Solar cell crystal silicon wafer series welding machine

A technology for solar cells and crystalline silicon wafers, applied in circuits, electric heating devices, electrical components, etc., can solve problems such as no detection system, low welding efficiency, and low welding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

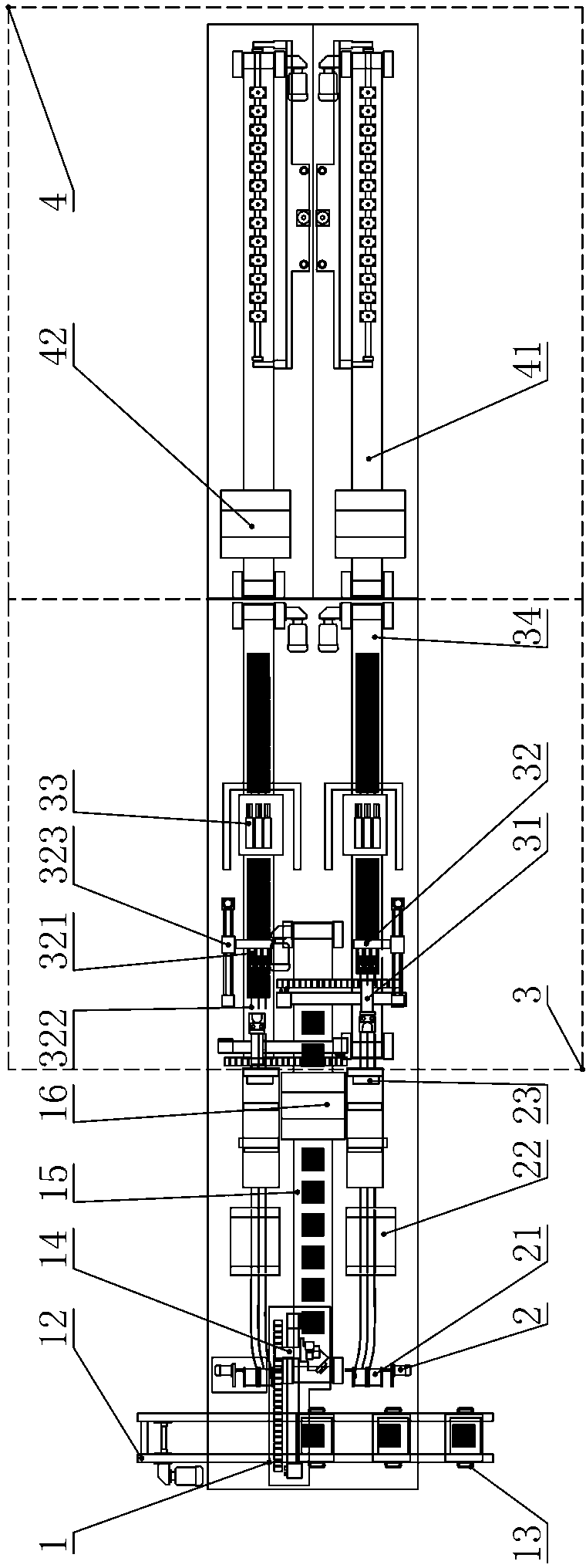

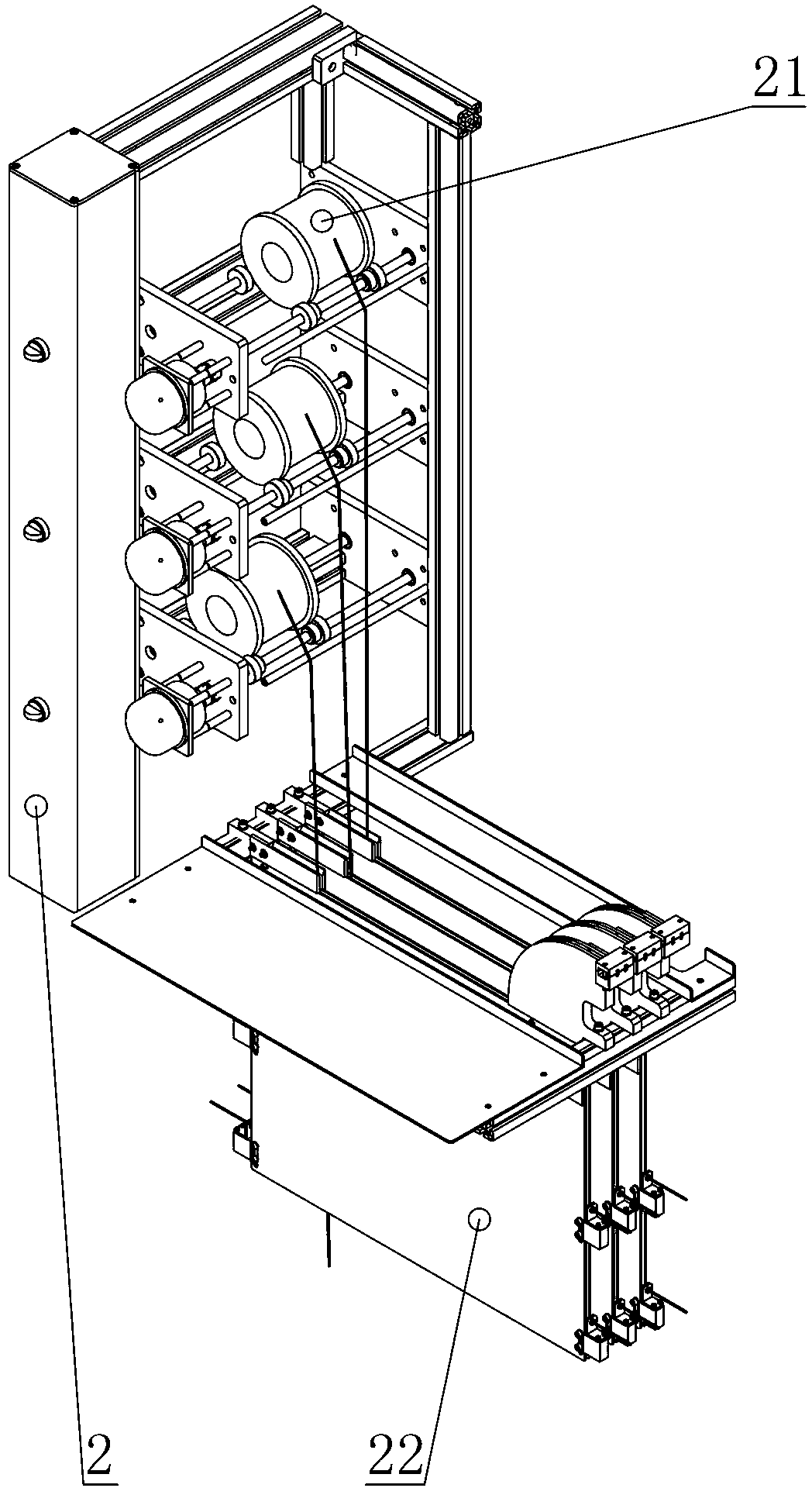

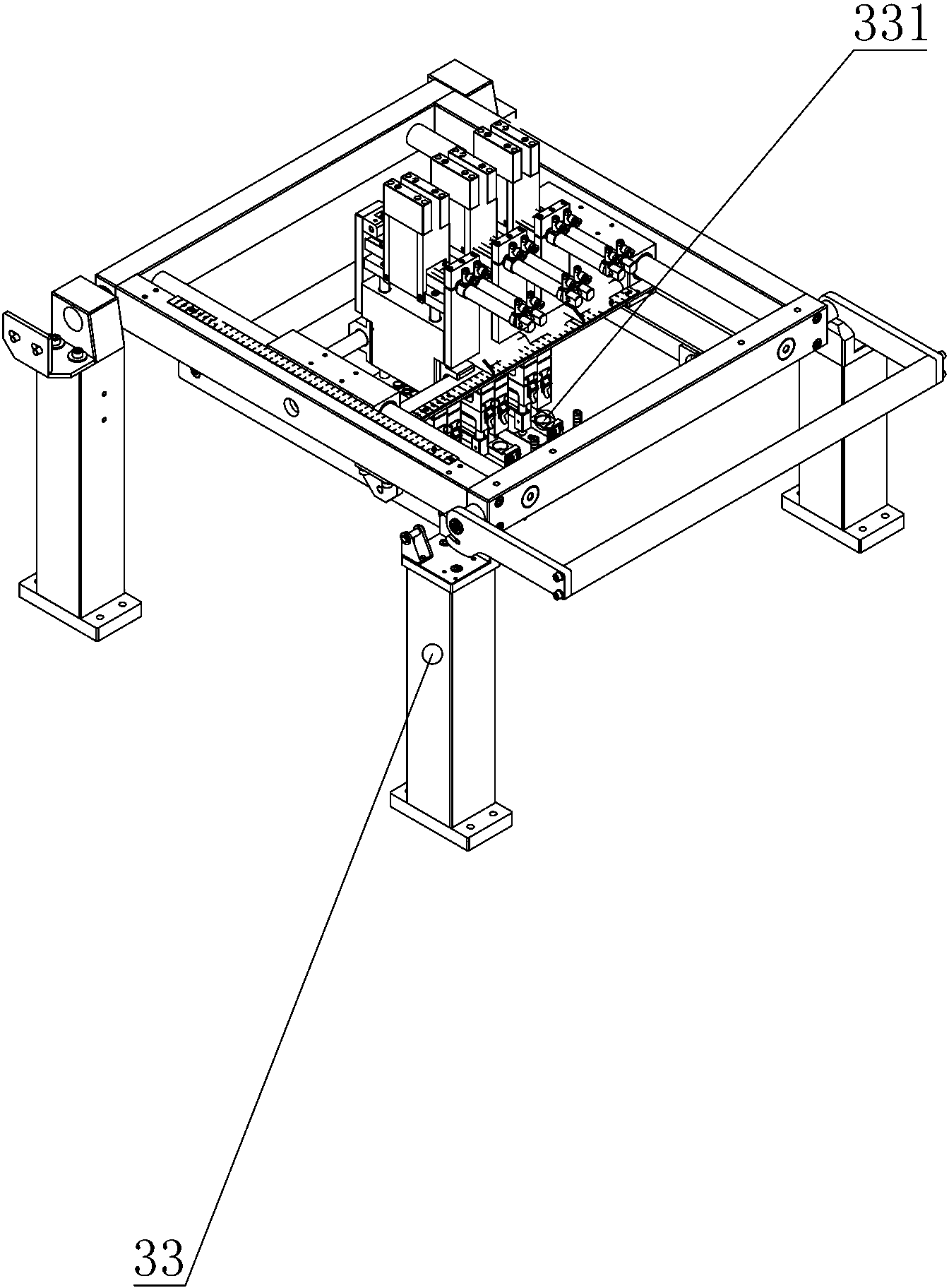

[0022] Such as figure 1 As shown, a solar cell crystalline silicon chip stringer includes a welding mechanism 1, and also includes a welding auxiliary mechanism directly or indirectly connected to the welding mechanism 3, and the welding auxiliary mechanism is an automatic feeding mechanism 1, a welding With feeding mechanism 2 or automatic discharging mechanism 4. The welding mechanism 3 includes a battery piece carrying and conveying unit 34 for supporting the battery pieces, a ribbon pulling unit 32 cooperating with the ribbon feeding mechanism 2 and a welding heating unit arranged above the battery piece carrying and conveying unit 34 Unit 33. The automatic feeding mechanism 1 includes a first conveying unit 12 and a second conveying unit 15, and also includes a picking manipulator 14 arranged between the first conveying unit 12 and the second conveying unit 15 and placed on the The material carrying unit 13 above the first conveying unit 12 . The ribbon pulling unit 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com