Patents

Literature

112 results about "Pulsed magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear magnetic resonance logger probe while drilling and nuclear magnetic resonance logger while drilling

ActiveCN102650208AGuaranteed normal rotationThe number of location switches decreasedBorehole/well accessoriesPulsed magnetNMR - Nuclear magnetic resonance

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

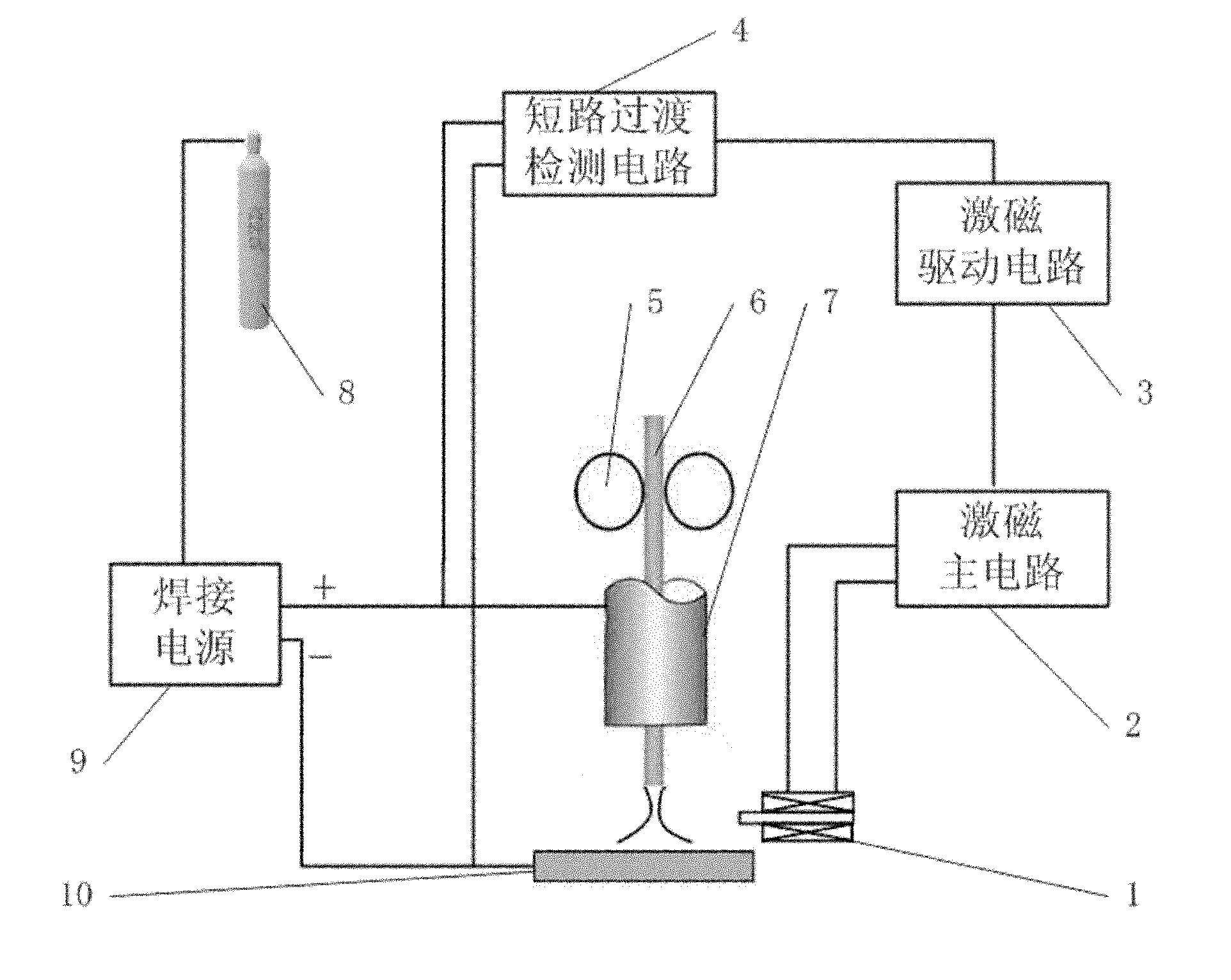

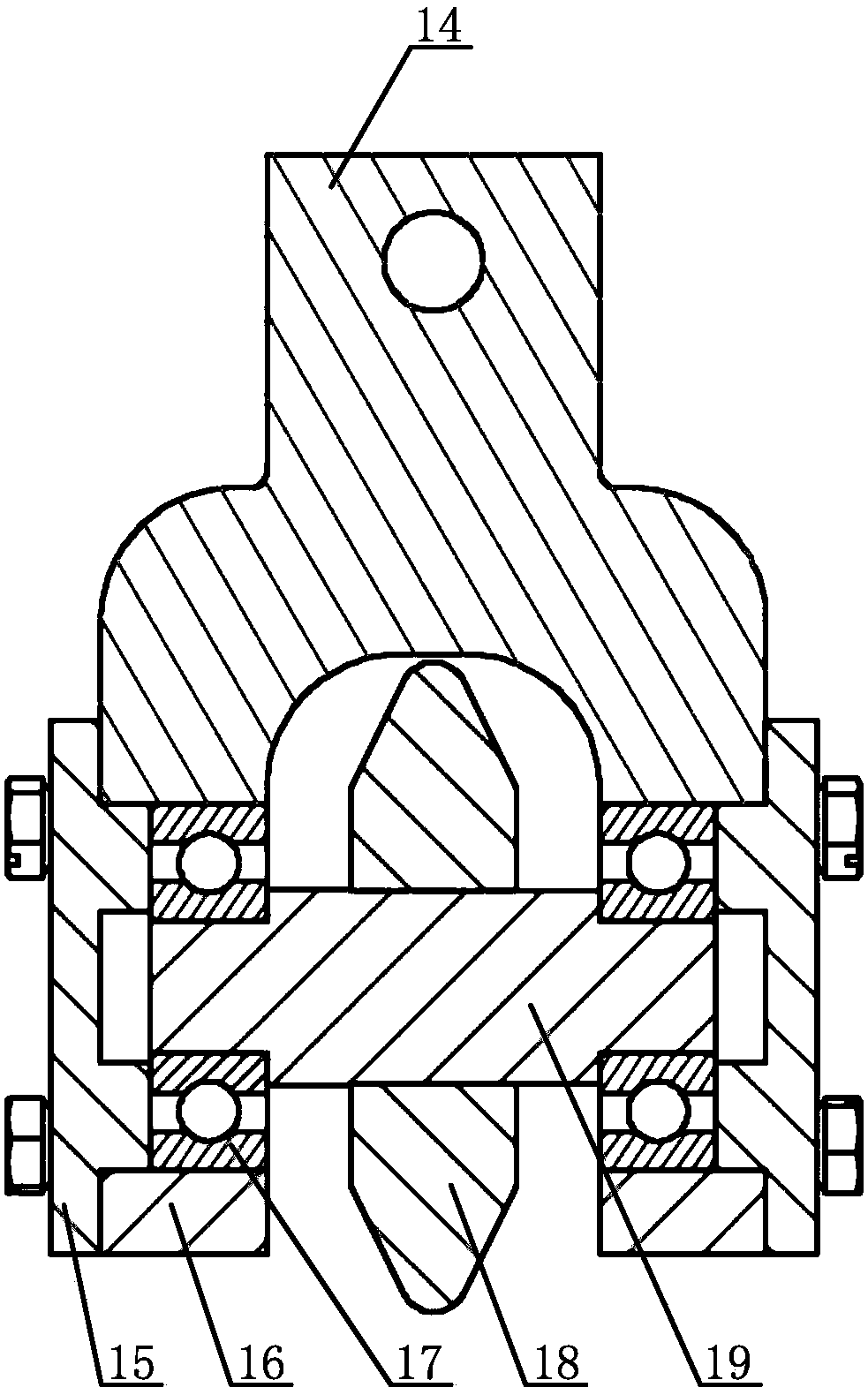

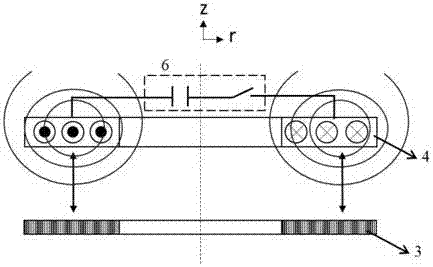

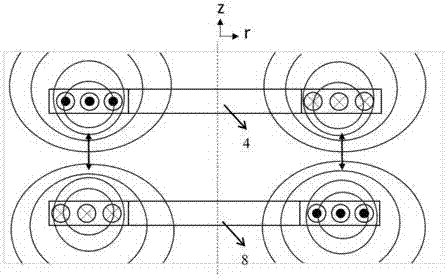

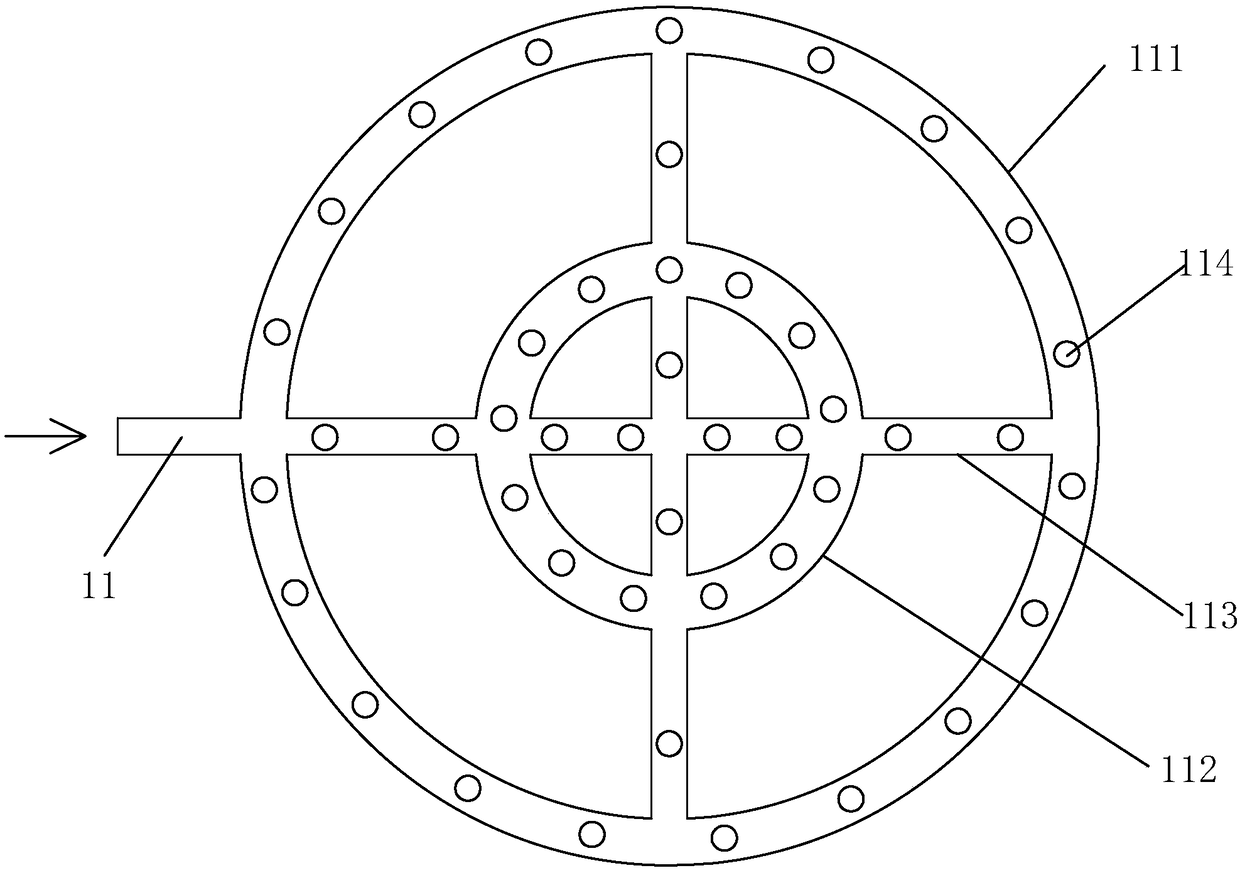

Device and method for assisting gas metal arc welding by using externally applied magnetic fields

InactiveCN102133679AImproving Short Circuit Transition Welding ProcessReduce peak currentArc welding apparatusElectricityPulsed magnet

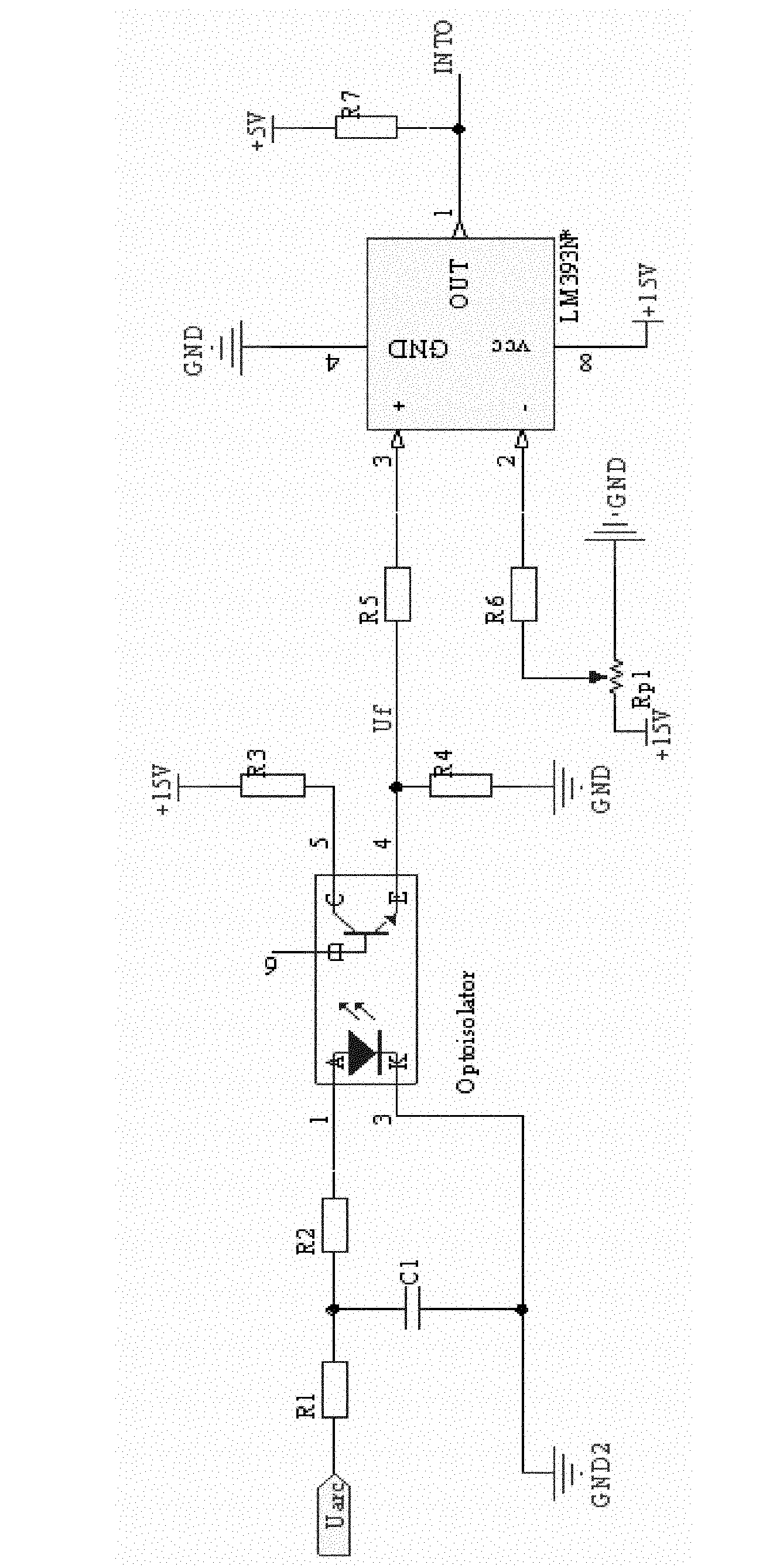

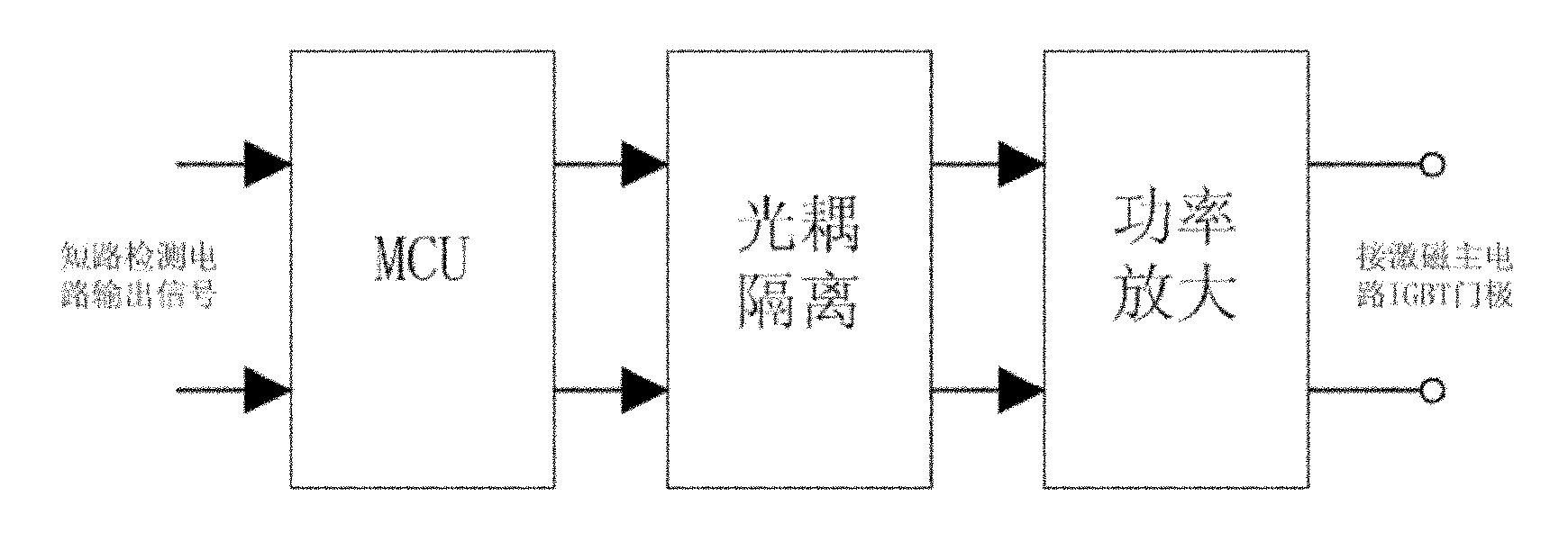

The invention discloses a device and a method for assisting gas metal arc welding by using externally applied magnetic fields, belonging to the field of welding techniques under the action of magnetic fields. The device comprises necessary conventional equipment for gas metal arc welding, a short circuiting transfer detection circuit, an exciting drive circuit, a main exciting circuit and a magnetic head device. According to the invention, during droplet short circuit period, a transverse pulsed magnet field which is acted on a short circuit liquid bridge and perpendicular to a welding-wire axis can be generated so as to promote the advanced fracture of the short circuit liquid bridge; and compared with the conventional method, the method provided by the invention has the advantages that the peak current during the short circuit period is reduced, the induced explosion and splash are lowered, and the regularity of a short circuit cycle in the process of short circuiting transfer welding can be improved. The device disclosed by the invention is simple in manufacturing, and the welding process of short circuiting transfer is obviously improved.

Owner:BEIJING UNIV OF TECH

Test method of electromagnetic compatibility of electronic instrument transformer

ActiveCN102565587AImprove anti-interference abilityLow failure rateTransformers testingMeasuring interference from external sourcesVoltage amplitudeAnti jamming

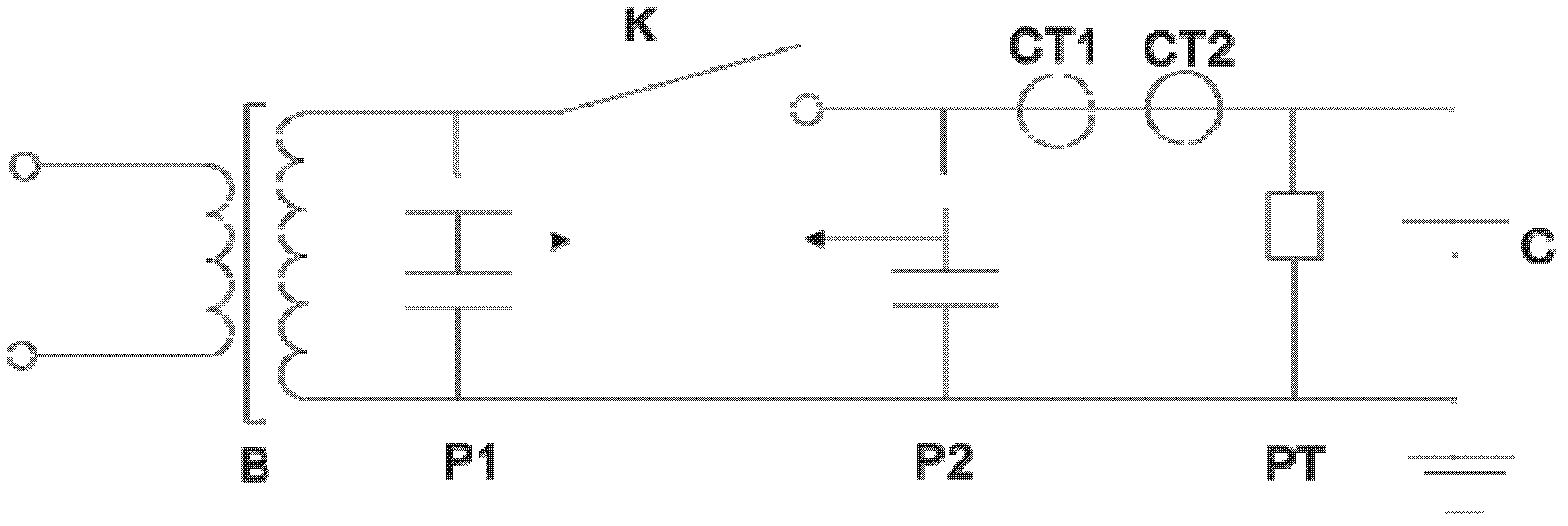

The invention discloses a test method of electromagnetic compatibility of an electronic instrument transformer. The output test voltage amplitude of a high-voltage transformer is same with the rated working main-loop voltage of a tested electronic instrument transformer, and the capacity of a load capacitor is selected according to a steady-state current value being 0.5 A after a disconnecting switch is connected. A primary part unit, a secondary connecting unit and an electronic merging unit of the tested electronic instrument transformer are systematically assembled and connected according to an actual use condition. In the test process, the electronic instrument transformer is powered on and operates in a normal working mode. In the process of the disconnecting switch connecting or disconnecting the capacitor, a main loop can generate many times of arc breakdown and extinguishing transient processes, and the transient processes can generate many times of pulse currents, transient over-voltages and pulsed magnet fields. The numerical value of primary voltage current waveforms is measured to compare with the output characteristic and working condition of the electronic instrument transformer, and the electromagnetic anti-jamming performance of the electronic instrument transformer is judged. The reliability of the field operation of the electronic instrument transformer is increased, and the equipment failure rate is reduced.

Owner:SHAANXI ELECTRIC POWER RES INST +2

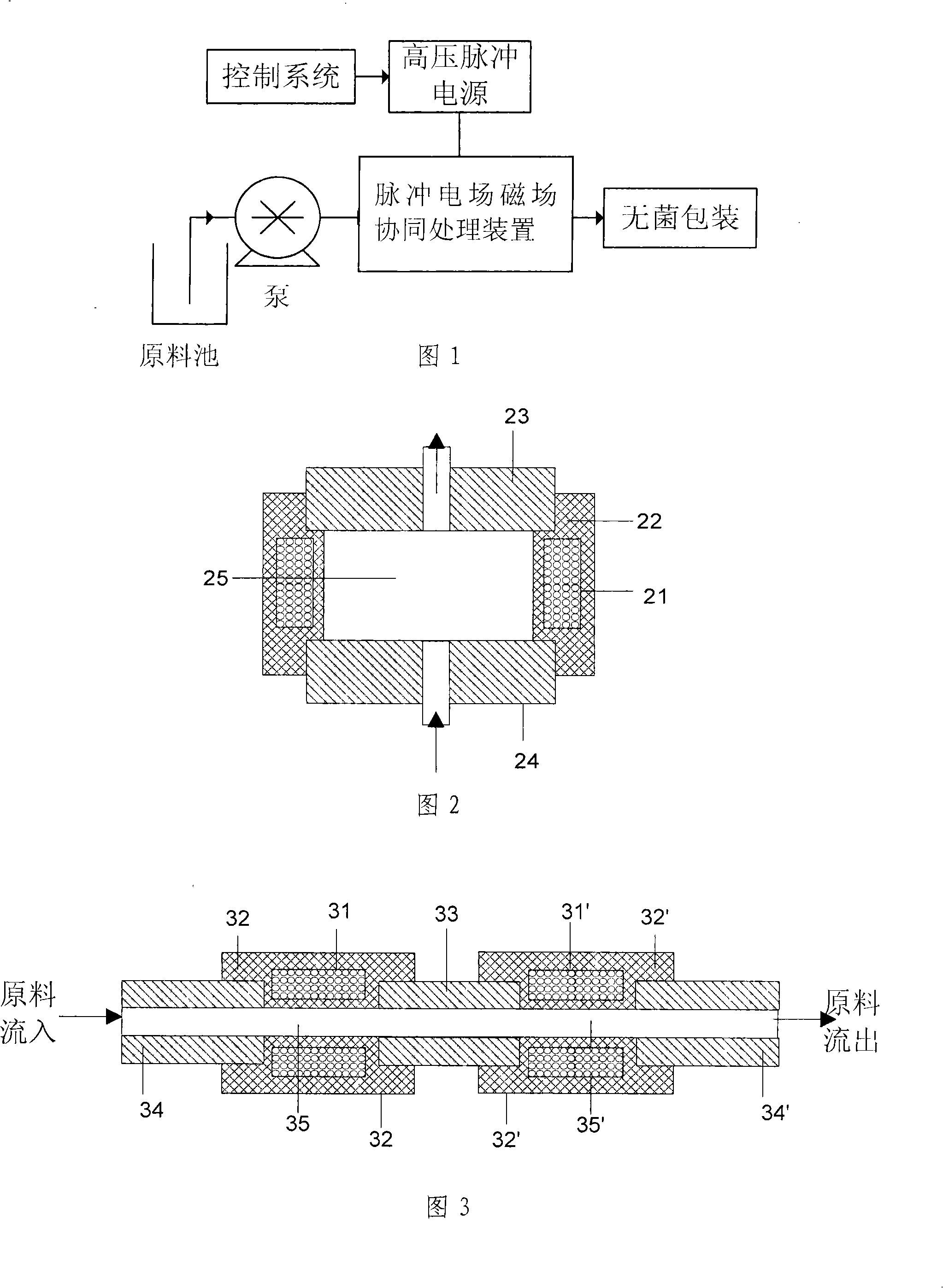

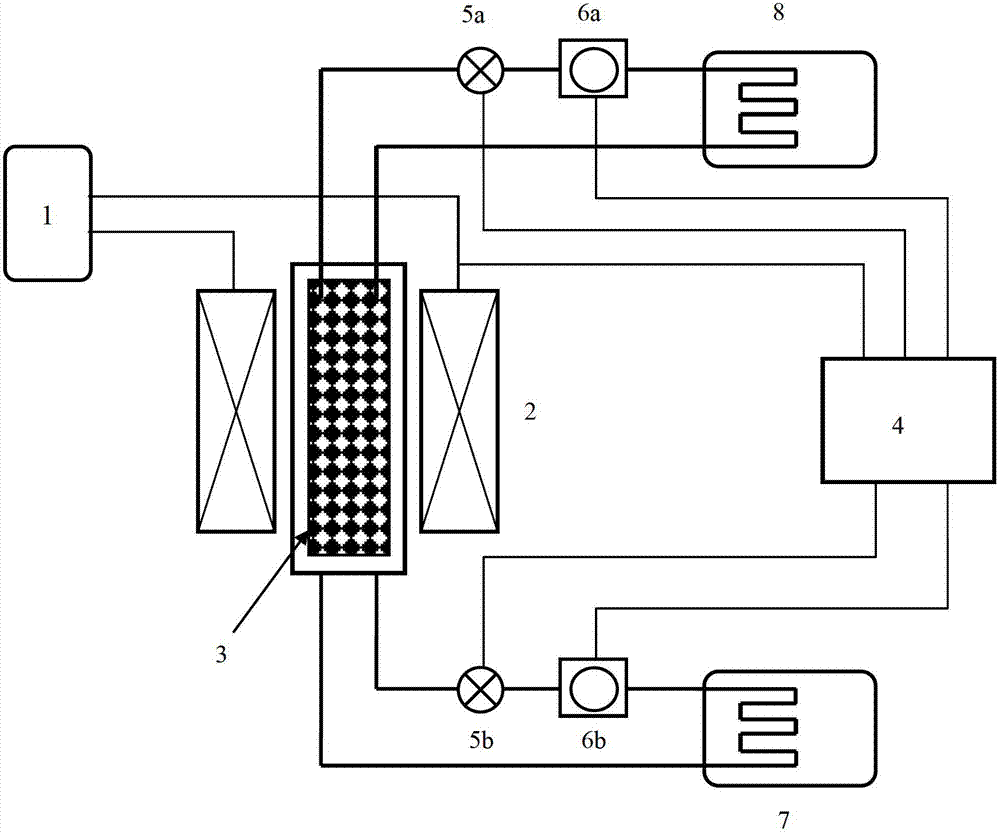

Method and apparatus for materials cooperation disinfection and enzyme dulling with impulse electric field and magnetic field

InactiveCN101292769AMaintain nutritional valueKeep the flavorMilk preservationFood preservationNutritive valuesElectromagnetic field

The invention provides a method that a pulsed electric field and a magnetic field cooperatively sterilize materials and inactivate enzyme and a device. The method comprises: materials to be processed continuously or discontinuously flow through the processing area of the cooperative processing device with the pulsed electric field and the magnetic field; a high pressure pulse power source imposes a pulsed magnet field of 0.1T-50T by the field coils which circle the processing area and a pulsed electric field of 5-100kV / cm by electrode plates at two sides of the processing area to carry out electric-magnetic-field cooperative processing of the materials in the processing area; the electric-magnetic-field cooperative processing device has novel conception, combines the magnetic field and the pulsed electric field, is convenient in installation and application and suitable for being adapted and used in a food sterilization processing system; the cooperative processing of materials by the pulsed electric field and the magnetic field takes a short time; the temperature of materials rises a little during the whole sterilizing course; the effect of sterilization and enzyme inactivation is increased, meanwhile, the original nutritive value and flavor of food are preserved to the maximum degree.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Cold treatment method for preparing high-toughness metal-base composite material

The invention relates to a cold treatment method for preparing high-toughness metal-base composite material, belonging to the technical field of material preparation. The method is that a pulsed magnet field is applied in the process of the deep cold treatment of the metal-base composite material to enable the material to have high toughness. By using the transient impact effect of the pulsed magnetic field, high-density dislocation structures in the material are enabled to move rapidly to induce the generation of nano twin crystals. After treatment, the composite material has organization characteristics of nanoscale coherent interfaces. The duration of the deep cold treatment is 1h-40h. The short-time pulsed magnetic field is applied at the later stage of the cold treatment, wherein the parameters the magnetic field: the magnetic induction intensity is 5-40T, the magnetic field frequency is 0.1-5Hz and the magnetic field treatment duration is 10-100s. The invention has the advantages that the solidification structure of the metal-base composite material prepared through the method is compact, the residual stress is small, the high-density nano twin crystals exist and the toughness of the composite material is synchronously and greatly improved.

Owner:JIANGSU UNIV

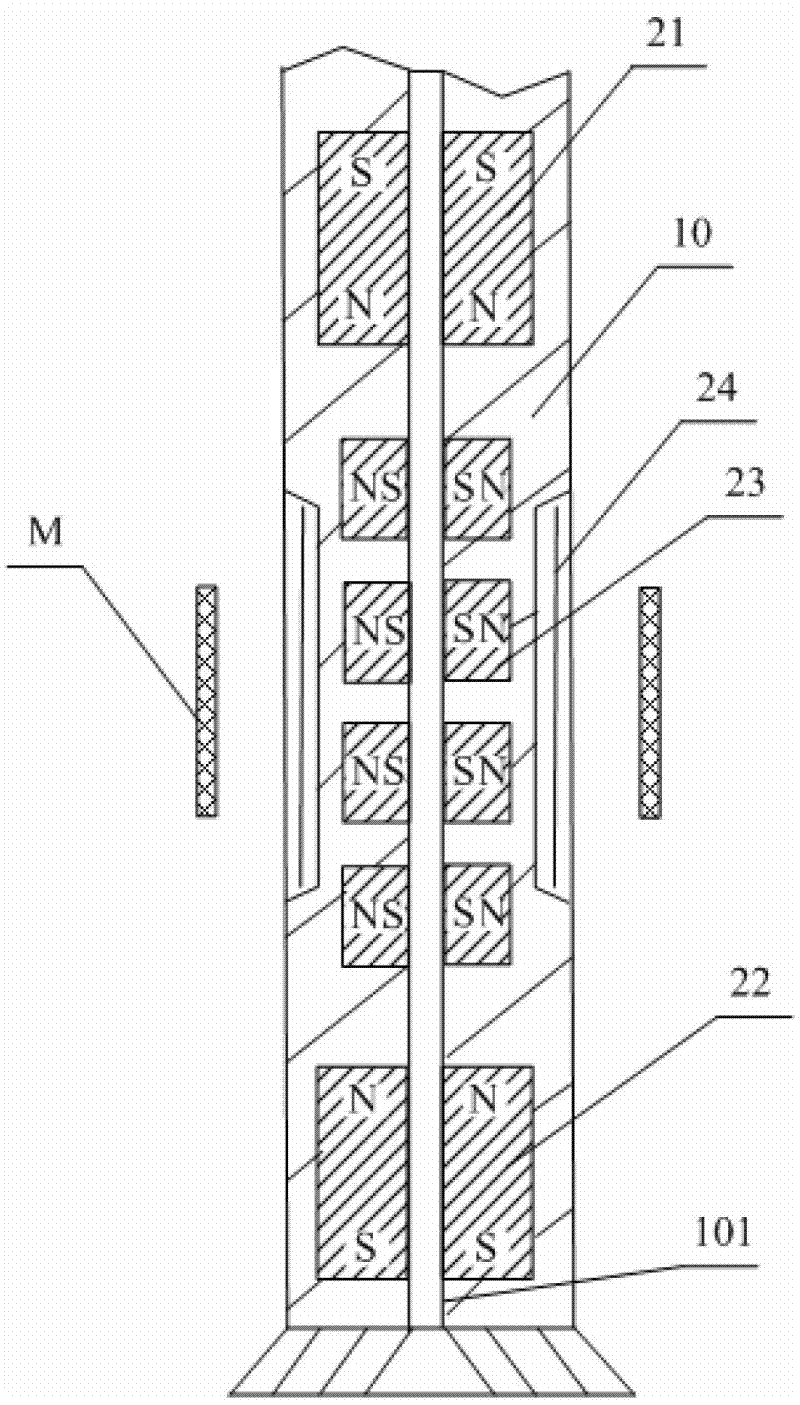

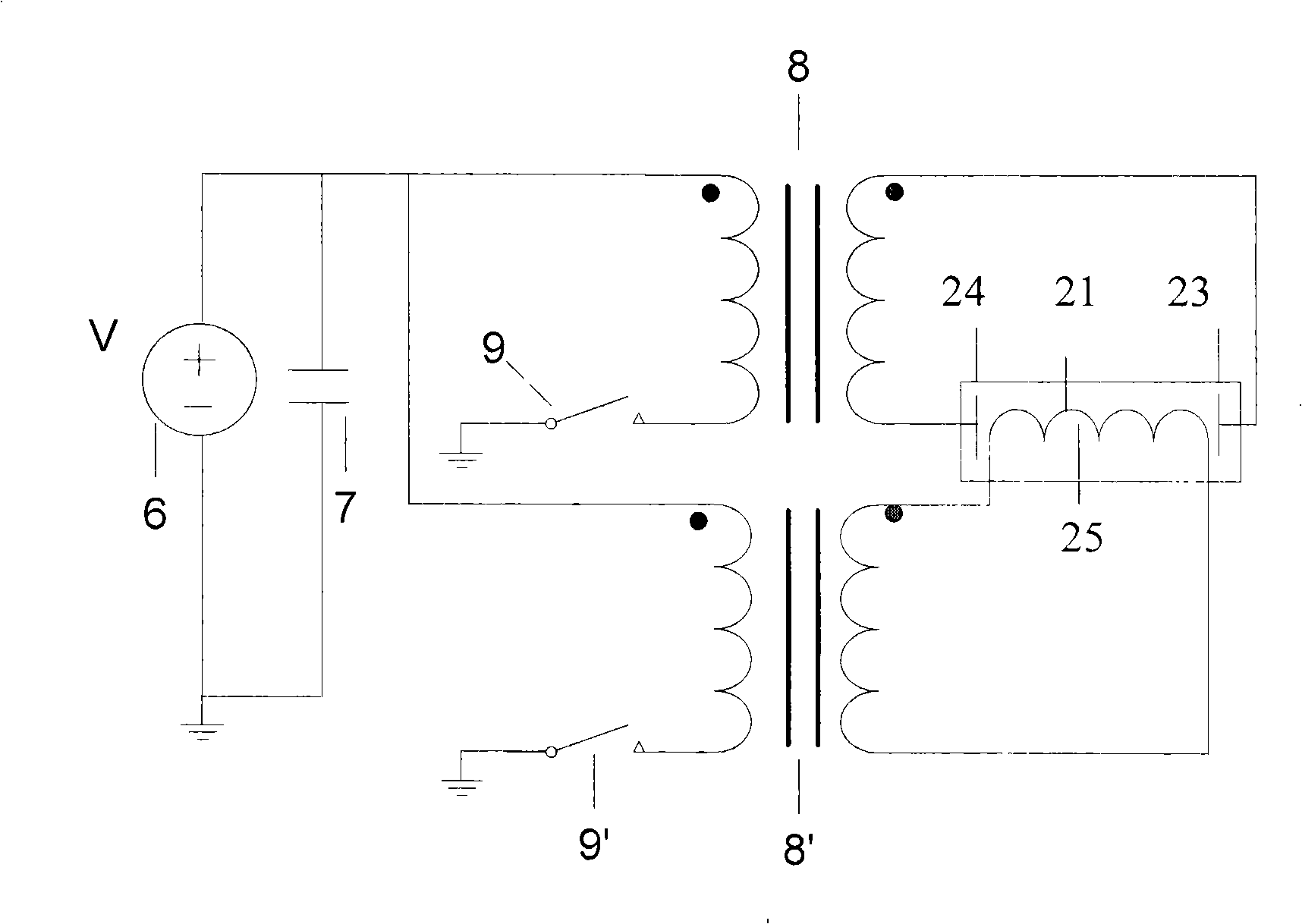

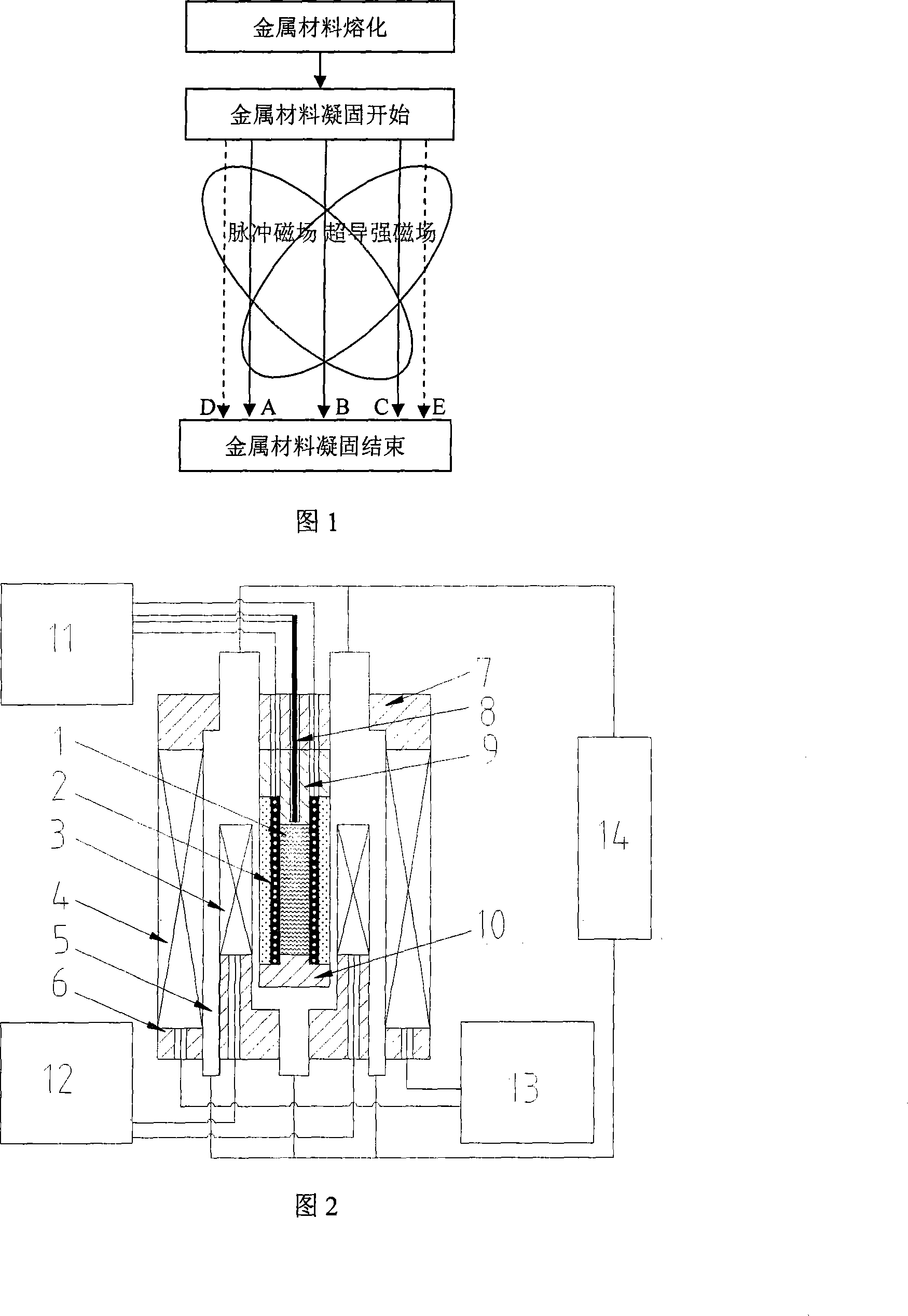

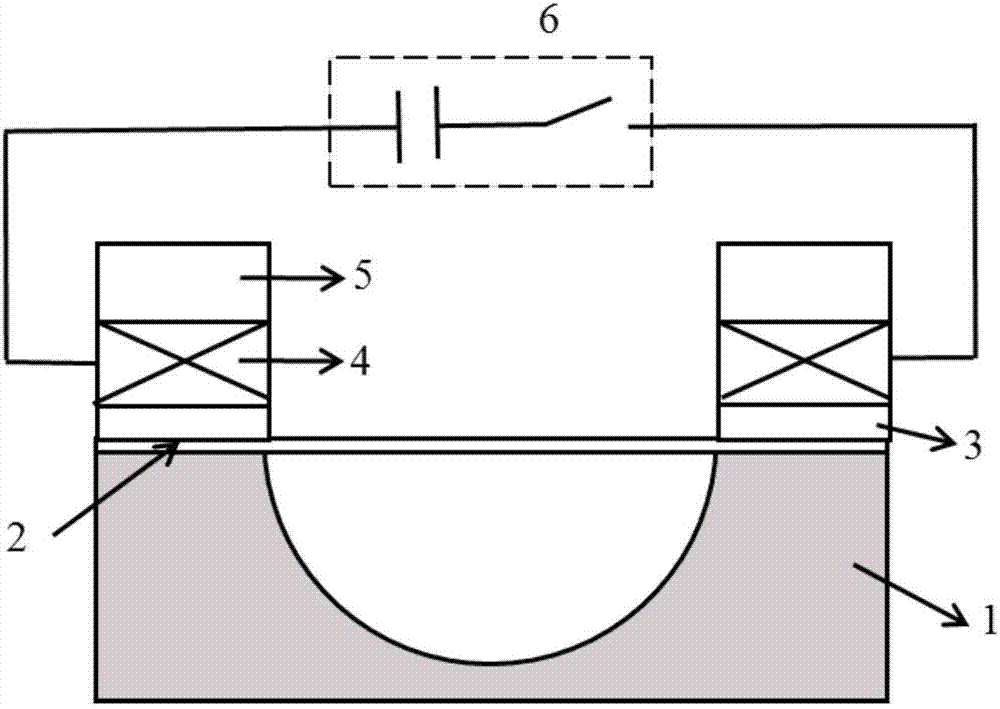

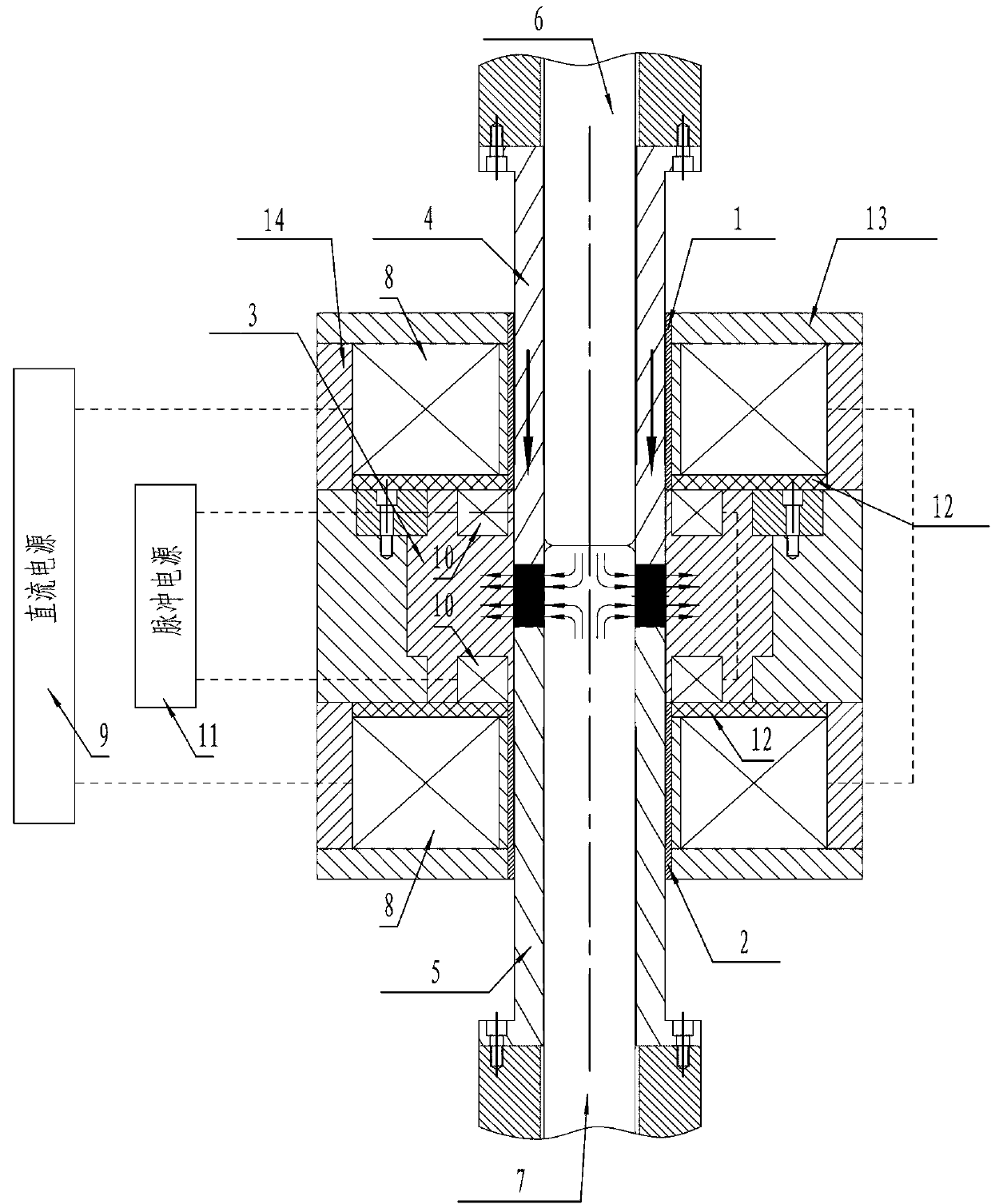

A method and apparatus for processing metallic material within complex magnetic field

InactiveCN101157125AImprove performanceReduce one heating processCrystal orientationMetallic materials

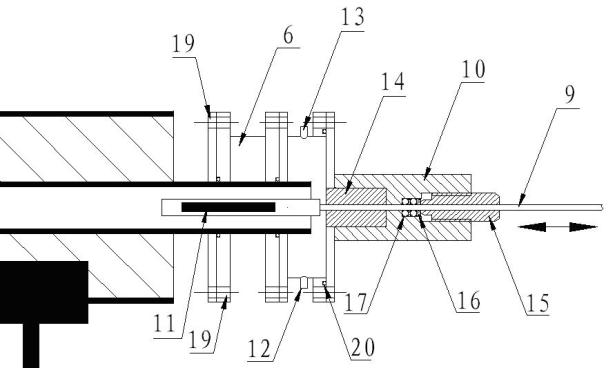

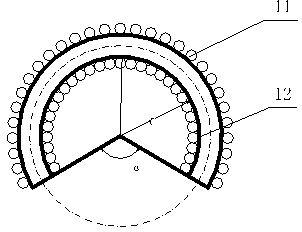

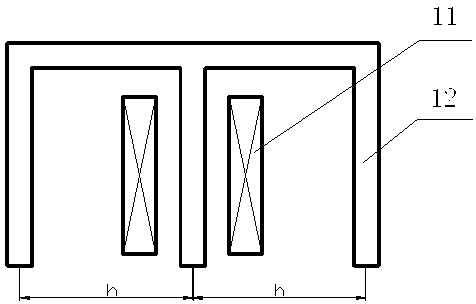

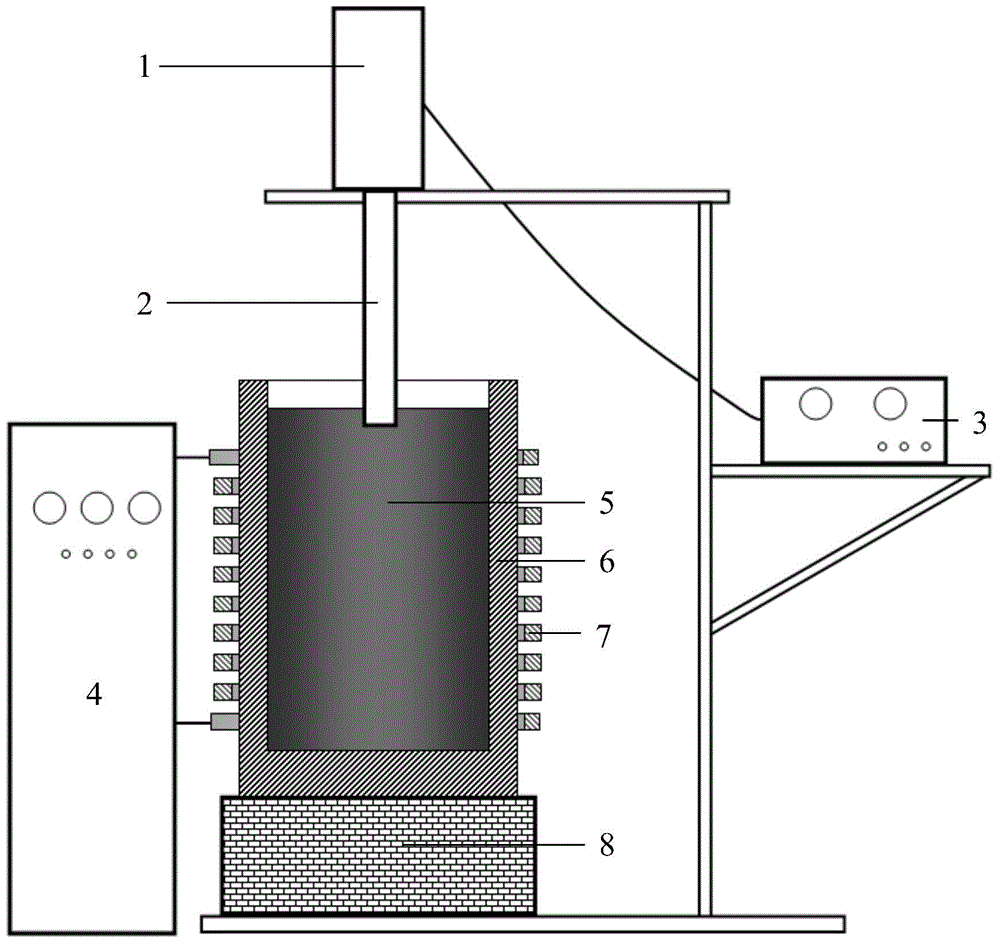

The invention relates to a method for the high temperature processing of metal material under a composite magnetic field. In the solidification process of the metal material, a pulsed magnetic field and a superconducting magnetic field which are coaxial in the same direction are applied to a metal bath, to control the grain size and the crystal orientation. A device applied by the method of the invention comprises a heating furnace body (2), a pulsed magnet (3), a superconducting magnet (4), a water cooling jacket (5), a heating control system (11), a pulsed magnet power (12), a superconducting magnet power (13), and a circulating cold water equipment (14). The central axle lines of the heating furnace body (2), the pulsed magnet (3), and the superconducting magnet (4) are coincident; the heating furnace body (2), the pulsed magnet (3), and the superconducting magnet (4) are nested layer by layers from inside to outside. The invention can perform the comprehensive optimal control to the organizational structure of the material, while the superconducting magnetic field optimizes the crystal orientation, the composite magnetic field also plays the function of strengthening the grain refinement; the two magnetic field technical methods of the prior pulsed magnetic field processing and the strong magnetic field processing are integrated into a whole, thereby simplifying the process flow, and reducing the energy consumption.

Owner:金山研究(大连)核磁共振科技有限公司

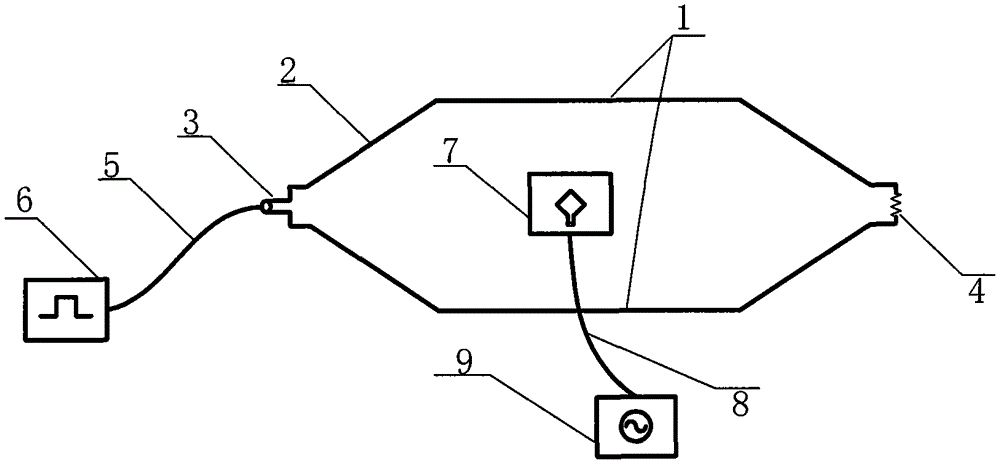

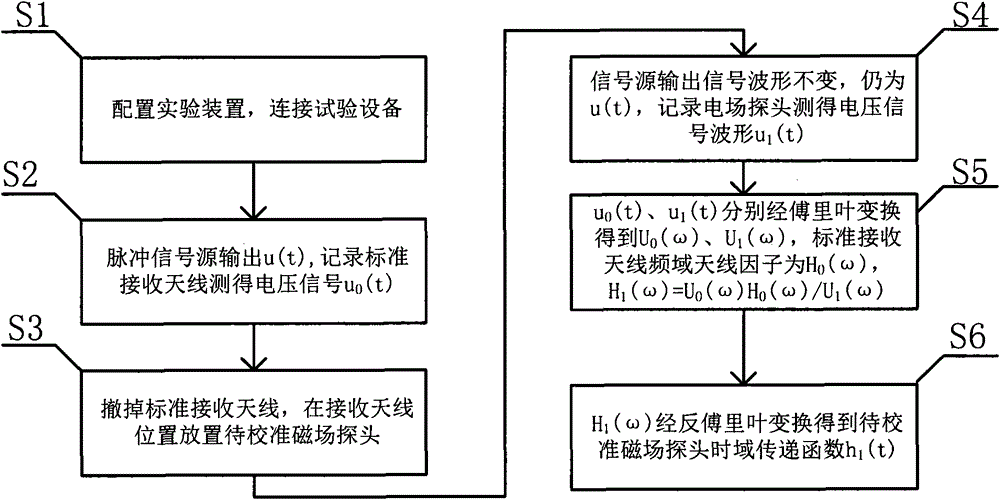

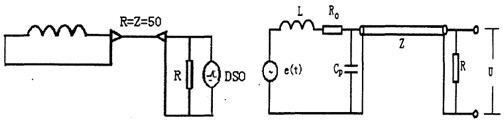

Time-domain calibration method for electromagnetic pulse magnetic-field probe

ActiveCN105093148AAchieving Time Domain CalibrationCalibration work is easy and convenientElectrical measurementsParallel plateElectromagnetic pulse

The present invention relates to a time-domain calibration method for an electromagnetic pulse magnetic-field probe. The method is used for calibrating an electromagnetic pulse magnetic-field probe in the time domain. The method comprises the steps of conducting the calibration test in a transmission line parallel-plate working space, connecting the tapered transition section of a parallel-plate transmission line and a pulse signal source with an adapter via coaxial cables, connecting the terminal of the parallel-plate transmission line with a matched load, connecting a digital oscilloscope with a standard antenna or a to-be-calibrated probe via a shielding radio frequency signal line, feeding a pulse voltage signal of the pulse signal source in the parallel-plate transmission line, forming a pulsed magnet field in the transmission line parallel-plate working space, recording a voltage signal waveform measured by the standard receiving antenna or the to-be-calibrated magnetic-field probe by the digital oscilloscope, and processing measured voltage signals according to a certain algorithm to obtain the time-domain transfer function of the to-be-calibrated magnetic-field probe. In this way, the time-domain calibration on the to-be-calibrated magnetic-field probe that is the same with the standard receiving antenna in frequency band can be realized.

Owner:中国人民解放军63973部队

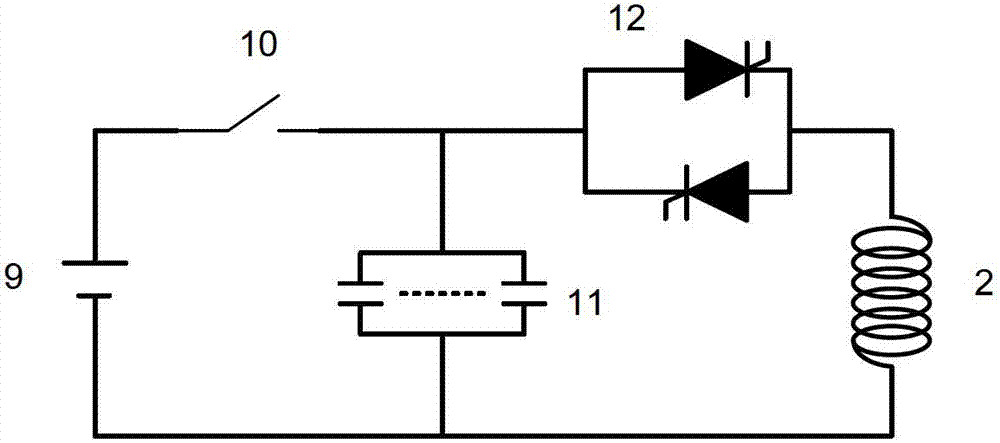

Magnetic refrigerating device based on repetitive pulsed magnetic field

InactiveCN102734977AImprove the magnetocaloric effectAchieving Static Magnetic RefrigerationEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringEnergy recovery

The invention discloses a magnetic refrigerating device based on a pulsed magnetic field. The device comprises a repetitive pulsed power supply without a continuous loop, a pulsed magnet, a magnetic refrigeration working medium, a hot end heat exchange unit and a cold end heat exchange unit, wherein the repetitive pulsed power supply discharges to the pulsed magnet, and part of electric energy flows back to the repetitive pulsed power supply to achieve energy recovery; during the discharge process, the pulsed magnet generates the pulsed magnetic field and causes the refrigeration working medium to magnetize and release heat, and the heat generated by the magnetic working medium is transferred to a high-temperature heat source through the hot end heat exchange unit; after the discharge is finished, the repetitive pulsed power supply is shut off, and the pulsed magnet stops generating the pulsed magnetic field, and the magnetic refrigeration working medium demagnetizes and absorbs the heat, and through heat absorption of a low-temperature heat source by the cold end heat exchange unit, the temperature of the low-temperature heat source is lowered, thus completing a discharge refrigeration cycle; and the discharge refrigeration cycle is circulated in a manner above to realize continuous refrigeration. According to the scheme disclosed by the invention, the controllable pulsed magnet generates the intermittent repetitive pulsed magnetic field to achieve the magnetic refrigeration, and the magnetic refrigerating device has the characteristics of high magnetic field intensity, no moving part, convenience and fastness of control, high efficiency and high refrigeration power.

Owner:HUAZHONG UNIV OF SCI & TECH

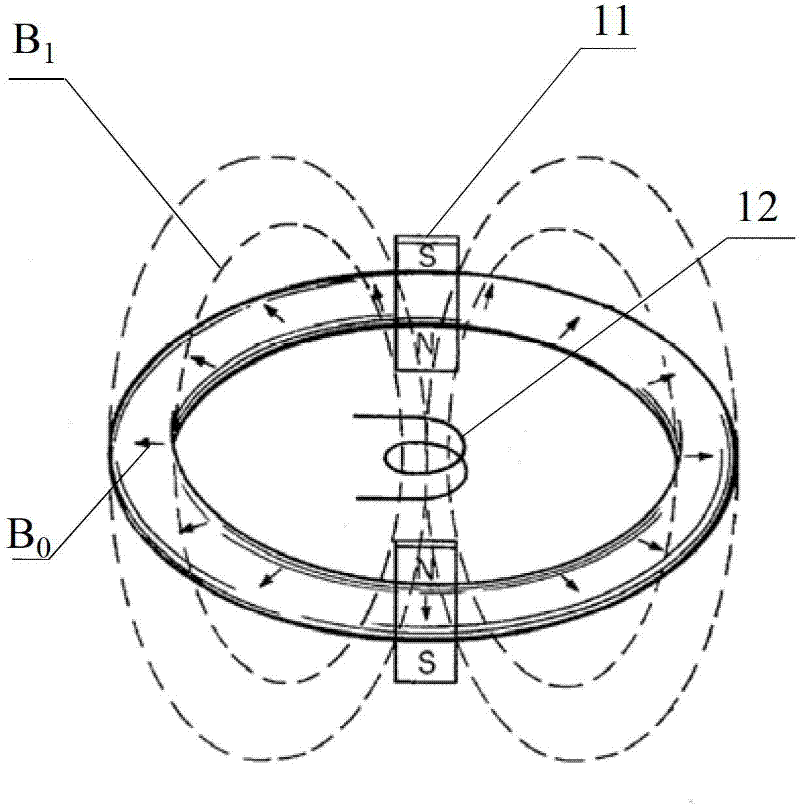

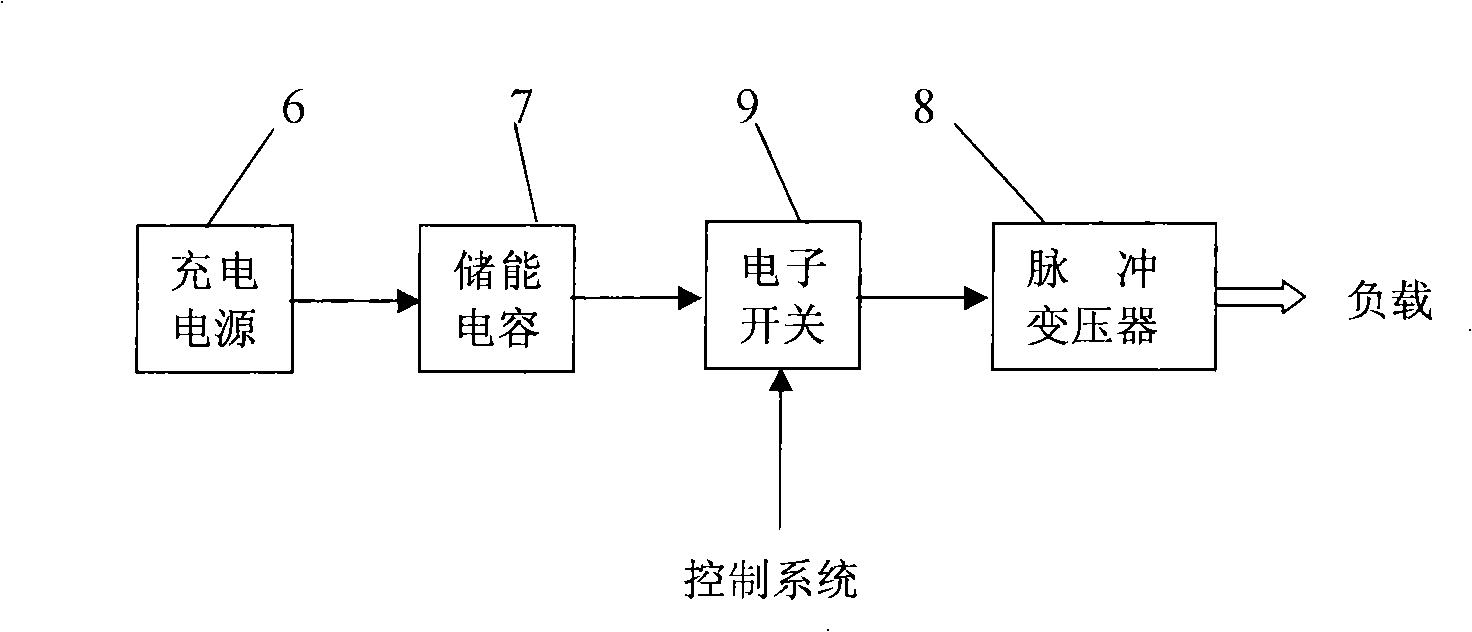

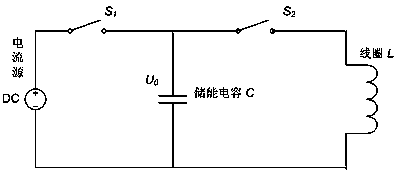

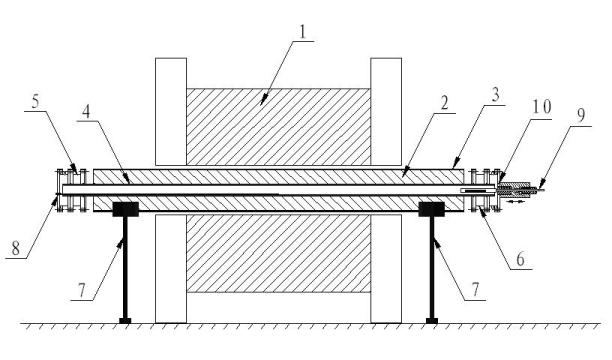

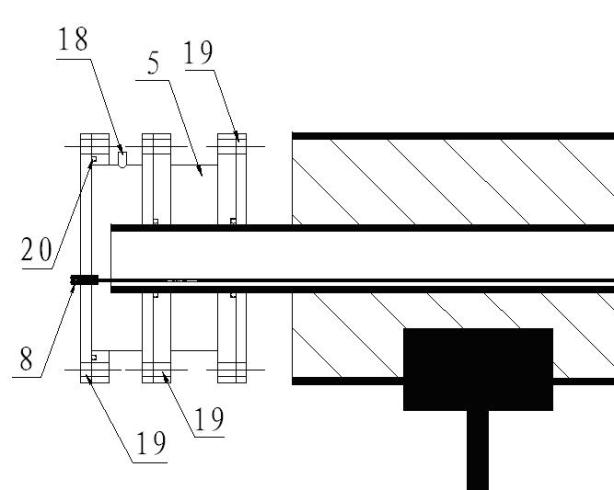

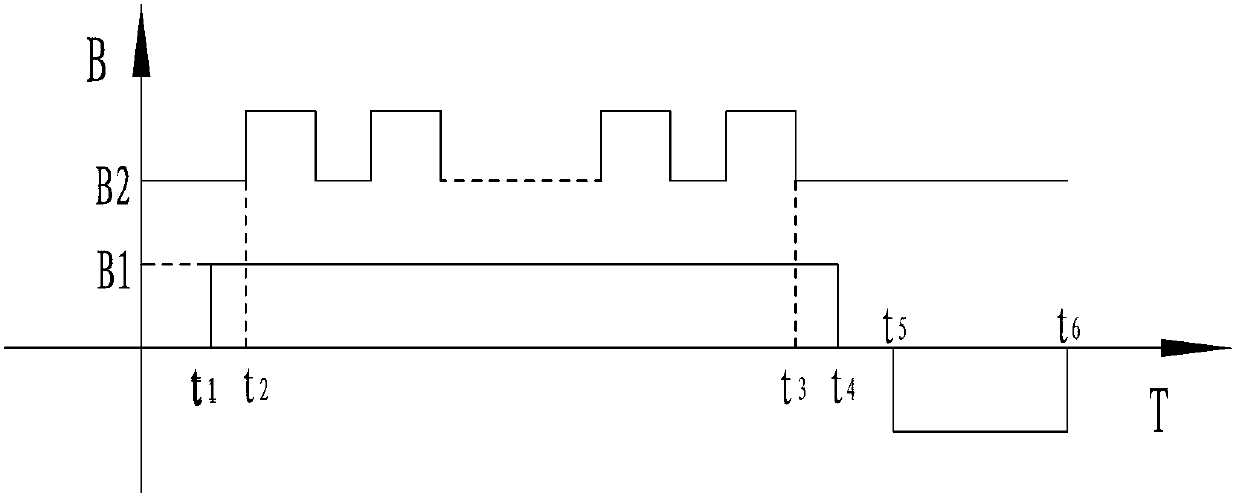

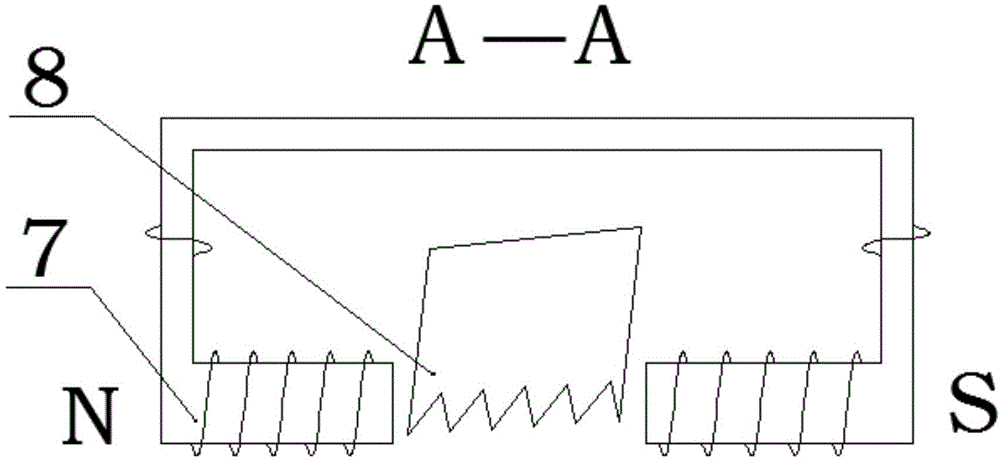

Low frequency pulsed magnet field fine-grain solidification method for causing melt oscillation through electromagnetic force

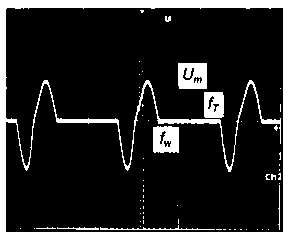

ActiveCN104209499ALow waveform frequencyInstantaneous magnetic field strength is largeMetallic materialsPulse power supply

The invention relates to a metal material preparative technology, in particular to a low frequency pulsed magnet field fine-grain solidification method for causing melt oscillation through electromagnetic force. A low frequency pulsed magnet field exciting coil is mounted outside a casting mold, when metal melt enters the casting mold through pouring equipment, a low frequency pulsed power supply is started, a pulse current generated by the low frequency pulsed power supply can generate a low frequency pulsed magnet field through the exciting coil, and the low frequency pulsed magnet field acts on the metal melt in the casting mold. The pulse discharge frequency fT is 1-25 Hz, the pulse waveform frequency fw is 1-50 Hz, and the pulse voltage Um is 0-500 V. The instantaneous magnetic field intensity of the low frequency pulsed magnet field technology is large, electromagnetic oscillation force with the direction varied in a reciprocating mode in the melt enables dendritic crystals to be broken more easily, no contact with the metal melt is achieved, pollution can be avoided, and the method can be applied to the solidification process of metal large-sized casting blank.

Owner:BAOSHAN IRON & STEEL CO LTD

Heat treatment device and heat treatment method for rapid heating in pulsed magnet field

ActiveCN102560014AImprove the efficiency of magnetic field actionQuick to warmPulsed magnetThermocouple

The invention relates to a heat treatment device and a heat treatment method thereof for rapid heating in a pulsed magnet field. The heat treatment device comprises a magnetic field coil, a heating system, a sealing system and a feeding device; the heat treatment method can achieve the heat treatment of the pulsed magnet field under vacuum atmosphere or specifical atmosphere, and adopts the principle that the pulsed magnet field is applied during the heat treatment process and the organizational structure of material is changed by utilizing the interaction of material and the magnet field as well as the anisotropy characteristic of the magnet field so as to obtain needed performances. A feeding rod is utilized to send samples to the position around a central armored thermocouple of a Quartz furnace tube, and the metal feeding rod achieves low heat capacity and low heat absorption, so that preset temperature can be achieved rapidly and heat preservation can be performed for a pluralityof hours. The heat treatment device and the heat treatment method thereof change the present situation that the samples can only be heated slowly in the heat treatment of the magnet field, and improve the efficiency of the heat treatment of the magnet field.

Owner:SHANGHAI UNIV

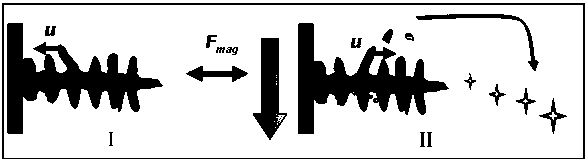

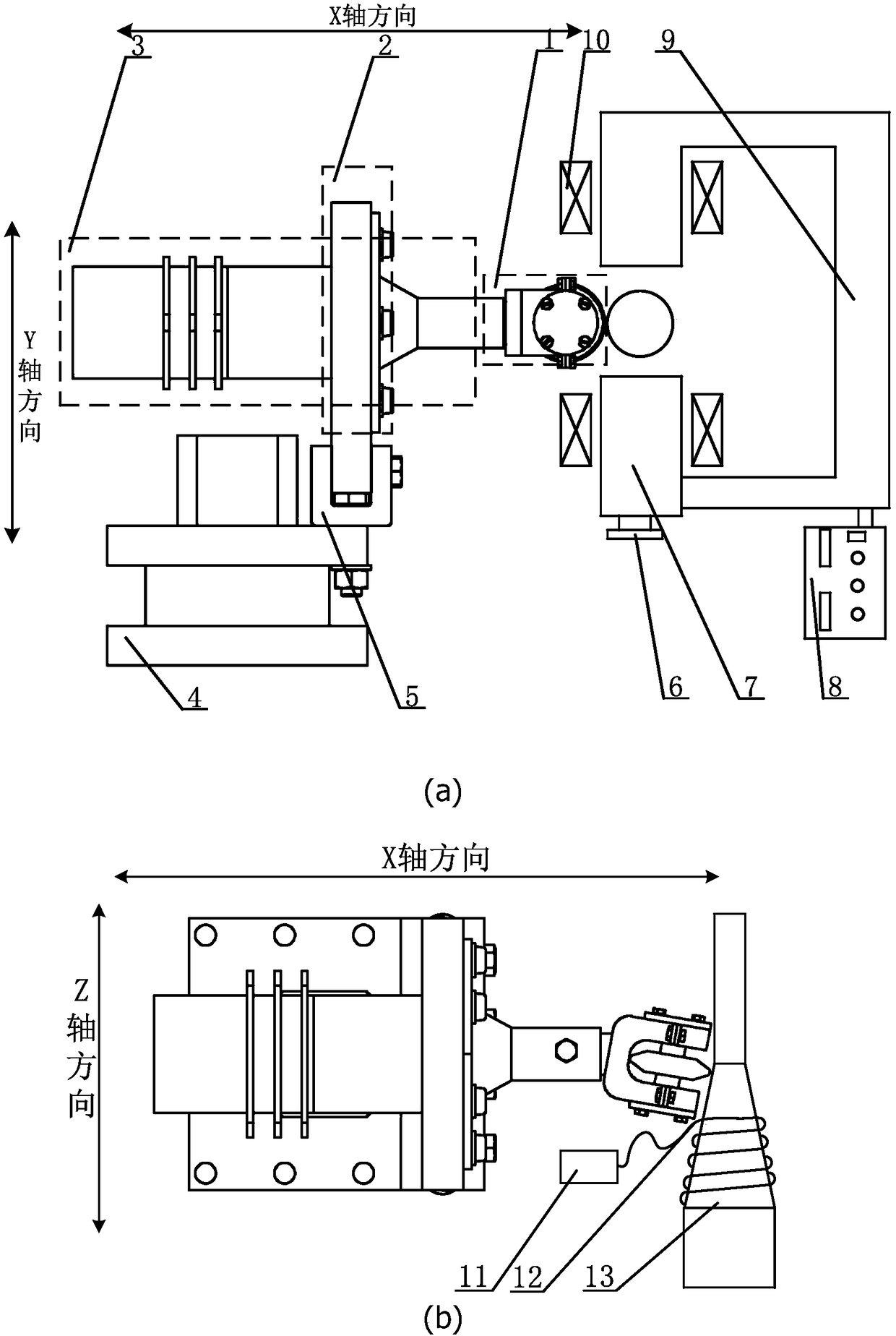

Method and device for refining weld joint structures by using pulsed magnet fields in welding process

ActiveCN102848058AStir wellImprove crystallizationWelding accessoriesWelding defectMaterials science

The invention relates to a processing technology for refining weld joint structures in a welding process, in particular to a method and a device for refining weld joint structures by using pulsed magnet fields in the welding process, and belongs to the technical field of welding. The method for refining weld joint structures by using pulsed magnet fields in the welding process includes that welding is performed by using an ordinary gas metal arc welding method, an applied magnetic field is added above a gas metal arc welding pool, mechanical movement and welding gun movement of the magnet fields are synchronous, electric arc and melt drip transition action is controlled by the magnet fields in a welding process, metal melt in the gas metal arc welding pool is forced to move, an electromagnetic stirring effect is produced, and weld joint structures are finally refined in the welding process. According to the method and the device, in the welding process, the weld joint structures are refined, welding defects are reduced, and further the cost is reduced, and the welding quality and the production efficiency are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

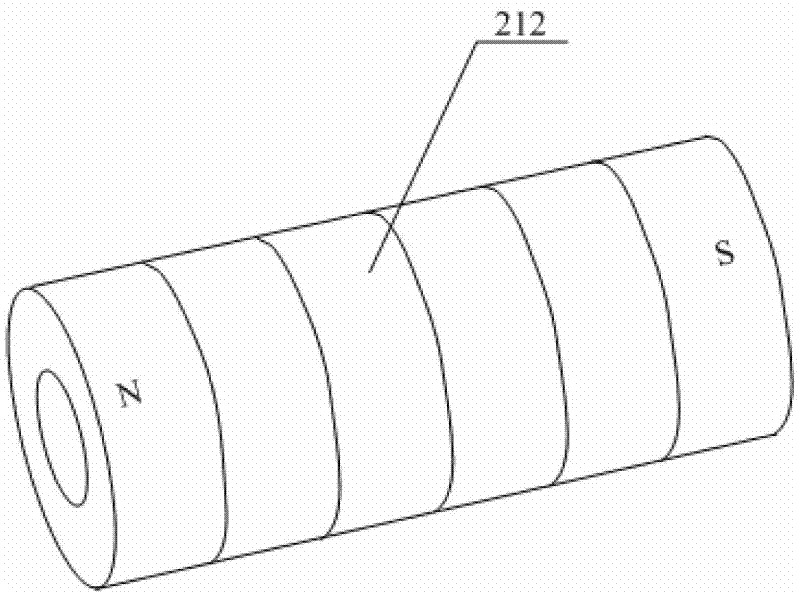

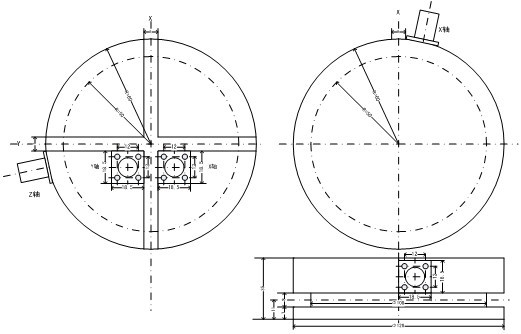

Three-dimensional pulsed magnetic field wave reconstruction method and three-dimensional magnetic field sensor

ActiveCN102162839AEasy to manufacturePromote reductionMagnitude/direction of magnetic fieldsPulsed magnetComputational physics

The invention discloses a three-dimensional pulsed magnetic field wave reconstruction method and a three-dimensional magnetic field sensor. The three-dimensional pulsed magnetic field wave reconstruction adopts a pulsed magnet field wave digital reconstruction method based on a full circuit expression; based on the method, no special requirements for the sizes of a sensor sampling resistance and self inductance are raised, so the sensor is convenient to manufacture and simultaneously a three-dimensional magnetic field is convenient to restore and synthesize. A framework of the three-dimensional sensor is made of non-magnetic materials; the frequency measuring range can be 1KHz to 200KHz; the three-dimensional sensor is mainly used for measuring the three-dimensional pulsed magnetic field,and can measure the magnetic fields in X-axis, Y-axis and Z-axis directions. The invention can truly reflect the three-dimensional pulsed magnetic field waves within the maximum amplitude dynamic range.

Owner:WUHAN UNIV

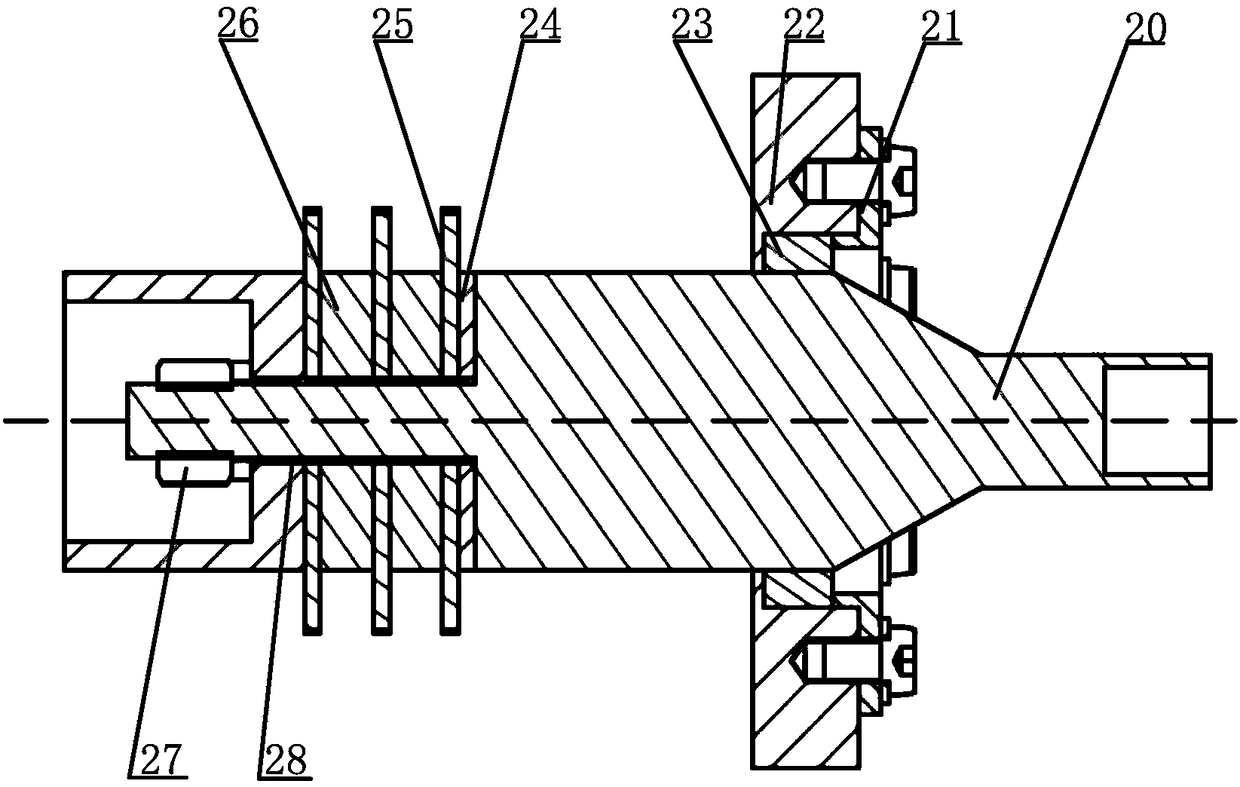

Multi-field coupling roll finishing device for conical surface

The invention provides a multi-field coupling roll finishing device for a conical surface. Multi-field coupling particularly means coupling of a high-temperature thermal field, a variable frequency pulsed magnet field and an ultrasonic field. The multi-field coupling roll finishing device comprises a rolling knife, an amplitude-change pole, a transducer, an ultrasonic generator, a thermocouple coil, a temperature controller, a pulsed magnet field intensifying system, a dynamometer and a mounting rack. A novel rolling knife structure is designed, so that different rolling wheels can be replacedaccording to different rolling workpieces, meanwhile, different rolling angles can be replaced according to different conical surface angles of workpieces, and accordingly, the use is convenient andreliable. According to the multi-field coupling roll finishing device, the heating temperatures of the workpieces can be controlled by a temperature controller, the rolling temperature of the workpieces is increased, and the atomic vitality of the workpieces is enhanced, dislocation movement is overcome, the resistance is reduced, and accordingly, a favorable rolling surface quality is acquired. The conical workpieces are placed in a pulsed magnet field acting region, so that the hardness and the wear resistance of the workpieces are improved. The value of a rolling force in a rolling processcan be monitored in real time by the dynamometer, and the rolling force in the rolling process is kept constant by feedback of a digital control system. An ultrasonic rolling system which can be mounted on a common lathe is designed to roll a conical-surface shaft part, the surface roughness of the part can be reduced, the surface hardness is improved, and favorable surface quality and mechanicalperformance are acquired.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

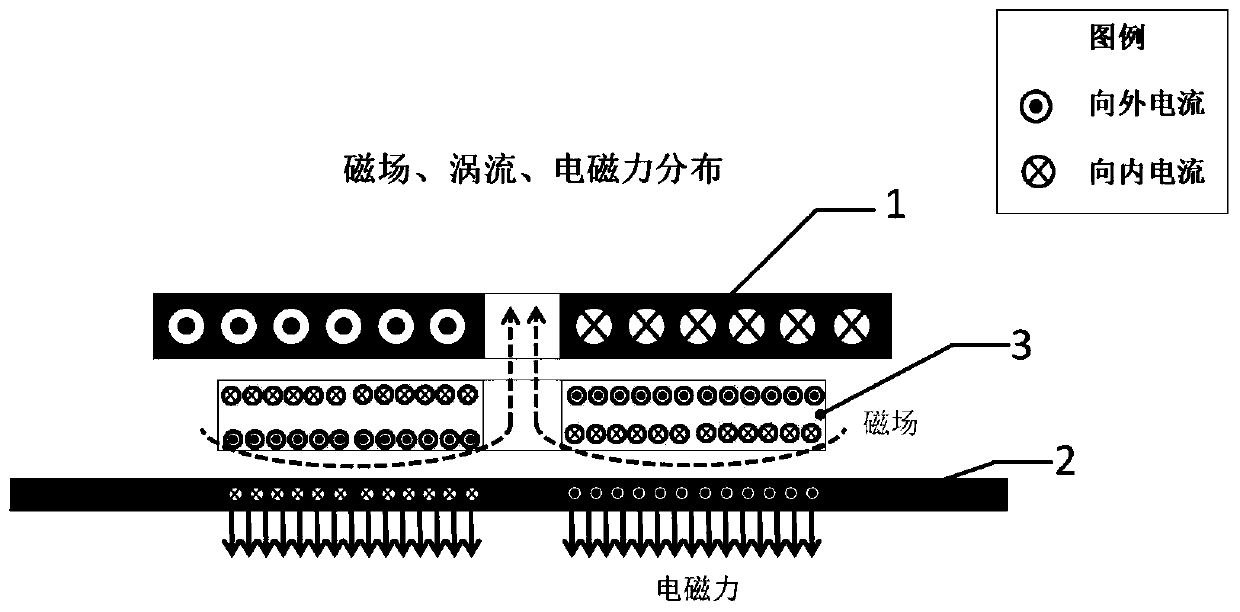

Electromagnetic repulsive force edge pressing method and device based on inertial confinement

PendingCN107413918AHigh edge force amplitudeGuaranteed mechanical stabilityPulsed magnetRepulsion force

The invention discloses an electromagnetic repulsive force edge pressing method and device based on inertial confinement. The method comprises the steps that an edge pressing coil is discharged; the edge pressing coil is arranged on the upper portion of an edge pressing copper ring; the edge pressing copper ring is arranged on the upper portion of the edge of a workpiece; the workpiece is arranged on the upper portion of a female die; the to-be-deformed workpiece is molded through the female die, a pulsed magnet field is generated in the discharging process of the edge pressing coil, induced eddy current correspondingly generated in the edge pressing copper ring and the pulsed magnet field interact, and thus electromagnetic repulsive force is generated between the edge pressing coil and the edge pressing copper ring; and edge pressing force to the edge of the workpiece is provided by the electromagnetic repulsive force between the edge pressing coil and the edge pressing copper ring so that the edge positions of the workpiece can be kept stable in the molding process, meanwhile, workpiece material flowing is controlled, and the workpiece is prevented from being wrinkled and broken in the molding process. Through the electromagnetic repulsive force between two edge pressing coils of between the edge pressing coil and the edge pressing copper ring, the edge pressing force can be flexibly controlled, the device manufacturing cost is reduced, the space size is reduced, and the power source energy of a system can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

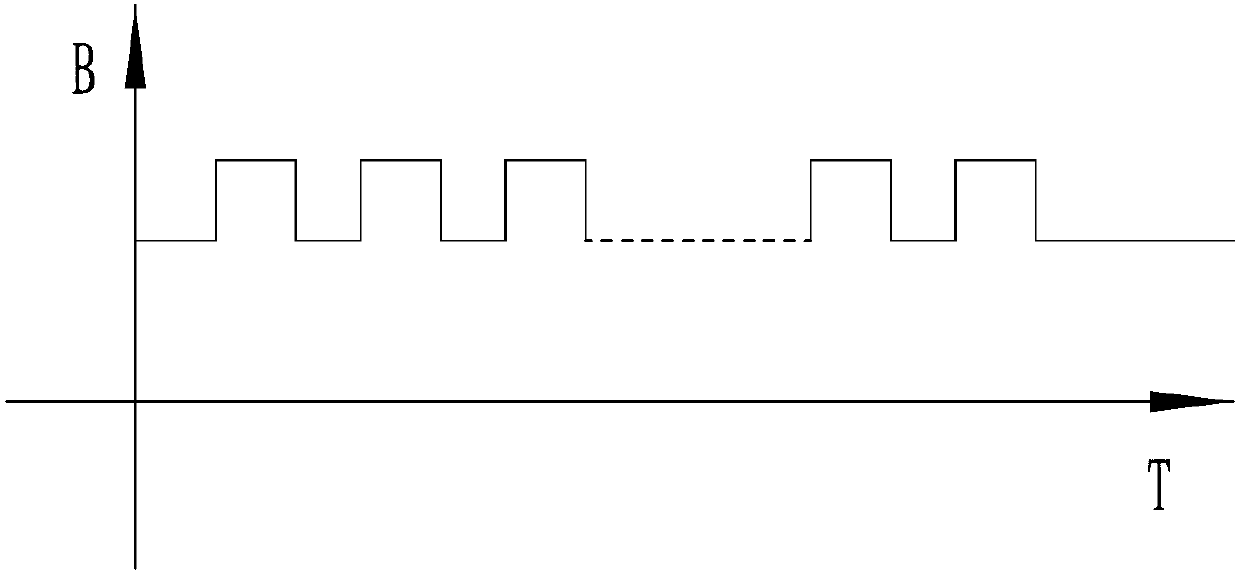

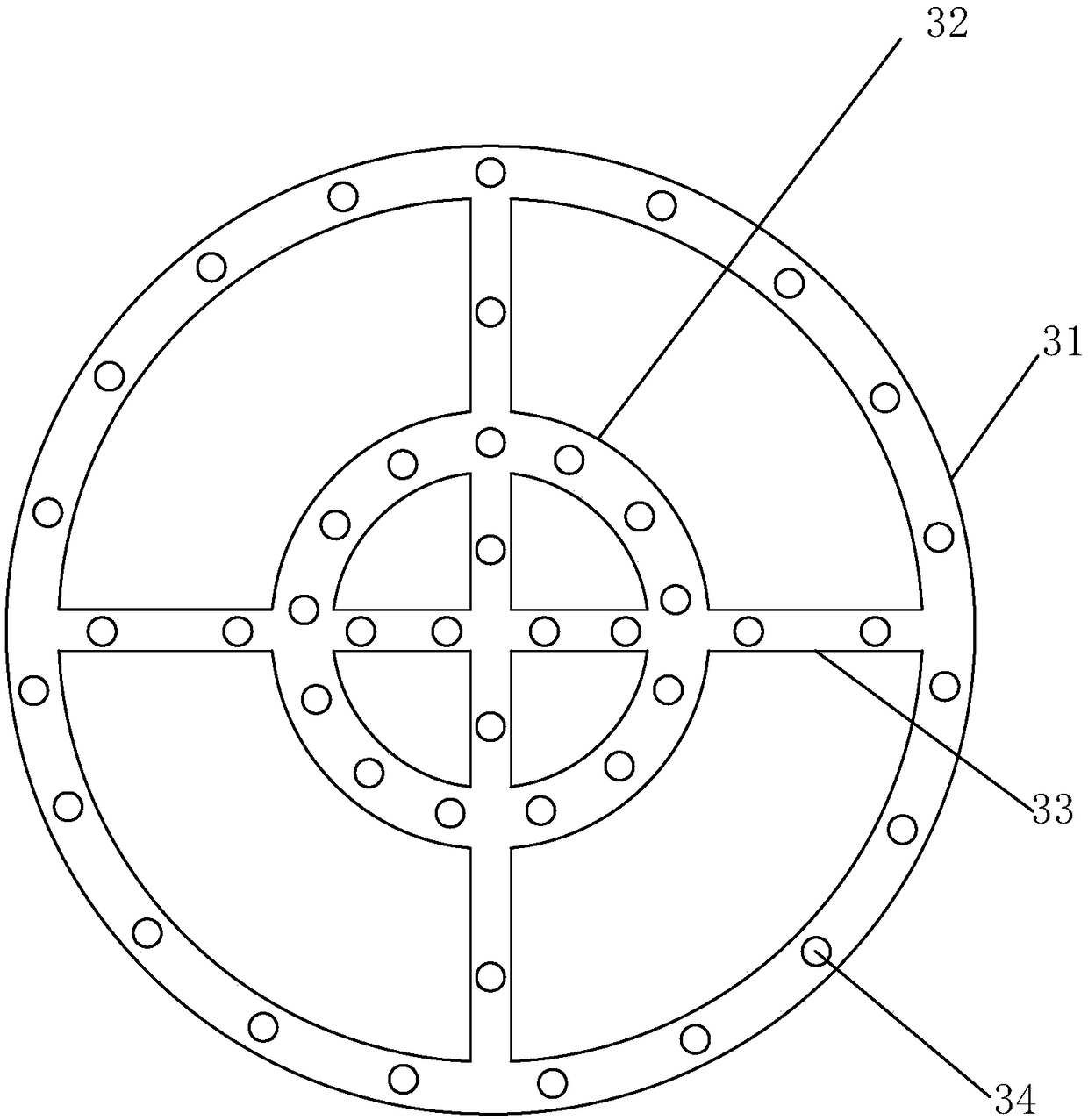

Anisotropism sintering rare earth permanent magnetic material radial orientation device and orientation method thereof

The invention provides an anisotropism sintering rare earth permanent magnetic material radial orientation device and an orientation method thereof. The orientation device comprises an upper mold sleeve, a lower mold sleeve, a female mold, an upper punch, a lower punch, an upper core bar, a lower core bar, a pair of direct current coils, a direct current power source, a pair of pulse coils and a pulse power source, wherein the female mold is placed between the upper mold sleeve and the lower mold sleeve, the upper punch is placed inside the upper mold sleeve, the lower punch is placed inside the lower mold sleeve, the upper core bar is placed inside the upper punch, the lower core bar is placed inside the lower punch, the pair of current direct coils are placed outside the upper mold sleeve and the lower mold sleeve, the direct current power source is connected with the pair of direct current coils, and the pulse power source is connected with the pair of pulse coils. The pair of pulse coils are respectively placed on the upper portion and on the lower portion of the female mold, magnetic field parameters produced by the direct current power source and the pair of direct current coils are 5000-600000NI, magnetic field parameters produced by the pulse power source and the pair of pulse coils are 5000-20000000NI, and the continuous pulse magnetizing frequency of a pulsed magnet field is 1-10 times per second. The orientation device and the orientation method thereof have the advantages that orientation is simultaneously conducted through direct current magnetic field and the pulse magnetic field, magnetic performance is improved, residual magnetism on the surface of a magnetic blank after orientation forming is lower than 2 gausses, and mold releasing is easy.

Owner:NINGBO CANMANG TECH

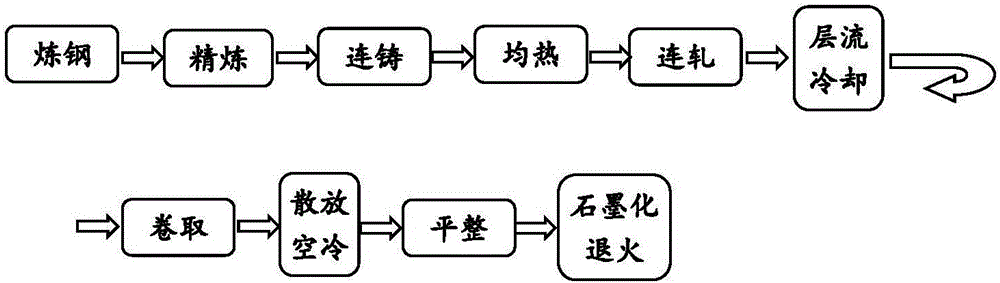

Preparation method of graphitizing hot rolled steel plate

The invention discloses a preparation method of a graphitizing hot rolled steel plate, which belongs to the technical field of metallurgy. The method mainly comprises the steps of steelmaking, refining, continuous casting, heating, hot continuous rolling, laminar cooling, coiling, steel coil spreading and air cooling, leveling and rolling, graphitizing annealing and the like. In order to increase the graphitizing rate and promote a graphitizing process, a pulsed magnet field is applied in a graphitizing annealing process, the magnetic field intensity is 10000 to 30000 A / m, and the magnetic field frequency is 20 to 100 Hz. Within the graphitizing time of 3 to 6 hours, the graphitizing rate can reach more than 90%, the diameter of graphite is 3 to 6 mum, the graphite is spherical or nearly spherical and is uniformly distributed, and the diameter range of ferrite grains is 20 to 30 mum. According to the structural features, the steel plate, especially the steel plate with high carbon content, has low hardness and high plasticity, therefore, the steel plate has good stamping and forming performance, and the preparation method is favorable for enlarging the application range of medium and high carbon steel plates in a stamping and forming process of components and parts in complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing metal matrix composite under compounding effect of low-pressure pulsed magnet field and ultrasound

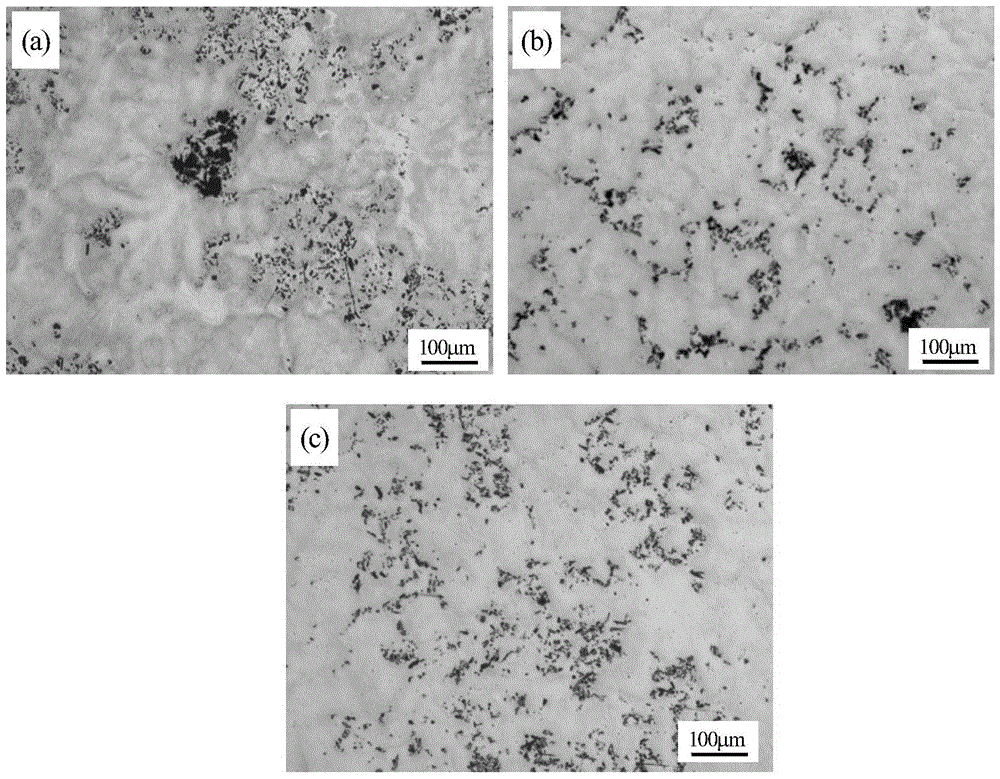

The invention relates to the field of solidification control of metal matrix composites and specifically relates to a method for preparing a metal matrix composite under a compounding effect of low-pressure pulsed magnet field and ultrasound. The method comprises the following steps: re-melting magnesium alloy or aluminum alloy serving as a matrix in a resistance furnace; reducing the heating power, reducing the melt temperature to semisolid temperature, adding a reinforcing phase whisker or carbon nano tube after keeping the temperature for a period of time and mechanically stirring; increasing the temperature to the temperature above liquidus and keeping the temperature for a period of time; injecting the melt into a preheated graphite jig and putting into the place under the compounding effect of low-pressure pulsed magnet field and ultrasound and processing till the alloy is completely solidified. According to the invention, the compounding effect of low-pressure pulsed magnet field and ultrasound is adopted for processing and realizing the preparation for the metal matrix composite, so that the uniformly distributed whisker or carbon nano tube is acquired; the dispersing problem of the reinforcing phase in the metal melt in the process of preparing the metal composite with larger long diameter ratio of the reinforcing phase at present is solved; the method is fit for preparing the metal matrix composites at various long diameter ratios of the reinforcing phase.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electromagnetic heat physiotherapy device

InactiveCN104353187AEasy to controlEasy to useElectrotherapyVibration massageVibration amplitudePulsed magnet

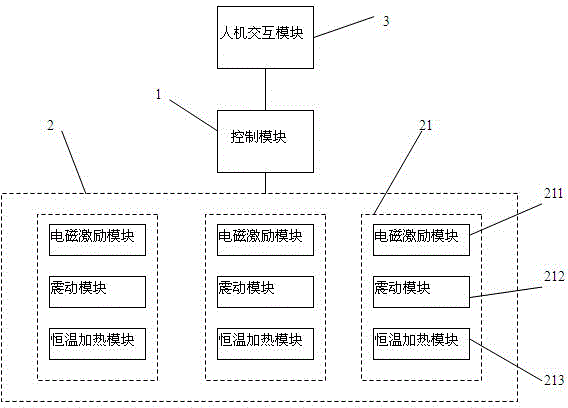

The invention relates to a physiotherapy device, in particular to an electromagnetic heat physiotherapy device. The electromagnetic heat physiotherapy device comprises a control module and a physiotherapy head. The physiotherapy head is connected with the control module. The electromagnetic heat physiotherapy device is characterized in that the physiotherapy head comprises two or more completely identical physiotherapy modules, each physiotherapy module comprises an electromagnetic excitation module, a vibration module and a constant temperature heating module, the electromagnetic excitation module is used for generating a pulsed magnet field through electric currents, the constant temperature heating module is used for generating constant temperature according to settings, and the vibration module is used for generating vibration according to settings. The electromagnetic heat physiotherapy device can be applied to multiple parts, such as the head, the neck and the stomach and joints of a human body, and has the advantages that the electromagnetic heat physiotherapy device has multiple choices of vibration frequencies and vibration amplitudes, and the magnetic field intensity is controllable. An electrothermal film heating mode is adopted, a temperature sensor monitors a contact surface in real time, a pulse low-frequency electromagnetic field is adopted, no permanent magnet material is included, control over the electromagnetic heat physiotherapy device is more accurate, and using is safer.

Owner:何成奇 +1

Steel wire hot dipping rare earth zinc alloy and hot dipping method

ActiveCN102330043AImprove corrosion resistanceFlat surfaceHot-dipping/immersion processesPulsed magnetRare earth

The invention relates to the technical field of metal surface cladding materials, and in particular relates to a steel wire hot dipping rare earth zinc alloy and a hot dipping method. With the method, the hot dipping alloy is adopted to carry out hot dipping on steel wires, and a pulsed magnet field is applied to a hot dipping alloy molten pool in the hot dipping process. The hot dipping alloy comprises the following components in percentage by mass: 0.02-0.06% of rare earth mixture 1 or rare earth mixture 2, 4.0-4.5% of Al, 0.11-0.2% of Ti, 0.05-0.10% of B, 0.01-0.05% of Sr and the balance of Zn and inevitable impurities, wherein the rare earth mixture 1 is composed of at least two of rare earth Ce, La and Pr at the mass ratio of 1:1, and the rare earth mixture 2 is composed of rare earth Ce, La and Pr at the mass ratio of 1:1:1. The parameter range of the pulsed magnet field is that the pulse width is 80-100ms, the action frequency is 1-2Hz, and the peak value intensity of the pulsed magnet field is 11-15T. According to the steel wire hot dipping rare earth zinc alloy, the clapping material quality is improved, and the consumption of rare earth and other metals is saved. The technology applied in the method is simple, and the existing technical equipment is mature, has low cost and is worthy of popularization.

Owner:马鞍山市顺泰稀土新材料有限公司

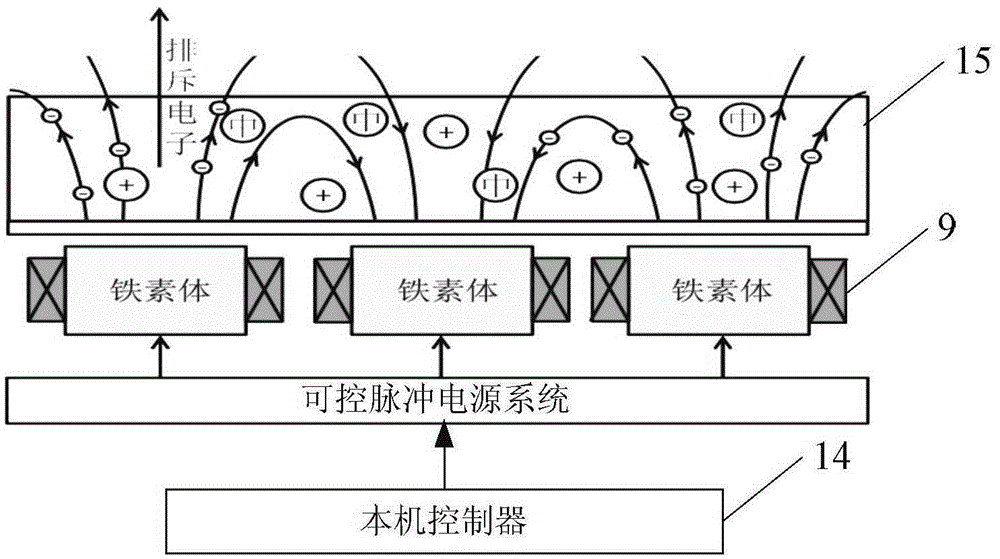

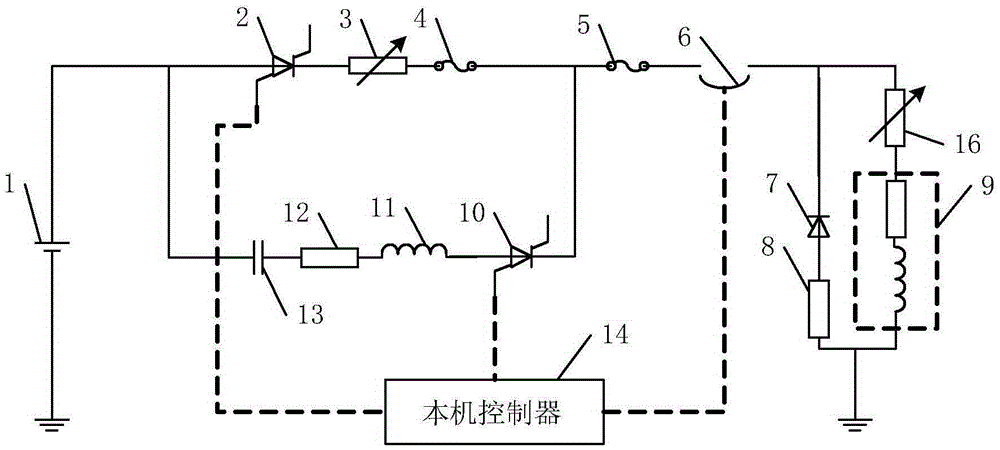

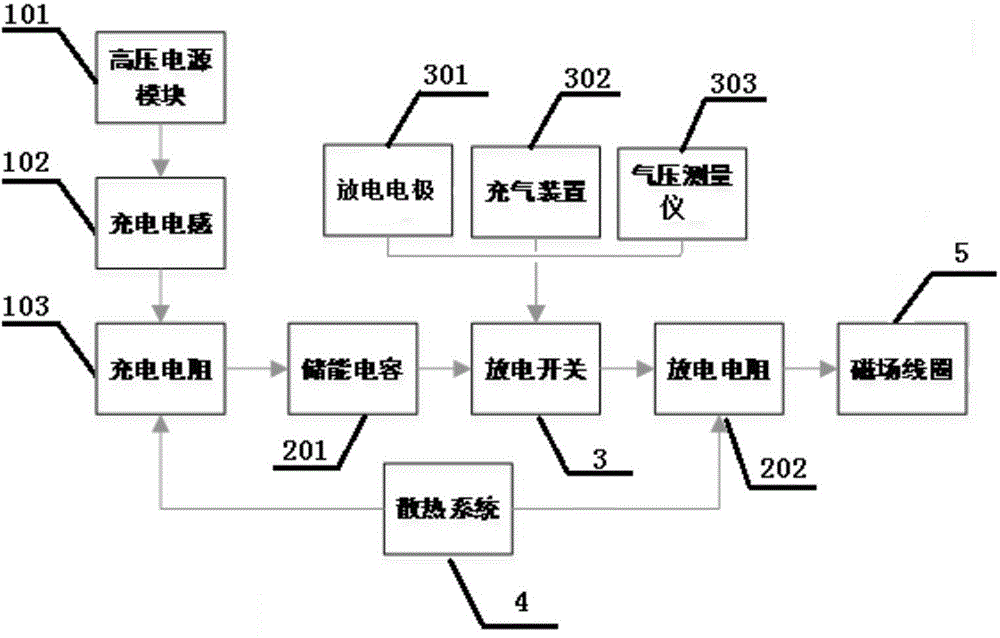

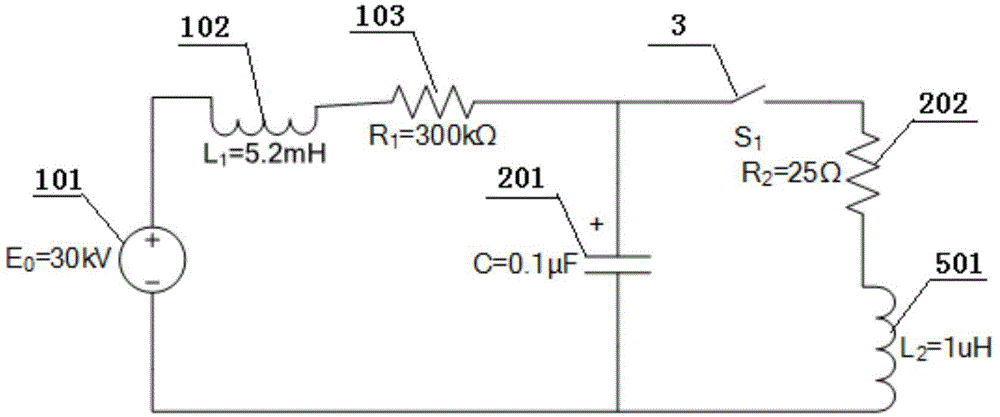

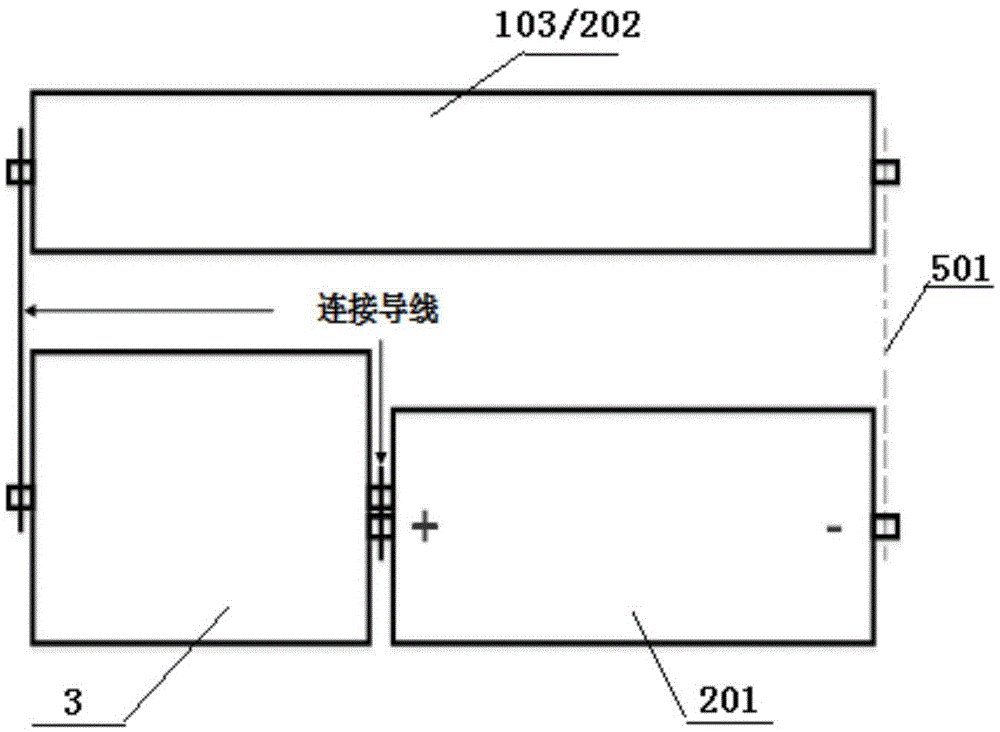

Method for relieving spacecraft communication blackout

ActiveCN105329465AMeeting Communication NeedsLittle aerodynamic impactCosmonautic vehiclesCosmonautic radiation protectionPulsed magnetEngineering

The invention provides a method for relieving spacecraft communication blackout, and belongs to the field of communication blackout relief. The method solves problems that an existing method for relieving communication blackout is large in system weight, large in electric energy requirement, and low in spacecraft tracking telemetry and control reliability. The method is realized based on a controlled pulsed power supply system, a pulsed magnet, and a local controller. The specific process of the method comprises: through the local controller, controlling the controlled pulsed power supply system to provide pulse current to the pulsed magnet, so that the pulsed magnet generates a magnetic field of more than 1T in a plurality of millisecond magnitude, the magnetic field magnetizes electrons near an antenna of the spacecraft, to generate a magnetic freezing effect, so as to form electromagnetic waves to pass through a window of plasma sheath, and relieve communication blackout of the spacecraft. The method is mainly used on a spacecraft.

Owner:HARBIN INST OF TECH

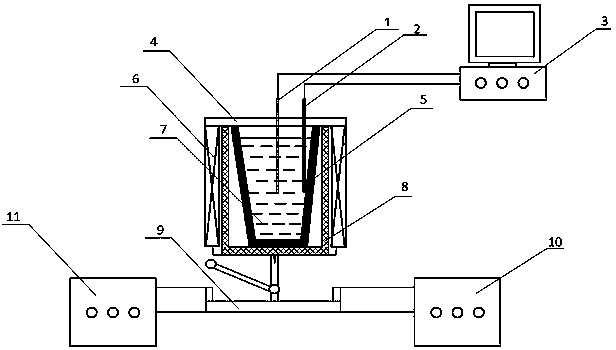

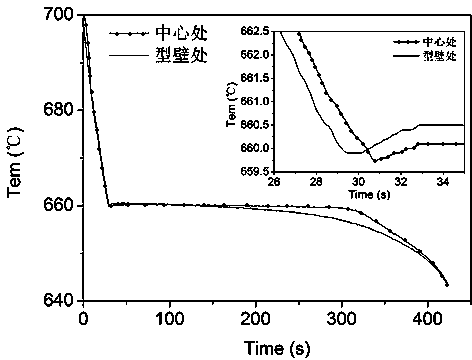

Device capable of continuously measuring temperature of metal melt in pulse magnetic oscillation processing technology

ActiveCN103586442AAccurate measurementEliminate pouring stepsCasting parameters measurement/indication devicesPulse power supplyMaterials science

The invention discloses a device capable of continuously measuring the temperature of metal melt in a pulse magnetic oscillation processing technology. The device comprises a temperature measurement and analysis system, a casting device and a pulse magnetic oscillation processing device. The casting device comprises a cast molding device, a medium-frequency induction power supply and an induction coil. The metal melt is contained in an inner cavity of the cast molding device. A head cover is arranged at an upper opening of the cast molding device and forms a thermocouple fixing device. The induction coil is controlled by the medium-frequency induction power supply through a switch device to generate a pulsed magnet field, makes solid metal contained in the cast molding device induce eddy currents, and enables the solid metal to emit heat and melt. The pulse magnetic oscillation processing device comprises a pulsed power supply and an electromagnetic coil, wherein the electromagnetic coil is controlled by the pulsed power supply to exert a pulse magnetic oscillation effect on the metal melt, and temperature information of the metal melt is recorded continuously through a temperature collecting and recording system. By means of the device, a temperature curve inside the metal melt subjected to pulse magnetic oscillation processing can be obtained through accurate measurement, the measurement device is easy and convenient to use, and measured data are accurate and reliable.

Owner:SHANGHAI UNIV

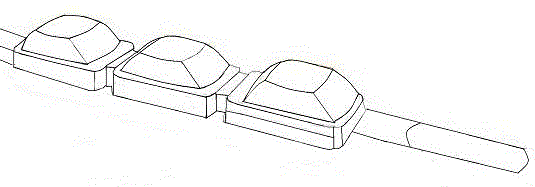

Electromagnetic forming device and method based on modular magnetic trap

The invention discloses an electromagnetic forming device and method based on modular magnetic traps. The electromagnetic forming device comprises a forming coil, a die, a workpiece and a plurality ofmagnetic trap modules. The workpiece and the die are placed adjacently, the modular magnetic traps and the workpiece are placed adjacently, an electromagnetic coil and the modular magnetic traps areplaced adjacently, and a power supply is connected with the forming coil through a cable. When a power supply switch is turned off, a pulse current passes through the forming coil, thus a pulsed magnet field is generated around, and the pulsed magnet field concentrates electromagnetic force in a target forming area through the magnetic concentrating effect of the modular magnetic traps to realizeexpected deformation behavior; and according to different forming needs, the different magnetic concentrating effects are achieved through flexible combination of the multiple magnetic trap modules. Through a modular work mode of the magnetic traps, an electromagnetic forming force field is effectively controlled, the flexibility of adjusting and control over the force field can be improved, the equipment cost is lowered, the various rich forming needs can be met through a single set of equipment, and the flexibility of the process is significantly expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

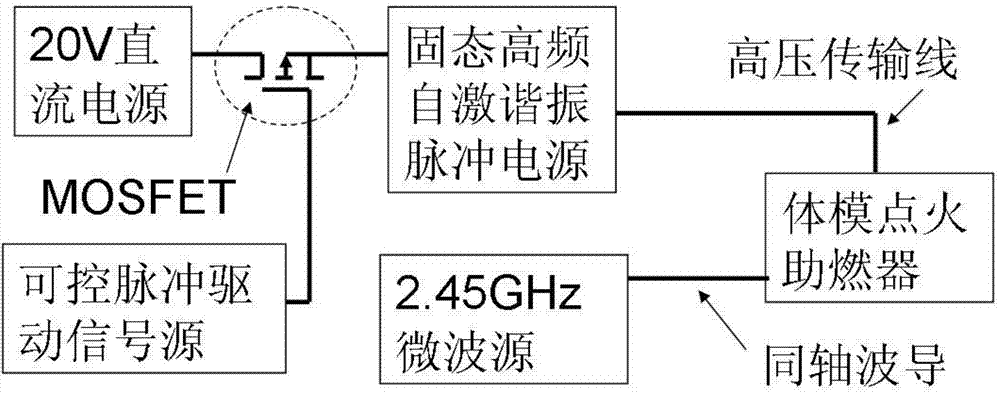

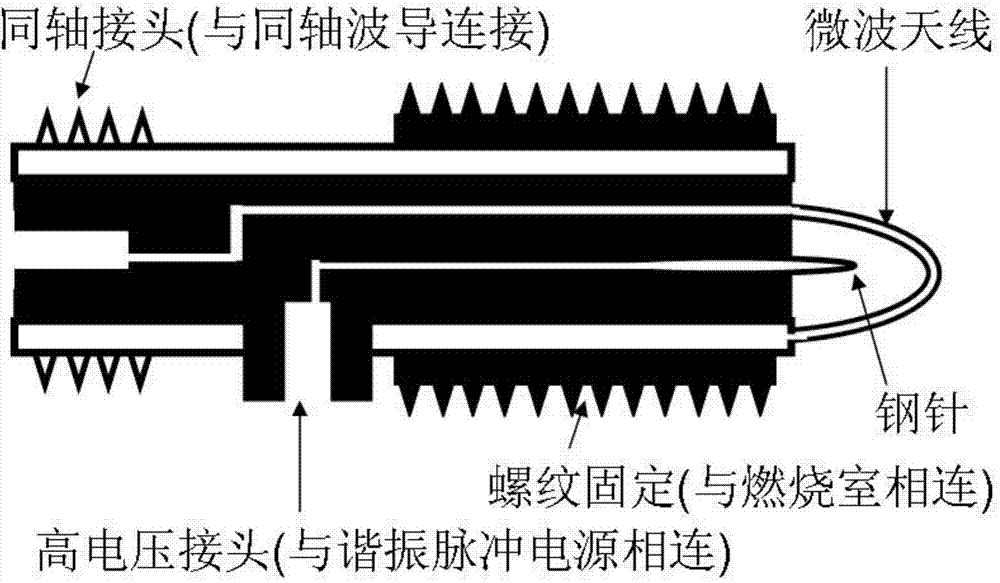

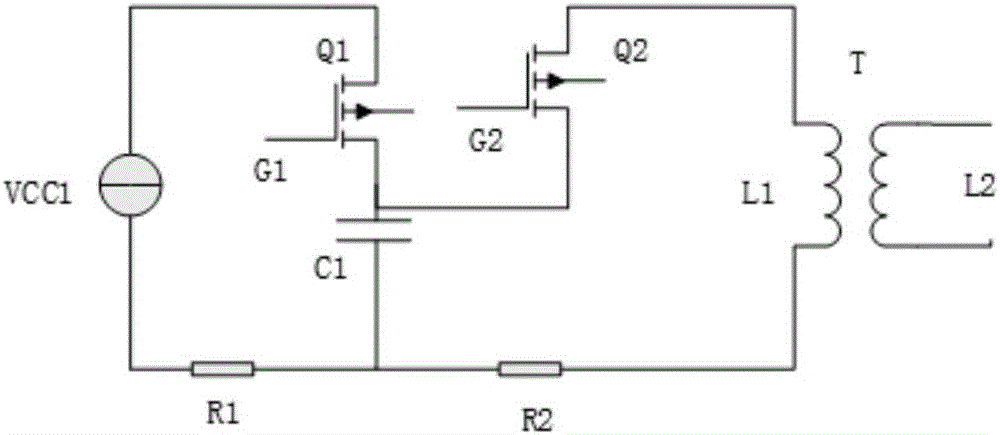

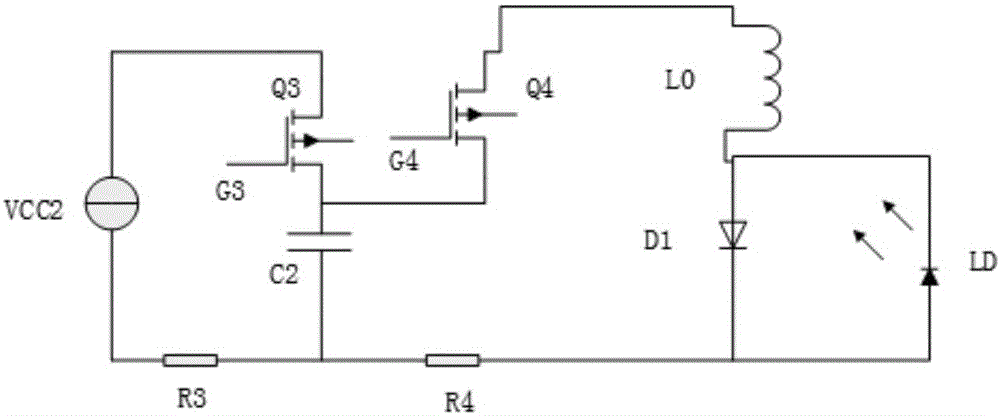

Pulse resonance electric spark trigger microwave discharge body model ignition combustion supporting device

ActiveCN103758678AControllableEase of implementationCombustion-air/fuel-air treatmentMachines/enginesMOSFETPulsed DC

The invention discloses a pulse resonance electric spark trigger microwave discharge body model ignition combustion supporting device. The pulse resonance electric spark trigger microwave discharge body model ignition combustion supporting device comprises a 20V direct current power source, a controllable pulse drive signal source, a metal oxide semiconductor field effect transistor (MOSFET), a solid high-frequency self-excitation resonance pulse power source, a 2.45Ghz microwave source and a body model ignition combustion supporting device, wherein the 20V direct current power source outputs direct voltage, direct current output of a switching pulse is achieved through connection and disconnection of the MOSFET, pulsed direct voltage is applied on a primary winding of a solid pulse air transformer through self-oscillation of a triode so as to achieve high frequency self-excitation magnetism, a pulsed magnet field passes through a secondary winding of the solid pulse air transformer, pulsed high-frequency high voltage is communicated with a high voltage connector of the body model ignition combustion supporting device through a high voltage transmission line, and microwave power output of the 2.45Ghz microwave source is communicated with a coaxial connector of the body model ignition combustion supporting device through coaxial waveguide. The pulse resonance electric spark trigger microwave discharge body model ignition combustion supporting device is characterized by being controllable, easy to achieve, low in cost, and easily transplanted so as to replace an existing ignition device.

Owner:ANHUI UNIV OF SCI & TECH

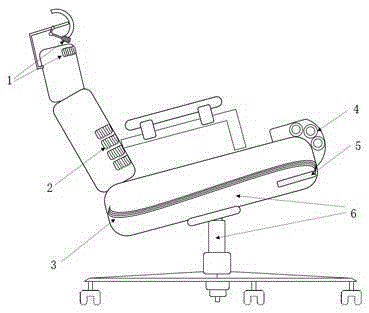

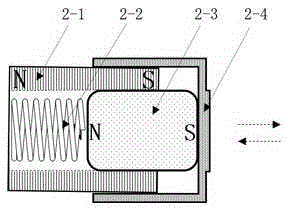

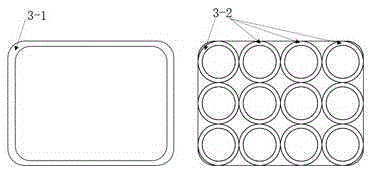

Physiotherapy chair based on pulsed magnet field

InactiveCN105363130AReduce volumeRelieve muscle fatigueElectrotherapyMagnetotherapy using coils/electromagnetsPulsed magnetReciprocating motion

The invention discloses a physiotherapy chair based on a pulsed magnet field. The physiotherapy chair is composed of a neck coil 1, waist and back coils 2, a cushion coil 3, knee coils 4, a peripheral circuit 5 and a chair 6. Each coil can contain the structures including an outer-layer coil, a spring, a permanent magnet and a coating layer. After recurrent pulse current with adjustable pulse width, frequency and amplitude is introduced into each oil, the permanent magnet can perform reciprocating motion under the action of the magnetic force and the elastic force; with the structure, the physiotherapy chair can carry out pulse magnetotherapy or vibration massage on a user independently, and also can carry out both the pulse magnetotherapy and vibration massage on the user according to the demands.

Owner:SHANXI BREATH TECH CO LTD

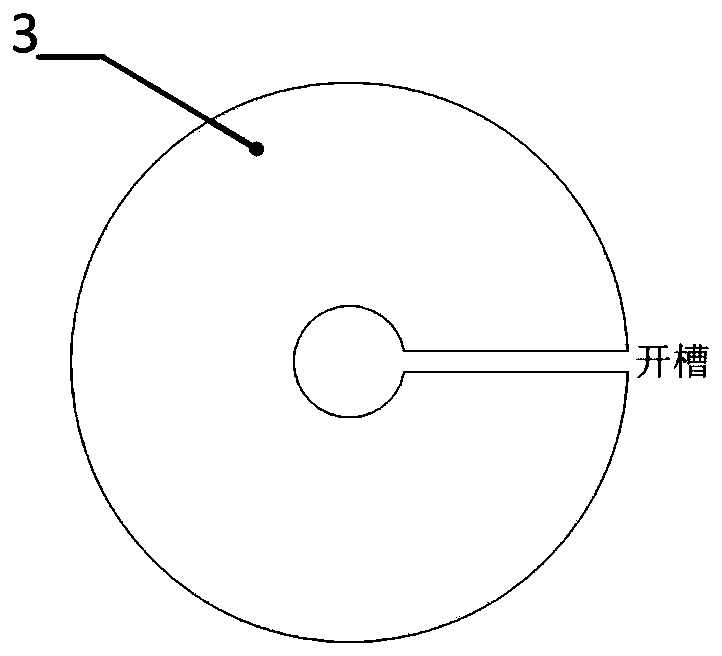

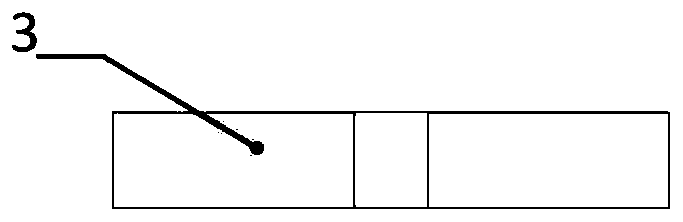

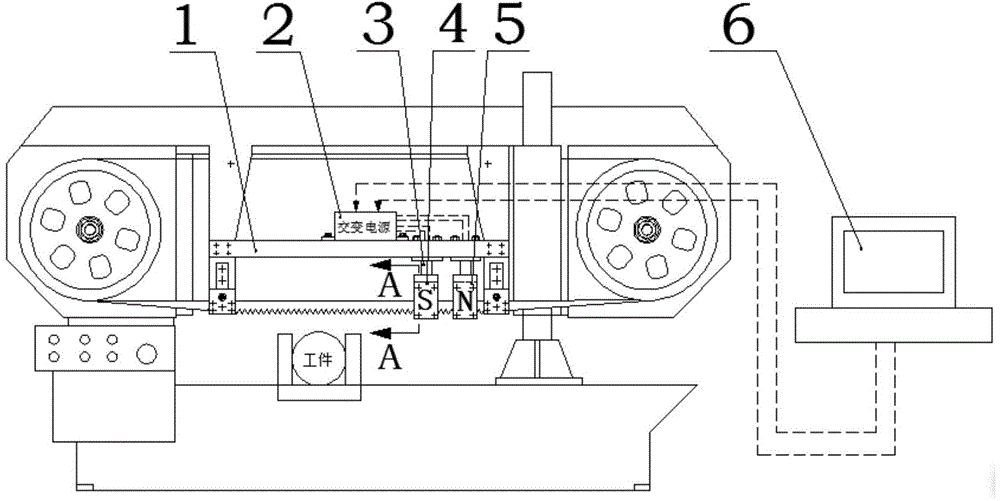

Pulsed magnet field removing device for sawtooth adhered scraps

InactiveCN104551230ARealize automatic dischargeReduce wearMetal sawing accessoriesMaintainance and safety accessoriesPulsed magnetElectric machinery

The invention discloses a pulsed magnet field removing device for sawtooth adhered scraps. The pulsed magnet field removing device for the sawtooth adhered scraps comprises a pulse alternating power supply, clamping mechanisms, a first electromagnetic coil, a second electromagnetic coil, an industrial personal computer and an iron core, wherein the iron core comprises a first iron core and a second iron core; the structures of the first iron core and the second iron core are the same completely; each iron core is of a rectangular structure; an opening is formed in the bottom side of each iron core; the first electromagnetic coil and the second electromagnetic coil are respectively wound on the iron cores and are opposite in winding direction; the first iron core and the second iron core are respectively fixed on a cross beam of a sawing machine through one clamping mechanism; one end face of each iron core is directed at one side face of a band-saw blade; the other end face of each iron core is directed at the other side face of the band-saw blade; the first electromagnetic coil and the second electromagnetic coil are respectively connected with the pulse alternating power supply; the pulse alternating power supply is connected with the industrial personal computer through an external cable. According to the pulsed magnet field removing device for the sawtooth adhered scraps, the functions of reducing the abrasion of the band-saw blade and reducing the cutting load of a motor and the roughness of the processed surface of a workpiece can be realized, and the cutting efficiency is improved.

Owner:HANGZHOU DIANZI UNIV

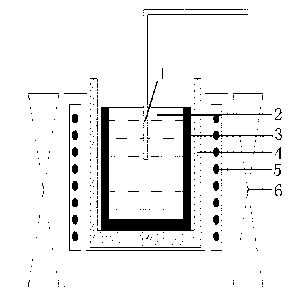

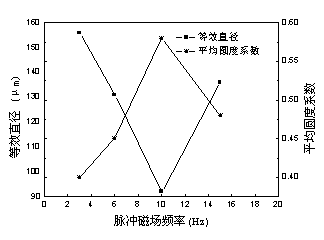

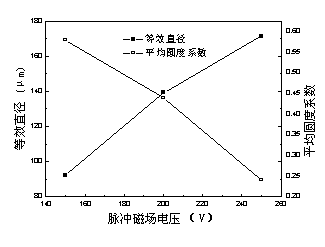

Method for preparing ZL114A aluminum alloy semi-solid slurry by using pulsed magnet field

The invention discloses a method for preparing ZL114A aluminum alloy semi-solid slurry by using a pulsed magnet field. The method comprises the following steps of: pouring a molten ZL114A aluminum alloy melt into a preheated preparation device; reducing the temperature to 0 to 30 DEG C above the liquidus temperature; applying the pulsed magnet field to the ZL114A alloy melt for oscillation treatment, wherein the frequency of the pulsed magnet field is 1 to 15Hz, the voltage of the pulsed magnet field is 10 to 250V, the cooling rate of the alloy melt is 0.1 to 2 DEG C / s when the melt is treated by using the pulsed magnet field, and the treatment temperature range of the pulsed magnet field is 0 to 30 DEG C above an alloy liquidus; finishing the treatment of the pulsed magnet field till the temperature of 5 to 35 DEG C below the liquidus, wherein the treatment time of the pulsed magnet field is 0.5 to 6 minutes, and the concrete treatment time and the final treatment temperature are determined according to the requirement of a product on the solid fraction; and preserving heat for 1 to 5 minutes to obtain a finished product. The process is simple, efficient and low in energy consumption; and by the method, high-quality ZL114A aluminum alloy semi-solid slurry can be prepared.

Owner:NANCHANG HANGKONG UNIVERSITY

High-strength uniform-induction electric field generator based on Archimedes spiral coil

ActiveCN104941069ASuppressor mutationSuppression amplitudeElectrotherapyMagnetotherapyPulsed magnetHigh intensity

The invention discloses a high-strength uniform-induction electric field generator based on an Archimedes spiral coil. According to the generator, a pulse current is generated through an LRC discharge circuit, the generated pulse current is introduced in the Archimedes spiral coil to generate a pulsed magnet field, and an induced electric field parallel to a coil plane surface is generated in the surface region of the coil. The induced electric field is high in amplitude value and uniform in distribution, and the coverage area of the induced electric field is the area, where the coil is positioned only. When the coil is close to tumor tissue of a body surface, the induced electric field concentrates on tissue in the coverage area of the coil, influences on surrounding normal tissue are avoided and the purpose of non-contact, non-invasion and accurate tumor treatment can be realized.

Owner:CHONGQING UNIV

Electromagnetic pulse fast solution-aging process for aluminum alloy component

The invention discloses an electromagnetic pulse fast solution-aging process for an aluminum alloy component. The electromagnetic pulse fast solution-aging process comprises the following steps that S1, firstly, the aluminum alloy component or a blank is put in a pulsed electric field, electrified and heated to solution temperature or above, thus the second phase of the aluminum alloy component orthe blank is dissolved fast, then the aluminum alloy component or the blank is cooled rapidly to indoor temperature with the rate larger than or equal to 80 DEG C / s, and supersaturated solid solutionis formed; and S2, the aluminum alloy component or the blank obtained after solution treatment is put in a pulsed magnet field, magnetic pulse fast aging treatment is conducted, aging treatment timeis 1-12 h, solute atoms obtained after solution treatment are nucleated and precipitated from a substrate, and a precipitated phase in dispersed distribution is formed. Fast solution-fast aging treatment can be conducted, thus comprehensive performance of the aluminum alloy component is promoted, and the purposes of energy saving and environmental protection are achieved.

Owner:WUHAN UNIV OF TECH

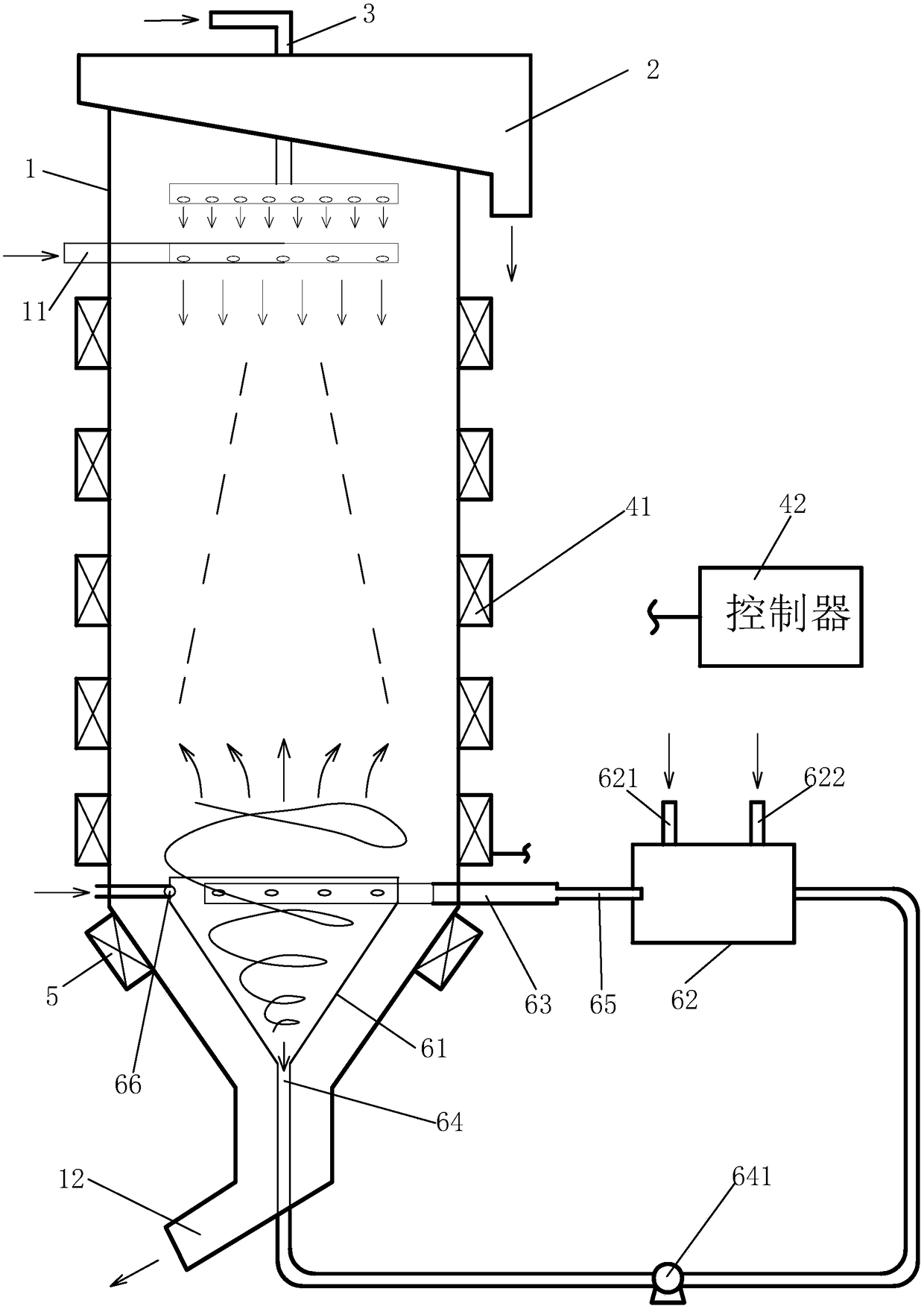

Floatation magnetic separation column device and combined type bubble generator

The invention discloses a floatation magnetic separation column device. The top of a column casing is provided with an overflow groove. The upper portion inside the column casing is provided with a spray device and an ore inlet. A pulsed magnet field and a demagnetizing device are mounted outside the column casing. The bottom of the column casing is provided with an iron ore concentrate outlet anda combined type bubble generator, wherein the combined type bubble generator comprises a conical barrel and a suction chamber. The conical barrel is arranged in the column casing in a sleeved manner,and a gap is reserved. The top of the column casing is open and communicates with the interior of the column casing. A tangential water pipe and a feeding pipe are arranged at the positions, on the upper portion of the conical barrel, inside the column casing. The bottom of the conical barrel is provided with a discharging pipe which extends out of the bottom of the column casing. The dischargingpipe is provided with a pump. The other end of the discharging pipe is connected to one side of the suction chamber. The suction chamber is provided with a gas inlet and an auxiliary agent addition opening. The other side of the suction chamber is connected with the feeding pipe of the conical barrel through a small-diameter throat pipe. The floatation magnetic separation column device is simplein structure, high in separation index and easy to operate; the grade of concrete can be remarkably raised; and by means of the combined type bubble generator, the generation quality of bubbles can beimproved, and the number of the generated bubbles can be increased; and the floatation treatment effect is improved.

Owner:JIANGSU DAFENG XINANDE MINING CO LTD

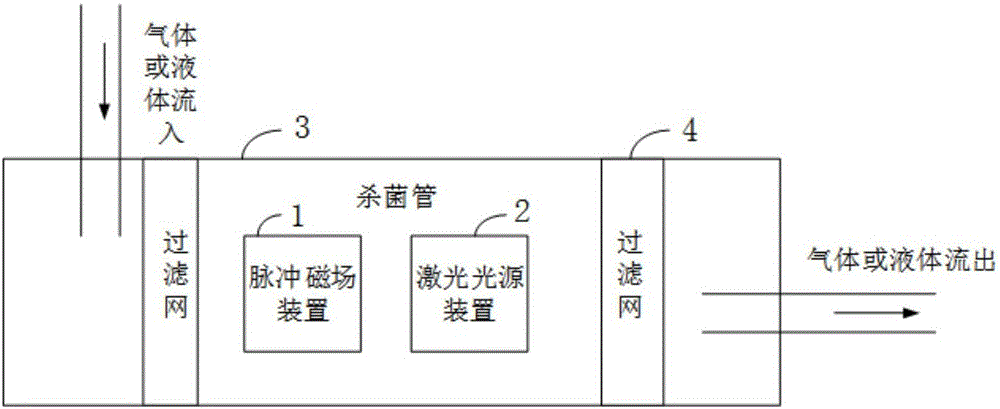

High-frequency sterilization system and method

ActiveCN106110348AEradicateCompletely eliminate dead endsLavatory sanitoryDeodrantsPulsed magnetHazardous substance

The invention belongs to the technical field of laser sterilization and provides a high-frequency sterilization system and method. The high-frequency sterilization system comprises a pulsed magnet field device and a laser source device. The pulsed magnet field device is used for producing a pulsed magnet field. The laser source device is used for producing pulse laser. The high-frequency sterilization system adopts the sterilization mode of combining laser scattering and the high-frequency pulse electromagnetic field to perform sterilization, improves the sterilizing rate, is especially suitable for sterilization of circulating air or flowing liquid, does not use hazardous substances in the whole sterilization process and improves the usage safety. In addition, a sterilization region is wide, and bacteria in an acting region can be thoroughly killed in a dead-angle-free mode.

Owner:魔水科技(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com