Patents

Literature

194results about "Combustible gas chemical modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

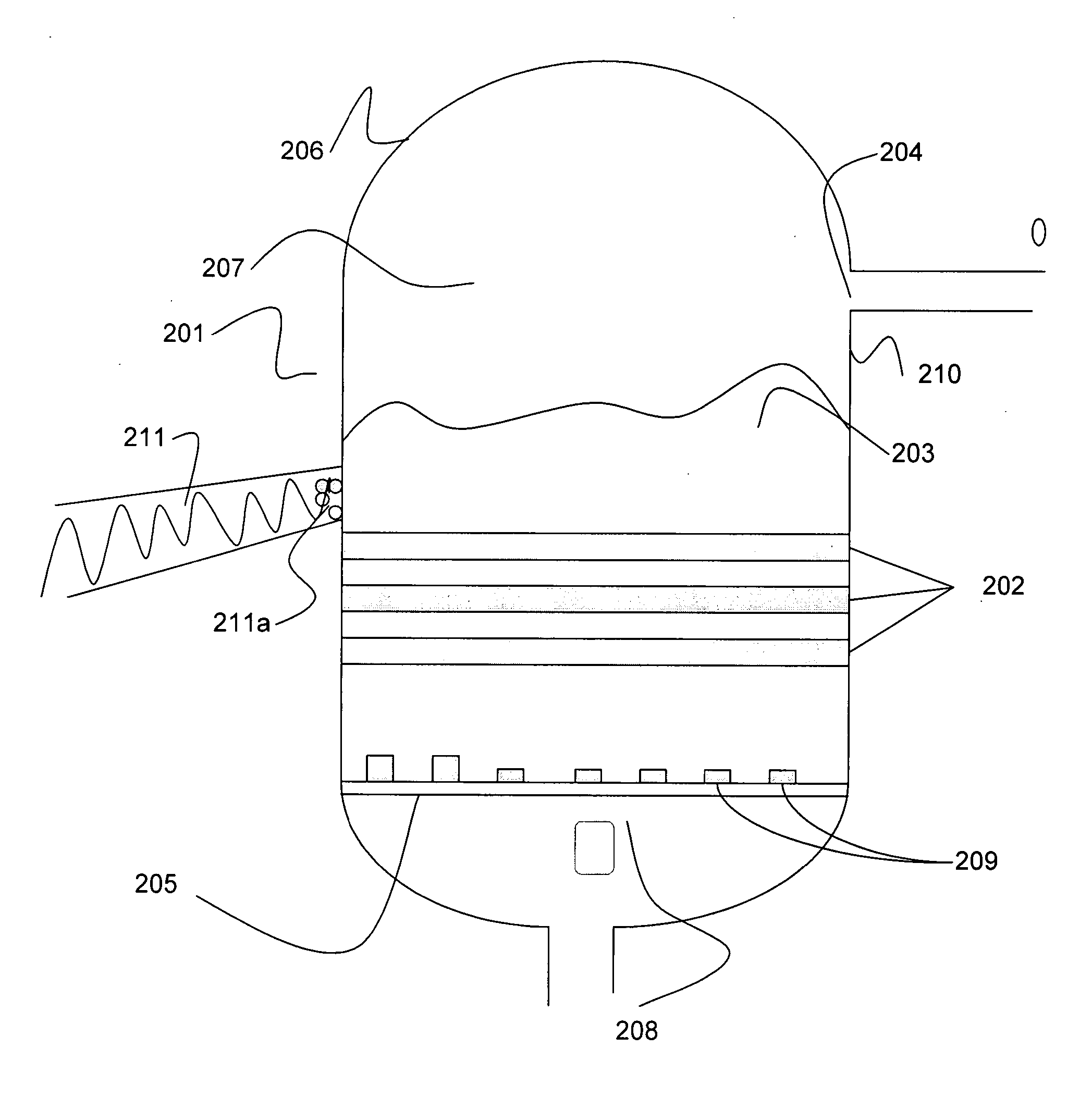

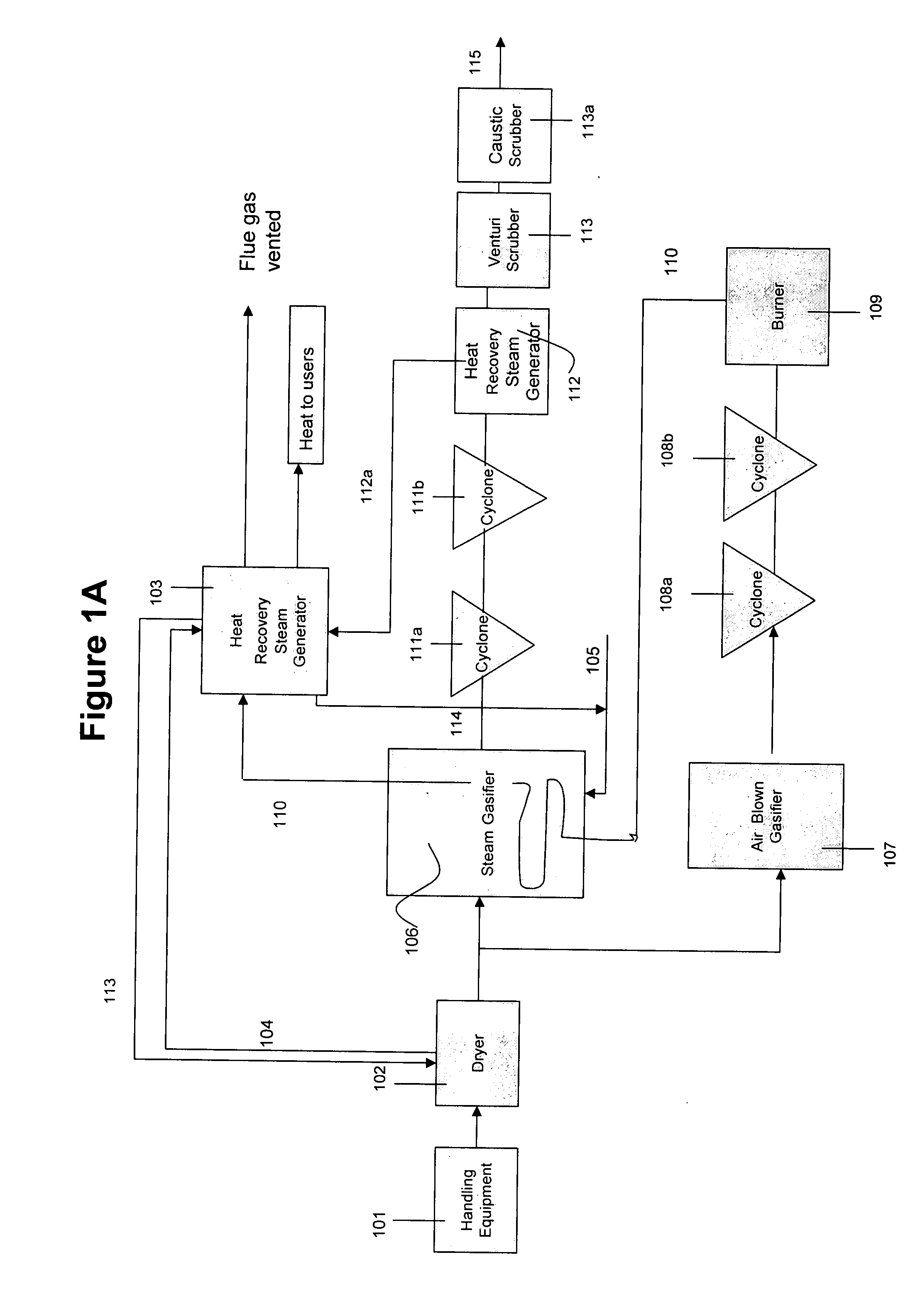

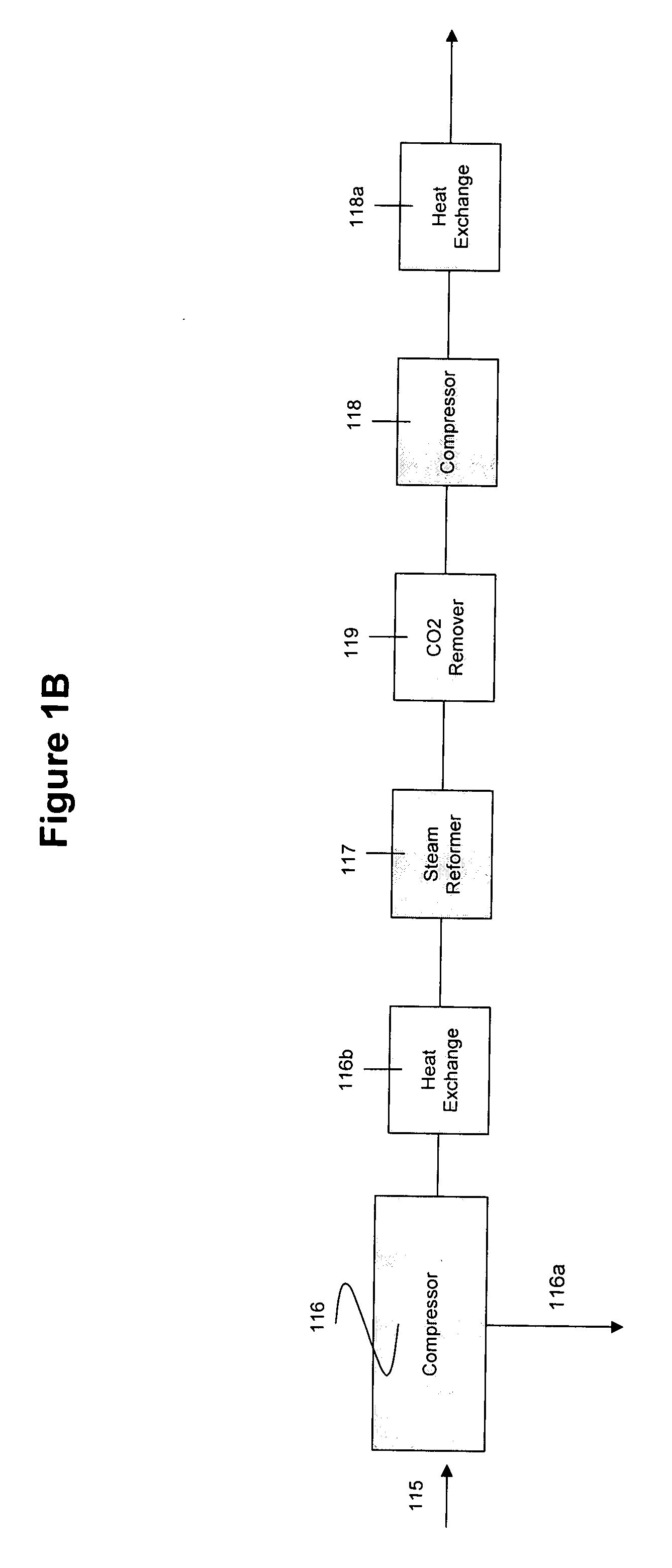

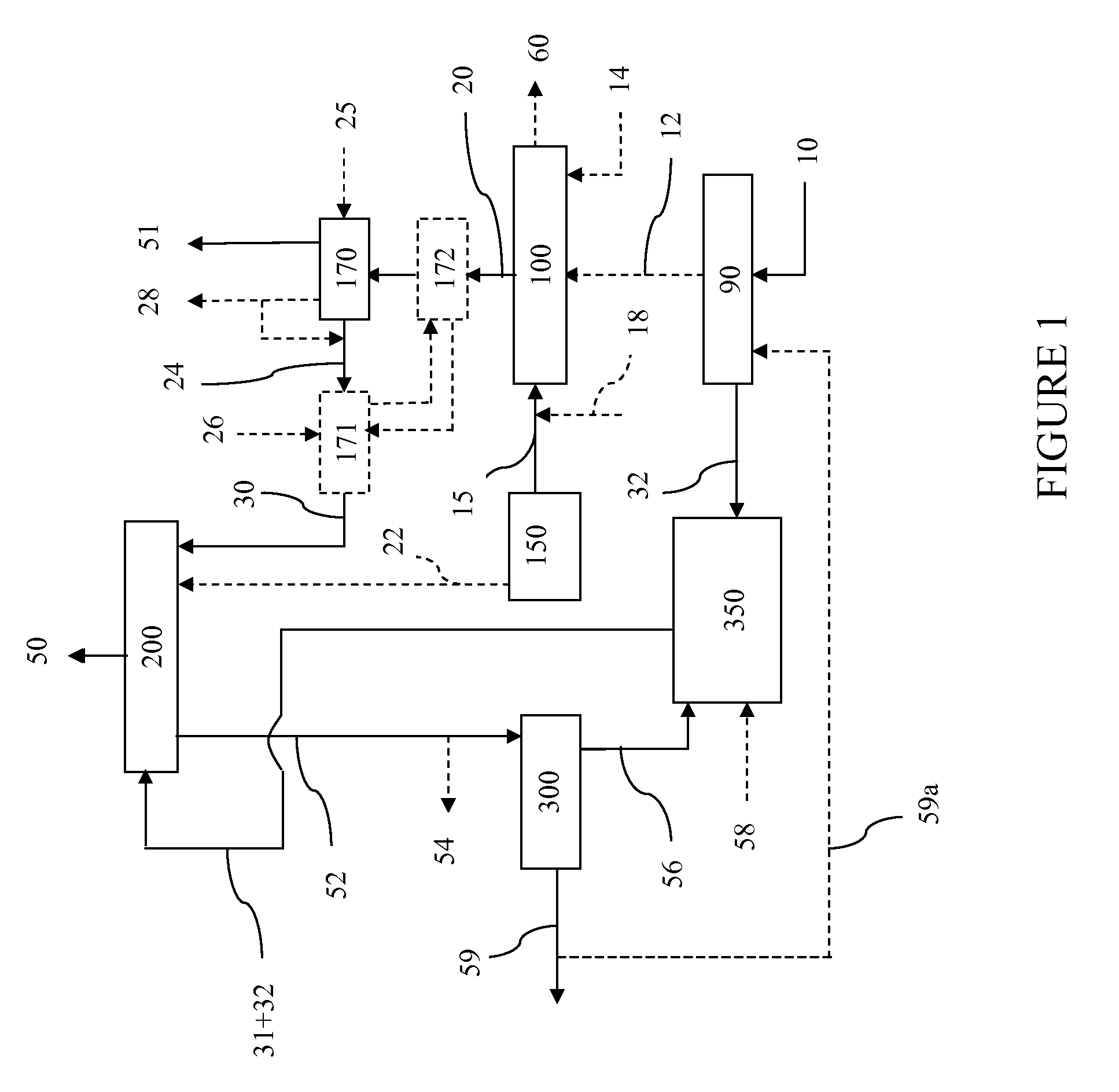

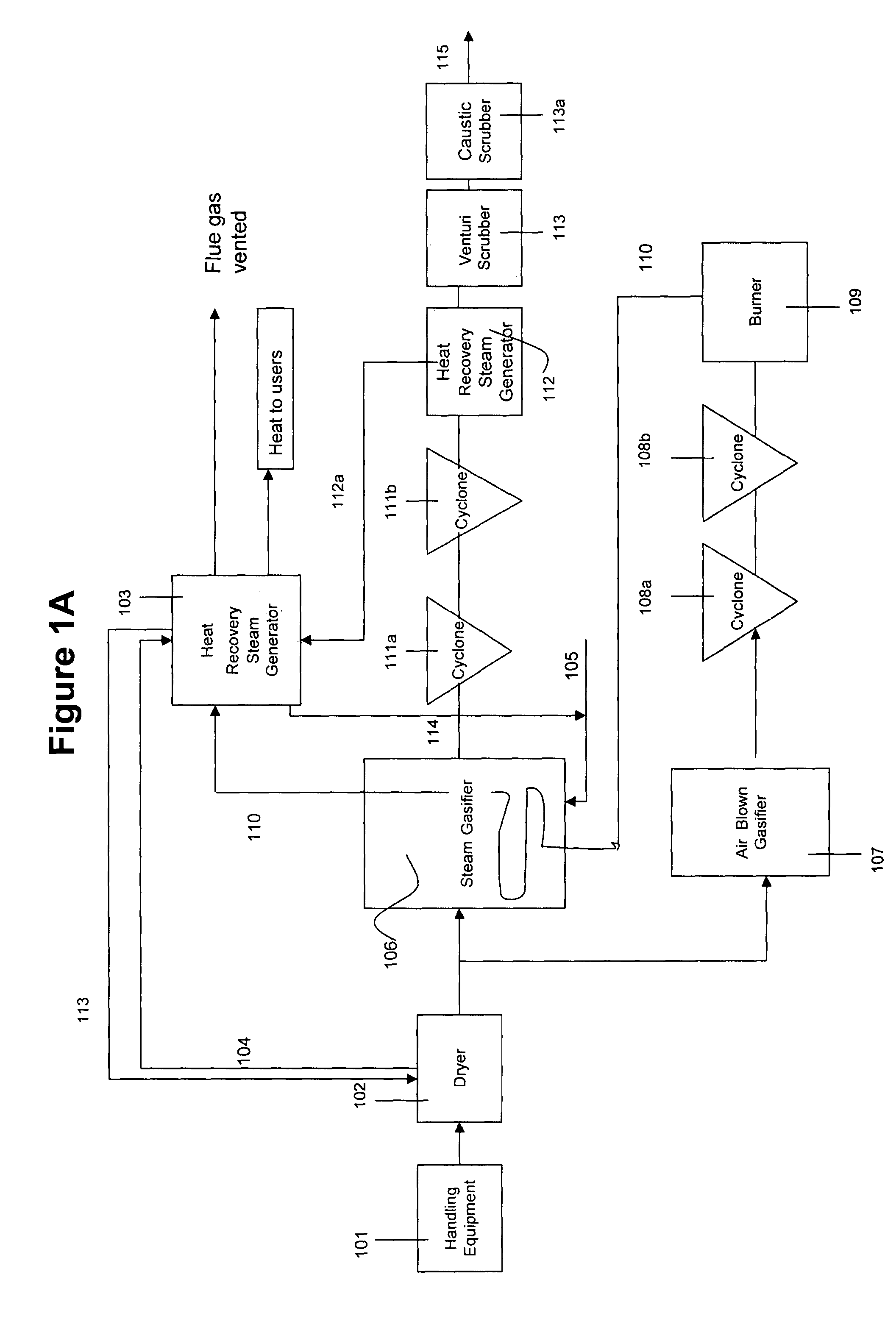

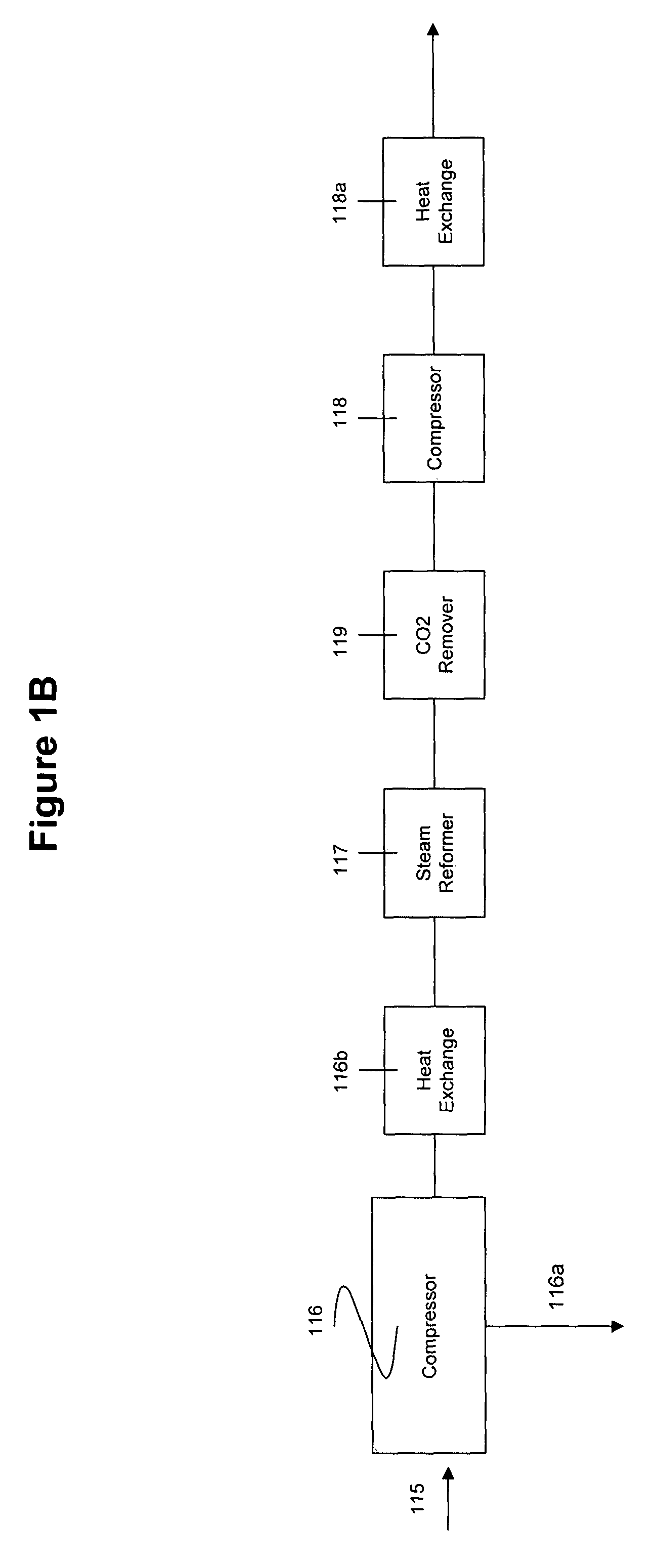

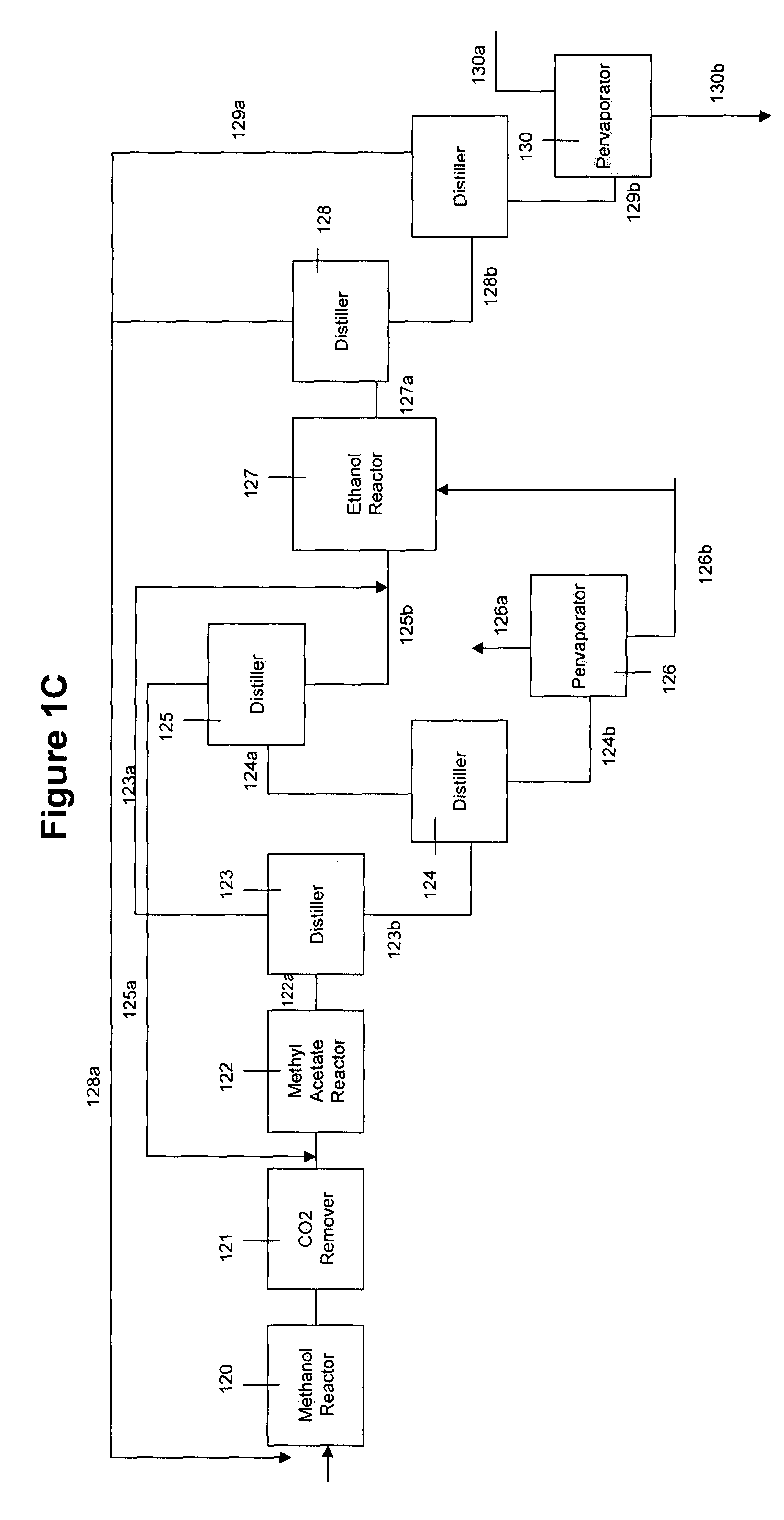

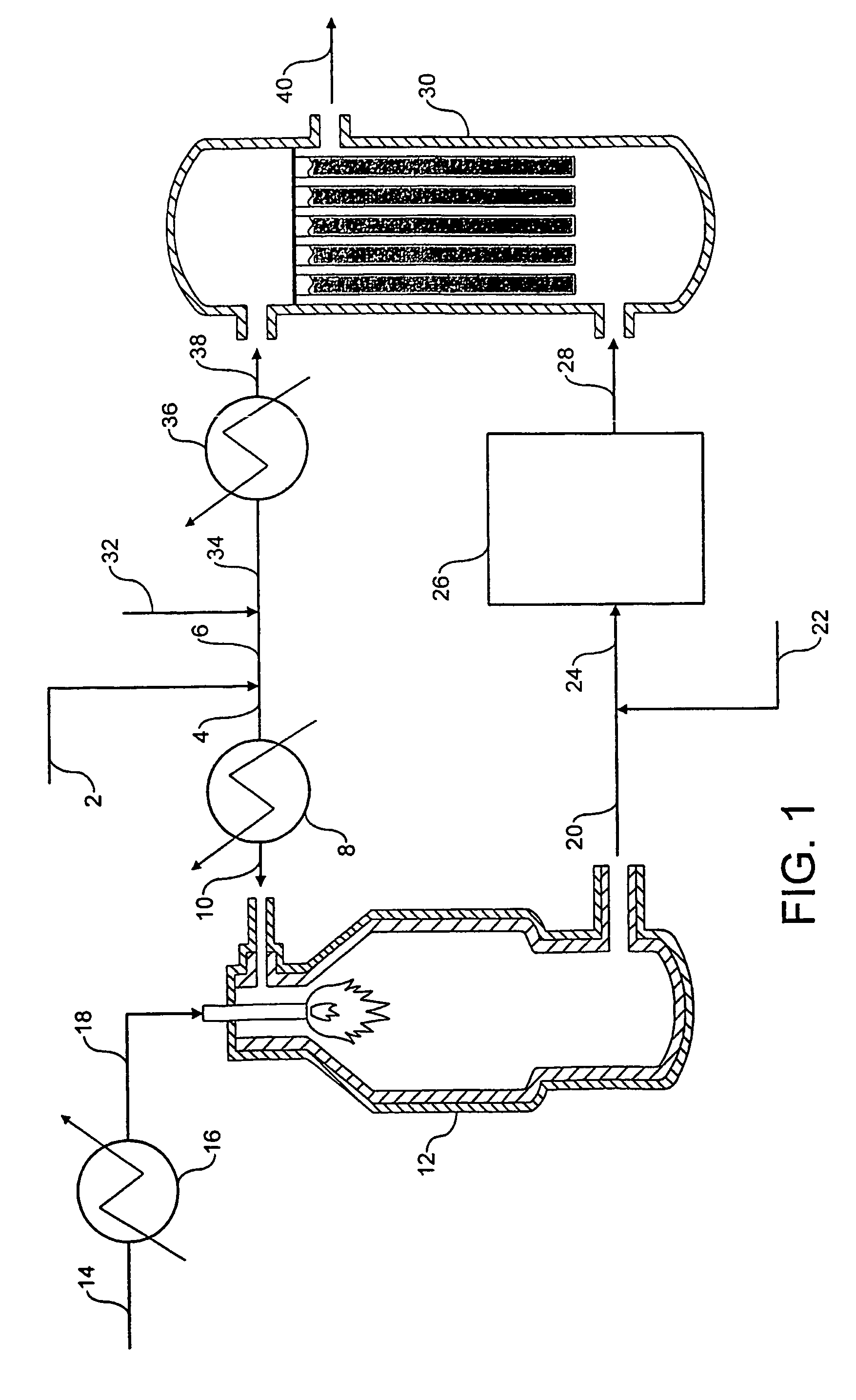

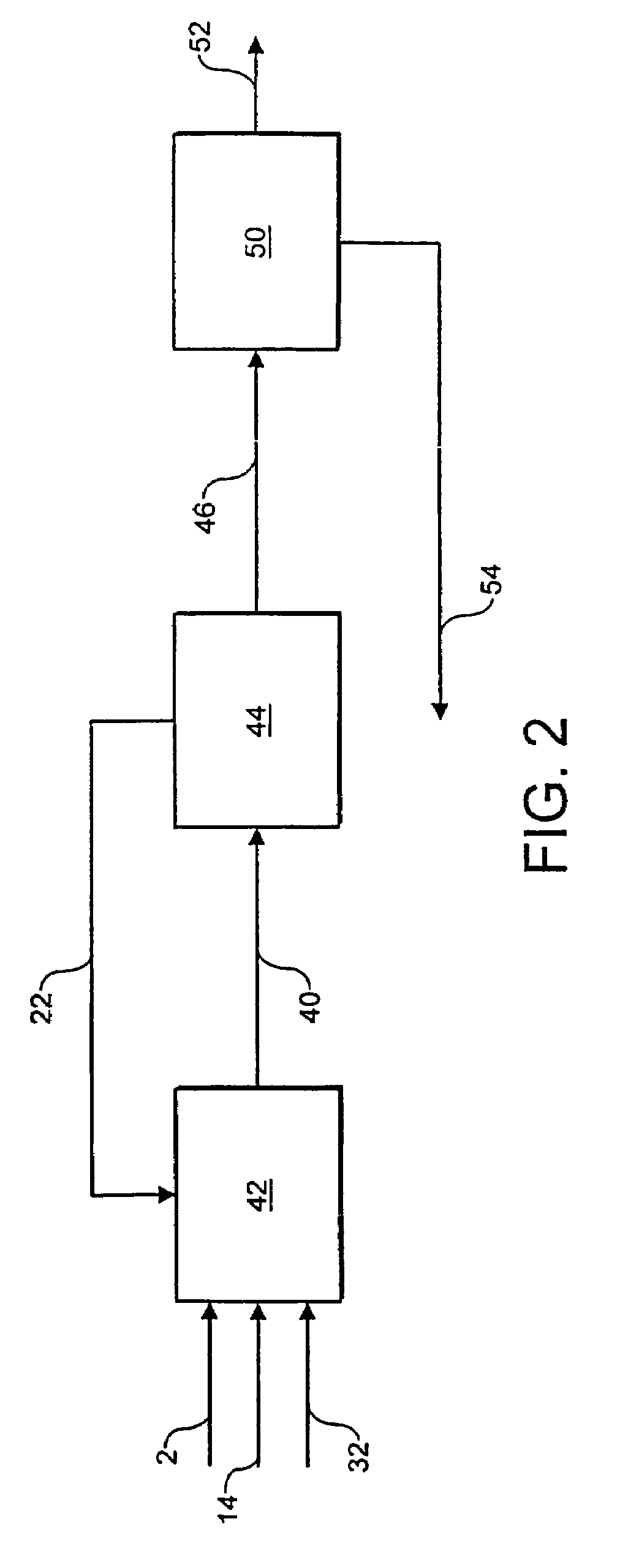

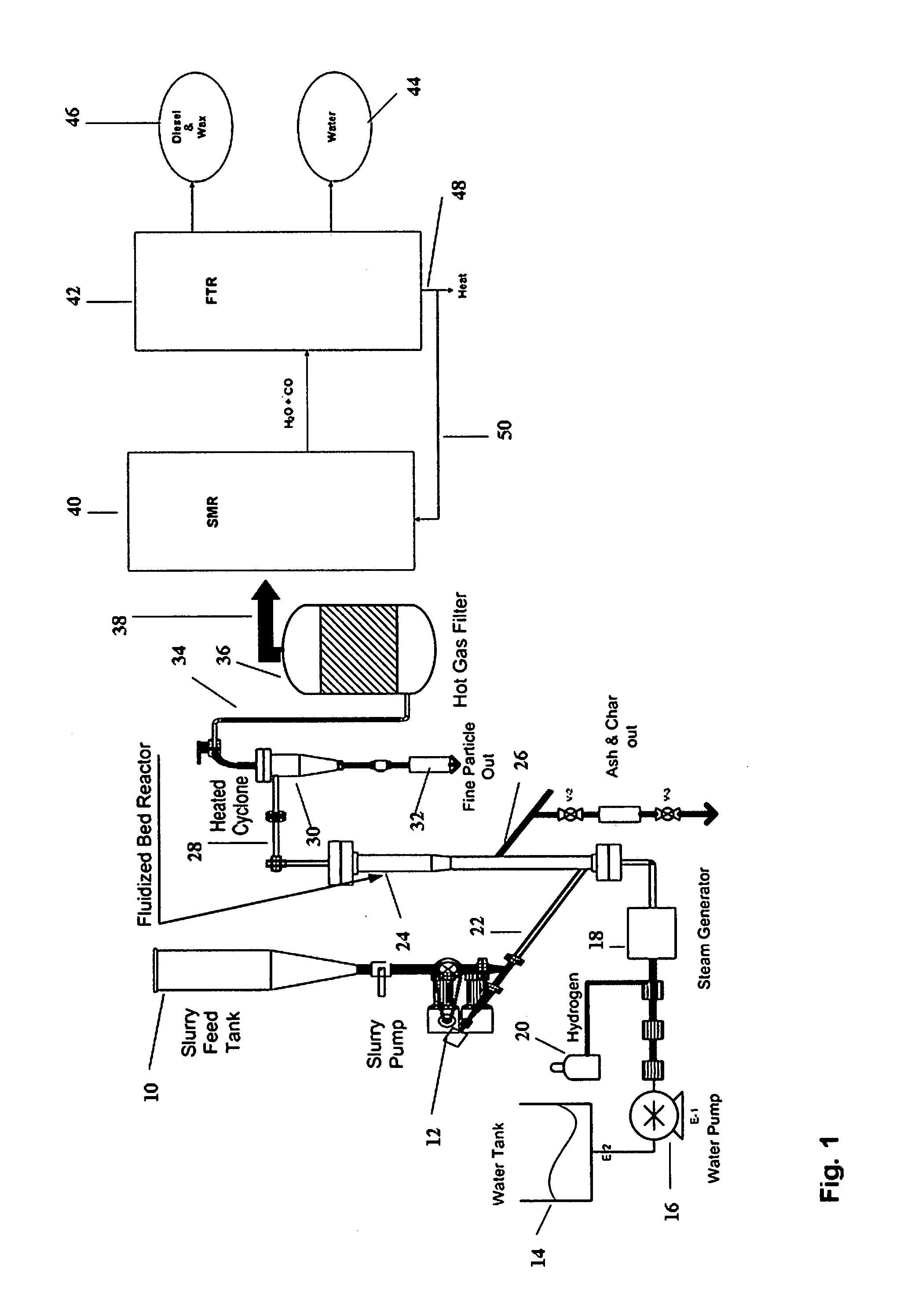

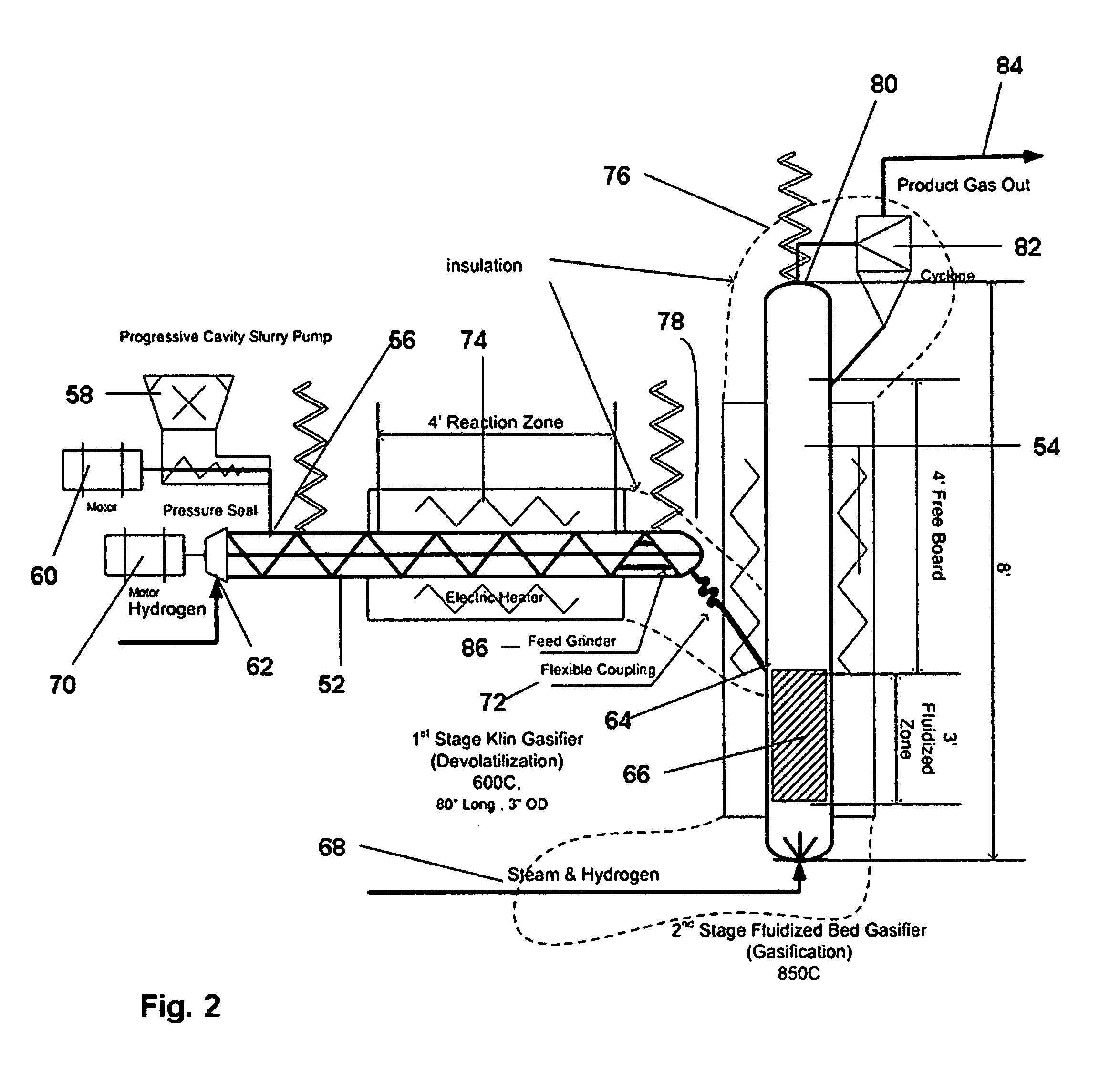

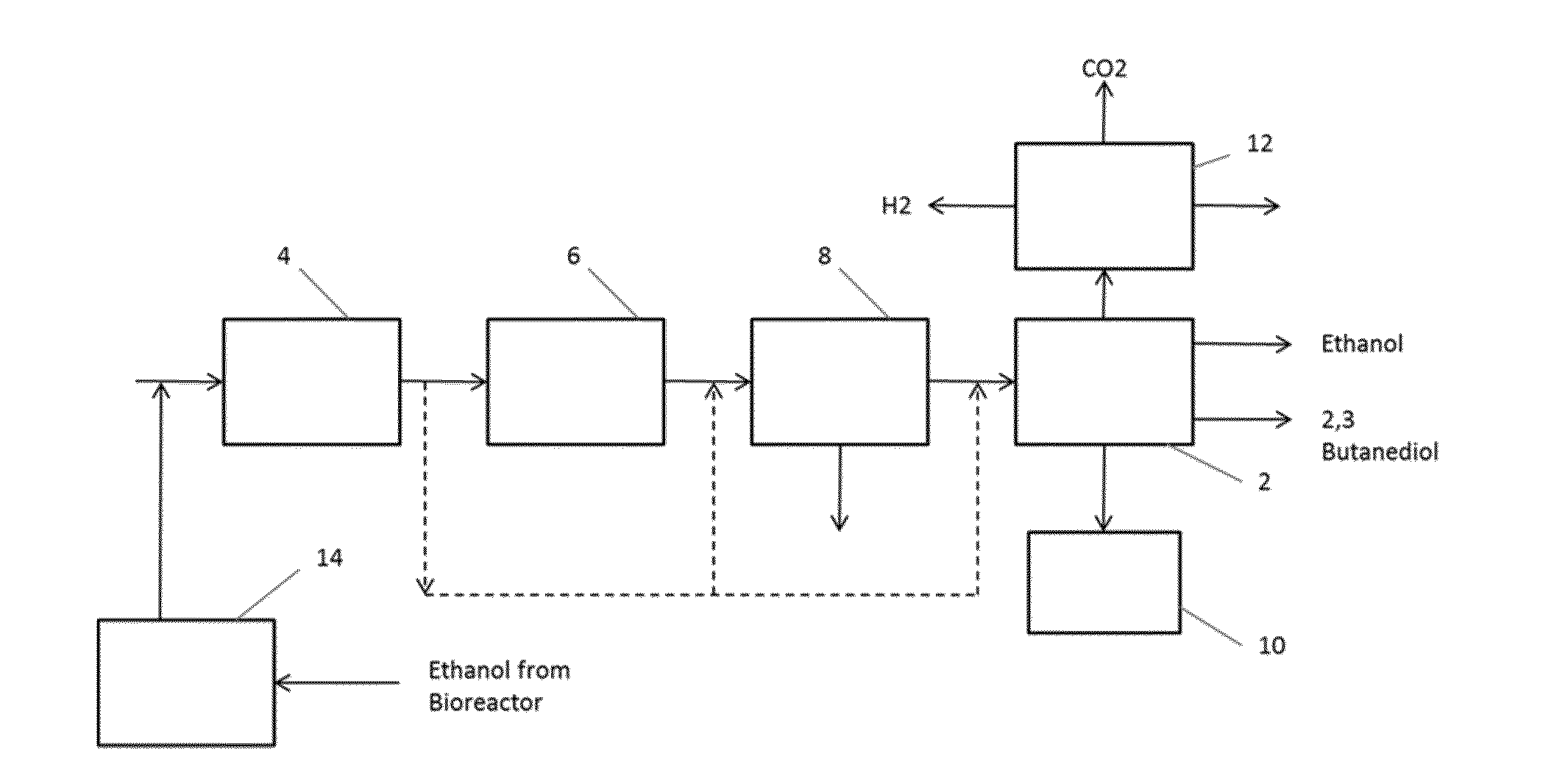

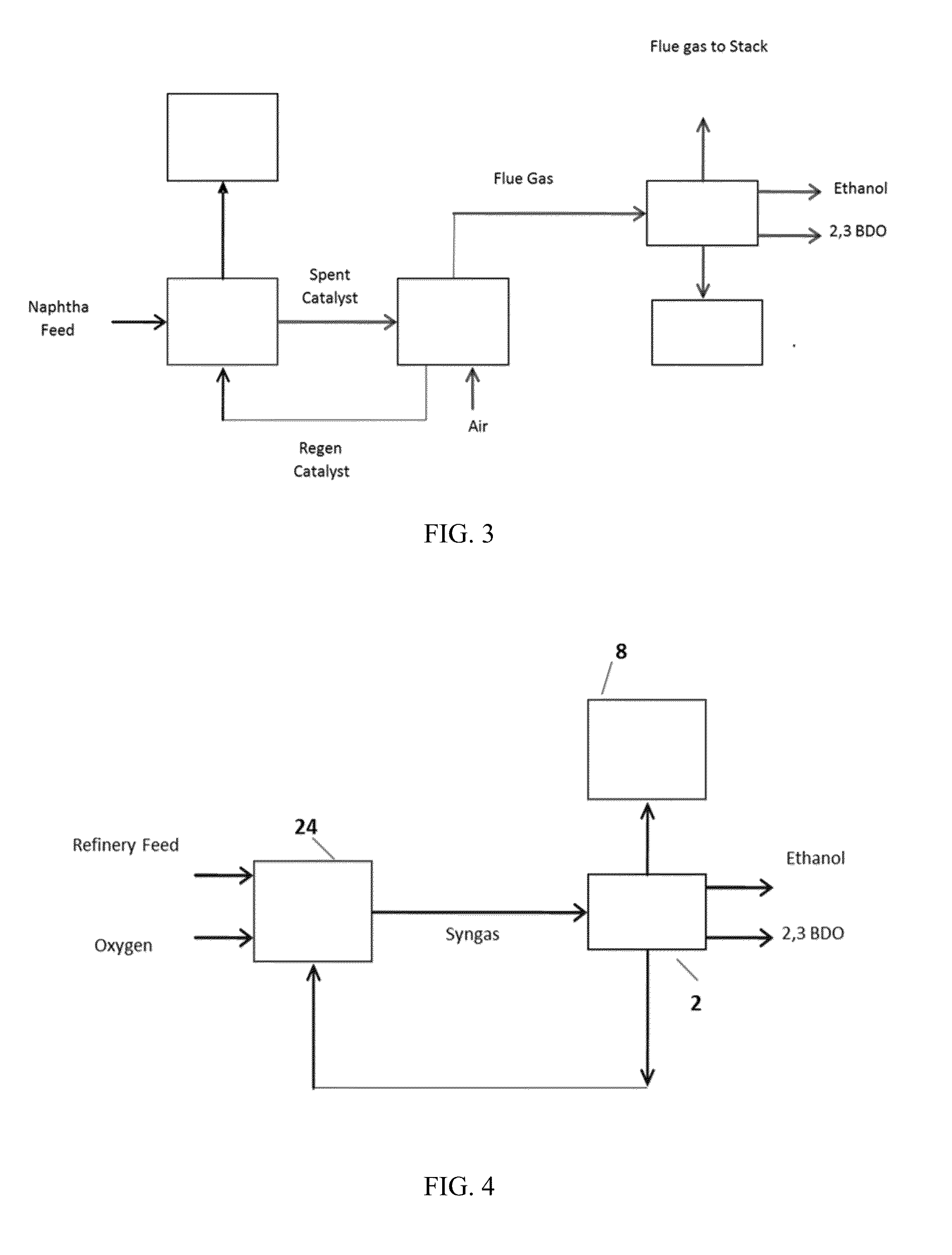

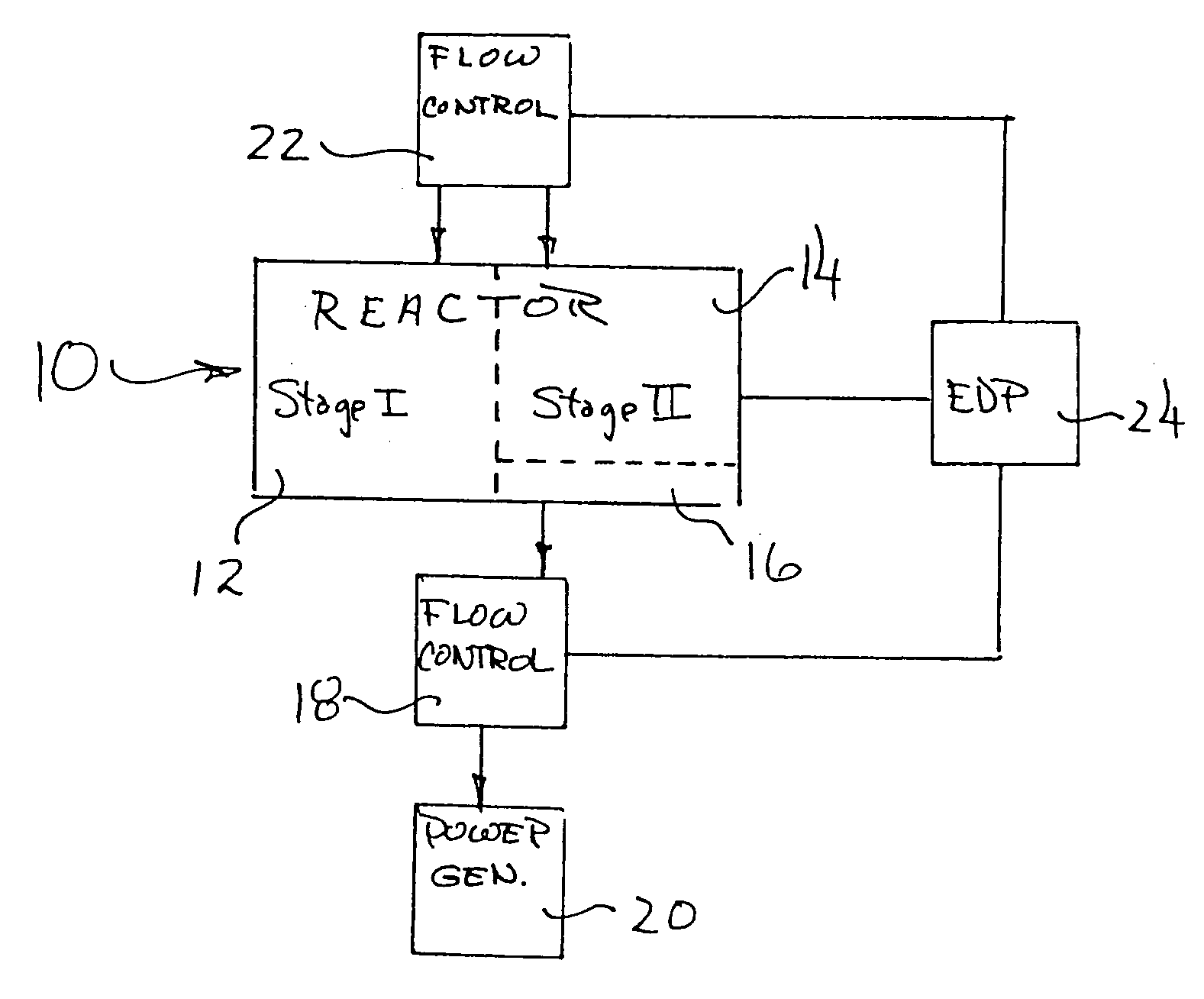

System and method for converting biomass to ethanol via syngas

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

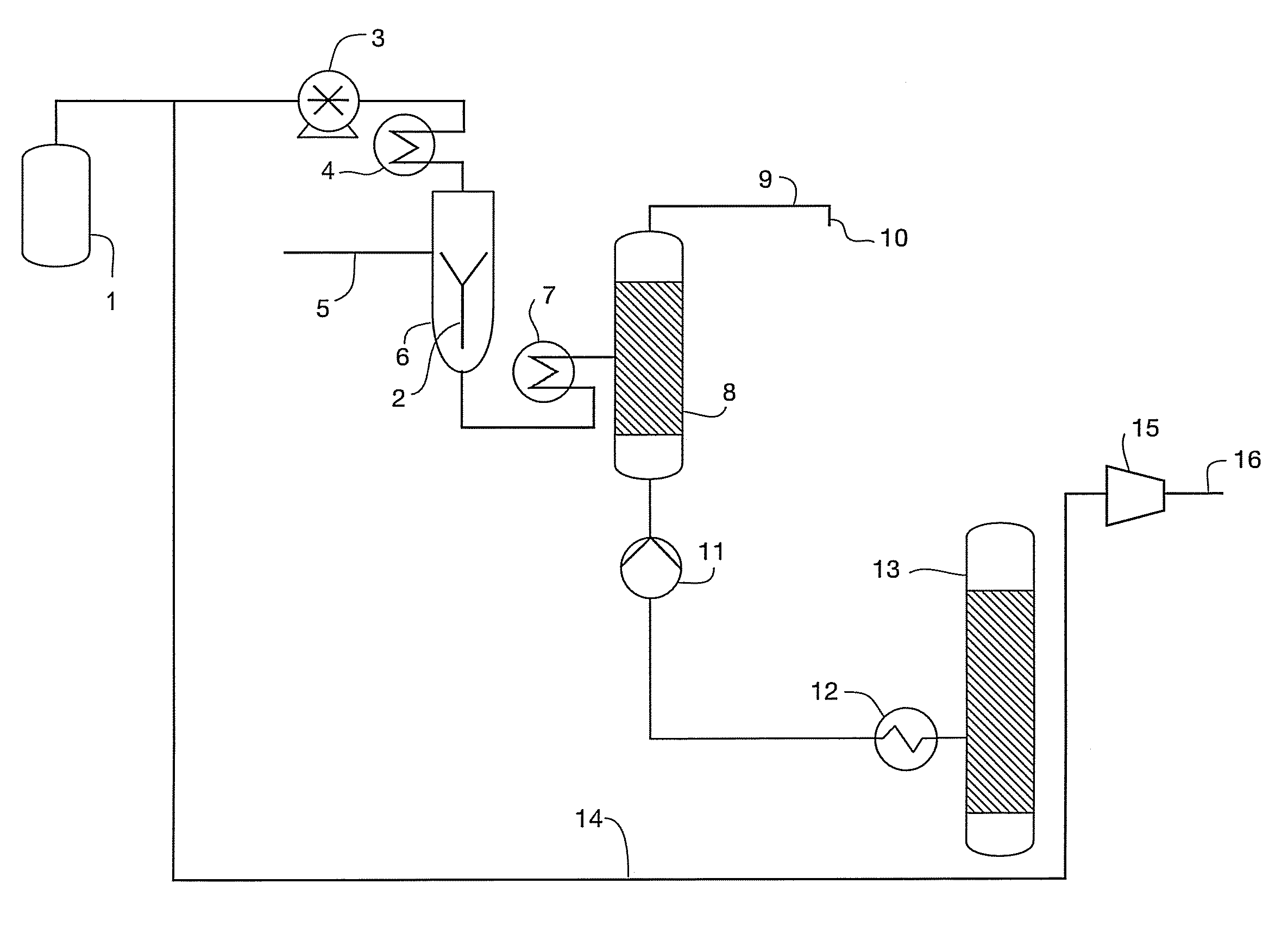

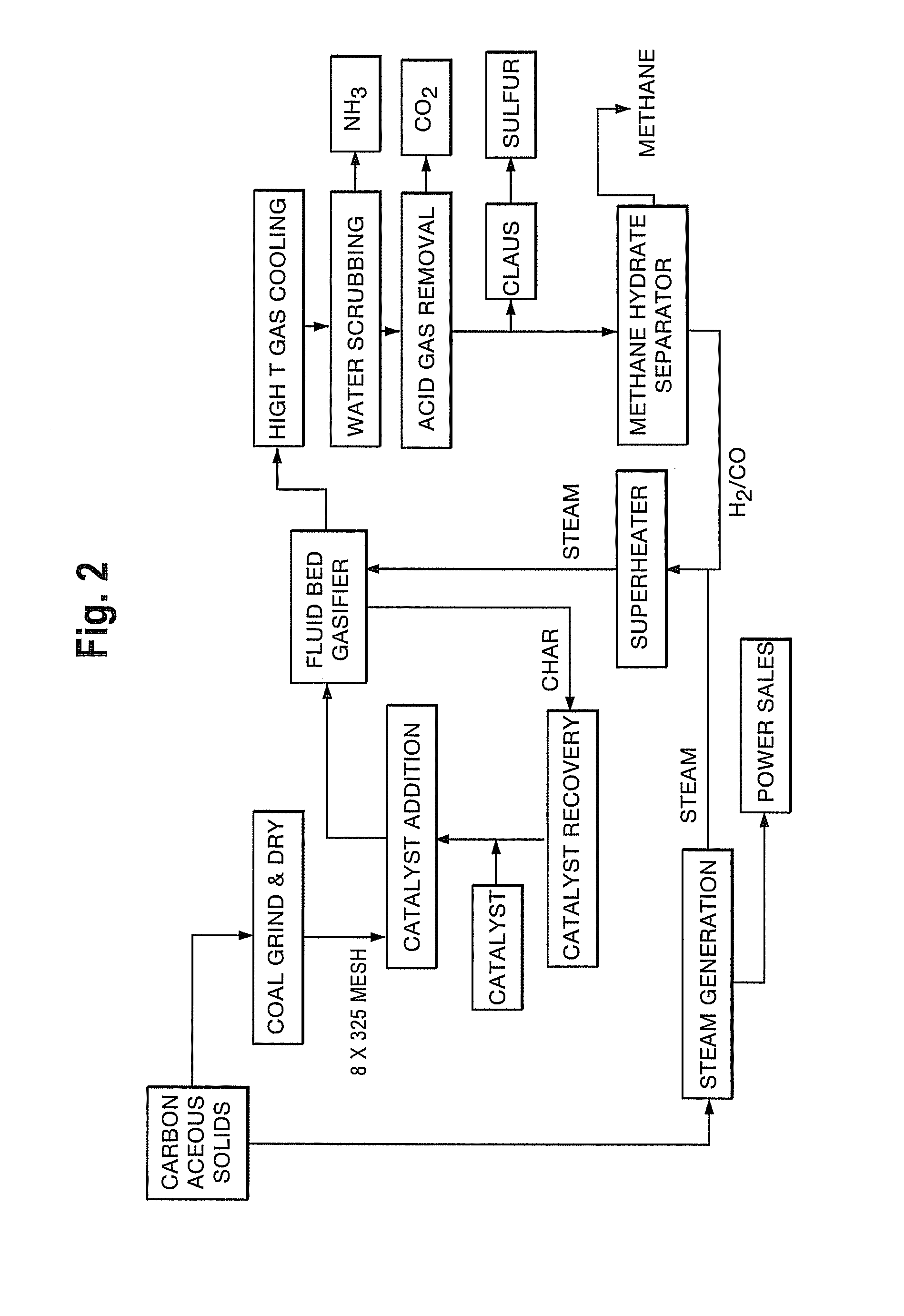

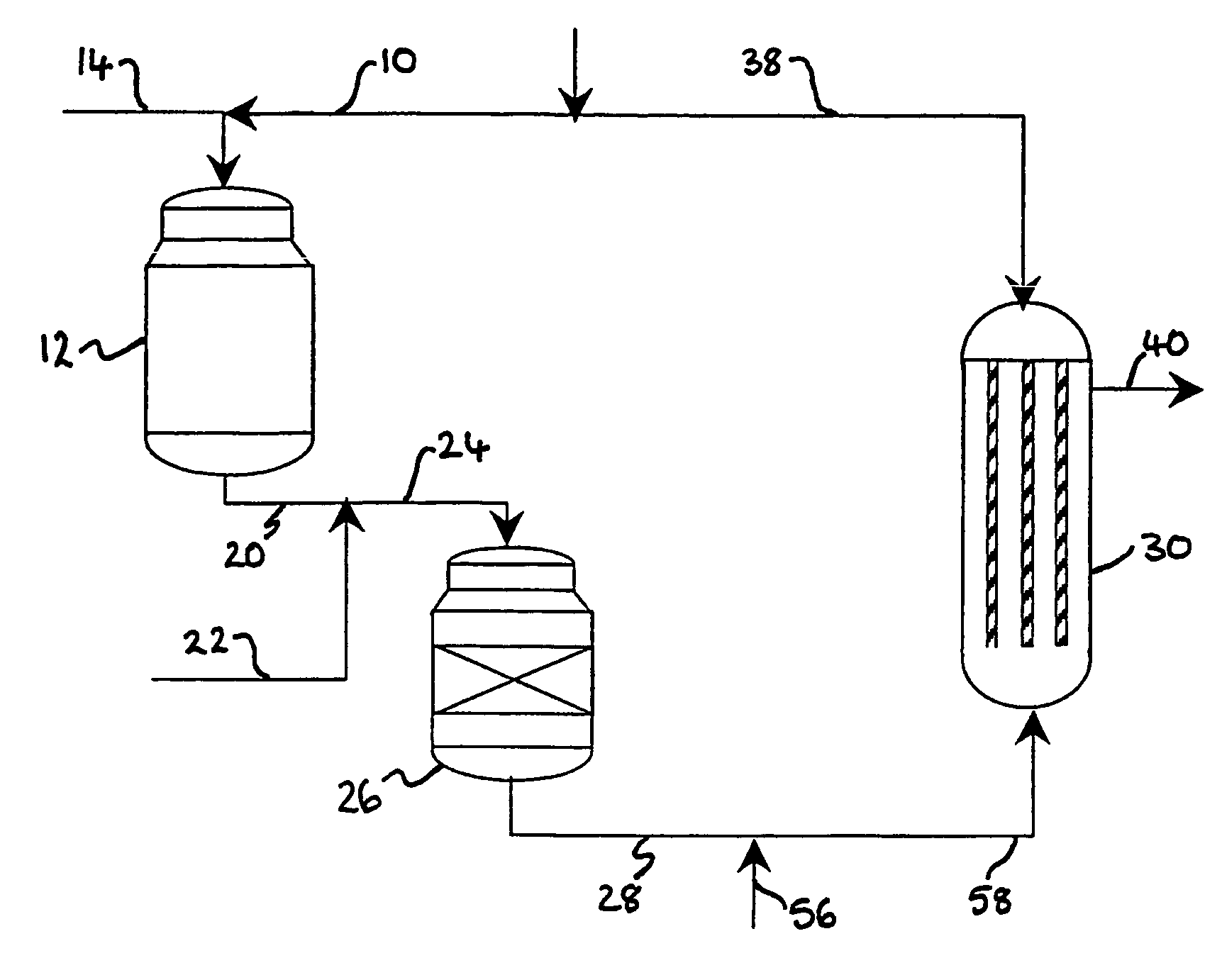

Process and Apparatus for the Separation of Methane from a Gas Stream

InactiveUS20090260287A1Combustible gas chemical modificationHydrogen separation using liquid contactHydrogenWater vapor

Processes for conversion of a carbonaceous composition into a gas stream comprising methane are provided, where an energy-efficient process and / or apparatus is used to separate methane out of a gas stream comprising methane, carbon monoxide, and hydrogen. Particularly, methane can be separated from hydrogen and carbon monoxide using novel processes and / or apparatuses that generate methane hydrates. Because hydrogen and carbon monoxide do not readily form hydrates, the methane is separated from a gas stream. The methane can be captured as a substantially pure stream of methane gas by dissociating the methane from the hydrate and separating out any residual water vapor.

Owner:SURE CHAMPION INVESTMENT LTD

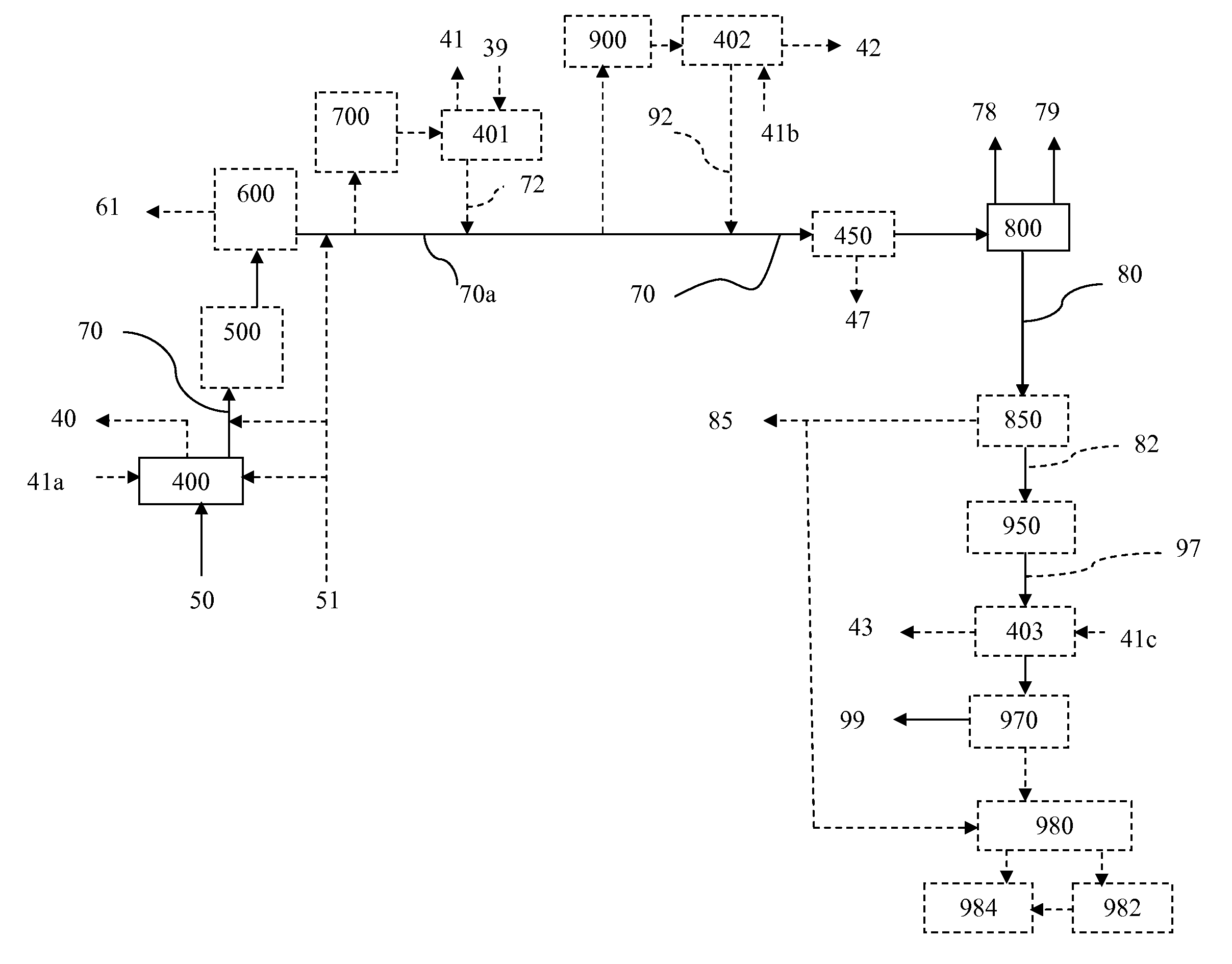

Processes for hydromethanation of a carbonaceous feedstock

InactiveUS20110062012A1Combustible gas chemical modificationCoke ovensMethanationCatalytic hydrogenation

The present invention relates to processes for preparing gaseous products, and in particular methane and / other value added gases such as hydrogen, via the catalytic hydromethanation of a carbonaceous feedstock in the presence of steam and syngas, wherein a hydromethanation reactor is combined with a syngas generator in a particular combination.

Owner:SURE CHAMPION INVESTMENT LTD

Processes for hydromethanation of a carbonaceous feedstock

InactiveUS20110031439A1Increase the amount of carbonIncrease volumeCombustible gas chemical modificationHydrocarbon from carbon oxidesPtru catalystPhysical chemistry

The present invention relates to processes for preparing gaseous products, and in particular a hydrogen product stream and optionally a methane product stream, via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen and a hydromethanation catalyst.

Owner:SURE CHAMPION INVESTMENT LTD

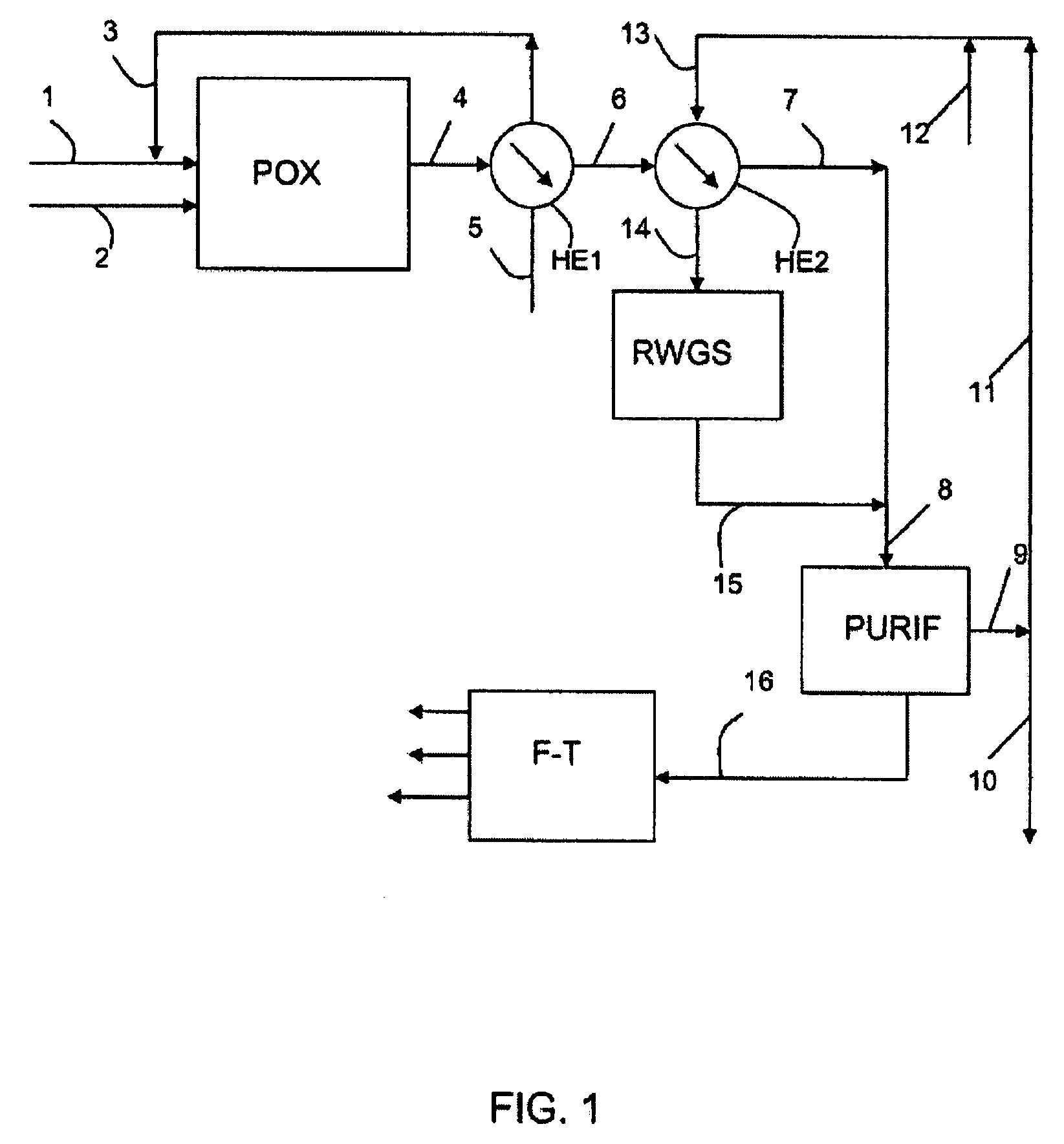

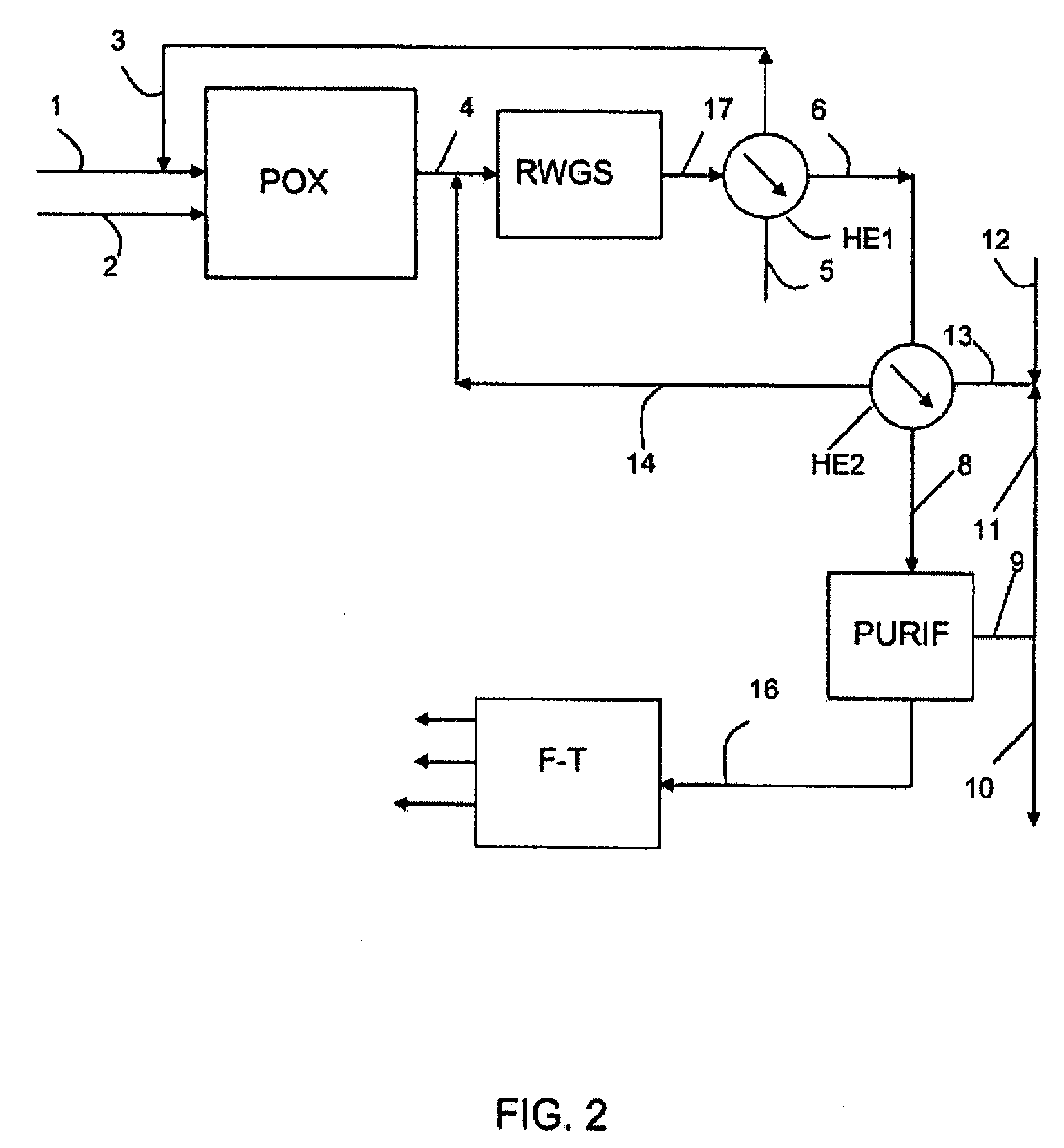

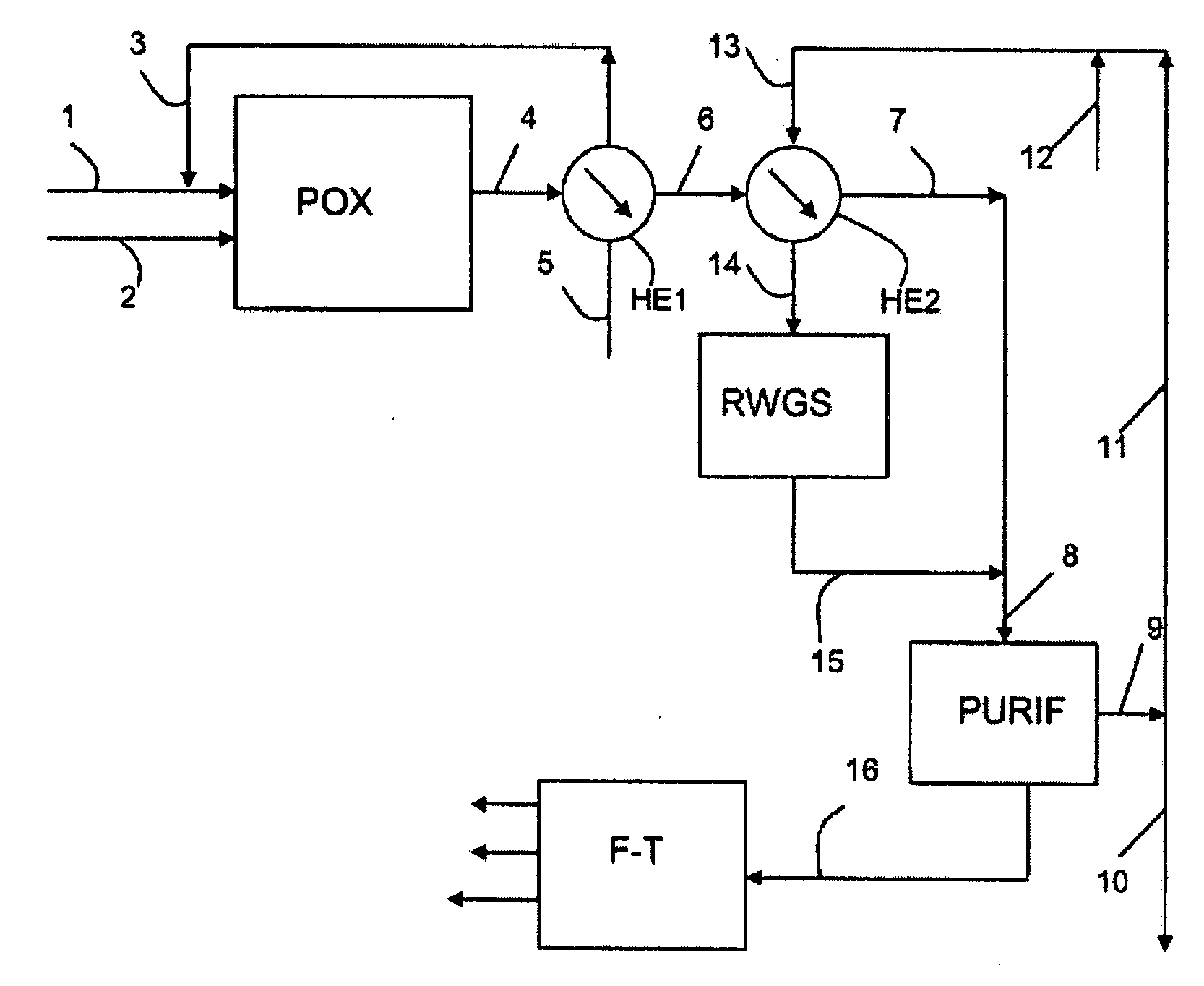

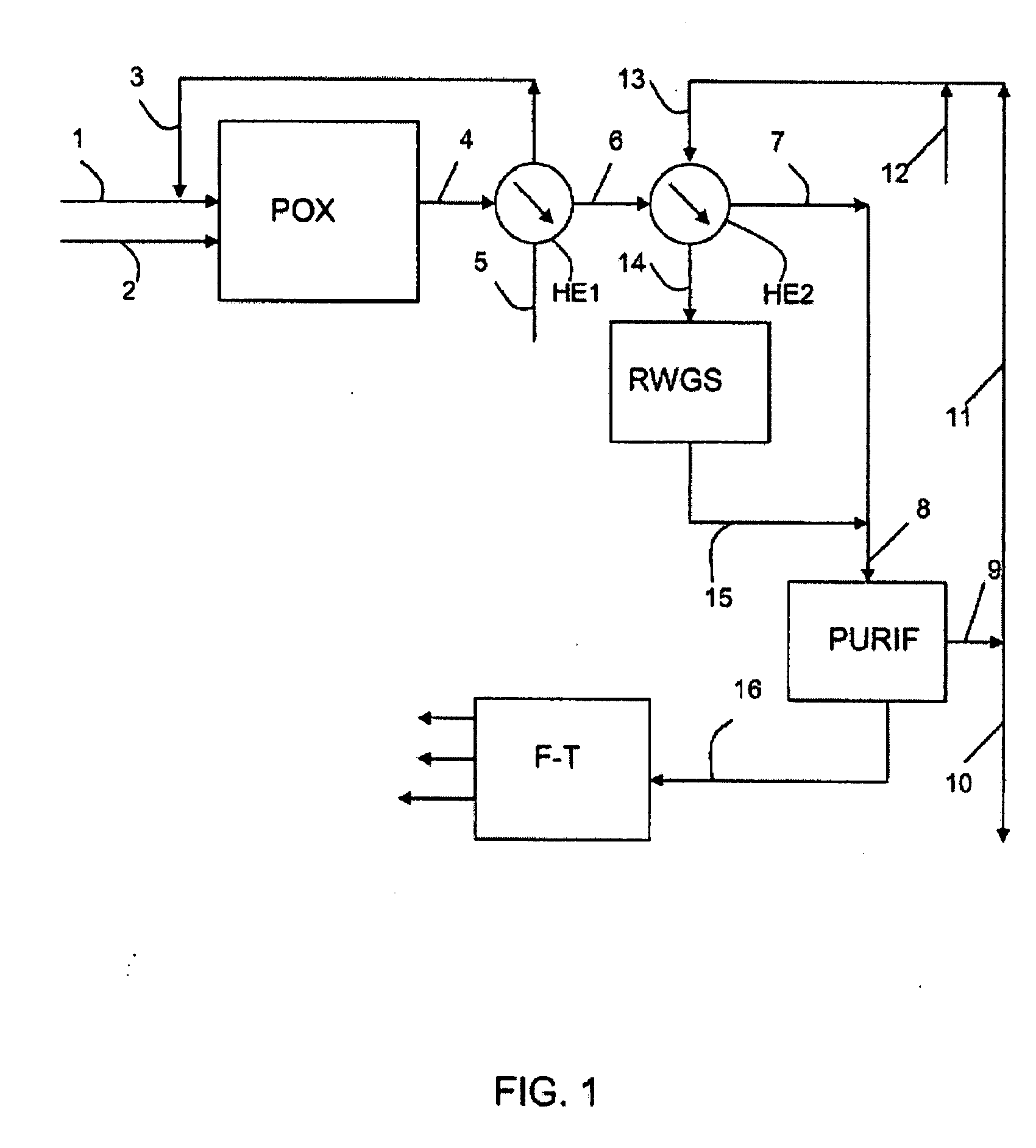

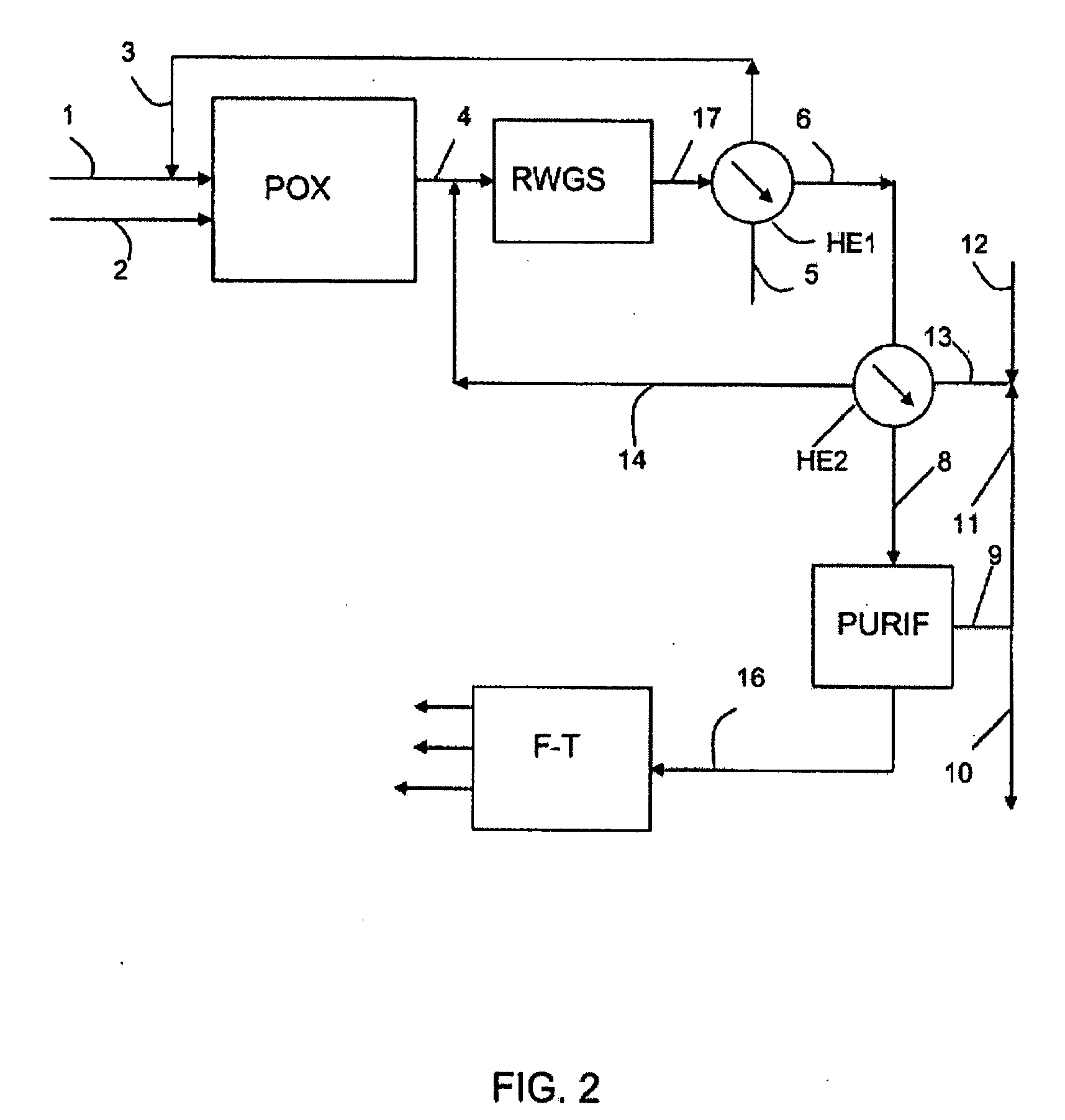

Process for the production of synthesis gas with conversion of CO2 into hydrogen

ActiveUS7846979B2Useful thermal recovery on the gasification effluentCombustible gas chemical modificationProductsSteam reformingPartial oxidation

Process for the production of liquid hydrocarbons from a feedstock that comprises at least one elementary feedstock from the group of biomass, coal, lignite, petroleum residues, methane, and natural gas, comprising: at least one stage a) for gasification of the feedstock by partial oxidation and / or steam reforming to produce a synthesis gas SG; a stage b) for separating CO2 from SG and a portion of the effluent of the subsequent stage c); the mixing of a portion of the CO2 that is separated with a gas of an H2 / CO ratio of more than 3; a stage c) for partial conversion with hydrogen, thermal or thermocatalytic, of the CO2 that is present in said first mixture according to the reaction: CO2+H2→CO+H2O in a specific reaction zone that is separated from said gasification zone or zones; a stage d) for Fisher-Tropsch synthesis on a synthesis gas that comprises at least a portion of SG and at least a portion of the CO that is produced by the conversion of CO2 into hydrogen.

Owner:INST FR DU PETROLE

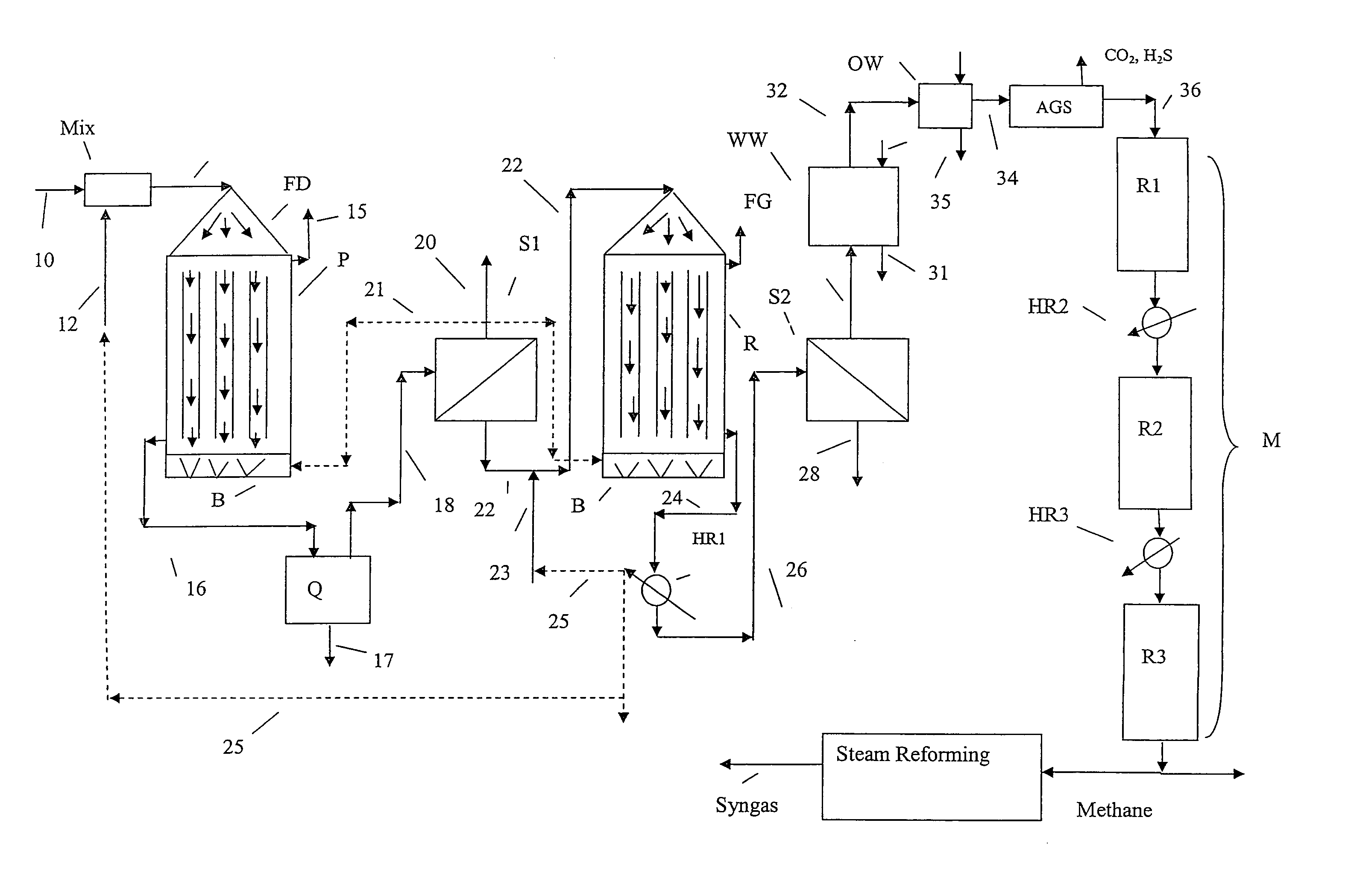

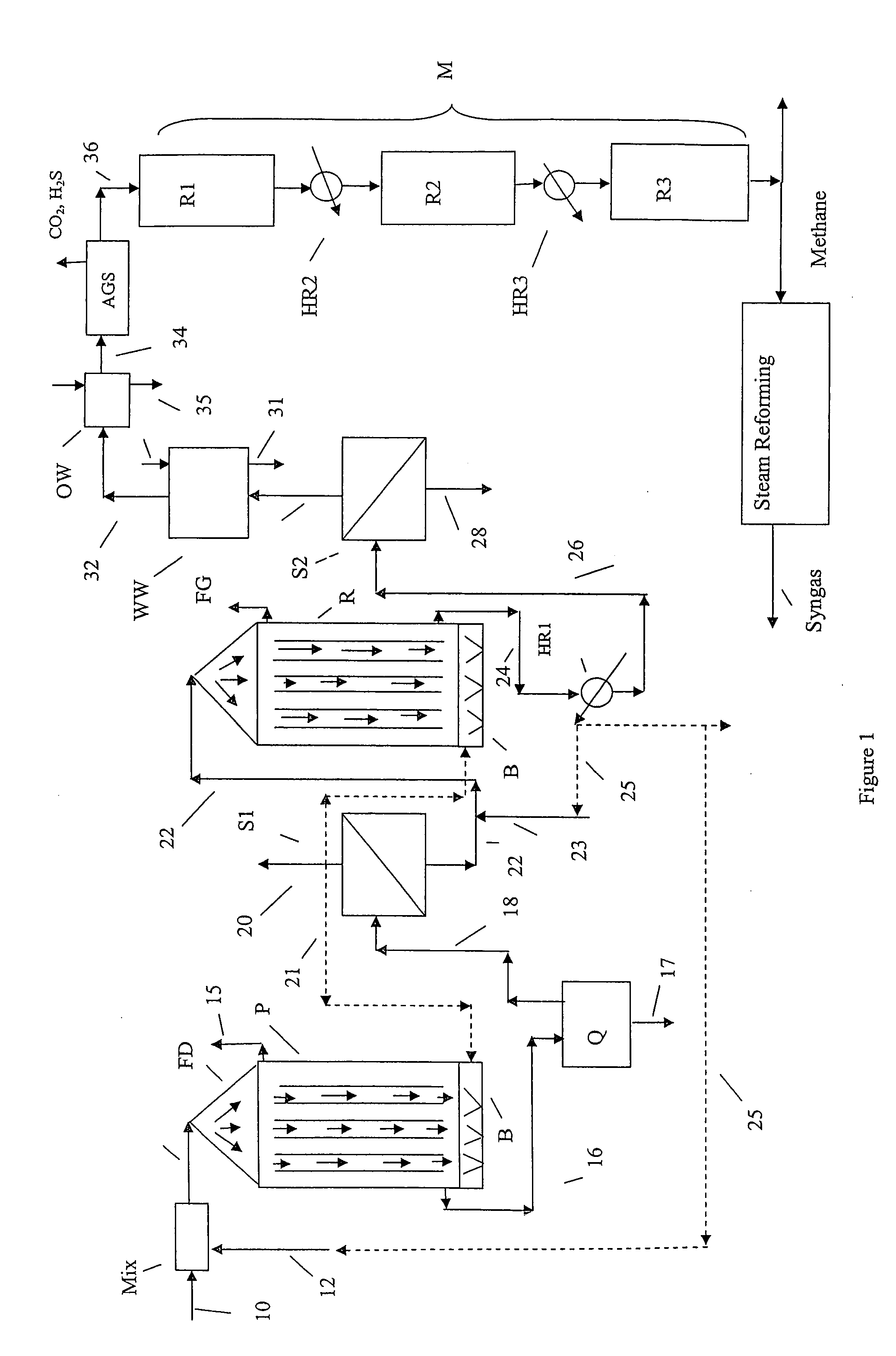

Conversion of carbonaceous materials to synthetic natural gas by pyrolysis, reforming, and methanation

InactiveUS20080016769A1Reduce the temperatureCombustible gas chemical modificationProductsSyngasSteam reforming

The production of synthetic natural gas from a carbonaceous material, preferably a biomass material, such as wood. The carbonaceous material is first pyrolyzed, then subjected to steam reforming to produce a syngas, which is then passed to several clean-up steps then to a methanation zone to produce synthetic natural gas.

Owner:CLEAN ENERGY LLC

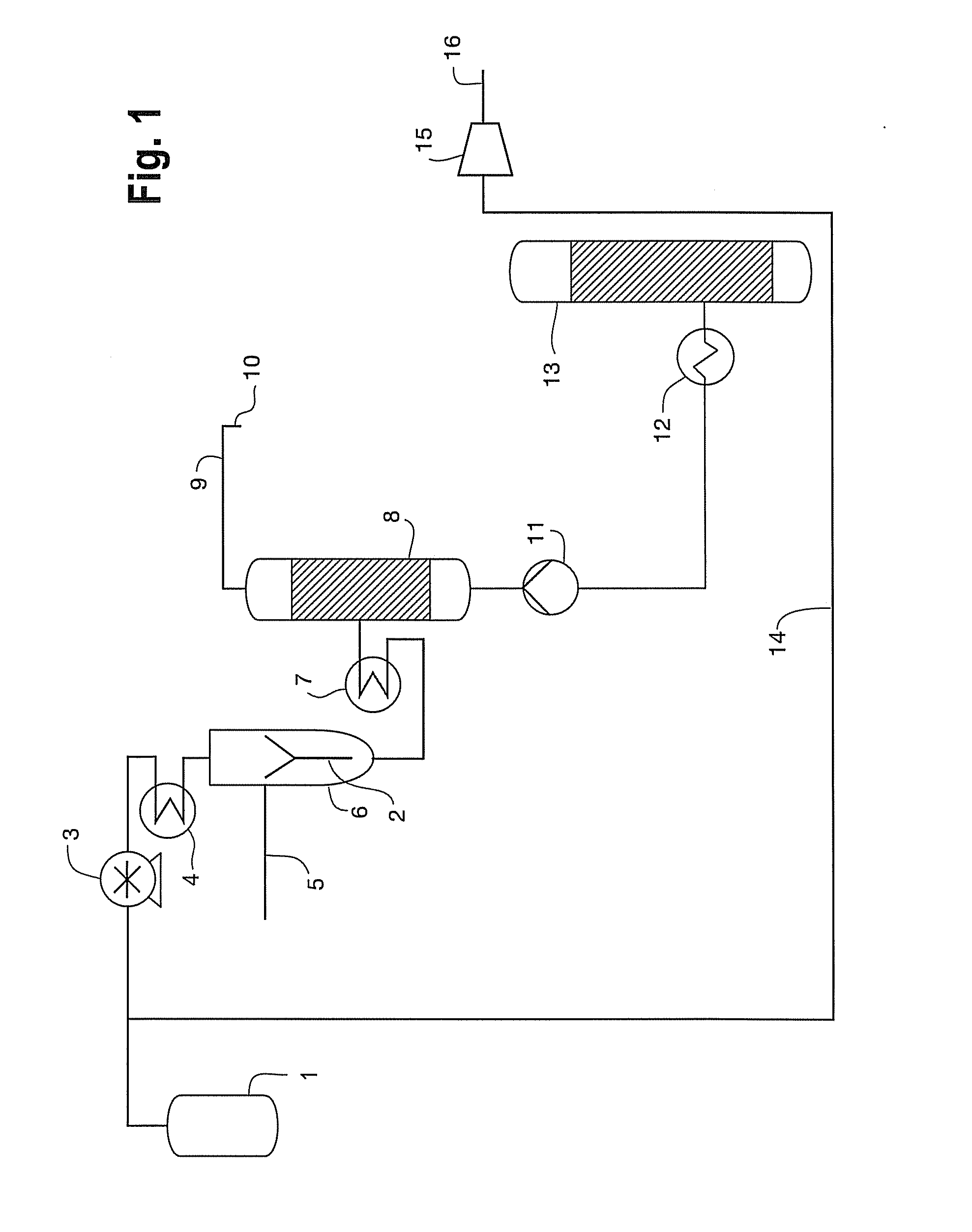

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS20060211777A1Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneHydrocotyle bowlesioides

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolysing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

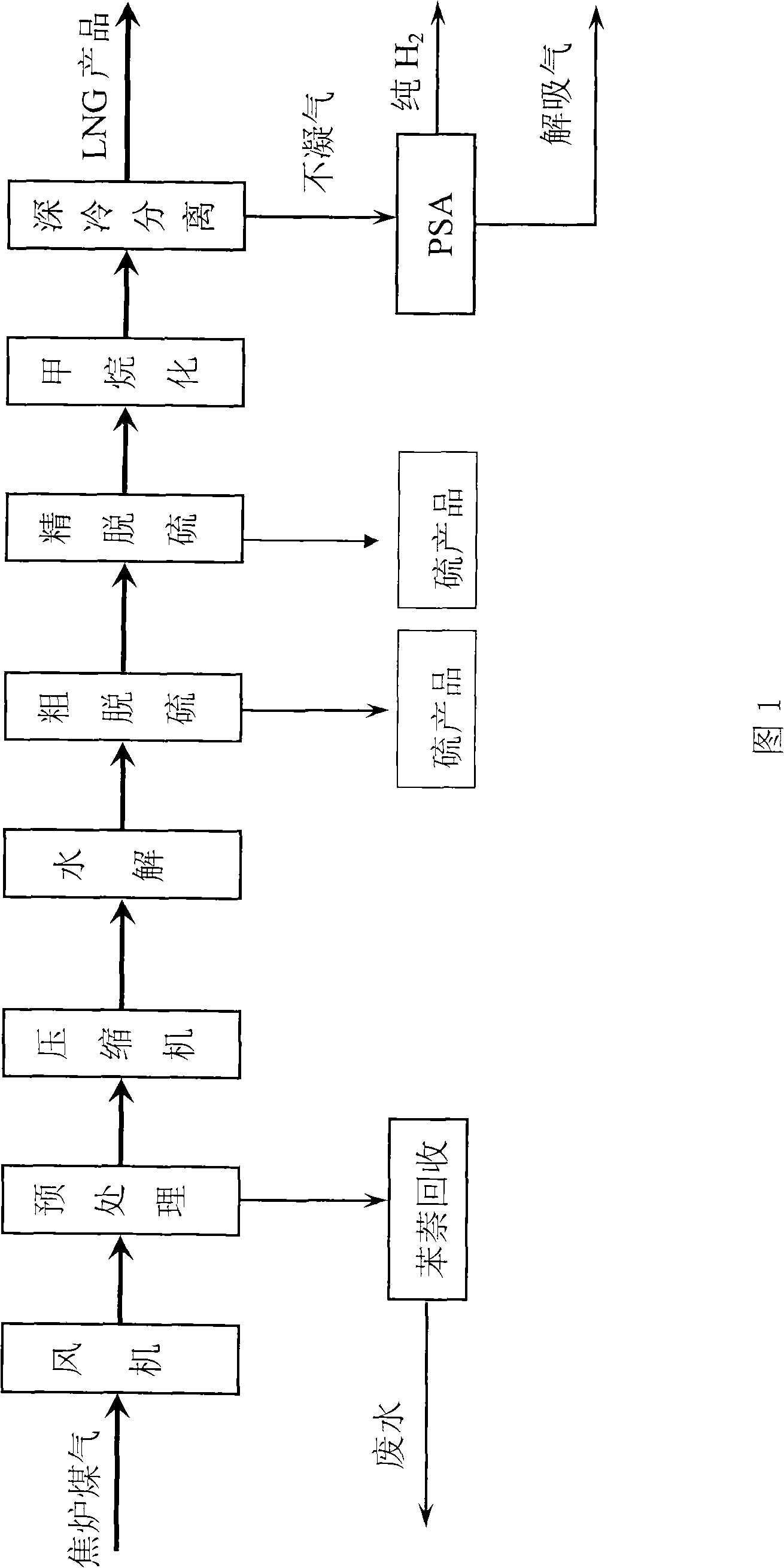

Method for preparing liquefied natural gas from coke oven gas

InactiveCN101280235ATo achieve coordinated developmentReasonable process combinationCombustible gas chemical modificationChemical industryMethanationImpurity

Disclosed is a method which uses coke-oven gas as the raw material to produce liquefied natural gas; the method includes that the coke-oven gas is pretreated firstly to enable the tar, naphthalene and benzene impurities contained in the coke-oven gas to be purified deeply; and the purified coke-oven gas is processed with methanation reaction after compression and desulfurization; the liquefied natural gas product which contains CH4 with the content of more than 85% through the cryogenic separation process; the residual non-condensable gas is prepared to obtain the hydrogen with the purity of 99% through the PSA separation technique; the residual desorbed gas can be used as manufactured gas. The method which uses the coke-oven gas as the raw material to produce liquefied natural gas has the advantages of making full use of the compositions, saving energy, water and the investment, simple process and realizing the trinity coordinated development of economy, environment and energy sources.

Owner:SHENGHE RESOURCES HLDG CO LTD

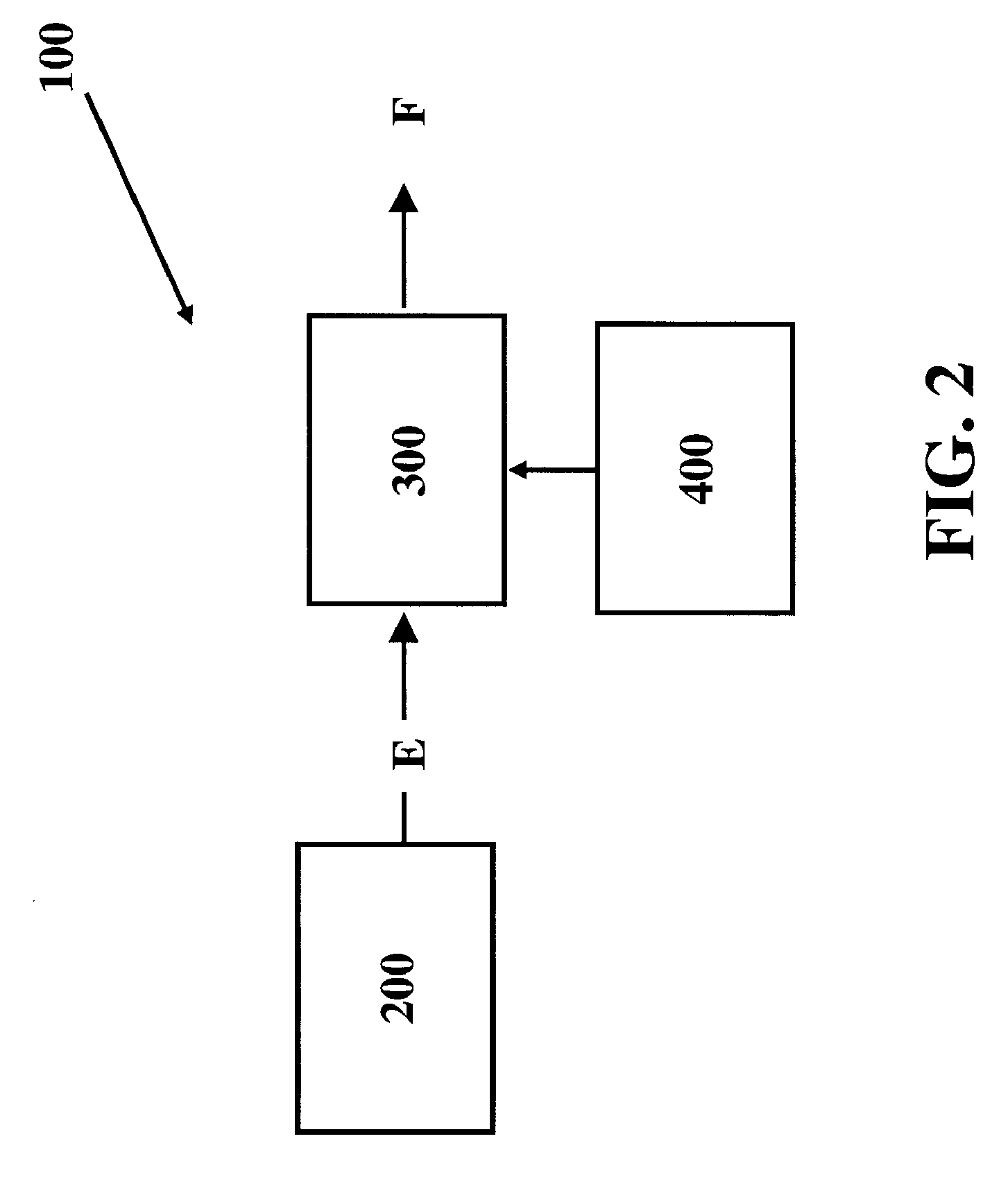

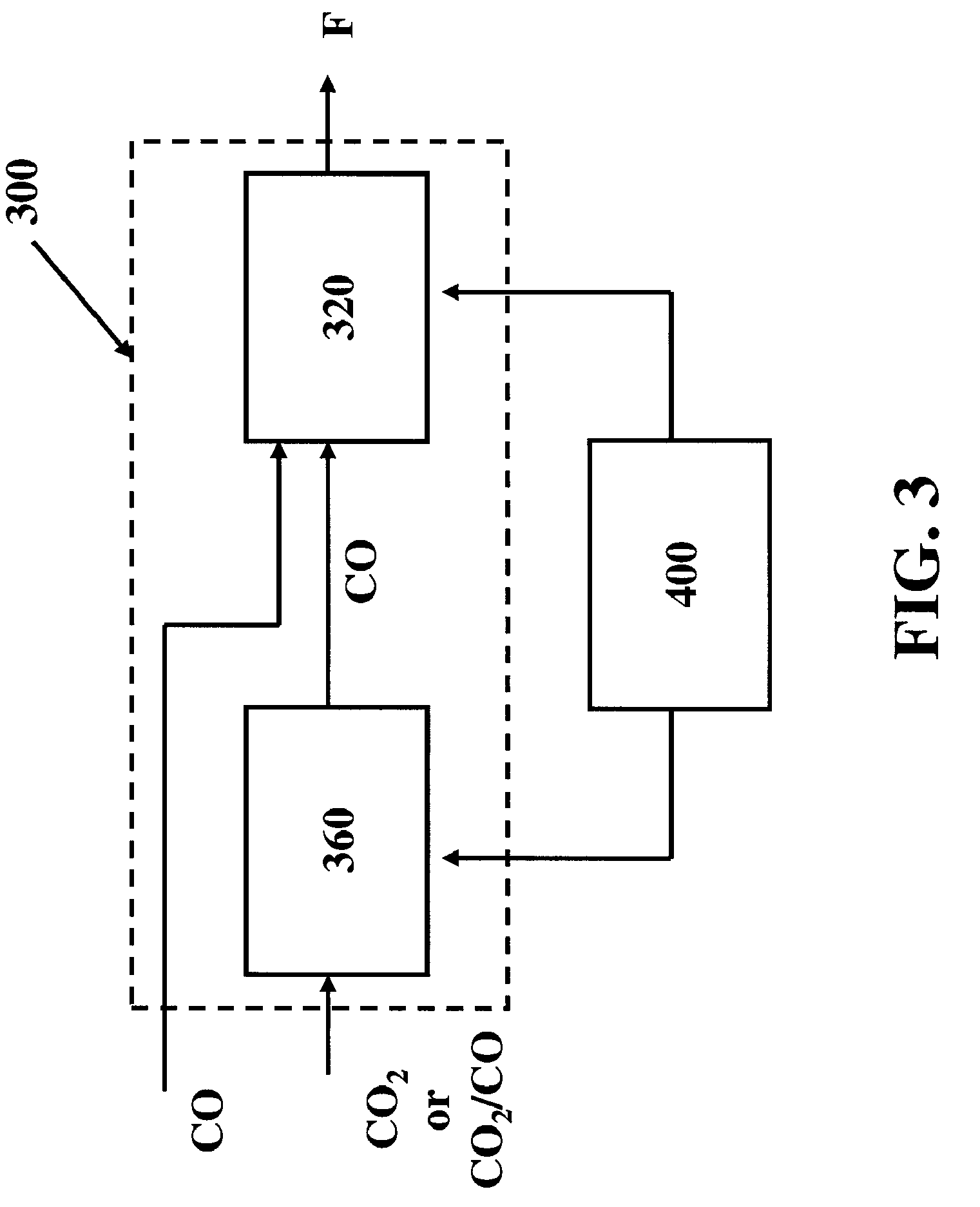

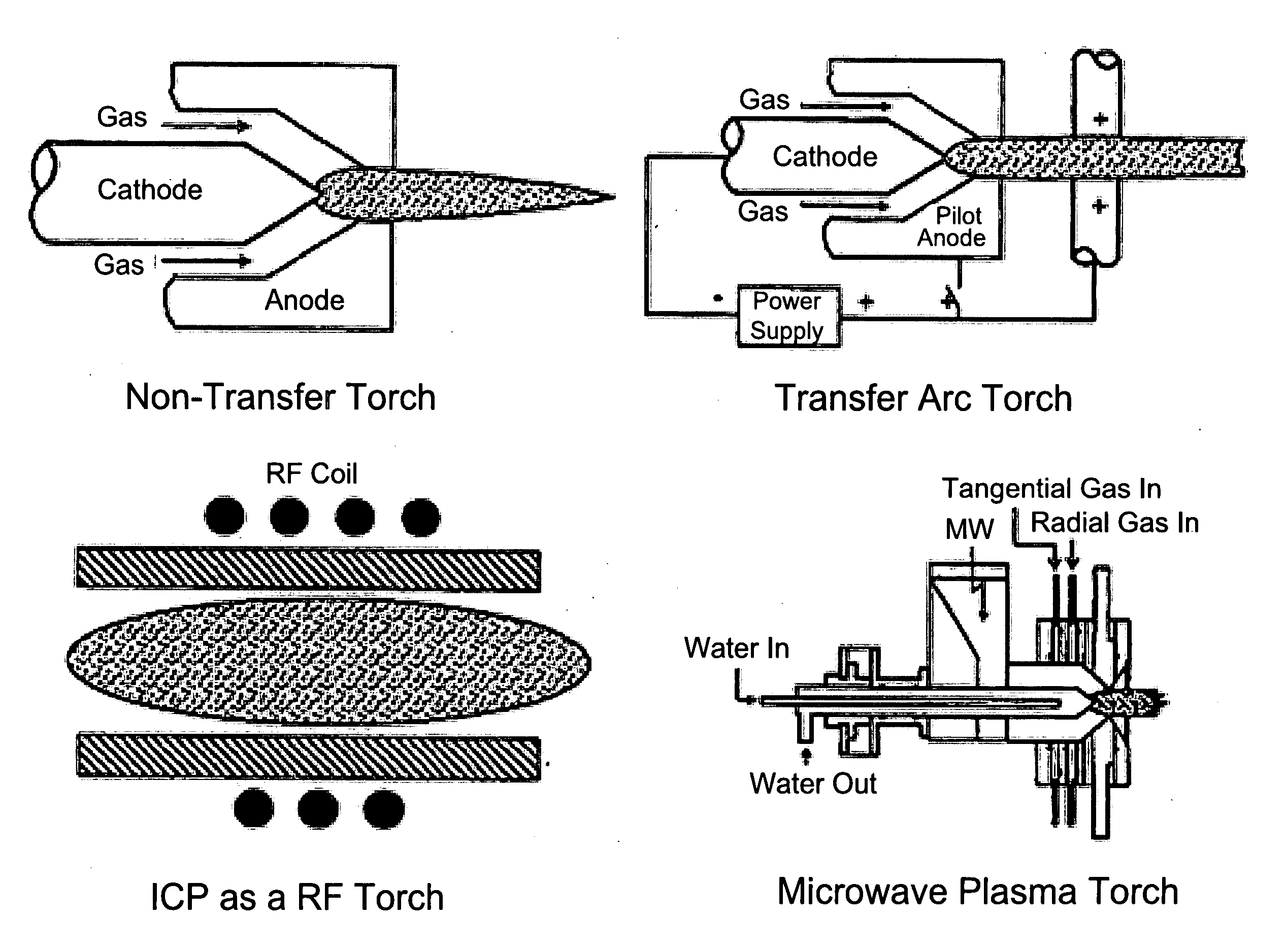

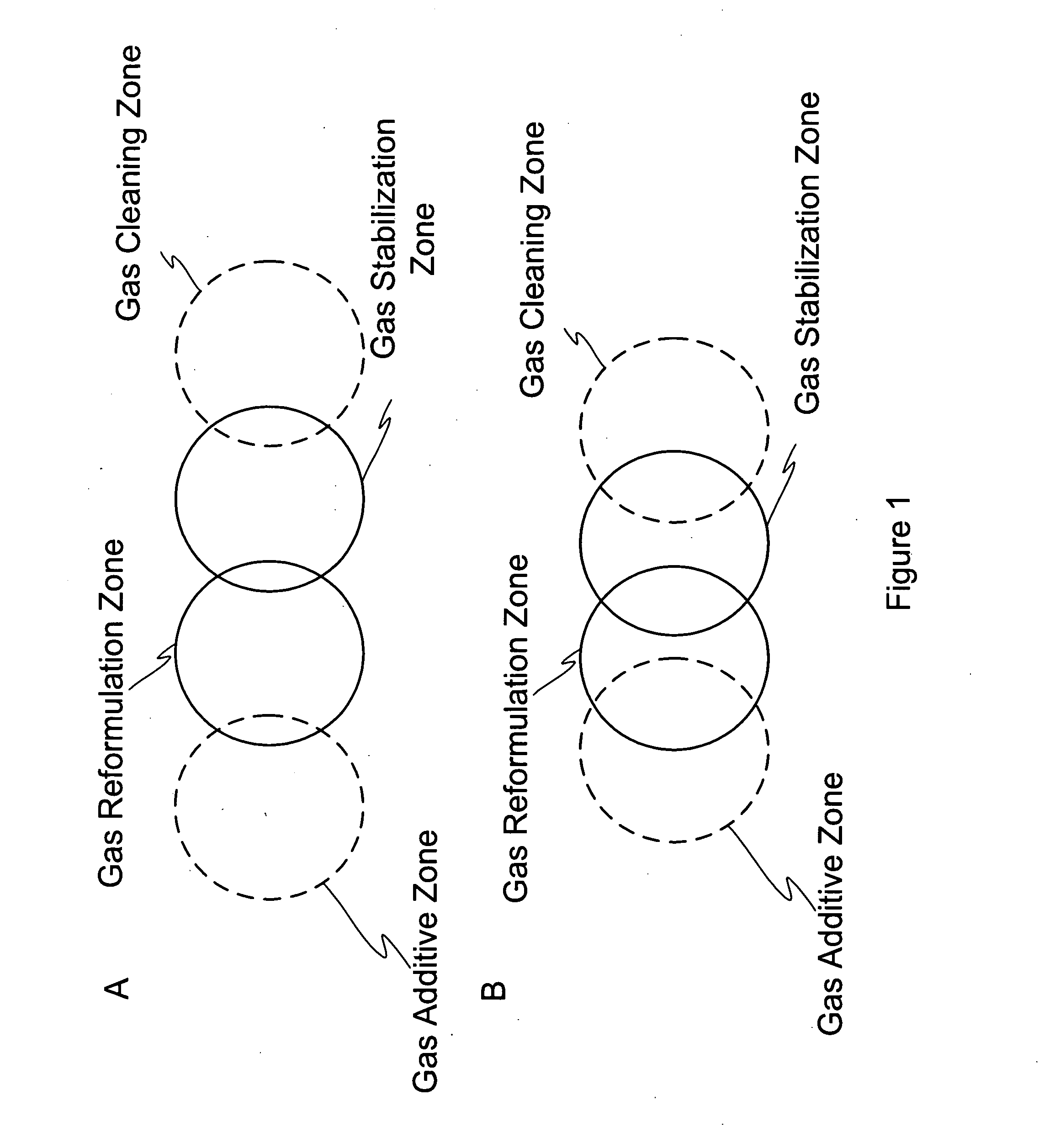

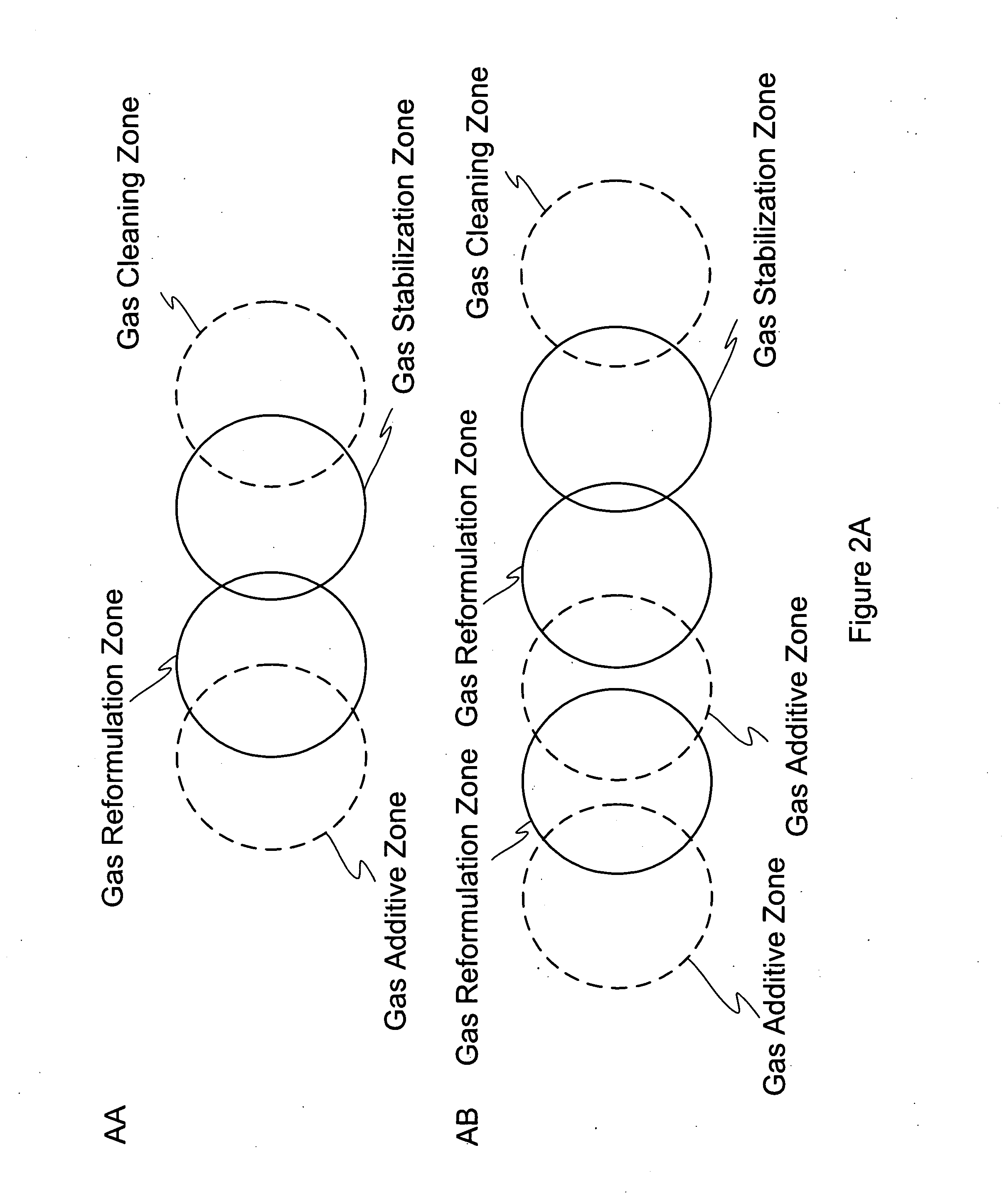

Gas reformulation system comprising means to optimize the effectiveness of gas conversion

InactiveUS20080277265A1Facilitate speedImprove efficiencyCombustible gas chemical modificationHydrogenHydrogenControl system

This invention provides a system and method for efficient reformulation of an initial gas with associated characteristics into an output gas with desired characteristic parameters, within a substantially sealed, contained, and controlled environment. The gas reformulating system uses a gas energizing field to disassociate the initial gas molecules and molecules of injected process additives of appropriate types and amounts, into their constituents that then recombine to form the output gas with the desired parameters. The gas reformulating system further comprises a control system that regulates the process and thereby enables the process to be optimized. The gas energizing field may be provided at least partly by hydrogen burners or plasma torches.

Owner:PLASCO ENERGY GROUP INC

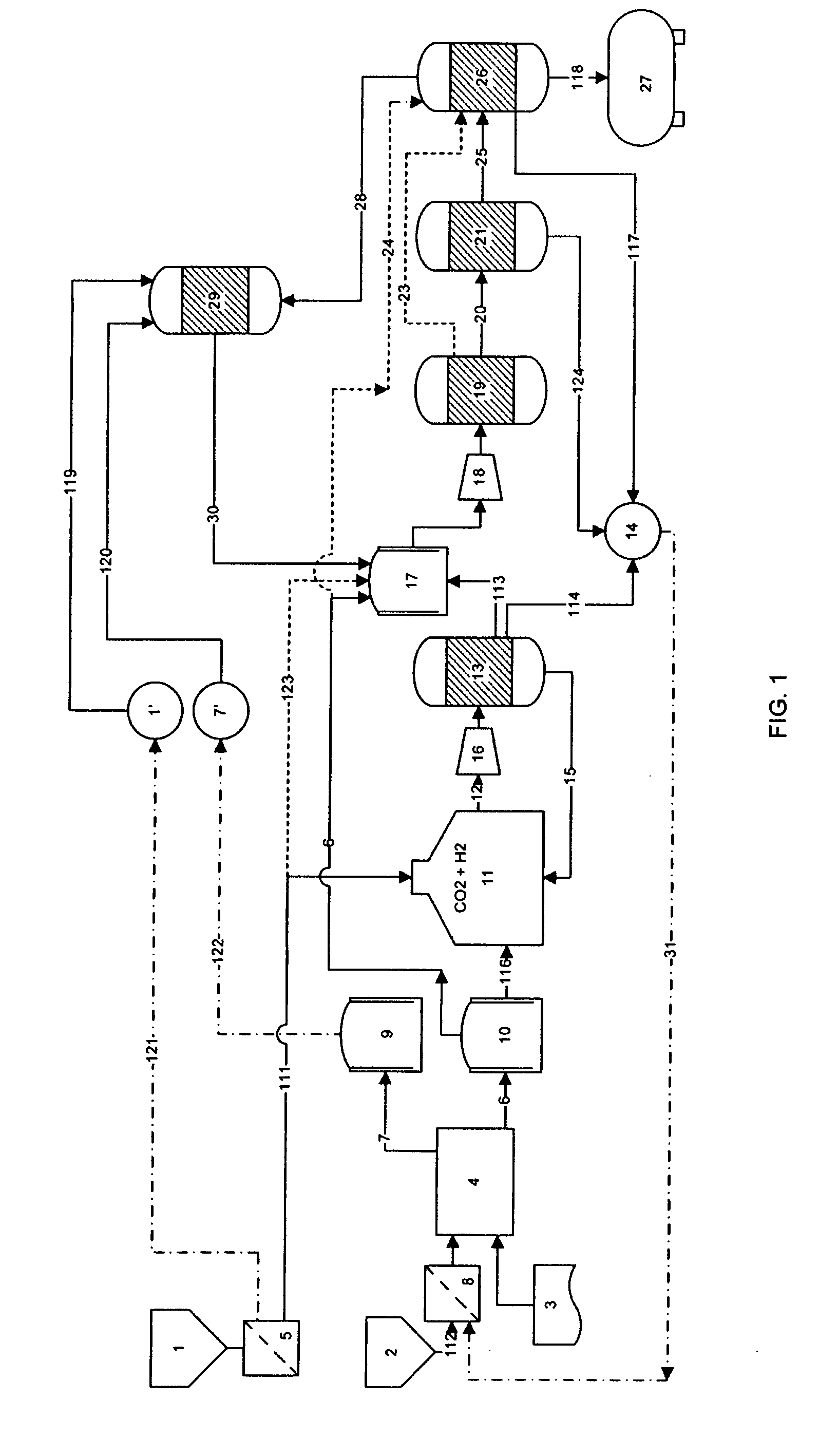

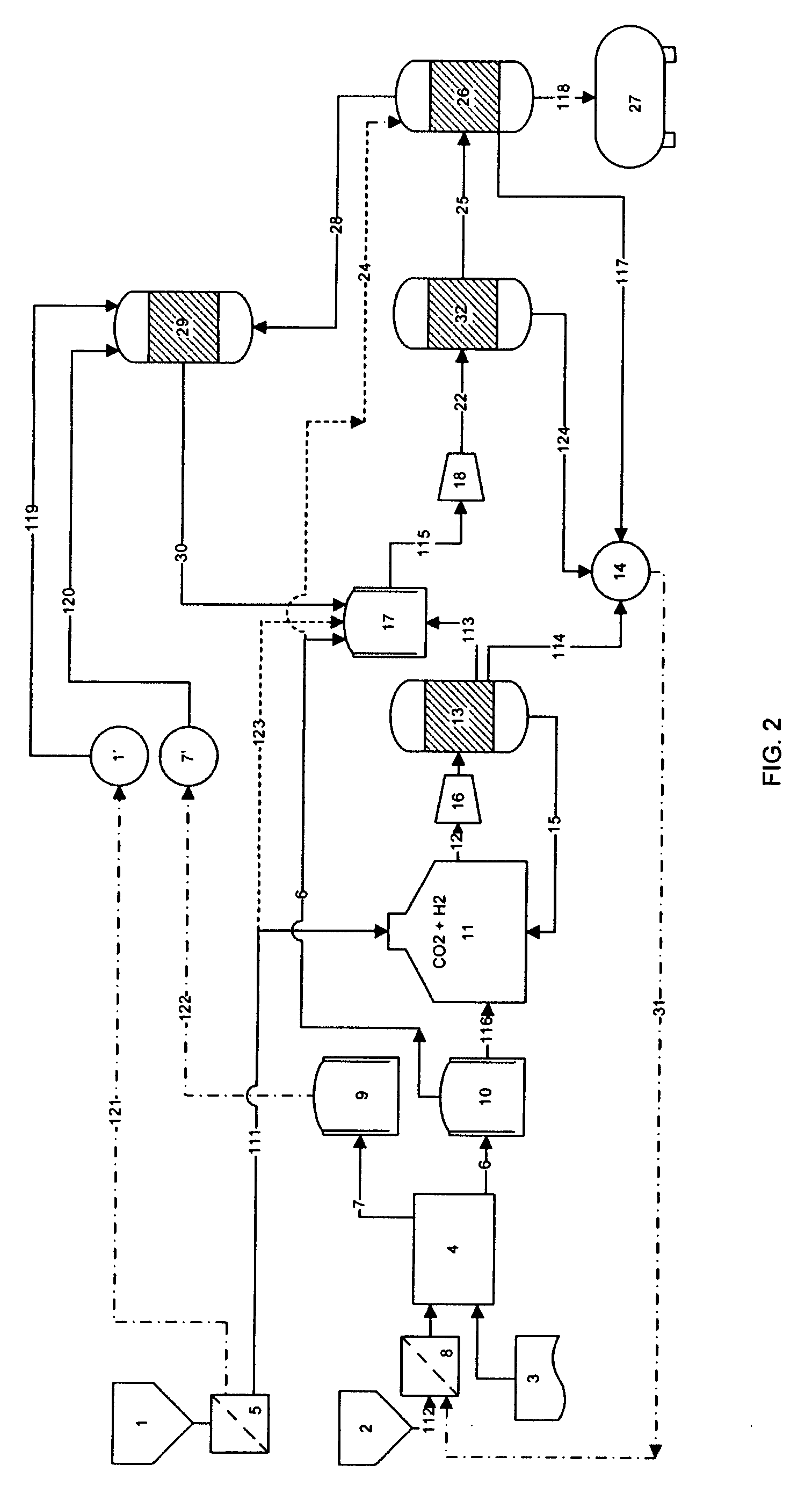

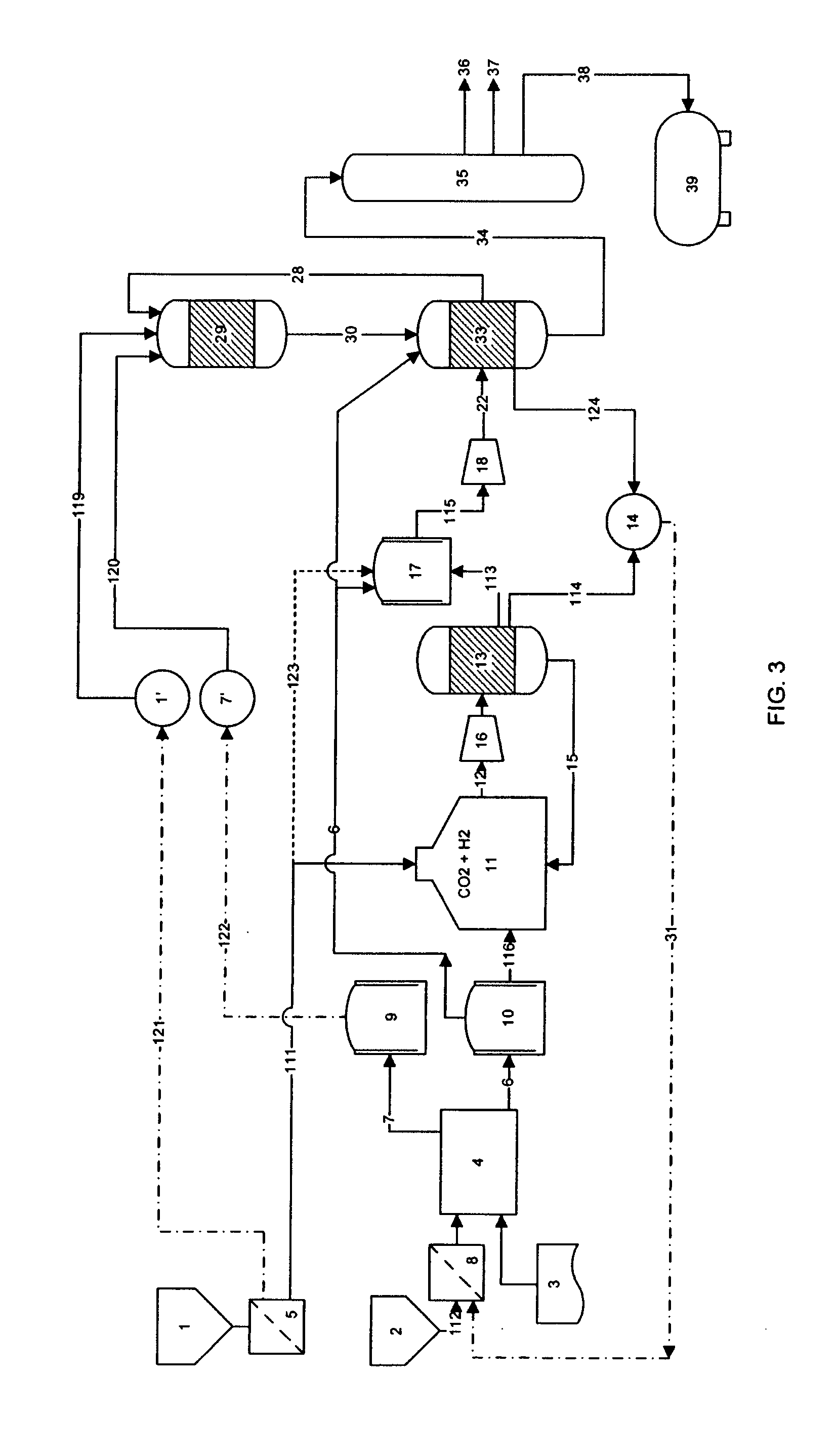

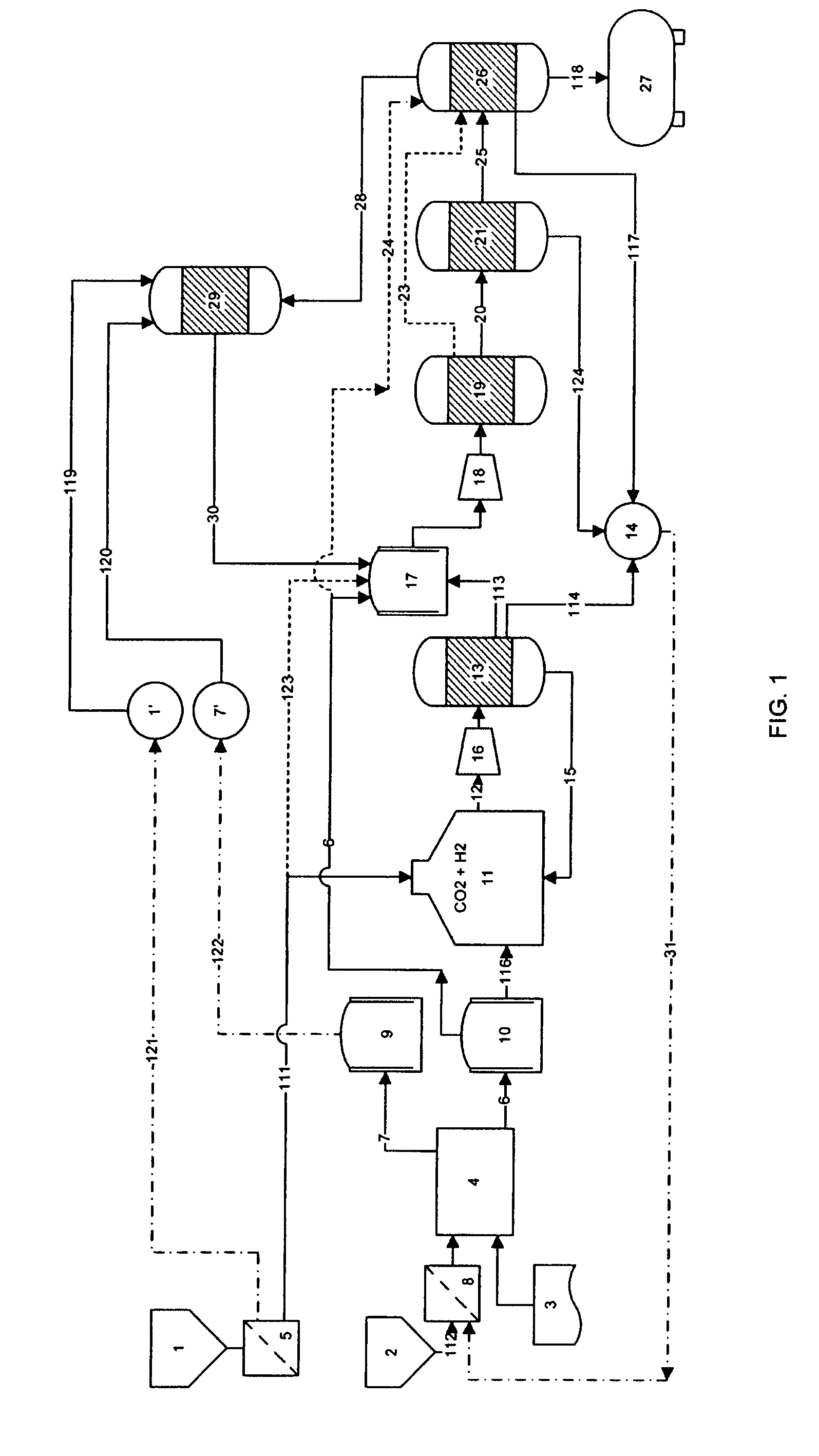

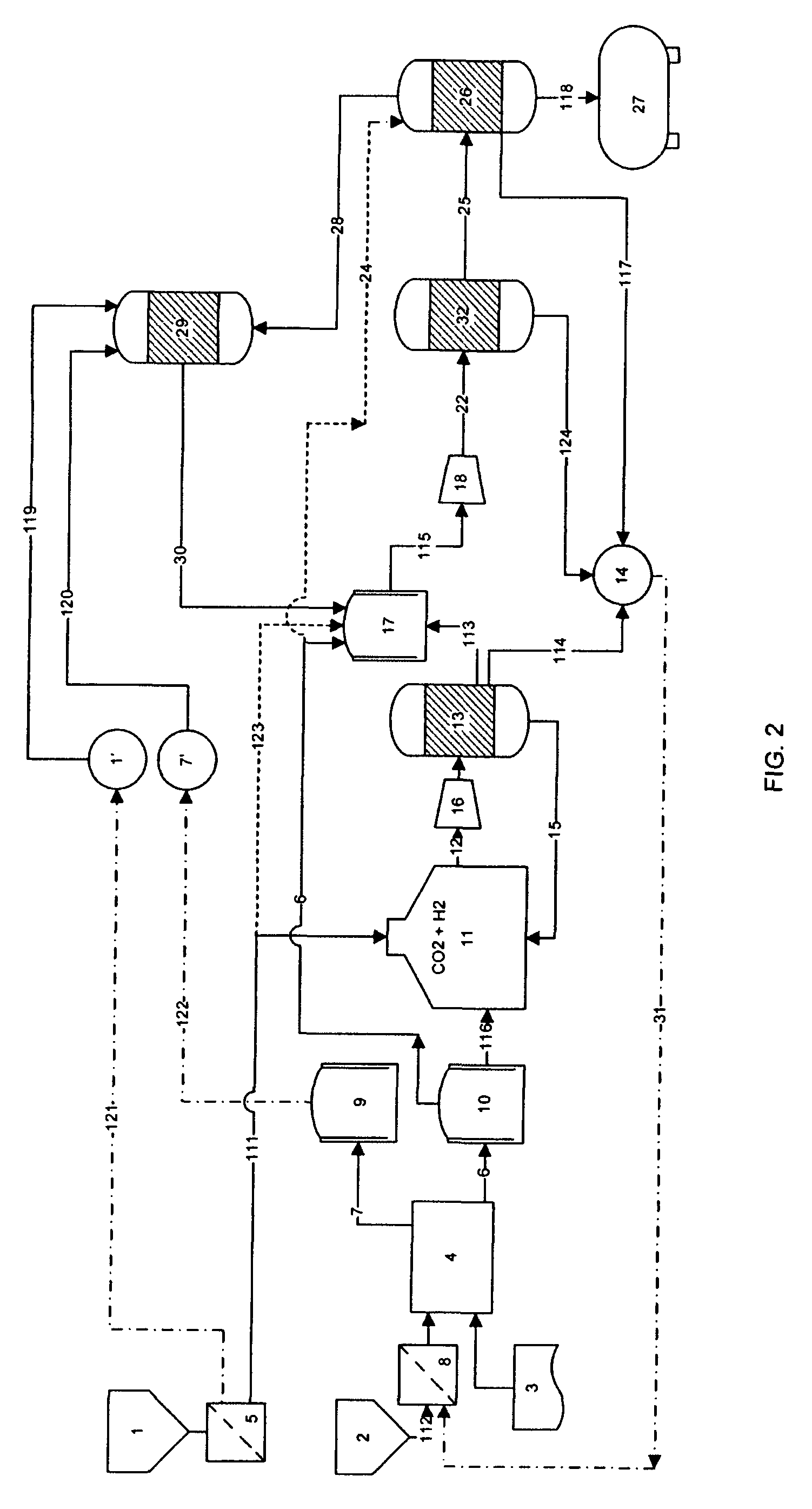

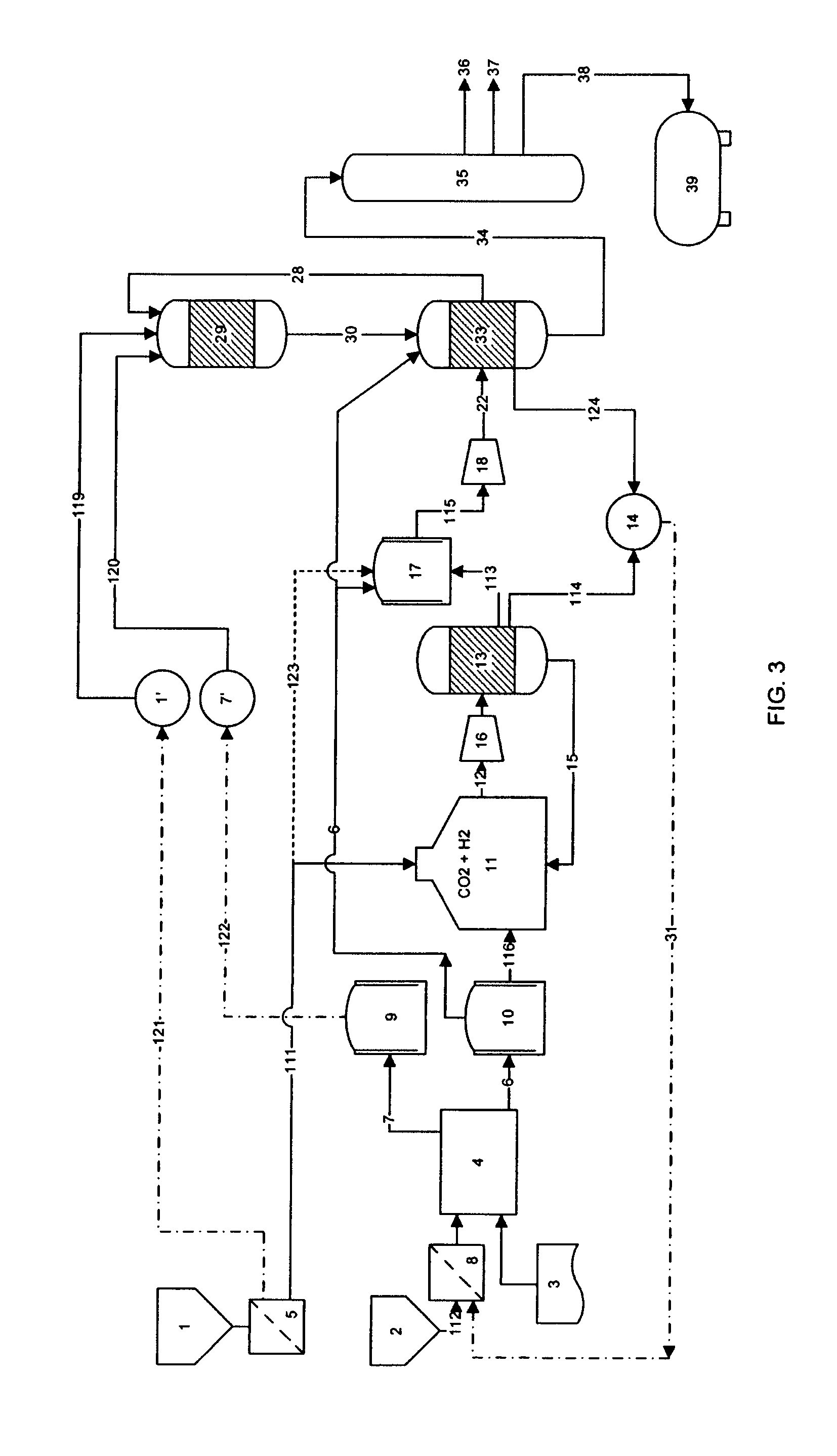

Process for the production of synthesis gas with conversion of CO2 into hydrogen

ActiveUS20090012188A1High carbon yieldImproved energy integrationCombustible gas chemical modificationProductsSteam reformingPartial oxidation

Process for the production of liquid hydrocarbons from a feedstock that comprises at least one elementary feedstock from the group of biomass, coal, lignite, petroleum residues, methane, and natural gas, comprising: at least one stage a) for gasification of the feedstock by partial oxidation and / or steam reforming to produce a synthesis gas SG; a stage b) for separating CO2 from SG and a portion of the effluent of the subsequent stage c); the mixing of a portion of the CO2 that is separated with a gas of an H2 / CO ratio of more than 3; a stage c) for partial conversion with hydrogen, thermal or thermocatalytic, of the CO2 that is present in said first mixture according to the reaction: CO2+H2→CO+H2O in a specific reaction zone that is separated from said gasification zone or zones; a stage d) for Fisher-Tropsch synthesis on a synthesis gas that comprises at least a portion of SG and at least a portion of the CO that is produced by the conversion of CO2 into hydrogen.

Owner:INST FR DU PETROLE

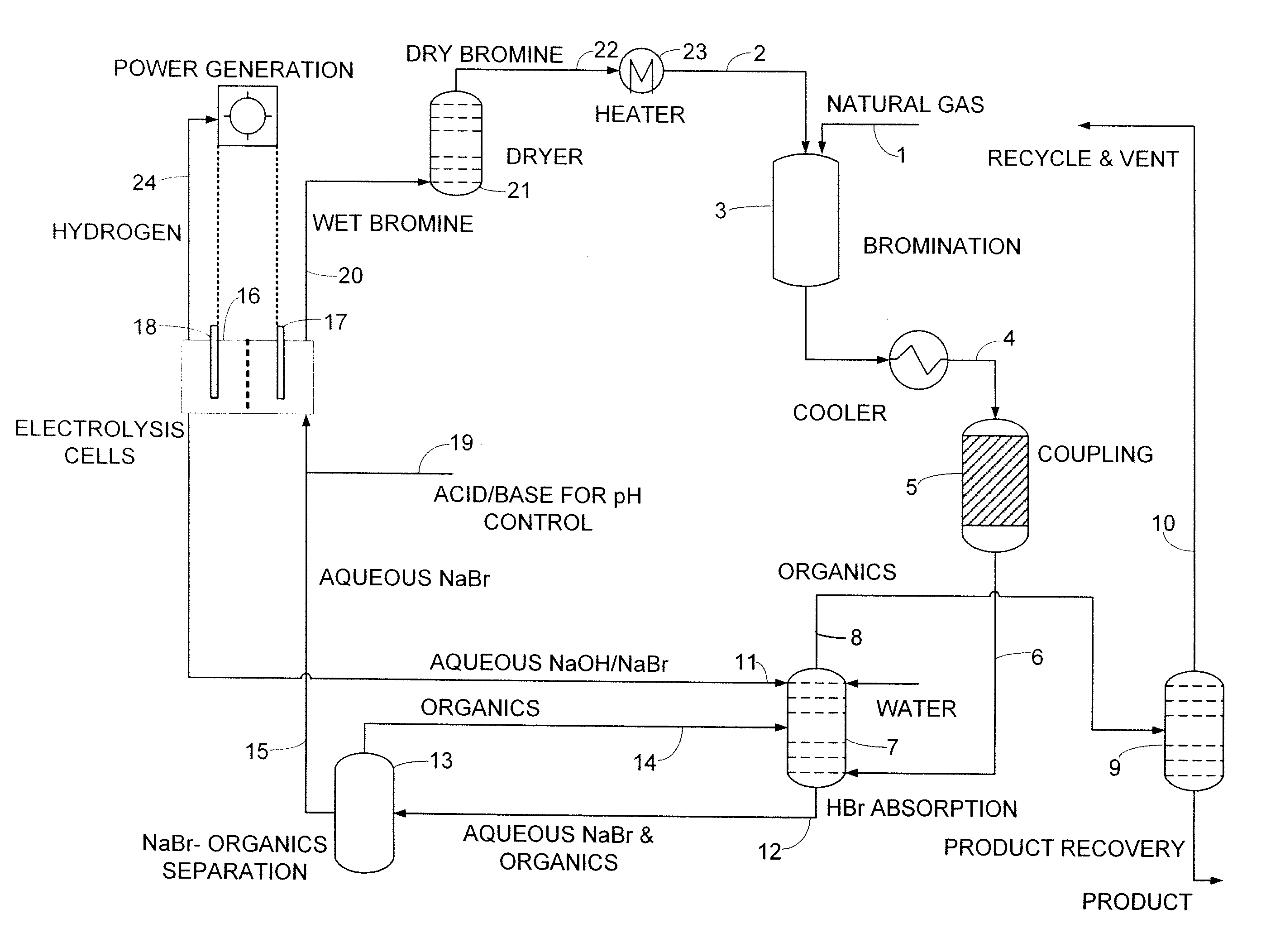

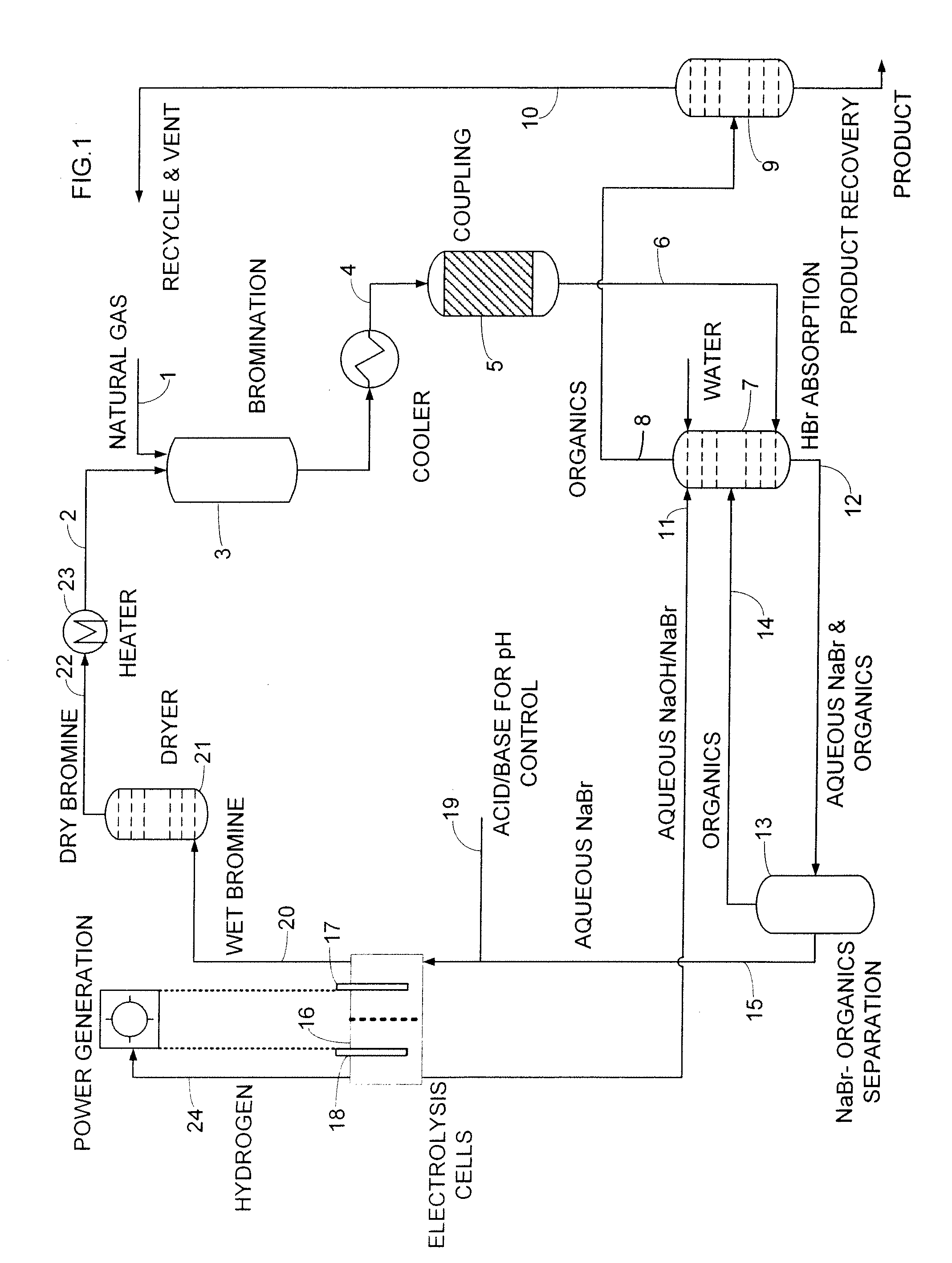

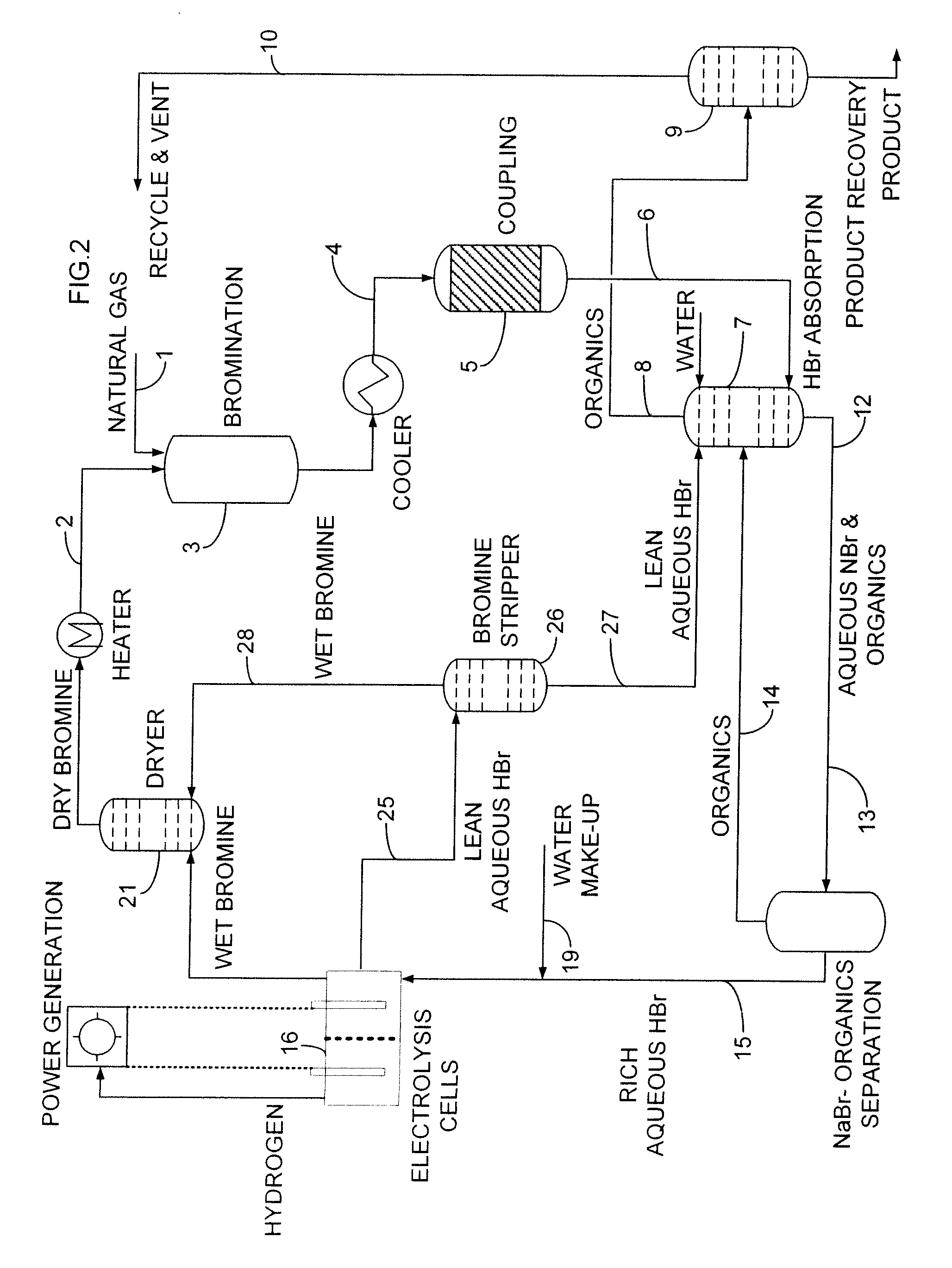

Process for converting hydrocarbon feedstocks with electrolytic recovery of halogen

InactiveUS20080314758A1Improve efficiencyReduced Power RequirementsSolid-state devicesHydroxy compound preparationHalogenHydrocotyle bowlesioides

An improved continuous process for converting methane, natural gas, and other hydrocarbon feedstocks into one or more higher hydrocarbons, methanol, amines, or other products comprises continuously cycling through hydrocarbon halogenation, product formation, product separation, and electrolytic regeneration of halogen, optionally using an improved electrolytic cell equipped with an oxygen depolarized cathode.

Owner:REACTION 35 LLC

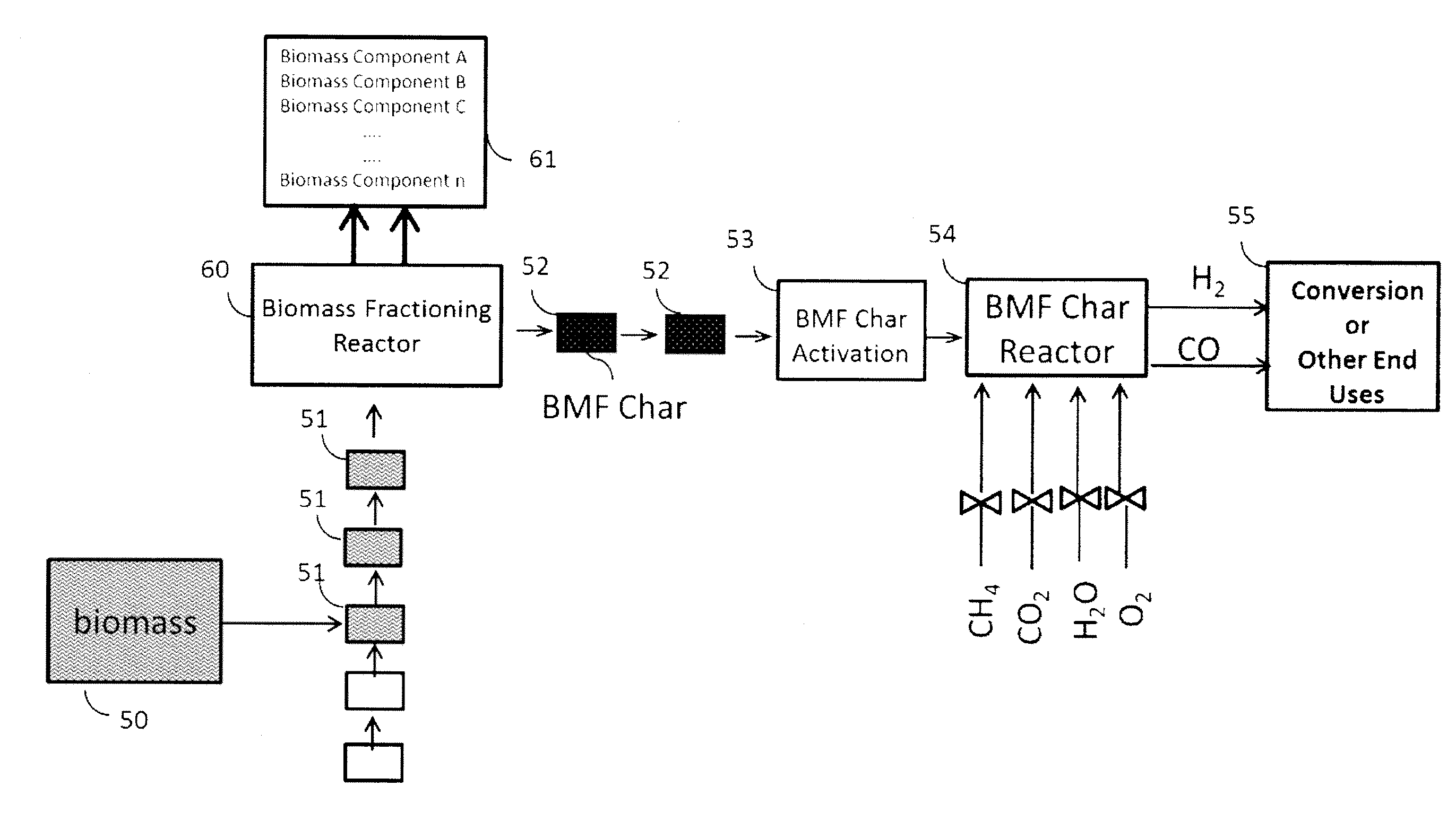

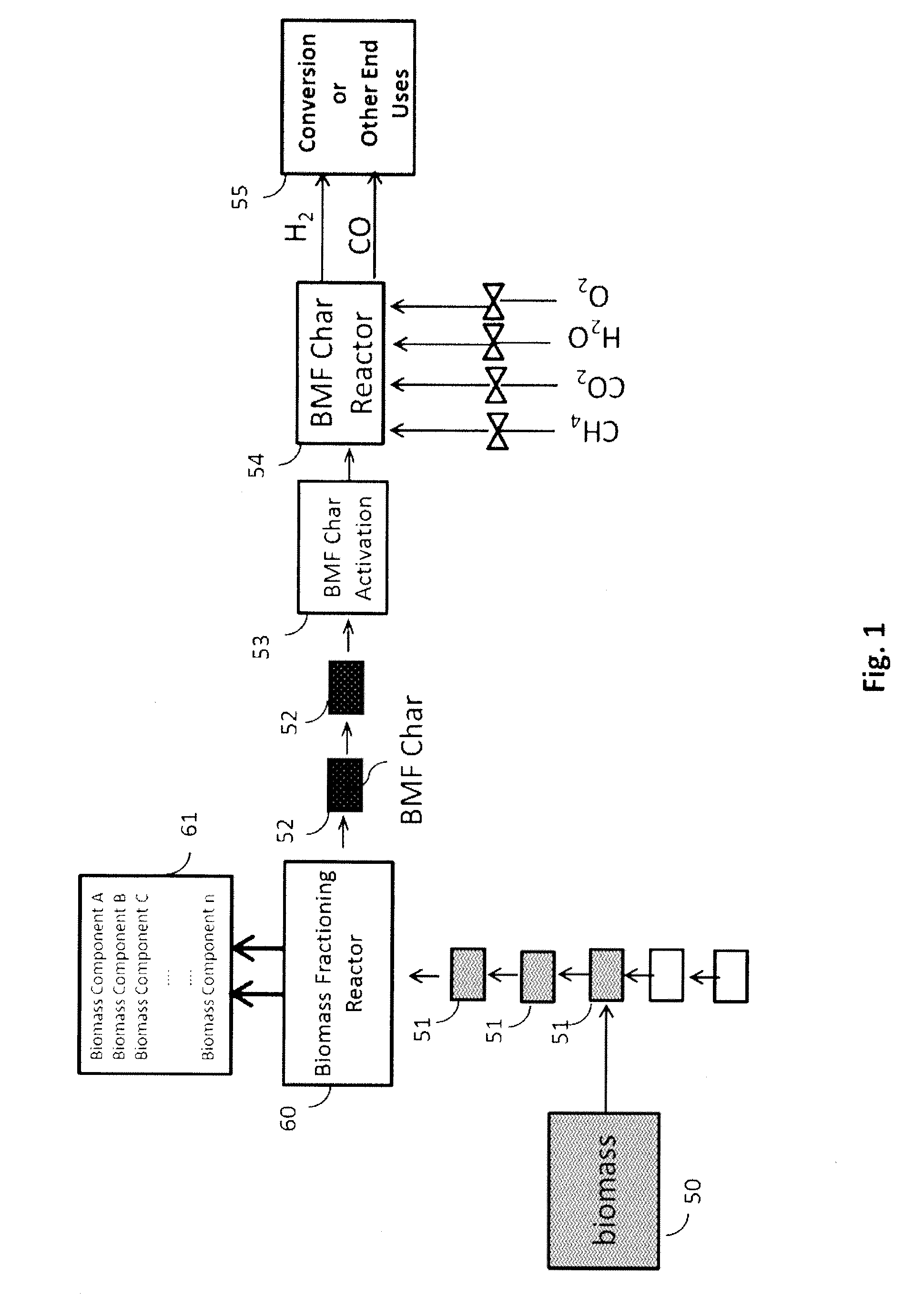

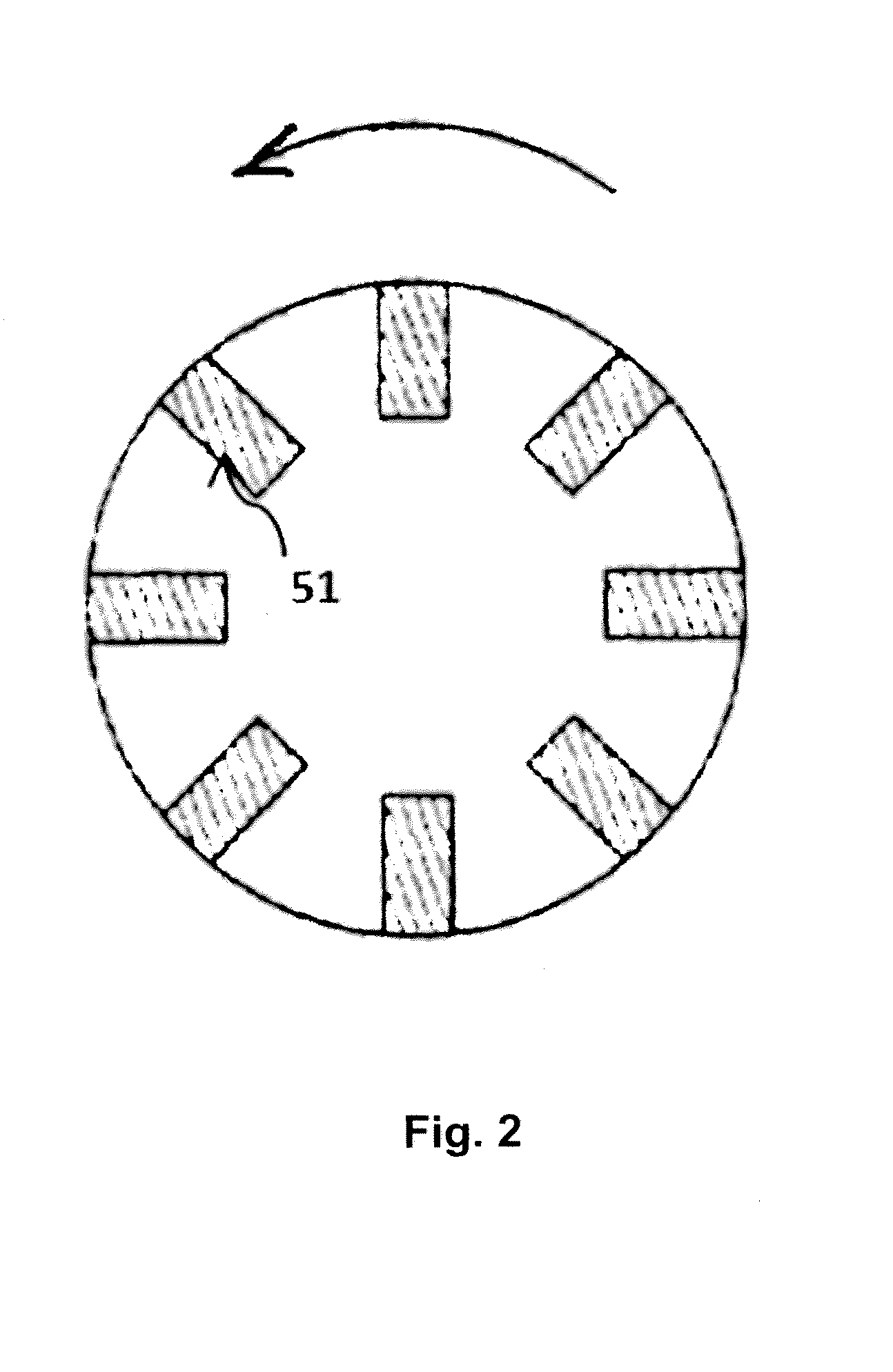

Process for biomass conversion to synthesis gas

Biomass is processed through a biomass fractioning system that creates, through the application of selective temperature ramps and pressure shocks, a series of useful volatile components and BMF char, wherein the BMF char is reacted sacrificially with any one stream of methane, carbon dioxide, steam or oxygen to create highly pure synthesis gas with a controllable range of compositions. The resulting synthesis gas may be used in any desired manner, including conversion to oxygenates such as methanol and dimethyl ether, and to hydrocarbons.

Owner:COOL PLANET ENERGY SYST

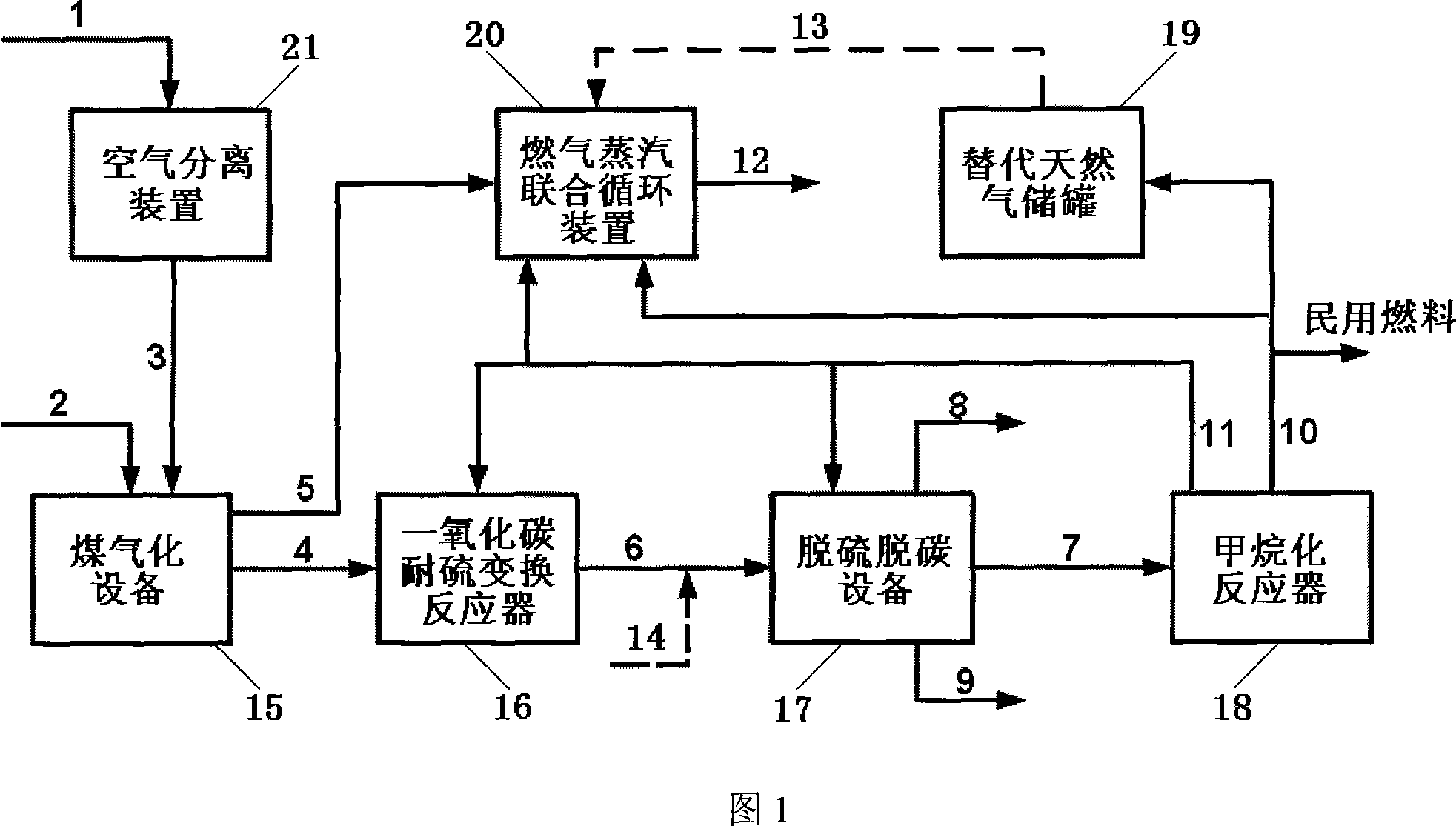

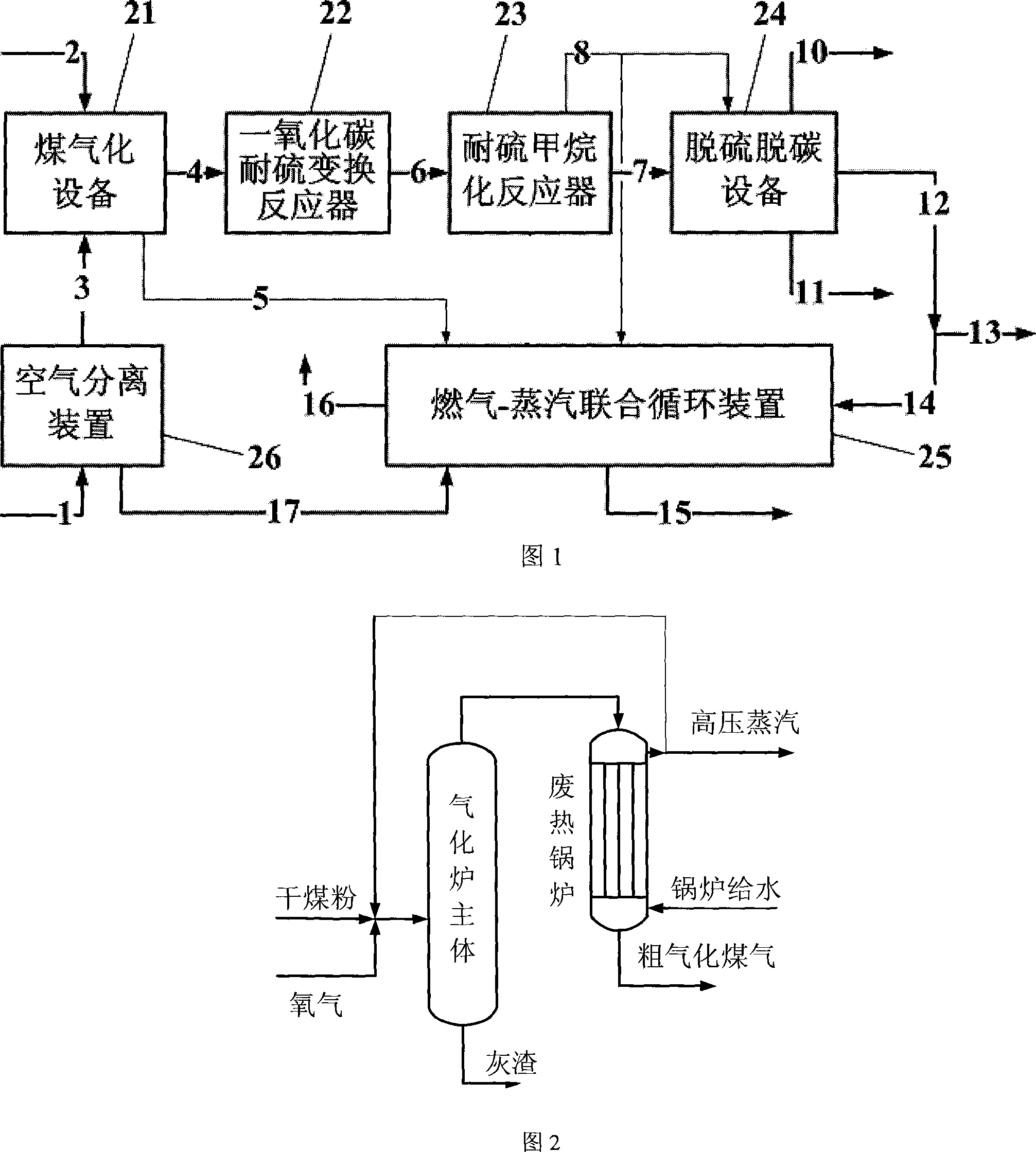

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

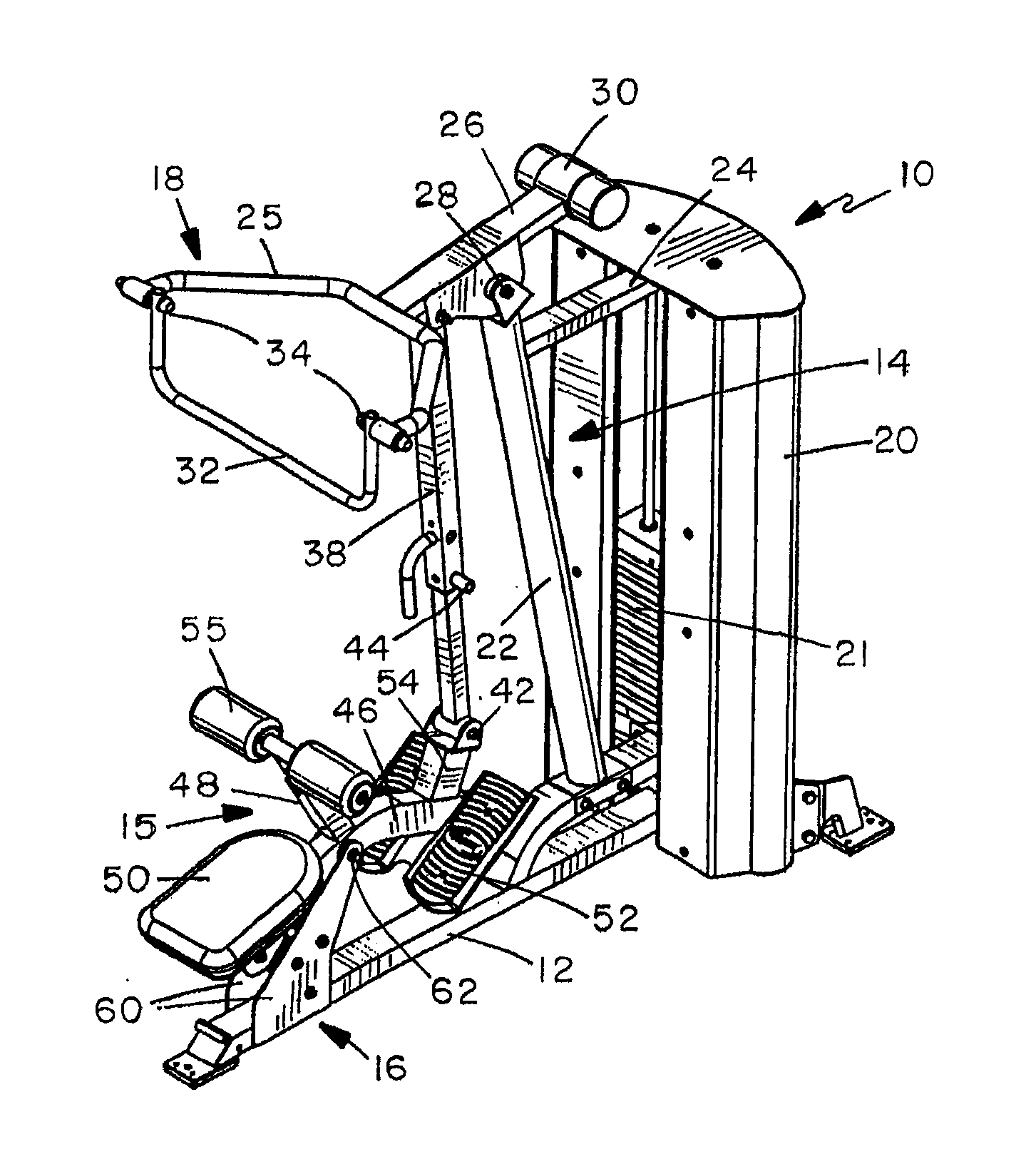

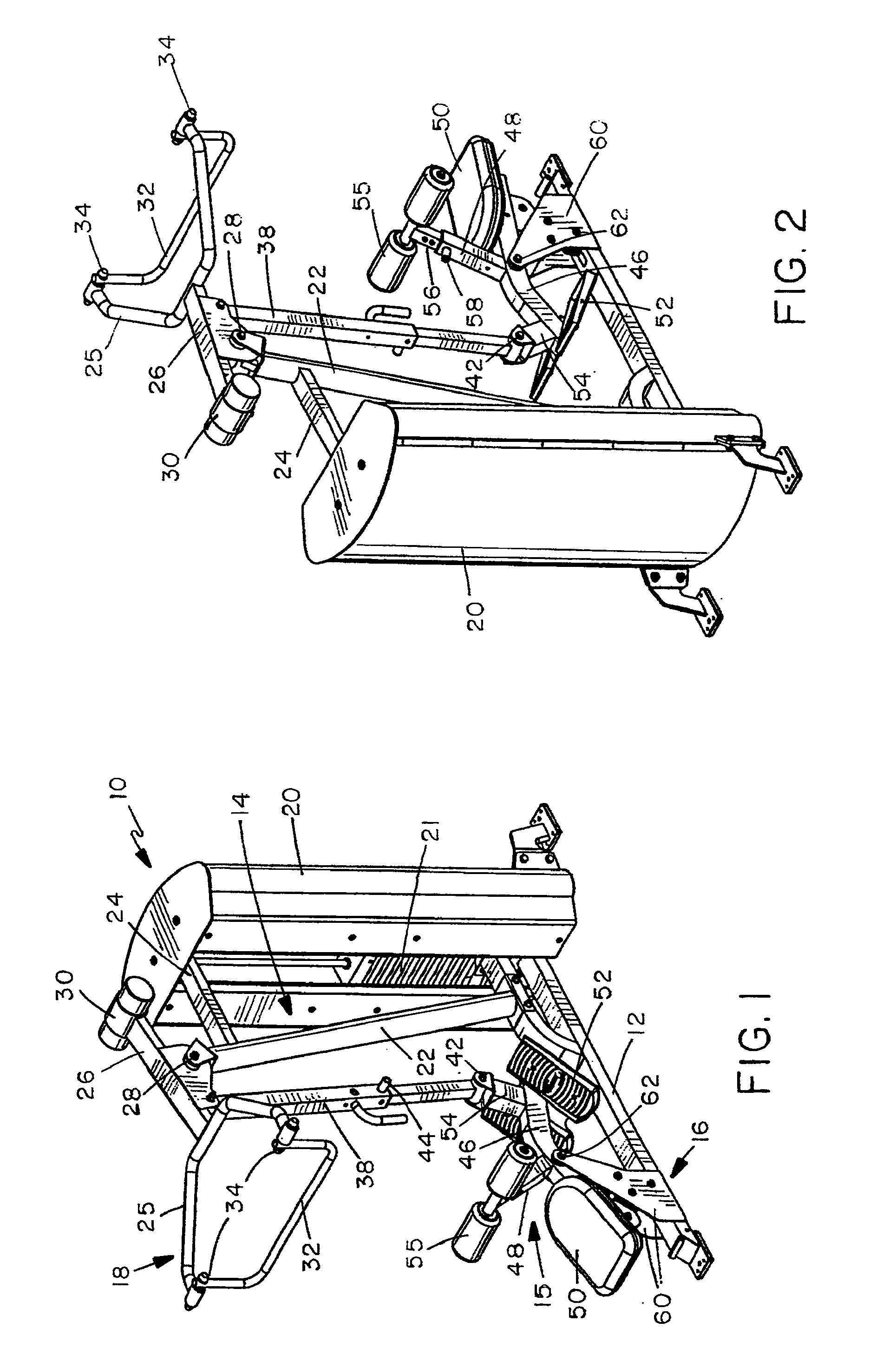

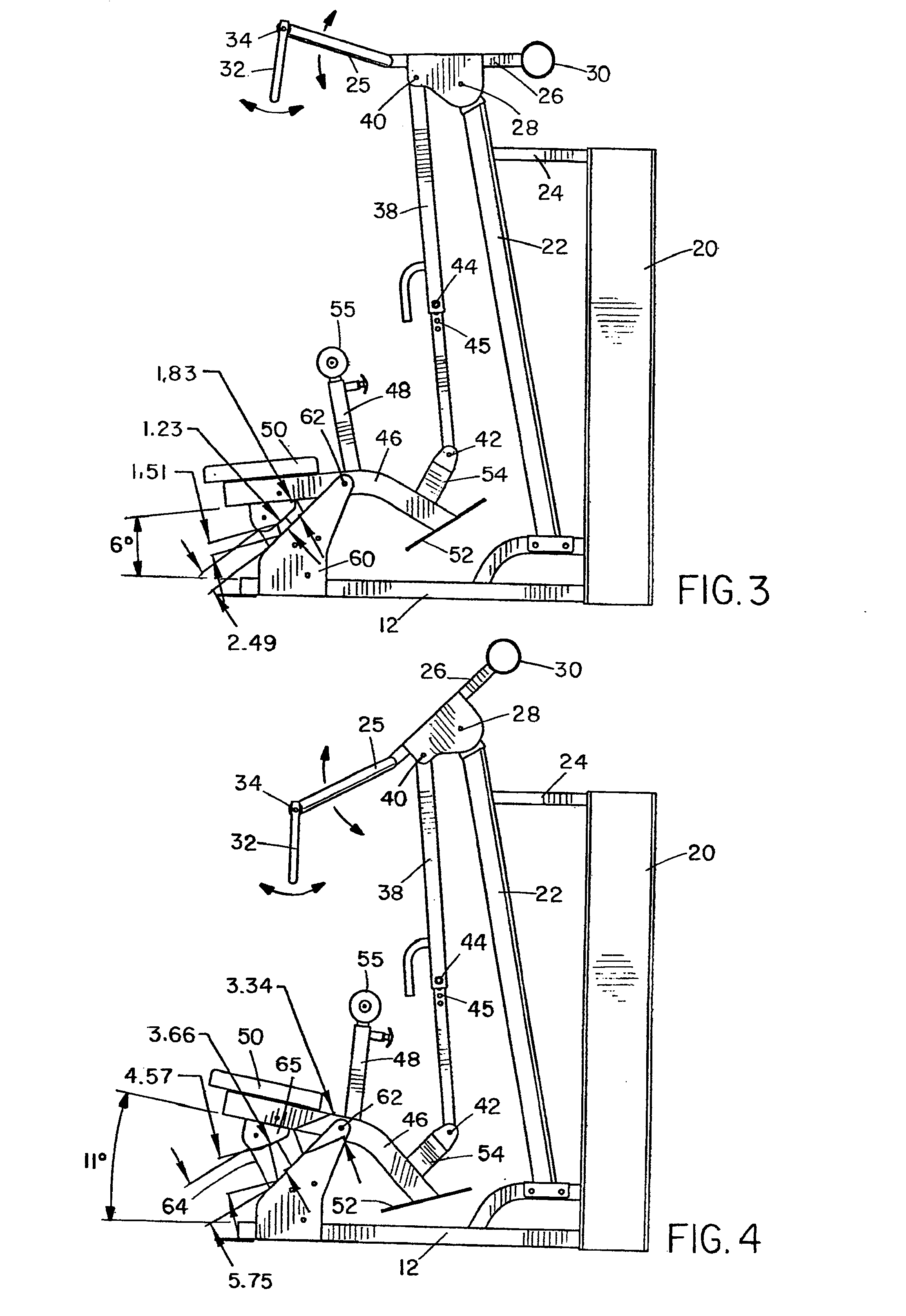

Rigid arm pull down exercise machine

ActiveUS20070232462A1Little effect on resistanceReduce resistanceCombustible gas chemical modificationCarburetting by solid carbonaceous material pyrolysisChinHand arm

An exercise machine for performing lat pull down exercises has a main frame having a user support pivot mount, a user support pivotally mounted on the user support pivot mount for supporting a user in a seated position, and an exercise arm having handles for gripping by a user movably mounted on the frame for movement between a start position located above the head of a user in a seated position on the user support and an end position lower than the start position and generally below the user's chin. A connecting linkage connects movement of the exercise arm to movement of the user support. A load resists movement of at least one of the moving parts of the machine. The combined motion of the user support frame and exercise arm substantially replicates the natural movement of the human body when performing a free bar chin up exercise.

Owner:HOIST FITNESS SYST

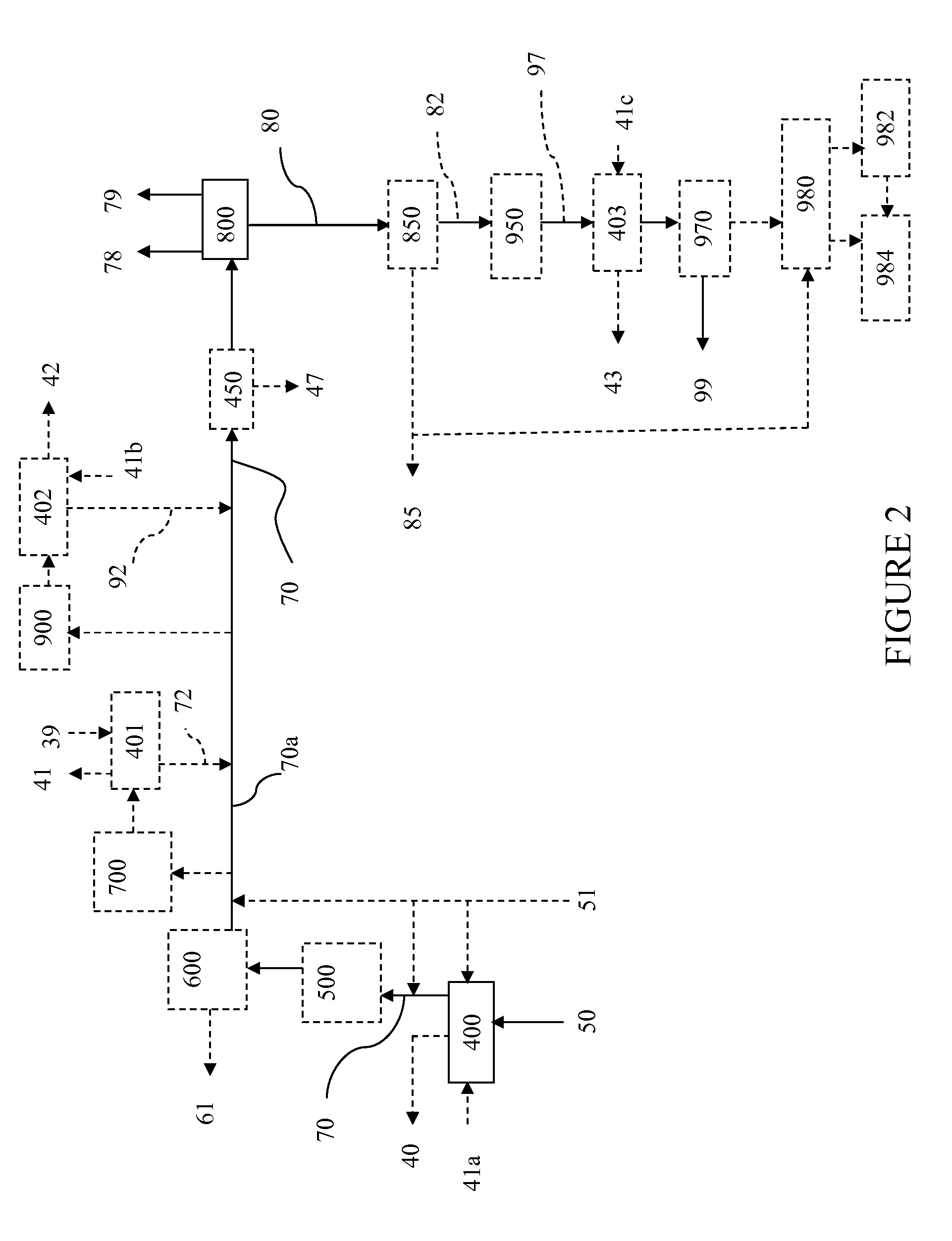

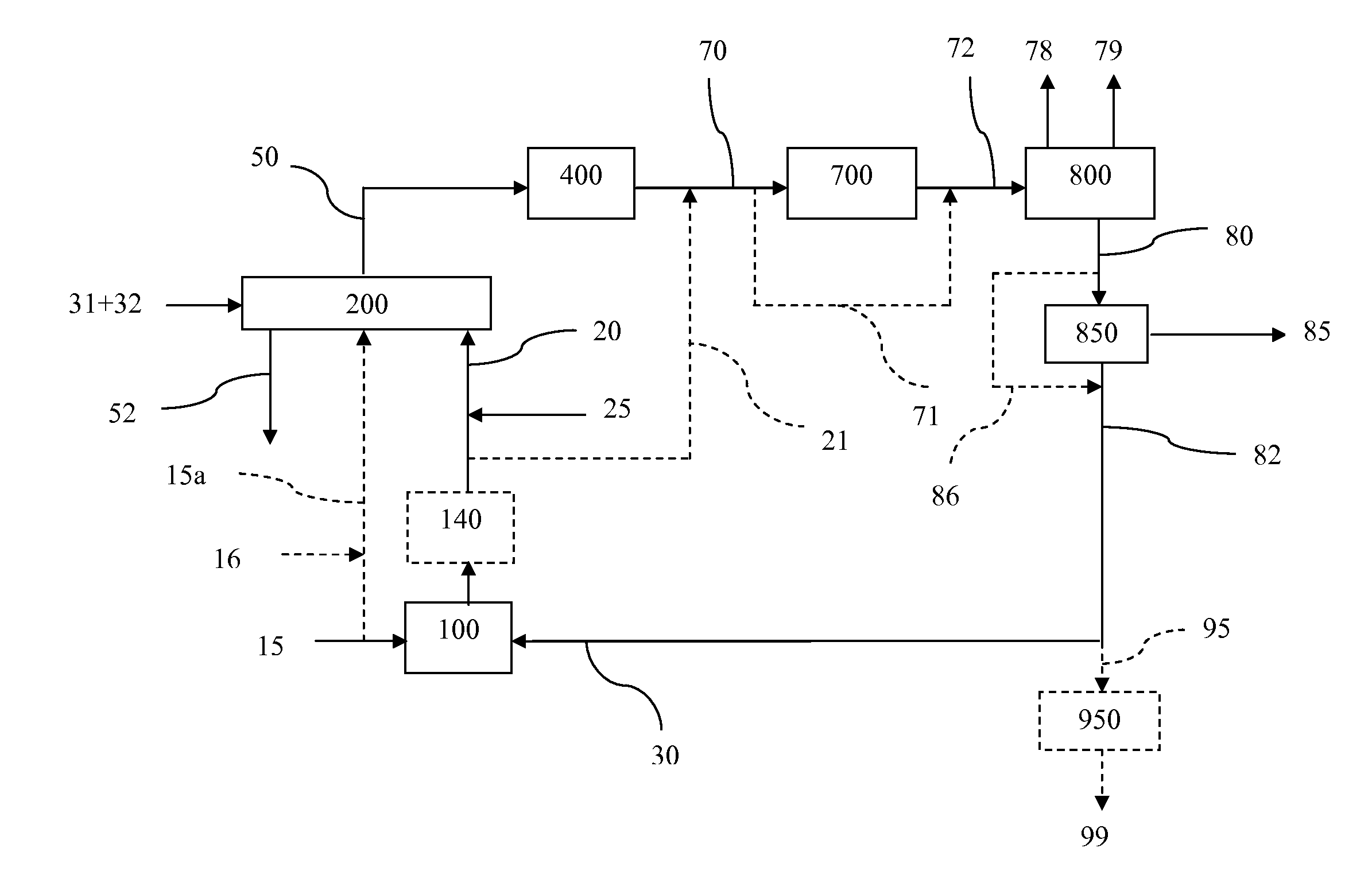

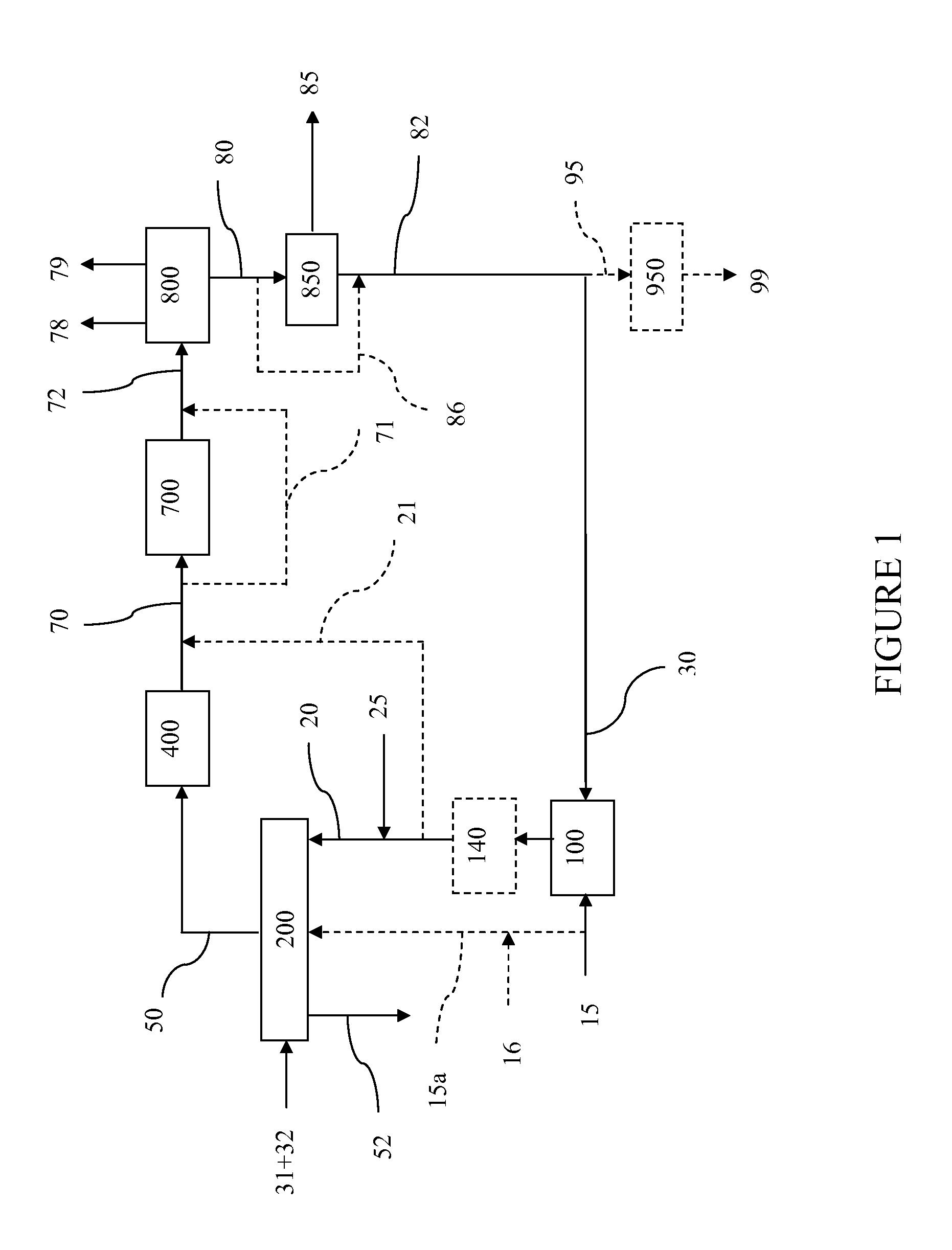

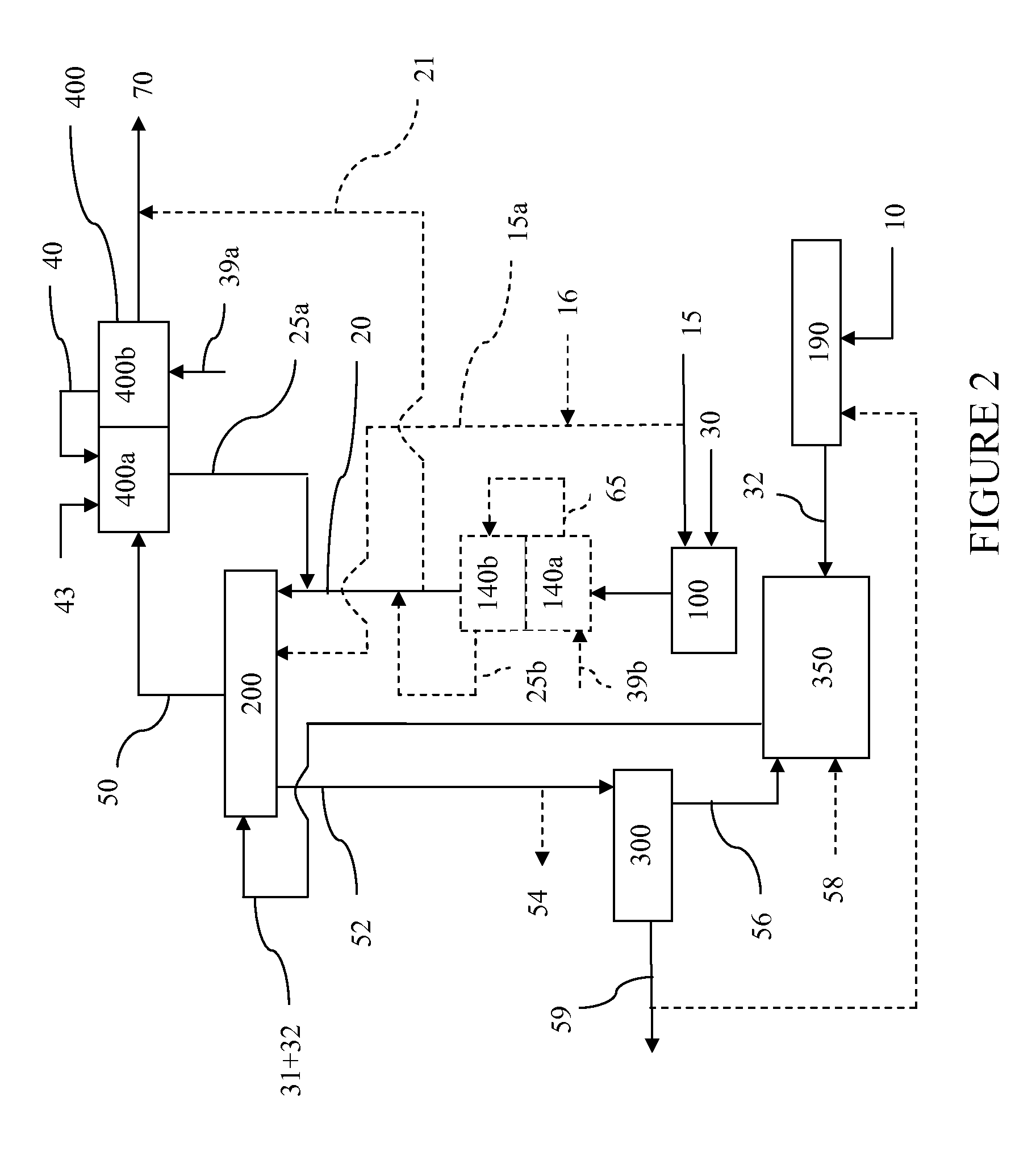

System and method for converting biomass to ethanol via syngas

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

Method for high-efficiency separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud

ActiveCN102851425AWon't breakReasonable useCombustible gas chemical modificationProcess efficiency improvementRed mudSlag

The invention provides a method for high-efficiency separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud. The method comprises the following steps of adding iron ore concentrate and coke powder into high-iron red mud as a raw material, pressing the mixture into red mud pellets, drying, pre-heating, directly reducing metallic oxides of iron and sodium by a rotary hearth furnace, feeding the reduced metalized pellets into an iron bath-type oxy-coal smelting reduction furnace, carrying out high-temperature melting separation, using separated iron for steel-making, recovering alumina from the modified high-aluminum slag, recovering the metallic oxide of sodium from smoke dust carried by exhaust gas, improving quality of mixed gas produced by the iron bath-type oxy-coal smelting reduction furnace, and feeding back the treated mixed gas to the rotary hearth furnace for use. The method provided by the invention can effectively realize high efficiency recovery and large-scale industrial comprehensive utilization of a red mud resource.

Owner:NORTHEASTERN UNIV

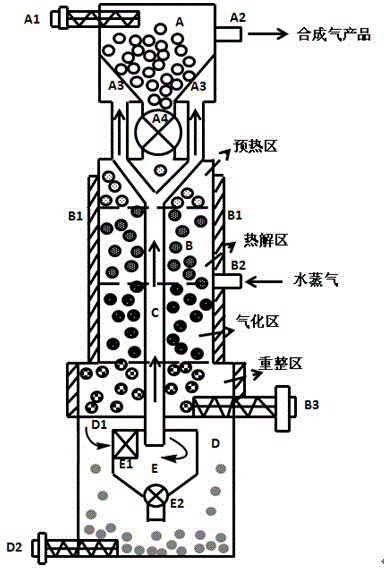

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Gas-steam combined cycle system and technique based on coal gasification and methanation

ActiveCN101245262AReduce energy consumptionEasy to recycleNitrogen purification/separationCombustible gas chemical modificationMethanationSubstitute natural gas

A combined cycle system based on coal gasification and methanation gas-steam and a technique thereof, wherein, the method comprises the following steps: oxygen produced by an air separation unit and coal powder or water-coal-slurry are sent into coal gasification equipment, the produced crude gasification gas is sent to a carbon monoxide sulfur-tolerant shift reactor to adjust the ratio of hydrogen and carbon after the sensible heat recollecting, and is then sent into sulfur-tolerant methanation reactor to produce methane and carbon dioxide, then the reaction product is sent into desulfurization and decarbonization equipment so that element sulfur can be recovered and carbon dioxide can be separated so as to obtain substitute natural gas with high content of methane, part of which is sent to the gas-steam combined cycle equipment while the other part is sent to a urban gas system. The enriched CO2 density of the system can reach 50 to 60 percent, technical probability is provided for reasonably realizing low-energy-consumption reduced exhaust of CO2, no change needs to be done with gas turbines, each chemical unit operates according to established rated condition and needs not to change load owing to power conditioning so as to improve the economy of the operation of power plants; compared with the prior art, the energy utilization efficiency of the whole system is improved so as to realize the efficient clean utilization of coal.

Owner:TSINGHUA UNIV

Process for producing liquid fuel from carbon dioxide and water

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

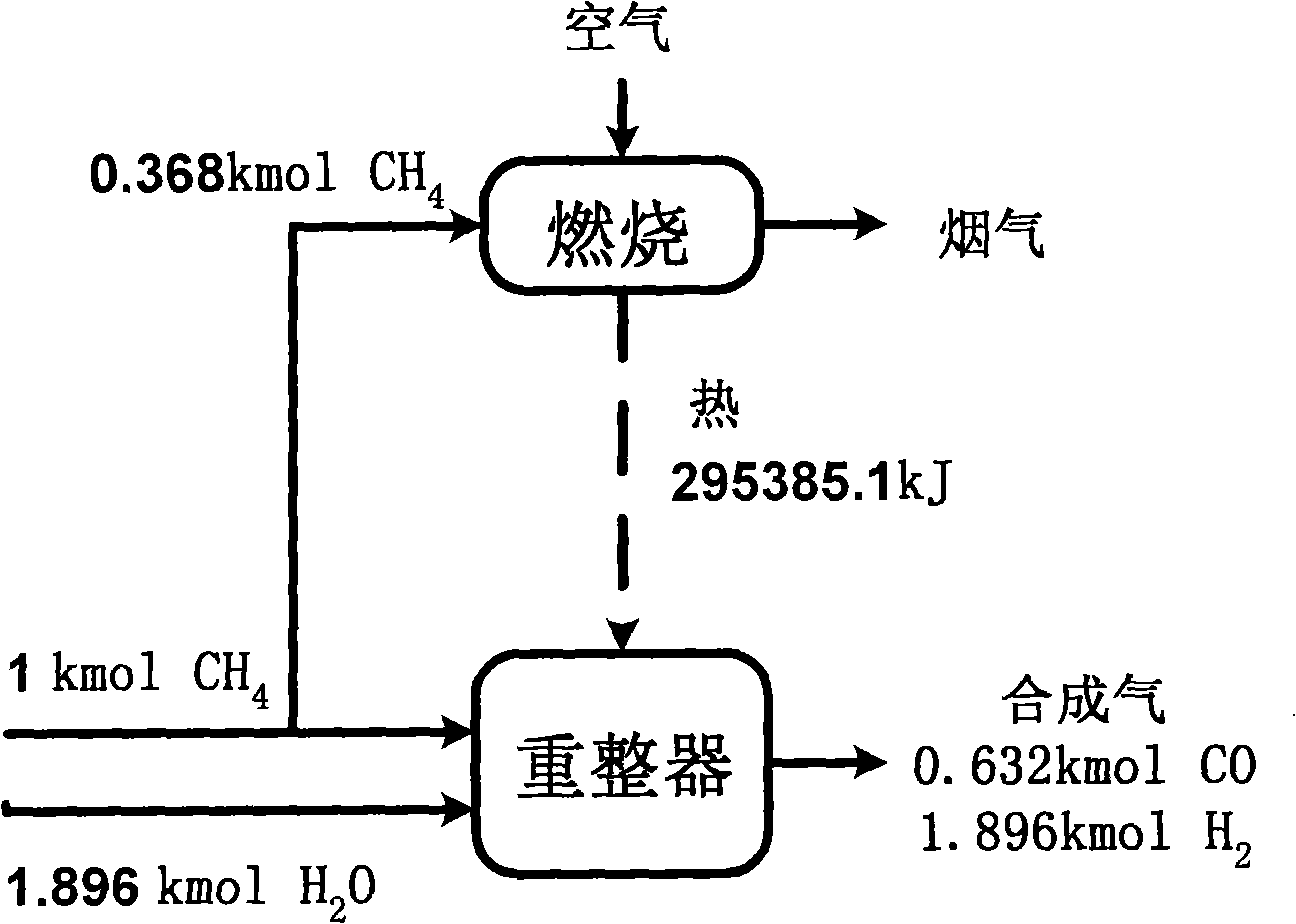

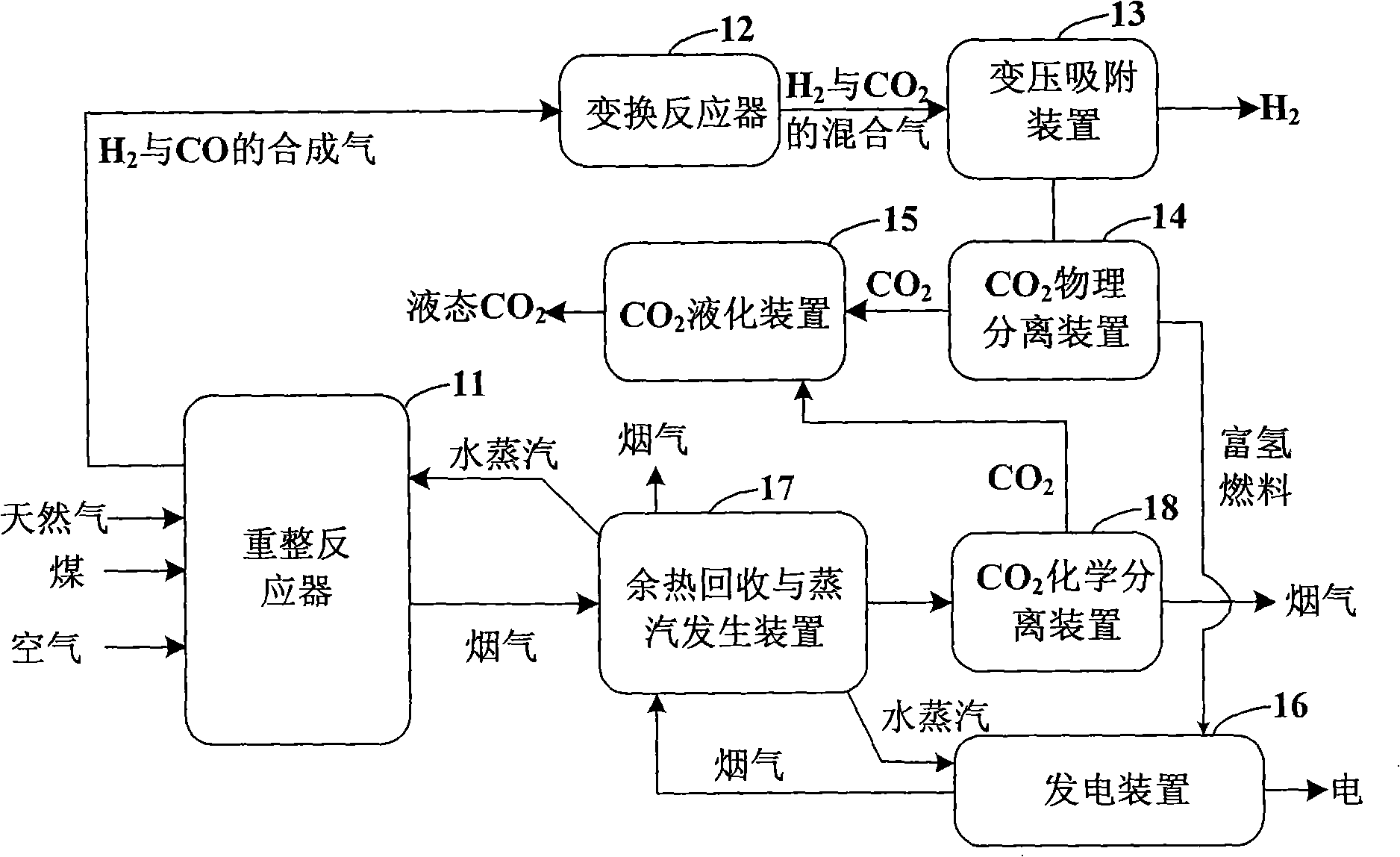

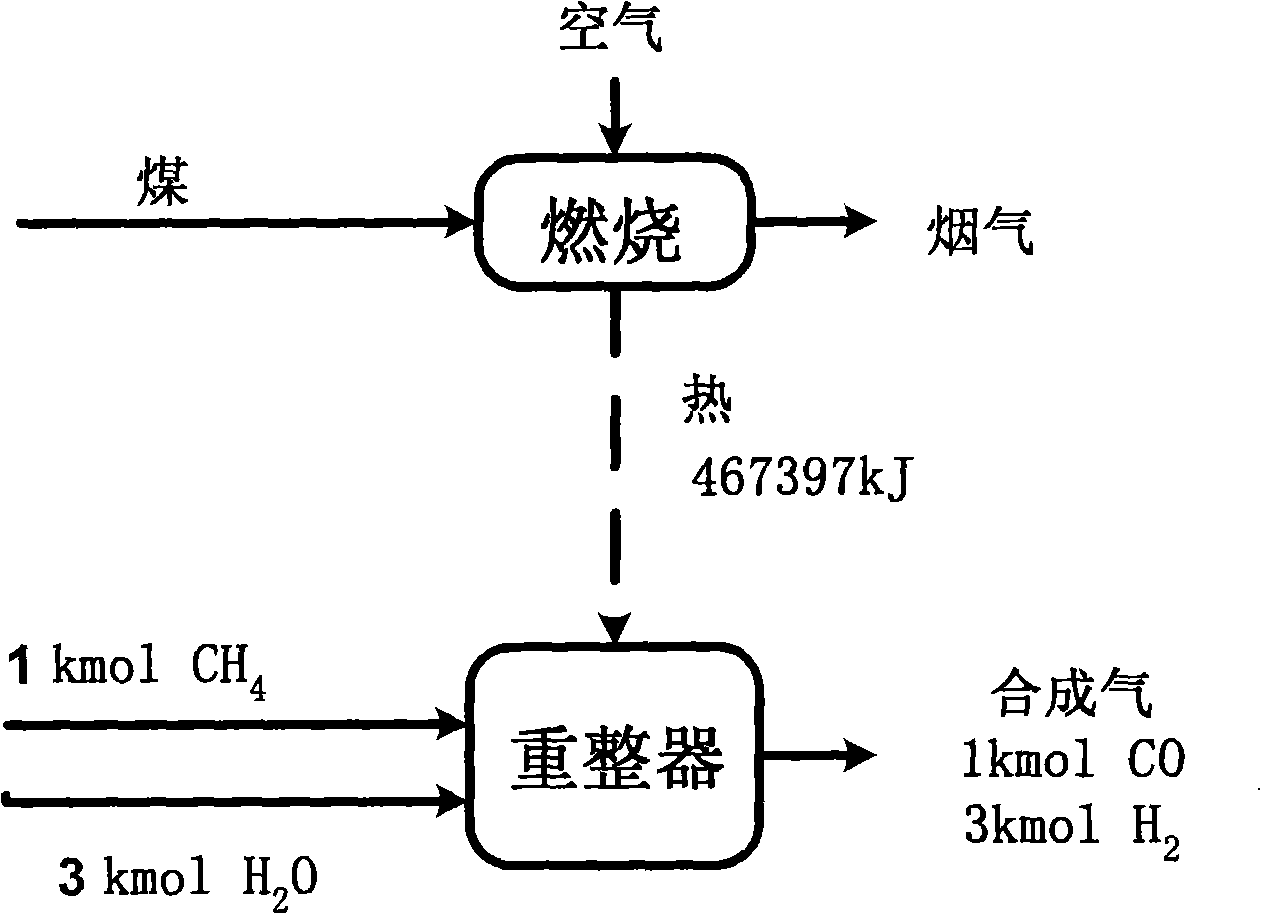

Multifunctional energy resource system

ActiveCN101285004AHuge lossReasonable useCombustible gas chemical modificationEnergy inputAtmospheric airNatural gas

The invention discloses a multifunctional energy system. In the system, coal and natural gases simultaneously enter a reforming reactor, and the coal fires in the reforming reactor to drive the reforming reaction of natural gases, which generates synthetic gases of H2 and CO; the synthetic gases pass through a shift converter to convert CO into CO2, and then enter a pressure swing adsorption device(PSA) for preparing hydrogen gases; tail gases generated in the PSA device are sent to a CO2 separator to separate out a majority of CO2, and then compressed and cooled to become liquid CO2, which is convenient for transportation and storage; hydrogen rich fuel gases remained after the separation of CO2 are sent to a generating set, and high-temperature flue gases enter a waste heat recovery and a steam generation device, and the flue gases, the waste heat of which is recovered, are discharged in air; the flue gases discharged by a dual fuel reformer are also enter the waste heat recovery and steam generation device for recovering the waste heat, and then enter the CO2 separator to separate CO2 contained in flue gases; purified CO2 is compressed and liquefied, and finally the flue gases are discharged in air. The multifunctional energy system has the advantages of improving the utilization rate of the fuel and realizing the control and recovery of CO2 with zero energy consumption.

Owner:中科思道(南京)储能技术有限公司

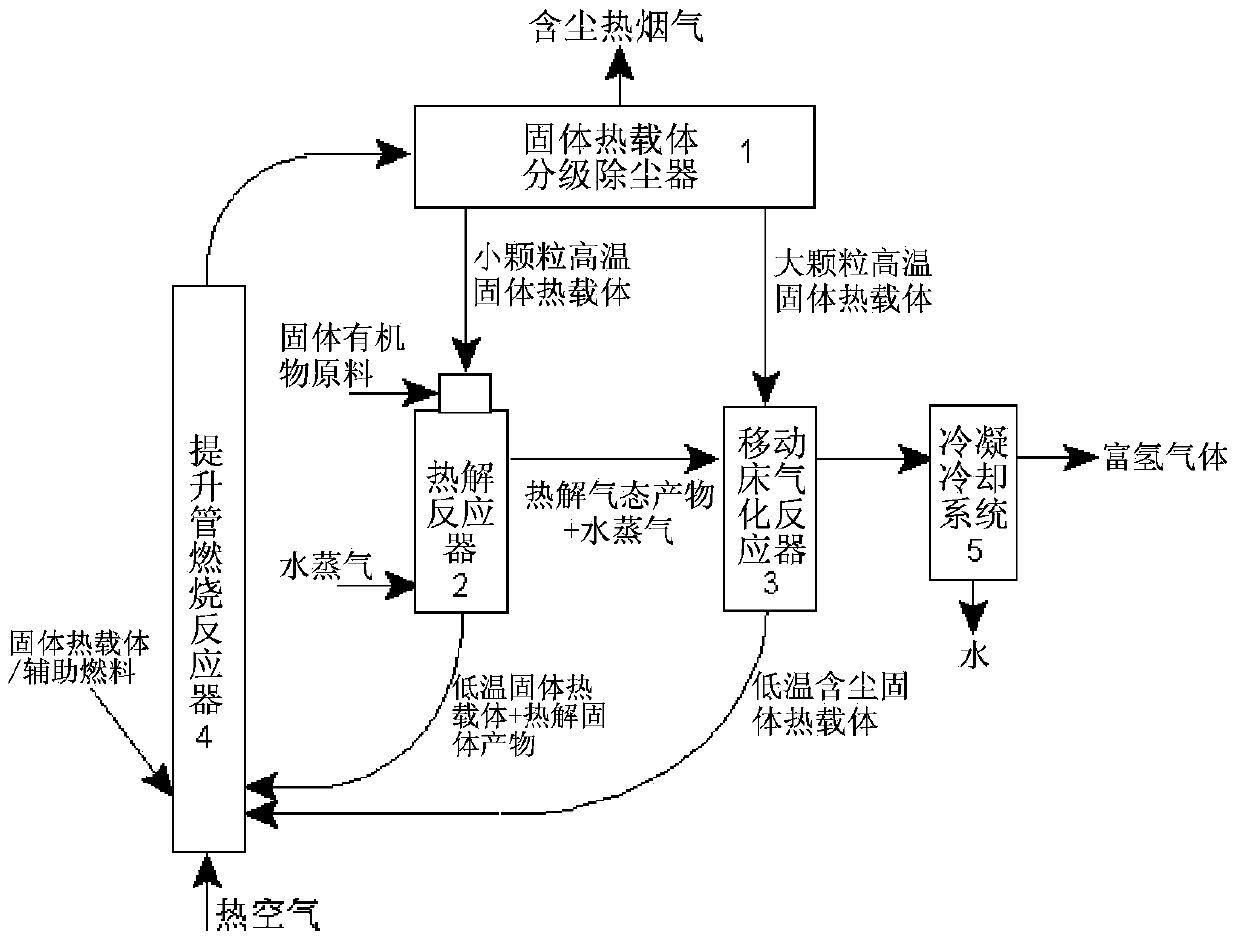

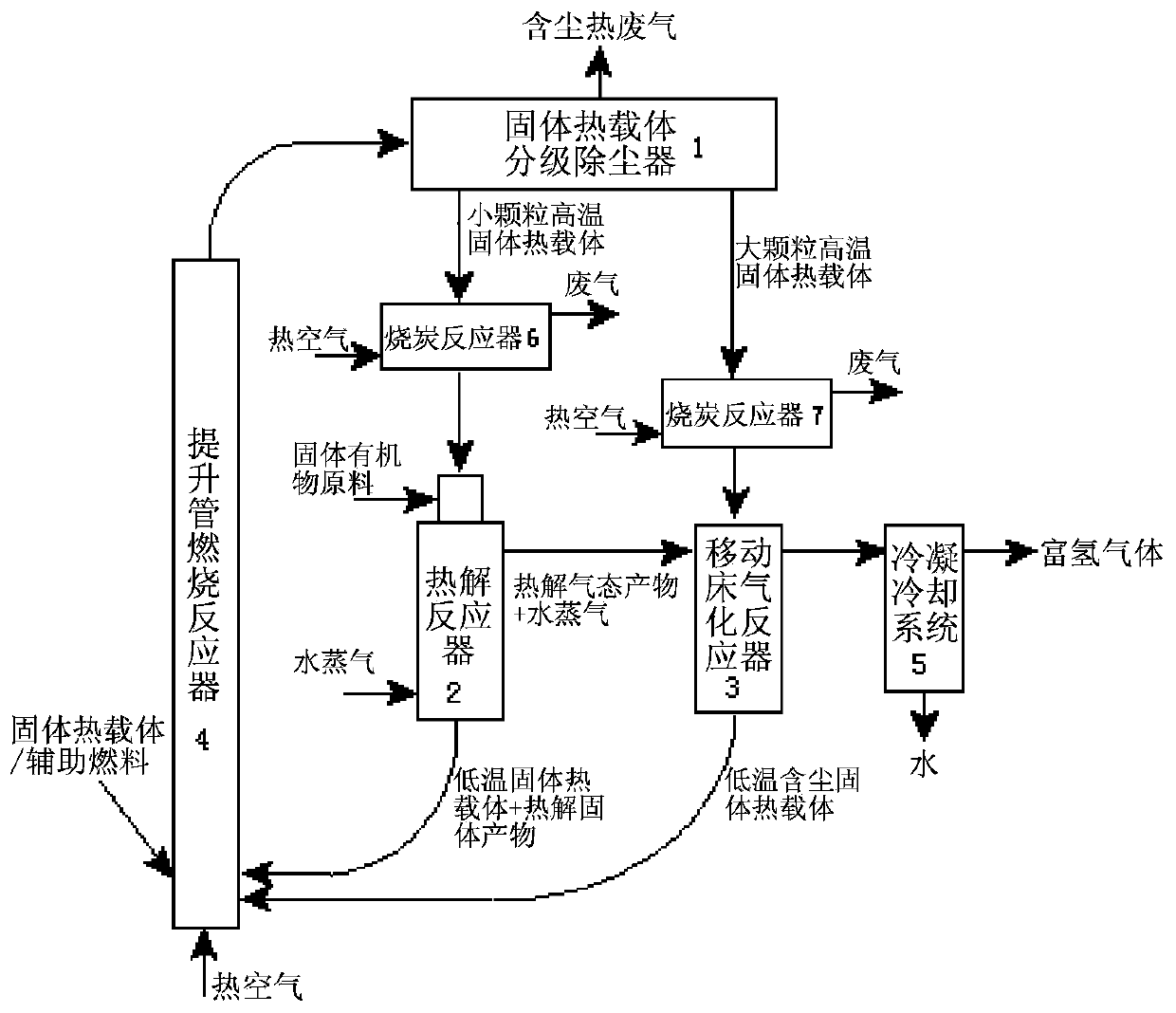

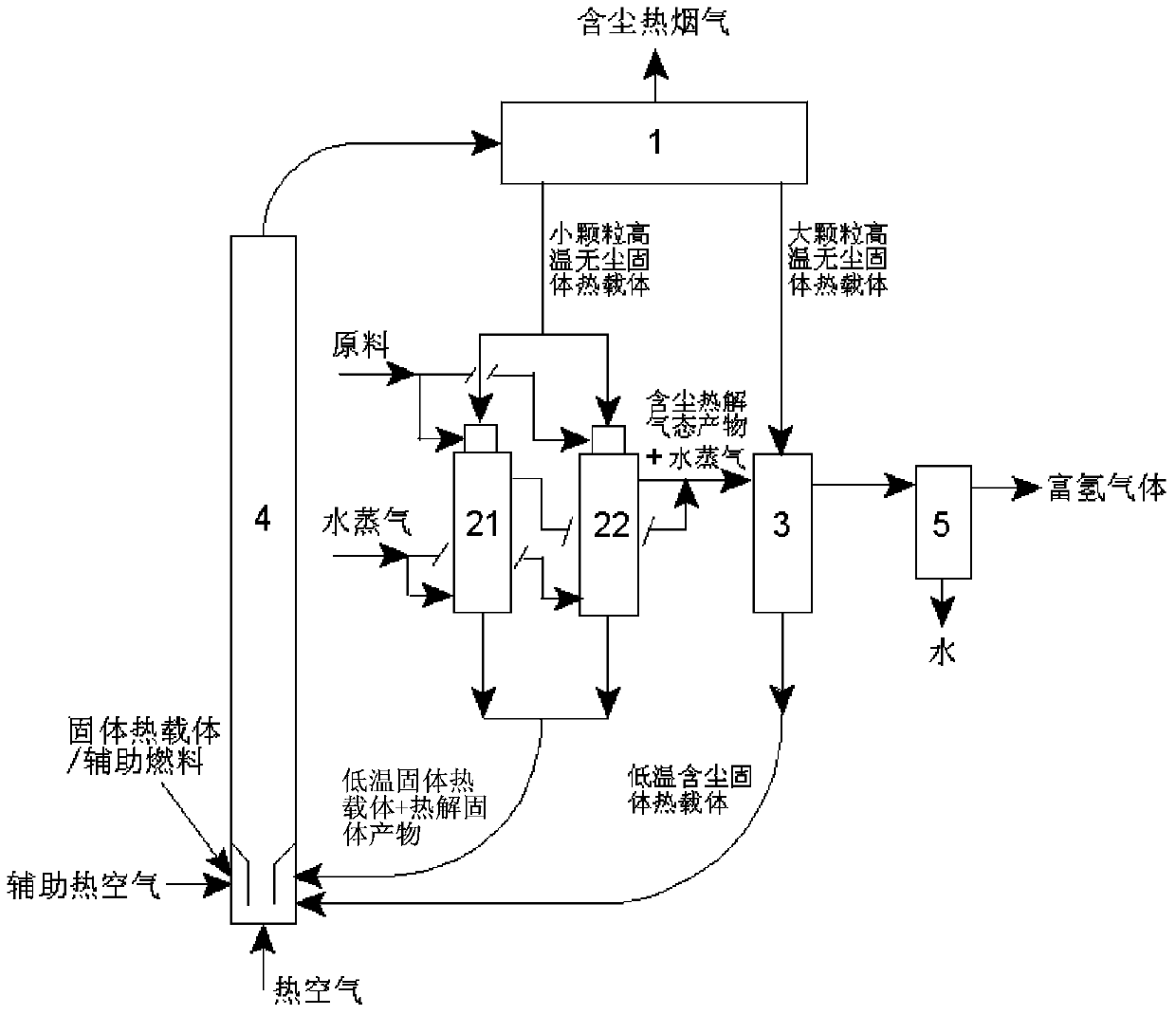

Preparation method for hydrogen-rich gas through steam gasification of solid organic matter

ActiveCN103468322AFast pyrolysisSimple processCombustible gas chemical modificationGasification catalystsWater vaporMoving bed

The invention provides a preparation method for hydrogen-rich gas through steam gasification of a solid organic matter. The method comprises the following steps: heating the raw material--the solid organic matter in a pyrolysis apparatus for pyrolysis; and subjecting a gaseous product produced after pyrolysis and steam to gasification in a moving bed gasification apparatus so as to produce the hydrogen-rich gas. The invention further provides a system for preparing the hydrogen-rich gas from the solid organic matter. The system comprises a solid thermal carrier gradient deduster, the pyrolysis apparatus, the moving bed gasification apparatus and a riser combustion reactor. The method provided by the invention is implemented at normal pressure, has simple process and is applicable to gasification and co-gasification of a variety of organic matters with high content of volatile components, including raw materials with high content of moisture, mineral matters and sulfur.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

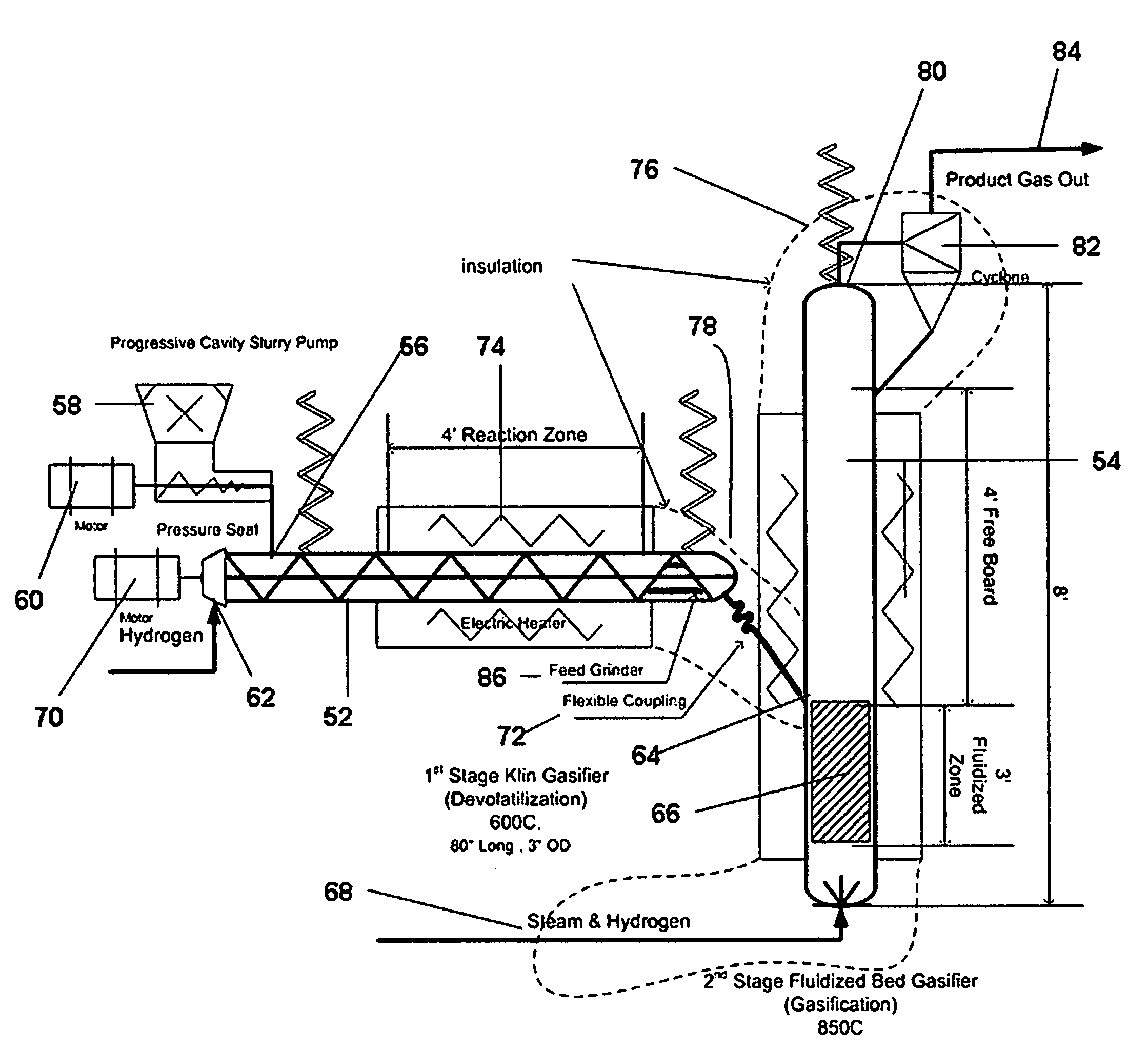

Process and apparatus for the production of synthesis gas

ActiveUS7670586B2Avoiding negatively affecting the mechanical integrity of the secondary unit.Lower Level RequirementsUsing liquid separation agentHydrogen productionSolid carbonSyngas

Owner:KANSAS STATE UNIV INST FOR COMMLIZATION +1

Method and apparatus for steam hydro-gasification in a fluidized bed reactor

InactiveUS20080021123A1Well mixedIncrease conversion rateCombustible gas chemical modificationHydrogenHydrogenFluidized bed

Owner:RGT UNIV OF CALIFORNIA

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS7642292B2Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneJet fuel

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolyzing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

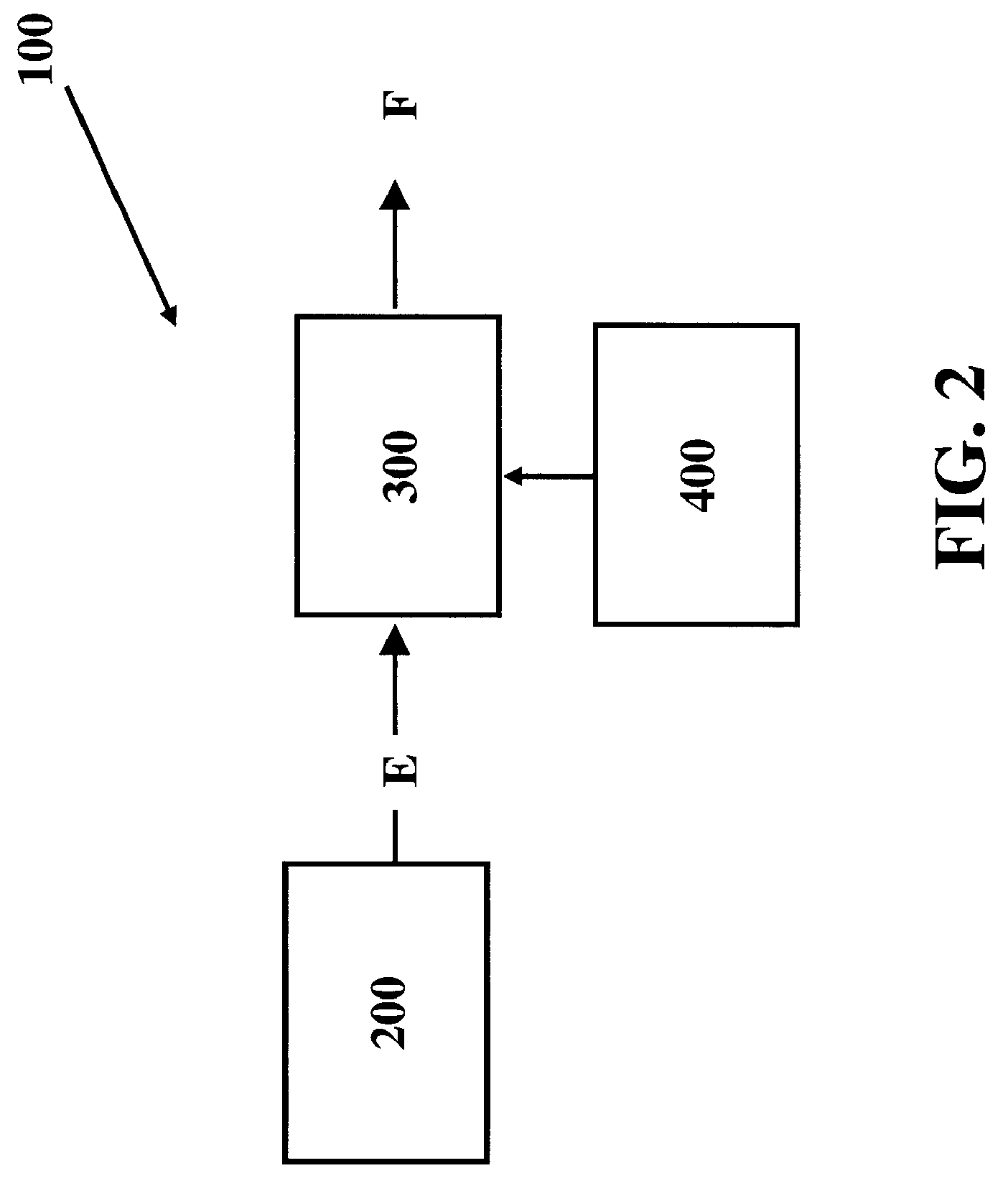

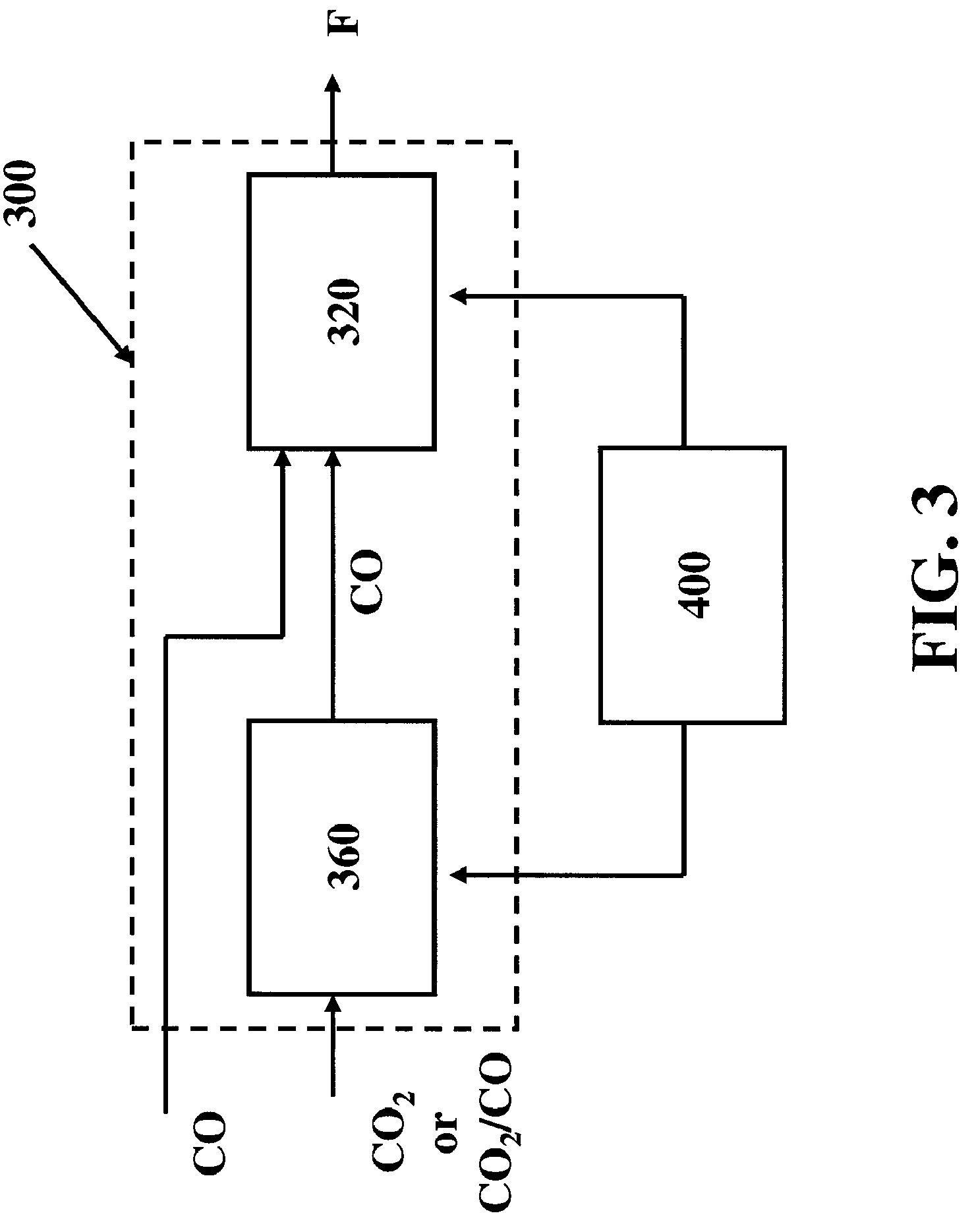

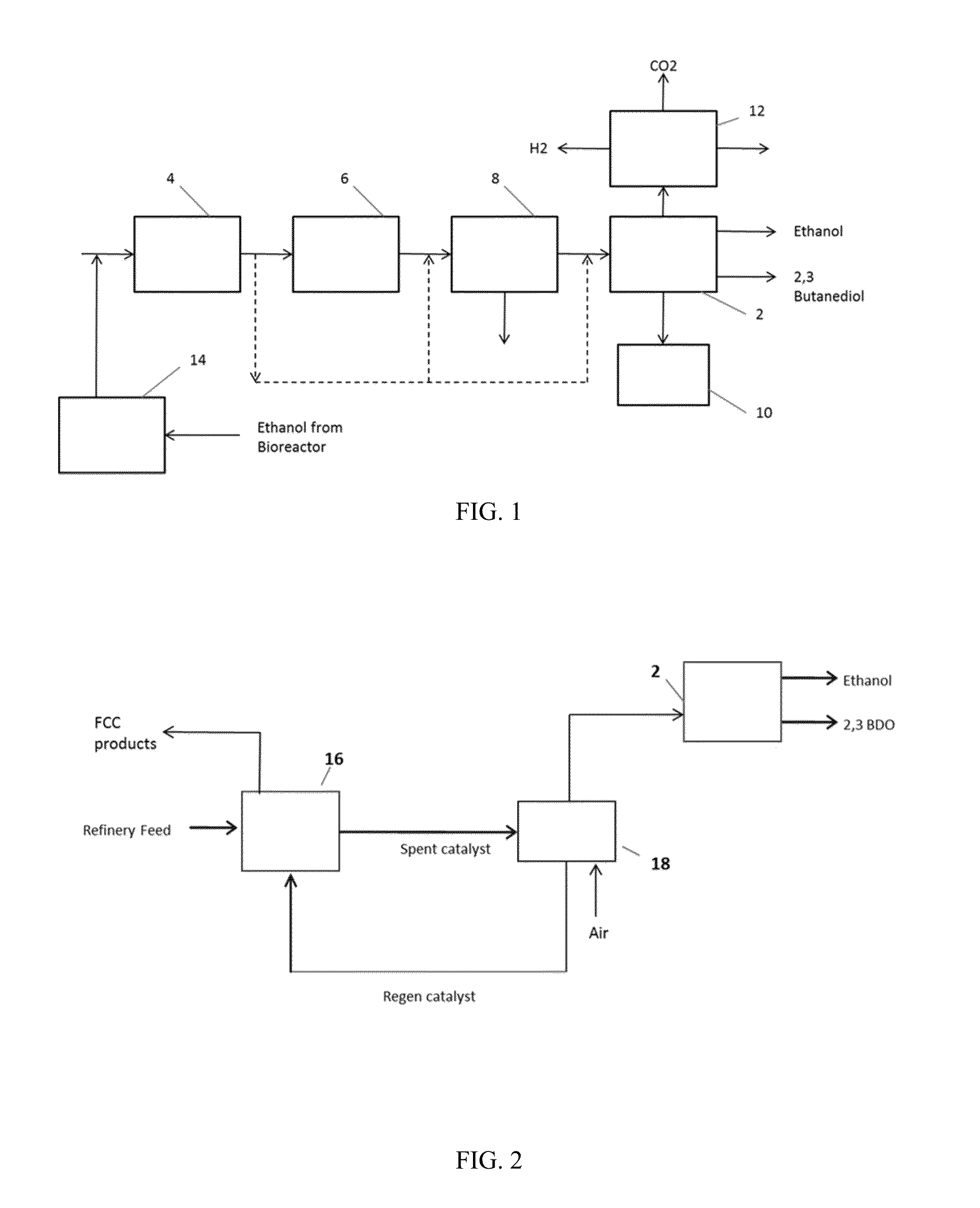

Methods and Systems for the Production of Hydrocarbon Products

ActiveUS20130210096A1Improving overall carbon captureImprove hydrogen production efficiencyThermal non-catalytic crackingBioreactor/fermenter combinationsSteam reformingBioreactor

Methods and systems for the production of hydrocarbon products, including providing a substrate comprising CO to a bioreactor containing a culture of one or more micro-organisms; and fermenting the culture in the bioreactor to produce one or more hydrocarbon products. The substrate comprising CO is derived from an industrial process selected from the group comprising steam reforming processes, refinery processes, steam cracking processes, and reverse water gas shift processes.

Owner:LANZATECH NZ INC

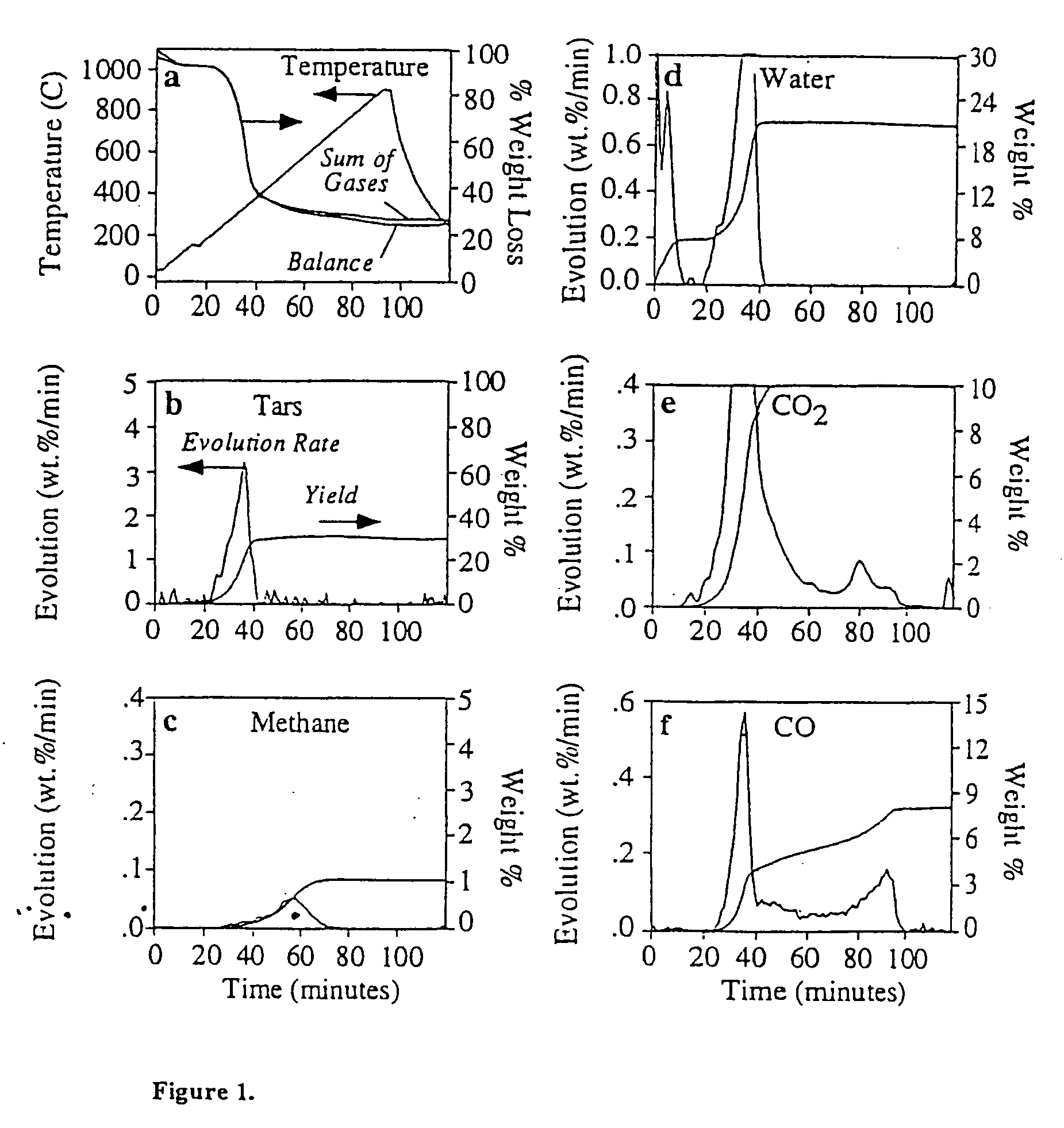

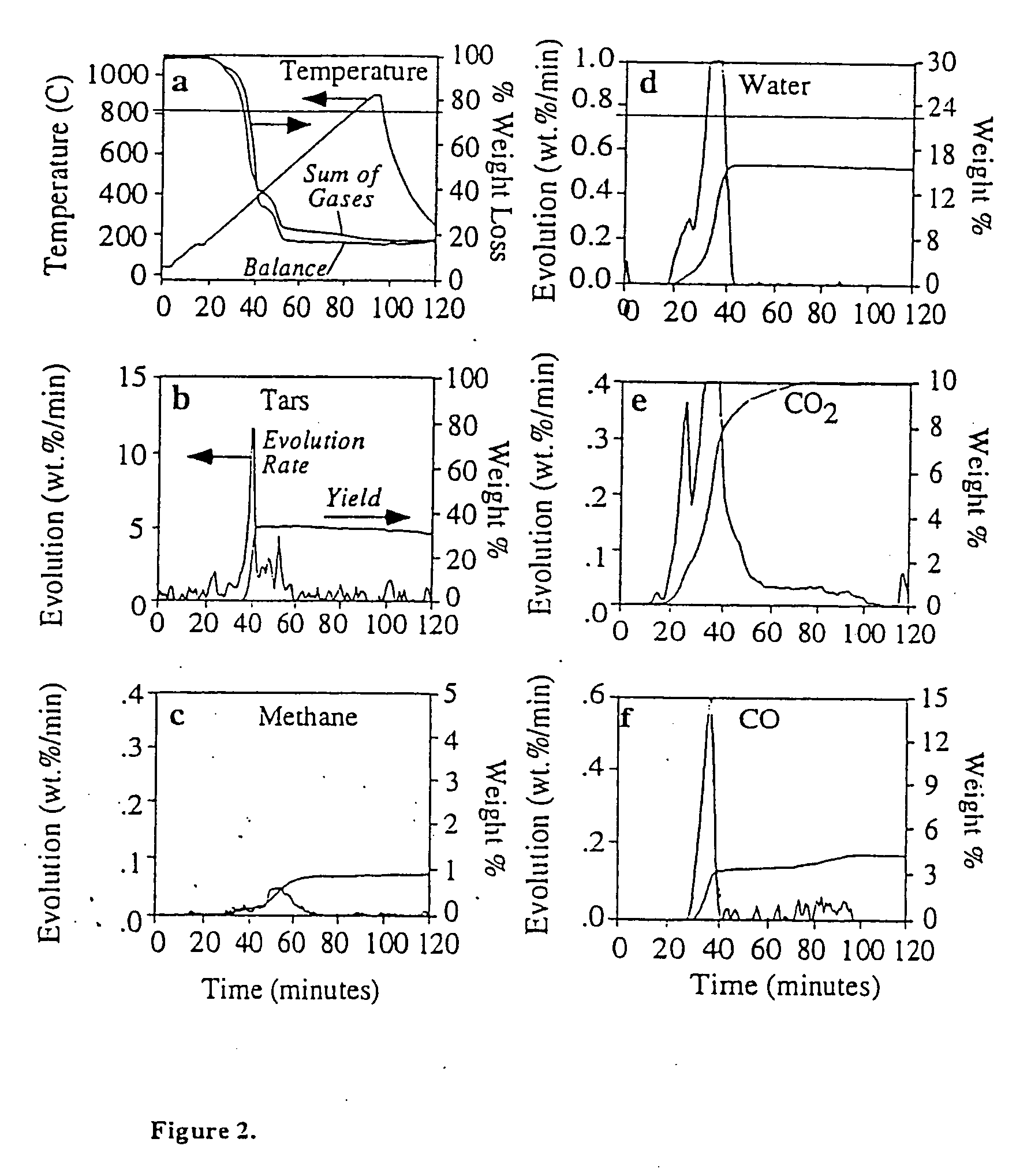

Pyrolysis process for producing fuel gas

Solid waste resource recovery in space is effected by pyrolysis processing, to produce light gases as the main products (CH4, H2, CO2, CO, H2O, NH3) and a reactive carbon-rich char as the main byproduct. Significant amounts of liquid products are formed under less severe pyrolysis conditions, and are cracked almost completely to gases as the temperature is raised. A primary pyrolysis model for the composite mixture is based on an existing model for whole biomass materials, and an artificial neural network models the changes in gas composition with the severity of pyrolysis conditions.

Owner:ADVANCED FUEL RES INC

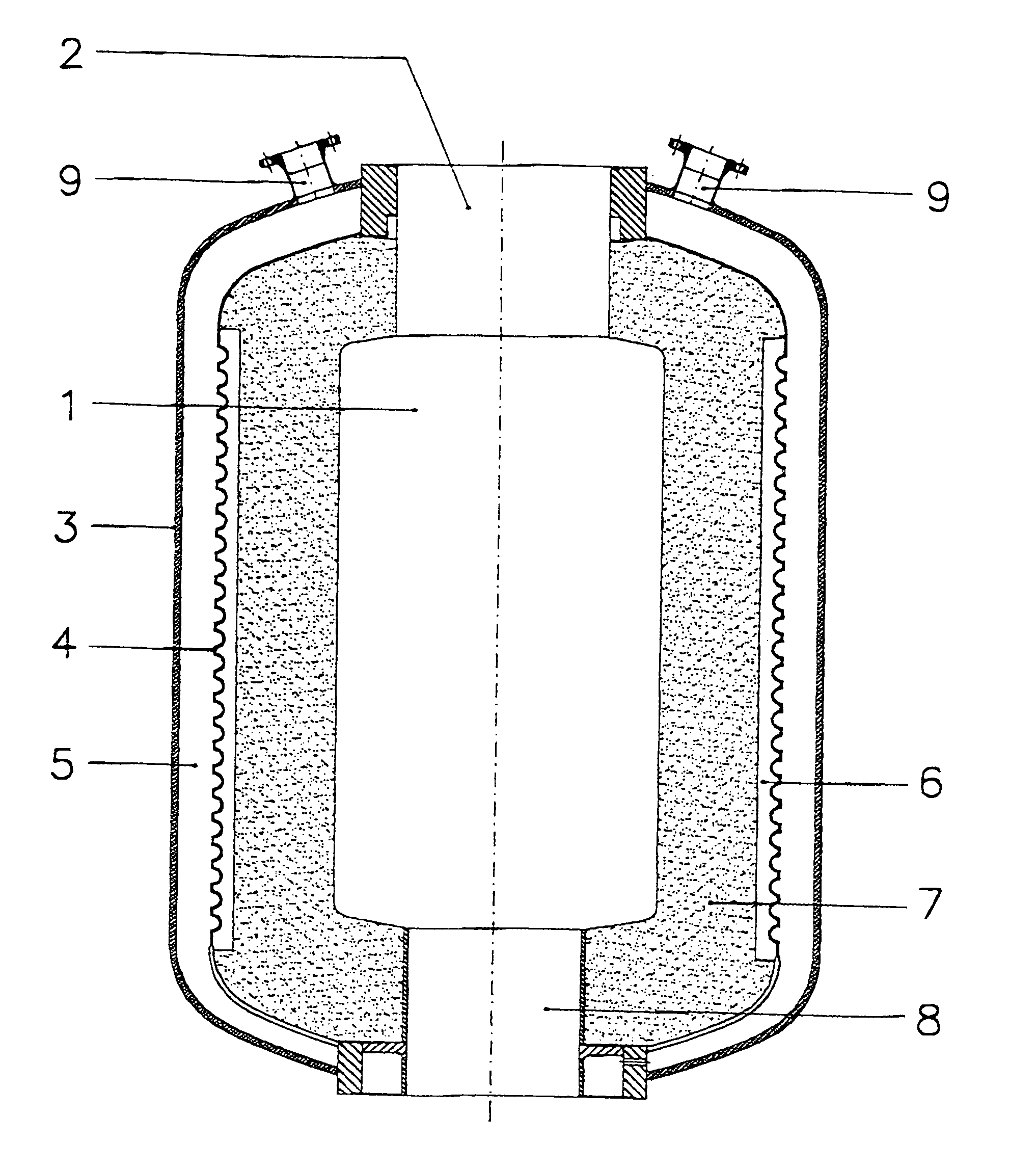

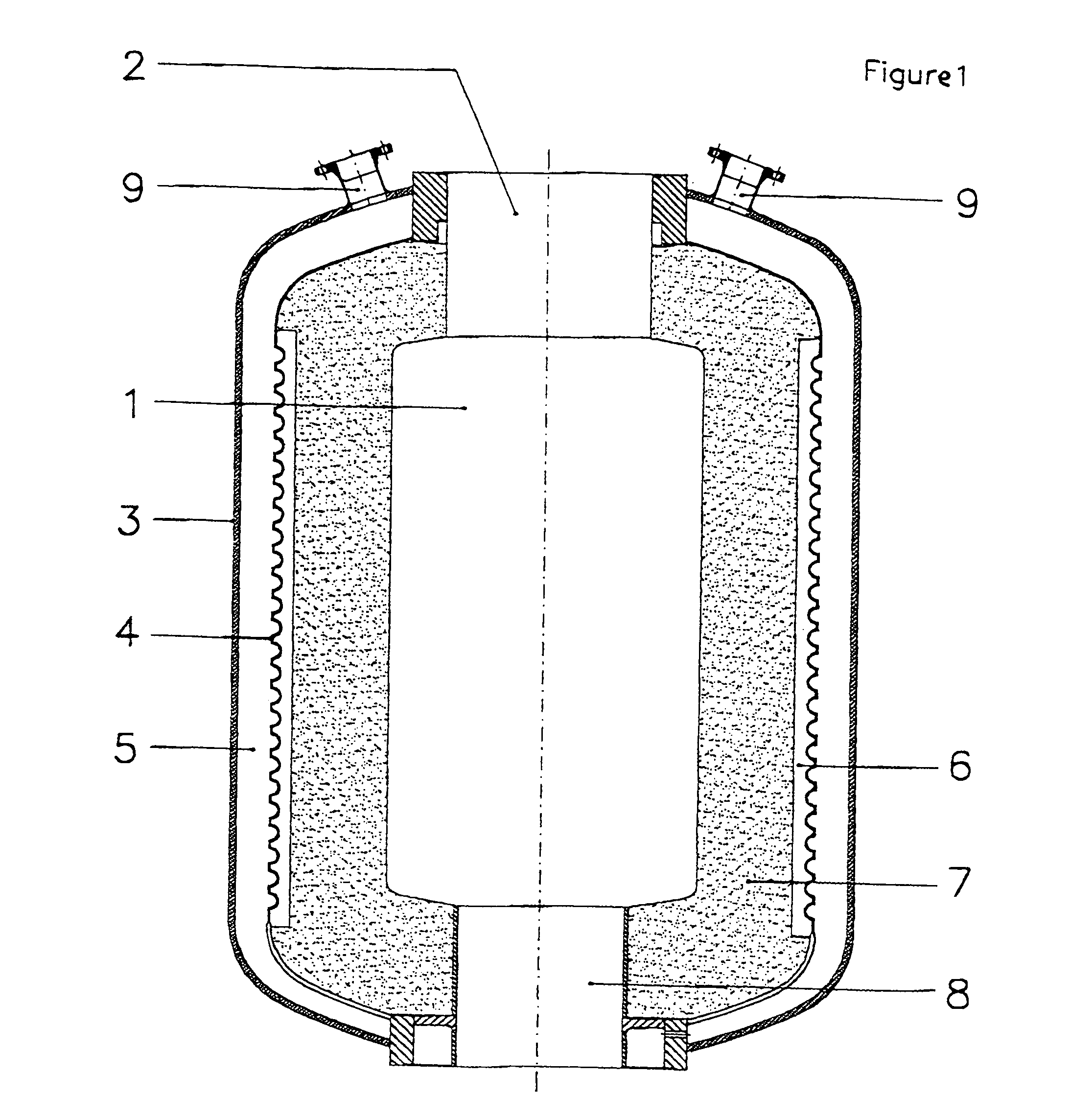

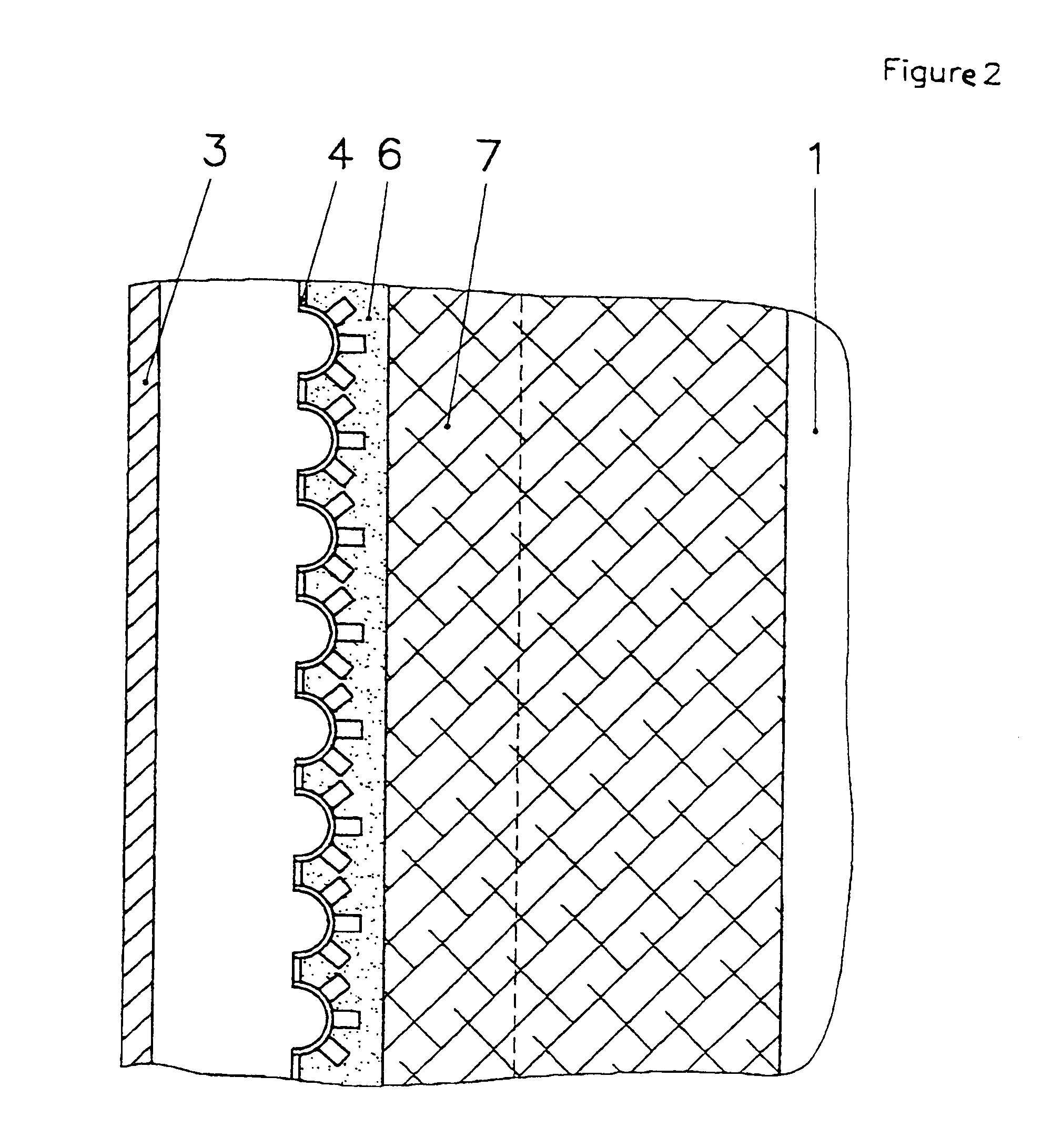

Device for gasifying combustible materials, residues and waste materials containing carbon

InactiveUS7037473B1Guaranteed uptimeEasy to operateCombustible gas chemical modificationPressurized chemical processSlagBoiling point

An appliance for the gasification of carbon- and ash-containing fuel, residual and waste materials using an oxygen-containing oxidizing agent at temperatures above the melting point of the inorganic fractions, in a reaction chamber which is designed as an entrained-bed reactor, at pressures between atmospheric pressure and 80 bar, preferably between atmospheric pressure and 30 bar, the contour of the reaction chamber being delimited by a cooled reactor wall. The cooled reactor wall having the following structure, from the outside inward: a pressure shell, a cooling wall, a water-cooled gap between the pressure shell and the cooling wall, a ceramic protection for the cooling wall, and a layer of slag. The pressure and temperature of the cooling gap between the pressure shell and the cooling wall is controlled in such a way that it can be operated above and below the boiling point of the cooling water. The pressure in the cooling gap is higher than the pressure in the gasification chamber.

Owner:SIEMENS AG +1

Mixed oxide based catalyst for the conversion of carbon dioxide to syngas and method of preparation and use

The invention relates to a catalyst and process for making syngas mixtures including hydrogen, carbon monoxide and carbon dioxide. The process comprises contacting a gaseous feed mixture containing carbon dioxide and hydrogen with the catalyst, where the catalyst comprises Mn oxide and an auxiliary metal oxide selected from the group consisting of La, Ca, K, W, Cu, Al and mixtures or combinations thereof. The process enables hydrogenation of carbon dioxide into carbon monoxide with high selectivity, and good catalyst stability over time and under variations in processing conditions. The process can be applied separately, but can also be integrated with other processes, both up-stream and / or down-stream including methane reforming or other synthesis processes for making products like alkanes, aldehydes, or alcohols.

Owner:SAUDI BASIC IND CORP SA

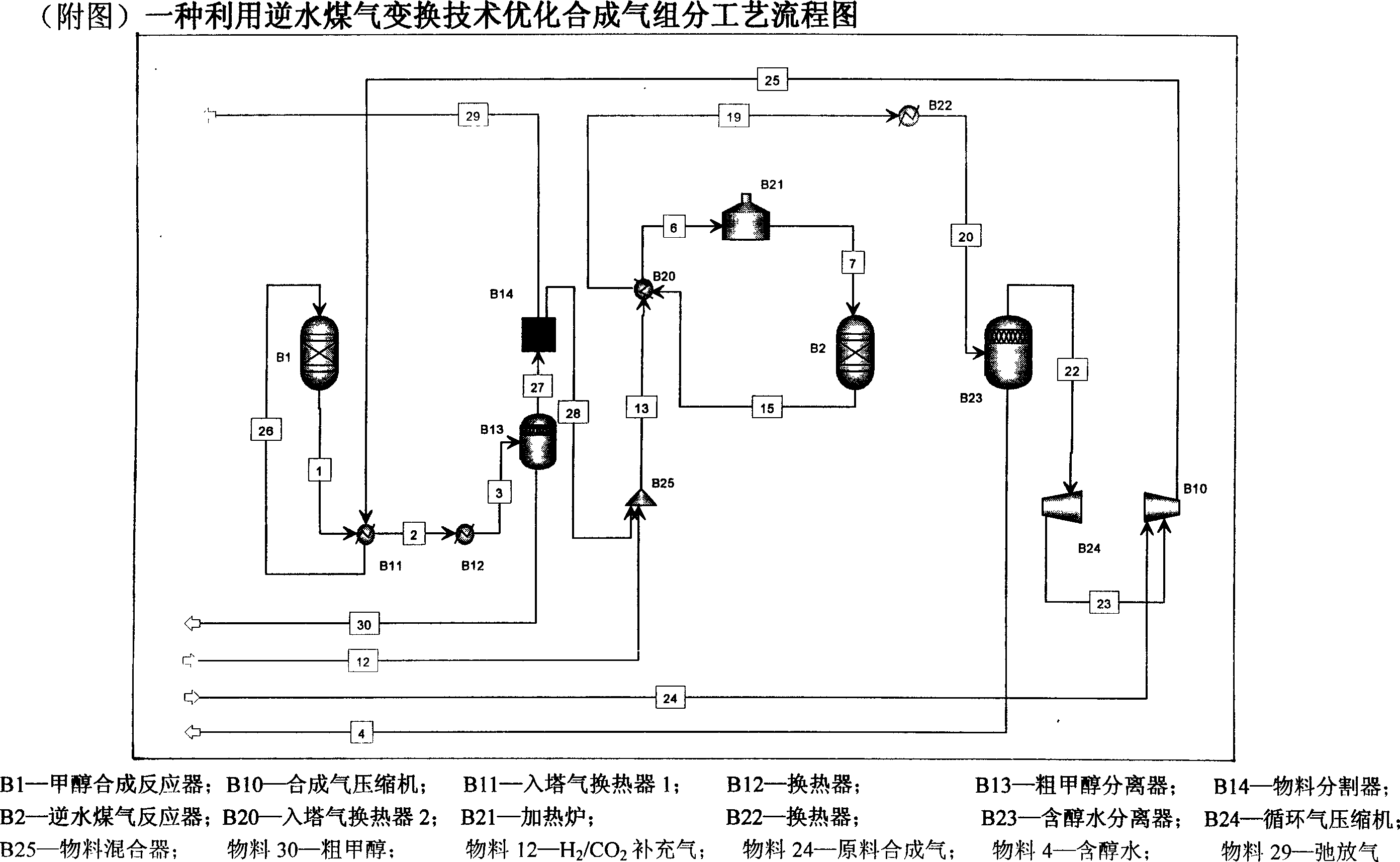

Method for optimization of synthetic gas components by reversed water-gas shift reaction technology and flow therefor

This invention relates to a method for improving methanol yield, comprising: do one or multi counter-water gas transformation reactions to synthetic gas(comprising hydrogen gas, carbon monoxide,carbon dioxide) to optimize the modulation of each component, especially to improve the CO concentration, so as to improve the space-time yield of the following methanol synthesizing. This method is specially useful in the component ratio modulation of synthetic gas produced by natural gas and steam transformation, and can be used in optimization of synthesizing reactions of methanol, dimethyl ether, liquid hydrocarbons and carbonylation raw gas.

Owner:刘勇

Popular searches

Gas purification by liquid washing Bulk chemical production Preparation by carbon oxide reduction Organic compound preparation Reagents Educts Oxygen compounds preparation by reduction Gasification processes details Preparation by carbon monoxide or formate reaction Carboxylic preparation from carbon monoxide reaction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com