Patents

Literature

1533results about "Heating appliances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

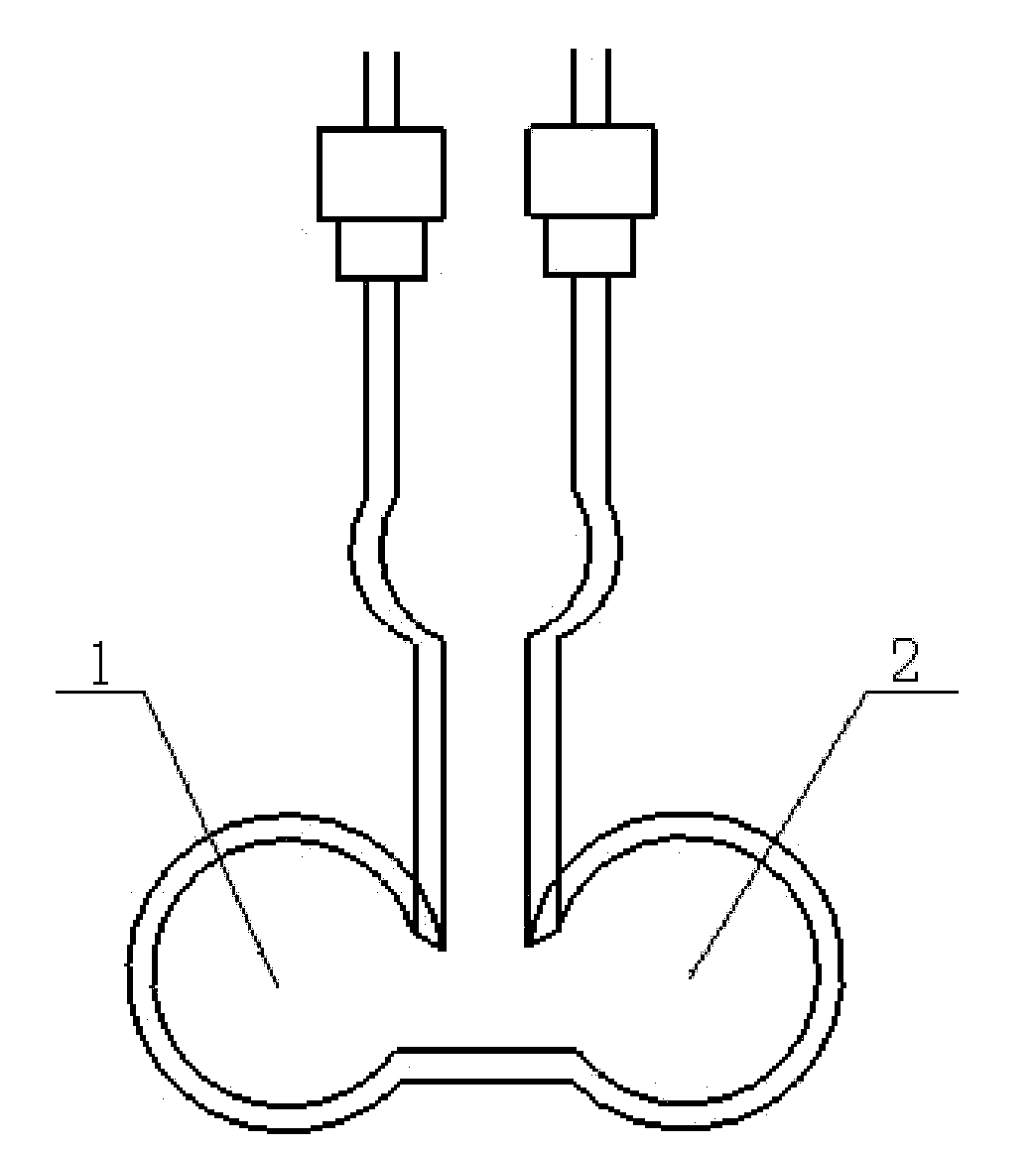

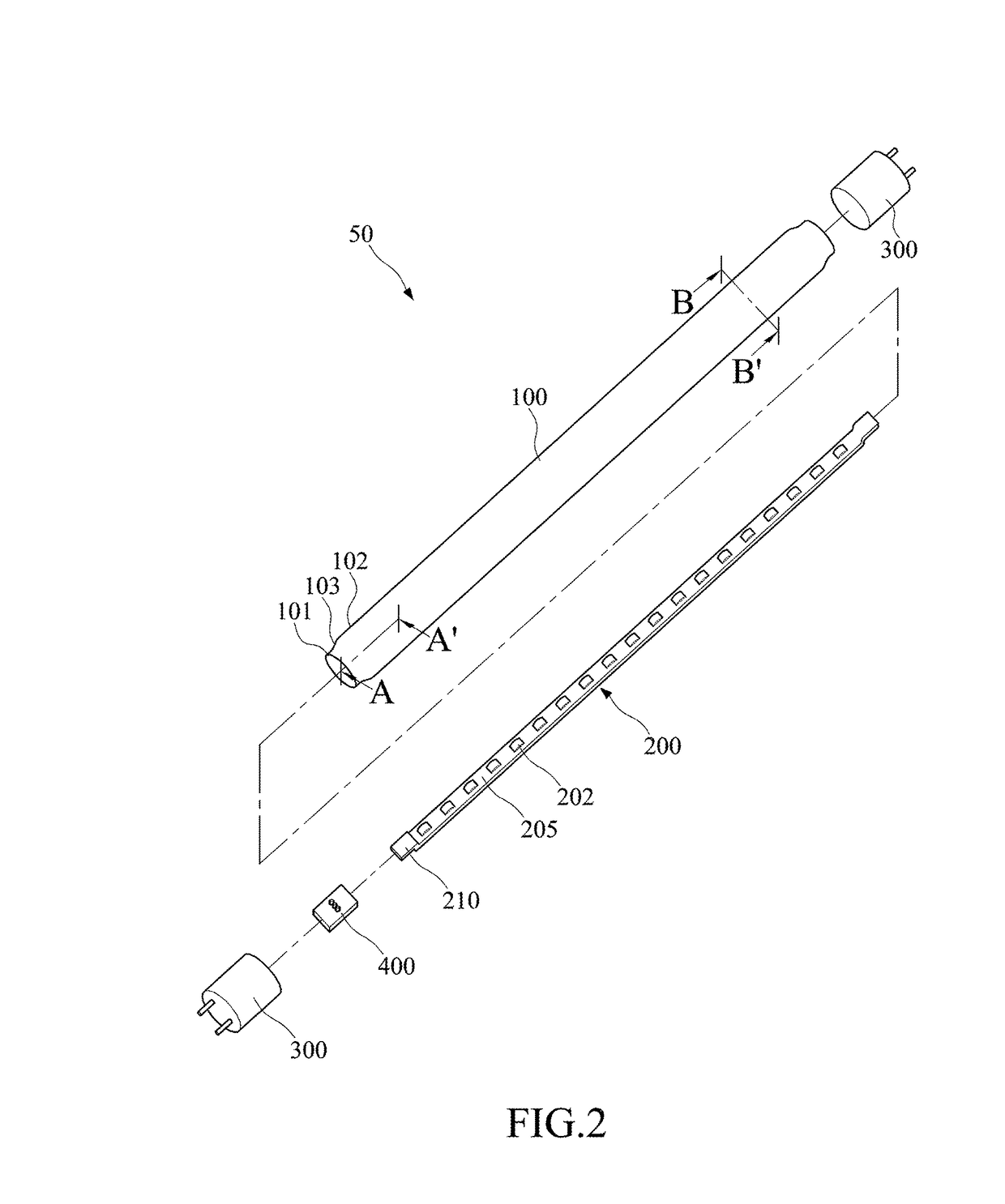

LED tube lamp

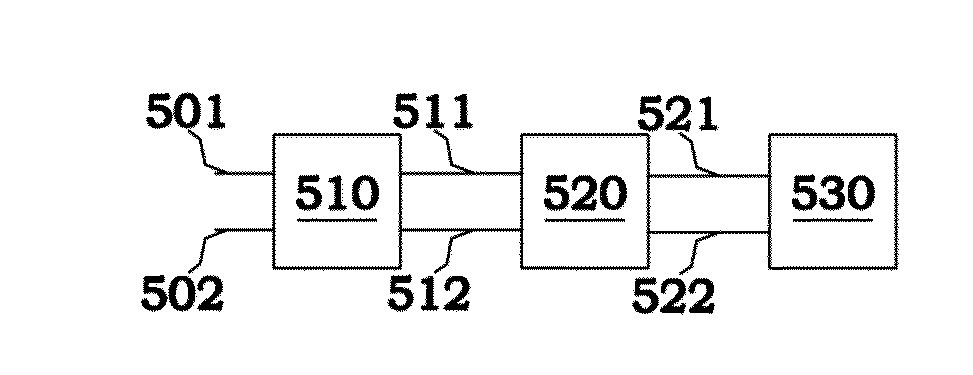

ActiveUS20160091147A1Better heat dissipation structureAvoid flickPoint-like light sourceElongate light sourcesCapacitanceComputer module

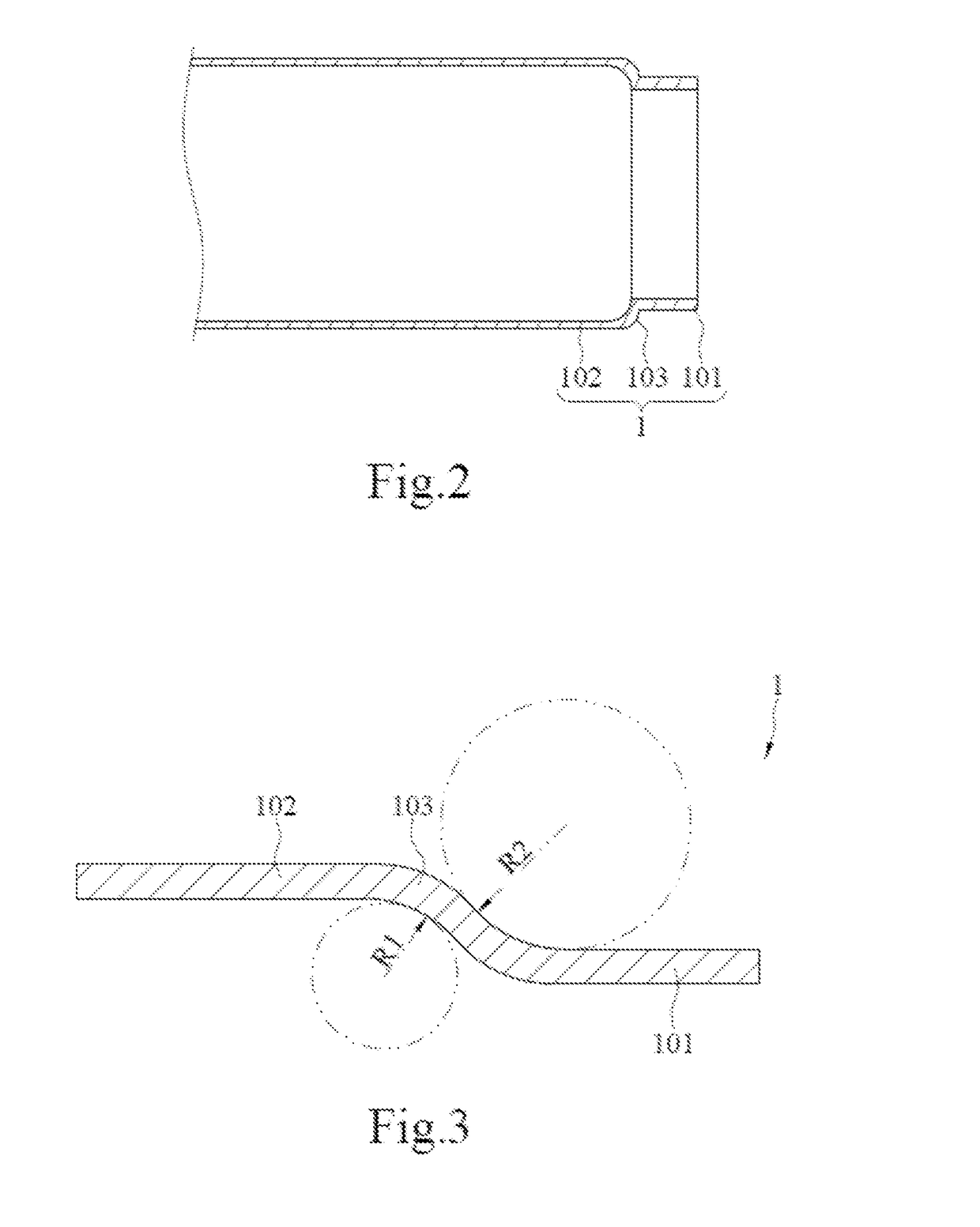

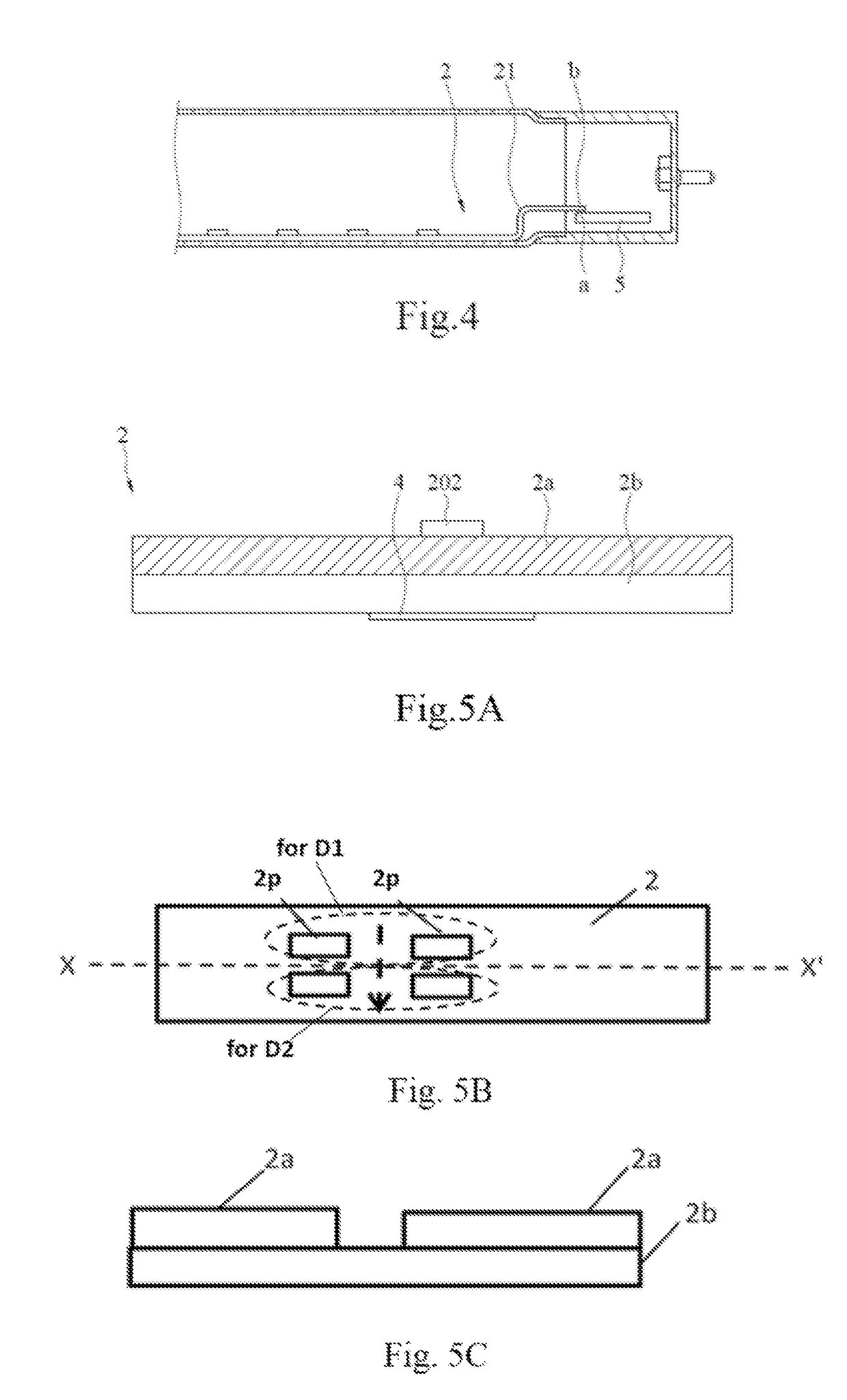

A light-emitting diode (LED) tube lamp comprises a lamp tube, a first rectifying circuit, a filtering circuit and an LED driving module. The lamp tube has a first pin and a second pin for receiving an external driving signal. The first rectifying circuit is coupled to the first and second pins, for rectifying the external driving signal to produce a rectified signal. The filtering circuit is coupled to the first rectifying circuit, for filtering the rectified signal to produce a filtered signal. The LED driving module is coupled to the filtering circuit to receive the filtered signal for emitting light. Wherein, the filtering circuit includes a capacitor and an inductor connected in parallel and between one of the first and second pins and the first rectifying circuit, and the parallel-connected capacitor and inductor are configured for presenting a peak equivalent impedance to the external driving signal at a specific frequency.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

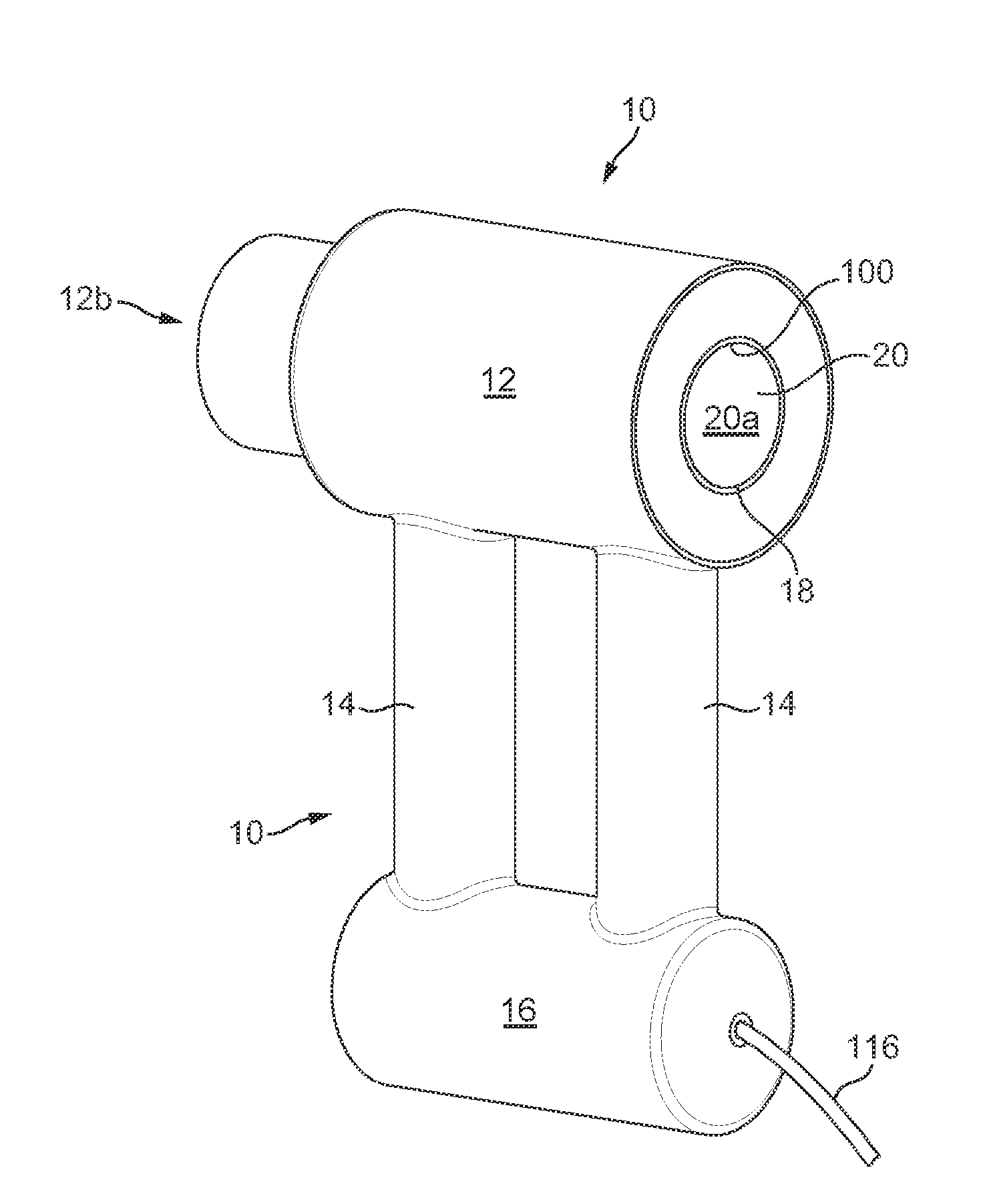

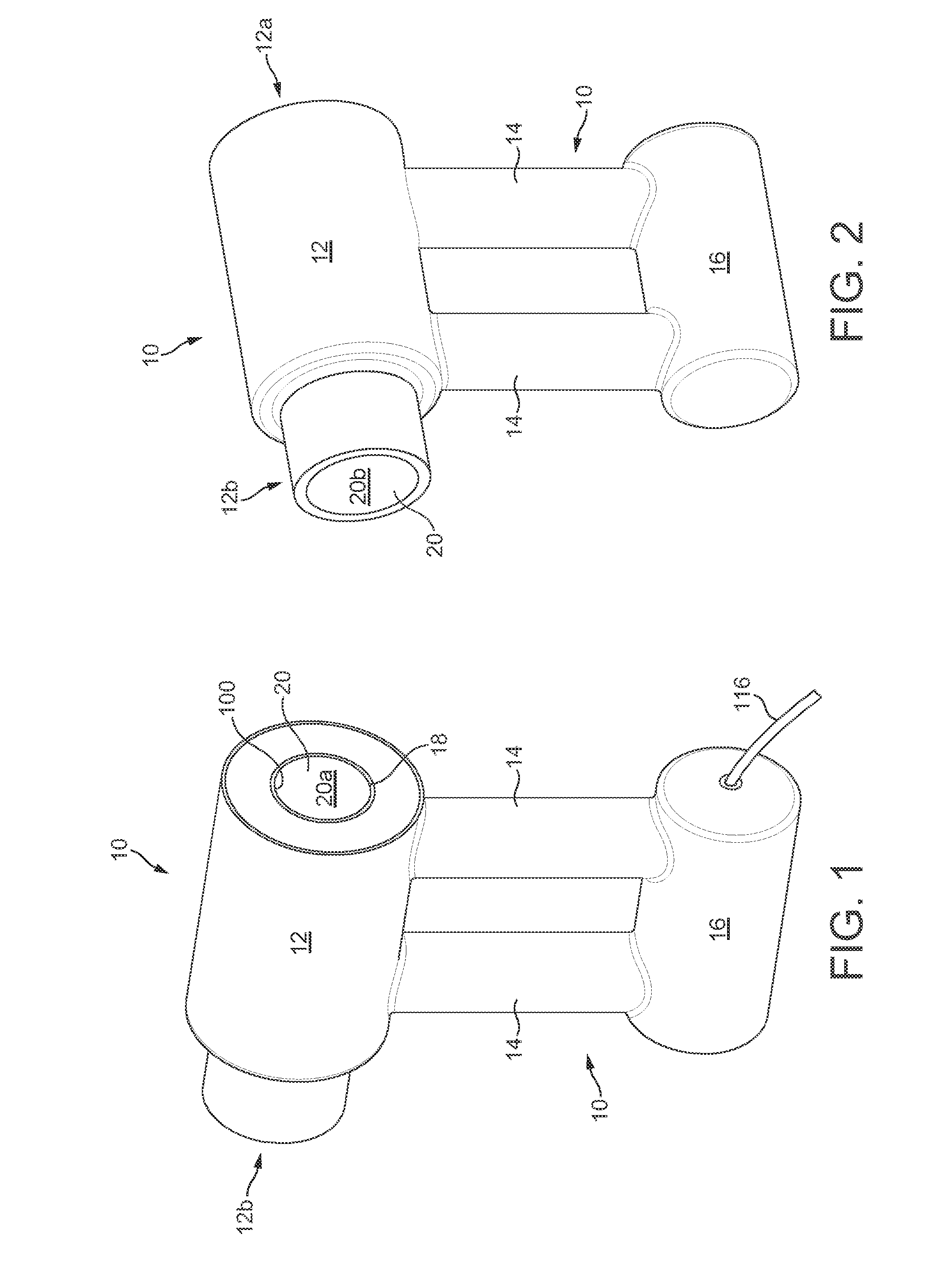

Hand held appliance

A hand held appliance, such as a hairdryer, includes at least one fluid inlet for admitting fluid into the appliance, at least one fluid outlet for emitting fluid from the appliance, at least one fluid flow path extending through the appliance, a heater, and a fluid chamber at least partially defined by an external wall of the appliance, the chamber being configured to provide a thermally insulating barrier between the heater and the external wall. The fluid flow path comprises two parallel sections.

Owner:DYSON TECH LTD

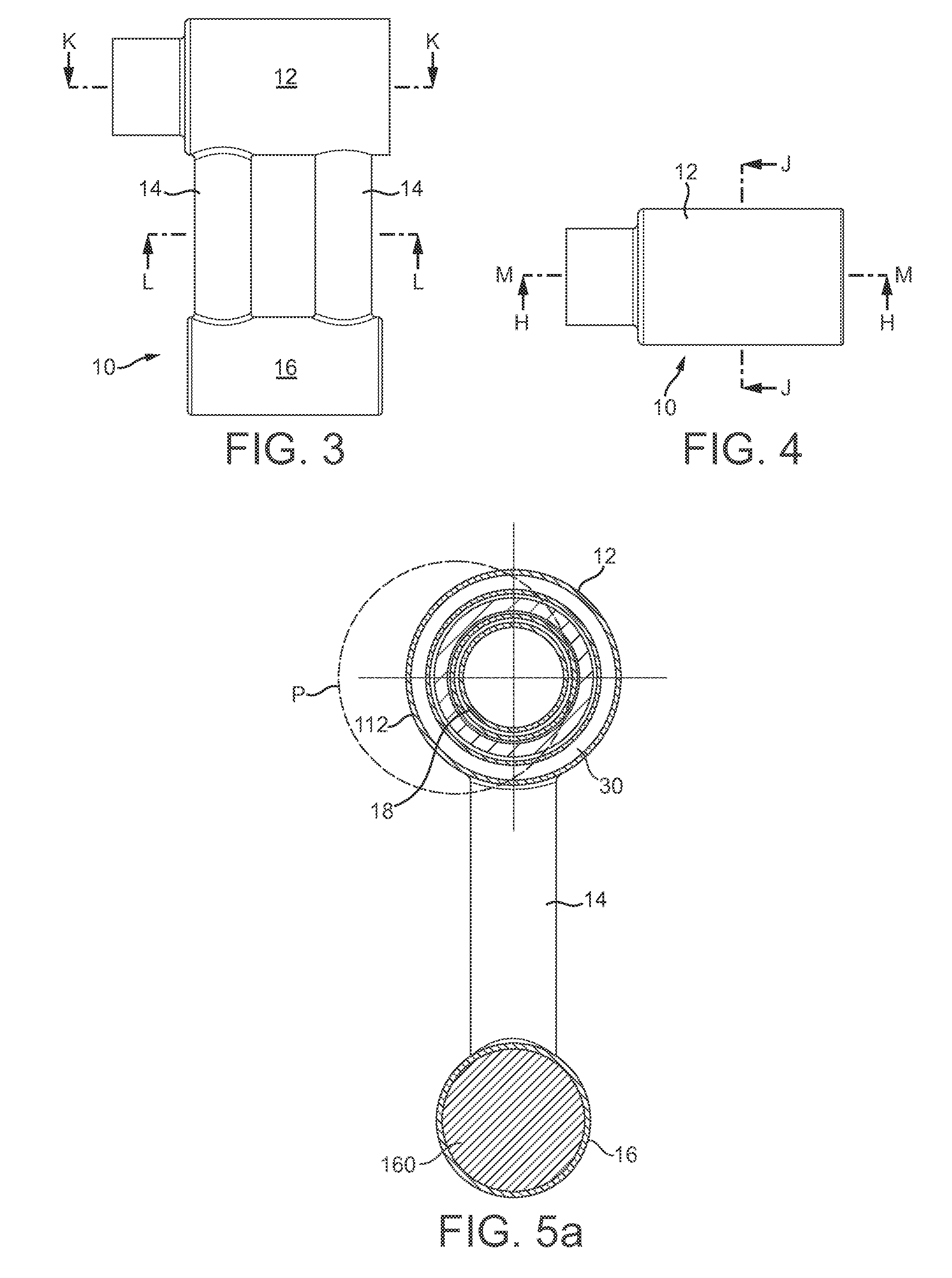

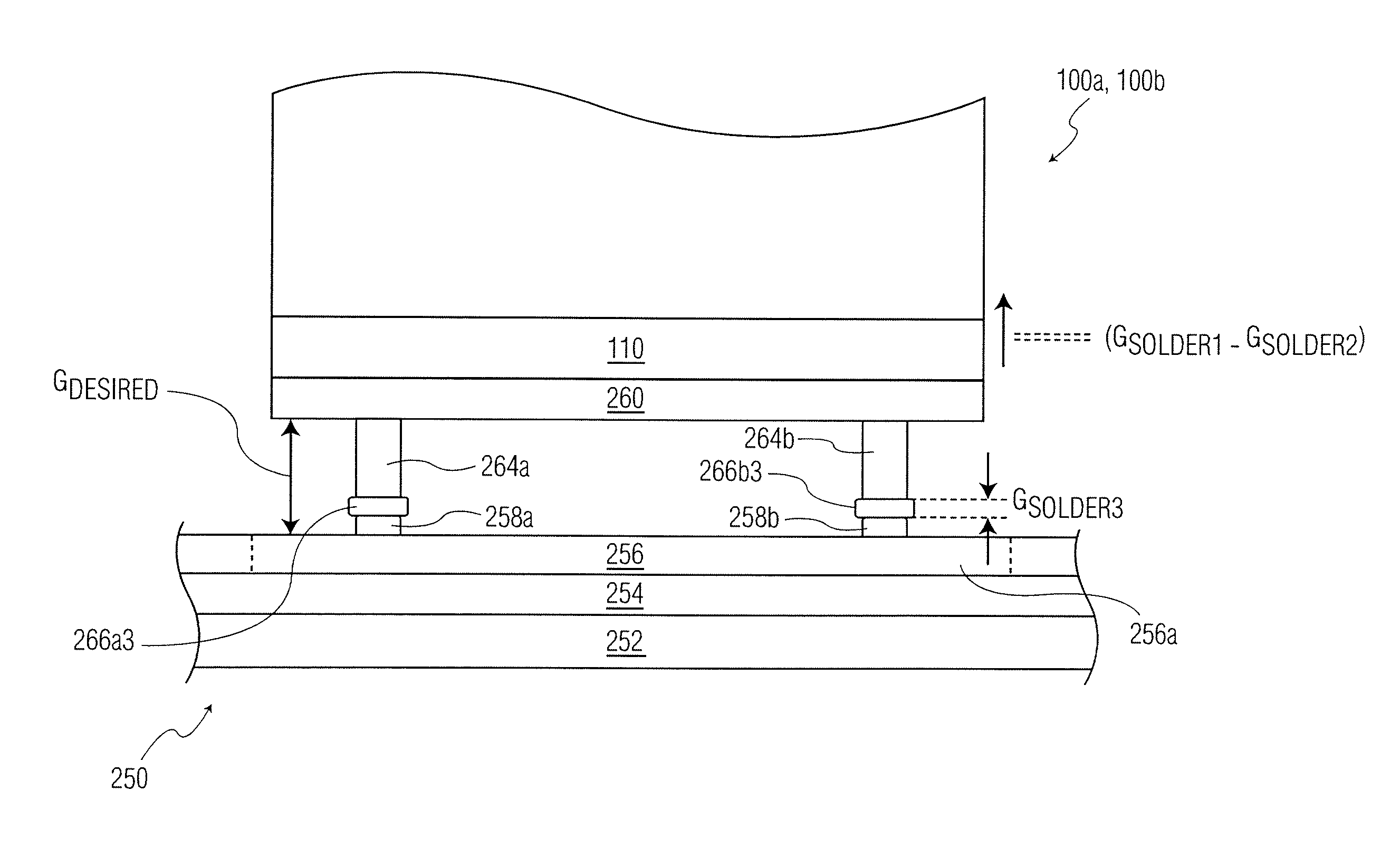

Method for bonding a sputter target to a backing plate and the assembly thereof

InactiveUS20050061857A1Electric discharge tubesVacuum evaporation coatingBond interfaceBonded interface

A method for solder bonding a sputter target to a backing plate having a plurality of spaced-apart ridges on its bonding surface to provide a uniform spacing and a uniform solder bonded interface; and the sputter target / backing plate assembly so produced.

Owner:PRAXAIR ST TECH INC

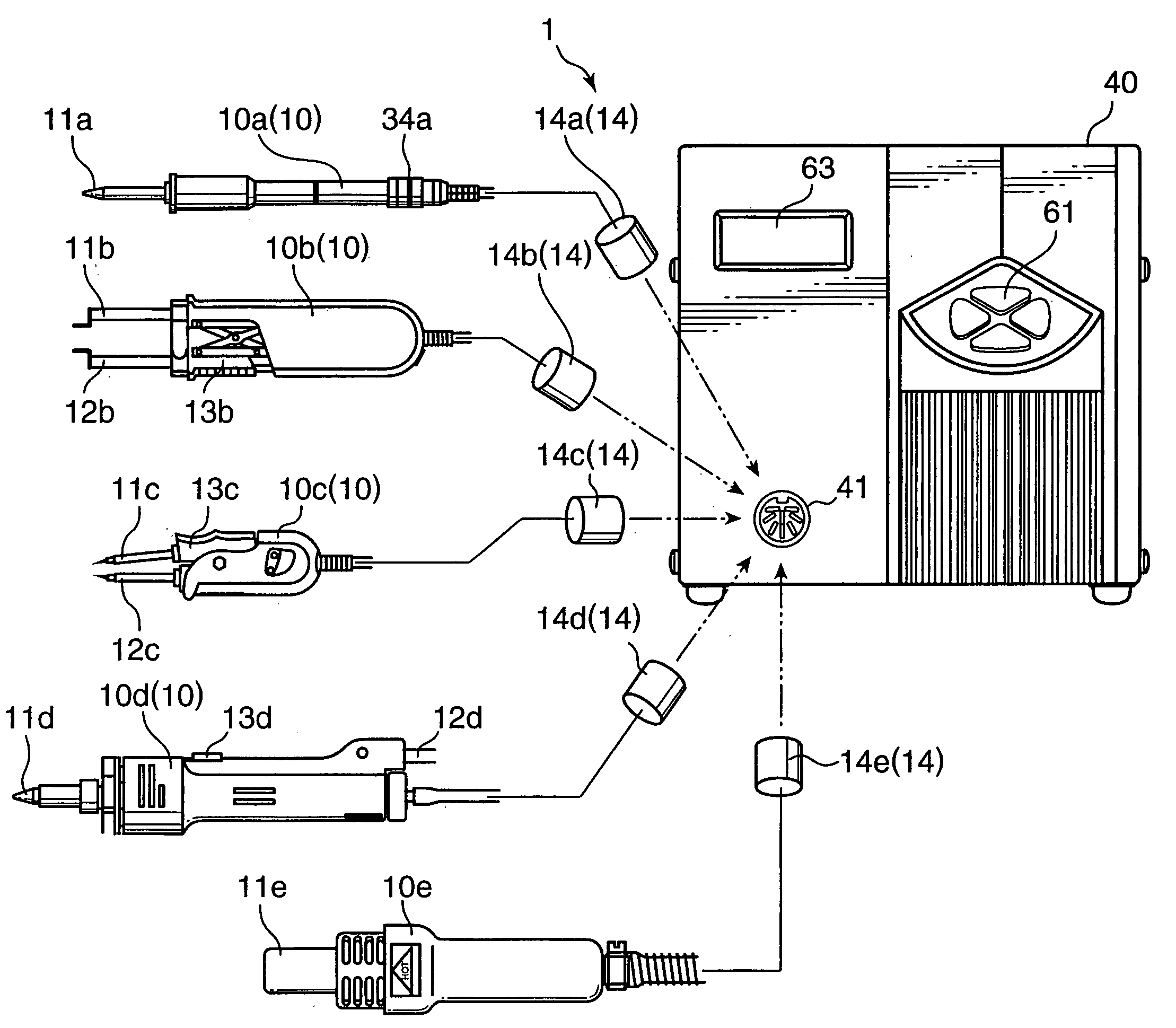

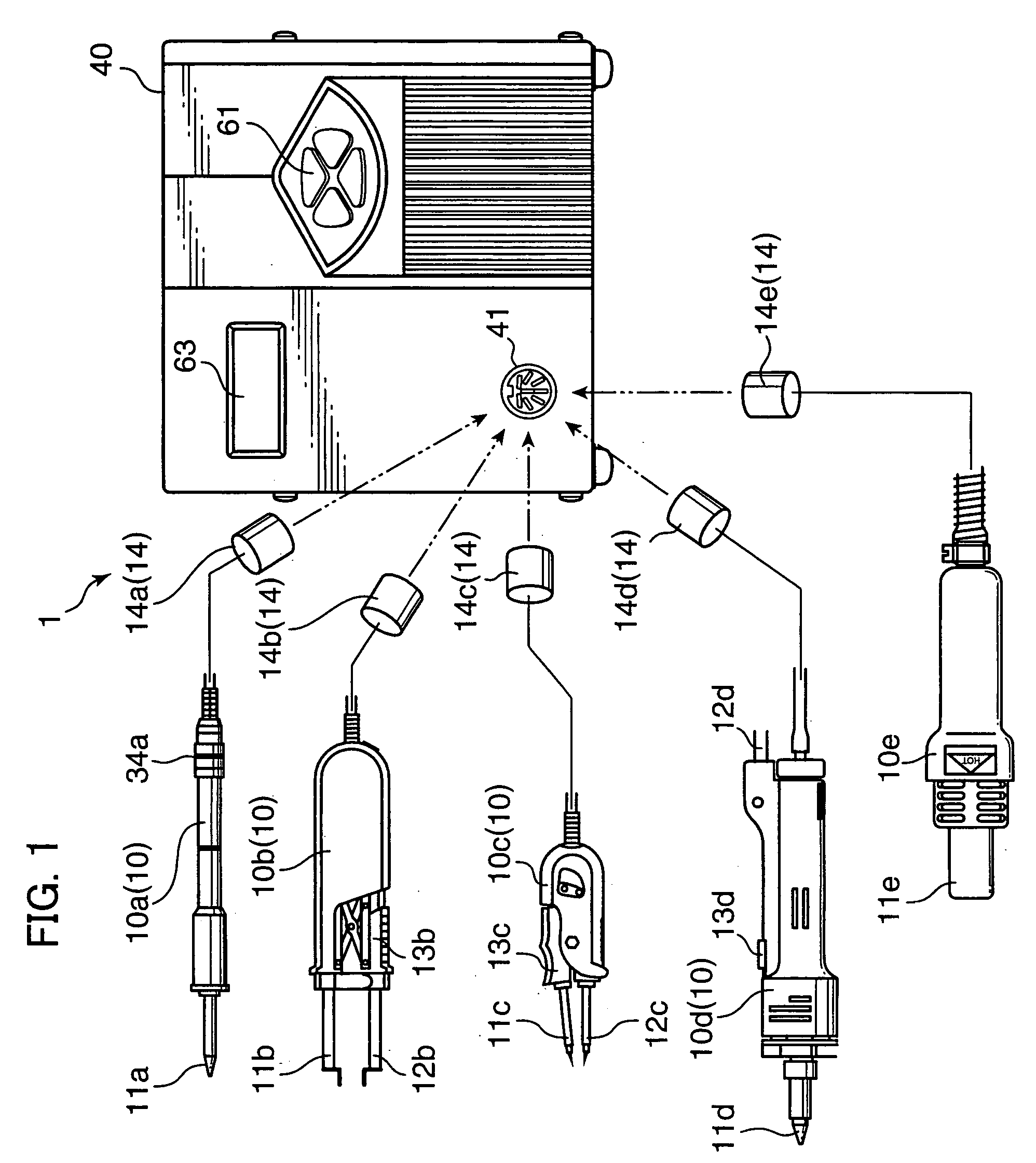

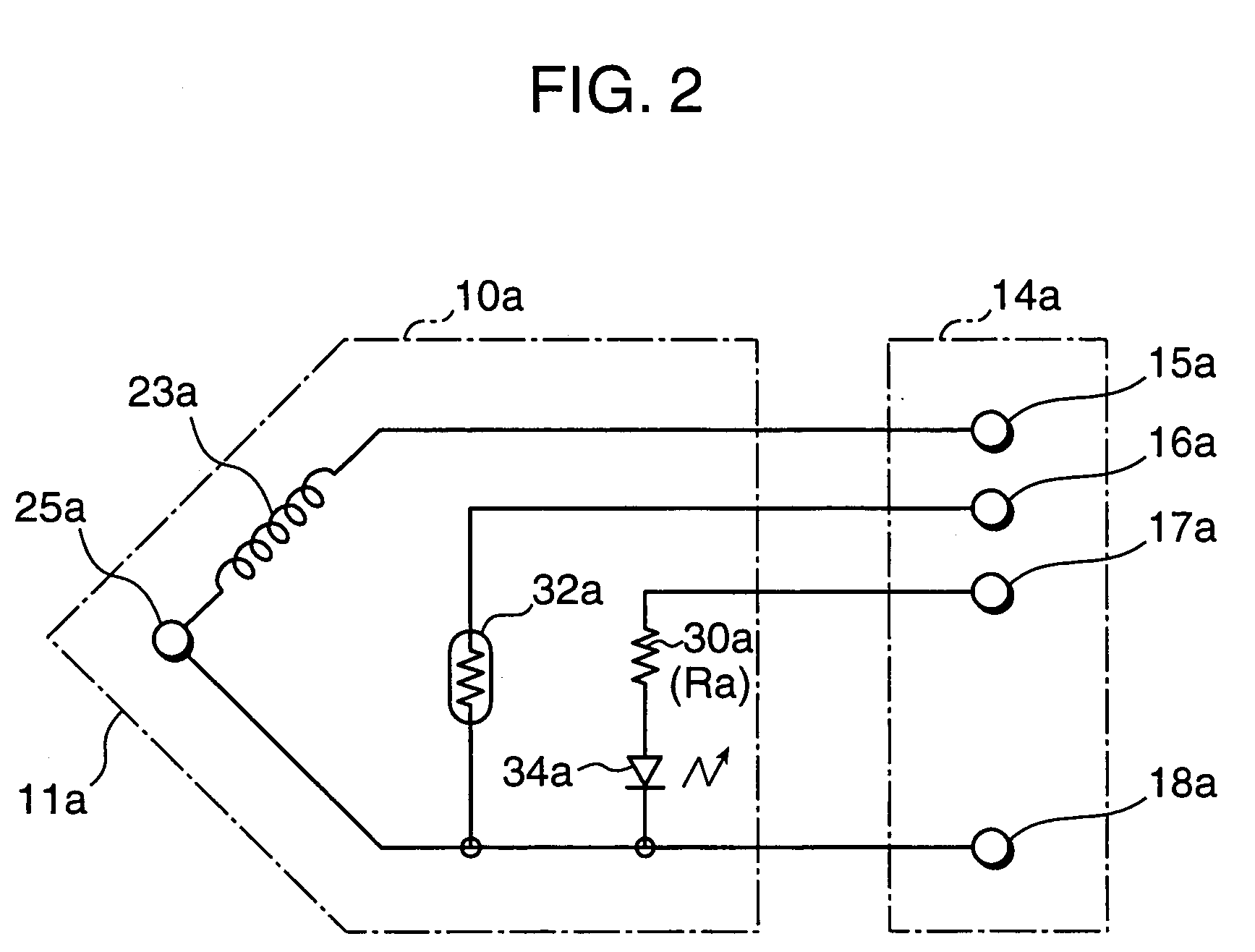

Temperature control system for solder handling devices and method for temperature control for those devices

InactiveUS20050121495A1Improve accuracyImprove reliabilityAutomatic control devicesPrecision positioning equipmentTemperature controlElectrical resistance and conductance

In a temperature control system for controlling a heating member or means of a solder handling device, a plurality of solder handling devices such as soldering iron, a heater tweezer, a solder sucker and a hot air blower are selectively coupled with a temperature controller which in turn identify the solder handling device connected thereto and controls temperature of the heater of the connected device with temperature control characteristic suitable for the device. Each solder handling device may have a resistor of which resistance value represents the type of the device so that the temperature controller identify the device by the resistance value.

Owner:HAKKO CO LTD

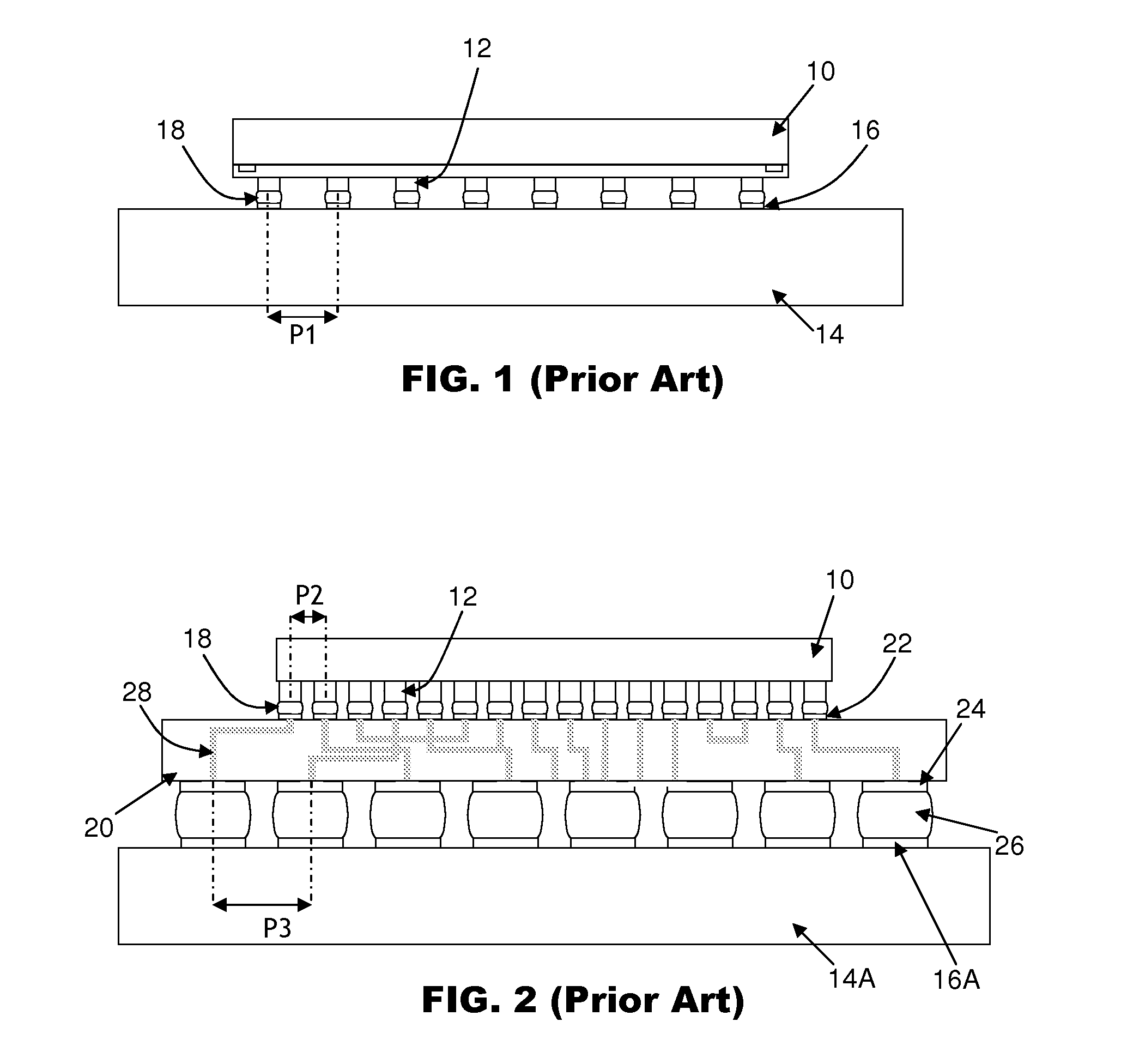

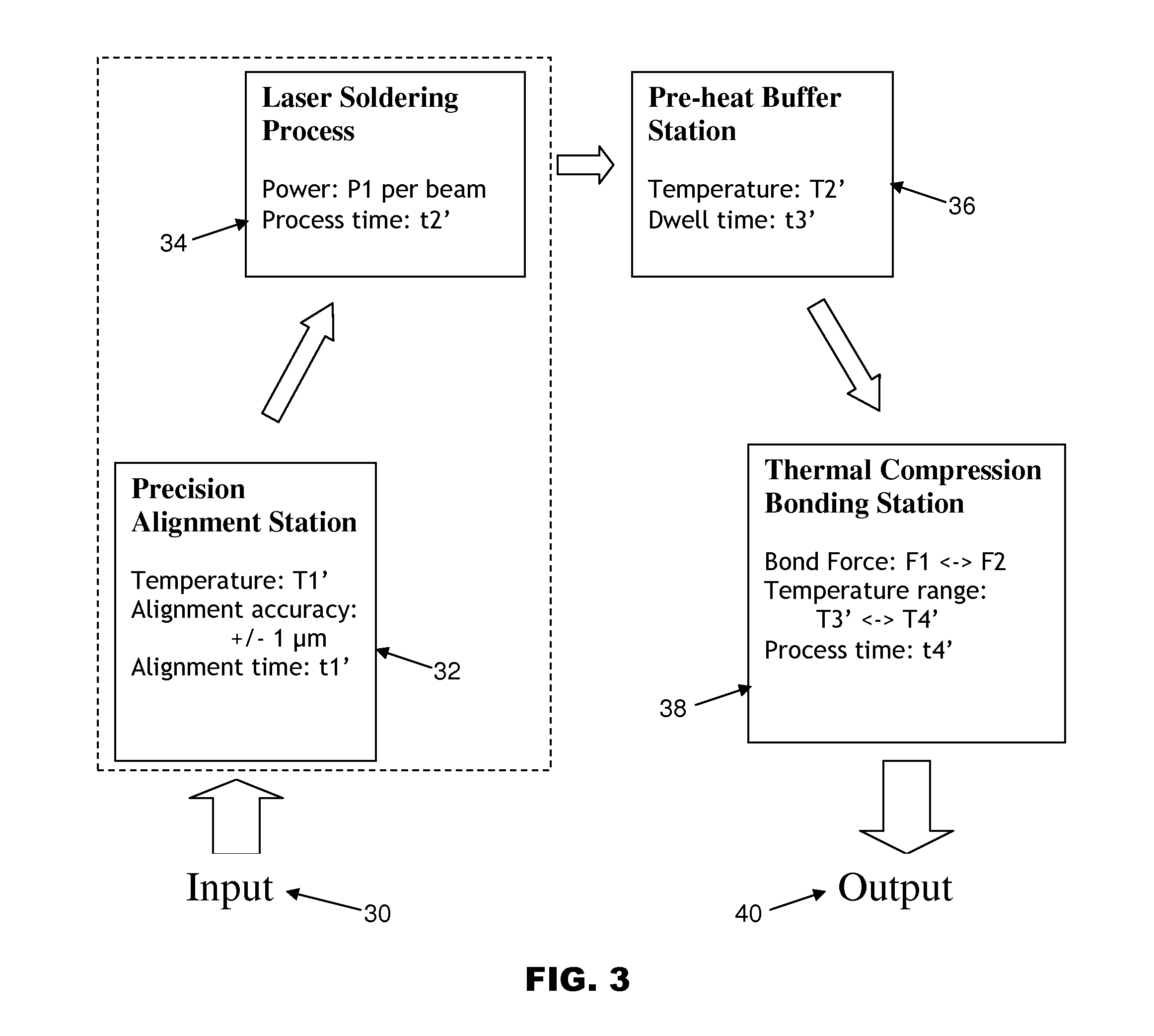

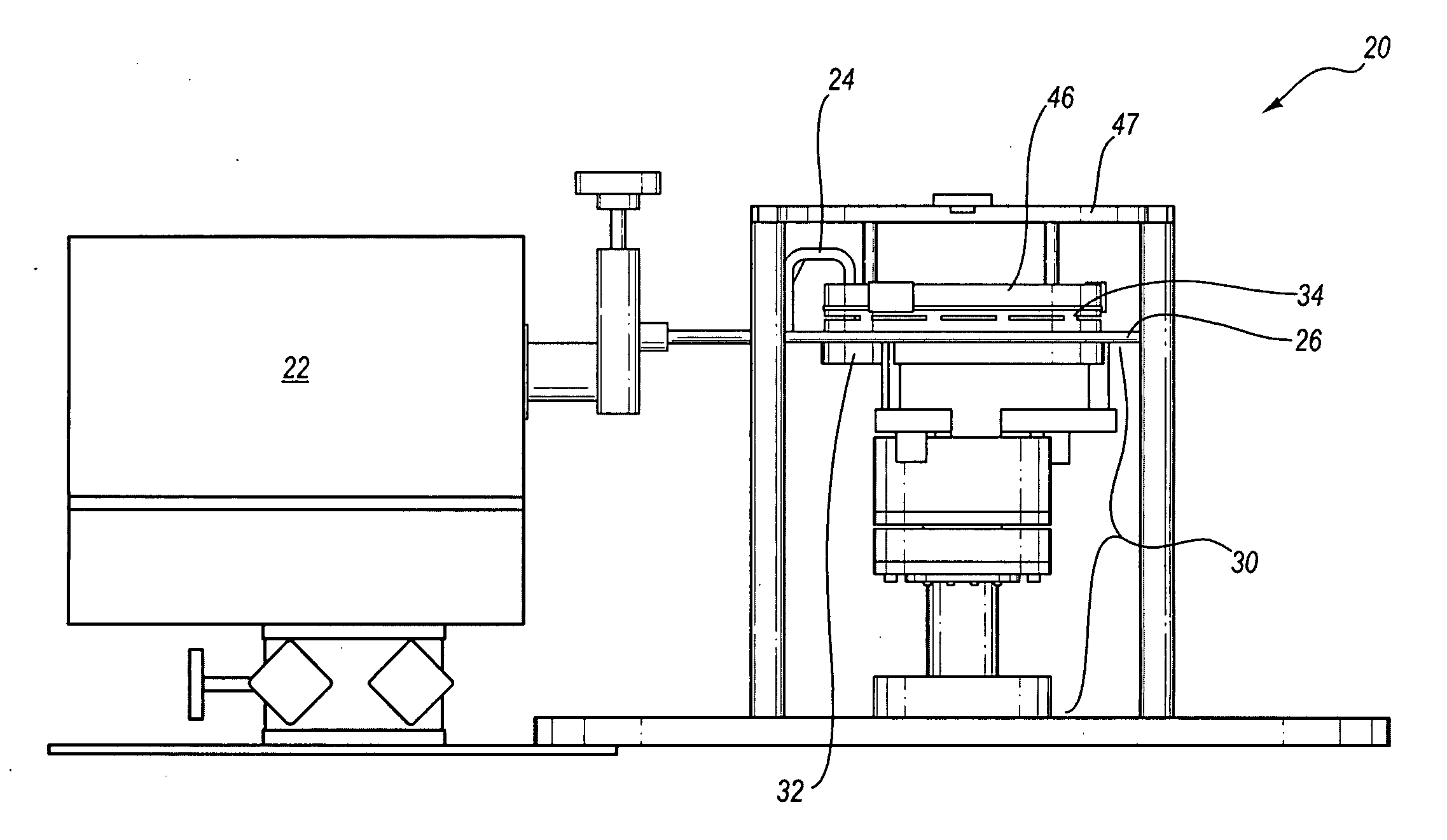

Thermal compression bonding of semiconductor chips

ActiveUS20130270230A1Improve throughputWelding/cutting auxillary devicesSolid-state devicesSemiconductor chipMaterials science

A die is prepared for thermal compression bonding by first aligning electrical contacts on the die to bond pads on a substrate onto which the die is to be mounted. Those electrical contacts are held against the bond pads on the substrate with a bonding tool. Partially bonding the die onto the substrate by providing heat to a portion of the die to elevate a temperature there to above a melting point of solder in the electrical contacts so as to melt at least some of the solder. Then thermally compress the whole die and heat it to above the melting point of the solder of the electrical contacts so that the solder of the electrical contacts outside the portion of the die are also melted to bond the die to the substrate.

Owner:ASMPT SINGAPORE PTE LTD

Method for producing aluminum plate-fin heat exchanger

InactiveCN1943973AHigh strengthLow strength, good cleaning qualityDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesShielding gasNitrogen

The process of producing aluminum plate-fin heat exchanger includes the steps of blanking, washing, mounting, brazing, argon arc welding and pressure test. The present invention adopts numerically controlled lathe with high machining precision for blanking; ultrasonic washing for high washing efficiency and high washing quality; continuous high purity nitrogen protected brazing for high brazing quality; and argon arc welding with welding robot for high welding quality and high production efficiency.

Owner:管保清 +1

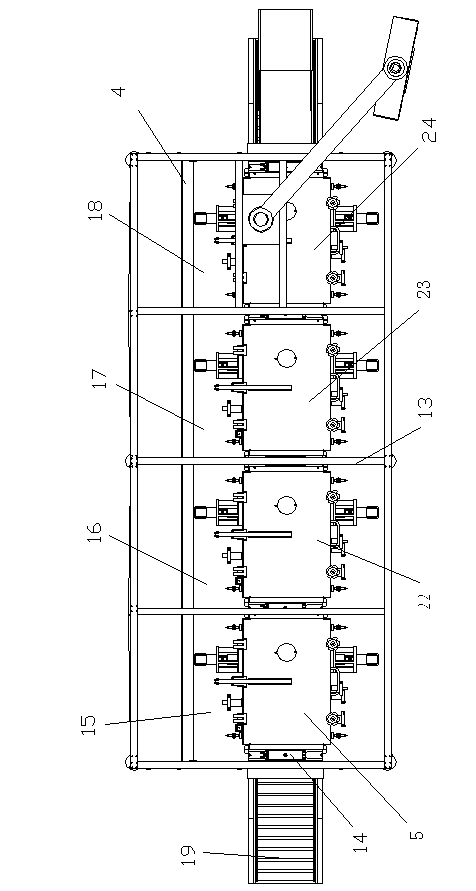

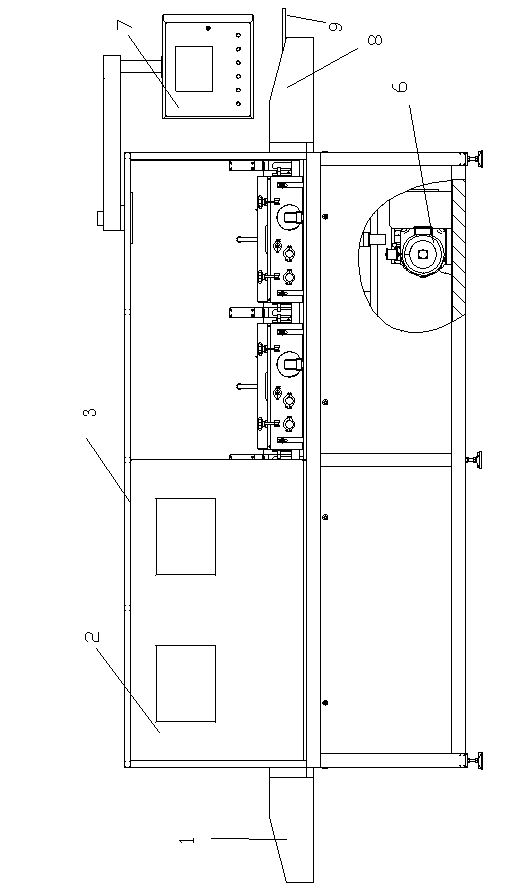

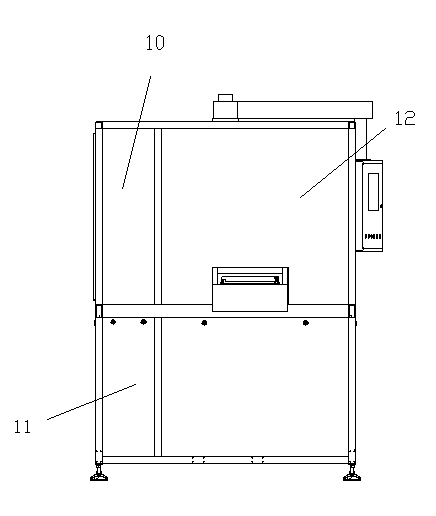

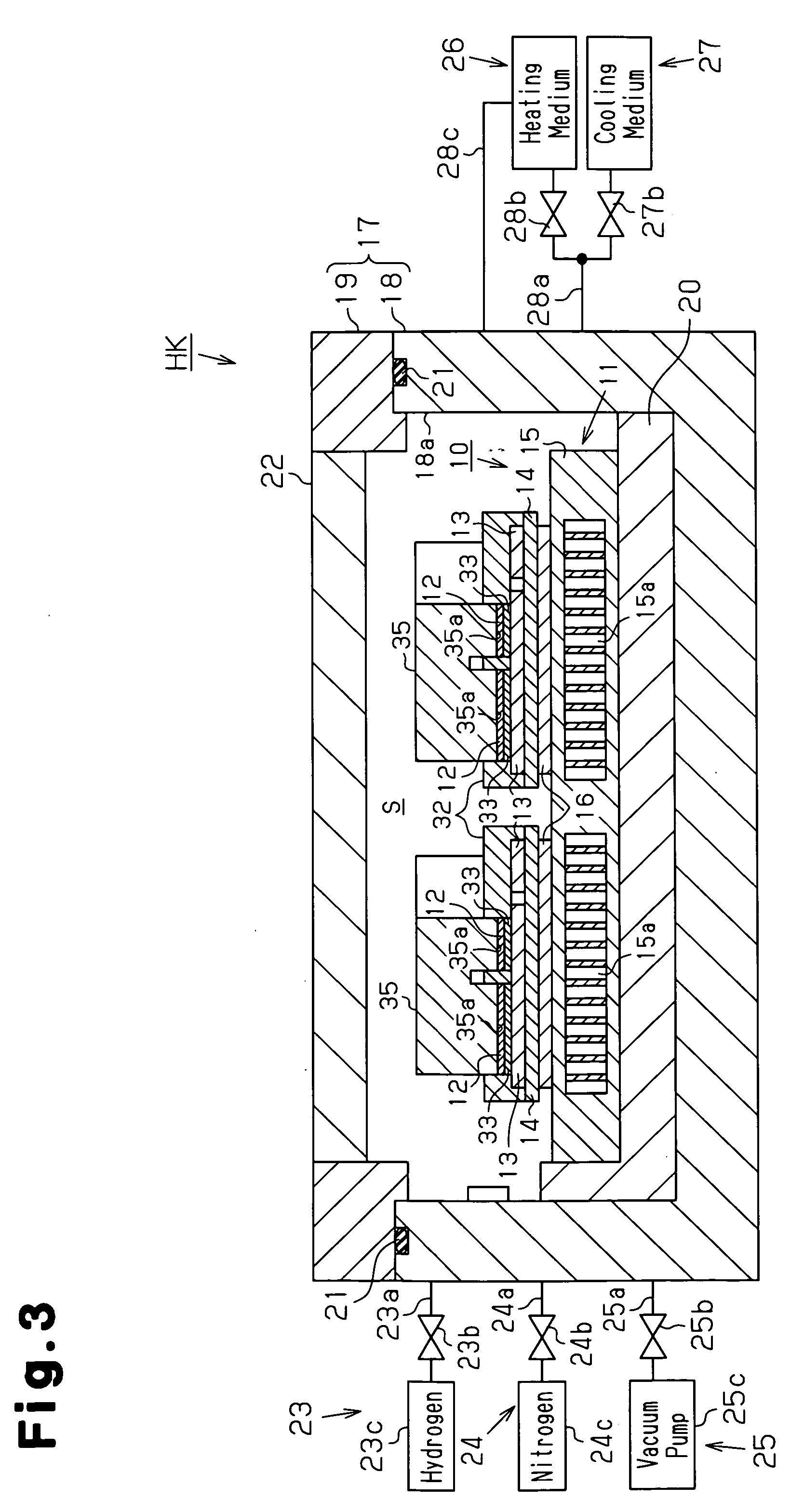

Continuous vacuum welding furnace and welding method for same

ActiveCN103056473AAvoid breakingAvoid deformationHeating appliancesMetal working apparatusControl systemEngineering

The invention discloses a continuous vacuum welding furnace which comprises a working chamber, a feed inlet and a discharge outlet. Four vacuum cavity components are sequentially arranged inside the working chamber side by side and are respectively provided with independent temperature regulation and control systems, transmission systems, measurement systems and regulation and control systems; and a preheating area, a welding area, a precooling area and a cooling area which are four independent systems are formed inside the vacuum welding furnace, so that different processing procedures including a preheating stage, a heating stage, a precooling stage and a cooling stage can be respectively carried out. The invention further discloses an application method for the vacuum welding furnace. The continuous vacuum welding furnace and the application method have the advantages that the heating procedure and the cooling procedure can be carried out without interfering with each other under a vacuum or protective atmosphere condition, repeated temperature rise and temperature drop are omitted, accordingly, the welding time and power consumption can be saved, and the work efficiency and the welding quality can be improved.

Owner:山东联盛电子设备有限公司

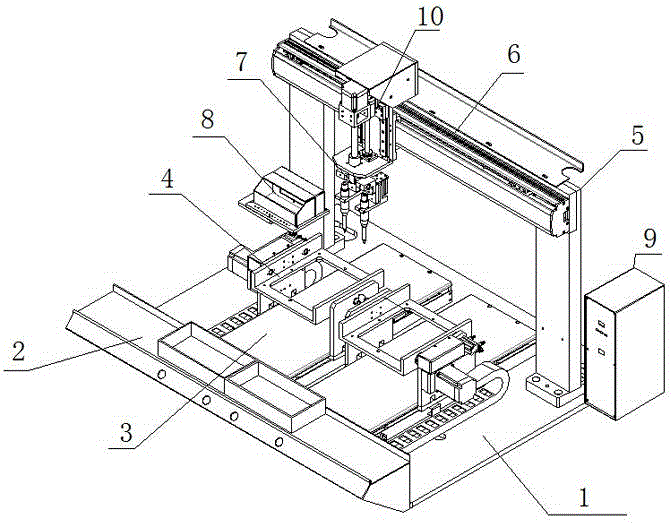

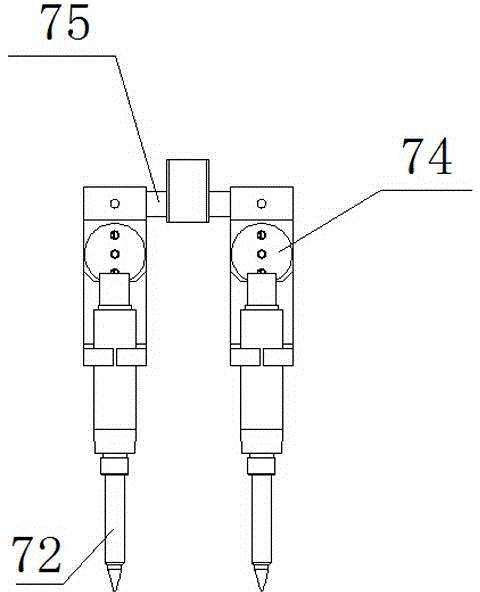

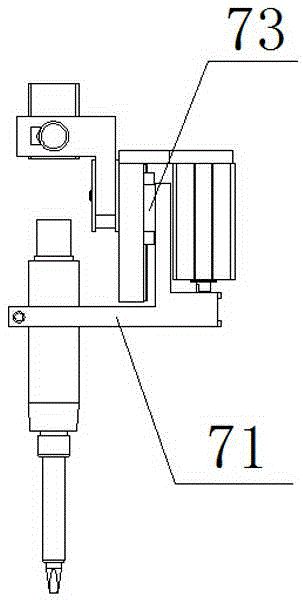

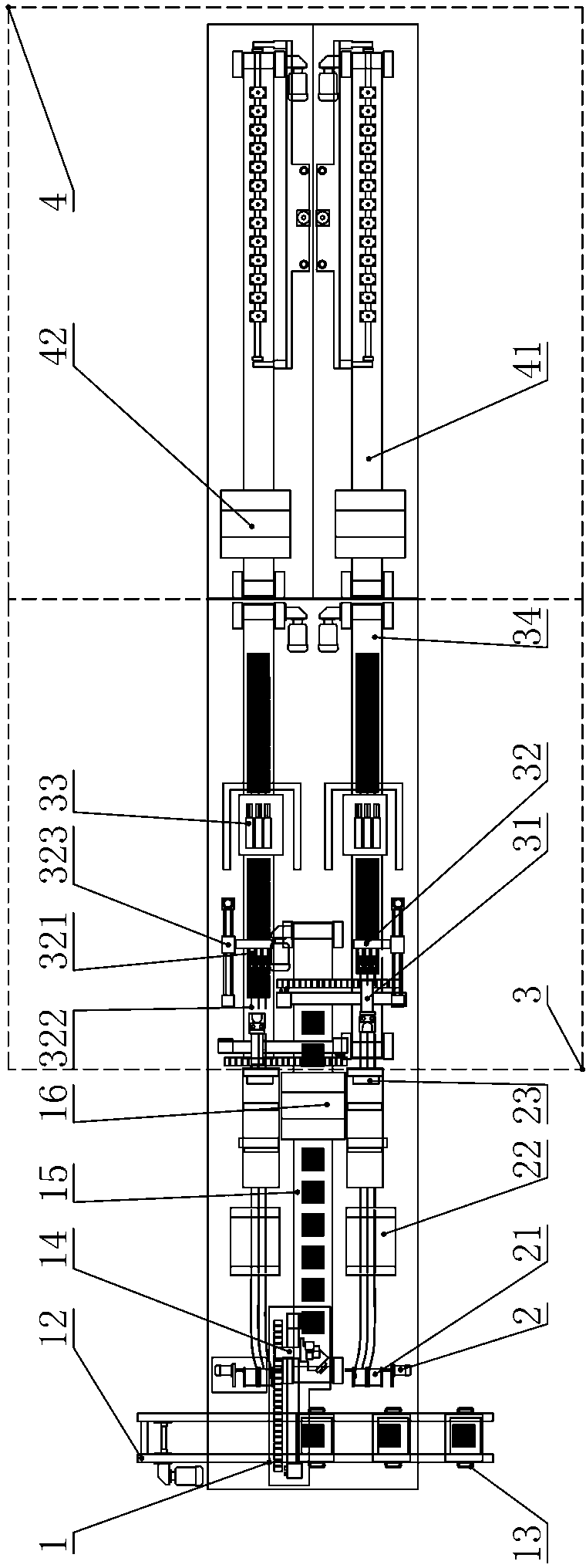

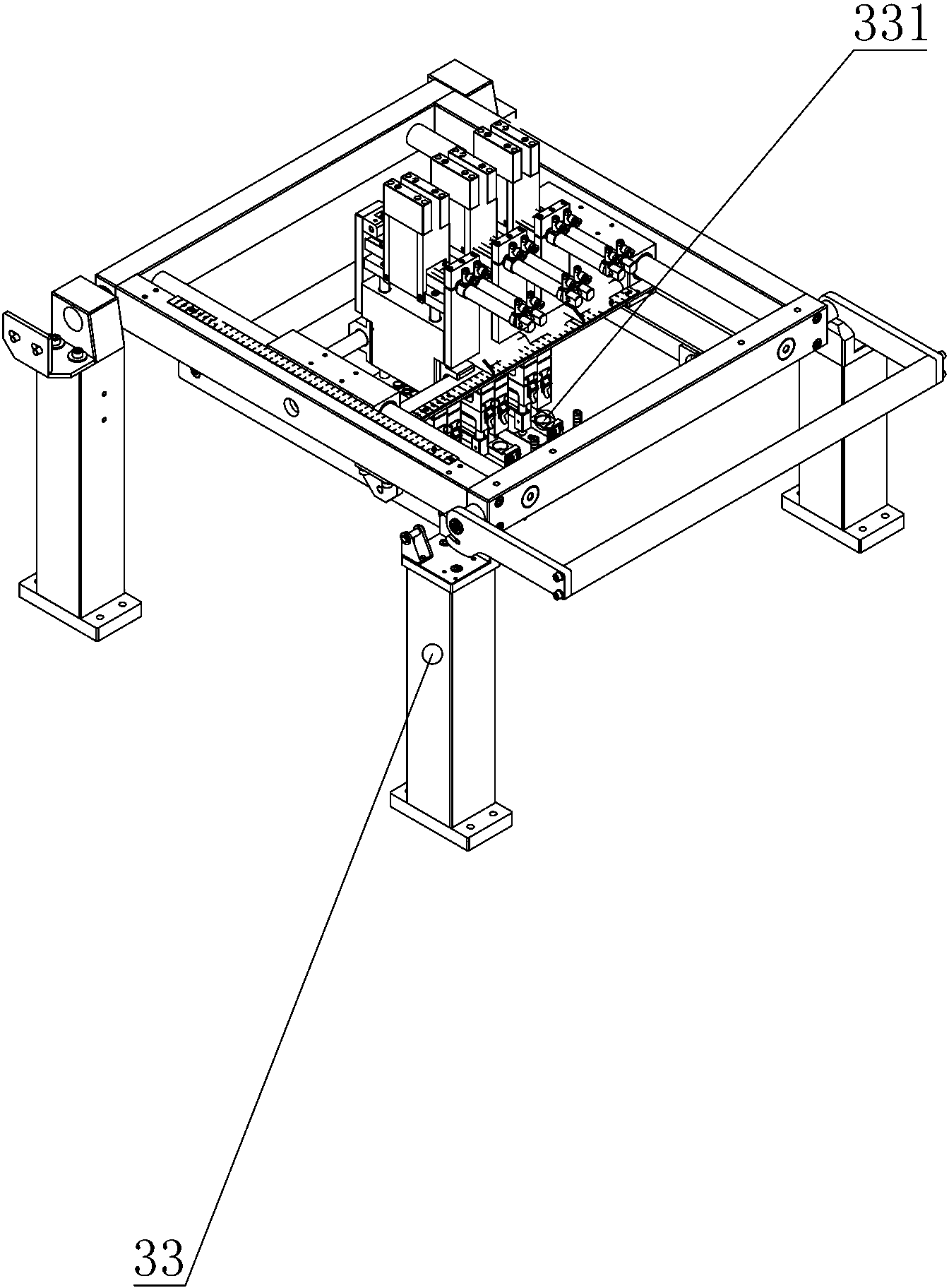

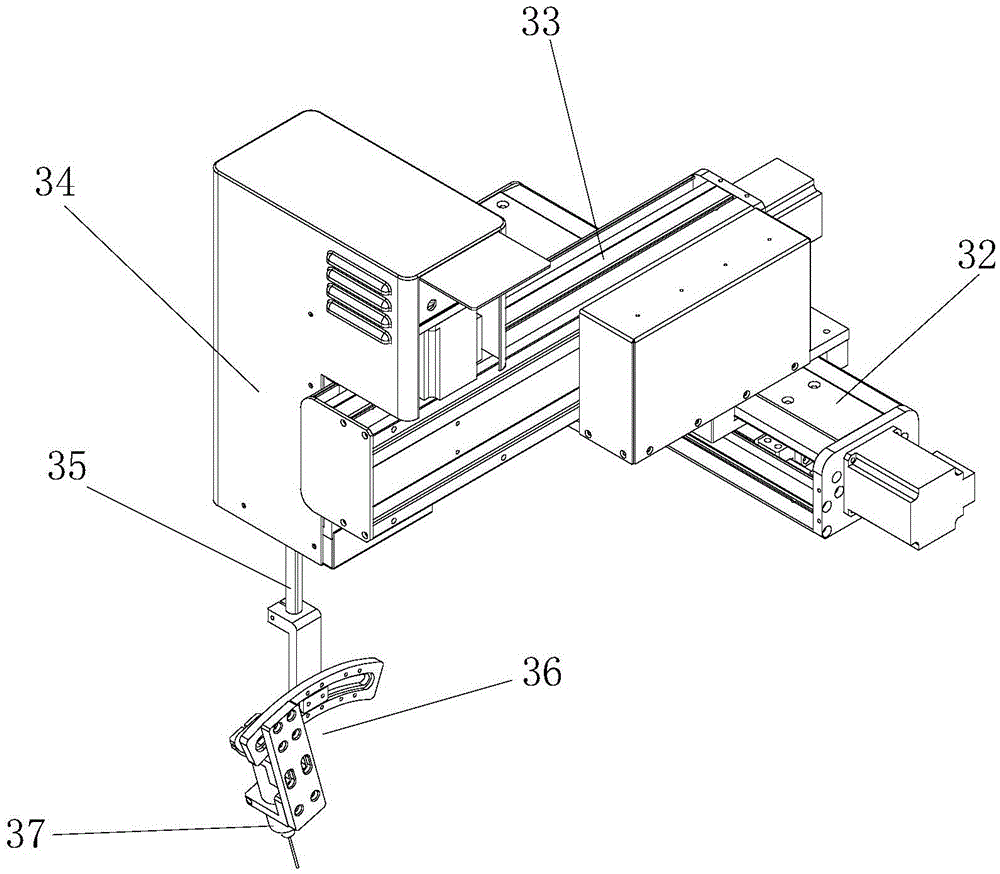

Multidirectional rotation working soldering tin machine capable of overturning jigs

ActiveCN104475900AImprove work efficiencyIncrease flexibilityHeating appliancesSoldering ironSlagTin

The invention relates to a multidirectional rotation working soldering tin machine capable of overturning jigs. The multidirectional rotation working soldering tin machine capable of overturning the jigs comprises a machine panel, a material station, Y-axis conveying mechanisms, overturning mechanisms, a welding bracket, an X-axis conveying mechanism, a multi-head independent control welding mechanism, a tin slag box, a welding station box, a soldering iron fixing block, a soldering iron, a sliding rail guide buffering assembly, a soldering iron left-and-right inclination angle regulating mechanism, a front-and-rear rotary regulating bracket and a soldering iron transfer cylinder. The multidirectional rotation working soldering tin machine capable of overturning the jigs can be used for determining to set the numbers of the overturning mechanisms and the Y-axis conveying mechanisms according to loading time and tin soldering time; by arranging more than one overturning mechanism paired with the Y-axis conveying mechanisms for use, a circuit board on which materials are loaded can be full-automatically overturned in a range of 180 degrees and the multi-head independent control welding mechanism can carry out non-stop tin soldering; the working efficiency is high; the working angle of the soldering iron in the random front-and-rear inclined direction can be regulated by the front-and-rear rotary regulating bracket; the working angle of the soldering iron in the random left-and-right inclined direction can be regulated by the soldering iron left-and-right inclination angle regulating mechanism; the multidirectional rotation working soldering tin machine capable of overturning the jigs has strong flexibility, has good effects and is low in cost.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

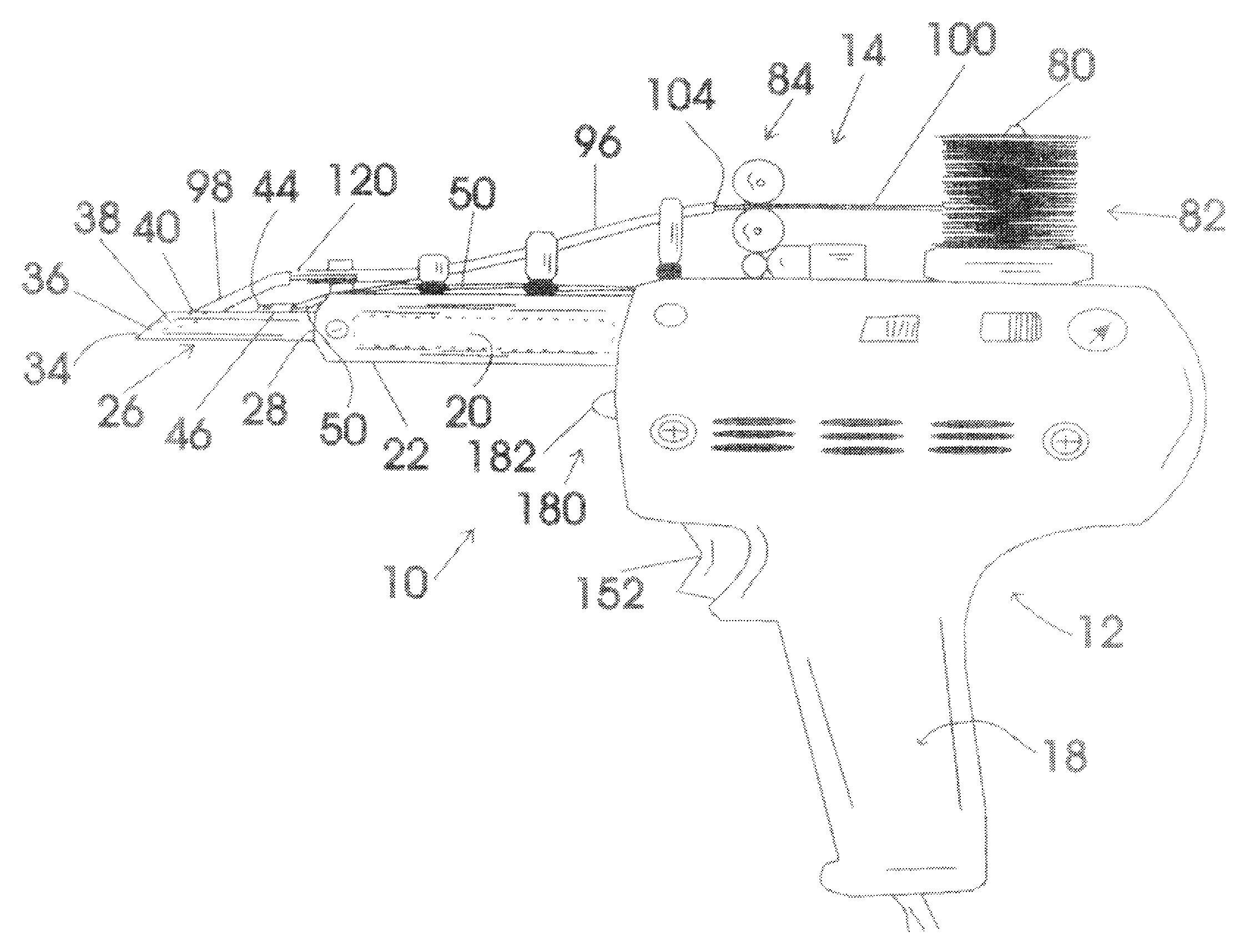

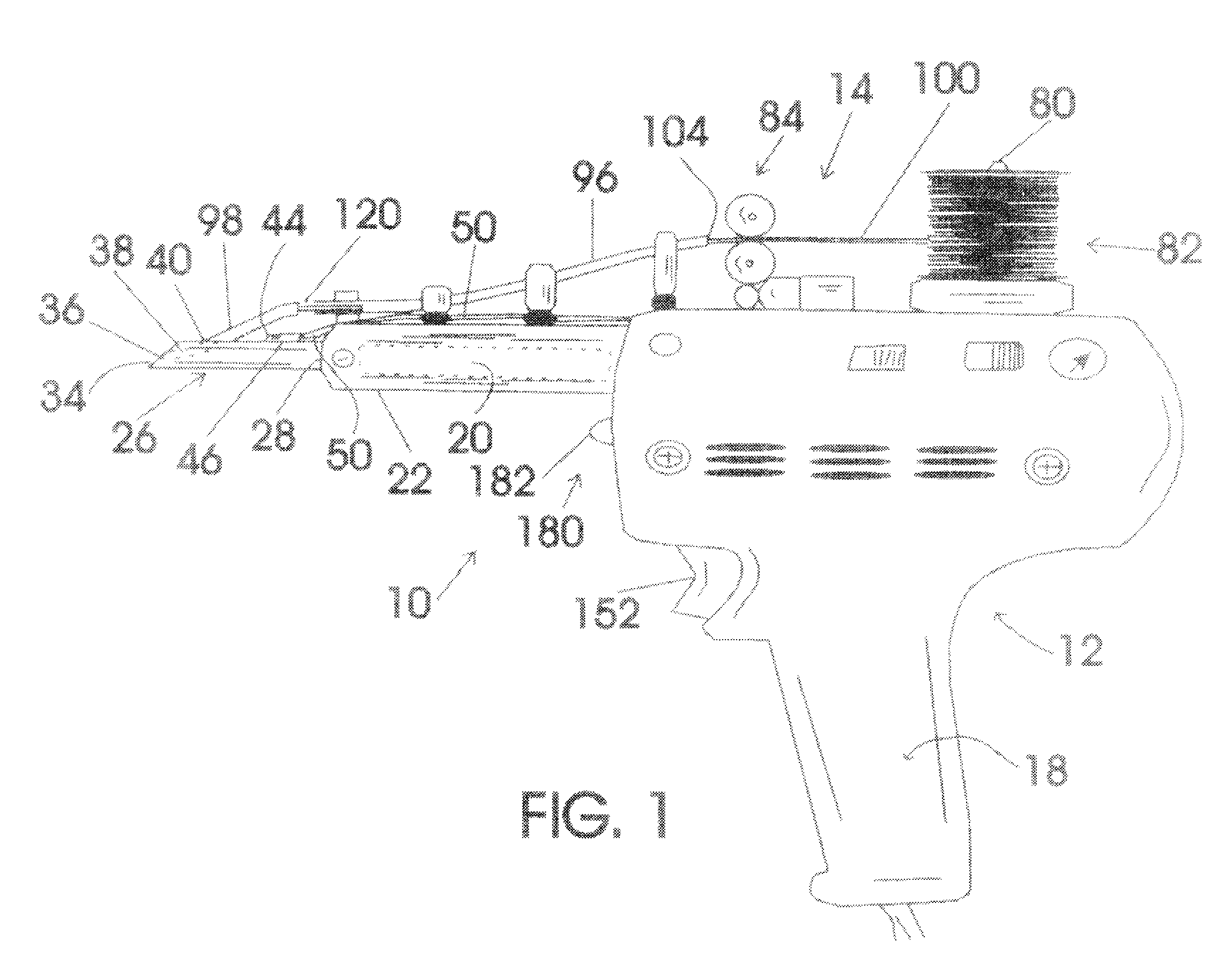

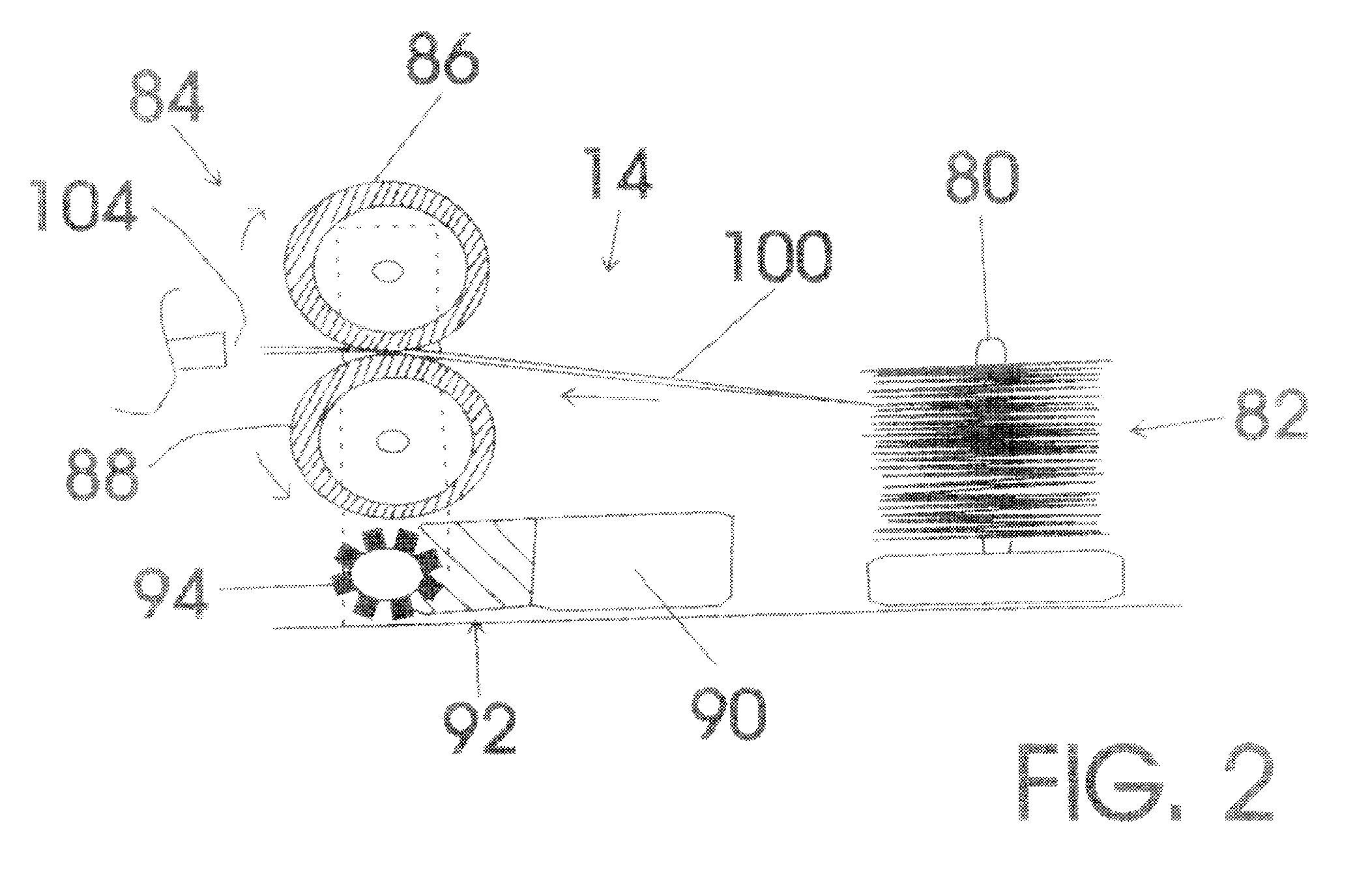

Self-feeding soldering device

A self feeding soldering device includes a soldering device; a solder feed mechanism carried on the soldering device; and a solder system controller in controlling connection with the soldering device and the solder feed mechanism. The solder feed mechanism allows the user to control the feed of solder wire onto the heated soldering tip of the soldering device or the area adjacent to the heated soldering tip to be soldered to free one hand of the user to secure the objects to be soldered.

Owner:MORRISON TERRY H

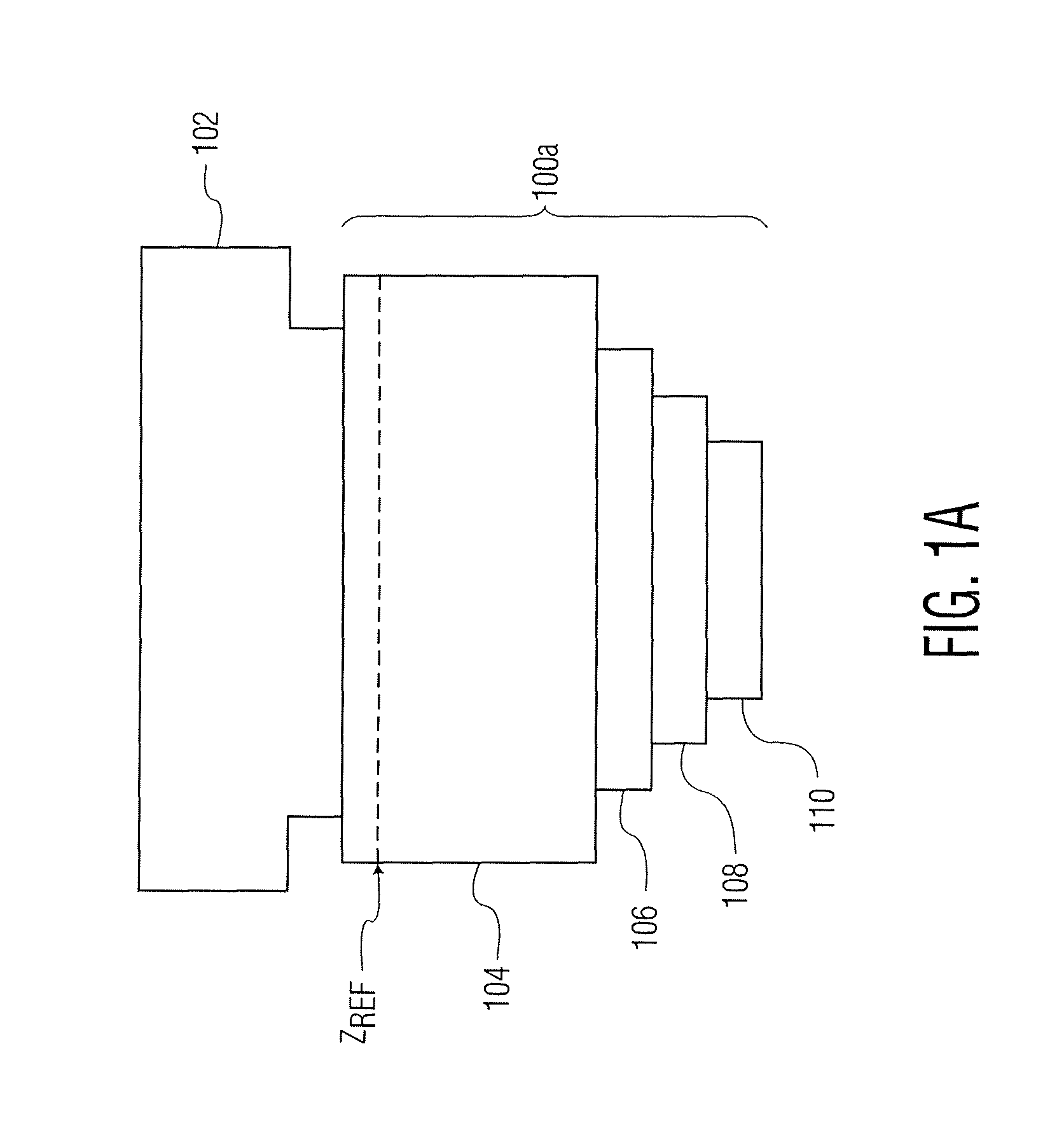

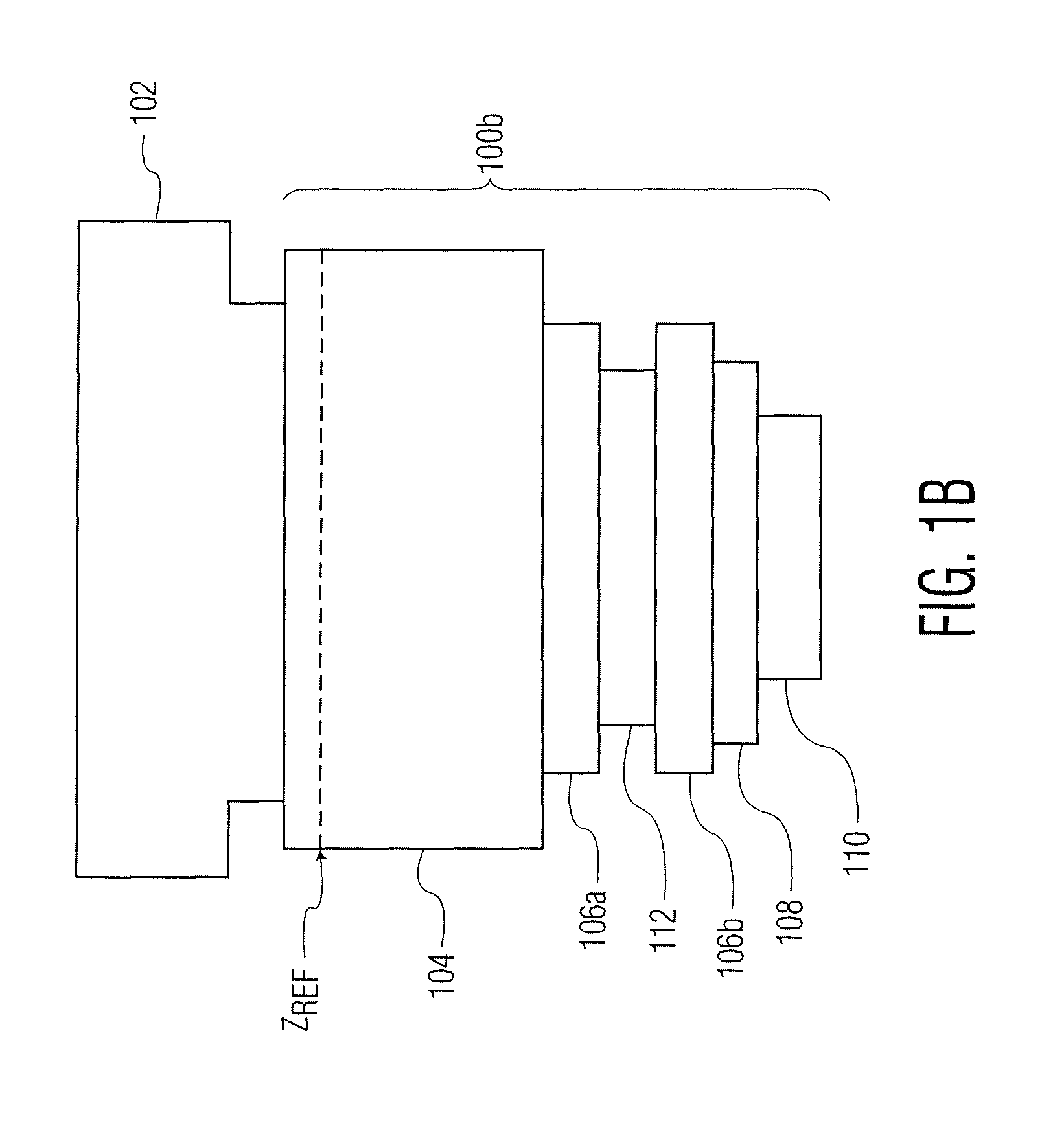

Methods of operating bonding machines for bonding semiconductor elements, and bonding machines

ActiveUS20150171049A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsBonding processEngineering

A method of operating a bonding machine for bonding semiconductor elements is provided. The method includes the steps of: (a) measuring a time based z-axis height measurement characteristic of a bond head assembly during a model bonding process; (b) determining a z-axis adjustment profile for a subsequent bonding process based on the measured time based z-axis height measurement characteristic; and (c) adjusting a z-axis position of the bond head assembly with a z-axis motion system during the subsequent bonding process using the z-axis adjustment profile.

Owner:KULICKE & SOFFA IND INC

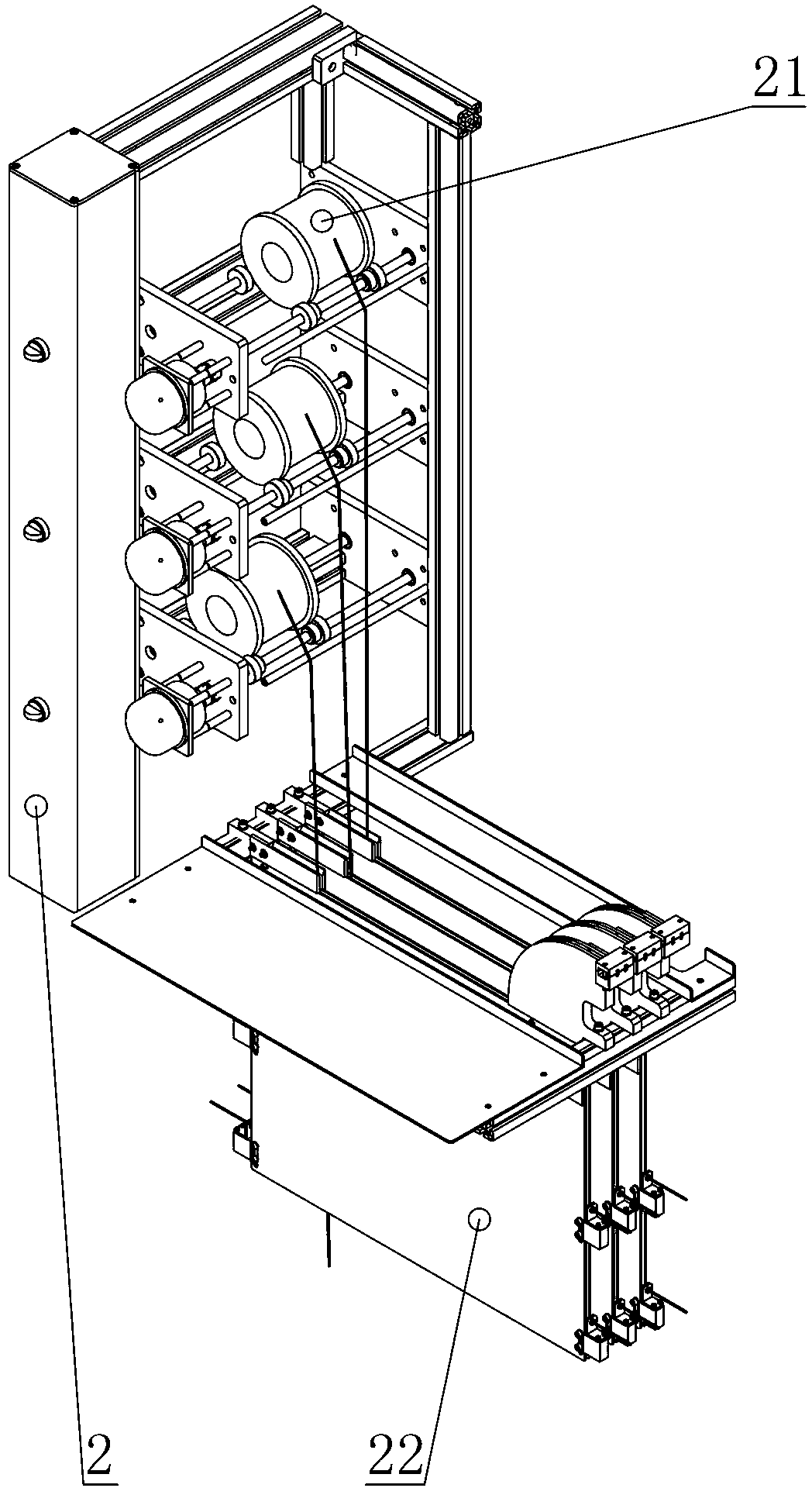

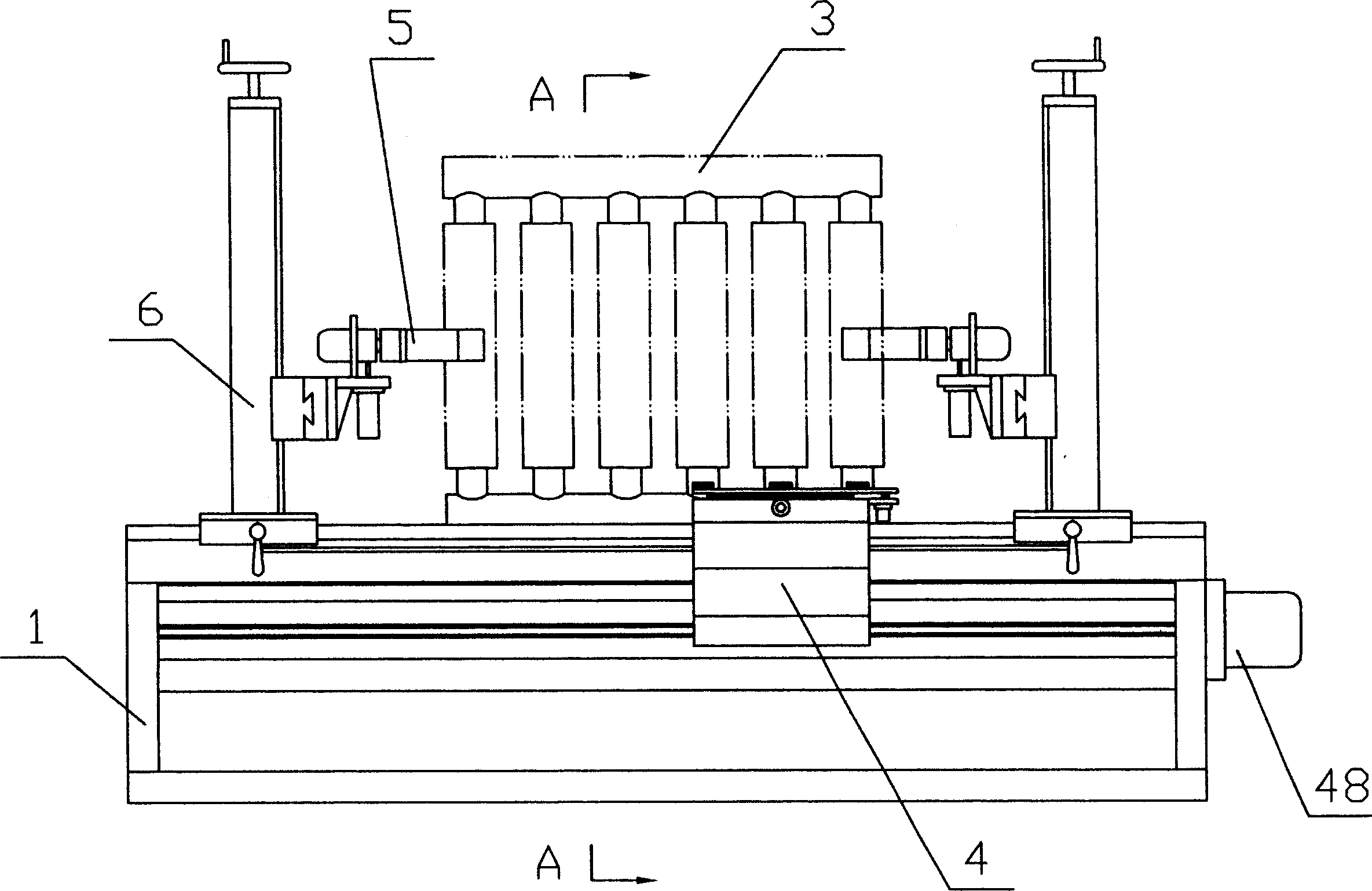

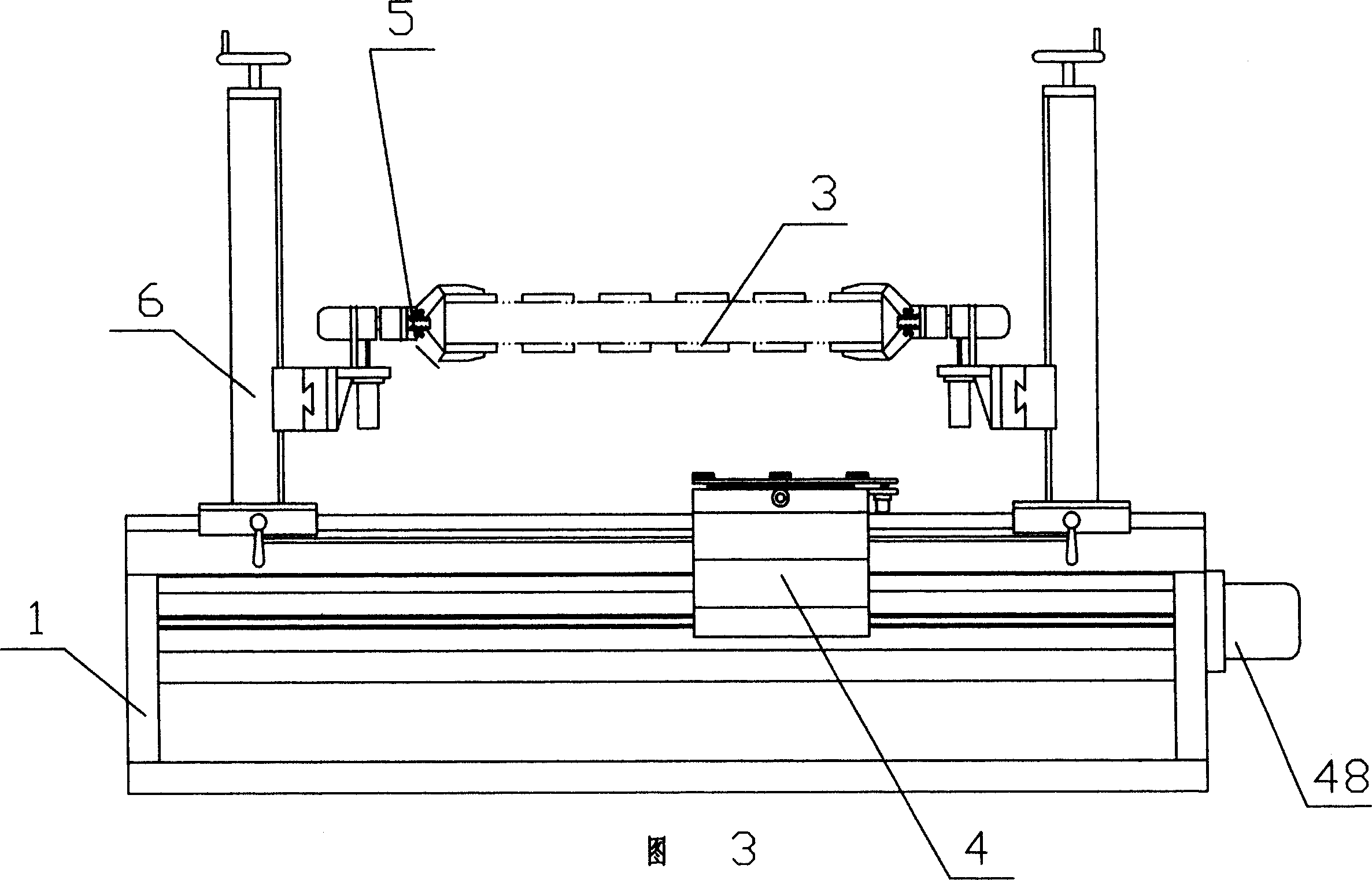

Solar cell crystal silicon wafer series welding machine

InactiveCN103182579AImprove work efficiencyAchieve integrationFinal product manufactureHeating appliancesEngineeringSolar cell

The invention discloses a solar cell crystal silicon wafer series welding machine, which comprises a welding mechanism and a welding assisting mechanism which is directly or indirectly connected with the welding mechanism, wherein the welding assisting is an automatic feeding mechanism, a welding strip feeding mechanism or an automatic discharging mechanism. The automatic feeding mechanism, the welding strip feeding mechanism, the welding mechanism and the automatic discharging mechanism are sequentially connected. All mechanisms work cooperatively and can realize the continuous, rapid and stable welding of cells.

Owner:深圳市晶拓光伏自动化设备有限公司

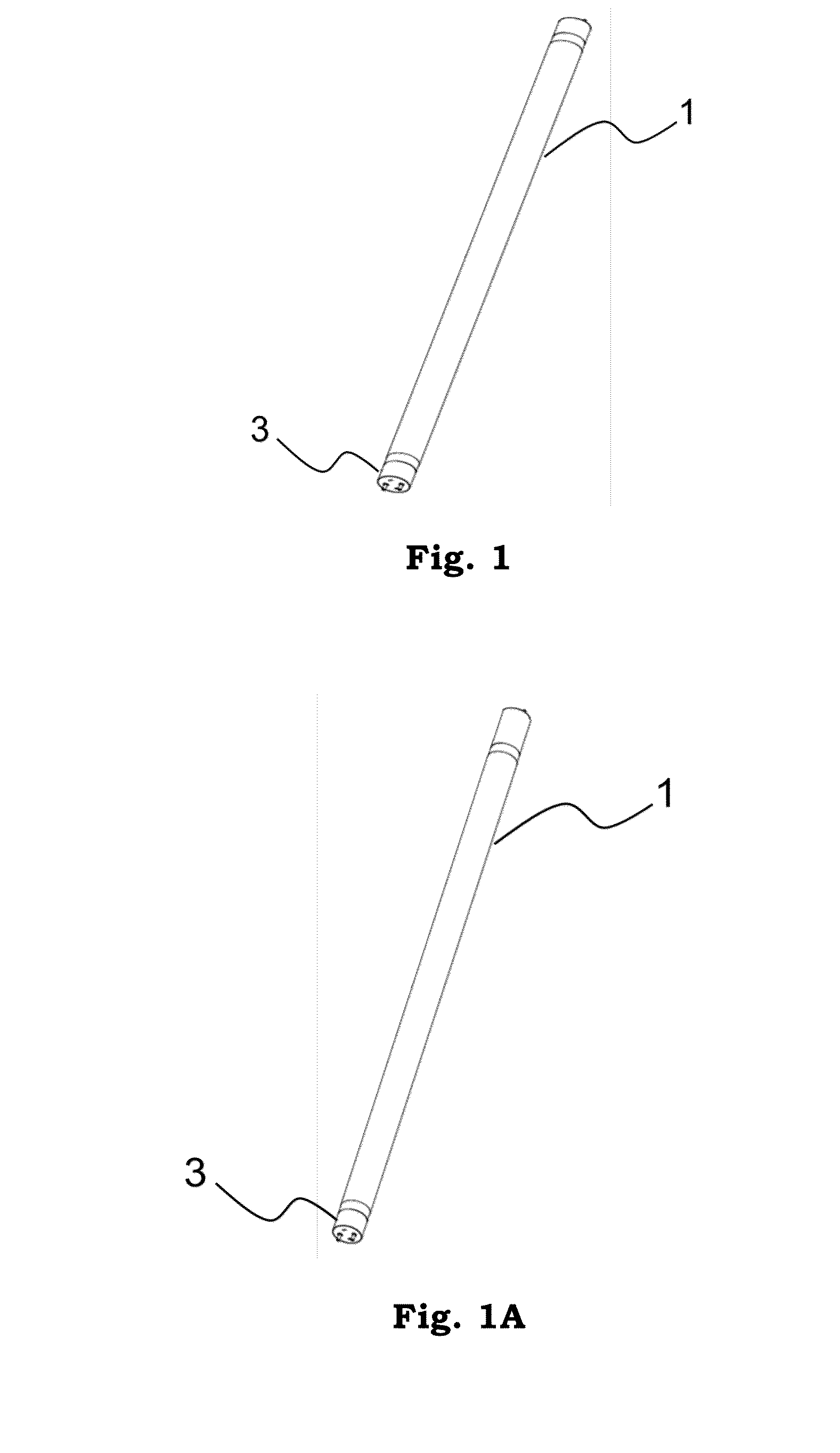

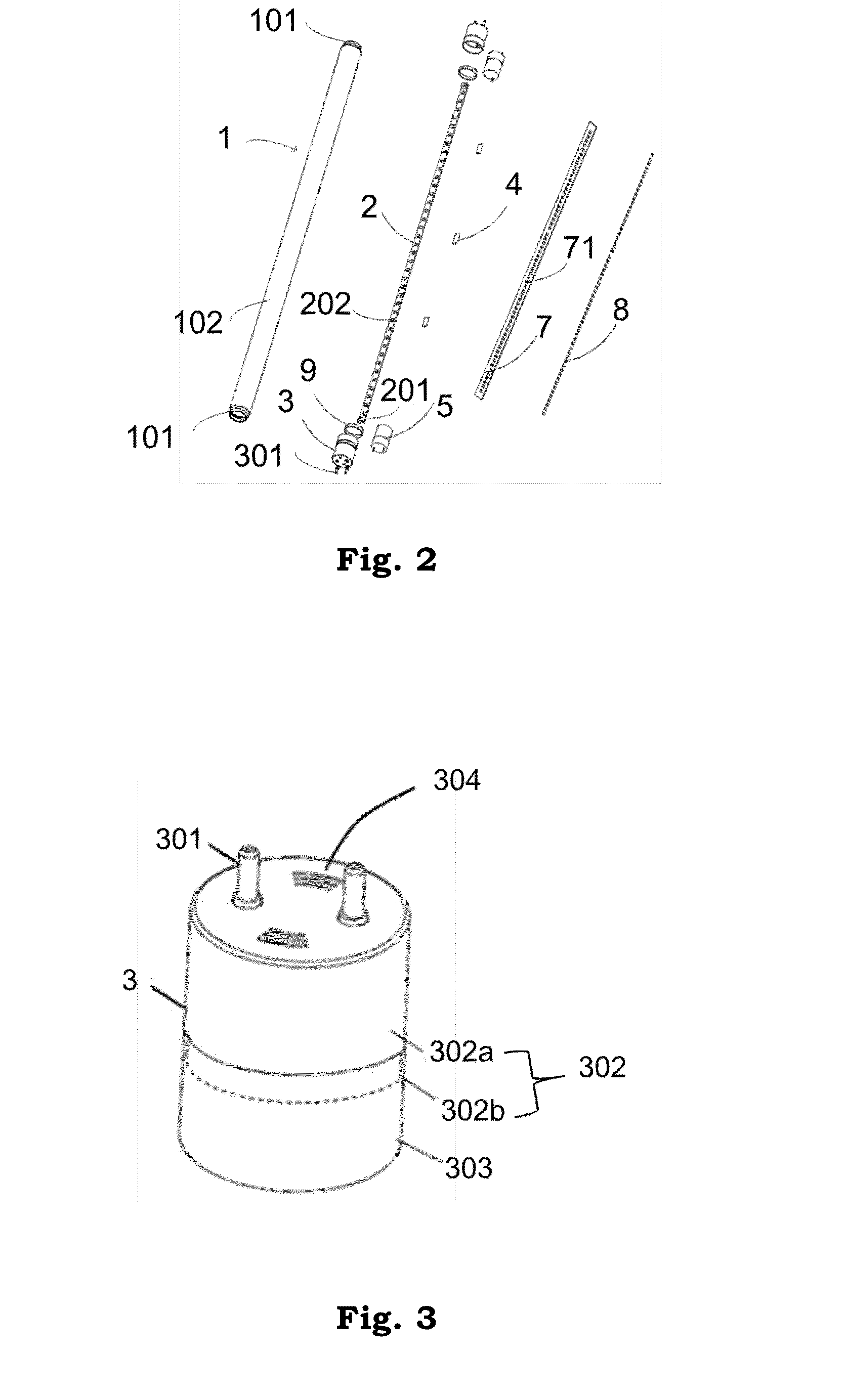

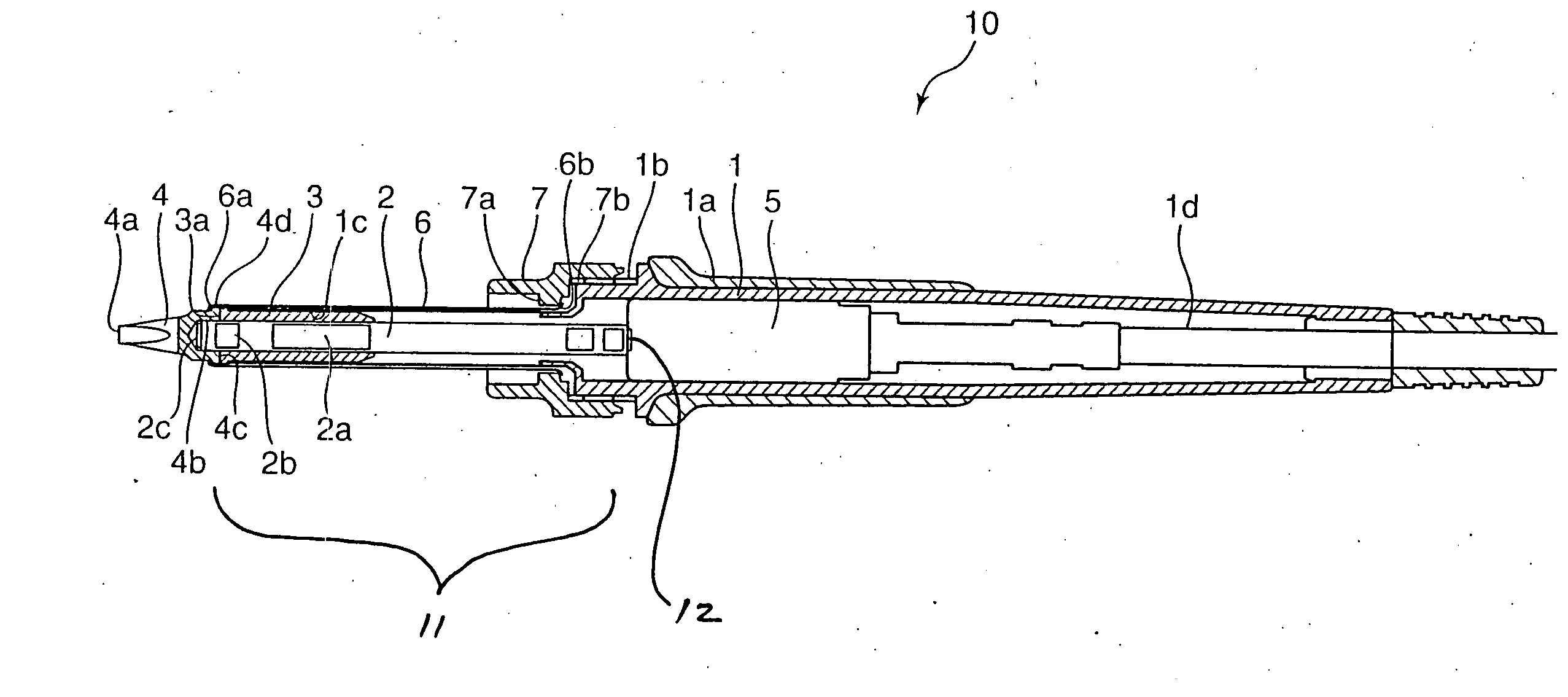

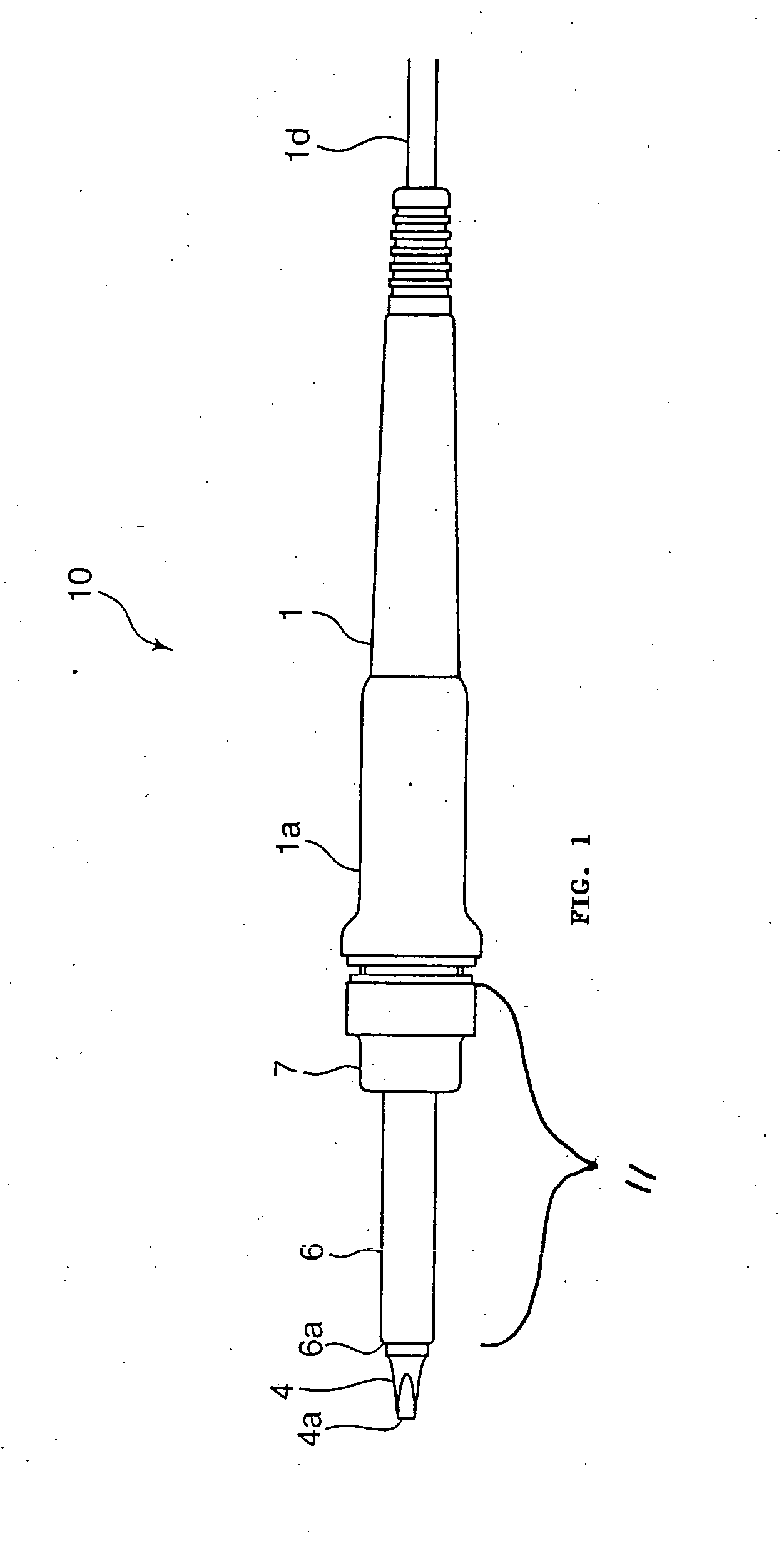

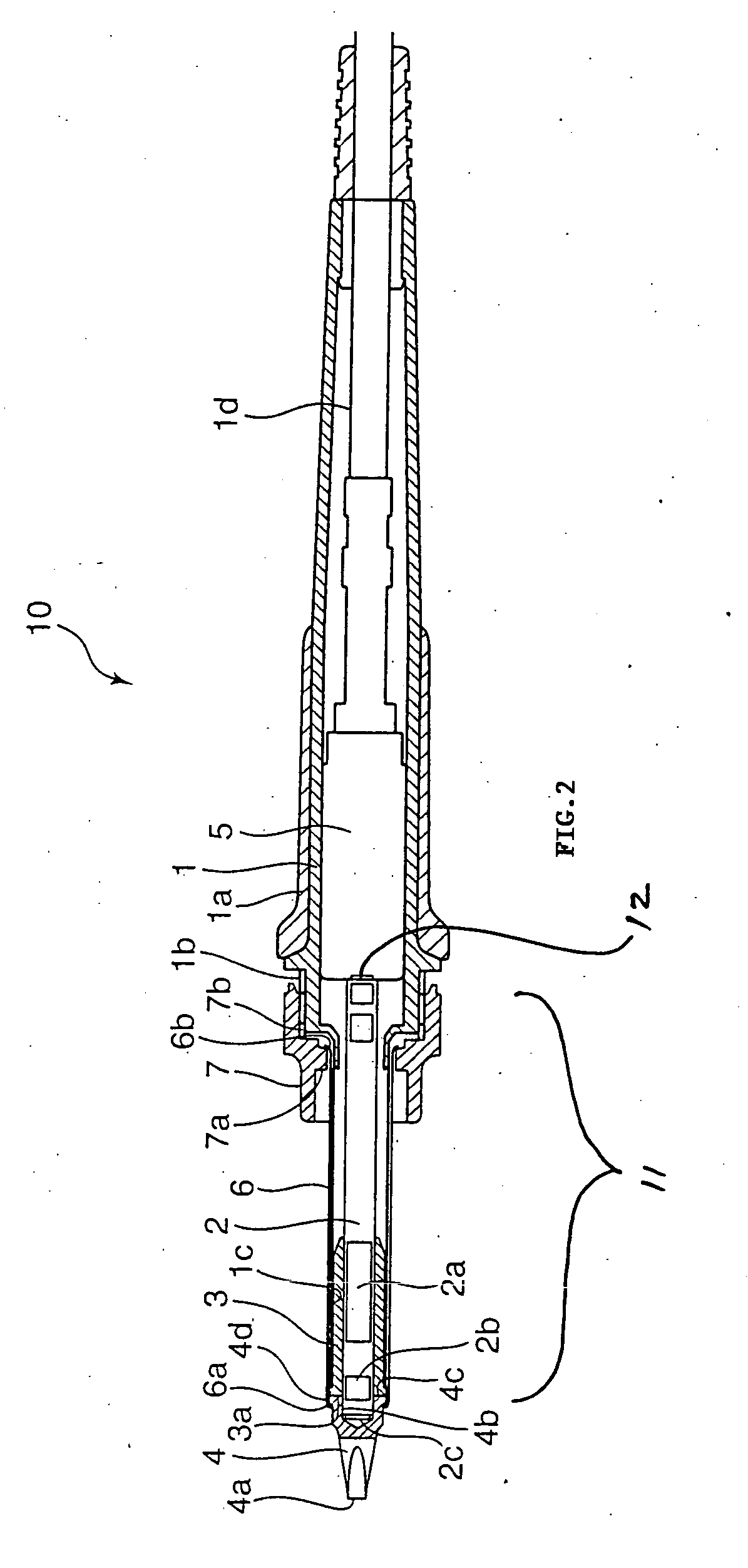

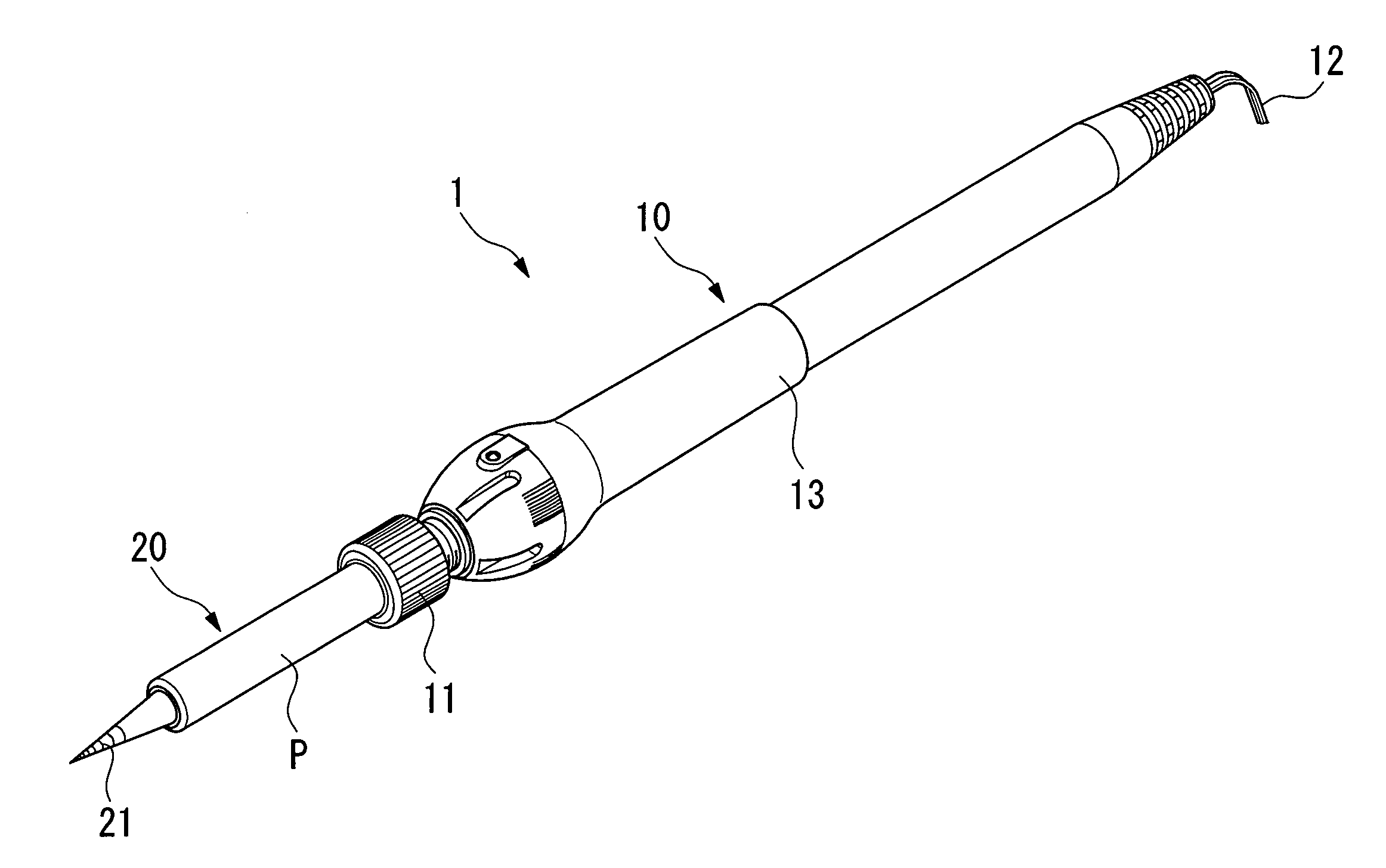

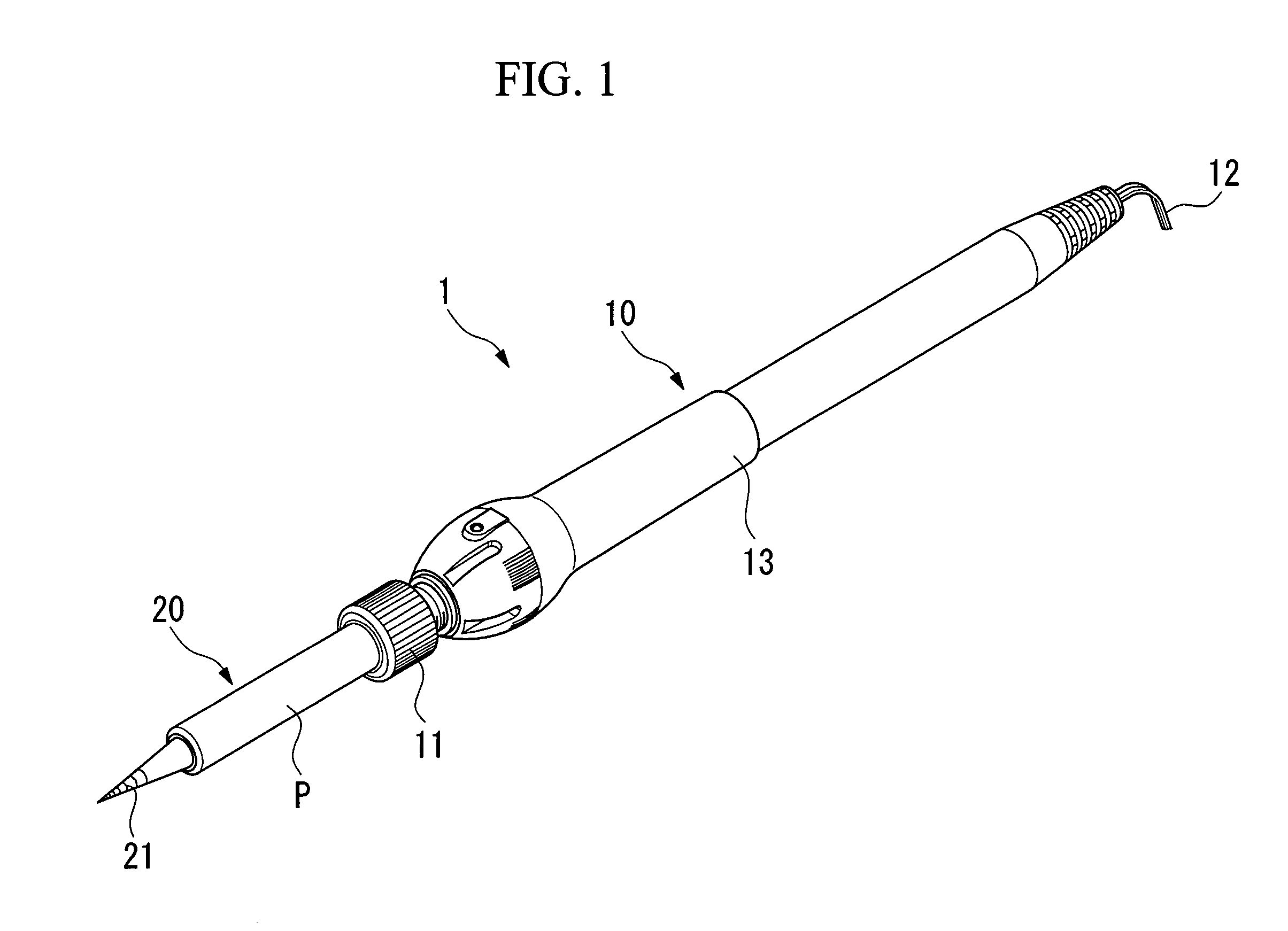

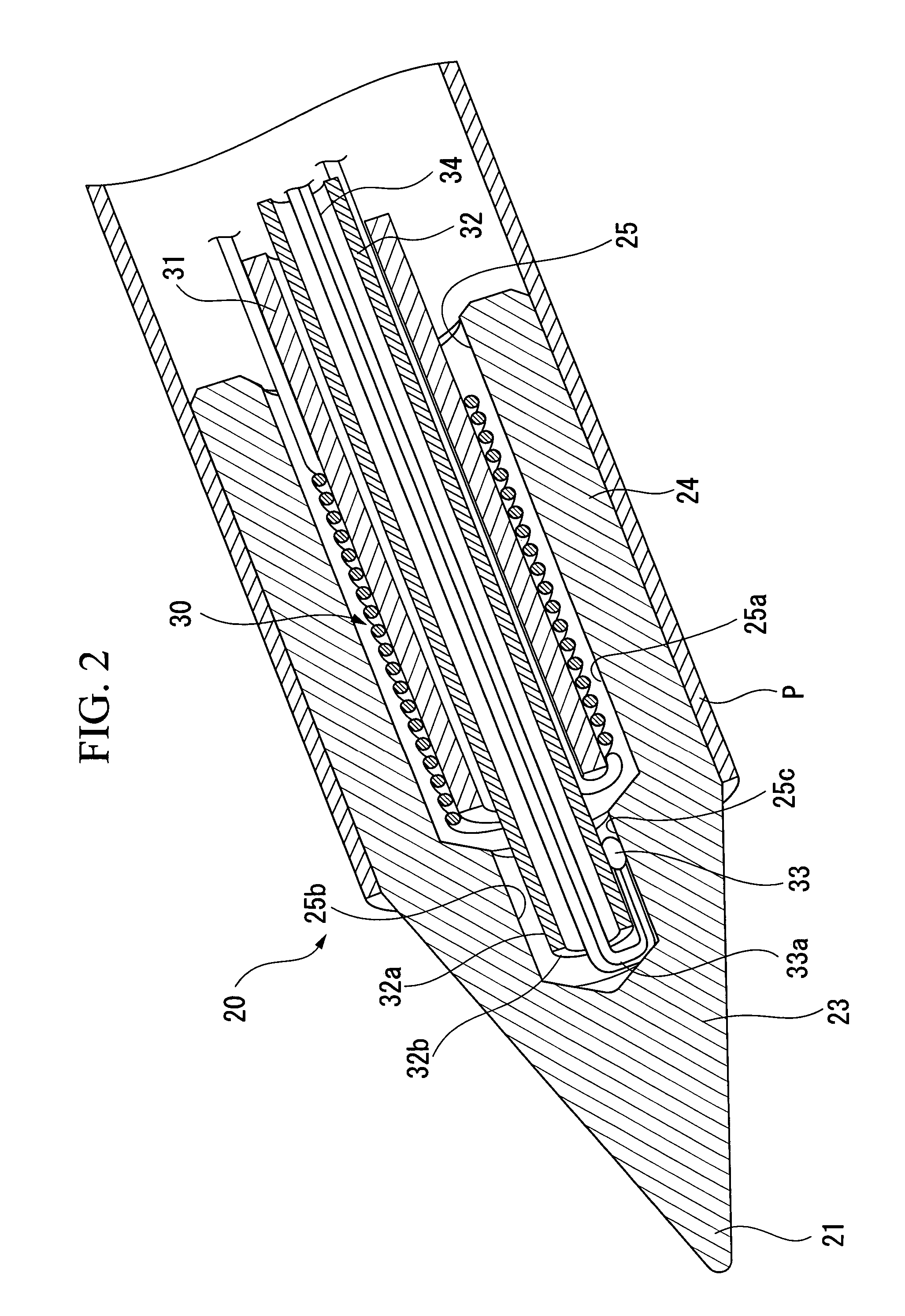

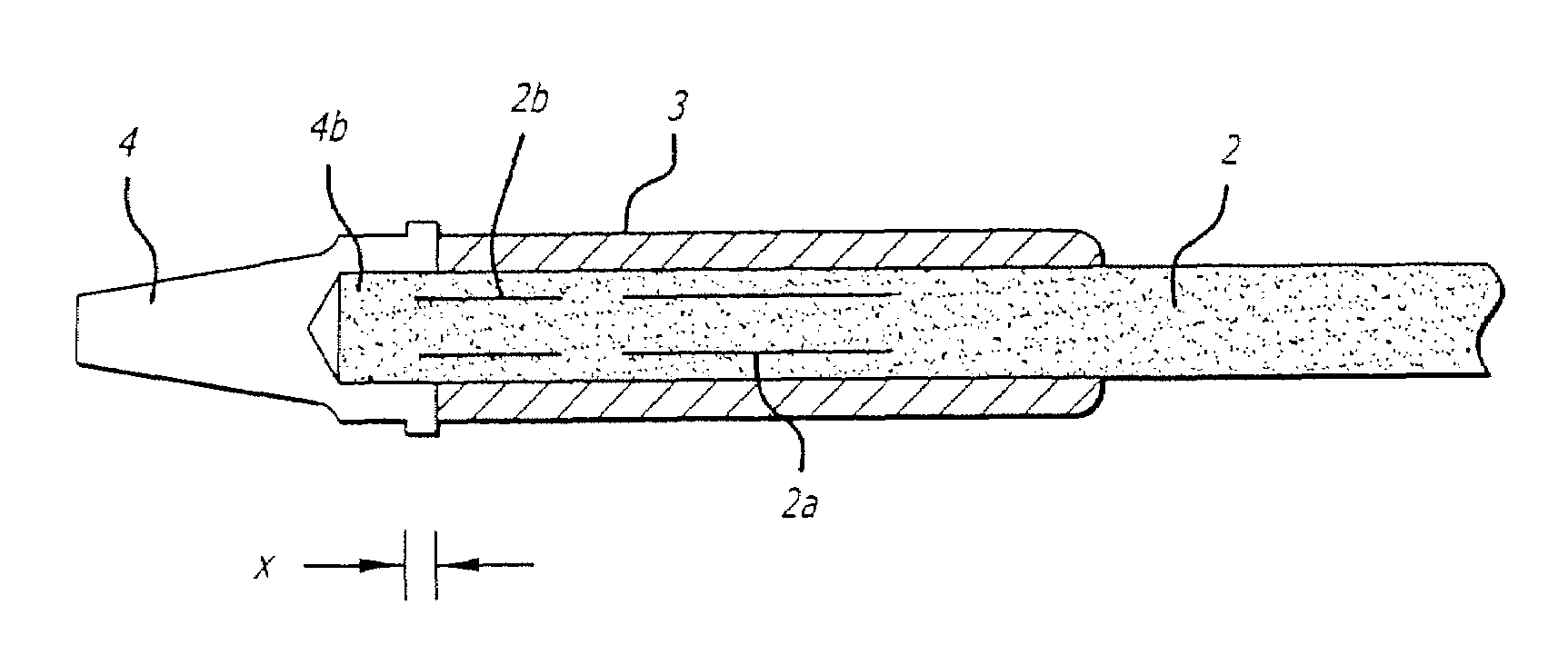

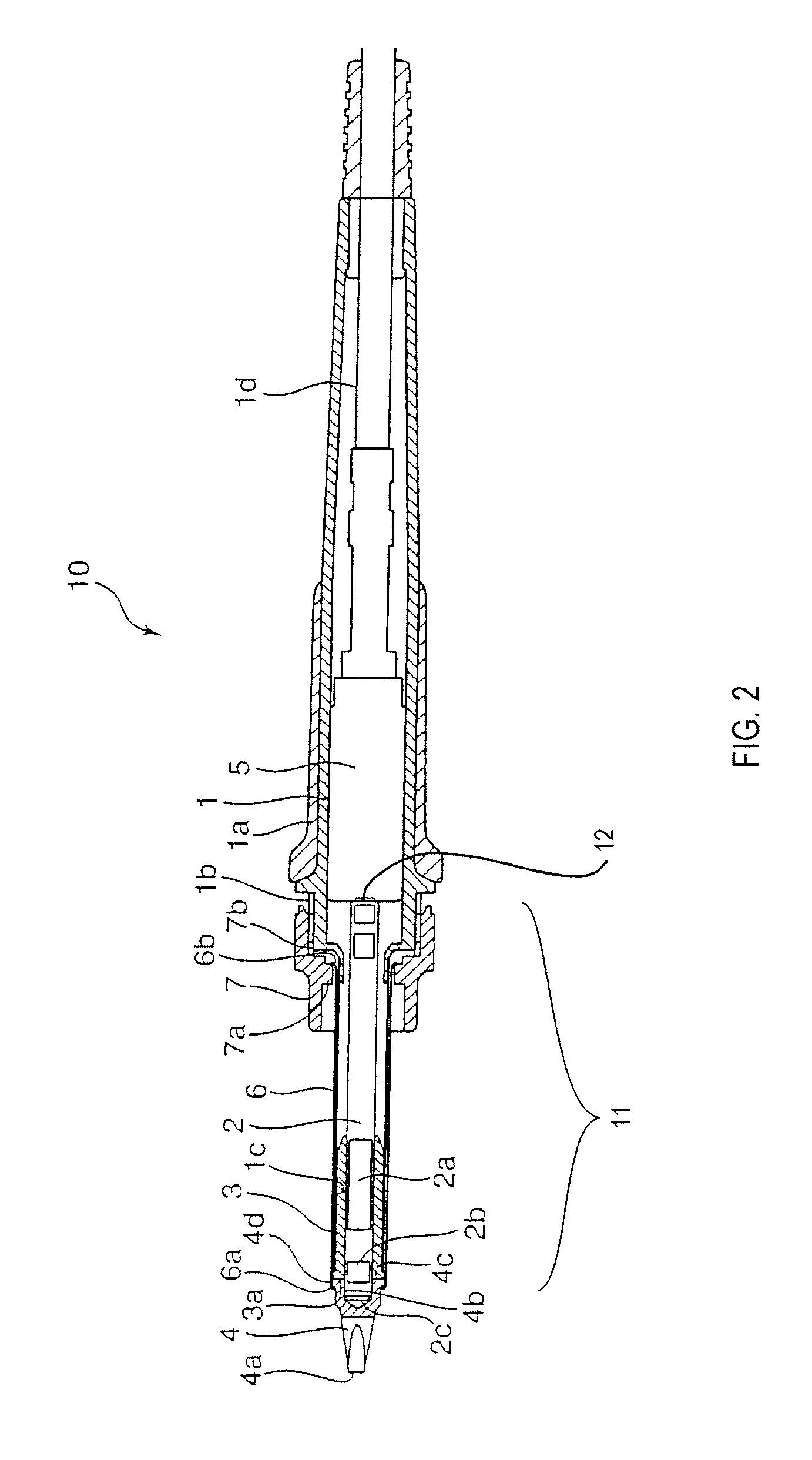

Replaceable soldering tip with sensor recess

ActiveUS20040232132A1Easy to monitorHeating fastHeating element shapesHeating appliancesSolderingBiomedical engineering

A soldering or a desoldering tool includes a replaceable tip with a recess adapted to receive a portion of a temperature sensor to measure the temperature of the tip. Positioning the temperature sensor within the tip allows the temperature to be quickly measured so that the temperature near the tip may be more accurately monitored and controlled. The temperature sensor may be also integrated with the heater near the tip such that the temperature sensor is between the tip and the heater and near both of them so that the temperature of the tip is substantially that of the temperature of the heater. A sleeve may enclose the temperature sensor and the heater with a portion of the temperature sensor extending out from the foreward end of the sleeve. The replaceable tip may also have a bore adapted to receive a head protruding from the foreward end of the sleeve to couple the tip at a predetermined orientation with respect to the sleeve. The combination of bore and head allows the replaceable tip to be coupled with the sleeve in a consistent manner so that the temperature of the replacement tips can be measured accurately and dependably.

Owner:HAKKO CO LTD

Method and device for soldering metal parts and components by adopting high-frequency induction brazing

ActiveCN102357695AThe steps are scientific and reasonableGood technical effectHeating appliancesWelding/cutting media/materialsRoom temperatureEngineering

The invention discloses a method for soldering metal parts and components by adopting high-frequency induction brazing, which can complete high-frequency brazing assembly molding of multiple soldering points of multiple soldering parts in one time. The method is dependent on a device, which comprises a high-frequency coil and a magnetic ring pressure lever, wherein the high-frequency coil and the magnetic ring pressure lever are connected with a high-frequency controller respectively, and are controlled uniformly by the high-frequency controller. By utilizing the device, the method comprises the following steps of: treating the surface of a part to be soldered; assembling the soldering device, and distributing the high-frequency coil and a magnetic head pressure lever; selecting a brazing filler metal to be matched with the part to be soldered, and preparing paste brazing flux FB303P; optimally allocating positions and quantities of the brazing filler metal and the brazing flux; setting corresponding process values by means of the high-frequency controller to perform heat soldering, preserving the temperature, switching off, and cooling by using cooling water to the room temperature. According to the method, one-time soldering molding can be realized by multiple soldering of multi-process multi-point and other processes.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

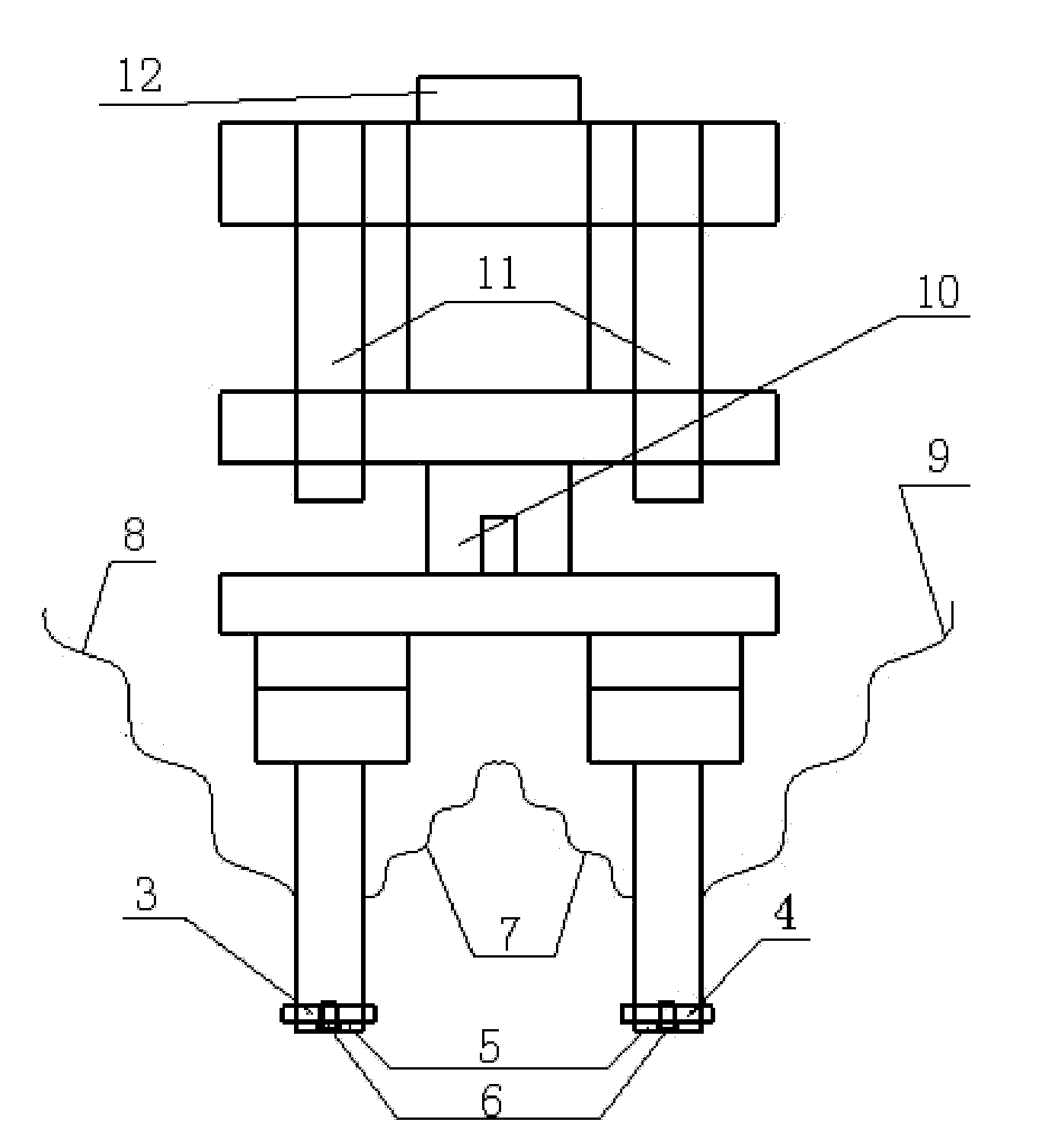

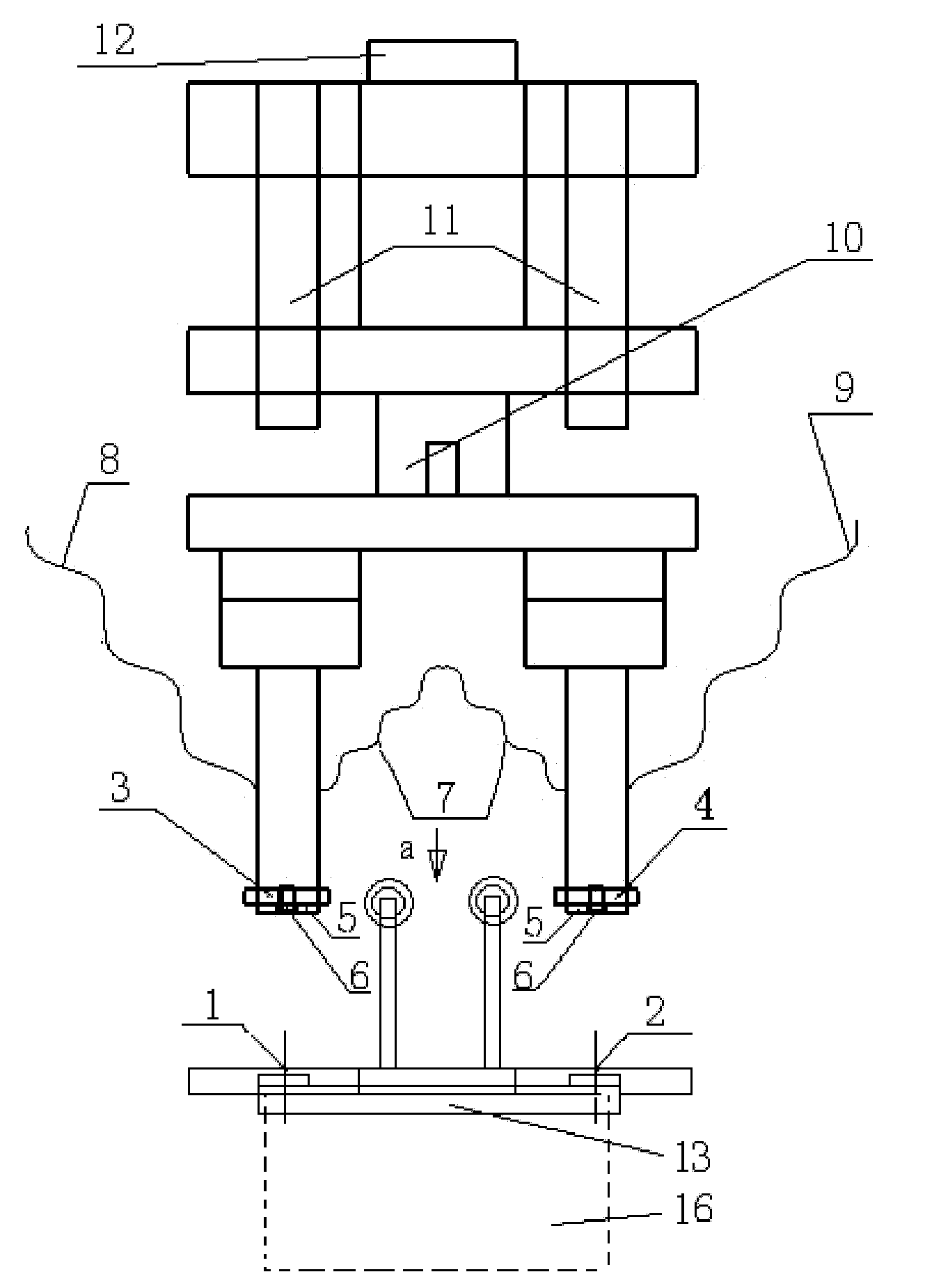

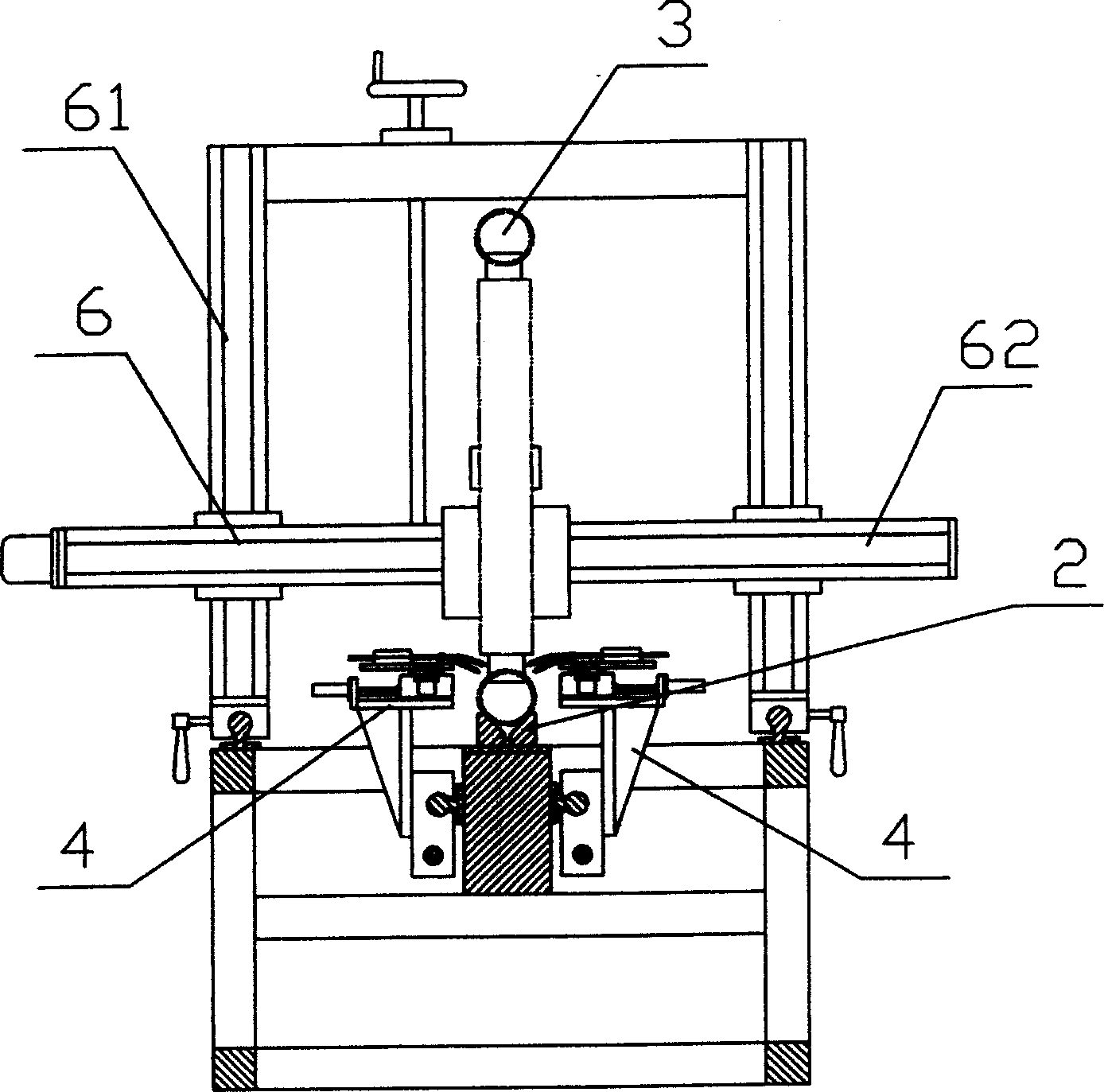

Full automatic brazing machine for radiator

InactiveCN1701888AImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention discloses full automation soldering machine for heating radiator and belongs to welding machine field, which comprises frame, locating device of heating radiator, welding device, clamping device and its arm brace composed clamp head, turn power device to bring clamp head turn and lifting power device to drive the lift of drive clamp head, radiator and power device. First, weld the branch pipe and connected link box pipe; then, lifting device drives clamp head, radiator and turn device to lift and leave their locating devices; turn device drives radiator to turn for 180Deg; lifting device drives clamp head, radiator and turn device to drop and locate and clamp, welding device take similar operation to other link points; finally, it comes to the finish of the automatic welding, which increases greatly the work efficiency.

Owner:杜明干

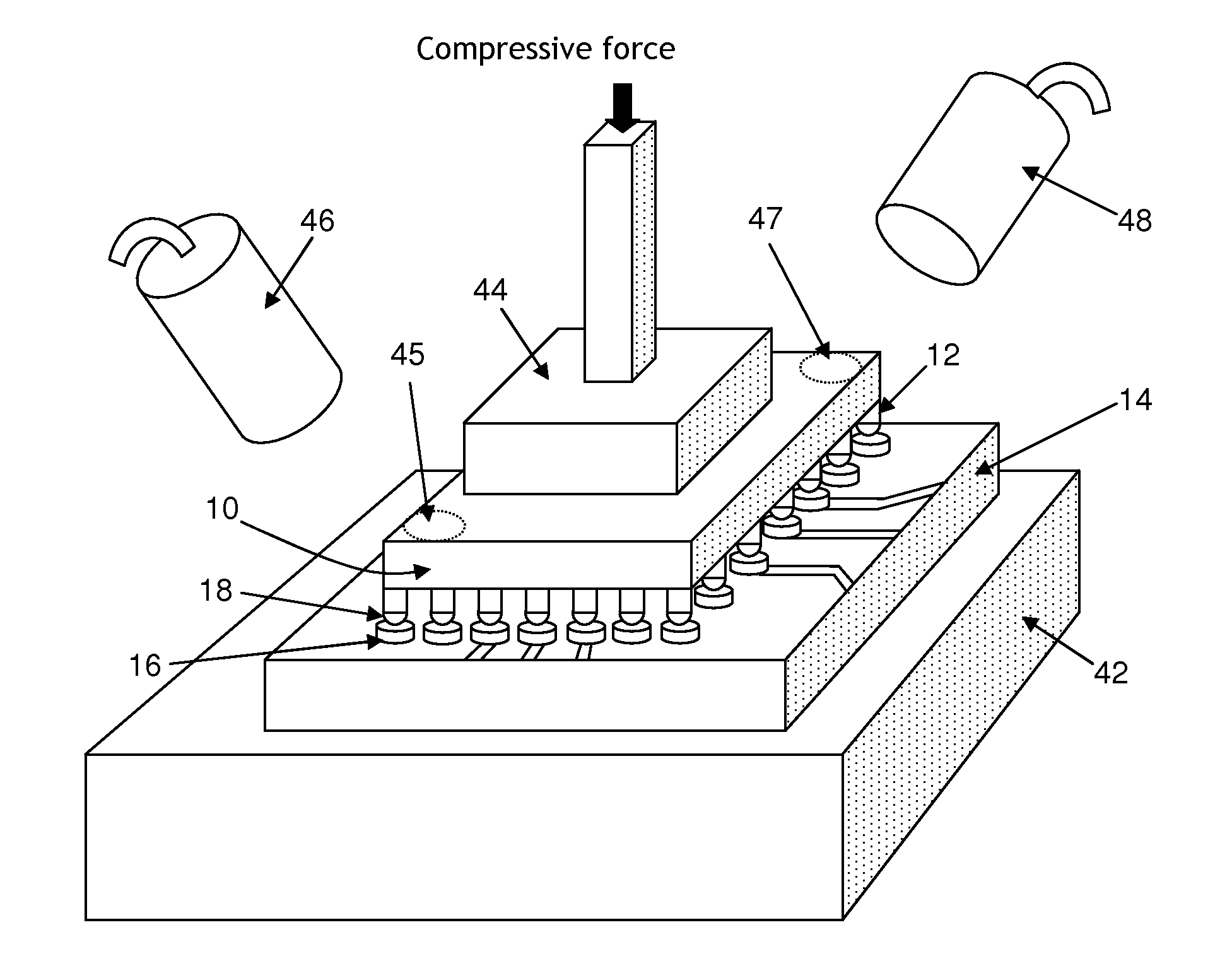

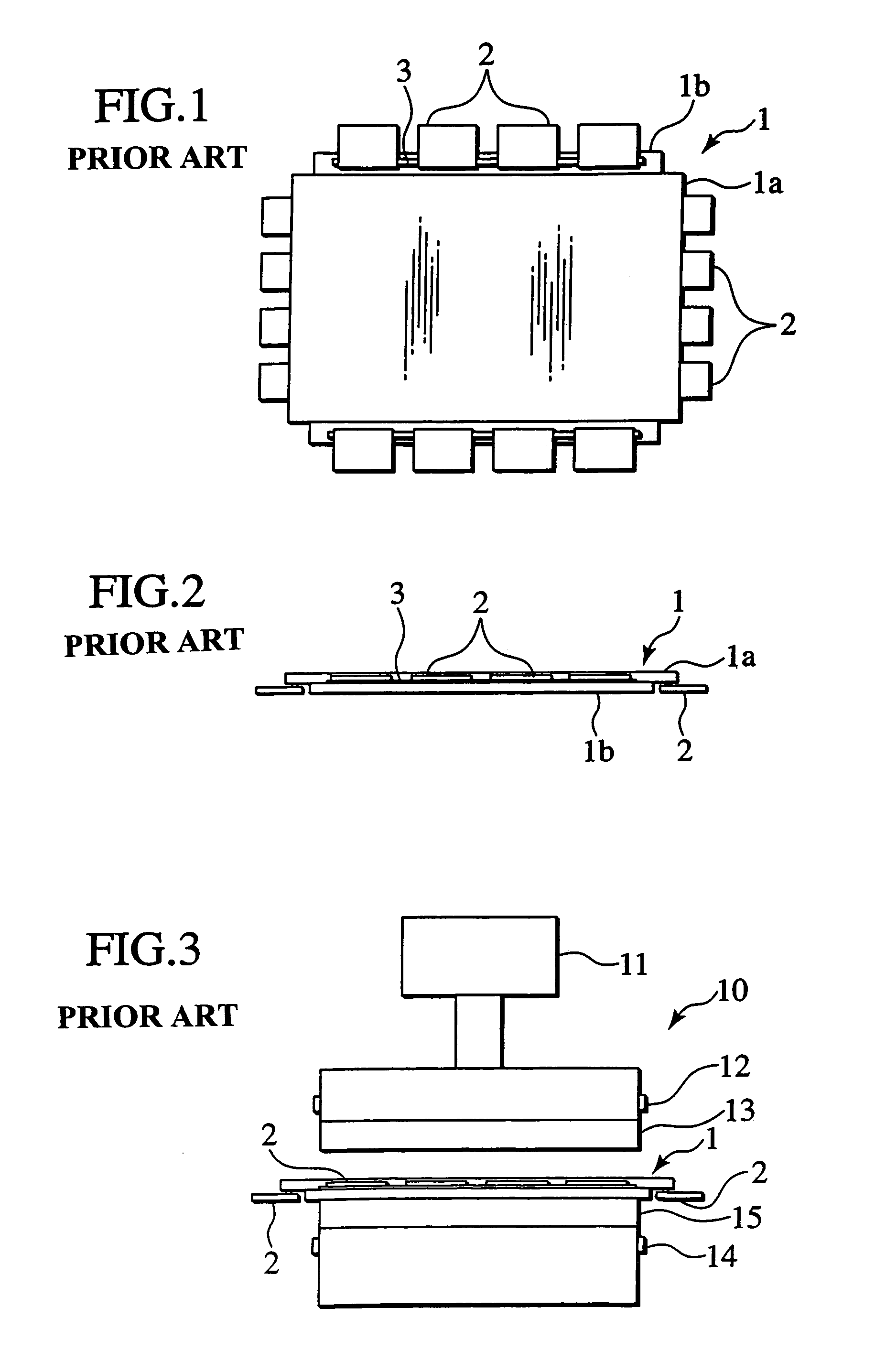

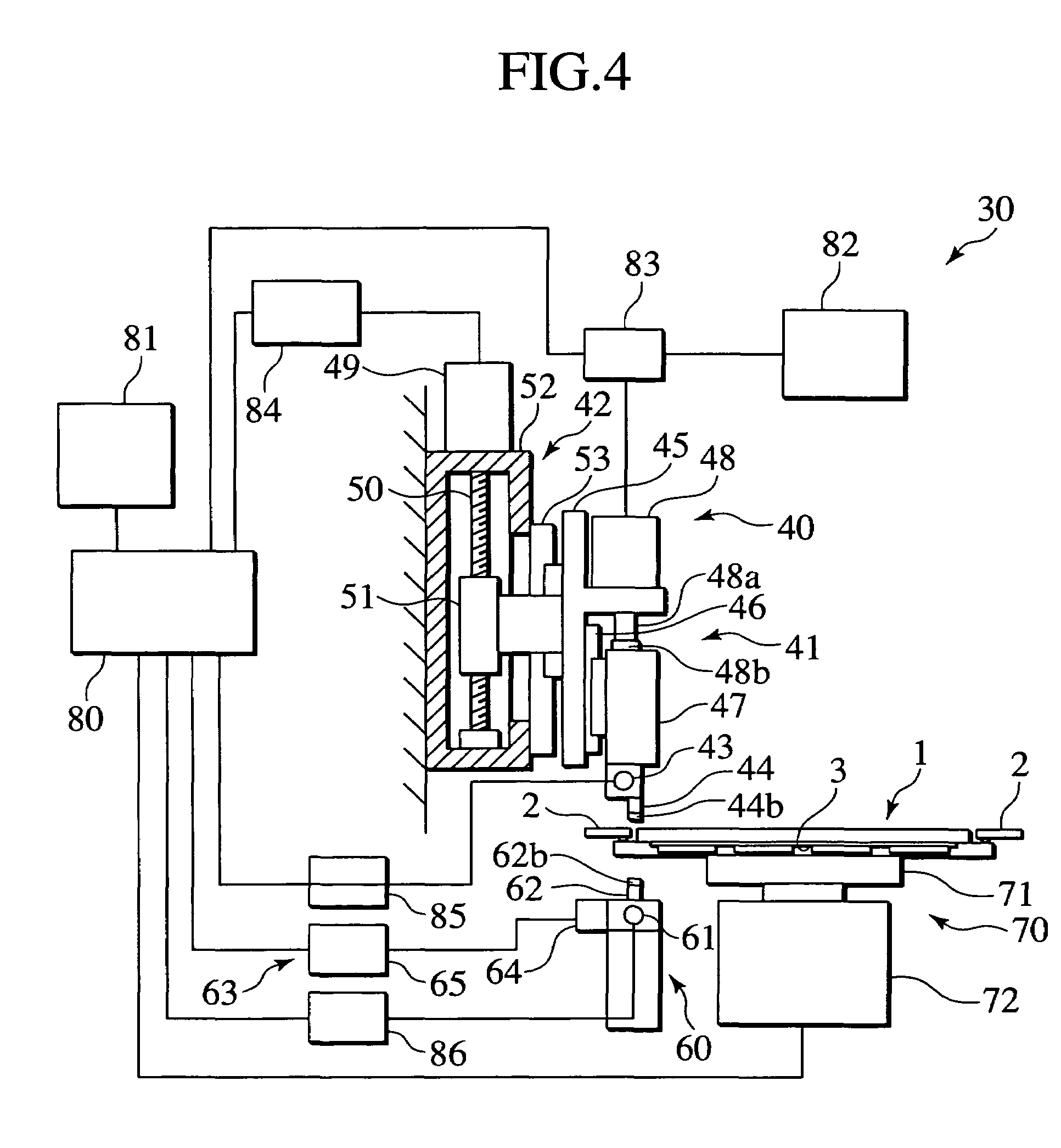

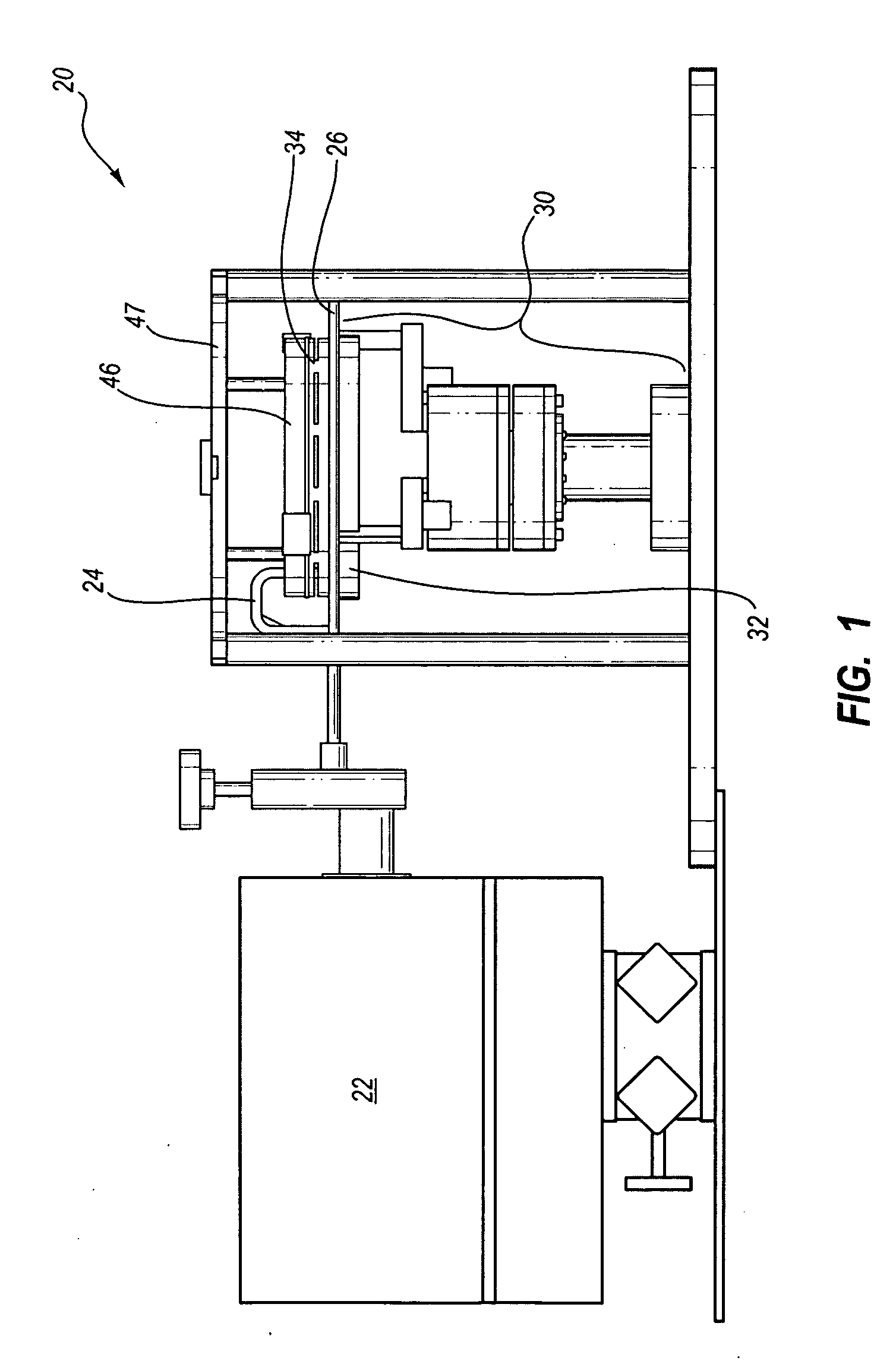

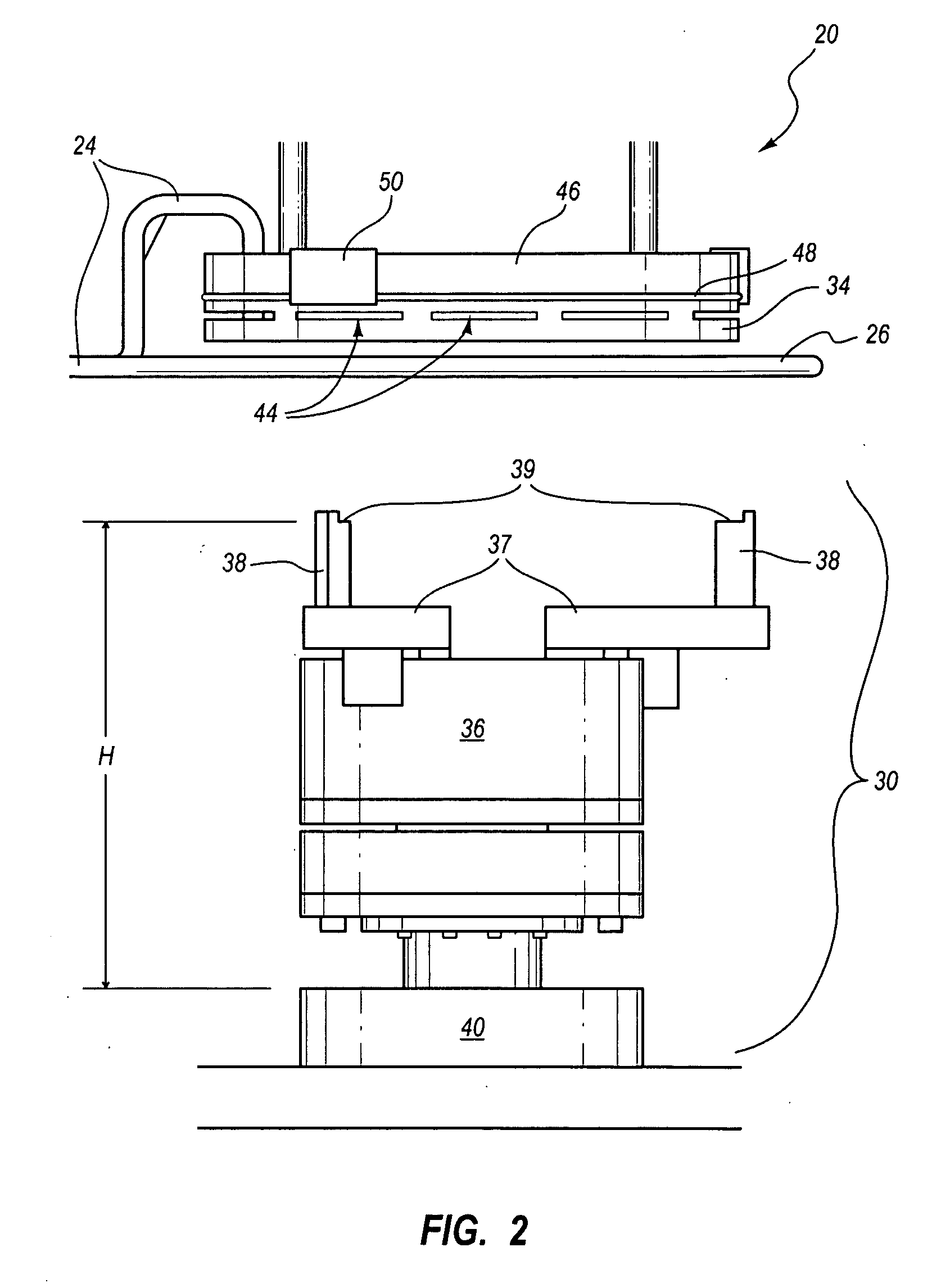

Electronic part compression bonding apparatus and method

InactiveUS7075036B2Easy to controlPrevent bad connectionSemiconductor/solid-state device manufacturingOhmic-resistance heating detailsTemperature controlEngineering

An electronic part compression bonding apparatus includes a compression bonding unit which bonds the electronic parts onto the substrate by thermocompression, a pressure supply unit, a pressure control unit which controls pressure, a heating unit which heats the compression bonding unit, a temperature control unit, and a thermocompression bonding control unit which controls the pressure control unit and the heating unit based on thermocompression bonding condition data in which at least one of pressure and heating temperature is variably set during a process from start until completion of a thermocompression bonding operation of the electronic parts. In the thermocompression bonding condition data, the pressure is set to a first pressure in a first stage in a process of the thermocompression bonding operation and a second pressure, which is lower than the first pressure, in a second stage that follows the first stage.

Owner:SHIBAURA MECHATRONICS CORP

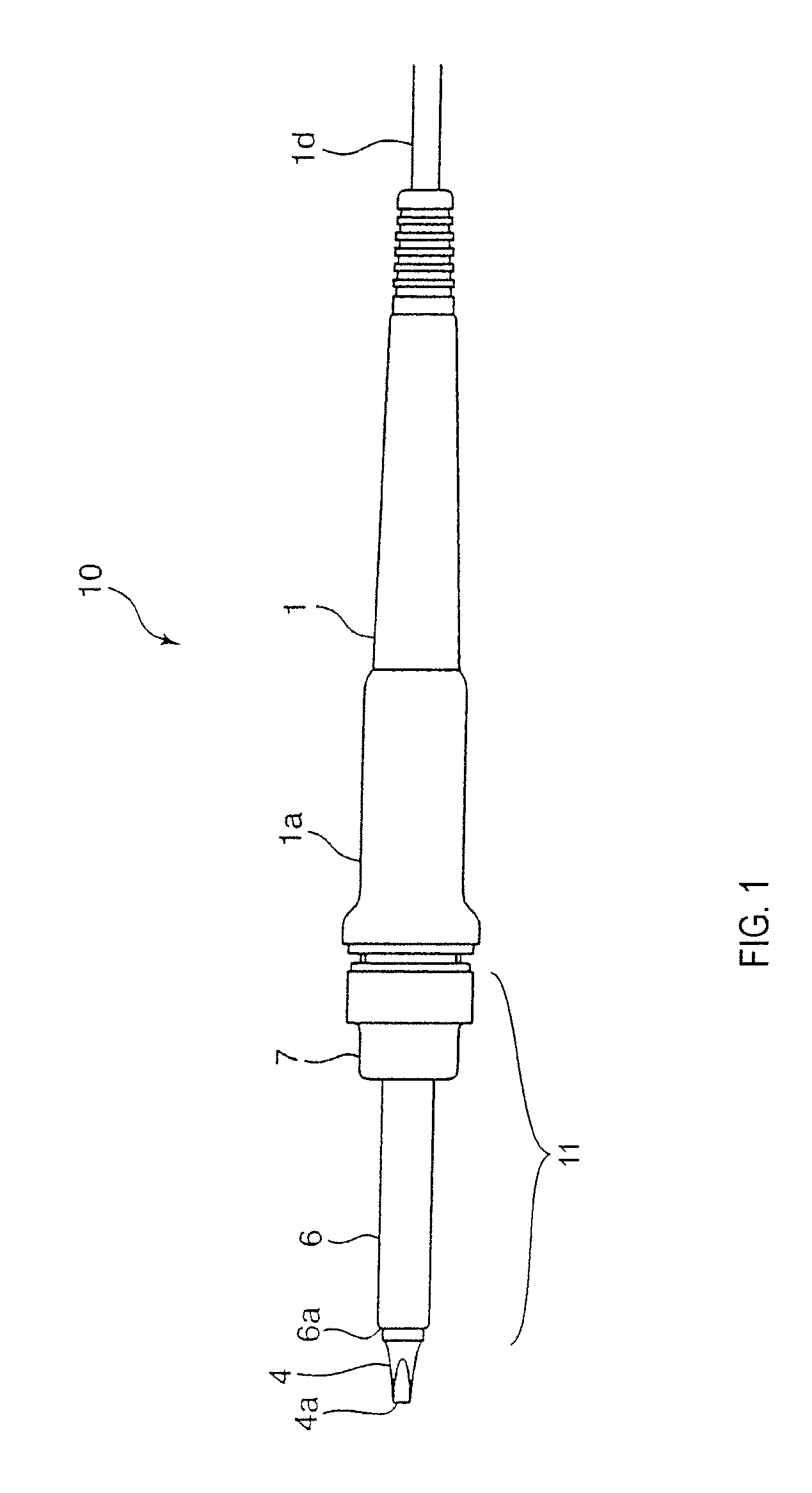

Soldering iron and method of manufacturing same

ActiveUS20060108345A1Heating fastIncrease heatHeating element shapesHeating appliancesBiomedical engineeringSoldering iron

A soldering iron provided with a soldering tip that melts solder at a distal end, having inside said soldering tip a substantially cylindrical insertion fit recess portion extending from a proximal end of the soldering tip to the distal end, opening at the proximal end, and a heater formed into a coil shape and whose surface is covered with an insulating oxide film being fittingly inserted into the insertion fit recess portion.

Owner:TAIYO ELECTRIC IND

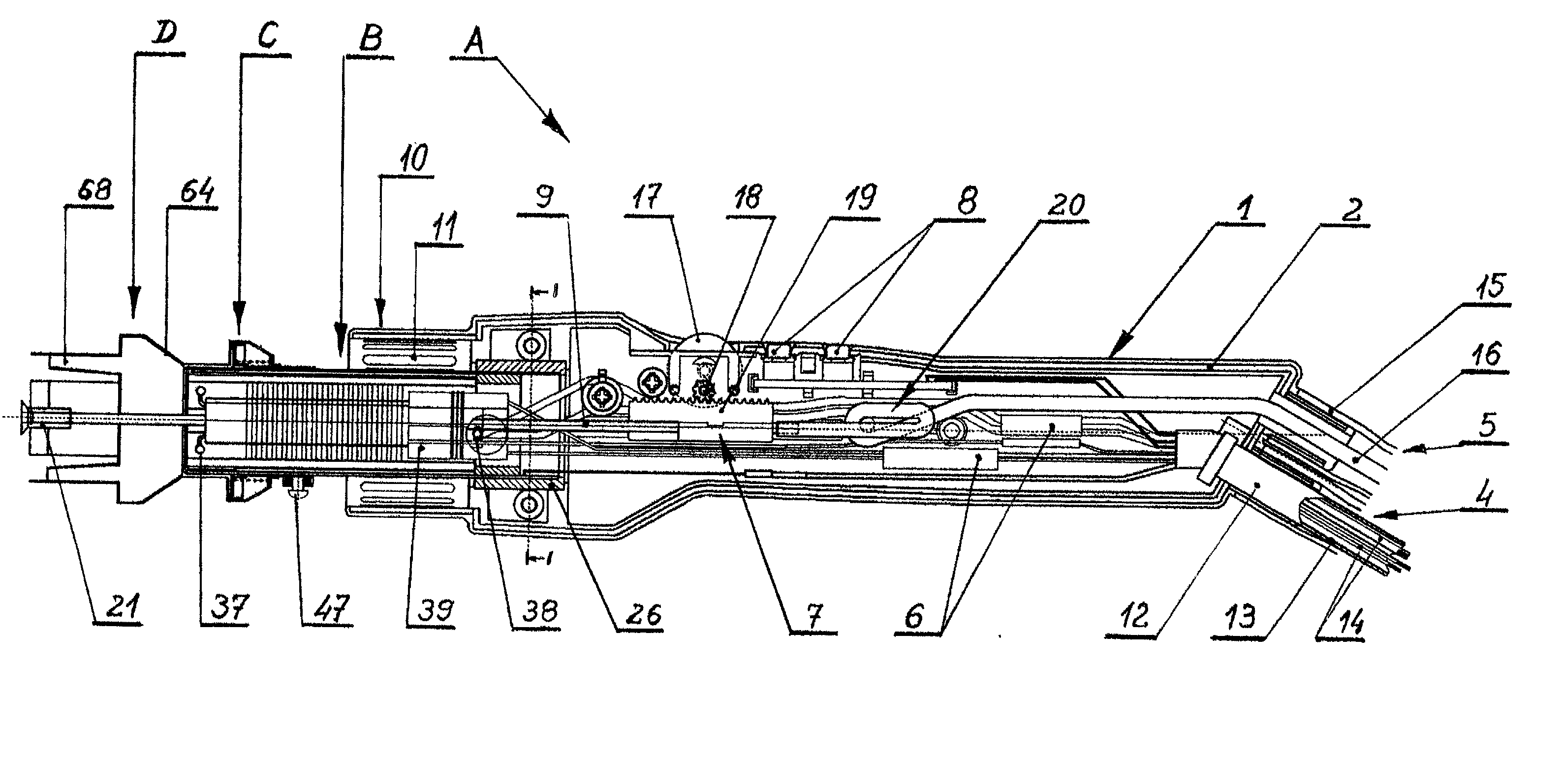

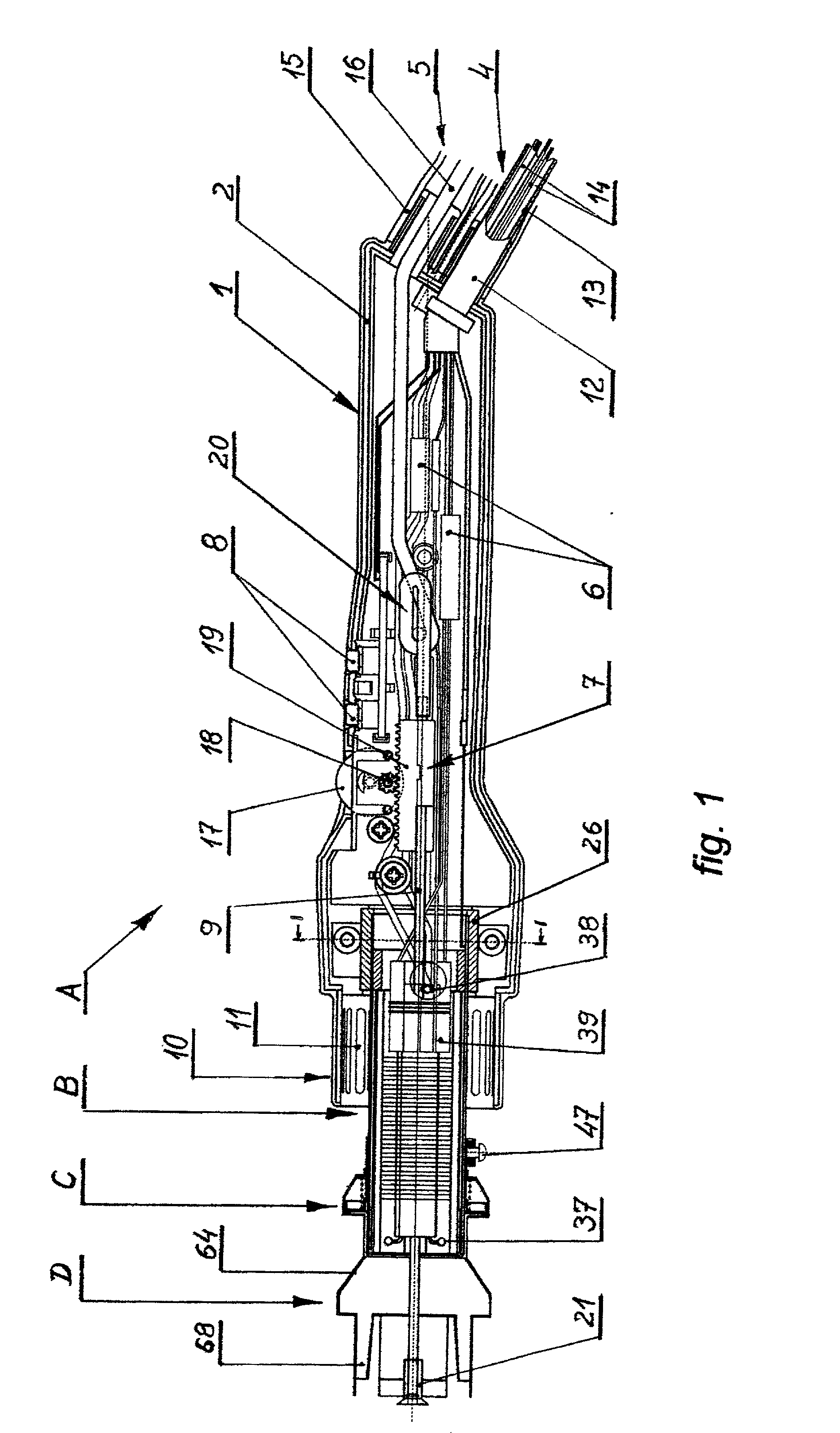

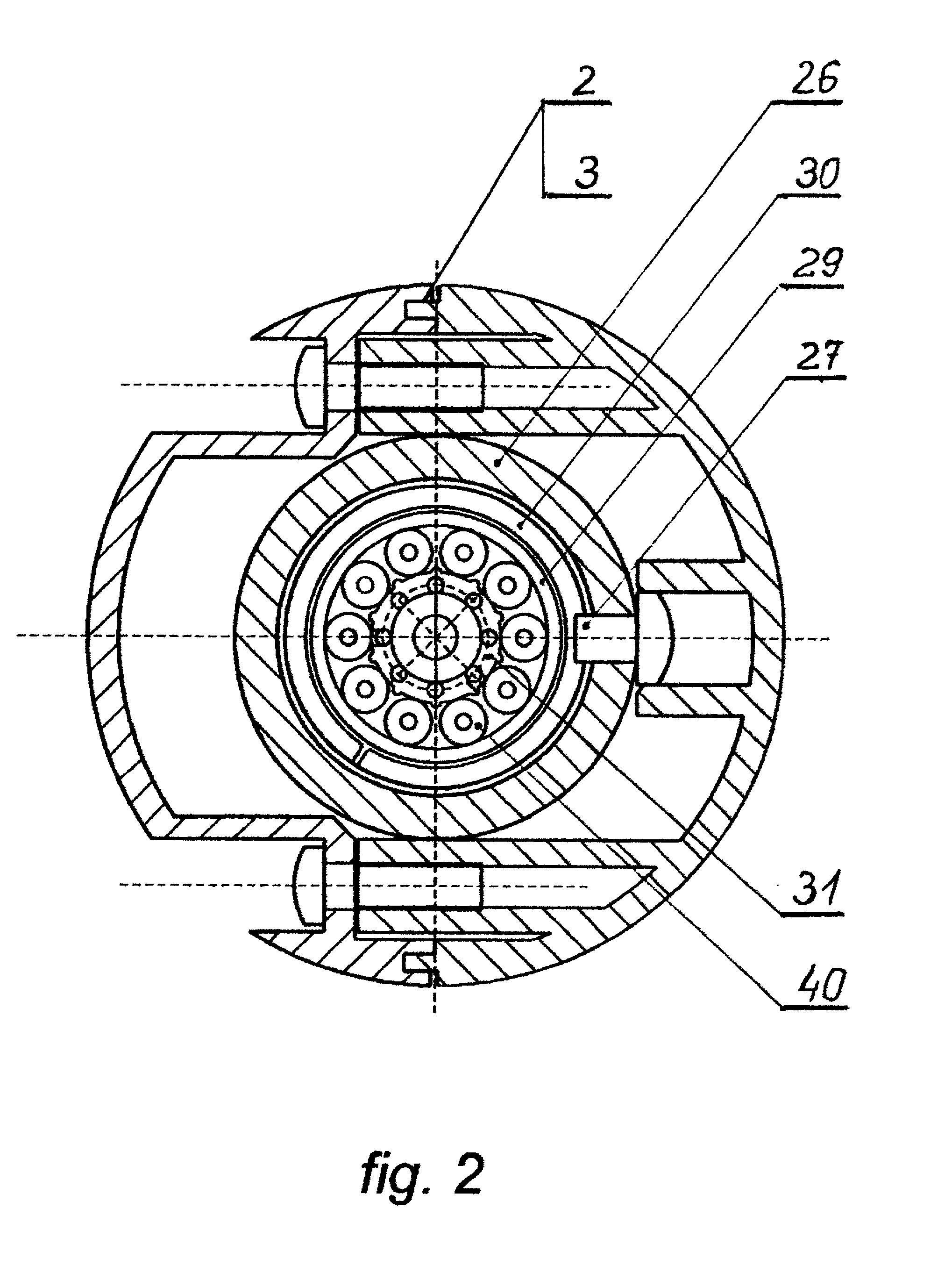

Heating head for soldering and de-soldering of SMD components

InactiveUS20020084307A1Ohmic-resistance heating detailsHeating element shapesLocking mechanismSurface mounting

A heating head for soldering and de-soldering surface mount devices (SMD's) using hot inert gas or air is comprised of a handle in which there is placed a heater sub-assembly on which there is secured a quick connect mechanism for mounting a heating nozzle. The heater sub-assembly is enclosed in a shroud and is secured to the end of the handle by a thermal insulating ring, such shroud housing a ceramic rod having elongated bosses on which a heating element is secured, while a laminar flow equilizer is used to provide more uniform gas flow across the heating element. Quick connect mechanism is secured to the heater sub-assembly shroud and uses a spring loaded winged locking mechanism to the secure heating nozzles to the heater head. In one embodiment, the heating nozzles have a truncated pyramid shaped chamber to which individual end nozzles made by folding a flat, thin sheet metal pattern are attached for directing gas flow, while in another embodiment a chamber having a centrally located circulation hole on the side walls and further circulation hole at the bottom edge of the each side wall near the corners of the chamber is provided.

Owner:RUSZOWSKI CZESLAW A

Apparatuses and methods for induction heating

A heating apparatus for induction heating is disclosed. The heating apparatus may comprise a bearing ring, at least one bearing element disposed in the bearing ring, and a braze material adjacent to the at least one bearing element and the bearing ring. The heating apparatus may additionally comprise an inductor positioned radially adjacent to at least a portion of the bearing ring. A current source may be electrically coupled to the inductor. A bearing orienting member may also abut a surface of the at least one bearing element. The bearing orienting member may orient a surface of the at least one bearing element. A heating method is also disclosed.

Owner:US SYNTHETIC CORP

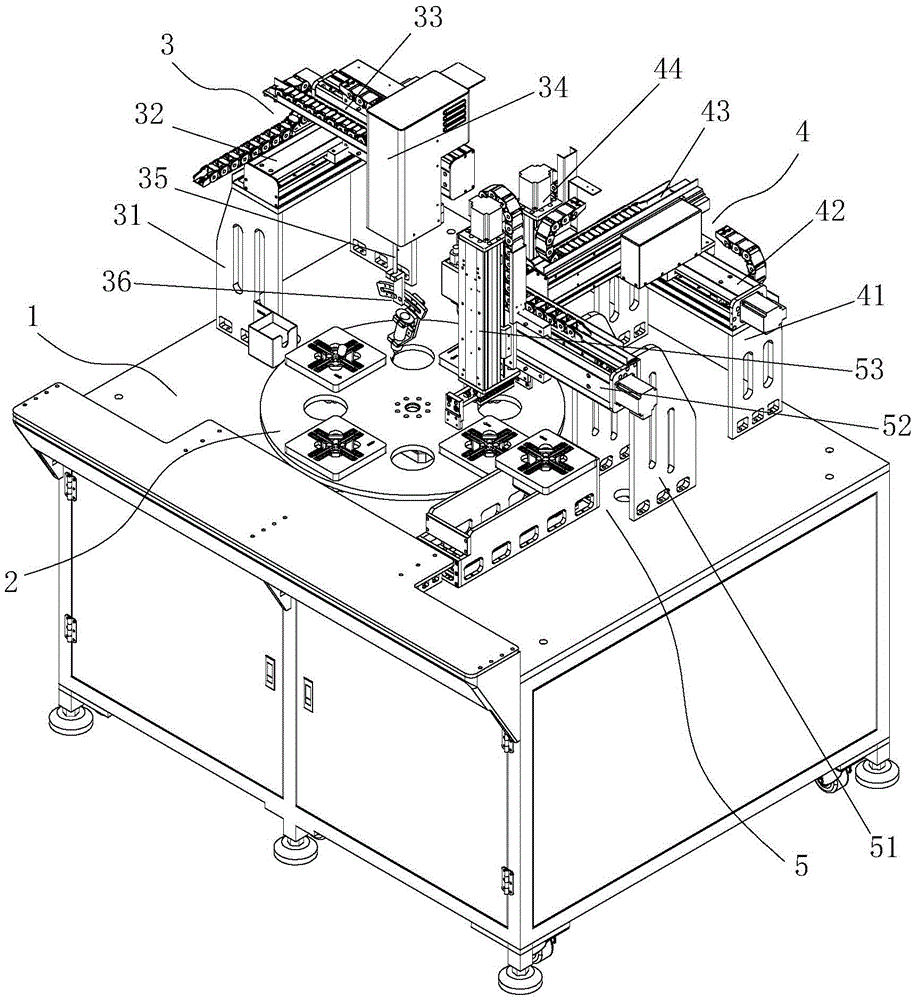

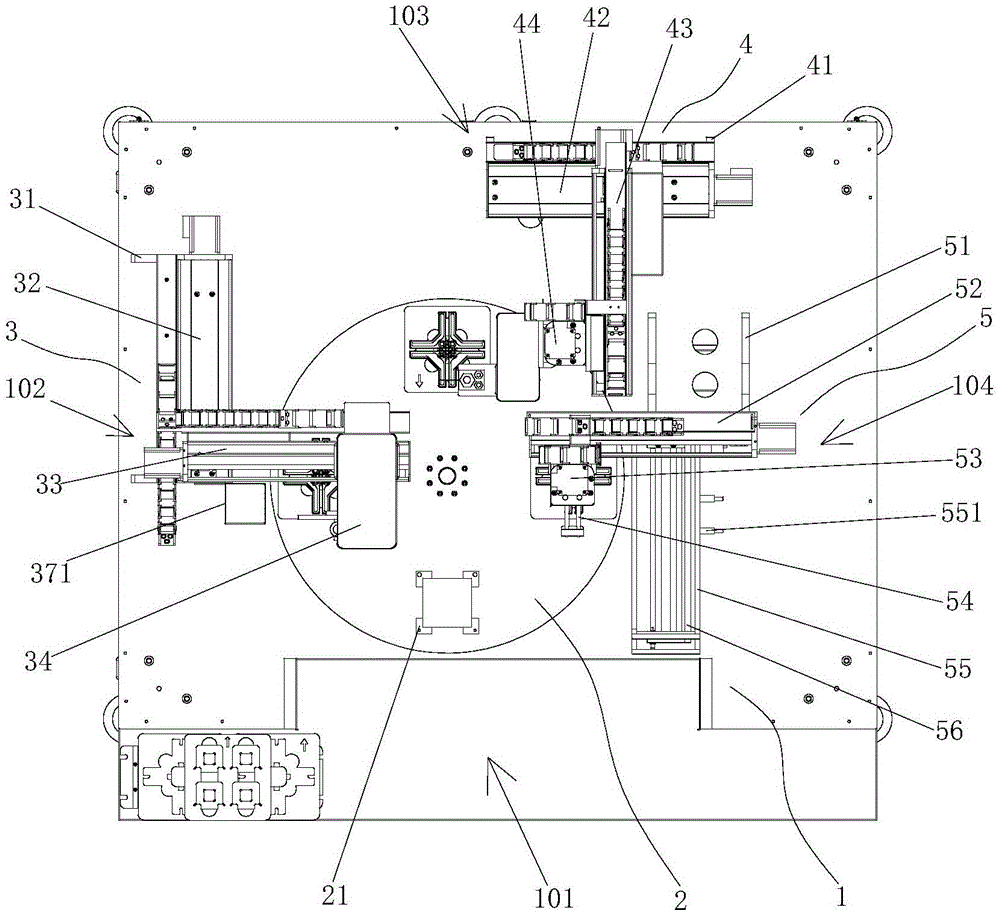

Automatic welding equipment

InactiveCN105562874AIncrease flexibilityHigh precisionHeating appliancesConductorsAutomatic test equipmentControl system

The invention relates to automatic welding equipment which is provided with a main machine platform. The automatic welding equipment comprises an index plate, a solder paste dripping assembly, a high-frequency soldering assembly and a blanking assembly which are arranged on the main machine platform. The index plate is uniformly provided with four workpiece positioning parts. Four working positions are formed on the part, on the periphery of the index plate, of the main machine platform. The first working position is the manual feeding working position, the solder paste dripping assembly is installed at the second working position, the high-frequency soldering assembly is installed at the third working position, and the blanking assembly is installed at the fourth working position. According to the automatic welding equipment, the solder paste dripping assembly and the high-frequency soldering assembly are controlled independently through independent control systems correspondingly, the precision is high, and the stability is good; compared with traditional scattered type welding working positions, the automatic welding equipment is provided with the multiple working positions integrally, and the working positions are arranged in a circle mode; the structure is compact, the occupied space is small, operation is smooth, and the production efficiency is high; in addition, operation can be conducted with only one person, and the security of the worker and the equipment is high.

Owner:GUANGDONG HUISU TELECOMM TECH

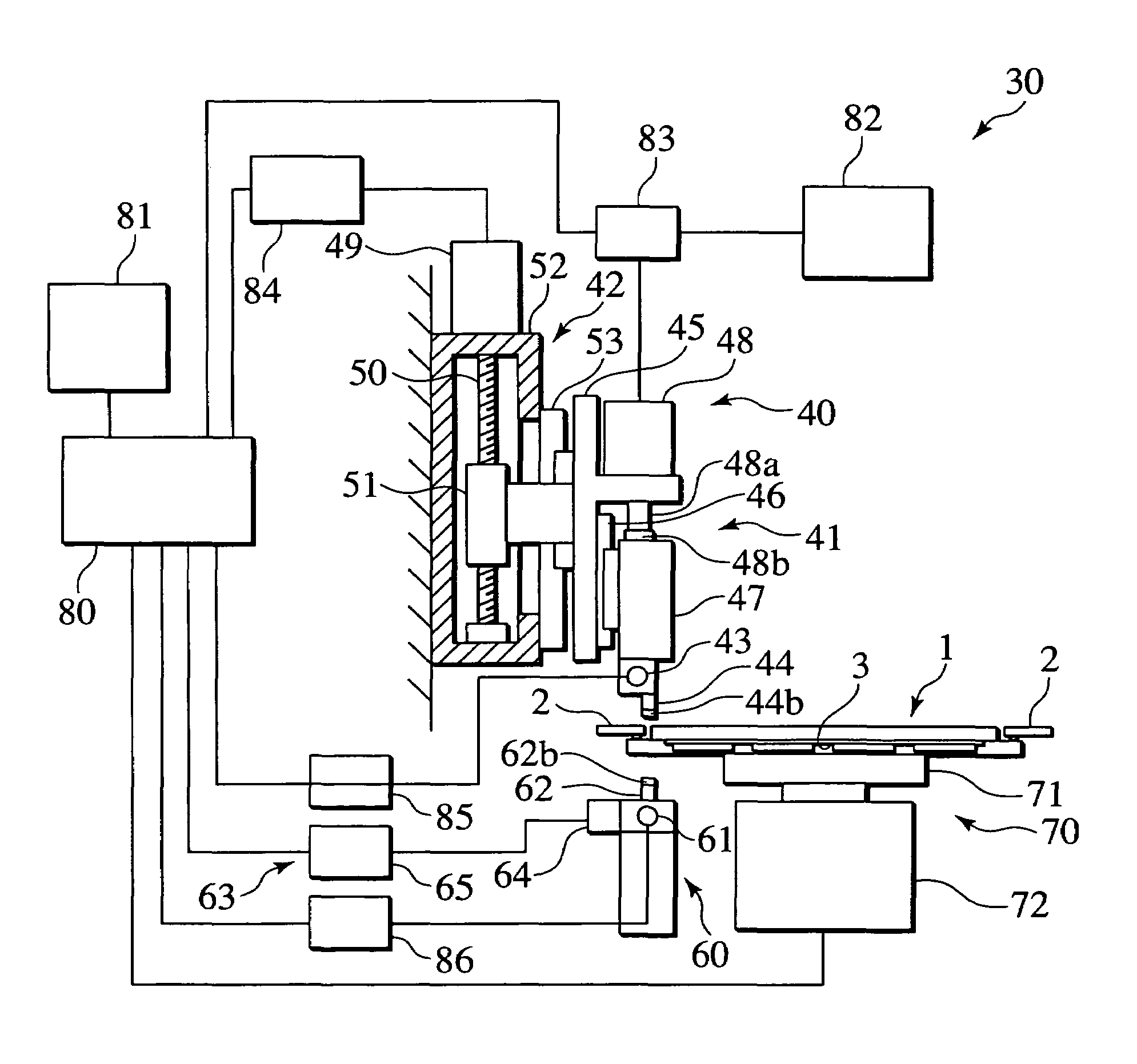

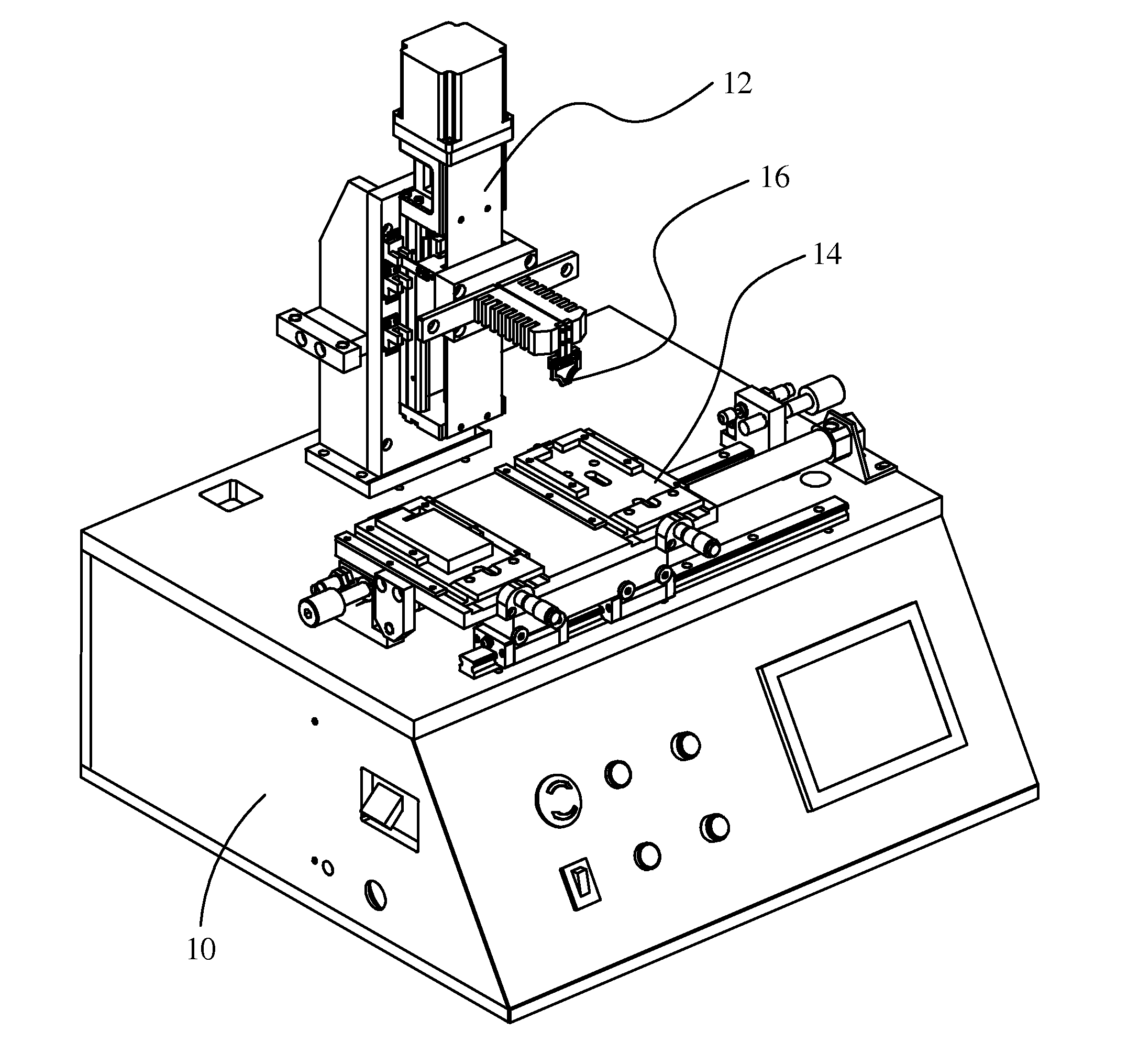

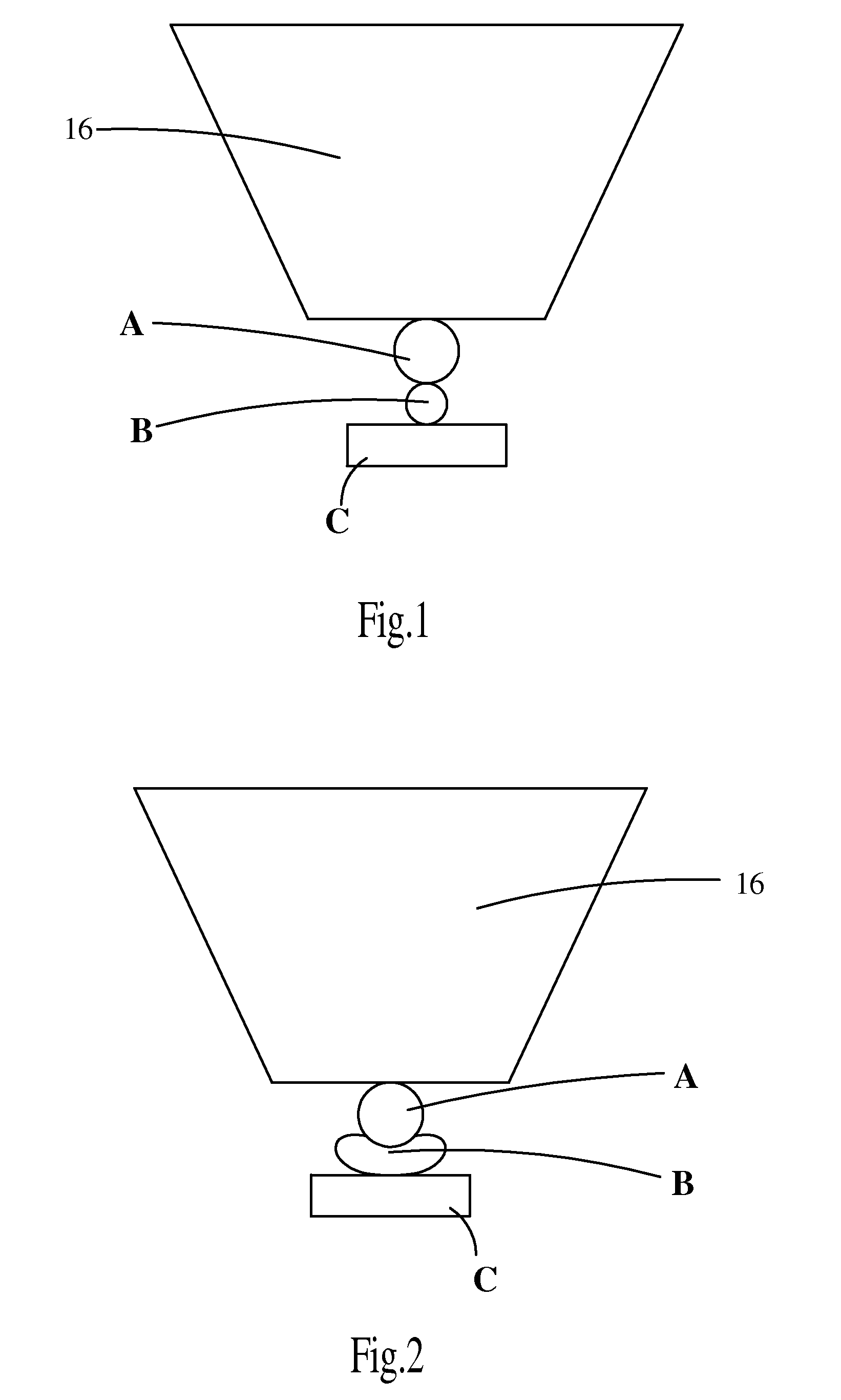

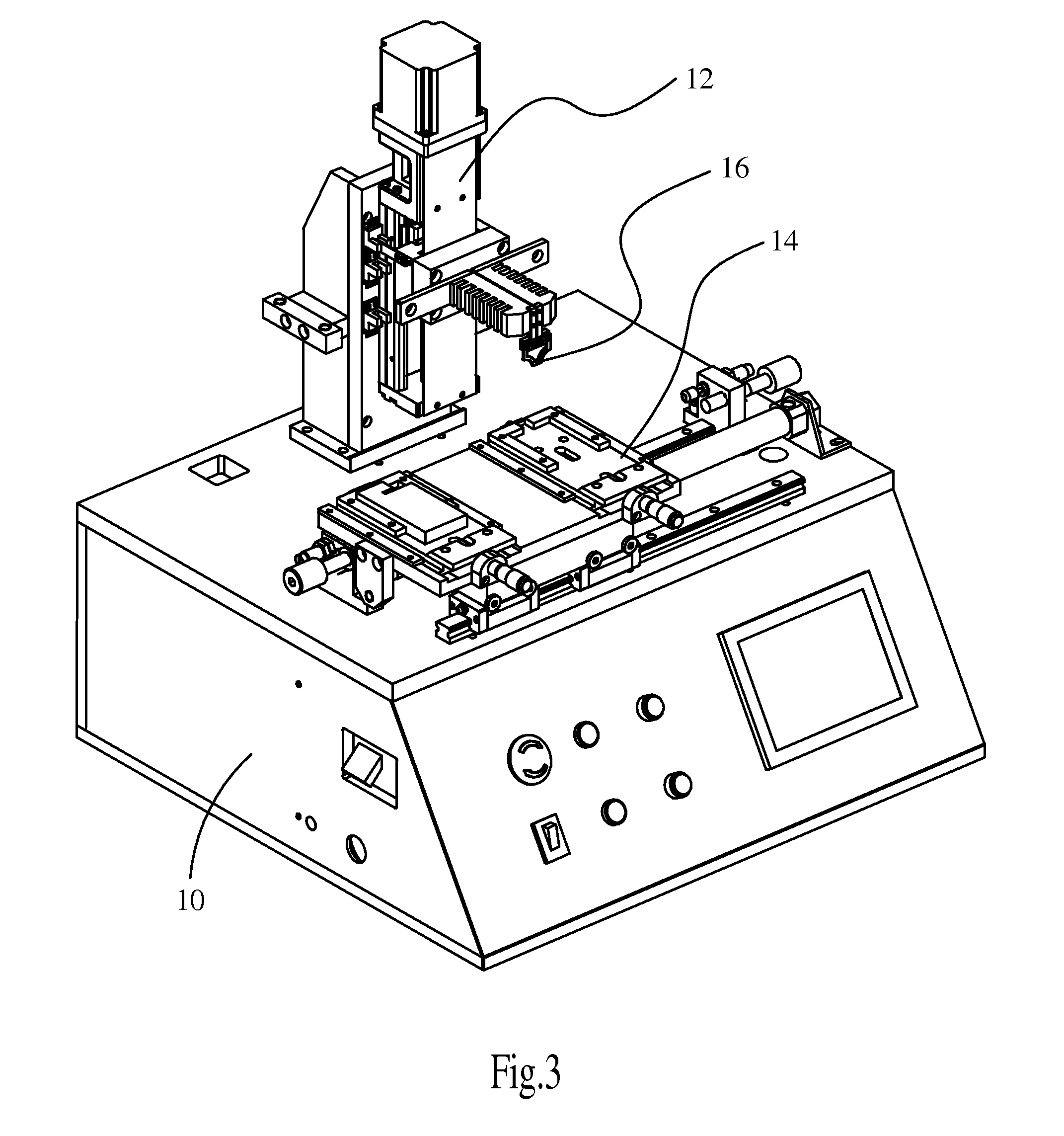

Automatic soldering apparatus and soldering method thereof

InactiveUS20120104077A1Avoid damageDamage to partWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectronic component

An automatic soldering apparatus and a soldering method thereof are provided. The soldering method has steps of: (S1) positioning a to-be-soldered part and an electronic component having a solder material; (S2) driving a hot press to firstly move, until the hot press is in contact with the part; (S3) heating the solder material by the hot press; and (S4) driving the hot press to secondly move to press the solder material after the solder material on the electronic component is melted, so as to connect the part to the melted solder material on the electronic component by soldering. When the automatic soldering apparatus and the soldering method of the present invention are used to execute a soldering process, a route of the hot press can be controlled to firstly melt the solder material and then deform it, so as to avoid the hot press from impacting and damaging the part.

Owner:CHENG UEI PRECISION IND CO LTD

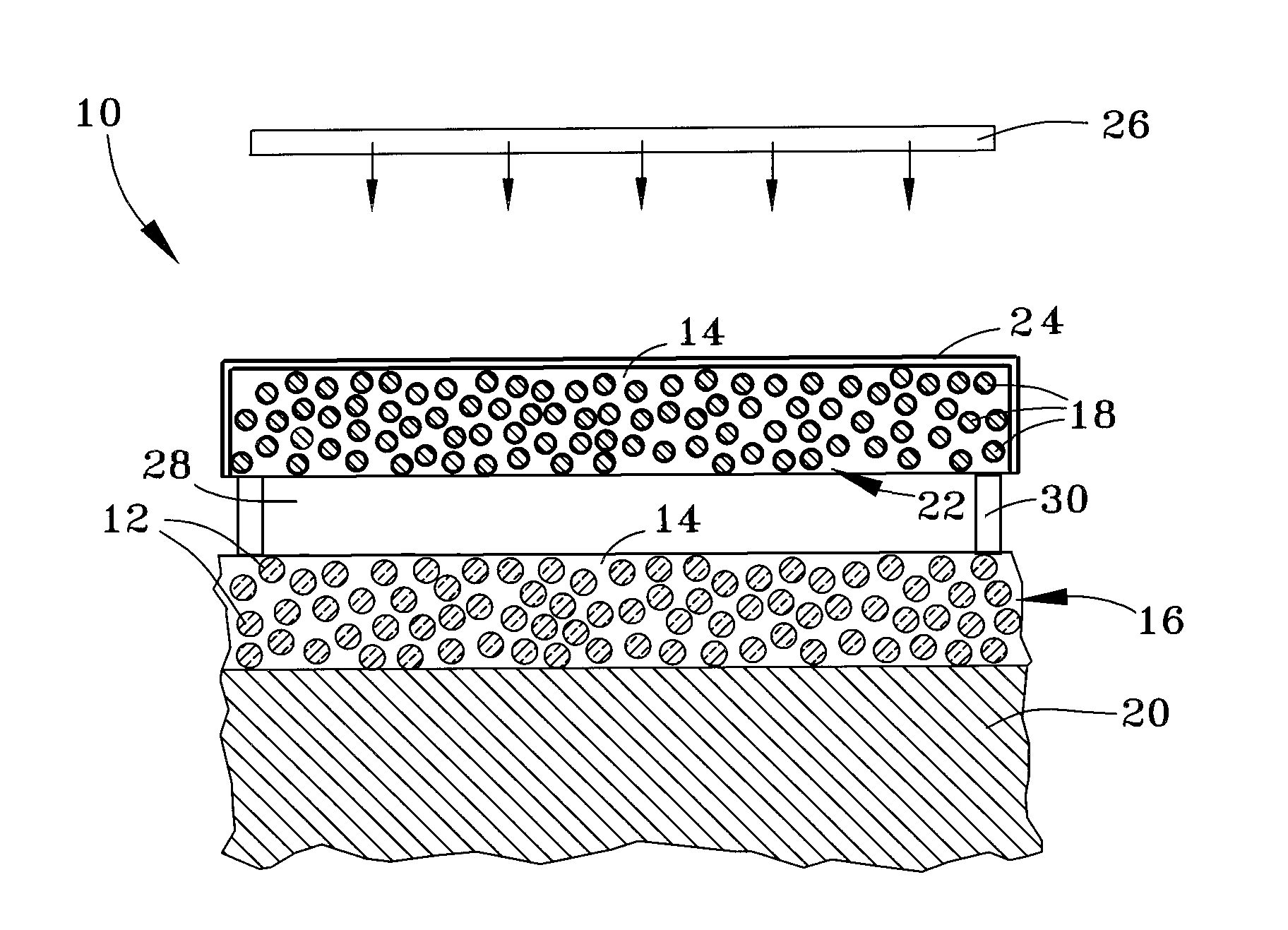

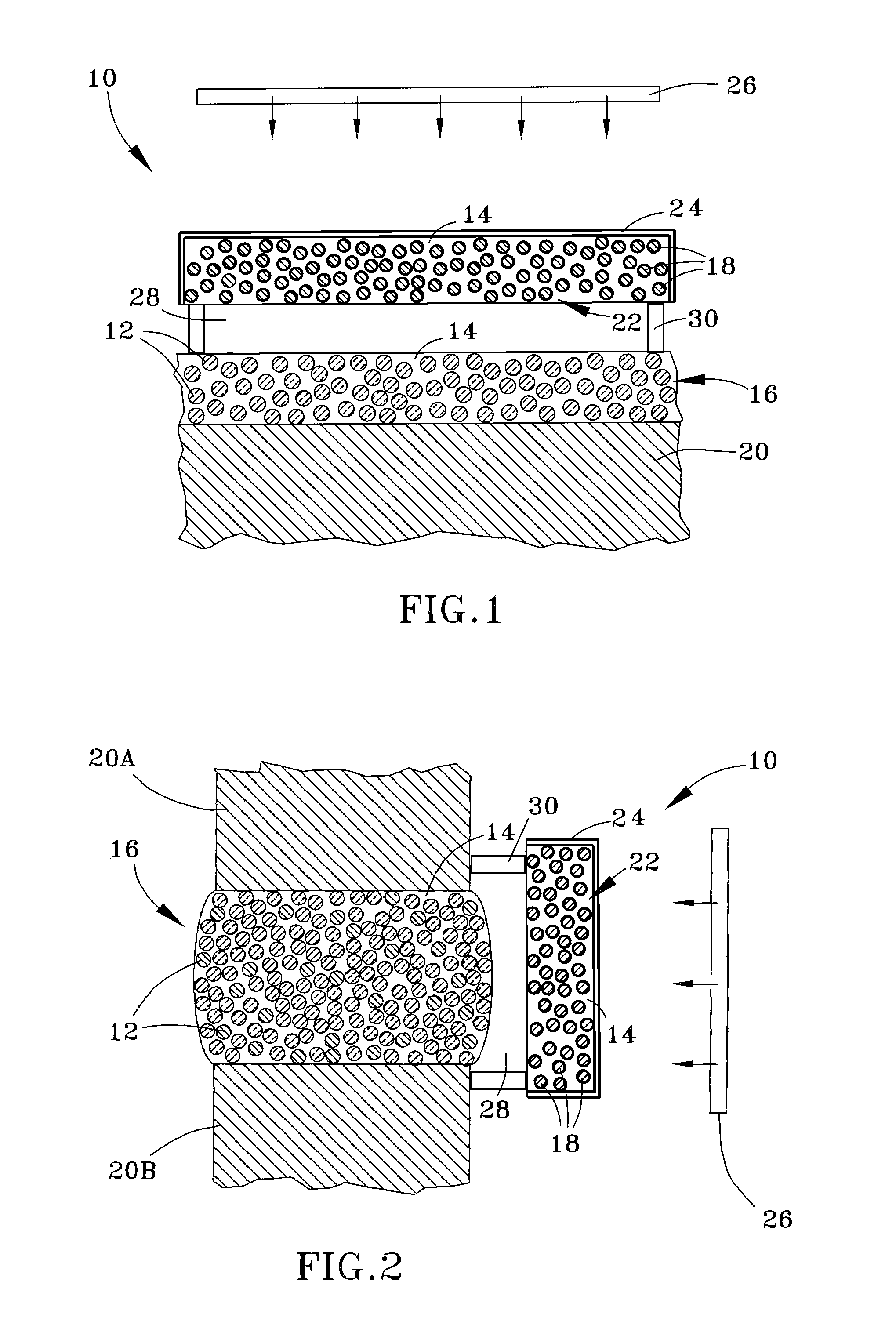

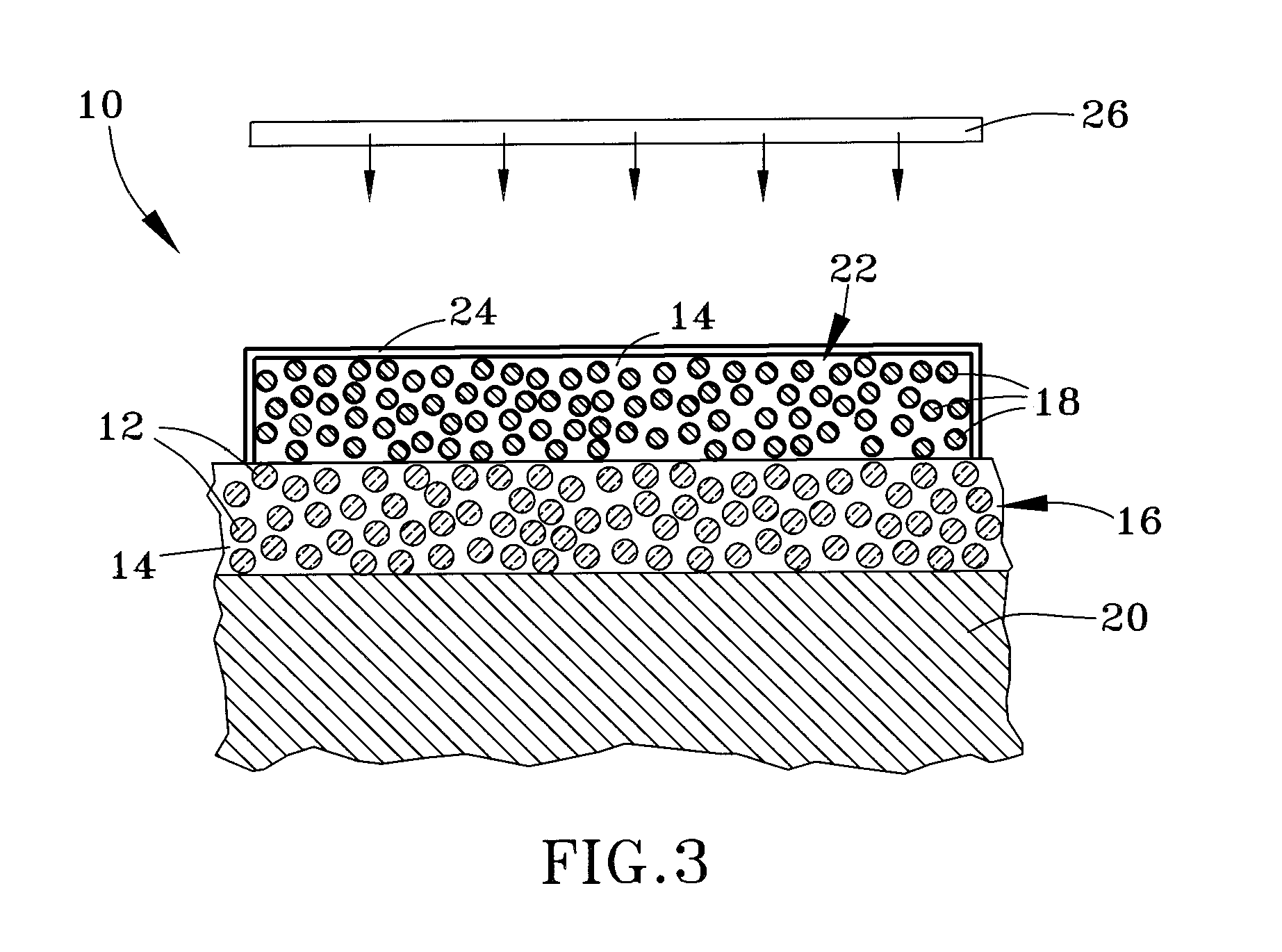

Microwave brazing process and assemblies and materials therefor

A brazing process and assembly utilizing microwave radiation and a plasma generator that is heated by microwave radiation and generates a localized plasma capable of selectively heating and melting a braze alloy. The plasma generator contains a microwave-susceptible material that is susceptible to heating by microwave radiation, and a plasma-generating material capable of volatilizing and generating the plasma when the plasma generator is subjected to heating and microwave radiation. The brazing process includes applying a braze material to a surface of a substrate, positioning the plasma generator in proximity to the braze material, and then subjecting the plasma generator to microwave radiation to volatilize the plasma-generating material and generate a plasma that melts the braze alloy within the braze material.

Owner:GENERAL ELECTRIC CO

LED tube lamp with operating modes compatible with electrical ballasts

ActiveUS10208898B2Improve power stabilityFacilitate conductionElectric circuit arrangementsGlobesPower flowElectrical ballast

A light emitting diode (LED) tube lamp configured to receive an external driving signal includes an LED module for emitting light, the LED module comprising an LED unit comprising an LED; a rectifying circuit for rectifying the external driving signal to produce a rectified signal, the rectifying circuit having a first output terminal and a second output terminal for outputting the rectified signal; a filtering circuit connected to the LED module, and configured to provide a filtered signal for the LED unit; and a protection circuit for providing protection for the LED tube lamp. The protection circuit includes a voltage divider comprising two elements connected in series between the first and second output terminals of the rectifying circuit, for producing a signal at a connection node between the two elements; and a control circuit coupled to the connection node between the two elements, for receiving, and detecting a state of, the signal at the connection node. The control circuit includes or is coupled to a switching circuit coupled to the rectifying circuit, and the switching circuit is configured to be triggered on or off by the detected state, upon the external driving signal being input to the LED tube lamp, to allow discontinuous current to flow through the LED unit.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

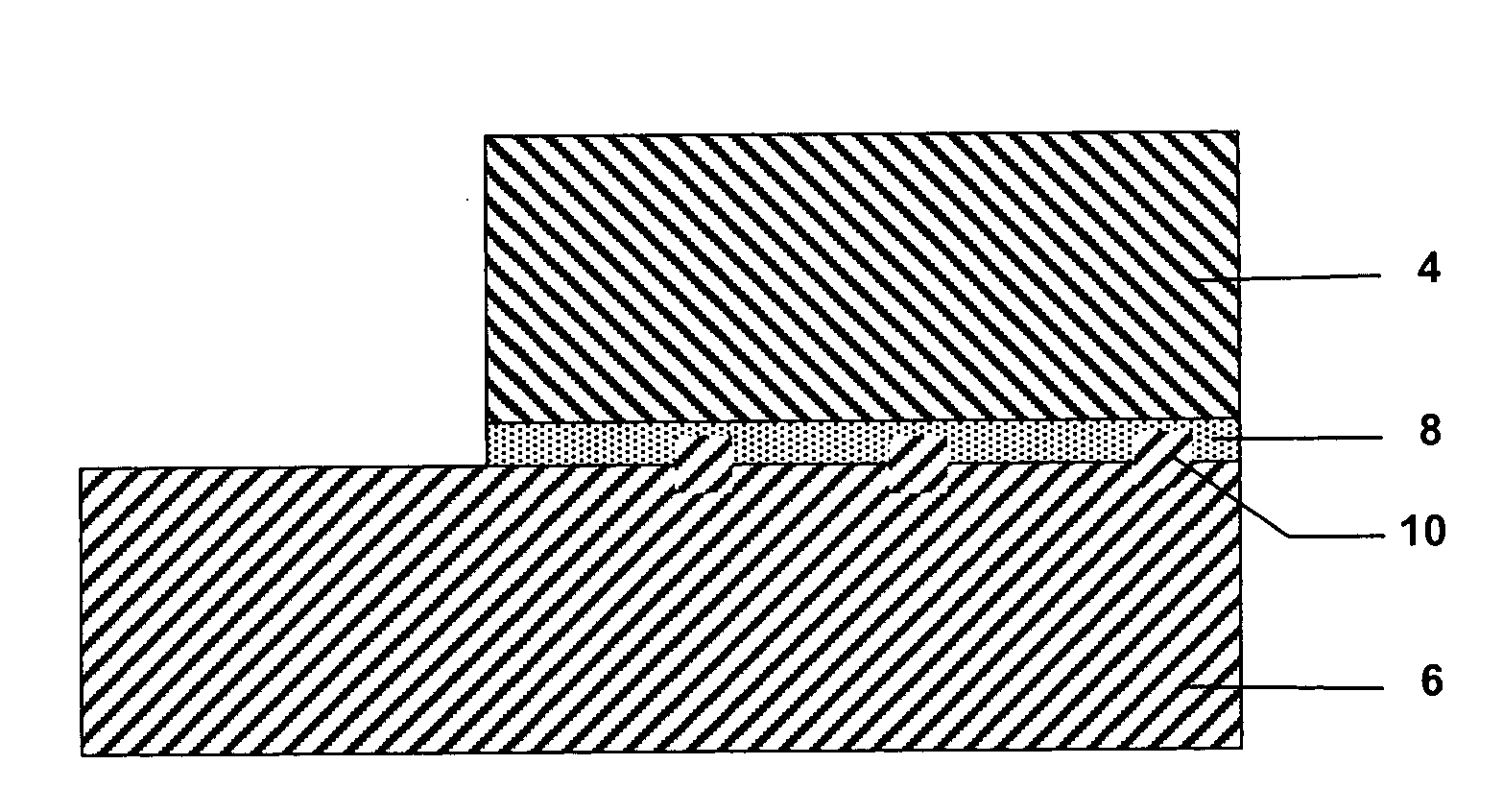

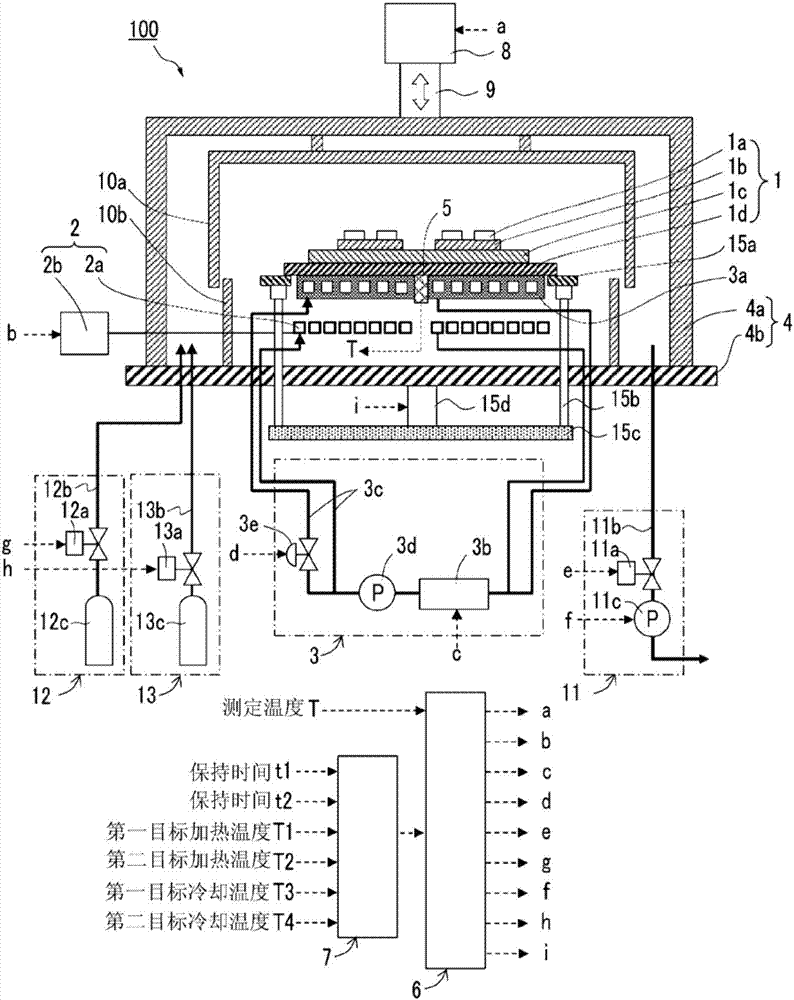

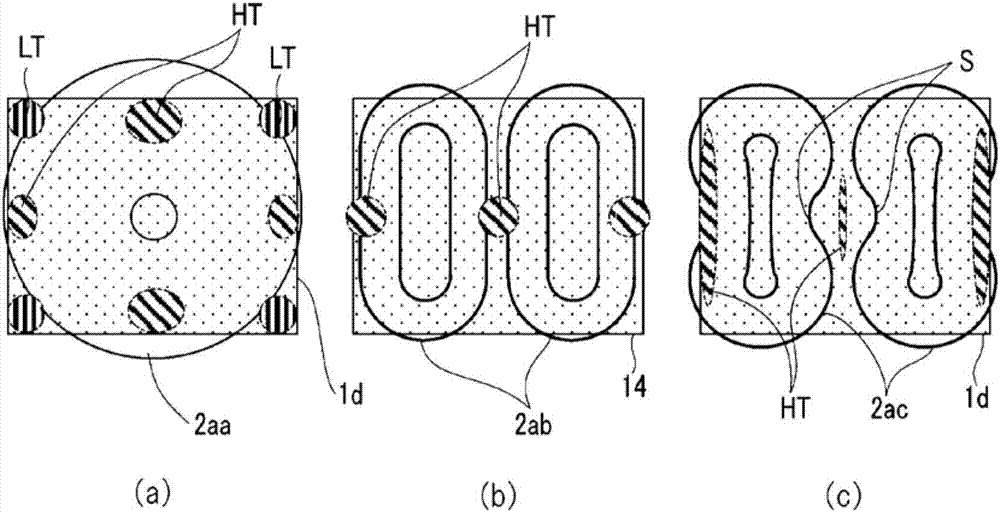

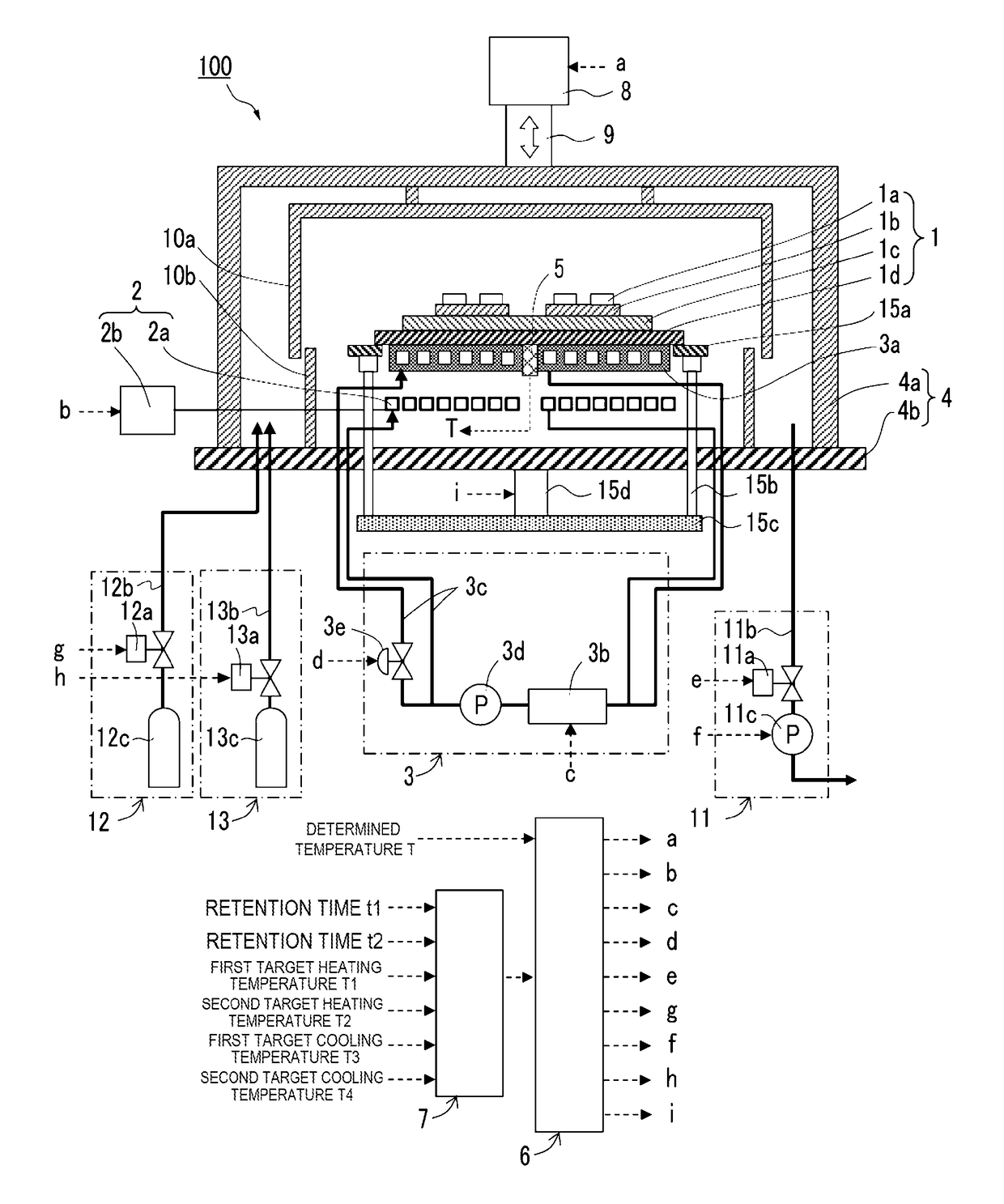

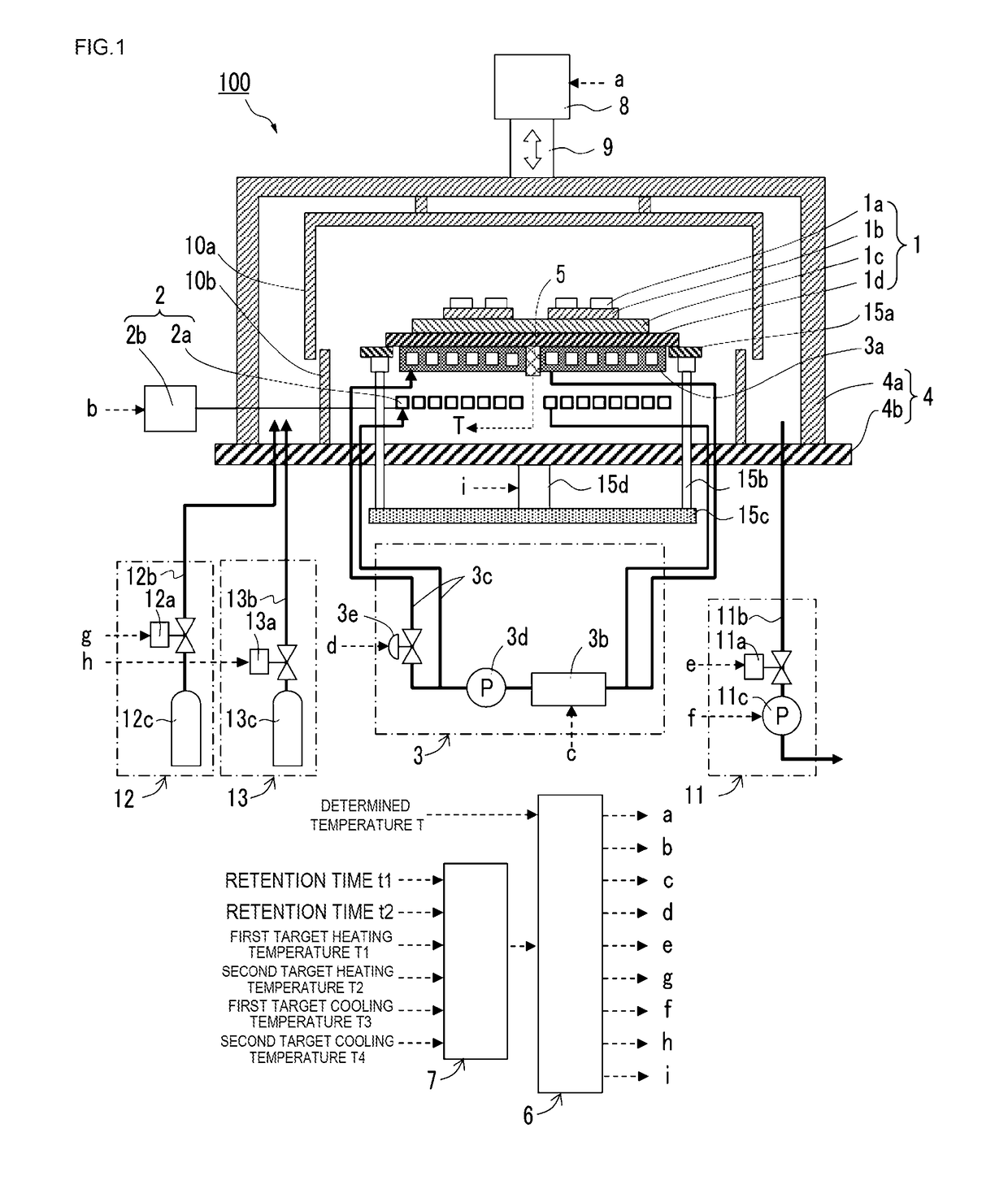

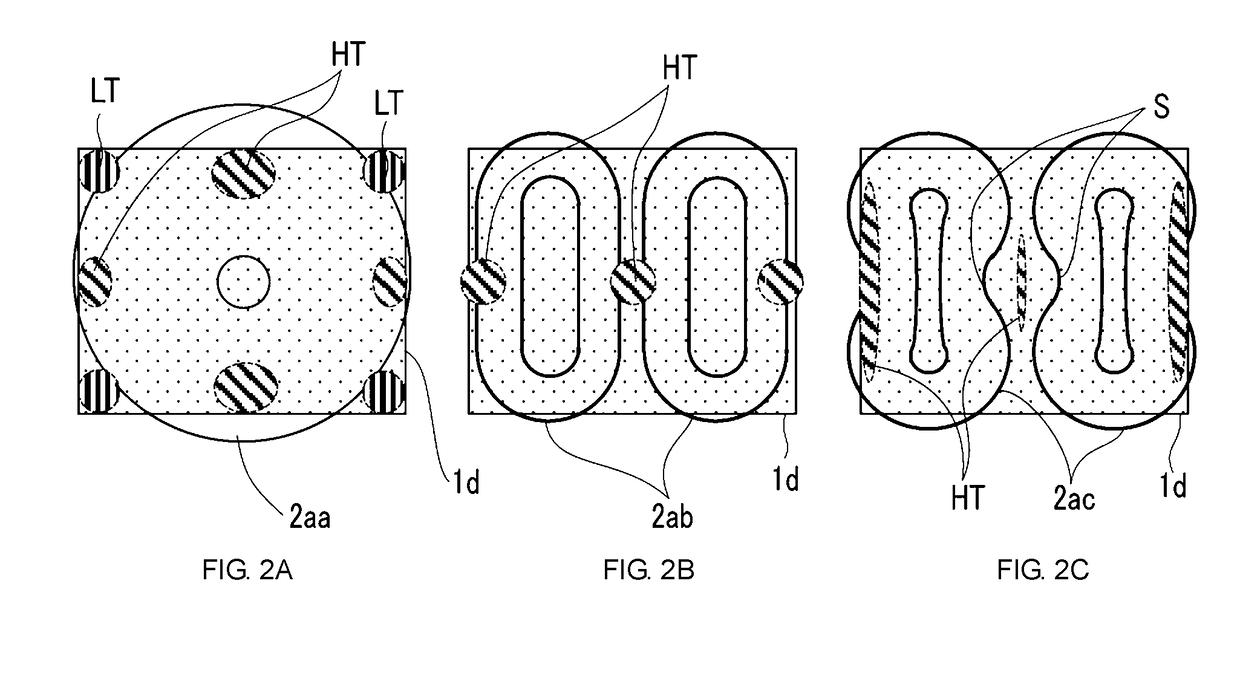

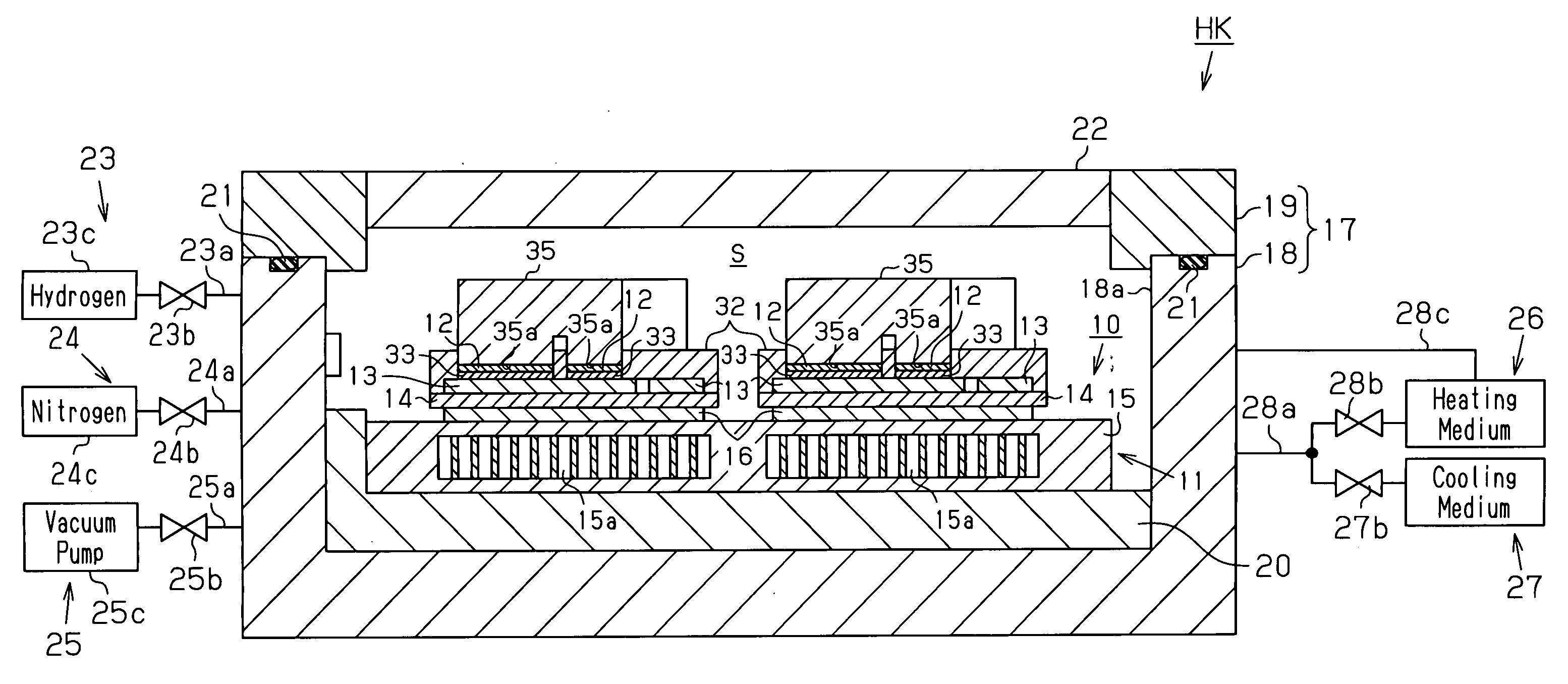

Heating and cooling device

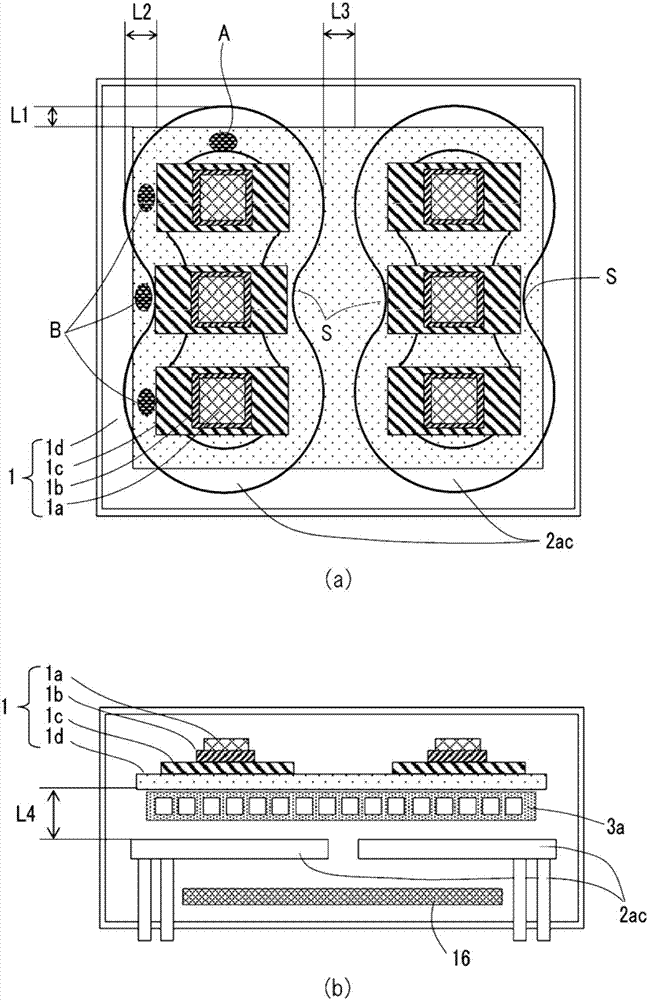

ActiveCN107112247AImprove cooling effectPrinted circuit assemblingSolid-state devicesEngineeringAir tightness

Provided is a heating and cooling device which is capable of performing heating and cooling processes within an airtight processing chamber, and which enables size reduction of the device, while increasing the heating and cooling efficiency. This heating and cooling device 100 is provided with: an airtight processing chamber 4; an induction heating device 2 that is composed of an induction heating coil 2a which heats a member to be processed 1; a cooling device 3 that cools the member to be processed 1; a temperature sensor 5 for measuring the temperature of the member to be processed 1; and a control device 6 that controls the induction heating device 2 and the cooling device 3. This heating and cooling device 100 is also provided with a move device 15 that moves at least one of the members to be processed 1 and a cooling unit 3a of the cooling device 3, thereby changing the distance between the member to be processed 1 and the cooling unit 3a.

Owner:FUJI ELECTRIC CO LTD

LED tube lamp

ActiveUS9618168B1Reduce the possibilityReduce decreaseElongate light sourcesElectric circuit arrangementsEngineeringLED lamp

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

Heating and cooling device

ActiveUS20170203377A1Improve cooling efficiencyPrinted circuit assemblingSemiconductor/solid-state device detailsTemperature controlEngineering

A heating and cooling device including: an airtight processing chamber openable to load a member-to-be-processed in the airtight processing chamber; a transfer apparatus to adjust a distance between the member-to-be-processed and a cooling unit that cools the member-to-be-processed, by moving the member-to-be-processed and / or the cooling unit; an induction heating apparatus to heat the member-to-be-processed, including a induction heating coil; a cooling apparatus to cool the member-to-be-processed by cooling the cooling unit; a temperature sensor to determine a temperature of the member-to-be-processed; and a controller to control the induction heating apparatus and the cooling apparatus based on the temperature determined by the temperature sensor.

Owner:FUJI ELECTRIC CO LTD

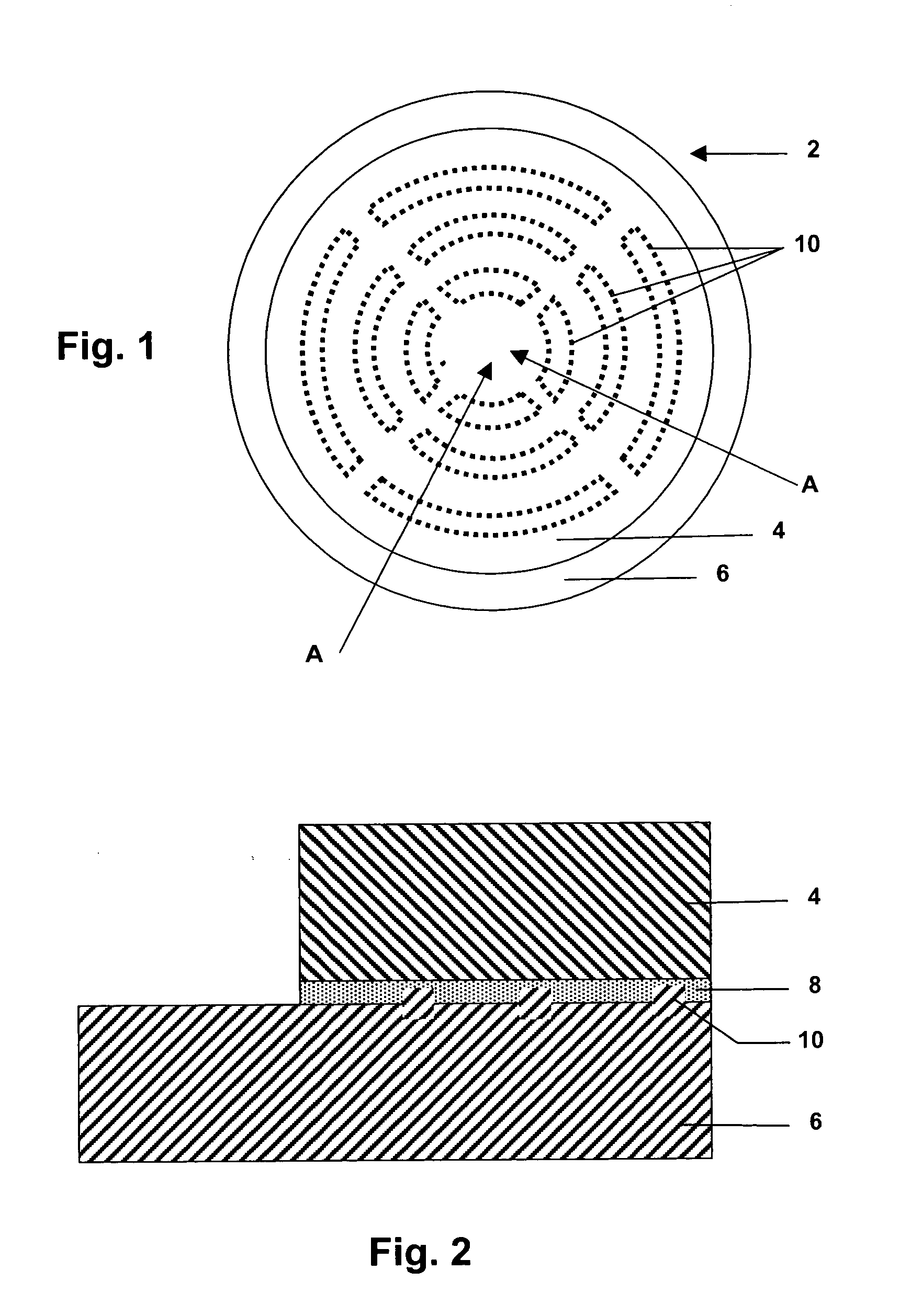

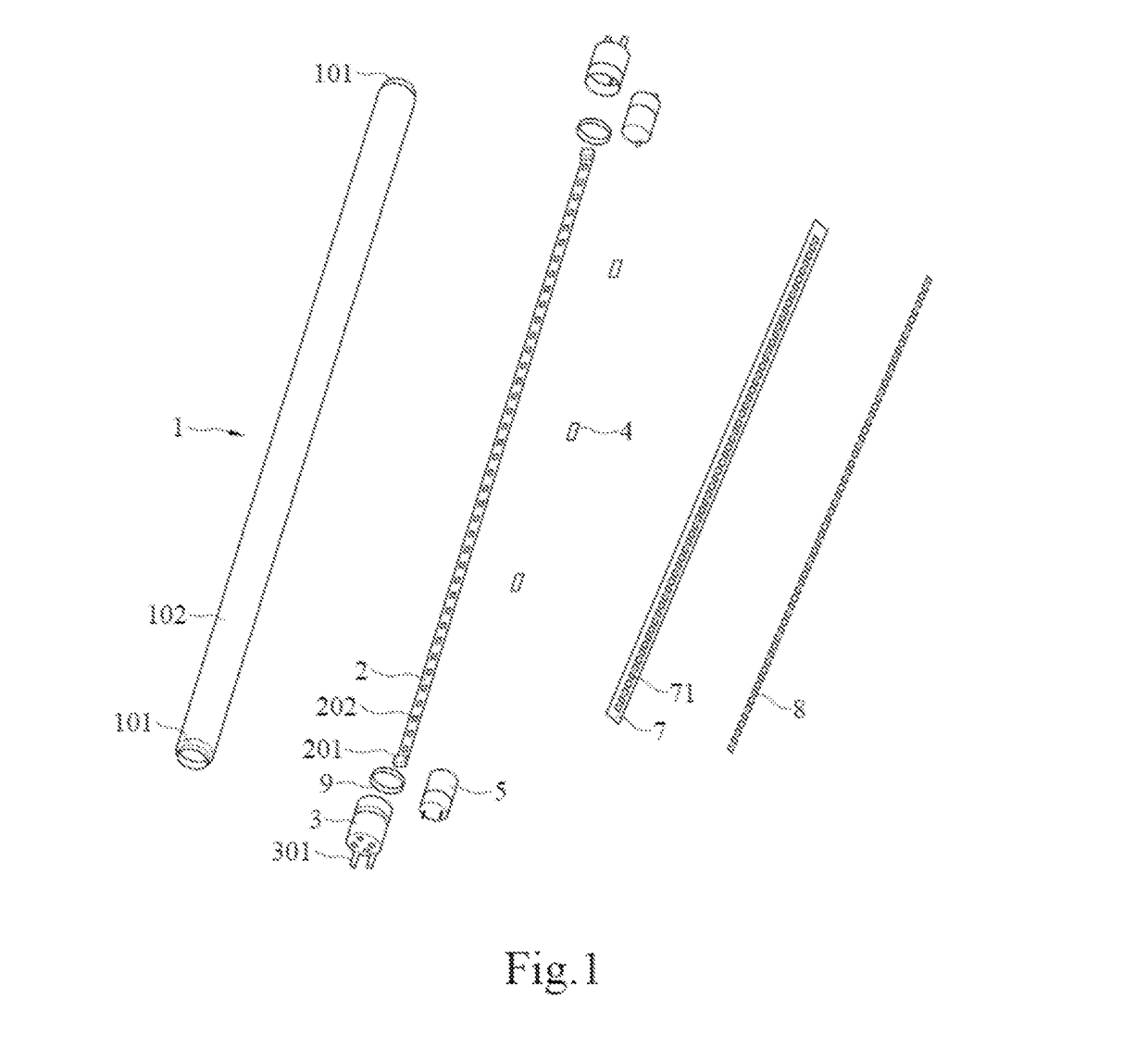

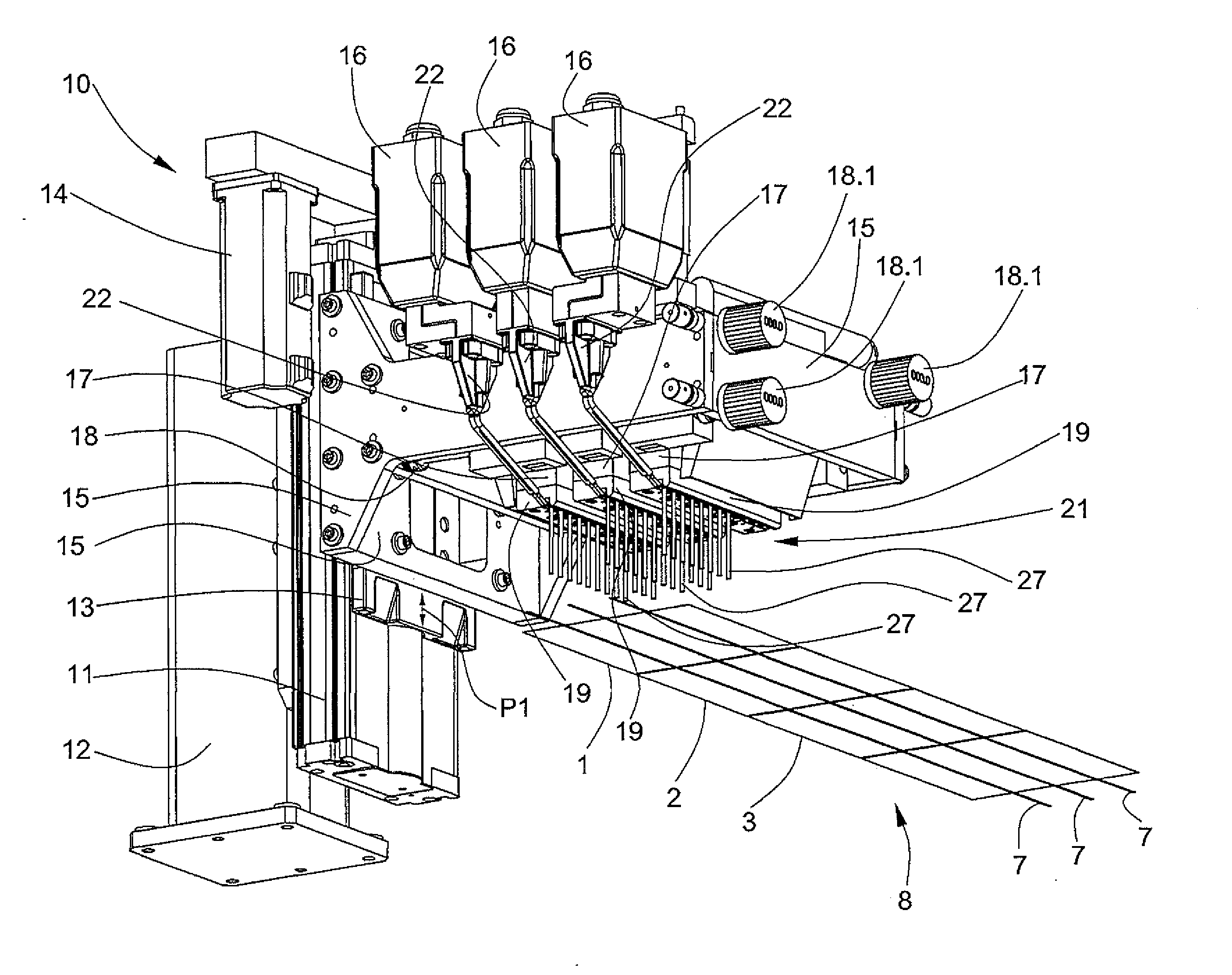

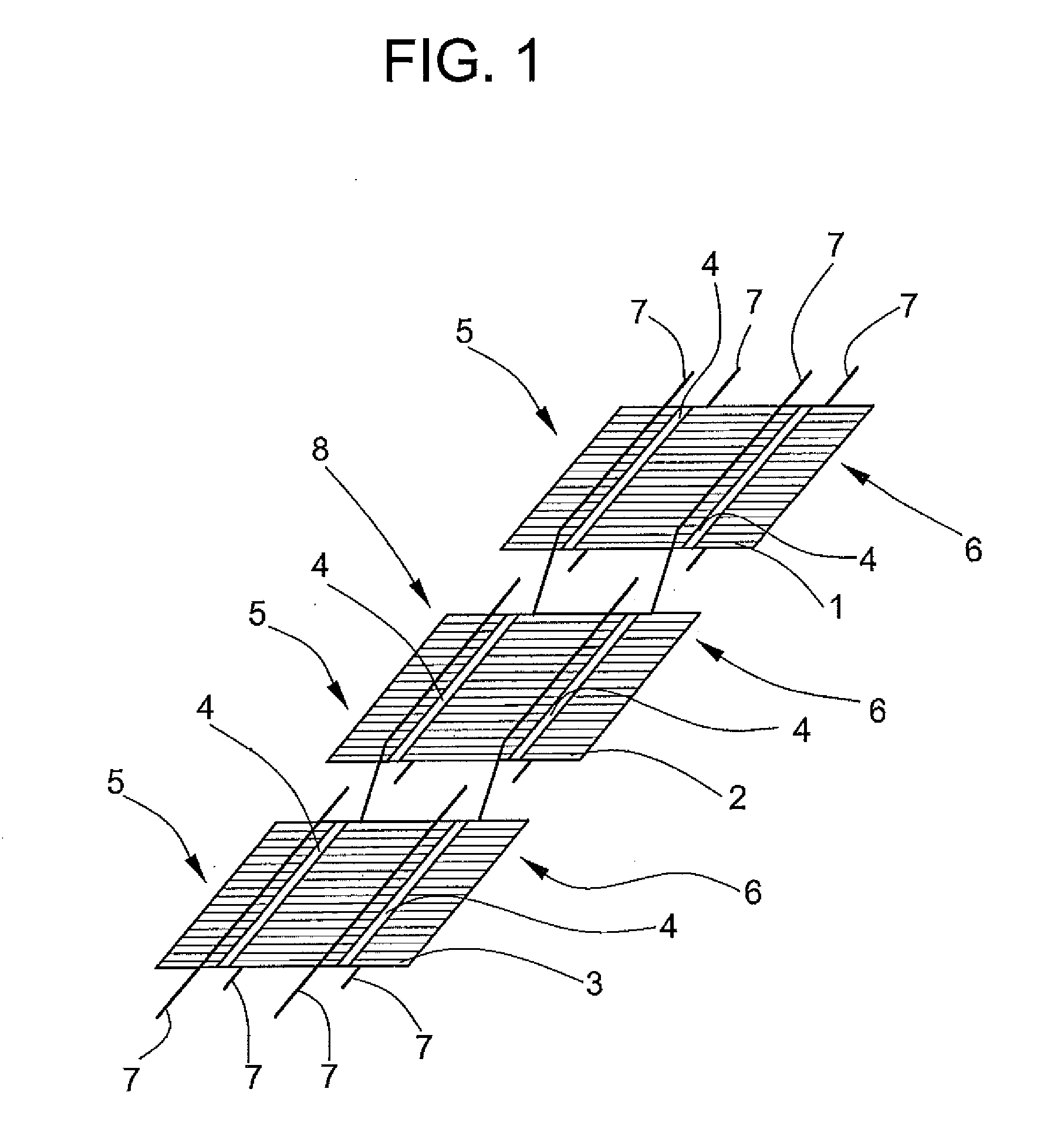

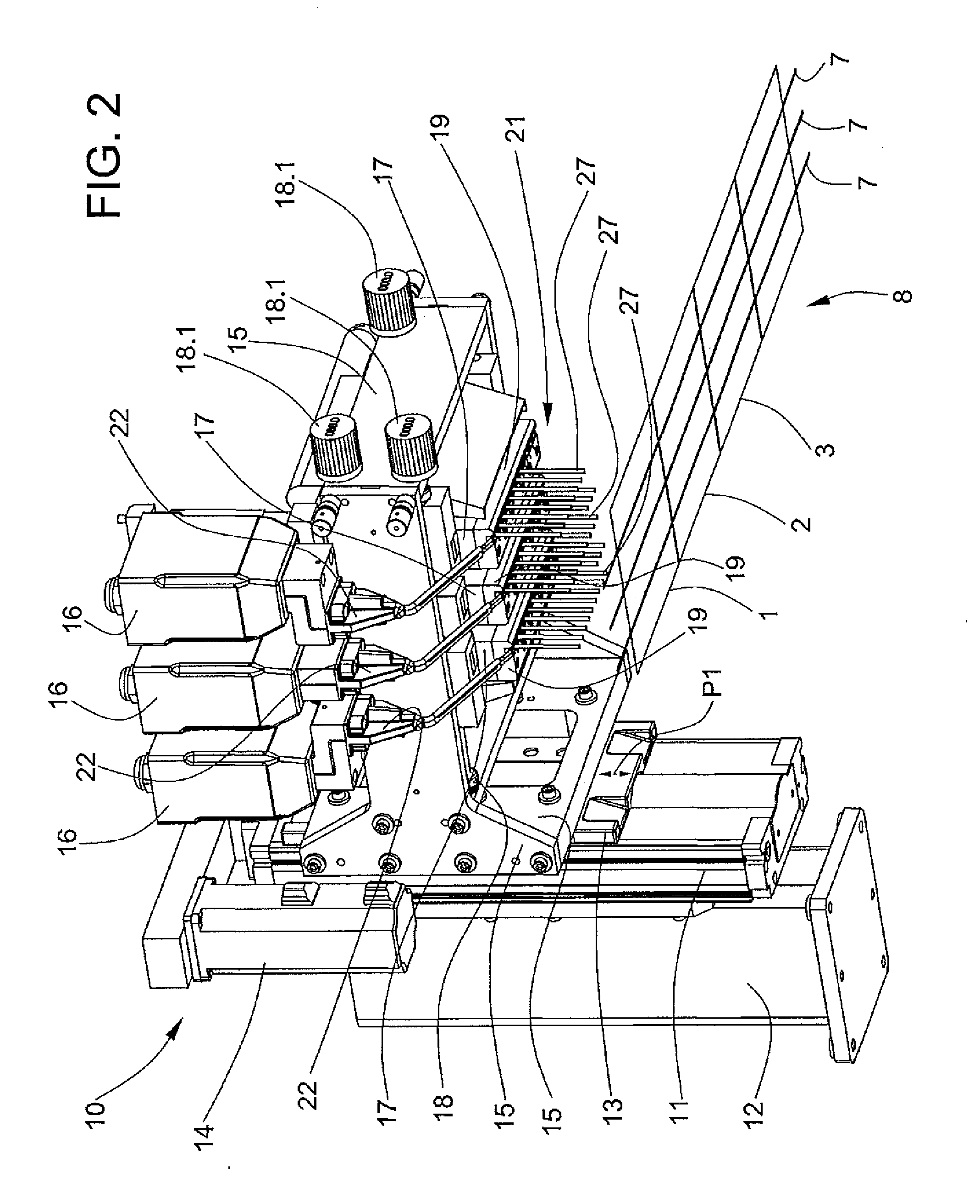

Inductive soldering device

InactiveUS20100038358A1Reduce the impactReduce impactHeating appliancesMetal working apparatusElectrical conductorMagnetic bead

A soldering apparatus for connecting solar cells includes an induction heat source to connect cell conducting tracks, provided with soldering medium, with electric conductors. The heat source has a high-frequency generator and an inductor loop in which the flow of a high-frequency current causes a high-frequency magnetic field to induce in the conducting track and in the electric conductor arranged along the conducting track eddy currents that generate the heat that is necessary for the soldering operation. The inductor loop includes a U-shaped loop element that has narrowings and widening in one arm that is positioned closer to the conductor. Ferrite beads and ferrite tubes at the widening concentrate the magnetic field to optimize the heat development in the soldering zone and thus also save energy.

Owner:KOMAX HOLDING

Soldering Method, Semiconductor Module Manufacturing Method, and Soldering Apparatus

InactiveUS20090184152A1Solid-state devicesWelding/cutting auxillary devicesEngineeringElectronic component

A soldering method for soldering an electronic component onto a circuit board is provided. The soldering method uses a cooling circuit board as the circuit board. The cooling circuit board includes an insulation substrate and a metal heat sink. The insulation substrate has a front surface with a metal circuit and a rear surface to which the heat sink is fixed. The heat sink has a refrigerant passage. The electronic component is arranged on the metal circuit with solder in between. A heated heating medium is supplied to the refrigerant passage when heating and melting the solder.

Owner:TOYOTA IND CORP

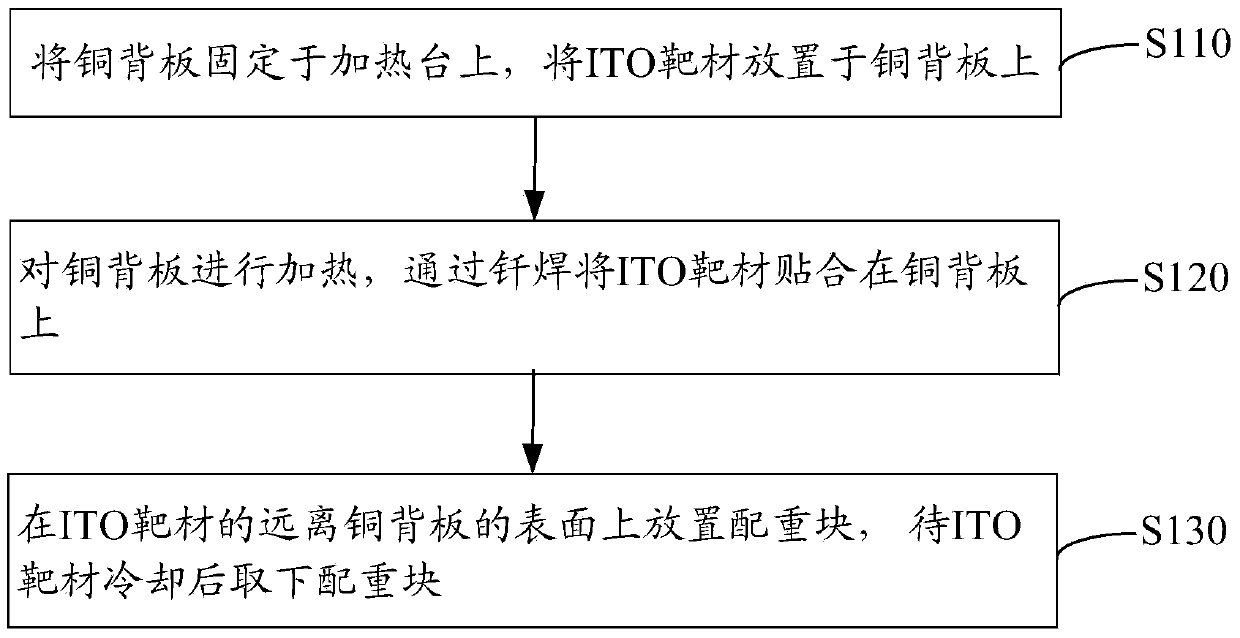

Method for binding ITO target to copper back plate

ActiveCN103737140ASmall amount of deformationImprove flatnessHeating appliancesSoldering auxillary devicesIndiumCopper

The invention relates to a method for binding an ITO target to a copper back plate. The method for binding the ITO target to the copper back plate comprises the steps of fixing a heating table on the copper back plate, and placing the ITO target on the copper back plate; heating the copper back plate, enabling the ITO target to adhere to the copper back plate by brazing; placing a balancing weight on the surface of the ITO target far away from the copper back plate, and taking down the balancing weight after the ITO target is cooled. According to the method, the copper back plate is fixed on the heating table, the deformation of the copper back plate in the temperature rising process is reduced, flatness of the adhesion surface is improved, preparation are made for high-quality ITO target binding, the balancing weight is placed on the ITO target after brazing, the problem of unevenness of indium liquidity is solved, generation of air holes of the adhesion surface is avoided, and accordingly binding quality of the ITO target and the copper back plate is improved.

Owner:WGTECH JIANGXI

Soldering or desoldering iron

ActiveUS7679032B2Low costSecurely holdHeating element shapesHeating appliancesSolderingBiomedical engineering

Owner:HAKKO CO LTD

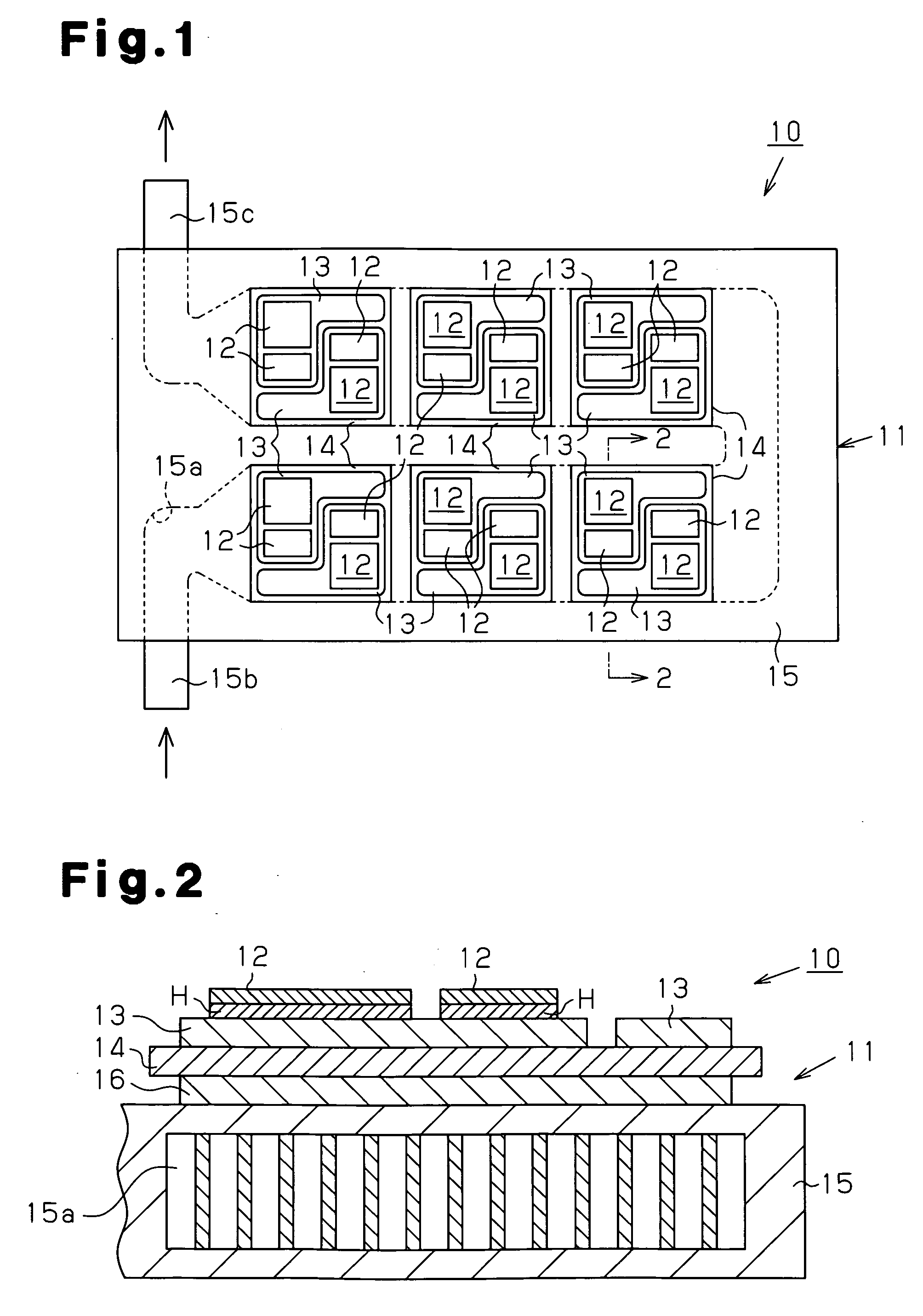

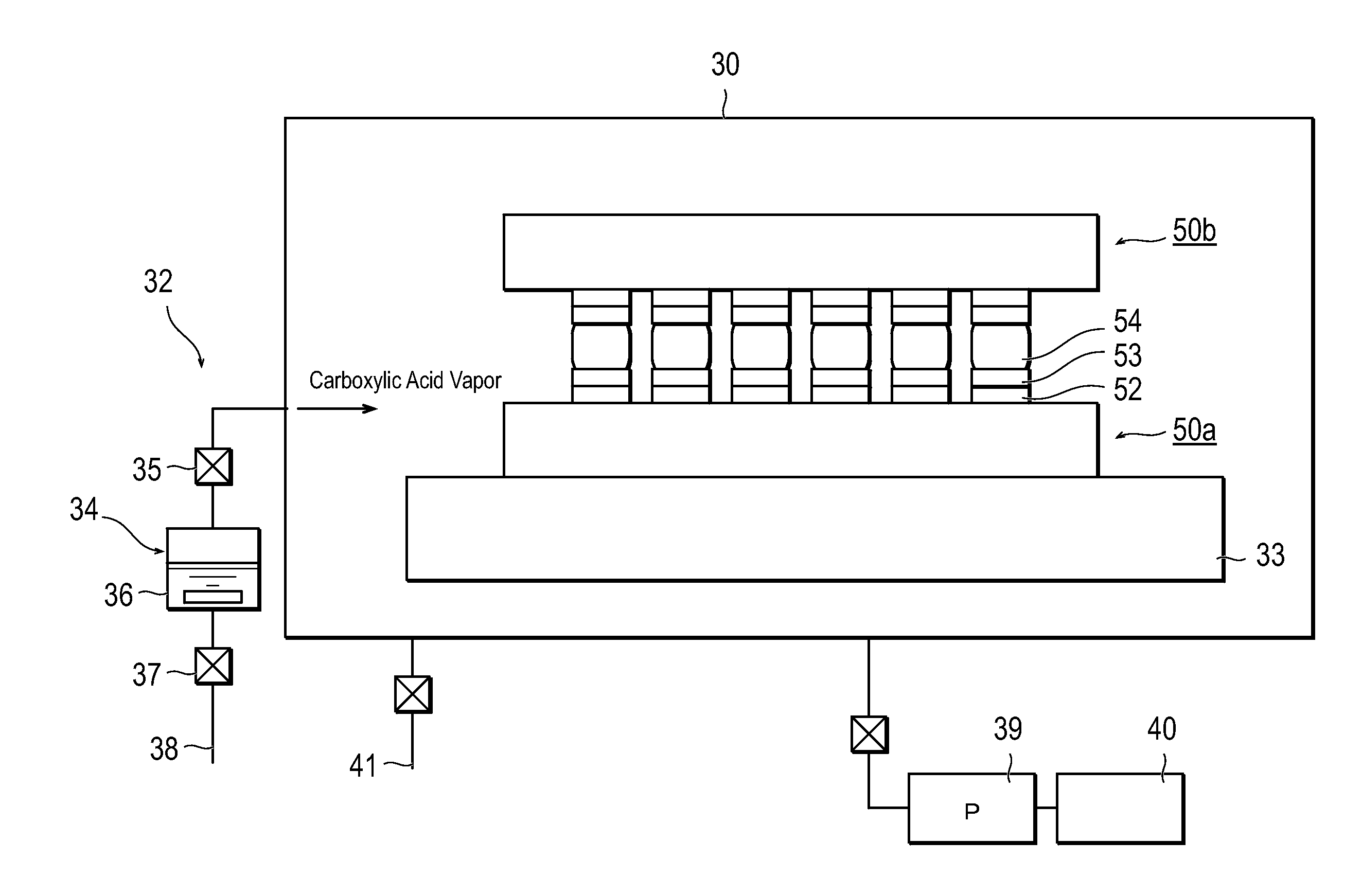

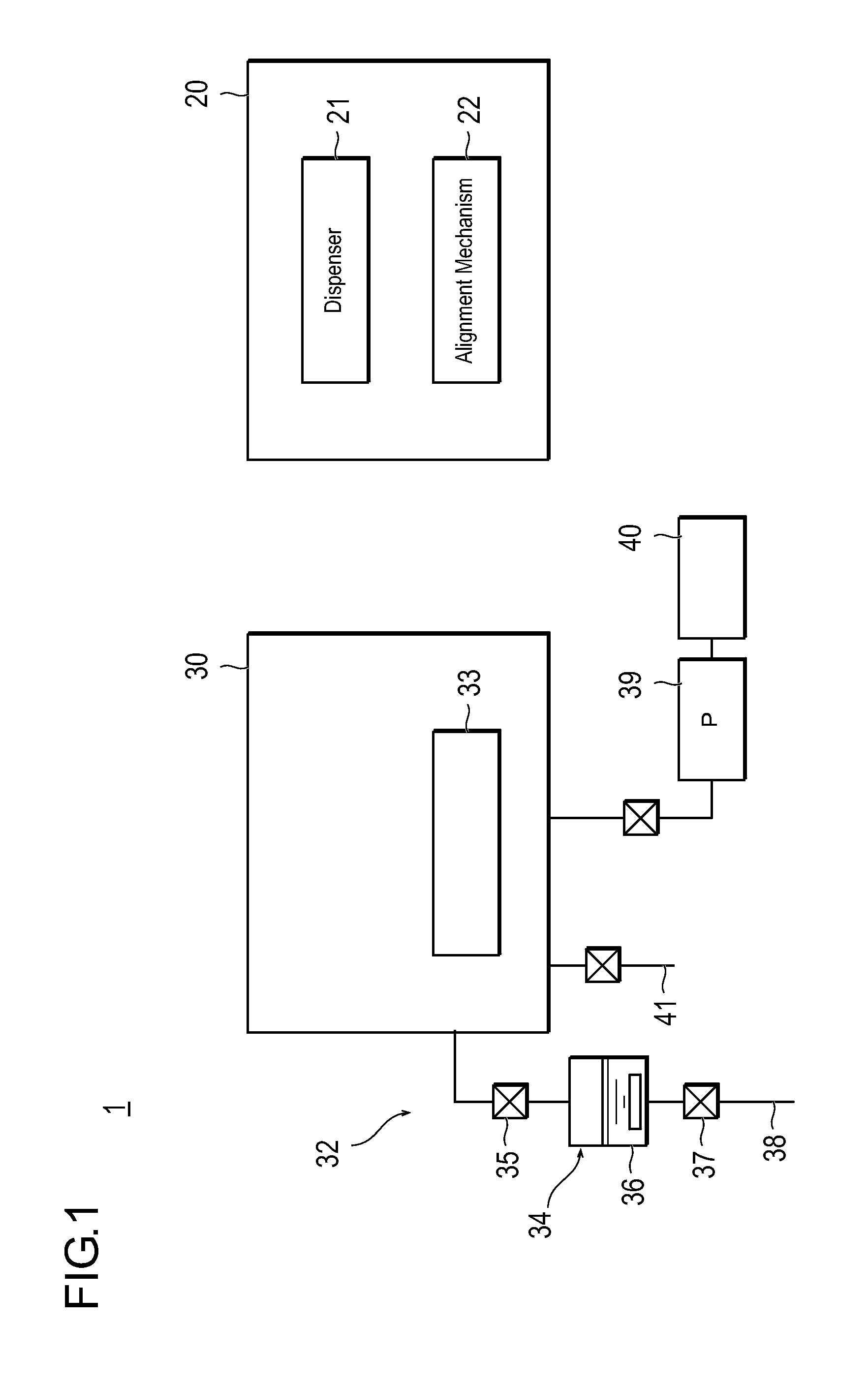

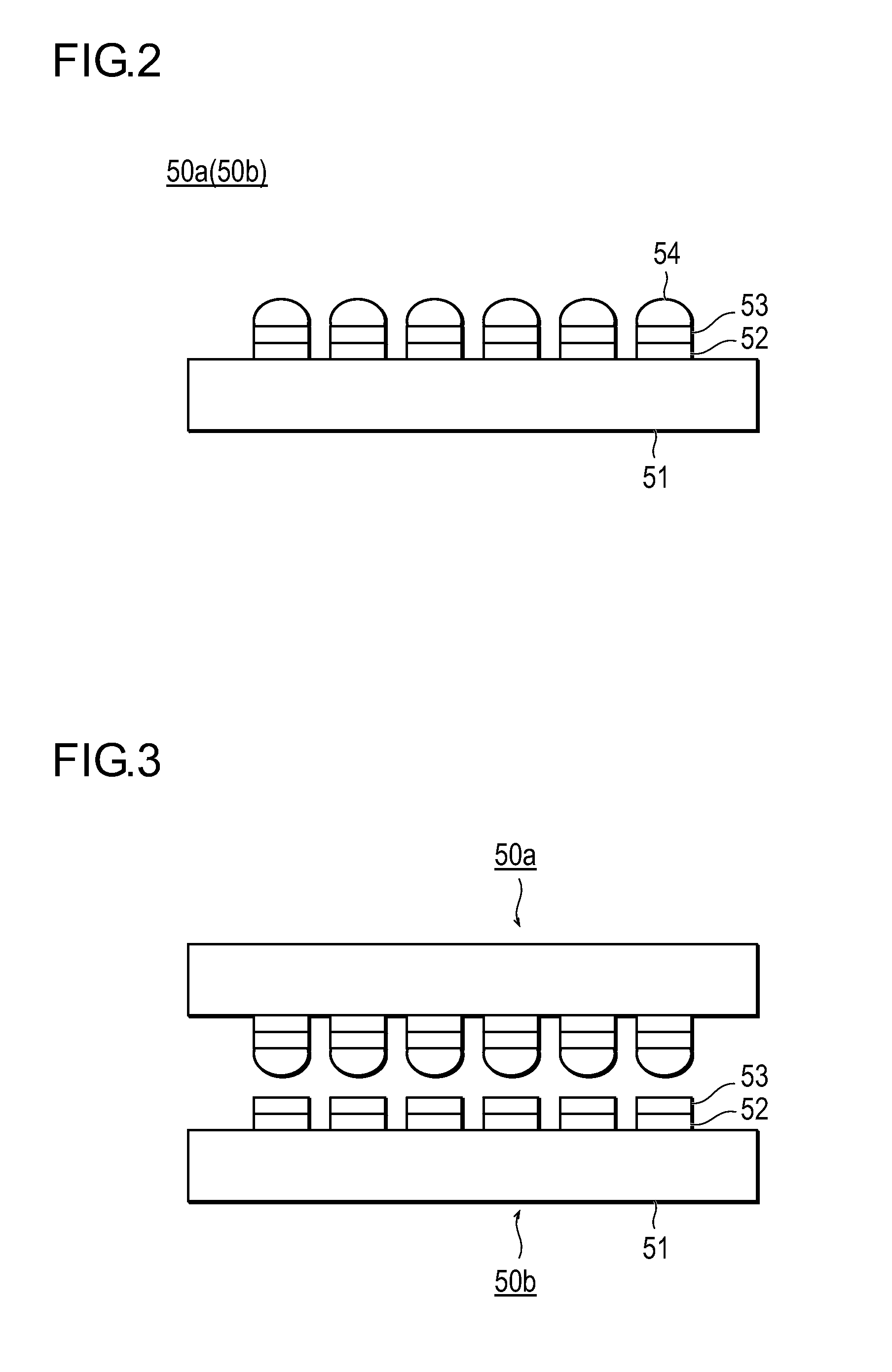

Bonding Structure Manufacturing Method, Heating And Melting Treatment Method, And System Therefor

ActiveUS20130105558A1Positional displacementPositional displacement of the solder material can be alleviatedFinal product manufactureSolid-state devicesSoldering

A soldering method capable of alleviating positional displacement between substrates even though a step of removing flux can be omitted is provided.A temporary bonding agent 55 is applied onto multiple substrates 50a, 50b, and a heater 33 heats the substrates while the substrates are temporarily bonded with the temporary bonding agent 55 interposed therebetween, and before the solder 54 is melted or while the solder 54 is melted, the temporary bonding agent 55 is evaporated, and the substrates 50a, 50b are bonded with solder with the melted solder 54 interposed therebetween.

Owner:AYUMI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com