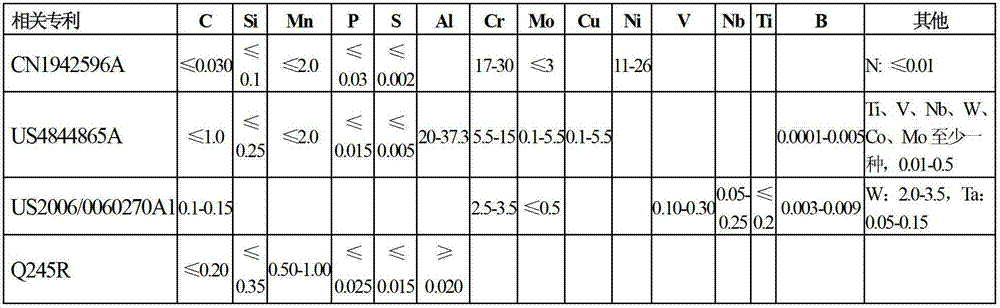

Patents

Literature

4690results about How to "Good welding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

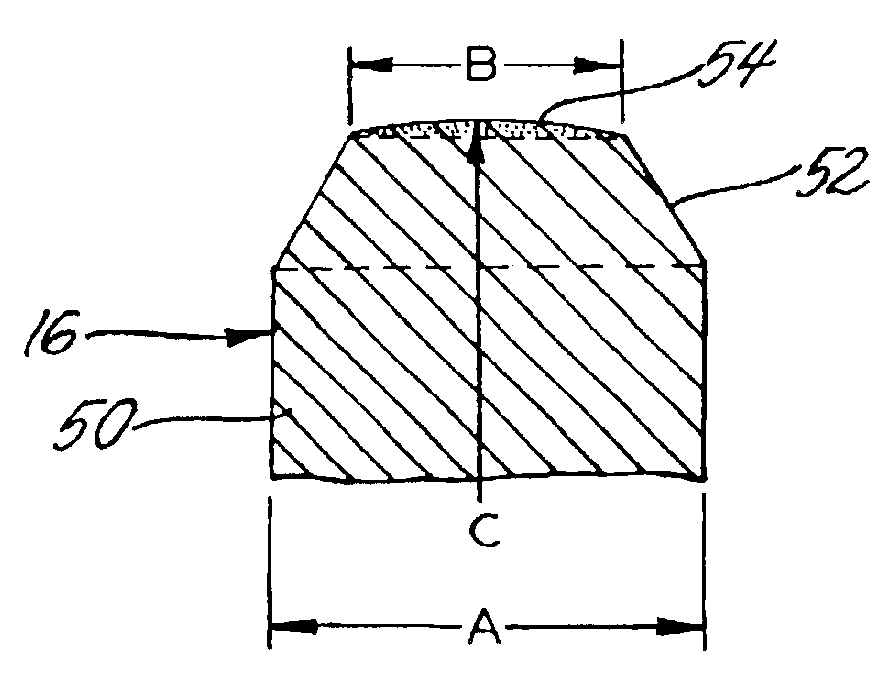

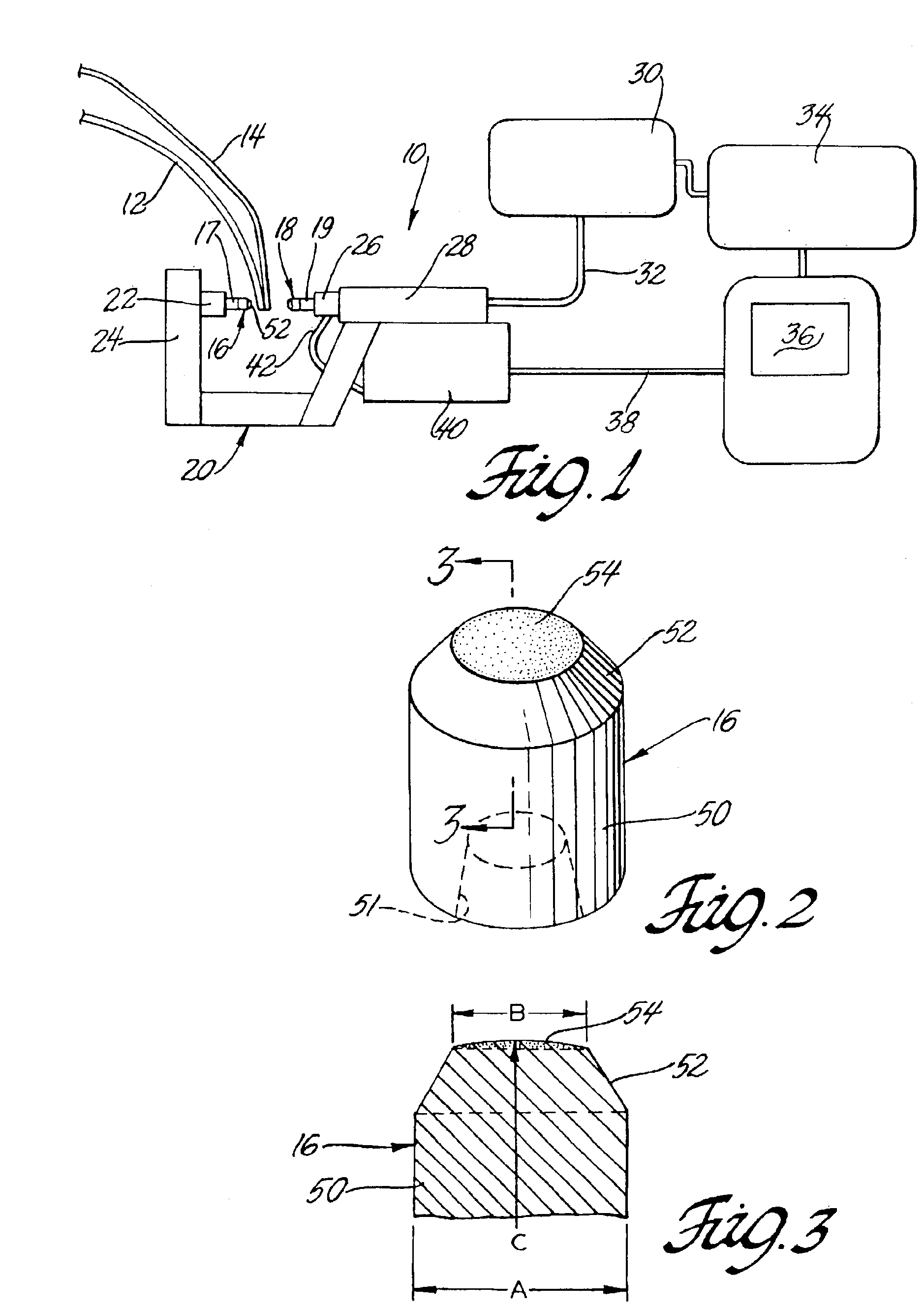

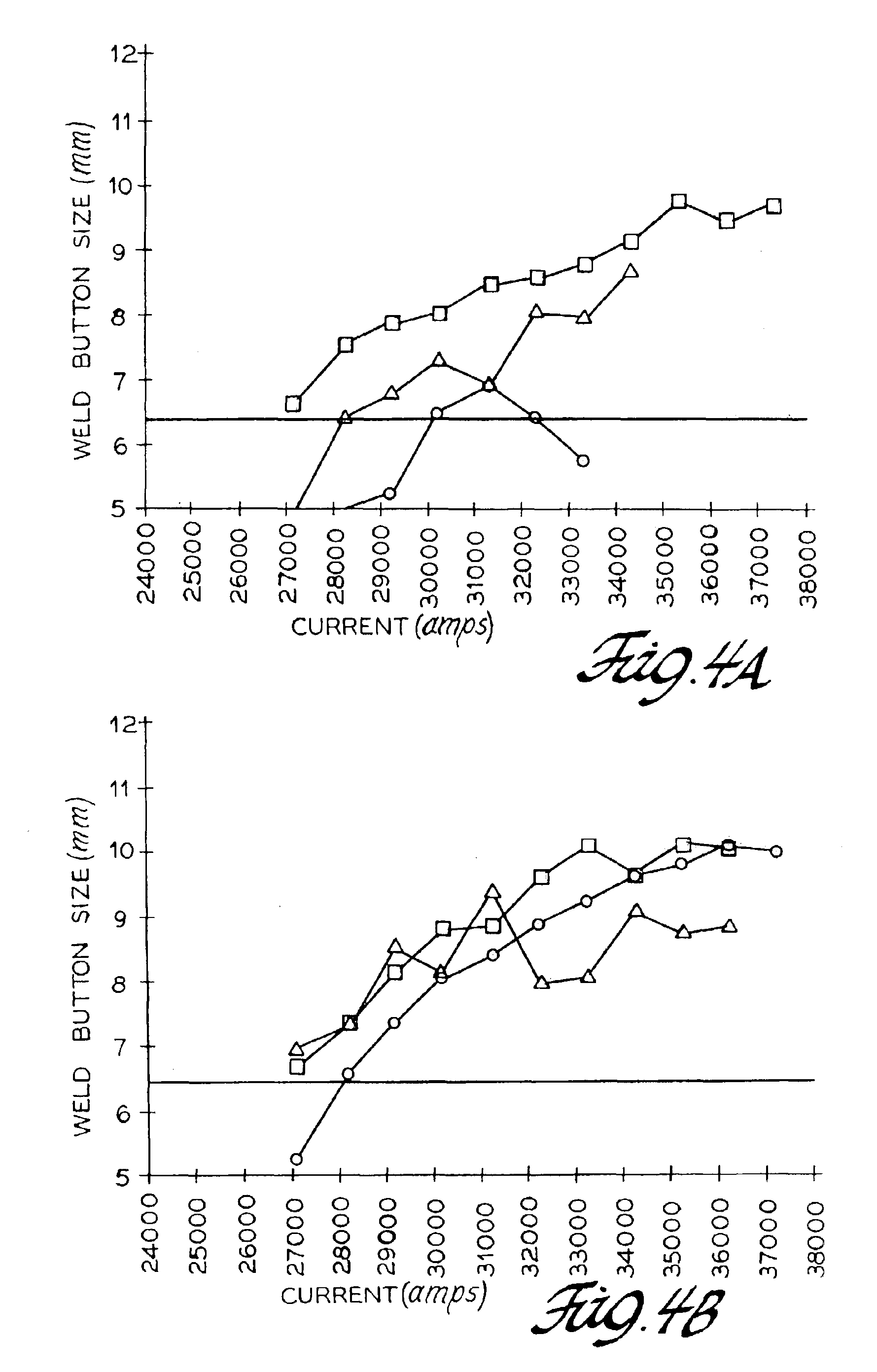

Welding electrode for aluminum sheets

InactiveUS6861609B2Good welding performanceCurvature of the face is more pronouncedOhmic-resistance electrodesPressure electrodesEngineeringAlloy

A design of copper welding electrode is disclosed. The electrode can be used in successive spot welding operations on assembled aluminum alloy sheet parts of widely varying thicknesses, e.g., from 0.9 to 4+ mm. The electrode has a round body terminating in a truncated cone with a crowned face. The face has a diameter of about eleven millimeters up to the diameter of the body and the radius of the crowned face is about twenty to thirty millimeters. The dimensions and shape of the electrode provide robust welding performances despite varying part thicknesses and off angle electrode positioning, and the textured surface provides good electrical contact.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

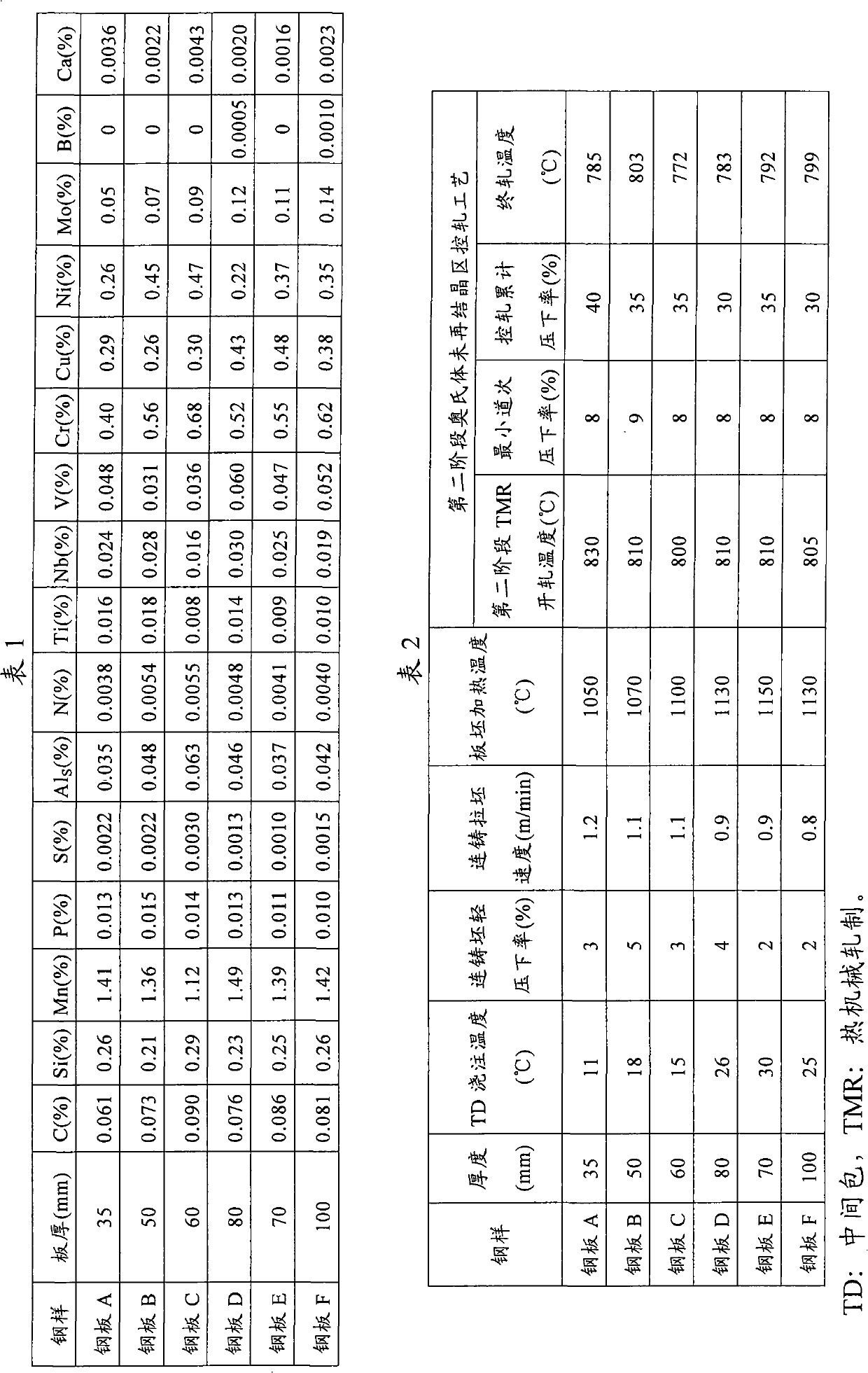

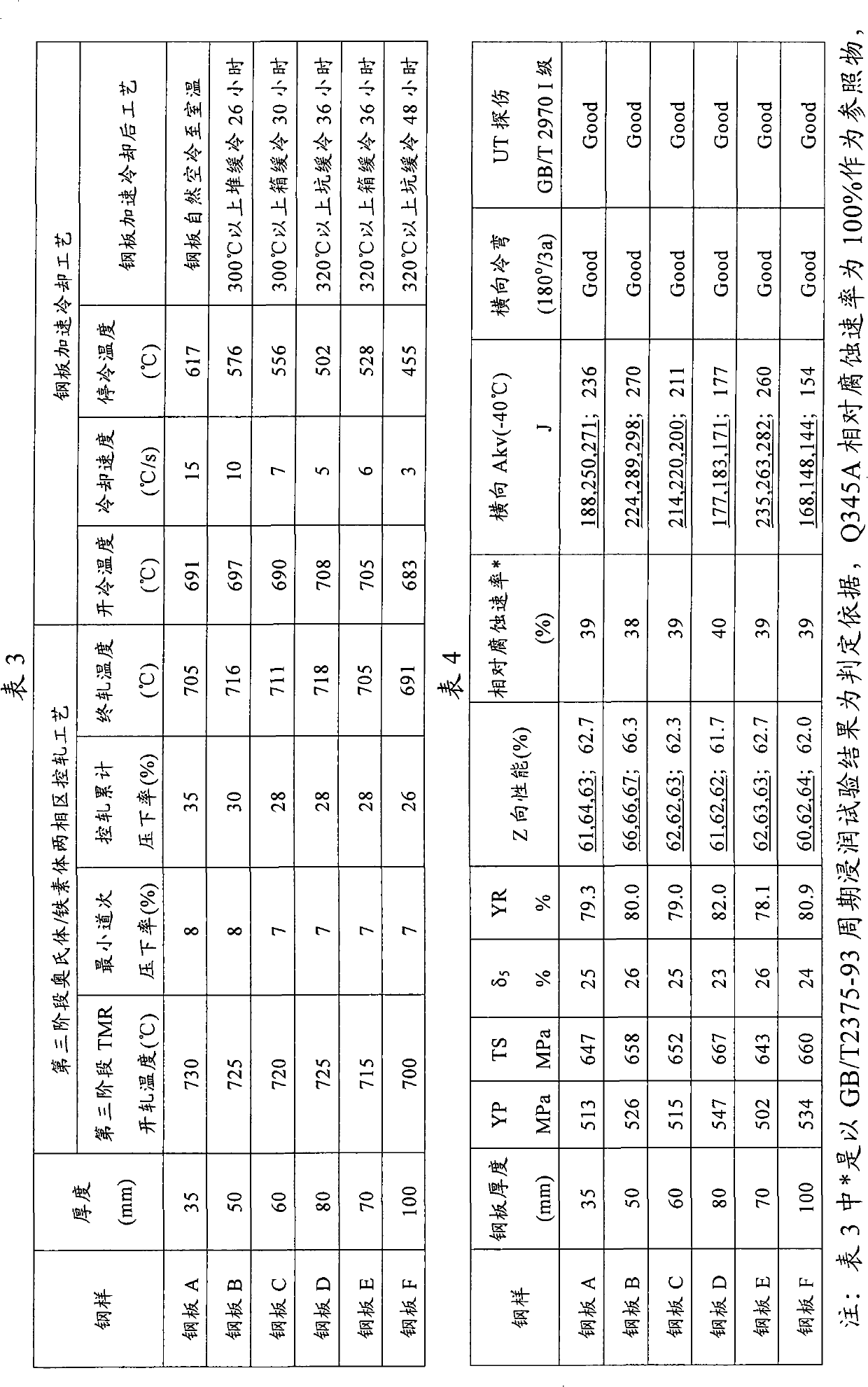

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

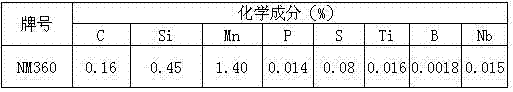

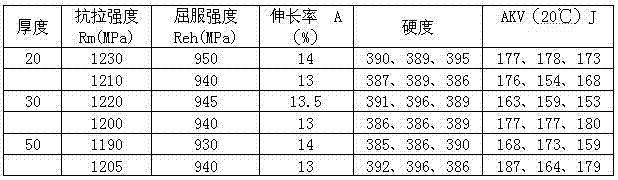

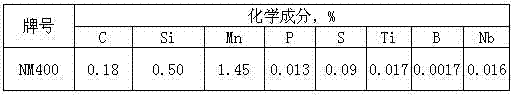

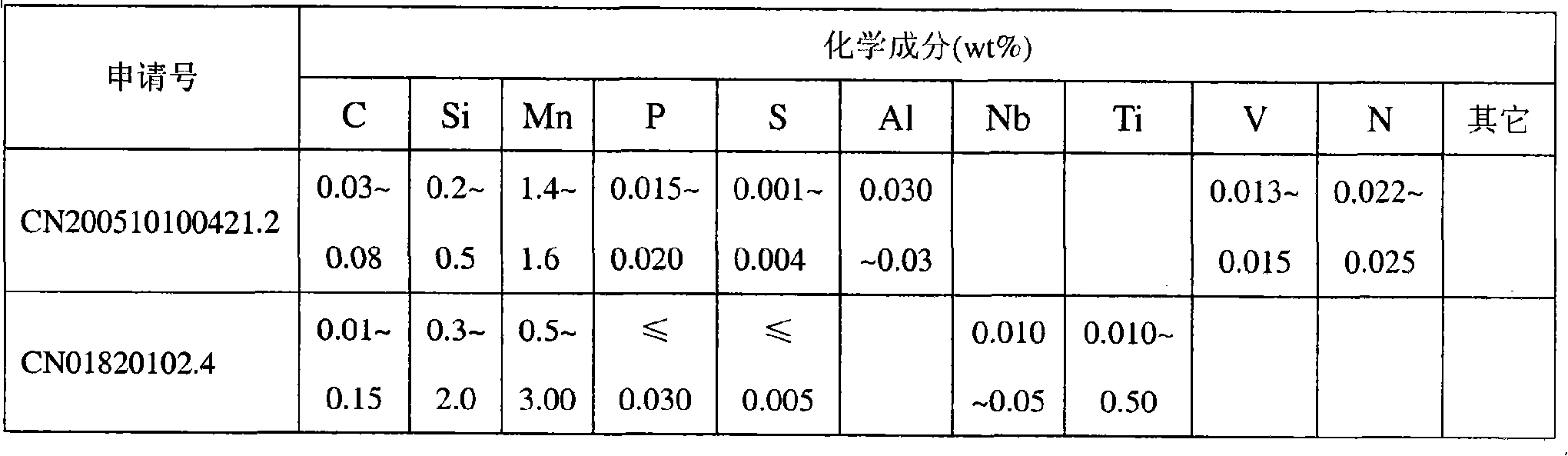

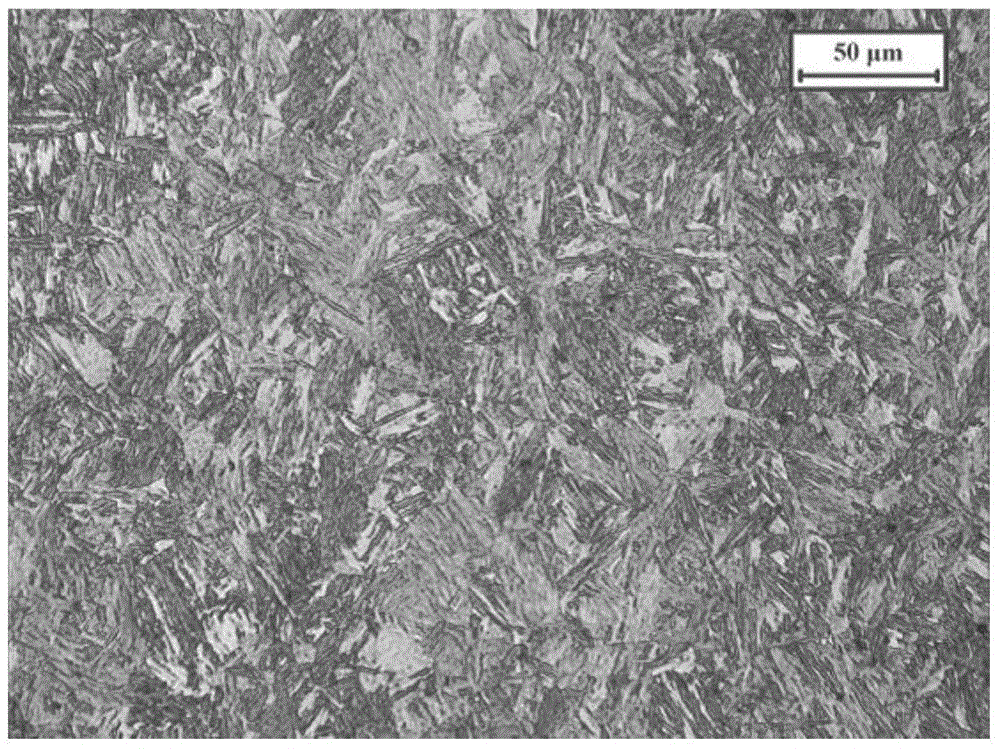

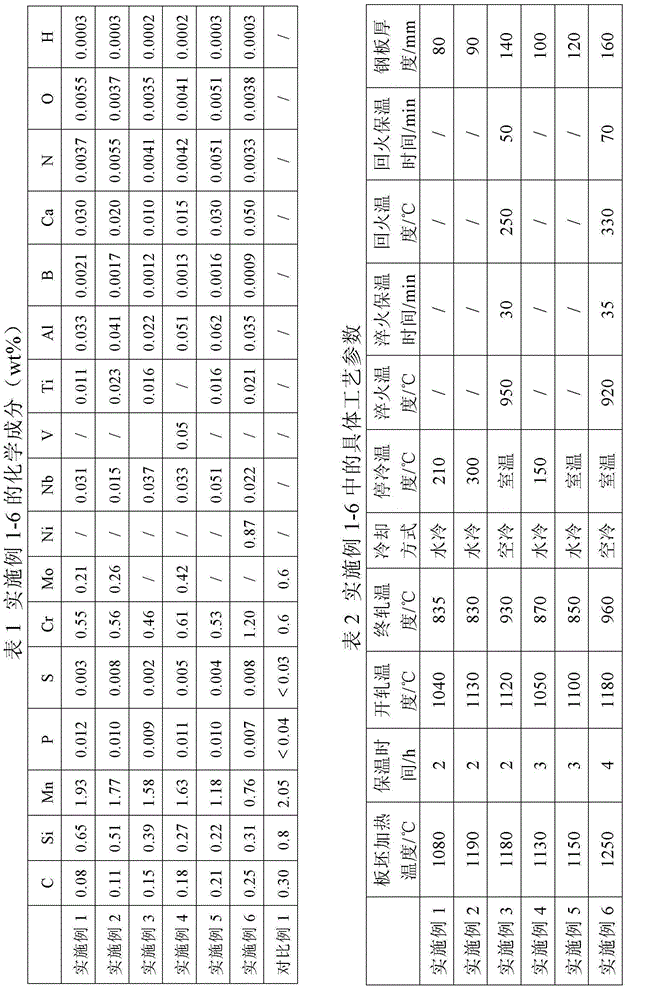

Method for producing wear-resisting steel plate

The invention relates to a method for producing a wear-resisting steel plate. Steel comprises the following chemical ingredients in percentage by mass: 0.15 to 0.20 percent of C, 0.4 to 0.7 percent of Si, 0.7 to 1.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.020 to 0.10 percent of Ti, 0.0005 to 0.0020 percent of B, 0.010 to 0.020 percent of Nb and the balance of Fe and inevitable impurities. A production process for the steel comprises the following steps of: desulfurizing by molten iron, smelting by a converter, refining, casting continuously, rolling and performing quenching-carbon partition (Q-P) treatment. In the ingredients of the wear-resisting steel, a C-Si-Mn-Nb-Ti ingredient system and the Nb and Ti micro alloy treatment are adopted, the hardenability of the steel is improved by adding B, an appropriate heat treatment process is adopted to ensure that the steel plate has high plasticity and toughness, and the impact energy of the steel plate is improved by over one time; and the heat treatment is performed by a Q-P process, lath martensite and lath retained austenite (between 5 and 10 percent) are formed and 50 to100 nanometers of carbide complex tissue is precipitated, so that the tissue is fine and uniform, and the tenacity of the steel plate is high.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

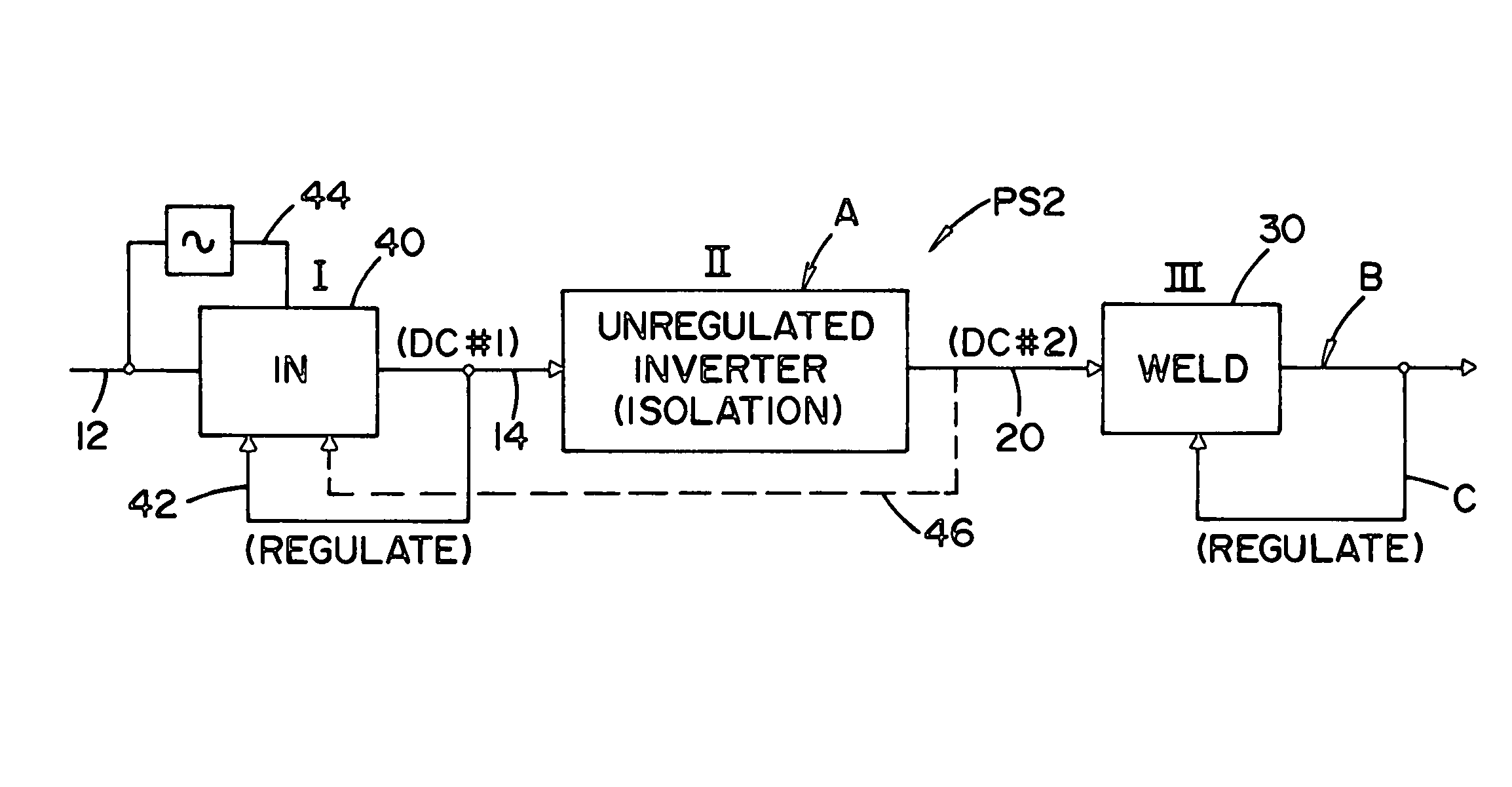

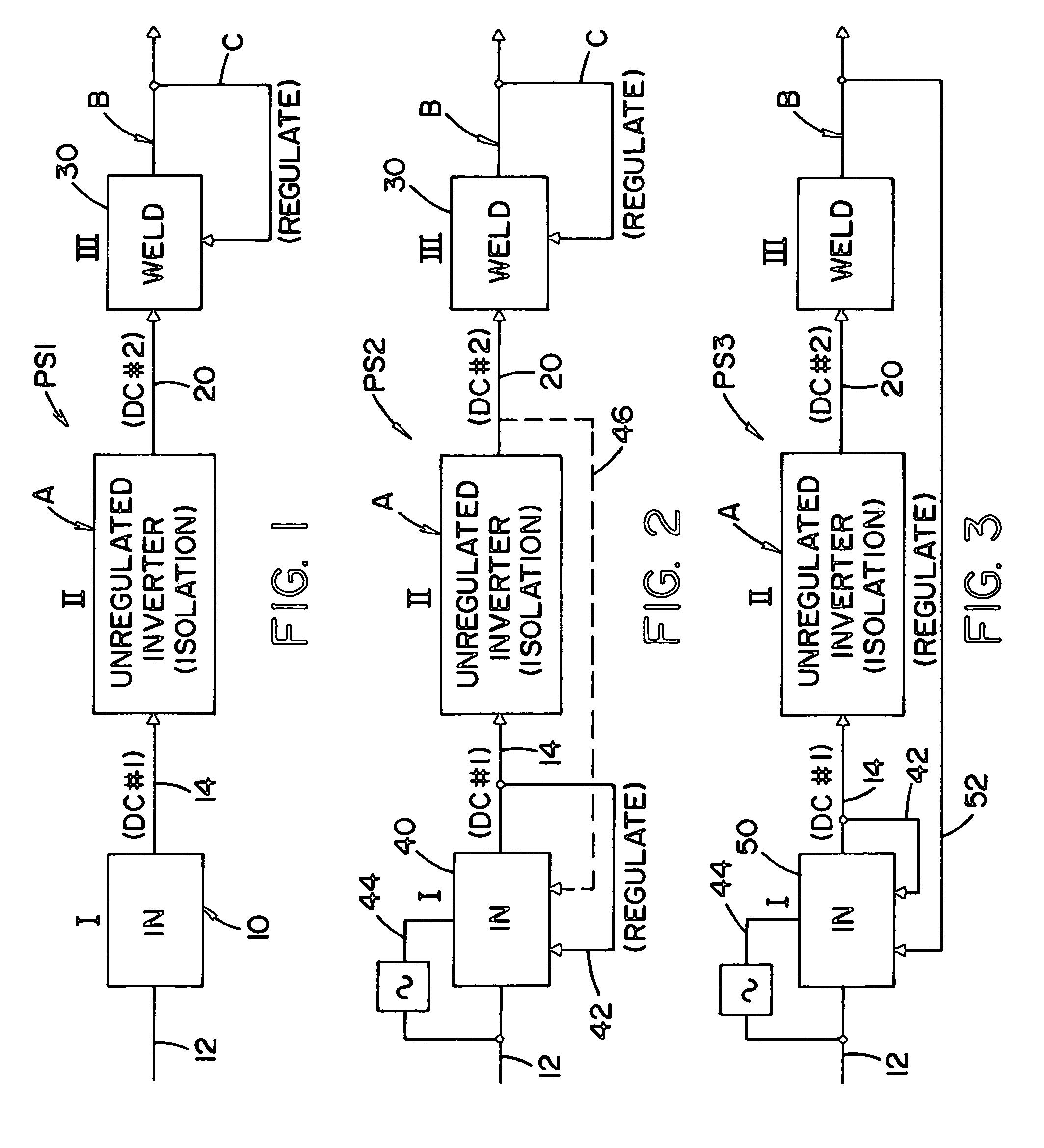

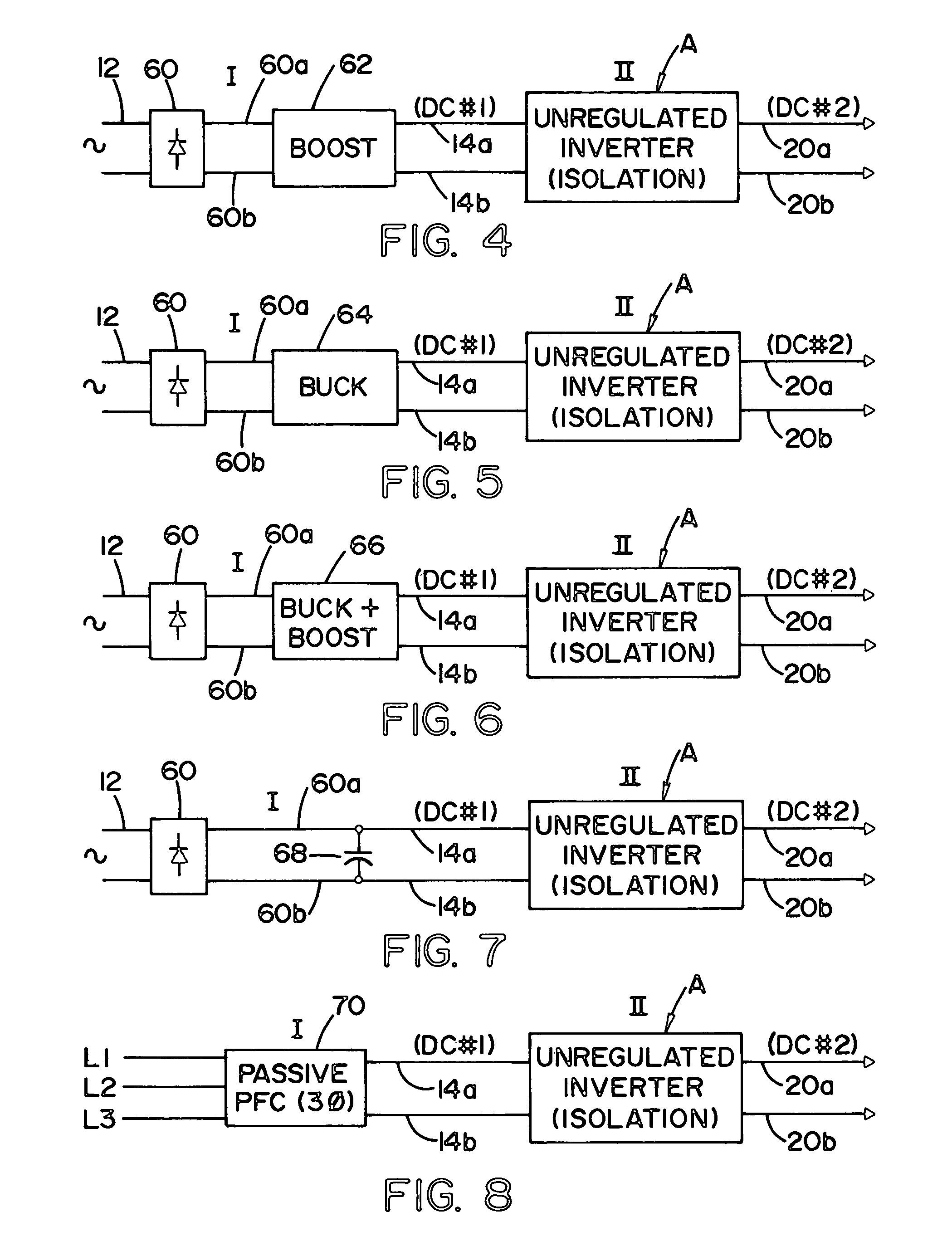

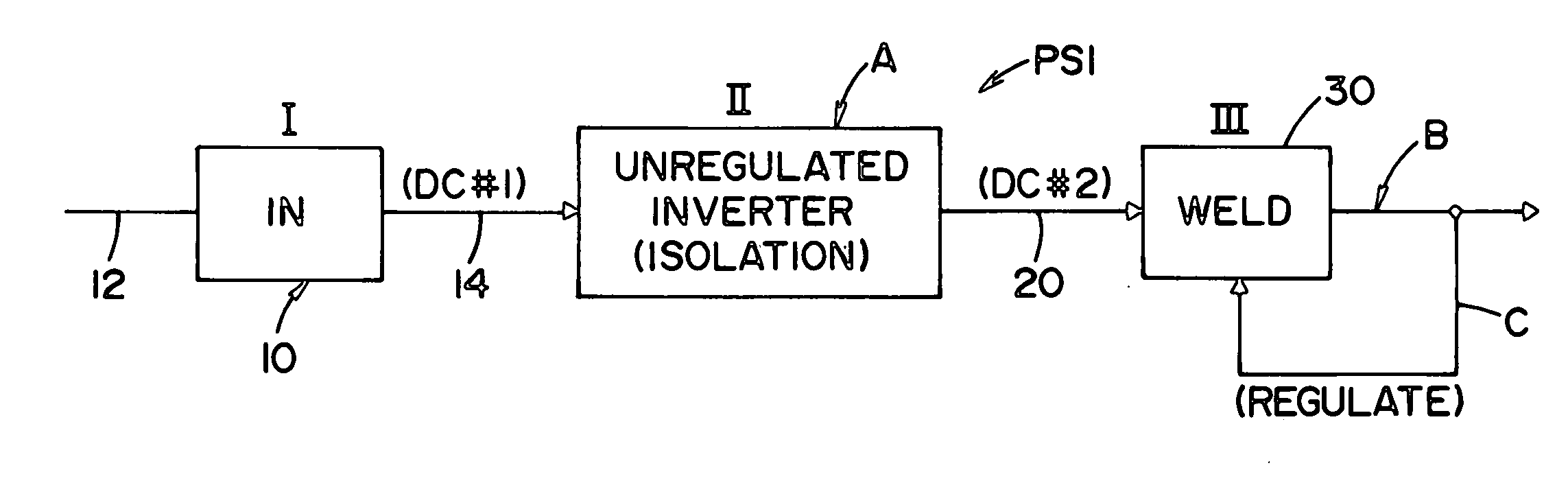

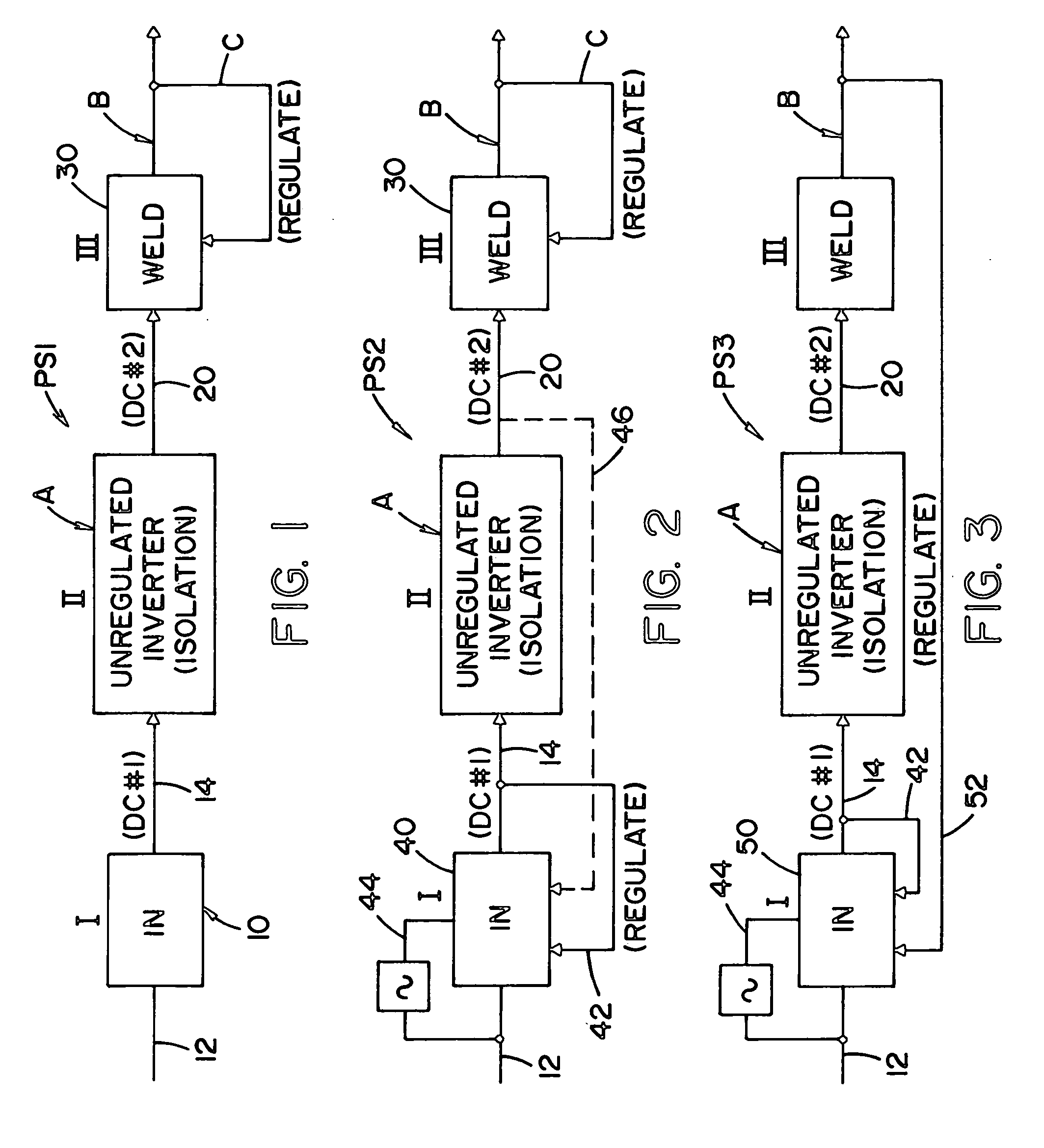

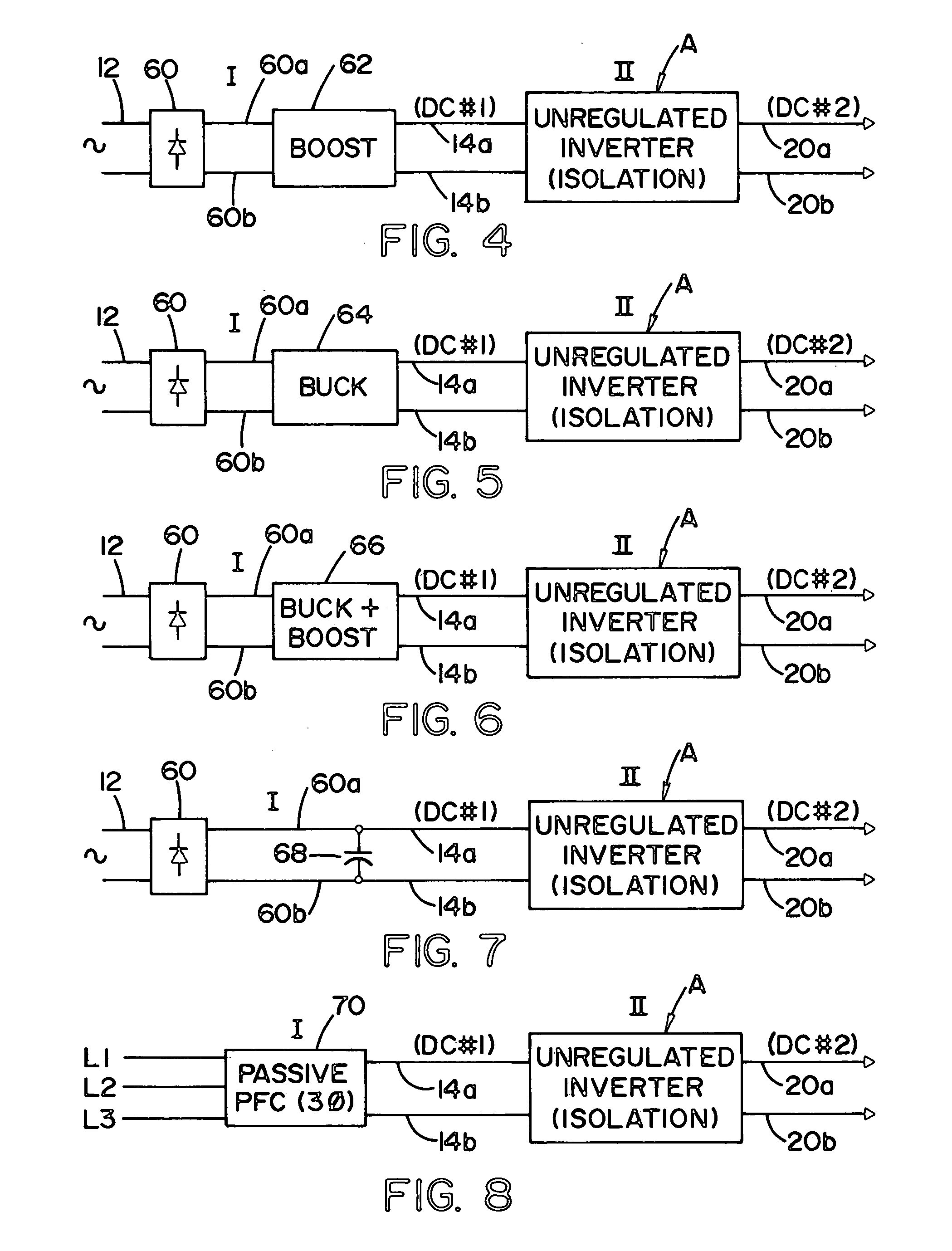

Power source for electric arc welding

A power source for an electric arc welding process, wherein the power source comprises an input stage having an AC input and a first DC output signal; a second stage in the form of an unregulated DC to DC converter having an input connected to the first DC output signal and an output in the form of a second DC output signal electrically isolated from the first DC output signal and with a magnitude of a given ratio to the first DC output signal; and, a third stage to convert the second DC output signal to a welding output for the welding process.

Owner:LINCOLN GLOBAL INC

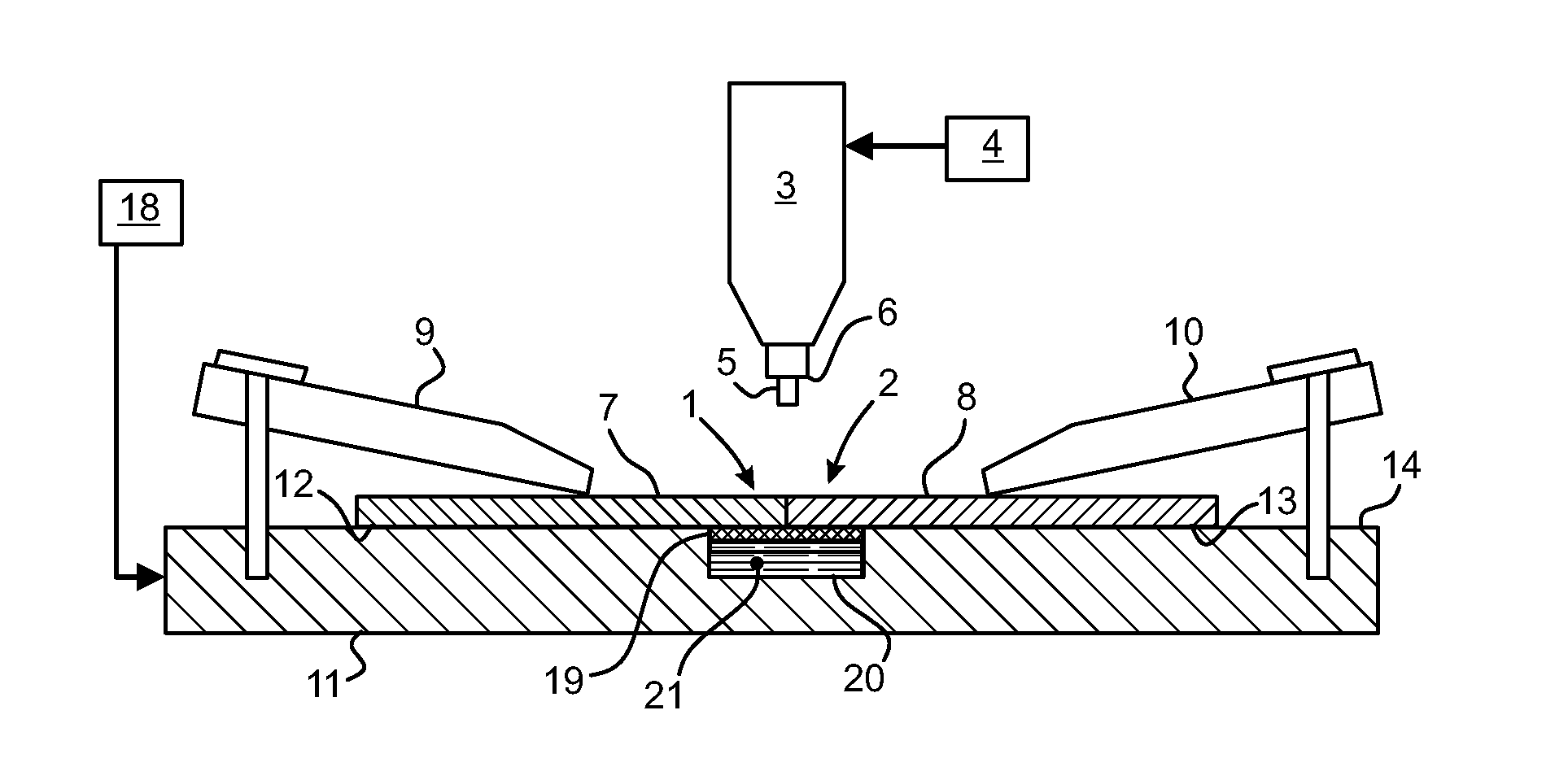

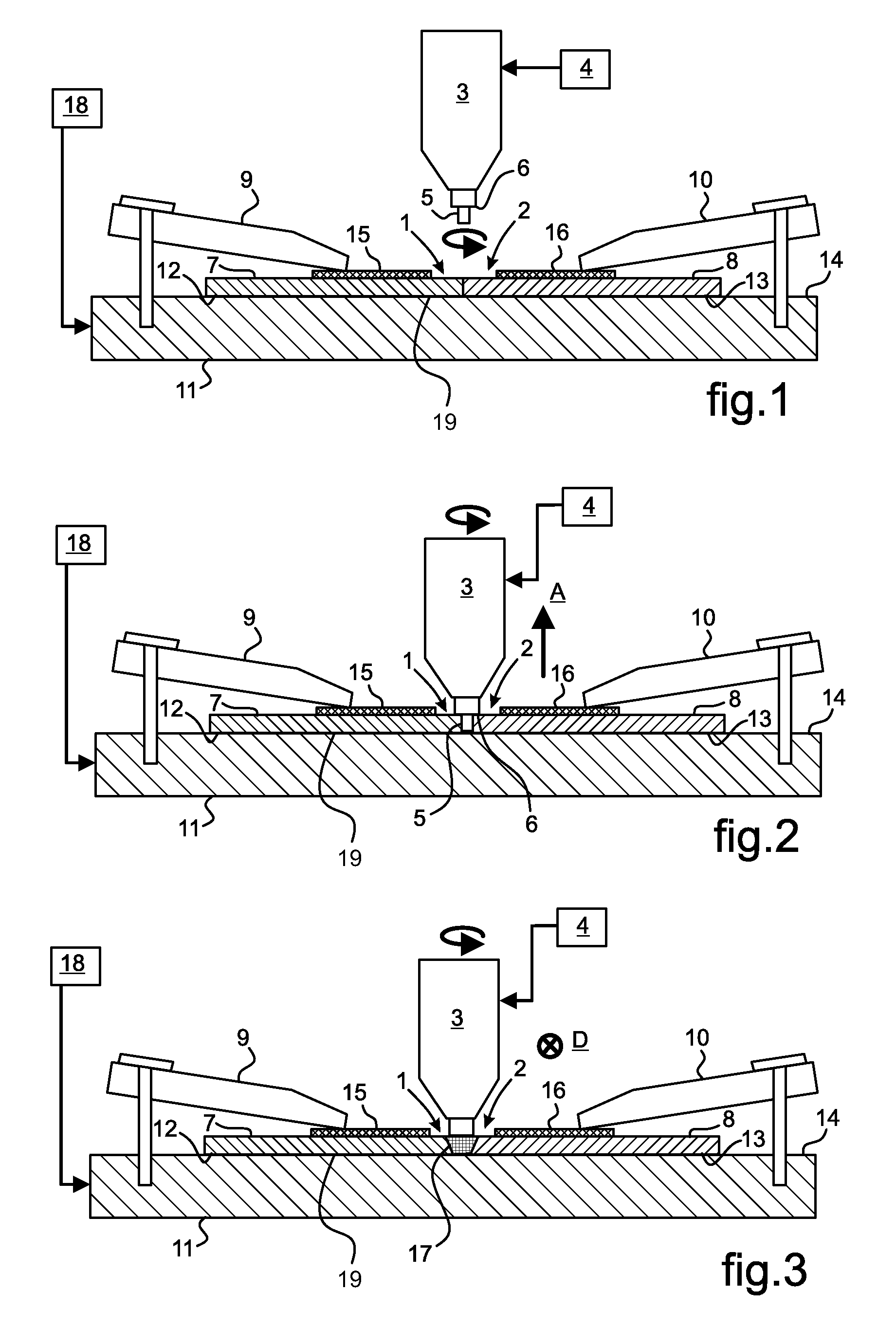

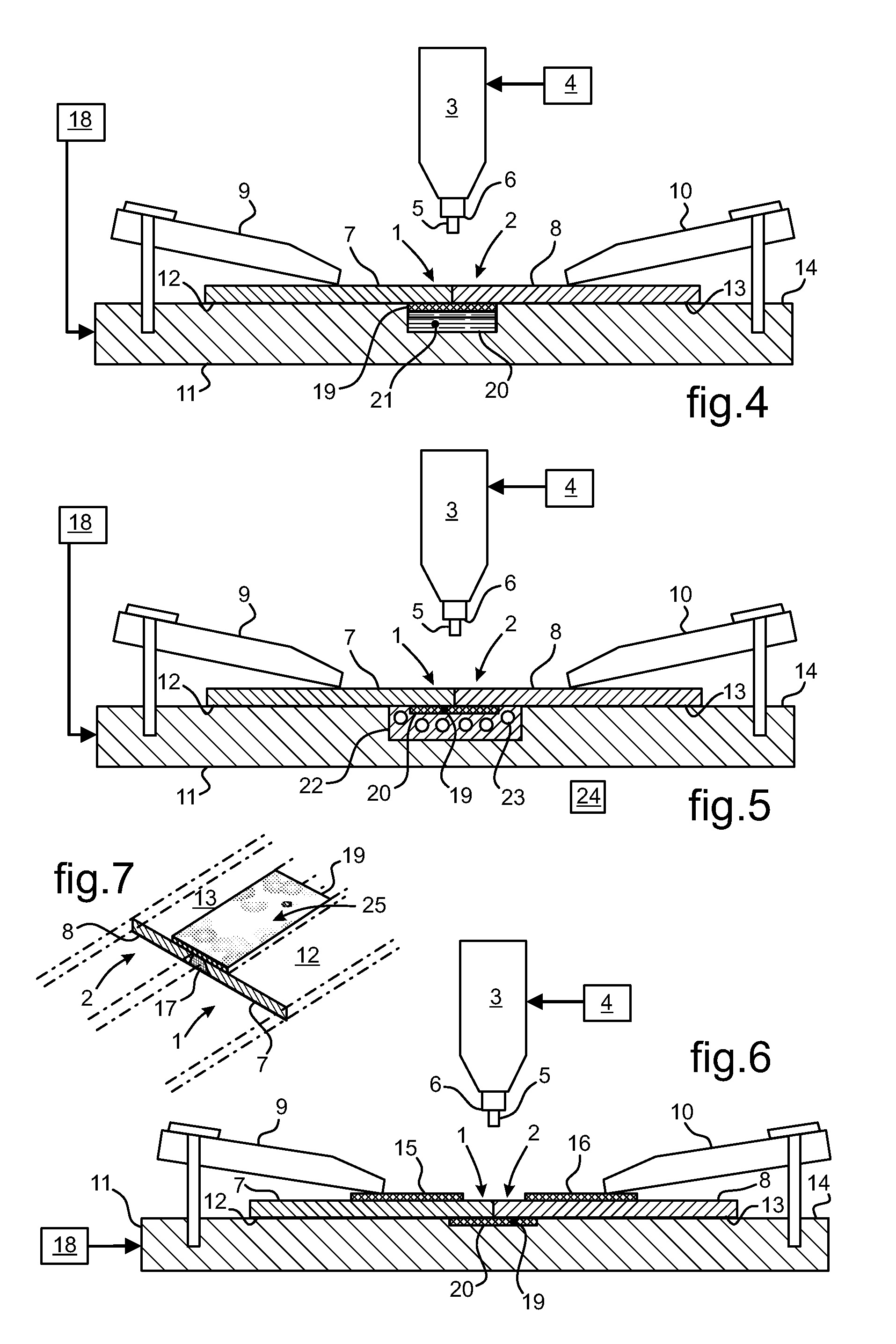

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS8393519B2Optimize rateHigh performance mechanical characteristicWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

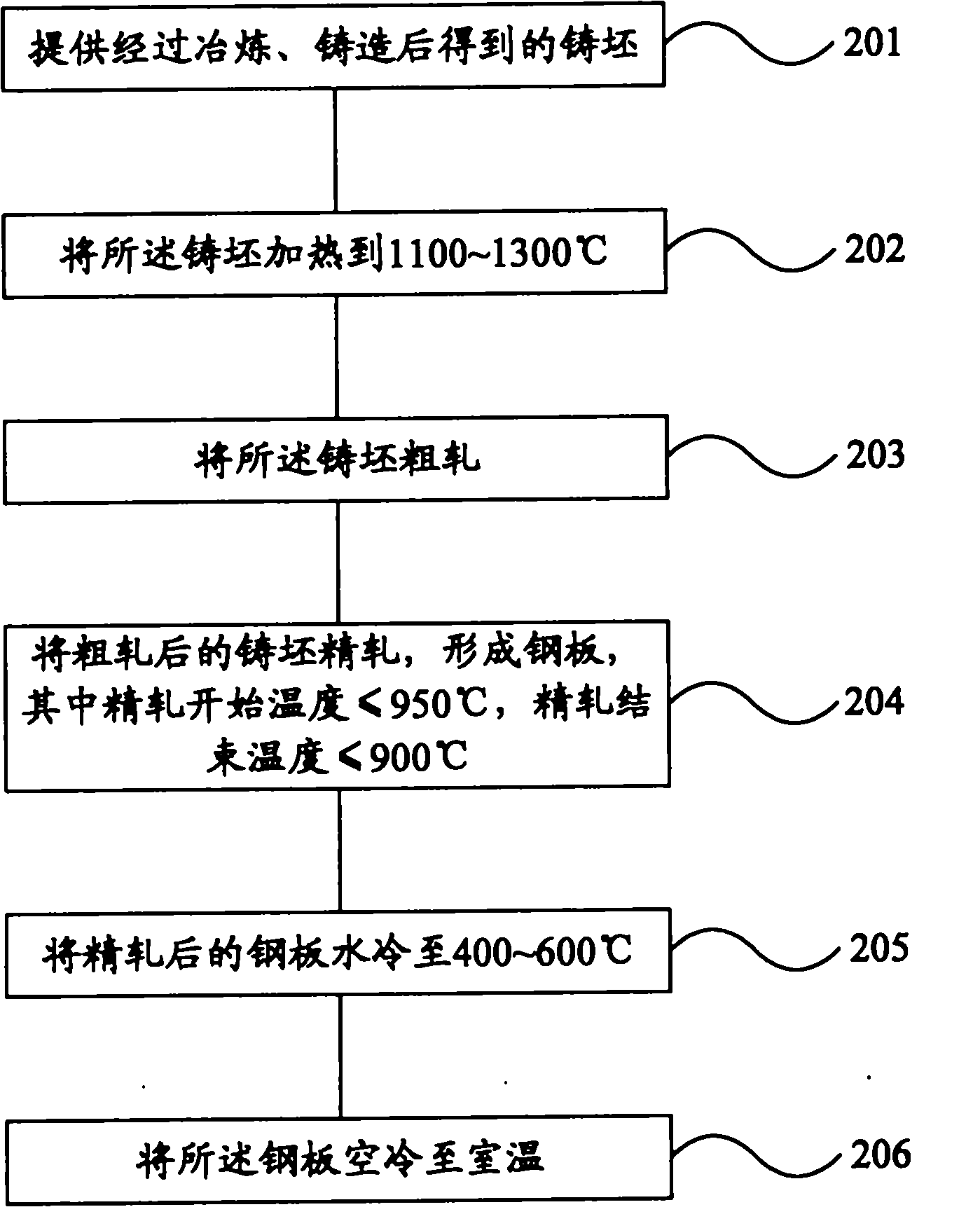

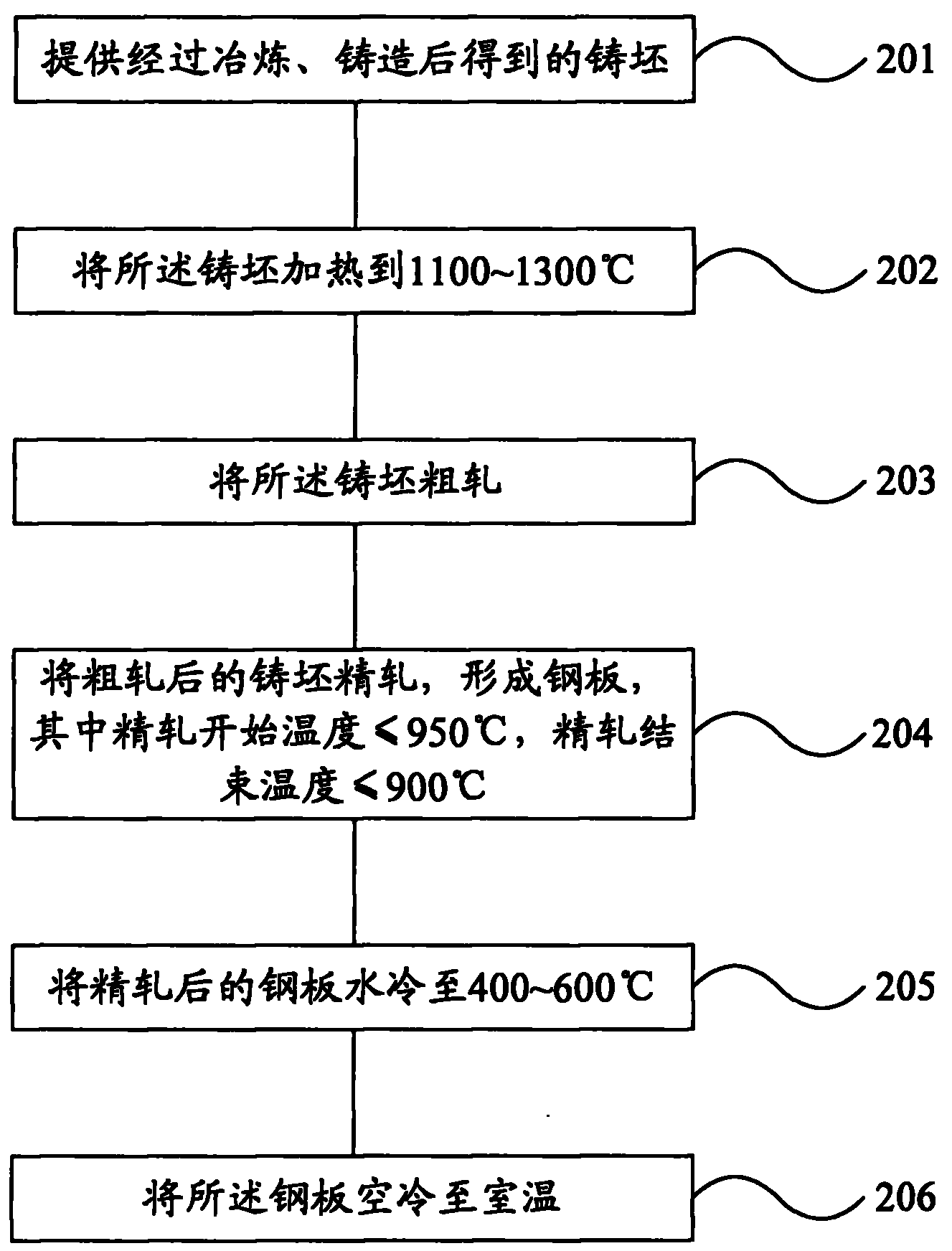

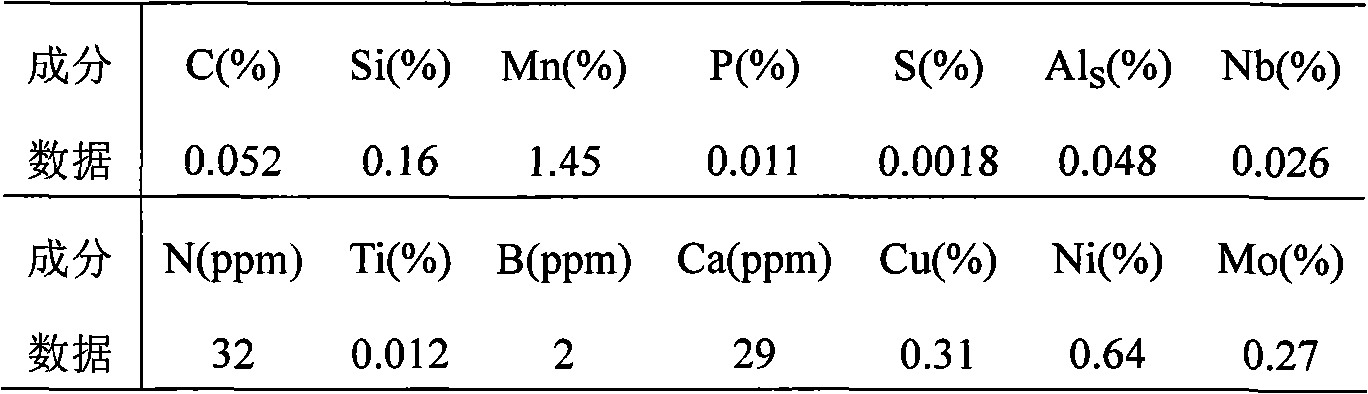

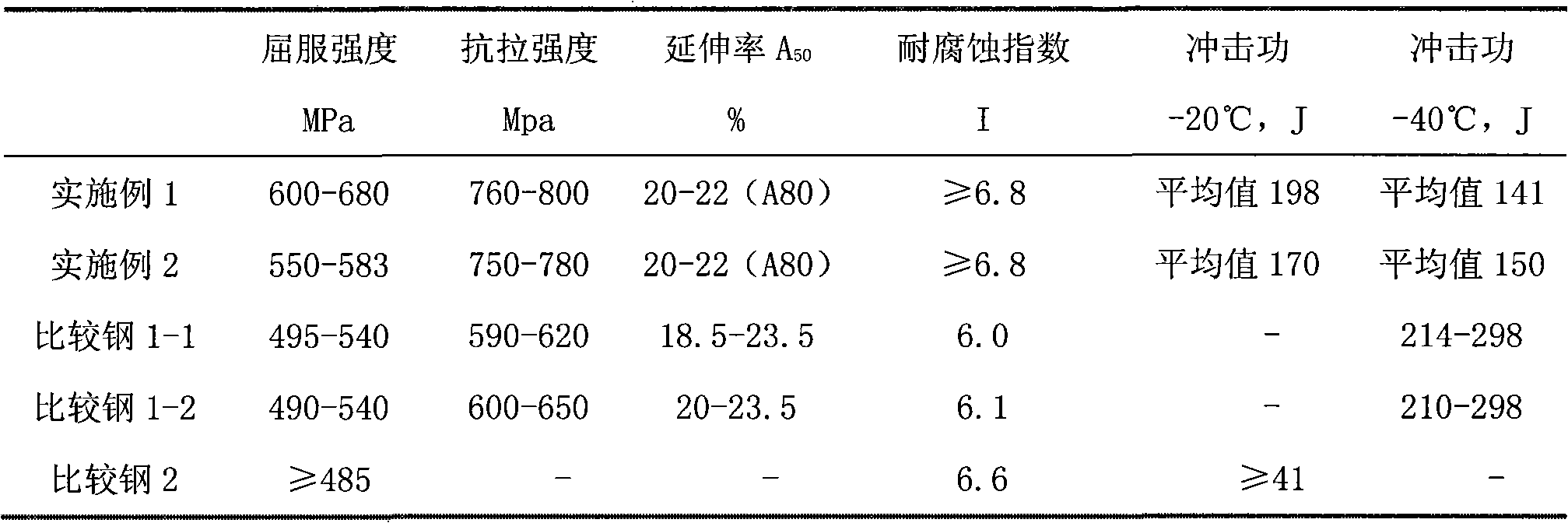

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

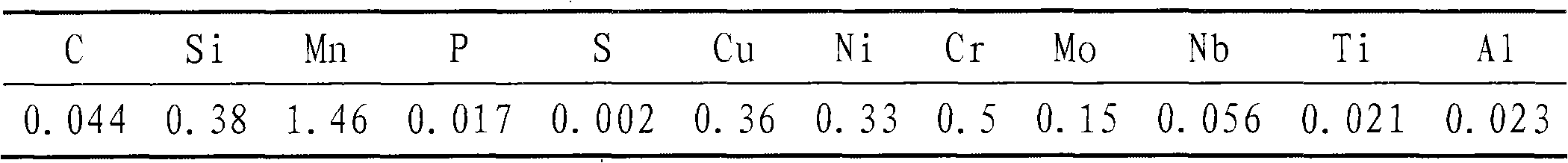

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

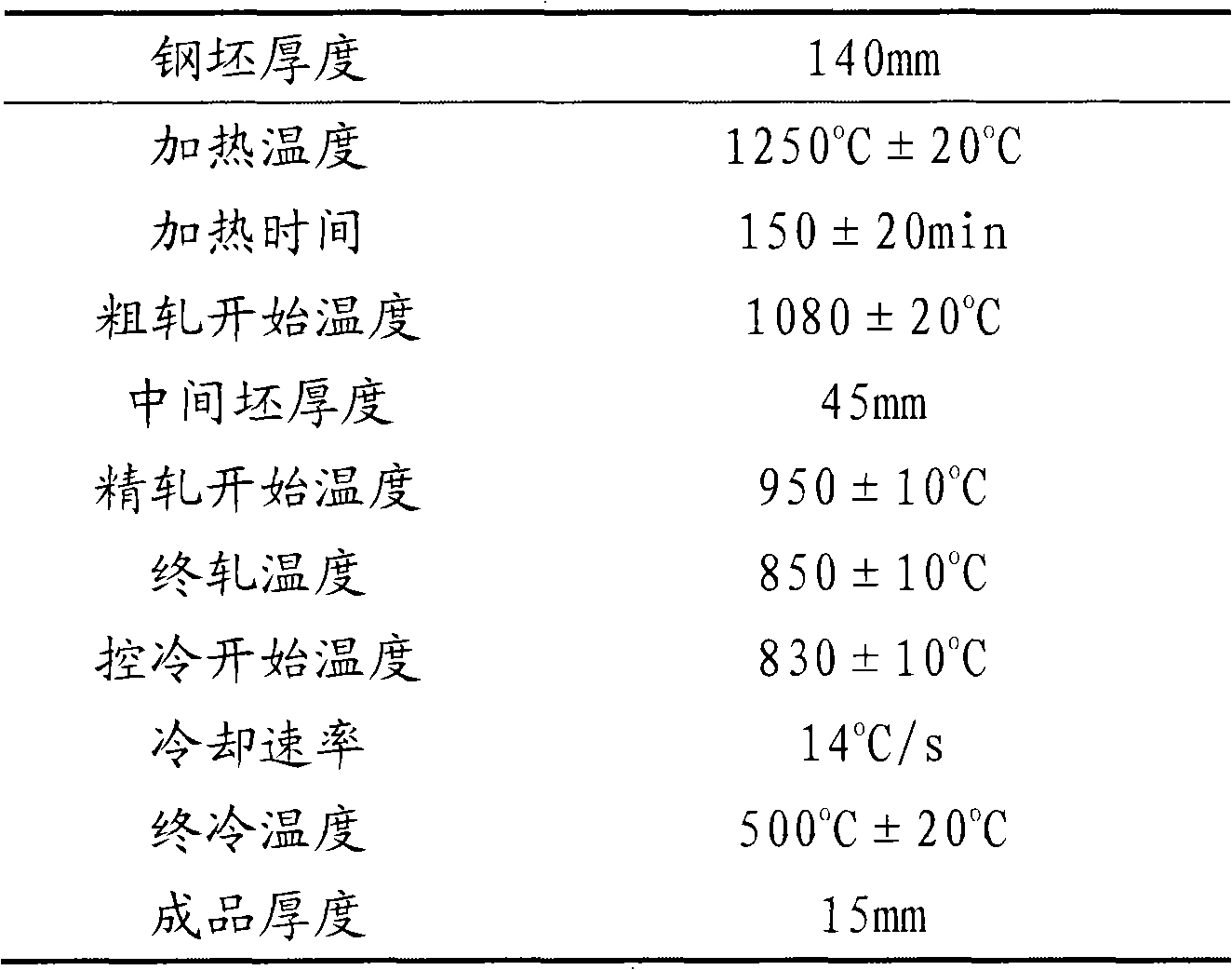

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-yield ratio, high heat input welding, high-strength and high ductility steel plate and method of manufacture

ActiveCN101289728AIncrease contentSimple processTemperature control deviceAlloy elementOil production

The invention provides a steel plate having low-temperature toughness, high tensile strength and low yield ratio, as well as a method for making the same. By combining simple combination design of alloying elements with optimized TMCP process, the method successfully solves the problem that low-temperature impact toughness and low yield ratio are in mutual conflict and difficult to reconcile in composition design and process design, which reduces the amount of steel material, saves cost, lightens the dead weight of a steel structure, increases stability and safety, and more importantly, improves the safety, stability and seismic damage resistance of the steel structure. The steel plate can be widely applied to large-scale high-rise building structures, bridge structures, offshore oil production platform structures, low temperature pressure vessels and large-scale ship structures.

Owner:BAOSHAN IRON & STEEL CO LTD

Power source for electric arc welding

ActiveUS20060011595A1Avoid lostSmall component sizeArc welding apparatusElectricitySignal transition

A power source for an electric arc welding process, wherein the power source comprises an input stage having an AC input and a first DC output signal; a second stage in the form of an unregulated DC to DC converter having an input connected to the first DC output signal and an output in the form of a second DC output signal electrically isolated from the first DC output signal and with a magnitude of a given ratio to the first DC output signal; and, a third stage to convert the second DC output signal to a welding output for the welding process.

Owner:LINCOLN GLOBAL INC

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

Normalizing type high-strength pressure vessel steel and manufacturing method thereof

The invention provides normalizing type high-strength pressure vessel steel, which comprises the following chemical components in percentage by weight: 0.12 to 0.18 percent of C, 0.15 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.10 to 0.40 percent of Ni, 0.01 to 0.05 percent of Nb and 0.01 to 0.03 percent of Ti, 0.015 to 0.050 percent of Als, one or both of less than or equal to 0.20 percent of V and less than or equal to 0.70 percent of Cu and the balance of Fe and inevitable impurities. In the normalizing type high-strength pressure vessel steel, the specification of the steel is controlled by utilizing a single-rolling process of a steel plate, and the uniform tissue of ferrite and pearlite is obtained by adopting normalizing heat treatment; and in the process of rolling and heat treatment, the sufficient strength and good impact properties are obtained by utilizing the effects of fine-grain strengthening, precipitation strengthening and solid solution strengthening of micro-alloying elements such as the Nb, the V, the Ti and the like. In addition, the normalizing type high-strength pressure vessel steel achieves the excellent welding performance by controlling carbon equivalent and can be welded by adopting methods of manual arc welding, hidden arc welding, gas shielded welding, electroslag welding or tungsten electrode inert gas shielded-arc welding and the like; and the normalizing type high-strength pressure vessel steel has the advantages of little used precious metals, easy control of the component of each element, simple process, low production cost and high efficiency.

Owner:武钢集团有限公司

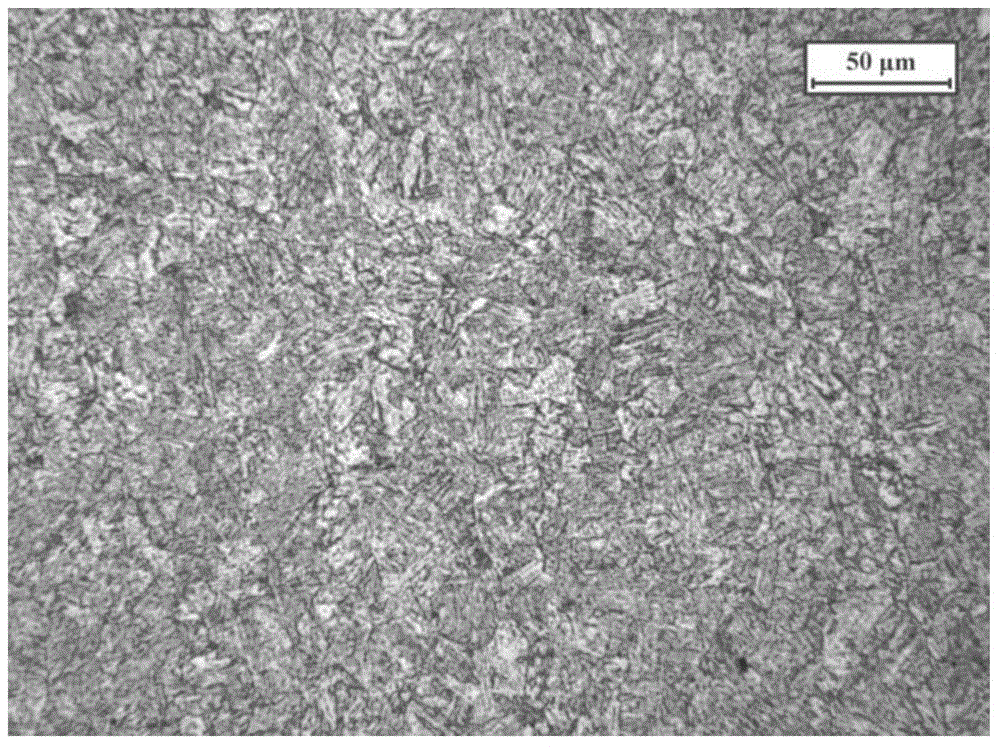

Super-strength high-toughness wear resistant steel plate and production method thereof

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

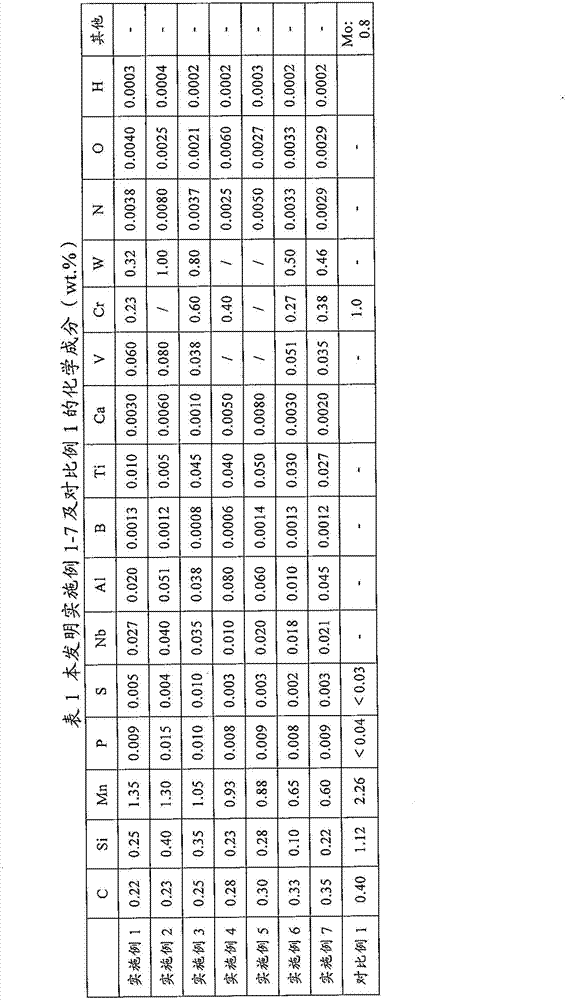

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Pealite like thermal treating steel rail and producing method thereof

ActiveCN1793403AMeet the use requirementsImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionFree cooling

The invention relates to pearly heat-treated steel rail and its manufacturing method. Its chemical composition percentage by weight includes: C:0.70%-0.95%, Si:0.20%-1.10%, Mn:0.50%-1.50%, V:0.01%-0.20%, Cr:0.15%-1.20%, P: not less than 0.035%, S:not less than 0.035%, and Al: not less than 0.005%. The method includes the following steps: smelting; casting; rolling; cooling from 650-880 centigrade degree to 400-500 centigrade degree or room temperature with 1-10 centigrade degree per second; heating to 850-1100 centigrade degree; natural cooling to 650-880 centigrade degree; cooling to 400-500 centigrade degree with 1-10 centigrade degree per second than stop cooling; and natural laying. The formed steel rail has good wear resistance.

Owner:PANZHIHUA IRON AND STEEL

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

X65 pipeline steel for use in acid condition and its making process

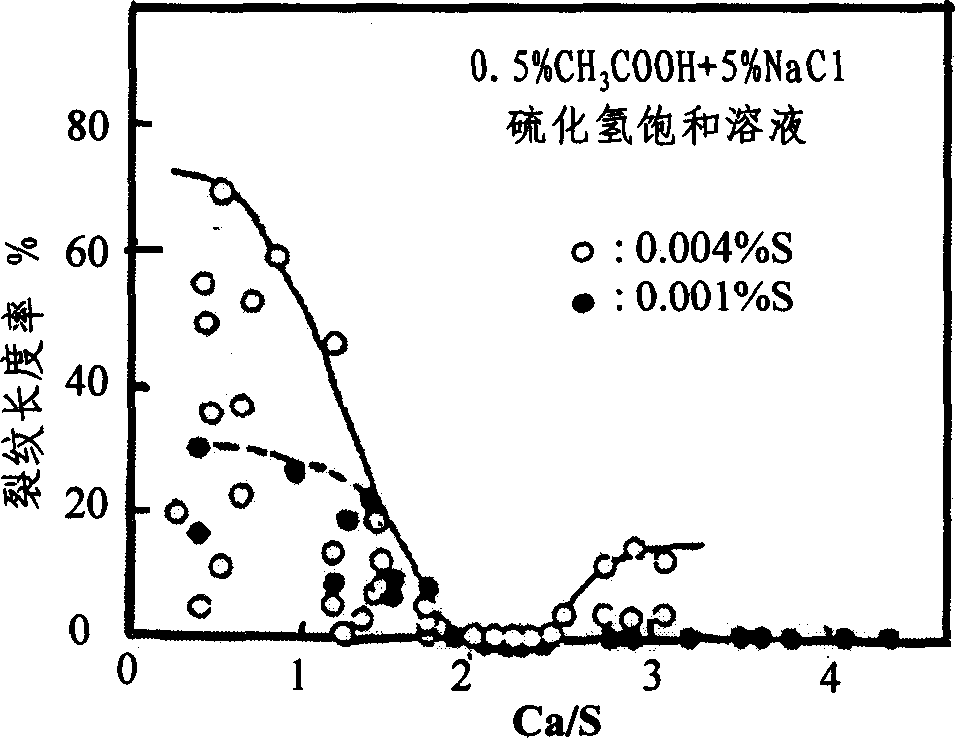

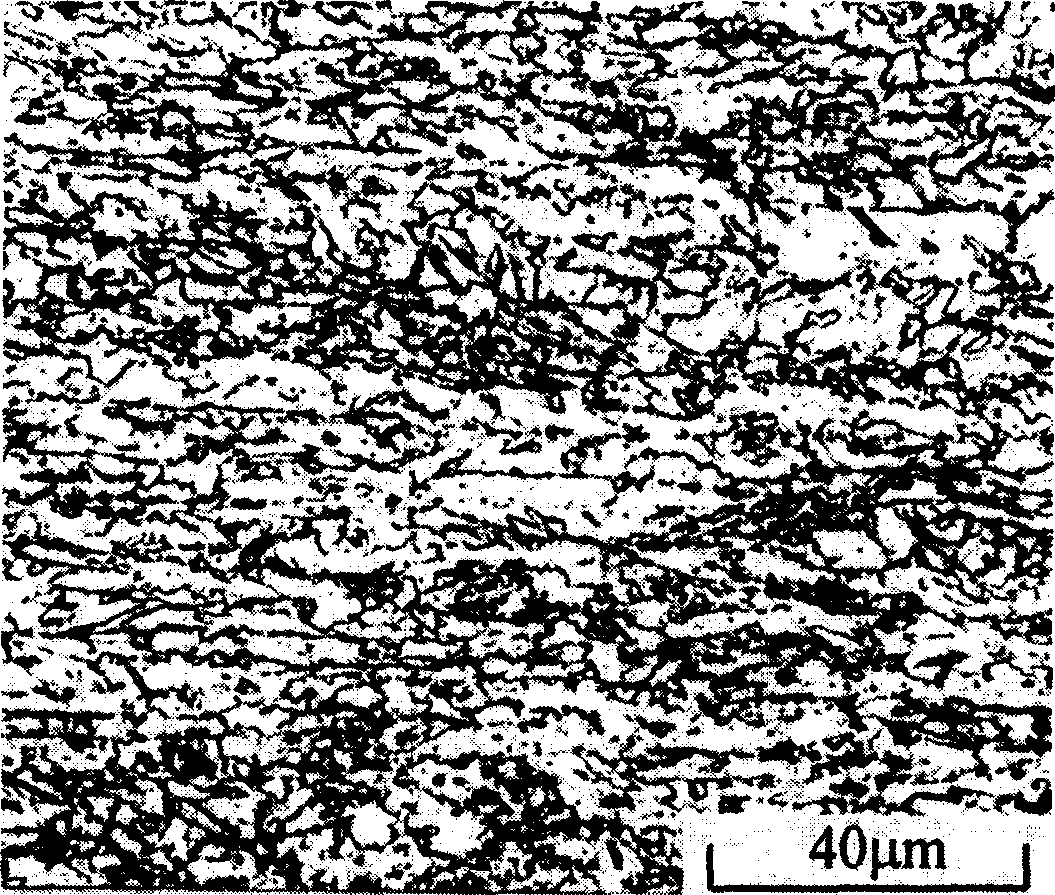

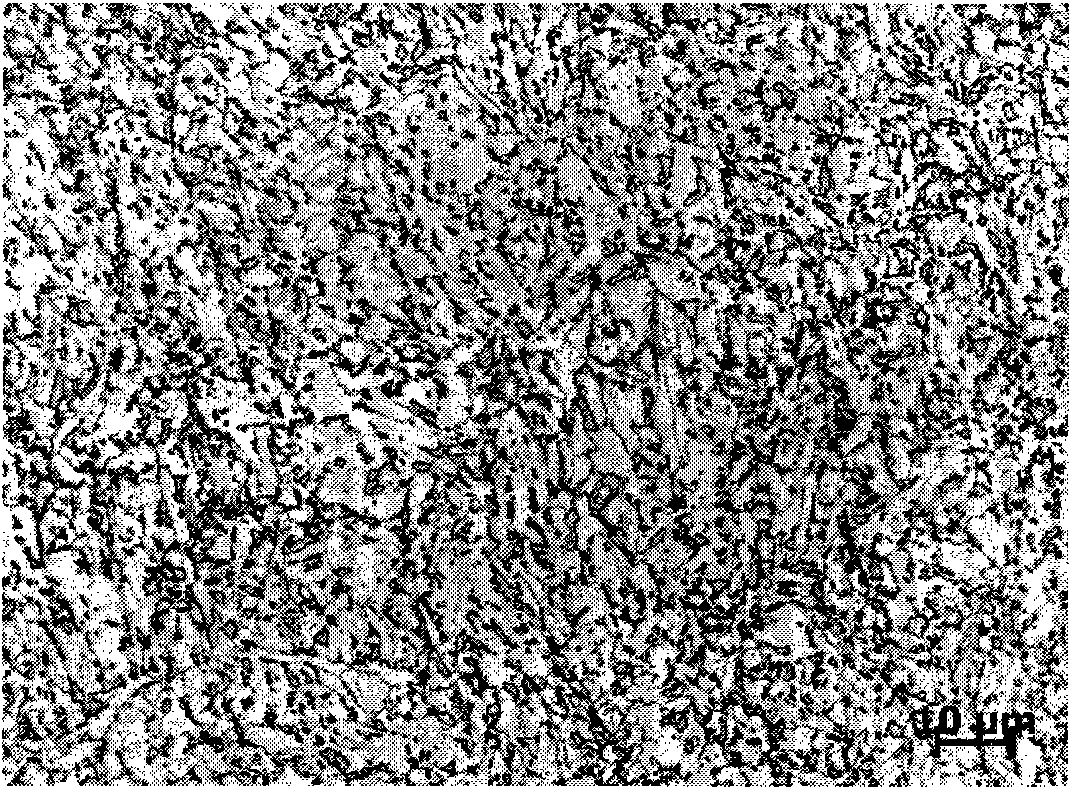

ActiveCN1811002AImprove the effect of controlled rollingImproved dynamic tear resistanceManufacturing convertersProcess efficiency improvementMetallurgyTear resistance

The X65 pipeline steel for use in acid condition consists of C 0.02-0.05 wt%, Mn 1.20-1.50 wt%, Si 0.10-0.50 wt%, S not more than 0.0020 wt%, P 0.004-0.012 wt%, Nb 0.05-0.07 wt%, Ti 0.005-0.025 wt%, Mo 0.050-0.195 wt%, Cu not more than 0.35 wt%, Ni not more than 0.35 wt%, N not more than 0.0080 wt%, Ca 0.0015-0.0045 wt% and Ca / S not less than 2.0 except Fe. Its making process includes the following steps: smelting in a converter or an electric furnace; secondary steel making including LF desulfurizing + RH vacuum deairing and Ca treatment; continuous casting; rolling with initial rolling termination temperature of 940-1020 deg.c and finish rolling termination temperature of 780-840 deg.c; and winding at 500-580 deg.c. The X65 pipeline steel has low manufacture cost, high HIC resistance, high dynamic tear resistance and high impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process

InactiveCN1888120ARaise Strength IndexMeet manufacturing requirementsRoll mill control devicesHeat treatment process controlHeat sensitiveUltimate tensile strength

The present invention discloses one kind of ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process. The ultra-high strength steel consists of C 0.05-0.12 wt%, Si 0.05-0.50 wt%, Mn 1.10-1.70 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Nb 0.025-0.070 wt%, V 0.005-0.080 wt%, Mo 0.20-0.50 wt%, Ni 0.30-0.80 wt%, Ti 0.005-0.025 wt%, Cu 0.25-0.80 wt%, B 0.0005-0.0020 wt%, and Cr 0.10-0.70 wt%, except Fe and inevitable impurities. It has carbon equivalent not lower than 0.65 % and heat sensitive coefficient not lower than 0.30 %. Its making process includes the steps of smelting, desulfurizing molten iron, combined blowing in converter, vacuum treatment, casting into plate blank, etc. It has yield strength not lower than 880 MPa, tensile strength not lower than 980 MPa and V-shaped notch Charpy absorbed-in-fracture energy at -20 deg.c not lower than 100J.

Owner:武钢集团有限公司

Hot rolled weatherproof bridge steel with yield strength of 500 MPa level and manufacturing method thereof

The invention relates to a hot rolled weatherproof bridge steel with yield strength of 500 MPa level and a preparation process thereof. The weatherproof bridge steel comprises the following chemical components in percentage by weight: 0.03-0.08% of C, no more than 0.5% of Si, 1.0-1.5% of Mn, no more than 0.015% of P, no more than 0.01% of S, 0.3-0.6% of Cu, 0.20-0.50% of Ni, 0.40-1.0% of Cr, 0.15-0.35% of Mo, 0.03-0.08% of Nb, no more than 0.04% of Ti, no more than 0.04% of Als and balance Fe and impurities, and the weatherproof bridge steel is mainly prepared by a control rolling and cooling process. The weatherproof bridge steel has the advantages of simple composition, low cost, yield strength more than 500 MPa, favorable low-temperature tenacity, weldability and weatherability, convenient preparation process and high controllability. The preparation method can be widely used in the production field of various bridge steels.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate for nuclear power plant containment and manufacture method thereof

The invention discloses a thick steel plate for a nuclear power plant containment. The nuclear power plant containment is 10-60mm in thickness. The thick steel plate comprises, by mass percent, 0.06-0.15% of C, 0.10-0.40% of Si, 1.0-1.5% of Mn, 0.10-0.30% of Mo, not more than 0.012% of P, not more than 0.003% of S, 0.015-0.050% of Al, 0.20-0.50% of Ni, and at least one of not more than 0.05% of V, not more than 0.03% of Ti, not more than 0.25% of Cr, not more than 0.03% of Nb, and 0.0005-0.0050% of Ca, and the balance Fe and other inevitable impurity. Correspondingly, the invention further discloses a manufacture method of the thick steel plate for the nuclear power plant containment. The thick steel plate for the nuclear power plant containment is high in rigidity, high in toughness, fine in impact toughness of base metal and heat affected zone at low temperature, and suitable for application in the manufacture field of nuclear power plant containments.

Owner:BAOSHAN IRON & STEEL CO LTD

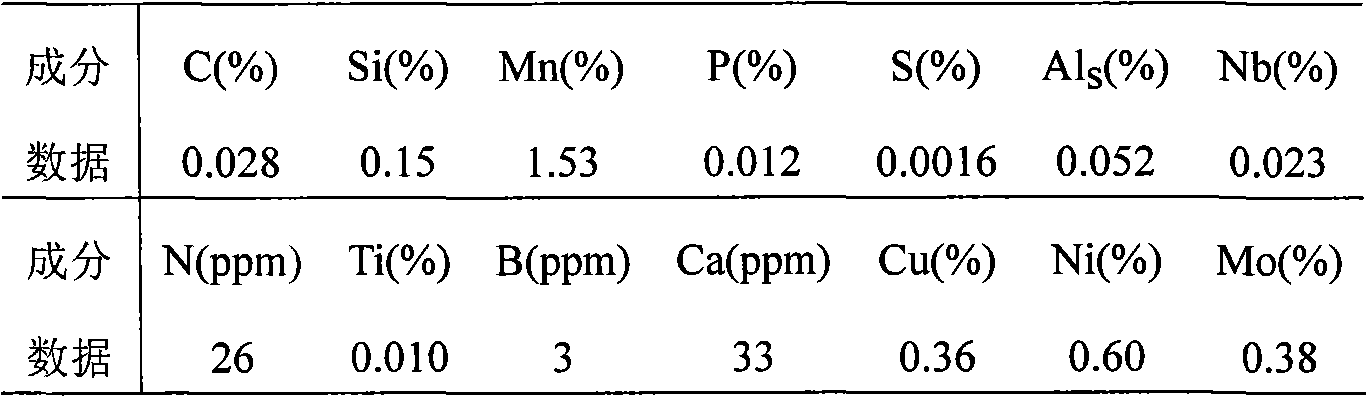

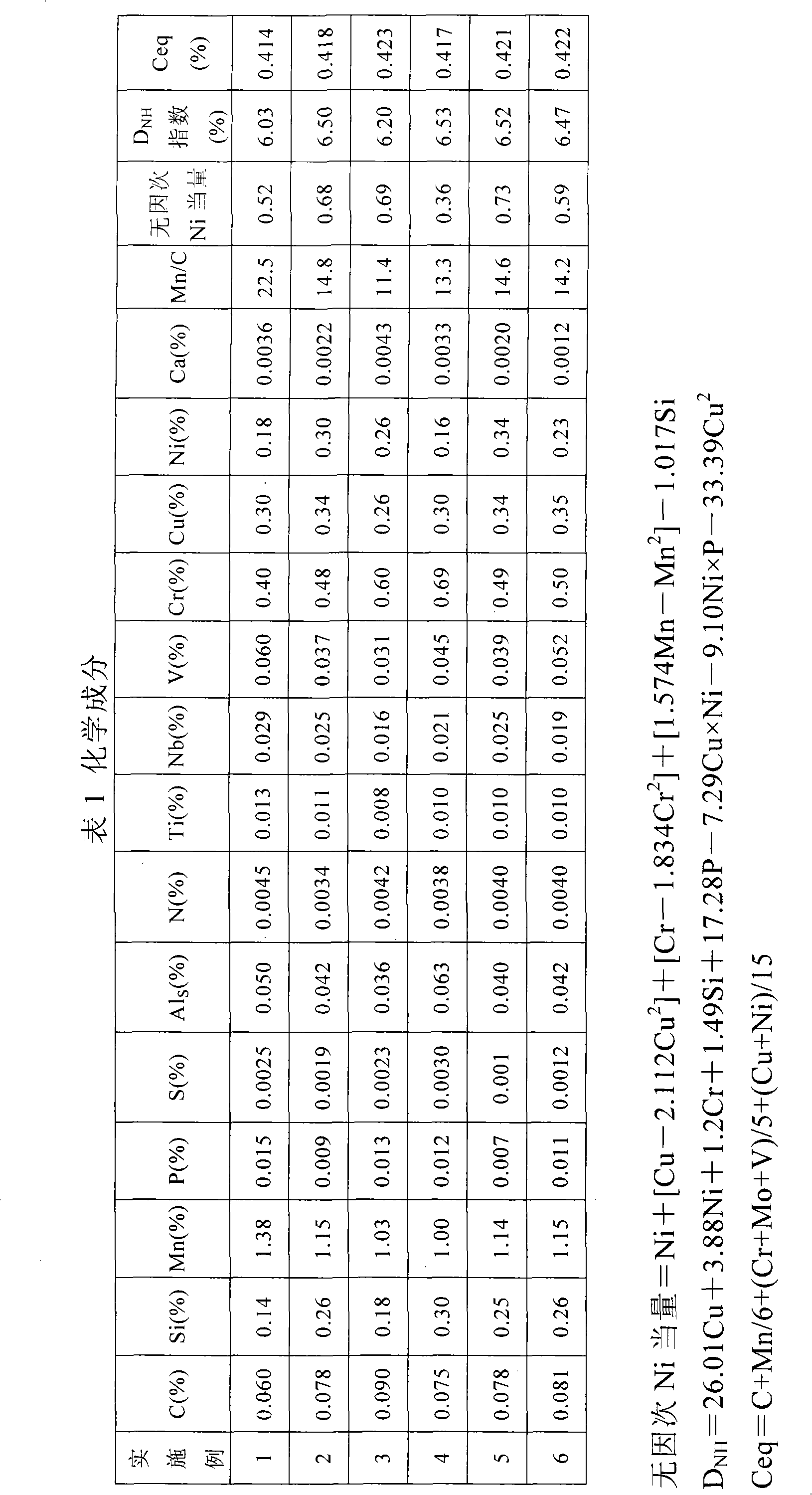

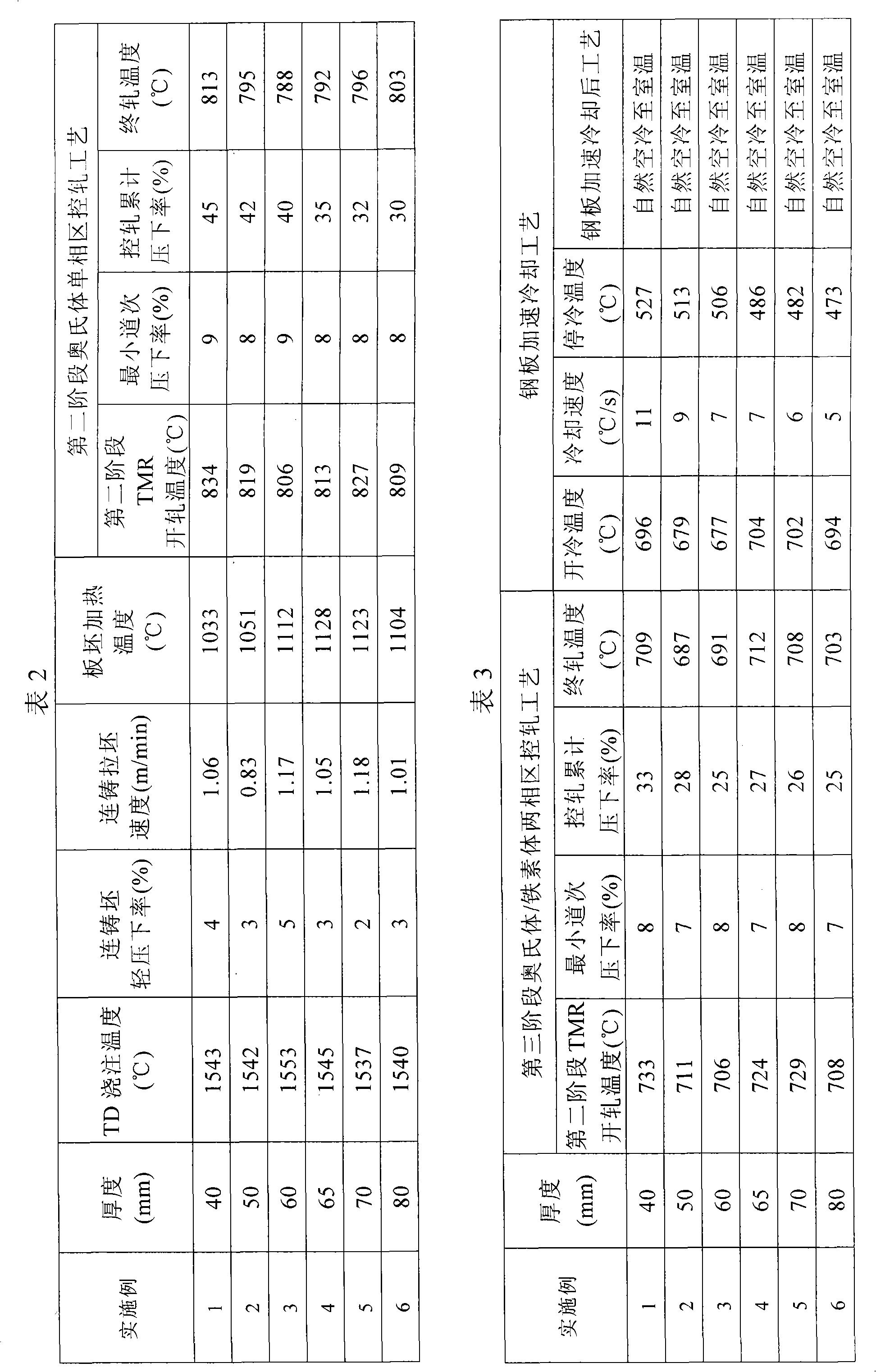

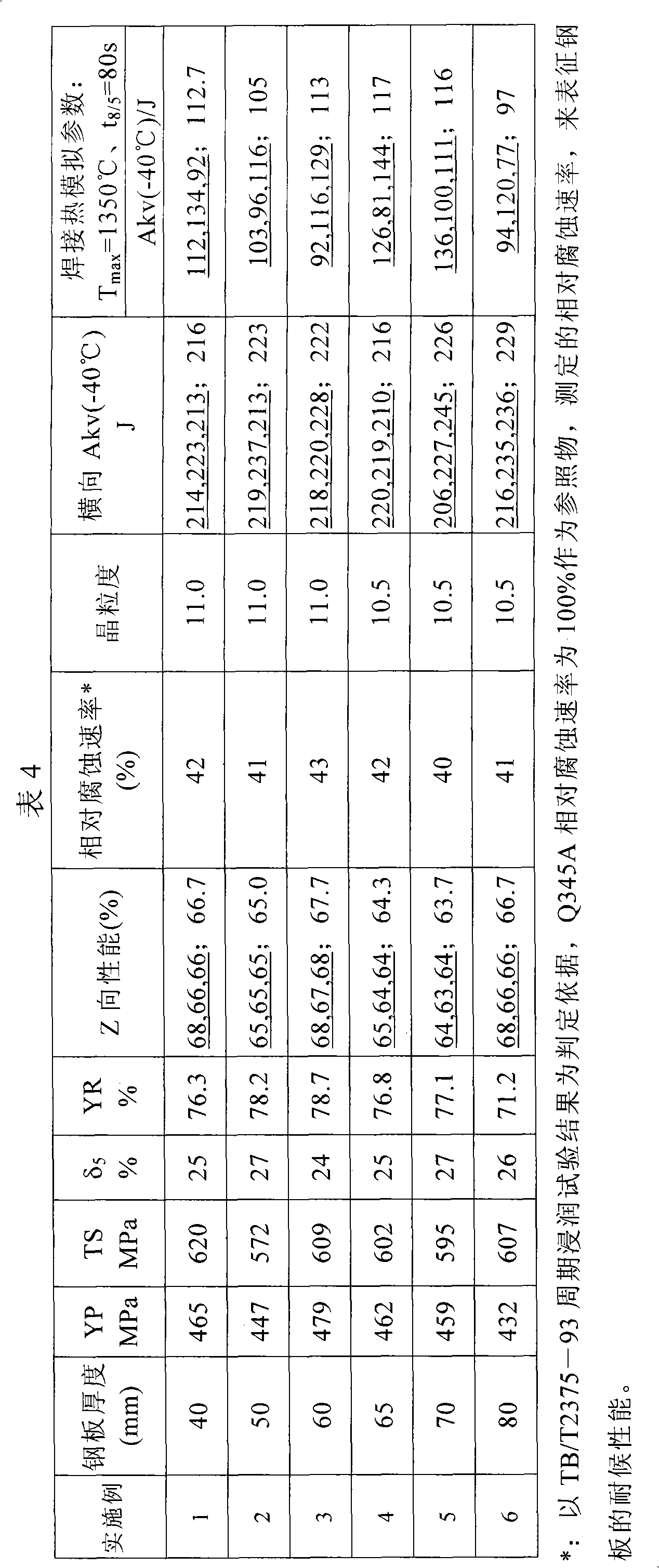

High-performance weather-proof building structural steel and manufacturing method thereof

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

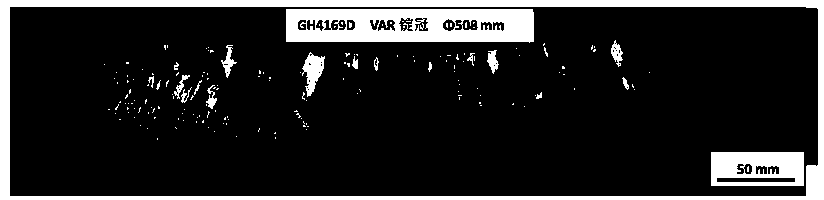

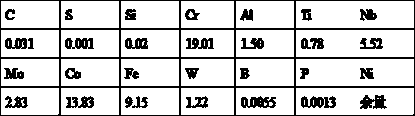

Smelting technique of novel nickel-iron-base high-temperature alloy GH4169D

The invention discloses a smelting technique of a novel nickel-iron-base high-temperature alloy GH4169D, which aims to smelt the novel high-temperature alloy GH4169D consumable ingot which has the advantages of lower raw material cost and favorable hot working properties in industrial production as well as high stability at high temperature. The scheme of the smelting technique is as follows: on the basis of the GH4169 alloy composition, the Fe content is lowered, the sum and proportion of Al and Ti are adjusted, and proper P and B are added; and by adopting a triple (VIM+PESR+VAR) smelting technique, proper slag and technological parameters are selected, and the burning loss of Al and Ti in the protective-atmosphere electroslag smelting process is controlled to obtain the precise contents of Al and Ti. The technique enhances the metallurgical quality of the high-temperature alloy, and fills up the blank of the high-temperature alloy in the aspect of the application temperature between 650 DEG C and 750 DEG C; the GH4169D alloy has the high strength, favorable hot working property and weldability of the GH4169 alloy, and has the high application temperature and other comprehensive properties of the GH4738 alloy; and the GH4169D alloy has long-term stability at 700 DEG C.

Owner:FUSHUN SPECIAL STEEL SHARES

Lithium-ion battery with high rate discharge performance

ActiveCN103730625AImprove rate discharge performanceImprove securitySecondary cellsCell component detailsHigh rateEngineering

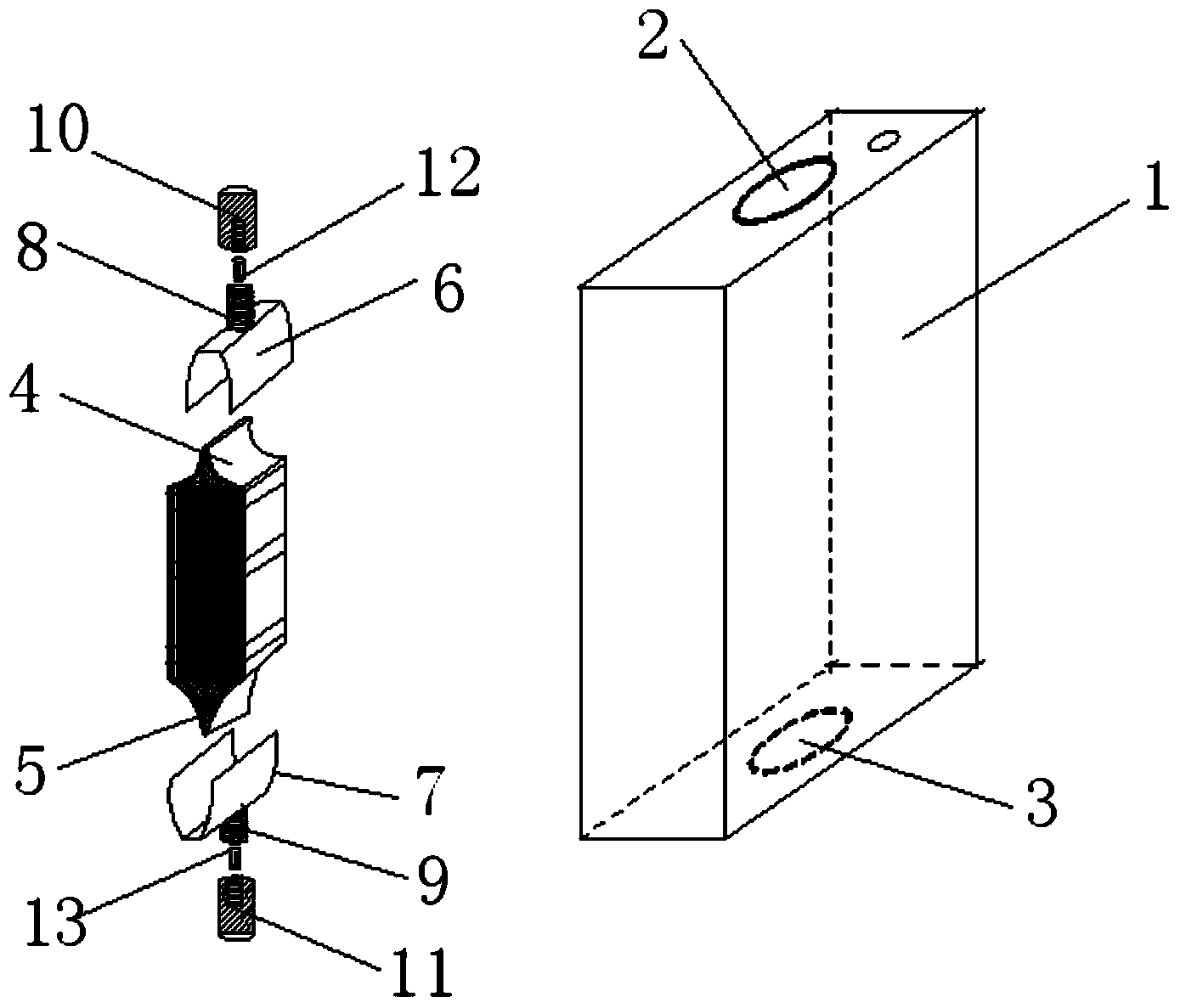

The invention discloses a lithium-ion battery with high rate discharge performance. The lithium-ion battery comprises a cover, a battery core in the cover, an upper cover plate, and a lower cover plate, wherein the battery core is prepared either by winding or laminating a positive pole piece with a positive pole ear, a negative pole piece with a negative pole ear and a diaphragm. The lithium-ion battery is characterized in that a positive pole piece clamping mechanism and a negative pole piece clamping mechanism are also arranged; the positive pole ear is packed and fixed inside of the positive pole piece clamping mechanism and a positive pole stud is arranged on the outside of the positive pole piece clamping mechanism and is in detachable connection with the upper cover plate; the negative pole ear is packed and fixed inside of the negative pole piece clamping mechanism and a negative pole stud is arranged on the outside of the negative pole piece clamping mechanism and is in detachable connection with the lower cover plate. The lithium-ion battery is particularly applicable to the fields of electrical motorcycles, electrical taxies and electrical buses, and the like, and can meet the requirements for high rate discharge performance of batteries when the vehicles are in the bad circumstances such as climbing, instantaneous starting and instantaneous accelerating.

Owner:安徽金鑫宏运新能源科技有限公司

Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

InactiveCN101660108AThe ingredients are designed to be simpleObvious effectManufacturing convertersSimple componentHigh intensity

The invention relates to a non-quenched acicular structure high strength low yield ratio weathering resistant steel and a production method thereof. The steel comprises components by weight percent: basic components: 0.03-0.08% of C, 0.30-0.60% of Si, 1.30-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cu, 0.20-0.50% of Ni, 0.40-0.80% of Cr, 0.10-0.40% of Mo, 0.030-0.080% of Nb and less than or equal to 0.04% of Ti; optional components are two or more in less than or equal to 0.04% of AlS and less than or equal to 0.40kg / t steel of RE or less than or equal to 0.005% of Ca; and the rest of Fe and impurities. Welding cold crack is low in susceptibility coefficient and high in corrosion resisting index. The steel has simple components as wellas excellent moldability, weatherability, weldability and low temperature toughness; meanwhile, the preparation technique is simple, heat treatment is not needed, the production period is short, and the production cost is low.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Steel series with high linear energy and low weld crack sensitivity and its preparing process

InactiveCN1396294ALow weld crack susceptibilityGood welding performanceUltimate tensile strengthPhase point

A high-strength steel as low-alloy steel contains low-C, Ti, Nb, B and two or more of Ni, V, Cu, Mo, Zr and RE, and is prepared through rolling and modifying heat-treatment to obtain high-toughness tempered sorbite texture and the high-smelting-point second-phase points and compound educed phase to suppress growth of welding coarse crystal region. Its advantages are high linear energy (60-70 kg) and low sensitivity to weld cracking.

Owner:武钢集团有限公司

Superhigh strength thick steel plate capable of large-line energy welding and its manufacturing method

ActiveCN1676656AReduce manufacturing costGood welding performanceHigh intensityUltimate tensile strength

This is a super intensive thick steel board which can be welded with jug line power. It contains 0.01-0.06%C, 0.10-0.50%Si, 1.00 -1.40%Mn, 0.010-0.050%Nb, 0.040-0.090%V, 0.60-1.00%Cu, 0.20-0.50%Cr, 0.20-0.50%Mo, 0.50-0.80%Ni, 5ppm-30ppmB, 0.005-0.020%Ti, 0.040-0.070%Als, and remained Fe and inevitable impurity: 0.065<=(%Cu*%V)<=0.085. The producing method includes: casting technique, slab heating, hot rolling, which is asynchronous rolling in austenite non-crystallized area, strain relaxation and direct cooling by quenching. This invention associates well the steel board's high intensity, high ductility and good weldability. It decreases the quantity of alloying agent and reduces the cost for steel board's production. It can as well improve the low-temperature flexibil ity and welability of the steel board, as it realizes welding with jug line power. As a result, it needs no pre-heating to weld steel board above 0 degree Centigrade.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com