Patents

Literature

1561results about How to "Strong mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/MoS2 compound nano material lithium ion battery electrode and preparation method thereof

InactiveCN102142537ALarge specific surface areaImprove mechanical propertiesNon-aqueous electrolyte accumulator electrodesLithium-ion batteryMaterials science

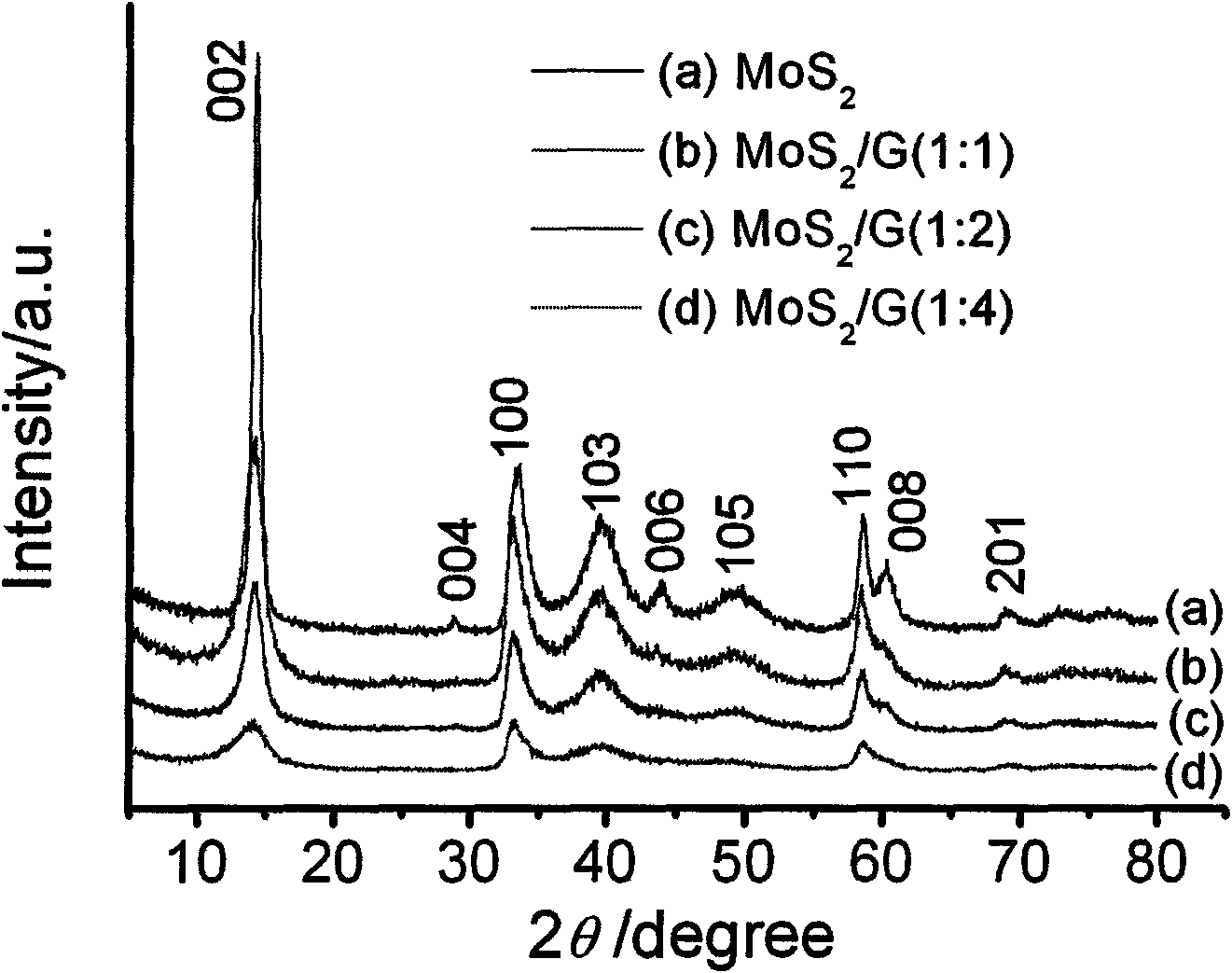

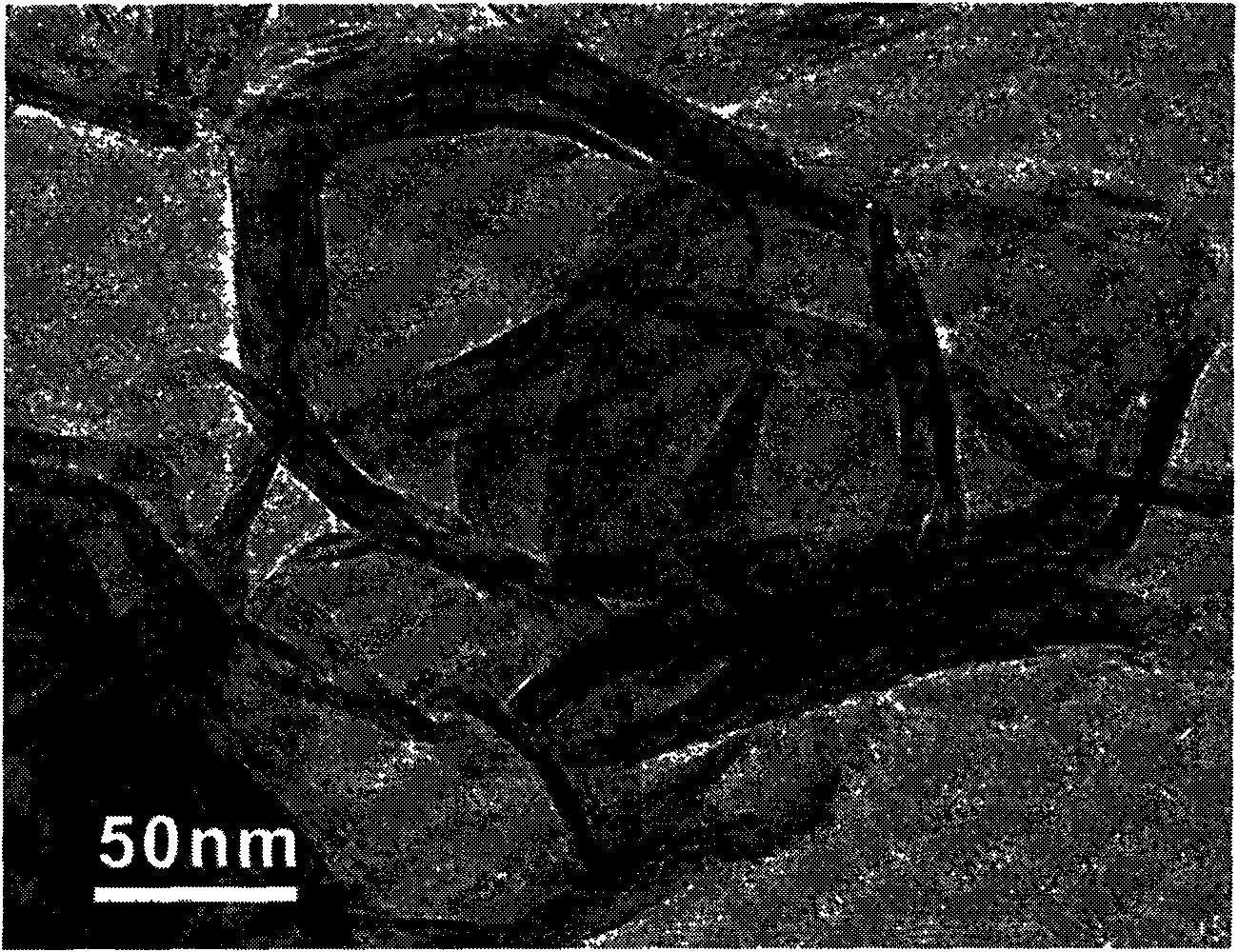

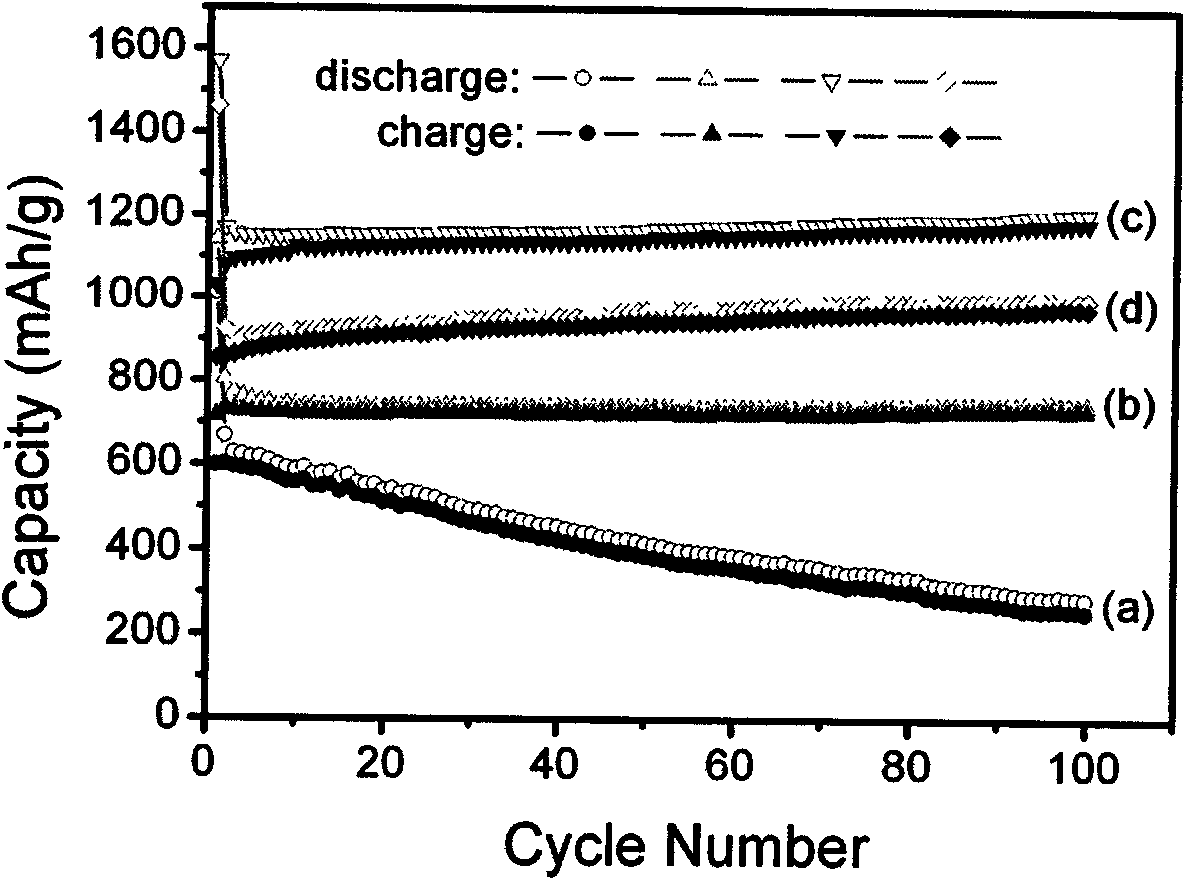

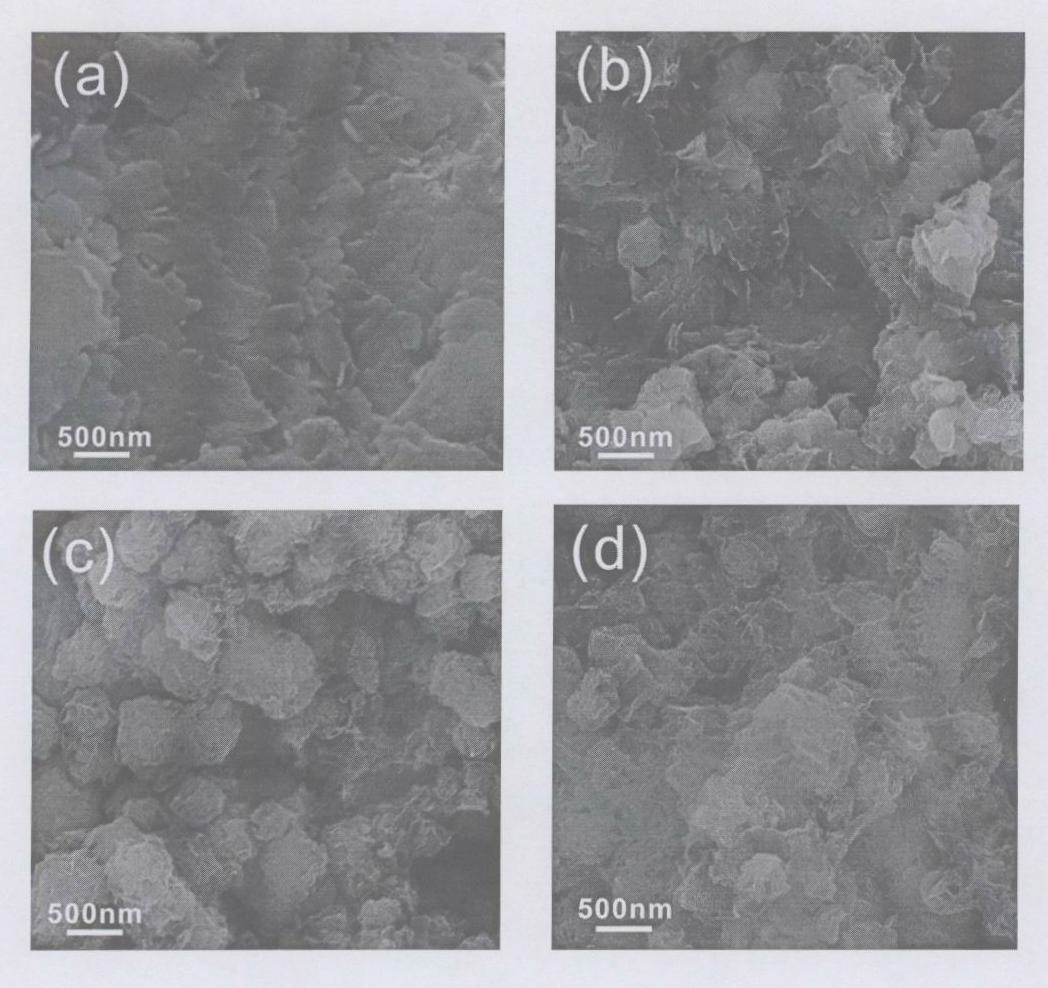

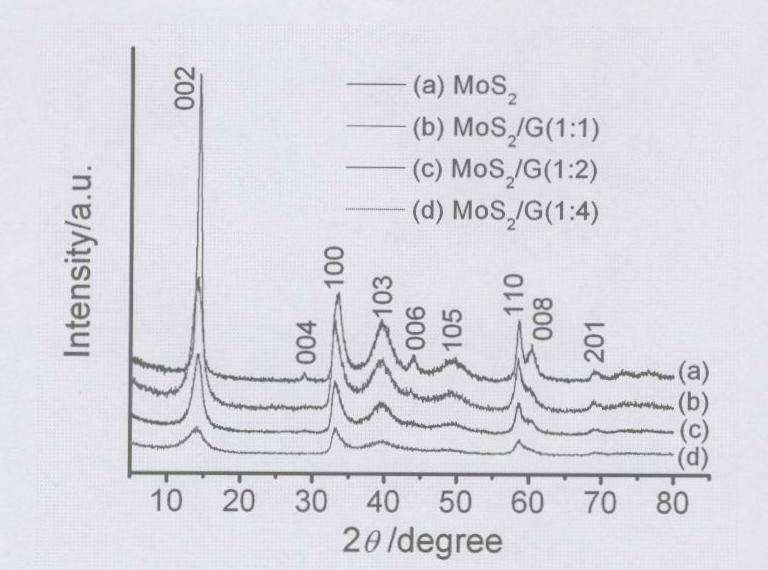

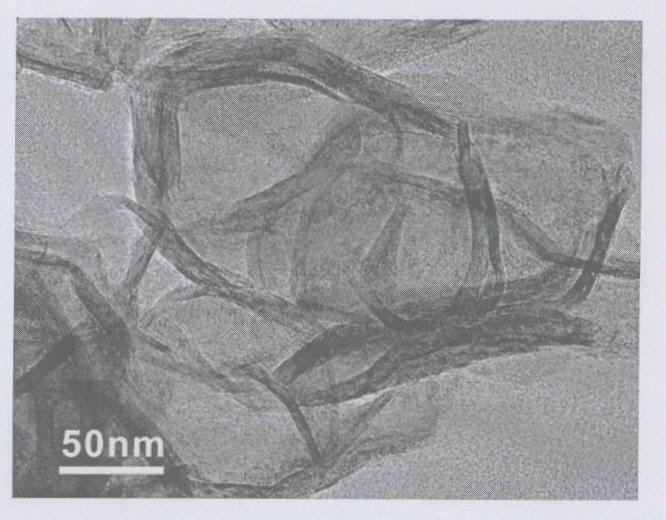

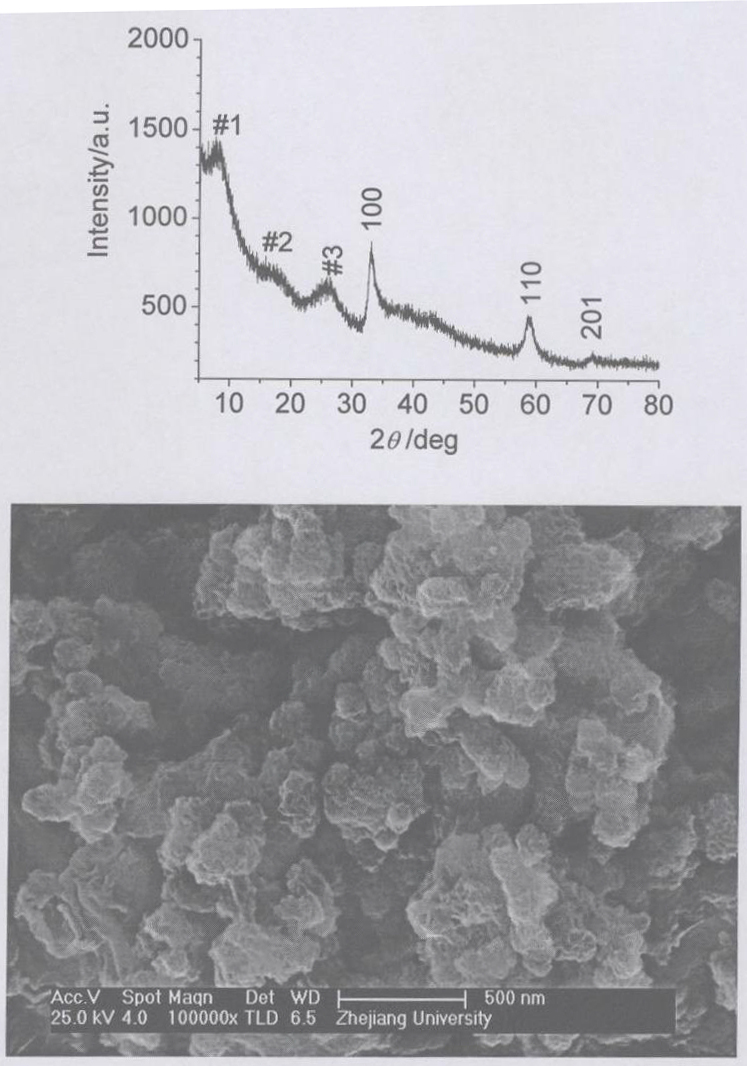

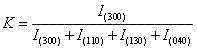

The invention discloses a graphene / molybdenum disulfide (MoS2) compound nano material lithium ion battery electrode and a preparation method thereof. The electrode comprises the following components in percentage by mass: 75 to 85 percent of compound nano material serving as an active substance, of a graphene nano slice and MoS2, and 5 to 10 percent of acetylene black and 10 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method of the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

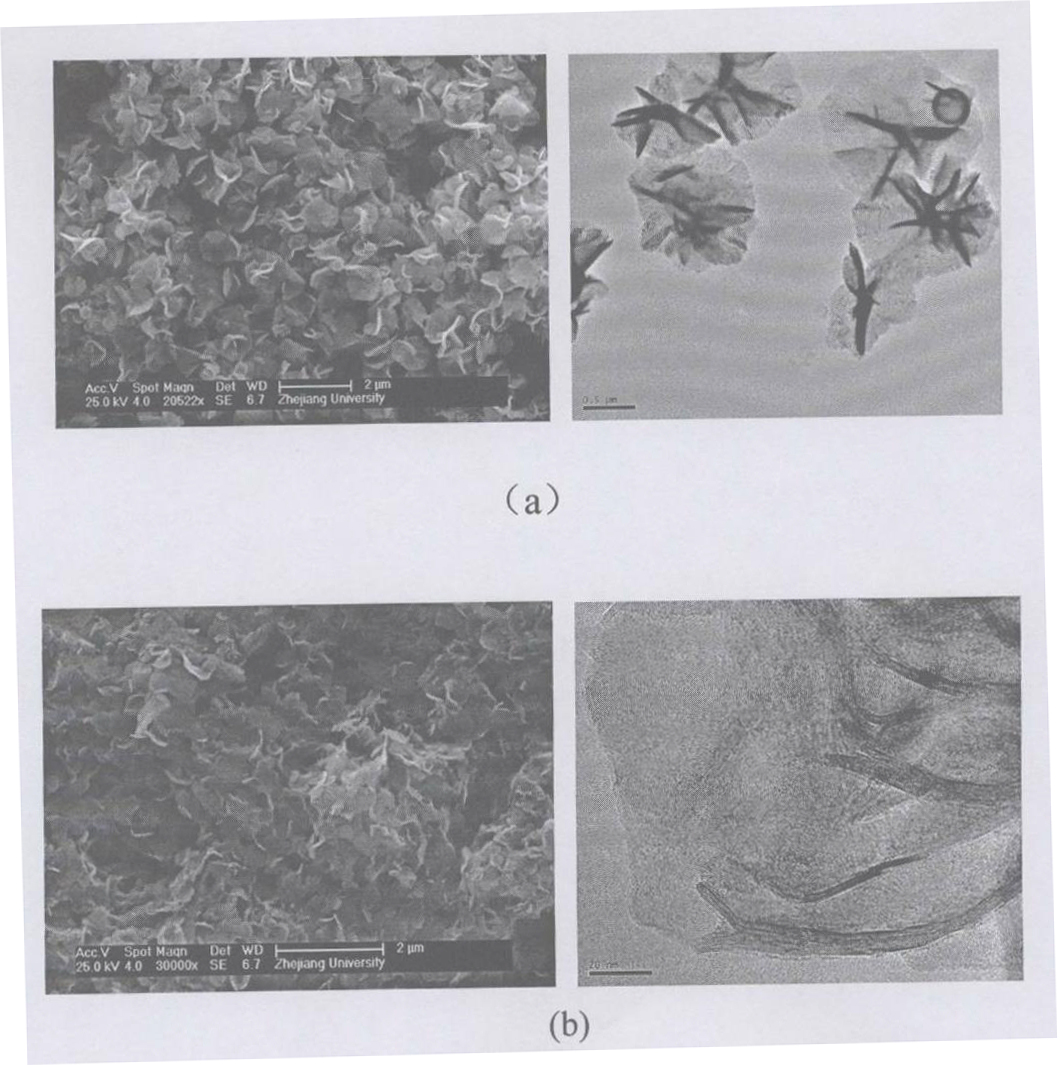

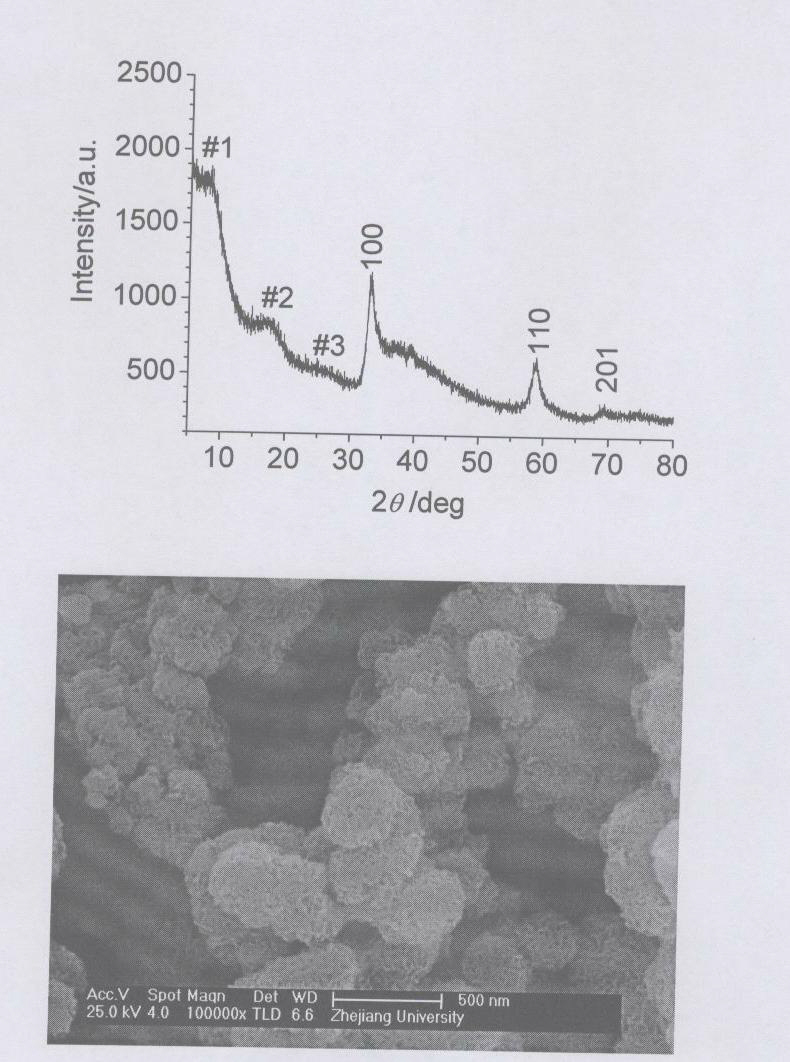

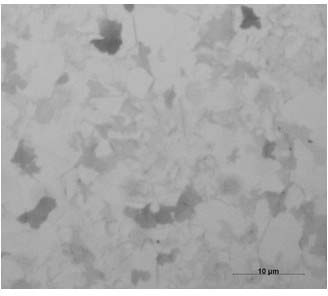

Compound nano material of graphene and MoS2 and preparation method thereof

InactiveCN102142548AMild reaction conditionsSimple preparation processMaterial nanotechnologyCell electrodesCysteine thiolateNew energy

The invention discloses a compound nano material of graphene and molybdenum disulfide (MoS2) and a preparation method thereof. The compound material is formed by mixing graphene and a MoS2 nano material in a mass ratio of (1 to 1)-(4 to 1). The preparation method comprises the following steps of: preparing an oxidized graphite nano slice from graphite by a chemical oxidization method; then dissolving molybdate into deionized water so as to form 0.02 to 0.07M of solution; adding L-cysteine serving as a sulfur source and a reduction agent, wherein the mass ratio of the L-cysteine to the molybdate is (5 to 1)-(12 to 1); adding the oxidized graphite nano slice into the solution, and ultrasonically treating so that the oxidized graphite nano slice can be fully dispersed in the hydrothermal reaction solution; transferring the mixture into a hydrothermal reaction kettle and sealing; and synthesizing by a one-step hydrothermal method to obtain the compound nano material of graphene and MoS2, wherein the mass ratio of the graphene nano slice to the MoS2 is (1 to 1)-(4 to 1). The method has the characteristics of mild reaction condition and simple process. The compound nano material of graphene and MoS2 synthesized by the method can be widely used as electrode materials of new energy batteries, high-performance national lubricants, catalyst carriers and the like.

Owner:ZHEJIANG UNIV

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

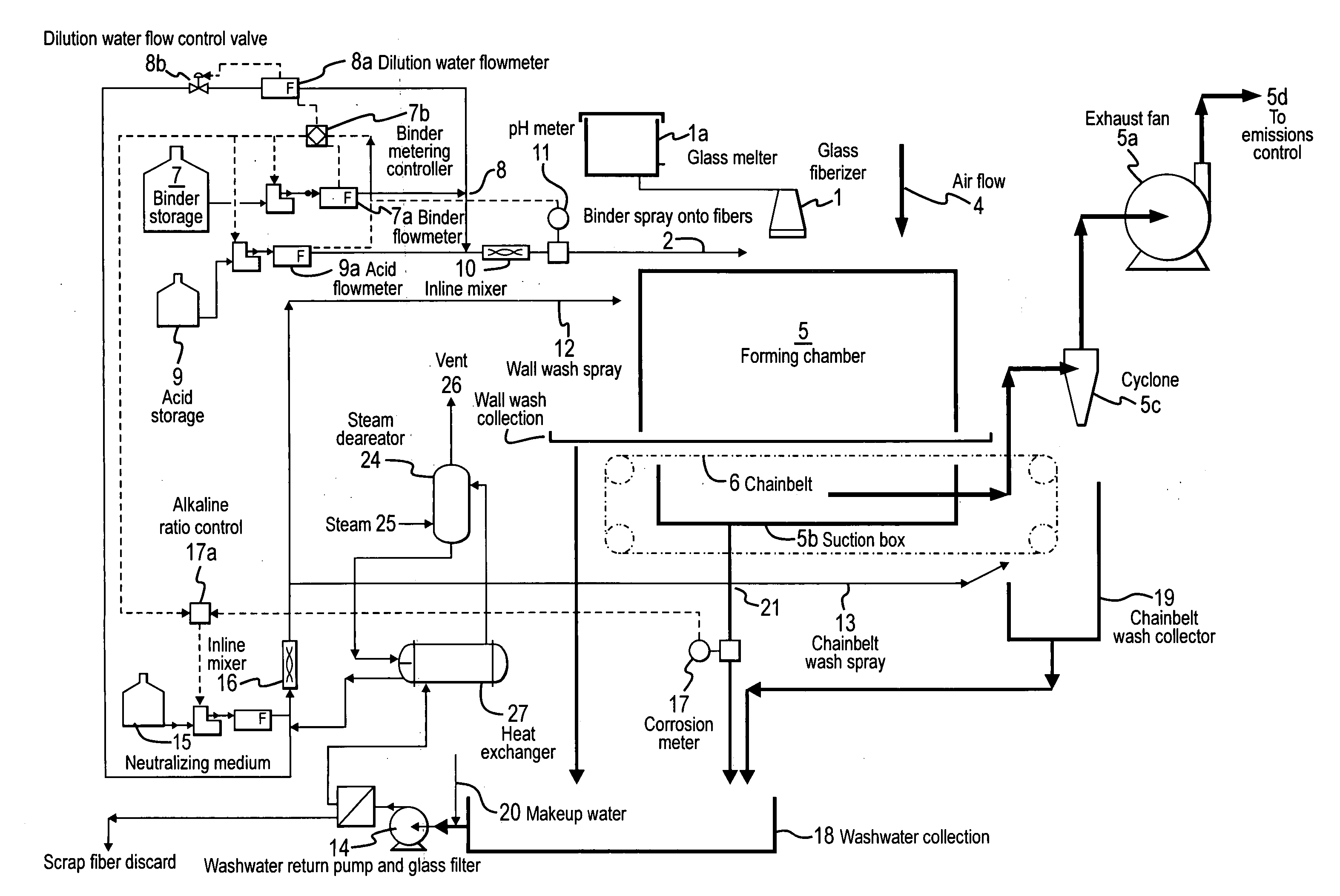

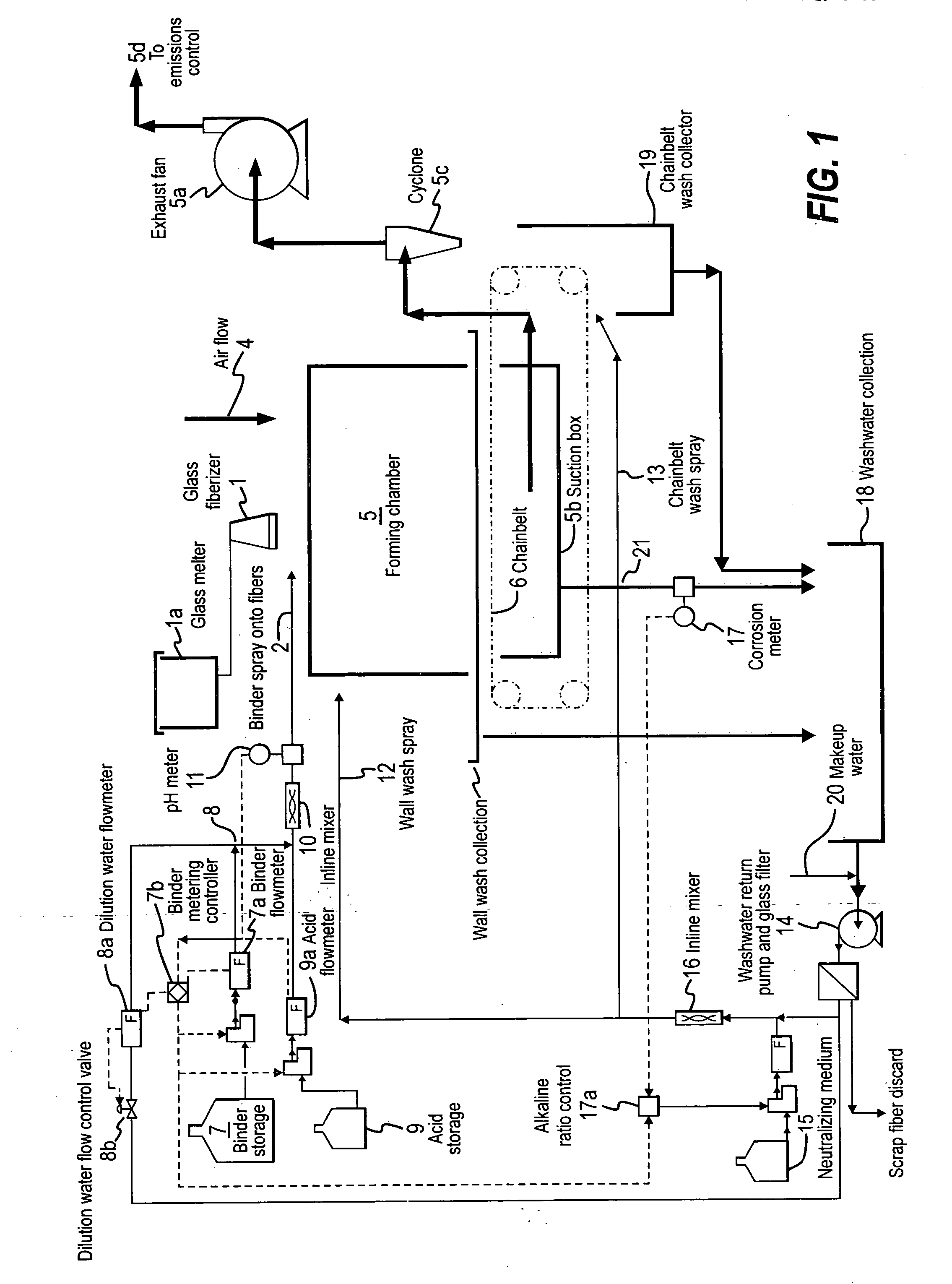

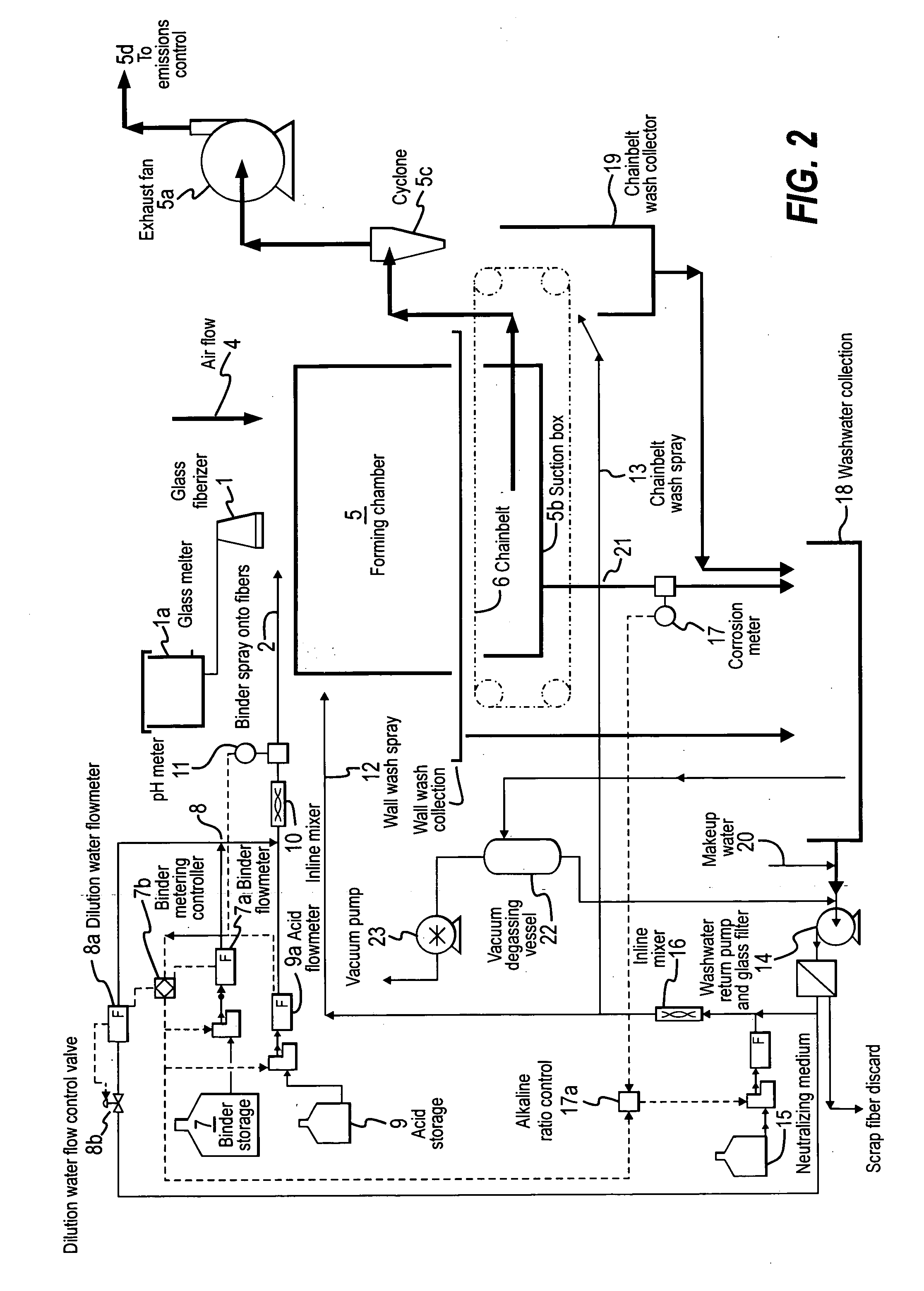

Method for reducing corrosion

InactiveUS20060198954A1Limiting amount of downtimeAvoid damageGlass making apparatusLiquid surface applicatorsGlass fiberWash water

A method for reducing corrosion of a wash water system for glass forming lines, by using a corrosion meter, is provided. Also provided is a fiberglass manufacturing process that utilizes the method.

Owner:FRECHEM BART SHANNON +2

Multi-component oxidation micro-electrolytic filler and preparation method thereof

ActiveCN102276021AIncrease contact areaAvoid separationWater/sewage treatment by sorptionActivated carbonIron powder

The invention belongs to the technical field of environmental engineering wastewater treatment, and particularly relates to multi-component oxidized micro-electrolysis filler and a preparation method thereof. The multi-component oxidized micro-electrolysis filler is mainly prepared from the following components in percentage by mass: 50-60% of iron, 20-30% of activated carbon, 12-15% of adhesive and 3-5% of catalyst through mixing, wherein iron is iron scrap or iron powder with particle size not more than 80 mesh; and activated carbon is in a powder and has particle size not more than 100 mesh. The preparation method of the multi-component oxidized micro-electrolysis filler comprises uniformly mixing iron, activated carbon, the adhesive and the catalyst according to the ratio, adding water, stirring and aging, then carrying out extrusion molding to obtain molded filler, demolding to obtain a filler blank, after naturally drying, drying, sintering in the absence of air, and cooling thefiller blank to obtain the multi-component oxidized electrolysis filler. According to the invention, the hardening, dead pool, stoppage and other practical problems existing in the use of the traditional micro-electrolysis fillers are solved.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

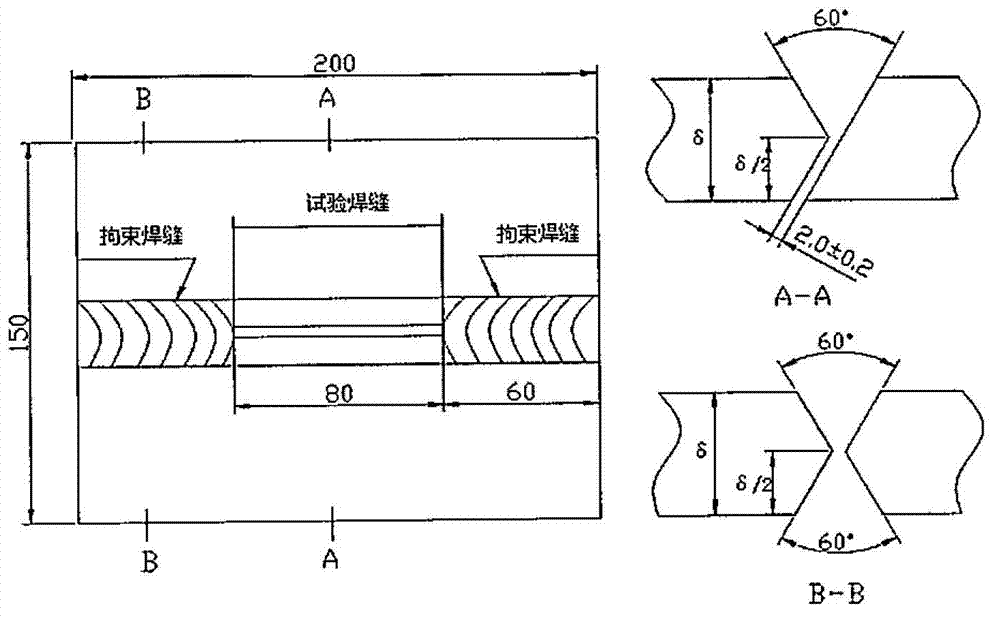

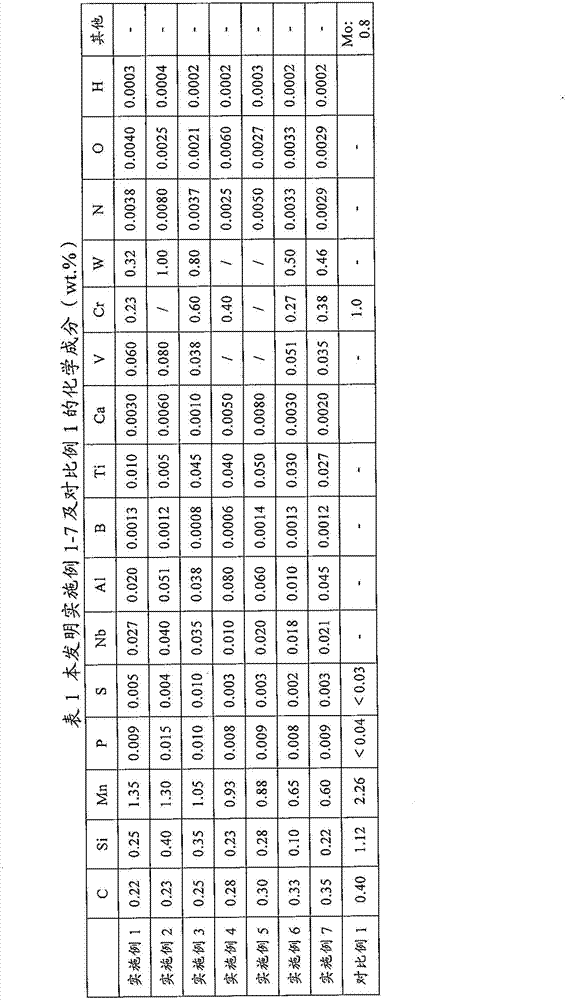

Super-strength high-toughness wear resistant steel plate and production method thereof

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of edible film with antibacterial and antioxidant functions

InactiveCN103159970AHas antibacterial propertiesAntioxidantFlexible coversWrappersAntioxidantGlycerol

The invention relates to a preparation method of an edible film with antibacterial and antioxidant functions, and belongs to the technical field of edible packaging materials. The preparation method disclosed by the invention comprises the following steps: 1) dissolving and gelatinizing corn starch; 2) dissolving gelatin; 3) dissolving chitosan; 4) adding glycerin and plant essential oil or essential oil components; 5) mixing, homogenizing and refining; 6) degassing; 7) tape-casting; and 8) drying and stripping the film. The preparation method disclosed by the invention has the beneficial effects that the chitosan, the corn starch and the gelatin are taken as base materials of the edible film, the sources of the raw materials are wide, the cost is low, and the prepared edible film has the advantages of strong mechanical properties, high barrier performance and great transparency. Oregano oil, carvacrol and cinnamaldehyde are taken as an antibacterial agent and an antioxidant so as to be added into the edible film, the processing process is simple and easy to operate, the cost is low, the edible film is non-toxic and safe to eat, and the prepared edible film has great antibacterial and antioxidant properties.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

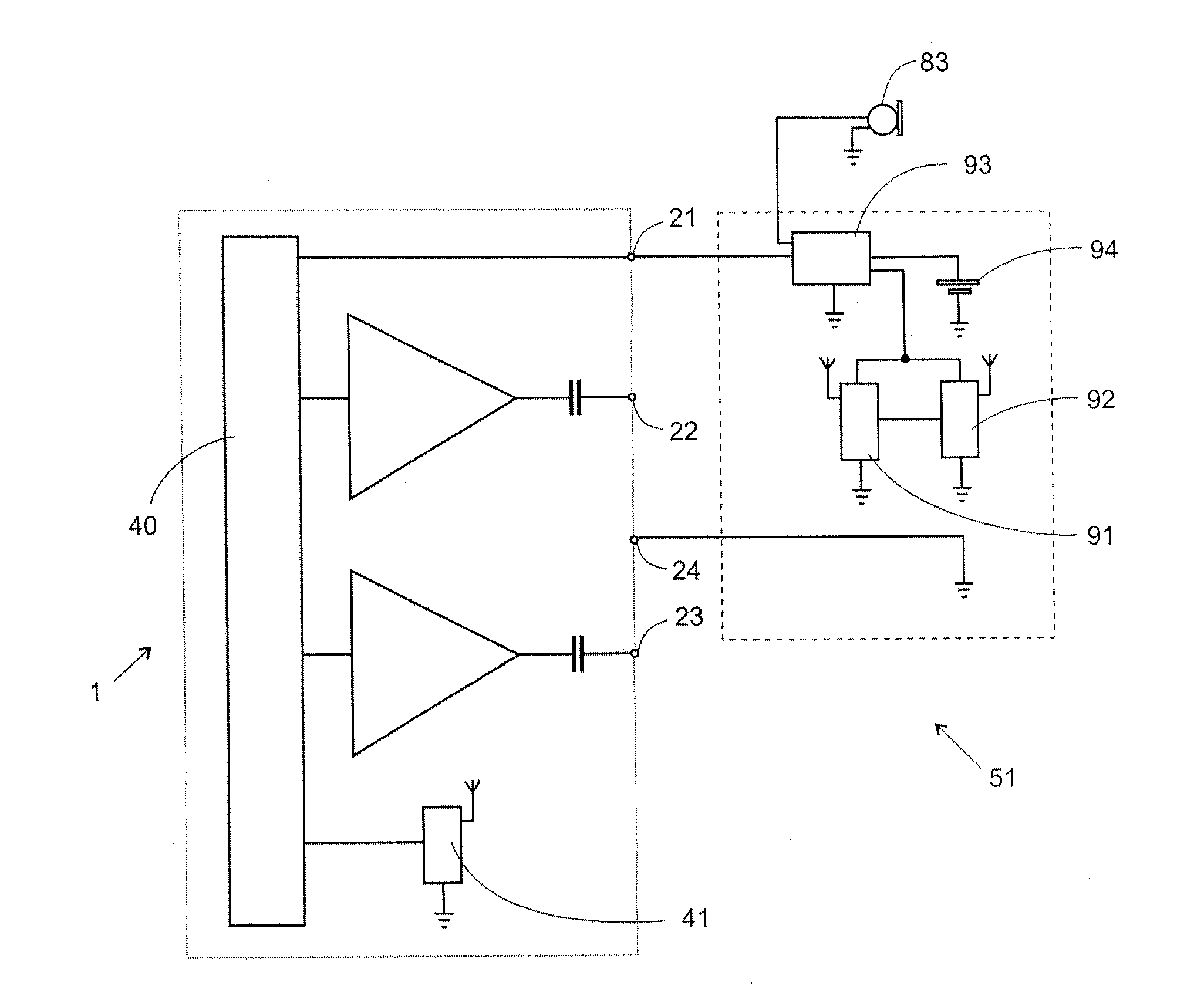

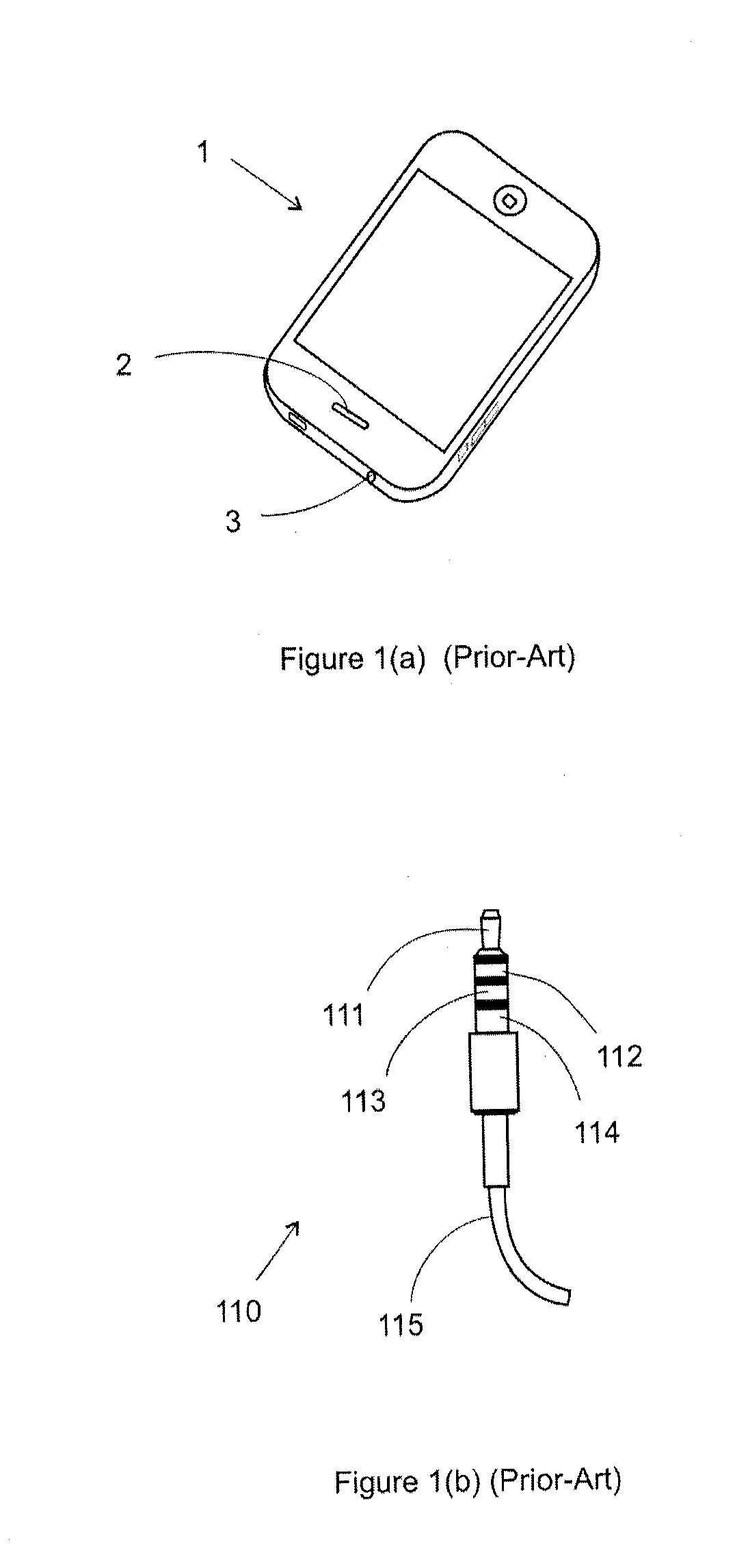

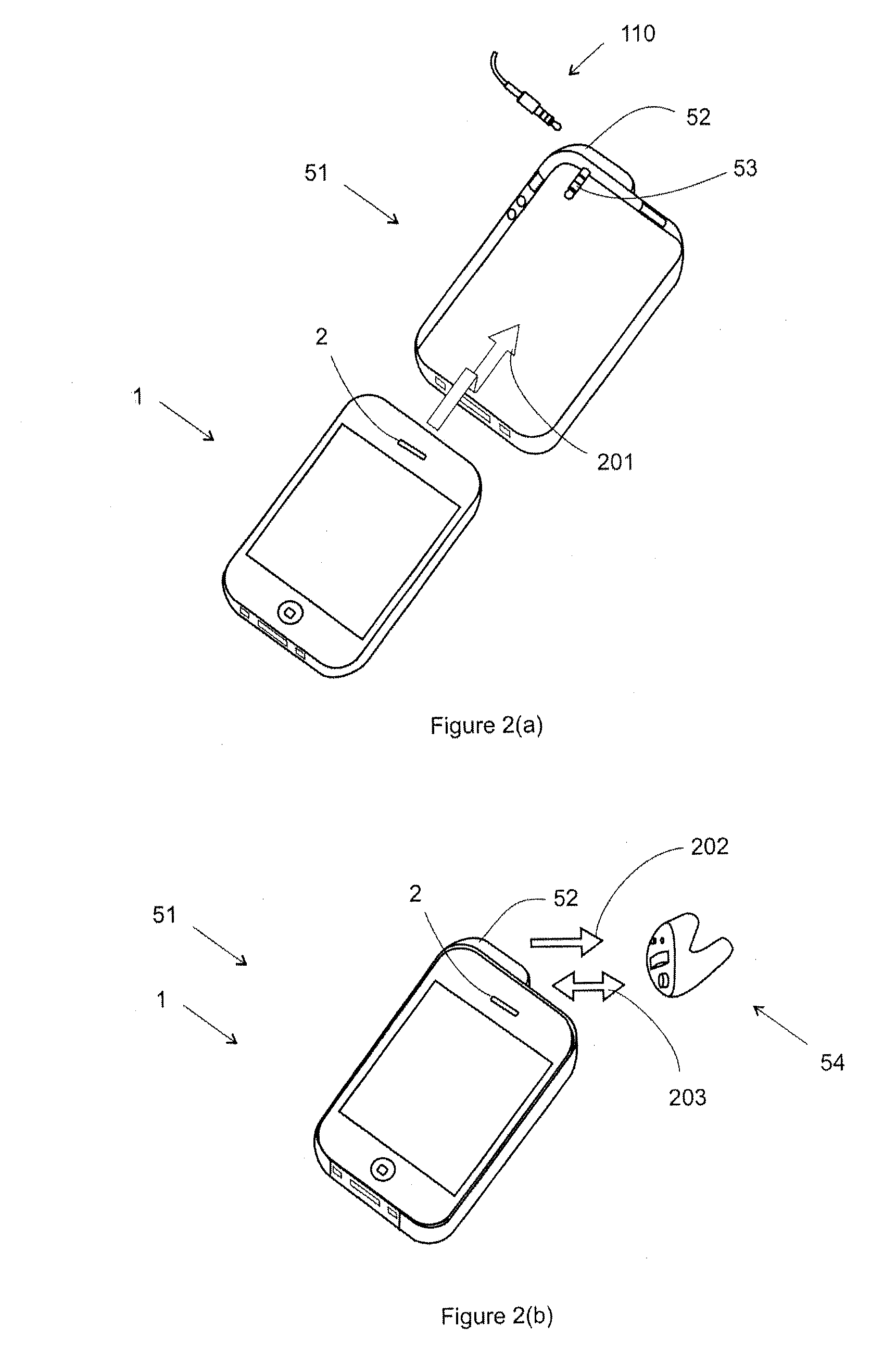

Communications apparatus

InactiveUS20140018016A1Avoid breakingSmall sizeBatteries circuit arrangementsPublic address systemsTransceiverThe Internet

A versatile communications (comms) apparatus to provide a means to measure the audio (earphone) output of an electronic device (e.g. a music player in a smartphone), and / or to provide a means for wireless communications between a first electronic device (e.g. a smartphone) and a second electronic device (e.g. a hearing aid, pacemaker, etc). In some embodiments, the comms apparatus does not need power and in other embodiments, its power may be harvested from the first electronic device, or drawn from a battery that may be recharged by harvesting means or charged directly. The first electronic device typically includes an audio (earphone) output, a microphone input (with a voltage bias), a long-range communications transceiver (e.g. GSM), and where pertinent, a short-range transceiver (e.g. Bluetooth) and is internet enabled. In one embodiment, the comms apparatus provides a means where the audio output (earphone) of the electronic device is sampled by its microphone input, or by electronics in the comms apparatus. In other embodiments, the comms apparatus is an intermediary communications device between the first electronic device and the second electronic device. The communications therein may be simplex and / or duplex, via either the audio output (earphone), microphone input, short-range transceiver, and / or a combination thereof. The communications data (via the comms apparatus) may be transmitted elsewhere, including via the internet by means of the internet enabled electronic device.

Owner:ADVANCED ELECTROACOUSTICS PRIVATE

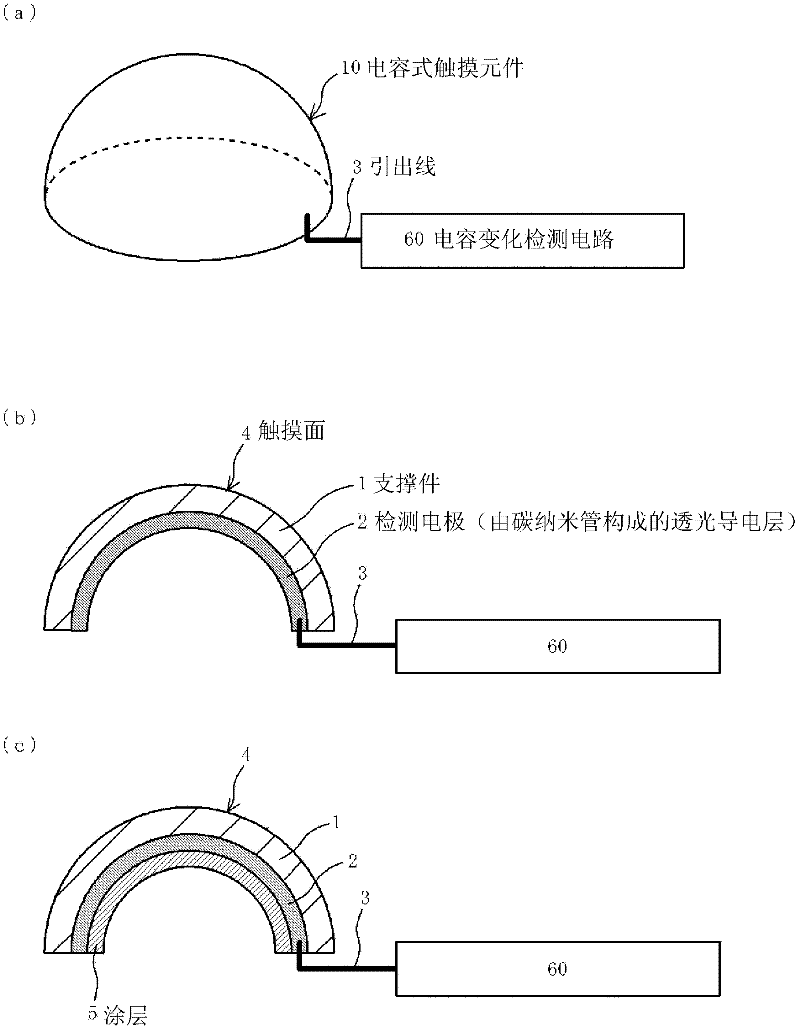

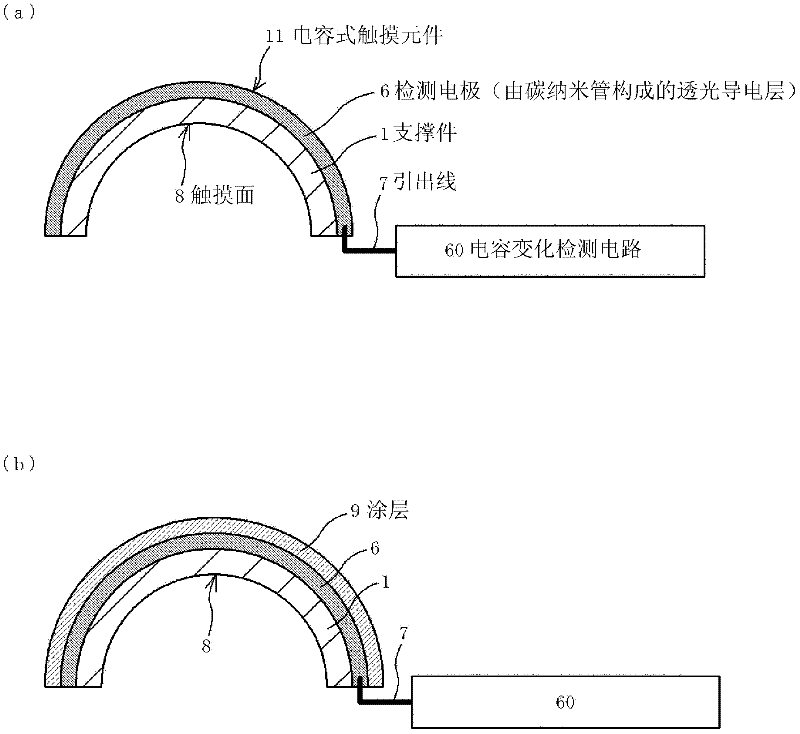

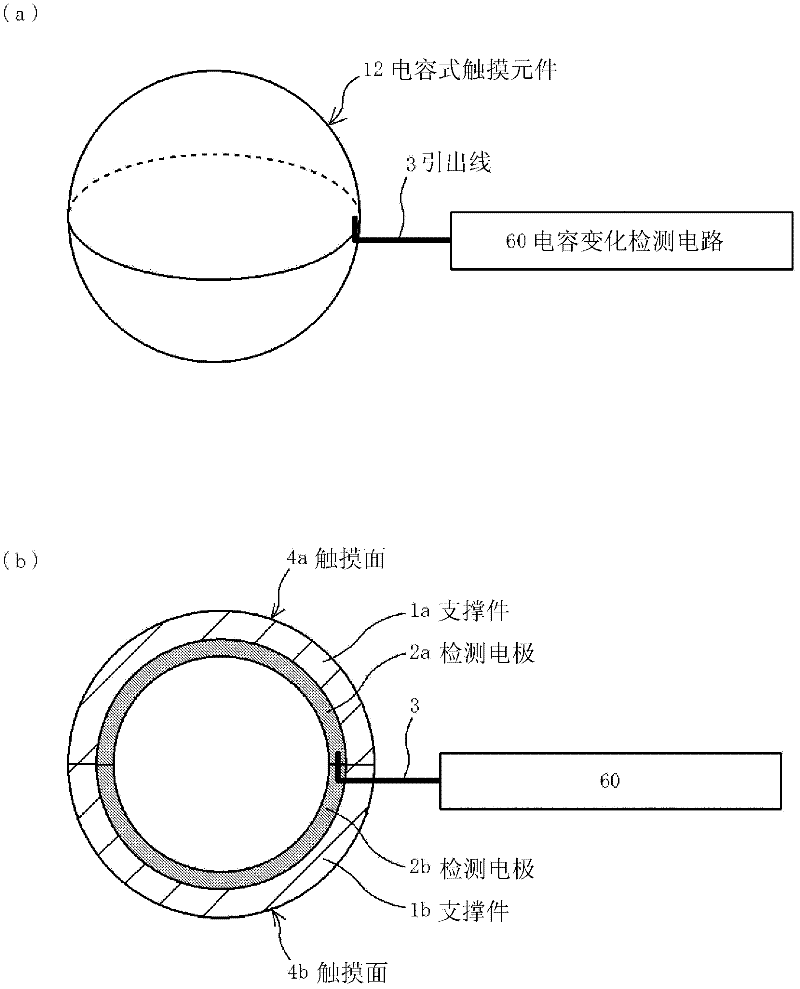

Capacitance type touch member and method for producing the same, and capacitance type touch detection device

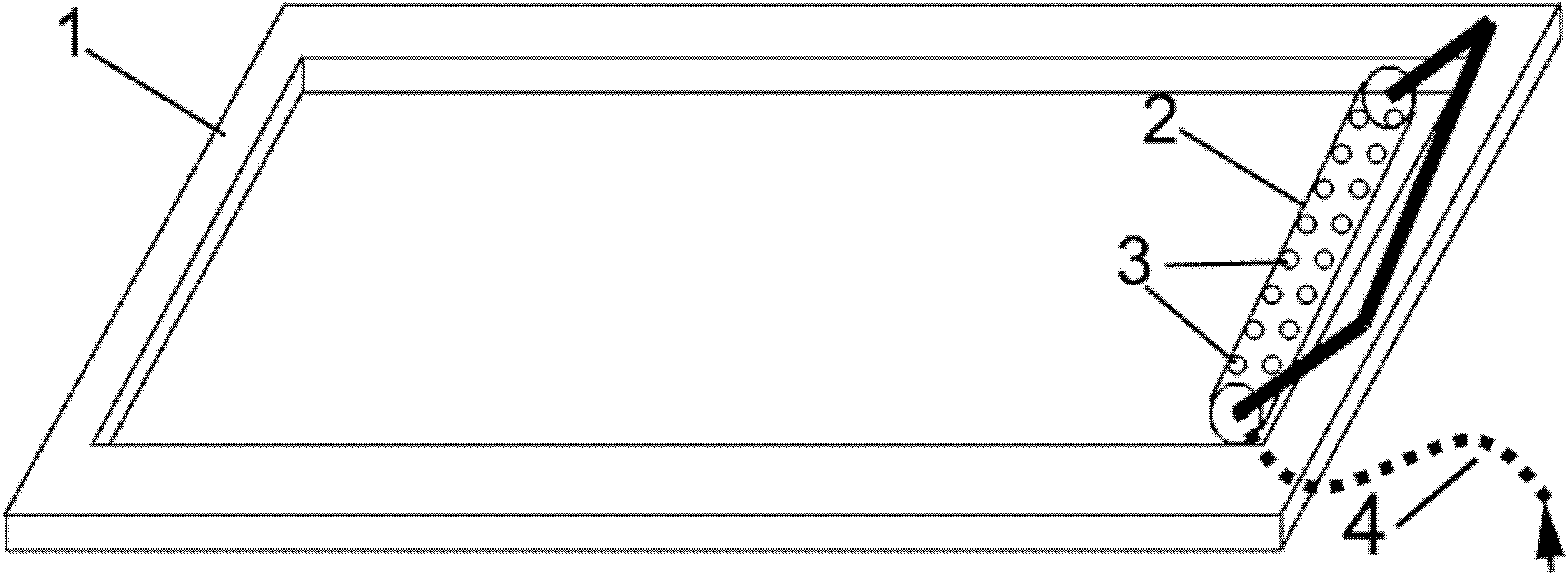

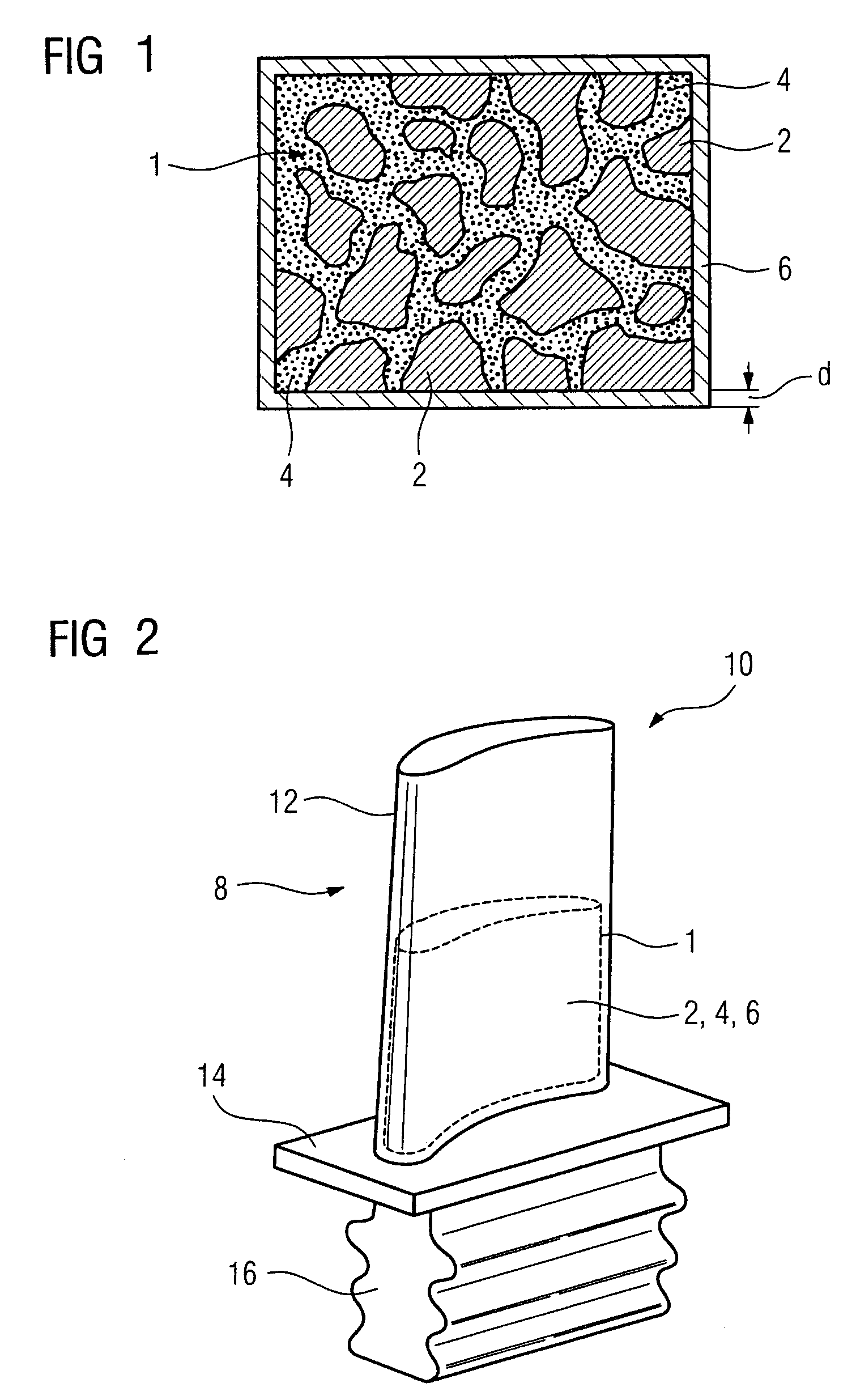

InactiveCN102365698AImprove conductivityConductivity is sufficientElectronic switchingMagnetic/electric field switchesCapacitanceTectorial membrane

Provided are a capacitance type touch member which has a flexible or stereoscopic shape and has a light transmissive detection electrode, and a method for producing the same; and a capacitance type touch detection device provided with the capacitance type touch member. A capacitance type touch member (10) comprised of a film-like or plate-like support element (1) composed of an insulating material, which has a flexible or stereoscopic shape; a detection electrode (2) which is disposed on at least a part of one surface of the support element (1), and is composed of a light transmissive conductive layer containing a carbon nano linear structure such as a carbon nanotube; and a lead wire (3) drawn from the detection electrode (2), is produced. A capacitance type touch detection device is comprised of the touch member (10) and a capacitance detection circuit (60) which is electrically connected to the detection electrode (2) via the lead wire (3), to detect the change of the capacitance due to the access or contact of a human body to a touch surface (4). The detection electrode (2) may be coated with a protection film, and the surface of the protection film may be used as a touch surface.

Owner:SONY CORP

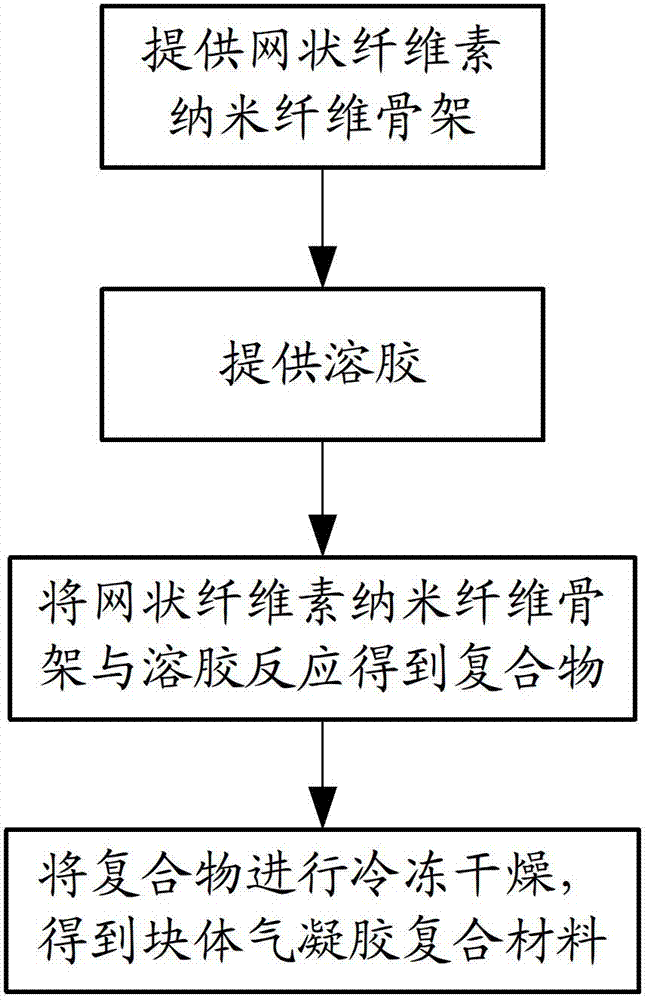

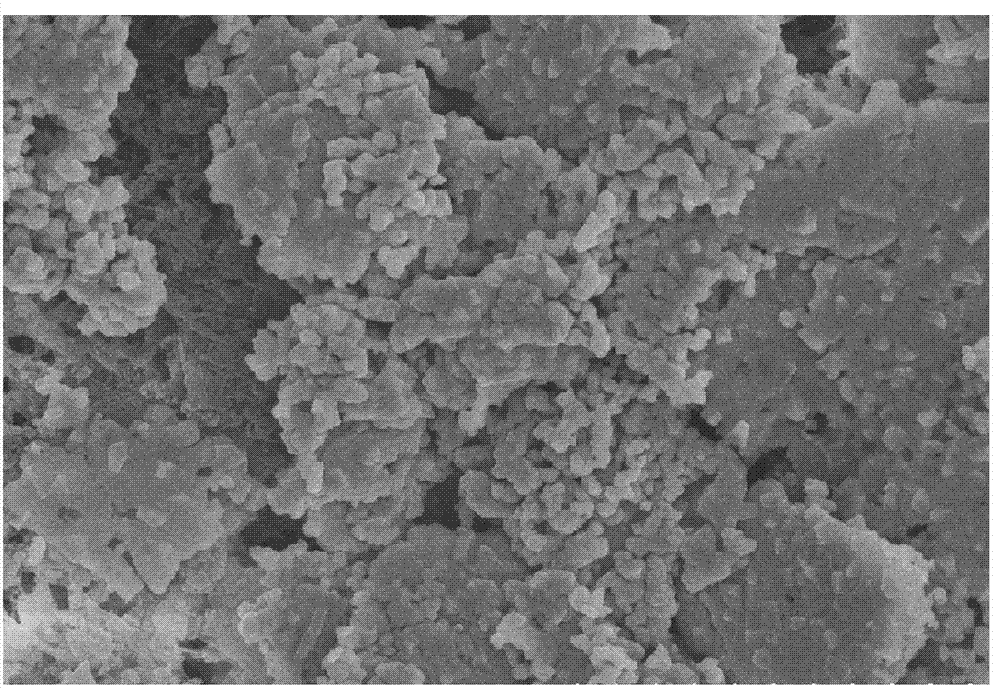

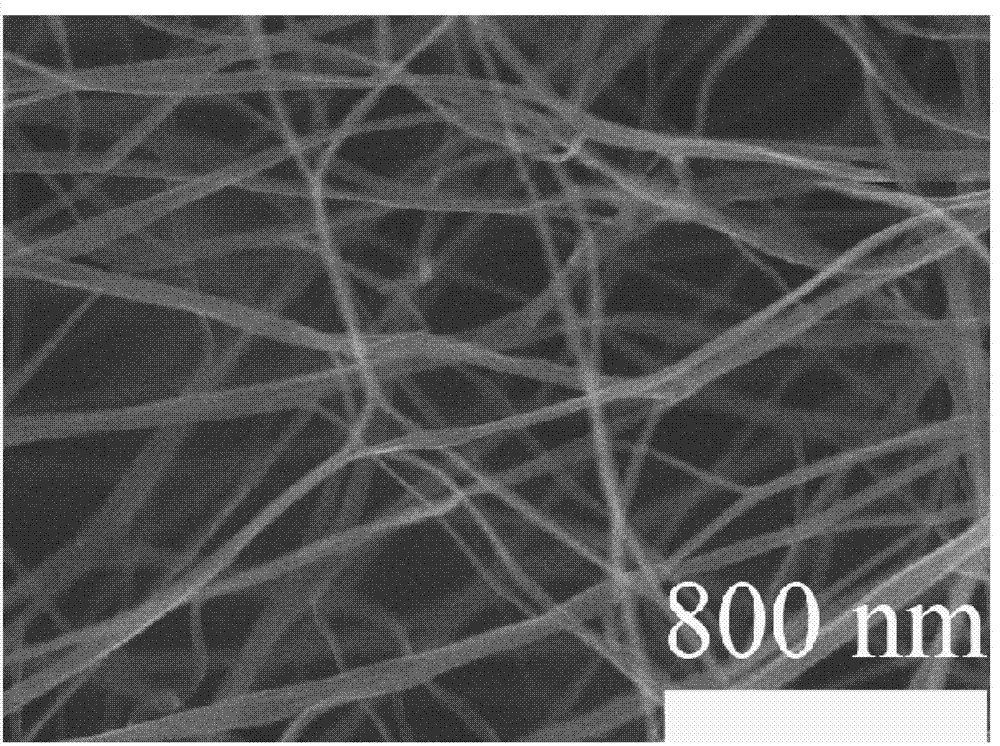

Block aerogel composite material and preparation method thereof

InactiveCN102807357AImprove mechanical propertiesLow thermal conductivitySupercritical dryingElastic modulus

The invention discloses a block aerogel composite material and a preparation method thereof. The block aerogel composite material consists of reticular cellulose nano fiber skeletons and sol in a combining way, wherein the porosity of the aerogel composite material is 80-99.5 percent, the density is 0.015-0.680g / cm<3>, the BET specific surface area is 150-1200m<2> / g, the coefficient of heat conductivity is 0.015-0.045Wm<-1>k<-1> and the modulus of elasticity is 0.5-150MPa. The block aerogel composite material provided by the embodiment of the invention has the advantages that since the material consists of the reticular cellulose nano fiber skeletons and the sol in the combining way, the mechanical property of the block aerogel composite material can be obviously improved, the heat conductivity is low, the density is small and the specific surface area is large; and besides, the equipment cost can be decreased by adopting a relatively low and safe freeze-drying method to replace the traditional supercritical drying method.

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS

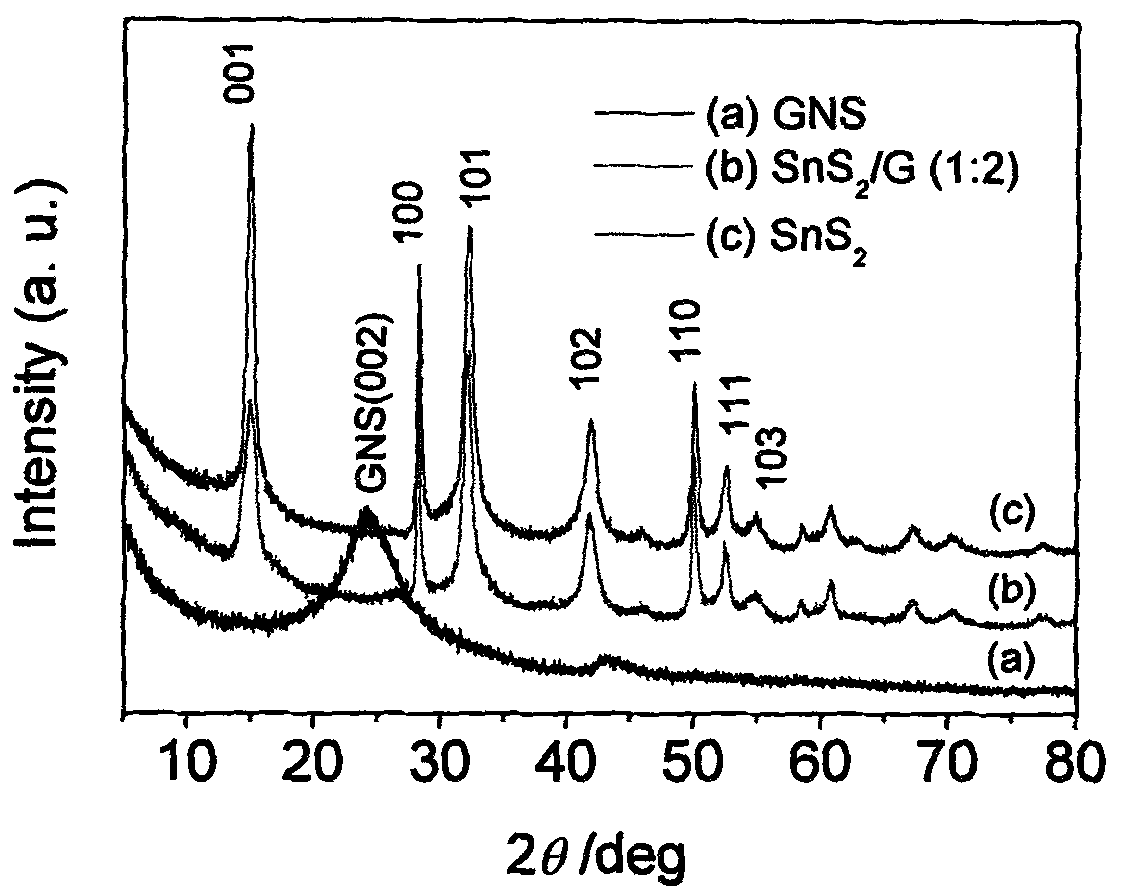

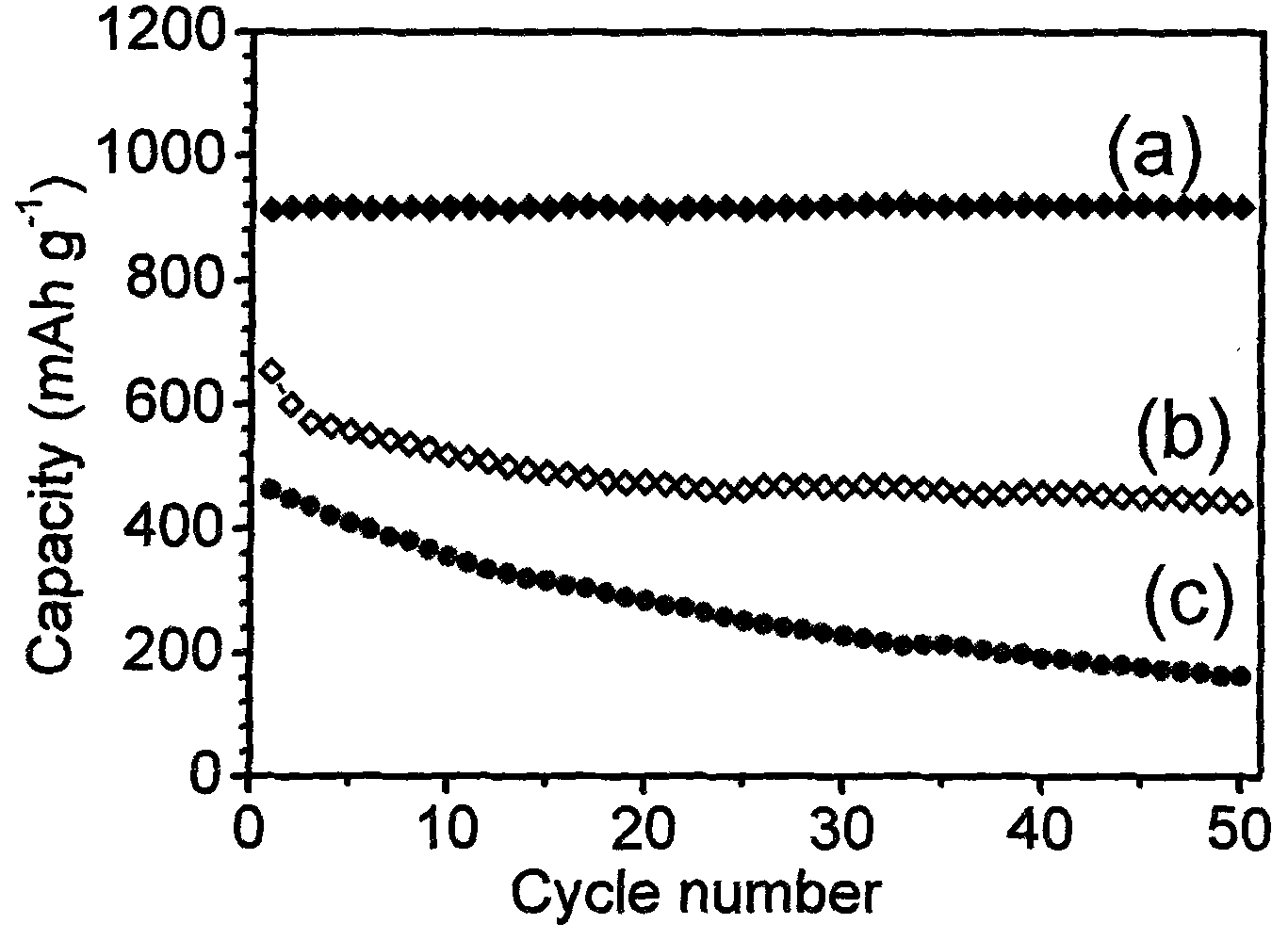

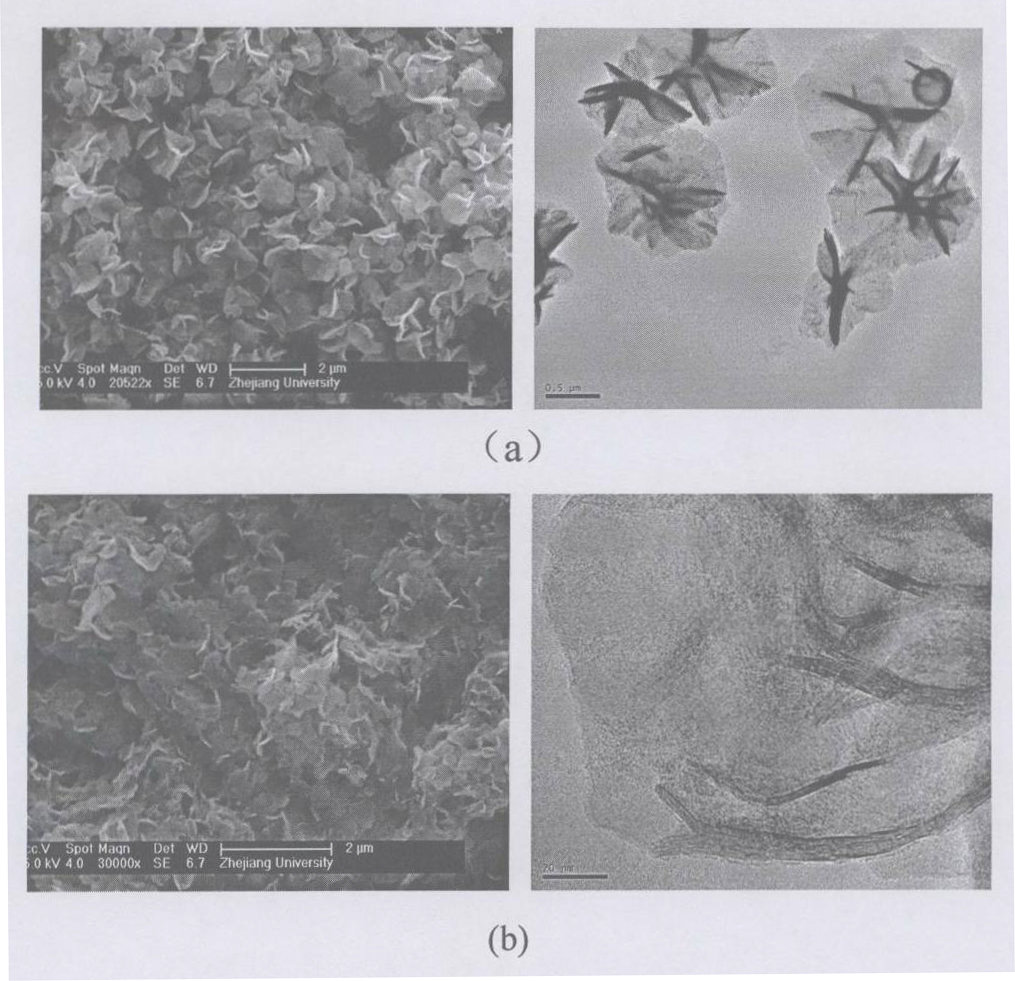

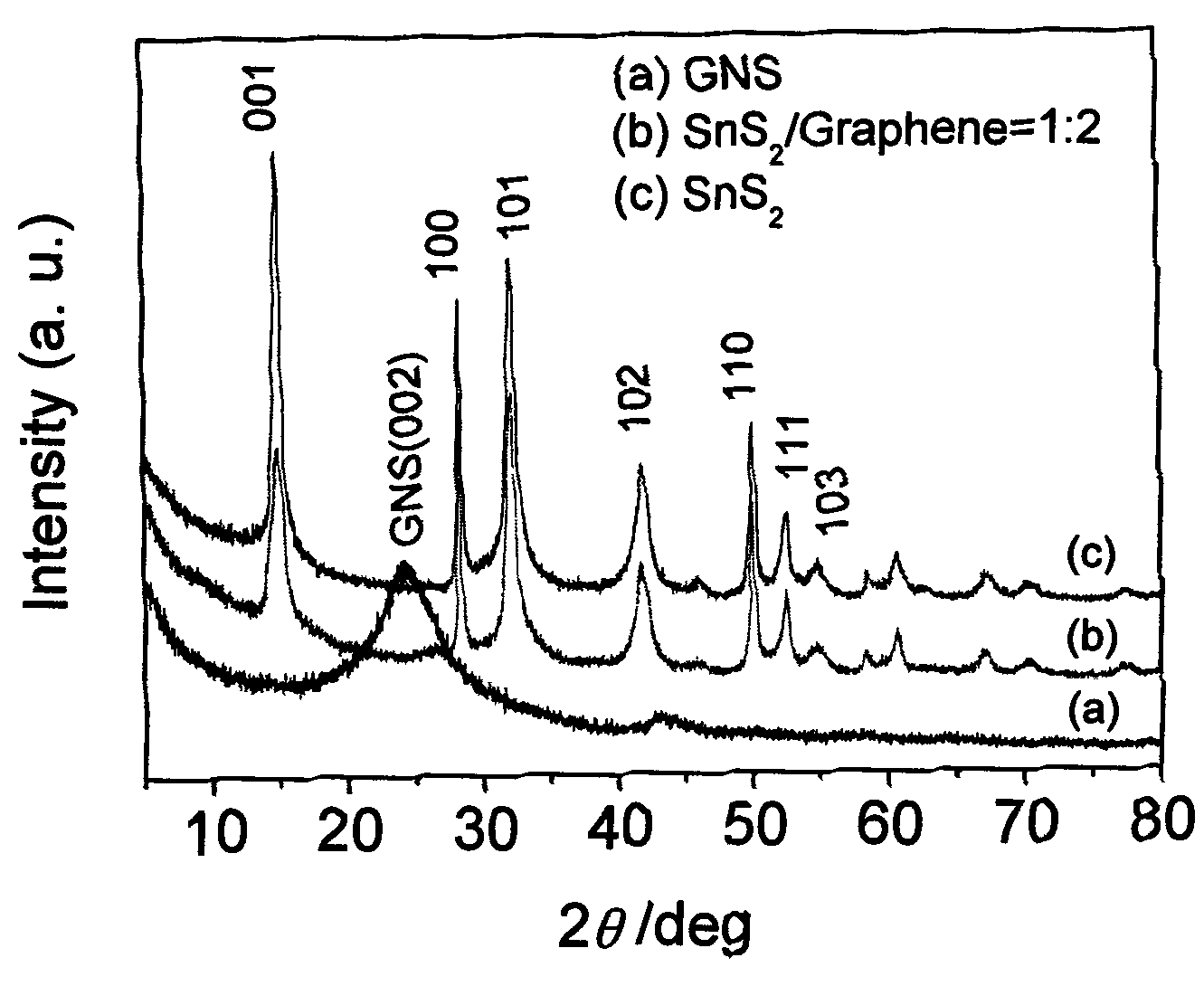

Lithium ion battery electrode made of graphene/SnS2 composite nanometer material and preparation method thereof

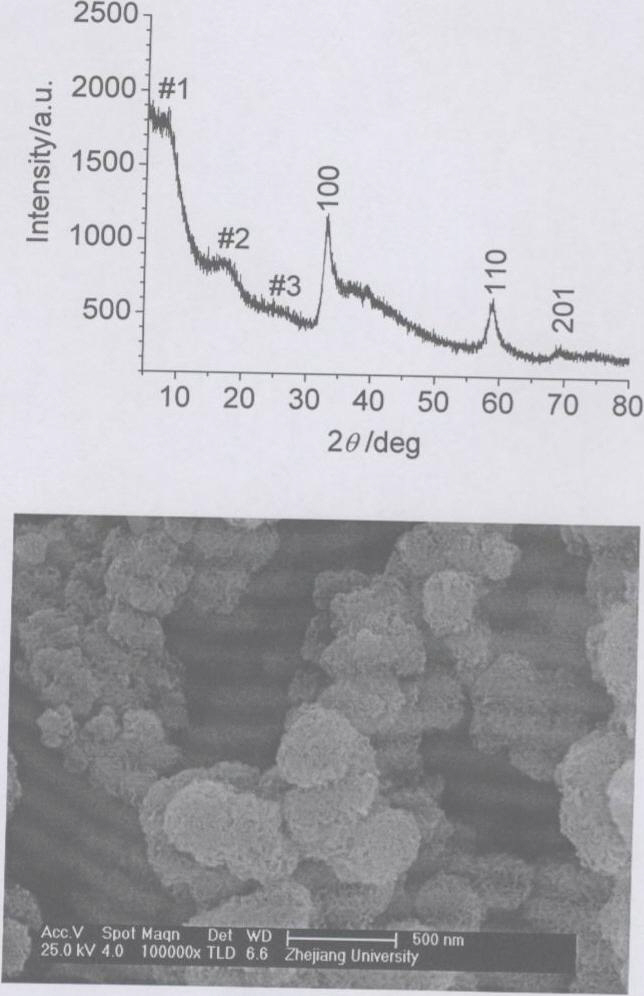

InactiveCN102142540AMild reaction conditionsSimple processCell electrodesMass ratioLithium-ion battery

The invention discloses a lithium ion battery electrode made of a graphene / SnS2 composite nanometer material and a preparation method thereof. The lithium ion battery electrode is characterized in that the active substance of the electrode is the graphene / SnS2 composite nanometer material, and the other components of the electrode are acetylene black and polyvinylidene fluoride. The lithium ion battery electrode comprises the following components in percentage by weight: 75-85% of the composite nanometer material active substance, 5-10% of the acetylene black and 10% of the polyvinylidene fluoride; and the mass ratio of the graphene to SnS2 nanometer material in the composite nanometer material active substance is (1:1)-(4:1). The electrode preparation method disclosed by the invention comprises the following steps: preparing a graphite oxide nanometer sheet by taking graphite as a raw material by virtue of a chemical oxidation method; in the presence of the graphite oxide nanometer sheet, synthetizing to obtain the graphene / SnS2 composite nanometer material by virtue of a one-step hydrothermal in-situ reduction method; and finally, taking the graphene / SnS2 composite nanometer material as the active substance to prepare the electrode. The electrode disclosed by the invention has the advantages of higher electrochemical lithium storage capacity and excellent cyclical stability and can be widely used in the new generation of lithium ion batteries.

Owner:ZHEJIANG UNIV

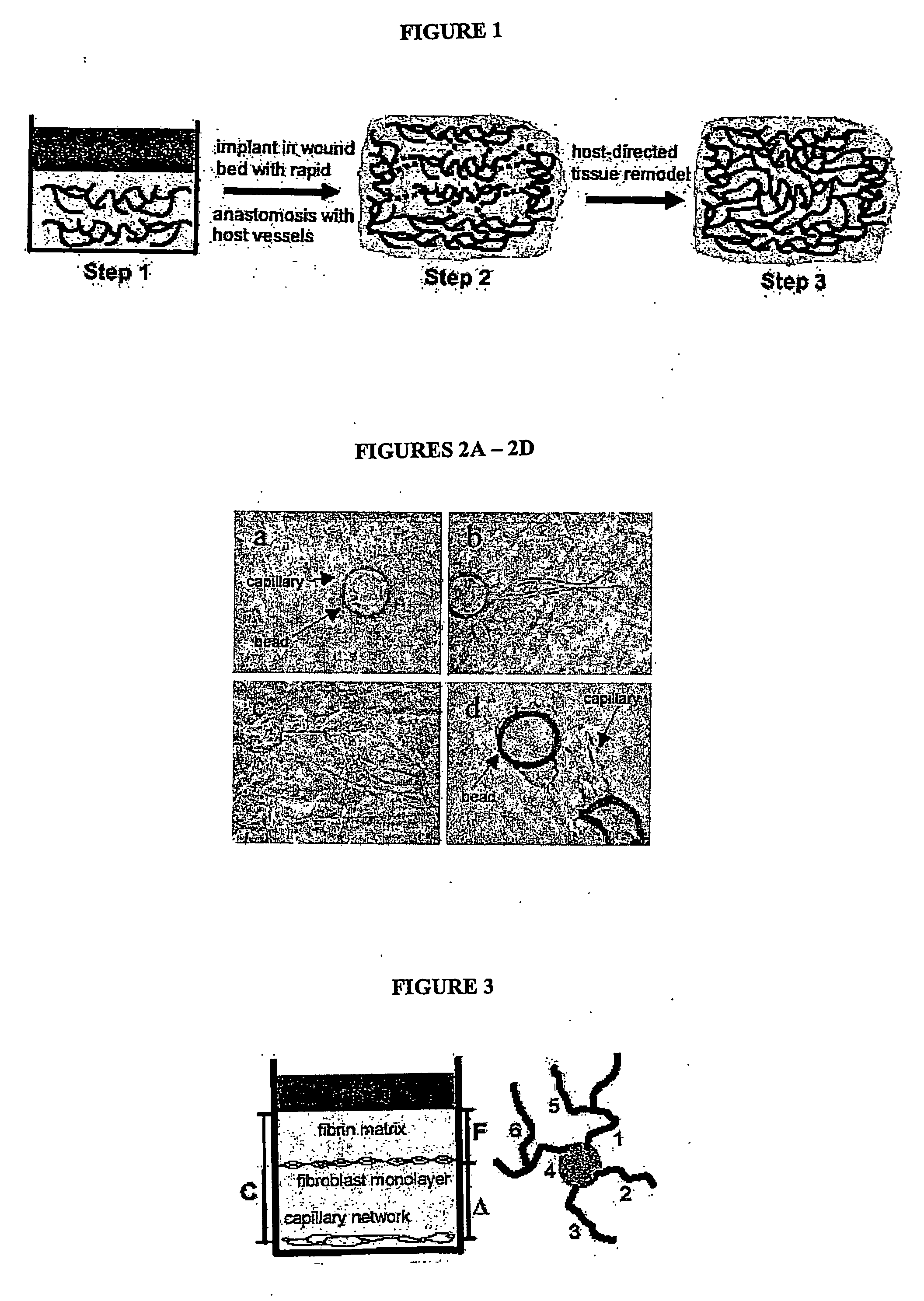

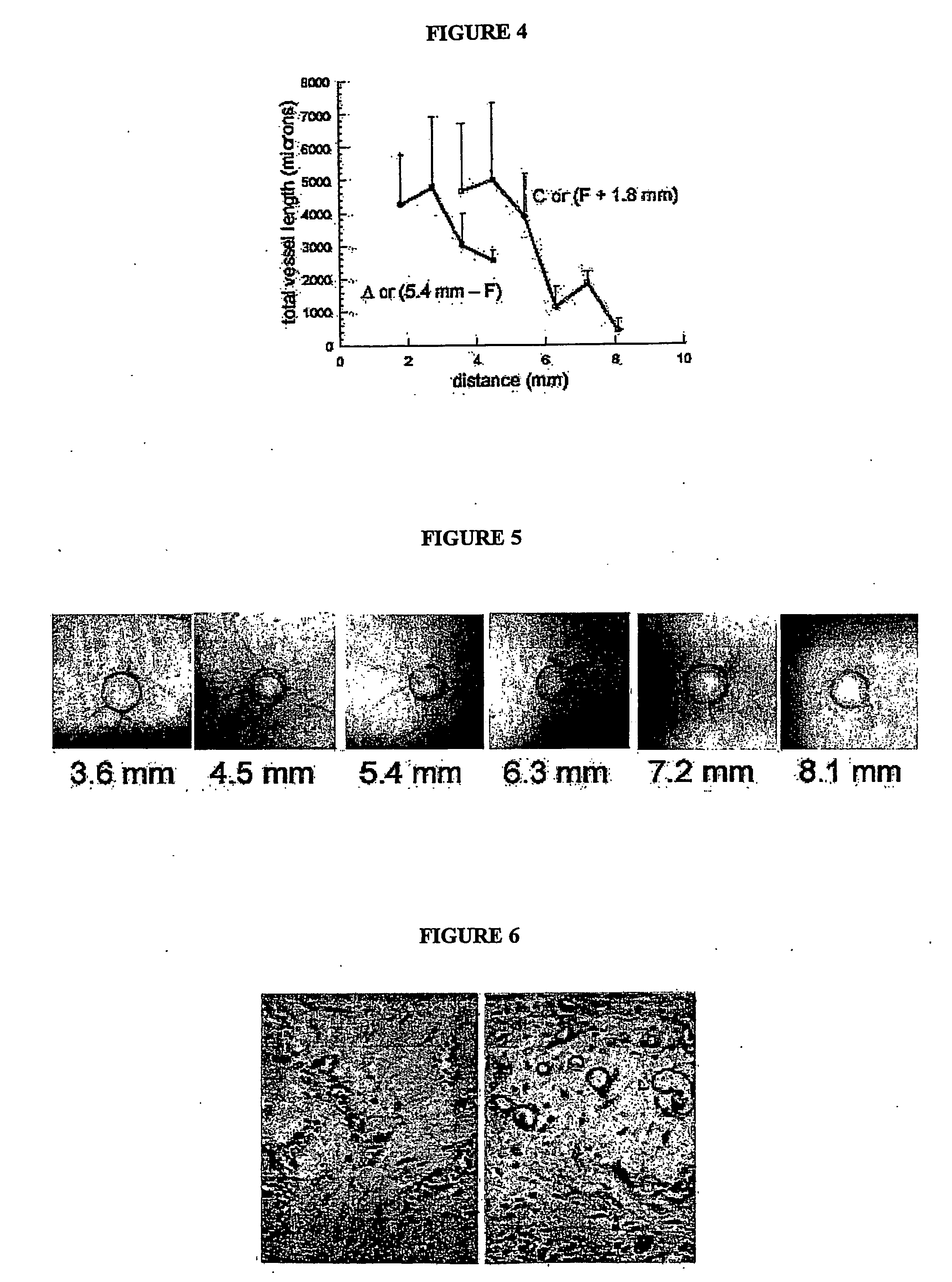

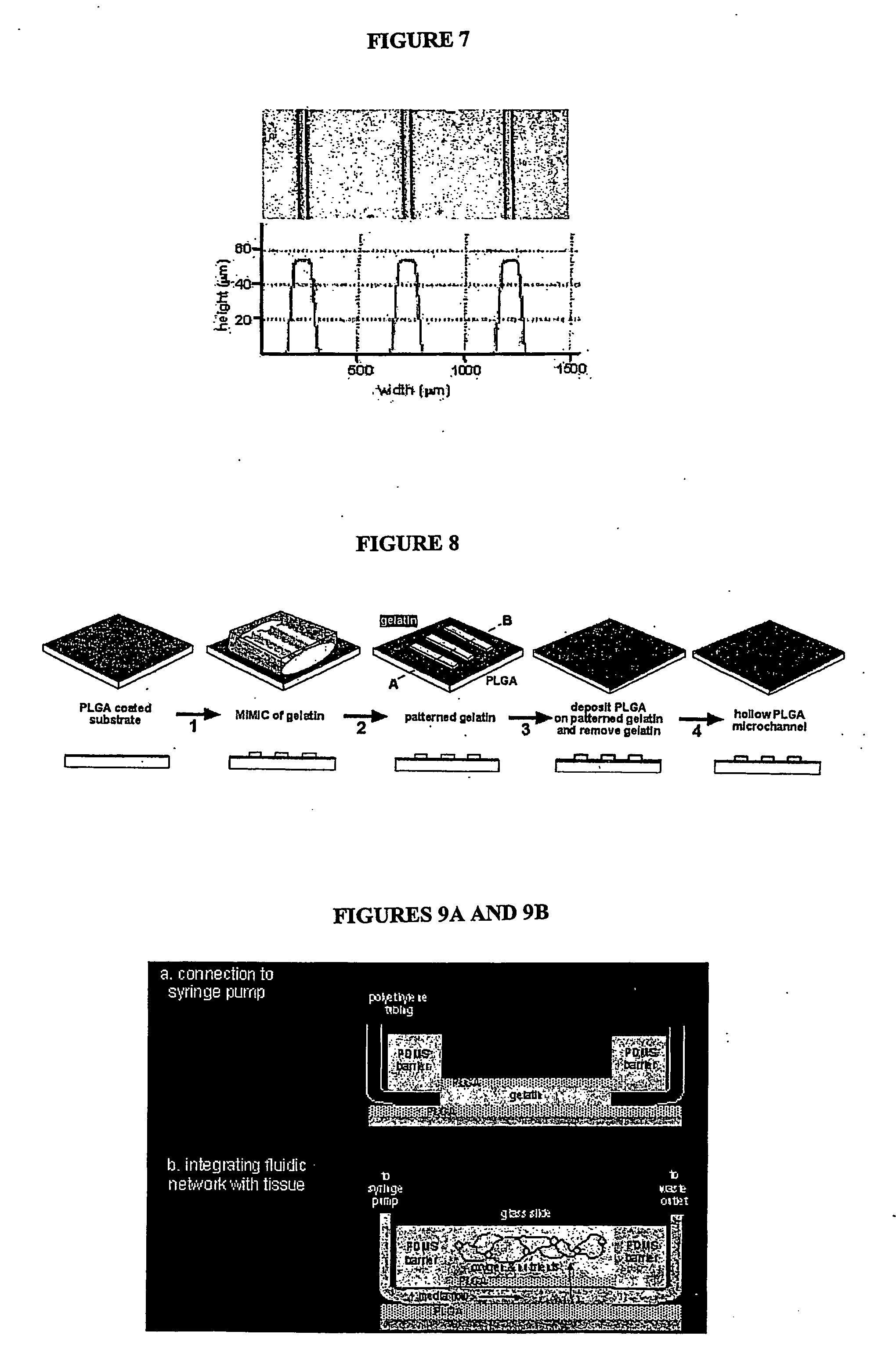

Vacsularized tissue for transplantation

InactiveUS20060018838A1Carefully controlledImprove practicalityBiocideGenetic material ingredientsCapillary networkTissue transplantation

Tissue engineering holds enormous potential to replace or restore function to a wide range of tissues. However, the most successful applications have been limited to thin avascular tissues in which delivery of essential nutrients occurs primarily by diffusion. Pursuant to the present invention, a prevascularized, thick tissue construct is created having a network of capillaries with lumens capable of nutrient and origin delivery and forming anastamoses to host vasculature. A tissue transplantation strategy is comprised of (1) in vitro vascularization of a tisue construct, (2) transplantation of prevascularized tissue to wound bed of host where vessels of implantable tissue and host rapidly anastomose, and (3) host-directed remodeling and reorganization of the tissue and vascular network.

Owner:RGT UNIV OF CALIFORNIA

Adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and preparation method and application thereof

ActiveCN105148744AHighly corrosiveStrong mechanical propertiesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAir atmosphereThin membrane

The invention belongs to the technical field of separating film materials, and discloses an adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and a preparation method and application thereof. The preparation method comprises the following steps of performing heat treatment on dicyandiamide or cyanurtriamide under an inert atmosphere to obtain caked g-C3N4; pulverizing the caked g-C3N4 and calcining under an air atmosphere to obtain g-C3N4 powder; dispersing the g-C3N4 powder in solvent to obtain g-C3N4 two-dimensional nanosheet solution; adding electrolyte solution for modifying; depositing a g-C3N4 two-dimensional nanosheet on a porous carrier of which the pore diameter is greater than 200 nanometers to form a two-dimensional g-C3N4 ultrathin film; and drying to remove the solvent so as to obtain the adjustable and controllable ultrathin two-dimensional nano g-C3N4 film loaded on the porous carrier. The g-C3N4 film is high in water permeability and high in separation efficiency, and has a wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Guided tissue regeneration membrane and its preparation method

The invention relates to a guided tissue regeneration membrane, which comprises a compact coating and a loose coating, wherein the compact coating is composed of collagen-I or collagen-I composite hyaluronic acid; and the loose coating is composed of collagen-I or collagen-I composite calcium salt. A preparation method of the guided tissue regeneration membrane comprises the following steps of: preparing a collagen solution or a collagen and hyaluronic acid mixed solution by the use of acetic acid; injecting the solution into a self-made die, and drying it in the air to prepare the compact coating; injecting the collagen solution or a mixed liquor of the collagen solution and calcium salt onto the compact coating, and uniformly spreading; precooling the die at ultralow temperature, followed by freeze-drying to prepare the guided membrane with the compact coating and loose coating structure; carrying out vacuum high-temperature crosslinking and chemical crosslinking; and finally cleaning. The regeneration membrane has good histocompatibility and mechanical strength, low antigenicity and strong guided tissue regeneration capability. Its degradation rate in vivo is 3-8 months. The method is easy to operate, is suitable for automatic and continuous large-scale production, and solves the problems of large size of collagen membrane and material uniformity during industrial production.

Owner:SHENZHEN LANDO BIOMATERIALS

Graphene/MoS2 graphene and amorphous carbon composite material and preparation method thereof

InactiveCN102142558ALarge specific surface areaImprove mechanical propertiesCell electrodesThioureaHeat treated

The invention discloses a graphene nanometer sheet / MoS2 graphene nanometer sheet and amorphous carbon composite material and a preparation method thereof. The composite material is characterized by being composed of the following components in percentage by weight: 4.2-15% of graphene nanometer sheet, 4.2-65% of MoS2 graphene nanometer sheet and the balance of amorphous carbon, wherein the molar ratio of the graphene nanometer sheet to the MoS2 graphene nanometer is (1:1)-(4:1). The preparation method comprises the following steps: preparing graphite into graphite nanometer sheets by a chemical oxidation method; then evenly dispersing the oxidized graphite nanometer sheets into a solution containing molybdate, thioacetamide or thiourea and glucose; obtaining an intermediate product by virtue of hydrothermal reaction; and carrying out heat treatment on the intermediate product at high temperature to obtain the graphene nanometer sheet / MoS2 graphene nanometer sheet and amorphous carbon composite material. The method disclosed by the invention has the characteristics of moderate reaction condition and simple process. The graphene nanometer sheet / MoS2 graphene nanometer sheet and amorphous carbon composite material, which is synthetized by the invention, can be widely applied by serving as an electrochemical storage lithium electrode material, an electrochemical storage magnesium electrode material and a catalyst carrier.

Owner:ZHEJIANG UNIV

Wood fiber reinforced inflaming retarding foam material and machining method thereof

InactiveCN102061059AImprove use valueSolve the "Three Rural Issues"Chemical recyclingFirming agentSURFACTANT BLEND

The invention discloses a wood fiber reinforced inflaming retarding foam material and a machining method thereof. The composite foam material is prepared from the following components in parts by weight: 40-95 parts of foaming flame-retarded resin, 0.1-8 parts of curing agent, 0.5-8 parts of surfactant, 1-50 parts of wood fiber and 0.5-10 parts of flexibilizer. The wood fiber is treated by using a coupling agent and then dried, and the coupling agent accounts for 0.15-0.5 percent of the mass of the wood fiber. A naturally expanded foaming method or die foaming method is adopted. The wood fiber reinforced inflaming retarding foam material can be widely applied to fields of insulation of building outer wall bodies, architectural ornament, traffic vehicles, water ships, aerospace, electromechanical equipment, industrial sound absorption, heat preservation and shock absorption and the like, and is a composite foaming material with actual application value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Improved microporous polymer film and preparation method thereof

The invention relates to an improved microporous polymer film and a preparation method thereof, and belongs to the field of chemistry. The improved microporous polymer film comprises the following compositions by weight percentage: 55% to 99.79% of polypropylene homopolymer, 0.01% to 5% of beta crystal nucleating agent, 0.1% to 20% of polymeric additive and 0.1% to 20% of inorganic modifier. The improved microporous polymer film is prepared by stretching a melt about 2 to 60 times at a speed of 1 m to 100 m / min in casting, calendering, extruding or film blowing process. Compared with the prior art, more beta crystals can be obtained within shorter time, the formed beta crystals have higher thermal stability, and have better film-forming stability and pore-forming properties, and the prepared microporous film has the characteristics of easiness in processing, higher permeability, excellent productivity, and strong mechanical properties and dimensional stability, and the porosity is further improved, and thereby the permeability of various media can be obviously improved.

Owner:CHENGDU WISEDONE TECH

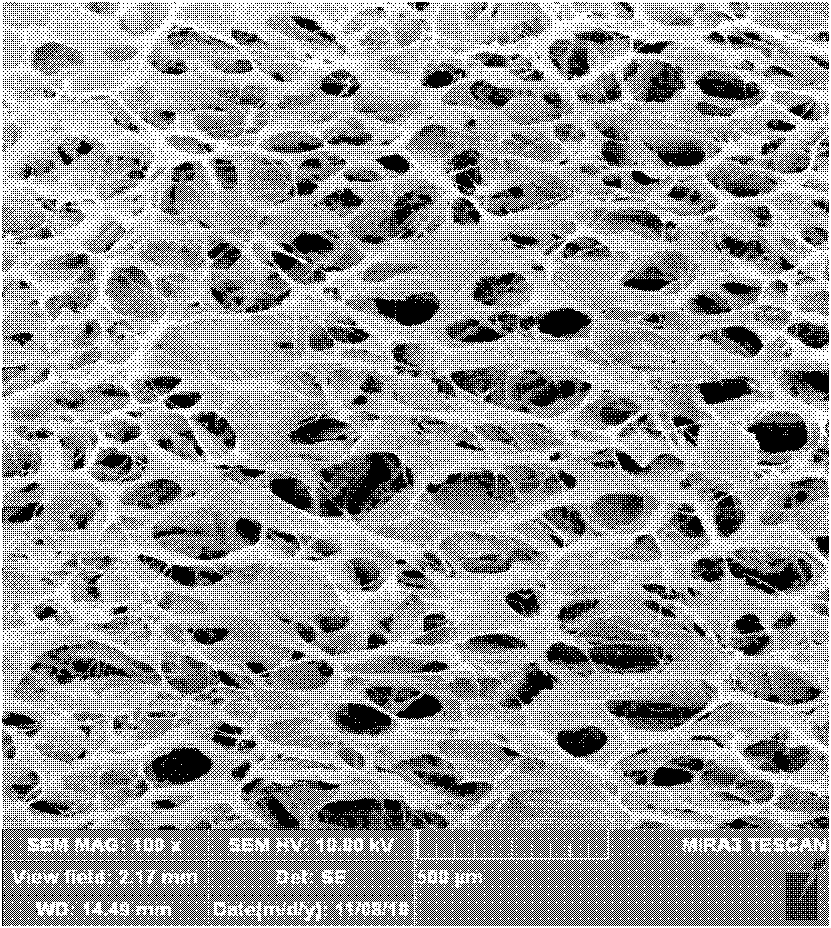

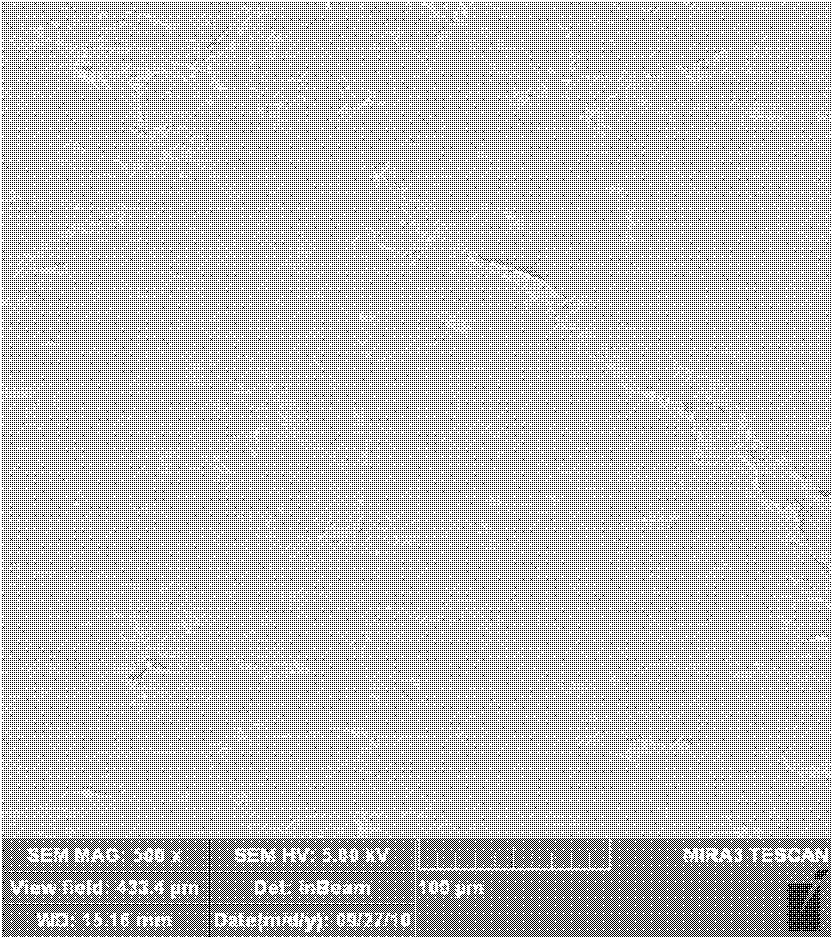

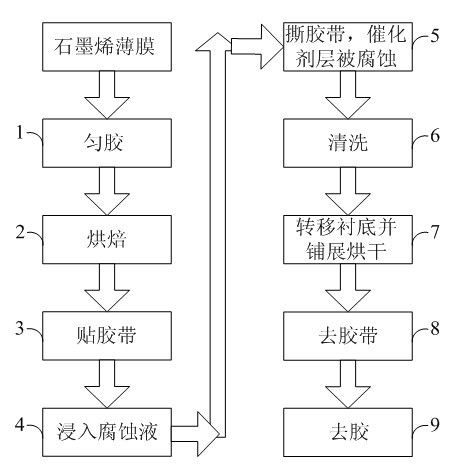

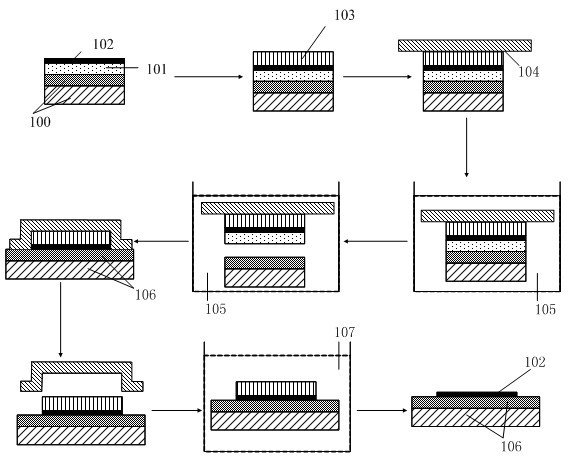

Method for transferring graphene film to substrate

ActiveCN102592964AThe transfer method is simple and easyLarge transfer areaSemiconductor/solid-state device manufacturingCvd grapheneCorrosion

The invention relates to a method for transferring a graphene film to a substrate, belonging to the field of semiconductor film. The method comprises the following steps: spin-coating an organic colloid on the surface of the graphene film, drying and hardening the film; adhering adhesive tape to the surface of the organic colloid; then putting a substrate material adhered the adhesive tape into a corrosive solution to corrode a metal catalyst layer under the graphene film; after the corrosion is finished, taking out the adhesive tape, the organic colloid and the graphene film which are adhered to the adhesive tape from the solution; uniformly spreading onto a target substrate, removing the adhesive tape by using a corresponding method, then dissolving the organic colloid away to finally finish the transfer of the graphene film to the target substrate. The method for transferring the graphene film to the substrate, disclosed by the invention, is simple and easy to implement, and can conveniently transfer the graphene film with a large area to any substrate material without causing a large damage. The method has the advantages of being large in transfer area, simple in processing steps, convenient in operation and can be combined with semiconductor techniques to prepare graphene semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

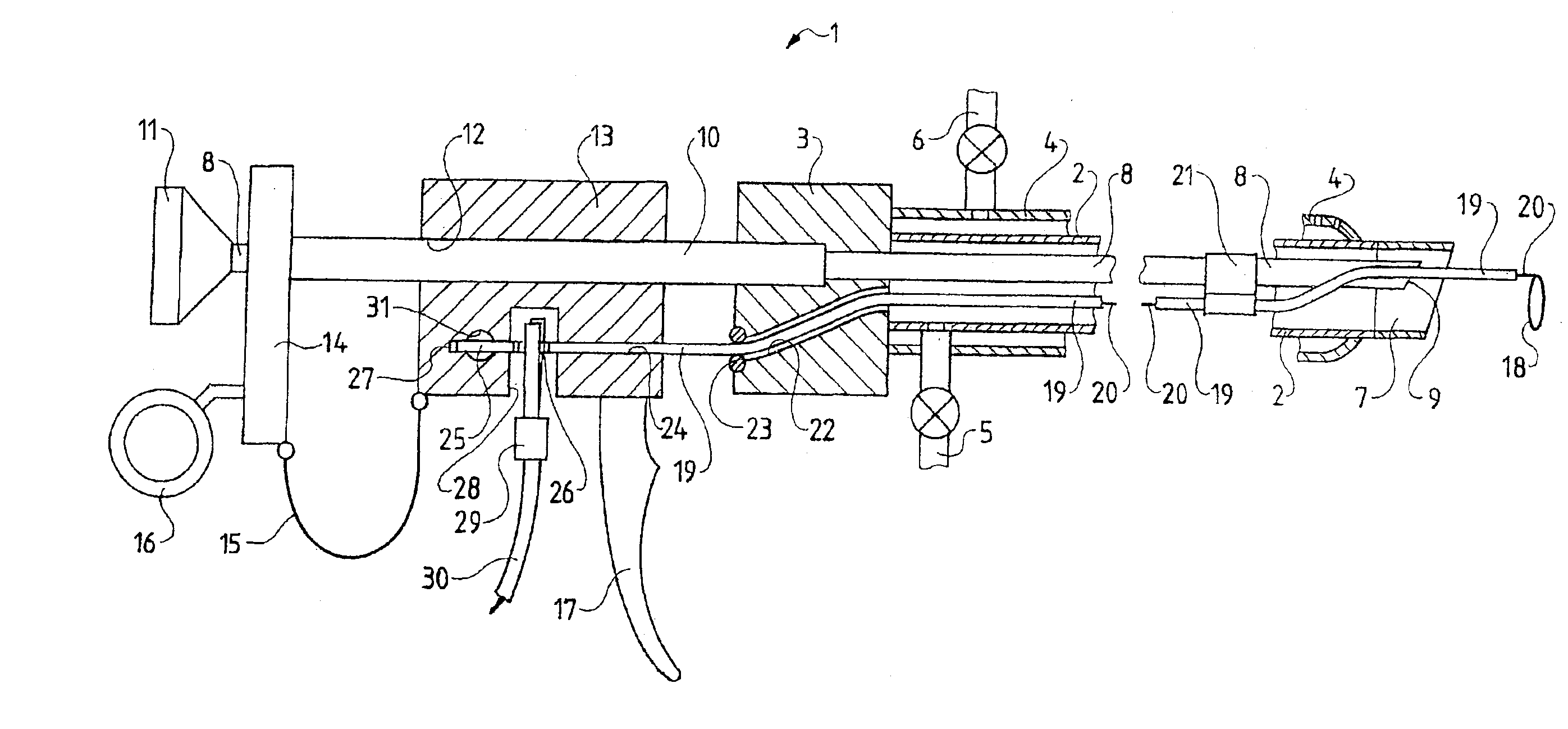

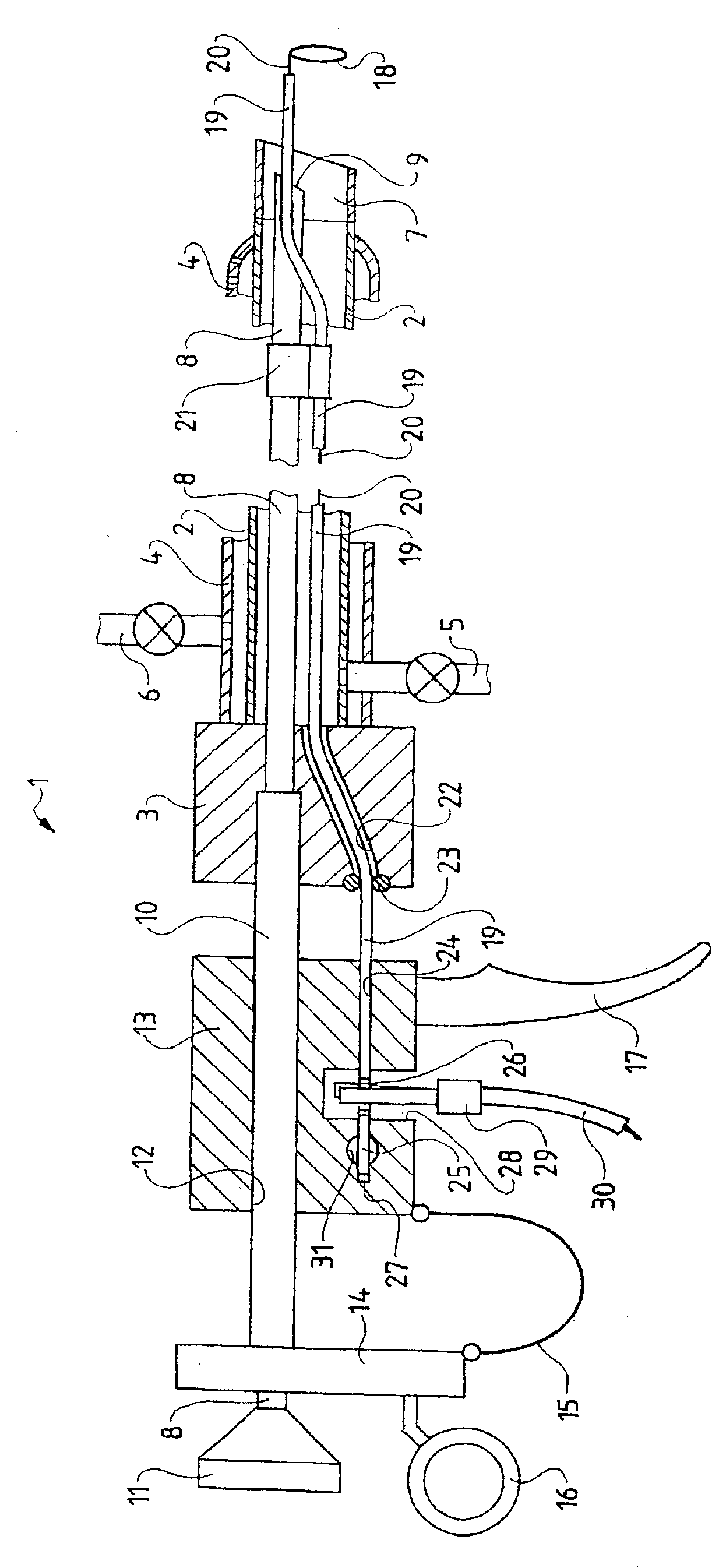

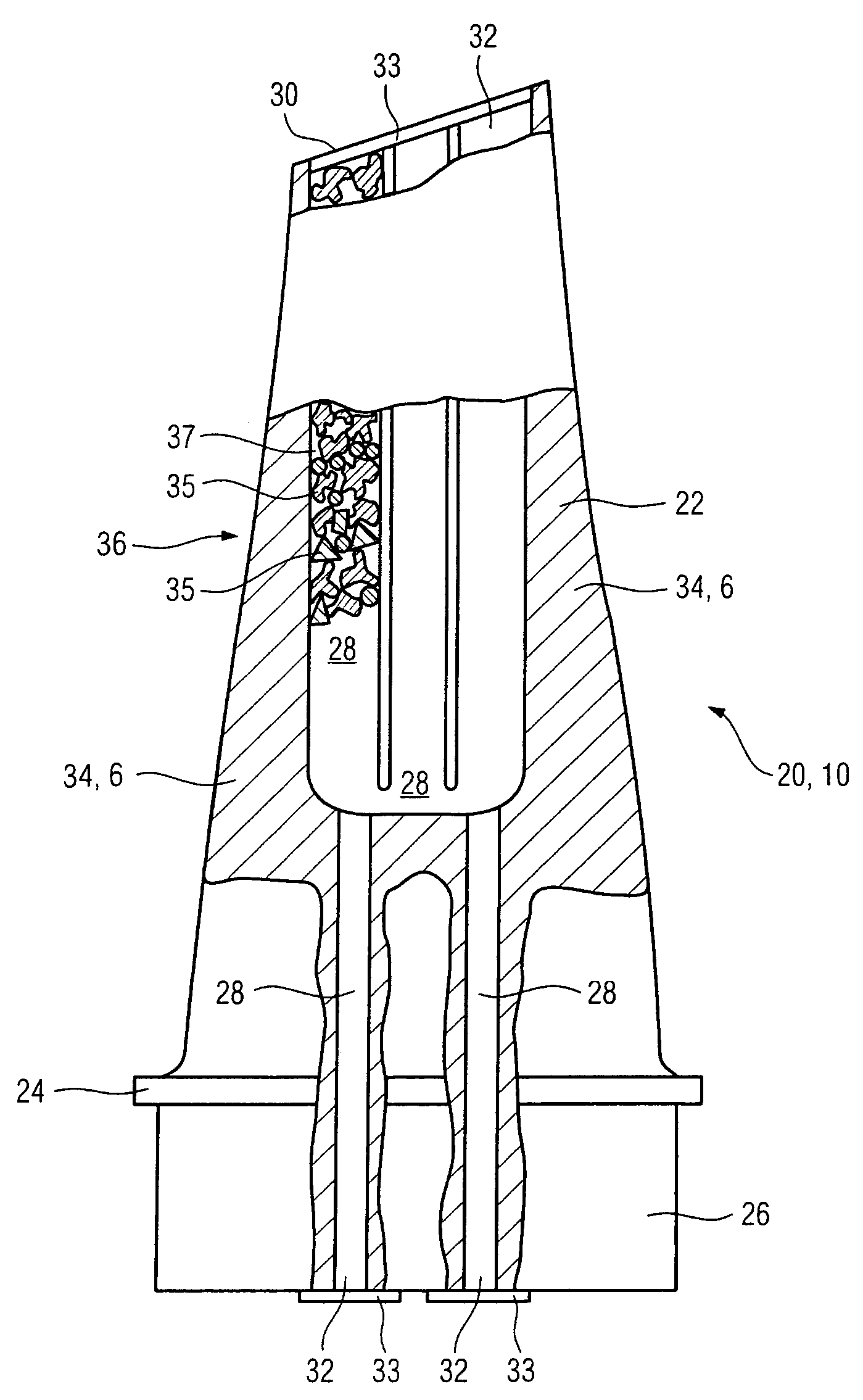

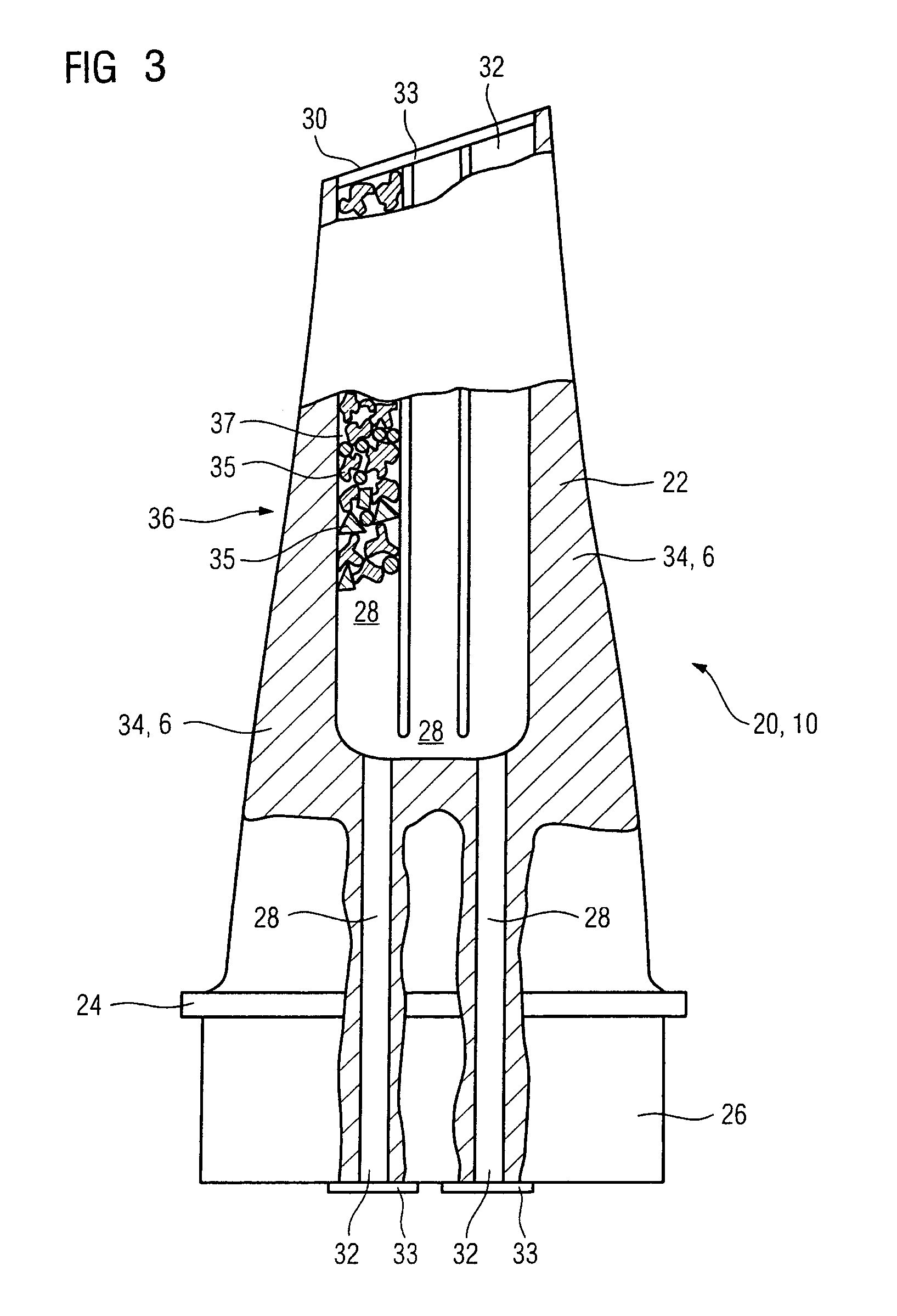

Urological electrosurgical resectoscope

InactiveUS6893441B2Increase clamping forceTighter pivotingSurgical instruments for heatingRESECTOSCOPEEngineering

A urological resectoscope having an axially extending shaft tube, the proximal end thereof being fixed to a main body. A sliding body is proximally positioned in relation to the main body, and can slide in a parallel manner in relation to the axis thereof. The sliding body includes a receiver, a fixing device and a contacting device. An electrode that can be subjected to a high frequency, including a rigid electrode carrier having one external, insulated conductive wire, can be positioned in the resectoscope such that it can axially slide beyond the distal end of the shaft tube. In the assembly position, the electrode carrier extends through the shaft tube and the main body into the receiver, and can be fixed by the fixing device and contacted by the contacting device. The fixing device is proximally arranged in relation to the contacting device on the sliding body.

Owner:OLYMPUS WINTER & IBE

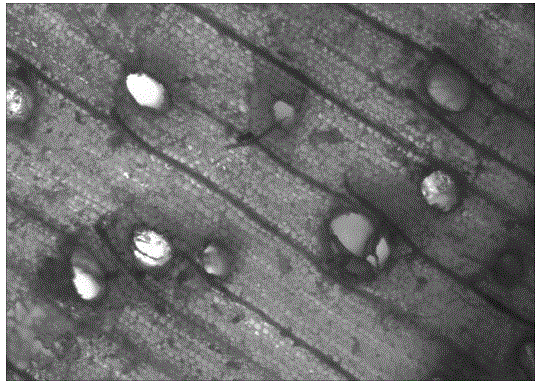

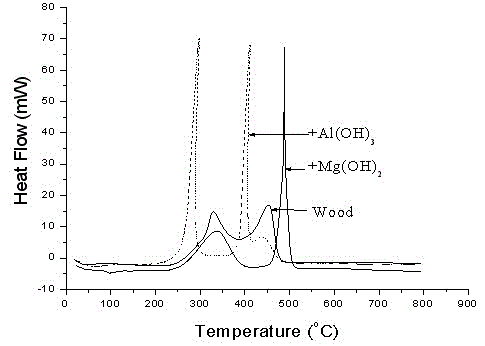

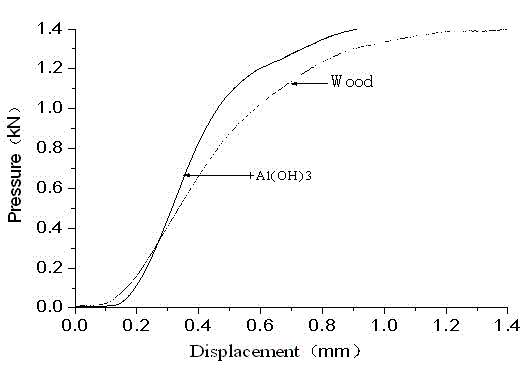

Nanometer hydroxide wood composite material and preparation method thereof

InactiveCN102873724AStrong mechanical propertiesImprove flame retardant performanceMaterial nanotechnologyWood impregnation detailsAluminum oxide hydroxideAluminium hydroxide

The invention discloses a nanometer hydroxide wood composite material. The nanometer hydroxide wood composite material is a high-quality composite wood material which consists of fast-growing wood serving as a base body and inorganic nanometer hydroxide serving as a reinforcing body. The inorganic nanometer hydroxide is uniformly filled in nanometer cavities among microfibers of the fast-growing wood, and is nanometer aluminum hydroxide, nanometer aluminum oxyhydroxide, nanometer magnesium hydroxide or nanometer magaldrate. The nanometer wood composite material is prepared from the fast-growing wood serving as the base body for the first time by a (microwave) hydrothermal method, surface activity and dispersion conditions of nanometer particles in a matrix and influence of a boundary structure on the mechanical property and the flame retardant property of the composite material are researched, so that filled wood is strengthened and has multiple functions of flame retardance, smoke suppression and the like, and the novel material with the excellent mechanical property and the good flame retardant property is obtained.

Owner:ANHUI AGRICULTURAL UNIVERSITY

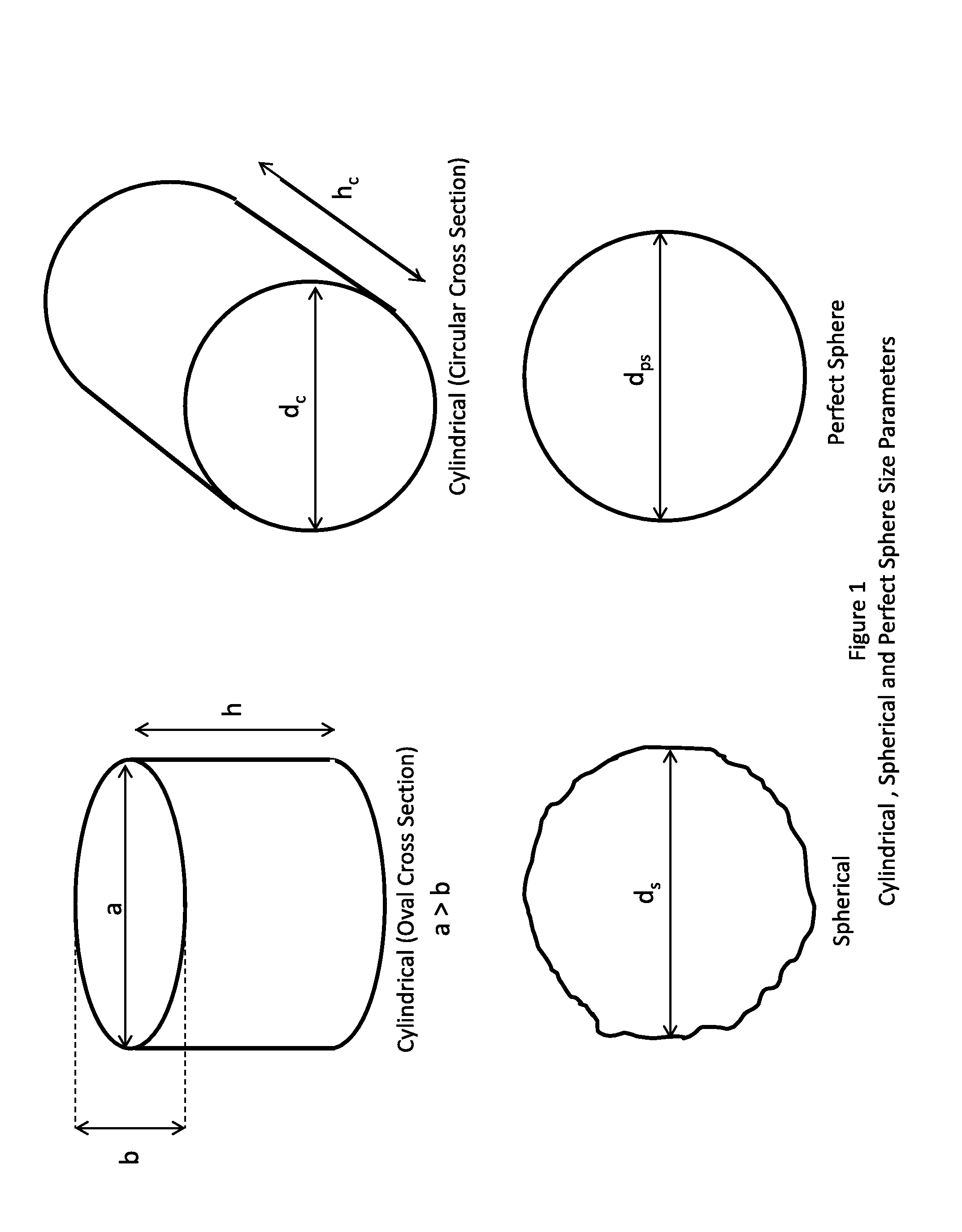

Cleaning method

ActiveUS20130283542A1Small surface areaIncrease in sizeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesWash water

The invention provides a method for the cleaning of a soiled substrate, the method comprising treating the substrate with a non-polymeric solid particulate cleaning material and wash water, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls and having a capacity of between 5 and 50 litres for each kg of fabric in the washload, wherein the solid particulate cleaning material comprises a multiplicity of non-polymeric particles at a particle to fabric addition level of 0.1:1-10:1 by mass, each of the particles being substantially cylindrical or spherical in shape, and wherein the drum comprising perforated side walls is rotated at a speed which generates G forces in the range of from 0.05 to 900 G. The non-polymeric particles may comprise particles of glass, silica, stone, wood, or any of a variety of metals or ceramic materials. Preferably the solid particulate cleaning material additionally comprises a multiplicity of polymeric particles each of which is substantially cylindrical or spherical in shape. Preferably, at least one detergent is employed in the cleaning process. The invention provides optimum cleaning performance as a result of improved mechanical interaction between substrate and cleaning media and is preferably used for the cleaning of textile fabrics. The method allows for significant reductions in the consumption of detergents, water and energy when compared with the conventional wet cleaning of textile fabrics, and also facilitates reduced washing-related textile fabric damage. The invention also envisages a cleaning composition comprising a solid particulate cleaning composition and at least one additional cleaning agent.

Owner:XEROS LTD

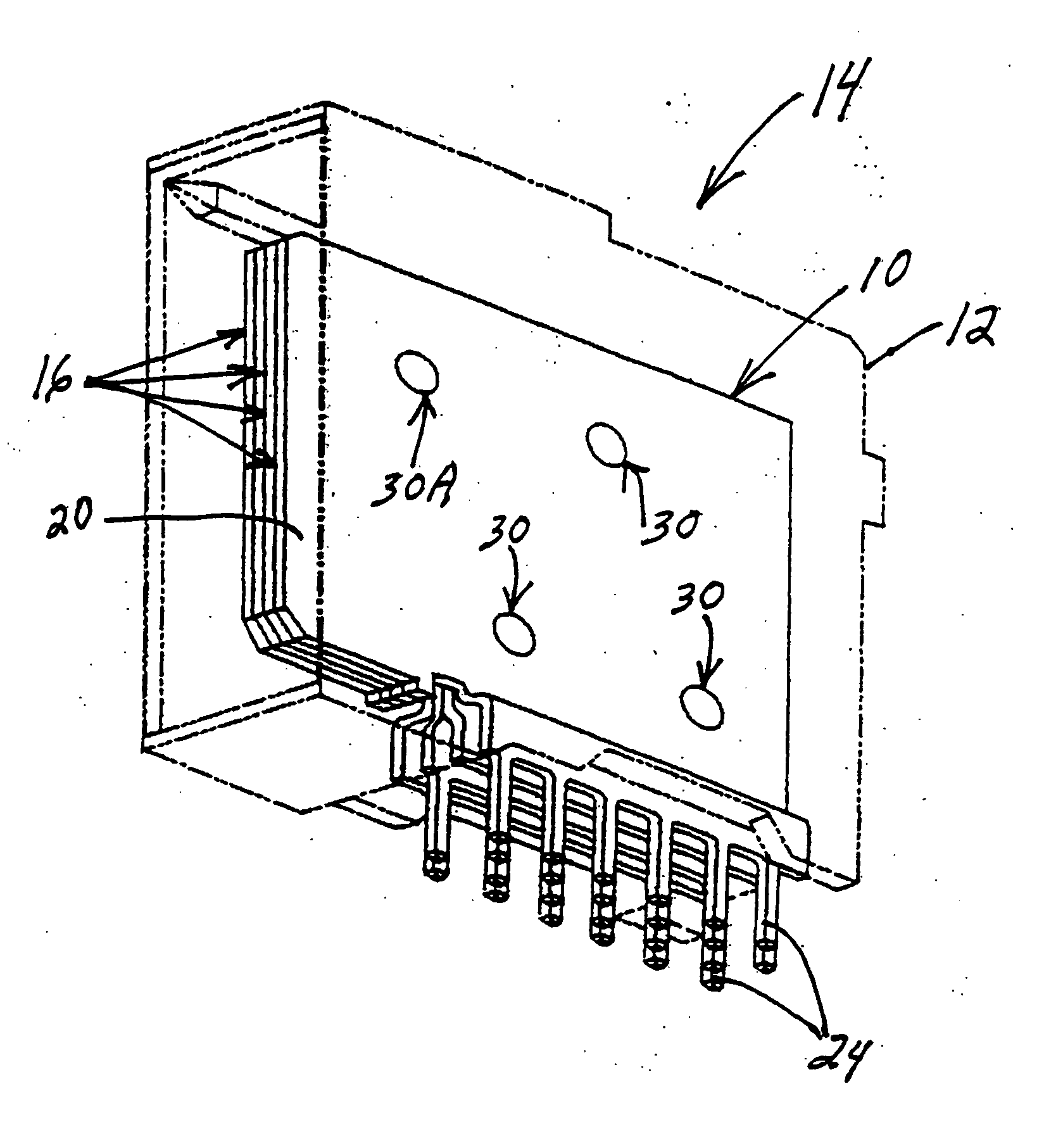

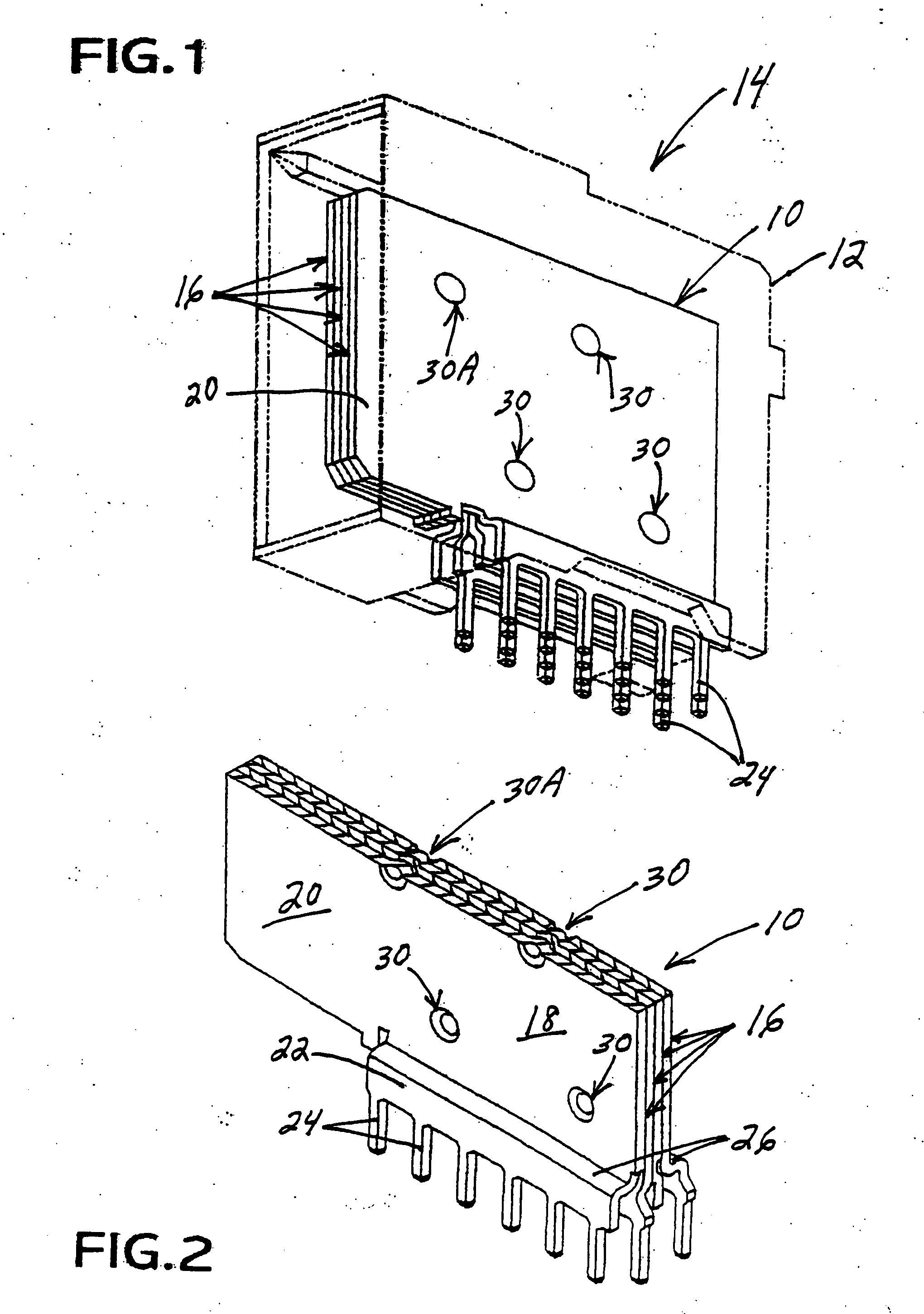

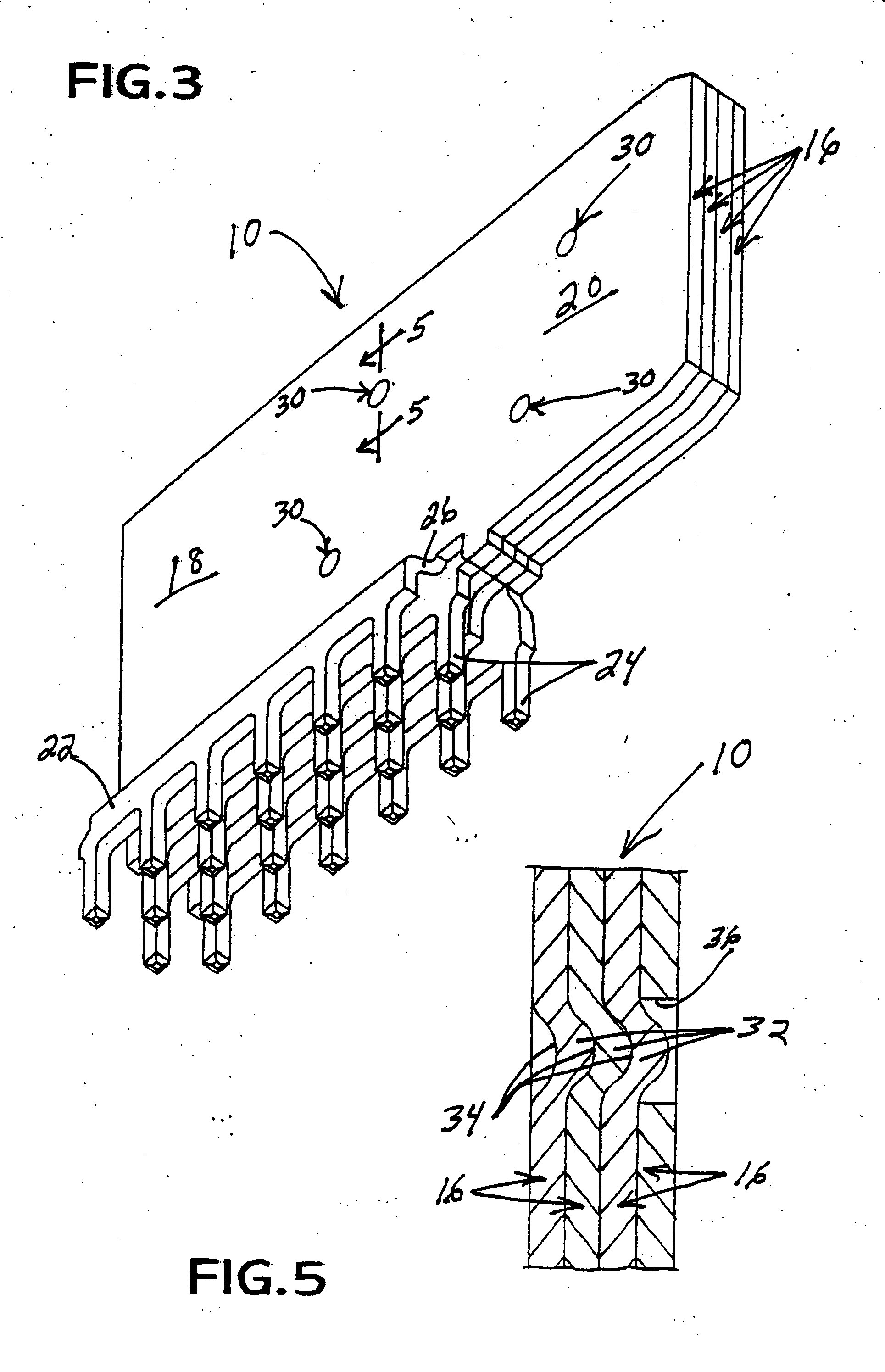

Laminated electrical terminal

InactiveUS20060189222A1Strong mechanical propertiesStrong mechanical and good electrical jointElectrically conductive connectionsCoupling contact membersEngineeringElectrical connector

A laminated terminal is provided for an electrical connector and includes a plurality of flat metal layers juxtaposed to form a laminated structure. Each metal layer includes a joining section, a contact section and a terminating section. A plurality of projections on the joining sections of the layers are interengaged within a respective plurality of recesses in adjacent layers to align the layers and provide a strong mechanical and good electrical joint between the layers. Solder tails extend linearly along the bottom edge of each joining section to form a plurality of rows of solder tails, and the terminating portions of the metal layers are bent outwardly to separate the rows of solder tails from each other. The contact section of one metal layer may include a generally planar finger which is coplanar with a planar finger of another of the metal layers.

Owner:MOLEX INC

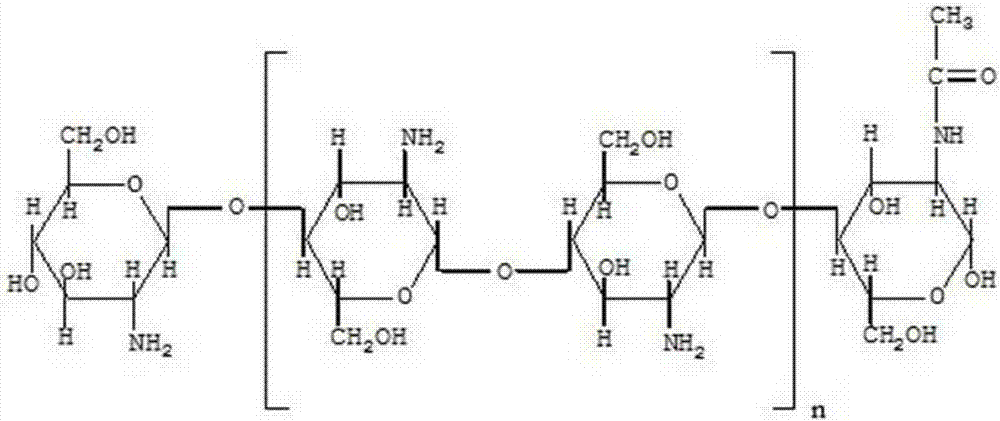

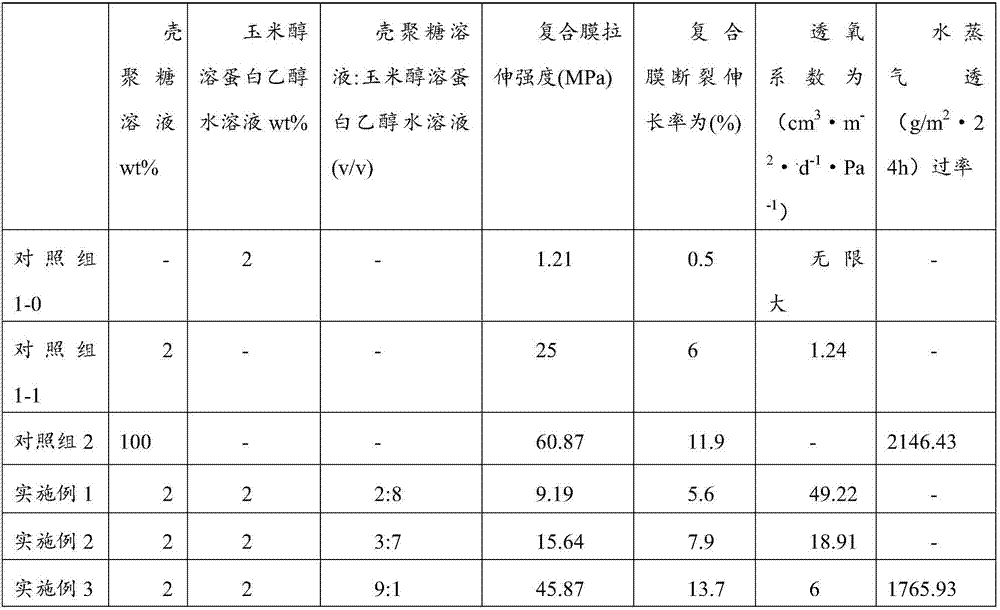

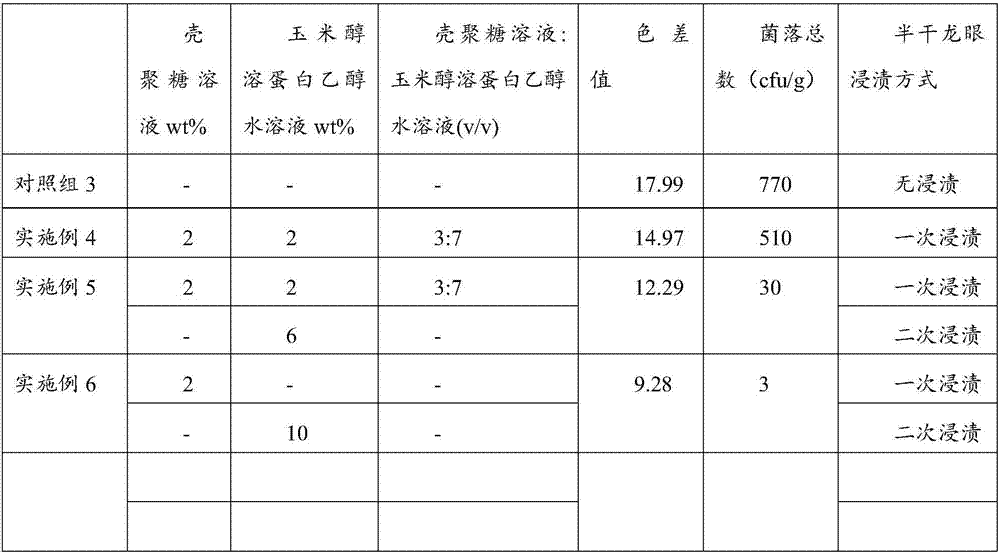

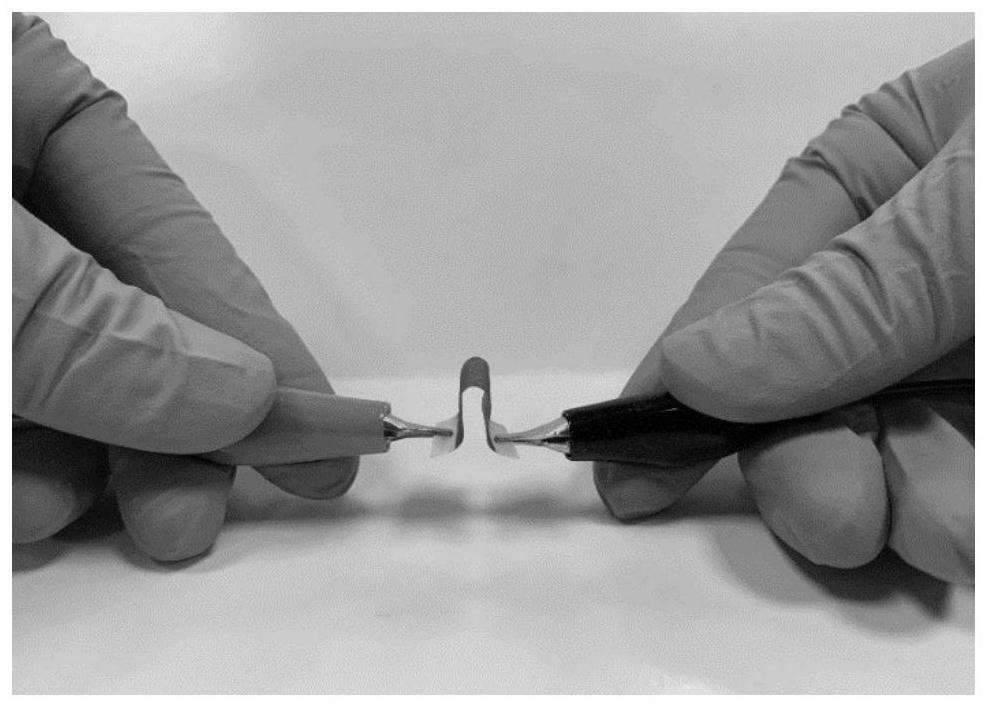

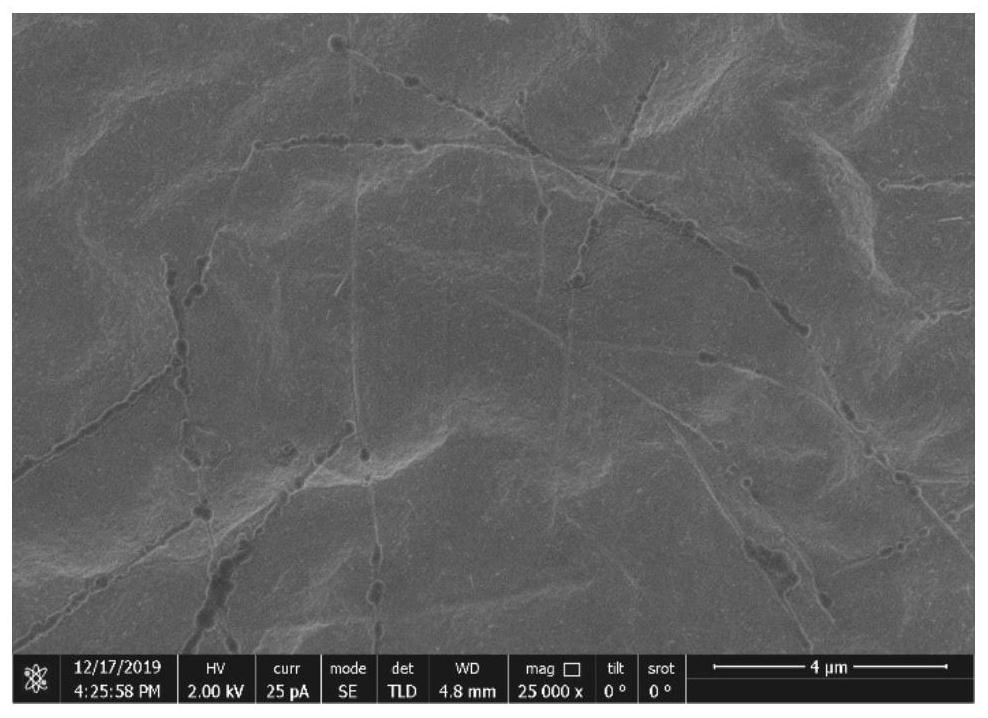

Method of preparing composite preservative film or coating from chitosan and alcohol soluble corn protein

InactiveCN106957458AStrong machineryLow costCoatingsFruits/vegetable preservation by coatingChemistryAqueous solution

The invention relates to a method of preparing a composite preservative film or coating from chitosan and alcohol soluble corn protein. The method mainly comprises the following steps: (1) preparing 2wt% chitosan solution; (2) preparing 1-10wt% ethanol aqueous solution of alcohol soluble corn protein; (3) mixing the solutions prepared in the steps (1) and (2) in a volume ratio of 1:9 to 9:1 (v / v) to obtain a composite film solution; (4) flow casting the composite film solution obtained in step (3) and drying to obtain a film; or sequentially overlaying the solutions prepared in the steps (1) and (2) to obtain a double-layer preservative film. The chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is not only improved in the moisture resistance and ultraviolet resistance of a chitosan film, but also improved in the barrier property, mechanical properties and antibacterial activity of a alcohol soluble corn protein film, and is degradable, edible, etc. When the chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is used to package or wrap foods such as meat, oils and fats, fruits and vegetables, the quality guarantee period thereof can be effectively prolonged. Thus, the method has an extensive application prospect.

Owner:GUANGXI UNIV

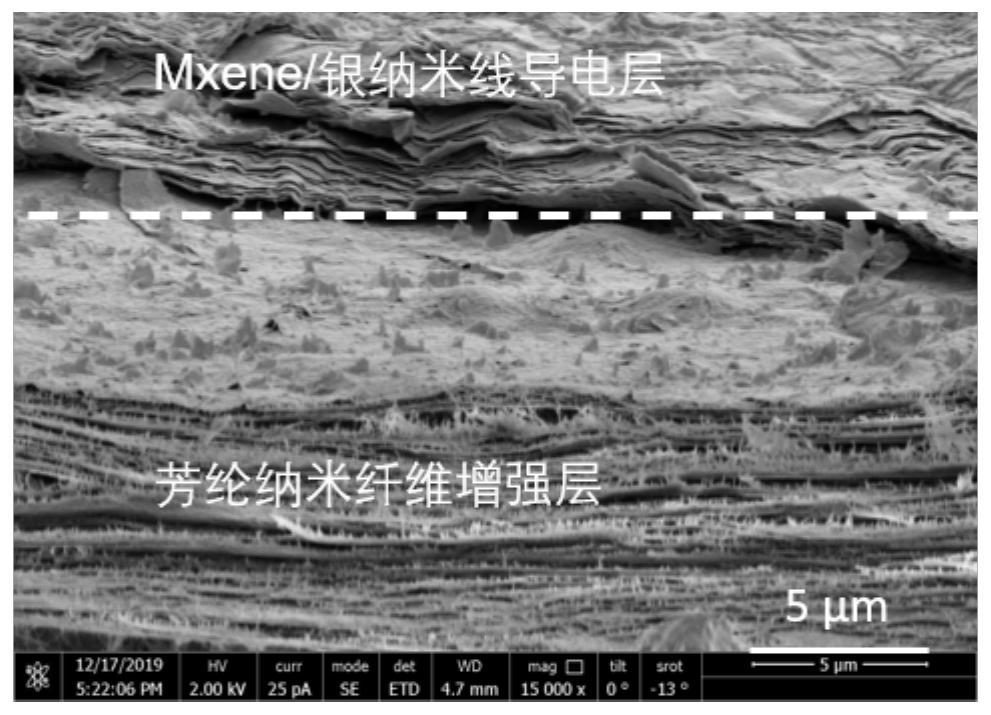

Flexible high-strength MXene-based electromagnetic shielding composite film and preparation method thereof

ActiveCN111809439AImprove conductivityImprove shielding effectSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesComposite filmNanofiber

The invention discloses a flexible high-strength MXene-based electromagnetic shielding composite film, which comprises a conductive layer Ti3C2Tx MXene / silver nanowire and a polymer enhancement layeraramid nanofiber, and is characterized in that the mass fraction of the Ti3C2Tx MXene / silver nanowire conductive layer is 10-80%; the mass ratio of the Ti3C2Tx MXene to silver nanowire is (10: 0.5)-(10: 1.5). The invention further discloses a preparation method of the flexible high-strength MXene-based electromagnetic shielding composite film. The composite film prepared by the invention has excellent flexibility and mechanical properties, good conductivity and broadband high electromagnetic shielding effectiveness, and can meet the application in the fields of aerospace, military engineering,artificial intelligence and flexible wearable electronic equipment.

Owner:SHAANXI UNIV OF SCI & TECH

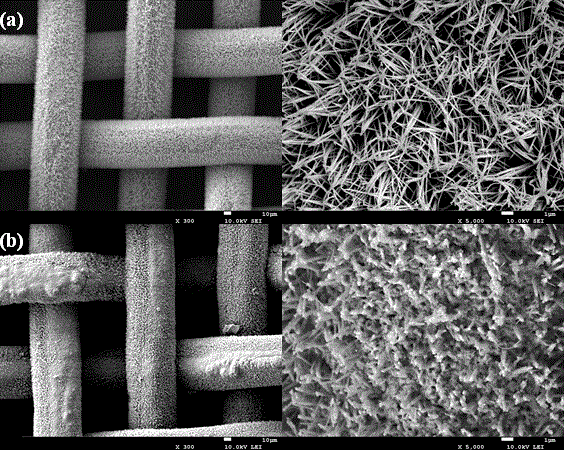

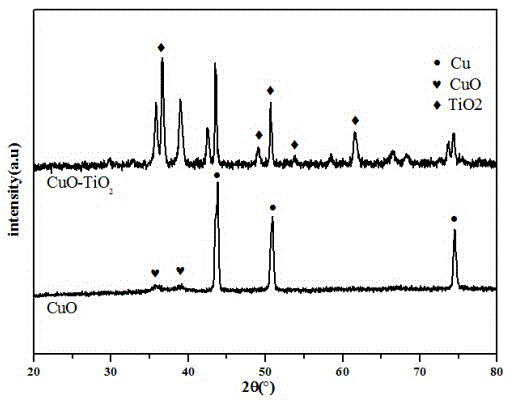

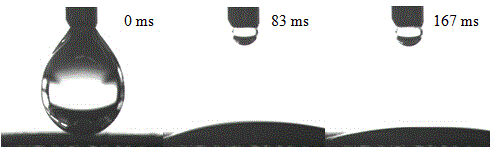

Preparation method of nano-structure oil-water separation net membrane with self-cleaning and underwater super-oleophobic characteristics

InactiveCN105641973AEasy to separateAvoid wastingNon-miscible liquid separationNano structuringCopper oxide

The invention discloses a preparation method of a metal net membrane with self-cleaning and underwater super-oleophobic characteristics. The metal net membrane can achieve efficient oil-water separation and self cleaning. A traditional oil-water separation membrane has the defects that a preparation technology is complex, regeneration is difficult, and repeated using can not be achieved. With a copper net being a substrate, an anodic oxidation method is adopted for generating a copper hydroxide nanowire array, multiple layers of titanium dioxide are deposited on the nanowire array through layer-by-layer self-assembly, and the copper net membrane covered by a copper oxide / titanium dioxide composite membrane layer is generated through roasting. The net membrane is high in mechanical performance and resistant to high heat, has the super-hydrophilic and underwater super-oleophobic characteristics, can efficiently separate an oil-water mixture and meanwhile can perform self cleaning under photocatalysis active illumination of the titanium dioxide layer to achieve regeneration and repeated using. Compared with the preparation technology of the existing oil-water separation membrane, the method facilitates scale expansion, preparation is easy, raw materials are environmentally friendly, the cost is low, cyclic reuse can be achieved, and the net membrane is a novel oil-water separation net membrane which is more environmentally friendly and affordable.

Owner:SICHUAN UNIV

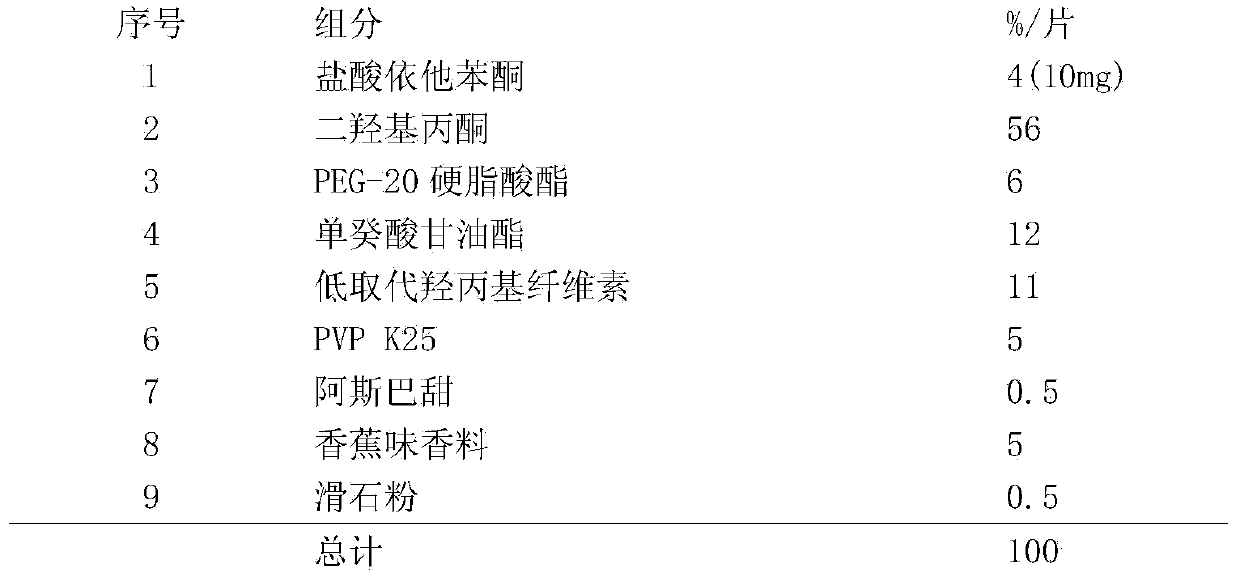

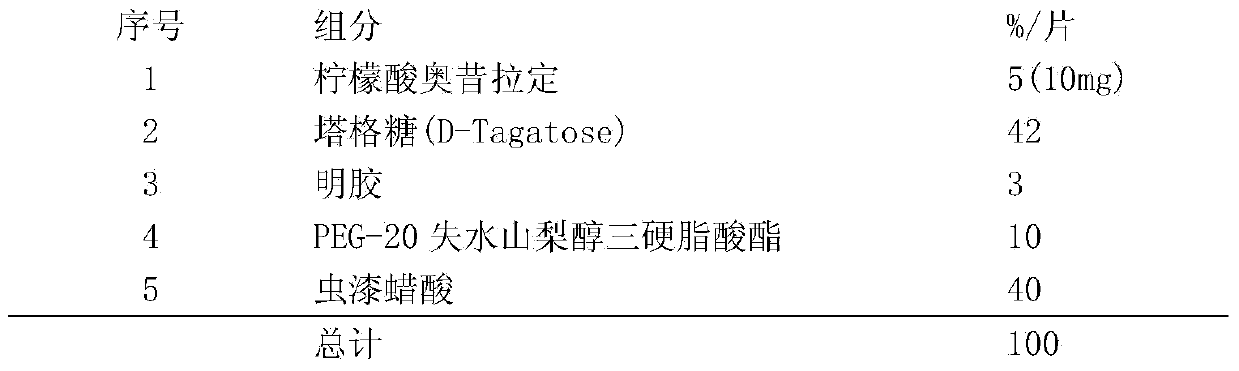

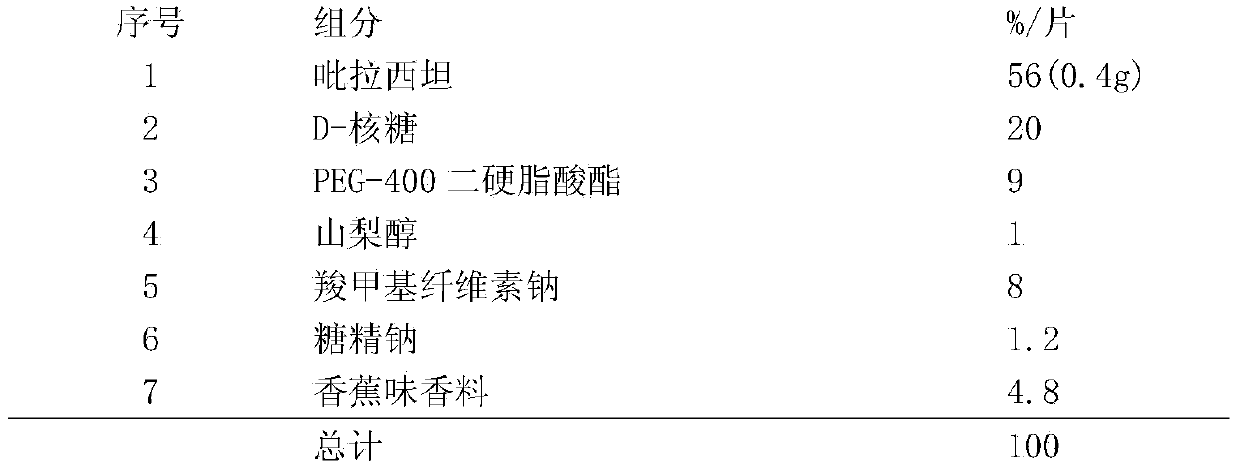

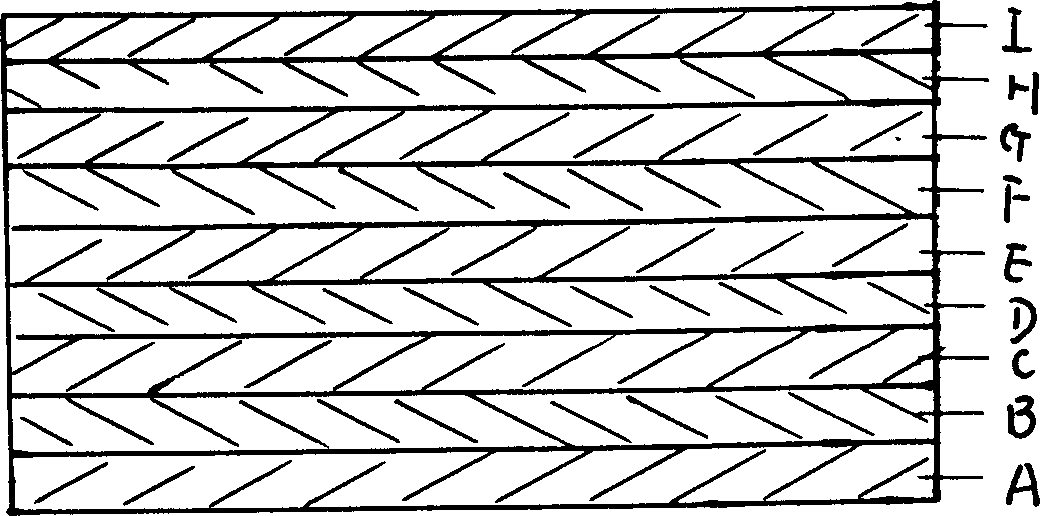

Improved-performance tablet and preparation method thereof

InactiveCN103432091AMaintain integrityPrevent or reduce cracksPill deliveryPorosityWeather resistance

The invention discloses an improved-performance tablet which comprises an active component A1, a hydrophilic diluent B1 and a meltable solid dispersion and / or a solid coating C1, wherein the diluent B1 and / or the active component A1 are / is bonded and bridged by the solidified melt of the meltable solid dispersion and / or solid coating C1; and / or the tablet comprises a hydrophilic diluent B2 and a meltable solid dispersion containing an active component A2 and / or a solid coating C2, wherein the diluent B2 is bonded and bridged by the solidified melt of the meltable solid dispersion and / or solid coating C2. The invention also discloses a preparation method of the tablet. The tablet has stronger mechanical performance and / or better weather resistance and / or better hydrophilcity or better disintegration property or better medicine dissolubility and higher porosity.

Owner:钟术光

High resistively nine-layer co-extrusion-blown moulding film and its preparation process

InactiveCN1724254AAvoid pollutionReduce processSynthetic resin layered productsSurface layerEngineering

A high-isolation 9-layer plastic film with 25-300 microns in thickness and high mechanical and optical performance has an external surface layer and a thermally sealed bottom layer and is prepared through extruding out 9 film layers, overlapping via a single die, and co-extruding out while blow moulding.

Owner:S & H SPECIAL NEW MATERIAL JIANGYIN

Method for preparing graphene oxide-chitosan composite material

The invention discloses a method for preparing a graphene oxide-chitosan composite material. The method includes the steps that a chitosan solution is prepared; secondly, a graphene oxide solution is prepared, a 1-ethyl-(3-dimethylaminopropyl)carbodiimide (EDC) solution is added into the graphene oxide solution during stirring, stirring reaction is conducted after dropwise addition, then an N-hydroxyl succinimide (NHS) solution is dropwise added into the graphene oxide solution, stirring reaction is conducted, and an activated hydroxyl graphene oxide solution is obtained; thirdly, the activated hydroxyl graphene oxide solution is dropwise added into the chitosan solution and stirred, the mixture is poured into a mould after being cooled to room temperature, and the cross-linked graphene oxide-chitosan composite material is obtained after freezing drying. The novel graphene oxide-chitosan composite material having an interface bonding function is provided, compared with non-cross-linked composite materials, mechanical properties of the composite material are greatly improved, and use of the composite material in the aspect of the bone induction technology is achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

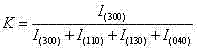

Graphene nano sheet and SnS2 composite nano material and synthesis method thereof

InactiveCN102142549ALarge specific surface areaStrong mechanical propertiesMaterial nanotechnologyCell electrodesSynthesis methodsTin

The invention discloses a graphene nano sheet and SnS2 composite nano material and a synthesis method thereof. The composite material is characterized by being formed by compounding a graphene nano sheet and a SnS2 nano material, wherein the substance amount ratio of the graphene nano sheet to the SnS2 nano material is 1:1-4:1. The preparation method comprises the following steps of: preparing a graphite oxide nano sheet from graphite by using a chemical oxidation method, then dissolving L-cysteine into deionized water, adding stannic chloride, and dissolving the stannic chloride with full stirring, wherein the molar ratio of the L-cysteine to the stannic chloride in the solution is 6:1-12:1; and adding the graphite oxide nano sheet into the solution, performing ultrasonic treatment so that the graphite oxide nano sheet is fully dispersed in the hydrothermal reaction solution, and synthesizing the graphene nano sheet and SnS2 composite nano material by a one-step hydrothermal method, wherein the mass ratio of the graphene nano sheet to the SnS2 nano material in the composite material is 1:1-4:1. The method has the characteristics of mild reaction condition and simple process. The synthesized graphene nano sheet and SnS2 composite nano material serving as an electrode material of a new energy battery or serving as other materials has wide application.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com