Method for increasing production of propylene

A production method and propylene technology, which can be used in ethylene production, biological raw materials, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of low carbon-based yield of propylene and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

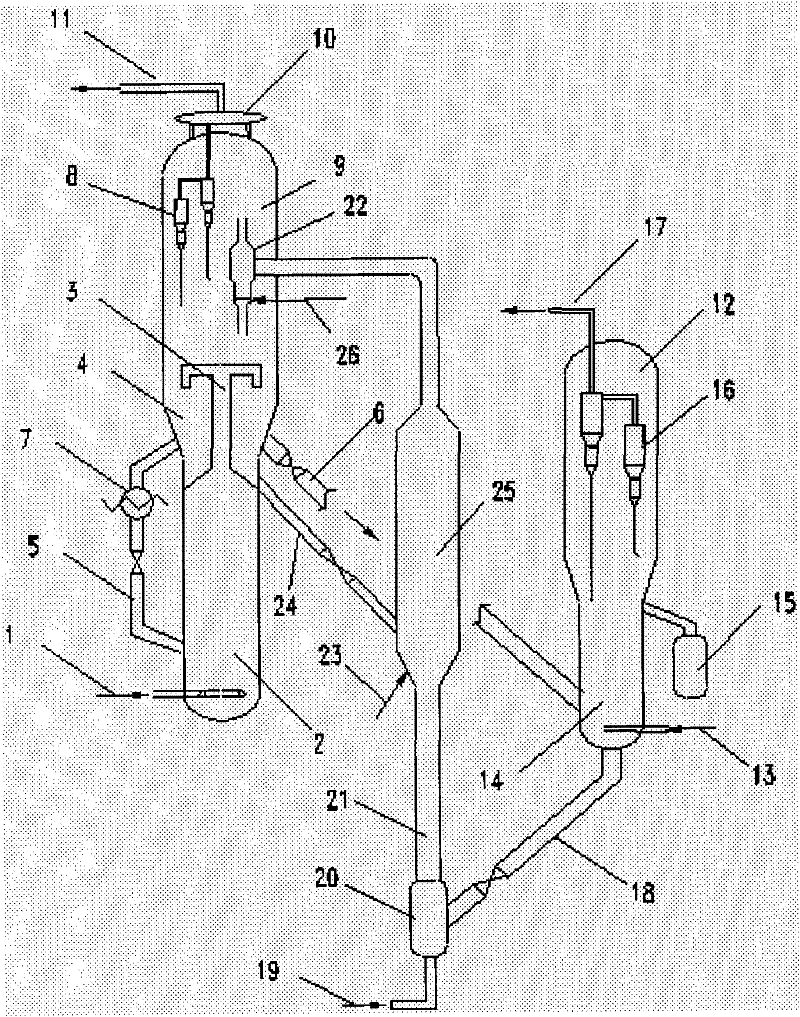

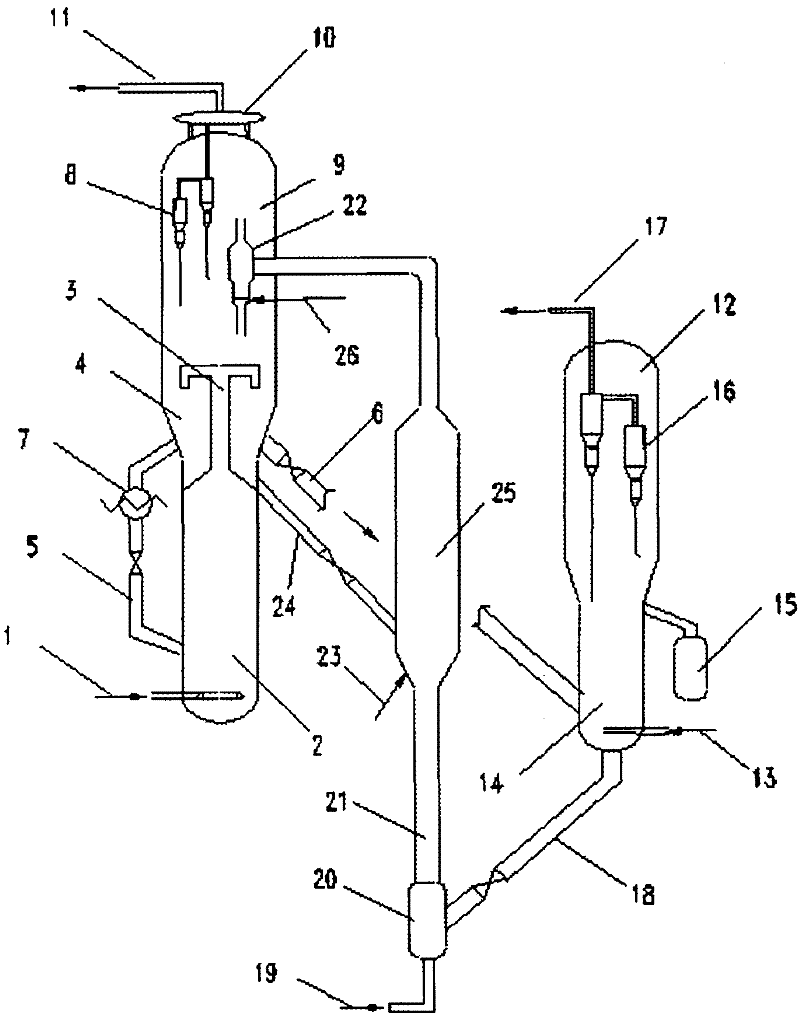

[0022] in such as figure 1 In the shown reaction device, the average temperature of the first fast bed reaction zone is 480°C, the reaction pressure is 0.1MPa in gauge pressure, and the gas linear velocity is 1.5 m / s; the average temperature of the riser reaction zone is 550°C, and the reaction pressure is The gauge pressure is 0.1MPa, the gas linear velocity is 5.0m / s; the average temperature of the second fast bed reaction zone is 470°C, the gauge pressure is 0.1MPa, and the gas linear velocity is 0.8m / s. The carbon deposition amount of the pre-carbon deposition catalyst is 0.5% by weight. The feed at the bottom of the first fast bed reaction zone is pure methanol, the feed is 2 kg / hour, the catalyzer is SAPO-34, and the second raw material is the hydrocarbons above carbon four generated in the product, wherein the mass content of carbon four olefins is 88%, The third raw material is methanol and ethylene, the weight ratio of methanol to ethylene is 0.3:1, and the ethylene ...

Embodiment 2

[0024] According to the conditions described in Example 1, the first fast bed reaction zone average temperature is 440°C, the reaction pressure is 0.2MPa in gauge pressure, and the gas linear velocity is 2.5 m / s; the riser reaction zone average temperature is 650°C, The reaction pressure is 0.2MPa in gauge pressure, the linear velocity of gas is 10.0m / s; the average temperature of the second fast bed reaction zone is 630°C, the reaction pressure is 0.2MPa in gauge pressure, and the linear velocity of gas is 2.0m / sec. The carbon deposition amount of the pre-carbon deposition catalyst is 1.8% by weight. The second raw material is hydrocarbons with carbon four or more, wherein the mass content of carbon four olefins is 91%, the third raw material is methanol and ethylene, and the weight ratio of methanol to ethylene is 0.5:1 to maintain the stability of catalyst flow control, and the reactor outlet product On-line gas chromatographic analysis shows that the carbon-based yield of ...

Embodiment 3

[0026] According to the conditions described in Example 1, the first fast bed reaction zone average temperature is 380°C, the reaction pressure is 0.01MPa in gauge pressure, and the gas linear velocity is 0.8 m / s; the riser reaction zone average temperature is 510°C, The reaction pressure is 0.01MPa in gauge pressure, the linear velocity of gas is 3.0m / s; the average temperature of the second fast bed reaction zone is 450°C, the reaction pressure is 0.01MPa in gauge pressure, and the linear velocity of gas is 1.0m / sec. The carbon deposition amount of the pre-carbon deposition catalyst is 1.2% by weight. The second raw material is hydrocarbons with carbon four or more, wherein the mass content of carbon four olefins is 61%, the third raw material is methanol and ethylene, and the weight ratio of methanol to ethylene is 0.3:1, so as to keep the stability of catalyst flow control, and the reactor outlet product On-line gas chromatographic analysis shows that the carbon-based yiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com