Minim calcium element chelated foliage fertilizer

A calcium and foliar fertilizer technology, applied in fertilization devices, fertilizer mixtures, food science and other directions, can solve the problems of unguaranteed fertilizer efficiency, difficult absorption of calcium elements, inconvenient use, etc., and achieve a reasonable distribution of internal nutrients. , The effect of obvious fertilizer efficiency and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

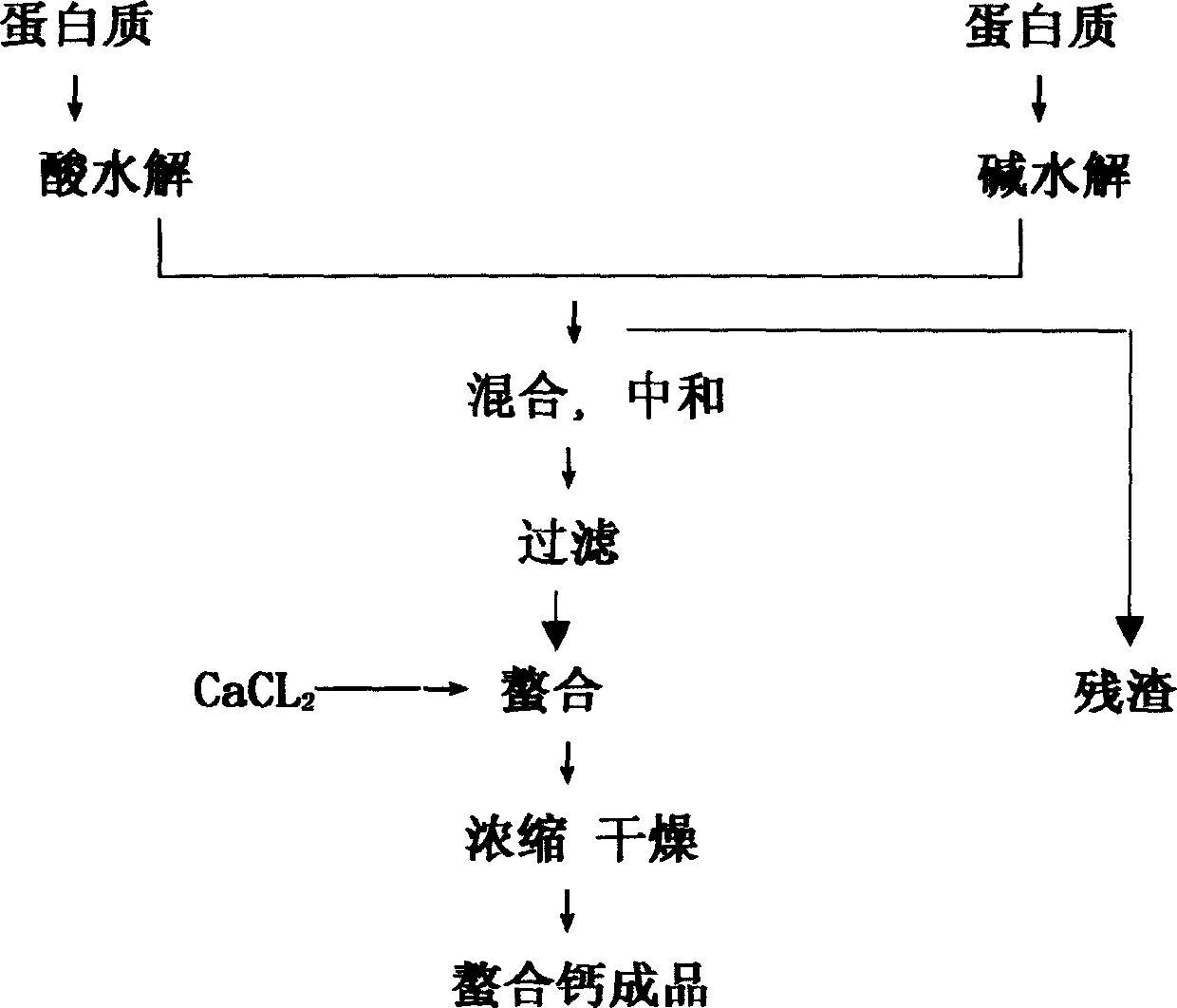

[0010] Embodiment 1: (acid hydrolysis method)

[0011] The acid hydrolysis method is characterized in that the waste protein is hydrolyzed to produce compound amino acids, which are then neutralized and chelated to form chelates. The production process is shown in Figure 1. The entire production process of the acid hydrolysis method adopts a complete set of chemical processes. For discarded protein water, add 30% HCI to the protein water for hydrolysis. After hydrolysis, the entire ion solution becomes acidic, and then add alkaline NaOH to neutralize the entire protein aqueous solution, then add CaOH to chelate and concentrate , dried, and finally made into calcium products. Thereby completing the whole manufacturing process. The content range of the organic components of the finished product is: amino acid 15%-20%; calcium 12%-17%.

Embodiment 2

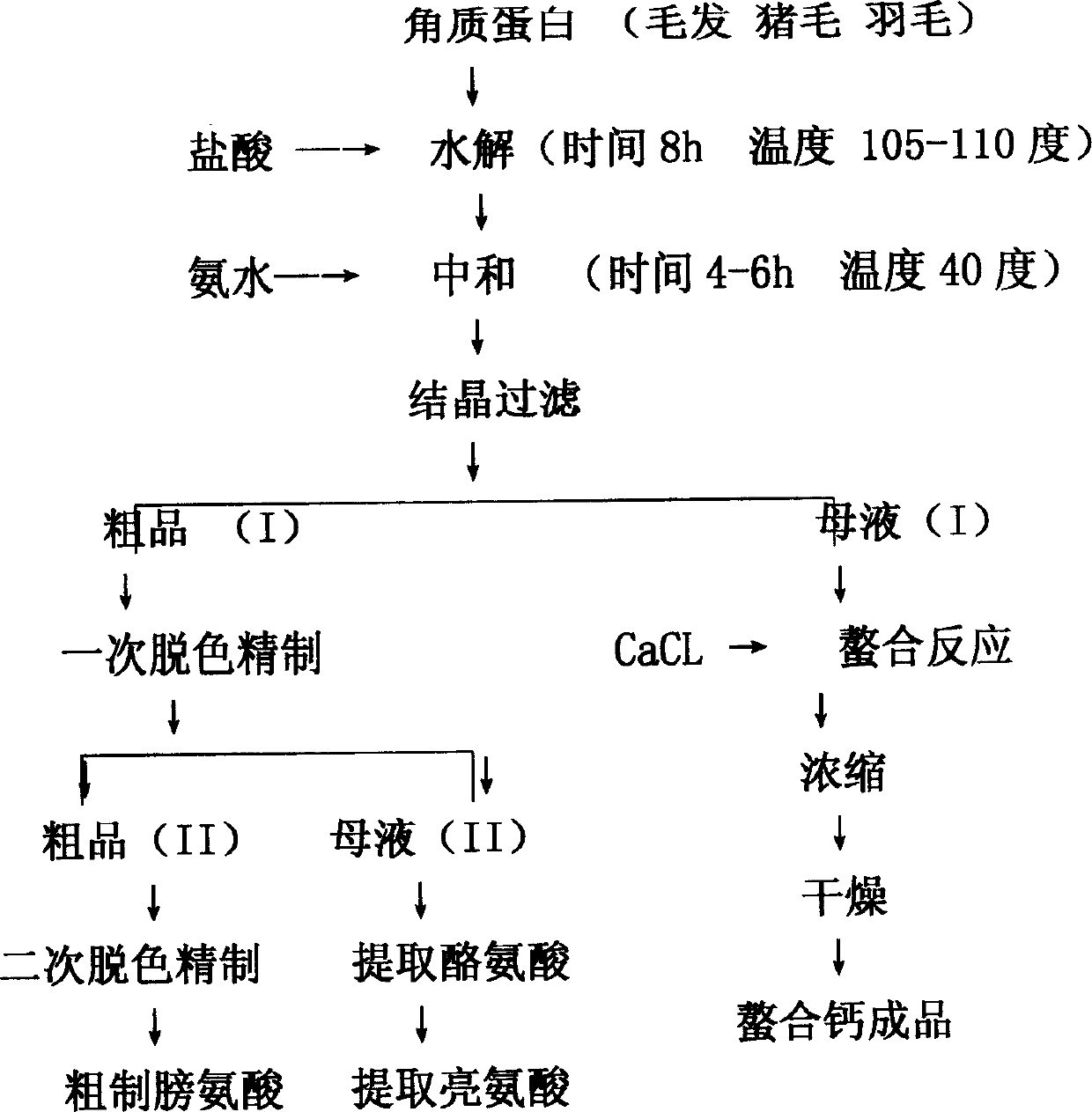

[0012] Embodiment 2: (acid, alkali hydrolysis method)

[0013] Using acid and alkali hydrolysis method: firstly hydrolyze two kinds of acid and alkali solutions respectively, and then mix and neutralize the two solutions, which saves the amount of acid and alkali, thus effectively reducing the production cost.

[0014] The whole manufacturing process is shown in Figure 2 below.

[0015] The whole production process of acid and alkali hydrolysis embodies the purpose of saving raw materials. It carries out acid hydrolysis and alkali hydrolysis respectively, and mixes and neutralizes the protein after hydrolysis, removes the residue through filtration, and then chelates. CaCL 2 Calcium ions are collected in the reaction, then concentrated and dried, and finally chelated into calcium products.

[0016] The organic content of this product is: amino acid 15%-20%, calcium 12%-17%

Embodiment 3

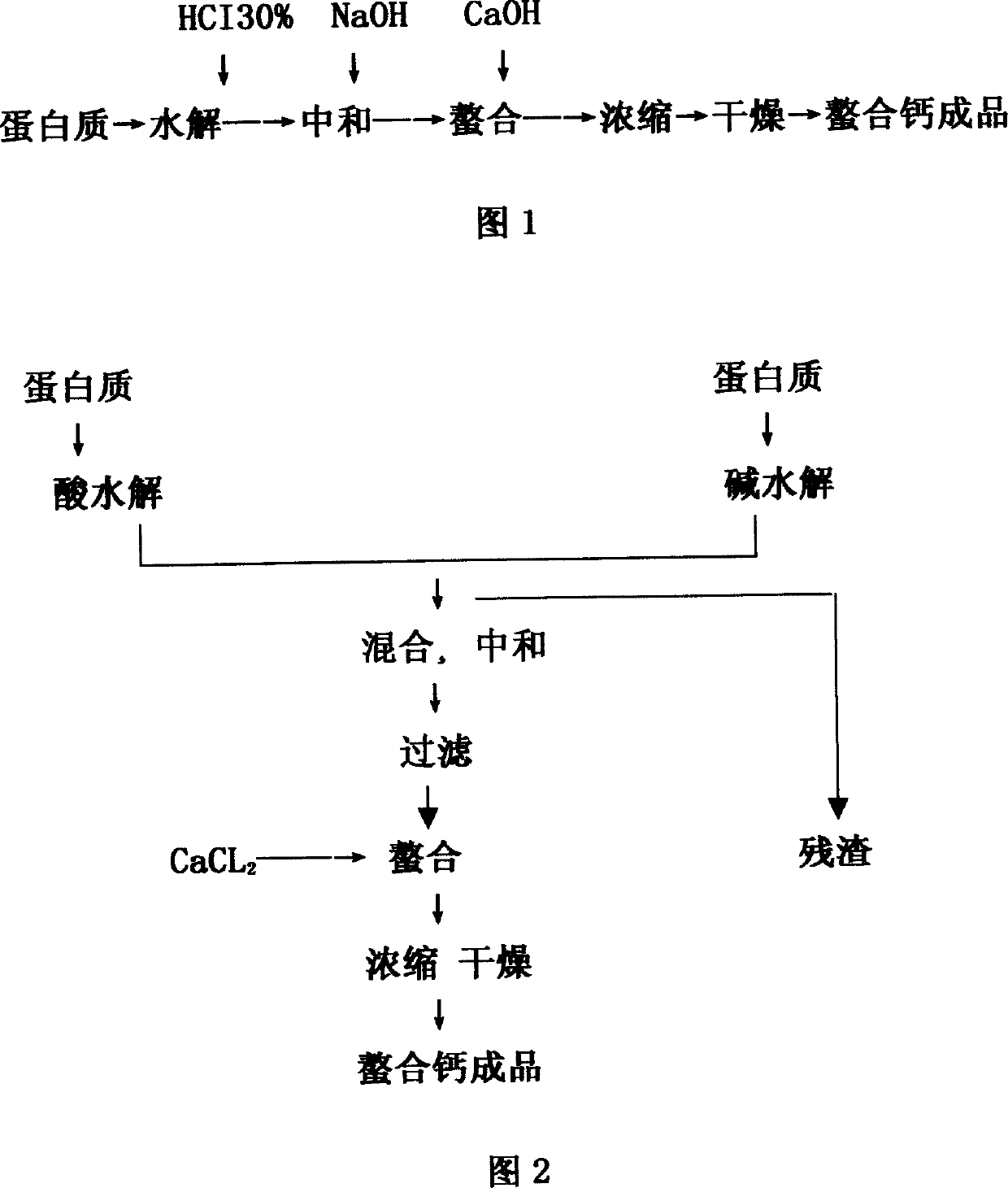

[0017] Embodiment 3: (comprehensive utilization method)

[0018] The method uses keratin as a raw material to extract high-value cystine, tyrosine, arginine, etc. in the keratin step by step, and the chelation process of the trace element calcium in the compound amino acid is shown in Figure 3.

[0019] The content range of the organic components of this finished product is: amino acid 15%-20%; calcium 12%-17% The problem of low absorption and utilization rate also effectively solves the problem of high fertilization cost. It has a good prospect of development and utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com