New technological process of synthesizing acetyl bromide, acetic acid, acetate from methane

A technology for acetyl bromide and methane, which is applied in the new process field of synthesizing acetyl bromide, acetic acid, and acetate from methane, and can solve the problems of low yield and unutilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

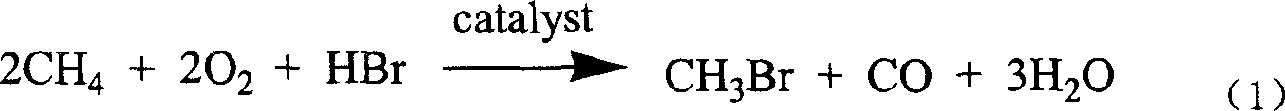

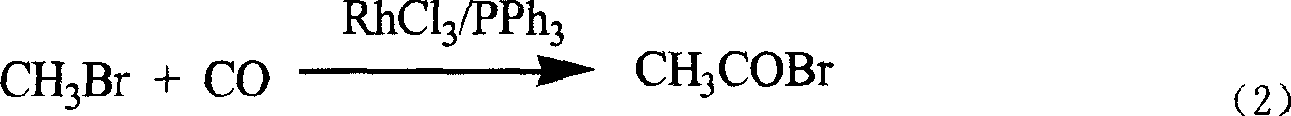

Method used

Image

Examples

example 1

[0020] Methane bromide oxidation catalyst RuNiBaLaO / SiO 2 Is 0.3897g La(NO 3 ) 3 ·6H 2 O, 0.2379g Ba(NO 3 ) 2 And 0.1238g Ni(NO 3 ) 2 ·6H 2 O is dissolved in 100mL of water to make a solution. Add 4.7200g to this solution and the specific surface area is 1.70m 2 / g of SiO 2 , Stirring at room temperature for half an hour, drying at 110°C for 4 hours, and then firing at 450°C for 12 hours to obtain a carrier. Add 12.8mL RuCl to this carrier 3 Aqueous solution (0.0008g(Ru) / mL), stirred at room temperature for half an hour, then dried at 110°C for 4 hours, and finally fired at 450°C for 12 hours to obtain the catalyst RuNiBaLaO / SiO 2 . Preparation of CO and CH 3 The reaction of Br is carried out in a fixed bed reactor, the amount of catalyst is 2.0000g, and the reaction gas CH 4 And O 2 The flow rate is 5.0mL / min, 40wt% HBr / H 2 The flow rate of O solution is 8.0 mL / h. Data was collected after 24 hours of reaction. At 660℃ and 1atm, the methane conversion rate is 70%, CO, CH 3 Br, CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com