Patents

Literature

488 results about "Refining (metallurgy)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In metallurgy, refining consists of purifying an impure metal. It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material, whereas in refining, the final material is usually identical chemically to the original one, only it is purer. The processes used are of many types, including pyrometallurgical and hydrometallurgical techniques.

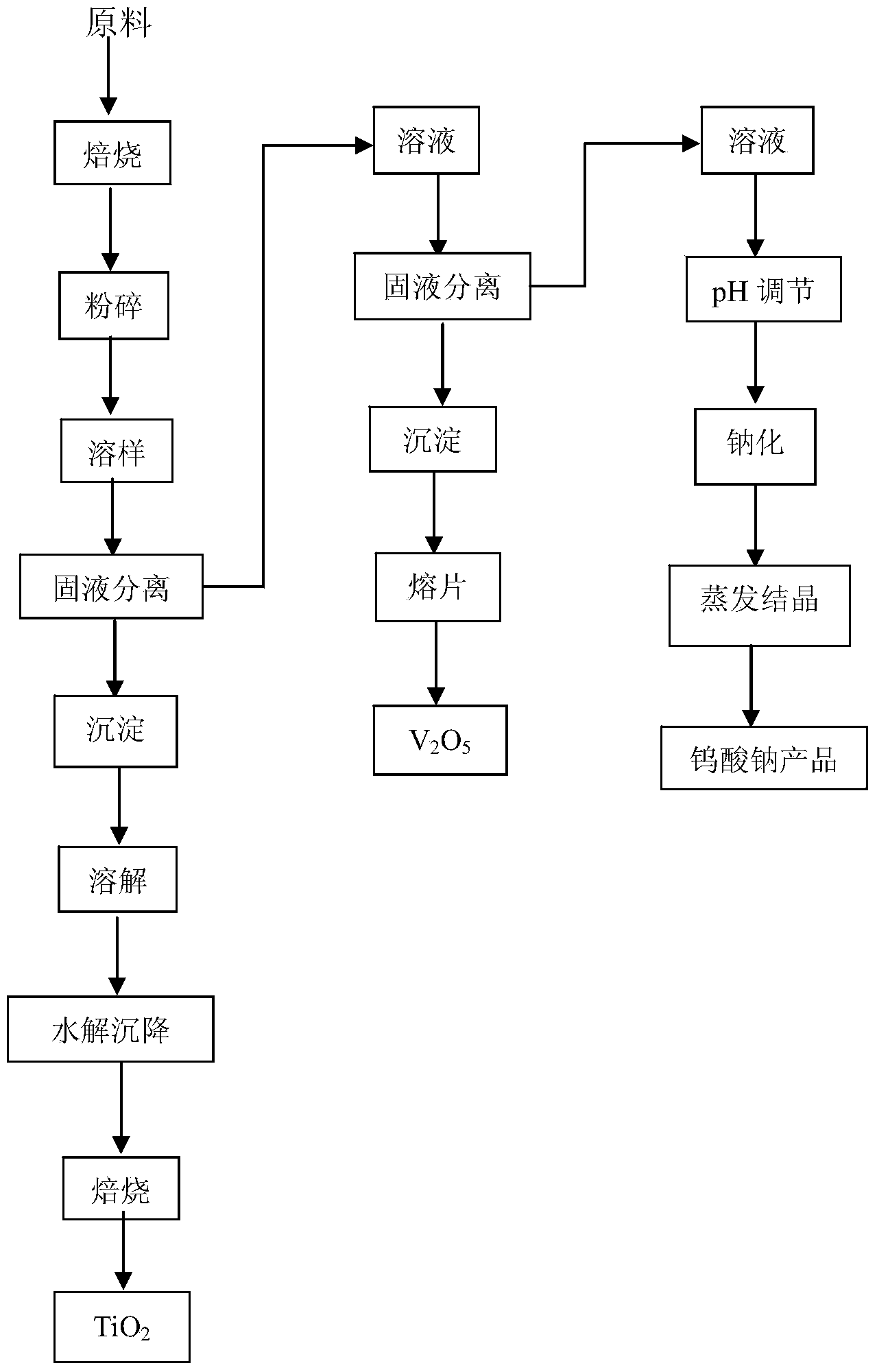

Recovery method for SCR waste flue gas denitration catalyst

ActiveCN103526031AEasy to operateSimple requirementsProcess efficiency improvementPtru catalystRefining (metallurgy)

The invention relates to a recovery method for an SCR waste flue gas denitration catalyst, and adopts a hydrometallurgy process. After the SCR waste flue gas denitration catalyst is smashed and subjected to pre-calcination treatment, a NaOH solution is added according to a ratio for dissolution. After the catalyst is dissolved, solid-liquid separation is performed, sulfuric acid is added into the obtained precipitation, and the precipitation is steeped, precipitated, hydrolyzed, subjected to salt treatment, and calcinated to obtain TiO2. Sulfuric acid is added into the solution obtained from the first solid-liquid separation to adjust the pH value, excess ammonium nitrate is added to precipitate vanadium, and second solid-liquid separation is performed. Ammonium metavanadate obtained from filtration is subjected to pre-calcination to obtain a V2O5 finished product. Hydrochloric acid is added into the solution obtained from the second solid-liquid separation to adjust the pH value, and NaCl is added to obtain sodium tungstate. The sodium tungstate is subjected to purification, filtration, ion exchange, and other processes to separate impurities, and subjected to evaporative crystallization to obtain a sodium tungstate finished product. The method provided by the invention is simple in technology, general in equipment, easily available in raw material, low in cost and high in recovery rate.

Owner:UNIV OF SCI & TECH BEIJING

High-silicon aluminum alloy cylinder sleeve material and preparation method thereof

InactiveCN101457318AImprove mechanical propertiesImprove tribological propertiesRefining (metallurgy)Manufacturing technology

The invention discloses a high silicon aluminum alloy cylinder sleeve material and a manufacturing method thereof., Ingredients of the material by weight percent are as follows: Si: 18.0%-25.0%; Fe: 3.5%-6.0%; Ni: 1%-2%; Cu: 1.5%-3.0%; Mg: 0.5%-1.0%; Mn: 0.5%-1.5%; V: 0.1%-0.5%; Sr: 0.05%-0.15%; and the balance of Al. The manufacturing method thereof comprises the following steps: 1, composition design and accurate mixture which uses an intermediate alloy for quantitative mixture; 2, smelting, covering and refining; 3, injection deposition; 4, extrusion processing; 5, heat treatment; 6, mechanical processing and honing processing. The material and the manufacturing method lead the high silicon aluminum alloy products to have high comprehensive mechanical property characteristics which are superior to mechanical property characteristics of cast iron cylinder sleeve material, have frictional property which are superior to frictional property of steel and cast iron cylinder sleeve material, and have great compatibility with thermophysical property of aluminum piston alloy material, thereby obviously narrowing the gap for cylinder matching. The manufacturing method is characterized in that: the manufacturing process of injection deposition is employed, which serves as a primary means in manufacturing the high silicon aluminum alloy, is superior to the powder metallurgy process and the die-casting process, and can use conventional processing equipment and process conditions.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Smelting method for low-silicon ultralow-sulphur steel

ActiveCN102134629ARealize the purpose of deep desulfurizationReduce the amount of siliconAlkalinitySmelting process

A smelting method for a low-silicon ultralow-sulphur steel belongs to the metallurgy technical field. The smelting process for producing low-silicon ultralow-sulphur steel comprises: molten iron 'complete-three-removal' pretreatment, decarburization converter smelting, and LF refining process. In order to ensure that silicon increase in molten steel during deep desulphurization is prevented, the sulphur content in molten steel for refining pull-in is firstly decreased by KR molten iron desulphurization pretreatment, and the pressure for LF deep desulphurization is reduced; then the silicon content in molten iron in a decarburization converter is decreased by desilication pretreatment in a dephosphorization converter to ensure the alkalinity of the slag in the decarburization converter is more than 4.0. The advantages are that the problem of the easy increase of silicon during the LF refining desulphurization process in the prior art is solved; the refining time is shortened; and the production efficiency is improved.

Owner:SHOUGANG CORPORATION

Mold steel electroslag re-melting slag system and use method of mold steel electroslag re-melting slag system

InactiveCN102605190AQuality improvementReduce contentIncreasing energy efficiencyRefining (metallurgy)Slow cooling

The invention provides a mold steel electroslag re-melting slag system and a use method of the mold steel electroslag re-melting slag system and belongs to the technical field of metallurgy engineering refining. The slag system consists of the following ingredients in percentage by mass: 65 to 70 percent of CaF2, 20 to 25 percent of Al2O3, 5 to 10 percent of SiO2 and 5 to 10 percent of MgO. A slag required by the refining is prepared according to the mass percentage being 4 to 6 percent of the mass of a mold steel electrode ingot to be refined. The use method comprises the following process steps of preparation and baking of electroslag re-melting slag, preparation of re-melting self consumption electrodes, arc smelting of electroslag re-melting, normal smelting of electroslag re-melting, smelting later-period feeding filling, electroslag steel ingot slow cooling heat insulation and electroslag re-melting steel ingot demolding. After the electroslag ingot heat insulation is completed, the demolding is immediately converted into the subsequent nodulizing annealing treatment. When the system and the method provided by the invention are adopted for refining, the sulfur and phosphor contents in mold steel are further reduced, in addition, the contents of active elements such as C, Si and Mn in the steel do not basically generate burnt loss, and the quality of the mold steel electroslag re-melting steel ingot is further improved.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

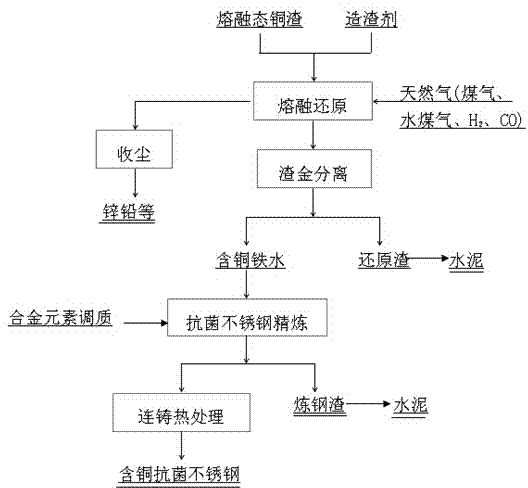

Method for directly smelting copper-bearing antibacterial stainless steel by utilizing copper slag for reducing molten iron

ActiveCN104120351AAchieve high valueRealize slag-free cleaning processSteelmakingRefining (metallurgy)

The invention belongs to the field of metallurgy, and particularly relates to a method for directly smelting copper-bearing antibacterial stainless steel by utilizing copper slag for reducing molten iron. According to the method, high-temperature molten-state copper slag is directly transferred and injected into a high-temperature reduction furnace, oxygen is sprayed and blown into the furnace to perform oxidation impurity removing pretreatment on the molten copper slag, then, slagging constituents are added in the furnace, inert gas and natural gas are sprayed and blown into the furnace for smelting reduction to obtain copper-bearing molten iron, the copper-bearing molten iron is conveyed to the steelmaking process, copper-bearing mother steel liquor is obtained, continuous casting is performed on the molten steel mother liquor obtained by refining to obtain a steel billet, hot rolling and annealing treatment are performed on the steel billet, and the antibacterial stainless steel is obtained. According to the method, the production cost of the antibacterial stainless steel is greatly reduced, and meanwhile the comprehensive utilization added value of valuable elements of the copper slag is greatly improved.

Owner:NORTHEASTERN UNIV

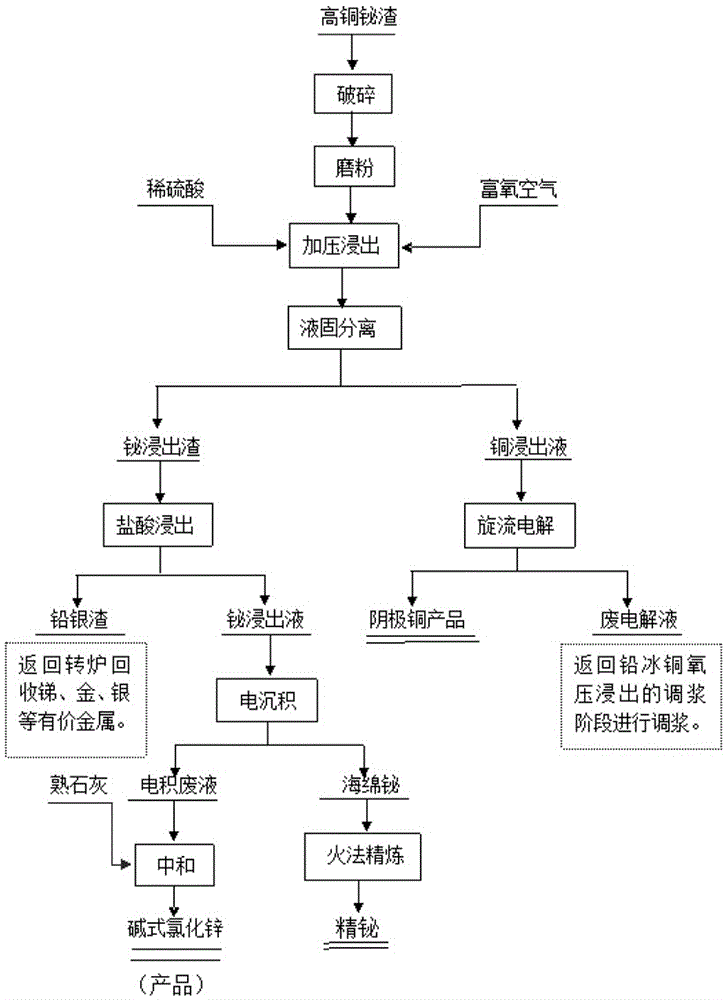

Method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag

InactiveCN106566928AStrong raw material adaptabilityEasy to operateProcess efficiency improvementBismuthPyrometallurgy

The invention discloses a method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag. According to the method, high-copper bismuth slag is taken as a raw material; high-copper bismuth slag powder obtained via smashing, grinding, and sieving and a sulfuric acid solution are subjected to size mixing at a certain ratio, and are delivered into a high-pressure autoclave; rich oxygen is introduced into the high-pressure autoclave, and oxygen pressure in the high-pressure autoclave is controlled for oxidizing leaching, wherein in the oxidizing leaching process, leaching of Cu in the form of Cu2+ is realized, and selective separation of copper with other non-zero valent elements is realized; a copper-containing leachate is subjected to acid adjusting, and is subjected to rotational flow electrolysis directly so as to extract copper in the copper-containing leachate and obtain copper products; a leaching residue is subjected to leaching separation of bismuth with concentrated hydrochloric acid, sponge bismuth is obtained via electro-deposition, and product refined bismuth is obtained via refining of sponge bismuth; and the rest slag is delivered into a lead pyrometallurgy system for comprehensive recycling of non-zero valent elements such as Pb, Ag, and Au. No environment pollution is caused by the method, no three wastes are discharged, and the method is a clean metallurgy technology.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

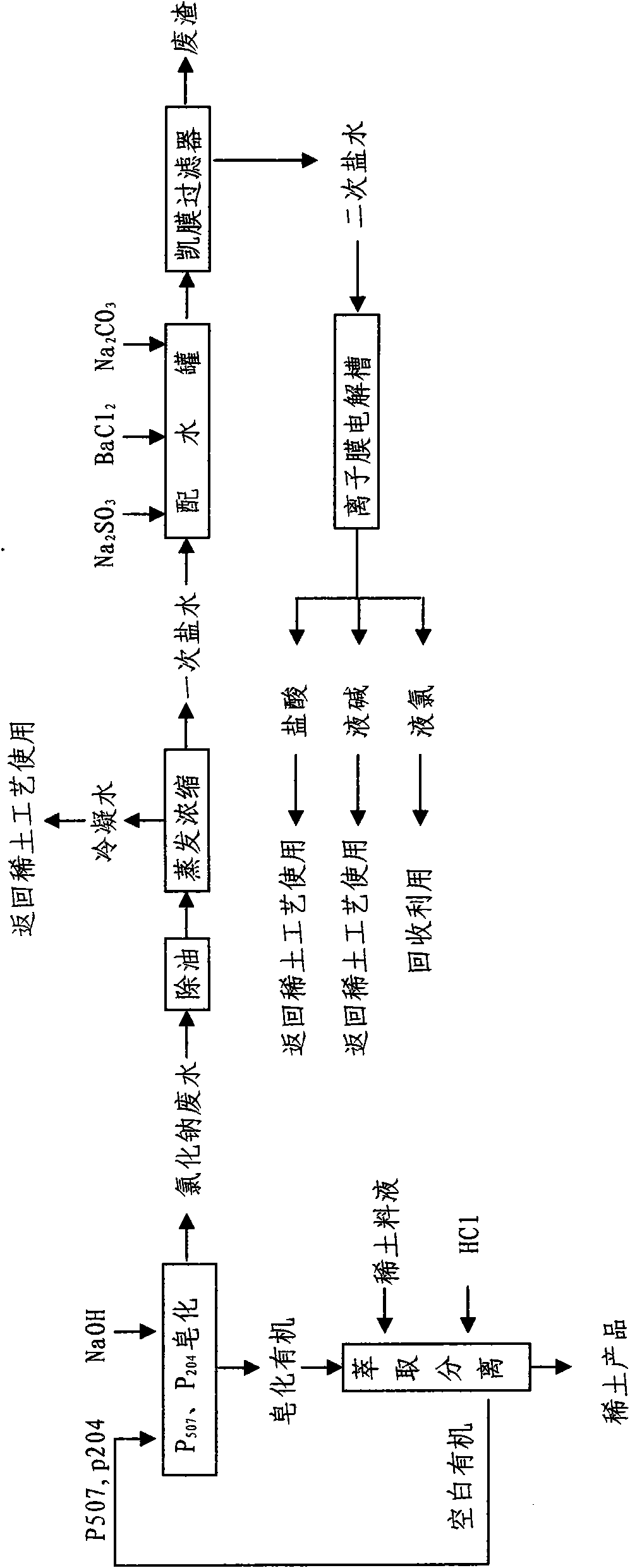

Rare earth extraction saponification waste-water cyclic utilization method

ActiveCN101549926AAchieve recyclingReduce salt contentElectrolysis componentsFatty/oily/floating substances removal devicesRare earthIon-exchange resin

The invention relates to a rare earth extraction saponification waste-water cyclic utilization method, belonging to the rare earth wet-process metallurgy field. The method comprises the following steps: concentrating the saponification waste water after adding crude salt, adding Na2SO3, BaCl2, Na2CO3 and removing impurities through a water distribution tank, refining the filtered secondary salt water by an ion exchange resin tower, Ca2+, Mg2+ ion <=20ppb; producing hydrochloric acid and liquid alkali using ion membrane electrolytic process wherein the hydrochloric acid and liquid alkali back to the rare earth technique. The treatment of the sodium chloride waste water realizes the cyclic utilization of the valuable element with features of source saving, product cost reducing, environmental pollution reducing. The method is an economic and an environmental friendly production method of rare earth extraction separation cyclic utilization, which realizes the cyclic utilization of the rare earth extraction separation sodium chloride saponification waste-water.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

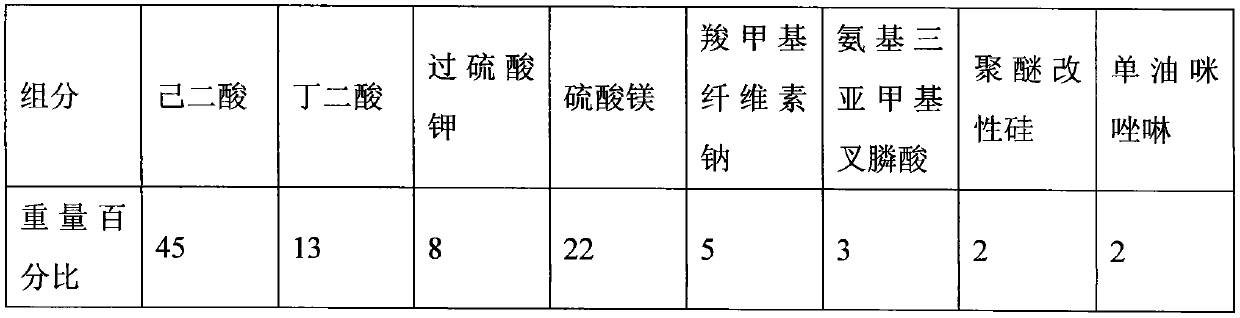

Composite refining agent for metallurgy and processing technique thereof

InactiveCN102653809AComponent content is reasonableShort production timeProcess efficiency improvementCelluloseSodium Bentonite

The invention relates to a composite refining agent for metallurgy and a processing technique thereof. The refining agent is characterized in that the refining agent comprises the following raw materials by weight percent: 25-38% of CaSi, 3-10% of SiC, 15-40% of CaF2, 5-15% of CaO, 1-5% of rare earth, 10-30% of metal manganese powder, 5-10% of calcium carbide and 2-8% of binder, wherein the binder is formed by natural calcium bentonite, sodium carbonate and cellulose sodium; and the composite refining agent is prepared through grinding, mixing, sieving and drying according to the formula of the components. The composite refining agent has the advantages of short smelting cycle, few product impurities, good molten steel purifying effect, high product quality and low energy consumption.

Owner:张晖

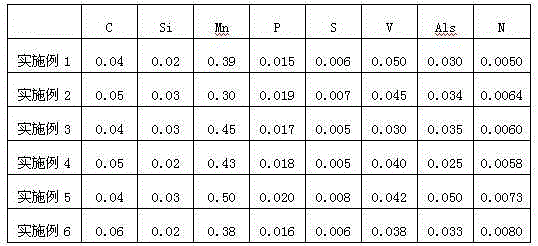

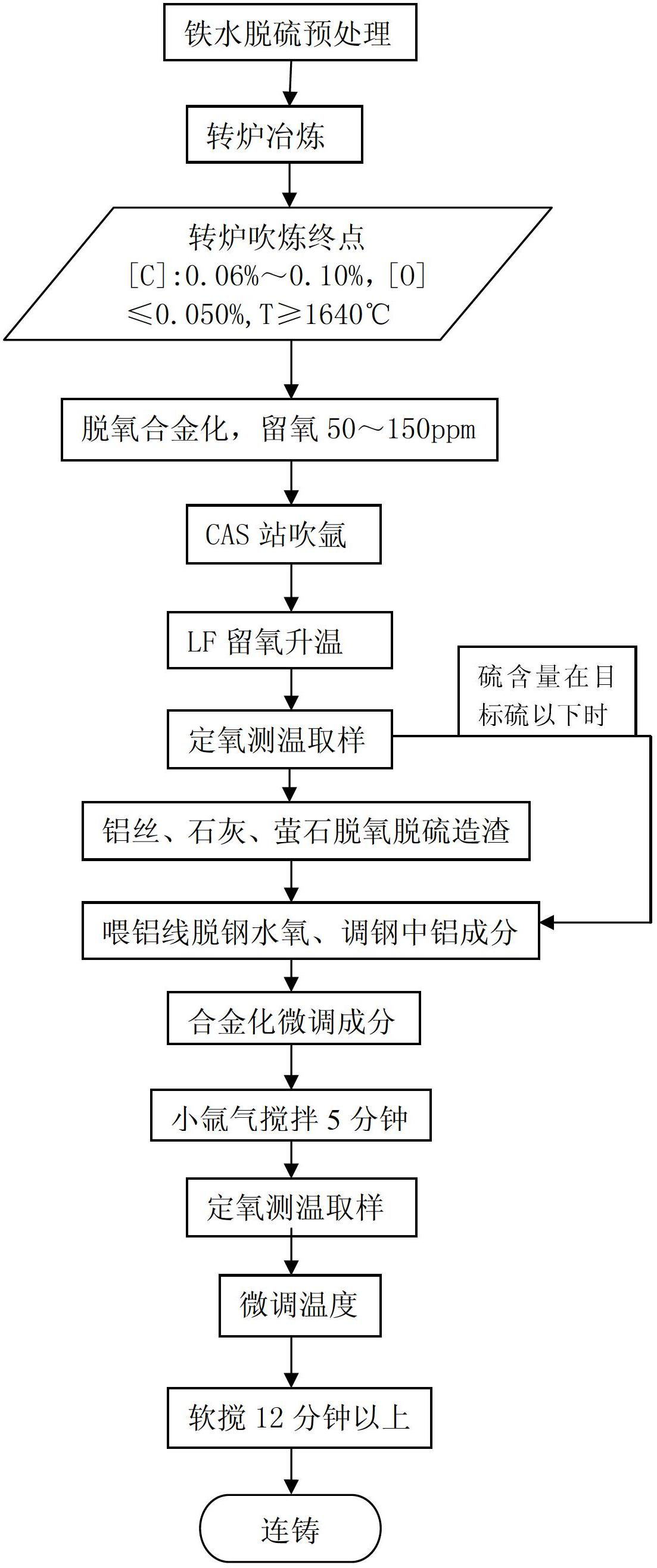

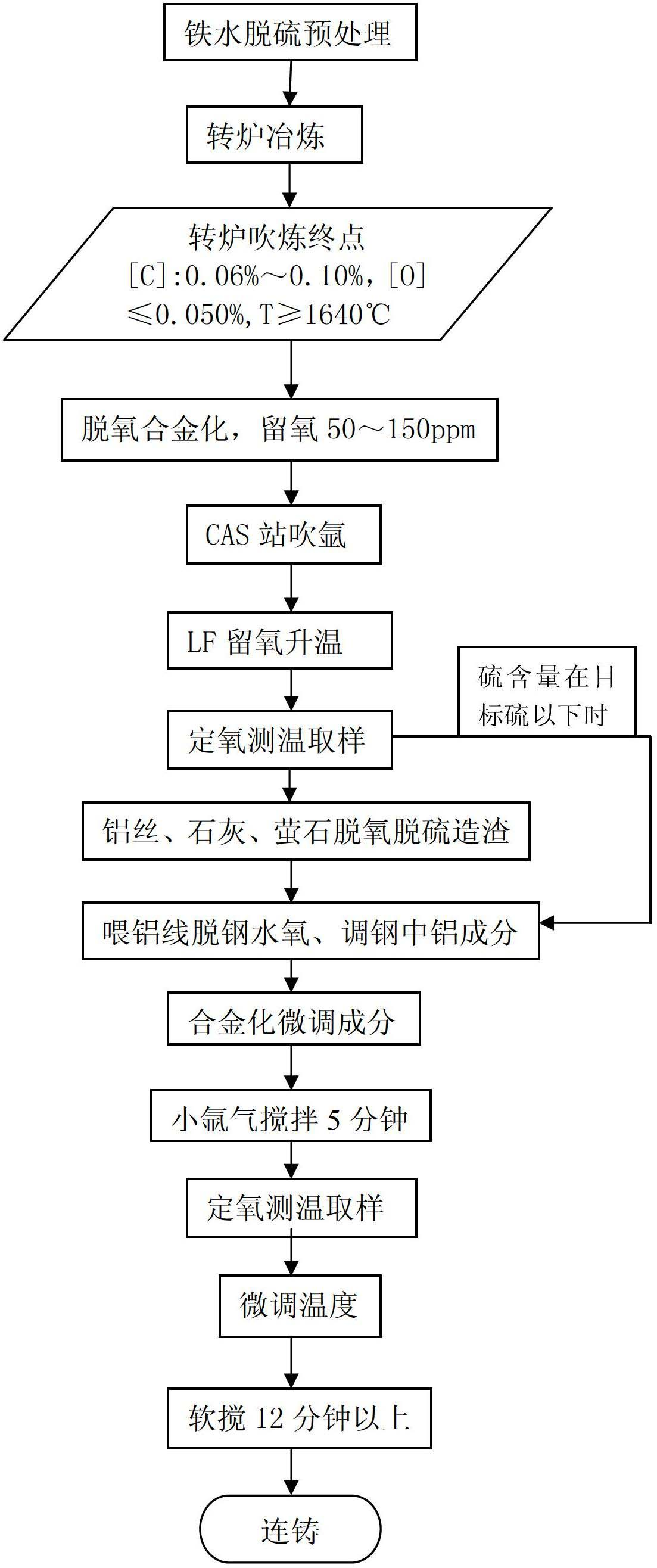

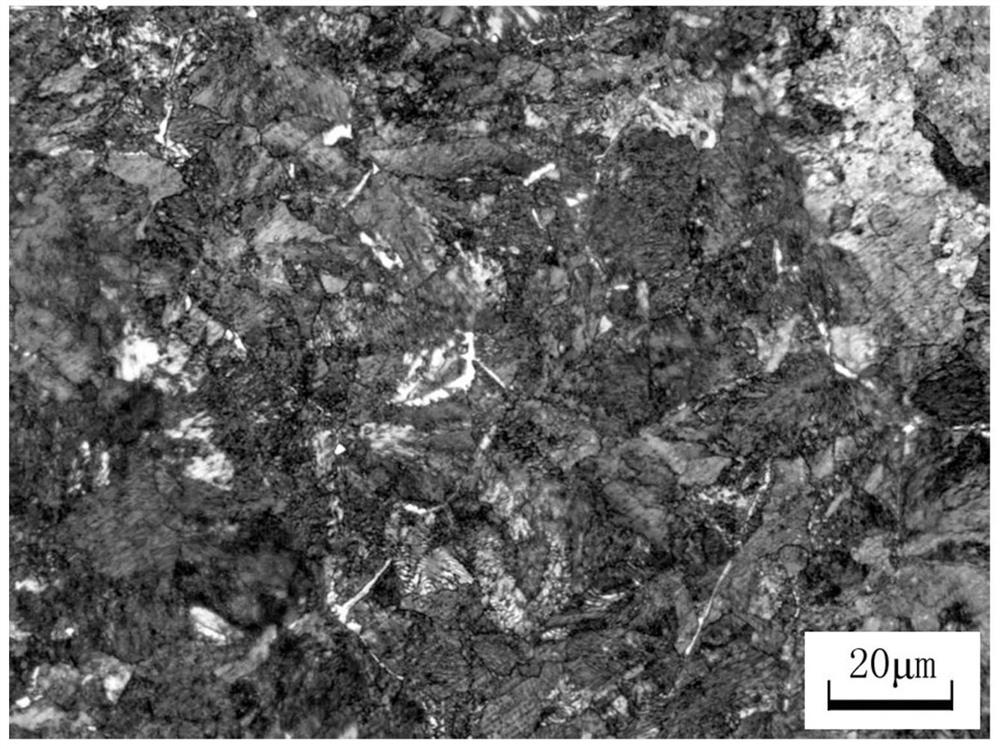

Production method of ultra-thin specification hot rolling punching steel with tensile strength of 390-510 MPa

The invention discloses a production method of ultra-thin specification hot rolling punching steel with the tensile strength of 390-510 MPa, and belongs to the technical field of metallurgy panels. The production method comprises the following steps of converter smelting, LF furnace refining, continuous casting, heating furnace heating, high-pressure water descaling before rough rolling, two-rack rough rolling, high-pressure water descaling before fine rolling, five-rack fine rolling, laminar cooling and coiling. By means of the component design and reasonable heating, rolling and cooling technology of a low-carbon and low-manganese V microalloying system, the rolling difficulty is lowered, cold-formed ultra-thin hot rolling punching steel strips good in welding performance are produced, and the improvement of the product profit space and the popularization of the ultra-thin hot rolling punching steel strips are facilitated.

Owner:TANGSHAN IRON & STEEL GROUP

Process for controlling smelting silicon content of low-silicon steel

ActiveCN102676727AImprove hit rateSolve control difficultiesManufacturing convertersSteelmakingTemperature control

The invention belongs to a steel-making process in the metallurgy field and relates to a process for preventing silicon increase in the smelting process of low-silicon steel and stably controlling silicon content at an end point of molten steel. By means of accurate ingredient and temperature control at a blowing end point of converter, steel-tapping deoxidization alloying and remaining oxygen operation, temperature rise of oxidizing slag at an earlier stage of a refining furnace and optimization of a slagging process in deoxidization desulfuration procedures, molten steel increase (Si) in the whole smelting process is smaller than 0.02%, the ingredient control at a smelting end point is stable and accurate, surfaces of casting blank and inside quality are excellent, the substandard rate of the casting blanks is reduced, and the economic profit is improved.

Owner:NANJING IRON & STEEL CO LTD

Corrosion-resistant high-strength pearlite steel rail and preparation method thereof

ActiveCN111607738AControl reachedEasy to useFurnace typesManufacturing convertersRefining (metallurgy)Impurity

The invention discloses a corrosion-resistant high-strength pearlite steel rail and a preparation method thereof, and belongs to the technical field of metallurgy. The steel rail comprises the following chemical components of, in percentage by mass, 0.65%-0.80% of C, 0.45%-0.85% of Si, 1.0%-1.5% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.68%-0.95% of Cr, 0.03%-0.06% of Nb, 0.8%-1.6% of Cu, 0.002%-0.006% of B, the balance Fe and unavoidable impurities. The steel rail is prepared through the processes of molten iron pretreatment, converter smelting, refining,vacuum treatment, continuous casting, rolling, online heat treatment and the like. According to the the steel rail designed by the preparation method, the room-temperature structure is fine lamellar pearlite and a small amount of ferrite, the lamellar spacing of the pearlite is 90-120nm, the tensile strength Rm is 1280-1350 MPa, the elongation A is 11%-13%, the tread hardness is 360-390 HB, and the room-temperature impact energy AKU is greater than 20 J.

Owner:武汉钢铁有限公司

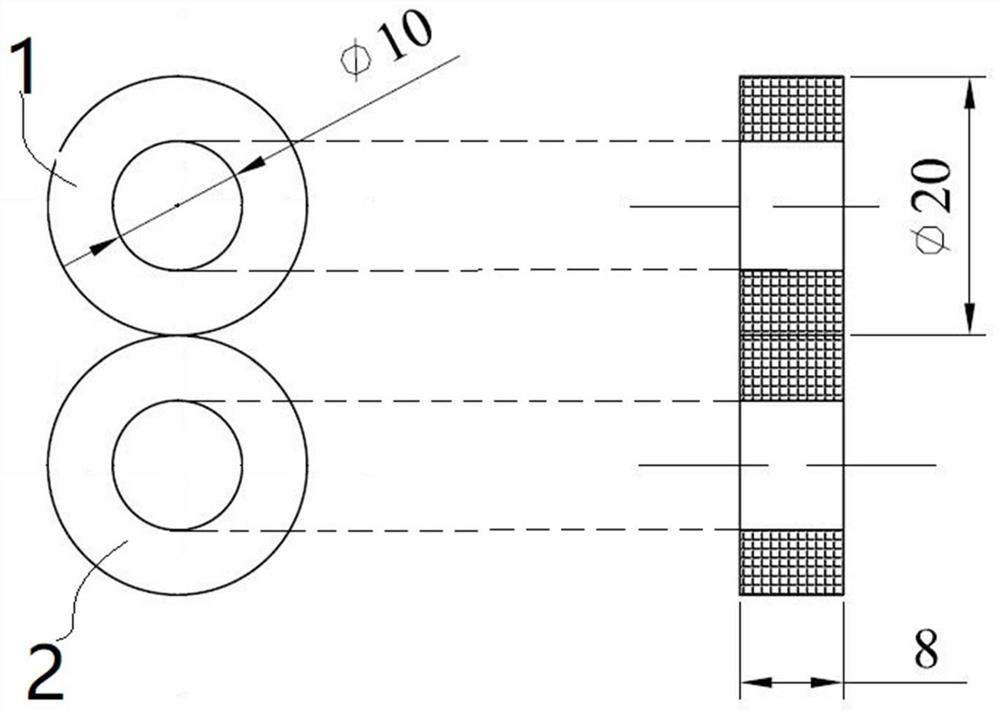

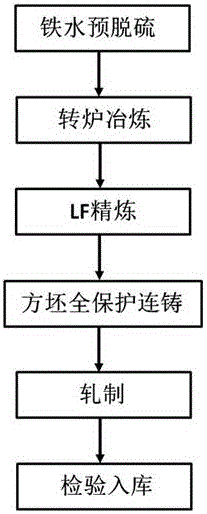

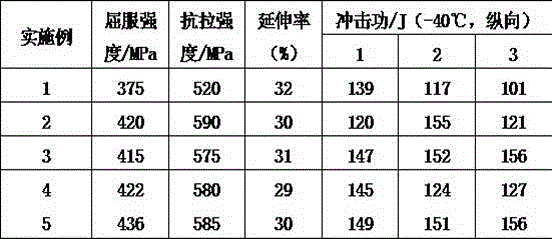

Low-temperature-resistant hot-rolled angle steel and preparation method thereof

The invention discloses low-temperature-resistant hot-rolled angle steel and a production method thereof, and belongs to the technical field of metallurgy. The angle steel consists of the following chemical components in percentage by mass: 0.10-0.15% of C, 0.20-0.50% of Si, 1.3-1.7% of Mn, 0.04-0.06% of V, 0.005-0.015% of Al, less than or equal to 0.01% of N, less than or equal to 0.006% of O, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method for the low-temperature-resistant hot-rolled angle steel comprises the following steps: molten iron pre-desulfurization, converter smelting, LF refining, and a continuous-casting and rolling process by a billet continuous casting machine, wherein sulfur content of the molten iron after desulfurization is less than or equal to 0.005wt%. According to the low-temperature-resistant hot-rolled angle steel and the production method thereof, a vanadium micro-alloying process and a steelmaking process are adopted, the control is simple and the alloy recovery rate is stable. The low-temperature-resistant hot-rolled angle steel is good in performance, and has impact energy greater than or equal to 100J at a temperature of (-)40 DEG C.

Owner:宣化钢铁集团有限责任公司

Spring steel round steel and production process thereof

The invention belongs to the field of metallurgy and discloses spring steel round steel and a production process thereof. The spring steel round steel comprises the following components in percentage by weight: 0.56 to 0.64 percent of carbon (C), 1.60 to 2.00 percent of silicon (Si), 0.70 to 1.00 percent of manganese (Mn), less than or equal to 0.025 percent of phosphorus (P), less than or equal to 0.025 percent of sulfur (S), 0.15 to 0.35 percent of chromium (Cr), less than or equal to 0.35 percent of nickel (Ni), less than or equal to 0.25 percent of copper (Cu) and the balance of Ferrum (Fe). The production process comprises the following steps of: converter or electric furnace smelting, LF refining, VD degassing, CCM continuous casting and bar rolling. The spring steel round steel of the invention has the characteristics of low alloying element content, low decarburizing tendency, high temper resistance, high hot-working performance, low cost, high performance after heat processing and the like of a common round steel; besides, the spring steel round steel simultaneously has high cold workability under the condition of air cooling after rolling. The process ensures that the rolled spring steel round steel obtains a texture of pearlite and a small number of ferrolites under the condition of air cooling, and has high plasticity and toughness during cold working, and every performance can meet the requirements of GB / T1222 after heat processing.

Owner:NANJING IRON & STEEL CO LTD

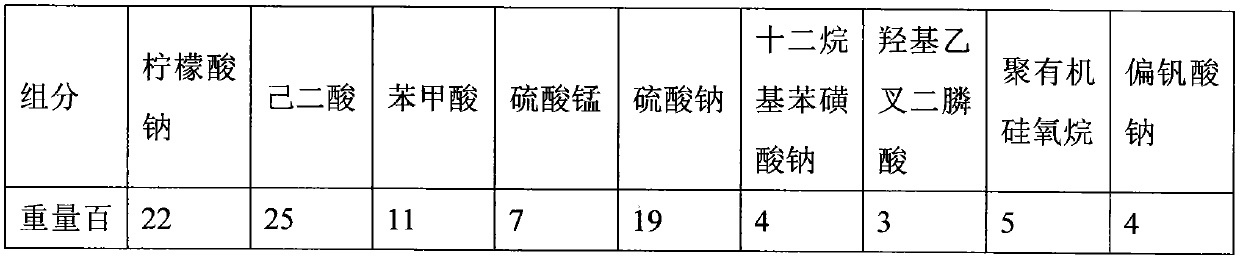

Energy-saving and efficiency-improving composite reagent for limestone gypsum desulfurization

InactiveCN104190241AImprove qualityIncrease profitDispersed particle separationRefining (metallurgy)Engineering

The invention discloses an energy-saving and efficiency-improving composite reagent for limestone gypsum desulfurization. The composite reagent is characterized in that the composite reagent is powdered solid formed by mixing 10-70% (wt%) of cosolvent, 1-40% (wt%) of pro-oxidant, 10-35% (wt%) of absorbent and 1-15% (wt%) of regulator at a room temperature. The addition amount of the energy-saving and efficiency-improving composite reagent is 300-1300mg / L. The composite reagent is simple to prepare and flexible in formula, and the corresponding energy-saving and efficiency-improving composite reagent can be prepared under different operating conditions. The energy-saving and efficiency-improving composite reagent for the limestone gypsum desulfurization has the characteristics of high efficiency-improving speed, wide efficiency-improving range, no secondary pollution and low cost, and has scale inhibition, defoaming and corrosion inhibition performances. The composite reagent can be used in a limestone gypsum desulfurization system in the fields of power, refining and chemical, metallurgy and the like, can reduce the energy consumption, and can obtain high desulfurization efficiency.

Owner:CECEP L&T ENVIRONMENTAL TECH

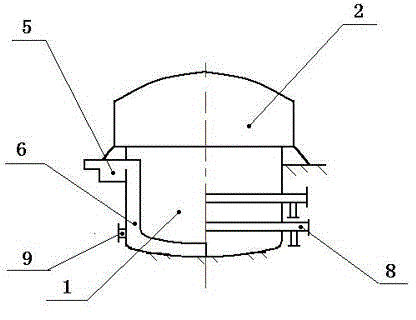

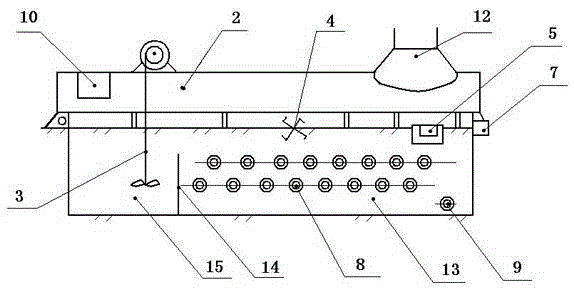

Device and method for continuously removing copper from liquid crude lead

ActiveCN102978416AContinuous copper removal achievedImprove energy savingSiphonRefining (metallurgy)

The invention relates to a device and a method for removing copper in crude lead pyro-refining in nonferrous metallurgy field, and in particular relates to a device and a method for continuously removing copper from liquid crude lead. The device comprises a pot body and a smoke hood which is covered on the pot body, wherein a stirrer, the stirring paddle of which extends to the liquid lead in the pot body, is fixedly arranged on the smoke hood; the pot body is divided into a stirring reaction region and a cooling liguation region by a baffle plate; the liquid lead and copper dross overflow to the upper part of the cooling liguation region from the stirring reaction region through the upper side of the baffle plate; a charging hole is arranged at the end part of the smoke hood on the stirring reaction region; a drossing hole and a lead discharging hole are arranged at the end part of the cooling liguation region; a smoke outlet is arranged at the end part of the smoke hood above the cooling liguation region; dross stirrers for stirring the copper dross floating on the liquid lead are fixedly arranged on the two side surfaces of the cooling liguation region; cooling water tubes for cooling the liquid lead are welded on the two sides of the pot; a siphon lead discharging tube is arranged on the pot side at the lead discharging hole; and the lower hole of the siphon lead discharging tube extends to the bottom of the pot body. According to the device and the method provided by the invention, energy is saved, environment-friendly effect is good, recovery rate of lead is high, automation degree is high, and labor intensity is low.

Owner:HENAN YUGUANG GOLD & LEAD

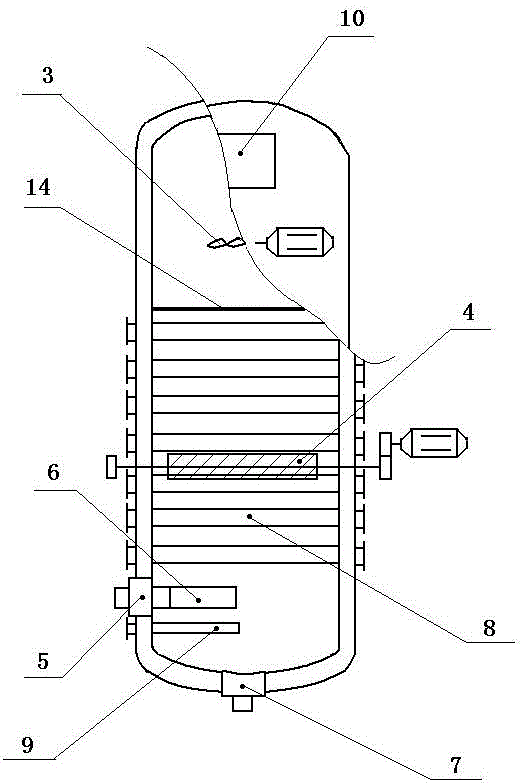

Technology for smelting ER70S-6 welding wire steel through utilizing vanadium-containing molten iron

InactiveCN102994686AHigh strengthImprove toughnessManufacturing convertersSteelmakingRefining (metallurgy)

The invention relates to a technology for smelting an ER70S-6 welding wire steel through utilizing vanadium-containing molten iron, which belongs to the technical field of metallurgy. The technical scheme is as follows: the vanadium-containing molten iron is taken as a raw material for converter vanadium extracting, semisteel refining, ladle furnace (LF) refining, continuous casting and steel rolling. The technology has the beneficial effects that the vanadium in the vanadium-containing molten iron is fully used, the chemical ingredients of the ER70S-6 welding wire steel are redesigned, a deoxidation technology is optimized, is a refining process mixed with less Al2O3 and only uses ferrosilicon powder for diffusible desoxydation, any material which contains Ca is not added during the whole smelting process, so that sparks are reduced during a welding process; and a certain amount of residual vanadium is controlled to exist in the welding wire steel, double functions of grain refining and precipitation strengthening of the vanadium in the steel are played, and the steel strength and the steel toughness are improved.

Owner:HEBEI IRON AND STEEL

Flux for smelting rare-earth-contained magnesium alloy and production method thereof

InactiveCN101376933AImprove refining effectNovel and simple production methodRare-earth elementLithium chloride

The invention belongs to the field of metal materials and metallurgy, and provides flux used to melt magnesium alloy containing rare earth; the mass percentage of the flux is as follows: 20 percent to 30 percent of magnesium chloride, 35 percent to 45 percent of potassium chloride, 10 percent to 15 percent of sodium chloride, 10 percent to 15 percent of lithium chloride, and 5 percent to 10 percent of sodium carbonate. The production method comprises the following steps: the magnesium chloride, the potassium chloride, the sodium chloride and the lithium chloride are mixed by the mass percentage and dried for more than 20 hours at 70 DEG C to 100 DEG C; and then the carbonate is added in the dried mixture, mechanically mixed for more than 12 hours in a planetary mill, and then put into a closed container for stand-by. The flux developed by the invention is used to melt magnesium alloy containing rare earth, and can serve as covering agent and refining agent in melting. The flux can greatly reduce the loss of rare earth elements in melting, has quite good adhesion capability of containing non-metal, simple and convenient production method, and low cost. The flux is also applicable to the magnesium alloy not containing rare earth.

Owner:HENAN UNIV OF SCI & TECH

Rare earth containing low-cost seamless steel pipe for L415N pipeline and production method thereof

InactiveCN103602904ALow Cu contentReduce residual stressProcess efficiency improvementRigid pipesChemical compositionRare earth

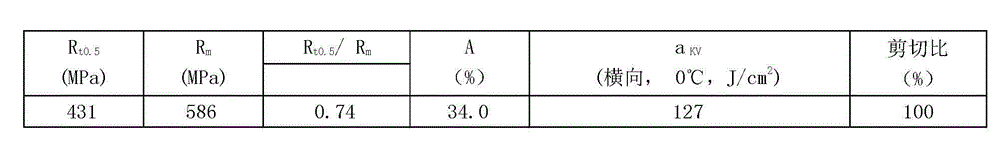

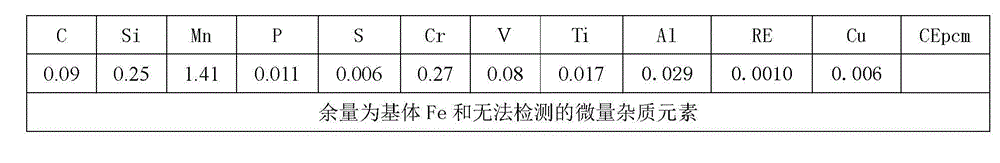

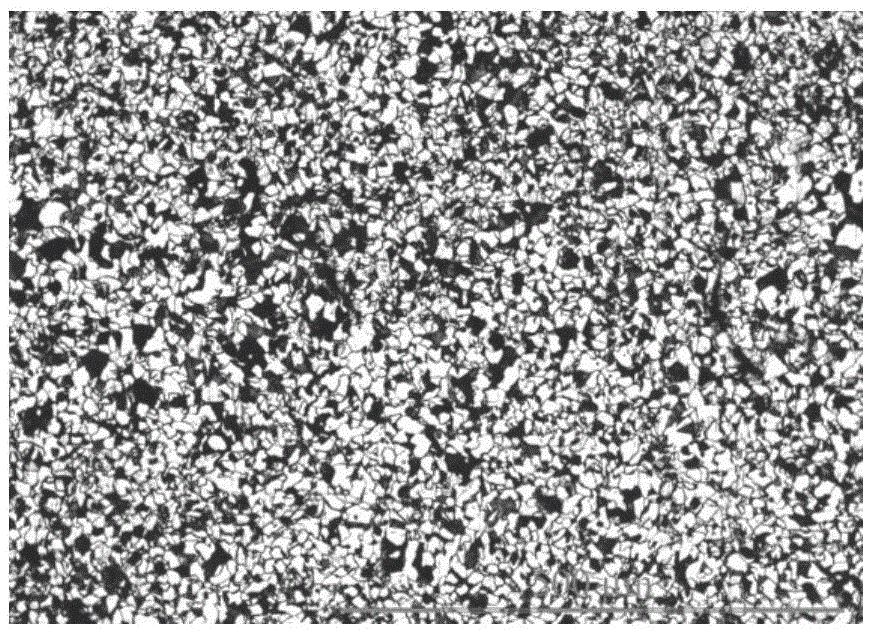

The invention relates to a rare earth containing low-cost seamless steel pipe for the L415N pipeline and a production method thereof, and belongs to the technical field of metallurgy and moulding. The raw material is composed of the following components in percentage by weight: 90 wt% of blast furnace molten iron and 10 wt% of high-quality waste steel. The pipe blank comprises the following chemical components in percentage by weight: 0.06 to 0.13 wt5% of C, 0.15 to 0.35 wt% of Si, 1.30 to 1.60 wt% of Mn, not more than 0.020 wt% of P, not more than 0.010 wt% of S, 0.20 to 0.40 wt% of Cr, 0.05 to 0.10 wt% of V, 0.01 to 0.03 wt% of Ti, 0.01 to 0.04 wt% of Al, 0.0005 to 0.010 wt% of rare earth (RE), less than 0.10 wt% of Cu, and the balance being substrate Fe and undetectable trace impurity elements. The technology process orderly comprises the following steps: molten iron pre-treating, smelting in a top-bottom combined blowing converter, refining in a LE furnace, VD vacuum processing, round continuous casting, cutting, heating the pipe blank, perforating, continuous rolling, sizing (stretch reducing), cooling, sawing, flaw detecting, and chamfering. The mechanical properties of the product are as follows: the yield strength is 420 to 460 MPa, the tensile strength is 560 to 620 MPa, the impact value is more than or equal to 80 J / cm<2>, the grain size is more than or equal to 8.5 grade, and the shear ratio is more than or equal to 80%. The product has the advantages of high toughness matching degree, small crystal grain, and low production cost in the condition of low carbon equivalence.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

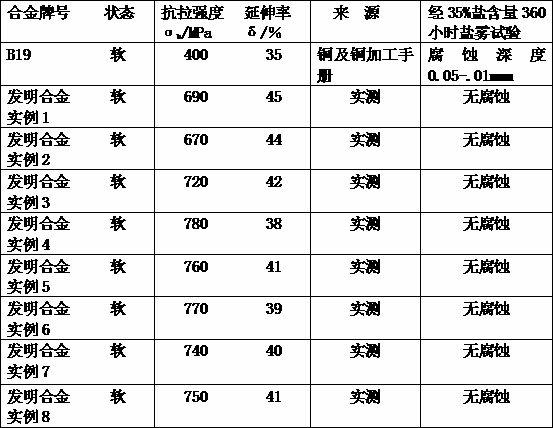

High-strength and high-corrosion-resistance cupronickel alloy and manufacturing method thereof

The invention relates to a high-strength and high-corrosion-resistance cupronickel alloy and a manufacturing method thereof. The high-strength and high-corrosion-resistance cupronickel alloy is characterized by comprising cathode copper and electrolytic nickel as main components, less zirconium sponge and metallic silicon powder, and less than or equal to 2.0% of impurities. According to the manufacturing method provided by the invention, a soft alloy end-product is formed by performing the steps of electrically smelting, refining, condensing and crusting, casting and molding, in a vacuum induction furnace, and the like. The high-strength and high-corrosion-resistance cupronickel alloy has high strength and high corrosion resistance, 670-770 MPa tensile strength and 38-45% extension property, so that the property is 40% higher than B19 property, the corrosion resistance is increased by 3 times and the machining property is excellent. The high-strength and high-corrosion-resistance cupronickel alloy has the characteristics of wide application, long service life and the like, and can be used for producing plates, belts, pipes, bars, lines and forging pieces. The high-strength and high-corrosion-resistance cupronickel alloy is widely applied to the industries, such as shipbuilding, chemical industry, manufacturing and metallurgy. The manufacturing method provided by the invention also has the advantages of simple steps of the cupronickel alloy processing technology, low processing cost, easiness in production, and meeting the demands of various application fields on the high-strength and high-corrosion-resistance cupronickel alloy.

Owner:沈阳有色金属研究所有限公司

Low-alloy high-strength large-diameter thick-walled seamless steel pipe and manufacturing method thereof

ActiveCN105586532AGuaranteed mechanical performance indexEnough deformationSteelmakingRefining (metallurgy)

The invention relates to the technical field of metallurgy, and provides a low-alloy high-strength large-diameter thick-walled seamless steel pipe and a manufacturing method thereof. The method comprises the steps of steelmaking, wherein smelting and refining are performed to obtain target molten steel, and ingot casting is performed on the target molten steel to obtain static ingots; pipe billet forging, wherein forging and annealing are performed on the static ingots to obtain pipe billets; pipe rolling, wherein the pipe billets are heated inside an annular furnace at the temperature of 1230-1270 DEG C, holes are formed after heating is performed, and rolling forming is performed through a pipe mill; normalizing heat treatment, wherein normalizing heat treatment is performed on rolled and formed steel pipes, the normalizing furnace discharge pipe temperature is 920-940 DEG C in the normalizing heat treatment process, and the cooling mode is the air-cooling or air-cooling and mist spraying mode. The steel pipe produced through the manufacturing method is uniform in texture, good in performance and capable of achieving high-strength and excellent subzero 20 DEG C low-temperature toughness, in addition, by adopting the simplified production technology, the production efficiency can be improved, the production cost can be lowered, and meanwhile the steel pipe has the good using safety due to the low yield ratio.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

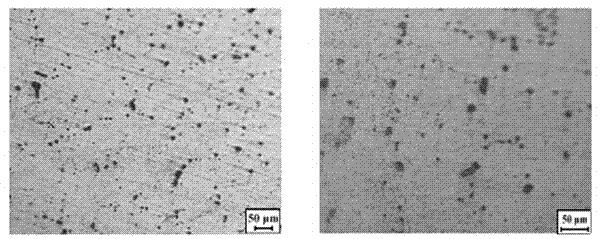

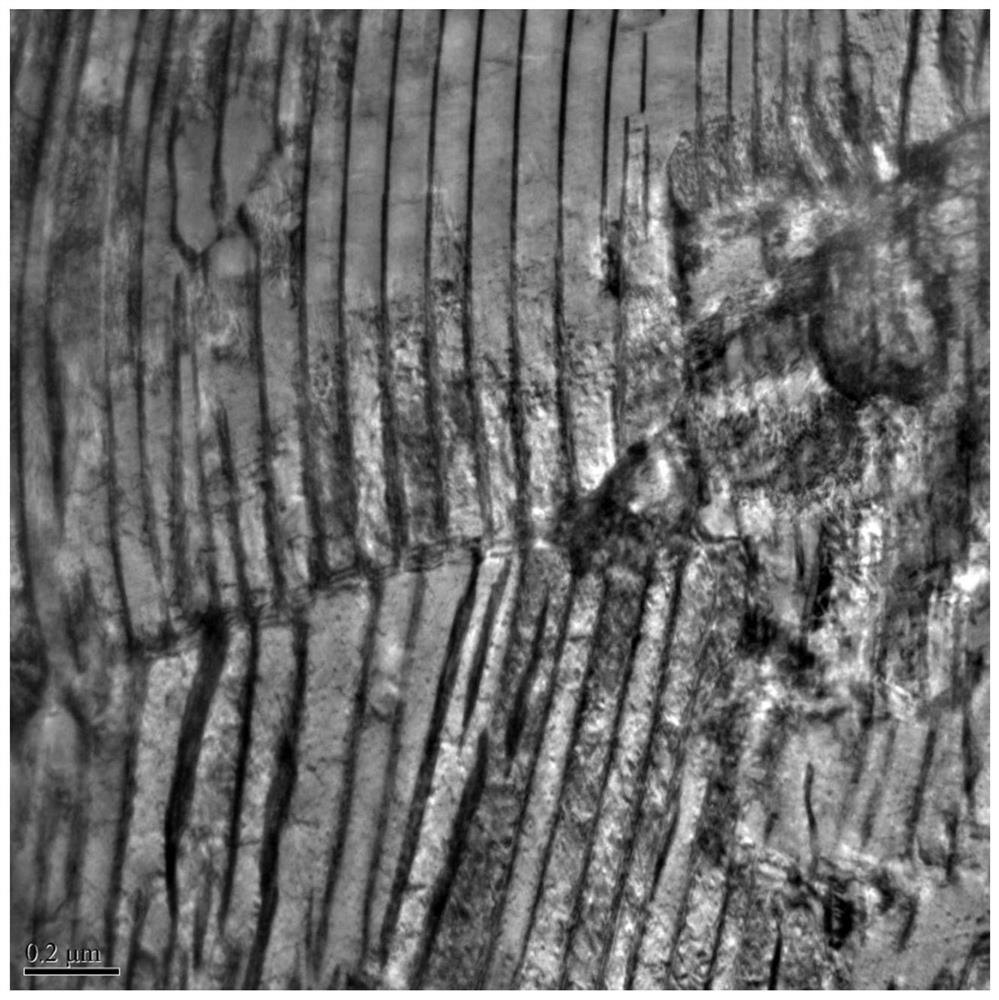

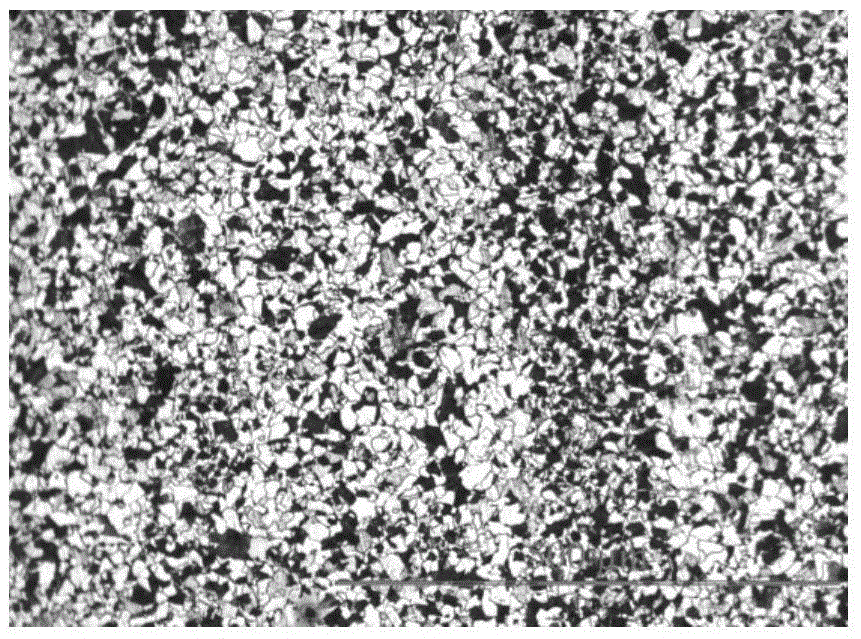

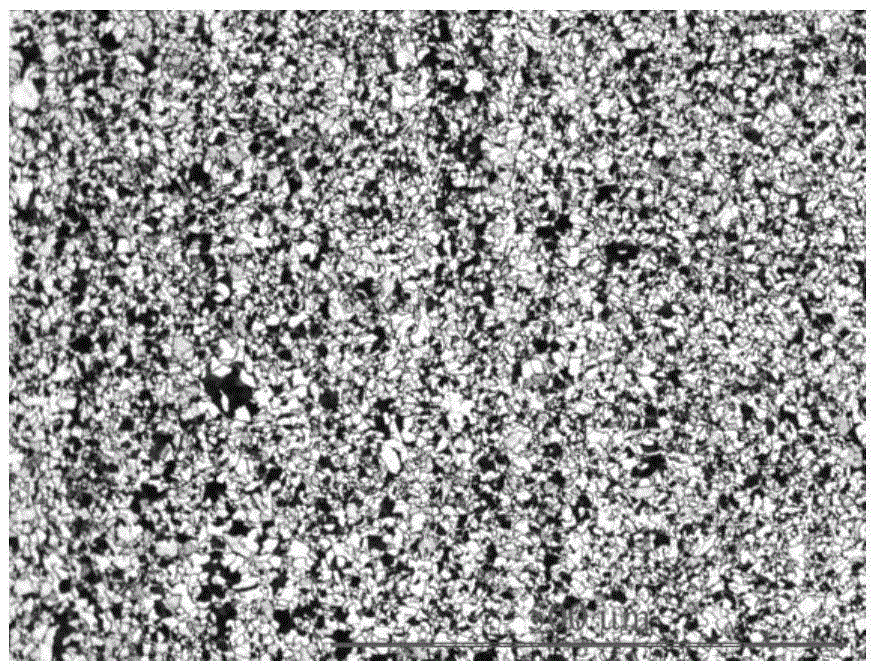

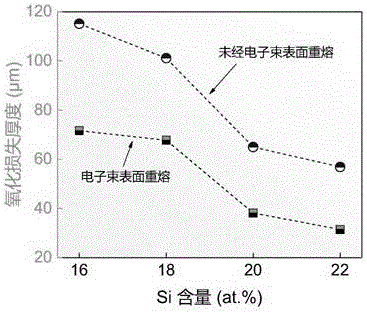

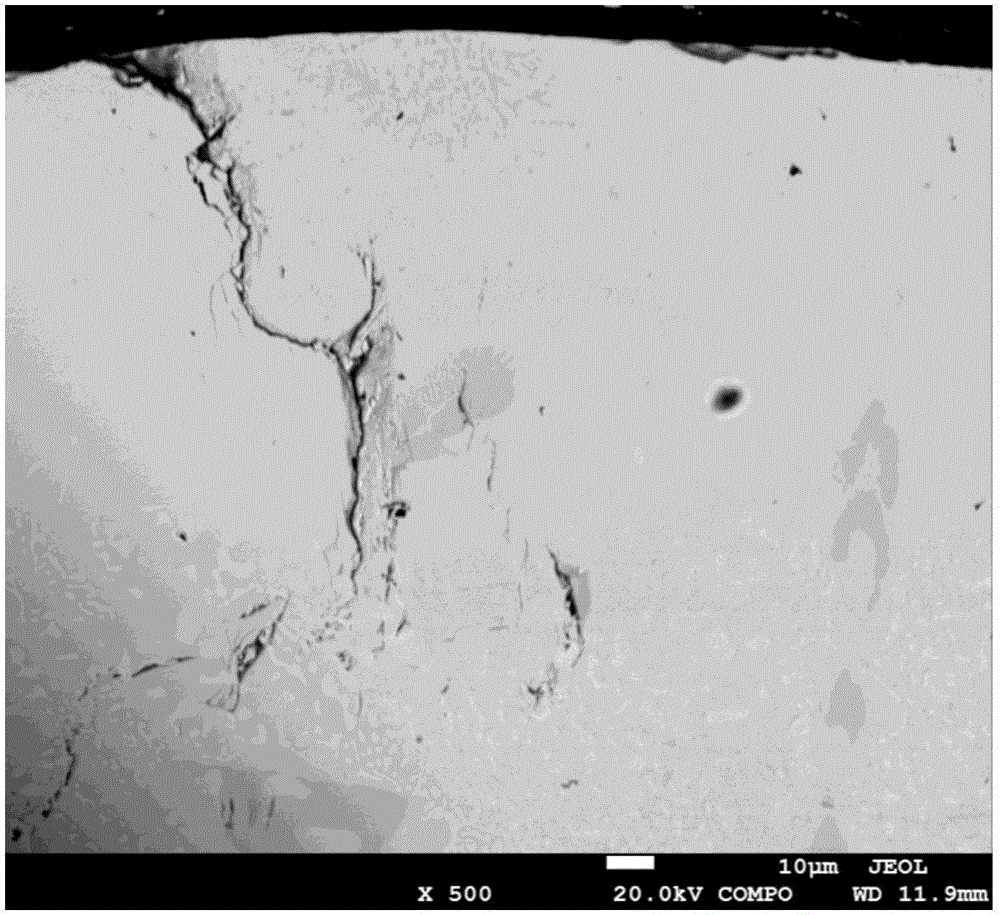

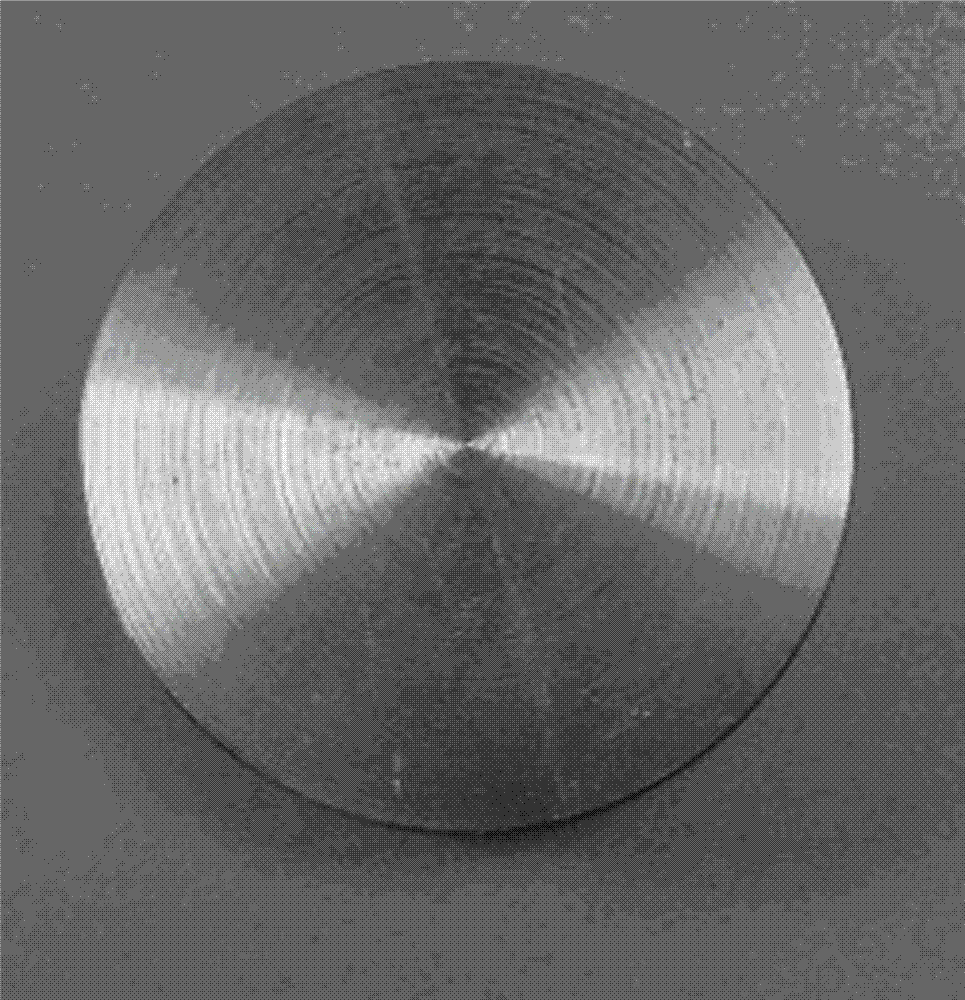

Method used for improving Nb-Si based alloy oxidation resistance via electron beam remelting

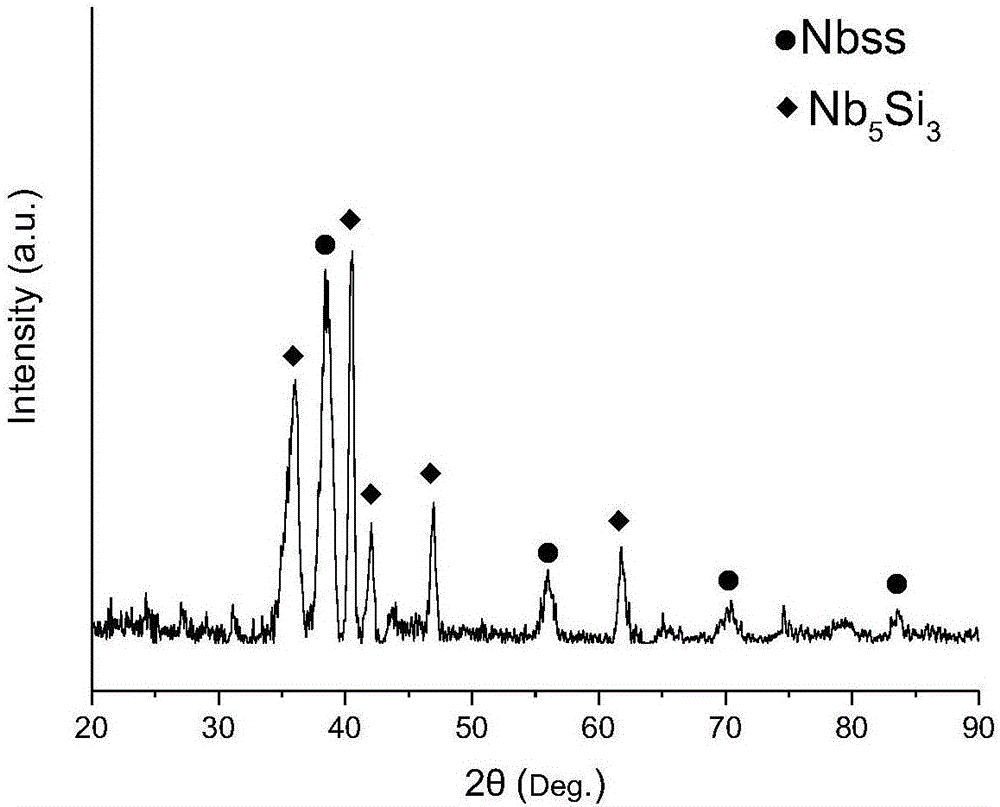

InactiveCN106521384AFine surface remelted layer structureUniform surface remelted layer structureAlloy substrateSuperalloy

The invention discloses a method used for improving Nb-Si based alloy oxidation resistance via electron beam remelting, and belongs to the field of ultrahigh temperature alloy material. According to the method, under high vacuum conditions, the surface of a Nb-Si based alloy substrate is treated with high-power electron beam so as to realize melting and rapid solidifying of the alloy surface, obtain a surface remelted layer with fine compact defect-free microstructures, and realize metallurgy combination of the surface remelted layer with the Nb-Si based alloy substrate, and the high temperature oxidation resistance of the Nb-Si based alloy is improved via refining of the surface structure. The method is capable of inhibiting generation of cracks of brittle Nb-Si based alloy in rapid solidification process; operation is simple; and practicability is relatively high.

Owner:BEIHANG UNIV

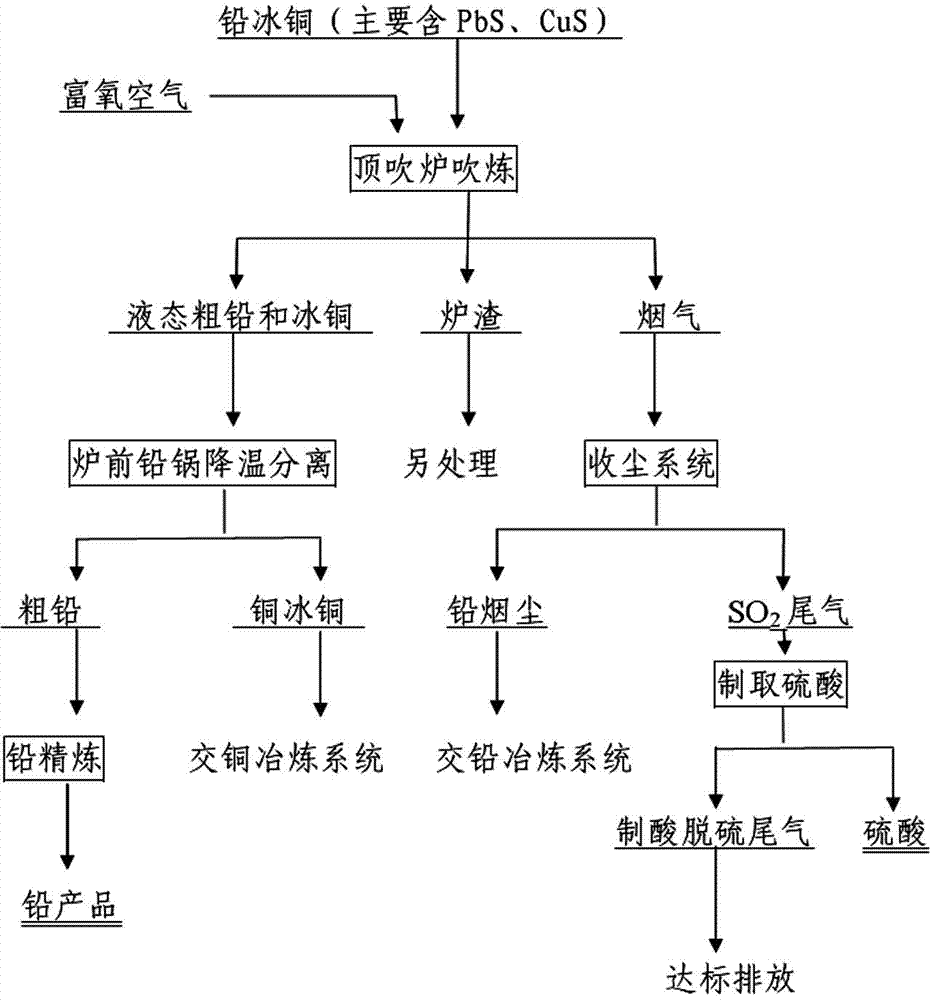

Oxygen-rich blowing technology for producing coarse lead and matte from lead matte in top-blowing furnace

InactiveCN103937990AImprove smelting recovery rateReduce operating costsRotary drum furnacesCrucible furnacesRefining (metallurgy)Nonferrous metal

The invention specifically relates to an oxygen-rich blowing technology for producing coarse lead and matte from lead matte in a top-blowing furnace, and belongs to the technical filed of nonferrous metal metallurgy. The technology comprises the following steps: leaving a FeO-SiO2-CaO three-element primary molten pool in a top-blowing furnace, continuously adding lead matte into the furnace, controlling the blowing temperature, spraying quantitative oxygen gas from a spray gun to carry out continuous oxidation blowing by adding, wherein the amount of the oxygen gas is calculated so as to completely covert the sulfur of the lead sulfide in the lead matte to SO2; stopping adding lead matte and oxygen-rich air after the top blowing is over, directly adding a reducing agent to carry out reduction smelting on liquid lead slag; wherein during the blowing process and the lead slag reduction smelting process, a mixture of molten coarse lead and copper sulfide is discharged out, cooling and settling the mixture in a lead boiler in front of the furnace, fishing out the copper sulfide in a solid matte form, and transporting the liquid coarse lead to a lead refining system. The technology has the advantages of high production efficiency, high lead and copper recovery rate, low cost, reduced discharge, and environment-friendliness.

Owner:YUNNAN TIN

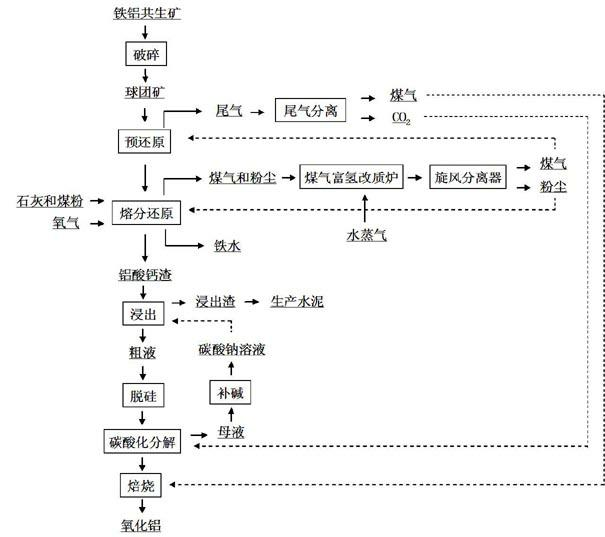

Comprehensive iron-aluminium paragenetic mineral utilization method

ActiveCN102605185AReduce iron oxide contentHigh dissolution rateProcess efficiency improvementRefining (metallurgy)Aluminium hydroxide

A comprehensive iron-aluminium paragenetic mineral utilization method belongs to the technical field of metallurgy. The comprehensive iron-aluminium paragenetic mineral utilization method is carried out according to the following steps: iron-aluminium paragenetic mineral is ground and made into pellets, and reducing gas is filled to pre-reduce the pellets, so that pre-reduced mineral is obtained;the pre-reduced mineral and lime are put into a reduction and melting furnace, and with oxygen as carrier gas, pulverized coal is jetted to carry out melting and reduction, so that molten iron and high-temperature aluminium-containing molten slag are obtained; the high-temperature aluminium-containing molten slag is cooled to normal temperature and naturally powdered, so that slag is obtained, and the slag is put into sodium carbonate solution and leached, so that leachate and leaching residue are obtained; the leachate is desiliconized under normal pressure and desiliconized under medium pressure, so that refined liquor is obtained; CO2 is filled into the refined liquor to carry out carbonation decomposition, so that decomposed mother liquor and aluminium hydroxide are obtained, and the aluminium hydroxide is roasted, so that alumina is produced; sodium carbonate is added into the decomposed mother liquor to replenish alkali, and the produced sodium carbonate solution is used for leaching. The comprehensive iron-aluminium paragenetic mineral utilization method not only can guarantee the high-efficiency dissociation and extraction of iron and aluminium, but also is feasible technically and economically, and the iron-aluminium paragenetic mineral resource in China is effectively and comprehensively utilized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Method for preparing CuCr alloy ingot through aluminothermic reduction-slag refining

The invention discloses a method for preparing a CuCr alloy ingot through aluminothermic reduction-slag refining, and belongs to the technical field of metallurgy. The method comprises the following steps: (1) CuO powder, Cr2O3 powder and Al powder are prepared to obtain a mixed material; a slag forming agent is added into the mixed material, and a product obtained from the last step is put in a reactor; metal magnesium powder is put on; the ignition is performed by using open fire under the effect of an electromagnetic field; and a high-temperature melt is obtained; (2) the alloy slag smelting separation is performed under the effect of the electromagnetic field; the reduction smelting slag is discharged 30-50% of the total quantity; and a smelting high-temperature melt is obtained; (3) premelting slag is added for refining and removing impurities under the effect of the electromagnetic field; deoxidizing agent and copper powder are injected in a bottom blowing and powder injecting manner; and refining slag is removed to obtain a refined alloy melt; and (4) the forced water cooling is performed until the refined alloy melt is cooled to the room temperature; the slag is removed; and the ingot is drawn. The method not only can prepare the copper-chrome alloy ingot with large size, homogeneity and compactness, but also can prepare copper-chrome alloys in such series as CuCr5-CuCr70; all operations are performed in the atmosphere, and are simple; and the requirements on process conditions are low.

Owner:NORTHEASTERN UNIV

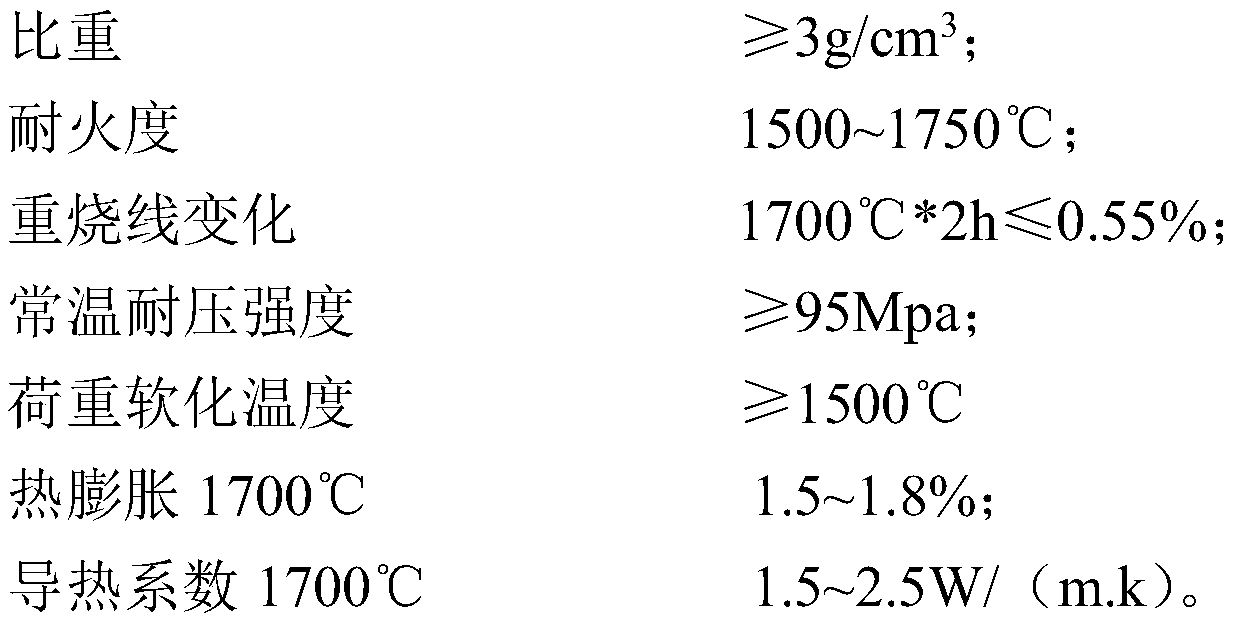

Fiber-reinforced refractory bricks and preparation method thereof

InactiveCN110563476ASolve the strength problemSolve heat resistanceMetallurgical industryFiber reinforcement

The invention relates to fiber-reinforced refractory bricks and a preparation method thereof, and belongs to the technical field of refractory materials for ferrous metallurgy. The fiber-reinforced refractory bricks comprise the following components in parts by weight: 70-90 parts of magnesium oxide and / or aluminum oxide, 1-4 parts of silicon carbide, 0.5-10 parts of graphite, 0.3-1 part of aluminum, 0.2-10 parts of refractory fibers and 1-8 parts of a binder. The refractory bricks are capable of solving problems in the prior art perferably that the strength, heat resistance, peeling resistance and erosion resistance of the existing refractory bricks cannot be taken into consideration at the same time; the cost is moderate; and the fiber-reinforced refractory bricks are especially suitableto be taken as furnace linings of electric furnaces, converters and refining furnaces in the metallurgical industry and flow steel bricks for casting.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

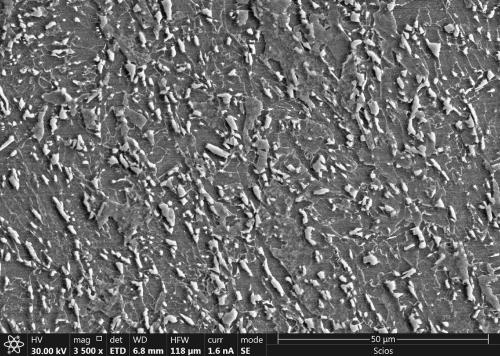

Preparation method of Cu-containing ultra-low titanium bearing steel GCr15-J

The invention belongs to the field of metallurgy, and particularly relates to a preparation method of the Cu-containing ultralow-titanium bearing steel GCr15-J. According to the technical scheme, themethod comprises the following steps of (1) carrying out the EBT electric furnace smelting, specifically, adopting the scrap steel and molten iron as the furnace burden, wherein the scrap steel is high-quality scrap steel without impurity elements, and the proportion is 15-35%; the molten iron is low-phosphorus and low-sulfur molten iron, and the proportion is 65-85%; (2) carrying out LF refining,specifically, electrifying to slag for 10 min, and salvaging the slag after slagging; then feeding an Al wire; adding a diffusion deoxidizing agent; adjusting the components to a target after deoxidation; 3) carrying out VD vacuum degassing, adjusting the Al to 0.025%-0.035%, wherein the VD entering temperature is 1570-1610 DEG C, the vacuum degree reaches 100 Pa or below, and the holding time islonger than or equal to 20 min; 4) continuously casting, specifically, manufacturing the square billets through a continuous casting machine; and 5) heating and rolling, rolling a casting blank intoa bar. According to the present invention, the indexes of low oxygen, low calcium, low inclusion content and the like of the bearing steel are guaranteed, and it is also guaranteed that the titanium content of the bearing steel reaches the quality level of the special-grade high-quality bearing steel.

Owner:BENGANG STEEL PLATES

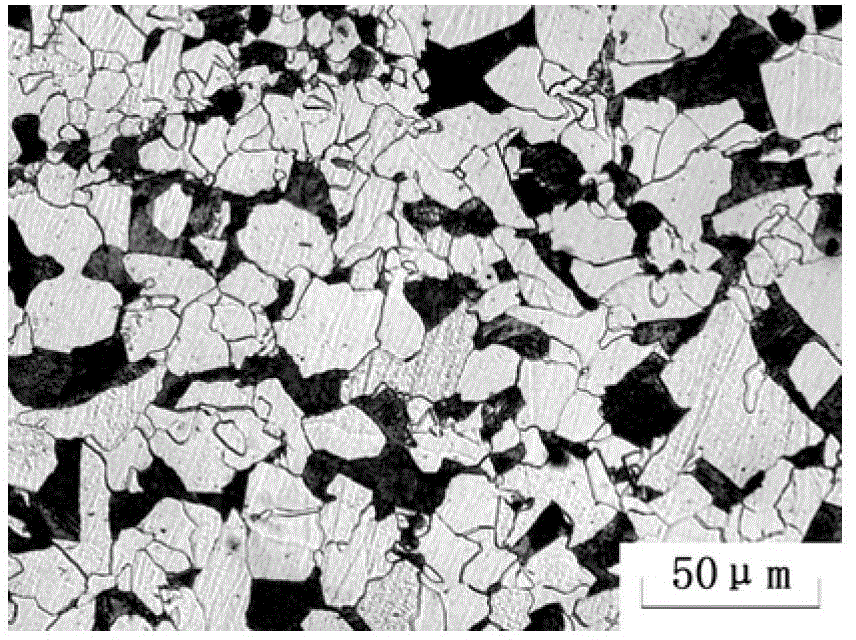

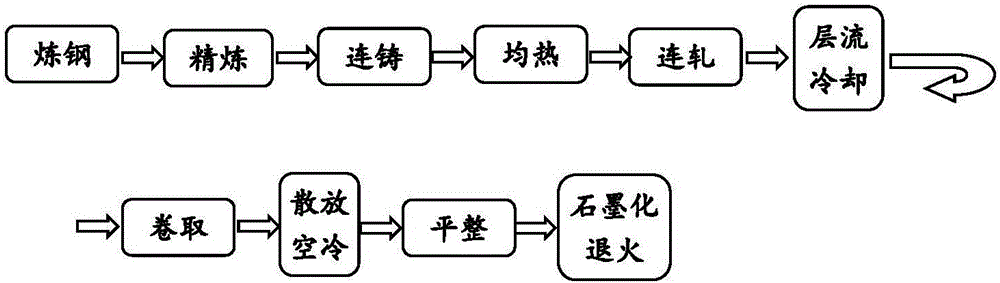

Preparation method of graphitizing hot rolled steel plate

The invention discloses a preparation method of a graphitizing hot rolled steel plate, which belongs to the technical field of metallurgy. The method mainly comprises the steps of steelmaking, refining, continuous casting, heating, hot continuous rolling, laminar cooling, coiling, steel coil spreading and air cooling, leveling and rolling, graphitizing annealing and the like. In order to increase the graphitizing rate and promote a graphitizing process, a pulsed magnet field is applied in a graphitizing annealing process, the magnetic field intensity is 10000 to 30000 A / m, and the magnetic field frequency is 20 to 100 Hz. Within the graphitizing time of 3 to 6 hours, the graphitizing rate can reach more than 90%, the diameter of graphite is 3 to 6 mum, the graphite is spherical or nearly spherical and is uniformly distributed, and the diameter range of ferrite grains is 20 to 30 mum. According to the structural features, the steel plate, especially the steel plate with high carbon content, has low hardness and high plasticity, therefore, the steel plate has good stamping and forming performance, and the preparation method is favorable for enlarging the application range of medium and high carbon steel plates in a stamping and forming process of components and parts in complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

500Mpa grade tough weather-resistant bridge steel and preparation method thereof

Belonging to the technical field of metallurgy, the invention relates to a 500Mpa grade tough weather-resistant bridge steel., which comprises the following chemical components by mass percentage: 0.04-0.06 of C, 0.25-0.35 of Si, 1.20-1.30 of Mn, 0.4-0.5 of Cr, 0.30-0.40 of Ni, 0.27-0.37 of Cu, 0.2-0.7 of Mo, less than 0.015 of P, less than 0.006 of S, 0.020-0.030 of Nb, 0.015-0.025 of V, 0.007-0.017 of Ti, 0.015-0.040 of Al and the balance Fe and inevitable impurities. The preparation method includes: smelting into molten iron, refining, vacuum treatment, protective continuous casting and thermal mechanical rolling. A multi-phase composite structure of acicular ferrite, bainite ferrite and M-A components is obtained through component and process design, and good matching of high strength,high toughness, weather resistance and weldability is achieved.

Owner:YANSHAN UNIV

Low-basicity synthetic slag for external refining

ActiveCN102382947AEasy to controlSolve the corrosion-prone ladleProcess efficiency improvementWire rodRefining (metallurgy)

The invention relates to a synthetic slag in the metallurgy field, in particular to a low-basicity synthetic slag for external refining. The low-basicity synthetic slag for external refining consists of the following components according to weight percentage: 30 to 40 percent of CaO, 35 to 45 percent of SiO, lower than or equal to 5 percent of Al2O3, 8 to 15 percent of MgO, 6 to 15 percent of CaF2, lower than or equal to 2 percent of FeO, the rest of the components is unavoidable impurities, and the sum of all the components is 100 percent. Due to the low-basicity synthetic slag for external refining disclosed by the invention, steel ladles can be effectively inhibited from corrosion while the impurities are plasticized, the control levels of the impurities of the manufactured spring steels and core thread wire rods steel are good, the cold drawing property is excellent, the widths of the impurities of the wire rods are stabilized below 10um, and most of the widths of the impurities of the wire rods are less than 5um.

Owner:NANJING IRON & STEEL CO LTD

Environment-friendly leadless free-cutting steel and metallurgy method thereof

The invention relates to an environment-friendly leadless free-cutting steel which comprise the following components by weight percent: 0.04 to 0.15 % of C, 0.95 to 1.40 % of Mn, 0.04 to 0.09 % of P. 0.25 to 0.45 % of S, less than or equal to 0.03 % of Si, 0.025 to 0.25 % of Bi, 0.10 to 0.35 % of Ca, less than or equal to 0.03 % of As, less than or equal to 0.03 % of Cu, less than or equal to 0.03 % of Cr, less than or equal to 0.03 % of Ni, less than or equal to 0.03 % of Mo, less than or equal to 0.03 % of Al and the balance being Fe. A metallurgy method of the environment-friendly leadless free-cutting steel comprises smelting by using a converter or an electric furnace firstly and a refining furnace secondly, and then continuously casting or molding into blanks, wherein nano-graphite accounting for 0.008 to 0.015 % of a total weight of molten steel is added during a smelting process in the refining furnace, so that 0.008 to 0.015 % of nano-solid C is contained in the product. By adding bismuth with a melting point less than that of the lead and carbon materials with excellent lubricating effect, lubrication effect on cutting tools is relatively good during a metallic material machining process, being nontoxic and harmless as well; and the method has advantages of simple process, strong operationality and low production cost.

Owner:徐芗明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com