Prefabricated shear wall rebar connecting joint

A technology for connecting nodes and prefabricated walls, applied in the direction of structural elements, building components, building reinforcements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

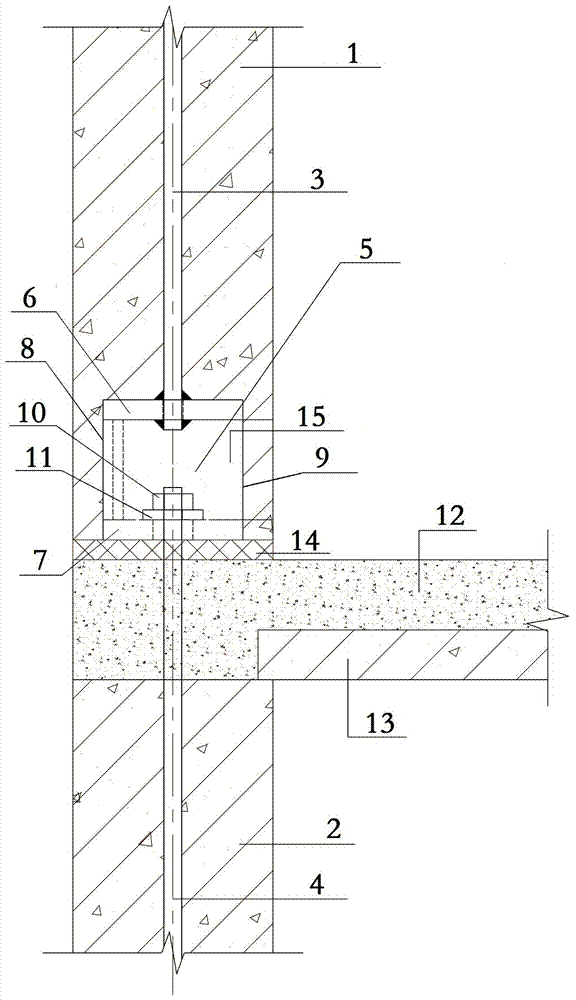

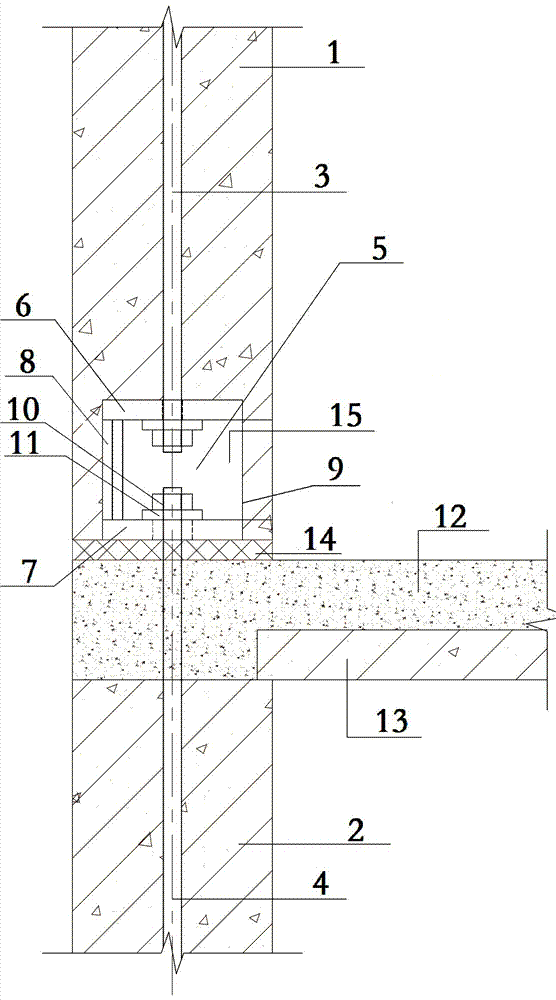

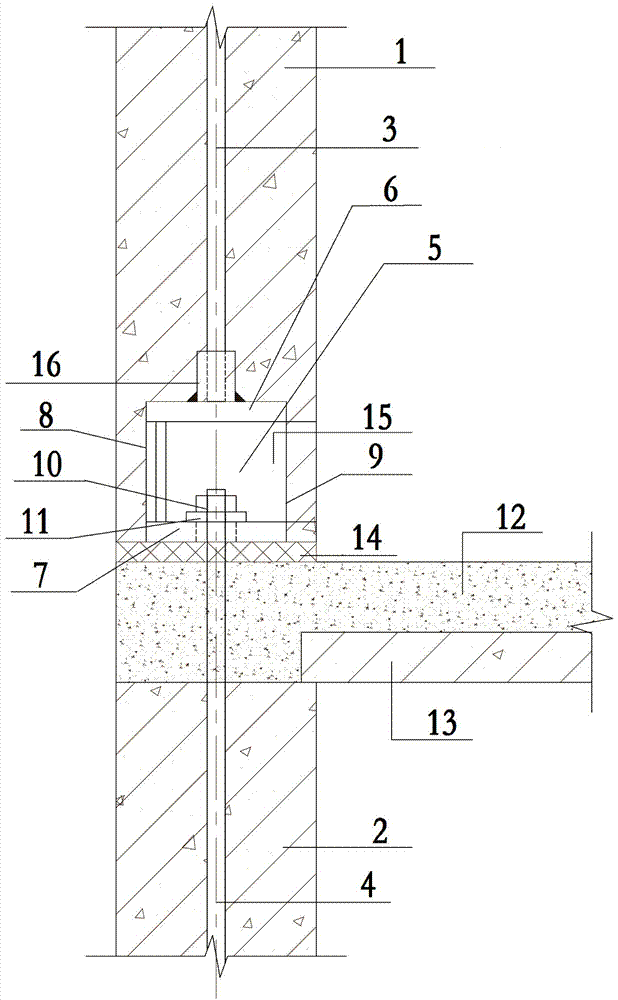

[0021] Referring to the accompanying drawings, the prefabricated shear wall reinforcement connection node of the present invention includes an upper prefabricated wall 1, a lower prefabricated wall 2 and a superimposed floor slab, and the superimposed floor slab includes a prefabricated layer 13 of a superimposed floor slab and a cast-in-place layer 12 of the superimposed floor slab , the lower end of the upper prefabricated wall is pre-buried with a connection box 5, the lower end of the connection steel bar 3 of the upper prefabricated wall is connected and fixed with the upper top plate of the connection box, and the upper end of the lower extension bar 4 of the lower prefabricated wall is cast in place through the superimposed floor slab Layer 12 and the lower bottom plate of the connection box 5, and finally the connection box and the end of the protruding steel bar are connected and fixed through the nut 10 and the washer 11. The junction box is a metal box with the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com