Adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and preparation method and application thereof

A two-dimensional nano, g-C3n4 technology, applied in the field of adjustable ultra-thin two-dimensional nano g-C3N4 film and its preparation, can solve the problem of poor controllability of graphene base film, cumbersome graphene preparation process, large consumption of reagents or Energy and other issues, to achieve the effects of chemical corrosion resistance and mechanical properties, the preparation method is simple and feasible, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Put dicyandiamide into an atmosphere furnace, heat treatment at 1°C / min to 700°C for 0.5h under an inert atmosphere, and then cool down to normal temperature naturally to obtain agglomerated g-C 3 N 4 ;

[0033] (2) the agglomerated g-C 3 N 4 Grind it, put it into the atmosphere furnace again, and heat it up to 500°C at 2°C / min to calcine for 3 hours in the air atmosphere, and then cool it down to room temperature naturally to obtain calcined g-C 3 N 4 powder;

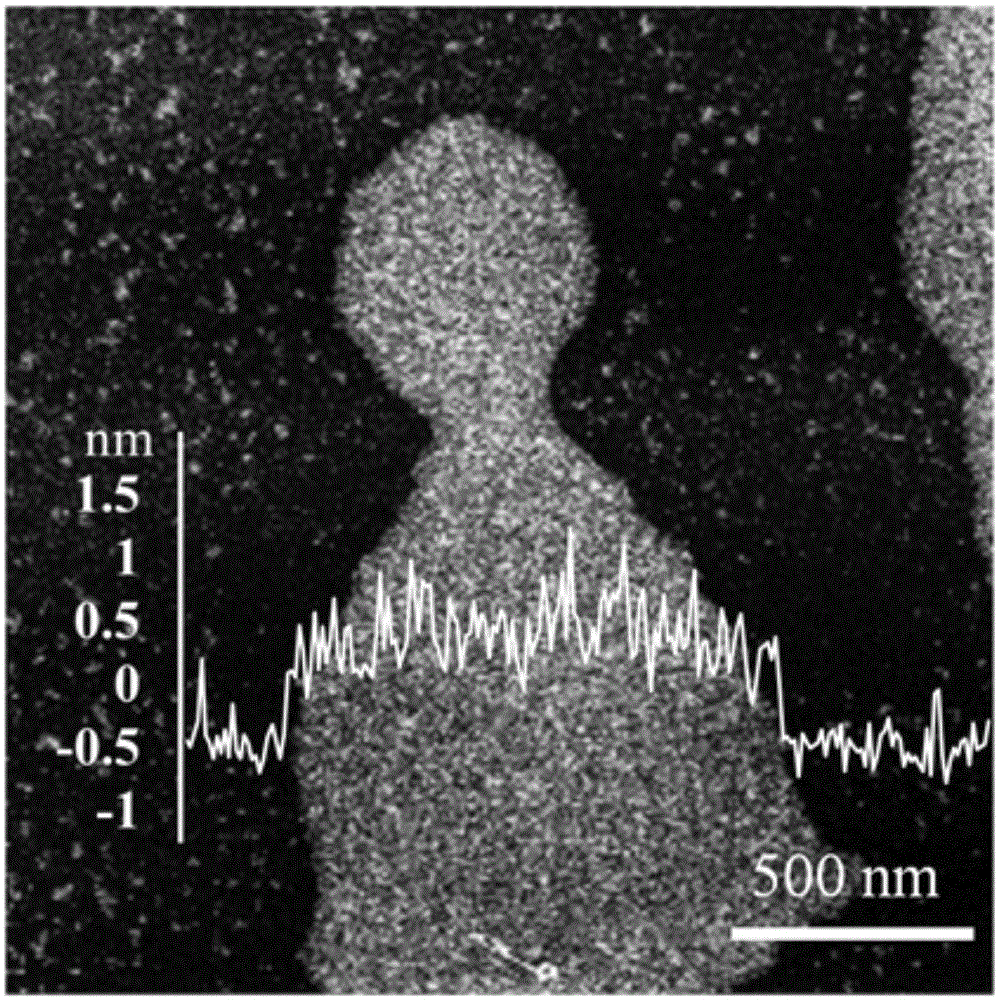

[0034] (3) Take 1g of calcined g-C 3 N 4 Disperse the powder in 1500ml deionized water, sonicate for 8h, then centrifuge at 2000r / min for 50min, and take the supernatant to obtain g-C 3 N 4 Two-dimensional nanosheet solution, its concentration measured by UV-Vis spectrophotometer is 0.04mg / ml;

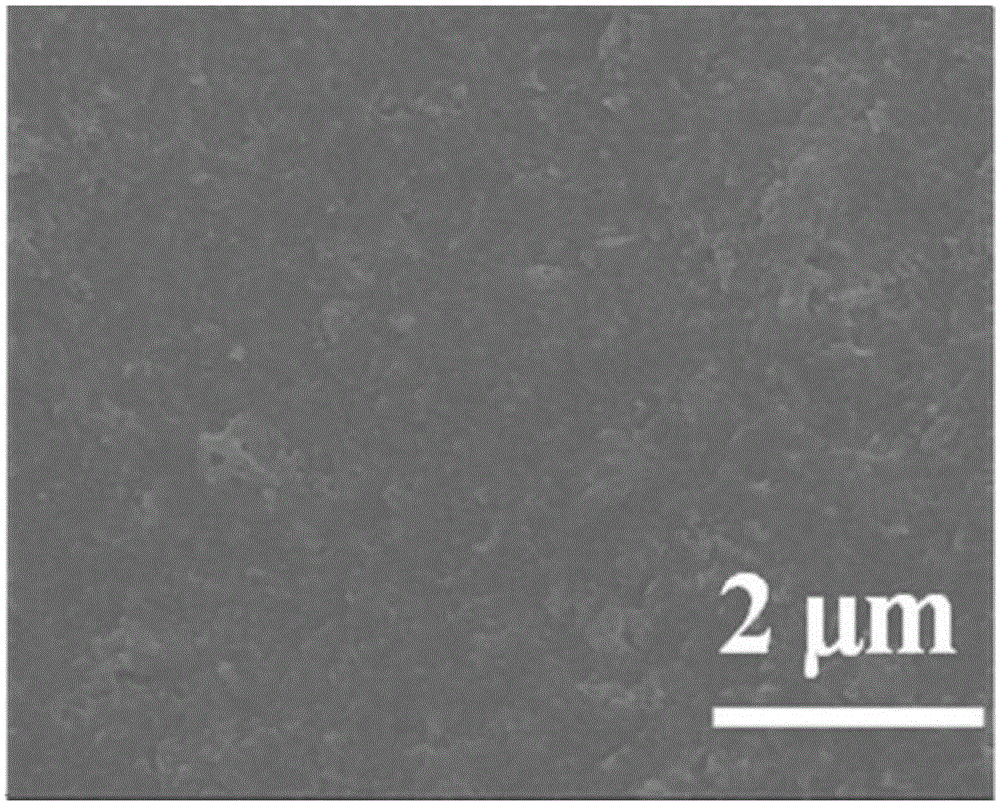

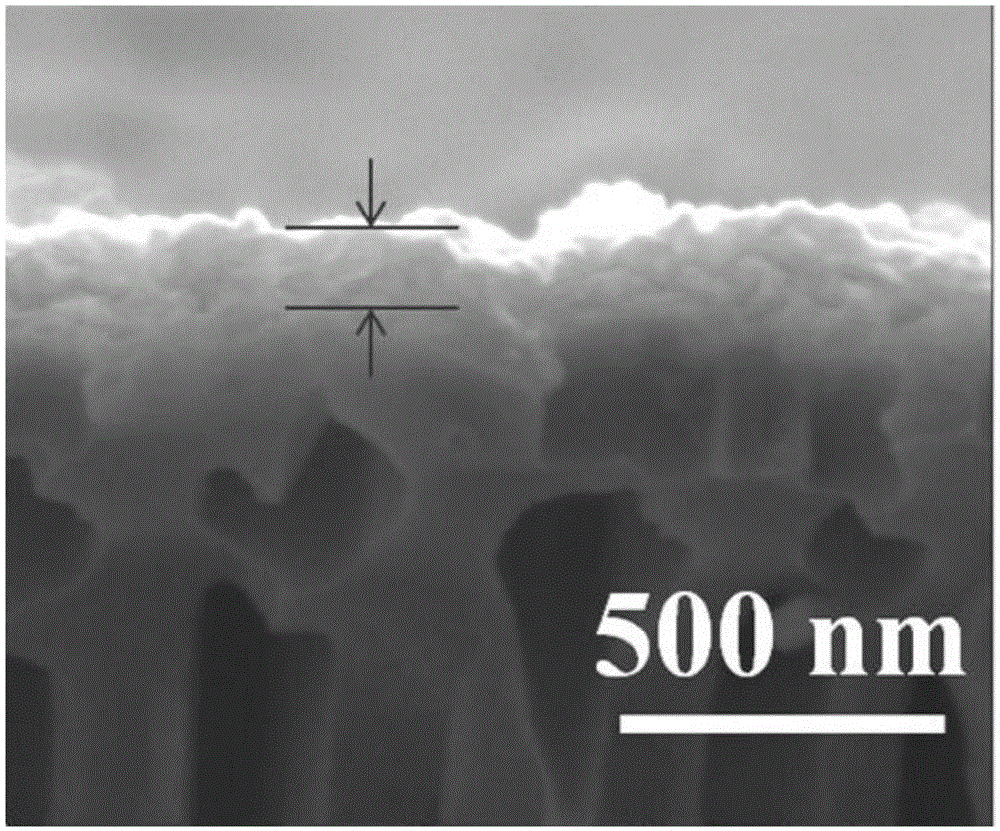

[0035] (4) Add 0.02mM KCl solution to the solution of step (3) for modification, then pass the modified solution through a polyvinylidene fluoride membrane with a pore size of 450nm under vacuum filtration c...

Embodiment 2

[0038](1) Put dicyandiamide into the atmosphere furnace, heat treatment at 3°C / min to 550°C for 3h under inert atmosphere, and then cool down to normal temperature naturally to obtain agglomerated g-C 3 N 4 ;

[0039] (2) the agglomerated g-C 3 N 4 Grind it, put it into the atmosphere furnace again, and heat it up to 500°C at 2°C / min for calcination for 2 hours in the air atmosphere, then cool it down to room temperature naturally to obtain calcined g-C 3 N 4 powder;

[0040] (3) Take 0.5g calcined g-C 3 N 4 Disperse the powder in 1000ml deionized water, sonicate for 8h, then centrifuge at 5000r / min for 50min, and take the supernatant to obtain g-C 3 N 4 Two-dimensional nanosheet solution, its concentration measured by UV-Vis spectrophotometer is 0.03mg / ml;

[0041] (4) in the solution of step (3), add the KCl solution of 0.005mM to modify, then the modified solution is passed through a polycarbonate membrane with a pore size of 450nm under vacuum filtration condition...

Embodiment 3

[0045] (1) Put the melamine into the atmosphere furnace, heat it at 2°C / min to 600°C for 4 hours under an inert atmosphere, then cool down to normal temperature naturally, and obtain agglomerated g-C 3 N 4 ;

[0046] (2) the agglomerated g-C 3 N 4 Grind it, put it into the atmosphere furnace again, and heat it up to 550°C at 2°C / min for calcination for 2 hours in the air atmosphere, then cool it down to room temperature naturally to obtain calcined g-C 3 N 4 powder;

[0047] (3) Take 2g of calcined g-C 3 N 4 Disperse the powder in 1500ml deionized water, sonicate for 8h, then centrifuge at 8000r / min for 30min, and take the supernatant to obtain g-C 3 N 4 Two-dimensional nanosheet solution, its concentration measured by UV-Vis spectrophotometer is 0.035mg / ml;

[0048] (4) Add 0.001mM KCl solution to the solution of step (3) for modification, and then the modified solution is passed through an anodic aluminum oxide membrane with a pore size of 200nm under vacuum filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com