UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

A technology for curing coatings and antifouling coatings, which can be used in coatings, biocide-containing paints, antifouling/underwater coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

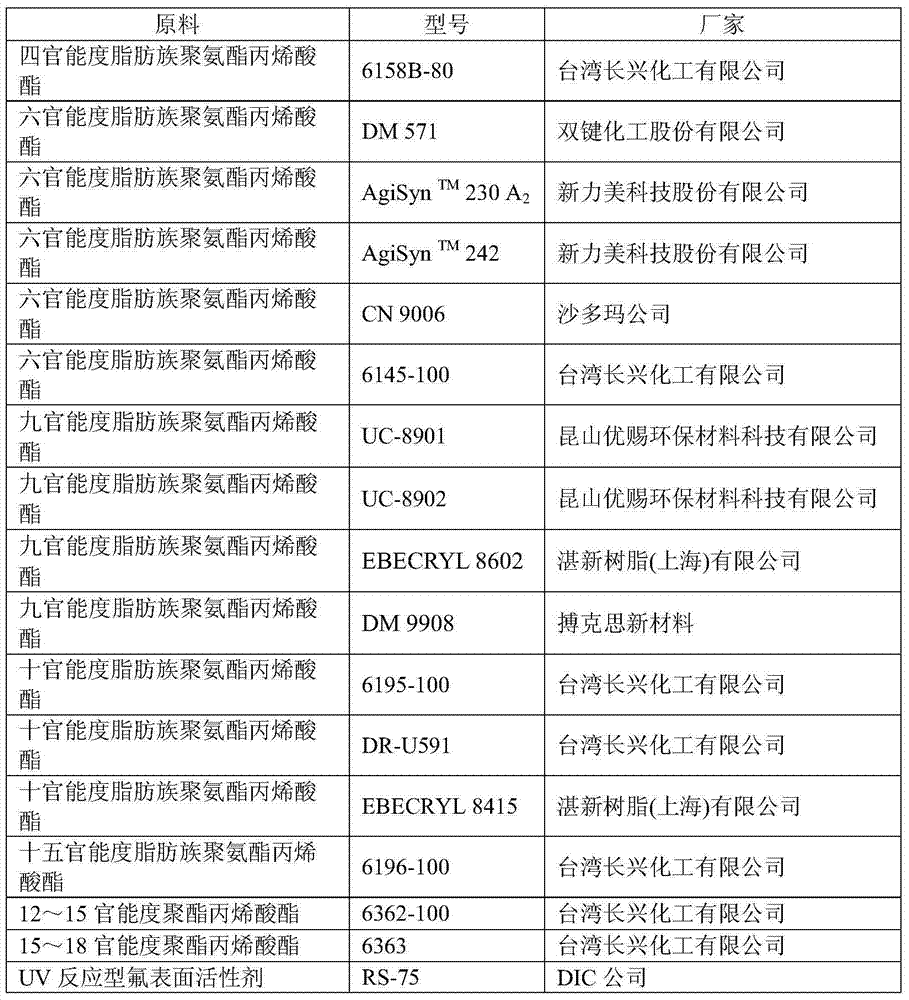

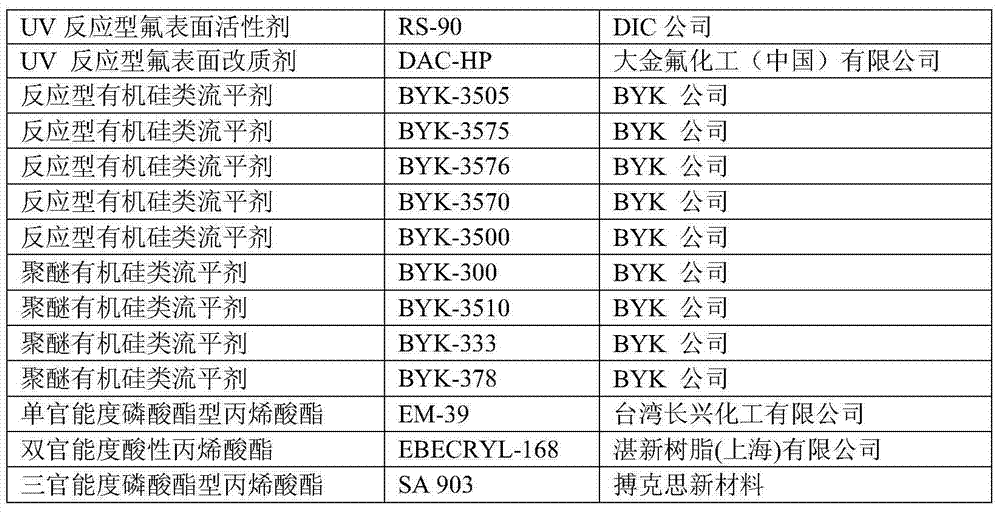

Image

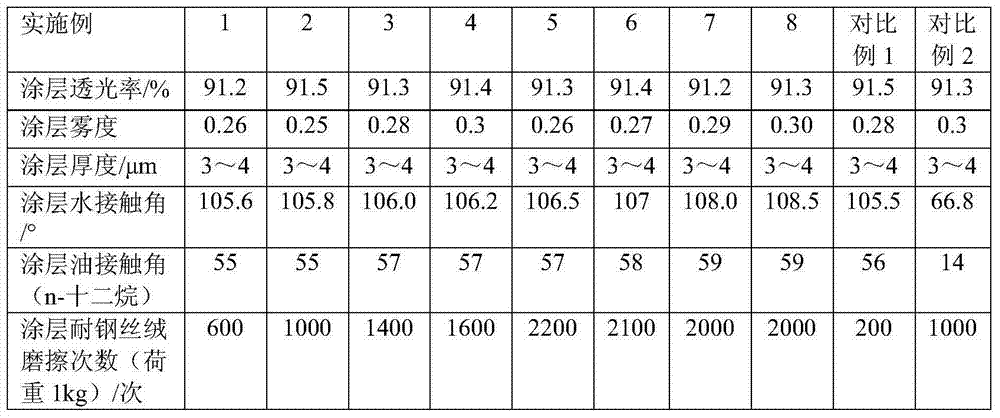

Examples

Embodiment 1

[0046]30g four-functionality aliphatic urethane acrylate prepolymer (6158B-80), 50g nine-functionality aliphatic urethane acrylate prepolymer (DM 9908), 20g pentaerythritol triacrylate (EM 235), and 0.2g mono Add functional phosphate ester acrylate (EM-39) into a mixed solvent of 100g isopropanol and 100g propylene glycol methyl ether, and stir evenly. After the prepolymer and the reactive reactive diluent were dissolved, 4.5g of photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone (IRGACURE 1173) was added to dissolve it in the system. Then add 1.6g UV reactive fluorosurfactant (RS-90), 0.5g hexafluorobutyl methacrylate (G 02), 0.2g polyether silicone leveling agent (BYK-300), 0.3g organic poly The silazane polymer (ML 20) was stirred evenly to obtain a hardened coating liquid composition. Use a wire bar coater to coat the cured coating liquid composition on one side of an optical-grade polyethylene terephthalate film (PET film) with a thickness of 125 μm, and dry it in an...

Embodiment 2

[0048] 35g six-functional aliphatic urethane acrylate prepolymer (6145-100), 40g nine-functional aliphatic urethane acrylate prepolymer (UC-8902), 25g pentaerythritol tetraacrylate (EM241), and 0.2g mono Add functional phosphate ester acrylate (EM-39) into a mixed solvent of 120g ethyl acetate and 80g propylene glycol butyl ether, and stir evenly. After the prepolymer and the reactive reactive diluent were dissolved, 4.5 g of photoinitiator 1-hydroxy-cyclohexyl-phenyl ketone (IRGACURE 184) was added to dissolve it in the system. Then add 1.7g UV reactive fluorosurfactant (RS-90), 0.8g hexafluorobutyl methacrylate (G 02), 0.4g organopolysilazane polymer (ML 33), 0.25g polyether silicone Like leveling agent (BYK-3510), stir evenly to obtain hardened coating liquid composition. Use a wire bar coater to coat the cured coating liquid composition on one side of an optical-grade polyethylene terephthalate film (PET film) with a thickness of 125 μm, and dry it in an oven at 80° C. fo...

Embodiment 3

[0050] 60g of six-functional aliphatic urethane acrylate prepolymer (CN9006), 20g of ten-functional aliphatic urethane acrylate prepolymer (6196-100), 20g of dipentaerythritol hexaacrylate (EM264), and 0.25g of bifunctional Add acidic acrylate (EBECRYL-168) into a mixed solvent of 60g propylene glycol methyl ether acetate and 140g butyl acetate, and stir evenly. After the prepolymer and the reactive reactive diluent are dissolved, add 4.0g photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-propanone (IRGACURE 1173), 1.0g2,4,6 (trimethyl Benzoyl)-diphenylphosphine oxide (DAROCUR TPO) to dissolve in the system. Then add 1.8 wt. g UV reactive fluorosurfactant (RS-90), 0.5 g dodecafluoroheptyl methacrylate (G 04), 0.4 g organopolysilazane polymer (ML 66), 0.2 g polyether Silicone leveling agent (BYK-333), stir evenly to obtain hardened coating liquid composition. Use a wire bar coater to coat the cured coating liquid composition on one side of an optical-grade polyethylene terephthal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com