Patents

Literature

67 results about "Carbon group" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The carbon group is a periodic table group consisting of carbon (C), silicon (Si), germanium (Ge), tin (Sn), lead (Pb), and flerovium (Fl). It lies within the p-block. In modern IUPAC notation, it is called Group 14. In the field of semiconductor physics, it is still universally called Group IV. The group was once also known as the tetrels (from the Greek word tetra, which means four), stemming from the Roman numeral IV in the group names, or (not coincidentally) from the fact that these elements have four valence electrons (see below). They are also known as the crystallogens.

Electrodes, lithium-ion batteries, and methods of making and using same

ActiveUS20120321959A1Facilitate communicationMaterial nanotechnologyConductive materialNanoparticleLithium-ion battery

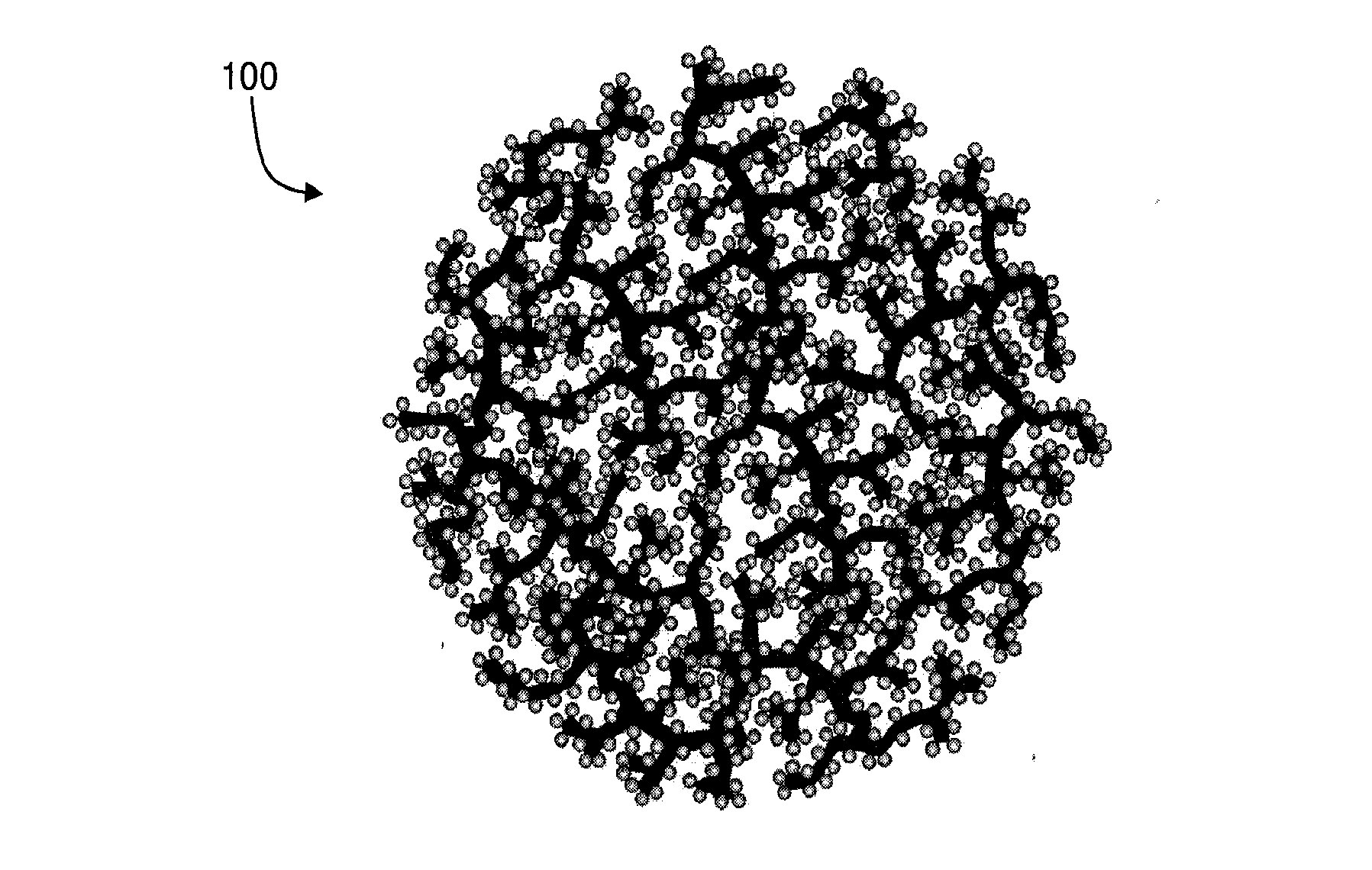

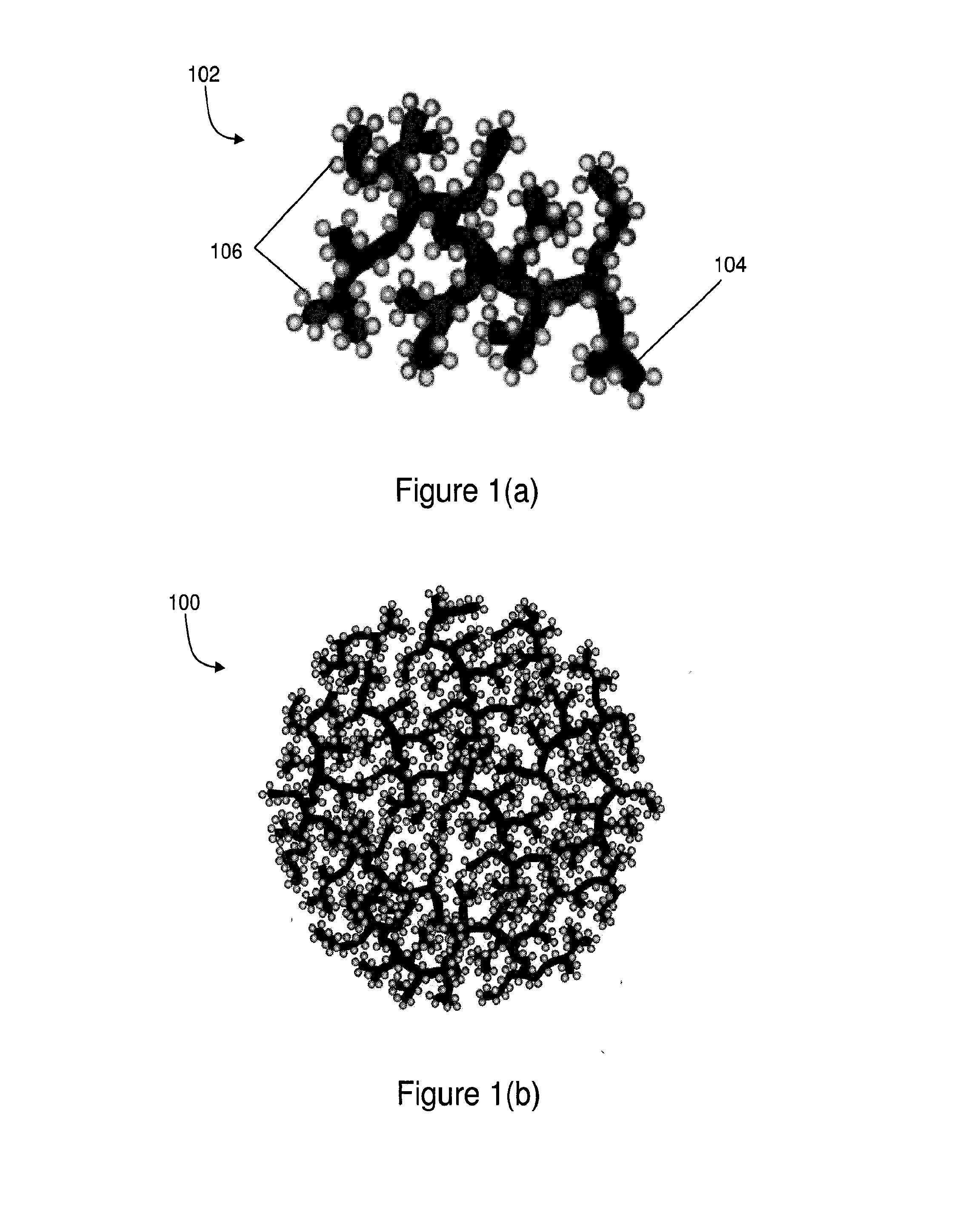

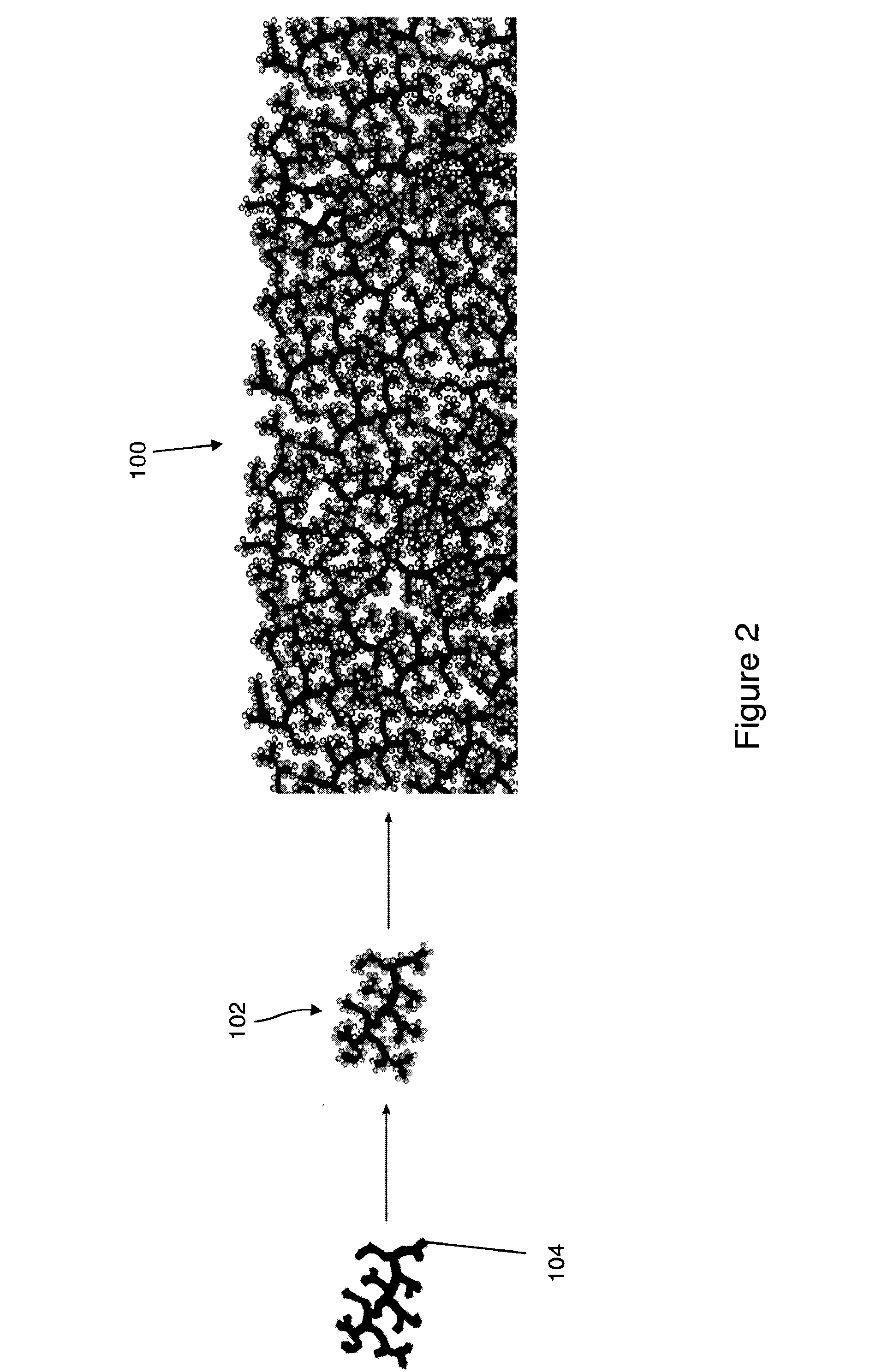

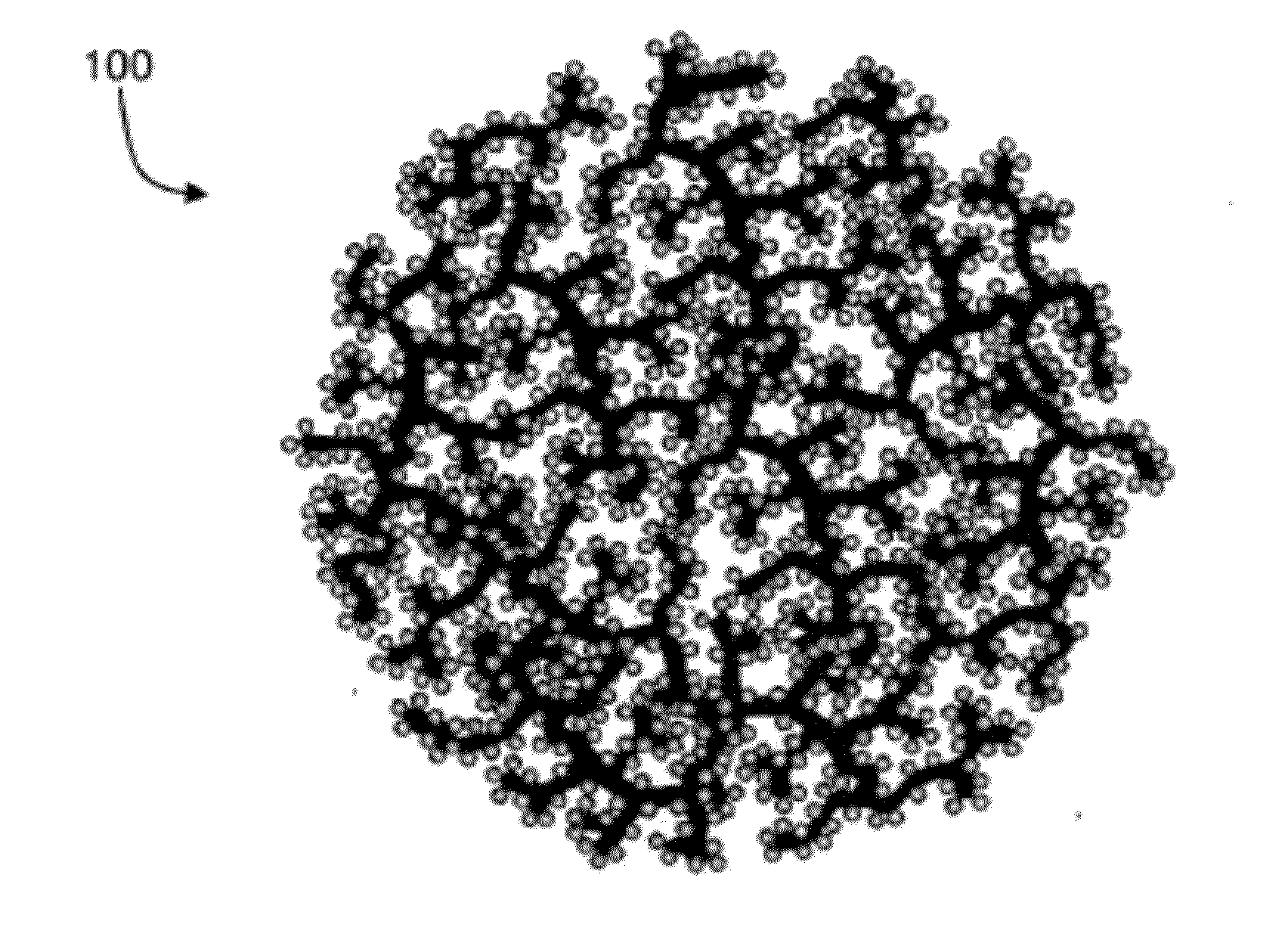

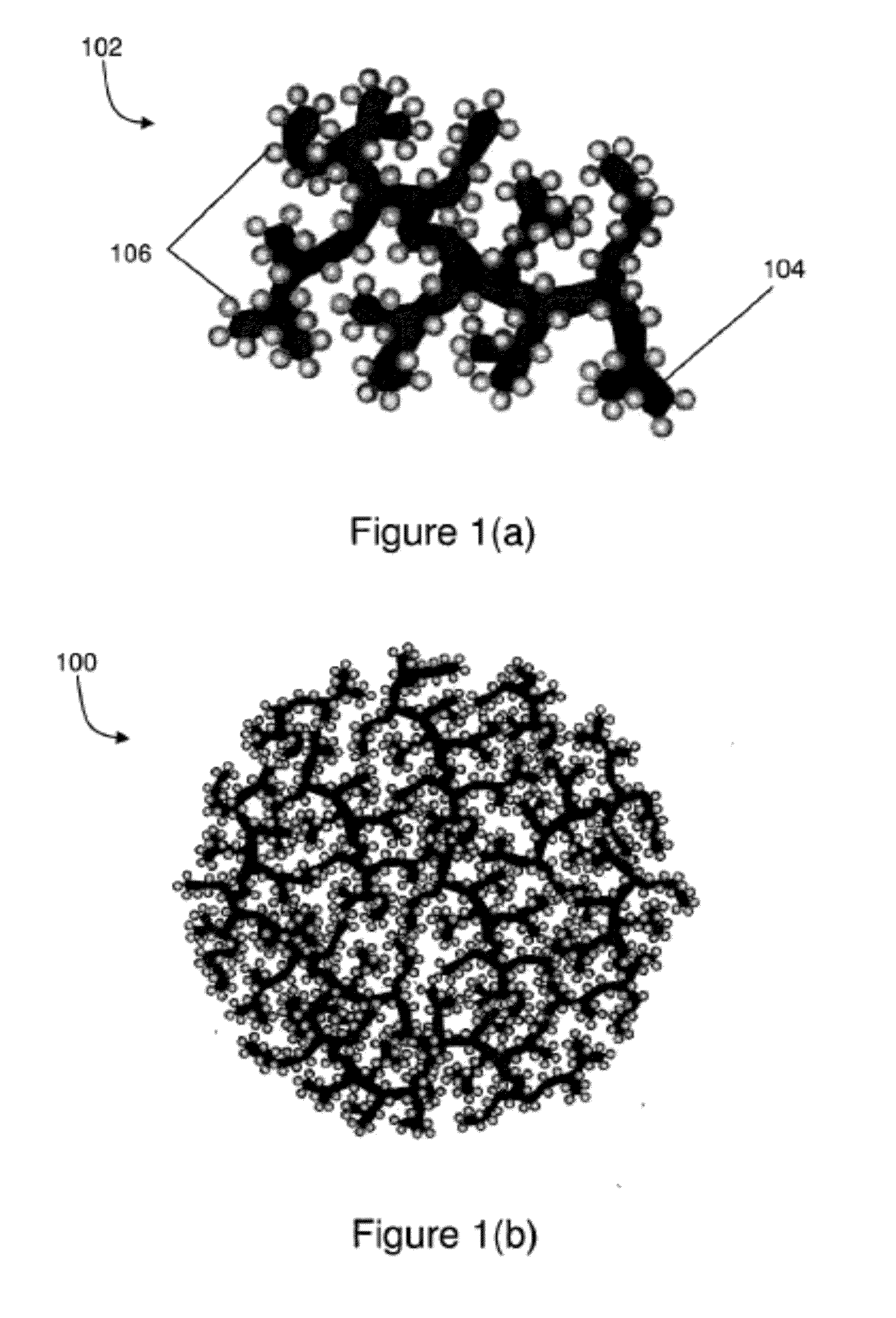

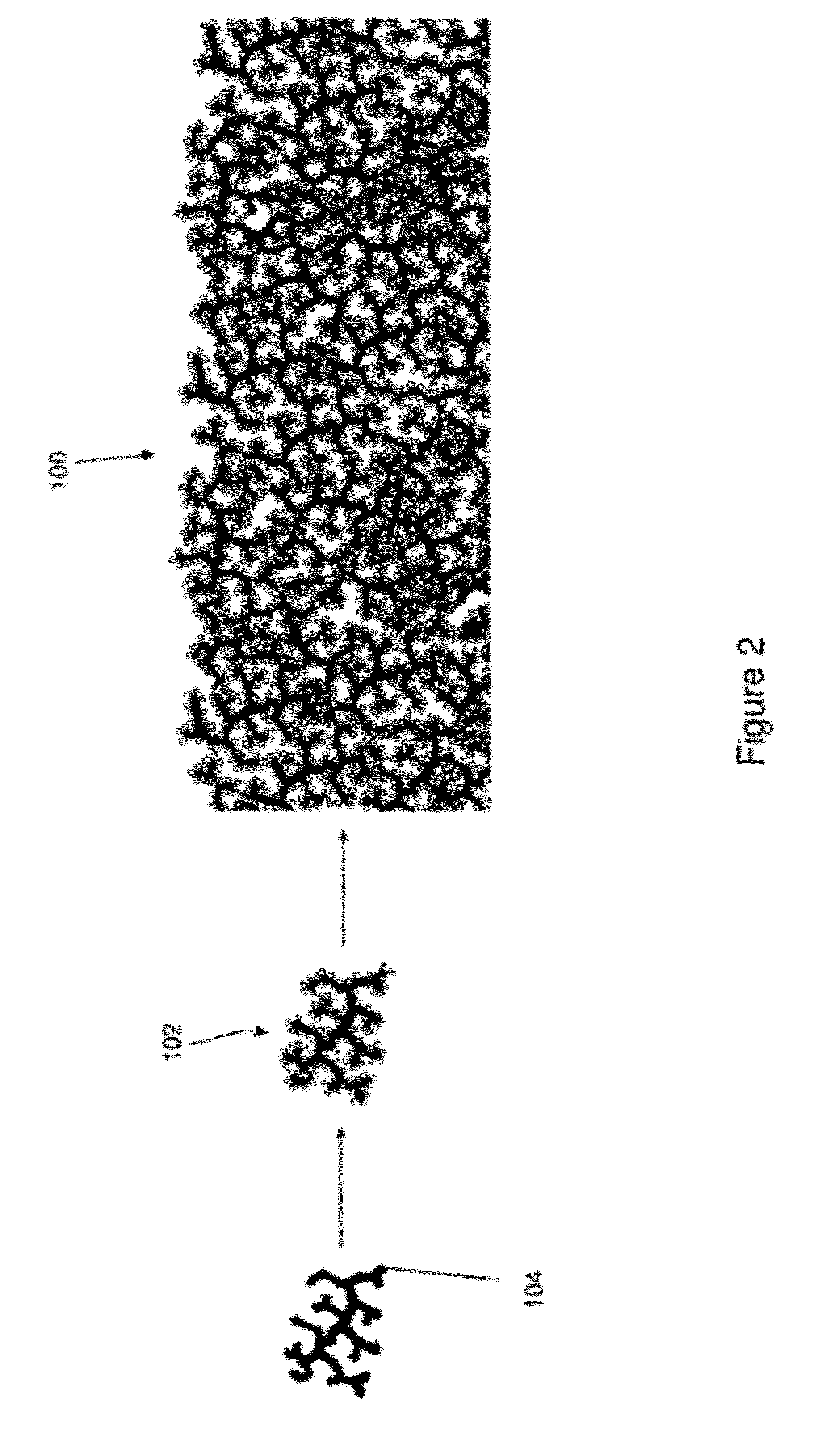

Described herein are improved composite anodes and lithium-ion batteries made therefrom. Further described are methods of making and using the improved anodes and batteries. In general, the anodes include a porous composite having a plurality of agglomerated nanocomposites. At least one of the plurality of agglomerated nanocomposites is formed from a dendritic particle, which is a three-dimensional, randomly-ordered assembly of nanoparticles of an electrically conducting material and a plurality of discrete non-porous nanoparticles of a non-carbon Group 4A element or mixture thereof disposed on a surface of the dendritic particle. At least one nanocomposite of the plurality of agglomerated nanocomposites has at least a portion of its dendritic particle in electrical communication with at least a portion of a dendritic particle of an adjacent nanocomposite in the plurality of agglomerated nanocomposites.

Owner:GEORGIA TECH RES CORP +1

Silicon carbide having low dielectric constant

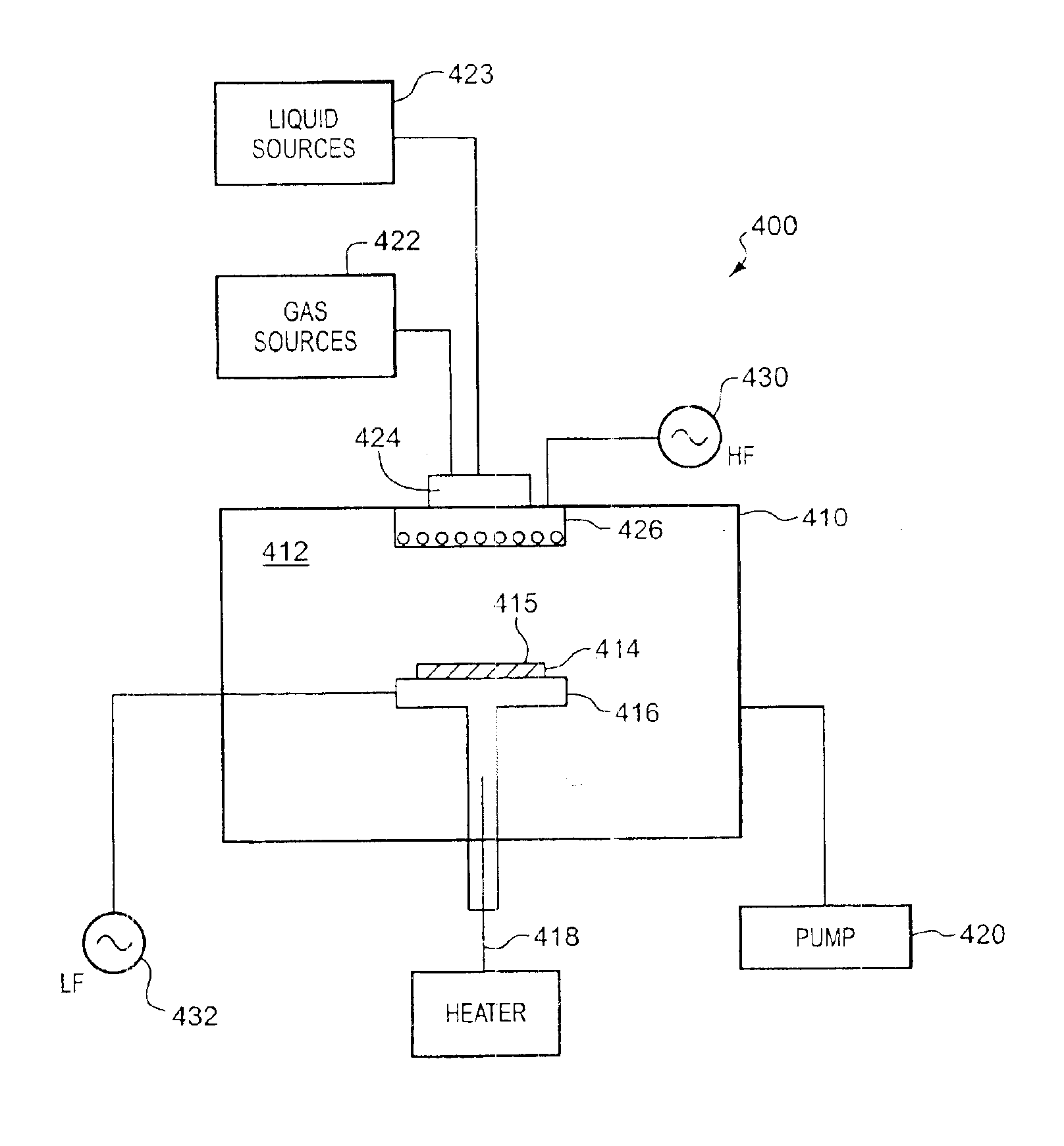

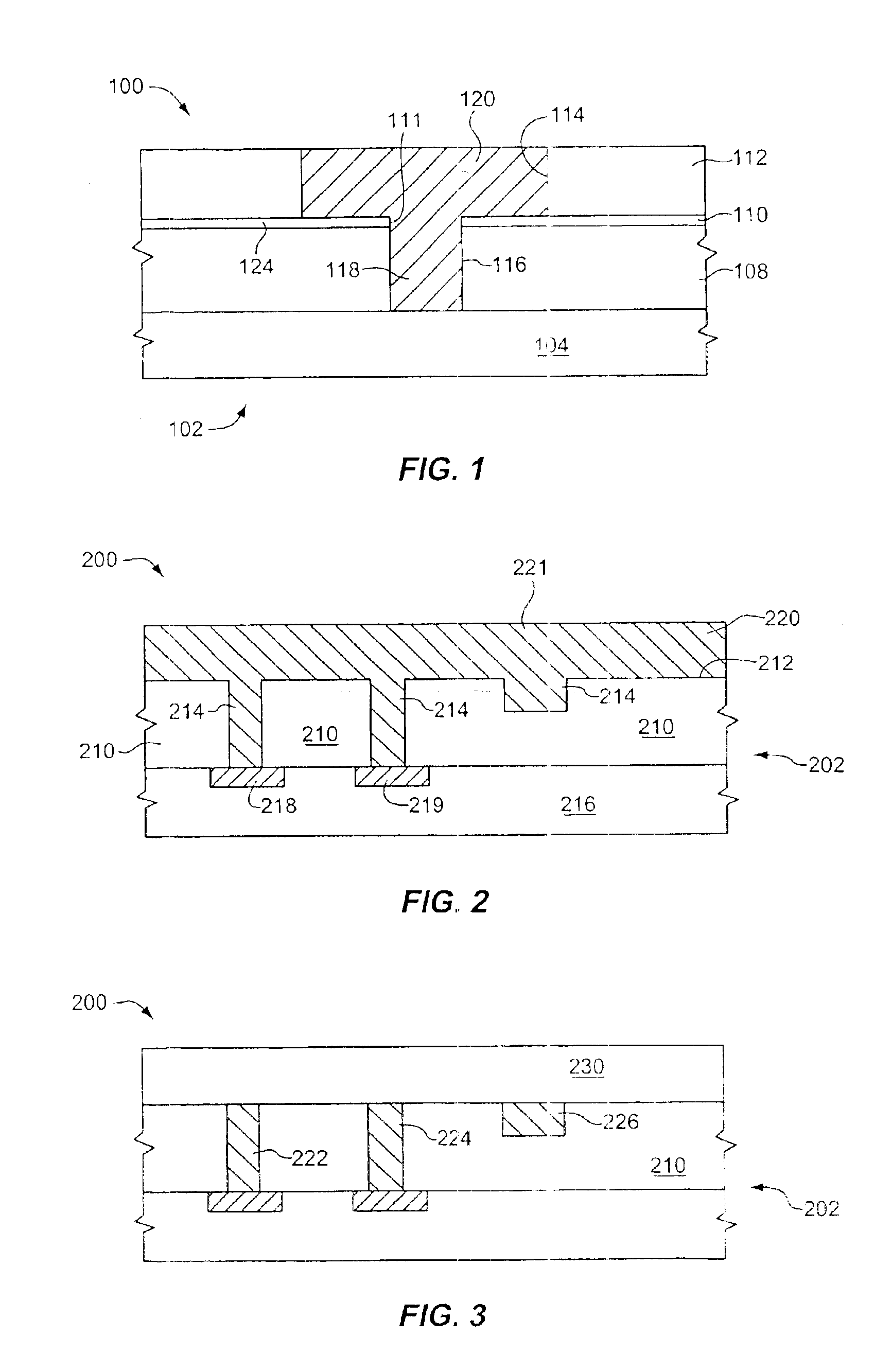

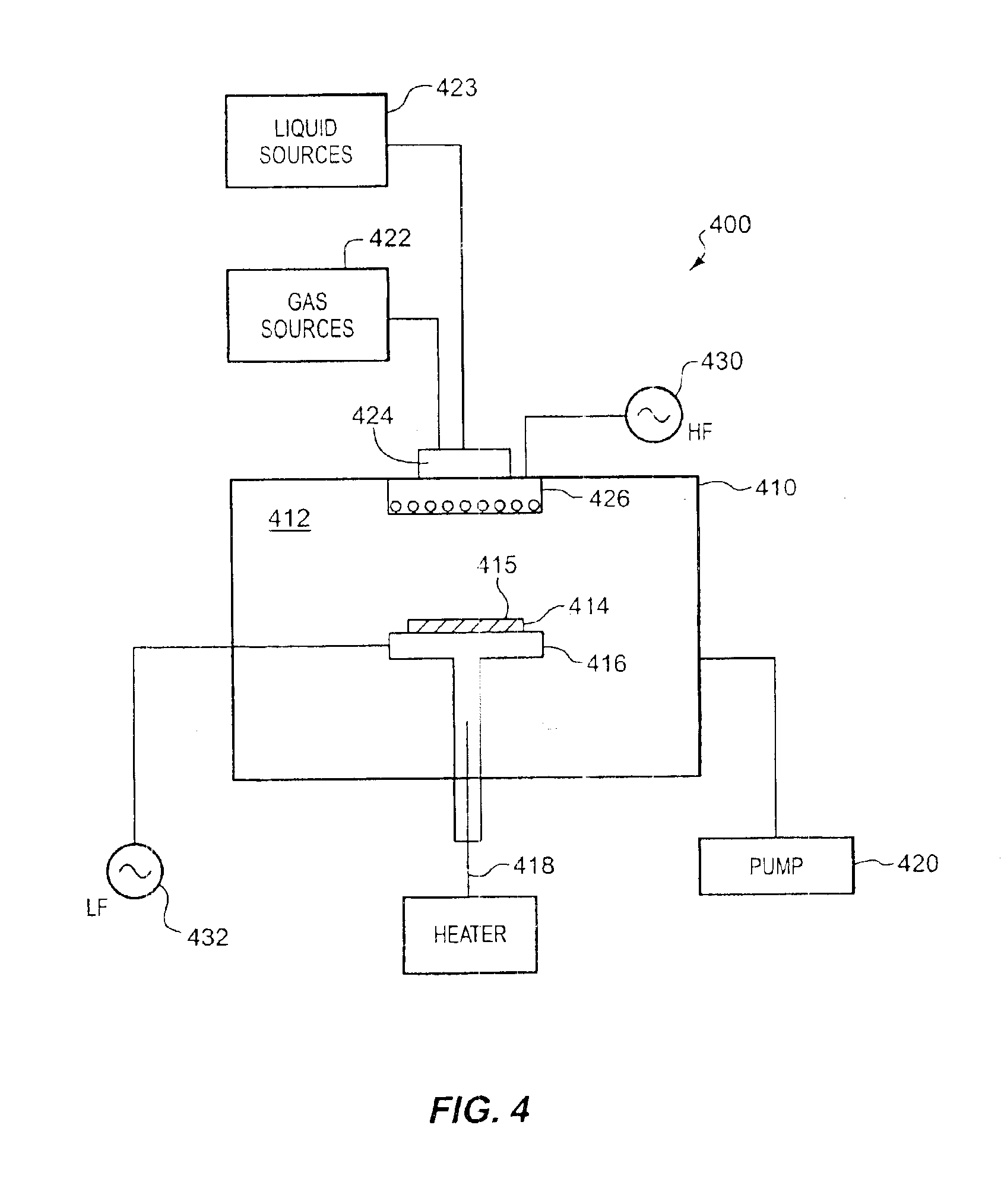

A low-k precursor reactant compound containing silicon and carbon atoms is flowed into a CVD reaction chamber. High-frequency radio-frequency power is applied to form a plasma. Preferably, the reaction chamber is part of a dual-frequency PECVD apparatus, and low-frequency radio-frequency power is applied to the reaction chamber. Reactive components formed in the plasma react to form low-dielectric-constant silicon carbide (SiC) on a substrate surface. A low-k precursor is characterized by one of: a silicon atom and a carbon—carbon triple bond; a silicon atom and a carbon—carbon double bond; a silicon—silicon bond; or a silicon atom and a tertiary carbon group.

Owner:NOVELLUS SYSTEMS

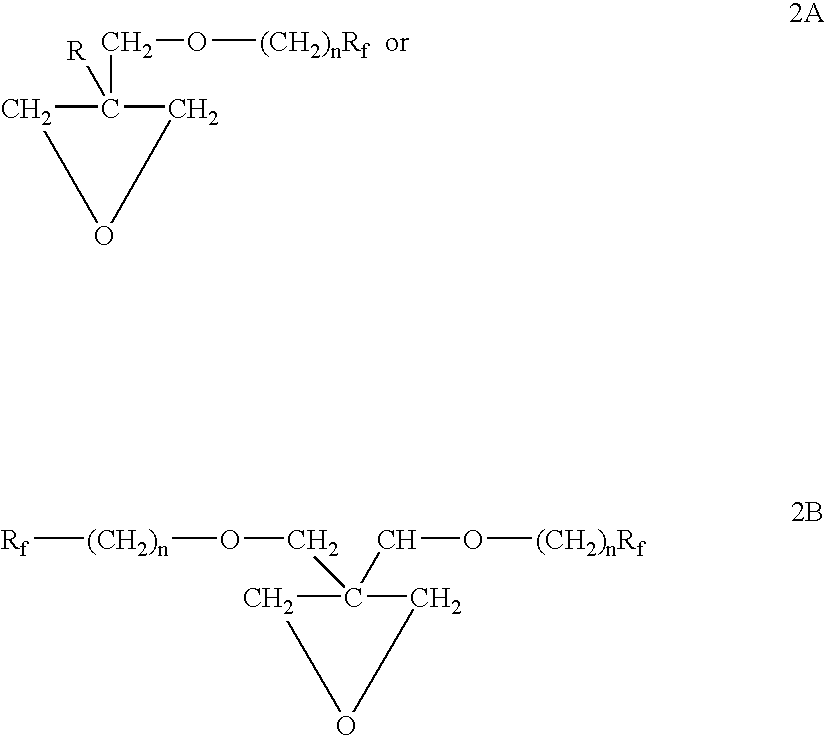

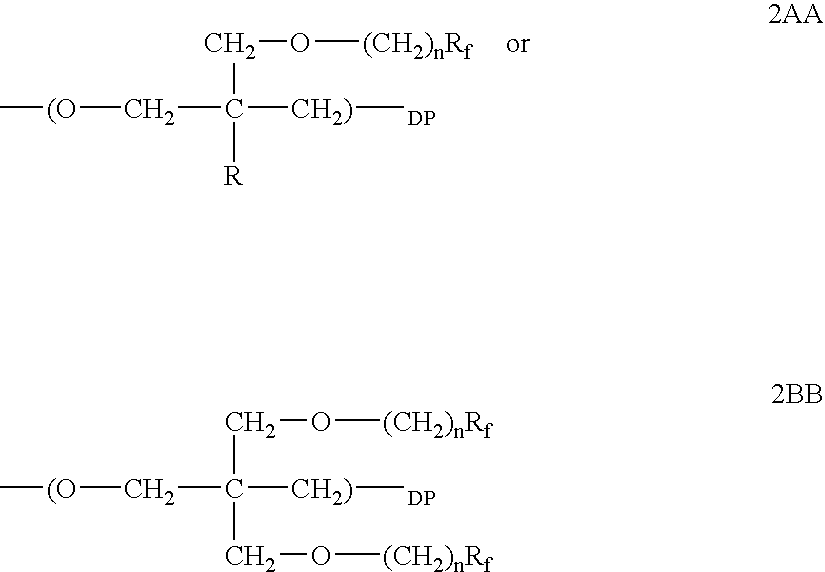

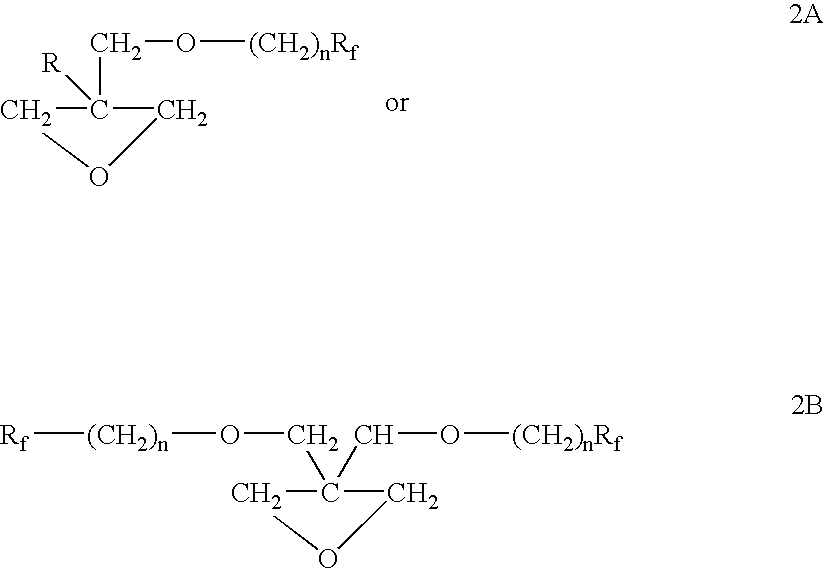

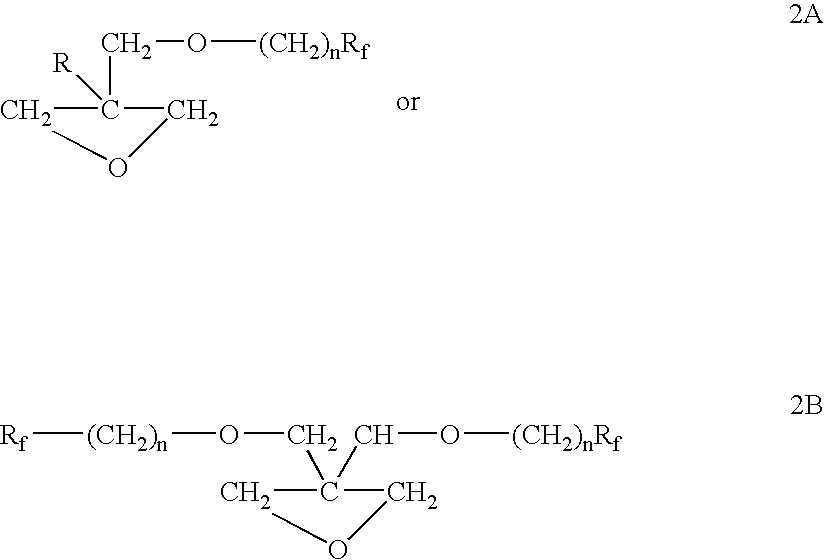

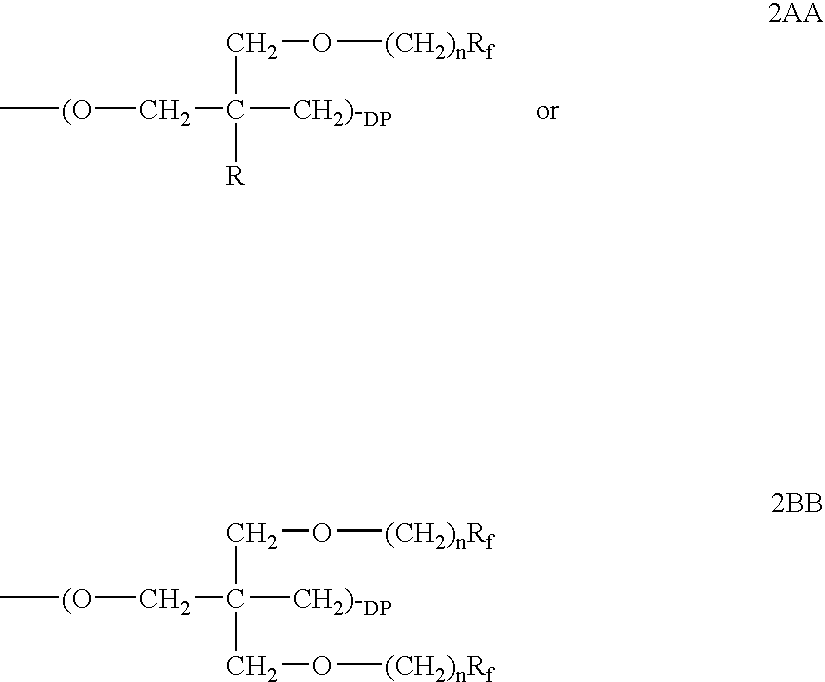

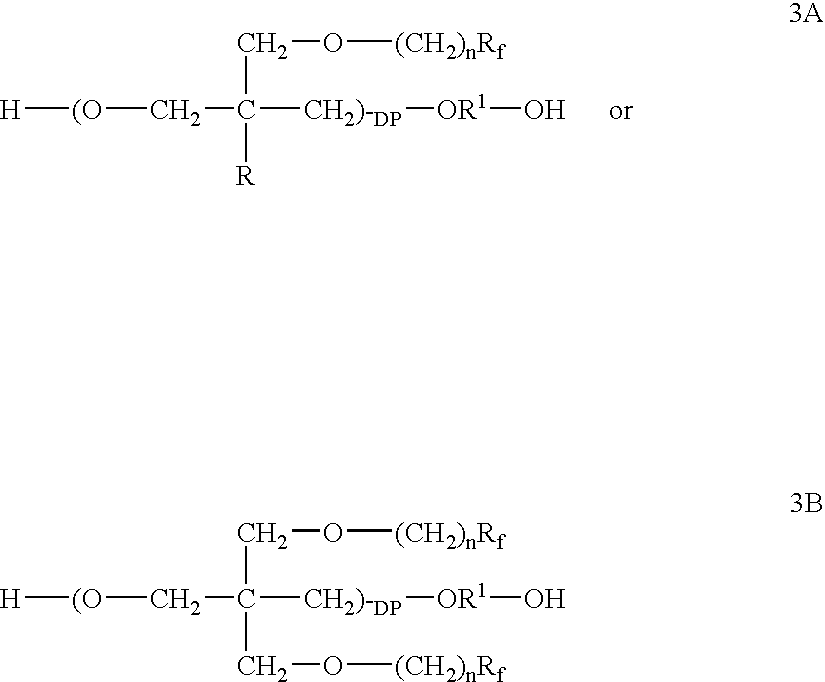

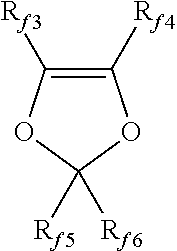

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS20040242804A1Good optical performanceHigh glossTransportation and packagingMixingPolymeric surfacePolymer science

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:DEUT BANK AG NEW YORK BRANCH AS SUCCESSOR AGENT

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:OMNOVA SOLUTIONS INC

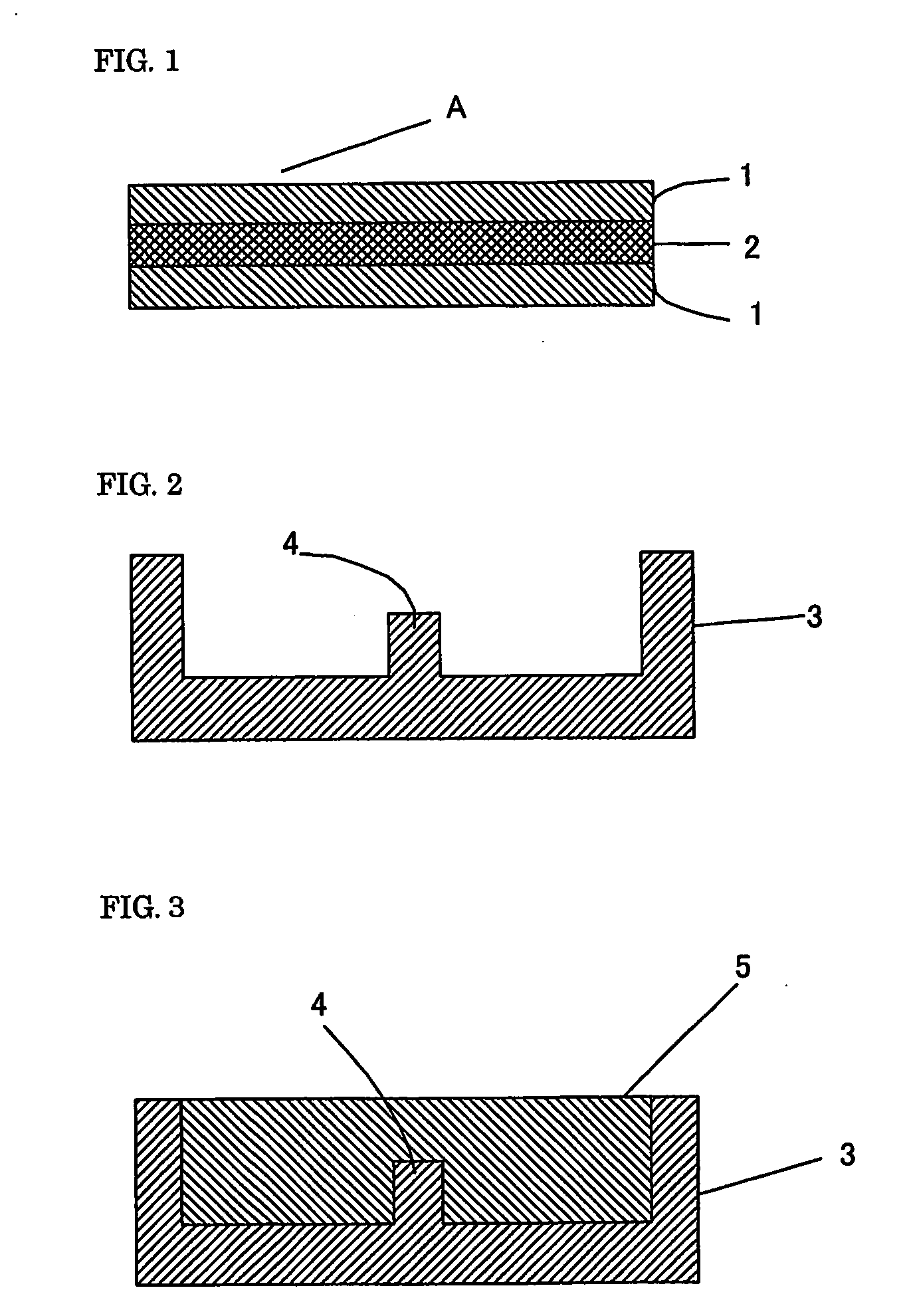

Curable organopolysiloxane resin composition for optical transmission components, optical transmission components, and fabrication process thereof

The present invention relates to a hydrosilation-curable organopolysiloxane resin composition comprising (A) an organopolysiloxane resin having three or more monovalent unsaturated aliphatic hydrocarbon groups and aromatic hydrocarbon carbon groups, (B) an organosilicon compound having two or more silicon-bonded hydrogen atoms and aromatic hydrocarbon groups, (C) a hydrosilation catalyst, and optionally (D) (d1) a solvent or (d2) a hydrosilation-reactive organosiloxane-based diluent, for optical transmission components, especially for optical transmission components serving as optical communication elements, relates to optical transmission components, represented by optical waveguides, comprisiong a hydrosilation-cured product of the aforementioned organopolysiloxane resin and organosilicon compound, and relates to a process for fabricatiing optical transmission components.

Owner:DOW CORNING CORP

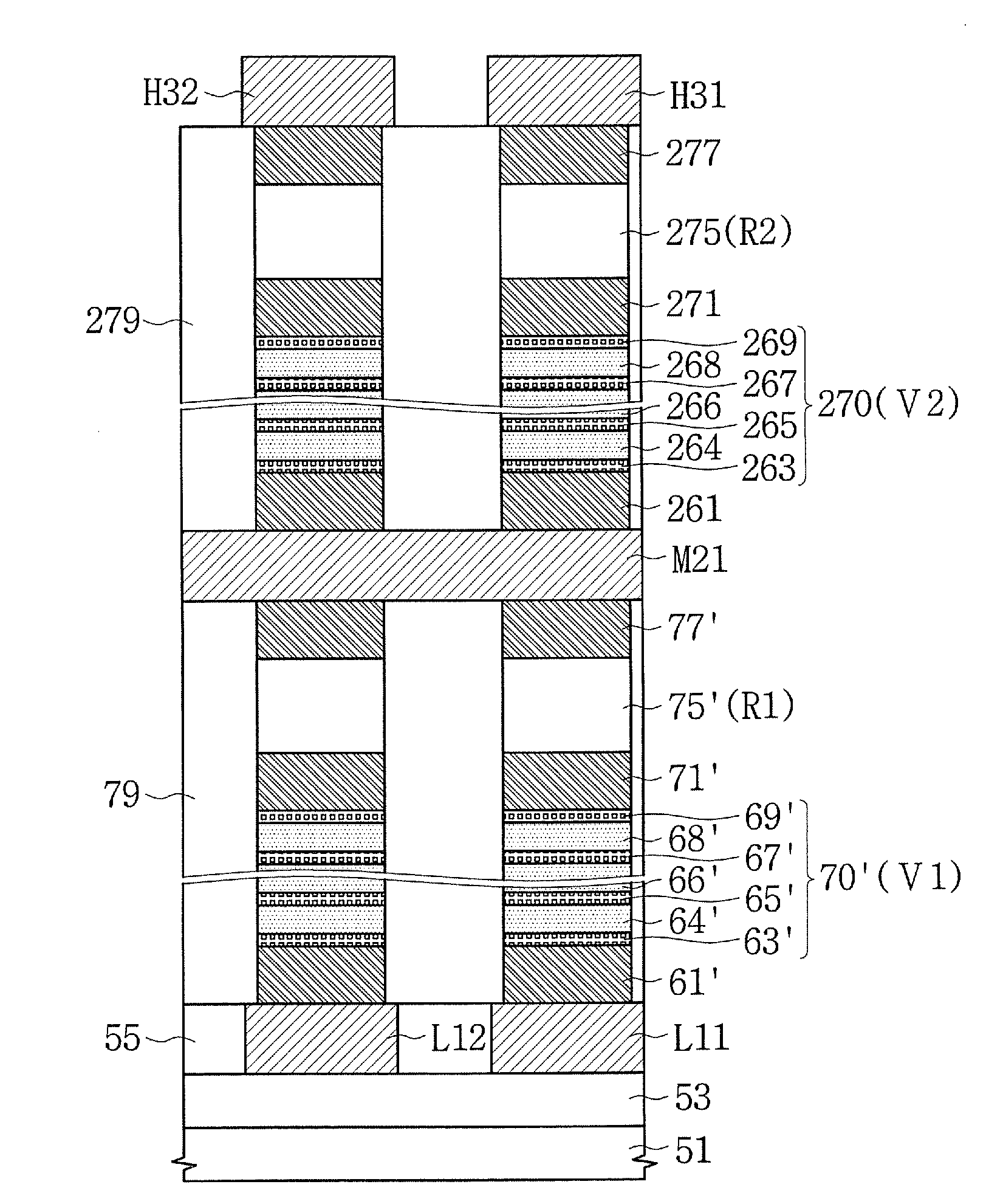

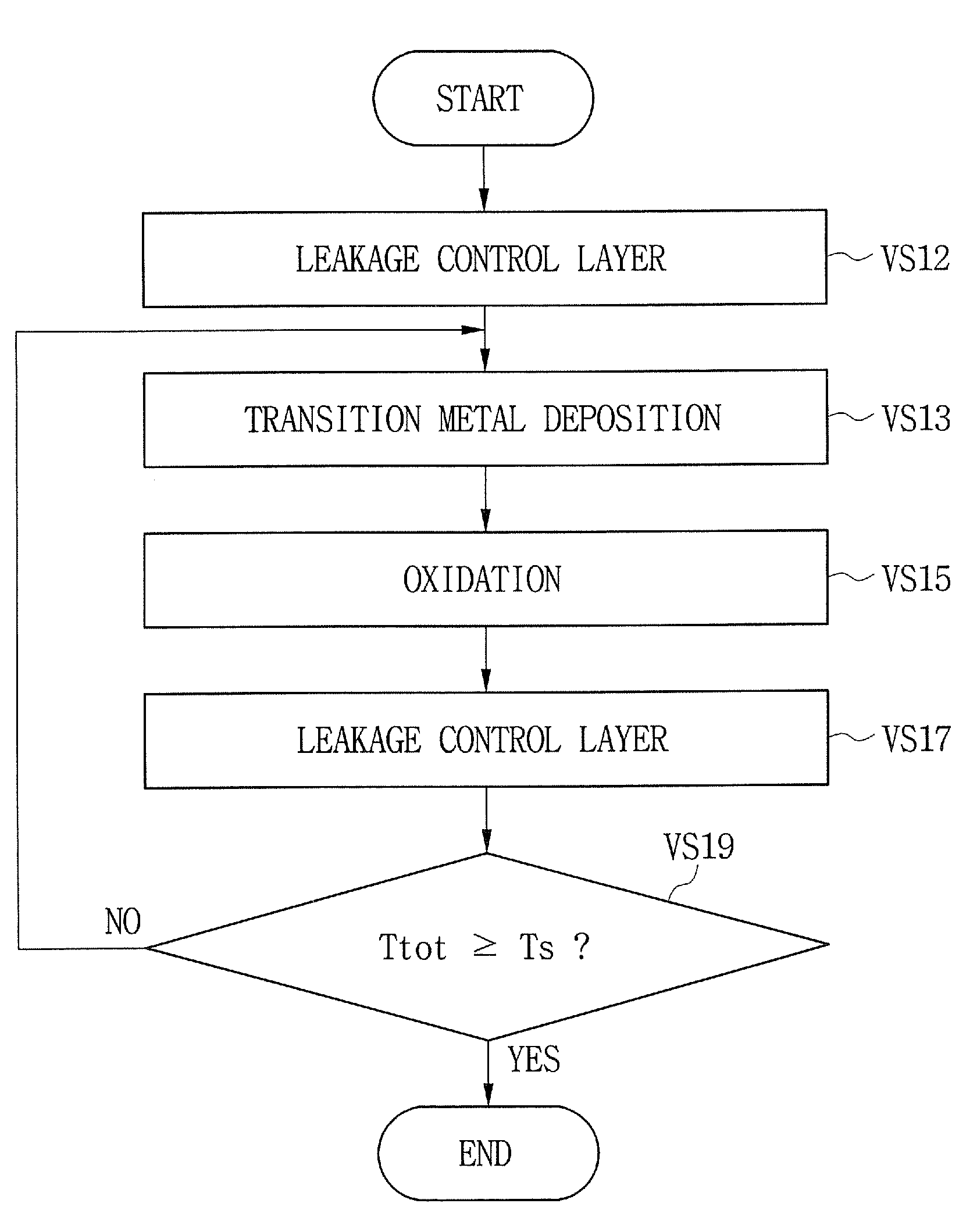

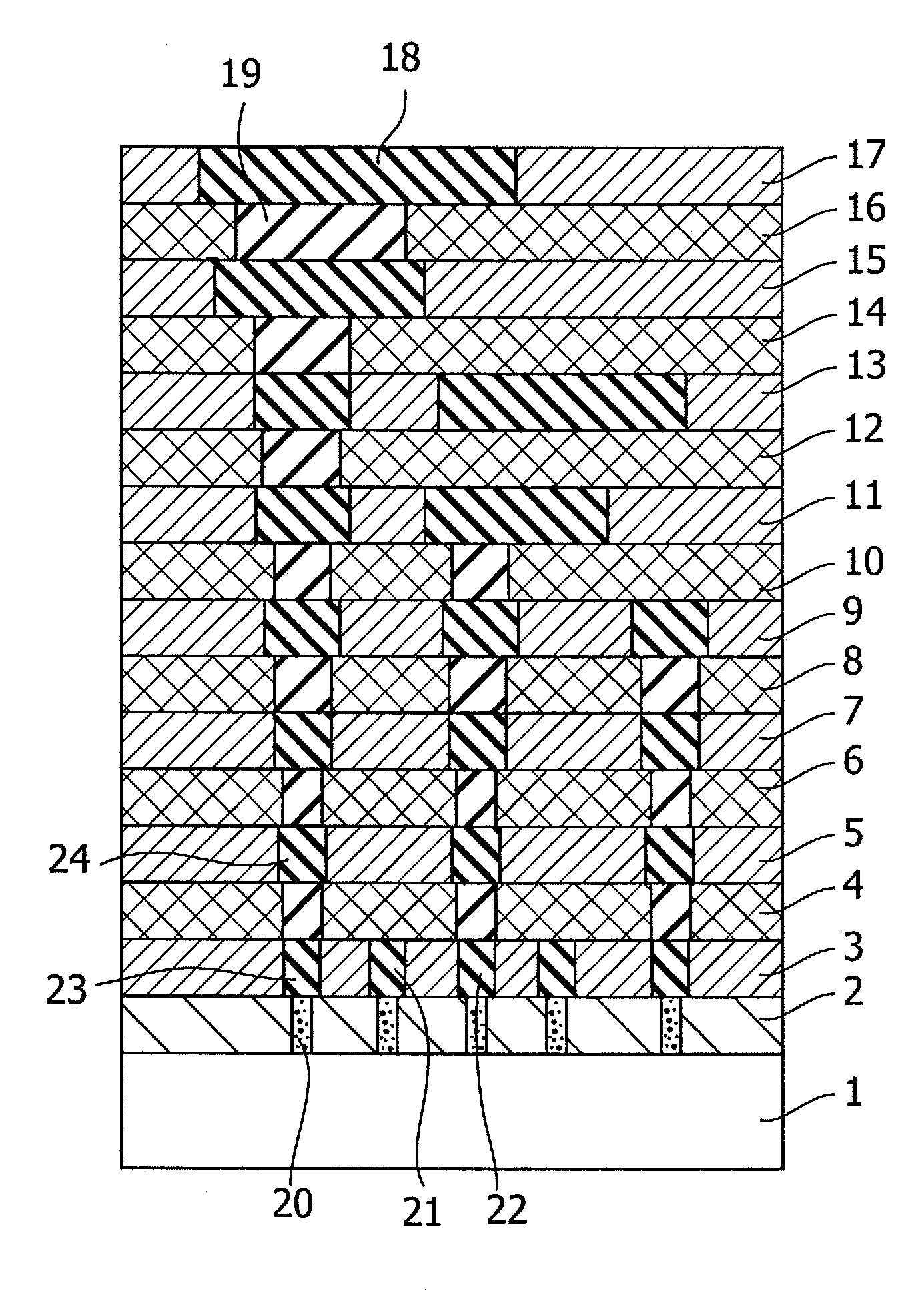

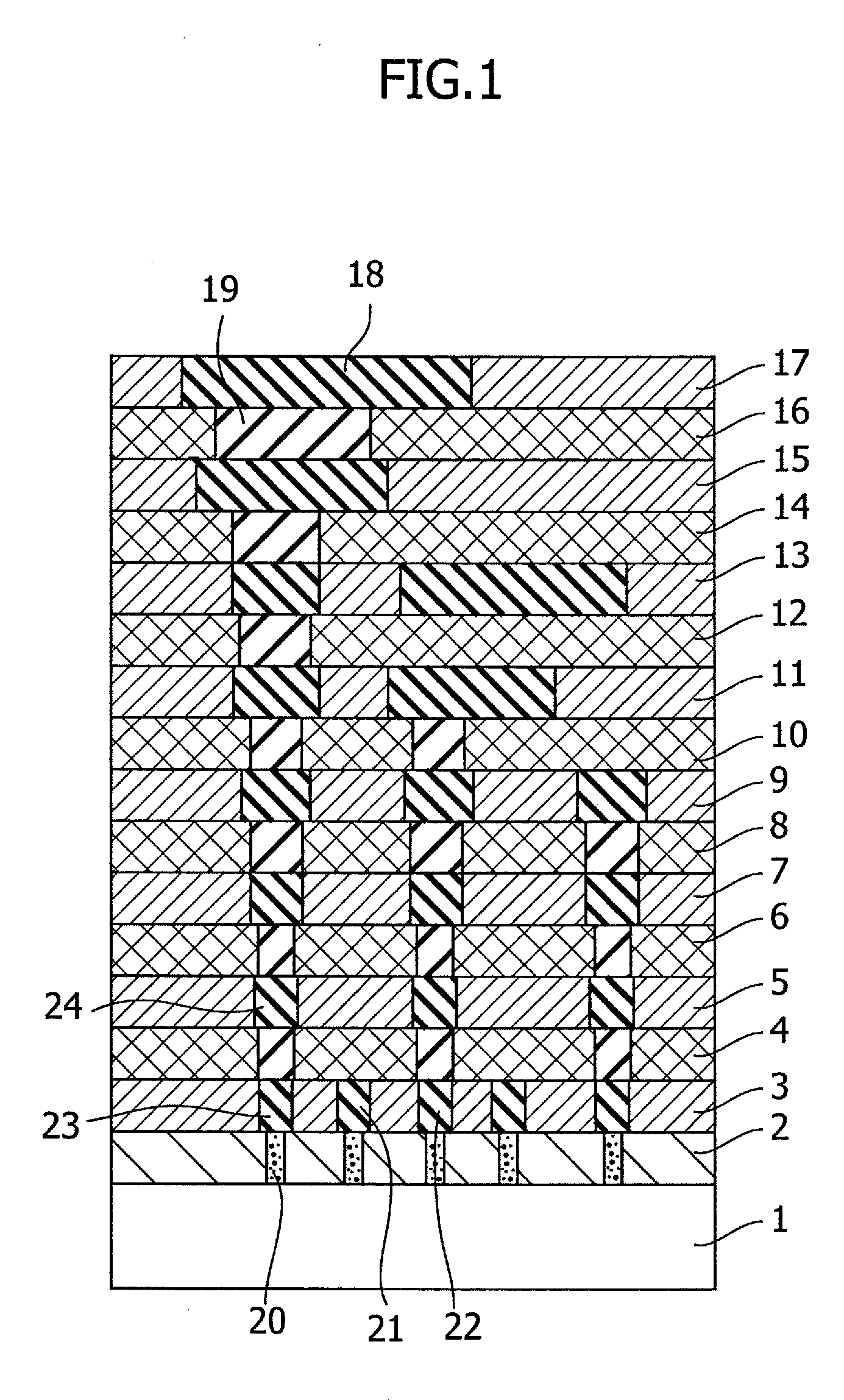

Method of manufacturing semiconductor device having transition metal oxide layer and related device

ActiveUS20090020745A1Solid-state devicesSemiconductor/solid-state device manufacturingStable stateControl layer

Provided is a method of manufacturing a semiconductor device having a switching device capable of preventing a snake current. First, a transition metal oxide layer and a leakage control layer are alternately stacked on a substrate 1 to 20 times to form a varistor layer. The transition metal oxide layer is formed to contain an excessive transition metal compared to its stable state. The leakage control layer may be formed of one selected from the group consisting of a Mg layer, a Ta layer, an Al layer, a Zr layer, a Hf layer, a polysilicon layer, a conductive carbon group layer, and a Nb layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS7022801B2Good optical performanceHigh glossTransportation and packagingMixingPolymeric surfacePolymer science

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:OMNOVA SOLUTIONS INC

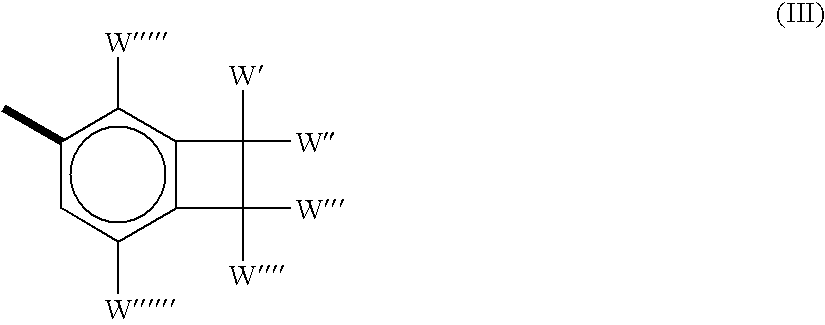

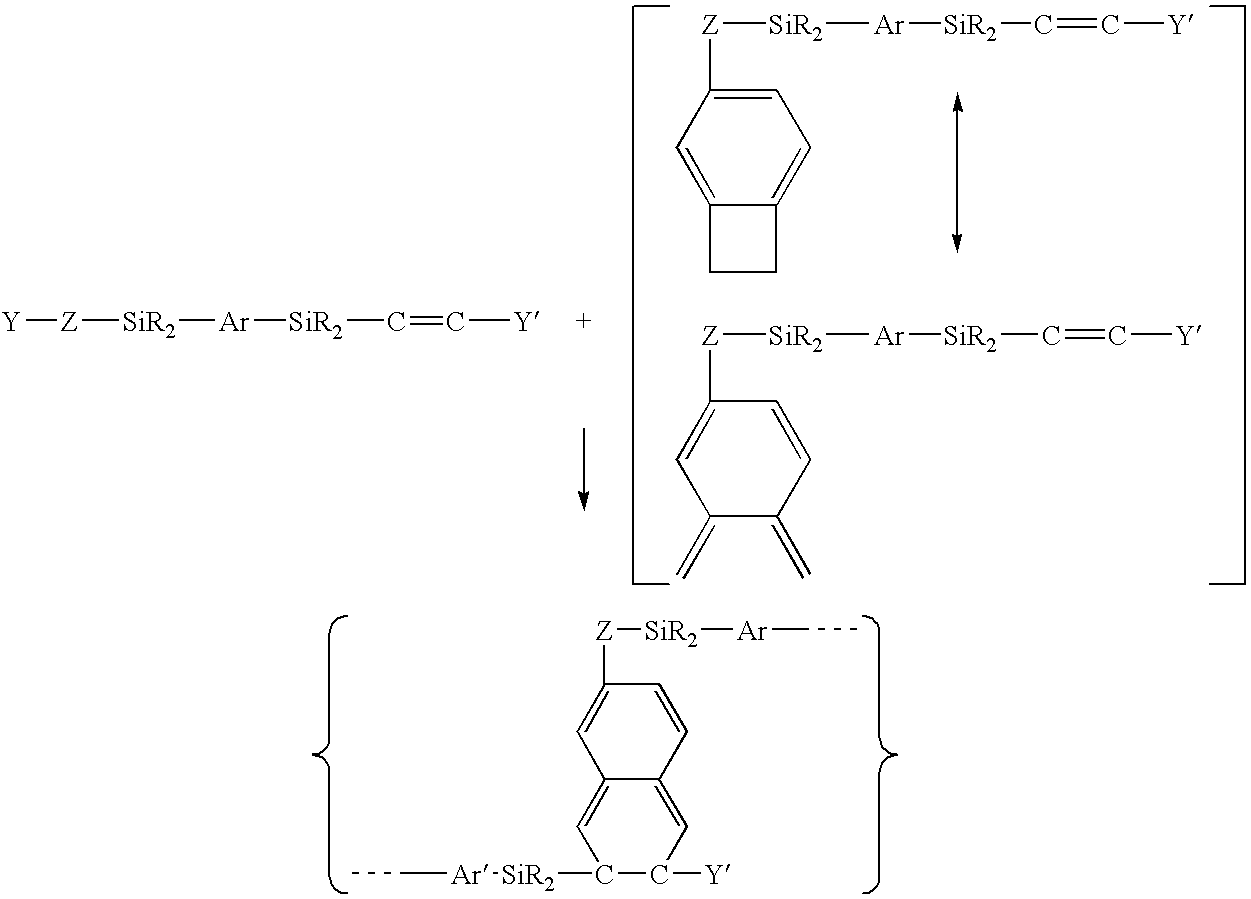

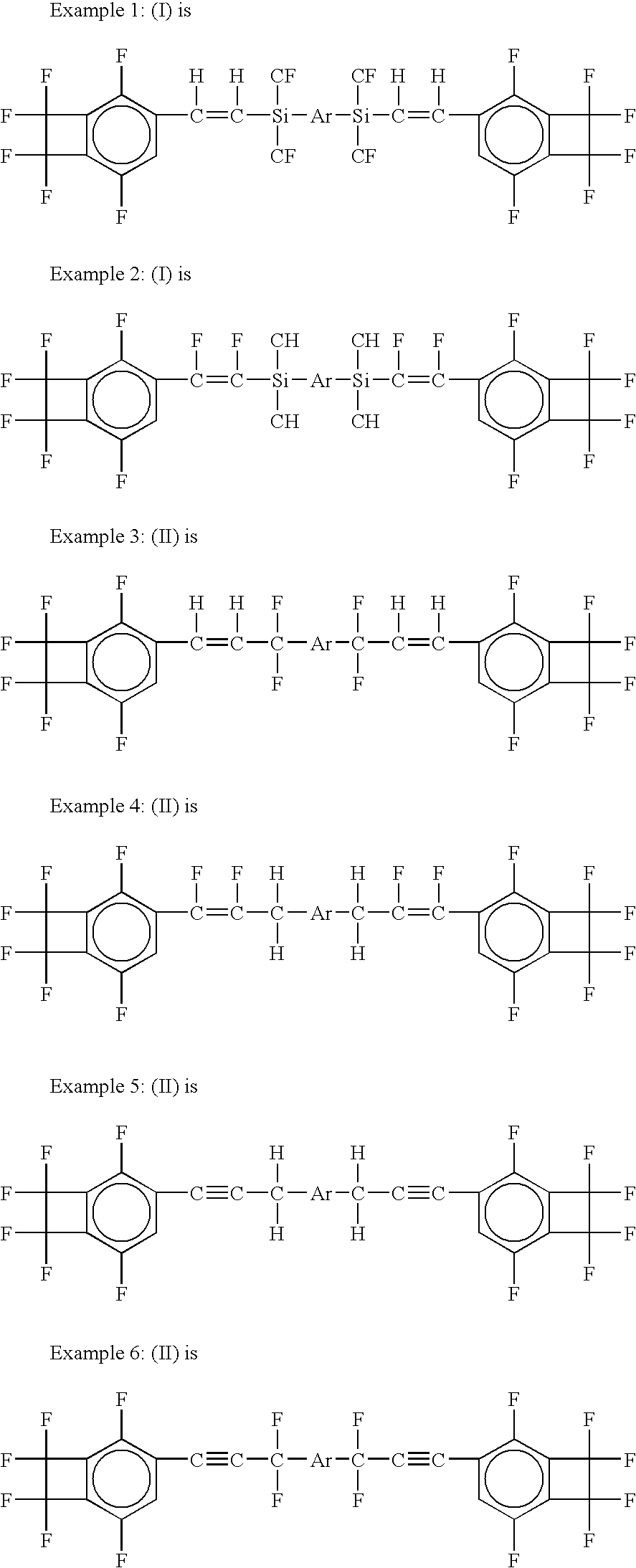

Dieletric thin films from fluorinated benzocyclobutane precursors

InactiveUS20030143341A1Good dimensional stabilityLiquid crystal compositionsSemiconductor/solid-state device detailsHigh dimensionalDielectric thin films

New precursors and processes are provided to generate fluorinated low dielectric constant, .epsilon. films that have higher dimensional stability and more rigid than fluorinated Poly (Para-Xylylenes). The low .epsilon. films are prepared primarily from polymerization of precursors consisting of both benzocyclobutane and unsaturated carbon-carbon groups such as vinyl (C.dbd.C) and ethylenic groups. The low .epsilon. polymers consists primarily of SP.sup.2C--F, hyperconjugated Sp.sup.3C.sub..alpha.--F type or / and Sp.sup.3Si.sub..alpha.--F fluorine. The low .epsilon. (<2.4) films are useful for fabrications of future<0.18 .mu.m ICs. Using low .epsilon. films prepared according to this invention, the integrity of dielectric, Cu and its barrier metals such as Ta can be kept intact; therefore reliability of these ICs can be assured.

Owner:DIELECTRIC SYST INT

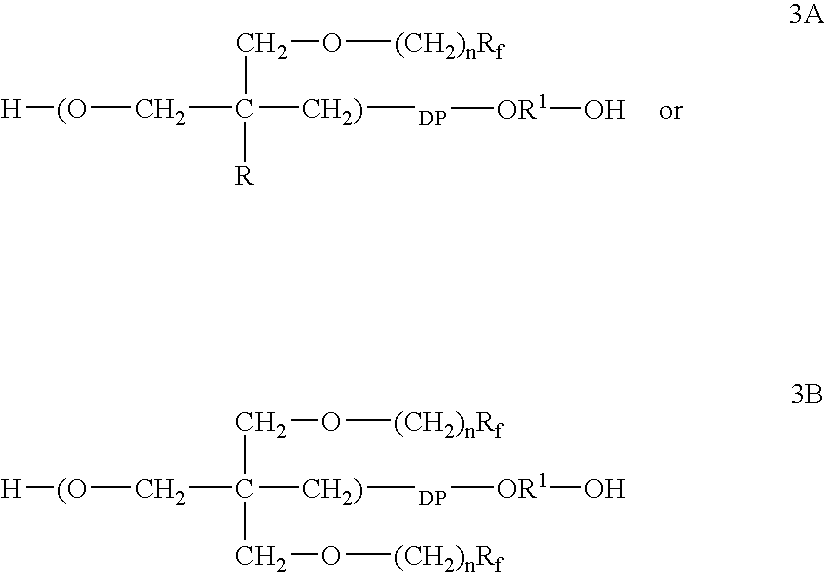

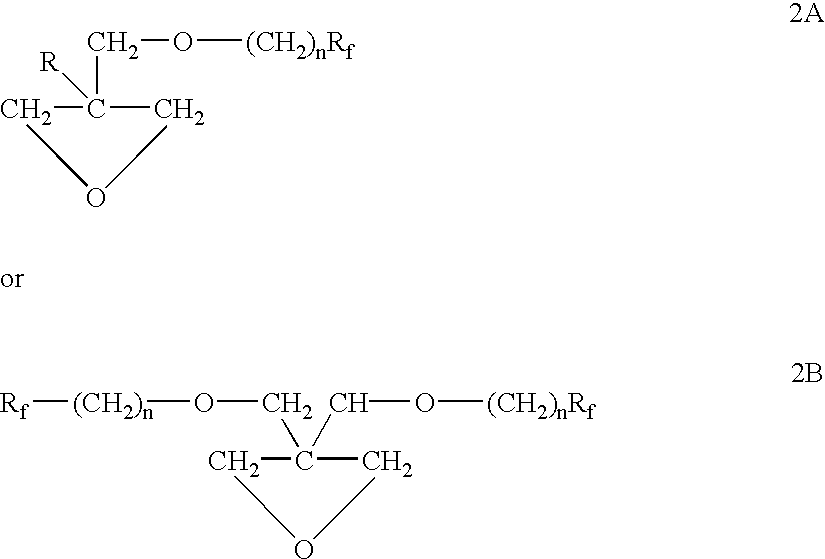

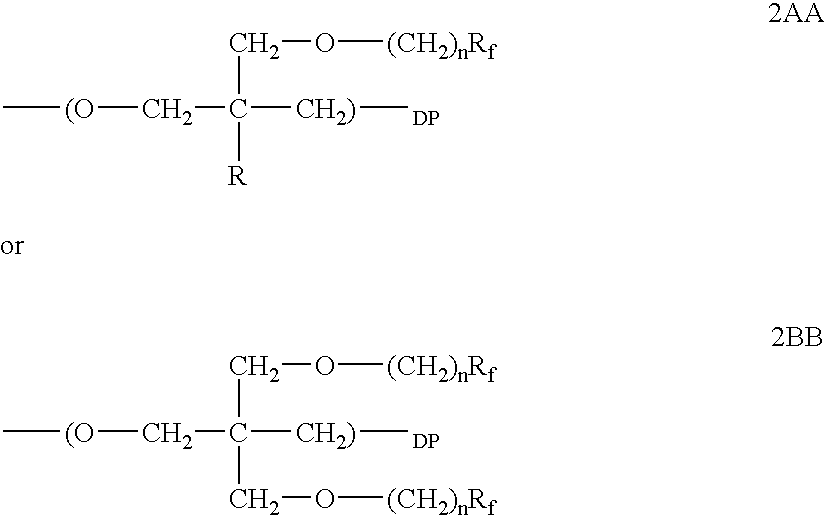

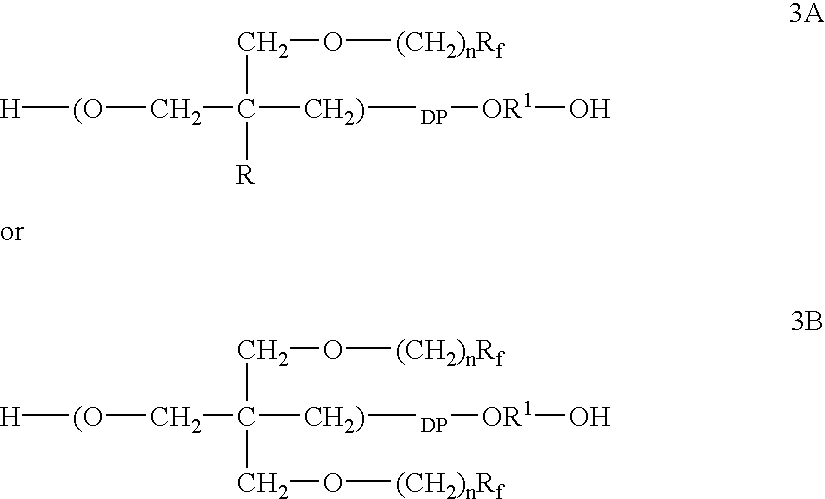

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS20040048957A1Good optical performanceHigh glossNon-fibrous pulp additionPaper/cardboardPolymeric surfaceCyclic ether

PURPOSE: To easily obtain the titled alcohol wherein one of both terminals is quantitatively capped, at a low cost, by polymerizing THF in the presence of an active hydrogen-containing compound using a Lewis acid and a cyclic ether as polymerization initiators. CONSTITUTION: A polyether monoalcohol is produced by polymerizing tetrahydrofuran in the presence of a compound containing one active hydrogen atom in one molecule using a Lewis acid and a 3-4-membered cyclic ether. The active hydrogen-containing compound is a compound having hydroxyl group, carboxyl group or thiol group, e.g. methanol, cyclohexanol, etc., and the ether is selected from epoxides or oxetanes.

Owner:OMNOVA SOLUTIONS INC

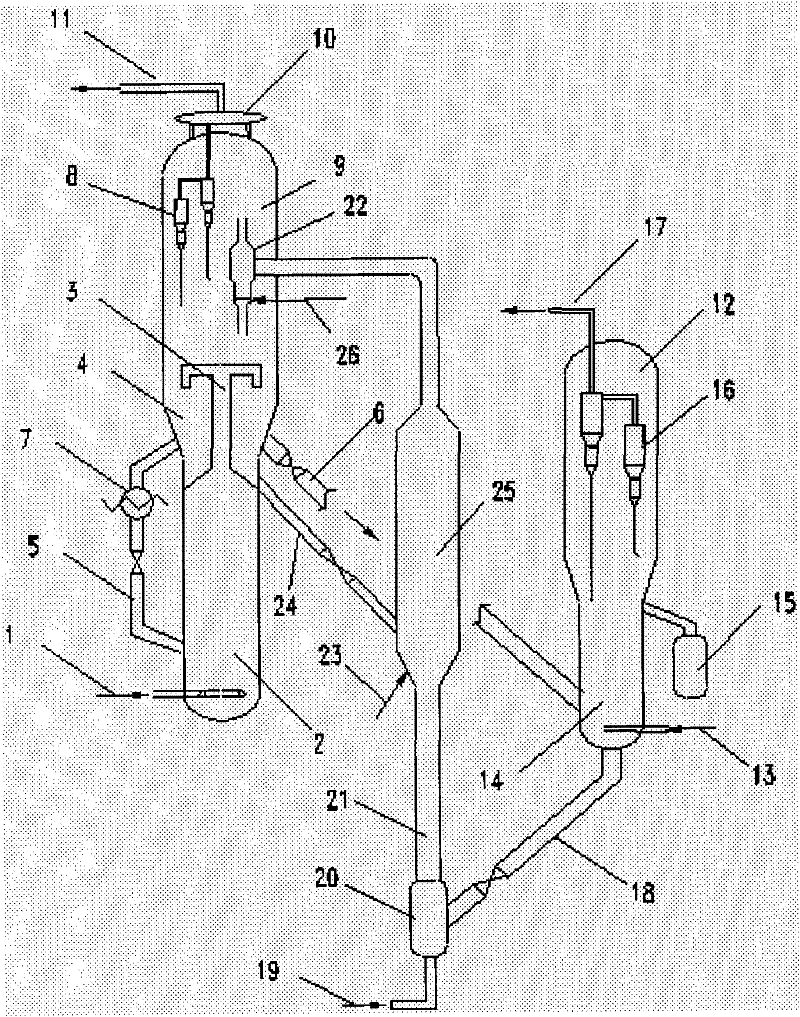

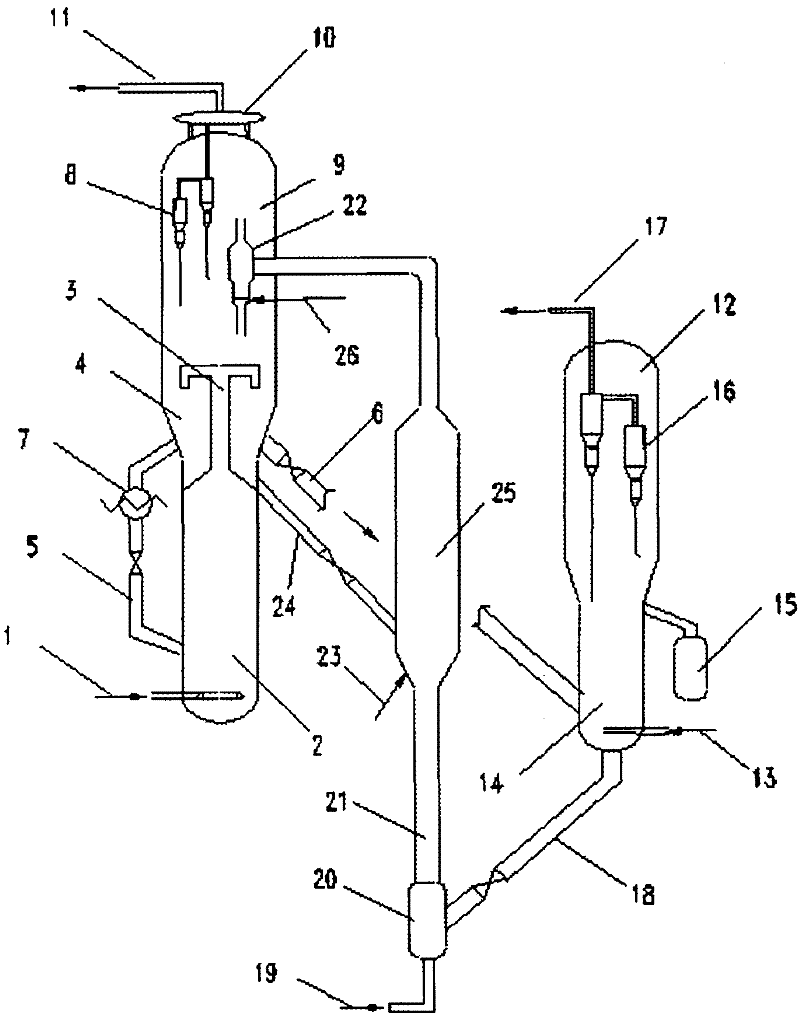

Method for increasing production of propylene

ActiveCN102276406AHydrocarbon from oxygen organic compoundsEthylene productionReaction zoneCarbon group

The invention relates to a method for increasing the yield of propylene, and mainly solves the problem that the yield of carbon groups of the propylene is low in the prior art. In the invention, the problem is better solved by the technical scheme that three reaction zones are set, the first fast bed reaction zone is used for preparing olefin through methanol transformation, and the riser reaction zone and the second fast bed reaction zone are connected in series and used for transforming ethylene, hydrocarbons above C4 and unreacted methanol or dimethyl ether; and the technical scheme can be used for the industrial production of low-carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

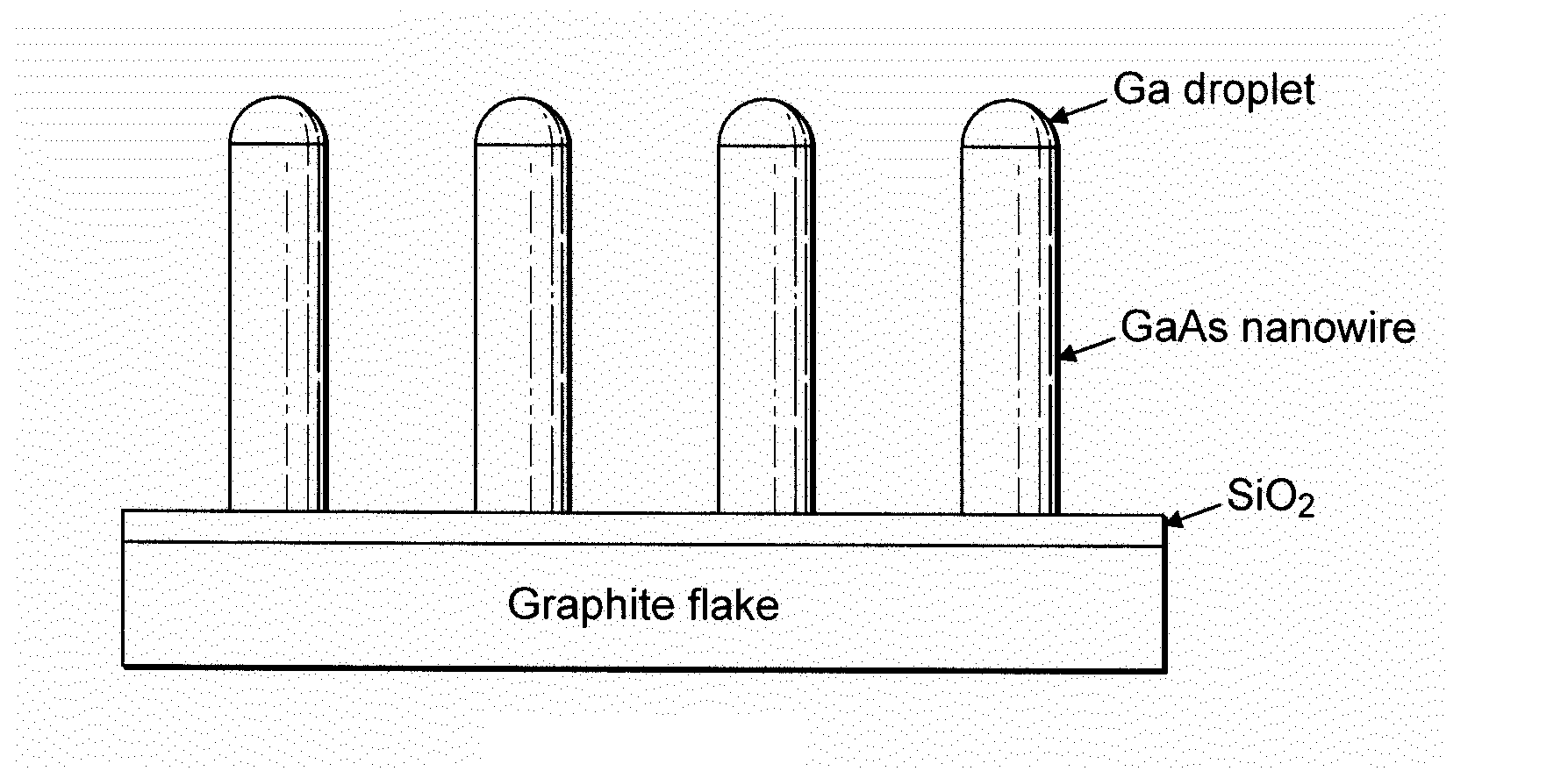

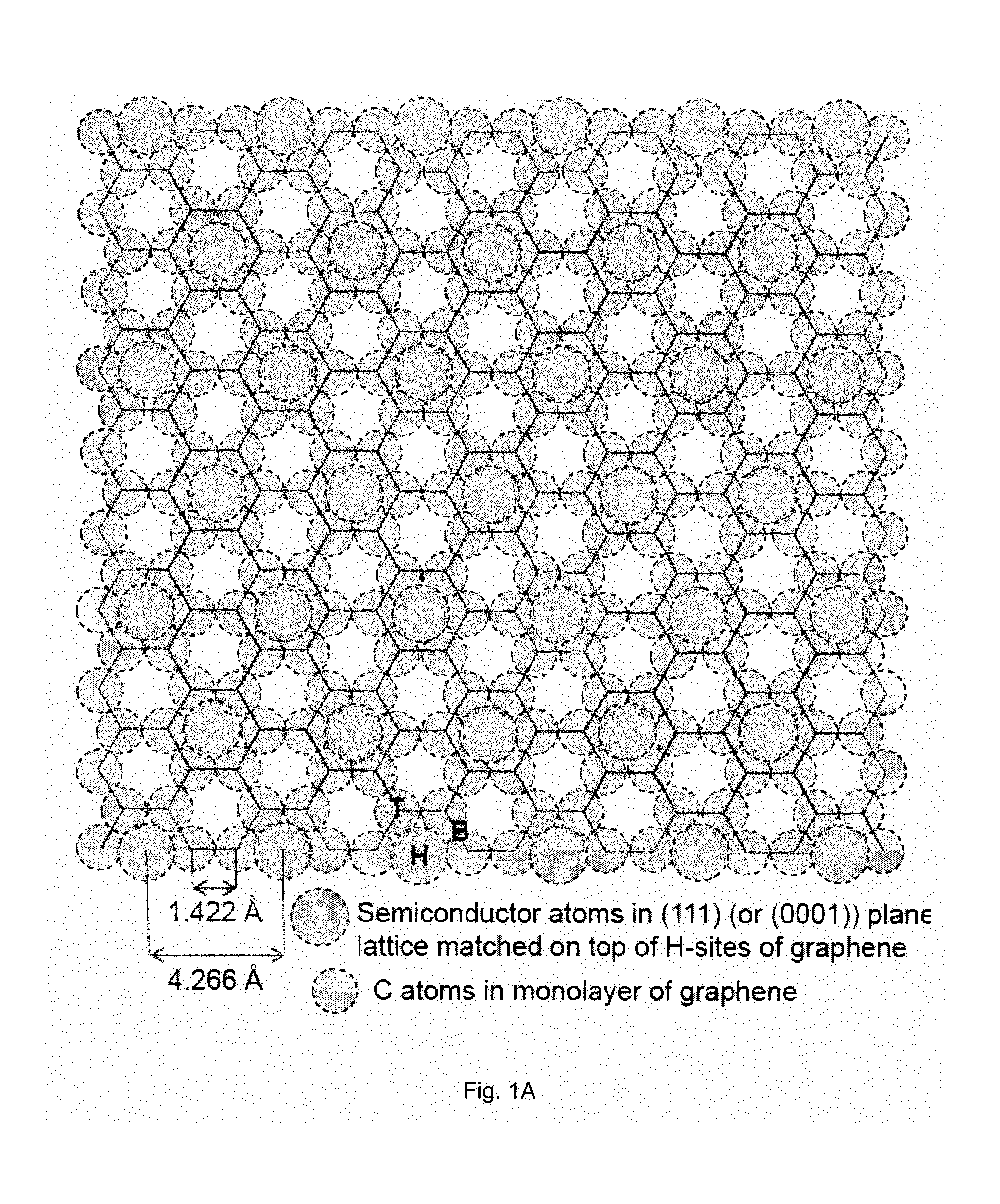

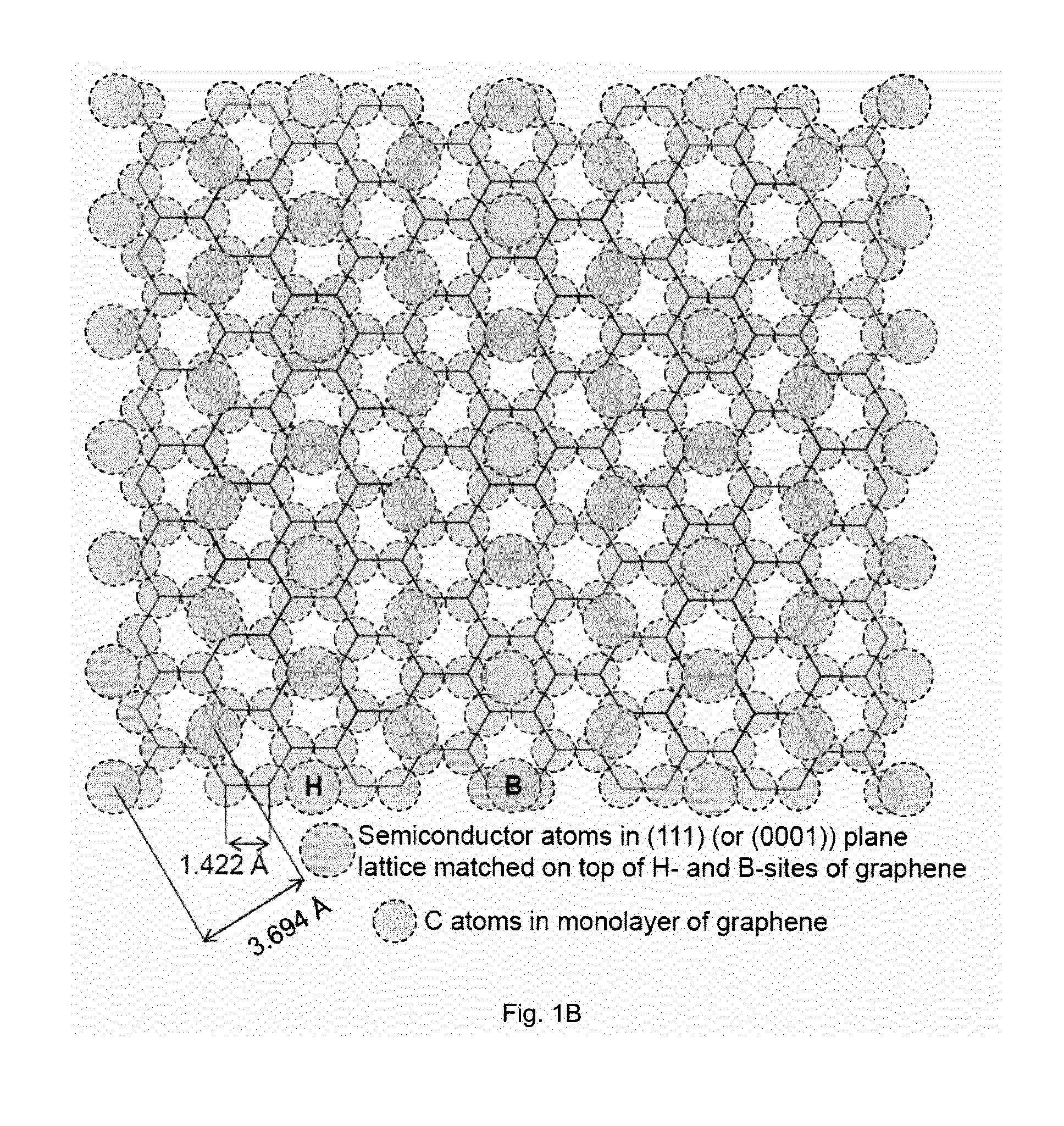

Nanowire epitaxy on a graphitic substrate

ActiveUS20130334497A1Epitaxial growthElectrical properties can be modifiedMaterial nanotechnologyNanoinformaticsNanowireGraphite

A composition of matter comprising at least one nanowire on a graphitic substrate, said at least one nanowire having been grown epitaxially on said substrate, wherein said nanowire comprises at least one group III-V compound or at least one group II-VI compound or comprises at least one non carbon group (IV) element.

Owner:NORWEGIAN UNIVERSITY OF SCIENCE AND TECHNOLOGY (NTNU)

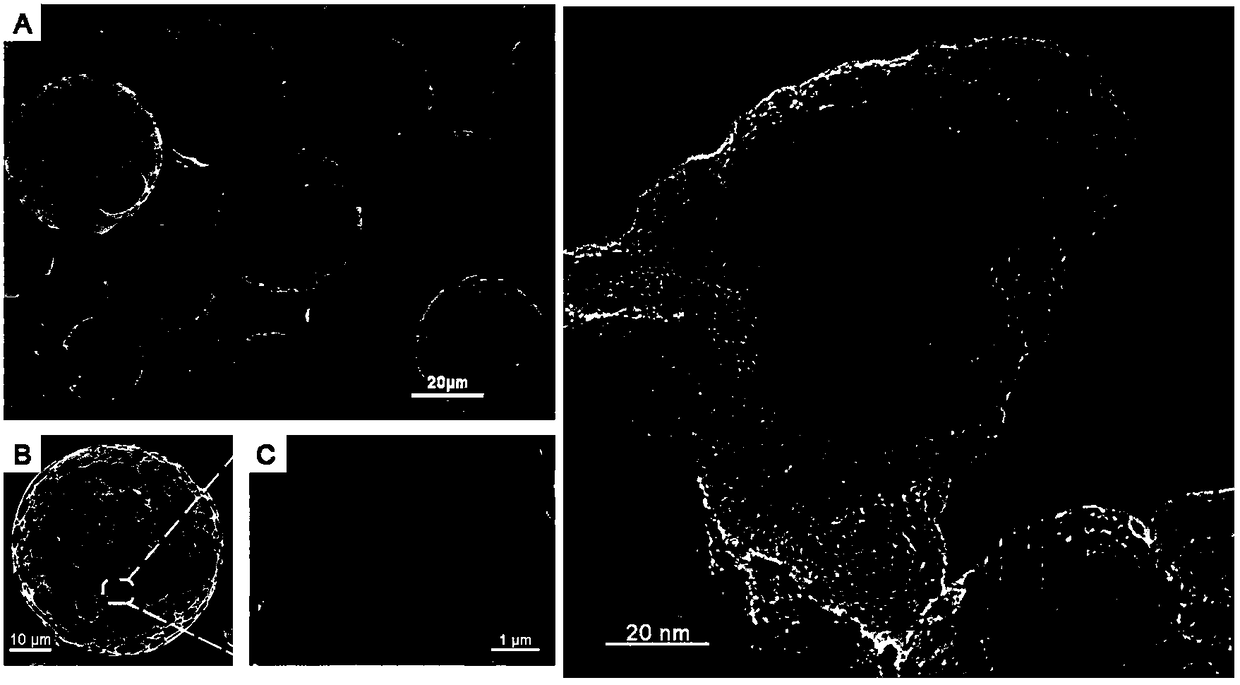

Electrodes, lithium-ion batteries, and methods of making and using same

ActiveUS20120328952A1Facilitate communicationNon-metal conductorsMaterial nanotechnologyNanoparticleLithium-ion battery

Described herein are improved composite anodes and lithium-ion batteries made therefrom. Further described are methods of making and using the improved anodes and batteries. In general, the anodes include a porous composite having a plurality of agglomerated nanocomposites. At least one of the plurality of agglomerated nanocomposites is formed from a dendritic particle, which is a three-dimensional, randomly-ordered assembly of nanoparticles of an electrically conducting material and a plurality of discrete non-porous nanoparticles of a non-carbon Group 4A element or mixture thereof disposed on a surface of the dendritic particle. At least one nanocomposite of the plurality of agglomerated nanocomposites has at least a portion of its dendritic particle in electrical communication with at least a portion of a dendritic particle of an adjacent nanocomposite in the plurality of agglomerated nanocomposites.

Owner:GEORGIA TECH RES CORP +1

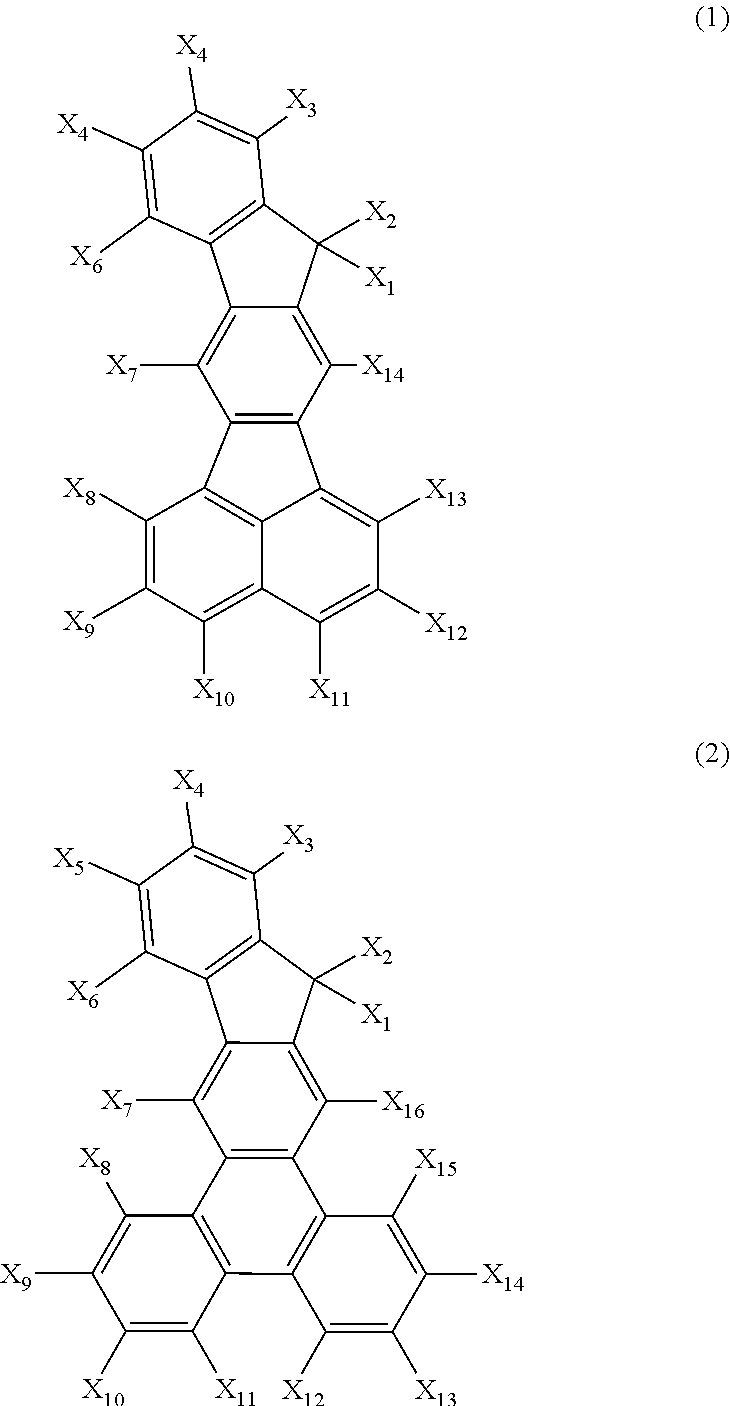

Organic Electroluminescence Device

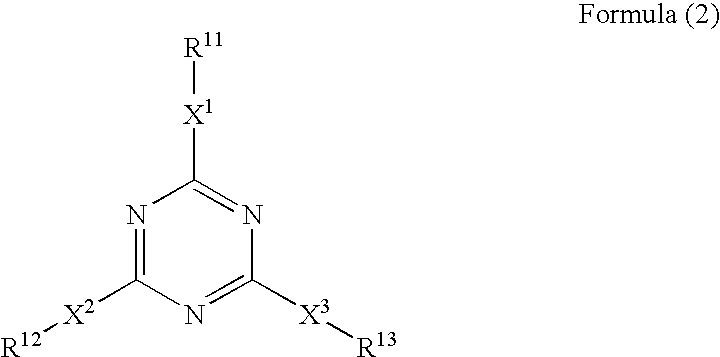

ActiveUS20110073845A1Improve luminous efficiencyLow luminous efficiencyOrganic chemistrySolid-state devicesArylHydrogen atom

An organic electroluminescence device includes an organic layer disposed between at least one pair of electrodes, wherein the organic layer includes at least one fluorescent compound selected from compounds represented by the following general formulae (1) and (2):wherein X1 to X16 each independently represents a hydrogen atom, a linear, branched or cyclic alkyl group having 1 to 20 carbon atoms, a linear, branched or cyclic alkoxy group having 1 to 20 carbon atoms, a substituted or unsubstituted aryl group having 6 to 30 carbon atoms, a substituted or unsubstituted aryloxy group having 6 to 30 carbon groups, a substituted or unsubstituted arylamino group having 6 to 30 carbon atoms, a substituted or unsubstituted alkylamino group having 1 to 30 carbon atoms, a substituted or unsubstituted arylalkylamino group having 7 to 30 carbon atoms or a substituted or unsubstituted alkenyl group having 8 to 30 carbon atoms; a pair of adjacent groups represented by X1 to X2 and a pair of adjacent substituents to groups represented by X1 to X2 may form a cyclic structure in combination; a pair of adjacent groups represented by X3 to X16 and a pair of adjacent substituents to groups represented by X3 to X16 may form a cyclic structure in combination; when the pair of adjacent substituents are aryl groups, the pair of substituents may be a single group; and in the formulae at least one of the substituents of X3 to X14 or X16 includes amino group.

Owner:RITDISPLAY

Universal preparation method and application of active site-electrode structure integrated air electrode

InactiveCN108365230AIncrease mass transfer rateFast electron transferCell electrodesActivation methodMicrosphere

The invention relates to a universal preparation method for an active site-electrode structure integrated air electrode. The universal preparation method is characterized in that various polymer microspheres having open internally-communicating hierarchical-pore structures are conjugated with active sites like noble metal groups, transition metal groups, and hetero atom-doped carbon groups in virtue of different treatment methods; the different treatment methods may be one or more selected from the group consisting of a carbon tetrachloride cross-linking method, a concentrated-sulfuric-acid sulfonation method, a carbon dioxide gas activation method, a dopamine coating method, an ammonia gas activation method, a polyaniline coating method, an in-situ precious-metal loading method, an in-situ transition metallide growth method and an in-situ heteroatom doping method. The universal method described in the invention can flexibly conjugate open internally-communicating hierarchical-pore electrode structures containing super-macro pores, macro pores, meso pores and micropores with a plurality of different highly-active catalytic sites by using appropriate methods, so the catalytic performance of the air electrode and the overall performance of a fuel cell and a metal-air battery are improved.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

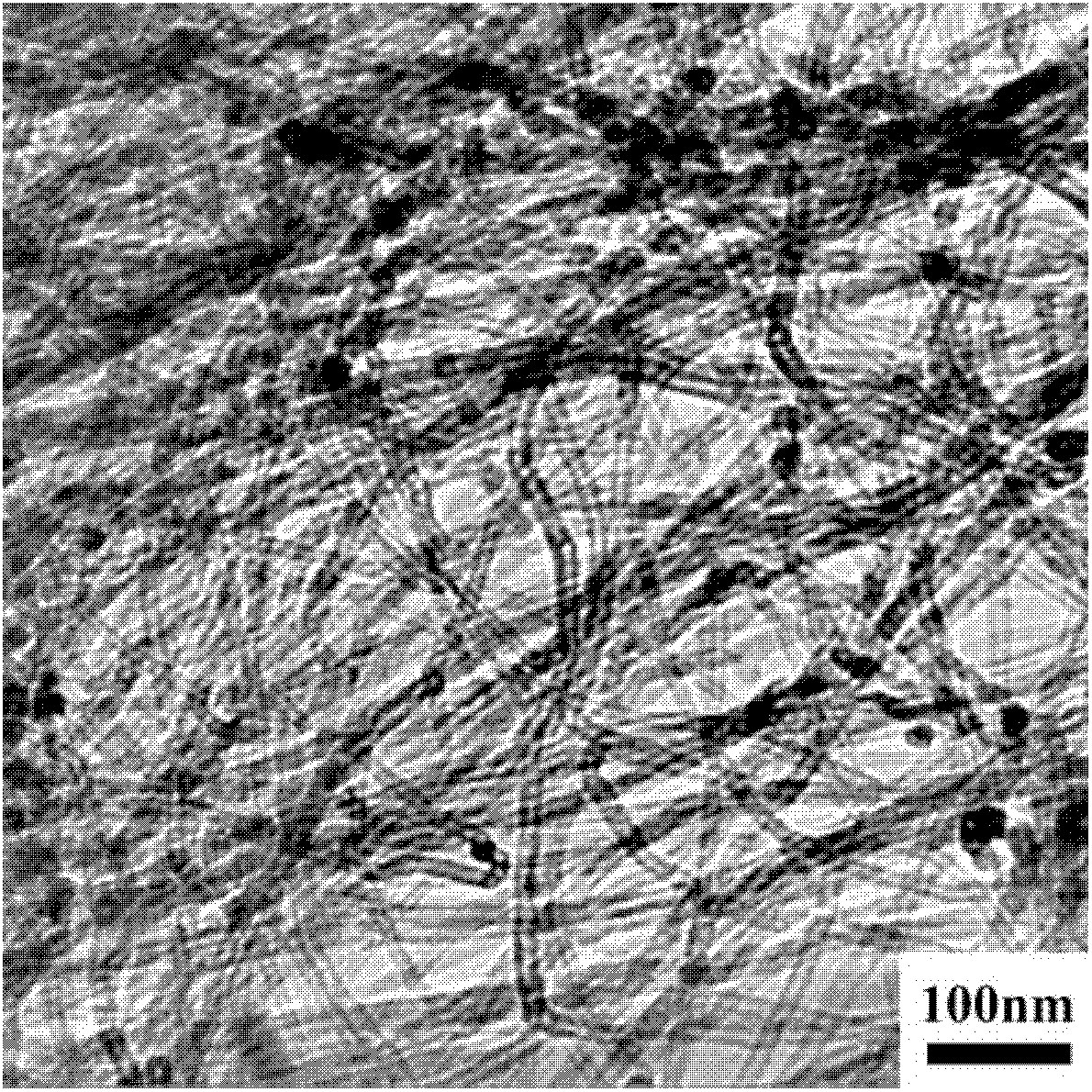

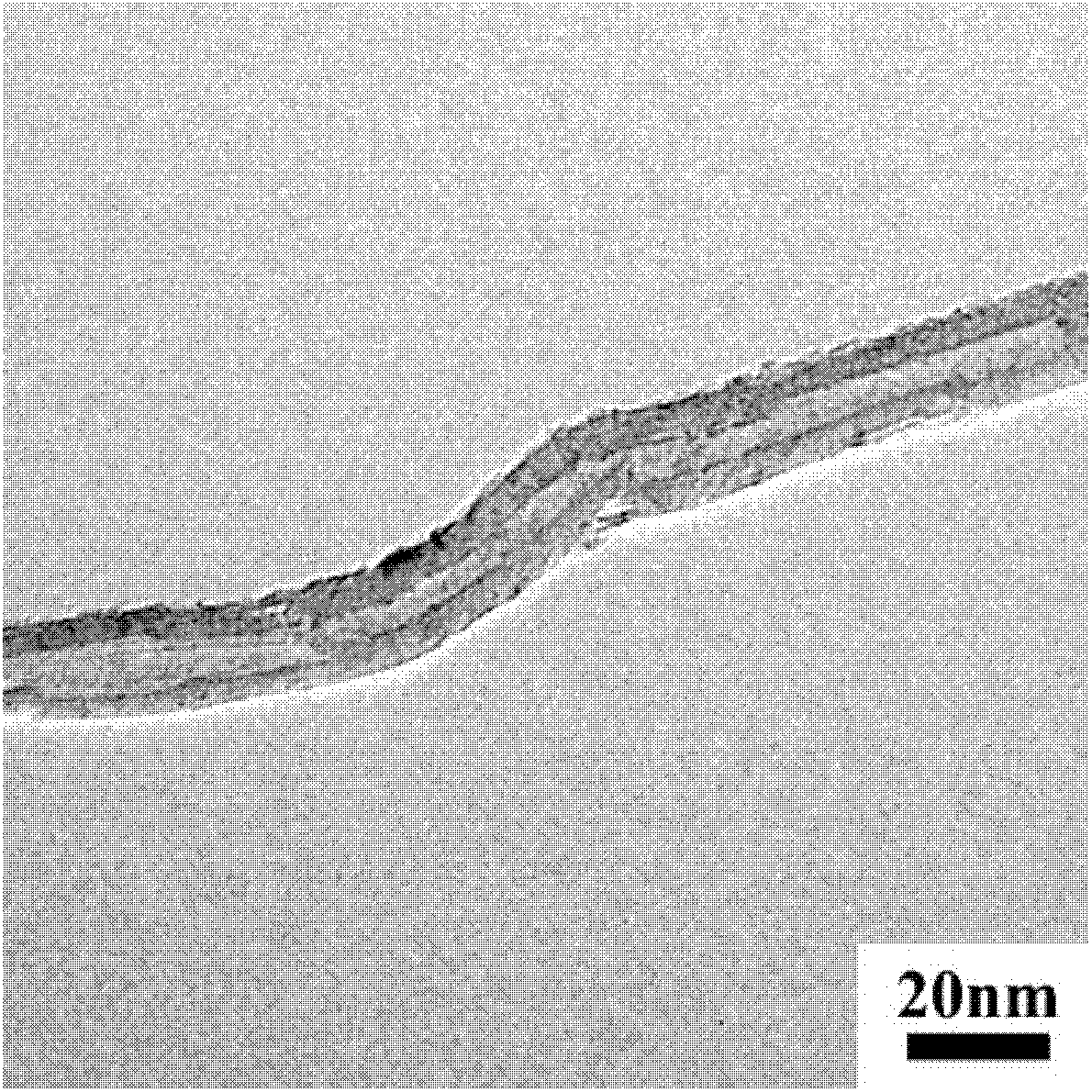

Method for preparing carbon nano tube enhanced titanium-base compound material by in-suit reaction

The invention relates to a method for preparing a carbon nano tube enhanced titanium-base compound material by in-suit reaction in order to solve the problems of low uniform dispersion and low structural completeness of a carbon nano tube in the conventional method for preparing the carbon nano tube enhanced titanium-base compound material and pollution to the titanium-base material caused by reaction of a carbon group and a titanium base body. The method comprises the following steps of: adding nickel nitrate hexahydrate and TiH2 powder into an ethanol solution, stirring and evaporating to obtain Ni-TiH2 compound powder; paving the Ni-TiH2 compound powder in a quartz boat, putting the quartz boat into deposition equipment, feeding H2, raising temperature, feeding CH4, and after the deposition is finished, stopping feeding the CH4 so as to obtain carbon nano tube / TiH2 compound power; pressing the carbon nano tube / TiH2 compound power into a block body, sintering, and re-pressing to obtain the carbon nano tube enhanced titanium-base compound material. Carbon nano tubes in the compound material are uniform to disperse and cannot be aggregated; the compound material is high in purity and has a complete structure; and reaction between the titanium and the defected carbon nano tube can be avoided.

Owner:HARBIN INST OF TECH

Lubricant composition and triazine ring-containing compound

InactiveUS20060068998A1Improve the lubrication effectReduce frictionOrganic chemistryAdditivesPhotochemistryFluorinated hydrocarbons

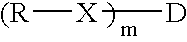

A lubricant composition comprising a compound represented by the following formula that can maintain a low friction and a high abrasion resistance on the sliding surface over an extended period of time: wherein D represents a cyclic group; X's each independently represent a single bond, an NR1 group (in which R1 represents a hydrogen atom or a C1-C30 alkyl group), an oxygen atom, a sulfur atom, a carbonyl group, a sulfonyl group or a divalent linking group comprising these groups in combination; R's each independently represent an alkyl group, an alkenyl group, an alkynyl group, an aryl group or a heterocyclic group; m represents an integer of from 2 to 11; and at least one of m groups of R's contains a partly fluorinated hydrocarbon group or a fluorinated carbon group.

Owner:FUJIFILM CORP

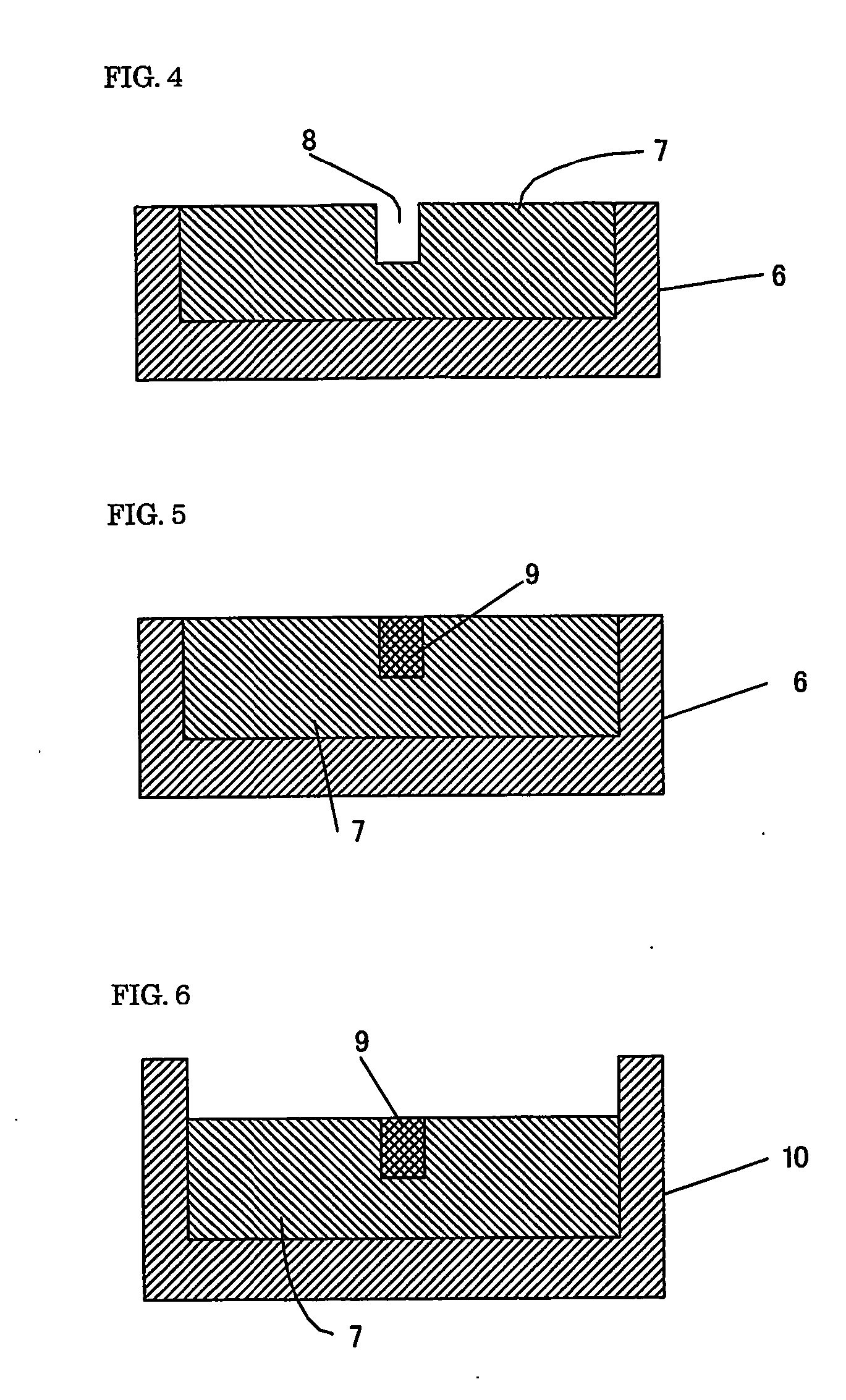

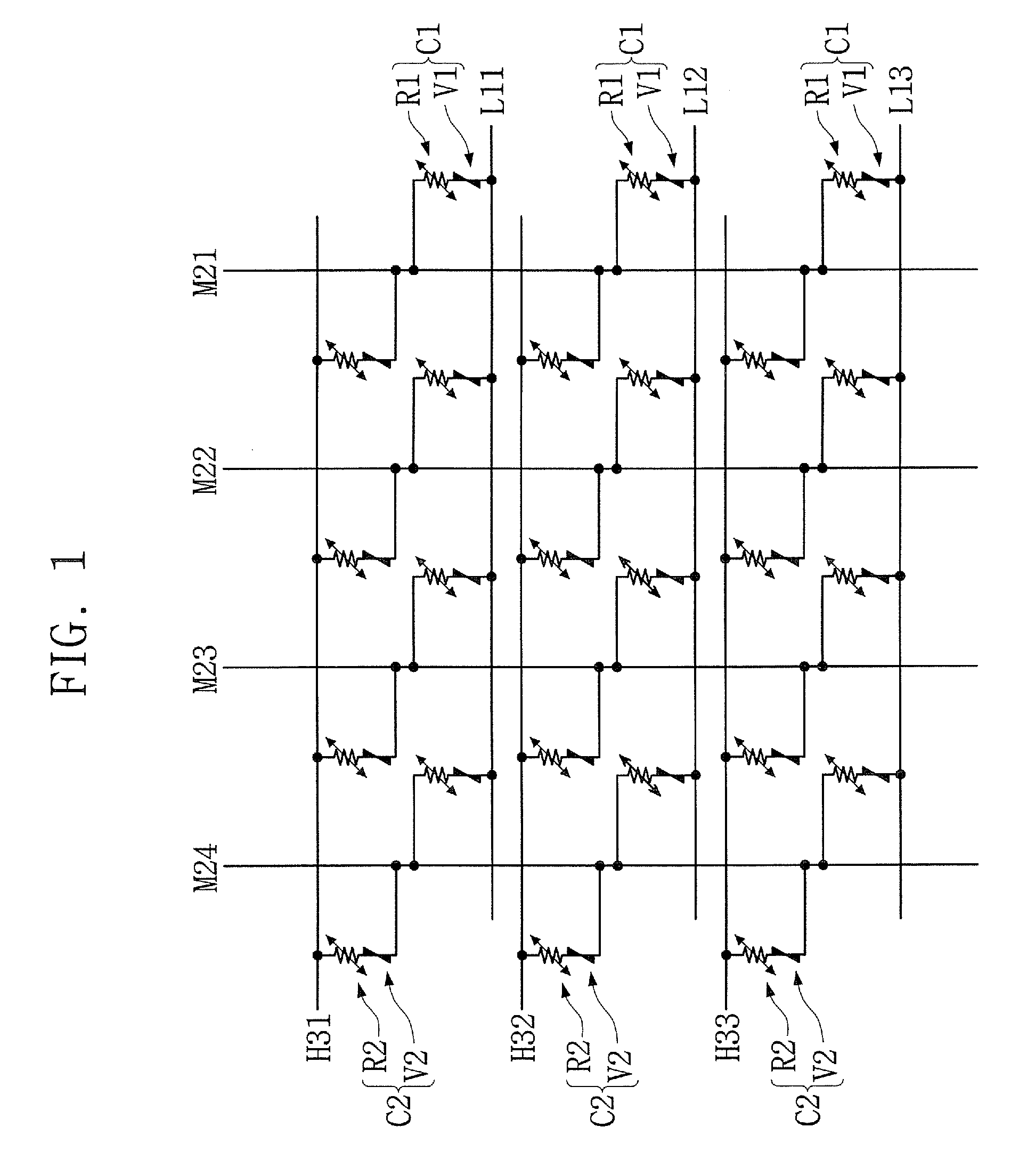

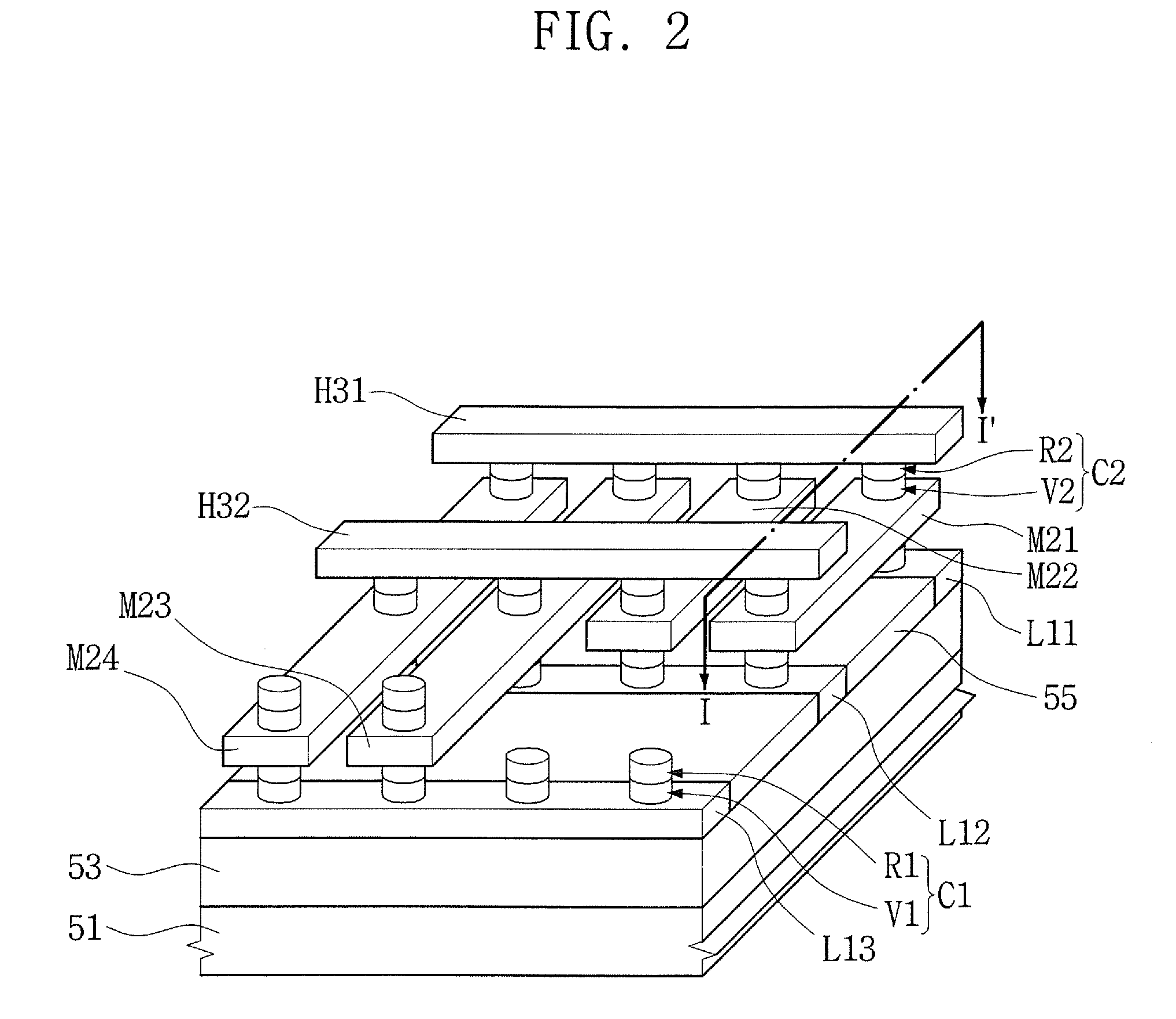

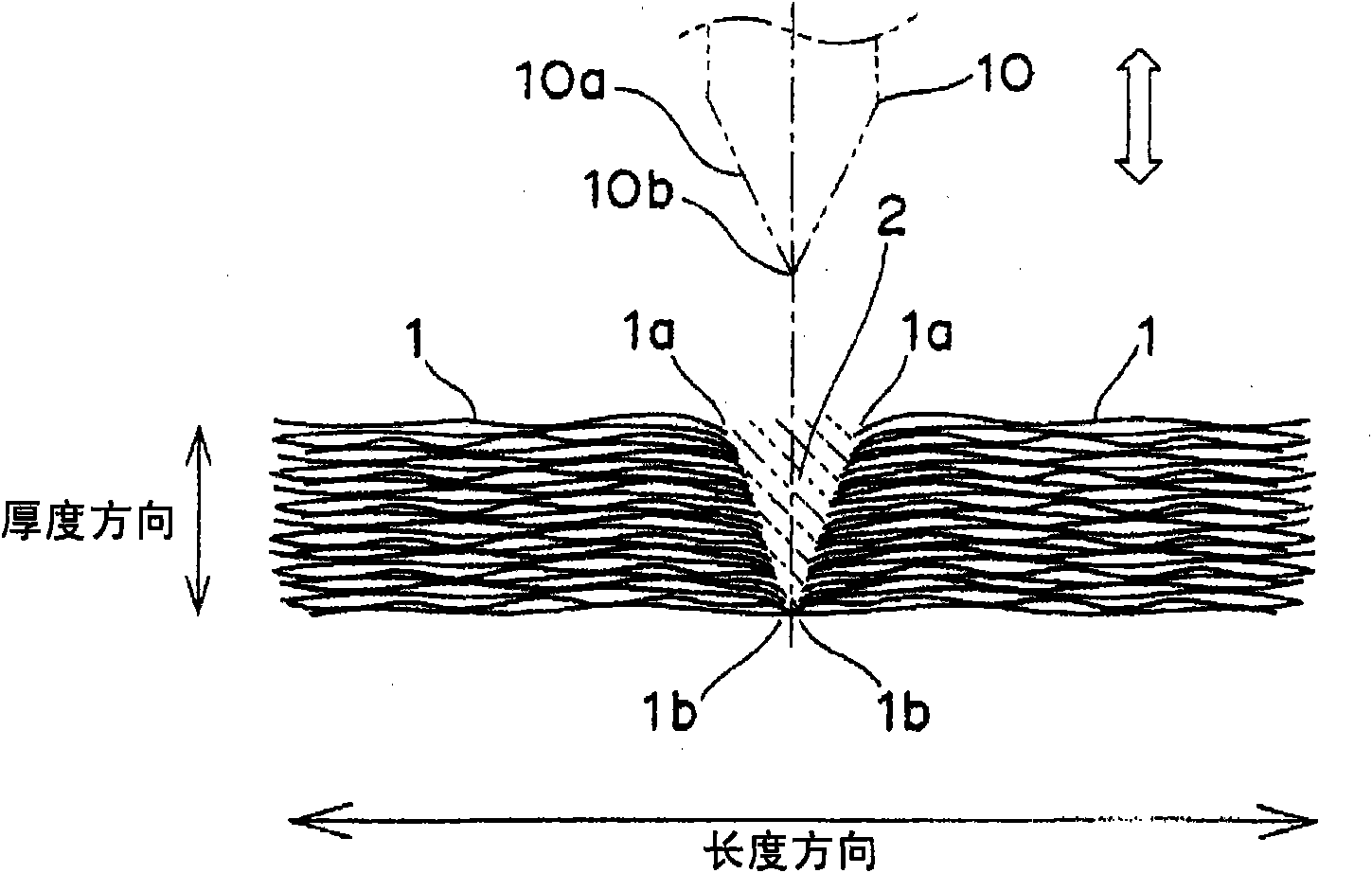

Heating-element unit, and heating device

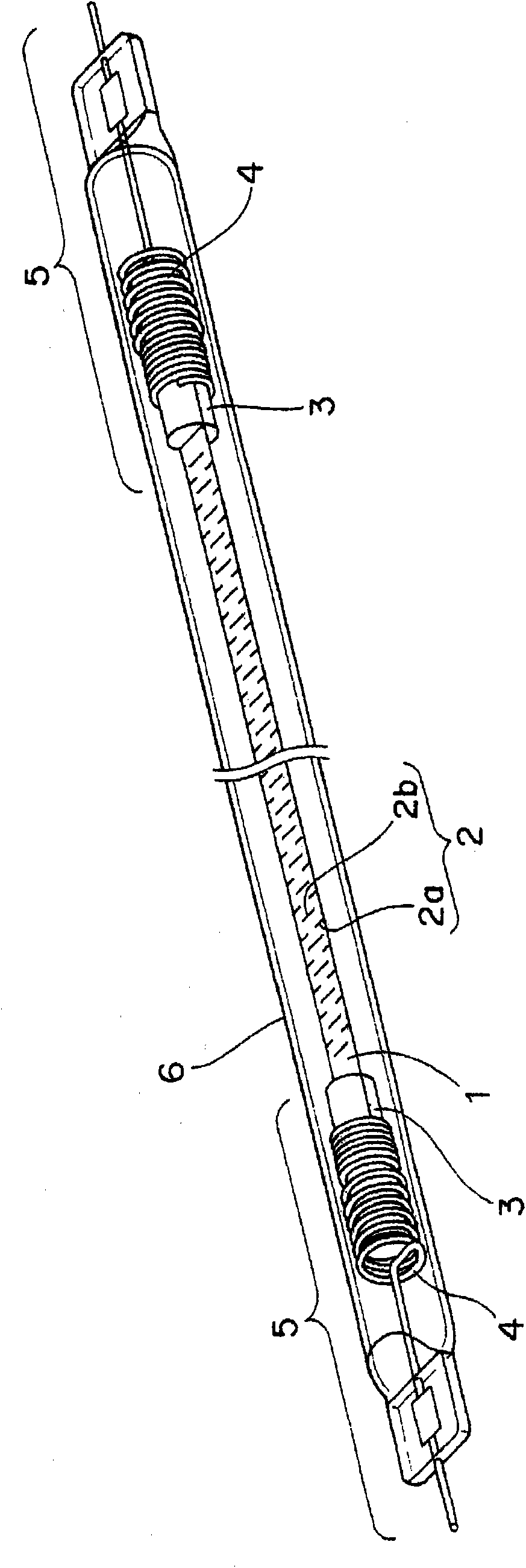

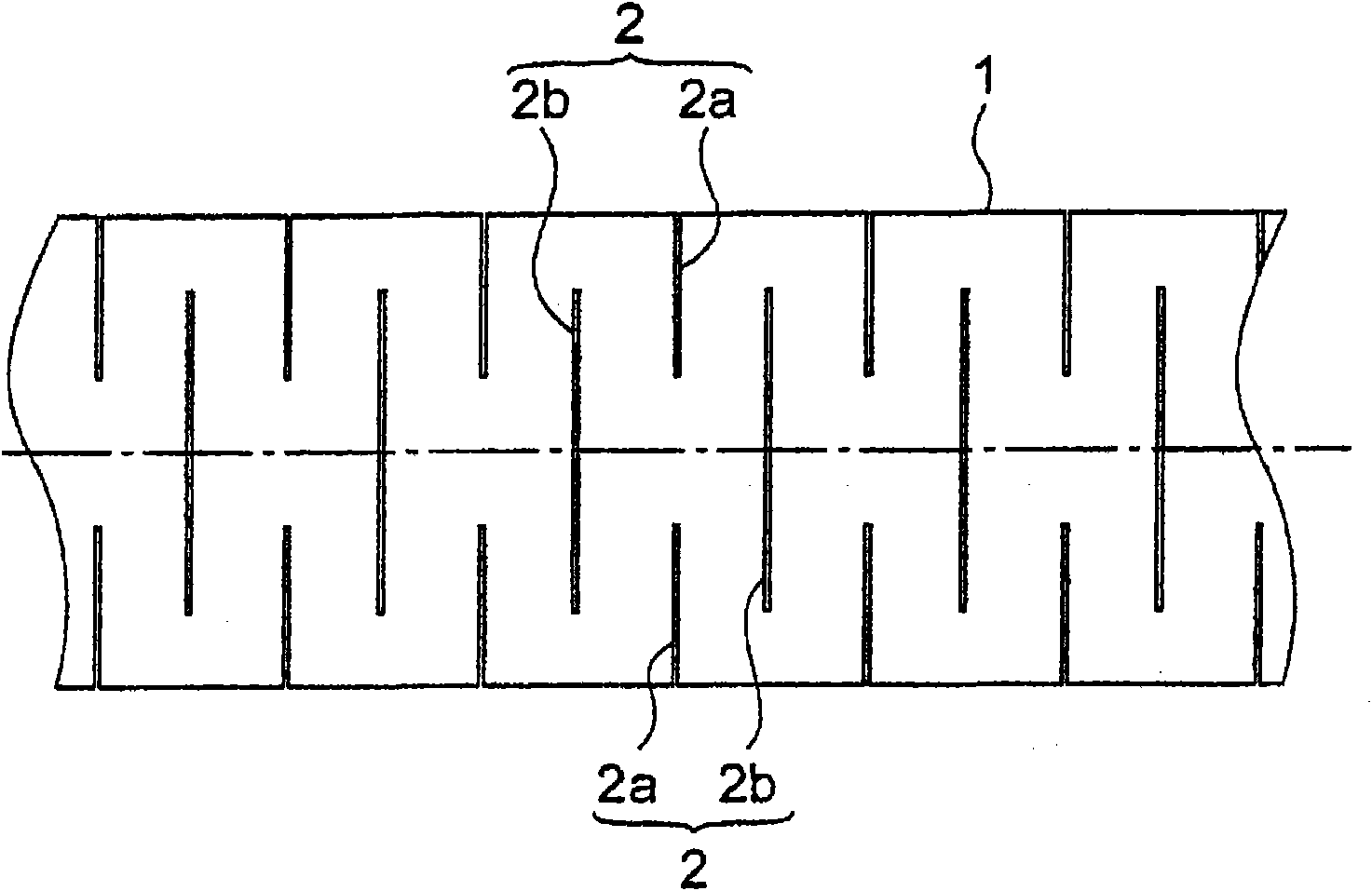

InactiveCN101861758AEasy to set resistance valueImprove cooling effectOhmic-resistance waterproof/air-tight sealsHeater elementsEngineeringCarbon group

This aims to provide a heating-element unit, in which a slender, sheet-shaped heating element (1) composed of mainly a carbon-group material has a plurality of layers laminated through gaps from each other in the thickness direction and in which current suppressing means (2) is formed to control the electric currents to flow through the individual layers laminated. The current suppressing means (2) is formed to have cuts by pushing blades in the thickness direction of the heating element (1), so that the electric current to flow in the longitudinal direction of the heating element (1) can be controlled to a desired value by forming the current suppressing means (2).

Owner:PANASONIC CORP

Method of manufacturing semiconductor device having transition metal oxide layer and related device

ActiveUS7871866B2Solid-state devicesSemiconductor/solid-state device manufacturingStable stateControl layer

Owner:SAMSUNG ELECTRONICS CO LTD

Fluoroelastomer composition

ActiveUS20130109797A1Easy to processImproved compression setFilm/foil adhesivesPolymer sciencePerfluoropolyether

The invention pertains to a (per)fluoroelastomer composition comprising:at least one (per)fluoroelastomer [fluoroelastomer (A)]; andfrom 0.1 to 30 weight parts, per hundred parts of fluoroelastomer (A), of at least one perfluoropolyether block copolymer [polymer (E)] comprising:A) one or more (per)fluoropolyoxyalkylene segment (chain Rt), that is to say a segment comprising recurring units having at least one catenary ether bond and at least one fluorocarbon moiety, andB) one or more polyalkylene segment (chain Ra) comprising recurring units of formula:—(CR1R2—CR3R4)—wherein R1, R2, R3, R4, equal to or different from each other, are selected from the group consisting of H, halogens (preferably F, Cl); C1-C6 (hydro)carbon groups, optionally containing fluorine or other heteroatoms, preferably perfluoroalkyl or (per)fluorooxyalkyl.

Owner:SOLVAY SOLEXIS

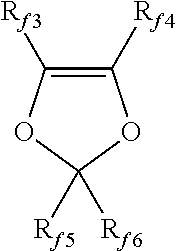

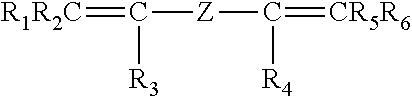

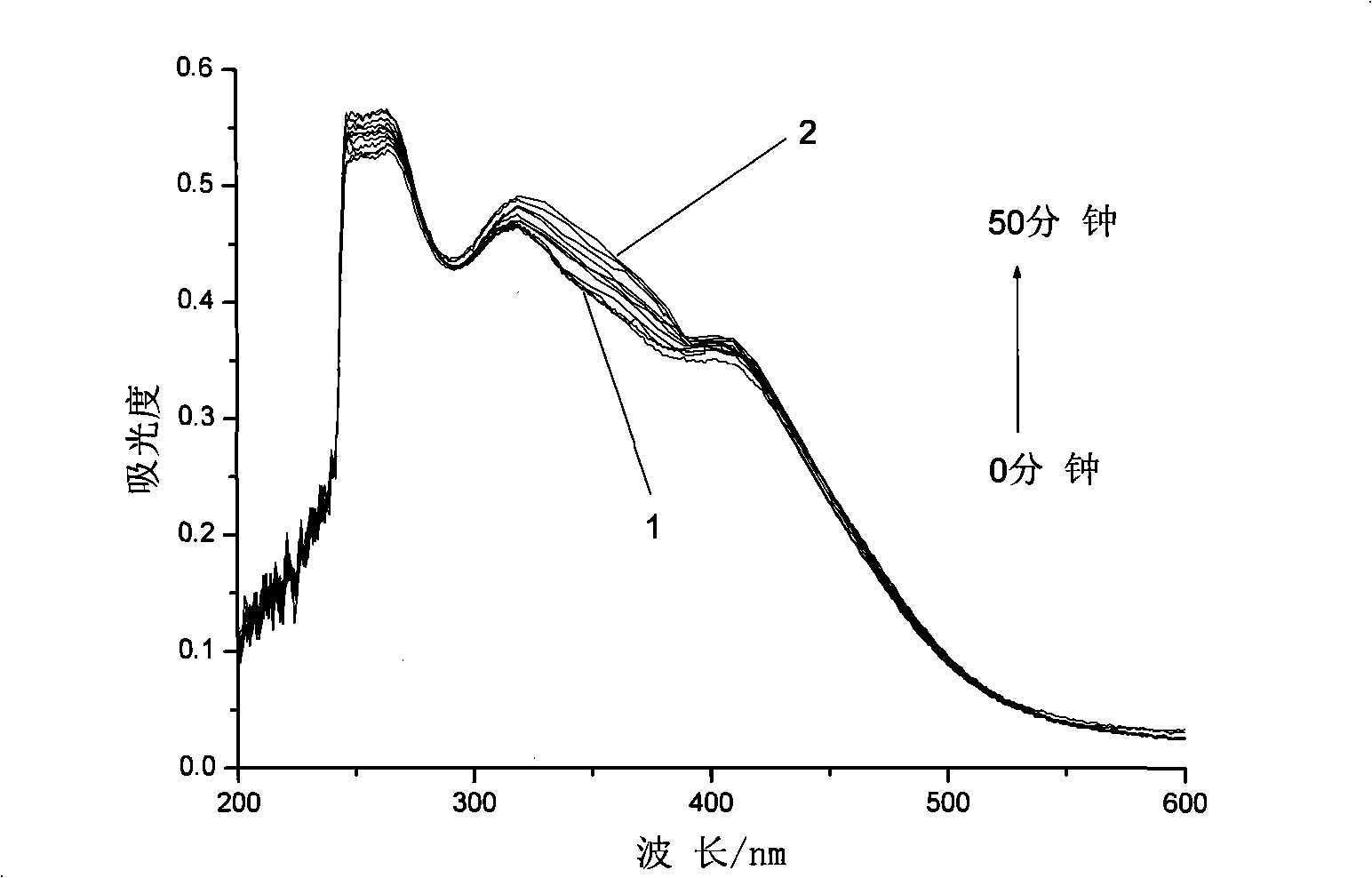

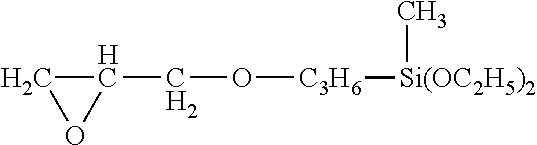

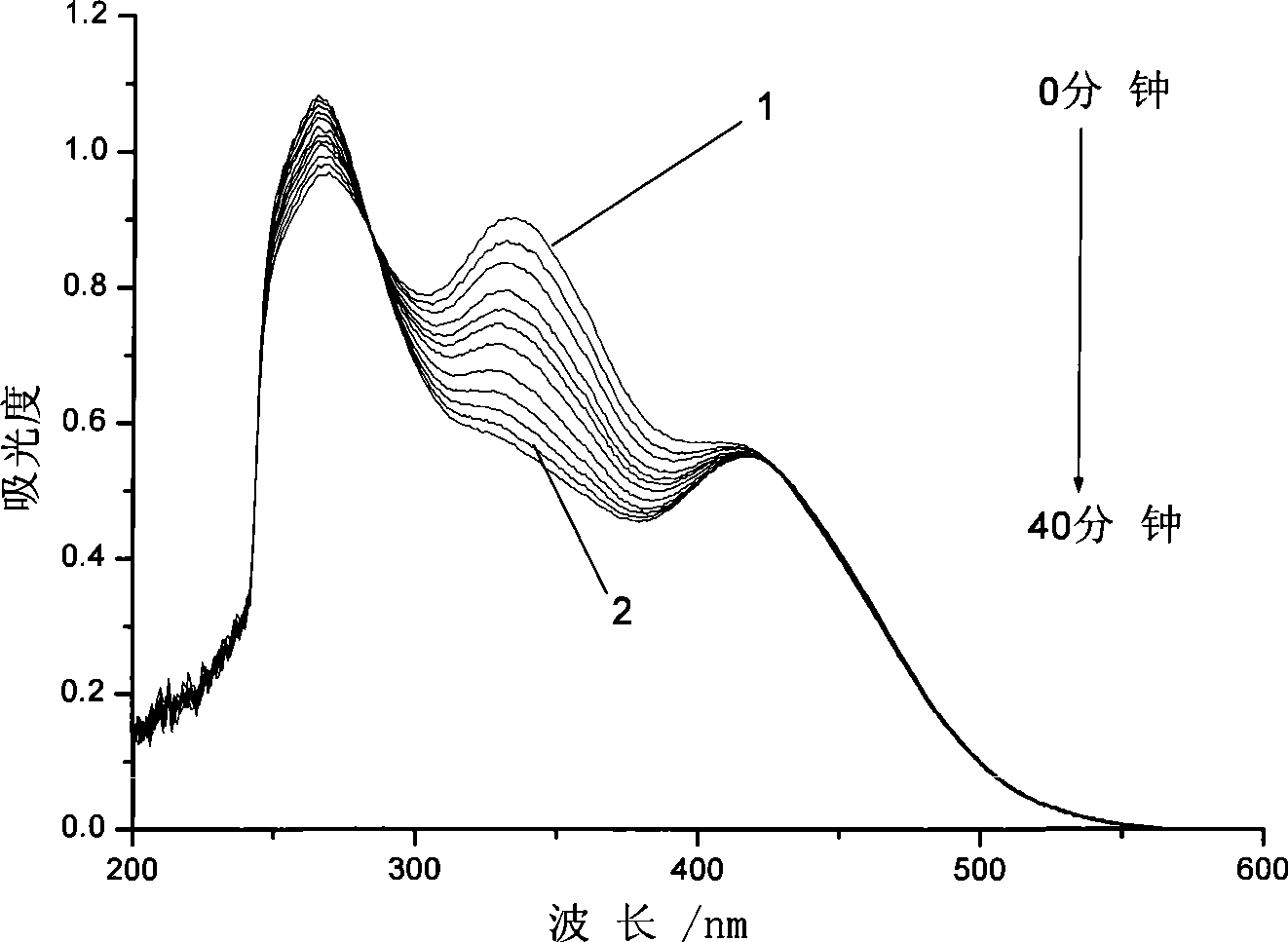

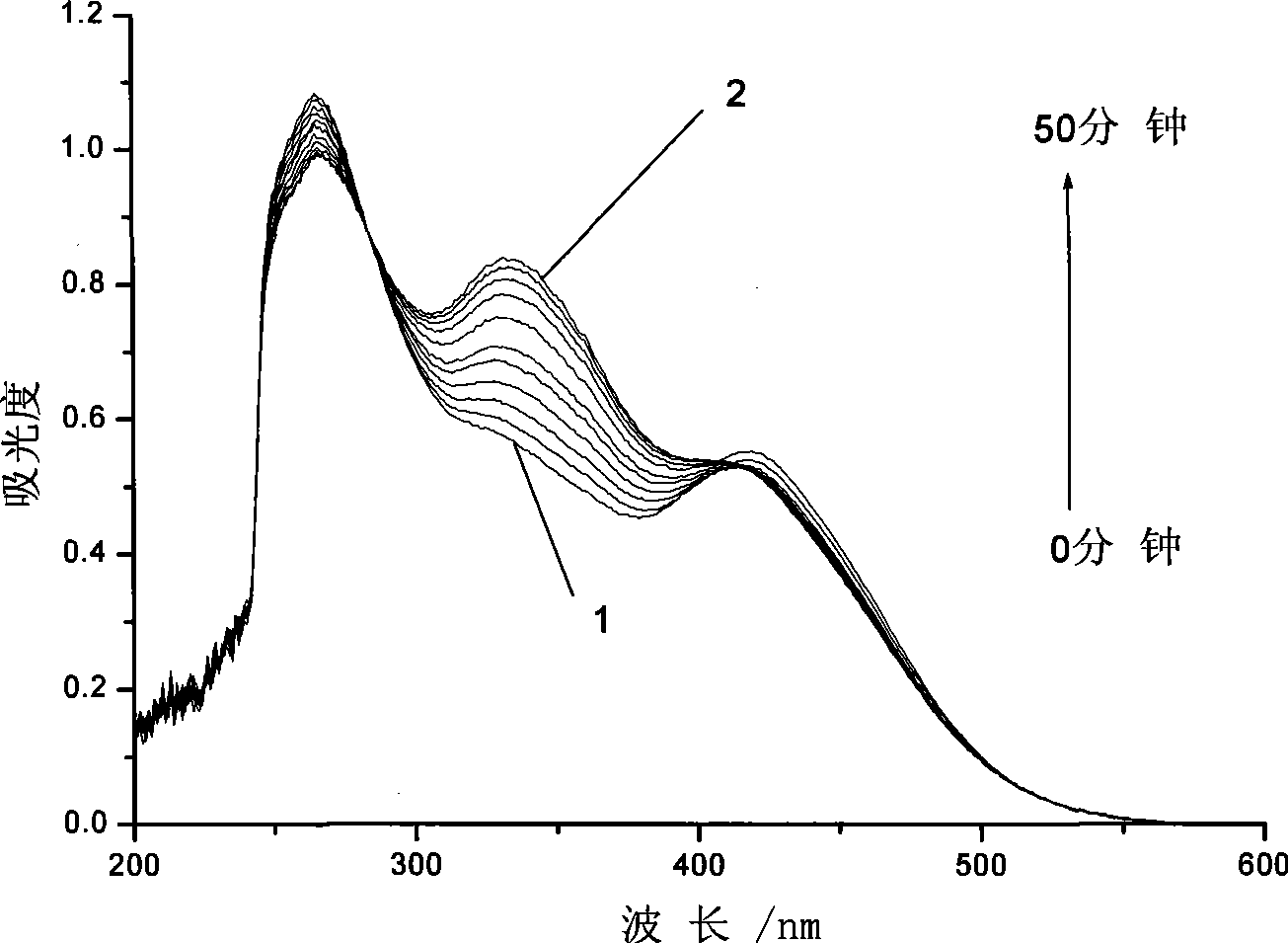

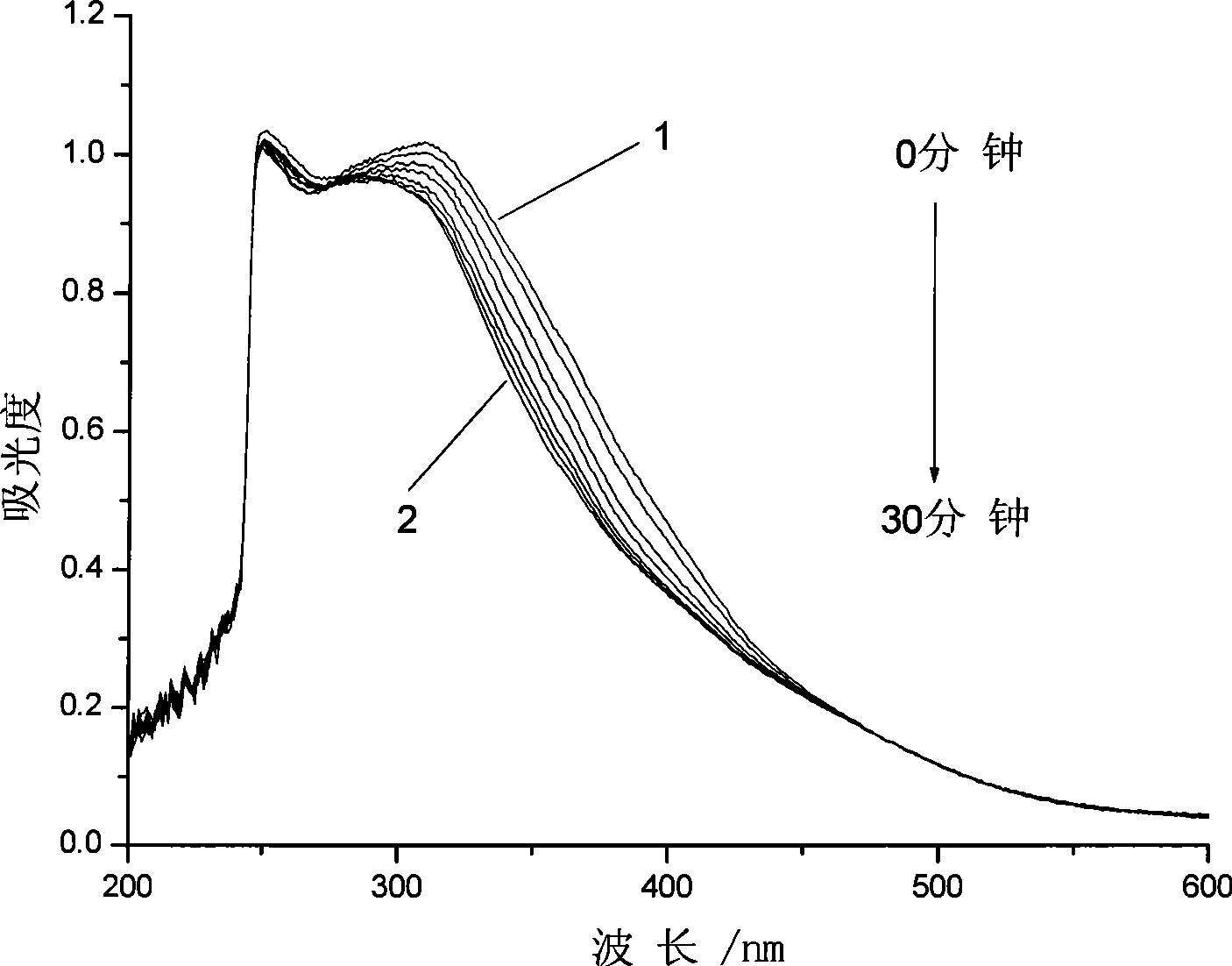

Azobenzene photochromicsm compound containing L-ethyl lactate chiral carbon and synthesis thereof

InactiveCN101492389APhotochromic phenomenon is obviousStable storageOrganic chemistryTenebresent compositionsMolecular switchEthyl fumarate

The invention relates to an azobenzene photochromic compound containing L-ethyl lactate chiral carbon and a synthetic method thereof. L-ethyl lactate chiral carbon groups are introduced into the azobenzene compound, therefore, the photochromic property is changed obviously. Before and after the inducing, the absorption spectrum of UV-Vis changes greatly, which means the absorption spectrum difference of cis and trans states is large, and the reservation at the room temperature is stable. Therefore, the application field of azobenzene photochromic material is enlarged, and the azobenzene photochromic material has wide potential application prospect in fields of data storing material, liquid crystal displaying material, nonlinear material, optical molecular switches, chiral recognition, and the like. The structure of the photochromic compound which contains chiral carbon and is synthesized by the invention has the general formula as is shown above.

Owner:DONGHUA UNIV

External Preparation For Skin

InactiveUS20080234224A1Improve adhesionHigh affinityOrganic active ingredientsBiocideHydrogen atomTopical preparation

The present invention provides an external preparation for skin, which comprises a multi-branched polysaccharide derivative with multi-branched polysaccharide skeleton consisting of saccharides as constituent units, wherein at least one of hydroxyl (OH) groups in the multi-branched polysaccharide skeleton is substituted by OR (wherein R represents a hydrogen atom, a hydrocarbon having 1 to 30 carbon groups or a hydrocarbon having 1 to 30 carbon groups which has hetero atom), which can give moisture and turgor to the skin, and cosmetics containing the external preparation.

Owner:SHOWA DENKO KK

Preparation method of superconductive, thermally-conductive, ultrahigh-strength graphene composite film

The invention relates to a preparation method of a superconductive, thermally-conductive, ultrahigh-strength graphene composite film, which comprises the following steps: step 1, mixing 10%-80% by mass of nanometer graphene and 20%-90% by mass of liquid or powdery bridging carbon groups in a nitrogen-filling mixer at room temperature for 1-10 hours; step 2, pumping the mixed materials into a heating box by a vacuum pump, heating the materials to 100-500 DEG C for 1-20 hours; step 3, after heating, allowing the mixed materials to fall freely into a material distribution zone, uniformly spreading out the mixed materials by a scraper and a material-distributing roller, feeding the materials into a pre-press roller with a controlled pressure of 0.1-1.0 Mpa, pressing the materials tightly with several groups of press rollers so as to pull out a composite film with a thickness less than 100 microns; step 4, scanning the composite film line by line through a laser beam, an electron beam or an ion beam to allow the temperature of the scanned part of the composite film to be above 3000 DEG C so as to realize carbonization, graphitization, crystal growth, and the perfect combination of the molecular skeleton of nanometer graphene and the molecular skeleton of the bridging carbon groups; step 5, trimming the scanned composite film and rolling up. The invention has simple and compact steps, and can realize production with high efficiency by one continuous apparatus.

Owner:耿世达

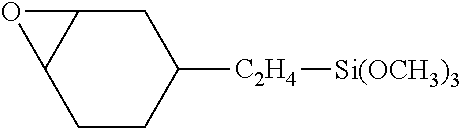

PVDF coating compositions

A vinylidene fluoride (VDF) polymer composition comprising:at least one VDF polymer [polymer (F)]; and at least one additive obtained by treating inorganic particles with a mixture of modifying agents comprising:at least one fluoro-containing modifying agent [agent (X)] of formula:X4-mAYm wherein m is an integer from 1 to 3, A is a metal selected from the group consisting of Si, Ti and Zr, each of Y, equal to or different from each other, is a hydrolysable group, each of X, equal to or different from each other is a C1-C24 (hydro)(fluoro)carbon group, wherein at least one of X is a fluorine-containing C1-C24 group; andat least one hydrogen-containing functional modifying agent [agent (Z)] of formula:Z4-pEYp wherein p is an integer from 1 to 3, E is a metal selected from the group consisting of Si, Ti and Zr, each of Y, equal to or different from each other, is a hydrolysable group, each of Z, equal to or different from each other is a C1-C24 hydrocarbon group, wherein at least one of Z comprises a functional group selected from the group consisting of ethylenically unsaturated group; epoxy group; mercapto group; carboxylic acid group, and sulphonic group.

Owner:SOLVAY SOLEXIS

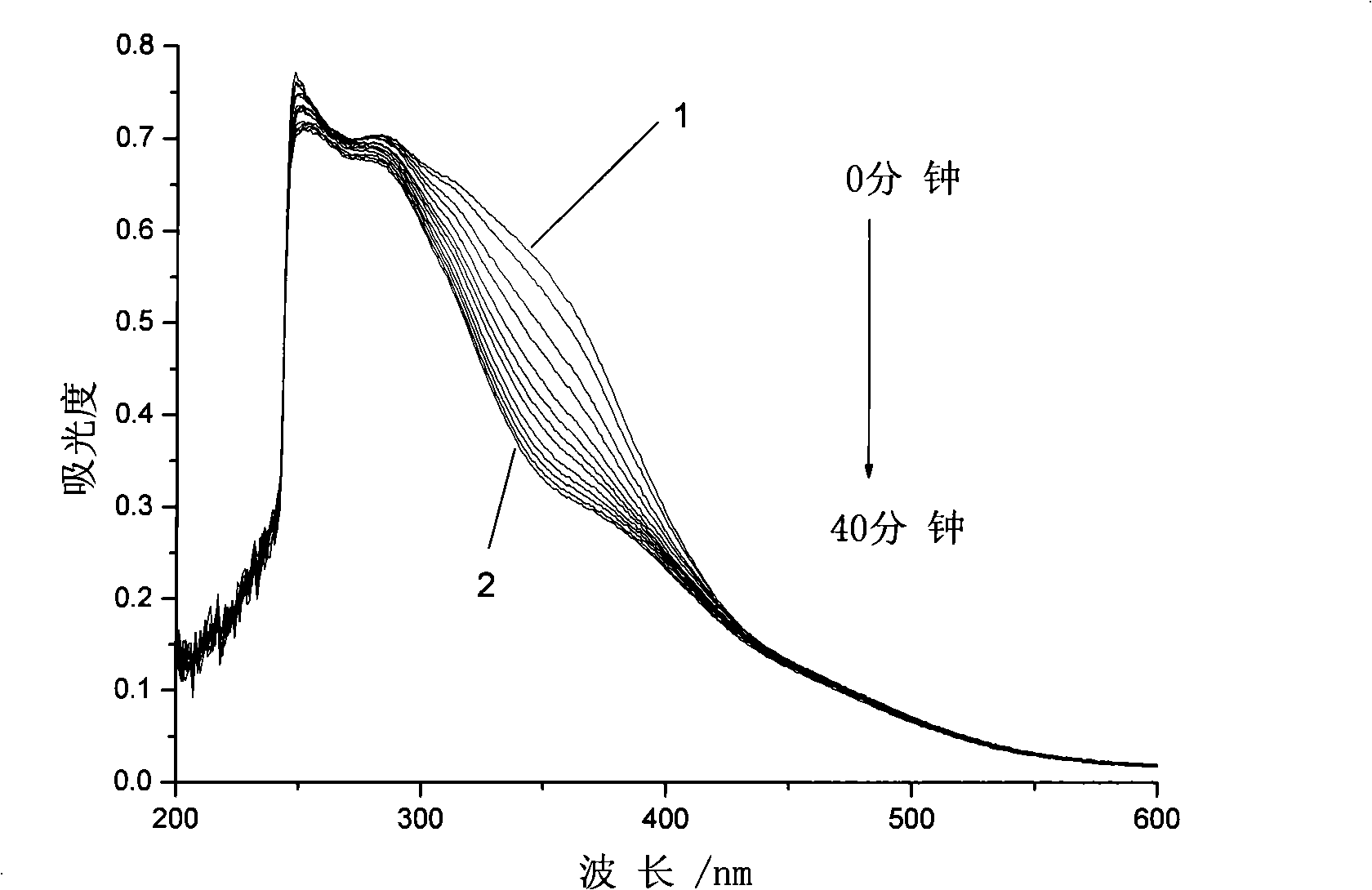

Azobenzol photochromic compound of fluorine-containing end group chiral carbon and method for synthesizing the same

InactiveCN101503376ALarge absorption spectrum changesObvious photochromic propertiesOrganic chemistryTenebresent compositionsEnd-groupMolecular switch

The invention relates to an azobenzol photochromism compound containing fluorine terminal group chiral carbon, and a synthesizing method thereof. As a fluorine terminal group chiral carbon group is introduced into an azobenzol compound, the photochromism property of the azobenzol compound undergoes obvious change, UV-Vis absorption spectrum changes greatly before and after inducement, i.e the absorption spectrum changes greatly in the two statuses of cis-form and trans-form, and the storage is stable at the room temperature. Hereby, the application scope of azobenzol-type photochromism materials is enlarged, and the azobenzol-type photochromism materials have wide and potential application prospect in the fields such as the data storage material field, the liquid crystal display material field, the non-linear material field, the optical molecular switch field, the chiral identification field, and the like. The synthesized azobenzol photochromism compound containing chiral carbon has a general formula shown in the drawing.

Owner:DONGHUA UNIV

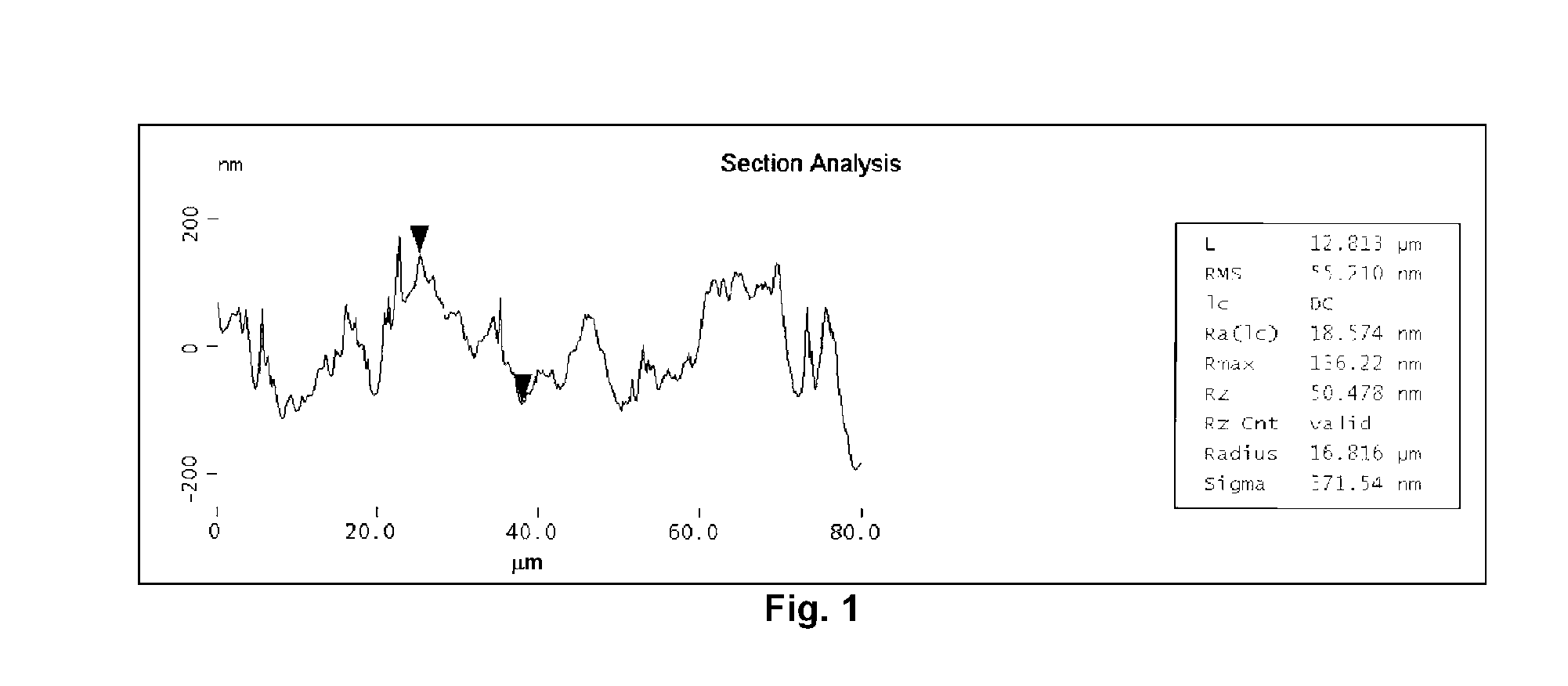

Process for Preparing a Zeolite-Containing Film

InactiveUS20080248328A1High mechanical strengthMechanical strengthPretreated surfacesSemiconductor/solid-state device manufacturingPolymer scienceWater vapor

The invention provides a preparation process of a zeolite-containing film which can raise a zeolite component therein, control the physical properties of the surface, and provide a highly smooth film. The process for preparing a zeolite-containing film has a step of forming a precursor film containing an amorphous silicon oxide portion and a zeolite-like recurring portion by using a material having an amorphous silicon oxide portion and a material having a zeolite-like recurring portion; and a dry gel conversion step of heating the precursor film in the presence of water vapor in order to grow the zeolite-like recurring portion. In this process, the material having an amorphous silicon oxide portion and / or the material having a zeolite-like recurring portion contain(s) a silicon atom bonded to the carbon atom of an organic group containing at least one carbon group.

Owner:PANASONIC CORP +1

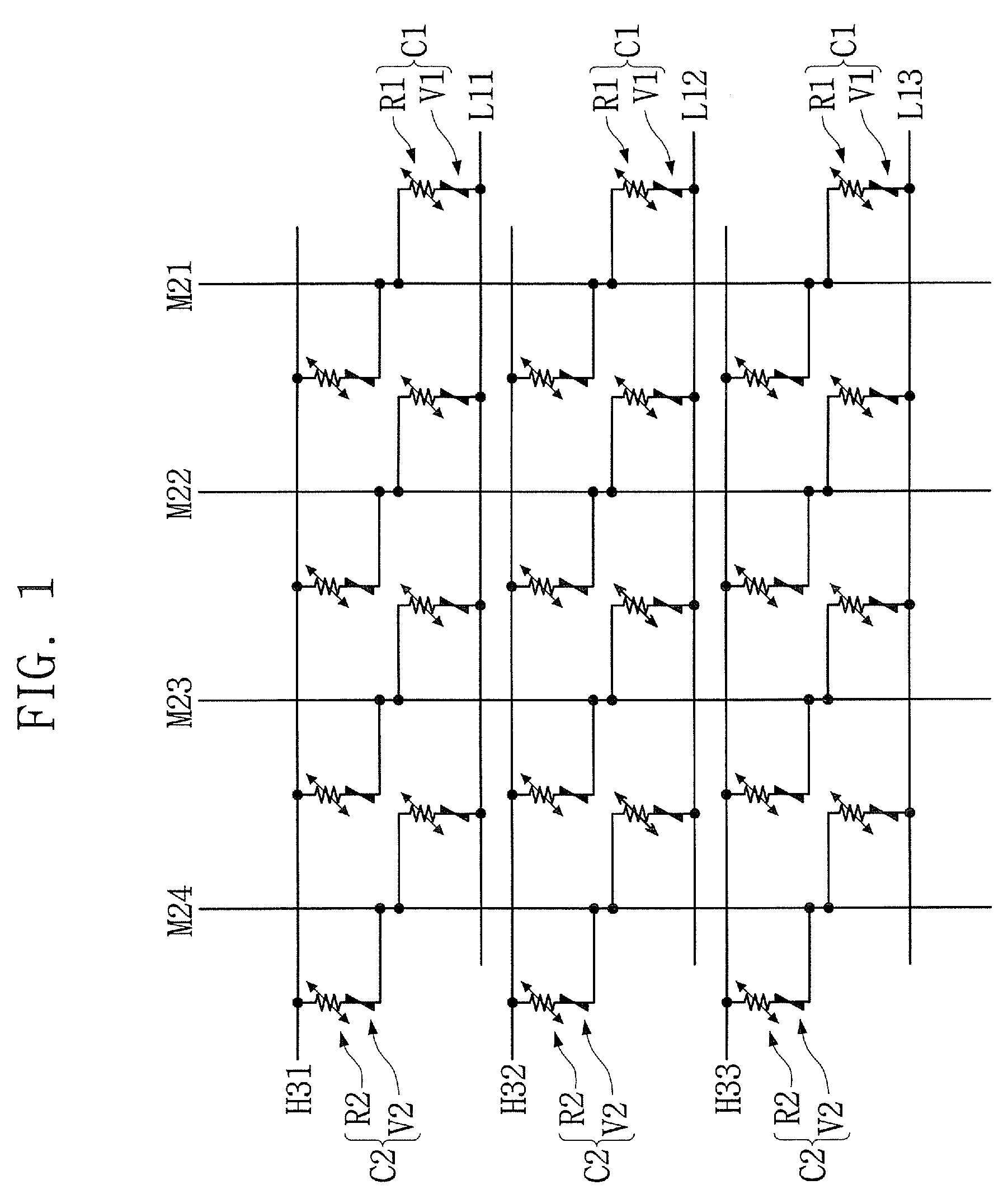

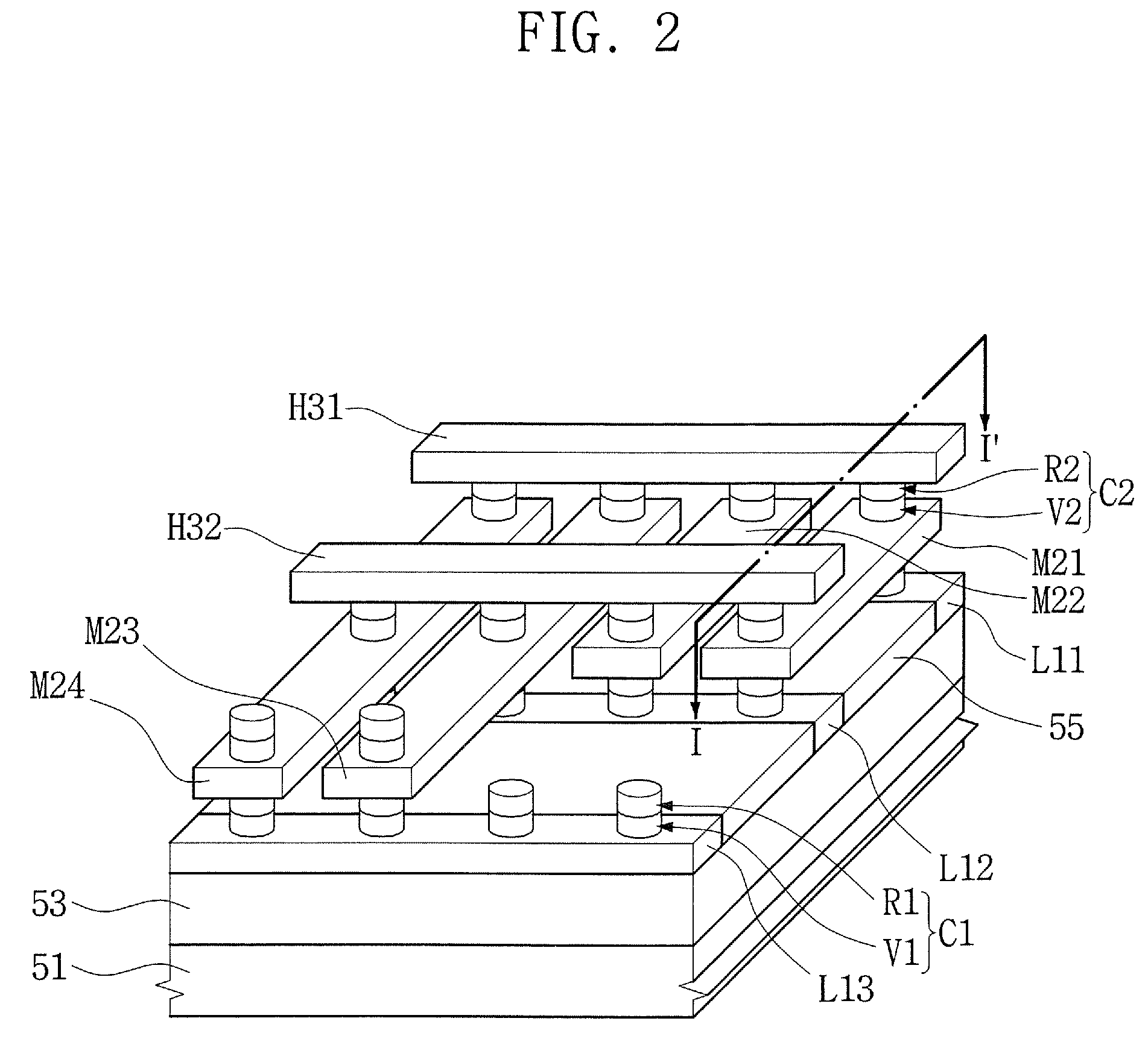

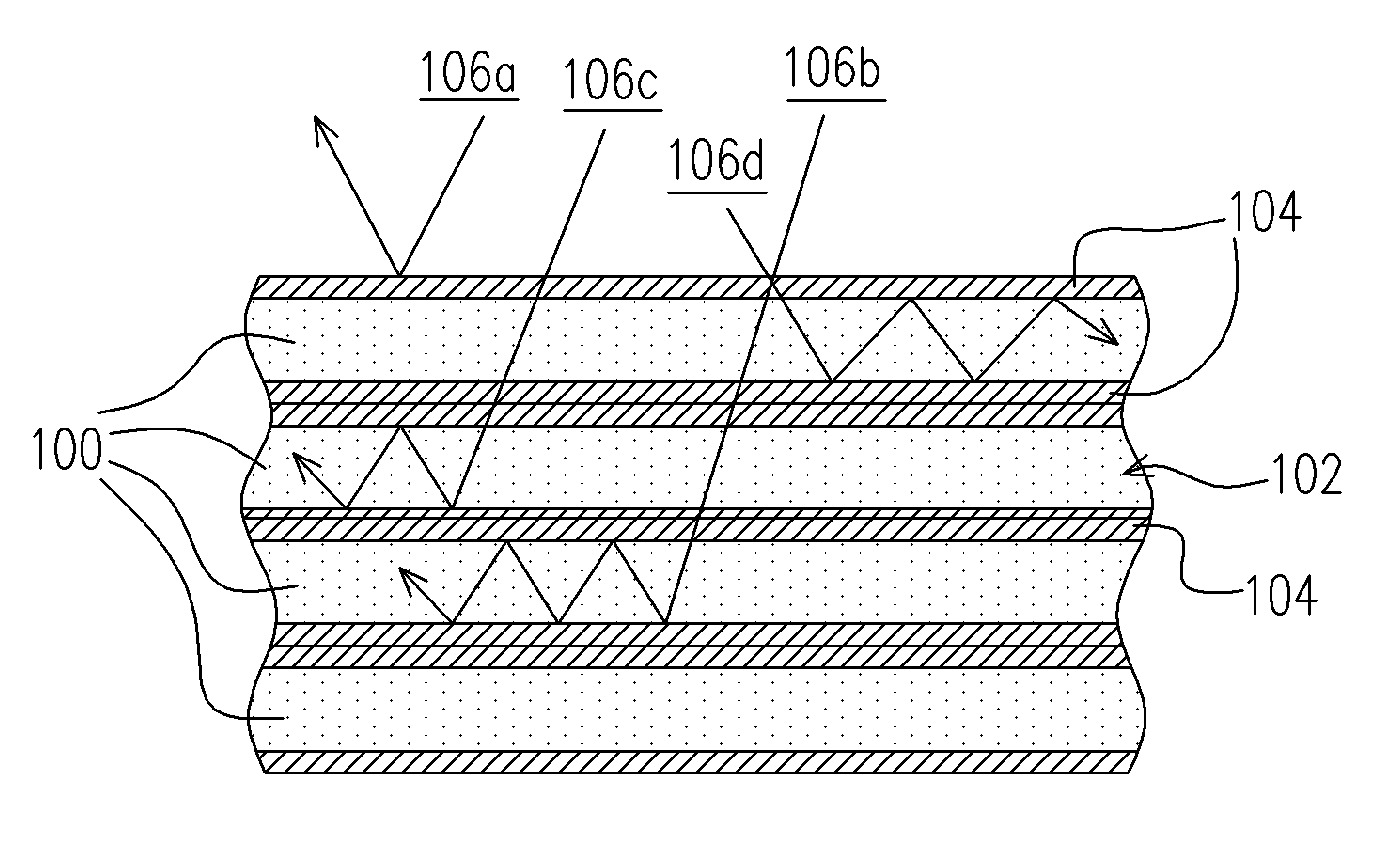

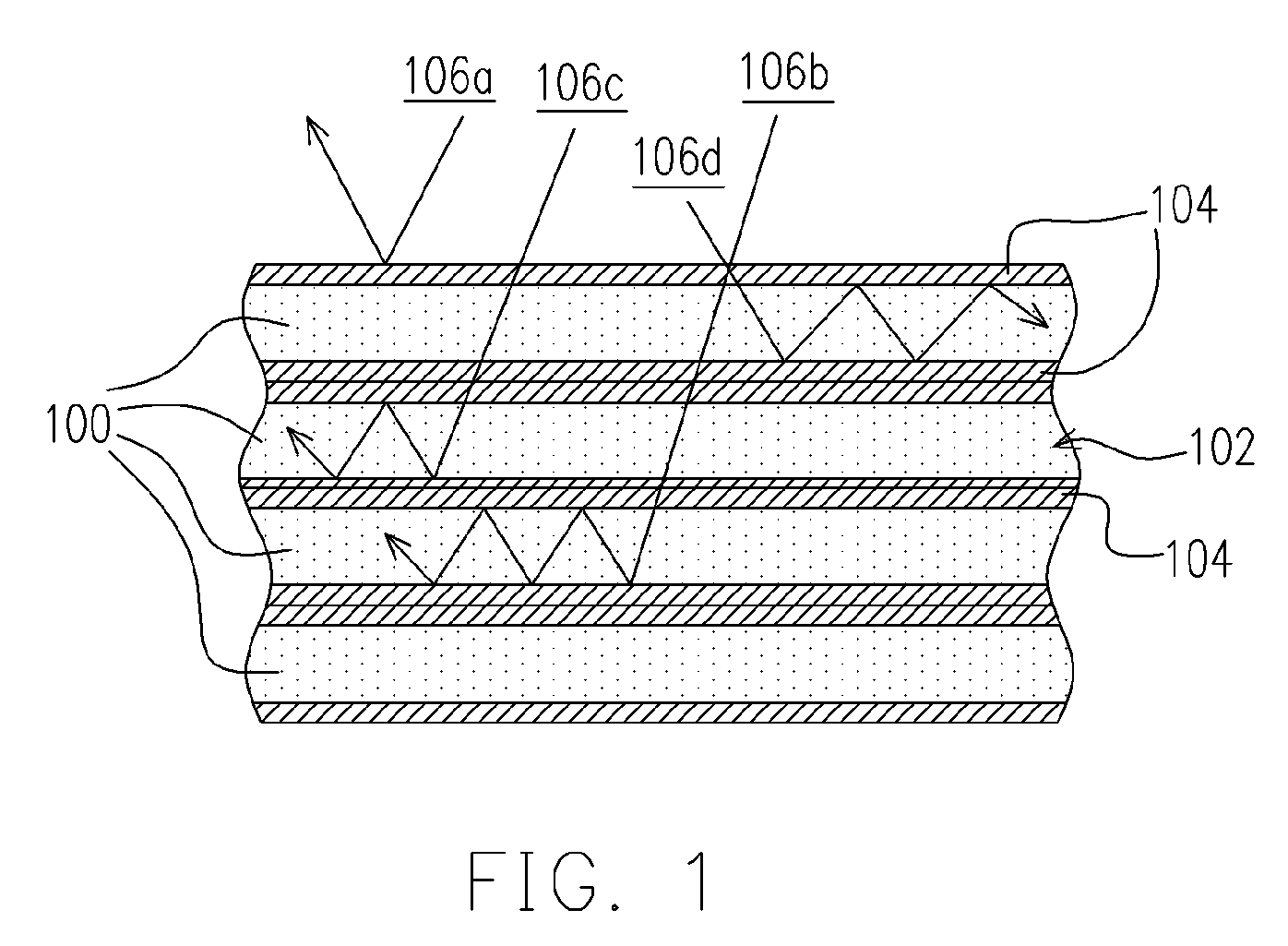

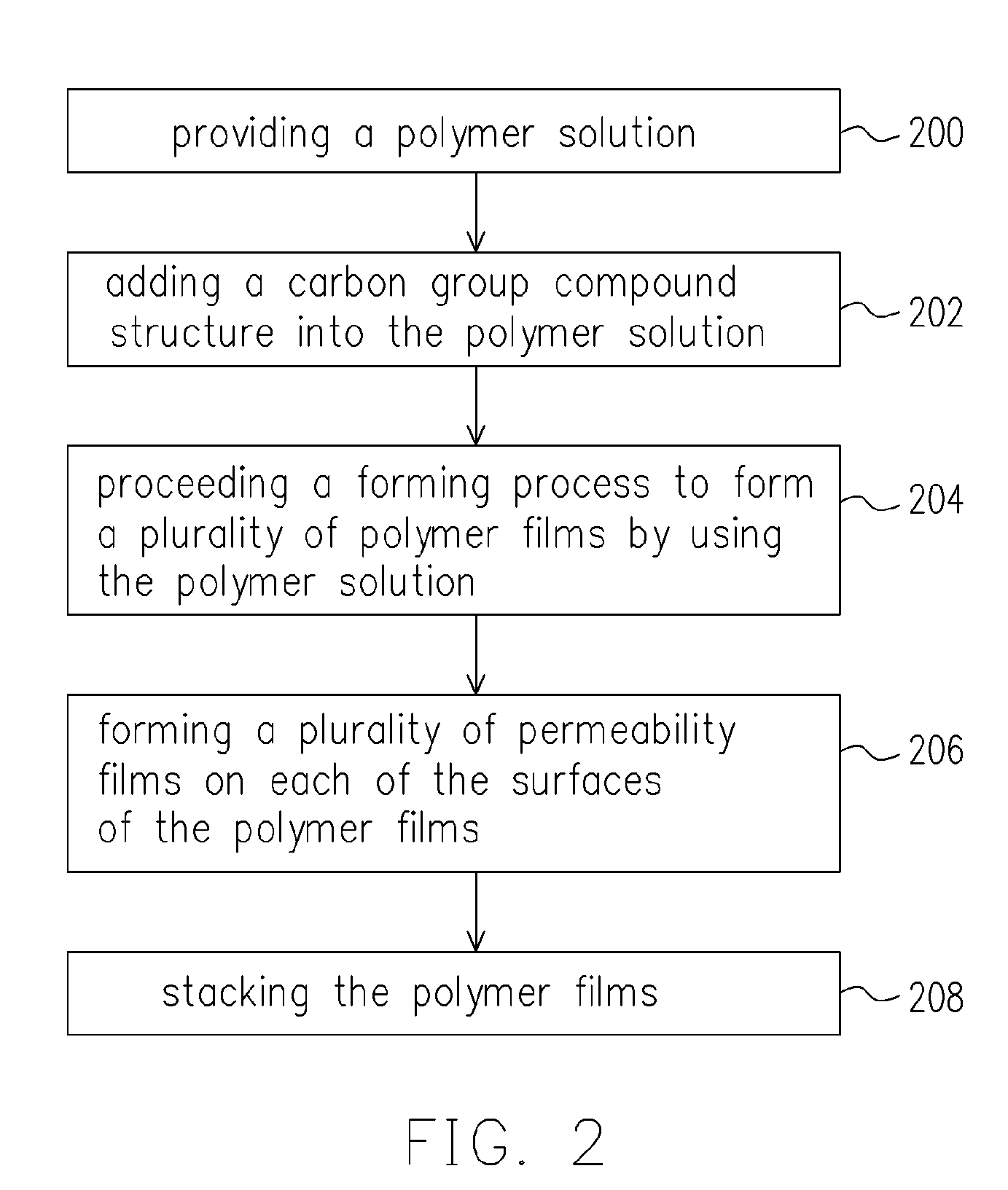

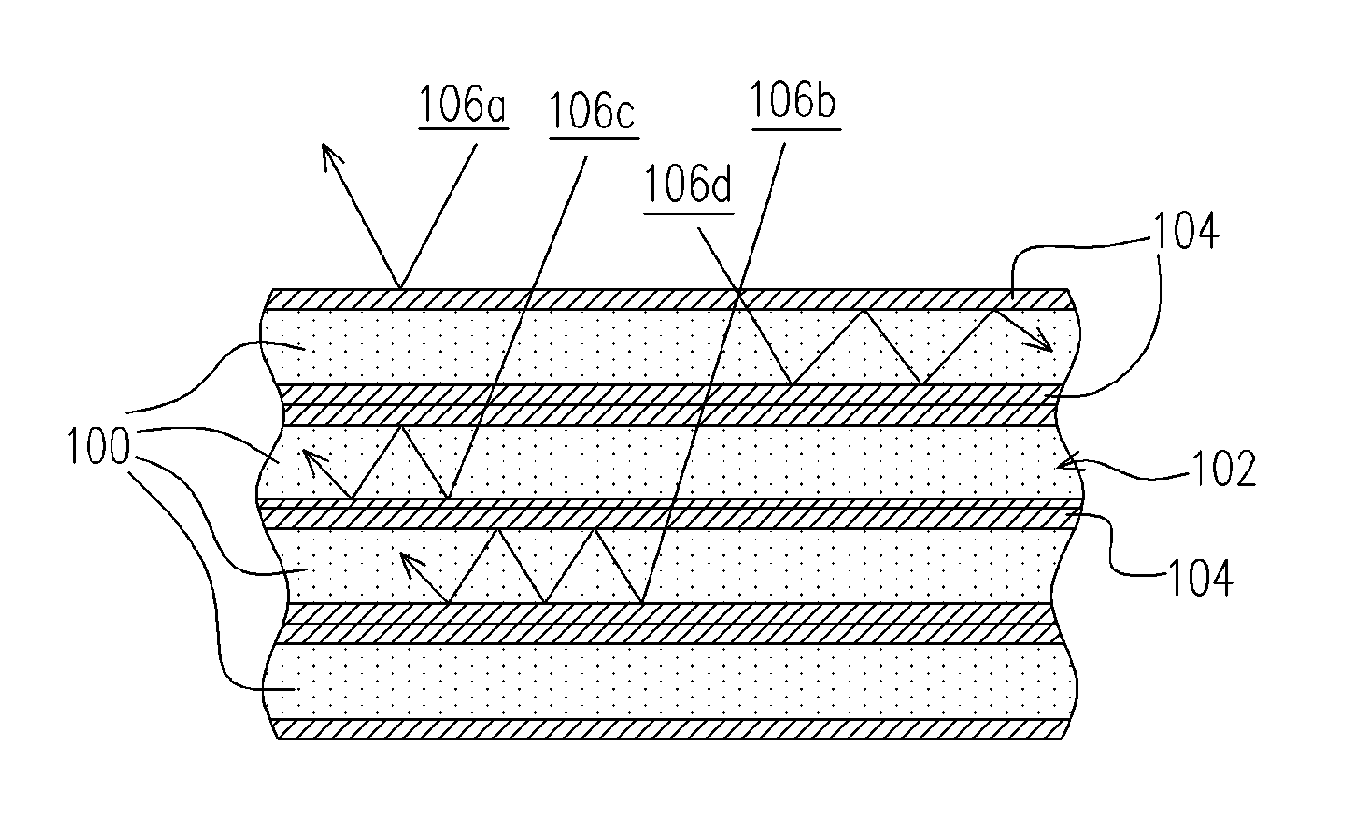

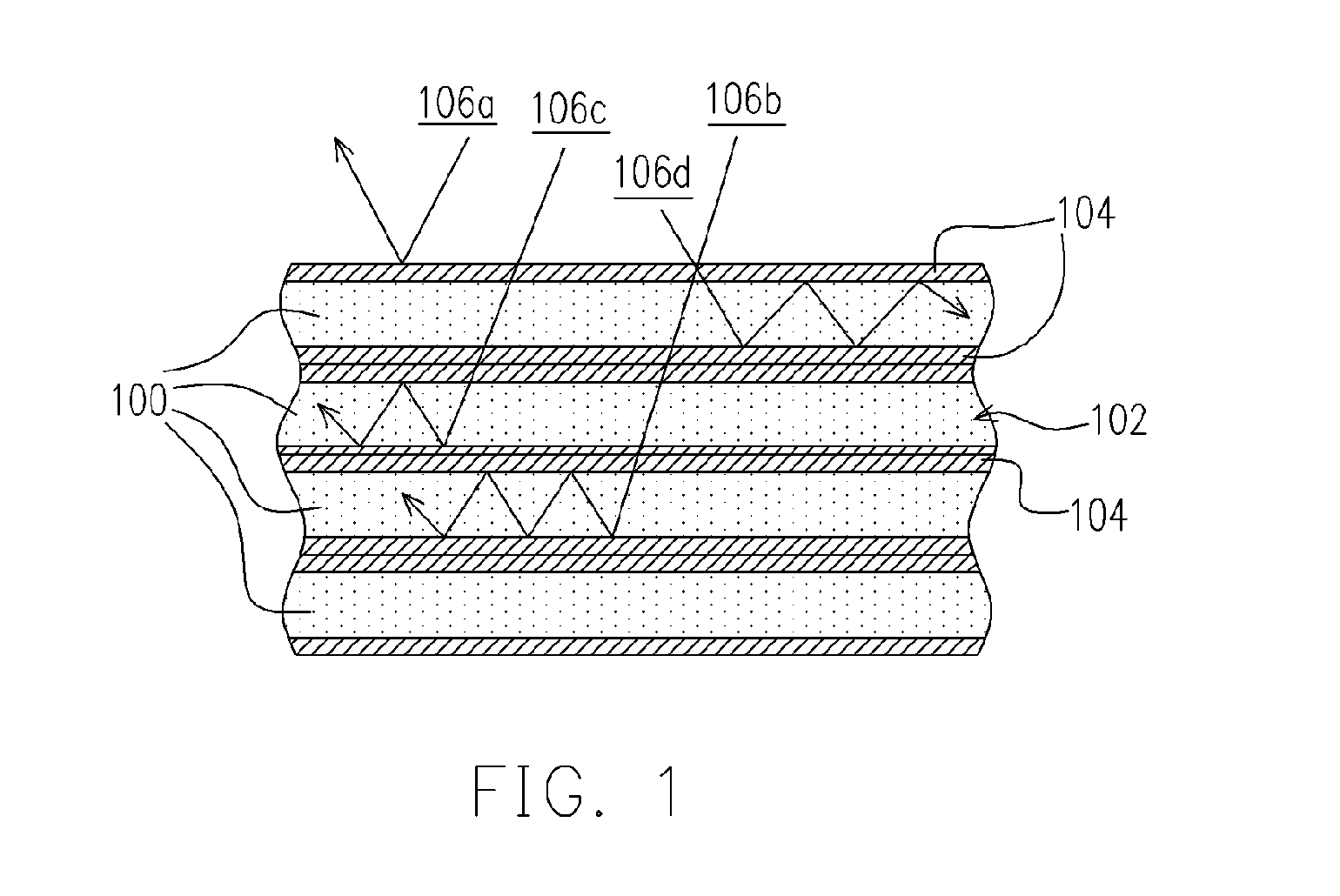

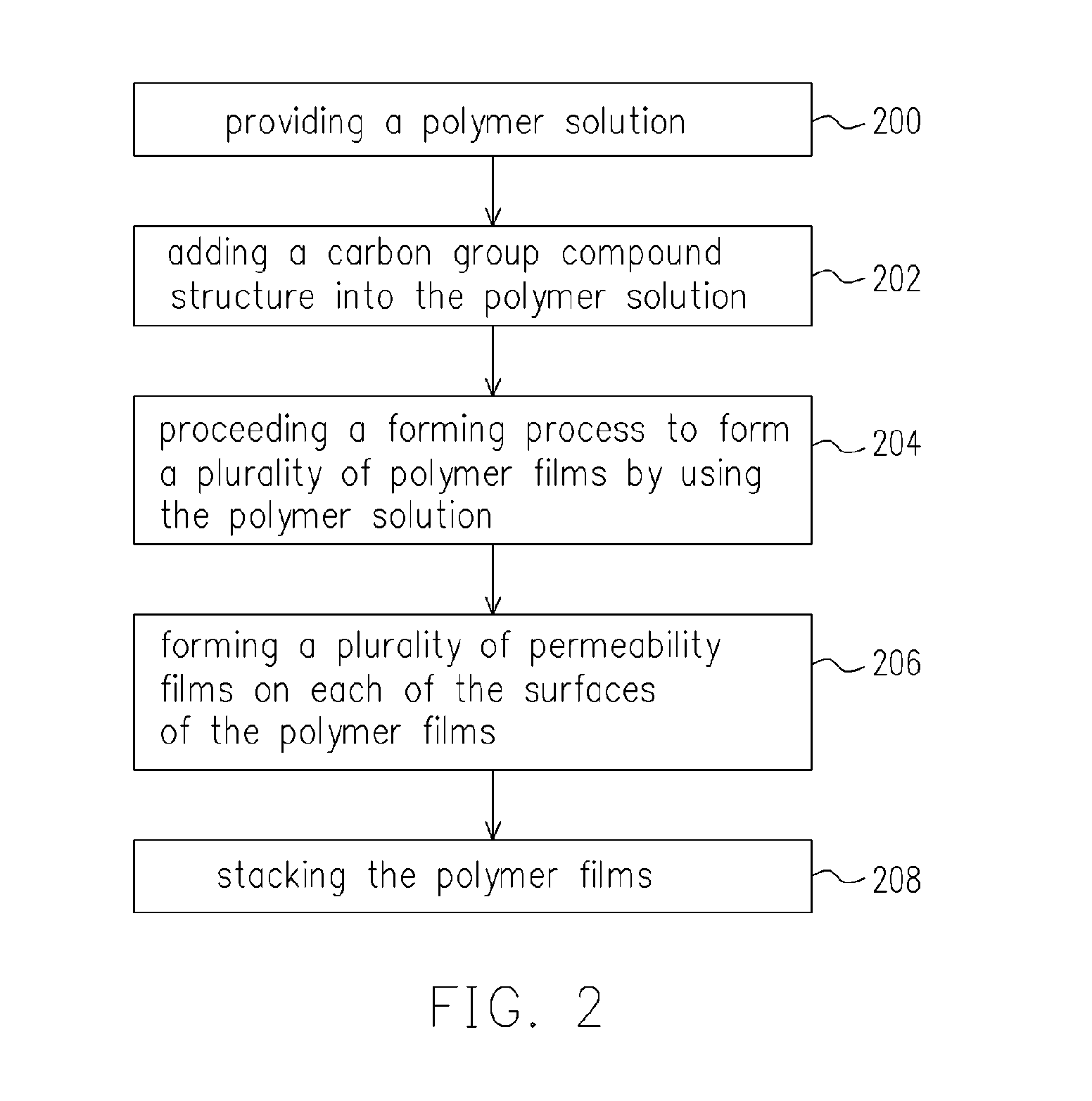

Multilayer structure for absorbing electromagnetic wave and manufacturing method thereof

InactiveUS6972366B2Magnetic/electric field screeningSynthetic resin layered productsThermal energyElectromagnetic electron wave

Owner:YEN LI HSIEN +1

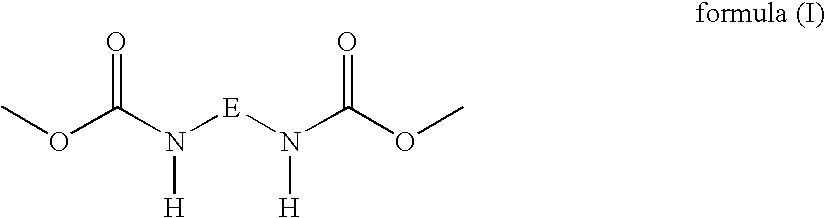

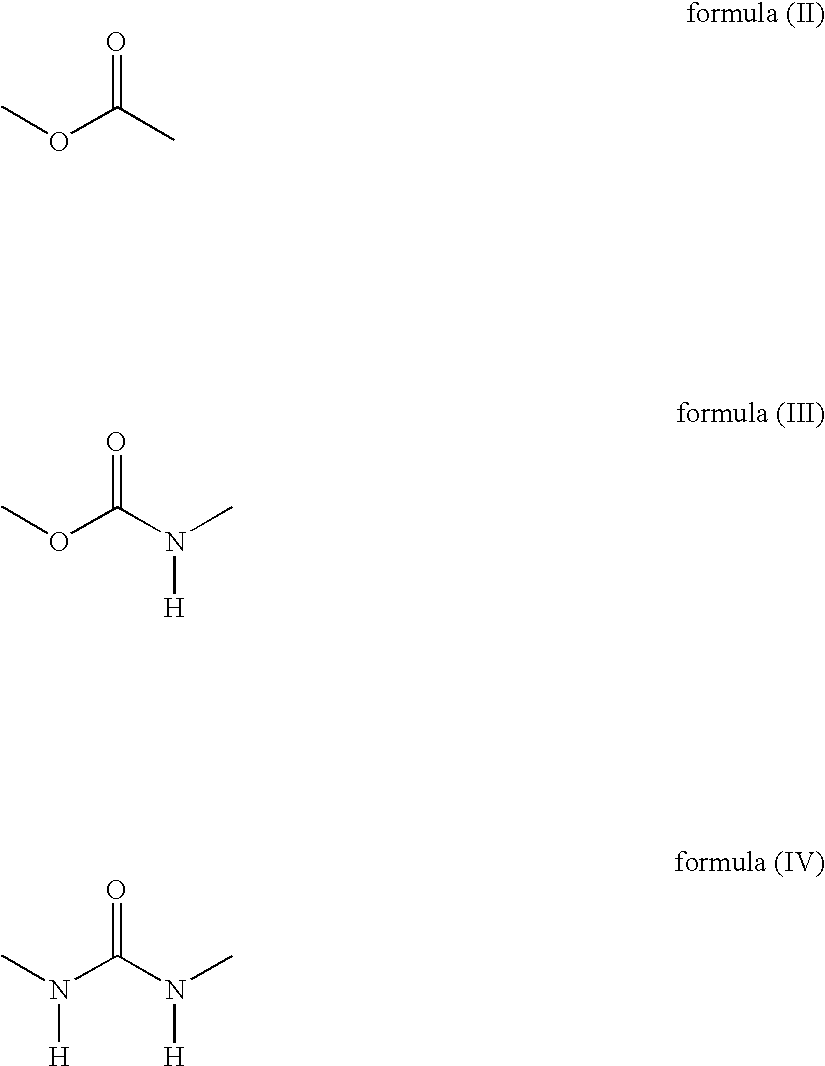

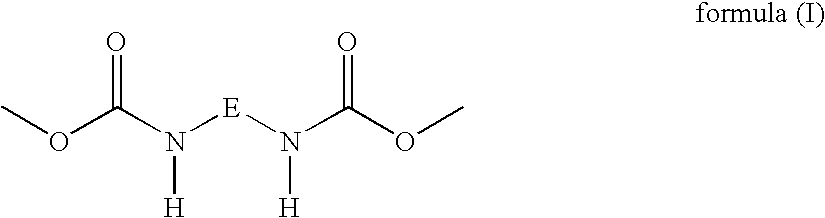

Fluorinated polyurethane composition

InactiveUS20100311893A1Durable and outstandingImprove propertiesStain/soil resistant fibresFilm/foil adhesivesCarbamatePolymer science

A composition useful for imparting durable stain repellence and soil release properties to textile substrates, a method for treating textile substrates using such composition, and the textile substrates obtained therefrom. The composition comprises: (A) at least one fluorinated ionisable polyurethane polymer (PUR) being free from perfluoroalkyl chains and comprising at least one fluorinated block comprising a fluoropolyoxyalkene chain, and at least one functional block comprising an hydrocarbon chain (RHC) having from 2 to 14 carbon atoms, said chain (RHC) comprising at least one ionisable group, said blocks being linked by urethane moieties of formula (I),wherein E is a divalent hydrocarbon carbon group; (B) at least one fluorocarbon polymer (F) comprising at least one perfluoroalkyl chain (Rf) linked by one or more ester moiety of formula (II) and / or urethane moiety of formula (III) and / or urea moiety of formula (IV); and (C) at least one crosslinking agent.

Owner:SOLVAY SOLEXIS

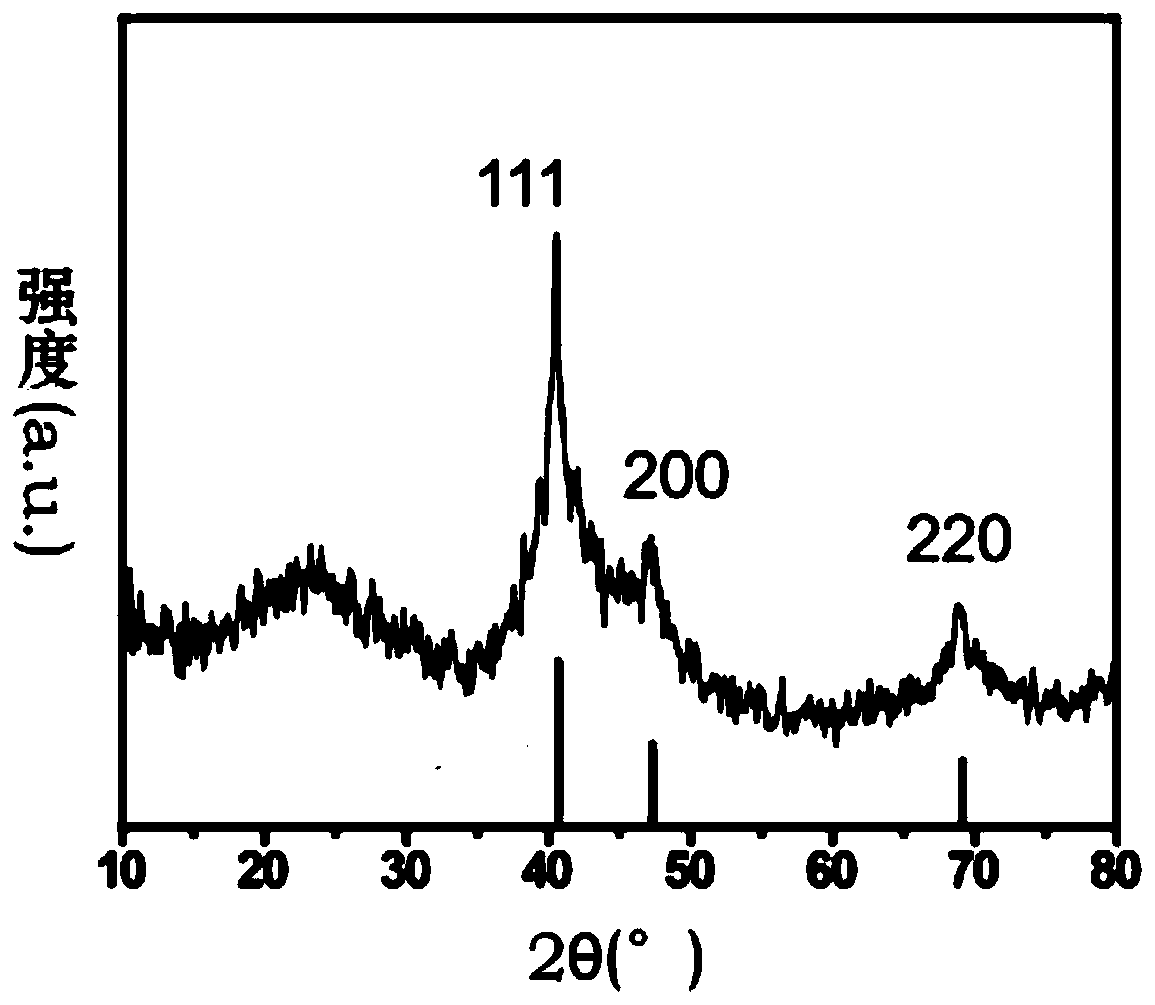

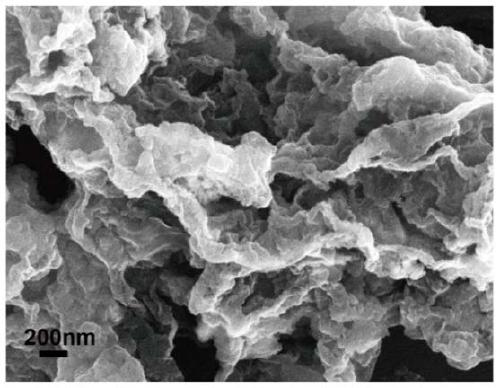

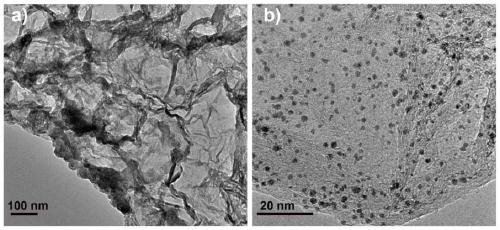

Double-carbon-confined iridium nanocluster and preparation method and application thereof

ActiveCN110292939AAvoid reunionBlocking volumePhysical/chemical process catalystsElectrodesIridiumS doping

The invention discloses a double-carbon-confined iridium nanocluster catalyst and a preparation method and application thereof. The double-carbon-confined iridium nanocluster catalyst is a composite material formed by dispersing iridium nanodots on a carbon matrix, and the carbon matrix is graphene oxide and S-doped mesoporous carbon. Ultra-small nano-sized iridium nanoclusters are prepared through the double confinement effect of two carbon groups, and the aggregation of iridium nano-particles can be effectively prevented. The finally obtained catalyst has large specific surface area, the active sites of the catalyst are increased, the overpotential and Tafel slope of electrolytic water reaction are greatly reduced, the performance of the catalyst is effectively improved, and the catalysthas long service life and good stability. In addition, the preparation method of the catalyst is simple, the raw materials are cheap and readily available, the reserves are abundant, the preparationprocess is simple and easy to operate, and the catalyst is a catalyst with practical value for electrolyzed water.

Owner:BEIJING UNIV OF CHEM TECH

Multilayer structure for absorbing electromagnatic wave and manufacturing method thereof

InactiveUS20050025986A1Magnetic/electric field screeningSynthetic resin layered productsThermal energyCompound structure

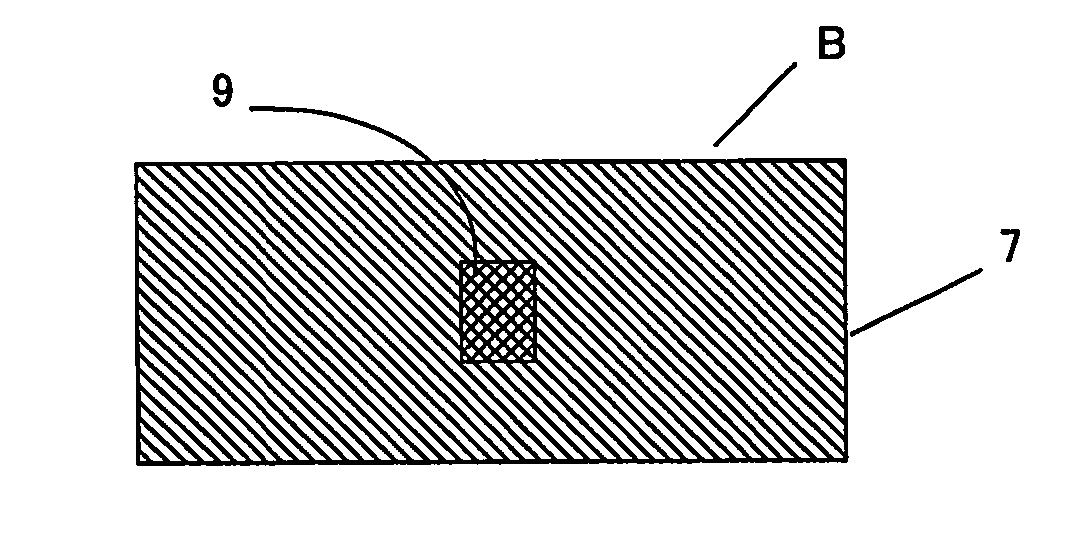

A film structure for absorbing electromagnetic wave and manufacturing method thereof is provided. The multilayer film structure is composed of a plurality of polymer films and a plurality of permeability films. The polymer films have a multi-film stacking structure and the polymer films are composed of a carbon group compound structure. The permeability films are formed on each surface of the polymer films. Thus, every neighboring permeability films will have magnetic moments in opposite direction, and all the emitted electromagnetic waves will be cancelled by the permeability films, or be reflected in any one of the polymer films until the energies of the electromagnetic waves are consumed, or be absorbed by the carbon group compound structure and be transferred into thermal energy.

Owner:YEN LI HSIEN +1

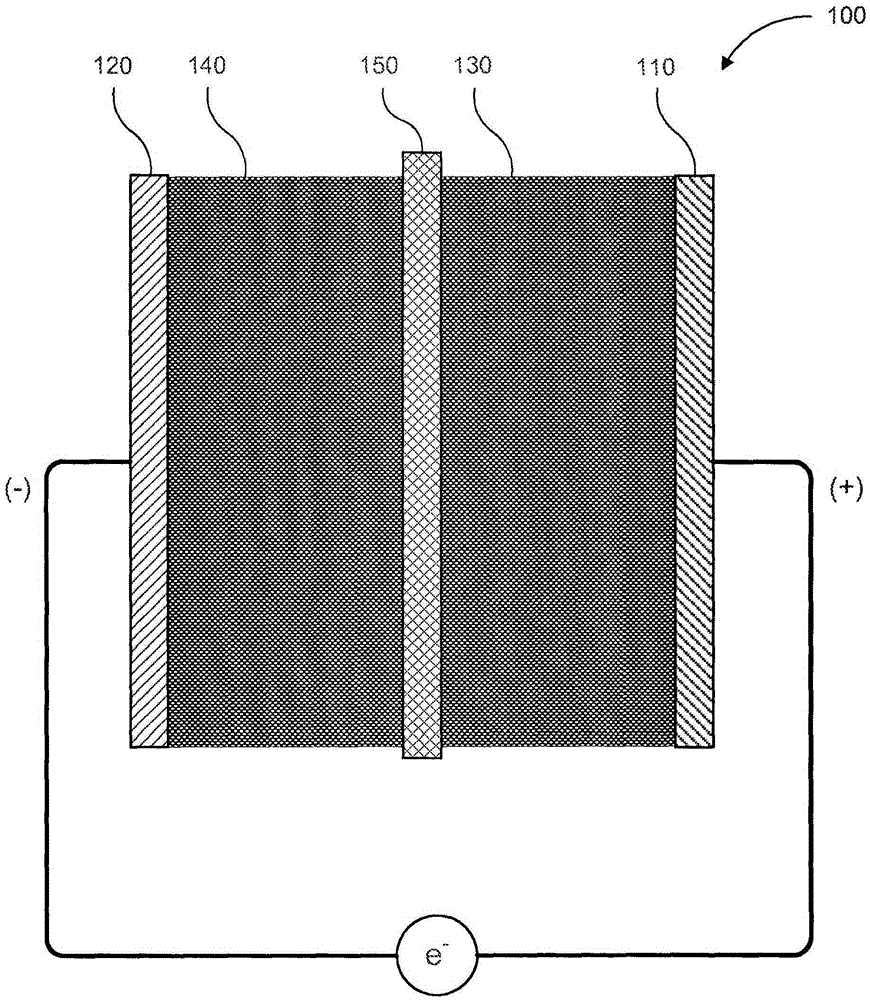

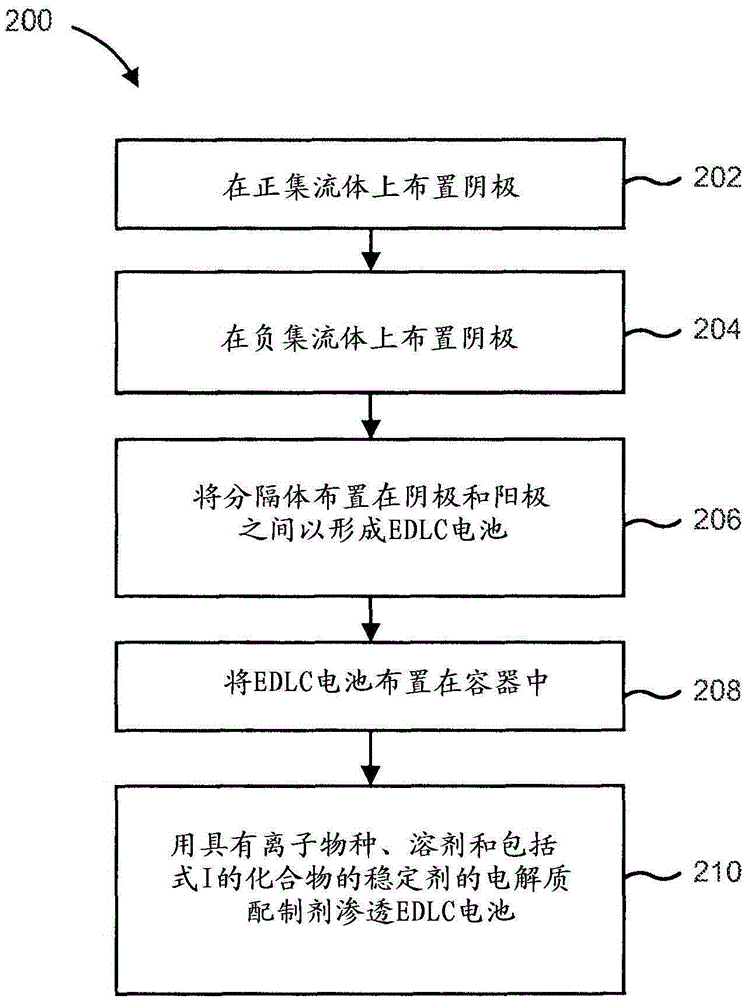

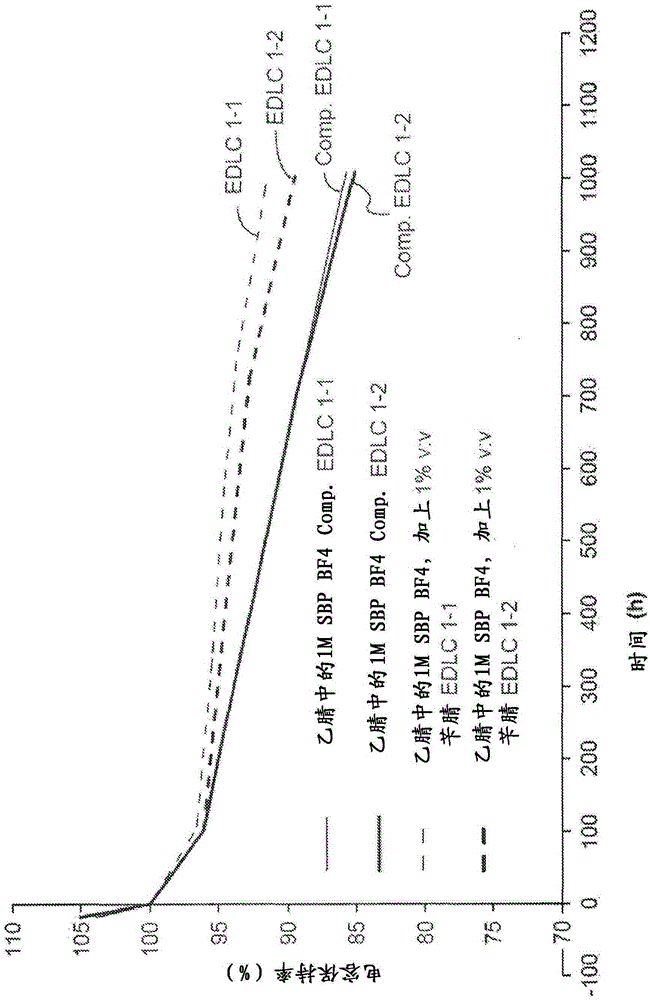

Stability enhancing additive for electrochemical devices

Embodiments described herein relate generally to electric double layer capacitors having an electrolyte formulation that includes a quantity of a stabilizing additive such that the electrochemical double layer capacitors retain cell capacitance for longer periods of time, generate less gas during operation, and experience less long term ESR. In some embodiments, an electrolyte formulation includes an ionic species, a solvent, and a stabilizer. In some embodiments the stabilizer contains a moiety that promotes adsorption to a surface, such as a carbon surface, and a moiety that promotes polarity of the stabilizer. In some embodiments, the solvent can be a nitrile compound and the stabilizer can be a compound of the formula I: Such that R is H, saturated or unsaturated, linear or branched, acyclic carbon group, OH, halogen NH2, NO2, (SO)2CF3, or monocyclic or polycyclic aryl, and n is an integer from 0 to 5.

Owner:系统动力建造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com