Patents

Literature

360results about How to "Easily hydrolyzed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

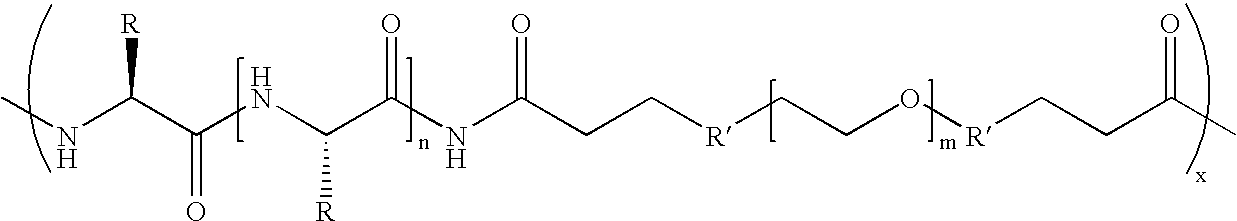

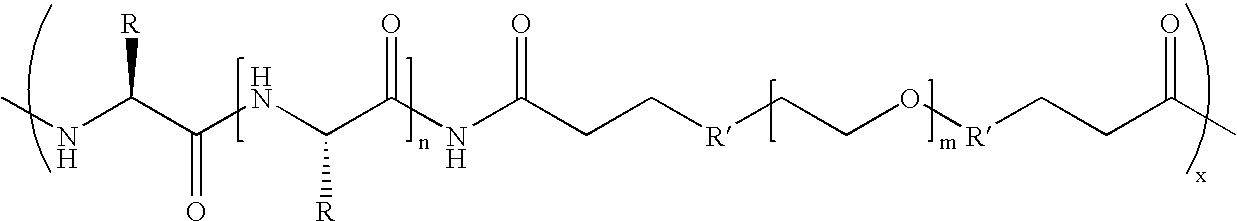

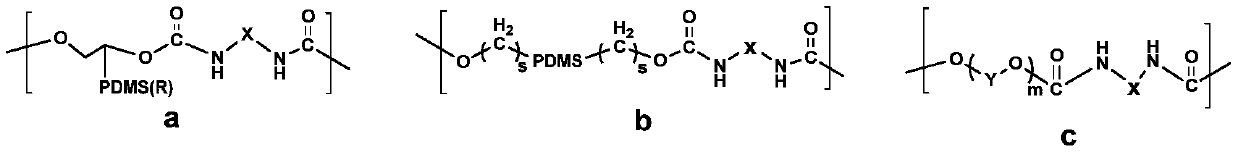

Biodegradable multi-block copolymers of poly(amino acid)s and poly(ethylene glycol) for the delivery of bioactive agents

InactiveUS20030147958A1Easy to chargeSmall sizePowder deliveryGenetic material ingredientsCarbamateHydrophilic polymers

This patent discloses the synthesis of a multi-block copolymer containing poly(amino acids) (PAA) and a hydrophilic polymer which are degradable under physiological conditions. Control over the degradation rate of the obtained copolymers is achieved by introducing ester, amide or urethane groups as a biodegradable linkage connecting the PAA and the hydrophilic polymer. The biodegradable multi-block copolymers display high transfection efficiency in plasmid delivery with low cytotoxicity.

Owner:EXPRESSION GENETICS INC

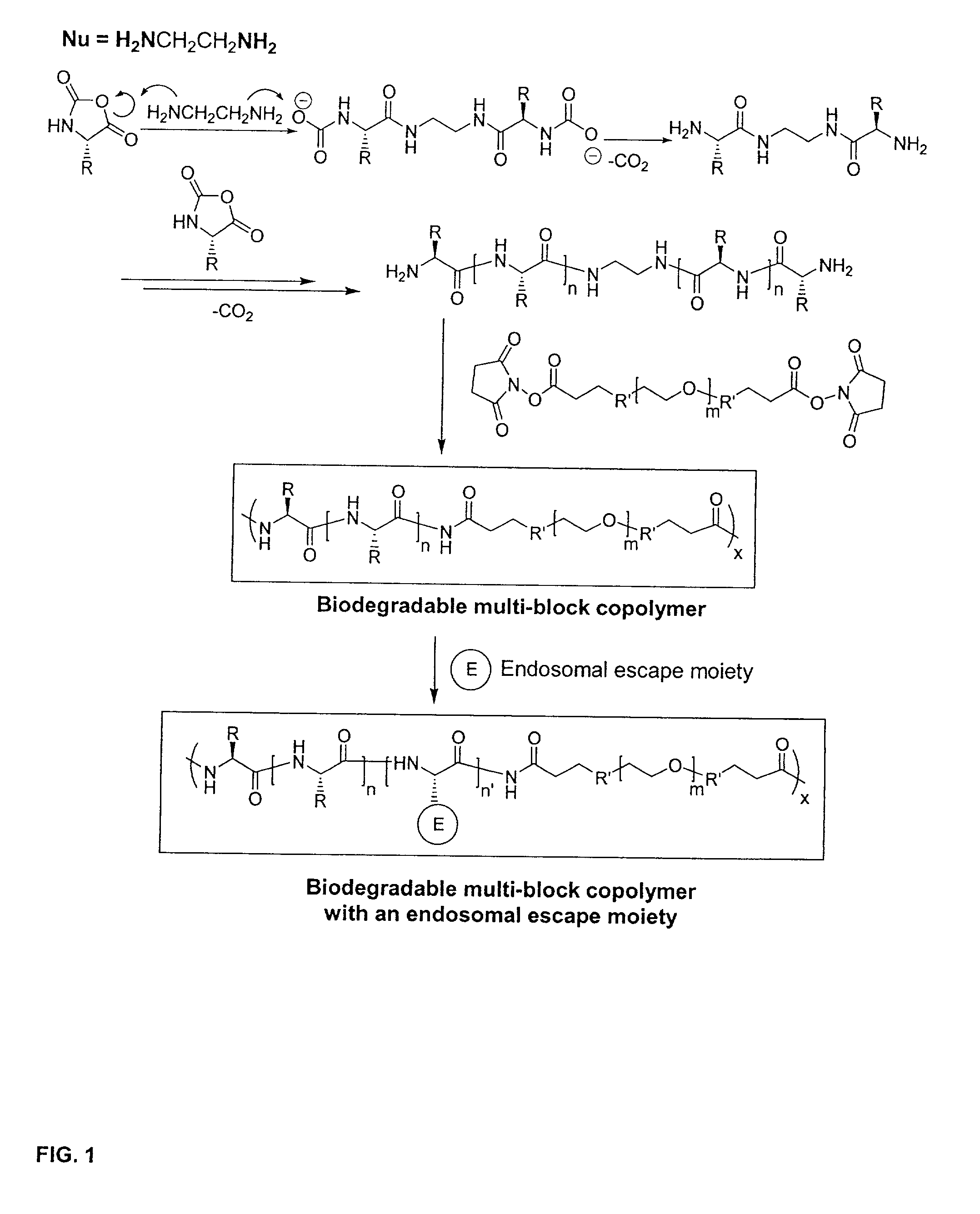

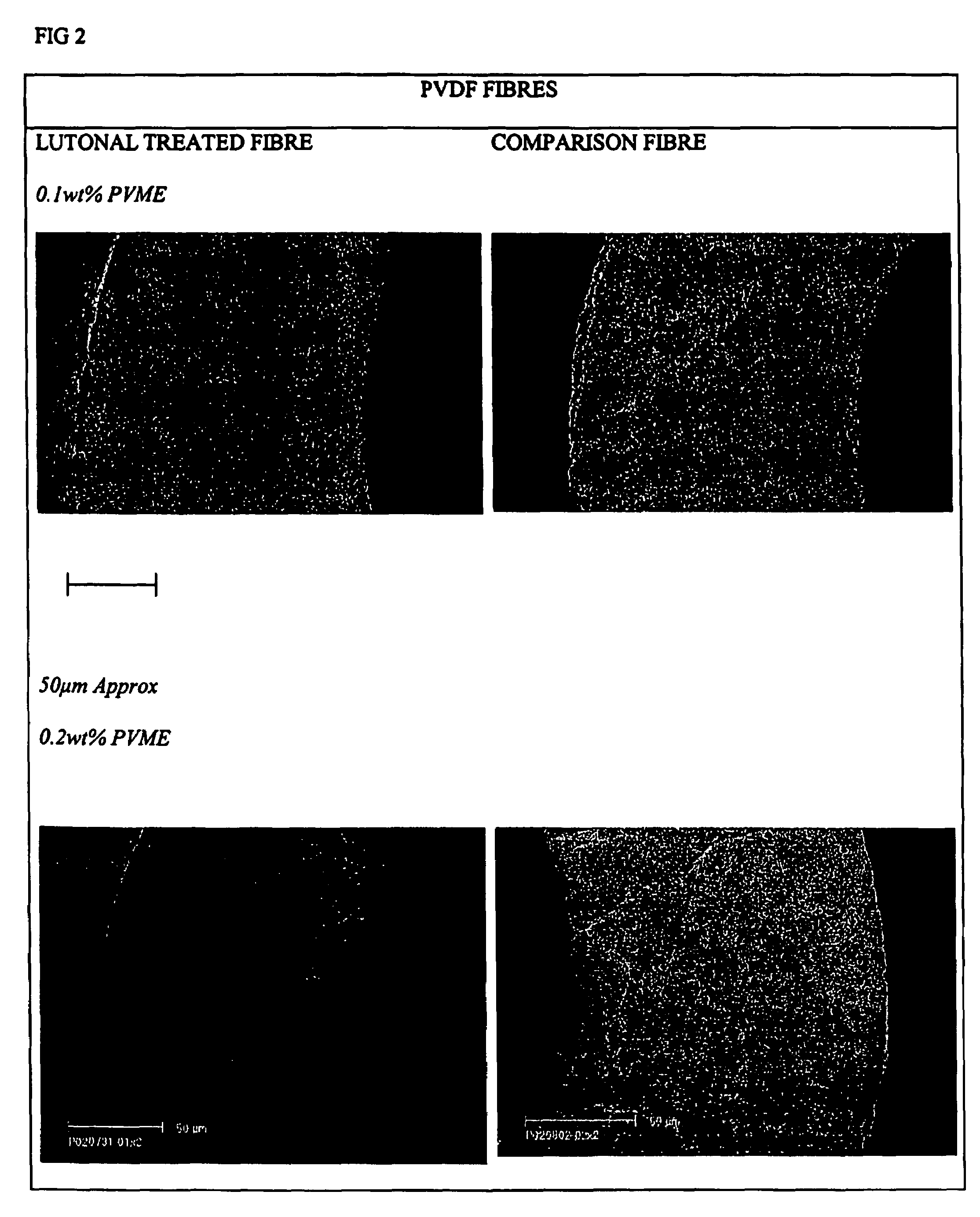

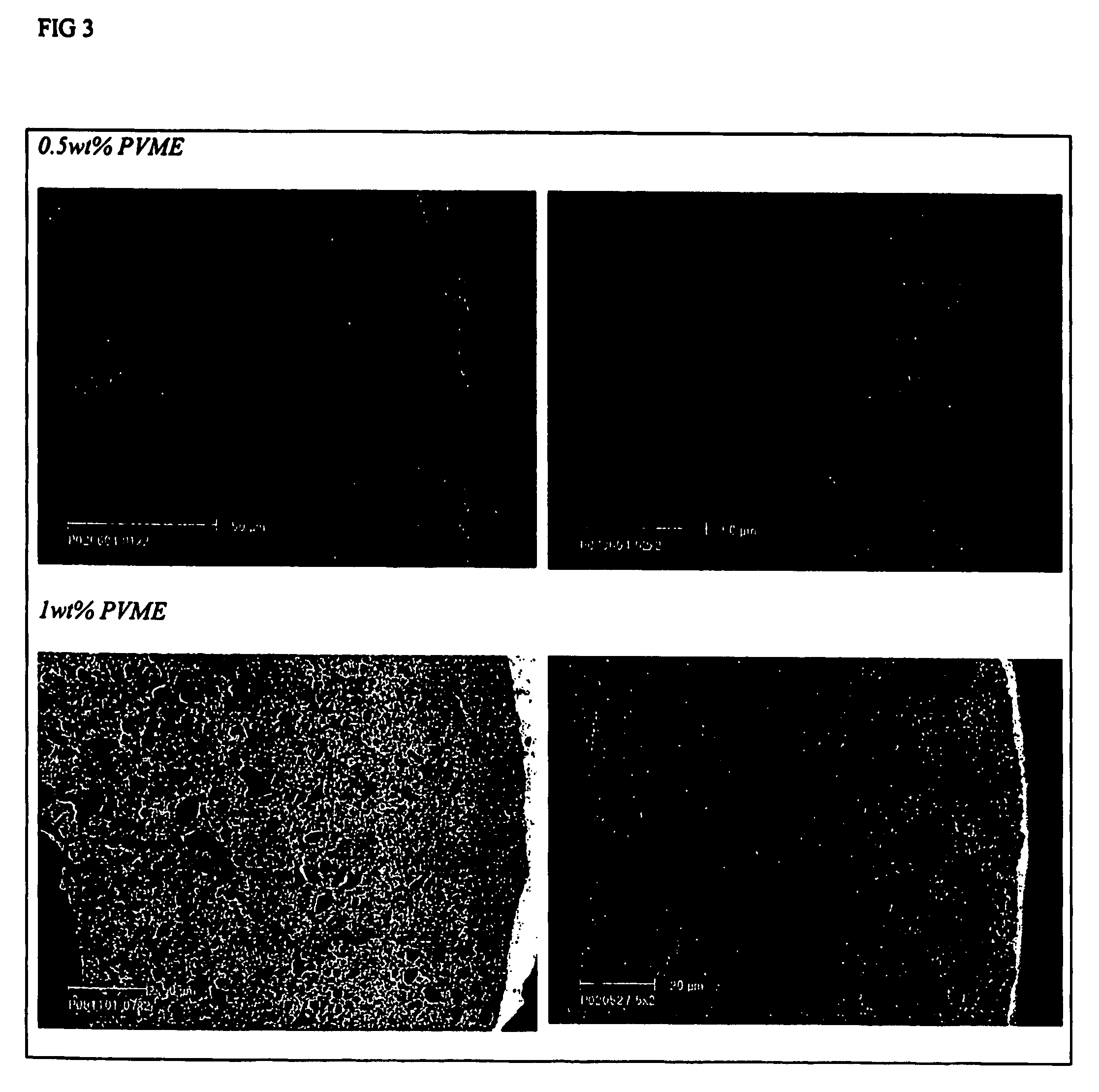

Membrane post treatment

InactiveUS7662212B2Low toxicityReduce riskSolid sorbent liquid separationPretreated surfacesHydrophilizationMicrofiltration membrane

The invention relates to polymeric ultrafiltration or microfiltration membranes of, for instance, Halar, PVDF or PP, incorporating PVME or vinyl methyl ether monomers. The PVME may be present as a coating on the membrane or dispersed throughout the membrane or both. The membranes are preferably hydrophilic with a highly asymmetric structure with a reduced pore size and / or absence of macrovoids as a result of the addition of PVME. The PVME maybe cross-linked. The invention also relates to methods of hydrophilising membranes and / or preparing hydrophilic membranes via thermal or diffusion induced phase separation processed.

Owner:EVOQUA WATER TECH LLC

Method and composition for preventing or treating lost circulation

InactiveUS7066285B2Easily hydrolyzedPreventing and alleviatingLiquid/gas jet drillingFlushingDirectional wellWell drilling

An improved composition and method is provided for preventing or alleviating lost circulation during the drilling of wellbores in subterranean formations, and particularly during the drilling of oil and gas wells. The method is suited for horizontal and directional wells as well as more vertical wells. The composition of the invention comprises a synergistic blend of resilient, angular, carbon-based material and a water-swellable, crystalline synthetic polymer. The method employs the composition of the invention in preventing lost circulation.

Owner:HALLIBURTON ENERGY SERVICES INC

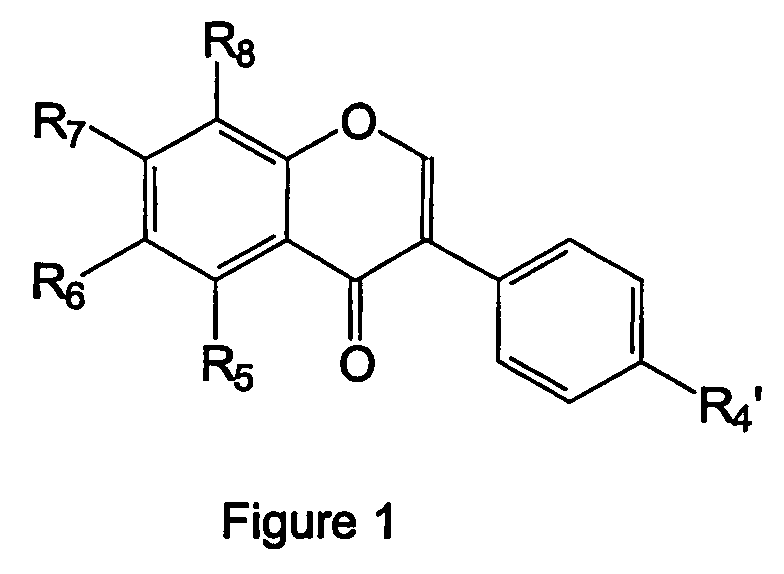

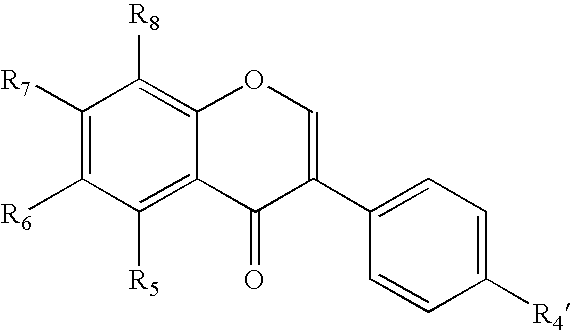

Isoflavone derivatives

InactiveUS20060251592A1Improve bioavailabilityEasily hydrolyzedCosmetic preparationsBiocideSolubilityPhosphate

Isoflavones are modified by esterification at one or more of the C4′, C5, C6, and C7 positions to promote bioavailability, and especially to enhance solubility over the corresponding unesterified isoflavones. Preferred modifications produce a carboxylic acid hemiester or a phosphate ester which is biologically hydrolysable. Preferred starting isoflavones are genistin and daidzin, and still more preferably comprises an aglycone form such as genistein or daidzein. Esterified isoflavones may be employed therapeutically or prophylactically for a variety of conditions, provided as a dietary supplement, or added to natural or processed food-stuffs. Further preferred uses include incorporation of contemplated compounds into topical formulations, and especially cosmetic topical formulations.

Owner:VYREXIP HLDG

Intensive processing method for stalk articles or agricultural castoff

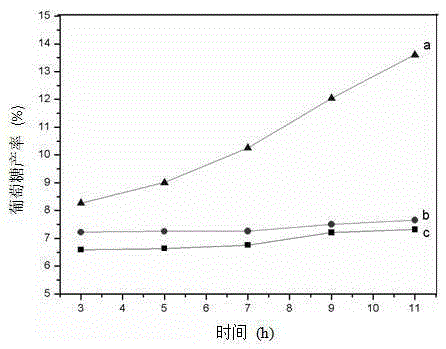

InactiveCN101492700AEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperature sterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

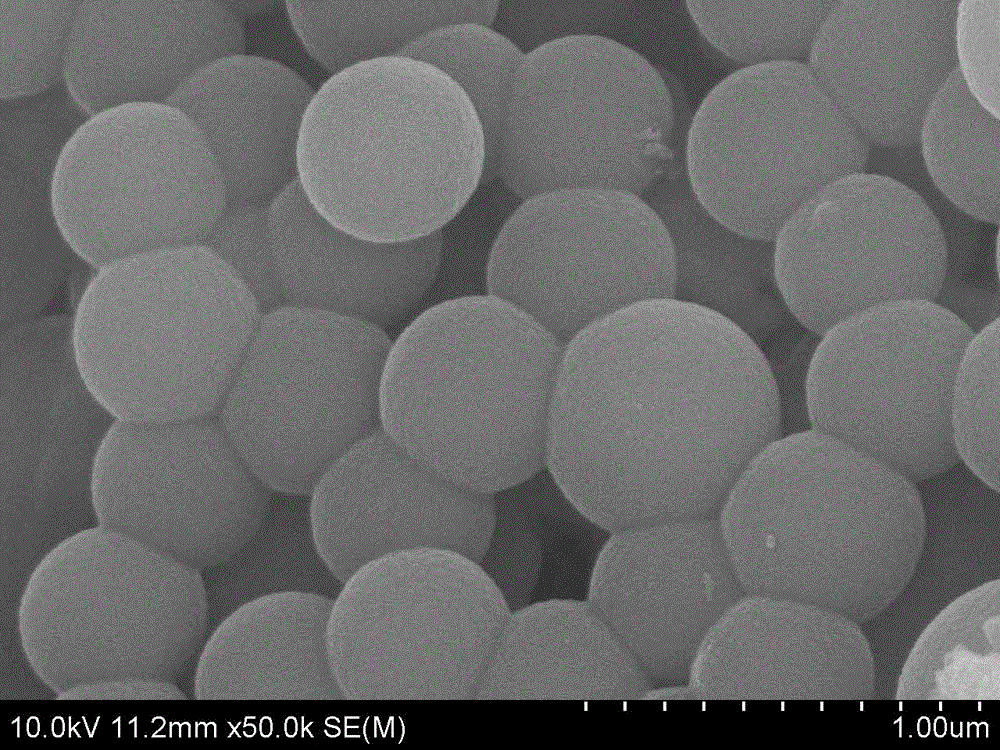

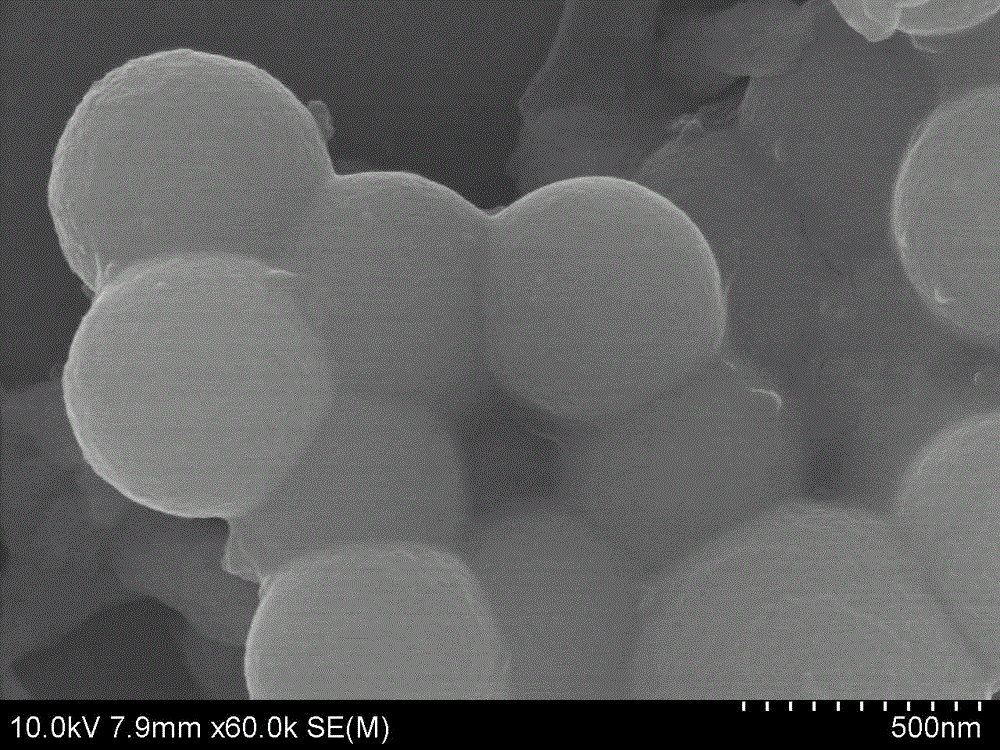

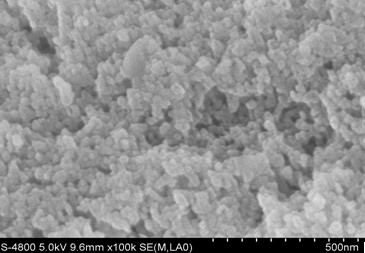

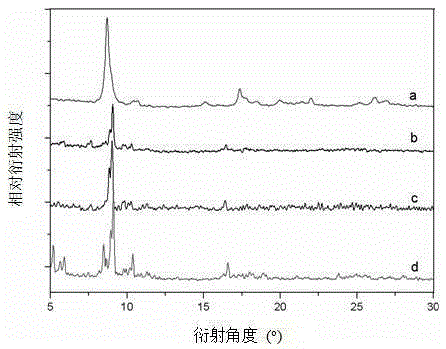

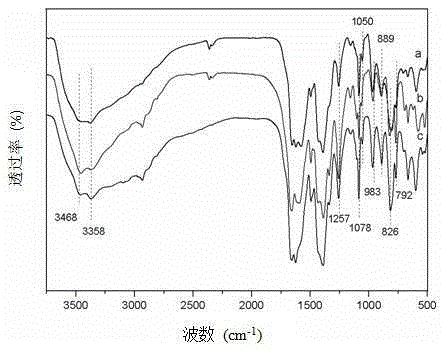

Preparation method of graphene-coated silicon dioxide nanoparticles

The invention discloses a preparation method of graphene-coated silicon dioxide nanoparticles. Graphite powder is taken as a raw material, graphene oxide with oxygen-containing functional groups is prepared with an improved Hummers method, the silicon dioxide nanoparticles are prepared with a hydrothermal method, a proper quantity of silane coupling agents are added to a solution containing silicon dioxide and uniformly stirred, the silane coupling agents are attached to the surfaces of silicon dioxide particles, and surface-modified silicon dioxide particles are obtained; graphene oxide is added to the modified silicon dioxide solution, and surfaces of the silicon dioxide particles are completely coated with graphene oxide under the interaction of functional groups. Finally, a reducing agent is added to the solution, graphene is formed by further removing the oxygen-containing functional groups of graphene oxide, and a composite with graphene completely coating silicon dioxide is prepared. The method has the advantages that a process is simple, the reaction time is short, regulation is easy and the like. The prepared composite has the characteristics of regular structure, high porosity, low density, good hydrophobicity and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

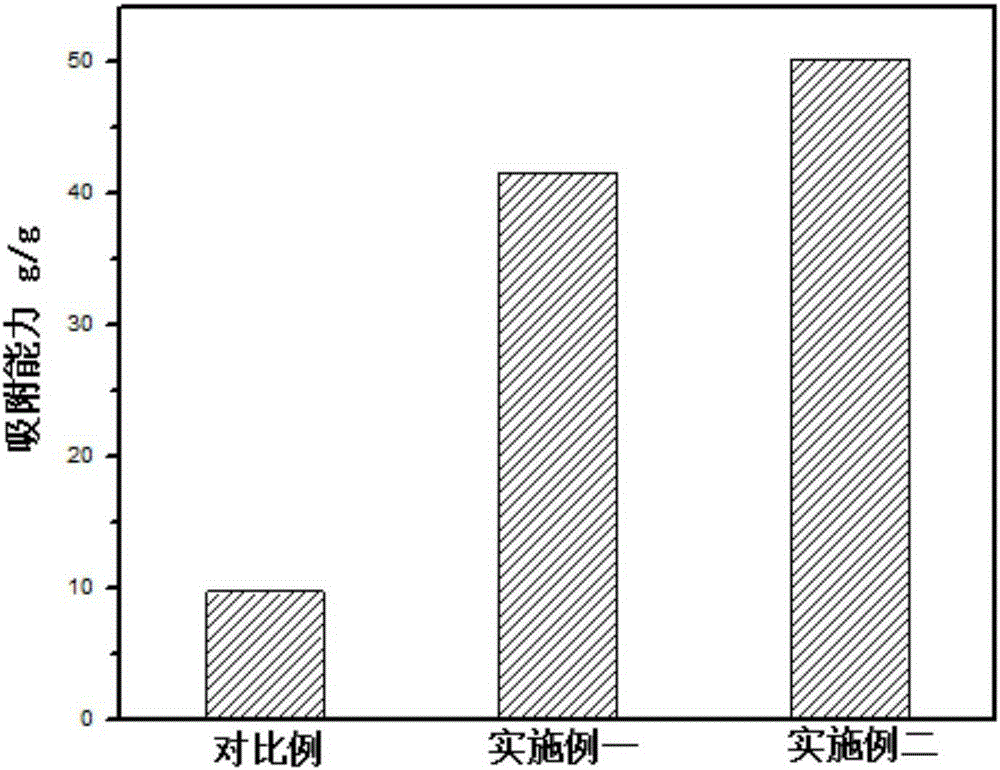

Preparation method of graphene oxide/silicon dioxide hybrid aerogel

A preparation method of graphene oxide / silicon dioxide hybrid aerogel comprises the following steps: A, adding 0.05-0.1 mol of a precursor into 9-18 ml of distilled water and dropwise adding a hydrolyst with its concentration of 0.2-0.6 mol / L into the precursor aqueous solution, wherein molar ratio of the hydrolyst to the precursor is 1:20-1:100; stirring at 20-30 DEG C for 5-8 h; adjusting pH value to 6-7 and stirring for 5-45 min so as to obtain a dispersion containing silicon dioxide microspheres; B, adding water to dilute the silicon dioxide microsphere dispersion by 5-50 times, carrying out iso-volume mixing on the diluted silicon dioxide microsphere dispersion and a graphene oxide dispersion with its concentration being 0.6-2 mg / ml, stirring for 10-30 min, carrying out ultrasonic treatment for 10-30 min so as to obtain graphene oxide / silicon dioxide hybrid aerogel; and C, freezing the hybrid aerogel under liquid nitrogen for 5-10 min, freeze-drying and dewatering to obtain the graphene oxide / silicon dioxide hybrid aerogel. The method is environmentally friendly, and the technology is simple. The prepared hybrid aerogel has advantages of complete gel network structure, high porosity, good adsorptivity, high strength, low density and the like.

Owner:SOUTHWEST JIAOTONG UNIV

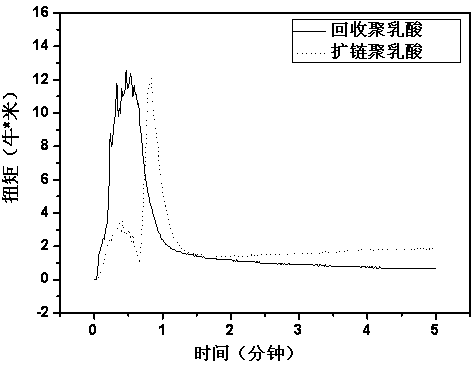

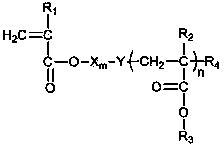

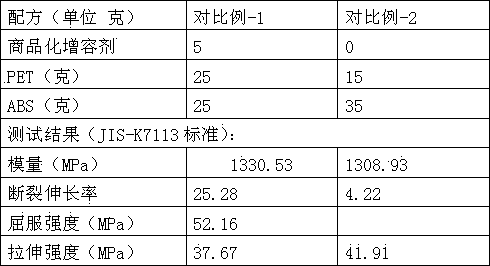

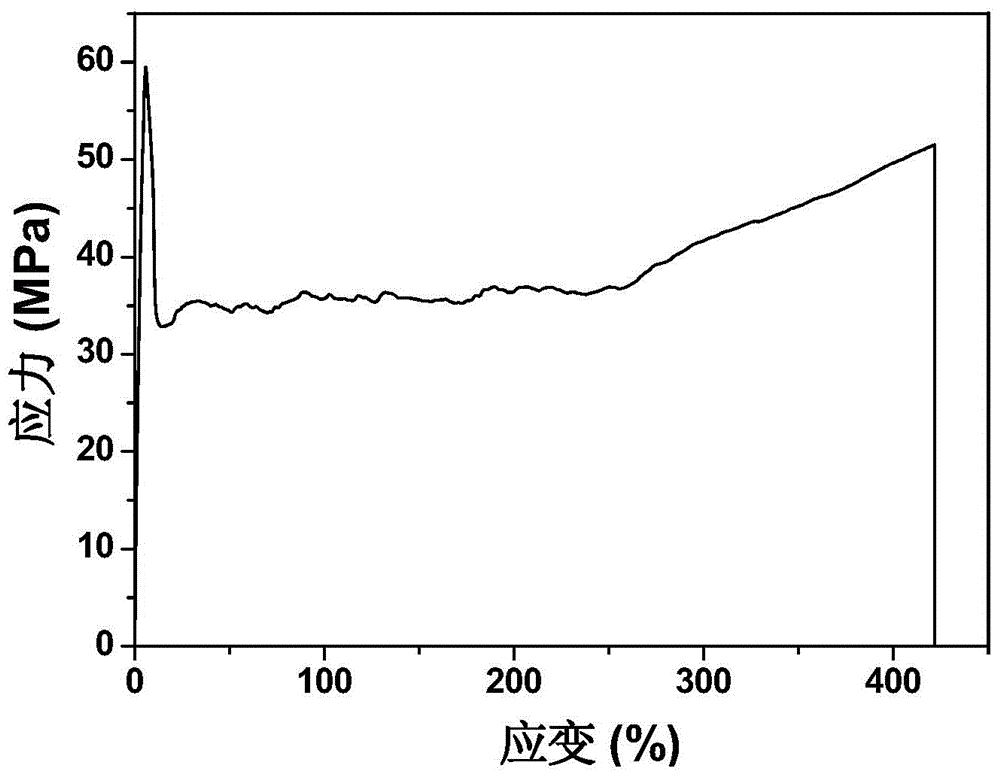

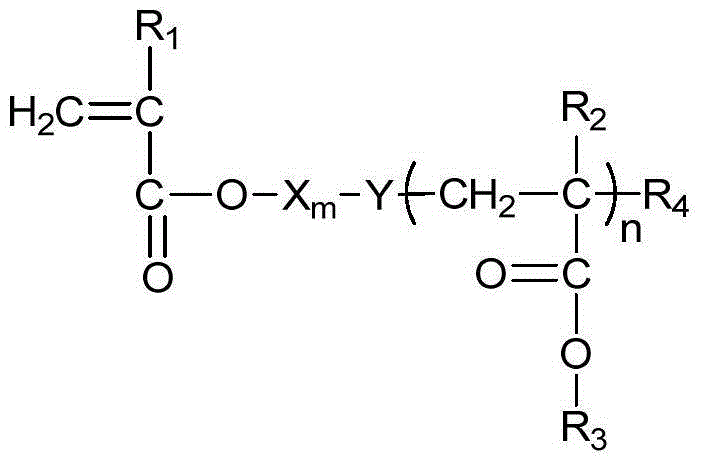

Comb-shaped stem grafting copolymer containing reactive group and preparation method and application thereof

The invention discloses a comb-shaped stem grafting copolymer containing reactive group and a preparation method and application thereof. The copolymer is a comb-shaped stem grafting copolymer by taking small molecule monomer B as the main chain, and giant molecule monomer A as the side chain. According to the method, the giant molecule monomer A and the small molecule monomer B are copolymerized to form the comb-shaped stem grafting copolymer of which the main chain is the small molecule monomer B and the side chain is the giant molecule monomer A. The comb-shaped stem grafting copolymer disclosed by the invention can serve as the chain extender of a polymer or a polymer blend, the compatibilizer of the polymer blend, the hydrolytic stabilizer, adhesive and anti-leakage agent of the polymer blend, and is used for coatings of wood, metal or plastic. The reactive group in the copolymer has very high reaction activity, and can react with various end groups of polyamide and polyester. Methacrylate monomers have thermodynamics compatibility with various polymers. The reactive group can react with the end hydroxyl group or the end carboxy group of polyester, so that the comb-shaped stem grafting copolymer can serve as the chain extender, and the processing and application properties of the material are improved.

Owner:HANGZHOU NORMAL UNIVERSITY

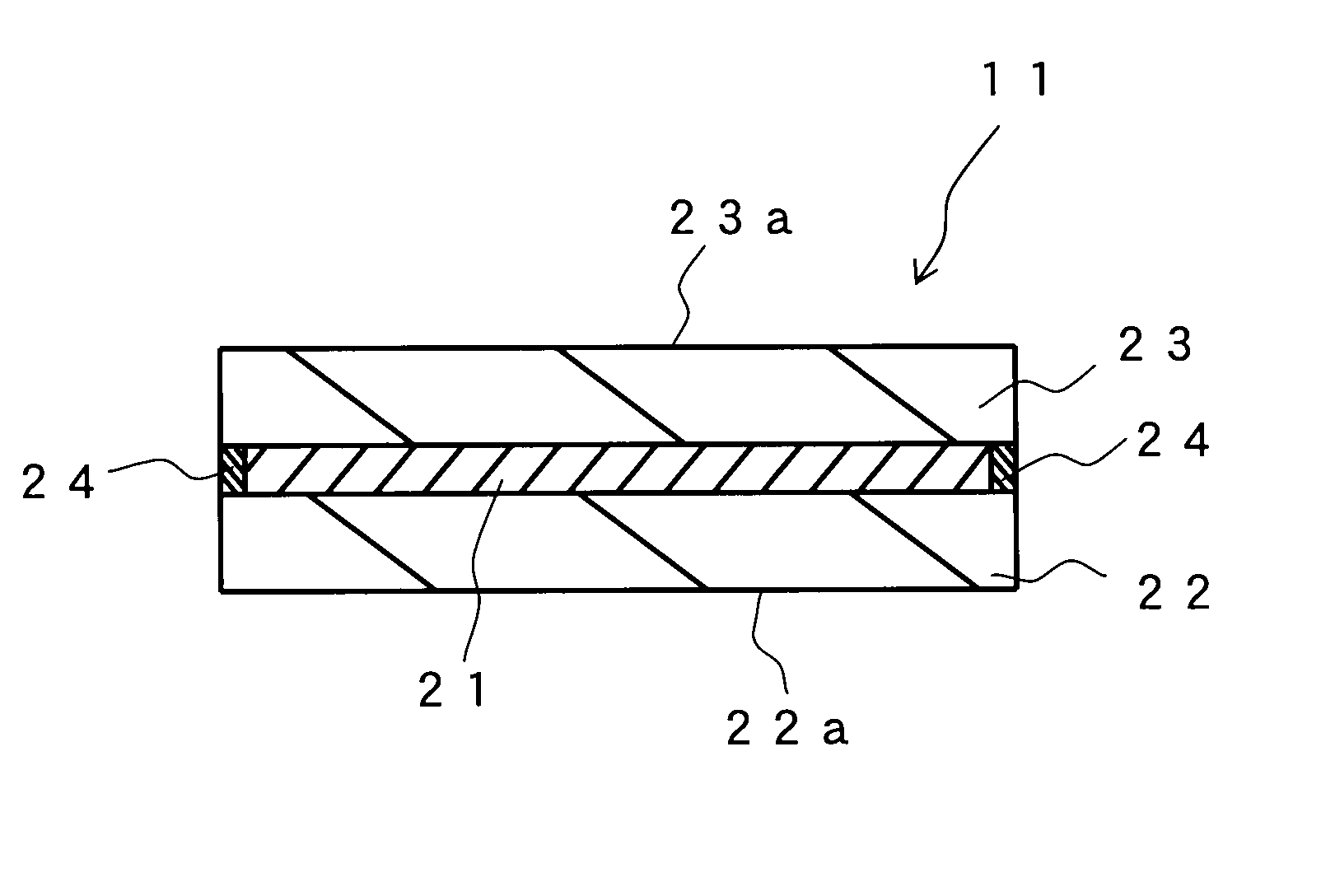

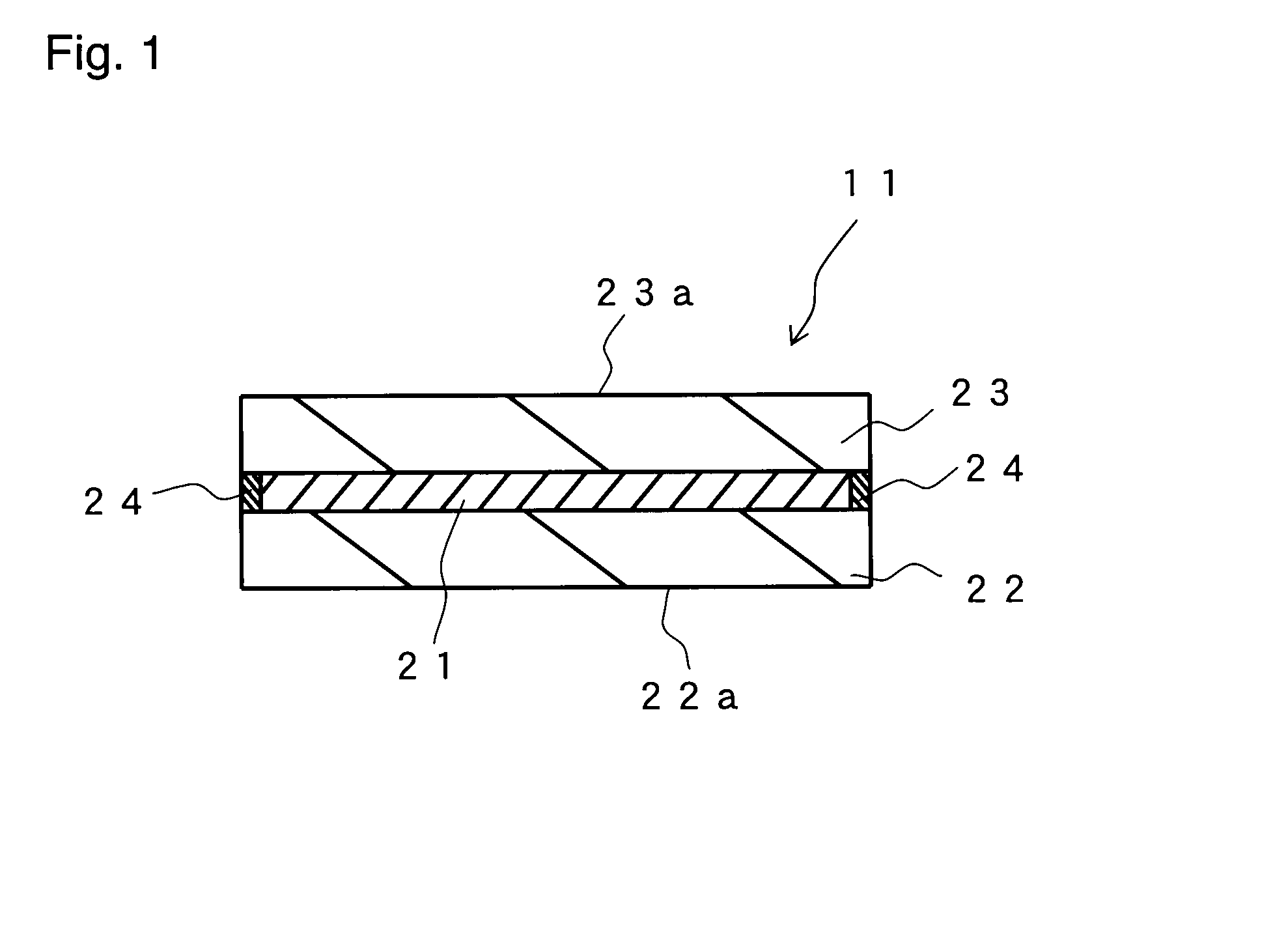

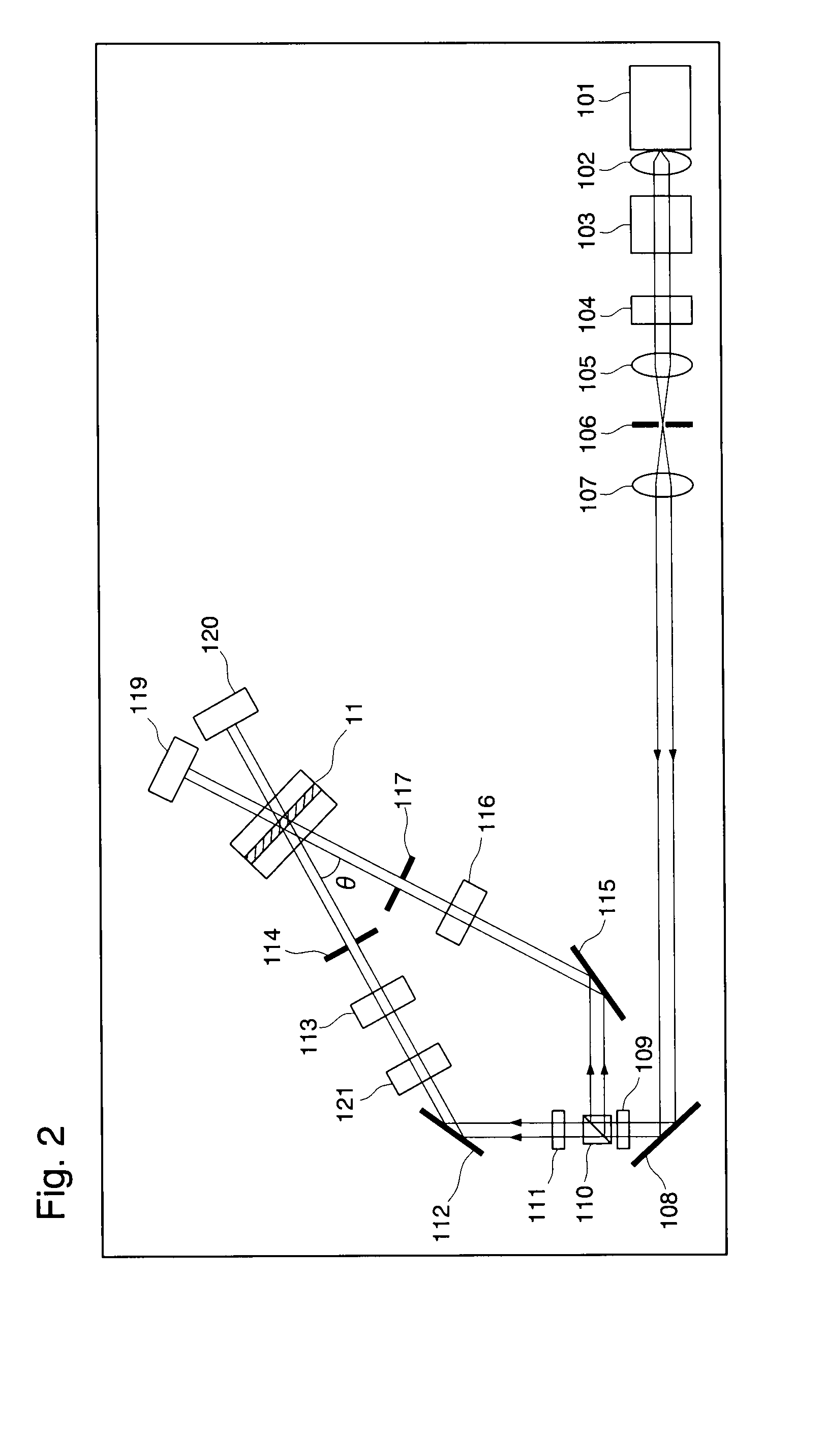

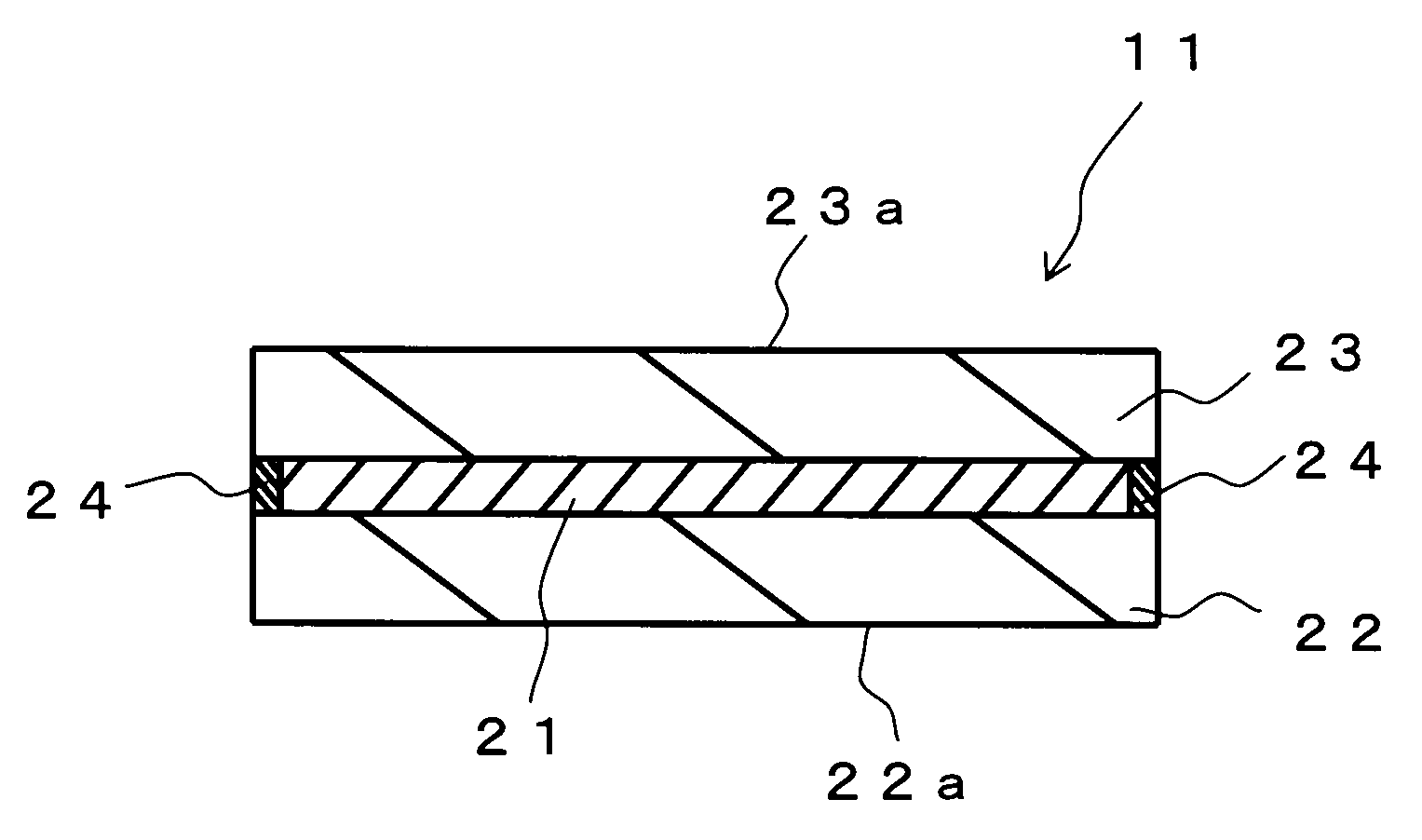

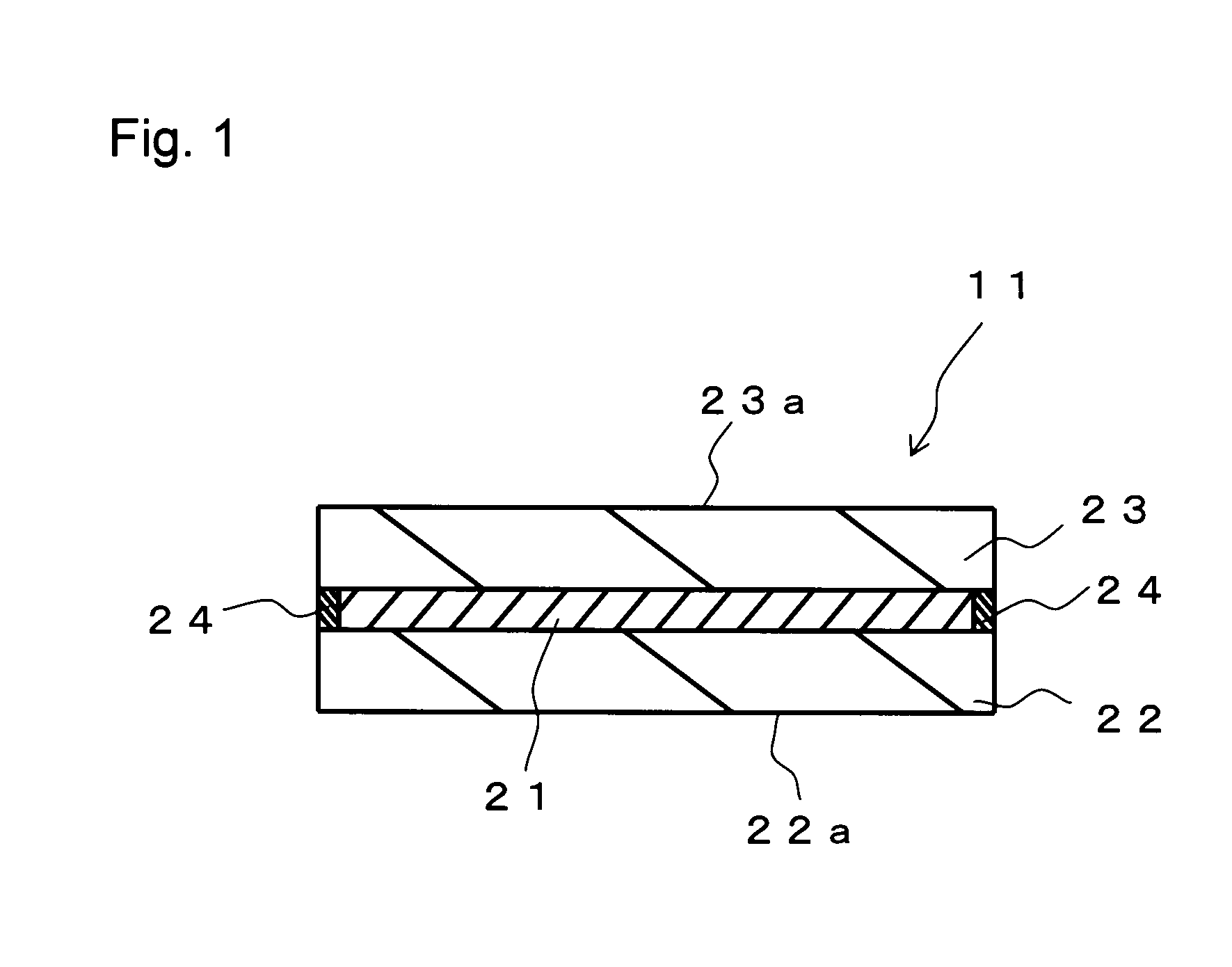

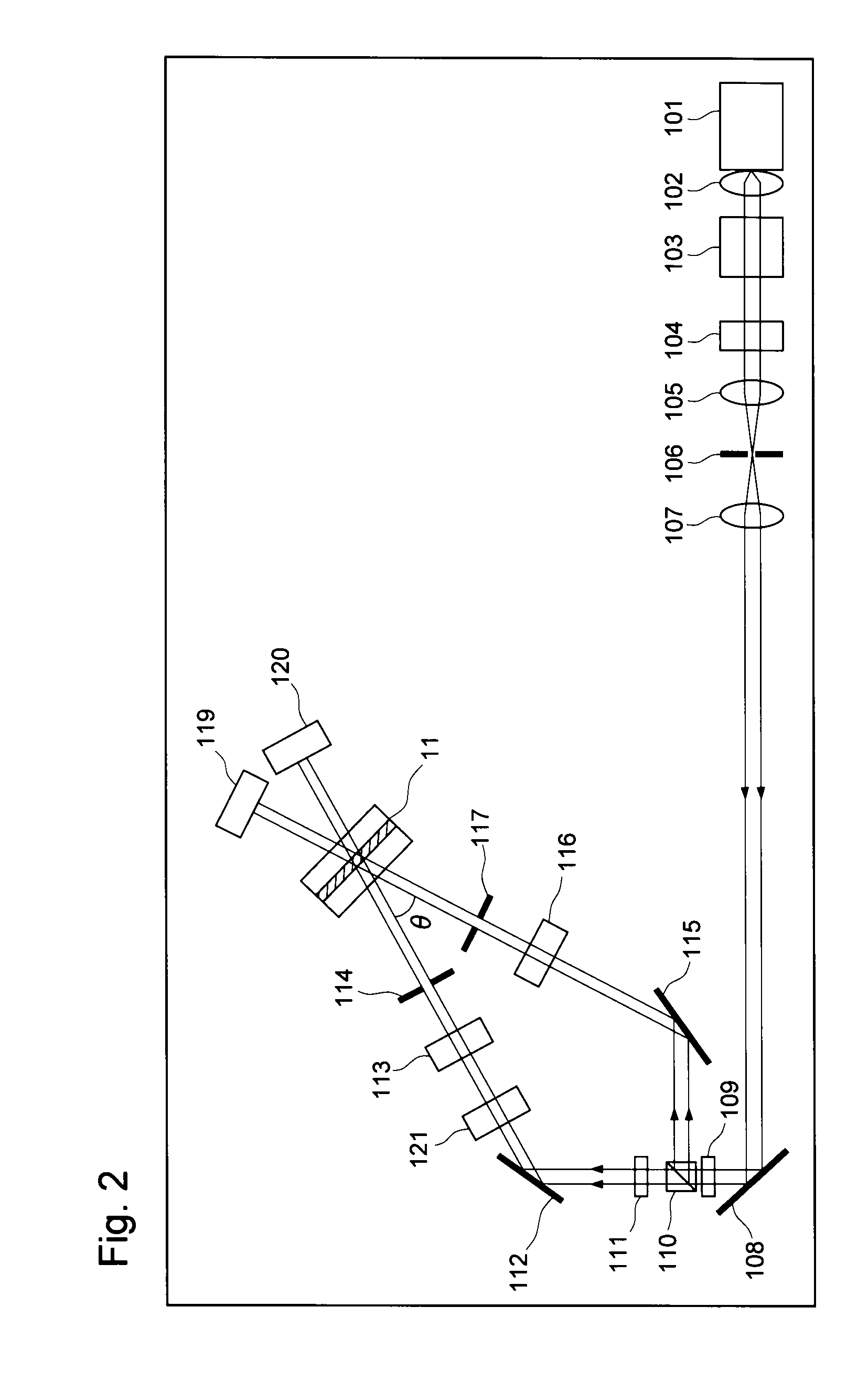

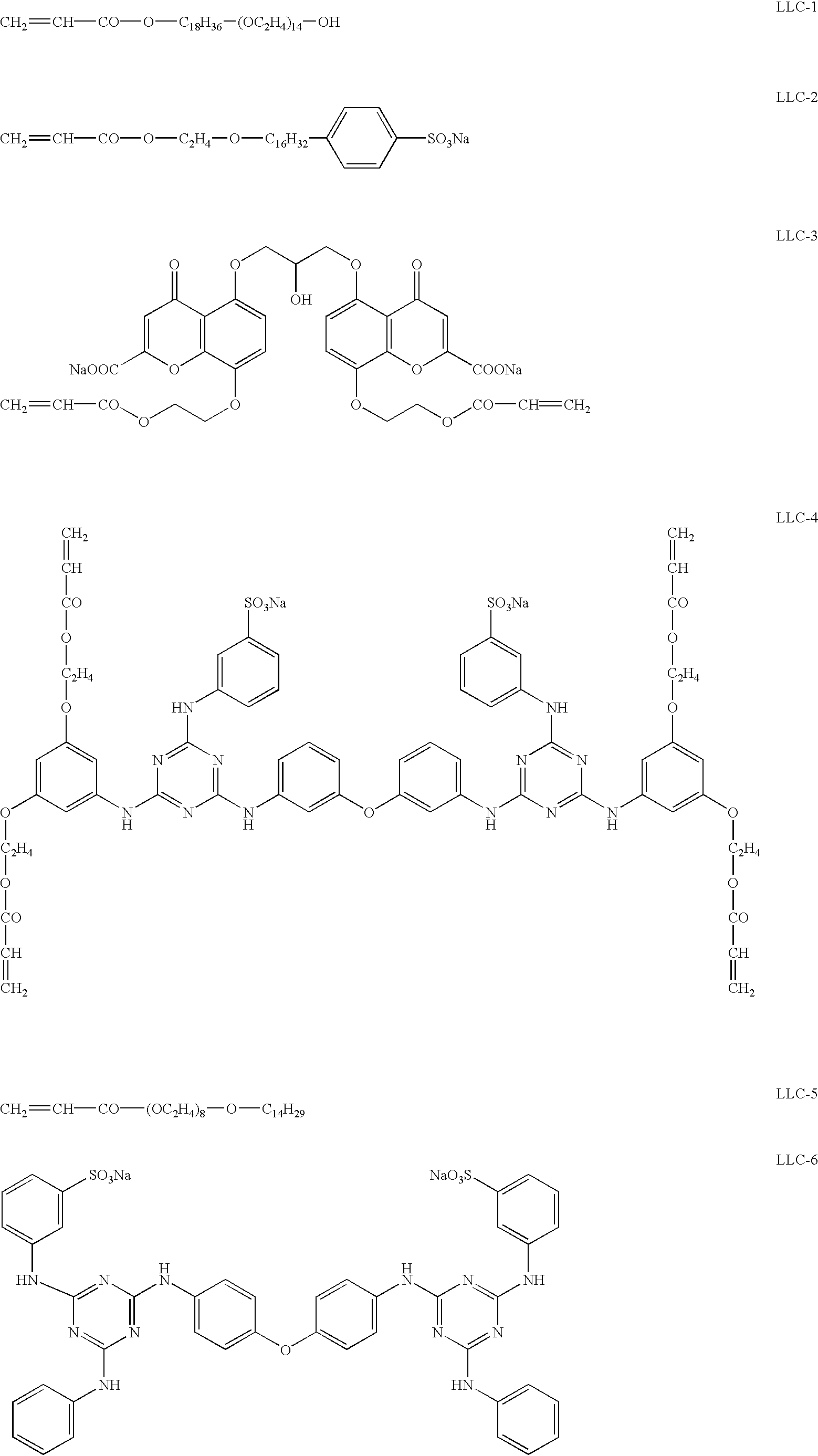

Hologram recording material and hologram recording medium

InactiveUS20080254375A1Addressing Insufficient SensitivityGood storage stabilityRecord information storagePhotosensitive materials for photomechanical apparatusMeth-Refractive index

Owner:TDK CORPARATION

Hologram recording material and hologram recording medium

InactiveUS20100086859A1Increased free volumePrevent shrinkagePhotomechanical apparatusRecord information storageVolume hologramMeth-

The present invention provides a hologram recording material and a hologram recording medium, which are suitable for volume hologram record and can attain high refractive index change, flexibility, high sensitivity, low scattering, environment resistance, that is, storage stability, durability, low dimensional change (low shrinkage) and high multiplicity in holographic memory recording using not only a green laser but also a blue laser. A hologram recording material comprising: a radical photopolymerizable compound; and a matrix which is a dispersion medium for the radical photopolymerizable compound, wherein the radical photopolymerizable compound comprises a (meth)acrylamide derivative represented by the following general formula (I): CH2═CR1—CONR2—CH2—O—R3 (I) wherein R1 represents H or a CH3 group, R2 represents H or an organic group, and R3 represents an organic group having 3 or more carbon atoms in total. A hologram recording medium 11 which has a hologram recording layer 21.

Owner:TDK CORPARATION

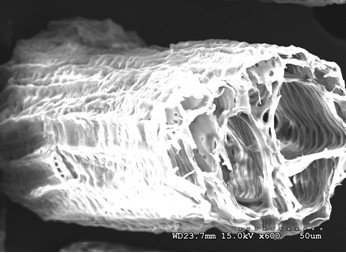

Short fiber food waste residue-based nano cellulose and preparation method thereof

InactiveCN102182089AFine granularityThe compactness of the crystal region is weakPretreatment with water/steamWashing/displacing pulp-treating liquorsFood additiveFiber

The invention relates to the field of processing of agricultural products, in particular to short fiber food waste residue-based nano cellulose and a preparation method thereof. The preparation method comprises three parts of pretreatment of short fiber food waste residues, acid hydrolysis of food residue fibers and homogenization. The nano cellulose prepared by the method has the granularity of 50-300nm, is short bar-shaped or microsphere-shaped and can be widely used for preparing a food additive or medicament excipient, and the like. In the method, acid hydrolysis is combined with high-pressure homogenization, thus the acid consumption and hydrolysis time are reduced, the granularity uniformity of the nano cellulose is improved; and the invention is suitable for mass production.

Owner:SOUTHWEST UNIV

Reactive group-contained comb-type graft copolymer, and preparation method and application thereof

ActiveCN104610515AHigh reactivityThermodynamically compatibleCoatingsGraft polymer adhesivesBackbone chainOrganic chemistry

The invention discloses a reactive group-contained comb-type graft copolymer, and a preparation method and application thereof. A small molecular monomer A and a macromolecular monomer B are copolymerized to form the comb-type graft copolymer with the small molecular monomer A as a main chain and the macromolecular monomer B as a side chain; the weight of the macromolecular monomer B accounts for 0.1-80wt% of the mass of the comb-type graft copolymer; the weight of the small molecular monomer A accounts for 99.9-20wt% of the mass of the comb-type graft copolymer. The reactive group-contained comb-type graft copolymer is the comb-type graft copolymer containing a reactive group on the side chain, and can be used as a compatibilizer and a chain extender.

Owner:HANGZHOU NORMAL UNIVERSITY

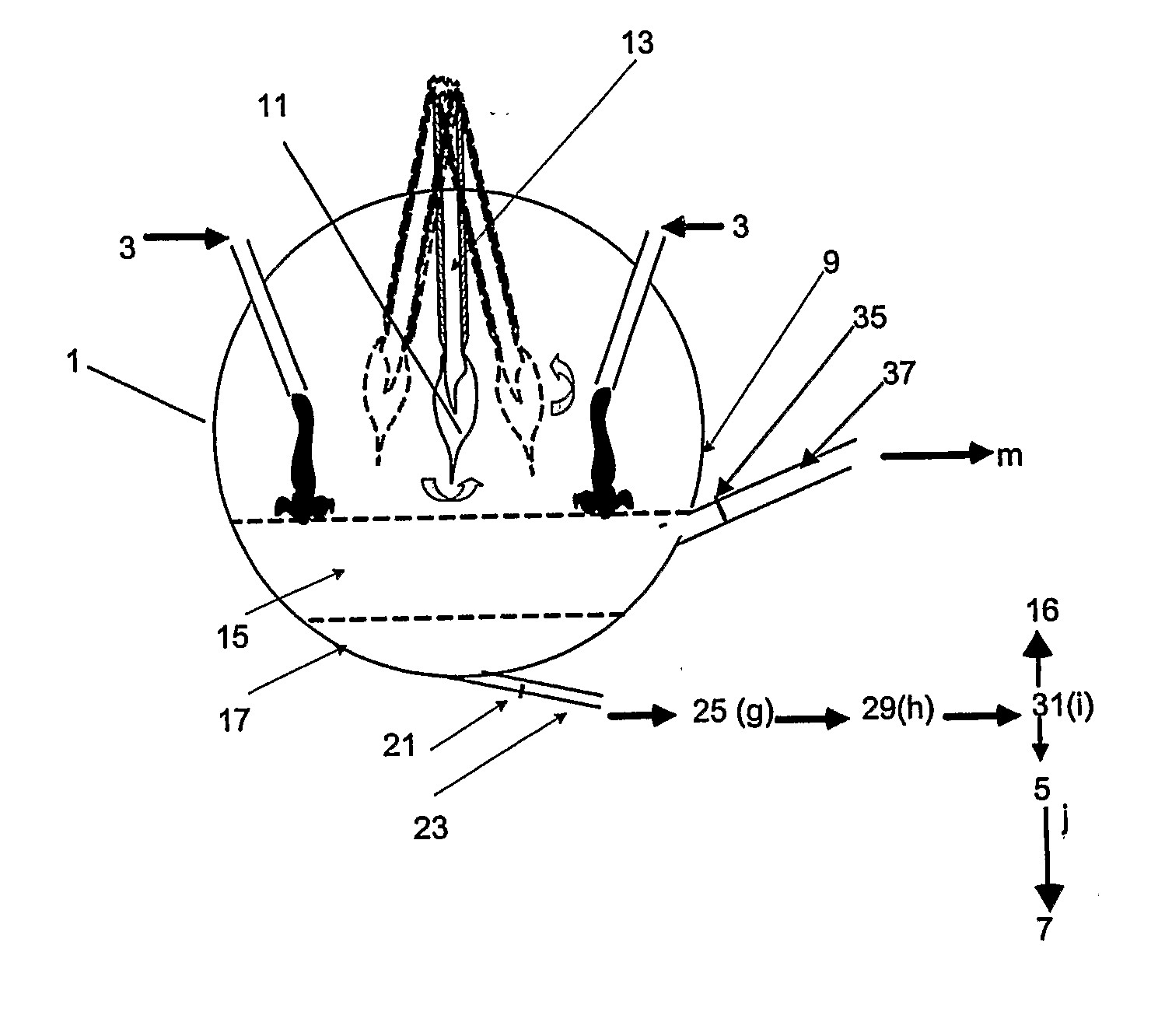

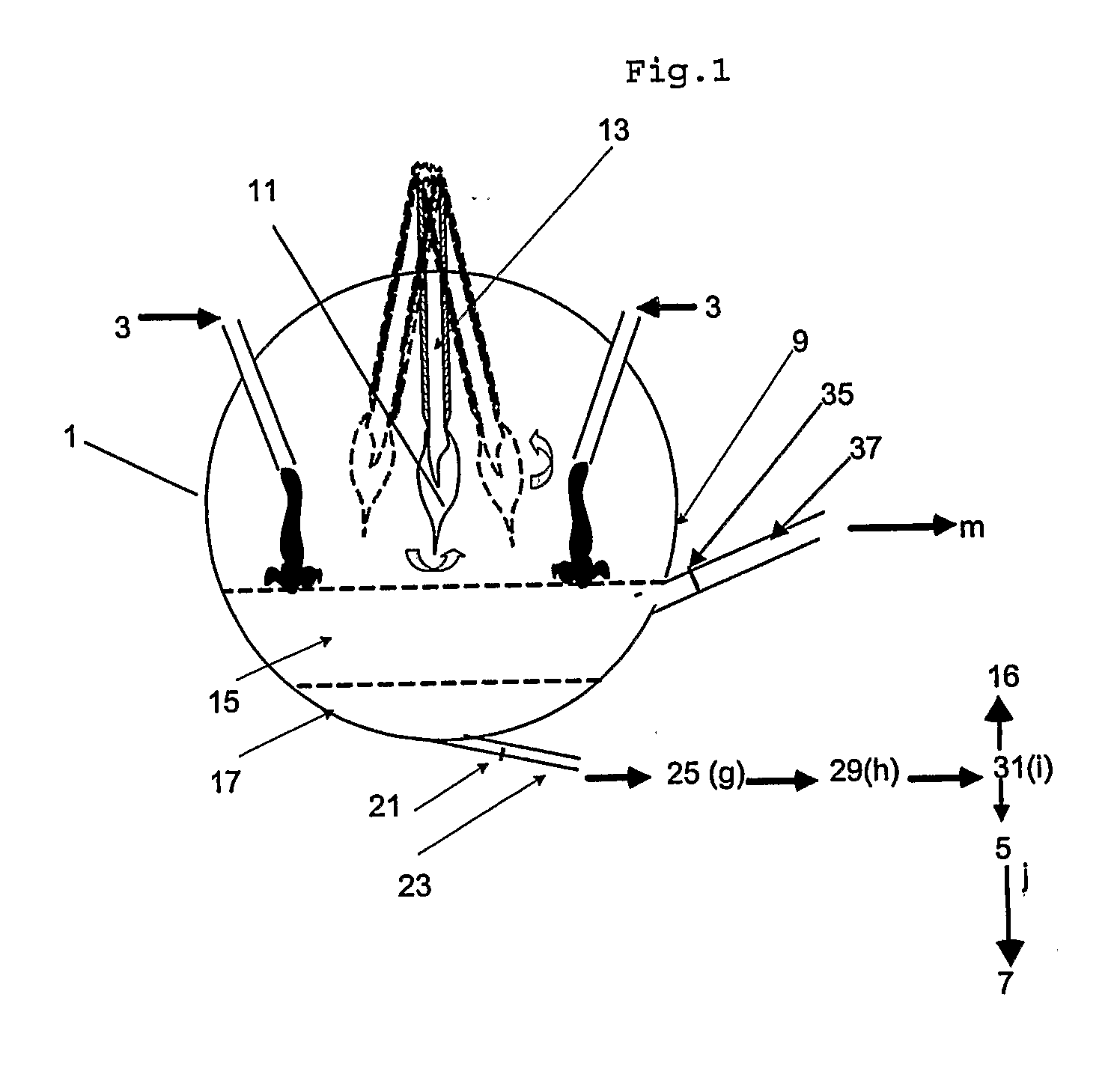

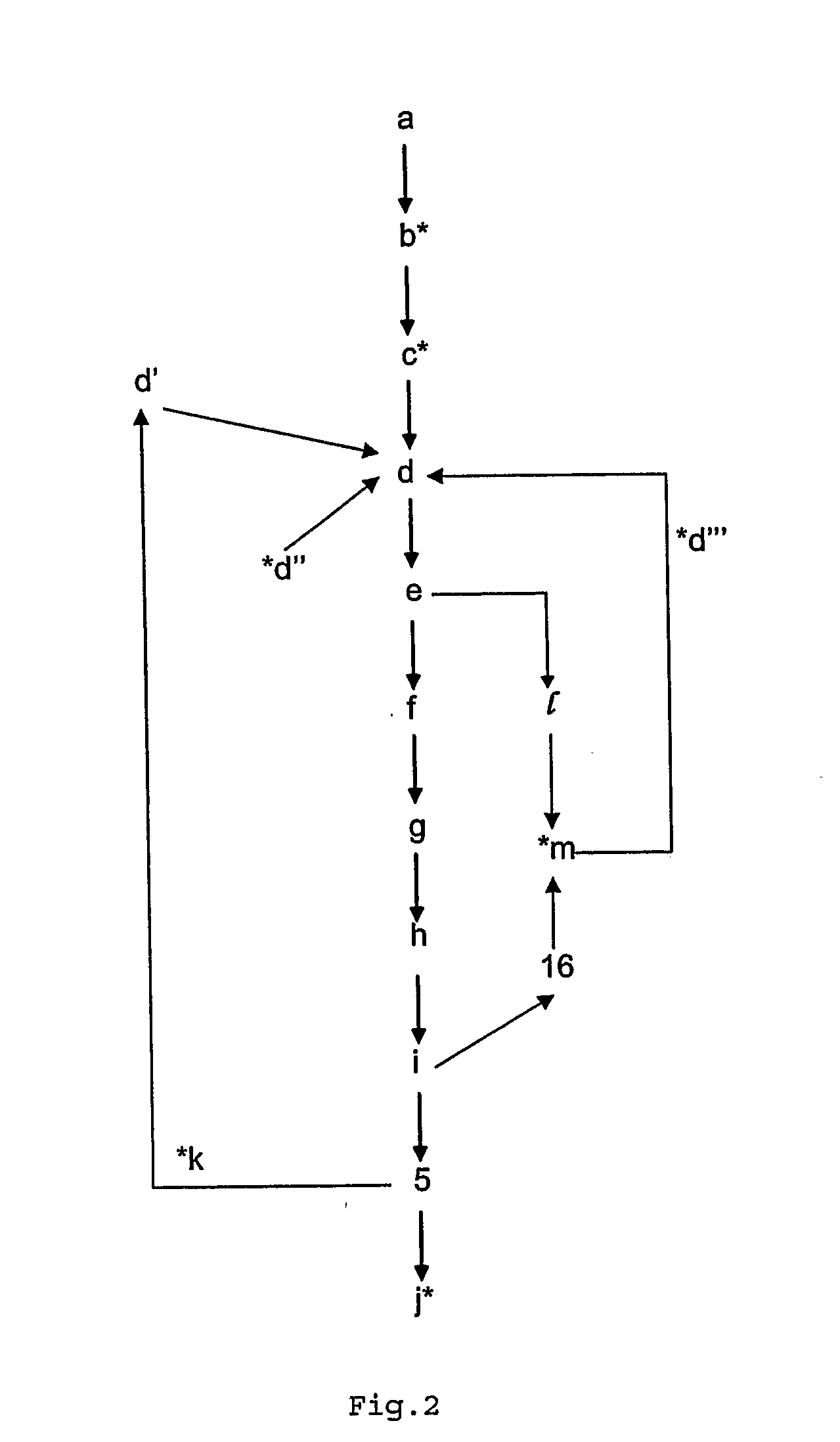

Plasma method and apparatus for recovery of precious metals

ActiveUS20110274580A1Quantity minimizationMaximise palladium (Pd) recovery ratePig casting plantsMetal boridesSlagCompound (substance)

The present invention relates to a method, and apparatus for the recovery of precious metals. Accordingly, it provides a continuous process for obtaining a precious metal composition from a feedstock material, the process comprising the steps of: (i) heating a feedstock material in a plasma furnace to form an upper slag layer and a lower molten metal layer; (ii) removing the slag layer; (iii) removing the molten metal layer; (iv) allowing the removed molten metal layer to solidify; (v) fragmenting the solidified metal layer to form fragments; and (vi) recovering a precious metal composition from the fragments; wherein the feedstock material comprises a precious metal containing material and a collector metal, said collector metal being a metal or an alloy that is capable of forming a solid solution, an alloy or an intermetallic compound with one or more precious metals. This allows for high recovery yields of precious metals. The apparatus comprises a plasma furnace, a casting table enabling continuous casting of the molten metal pool to form a solidified sheet, a fragmentation device and a separation unit for recovering precious-metal-rich alloy from the sheet fragments.

Owner:TETRONICS INT

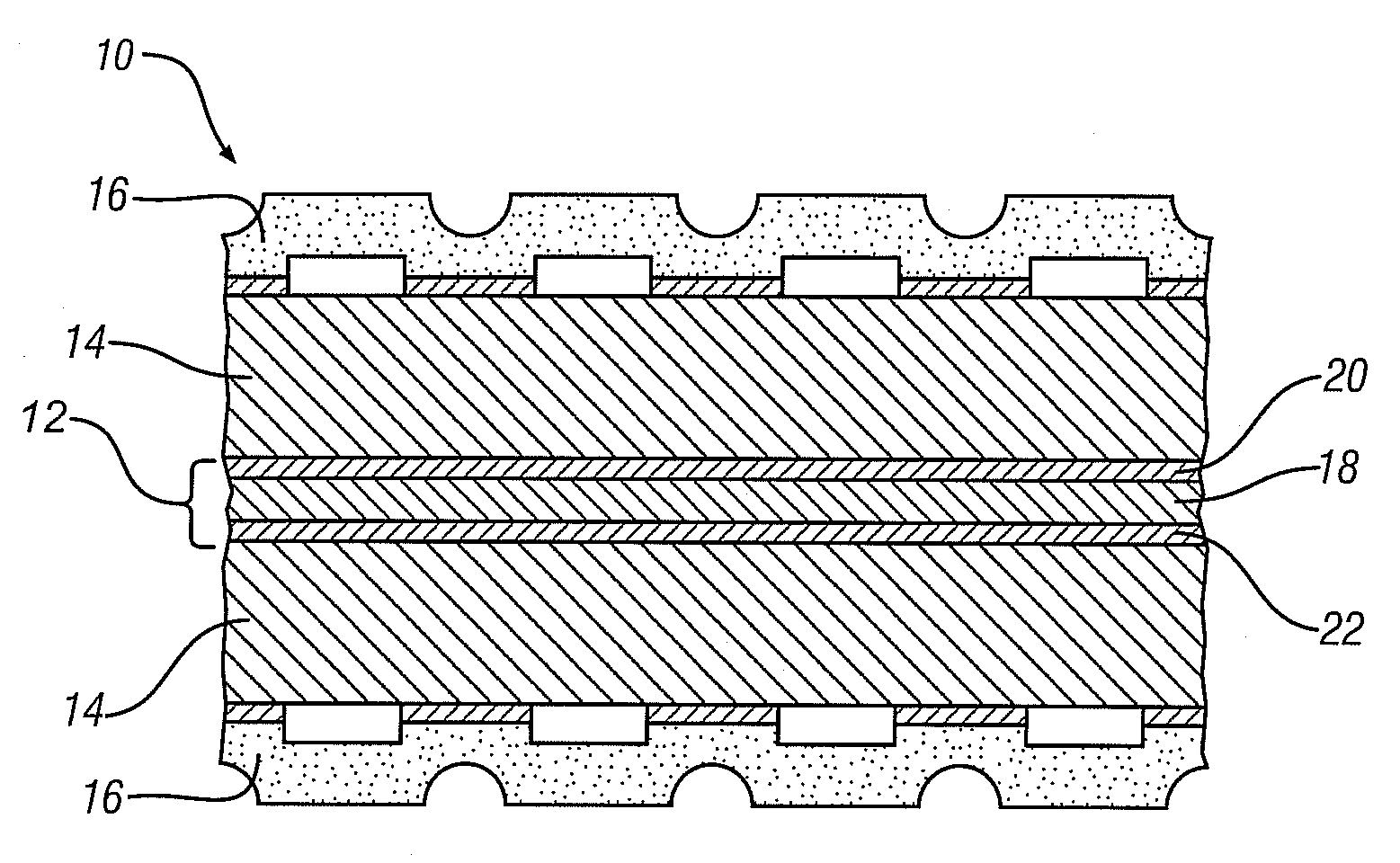

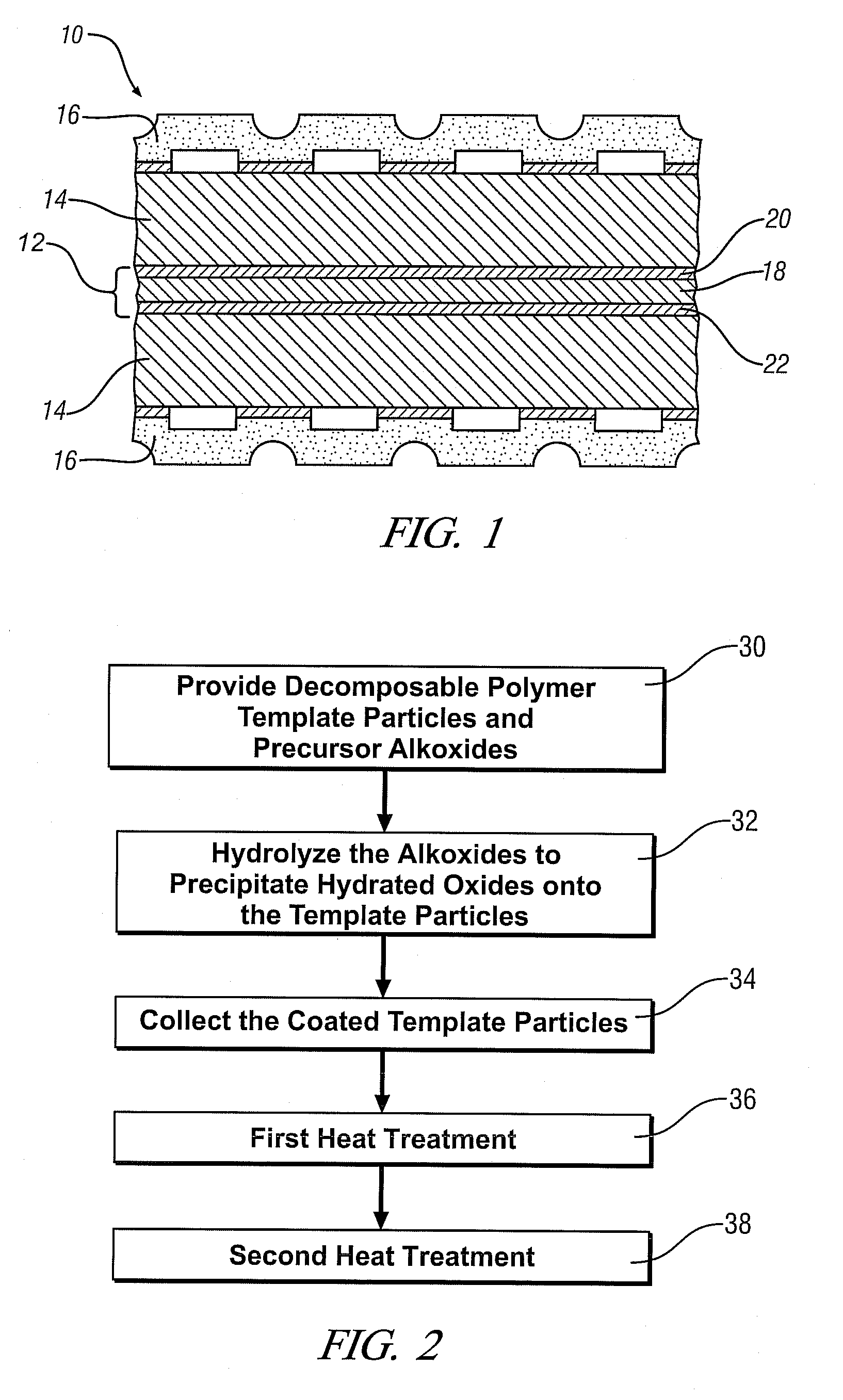

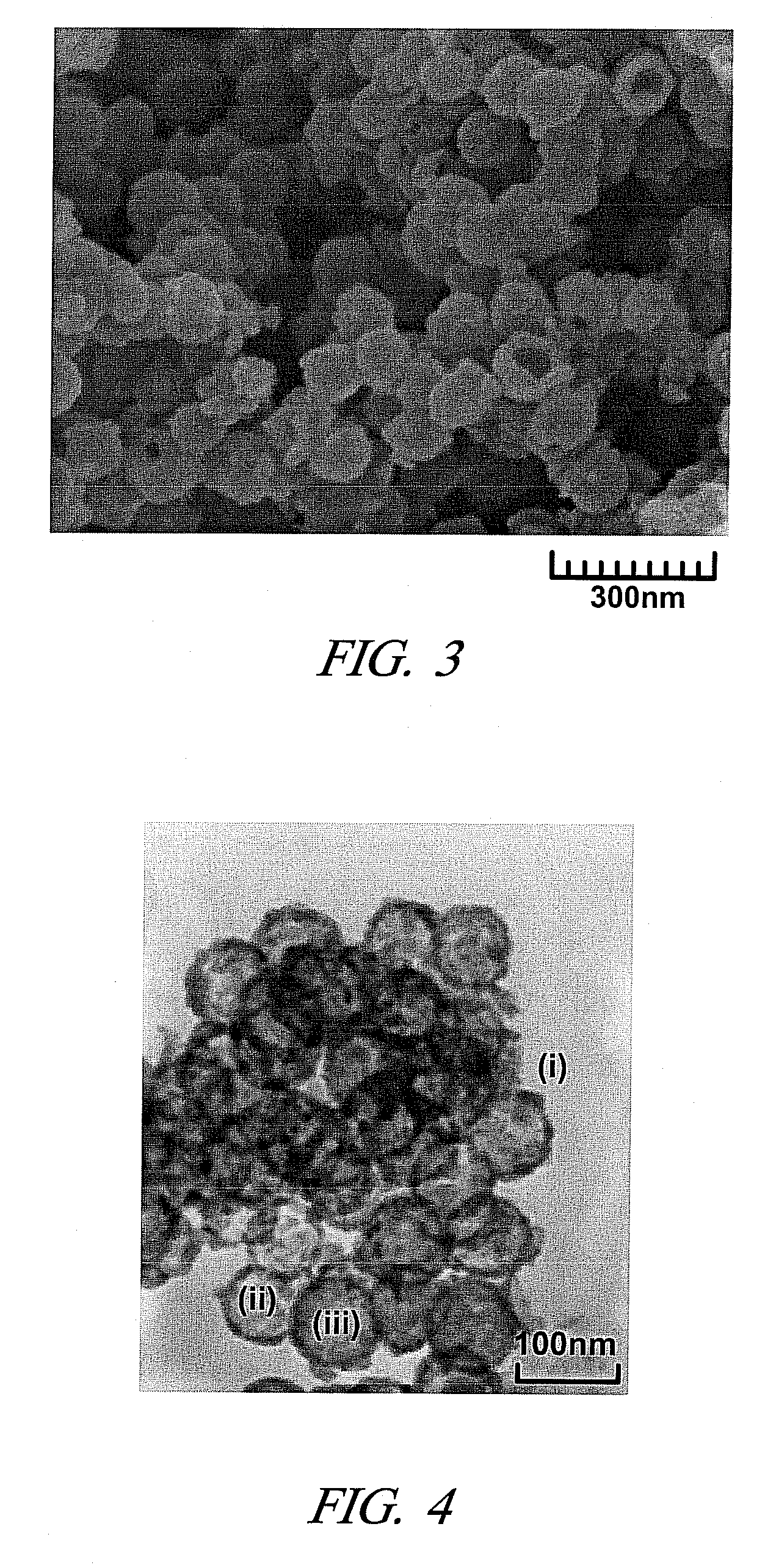

Mesoporous electrically conductive metal oxide catalyst supports

InactiveUS20090312181A1Increased electrical resistivitySolve Porosity InsufficiencyCell electrodesHeterogenous catalyst chemical elementsPorosityRutile

A catalyst support material comprising TiO2, and optionally being doped with a transition metal element, and a method for synthesizing the same have been developed. The catalyst support material exhibits an electrical conductivity comparable to widely-used carbon materials. This is because the TiO2 present is primarily arranged in its rutile crystalline phase. Furthermore, a mesoporous morphology provides the catalyst support material with appropriate porosity and surface area properties such that it may be utilized as part of a fuel cell electrode (anode and / or cathode). The TiO2-based catalyst support material may be formed using a template method in which precursor titanium and transition metal alkoxides are hydrolyzed onto the surface of a latex template, dried, and heat treated.

Owner:GM GLOBAL TECH OPERATIONS LLC

Phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and preparation method and application thereof

InactiveCN105344378AEnsure loading efficiencyEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionCellulosePolymer science

The invention discloses a phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and a preparation method and application thereof. According to the invention, organic ligand with strongly electronegative groups and basic groups is screened out and participates in coordination reaction of a metal organic skeletal material so as to realize functionalization, phospho-tungstic acid is directly added into a synthesis system, and immobilization is realized in the process of synthesis. The prepared phosphotungstic acid-metal organic skeleton reduces the frequency of contact with glucose through formation of a hydrogen bond with cellulose so as to reduce side reaction of glucose under the catalysis of acid, high glucose selectivity is obtained, and oriented conversion of cellulose to glucose can be realized; meanwhile, the effect of the hydrogen bond can weaken the effect of a hydrogen bond in cellulose, reduces the crystallization degree of cellulose, enables cellulose to be easier to hydrolyze and improves hydrolysis efficiency.

Owner:SOUTH CHINA UNIV OF TECH

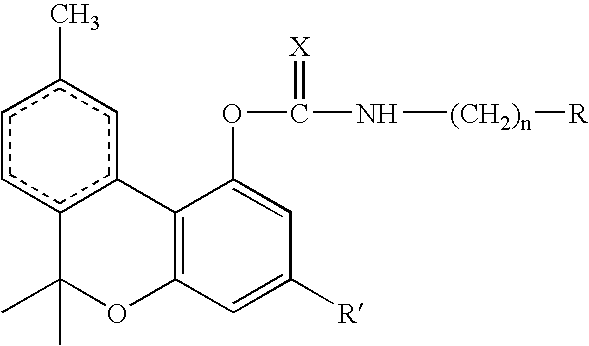

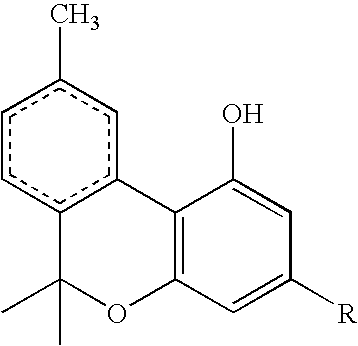

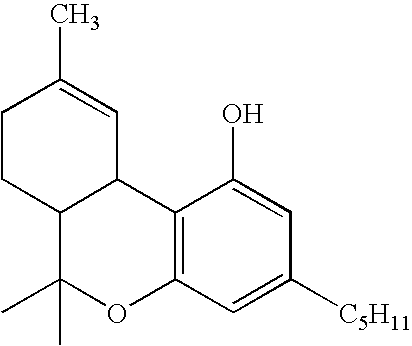

Separation of tetrahydrocannabinols

An individual tetrahydrocannabinol isomer of interest is separated from a mixture containing two or more such isomers, by treating the mixture with an isocyanate or isothiocyanate of formula I: R—(CH2)n—N═C═X (I) where R represents an aromatic ring optionally substituted with one or more electron withdrawing groups, n=0 or 1 and X is oxygen or sulphur; so as to produce a crystallizable THC carbamate of formula II: wherein X and R are as defined above, R′ is a C3-C10 alkyl group and the dotted lines indicate optional unsaturation including aromatic, separating the compound of formula II from solution in isolation of other THC derivatives, and hydrolyzing the compound of formula II to form the individual tetrahydrocannabinol isomer of interest.

Owner:SANDOZ INC

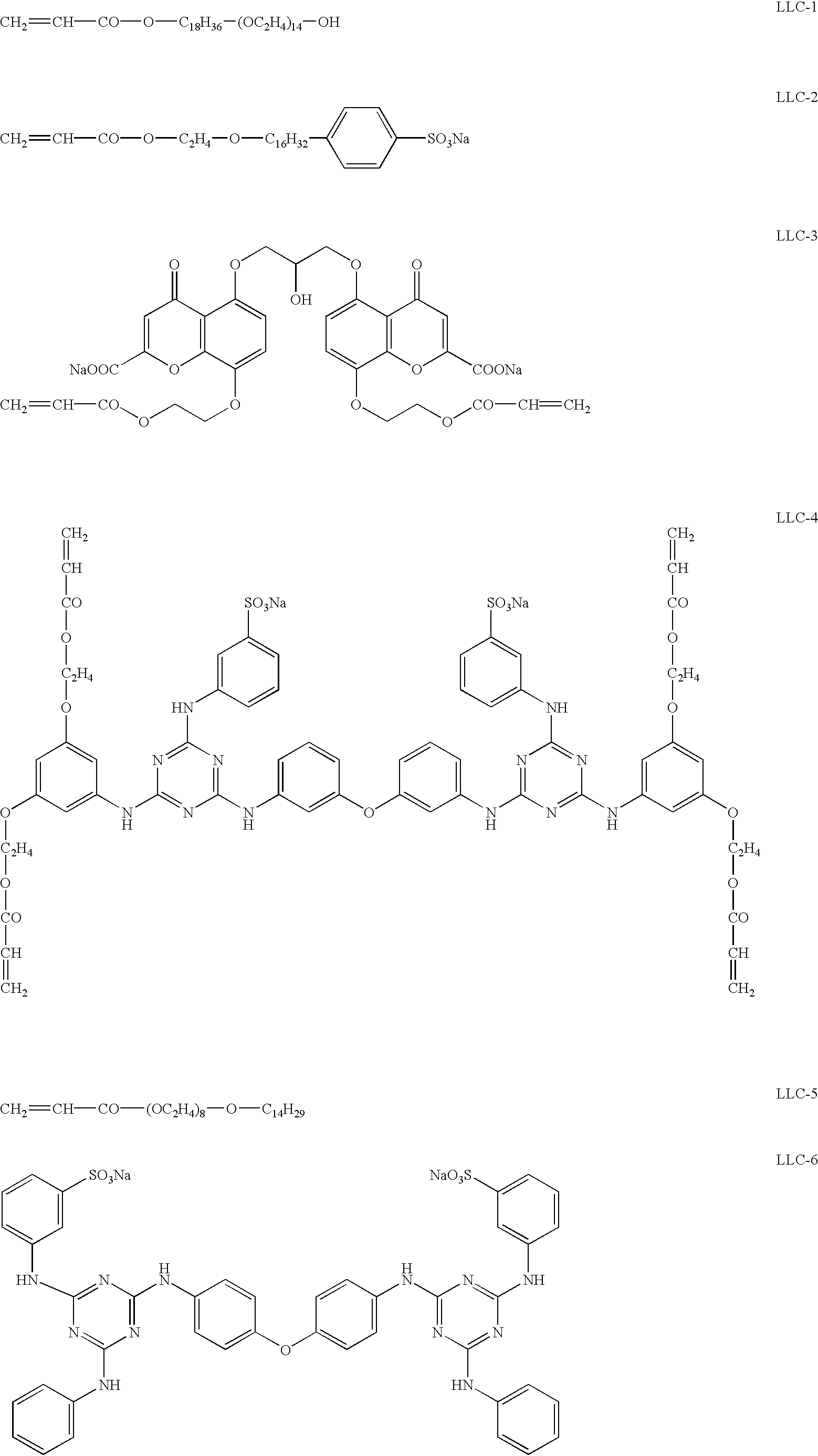

Lyotropic liquid crystal composition

InactiveUS6696113B2Easy to removeEasy to separateLiquid crystal compositionsPolarising elementsSilver halideMaterials science

A lyotropic liquid crystal composition comprises silver halide grains, silver grains or optically anisotropic grains dispersed in lyotropic liquid crystal. The grains have an aspect ratio of not less than 2.

Owner:FUJIFILM CORP

Process for preparing glycine using hydroxy-acetonitrile method

InactiveCN1962611BReduce generationEasily hydrolyzedOrganic compound preparationAmino-carboxyl compound preparationGlycineAcetonitrile

The invention discloses a glycine preparing method, which comprises the following steps: 1) blending hydroxy acetonitrile solution or composition to produce hydroxy acetonitrile with ammonia composition to obtain ammonization reacting liquid; 2) blending the ammonization reacting liquid and inorganic alkaline to obtain the alkaline hydrolytic solution; 3) neutralizing the alkaline hydrolytic solution through inorganic acid to obtain the neutralized liquid; 4) disposing the neutralized liquid to obtain the glycine.

Owner:重庆三峡英力化工有限公司

Method for extracting rapeseed peptides through wet milling combined with enzymic method

The invention discloses a method for extracting rapeseed peptides through wet milling combined with an enzymic method. The method comprises the following steps of: taking dry degreased and unshelled rapeseed dregs, grinding and filtering the dry degreased and unshelled rapeseed dregs through a 40-mesh sieve, adding water which is 5 times of the materials in weight, adding 5-10 u / g of cellulase, and performing wet grinding on black soybean meal for 1-3 hours under the condition of a rotating speed in the range from 250 to 400 rpm (revolutions per minute) by using a ball mill to obtain an ultrathin powder turbid liquid; (2) supplementing water to the ultrathin powder turbid liquid until the concentration of the dry materials is in the range from 50 to 100 g / l, adjusting the pH to 7.0, adding 40u / g of protease, maintaining the temperature at 55 DEG C and the pH at 7.0, and hydrolyzing for 1-2 hours; (3) centrifuging the enzymatic hydrolysate for 15 minutes under the condition of 10000 rpm, continuously adding water which is 5-10 times of residues in weight to the residues, adding 20u / g of protease, hydrolyzing for 1-2 hours at the temperature of 55 DEG C and the pH of 7.0, centrifuging, and blending the two supernates to obtain a rough peptide solution. According to the invention, cellulose dissolving causes large-molecular materials such as protein to be hydrolyzed more easily, and also the hydrolysis rate of the protein can be increased; in addition, the conversion rate of the peptides is greatly increased.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

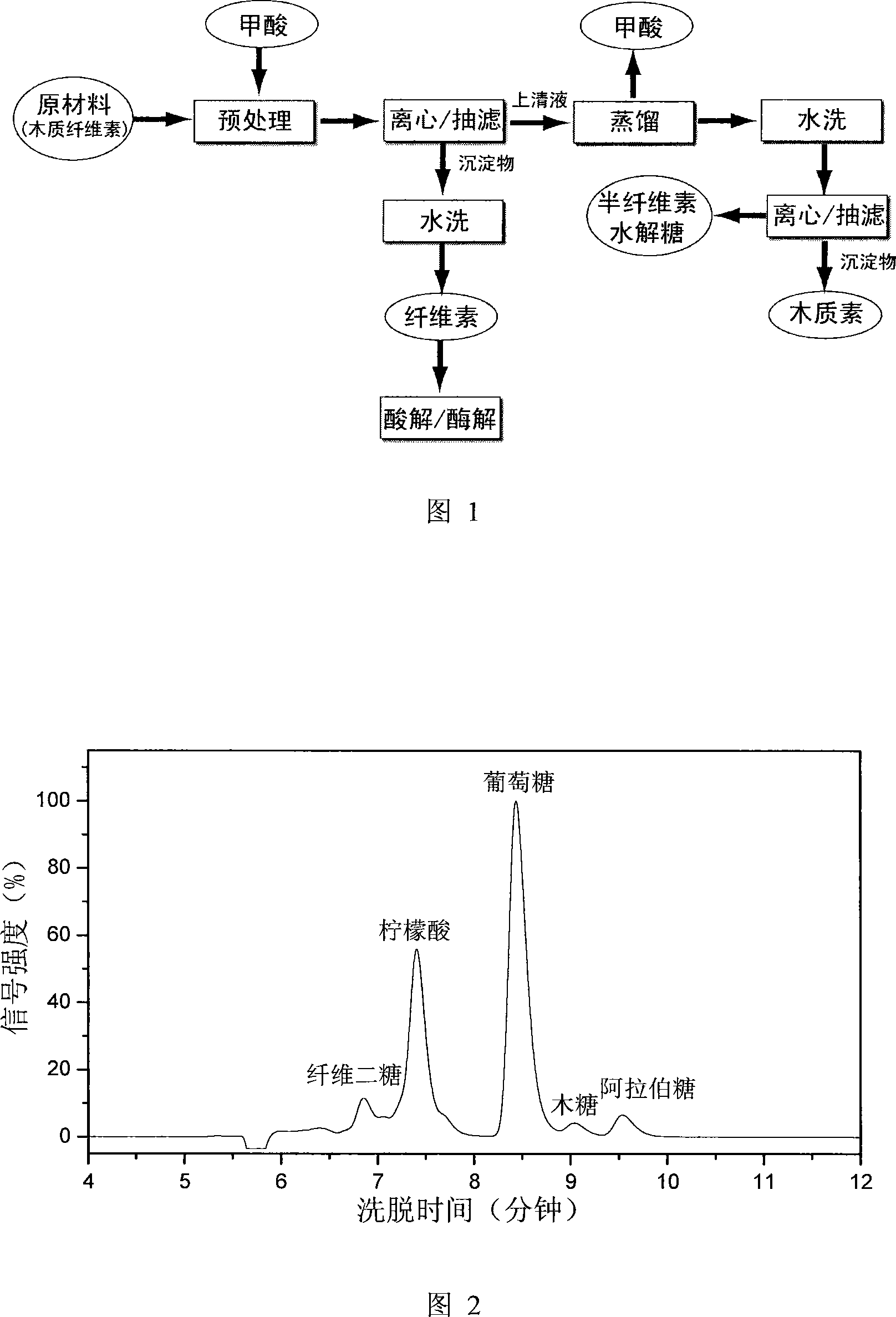

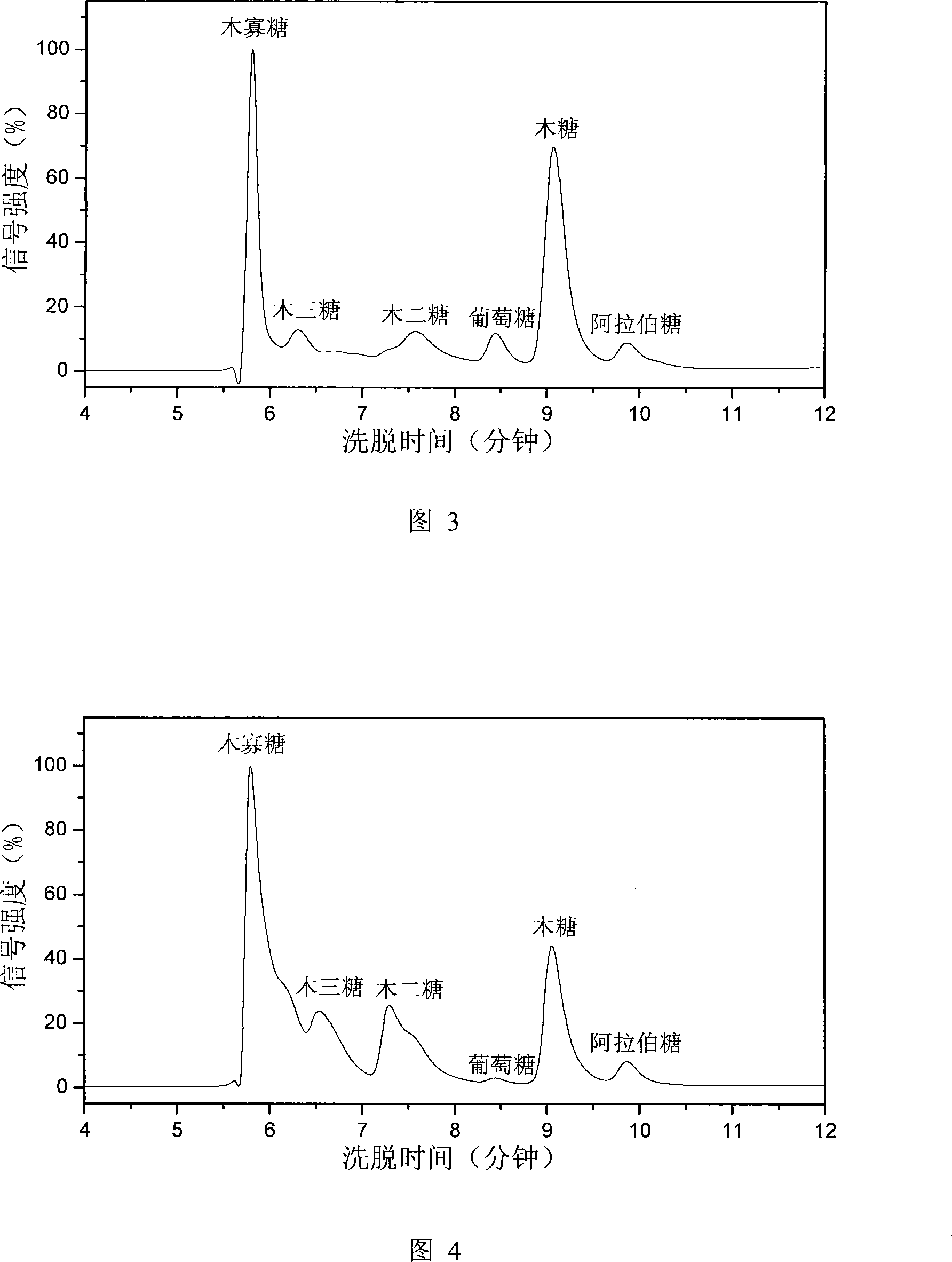

Method for separating lignocellulose-containing biomass with methanoic acid

InactiveCN101220566AEasy separation of componentsFast and easy method for component separationPaper material treatmentCellulaseSolvent

The invention relates to a method for using formic acid to separate biomass of lignocelluloses which includes the following steps: the formic acid solution with little hydrochloride is added into the agroforestrial waste, and reaction carries out for 1 to 10h at the temperature of 50 to 100 DEG C; the solid substances are separated and hydrolyzed after being water washed and dried in the buffer solution with the pH value of 4.8 by the cellulose enzyme under the temperature of 50 DEG C, the formic acid is recycled from the obtained liquid material, the lignose obtained by separating the lignose (formic acid lignose) solid-liquid, which is not dissolved in water can be used for the high-value transformation after being washed by water. The main components of the liquid material are reduced sugars obtained by hydrolyzing xylose, wood oligose and other hemicelluloses. The invention has the advantages of separating the lignocellulose into components, realizing the using of the whole biomasses, and finishing the green technique route of the solvent recovery.

Owner:TIANJIN UNIV

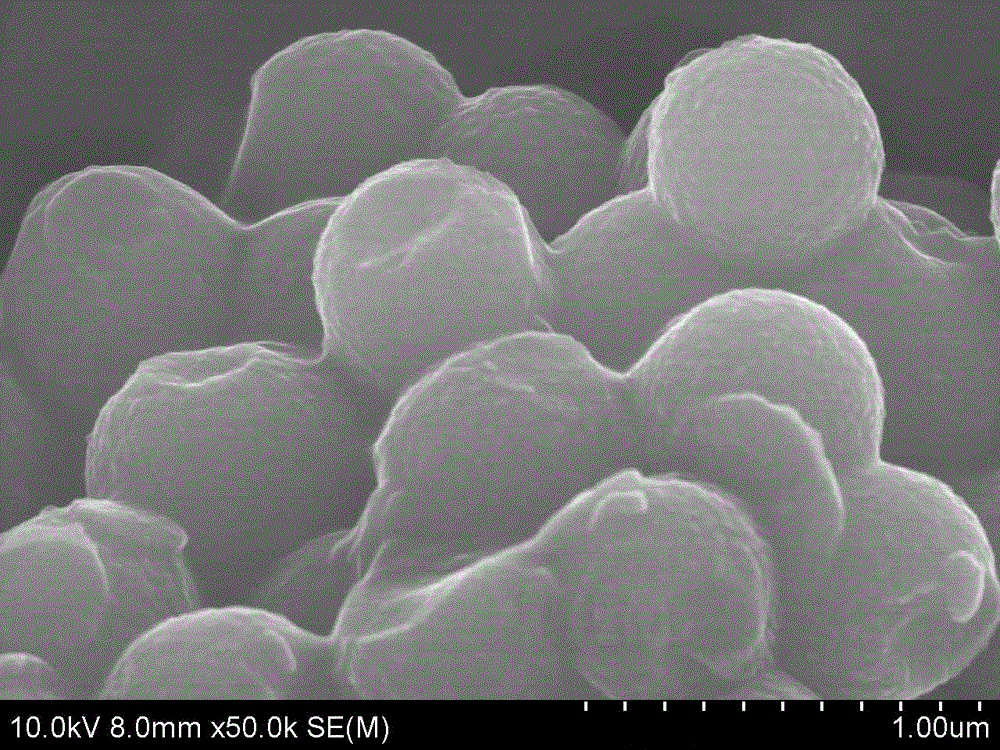

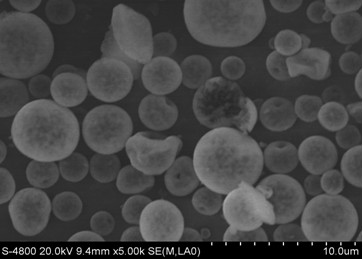

Preparation method of hydroxy apatite / polylactic acid / chitosan composite microballoon

InactiveCN102489231AImprove mechanical propertiesEvenly dispersedPharmaceutical non-active ingredientsMicroballoon preparationMicrosphereApatite

The invention discloses a preparation method of a hydroxy apatite / polylactic acid / chitosan composite microballoon. The hydroxy apatite / polylactic acid / chitosan composite microballoon is prepared by using hydroxy apatite HA, polylactic acid PLA and chitosan CS as raw materials and employing manufacturing principles of a solution blending method and an emulsion method. The method comprises steps of: dropping a prepared apatite / polylactic acid / chitosan acetate acid gracial solution into a stirred liquid paraffin / petroleum ether mixed liquor ; carrying out stewing; removing the liquid paraffin / petroleum ether mixed liquor; washing; carrying out stewing; and refrigerating drying to obtain the composite microballoon product. The hydroxy apatite / polylactic acid / chitosan composite microballoon of the invention compounds three materials with different performances to solve problems of strength, toughness and biocompatibility of the material; and the hydroxy apatite / polylactic acid / chitosan composite microballoon is mainly used in bone tissue restoration material, cell engineering and transmission of medicament and bioactive molecule.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lyotropic liquid crystal composition

InactiveUS20030047711A1Easy to removeEasy to separateLiquid crystal compositionsNanoopticsSilver halideMaterials science

A lyotropic liquid crystal composition comprises silver halide grains, silver grains or optically anisotropic grains dispersed in lyotropic liquid crystal. The grains have an aspect ratio of not less than 2.

Owner:FUJIFILM CORP

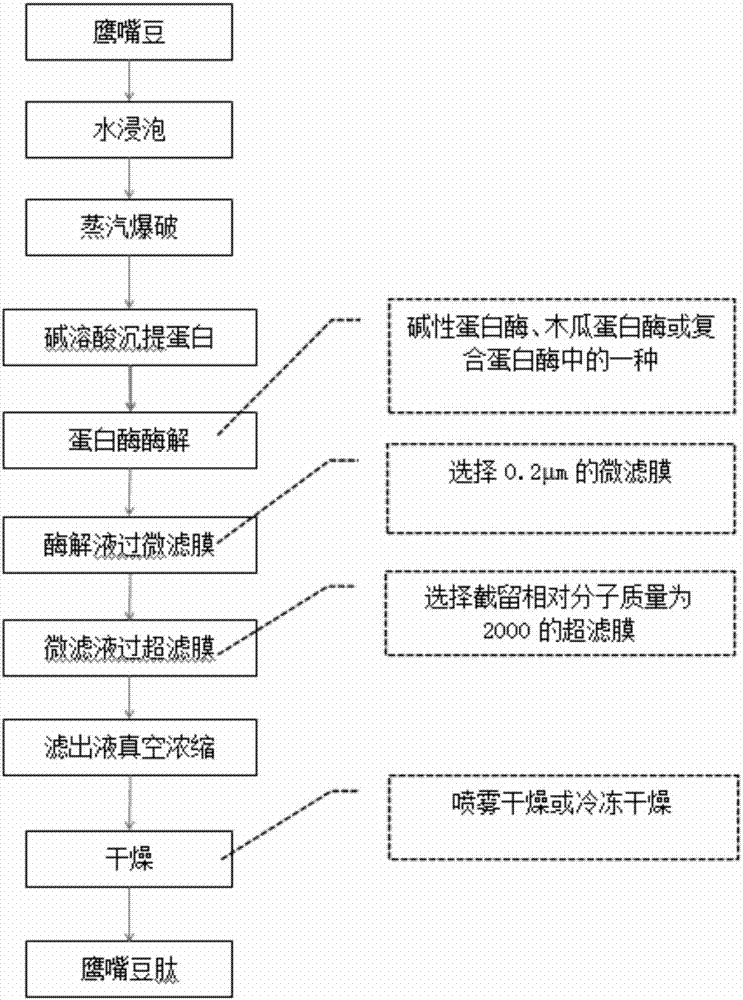

Preparation method of chickpea peptides

InactiveCN106947798AFully extractedEasily hydrolyzedPeptide preparation methodsFermentationProteinase activityOrganic solvent

The invention relates to a preparation method of chickpea peptides. The preparation method comprises following steps: chickpeas with skin are immersed, and are subjected to steam explosion pretreatment; alkali dissolution and acid precipitation are adopted so as to obtain a protein precipitate; protease hydrolysis is adopted so as to obtain a small molecule polypeptide solution; membrane separation purification and condensation drying are adopted so as to obtain a chickpea peptide powder. According to the preparation method, steam explosion is adopted for pretreatment of chickpeas with skin, so that steps in the prior art such as peeling, smashing, and organic solvent degreasing are avoided; at the same time, after steam explosion, extraction of chickpea protein is more complete, the obtained chickpea protein can be hydrolyzed with protease more easily, and product yield and purity are increased greatly; operation of the preparation method is simple; and the preparation method is green, is friendly to the environment, and is more suitable for large-scale industrialized production.

Owner:乐康珍泰(天津)生物技术有限公司

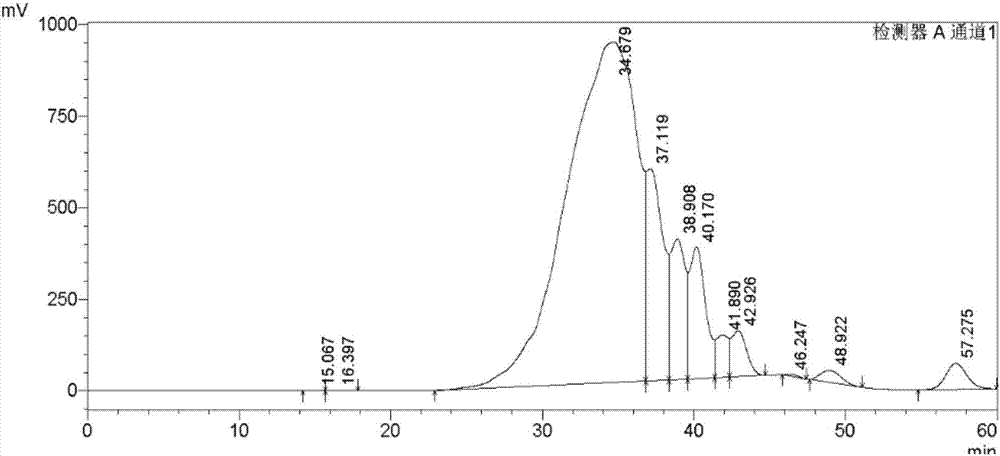

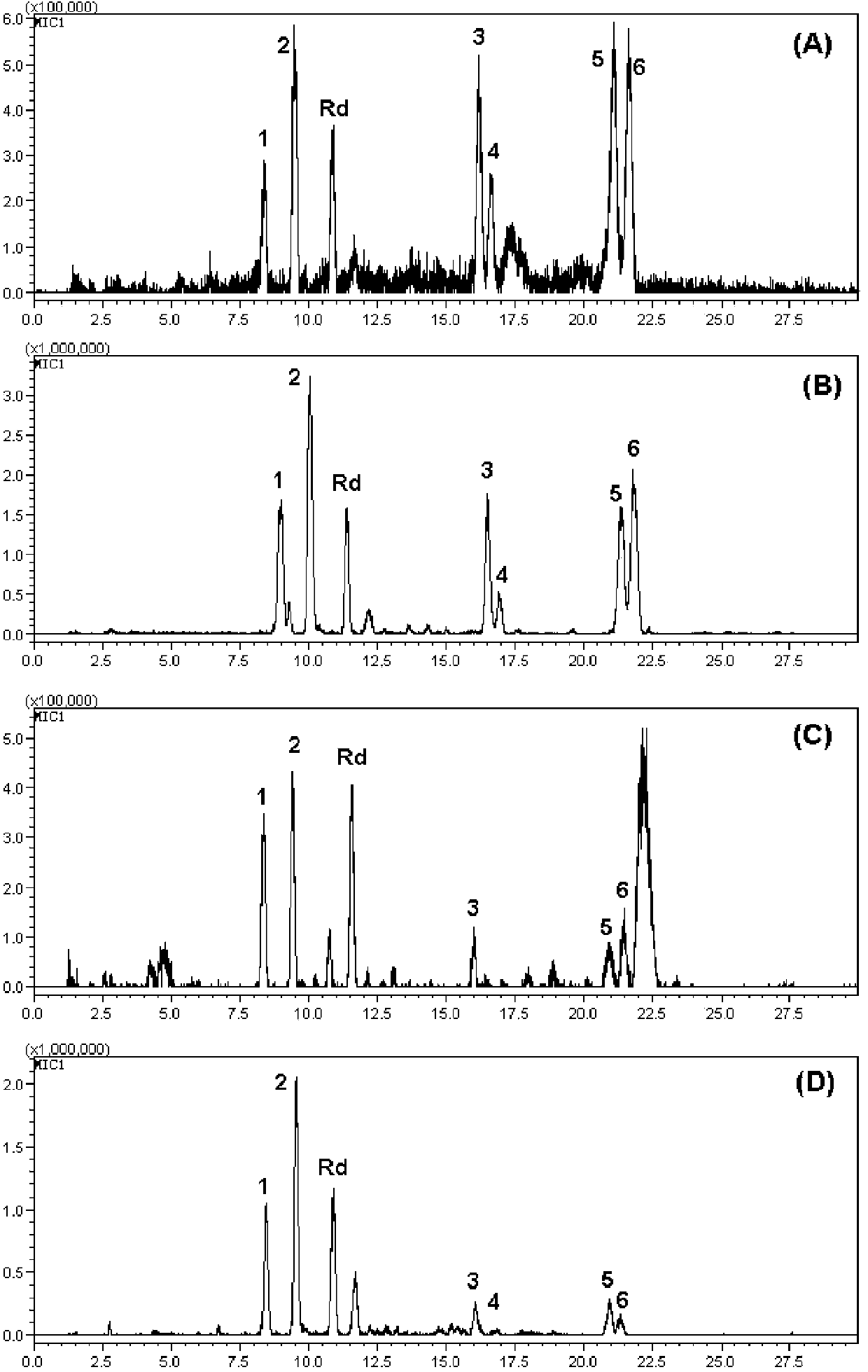

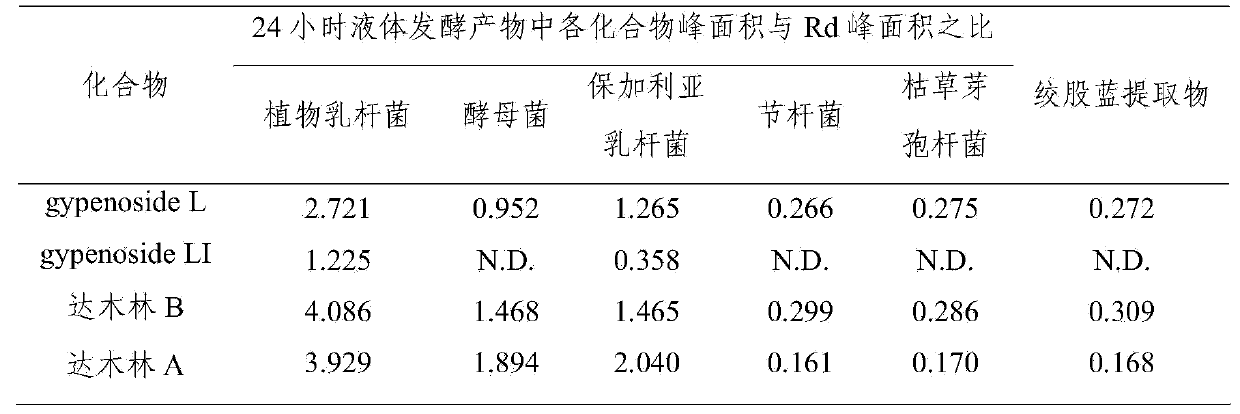

Preparing method of gynostemma pentaphyllum extraction product rich in gypenosides

InactiveCN103908486AIncrease contentEasily hydrolyzedPlant ingredientsLaboratory cultureLactobacillus plantarum

The invention provides a preparing method of a gynostemma pentaphyllum extraction product rich in gypenosides. The method includes fermenting a gynostemma pentaphyllum ethanol extraction product in a microbe culture medium at 27-40 DEG C for 1-7 days, extracting the fermented total gynostemma pentaphyllum extraction product with n-butanol with the same volume for 1-6 times, concentrating under vacuum, and drying to obtain a gynostemma pentaphyllum post-fermentation extraction product. The microbe is lactobacillus plantarum or saccharomycetes.

Owner:CHINA AGRI UNIV

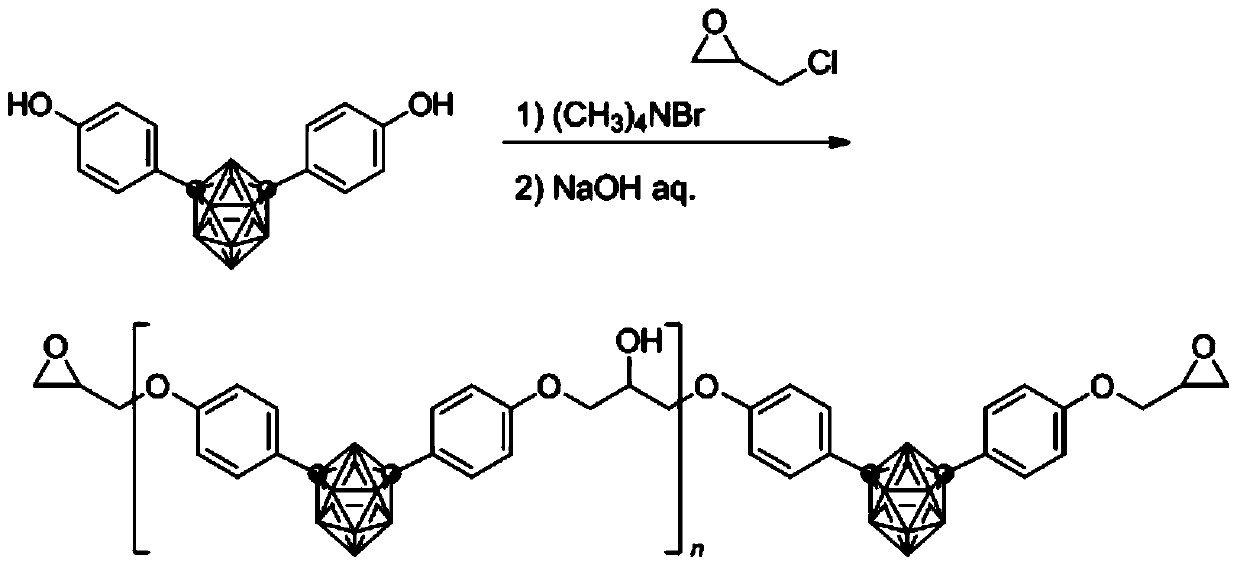

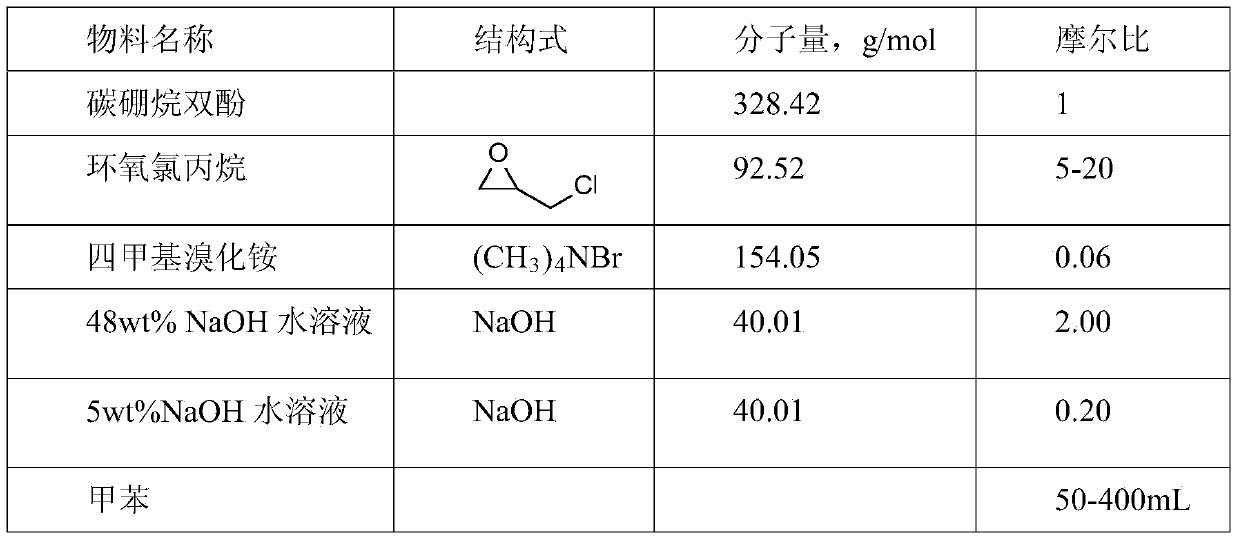

Synthesizing and curing method of carborane epoxy resin

The invention provides a synthesizing and curing method of carborane epoxy resin. The method is used for preparing carborane epoxy resin from raw materials, namely, diphenyl carborane and epoxy chloropropane through two-step condensation polymerization. The synthesizing and curing method has the advantages of short reaction time, stability in operation, small temperature fluctuation, easiness for control, short alkaline adding time, capability of preventing a great deal of epoxy chloropropane from hydrolyzing, good and stable product quality and high yield. The obtained resin is simple and feasible in curing process, no harsh pollution control measures are needed, a cured product has excellent high-temperature carbon yield and high-temperature adhesive property, and the carborane epoxy resin can be used as a high-temperature-resistant adhesive.

Owner:BEIJING UNIV OF CHEM TECH

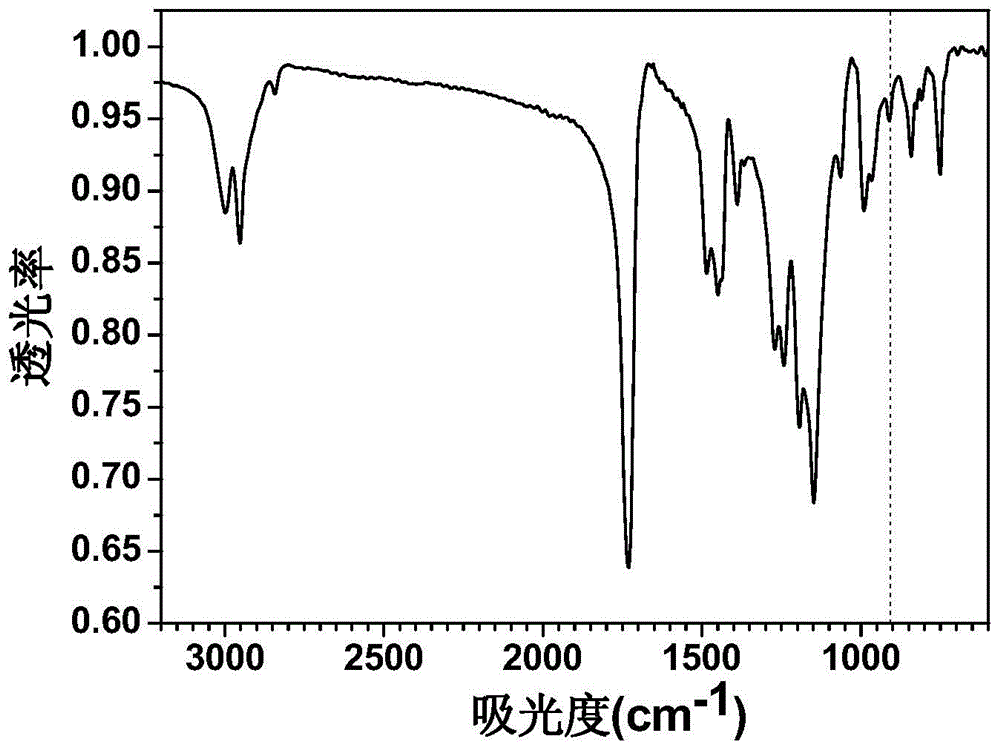

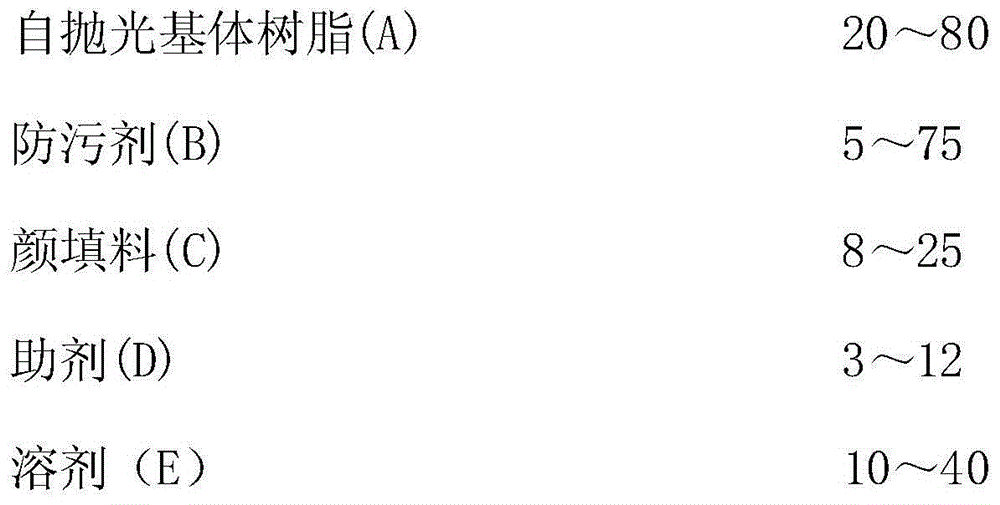

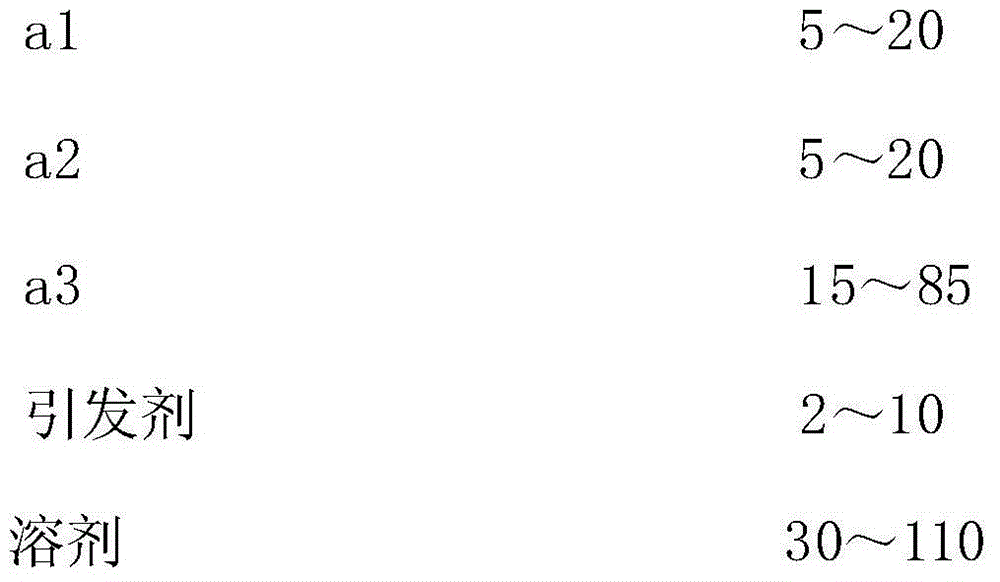

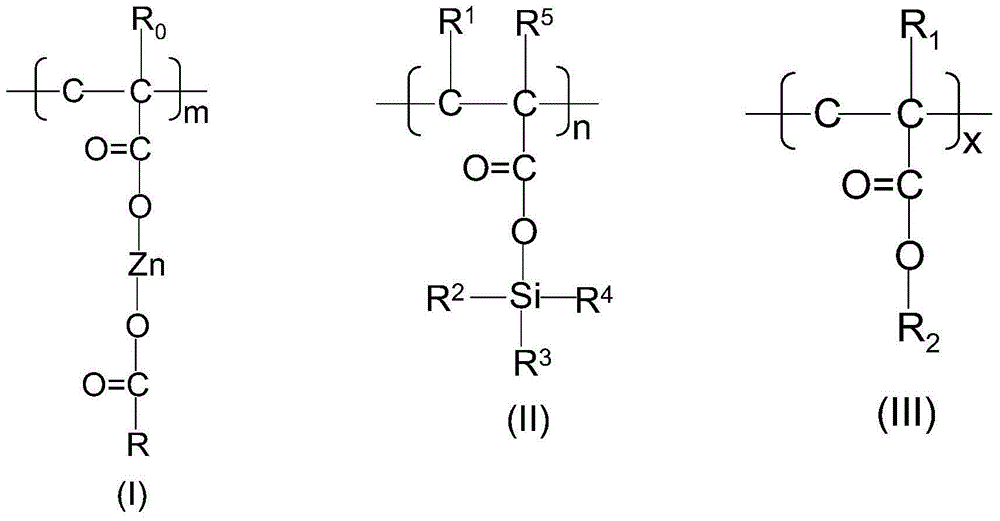

Matrix resin having self-polishing performance and self-polishing antifouling coating prepared by same

ActiveCN104974631AGood self-polishing performanceControllable self-polishing performanceAntifouling/underwater paintsPaints with biocidesCoated surfaceSurface layer

The invention relates to a matrix resin having self-polishing performance and an environmentally-friendly type self-polishing antifouling coating prepared by the same; the matrix resin contains a functional group, so that the matrix resin has good self-polishing performance; according to the antifouling coating prepared by the matrix resin, the functional group-containing matrix resin on the surface of an antifouling coating layer is subjected to a hydrolysis reaction with weak alkaline seawater to generate a hydrophilic resin and is gradually dissolved in the seawater, at the same time, a coated antifouling agent is released, denudation of a surface layer is achieved, a newly-exposed coating layer continues to undergo a hydrolysis reaction with the seawater, and finally, the self-polishing effect of layer-by-layer stripping of the coating layers is achieved. The antifouling coating prepared by the matrix resin has the characteristics of controllable self-polishing performance, long anti-fouling efficiency period, excellent antifouling performance and the like.

Owner:MARINE CHEM RES INST

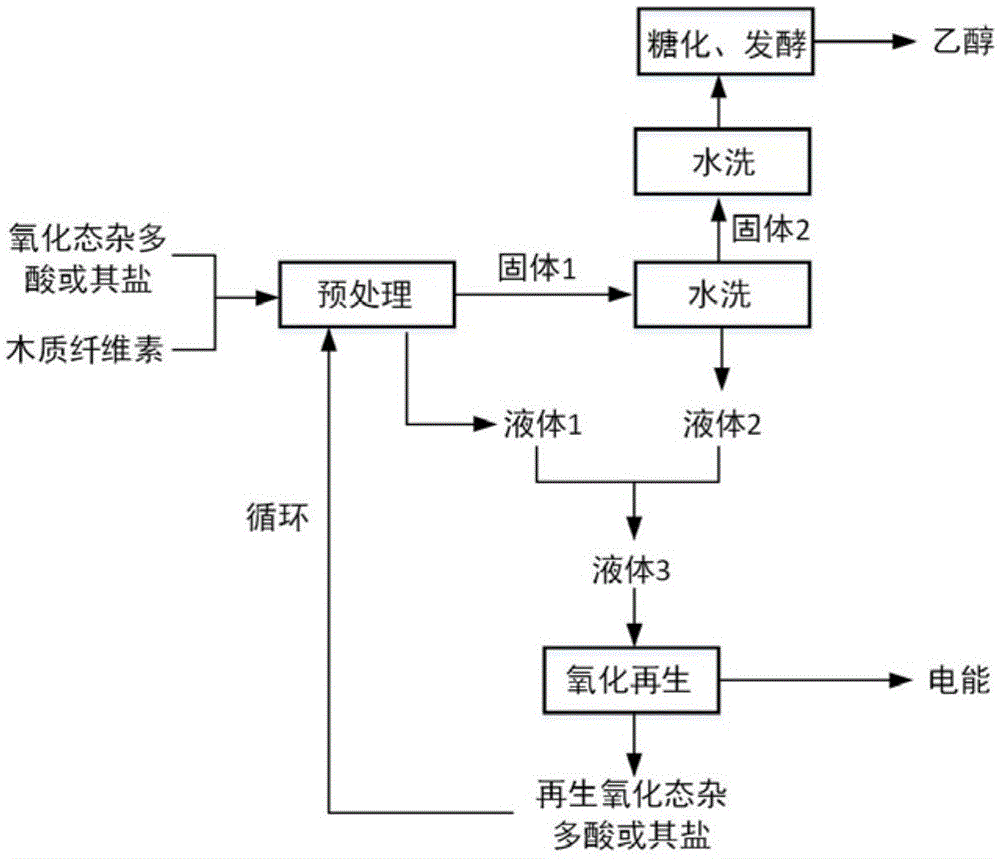

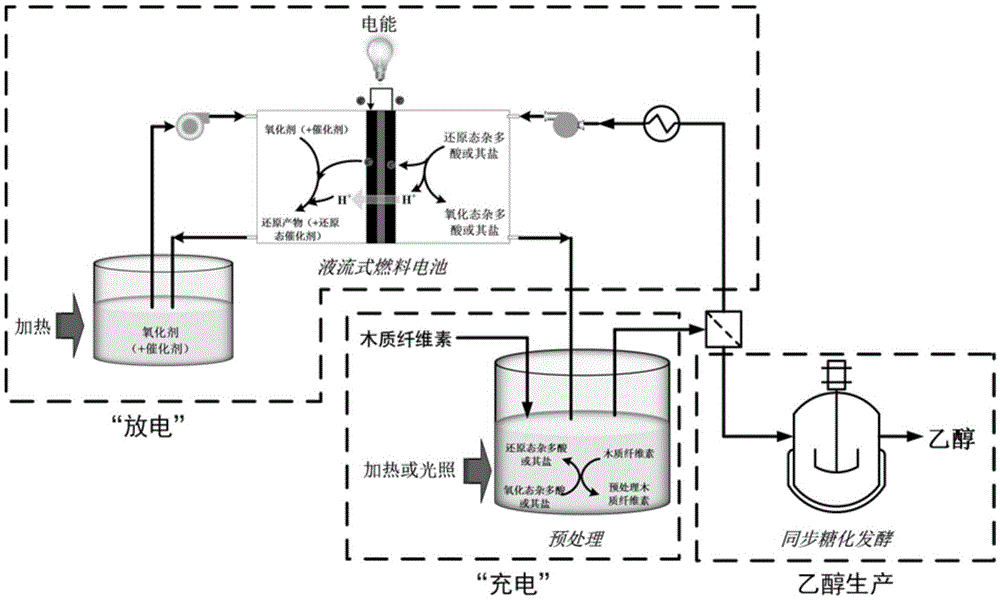

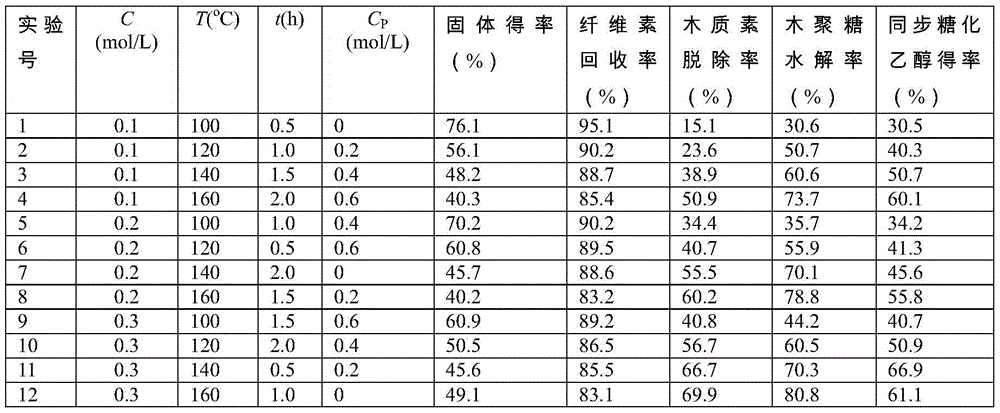

Method for using lignocellulose as raw material to co-produce ethyl alcohol and electric energy

ActiveCN105420289AReduce the degree of polymerizationImprove stabilityRegenerative fuel cellsBiofuelsAlcoholFuel cells

The invention discloses a method for using lignocellulose as a raw material to co-produce ethyl alcohol and electric energy. According to the method, oxidation-state heteropolyacid or its salt is adopted to pretreat the lignocellulose, most of lignin and hemicellulose are oxidized so that the accessibility of the cellulose can be remarkably improved, further conversion from the lignocellulose to ethanol is facilitated, and the heteropolyacid or its salt is reduced. The reduced-state heteropolyacid or its salt performs discharge in a liquid flow type fuel cell, so that the reduced-state heteropolyacid or its salt is re-oxidized into regenerated oxidation-state heteropolyacid or its salt while electric energy is obtained, and the oxidation-state heteropolyacid or its salt is cyclically used for pretreatment of the lignocellulose. By means of the method, the pretreated lignocellulose and biomass are directly converted into electric energy for coupling, the pretreatment process is regarded as the 'charging' process, the oxidization and regeneration process of the reduced-state heteropolyacid or its salt is regarded as the 'discharging' process, and accordingly ethyl alcohol and electric energy co-production is achieved by utilizing the lignocellulose under the mild conditions.

Owner:TSINGHUA UNIV

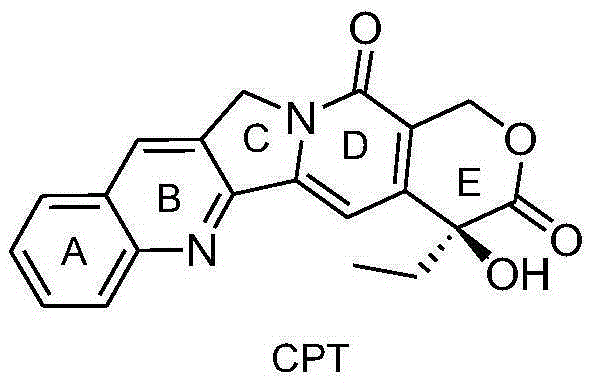

Acid-sensitive camptothecin-site 20 norcantharidate derivative and antineoplastic application thereof

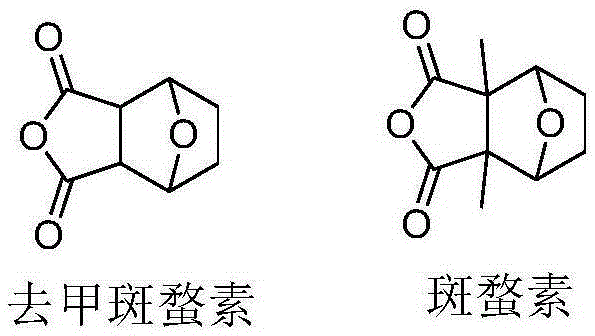

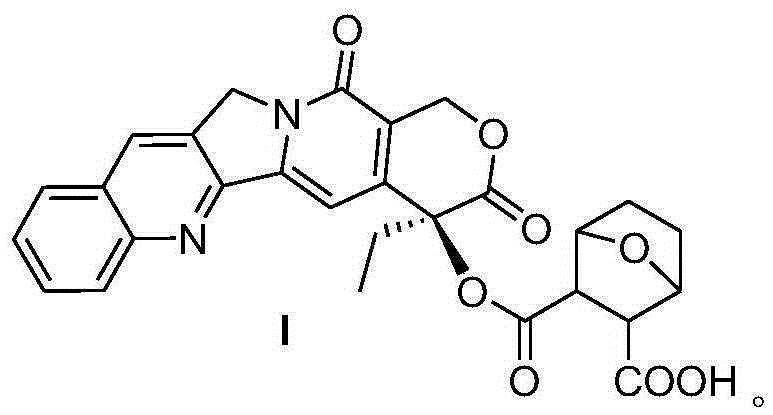

InactiveCN105399757AImprove anti-tumor effectHigh inhibition rate in vitroOrganic chemistryAntineoplastic agentsSolubilityCantharidin

The invention provides a camptothecin-site 20 norcantharidate derivative with a structural formula as shown in I which is described in the specification, and a preparation method and antineoplastic application thereof. Results of activity test prove that the camptothecin-site 20 norcantharidate derivative as shown in I is an appropriate candidate antineoplastic drug, especially a candidate drug for resisting liver cancers, stomach cancers and colorectal cancers. Compared with positive contrast drugs, i.e., camptothecin and cantharidin, the camptothecin-site 20 norcantharidate derivative has improved water solubility and stability; and the camptothecin-site 20 norcantharidate derivative is sensitive to acid and can be easily hydrolyzed. Moreover, the preparation method for the camptothecin-site 20 norcantharidate derivative employs easily available raw materials, has high yield and is easy to operate and implement.

Owner:ZUNYI MEDICAL UNIVERSITY

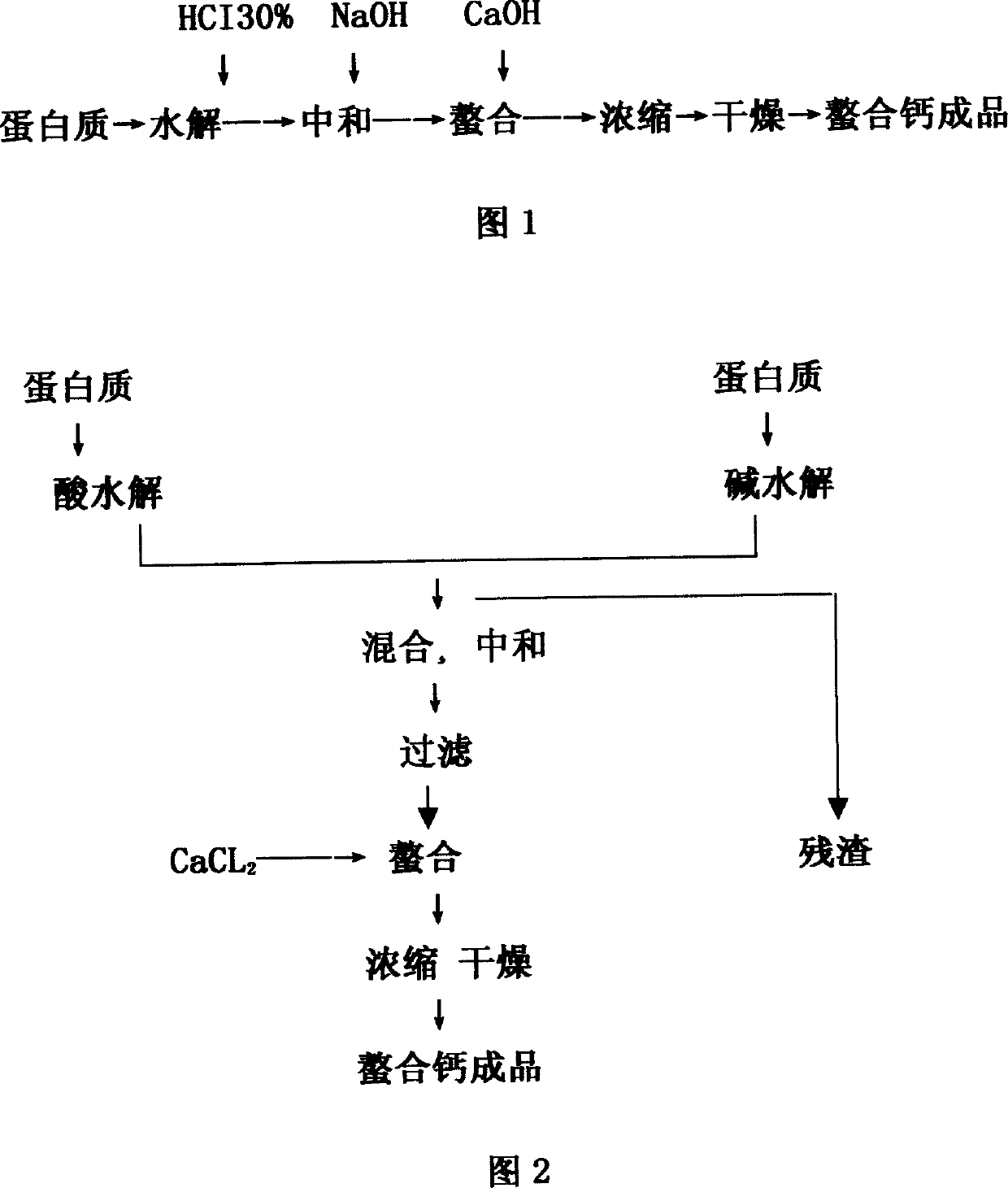

Minim calcium element chelated foliage fertilizer

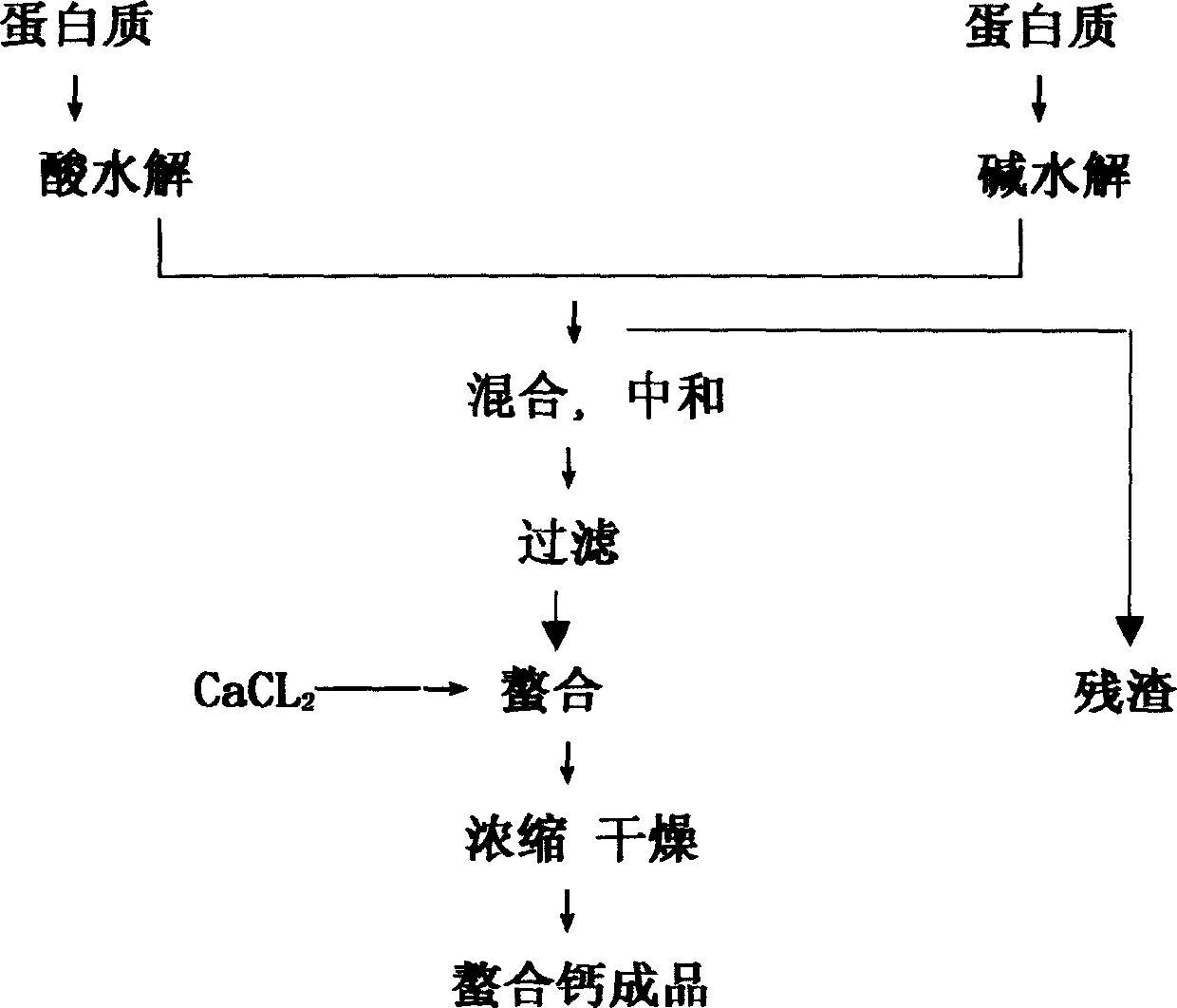

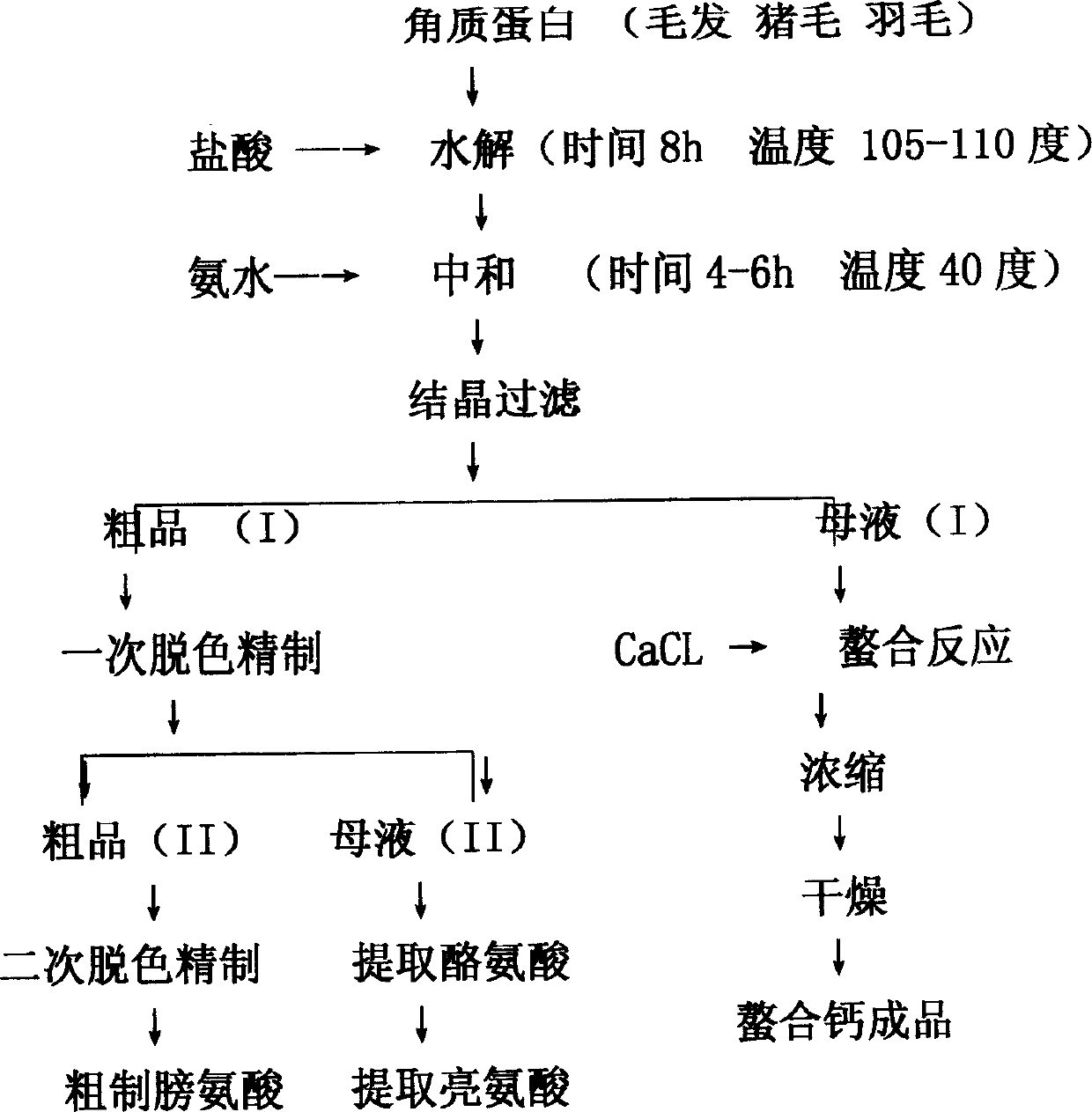

InactiveCN1621393AEasily hydrolyzedMeet the greatest need for absorptionProtein foodstuffs working-upFertilizer mixturesCalcium contentProtein materials

The present invention relates to foliage fertilizer, and is especially one kind of foliage fertilizer with medium amount of calcium element chelate. By means of three production processes of acidolysis, acid and alkali hydrolysis and comprehensive utilization, waste protein material is prepared into ion level organic component. The product has amino acid content of 5-20 wt% and calcium content of 12-17 wt%. The said foliage fertilizer is easy to hydrolyze, and has reasonable components, obvious fertilizer effect and high bioavailability.

Owner:卢卫江

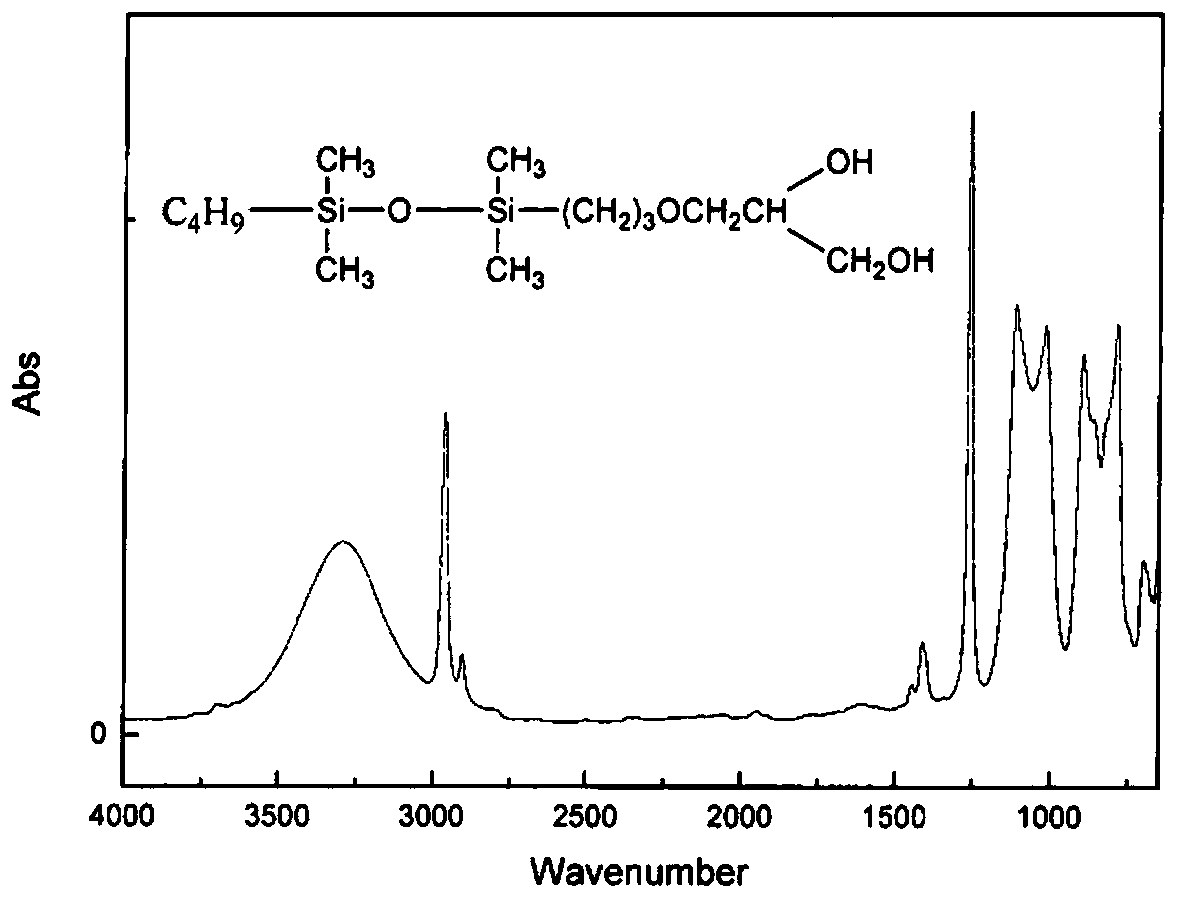

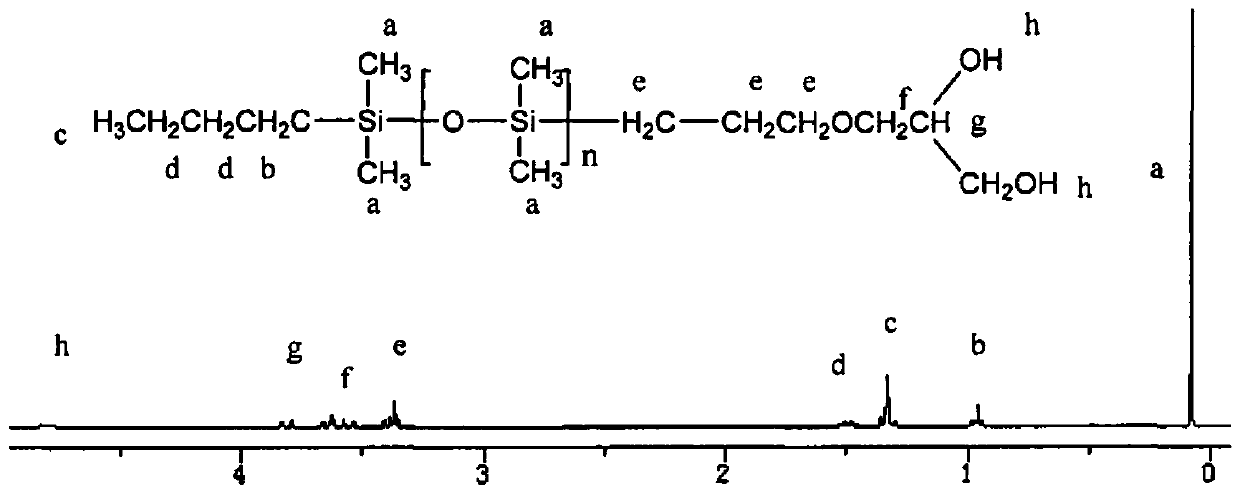

Organosilicone polyurethane anti-fouling material with low surface energy and hydrolyzed self-polishing function and application thereof

PendingCN109852225AReduce adhesionLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceBackbone chain

The invention discloses an organosilicone polyurethane anti-fouling material with low surface energy and a hydrolyzed self-polishing function and application thereof in the field of hydrolyzed self-polishing marine anti-fouling paint. The organosilicone polyurethane anti-fouling material is prepared through firstly synthesizing a single-terminal bishydroxyl siloxane polymer monomer, and polymerizing the single-terminal bishydroxyl siloxane polymer monomer, a double-terminal hydroxyl siloxane polymer monomer, a diol monomer for regulating softness and hardness and an isocyanate monomer throughfree radicals. According to the organosilicone polyurethane anti-fouling material and the application thereof, the material can have low surface energy through adding silicon groups to a principal chain and lateral chains; and an ammonia ester bond formed by silicon hydroxyl and isocyanate is prone to hydrolyzed breakage, so that the material can be decomposed in water to achieve a self-polishingeffect. The final obtained material has low surface energy and self-polishing capacity and has a relatively good application prospect in the field of marine anti-fouling.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com