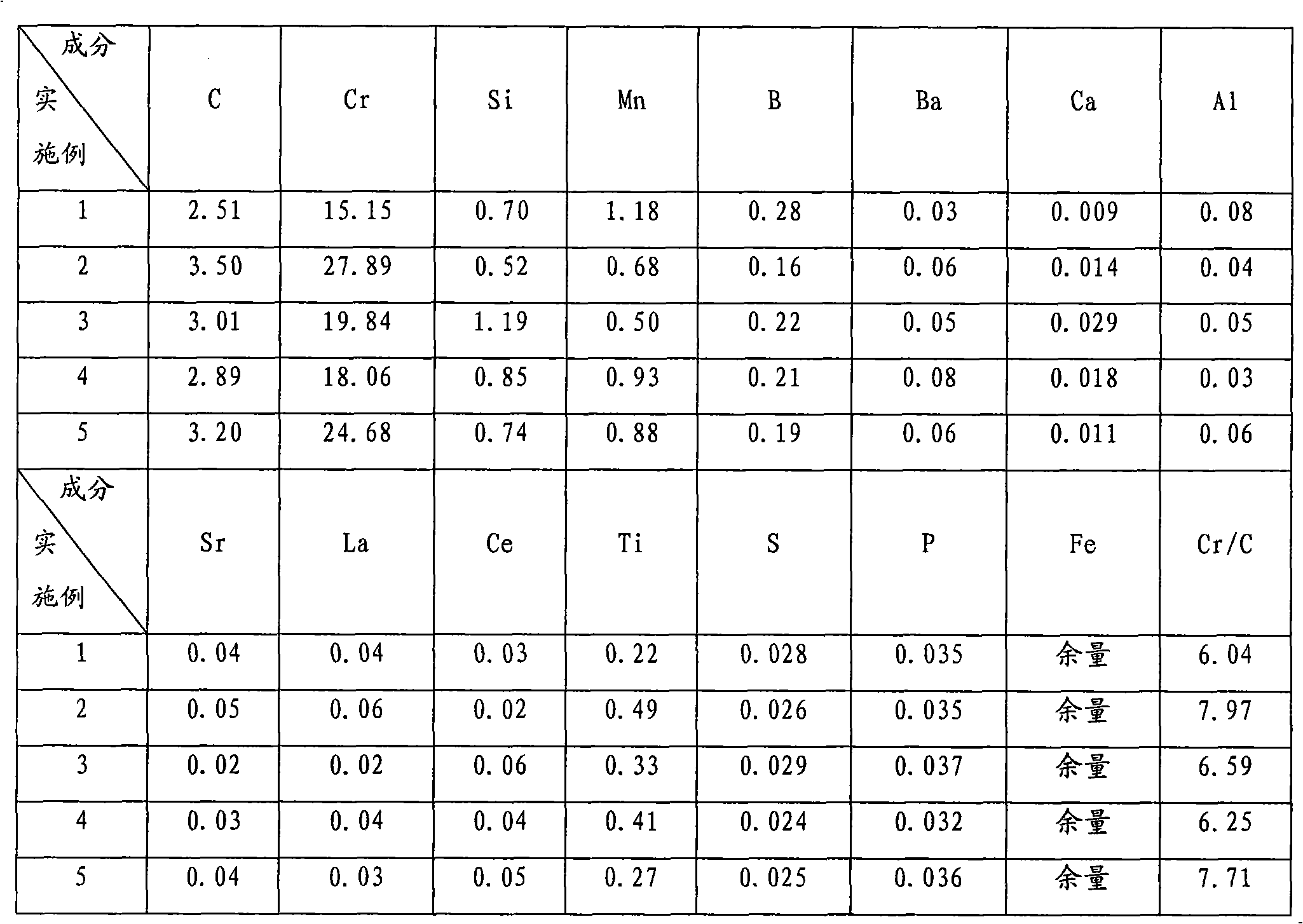

The invention relates to boracic high chromium wear resistant cast iron and a preparation method thereof, belonging to the wear resistant metal material technical field. The prior boracic high chromium cast iron has poor toughness and high cost. The cast iron of the invention comprises the following compositions in percentage by weight (wt percent): 2.5 to 3.5 percent of carbon, 15 to 28 percent of chromium, 0.5 to 1.2 percent of silicon, 0.5 to 1.2 percent of manganese, 0.15 to 0.3 percent of boron, 0.008 to 0.03 percent of calcium, 0.03 to 0.08 percent of barium, 0.02 to 0.05 percent of strontium, 0.03 to 0.08 percent of aluminum, 0.20 to 0.5 percent of titanium, 0.02 to 0.06 percent of lanthanum, 0.02 to 0.06 percent of cerium, less than 0.04 percent of sulfur, less than 0.05 percent of phosphor, the balance being iron; the content of lanthanum and cerium is more than or equal to 0.05 percent and less than or equal to 0.1 percent; the content of chromium or carbon is more than or equal to 6 percent and less than or equal to 8 percent. In the invention, the temperature of cast iron is kept between 980 DEG C and 1050 DEG C for 4h to 6h, then kept between 250 DEG C and 500 DEG C for 8h to 10h, thereby obtaining the cast iron. The boracic high chromium wear resistant cast iron has the advantages of high intensity and rigidity, good toughness and wear resistance, low production cost, etc.

Owner:BEIJING UNIV OF TECH

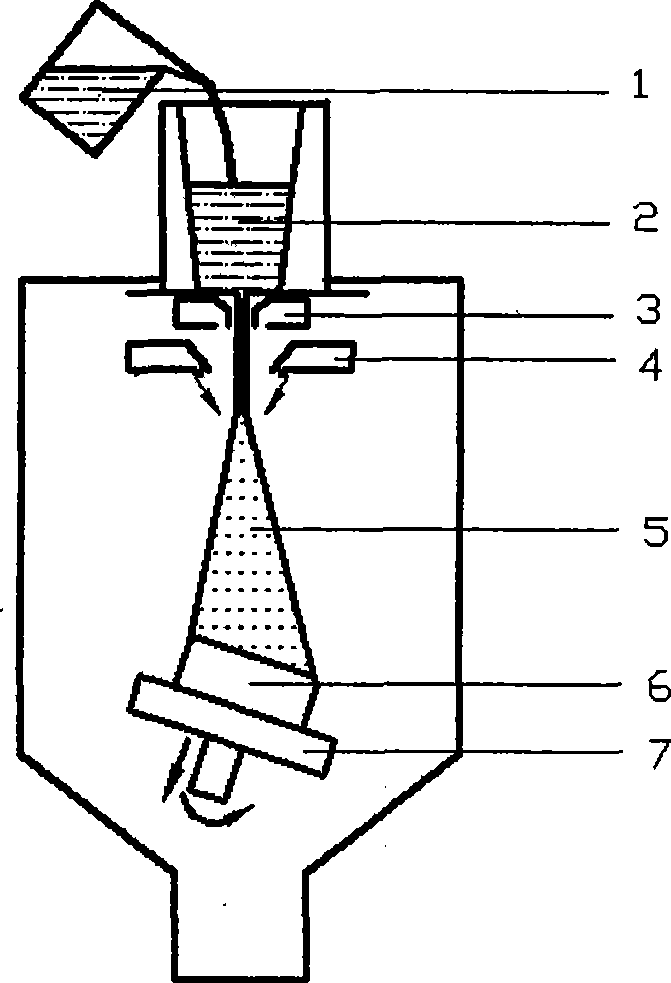

Cast iron inoculant and method for production of cast iron inoculant

InactiveUS6102983AEliminate segregationIncrease the number ofBlast furnace componentsBlast furnace detailsCeriumManganese

The invention relates to an inoculant for the manufacture of cast iron with lamellar, compacted or spheroidal graphite. The inoculant comprises between 40 and 80% by weight of silicon, between 0.5 and 10% by weight of calcium and / or strontium and / or barium, between 0 and 10% by weight of cerium and / or lanthanum, between 0 and 5% by weight of magnesium, less than 5% by weight of aluminium, between 0 and 10% by weight of manganese and / or titanium and / or zirconium, between 0.5 and 10% by weight of oxygen in the form of one or more metal oxides, the balance being iron, said inoculant further comprising between 0,1 and 10% by weight of sulphur in the form of one or more metal sulphides. The invention further relates to a method for the production of the inoculant.

Owner:ELKEM

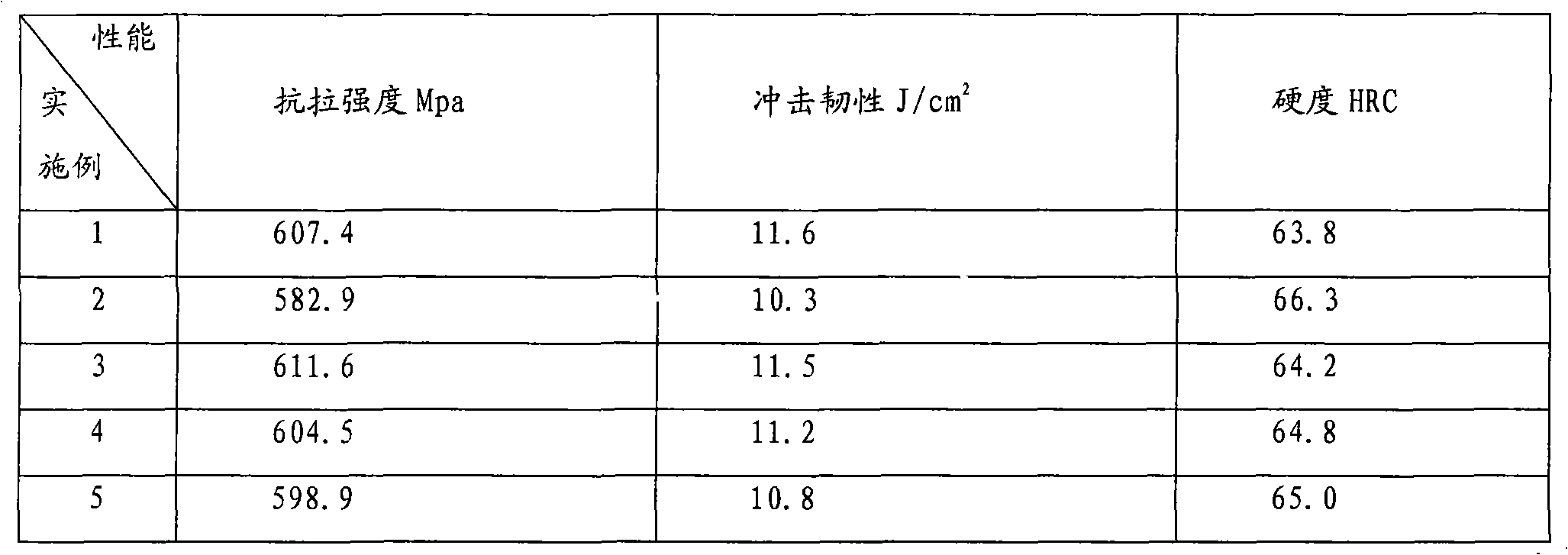

High chromium multielement alloy wear resisting ball and manufacturing method thereof

The invention discloses a high chromium multielement alloy wear resisting ball which comprises the chemical components by weight percentage as follows: 2.5-2.8% of C, 0.8-1.2% of Si, 1.2-1.4% of Mn, 12.5-14.0% of Cr, 0.4-0.6 of Mo, 0.7-1.0% of Ni, 0.8-1.2% of Cu, 0.05-0.1% of V, W smaller than or equal to 0.02, 0.03-0.05% of Ti, 0.02-0.04% of B, 0.03-0.04% of Nb, P smaller than or equal to 0.05%, S smaller than or equal to 0.05%, and the balance of Fe. According to the invention, wear resistance, high hardness, high tenacity and high impact resistance of the grinding ball are ensured by optimizing material formula to high chromium white iron, regulating the casting and melting process and combining a reasonable thermal processing method. Not only is production efficiency of a ball grinding mill improved, but also the production cost and energy consumption are further effectively reduced, the limited resources are saved, and extremely high economical value and social benefit are obtained.

Owner:MAANSHAN HENGDA WEAR RESISTANT MATERIALS

Compound high speed steel roll and its making process

InactiveCN1846887AImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Aluminum-silicon based aluminum section and preparation technology thereof

The invention discloses an aluminum-silicon based aluminum section. The aluminum section is composed of, by weight, 5.0-14.0% of silicon, 0.2-0.7% of magnesium, less than 0.03% of boron, less than 0.06% of strontium, 0.1-6.55% of strengthening elements, less than 0.25% impurity elements, and the balance aluminum. The aluminum-silicon based aluminium section has the advantages of high strength, high hardness, good wear resistance, etc. the invention also discloses a preparation technology for the aluminum-silicon based aluminum section, which comprises a first step of adding aluminum-silicon alloy to a graphite crucible and heating the alloy to form melt; a second step of adding the magnesium, the silicon and the strengthening elements; a third step of adding hexachloroethane for refinement; a forth step of adding the strontium for deterioration, casting to a cast iron die to form an ingot casting; and a fifth step of hot extruding, hot rolling for deformation, solid solution treating and aging treating in sequence after annealing the ingot casting, thereby obtaining the aluminum-silicon based aluminum section. The preparation technology is simple.

Owner:SOUTHEAST UNIV

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveUS20100189588A1Efficient use of resourcesEffective utilization of rareWelding/cutting media/materialsSoldering mediaChromium carbideHigh carbon

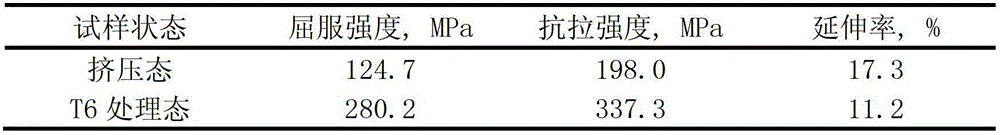

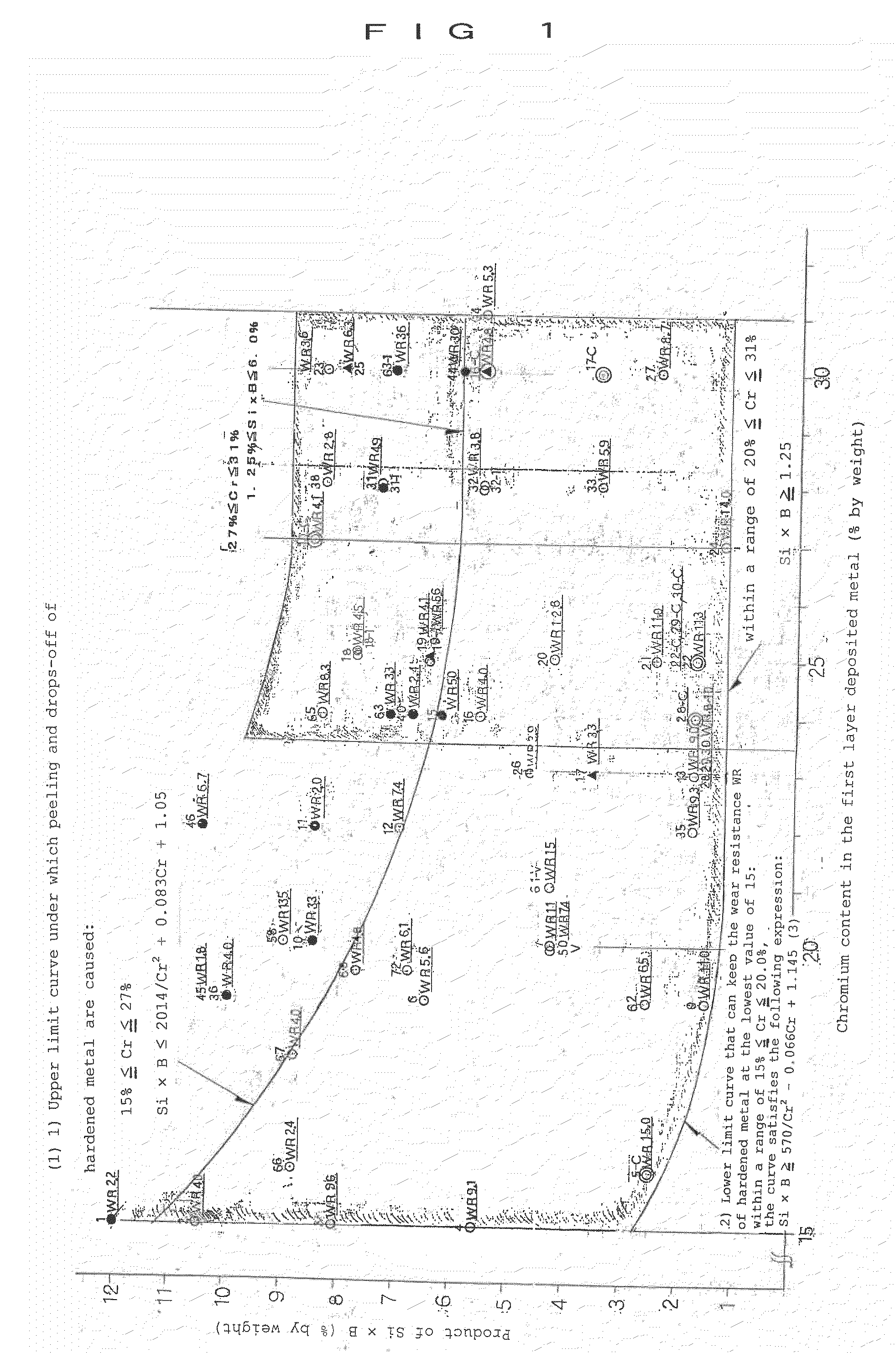

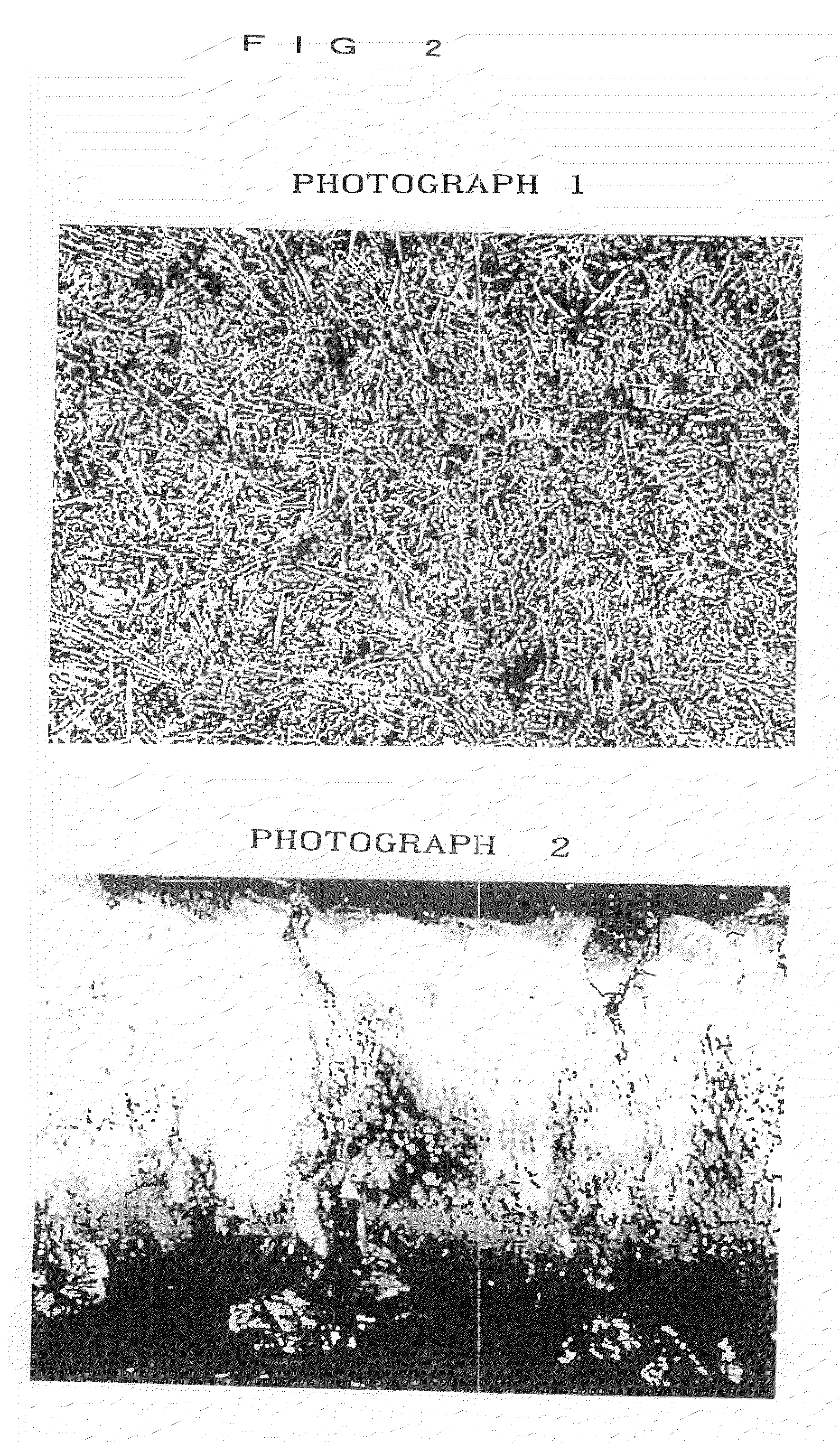

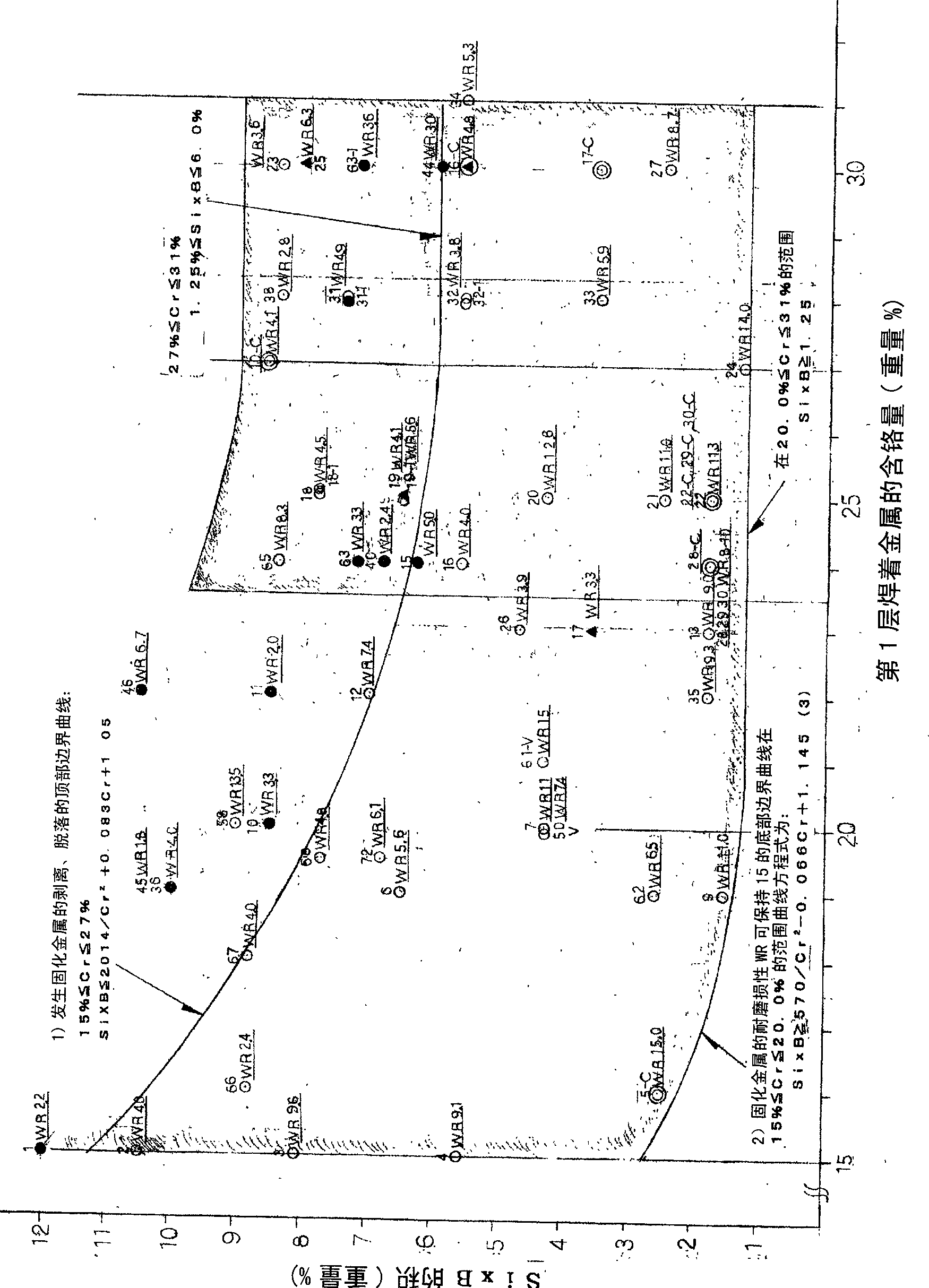

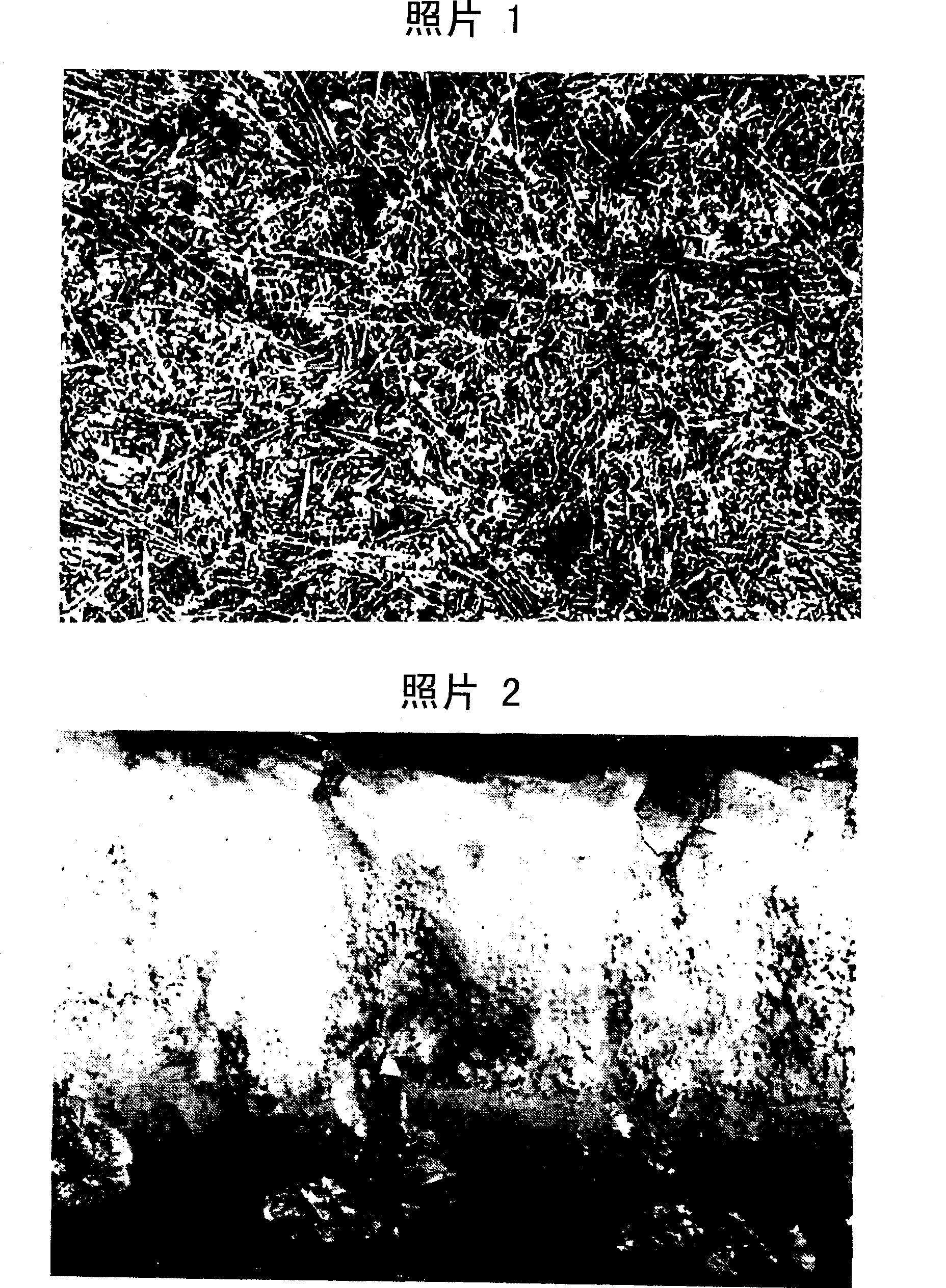

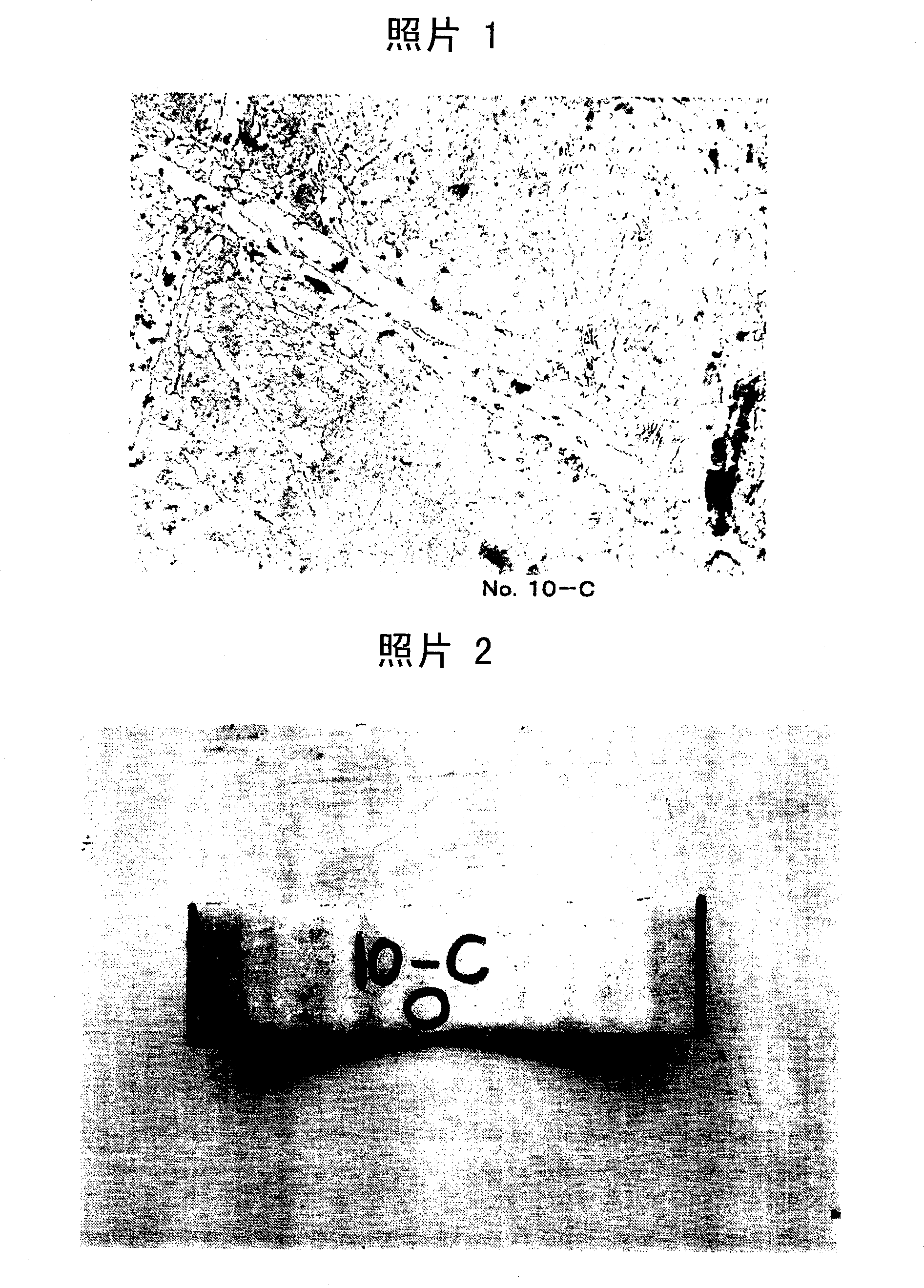

To provide a high-performance, inexpensive low C-high Si-high Cr—B—Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si—containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0≦Nb+V≦8%, and in this structure, within a range of 15% Cr≦Cr<27%, (Si×B)≦2014 / Cr2+0.083Cr+1.05 is satisfied, within a range of 27%≦Cr≦31%, 1.25%≦(Si×B) 6.0% is satisfied, within a range of 15%≦Cr<20%, (Si×B) 570 / Cr2−0.066Cr+1.145 is satisfied, and within a range of 20%≦Cr≦31%, (Si×B)≧1.25 is satisfied.

Owner:ING SHOJI

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

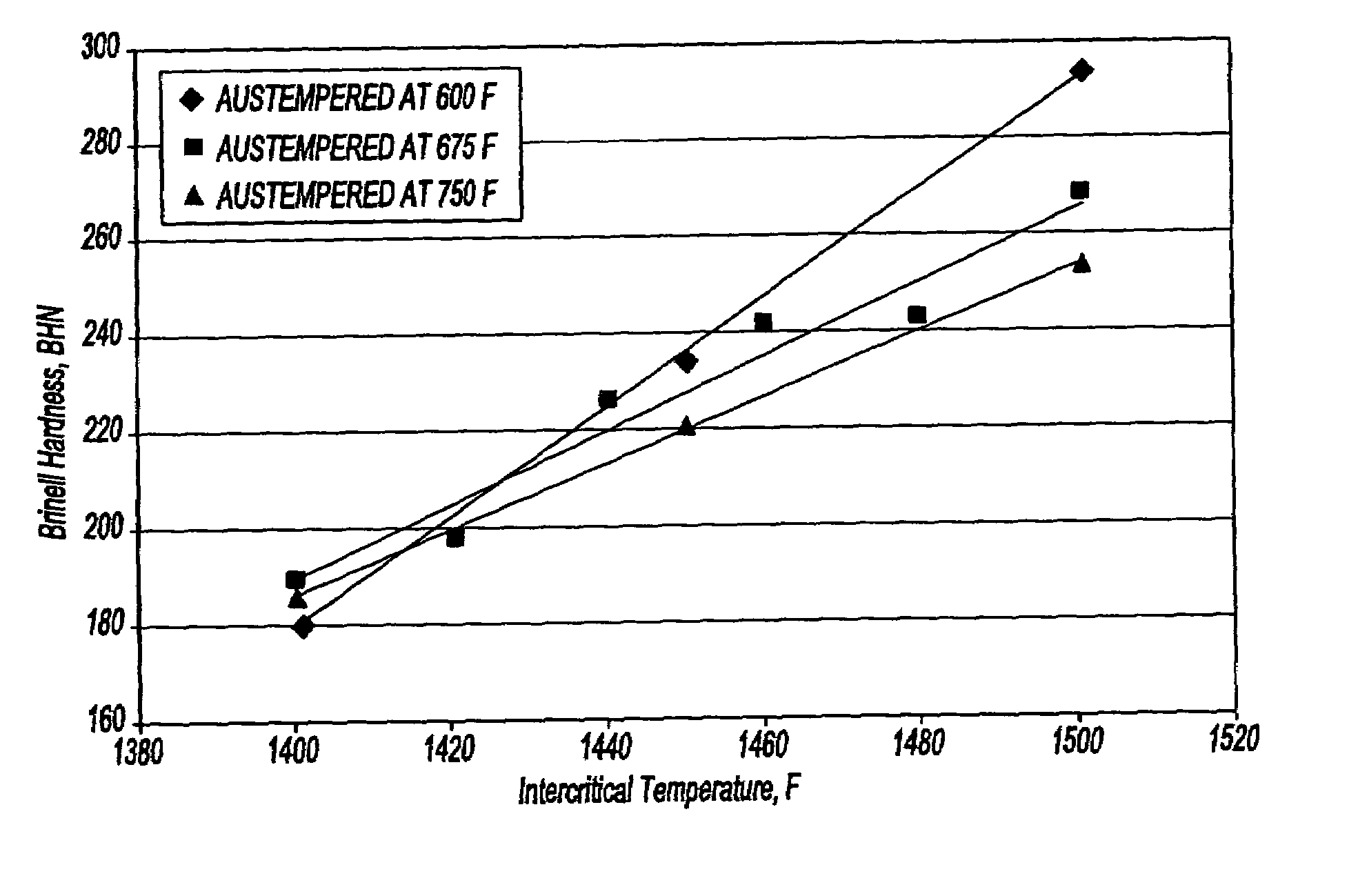

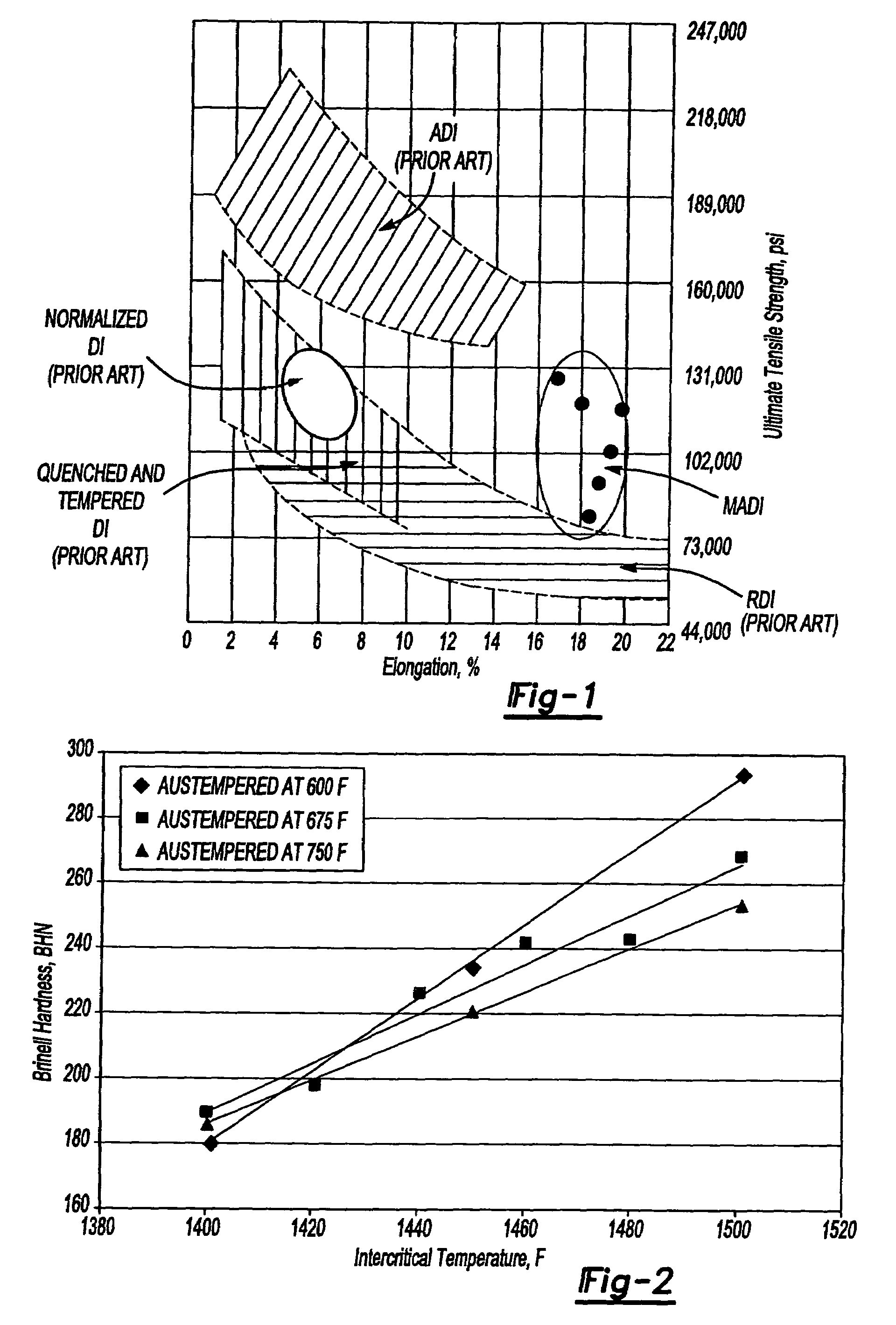

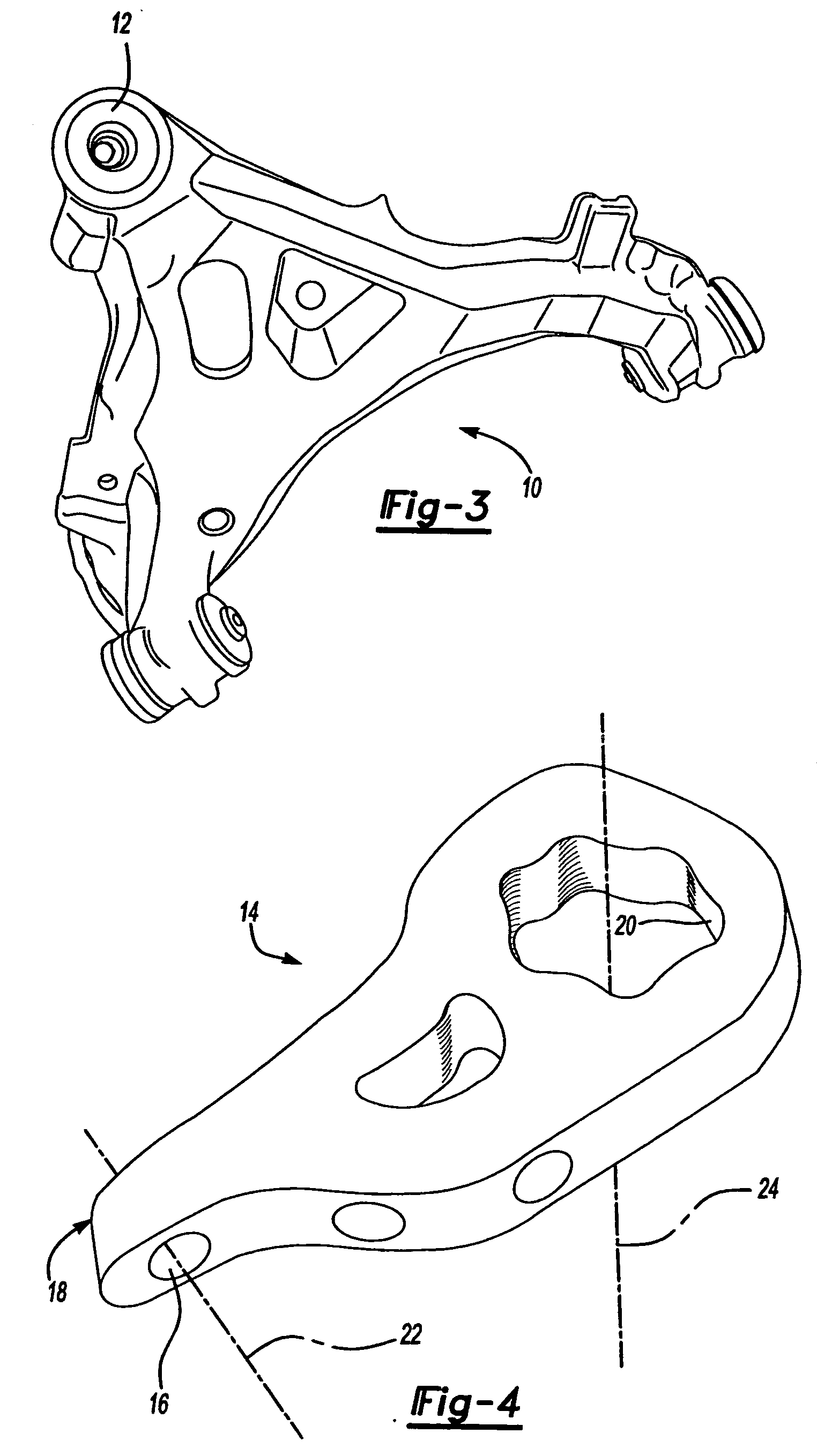

Machinable austempered cast iron article having improved machinability, fatigue performance, and resistance to environmental cracking and a method of making the same

InactiveUS7070666B2Extension of timeInhibition formationFurnace typesQuenching agentsPearliteUltimate tensile strength

A machinable austempered cast iron article has improved strength, machinability, fatigue performance, and resistance to environmental cracking. A method of making the machinable austempered cast iron article includes austenitizing an iron composition having a substantially pearlitic microstructure in an intercritical temperature range of between 1380° F. and 1500° F. This produces a ferritic plus austenitic microstructure. The ferritic plus austenitic microstructure is quenched into an austempering temperature range of between 575° F. and 750° F. within 3 minutes to prevent formation of pearlite. The ferritic plus austenitic microstructure is then austempered in the austempering temperature range of between 575° F. and 750° F. to produce a microstructure of a continuous matrix of equiaxed ferrite with islands of austenite. Finally, the microstructure of the continuous matrix of equiaxed ferrite with islands of austenite is cooled to ambient temperature to produce the machinable austempered cast iron article.

Owner:INTERMET CORP

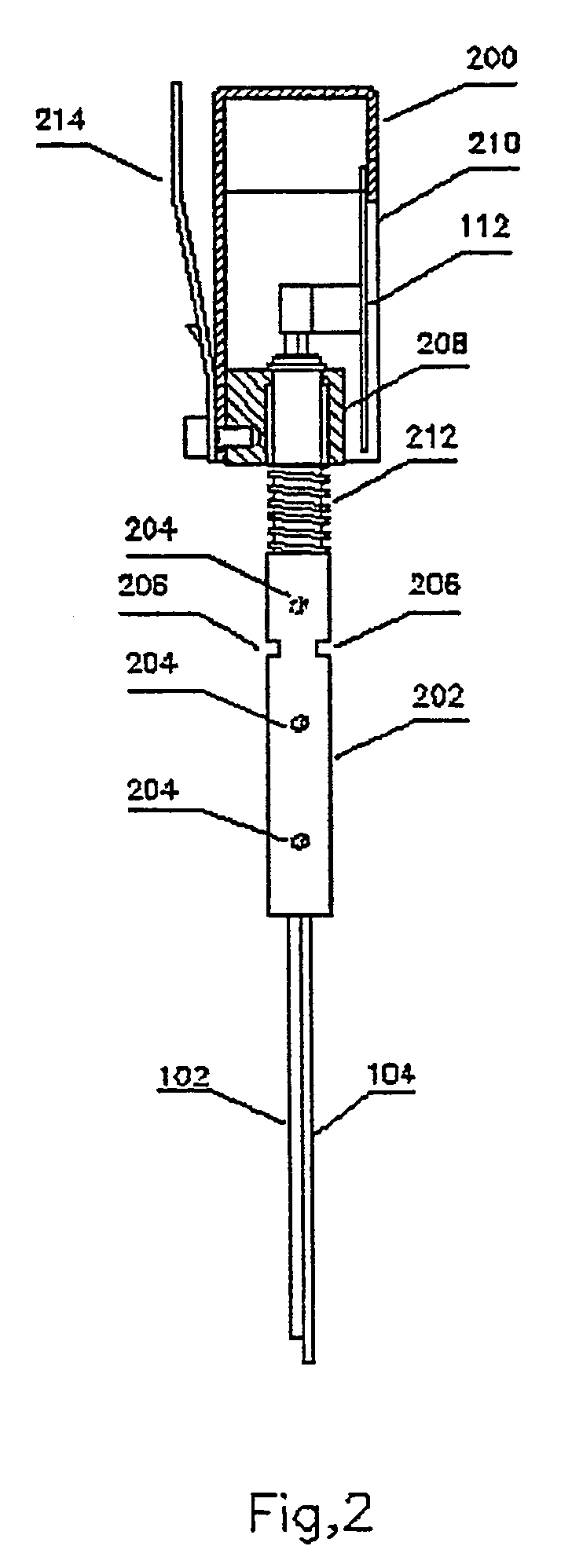

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

Cast iron inoculant and method for production of cast iron inoculant

The invention relates to an inoculant for the manufacture of cast iron with lame llar, compacted or spheroidal graphite. The inoculant comprises between 40 and 80 % by weight of silicon, between 0.5 and 10 % by weight of calcium and / or strontium and / or barium, between 0 and 10 % by weight of cerium and / or lanthanum, between 0 and 5 % by weight of magnesium, less than 5% by weight of aluminium, between 0 and 10 % by weight of manganese and / or titanium and / or zirconium, between 0.5 and 10 % by weight of oxygen in the form of one or more metal oxides, the balanc e being iron, said inoculant further comprising between 0,1 and 10 % by weight of sulphur in the form of one or more metal sulphides. The invention further relate s to a method for the production of the inoculant.

Owner:ELKEM

Vermicular graphite cast iron for producing brake drum of high-speed and heavy-load automobile

The invention discloses alloyed vermicular graphite cast iron produced by alloying the ordinary vermicular graphite cast iron. The cast iron comprises an alloy of two or more of elements such as Cu, Cr, Mo, Ni, Sn, Sb, B, Ti, Al, V and the like. The vermicular graphite cast iron comprises the following chemical ingredients in percentage by weight: 3.00-3.80 percent of C, 2.00-2.80 percent of Si, 0.45-0.95 percent of Mn, less than 0.06 percent of P, less than or equal to 0.02 percent of S, and 0.02-0.60 percent of alloy ingredient. The technical indexes of the vermicular graphite cast iron are that: VG is more than or equal to 80 percent, Rm is more than or equal to 380 MPa, hardness is between 180 HBW and 258 HBW, cast pearlite is more than or equal to 60 percent, and elongation rate is between 1 percent and 2 percent. The vermicular graphite cast iron has the advantages of high intensity, high heat conductivity, high wear resistance, high thermal fatigue resistance, small deformation, simple casting process and easiness in mechanical production. The service life of a produced brake drum for a high-speed and heavy-load automobile is remarkably prolonged, and safety is ensured.

Owner:罗云

Coating for lost foam cast iron

InactiveCN101569918AStrong ability to absorb EPSExempt from cleanupFoundry mouldsFoundry coresSodium BentoniteHigh surface

The invention belongs to the technical field of coatings for lost foam, in particular to a coating for lost foam cast iron. The invention provides the coating for the lost foam cast iron, which comprises the following components (calculated as the weight): 70 portions of bauxite, 30 portions of quartz powder, 2 to 5 portions of bentonite, 0.5 to 2 portions of white latex, 0.5 to 1.0 portion of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.5 to 2 portions of attapulgite, 2 to 5 portions of spodumene powder, 0.01 to 0.03 portion of surfactant, and 0.01 to 0.02 portion of defoaming agent. The coating has thin and even coatings and good air permeability; the surfaces of castings are smooth, clean, and level and easy to peel off, and black defects are eliminated; and the castings have level surfaces and high surface quality.

Owner:山东醴泉机械科技有限公司

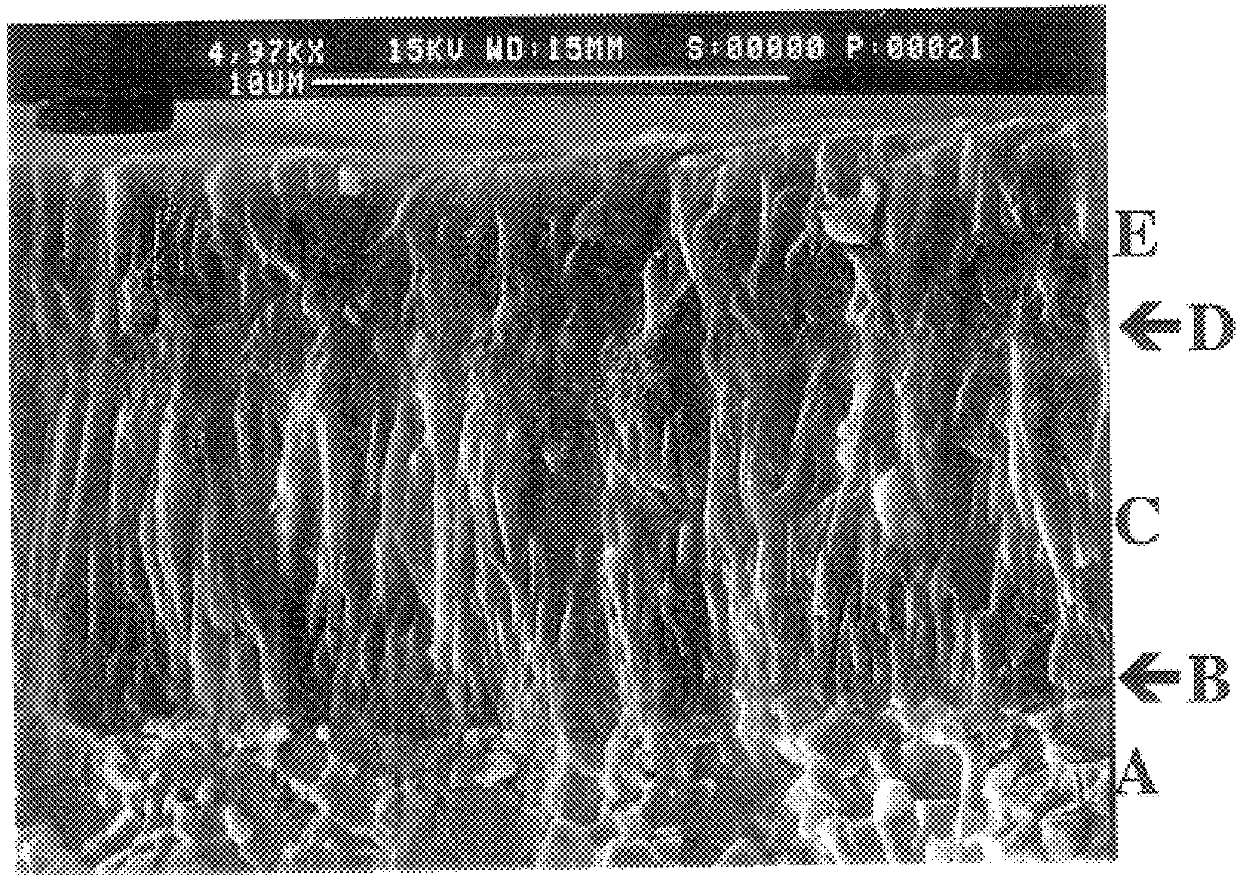

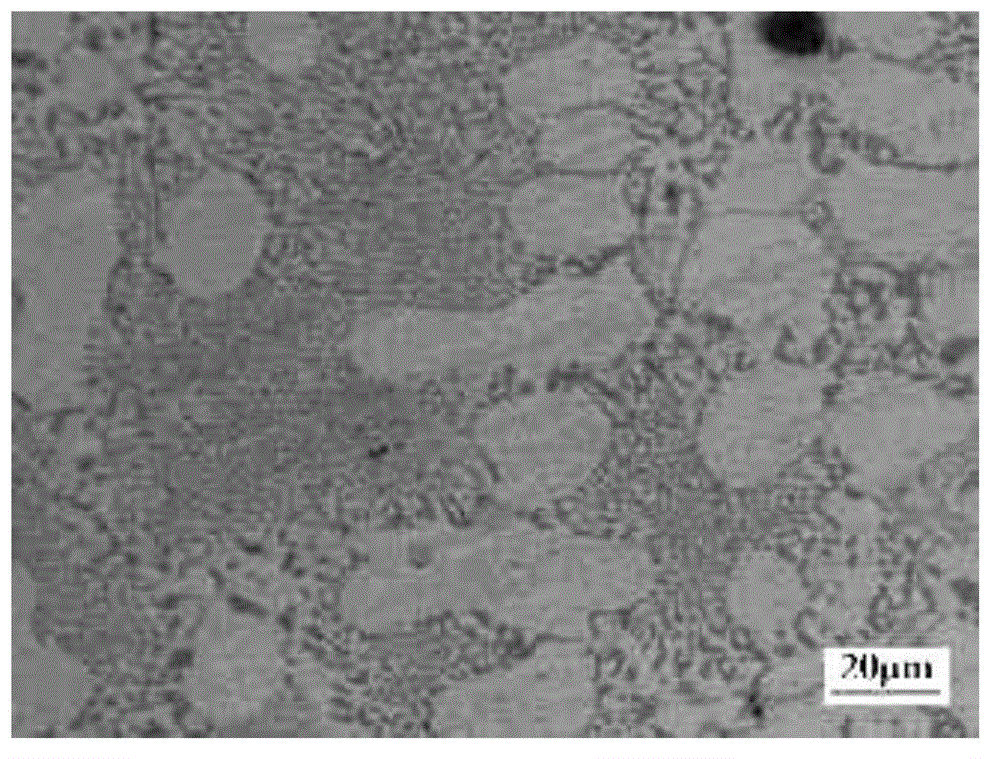

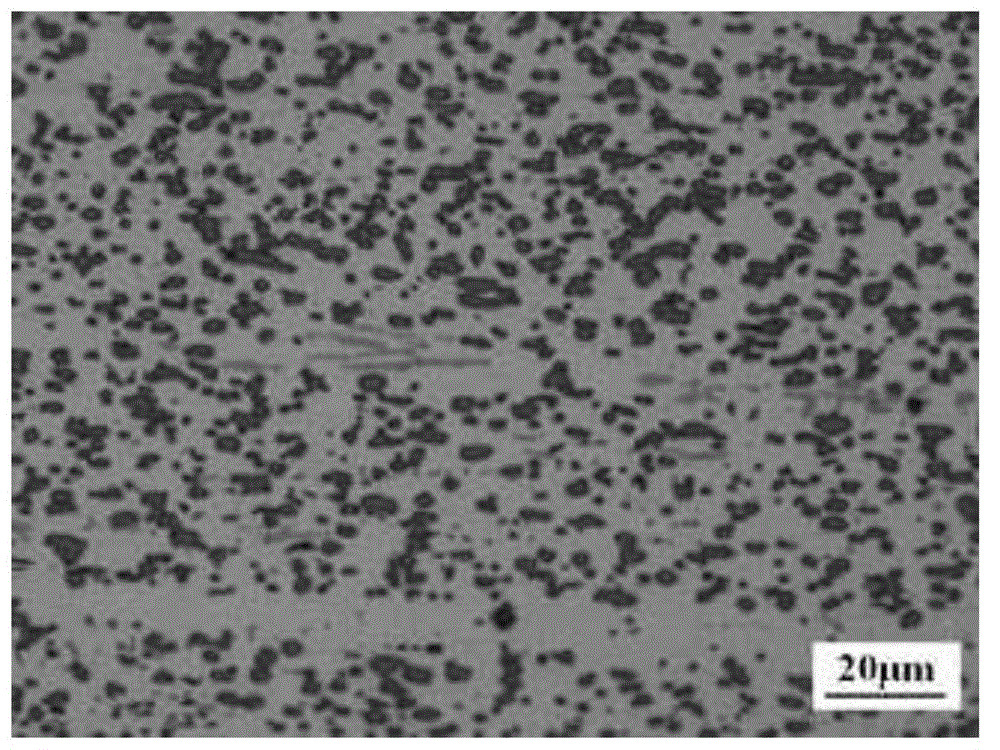

Centrifugal composite modified indefinite chilled cast iron roller and preparation method thereof

InactiveCN101177759AFine structure of roll bodyEvenly distributedRollsMetal rolling arrangementsCrazingImpurity

The invention relates to a centrifugal combined indefinite chill cast-iron roller and a preparation method thereof, pertaining to steel rolling technical field. The chemical composition of a roll barrel is (weight percent): 3.2-3.8 C, 3.8-4.5 Ni, 1.2-1.8 Cr, 0.2-0.4 Mo, 0.2-0.5Cu, 1.0-1.8 Si, <0.8Mn, 0.10-0.30 Nb, 0.05-0.20 V, 0.05-0.20 Ti, 0.04-0.07Mg, 0.02-0.05 Y, 0.01-0.03 Sb, and the rest are Fe and unavoidable microimpurity. The invention employs a electric stove to produce a roller, and the roller is moulded with centrifugal casting method; the roller is characterized by high strength and hardness, good toughness, hardness uniformity and hardenability, excellent wear resistance and oxidation resistance and the anti-cold shock and heat shock properties are also good; no phenomena like breaking, peeling, crazing and steel sticking are in the operation process; the service performance is apparently better than high nickel-chrome indefinite chill cast-iron roller; the processing technique is simple, high-heat treatment is not needed and the production cost is low. The invented roll has the advantages that: the rolling mill operating rate is significantly improved, the production cost of mill bar is reduced, the surface quality of the mill bar is improved and the economic and social benefits are good.

Owner:BEIJING UNIV OF TECH

High-hardness hypereutectic high chromium, manganese, molybdenum and tungsten alloy wear resistant steel material and use thereof

The invention discloses a high-hardness hypereutectic high Cr-Mn-Mo-tungsten alloy abrasion-resistant steel and iron material which adopts multivariant alloying and has the advantages of good hardenability, high hardness, better abrasion-resistance and wear resistance, and the like compared with the prior high-chromium cast iron especially the addition of C, Cr, Mn, Mo and tungsten, thereby enlarging the application range of materials. The invention is suitable for preparing wearing and corrosive wearing parts, in particular to parts used for impacting corrosive wearing working conditions.

Owner:JINAN UNIVERSITY

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveCN101505910AOvercoming brittlenessOvercome vulnerabilityWelding/cutting media/materialsSoldering mediaChromium carbideWear resistant

To provide a high-performance, inexpensive low C-high Si-high Cr-B-Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si-containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0+0.083Cr+1.05 is satisfied, within a range of 27% / =570 / Cr-0.066Cr+1.145 is satisfied, and within a range of 20% / =1.25 is satisfied.

Owner:ING SHOJI

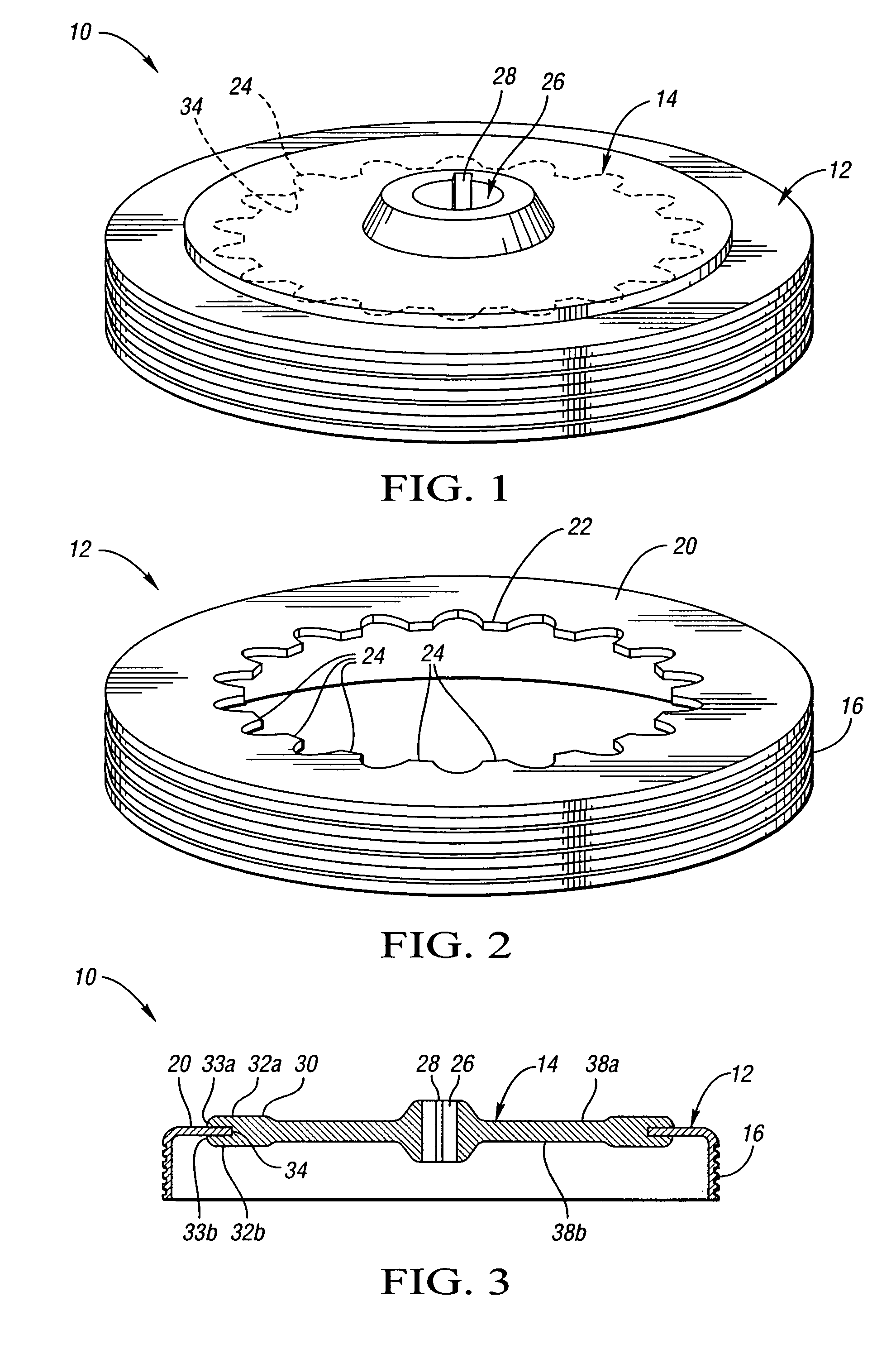

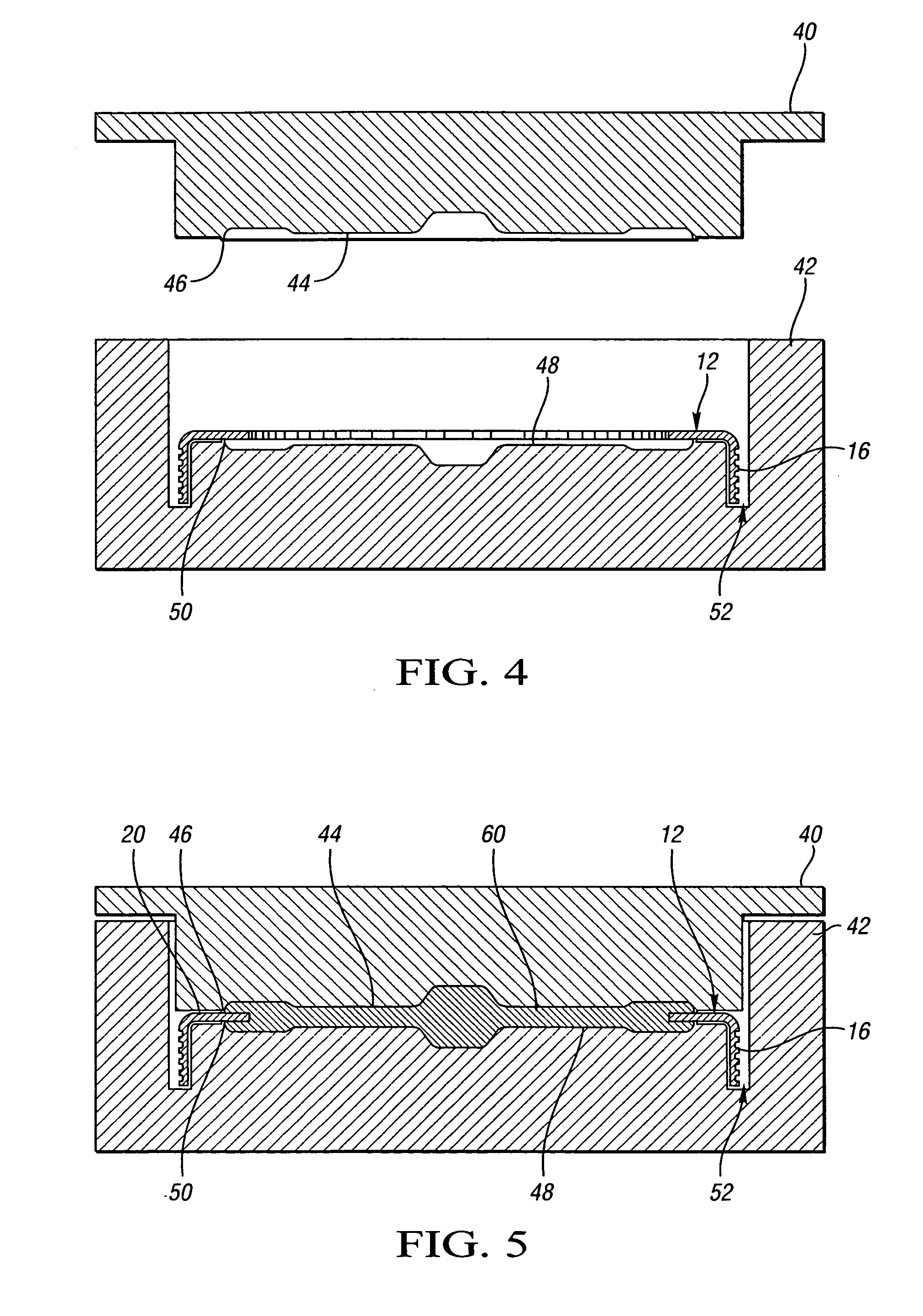

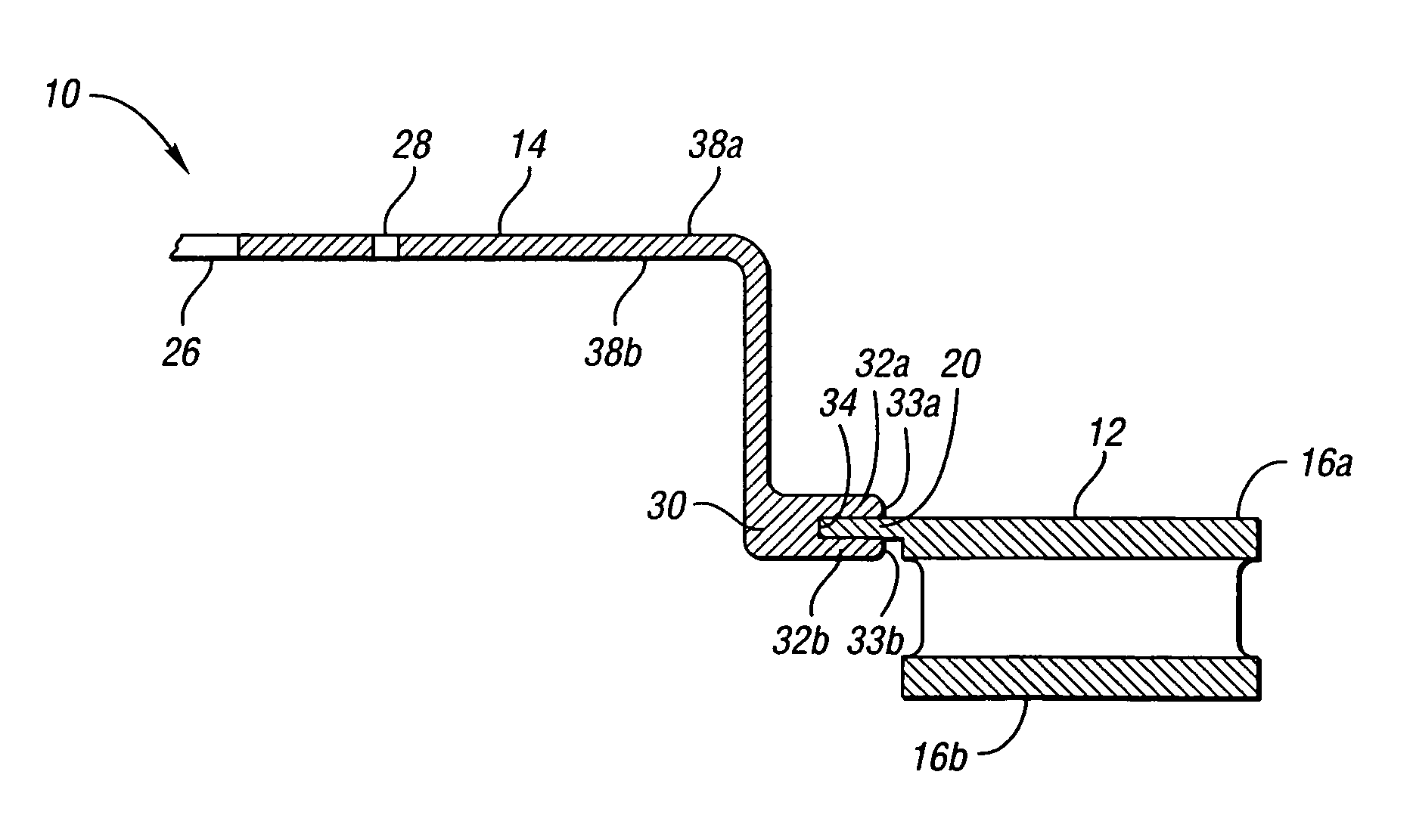

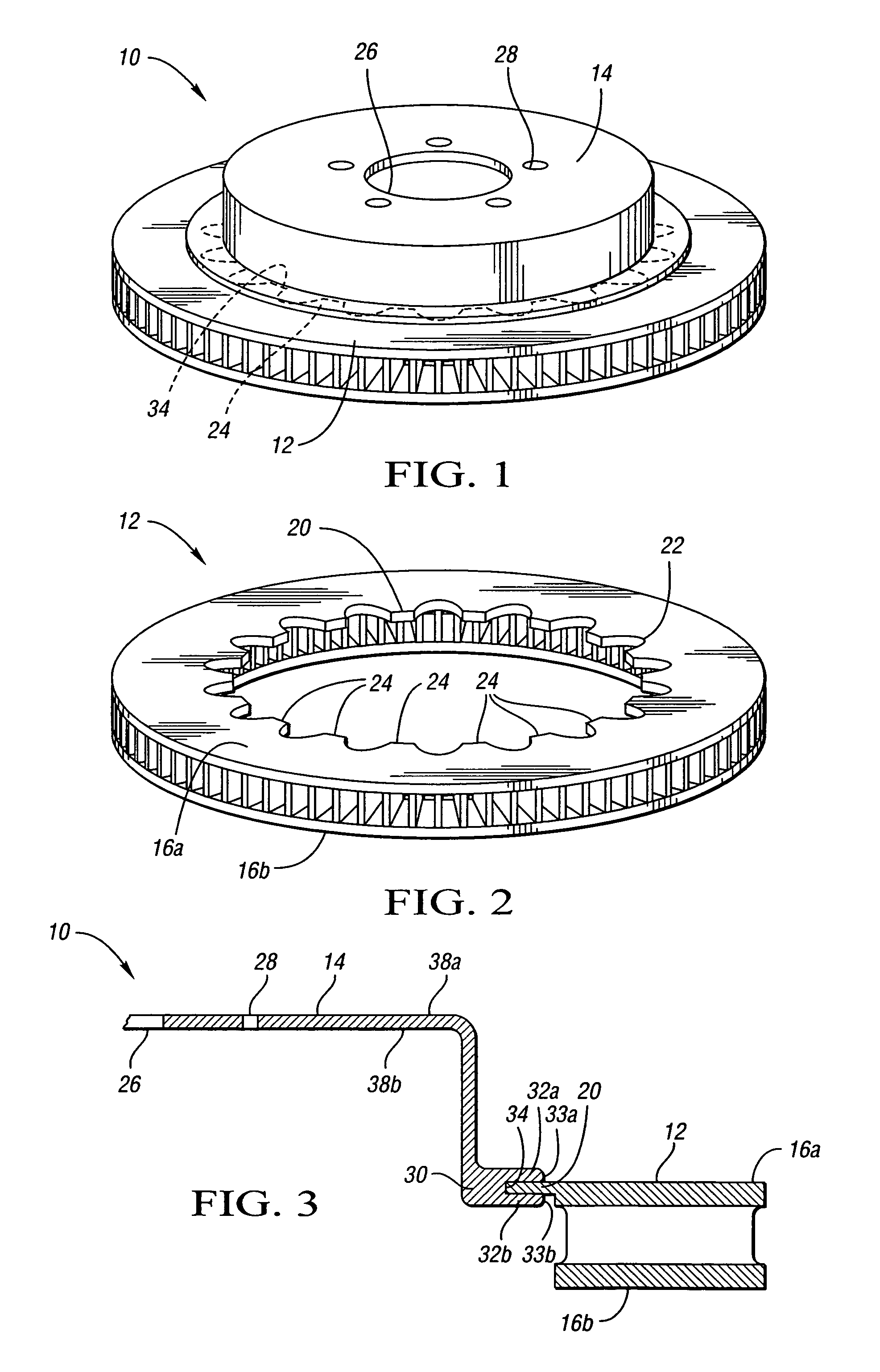

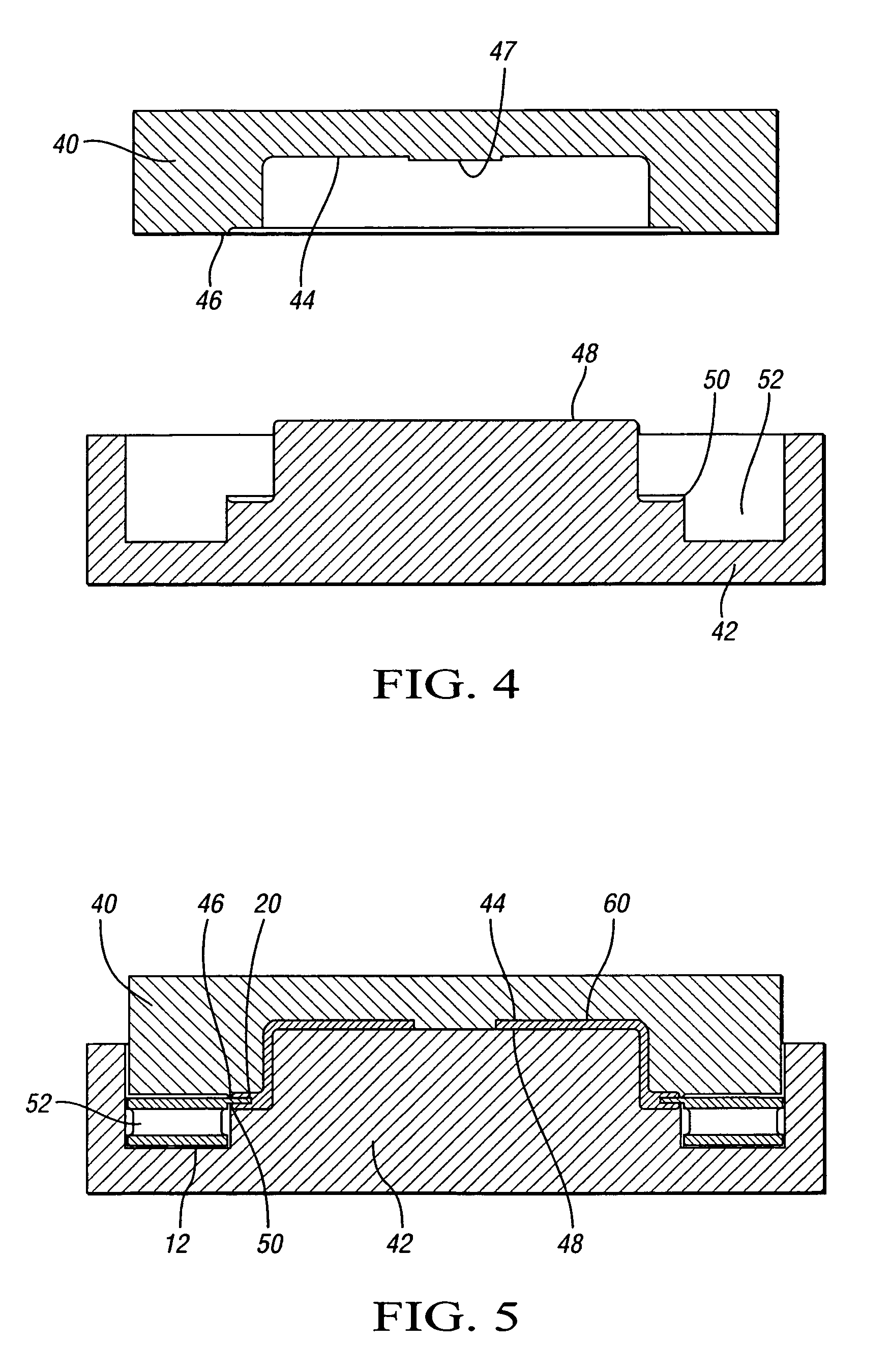

Rotor assembly and method

The apparatus of the present invention provides a brake rotor assembly. The brake rotor assembly includes a generally annular rotor having a frictional surface and a radially inner rotor flange defining a plurality of rotor teeth. The brake rotor assembly also includes a hub section integrally formed onto the rotor. The hub section has a peripheral hub flange configured to engage the plurality of rotor teeth and thereby prevent rotation of the hub section relative to the rotor. The rotor is preferably composed of a first material such as steel or cast iron, and the hub section is preferably composed of a second material such as aluminum or magnesium that is lighter by volume than the first material. Accordingly, the overall weight of the rotor assembly is less than that of a comparable rotor assembly composed entirely of steel or cast iron.

Owner:GM GLOBAL TECH OPERATIONS LLC

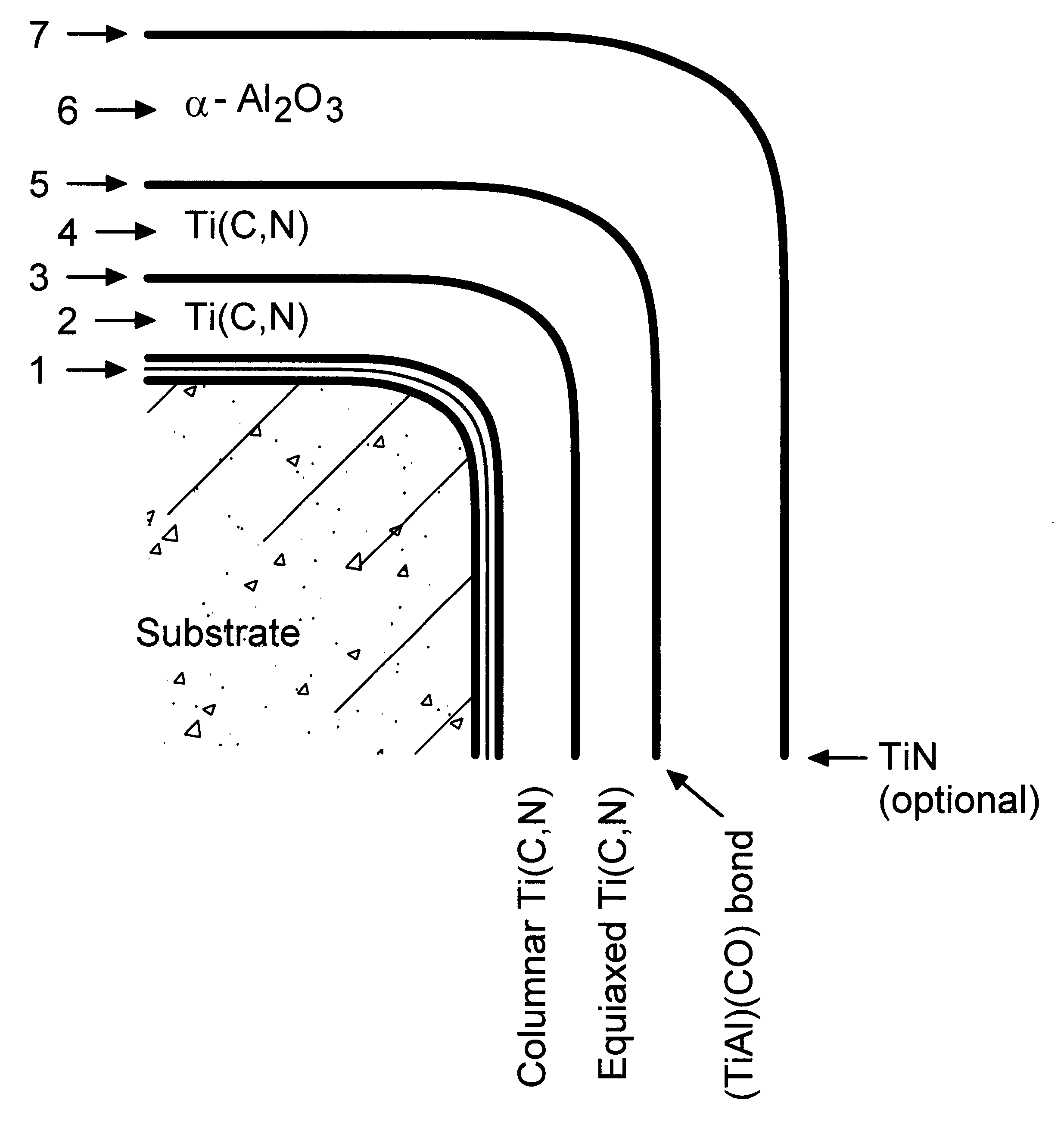

Grade for cast iron

An improved coated cemented carbide insert for the cutting of cast iron is provided. The insert has multi-layer TiCN between the substrate and the alpha-Al2O3 coating. The innermost portion of the TiCN layer is composed of large columnar grains while the outermost portion is of small equiaxed grains.

Owner:SECO TOOLS AB

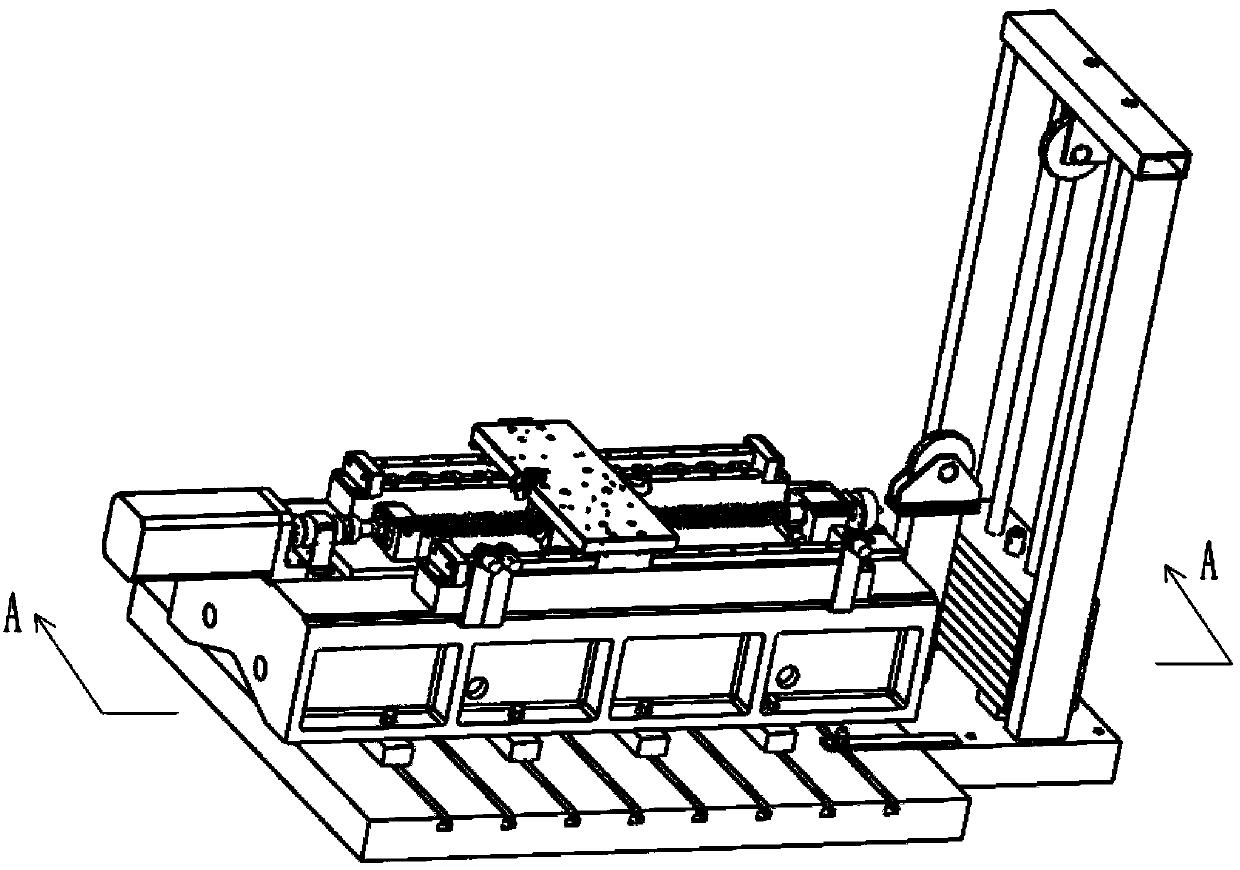

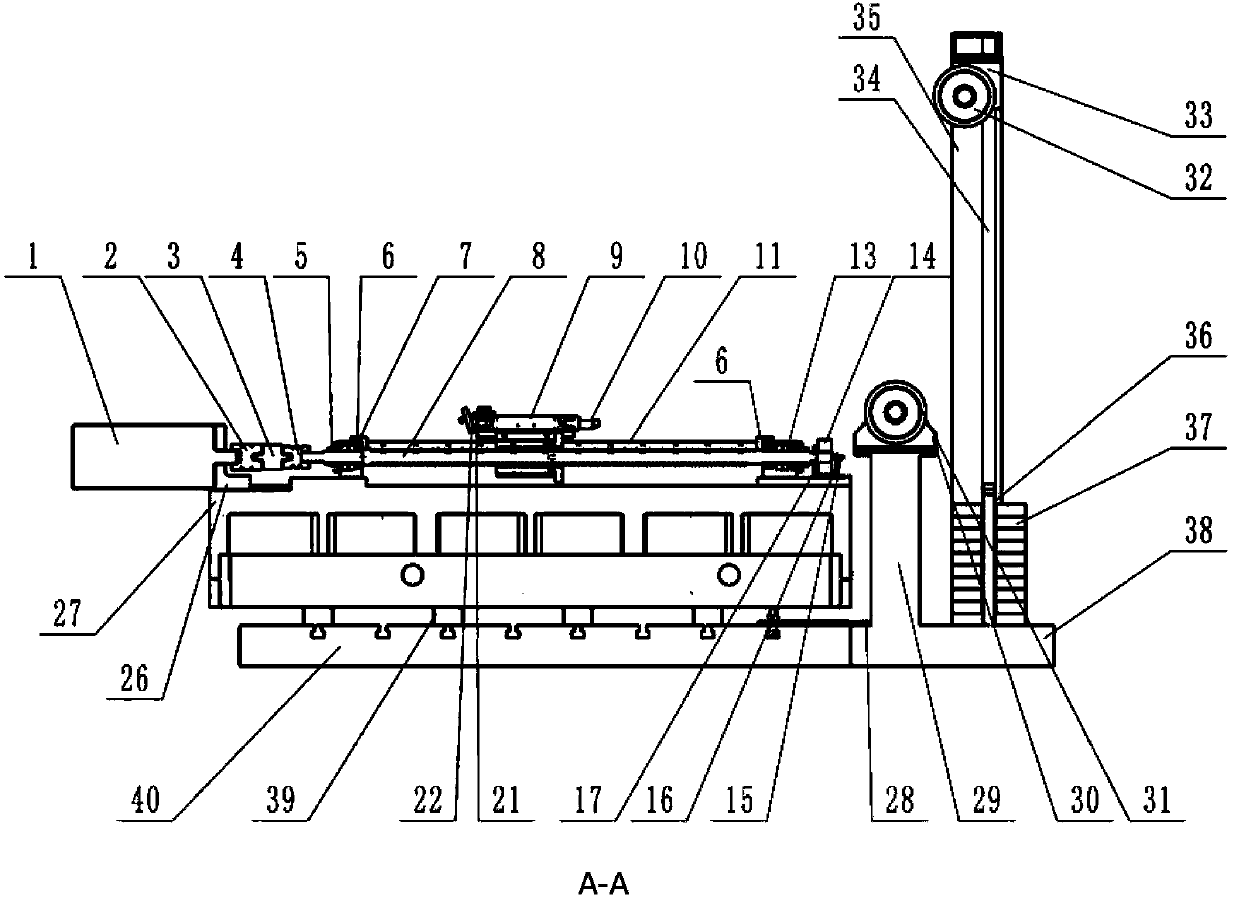

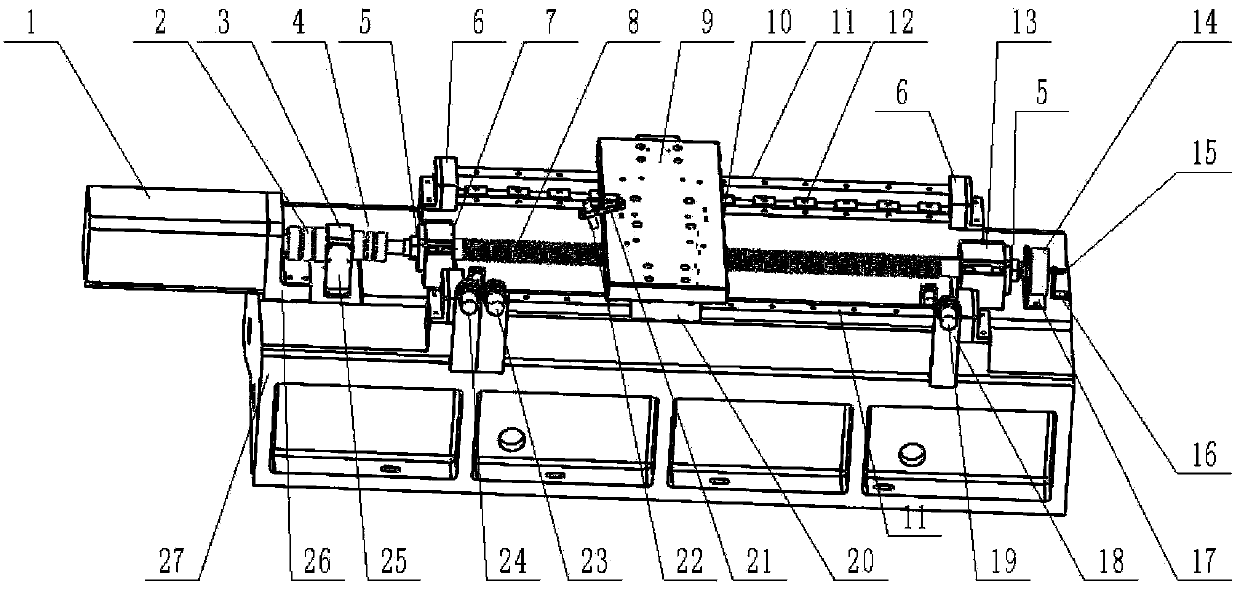

Device for detecting comprehensive performance of ball screw assembly in loaded state

InactiveCN103389205ARealize detectionReal-time detection of the number of rotationsMachine gearing/transmission testingCouplingBall screw

A device for detecting comprehensive performance of a ball screw assembly in a loaded state comprises a testboard machine body fixed on a cast iron platform, wherein a servomotor is arranged at one end of the testboard machine body; the output shaft of the servomotor is connected to one end of the ball screw assembly through a first coupler, a dynamic torque sensor and a second coupler; an eddy current sensor and a rotary encoder are arranged at the other end of the testboard machine body; a grating scale and an infrared temperature sensor are arranged on the testboard machine body; a rolling guide rail is arranged on the testboard machine body, and is provided with an analog working table; the analog working table is connected to the rolling guide rail through a rolling guide rail slide block, and is connected to a loading device; a ball screw assembly nut is arranged on the analog working table through a nut support base. The device is stable in properties, quick in movement and testing response speed, comprehensive and accurate in testing performance parameters, and simple in structure, and can realize the comprehensive performance detection of ball screw assemblies with different models in no-loaded states or loaded states.

Owner:XI AN JIAOTONG UNIV

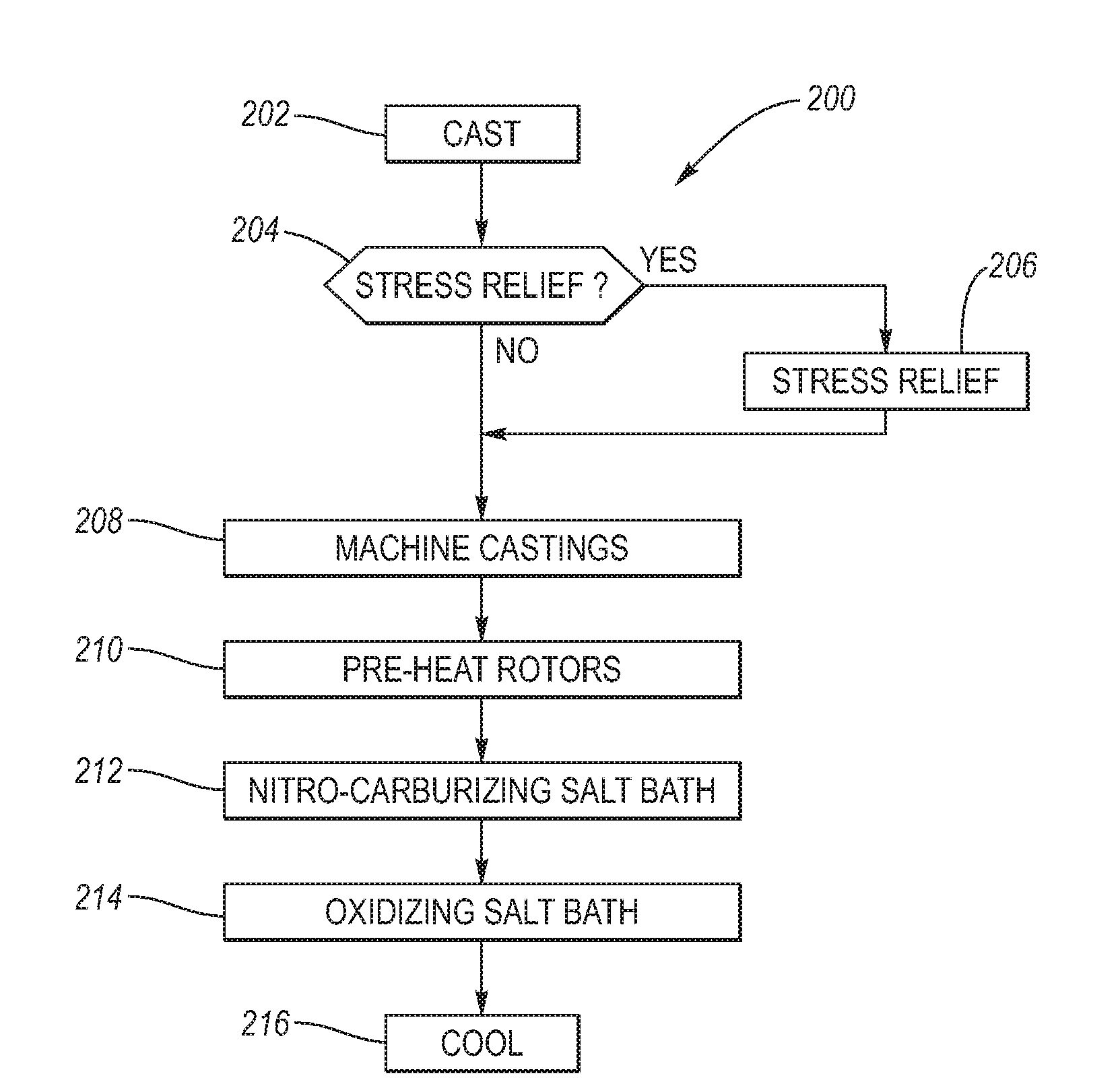

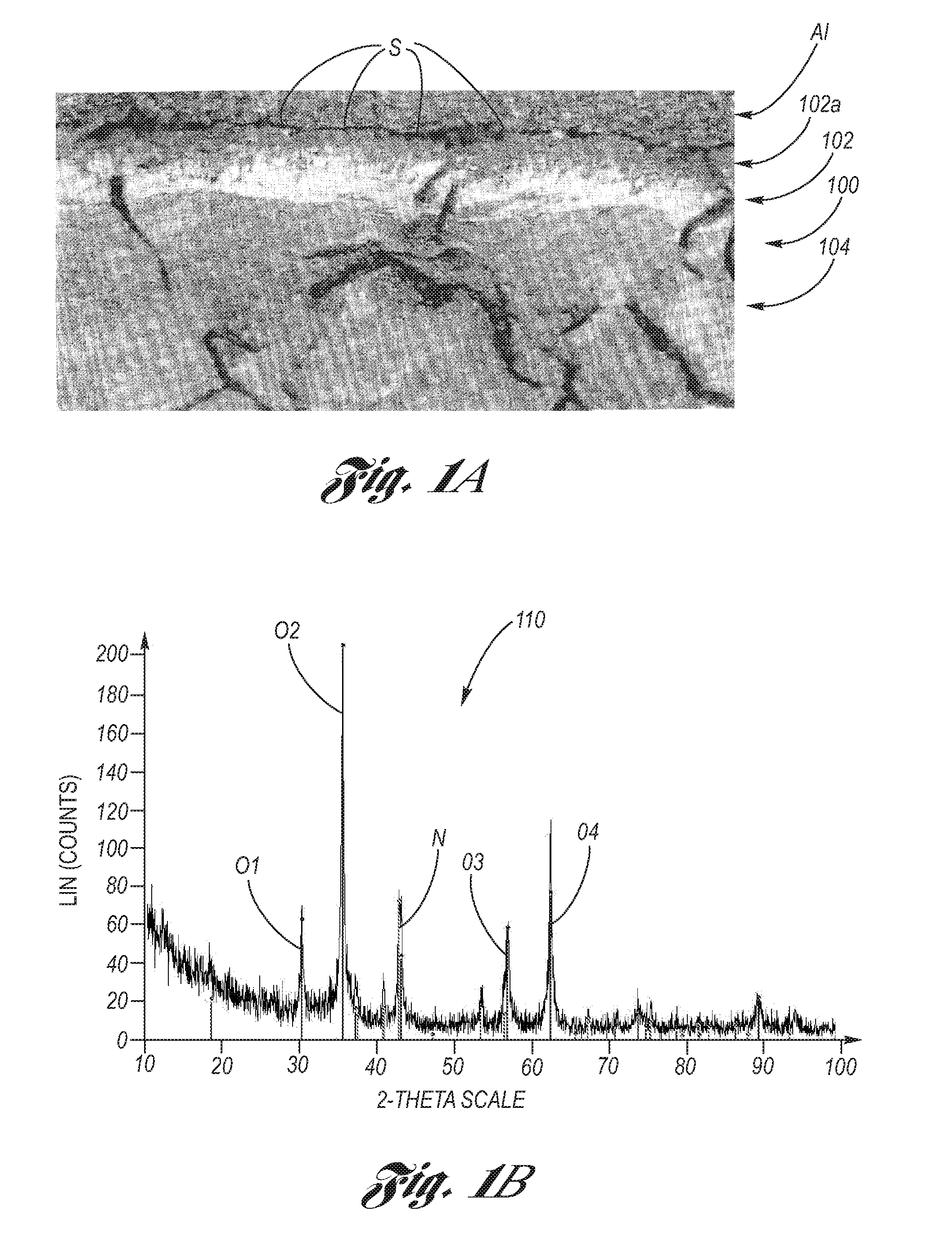

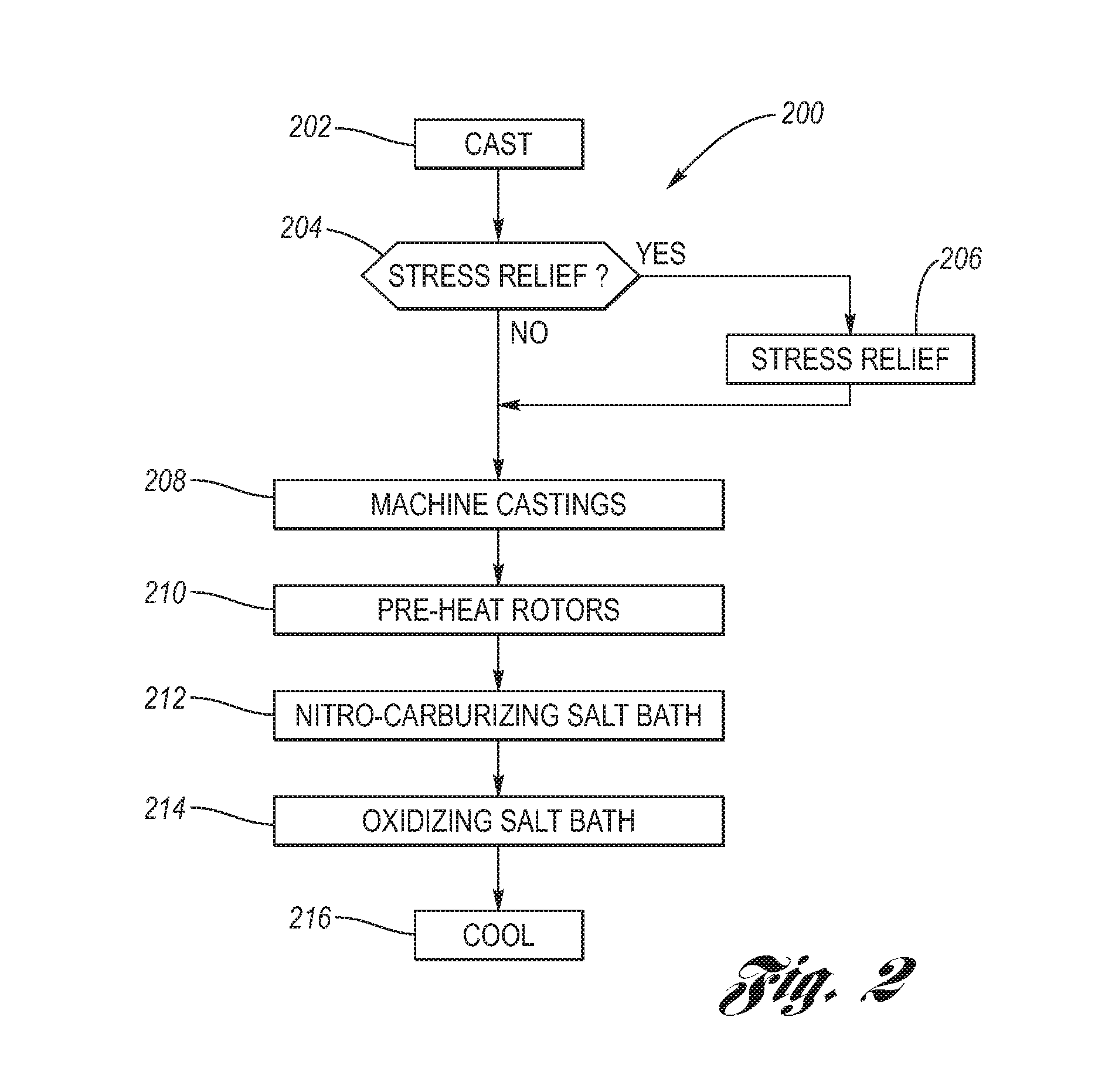

Salt Bath Ferritic Nitrocarburizing of Brake Rotors

ActiveUS20080000550A1Absence of distortionProvide resistanceBraking discsSolid state diffusion coatingRoom temperatureNitrogen

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:KOLENE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com