Floatation magnetic separation column device and combined type bubble generator

A technology of bubble generator and magnetic separation column, used in flotation, solid separation and other directions, can solve the problems of complex addition of chemicals, low separation index, and improve concentrate grade, etc., to improve the quality and quantity of production, simple structure, The effect of boosting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

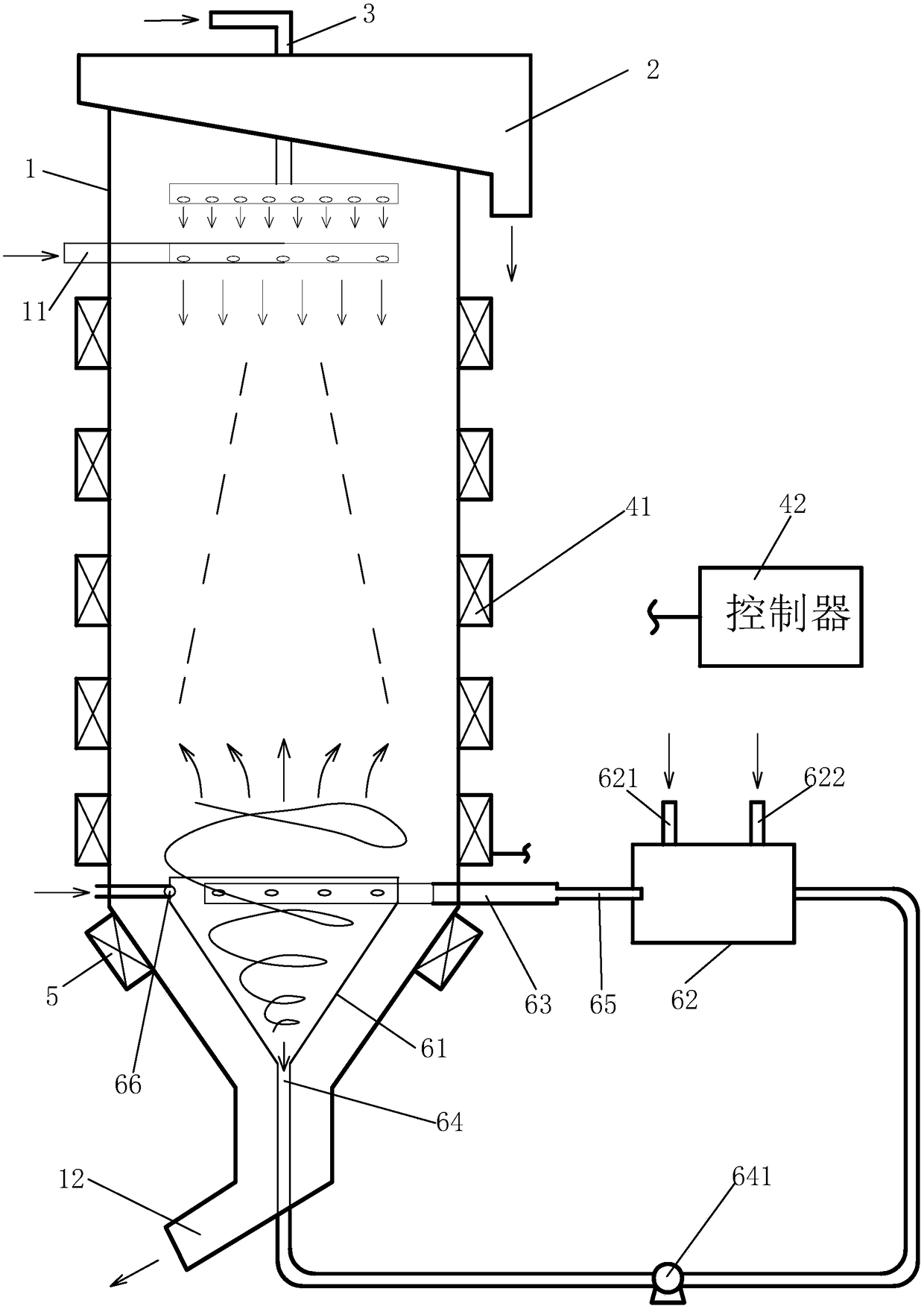

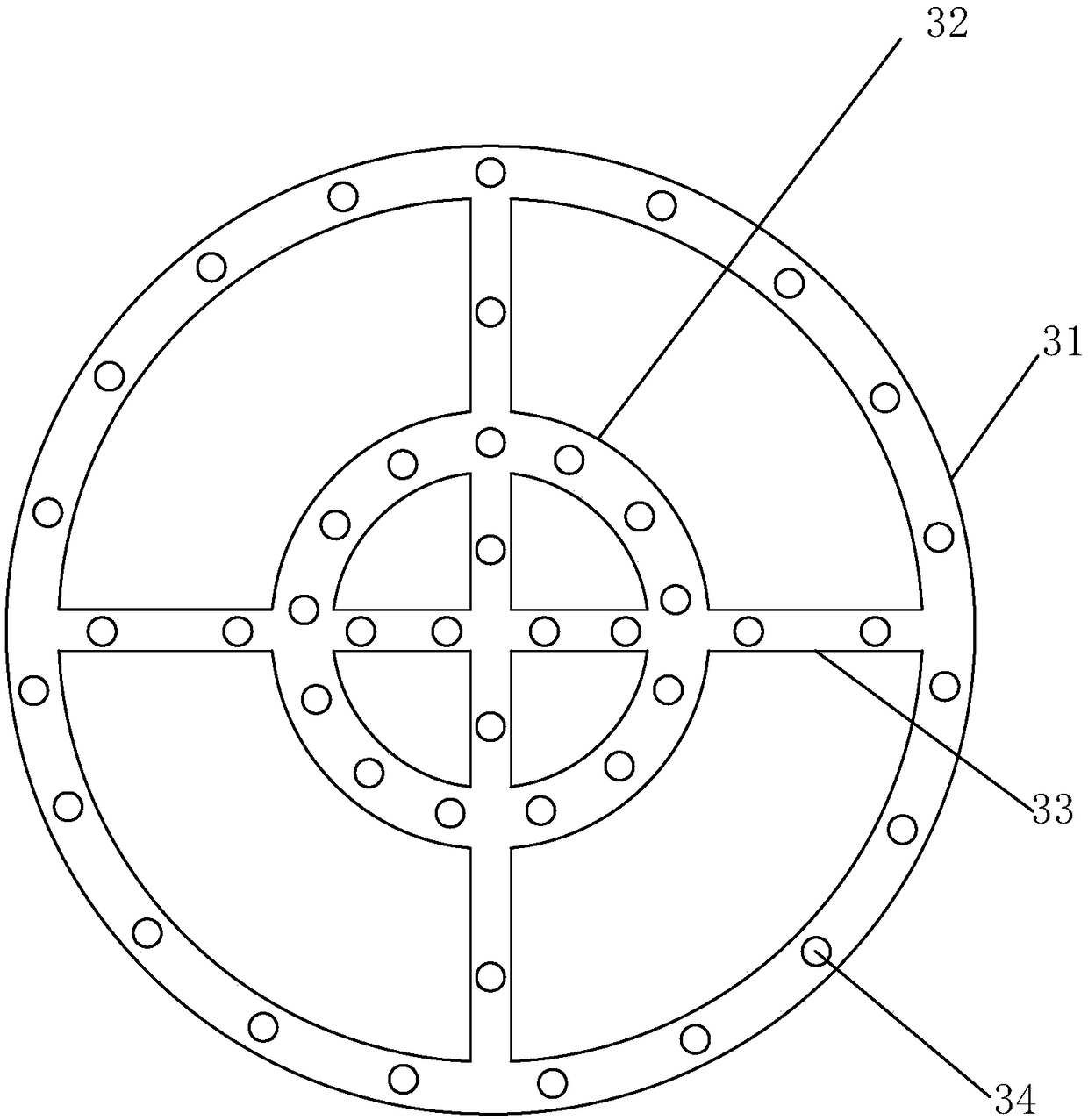

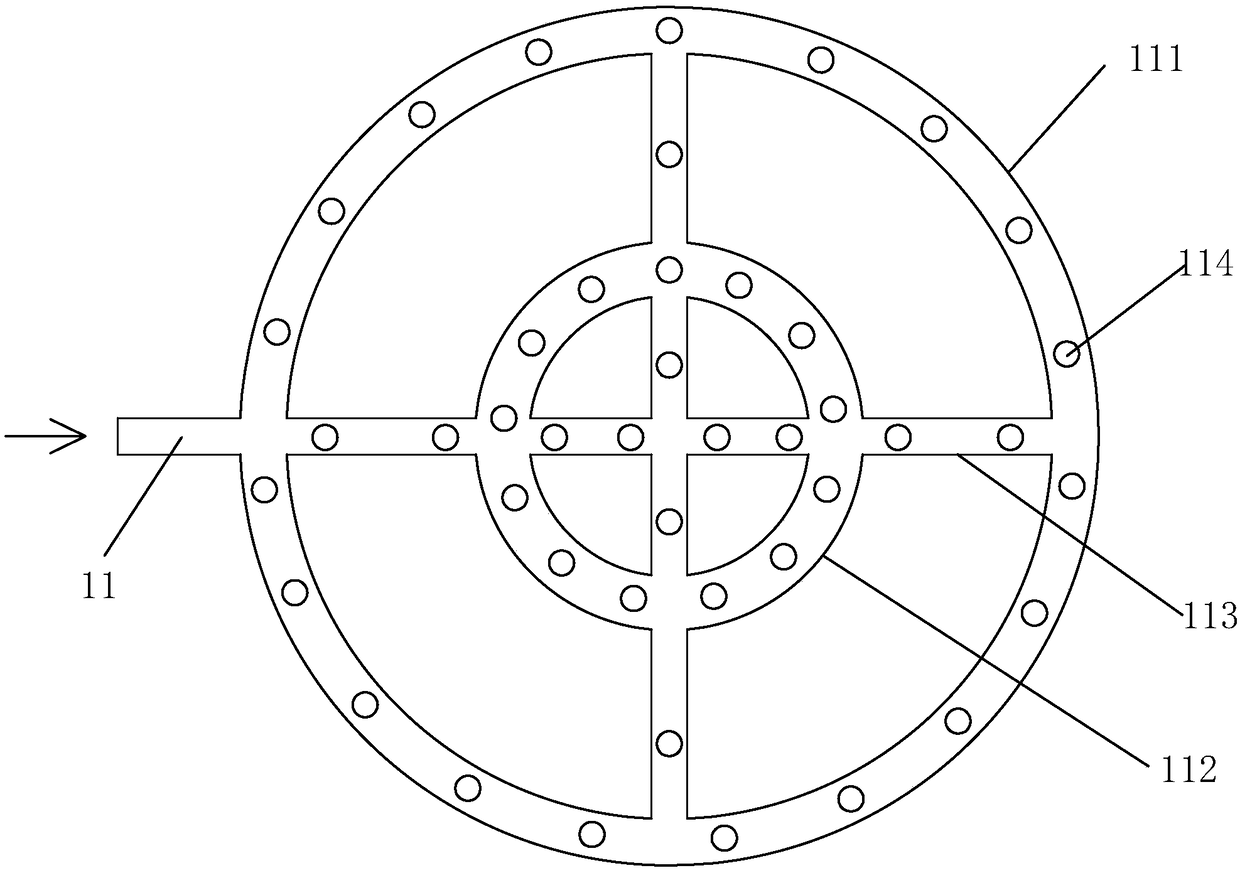

[0036] Such as Figure 1 to Figure 7 As shown, the present invention discloses a floating magnetic column separation device. An overflow tank 2 is arranged on the top of the column barrel 1, a sprinkler 3 is arranged on the upper part of the column barrel 1 and an ore inlet 11 is opened, and the outer inlet of the column barrel 1 is A pulsed magnetic field generator 4 is installed below the mine mouth 11, a demagnetizer 5 is installed outside the column 1 below the pulsed magnetic field generator 4, the diameter of the bottom of the column 1 is gradually reduced to form an iron concentrate outlet 12, and the bottom of the column 1 is installed Combined bubble generator6.

[0037] The combined air bubble generator 6 disclosed by the present invention includes a cone 61 and a suction chamber 62, the cone 61 is sleeved in the column 1, there is a gap between the cone 61 and the column 1, and the top of the cone 61 is The opening is provided for communicating with correspondingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com