Cobalt-based compounded catalyst and preparing method and application thereof

A catalyst and Tropsch synthesis technology, applied in the field of preparation of cobalt-based Fischer-Tropsch synthesis catalysts, can solve the problems of complex preparation process, increased catalyst cost, etc., and achieve the effects of high selectivity, promotion of adsorption and dissociation, and high reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

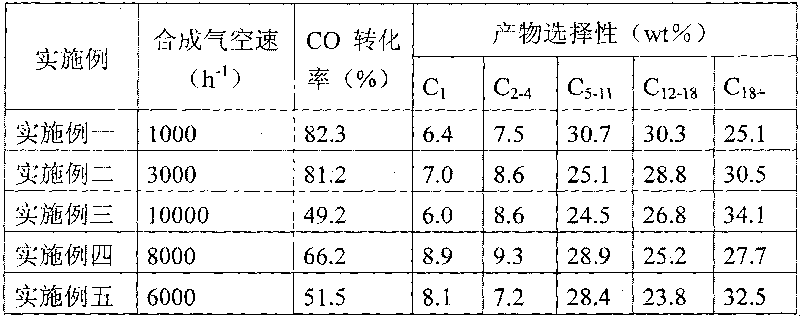

Examples

preparation example Construction

[0040] The preparation method of described cobalt-based Fischer-Tropsch synthesis catalyst is as follows:

[0041] Step (1) will predetermine the amount of Al 2 O 3 The carrier is put into a muffle furnace, calcined at 350~550℃ for 4~10h, taken out and placed in a desiccator for use;

[0042] Step (2) take by weighing the nitrates of cobalt nitrate, the second metal component and the third metal component of the calculated consumption, and dissolve them in deionized water together, so that they are fully dissolved and mixed uniformly;

[0043] Step (3) adopts the full-hole impregnation method, and the solution of step (2) is immersed in Al on a rotary evaporator. 2 O 3 On the carrier, vacuum drying at 70~110℃;

[0044] Step (4) The dried catalyst is aged at room temperature for 4-24 hours, then dried at 100-120° C. for 6-24 hours, and calcined at 300-500° C. for 2-24 hours to obtain a finished catalyst.

[0045] The preparation method of the described cobalt-based Fischer...

Embodiment 1

[0057] Weigh an appropriate amount of Al 2 O 3 For the carrier, 100 g of the carrier was pre-baked in a muffle furnace at 550° C. for 4 h and used for later use. Weigh 53.6g of cobalt nitrate hexahydrate, 1.7g of cerium nitrate hexahydrate, and 11.8g of ruthenium nitrosyl nitrate, dissolve them in deionized water, stir to fully dissolve and mix well, and dilute the solution volume to 110ml. The solution was impregnated to 100 g Al using the full pore impregnation method. 2 O 3on the carrier. The impregnated catalyst was vacuum-dried in a water bath at 80°C, and then aged at room temperature for 24h. After aging, it was placed in a muffle furnace and slowly heated to 120 °C, dried at 120 °C for 6 hours, and then heated to 500 °C for 8 hours. The composition of the prepared catalyst is: Co: Ce: Ru: Al 2 O 3 =10:0.5:3:86.5.

[0058] Catalyst activation was carried out on a pressurized fixed-bed reactor: take 20 ml of the prepared catalyst, put it into the reactor, and use...

Embodiment 2

[0061] Weigh an appropriate amount of Al 2 O 3 For the carrier, 100 g of the carrier was pre-baked at 350° C. in a muffle furnace for 10 h and used for later use. Weigh 93.8g of cobalt nitrate hexahydrate, 39.1g of lanthanum nitrate hexahydrate, and 4.65g of platinum nitrate, dissolve them in deionized water, stir to fully dissolve and mix them evenly, and dilute the solution volume to 90ml. Using the full pore dipping method, the solution was dipped into 95g Al 2 O 3 on the carrier. The impregnated catalyst was vacuum-dried in a water bath at 90°C, and then aged at room temperature for 4h. After aging, it was placed in a muffle furnace and slowly heated to 110 °C, dried at 110 °C for 6 h, and then heated to 400 °C for 16 h. The composition of the prepared catalyst is: Co:La:Pt:Al 2 O 3 =15:10:1:74.

[0062] Catalyst activation was carried out on a pressurized fixed-bed reactor: take 20ml of the prepared catalyst, put it into the reactor, pure H 2 (purity>99.9%) is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com