Patents

Literature

1173 results about "Antifouling coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomimetic compounds and synthetic methods therefor

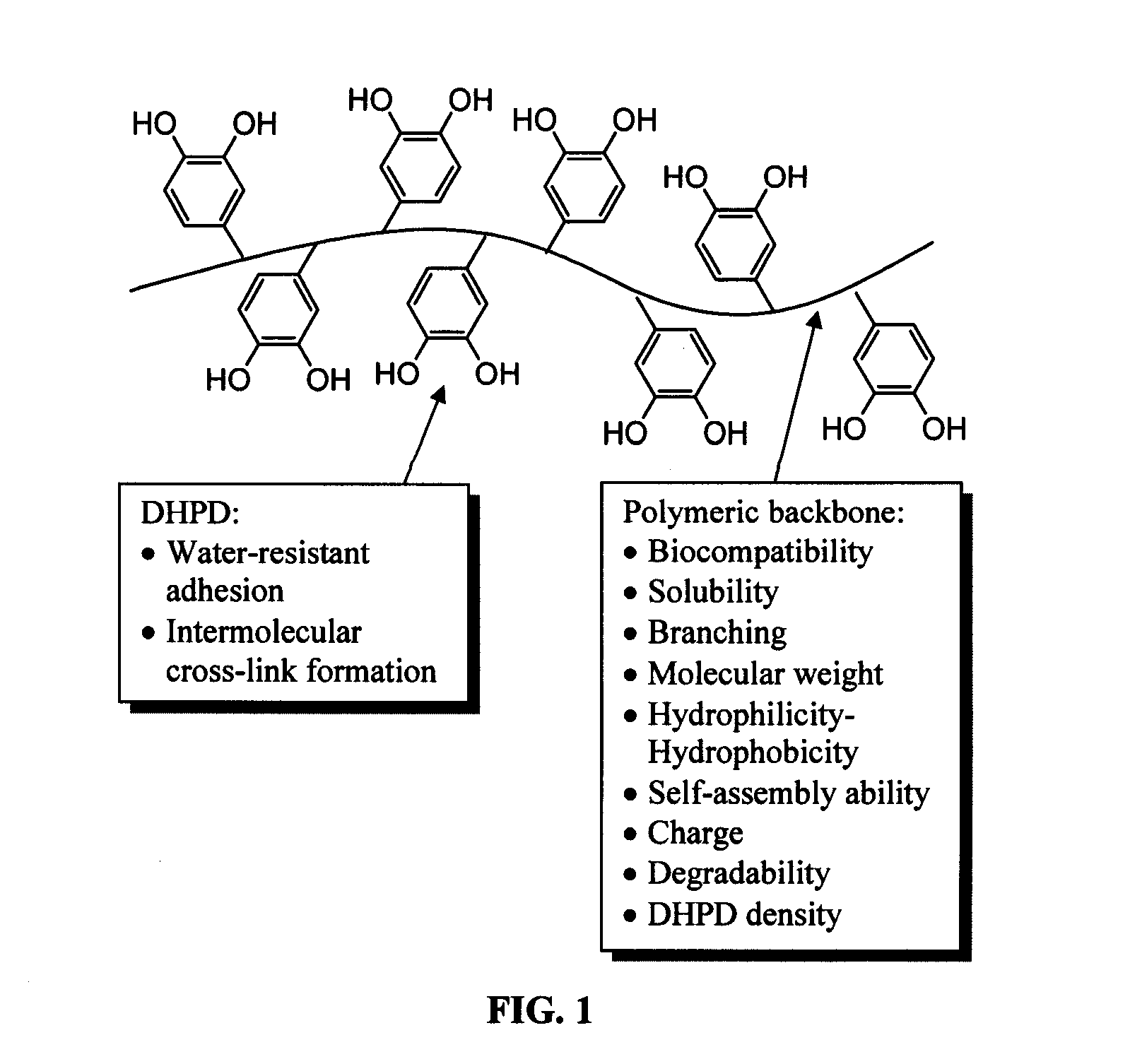

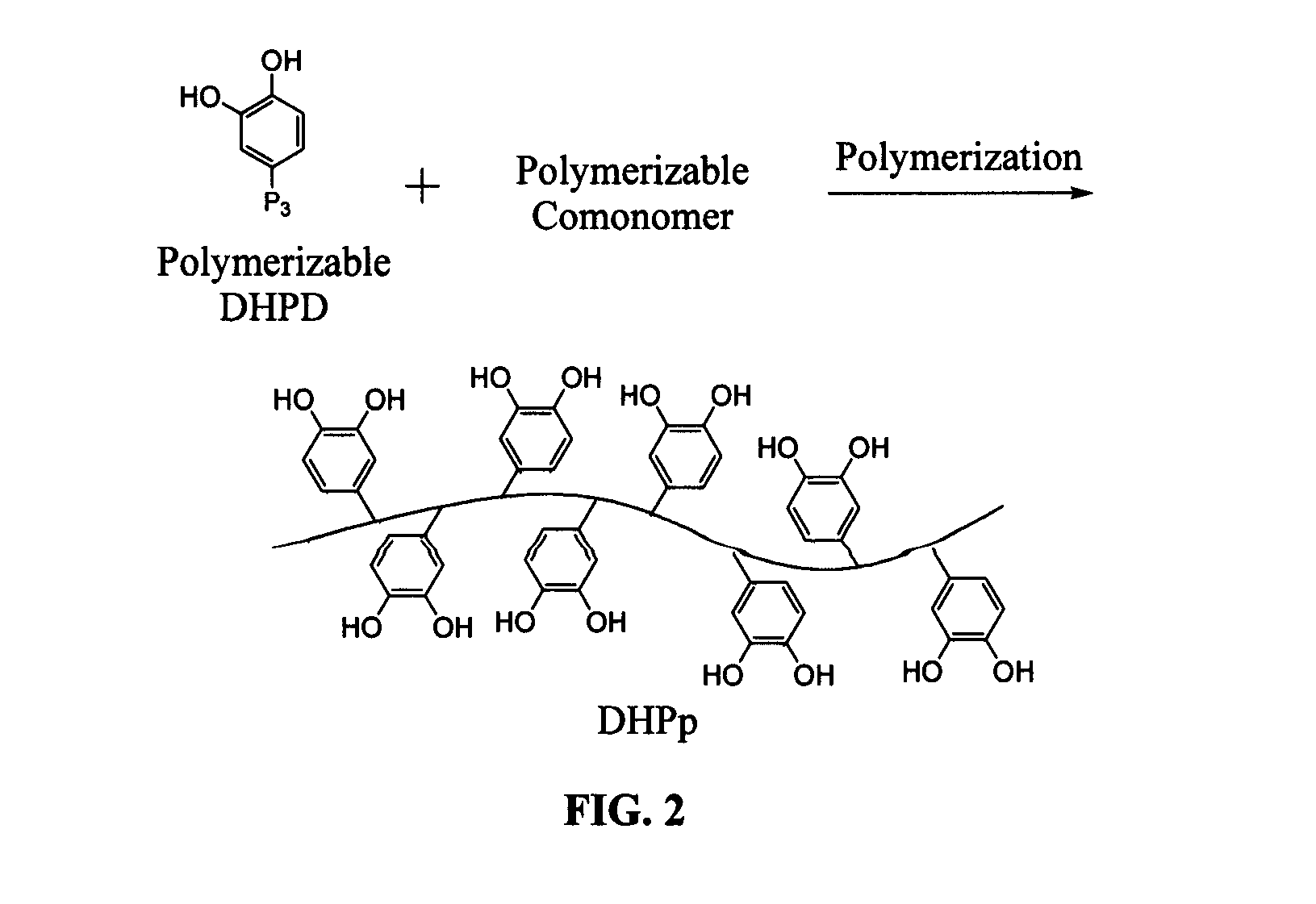

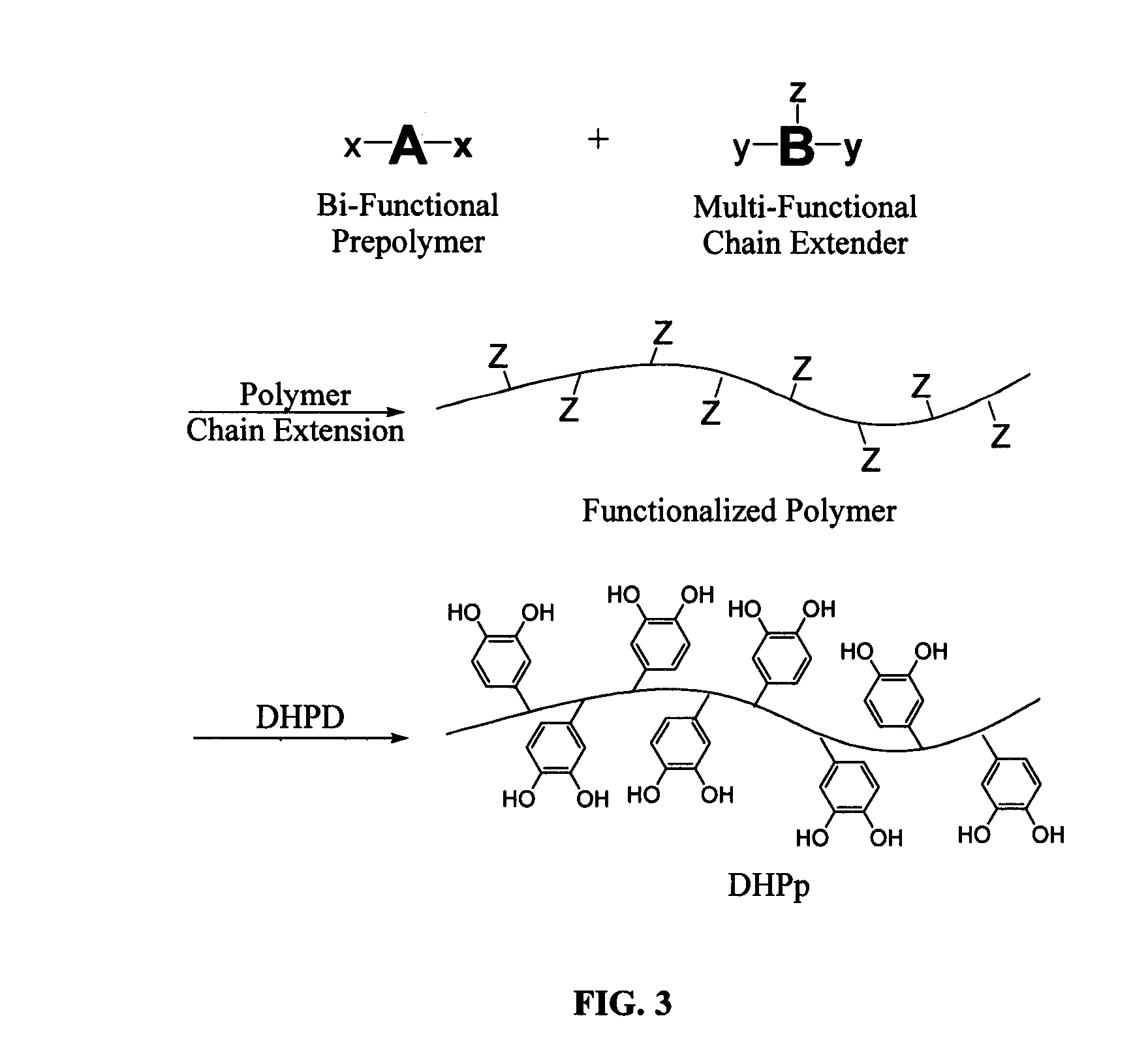

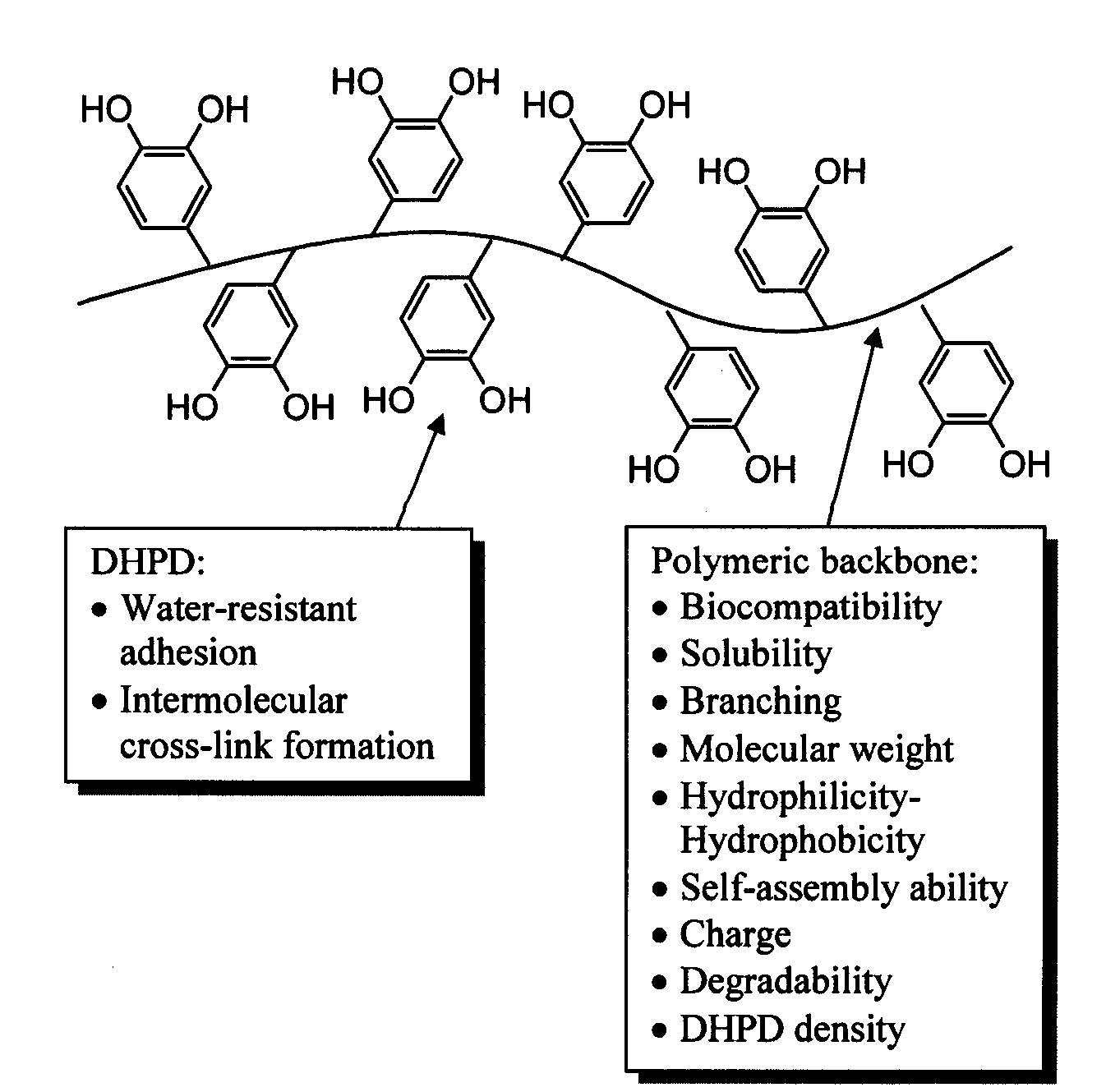

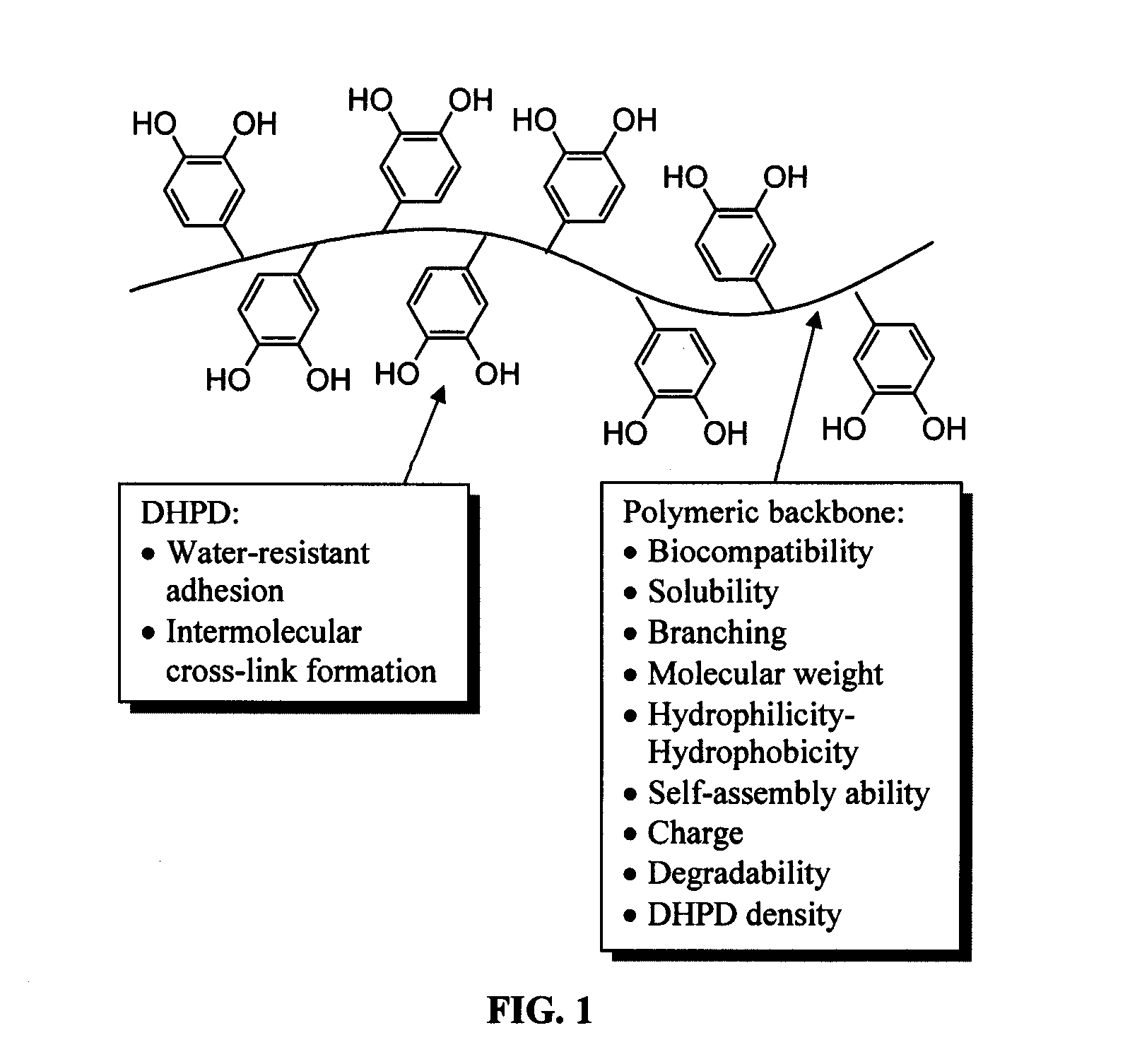

Synthesis methods for creating polymeric compounds comprising dihydroxyphenyl derivatives (DHPD), or DHPp i.e. polymers modified with DHPD, with desired surface active effects are described. The polymer backbone of DHPp has structural or performance features that can be tailored to control physical properties of DHPp, allowing it to be useful for different applications i.e. tissue adhesives or sealants, adhesion promoting coatings, and antifouling coatings.

Owner:KENSEY NASH CORP

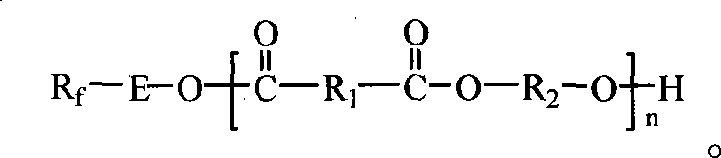

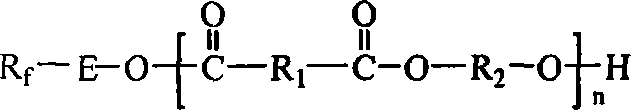

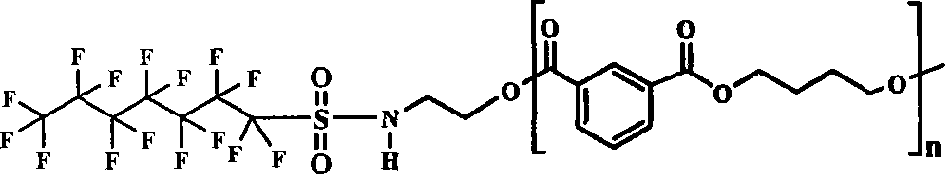

Fluorinated polyesters with low surface energy and preparation method thereof

The present invention belongs to the field of mnacromolecule, relating to the fluorine-containing polyester of low surface energy and the preparation method of the fluorine-containing polyester. The polyester has the following chemical structure (1): wherein R f C is the straight chain of 2 - 21 C or the branch-chain pseudo-perfluoroalkyl; R1, R2 is the alkyl, aryl, or naphthenic base of the C1-C8; E is -(CH2) m-; formula (3) or formula (4); R' is H or the straight chain or the branch-chain alkyl under C4; m is an integer between 0 or 10. The polyester preparation method is that dibasic acid or the correspondent diester, dihydric alcohol and perfluoroalkane, which are 0.05 percent to 10 percent of the total material weight, are fused and polymerized under vacuum condition. The polyester preparation method at the pseudo-perfluoroalkyl sealed end is simple, and is of good drainage and oil dredging properties. The present invention can be widely used in antifouling coatings, and is of important development and application value.

Owner:DALIAN UNIV OF TECH

Silyl (METH) acrylate copolymers, processes for preparing the same, antifouling paint compositions containing the silyl (METH) acrylate copolymers, antifouling coating films formed from the antifouling paint compositions, antifouling methods using the antifouling paint compositions, and hulls or underwater structures coated with the antifouling coating films

InactiveUS6458878B1Improve antifouling performanceSuppressed hydrolysis rateAntifouling/underwater paintsPaints with biocidesMeth-Unsaturated monomer

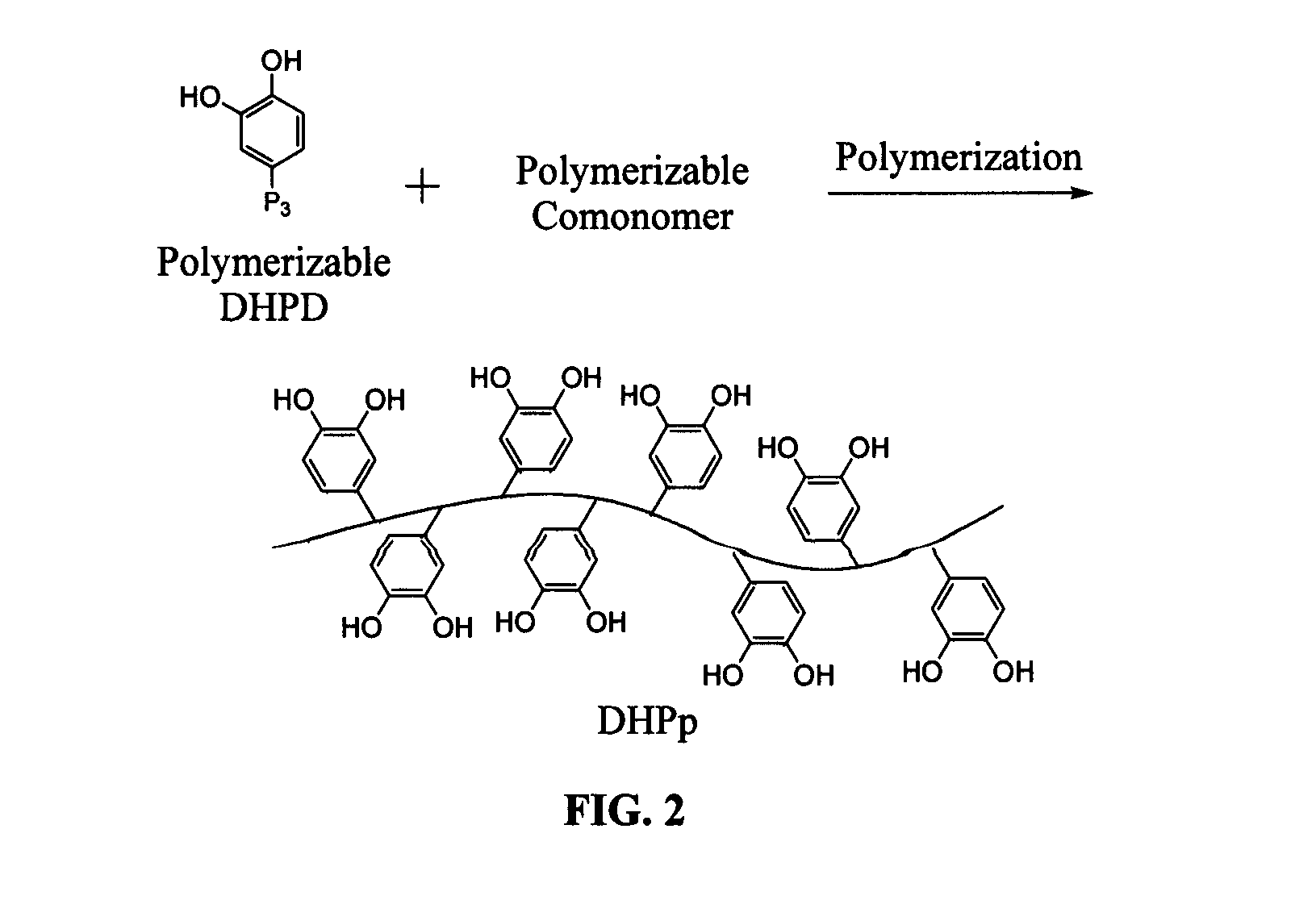

Disclosed is a silyl (meth)acrylate copolymer which comprises 20 to 80% by weight of (a) silyl (meth)acrylate constituent units (I), 0.01 to 40% by weight of (b) acrylic unsaturated monomer constituent units (II) and 5 to 79.9% by weight of Ĉ unsaturated monomer constituent units other than the constituent units (a) and (b). Also disclosed is a process for preparing the silyl (meth)acrylate copolymer, an antifouling paint composition comprising the copolymer, a coating film formed from the paint composition, a hull with the coating film and an antifouling method using the paint composition.

Owner:CHUGOKU MARINE PAINTS

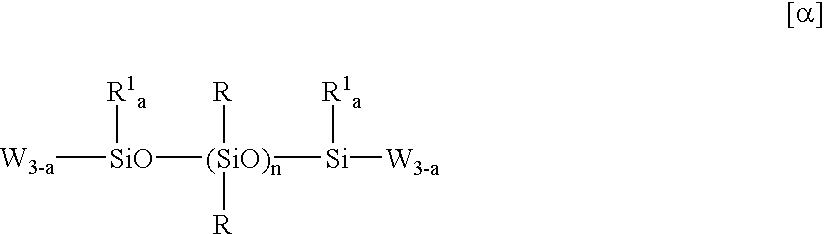

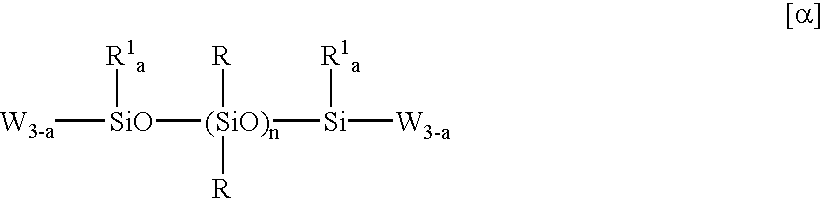

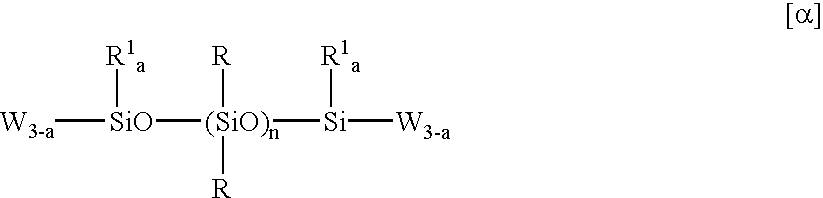

Curable composition, coating composition, paint, antifouling paint, cured product thereof and method of rendering base material antifouling

InactiveUS20020197490A1Shorten the running cycleExcellent in uniformity of coating film surfaceAntifouling/underwater paintsLayered productsHydrophobic silicaHardness

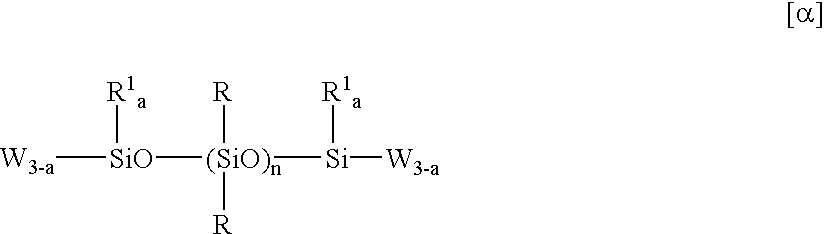

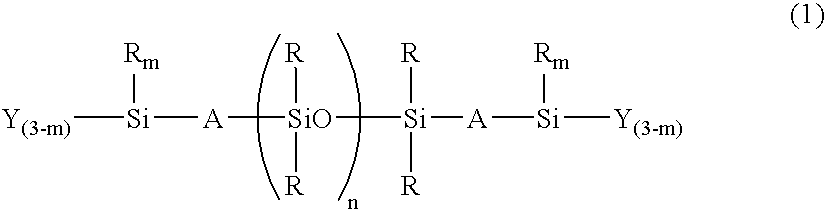

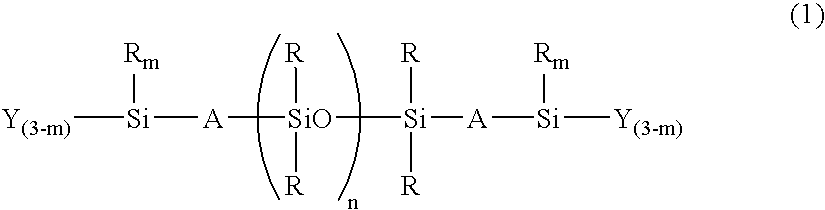

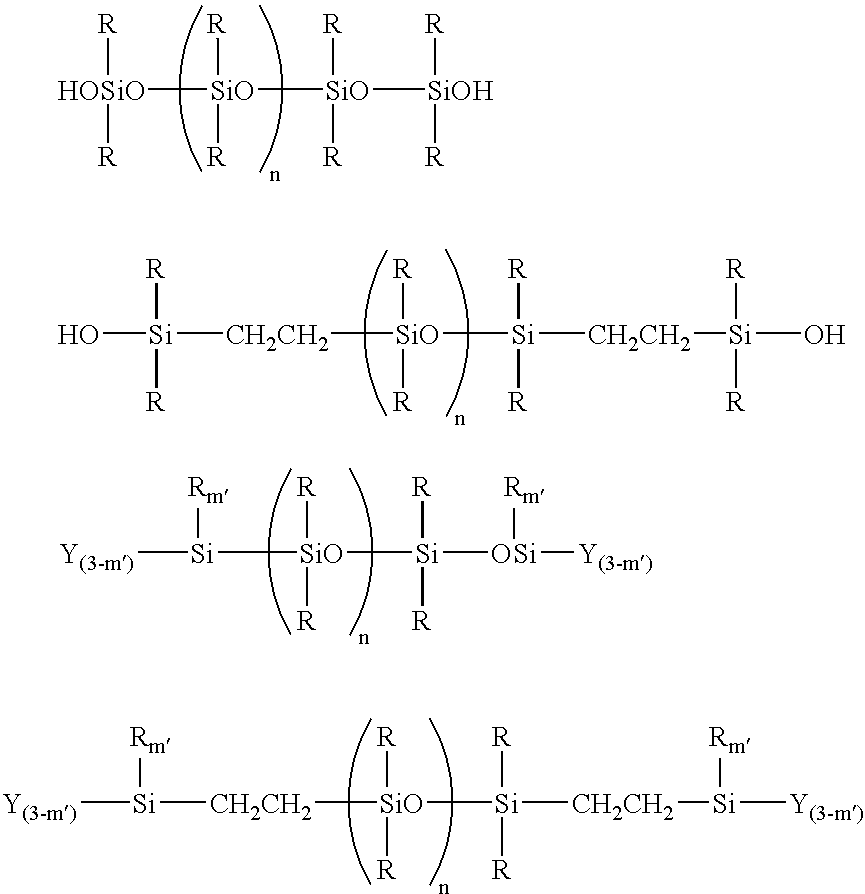

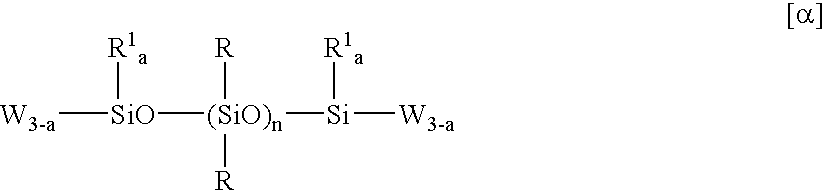

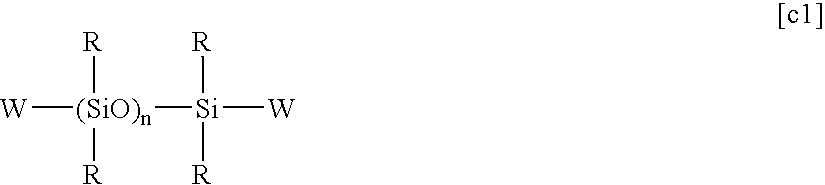

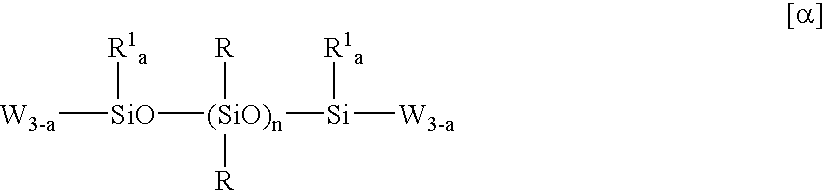

A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-1) a hydrophobic silica and a hydrophilic silica. A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-2) a hydrophobic silica, wherein the hydrophobic silica (B-2) is thermally treated together with the organopolysiloxane (A). The organopolysiloxane (A) is preferably represented by the formula: W3-a(R1a)Si(R2)O-(Si(R2)O)n-Si(R1a)W3-a [alpha] (wherein W represents a hydroxyl group or a hydrolyzable group; each of R1 and R independently represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 12 carbon atoms, provided that the hydrocarbon groups R1 as well as the hydrocarbon groups R may be identical with or different from each other; n is an integer of 5 or greater; and a is 0, 1 or 2). When, in the formula [alpha], W represents a hydroxyl group and a is 2, the curable composition preferably comprises, in addition to the components (A) and either (B-1) or (B-2), (C) an organosilane represented by the formula: R1bSiX4-b [I] (wherein R1 represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 8 carbon atoms; X represents a hydrolyzable group; and b is 0 or 1), or a partial hydrolyzate of the organosilane. Thus, a curable composition, especially a curable paint composition and an antifouling paint composition, and an antifouling coating film of the following characteristics can be provided. The curable composition, in particular when used as a coating material or a paint, is excellent in sprayability and enables forming a thick coating film by one-time application. The curable composition enables shortening the operating period for coating, and a coating film of uniform thickness can be obtained by the application thereof. The obtained coating film is excellent in film strength and film hardness and, when used for antifouling purposes, exerts excellent antifouling capability for a prolonged period of time. Further, the curable composition ensures excellent storage stability before application thereof.

Owner:CHUGOKU MARINE PAINTS +1

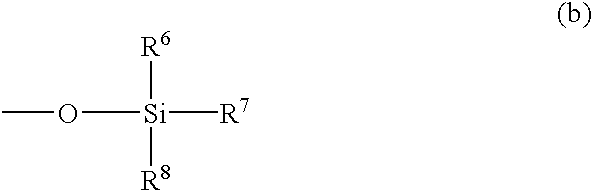

Antifouling coating compositions and coated articles

InactiveUS20050227092A1Antifouling/underwater paintsLighting and heating apparatusPolymer scienceSilylene

An antifouling coating composition is provided comprising an organosilicon compound having a one end-blocked diorganopolysiloxane group and a condensation-curable silyl group in a common molecule, and optionally a heat-curable compound. The composition is applied and cured to a substrate to form a coat which has an improved surface protective function and durable water repellent and antifouling properties.

Owner:SHIN ETSU CHEM IND CO LTD

Curable composition, coating composition, paint, antifouling paint, cured product thereof and method of rendering base material antifouling

InactiveUS6451437B1Improve balanceShorten the running cycleAntifouling/underwater paintsLayered productsPolymer scienceHydrophobic silica

A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-1) a hydrophobic silica and a hydrophilic silica. A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-2) a hydrophobic silica, wherein the hydrophobic silica (B-2) is thermally treated together with the organopolysiloxane (A).

Owner:CHUGOKU MARINE PAINTS +1

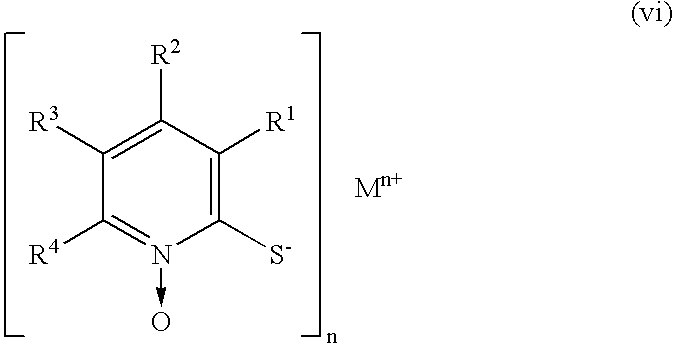

Marine antifouling coating compositions

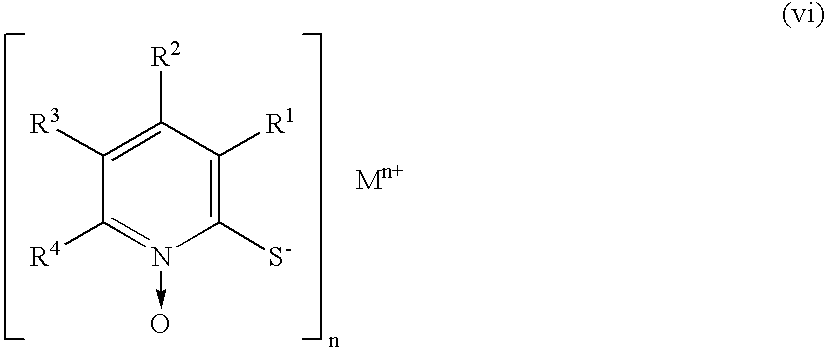

InactiveUS7335248B2Toxic reductionMinimize bio-foulingBiocideSulfur/selenium/tellurium active ingredientsMarine coatingsOrganism

Disclosed are marine coating compositions that are useful to inhibit the fouling of a marine structure by a broad spectrum of organisms. Generally, the marine coating composition comprises an antifouling agent and an organic vehicle.

Owner:NOVUS INTERNATIONAL INC

Antifouling coating composition

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix. A primer composition is also provided and is a mixture of an epoxy, an alkoxy-functionalized siloxane and a silane capable of compatabilizing the epoxy and the alkoxy-functionalized siloxane; a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane.

Owner:MICROPHASE COATINGS

High-solid hydroxyl fluorine-containing acrylic resin and preparation method thereof

The invention relates to high-solid hydroxyl fluorine-containing acrylic resin and a preparation method thereof. The high-solid hydroxyl fluorine-containing acrylic resin comprises the following components in parts by weight: 10-25 parts of fluorine-containing acrylic ester monomer, 10-30 parts of hydroxyl group-containing acrylic ester monomer, 5-20 parts of methyl acrylic alkyl ester monomer, 5-15 parts of acrylic alkyl ester monomer, 0.3-6 parts of initiator, 0.2-4 parts of chain transfer and 30-50 parts of solvent. According to the hydroxyl fluorine-containing acrylic resin, the solid content reaches up to 75-90 percent, the viscosity is only 900-3,000 mPa.s, the number-average molecular weight is 1,200-6,000, and the molecular weight distribution index is 1.4-2.5; and the resin has the advantages of superior performance, high transparency, no odor of mercaptan, low VOC (Volatile Organic Compound) content, a fluorine carbon group included on a polymer chain and superior corrosion resistance of the resin and can be applied to the fields such as heavy anticorrosive coatings, marine antifouling coatings, aircraft surface coatings, anti-doodling coatings, exterior wall coatings of high weathering resistance and the like.

Owner:SOUTHEAST UNIV

Antifouling coating composition

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix.

Owner:MICROPHASE COATINGS

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Milled submicron chlorothalonil with narrow particle size distribution, and uses thereof

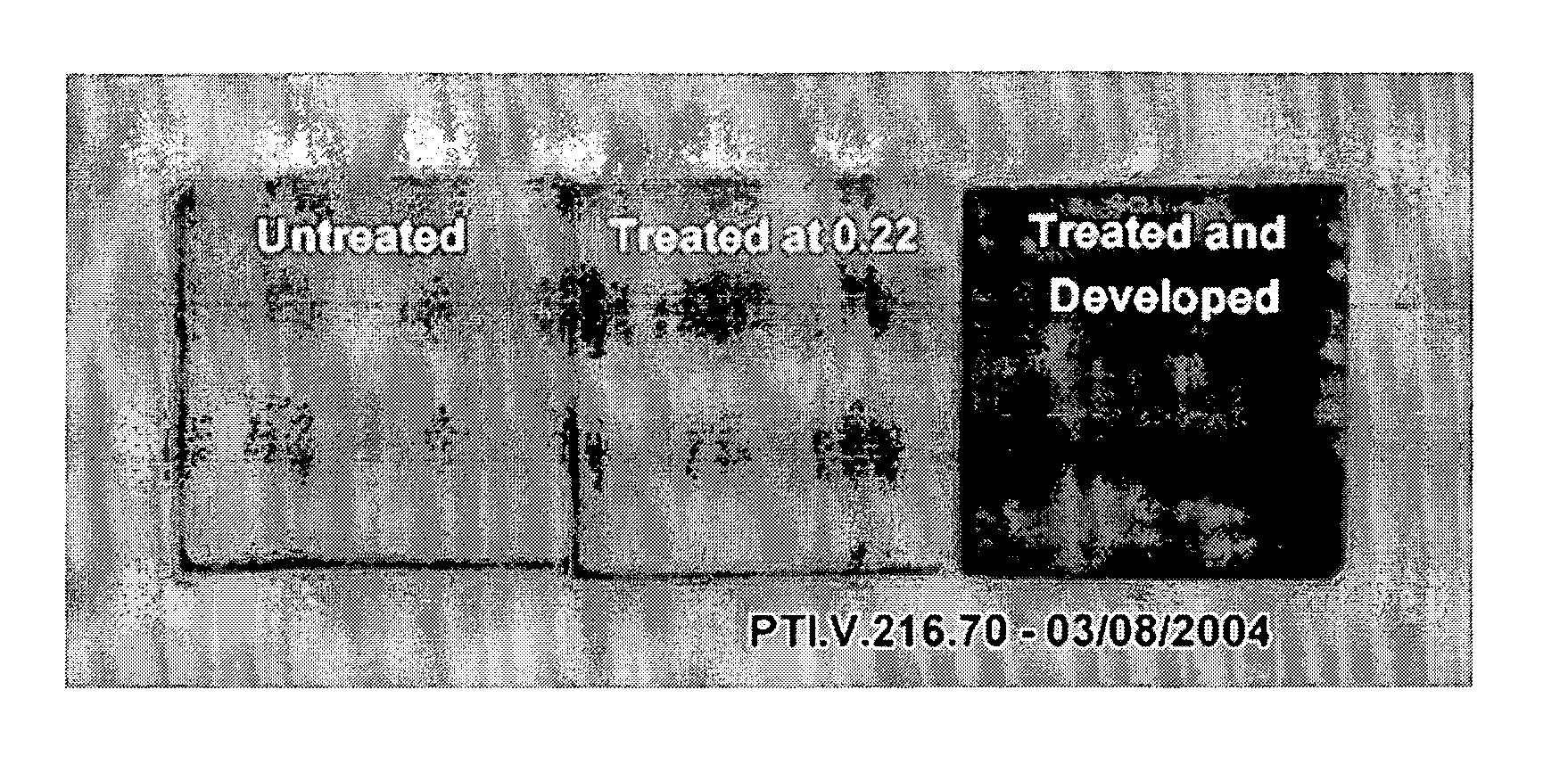

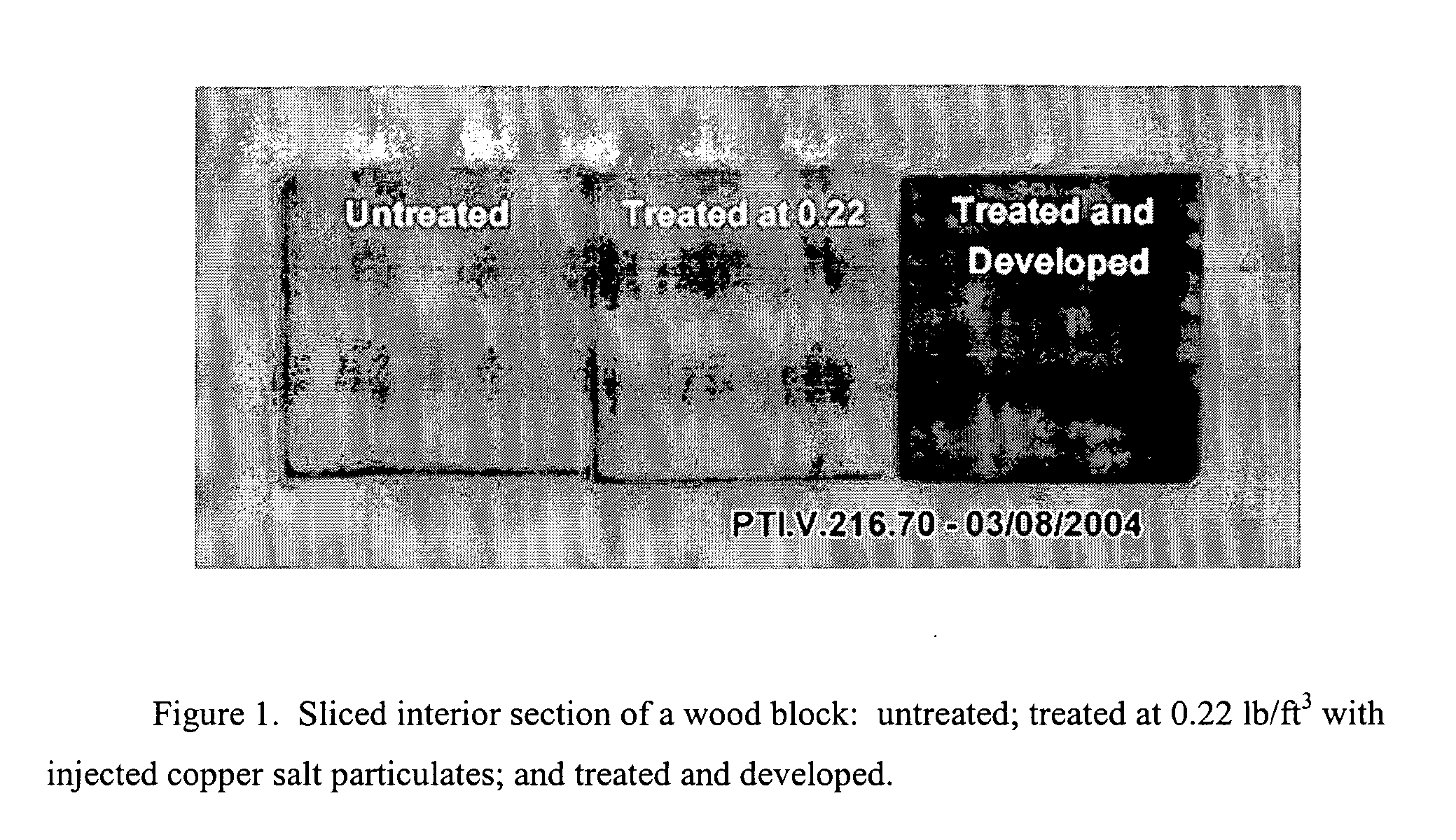

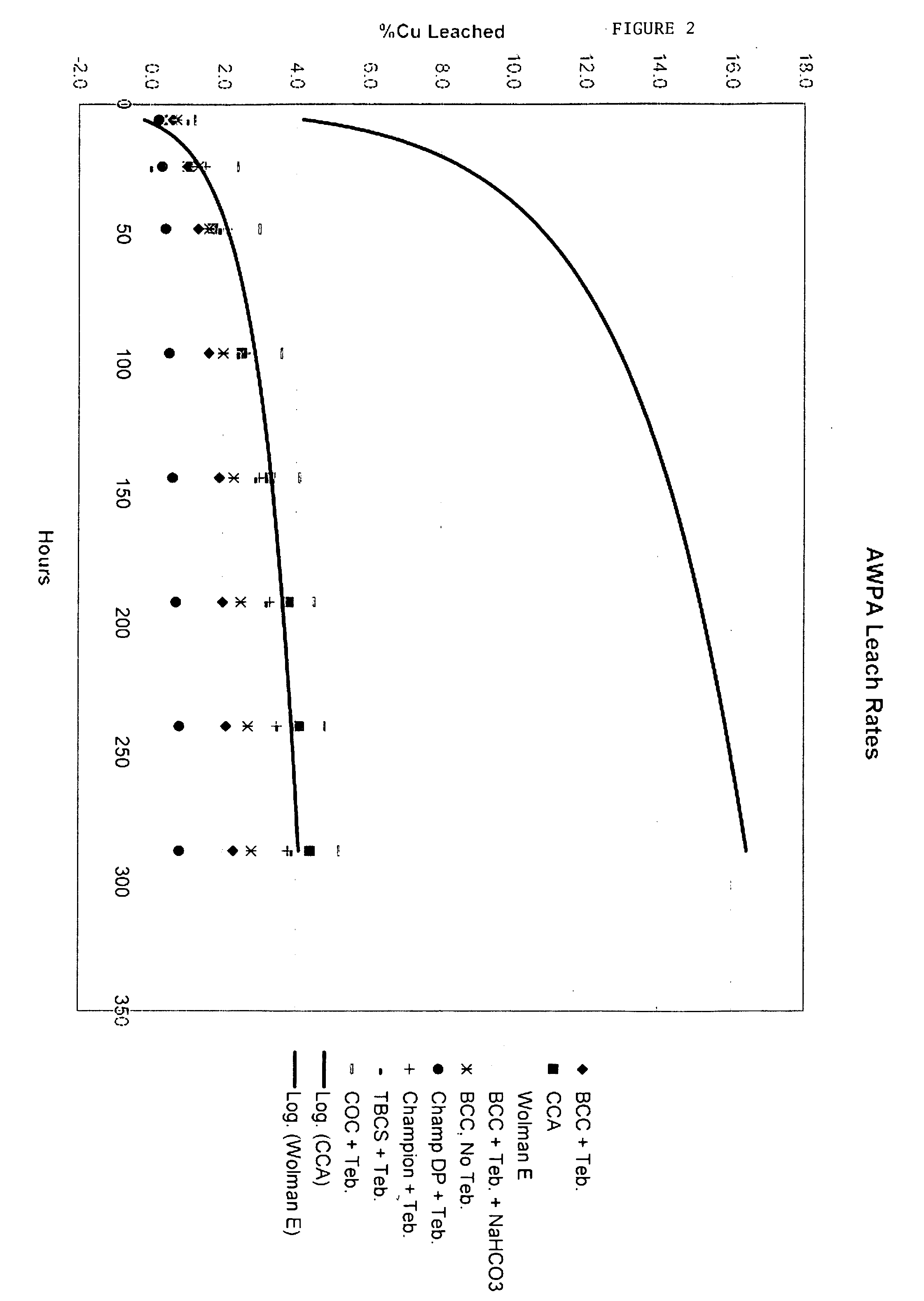

A method of milling chlorothalonil to form a sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the chlorothalonil with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the chlorothalonil suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid chlorothalonil particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

Antifouling paint composition comprising rosin and enzyme

An antifouling paint composition comprising an enzyme, such as endopeptidase, Subtilisin (EC 3.4.21.62) and Alcalase(R), and a rosin compound, wherein the enzyme is effective to reduce or prevent fouling by aquatic organisms of a surface coated with the composition. Also disclosed is a method for preventing fouling of a surface by aquatic organisms.

Owner:BIOLOCUS

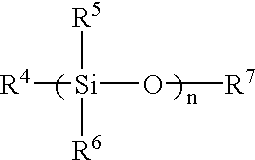

Room-temperature curable organopolysiloxane composition

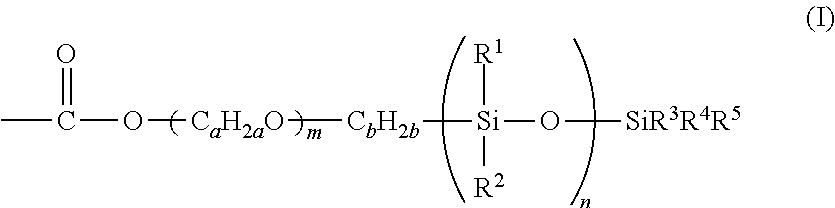

InactiveUS6906161B2Superior long-term endurance of antifoulingPrevent adhesionAntifouling/underwater paintsPaints with biocidesPartial hydrolysisLong term durability

A room-temperature curable organopolysiloxane composition is provided, which includes (A) an organopolysiloxane with the terminals blocked with a hydroxyl group, a hydrolysable group, or both these types of groups, and (B) an organosilicon compound containing a hydrolysable group, a partial hydrolysis-condensation product thereof, or a mixture of the two, and (C) a polysiloxane containing an oxyalkylene group bonded to a silicon atom via, for example, a C—C—Si linkage. Application of this composition to an underwater structure is able to generate an antifouling coating that is effective in preventing the adhesion and growth of aquatic organisms on the surface of the underwater structure, and displays superior long term endurance of this antifouling effect.

Owner:SHIN ETSU CHEM IND CO LTD

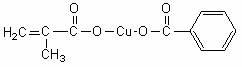

Synthesis technology of zinc acrylate or copper acrylate self-polishing anti-fouling resin

InactiveCN102167775AShort reaction timeReduce manufacturing costAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic chemistry

The invention relates to a synthesis technology of zinc acrylate or copper acrylate self-polishing anti-fouling resin. The synthesis technology comprises the following steps: firstly, zinc acrylate or copper acrylate micromolecular monomer is generated; and secondly, zinc acrylate monomer or copper acrylate monomer and acrylic soft-hard monomers are used to perform radical polymerization in mixed solvent under the action of initiator and prepare zinc acrylate or copper acrylate self-polishing anti-fouling resin with a certain hydrolysis ratio. By adopting the synthesis technology, the reaction time can be greatly shortened, thus the production cost can be reduced by 20-30% and the synthesis technology can be optimized. The technology belongs to the technical field of the ocean ship anti-fouling paint. The zinc acrylate or copper acrylate resin prepared by the technology has good adhesion to the substrate and has scratch resistance; the pencil hardness of the resin is above 4H; and the resin has a certain self-polishing rate and can be used as the main film forming material of the ocean ship anti-fouling paint.

Owner:SHANGHAI UNIV

Anti-fouling coating material with excellent compatibility and use thereof

InactiveCN102558989AGood compatibilityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to the field of anti-fouling coating materials, in particular to an anti-fouling coating material with excellent compatibility. The anti-fouling coating material with excellent compatibility contains liquid bisphenol A epoxy resin, polished acrylic resin, at least two thermoplastic resins for a coating film-forming material, at least two antifouling agents, at least two pigments and fillers, at least two solvents and at least two additives. With the adoption of the anti-fouling coating material with excellent compatibility, the excellent compatibility between a new / old anti-corrosion coating layer and an old antifouling coating layer can be provided, a connecting layer cannot be a coating layer necessary to be coated any more, the processes of coating are reduced, and excellent attachment and antifouling performances are shown after the long-term application of the anti-fouling coating material.

Owner:MARINE CHEM RES INST

Biomimetic compounds and synthetic methods therefor

Synthesis methods for creating polymeric compounds comprising dihydroxyphenyl derivatives (DHPD), or DHPp i.e. polymers modified with DHPD, with desired surface active effects are described. The polymer backbone of DHPp has structural or performance features that can be tailored to control physical properties of DHPp, allowing it to be useful for different applications i.e. tissue adhesives or sealants, adhesion promoting coatings, and antifouling coatings.

Owner:KENSEY NASH CORP

Antifouling coating composition, coating film therefrom, base material covered with the coating film and antifouling method

InactiveUS20030207962A1Less peeling tendencyImprove adhesionFireproof paintsVessel cleaningSilyleneCarboxylic acid

An antifouling coating composition comprising (A) a silyl ester copolymer containing constituent units derived from a polymerizable unsaturated carboxylic acid silyl ester; (B) a carboxylic acid; (C) a bivalent or trivalent metal compound; and (D) a dehydrating agent. It is preferred that the component (C) be contained in an amount of 1.2 equivalents or more, in terms of the number of equivalents of metal as a constituent of the component (C), per equivalent of carboxyl group of the carboxylic acid (B); that the component (C) be a bivalent metal compound; and that the component (C) be a compound of at least one metal selected from the group consisting of zinc, copper, magnesium, calcium and barium. From the antifouling coating composition, there can be obtained an antifouling coating film which exhibits less cracking tendency, excellent adherence so as to ensure less peeling tendency and desirably controlled hydrolysis rate so as to be excellent in antifouling performance, in particular, antifouling properties in highly fouling environment and long-term antifouling properties. With respect to the provided antifouling coating composition, its storage stability is high, its concentration can be increased, the amount of solvent used therefor can be reduced, and its applicability is high.

Owner:CHUGOKU MARINE PAINTS

Antifouling coating composition

InactiveUS6476095B2Antifouling/underwater paintsSynthetic resin layered productsEpoxyPolymer science

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix. A primer composition is also provided and is a mixture of an epoxy, an alkoxy-functionalized siloxane and a silane capable of compatabilizing the epoxy and the alkoxy-functionalized siloxane; a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane.

Owner:MICROPHASE COATINGS

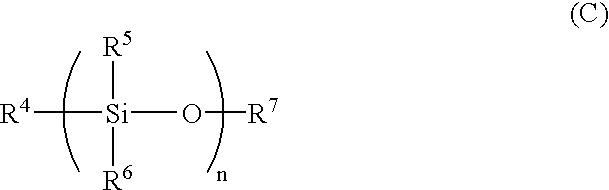

POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and preparation method thereof

InactiveCN102775567AMild surface energyLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceCopolymer

The invention discloses a POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and a preparation method thereof. The preparation method includes subjecting hydrogen-terminated polysiloxane and vinylcarbinol to reaction to obtain hydroxy-terminated polysiloxane; subjecting the hydroxy-terminated polysiloxane and carboxyl thiocarbonic acid ester to reaction to obtain polysiloxane macromolecular RAFT (reversible addition-fragmentation chain transfer polymerization) reagent; polymerizing the polysiloxane macromolecular RAFT reagent, acrylate monomer and POSS monomer with initiator to prepare the POSS contained polyacrylate-polysiloxane block copolymer. The method has the advantages of simple operation and mild reaction conditions, reaction products have better surface performance and bonding performance with substrates, and further, the reaction products can be used in low-surface-energy lyophobic coating materials and used for preparing ice and snow preventive and antifouling coatings.

Owner:TIANJIN UNIV

Graphene-containing marine anticorrosion antifouling coating and preparation method thereof

InactiveCN103589282AImprove anti-corrosion performanceImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesEpoxyGraphene

The invention discloses a graphene-containing marine anticorrosion antifouling coating and a preparation method thereof. Graphene having an antibacterial function is used as a filling material and is added into epoxy resin by surface modification, and the nano composite antifouling coating having antibacterial and anticorrosion properties is prepared. The graphene is added into the epoxy resin to form the marine antifouling coating; the excellent characteristics of the two materials are fully combined, so the coating has both the antifouling characteristic and the anticorrosion characteristic, that is to say, graphene and the epoxy resin are composited, so the antibacterial property of graphene and the anticorrosion property of the epoxy resin are organically combined jointly, and thus the novel antifouling coating having both the anticorrosion property and the antifouling property is developed.

Owner:TIANJIN UNIV

Antifouling coating composition

Owner:MICROPHASE COATINGS

Water-based innocuous long-acting antifouling coating and preparation method thereof

ActiveCN101935493AImprove antifouling performanceExtended antifouling periodAntifouling/underwater paintsPaints with biocidesWater basedBiopolymer

Owner:YEJIAN NEW MATERIAL

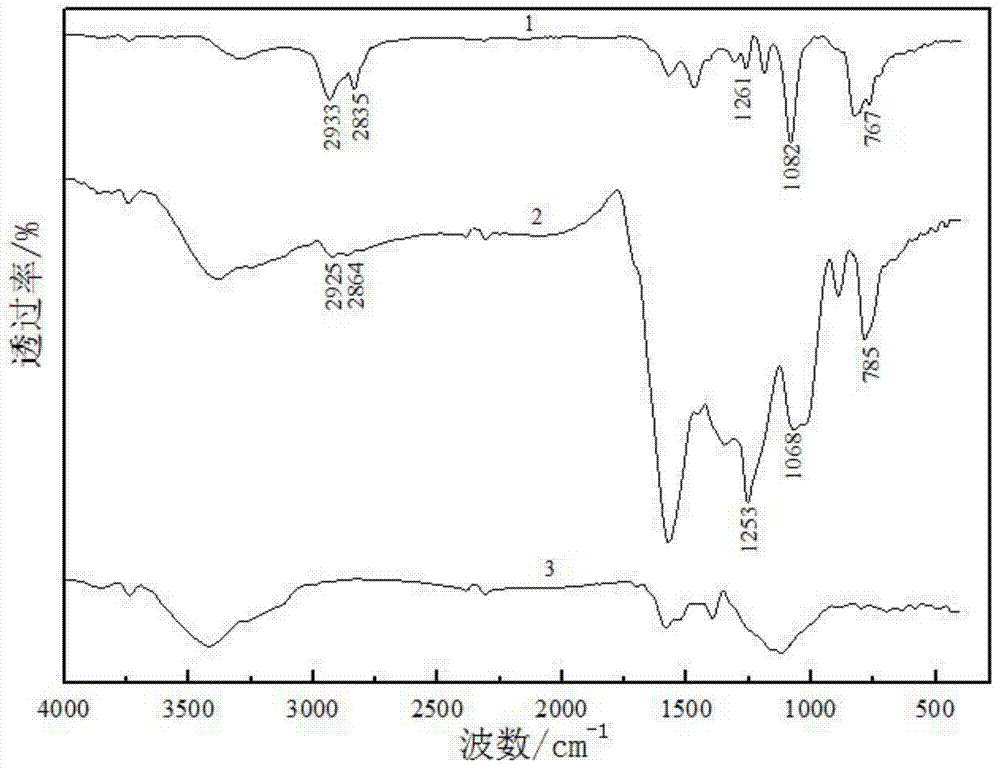

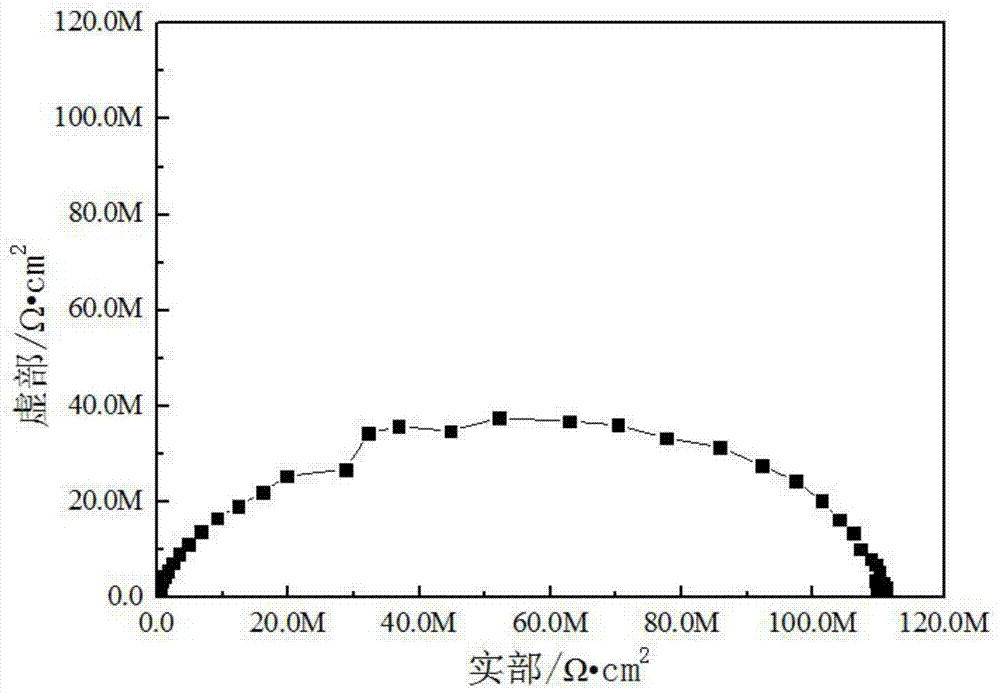

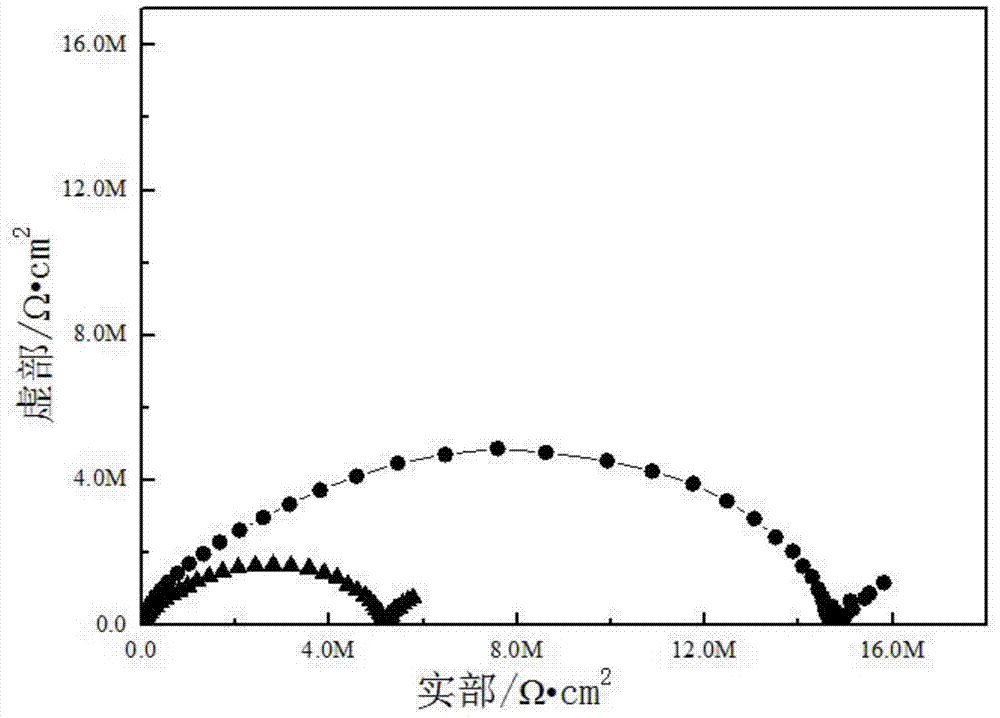

Preparation and application of zinc acrylate-type self-polishing matrix resin for antifouling coating

ActiveCN103897092AGood self-polishing propertiesEasy to control dissolution rateAntifouling/underwater paintsPaints with biocidesToxic materialZinc

The invention relates to preparation and application of zinc acrylate-type self-polishing matrix resin for an antifouling coating. The matrix resin has good self-polishing property, and the antifouling coating prepared by using the matrix resin has the characteristics of being long in anti-fouling period, excellent in anti-fouling property, excellent in polishing and drag-reduction performances and the like. The invention provides the anti-fouling coating prepared from the zinc acrylate-type self-polishing matrix resin for the antifouling coating. The matrix resin has good self-polishing property, and the anti-fouling coating prepared by the matrix resin has the characteristics of being long in antifouling period, excellent in antifouling property, excellent in polishing and drag-reduction performances and the like. The anti-fouling coating does not contain toxic substances such as tin and dichloro-diphenyl-tricgloroethane (DDT), has the characteristics of being friendly to the marine environment, simple and convenient to construct, easy to maintain and the like, and can meet the requirements of underwater facilities on the long-term antifouling coating in the sea.

Owner:MARINE CHEM RES INST

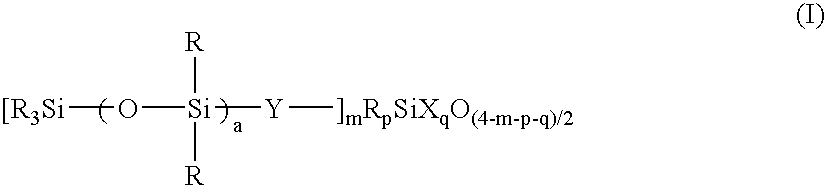

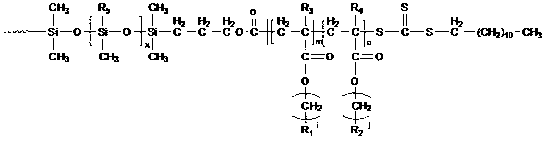

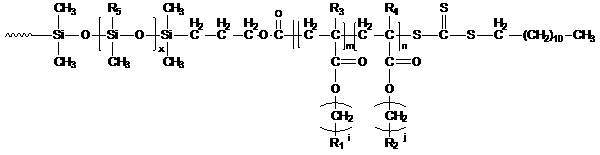

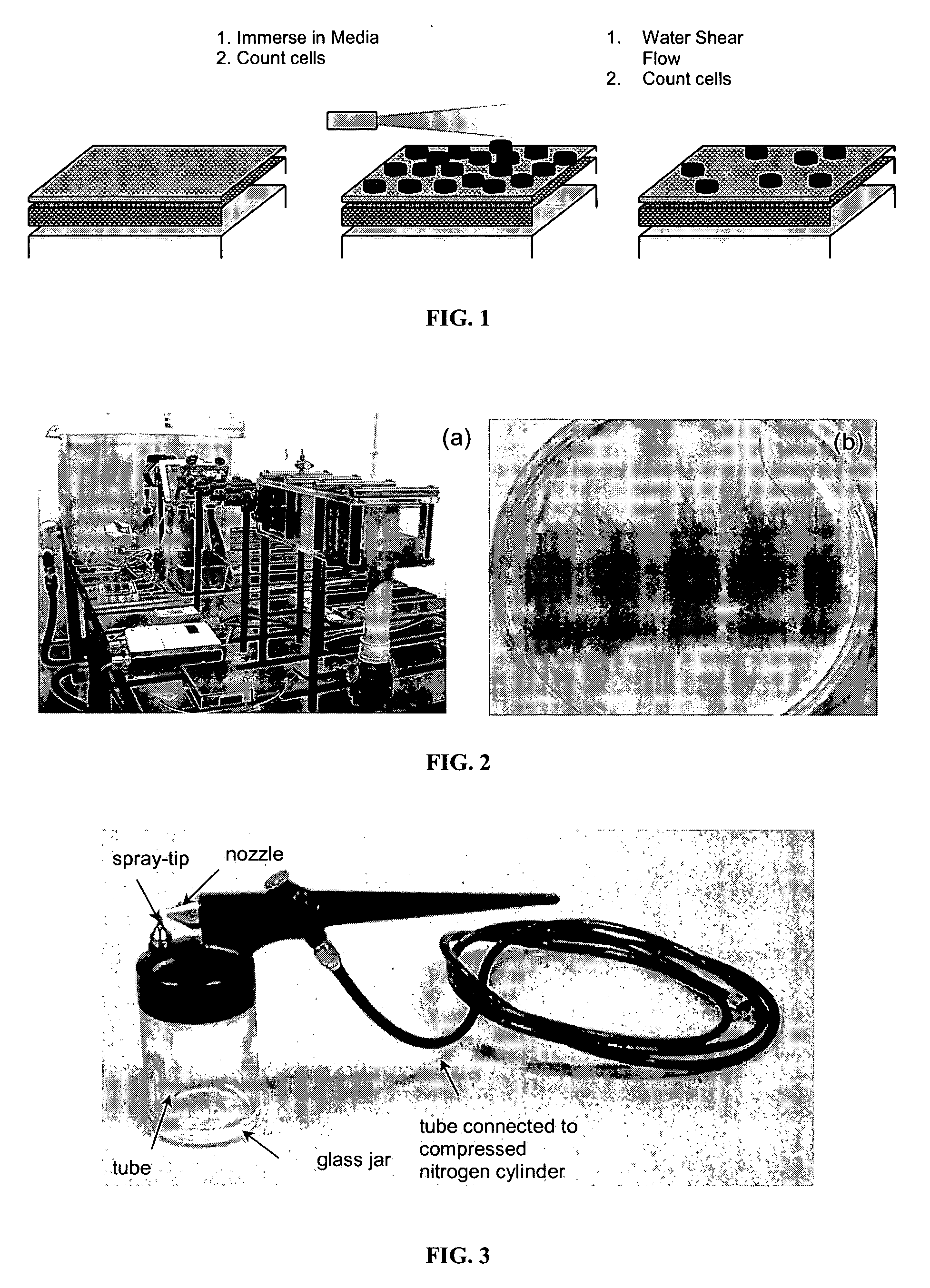

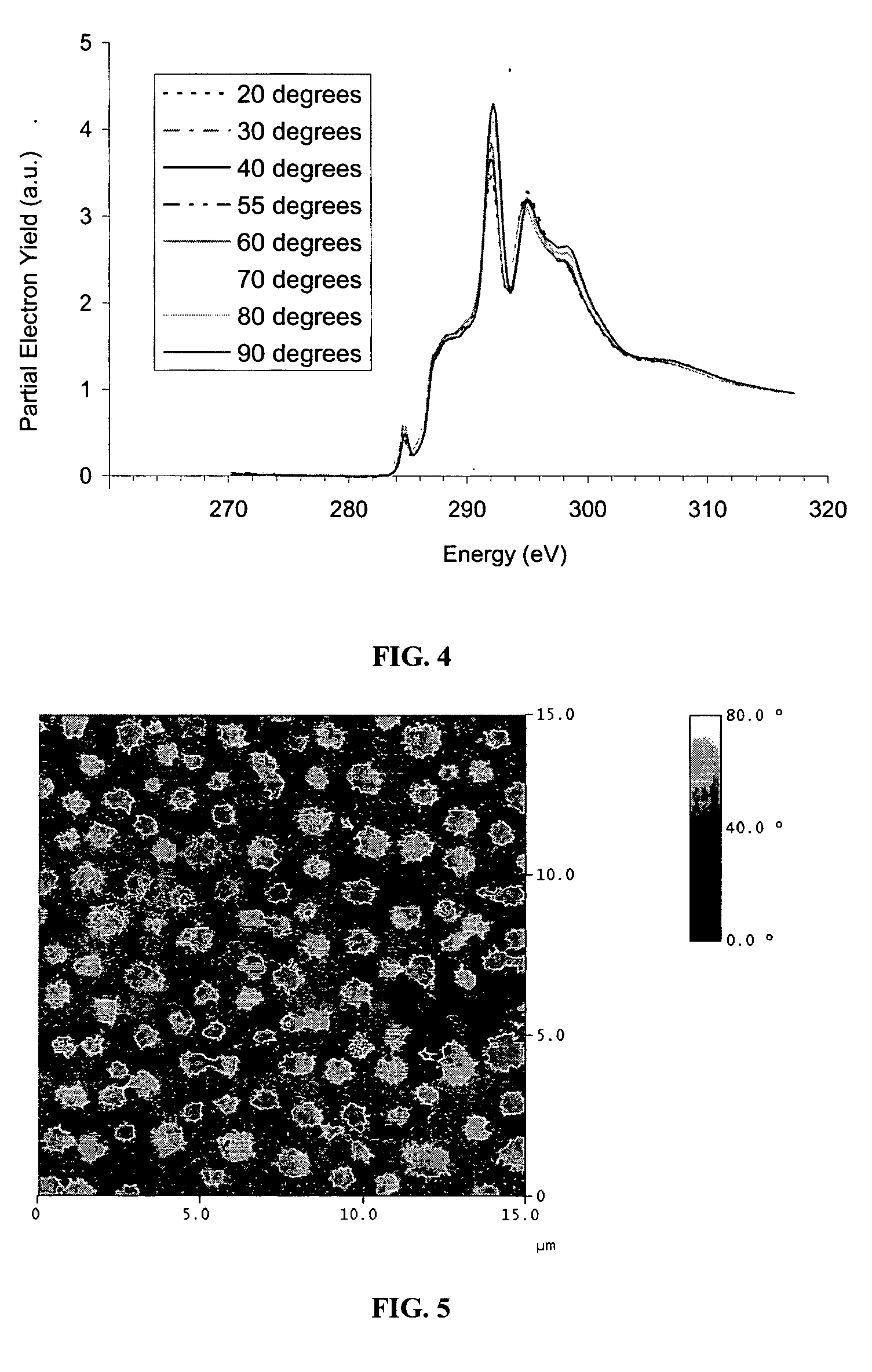

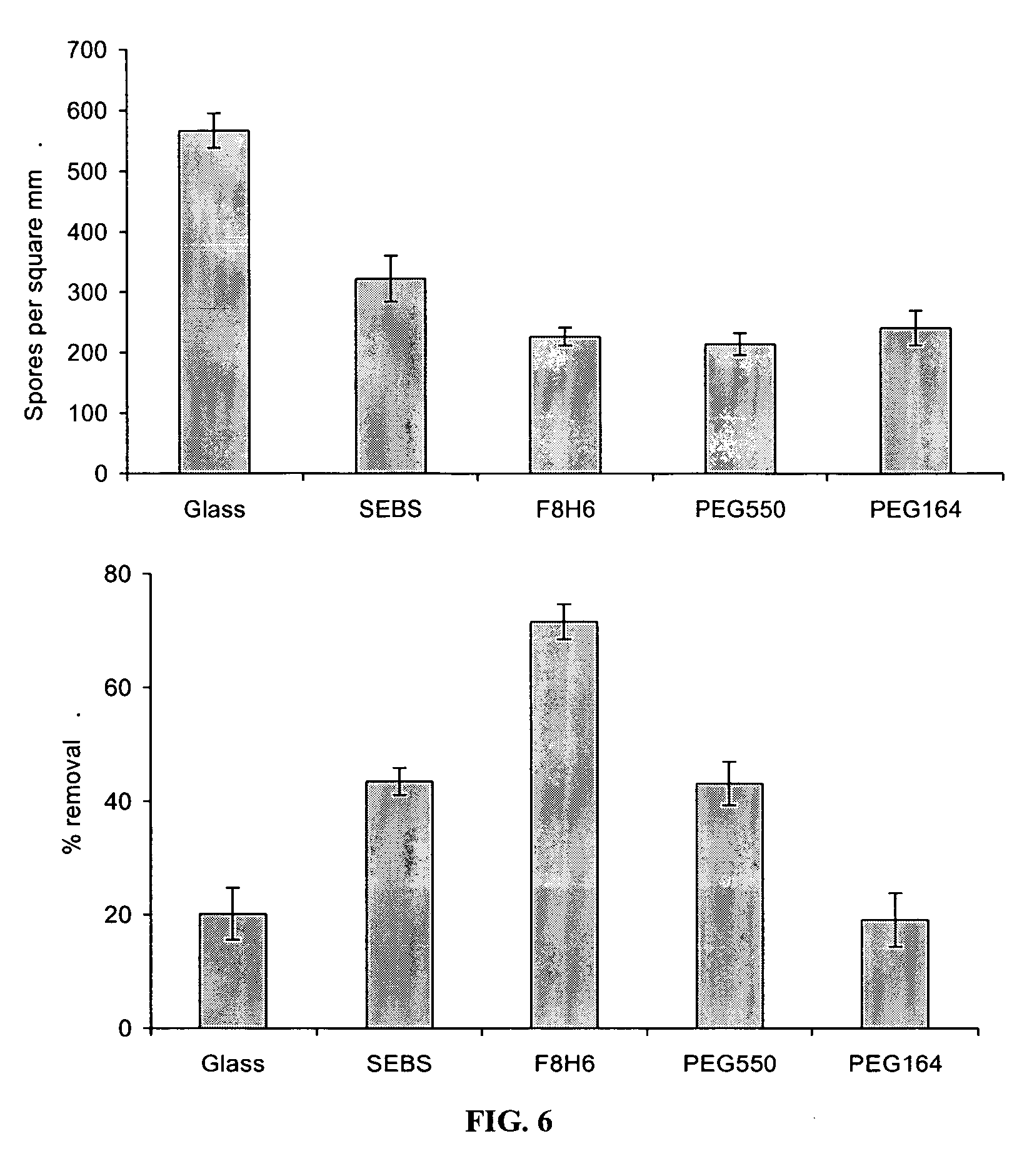

Polymer coatings

InactiveUS20060083854A1Minimize adhesion strengthImprove adhesionPretreated surfacesLiquid/solution decomposition chemical coatingPolymer scienceSide chain

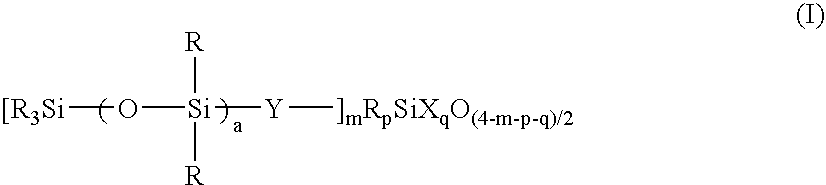

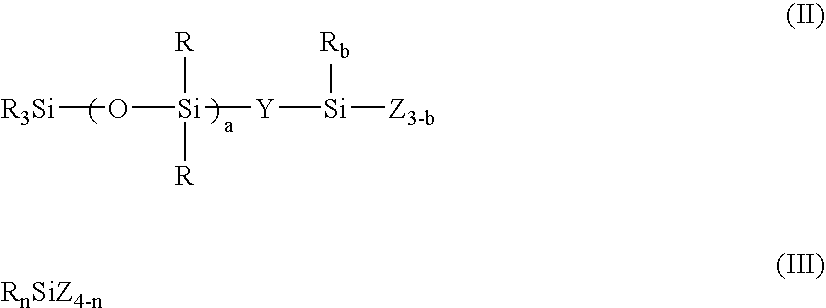

The present invention provides compounds of formulae (I), (II), and (III), which can be block copolymers with various substituents and side-chain groups. The side-chains can include semifluorinated alkyl- and PEG-derived groups. The block copolymers can be surface active block copolymers (SABCs) and can be used as antifouling coatings. Coating compositions employing the compounds of the invention and methods for their use are also provided.

Owner:CORNELL RES FOUNDATION INC

Environmental protection composite antifouling paint

InactiveCN1557896AInhibit growthNon-toxic withAntifouling/underwater paintsPaints with biocidesDisinfectantMildew

The environment protecting composite antifouling paint is prepared with organic resin, hot natural plant material, non-toxic mildew-preventing disinfectant, inorganic pigment, stuffing, assistant, exudation aid and solvent, and through physical mixing. The environment protecting composite antifouling paint has no toxicity, no pollution to marine environment and wide application range. It has the functions of resisting bacteria and preventing marine organism from attaching.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

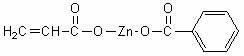

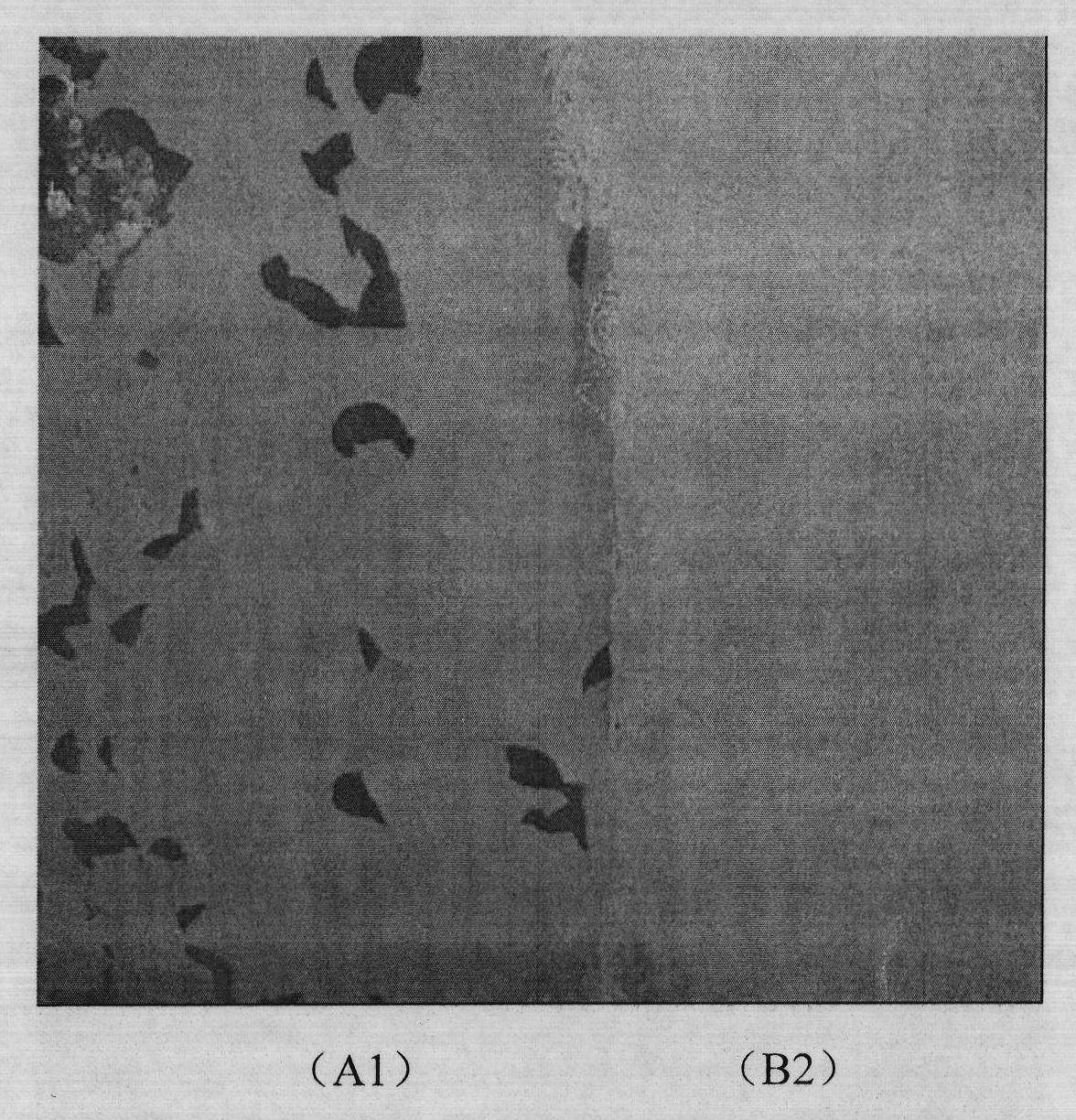

Method of forming antifouling coating film

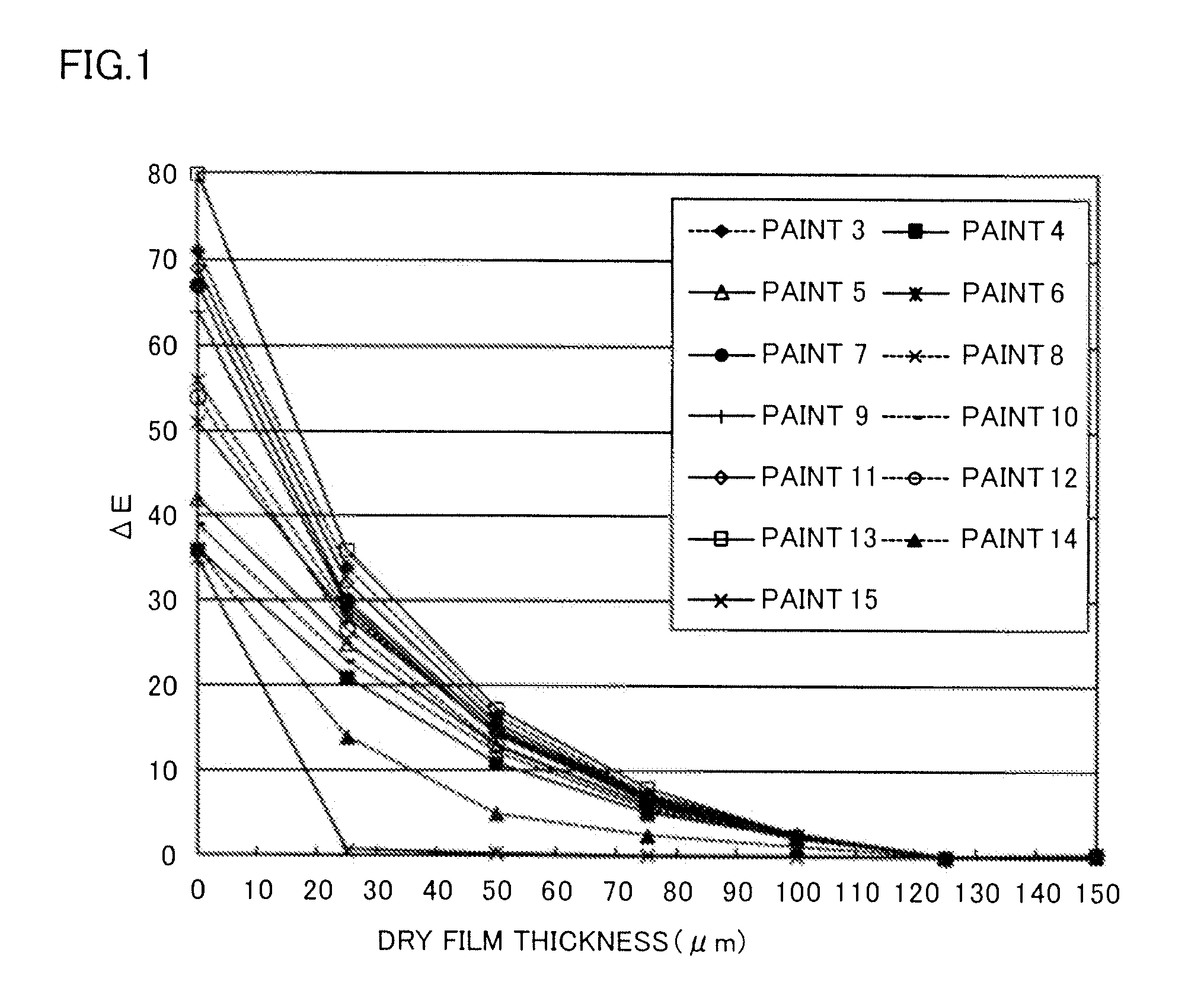

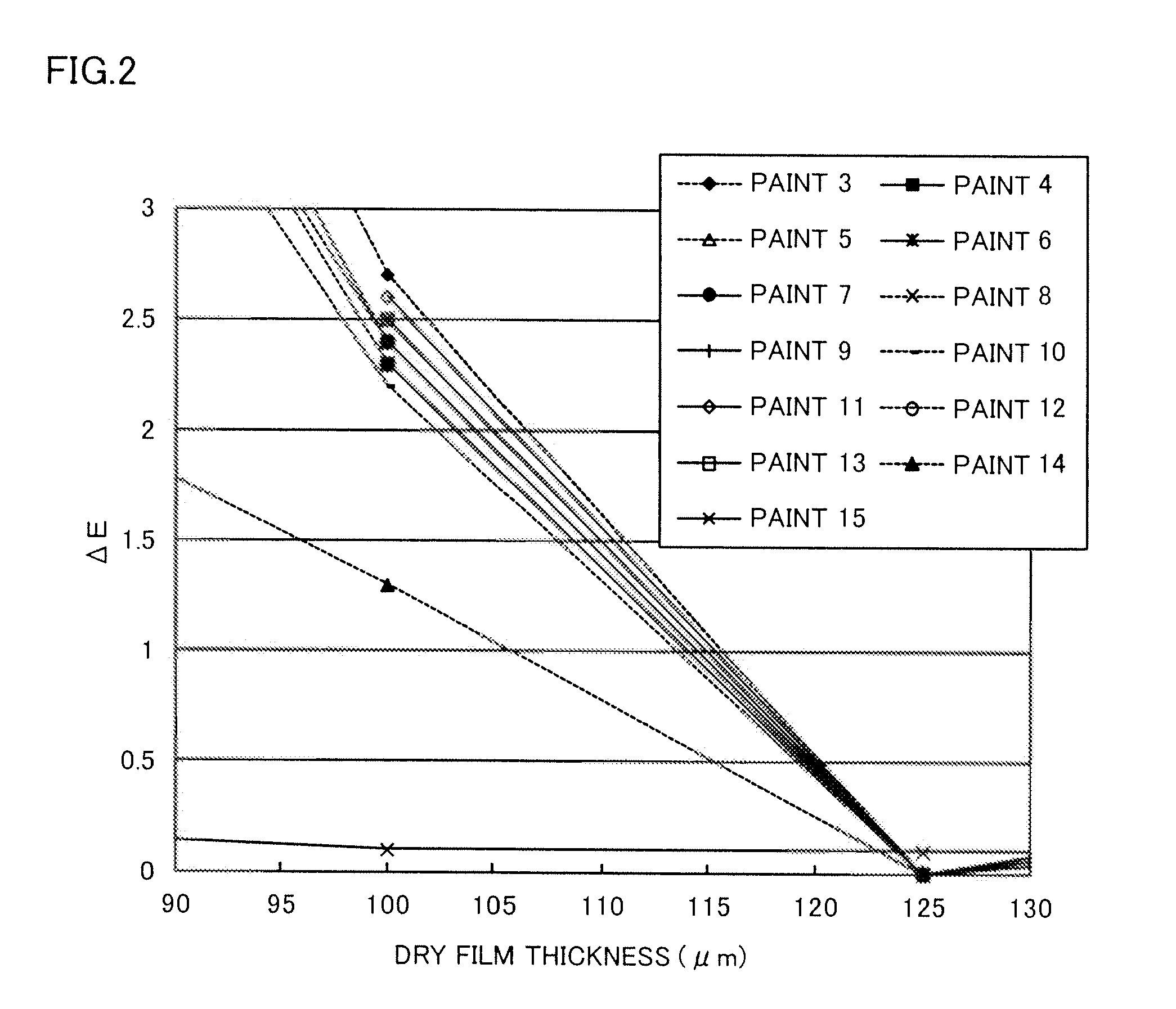

ActiveUS20120294825A1Paint be saveResistant to crackAntifouling/underwater paintsPaints with biocidesColor differencePolymer chemistry

Provided is a method of forming an antifouling coating film including the steps of [1] preparing a colored antifouling paint containing a prescribed Si-containing hydrolyzable resin and a color pigment such that a coating film having a target dry film thickness T completely hides a surface of an object to be coated, the colored antifouling paint has a color difference ΔE1 between the coating film having the thickness T and a coating film having a dry film thickness of 0.8 T, at least 2.0, and preferably the colored antifouling paint has a color difference ΔE2 between the coating film having the thickness T and a coating film having a dry film thickness of 1.2 T, less than 1, and [2] coating a surface of the object with the colored antifouling paint until the surface of the object is completely hidden by the coating film formed from the colored antifouling paint.

Owner:NIPPON PAINT MARINE COATINGS

Tei Coat for Organopolysiloxane Antifouling Coat, Composite Coats, and Ships and Underwater Structures Covered with the Composite Coats

InactiveUS20090042042A1Big burden to solveWell formedAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond properties

Disclosed is a tie coat which is formed on a surface of a base or an undercoating film prior to formation of an organopolysiloxane-based antifouling coating film and is formed from a moisture-curing organopolysiloxane-based composition comprising (b1) organopolysiloxane having condensing functional groups at both ends of a molecule and / or (b2) a curing composition formed by subjecting the component (b1) and an extender pigment selected from the group consisting of silica, calcium carbonate, talc, mica, clay, kaolin and barium sulfate to contact treatment with heating or without heating. Also disclosed is a composite coating film wherein on a surface of the above tie coat is formed a finish coat formed from a three-pack type organopolysiloxane-based curing composition comprising (c1) a main agent comprising the component (b1), (c2) a curing agent component comprising tetraalkoxysilicate or its condensate and (c3) a curing accelerator component comprising a metallic compound. Further disclosed is a composite coating film wherein an epoxy-based sealer coat, the tie coat and the finish coat are formed in this order on a surface of an old antifouling coating film (G). There is provided by the invention a tie coat capable of forming a composite coating film having excellent interlaminar bond property. The composite coating film is favorably formed on a surface of a base, an undercoating film, an old antifouling coating film or the like, has excellent interlaminar bond strength and antifouling property and is preferably used for coating outer surfaces of ships, submerged parts of marine structures, water supply / drainage channels of atomic power plant, etc.

Owner:CHUGOKU MARINE PAINTS

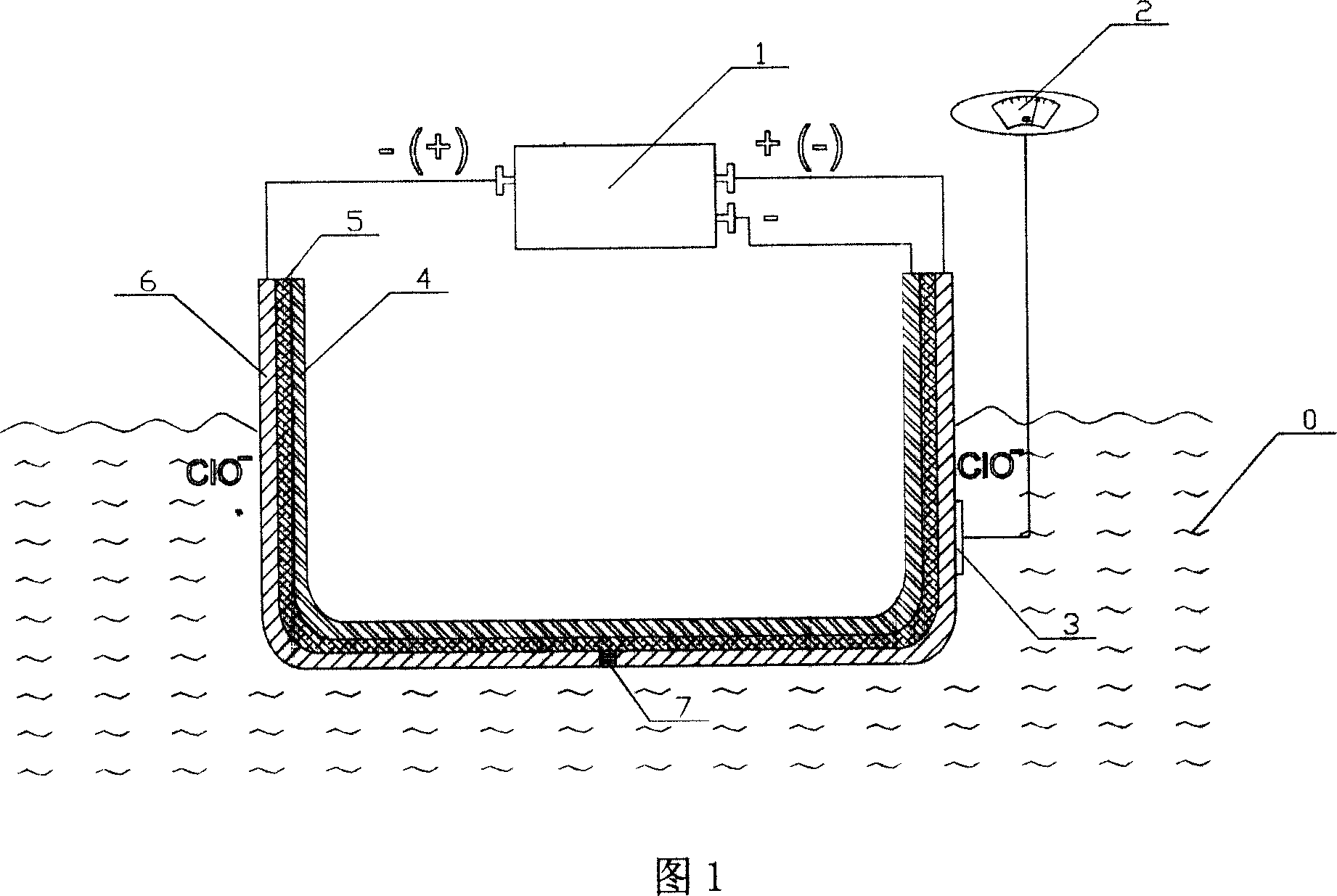

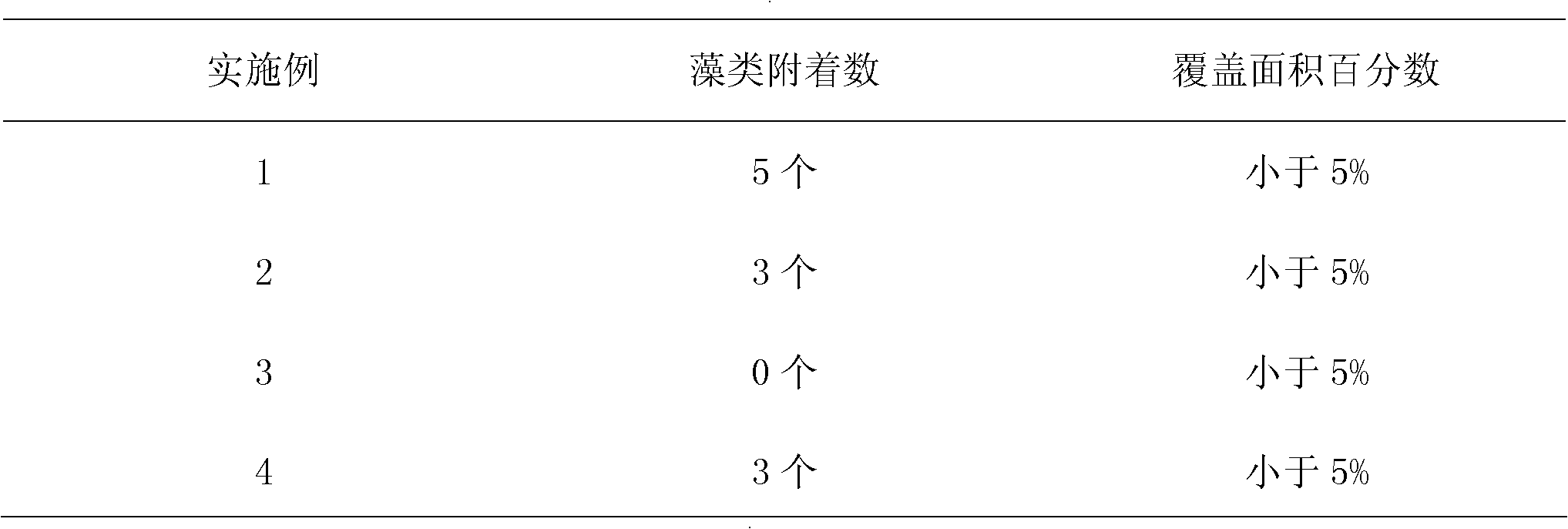

Anti-corrosion anti-dirt method or biological anti-dirt and conductive anti-dirt combination

InactiveCN101024741AImprove conductivityExtended service lifeVessel cleaningRubber derivative coatingsSolventSeawater

The invention relates to an antisepsis antifouling method that combines biology antifouling and conductive antifouling. The biology antifouling coating includes film forming resin, natural products, solvent, dye, defrother, and plasticizer. The conductive antifouling coating is coated on the steel board of bull contacting to sea water, coating conductive antifouling coating that is used as anode. While conducting small current, the sea water would be electrolyzed, and the surface would be covered by deutero chlorine ion to avoid the adhesion of sea biology. The invention has the advantages of high conductivity, stability, acid and alkali resistant, no pollution to sea water environment, etc.

Owner:CHONGQING UNIV +1

Environmentally-friendly marine antifouling coating and preparation method thereof

InactiveCN102010639AGood antibacterial effectLower surface energyAntifouling/underwater paintsPaints with biocidesSodium PyrithioneAcrylic resin

The invention provides a marine antifouling coating. The coating comprises a film forming substance, an antifouling agent and a dilute serving as raw material components, wherein the film forming substance is organic silicon modified acrylic resin; and the antifouling agent comprises nano silver, zinc oxide and a pyrithione coordination compound. An environmentally-friendly marine antifouling coating is prepared by taking the organic silicon modified acrylic resin as the film forming substance, a silane coupling agent and polyamide as curing agents and the nano silver, the zinc oxide and the pyrithione coordination compound as composite disinfection anti-alga agents. The organic silicon modified acrylic resin has low surface energy, so that ordinary microorganisms are difficult to be attached to the surface of the resin; simultaneously, the nano silver and the pyrithione coordination compound have good disinfection and bacteriostasis effects and can effectively prevent the adhesion of marine microorganisms. Moreover, the coating provided by the invention does not contain the conventional cuprous oxide and organic tin antifouling agent, so that the environment is protected well.

Owner:上海暄洋化工材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com