Patents

Literature

685results about How to "Improve build quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

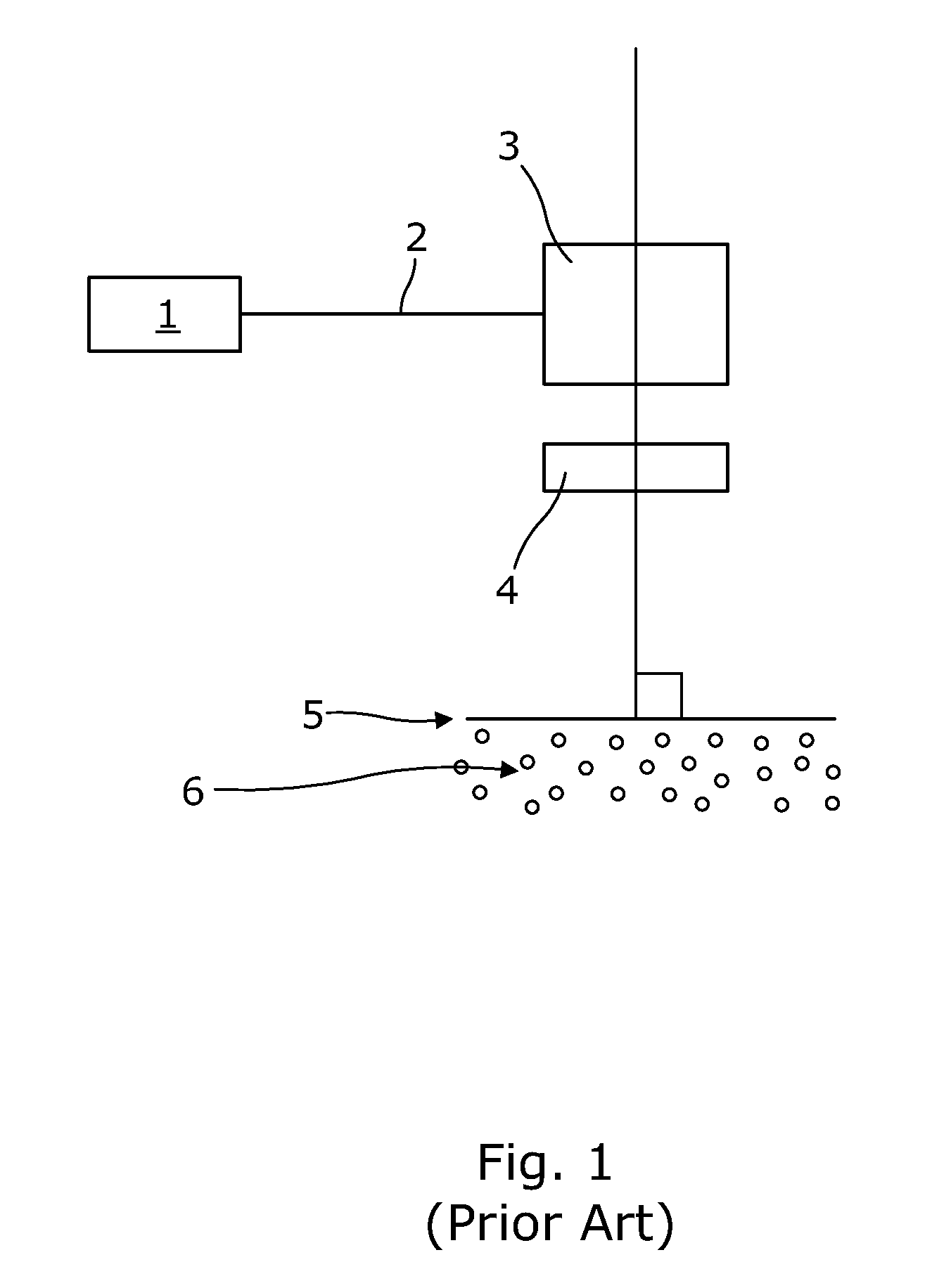

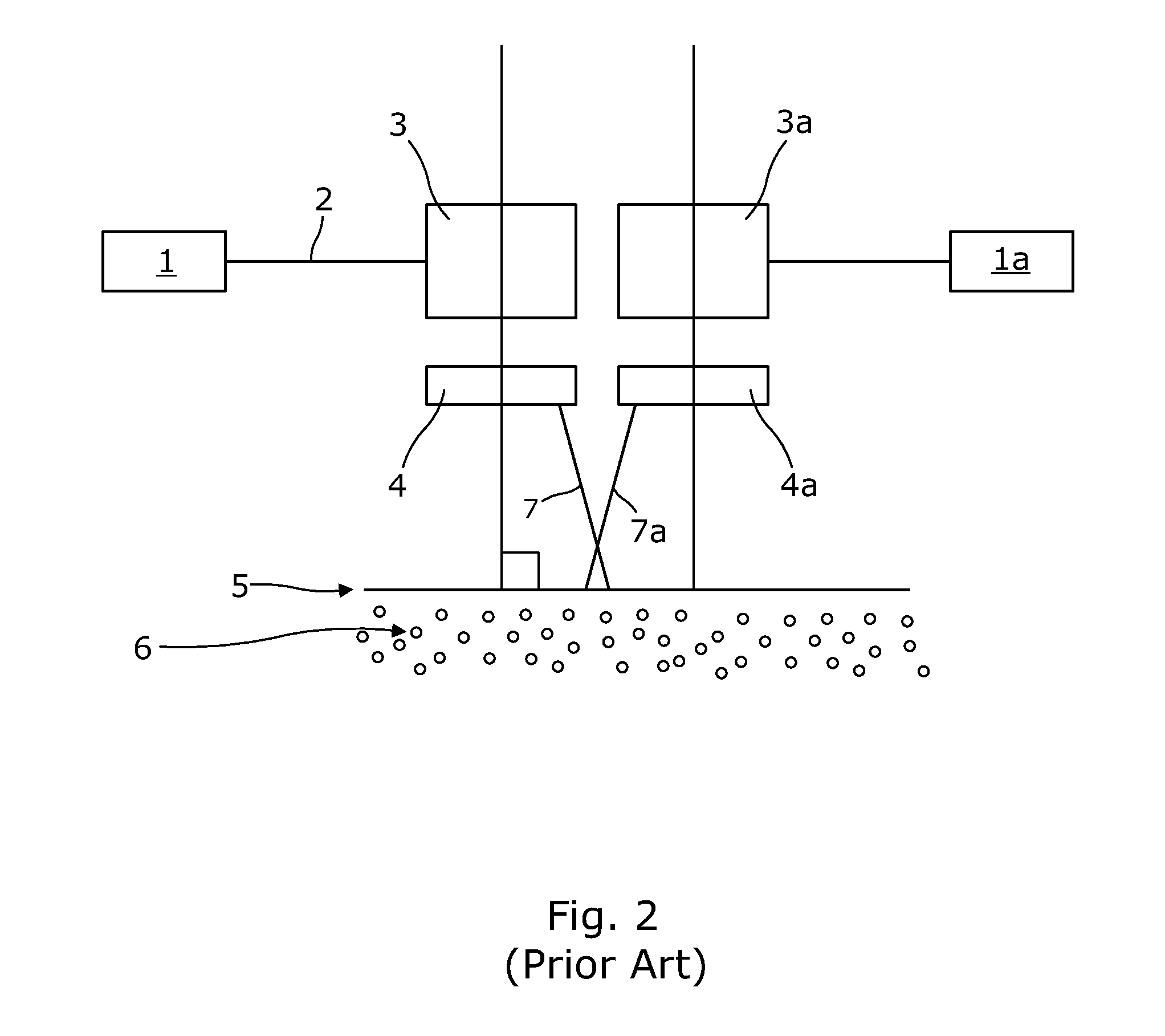

Apparatus and methods for additive-layer manufacturing of an article

ActiveUS20130270750A1Minimise impactSmall spot sizeAdditive manufacturing apparatusAuxillary shaping apparatusOptoelectronicsLaser beams

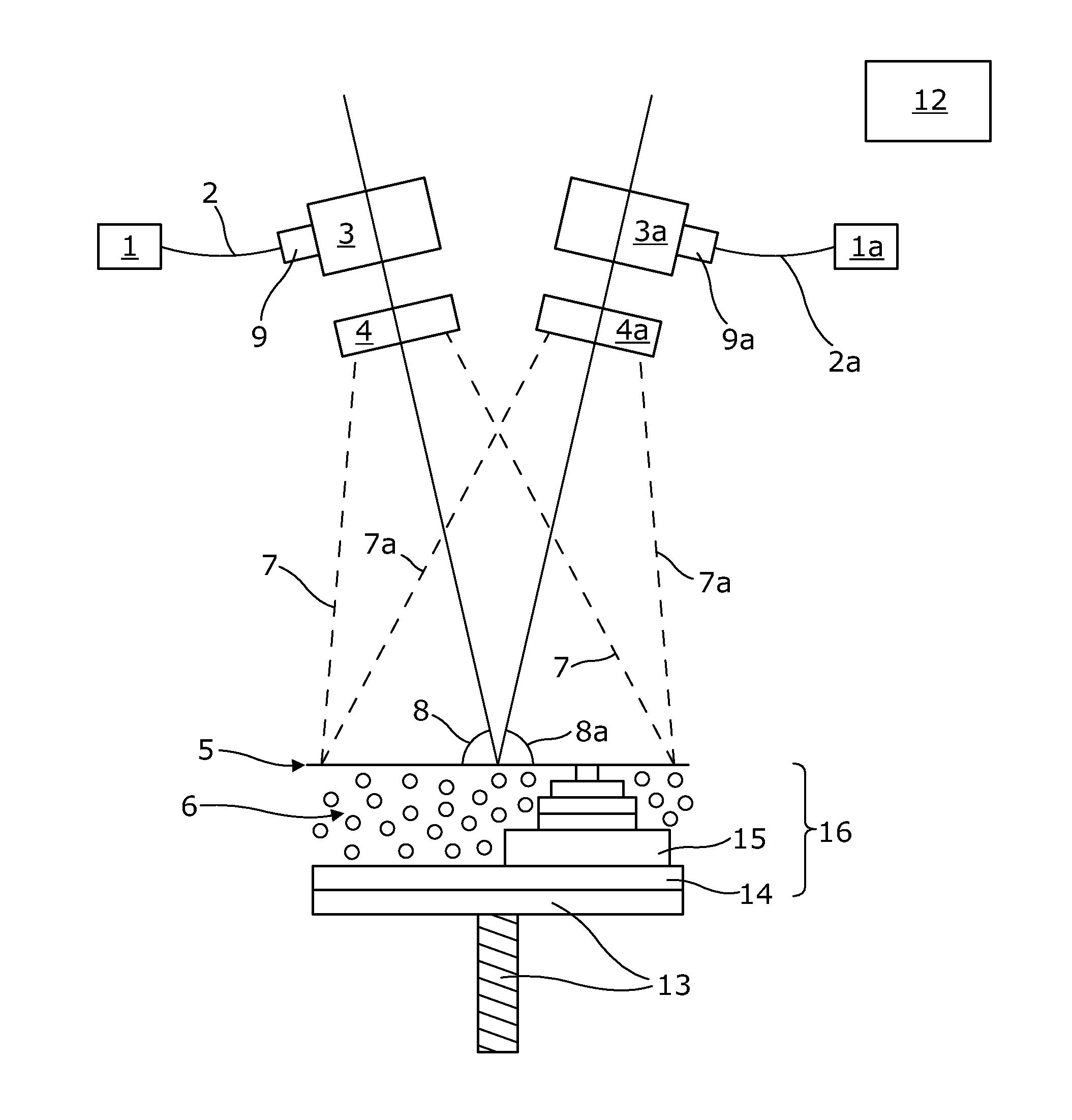

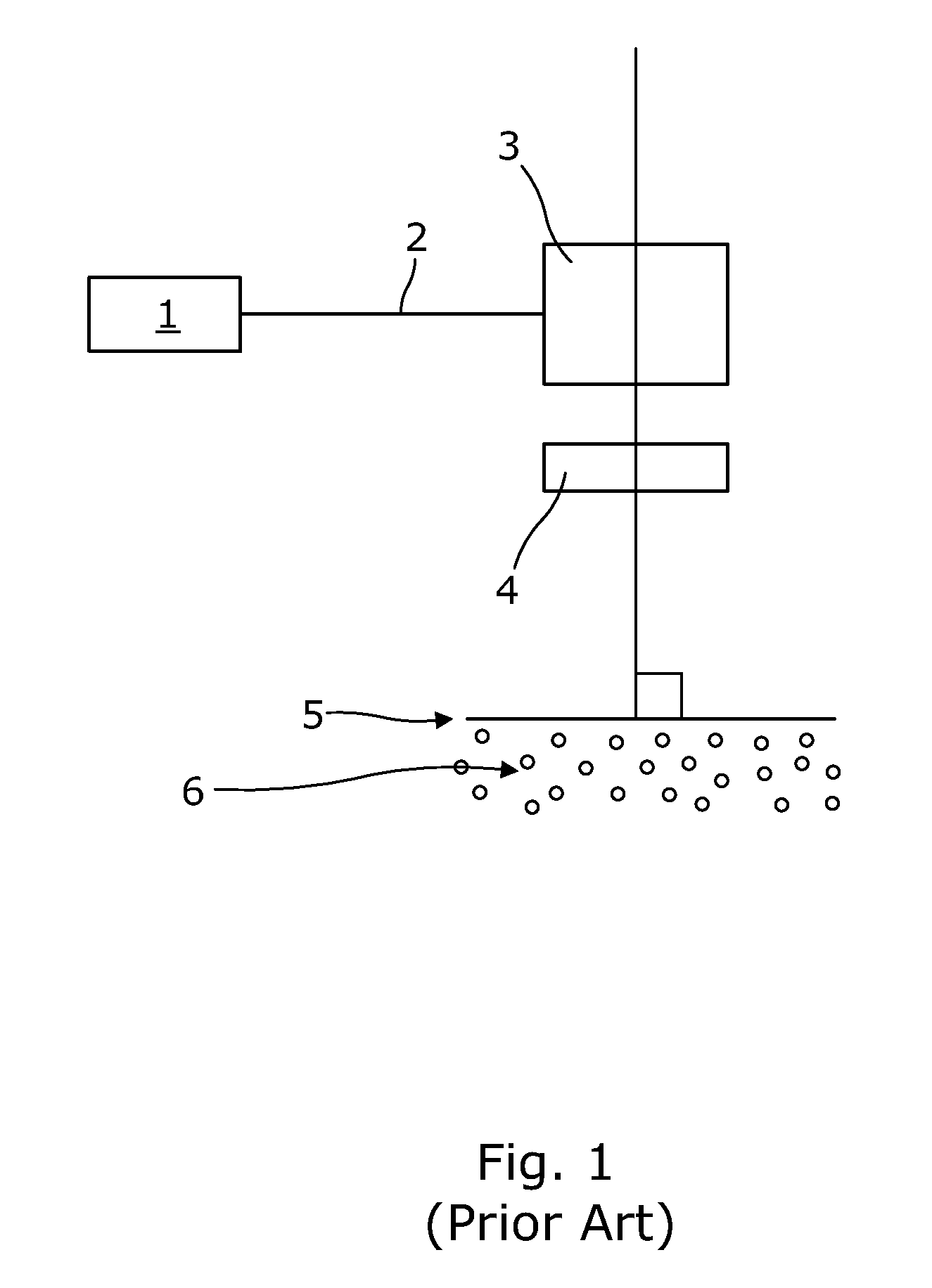

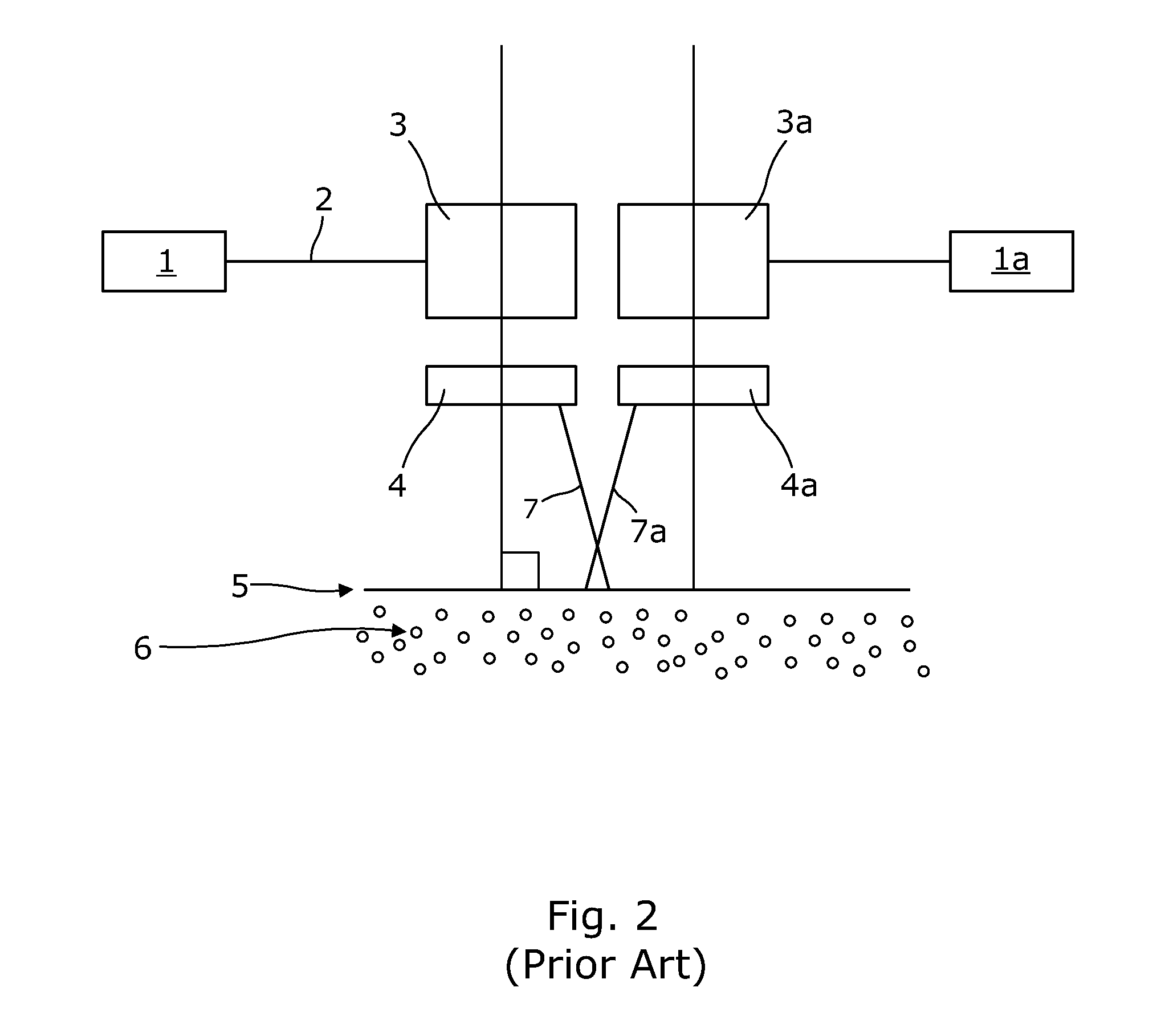

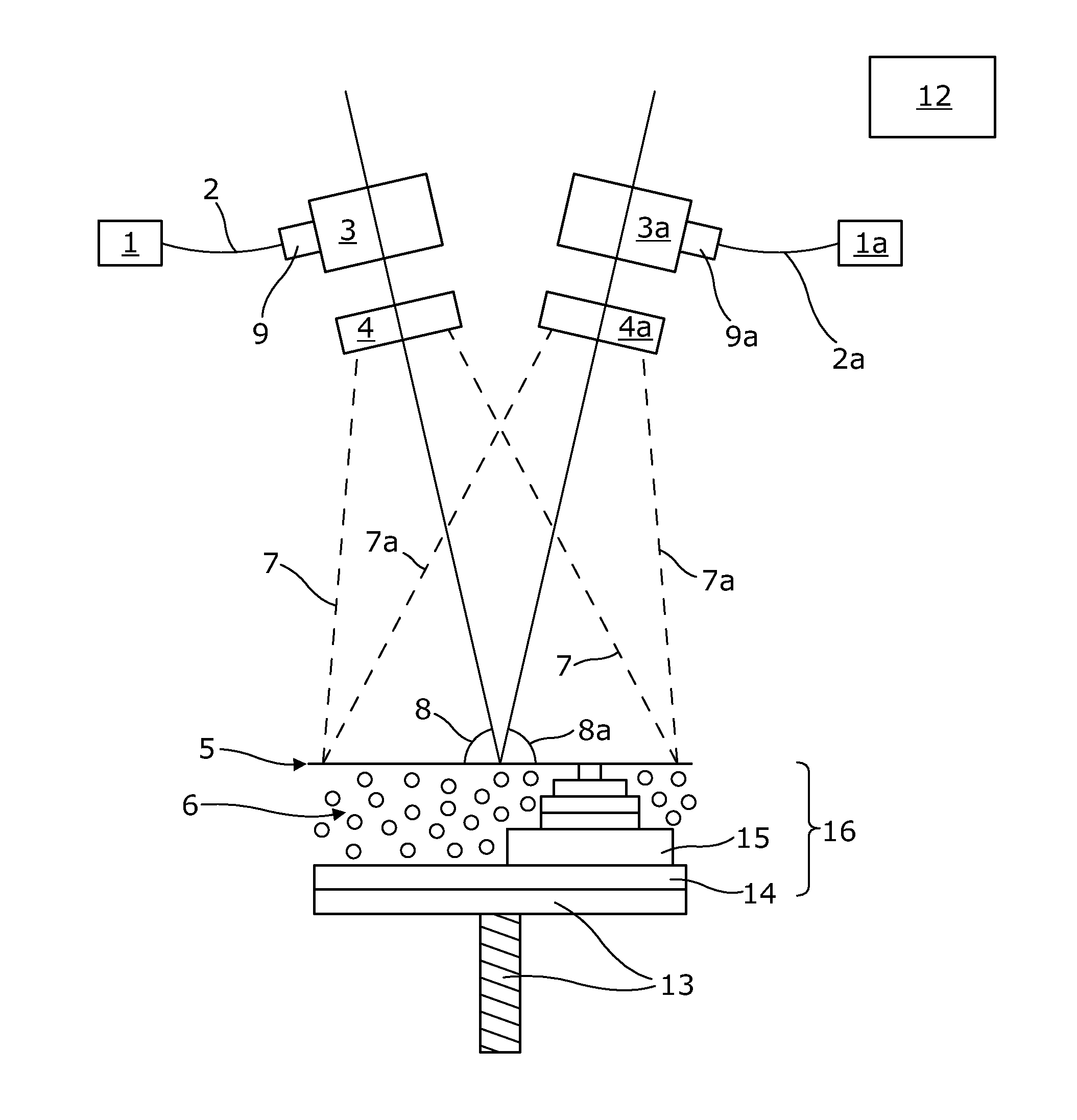

Apparatus is for additive layer manufacturing of an article from a material which can be rendered solid locally by application of a focused beam of laser radiation at a planar focal plane. The apparatus includes at least two laser beams, respective scanners for each laser beam for scanning the respective laser beams over a planar field, and a support movable stepwise to allow successive manufacturing layer cycles and for supporting material within the field. The entire planar field is common to each scanner and at least one scanner is tilted with respect to the planar field, and the at least one scanner is provided with a lens arranged to generate a focal plane tilted with respect to that scanner.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Apparatus for additive layer manufacturing of an article

ActiveUS9314972B2Minimising any impact on the resultant build qualitySmall and precise spot sizeAdditive manufacturing apparatusAuxillary shaping apparatusOptoelectronicsLaser beams

Apparatus is for additive layer manufacturing of an article from a material which can be rendered solid locally by application of a focused beam of laser radiation at a planar focal plane. The apparatus includes at least two laser beams, respective scanners for each laser beam for scanning the respective laser beams over a planar field, and a support movable stepwise to allow successive manufacturing layer cycles and for supporting material within the field. The entire planar field is common to each scanner and at least one scanner is tilted with respect to the planar field, and the at least one scanner is provided with a lens arranged to generate a focal plane tilted with respect to that scanner.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

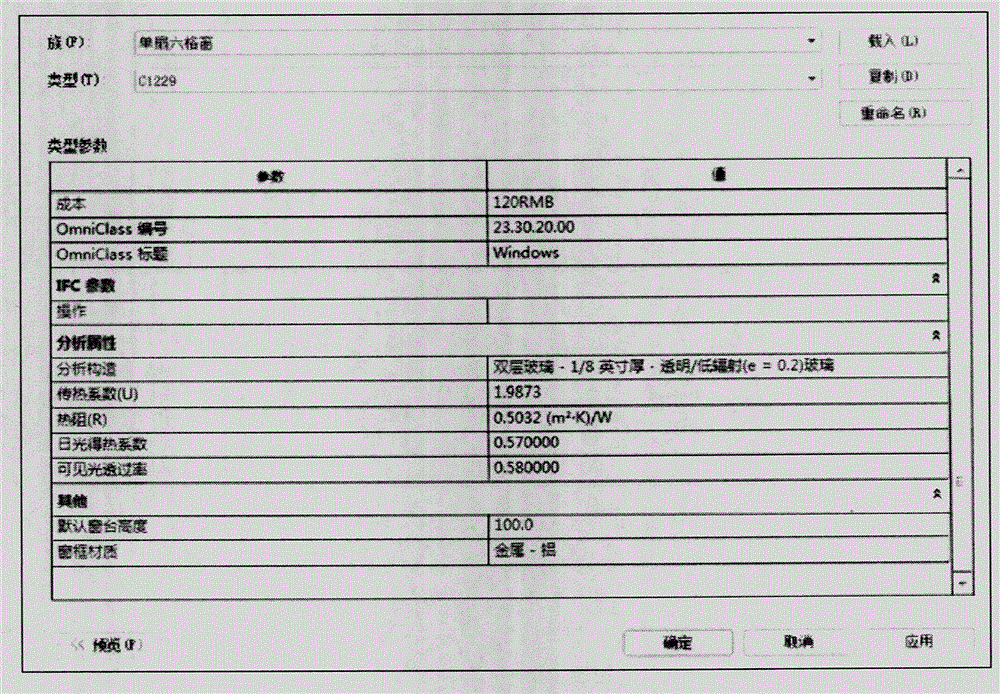

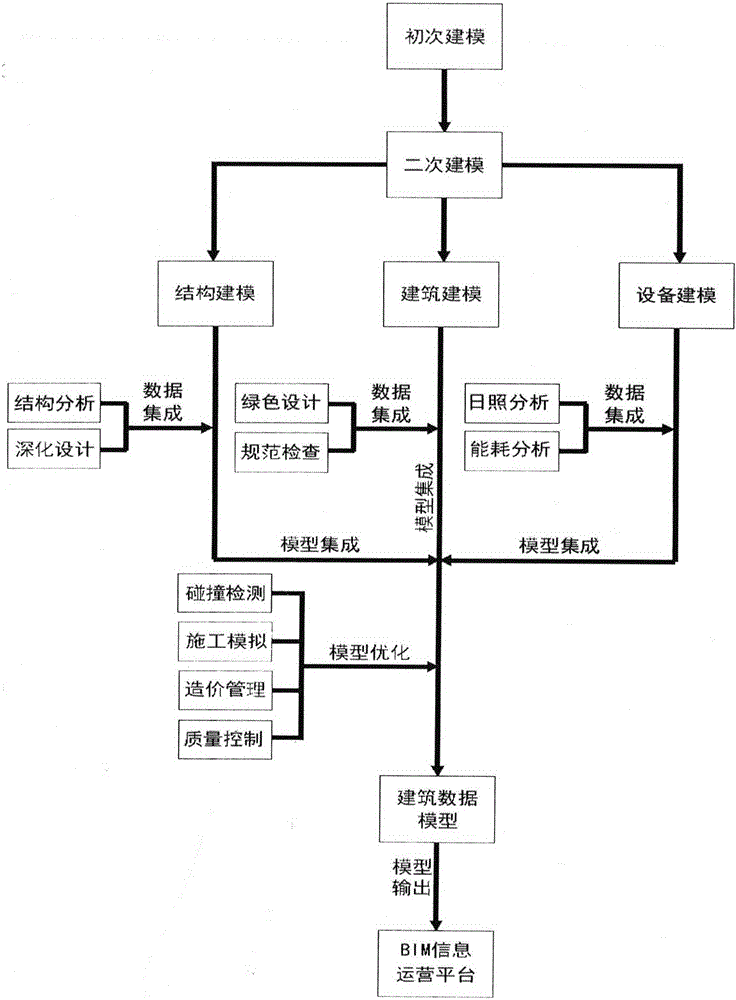

Construction engineering data modeling method based on BIM (Building Information Modeling) technology

InactiveCN105868440AImprove build qualityGood interaction abilityGeometric CADSpecial data processing applicationsInformatizationData modeling

The invention relates to a construction engineering data modeling method based on the BIM (Building Information Modeling) technology. The technical scheme of the construction engineering data modeling method comprises the steps of: primary modeling: carrying out visual geometric modeling design on a project through Rhino software, and determining a building shape scheme; secondary modeling: finishing the informatization definition of a three-dimensional primitive in Revit software, wherein the informatization definition of the three-dimensional primitive includes building modeling, structure modeling and equipment modeling, and the building modeling, the structure modeling and the equipment modeling are simultaneously carried out and are mutually associated; model optimization: on the basis of a software analysis platform, carrying out analogue simulation on the model finished in the second step, and finally finishing the further optimization of the model; and integrating a building data model into a BIM information operation platform. The construction engineering data modeling method overcomes the problems that traditional AutoCAD (Computer Aided Design) software information transmission has the defects of losses or distortion, poor cooperativity, lack of equipment data information and the like and the defect that a simulation test can not be carried out. Data on a traditional drawing and text is imported into a three-dimensional model, resources are integrated through the integrated data model, an interactive cooperative capability is good, engineering quality is improved, construction cost is lowered, a construction period is shortened, and safety is improved.

Owner:YANGZHOU UNIV

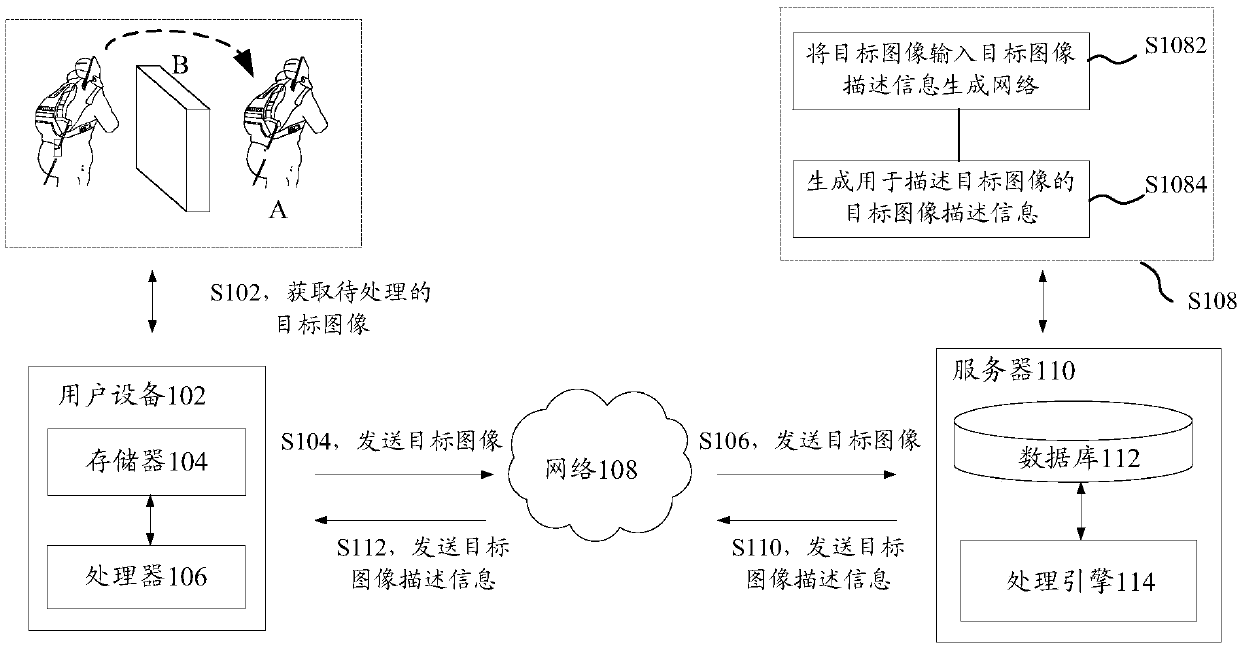

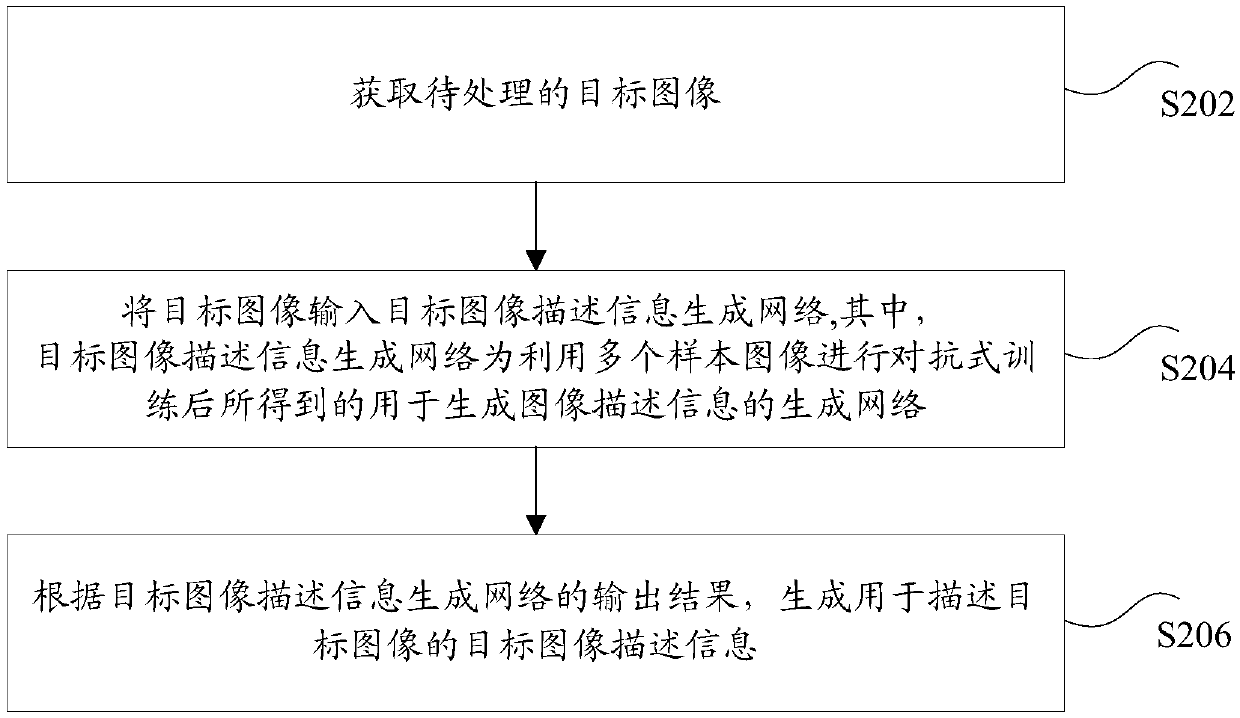

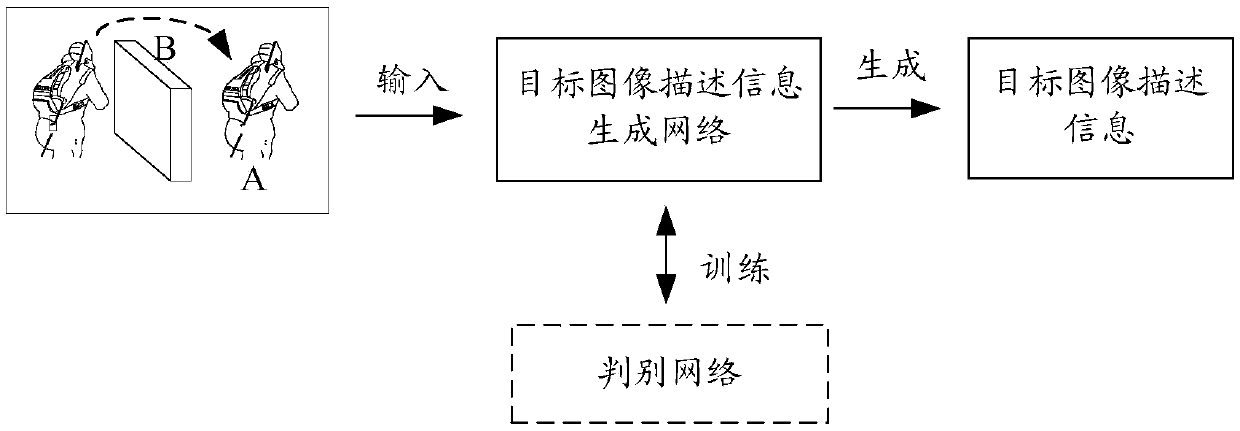

An image description information generation method and device and an electronic device

ActiveCN109685116AImprove build qualityOvercoming technical issues with poor build qualityCharacter and pattern recognitionArtificial lifeComputer graphics (images)Image description

The invention discloses an image description information generation method and device and an electronic device. The method comprises the steps of obtaining a to-be-processed target image; Inputting the target image into a target image description information generation network, wherein the target image description information generation network is a generation network which is obtained by performing adversarial training by utilizing a plurality of sample images and is used for generating image description information; wherein the adversarial training is alternating training based on an initialized image description information generation network matched with the target image description information generation network and an initialized judgment network, and the judgment network is used forjudging an output result of the image description information generation network; And generating an output result of the network according to the target image description information, and generatingtarget image description information for describing the target image. The image description information generation method and device solve the technical problem that an image description information generation method provided by related technologies is poor in generation quality.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Autoclaved aerated concrete block made of gold tailings and its production process

InactiveCN1631836AKeep healthyTake advantage ofSolid waste managementSlagAutoclaved aerated concrete

The invention relates to gold tail mine concrete block and its productive technique, which belongs to wall material for building and productive technical field. Its characteristics is that the main raw material for making concrete block includes slag, cement, burnt lime, aluminum powder and water, and their mess ratio is: slag 60~70%, cement-6~10%, burnt lime-20~30% aluminum powder -0.01~0.05% and the water content can be changed according to the requirement of gold tail slime density. The invention can reach the purposes of environmental protection, energy saving, using the waste, increasing the building's quality and assuring people's health, it can use waste slag completely, with good resistance to coldness and without radioactive harm, can be compound with mortar so that solve the problem of wall surface falling down.

Owner:QIXIA HONGJIAN NOVEL BUILDING MATERIAL

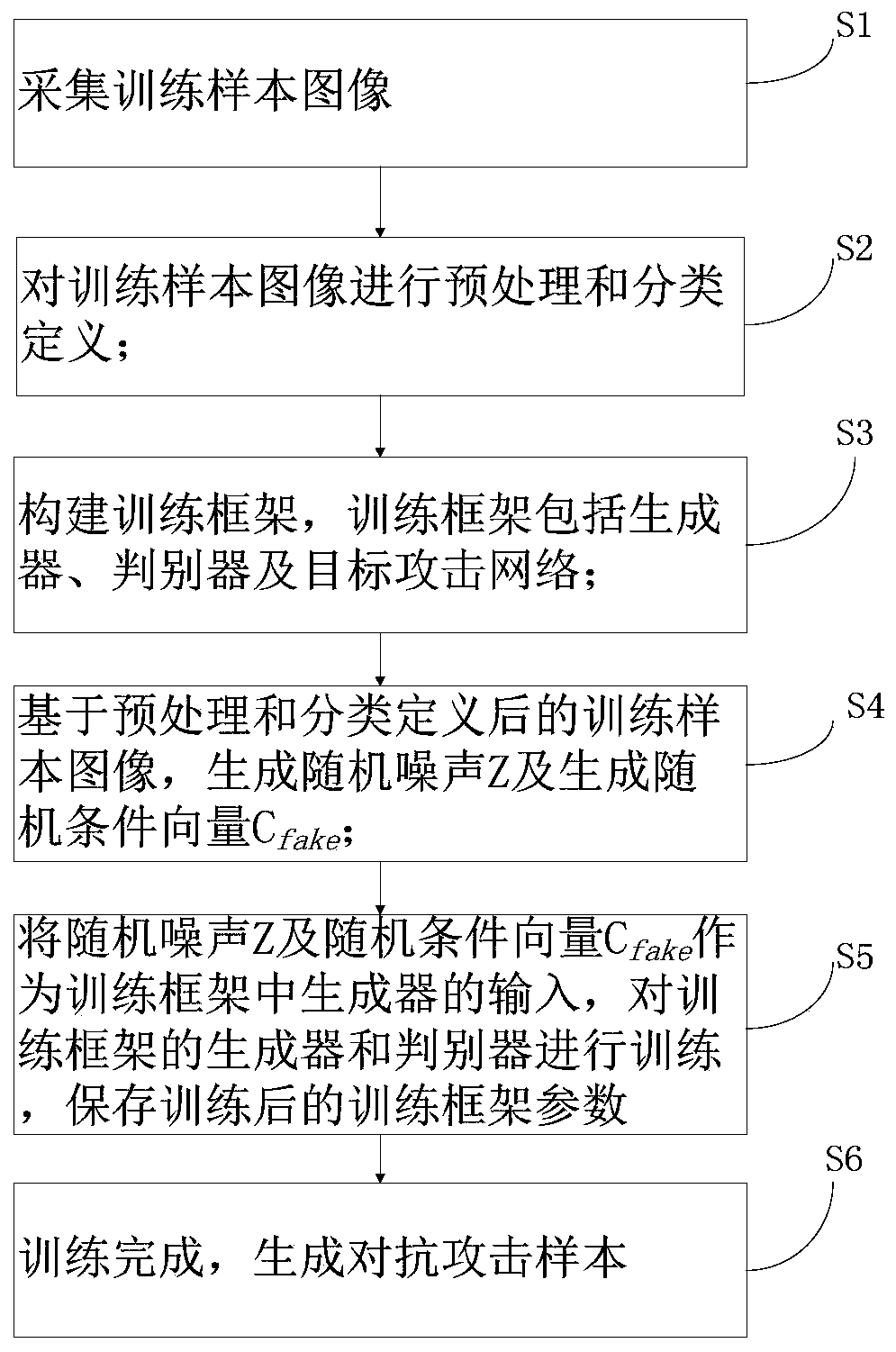

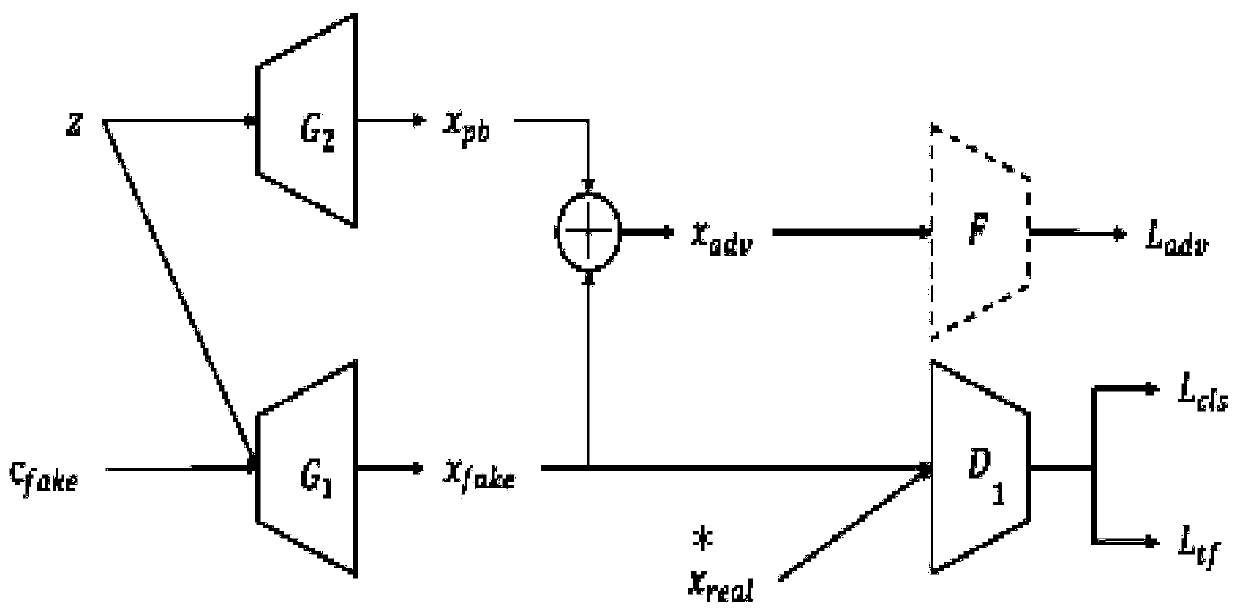

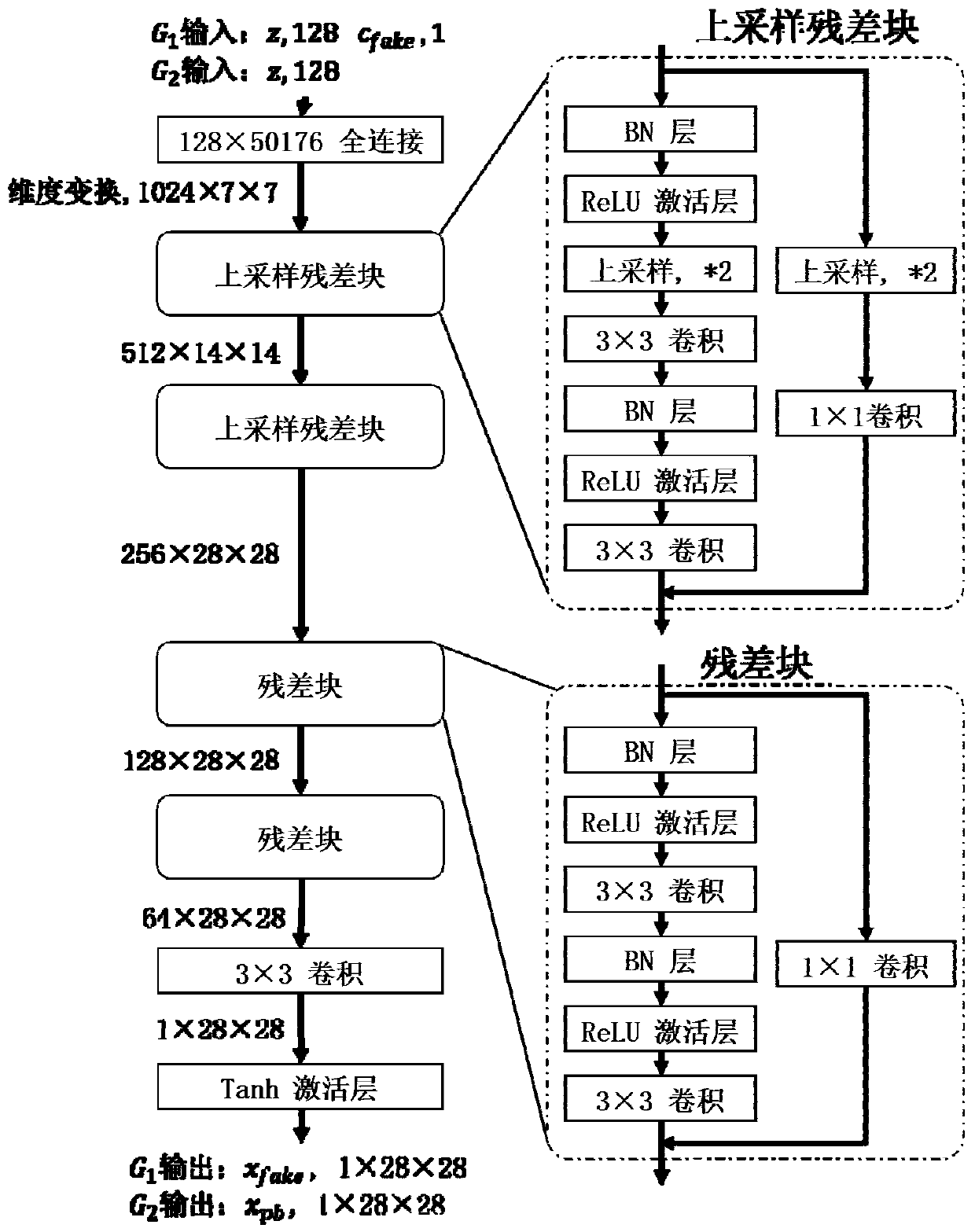

Generative adversarial network-based adversarial attack sample generation method

ActiveCN111275115AStrong data learning abilityImprove build qualityCharacter and pattern recognitionNeural architecturesAlgorithmGenerative adversarial network

The invention provides a generative adversarial network-based adversarial attack sample generation method. The method comprises the steps of S1, collecting a training sample image; s2, preprocessing and classification definition; s3, constructing a training framework, wherein the training framework comprises a generator, a discriminator and a target attack network; s4, generating random noise anda random condition vector based on the training sample images after preprocessing and classification definition; s5, taking the random noise and the random condition vector as input of a generator inthe training framework, training the generator and a discriminator of the training framework, and storing trained training framework parameters; and S6, finishing training, and generating an adversarial attack sample. The method provided by the invention has relatively strong data learning capability and relatively high robustness, overcomes the defect that an existing method lacks learning capability for data distribution based on an optimization equation and matrix measurement of a simple pixel space, and improves the generation quality and efficiency of an anti-attack sample.

Owner:星汉智能科技股份有限公司

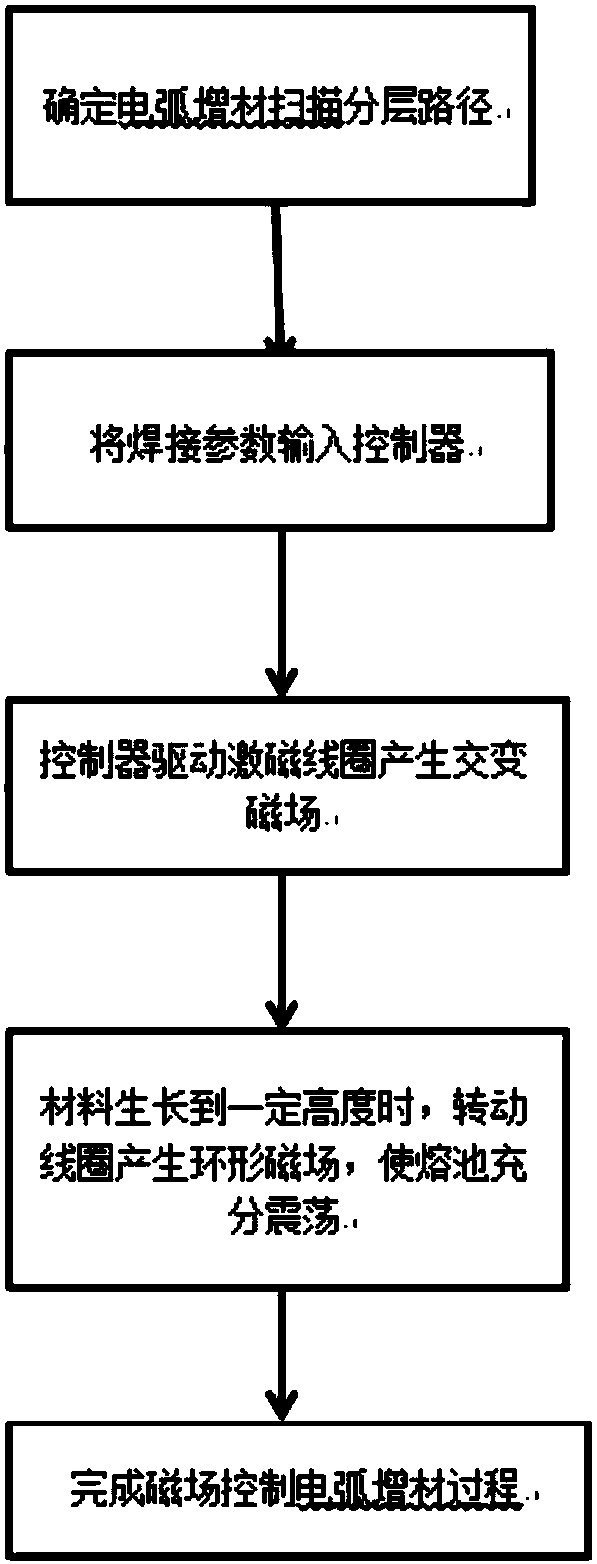

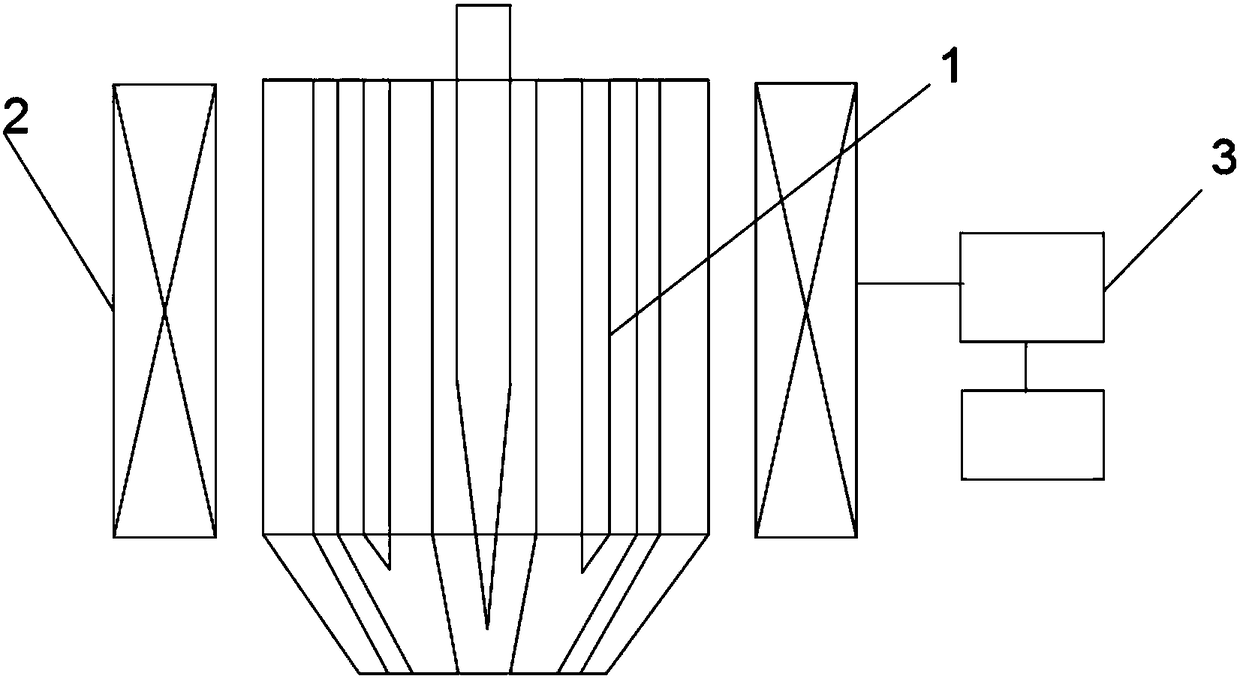

Magnetic field control type additive forming method and device adopting electric arc robot

The invention discloses a magnetic field control type additive forming method adopting an electric arc robot. The method comprises the steps that welding parameters of electric arc additive manufacturing are input into a controller; the controller drives an excitation power supply in a magnetic field generating device to generate longitudinal magnetic fields with different intensities according tothe real-time change of the manufacturing parameters; when air pores are generated on the overlaying surface of an additive part, a hollow shaft motor is used to control exciting coils to rotate to generate an annular magnetic field, and oscillation stirring is carried out on a molten pool at different degrees; and finally the magnetic fields control the electric arc robot to carry out layer-by-layer accumulation for automatic additive forming on molten wire material according to the forming path. According to the magnetic field control type additive forming method adopting the electric arc robot, control over the form and the motion state of an electric arc in the material adding process can be facilitated; and the annular magnetic field is adopted for stirring so that the floating speedof inclusions such as the air pores in the molten pool can be increased, rotary spray transfer with good stability and good controllability can be obtained, the defects of the air pores and the likein an additive manufacturing part can be greatly reduced, and continuous consistency of the forming morphology of an additive forming part formed through the electric arc robot is improved.

Owner:NANJING UNIV OF SCI & TECH

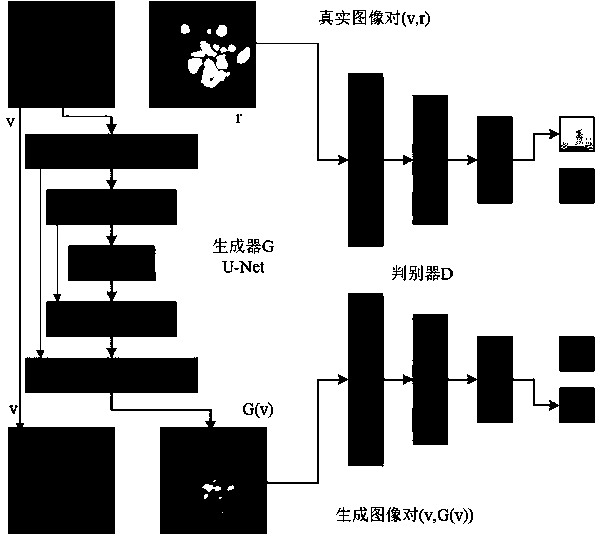

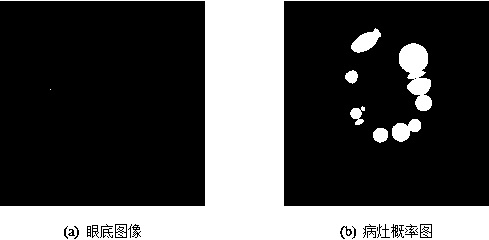

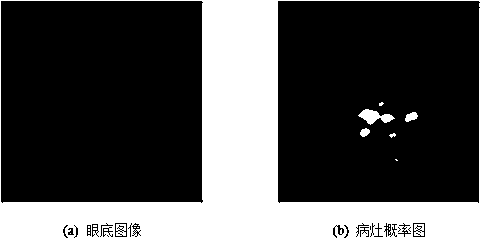

Fundus image focus area labeling method based on deep learning

PendingCN110097559AFeature extraction is sufficientImprove build qualityImage enhancementImage analysisDiscriminatorHorizontal and vertical

The invention discloses a fundus image focus area labeling method based on deep learning, and the method comprises the steps: selecting a sample, and carrying out the preprocessing: carrying out the cutting of an image, and carrying out the horizontal and vertical overturning and normalization processing; constructing a convolutional neural network and a deconvolutional neural network as an imagegenerator, inputting the preprocessed color fundus image, and outputting a corresponding focus probability graph; constructing a convolutional neural network as a discriminator, inputting and generating a focus image and a real focus image, and outputting a probability that the focus image is judged to be a real image; alternately training the generation network and the discrimination network until a satisfaction result can be generated; and marking a focus area in the fundus image according to the generated focus probability graph. The fundus image focus probability graph is generated by using the deep convolutional neural network, and the fundus image focus area is automatically labeled. The automatic labeling can provide an auxiliary basis for the diagnosis of doctors, and meanwhile, the cost of manual labeling can be greatly reduced.

Owner:南京星程智能科技有限公司

Assembly ship building unit element, modularization designing method

InactiveCN1948081AImprove build qualityGuaranteed Build QualityVessel partsModular designComputer module

A modular design method for building all units and assembling them together includes such steps as 3D modeling of ship body, 3D arrangement modeling for assembling, dividing it into functional or regional units or modules, providing the interfaces between units or modules, designing and drawing them, and integrating them together in frame mode while preserving the interfaces between them.

Owner:DALIAN SHIPBUILDING IND

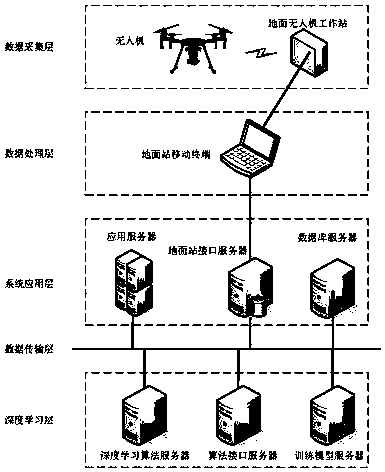

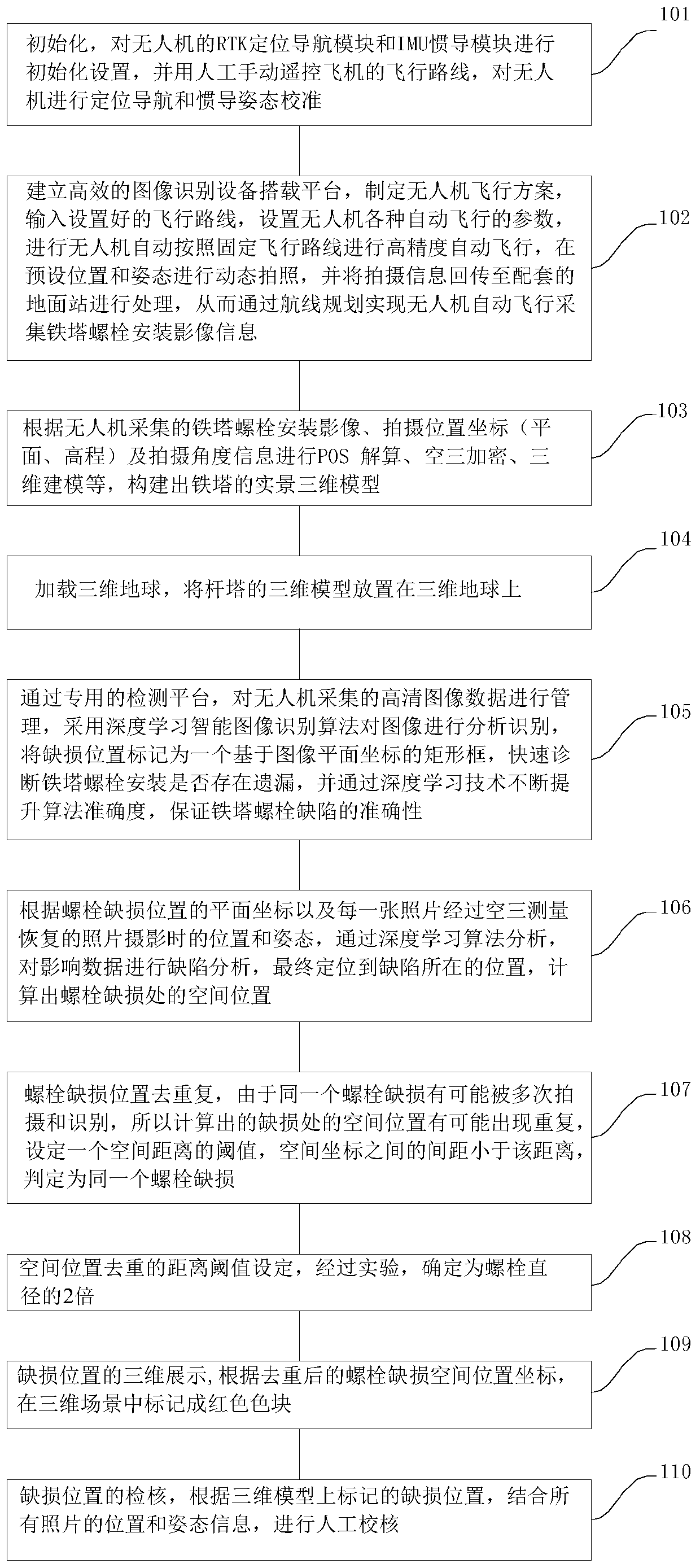

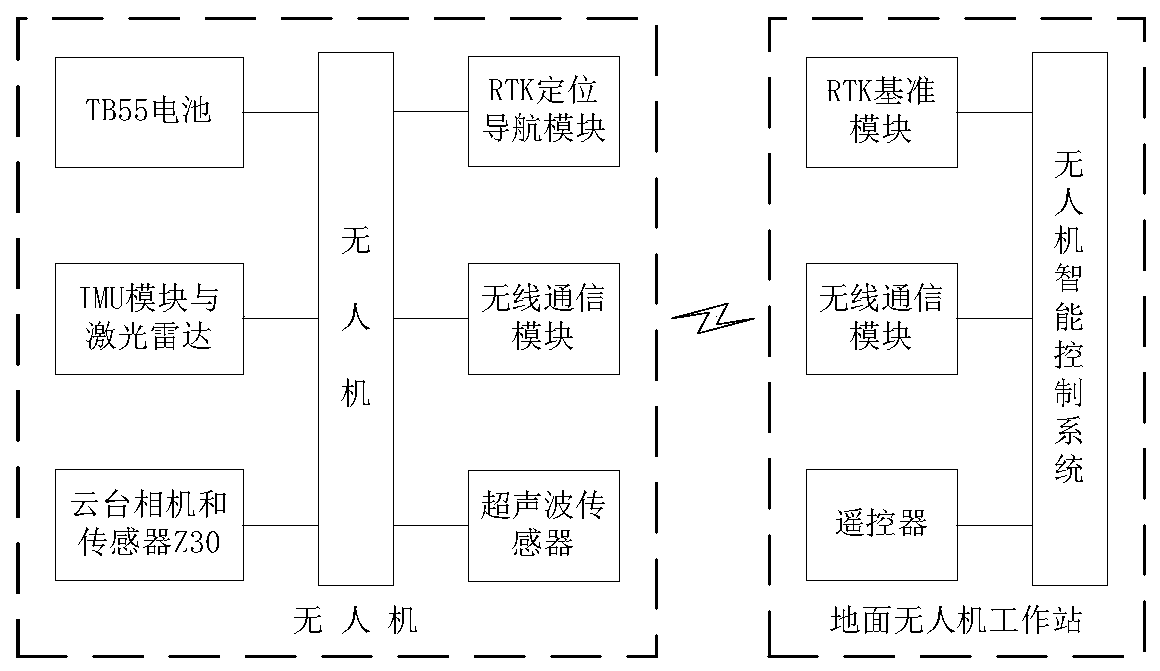

Iron tower bolt defect display method and system based on three-dimensional live-action model

ActiveCN111537515AGuaranteed integrity testingImprove build qualityNavigation by speed/acceleration measurementsScene recognitionTriangulationSimulation

The invention provides an iron tower bolt defect display method and system based on a three-dimensional live-action model. The method comprises: achieving automatic flight of an unmanned aerial vehicle through air route planning, collecting iron tower bolt installation image information, shooting position coordinates (planes and elevations) and shooting angle information, and carrying out POS calculation, aerial triangulation encryption, three-dimensional modeling and the like to construct a live-action three-dimensional model of an iron tower; placing the three-dimensional model of the iron tower on a three-dimensional earth, and analyzing and recognizing the image by using a deep learning intelligent image recognition algorithm; locating the location of a defect, and marking a red colorblock in the three-dimensional scene; and according to the marked defect position on the three-dimensional model, calculating the position coordinates of the bolt defect by using the principle of forward intersection in combination with the position and attitude information of all photos, and carrying out manual checking. According to the invention, with the method and the system, detection of thebolt integrity rate of the power transmission line iron tower is guaranteed, on-site construction acceptance is assisted, the construction quality of the power transmission line is improved, and safety risks caused by human factors are reduced.

Owner:CHAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +2

Image enhancement and abstraction method based on anisotropic filtering

ActiveCN102800063AImprove featuresImprove sense of directionImage enhancementKuwahara filterImaging quality

The invention provides an image enhancement and abstraction method based on anisotropic filtering. The method comprises the following steps: calculating the smooth continuous characteristic-preserved edge tangential flow field of an input image by use of a structure tensor smoothing technology; performing adaptive smoothing on the image along the direction of the edge tangential flow; performing unsharp image enhancement based on a Gaussian difference mask along the gradient direction; and performing improved bilateral filtering based on characteristic flow or improved Kuwahara filtering based on characteristic flow to obtain a characteristic-enhanced abstract image. The method provided by the invention can obviously improve the generation quality of the existing image abstraction method; and the obtained abstract image has obviously-enhanced boundary characteristics, clear image quality and distinct layers.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

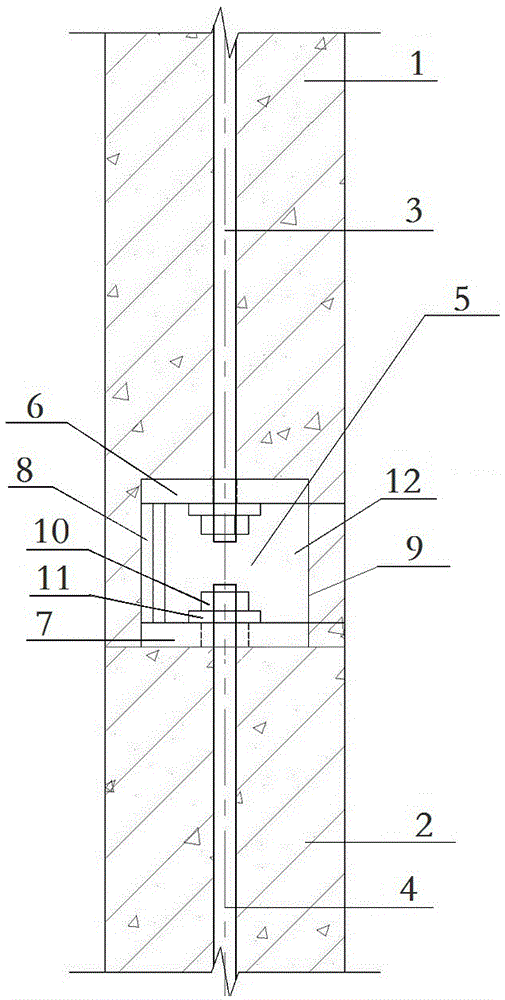

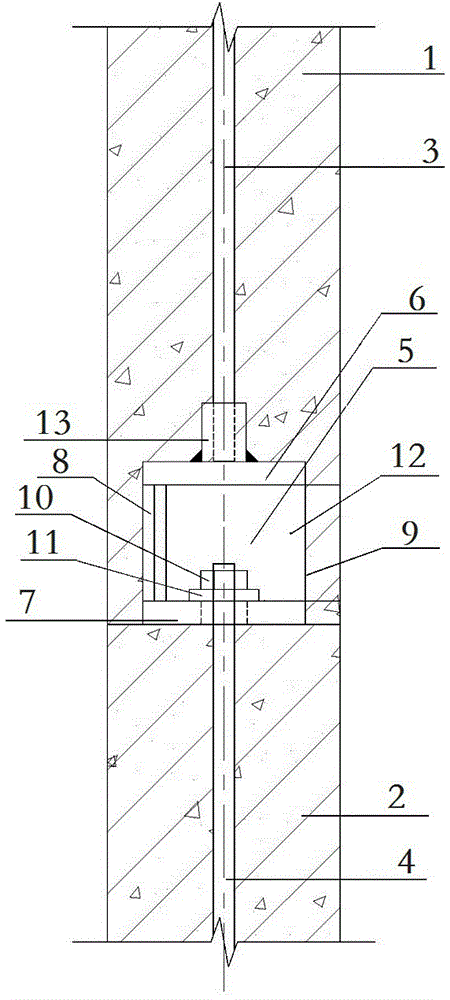

Steel bar connection structure of prefabricated parts

InactiveCN106638981AThe docking tolerance is largeAllowable deviation is largeBuilding reinforcementsButt jointEngineering

The invention discloses a steel bar connection structure of prefabricated parts. The steel bar connection structure of the prefabricated parts comprises a first prefabricated concrete member and a second prefabricated concrete member, and a connection box is embedded at the end, adjacent to the second prefabricated concrete member, on the first prefabricated concrete member; the connection box is provided with an opening side, and an opening of the opening side of the connection box is communicated with the surface of one side of the first prefabricated concrete member; the tail end of a first connecting steel bar in the first prefabricated concrete member is fixedly connected to a first side of the connection box, the tail end of a second connecting steel bar in the second prefabricated concrete member penetrates through a lower steel bar inserting hole in the lower bottom of the connection box, and the end of the upper end of the second connecting steel bar is connected and fixed to a nut and a pad sheet through a threaded screw thread. By the adoption of the steel bar connection structure of prefabricated parts, steel bar connection among prefabricated concrete parts becomes very easy, the steel bar butt joint is big in allowable variation, the construction difficulty is low, the steel bar connection is convenient, fast in speed and efficient, the technical problem in the construction industry that steel bar butt joint is difficult for many years is solved, the structure itself is mechanically connected, no aging exists, the structural strength is high, the service life is long, and the construction quality is good.

Owner:HUNAN YUANDA ENG DESIGN CO LTD

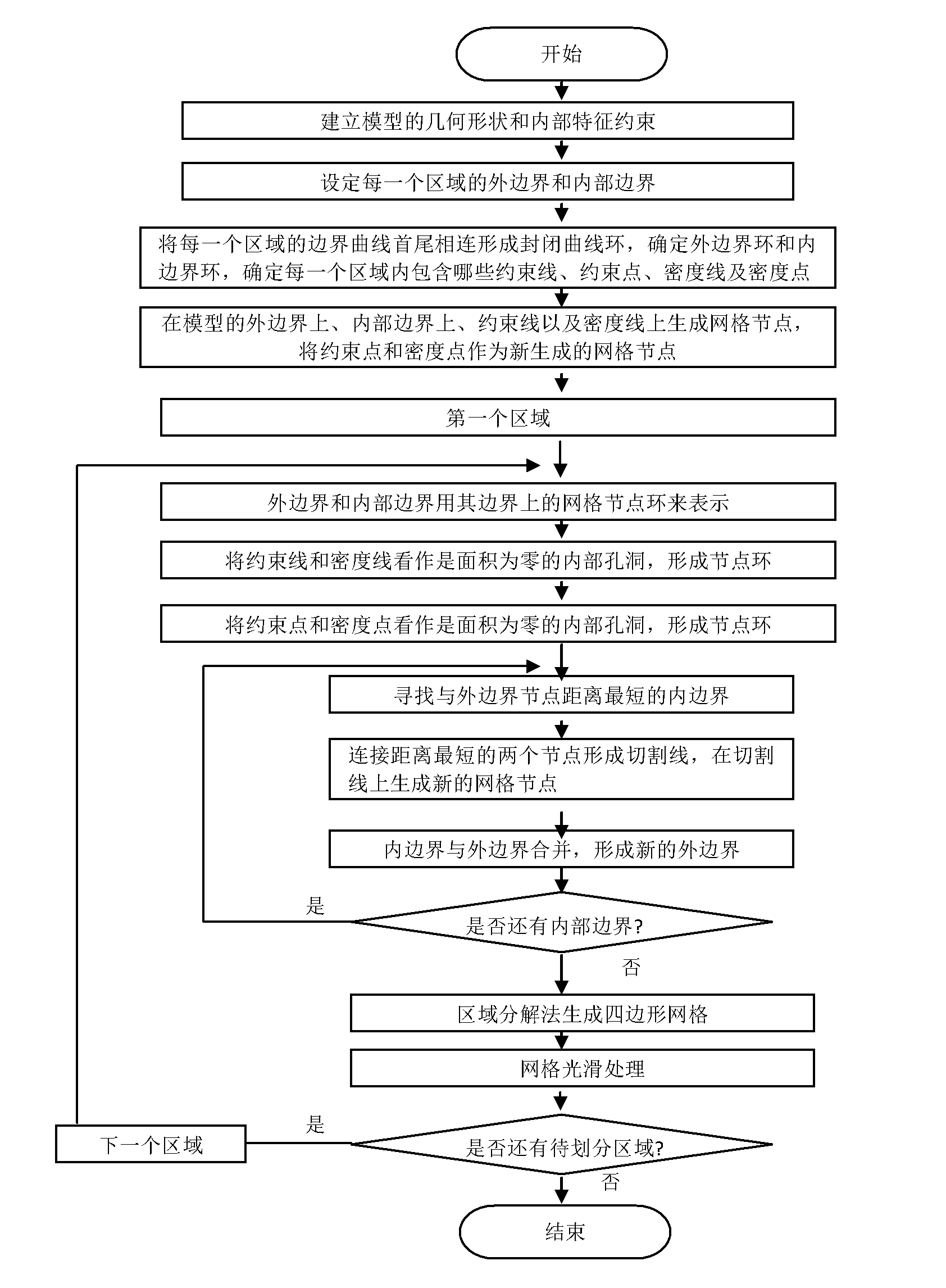

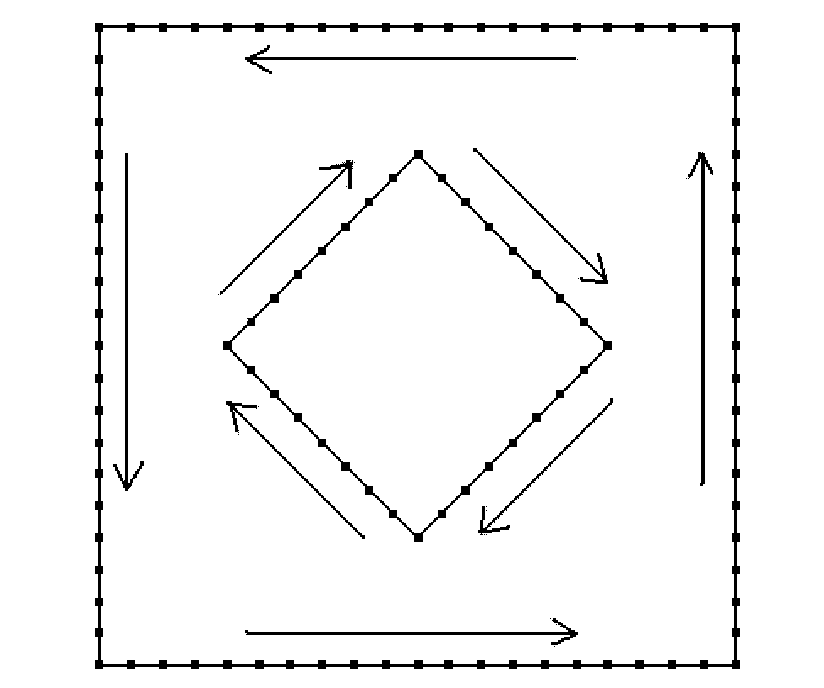

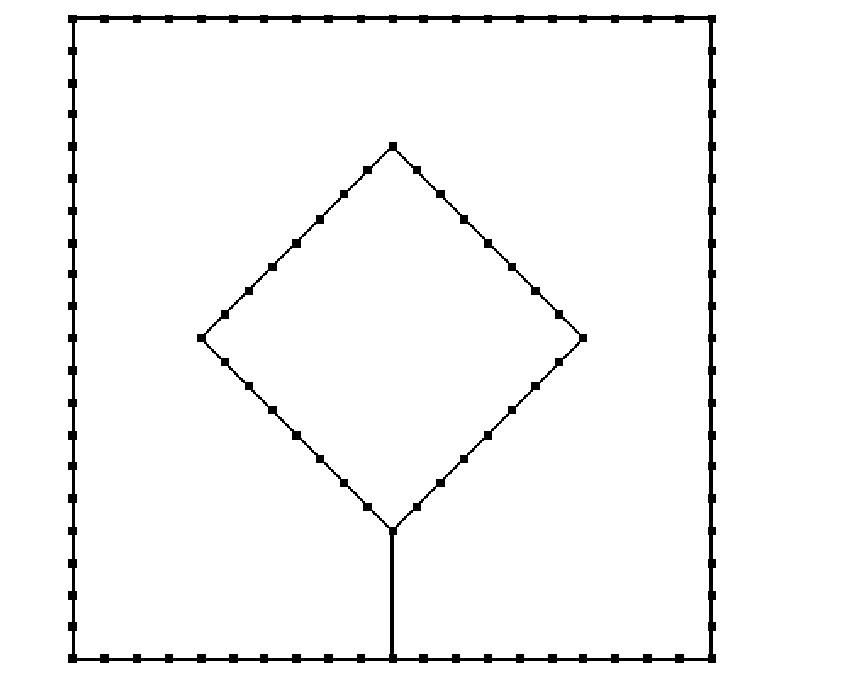

Generation method of quadrilateral grid of geometric model with any internal feature constraints

The invention relates to a generation method of quadrilateral grids of a geometric model with any internal feature constraints, which outstandingly enhances the generation quality and efficiency of the quadrilateral grids and has convenience and practicability. The generation method comprises the following steps of: (1.1) building an entitative geometric model according to an entity to be analyzed by utilizing a computer; and determining the shapes and the positions of constraint lines and density lines of the entitative geometric model, the positions of constraint points and density points and the range and the inner and outer boundaries of each region; (1.2) generating grid nodes on the inner and outer boundaries, the constraint lines and the density lines of the entitative geometric model according to grid size information set by a user, and numbering the grid nodes; viewing the constraint points and the density points as newly generated grid nodes, and numbering the newly generated grid nodes; (1.3) viewing the constraint lines, the density lines, the constraint points and the density points as internal cavities with areas of zero, generating node rings on the inner and outer boundaries of each region, and transforming a multiply connected region with the internal feature constraints into a simply connected region; (1.4) dividing the quadrilateral grids in each region; and finally generating the quadrilateral grids with the internal feature constraints.

Owner:SHANDONG UNIV

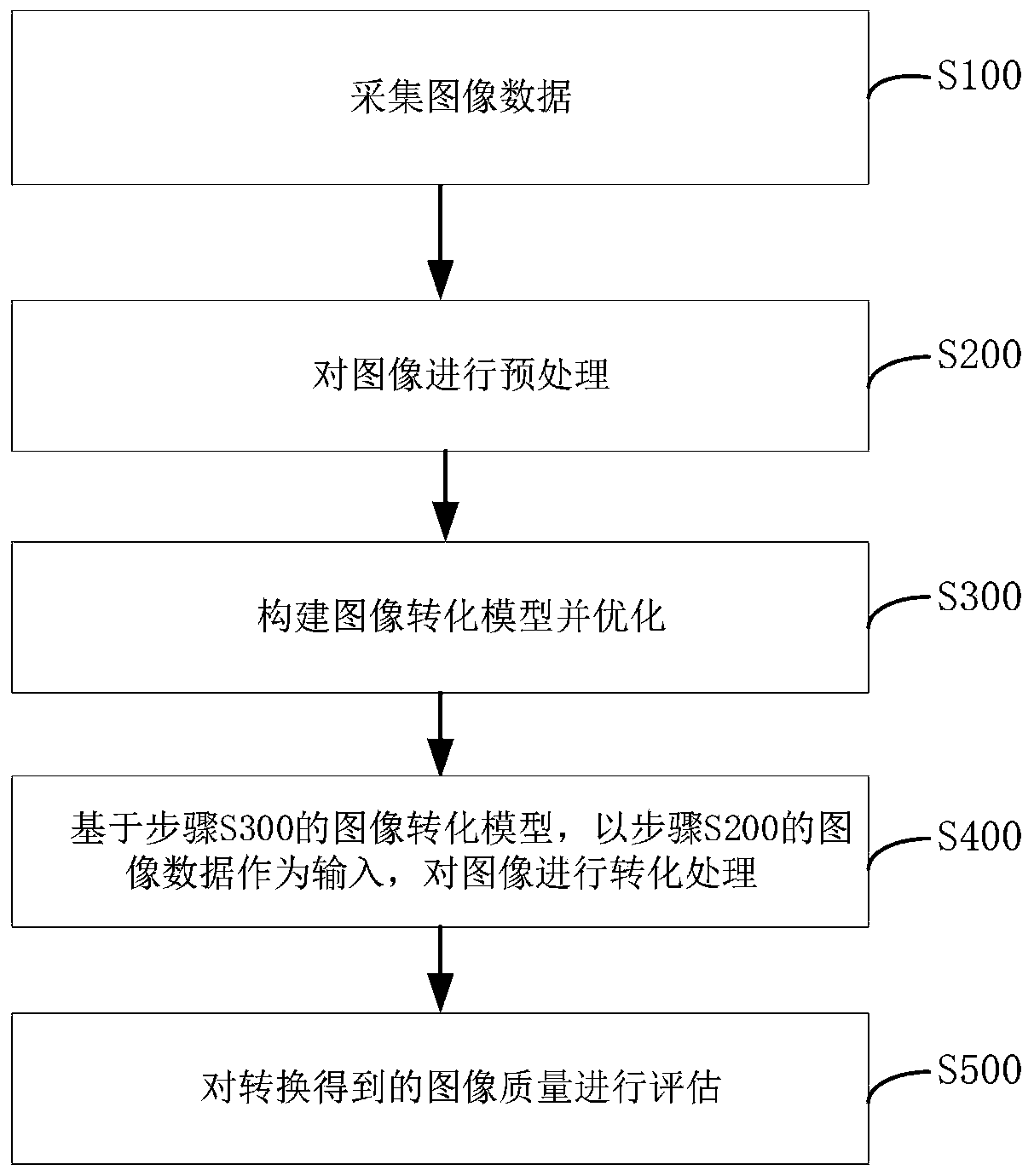

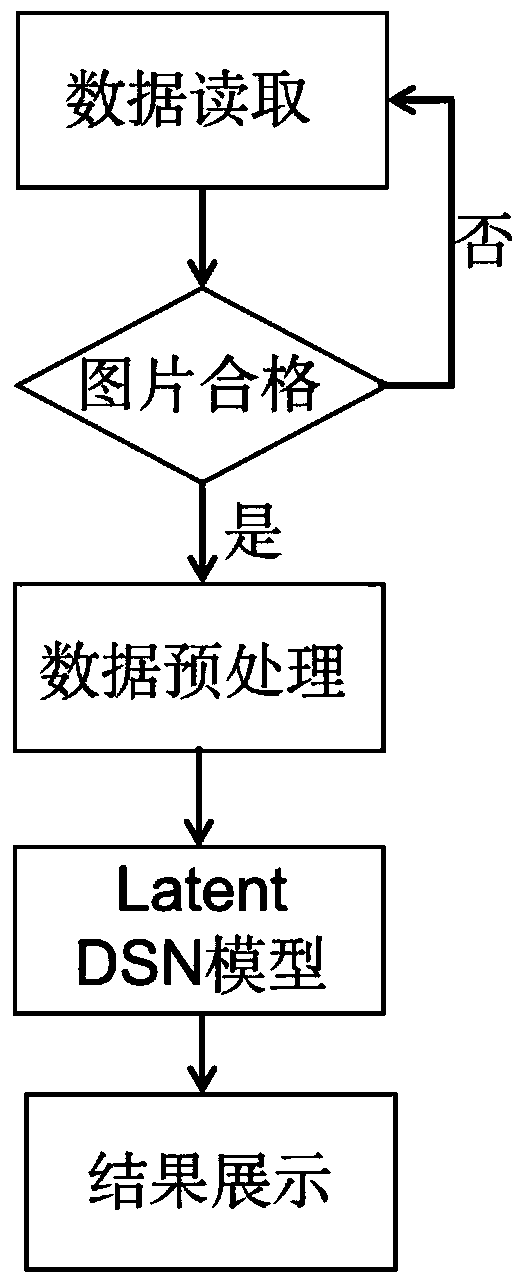

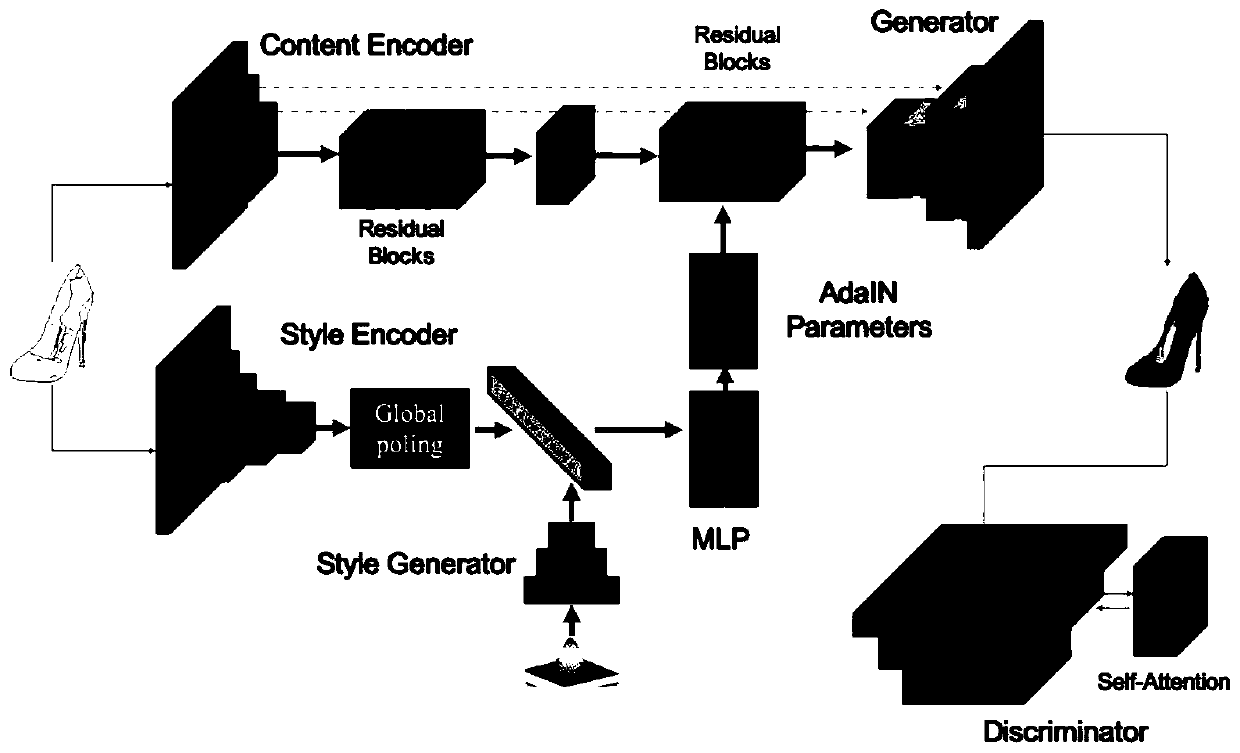

Image multi-style conversion method based on latent variable feature generation

ActiveCN110992252ASolve technical problems that cannot meet the needsIncrease freedomInternal combustion piston enginesGeometric image transformationComputer graphics (images)Imaging quality

The image multi-style conversion method based on latent variable feature generation can solve the technical problem that the existing image conversion method cannot meet the requirements in style representation and image quality. The method comprises the following steps: S100, collecting image data; s200, preprocessing the image; s300, an image conversion model is constructed and optimized; s400,based on the image conversion model in the step S300, taking the image data in the step S200 as input, and performing conversion processing on the image; and S500, evaluating the quality of the imageobtained by conversion. According to the method, the model is expanded and improved on the basis of MUNIT, and sufficient transmission of content feature information is provided for style conversion of the image by designing jump connection; the style code generator learns potential variables of image style codes, and rich image style conversion can be achieved; and meanwhile, the model can realize conversion of a specific style by taking an input style image as a reference, and has important guiding significance for development of a specific style conversion task.

Owner:HEFEI INNOVATION RES INST BEIHANG UNIV

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

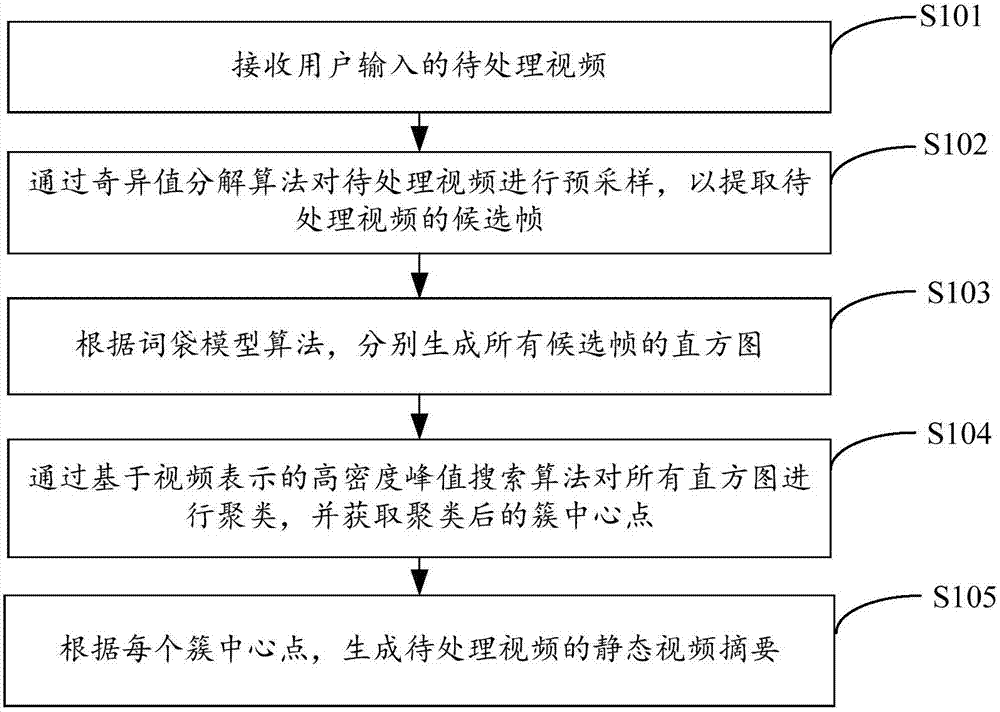

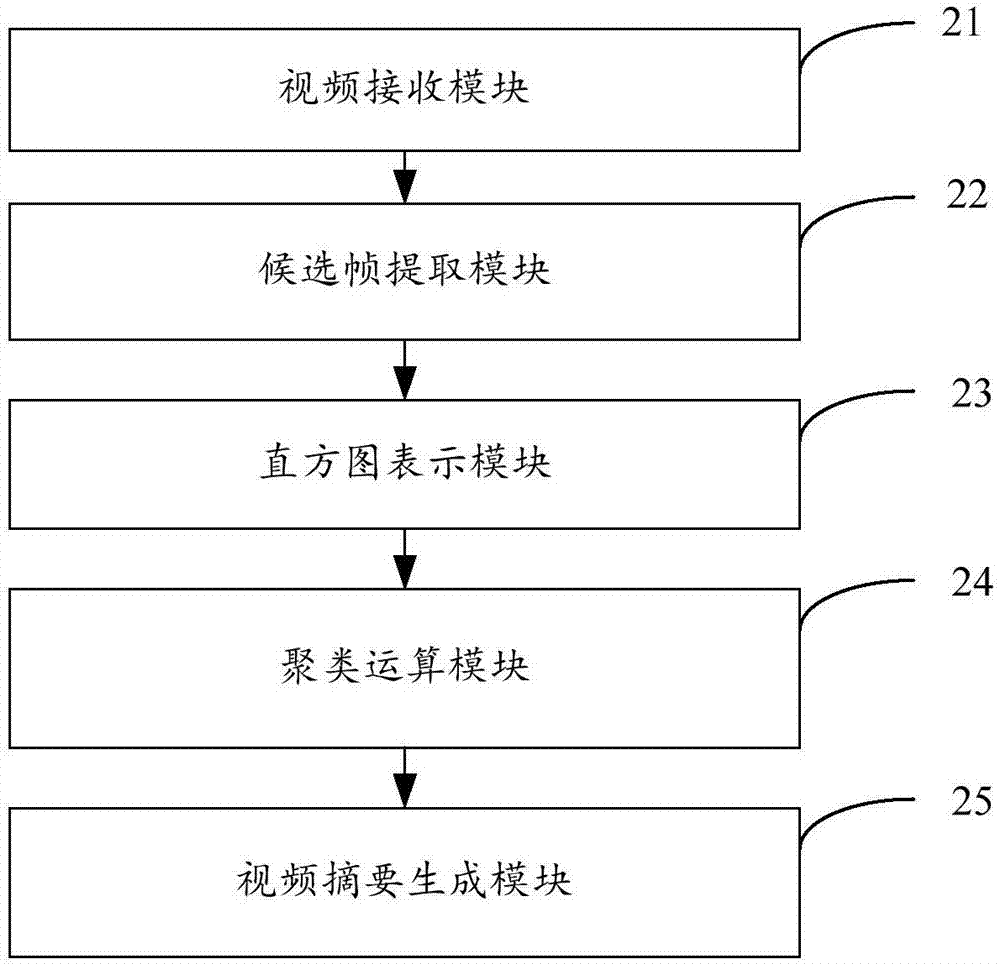

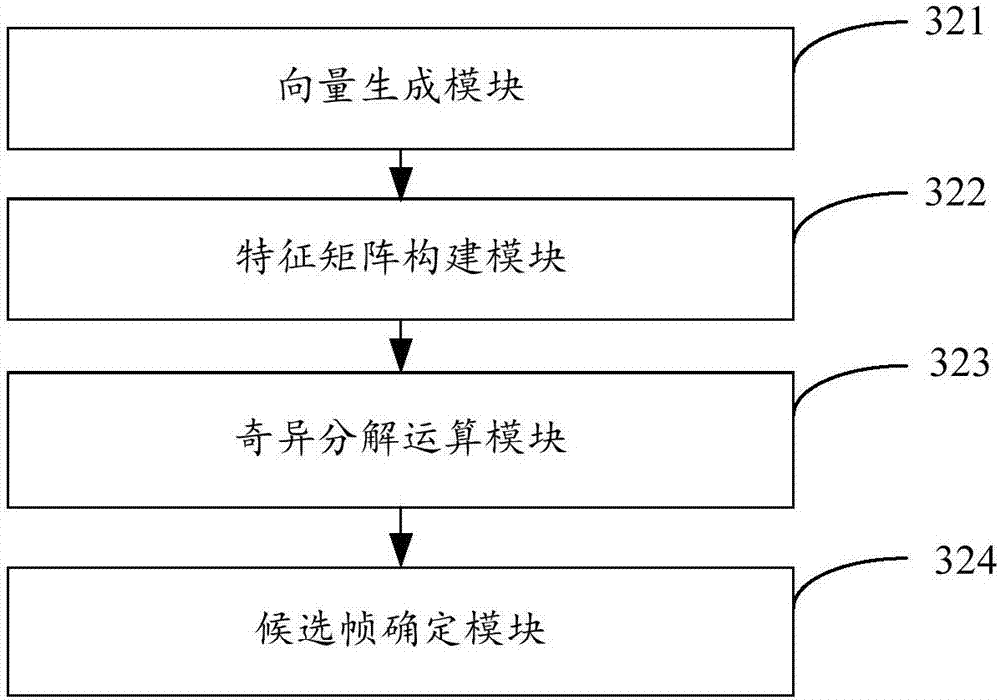

Method and apparatus for generating still video abstract

InactiveCN107223344AImprove the de-redundancy effectImprove stabilityCharacter and pattern recognitionSelective content distributionSingular value decompositionBag-of-words model

The invention belongs to the technical field of computers, and provides a method and apparatus for generating a still video abstract. The method includes the following steps: receving a to-be-processed video which is input by a user; pre-sampling the to-be-processed video through a singular value decomposition algorithm so as to extract a candidate frame of the to-be-processed video; based on a bag of words model, separately generating a histogram which is used to represent each candidate frame; by means of a high intensity peak value search algorithm which is based on video representation, clustering all histograms, and acquiring a clustering center point after performing clustering; based on each clustering center point, generating a still video abstract of the to-be-processed video. The method herein can, by candidate frame generation and histogram representation, deeply remove redundant frames, can adaptively generate clustering center points in the clustering process, obviates the need for setting the number of clusters in advance and has no iterative process, effectively increases clustering stability and adaptivenes, reduces time complexity of clustering, and further effectively increases the efficiency and quality in generating still video abstracts.

Owner:SHENZHEN UNIV

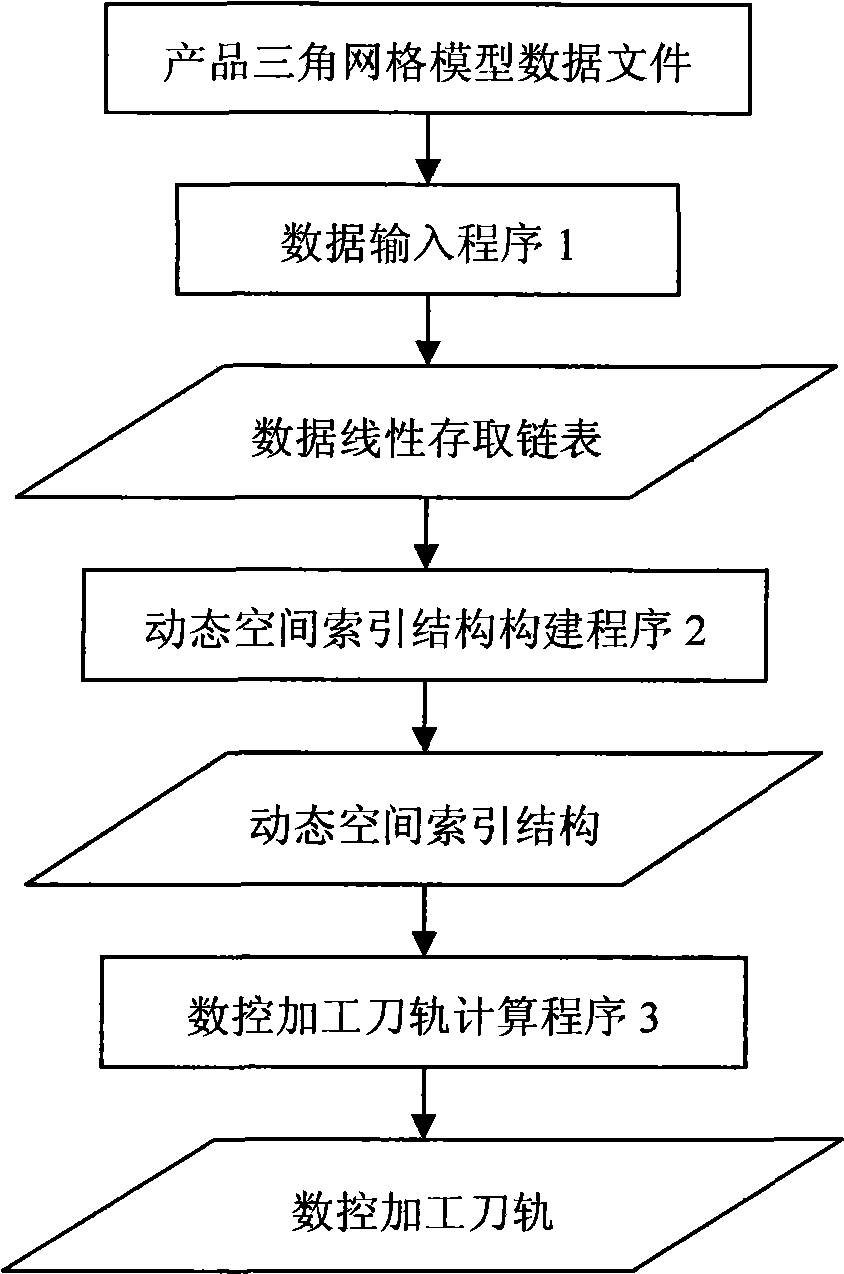

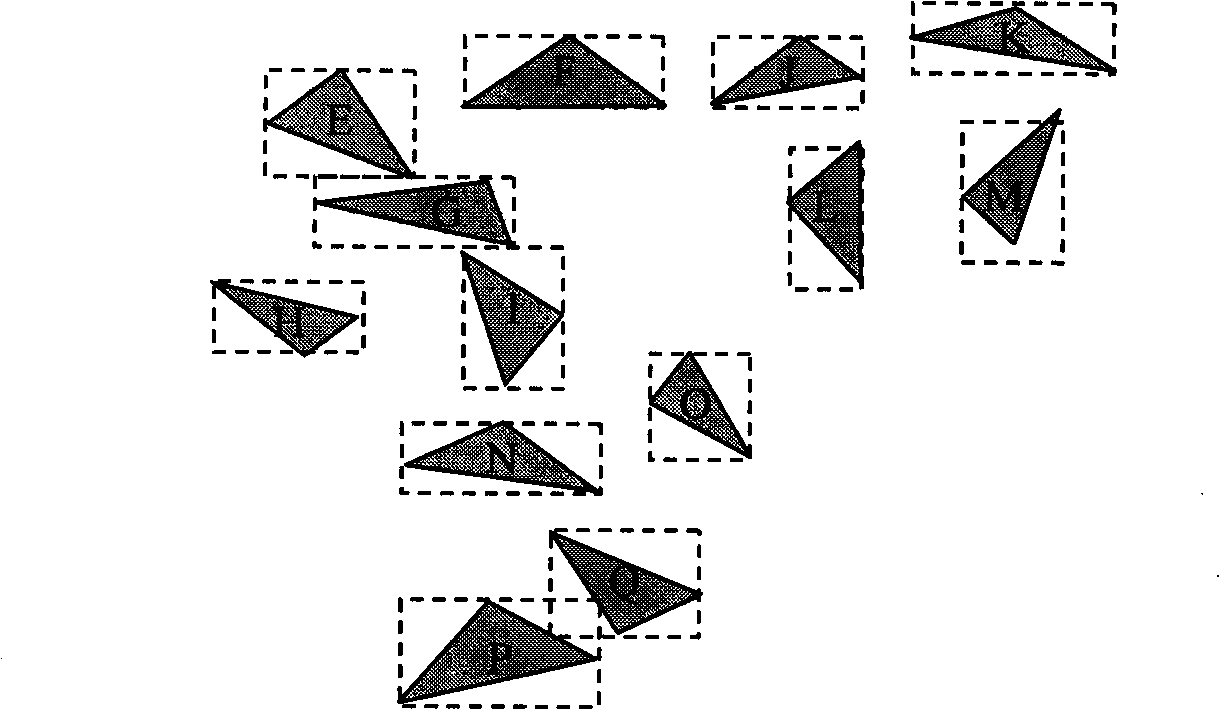

Multi-shaft numerical control machining knife rail generating method for product triangle grid model

InactiveCN101510086AImplement queryImprove production efficiencyProgramme controlComputer controlNumerical controlPath generation

The invention provides a multi-axis numerical control machining tool path generation method for the triangular mesh model of a product, and is characterized in that: a R*S-tree dynamic space index structure organization triangle patch topological neighbor relationship is adopted; based on the structure, the intersection is carried out to the tool-path cross-section and the triangular mesh model for obtaining a cross-section data point; according to an area averaging method, the vector of the corresponding cross-section data point is calculated; the instantaneous processing area corresponding to each cross-section data point is inquired; according to the tangent relationship between the tool and the surface, edge, and vertex of each triangle in the instantaneous processing area, a tool path calculation method of surface tangency, edge tangebcy or vertex tangency is adopted for obtaining corresponding cutting points; a minimum tree generation method is adopted for arranging the cutting points in sequence; and a multi-axis numerical control machining tool path is generated. The method is suitable for the generation of the multi-axis numerical control machining tool path of various complex triangular mesh models, and has high algorithm running efficiency.

Owner:SHANDONG UNIV OF TECH

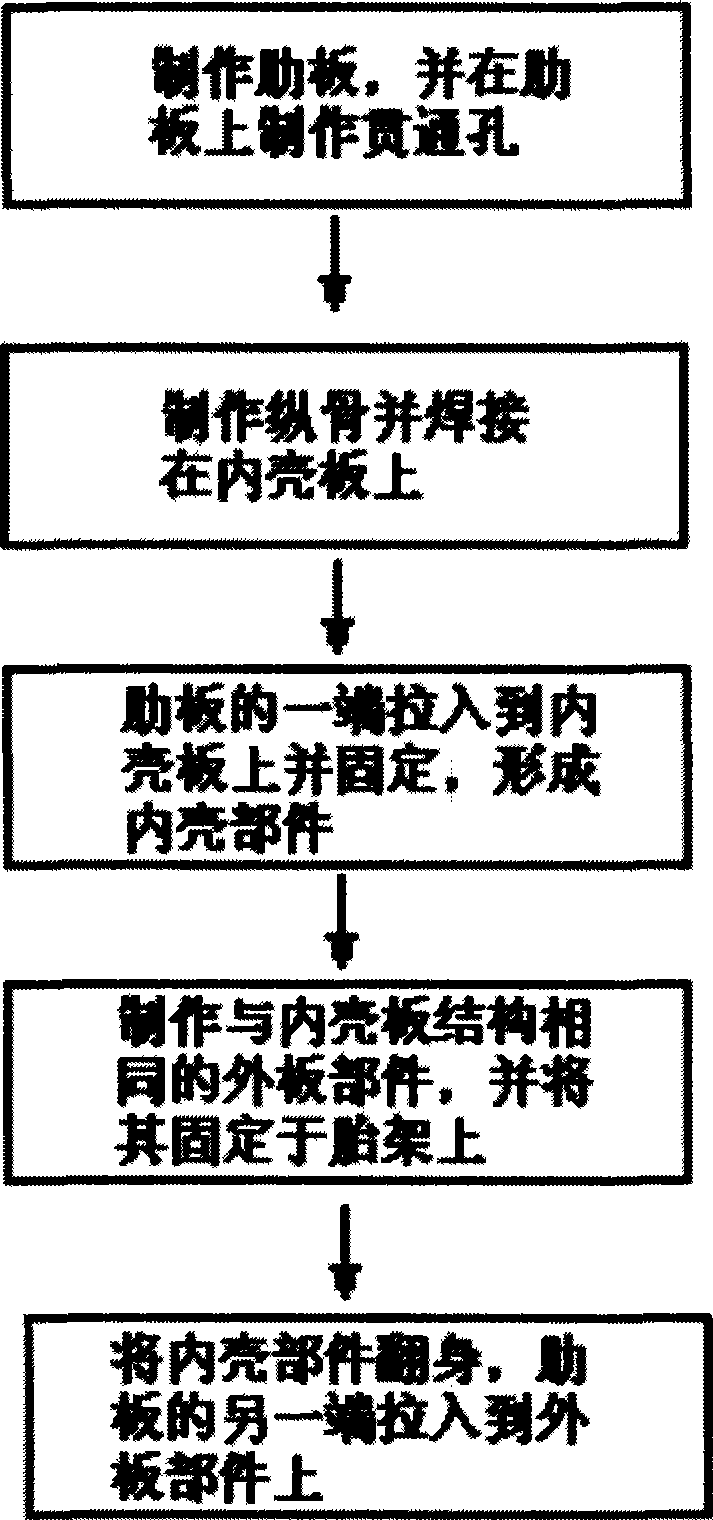

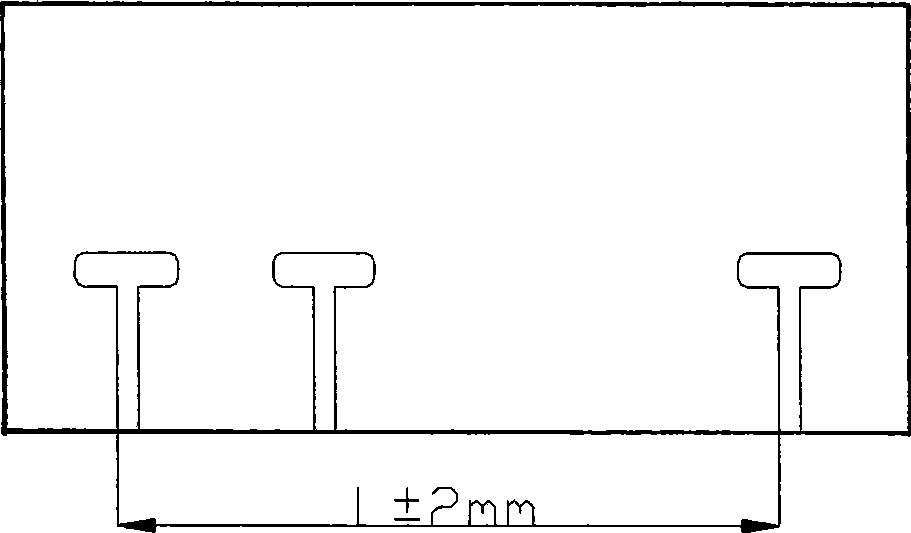

Method for drawing costal scute in shipbuilding

ActiveCN101372258AAdvantages of the pull methodBuild Quality ApprovalVessel partsMarine engineeringScute

The invention relates to a floor pull-in method in shipbuilding, which includes the following steps: the shape of a floor and a through hole of the floor are cut according to the accuracy requirements of ships; a longitudinal frame is manufactured according to the accuracy requirements; inner hulls are pieced together by welding and the longitudinal frame is installed by welding; a first floor is pulled in the inner hull and is welded to form an inner hull component; the inner hull component is measured and the first floor is rigidly reinforced; a hoisting ring is arranged on the inner hull component; an outside plate component is made and fixed on a moulding bed, a hoisting apparatus is used for hauling the hoisting ring to overturn the inner hull component and to cause the upper through hole of the floor to be aligned with a longitudinal frame terminal of the outside plate component, and then a second floor of the inner hull component is pulled in; a welding technique is determined, and the inner hull component and the outside plate component are welded to form whole ship sections. On the basis of a single floor pull-in method, the method can further improve the pull-in accuracy of floors, thus greatly reducing the quantity of patches required in shipbuilding in sections and improving the production efficiency of building in sections.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING +1

Fire-water correcting technology of aluminum-magnesium alloy ship

A water-fire technique for correcting the deformation of ship body made of Al-alloy features that after the deformed Al-alloy plate is heated by oxy-acetylene flame it is cooled by water. The distance between Al-alloy plate and flame is 20-30 mm. The moving speed of flame is 1200-1500 mm / min. The minimal gap between flame and cooling water is 40-60 mm.

Owner:JIANGNAN SHIPYARD GRP CO LTD

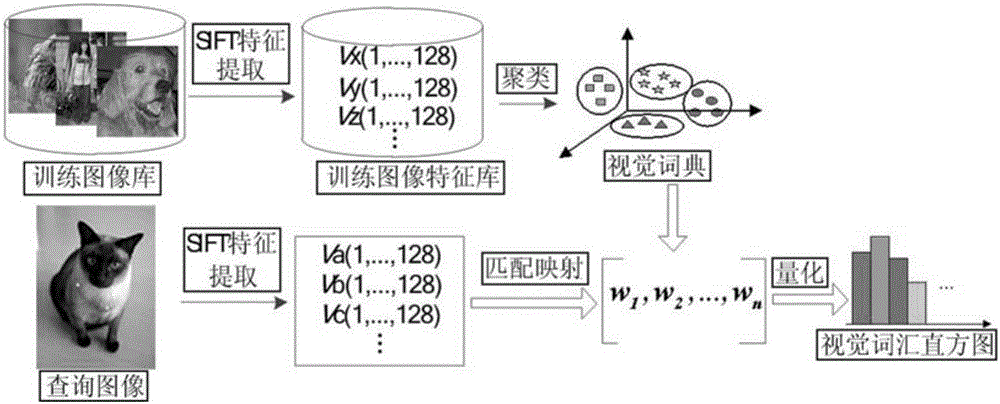

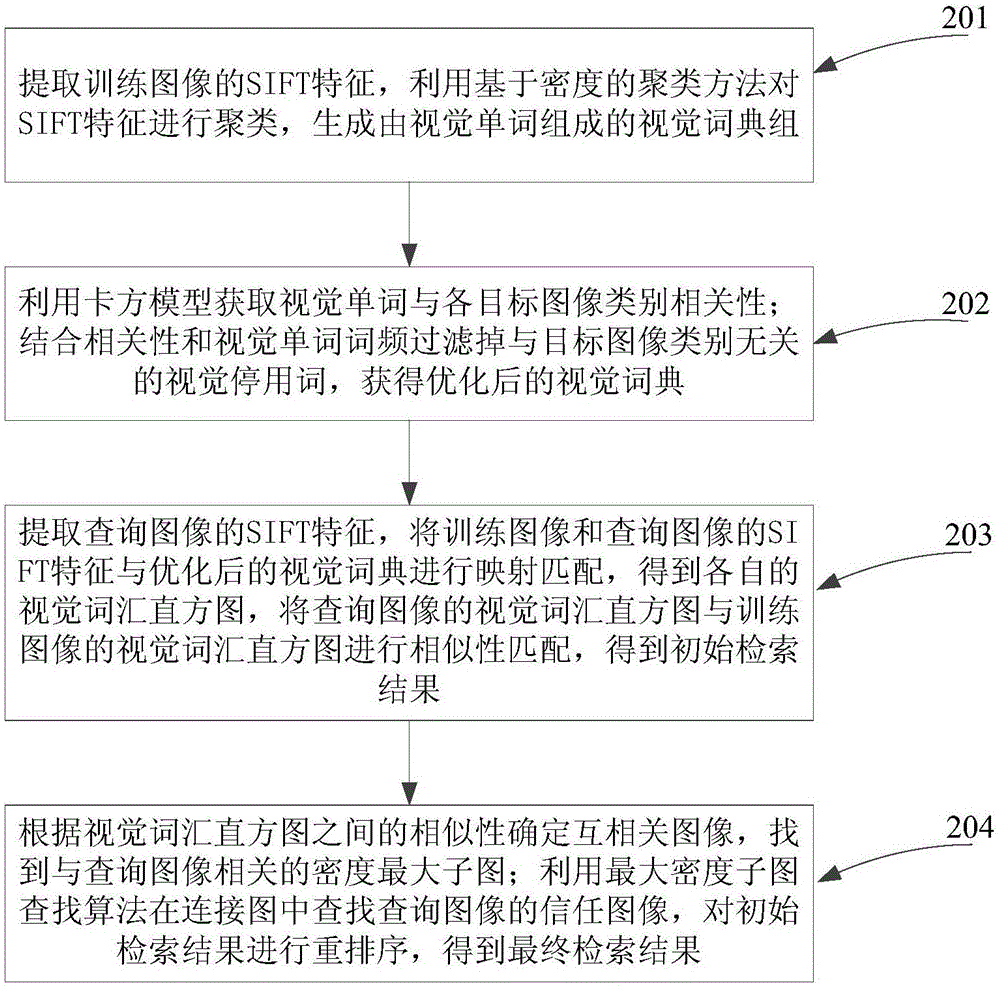

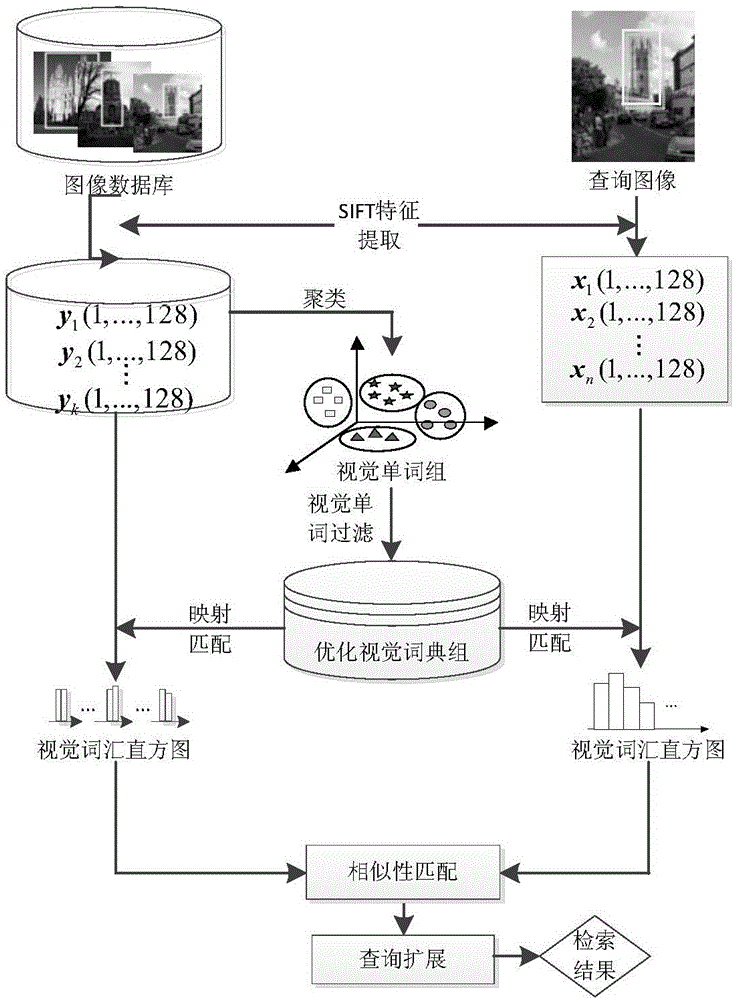

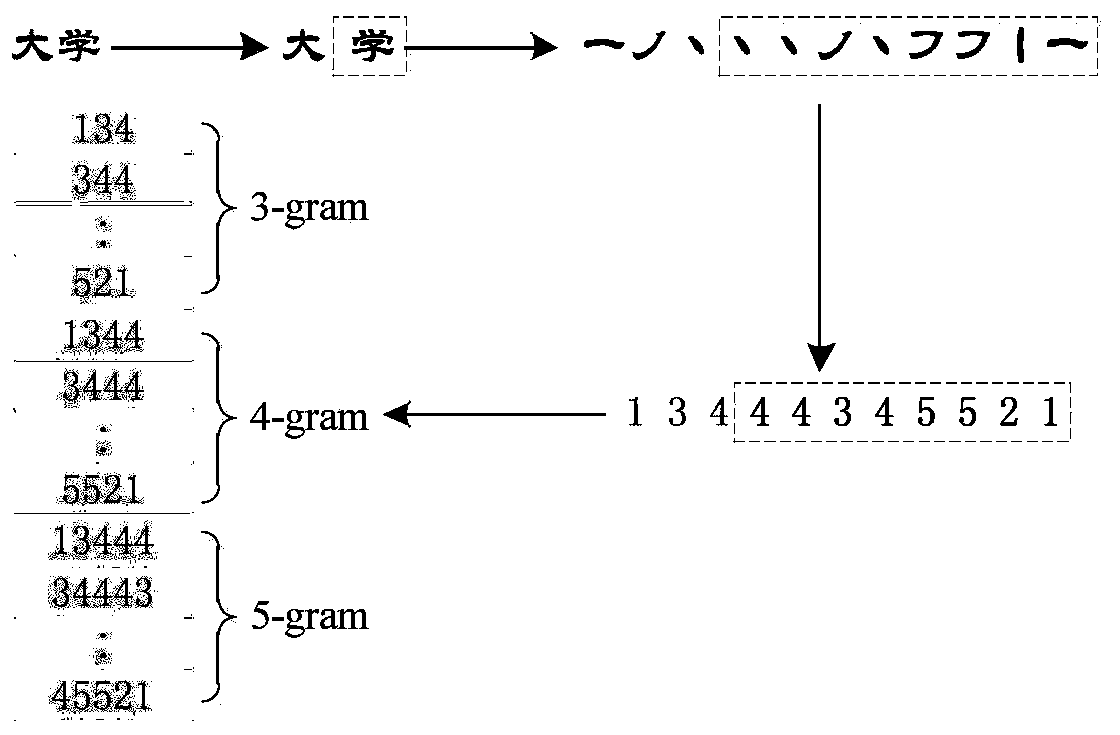

Image retrieval method based on BoVW (Bag of Visual Words) optimization and query expansion

InactiveCN106156374AImprove production efficiencyImprove build qualityCharacter and pattern recognitionSpecial data processing applicationsVision basedVisual perception

The invention discloses an image retrieval method based on BoVW (Bag of Visual Words) optimization and query expansion. The image retrieval method comprises: extracting SIFT features of a training image, and carrying out clustering on the SIFT features by utilizing a density-based clustering method to generate a BoVW set; analyzing correlation of visual words and a target category by a chi-square model, and simultaneously, filtering out a certain number of visual stop words by combining word frequencies of the visual words; carrying out mapping matching on the SIFT features and an optimized BoVW to obtain a visual word histogram; carrying out similarity matching on a visual word histogram of an query image and the visual word histogram of the training image, and according to a primary matching result, carrying out secondary or repeated retrieval by combining a query expansion strategy so as to obtain a final retrieval result. The invention provides the image retrieval method based on BoVW optimization and query expansion, which aims to improve image retrieval accuracy.

Owner:HUAQIAO UNIVERSITY

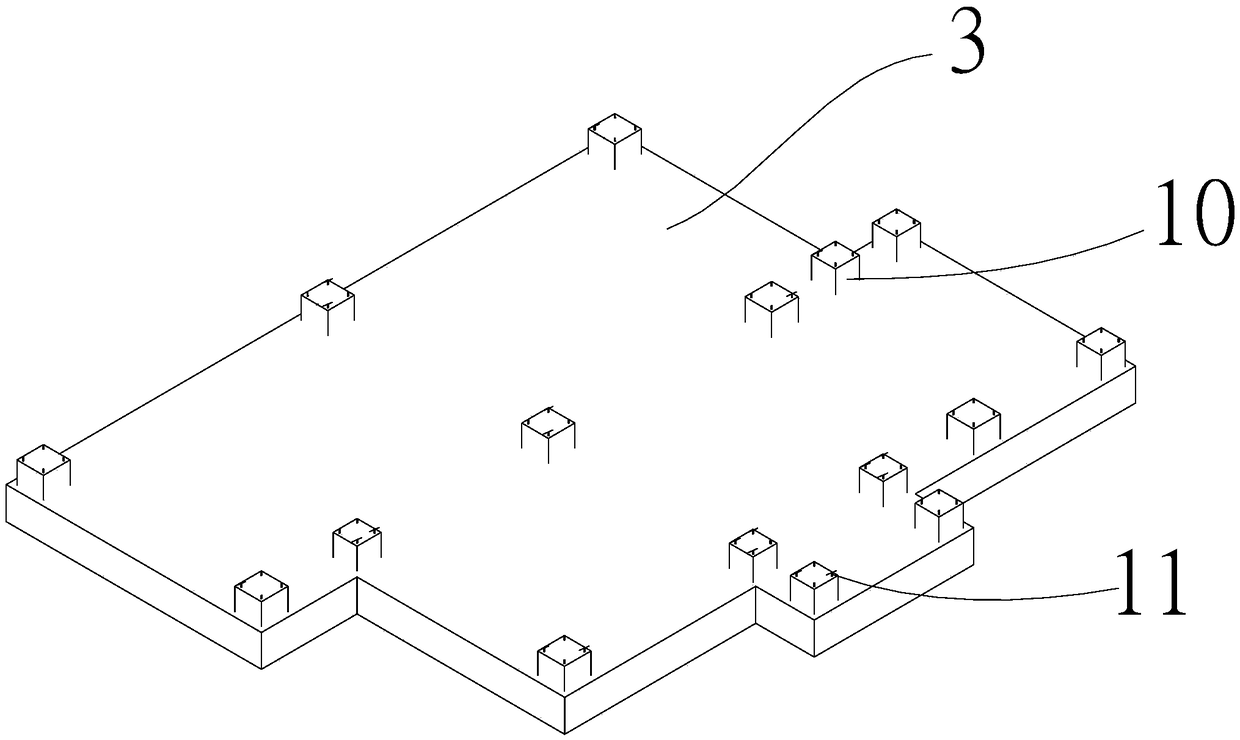

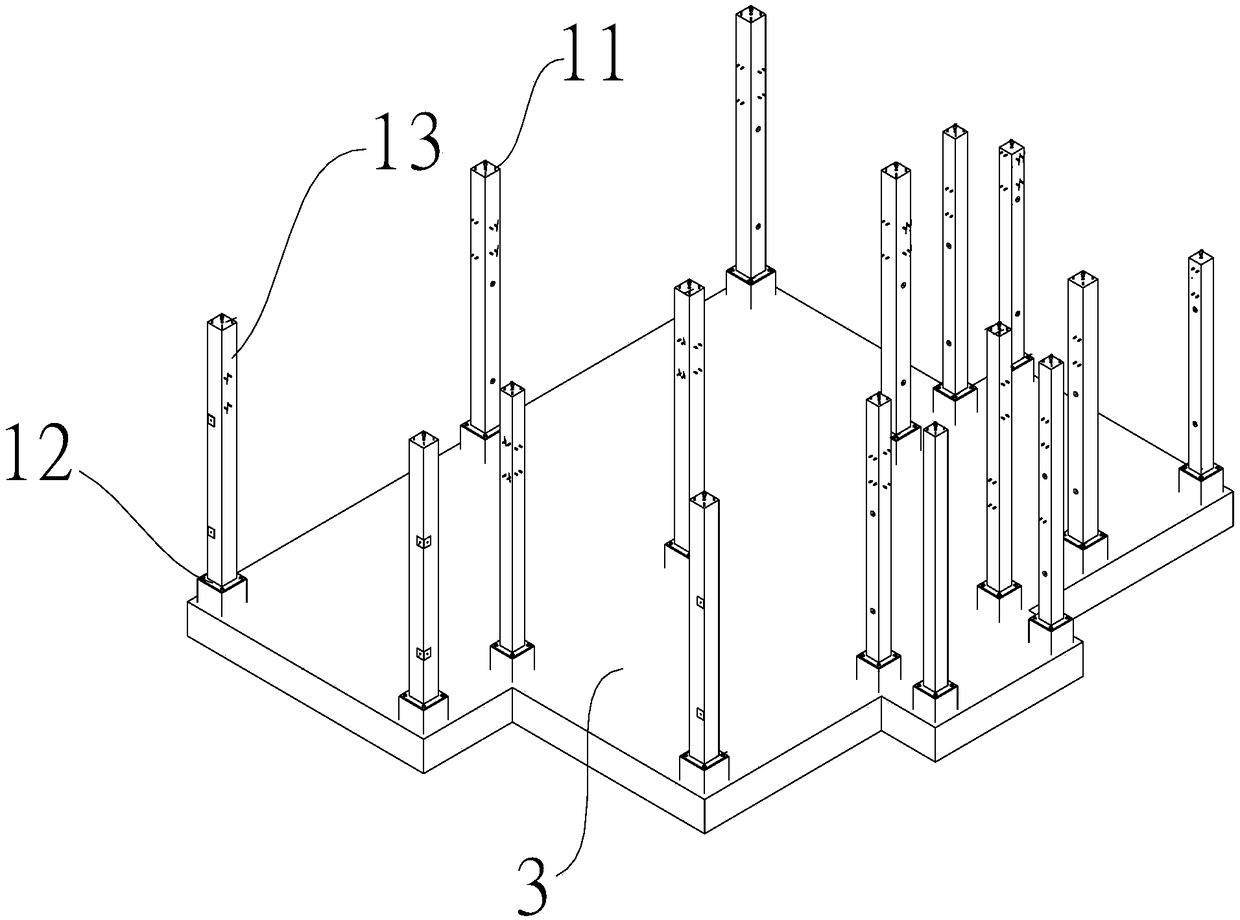

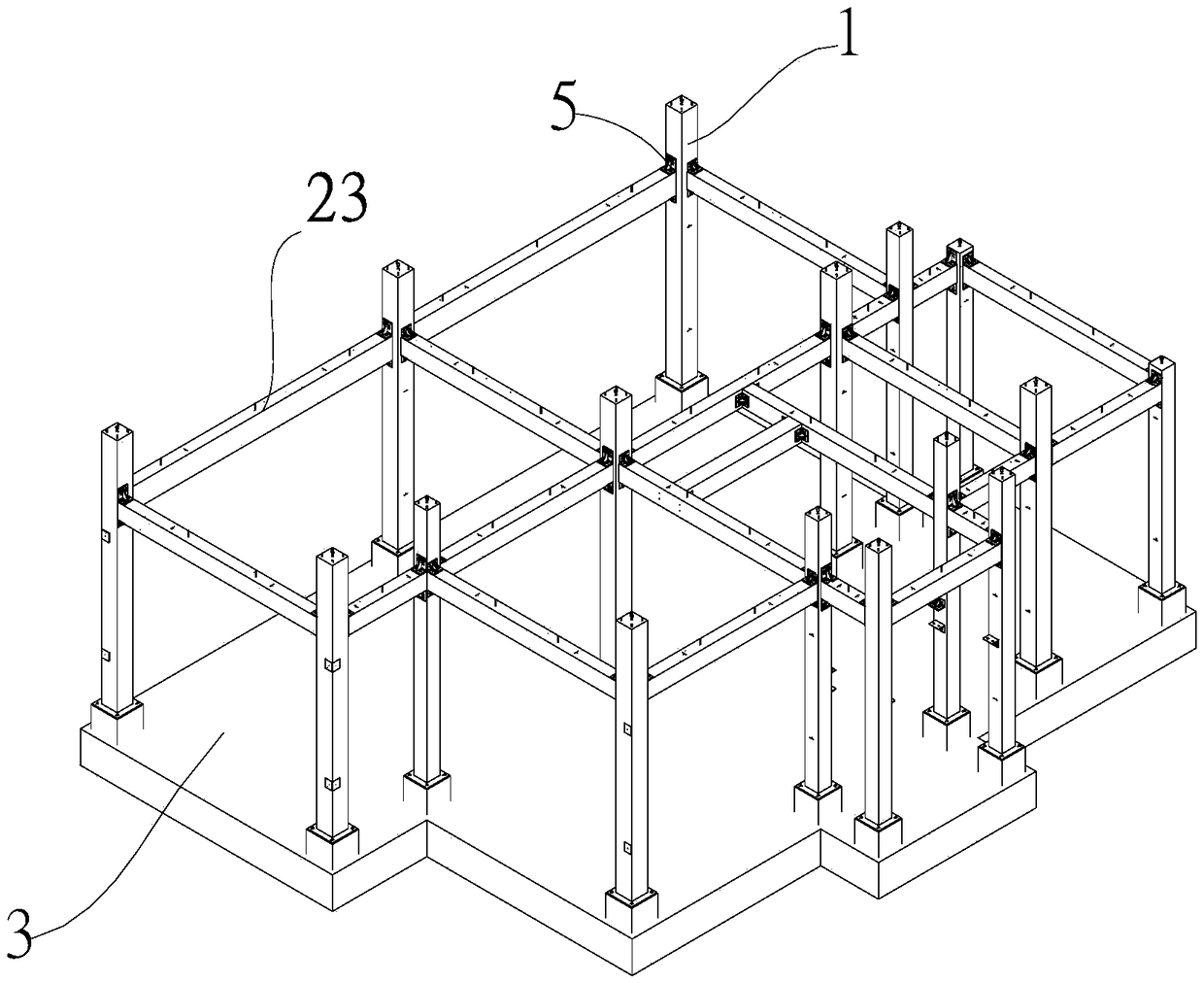

Assembly method for low-layer frame structure system

The invention relates to an assembly method for a low-layer frame structure system. The method includes the following steps that 1, a foundation is arranged, and frame pillars are installed; 2, a second-layer beam is assembled, wherein prefabricated beams are lifted, side pillars and middle pillars are fixedly connected with two or more oppositely-arranged prefabricated beams, connecting parts arearranged on the upper portions and the lower portions of the prefabricated beams, the connecting parts at least comprise first connecting plates and second connecting plates, the first connecting plates and the second connecting plates are perpendicular to each other and abut against the frame pillars and the prefabricated beams respectively, horizontally-arranged split bolts penetrate through the frame pillars and then are fixedly connected with the first connecting plates on the two sides of the frame pillars, and vertically-arranged split bolts penetrate through the prefabricated beams andthen are fixedly connected with the second connecting plates on the two sides of the prefabricated beams; 3, a second-layer floor slab is assembled; 4, a roof beam is assembled, and the assembling process is identical with that in the second step; 5, a roof panel is assembled. All the components in the method are connected through a dry method, connecting joints of all the components form dry type connection and form an integral, processes are reduced, construction speed is high, and construction is environmentally friendly.

Owner:中民筑友房屋科技集团有限公司

Method for forming functionally graded material on basis of selection laser melted powder metallurgy

ActiveCN106623924AQuick and precise preparationPrecise thickness controlAdditive manufacturing apparatusIncreasing energy efficiencyFunctionally graded materialLaser

The invention provides a method for forming a functionally graded material on basis of selection laser melted powder metallurgy. The forming method comprises the steps that an SLM technology and a powder sintering technology are combined, SLM forming is conducted firstly, a material with different components are laid on different cross sections of parts, the contour of the material and the partial structure inside the part are formed through laser melting, after the contour of the whole part is formed, the part is subjected to high-temperature sintering, and unmelted powder inside the contour of the part is sintered. According to the method, the thickness of the functionally graded material can be accurately controlled, and an FGM material with the excellent quality is prepared; meanwhile, parts with any complex shapes can be manufactured rapidly and accurately, the manufacturing procedures are greatly simplified, the processing cycle is shortened, and the production cost is lowered.

Owner:山西阳宸中北科技有限公司

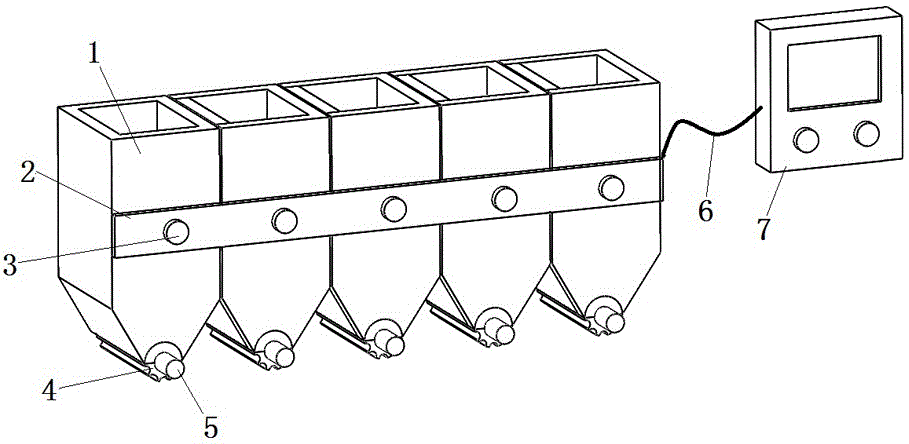

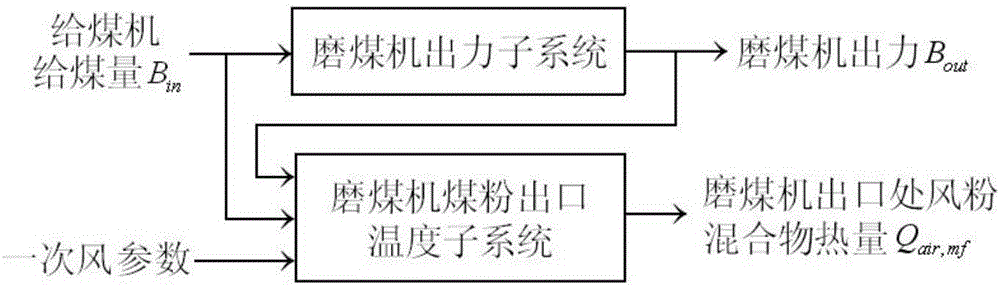

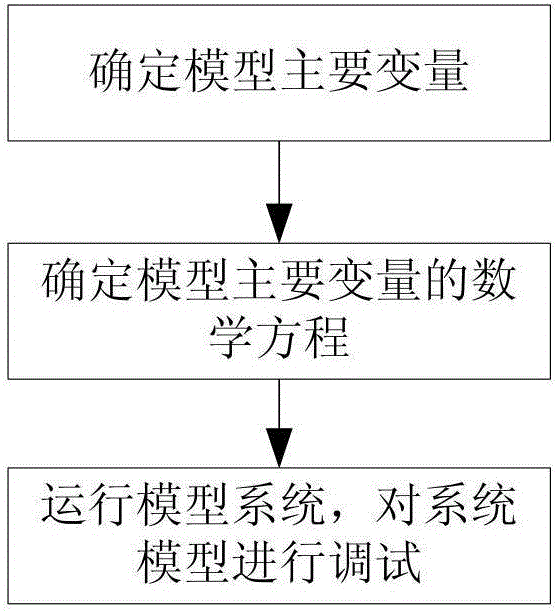

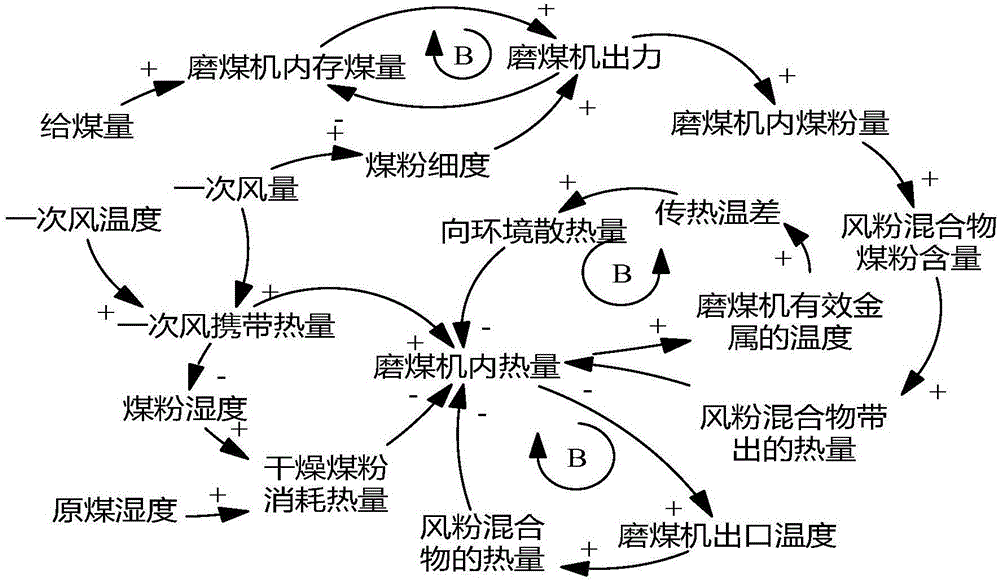

Medium-speed coal mill model building method based on system dynamics

InactiveCN106622620AImprove build qualityGuaranteed stabilityDesign optimisation/simulationGrain treatmentsPowder mixturePower station

The invention provides a medium-speed coal mill model building method based on system dynamics. According to the method, two subsystems are arranged in a medium-speed coal mill model and include the coal mill power output subsystem and the coal mill pulverized coal outlet temperature subsystem, wherein the coal feed quantity of a coal feeder is input into the coal mill power output subsystem, and the coal mill power output subsystem outputs power to a coal mill; primary parameters, output power of the coal mill and the coal feed quantity of the coal feeder are input into the coal mill pulverized coal outlet temperature subsystem, and the coal mill pulverized coal outlet temperature subsystem outputs heat of wind-powder mixtures at an outlet of the coal mill. According to the method, the medium-speed coal mill is modeled from the balanced angle of matter and energy according to the system dynamics principle. By means of the method, a simple, practical, reasonable and reliable model can be provided for analysis and control over the medium-speed coal mill, so that guarantees are provided for safe, stable and economical operation of power station boilers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

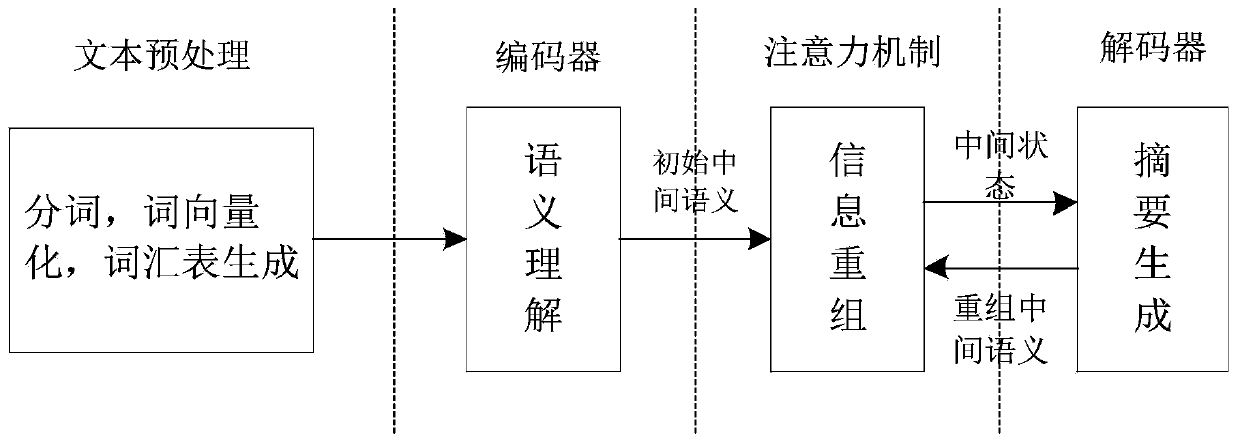

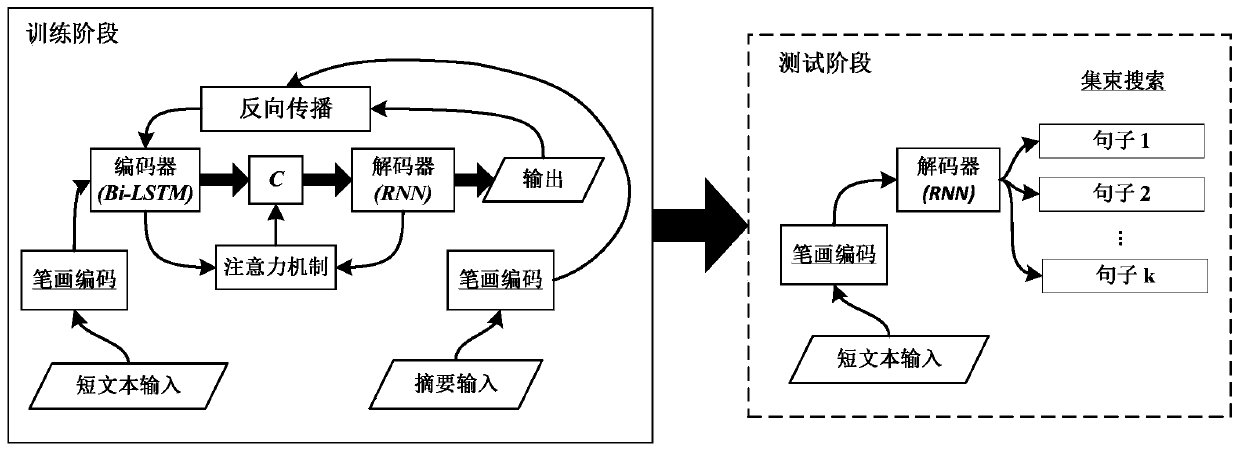

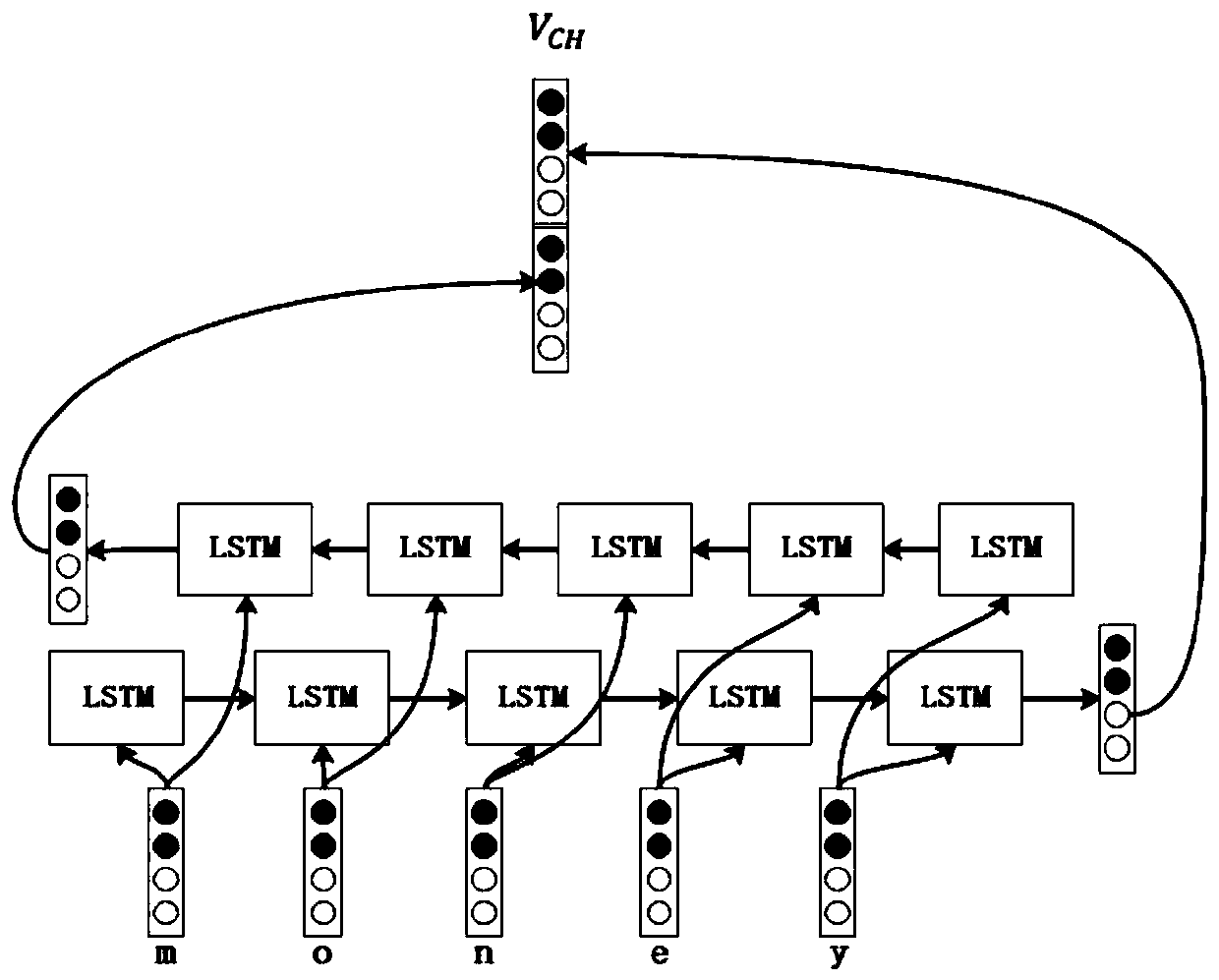

Chinese abstract generation method and system and storage medium

ActiveCN110532554AFeatures needed to increase understandingImprove build qualityNeural architecturesEnergy efficient computingSemantic vectorSemantics

The invention discloses a Chinese abstract generation method and system and a storage medium, and the method comprises the steps: obtaining a target text, and determining a Chinese word vector sequence of the target text; inputting the Chinese word vector sequence into a pre-trained encoder to generate a semantic vector; reconstructing full-text semantics most suitable for the current moment according to the semantic vector, and transmitting intermediate semantics summarizing the full-text semantics after reconstruction to a pre-trained decoder; and enabling the decoder to deduce the distribution of the words at the next moment according to the words predicted at the previous moment and the intermediate semantics summarizing the full-text semantics, wherein the finally generated word sequence is the abstract of the target text. The generation quality and readability of the Chinese text abstract can be improved.

Owner:NANJING COLLEGE OF INFORMATION TECH

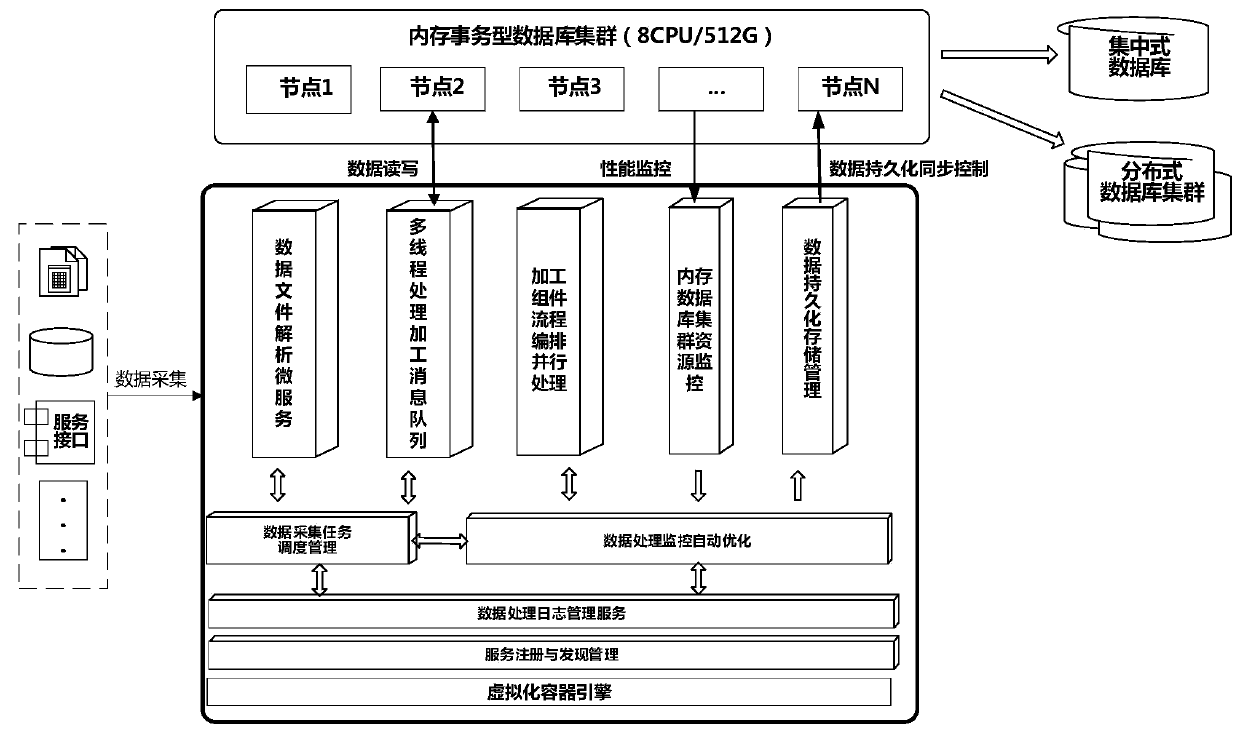

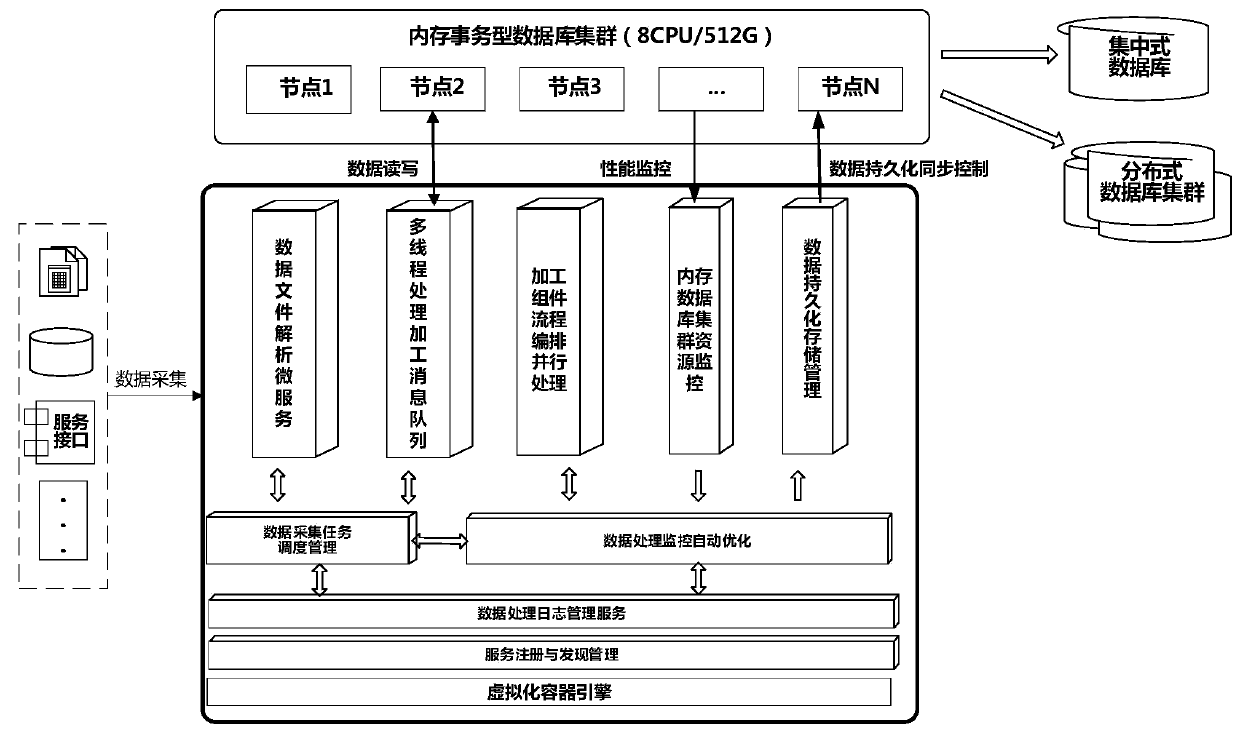

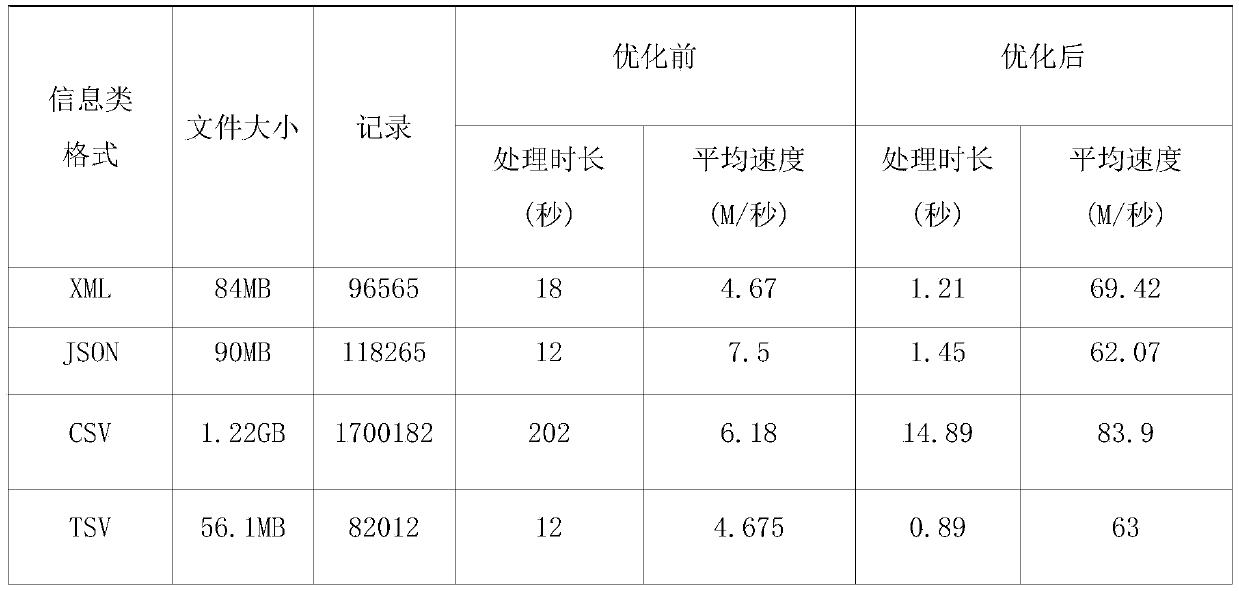

Time-limited automatic processing method for multi-source heterogeneous mass data

PendingCN111124679AEasy to storeOptimize data access designResource allocationDatabase management systemsSemi-structured dataData file

The invention discloses a time-limited automatic processing method for multi-source heterogeneous mass data. The method comprises the following steps of building a data processing operation environment based on a container technology; establishing data acquisition task scheduling management; analyzing and optimizing a design data file; performing distributed parallel processing on data processing;enabling the modular design processing flow arrangement to be controllable; automatically optimizing data processing and monitoring; designing events and messages; optimizing storage and data accessdesign; optimizing data acquisition management. Through the automatic optimization design of the data processing flow and the optimization design that the process can be flexibly controlled, the analysis, processing and processing efficiency of the semi-structured data file is greatly improved, and the association and fusion efficiency of massive historical data and real-time data is greatly improved.

Owner:NANJING LES INFORMATION TECH

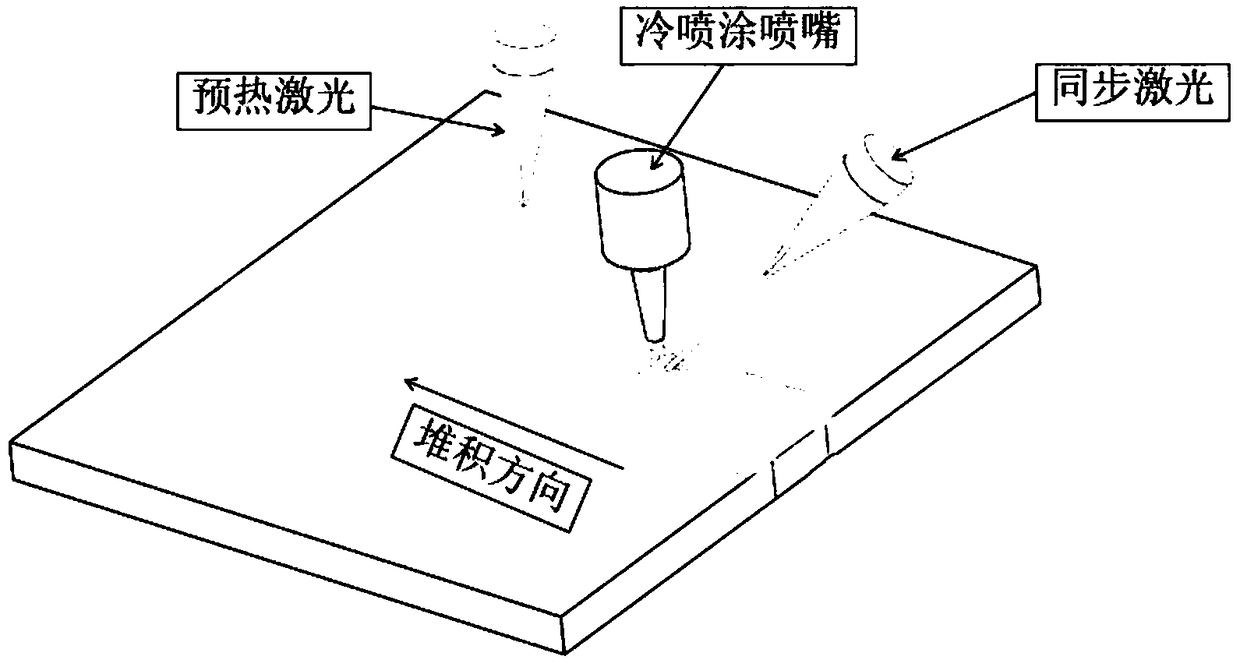

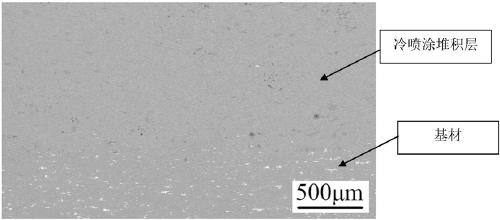

Laser-assisted cold spraying method for manufacturing additives

InactiveCN109161886AGuaranteed speedQuality assuranceAdditive manufacturing apparatusIncreasing energy efficiencySpray coatingLaser assisted

The invention discloses a laser-assisted cold spraying method for manufacturing additives. The method comprises the following steps: preheating a base material by preheating laser to enable the temperature of the base material to be raised to 300-400 DEG C and lower than the melting point of the base material by at least 200 DEG C to obtain a preheated base material; performing additive accumulation on the preheated base material with a cold spraying technology, and performing surface treatment on cold sprayed coatings obtained by additive accumulation synchronously by synchronous laser. The accumulation combination effect of cold spraying additive manufacturing can be substantially improved, the accumulation coatings are not prone to falling off, accumulation efficiency is higher, flexibility is better, quality of the additives is substantially improved, and surface molding can be effectively controlled.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

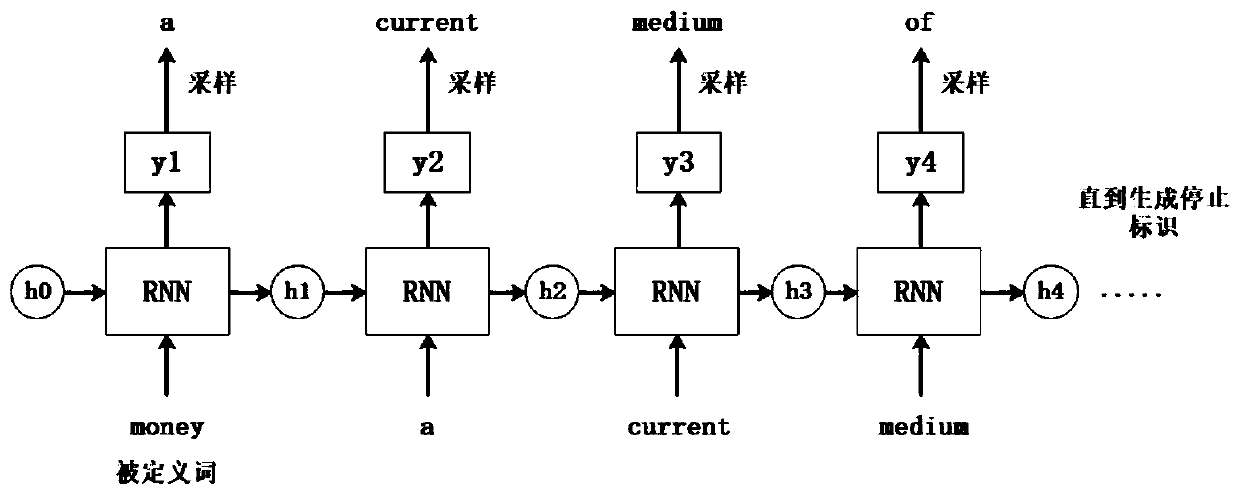

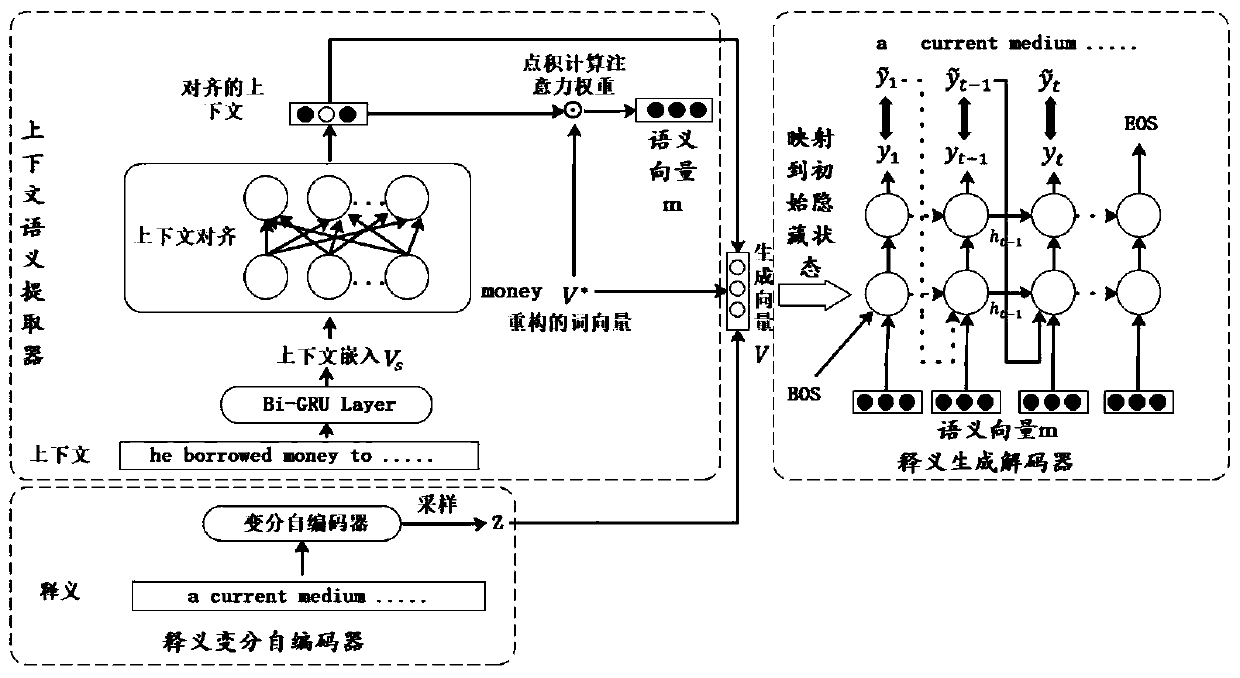

Word definition generation method based on recurrent neural network and latent variable structure

ActiveCN110083710AEasy to understandMake up for deficienciesCharacter and pattern recognitionNeural architecturesParaphraseAlgorithm

The invention relates to a word definition generation method based on a recurrent neural network and a latent variable structure in the field of natural language processing. On the basis of a recurrent neural network, a variational auto-encoder (VAE) is used for modeling paraphrases, latent variable characteristics are combined. The paraphrases are extracted according to context information of defined words to generate paraphrases of the words, and the method specifically comprises the steps of establishing and arranging a basic corpus; selecting a synonym set of the defined words, and expanding the basic corpus to form a final corpus; carrying out expansion reconstruction on the word vectors of the defined words; constructing a structure model based on the recurrent neural network and thelatent variable; training a latent variable structure model based on a recurrent neural network; and inputting the to-be-paraphrased words and the context information thereof into the trained model to realize semantic paraphrasing of the to-be-paraphrased words in a specific context, thereby achieving polysemy.

Owner:BEIJING UNIV OF TECH

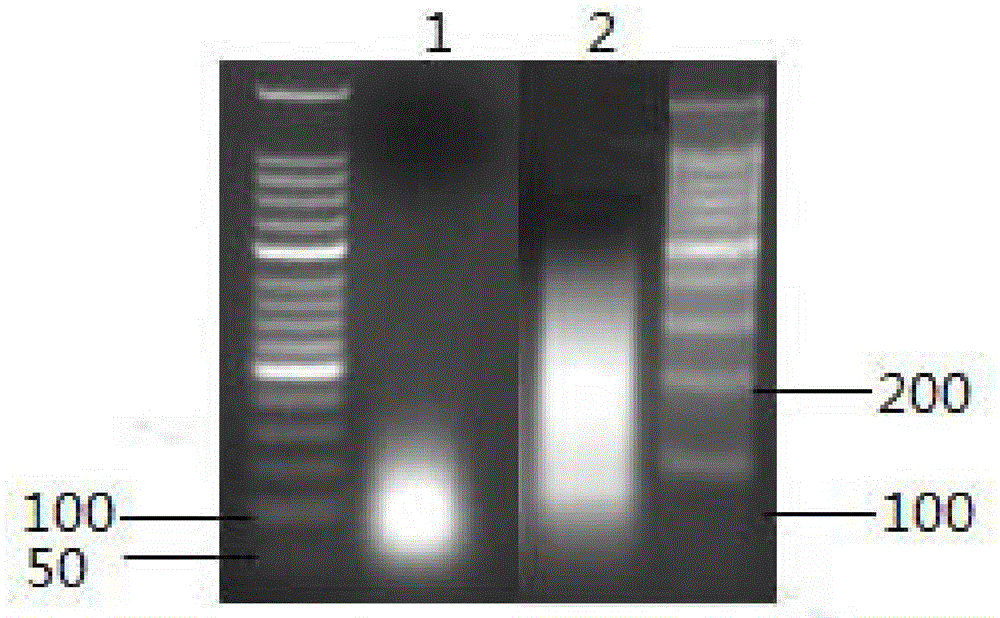

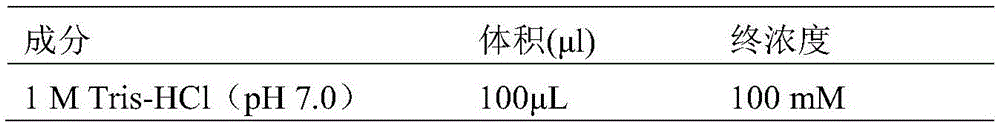

Construction method of RNA methylation sequencing library

The invention provides a construction method of an RNA methylation sequencing library. The construction method comprises the following steps: (S1) carrying out fragmentation on an RNA sample, so as to obtain fragmented RNA; (S2) carrying out co-immunoprecipitation on the fragmented RNA by virtue of an RNA methylation specific antibody, so as to obtain precipitates; (S3) digesting the precipitates by virtue of protease, so as to obtain a digestion product; (S4) extracting RNA from the digestion product, and carrying out reverse transcription on extracted RNA, so as to obtain cDNA; and (S5) constructing a sequencing library by virtue of the cDNA, so as to obtain the RNA methylation sequencing library. The digestion of protease is stronger than the competitive elution of analogues, so that the yield of RNA can be increased, the noise generated due to the introduction of methylation site analogues is avoided, the problem of high noise of constructed libraries in the prior art is solved, the library construction quality is improved, and therefore, the utilization rate of valid data output by the sequencing library is increased.

Owner:BEIJING NOVOGENE TECH CO LTD

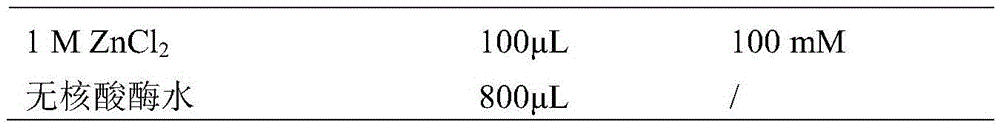

Design method for durable bituminous pavement with layer-by-layer progressively-increased structural layer life

ActiveCN103669154AImprove the design levelExtended service lifeIn situ pavingsSurface layerRoad surface

A disclosed design method for durable bituminous pavement with layer-by-layer progressively-increased structural layer life consists of a durable surface layer, a long-life basic layer and a permanent roadbed; the durable surface layer is disposed on the long-life basic layer, and the long-life basic layer is disposed on the permanent roadbed; and the durable surface layer consists of a middle-upper surface layer and a lower surface layer, wherein the middle-upper surface layer is disposed on the lower surface layer. The method helps to change the damage mode of bituminous pavements and establish the bituminous pavement with the layer-by-layer progressively-increased structural layer life, so that the damage of the bituminous pavement firstly happens at the upper part of the pavement, and the bituminous pavement only needs milling and plane operation and overlay restoration at the surface when maintenance is carried out, and thus the repaving thickness during maintenance repaving is relatively thin. The design method helps to substantially improve the design level and the service life of the bituminous pavement, effectively reduce the life-cycle cost of bituminous pavement and extremely improve the construction quality and the service level of roads.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

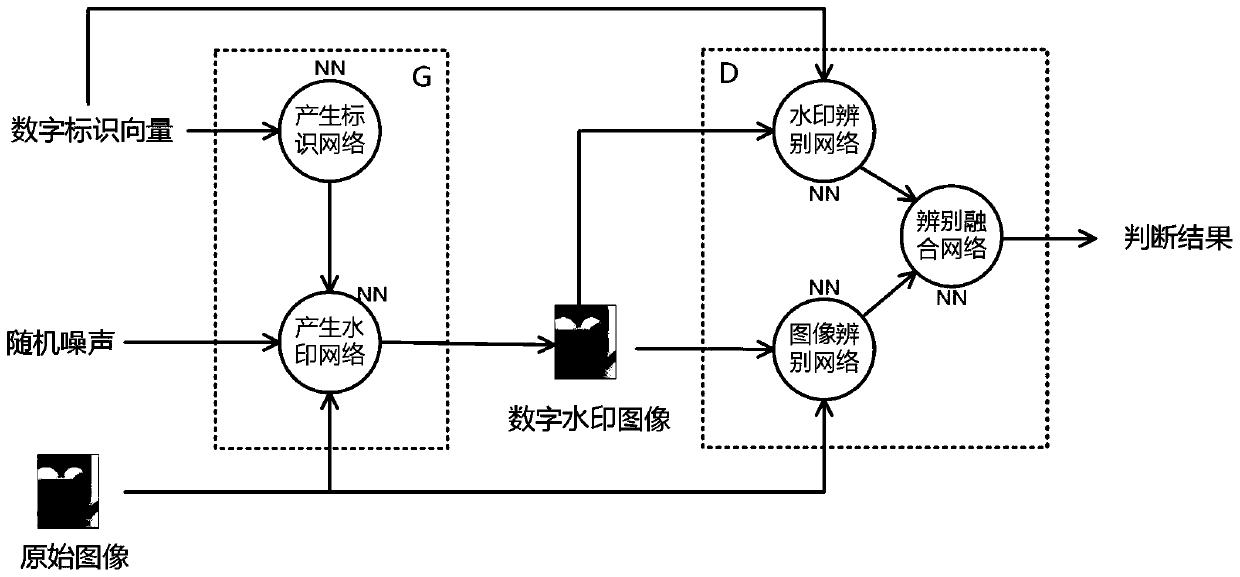

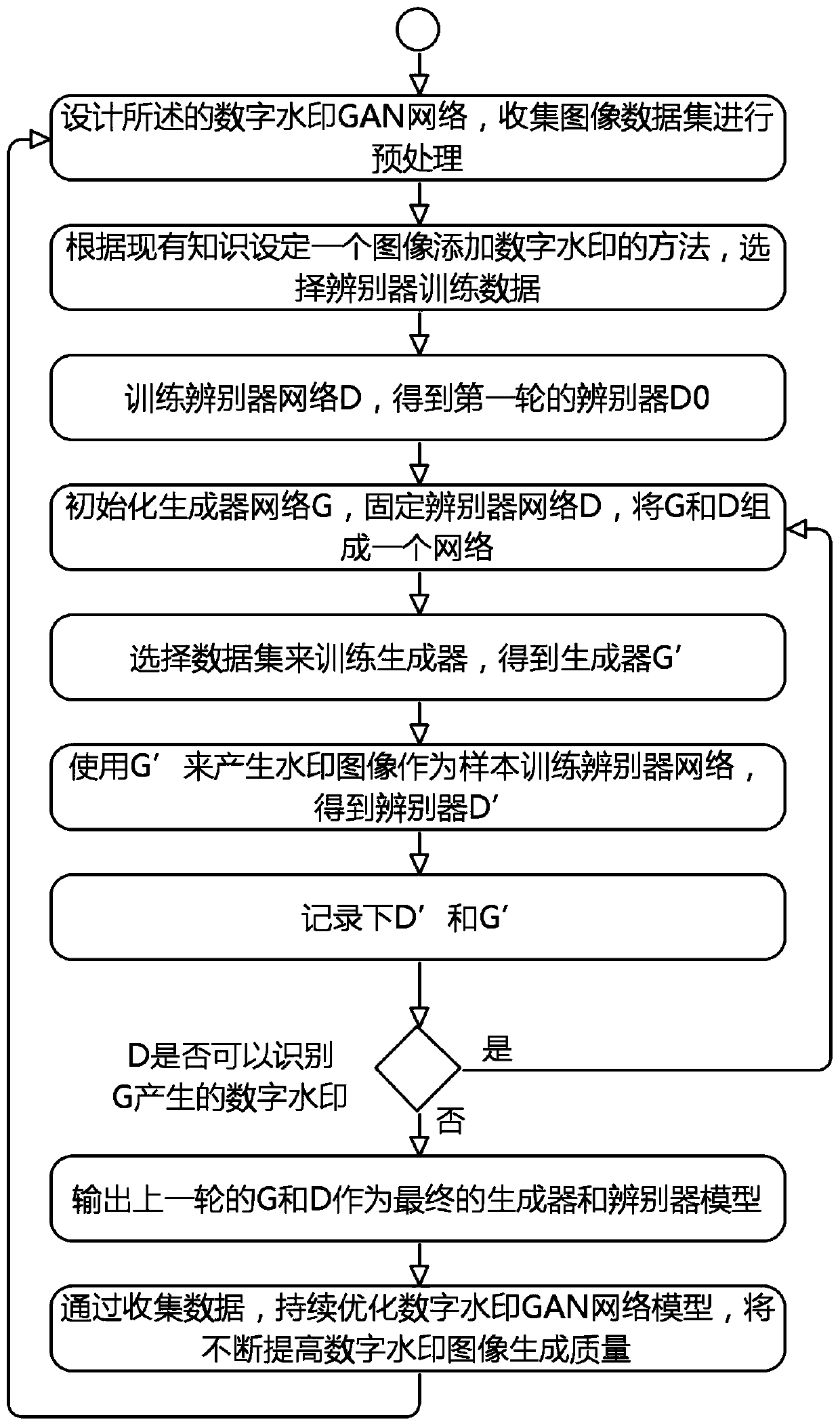

Image digital watermark generation and identification system and method based on GAN network

ActiveCN110276708AIncrease diversityEffective protectionInternal combustion piston enginesImage data processing detailsPattern recognitionDiscriminator

The invention provides an image digital watermark generation and identification system and method based on a GAN network, and belongs to the technical field of digital watermarks, information hiding, deep learning and neural networks. The image digital watermark generation and identification system and method adopt the GAN network to efficiently and quickly generate unperceptible image digital watermarks and effectively identify watermarks, and can gradually improve the digital watermark quality by repeatedly training a digital watermark generator and a discriminator.

Owner:SHANDONG INSPUR SCI RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com