Comb-shaped stem grafting copolymer containing reactive group and preparation method and application thereof

A technology of graft copolymers and reactive groups, which is applied in the field of comb-shaped polymethyl (meth)acrylate and its preparation, and can solve the problems of low compatibilization efficiency and large addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

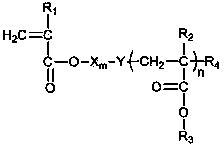

Method used

Image

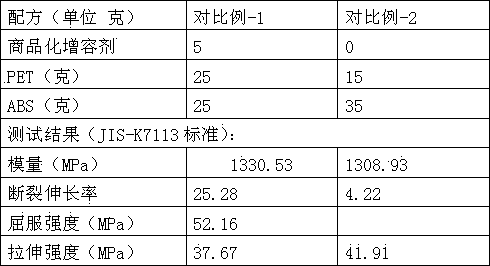

Examples

Embodiment 1-1

[0079] Under nitrogen atmosphere, 100g methyl methacrylate, 4g mercaptoacetic acid, 2.8g as the polymerization initiator 4,4'-azobis (4-cyanovaleric acid) and 100g as the toluene of solvent mix homogeneously, will The temperature of the reactor was raised to 70° C. for 5 hours. Then 0.06 g of hydroquinone as a polymerization inhibitor and 0.07 g of N,N-dimethylbenzylamine as a catalyst were added. The temperature of the reactor was raised to 100°C and stirred for 30 minutes. Add 10 grams of glycidyl methacrylate, then react at reflux temperature for 10 hours, remove the solvent under reduced pressure to obtain macromonomer A, denoted as M1-2000, and the molecular weight of macromolecular monomer A is 2000.

Embodiment 1-2

[0081] In embodiment 1-1, the content of mercaptoacetic acid as chain transfer agent is replaced by 2g, the content of hydroquinone as polymerization inhibitor is replaced by 0.03g, the N,N-dimethylbenzylamine as catalyst The content was replaced by 0.04g, glycidyl methacrylate was changed to 4 grams, other experimental conditions were consistent with Example 1, and macromonomer A was prepared, which was denoted as M1-6000, and the molecular weight of macromonomer A was 6000.

Embodiment 1-3

[0083] In embodiment 1-1, the content of mercaptoacetic acid as chain transfer agent is replaced by 1.5 grams, and the content of hydroquinone as polymerization inhibitor is replaced by 0.02 grams, and the N,N-dimethylbenzylamine as catalyst The content was replaced by 0.03 grams, and the glycidyl methacrylate was changed to 2.5 grams. Other experimental conditions were consistent with Example 1, and macromonomer A was prepared, which was denoted as M1-10000. The molecular weight of macromonomer A was 10000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com