Steel bar connection structure of prefabricated parts

A technology of prefabricated components and connecting structures, applied in the direction of structural elements, building components, building reinforcements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

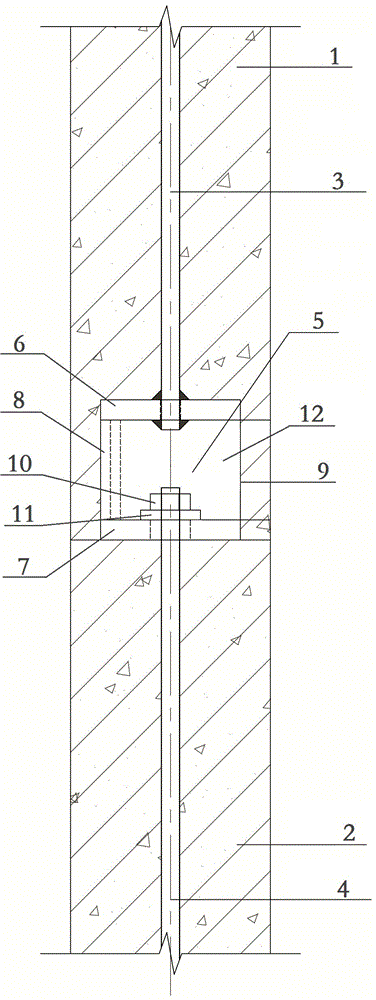

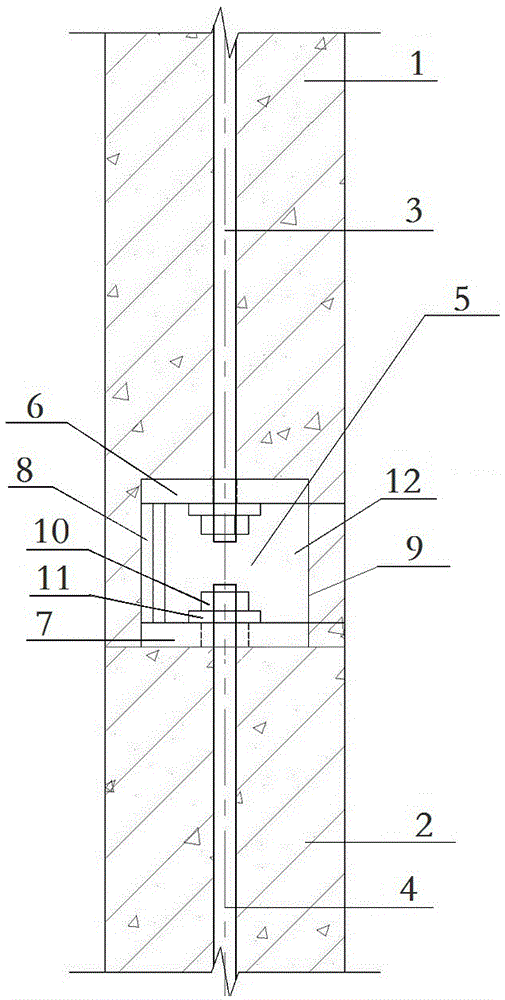

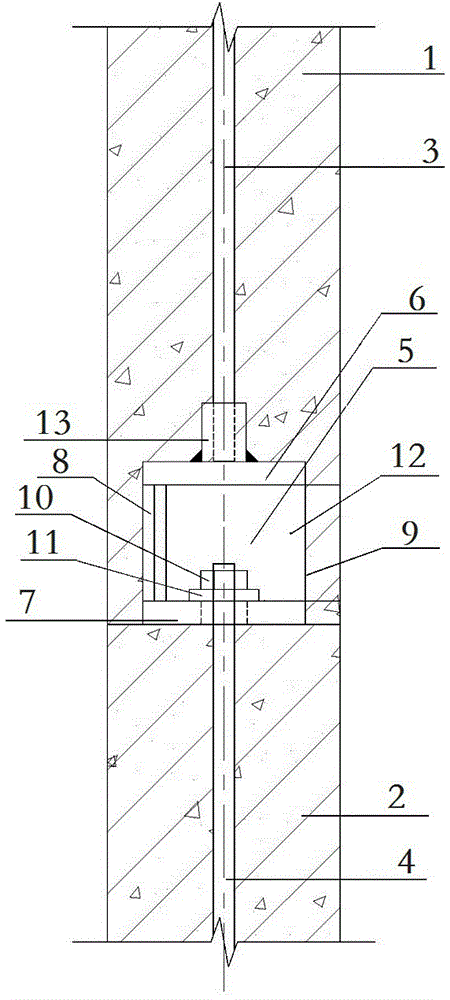

[0031] Referring to the accompanying drawings, the steel bar connection structure of prefabricated components of the present invention includes a first prefabricated concrete component and a second prefabricated concrete component, the lower end of the first prefabricated concrete component is pre-embedded with a connection box, and the first prefabricated concrete component The lower end of the connecting steel bar is connected and fixed to the upper top plate of the connecting box, and the upper end of the second connecting steel bar of the second prefabricated concrete member passes through the lower reinforcing bar insertion hole of the lower bottom plate of the connecting box, and the upper end of the second connecting steel bar is passed through a screw thread Connecting the fixing nuts and washers, the first prefabricated concrete component is an upper prefabricated concrete wall panel, and the second prefabricated concrete component is a lower prefabricated concrete wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com